Page 1

MVI56-BDW

ControlLogix Platform

BARDAC Drive Web Interface

September 04, 2008

USER MANUAL

Page 2

Please Read This Notice

Successful application of this module requires a reasonable working knowledge of the Rockwell Automation

ControlLogix hardware, the MVI56-BDW Module and the application in which the combination is to be used. For this

reason, it is important that those responsible for implementation satisfy themselves that the combination will meet the

needs of the application without exposing personnel or equipment to unsafe or inappropriate working conditions.

This manual is provided to assist the user. Every attempt has been made to ensure that the information provided is

accurate and a true reflection of the product's installation requirements. In order to ensure a complete understanding

of the operation of the product, the user should read all applicable Rockwell Automation documentation on the

operation of the Rockwell Automation hardware.

Under no conditions will ProSoft Technology be responsible or liable for indirect or consequential damages resulting

from the use or application of the product.

Reproduction of the contents of this manual, in whole or in part, without written permission from ProSoft Technology

is prohibited.

Information in this manual is subject to change without notice and does not represent a commitment on the part of

ProSoft Technology Improvements and/or changes in this manual or the product may be made at any time. These

changes will be made periodically to correct technical inaccuracies or typographical errors.

Warnings

UL Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

C Suitable for use in Class I, division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having

jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be

used only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Electrical Ratings

Backplane Current Load: 800 mA @ 5 V DC; 3mA @ 24V DC

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Shock: 30g Operational; 50g non-operational; Vibration: 5 g from 10 to 150 Hz

Relative Humidity 5% to 95% (non-condensing)

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Page 3

Markings:

II 3 G 0C <=Ta<= 60C EEx nA IIC T4 DEMKO 07ATEX0710717X

Battery Life Advisory

All modules in the MVI series use a rechargeable Lithium Vanadium Pentoxide battery to backup the 512K SRAM

memory, real-time clock, and CMOS. The battery should last for the life of the module.

The module must be powered for approximately twenty hours before it becomes fully charged. After it is fully charged,

the battery provides backup power for the CMOS setup and configuration data, the real-time clock, and the 512K

SRAM memory for approximately 21 days.

Before you remove a module from its power source, ensure that the battery within the module is fully charged. A fully

charged battery will hold the BIOS settings (after being removed from its power source) for a limited number of days.

When the battery is fully discharged, the module will revert to the default BIOS settings.

Note: The battery is not user replaceable.

ProSoft® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD and are

available at no charge from our web site: http://www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33.5.34.36.87.20

Latin America: +1.281.298.9109

North America: +1.661.716.5100

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about the product, documentation or support, please write or call us.

ProSoft Technology

1675 Chester Avenue, Fourth Floor

Bakersfield, CA 93301

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

http://www.prosoft-technology.com

Copyright © ProSoft Technology, Inc. 2000 - 2008. All Rights Reserved.

MVI56-BDW User Manual

September 04, 2008

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk® and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc.

Page 4

Page 5

Contents MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Contents

Please Read This Notice 2

Warnings............................................................................................................................................. 2

Battery Life Advisory ...........................................................................................................................3

ProSoft® Product Documentation....................................................................................................... 3

Your Feedback Please........................................................................................................................3

Guide to the MVI56-BDW User Manual 7

1 Start Here 9

1.1 System Requirements............................................................................................... 9

1.2 Package Contents...................................................................................................10

1.3 Install ProSoft Configuration Builder Software........................................................ 10

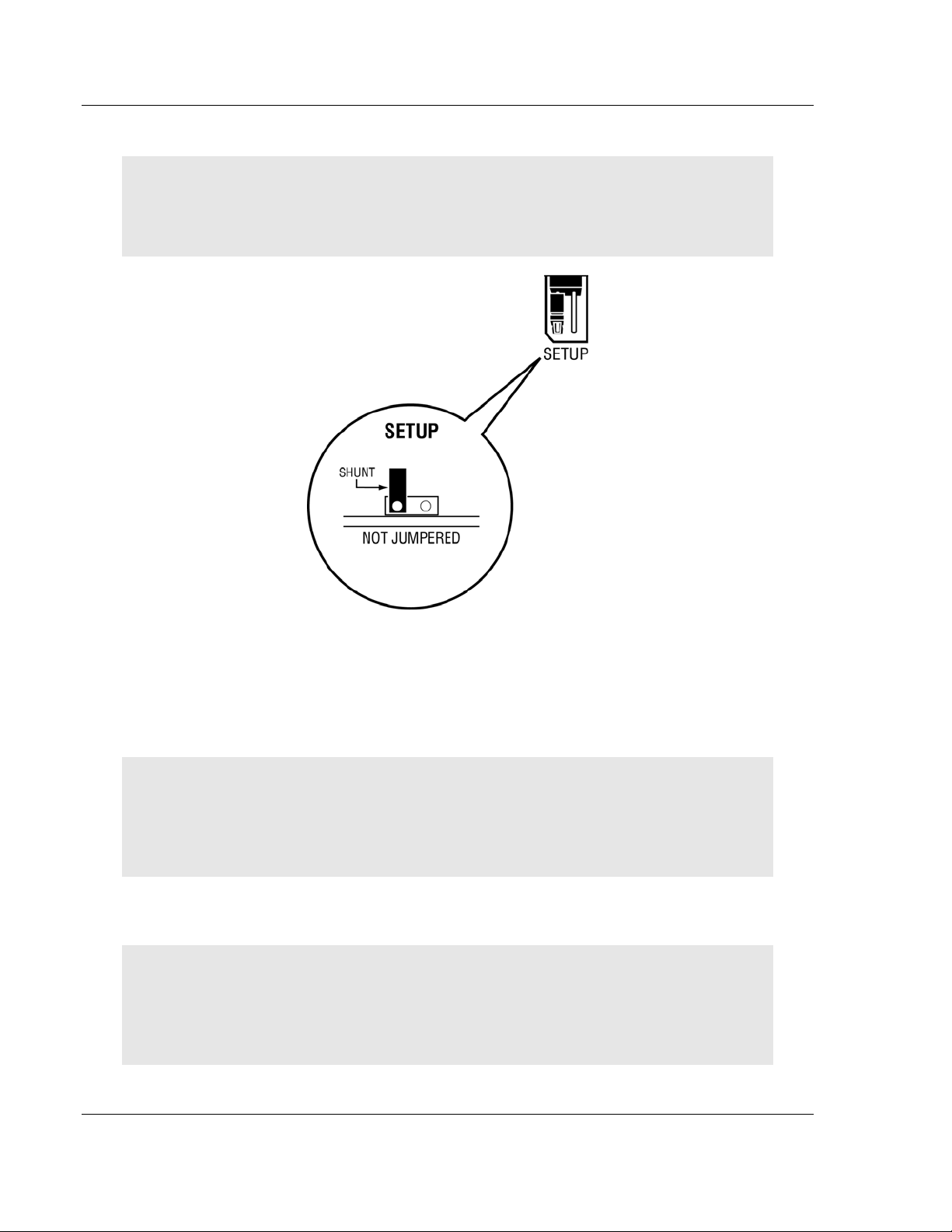

1.4 Setting Jumpers ......................................................................................................12

1.5 Install the Module in the Rack .................................................................................12

1.6 Connect your PC to the Processor.......................................................................... 14

1.7 Open the Sample Ladder Logic ..............................................................................14

1.8 Download the Sample Program to the Processor................................................... 18

1.9 Connect your PC to the Module ..............................................................................19

2 Module Configuration 21

2.1 Installing and Configuring the Module..................................................................... 21

2.2 Modifying the Configuration File.............................................................................. 29

2.3 Download the Project to the Module ....................................................................... 37

3 Ladder Logic 39

4 Diagnostics and Troubleshooting 41

4.1 Reading Status Data from the Module.................................................................... 41

4.2 LED Status Indicators..............................................................................................52

5 Reference 55

5.1 Product Specifications.............................................................................................55

5.2 Functional Overview................................................................................................57

5.3 Cable Connections..................................................................................................67

5.4 MVI56-BDW Status Data Definition ........................................................................71

6 Support, Service & Warranty 73

6.1 How to Contact Us: Technical Support ................................................................... 73

6.2 Return Material Authorization (RMA) Policies and Conditions................................74

ProSoft Technology, Inc. Page 5 of 82

September 4, 2008

Page 6

Contents MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

6.3 LIMITED WARRANTY............................................................................................ 76

Index 81

Page 6 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 7

Start Here MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Guide to the MVI56-BDW User Manual

Function Section to Read Details

Introduction

(Must Do)

Verify Communication,

Diagnostic and

Troubleshooting

Reference

Product Specifications

Functional Overview

Glossary

Support, Service, and

Warranty

Index

→

→

→

→

Start Here (page 9)

Verifying

Communication

(page 52)

Diagnostics and

Troubleshooting

(page 41)

Reference (page 55)

Functional Overview

(page 57)

Product

Specifications (page

55)

Support, Service

and Warranty (page

73)

This Section introduces the customer to the

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

This section describes how to verify

communications with the network. Diagnostic

and Troubleshooting procedures.

These sections contain general references

associated with this product, Specifications, and

the Functional Overview.

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 7 of 82

September 4, 2008

Page 8

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

Page 8 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 9

Start Here MVI56-BDW ♦ ControlLogix Platform BARDAC Drive Web Interface

1 Start Here

In This Chapter

System Requirements .............................................................................9

Package Contents .................................................................................10

Install ProSoft Configuration Builder Software.......................................10

Setting Jumpers ....................................................................................12

Install the Module in the Rack ...............................................................12

Connect your PC to the Processor........................................................ 14

Open the Sample Ladder Logic.............................................................14

Download the Sample Program to the Processor.................................. 18

Connect your PC to the Module ............................................................19

Installing the MVI56-BDW module requires a reasonable working knowledge of

the Rockwell Automation hardware, the MVI56-BDW Module and the application

in which they will be used.

Caution: It is important that those responsible for implementati on can complete the

application without exposing personnel, or equipment, to unsafe or inappropriate working

conditions. Safety, quality and experience ar e key factors in a successful installation.

1.1 System Requirements

The MVI56-BDW module requires the following minimum hardware and software

components:

Rockwell Automation ControlLogix™ processor, with compatible power

supply and one free slot in the rack, for the MVI56-BDW module. The module

requires 800mA of available power.

Rockwell Automation RSLogix 5000 programming software version 2.51 or

higher.

Rockwell Automation RSLinx communication software

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

ProSoft Technology, Inc. Page 9 of 82

September 4, 2008

Page 10

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 × 768 recommended)

CD-ROM drive

HyperTerminal or other terminal emulator program.

Note: You can install the module in a local or remote rack. For remote rack installation, the modul e

requires EtherNet/IP or ControlNet communication with the processor.

1.2 Package Contents

The following components are included with your MVI56-BDW module, and are

all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

Qty. Part Name Part Number Part Description

1

1 Cable

1 Cable

1

MVI56-BDW

Module

inRAx

Solutions CD

MVI56-BDW BARDAC Drive Web Interface

Cable #15, RS232

Null Modem

RJ45 to DB9 Male

Adapter

For RS232 Connection to the CFG Port

For DB9 Connection to Module's Port

Contains sample programs, utilities and

documentation for the MVI56-BDW module.

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

1.3 Install ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software in order to

configure the MVI56-BDW module. You can always get the newest version of

ProSoft Configuration Builder from the ProSoft Technology web site.

To install ProSoft Configuration Builder from the ProSoft Web Site

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the Download Here link to download the latest version of ProSoft

Configuration Builder.

Page 10 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 11

Start Here MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

3 Choose "Save" or "Save File" when prompted. The following illustrations

show the file download prompt for two of the most common web browsers.

4 Make a note of the location where you saved the file, for example "Desktop",

or "My Documents", so you can start the installation program.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions CD-ROM, included in the package with your

MVI56-BDW module.

To install ProSoft Configuration Builder from the CD-ROM

1 Insert the ProSoft Solutions CD-ROM into the CD drive of your PC. Wait for

the startup screen to appear.

2 On the startup screen, click Product Documentation. This action opens an

explorer window.

3 Click to open the Utilities folder. This folder contains all of the applications

and files you will need to set up and configure your module.

4 Double-click the ProSoft Configuration Builder Setup program and follow the

instructions on your screen to install the software on your PC.

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

ProSoft Technology, Inc. Page 11 of 82

September 4, 2008

Page 12

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

1.4 Setting Jumpers

Note: The Setup Jumper acts as "write protection" for the module's flash memory. In "write

protected" mode, the Setup pins are not connected, and the module's firmware cannot be

overwritten. Do not jumper the Setup pins together unless you are directed to do so by ProSoft

Technical Support.

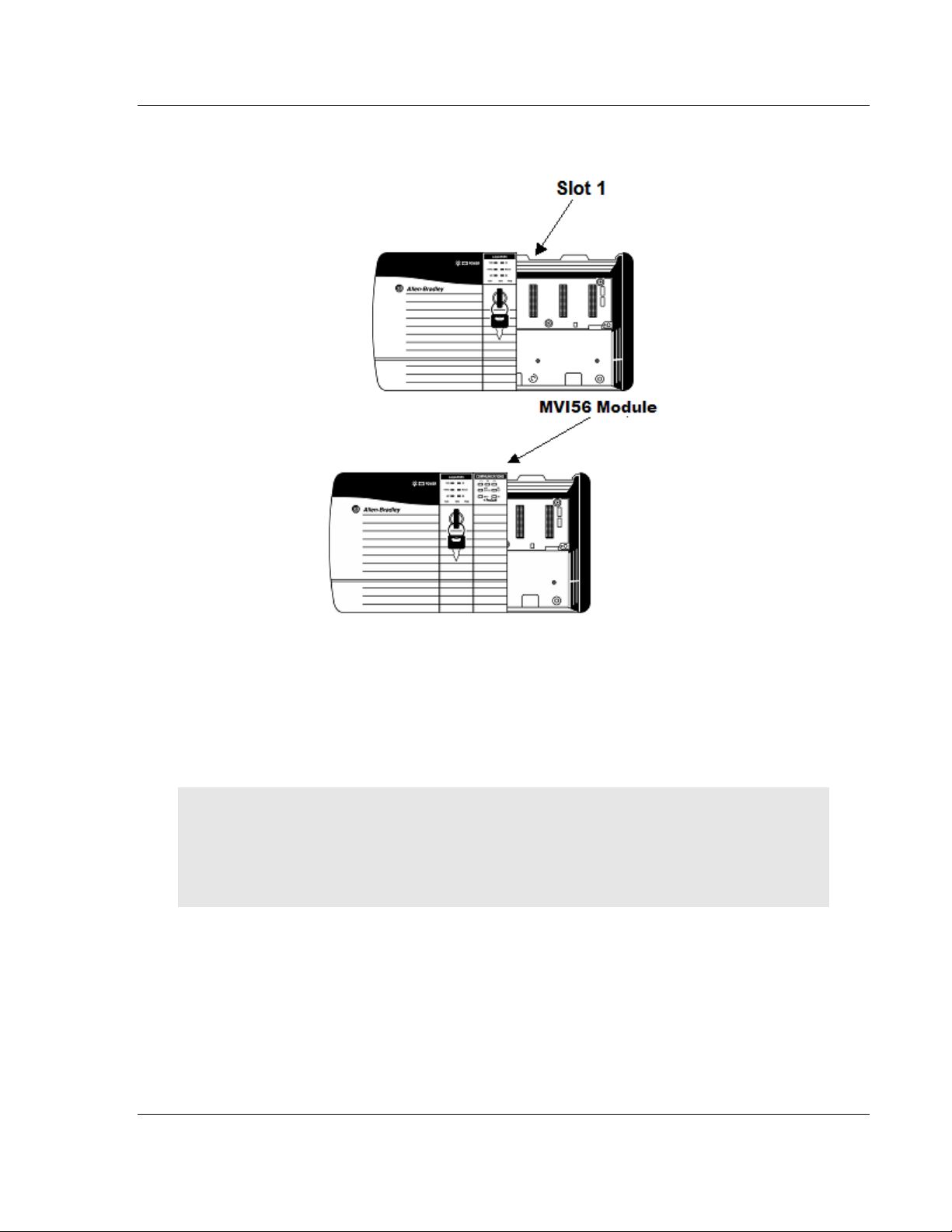

1.5 Install the Module in the Rack

If you have not already installed and configured your ControlLogix processor and

power supply, please do so before installing the MVI56-BDW module. Refer to

your Rockwell Automation product documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures ar e in place before installing or servicing the

device.

After you have checked the placement of the jumpers, insert MVI56-BDW into

the ControlLogix chassis. Use the same technique recommended by Rockwell

Automation to remove and install ControlLogix modules.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can occur. This could cause an explosion in hazardous location installations. Verify that power is

removed or the area is non-hazardous before proceeding. Repeated electrical arcing causes

excessive wear to contacts on both the module and its mating connector. Worn contacts may

create electrical resistance that can affect module operation.

1 Turn power OFF.

Page 12 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 13

Start Here MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

2 Align the module with the top and bottom guides, and slide it into the rack

until the module is firmly against the backplane connector.

3 With a firm but steady push, snap the module into place.

4 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

5 Make a note of the slot location. You will need to identify the slot in which the

module is installed in order for the sample program to work correctly. Slot

numbers are identified on the green circuit board (backplane) of the

ControlLogix rack.

6 Turn power ON.

Note: If you insert the module improperly, the system may stop working, or may behave

unpredictably.

Note: If you are installing MVI56-BDW with other modules c onnected to the PCI bus, the peripheral

modules will not have holding clips. Make sure all of the modules are aligned with their respective

slots before you snap them into place.

ProSoft Technology, Inc. Page 13 of 82

September 4, 2008

Page 14

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

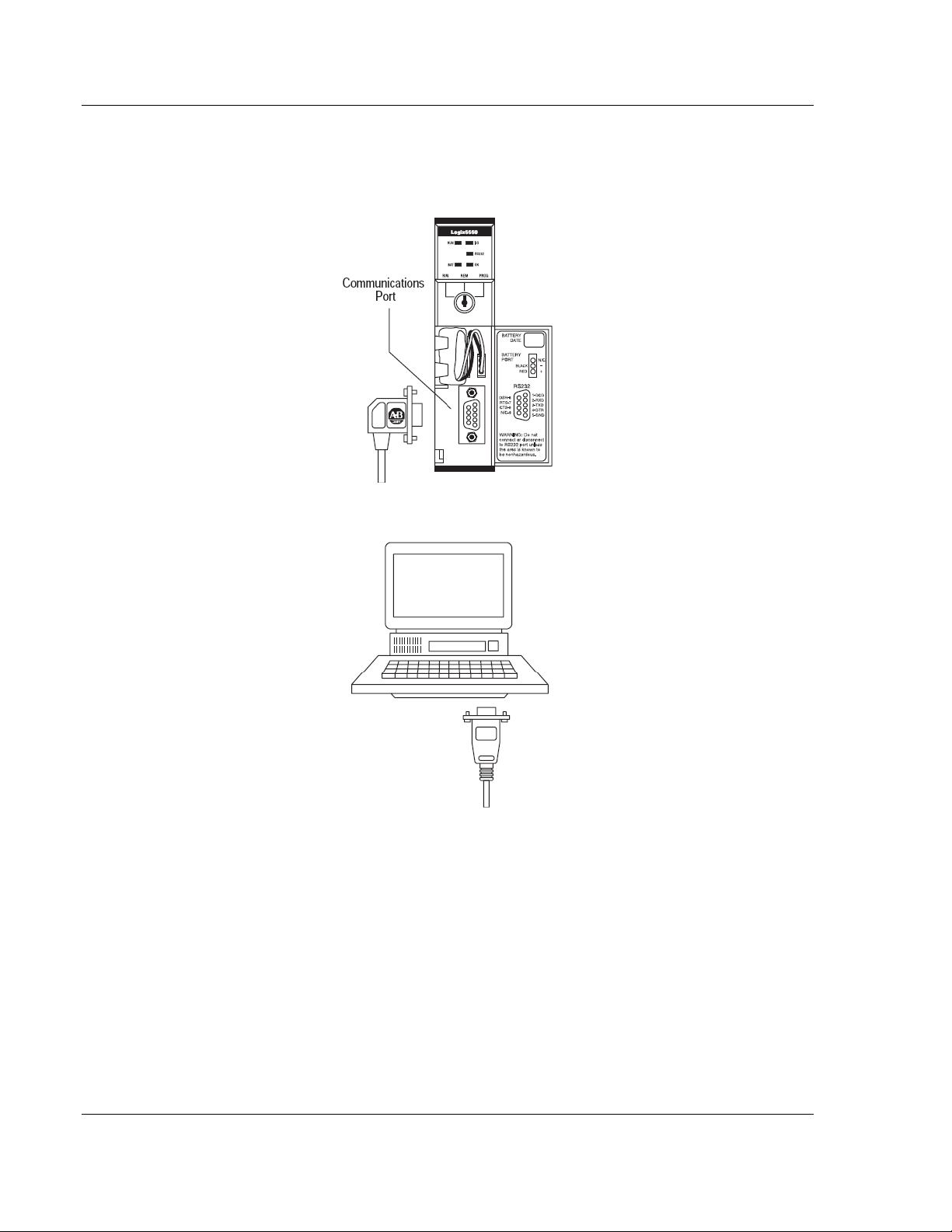

1.6 Connect your PC to the Processor

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

1.7 Open the Sample Ladder Logic

The sample program for your MVI56-BDW module includes custom tags, data

types and ladder logic for data I/O and status monitoring. For most applications,

you can run the sample ladder program without modification, or, for advanced

applications, you can incorporate the sample program into your existing

application.

The inRAx Solutions CD provides one or more versions of the sample ladder

logic. The version number appended to the file name corresponds with the

firmware version number of your ControlLogix processor. The firmware version

and sample program version must match.

Page 14 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 15

Start Here MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

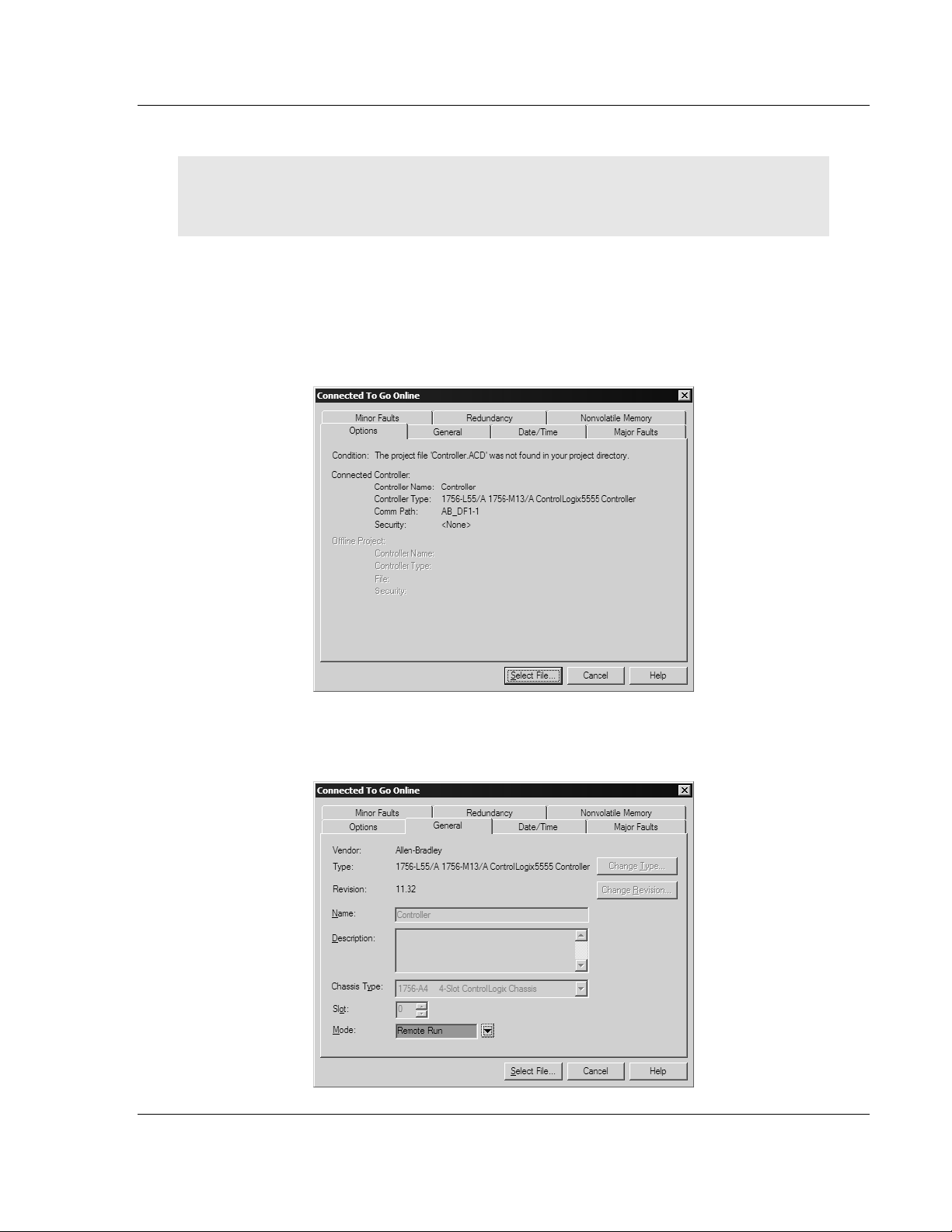

1.7.1 To Determine the Firmware Version of your Processor

Important: The RSLinx service must be installed and running on your computer in order for

RSLogix to communicate with the processor. Refer to your RSLinx and RSLogix documentation for

help configuring and troubleshooting these applications.

1 Connect an RS-232 serial cable from the COM (serial) port on your PC to the

communication port on the front of the processor.

2 Start RSLogix 5000 and close any existing project that may be loaded.

3 Open the Communications menu and choose Go Online. RSLogix will

establish communication with the processor. This may take a few moments.

4 When RSLogix has established communication with the processor, the

Connected To Go Online dialog box will open.

5 On the Connected To Go Online dialog box, click the General tab. This tab

shows information about the processor, including the Revision (firmware)

version. In the following illustration, the firmware version is 11.32

ProSoft Technology, Inc. Page 15 of 82

September 4, 2008

Page 16

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

1.7.2 Select the Slot Number for the Module

The sample application is for a module installed in Slot 1 in a ControlLogix rack.

The ladder logic uses the slot number to identify the module. If you are installing

the module in a different slot, you must update the ladder logic so that program

tags and variables are correct, and do not conflict with other modules in the rack.

To change the slot number

1 In the Controller Organization list, select the module [1] 1756-MODULE

MVI56, and then click the right mouse button to open a shortcut menu.

2 On the shortcut menu, choose Properties. This action opens the Module

Properties dialog box.

3 In the Slot: field, use the spinners on the right side of the field to select the

slot number where the module will reside in the rack, and then click OK.

RSLogix will automatically apply the slot number change to all tags, variables

and ladder logic rungs that use the MVI56-BDW slot number for computation.

1.7.3 Configuring RSLinx

If RSLogix is unable to establish communication with the processor, follow these steps:

1 Open RSLinx.

2 Open the Communications menu, and choose Configure Drivers.

Page 16 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 17

Start Here MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

This action opens the Configure Drivers dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the

Available Driver Types list. The recommended driv er type to choose for serial communicatio n with

the processor is "RS-232 DF1 Devices".

3 Click to select the driver, and then click Configure. This action opens the

Configure Allen-Bradley DF1 Communications Device dialog box.

4 Click the Auto-Configure button. RSLinx will attempt to configure your serial

port to work with the selected driver.

5 When you see the message "Auto Configuration Successful", click the OK

button to dismiss the dialog box.

ProSoft Technology, Inc. Page 17 of 82

September 4, 2008

Page 18

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

Note: If the auto-configuration procedure fails, verify that the cables are connected correc tly

between the processor and the serial port on your computer, and then try again. If you ar e still

unable to auto-configure the port, refer to yo ur RSLinx documentation for further troubleshooti ng

steps.

1.8 Download the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix module must be in the REM position.

To download the sample program from RSLogix 5000 to the ControlLogix processor

1 If you are not already online to the processor, open the Communications

menu, and then choose Download. RSLogix will establish communication

with the processor.

2 When communication is established, RSLogix will open a confirmation dialog

box. Click the Download button to transfer the sample program to the

processor.

3 RSLogix will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix will open another confirmation

dialog box. Click OK to switch the processor from Program mode to Run

mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

Page 18 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 19

Start Here MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

1.9 Connect your PC to the Module

With the module securely mounted, connect your PC to the

Configuration/Debug port using an RJ45-DB-9 Serial Adapter Cable and a Null

Modem Cable.

1 Attach both cables as shown.

2 Insert the RJ45 cable connector into the Configuration/Debug port of the

module.

3 Attach the other end to the serial port on your PC or laptop.

ProSoft Technology, Inc. Page 19 of 82

September 4, 2008

Page 20

MVI56-BDW ♦ ControlLogix Platform Start Here

BARDAC Drive Web Interface

Page 20 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 21

Module Configuration MVI56-BDW ♦ ControlLogix Platform BARDAC Drive Web Interface

2 Module Configuration

In This Chapter

Installing and Configuring the Module ...................................................21

Modifying the Configuration File ............................................................ 29

Download the Project to the Module......................................................37

This document contains the setup procedure, data and ladder logic requirements for successful application of the MVI56-BDW module. Each step in the setup procedure is defined in order to simplify the use of the module. Go to the Installing and Configuring the Module section to begin installing and configuring the module. Additionally, this document contains a discussion on configuring the module using the BARDACDW.CFG file. All configuration information used by the module is stored in this file. Go to the Configuration File section to begin setting up this file.

The document also contains a discussion of the data object defined for the

module. This single object completely encapsulates all the data required for

module operation. It is important to understand each element of the object for

proper application of the module. Go to the Module Data Object section for the

presentation of the object.

The ladder logic requirement section defines the minimum ladder logic required

to apply the module in a user application. The logic is simple to understand and

implement. Go to the Ladder Logic section for a complete discussion of the

ladder logic requirements.

2.1 Installing and Configuring the Module

The configuration process consists of the following steps.

1 Download the sample program to the processor.

Note: For most applications, the sample program will work without modification. We strongly

recommend setting up the module first with the s ample program, before attempting to add the

module to an existing application or create a custom application.

Modify the module's configuration files to meet the needs of your application, and

copy the updated configuration to the module. Example configuration files are

provided on the CD-ROM. Refer to Modifying the Configuration File (page 32) for

more information on the configuration files.

ProSoft Technology, Inc. Page 21 of 82

September 4, 2008

Page 22

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

First, define the module to the system. Right-click the mouse button on the I/O

Configuration option in the Controller Organization window to display a pop-up

menu. Select the New Module… option from the I/O Configuration menu.

This action opens the following dialog box:

Page 22 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 23

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Select the 1756- Module (Generic 1756 Module) from the list and click the OK

button. The following dialog box appears:

Fill in the dialog boxes as shown adjusting the Name, Description and Slot

options for your application. You must select the Comm Format as Data - INT in

the dialog box. Failure to set the Assembly Instance and Size values correctly

will result in a module that will not communicate over the backplane of the

ControlLogix rack. Click Next to display the next dialog box.

Select the Request Packet Interval value for scanning the I/O on the module.

This value represents the minimum frequency the module will handle scheduled

events. This value should not be set to less than 1 millisecond. Values between 1

and 10 milliseconds should work with most applications.

ProSoft Technology, Inc. Page 23 of 82

September 4, 2008

Page 24

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

After completing the module setup, the Controller Organization window will

display the module's presence. The data required for the module will be defined

to the application, and objects will be allocated in the Controller Tags data area.

An example of the Controller Organization window is shown below:

Next, define the User Defined Data Types to be used with the module. Copy

these data types from the example ladder logic if you are not using the example.

They will be defined if you are starting from the example ladder logic. The

Controller Organization window should display the User Defined Data Types

shown below:

Next, define the data to be used to interface with the module and the ladder logic.

Open the Controller Tags Edit Tags dialog box and enter the values required for

the application. The MVI56-BDW module is defined in the example as BARDACDW1. You can set the tag name to any valid tag name you desire. If you are

using the example ladder logic, this step has already been performed.

Page 24 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 25

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

The last step in the module setup is to add the ladder logic. If you are using the

example ladder logic, adjust the ladder to fit your application. If you are not using

the ladder example, copy the ladder logic shown in the Controller Organization

window below to your application.

It is now time to edit the BARDACDW.CFG file to set up the module for the

specific application. Refer to the Configuration File section of this document.

The module is now set up and ready to be used with your application. Insert the

module in the rack and attach the serial communication cable and the network

cable. Download the new application to the controller and place the processor in

run mode. Download the new BARDACDW.CFG file to the module using the

HyperTerminal program or any other terminal emulation program. If all the

configuration parameters are set correctly and the module is attached to a

network, the module's Application LED (APP LED) should remain off and the

backplane activity LED (BP ACT) should blink very rapidly. Refer to the Trouble

Shooting section of this manual if you encounter errors. Attach a computer or

terminal to Port 1 on the module and look at the status of the module using the

Configuration/Debug Menu in the module. Refer to the Configuration/Debug

section for a complete discussion of the use of this feature.

ProSoft Technology, Inc. Page 25 of 82

September 4, 2008

Page 26

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

2.1.1 Module Data Object (BDDWModuleDef)

All data related to the MVI56-BDW is stored in a user defined data type. An

instance of the data type is required before the module can be used. This is done

by declaring a variable of the data type in the Controller Tags Edit Tags dialog

box. The structure of the object is displayed in the following illustration:

This object contains objects that define the configuration, user data, status and

command control data related to the module. Each of these object types is

discussed in the following topics of the document.

2.1.2 Backplane Control Object

This data object stores the variables required for the data transfer between the

processor and the MVI56-BDW module. The structure of the object is shown

below:

Page 26 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 27

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

2.1.3 User Data Objects

These objects hold data to be transferred between the processor and the MVI56BDW module. The user data is the read and write data transferred between the

processor and the module as "pages" of data up to 200 words long.

The read data (ReadData) is an array set to match the value entered in the Read

Register Count parameter of the BARDACDW.CFG file. For ease of use, this

array should be dimensioned as an even increment of 200 words. This data is

paged up to 200 words at a time from the module to the processor. The

ReadData task is responsible for placing the data received into the proper

position in the read data array. Use this data for status and control in the ladder

logic of the processor.

The write data (WriteData) is an array set to match the value entered in the

Write Register Count parameter of the BARDACDW.CFG file. For ease of use,

this array should be dimensioned as even increments of 200 words. This data is

paged up to 200 words at a time from the processor to the module. The

WriteData task is responsible for placing the write data into the output image for

transfer to the module. This data is passed from the processor to the module for

status and control information for use in other nodes on the network.

2.1.4 Status Data

This object views the status of the module. The BDDWInStat object shown

below is updated each time a read block is received by the processor. Use this

data to monitor the state of the module at a "real-time rate".

ProSoft Technology, Inc. Page 27 of 82

September 4, 2008

Page 28

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

This object contains a structure that includes the status information for the data

transfer operations between the processor and the module. The structure of this

object is displayed below:

Additionally, the status object contains a structure for the BARDAC-DW clients.

The structure used for each is shown below:

Refer to the Reference chapter for a complete listing of the data stored in status

object.

Page 28 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 29

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

2.1.5 Event Command Data

The BDDWEvent object is not placed in the module definition object and is only

required when event commands are utilized in the application. This structure

holds the information required for an event command. An array of these objects

should be defined and hold the event command set to be employed in the

application. The structure of the object is shown below:

2.2 Modifying the Configuration File

2.2.1 ProSoft Configuration Builder

ProSoft Configuration Builder (PCB) provides a quick and easy way to manage

module configuration files customized to meet your application needs. PCB is not

only a powerful solution for new configuration files, but also allows you to import

information from previously installed (known working) configurations to new

projects.

ProSoft Technology, Inc. Page 29 of 82

September 4, 2008

Page 30

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

Set Up the Project

To begin, start ProSoft Configuration Builder. If you have used other Windows

configuration tools before, you will find the screen layout familiar. ProSoft

Configuration Builder's window consists of a tree view on the left, an information

pane and a configuration pane on the right side of the window. When you first

start ProSoft Configuration Builder, the tree view consists of folders for Default

Project and Default Location, with a Default Module in the Default Location

folder. The following illustration shows the ProSoft Configuration Builder window

with a new project.

Your first task is to add the MVI56-BDW module to the project.

1 Use the mouse to select "Default Module" in the tree view, and then click the

right mouse button to open a shortcut menu.

Page 30 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 31

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

2 On the shortcut menu, choose "Choose Module Type". This action opens the

Choose Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select MVI56. In the Select

Module Type dropdown list, select MVI56-BDW, and then click OK to save

your settings and return to the ProSoft Configuration Builder window.

The next task is to set the module parameters.

Adding a Project

To add a project to an existing project file:

1 Select the Default Project icon.

2 Choose Project from the Project menu, then choose Add Project. A new

project folder appears.

Adding a Module

To add a module to your project:

1 Double-click the Default Module icon to open the Choose Module Type dialog

box.

2 On the Choose Module Type dialog box, select the module type.

Or

1 Open the Project menu and choose Location.

2 On the Location menu, choose Add Module.

ProSoft Technology, Inc. Page 31 of 82

September 4, 2008

Page 32

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

To add a module to a different location:

1 Right-click the Location folder and choose Add Module. A new module icon

appears.

Or

1 Select the Location icon.

2 From the Project menu, select Location, then select Add Module.

Set Module Parameters

Notice that the contents of the information pane and the configuration pane

changed when you added the MVI56-BDW module to the project.

At this time, you may wish to rename the "Default Project" and "Default Location"

folders in the tree view.

To rename an object:

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose Rename.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

Page 32 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 33

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Module Entries

To configure module parameters

1 Click on the plus sign next to the icon

to expand module

information.

2 Double-click the

icon to open the Edit dialog box.

3 To edit a parameter, select the parameter in the left pane and make your

changes in the right pane.

4 Click OK to save your changes.

Comment Entries

To add comments to your configuration file:

1 Click the plus sign to the left of the

icon to expand the Module

Comments.

2 Double-click the

icon. The Edit - Module Comment dialog

appears.

3 Enter your comment and click OK to save your changes.

Printing a Configuration File

To print a configuration file:

1 Select the Module icon, and then click the right mouse button to open a

shortcut menu.

2 On the shortcut menu, choose View Configuration. This action opens the

View Configuration window.

3 On the View Configuration window, open the File menu, and choose Print.

This action opens the Print dialog box.

4 On the Print dialog box, choose the printer to use from the dropdown list,

select printing options, and then click OK.

ProSoft Technology, Inc. Page 33 of 82

September 4, 2008

Page 34

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

2.2.2 MVI56-BDW Communication Module Configuration

[Section]/Item Value Range Description

[MODULE] Configuration header for general module information

Module Name: Up to 80

chars

Password: Up to 20

chars

Error/Status Pointer: -1 to 4955 Starting register location in virtual database for the

Write Register Start: 0 to 4999 This parameter specifies the starting register in the module

Write Register Count: 0 to 5000 This parameter specifies the number of registers to transfer

Read Register Start: 0 to 4999 This parameter specifies the starting register in the module

Read Register Count: 0 to 5000 This parameter specifies the number of registers to be

Failure Flag Count: 0 to 65535 This parameter specifies the number of successive transfer

Initialize Output Data: 0 or 1 This parameter determines if the output data for the module

[Section]/Item Value Range Description

[BARDAC DW CLIENT x] Start header for Client x (x=0 to 3)

Error/Status Pointer: -1 to 4990 Starting register location in virtual database for the

Name of the module for use on reports. Use this parameter

to identify your module in your system.

This parameter sets the password for the module. If the

parameter is not set, the module will not be password

protected. The module interprets the password as a casesensitive string. Do not include spaces or special characters

in the password. Only alpha and numeric characters should

be used.

error/status table. If a value of -1 is entered, the error/status

data will not be placed in the database. All other valid

values determine the starting location of the data. This data

area includes the module version information and all server

error/status data.

where the data transferred from the processor will be

placed. Valid range for this parameter is 0 to 4999.

from the processor to the module. Valid entry for this

parameter is 0 to 5000.

where data will be transferred from the module to the

processor. Valid range for this parameter is 0 to 4999.

transferred from the module to the processor. Valid entry for

this parameter is 0 to 5000.

errors that must occur before the communication ports are

shut down. If the parameter is set to 0, the communication

ports will continue to operate under all conditions. If the

value is set larger than 0 (1 to 65535), communications will

cease if the specified number of failures occur.

should be initialized with values from the processor. If the

value is set to 0, the output data will be initialized to 0. If the

value is set to 1, the data will be initialized with data from

the processor. Use of this option requires associated ladder

logic to pass the data from the processor to the module.

error/status table for this client. If a value of -1 is entered,

the error/status data will not be placed in the database. All

other valid values determine the starting location of the

data.

Page 34 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 35

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

[Section]/Item Value Range Description

Minimum Command Delay: 0 to 65535 This parameter specifies the number of milliseconds to wait

between the initial issuance of a command. This parameter

can be used to delay all commands sent to slaves to avoid

"flooding" commands on the network. This parameter does

not affect retries of a command as they will be issued when

failure is recognized.

Command Error Pointer: -1 to 4999 This parameter sets the address in the internal database

where the command error data will be placed. If the value is

set to -1, the data will not be transferred to the database.

Response Timeout: 0 to 65535 This parameter represents the message response timeout

period in 1 ms increments. This is the time that a client will

wait before re-transmitting a command if no response is

received from the addressed slave. The value is set

depending upon the communication network used and the

expected response time of the slowest device on the

network.

Retry Count: 0 to 25 This parameter specifies the number of times a command

will be retried if it fails.

The command list for the client in the module is located in the [ ] section of the

file. The following table describes the functions supported by the module and the

format of each command:

Parameter Range Description

Enable 0 ,1,2 This field defines whether or not the command is to be executed and under

what conditions.

Value Description

0 The command is disabled and will not be executed in the

normal polling sequence.

1 The command is executed each scan of the command list if

the Poll Interval Time is set to zero. If the Poll Interval time is

set, the command will be executed, when the interval timer

expires.

2 The command will execute only if the internal data associated

with the command changes. This value is valid only for write

commands.

Internal Address 0 to 4999

This field specifies the internal database register to be associated with the

command.

- If the command is a read function, the data read from the Server device will

be placed starting at the register value entered in this field.

- If the command is a write function, the data written to the Server device will

be sourced from the address specified.

ProSoft Technology, Inc. Page 35 of 82

September 4, 2008

Page 36

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

Parameter Range Description

Poll Interval 0 to 65535 This parameter specifies the minimum interval to execute continuous

commands (Enable code of 1). The parameter is entered in units of 1/10

seconds. Therefore, if a value of 10 is entered for a command, the command

will execute no more frequently than every 1 second.

Swap Code 0 or,1 This parameter defines if the data received from the Server is to be ordered

differently than received from the Server device. This parameter can be set to

order the register data received in an order useful by other applications. The

following table defines the values and their associated operations:

Swap Code Description

0 None - No Change is made in the byte ordering

(1234 = 1234)

1 Bytes - The bytes in each word are swapped

Node IP

Address

Function Code 0 or 1 This parameter specifies the BARDAC DW function to be executed by the

Device Address This parameter specifies the PIN value for the data value or parameter to be

xxx.xxx.xxx.xxx The IP address of the device being addressed by the command.

command. The following table defines the purpose of each function supported

by the module.

Function Code Description

0 Get (read data)

1 Set (write data)

considered by the command. Refer to the drive manual for a complete listing

of valid PIN's for your specific application.

(1234=2143)

th

2.2.3 Command List Overview

In order to interface the MVI56-BDW module with BARDAC-DW capable drives,

you must construct a command list for each of the four clients. The commands in

the list specify the Server device to be addressed, the function to be performed

(get or set), the data area in the device to interface with and the registers in the

internal database to be associated with the device data. The Client Command

List supports up to 100 commands for each client. The command list is

processed from top (command #0) to bottom independently by each client. A poll

interval parameter is associated with each command to specify a minimum delay

time in tenths of a second between the issuance of a command. If the user

specifies a value of 10 for the parameter, the command will be executed no more

frequently than every 1 second.

Write commands have a special feature, as they can be set to execute only if the

data in the write command changes. If the register data values in the command

have not changed since the command was last issued, the command will not be

executed. If the data in the command has changed since the command was last

issued, the command will be executed. Use of this feature can lighten the load on

the network. In order to implement this feature; set the enable code for the

command to a value of 2.

Page 36 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 37

Module Configuration MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

2.2.4 Commands Supported by the Module

The format of each command in the list is dependent on the BARDAC DW

Function Code being executed. The tables below list the functions supported by

the module:

Function Code Definition Supported in Client

0 Get (read data) X

1 Set (write data) X

Each command list record has the same general format. The first part of the

record contains the information relating to the communication module and the

second part contains information required to interface to the BARDAC-DW

UDP/IP Server device.

2.3 Download the Project to the Module

In order for the module to use the settings you configured, you must download

(copy) the updated Project file from your PC to the module.

To Download the Project File

1 In the tree view in ProSoft Configuration Builder, click once to select the

MVI56-BDW module.

2 Open the Project menu, and then choose Module / Download. The program

will scan your PC for a valid com port (this may take a few seconds). When

PCB has found a valid com port, the following dialog box will open.

3 Choose the com port to use from the dropdown list, and then click the

Download button.

ProSoft Technology, Inc. Page 37 of 82

September 4, 2008

Page 38

MVI56-BDW ♦ ControlLogix Platform Module Configuration

BARDAC Drive Web Interface

The module will perform a platform check to read and load its new settings.

When the platform check is complete, the status bar in ProSoft Configuration

Builder will be updated with the message "Module Running".

Page 38 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 39

Ladder Logic MVI56-BDW ♦ ControlLogix Platform BARDAC Drive Web Interface

3 Ladder Logic

Ladder logic is required for application of the MVI56-BDW module. Tasks that

must be handled by the ladder logic are module data transfer, special block

handling and status data receipt. Additionally, a power-up handler may be

needed to handle the initialization of the module's data and to clear any

processor fault conditions.

The sample ladder logic, on the ProSoft Solutions CD-ROM, is extensively

commented, to provide information on the purpose and function of each rung. For

most applications, the sample ladder will work without modification.

ProSoft Technology, Inc. Page 39 of 82

September 4, 2008

Page 40

MVI56-BDW ♦ ControlLogix Platform Ladder Logic

BARDAC Drive Web Interface

Page 40 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 41

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform BARDAC Drive Web Interface

4 Diagnostics and Troubleshooting

In This Chapter

Reading Status Data from the Module ..................................................41

LED Status Indicators............................................................................ 52

The module provides information on diagnostics and troubleshooting in the

following forms:

Status data values are transferred from the module to the processor.

Data contained in the module can be viewed through the

Configuration/Debug port attached to a terminal emulator.

LED status indicators on the front of the module provide information on the

module's status.

4.1 Reading Status Data from the Module

The MVI56-BDW module returns a 47-word Status Data block that can be used

to determine the module's operating status. This data is located in the module's

database at a user set location. This data is transferred to the ControlLogix

processor continuously with each normal data read block. For a complete listing

of the status data object, refer to the Module Set Up section.

4.1.1 Required Hardware

You can connect directly from your computer's serial port to the serial port on the

module to view configuration information, perform maintenance, and send

(upload) or receive (download) configuration files.

ProSoft Technology recommends the following minimum hardware to connect

your computer to the module:

80486 based processor (Pentium preferred)

1 megabyte of memory

At least one UART hardware-based serial communications port available.

USB-based virtual UART systems (USB to serial port adapters) often do not

function reliably, especially during binary file transfers, such as when

uploading/downloading configuration files or module firmware upgrades.

A null modem serial cable.

ProSoft Technology, Inc. Page 41 of 82

September 4, 2008

Page 42

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

4.1.2 The Configuration/Debug Menu

The Configuration and Debug menu for this module is arranged as a tree

structure, with the Main Menu at the top of the tree, and one or more sub-menus

for each menu command. The first menu you see when you connect to the

module is the Main menu.

Because this is a text-based menu system, you enter commands by typing the

command letter from your computer keyboard in the diagnostic window in

ProSoft Configuration Builder (PCB). The module does not respond to mouse

movements or clicks. The command executes as soon as you press the

command letter — you do not need to press [Enter]. When you type a command

letter, a new screen will be displayed in your terminal application.

Using the Diagnostic Window in ProSoft Configuration Builder

To connect to the module's Configuration/Debug serial port:

1 Start PCB program with the application file to be tested. Right click over the

module icon.

2 On the shortcut menu, choose Diagnostics.

Page 42 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 43

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

3 This action opens the Diagnostics dialog box. Press "?" to display the Main

Menu.

Important: The illustrations of configuration/debug menus in this section are intended as a general

guide, and may not exactly match the configuration/debug menus in your own module.

If there is no response from the module, follow these steps:

1 Verify that the null modem cable is connected properly between your

computer's serial port and the module. A regular serial cable will not work.

2 On computers with more than one serial port, verify that your communication

program is connected to the same port that is connected to the module.

If you are still not able to establish a connection, contact ProSoft Technology for

assistance.

Navigation

All of the sub-menus for this module contain commands to redisplay the menu or

return to the previous menu. You can always return from a sub-menu to the next

higher menu by pressing [M] on your keyboard.

The organization of the menu structure is represented in simplified form in the

following illustration:

ProSoft Technology, Inc. Page 43 of 82

September 4, 2008

Page 44

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

The remainder of this section shows you the menus available for this module,

and briefly discusses the commands available to you.

Keystrokes

The keyboard commands on these menus are almost always non-case sensitive.

You can enter most commands in lower case or capital letters.

The menus use a few special characters ([?], [-], [+], [@]) that must be entered

exactly as shown. Some of these characters will require you to use the [Shift],

[Ctrl] or [Alt] keys to enter them correctly. For example, on US English

keyboards, enter the [?] command as [Shift][/].

Also, take care to distinguish capital letter [I] from lower case letter [l] (L) and

number [1]; likewise for capital letter [O] and number [0]. Although these

characters look nearly the same on the screen, they perform different actions on

the module.

4.1.3 Main Menu

When you first connect to the module from your computer, your terminal screen

will be blank. To activate the main menu, press the [?] key on your computer's

keyboard. If the module is connected properly, the following menu will appear on

your terminal screen:

Caution: Some of the commands available to you from this menu ar e designed for advanced

debugging and system testing only, and can cause the module to stop communicating with the

processor or with other devices, resulting in potential data loss or other failures. Only use these

commands if you are specifically directed to do so by ProSoft Technology Technical Support staff.

Some of these command keys are not listed on the menu, but are active nevertheless. Please be

careful when pressing keys so that you do not accidentally execute an unwanted command.

Viewing Block Transfer Statistics

Press [B] from the Main Menu to view the Block Transfer Statistics screen.

Use this command to display the configuration and statistics of the backplane

data transfer operations between the module and the processor. The information

on this screen can help determine if there are communication problems between

the processor and the module.

Page 44 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 45

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Tip: To determine the number of blocks transferred each second, mark the numbers displayed at a

specific time. Then some seconds later activate the command again. Subtract the previous

numbers from the current numbers and divide by the quantity of seconds passed between the two

readings.

Viewing Module Configuration

Press [C] to view the Module Configuration screen.

Use this command to display the current configuration and statistics for the

module.

Opening the Database Menu

Press [D] to open the Database View menu. Use this menu command to view the

current contents of the module's database.

Opening the Command Error List Menu

Press [E], [F], [G] or [H] to open the Command Error List for clients 1 through 4

respectively. This list consists of multiple pages of command list error/status

data. Press [?] to view a list of commands available on this menu.

Opening the Command List Menu

Press [I], [J], [K] or [L] to open the Command List menu for clients 1 through 4

respectively. Use this command to view the configured command list for the

module.

Transferring the Configuration File from PC to MVI56 module

Press [R] to send (upload) the configuration file from your PC to the module and

store the file on the module's Compact Flash Disk.

Press [Y] to confirm the file transfer, and then follow the instructions on the

terminal screen to complete the file transfer process.

After the file has been successfully downloaded, the module will restart the

program and load the new configuration information. Review the new

configuration using menu commands [6] and [0] to verify that the module is

configured correctly.

Transferring the Configuration File from MVI56 module to PC

Press [S] to receive (download) the configuration file from the module to your

PC.

Press [Y] to confirm the file transfer, and then follow the instructions on the

terminal screen to complete the file transfer process.

After the file has been successfully downloaded, you can open and edit the file to

change the module's configuration.

ProSoft Technology, Inc. Page 45 of 82

September 4, 2008

Page 46

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

Resetting diagnostic data

Press [U] to reset the status counters for the client and/or servers in the module.

Viewing Version Information

Press [V] to view Version information for the module.

Use this command to view the current version of the software for the module, as

well as other important values. You may be asked to provide this information

when calling for technical support on the product.

Values at the bottom of the display are important in determining module

operation. The Program Scan Counter value is incremented each time a

module's program cycle is complete.

Tip: Repeat this command at one-second intervals to determine the frequency of program

execution.

Warm Booting the Module

Caution: Some of the commands available to you from this menu ar e designed for advanced

debugging and system testing only, and can cause the module to stop communicating with the

processor or with other devices, resulting in potential data loss or other failures. Only use these

commands if you are specifically directed to do so by ProSoft Technology Technical Support staff.

Some of these command keys are not listed on the menu, but are active nevertheless. Please be

careful when pressing keys so that you do not accidentally execute an unwanted command.

Press [W] from the Main Menu to warm boot (restart) the module. This command

will cause the program to exit and reload, refreshing configuration parameters

that must be set on program initialization. Only use this command if you must

force the module to re-boot.

Viewing Client Status

Press [1], [2], [3] or [4] to display the statistics of clients 1 through 4,

respectively.

Viewing Client Configuration

Press [5] to display the configuration information for the client.

Opening the Network Menu

Press [@] to open the network menu. The network menu allows you to send,

receive and view the WATTCP.CFG file that contains the IP, gateway and other

network specification information. You can find more information about the

commands on this menu in the Network Menu (page 51) section.

Page 46 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 47

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Exiting the Program

Caution: Some of the commands available to you from this menu ar e designed for advanced

debugging and system testing only, and can cause the module to stop communicating with the

processor or with other devices, resulting in potential data loss or other failures. Only use these

commands if you are specifically directed to do so by ProSoft Technology Technical Support staff.

Some of these command keys are not listed on the menu, but are active nevertheless. Please be

careful when pressing keys so that you do not accidentally execute an unwanted command.

Press [Esc] to restart the module and force all drivers to be loaded. The module

will use the configuration stored in the module's Flash ROM to configure the

module.

4.1.4 Database View Menu

Press [D] from the Main Menu to open the Database View menu. Use this menu

command to view the current contents of the module's database. Press [?] to

view a list of commands available on this menu.

Viewing Register Pages

To view sets of register pages, use the keys described below:

Command Description

[0]

[1]

[2]

Display registers 0 to 99

Display registers 1000 to 1099

Display registers 2000 to 2099

And so on. The total number of register pages available to view depends on your

module's configuration.

ProSoft Technology, Inc. Page 47 of 82

September 4, 2008

Page 48

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

Displaying the Current Page of Registers Again

This screen displays the current page of 100 registers in the database.

Moving Back Through 5 Pages of Registers

Press [-] from the Database View menu to skip back to the previous 500

registers of data.

Viewing the Previous 100 Registers of Data

Press [P] from the Database View menu to display the previous 100 registers of

data.

Skipping 500 Registers of Data

Hold down [Shift] and press [=] to skip forward to the next 500 registers of data.

Viewing the Next 100 Registers of Data

Press [N] from the Database View menu to select and display the next 100

registers of data.

Viewing Data in Decimal Format

Press [D] to display the data on the current page in decimal format.

Viewing Data in Hexadecimal Format

Press [H] to display the data on the current page in hexadecimal format.

Viewing Data in Floating Point Format

Press [F] from the Database View menu. Use this command to display the data

on the current page in floating point format. The program assumes that the

values are aligned on even register boundaries. If floating-point values are not

aligned as such, they are not displayed properly.

Viewing Data in ASCII (Text) Format

Press [A] to display the data on the current page in ASCII format. This is useful

for regions of the database that contain ASCII data.

Page 48 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 49

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Returning to the Main Menu

Press [M] to return to the Main Menu.

4.1.5 Master Command Error List Menu

Use this menu to view the command error list for the module. Press [?] to view a

list of commands available on this menu.

Redisplaying the Current Page

Press [S] to display the current page of data.

Viewing the Previous 20 Commands

Press [-] to display data for the previous 20 commands.

Viewing the Previous Page of Commands

Press [P] to display the previous page of commands.

Viewing the Next 20 Commands

Press [+] to display data for the next 20 commands.

Viewing the Next Page of Commands

Press [N] to display the next page of commands.

Returning to the Main Menu

Press [M] to return to the Main Menu.

ProSoft Technology, Inc. Page 49 of 82

September 4, 2008

Page 50

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

4.1.6 Master Command List Menu

Use this menu to view the command list for the module. Press [?] to view a list of

commands available on this menu.

Redisplaying the Current Page

Press [S] to display the current page of data.

Viewing the Previous 50 Commands

Press [-] to view the previous 50 commands.

Viewing the Previous Page of Commands

Press [P] to display the previous page of commands.

Viewing the Next 50 Commands

Press [+] to view the next 50 commands from the master command list.

Viewing the Next Page of Commands

Press [N] to display the next page of commands.

Returning to the Main Menu

Press [M] to return to the Main Menu.

Page 50 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 51

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

4.1.7 Network Menu

The network menu allows you to send, receive and view the WATTCP.CFG file

that contains the IP and gateway addresses, and other network specification

information.

Transferring WATTCP.CFG to the module

Press [R] to transfer a new WATTCP.CFG file from the PC to the module. Use

this command to change the network configuration for the module (for example,

the module's IP address).

Press [Y] to confirm the file transfer, and then follow the instructions on the

terminal screen to complete the file transfer process.

Transferring WATTCP.CFG to the PC

Press [S] to transfer the WATTCP.CFG file from the module to your PC.

Press [Y] to confirm the file transfer, and then follow the instructions on the

terminal screen to complete the file transfer process.

After the file has been successfully transferred, you can open and edit the file to

change the module's network configuration.

Viewing the WATTCP.CFG file on the module

Press [V] to view the module's WATTCP.CFG file. Use this command to confirm

the module's current network settings.

Returning to the Main Menu

Press [M] to return to the Main Menu.

ProSoft Technology, Inc. Page 51 of 82

September 4, 2008

Page 52

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

4.2 LED Status Indicators

The LEDs indicate the module's operating status as follows:

ProSoft

Module

CFG Green

BP ACT Amber

OK Red/

Color Status Indication

On

Off No data is being transferred on the Configuration/Debug port.

On Port not used P1 Green

Off Port not used

On Port not used P2 Green

Off Port not used

Off The MVI56-BDW is working normally. APP Amber

On

On

Off

Off

Green

Green The module is operating normally.

Red

Off The battery voltage is OK and functioning. BAT Red

On

Data is being transferred between the module and a remote

terminal using the Configuration/Debug port.

The MVI56-BDW module program has recognized a

communication error.

The LED is on when the module is performing a write

operation on the backplane.

The LED is off when the module is performing a read

operation on the backplane. Under normal operation, the LED

should blink rapidly on and off.

The card is not receiving any power and is not securely

plugged into the rack.

The program has detected an error or is being configured. If

the LED remains red for over 10 seconds, the program has

probably halted. Remove the card from the rack and re-insert

the card to restart the module's program.

The battery voltage is low or battery is not present. Allow

battery to charge by keeping module plugged into rack for 24

hours. If BAT LED still does not go off, contact ProSoft

Technology, as this is not a user serviceable item.

If a configuration error is found for the client, the client configuration error word

will have a value other than zero. The configuration error word bits have the

following definitions:

Bit Description Value

0 0x0001

1 0x0002

2 0x0004

3 0x0008

4 Invalid retry count parameter 0x0010

5 0x0020

6 0x0040

7 0x0080

8 0x0100

9 0x0200

10 0x0400

Page 52 of 82 ProSoft Technology, Inc.

September 4, 2008

Page 53

Diagnostics and Troubleshooting MVI56-BDW ♦ ControlLogix Platform

BARDAC Drive Web Interface

Bit Description Value

11 0x0800

12 0x1000

13 0x2000

14 0x4000

15 0x8000

Correct any invalid data in the configuration for proper module operation. When

the configuration contains a valid parameter set, all the bits in the configuration

word will be clear. This does not indicate that the configuration is valid for the

user application. Make sure each parameter is set correctly for the specific

application.

If the APP, BP ACT and OK LEDs blink at a rate of every one-second, this

indicates a serious problem with the module. Call ProSoft Technology support to

arrange for repairs.

4.2.1 Ethernet LED Indicators

LED State Description

Off No activity on the port. Data

Green Flash The port is either actively transmitting or receiving data.

Off No connection to hub or network is detected. Link

Green Solid

Connected to hub or network correctly. This is the normal

operating state.

4.2.2 Clearing a Fault Condition

Typically, if the OK LED on the front of the module turns red for more than ten

seconds, a hardware problem has been detected in the module, or the program

has exited.

To clear the condition, follow these steps:

1 Turn off power to the rack

2 Remove the card from the rack

3 Verify that all jumpers are set correctly

4 If the module requires a Compact Flash card, verify that the card is installed

correctly

5 Re-insert the card in the rack and turn the power back on

6 Verify the configuration data being transferred to the module from the

ControlLogix processor.

If the module's OK LED does not turn green, verify that the module is inserted

completely into the rack. If this does not cure the problem, contact ProSoft

Technology Support.

ProSoft Technology, Inc. Page 53 of 82

September 4, 2008

Page 54

MVI56-BDW ♦ ControlLogix Platform Diagnostics and Troubleshooting

BARDAC Drive Web Interface

4.2.3 Troubleshooting

Use the following troubleshooting steps if you encounter problems when the

module is powered up. If these steps do not resolve your problem, please contact

ProSoft Technology Technical Support.

Processor Errors

Problem Description Steps to take

Processor Fault

Processor I/O LED

flashes

Module Errors

Problem Description Steps to take

BP ACT LED remains

off or blinks slowly

OK LED remains red

Verify that the module is plugged into the slot that has been configured

for the module.

Verify that the slot in the rack configuration has been set up correctly in

the ladder logic.

This indicates a problem with backplane communications. Verify that all

modules in the rack are configured in the ladder logic.

This indicates that backplane transfer operations are failing. Connect to

the module's Configuration/Debug port to check this.

To establish backplane communications, verify the following items:

The processor is in Run mode.

The backplane driver is loaded in the module.

The module is configured for read and write block data transfer.

The ladder logic handles all read and write block situations.

The module is configured in the processor.

The program has halted or a critical error has occurred. Connect to the

Configuration/Debug port to see if the module is running. If the program

has halted, turn off power to the rack, remove the card from the rack and

re-insert the card in the rack, and then restore power to the rack.

Page 54 of 82 ProSoft Technology, Inc.