Page 1

ILX34-MBS

User Manual

Modbus Serial Module for

CompactLogix L1 and Point I/O

Adapters

February 18, 2015

USER MANUAL

Page 2

Page 3

User Manual

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions,

comments, compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave, 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2015 ProSoft Technology, Inc., All rights reserved.

ILX34-MBS User Manual

February 18, 2015

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product

shipments. User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the

enclosed DVD in Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be

freely downloaded from our web site: www.prosoft-technology.com

ProSoft Technology, Inc. Page 3 of 34

February 18, 2015

Page 4

ILX34-MBS User Manual

Page 4 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 5

ILX34-MBS User Manual

Contents

Your Feedback Please ........................................................................................................................ 3

How to Contact Us .............................................................................................................................. 3

ProSoft Technology® Product Documentation .................................................................................... 3

1 Start Here 7

1.1 ILX34-MBS Overview ................................................................................................ 7

1.2 Package Content ....................................................................................................... 7

1.3 System Requirements ............................................................................................... 7

2 Installing the Adapter 9

2.1 Installing the Mounting Base/Wiring Base Assembly ................................................ 9

2.2 Installing an I/O Module........................................................................................... 10

2.3 Installing the Removable Terminal Block ................................................................ 11

2.4 Removing a Mounting Base .................................................................................... 11

2.5 Connecting Power ................................................................................................... 12

2.5.1 CompactLogix L16/L18 Processor Power Connectivity .......................................... 12

2.5.2 Module Terminations ............................................................................................... 13

3 Configuration 15

3.1 1734-AENT and 1734-AENTR ................................................................................ 15

3.2 1734-ACNR ............................................................................................................. 15

3.3 1769-L16ER-BB1B, L18ER-BB1B, and L18ERM-BB1B ......................................... 15

3.4 Sample Configuration Procedure ............................................................................ 15

3.4.1 Create Module I/O Configuration ............................................................................ 18

3.4.2 Configure Controller Tags ....................................................................................... 25

3.5 Downloading the Sample Program to the Processor .............................................. 27

3.6 Master Command Structure .................................................................................... 28

3.7 Data Handling .......................................................................................................... 29

3.8 Module Status ......................................................................................................... 30

4 General Features & Specifications 31

4.1 General Specifications – Modbus Master/Slave .................................................... 31

4.2 Hardware Specifications.......................................................................................... 32

4.3 Agency Approvals ................................................................................................... 32

5 Support, Service & Warranty 33

Contacting Technical Support ........................................................................................................... 33

5.1 Warranty Information ............................................................................................... 34

ProSoft Technology, Inc. Page 5 of 34

February 18, 2015

Page 6

Page 7

Start Here

Qty.

Part Name

Part Number

Part Description

1

ILX34-MBS Adapter

ILX34-MBS

POINT I/O Adapter

1 Start Here

This Quick Start Guide will help you quickly set up and configure the ILX34-MBS

module. You should be somewhat familiar with the following:

Rockwell Automation® Studio 5000 Logix Designer v21 (for

CompactLogix L1 processors) or Rockwell Automation® RSLogix™ 5000

version 16 or greater (for 1734 Point I/O adapters).

Hardware Installation and Wiring

1.1 ILX34-MBS Overview

The ILX34-MBS modules are the ideal solution for the many distributed I/O

applications where Modbus connectivity can be integrated into an Allen Bradley

System. The ILX34-MBSxxx comes with an Add-On profile and is configured

using Rockwell Automation Studio 5000 (CompactLogix L1) and RSLogix 5000

(Point I/O Controllers). The modules work in both the 1734 Point I/O adapters

and the CompactLogix L1 processors.

1.2 Package Content

The following components are included with your ILX34-MBS adapter, and are all

required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

1.3 System Requirements

The ILX34-MBS requires the following minimum hardware and software

components:

Rockwell Automation® processor, with compatible power supply

o CompactLogix™ L1 Processors or 1734- Point I/O adapters,

Rockwell Automation RSLogix 5000/Studio 5000 programming software

Rockwell Automation RSLinx communication software version 2.54 or higher

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o Microsoft Windows

o Microsoft Windows Vista

®

7

ProSoft Technology, Inc. Page 7 of 34

February 18, 2015

Page 8

Start Here

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

Microsoft Windows Explorer version 7

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 768 recommended)

DVD drive

Note: The Hardware and Operating System requirements in this list are the minimum

recommended to install and run software provided by ProSoft Technology. Other third party

applications may have different minimum requirements. Refer to the documentation for any third

party applications for system requirements.

Page 8 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 9

Installing the Adapter

2 Installing the Adapter

2.1 Installing the Mounting Base/Wiring Base Assembly

The wiring base assembly consists of a mounting base and a removable terminal

block. You can install the assembly or just the mounting base. Perform the

following to install the base/wiring base assembly:

1. Position the mounting base/wiring base assembly vertically above the

installed units (adapter, power supply, or existing module).

2. Slide the mounting base down allowing the interlocking side pieces to

engage the adjacent module or adapter.

3. Press firmly to seat the mounting base on the DIN Rail. The mounting

base snaps into place.

4. To remove the mounting base from the DIN rail, remove any installed

module (and any module immediately to the right) and use a small blade

screwdriver to rotate the DIN rail locking screw to a vertical position. This

releases the locking mechanism. Lift straight up to remove the mounting

base.

5. Repeat this procedure for the next mounting base assembly.

ProSoft Technology, Inc. Page 9 of 34

February 18, 2015

Page 10

Installing the Adapter

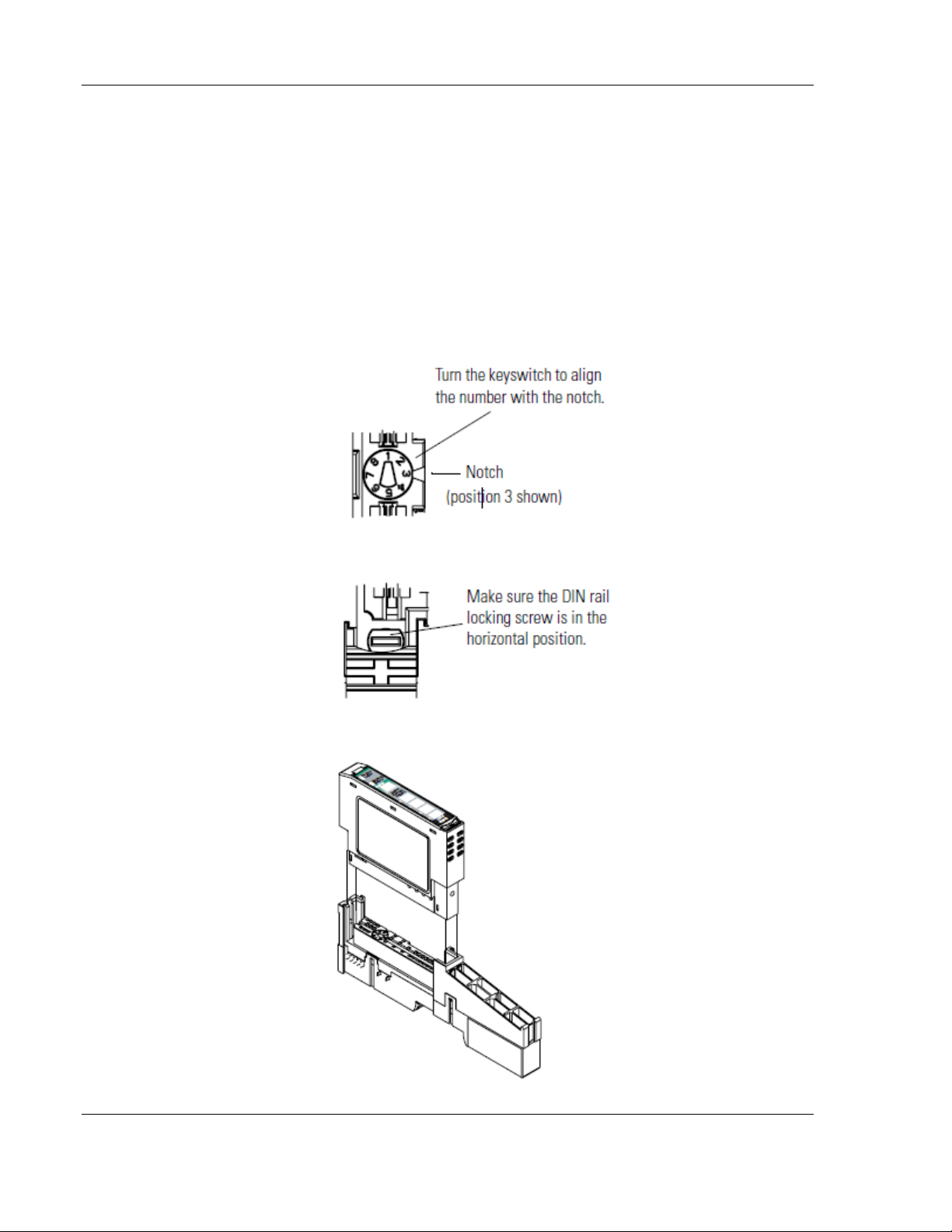

2.2 Installing an I/O Module

Make sure that the mounting base is correctly keyed before installing the module

into the mounting base. In addition, make sure the mounting base locking screw

is positioned horizontal referenced to the base.

Warning: When you insert or remove the module while backplane power is on,

an electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is non-hazardous before proceeding.

1. Using a bladed screwdriver, rotate the key switch on the mounting base

clockwise until the number required for the type of module being installed

aligns with the notch in the base.

2. Make certain the DIN-rail locking screw is in the horizontal position. You

cannot insert the module if the locking mechanism is unlocked.

3. Insert the module straight down into the mounting base and press to

secure. The module locks into place.

Page 10 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 11

Installing the Adapter

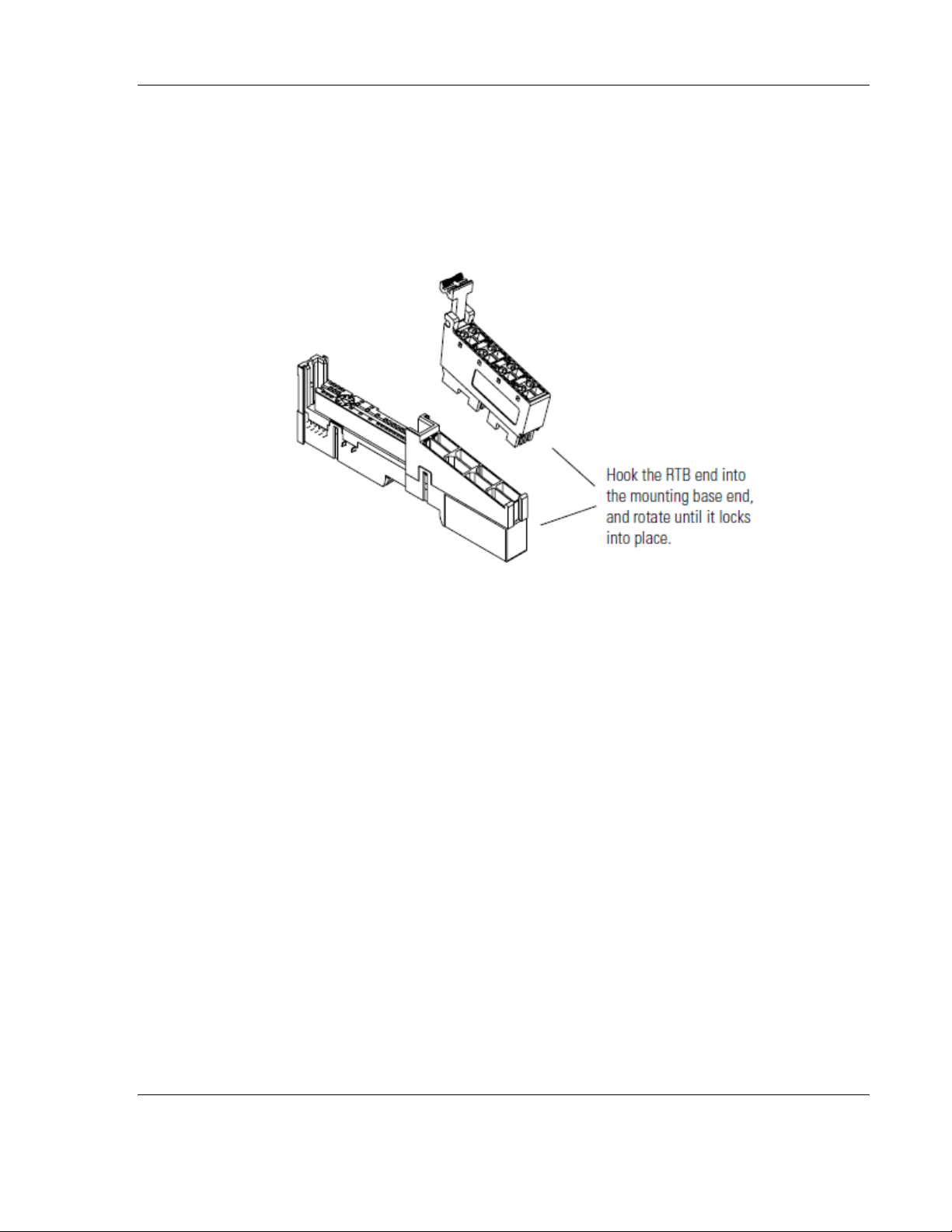

2.3 Installing the Removable Terminal Block

A removable terminal block is supplied with the mounting base assembly. To

remove, pull up on the RTB handle. This allows the base to be removed and

replaced as necessary without removing any of the wiring. Follow the following

instructions to reinsert the removable terminal block:

1. Insert the RTB end opposite the handle into the base unit. This end has a

curved section that engages with the mounting base.

Warning: When you connect or disconnect the Removable Terminal Block

(RTB) with the field side power applied, an electrical arc can occur. This could

cause an explosion in hazardous location installations.

Be sure that power is removed or the area is non-hazardous before proceeding.

2. Rotate the terminal block into the mounting base until it locks itself in

place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

2.4 Removing a Mounting Base

In order to remove a mounting base, you must remove any installed module, and

remove the Removable Terminal Block (if wired).

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the Removable Terminal Block.

Warning: When you connect or disconnect the Removable Terminal Block

(RTB) with the field side power applied, an electrical arc can occur. This could

cause an explosion in hazardous location installations.

Be sure that power is removed or the area is non-hazardous before proceeding.

3. Press in on the module lock on the top of the module and pull up on the

I/O module to remove from the base.

ProSoft Technology, Inc. Page 11 of 34

February 18, 2015

Page 12

Installing the Adapter

Warning: When you insert or remove the module while backplane power is on,

an electrical arc can occur. This could cause an explosion in a hazardous

location.

Be sure that power is removed or the area is non-hazardous before proceeding.

4. Remove the module to the right of the base you are removing (The

interlocking portion of the base sits under the adjacent module.).

5. Use a small blade screwdriver to rotate the orange DIN-rail locking screw

on the mounting base to a vertical position. This releases the locking

mechanism.

6. Lift the mounting base straight up and remove.

2.5 Connecting Power

Refer to the appropriate L1Y or Remote Adapter installation guides for adapter

configuration instructions.

2.5.1 CompactLogix L16/L18 Processor Power Connectivity

When using an L16/L18 CompactLogix Processor, make sure that the Field

Power (FP) is jumped to the Power on the CompactLogix (VDC).

VDC+ to FP+

VDC- to FP-

Page 12 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 13

Installing the Adapter

2.5.2 Module Terminations

Caution: Do not connect 120/240V ac power to this supply.

Warning: If you connect or disconnect wiring while the field-side power is on, an electrical arc can

occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

ProSoft Technology, Inc. Page 13 of 34

February 18, 2015

Page 14

Page 15

Configuration

3 Configuration

The ILX34-MBS module supports several Point I/O Controllers and Adapters.

This includes:

1734-AENT and AENTR

1734-ACNR

1769-L16ER-BB1B

1769-L18ER-BB1B

1769-L18ERM-BB1B

3.1 1734-AENT and 1734-AENTR

To configure the ILX34-MBS module with a 1734-AENT adapter:

1. Refer to the 1734-AENT documentation for information on configuring the

adapter.

2. Refer to Create Module I/O Configuration on page 18 to configure the

ILX34-MBS module for this adapter.

3. Set the chassis size as described in the 1734-AENT/AENTR

documentation.

3.2 1734-ACNR

To configure the ILX34-MBS module with a 1734-ACNR adapter:

1. Refer to the 1734-AENT documentation for information on configuring the

adapter.

2. Refer to Create Module I/O Configuration on page 18 to configure the

ILX34-MBS module for this adapter.

3. Schedule the ControlNet as described in the 1734-ACNR documentation.

3.3 1769-L16ER-BB1B, L18ER-BB1B, and L18ERM-BB1B

Follow the instructions is the Sample Configuration procedure in this section.

3.4 Sample Configuration Procedure

Note: The following example procedures are accomplished using Rockwell

Automation's Studio 5000 Designer, but apply to RSLogix as well. If you are

installing this module into a 1734-AENT or ACNR, use RSLogix 5000 v16 or

greater and skip to the section entitled Create Module I/O Configuration.

1. Open Studio 5000 and click Create New Project.

2. Expand CompactLogix 5370 Controller. Select the appropriate

processor from the list:

ProSoft Technology, Inc. Page 15 of 34

February 18, 2015

Page 16

Configuration

1769-L16ER-BB1B

1769-L18ER-BB1B

1769-L18ERM-BB1B

3. Select the appropriate PLC and type in a Name for the Project.

4. Click Next. The Project Configuration dialog opens.

Page 16 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 17

Configuration

5. Select the Expansion I/O module number. If the modules present do not

match the modules specified in the Project, unexpected control may

occur. The Expansion I/O setting must match the actual number of

modules.

6. Click Finish. The following window opens.

ProSoft Technology, Inc. Page 17 of 34

February 18, 2015

Page 18

Configuration

3.4.1 Create Module I/O Configuration

1. Right-click on Expansion I/O and select New Module. The Select

Module Type dialog opens.

2. Locate 1734-MODULE (Generic 1734 Module) by scrolling the list or

using the Search filter.

3. Click Create. The New Module dialog opens.

Page 18 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 19

Configuration

Register/Discrete

Max Size per

Modbus Message

Input

Assy

Instance

Input

Size

Output

Assy

Instance

Output

Size

Configuration

Assy

Instance

Configuration

Size

8/128

101

34

102

26

103

38

24/384

105

66

106

58

103

38

36/576

107

90

108

82

103

38

4. Enter a Name for the module.

5. Enter Connection Parameters. The Connection Parameters section is

dependent on the application that you are using. There are three different

sizes allowed by the module.

6. Ensure that the Comm Format is set to Data-SINT and that the Slot field

matches the Slot Number that the module will reside in.

ProSoft Technology, Inc. Page 19 of 34

February 18, 2015

Page 20

Configuration

7. Click OK. The Module Properties Report dialog opens.

8. Set the RPI time to a value larger than 50 ms.

9. Click Apply.

10. Click OK. The module now appears under Expansion Module in the tree.

Page 20 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 21

Configuration

11. Under Tasks, expand Main Task > Main Program.

12. Double-click on the Main Routine to open it.

ProSoft Technology, Inc. Page 21 of 34

February 18, 2015

Page 22

Configuration

13. Right-click anywhere in the ladder and select Import Rungs...

14. Navigate to the location of the Add-On rung and click Import. The Import

Configuration page opens. You can obtain the Add-On rung from

http://psft.com/ilx34-mbs/dl.

Page 22 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 23

Configuration

15. Click OK. The Add-On rung appears in the Main Routine.

16. Double-click Controller Tags from the Controller Organizer.

ProSoft Technology, Inc. Page 23 of 34

February 18, 2015

Page 24

Configuration

17. Controller tags open for editing.

Page 24 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 25

Configuration

Label

Description

Baud Rate

0=19200

2=2400

3=4800

4=9600

5=38400

Serial Comm

0=7N2

1=7E1

2=7O1

3=8N1

4=8N2

5=8E1

6=8O1

Protocol

0=ASCII

1=RTU

Label

Description

Type

Set this to “0” for Master

Timeout

Timeout in centiseconds. The time that

the master waits for a response from

the Slave.

3.4.2 Configure Controller Tags

1. Expand the MBS_Config controller tag.

Serial Port

Set the following parameters to configure the Serial Port.

Master Configuration

The following parameters must be set to use the module as a Master.

ProSoft Technology, Inc. Page 25 of 34

February 18, 2015

Page 26

Configuration

Label

Description

Type

Set this to “1” for Slave.

Slave ID

1-255. Set this to the desired Slave ID

that the Master is attempting to access.

The following example shows the module configured as a Master, 19200 baud,

8N1 (8 Data bits, No Parity, and 1 Stop Bit) Framing, RTU mode with a three

second timeout.

Slave Configuration

The Count parameters determine that maximum address that the Master can

access for the ILX34-MBS. The default values represent the max addresses

allowed for the provided Add-On instruction. Valid ranges are: 00001 – 00576,

10001 – 10576, 30001 – 30501 and 40001 – 40501..

Coldboot Bit - If parameters change after initial configuration, use the Coldboot

bit to initiate the changes.

Page 26 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 27

Configuration

3.5 Downloading the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix processor must be in the

REM or Prog position.

1. If you are not already online with the processor, open the

Communications menu, and then choose Download. You do not have to

download through the processor’s serial port. You may download through

any network connection.

2. When communication is established, Studio 5000 (or RSLogix 5000)

opens a configuration dialog box. Click the Download button to transfer

the sample program to the processor.

3. Studio 5000 (or RSLogix 5000) compiles the program and transfers it to

the processor. This process may take a few minutes.

4. When the download completes, the configuration program opens another

Confirmation dialog box. If the key switch is in the REM position, click OK

to switch the processor from PROGRAM mode to RUN mode.

Note: If you receive an error message during these steps, refer to the Rockwell

Automation documentation to interpret and correct the error.

ProSoft Technology, Inc. Page 27 of 34

February 18, 2015

Page 28

Configuration

Label

Description

Enable

0=Disable

1=Enable the Command: Polling and

Trigger allowed.

2=Enable the Command: Only Trigger

allowed.

Node

Node address of the target device on

the network (1-255).

Function

Function code for the command. 1, 2,

3, 4, 5, 6, 15 and 16 allowed for Master

and Slave. 8 allowed for Slave only.

DeviceAddress

Address in remote device associated

with the command (0-65535).

Count

Number of points associated with the

command.

InternalAddress

PLC Tag Internal address associated

with the command.

PollInterval

Minimum number of milliseconds

between issuance of command (0-2,

147, 483, 647ms).

Swap

0=None. No change is made in byte

ordering.

1=Words – The words are swapped.

2=Words & Bytes – The words are

swapped, and then the bytes in each

word are swapped.

3=Bytes – The bytes in each word are

swapped.

The words should be swapped only

when using an even number of words.

Trigger

1=Trigger the message. Can be

triggered anytime the command is

enabled.

3.6 Master Command Structure

Page 28 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 29

Configuration

Label

Description

InputBit

Incoming discreet data for address

ranges 0x and 1x from other devices.

Functions 5 and 15 when device is

configured as a Slave. Functions and 1

and 2 when configured as a Master.

InputRegister

Incoming register data for address

ranges 3x and 4x from other devices.

Functions 6 and 16 when device is

configured as a Slave. Functions and 3

and 4 when configured as a Master.

OutputBit

Outgoing discreet data for address

ranges 0x and 1x from other devices.

Functions 1 and 2 when device is

configured as a Slave. Functions and 5

and 15 when configured as a Master.

OutputRegister

Outgoing register data for address

ranges 3x and 4x from other devices.

Functions 3 and 4 when device is

configured as a Slave. Functions and 6

and 16 when configured as a Master.

3.7 Data Handling

These are the PLC data tags that are use for the Master and Slave. For the

Master, the following tags represent the internal addresses used by the Master

commands. For the Slave, the following tags represent the addresses accessed

by a remote Master.

ProSoft Technology, Inc. Page 29 of 34

February 18, 2015

Page 30

Configuration

Label

Description

Module

Module Status

1=Ready for Command

2=Processing Command

3=Waiting for Response

4=Processing Response

RXCnt

Number of messages received

TXCnt

Number of messages transmitted

ErrorCnt

Number of errors

CmdError [x]

The error represented for

MBS.MASTERCMD[x].

1= Invalid Function

2=Invalid Address

3=Invalid Data

20=Checksum Error

21=Modbus Invalid Message

22=Modbus Timeout

26=Float Word Swap Uneven Word

Count

209=Parity Error

3.8 Module Status

Page 30 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 31

General Features & Specifications

Configuration Environment

RSLogix 5000/Studio 5000

Max Modbus Command Size

Modbus command sizes are limited to 8, 16, and 36

words per command, depending on AOI selected

Max Modbus Commands

30

Communication Parameters

Baud Rate: 110 – 38.4K baud

Stop Bits: 1 or 2

Data Size: 7 or 8 bits

Parity: None, Even, Odd

Modbus Modes

RTU mode (binary) with CRC-16

ASCII mode with LRC error checking

Node Address

1 to 247

Supported Modbus Function

Codes:

1: Read Coil Status

2: Read Input Status

3: Read Holding Registers

4: Read Input Registers

5: Force (Write) Single Coil

6: Preset (Write) Single Holding Register

8: Diagnostics (Slave Only. Responds to Sub-function 00

15: Force (Write) Multiple Coils

16: Preset (Write) Multiple Holding Registers

4 General Features & Specifications

Add-On instruction creates UDTs, providing logical definitions for I/O,

status, and control data

Diagnostic data available in RSLogix 5000/Studio 5000 controller tags,

allowing decisions to be made based upon node health

Module configuration is backed up in the CompactLogix project (ACD file)

Serial port enable/disabled through ladder logic

Supports up to 1000 words of data

Supports up to 30 Modbus commands and up to 36 words per command

The Serial Port can be configured as a Modbus Master or Modbus Slave

device

Suitable for SCADA and field device interface applications

4.1 General Specifications – Modbus Master/Slave

ProSoft Technology, Inc. Page 31 of 34

February 18, 2015

Page 32

General Features & Specifications

Pointbus Current

75 mA @ 5 VDC

Number of Inputs

1 Dull duplex

Module Location

1734-TB or –TBS wiring base assembly (not included)

LED Indicators

1 green/red module status indicator

1 green/red network status indicator

2 green TXD, RXD status indicators

Operating Temperature

-4°F to 131°F (-20°C to 55°C)

Storage Temperature

-40°F to 185°F (-40°C to 85°C)

Relative Humidity

5% to 95% RH with no condensation

Dimensions

(H x W x L)

2.21 x 0.47 x 2.97 in

56 x 12 x 75.5 mm

Shock

30g Peak acceleration (operating)

50g Peak acceleration (non-operating)

Vibration

Tested 5g @ 10 to 500 Hz

ESD Immunity

6 kV contact discharges

8 kV air discharges

Agency

Applicable Standard(s)

UL/cUL

Class 1, Div. 2 Groups A, B, C, D

ATEX

Category 3, Zone 2

CE Mark

CB Safety

4.2 Hardware Specifications

4.3 Agency Approvals

Page 32 of 34 ProSoft Technology, Inc.

February 18, 2015

Page 33

Support, Service & Warranty

5 Support, Service & Warranty

Contacting Technical Support

ProSoft Technology, Inc. (ProSoft) is committed to providing the most efficient

and effective support possible. Before calling, please gather the following

information to assist in expediting this process:

Product Version Number

System architecture

Network details

If the issue is hardware related, we will also need information regarding:

Module configuration and associated ladder files, if any

Module operation and any unusual behavior

Configuration/Debug status information

LED patterns

Details about the serial, Ethernet or fieldbus devices interfaced to the module,

if any.

Note: For technical support calls within the United States, an after-hours answering system allows

24-hour/7-days-a-week pager access to one of our qualified Technical and/or Application Support

Engineers. Detailed contact information for all our worldwide locations is available on the following

page.

ProSoft Technology, Inc. Page 33 of 34

February 18, 2015

Page 34

Support, Service & Warranty

Internet

Web Site: www.prosoft-technology.com/support

E-mail address: support@prosoft-technology.com

Asia Pacific

(location in Malaysia)

Tel: +603.7724.2080, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Asia Pacific

(location in China)

Tel: +86.21.5187.7337 x888, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Europe

(location in Toulouse,

France)

Tel: +33 (0) 5.34.36.87.20,

E-mail: support.EMEA@prosoft-technology.com

Languages spoken include: French, English

Europe

(location in Dubai, UAE)

Tel: +971-4-214-6911,

E-mail: mea@prosoft-technology.com

Languages spoken include: English, Hindi

North America

(location in California)

Tel: +1.661.716.5100,

E-mail: support@prosoft-technology.com

Languages spoken include: English, Spanish

Latin America

(Oficina Regional)

Tel: +1-281-2989109,

E-Mail: latinam@prosoft-technology.com

Languages spoken include: Spanish, English

Latin America

(location in Puebla, Mexico)

Tel: +52-222-3-99-6565,

E-mail: soporte@prosoft-technology.com

Languages spoken include: Spanish

Brasil

(location in Sao Paulo)

Tel: +55-11-5083-3776,

E-mail: brasil@prosoft-technology.com

Languages spoken include: Portuguese, English

5.1 Warranty Information

For complete details regarding ProSoft Technology’s TERMS & CONDITIONS

OF SALE, WARRANTY, SUPPORT, SERVICE AND RETURN MATERIAL

AUTHORIZATION INSTRUCTIONS please see the documents on the Product

DVD or go to www.prosoft-technology/warranty

Documentation is subject to change without notice.

Page 34 of 34 ProSoft Technology, Inc.

February 18, 2015

Loading...

Loading...