Page 1

ILX56-MM

ControlLogix Platform

InRAx Message Manager for

Industrial Communication

February 6, 2012

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2012 ProSoft Technology, Inc., all rights reserved.

ILX56-MM User Manual

February 6, 2012

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Important Safety Information

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Markings

CSA/cUL C22.2 No. 213-1987

CSA CB Certified IEC61010

243333

Temp Code T5

0° C <= Ta <= 60° C

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%.

D DO NOT OPEN WHEN ENERGIZED.

Electrical Ratings

Backplane Current Load: 1000 mA @ 5 V DC

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: -40 to 80°C (-40 to 176°F)

Shock: 30g Operational; 50g non-operational; Vibration: 5 g from 10 to 150 Hz

Relative Humidity 5% to 95% (non-condensing)

All phase conductor sizes must be at least 1.3 mm (squared) and all earth ground conductors must be at least

4mm (squared).

Page 4

Battery Life Advisory

This module uses a Lithium Vanadium Pentoxide battery to backup the date/time settings of the real-time clock and

the BIOS settings in CMOS. The battery recharges whenever the module is receiving power and should not need to

be replaced for the life of the module. The module must be powered for approximately twenty hours before the

battery becomes fully charged.

If the module is left in an unpowered state for approximately 21 or more days, the battery will be completely drained

and the module BIOS, date, and time will revert to their default settings. Before you remove a module from its power

source, ensure the battery is fully charged. You can tell the battery is fully charged when the Battery State (ERR) LED

is OFF.

Note: The battery is not user-replaceable.

Page 5

ILX56-MM ♦ ControlLogix Platform Contents

InRAx Message Manager for Industrial Communication User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Safety Information ............................................................................................................... 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 4

Guide to the ILX56-MM User Manual 9

1 Start Here 11

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

Overview.................................................................................................................. 12

Deployment Checklist .............................................................................................. 13

System Requirements ............................................................................................. 14

Package Contents ................................................................................................... 15

Setup Jumper .......................................................................................................... 16

Install the Module in the Rack ................................................................................. 17

Connect to the Module's Web page ........................................................................ 18

Logging In ................................................................................................................ 20

2 Administration 21

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.6.1

2.6.2

2.6.3

2.6.4

Device Information .................................................................................................. 22

Network Settings ..................................................................................................... 23

System Functions .................................................................................................... 25

Time Sync ............................................................................................................... 27

Audit Log ................................................................................................................. 29

User Administration ................................................................................................. 30

Security.................................................................................................................... 31

Adding a New User ................................................................................................. 32

Editing an Existing User .......................................................................................... 33

Deleting a User ........................................................................................................ 34

Scanner Modes ....................................................................................................... 35

3 Configure the ILX56-MM module 37

3.1

3.2

3.2.1

3.2.2

3.2.3

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.4

3.4.1

Editing Configuration Objects .................................................................................. 39

Interfaces and Devices ............................................................................................ 40

Allen-Bradley PLCs ................................................................................................. 41

Siemens Step 7 (S7) PLCs ..................................................................................... 45

Modbus TCP/IP (Schneider Electric Quantum PLCs) ............................................. 46

Tags ......................................................................................................................... 49

ControlLogix, CompactLogix, FlexLogix .................................................................. 50

PLC5, MicroLogix and SLC ..................................................................................... 51

Schneider Electric Quantum PLCs .......................................................................... 52

Siemens S7 ............................................................................................................. 53

Transfer Lists ........................................................................................................... 55

Data Conversion During Transfers .......................................................................... 55

ProSoft Technology, Inc. Page 5 of 112

February 6, 2012

Page 6

Contents ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

3.4.2

3.5

3.6

3.7

3.8

3.4.3

3.5.1

3.5.2

3.5.3

Editing Transfer Lists .............................................................................................. 56

Execution of Transfer Lists ..................................................................................... 56

Triggers ................................................................................................................... 57

Hysteresis Example ................................................................................................ 58

Range Example ...................................................................................................... 58

Trigger Scanning .................................................................................................... 58

Saving the Configuration ........................................................................................ 59

Reloading the Configuration ................................................................................... 60

Resetting the Configuration .................................................................................... 61

4 Verify Communication 63

4.1

4.2

4.3

Viewing Data Transfer Statistics in the ILX56-MM Module .................................... 64

Viewing Trigger Statistics in the ILX56-MM Module ............................................... 65

Viewing Controller Tags .......................................................................................... 66

5 Diagnostics and Troubleshooting 67

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

Cannot Log in.......................................................................................................... 68

Setup Mode ............................................................................................................. 69

Status ...................................................................................................................... 70

Device Status .......................................................................................................... 70

Runtime Status ....................................................................................................... 71

Tranferring Diagnostic Information from MM to a Controller on the Network ......... 76

Event Logs .............................................................................................................. 79

Chassis Status ........................................................................................................ 80

Resource Status ..................................................................................................... 81

6 Reference 83

6.1

6.1.1

6.1.2

6.1.3

6.1.4

6.1.5

6.1.6

6.2

6.3

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

6.3.6

6.3.7

6.3.8

6.4

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

Product Specifications ............................................................................................ 84

Functional Overview ............................................................................................... 84

Triggers ................................................................................................................... 84

Transfer Lists .......................................................................................................... 86

Data Transfer .......................................................................................................... 86

Bridging ................................................................................................................... 87

Configuration Editor ................................................................................................ 87

Tag Filters ............................................................................................................... 88

Base Data Type Conversion Rules ........................................................................ 90

Boolean ................................................................................................................... 90

INT8, UINT8, CHAR, or BYTE ................................................................................ 90

INT16, UINT16, or WORD ...................................................................................... 91

INT32, UINT32, or DWORD ................................................................................... 91

INT64, UINT64, or QWORD ................................................................................... 92

Float32 .................................................................................................................... 92

Float64 .................................................................................................................... 92

String ....................................................................................................................... 93

Errors ...................................................................................................................... 94

Level 0: Permanent Errors ...................................................................................... 94

Level 1: Clearable Errors ........................................................................................ 95

Level 2: Warnings ................................................................................................... 95

Level 3: Informational Events ................................................................................. 95

Level 4 Verbose Informational Events .................................................................... 95

Page 6 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 7

ILX56-MM ♦ ControlLogix Platform Contents

InRAx Message Manager for Industrial Communication User Manual

6.4.6

6.4.7

6.4.8

Operation of Transfer Status ................................................................................... 96

Commonly Posted Context Strings ....................................................................... 102

Clearing the Error Counts...................................................................................... 102

7 Support, Service & Warranty 103

Contacting Technical Support ......................................................................................................... 103

7.1

7.2

7.1.1

7.1.2

7.1.3

7.2.1

7.2.2

7.2.3

7.2.4

7.2.5

7.2.6

7.2.7

7.2.8

7.2.9

7.2.10

Return Material Authorization (RMA) Policies and Conditions.............................. 105

Returning Any Product .......................................................................................... 105

Returning Units Under Warranty ........................................................................... 106

Returning Units Out of Warranty ........................................................................... 106

LIMITED WARRANTY ........................................................................................... 107

What Is Covered By This Warranty ....................................................................... 107

What Is Not Covered By This Warranty ................................................................ 108

Disclaimer Regarding High Risk Activities ............................................................ 108

Intellectual Property Indemnity .............................................................................. 109

Disclaimer of all Other Warranties ........................................................................ 109

Limitation of Remedies ** ...................................................................................... 110

Time Limit for Bringing Suit ................................................................................... 110

No Other Warranties ............................................................................................. 110

Allocation of Risks ................................................................................................. 110

Controlling Law and Severability ........................................................................... 110

Index 111

ProSoft Technology, Inc. Page 7 of 112

February 6, 2012

Page 8

Contents ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

Page 8 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 9

ILX56-MM ♦ ControlLogix Platform Guide to the ILX56-MM User Manual

InRAx Message Manager for Industrial Communication User Manual

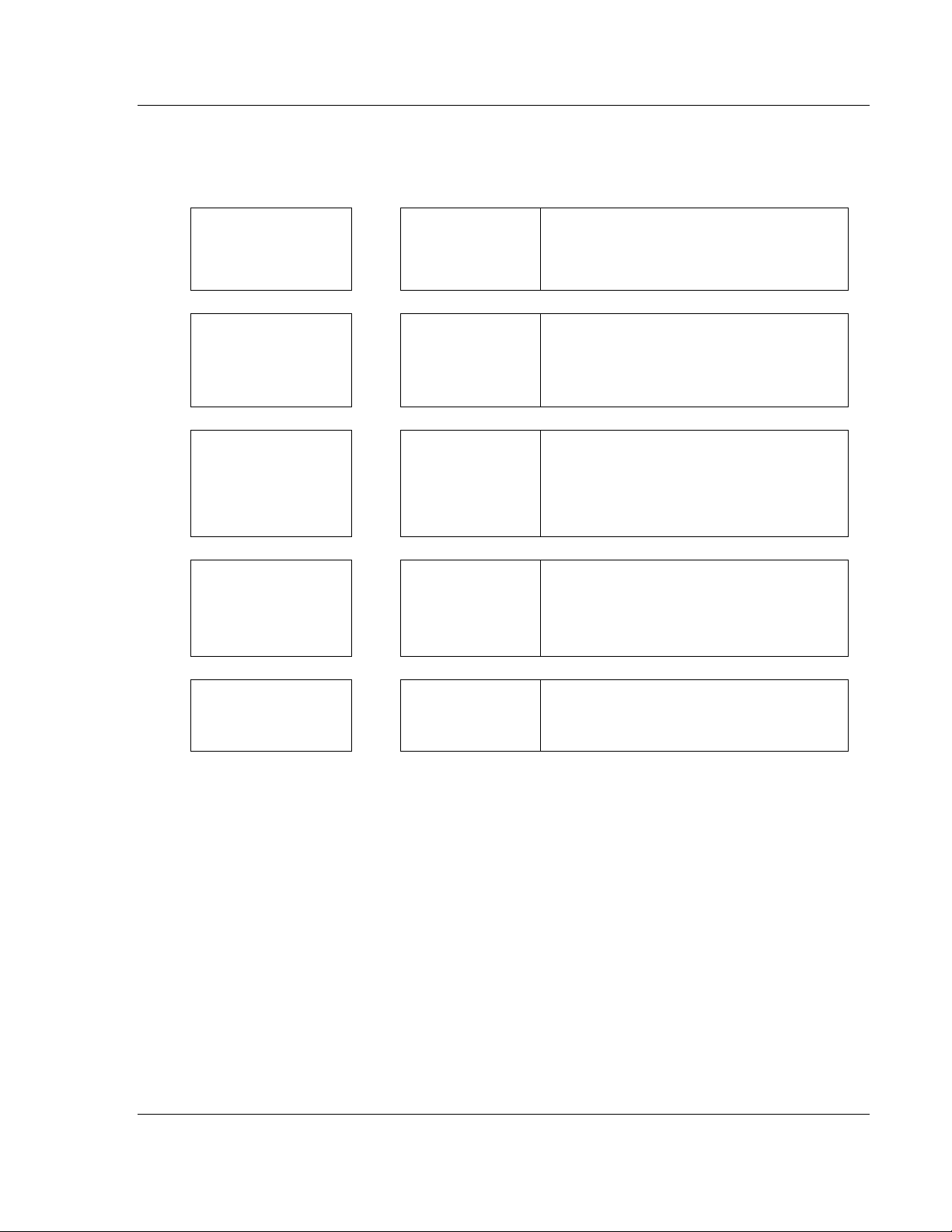

Guide to the ILX56-MM User Manual

Function Section to Read Details

Introduction

(Must Do)

Logging In,

Administration and

Module Configuration

Verify Communication

Diagnostic and

Troubleshooting

Reference

Product Specifications

Functional Overview

Glossary

Support, Service, and

Warranty

Index

→

→

→

→

→

Start Here (page 10) This Section introduces the customer to the

module. Included are: package contents,

system requirements, and hardware installation.

Logging In (page 20)

Administration (page

21)

Configuration (page

37)

Verifying

Communication

(page 63)

Diagnostics and

Troubleshooting

(page 67)

Reference (page 83)

Functional Overview

Product

Specifications

Support, Service

and Warranty (page

103)

This section describes how to log in, how to

administer the module, and how to configure

the module.

This section describes how to verify

communications with the network. Diagnostic

and Troubleshooting procedures.

These sections contain general references

associated with this product, Specifications, and

the Functional Overview.

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 9 of 112

February 6, 2012

Page 10

Guide to the ILX56-MM User Manual ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

Page 10 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 11

ILX56-MM ♦ ControlLogix Platform Start Here

InRAx Message Manager for Industrial Communication User Manual

1 Start Here

In This Chapter

Overview ............................................................................................... 12

Deployment Checklist ............................................................................ 13

System Requirements ........................................................................... 14

Package Contents ................................................................................. 15

Setup Jumper ........................................................................................ 16

Install the Module in the Rack ............................................................... 17

Connect to the Module's Web page ....................................................... 18

Logging In .............................................................................................. 20

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module and safely connect

Message Manager and ControlLogix devices to a power source and to the

ILX56-MM module's application ports

Caution: You must be able to complete the application without exposing personnel or

equipment to unsafe or inappropriate working conditions.

ProSoft Technology, Inc. Page 11 of 112

February 6, 2012

Page 12

Start Here ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

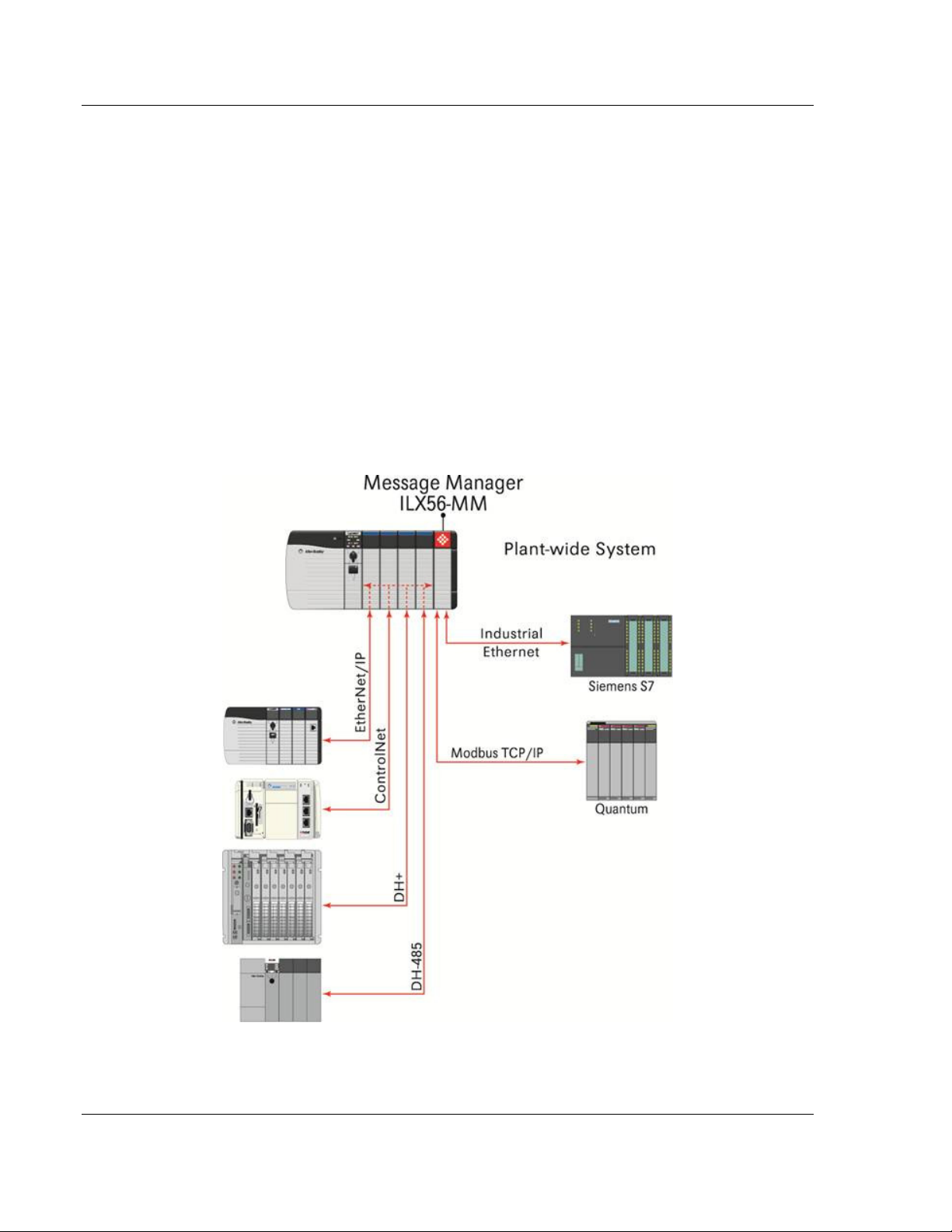

1.1 Overview

The ILX56-Message Manager is a communications interface that can be installed

in a Rockwell Automation® ControlLogix® 1756 chassis to provide data transfer

functionality between automation systems based on a diverse range of

controllers and processors. Supported systems include:

Rockwell Automation (RA) ControlLogix Programmable Automation Controller

(PAC) systems

RA CompactLogix™ (CPLX) PAC systems

Allen-Bradley® (A-B) PLC5® systems

A-B SLC™ systems

A-B MicroLogix™ systems

Siemens Step 7® systems with Industrial Ethernet communications (does not

support configured TSAP connections)

Schneider Electric® Quantum™ PLC systems with Modbus TCP/IP

communications

Any devices that support Modbus TCP/IP Protocol

Page 12 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 13

ILX56-MM ♦ ControlLogix Platform Start Here

InRAx Message Manager for Industrial Communication User Manual

1.2 Deployment Checklist

Before you begin configuring the module, consider the following questions. Your

answers will help you determine the scope of your project and the configuration

requirements for a successful deployment.

1 ____________ Will the ILX56-MM require a static IP address for either or

both Ethernet ports, or will it obtain IP address(es) from a DHCP Server?

Obtain IP address information from your Network Administrator, and then

record the IP Address settings in the following table:

Ethernet Ports Port 1 Port 2

DHCP? (Yes/No)

Static IP Address

Subnet Mask

Default Gateway

2 ____________ How many controllers and processors will be exchanging data

in your application?

3 ____________ What kinds of processors need to be linked for your

application?

4 ____________ What network protocols are used for the links?

5 ____________ What types of user accounts do you need to create? Users

(to modify configurations) or Administrators (to control configuration access)

6 ____________ Which data transfers should happen on a regular timed-

interval basis? Which transfers should happen only on data change or logic

events?

7 ____________ Do you need controllers or other communications modules

installed in the same chassis as the ILX56-MM?

ProSoft Technology, Inc. Page 13 of 112

February 6, 2012

Page 14

Start Here ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

1.3 System Requirements

The ILX56-MM module requires the following minimum hardware and software

components:

Rockwell Automation® ControlLogix™ processor, with compatible power

supply and one free slot in the rack for the ILX56-MM module. The module

requires 1 Amp of available 5 VDC power

Rockwell Automation RSLogix 5000 programming software version 16 or

higher

Rockwell Automation RSLinx communication software version 2.51 or higher

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or higher)

recommended

Supported operating systems:

o

Microsoft Windows Vista

o

Microsoft Windows XP Professional with Service Pack 1 or 2

o

Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o

Microsoft Windows Server 2003

Microsoft Internet Explorer version 7, or higher. Other web browsers are not

supported at this time

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 × 768 recommended)

CD-ROM drive

Note: The Hardware and Operating System requirements in this list are the minimum

recommended to install and run software provided by ProSoft Technology. Other third party

applications may have different minimum requirements. Refer to the documentation for any third

party applications for system requirements.

Page 14 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 15

ILX56-MM ♦ ControlLogix Platform Start Here

InRAx Message Manager for Industrial Communication User Manual

1.4 Package Contents

The following components are included with your ILX56-MM module, and are all

required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

Qty. Part Name Part Number Part Description

1 ILX56-MM Module ILX56-MM InRAx Message Manager for Industrial

1 ProSoft Solutions CD CD-014 Contains sample programs, utilities, and

1 Cable RL-CBL025 5 foot Ethernet Straight-Through Cable

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

Communication

documentation for the ILX56-MM module.

(Gray)

ProSoft Technology, Inc. Page 15 of 112

February 6, 2012

Page 16

Start Here ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

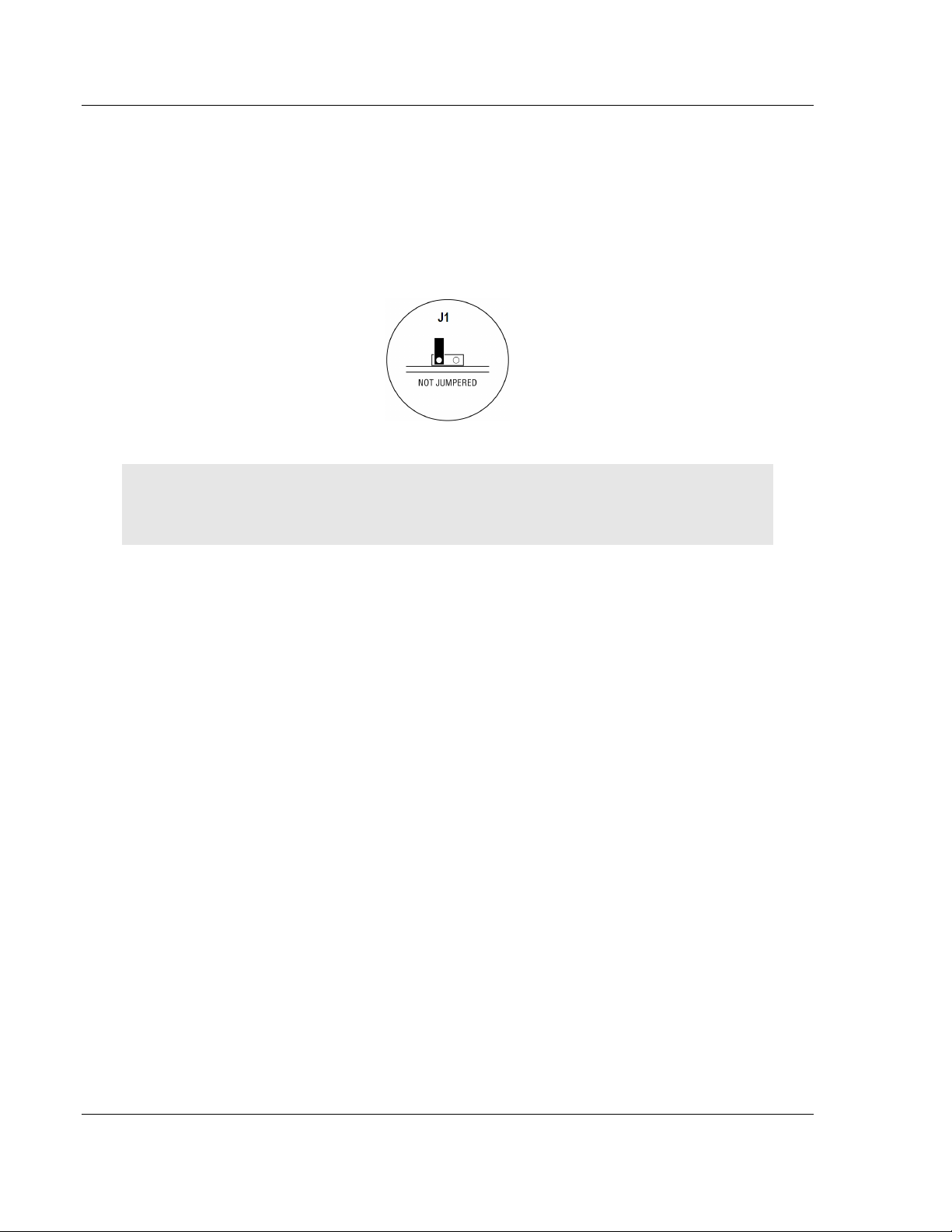

1.5 Setup Jumper

There is one S

Setup Jumper acts as "write protection" for the module's firmware. In "write

protected" mode, the Setup pins are not connected, and the module's firmware

cannot be overwritten.

The following illustration shows the ILX56-MM jumper configuration, with the

Setup Jumper OFF.

If you need to update the firmware, apply the Setup jumper to both pins.

Note: If you are installing the module in a remote rack, you may prefer to leave the Setup pins

jumpered. That way, you can update the module's firmware without requiring physical access to the

module.

ETUP JUMPER

located on the back of the module, labeled J1. The

Page 16 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 17

ILX56-MM ♦ ControlLogix Platform Start Here

InRAx Message Manager for Industrial Communication User Manual

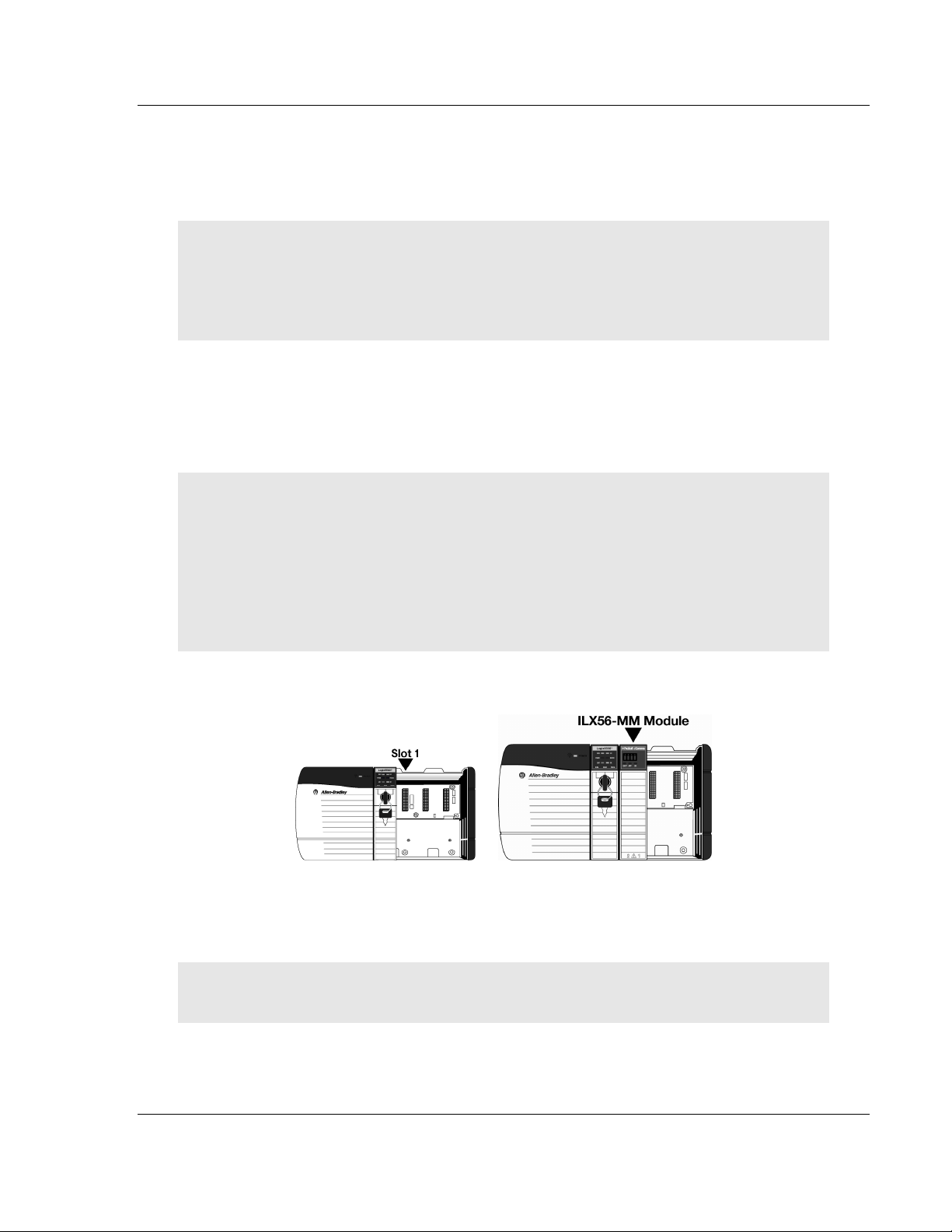

1.6 Install the Module in the Rack

If you have not already installed and configured your ControlLogix processor and

power supply, please do so before installing the ILX56-MM module. Refer to your

Rockwell Automation product documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures are in place before installing or servicing the

device.

After you have checked the placement of the jumper, insert ILX56-MM into the

ControlLogix chassis. Use the same technique recommended by Rockwell

Automation to remove and install ControlLogix modules.

You can install or remove ControlLogix system components while chassis power

is applied and the system is operating. However, please note the following

warning.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can occur. An electrical arc can cause personal injury or property damage by:

sending an erroneous signal to your system's actuators causing unintended machine motion or

loss of process control

causing an explosion in a hazardous environment

Verify that power is removed or the area is non-hazardous before proceeding. Repeated electrical

arcing causes excessive wear to contacts on both the module and its mating connector. Worn

contacts may create electrical resistance that can affect module operation.

1 Align the module with the top and bottom guides, and then slide it into the

rack until the module is firmly against the backplane connector.

2 With a firm but steady push, snap the module into place.

3 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

4 Turn power ON.

Note: If you insert the module improperly, the system may stop working, or may behave

unpredictably.

ProSoft Technology, Inc. Page 17 of 112

February 6, 2012

Page 18

Start Here ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

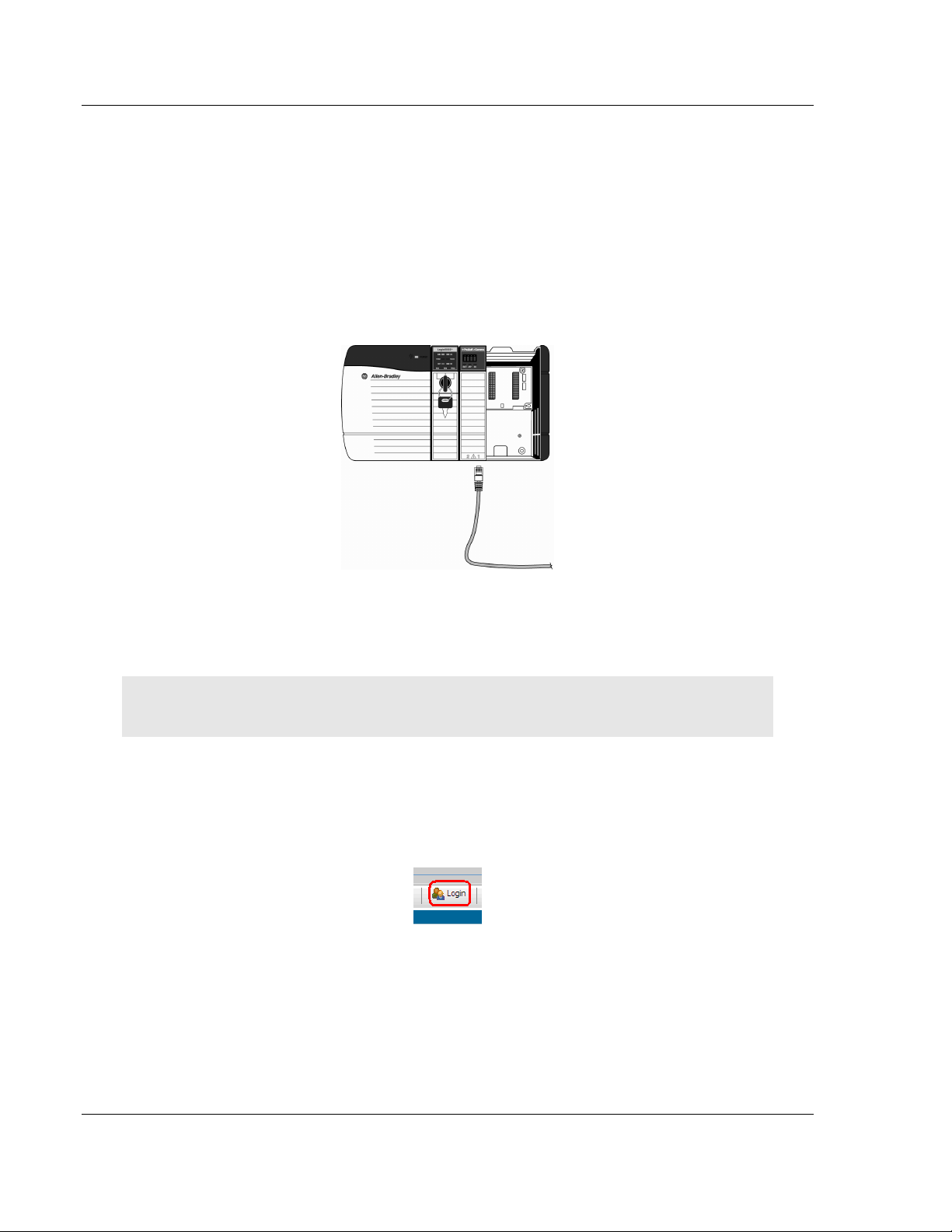

1.7 Connect to the Module's Web page

If your network is configured to use IP addresses in the range 192.168.1.xxx,

open Microsoft Internet Explorer (version 7, or higher), and connect to the

following address:

http://192.168.1.254

If your network is configured to use a different IP range, follow these steps:

1 Disconnect your PC from the network

2 Connect the Ethernet cable between the Ethernet port on your PC and Port 1

on the module

3 Temporarily change the IP address and Subnet Mask on your PC to match

the network configuration on the module:

IP address: 192.168.1.1

Subnet mask: 255.255.255.0

Important: Make a note of your IP Address settings. You will need to restore these settings before

you reconnect to the network.

4 Open Microsoft Internet Explorer (version 7, or higher) and connect to the

following address:

http://192.168.1.254

5 Click the L

OGIN

button at the bottom of the screen, and use the following

username and password to login.

Username:

Password:

6 Click the A

admin

admin

DMINISTRATION

tab, and then the N

ETWORK

tab. Configure the IP

Address, Subnet Mask, and Default Gateway to work with your network.

7 Click the S

AVE

button to apply the updated settings.

8 Change the IP Address and Subnet Mask settings on your PC back to their

original values, and then reconnect your PC to the network.

Page 18 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 19

ILX56-MM ♦ ControlLogix Platform Start Here

InRAx Message Manager for Industrial Communication User Manual

9 Connect to the module's web page again at the module's new IP address.

The following table describes the default Ethernet port configuration and login

information.

Factory Default settings

Ethernet Ports:

IP: 192.168.1.254. DHCP

User Name: admin

Password: admin

Port 1 Port 2

Important: The User Name and Password are case-sensitive.

ProSoft Technology, Inc. Page 19 of 112

February 6, 2012

Page 20

Start Here ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

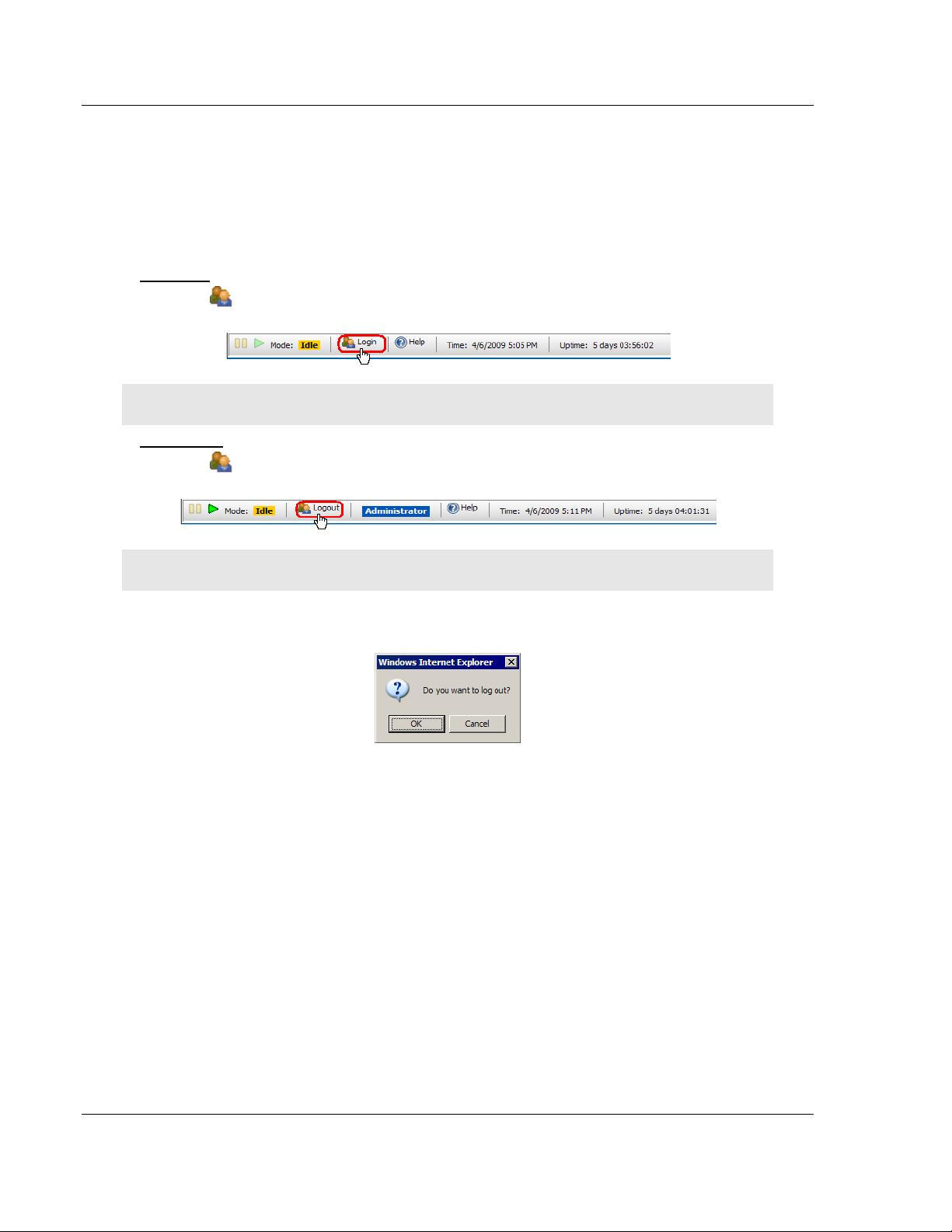

1.8 Logging In

You can view the status and configuration of the ILX56-MM module without

logging in. However, to modify the module's configuration, or to perform

maintenance tasks, you must log in.

The L

OGIN

and L

module's web page.

To Log In

Click the L

Note: Only one user can be logged into the module at a time.

To Log Out

Click the L

OGOUT

OGIN

OGOUT

buttons are located in the status bar at the bottom of the

button on the status bar at the bottom of the page.

button on the status bar at the bottom of the page.

Note: When you close the browser, you are automatically logged out of the module.

If you attempt to log out of the module without saving changes that you have

made, you are prompted to save or cancel the changes.

Click OK to save the changes. Click C

saving.

ANCEL

to discard the changes without

Page 20 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 21

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

2 Administration

In This Chapter

Device Information ................................................................................ 22

Network Settings ................................................................................... 23

System Functions .................................................................................. 25

Time Sync ............................................................................................. 27

Audit Log ............................................................................................... 29

User Administration ............................................................................... 30

Scanner Modes ..................................................................................... 35

The A

DMINISTRATION

The following table describes the tabs on the Administration page.

Tab Function

Device Configure device information.

Network Configure the network ports.

System Execute system functions.

Time Sync Configure the time on the module

Audit Log View the audit log. The audit log consists of system operational events that

Users Create and manage user accounts.

page allows you to view or modify administration functions.

Configure time synchronization for the controllers.

have occurred since the module was first started. For example, whenever

the system mode is changed from run to idle or idle to run, this event will be

in the log.

You must be logged in with Administrator privilege to view this tab.

Note: You must be logged on as a user with Administrator privilege to modify the settings on this

page.

See also Security (page 31).

ProSoft Technology, Inc. Page 21 of 112

February 6, 2012

Page 22

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

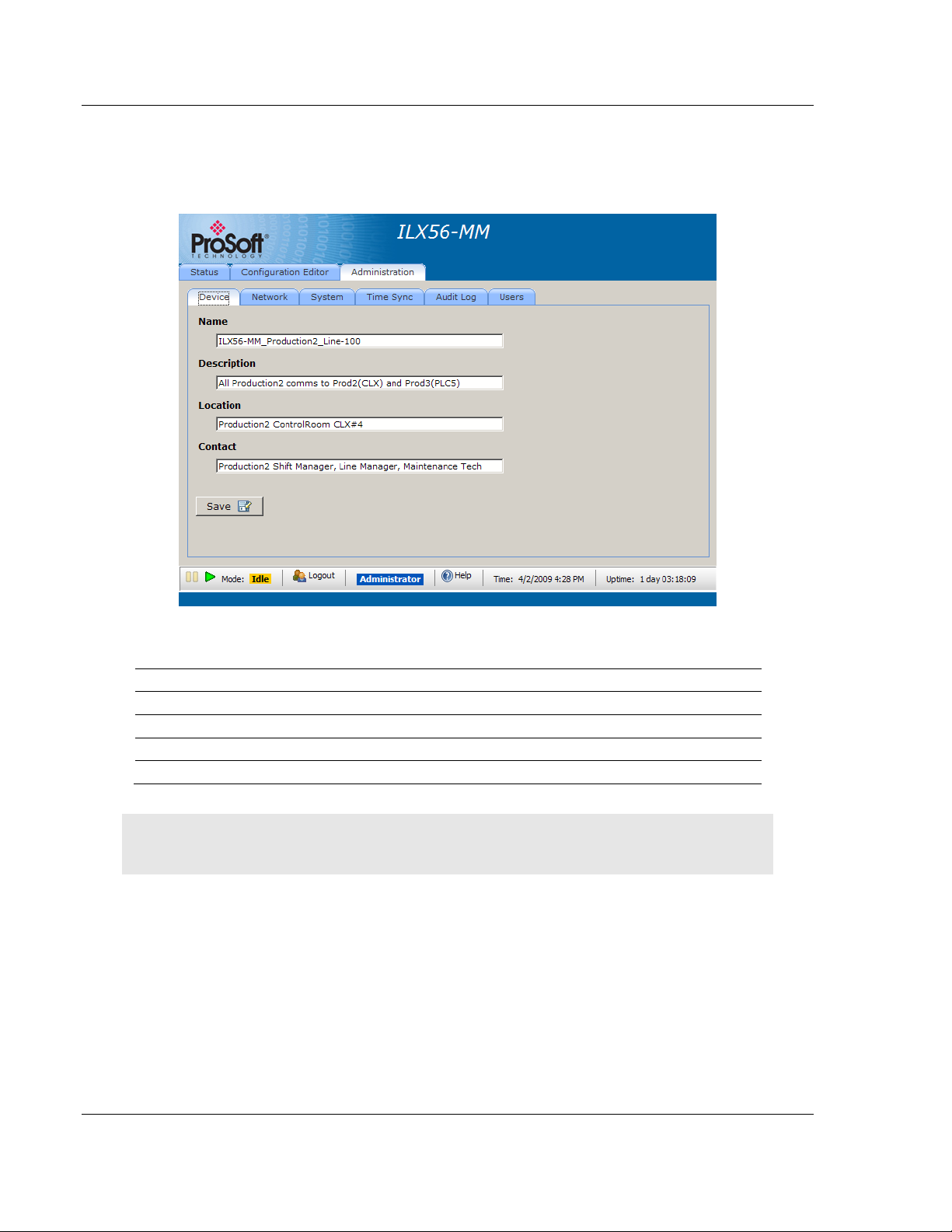

2.1 Device Information

To open the D

click the D

EVICE

EVICE INFORMATION

tab.

page, click the A

DMINISTRATION

tab, and then

The following table describes the fields on the D

EVICE INFORMATION

tab. The

values you enter here are displayed on the Device Status page (page 70).

Field Description

Name Name of the module.

Description Description of the module.

Location Location of the module.

Contact The person responsible for the module.

Click the S

AVE

button to save your changes.

Note: You must be logged on as a user with Administrator privilege to modify the settings on this

page.

See also Administration (page 21).

Page 22 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 23

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

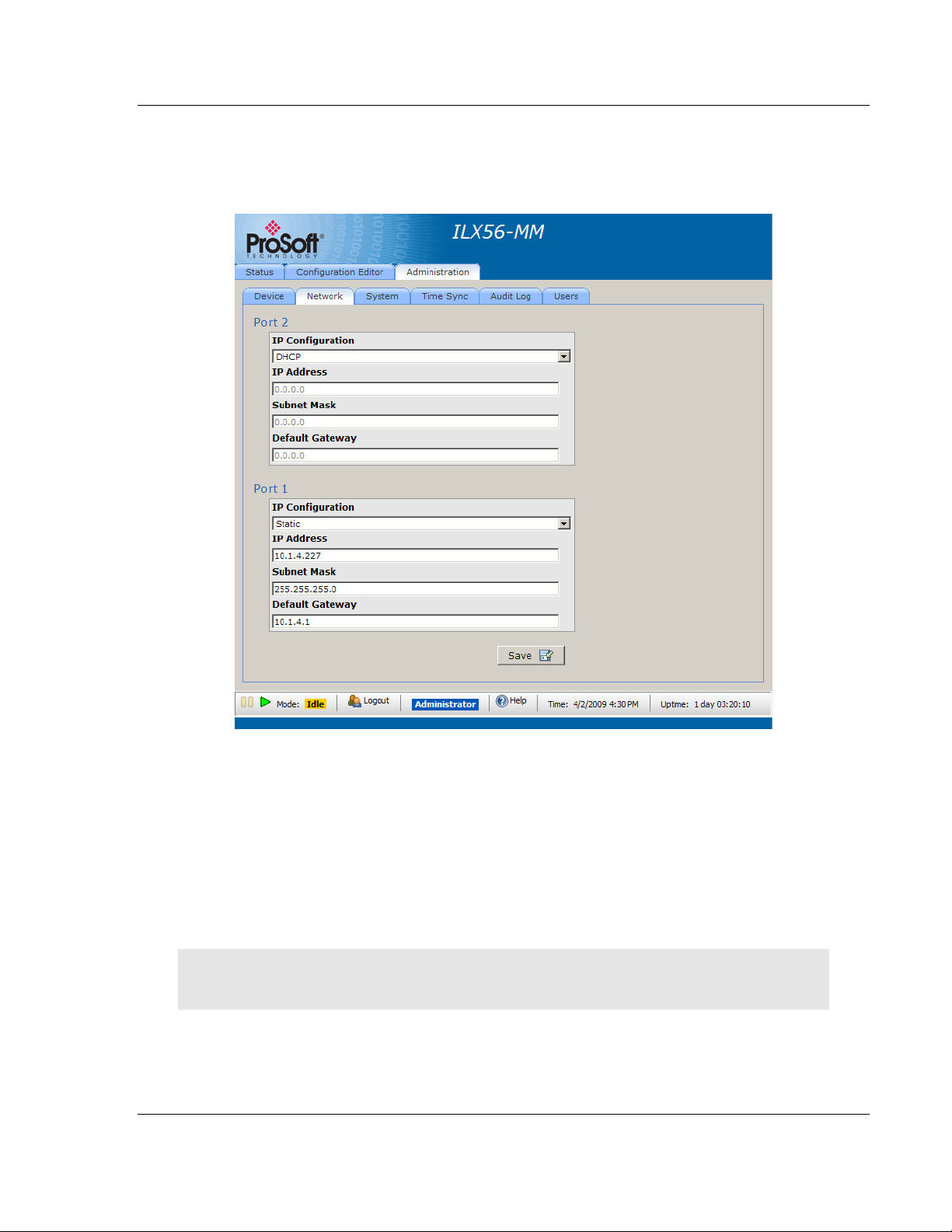

2.2 Network Settings

To open the N

click the N

ETWORK

ETWORK SETTINGS

tab.

page, click the A

DMINISTRATION

tab, and then

The module has two RJ45 Ethernet ports, located at the bottom of the front panel

on the module. You can configure the following settings for each port.

Disabled

Static IP Address

o

Subnet Mask

o

Default Gateway (optional)

DHCP (auto-configured through a DHCP server)

Click the S

AVE

button to update these settings on the module.

Note: The only way to use both ports on the same subnet or Ethernet is to use a redundant wire

solution. Without this each port must be on a separate Ethernet network.

ProSoft Technology, Inc. Page 23 of 112

February 6, 2012

Page 24

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

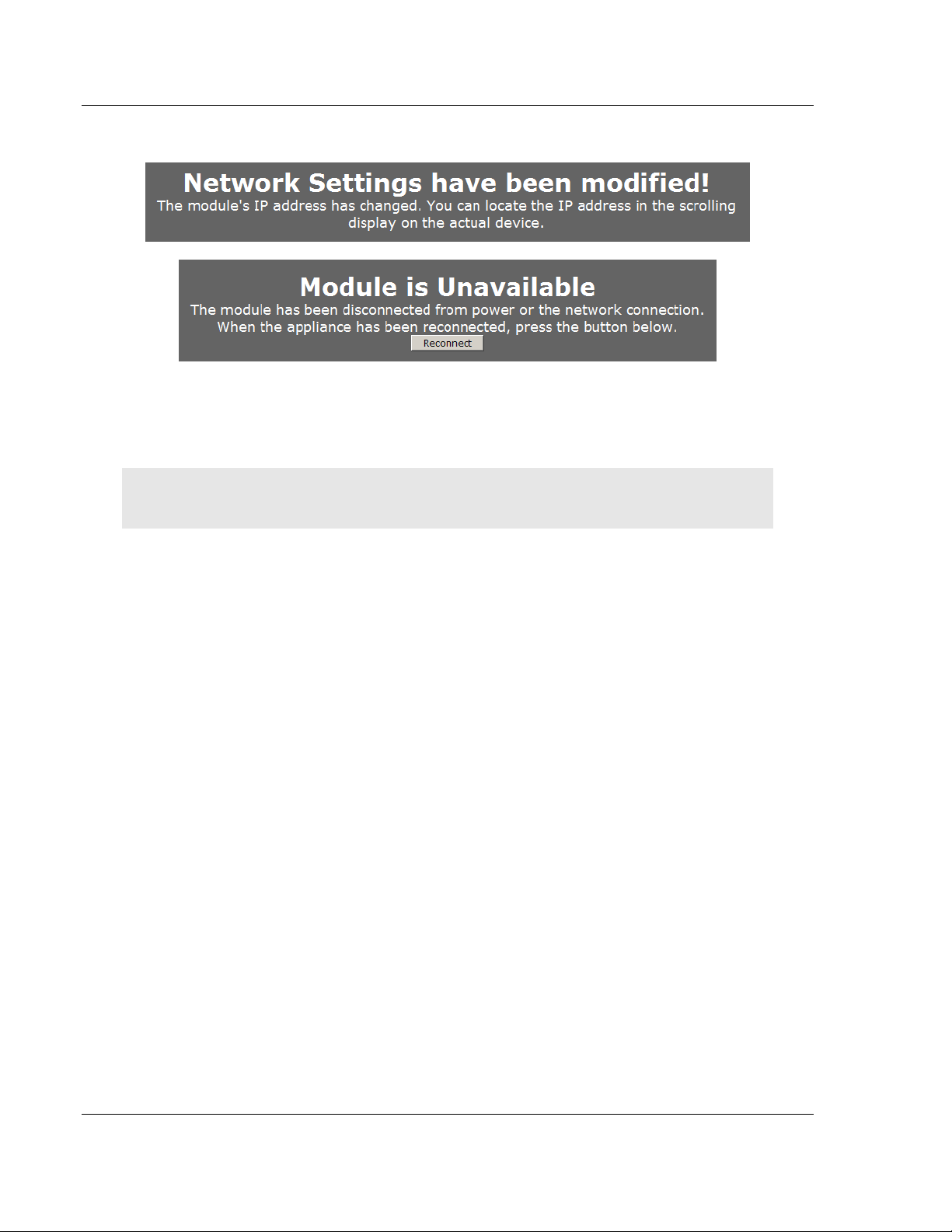

When you save the network settings, the module will log you out.

Click the R

ECONNECT

button, or press [F5] to reconnect to the module.

If you lose connection with the module, you can put the module in Setup Mode to

temporarily set the network port settings back to the default values (page 16).

This will allow you to connect to the module and correct the network settings.

Note: You must be logged on as a user with Administrator privilege to modify the settings on this

page.

Page 24 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 25

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

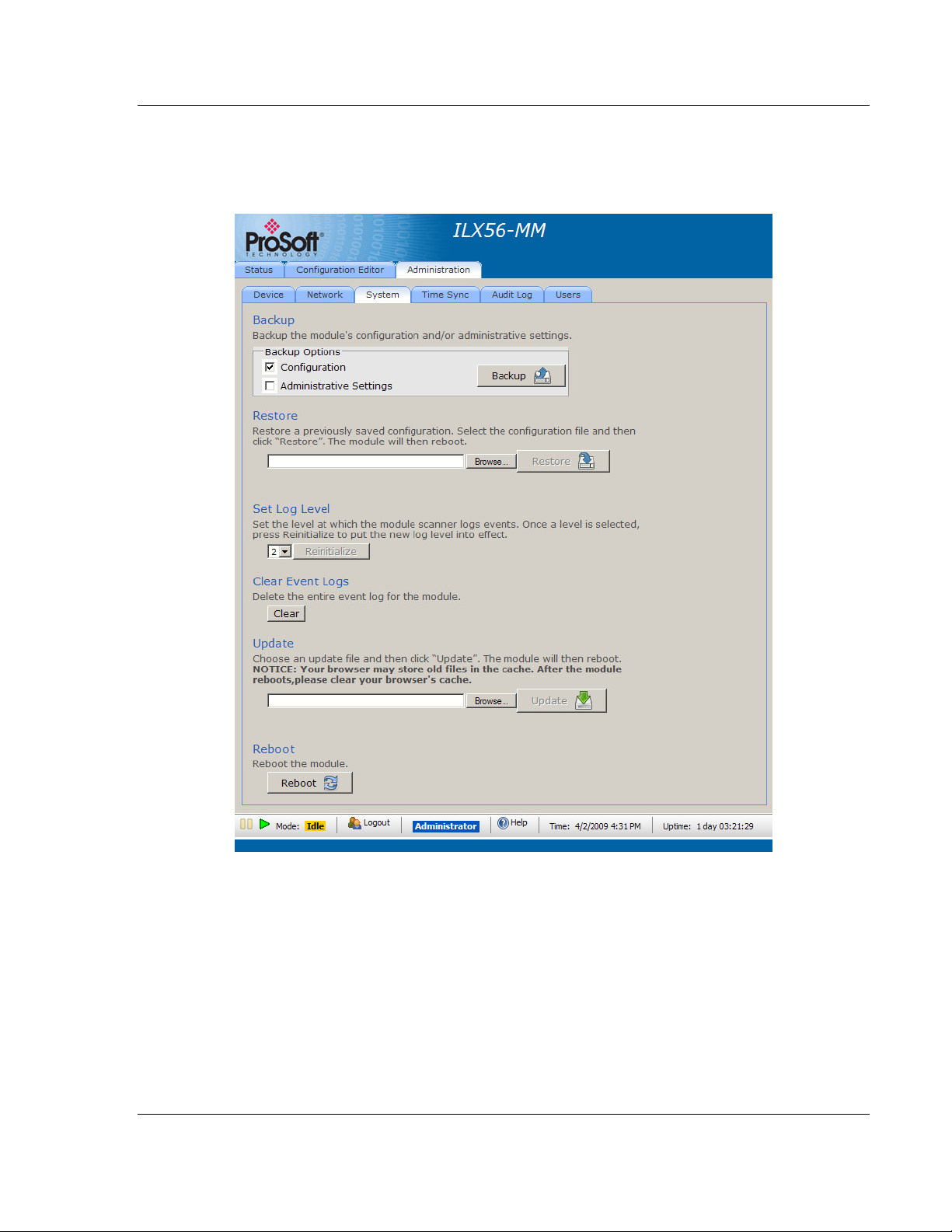

2.3 System Functions

To open the S

click the S

YSTEM

YSTEM FUNCTIONS

tab.

page, click the A

DMINISTRATION

tab, and then

ProSoft Technology, Inc. Page 25 of 112

February 6, 2012

Page 26

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

System functions you can execute on the module include

Function Description

Backup Choose which settings from the module you would like to backup by

checking C

B

ACKUP

ONFIGURATION

and/or A

DMINISTRATIVE SETTINGS

. Then click the

button to backup the current module configuration(s) to a file on

your computer.

A

DMINISTRATIVE SETTINGS

backs up all module configuration settings,

including network settings, device name, and so on.

C

ONFIGURATION

backs up the only the information that pertains to the

transfer of data. You can then use this backup file to configure another

module with the same settings.

Restore

Click the B

ROWSE

button to select a previously saved configuration file

from your computer.

Click the R

ESTORE

button to restore the module to the state saved in the

configuration file.

The module is rebooted after the configuration is restored. You will be

prompted to confirm the configuration restore and reboot.

Set Log Level Set the log level at which the scanner module will record events.

Level 1 logs errors only. This is the recommended setting for most

applications.

Levels 2 through 4 log informational events in increasing detail. Use

these levels for troubleshooting and support.

Level 0 logs only internal system errors.

The scanner must be restarted before the new log level will take effect.

Click the R

EINITIALIZE

button to restart the scanner. You will be prompted

to confirm the reinitialize.

Clear Event Logs Clears the entire Event Log from the module. This cannot be undone.

Update

You can update the module's firmware from this page. You should only

update the firmware if you have been directed to do so by ProSoft

Technical Support.

Click the B

ROWSE

button to select the firmware file on your computer.

Firmware files have the file extension "fwa".

Click the U

PDATE

button to perform the update on the module. You will be

prompted to confirm the update.

IMPORTANT: Do not cycle power or disconnect the

Ethernet cable until the update is complete.

Important: You must clear your browser's cache (Tools/Delete Browsing

History/Temporary Internet Files) after rebooting the module to ensure

the old pages have been cleared from your browser's memory.

Reboot

Click the R

confirm the reboot.

EBOOT

button to reboot the module. You will be prompted to

Note: You must be logged on as a user with Administrator privilege to modify the settings on this

page.

Page 26 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 27

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

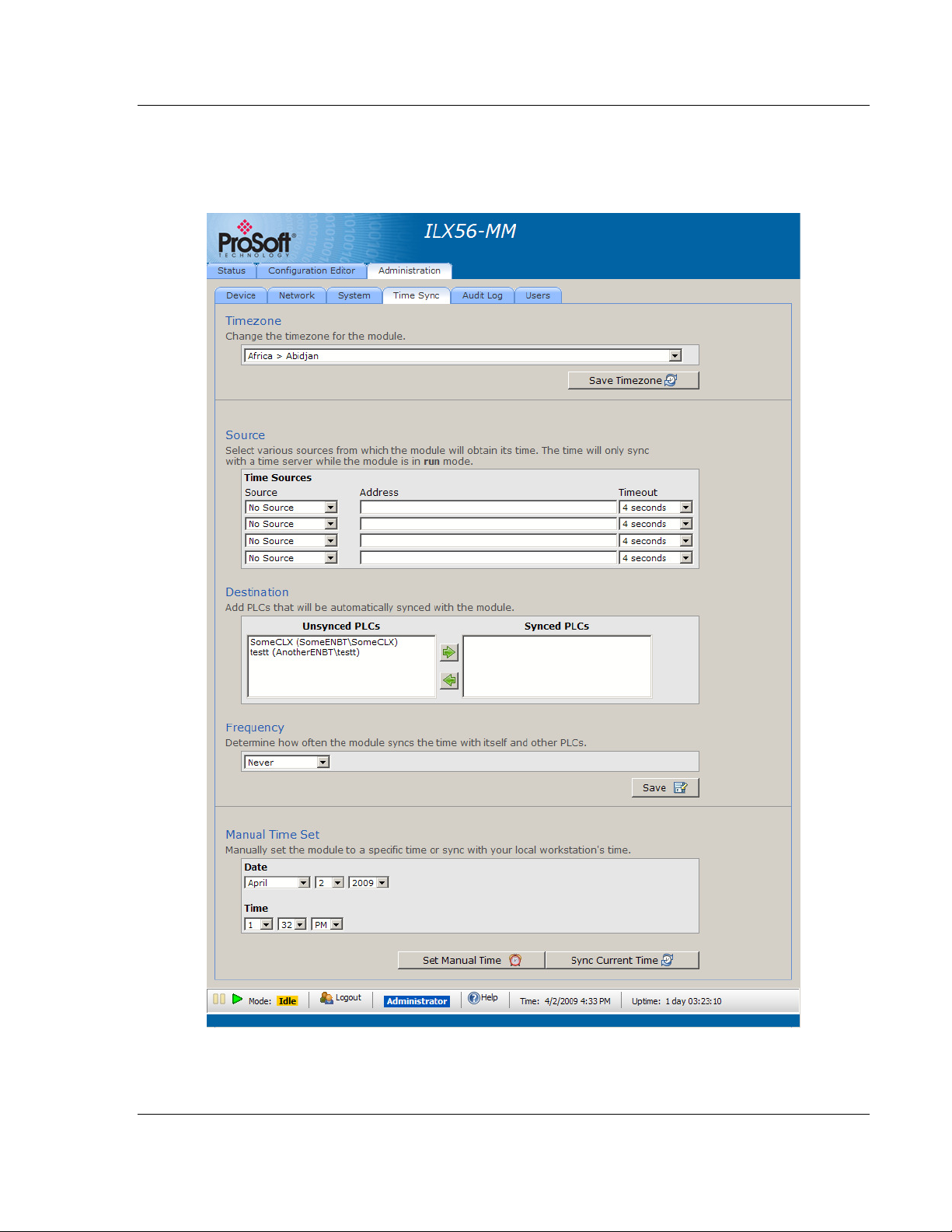

2.4 Time Sync

To open the T

T

IME SYNC

tab.

IME SYNC

page, click the A

DMINISTRATION

tab, and then click the

ProSoft Technology, Inc. Page 27 of 112

February 6, 2012

Page 28

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

The ILX56-MM module can acquire a time signal from an SNTP time server on

the Internet, or from the ControlLogix processor in the same rack with the ILX56MM.

The ILX56-MM can also set the time on ControlLogix, CompactLogix, and

FlexLogix processors defined as Devices.

Note: The module will only obtain, and push, time while in R

Field Description

Timezone Select the time zone for the module.

Source The module can poll one or more sources for a time signal.

T

IME SOURCES

module will attempt to synchronize with each of these sources in the

specified order until it is successful.

T

IMEOUT

signal from each source.

Destination Select other devices that will be synchronized to the time on the module.

The items on this list are derived from the devices you have defined in

the Configuration Editor.

Frequency Specify how often the module will receive and send time synchronization.

A Time Sync cycle will be started when the module is switched to Run.

Click the S

Manual Time Set

Set the time and date, and then click the S

To synchronize the time and date on the module to the time and date on

your local computer, click the S

specify the IP addresses for the time synchronization. The

is the number of seconds the module will wait to receive the time

AVE

button to save your Time settings to the module.

UN

mode.

ET MANUAL TIME

YNC CURRENT TIME

button.

button.

Note: You must be logged on as a user with Administrator privilege to modify the settings on this

page.

Page 28 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 29

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

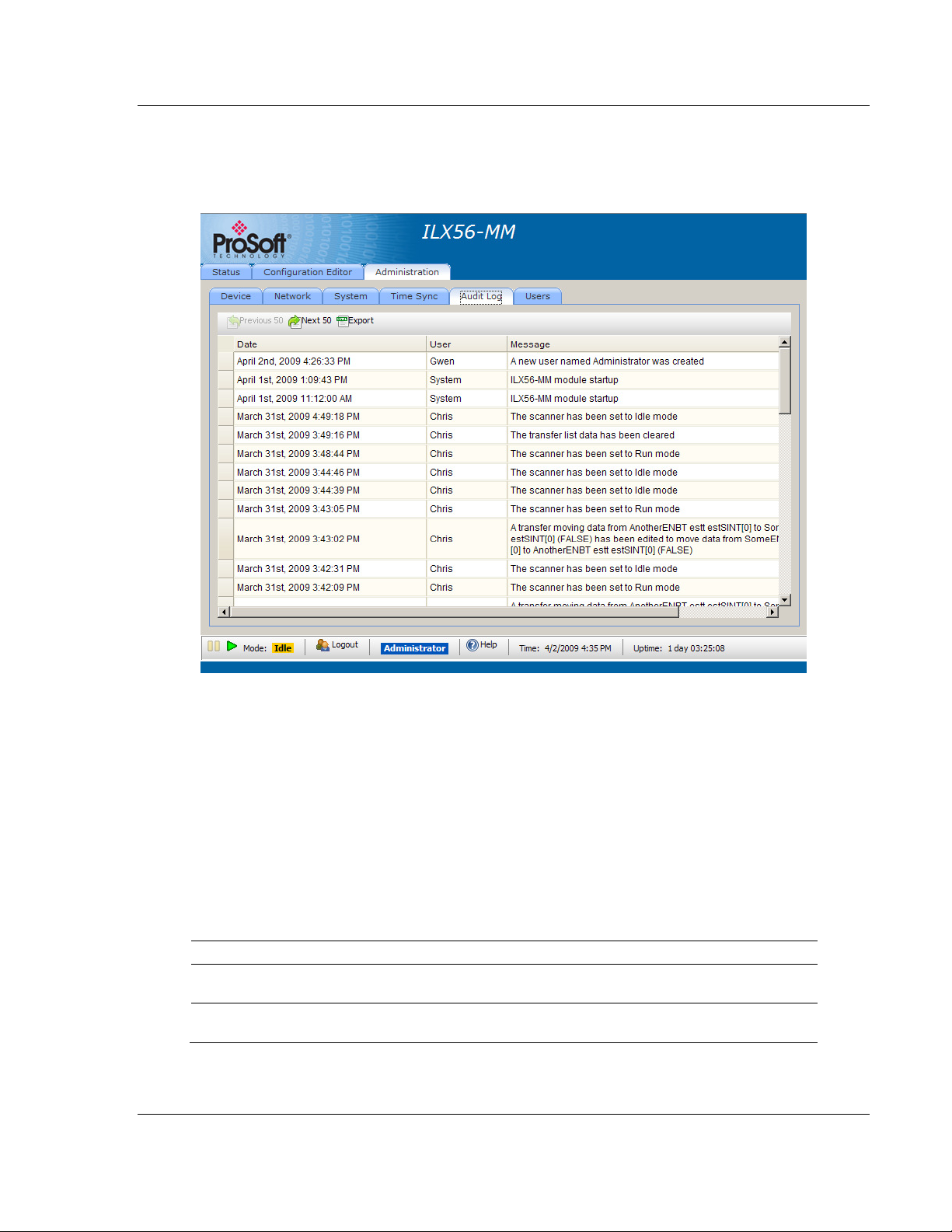

2.5 Audit Log

To open the A

A

UDIT LOG

tab.

UDIT LOG

page, click the A

DMINISTRATION

tab, and then click the

The audit log is a chronological log of operational system events that have

occurred since the module was first started. The audit log displays 50 records per

page, in order from newest, at the top, to oldest, at the bottom.

The Audit Log records the following types of events

Changing the module's operational mode

Modifying the configuration

Changing the event log level

Reinitializing the module

Backing up the configuration

Restoring the configuration

Updating the module

Other less frequent system events

Operation Description

Next 50

Previous 50

See also Security (page 31), Setup Mode (page 69), Administration (page 21).

Click the N

current 50 events begin displayed.

Click the P

the current 50 events begin displayed.

EXT 50

button to view the 50 events that occurred prior to the

REVIOUS

50 button to view the 50 events that occurred after

ProSoft Technology, Inc. Page 29 of 112

February 6, 2012

Page 30

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

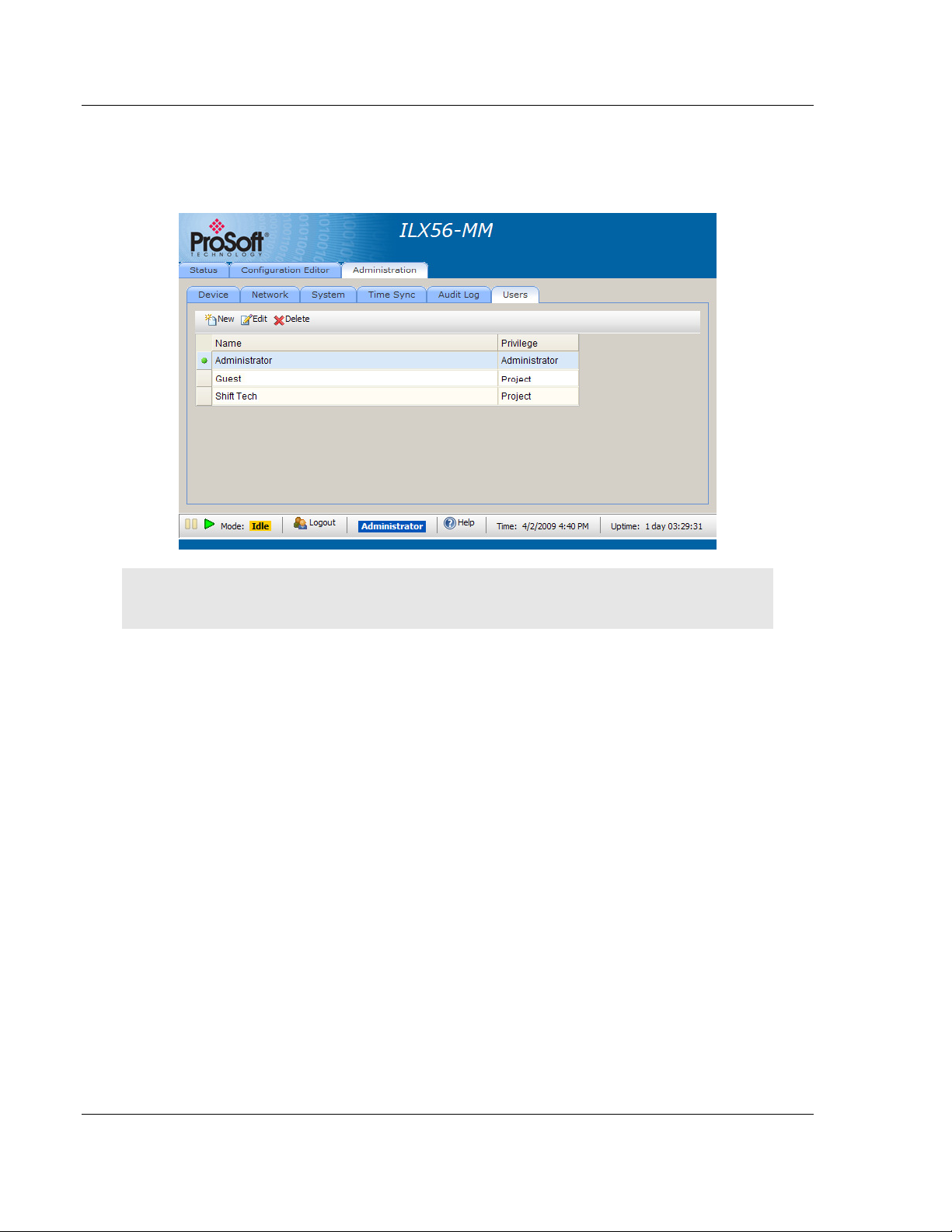

2.6 User Administration

To open the U

the U

SERS

SER ADMINISTRATION

tab.

page, click the A

DMINISTRATION

tab, then click

Note: You must be logged on as a user with Administrator privilege to modify the settings on this

page.

Page 30 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 31

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

2.6.1 Security

The ILX56-MM provides three levels of security:

G

UEST:

No user login account is required.

P

ROJECT:

A

DMINISTRATOR.

You must be logged in as a user with Project privilege

You must be logged in as a user with Administrator privilege.

Note: When you close the browser, you are automatically logged out. If you have problems logging

in, double-check your username and password. The Login dialog will notify you if the username is

not correct or the password is not correct. If you are sure you are using your correct username and

password and you still cannot log in, see Cannot Login (page 68).

The following table describes functions that require security privilege.

Location Function Privilege Required

Status Bar Set Mode Project

Configuration Editor All Functions Project

Administration All Functions Administrator

Administration/Users This page cannot be viewed without

Administrator privilege

Administrator

Note: Administrator privilege includes all Project privilege functions.

When you receive a new module, it comes configured with one default user who

has Administrator privileges (full access to all module functions).

Username:

Password:

admin

admin

After configuring your user and administrator accounts, you should delete the

default "admin" user for additional security.

If you forget your username and/or password you can reset the admin password

(page 16). If you have deleted the default admin user, the default admin user will

be restored with Administrator privilege.

ProSoft Technology, Inc. Page 31 of 112

February 6, 2012

Page 32

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

2.6.2 Adding a New User

1 Click N

EW

to add a new user. This action opens the N

EW USER INFO

box.

2 Enter the User Name for the user.

3 Select the desired Privilege for the user: Project or Administrator.

4 Enter a Password for the user.

5 Enter the password again in the Confirm Password field.

6 Click OK to add the new user.

dialog

Page 32 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 33

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

2.6.3 Editing an Existing User

1 Select a user and click the E

dialog box

DIT

button. This action opens the E

DIT USER INFO

2 You can change the Username, Privilege, or Password.

If you change the password, you must also enter the new password in the

Confirm Password edit box.

ProSoft Technology, Inc. Page 33 of 112

February 6, 2012

Page 34

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

2.6.4 Deleting a User

1 Select a user and click D

2 You will be prompted to confirm the deletion of the user.

3 To select multiple users for deletion, hold down the [S

while selecting users.

ELETE,

or press the [DEL] key to delete a user.

HIFT]

or [CTRL] key

See also Security (page 31), Setup Mode (page 69), Administration (page 21).

Page 34 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 35

ILX56-MM ♦ ControlLogix Platform Administration

InRAx Message Manager for Industrial Communication User Manual

2.7 Scanner Modes

The scanner mode controls the scanning of Triggers (page 57) and the transfer

of data between Devices. The scanner can be in one of the following modes:

In S

In I

In R

You must be logged into the module with Project or Administrator privilege to

change the scanner mode. To change the scanner mode, click the I

R

UN

illustration shows the ILX56-MM in I

TOP

mode, Triggers are not scanned and none of the Interfaces are

active. The scanner only goes into Stop mode when a serious error has

occurred. You cannot put the scanner into Stop mode yourself.

DLE

mode, Triggers are not scanned but the Interfaces are active. In Idle

mode, you can configure the scanner using the Configuration Editor.

UN

mode, Triggers are scanned and the Interfaces are active. Data is

actively transferred between controllers based on Trigger logic. You cannot

configure the scanner while it is in Run mode.

buttons on the status bar at the bottom of the page. The following

DLE

mode.

DLE

or

ProSoft Technology, Inc. Page 35 of 112

February 6, 2012

Page 36

Administration ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

Page 36 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 37

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

3 Configure the ILX56-MM module

In This Chapter

Editing Configuration Objects ................................................................ 39

Interfaces and Devices .......................................................................... 40

Tags ...................................................................................................... 49

Transfer Lists ......................................................................................... 55

Triggers ................................................................................................. 57

Saving the Configuration ....................................................................... 59

Reloading the Configuration .................................................................. 60

Resetting the Configuration ................................................................... 61

To open the Configuration Editor page, click the C

ONFIGURATION EDITOR

tab.

Note: To modify the settings on this page, you must be logged on as a user with Administrator or

Project privilege, and the scanner must be in I

scanner is in R

UN

mode, you can view these settings, but you cannot change them.

DLE

mode (page 35). If you are not logged in, or if the

ProSoft Technology, Inc. Page 37 of 112

February 6, 2012

Page 38

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

The Configuration Editor page is divided into two panes.

The left pane is a tree view of Interfaces, Transfer Lists and Triggers. Click

the [+] icon next to each object to expand or collapse the tree view.

The right pane shows the properties of objects you select in the tree view.

The following table describes the types of objects you can configure.

Name Description

Interfaces Physical objects located in slots in the ControlLogix rack, or physical

objects connected to ports on the module.

Devices Physical objects (bridges) linking a controller to one of the Interfaces. See

Interfaces and Devices (page 40).

Tags Individual data objects in the controllers that can be transferred to another

controller. See Tags (page 49).

Triggers Define when to transfer data from one Interface (programmable controller)

to another. See Triggers (page 57).

Transfer lists Define what data to transfer between Devices. See Transfer Lists (page

55).

Page 38 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 39

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

3.1 Editing Configuration Objects

To use the Configuration Editor, expand the Tree View (left pane), and then

select the object to edit.

Click the N

object.

Click the E

double-click the selected object in the tree view.

Click the D

then press the [DEL] key to Delete (permanently remove) the object.

EW

button on the toolbar to create a new object under the selected

DIT

button to view or modify the selected object. Or, you can

ELETE

button to delete the selected object. Or, select an object and

ProSoft Technology, Inc. Page 39 of 112

February 6, 2012

Page 40

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

3.2 Interfaces and Devices

You can configure the module to send and receive tag data to/from controllers in

the local ControlLogix rack, connected remotely through a bridge, or via one of

the Ethernet ports on the module. Interfaces are used to configure controllers or

bridges in the local ControlLogix rack. Devices are used to configure bridges and

controllers that are remotely connected through bridges in the local rack or one of

the Ethernet ports on the module.

Data transferred to or from a PLC 5®, SLC™, or MicroLogix™ may be transferred

via one of the supported bridges or one of the Ethernet ports on the module.

Data transferred to or from a, or ControlLogix® Programmable Automation

Controller (PAC) can be transferred directly to/from a controller in the

ControlLogix rack or to/from a remote ControlLogix PAC via one of the supported

bridges or one of the Ethernet ports on the module.

Data transferred to or from a Siemens Step 7 (S7) PLC or Schneider Electric

Quantum PLC must be done through one of the Ethernet ports of the module.

Use the Configuration Editor to create, modify, or delete Interfaces and Devices.

Select the Interfaces node in the Configuration Editor tree. The content pane will

display a table containing all of the Interfaces.

Click NEW to create a new Interface.

Click E

Click D

You can also edit an Interface by double clicking on the Interface in the

Configuration Editor tree or in the content pane.

DIT

to edit the selected Interface.

ELETE

or press the [DEL] key to delete the selected Interface.

Page 40 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 41

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

3.2.1 Allen-Bradley PLCs

An Allen-Bradley (AB) PLC can be defined as an Interface or as a Device.

A Device defined as an Interface (controller) will contain a Tags node under it

in the Configuration Editor tree. The Tags node contains all the Tags

referenced for that controller.

A Device defined as a Bridge will contain a Devices node under it in the

Configuration Editor tree.

ProSoft Technology, Inc. Page 41 of 112

February 6, 2012

Page 42

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

Each Interface and Device has a unique Name, a Timeout, and addressing

information.

The Timeout specifies the timeout value in milliseconds to be used in

communicating with the device.

The addressing information contains information to address the device on the

network or in the rack where the device is located.

Depending on the Interface Type and Device Type, other parameters may also

be available. The following table describes the addressing parameters for each

interface/device type.

Parameter Description

Interfaces Addressing is specified as a slot number.

ControlNet bridge Addressing is specified as a node number.

DHRIO bridge Addressing is specified as a channel and node number.

DH485 bridge Addressing is specified as a channel and node number.

Bridges (ControlLogix Backplane)

Devices are configured under a bridge interface in the local rack. Select the

D

EVICES

node in the Configuration Editor tree. The content pane will display a

table containing all of the Devices defined for that bridge.

The ILX56-MM supports the following bridges:

EtherNet/IP®

DHRIO

DH485

ControlNet ™

Page 42 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 43

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

EtherNet/IP Bridge

A 1756 EtherNet/IP bridge in the local rack can be connected directly to a PLC 5,

SLC, or MicroLogix.

An EtherNet/IP bridge can also be connected to another EtherNet/IP bridge or

CompactLogix PAC in a remote rack.

An EtherNet/IP bridge in a remote rack can be connected to a ControlLogix PAC

in that rack or an EtherNet/IP bridge, ControlNet bridge, DHRIO bridge, or

DH485 bridge in that remote rack.

An EtherNet/IP bridge rack can be connected to a CompactLogix PAC.

DHRIO Bridge

A DHRIO bridge in the local rack can be connected directly to a PLC 5 or SLC,

or, connected to another DHRIO bridge in a remote ControlLogix rack.

A DHRIO bridge in a remote rack can be connected to a ControlLogix PAC in

that rack or an EtherNet/IP bridge, ControlNet bridge, DHRIO bridge, or DH485

bridge in that remote rack.

ProSoft Technology, Inc. Page 43 of 112

February 6, 2012

Page 44

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

ControlNet Bridge

A ControlNet bridge in the local rack can be connected directly to a PLC 5 or,

connected to another ControlNet bridge in a remote ControlLogix rack.

A ControlNet bridge in a remote rack can be connected to a ControlLogix PLC in

that rack or an EtherNet/IP bridge, ControlNet bridge, DHRIO bridge, or DH485

bridge in that remote rack.

DH485 Bridge

A DH485 bridge in the local rack can be connected directly to an SLC,

MicroLogix, or ControlLogix PAC, or, connected to another DH485 bridge in a

remote ControlLogix rack.

A DH485 bridge in a remote rack can be connected to a ControlLogix PAC in that

rack or an EtherNet/IP bridge, ControlNet bridge, DHRIO bridge, or DH485

bridge in that remote rack.

Page 44 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 45

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

ControlLogix PLC

A ControlLogix PAC in the local rack can be connected through a bridge module

to a PLC 5, SLC, MicroLogix, or ControlLogix PAC, or, connected to another

ControlLogix PAC in a remote ControlLogix rack.

A ControlLogix PAC in a remote rack can be connected to a ControlLogix PAC in

that rack or an EtherNet/IP bridge, ControlNet bridge, DHRIO bridge, or DH485

bridge in that remote rack.

3.2.2 Siemens Step 7 (S7) PLCs

An Interface defined as a Siemens S7 will contain a Tags node under it in the

Configuration Editor tree. The Tags node contains all the Tags referenced for

that controller.

Each Interface has a unique Name, IP address, Remote Rack Number, Remote

Slot Number, number of Retries, and Timeout.

The Timeout specifies the timeout value in milliseconds to be used in

communicating with the device.

The addressing information: IP address, Remote Rack Number, and Remote Slot

Number contains information to address the device on the S7 Industrial Ethernet

network.

ProSoft Technology, Inc. Page 45 of 112

February 6, 2012

Page 46

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

3.2.3 Modbus TCP/IP (Schneider Electric Quantum PLCs)

An Interface defined as Modbus TCP/IP will contain a Devices node under it in

the Configuration Editor tree.

Each Devices node will contain a Tags node under it in the Configuration Editor

tree. The Tags node contains all the Tags referenced for that controller.

Each Interface has a unique Name, IP Address and Timeout. The Timeout

specifies the timeout value in milliseconds to be used in communicating with the

device.

Page 46 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 47

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

Each Device has the following unique parameters.

Parameter Description

Node Address The Modbus Node Address of the slave device to connect to the

module. If you are connecting to a Quantum PLC via a bridge, enter the

Modbus node address of the device connect to the module. If you are

directly connecting to a Quantum PLC, set this to 0.

Message Idle Time The idle time between messages in milliseconds. Range is 0 to 50.

Register Addressing Type The type of addressing used to access Long Integers and Floating Point

data, where:

Normal Longs/Floats occupy two 16-bit registers.

Register order is normal.

Modicon Longs/Floats occupy two 16-bit registers.

Register addressing order is WORD reversed.

32-bit Longs/Floats occupy one 32-bit register.

Maximum Data Bytes The maximum number of register or coil data bytes contained in a

single MODBUS message body. Valid options are 4, 32, 64, 128, 192,

and 244. If an array tag is larger than this value, multiple messages

may be used to complete the data access.

ProSoft Technology, Inc. Page 47 of 112

February 6, 2012

Page 48

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

Parameter Description

Maximum Data Byte Gap The byte gap allowed in the reading of the register or coil data block.

Valid options are:

0 No gaps are allowed in the reg/coil data block.

Only sequential contiguous reg/coil read

requests may be combined in a request

message. For example, sequential reads of

Status Bits 10001 and 10003 will result in two

read request messages.

1 Scattered Coil (0x0000) and Status Bit (1x0000)

read requests with up to a 1 byte (8 bit) gap may

be combined in a single request message. For

example, sequential reads of 10001 and 10003

will result in a single request message with

10002 being discarded. Scattered sequential

Holding (4x0000) and Input (3x0000) register

accesses must be contained or exactly

adjacent.

8 Scattered sequential reg/coil read requests that

have up to an 8 byte gap may be combined in

the same read request message.

16 Scattered sequential reg/coil read requests that

have up to a 16 byte gap may be combined in

the same read request message.

32 Scattered sequential reg/coil read requests that

have up to a 32 byte gap may be combined in

the same read request message.

64 Scattered sequential reg/coil read requests that

have up to a 64 byte gap may be combined in

the same read request message.

128 Scattered sequential reg/coil read requests that

have up to a 128 byte gap may be combined in

the same read request message.

Single Register Writes Determines if multiple or single register writes will occur. If this option is

"ON", 16-bit register writes will be executed one at a time, 32-bit writes

will be executed one at a time, and coil writes will be executed one at a

time. Array writes will require multiple messages to complete.

Timeout The timeout value in milliseconds to be used in communicating with the

device.

You must be logged on as a user with Project or Administrator privilege to modify

the module data transfer configuration.

See also Configuration Editor, Tags

Page 48 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 49

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

3.3 Tags

Tags refer to individual data objects in the controllers that can be transferred to

another controller.

Tags can be created and deleted, but cannot be modified. In the Configuration

Editor tree, each controller contains a node named Tags. When you select the

Tags node under any controller, in the content pane a table is displayed

containing all of the Tags currently defined for that controller. The read/write

status of a tag is shown in the last column as a "Read Only" check box. If the

Read Only check box is selected, you cannot use this tag as as a destination in a

transfer list.

When the Tags node is selected, you can add or delete Tags from the controller.

Click NEW to create a new Tag. Click the Delete button to delete the selected

Tag.

For ControlLogix PACs, the actual Tags in the controller are enumerated.

From this enumeration, the user can select which tags to reference in the

module. See also New Tag dialog box (ControlLogix/CompactLogix/Flex

Logix).

For PLC 5, MicroLogix and SLC processors, Tags are created to access

various indexes in the controller files (PLC 5, MicroLogix and SLC). See also

New Tag dialog box (PLC 5, MicroLogix and SLC).

For Siemens S7 and Schneider Electric Quantum PLCs, the tag references

must be entered by the user. Automated enumeration is not supported. See

also New Tag dialog box (Siemens S7) and New Tag dialog box (Schneider

Electric Quantum PLCs).

You must be logged on as a user with Project or Administrator privilege to modify

the module's data transfer configuration.

See also Configuration Editor.

This option allows you to set up transfer lists and these can now be transferred to

other interface devices using other diagnostics tags used in transfer lists. For

additional information for how to use these tags, see Transferring Internal

Diagnostic

Tags.

ProSoft Technology, Inc. Page 49 of 112

February 6, 2012

Page 50

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

3.3.1 ControlLogix, CompactLogix, FlexLogix

You can use the ControlLogix, CompactLogix and FlexLogix N

to add references of Tags to the module's configuration. To open the N

dialog box, you select the T

AGS

node under a ControlLogix, CompactLogix or

EW TAG

dialog box

EW TAG

FlexLogix controller in the Configuration Editor tree and then click the NEW button

on the toolbar.

When the dialog first comes up, no Tags are displayed in the Tag tree. At the top

of the dialog is an edit box named Tag Filter. Enter a filter for the Tags and click

the G

ET TAGS

button or press the [E

NTER]

key. All Tags that match the specified

filter will be loaded into the tag tree. Or, to get all Tags, leave the Tag Filter

empty and click the G

ET TAGS

button or press the [E

NTER]

key. See also Tag

Filter Help (page 88).

After the Tags matching the filter are loaded into the Tag tree, select a Tag. The

Name, Data Type, and Number of Elements associated with the Tag are

displayed on the right hand side of the New Tag dialog box. You cannot modify

any of the Tag values. Click the A

DD

button to add the Tag reference to the

module's configuration.

Click D

See also Tags

ONE

to close the New Tag dialog box.

Page 50 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 51

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

3.3.2 PLC5, MicroLogix and SLC

You can use the PLC5, MicroLogix and SLC New Tag dialog box to add Tags

from a PLC 5, MicroLogix or SLC controller to the module's configuration. To

open the PLC5, MicroLogix and SLC New Tag dialog box, you select the Tags

node under a PLC5, MicroLogix or SLC controller in the Configuration Editor tree

and then click the N

EW

button on the toolbar.

When the dialog box first comes up, the location tree is loaded with Tag locations

within the controller. For a PLC5, MicroLogix or SLC, these are file references.

Select a Tag location in the location tree. The File Address, Data Type and

Name, associated with the Tag are displayed on the right hand side of the N

T

AG

dialog box. You can modify the name of the tag to a Tag name that is

EW

meaningful to you. You can modify the number of elements to specify how many

data items at this location will be associated with this tag. When number of

elements is greater than 1 this Tag will be handled as an array. Click the ADD

button to add the Tag to module's configuration.

Click D

See also Tags

ONE

to close the PLC5, MicroLogix and SLC N

EW TAG

dialog box.

ProSoft Technology, Inc. Page 51 of 112

February 6, 2012

Page 52

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

3.3.3 Schneider Electric Quantum PLCs

Use the Modbus TCP/IP New Tag dialog box to add Tags from a Schneider

Electric Quantum PLC (Unity or Concept) controller to the module's configuration.

To open the Modbus TCP/IP New Tag dialog box, you select the Tags node

under a Schneider Electric Quantum PLC controller in the Configuration Editor

tree and then click the NEW button on the toolbar.

The dialog box allows the user to enter the following parameters.

Parameter Description

Tag Name The desired name of the tag and is completely at the discretion of the

user. It is suggested that it resemble the tag as it is labeled in the

Schneider Electric Quantum controller.

Register/Coil The desired area of the state RAM to be accessed. The four areas are

Coils (0x0000), Input Status bits (1x0000), Input register (3x0000), and

Holding Register (4x0000). Each area designation is followed by the

most significant digit of the Concept (direct) address, shown in

parenthesis.

Offset The desired offset, within the state RAM, of the data to be accessed.

This, coupled with the register/coil selection, will determine the

complete address of the data to be accessed. For example, selecting

Holding Register with an offset of 00180 would produce a final address

of 400180.

Data Type The desired format for accessing the data. Register/coil types of coil

and input bit can only be accessed as byte_bools. Registers may be

accessed as one of the following:

Int16 - 16-bit Signed Integers

Int32 - 32-bit Signed Long Integers

Uint16 - 16-bit Unsigned Integers

Uint32 - 32-bit Unsigned Long Integers

Float32 - 32-bit Floating Point

Number of Elements The number of elements to be accessed. This allows for array transfers.

See also Tags

Page 52 of 112 ProSoft Technology, Inc.

February 6, 2012

Page 53

ILX56-MM ♦ ControlLogix Platform Configure the ILX56-MM module

InRAx Message Manager for Industrial Communication User Manual

3.3.4 Siemens S7

Use the Siemens S7 New Tag dialog box to add Tags from a Siemens S7

controller to the module's configuration. To open the Siemens S7 New Tag dialog

box, you select the Tags node under a Siemens S7 controller in the

Configuration Editor tree and then click the NEW button on the toolbar.

The dialog box allows the user to enter the following parameter.

Parameter Description

Tag Name The desired name of the tag and is completely at the discretion of the

user. It is suggested that it resemble the tag as it is labeled in the

Siemens S7 controller.

Address Type The type of memory to be accessed: Input, Output, Peripheral Input,

Flag Bit, Timers, Counters, or Data Blocks.

Input The memory that contains the last scan of the input modules. The S7

notation (IEC) for this area is "I". This memory is read-only for module

access.

Output The memory that contains the desired output values to be written to the

output modules at the end of the next scan cycle. The S7 notation (IEC)

for this area is "Q". This memory is read only for module access.

Peripheral Input The actual physical hardware of the input modules. The S7 notation

(IEC) for this area is "PI". This area is read only for module access.

Flag Bit The memory that is intended to store interim results calculated in the

program of the PLC. The S7 notation (IEC) for this area is "M". This

memory is read/write for module access.

Timers The memory that contains the accumulators for the timers in the S7

PLC. The S7 notation (IEC) for the timers is "T". This memory is read

only for module access and the format is in BCD. The number

represents the number of milliseconds that the timer has been active

with a maximum value of 3999.

Counters The memory that contains the accumulators for the counters in the S7.

The S7 notation (IEC) for the counters is "C". This memory is read only

for module access and the format is in BCD. The number represents

the accumulated value of the counter since the counter has been active

with a maximum value of 999.

ProSoft Technology, Inc. Page 53 of 112

February 6, 2012

Page 54

Configure the ILX56-MM module ILX56-MM ♦ ControlLogix Platform

User Manual InRAx Message Manager for Industrial Communication

Parameter Description

Data Blocks The memory that contains information for the program of the S7 PLC.

They may contain the following data types: BOOL, BYTE, WORD,

DWORD, INT, DINT, REAL, S5TIME, DATE, TIME, TIME_OF_DAY,

CHAR, DATE_AND_TIME, STRING, or ARRAY. Descriptions of these

data types should be available in the S7 PLC or Step 7 Programming

Software documentation. This memory is read/write for module access.

DB Number The number of the desired Data Block to access. This field is only valid

if the Address Type selected is Data Blocks (DB).

Offset The desired offset/number of the associated Address Type element.

The following is a description of this field’s meaning for each address

type:

Input,

Peripheral Input

& Output

Flag Bit Enter the byte offset within the Flag Bit memory of

Timers &

Counters

Data Blocks Enter the number of the desired data block.

Bit ID The desired bit number within the data element.

Data Type The desired format for accessing the data. This field depends on the