Remeha ENER-G CHP Technical Information

We put all our energy into energy efficiency.

ENER-G CHP

Sustainable heating with maximum efficiency

GAS HP 35A HT

SPECIFICATION TECHNICAL G4-ENER REMEHA

2

ENER-G4 |

|

GAS ENGINE UNIT |

Boiler Model |

|

ENER-G4 |

Product Code |

|

CP4WE |

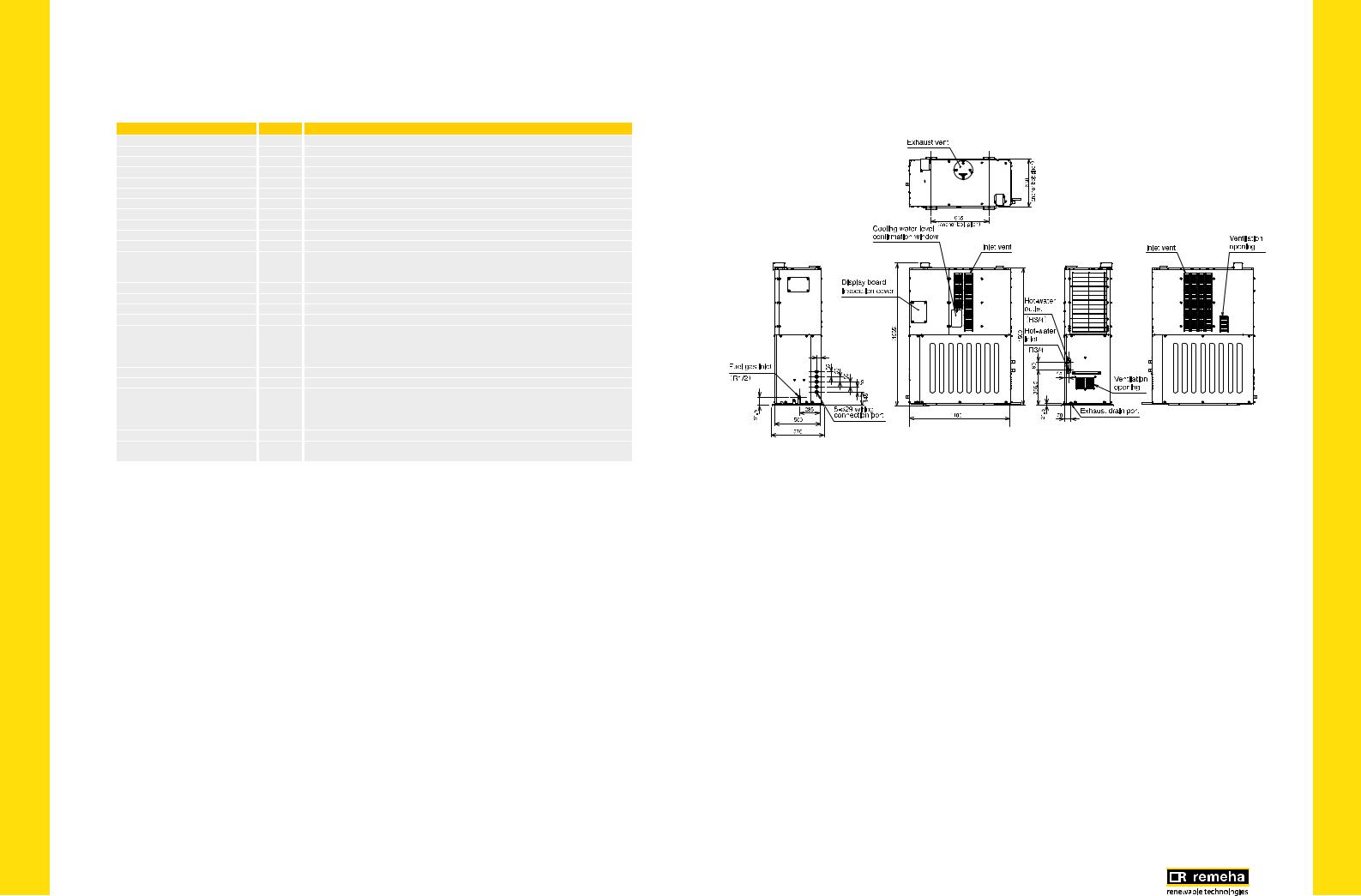

Dimensions W x D x H |

mm |

1100 x 500 (570 including protrusion) x 1500 (1555 including cover) |

Net Weight |

kg |

410 (including cooling water and lubricant) |

Rated Output |

kW |

3.87*1 |

Frequency |

Hz |

50 |

Voltage |

V |

230 |

Current |

A |

AC 16.0 |

Phase/Wires |

|

Single phase, two wires |

Power Factor |

% |

97 or more |

Recovered Heat |

kW |

8.38 |

Hot Water Temperature |

|

|

Inlet |

°C |

60 |

Outlet |

°C |

65 |

Hot Water Flow Rate |

L/min |

24.3*2 |

Total Efficiency |

% |

84.5 |

Electrical Generation Efficiency |

% |

26.7 |

Exhaust Heat Recovery Ratio |

% |

57.8 |

Sound Pressure Level for Rated Load |

|

|

Radiator Fan Stopped |

dB (A) |

51 |

Radiator Fan Operating |

dB (A) |

53 |

— |

dB (A) |

— |

Voltage |

ACV |

230 |

Startup Current |

A |

13 (average electric current) |

Power Consumption (Rated) |

|

|

Radiator Fan Stopped |

kW |

0.19 |

Radiator Fan Operating |

kW |

0.28 |

Space Heater (below 5°C) |

dB (A) |

0.25 (for cold regions) |

Fuel Consumption (LHV basis) |

kW |

14.5*3 |

Gas Supply Pressure |

|

|

Category 2H |

mbar |

20 |

1The heat recovery and efficiency values are those for rated output in standard atmospheric conditions.

2The operating sound levels are maximum values measured in 4 directions at a point 1m from the side of the unit and 1.2m above the ground in an anechoic room simulation. The sound levels during actual operation are usually higher than the simulated values due to ambient noise and echoes.

3The values for the external dimensions do not include piping, piping connections, or protruding parts.

4The amount of fuel consumption is based on lower calorific values.

*1 Power consumption is included

*2 Max of +5%; 25.5l/min

*3 Tolerance +5% is not included

SPECIFICATION TECHNICAL G4-ENER REMEHA

3

SPECIFICATION TECHNICAL G4-ENER REMEHA

4

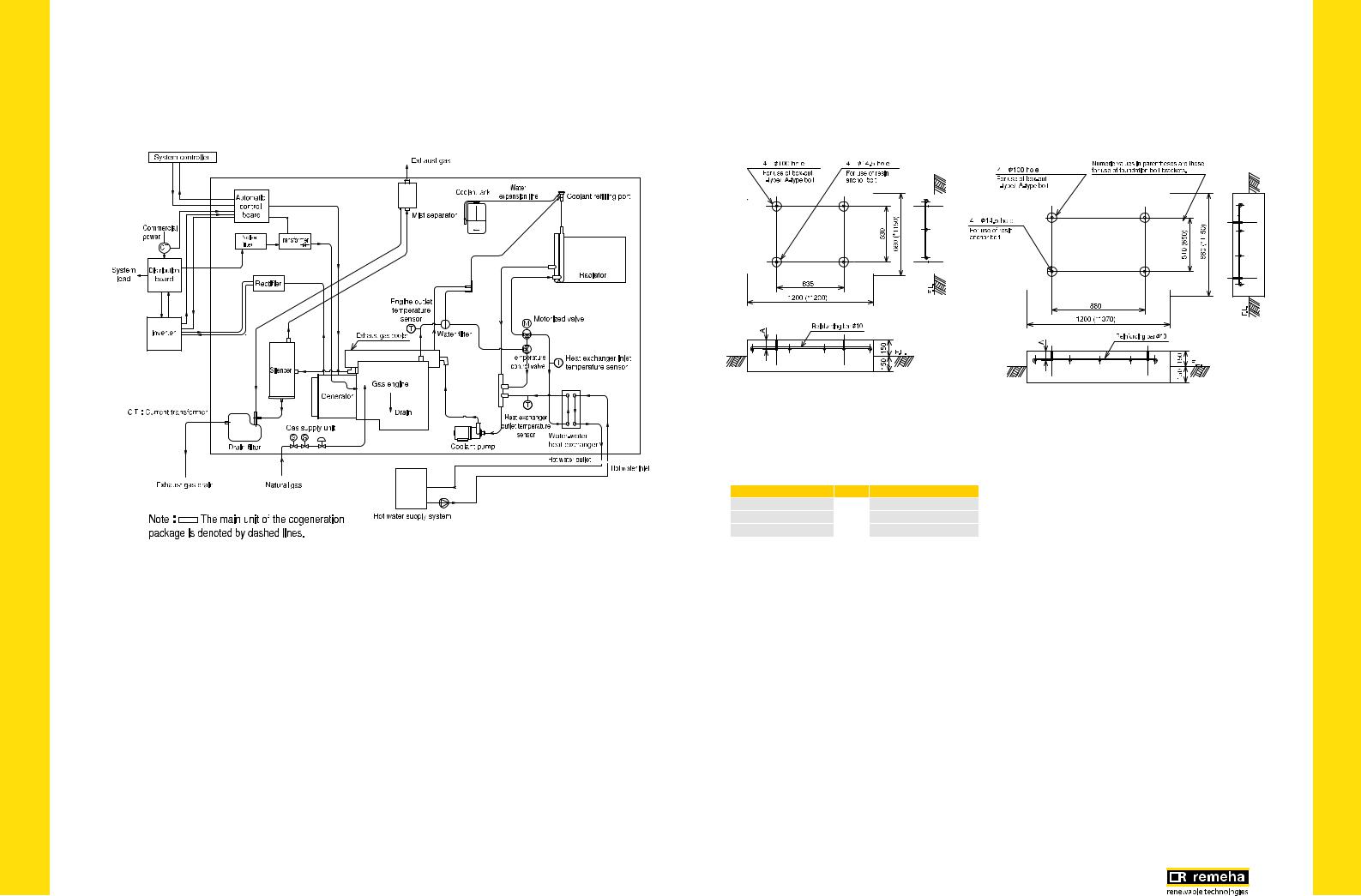

SYSTEM FLOWCHART

DIMENSIONAL DRAWING OF BASE

1. Direct Mount |

|

|

|

|

2. Anti-Vibration Mount |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When the unit is installed indoors, a syphon (option) should be installed.

If the back pressure of the exhaust-piping extension exceeds 500Pa, use a long syphon and make the height of the base from F.L. to 250mm or more.

Type of Anchor Bolt |

Size |

Embedded Depth A (mm) |

L-type/LA-type |

|

150 |

|

||

Resin |

M12 |

90 |

Male screw mechanical |

|

60 |

|

|

|

Notes:

1For use of box-out L-type/LA-type bolt.

When laying the concrete for the base, provide a box-out for fixing the anchor bolts, fix the anchor bolts and then secure them in the concrete.

2It is sometimes necessary to change the thickness of the base depending on the foundation strength, so carry out the work after consulting construction engineers.

3Earthquake-resistance strength: Horizontal seismic coefficient of 0.6 (Numeric values with * show the dimensions in the case of a horizontal seismic coefficient 1.0).

4When using a smaller base, join the base and the structure with reinforcing bars.

SPECIFICATION TECHNICAL G4-ENER REMEHA

5

SPECIFICATION TECHNICAL G4-ENER REMEHA

6

INSTALLATION SPACE

1. Single Unit Installation |

2. Multiple Units Installation |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes

1.When surrounding the unit with soundproof walls, attach openings (louvres or the like) to the bottom of the soundproof walls. (To prevent the short circuits of radiating air).

2.Decide installation space after consideration of the piping space.

3.If the distance of retention is specified by local-government fire prevention ordinances and enforcement regulations, secure the installation space according to these regulations.

4.Give consideration not to cause problems for neighbouring houses due to operating noise, radiating air, or hot ventilation air.

5.Depending on the situation, the site may be filled with radiating air and this has an effect on performance. Prevent the short circuits with the optional wind direction boards, etc.

ENER-G4 DATASHEET

General Description

Fuel Type |

Natural Gas |

Minimum Methane Number |

80 |

Electrical Output |

3.9kW |

Heat Output (Exhaust Cooled to 69°C) |

8kW |

Fuel Input Net/Gross (CV 10kWh/Nm³) |

15/16kW |

Min/Max Dynamic Gas Pressure |

10/25 mbar |

Max Return/Flow Water Temp: |

55/65°C |

Unit Efficiency |

84.8% |

Prime Mover

Type |

Reciprocating Engine |

Combustion Cycle |

4-stroke Spark Ignition |

Cylinders |

3 |

Speed |

2000 |

NOx Emissions |

283 mg/Nm3 |

CO Emissions |

36 mg/Nm3 |

Aspiration |

Natural |

Generator

Type |

PMG DC & DC/AC Inverter |

Frequency |

50 Hz |

Voltage |

230 V |

Phase(s) |

1-Phase |

Heat Recovery System

Fully closed primary water circuit

Exhaust gas heat exchanger in primary circuit

PHE between primary and secondary circuits.

Primary water pump

Auto heat output modulation

Control and Protection

On board computer control, protection and monitoring

Engine stop/start, synchronising, modulation

Mechanical, electrical and thermal protection

BMS interface signals

Standard Equipment

Internal Exhaust silencers

Secondary water pump

Optional Equipment/Configuration:

Export control panel

Remote monitoring

Heat and gas metering

System controller

Anti-vibration mounts

Exhaust extension kit

Electrical output is based on output at the generator terminals at a power factor of 0.95. Energy quantities subject to reduction when modulating in response to external conditions. We reserve the right to alter the Engine Type, at any time, to meet the system specifications. Performance figures are subject to original Engine manufacturer’s declared performance, tolerances and test conditions. Output figures are based on operation at ISO3046 conditions with the exception of the exhaust output, temperature stated above. Technical Datasheets are subject to change, without notice, due to our commitment to on-going product improvement.

SPECIFICATION TECHNICAL G4-ENER REMEHA

7

SPECIFICATION TECHNICAL G10-ENER REMEHA

8

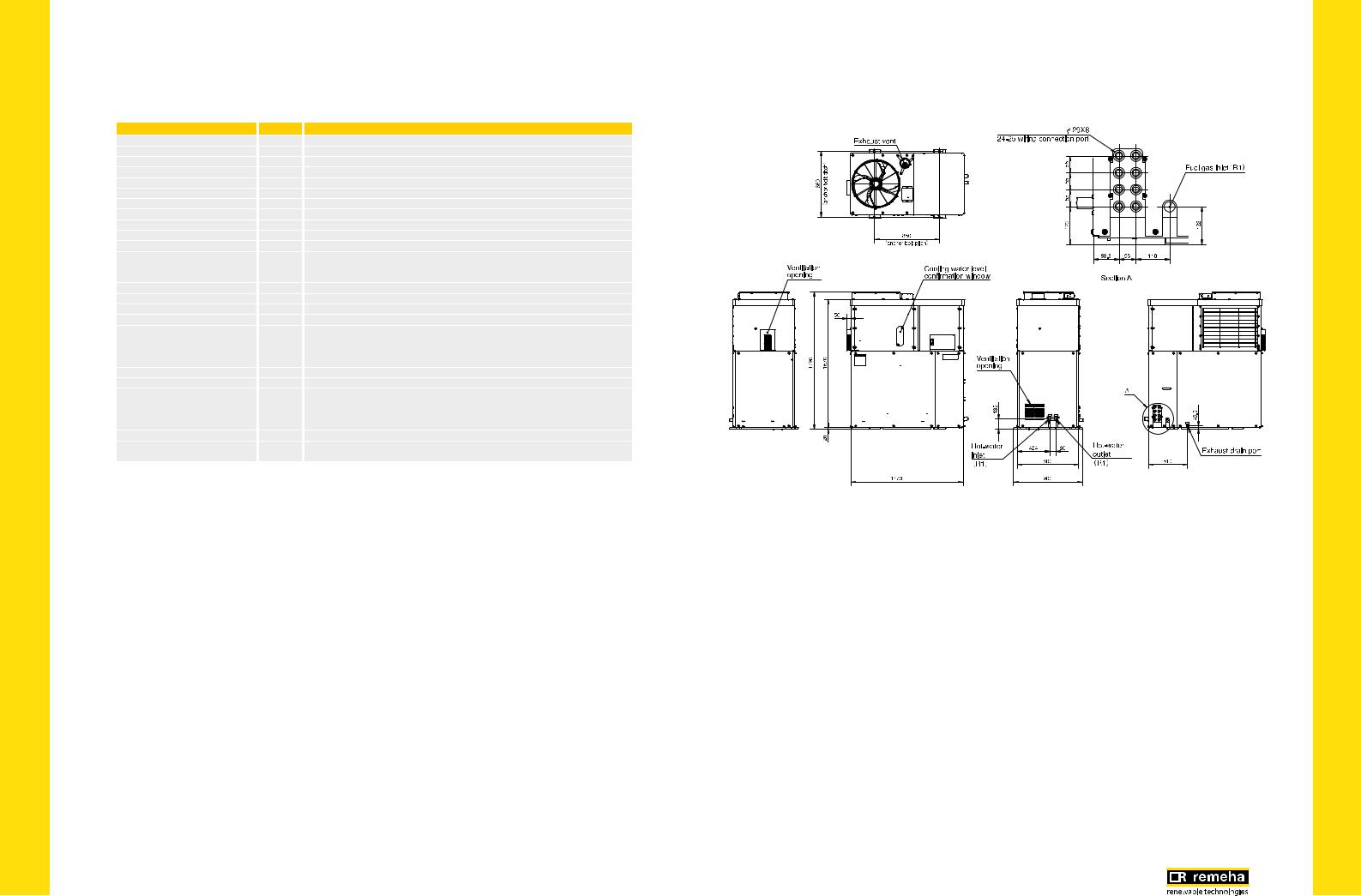

ENER-G10 |

|

|

GAS ENGINE UNIT |

Boiler Model |

|

ENER-G10 |

|

Product Code |

|

CP10WE |

|

Dimensions W x D x H |

mm |

1470 x 800 (900 including protrusion) x 1790 |

|

Net Weight |

kg |

790 (including cooling water and lubricant) |

|

Rated Output |

kW |

10.00*1 |

|

Frequency |

Hz |

50 |

|

Voltage |

V |

AC400 |

|

Current |

A |

14 |

|

Phase/Wires |

|

Three phase, four wires |

|

Power Factor |

% |

97 or more |

|

Recovered Heat |

kW |

17.3 |

|

Hot Water Temperature |

|

|

|

Inlet |

°C |

65 |

|

Outlet |

°C |

70 (Max 78) |

|

Hot Water Flow Rate |

L/min |

48.2*2 |

|

Overall Efficiency |

% |

84.0 |

|

Electrical Generation Efficiency |

% |

30.7 |

|

Exhaust Heat Recovery Ratio |

% |

53.3 |

|

For Rated Load |

|

|

|

Radiator Fan Stopped |

dB (A) |

54 |

|

Radiator Fan Operating |

dB (A) |

56 |

|

— |

dB (A) |

— |

|

Voltage |

ACV |

230 |

|

Startup Current |

A |

22.6 |

(average electric current) |

Power Consumption (Rated) |

|

|

|

Radiator Fan Stopped |

kW |

0.28 |

|

Radiator Fan Operating |

kW |

0.53 |

|

Space Heater (below 5°C) |

dB (A) |

0.50 |

(for cold regions) |

Fuel Consumption (LHV basis) |

kW |

32.6*3 |

|

Gas Supply Pressure |

|

|

|

Category 2H |

mbar |

20 |

|

1 The heat recovery and efficiency values are those for rated output in standard atmospheric conditions.

2 The operating sound levels are maximum values measured in 4 directions at a point 1m from the side of the unit and 1.2m above the ground in an anechoic room simulation. The sound levels during actual operation are usually higher than the simulated values due to ambient noise and echoes.

3The values for the external dimensions do not include piping, piping connections, or protruding parts.

4The amount of fuel consumption is based on lower calorific values.

5As for G83, the examination was carried out by New and Renewable Energy Centre (NaREC) in U.K.

*1 Power consumption is included

*2 Max of +5%; 50.6l/min

*3 Tolerance +5% is not included

SPECIFICATION TECHNICAL G10-ENER REMEHA

9

Loading...

Loading...