Page 1

ILX69-PBS

CompactLogix or MicroLogix Platform

PROFIBUS Slave Communication

Module

March 20, 2015

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

© 2015 ProSoft Technology, Inc. All rights reserved.

ILX69-PBS User Manual

March 20, 2015

ProSoft Technology®, is a registered copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD and are

available at no charge from our web site: http://www.prosoft-technology.com

Important Safety Information

THIS EQUIPMENT IS AN OPEN-TYPE DEVICE AND IS MEANT TO BE INSTALLED IN AN ENCLOSURE

SUITABLE FOR THE ENVIRONMENT SUCH THAT THE EQUIPMENT IS ONLY ACCESSIBLE WITH THE USE OF

A TOOL.

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS LIVE OR

UNLESS THE AREA IS KNOWN TO BE FREE OF IGNITABLE CONCENTRATIONS.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENT MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

DEVICES SHALL BE USED WITH ALLEN BRADLEY 1769 BACKPLANES

INPUT TO THE DEVICES SHALL BE FUSED AT 5A MAXIMUM.

Page 3

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Safety Information ............................................................................................................... 2

1 Introduction 7

1.1 About the User Manual .............................................................................................. 7

1.1.1 Intended Audience .................................................................................................... 7

1.2 General Information ILX69-PBS ................................................................................ 7

1.3 Reference Systems ................................................................................................... 8

1.4 1769 Programmable Controller Functionality ............................................................ 8

1.5 Requirements ............................................................................................................ 9

1.5.1 Software Requirements ............................................................................................. 9

1.5.2 Hardware Requirements ........................................................................................... 9

2 Safety 11

2.1 General Note ........................................................................................................... 11

2.2 Personnel Qualification ........................................................................................... 11

2.3 Safety Instructions to Avoid Personal Injury............................................................ 11

2.3.1 Electrical Shock Hazard .......................................................................................... 12

2.3.2 Communication Stop During Firmware Update ...................................................... 12

2.4 Safety Instructions to Avoid Property Damage ....................................................... 12

2.4.1 Device Destruction if ILX69-PBS is Installed to Powered PLC ............................... 13

2.4.2 Device Destruction by Exceeding Allowed Supply Voltage .................................... 13

2.4.3 Device Destruction by Exceeding Allowed Signaling Voltage................................. 13

2.4.4 Electrostatically sensitive devices ........................................................................... 13

2.5 Labeling of Safety Messages .................................................................................. 14

2.6 Safety References ................................................................................................... 15

3 About the ILX69-PBS 17

3.1 Device Drawing ILX69-PBS .................................................................................... 17

3.2 PROFIBUS Interface ............................................................................................... 18

3.2.1 Wiring Instructions ................................................................................................... 18

3.3 Ethernet Interface .................................................................................................... 20

3.3.1 Ethernet Pin Assignment at the RJ45 Socket ......................................................... 20

3.3.2 Ethernet Connection Data ....................................................................................... 21

3.4 Removable Memory Card ....................................................................................... 21

3.5 Power Supply .......................................................................................................... 21

4 Installation 23

4.1 Consideration when planning the system ............................................................... 23

4.2 ILX69-PBS Hardware Installation ............................................................................ 24

4.2.1 Safety Precautions .................................................................................................. 24

4.2.2 Installing the ILX69-PBS Module ............................................................................ 24

4.3 Uninstalling ILX69-PBS Hardware .......................................................................... 25

ProSoft Technology, Inc. Page 3 of 102

March 20, 2015

Page 4

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

5 Configuration and Start-Up 27

5.1 Creating the Module in an RSLogix 5000 Project................................................... 27

5.1.1 Creating a Module in the Project Using an Add-On Profile .................................... 28

5.1.2 Manually Creating a Module in the Project ............................................................. 35

5.1.3 Importing the Ladder Rung ..................................................................................... 39

5.2 Slave Configuration ................................................................................................ 45

5.2.1 GSD File ................................................................................................................. 45

5.2.2 Configuration by Master .......................................................................................... 45

5.2.3 Configuration by Controller Application .................................................................. 46

5.2.4 Configuration Parameters ....................................................................................... 47

5.3 SD Card .................................................................................................................. 49

5.3.1 Start-up Behavior with or without SD Card ............................................................. 49

5.3.2 STARTUP.INI File ................................................................................................... 50

5.3.3 Reset Device to Factory Settings with Memory Card ............................................. 50

6 Communication 51

6.1 Studio 5000 PROFIBUS Data Values .................................................................... 51

6.1.1 PROFIBUS Network Output Data ........................................................................... 51

6.1.2 PROFIBUS Network Input Data .............................................................................. 52

6.2 I/O Communication and Memory Map .................................................................... 52

6.2.1 I/O Arrays Overview ................................................................................................ 52

6.2.2 Input Array .............................................................................................................. 53

6.2.3 Output Array ............................................................................................................ 59

6.3 Acyclic Messaging .................................................................................................. 60

6.3.1 Supported PROFIBUS DP Messages .................................................................... 60

6.3.2 Standard Messaging ............................................................................................... 61

6.3.3 DPV1 Messaging .................................................................................................... 64

6.3.4 CIP Messaging Error Codes ................................................................................... 68

7 Diagnostics and Troubleshooting 71

7.1 Web Page ............................................................................................................... 71

7.1.1 General Device and Diagnostics Information ......................................................... 72

7.1.2 Firmware Update .................................................................................................... 76

7.2 Hardware LEDs....................................................................................................... 84

7.2.1 CompactLogix LEDs ............................................................................................... 84

7.2.2 ILX69-PBS LEDs .................................................................................................... 85

7.3 Troubleshooting ...................................................................................................... 88

8 Technical Data 89

8.1 Technical Data - ILX69-PBS ................................................................................... 89

8.2 Technical Data - PROFIBUS .................................................................................. 92

9 Annex 93

9.1 PROFIBUS Functionality ........................................................................................ 93

9.1.1 DPV0 Services ........................................................................................................ 93

9.1.2 DPV1 Services ........................................................................................................ 94

9.2 Disposal of Electronic Equipment Waste ................................................................ 95

Page 4 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 5

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

9.3 References .............................................................................................................. 95

9.4 Glossary .................................................................................................................. 96

10 Support, Service & Warranty 99

10.1 Contacting Technical Support ................................................................................. 99

10.2 Warranty Information ............................................................................................. 100

Index 101

ProSoft Technology, Inc. Page 5 of 102

March 20, 2015

Page 6

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Page 6 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 7

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

About the User Manual ........................................................................... 7

General Information ILX69-PBS ............................................................. 7

Reference Systems................................................................................. 8

1769 Programmable Controller Functionality .......................................... 8

Requirements ......................................................................................... 9

PROFIBUS Slave Communication Module User Manual

1 Introduction

1.1 About the User Manual

This user manual provides descriptions and detailed information about:

How to assemble the ILX69-PBS into a CompactLogix™ system.

PROFIBUS wiring

Configuration and start-up

Communication

Diagnostics

LED displays

Technical data and electrical/environmental specifications

1.1.1 Intended Audience

The intended audiences for this manual are the individuals responsible for designing,

installing, programming, or troubleshooting control systems that use the Rockwell

CompactLogix™ 1769 programmable controller and the ILX69-PBS. You should have a

basic understanding of electrical circuitry and familiarity with relay logic. If you do not, obtain

the proper training before using this product.

1.2 General Information ILX69-PBS

The ILX69-PBS is a slot extension module for Rockwell's CompactLogix™ 1769 system

which allows the PLC to exchange data on a PROFIBUS network.

The ILX69-PBS PROFIBUS DPV1 slave exchanges data with the connected PROFIBUS DP

master.

The configuration is stored permanently in the on-board FLASH memory of the ILX69-PBS

and is available immediately on power up. The data exchange between controller and

module is done via the I/O process data image using CompactLogix™ backplane

technology.

The diagnostics of the ILX69-PBS can be done using the CompactLogix™ PLC program, via

the ProSoft web pages or by help of the master configuration and diagnostics software.

ProSoft Technology, Inc. Page 7 of 102

March 20, 2015

Page 8

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

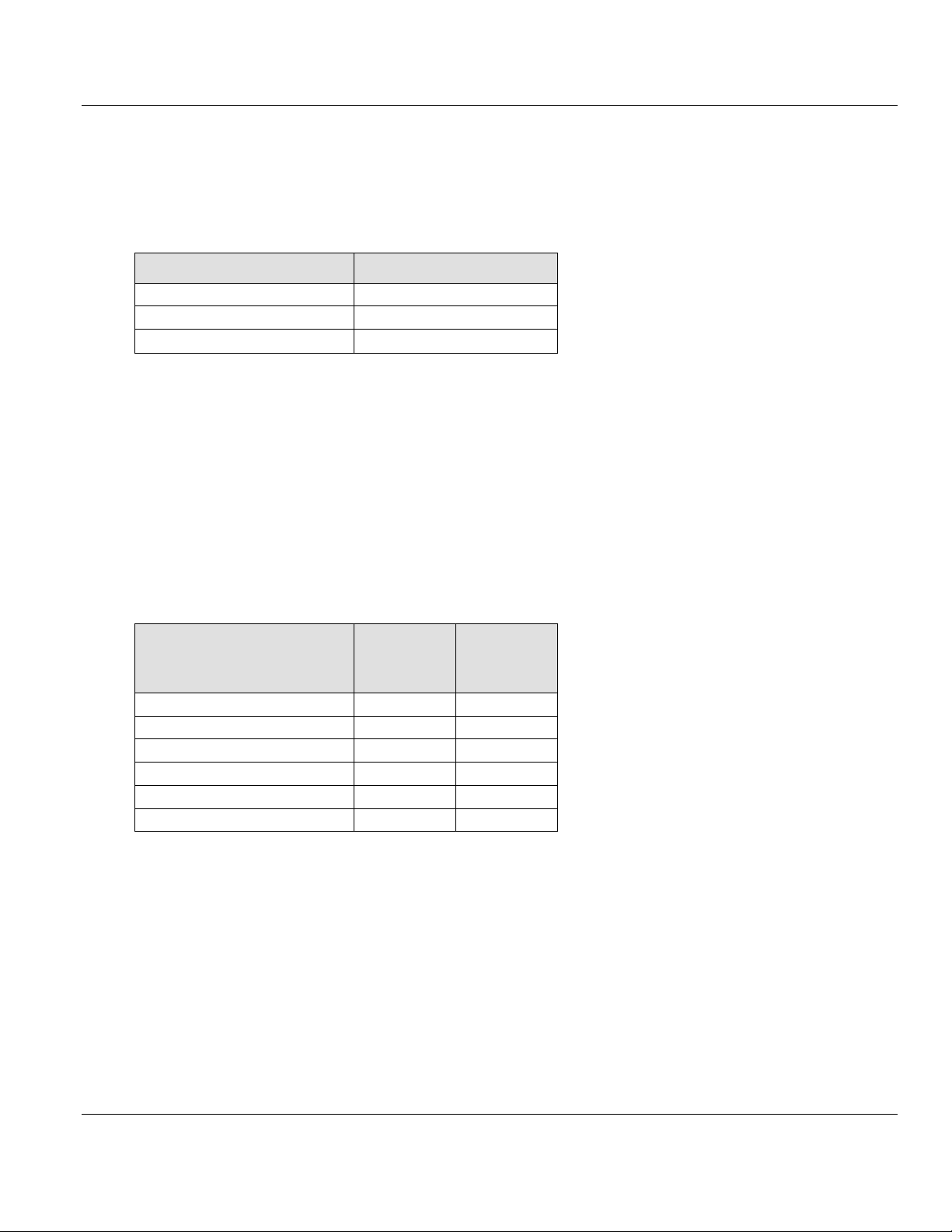

Controller

Firmware

CompactLogix™ 1769-L23

V17.05

CompactLogix™ 1769-L32E

V20.13

CompactLogix™ 1769-L36ERM

V21.11

Processor

I/O (cyclic)

CIP

Messaging

(acyclic)

CompactLogix™ 1769-L23

Yes

Yes

CompactLogix™ 1769-L30

Yes

No

CompactLogix™ 1769-L31

Yes

Yes

CompactLogix™ 1769-L32E

Yes

Yes

CompactLogix™ 1769-L35E

Yes

Yes

CompactLogix™ 1769-L36ERM

Yes

Yes

User Manual PROFIBUS Slave Communication Module

1.3 Reference Systems

The firmware of the ILX69-PBS was developed and tested with the following

CompactLogix™ controller types and firmware revisions.

CompactLogix System

1.4 1769 Programmable Controller Functionality

PROFIBUS DP supports acyclic services through messages. These PROFIBUS DP

services are supported by the Studio 5000 programming tool using CIP messages. Not all of

the 1769 programmable controllers support CIP messaging.

The basic PROFIBUS DP acyclic services Global Control or slave Diagnostics request are

also executable in addition to the CIP method by using the I/O area. The following table

displays the 1769 programmable controllers and the functionalities they support.

CompactLogix System

Yes = Functionality supported

No = Functionality not supported

Page 8 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 9

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

1.5 Requirements

1.5.1 Software Requirements

The software requirements for using the ILX69-PBS within a CompactLogix™ system are

listed below. You must have the following software installed on your PC unless otherwise

noted:

CompactLogix System

Studio 5000 programming software, V21.00 or higher

RSLogix™ 5000 programming software, V20.00 or higher

1.5.2 Hardware Requirements

The following minimum hardware is required to use the ILX69-PBS:

Windows PC with SD card slot or SD card reader

Ethernet cable for ILX69-PBS web page connection

CompactLogix System

Personal Computer

1769 – Programmable controller (1769-L23, 1769-L32E and 1769-L36ERM)

1769 – Power supply

1769 – Right or left handed termination end cap

Ethernet cable for interface to the 1769 programmable controller

ProSoft Technology, Inc. Page 9 of 102

March 20, 2015

Page 10

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Page 10 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 11

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

General Note .........................................................................................11

Personnel Qualification ..........................................................................11

Safety Instructions to Avoid Personal Injury ...........................................11

Safety Instructions to Avoid Property Damage ......................................12

Labeling of Safety Messages .................................................................14

Safety References .................................................................................15

PROFIBUS Slave Communication Module User Manual

2 Safety

2.1 General Note

The documentation in the form of a user manual, an operating instruction manual or other

manual types, as well as the accompanying texts have been created for the use of the

products by educated personnel. When using the products, all Safety Messages, Integrated

Safety Messages, Property Damage Messages and all valid legal regulations must be

obeyed. Technical knowledge is presumed. The user must assure that all legal regulations

are obeyed.

2.2 Personnel Qualification

The ILX69-PBS must only be installed, configured, and removed by qualified personnel.

Job-specific technical skills for people professionally working with electricity must be present

concerning the following topics:

Safety and health at work

Mounting and connecting of electrical equipment

Measurement and analysis of electrical functions and systems

Evaluation of the safety of electrical systems and equipment

Installing and configuring IT systems

2.3 Safety Instructions to Avoid Personal Injury

To ensure your own personal safety and to avoid personal injury, you necessarily must read,

understand and follow the safety instructions and safety messages in this manual before

you install and operate the ILX69-PBS.

ProSoft Technology, Inc. Page 11 of 102

March 20, 2015

Page 12

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

2.3.1 Electrical Shock Hazard

The danger of a lethal electrical shock caused by parts with more than 50V may occur if you

power a PLC power supply module when its housing is open.

HAZARDOUS VOLTAGE is present inside of a powered PLC power supply module.

Strictly obey all safety rules provided by the device manufacturer in the documentation.

Disconnect the network power (power plug) from the power supply module before you

disconnect the PLC module from the backplane.

When you disconnect the PLC module from the power supply module, use end cap

terminators and close the power supply module housing.

An electrical shock is the result of a current flowing through the human body. The resulting

effect depends on the intensity and duration of the current and on its path through the body.

Currents in the range of approximately ½ mA can cause effects in persons with good health,

and indirectly cause injuries resulting from startling responses. Higher currents can cause

more direct effects, such as burns, muscle spasms, or ventricular fibrillation.

In dry conditions, permanent voltages up to approximately 42.4 V peak or 60 V are not

considered as dangerous if the contact area is equivalent to the size of a human hand.

More information is located at Safety References (page 15).

2.3.2 Communication Stop During Firmware Update

If you plan a firmware update via the ProSoft web pages, please yield:

During the firmware update procedure, a device reset is performed and stops all module

communication functions with network devices. An unintended plant stop can cause

personal injury.

Initiating a device reset causes a device reboot. A reboot stops all communication

immediately.

Personal injury by consequence of careless use caused plant stop can not be excluded.

All fieldbus devices should be placed in a fail-safe condition under direct supervision

before starting a firmware update.

Before you initiate a reset, make sure your system is in an idle state and operating under

maintenance conditions in order to prevent personal injury.

Stop the PLC program before you start the firmware update.

More firmware update information is located at Firmware Update.

2.4 Safety Instructions to Avoid Property Damage

To avoid system damage and device destruction to the ILX69-PBS, you necessarily must

read, understand and follow the following safety instructions and safety messages in this

manual before you install and operate the ILX69-PBS.

Page 12 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 13

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Mandatory supply voltage information is located at Power Supply (page 21).

Mandatory signaling voltage information is located at Power Supply (page 21).

PROFIBUS Slave Communication Module User Manual

2.4.1 Device Destruction if ILX69-PBS is Installed to Powered PLC

To avoid device destruction when the ILX69-PBS is powered up:

Strictly obey to all safety rules provided by the PLC device manufacturer documentation.

Shut off the power supply of the PLC, before you install the ILX69-PBS module.

2.4.2 Device Destruction by Exceeding Allowed Supply Voltage

To avoid device destruction due to high supply voltage to the ILX69-PBS, you must observe

the following instructions.

The ILX69-PBS may only be operated with the specified supply voltage. Make sure that

the limits of the allowed range for the supply voltage are not exceeded.

A supply voltage above the upper limit can cause severe damage to the ILX69-PBS.

A supply voltage below the lower limit can cause malfunction in the ILX69-PBS.

The allowed range for the supply voltage is defined by the tolerances specified in this

manual.

2.4.3 Device Destruction by Exceeding Allowed Signaling Voltage

To avoid device destruction due to high signal voltage to the ILX69-PBS, you must observe

the following instructions.

All I/O signal pins at the ILX69-PBS tolerate only the specified signaling voltage.

Operation of the ILX69-PBS with a signaling voltage other than the specified signaling

voltage may lead to severe damage to the module.

2.4.4 Electrostatically sensitive devices

This equipment is sensitive to electrostatic discharge, which can cause internal damage and

affect normal operation. Therefore, adhere to the necessary safety precautions for

components that are vulnerable with electrostatic discharge when handling the ILX69-PBS.

Follow the guidelines listed when you handle this equipment:

Touch a grounded object to discharge potential static.

Wear an approved grounding wrist strap.

Do not touch connectors or pins on the ILX69-PBS.

Do not touch circuit components inside the equipment.

If available, use a static-safe workstation.

When not in use, store the equipment in appropriate static-safe packaging.

More information is located at Safety References (page 15).

ProSoft Technology, Inc. Page 13 of 102

March 20, 2015

Page 14

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

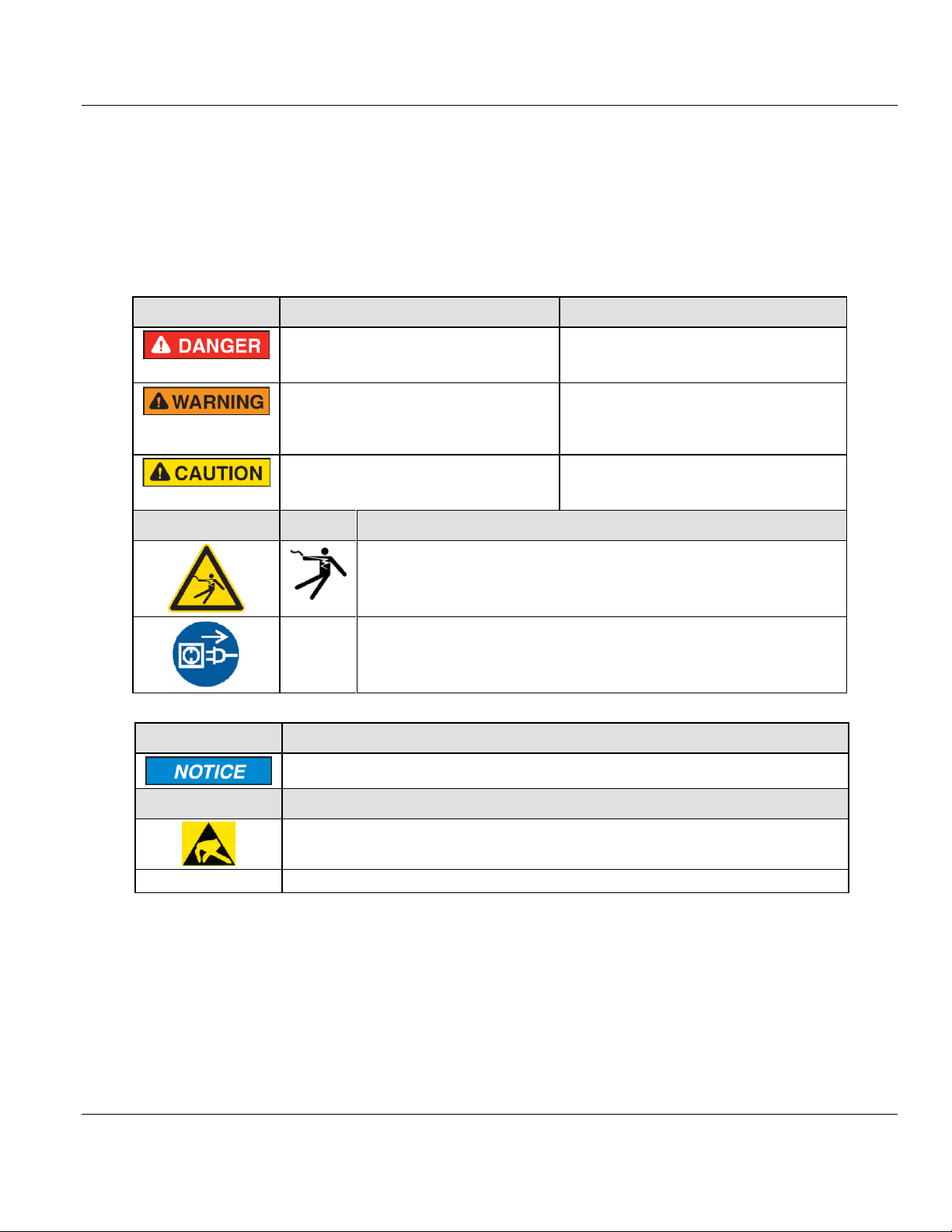

Signal Word

Meaning (International)

Meaning (USA)

Indicates a direct hazard with high risk,

which will have a consequence of death or

grievous bodily harm if it is not avoided.

Indicates a hazardous situation which if not

avoided, will result in death or serious injury.

Indicates a possible hazard with medium

risk, which will have a consequence of

death or (grievous) bodily harm if it is not

avoided.

Indicates a hazardous situation which if not

avoided, could result in death or serious

injury.

Indicates a minor hazard with medium risk,

which could have a consequence of simple

battery if it is not avoided.

Indicates a hazardous situation which if not

avoided, may result in minor or moderate

Injury.

Safety Sign

USA

Warning or Principle

Warning of lethal electrical shock

Principle: Disconnect the power plug

Signal Word

Meaning (International and USA)

Indicates a property damage message.

Safety Sign

Warning or Principle

Warning on damages by electrostatic discharge

-

Example: Warning of device destruction due to exceedingly high supply voltage

User Manual PROFIBUS Slave Communication Module

2.5 Labeling of Safety Messages

The Safety Messages at the beginning of a chapter are pinpointed particularly and

highlighted by a signal word according to the degree of endangerment. The type of

danger is specified by the safety message text and optionally by a specific safety sign.

The Integrated Safety Messages within an instruction description are highlighted with a

signal word according to the degree of endangerment. The type of danger is specified by

the safety message text.

In this document, all Safety Instructions and Safety Messages are designed according both

to the international used safety conventions as well as to the ANSI Z535.6 standard, refer to

Safety References (page 15).

In this document, the signal words ‘WARNING’, ‘CAUTION’ and ‘NOTICE’ are used

according to ANSI Z535.6 standard. The meaning given in ISO/IEC 26514 [4] section ‘11.11

Contents of warnings and cautions is not relevant in this manual.

Page 14 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 15

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

[S1]

ANSI Z535.6-2006 American National Standard for Product Safety Information in Product

Manuals, Instructions, and Other Collateral Materials

[S2]

IEC 60950-1, Information technology equipment - Safety - Part 1: General requirements, (IEC

60950-1:2005, modified); German Edition EN 60950-1:2006

[S3]

EN 61340-5-1 and EN 61340-5-2 as well as IEC 61340-5-1 and IEC 61340-5-2

[S4]

26514-2010 - IEEE Standard for Adoption of ISO/IEC 26514:2008 Systems and Software

Engineering--Requirements for Designers and Developers of User Documentation

PROFIBUS Slave Communication Module User Manual

2.6 Safety References

ProSoft Technology, Inc. Page 15 of 102

March 20, 2015

Page 16

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Page 16 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 17

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

Device Drawing ILX69-PBS ...................................................................17

PROFIBUS Interface..............................................................................18

Ethernet Interface ..................................................................................20

Removable Memory Card ......................................................................21

Power Supply .........................................................................................21

PROFIBUS Slave Communication Module User Manual

3 About the ILX69-PBS

3.1 Device Drawing ILX69-PBS

ProSoft Technology, Inc. Page 17 of 102

March 20, 2015

Page 18

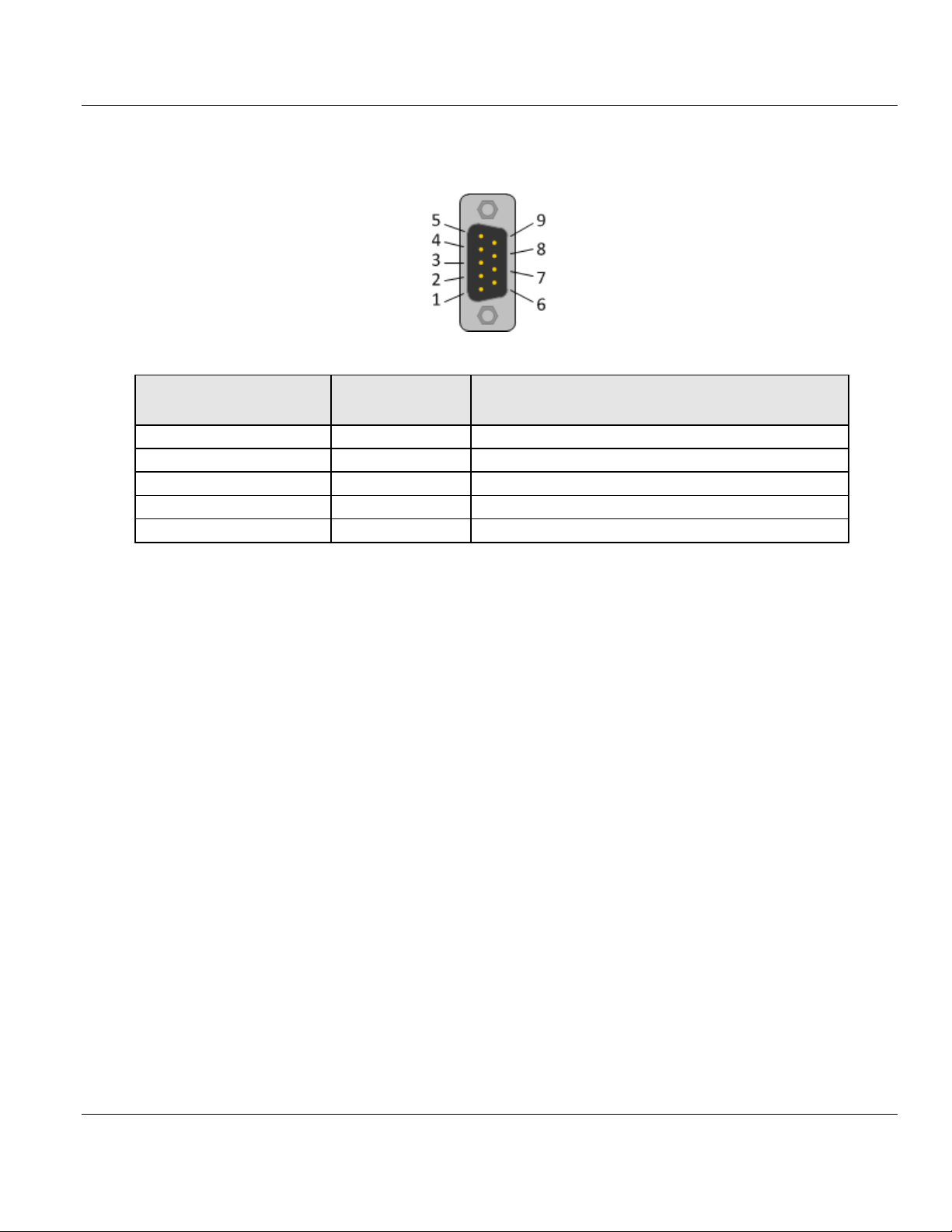

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Connection with DSub female connector

Signal

Description

3

RxD / TxD-P

Receive/Send Data-P, respectively connection B plug

4

CNTR-P

Repeater-Control

5

DGND

Data Ground

6

VP

Positive supply voltage

8

RxD / TxD-N

Receive/Send Data-N, respectively connection A plug

User Manual PROFIBUS Slave Communication Module

3.2 PROFIBUS Interface

PROFIBUS Interface (D-Sub female connector, 9 pin):

3.2.1 Wiring Instructions

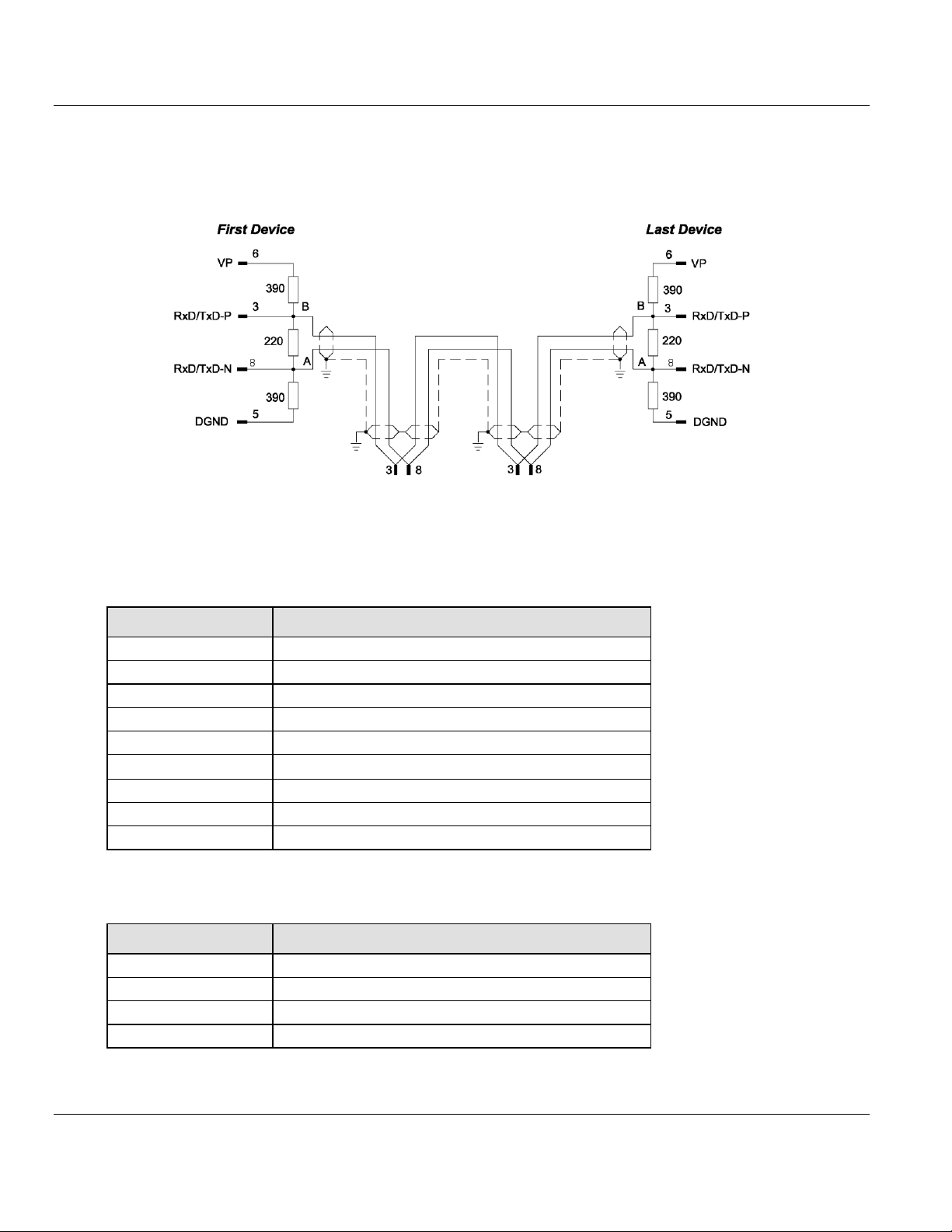

Please ensure that termination resistors are available at both ends of the PROFIBUS

network cable. If special PROFIBUS connectors are being used, these resistors are often

found inside the connector and must be switched on at each end of the PROFIBUS network

cable.

For baud rates above 1.5 MBaud, use only special connectors for higher baud rates. These

include additional inductance.

It is not permitted to have T-stubs on PROFIBUS high baud rates. Use only a special cable

which is approved for PROFIBUS DP. Make a solid connection from the cable shield to

ground at every device and make sure that there is no potential difference between the

grounds at the devices.

Page 18 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 19

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Baud rate in kBit/s

Maximum distance

9.6 1,200 meters

3,940 feet

19.2

1,200 m

3,940 ft

93.75

1,200 m

3,940 ft

187.5

1,000 m

3,280 ft

500 400 m

1,310 ft

1,500

200 m

656 ft

3,000

100 m

328 ft

6,000

100 m

328 ft

12,000

100 m

328 ft

Parameter

Value

Impedance

35 to 165 Ohm at frequencies from 3 to 20 Mhz

Capacity per units length

< 30 pF/m

Loop resistance

110 Ohm/km

Wire gauge

0.64 mm

PROFIBUS Slave Communication Module User Manual

If the ILX69-PBS is linked with only one other device on the bus, both devices must be

connected to the ends of the bus line. These devices must deliver the supply voltage for the

termination resistors. If three or more devices are connected to the bus, the ILX69-PBS can

be connected at any desired position.

Up to 32 PROFIBUS devices can be connected to one bus segment, without repeaters. If

several bus segments are linked to each other with repeaters, there can be up to 127

devices on the network.

The maximum permissible cable length of a PROFIBUS segment depends on the baud rate

used, see the following table.

Only PROFIBUS certified cables, preferably the cable type A, should be used. The following

table contains important electrical data concerning PROFIBUS certified cable:

ProSoft Technology, Inc. Page 19 of 102

March 20, 2015

Page 20

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Note: The device supports the Auto Crossover function. The RX and TX

can be switched. The following figure shows the RJ45 standard pin

assignment.

Pin

Signal

Description

1

TX+

Transmit Data +

2

TX–

Transmit Data –

3

RX+

Receive Data +

4

Term 1

Connected to each other and

terminated to PE through RC circuit*

5

Term 1

6

RX–

Receive Data –

7

Term 2

Connected to each other and

terminated to PE through RC circuit*

8

Term 2

*Bob Smith Termination

User Manual PROFIBUS Slave Communication Module

3.3 Ethernet Interface

The Ethernet cable should contain an RJ45 connector. It should have a twisted pair cable of

category 5 (CAT5) or higher, which consists of 4 twisted cores and has a maximum

transmission rate of 100 MBit/s (CAT5).

3.3.1 Ethernet Pin Assignment at the RJ45 Socket

Page 20 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 21

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Medium

2 x 2 Twisted-pair copper cable, CAT5 (100 MBit/s) or better

Length of cable

Maximum 100 m

Transmission rate

10 MBit/s / 100 MBit/s

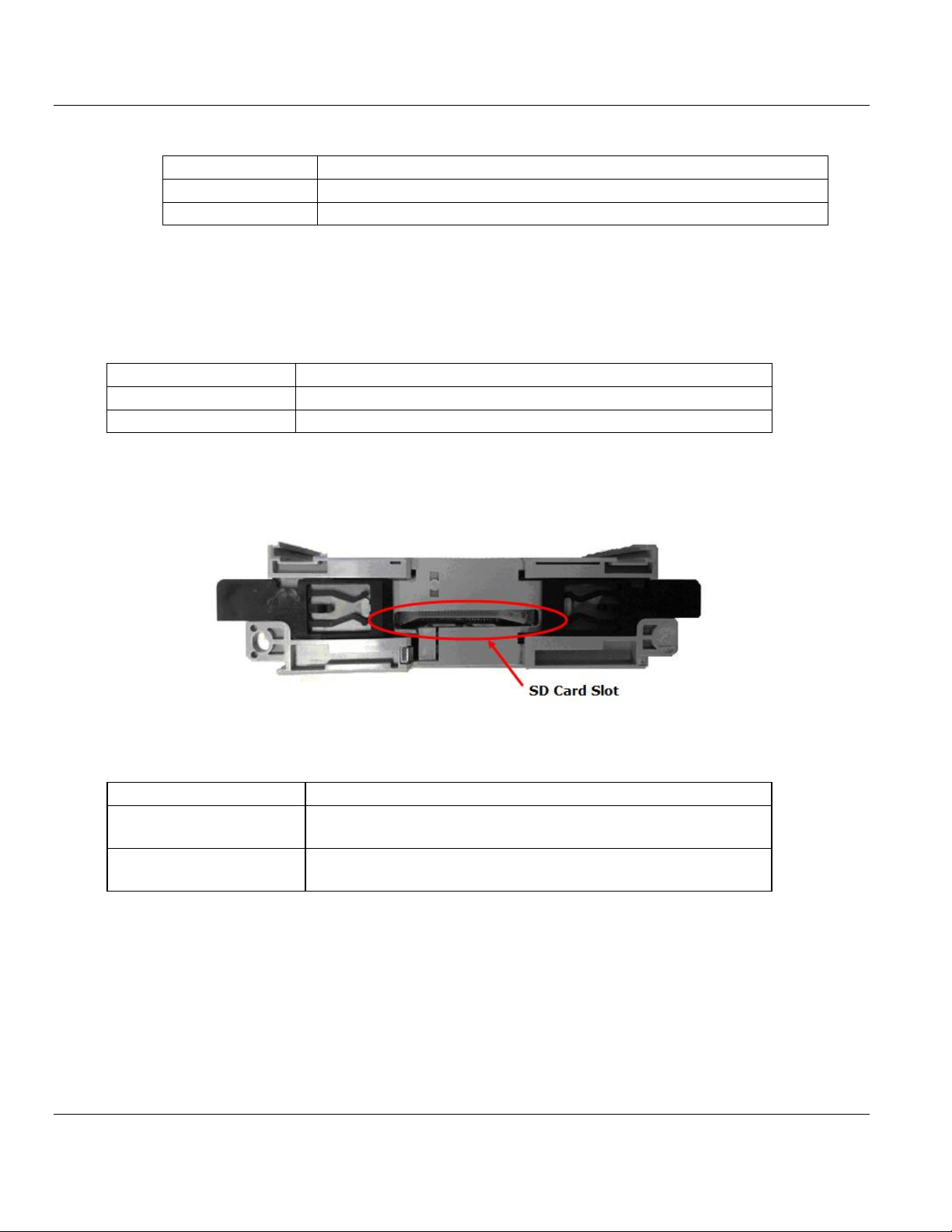

Type

SD card (HDSC format is not supported)

Maximum storage capacity

4 GByte

Required formatting

FAT16 format (no FAT32)

Power supply

5V from backplane

Current Load

CompactLogix

570 mA Max. @ 5 VDC

Power rating of 2

Backplane power

5 VDC: Min: 4.75 V at Module; Max: 5.40 V at Module

24 VDC: Min: 19.9 V at Module; Max: 26.4 V at Module

PROFIBUS Slave Communication Module User Manual

3.3.2 Ethernet Connection Data

3.4 Removable Memory Card

Memory Card

SD Card Connector

SD Card Connector, e.g. FPS009-2405-0 push/push

3.5 Power Supply

ProSoft Technology, Inc. Page 21 of 102

March 20, 2015

Page 22

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Page 22 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 23

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

Consideration when planning the system ..............................................23

ILX69-PBS Hardware Installation ..........................................................23

Uninstalling ILX69-PBS Hardware .........................................................25

PROFIBUS Slave Communication Module User Manual

4 Installation

4.1 Consideration when planning the system

Issues for the Network Conception

The ILX69-PBS has address rotary switches to set an station address from 0 to 99. If set

to 0, address will be taken from the configuration assembly. Using the PLCs

configuration data, an address range from 0 to 125 is adjustable.

The ILX69-PBS is capable of automatic baud rate detection.

A 1769-ECR (right end cap) or 1769-ECL (left end cap) is required to terminate the end

of the Compact I/O bus.

Each bank of Compact I/O must have its own power supply.

A Compact I/O power supply has limits on the amount of +5 VDC and +24 VDC current it

can supply to modules in its I/O bank. These limits depend on the catalog number (e.g.

1769-PA2) of the supply. A bank of modules must not exceed the current limits of the I/O

bank power supply. Refer to the Compact 1769 Expansion I/O Power Supplies

Installation Instructions.

The ILX69-PBS has a distance rating of 2. Therefore, the module must be within 2 slots

of the I/O bank’s power supply.

Configuration and Network Communication

Determine the PROFIBUS baud rate based on standard PROFIBUS system

considerations.

Identify the number of words of I/O data each slave supports.

ProSoft Technology, Inc. Page 23 of 102

March 20, 2015

Page 24

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Electrostatically sensitive devices

To prevent damage to the PLC and the ILX69-PBS, make sure that the ILX69-PBS is

grounded via the backplane of the PLC. Also make sure that you are discharged when

you install/uninstall the ILX69-PBS.

Device Destruction

Shut off the power supply of the PLC before you install the ILX69-PBS. Then install or

remove the ILX69-PBS to/from the PLC..

Use only the permissible supply voltage to operate the ILX69-PBS.

All I/O signal pins at the ILX69-PBS tolerate only the specified signaling voltage.

A detailed description the installation of communication modules in

CompactLogix™ systems can be found in the installation manual for the

1769 CompactLogix™ controller from Rockwell Automation.

User Manual PROFIBUS Slave Communication Module

4.2 ILX69-PBS Hardware Installation

This section describes how to install/uninstall the ILX69-PBS into a CompactLogix™ system.

4.2.1 Safety Precautions

Obey the following property damage messages when installing, uninstalling or replacing the

ILX69-PBS.

4.2.2 Installing the ILX69-PBS Module

1 Install the ILX69-PBS into a free slot in the CompactLogix™ controller. Make sure it is

within 2 slots of a power supply.

2 Check that the bus lever of the ILX69-PBS is in the unlocked (fully right) position.

3 Assemble the ILX69-PBS and the CompactLogix™ module together by using the upper

and lower tongue-and-groove slots.

4 Move the ILX69-PBS back along the tongue-and-groove slots until the bus connectors

line up with each other.

5 Move the ILX69-PBS bus lever fully to the left until it clicks. Ensure it is locked firmly in

place.

6 Attach and lock an end cap terminator to the ILX69-PBS by using the tongue-and-groove

slots as before.

7 Apply power to the Rockwell CompactLogix™ controller.

Page 24 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 25

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

4.3 Uninstalling ILX69-PBS Hardware

1 Adhere to the safety precautions.

2 Shut off the power of the Rockwell CompactLogix™ controller.

3 Discharge yourself.

4 Unlock the end cap bus terminator.

5 Remove the end cap terminator from the ILX69-PBS by using the tongue-and-groove

slots.

6 Move the ILX69-PBS bus lever in the unlocked (fully right) position.

7 Remove the ILX69-PBS along the tongue-and-groove slots.

8 Reassemble the end cap terminator and the CompactLogix™ system together by using

the upper and lower tongue-and-groove slots.

ProSoft Technology, Inc. Page 25 of 102

March 20, 2015

Page 26

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Page 26 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 27

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

Creating the Module in an RSLogix 5000 Project ..................................27

Slave Configuration ...............................................................................45

SD Card ................................ ................................................................ .49

PROFIBUS Slave Communication Module User Manual

5 Configuration and Start-Up

This chapter provides descriptions about the configuration and start-up of the ILX69-PBS.

ILX69-PBS Configuration and Parameterization Steps:

The configuration and parameterization of the ILX69-PBS is carried out in three steps:

1 Configuration of the module in a CompactLogix™ project of the Studio 5000 or RSLogix

5000 programming tool.

2 Parameterization and configuration of the ILX69-PBS using the master configuration

software. The slave module can use this configuration during startup.

3 Creating the data objects and the ladder diagram in Studio 5000/RSLogix 5000.

5.1 Creating the Module in an RSLogix 5000 Project

In an RSLogix 5000 project, there are two ways you can add the ILX69-PBS module to the

project.

You can use an Add-On Profile (AOP) from ProSoft Technology. The AOP contains all

the configuration information needed to add the module to the project. This is the

preferred way, but requires RSLogix version 15 or later.

You can manually create the module using a generic 1769 profile, and then manually

configure the module parameters. Use this method if you have RSLogix version 14 or

earlier.

ProSoft Technology, Inc. Page 27 of 102

March 20, 2015

Page 28

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

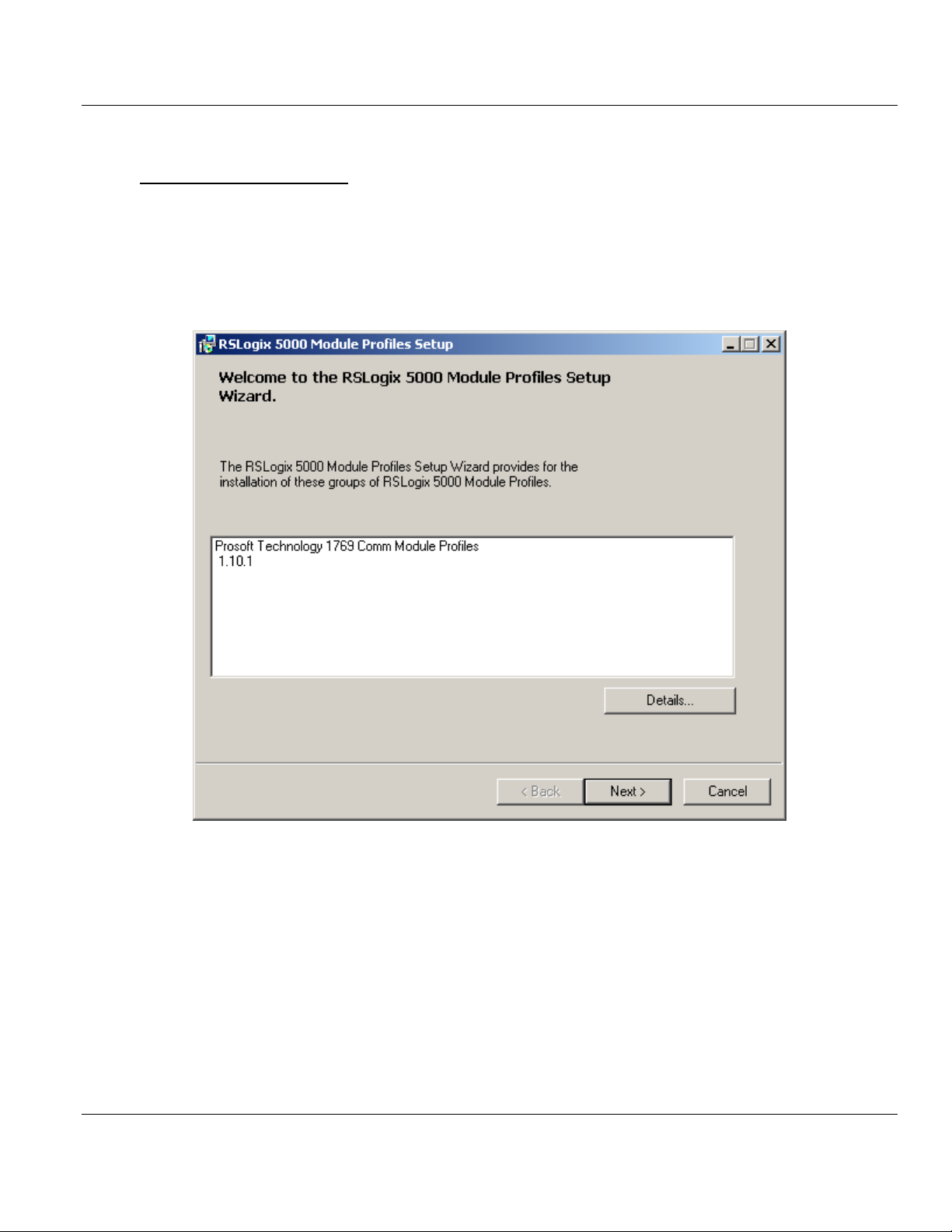

5.1.1 Creating a Module in the Project Using an Add-On Profile

Installing an Add-On Profile

Download the MPSetup.exe file from the product web page (found at

http://www.prosoft-technology.com) or from the ProSoft Solutions DVD onto the local hard

drive. Make sure RSLogix 5000 and RSLinx have been shut down before installing the AddOn Profile (AOP).

1 Run the MPSetup.exe file to start the Setup Wizard. Follow the Setup Wizard to install

the AOP. (The version may be different than shown below).

Page 28 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 29

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

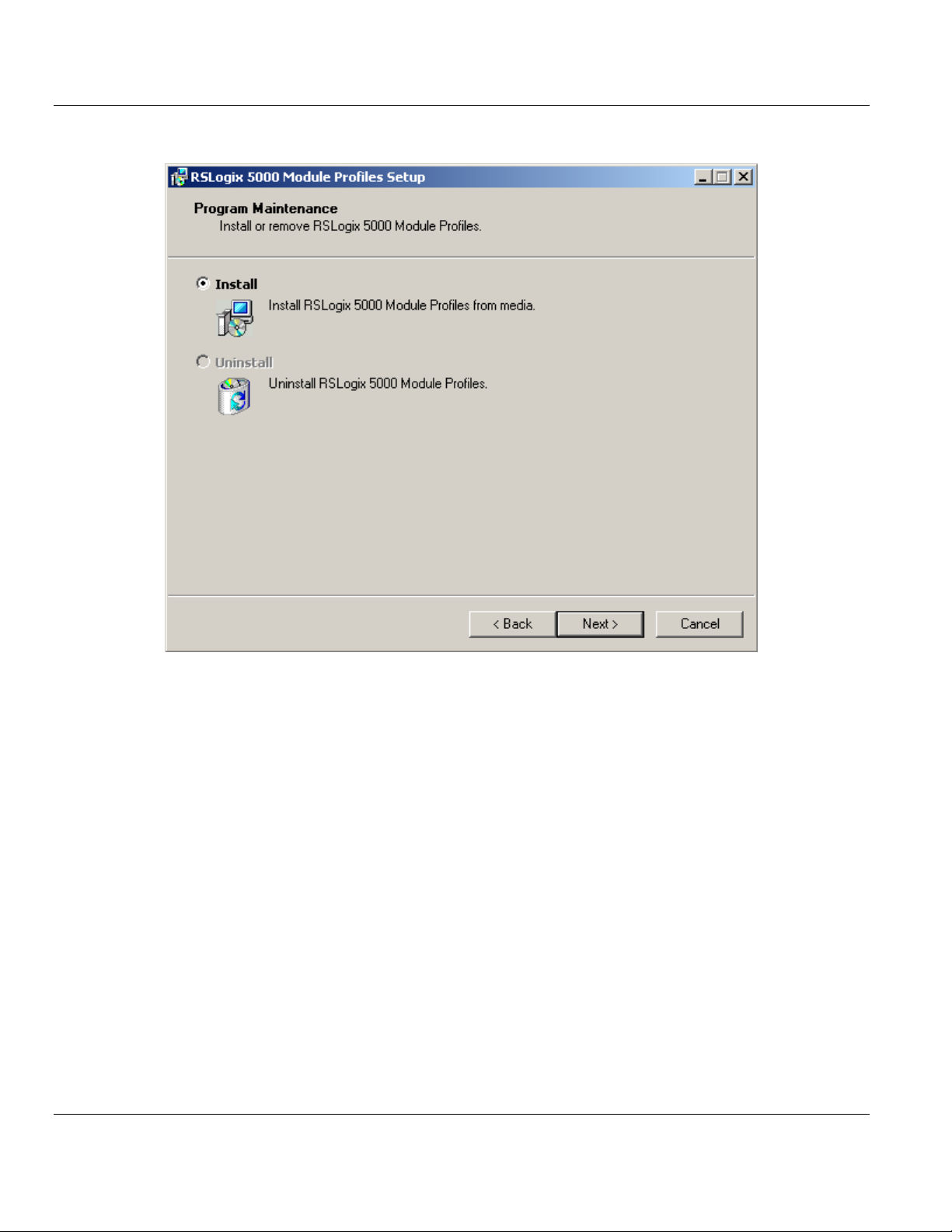

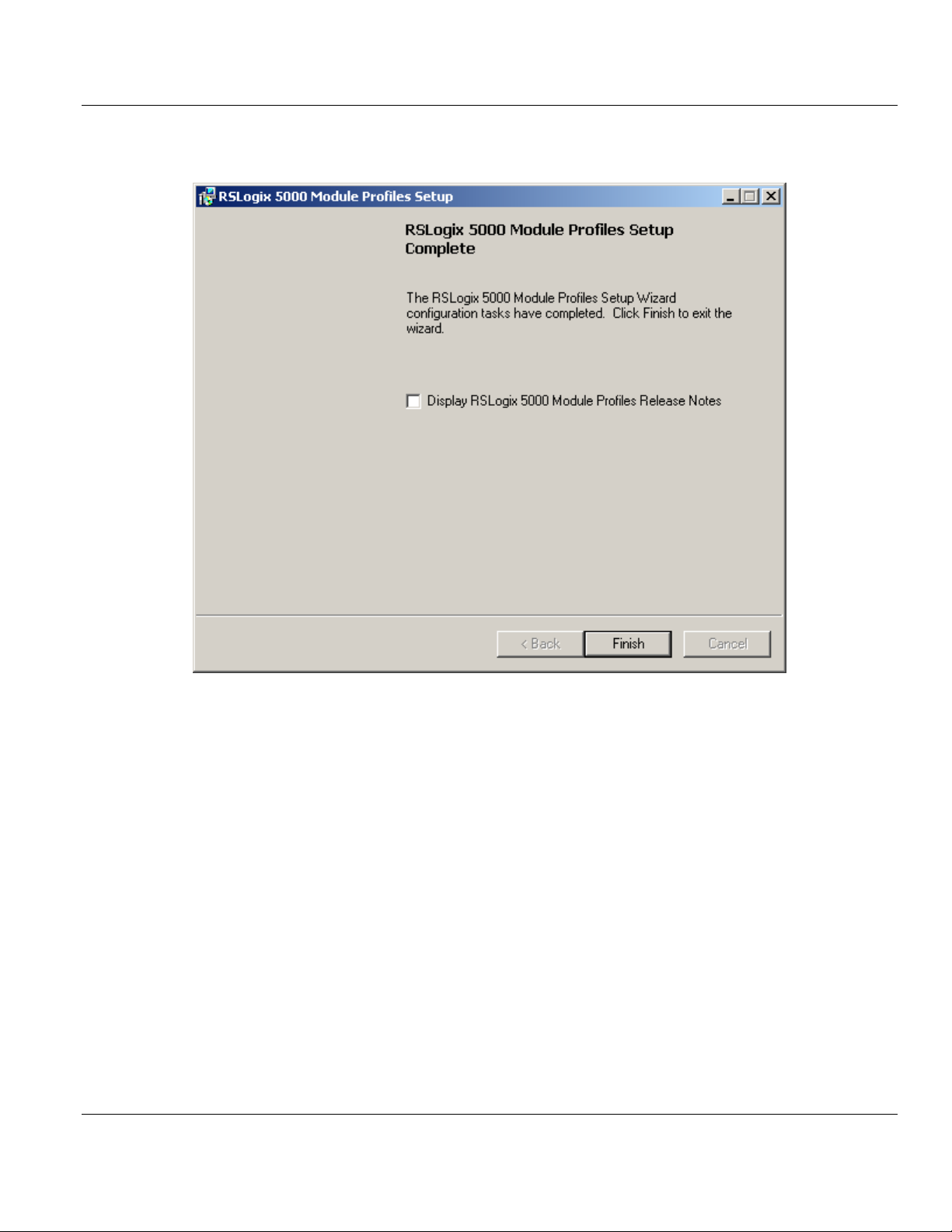

2 Continue to follow the steps in the wizard to complete the installation.

ProSoft Technology, Inc. Page 29 of 102

March 20, 2015

Page 30

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

3 Click FINISH when complete. The AOP is now installed in RSLogix 5000. You do not

need to reboot the PC.

Page 30 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 31

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

Using an Add-On Profile

1 In RSLogix 5000, expand the I/O CONFIGURATION folder in the Project tree. Right-click

the appropriate communications bus and choose NEW MODULE.

This opens the Select Module Type dialog box. In the Module Type Vendor Filters area,

uncheck all boxes except the PROSOFT TECHNOLOGY box. A list of ProSoft Technology

modules appears in the dialog box.

ProSoft Technology, Inc. Page 31 of 102

March 20, 2015

Page 32

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

2 Select the ILX69-PBS module in the list and click CREATE:

Page 32 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 33

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

3 A New Module dialog box opens. In the GENERAL tab, enter "ILX69PBS" in the NAME

field and the appropriate SLOT for the module.

4 Click on the CONFIGURATION tab (Offline). This option assigns the IP Address, Subnet

Mask, and Gateway Address of the module. If applicable, select MANUALLY CONFIGURE

IP SETTINGS from the IP Settings field to manually enter your values.

ProSoft Technology, Inc. Page 33 of 102

March 20, 2015

Page 34

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

5 Click on the ADVANCED tab (Offline). This option assigns the STATION ADDRESS

(PROFIBUS Slave ID) of the ILX69-PBS.

It also determines how the ILX69-PBS obtains its configuration by CONFIGURATION TYPE.

In most applications, OBTAIN FROM MASTER is sufficient. With this option, the

configuration is done within the PROFIBUS master software and sent to the ILX69-PBS.

The OBTAIN FROM LADDER option is a unique option that allows the CompactLogix

controller to "lock" the ILX69-PBS PROFIBUS configuration. Once this option is

selected, you will manually configure the PROFIBUS I/O data in the Module

Configuration section of the tab. The PROFIBUS Master’s configuration for this slave

must match 100%, or communications will fail.

6 Click OK.

7 The ILX69-PBS module is now visible in the I/O Configuration tree.

Page 34 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 35

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

5.1.2 Manually Creating a Module in the Project

This section covers the manual configuration of the ILX69-PBS in a CompactLogix™

system. When complete, please see Configuration by Controller Application 46 for modulespecific configuration parameters.

Creating a New Project

1 Open the FILE menu, and select NEW.

2 Select your controller TYPE and REVISION 16 or newer.

3 Click OK.

4 Right click on the I/O configuration > CompactBus Local of the controller project.

ProSoft Technology, Inc. Page 35 of 102

March 20, 2015

Page 36

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

5 Select New Module from the context menu as shown below.

The following dialog box appears.

6 Select "1769-MODULE Generic 1769 module" and click OK. The Module Properties

dialog will open.

Page 36 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 37

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

Module Properties 1

1 The communications parameters for the module should be set as shown in the dialog

below.

2 Enter PBS as the NAME and enter a short description for the module.

3 Select the Slot number in which the module is installed in the CompactLogix system. It

must be within 2 slots of a power supply.

4 Select Data - INT as the Comm_Format.

5 Set the Connection Parameters as they are shown in the dialog above.

6 Select Next >> or OK for the next configuration dialog.

ProSoft Technology, Inc. Page 37 of 102

March 20, 2015

Page 38

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Module Properties 2

The Requested Packet Interval RPI is shown in the following dialog. Within this time interval,

the I/O data between module and controller are exchanged.

1 Edit the REQUESTED PACKET INTERVAL (RPI) value, if needed.

2 Click Finish>>

3 Save the project.

Page 38 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 39

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

5.1.3 Importing the Ladder Rung

1 In the Controller Organization window, expand the TASKS folder and subfolder until you

reach the MAINPROGRAM folder.

2 In the MAINPROGRAM folder, double-click to open the MAINROUTINE ladder.

3 Select an empty rung in the new routine, and then click the right mouse button to open a

shortcut menu. On the shortcut menu, choose IMPORT RUNGS.

4 Navigate to the location on your PC where the .L5X Add-On Instruction (for example, My

Documents or Desktop) is saved. Select IMPORT...

ProSoft Technology, Inc. Page 39 of 102

March 20, 2015

Page 40

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

This action opens the Import Configuration dialog box, showing the controller tags that

will be created.

5 Verify that the slot number is correct for the module in the Local:x tags. This must match

the physical slot number location of the ILX69-PBS in the CompactLogix™ bus.

Page 40 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 41

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

6 Click OK to confirm the import.

When the import is completed, the new Add-On Instruction rung will appear in the

ladder.

The procedure has also imported new user-defined data types, controller tags and the

Add-On instruction for your project.

7 Save the project.

ProSoft Technology, Inc. Page 41 of 102

March 20, 2015

Page 42

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

Read Request

When the AOI is imported into the project, the ILX69-PBS MSG tags reference slot 1 in its

path configuration. If the ILX69-PBS is not located in slot 1, you will need to edit the MSG

instruction Communication Path to the proper slot number.

1 Locate the MSG instructions within the ILX69-PBS AOI rung.

2 To edit a MSG instruction, click on the "..." box to open the Message Configuration

window.

Page 42 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 43

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Slave Communication Module User Manual

3 Select the COMMUNICATION tab at the top of the window. Click BROWSE... to open the

Message Path Browser window.

4 In the Message Path Browser window, select the slot location of the ILX69-PBS. The

Path field updates when the module is selected. Click OK.

ProSoft Technology, Inc. Page 43 of 102

March 20, 2015

Page 44

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Slave Communication Module

5 Back In the Message Configuration window, the Path field shows the ILX69-PBS

properly in place. Click APPLY, then click OK.

6 Repeat these steps for each MSG instruction in the ILX69-PBS AOI.

7 Save the project. It is ready to be downloaded to the CompactLogix™ controller.

Page 44 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 45

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Note: The PROFIBUS DP master can send a new configuration to the slave at

any time. This can cause inconsistency if the new configuration does not match

to the controller application. A safer method can be done by "Configuration by

Controller Application" located in the next section. With this method, the slave

module does not start any communication as long as the slave configuration

and the master configuration do not match to each other.

PROFIBUS Slave Communication Module User Manual

5.2 Slave Configuration

The following section details the basics the ILX69-PBS configuration.

There are two ways to configure the ILX69-PBS:

Configuration by Master

With the PROFIBUS master and ILX69-PBS connected on the network, the slave

configuration is sent from the master to the ILX69-PBS during PROFIBUS network startup.

Configuration by Controller Application

The slave configuration can be loaded via configuration parameters from the

CompactLogix™ PLC program to the ILX69-PBS.

5.2.1 GSD File

A GSD (Generic Station Description) file is an electronic datasheet used for a particular

PROFIBUS slave device. The ILX69-PBS GSD file contains the information that is specific

to the ILX69-PBS.

The ILX69-PBS GSD file is named "PSFT0EE1.GSD". It is located on the ProSoft Solutions

DVD. You must provide this file to the PROFIBUS master configuration software. Refer to

the master's documentation of how to import GSD files.

5.2.2 Configuration by Master

Configuration by Master is the easiest way to configure the slave. The ILX69-PBS sample

ladder and AOI contains the use of this method. This example is described in section Studio

5000 Example Program.

During the network startup phase, the PROFIBUS master sends the expected slave

configuration over the network to compare it with the real configuration of the slaves

connected to the bus. The ILX69-PBS automatically takes over the configuration which is

sent by the master during its comparison of the configuration. This method is activated by

default, since the parameter "Force User Config" in the configuration area is set to 0. The

only setting required by the user is setting the Address rotary switches on the front of the

ILX69-PBS.

ProSoft Technology, Inc. Page 45 of 102

March 20, 2015

Page 46

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Word

Offset

Configuration

word

Data

type

Low/High

Byte

Description

Valid values

0

Local:1:C.Data[0]

INT

LOW Byte

Reconfiguration Event 0

Reserved, set to 0

HIGH Byte

Reconfiguration Event 1

1

Local:1:C.Data[1]

INT

LOW Byte

Reconfiguration Event 2

Reserved, set to 0

HIGH Byte

Reconfiguration Event 3

2

Local:1:C.Data[2]

INT

LOW Byte

Bus Address

0 to 125

0 = ForceMasterConfig

1 = ForceUserConfig

HIGH Byte

Force User Configuration

3

Local:1:C.Data[3]

INT Reserved

4

Local:1:C.Data[4]

INT Watchdog Time

0 to FFFFh

5

Local:1:C.Data[5]

INT Number of valid config bytes

(starting with Local:1:C.Data[8])

2 to 48

6

Local:1:C.Data[6]

INT Reserved

7 Local:1:C.Data[7]

INT Reserved

8

Local:1:C.Data[8]

INT

LOW Byte

Module 1 Type

HIGH Byte

Module 1 Length

9

Local:1:C.Data[9]

INT

LOW Byte

Module 2 Type

HIGH Byte

Module 2 Length

...

...

...

...

31

Local:1:C.Data[31]

INT

LOW Byte

Module 24 Type

HIGH Byte

Module 24 Length

32

Local:1:C.Data[32]

BOOL

-

IP Config flags 1, Static or

Dynamic

0 or 1

33

Local:1:C.Data[33]

BOOL

-

IP Config flags 2, Static or

Dynamic

0 or 1

34

Local:1:C.Data[34]

INT - IP Configuration

0 = BOOTP

1 = DHCP

2 = FIXED IP

35

Local:1:C.Data[35]

SINT

LOW Byte

IP Address

00.00.00.00 through

FF.FF.FF.FF

…

…

HIGH Byte

User Manual PROFIBUS Slave Communication Module

5.2.3 Configuration by Controller Application

The second option to configure the ILX69-PBS is through the controller application. If you’re

unable to install the AOP due to company policy or other reasons, you will need to manually

configure the module through the controller application.

The "Force User Config" parameter in this array must be set to 1. With this method, the

ILX69-PBS will not start any network communication unless the master and ILX69-PBS

configuration match. The following table outlines the mapping of the configuration data

image.

Page 46 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 47

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Word

Offset

Configuration

word

Data

type

Low/High

Byte

Description

Valid values

37

Local:1:C.Data[37]

SINT

LOW Byte

Net Mask

00.00.00.00 through

FF.FF.FF.FF

…

…

HIGH Byte

39

Local:1:C.Data[39]

SINT

LOW Byte

Gateway Address

00.00.00.00 through

FF.FF.FF.FF

…

…

HIGH Byte

41

Local:1:C.Data[41]

- - Reserved

Set to 0

Address

Switches

Configuration

Address Parameter

Active

Bus Address

Description

1 to 99

N/A

1 to 99

Address switches are valid

0

0 to 125

0 to 125

Configuration parameter is valid

0

> 125

N/A

Invalid (will cause an initialization error)

PROFIBUS Slave Communication Module User Manual

5.2.4 Configuration Parameters

Bus Address

The ILX69-PBS has two rotating address switches to set the network address from 0 to 99.

If you need to assign the ILX69-PBS to an address above 99, set both address switches to

0. The module will take the address parameter from the configuration data array.

Force User Configuration

If this value is set to 1, the ILX69-PBS will not start network communication until the master

and slave configurations match.

If this value is set to 0, the slave accepts the configuration sent from the master.

ProSoft Technology, Inc. Page 47 of 102

March 20, 2015

Page 48

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Parameter

Data Type

Valid values

Description

Module Type

SINT

0 = IN Byte

1 = IN Word

2 = OUT Byte

3 = OUT Word

4 = IN Byte con

5 = IN Word con

6 = OUT Byte con

7 = OUT Word con

8 = Blank space

Input Byte without consistence

Input Word without consistence

Output Byte without consistence

Output Word without consistence

Input Byte with consistence

Input Word with consistence

Output Byte with consistence

Output Word with consistence

Blank space

Module Length

SINT

0

1

2

3

4

5

6

7

8

9

1 Byte/Word

2 Byte/Word

3 Byte/Word

4 Byte/Word

8 Byte/Word

12 Byte/Word

16 Byte/Word

20 Byte/Word

32 Byte/Word

64 Byte/Word

User Manual PROFIBUS Slave Communication Module

Watchdog Timeout

The ILX69-PBS supervises its I/O exchange with the controller within a specific time frame.

If the controller does not update the output data within this time, the slave stops the cyclic

data exchange with the master and goes into a safe state.

If the ‘ForceUserConfiguration’ parameter is set to 0, the ILX69-PBS automatically

calculates a timeout value by the RPI (Requested Packet Intervall). The calculated

watchdog calculates to 2x the RPI (+/- 5ms). The smallest watchdog value is 15 ms. The

module rounds the watchdog value to multiples of 5 ms.

WATCHDOG_TIME (ms) = MAX ( 2 x RPI)

If the "ForceUserConfiguration" parameter is set to 1, the ILX69-PBS will take the watchdog

value from the configuration array. Make sure the watchdog value is not smaller than the

RPI. The ILX69-PBS rounds the watchdog to multiples of 5ms.

Number of Valid Configuration Bytes

This parameter holds the number of valid configuration bytes that define PROFIBUS

Input/Output modules.

Module Type / Module Length

The ILX69-PBS offers a flexible, modular composition of its I/O data. Parts of the input and

output image can be viewed as single modules. The master can put the different modules

from the ILX69-PBS to different locations in its I/O area. The individually configured modules

are mapped linearly in the I/O area of the ILX69-PBS. It is possible to configure up to 24 I/O

modules. A module is defined by a Module Type and its Module Length:

Page 48 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 49

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Note: Please notice the definition of Input/Output modules and do not

confuse them with the input and output area of the ILX69-PBS in the

controller memory map.

Inputs and Outputs modules are always defined from viewpoint of the

PROFIBUS master. If you configure an Output module, you will see this in

the input area of the ILX69-PBS, because the input area of the controller

memory map is the output area from point of view of a PROFIBUS master.

The same applies to an Input module. If you define an Input module, it is

mapped in the output area of the controller memory map, because the

output area of the ILX69-PBS is the input area from viewpoint of a

PROFIBUS master.

PROFIBUS Slave Communication Module User Manual

The sample ladder and AOI can also be used as an example for a module configuration by

the controller application. You only have to set the "ForceUserConfiguration" parameter from

0 to 1 in the configuration array. Section Studio 5000 Example Program explains the predefined configuration parameter of the sample ladder/AOI.

5.3 SD Card

5.3.1 Start-up Behavior with or without SD Card

The start-up behavior of the ILX69-PBS depends on whether an SD memory card is inserted

in the module or not.

Start-up without Memory Card

On power-up, the ILX69-PBS and the firmware are started and the configuration data is

loaded from the CompactLogix processor using the Local:x:C.Data array into the ILX69-PBS

internal flash memory. Depending on the amount of stored configuration data, this can last

for approximately 4 seconds.

Start-up with Memory Card

The ILX69-PBS supports firmware upgrade utilizing an optional SD card. Contact ProSoft

technical support to obtain this firmware image. Firmware can also be loaded via the ILX69PBS webpage. Configuration of the module is always obtained from the Local:x:C.Data

array from the CompactLogix processor.

On power-up, the firmware data are restored from the SD memory card flash image into the

ProSoft Technology, Inc. Page 49 of 102

March 20, 2015

ILX69-PBS internal flash memory only when the ILX69-PBS is not connected over the

backplane to a CompactLogix processor. The following is the power-up sequence:

Page 50

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Note: The STARTUPINI file is automatically created if ‘Store’ and

are used. The user does not need to create this file.

User Manual PROFIBUS Slave Communication Module

After return of power, the SYS LED indicates a fast blinking in green for approximately

10 seconds. During this time the SD memory card can be removed from the module to

prevent the data transfer.

o After 10 seconds, the following files are transferred from the SD memory card into

the non-volatile flash memory of the ILX69-PBS:

• Firmware *.nxf

• Web pages

This operation takes (typically) up to 30 seconds. During this operation the SYS LED

is static yellow.

When complete, the new firmware starts automatically and the ILX69-PBS boots with the

new configuration. The COM LED illuminates or blinks as described in section

Communication Status. Connection over the backplane to the CompactLogix processor

can then be restored.

5.3.2 STARTUP.INI File

The STARTUP.INI file contains the following:

1 [Global]

2 Notify=10

3 Restore=always

4 RestorePoint=SDMMC:/backup

Notify=10: The value for ‘Notify’ is ‘10’. It takes 10 seconds to copy the files from the SD

memory card to the internal flash of the ILX69-PBS.

Restore=always: The second stage bootloader copies the files in any case.

RestorePoint=SDMMC:/backup: All data stored under the backup folder is copied to the

SD memory card.

5.3.3 Reset Device to Factory Settings with Memory Card

Using a memory card that has the basic firmware stored on it, the ILX69-PBS can be

restored back to factory settings.

1 Copy the STARTUP.INI file and the backup directory (including all subdirectories) from

the ProSoft Solutions DVD into the root directory of an empty memory card.

2 Prepare the memory card and reset the module to the factory settings as described in

section Steps for Project File Backup and SD Card Handling.

Page 50 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 51

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

Studio 5000 PROFIBUS Data Values ....................................................51

I/O Communication and Memory Map ...................................................52

Acyclic Messaging .................................................................................60

PROFIBUS Slave Communication Module User Manual

6 Communication

6.1 Studio 5000 PROFIBUS Data Values

The ILX69-PBS PROFIBUS network data values (input and output) are located in the

Controller Tags of Studio 5000.

6.1.1 PROFIBUS Network Output Data

The PROFIBUS network data received from the PROFIBUS master (output data) is stored in

the ILX69PBS.DATA.INPUT array.

ProSoft Technology, Inc. Page 51 of 102

March 20, 2015

Page 52

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Offset

Register Type

Name

0

Device Status Register

Status Bits

1

Reserved

Reserved

2

Reserved

Reserved

3

Reserved

Reserved

4

Firmware Revision

Minor Version

5

Firmware Revision

Major Version

6 to 7

Reserved

Reserved

8 to 9

Slave Status Information

ExtStaSelect

10 to 11

Slave Status Information

ExtStaLen

12 to 13

Slave Status Information

Baudrate

14

Slave Status Information

Busaddress

15

Slave Status Information

UserFlags

16 to 17

Slave Status Information

Ident

User Manual PROFIBUS Slave Communication Module

6.1.2 PROFIBUS Network Input Data

The PROFIBUS network data sent to the PROFIBUS master (input data) is stored in the

ILX69PBS.DATA.OUTPUT array.

6.2 I/O Communication and Memory Map

The following sections contain the I/O memory mappings of the ILX69-PBS. The I/O area is

used for communication status and cyclic I/O data.

6.2.1 I/O Arrays Overview

Input Array

Below is a summary of the register layout of the input area of the ILX69-PBS. The offset

values are defined in bytes.

Page 52 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 53

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Offset

Register Type

Name

18 to 19

Slave Status Information

TaskState

20 to 21

Slave Status Information

InputDataLen

22 to 23

Slave Status Information

OutputDataLen

24 to 25

Slave Status Information

ErrorCount

26

Slave Status Information

LastError

27

Slave Status Information

Reserved

28 to 29

Slave Status Information

WatchdogTime

30 to 31

Slave Status Information

IrqCounter

32 to 37

Slave Status Information

Dpv1StatusRegister

38 to 39

Slave Status Information

Reserved

40 to 135

Slave Status Information

ExtStatusInfo[96]

136 to 379

PROFIBUS Output Area

PBOutputData

Offset

Register Type

Name

0

Device Command Register

Command Bits

1

Device Command Register

Reserved

2

Device Command Register

Reserved

3

Device Command Register

ExtStaSelect

4 to 248

PROFIBUS Input Area

PBInputData, 244 bytes

Byte

Offset

Structure

Member

Data

Type

Description

0

MSB

SINT

Module Status Bits, see table below

1

Reserved

SINT

Reserved

2

BTO

SINT

Block Transfer Out

3

BTI

SINT

Block Transfer In

PROFIBUS Slave Communication Module User Manual

Output Array

Below is a summary of the register layout of the output area of the ILX69-PBS. The offset

values are defined in bytes.

6.2.2 Input Array

Status Registers

The ILX69-PBS uses the first 4 bytes of the PLC input area to transfer device status register

information. The Status Registers contain the ILX69-PBS communication status and

command status. The mapping is shown in the table below.

Device State Register

ProSoft Technology, Inc. Page 53 of 102

March 20, 2015

Page 54

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

Bit

Offset

Structure

Member

Data

Type

Description

0

Reserved

BOOL

Reserved, set to 0

1

Reserved

BOOL

Reserved, set to 0

2

Reserved

BOOL

Reserved, set to 0

3

Reserved

BOOL

Reserved, set to 0

4

Reserved

BOOL

Reserved, set to 0

5

COM

BOOL

Communication - When this bit is set, the communication

has started and the module is engaged in cyclic data

exchange with the master.

0 = Not communicating, 1 = Communicating

6

RUN

BOOL

Run - When this bit is set, the module is ready for

communication. Otherwise, an initialization error or

incorrect parameterization has occurred.

0 = Not running, 1 = Running

7

RDY

BOOL

Ready - When this bit is set, the module is operational. The

RDY bit should always be set by the module. If this bit is

not set, a system error has occurred and the

communication between controller and module is not

active.

0 = Not ready, 1 = Ready

Byte

Offset

Structure

Member

Data

Type

Description

4

FwMinor

SINT

Firmware Minor Revision

5

FwMajor

SINT

Firmware Major Revision

6 to 7

Reserved

-

Reserved

FW Revision

FW Major

FW Minor

V01.000

10

00

V01.001

10

01

…

User Manual PROFIBUS Slave Communication Module

MSB - Module Status Bits

Firmware Revision

This data field contains the current Firmware Revision of the ILX69-PBS. The Minor revision

is the low byte and the Major revision is the high byte. The mapping is shown below.

Example:

If FwMajor = 10 and FwMinor = 1 then the firmware revision is 10.1.

Due to a different internal firmware numbering scheme than Major/Minor version, the

following method is used to utilize this information to support requirements for a major

revision/minor revision of the CompactLogix controller. Because the first release of the

ILX69-PBS internal firmware will start with at least V01.000, the first firmware version in

Major Minor scheme will be at least 10.00. Details are provided in the table below.

Page 54 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 55

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Byte

Offset

Structure

member

Data

type

Description

Valid Values

8 to 9

ExtStaSelect

INT

Shows the extended status

information that is currently

transmitted in the field

"Extended Status Information"

0 = No extended status information

1 = Firmware version

2 = Slave configuration

3 = Master configuration

4 = Parameter data

6 = Reserved

10 to 11

ExtStaLen

INT

Number of valid bytes in the

region "Extended Status

Information"

Depends on the selected extended status

0 = 0 Byte

1 = 32 Byte

2 = 49 Byte

3 = 49 Byte

4 = 33 Byte

6 = 80 Byte

12 to 13

Baudrate

INT

Baud Rate on PROFIBUS

network

12000 = 12 MBaud

6000 = 6 MBaud

3000 = 3 MBaud

1500 = 1.5 MBaud

500 = 500 kBaud

187 = 187.5 kBaud

93 = 93.75 kBaud

9 = 9.6 kBaud

0 = Not detected

14

Busaddress

SINT

Bus Address of the slave

0 to 125

15

UserFlags

SINT

User Flags

D0 = Parameter data changed

D1 = Configuration data changed

D2 to D7 = Not Applicable

16 to 17

Ident

INT

Slave identification number

0EE1h

18 to 19

Reserved

INT

Reserved

Set to 0

20 to 21

InputDataLen

INT

Length of input data(*)

0 to 244

22 to 23

OutputDataLen

INT

Length of output data(*)

0 to 244

24 to 25

Reserved

INT

Reserved

Set to 0

26

Reserved

SINT

Reserved

Set to 0

27

Pad

SINT

Reserved

Set to 0

28 to 29

Watchdog

Time

INT

Current watchdog time

5 to 65535 ms

30 to 31

IrqCounter

INT

Indication of bus activity

0 to 0xFFFF

32 to 37

Dpv1StatReg

INT

DPV1 Status Register

See following section

38 to 39

Reserved

SINT

Reserved

Reserved

40 to 135

ExtStatusInfo

SINT[96]

Extended Status Information

See following section

PROFIBUS Slave Communication Module User Manual

Slave Status

A 128 byte Slave Status field is transferred to the user program via the input data area

image. It contains the ILX69-PBS status, beginning with byte 8 of the input region. The

status information encompasses 32 bytes of static information and 96 bytes bytes reserved

for the extended status field. The content of the extended status is controlled by the

command "ExtStaSelect" byte in the Device Command Register in the user program (byte

offset 8 to 9).

ProSoft Technology, Inc. Page 55 of 102

March 20, 2015

Page 56

Contents ILX69-PBS ♦ CompactLogix or MicroLogix Platform

(*) Note: The status information ‘InputDataLen’ and ‘OutputDataLen’ are

related to the definition of inputs and outputs from point of view of a

PROFIBUS master.

Example: If the ‘OutputDataLen’ indicates a value of 4 Bytes, then it is

related to the input area of the ILX69-PBS, because the input area of the

ILX69-PBS are outputs from point of view of a PROFIBUS master. The

same relation applies to the status ‘InputDataLen’ and the output area of

the ILX69-PBS.

Byte

Offset

Structure

Member

Data

Type

Data

Type

Description

32

RWInd

SINT

Read/Write Indication

A Read/Write Request has been received

33

RWIndCnt

SINT

Read/Write Indication Counter

Increments on every new DPV1 request

34

MasterAdr

SINT

Master Address

Address of Requesting Master

35

Slot

SINT

Slot number

Requested Slot Number

36

Index

SINT

Index

Requested Index

37

DataLen

SINT

Date Length

Requested Data Length

Bit

Offset

Structure

Member

Data

Type

Description

0

ReadReq

BOOL

1 = Indicates a Read Request

1

WriteReq

BOOL

1 = Indicates a Write Request

2

Reserved

BOOL

Reserved

3

Reserved

BOOL

Reserved

4

Reserved

BOOL

Reserved

5

Reserved

BOOL

Reserved

6

Reserved

BOOL

Reserved

7

Reserved

BOOL

Reserved

User Manual PROFIBUS Slave Communication Module

DPV1 Status Registers

The controller application program uses the DPV1 status registers as an indication that the

network master has sent an unsolicited DPV1 Read/Write request. The first will contain two

bits which indicate if a read or write needs to be processed. If this register contains a non-

zero value, the slave’s user program must create an appropriate response to this request by

using a CIP MSG command (shown in Messaging section). The table below contains the

mapping of these registers.

DPV1 Read/Write Indication Status Bits

Page 56 of 102 ProSoft Technology, Inc.

March 20, 2015

Page 57

ILX69-PBS ♦ CompactLogix or MicroLogix Platform Contents

Note: Every DPV1 read or write request must be acknowledged by the

PLC application program. Otherwise, the PROFIBUS master shuts down

communication for both channels, V0 (cyclic IO data) and V1 (non-cyclic

messages). This can cause unexpected lost of data between the master

and the ILX69-PBS.

Structure member

Data type

Description

FwName

SINT[8]

Firmware Name

FwType

SINT[8]

Firmware Type

FwVersion

SINT[8]

Firmware Version

FwDate

SINT[8]

Firmware Date

Structure member

Data type

Description

CfgLength

SINT