Roberts Gorden CRV-B-8, CRV-B-6, CRV-B-4, CRV-B-2 User Manual

®

CoRayVac

Custom Engineered,

Gas-Fired, Low-Intensity

Infrared Heating System

CRV-B-2

CRV-B-4

CRV-B-6

CRV-B-8

CRV-B-10

CRV-B-12

CRV-B-12A

Design Manual

All designs must be installed in strict accordance with the CORAYVAC®

Installation, Operation and Service Manual (P/N 127102NA).

Roberts-Gordon LLC

1250 William Street

P.O . B o x 44

Buffalo, New York 14240-0044

Telephone: 716.852.4400

Fax: 716.852.0854

Toll Free: 800.828.7450

CRV-B-9

© 2009 Roberts-Gordon LLC

www.rg-inc.com

www.radiantheaters.com

www.corayvac.com

P/N 127500NA Rev D 05/09

© 2009

Roberts-Gordon LLC

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon LLC.

TABLE OF CONTENTS

SECTION 1: Concept ..............................................................1

SECTION 2: The CRV-Series System.....................................2

2.1 Safety...........................................................................2

2.2 Zero Regulator ............................................................. 2

2.3 Fuel Savings and Comfort ...........................................4

SECTION 3: Clearances to Combustibles.............................5

3.1 Required Clearances to Combustibles.........................5

SECTION 4: Sizing and Design Considerations...................9

4.1 Radiant Adjustment to Heat Loss ................................9

4.2 Radiant Height Adjustment Factor...............................9

4.3 Selecting the Burners ................................................ 10

4.4 Radiant Distribution ................................................... 10

SECTION 5: Flow Loading.................................................... 12

5.1 Radiant Branch Flow .................................................12

5.2 Pump Capacity ..........................................................14

5.3 Tailpipe Flow.............................................................. 14

SECTION 6: Radiant Tube and Tailpipe............................... 15

6.1 Radiant Tube Length.................................................. 15

6.2 Tailpipe.......................................................................15

6.3 Design Parameters .................................................... 16

6.4 CRV-Series Design Methods ..................................... 16

6.5 Tailpipe Design Method ............................................. 18

SECTION 7: Example CRV-Series System Layouts............21

7.1 Example System Layout (Option 1) ............................ 21

7.2 Example System Layout (Option 2) ............................ 22

7.3 Example System Layout (Option 3) ............................ 22

7.4 Example System Layout (Option 4) ............................ 23

7.5 Example System Layout (Option 5) ............................ 23

7.6 Example System Layout (Option 6) ............................ 24

7.7 Example System Layout (Option 7, 8 and 9)............... 25

SECTION 8: Control Methods .............................................. 26

8.1 ROBERTS GORDON

(P/N 02770002) .........................................................26

8.2 ROBERTS GORDON® ULTRAVAC™..........................26

8.3 SPST Transformer Relay (P/N 90417600K)...............27

8.4 DPST Transformer Relay (P/N 90436300).................27

8.5 Pressure Switch .........................................................27

SECTION 9: Air Supply System ...........................................28

9.1 Pressurized................................................................28

9.2 Non-Pressurized ........................................................ 28

9.3 Outside Air System Design Requirements.................28

SECTION 10: ROBERTS GORDON

Requirements.................................................31

SECTION 11: CRV-Series Equipment Specifications......... 32

11.1 Burner and Burner Controls......................................32

11.2 Equipment ................................................................32

®

System Control

®

ULTRAVAC™ Design

Printed in U.S.A.

TABLE OF FIGURES

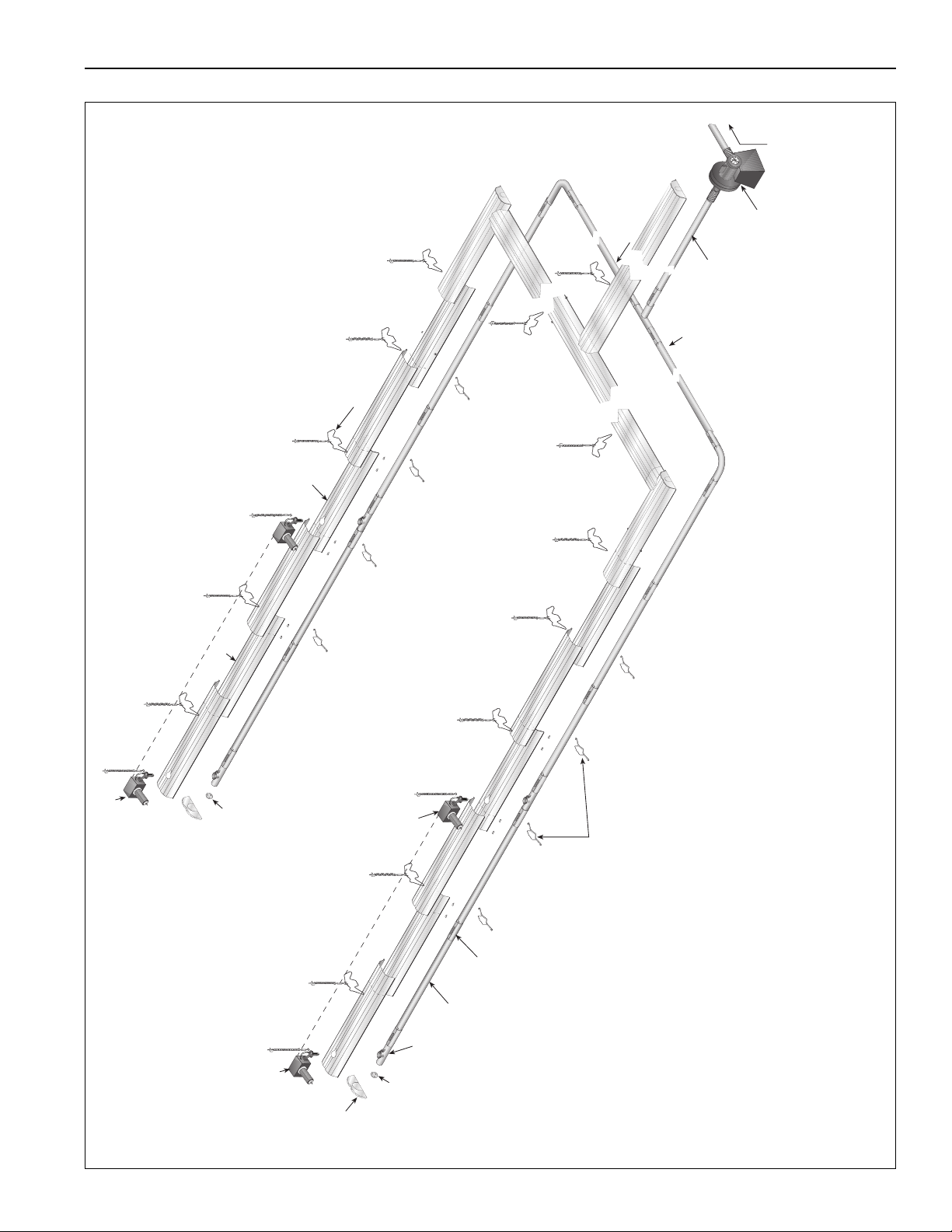

Figure 1: Assembly Overview (Two Branch System Shown).....3

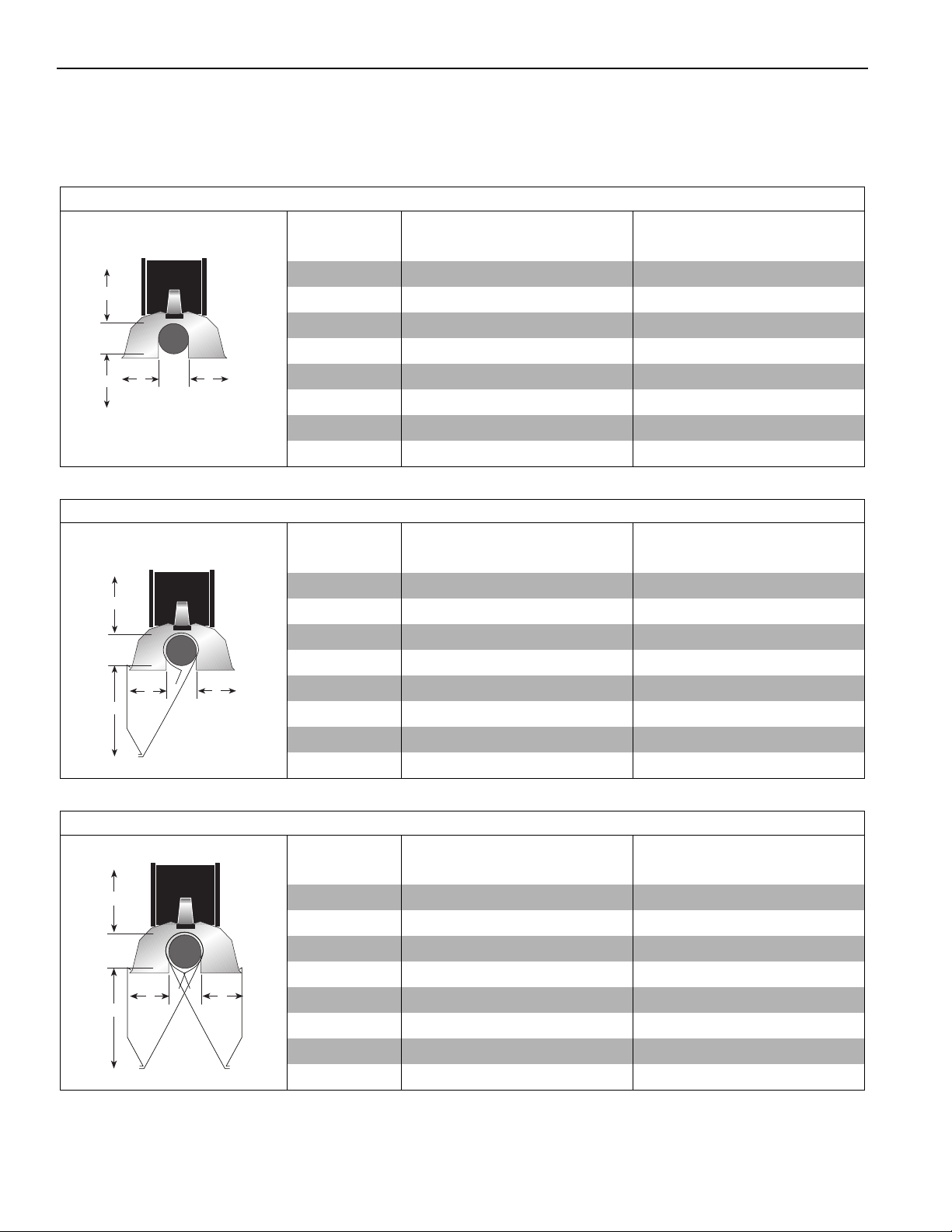

Figure 2: Standard Reflector .....................................................6

Figure 3: One Side Reflector.....................................................6

Figure 4: Two Side Reflectors ...................................................6

Figure 5: Universal Shield, Position 1 .......................................7

Figure 6: Universal Shield, Position 2 .......................................7

Figure 7: Universal Shield, Position 3 .......................................7

Figure 8: 2-Foot Deco Grille......................................................8

Figure 9: Barrier Shield .............................................................8

Figure 10: Protective Grille........................................................8

Figure 11: Radiant Distribution (Average Coverage)............... 11

Figure 12: Radiant Distribution (Increased Coverage) ............ 11

Figure 13: Radiant Distribution (Heavy Coverage).................. 11

Figure 14: Burner Flow Units .................................................. 13

Figure 15: Vacuum Loss Curve for 4" Shared Tailpipe...........14

Figure 16: Tube Length vs. Efficiency...................................... 16

Figure 17: Possible Damper Coupling Locations ....................20

Figure 18: Example System Layout (Option 1)....................... 21

Figure 19: Example System Layout (Option 2)....................... 22

Figure 20: Example System Layout (Option 3)....................... 22

Figure 21: Example System Layout (Option 4)....................... 23

Figure 22: Example System Layou

Figure 23: Example System Layout (Option 6)....................... 24

Figure 24: Example System Layout (Option 7)....................... 24

Figure 25: Example System Layout (Option 8)....................... 24

Figure 26: Example System Layout (Option 9)....................... 25

Figure 27: Air Supply System Capacity by Duct Length and

Diameter ................................................................28

Figure 28: Outside Air Blower .................................................29

Figure 29: Sample Layout for Pressurized Outside Air

Systems..................................................................30

t (Option 5).......................23

LIST OF TABLES

Table 1: CORAYVAC® Design Parameters ............................12

Table 2: Pump Capacity..........................................................14

Table 3: Pump Exhaust Requirements ...................................14

Table 4: Allowable Tailpipe Lengths .......................................17

Table 5: Operating Characteristics; Condensing or

Non-Condensing ......................................................18

SECTION 1: CONCEPT

The concept of CRV-Series is easy to understand.

However, it means discarding old ideas because CRVSeries is a different kind of heating system.

CRV-Series is a gas-fired, vacuum-operated, low-

intensity infrared heating system incorporating a patented incremental burner system.

Gas-Fired means it uses clean-burning Natural or

Propane gas.

Vacuum-Operated means that the pump draws all

the products of combustion through the system and

expels them outdoors.

Low-Intensity means the radiant surfaces of the

tubes do not glow red; instead they operate at a lower

temperature (less than 900° F or 482.2° C) and radiate

heat at lower intensity per square foot of radiating sur-

face. Area coverage is provided by long runs of 4" (10

cm) O.D. tubing which hang from the ceiling or roof

supports. Reflectors direct the radiant heat downward

to occupied areas.

SECTION 1: CONCEPT

Radiant refers to the heat radiated by the CRV-Series

system. Because this heat is in the form of infrared

rays, it does not directly heat the air. Instead, the rays

heat objects such as floors, people, walls, cars,

machines, tools, etc. The warm objects, in turn, heat

the air throu

gh convection.

Incremental Burner System means that several

burners can operate in-series and fire into the same

run of steel tube that carries the combustion gases

from upstream burners. Each of these burners in a

radiant branch may have different firing rates; also, the

space between burners may vary. This allows the

designer to match heat gain to heat loss for each area

of the building. Firing burners in-series provides higher

thermal and radiant efficiency.

In a properly designed low-intensity radiant system,

the occupants should be barely aware of the radiant

heat when the system is firing. They will feel little or no

change when the thermostat is satisfied and the system is not firing. This combines with warm floors,

warm walls and draft-free operation to improve the

mean radiant temperature of the space. This is the key

to the exceptional comfort and fuel efficiency provided

by the CRV-Series system.

1

CRV-SERIES DESIGN MANUAL

SECTION 2: THE CRV-SERIES SYSTEM

A CRV-Series system consists of one pump, a control

system, and a number of burners, see Page 3, Figure

1. It also includes an extended tube surface (4" (10

cm) steel tubing) covered by highly efficient reflectors

to direct the radiant heat downward to the floor. The

tubing nearest the burners radiates with the most

intensity and is called radiant tube. This should be

located over areas with the greatest heat loss. The

rest of the tubing surface (located between the radiant

tube and the pump) radiates with less intensity and is

called tailpipe. This can be located in areas with

lower heat loss.

While it is important to locate radiant tubes over areas

with high heat loss, such as the perimeter of the build-

ing, it is not essential to cover all areas directly with

radiant heat. Center areas (away from external walls)

and other areas of low heat loss can be adequately

heated without direct coverage as long as the input of

the system is adequate for the total building heat loss.

However, to achieve the highest degree of comfort and

fuel savings, it is recommended that the CRV-Series

system be located to provide as complete and even a

distribution as is practical. In addition, several different

reflector and shield configurations are available to

direct the radiant heat to or away from desired areas.

With CRV-Series, all equipment and controls are

C.S.A. design certified, both as individual parts and

also as a complete heating system. Also, individual

electrical component parts are listed as applicable.

2.2 Zero Regulator

CRV-Series uses a 100% pre-mix burner with the input

dependent on system vacuum. With no vacuum, the

zero regulator prevents gas flow. When vacuum is

present, the burner fires and input increases as vac-

uum increases. As the input increases, the amount of

air also increases. Over the normal range of operating

vacuum, the gas/air ratio is essentially linear.

This unique and patented feature provides optimum

combustion conditions at all times. Combustion condi-

tions are unaffected by fluctuations in fuel pressure,

vacuum, dirty air filters, changes in atmospheric pressure, wind velocity or other climate conditions.

Page 3, Figure 1 illustrates the components of a typi-

cal CRV-Series system. The system shown is a four

burner system composed of two branches. A branch

consists of a single run of tubing, including an end

burner, followed by any burners downstream. A

branch ends at a tee or a cross (where other branches

connect). For a single branch system, the branch ends

at the pump.

2.1 Safety

Safety is a prime consideration of CRV-Series. First,

there is a pre-purge of the complete tube network prior

to flame ignition. Then, to ensure that there will be no

gas flow unless the pump is operating, a pressure

switch located at the pump must activate prior to igni-

tion. After the pressure switch has closed, there are

two valves in-series in each burner that must be ener-

gized, as well as a zero regulator. Additionally, slow

opening gas valves provide smooth ignition and

enhance reliability. Once the thermostat has been satisfied, the burners turn off and the pump continues to

run for two minutes to purge the entire system of flue

gases.

2

FIGURE 1: Assembly Overview (Two Branch System Shown)

Pump

End

Vent

Combustion

Chamber

End Burner

Radiant

Tube

Coupling

Reflector

End Cap

Reflector

Support

Burner

Tube &

Reflector

Hanger

Reflector

Reflector

with Hole

End Vent

Exhaust to

Outside

Shared Tailpipe

End Burner

Tailpipe

Tailpipe

1. Radiant tubing between burners, and 20-50' (6-15 m)

downstream of the last burner is normally hot rolled steel or

heat-treated aluminized steel. All tailpipe tubing must be por-

celain coated steel or heat-treated aluminized steel.

2. Damper couplings are required when layout has unequal

branches. Unequal branches are achieved by unequal

geometry, burner quantity or burner firing rates.

3. Plain couplings are used to connect combustion chambers

to radiant tubing and radiant tubing to tailpipe tubing. All

tailpipe couplings must be lined.

SECTION 2: THE CRV-SERIES SYS TEM

3

CRV-SERIES DESIGN MANUAL

2.3 Fuel Savings and Comfort

Space heating can be accomplished with less input

capacity when a radiant heating system is utilized,

rather than with a conventional convective heating

system. Why is this so?

A conventional, convective heating system, such as a

unit heater or central furnace works by heating the air,

which then indirectly heats the area and

occupants. CRV-Series utilizes infrared energy to heat

objects, people and surfaces directly, not the air. The

warm objects and floor create a heat reservoir, which

then re-radiates to the surroundings and also heats

the air by convection.

The radiant energy received by the occupants, directly

from the heater or indirectly from the

surroundings via re-radiation, serves to increase the

mean radiant temperature (MRT) of the space. In a

manner similar to direct sunlight, the increased MRT

allows the occupant to perceive a comfort condition at

a reduced air temperature. The resulting reduced air

temperature within the space provides the

following fuel-saving advantages:

• Reduced stratification of air in the space.

• Reduced transmission heat loss due to lower temperature inside than assumed design

condition.

• Redu

ced air change heat loss, to the extent that

exfiltration through cracks or openings near the

roof will be decreased because of decreased

stack effect.

• Decreases the actual degree days experienced.

4

SECTION 3: CLEARANCES TO COMBUSTIBLES

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to

combustibles away from heater.

Some objects will catch fire or explode when

placed close to heater.

Failure to follow these instructions can result

in death, injury or property damage.

3.1 Required Clearances to Combustibles

Clearances are the required distances that combusti-

ble objects must be away from the heater to prevent

serious fire hazards. Combustibles are materials,

which may catch on fire and include common items

such as wood, paper, rubber, fabric, etc. Maintain

clearances to combustibles at all times for safety.

Clearances for all heater models are located on the

burner assembly and on Page 6, Figure 3 through

Page 8, Figure 10 in this manual. Check the clear-

ances on each burner for the model heater being

installed to make sure the product is suitable for your

application and the clearances are maintained. Read

and follow the safety guidelines below:

• Keep gasoline or other combustible materials

including flammable objects, liquids, dust or

vapors away from this heater or any other appli-

ance.

SECTION 3: CLEARANCES TO C OMBUSTIBLES

• Hang heater in accordance to the minimum sus-

pension requirements.

• If the radiant tubes must pass through the building

structure, be sure that adequate sleeving and fire

stop is installed to prevent scorching and/or fire

hazard.

•

The stated clearances to combustibles represents

a surface temperature of 90° F (32° C) above

room temperature. Building materials with a low

heat tolerance (such as plastics, vinyl siding, canvas, tri-ply, etc) may be subject to degradation at

lower temperatures. It is the installer’s responsibility to assure that adjacent materials are protected

from degradation.

• Maintain clearances from heat sensitive

equipment and workstations.

• Maintain clearances from vehicles parked below

the heater.

• Maintain clearances from swinging and overhead

doors, overhead cranes, vehicle lifts, partitions,

storage racks, hoists, building construction, etc.

• In locations used for the storage of combustible

materials, signs must be posted to specify the

maximum permissible stacking height to maintain

required clearances from the heater to the combustibles. Signs must be posted adjacent to the

heater thermostat. In the absence of a thermostat, signs must be posted in a conspicuous location.

• Consult local Fire Marshal, Fire Insurance Carrier

or other authorities for approval of proposed

installation when there is a possibility of exposure

to combustible airborne materials or vapors.

5

CRV-SERIES DESIGN MANUAL

B

C

D

A

A

B

C

D

A

B

C

D

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, elbows, tees and crosses.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream from

where the combustion chamber and the tube connect.

FIGURE 2: STANDARD REFLECTOR

Model A B C D A B C D

CRV-B-2 4 20 48 20 11 51 122 51

CRV-B-4 4 20 48 20 11 51 122 51

CRV-B-6 4 20 48 20 11 51 122 51

CRV-B-8 4 20 48 20 11 51 122 51

CRV-B-9 4 36 60 36 11 92 153 92

CRV-B-10 4 366036119215392

CRV-B-12 4 36 60 36 11 92 153 92

CRV-B-12A 4 36 60 36 11 92 153 92

.

(inches) (centimeters)

FIGURE 3: ONE SIDE REFLECTOR

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 56 20 11 31 143 51

CRV-B-4 4 12 56 20 11 31 143 51

CRV-B-6 4 12 56 20 11 31 143 51

CRV-B-8 4 12 56 20 11 31 143 51

CRV-B-9 4 12 60 42 11 31 153 107

CRV-B-10 4 12 60 42 11 31 153 107

CRV-B-12 4 12 60 42 11 31 153 107

CRV-B-12A 4 12 60 42 11 31 153 107

FIGURE 4: TWO SIDE REFLECTORS

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 56 12 11 31 143 31

CRV-B-4 4 12 56 12 11 31 143 31

CRV-B-6 4 12 56 12 11 31 143 31

CRV-B-8 4 12 56 12 11 31 143 31

CRV-B-9 4 12 60 12 11 31 153 31

CRV-B-10 4 12 60 12 11 31 153 31

CRV-B-12 4 12 60 12 11 31 153 31

CRV-B-12A 4 12 60 12 11 31 153 31

6

Loading...

Loading...