CLA 2 5 - 1 0 0

Au t om at i c

Oi l / Gas Hea ter s

Ed i t i on GB- 7 0 9

Oper a t i on

Tech n ol og y

Or i g i n a l

REM KO

Sp a r e Pa r t s

REM KO - al l es b är en st a r k .

Op er a t i n g i nst r uct i ons

Make sure to read these instructions carefully before starting/using the unit!

Our guarantee will become void when the unit supplied by us is used and

installed for inadequate purposes, or maintained incorrectly, etc.,

or if it is changed without our prior consent.

M ob i l e o i l / ga s he a t er s

CLA 25 / 40 / 50

Con t en t s Page

Safety Hints 3

Installation Requirements 3-4

Waste Gas Pipes 4

Safety Facility 5

Starting 5-6

Shut Down 6

Maintenance 7

Always keep these operating instructions near or on the device!

G

CLA 100

Con t en t s Page

Service 7

Drawing CLA 8

List of Spare Parts CLA 9

Technical Data CLA 10

Wiring Diagram 10

Troubleshooting Instructions 11

G

2

Saf et y Hi nt s

When using this unit make sure always to observe

the applicable building- and fire-protection regula-

tions as well as the rules of the trade cooperative

association.

• The unit may be operated only by those persons who

have been instructed accordingly.

• The unit is to be installed and operated in such a way

as to ensure that the employees are not endangered

by waste gases and radiation heat and that no fire

can break out.

• The unit may only be installed and operated in rooms,

when the air-rate fed to the unit is sufficient for com-

bustion.

• Mobile fuel reservoirs may be installed only when the

technical rules for combustible liquids “TRBF 210 and

280” are observed.

• Units without waste gas pipes my be operated only

in well aerated rooms.

• Persons are not allowed to stay permanently in the

room where the unit has been installed. Relevant pro-

hibition signs are to be fastened to the entrances.

• The unit is to be installed only on a non-combustible

ground.

• The unit may not be installed and operated in in-

flammable and explosive surroundings.

• A safety zone of 1.5 m around the unit and a mini-

mum distance of 3 m at the unit’s waste gas opening

are to be observed, even regarding non-combustible

objects.

• The protective air suction lattice is always to be kept

free from dirt and loose objects.

• Make sure not to introduce foreign matters into the

unit.

• Make sure not to expose the unit to direct water jets.

• All electric cables outside the unit are to be protected

from damage (e.g. caused by animals, etc.).

• Make sure always to pull the mains plug out of

the mains socket when maintenance and repairs

are carried out.

• An operation or use other than that indicated

in these operating instructions is prohibited!

In case of non-observation we will not be held

responsible and our guarantee will become void.

I n sta l l a ti on Requ i r e-

m en t s

The heaters may only be installed and operated in com-

pliance with the relevant regulations, especially regula-

tions governing the installation and operation of fire-

places and furnaces.

Operators

The units may be operated only by persons who have

been trained in this field.

Installation

Install the heaters in a stable position.

Install and operate the heaters so as to avoid any ha-

zard to the personnel by fumes and radiation heat, well

as to avoid any risk of fire.

The heaters may only be installed and operated inside

rooms if they are supplied with sufficient air for combus-

tion and if the flue gases escape into the open through

flue-pipes.

The air supply is sufficient for combustion when, for

example, the cubic capacity of a room is at least ten

times the nominal thermal load of all heaters in the

room, and a natural exchange of air is ensured by me-

ans of windows and doors.

Heaters without waste gas pipe may be used in rooms,

provided that these are well aerated and the percentage

of substances which are injurious to health in the brea-

thed in air do not reach inadmissible concentrations.

The airing is sufficient when, for example,

1. the room capacity in m³ is at least 30 times the nomi-

nal thermal load in kW of all heaters in the room, and

a natural exchange of air is ensured by means of

windows and doors, or

2. there are air inlet and outlet openings, which cannot

be closed, near the ceiling and the ground; the size

of which in m² must be at least 0.003 times the nomi-

nal load in kW of all heating devices in the room.

Do not install or operate the heaters in rooms or areas

exposed to fire or explosion hazards.

Room Drying

The heaters may be operated in order to dry rooms with-

out evacuating the generated gases through waste gas

pipes outside, if the air supplied to those rooms is suffi-

cient for combustion. Persons are not allowed to stay

permanently in those rooms. Relevant prohibition signs

are to be fixed at the entrances.

Test

The units are to be tested depending on the operational

conditions when necessary, but a least once a year as

to their operational reliability. These tests are to be car-

ried out by an expert.

3

The burner is to be tested to determine its waste gas

values.

Supervision

The persons charged with the operation of the units

have to control the units before starting to work to make

sure that there are no visible defects on the control and

safety devices and that all the protection devices have

been correctly set.

If defects are detected, the supervisor is to be informed.

If the detected defects jeopardize the unit’s operational

safety, the unit is to be put out of action.

Open-air Installation

Heaters operated in the open air must be so installed

and protected against atmospheric influence that they

do not cause any hazards or inacceptable annoyance.

We recommend that a burner cover (REMKO accesso-

ries) is used.

Installation in closed, well aerated rooms wi-

thout connection to a chimney

The operation of the units is admissible when the mini-

mum air quantity needed for combustion is supplied.

A safe exhaustion of the waste gases is to be ensured

to exclude inadmissible pollution.

Fresh air is fed from below ;

waste gases are exhausted towards the top.

Room Heating

For room heating, hot air generators may only be ope-

rated with a room thermostat (accessories). Make sure

that sufficient fresh air is fed to ensure perfect combus-

tion. Fresh air is to be fed preferrably through windows

and doors or through sufficiently dimensioned openings

in the outer wall.

Attention!

Avoid under- or overpressure in the room where the unit

is installed, as this would result in combustion troubles.

Please make absolutely sure that the suction and out-

going air opening is adapted to the fan power con-

cerned (see rating plate).

If this is not possible, the burner has to be equipped

with a separate air supply device to ensure perfect com-

bus-tion.

Safety Distances

Make sure to observe the following safety distances to

ensure a safe operation of the unit:

- towards the top, without waste gas pipe 3,0 m

- towards the top, fire-retarding ceiling 1.5 m

- towards the sides, non-burning objects 0.6 m

- blow-off side, non-burning objects 3.0 m

- suction side, for perfect air supply 1.0 m

The floor and the ceiling must be from fire-retarding

materials. Suction and blow-off cross sections may not

be reduced.

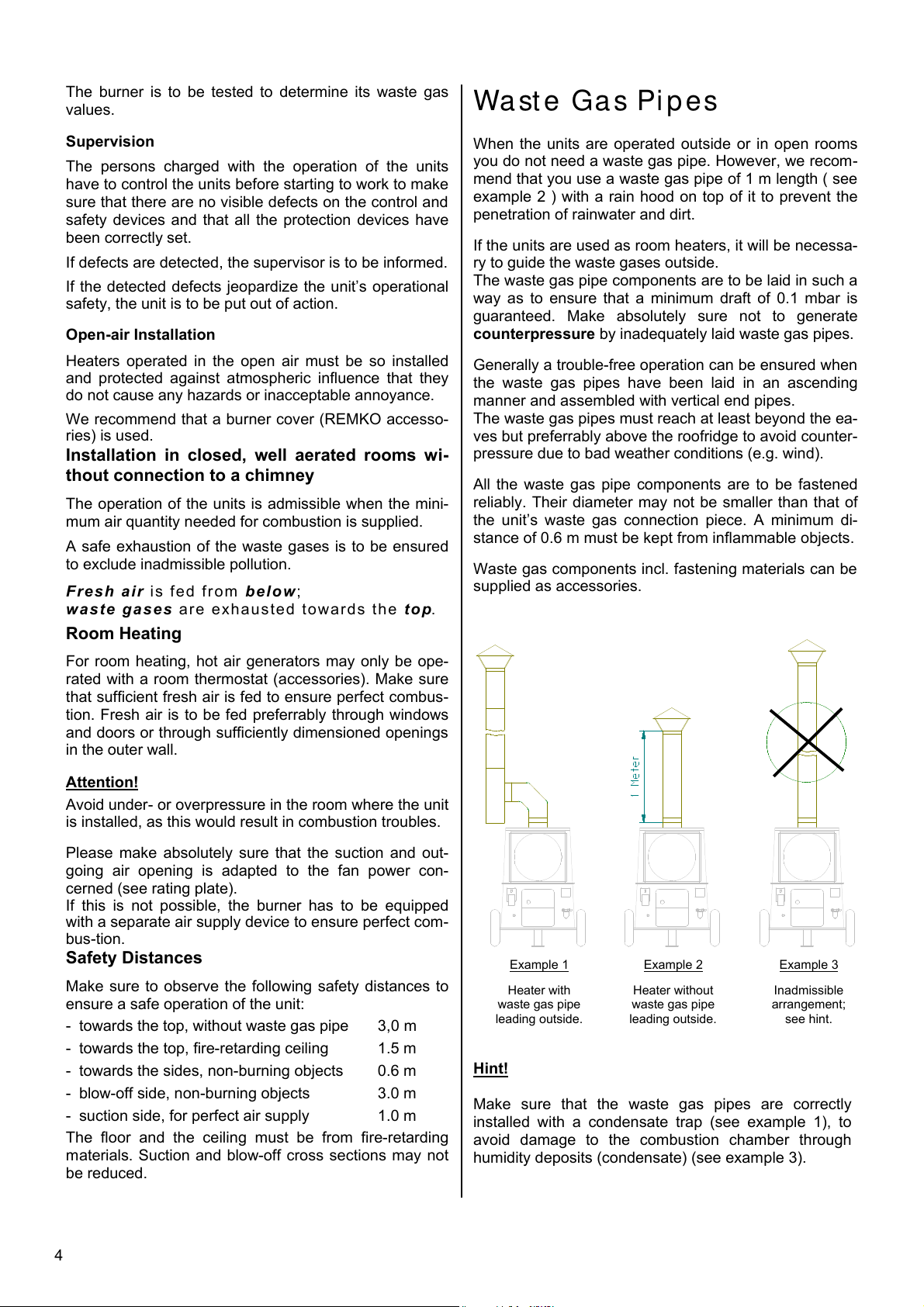

Wa st e Ga s Pi pes

When the units are operated outside or in open rooms

you do not need a waste gas pipe. However, we recom-

mend that you use a waste gas pipe of 1 m length ( see

example 2 ) with a rain hood on top of it to prevent the

penetration of rainwater and dirt.

If the units are used as room heaters, it will be necessa-

ry to guide the waste gases outside.

The waste gas pipe components are to be laid in such a

way as to ensure that a minimum draft of 0.1 mbar is

guaranteed. Make absolutely sure not to generate

counterpressure by inadequately laid waste gas pipes.

Generally a trouble-free operation can be ensured when

the waste gas pipes have been laid in an ascending

manner and assembled with vertical end pipes.

The waste gas pipes must reach at least beyond the ea-

ves but preferrably above the roofridge to avoid counter-

pressure due to bad weather conditions (e.g. wind).

All the waste gas pipe components are to be fastened

reliably. Their diameter may not be smaller than that of

the unit’s waste gas connection piece. A minimum di-

stance of 0.6 m must be kept from inflammable objects.

Waste gas components incl. fastening materials can be

supplied as accessories.

Example 1

Heater with

waste gas pipe

leading outside.

Hint!

Make sure that the waste gas pipes are correctly

installed with a condensate trap (see example 1), to

avoid damage to the combustion chamber through

humidity deposits (condensate) (see example 3).

Example 2

Heater without

waste gas pipe

leading outside.

Example 3

Inadmissible

arrangement;

see hint.

4

Saf et y Fa cil i t y

Triple combination control according to DIN 3440

The device has 3 functions:

1. Fan Control (TR)

The tripping point is set with the adjusting lever (fan).

Rated value approx. 35 to 40°C.

2. Burner Temperature Monitor (TW)

The tripping point is set with the adjusting lever

(burner). Rated value approx. 110 to 115°C.

3. Safety Temperature Limiter (STB)

The tripping point is fixed according to DIN 3440.

After tripping, a burner restart is prevented.

The reset button is operated from outside.

Before a reset, check the operating conditions

G

of the device to ensure that the STB-

temperature is not exceeded again.

TR

Switching

lever

Switching Lever

"AUTO" Automatic control of the air supply fan via fan

control (TR) depending on the temperature of the air.

"MAN" The fan works independent of the temperature

of the air and can be used for continuous ventilation.

Note!

The device is equipped with a sensor monitoring feature

and is cold-resistant down to -20°C; below -20°C the de-

vice switches off; when the temperature rises above this

temperature, it switches on again.

When the sensor or the capillary tube is damaged, or

when an overtemperature of approximately 220°C is re-

ached, the filling medium is emptied and the device per-

forms a safety switch-off operation.

The device is no longer operable and must be replaced.

When the safety facility has to be replaced, take care not

to damage or excessively bend the capillary tubes. Use

only the original spare part, reference no. 1102561.

STB

TW

St ar t in g

Make sure to charge a person with the operation and

supervision of the unit who has been instructed

sufficiently regarding the handlings concerned.

Prior to starting, the unit is to be checked to make sure

that there are no visible defects on the control and

safety devices, that the unit has been installed correctly

and that it has been properly connected to the mains.

• Install unit in a stable position.

• Make sure that air is supplied for combustion.

• Make sure that the air can be sucked in and be

exhausted freely.

• Avoid overpressure and underpressure in the room

where the unit has been installed.

• Make sure that enough fuel is supplied.

(only use clean fuel oil EL and diesel, respectively)

Attention!

A sufficient quantity of free-flowing fuel oil must be

available even with low outside temperatures.

Paraffine formation can start even at a temperature of

5° C. Adequate measures are to be taken to avoid this.

Hint!

Any additional clauses of the relevant building

regulations and technical rules for combustible liquids

(TRBF 210 and 280”) are to be observed.

The waste gas values of the oil- or gas-burner are to be

checked and adjusted properly by authorized experts in

accordance with the local conditions.

Connection to the Mains

The units are operated with alternating current of 230 V.

Connection to the mains is carried out by means of an

installed mains cable with earthing-contact plug.

Possibly required extension cables must be selected

according to the existing cable length, the unit’s

connecting line and the intended purpose.

All extension cables are to be used only after

having been removed from the roller.

• Do not bend the sensor spirals near to solder points.

• When mounting, the sensor spirals may not be dama-

ged or bended sharply edged.

• The sensors must be fixed in the mounting brackets

provided by the factory.

• The sensors must always be free from dust and dirt.

Do not jumper or obstruct the safety features while the heater is in operation!

G G

Put operating switch (1) into “0” position

( = OFF).

5

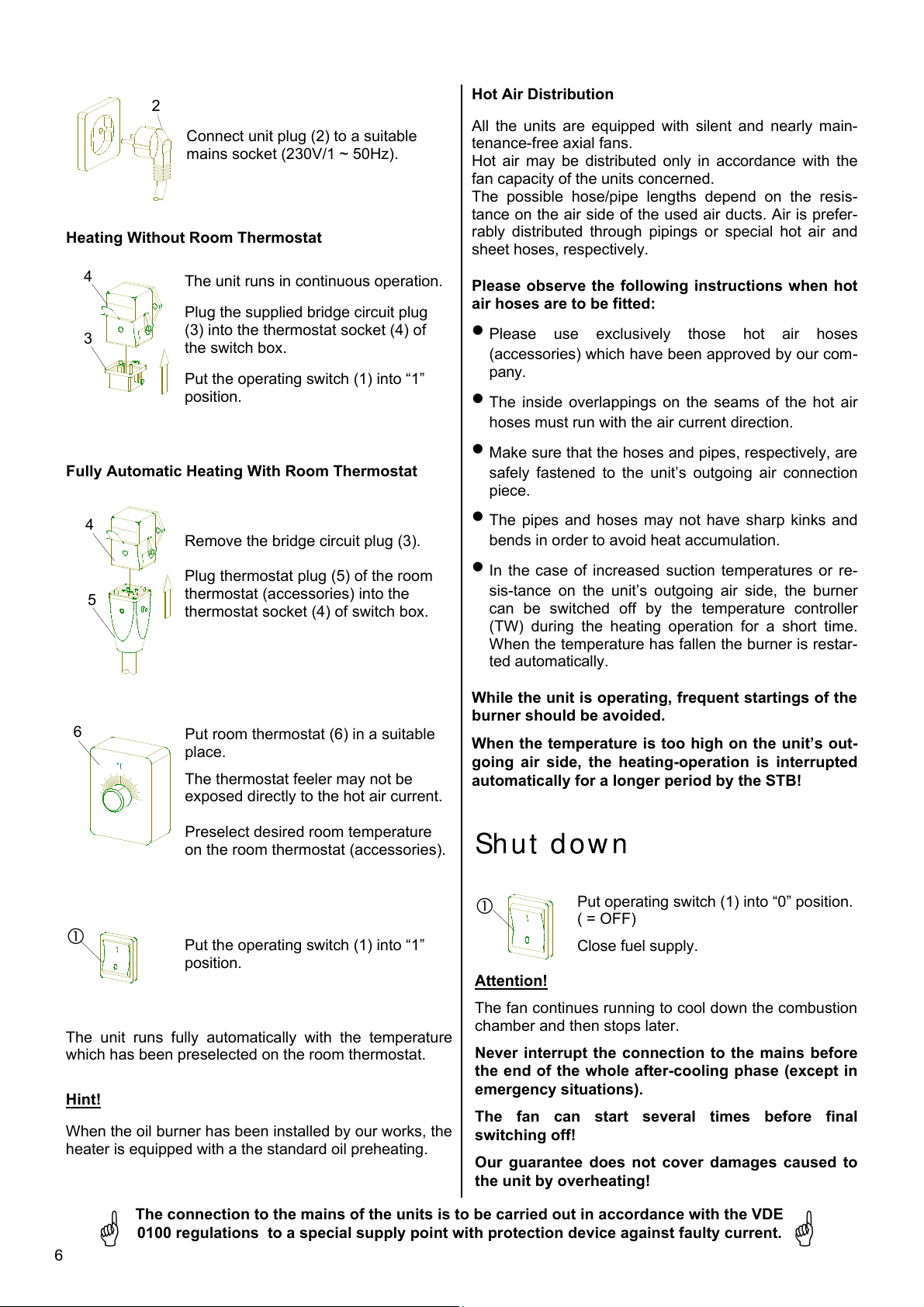

2

Connect unit plug (2) to a suitable

mains socket (230V/1 ~ 50Hz).

Heating Without Room Thermostat

4

3

Fully Automatic Heating With Room Thermostat

The unit runs in continuous operation.

Plug the supplied bridge circuit plug

(3) into the thermostat socket (4) of

the switch box.

Put the operating switch (1) into “1”

position.

Hot Air Distribution

All the units are equipped with silent and nearly main-

tenance-free axial fans.

Hot air may be distributed only in accordance with the

fan capacity of the units concerned.

The possible hose/pipe lengths depend on the resis-

tance on the air side of the used air ducts. Air is prefer-

rably distributed through pipings or special hot air and

sheet hoses, respectively.

Please observe the following instructions when hot

air hoses are to be fitted:

• Please use exclusively those hot air hoses

(accessories) which have been approved by our com-

pany.

• The inside overlappings on the seams of the hot air

hoses must run with the air current direction.

• Make sure that the hoses and pipes, respectively, are

safely fastened to the unit’s outgoing air connection

piece.

4

Remove the bridge circuit plug (3).

Plug thermostat plug (5) of the room

5

6

The unit runs fully automatically with the temperature

which has been preselected on the room thermostat.

Hint!

When the oil burner has been installed by our works, the

heater is equipped with a the standard oil preheating.

thermostat (accessories) into the

thermostat socket (4) of switch box.

Put room thermostat (6) in a suitable

place.

The thermostat feeler may not be

exposed directly to the hot air current.

Preselect desired room temperature

on the room thermostat (accessories).

Put the operating switch (1) into “1”

position.

• The pipes and hoses may not have sharp kinks and

bends in order to avoid heat accumulation.

• In the case of increased suction temperatures or re-

sis-tance on the unit’s outgoing air side, the burner

can be switched off by the temperature controller

(TW) during the heating operation for a short time.

When the temperature has fallen the burner is restar-

ted automatically.

While the unit is operating, frequent startings of the

burner should be avoided.

When the temperature is too high on the unit’s out-

going air side, the heating-operation is interrupted

automatically for a longer period by the STB!

Shut d ow n

Attention!

The fan continues running to cool down the combustion

chamber and then stops later.

Never interrupt the connection to the mains before

the end of the whole after-cooling phase (except in

emergency situations).

The fan can start several times before final

switching off!

Our guarantee does not cover damages caused to

the unit by overheating!

Put operating switch (1) into “0” position.

( = OFF)

Close fuel supply.

6

The connection to the mains of the units is to be carried out in accordance with the VDE

0100 regulations to a special supply point with protection device against faulty current.

G

G

M ai nt en an ce

The unit is to be maintained regularly whereby some

fundamental rules are to be observed to ensure a long

service life and trouble-free operation.

Use a clean slightly humid cloth for cleaning and wiping

the dirt off the surface. In case of obstinate dirt only sui-

table cleaning agents should be used.

Prior to starting any work make sure to pull

the mains plug out of the mains socket!

G

• The unit is to be kept free from dust and other depo-

sits and is to be cleaned only with a dry or humid

cloth (do not use water jet).

• Do not use any aggressive cleaning agents or those

which are harmful or environmentally unfriendly.

• Do not use cleaning agents which contain solvents.

• Use only clean fuel oil EL and diesel, respectively

(make sure to avoid paraffine formation).

• Check oil filters or gas filters regularly and replace

dirty filters.

• Check whether the unit is free from mechanical da-

mage, if not, replace faulty parts.

• Check fan wings and combustion chamber with heat

exchanger in regular intervals and clean them when

they are dirty.

• Check oil tank regularly and clean it when necessary

to remove dirt and foreign matters.

• Make sure that the waste gas and combustion air

can be always evacuated properly.

• Check safety devices regularly.

• The unit is to be maintained and cleaned in regular

intervals.

• Keep feelers of triple combination control always free

from dust and dirt.

• Have the waste gas values of the oil or gas burner

checked regularly by authorized experts.

For safety reasons we recommend that you conclude

a maintenance contract!

• Make sure to store the unit in a dust-free and dry

place when it is not used for a longer period.

Ser vi ce

The complete unit including heat exchanger,

combustion chamber and oil burner is to be cleaned

from dust and dirt after every heating period, or even

earlier, depending on the operational conditions.

Expendable parts, such as flue gas suppressors,

gaskets, oil filter inserts, and oil nozzles are to be

checked and replaced, if necessary.

Heat Exchanger Cleaning

² Cut unit from the mains

² Disassemble connection piece for outgoing air (only

CLA 25/40/50)

² In addition CLA 100:

- disassemble jack ring (pos. 14)

- disassemble cover plate (pos. 1)

- disassemble upper insulation (pos. 12)

² Remove revision cover (pos. 22)

² Pull flue gas suppressor (pos. 22) out of unit

² Clean flue gas passes. Special cleaning brushes

can be obtained as accessories.

² Clean flue gas suppressor or replace them,

if necessary.

² Check gaskets and revision cover and replace,

if necessary.

² Assembly is to be carried out in reverse order,

where-by you should make sure that the gaskets

and the revision cover is correctly seated.

Combustion Chamber Cleaning

² Cut unit from the mains

² Remove burner

² Clean combustion chamber through its opening by

means of a vacuum cleaner. Special cleaning sets

can be obtained as accessories to the REMKO in-

dustrial vacuum cleaner.

² Install burner; check flange gasket and replace,

if necesary.

Make sure that the burner is exclusively maintained

by authorized experts.

Make sure to observe the limit values for waste gas

losses according to the regulations for small-sized

fireplaces.

Setting and maintenance is to be carried out only by authorized experts!

G G

7

CLA 2 5 / 4 0 / 5 0

CLA 1 0 0

8

We reserve the right to make modifications in dimensions and construction in the interests of technical progress.

Nr.

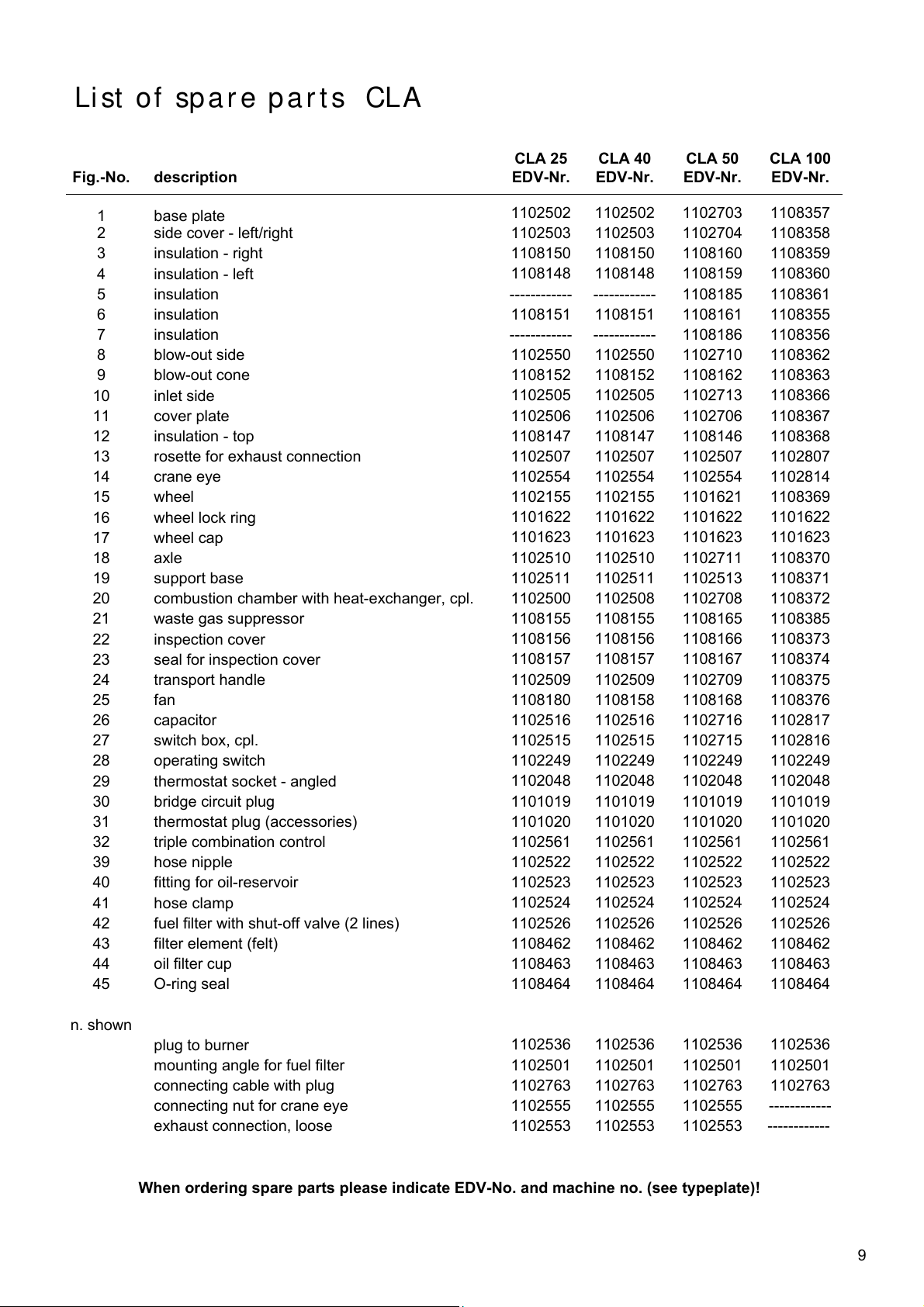

Li st o f spa r e pa r ts CLA

Fig.-No. description

1 base plate

2 side cover - left/right

3 insulation - right

4 insulation - left

5 insulation

6 insulation

7 insulation

8 blow-out side

9 blow-out cone

10 inlet side

11 cover plate

12 insulation - top

13 rosette for exhaust connection

14 crane eye

15 wheel

16 wheel lock ring

17 wheel cap

18 axle

19 support base

20 combustion chamber with heat-exchanger, cpl.

21 waste gas suppressor

22 inspection cover

23 seal for inspection cover

24 transport handle

25 fan

26 capacitor

27 switch box, cpl.

28 operating switch

29 thermostat socket - angled

30 bridge circuit plug

31 thermostat plug (accessories)

32 triple combination control

39 hose nipple

40 fitting for oil-reservoir

41 hose clamp

42 fuel filter with shut-off valve (2 lines)

43 filter element (felt)

44 oil filter cup

45 O-ring seal

n. shown

plug to burner

mounting angle for fuel filter

connecting cable with plug

connecting nut for crane eye

exhaust connection, loose

CLA 25 CLA 40 CLA 50 CLA 100

EDV-Nr. EDV-Nr. EDV-Nr. EDV-

1102502 1102502 1102703 1108357

1102503 1102503 1102704 1108358

1108150 1108150 1108160 1108359

1108148 1108148 1108159 1108360

------------ ------------ 1108185 1108361

1108151 1108151 1108161 1108355

------------ ------------ 1108186 1108356

1102550 1102550 1102710 1108362

1108152 1108152 1108162 1108363

1102505 1102505 1102713 1108366

1102506 1102506 1102706 1108367

1108147 1108147 1108146 1108368

1102507 1102507 1102507 1102807

1102554 1102554 1102554 1102814

1102155 1102155 1101621 1108369

1101622 1101622 1101622 1101622

1101623 1101623 1101623 1101623

1102510 1102510 1102711 1108370

1102511 1102511 1102513 1108371

1102500 1102508 1102708 1108372

1108155 1108155 1108165 1108385

1108156 1108156 1108166 1108373

1108157 1108157 1108167 1108374

1102509 1102509 1102709 1108375

1108180 1108158 1108168 1108376

1102516 1102516 1102716 1102817

1102515 1102515 1102715 1102816

1102249 1102249 1102249 1102249

1102048 1102048 1102048 1102048

1101019 1101019 1101019 1101019

1101020 1101020 1101020 1101020

1102561 1102561 1102561 1102561

1102522 1102522 1102522 1102522

1102523 1102523 1102523 1102523

1102524 1102524 1102524 1102524

1102526 1102526 1102526 1102526

1108462 1108462 1108462 1108462

1108463 1108463 1108463 1108463

1108464 1108464 1108464 1108464

1102536 1102536 1102536 1102536

1102501 1102501 1102501 1102501

1102763 1102763 1102763 1102763

1102555 1102555 1102555 ------------

1102553 1102553 1102553 ------------

When ordering spare parts please indicate EDV-No. and machine no. (see typeplate)!

9

Techni cal Da t a

Series CLA 25 CLA 40 CLA 50 CLA 100

rated heat power max. kW 29 36 58 106

ratedheat output kW 26,5 30 50 91

rated air output m³/h 1150 1600 3200 5200

fuel heating oil EL or liquid gas

fuel consumption, max. kg/h 2,6 3,0 5,0 9,0

nozzle (Steinen) 2) USG/°S 0,65/60° 0,75/60° 1,25/60° 2,25/60°

pump-pressure (mit ÖV)

flue gas loss % 9,4 10 10 10

electrical connection 1~ V 230 230 230 230

frequency Hz 50 50 50 50

rated current A 1,95 1,95 3,3 4,7

power take-up kW 0,4 0,4 0,7 1,0

capacitor (fan) µF 3 3 8 14

fuse protection (required) A 10 10 10 10

sound pressure level L

air outlet Ø mm 285 285 345 500

waste gas connection Ø mm 180 180 180 200

weight (without burner) kg 110 110 153 260

dimensions: length, total mm 1385 1385 1685 1955

width, total mm 640 640 770 1020

hight, total mm 930 930 1030 1240

1) noise measuring (without burner) DIN 45635 - 01 - KL 3

2) The mentionend nozzle-sizes and pump-pressures result from coordination tests on the test bench. The fuel consumption had been

measured out.

On account of tolerances and oil-temperature these specifications must be considered as guiding values.

2)

bar 11-12 11-12 11-12 11-12

1)

pA 1m

dB(A) 54 56 66 64

Dimensions and specifications subject to change

Wi r i ng Di a gr am

S = operating switch

KL = terminal strip

SK = switch box, cpl.

C = capacitor

(CLA 100: capacitor in

terminal box of fan)

RT = room thermostat socket

M = fan motor

TR = fan control thermostat

STB = safety temperature limiter

TW = burner temperature monitor

KB = triple combination control, cpl.

WS = plug to burner, 7 poles

(only if burner has been

installed by our works)

blau = blue

braun = brown

schwarz = black

10

Troub l esh oot ing I n st r u ct i on s

Unit does not start:

² Check connection to the mains

² Check safety thermostat (STB)

² Put operating switch into “I” position

² Check whether bridge circuit plug has been plugged

in correctly

² Check room thermostat and its plug, respectively.

The temperature set at the room thermostat must be

higher than the room temperature.

² Set change lever of triple combined regulator to

“MAN” position. When the fan starts running the fault

is to be eliminated in the burner area.

Burner does not start:

² Check whether fuel filter is dirty

² Open stop valve of fuel filter

² Check whether the fuel quantity in the reservoir is

still sufficient

² Check whether paraffine has been formed in the

filter and fuel (this can happen even at 5 °C)

² Check whether oil hoses have been damaged (air

suction, air bubbles)

² Check safety temperature limiter (STB); if the STB

has been released make sure to find the reasons

why, e.g.:

l unit could not cool down, as the electric power

has been cut off

l temperature of blown out air too high because

of inadequate air guidance

l no free air inlet and outlet

² Check temperature controller (TW) in the triple

combined regulator (by bridging)

² Check whether the feeler or capillary tube of the

triple combined regulator has been damaged (see

description “safety device”).

² Check whether the interference lamp of burner relay

has been lit up;

² if so, unlock relay by pressing the anti-interference

button.

The burner tries to start (take delayed burner start

due to oil preheating into account).

Attention!

If the burner is switched off once more after the star-

ting phase because of a fault, another unlocking

may not be carried out before a waiting time of 5 mi-

nutes has lapsed.

Make sure to avoid any further unlocking (danger of

deflagration).

For safety reasons all repairs and maintenance

work regarding the burner is to be carried out

only by authorized experts.

Fan Does not Start:

² Check whether fan wing is freely running

² Check whether electric cable of fan has been

damaged

² Check operating capacitor of fan

² Check fan regulator (TR) in the triple combined re-

gulator (by bridging).

Attention!

Repairs regarding the electric installations may

be carried out only by authorized electricians!

During the unit’s operation safety devices may

neither be bridged nor blocked!

If all the controls regarding the different functions have been carried

out without a result, you should contact an authorized service center.

Important Hint!

An operation/use other than that indicated in these instructions is prohibited! In the case of

non-observation we will not be held responsible and our guarantee will become void.

Any claims under guarantee regarding materials can be accepted only when the orderer or his customer has

filled in completely the “guarantee certificate” which is enclosed with every REMKO-heater and has

returned it to REMKO GmbH & Co. KG in due time after the unit’s sale and commissioning.

11

REMKO GmbH & Co. KG

Klima- und Wärmetechnik

D-32791 Lage · Im Seelenkamp

12

D-32777 Lage · Postfach 1827

Telefon (0 52 32) 606 - 0

Telefax (0 52 32) 606260

Loading...

Loading...