Renault Clio, Trafic, Fuego, 5, 9 Workshop Repair Manual

...

C

"The repair methods given by the manufacturer in this

document are based on the technical specifications

current when it was prepared.

The methods may be modified as a result of changes

introduced by the manufacturer in the production of

the various component units and accessories from which

his vehicles are constructed."

All copyrights reserved by Renault.

Copying or translating, in part or in full, of this

document or use of the service part reference

numbering system is forbidden without the prior

written authority of Renault.

77 11 193 528 Edition Anglaise

RENAULT 1997

AUTOMATIC TRANSMISSION

Cancels and replaces Workshop Manual M.R. T.A.M., Part Number : 77 11 088 275

and N.T. N° 1275 - 1599 - 1769 - 1770 - 2061

Type Range

Renault 5

Extra

Renault 9/11

Renault 19

Clio

Twingo

Renault 5

Renault 9/11

Renault 19

Renault 18

Renault Fuego

Renault 18

Renault Fuego

Renault 20

Renault 21

Renault 25

Renault Trafic

MB1

MB3

MJ1

MJ3

ML1

Workshop repair manual

Contents

AUTOMATIC TRANSMISSION

Diagram 23-1

Using 23-3

Identification 23-4

Gear change thresholds 23-7

Gear ratios 23-11

Specifications 23-13

Parts to be replaced (after removal) 23-13

Consumables 23-13

Maintenance 23-14

Piston (Identification) 23-20

Number of discs 23-20

Transmission operation 23-21

Cross section and tightening torques

(in daN.m) 23-23

Strainer 23-27

Hydraulic distributor 23-32

Solenoid valves 23-37

Speedo shaft seal (MJ - ML) 23-38

Speedo drive (MB) 23-39

Speedo drive (J) 23-40

Differential seal (MB) 23-41

Differential seal (MJ) 23-42

Differential seal and nut (ML) 23-43

Converter 23-44

Drive plate 23-46

Stator shaft 23-48

Converter seal 23-49

Gear section casing 23-52

Final drive assembly (MB) 23-73

Final drive assembly (MJ) 23-86

Final drive assembly (ML) 23-98

Exploded view 23-107

Exploded view of mechanisms 23-109

Final drive exploded view (MJ) 23-110

Final drive exploded view (MB) 23-111

Computer and wiring 23-112

Kickdown 23-116

Computer 23-117

Multifunction switch 23-119

Speed sensor 23-122

Oil pressure 23-124

Vacuum capsule 23-126

Special tooling 23-127

37

Page Page

Fault finding- Introduction 23-132

Vehicles concerned 23-133

FFFFIIIICCCCHHHHEEEE NN

NN

° 1

General 23-137

XR25 fiche 23-140

Meaning of the bargraphs 23-141

Adjusting the load potentiometer 23-143

Fault finding using bargraph

illumination 23-144

Fault finding - Control unitB. Vi. 958 23-152

Fault finding- Checking connectors

23-167

FFFFIIIICCCCHHHHEEEE NN

NN

° 24

General 23-173

XR25 fiche 23-179

Meaning of the bargraphs 23-180

Additional checks 23-183

FFFFIIIICCCCHHHHEEEE NN

NN

° 26

General 23-189

Fiche XR25 23-195

Meaning of the bargraphs 23-196

Additional checks 23-200

FFFFIIIICCCCHHHHEEEESSSS NN

NN

° 24 and 26

Fault finding using bargraph

illumination 23-207

Fault finding aid 23-223

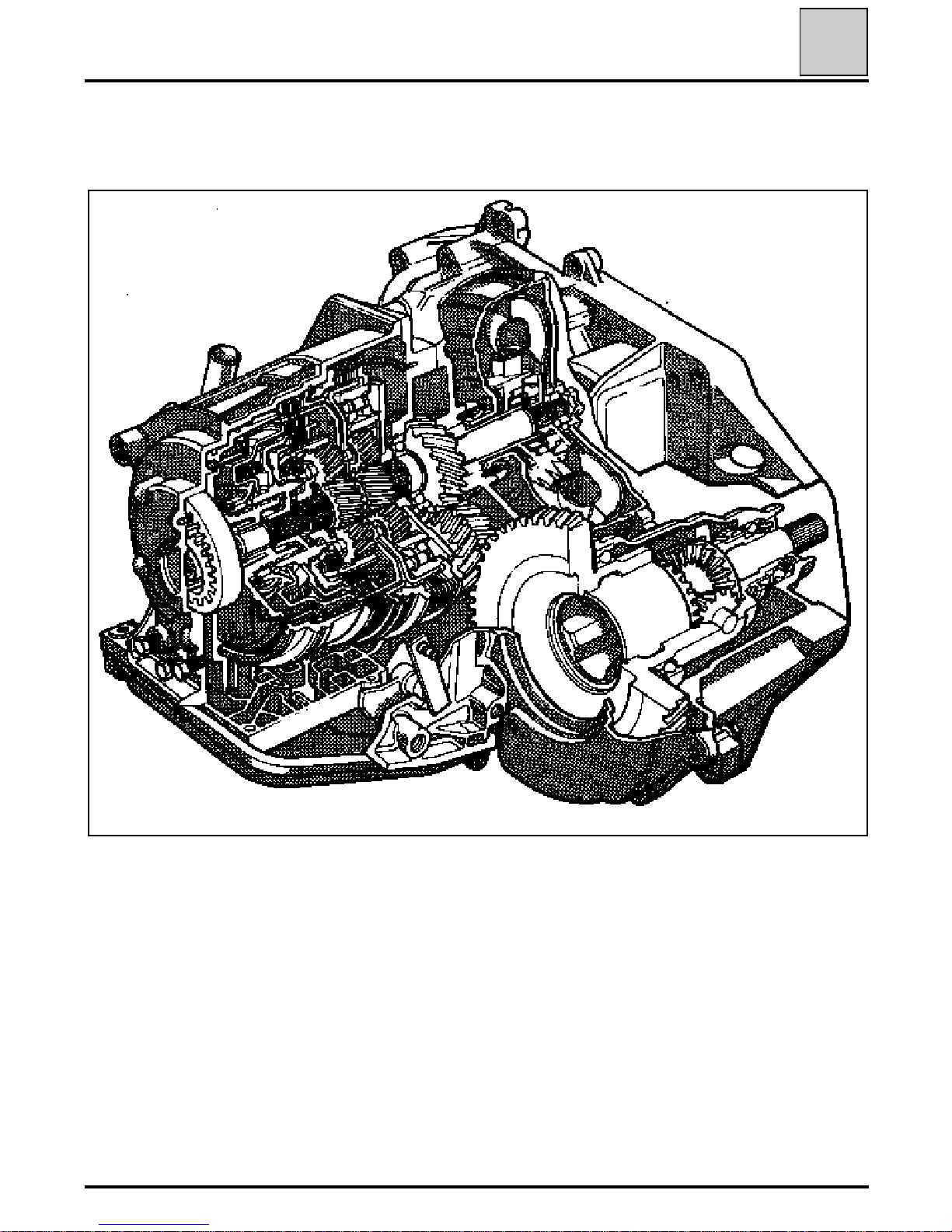

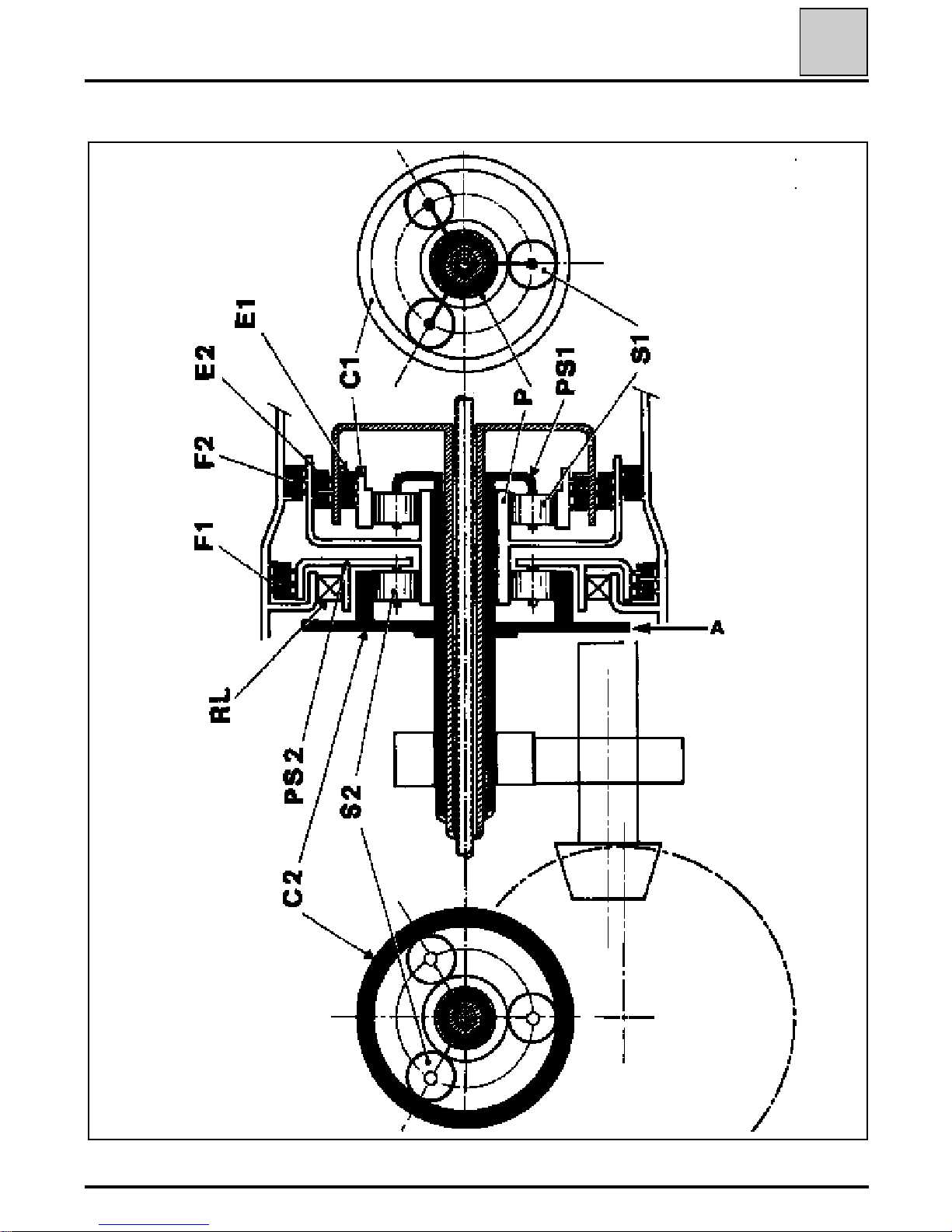

AUTOMATIC TRANSMISSION

Diagram

This diagram represents an automatic transmission

TTTTyyyyppppeeee MMMMBB

BB

23

DI2325

23-1

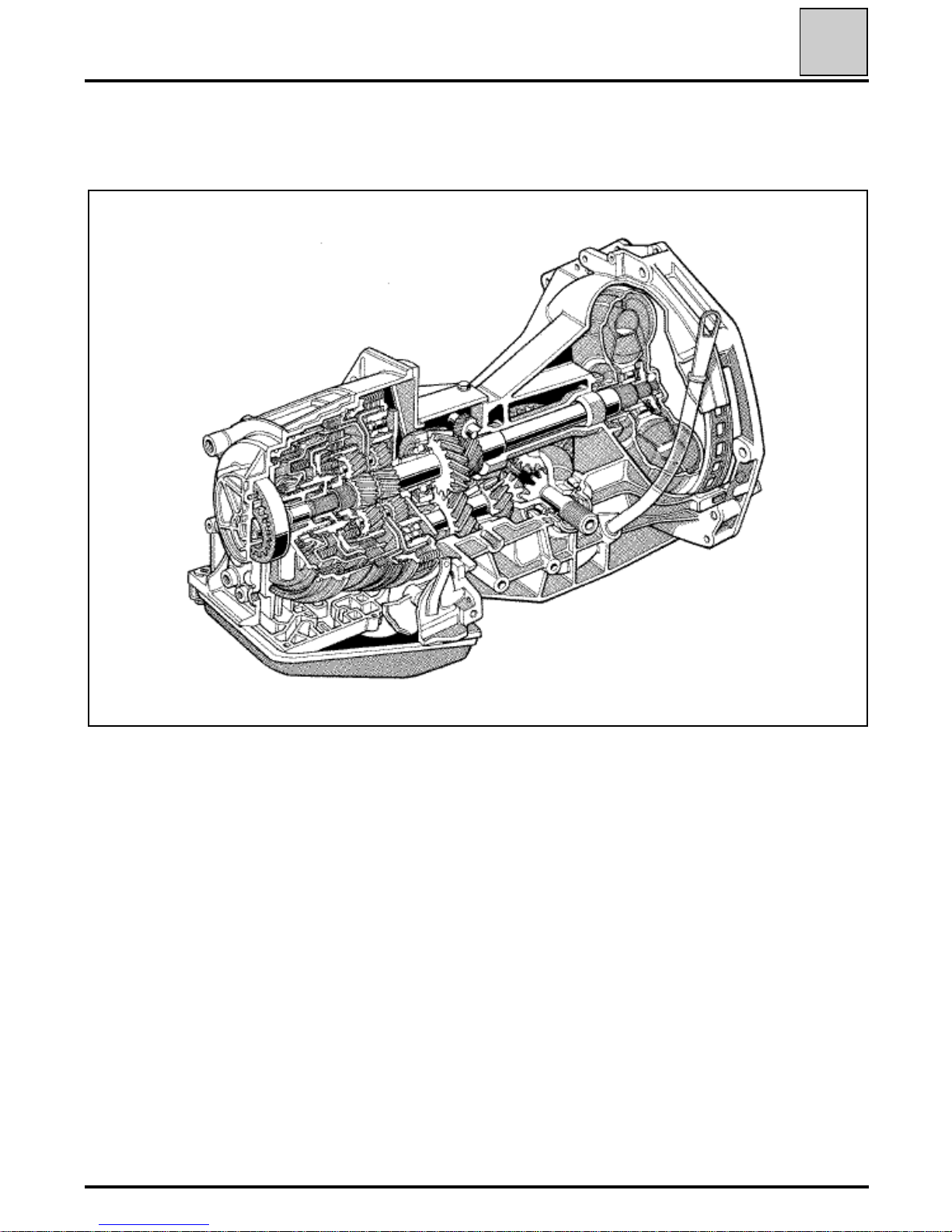

AUTOMATIC TRANSMISSION

Diagram

This diagram represents an automatic transmission

TTTTyyyyppppeeee MMMMJJ

JJ

23

DI2328

23-2

AUTOMATIC TRANSMISSION

Using

23

DDDDRRRRIIIIVVVVIIIINNNNGG

GG

As the automatic transmission is lubricated under

pressure, lubrication only occurs if the engine is

running.

Consequently, the following instructions must be

respected in order to avoid serious damage:

- Never move the vehicle with the ignition off

(when going down a slope for example), the

danger of such a measure cannot be

emphasised too greatly.

- Never have the vehicle pushed (for example in

order to reach the next service station), unless

precautions taken in the "Towing" are followed).

In addition, the vehicle can only be driven if the

engine is running. It is therefore impossible to

start the engine on a vehicle with automatic transmission by pushing the vehicle.

TTTTOOOOWWWWIIIINNNNGG

GG

The front of the vehicle must be raised, however if

this is impossible towing can be carried out in exceptional cases with the wheels on the ground in

the following conditions:

1 - Add an additional 2 litres of oil to the auto-

matic transmission ("Elf Renaultmatic D2" or

Mobil ATF 220).

2 - When towing, do not exceed a speed of

25 mph (40 km/h) or a distance of 30 miles

(50 km) maximum (lever in N).

Remember to drain off the excess oil at the end of

the towing operation.

23-3

AUTOMATIC TRANSMISSION

Identification

23

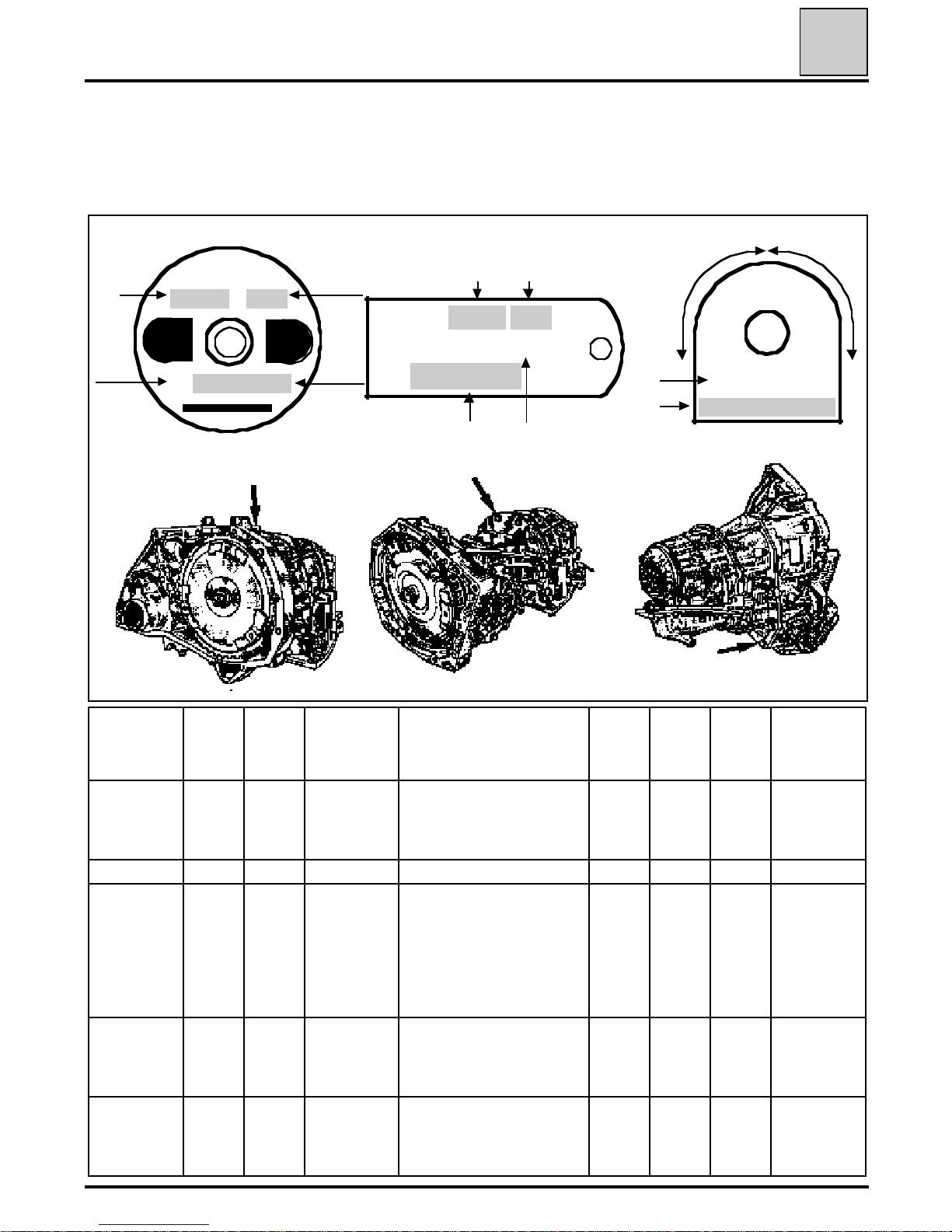

The identification plate indicates:

- at A : the type of automatic transmission,

- at B : the type suffix,

- at C : the fabrication number,

- at D : the manufacturing factory.

DI2329

Vehicle

Type of

A.T.

Suffix Final drive ratio Step-down gear ratio

Speedo

drive

ratio

Oil

pressure

in bar

±0.1 bar)

No. of

planet

wheels

Computer

number

B/C 403

B/C 40J

MB1

600

601

602

603

17/56 29/24 21/20 4.4 3

21

221

135

B/C 408 MB3 001 16/57 29/24 21/19 4.4 3 134

L 423

B/C 373

MB1

000

001

007

013

017

021

025

16/57 25/23 21/19 4.4 3

05

24

224

228

125

B 373 MB1

002

008

014

018

16/57 25/23 Electric 4.4 3

05

24

224

L 423

B/C 373

Switzerland

MB1

003

011

015

019

16/57 25/23 21/19 4.4 3

11

25

125

90775

86304S 85710S

TYPE

XXX - XX

X 000000

D

A

C

B

TYPE XXX XX

BP AUTO X

000000

B

DC

A

B

0

X

0 0 0 0 0 0

X

X

0

0

0

A

D

C

MB

MMMMBBBB ---- MMMMJJ

JJ

ML

23-4

AUTOMATIC TRANSMISSION

Identification

23

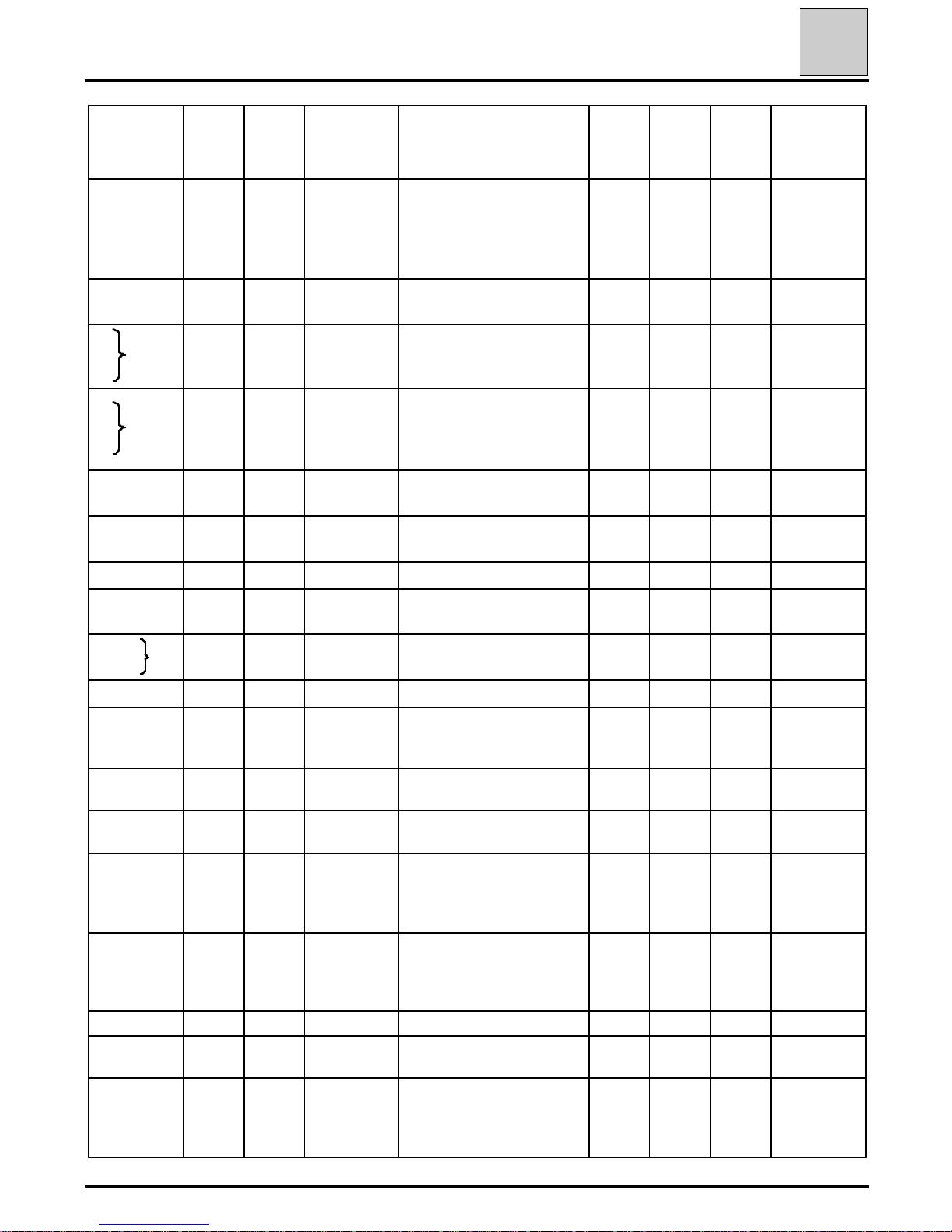

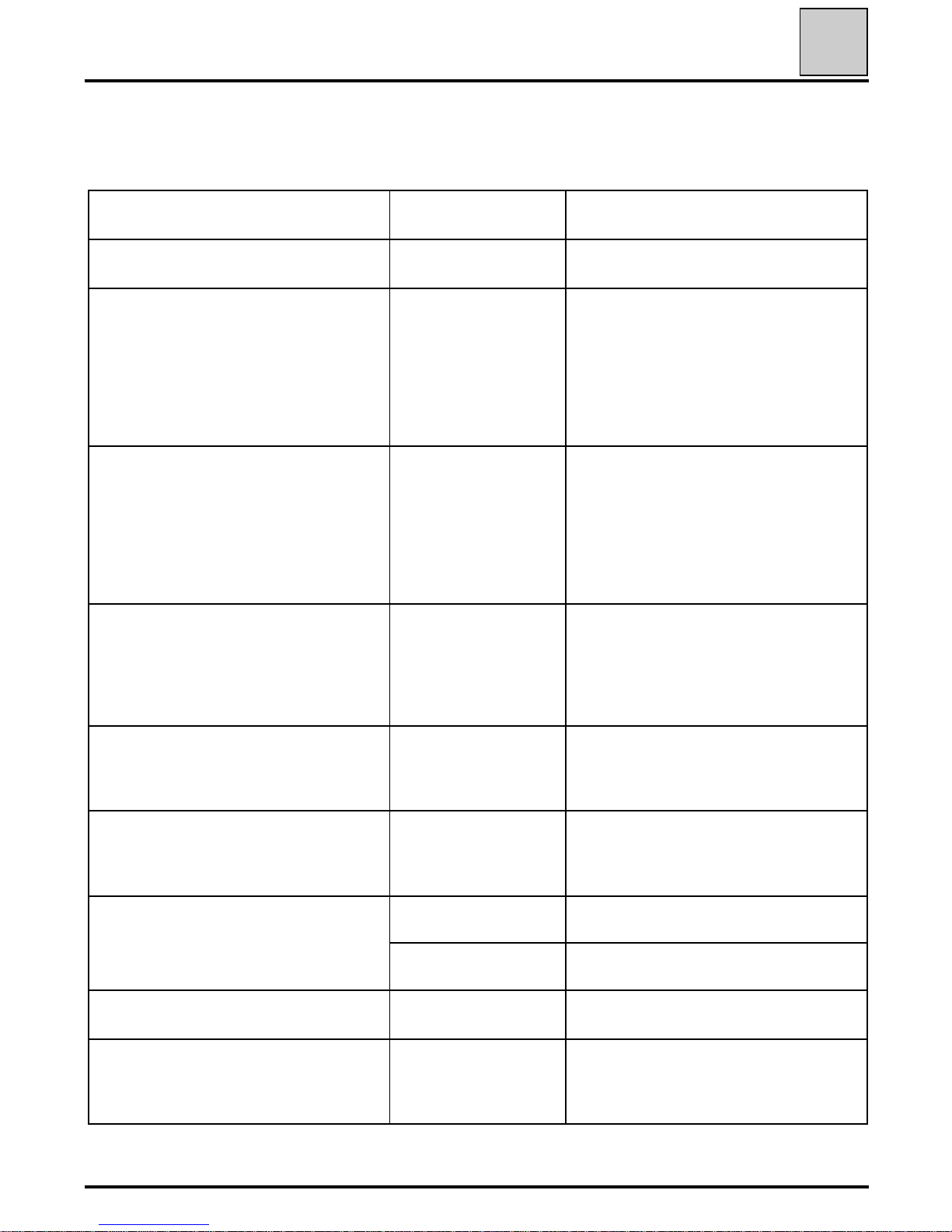

Vehicle

Type of

A.T.

Suffix

Final drive

ratio*

Step-down gear ratio

Speedo

drive

ratio

Oil

pressure

(in bar

±0.1 bar)

No. of

planet

wheels

Computer

number

L 423

B/C 373

DAI

MB1

500

501

502

503

504

15/58 25/23 21/19 4.4 3

11

25

125

129

L 426

B 376

MB3

001

356

16/57 29/24 21/19 4.4 3

132

133

B

C 53B

L

MB3

003

005

16/57 29/24 21/19 4.4 3

132

137

B

C 537/ALMB1

023

027

031

300

15/58 29/24 21/19 4.4 3

138

140

1342

1352

MJ1 000 9/32 25/23 7/20 4.2 3 04

1342

1352

MJ1 001 9/32 25/23 7/20 4.4 3

04

104

1362 MJ1 100 9/32 26/25 6/18 4.2 3 04

1362 MJ1 101 9/32 26/25 6/18 4.4 3

04

104

1341

1351

MJ1 500 9/32 25/26 6/20 4.4 3

10

110

1363 MJ3 300 9/32 26/25 6/18 4.6 4 03

1343

1353

1363

MJ3

301

351

352

9/32 26/25 6/18 4.6 4

03

103

107

1344

1354

MJ3 200 9/32 25/22 7/19 4.2 3 08*

1344

1354

MJ3 201 9/32 25/22 7/19 4.2 3 14

1279 MJ3

000

001

002

102

9/32 26/25 6/18 4.8 4

02

102

1277 MJ3

002

100

101

102

9/32 26/25 6/18 4.6 4

02

102

1277 DAI MJ3 500 9/32 23/25 6/19 4.6 4 02

F40 MB1

031

038

15/58 29/24 21/19 4.15 3 141

X57 B/T

B 573

C573

MB1

021

026

029

030

16/57 29/24 21/20 4.4 3 139

DAI

* The instrument panel warning light must be disconnected.

23-5

AUTOMATIC TRANSMISSION

Identification

23

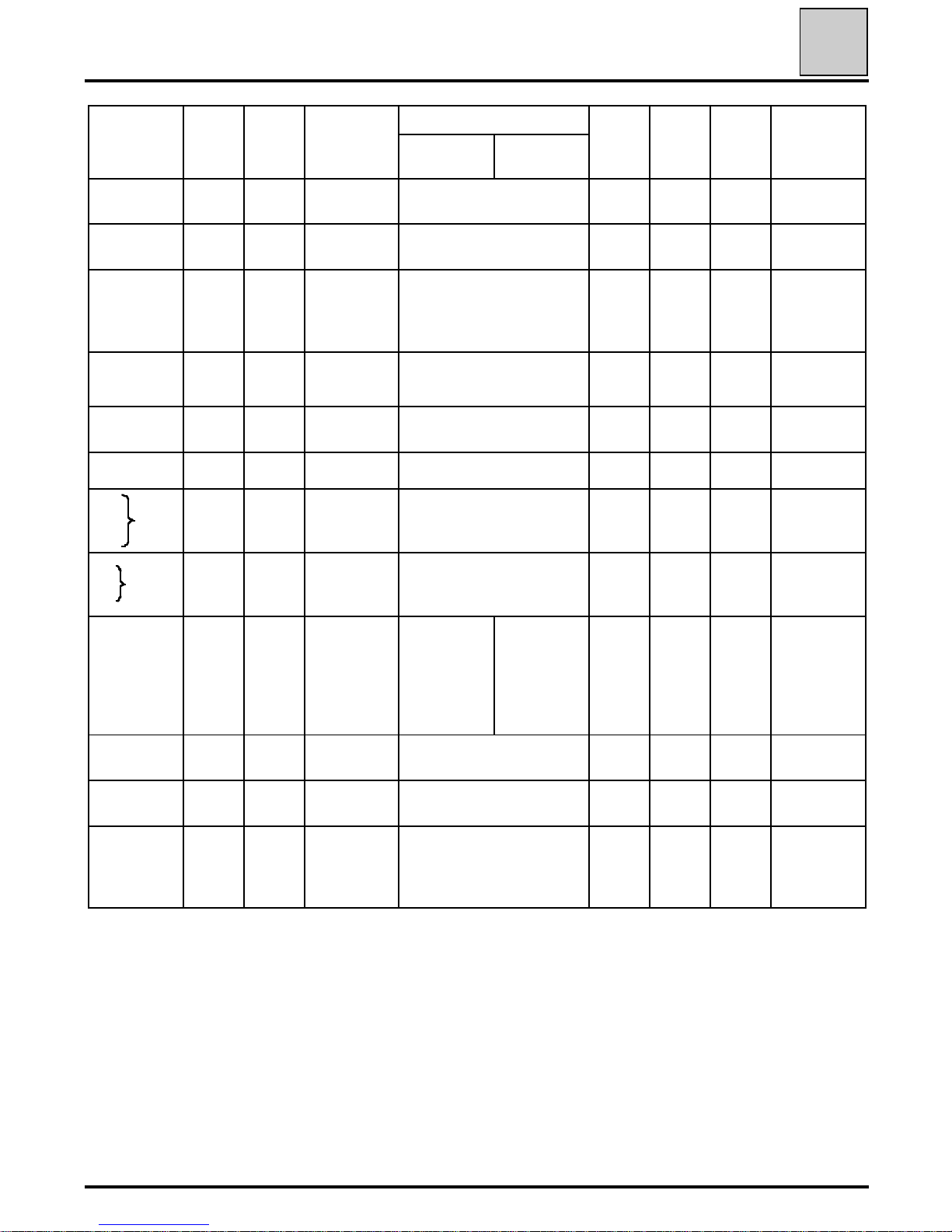

Vehicle

Type of

A.T.

Suffix Final drive ratio

Step-down gear ratio

Step down

mechanisms

Differential step

down

Speedo

drive

ratio

Oil

pressure

(in bar

±0.1 bar)

No. of

planet

wheels

Computer

number

B 297 MJ3

110

111

9/32 Elec. 4.5 4

13

113

B 297 MJ3

120

121

9/32 7/19 4.5 4

13

113

B297

B29B

with cruise

control

MJ3

012

116

112

9/37 Elec. 4.5 4

13

113

B29B

B297

MJ3 126 9/37 7/20 4.5 4 113

B29E MJ3

011

010

9/32 Elec. 4.7 4

13

113

B29E MJ3 016 9/37 Elec. 4.7 4 113

483

48K

489

MJ3

800 (1)

801 (2)

9/37 7/19 4.7 4

130

126

L 48A

K (USA)

MJ3

760

761

762

9/37 7/19 4.7 4 126

Txx1 ML1

001

004

005

006

007

008

9/32 28/25 23/32

5/20

5/21

4.7 3

20

120

C06 MB1 033 15/58 21/20

4.15 ±

0.05

3 143

F40 MB1

031

038

15/58 21/19 4.15 3 141

X57 B/T

B573

C573

MB1

024

026

029

030

16/57 21/20 4.4 3 139

(1) Sump 6 mm deeper, felt gauze strainer with increased surface area, leaktight dipstick with reduced level.

(2) Sump 6 mm deeper, felt gauze strainer with increased surface area; leaktight dipstick with reduced level.

Unidirectional differential output seals (specific to right hand/left hand sides).

25/23

25/23

26/21

26/21

25/23

26/21

26/20

26/20

29/24

L

K

29/24

29/24

23-6

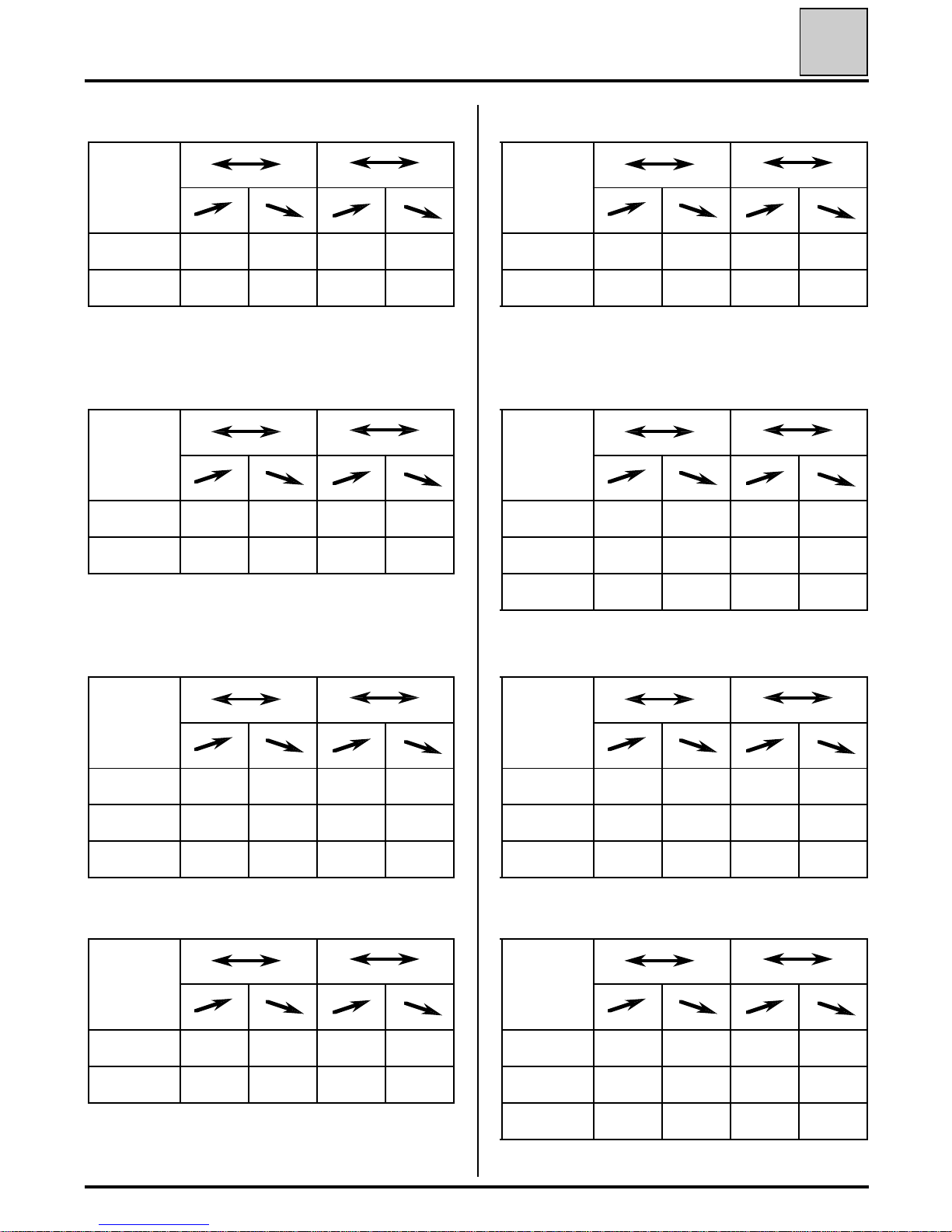

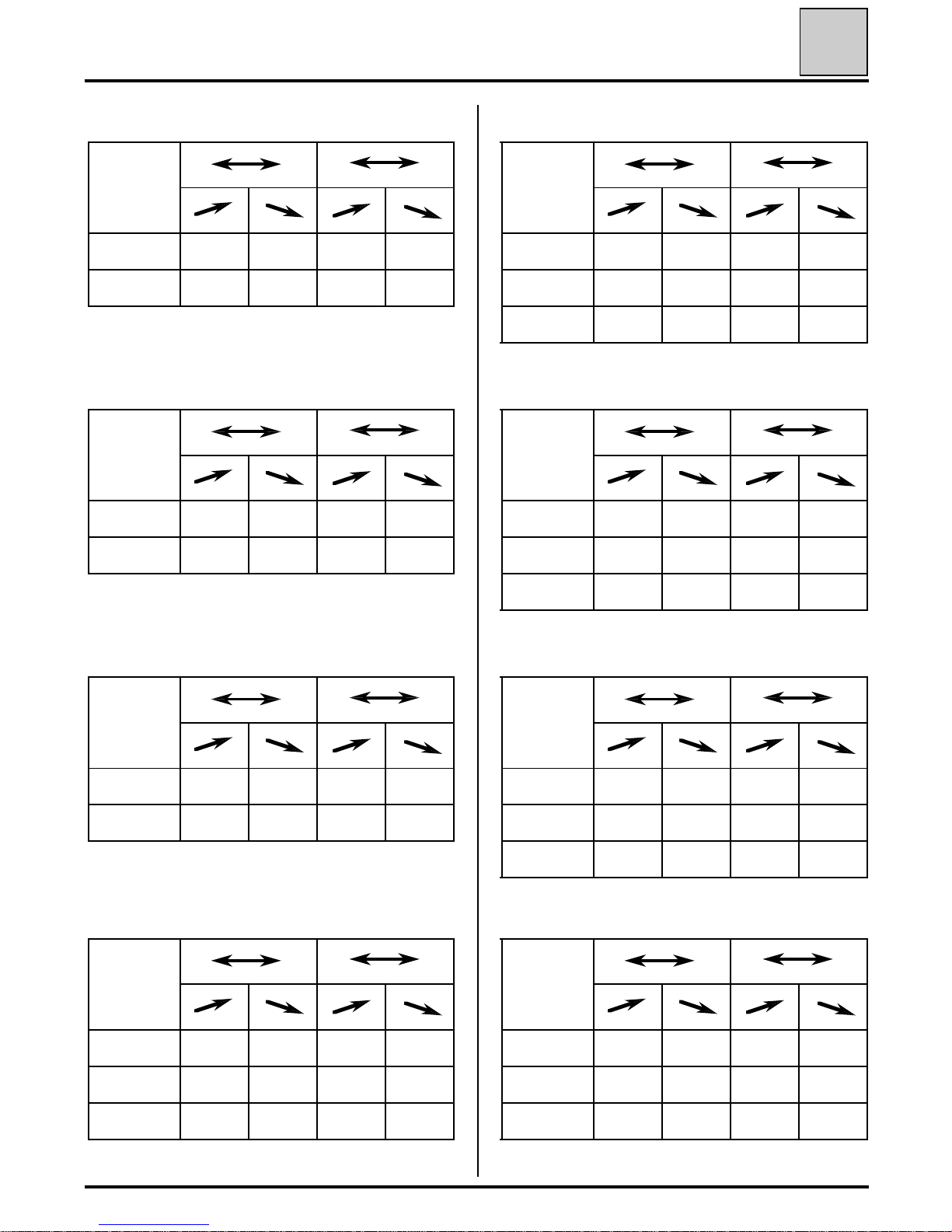

AUTOMATIC TRANSMISSION

Gear change thresholds

23

(The kickdown switch is integrated into the

computer).

B408 - C408

B403 - C403

Pedal

position

1223

No load 25* 15 35* 30

Full load 75 60 20 110

(The kickdown switch is integrated into the

computer).

L423 - B373 - C373

Pedal

position

1223

No load 23 15 33 26

Full load 68 54 108 98

L423 - B373 - C373 (DAI)

Pedal

position

1223

No load 25 15 45 25

Full load 70 55 110 95

Kickdown 66 55 109 95

(The kickdown switch is integrated into the

computer).

Pedal

position

1223

No load 20 15 35 25

Full load 60 55 100 90

(The kickdown switch is integrated into the

computer).

1342 - 1352 - 1343 - 1353 - 1277 - 1279

L423 - B373 - C373 (Switzerland)

Pedal

position

1223

No load 22* 15 38* 25

Full load 67 60 110 95

1362

Pedal

position

1223

No load 25* 15 50* 25

Full load 65 45 115 85

Kickdown 70 60 125 105

1363

Pedal

position

1223

No load 22* 12 44* 25

Full load 62 42 110 79

Kickdown 68 56 117 100

* These values are given as an example.

Pedal

position

1223

No load 22* 12 46* 25

Full load 65 44 113 81

Kickdown 70 58 121 103

23-7

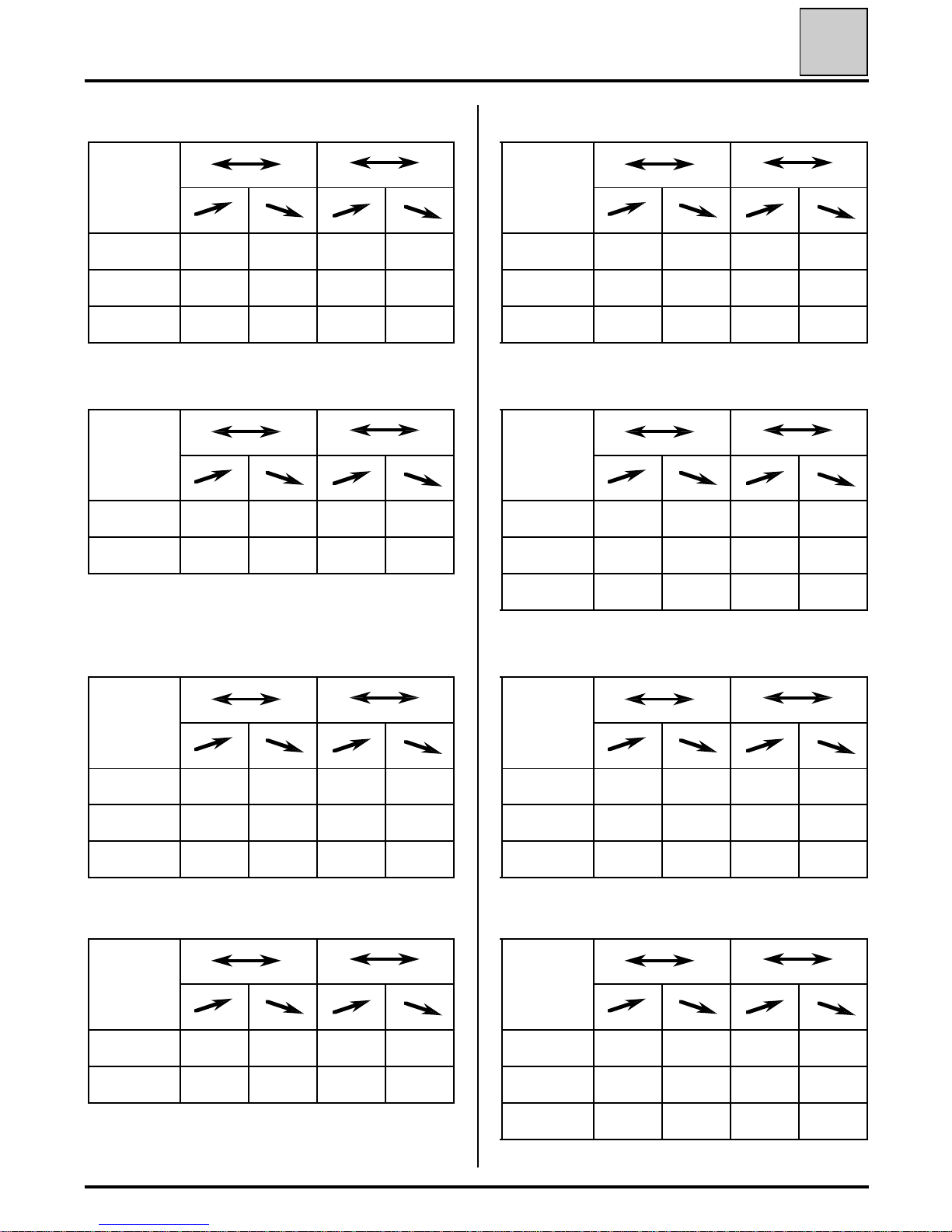

AUTOMATIC TRANSMISSION

Gear change thresholds

23

(The kickdown switch is integrated into the

computer).

L42

L48K - L483 - L489 - L/K 48A

Pedal

position

1223

No load 26 17 43 30

Full load 75 66 122 107

(The kickdown switch is integrated into the

computer).

B297 - B29B - B29E

Pedal

position

1223

No load 22 14 37 25

Full load 67 58 109 94

Pedal

position

1223

No load 25* 15 35* 30

Full load 75 60 125 110

Pedal

position

1223

No load 20* 10 35* 20

Full load 45 30 70 53

Kickdown 50 40 80 70

B/C 373/573

Pedal

position

1223

No load 23 15 33 26

Full load 71 43 120 80

Kickdown 71 60 120 107

F40 (031)

Pedal

position

1223

No load 21 14 29 22

Full load 74 48 126 99

Kickdown 74 62 126 114

F40 (038)

Pedal

position

1223

No load 19 12 27 20

Full load 68 44 116 91

Kickdown 68 56 116 105

* These values are given as an example.

Pedal

position

1223

No load 21 16 37 27

Full load 72 47 123 94

Kickdown 72 60 123 114

(The kickdown switch is integrated into the

computer).

Txx1

XXXX55557777 BBBB////TT

TT

23-8

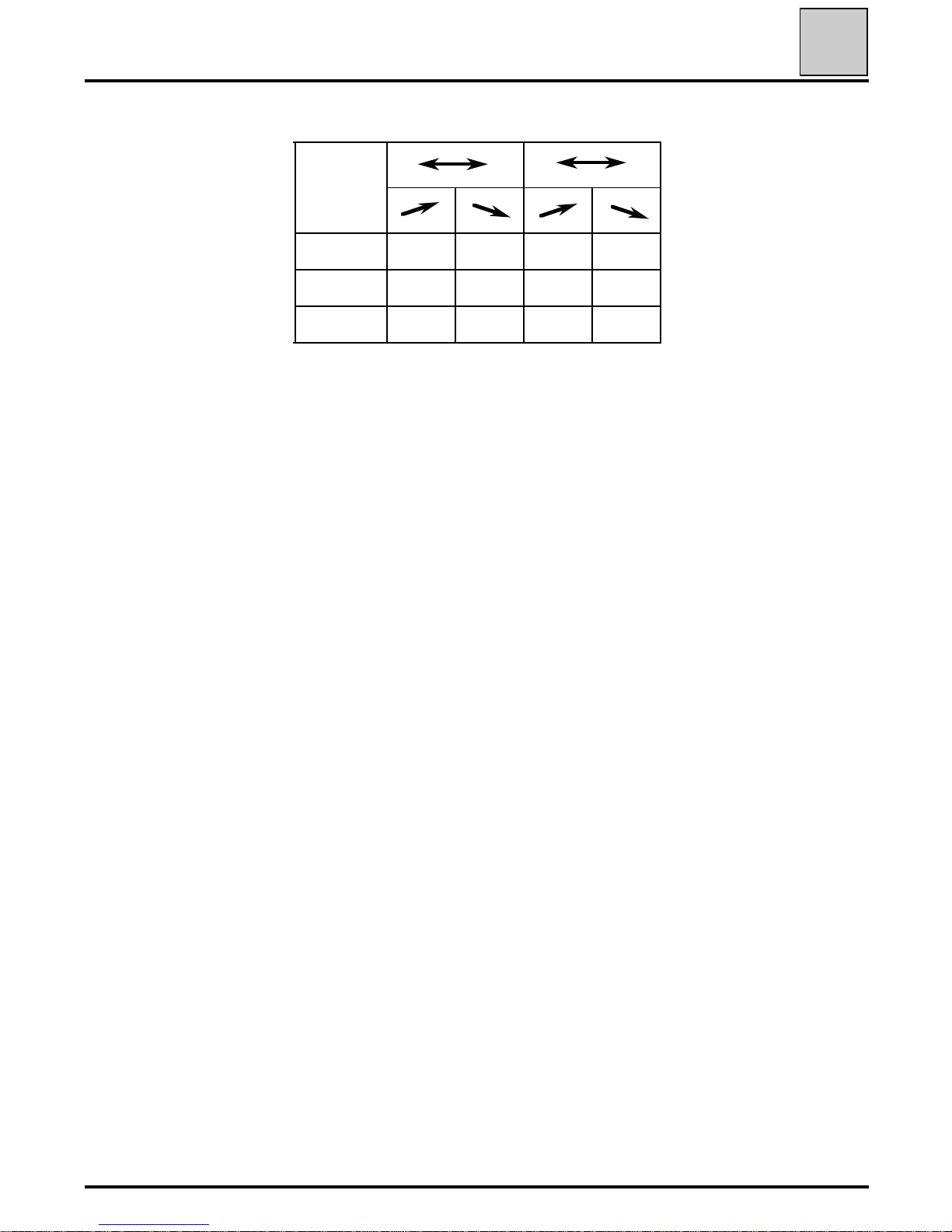

AUTOMATIC TRANSMISSION

Gear change thresholds

23

1343 - 1353 - 1363 (Argentina)

1343 - 1353 - 1363

Pedal

position

1223

No load 23 14 45 26

Full load 65 43 112 81

Kickdown 70 57 120 101

(The kickdown switch is integrated into the

computer).

1341 - 1351 (DAI)

Pedal

position

1223

No load 20 15 35 25

Full load 60 55 100 85

Pedal

position

1223

No load 20* 10 40* 25

Full load 60 40 100 75

Kickdown 65 50 110 90

Pedal

position

1223

No load 15* 10 40* 20

Full load 60 45 105 90

B53B - C53B - L53B

Pedal

position

1223

No load 24 15 40 27

Full load 72 63 118 102

Kickdown 72 63 118 102

XXXX55553333AA

AA

Pedal

position

1223

No load 23 13 46 26

Full load 62 40 102 74

Kickdown 67 54 109 94

1277 (DAI)

Pedal

position

1223

No load 20 13 28 21

Full load 71 46 121 95

Kickdown 71 59 121 110

* These values are given as an example.

Pedal

position

1223

No load 20* 15 45* 25

Full load 60 40 110 80

Kickdown 65 55 115 95

1344 - 1354

B537 - C537 - L537

(The kickdown switch is integrated into the

computer).

23-9

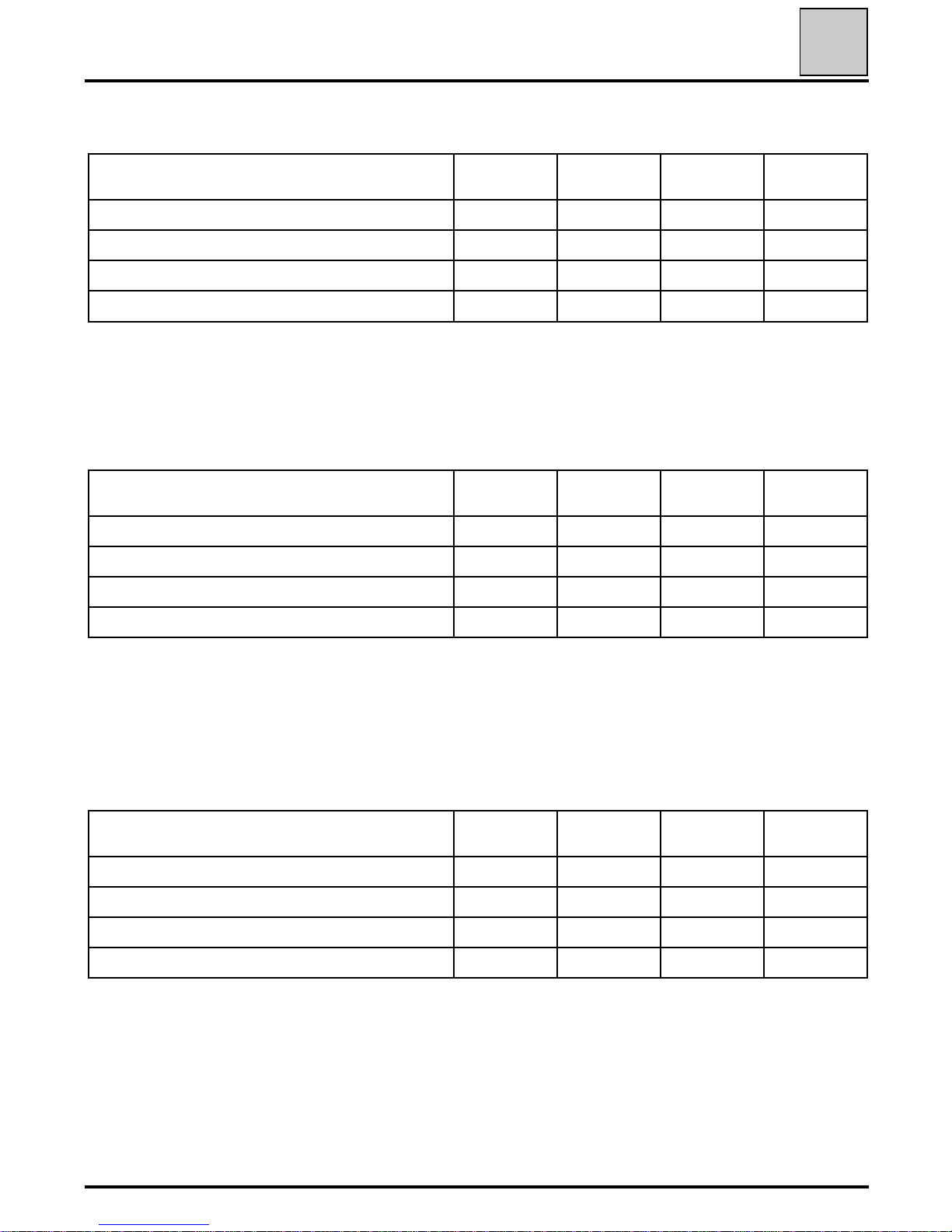

AUTOMATIC TRANSMISSION

Gear change thresholds

23

C06

Pedal

position

1223

No load 19 15 41 29

Full load 65 45 111 92

Kickdown 67 57 113 106

(The kickdown switch is integrated into the

computer).

The figures in the tables indicate the theoretical

average gear change speeds (actual time speed).

These figures may vary depending on the accepted tolerance limits on the component units

and tyres fitted.

No load = Foot off accelerator pedal.

Full load = Kickdown switch disconnected,

full throttle.

Kickdown = Kickdown connected, full throttle.

23-10

AUTOMATIC TRANSMISSION

Gear ratios

23

For vehicles B53A - C53A - L53A - B537 - C537 - L537

Gear ratio 1st 2nd 3rd Reverse

Gear reduction 2.5 1.5 1 2

Gear reduction + stepdown 2.069 1.241 0.828 1.655

Overall reduction 7.999 4.799 3.199 6.399

Speed in km/h per 1000 rpm. * 12.937 21.562 32.343 16.171

For vehicles B53B - C53B - L53B

Gear ratio 1st 2nd 3rd Reverse

Gear reduction 2.5 1.5 1 2

Gear reduction + stepdown 2.069 1.241 0.828 1.655

Overall reduction 7.370 4.422 2.948 5.896

Speed in km/h per 1000 rpm. * 14.042 23.403 35.105 17.552

* For vehicles fitted with 165/70 R13 tyres.

For vehicles B 573 - C 573

Gear ratio 1st 2nd 3rd Reverse

Gear reduction 2.5 1.5 1 2

Gear reduction + stepdown 2.069 1.241 0.828 1.655

Overall reduction 7.370 4.422 2.948 5.896

Speed in km/h per 1000 rpm. * 13.431 22.385 33.578 16.789

* For vehicles fitted with 165/65 R13 tyres.

23-11

AUTOMATIC TRANSMISSION

Gear ratios

23

For vehicles C06

Gear ratio 1st 2nd 3rd Reverse

Gear reduction 2.5 1.5 1 2

Gear reduction + stepdown 2.069 1.241 0.827 1.655

Overall reduction 8 4.8 3.2 6.4

Speed in km/h per 1000 rpm. 12.52 20.87 31.31 15.656

For vehicles F40

Gear ratio 1st 2nd 3rd Reverse

Gear reduction 2.5 1.5 1 2

Gear reduction + stepdown 2.069 1.241 0.827 1.655

Overall reduction 8 4.8 3.2 6.4

Speed in km/h per 1000 rpm. 13.2 22 33 16.5

Tyres: 155 R 13.

Tyres: 155/70 R 13.

23-12

AUTOMATIC TRANSMISSION

Specifications

23

RRRREEEEPPPPLLLLAAAACCCCEEEEMMMMEEEENNNNTTTT IIIINNNNSSSSTTTTRRRRUUUUCCCCTTTTIIIIOOOONNNNSS

SS

• Damaged brakes or clutch:

1st possibility:

Repair the gear section and clean the final drive,

oil cooler, converter* and check the hydraulic distributor.

2

nd

possibility:

Change the gear section alone. (Adjust the end

float and the oil pressure setting). Or change the

entire automatic transmission (service exchange

or new transmission).

* The cleaning method is given in the "Torque

converter" section.

• Bearing(s) which is/are noisy but not broken:

Change the bearing(s) and the filter.

• Bearing(s) or other mechanical component

damaged:

If the damage is extensive, change the automatic

transmission (service exchange or new transmission).

For a service exchange:

Return the worn transmission with the packaging

in which the new part was delivered.

Parts to be replaced (after removal)

- roll pins,

- O and square section seals,

- lip seals,

- paper seals,

- bearings (if they have had to be removed),

- circlips,

- differential bank (MJ),

- speedometer drive shaft (MB),

- speedometer drive gears (if they have had to

be removed),

- the entire free wheel (if there is a problem),

- the quadrants with the drive hub (if they are

seized in the hub).

Consumables

Name Packaging To be used for:

LOCTITE FORMAJOINT 50 ml bottle Housing joint faces

LOCTITE FRENETANCH 24 ml bottle 1 drop on converter drive plate

bolt at crankshaft end.

LOCTITE SCELBLOC 24 ml bottle 1 drop on converter seal (MB).

Transmission oil

ELF RENAULTMATIC D2 or

MOBIL ATF 220

Immersion of all parts before

assembly (except those for ML

final drive).

Final drive oil

SAE 80 W or 75 W

Immersion of final drive

components (ML).

23-13

AUTOMATIC TRANSMISSION

Maintenance

23

MMMMBBBB....MMMMJJJJ

automatic transmissions have a single oil level and a single oil grade for all sections (converter, final

drive, gear section). ML type automatic transmission has two different oil levels and grades .

1°) Oil for MB.MJ automatic transmission and for ML converter and gear section

Grade:

EEEELLLLFFFF RRRREEEENNNNAAAAUUUULLLLTTTTMMMMAAAATTTTIIIICCCC DDDD22

22

otherwise use MOBIL ATF 220

Capacity in litres (approximately) :

AT MB MJ ML

Theoretical total 4.5 6 5

After oil change 2 2.5 2.5

2°) Oil for ML final drive section

AAAAPPPPIIII GGGGLLLL55

55

Oil grade or

MMMMIIIILLLL LLLL2222111100005555 BBBB oooorrrr CC

CC

SAE 80 W: Hot and temperate countries

Viscosity SAE 75 W: Cold countries

Capacity in litres: Final drive 0.8

23-14

AUTOMATIC TRANSMISSION

Maintenance

23

85546R1

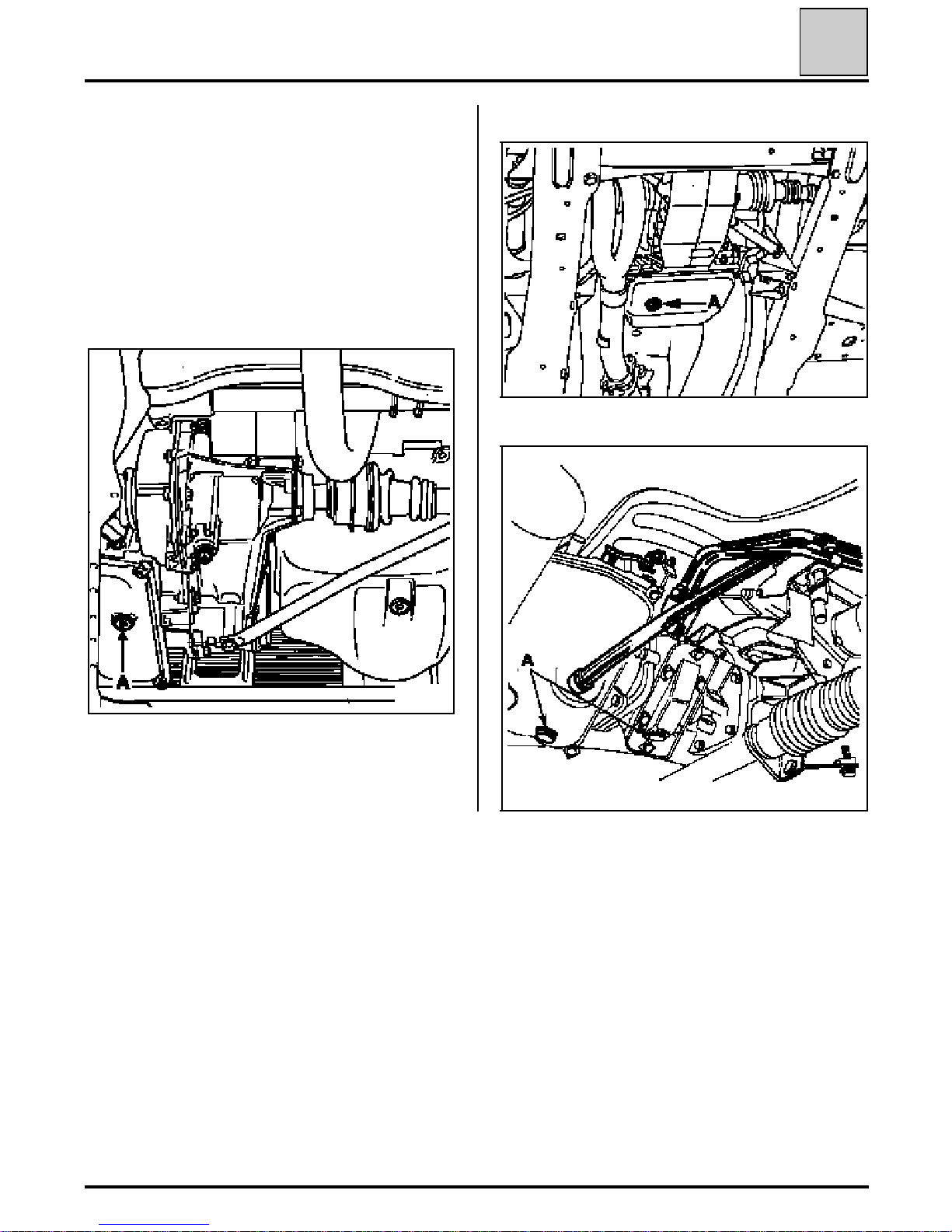

DDDDRRRRAAAAIIIINNNN ---- RRRREEEEFFFFIIIILLLLLL

LL

ML, MB and MJ gear sections

The oil must be drained when the engine is cold

and with dipstick and plugs (A) removed.

Allow the oil to drain out for as long as possible.

Refit the plugs with new seals.

DI2330

MJ

ML

88148R

MB

23-15

AUTOMATIC TRANSMISSION

Maintenance

23

87297R

The oil is refilled via the dipstick tube.

Use a funnel fitted with a 15/100 mesh filter to

trap any impurities in the oil.

When the oil has been drained, refill with the rec-

ommended oil.

Start the engine and let it idle, check the oil level

and top up if necessary.

EXAMPLE : MB

MJ

85935R1

Fit plug (C).

The oil is refilled through plug (B) and the oil

should be level with the bottom of the aperture

of plug (B).

CCCCHHHHEEEECCCCKKKKIIIINNNNGGGG TTTTHHHHEEEE LLLLEEEEVVVVEEEELLLL ((((ggggeeeeaaaarrrr sssseeeeccccttttiiiioooonnnn ooooiiiillll))

))

The vehicle must be unladen.

The oil is at ambient temperature (engine cold).

Place the vehicle on a flat, horizontal surface.

Place the selector lever in "Park" (P).

Start the engine and wait one or two minutes for

the converter and cooler to fill with oil

Remove the dipstick with the engine running.

The oil level must not be below the MIN COLD

mark (risk of damage) or above the MAX COLD

mark (risk of damage).

2) ML final drive

The oil must be drained with plugs (B) and (C) removed.

84495R

A Min cold

B Max cold

AAAATTTTTTTTEEEENNNNTTTTIIIIOOOONNNN::

::

Too much oil will lead to

- the oil overheating abnormally,

- leaks.

Too little oil will lead to:

- the gear section being damaged.

23-16

AUTOMATIC TRANSMISSION

Maintenance

23

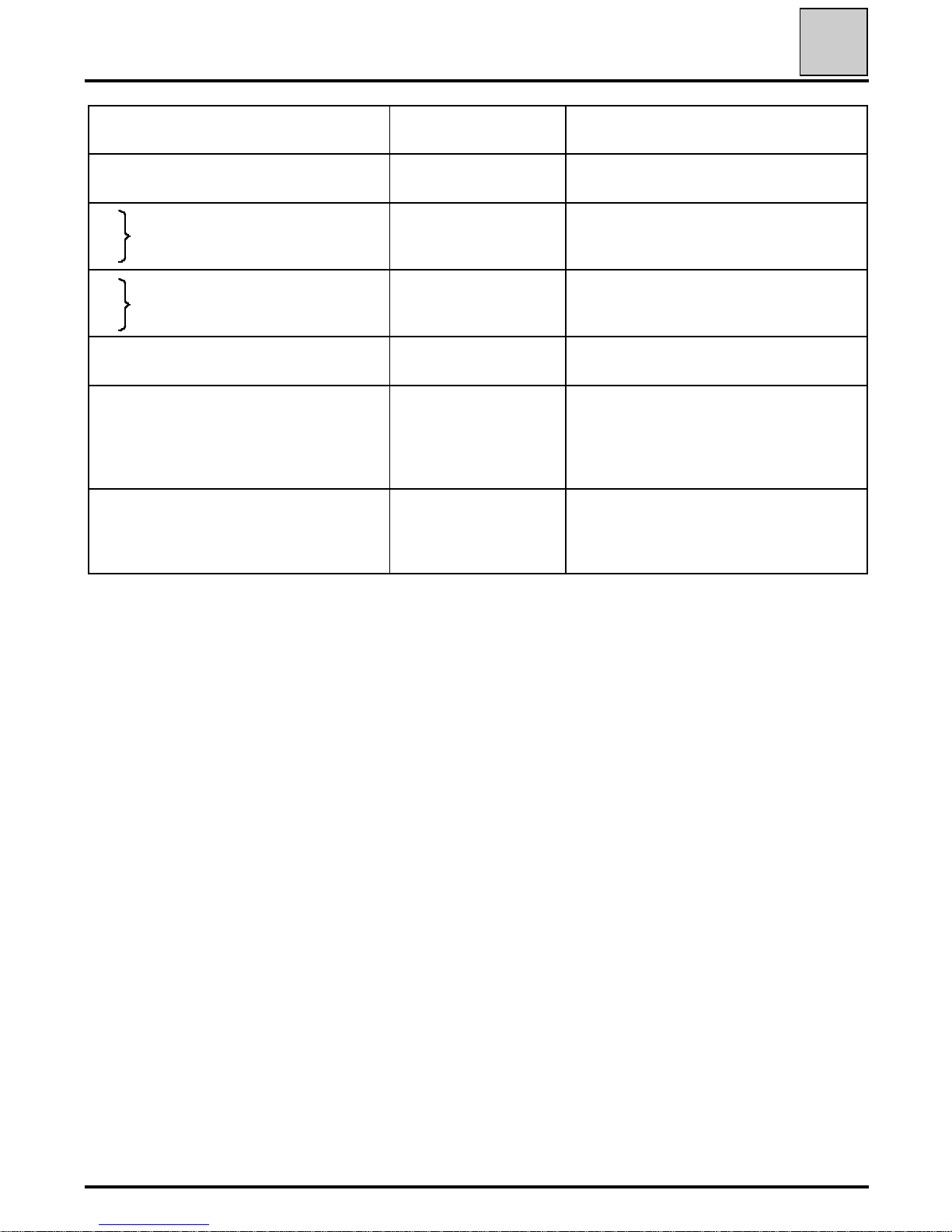

CCCCOOOONNNNFFFFOOOORRRRMMMMIIIITTTTYYYY OOOOFFFF TTTTHHHHEEEE DDDDIIIIPPPPSSSSTTTTIIIICCCCKK

KK

IIIIMMMMPPPPOOOORRRRTTTTAAAANNNNTTTT::

::

in order to ensure that the oil level is correct, you must check the conformity of the dipstick .

1341 - 1342 - 1351 - 1352 - 1362

No PAS - no CA

Grey (1)

L = 225 mm

MJ1 001

1341 - 1342 - 1351 - 1352 - 1362

with PAS and CA

Yellow (1)

L = 660 mm

MJ1 500

501

1343 - 1353 - 1363 - 1277 - 1279

B29E - B297 - B29B

Green (1)

L = 243 mm

MJ3 301

350

010

012

112

120

122

110

B29E - B29B - B297

L/K 483 - L/K 48K - L/K 489

Blue (2)

L = 247 mm

MJ3 015

016

115

116

125

126

800

801

B/C 403 - B/C 408 - B/C 40J

L423 - B/C 373

Green (2)

L = 243 mm

MB3 All types

MB1 000 011 021

001 013 504

002 015 600

003 017 601

007 019 602

L423 - L426 Red (1)

L = 252 mm

MB1 500

501

502

503

C40J - C403/B Red (2)

L = 243 mm

MB1 500

501

502

503

C57/3/B Red (2)

L = 243

Orange (2)

L = 231 mm

MB1 024

026

MB1 029

F40 Violet (2)

L = 347 mm

MB1 031

038

L423 - B/C 373 DAI

with air pre-filter

White (1)

L = 324 mm

MB1 500

501

502

503

23-17

AUTOMATIC TRANSMISSION

Maintenance

23

1344 - 1354 Yellow (1)

L = 240 mm

MJ3 200

201

L/K 48A

(deeper sump)

Grey (2)

L = 247 mm

MJ3 761

762

B

C 53B

L

Red (2)

L = 243 mm

MB3 003

005

B

C 537

L

Yellow (2)

L = 334 mm

MB1 023

027

X06 Light grey (2)

L = 338 mm

MB1 033

C373 Green (2)

L = 243 mm

MB1 001 011 019

002 013 021

003 015 504

007 017

MB3

B373 (1)

L = 252 mm

MB1 500

501

502

503

23-18

AUTOMATIC TRANSMISSION

Maintenance

23

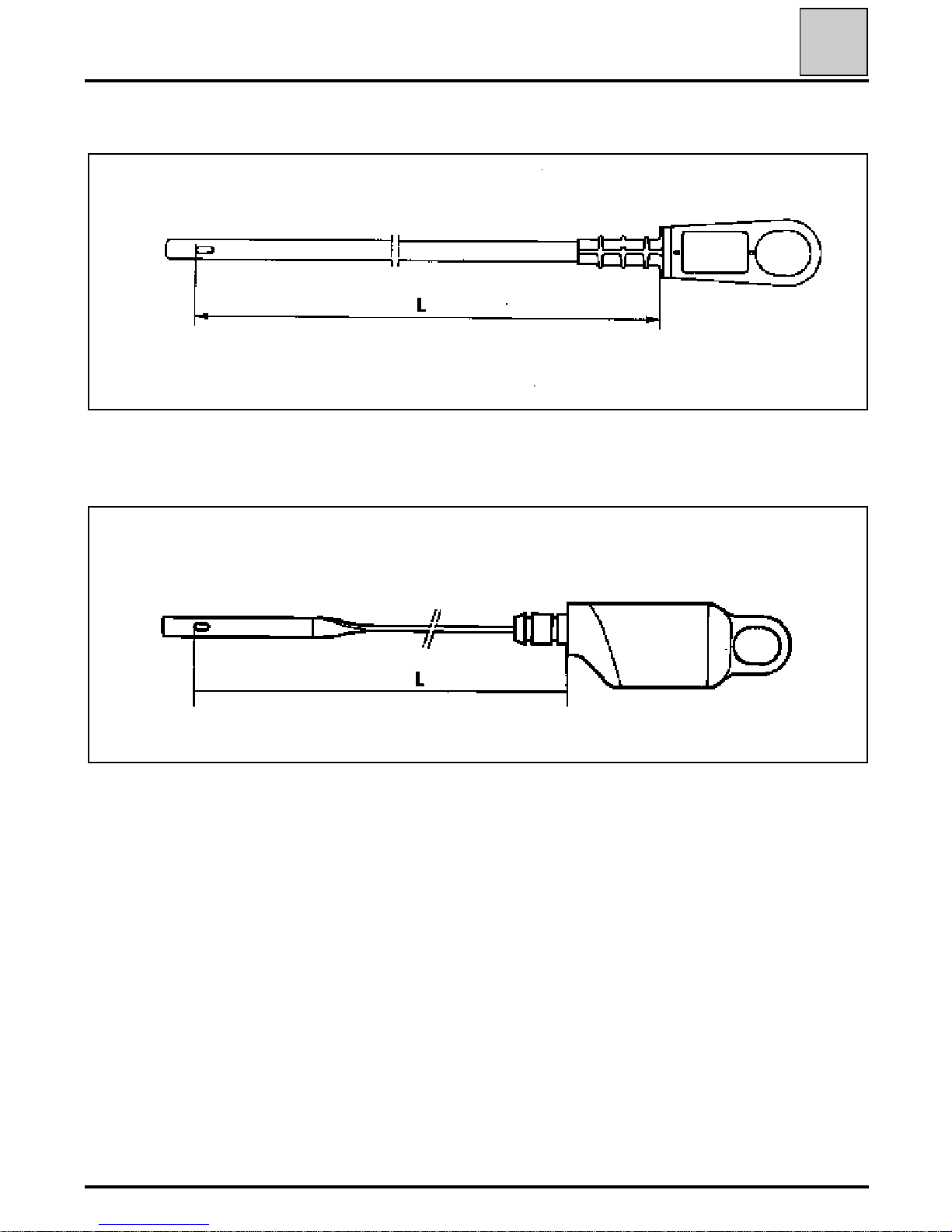

88860R

1

2

91193R1

23-19

AUTOMATIC TRANSMISSION

Identification

23

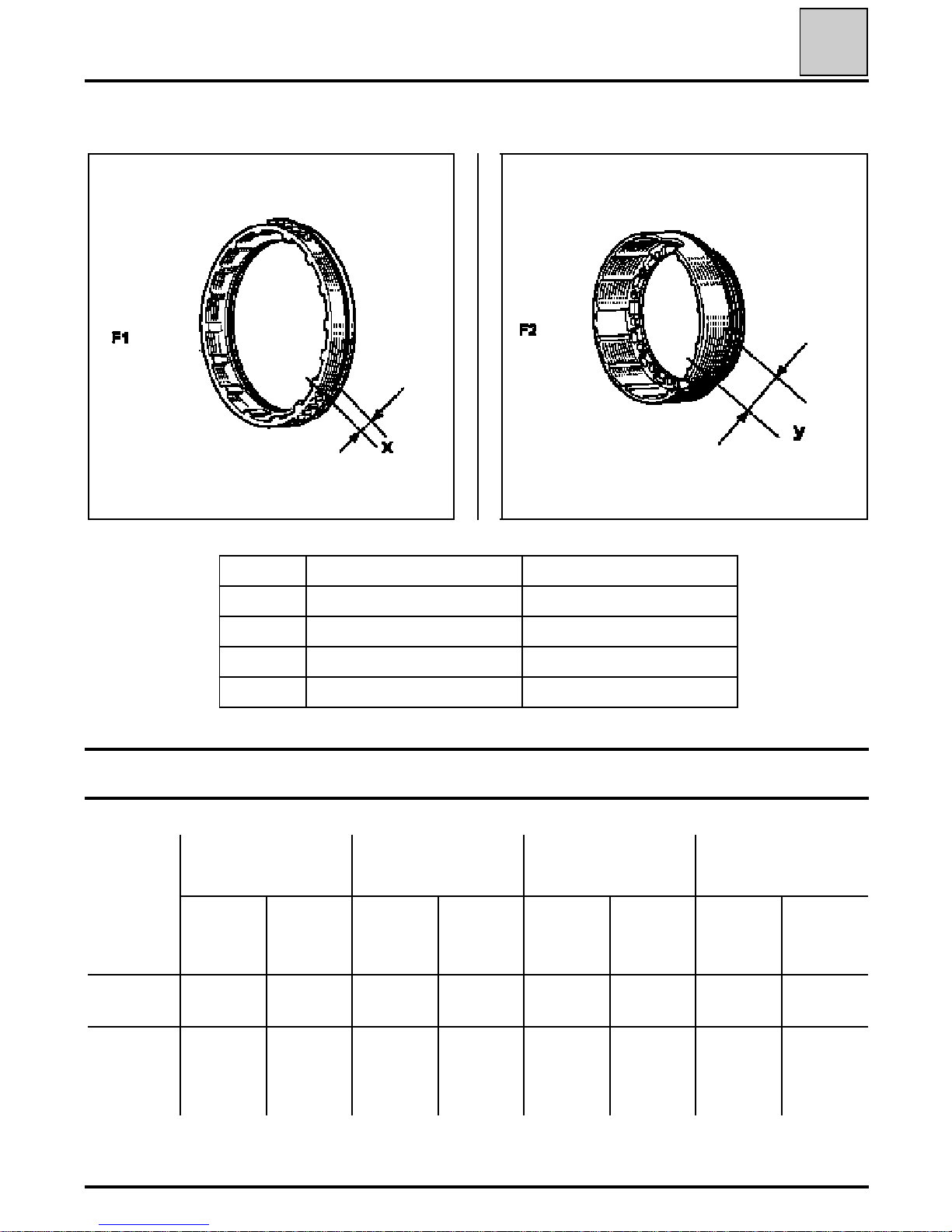

Identification of pistons F1 - F2

DI2332DI2331

AAAA....TTTT..

..

Dimension F1 (x in mm) Dimension F2 (y in mm)

MB1 25.7 ± 0.35 62.4 ± 0.2

MJ 21.8 ± 0.35 58.4 ± 0.2

ML 21.8 ± 0.35 58.4 ± 0.2

MB3 21.8 ± 0.35 58.4 ± 0.2

Number of discs

TTTTYYYYPPPPEE

EE

OF

AT

F1

Steel discs

Lined

discs

F2

Steel discs

Lined

discs

E1

Steel discs

Lined

discs

E2

Steel discs

Lined

discs

MB1 33434444

MJ

ML

MB3

44545555

One undulated disc is fitted to each group of brakes and clutches.

23-20

AUTOMATIC TRANSMISSION

Operation of the transmission

OOOOPPPPEEEERRRRAAAATTTTIIIINNNNGGGG CCCCOOOOMMMMPPPPOOOONNNNEEEENNNNTTTTSS

SS

23

DI2333

A Park wheel

23-21

AUTOMATIC TRANSMISSION

Operation of the transmission

OOOOPPPPEEEERRRRAAAATTTTIIIINNNNGGGG CCCCOOOOMMMMPPPPOOOONNNNEEEENNNNTTTTSSSS

23

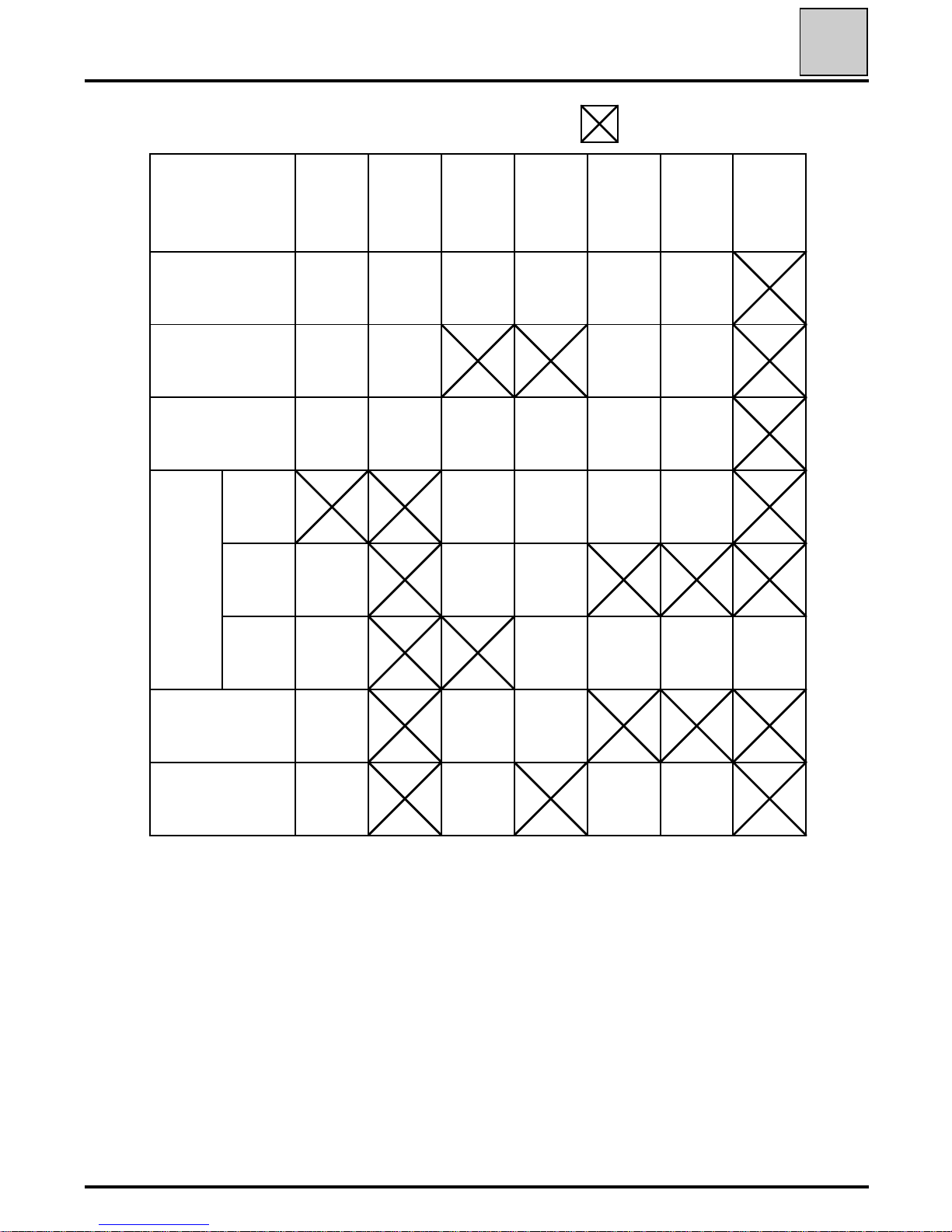

Lever

position

P

R

N

D

2222nnnndddd GGGGEEEEAAAARRRR HHHHOOOOLLLLDD

DD

RL E1 E2 F1 F2 EL1 EL2

1111sssstttt GGGGEEEEAAAARRRR HHHHOOOOLLLLDD

DD

RL = Free wheel

E1 = Clutch 1

E2 = Clutch 2

F1 = Brake 1

F2 = Brake 2

EL1 = Solenoid pilot valve 1

EL2 = Solenoid pilot valve 2

1

2

3

23-22

AUTOMATIC TRANSMISSION

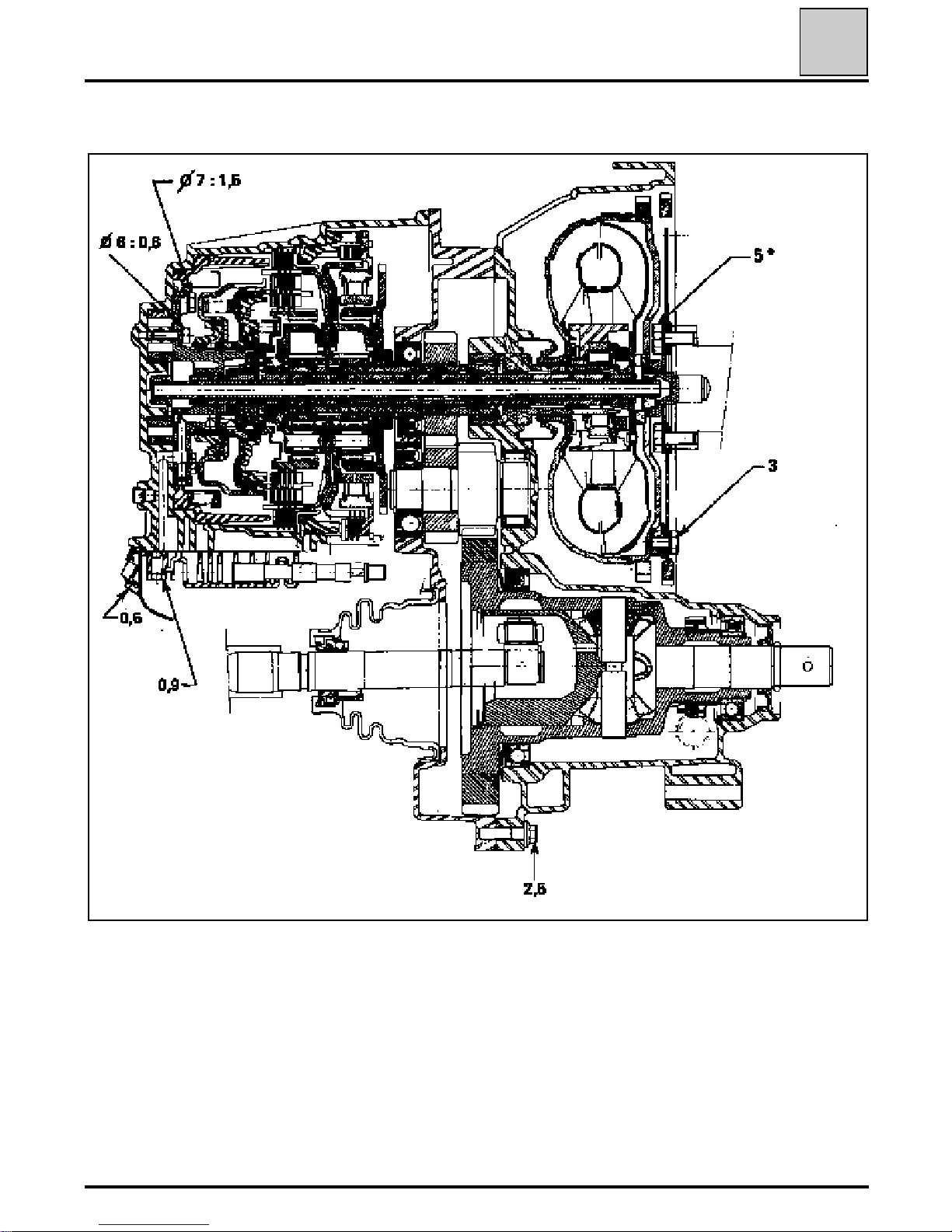

Cross section and tightening torques (in daN.m)

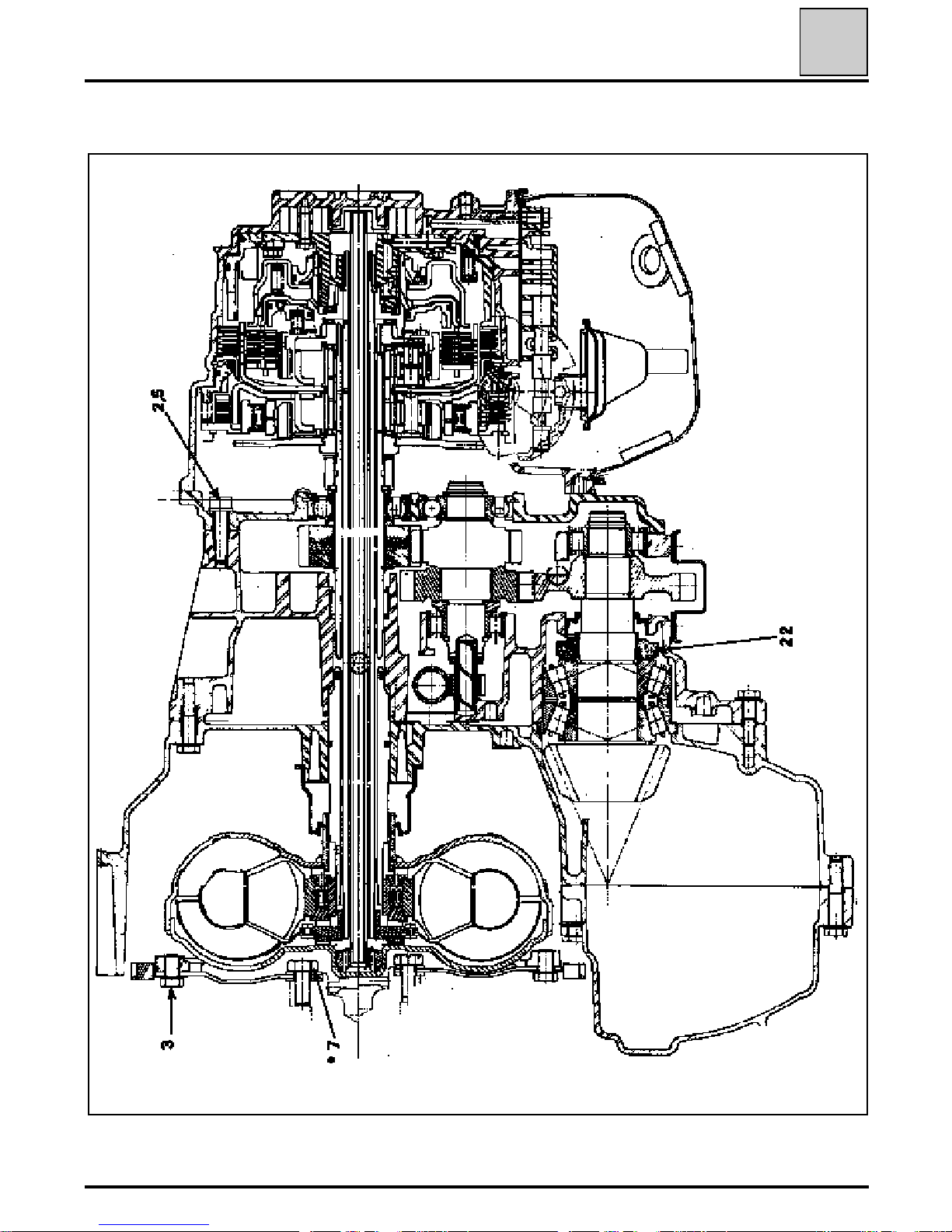

MMMMBBBB AAAAUUUUTTTTOOOOMMMMAAAATTTTIIIICCCC TTTTRRRRAAAANNNNSSSSMMMMIIIISSSSSSSSIIIIOOOONN

NN

23

* Bolts coated with "

LLLLooooccccttttiiiitttteeee FFFFRRRREEEENNNNEEEETTTTAAAANNNNCCCCHH

HH

".

86293-1R

23-23

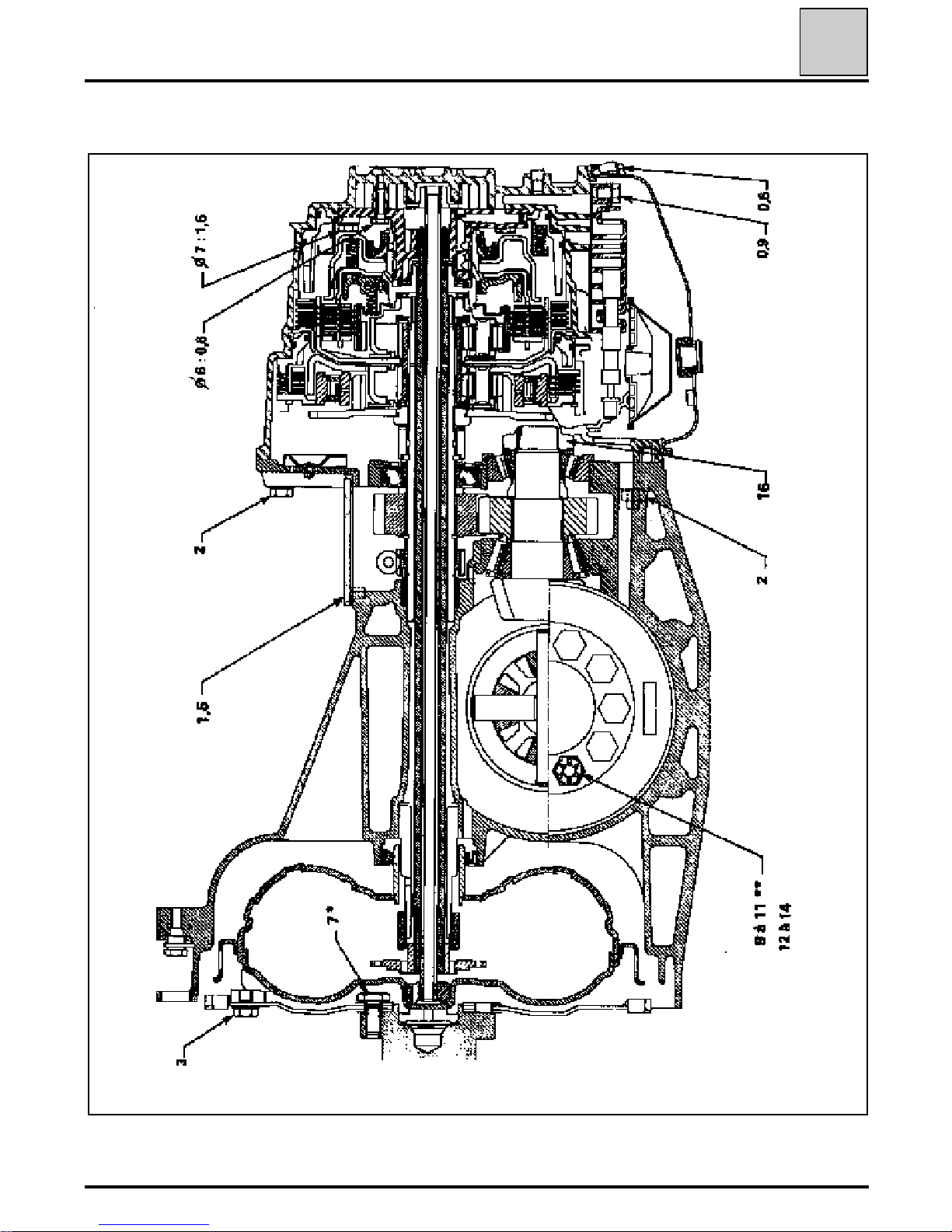

AUTOMATIC TRANSMISSION

Cross section and tightening torques (in daN.m)

MMMMJJJJ AAAAUUUUTTTTOOOOMMMMAAAATTTTIIIICCCC TTTTRRRRAAAANNNNSSSSMMMMIIIISSSSSSSSIIIIOOOONN

NN

23

* Bolts coated with "

LLLLooooccccttttiiiitttteeee FFFFRRRREEEENNNNEEEETTTTAAAANNNNCCCCHH

HH

".

85615R

Differential cover

plate: 2

23-24

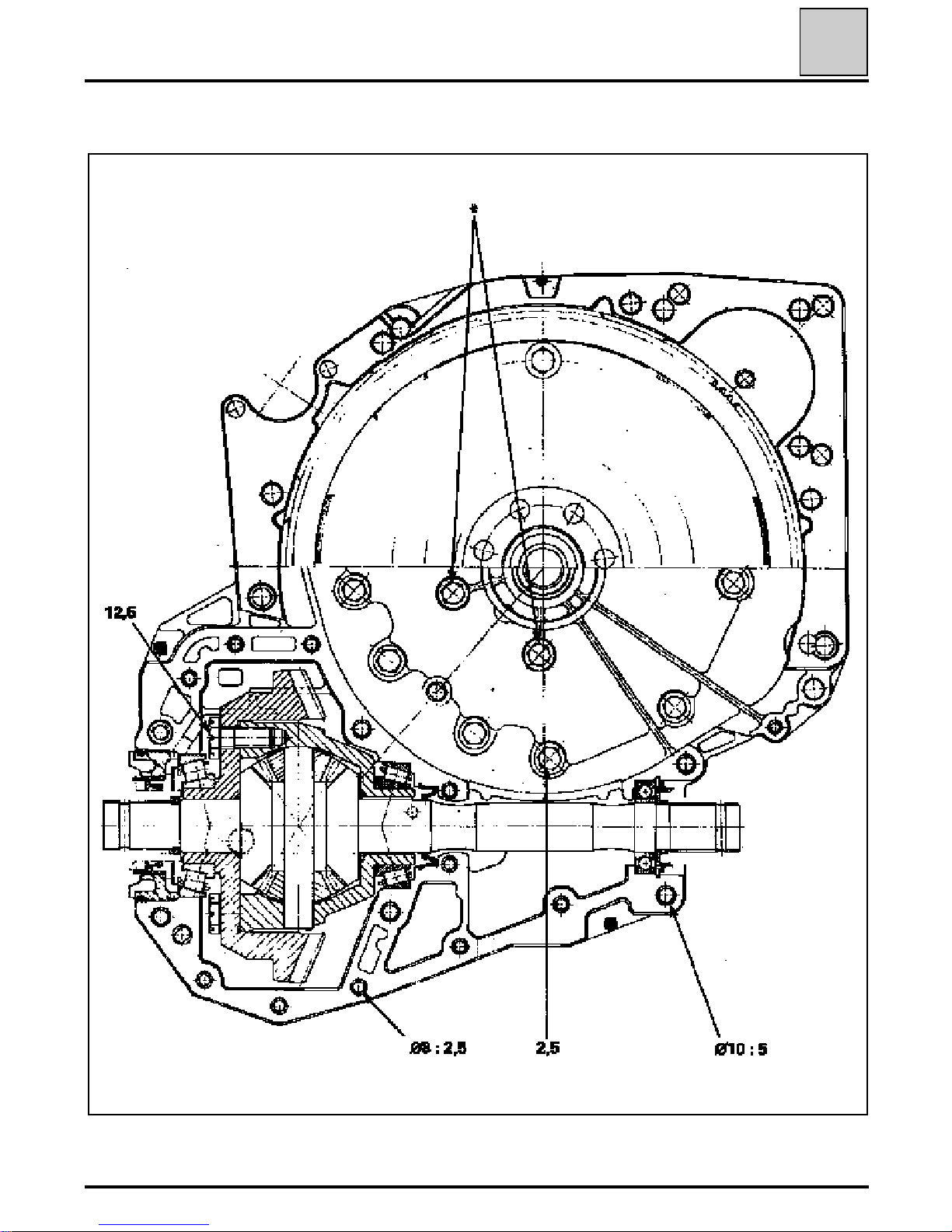

AUTOMATIC TRANSMISSION

Cross section and tightening torques(in daN.m)

MMMMLLLL AAAAUUUUTTTTOOOOMMMMAAAATTTTIIIICCCC TTTTRRRRAAAANNNNSSSSMMMMIIIISSSSSSSSIIIIOOOONN

NN

23

Gear train housing bolts on spacer housing... 2.5.

* Bolts coated with "

LLLLooooccccttttiiiitttteeee FFFFRRRREEEENNNNEEEETTTTAAAANNNNCCCCHH

HH

".

DI2334

23-25

AUTOMATIC TRANSMISSION

Cross section and tightening torques (in daN.m)

MMMMLLLL AAAAUUUUTTTTOOOOMMMMAAAATTTTIIIICCCC TTTTRRRRAAAANNNNSSSSMMMMIIIISSSSSSSSIIIIOOOONN

NN

23

* Pre-coated with "

LLLLooooccccttttiiiitttteeee FFFFOOOORRRRMMMMAAAAJJJJOOOOIIIINNNNTT

TT

".

DI2335

23-26

AUTOMATIC TRANSMISSION

Strainer

23

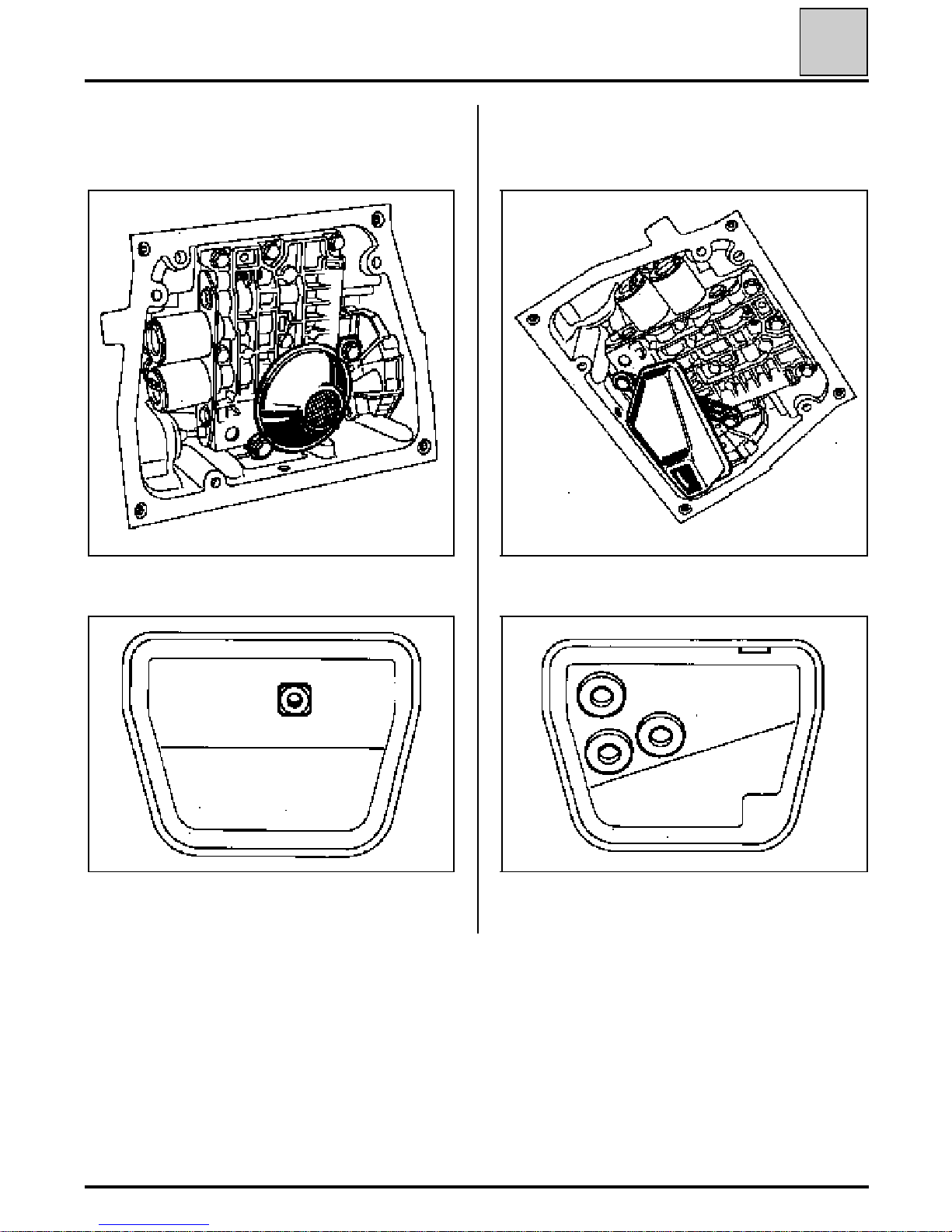

The strainer filters the oil and ensures that the

automatic transmission operates correctly.

Tightening torques (in daN.m)

Distributor bolt 0.9

(strainer bolt)

Sump bolts 0.6

RRRREEEEMMMMOOOOVVVVAAAALL

LL

Drain the oil and remove:

- the sump (for vehicles fitted with

MMMMBBBB AAAAUUUUTTTTOOOO--

--

MMMMAAAATTTTIIIICCCC TTTTRRRRAAAANNNNSSSSMMMMIIIISSSSSSSSIIIIOOOONN

NN

, this must be raised

up),

- the strainer and its seal.

Before refitting, clean the sump and its magnets

and replace them as shown in the diagrams (see

following page).

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

GG

Refit:

- the new strainer with its seal, check the as-

sembly direction (see diagram) and tighten to

a torque of 0.9 daN.m,

- the sump and refill with oil.

23-27

AUTOMATIC TRANSMISSION

Strainer

23

Original fitment

MMMMBBBB ---- MMMMJJ

JJ

88163-2S

With sump.

88162-1S

Second fitment (check assembly direction)

MB

88163-5S

With sump and three magnets*.

88162-3S

* Direction for fitting magnets: ribbed side

against plate.

23-28

Loading...

Loading...