Page 1

ILX69-PBM

CompactLogix or MicroLogix Platform

PROFIBUS Master Communication

Module

February 4, 2015

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

© 2015 ProSoft Technology, Inc. All rights reserved.

ILX69-PBM User Manual

February 4, 2015

ProSoft Technology®, is a registered copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD and are

available at no charge from our web site: http://www.prosoft-technology.com

Important Safety Information

THIS EQUIPMENT IS AN OPEN-TYPE DEVICE AND IS MEANT TO BE INSTALLED IN AN ENCLOSURE

SUITABLE FOR THE ENVIRONMENT SUCH THAT THE EQUIPMENT IS ONLY ACCESSIBLE WITH THE USE OF

A TOOL.

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS LIVE OR

UNLESS THE AREA IS KNOWN TO BE FREE OF IGNITABLE CONCENTRATIONS.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENT MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

DEVICES SHALL BE USED WITH ALLEN BRADLEY 1769 BACKPLANES

INPUT TO THE DEVICES SHALL BE FUSED AT 5A MAXIMUM.

Page 3

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Safety Information ............................................................................................................... 2

1 Introduction 7

1.1 About the User Manual .............................................................................................. 7

1.1.1 Intended Audience .................................................................................................... 7

1.2 General Information ................................................................................................... 7

1.3 Reference Systems ................................................................................................... 8

1.4 1769 Programmable Controller Functionality ............................................................ 9

1.5 Requirements ............................................................................................................ 9

1.5.1 Software Requirements ............................................................................................. 9

1.5.2 System Requirements ............................................................................................. 10

1.5.3 Hardware Requirements ......................................................................................... 10

2 Safety 11

2.1 General Note ........................................................................................................... 11

2.2 Personnel Qualification ........................................................................................... 11

2.3 Safety Instructions to Avoid Personal Injury............................................................ 11

2.3.1 Electrical Shock Hazard .......................................................................................... 12

2.3.2 Communication Stop During Firmware Update ...................................................... 12

2.4 Safety Instructions to Avoid Property Damage ....................................................... 12

2.4.1 Device Destruction if ILX69-PBM is Installed to Powered PLC .............................. 13

2.4.2 Device Destruction by Exceeding Allowed Supply Voltage .................................... 13

2.4.3 Device Destruction by Exceeding Allowed Signaling Voltage................................. 13

2.4.4 Electrostatically sensitive devices ........................................................................... 13

2.5 Labeling of Safety Messages .................................................................................. 14

2.6 Safety References ................................................................................................... 15

3 About the ILX69-PBM 17

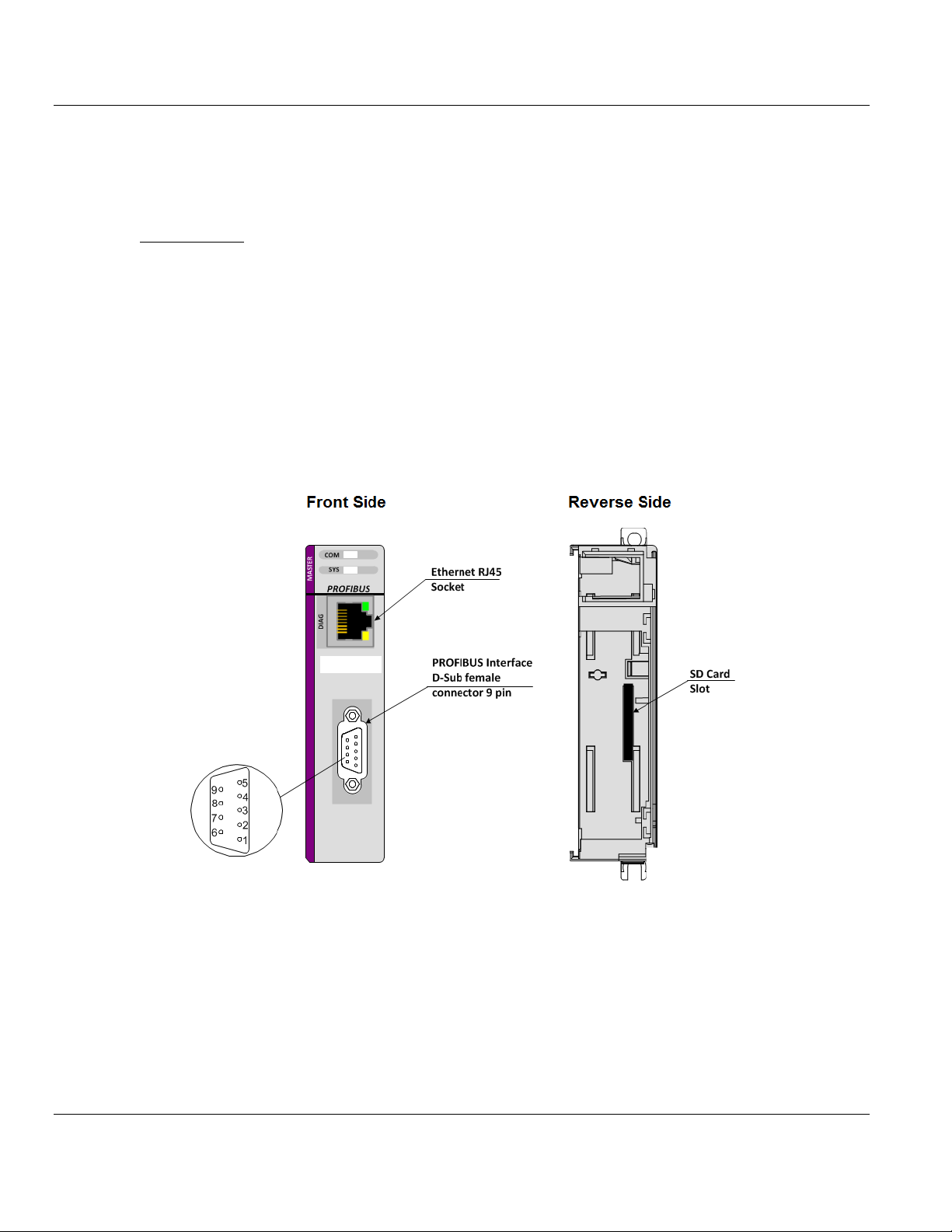

3.1 Device Drawing ....................................................................................................... 17

3.2 PROFIBUS Interface ............................................................................................... 18

3.2.1 Wiring Instructions ................................................................................................... 18

3.3 Ethernet Interface .................................................................................................... 20

3.3.1 Ethernet Pin Assignment at the RJ45 Socket ......................................................... 20

3.3.2 Ethernet Connection Data ....................................................................................... 20

3.4 Removable Memory Card ....................................................................................... 21

3.5 Power Supply .......................................................................................................... 21

4 Installation 23

4.1 System Planning Considerations ............................................................................ 23

4.2 Software Installation ................................................................................................ 24

4.2.1 Installing ProSoft fdt Configuration Manager in Windows 7 .................................... 24

4.3 ILX69-PBM Hardware Installation ........................................................................... 26

ProSoft Technology, Inc. Page 3 of 124

February 4, 2015

Page 4

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

4.3.1 Safety Precautions .................................................................................................. 26

4.3.2 Installing the ILX69-PBM Module ........................................................................... 27

4.4 Uninstalling ILX69-PBM Hardware ......................................................................... 27

5 Configuration and Start-Up 29

5.1 CompactLogix Project ............................................................................................. 29

5.1.1 Creating a New Project ........................................................................................... 29

5.1.2 Module Properties 1 ................................................................................................ 32

5.1.3 Module Properties 2 ................................................................................................ 33

5.1.4 Importing the Ladder Rung ..................................................................................... 34

5.2 ProSoft fdt Configuration Manager ......................................................................... 37

5.2.1 Creating a New ILX69-PBM Project ....................................................................... 37

5.2.2 PROFIBUS Master Configuration ........................................................................... 39

5.2.3 PROFIBUS Slave Configuration ............................................................................. 40

5.3 Downloading the Project to the ILX69-PBM ........................................................... 45

5.3.1 Assigning an IP Address ......................................................................................... 45

5.3.2 Downloading the Project ......................................................................................... 47

5.4 Adjusting Input/Output Data Lengths in the Project ............................................... 51

5.4.1 Determining the Number of PROFIBUS Inputs/Outputs Used ............................... 51

5.4.2 Studio 5000 Adjustment (Optional) ......................................................................... 53

5.5 Project Storage ....................................................................................................... 56

5.5.1 Store Function......................................................................................................... 57

5.5.2 Restore Function .................................................................................................... 57

5.5.3 Project File Backup and SD Card Handling ............................................................ 58

5.5.4 Start-up Behavior with or without SD Card ............................................................. 60

5.5.5 STARTUP.INI File ................................................................................................... 61

5.5.6 Reset Device to Factory Settings with Memory Card ............................................. 61

6 Communication 63

6.1 Studio 5000 PROFIBUS Data Values .................................................................... 63

6.1.1 PROFIBUS Network Input Data .............................................................................. 63

6.1.2 PROFIBUS Network Output Data ........................................................................... 63

6.2 I/O Communication and Memory Map .................................................................... 64

6.2.1 I/O Arrays Overview ................................................................................................ 64

6.2.2 Input Array .............................................................................................................. 65

6.2.3 Output Array ............................................................................................................ 77

6.3 Acyclic Messaging .................................................................................................. 82

6.3.1 Supported PROFIBUS DP Messages .................................................................... 82

6.3.2 Standard Messaging ............................................................................................... 82

6.3.3 DPV1 Messaging .................................................................................................... 85

6.3.4 CIP Message Error Codes ...................................................................................... 88

7 Diagnostics and Troubleshooting 93

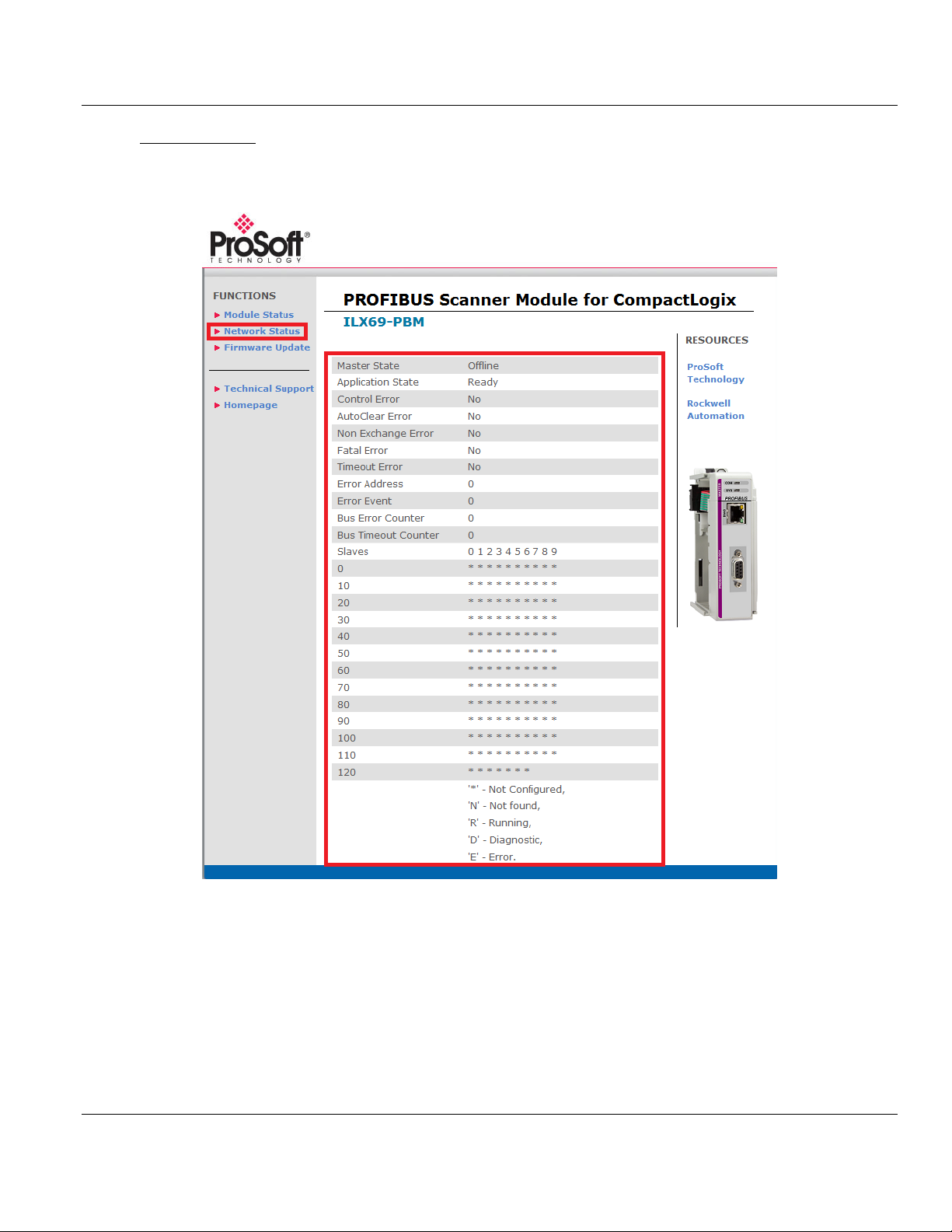

7.1 Web Page ............................................................................................................... 93

7.1.1 General Device and Diagnosis Information ............................................................ 94

7.1.2 Firmware Update .................................................................................................. 100

7.2 Hardware LEDs..................................................................................................... 106

7.2.1 CompactLogix LEDs ............................................................................................. 106

7.2.2 ILX69-PBM LEDs .................................................................................................. 107

7.3 Troubleshooting .................................................................................................... 110

Page 4 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 5

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

8 Technical Data 111

8.1 Technical Data - ILX69-PBM ................................................................................. 111

8.2 Technical Data - PROFIBUS ................................................................................. 113

9 Annex 115

9.1 PROFIBUS Functionality ....................................................................................... 115

9.1.1 DPV0 Services ...................................................................................................... 115

9.1.2 DPV1 Services ...................................................................................................... 116

9.2 Disposal of Electronic Equipment Waste .............................................................. 117

9.3 References ............................................................................................................ 117

9.4 Glossary ................................................................................................................ 118

10 Support, Service & Warranty 121

10.1 Contacting Technical Support ............................................................................... 121

10.2 Warranty Information ............................................................................................. 122

Index 123

ProSoft Technology, Inc. Page 5 of 124

February 4, 2015

Page 6

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Page 6 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 7

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

About the User Manual ........................................................................... 7

General Information ................................................................................ 7

Reference Systems................................................................................. 8

1769 Programmable Controller Functionality .......................................... 9

Requirements ......................................................................................... 9

PROFIBUS Master Communication Module User Manual

1 Introduction

1.1 About the User Manual

This user manual provides descriptions and detailed information about:

How to assemble the ILX69-PBM into a CompactLogix™ system.

PROFIBUS wiring

Configuration and start-up

Communication

Diagnostics

LED displays

Technical data and electrical/environmental specifications

1.1.1 Intended Audience

The intended audiences for this manual are the individuals responsible for designing,

installing, programming, or troubleshooting control systems that use the Rockwell

CompactLogix™ 1769 programmable controller and the ILX69-PBM. You should have a

basic understanding of electrical circuitry and familiarity with relay logic. If you do not, obtain

the proper training before using this product.

1.2 General Information

The ILX69-PBM is a PROFIBUS DP master module for the CompactLogix™ platform which

allows the PLC to control data exchange on a PROFIBUS network. The ILX69-PBM handles

the cyclic data exchange between the connected PROFIBUS slaves.

The data exchange between the CompactLogix™ controller and the ILX69-PBM is done via

the I/O process data image using CompactLogix™ backplane technology. The process

image of the CompactLogix™ and of the ILX69-PBM is updated automatically during

runtime.

ProSoft Technology, Inc. Page 7 of 124

February 4, 2015

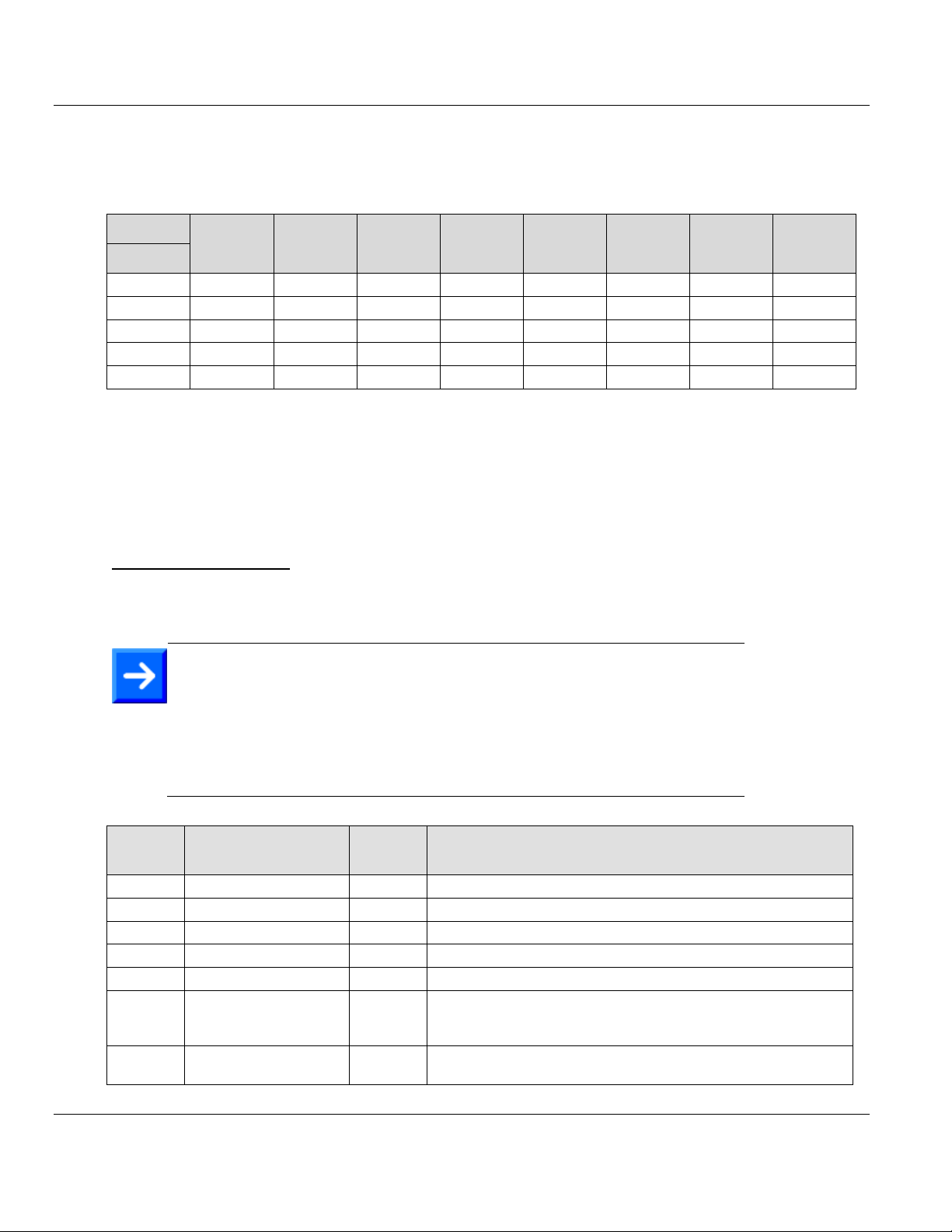

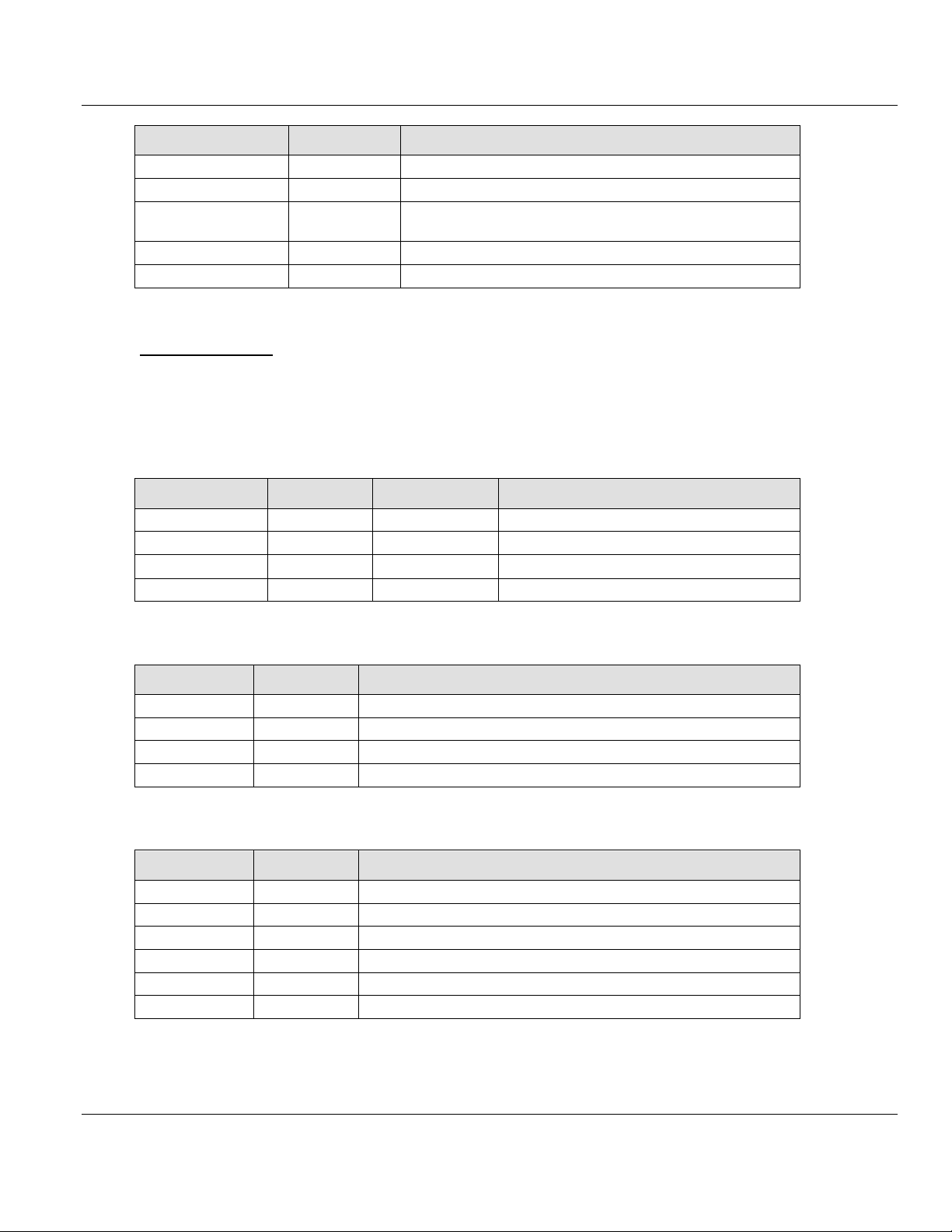

Page 8

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Controller

Firmware

CompactLogix™ 1769-L23

V17.05

CompactLogix™ 1769-L32E

V20.13

CompactLogix™ 1769-L36ERM

V21.11

User Manual PROFIBUS Master Communication Module

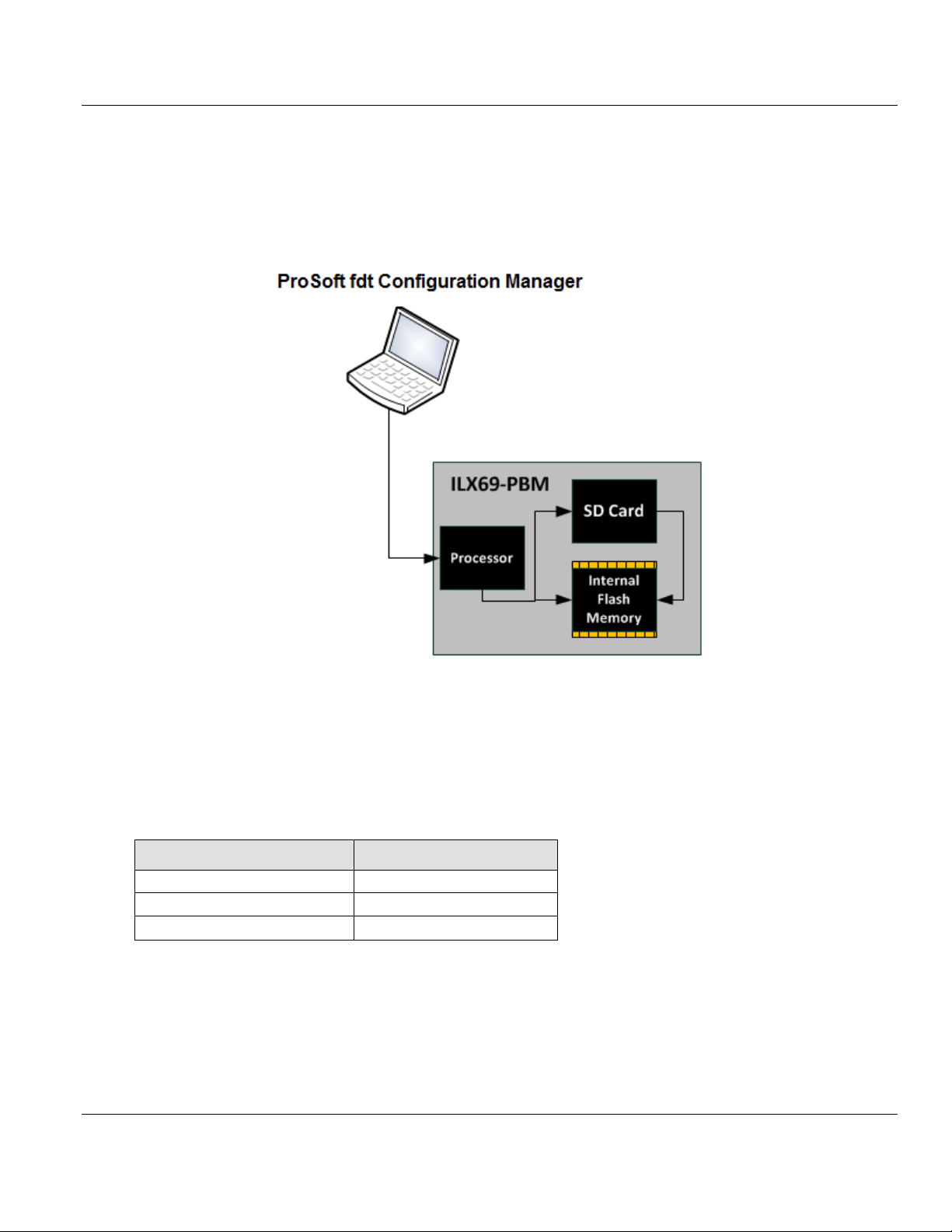

The configuration and diagnostics of the ILX69-PBM is done using the ProSoft fdt

Configuration Manager software over an Ethernet connection. The configuration is stored

permanently using the on-board FLASH memory of the ILX69-PBM and is available

immediately on power up. ProSoft fdt Configuration Manager allows you to backup the

configuration project files from the internal flash memory to an inserted SD memory card.

Basic diagnostics of the ILX69-PBM can be done via its web page.

1.3 Reference Systems

The firmware of the ILX69-PBM was developed and tested with the following

CompactLogix™ controller types and firmware revisions.

CompactLogix System

Page 8 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 9

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Processor

I/O (cyclic)

CIP

Messaging

(acyclic)

CompactLogix™ 1769-L23

Yes

Yes

CompactLogix™ 1769-L30

Yes

No

CompactLogix™ 1769-L31

Yes

Yes

CompactLogix™ 1769-L32E

Yes

Yes

CompactLogix™ 1769-L35E

Yes

Yes

CompactLogix™ 1769-L36ERM

Yes

Yes

PROFIBUS Master Communication Module User Manual

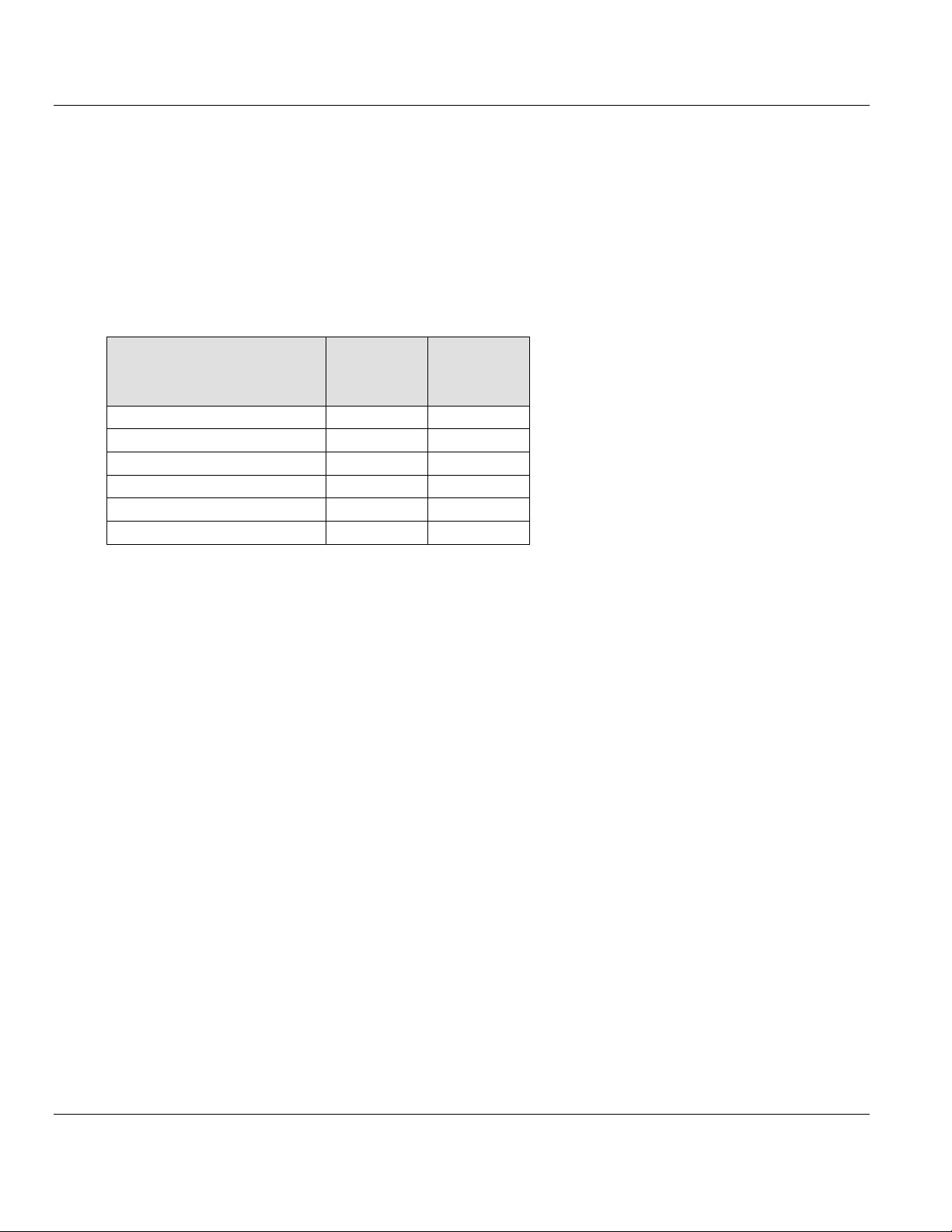

1.4 1769 Programmable Controller Functionality

PROFIBUS DP supports acyclic services through messages. These PROFIBUS DP

services are supported by the Studio 5000 programming tool using CIP messages. Not all of

the 1769 programmable controllers support CIP messaging.

The basic PROFIBUS DP acyclic services Global Control or slave Diagnostics request are

also executable in addition to the CIP method by using the I/O area. The following table

displays the 1769 programmable controllers and the functionalities they support.

CompactLogix System

Yes = Functionality supported

No = Functionality not supported

1.5 Requirements

1.5.1 Software Requirements

The software requirements for using the ILX69-PBM within a CompactLogix™ system are

listed below. You must have the following software installed on your PC unless otherwise

noted:

CompactLogix System

Studio 5000 programming software, V21.00 or higher

RSLogix™ 5000 programming software, V20.00 or higher

ProSoft Configuration Software

ProSoft fdt Configuration Manager for Rockwell Interfaces V1.0.x.x or higher

ProSoft Technology, Inc. Page 9 of 124

February 4, 2015

Page 10

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Note: If the solution file is saved and opened again, or if the solution file is

used on another PC, the system requirements must match. Particularly,

the DTM must be installed on the used PC.

User Manual PROFIBUS Master Communication Module

1.5.2 System Requirements

ProSoft fdt Configuration Manager software

PC with 1 GHz processor or higher

Windows® 7 (32 bit) SP1, Windows® 7 (64 bit) SP1, Windows® XP (32 bit) SP3

Administrator privilege required for installation

Internet Explorer 5.5 or higher

The software Microsoft .NET Framework 3.5 or 4.0 (Included in the ProSoft fdt

Configuration Manager installation package)

Free disk space: minimum 400 MB

DVD ROM drive

RAM: minimum 512 MB, recommended 1024 MB

Graphic resolution: minimum 1024 x 768 pixel

Keyboard and Mouse

Restrictions

Touch screen is not supported.

When ProSoft fdt Configuration Manager is installed on a PC, Hilscher standard

SYCON.net and legacy PROSOFT.fdt cannot be and shall not be installed, and viceversa.

1.5.3 Hardware Requirements

The following minimum hardware is required to use the ILX69-PBM:

Windows PC for the ProSoft fdt Configuration Manager software (advantageous with SD

card slot or SD card reader). Refer to section System Requirements (page 10).

Ethernet cable for ProSoft fdt Configuration Manager or ILX69-PBM web page

connection.

CompactLogix System

Personal Computer

1769 – Programmable controller (1769-L23, 1769-L32E and 1769-L36ERM)

1769 – Power supply

1769 – Right or left termination end cap

Ethernet cable for interface to the 1769 programmable controller.

Page 10 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 11

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

General Note .........................................................................................11

Personnel Qualification ..........................................................................11

Safety Instructions to Avoid Personal Injury ...........................................11

Safety Instructions to Avoid Property Damage ......................................12

Labeling of Safety Messages .................................................................14

Safety References .................................................................................15

PROFIBUS Master Communication Module User Manual

2 Safety

2.1 General Note

The documentation in the form of a user manual, an operating instruction manual or other

manual types, as well as the accompanying texts have been created for the use of the

products by educated personnel. When using the products, all Safety Messages, Integrated

Safety Messages, Property Damage Messages and all valid legal regulations must be

obeyed. Technical knowledge is presumed. The user must assure that all legal regulations

are obeyed.

2.2 Personnel Qualification

The ILX69-PBM must only be installed, configured, and removed by qualified personnel.

Job-specific technical skills for people professionally working with electricity must be present

concerning the following topics:

Safety and health at work

Mounting and connecting of electrical equipment

Measurement and analysis of electrical functions and systems

Evaluation of the safety of electrical systems and equipment

Installing and configuring IT systems

2.3 Safety Instructions to Avoid Personal Injury

To ensure your own personal safety and to avoid personal injury, you necessarily must read,

understand and follow the safety instructions and safety messages in this manual before

you install and operate the ILX69-PBM.

ProSoft Technology, Inc. Page 11 of 124

February 4, 2015

Page 12

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

2.3.1 Electrical Shock Hazard

The danger of a lethal electrical shock caused by parts with more than 50V may occur if you

power a PLC power supply module when its housing is open.

HAZARDOUS VOLTAGE is present inside of a powered PLC power supply module.

Strictly obey all safety rules provided by the device manufacturer in the documentation.

Disconnect the network power (power plug) from the power supply module before you

disconnect the PLC module from the backplane.

When you disconnect the PLC module from the power supply module, use end cap

terminators and close the power supply module housing.

An electrical shock is the result of a current flowing through the human body. The resulting

effect depends on the intensity and duration of the current and on its path through the body.

Currents in the range of approximately ½ mA can cause effects in persons with good health,

and indirectly cause injuries resulting from startling responses. Higher currents can cause

more direct effects, such as burns, muscle spasms, or ventricular fibrillation.

In dry conditions, permanent voltages up to approximately 42.4 V peak or 60 V are not

considered as dangerous if the contact area is equivalent to the size of a human hand.

More information is located at Safety References (page 15).

2.3.2 Communication Stop During Firmware Update

If you plan a firmware update via the ProSoft web pages, please yield:

During the firmware update procedure, a device reset is performed and stops all module

communication functions with network devices. An unintended plant stop can cause

personal injury.

Initiating a device reset causes a device reboot. A reboot stops all communication

immediately.

Personal injury by consequence of careless use caused plant stop can not be excluded.

All fieldbus devices should be placed in a fail-safe condition under direct supervision

before starting a firmware update.

Before you initiate a reset, make sure your system is in an idle state and operating under

maintenance conditions in order to prevent personal injury.

Stop the PLC program before you start the firmware update.

More firmware update information is located at Firmware Update (page 100).

2.4 Safety Instructions to Avoid Property Damage

To avoid system damage and device destruction to the ILX69-PBM, you necessarily must

read, understand and follow the following safety instructions and safety messages in this

manual before you install and operate the ILX69-PBM.

Page 12 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 13

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Mandatory supply voltage information is located at Power Supply (page 21).

Mandatory signaling voltage information is located at Power Supply (page 21).

PROFIBUS Master Communication Module User Manual

2.4.1 Device Destruction if ILX69-PBM is Installed to Powered PLC

To avoid device destruction when the ILX69-PBM is powered up:

Strictly obey to all safety rules provided by the PLC device manufacturer documentation.

Shut off the power supply of the PLC, before you install the ILX69-PBM module.

2.4.2 Device Destruction by Exceeding Allowed Supply Voltage

To avoid device destruction due to high supply voltage to the ILX69-PBM, you must observe

the following instructions.

The ILX69-PBM may only be operated with the specified supply voltage. Make sure that

the limits of the allowed range for the supply voltage are not exceeded.

A supply voltage above the upper limit can cause severe damage to the ILX69-PBM.

A supply voltage below the lower limit can cause malfunction in the ILX69-PBM.

The allowed range for the supply voltage is defined by the tolerances specified in this

manual.

2.4.3 Device Destruction by Exceeding Allowed Signaling Voltage

To avoid device destruction due to high signal voltage to the ILX69-PBM, you must observe

the following instructions.

All I/O signal pins at the ILX69-PBM tolerate only the specified signaling voltage.

Operation of the ILX69-PBM with a signaling voltage other than the specified signaling

voltage may lead to severe damage to the module.

2.4.4 Electrostatically sensitive devices

This equipment is sensitive to electrostatic discharge, which can cause internal damage and

affect normal operation. Therefore, adhere to the necessary safety precautions for

components that are vulnerable with electrostatic discharge when handling the ILX69-PBM.

Follow the guidelines listed when you handle this equipment:

Touch a grounded object to discharge potential static.

Wear an approved grounding wrist strap.

Do not touch connectors or pins on the ILX69-PBM.

Do not touch circuit components inside the equipment.

If available, use a static-safe workstation.

When not in use, store the equipment in appropriate static-safe packaging.

More information is located at Safety References (page 15).

ProSoft Technology, Inc. Page 13 of 124

February 4, 2015

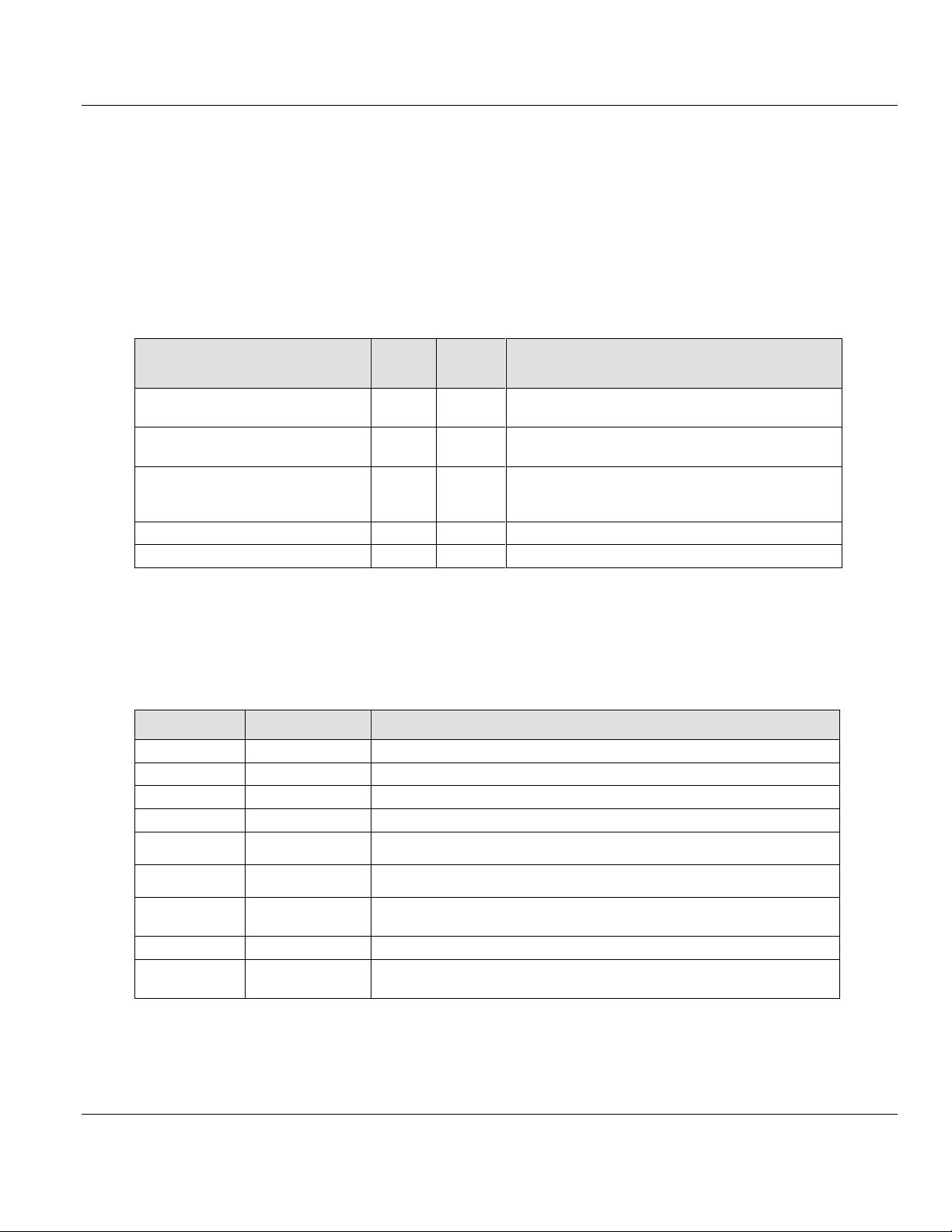

Page 14

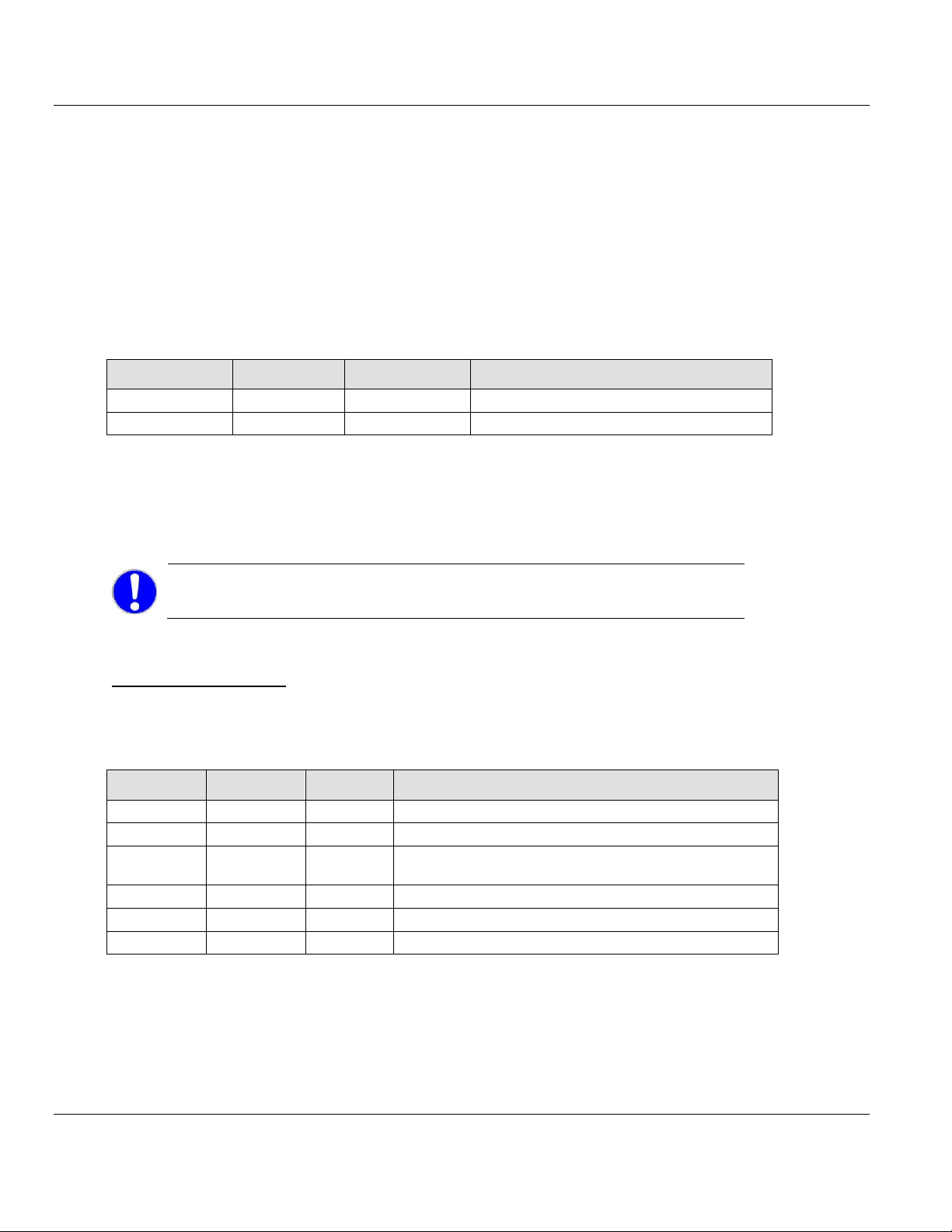

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Signal Word

Meaning (International)

Meaning (USA)

Indicates a direct hazard with high risk,

which will have a consequence of death or

grievous bodily harm if it is not avoided.

Indicates a hazardous situation which if not

avoided, will result in death or serious injury.

Indicates a possible hazard with medium

risk, which will have a consequence of

death or (grievous) bodily harm if it is not

avoided.

Indicates a hazardous situation which if not

avoided, could result in death or serious

injury.

Indicates a minor hazard with medium risk,

which could have a consequence of simple

battery if it is not avoided.

Indicates a hazardous situation which if not

avoided, may result in minor or moderate

Injury.

Safety Sign

USA

Warning or Principle

Warning of lethal electrical shock

Principle: Disconnect the power plug

Signal Word

Meaning (International and USA)

Indicates a property damage message.

Safety Sign

Warning or Principle

Warning on damages by electrostatic discharge

-

Example: Warning of device destruction due to exceedingly high supply voltage

User Manual PROFIBUS Master Communication Module

2.5 Labeling of Safety Messages

The Safety Messages at the beginning of a chapter are pinpointed particularly and

highlighted by a signal word according to the degree of endangerment. The type of

danger is specified by the safety message text and optionally by a specific safety sign.

The Integrated Safety Messages within an instruction description are highlighted with a

signal word according to the degree of endangerment. The type of danger is specified by

the safety message text.

In this document, all Safety Instructions and Safety Messages are designed according both

to the international used safety conventions as well as to the ANSI Z535.6 standard, refer to

Safety References (page 15).

In this document, the signal words ‘WARNING’, ‘CAUTION’ and ‘NOTICE’ are used

according to ANSI Z535.6 standard. The meaning given in ISO/IEC 26514 [4] section ‘11.11

Contents of warnings and cautions is not relevant in this manual.

Page 14 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 15

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

[S1]

ANSI Z535.6-2006 American National Standard for Product Safety Information in Product

Manuals, Instructions, and Other Collateral Materials

[S2]

IEC 60950-1, Information technology equipment - Safety - Part 1: General requirements, (IEC

60950-1:2005, modified); German Edition EN 60950-1:2006

[S3]

EN 61340-5-1 and EN 61340-5-2 as well as IEC 61340-5-1 and IEC 61340-5-2

[S4]

26514-2010 - IEEE Standard for Adoption of ISO/IEC 26514:2008 Systems and Software

Engineering--Requirements for Designers and Developers of User Documentation

PROFIBUS Master Communication Module User Manual

2.6 Safety References

ProSoft Technology, Inc. Page 15 of 124

February 4, 2015

Page 16

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Page 16 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 17

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

Device Drawing ......................................................................................17

PROFIBUS Interface..............................................................................18

Ethernet Interface ..................................................................................20

Removable Memory Card ......................................................................21

Power Supply .........................................................................................21

PROFIBUS Master Communication Module User Manual

3 About the ILX69-PBM

3.1 Device Drawing

ProSoft Technology, Inc. Page 17 of 124

February 4, 2015

Page 18

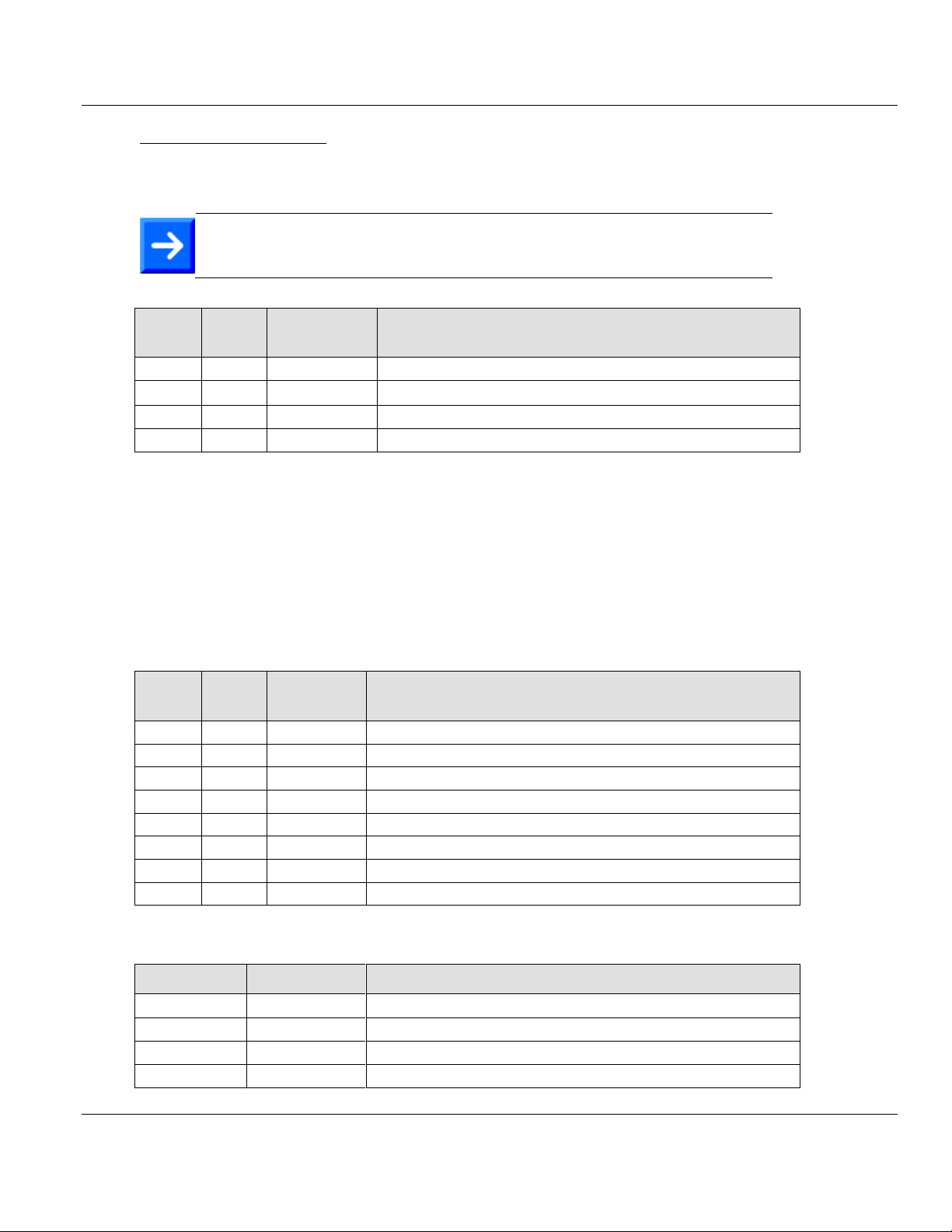

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

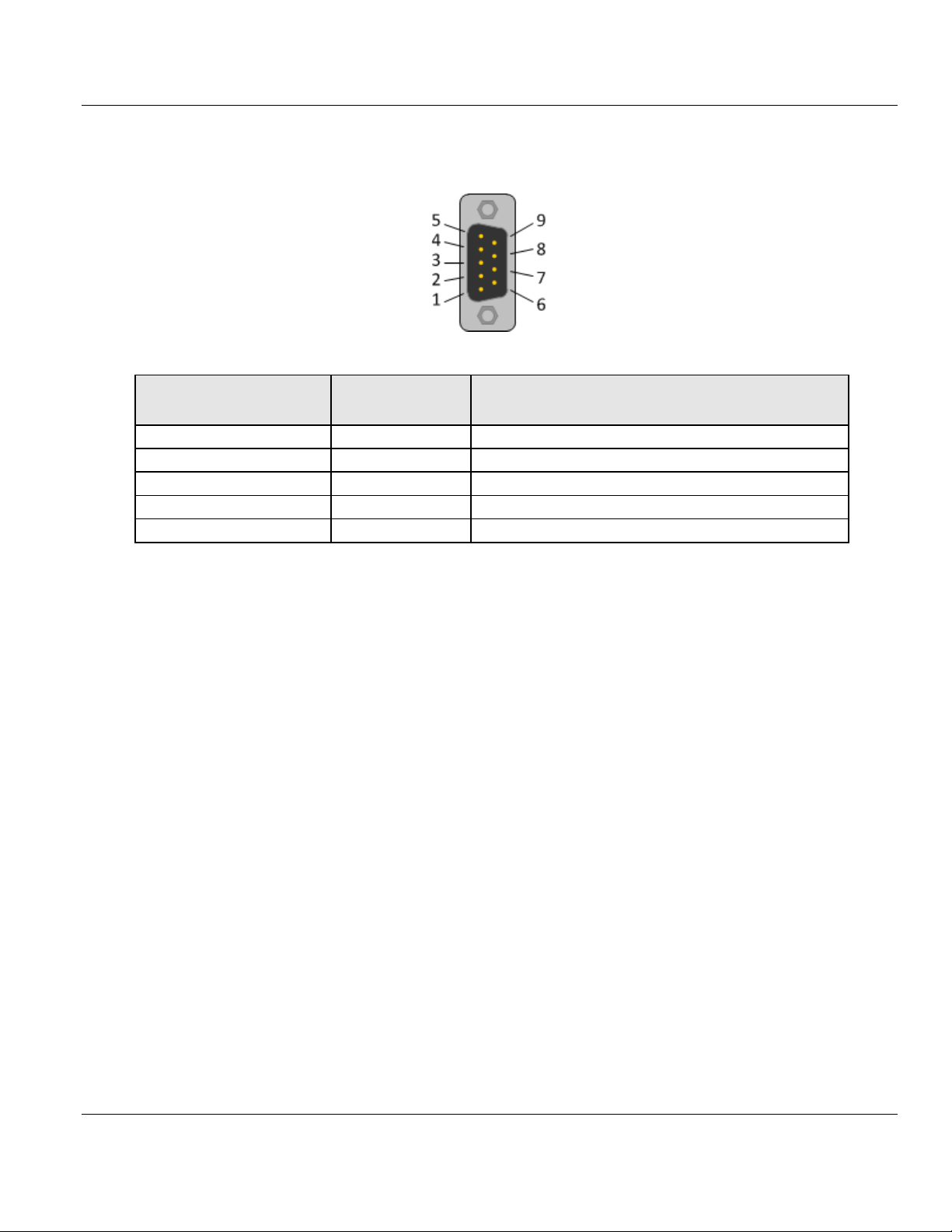

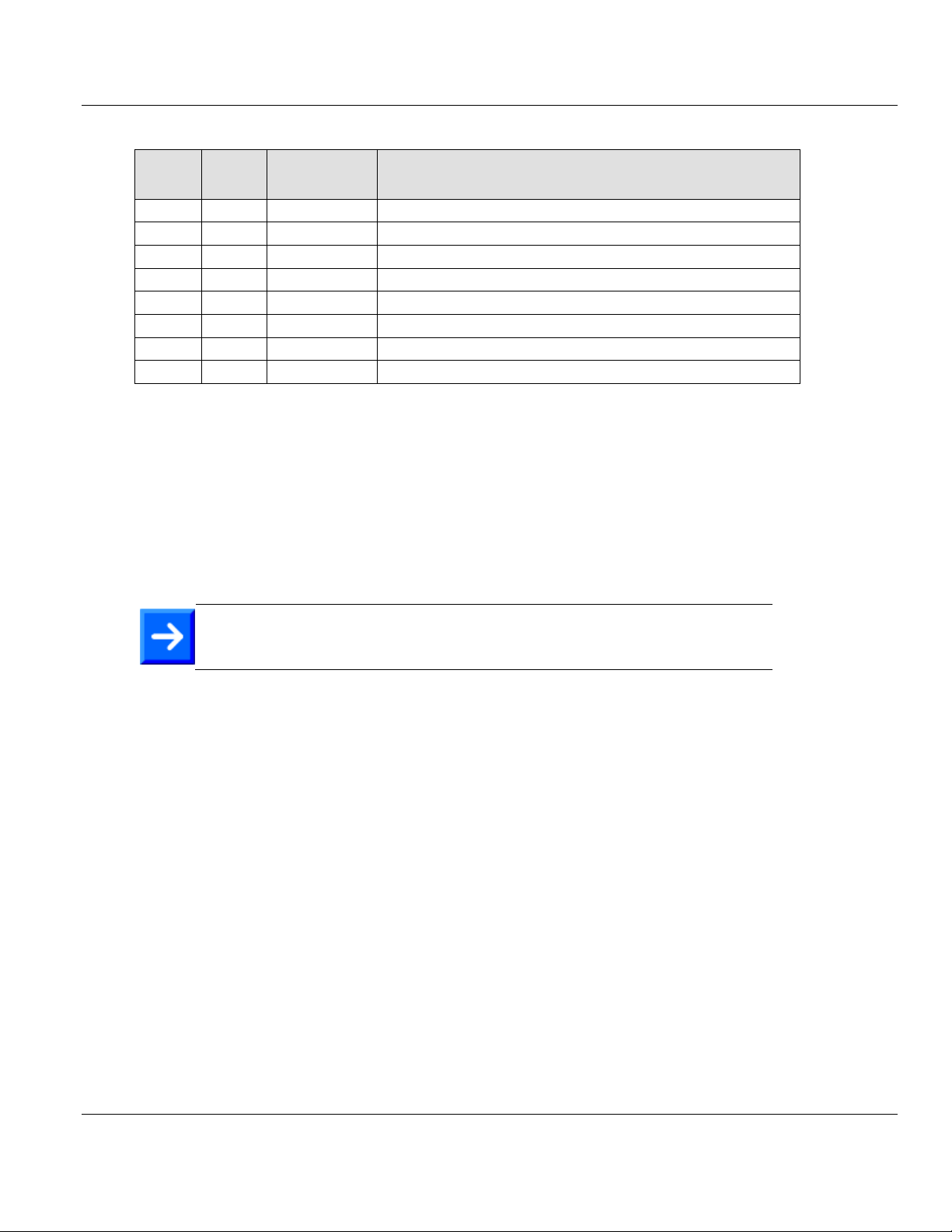

Connection with DSub female connector

Signal

Description

3

RxD / TxD-P

Receive/Send Data-P, respectively connection B plug

4

CNTR-P

Repeater-Control

5

DGND

Data Ground

6

VP

Positive supply voltage

8

RxD / TxD-N

Receive/Send Data-N, respectively connection A plug

User Manual PROFIBUS Master Communication Module

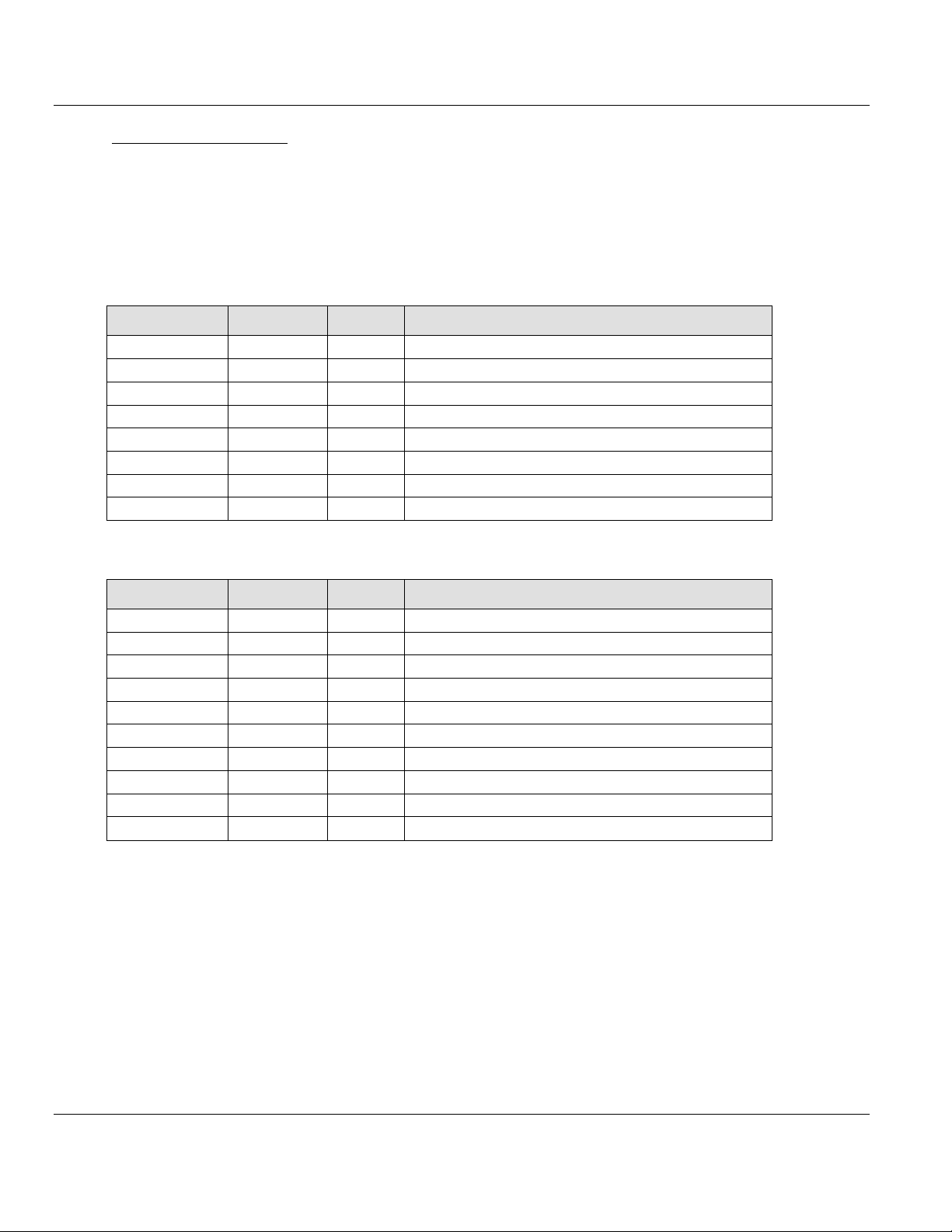

3.2 PROFIBUS Interface

PROFIBUS Interface (D-Sub female connector, 9 pin):

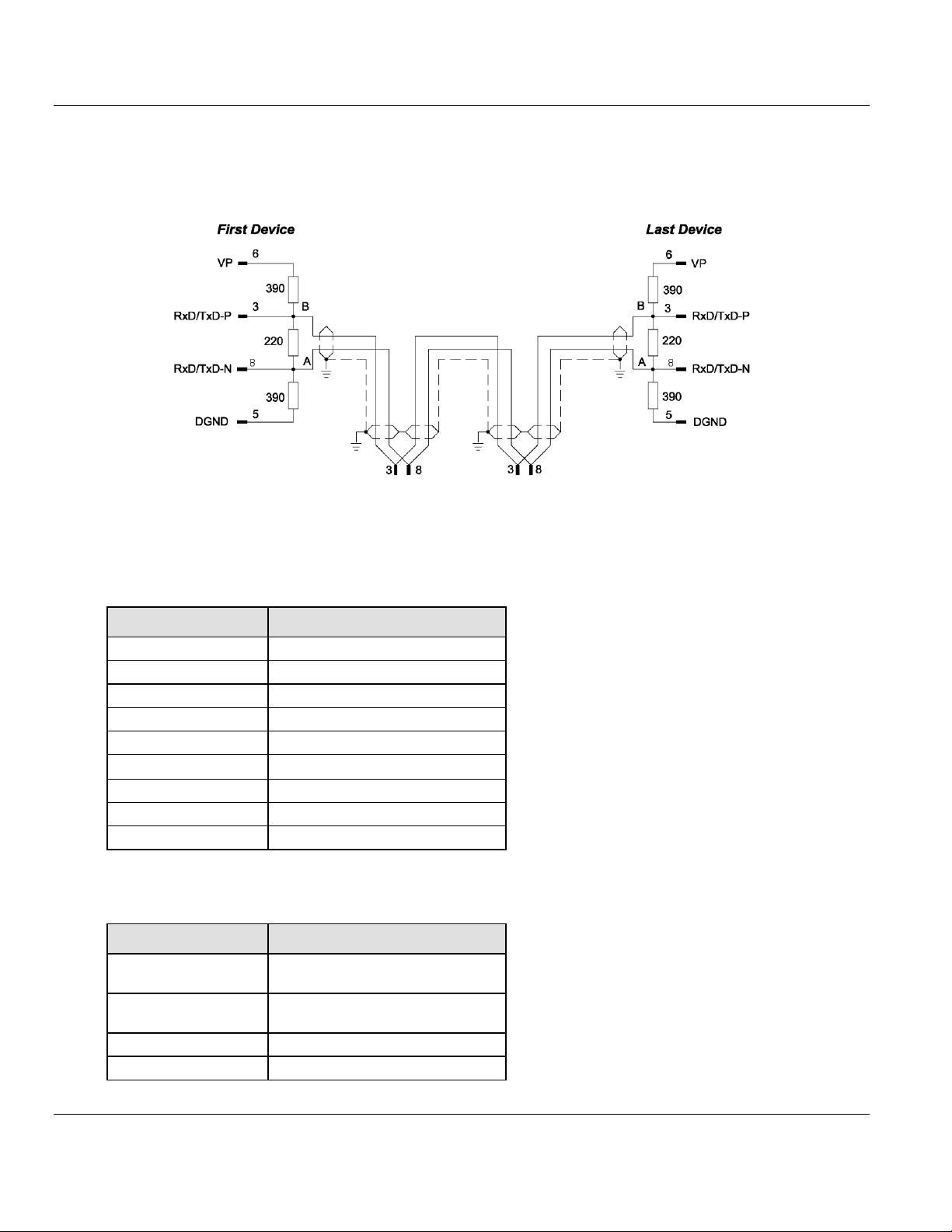

3.2.1 Wiring Instructions

Please ensure that termination resistors are available at both ends of the PROFIBUS

network cable. If special PROFIBUS connectors are being used, these resistors are often

found inside the connector and must be switched on at each end of the PROFIBUS network

cable.

For baud rates above 1.5 MBaud, use only special connectors for higher baud rates. These

include additional inductance.

It is not permitted to have T-stubs on PROFIBUS high baud rates. Use only a special cable

which is approved for PROFIBUS DP. Make a solid connection from the cable shield to

ground at every device and make sure that there is no potential difference between the

grounds at the devices.

Page 18 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 19

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

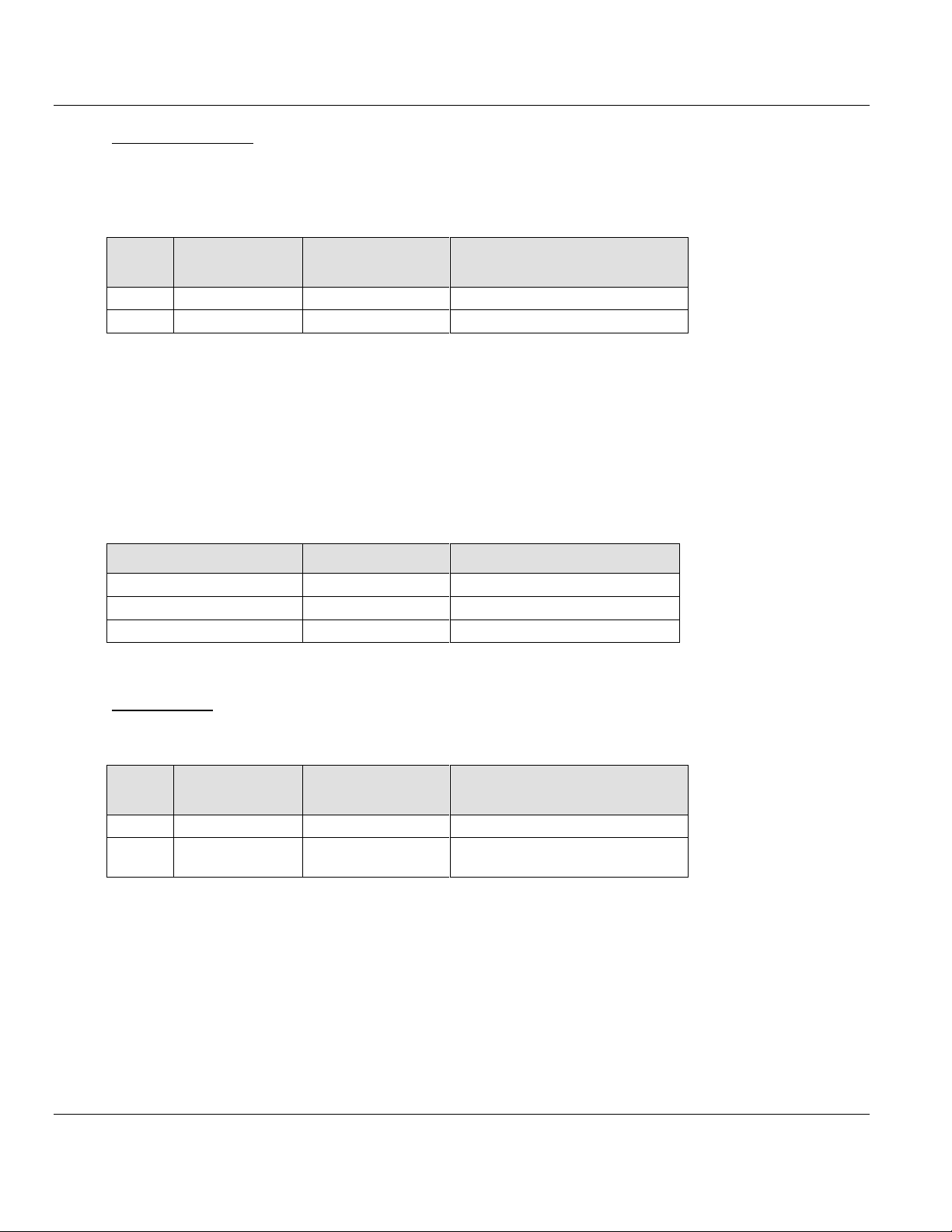

Baud rate in kBit/s

Maximum distance

9.6 1,200 meters

3,940 feet

19.2

1,200 m

3,940 ft

93.75

1,200 m

3,940 ft

187.5

1,000 m

3,280 ft

500 400 m

1,310 ft

1,500

200 m

656 ft

3,000

100 m

328 ft

6,000

100 m

328 ft

12,000

100 m

328 ft

Parameter

Value

Impedance

35 to 165 Ohm at frequencies from

3 to 20 Mhz

Capacity per units

length

< 30 pF/m

Loop resistance

110 Ohm/km

Wire gauge

0.64 mm

PROFIBUS Master Communication Module User Manual

If the ILX69-PBM is linked with only one other device on the bus, both devices must be

connected to the ends of the bus line. These devices must deliver the supply voltage for the

termination resistors. If three or more devices are connected to the bus, the ILX69-PBM can

be connected at any desired position.

Up to 32 PROFIBUS devices can be connected to one bus segment, without repeaters. If

several bus segments are linked to each other with repeaters, there can be up to 127

devices on the network.

The maximum permissible cable length of a PROFIBUS segment depends on the baud rate

used, see the following table.

Only PROFIBUS certified cables, preferably the cable type A, should be used. The following

table contains important electrical data concerning PROFIBUS certified cable:

ProSoft Technology, Inc. Page 19 of 124

February 4, 2015

Page 20

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

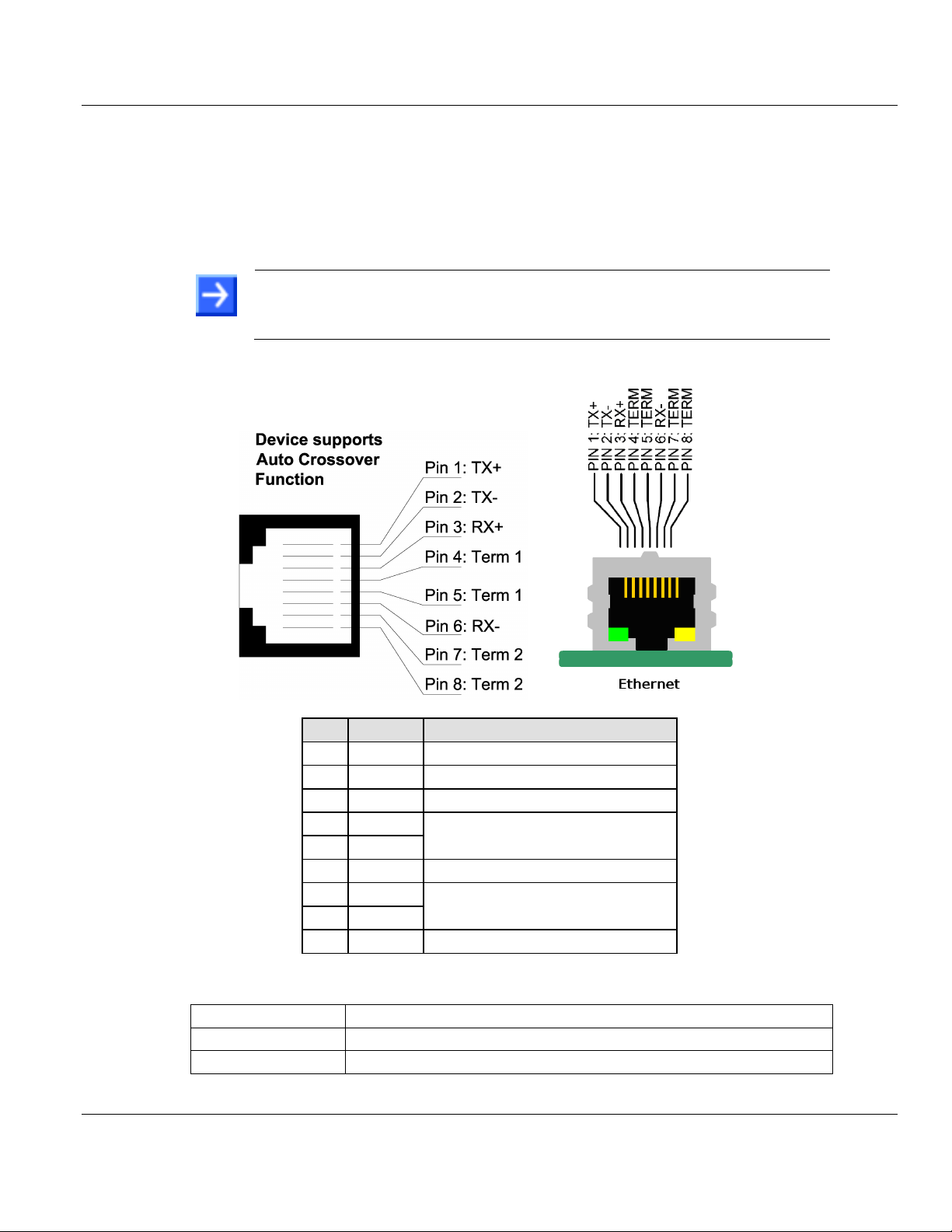

Note: The device supports the Auto Crossover function. The RX and TX

can be switched. The following figure shows the RJ45 standard pin

assignment.

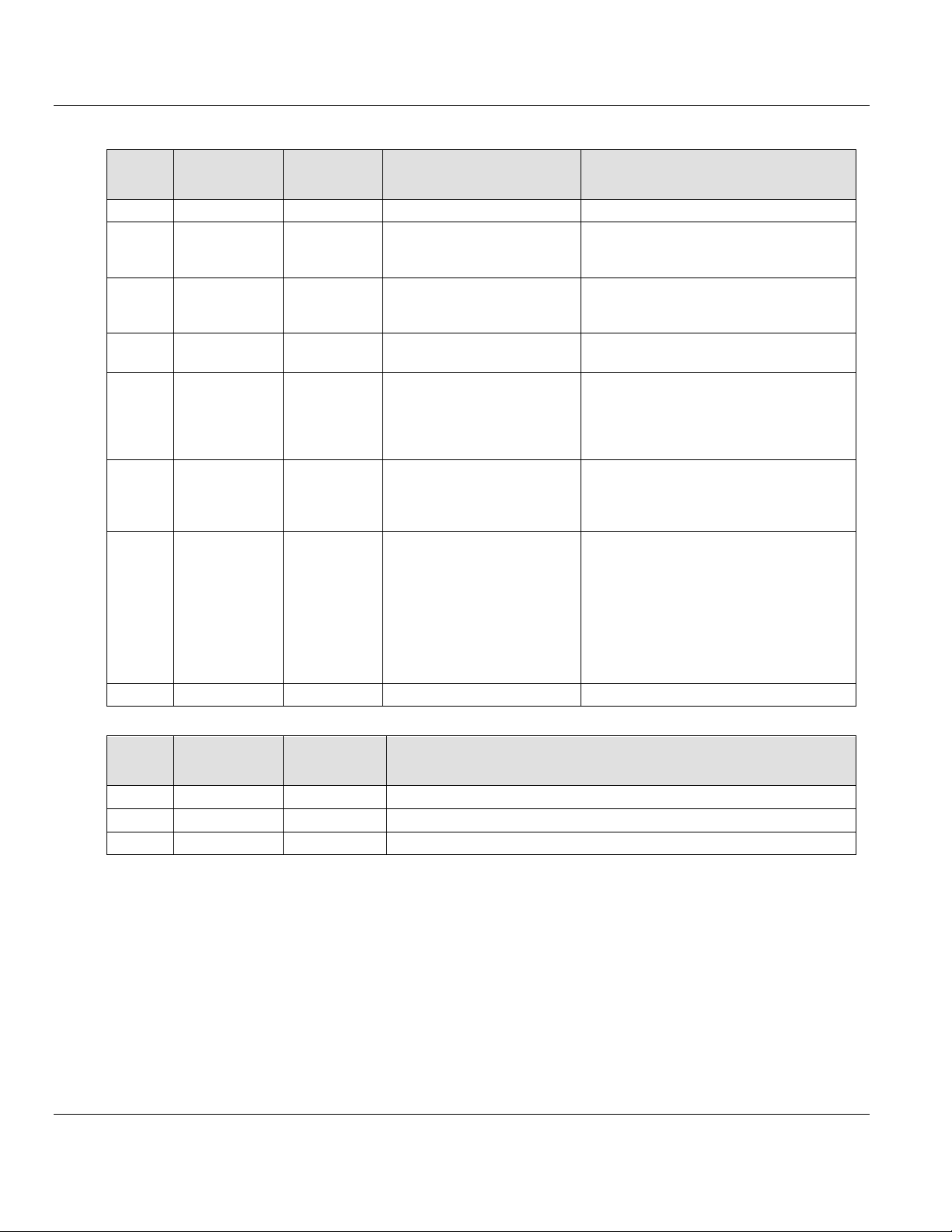

Pin

Signal

Description

1

TX+

Transmit Data +

2

TX–

Transmit Data –

3

RX+

Receive Data +

4

Term 1

Connected to each other and

terminated to PE through RC circuit*

5

Term 1

6

RX–

Receive Data –

7

Term 2

Connected to each other and

terminated to PE through RC circuit*

8

Term 2

*Bob Smith Termination

Medium

2 x 2 Twisted-pair copper cable, CAT5 (100 MBit/s) or better

Length of cable

Maximum 100 m

Transmission rate

10 MBit/s / 100 MBit/s

User Manual PROFIBUS Master Communication Module

3.3 Ethernet Interface

The Ethernet cable should contain an RJ45 connector. It should have a twisted pair cable of

category 5 (CAT5) or higher, which consists of 4 twisted cores and has a maximum

transmission rate of 100 MBit/s (CAT5).

3.3.1 Ethernet Pin Assignment at the RJ45 Socket

3.3.2 Ethernet Connection Data

Page 20 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 21

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Type

SD card (HDSC format is not supported)

Maximum storage capacity

4 GByte

Required formatting

FAT16 format (no FAT32)

Power supply

5V from backplane

Current Load

CompactLogix

570 mA Max. @ 5 VDC

Power rating of 2

Backplane power

5 VDC: Min: 4.75 V at Module; Max: 5.40 V at Module

24 VDC: Min: 19.9 V at Module; Max: 26.4 V at Module

PROFIBUS Master Communication Module User Manual

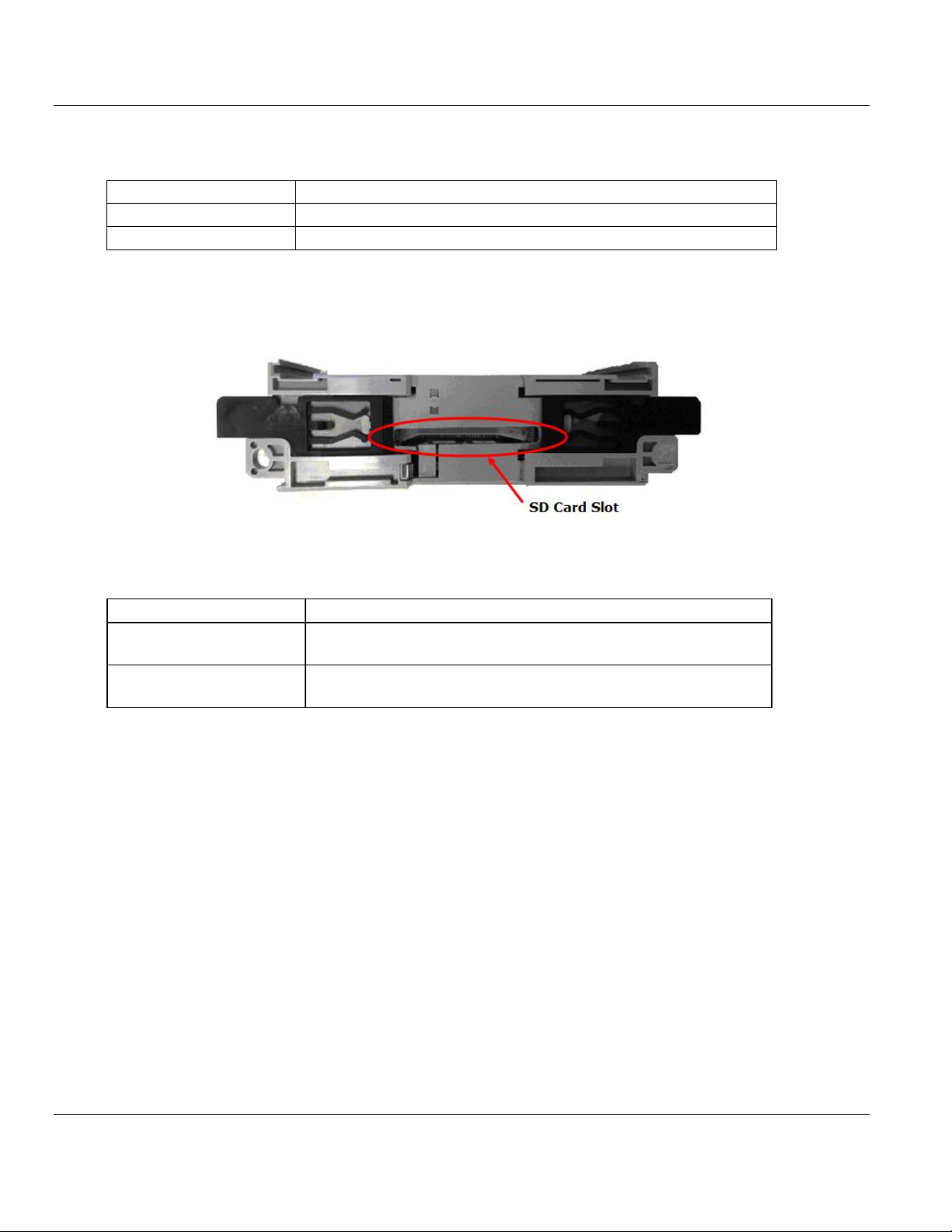

3.4 Removable Memory Card

Memory Card

SD Card Connector

SD Card Connector, e.g. FPS009-2405-0 push/push

3.5 Power Supply

ProSoft Technology, Inc. Page 21 of 124

February 4, 2015

Page 22

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Page 22 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 23

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

System Planning Considerations ...........................................................23

Software Installation...............................................................................24

ILX69-PBM Hardware Installation ..........................................................26

Uninstalling ILX69-PBM Hardware ........................................................27

PROFIBUS Master Communication Module User Manual

4 Installation

4.1 System Planning Considerations

Network Conception

The ILX69-PBM can communicate with up to 125 PROFIBUS slave devices.

A 1769-ECR (right end cap) or 1769-ECL (left end cap) is required to terminate the end

of the Compact I/O bus.

Each bank of CompactLogix I/O must have its own power supply.

A CompactLogix I/O power supply has limits of +5V to +24V DC. These limits depend

on the catalog number (e.g. 1769-PA2) of the power supply. A bank of modules must not

exceed the current limits of the I/O bank power supply. Refer to the Compact 1769

Expansion I/O Power Supplies Installation Instructions.

The ILX69-PBM has a distance rating of 2. Therefore, the module must be within 2 slots

of the I/O bank’s power supply.

Configuration and Network Communication

Determine the PROFIBUS baud rate based on standard PROFIBUS system

considerations.

Identify the number of words of I/O data each slave supports.

ProSoft Technology, Inc. Page 23 of 124

February 4, 2015

Page 24

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Note:

When ProSoft fdt Configuration Manager is installed on a PC, Hilscher standard

SYCON.net as well as legacy PROSOFT.fdt cannot be and shall not be installed, and

vice-versa.

You need administrator privileges under Windows® 7 to install the configuration

software ProSoft fdt Configuration Manager on your PC.

User Manual PROFIBUS Master Communication Module

4.2 Software Installation

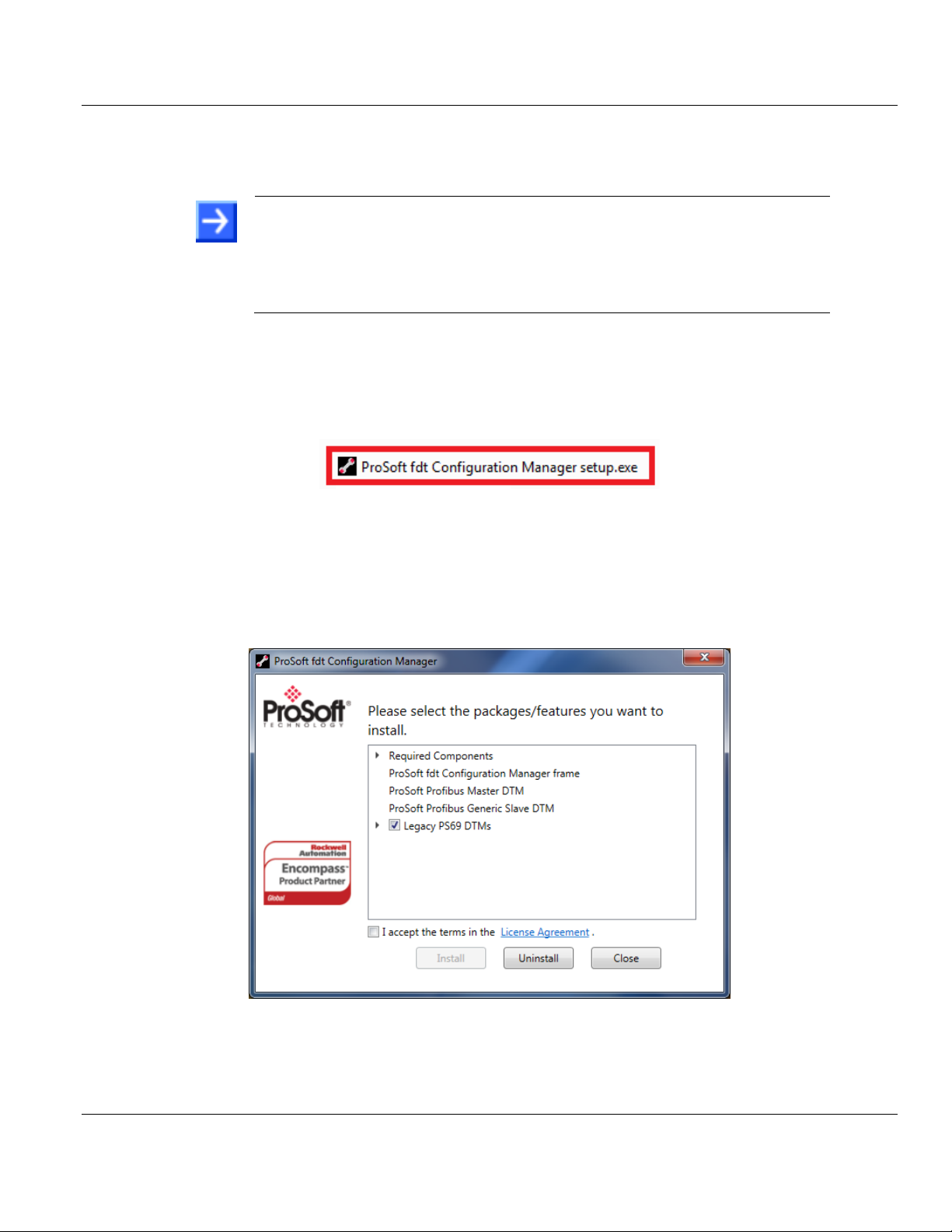

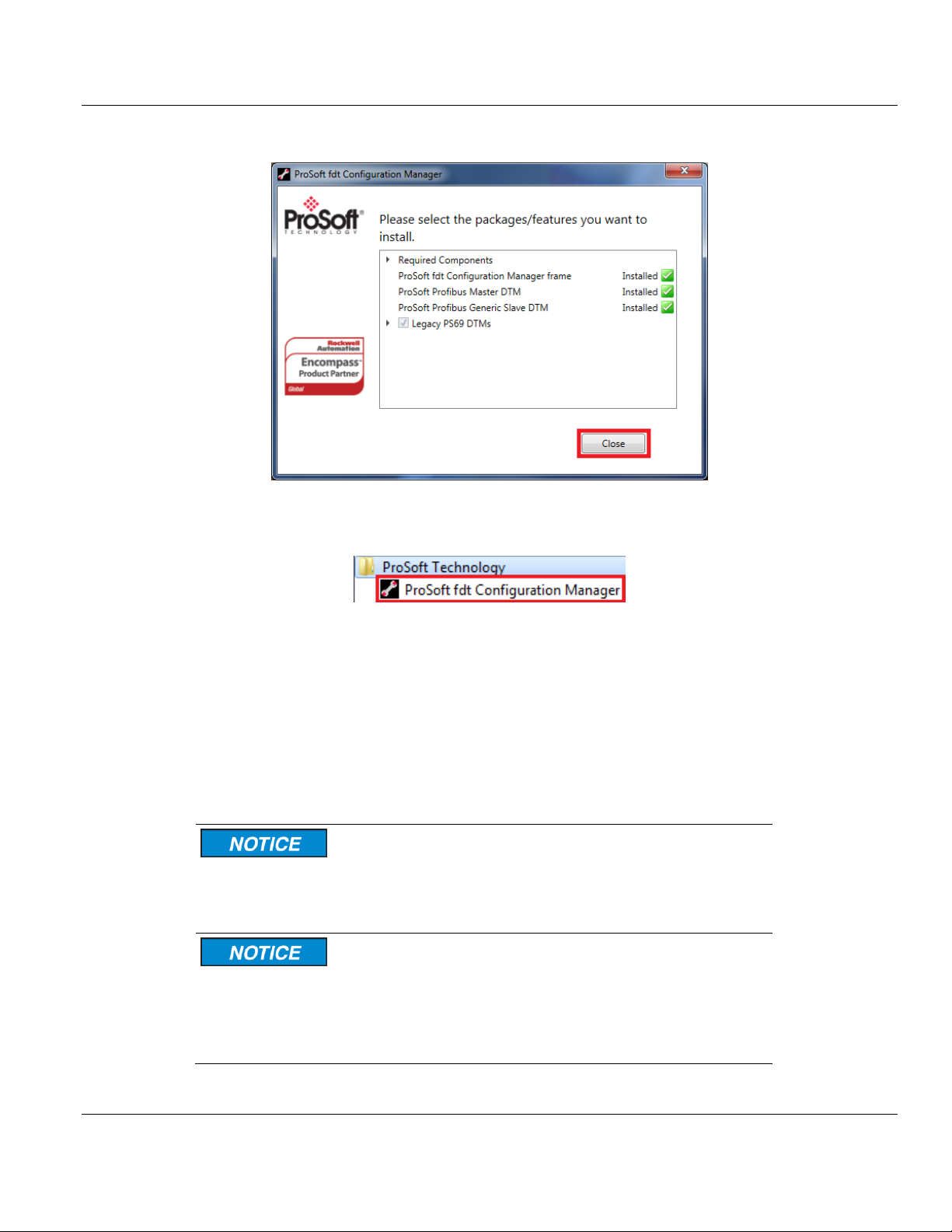

4.2.1 Installing ProSoft fdt Configuration Manager in Windows 7

1 Close all application programs on the system and insert the ProSoft Solutions DVD into

the local DVD-ROM drive. If you do not have the DVD, please visit www.prosofttechnology.com

2 Double-click ProSoft fdt Configuration Manager setup.exe from the DVD.

3 Select Yes at the Windows® security question.

4 Alternatively, you can reduce the number of Windows® safety questions by running the

setup via Run as Administrator. Right-click on the ProSoft fdt Configuration

Manager.exe file and click Run as Administrator and answer the Windows® security

question with Yes.

The ProSoft fdt Configuration Manager pane is displayed.

5 If required, select Legacy PS69 DTMs if the PC running the new version of

PROSOFT.fdt Configuration Manager is also going to be used to configure legacy

ProSoft PS69-DPM modules.

Page 24 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 25

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

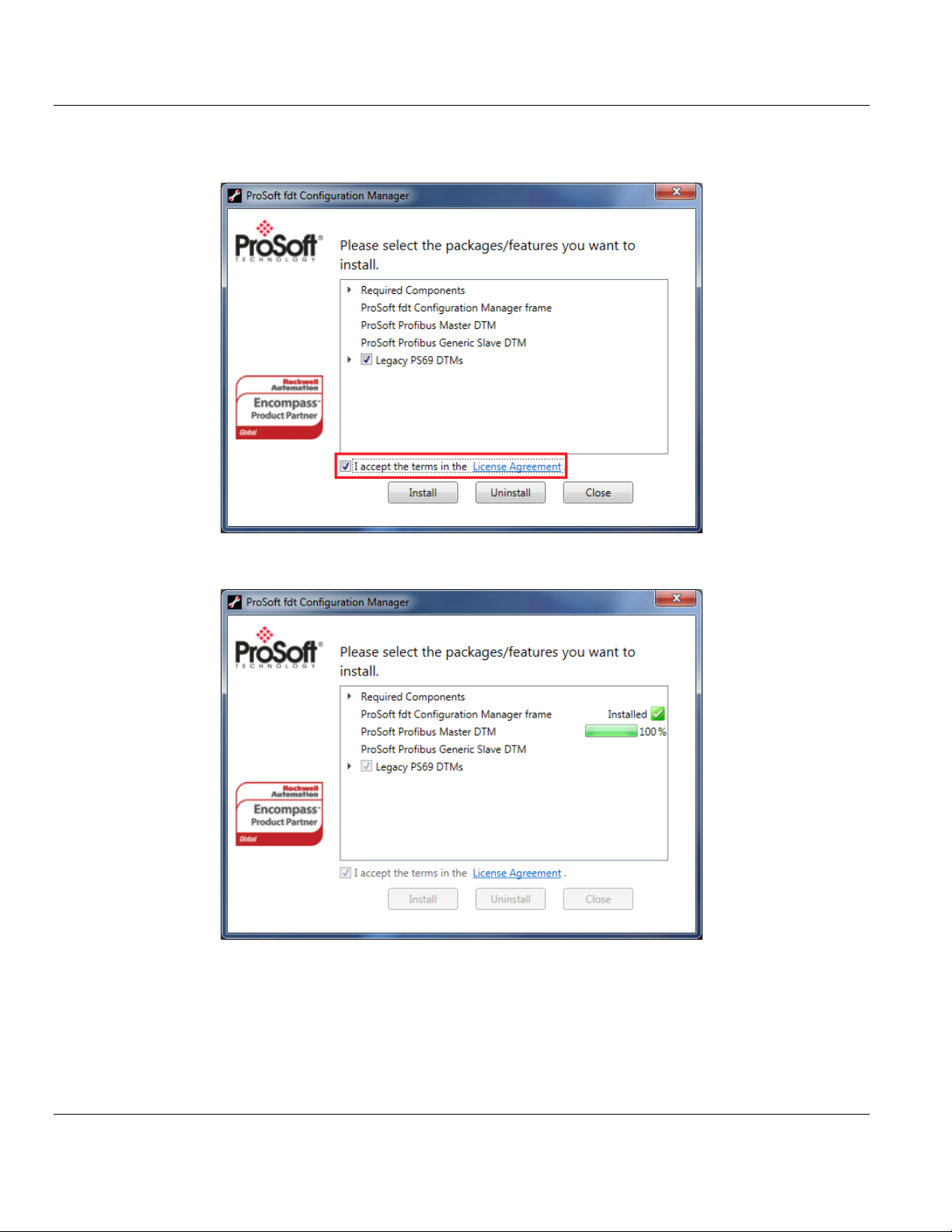

6 When ready, select the I accept the terms in the License Agreement box.

7 Click Install to continue the installation.

The installation will take several minutes.

ProSoft Technology, Inc. Page 25 of 124

February 4, 2015

Page 26

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Electrostatically sensitive devices

To prevent damage to the PLC and the ILX69-PBM, make sure that the ILX69-PBM is

grounded via the backplane of the PLC. Also make sure that you are discharged when

you install/uninstall the ILX69-PBM.

Device Destruction

Shut off the power supply of the PLC before you install the ILX69-PBM. Then install or

remove the ILX69-PBM to/from the PLC..

Use only the permissible supply voltage to operate the ILX69-PBM.

All I/O signal pins at the ILX69-PBM tolerate only the specified signaling voltage.

User Manual PROFIBUS Master Communication Module

8 Click Close when installation is complete.

The ProSoft fdt Configuration Manager is now installed. It can be launched from the

Windows Start menu.

4.3 ILX69-PBM Hardware Installation

This section describes how to install/uninstall the ILX69-PBM in a CompactLogix™ system.

4.3.1 Safety Precautions

Obey the following property damage messages when installing, uninstalling or replacing the

ILX69-PBM.

Page 26 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 27

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

A detailed description the installation of communication modules in

CompactLogix™ systems can be found in the installation manual for the

1769 CompactLogix™ controller from Rockwell Automation.

PROFIBUS Master Communication Module User Manual

4.3.2 Installing the ILX69-PBM Module

1 Install the ILX69-PBM into a free slot in the CompactLogix™ controller. Make sure it is

within 2 slots of a power supply.

2 Check that the bus lever of the ILX69-PBM is in the unlocked (fully right) position.

3 Assemble the ILX69-PBM and the CompactLogix™ module together by using the upper

and lower tongue-and-groove slots.

4 Move the ILX69-PBM back along the tongue-and-groove slots until the bus connectors

line up with each other.

5 Move the ILX69-PBM bus lever fully to the left until it clicks. Ensure it is locked firmly in

place.

6 Attach and lock an end cap terminator to the ILX69-PBM by using the tongue-and-

groove slots as before.

7 Apply power to the Rockwell CompactLogix™ controller.

4.4 Uninstalling ILX69-PBM Hardware

1 Adhere to the safety precautions.

2 Shut off the power of the Rockwell CompactLogix™ controller.

3 Discharge yourself.

4 Unlock the end cap bus terminator.

5 Remove the end cap terminator from the ILX69-PBM by using the tongue-and-groove

slots.

6 Move the ILX69-PBM bus lever in the unlocked (fully right) position.

7 Remove the ILX69-PBM along the tongue-and-groove slots.

8 Reassemble the end cap terminator and the CompactLogix™ system together by using

the upper and lower tongue-and-groove slots.

ProSoft Technology, Inc. Page 27 of 124

February 4, 2015

Page 28

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Page 28 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 29

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

CompactLogix Project ............................................................................29

ProSoft fdt Configuration Manager ........................................................37

Downloading the Project to the ILX69-PBM ...........................................45

Adjusting Input/Output Data Lengths in the Project ...............................51

Project Storage ......................................................................................56

PROFIBUS Master Communication Module User Manual

5 Configuration and Start-Up

This chapter provides descriptions about the configuration and start-up of the ILX69-PBM.

ILX69-PBM Configuration and Parameterization Steps:

The configuration and parameterization of the ILX69-PBM is carried out in three steps:

1 Configuration of the module in a CompactLogix™ project using the Studio 5000 or

RSLogix 5000 programming tool.

2 Parameterization and configuration of the ILX69-PBM with the ProSoft fdt Configuration

Manager configuration software.

3 Creating the data objects and the ladder diagram in Studio 5000/RSLogix 5000.

5.1 CompactLogix Project

This section covers the configuration of the ILX69-PBM in a CompactLogix™ system.

5.1.1 Creating a New Project

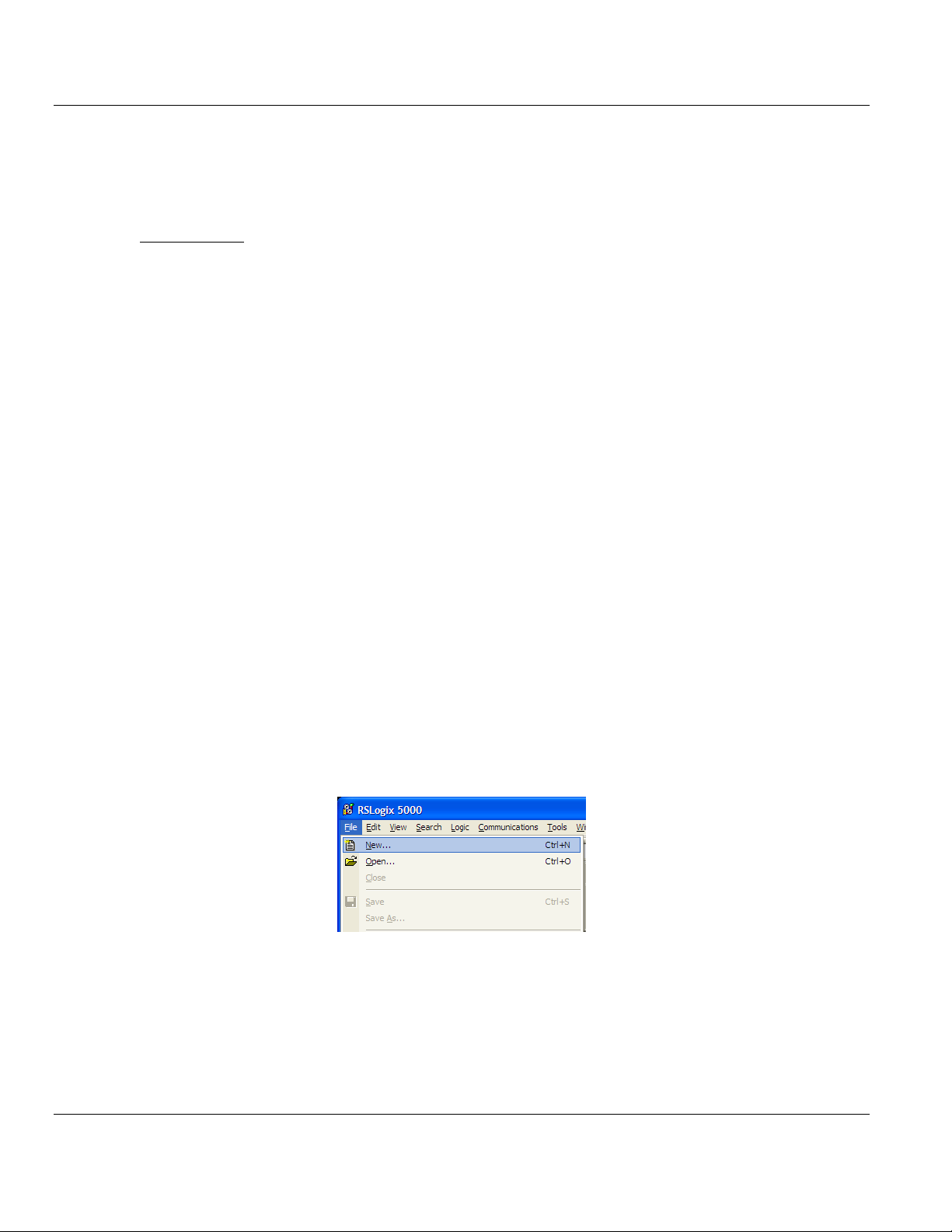

1 Open the FILE menu, and select NEW.

ProSoft Technology, Inc. Page 29 of 124

February 4, 2015

Page 30

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

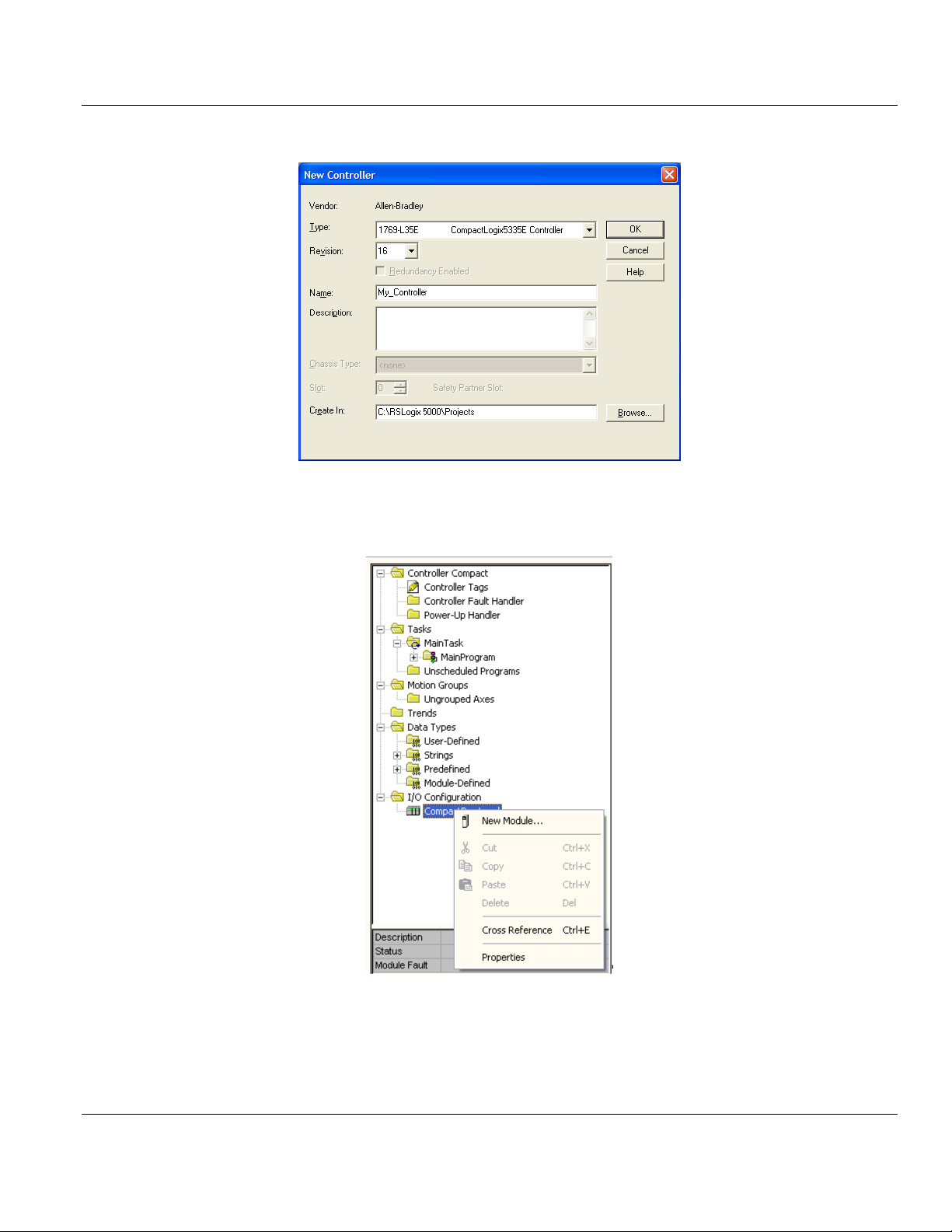

2 Select your controller TYPE and REVISION 16 or newer.

3 Click OK.

4 Right click on the I/O configuration > CompactBus Local of the controller project.

5 Select New Module from the context menu as shown below.

Page 30 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 31

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

The following dialog box appears.

6 Select "1769-MODULE Generic 1769 module" and click OK. The Module Properties

dialog will open.

ProSoft Technology, Inc. Page 31 of 124

February 4, 2015

Page 32

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Connection Parameter

Assembly Instance

Size (in Words)

Input

101

44 + X (Where X = 0 to 204) = 248 max

Output

100

8 + Y (Where Y = 0 to 240) = 248 max

Configuration

102

0

Note: The Size parameters vary for each PROFIBUS network. You can

customize these values using section Adjusting Input/Output Data Lengths in

the Project 51.

User Manual PROFIBUS Master Communication Module

5.1.2 Module Properties 1

1 The communications parameters for the module are configured in the Module Properties

dialog.

2 Enter PBM as the NAME and enter a short description for the module.

3 Select the Slot number in which the module is installed in the CompactLogix system. It

must be within 2 slots of a power supply.

4 Select Data - INT as the Comm_Format.

5 Set the connection parameters as they are shown in the dialog. The Connection

Parameter SIZE(s) may vary.

X = Number of Words configured for the ILX69-PBM (PROFIBUS input data); input size can

be in the range between 44 and 248 words

Y = Number of Words configured for the ILX69-PBM (PROFIBUS output data); output size

can be in the range between 8 and 248 words

Page 32 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 33

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

Input Size – The input size must be at least 88 Bytes (44 Words). It must be large

enough to accommodate the status information required by the module, which is 88

Bytes (44 Words) and the total number of PROFIBUS input data values from the slaves

in the network. You can increase the size of this area using the size of each Input

module connected. The Input image starts with byte 88.

Output Size – The output size must be at least 16 Bytes (8 Words). It must be large

enough to accommodate the command information required by the module, which is 16

bytes (8 Words), and the total number of PROFIBUS output data values to the slaves in

the network. You can increase the size of this area using the size of each Output module

connected. The Output image starts with byte 16.

6 Select Next >> or OK for the next configuration dialog.

5.1.3 Module Properties 2

The Requested Packet Interval RPI is shown in the following dialog. Within this time interval,

the I/O data between module and controller are exchanged.

1 Edit the REQUESTED PACKET INTERVAL (RPI) value, if needed.

It is not possible to change the RPI in this dialog separately for each module. The RPI

can be changed in the properties dialog of the "CompactBus Local" for all I/O modules.

2 Click Finish>>

3 Save the project.

ProSoft Technology, Inc. Page 33 of 124

February 4, 2015

Page 34

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

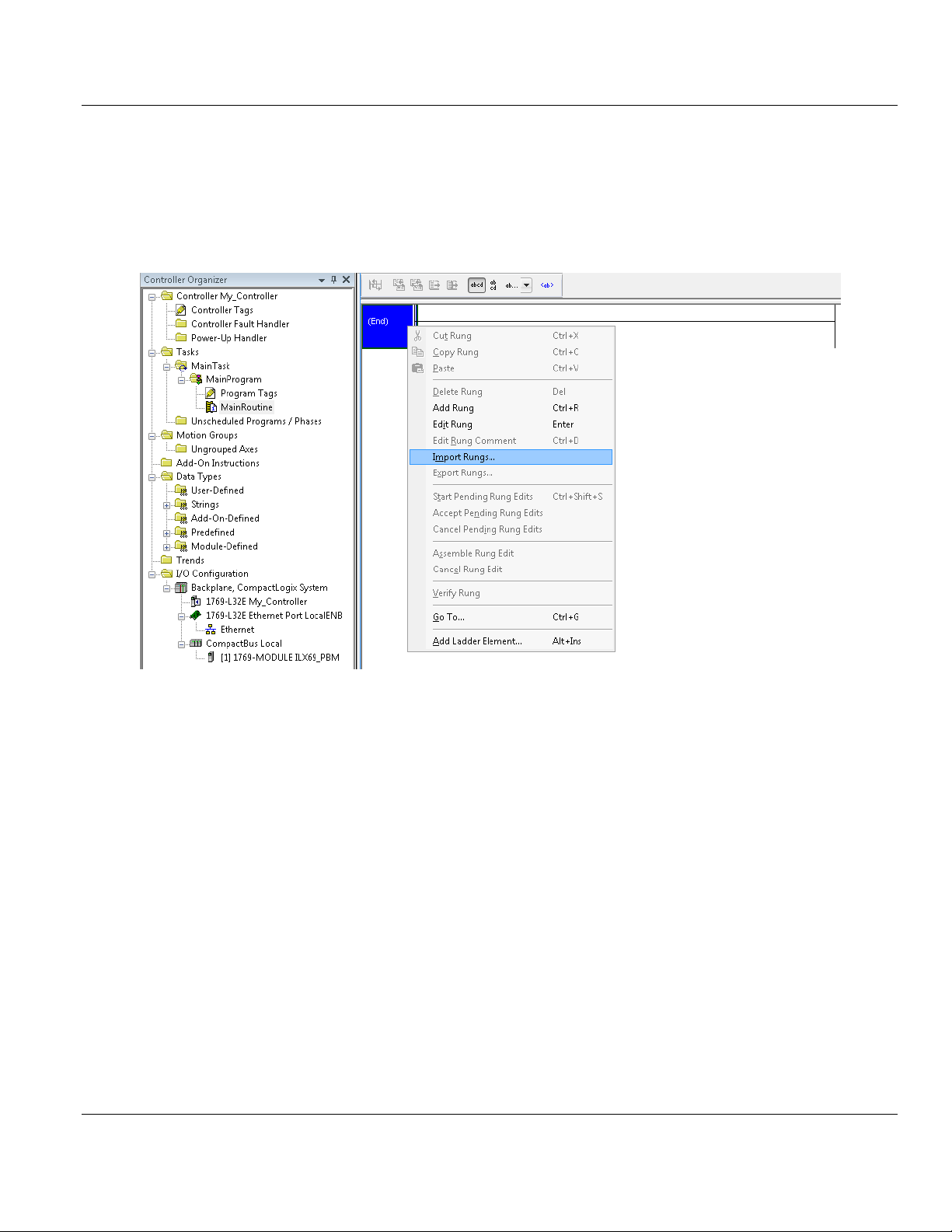

5.1.4 Importing the Ladder Rung

1 In the Controller Organization window, expand the TASKS folder and subfolder until you

reach the MAINPROGRAM folder.

2 In the MAINPROGRAM folder, double-click to open the MAINROUTINE ladder.

3 Select an empty rung in the new routine, and then click the right mouse button to open a

shortcut menu. On the shortcut menu, choose IMPORT RUNGS.

Page 34 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 35

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

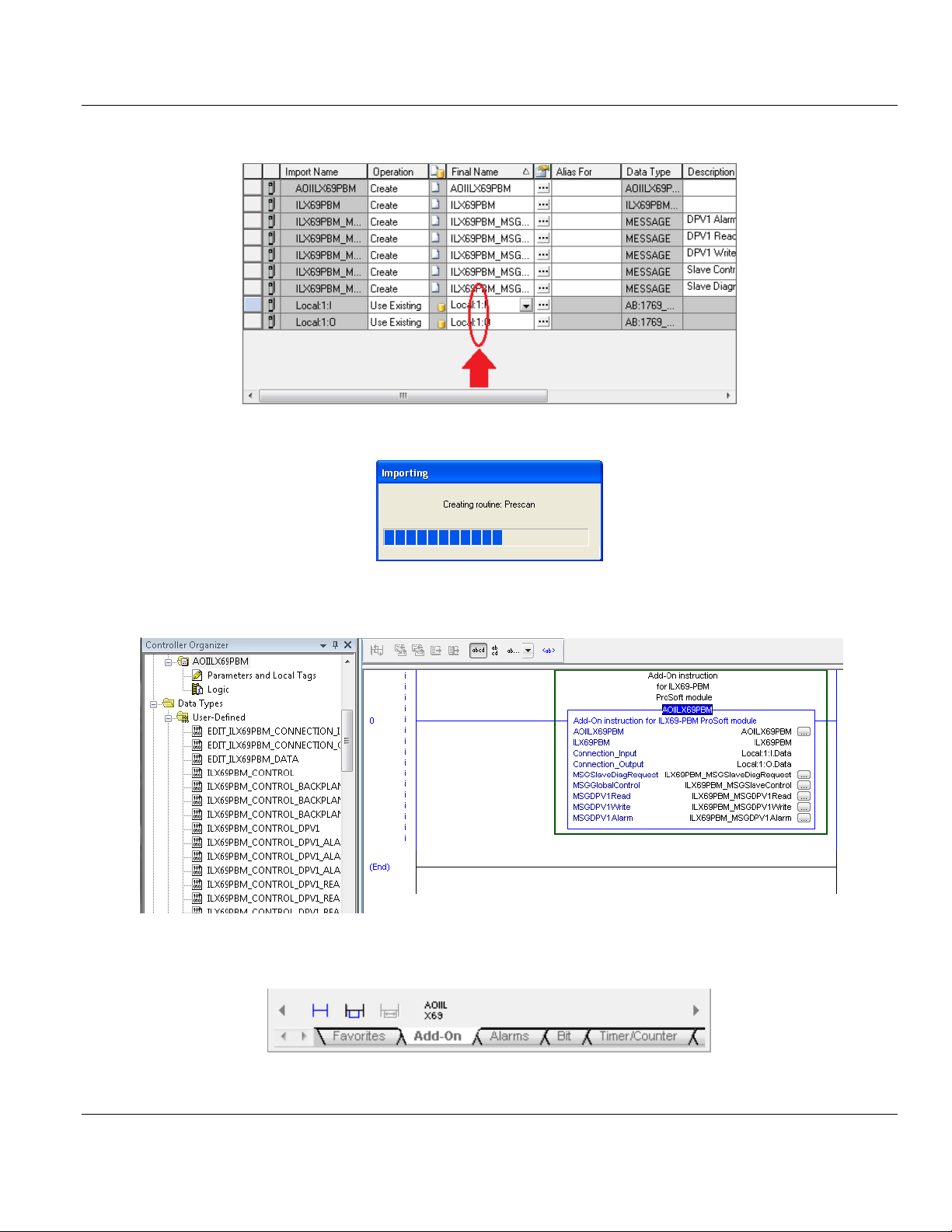

4 Navigate to the location on your PC where the .L5X Add-On Instruction (for example, My

Documents or Desktop) is saved. Select IMPORT...

This action opens the Import Configuration dialog box, showing the controller tags that

will be created.

ProSoft Technology, Inc. Page 35 of 124

February 4, 2015

Page 36

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

5 Verify that the slot number is correct for the module in the Local:x tags.

6 Click OK to confirm the import.

When the import is completed, the new Add-On Instruction rung will appear in the

ladder.

The procedure has also imported new user-defined data types, controller tags and the

Add-On instruction for your project.

7 Save the project.

Page 36 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 37

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

5.2 ProSoft fdt Configuration Manager

This section details the basics of using the ProSoft fdt Configuration Manager sofware to

configure the ILX69-PBM and Slave I/O system. The configuration is downloaded via

Ethernet to the module and stored into the Flash memory of the ILX69-PBM.

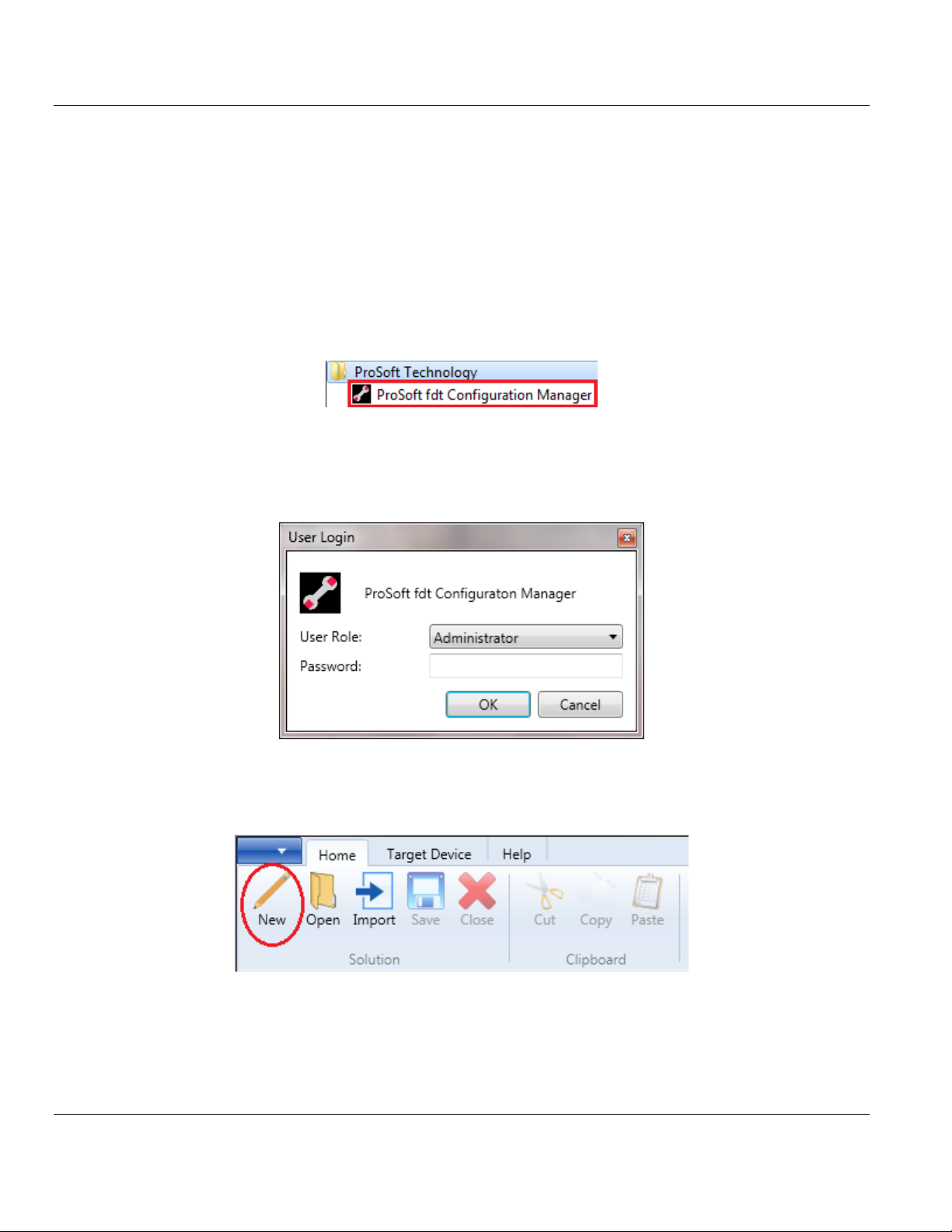

5.2.1 Creating a New ILX69-PBM Project

1 Launch the ProSoft fdt Configuration Manager from the Windows Start menu.

2 At the User Login dialog, use the following:

USER ROLE: Administrator

PASSWORD: (blank)

3 Click OK to open the ProSoft fdt Configuration Manager project window.

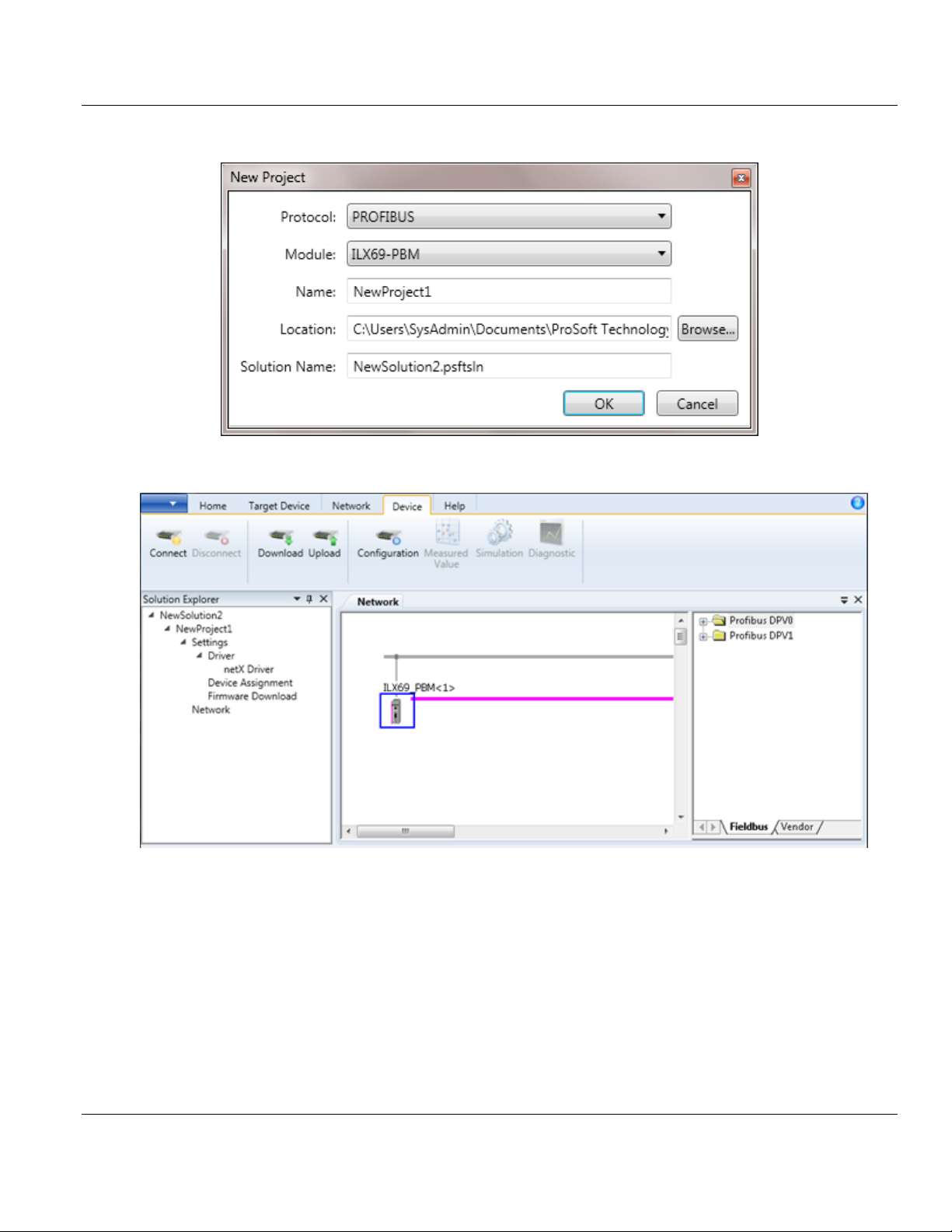

4 Create a new PROFIBUS project by selecting the HOME tab and clicking NEW. The New

Project dialog opens.

ProSoft Technology, Inc. Page 37 of 124

February 4, 2015

Page 38

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

5 If needed, edit the NAME, LOCATION, and SOLUTION NAME. Then click OK.

6 The ILX69-PBM Network bus is displayed.

Page 38 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 39

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

5.2.2 PROFIBUS Master Configuration

1 Double-click on the ILX69_PBM icon that appears in the Network View. In the navigation

area on the left side of the Configuration dialog box, select BUS PARAMETERS.

2 Select the BAUD RATE and STATION ADDRESS for the ILX69-PBM. The other parameters

do not need adjustment. The default settings should be sufficient for most networks.

3 Click OK.

ProSoft Technology, Inc. Page 39 of 124

February 4, 2015

Page 40

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

5.2.3 PROFIBUS Slave Configuration

The ProSoft fdt Configuration Manager comes pre-loaded with various PROFIBUS DPV0

and DPV1 slave GSD profiles. You can search them by FIELDBUS or VENDOR tabs at the

bottom of the slave list pane.

If you do not see your slave(s) listed, you will need to import them into the software.

Importing a slave profile into the ProSoft fdt Configuration Manager

Importing a slave to the ProSoft fdt Configuration Manager depends on the configuration

method of the slave. It is done by importing the PROFIBUS GSD file (typical) or using the

FDT/DTM technology.

Slave with DTM Technology

If the slave is configured by DTM technology, install the DTM software on your PC that was

delivered with the slave. Then reload the Device Catalog in ProSoft fdt Configuration

Manager.

Page 40 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 41

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

Importing a GSD File

1 Select the NETWORK tab at the top of the project window and click on IMPORT DEVICE

DESCRIPTION.

2 The netDevice – Import Device Description dialog opens. Navigate to the GSD file

location on your PC and click OPEN.

3 Follow the steps to import the GSD file. When prompted, select YES to Reload Device

Catalog.

4 The slave is now listed in the device catalog.

ProSoft Technology, Inc. Page 41 of 124

February 4, 2015

Page 42

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Adding a Slave to the Project

1 In the ProSoft fdt Configuration Manager project screen, locate the slave in the slave

catalog.

2 Drag and drop the slave onto the magenta PROFIBUS network line.

Page 42 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 43

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

Slave Settings

1 Double-click on the slave icon in the Network view. A slave-specific configuration dialog

box similar to the one shown below appears.

2 Under CONFIGURATION > MODULES, highlight and click INSERT on the appropriate inputs

and outputs you will use for the slave.

3 Click APPLY and then OK.

ProSoft Technology, Inc. Page 43 of 124

February 4, 2015

Page 44

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Editing the Slave Address

Assigning and editing a slave address is done in the ILX69-PBM configuration window.

1 Double-click on the ILX69_PBM icon in the Network pane.

2 This opens the netDevice – Configuration ILX69_PBM<x> window.

3 In the CONFIGURATION > STATION TABLE selection, edit the slave’s address under the

Station Address parameter.

4 When complete, click APPLY, then OK.

5 Save the project.

Page 44 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 45

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

5.3 Downloading the Project to the ILX69-PBM

Once saved, the project is now ready to be downloaded to the ILX69-PBM. Make sure the

ILX69-PBM is connected to the same Ethernet network as your PC.

5.3.1 Assigning an IP Address

1 Select the TARGET DEVICE tab at the top of the project window and click on IP SETTINGS.

2 The software will automatically scan for the ILX69-PBM on the network.

ProSoft Technology, Inc. Page 45 of 124

February 4, 2015

Page 46

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

3 Once found, the ILX69-PBM information appears in the Select the Device dialog. Click

NEXT >.

4 Assign the IP address of the ILX69-PBM in the Set the Network Address dialog.

Page 46 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 47

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

5 When ready, click FINISH to download the IP address information to the ILX69-PBM. The

module reboots during this process.

6 When prompted, click OK when complete.

5.3.2 Downloading the Project

1 Double-click on the DEVICE ASSIGNMENT selection in the Solution Explorer pane. In the

Device Assignment view, make sure the ILX69-PBM device is selected.

ProSoft Technology, Inc. Page 47 of 124

February 4, 2015

Page 48

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

2 Double-click on the NETWORK selection in the Solution Explorer pane to return to the

Network view.

3 Right-click on the ILX69_PBM icon and select DOWNLOAD. (You can also highlight the

ILX69-PBM icon and select DEVICE > DOWNLOAD from the top menu).

Page 48 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 49

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

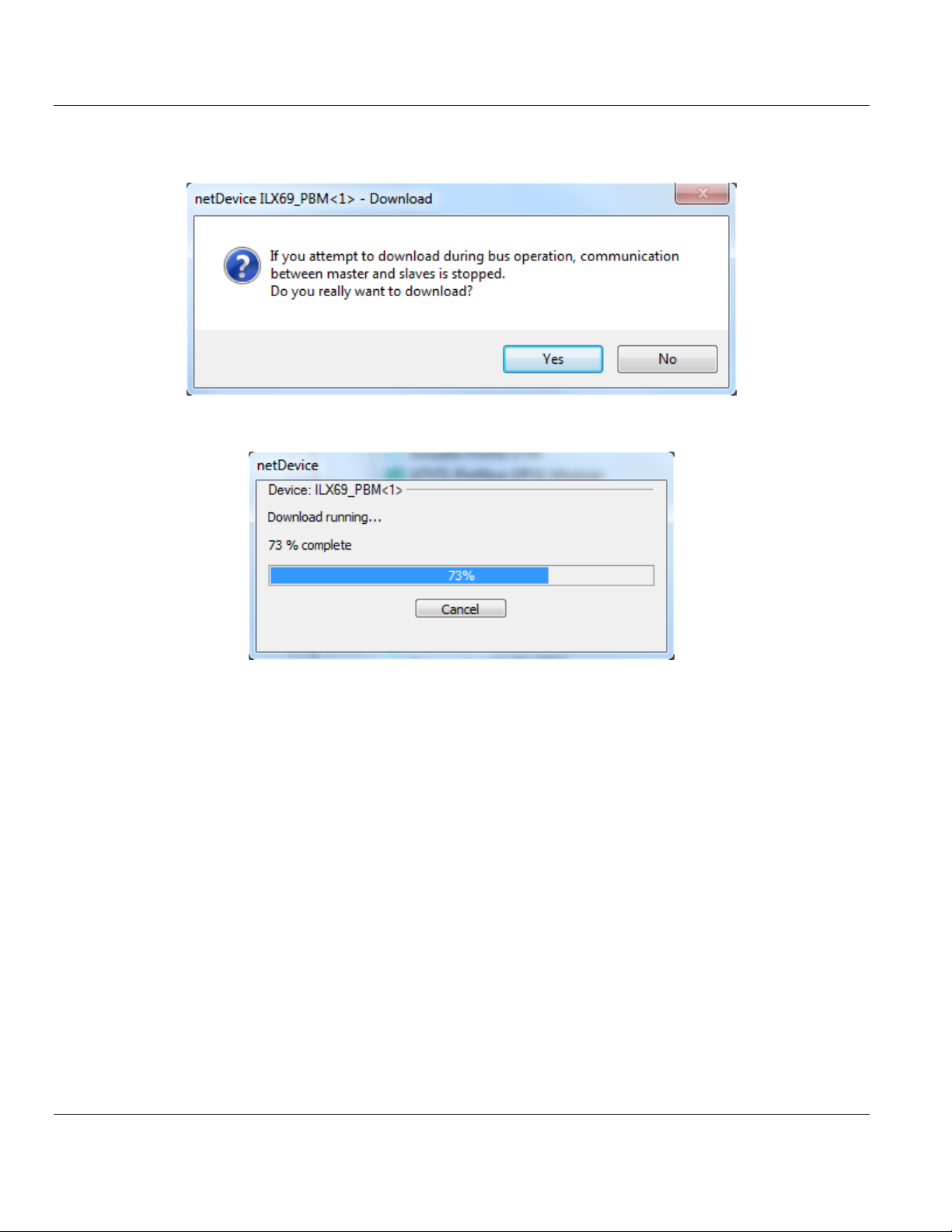

4 PROFIBUS network communications are stopped during configuration download. When

ready to download, click YES.

5 The configuration download begins.

ProSoft Technology, Inc. Page 49 of 124

February 4, 2015

Page 50

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

6 The pane at the bottom of the window logs the project activity. The status of the

download is shown here.

7 With a successful download, the ILX69-PBM is now active on the PROFIBUS network

with the new configuration.

Page 50 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 51

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

5.4 Adjusting Input/Output Data Lengths in the Project

If you are using less than 408 bytes of input or 480 bytes of output data, the AOI can be

adjusted to fit the needs of your PROFIBUS network. This section shows you how to

determine the size and parameters to adjust.

5.4.1 Determining the Number of PROFIBUS Inputs/Outputs Used

The ProSoft fdt Configuration Manager shows the total number of inputs and outputs

assigned to all slaves on the PROFIBUS network. This information is used to determine the

adjustment needed in Studio 5000.

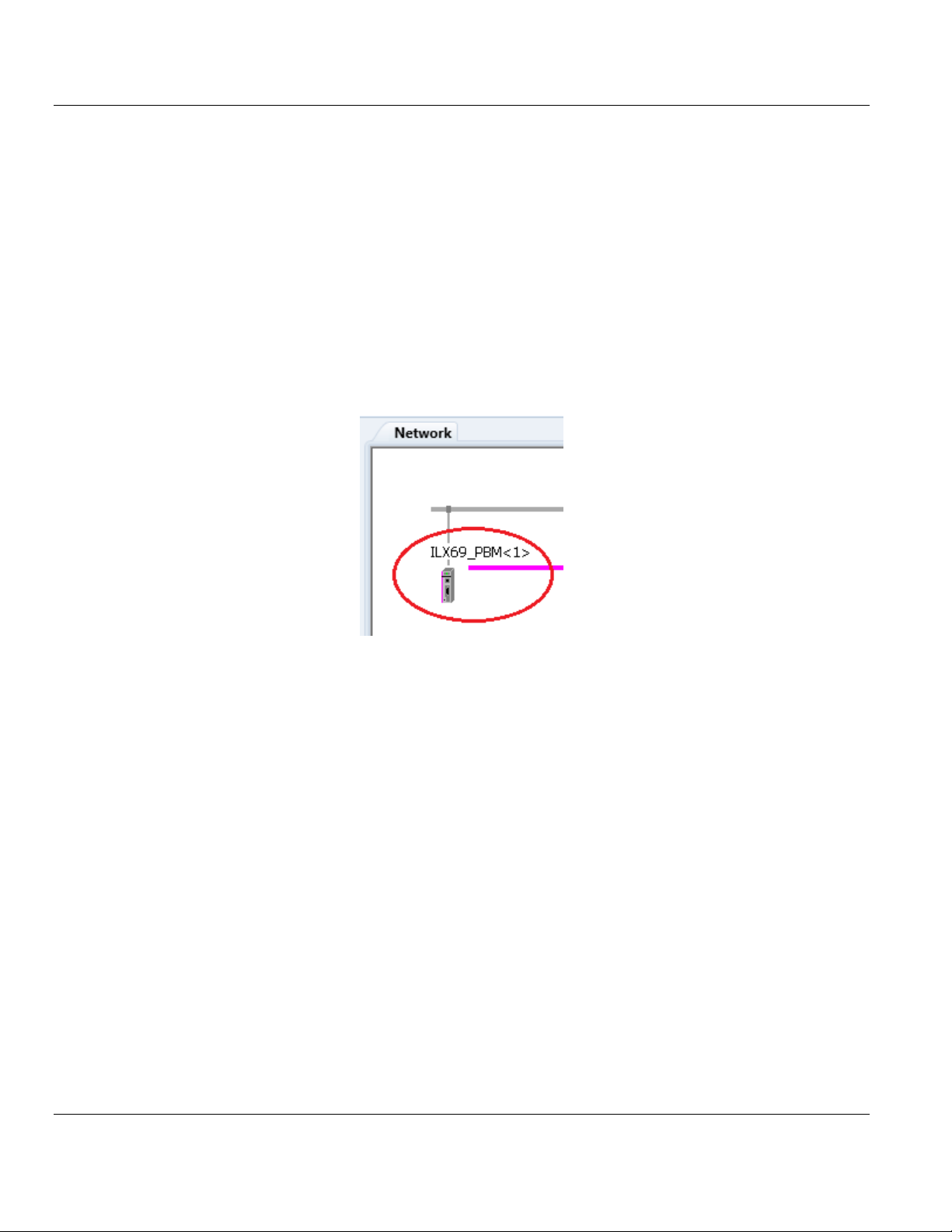

1 In the ProSoft fdt Configuration Manager, double-click on the ILX69_PBM icon in the

Network view.

ProSoft Technology, Inc. Page 51 of 124

February 4, 2015

Page 52

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

2 In the Configuration ILX69_PBM dialog, select the ADDRESS TABLE option to display the

individual inputs and outputs assigned to each slave. The example below shows 8 bytes

of input and 8 bytes of output assigned to slave 2. This is the only slave on the

PROFIBUS network.

Notice as the inputs/outputs are added, they accumulate numerically

3 Using this information, the necessary adjustments in Studio 5000 can be made.

Page 52 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 53

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

5.4.2 Studio 5000 Adjustment (Optional)

This (optional) section allows you to tailor the ILX69-PBM input/output sizes to conserve

memory space in the CompactLogix™ processor.

Module Properties

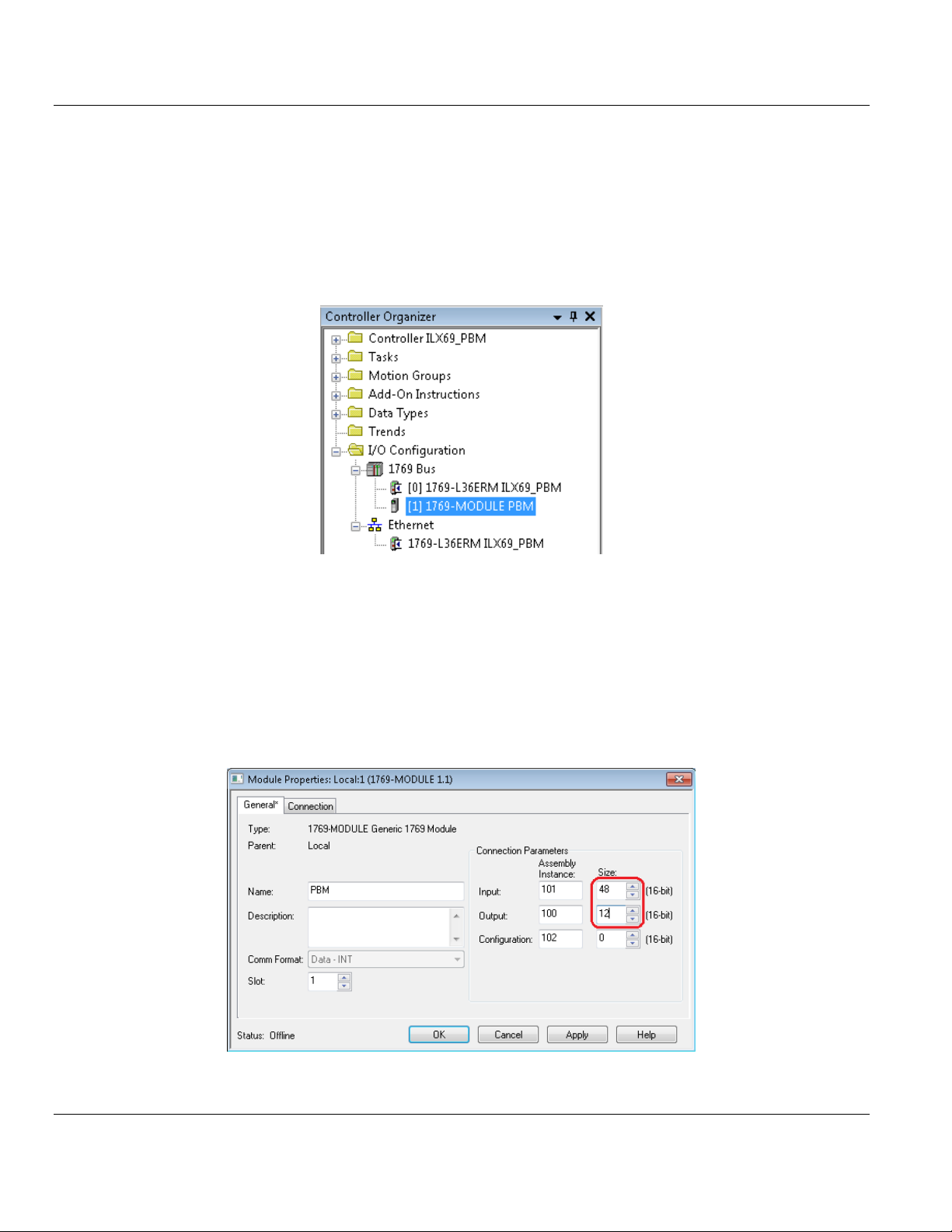

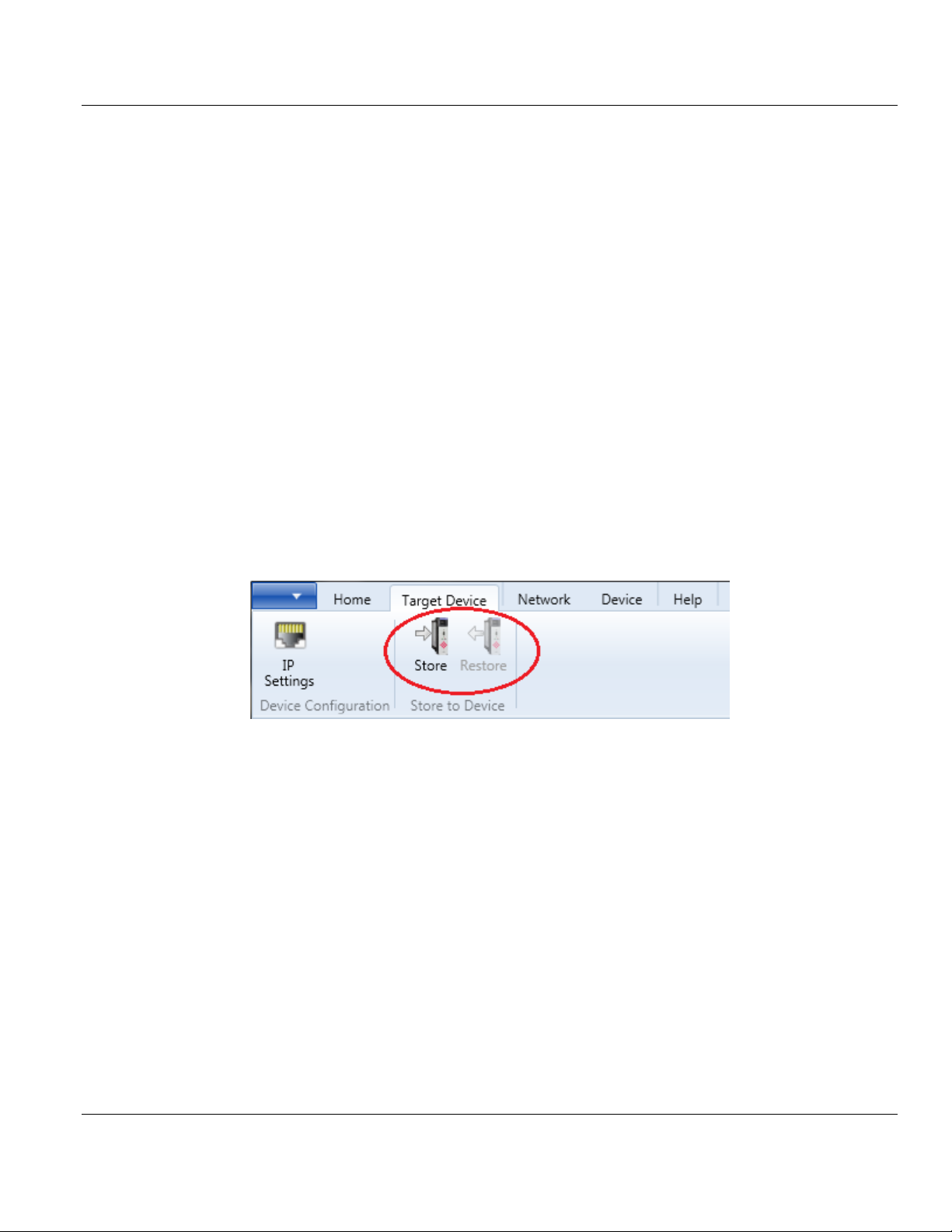

1 With the CompactLogix controller in Offline mode, double-click on the MODULE PBM in

the I/O Configuration dialog to open the Module Properties.

2 In the Module Properties dialog, edit the Connection Parameters INPUT SIZE to the sum

of PROFIBUS Input words + 44.

In the example, there are 8 PROFIBUS input bytes, or (4) 16-bit words: 4 + 44 = 48.

For outputs, edit the Connection Parameters OUTPUT SIZE to the sum of PROFIBUS

Output words + 8.

In the example, there are 8 PROFIBUS output bytes, or (4) 16-bit words: 4 + 8 = 12.

3 Click APPLY, then OK.

ProSoft Technology, Inc. Page 53 of 124

February 4, 2015

Page 54

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

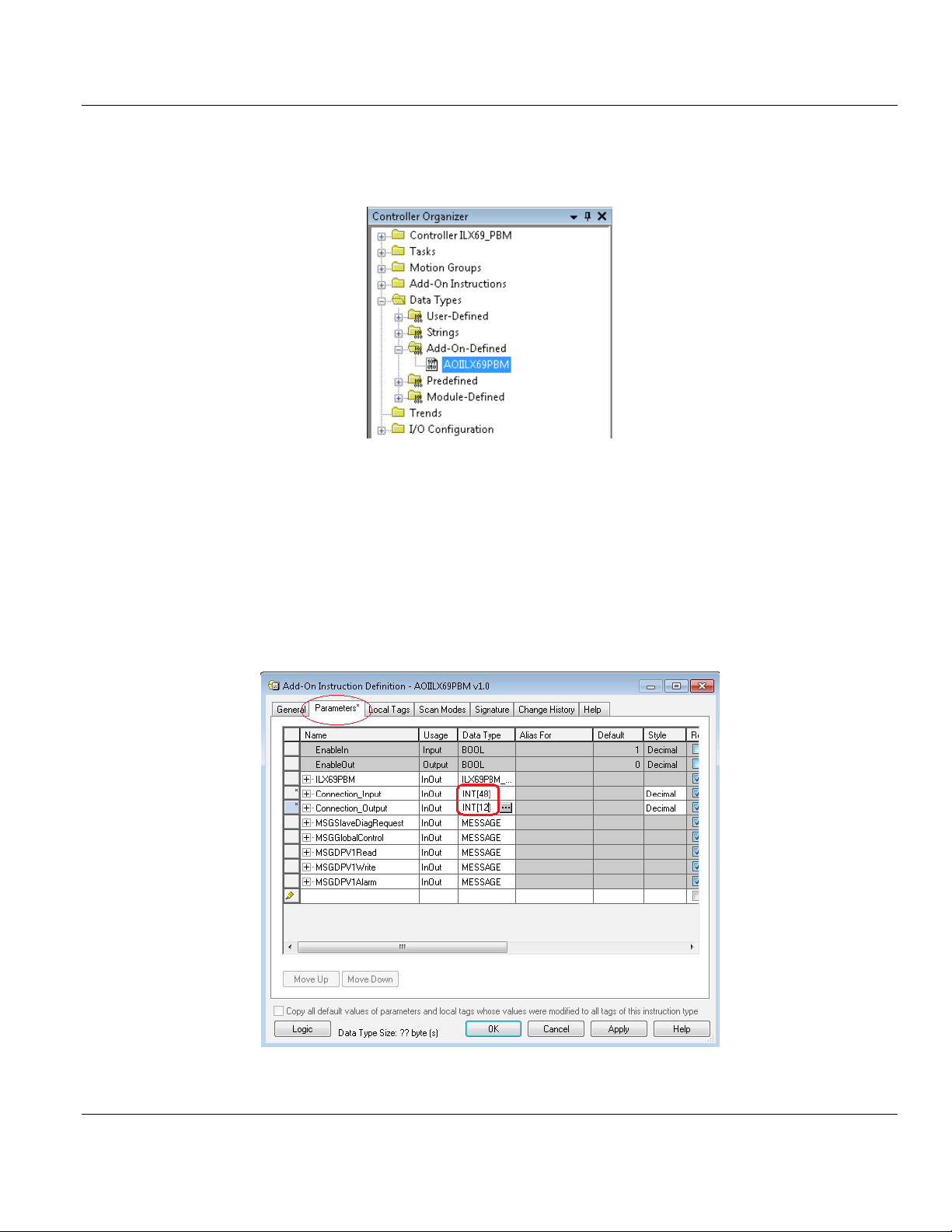

Add-On Instruction Definition

1 Double-click on the AOIILX69PBM Add-On-Defined Data Type to open the Add-On

Instruction Definition dialog.

2 Under the Parameters tab, edit the Connection_Input Data Type size to the sum of

PROFIBUS Input words + 44.

In the example, there are 8 PROFIBUS input bytes, or (4) 16-bit words: 4 + 44 = 48.

For outputs, edit the Connection_Output Data Type size to the sum of PROFIBUS

Output words + 8.

In the example, there are 8 PROFIBUS output bytes, or (4) 16-bit words: 4 + 8 = 12.

3 Click APPLY, then OK.

Page 54 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 55

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

PROFIBUS Master Communication Module User Manual

User-Defined Data Type

1 Double-click on the EDIT_ILX69PBM_DATA User-Defined Data Type (UDT).

2 Edit the SINT Data Type array size to match the number of inputs and outputs assigned

to the slaves in the PROFIBUS network, as defined in the ProSoft fdt Configuration

Manager. The example uses 8 inputs and 8 outputs total.

3 Click APPLY, then OK.

4 The ILX69PBM.DATA.INPUT and OUTPUT arrays reflect the changes.

5 Save the project. The project is now ready to be downloaded to the 1769 controller.

ProSoft Technology, Inc. Page 55 of 124

February 4, 2015

Page 56

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

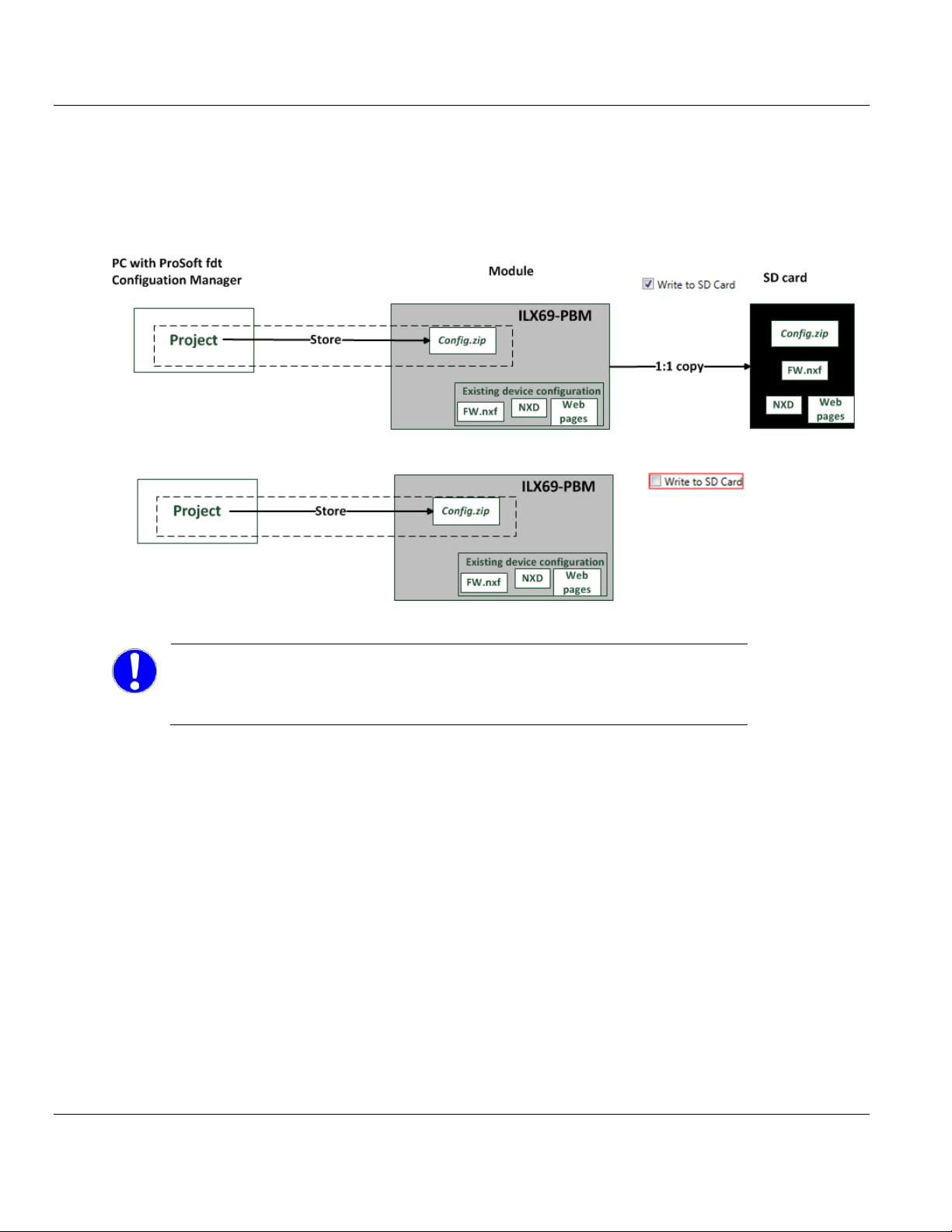

5.5 Project Storage

The ProSoft fdt Configuration Manager provides procedures to store or restore project

backup data directly to and from the ILX69-PBM internal flash memory. A 1:1 copy from the

internal flash memory data can be made to an external SD memory card inserted into the

module. The project backup data comprises of the ProSoft fdt Configuration Manager

solution files, including the GSD files used in this solution. It is zipped as a single config.zip

file.

The STORE function allows you to download the current project file with all related

information, including GSD files. These are zipped together from the PC to the internal flash

memory of the ILX69-PBM. This is allowed only if the user is logged in as Administrator

(ProSoft fdt Configuration Manager User Access Control).

The RESTORE function allows you to upload the project data to the PC. This is helpful when

the PC with the original configuration is not at your disposal. As the project backup is saved

in the device via the Restore function, you can use the diagnostics functions in the ProSoft

Configuration Manager. The functions Store, Restore and Write to an SD card are not

available for legacy projects.

Page 56 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 57

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Important:

Make a safe copy of the SD card data before you insert the SD card to the card slot.

The Store function of ProSoft fdt Configuration Manager overwrites all existing data on

the SD card.

PROFIBUS Master Communication Module User Manual

5.5.1 Store Function

If Writing to SD Card is checked (default setting) the ProSoft fdt Configuration Manager is

making a 1:1 copy from the internal flash memory to the external SD memory card. The

copy includes both the zipped ‘project backup’ and the existing device configuration files

(firmware, configuration and web pages).

5.5.2 Restore Function

Via the Restore button, you can upload the project backup data from the internal flash

memory from the ILX69-PBM to the PC. The project backup data can only be restored from

the internal flash, not from an external SD memory card.

To load the copied data from the external SD memory card to the internal flash of the ILX69PBM, you must power cycle the module.

ProSoft Technology, Inc. Page 57 of 124

February 4, 2015

Page 58

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

Lethal Electrical Shock caused by Parts with more than 50V!

HAZARDOUS VOLTAGE is present inside of a powered PLC power supply module. The

danger of a lethal electrical shock caused by parts with more than 50V may occur if you

power a PLC power supply module when its housing is open.

Strictly obey to all safety rules provided by the device manufacturer in the documentation.

Disconnect the network power (power plug) from the power supply before you disconnect

the module from the backplane.

When you disconnect the PLC module from the power supply module, use end cap

terminators and close the power supply module housing.

User Manual PROFIBUS Master Communication Module

5.5.3 Project File Backup and SD Card Handling

Using an SD memory card makes it possible to load the same configuration (plus firmware

and web pages) into multiple ILX69-PBM modules without using a PC. The memory card

must be prepared by a PC beforehand.

Restoring a configuration from an SD card can only be done when there is no backplane

communications between the ILX69-PBM and CompactLogix processor. Make sure that the

CompactLogix processor is disconnected from the power supply in order to restore a

configuration from the SD card.

Safety Precautions for the ILX69-PBM Installation

Obey to the following safety messages on personal injury when powering a disconnected

PLC power supply.

SD Memory Card

Prerequisite for Memory Cards

Maximum capacity of 4 GByte.

The memory card must be formatted in FAT format. The FAT12/16/32 formats are

supported. The exFAT format is not supported.

Memory cards of the type SD card (SD and SDHC both with SPI) can be used.

Steps to Prepare Memory Card

1 Create and save the project on a standard PC using the ProSoft fdt Configuration

Manager or open an existing project.

2 Download the configuration from the PC to the ILX69-PBM. The configuration is stored

in a non-volatile memory location within the module and will be available after power up.

3 Insert a formatted SD memory card into the SD card slot of the module.

Page 58 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 59

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Lethal Electrical Shock caused by Parts with more than 50V!

Disconnect the network power (power plug) from the power supply before you disconnect

the module from the backplane.

When you disconnect the PLC module from the power supply module, use end cap

terminators and close the power supply module housing.

Important: Make sure that there are (valid) firmware or configuration

database (NXD) files on the SD card. Otherwise, overwriting the content of

the internal flash memory will leave no (valid) firmware or configuration

database (NXD) file in the internal flash memory.

PROFIBUS Master Communication Module User Manual

4 Using the Store function in ProSoft fdt Configuration Manager, download the project into

the ILX69-PBM internal flash memory. It will also copy the configuration from the internal

flash memory to the SD memory card if the Writing to SD Card box is checked

(default).

The SD memory card will contain the following files:

• STARTUP.INI

• Firmware *.nxf

• Database files

config.nxd (network configuration for PBM)

nwid.nxd (IP address settings)

• Web pages

• Project backup file config.zip

5 Once complete, remove the SD memory card from the module.

Steps to Transfer Files from Memory Card into the ILX69-PBM

1 Insert the prepared SD memory card into the SD card slot of the ILX69-PBM until it

snaps in.

2 Reconnect the power supply module to the network power.

All files from the SD memory card are copied into the non-volatile flash memory of the

ILX69-PBM. For more information, see section Start-up Behavior with or without SD

Card (page 60).

3 For a faster power-up sequence, remove the SD memory card from the ILX69-PBM

since the copy operation is being executed again.

ProSoft Technology, Inc. Page 59 of 124

February 4, 2015

Page 60

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

5.5.4 Start-up Behavior with or without SD Card

The start-up behavior of the ILX69-PBM depends on whether an SD memory card is

inserted in the module or not.

Start-up without Memory Card

On power-up, the ILX69-PBM and the firmware are started and the configuration data is

loaded from the CompactLogix processor using the Local:x:C.Data array into the ILX69PBM internal flash memory. Depending on the amount of stored configuration data, this can

last for approximately 4 seconds.

Start-up with Memory Card

The ILX69-PBM supports firmware upgrade utilizing an optional SD card. Contact ProSoft

technical support to obtain this firmware image. Firmware can also be loaded via the ILX69PBM webpage. Configuration of the module is always obtained from the Local:x:C.Data

array from the CompactLogix processor.

On power-up, the firmware data are restored from the SD memory card flash image into the

ILX69-PBM internal flash memory only when the ILX69-PBS is not connected over the

backplane to a CompactLogix processor. The following is the power-up sequence:

After return of power, the SYS LED indicates a fast blinking in green for approximately

10 seconds. During this time the SD memory card can be removed from the module to

prevent the data transfer.

o After 10 seconds, the following files are transferred from the SD memory card into

the non-volatile flash memory of the ILX69-PBM:

• Firmware *.nxf

• Web pages

This operation takes (typically) up to 30 seconds. During this operation the SYS LED

is static yellow.

When complete, the new firmware starts automatically and the ILX69-PBM boots with

the new configuration. The COM LED illuminates or blinks as described in section

Communication Status (page 107). Connection over the backplane to the CompactLogix

processor can then be restored.

Page 60 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 61

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Note: The STARTUPINI file is automatically created if ‘Store’ and

are used. The user does not need to create this file.

PROFIBUS Master Communication Module User Manual

5.5.5 STARTUP.INI File

The STARTUP.INI file contains the following:

1 [Global]

2 Notify=10

3 Restore=always

4 RestorePoint=SDMMC:/backup

Notify=10: The value for ‘Notify’ is ‘10’. It takes 10 seconds to copy the files from the SD

memory card to the internal flash of the ILX69-PBM.

Restore=always: The second stage bootloader copies the files in any case.

RestorePoint=SDMMC:/backup: All data stored under the backup folder is copied to the

SD memory card.

5.5.6 Reset Device to Factory Settings with Memory Card

Using a memory card that has the basic firmware stored on it, the ILX69-PBM can be

restored back to factory settings.

1 Copy the STARTUP.INI file and the backup directory (including all subdirectories) from

the ProSoft Solutions DVD into the root directory of an empty memory card.

2 Prepare the memory card and reset the module to the factory settings as described in

section Project File Backup and SD Card Handling (page 58).

ProSoft Technology, Inc. Page 61 of 124

February 4, 2015

Page 62

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

User Manual PROFIBUS Master Communication Module

Page 62 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 63

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

In This Chapter

Studio 5000 PROFIBUS Data Values ....................................................63

I/O Communication and Memory Map ...................................................64

Acyclic Messaging .................................................................................82

PROFIBUS Master Communication Module User Manual

6 Communication

6.1 Studio 5000 PROFIBUS Data Values

The ILX69-PBM PROFIBUS network data values (input and output) are located in the

Controller Tags of Studio 5000.

6.1.1 PROFIBUS Network Input Data

The PROFIBUS network input data is stored in the ILX69PBM.DATA.INPUT array. All

incoming data received from the PROFIBUS slaves is stored here.

6.1.2 PROFIBUS Network Output Data

The PROFIBUS network output data is stored in the ILX69PBM.DATA.OUTPUT array. All

outgoing data from the ILX69-PBM to be sent to the PROFIBUS slaves is to be placed here.

ProSoft Technology, Inc. Page 63 of 124

February 4, 2015

Page 64

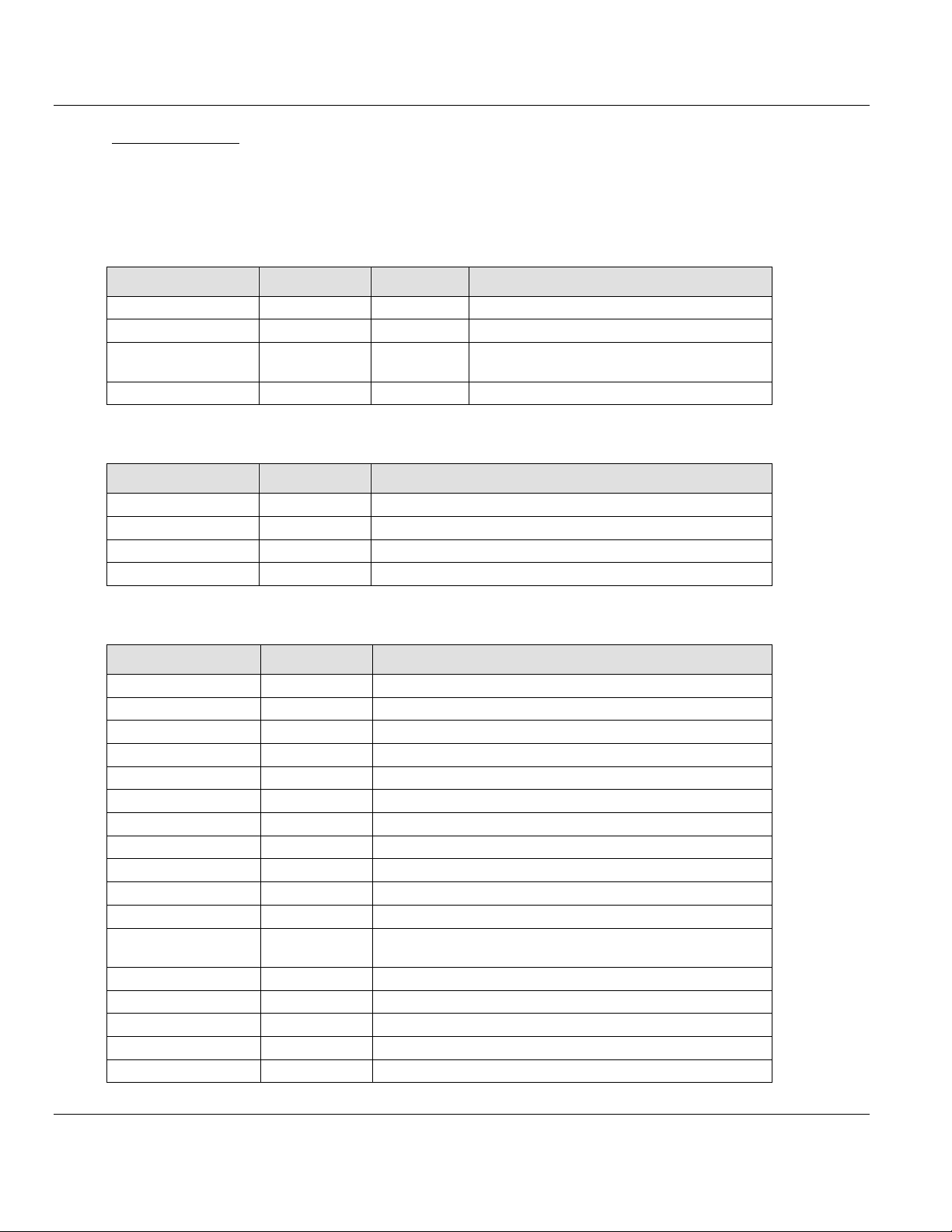

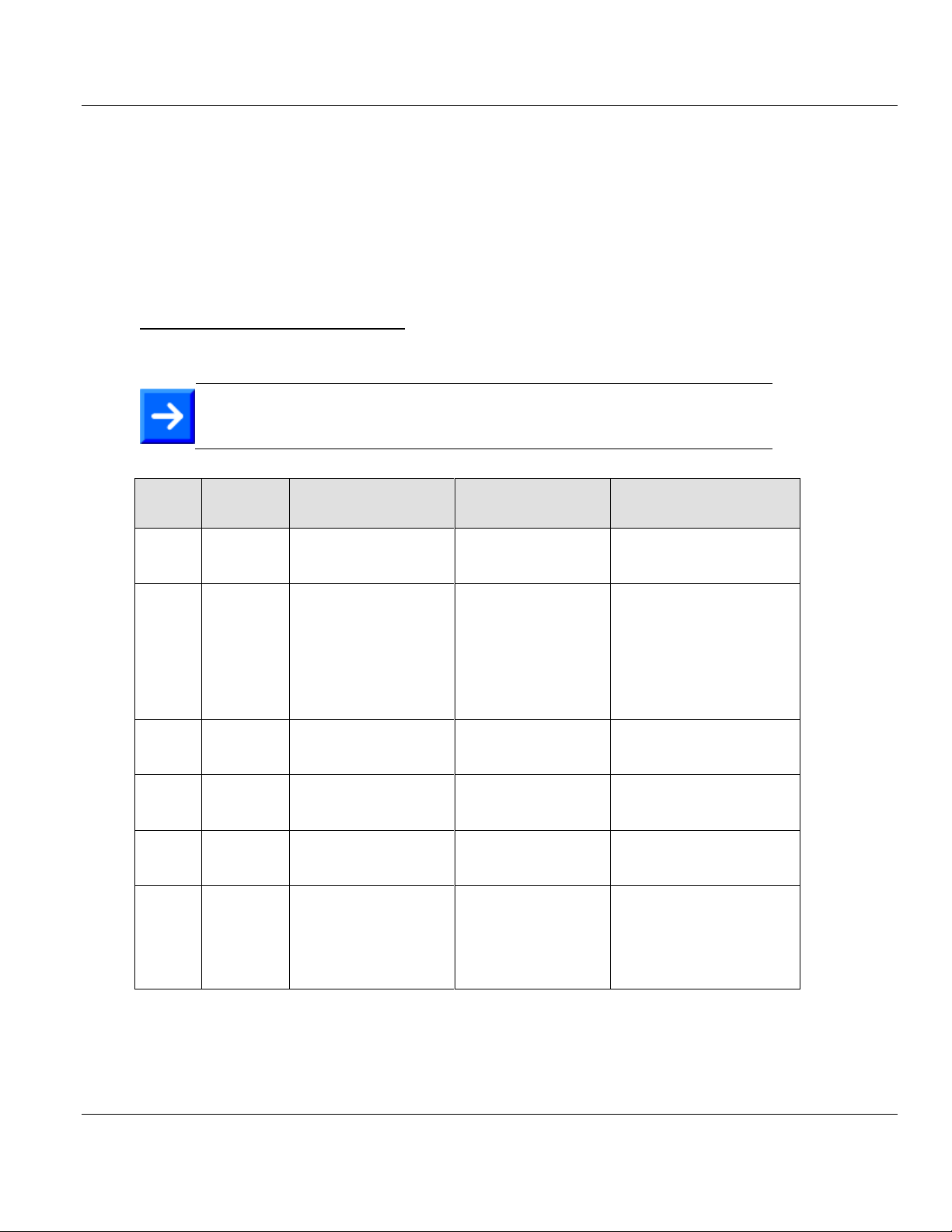

Contents ILX69-PBM ♦ CompactLogix or MicroLogix Platform

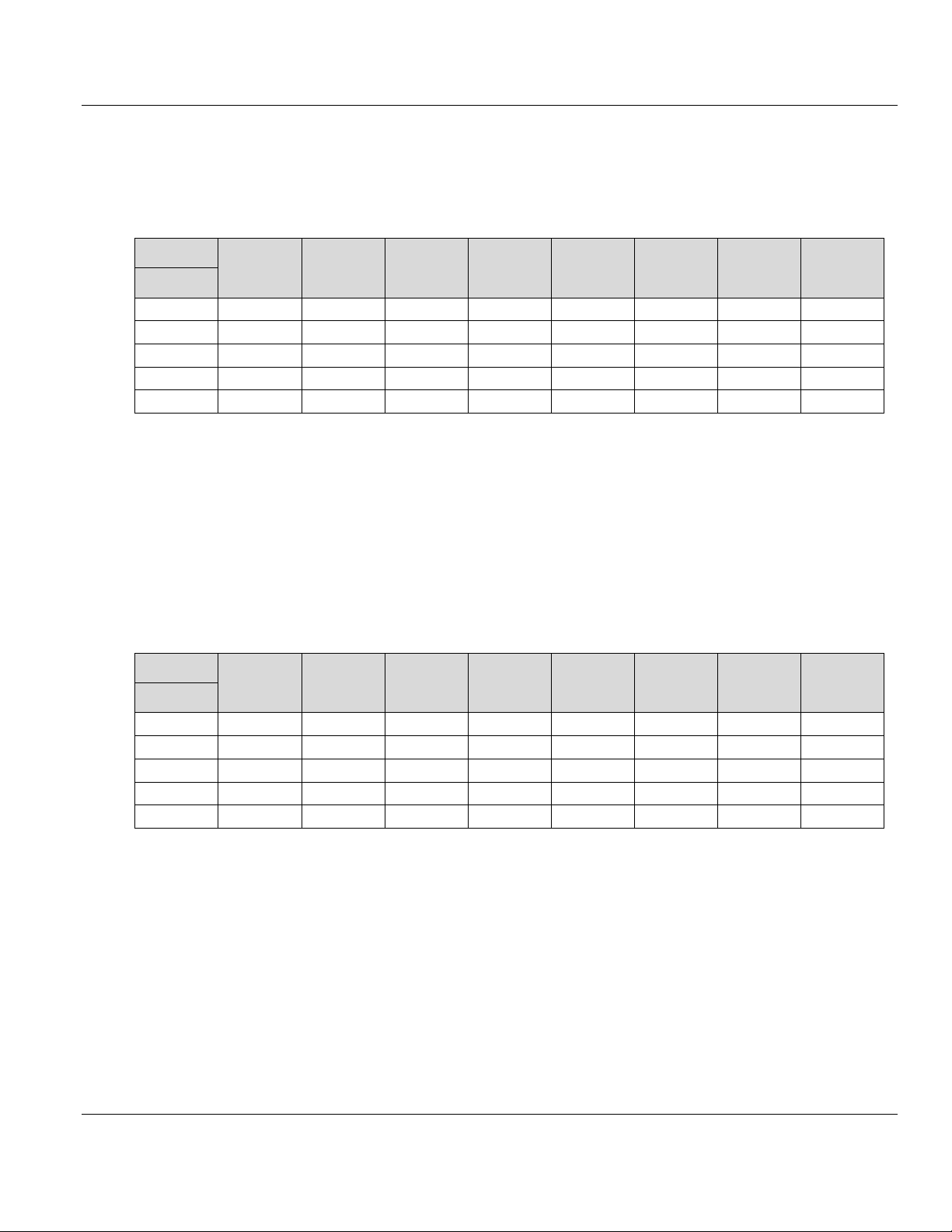

Offset

Register Type

Name

0

Status Register

Module Status Bits

1

Status Register

Handshake Acknowledge Bits

2

Status Register

Block Transfer Out

3

Status Register

Block Transfer In

4

Firmware Revision

Minor Version

5

Firmware Revision

Major Version

6

Input Block Count

Input Block Count

7

Output Block Count

Output Block Count

8

Global State Field

Global Bits

9

Global State Field

DPM_State

10

Global State Field

Reserved[14], set to 0

24 to 39

Global State Field

Sl_cfg[16]

40 to 55

Global State Field

Sl_state[16]

56 to 71

Global State Field

Sl_diag[16]

72

Slave Diagnostics Field

Slave Address

73

Slave Diagnostics Field

Slave Diag Failure

74

Slave Diagnostics Field

Station Status_1

75

Slave Diagnostics Field

Station Status_2

76

Slave Diagnostics Field

Station Status_3

77

Slave Diagnostics Field

Master Address

78 to 79

Slave Diagnostics Field

Ident Number

80

DPV1 Alarm Indication

Alarm_Status

81

DPV1 Alarm Indication

Rem_Add

82

DPV1 Alarm Indication

Alarm_Cnt

83

DPV1 Alarm Indication

Slot_Number

84

DPV1 Alarm Indication

Seq_Nr

85

DPV1 Alarm Indication

Alarm_Type

86

DPV1 Alarm Indication

Alarm_Spec

87

DPV1 Alarm Indication

Reserved, set to 0

88 to 495

PROFIBUS Input Area

Inputs[408] (5712 bytes in block transfer)

User Manual PROFIBUS Master Communication Module

6.2 I/O Communication and Memory Map

The following sections contain the I/O memory mappings of the ILX69-PBM. The I/O area is

used for communication status, command information, and cyclic I/O data.

6.2.1 I/O Arrays Overview

Input Array

Below is a summary of the register layout of the input area of the ILX69-PBM. The offset

values are defined in bytes.

Page 64 of 124 ProSoft Technology, Inc.

February 4, 2015

Page 65

ILX69-PBM ♦ CompactLogix or MicroLogix Platform Contents

Offset

Register Type

Name

0

Device Command Register

Command Bits

1

Device Command Register

Handshake Request Bits

2

Device Command Register

Block Transfer Out

3

Device Command Register

Block Transfer In

4