Roberts Gorden CTCU, CTCU 11, CTCU 15, CTCU 27, CTCU 22 User Manual

...

FOR YOUR SAFETY |

|

|

|

||||

If you smell gas: |

|

|

® |

||||

|

|

||||||

1. |

Open windows. |

|

|

||||

2. |

DO NOT try to light any appliance. |

|

|

||||

3. |

DO NOT use electrical switches. |

|

C |

mbat |

|||

4. |

DO NOT use any telephone in |

|

|||||

|

your building. |

|

|||||

5. |

Leave the building. |

|

|||||

6. |

Immediately call your local gas |

|

|||||

|

Follow the gas supplier’s |

Compact Tubular Unit Heaters |

|||||

|

supplier after leaving the building. |

|

|

|

|||

|

instructions. |

Installation, Commissioning, |

|||||

7. |

If you cannot reach your gas |

||||||

|

|

|

|||||

|

supplier, call the Fire Department. |

Operation & Service Manual |

|||||

|

|

|

|

||||

|

|

|

|

||||

|

WARNING |

||||||

|

|

|

Models CTCU 7 |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

CTCU 11 |

|

|

|

|

|

|

|

CTCU 15 |

|

|

|

|

|

|

|

CTCU 22 |

|

|

|

|

|

|

|

||

|

Fire Hazard |

|

|

CTCU 27 |

|||

|

|

|

CTCU 32 |

||||

Do not store or use petrol or other |

|

|

|||||

flammable vapours and liquids in the |

|

|

|

||||

vicinity of this or any other appliance. |

|

|

|

||||

Some objects will catch fire or explode |

|

|

|

||||

when placed close to heater. |

|

|

|

||||

Failure to follow these instructions can |

|

|

|

||||

result in death, injury or property |

|

|

|

||||

damage. |

|

|

|

||||

|

|

|

|

|

|

|

|

WARNING |

|

|

Installer |

||

|

|

|

|||

|

|

|

|

|

|

|

|

|

Please take the time to read and understand |

||

Improper installation, adjustment, alteration, service |

|||||

|

|

these instructions prior to any installation. |

|||

or maintenance can result in death, injury or property |

|

|

|||

|

|

Installer must give a copy of this manual to the owner. |

|||

damage. Read the installation, operation and service |

|

|

|||

|

|

|

|

||

manual thoroughly before installing or servicing |

|

|

Owner |

||

this equipment. |

|

|

|||

|

|

|

|

||

|

|

Keep this manual in a safe place in order to provide |

|||

|

|

|

|||

|

|||||

Installation must be done by a registered installer/ |

|||||

|

|

your serviceman with necessary information. |

|||

contractor qualified in the installation and service |

|

|

|

|

|

of gas-fired heating equipment or your gas supplier. |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Roberts-Gordon Europe Limited |

|

Oxford Street |

|

Bilston, West Midlands WV14 7EG UK |

|

Telephone: +44(0) 1902 494425 |

|

Fax: +44(0) 1902 403200 |

|

Service Telephone: +44(0) 1902 498733 |

|

Service Fax: +44(0) 1902 401464 |

|

E-mail: uksales@rg-inc.com |

|

E-mail: export@rg-inc.com |

Quality in Any Language™ |

www.rg-inc.com |

|

|

© Copyright 2006 Roberts-Gordon, LLC |

P/N 111100UK Rev B 10/06 |

TABLE OF CONTENTS

SECTION 1: Heater Safety...................................................... |

2 |

SECTION 13: Conversion Between Gases .......................... |

21 |

||

SECTION 2: Installer Responsibility ..................................... |

2 |

13.1 |

General .................................................................... |

21 |

|

2.1 |

Clearances to Combustibles ........................................ |

2 |

13.2 |

Burner Conversion ................................................... |

21 |

2.2 |

Corrosive Chemicals.................................................... |

2 |

13.3 |

Gas Valves ............................................................... |

21 |

2.3 |

National Standards and Applicable Codes .................. |

2 |

SECTION 14: Troubleshooting ............................................. |

22 |

|

SECTION 3: Critical Considerations ..................................... |

3 |

14.1 |

General .................................................................... |

22 |

|

3.1 |

Basic Information ......................................................... |

3 |

14.2 |

Troubleshooting For Automatic Ignition |

|

3.2 |

Location and Suspension ............................................ |

3 |

|

Burner Systems ....................................................... |

23 |

3.3 |

Minimum Required Installation Clearances ................. |

3 |

14.3 |

Troubleshooting for Flame Supervision System ....... |

24 |

3.4 |

Clearances to Combustibles ........................................ |

3 |

14.4 |

Troubleshooting for Solenoid Valves ........................ |

25 |

3.5 |

Ventilation .................................................................... |

3 |

14.5 |

Troubleshooting for Main Fan ................................... |

25 |

3.6 |

Gas Supply .................................................................. |

3 |

SECTION 15: Removal and Replacement Parts.................. |

26 |

|

3.7 |

Electrical Supply .......................................................... |

3 |

15.1 |

Gas Valve ................................................................. |

26 |

3.8 |

Flue.............................................................................. |

3 |

15.2 |

Burner Compartment ............................................... |

27 |

SECTION 4: Specifications .................................................... |

5 |

15.3 |

Ignition Electrode and Flame Probe ......................... |

28 |

|

4.1 |

CTCUA (All Models) .................................................... |

5 |

15.4 |

Flue Fan Vertical Installation .................................... |

29 |

4.2 |

General Technical Data Table (All Models) .................. |

6 |

15.5 |

Pressure Switch........................................................ |

30 |

4.3 |

Technical Data Table (All Models)................................ |

6 |

15.6 |

Ignition Control ......................................................... |

31 |

SECTION 5: Heater Installation.............................................. |

7 |

15.7 |

CTCUA Axial Fan/Guard/Motor Assembly ............... |

31 |

|

5.1 |

General ........................................................................ |

7 |

15.8 |

Fan and Limit Thermostats ...................................... |

31 |

5.2 |

Shelf Mounting and Suspension .................................. |

7 |

|

|

|

5.3 |

Wall Mounting .............................................................. |

7 |

|

|

|

SECTION 6: Flue Installation ................................................. |

9 |

|

|

|

|

6.1 |

Changing Flue and Air Intake Orientation.................... |

9 |

|

|

|

6.2 |

Flue Installation............................................................ |

9 |

|

|

|

6.3 |

Type C12, C32 & C62 Appliance ...................................... |

9 |

|

|

|

6.4 |

Type B22 Appliance....................................................... |

9 |

|

|

|

SECTION 7: Air Supply......................................................... |

11 |

|

|

|

|

7.1 Room Sealed Installation ........................................... |

11 |

|

|

|

|

7.2 Open Flued Installation .............................................. |

11 |

|

|

|

|

7.3 Building Ventilation ..................................................... |

11 |

|

|

|

|

SECTION 8: Gas Piping........................................................ |

12 |

|

|

|

|

8.1 |

Connections............................................................... |

12 |

|

|

|

SECTION 9: Wiring and Electrical Information................... |

13 |

|

|

|

|

9.1 |

Electrical Supply ........................................................ |

13 |

|

|

|

9.2 |

Remote Controls ........................................................ |

13 |

|

|

|

9.3 |

CTCUA Wiring Diagram Models 7 - 32 ...................... |

14 |

|

|

|

SECTION 10: Commissioning.............................................. |

15 |

|

|

|

|

10.1 Pre-Commission Checks.......................................... |

15 |

|

|

|

|

10.2 Begin Commissioning .............................................. |

15 |

|

|

|

|

10.3 Complete the Commissioning .................................. |

17 |

|

|

|

|

SECTION 11: User Instructions............................................ |

18 |

|

|

|

|

11.1 User Instructions....................................................... |

18 |

|

|

|

|

11.2 Heater Operation ...................................................... |

18 |

|

|

|

|

11.3 Common User Controls ............................................ |

18 |

|

|

|

|

11.4 Lighting Instructions.................................................. |

18 |

|

|

|

|

11.5 Simple Fault Finding ................................................. |

19 |

|

|

|

|

SECTION 12: Servicing......................................................... |

20 |

|

|

|

|

12.1 Servicing Instructions .............................................. |

20 |

|

|

|

|

12.2 Burner Maintenance ................................................ |

20 |

|

|

|

|

12.3 Fan/Motor Assembly Maintenance........................... |

20 |

|

|

|

|

12.4 Heat Exchanger Maintenance.................................. |

20 |

|

|

|

|

12.5 Gas Control Valve Maintenance............................... |

20 |

|

|

|

|

12.6 Flue Fan................................................................... |

20 |

|

|

|

|

© 2006 Roberts-Gordon, LLC

All rights reserved. No part of this work covered by the copyrights herein may be reproduced or copied in any form or by any means - graphic, electronic, or mechanical, including photocopying, recording, taping or information storage and retrieval systems - without the written permission of Roberts-Gordon, LLC.

Printed in U.S.A.

TABLE OF FIGURES |

|

Figure 1: Installation Clearances and Clearances to |

|

Combustibles.............................................................. |

4 |

Figure 2: Suspension Methods ................................................. |

7 |

Figure 3: Shelf Mounting and Hanging Suspension.................. |

8 |

Figure 4: Vertical Louvres (Optional) ........................................ |

8 |

Figure 5: Flue and Roof Detail .................................................. |

9 |

Figure 6: Vertical and Horizontal Flue Termination - |

|

Type B22 Appliance ................................................... |

10 |

Figure 7: Vertical and Horizontal Flue Termination - |

|

Type C12 C32 & C62 Appliances.................................. |

10 |

Figure 8: Gas Connection with Stainless Steel |

|

Flex Connector ......................................................... |

12 |

Figure 9: Automatic Burner Control Box Sequence ................ |

16 |

Figure 10: Gas Valve for Heater Models 7 - 32 ....................... |

16 |

Figure 11: Heater Operating Sequence................................... |

18 |

COMBAT® Compact Tubular Unit Heaters are high efficiency heaters and are listed on the Enhanced Capital Allowance Scheme ’Energy Technology Product List’. The ETL symbol is a UK registered certification mark of The Carbon Trust.

Product Approval

ROBERTS GORDON® appliances have been tested and CE certified as complying with the essential requirements of the Gas Appliance Directive, the Low Voltage Directive, the Electromagnetic Compatibility Directive and the Machinery Directive for use on natural gas and LPG when installed, commissioned and maintained in accordance with these instructions.

These instructions refer to appliances designed to operate in the European Union. Appliances designed for other countries (non European Union) are available on request.

This appliance must be installed in accordance with the local and national codes in force and used only in a sufficiently ventilated space, as specified in these instructions.

Before installation, check that the local gas distribution systems, nature of gas and pressure, and adjustment of the appliance are compatible.

1

COMBAT® CTCU UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 1: HEATER SAFETY

Your Safety is Important to Us! This symbol is used throughout the manual to notify you of possible fire,

electrical or burn hazards. Please pay special attention when reading and following the warnings in these sections.

Installation, service and annual inspection of heater must be done by a registered installer/contractor qualified in the installation and service of gas-fired heating equipment.

Read this manual carefully before installation, operation, or service of this equipment.

This heater is designed for heating non-residential indoor spaces. Do not install in residential spaces. These instructions, the layout drawing, local codes and ordinances and applicable standards that apply to gas piping, electrical wiring, venting, etc. must be thoroughly understood before proceeding with the installation.

SECTION 2: INSTALLER RESPONSIBILITY

•To install the heater, as well as the gas and electrical supplies, in accordance with applicable specifications and codes. Roberts-Gordon recommends the installer contact a local building inspector, Fire Officer or insurance company for guidance.

•To use the information given in the manual together with the local and national codes to perform the installation.

•To install the heater in accordance with the clearances to combustibles of this heater.

•To furnish all needed materials not furnished

as standard equipment.

•To plan location of supports, flues and air intakes.

•To provide access to burners for servicing.

•To provide the owner with a copy of this Installation, Commissioning, Operation and Service Manual.

•To never use heater as support for ladder or other access equipment and never hang or suspend anything from heater.

•To ensure that there is sufficient ventilation in the area to comply with the requirements of

all relevant local and national codes.

2.1 Clearances to Combustibles

In all situations, clearances to combustibles must be maintained. Caution must be used when running the heater near combustible materials such as wood, paper, rubber, etc. A wall tag is on the back cover of this manual as a permanent reminder of the safety instructions and the importance of the required

clearances to combustibles. Affix the tag on a wall near the heater.

2.2 Corrosive Chemicals

CAUTION

CAUTION

Do not use heater in an area containing corrosive chemicals.

Corrosive chemicals will damage the burner and heat exchanger parts.

Failure to follow these instructions can result in property damage.

Roberts-Gordon cannot be responsible for ensuring that all appropriate safety measures are undertaken prior to installation; this is entirely the responsibility of the installer. It is essential that the contractor, the sub-contractor, or the owner identifies the presence of combustible materials, corrosive chemicals or halogenated hydrocarbons* anywhere in the premises.

* Halogenated Hydrocarbons are a family of chemical compounds characterized by the presence of halogen elements (fluorine, chlorine, bromine, etc.). These compounds are frequently used in refrigerants, cleaning agents, solvents, etc. If these compounds enter the air supply of the burner, the lifespan of the heater components will be greatly reduced. Warranty will be invalid if the heater is exposed to halogenated hydrocarbons.

2.3 National Standards and Applicable Codes

All appliances must be installed in accordance with the latest revision of applicable standards and local and national codes. This refers also to the electric, gas and venting installation. Note: Additional standards for installations in public garages, aircraft hangars, etc. may be applicable.

2

SECTION 3: CRITICAL CONSIDERATIONS

SECTION 3: CRITICAL CONSIDERATIONS 3.1 Basic Information

CTCU heaters have automatic ignition burners for ON/OFF operation only.

3.2 Location and Suspension

All models:

•Must be installed indoors.

•Must be installed in a level position with horizontal or vertical discharge.

•May be mounted on a shelf of non-combustible material. (See Page 5, Section 4 and Page 7, Figure 2 for support points.)

•May be suspended from above (See Page 7, Figure 2) or from wall brackets of sufficient strength to support the heater as listed in the Dimension Data Table on Page 5, Section 4.1. Drop rods must be a minimum of 10 mm diameter mild steel. Four suspension points (M10 nuts) are located on top and back side of the heater.

•Must be installed in a manner which allows access to all serviceable components.

3.8 Flue

Choose heater siting to allow for the proper location of the flue. Each heater must be fitted with an individual and correctly sized sealed flue system (See Page 9, Section 6).

No other appliance may be connected to the flue. For room sealed installation, the air intake must be the same size sealed system and the flue/air intake must terminate at an approved concentric wall or roof terminal.

3.3 Minimum Required Installation Clearances

Clearances around the heater and flue must be as indicated on Page 4, Figure 1; Page 9, Figure 5 through Page 10, Figure 7 to ensure access for servicing, and correct operation.

3.4 Clearances to Combustibles

Clearances must be as indicated on Page 4, Figure 1. If clearances to combustibles are not indicated, then installation clearances apply.

3.5 Ventilation

It is important to ensure that there is adequate air circulation around the heater to supply air for combustion, ventilation and distribution in accordance with local and national codes.

3.6 Gas Supply

It is important that the gas supply pipe is sized correctly to provide the inlet pressure as stated on the heater data plate. The gas supply pipe and electrical connections must not support any of the heater's weight.

3.7 Electrical Supply

A permanent 230 V 50 Hz 1 Ø electrical supply is required at the main electrical terminals. The heater also requires suitable energy controls in accordance with Section 9.

3

COMBAT® CTCU UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

WARNING

WARNING

Fire Hazard

Some objects will catch fire or explode when placed close to heater.

Keep all flammable objects, liquids and vapours the required distance away from the heater.

Failure to follow these instructions can result in death, injury or property damage.

Figure 1: Installation Clearances and Clearances to Combustibles

|

|

|

Clearances to Combustibles |

Installation Clearances |

|

||

|

Roof Terminal |

||

Roof Terminal |

|

||

|

|

||

Air |

|

|

15 cm |

|

15 cm |

|

|

Intake |

|

|

|

|

|

50 cm** |

10 cm |

Wall |

Flue |

3 m |

|

|

|

|

|

Terminal 25 cm |

|

30 cm |

|

|

|

|

|

|

|

3 m |

|

|

|

2.5 - 3.5 m* |

|

* Heaters may be mounted at a higher level if destratification |

**80 cm is necessary to service |

fans are installed. |

heater. |

The heater must always be installed at least 1.8 m above the floor.

The flue pipe must have clearance from combustibles by 5 cm.

If installed at low levels where individuals can come in contact with hot heat exchanger components, adequate guarding must be provided.

All distances are minimum clearance requirements for service access, air flow and safety.

4

SECTION 4: SPECIFICATIONS

SECTION 4: SPECIFICATIONS

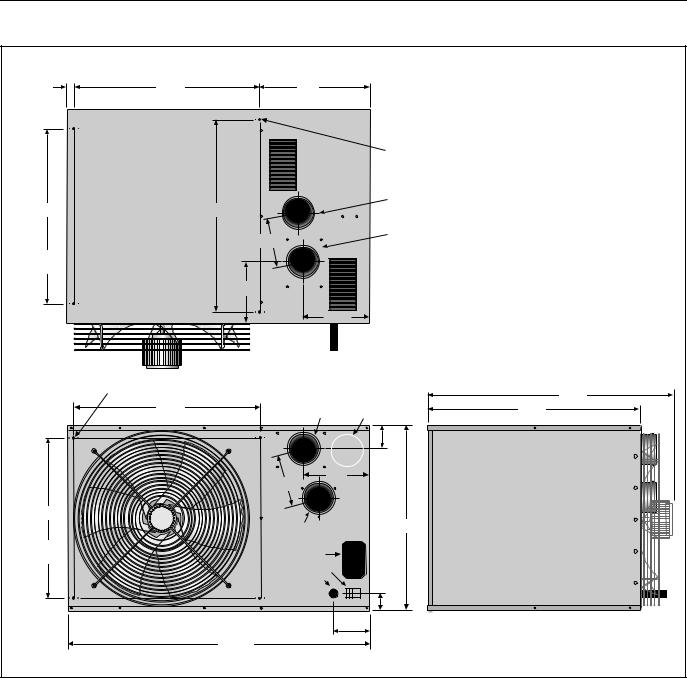

4.1 CTCUA (All Models)

Top View |

|

|

|

|

|

14 |

448 |

265 |

|

|

|

|

|

|

|

4 x M10 Captive Nuts Provided |

|

|

|

|

|

Air Intake |

|

422 |

463 |

|

|

(Optional Position) |

|

|

120 |

|

|

Flue |

|

|

|

|

(Optional Position) |

|

|

Mounting |

|

|

|

|

|

Holes |

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

171 |

|

|

Rear View |

4 x M10 Captive Nuts Provided |

|

|

End View |

660 |

|

448 |

Flue |

Air Intake |

514 |

|

|

on Model 22 |

||||

|

|

|

|

D |

|

|

120 |

171 |

|

||

|

|

* |

|

|

|

B |

|

|

|

A |

|

|

|

Air Intake |

|

||

Mounting |

|

Electrical |

|

|

|

Holes |

|

Connection |

|

|

|

|

|

Lockout Reset |

|

|

|

|

|

Gas Supply |

|

|

|

|

|

|

|

45 |

|

|

|

|

|

85 |

|

|

728 |

|

|

|

|

* 140 for 27 - 32 |

|

|

|

|

|

Dimension Data - CTCUA (All Models)

|

|

Model |

CTCU-7 |

CTCU-11 |

CTCU-15 |

CTCU-22 |

CTCU-27 / 32 |

|

|

|

|

|

|

|

|

A |

Height |

mm |

304 |

304 |

450 |

450 |

578 |

(in) |

(12.0) |

(12.0) |

(17.7) |

(17.7) |

(22.8) |

||

B |

Mounting Hole Spacing |

mm |

239 |

239 |

385 |

385 |

513 |

(in) |

(9.4) |

(9.4) |

(15.2) |

(15.2) |

(20.2) |

||

C |

Centre of Flue (Top Option) |

mm |

151 |

151 |

151 |

172 |

149 |

(in) |

(5.9) |

(5.9) |

(5.9) |

(6.8) |

(5.9) |

||

D |

Centre of Flue |

mm |

68 |

68 |

68 |

46 |

59 |

(in) |

(2.7) |

(2.7) |

(2.7) |

(1.8) |

(2.3) |

||

|

|

|

|

|

|

|

|

|

Weight |

kg |

28 |

30.5 |

38.5 |

41 |

52.3 |

|

|

|

|

|

|

|

|

5

COMBAT® CTCU UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

4.2 General Technical Data Table (All Models)

|

Model |

CTCU-7 |

CTCU-11 |

CTCU-15 |

CTCU-22 |

CTCU-27 / 32 |

|

|

|

|

|

|

|

CTCUA, Axial Fans |

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Electrical Load |

W |

260 |

274 |

336 |

384 |

345 |

|

|

|

|

|

|

|

Run Current |

A |

1.1 |

1.2 |

1.5 |

1.7 |

1.5 |

|

|

|

|

|

|

|

Start Current |

A |

1.7 |

1.8 |

2.5 |

2.9 |

2.6 |

|

|

|

|

|

|

|

Air Flow |

m3/h |

1120 |

1220 |

2710 |

2750 |

4474 |

|

|

|

|

|

|

|

|

[NR] |

[31] |

[35] |

[39] |

[42] |

[42] |

Sound Pressure Level at 3 m |

dB(A) |

37 |

41 |

45 |

48 |

48 |

|

|

|

|

|

|

|

Flue and AIr Intake |

|

|

|

|

|

|

|

|

|

|

|

|

|

Flue and Air Intake Size |

mm Ø |

80 |

80 |

80 |

80 |

100 |

|

|

|

|

|

|

|

*Maximum Straight Flue/Air Intake |

m |

2.5 |

4 |

5 |

5 |

5 |

|

|

|

|

|

|

|

Electrical load at 230 V 50 Hz measured by calculating from total run current of appliance.

* Do not exceed the maximum length of flue stated or heater may not operate properly. Reduce the maximum length stated by 1 m for each 90° bend installed.

**If minimum air flow requirements are not met, then temperature limit devices will shut down the heater.

4.3 Technical Data Table (All Models)

Appliance Category II 2H/L 3B/P

|

Model |

CTCU-7 |

CTCU-11 |

CTCU-15 |

CTCU-22 |

CTCU-27 |

CTCU-32 |

|

|

|

|

|

|

|

|

Heat Input |

kW |

8.5 |

13.4 |

18.3 |

27.5 |

33 |

38.5 |

Gross CV |

(Btu/h) x (1000) |

29 |

46 |

62 |

94 |

113 |

131 |

|

|

|

|

|

|

|

|

Heat Input |

kW |

7.7 |

12.1 |

16.5 |

24.8 |

29.7 |

34.7 |

Net CV |

(Btu/h) x (1000) |

26 |

41 |

56 |

85 |

101 |

118 |

|

|

|

|

|

|

|

|

Approximate |

kW |

7.1 |

11.1 |

15.1 |

23 |

27.2 |

31.7 |

Heat Output |

(Btu/h) x (1000) |

24 |

38 |

52 |

78 |

93 |

108 |

|

|

|

|

|

|

|

|

Natural Gas (G20) Data - Inlet Pressure 20 mbar (7.8 in WG) Min. 17 mbar (6.8 in WG) Max. 25 mbar (10 in WG) |

|||||||

|

|

|

|

|

|

|

|

Burner Pressure |

mbar |

9.5 |

9.5 |

9.5 |

9.5 |

9.0 |

9.0 |

|

|

|

|

|

|

|

|

Gas Rate |

m3/h |

0.8 |

1.3 |

1.7 |

2.6 |

3.1 |

3.6 |

ft3/h |

29 |

45 |

62 |

93 |

110 |

127 |

|

|

|

|

|

|

|

|

|

Natural Gas (G25) Data - Inlet Pressure 25 mbar (10 in WG) Min. 20 mbar (7.8 in WG) Max. 30 mbar (12 in WG) |

|||||||

|

|

|

|

|

|

|

|

Burner Pressure |

mbar |

9.0 |

9.0 |

9.5 |

9.2 |

9.2 |

9.3 |

|

|

|

|

|

|

|

|

Gas Rate |

m3/h |

0.9 |

1.5 |

2.0 |

3 |

3.6 |

4.2 |

ft3/h |

33 |

52 |

72 |

108 |

127 |

148 |

|

|

|

|

|

|

|

|

|

LPG / Propane (G31) Data - Inlet Pressure 37 mbar (14.6 WG) Min. 25 mbar (10 in WG) Max. 45 mbar (18 in WG) |

|||||||

Alternative where permitted 50 mbar (20 in WG) Min. 42.5 bar (17 in WG) Max. 57.5 mbar (23 in WG) |

|

||||||

|

|

|

|

|

|

|

|

Burner Pressure |

mbar |

25.6 |

29.4 |

29.4 |

28.6 |

29.9 |

29.9 |

|

|

|

|

|

|

|

|

|

m3/h |

0.3 |

0.5 |

0.7 |

1 |

1.2 |

1.4 |

Gas Rate |

kg3/h |

0.16 |

0.25 |

0.34 |

0.51 |

.61 |

.71 |

|

|

|

|

|

|

|

|

LPG / Butane (G30) Data - Inlet Pressure 29 mbar (11,4 in WG) Min. 20 mbar (7.8 in WG) Max. 35 mbar (13.8 WG)

Burner Pressure |

mbar |

19.2 |

21.9 |

22.9 |

21.4 |

21.4 |

22.4 |

|

|

|

|

|

|

|

|

|

m3/h |

0.2 |

0.4 |

0.5 |

0.8 |

.9 |

1.1 |

Gas Rate |

kg3/h |

0.09 |

0.14 |

0.19 |

0.29 |

.34 |

.42 |

|

|

|

|

|

|

|

|

Gas rates corrected to standard conditions 1013.25 mbar 15° C.

6

Loading...

Loading...