Page 1

Allen-Bradley

ControlNet™

Communications

Module

Cat. No. 1203-CN1

Firmware 2.xxx

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes

some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Rockwell

Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• Identify a hazard.

• Avoid the hazard.

• Recognize the consequences.

Important: Identifies information that is critical for successful

application and understanding of the product.

death, property damage or economic loss.

Page 3

Summary of Changes

Summary of Changes

Updated Information

Getting Started

Appendix A

Appendix B

Parameter 21 Serial Port Rate

The following changes to this manual have occurred since Publication

1203-5.13 – July 1998, P/N189939 (02).

Section: Establishing a Serial Connection with the 1203-CN1 Module

Paragraph added:

DriveExplorer (v1.01 or higher) software can now also be used on

1203-CN1s that are v2.001 or higher. Do not use DriveExplorer

software with v1.xxx CN1s.

Power Consumption specification updated to 250mA at 24V DC

(-20% / +30%).

Valid Value/Settings updated.

0 = 2400

1 = 4800

2 = 9600

3 = 19.2K

4 = 38.4K

Appendix D

Default setting updated.

2 = 9600

Important statement added to description.

Important: These settings are valid for v1.004 or higher CN1s.

v1.003 or lower CN1s only have two settings: 0 = 9600 and

1 = 19.2K.

Section: Class Code 0x99 - SCANport Pass-Through Link Object

Common Services:

Service Code updated.

0x0E

0x10

Publication 1203-5.13 – February, 2002

Page 4

Notes:

Summary of Changes

Publication 1203-5.13 – February, 2002

Page 5

Table of Contents

Preface Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

Who Should Use This Manual?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

What Is the 1203-CN1 ControlNet Communications Module? . . . . . . . . . . . . . . . . . .P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-3

Terms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-3

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Rockwell Automation Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Overview Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Overview of the 1203-CN1 ControlNet Communications Module . . . . . . . . . . . . . . . .1-1

What Is ControlNet? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

SCANport Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

What Hardware Is Included?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Overview of Setting Up the 1203-CN1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installation Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Selecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

SCANport Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

ControlNet Cable Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Installing Your 1203-CN1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Removing the 1203-CN1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Publication 1203-5.13 – February, 2002

Page 6

ii Table of Contents

Getting Started Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Factory-Default Settings for the 1203-CN1 Module’s Parameters. . . . . . . . . . . . . . . 3-1

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Establishing a Serial Connection with the 1203-CN1 Module . . . . . . . . . . . . . . . . . . 3-2

Using a PC Running Terminal Emulation Software . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Using a VT100-Compatible Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Navigation Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Editing Parameters in the 1203-CN1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Displaying and Clearing the Event Queue in the 1203-CN1 Module. . . . . . . . . . . . 3-10

Displaying the 1203-CN1 module’s Current I/O Data . . . . . . . . . . . . . . . . . . . . . . . 3-11

Displaying the DF1 Protocol Statistics in the 1203-CN1 Module. . . . . . . . . . . . . . . 3-12

Viewing Your 1203-CN1 Module’s Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Performing a Flash Upgrade to the 1203-CN1 Module . . . . . . . . . . . . . . . . . . . . . . 3-14

Configuring a

Controller to

Communicate with the

1203-CN1 Module

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

What is RSNetWorx?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Required Equipment and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuring a Controller to Communicate with the 1203-CN1 Module . . . . . . . . . . . 4-2

Using Online Mode in RSNetWorx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Mapping the 1203-CN1 Module to the ControlNet Network . . . . . . . . . . . . . . . . . 4-6

Verifying Network Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

PLC Ladder Logic

Programming

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

What Is RSLogix5? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

What Are PLC Ladder Logic Programs? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Required Equipment and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Example Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Using Messages Chapter 6

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Required Equipment and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Using Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Example PLC-5 Typed Read of 10 Parameter Values . . . . . . . . . . . . . . . . . . . . . . 6-2

Example PLC-5 Typed Read of All Information about a Parameter. . . . . . . . . . . . 6-4

Example Fault Queue Read Emulated Block Transfer. . . . . . . . . . . . . . . . . . . . . . 6-6

More Information on Emulated Block Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Publication 1203-5.13 – February, 2002

Page 7

Troubleshooting Chapter 7

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

LEDs on the 1203-CN1 Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Understanding the ControlNet LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Understanding the SCANport LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Understanding the Module LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Specifications Appendix A

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table of Contents iii

1203-CN1 Module

Parameters

Appendix B

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

What Are Datalinks? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

What Are Fault Configurable Inputs? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

N-File Structure Appendix C

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

N-File Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

ControlNet Objects Appendix D

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Object Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Class Code 0x01 — Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Class Code 0x02 — Message Router Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Class Code 0x04 — Assembly Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Class Code 0x06 — Connection Manager Object. . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Publication 1203-5.13 – February, 2002

Page 8

iv Table of Contents

Class Code 0x07 — Register Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-11

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-11

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-11

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12

Class Code 0x0F — Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-14

Bit definitions for Instance Attribute 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-15

Data Types for Instance Attribute 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-16

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-17

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-17

Object Specific Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-18

Class Code 0x10 — Parameter Group Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-19

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-19

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-19

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-19

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20

Class Code 0xF0 — ControlNet Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-23

Class Code 0xA1 — Non-Volatile Storage Object. . . . . . . . . . . . . . . . . . . . . . . . . . D-24

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-24

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-24

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-25

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-25

Class Specific Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-25

Class Code 0x93 — SCANport Pass-Through Parameter Object. . . . . . . . . . . . . . D-26

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-26

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-26

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-26

Object-Specific Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-26

Class Code 0x97 — SCANport Pass-Through Fault Object . . . . . . . . . . . . . . . . . . D-27

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-27

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-27

Class Code 0x98 — SCANport Pass-Through Warning Object . . . . . . . . . . . . . . . D-28

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-28

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-28

Publication 1203-5.13 – February, 2002

Page 9

Table of Contents v

Class Code 0x99 — SCANport Pass-Through Link Object . . . . . . . . . . . . . . . . . . . D-29

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29

Object-Specific Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29

Class Code 0x67 — PCCC Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

Object Specific Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

Message Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

Supported PCCC

Messages

Supported Emulated

Block Transfer

Commands

Appendix E

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Supported PCCC Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

PCCC Error Response Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Related documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Appendix F

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Supported Emulated Block Transfer Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Emulated Block Transfer Status Word. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Parameter Value Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Parameter Value Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Parameter Read Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Product ID Number Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

Scattered Parameter Value Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-10

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-11

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-11

Scattered Parameter Value Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-12

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . F-12

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-13

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-13

Publication 1203-5.13 – February, 2002

Page 10

vi Table of Contents

NVS Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

Fault Command Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-15

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . F-15

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-15

Fault Queue Entry Read Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-16

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . F-16

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-17

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-17

Fault Queue Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-18

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . F-18

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-18

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-18

Trip Fault Queue Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-19

PLC Block Transfer Emulation Instruction Data . . . . . . . . . . . . . . . . . . . . . . . . . . F-19

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-19

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-19

Index Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Publication 1203-5.13 – February, 2002

Page 11

Preface

Preface

Objectives

Who Should Use This Manual?

Read this preface to become familiar with the rest of the manual. This

preface covers the following topics:

• Who should use this manual.

• An overview of the 1203-CN1 ControlNet™ communications

module.

• The purpose of this manual.

• Terms and abbreviations.

• Conventions used in this manual.

• Rockwell Automation support.

Use this manual if you are responsible for installing, wiring,

programming, or troubleshooting control systems that use the

1203-CN1 ControlNet communications module.

This manual is intended for qualified service personnel responsible

for setting up and servicing the 1203-CN1 module. You must have

previous experience with and a basic understanding of electrical

terminology, programming procedures, required equipment, required

software, networking, and safety precautions.

What Is the 1203-CN1 ControlNet

Communications Module?

Purpose of this Manual

The 1203-CN1 ControlNet communications module provides an

interface between a ControlNet network and a single SCANport™

product.

This manual is a learning and reference guide for the 1203-CN1

ControlNet communications module. It describes the procedures

needed to install, configure, and troubleshoot the module. Before you

initialize, operate, or service the module, you should read this manual

in its entirety.

Publication 1203-5.13 – February, 2002

Page 12

P-2 Preface

Contents of this Manual

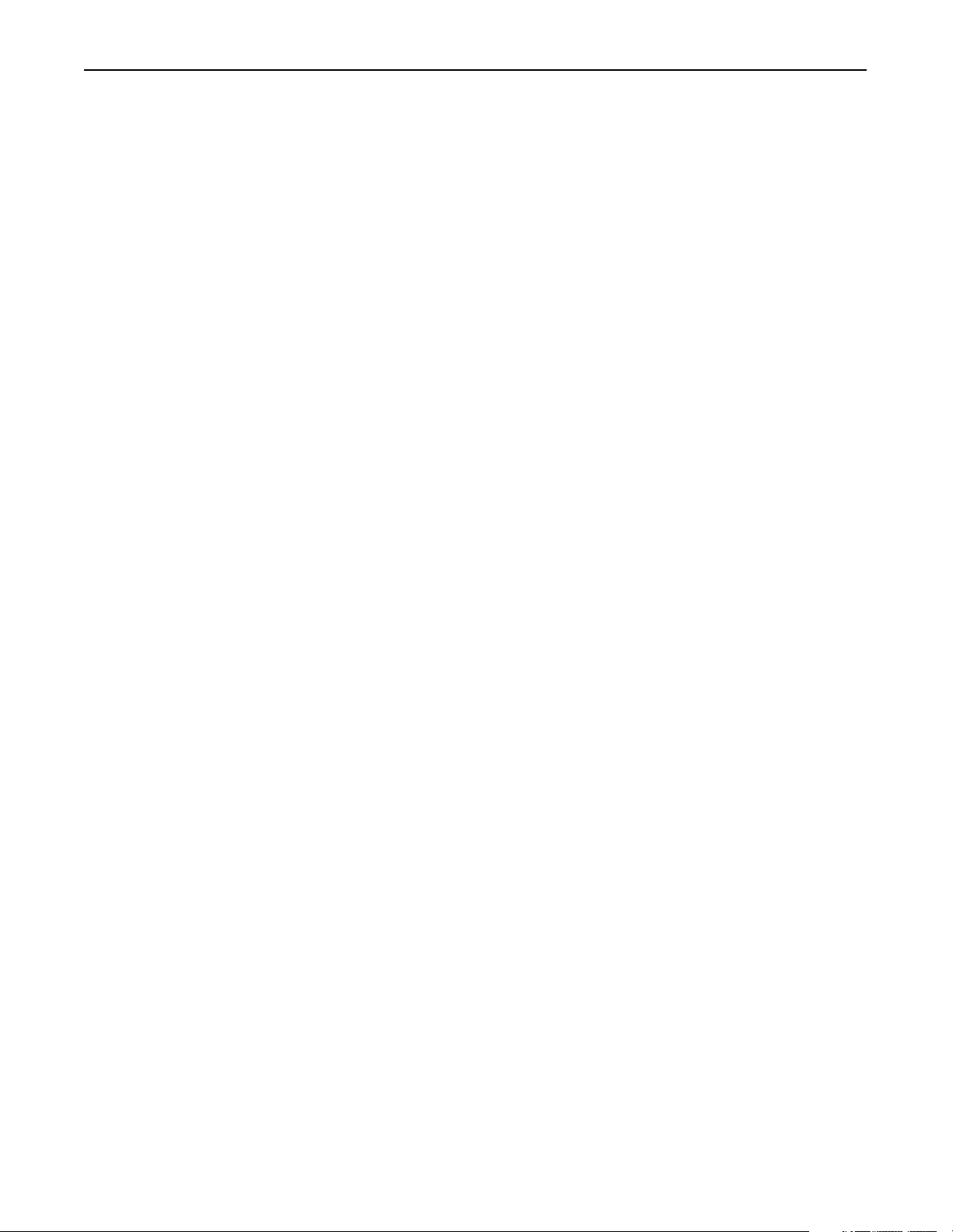

This manual contains the following information:

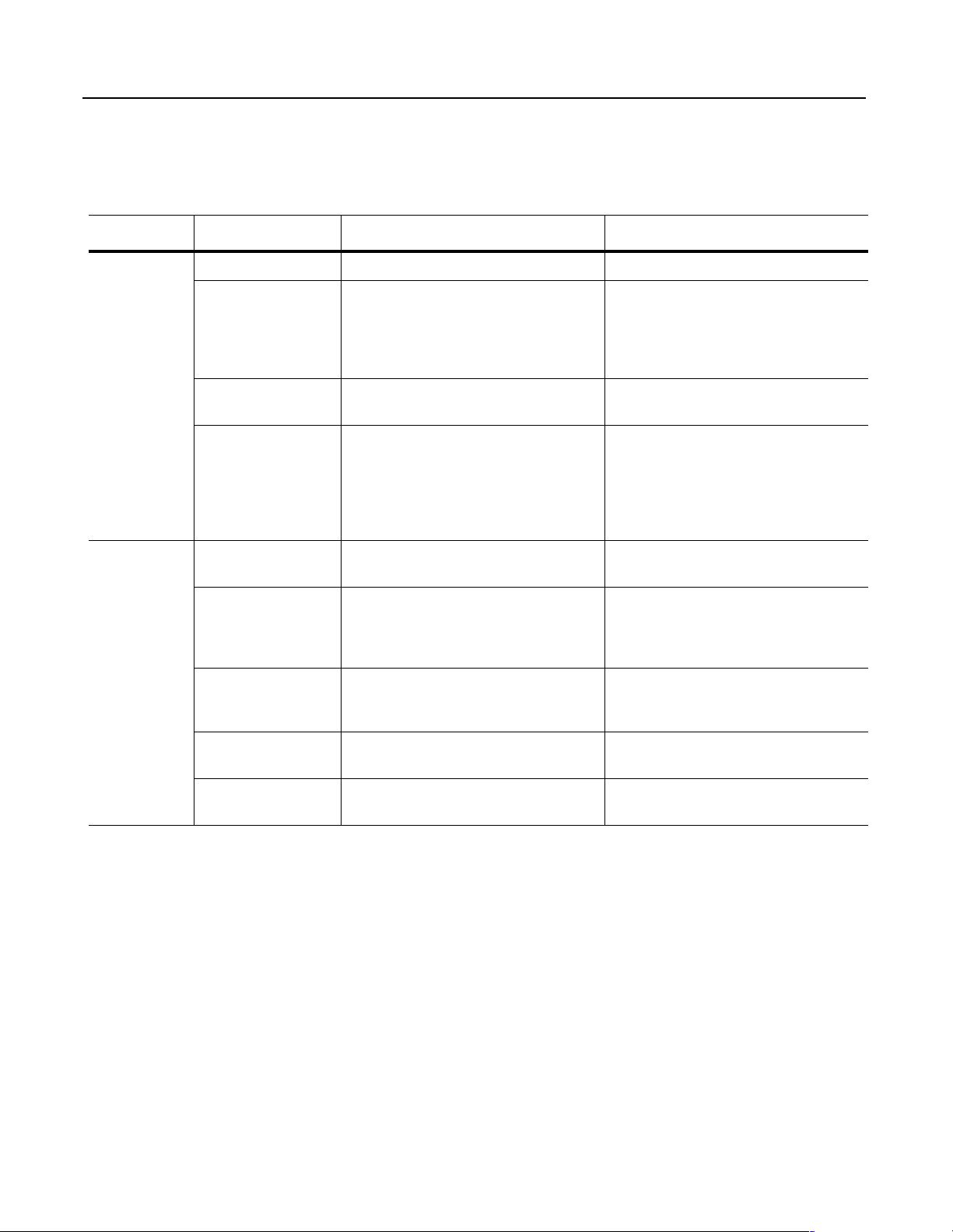

Chapter Title Contents

Preface Describes the purpose, background, and

scope of this manual. Also provides

information on safety precautions and

technical support.

1 Overview Provides an overview of the 1203-CN1

module, ControlNet, and SCANport.

2 Installation Provides procedures for installing the

1203-CN1 module.

3 Getting Started Provides procedures for configuring the

1203-CN1 module, including how to set

up a serial connection to the module,

navigate in the module’s software, edit its

parameters, view its serial number,

perform a flash upgrade to its firmware,

and view its event queue.

4 Configuring a Controller to

Communicate with the

1203-CN1 Module

5 PLC Ladder Logic

Programming

6 Using Messages Provides information on and examples of

7 Troubleshooting Explains how to troubleshoot the

A Specifications Provides specifications for the 1203-CN1

B 1203-CN1 Module

Paramet ers

C N-File Structure Lists the N-file structure for the 1203-CN1

Provides procedures for using

RSNetWorx to set up a ControlNet

network and configure controllers to

communicate with devices, such as the

1203-CN1 module.

Provides information on and an example

of a ladder logic program used to control

the SCANport product.

messages used to set and monitor data in

the SCANport product.

1203-CN1 module using its LEDs.

module.

Provides information on datalinks,

information on fault configurable inputs,

and a list of the 1203-CN1 module’s

parameters.

module and attached SCANport

products.

Publication 1203-5.13 – February, 2002

D ControlNet Objects Provides a reference list of ControlNet

objects.

E Supported PCCC

Messages

F Supported Emulated Block

Transfer Commands

Provides a reference list of PCCC

messages supported by the 1203-CN1

module.

Provides a reference list of emulated

block transfer commands.

Page 13

Preface P-3

Safety Precautions

Please read the following safety precautions carefully.

ATTENTION: Only personnel familiar with

SCANport devices and the associated machinery should

!

plan or implement the installation, start-up,

configuration, and subsequent maintenance of the

1203-CN1 module. Failure to comply may result in

personal injury and/or equipment damage.

ATTENTION: The 1203-CN1 ControlNet

communications module contains ESD (Electrostatic

!

Discharge) sensitive parts. Static control precautions are

required when installing, testing, or servicing this

module. Device malfunction may occur if you do not

follow ESD control procedures. If you are not familiar

with static control procedures, refer to Allen-Bradley

publication 8000-4.5.2, Guarding Against Electrostatic

Damage, or other applicable ESD protection handbook.

Terms and Abbreviations

The following terms and abbreviations are specific to this product.

For a complete listing of Allen-Bradley terminology, refer to the

Allen-Bradley Industrial Automation Glossary, Publication AG-7.1.

Term: Definition

ControlNet An open network that provides deterministic I/O control and

unscheduled messaging through a time division multiplexing scheme.

ControlNet offers a redundant media option.

SCANport A standard peripheral communications interface for various

Allen-Bradley drives and power products.

SCANport

Peripheral

SCANport

Product

1203-CN1

ControlNet

Communications

Module

A device that provides an interface between SCANport and a

network. It is often referred to as an adapter. For example, the

1203-CN1 module is a SCANport peripheral.

A device that uses the SCANport communications interface to

communicate with one or more peripheral devices. For example, a

motor drive such as a 1336 PLUS is a SCANport product.

In this manual, it is also called “1203-CN1 module” or “module.”

Publication 1203-5.13 – February, 2002

Page 14

P-4 Preface

Conventions Used in this Manual

Rockwell Automation Support

The following conventions are used throughout this manual:

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Italic type is used for chapter names and for parameter names.

• Bold type is used for names of menus, menu options, screens, and

dialog boxes.

Important: This type of paragraph contains tips or notes that have

been added to call attention to useful information.

Rockwell Automation offers support services worldwide, with over

75 sales/support offices, over 500 authorized distributors, and over

250 authorized systems integrators located through the United States

alone. In addition, Rockwell Automation representatives are in every

major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• Sales and order support.

• Product technical training.

• Warranty support.

• Support service agreements.

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

please review the information in the Troubleshooting chapter first. If

you are still having problems, then call your local Rockwell

Automation representative.

Refer to http://www.ab.com for updates and supporting

documentation.

Publication 1203-5.13 – February, 2002

Page 15

Overview

Chapter

1

Chapter Objectives

Overview of the 1203-CN1

ControlNet Communications

Module

Chapter 1 provides an overview of your 1203-CN1 ControlNet

communications module. It provides the following information:

• Description of how the 1203-CN1 module works.

• Overview of ControlNet.

• Overview of SCANport products.

• Parts of the 1203-CN1 module.

• Overview of setting up the module.

• Required equipment and tools.

The 1203-CN1 ControlNet communications module provides an

electronic communications interface between a ControlNet network

and any single SCANport product.

Figure 1.1

Example of 1203-CN1 Modules Connecting SCANport Products to ControlNet

1305

1336 IMPACT

1336 PLUS

ControlNet

A SCANport cable connects the module to a SCANport product

through a SCANport interface port on the SCANport product. One or

two ControlNet cable taps connect the module to the ControlNet bus,

depending on whether you are using non-redundant or redundant

connections.

Publication 1203-5.13 – February, 2002

Page 16

1-2 Overview

The module translates the ControlNet messages into SCANport

messages that can be understood by the SCANport product. Both

scheduled I/O data and unscheduled messages can be transferred

through the module. ControlNet capability enhances the functionality

and usefulness of the connected product and lets you communicate

with the SCANport product from any node on the ControlNet

network.

What Is ControlNet?

ControlNet is a real-time, control-layer network providing high-speed

transport of both scheduled time-critical I/O data and unscheduled

messaging data, including upload/download of programming and

configuration data and peer-to-peer messaging, on a single physical

media link. Deterministic and repeatable, ControlNet’s high-speed (5

Mbps) control and data capabilities significantly enhance the size and

speed of I/O data and messaging data transfers.

Specifically, ControlNet provides:

• Bandwidth for I/O, real-time interlocking, peer-to-peer

messaging and programming—all on the same link, without

impacting time-critical I/O.

• Deterministic, repeatable performance for both discrete and

process applications.

• Multicast of both inputs and peer-to-peer data.

• Fiber media, media redundancy and intrinsically safe options.

• Simple and flexible installation requiring no special tools to

install or tune the network.

• Network access for any node.

Publication 1203-5.13 – February, 2002

• Support for up to 99 nodes per subnet to help flatten architectures

and support more distributed systems.

• User-configured real-time remote analog updates for more

flexibility and process capabilities.

Page 17

Overview 1-3

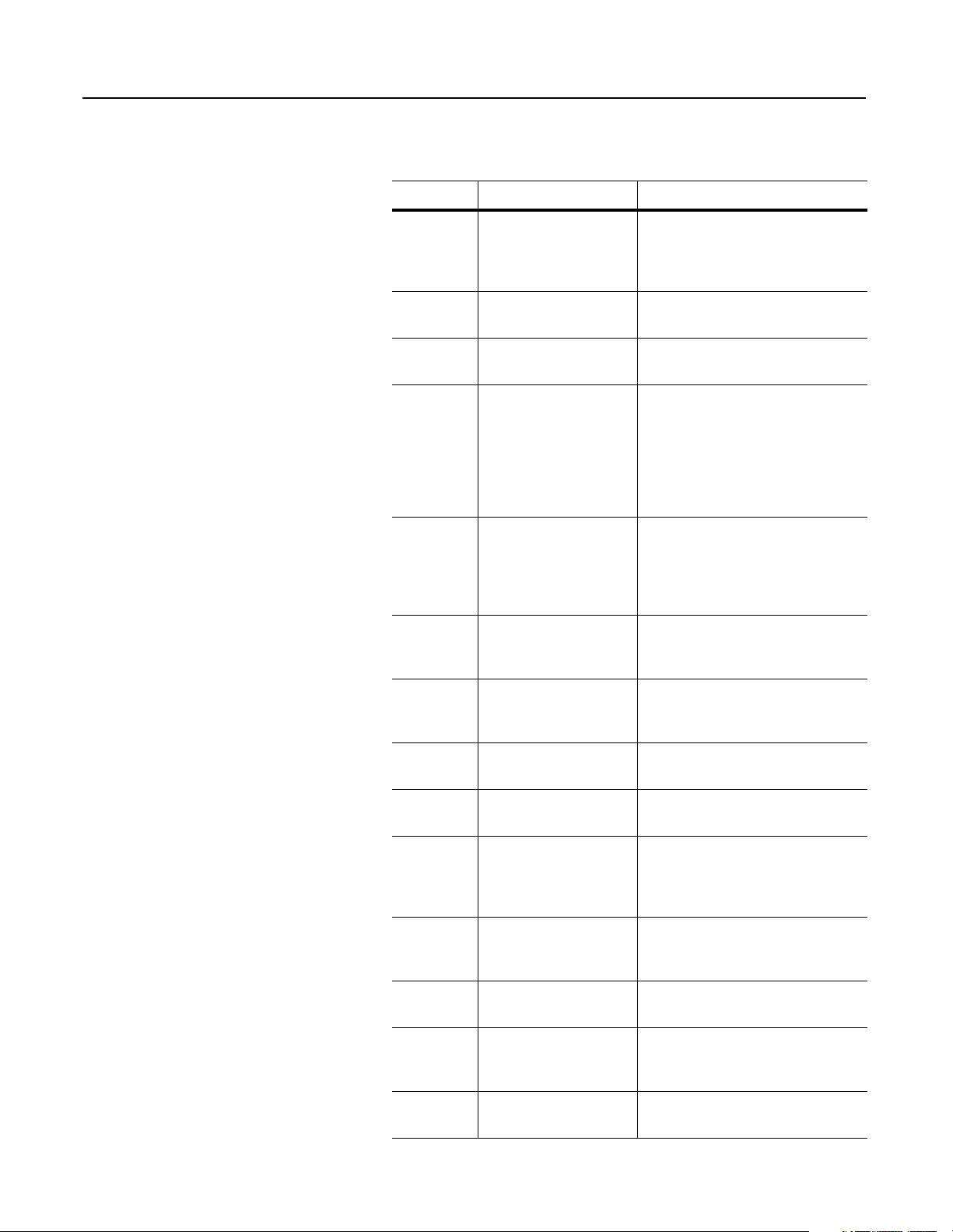

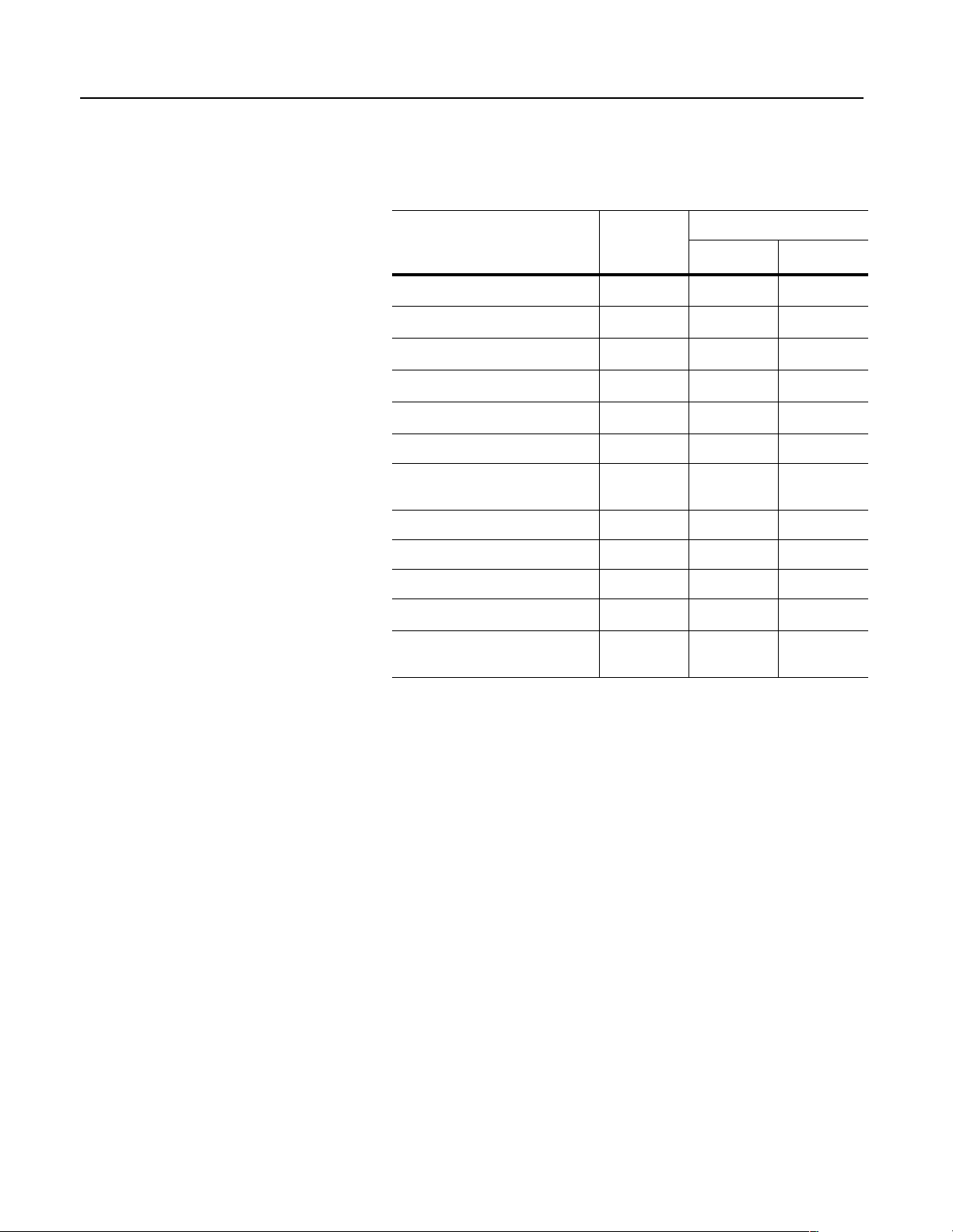

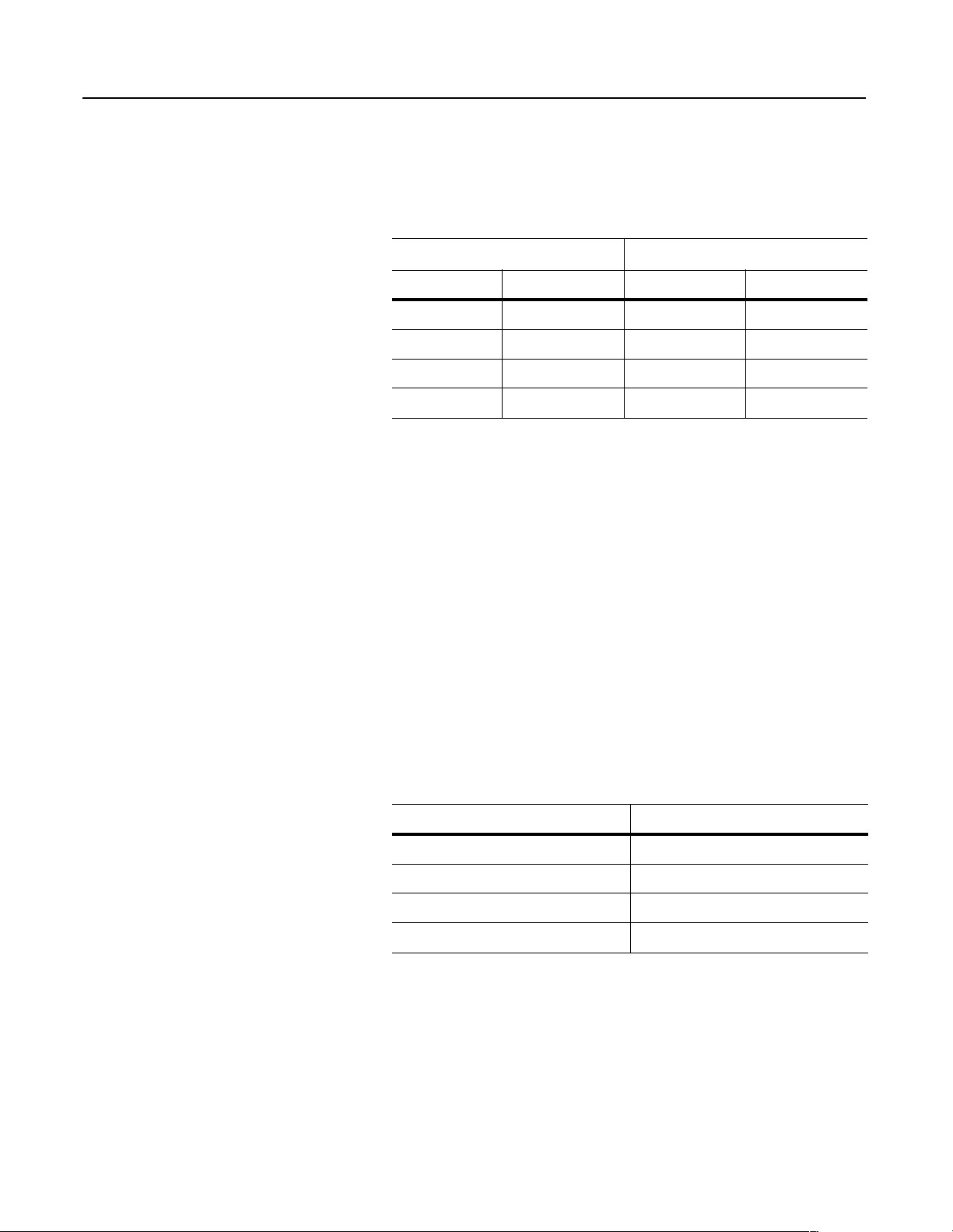

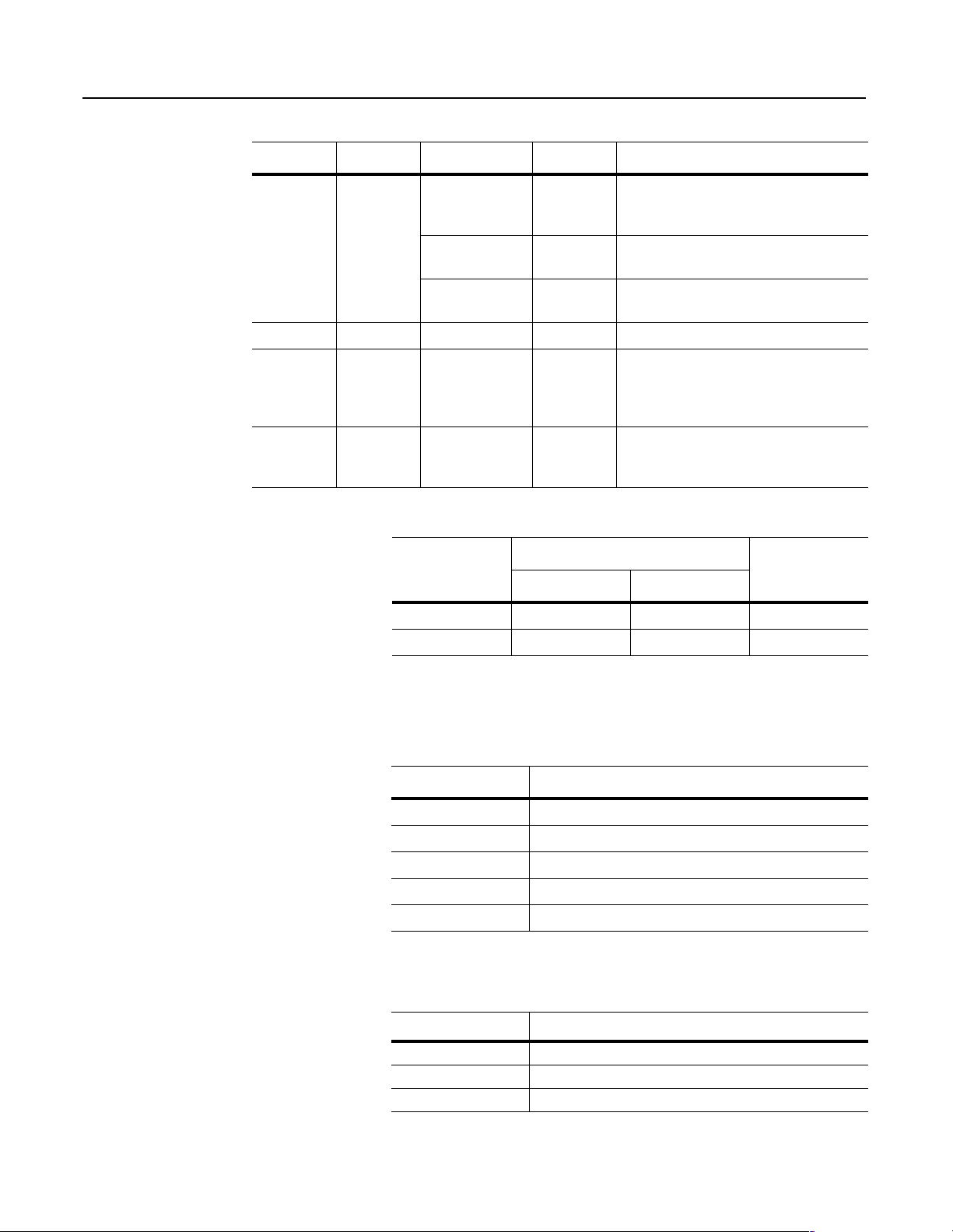

SCANport Products

Some SCANport products support one peripheral; others support up

to six peripherals. The table below lists SCANport products, the

number of peripherals each supports, and the minimum and

maximum I/O words allowed between the product and module.

Number of

Product

1305 AC MICRO Drive

1336 IMPACT™ Drive

1336 PLUS AC Drive

1336 PLUS II Drive

1336 FORCE™ Drive

1336 Line Regeneration Package 2 0 2

1394 AC Mult-Axis Motion Control

System

SMC Dialog Plus 1 0 2

SMP-3 Smart Motor Protector 2 0 2

Peripherals

Supported

➀

5

➁

6

➁

6

➁

6

➁

6

6

I/O Words

Minimum Maximum

010

010

010

010

010

010

1397 Digital DC Drive 5 0 10

1557 Medium Voltage Drive

2364 RGU DC Bus Regeneration

Front End

➀

Early versions of the 1305 AC MICRO Drive firmware may not support some types of

communications.

➁

Lower horsepower products may not support a sixth peripheral. Refer to your user

manual to verify that your product supports a sixth peripheral.

5

6

010

010

Important: If you intend to use datalinks to communicate with and

control your SCANport product, verify that your SCANport product

supports datalinks before enabling them in the module.

Important: To connect multiple peripherals to a SCANport product,

a port expander may be required. Refer to your product’s

documentation for more information.

Publication 1203-5.13 – February, 2002

Page 18

1-4 Overview

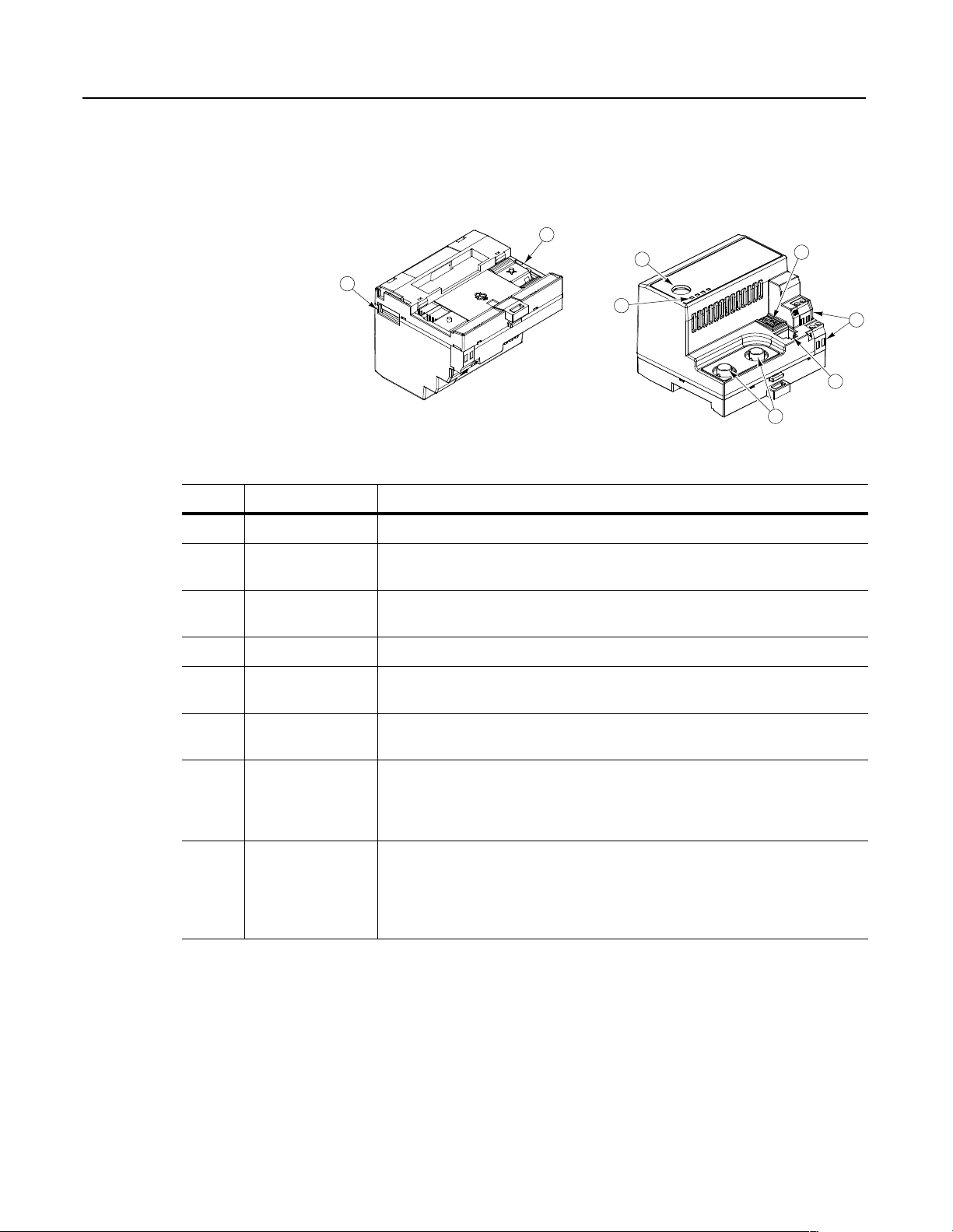

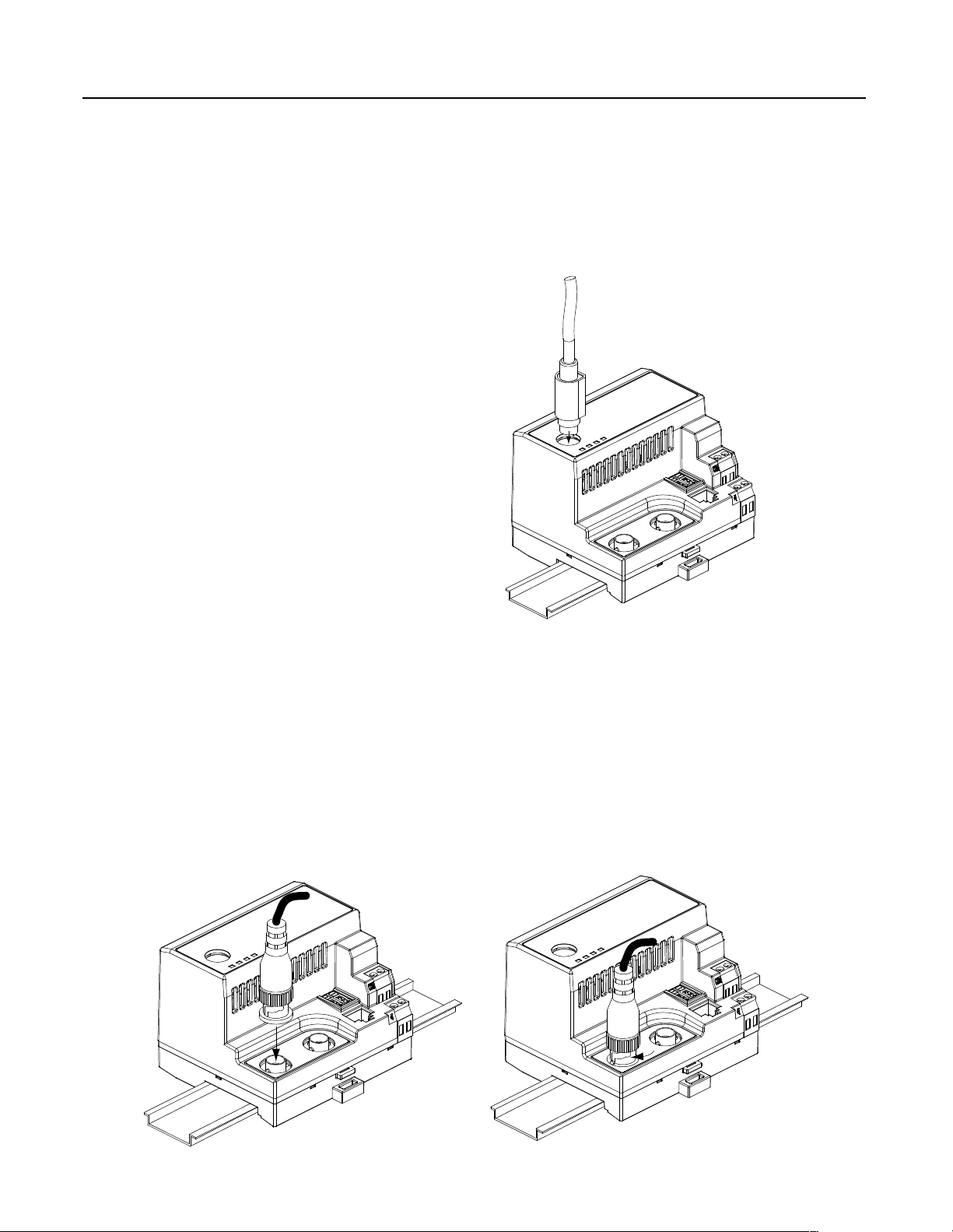

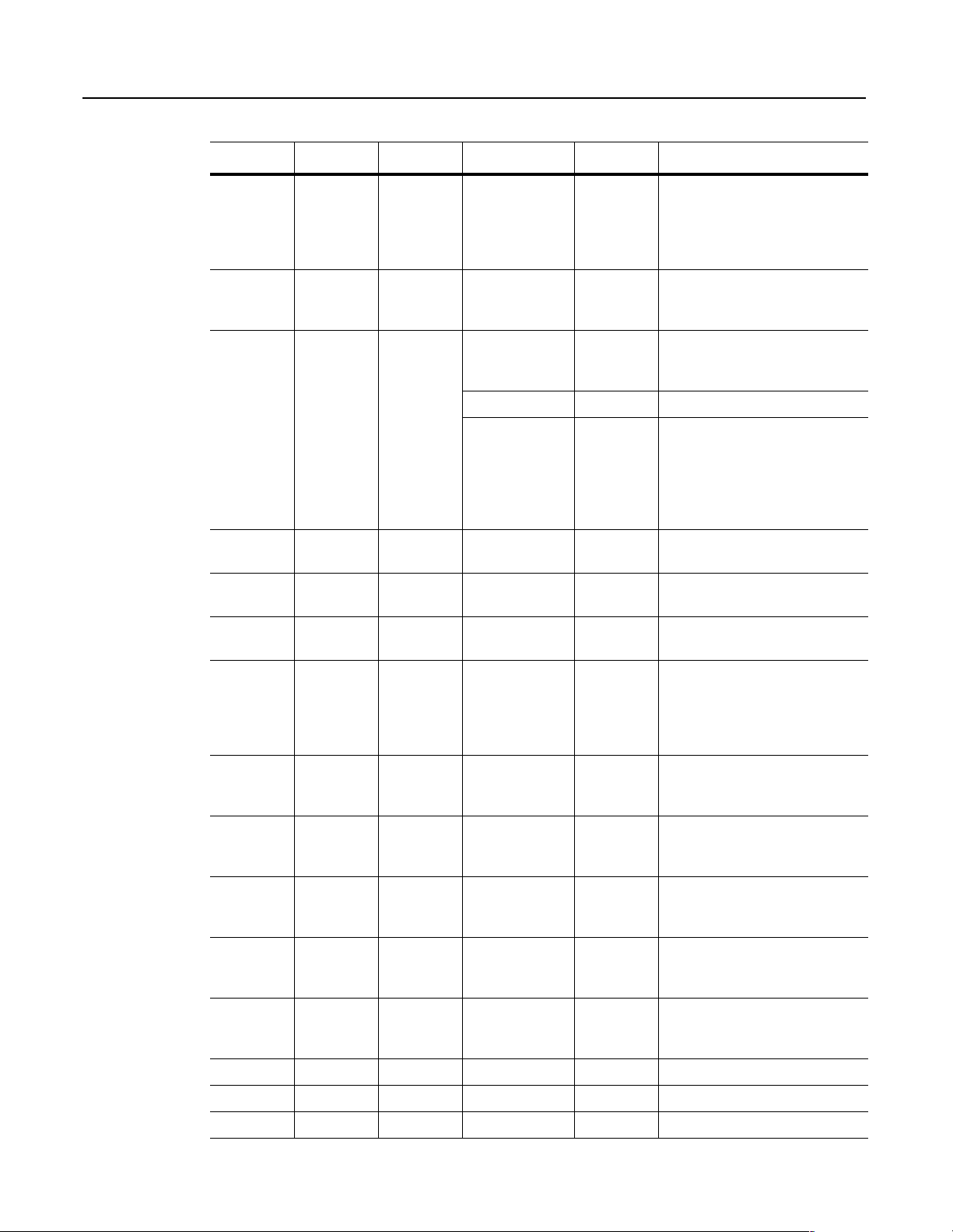

What Hardware Is Included?

Number Part Description

1 DIN Rail Mount Securely attaches and electronically grounds the module to the DIN rail.

2 ControlNet Coax

Connections

Figure 1.2 and the table below illustrate and list the main parts of the

1203-CN1 ControlNet communications module:

Figure 1.2

Parts of the Communications Module

1

4

8

3

Provide connections for ControlNet cable taps to allow either redundant or non-redundant

communications over the ControlNet network.

5

6

7

2

3 Bi-Color LEDs Indicate the status of each ControlNet media channel, of the SCANport connection, and of

the module. For more information, refer to Chapter 7, Troubleshooting.

4 SCANport Connection Provides a standard SCANport 8-pin circular mini-DIN connector for the SCANport cable.

5 ControlNet Node

Address Indicator

6 +24V DC Power

Connections

7 ControlNet Network

Access Port

8 RS-232 Serial Port Provides a connection for terminals capable of RS-232 serial communications. This por t can

Displays the ControlNet node address for the module. Use the push buttons to set the

address before applying power.

Provide for a +24V DC power supply connection. Multiple connections let you daisy chain

power through a group of modules placed close to each other.

Provides an RJ-45 connection for devices capable of communicating over ControlNet. The

module as well as other operational network devices can be accessed. A ControlNet network

access cable (1786-CP) and 1784-KTCX communication card, 1784-PCC communication

card, or 1770-KFC communication interface are required to use this por t.

be used to edit the module’s parameters, download a file needed to perform a flash to the

module’s operating code, and support devices that monitor and test the module. A 1203-SFC

serial cable and a PC running a terminal emulation program or a VT100-compatible terminal

are required to use this port.

Publication 1203-5.13 – February, 2002

Page 19

Overview 1-5

Overview of Setting Up the

1203-CN1 Module

Required Tools and Equipment

To set up the 1203-CN1 module, you must perform the following

tasks:

1. Install the module. Refer to Chapter 2, Installation.

2. If desired, configure the module’s parameters. Refer to Chapter 3,

Getting Started.

3. Configure the module on the ControlNet network. Refer to

Chapter 4, Configuring a Controller to Communicate with the

1203-CN1 Module.

To install and configure a 1203-CN1 module, you need the following

equipment:

• Grounding wrist strap (shipped with the module).

• 1203-CN1 ControlNet communications module.

• 35 x 7.5 mm DIN rail A (Allen-Bradley part number (199-DR1;

46277-3; EN 50022).

• 1/8 in. (3.2 mm) flathead screwdriver.

• Blunt, pointed instrument (not pen or pencil) for setting the node

address.

•Ohm meter.

• Appropriate cables for SCANport and ControlNet connections.

Refer to Chapter 2, Installation, for more information.

• 1203-SFC serial cable.

• Either a PC running a Windows™ terminal emulation program

(e.g., HyperTerminal) or a VT100-compatible terminal.

• PC that is:

– Running RSNetWorx™, RSLogix5™, and RSLinx™.

– Connected to the ControlNet network using a 1784-KTCX

card, 1784-PCC card, or 1770-KFC adapter.

Publication 1203-5.13 – February, 2002

Page 20

1-6 Overview

Notes:

Publication 1203-5.13 – February, 2002

Page 21

Installation

Chapter

2

Chapter Objectives

Required Tools and Equipment

Chapter 2 provides the information that you need to install the

1203-CN1 ControlNet communications module. This information

includes:

• A list of tools and equipment needed for the installation.

• A discussion of available cables for SCANport and ControlNet

connections.

• Instructions for installing the module.

• Instructions for removing the module.

After installing the module, refer to Chapter 3, Getting Started, for

procedures on how to configuring the module’s parameters and refer

to Chapter 4, Configuring a Controller to Communicate with the

1203-CN1 Module, for information on configuring the module on the

ControlNet network.

To install your 1203-CN1 module, you will need the following tools

and equipment:

• Grounding wrist strap.

• 1203-CN1 ControlNet communications module.

Selecting Cables

• 35 x 7.5 mm DIN rail A (Allen-Bradley part number 199-DR1;

46277-3; EN 50022).

• 1/8 in. (3.2 mm) flathead screwdriver.

• Blunt, pointed instrument (not pen or pencil) for setting the node

address.

• Appropriate cables for SCANport and ControlNet connections.

Refer to the Selecting Cables section in this chapter.

•Ohm meter.

To connect the 1203-CN1 module to the SCANport product and the

ControlNet network, you must select an appropriate SCANport cable

and one or two ControlNet cable tap(s). Use the following

information to select appropriate cables for each connection.

Publication 1203-5.13 – February, 2002

Page 22

2-2 Installation

SCANport Cables

When selecting the SCANport cable to connect the module to the

SCANport product, you need to:

• Use an Allen-Bradley SCANport cable. Refer to the table below.

Male to Male Connection

Length Catalog Number Length Catalog Number

1/3 m 1202-C03 1/3 m 1202-H03

1 m 1202-C10 1 m 1202-H10

3 m 1202-C30 3 m 1202-H30

9 m 1202-C90 9 m 1202-H90

➀

For most installations, a male-to-male connection on the cable is required.

➀

Male to Female Connection

• Do not exceed 10 meters (33 feet) of cable between the

SCANport product and module.

• Keep SCANport cables away from high power cables to guard

against introducing noise into your system.

ControlNet Cable Taps

A tap connects a node on the ControlNet network, such as a module,

to the cable system via an integral 1 m (39.6 in.) drop cable. When

selecting a tap to connect the module to the ControlNet network, you

need to:

• Determine if your network uses a redundant media system. If so,

you will need two taps.

• Use one or two Allen-Bradley tap(s). Refer to the table below.

Type Catalog Number

Straight T-Tap 1786-TPS

Straight Y-Tap 1786-TPYS

Right-Angle T-Tap 1786-TPR

Right-Angle Y-Tap 1786-TPYR

For more information on ControlNet taps and ControlNet networks,

refer to Publication 1786-6.2.1, ControlNet Cable System Planning

and Installation Manual.

Publication 1203-5.13 – February, 2002

Page 23

Installation 2-3

Electrostatic Discharge

Precautions

Please read the following safety precautions carefully before

installing the 1203-CN1 module

ATTENTION: The 1203-CN1 ControlNet

communications module contains ESD (Electrostatic

!

Important: You must wear a grounding wrist strap that is properly

grounded when you handle the 1203-CN1 module.

Discharge) sensitive parts. Static control precautions

are required when installing, testing, or servicing this

module. Device malfunction may occur if you do not

follow ESD control procedures. If you are not familiar

with static control procedures, refer to Allen-Bradley

publication 8000-4.5.2, Guarding Against Electrostatic

Damage, or other applicable ESD protection handbook.

Publication 1203-5.13 – February, 2002

Page 24

2-4 Installation

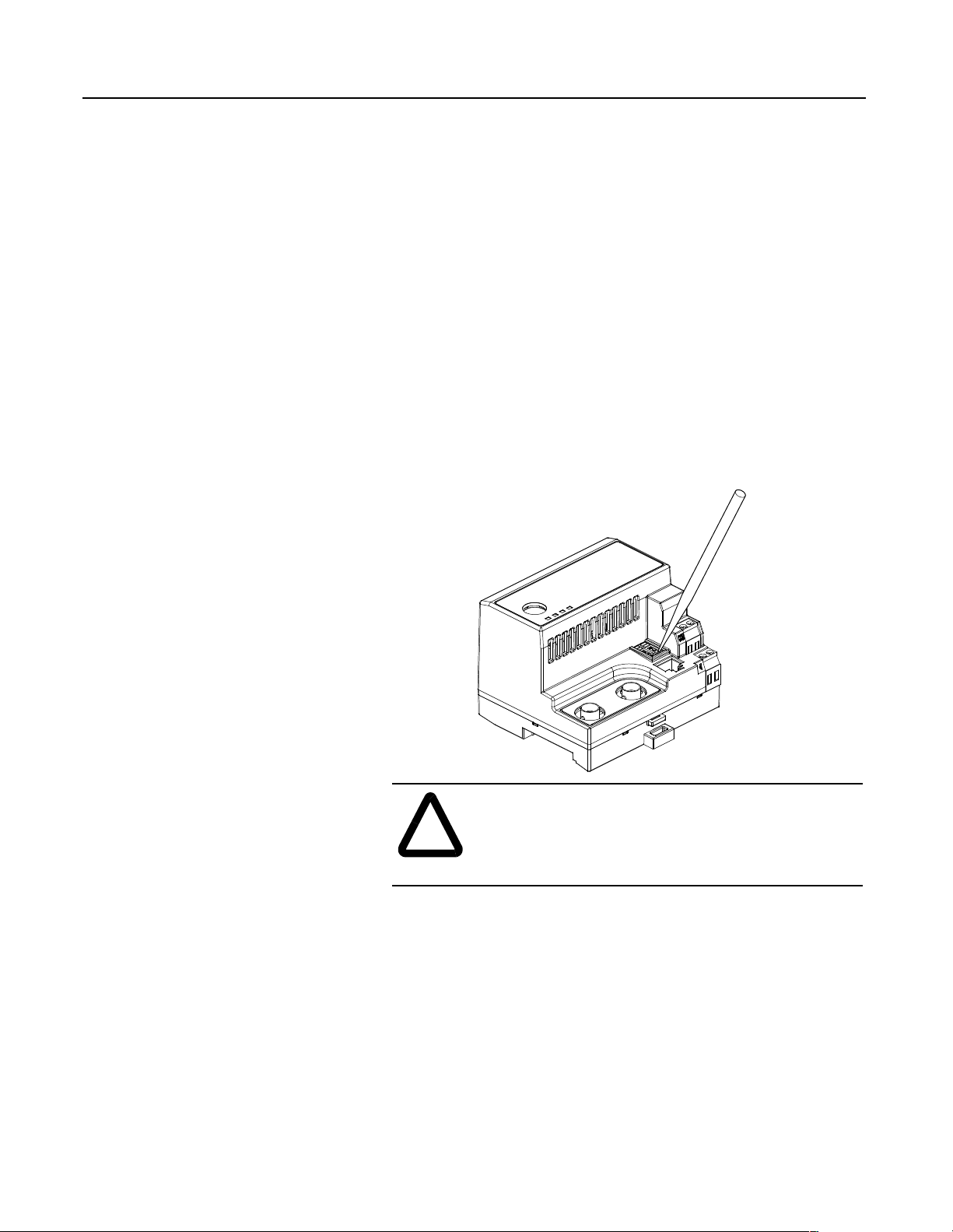

Installing Your 1203-CN1 Module

The following instructions explain how to physically install your

1203-CN1 module.

Important: To guard against device malfunction, you must wear a

grounding wrist strap when installing the 1203-CN1 module.

1. Set the module’s ControlNet node address by clicking the + or button to the desired value for each digit.

Important: Each node on the ControlNet network must have a

unique address.

Important: The node address must be set before power is applied

because the module uses the node address it detects when it first

receives power. To change a node address, you must set the new value

and then remove and reapply power to or reset the module.

Figure 2.1

Setting the Module’s Node Address

Publication 1203-5.13 – February, 2002

ATTENTION: When setting the node address, use a

blunt, pointed instrument. Do not use a pencil or pen

!

2. Ensure the DIN rail to which the module will be attached is

connected to an earth ground.

Important: If EMC compliance is required, the DIN rail should be

properly grounded inside a full metal enclosure. The enclosure should

also be properly connected to an earth ground.

because lead (graphite) or ink may damage the switch

assembly.

Page 25

Installation 2-5

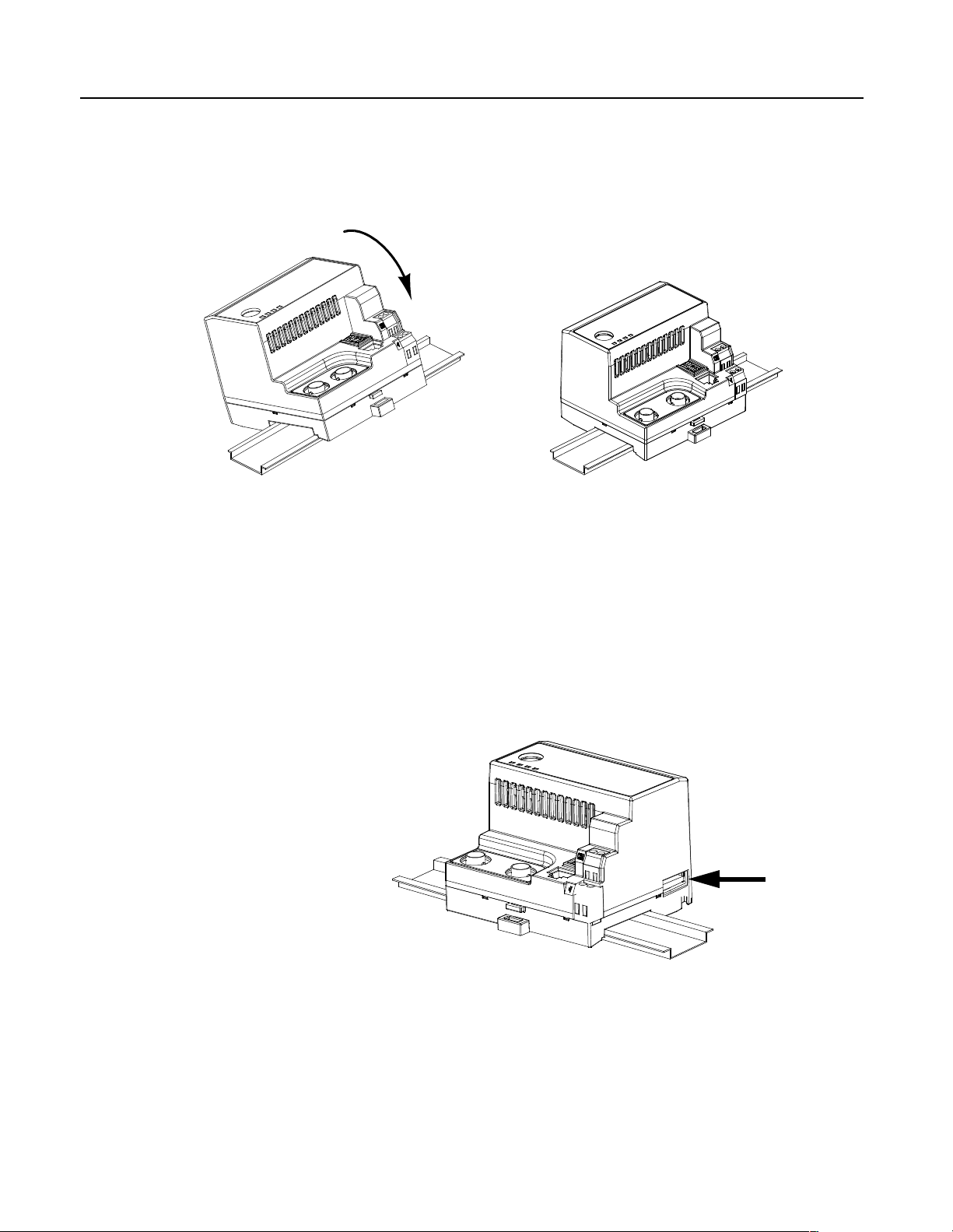

3. Hook the top lip of the module’s DIN rail mount onto the top of

the DIN rail and then rotate the module onto the DIN rail. You

will hear the module snap into a locked position.

Figure 2.2

Connecting the Module to the DIN Rail

4. Verify the module is correctly grounded to the DIN rail by using

an Ohm meter to measure between:

• DIN rail’s earth ground.

• Metal shell in the module’s RS-232 serial port.

If the reading is greater than 2 Ohms, you must reconnect the

module to the DIN rail, making sure it attaches securely.

Figure 2.3

Metal Shell of the Module’s RS-232 Serial Port

Publication 1203-5.13 – February, 2002

Page 26

2-6 Installation

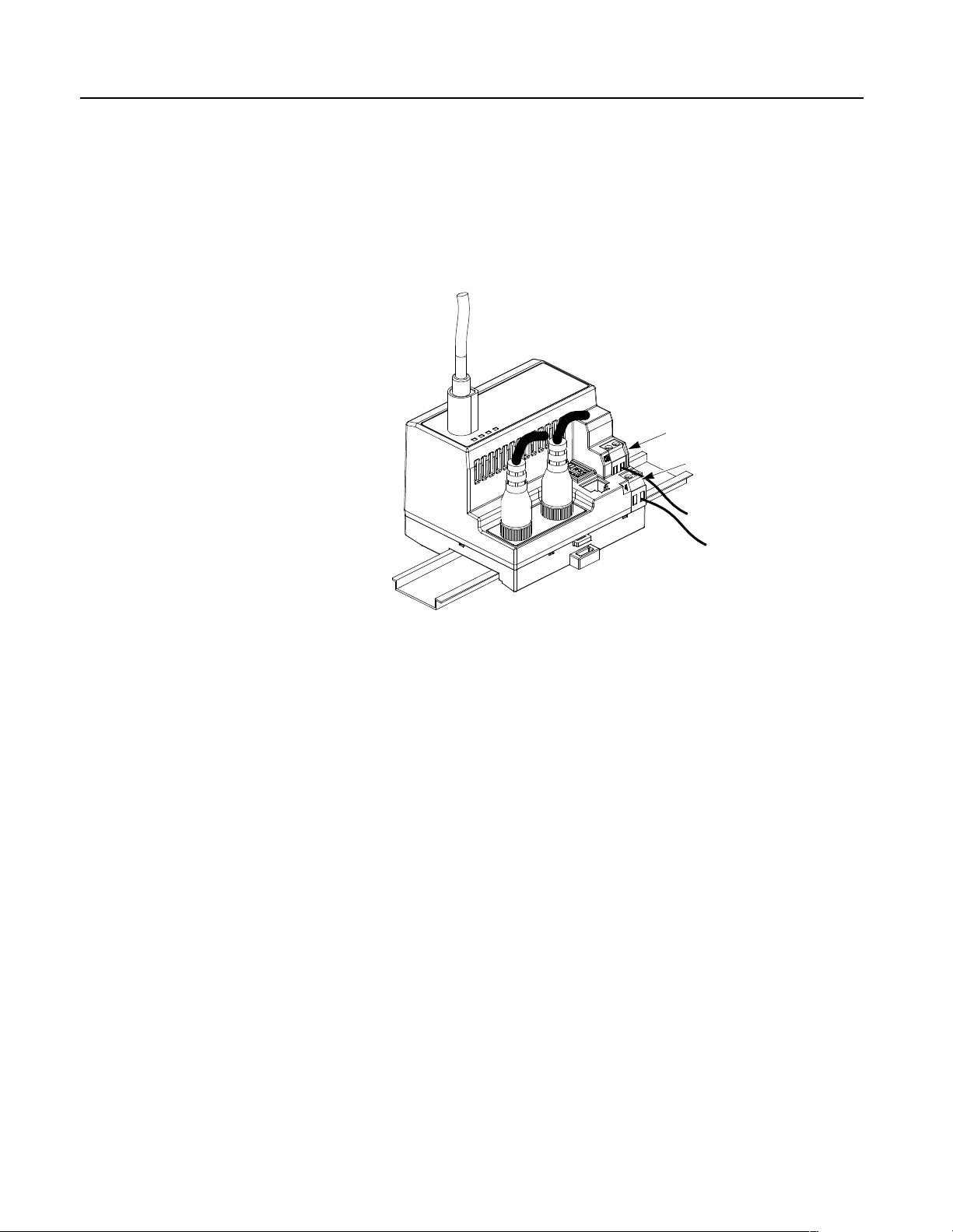

5. Connect the SCANport cable to the SCANport product and the

module.

To connect the cable to the module, align the pins on the cable

with the holes in the SCANport connection and then insert the

SCANport cable. The cable will click into a locked position.

Figure 2.4

Connecting the SCANport Cable to the Module

6. Connect the ControlNet cable tap(s) to the ControlNet media and

the module.

To connect the cable tap(s) to the module, twist each onto the

ControlNet Coax connection(s). You will hear the tap(s) click

into a locked position.

Important: Make sure you connect the Channel A cable to the

Channel A connection and the Channel B cable to the Channel B

connection.

Figure 2.5

Connecting a Straight ControlNet Tap to the Module

Publication 1203-5.13 – February, 2002

Page 27

Installation 2-7

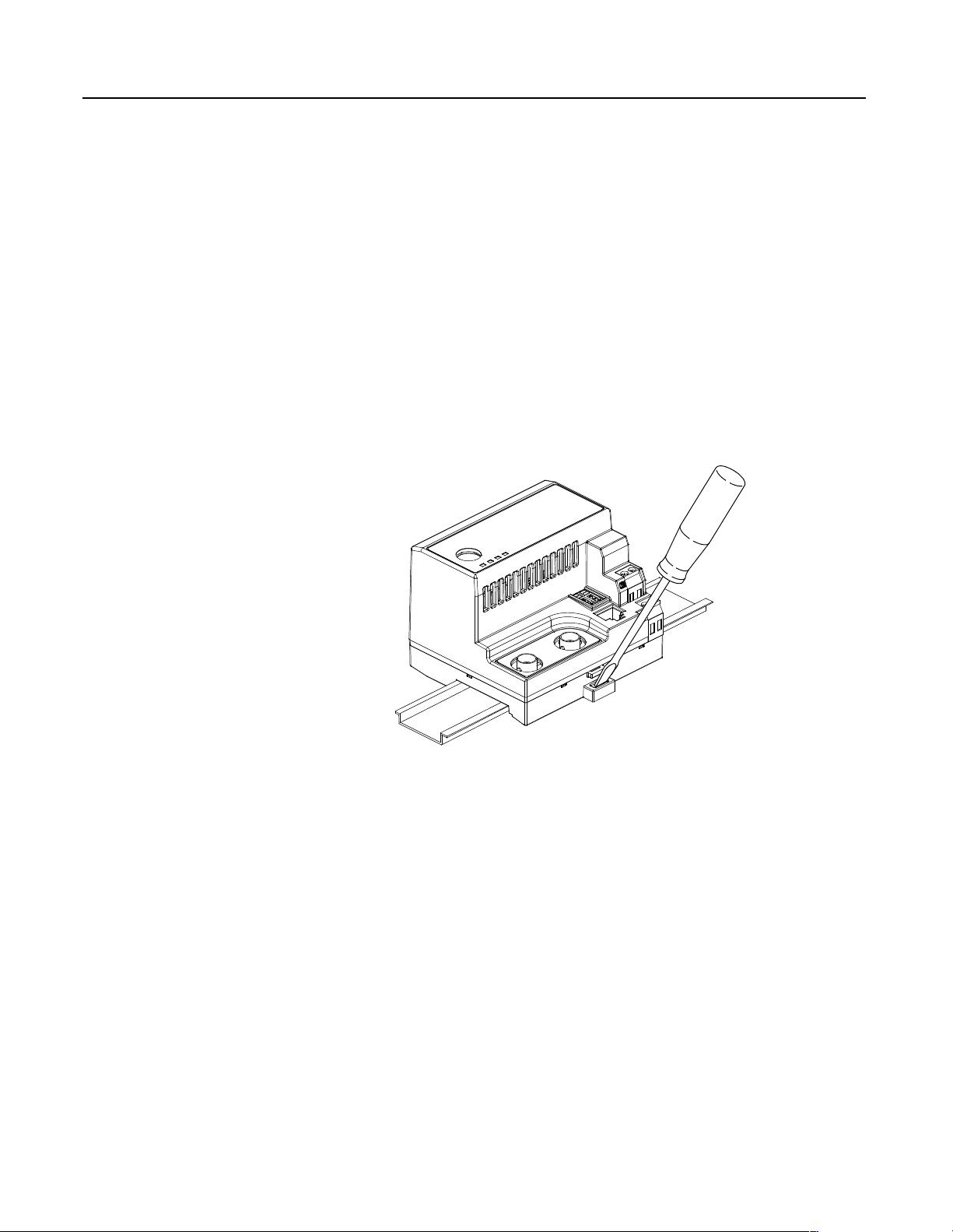

7. Connect a +24V power supply. If necessary, loosen the screw to

insert the power supply connection and then re-tighten the screw.

Important: You can use the two sets of holes to daisy chain the

power supply between multiple 1203-CN1 modules placed close

together.

Figure 2.6

Connecting the Power Supply to the Module

COMMON

+ 24 VDC

The module is now physically installed. Its SCANport and

ControlNet LEDs are solid green, and its Module LED is flashing

green. (If your module’s LEDs differ, refer to Chapter 7,

Troubleshooting, for troubleshooting information.)

The flashing green Module LED means that the module is not yet

able to provide an interface between the ControlNet network and the

SCANport product. For it to do so, you must:

1. Configure, if necessary, the module by editing its parameters.

Refer to Chapter 3, Getting Started.

2. Configure the controller on the ControlNet network to recognize

and communicate with the module. Refer to Chapter 4,

Configuring a Controller to Communicate with the 1203-CN1

Module.

3. If desired, write a PLC Ladder Logic program to control the

SCANport product. Refer to Chapter 5, PLC Ladder Logic

Programming.

Important: The 1203-CN1 ControlNet communications module will

not communicate over ControlNet without being connected to a

SCANport product which is powered and operational.

Publication 1203-5.13 – February, 2002

Page 28

2-8 Installation

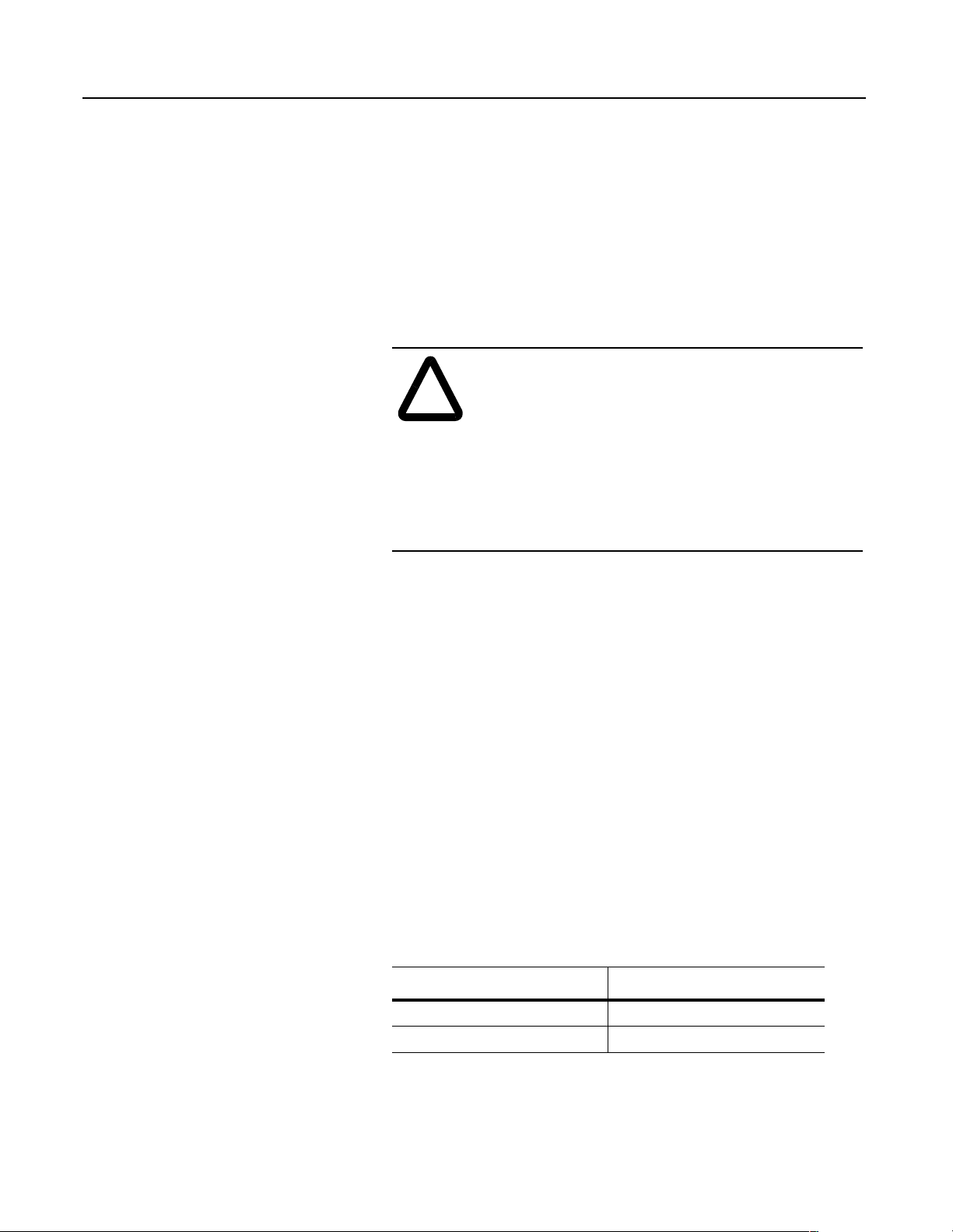

Removing the 1203-CN1 Module

If you want to remove the 1203-CN1 module, you need to:

Important: To guard against device malfunction, you must wear a

grounding wrist strap when removing the 1203-CN1 module.

1. Turn off the power supply to the module.

2. Disconnect all cables and the power supply from the module.

Important: To disconnect the SCANport cable, gently push in the

cable and then pull it out.

3. With a screw driver in the tab release, gently push its handle

towards the module to release the connection tab, and then pull

the module off of the DIN Rail.

Figure 2.7

Removing the Module from the DIN Rail

Publication 1203-5.13 – February, 2002

Page 29

Getting Started

Chapter

3

Chapter Objectives

Factory-Default Settings for the

1203-CN1 Module’s Parameters

Chapter 3 provides information that you need to configure the

1203-CN1 ControlNet Communications module. This includes:

• Information on the 1203-CN1 module’s default setting.

• Equipment needed to make a serial connection to the module.

• Instructions on how to connect a PC running terminal emulation

software or a VT100-compatible terminal to the module.

• Navigation techniques to use in the module’s software.

• Instructions for editing the module’s parameters.

• Instructions for displaying and clearing the module’s event queue.

• Instructions for displaying the modules I/O data.

• Instructions for displaying DF1 Protocol statistics.

• Instructions for viewing the module’s serial number.

• Instructions for performing a flash upgrade to the module.

The factory-default settings of the 1203-CN1 module enable the

following functions:

• 16-bit Logic Command/Status.

• 16-bit Reference/Feedback.

• If the PLC is put into program mode or the network fails, the

SCANport product will be faulted by the module.

• All datalinks are disabled.

• Baud rate is 9600.

If you wish to change any of these functions (e.g., Fault Configurable

inputs) or add more functions (e.g., datalinks), you must edit the

module’s parameters. To do so, refer to:

• Appendix B, 1203-CN1 Module Parameters, for detailed

information about each of the module’s parameters.

• Instructions in this chapter on establishing a serial connection.

• Instructions in this chapter on how to edit the parameters.

Publication 1203-5.13 – February, 2002

Page 30

3-2 Getting Started

Required Tools and Equipment

Electrostatic Discharge

Precautions

To make a serial connection to the module, you need the following:

• Grounding wrist strap.

• 1203-SFC serial cable.

• Either a PC running a Windows terminal emulation program

(e.g., HyperTerminal) or a VT100-compatible terminal.

Please read the following safety precautions carefully before making

a serial connection to the 1203-CN1 module

ATTENTION: The 1203-CN1 ControlNet

communications module contains ESD (Electrostatic

!

Discharge) sensitive parts. Static control precautions

are required when installing, testing, or servicing this

module. Device malfunction may occur if you do not

follow ESD control procedures. If you are not familiar

with static control procedures, refer to Allen-Bradley

publication 8000-4.5.2, Guarding Against Electrostatic

Damage, or other applicable ESD protection handbook.

.

Establishing a Serial Connection

with the 1203-CN1 Module

You must wear a grounding wrist strap that is properly grounded

when you handle the 1203-CN1 module.

The module’s software lets you do the following:

• Edit the module’s parameters.

• View its serial number.

• View its event queue.

• View its current I/O data.

• View DF1 statistics.

• Perform a flash upgrade.

To access its software, you must make a serial connection between the

module and either a PC running terminal emulation software or a

terminal. Refer to the following table:

If Using: Refer to Page

PC running terminal emulation software 3-3

VT100-compatible terminal 3-7

Publication 1203-5.13 – February, 2002

DriveExplorer (v.101 or higher) software can now also be used on

1203-CN1s that are v2.001 or higher. Do not use DriveExplorer

software with v1.xxx CN1s.

Page 31

Getting Started 3-3

Using a PC Running Terminal Emulation Software

A variety of terminal emulation programs can be used to establish a

serial connection to the module. The following instructions describe

how to establish the initial serial connection to the module using a PC

running Windows 95 HyperTerminal software. Future connections to

the module can use this same configuration by clicking the icon added

to the initial screen when the configuration is saved.

Important: If you are not using Windows 95 HyperTerminal, steps to

establish a serial connection may vary from the following steps.

1. Connect a 1203-SFC serial cable to your PC’s serial port and then

to the RS-232 serial port on the module.

Figure 3.1

Connecting the 1203-SFC Serial Cable to the Module’s RS-232 Serial Port

2. In the Start menu, select Programs, Accessories, and then

HyperTerminal. A HyperTerminal dialog box appears.

Figure 3.2

Example HyperTerminal Dialog Box

Publication 1203-5.13 – February, 2002

Page 32

3-4 Getting Started

3. Double-click HyperTrm.exe. The Connection Description

dialog box appears.

Figure 3.3

Example Connection Dialog Box

4. Enter a name in the Name field and select any icon in the Icon

field. In this example, we enter “1203-CN1” in the Name field.

5. Click OK. The Phone Number dialog box appears.

Figure 3.4

Example Phone Number Dialog Box

Publication 1203-5.13 – February, 2002

6. In the Connect Using field, select the appropriate

communications port (usually COM1 or COM2).

Page 33

Getting Started 3-5

7. Click OK. The Comm Properties dialog box appears.

Figure 3.5

Example Comm Properties Dialog Box

8. Select the following settings:

• 9600 in the Bits per second field.

If you have previously set the module’s Serial Port Rate

(Parameter 21) to enable 19200 bps, set the bps to 19200 in

this field.

• 8 in the Data bits field.

• None in the Parity field.

• 1 in the Stop bits field.

• None in the Flow Control field.

9. Click OK. A blank HyperTerminal screen appears.

Publication 1203-5.13 – February, 2002

Page 34

3-6 Getting Started

10. In the File menu, select Properties. The Properties dialog box

appears.

Figure 3.6

Properties Dialog Box

11. Click the Settings tab.

12. In the Function, arrow, and ctrl keys act as box, verify

Ter mi na l ke y s is selected.

13. In the Emulation field, verify VT100 is selected.

14. Click OK.

15. In the File menu, select Save. The configuration is saved and the

icon you selected will appear in the initial HyperTerminal

window next time you start HyperTerminal.

Figure 3.7

Example Initial HyperTerminal Window

Publication 1203-5.13 – February, 2002

Important: Next time you need to make a connection to the module,

double-click the icon just created. In Figure 3.7, double-clicking the

1203-CN1.ht icon would re-establish the connection to the module.

Page 35

Getting Started 3-7

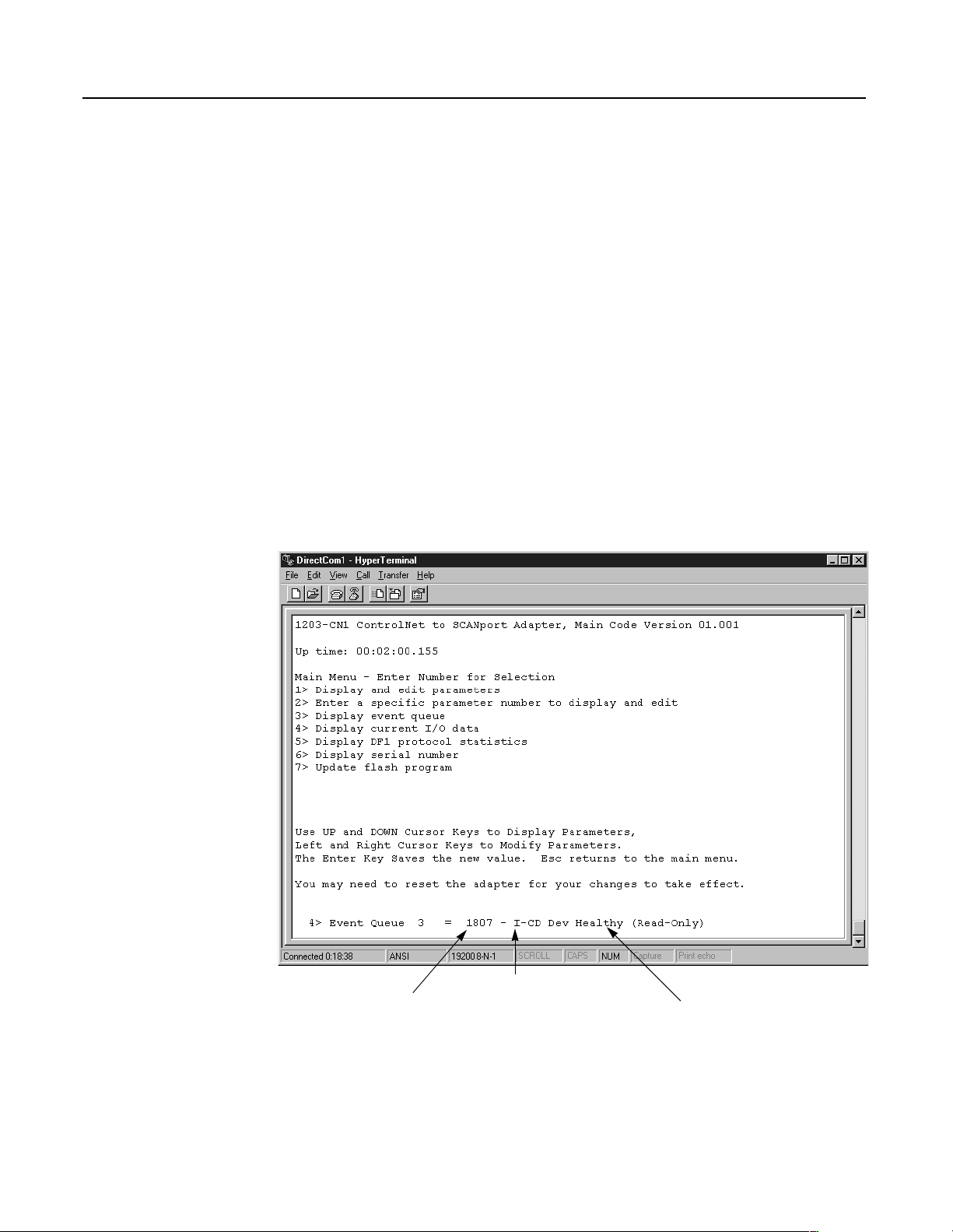

16. Press the Enter key. The main menu of the1203-CN1 ControlNet

to SCANport Adapter application appears.

Figure 3.8

Main Menu

You now have access to the module’s software. Go to the Navigation

Techniques section on page 3-8 for more information on using it.

Using a VT100-Compatible Terminal

Important: If you are using a PC, skip this section.

The following instructions describe how to establish a serial

connection to the module using a VT100-compatible terminal.

1. Connect a 1203-SFC serial cable to your terminal and then to the

RS-232 serial port on the module. Refer to Figure 3.1.

2. Start your terminal.

3. Select the following settings:

• 9600 in the Bits per second field.

If you have previously set the module’s Serial Port Rate

(Parameter 21) to enable 19200 bps, set the bps to 19200.

• 8 in the Data bits field.

• None in the Parity field.

• 1 in the Stop bits field.

• None in the Flow Control field.

Publication 1203-5.13 – February, 2002

Page 36

3-8 Getting Started

4. Press the Enter key. The main menu of the 1203-CN1 ControlNet

to SCANport Adapter application appears.

Refer to the Navigation Techniques section in this chapter for

information on navigating in the software.

Figure 3.9

Main Menu

Navigation Techniques

You now have access to the module’s software. Go to the Navigation

Techniques section on page 3-8 for more information on using it.

To perform any of the functions in the software (e.g., editing

parameters), you need to know the following navigation techniques:

Press: To

1, 2, 3, 4, 5, 6, 7, 8, 9, 0 Select an option in the Main Menu (1 – 5) or enter a value

for a parameter in the Parameter screen (0 – 9).

Escape Return to Main Menu or abort changes to a parameter.

Down Arrow View the next parameter.

Up Arrow View the previous parameter.

Right Arrow

Left Arrow

Enter Save a value for a parameter.

➀

In the

Fault Config Logic Command

navigate through the 16 bits.

View the next value for a parameter.

View the previous value for a parameter.

parameter (11), the right and left arrow keys let you

➀

➀

Publication 1203-5.13 – February, 2002

Page 37

Getting Started 3-9

Editing Parameters in the 1203-CN1

Module

The 1203-CN1 module has many configurable parameters. Refer to

Appendix B, 1203-CN1 Module Parameters, for a detailed list. If you

do not want to use the module’s default settings, edit its parameters.

Important: You may also edit parameters over the ControlNet

network using PCCC or emulated block transfer messages. Refer to

Chapter 6, Using Messages, for information on and examples of

messaging and refer to the appendixes for information needed to build

messages.

To edit parameters using a serial connection, you need to:

1. Establish a serial connection to access the module’s software.

Refer to the Establishing a Serial Connection with the 1203-CN1

Module section earlier in this chapter.

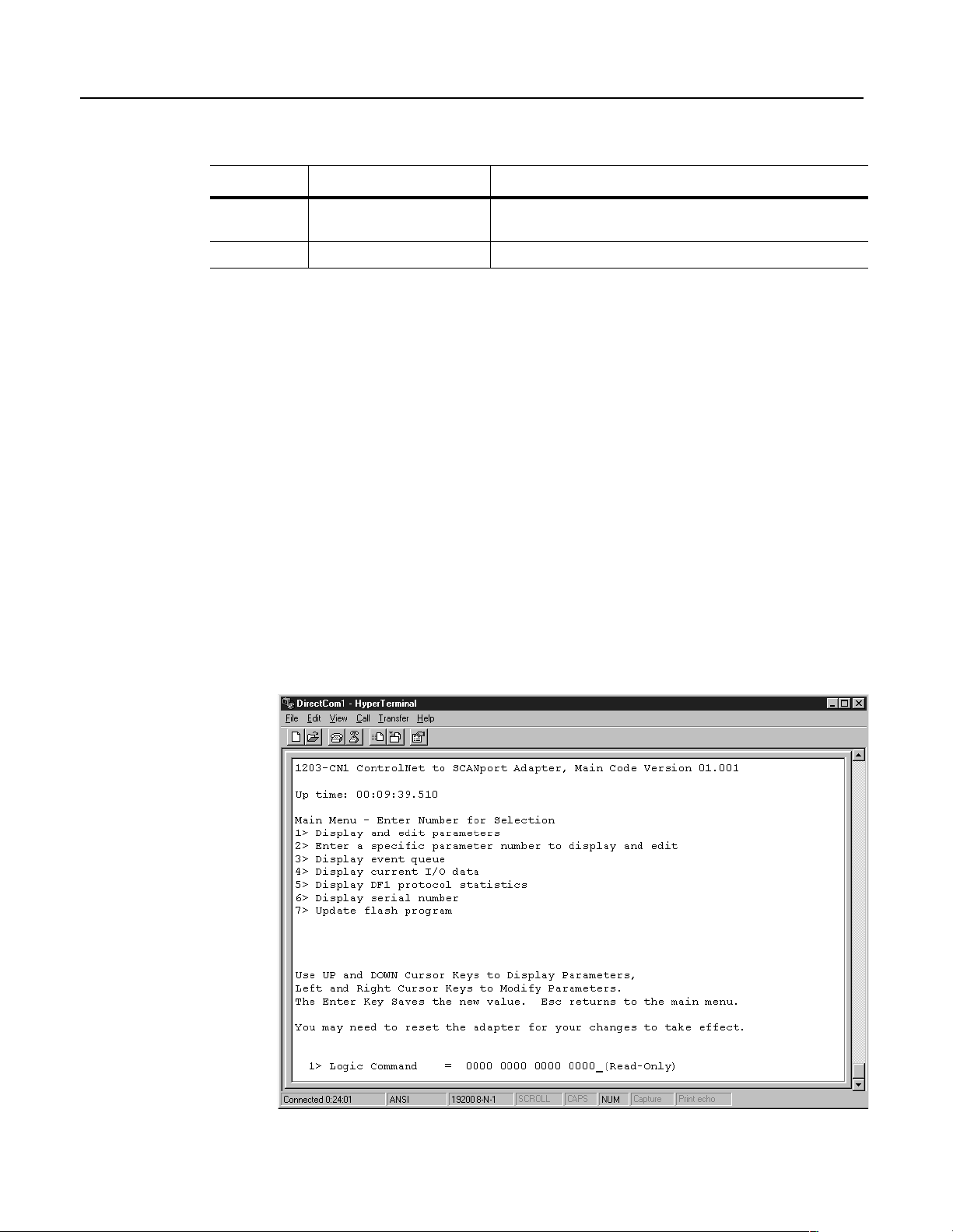

2. Press 1 to select 1> Display Parameters. The first parameter

appears on the bottom of the screen.

Figure 3.10

Example Display Parameters Screen

Important: If you know the number of the parameter you intend to

edit, press 2 to select 2> Enter Specific Parameter Number and

then enter the parameter number.

3. If necessary, scroll through the list of parameters by pressing the

Up Arrow or Down Arrow key.

Publication 1203-5.13 – February, 2002

Page 38

3-10 Getting Started

4. Edit parameters as necessary using the Left Arrow and Right

Arrow keys. Refer to Navigation Techniques earlier in this

chapter for information on changing values. Refer to Appendix B,

1203-CN1 Module Parameters, for valid values.

5. If necessary, reset power to the module by enabling the Reset

Adapter parameter (22). Refer to Appendix B, 1203-CN1 Module

Param et ers , to see if the parameter you changed requires the

module to be reset in order to take effect.

Displaying and Clearing the Event

Queue in the 1203-CN1 Module

If an unexpected problem occurs with the module, you may need to

check the event queue to view events that have happened in the

module. Follow these instructions:

1. Establish a serial connection to access the module’s software.

Refer to the Establishing a Serial Connection with the 1203-CN1

Module section earlier in this chapter.

2. Press 3 to select 3> Display event queue. The event queue

appears.

Figure 3.11

Example Event Queue

Publication 1203-5.13 – February, 2002

Internal

Fault ID

Level of Fault

I = information

W = warning

S = severe

F = fatal

Description

Page 39

Getting Started 3-11

3. Scroll through the list of Event Queue parameters by pressing the

Up Arrow or Down Arrow key.

Number Name Description

1 Clr Event Queue Enable = Clears the event queue.

Ready = Leaves the event queue as is.

2 – 33 Event Queue 1 – Event Queue 32 Event in the event queue. Most recent event is listed in Event Queue 1.

4. If desired, clear the current fault in the adapter by setting Clr

Event Queue (1) to Enable and pressing the Enter key.

Important: The Fault is cleared in the module and a “Clear Fault”

event is added to the Event Queue.

5. Press the Escape key to return to the main menu.

Displaying the 1203-CN1 module’s

Current I/O Data

You may need to do diagnostic testing to verify I/O data is passing

through the module. To view the I/O data transmitted through the

module, follow these instructions:

1. Establish a serial connection to access the module’s software.

Refer to the Establishing a Serial Connection with the 1203-CN1

Module section earlier in this chapter.

2. Press 4 to select 4> Display current I/O data. The I/O Data

screen appears.

Figure 3.12

Example I/O Data Screen

Publication 1203-5.13 – February, 2002

Page 40

3-12 Getting Started

Number Name Description

5 – 20 Data A1 In Val – Data D2 Out Val Data going to (Input) or coming from (Output) the SCANport device

3. Scroll through the list of I/O Data parameters by pressing the Up

Arrow or Down Arrow key.

1 Logic Command Buffer for Logic Command data

2 Logic Status Buffer for Logic Status data

3 Reference Data Buffer for Reference data

4 Feedback Data Buffer for Feedback data

4. Press the Escape key to return to the main menu.

Displaying the DF1 Protocol

Statistics in the 1203-CN1 Module

If you are working with DF1 communications, you may need to know

how the module is using DF1 communications. To view statistics on

DF1 communications, follow these directions:

1. Establish a serial connection to access the module’s software.

Refer to the Establishing a Serial Connection with the 1203-CN1

Module section earlier in this chapter.

2. Press 5 to select 5> Display DF1 protocol statistics. The DF1

Protocol screen appears.

Figure 3.13

Example DF1 Protocol Statistic

Publication 1203-5.13 – February, 2002

Page 41

Getting Started 3-13

3. Scroll through the list of DF1 statistic parameters by pressing the

Up Arrow or Down Arrow key.

Number Name Description

1 Clear DF1 Counts Ready = Accept default

Enable = Reset all status parameters

2 DF1 Packets Sent Total number of DF1 packets sent by the module

3 DF1 Packets Rcvd Total number of DF1 packets received by the module

4 Undelivered Msgs Total number of messages sent that were not acknowledged

5 ENQ Sent Total number of inquiries sent by the module

6 ENQ Rcvd Total number of inquiries received by the module

7 NAKs Received Total number of NAKs received by the module

8 NAK Bad Packet Total number of NAKs received by the module

9 NAK No Memory Total number of NAKs sent by the module because the previous

command did not yet complete and there was no place to save the new

command

10 Duplicate Msgs Total number of messages received by the module with the TNS number

4. If desired, reset the current DF1 protocol statistics by setting

Clear DF1 Counts to Enable and pressing the Enter key.

Viewing Your 1203-CN1 Module’s

Serial Number

5. Press the Escape key to return to the main menu.

Each 1203-CN1 module has a unique serial number. To view the

serial number, follow these instructions:

1. Establish a serial connection to access the module’s software.

Refer to the Establishing a Serial Connection with the 1203-CN1

Module section earlier in this chapter.

2. Press 6 to select 6> Display serial number. The serial number

for your communications module appears.

3. Press Escape to return to the Main Menu.

Publication 1203-5.13 – February, 2002

Page 42

3-14 Getting Started

Performing a Flash Upgrade to the

1203-CN1 Module

To upgrade the 1203-CN1 module’s flash firmware using the

module’s serial port, you need to perform a flash upgrade.

Important: To perform a flash upgrade to your module’s firmware,

you must use a PC running terminal emulation software.

Important: To exit the flash upgrade option before the download has

started, simultaneously press the Control and X keys.

ATTENTION: Exiting the flash upgrade procedure

once the download has begun can cause the module to

!

To perform a flash upgrade, you need to:

1. Obtain the software file that contains the upgrade and record its

location.

2. Establish a serial connection to access the module’s software.

Refer to the Establishing a Serial Connection with the 1203-CN1

Module section earlier in this chapter.

become inoperable. If the module becomes inoperable,

you must perform and complete a flash upgrade to fix

the module.

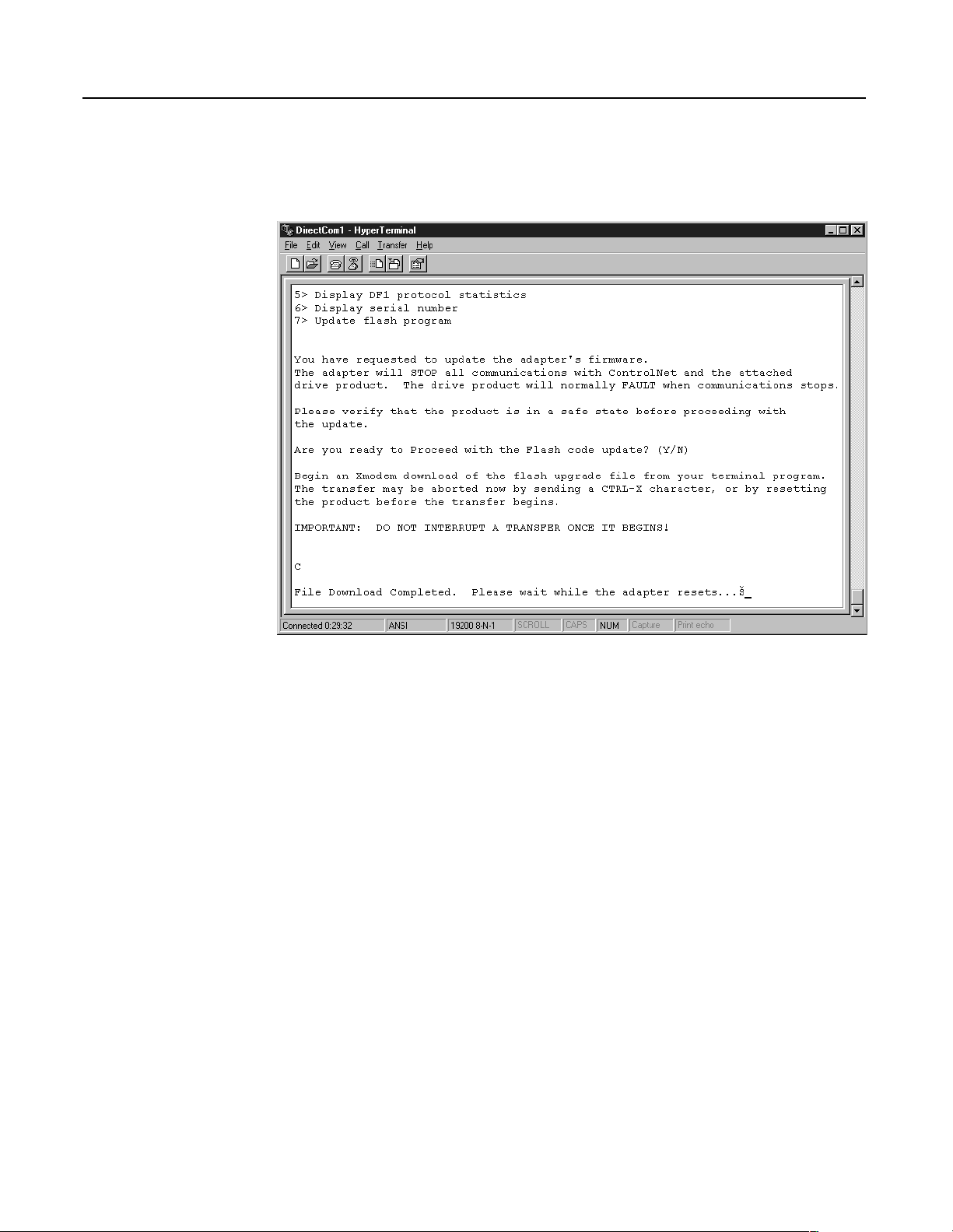

3. Press 7 to select 7> Update Flash Program. The following

screen appears.

ATTENTION: Hazard of personal injury or death

exists when stopping a drive to perform a flash upgrade.

!

When you perform a flash upgrade, the drive will fault

and stop the motor if the drive is receiving control data

from the 1203-CN1 module. Make sure the motor will

stop safely or the drive will receive control data from

an alternate source before beginning a flash upgrade.

Publication 1203-5.13 – February, 2002

Page 43

Figure 3.14

Initial Update Flash Program Screen

Getting Started 3-15

4. Press Y to verify that you want to perform a flash upgrade when

prompted.

5. In the Trans fer menu, select Send File. The Send File dialog

box appears.

Figure 3.15

Send File Dialog Box

6. In the Filename field, select the file that contains the flash

upgrade.

Important: You can click the Browse button to locate the file that

contains the flash upgrade.

7. In the Protocol field, select Xmodem.

Publication 1203-5.13 – February, 2002

Page 44

3-16 Getting Started

8. Click Send. A dialog box appears to report the flash is in

progress. When the flash is complete, a message appears to tell

you the download is complete and the module will reset itself.

Figure 3.16

Message Reporting the Flash Is Complete

The module resets itself, and then the Main menu appears. You must

clear the drive’s fault in order to restart the drive.

Publication 1203-5.13 – February, 2002

Page 45

Chapter

4

Configuring a Controller to Communicate

with the 1203-CN1 Module

Chapter Objectives

What is RSNetWorx?

Chapter 4 provides instructions for configuring your controller to

communicate with the 1203-CN1 ControlNet communications

module. This allows the product connected to the 1203-CN1 module

to be an active node on the ControlNet network. This chapter provides

information on:

•RSNetWorx.

• Equipment and software needed for the configuration.

• Configuring a controller to communicate with the 1203-CN1

module.

This chapter assumes you have experience using RSNetWorx to

configure a ControlNet network.

RSNetWorx for ControlNet is a 32-bit Windows application program

that lets you configure ControlNet networks. Using a graphical

representation of your network, you can configure network-wide

parameters and the network-wide schedule.

After installing and configuring the module, you must use

RSNetWorx to configure the controller to recognize and

communicate with the module.

Required Equipment and Software

For more information on RSNetWorx, refer to:

• Getting Results with RSNetWorx for ControlNet, Doc. ID

9399-CNETGR.

• Hardware Configuration Reference Guide, Doc. ID

9399-HDWAREREF.

• RSNetWorx online help.

Before configuring the controller, your PC must be:

• Running RSNetWorx and RSLinx applications. Refer to

http://www.software.rockwell.com for more information on these

products.

• Connected to and communicating with the ControlNet network

using a 1784-KTCX card, 1784-PCC card, or 1770-KFC adapter.

Publication 1203-5.13 – February, 2002

Page 46

4-2 Configuring a Controller to Communicate with the 1203-CN1 Module

Configuring a Controller to

Communicate with the 1203-CN1

Module

For the controller on the ControlNet network to transmit control I/O

and/or messages to the 1203-CN1 module, you must configure it to

recognize and communicate with the 1203-CN1 module.

These instructions describe how to use RSNetWorx to configure a

new ControlNet network in online mode. The main steps in the

configuration are:

• Using online mode in RSNetWorx.

• Mapping the 1203-CN1 module to the network.

• Verifying the network properties.

Important: RSNetWorx 1.6 and RSLinx 2.0.82 were used for these

instructions. If you are using other versions, you may notice

differences between these instructions and your screens.

Using Online Mode in RSNetWorx

It is easiest to configure the ControlNet network online because you

can view a graphical representation of your network in RSNetWorx.

Follow these instructions:

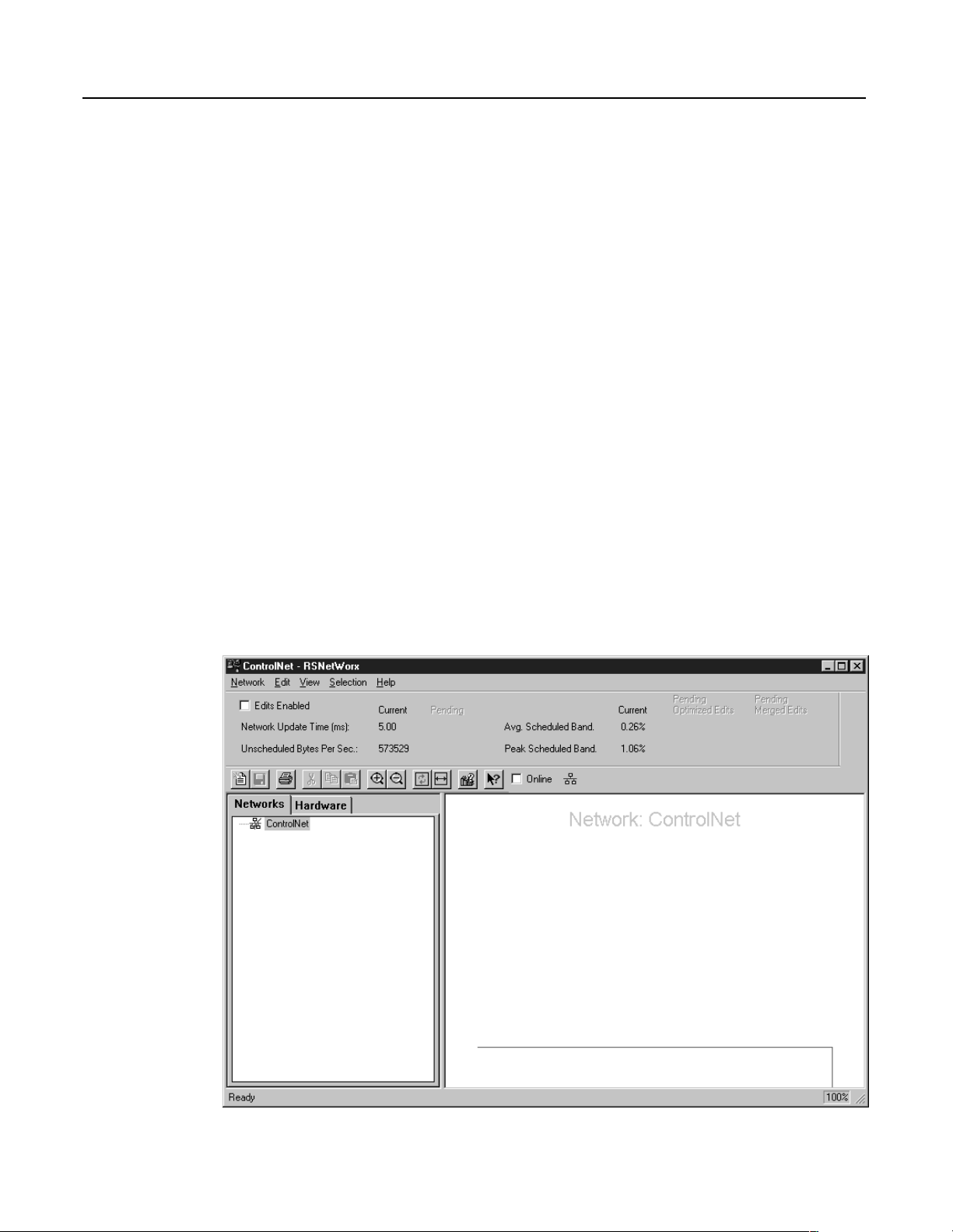

1. Start RSNetWorx. The RSNetWorx screen appears.

Figure 4.1

RSNetWorx Screen

Publication 1203-5.13 – February, 2002

Page 47

Configuring a Controller to Communicate with the 1203-CN1 Module 4-3

2. Click the Online box. RSLinx starts in the background to provide

a communications interface and then the Browse for Network

dialog box appears.

Figure 4.2

Example Browse for Network Dialog Box

3. If available, click the Autobrowse box.

4. If necessary, click the plus sign to view the available networks.

Figure 4.3

Example Browse for Network Dialog Box with Available Networks Displayed

Publication 1203-5.13 – February, 2002

Page 48

4-4 Configuring a Controller to Communicate with the 1203-CN1 Module

5. Select your ControlNet network and click OK. A graphical

representation of your network appears.

Figure 4.4

Example Network Displayed in RSNetWorx

Publication 1203-5.13 – February, 2002

Important: Note the following about our example:

• In Figure 4.4, Node 1 is the controller (PLC-5), Node 4 is the

SCANport product to which the 1203-CN1 module is

connected, and Node 20 is the PC we are using to configure

the network.

• The 1203-CN1 module is transparent on the ControlNet

network, so an icon for the SCANport product connected to it

is displayed in RSNetWorx. In our example, we used a 1305

drive and set the node address on the 1203-CN1 module to

Node 4.

• Above the icons are plus flags that indicate the devices are

not configured for the network.

Page 49

Configuring a Controller to Communicate with the 1203-CN1 Module 4-5

6. In the Network menu, select Actions and then Configurations

List. The ControlNet Configuration dialog box appears.

Figure 4.5

Example ControlNet Configuration Dialog Box

7. Identify the device(s) that need(s) to be mapped to the network.

The Current Configuration list (blank in Figure 4.5) shows the

devices configured on the ControlNet network. The Network

Configuration list shows devices on the network. Because we are

creating a new ControlNet network from scratch in our example,

no devices are currently configured. Your network may already

have devices configured on it.

The only device that we will need to map to the network is the

1203-CN1 module. The other devices (PLC-5/40

®

) and

(1784-KTCX) do not need to be configured on the network.

8. Click OK to close the dialog box. The RSNetWorx screen

reappears.

You are now in online mode and know which device(s) need to be