Page 1

Page 2

SV61891 Rev. A ©2006 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion or stored in a

retrieval system of any type or transmitted by any means, electronically or mechanically, without the

express, written permission of Pitney Bowes.

We have made every reasonable effort to ensure the accuracy and usefulness of this manual;

however, we cannot assume responsibility for errors or omissions or liability for the misuse or

misapplication of our products.

Due to our continuing program of product improvement, equipment and material specifications as

well as performance features are subject to change without notice. Your postage meter may not

have some of the features described in this book.

E-Z Seal®, Postage By Phone®, and IntelliLinkTM Control Centre are trademarks or registered

trademarks of Pitney Bowes Inc. ENERGY STAR is a registered trademark of the United States

Environmental Protection Agency.

Page 3

Alerting Messages

Various messages are used throughout this guide to alert you to potentially

hazardous or error causing conditions. These messages are as follows:

WARNING! Alerts you to conditions or practices that could cause

serious injury.

CAUTION: Alerts you to conditions or practices that could cause

damage to the equipment or to the material being run.

NOTE: Provides a comment or explanation of the associated topic.

IMPORTANT! Alerts you to conditions or practices that could adversely affect

equipment operation if instructions are not followed exactly.

Page 4

FCC Compliance

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

interference to radio communications. Operation of this equipment in a

residential area is likely to cause interference, in which case the user will

be required to correct the interference at his own expense.

Use only a shielded interface cable to operate this equipment with a scale

or other peripheral device.

CAUTION: Changes or modifications to this equipment not expressly approved by the party responsible for compliance (Pitney

Bowes) could void the user’s authority to operate the equipment.

Page 5

FCC Compliance of Modem

This equipment complies with Part 68 of the FCC rules and the requirements adopted by ACTA. On the top

of the control centre of this equipment is a label that contains, among other information, a product identifier in

the format US:AAAEQ##TXXXX. If requested, this number must be provided to the telephone company. The

equipment is designed to connect to a two-wire, local switch, access loop start (Facility Interface Code 02LS2)

with a standard RJ-11 interface.

The REN is used to determine the quantity of devices that may be connected to the telephone line. Excessive

RENs on the telephone line may result in the devices not ringing in response to an incoming call. In most, but

not all areas, the sum of the RENs should not exceed five. To be certain of the number of devices that may be

connected to the line, contact the telephone company to determine the maximum REN for your calling area.

The REN for this product is part of the product identifier that has the format US:AAAEQ##TXXXX. The digits

represented by ## are the REN without a decimal point (for example 03 is a REN of 0.3).

If this modem causes harm to the telephone network, the telephone company may discontinue your service

temporarily. You will be notified in advance or as soon as possible. You will be advised of your right to register

a complaint with the FCC. If the user experiences trouble using this equipment, the user shall disconnect the

equipment from the telephone line to determine if the equipment is malfunctioning. If the equipment is malfunctioning, the use of the equipment shall be discontinued until the problem is corrected.

The telephone company may make changes to its facilities, equipment operations, or procedures that could

affect the operation of this equipment. In this event, the telephone company will provide advance notice for you

to make necessary modifications to maintain uninterrupted service.

If you experience trouble with this modem, please refer to the warranty information provided with this equipment. If the trouble is causing harm to the network, the telephone company may request that you remove the

equipment from the network until the problem is resolved.

This equipment may not be used with party lines or coin lines.

This equipment is not intended to be serviceable. Please refer to the warranty information if problems occur.

Failed units will be withdrawn by approved Pitney Bowes service engineers and returned to the U.S. Service Centre. For reference purposes, the U.S. Service Centre contact address is: Pitney Bowes Inc., Walter

Wheeler Drive, Stamford, CT 06926-0700.

A plug and jack used to connect this equipment to the premises wiring and telephone network must comply

with the applicable FCC Part 68 rules and requirements adopted by ACTA. A compliant telephone cord and

modular plug is provided with this product. It is designed to be connected to a compatible modular jack that is

also compliant. See installation instructions for details. If the installation site has specially wired alarm equipment connected to the telephone line, ensure the installation of this equipment does not disable the alarm

equipment. If you have questions about what will disable alarm equipment, consult your telephone company or

a qualified installer.

Page 6

DM230L/DM330L/DM350L Digital Mailing System

Operating Guide

Table of Contents

Contacts

Pitney Bowes Contact Information List .........................................xii

Pitney Bowes Web Sites ...................................................xii

Our Help Desk .................................................................xiii

Postage By Phone® .......................................................... xiii

Pitney Bowes Supplies ....................................................xiii

Chapter 1–Specifications and Safety Information

What is IntelliLinkTM ..................................................................... 1-2

Add Features On Demand .............................................. 1-2

Download Postal Rate Updates ...................................... 1-2

Keep Your System Current .............................................

Postal Requirements ..................................................................1-3

Canada Post Corporation Requirements ........................ 1-3

The Quick Reference Guide ....................................................... 1-3

Specifications .............................................................................. 1-4

Equipment ....................................................................... 1-4

Material .......................................................................... 1-5

Important Safety Notes ............................................................... 1-6

Important Telephone Safety Instructions !!! ................................ 1-8

1-2

Chapter 2–What's What

Parts of the DM230L/DM330L System ....................................... 2-2

Parts of the DM350L System ......................................................

DM350L Autofeeder Control Panel .............................................

IntelliLinkTM Control Centre - DM230L/DM330L .......................... 2-8

IntelliLinkTM Control Centre - DM350L ....................................... 2-10

Machine Features - Side, Rear of DM230L/DM330L

and DM350L ............................................................................. 2-12

SV61891 Rev. A v

2-4

2-6

Page 7

Table of Contents

Chapter 3–Running Mail

Before You Begin ........................................................................ 3-2

Checklist ..................................................................................... 3-2

The Ready Screen ...................................................................... 3-2

Applying Postage and Running Mail ........................................... 3-3

Printing Postage on an Envelope ...............................................3-4

Processing Lettermail on the DM230L/DM330L

System without the optional weight platform ................... 3-4

Mail In a Minute – Processing a Letter Using

the Integrated Weigh Platform ........................................

Processing and Feeding Lettermail

on the DM350L System ..................................................

Printing Postage on Tape Strips .............................................. 3-11

DM230L/DM330L: Printing Tapes ................................ 3-11

DM350L: Printing Tapes ................................................ 3-12

Processing a Parcel Without Using

the Optional Parcel Rate Module .................................. 3-13

Processing a Parcel Using

the Optional Parcel Rate Module .................................. 3-14

Printing Postage Using Presets ................................................ 3-17

Selecting the Normal Preset ......................................... 3-17

Selecting a Custom Preset ...........................................3-17

Sealing the Envelopes Only ...................................................... 3-18

Selecting a Class or Special Service ........................................ 3-19

Before Selecting or Changing a Class .......................... 3-19

Selecting or Changing a Class ...................................... 3-20

Selecting a Postal Code or Zone .................................. 3-21

Selecting a Country ....................................................... 3-21

Selecting a Special Service ..........................................3-22

Printing an Advertisement .........................................................

Printing an Advertisement with the Postage .................

Printing only an Advertisement - No Postage ...............

Printing the Date and Time on Incoming Mail ...........................

Changing the Date on Your Mail ...............................................

Advancing the Date ....................................................... 3-24

Resetting the Date and Time ........................................ 3-24

Selecting an Account ................................................................ 3-25

Checking and Clearing the Batch Count ................................. 3-25

Checking the Batch Count ............................................ 3-25

Printing a Record of this Information ............................ 3-26

Clearing the Batch Count .............................................. 3-27

3-6

3-8

3-23

3-23

3-23

3-23

3-24

vi SV61891 Rev. A

Page 8

DM230L, DM330L, DM350L Operating Guide

Viewing the Weight in Imperial Units ........................................ 3-27

Adding or Correcting Postage ................................................... 3-28

Printing a Statement of Mailing / Manifest ................................ 3-30

Test Print / Zero Dollar Indic

Chapter 4–System Setup

The Options Key: Navigating the Menus .................................... 4-2

Overview of Mailing System Setup ............................................. 4-3

Adjusting the DisplayContrast ..................................................... 4-4

Setting the System Clock ............................................................ 4-4

Changing the System Date/Time .................................... 4-4

Setting Daylight Savings Time ........................................ 4-4

Changing the Automatic Date Advance Time .................. 4-5

Setting the Normal Preset Timer .....................................

Changing the Lock Code or Password ....................................... 4-6

Changing the Lock Code ...............................................4-6

Changing the Password .................................................. 4-7

Setting Up the Phone Connection ..............................................4-8

Choosing the Dial Method ............................................... 4-8

Entering the Dial Prefix ................................................... 4-8

Entering the Pitney Bowes Phone Number ..................... 4-9

Selecting the Modem Type ........................................... 4-10

Entering the Modem Initialization String ....................... 4-11

Setting the Distributor Parameters ................................ 4-12

Setting Up the Postage By Phone® Refill Options .................... 4-14

Enter Your Postage By Phone

Setting the Default Refill Amount .................................. 4-15

Password Protecting the Adding Postage Process .......

Removing Funds and Purging Ink from Your System ...

Setting the Postage Funds Warnings .......................................

Setting the Low Funds Warning .................................... 4-16

Setting the High Value Warning .................................... 4-16

Setting Up an Attached

Selecting the Scale Vibration Mode .............................. 4-18

Zero the Scale ............................................................... 4-18

Turning Auto

Setting the Scale Location Code ................................... 4-19

Setting the AutoClear Function ..................................... 4-20

Setting the Clear Zone Option ......................................4-20

Entering a Canada Post Contract Discount Code ......... 4-21

Scale ................................................... 4-17

Scale On and Off ..................................... 4-19

ia ................................................... 3-32

4-5

®

Account Number ......... 4-14

4-15

4-15

4-16

SV61891 Rev. A vii

Page 9

Table of Contents

Defining Presets .......................................................................4-22

Storing a Current Setting ..............................................4-22

Viewing a Preset ...........................................................

Renaming a Preset ....................................................... 4-24

Deleting a Preset ..........................................................4-24

Performing Updates, Add-Ons, and Enabling Features ...........4-25

Rebooting Your System after an Update or Add on ......

Using IntelliLinkTM to Check for Updates ....................... 4-26

Enabling Accounting or Adding more Ac

Downloads from the Data Centre to Your Machine ....... 4-28

Getting Information About Your Control Centre ........................

Chapter 5–Adding Postage

A Word About Refills ................................................................... 5-2

Connecting Your IntelliLink

Analog Phone Line .....................................................................5-2

Checking Postage Funds Available ............................................

Printing a Record of this Information on the

DM230L/DM330L ............................................................ 5-2

Printing a Record of this Information on the DM350L ..... 5-3

Checking Your

Performing a Modem Refill ......................................................... 5-4

Printing a Refill Summary ........................................................... 5-5

Postage By Phone® Account Balance ................ 5-4

TM

4-23

4-25

counts ............4-27

4-29

Control Centre to an

5-2

Chapter 6–Maintenance

Filling theMoistener ..................................................................... 6-2

The DM230L/DM330L System .......................................

The DM350L System .....................................................

Maintaining the Moistener ........................................................... 6-4

Removing and Cleaning the DM230L/DM330L ..............6-4

Removing and Cleaning the DM350L ............................. 6-6

Loading the Tape Strip Feeder ...................................................

The DM230L/DM330L ..................................................... 6-9

The DM350L ................................................................... 6-9

Calibrating the Tape Length ......................................................

Maintaining the Printer .............................................................. 6-11

Purging the Printhead ................................................... 6-11

Testing

Adjusting the Print Position ....................................................... 6-13

Replacing the Ink Cartridge ...................................................... 6-14

“Low Ink” ....................................................................... 6-14

“Out of Ink” .................................................................... 6-14

Replacing the Printhead ...........................................................6-15

Print Quality ...................................................... 6-12

6-2

6-3

6-9

6-10

viii SV61891 Rev. A

Page 10

DM230L, DM330L, DM350L Operating Guide

Chapter 7–Troubleshooting

Getting Help ................................................................................ 7-2

Before You Call... ............................................................

Power Problems .........................................................................7-3

Envelope Feeding Problems - DM230L/DM330L ....................... 7-3

Envelope Tape/Feeding Problems - DM350L .............................

Tape Feeding Problems ..............................................................

Printing Problems .......................................................................7-9

Display Problems ........................................................................ 7-9

Moistening Problems ................................................................ 7-10

Refill Problems .......................................................................... 7-11

Display Messages ..................................................................... 7-12

Blink Codes ............................................................................... 7-13

Postage By Phone® Error Codes .............................................. 7-16

Chapter 8–Supplies and Options

Supplies and Accessories ........................................................... 8-2

Options .......................................................................................8-3

Departmental Accounting ................................................

Printing ............................................................................ 8-3

Weighing .........................................................................

7-2

7-4

7-7

8-3

8-4

Appendix A–Reports

Overview of Reports ...................................................................A-2

Accessing Reports ......................................................................A-2

Account Reports .............................................................A-3

Refill Summary ................................................................A-3

Configuration Report .......................................................A-4

Error Report ....................................................................A-4

Meter Setup Report .........................................................A-4

Appendix B–Accounting Setup

Overview of Accounting ..............................................................B-2

Setting Up Accounts ..................................................................B-2

Selecting Accounting Status .......................................................

Creating an Account ...................................................................

Changing an Account ..................................................................B-4

Deleting an Account ....................................................................B-4

Clearing All

Enabling Passwords ...................................................................B-6

Enabling the Clear Individual Accounts Feature .........................B-7

Accounts ..................................................................B-5

Index

Index ............................................................................................ I-1

B-3

B-3

SV61891 Rev. A ix

Page 11

Table of Contents

x SV61891 Rev. A

Page 12

Contacts

Chapter Contents

This section lists all of the Pitney Bowes contact

information.

Pitney Bowes Contact

Information List ...................................................xii

SV61891 Rev. A

Page 13

Contacts

Pitney Bowes Contact Information List

Pitney Bowes Web Sites

Go to www.pitneybowes.ca to:

• View frequently asked questions (FAQs),

• Order PB supplies and accessories,

• Place requests for service,

• View order status for supplies, and

• Add postage to your Postage By Phone

®

account.

xii SV61891 Rev. A

Page 14

DM230L, DM330L, DM350L Operating Guide

Our Help Desk

For direct questions, call: 1.800.672.6937. Customer Service

Representatives are available Monday through Friday,

8:00 AM – 7:45 PM EST.

Postage By Phone

®

To contact Postage By Phone®, call 1.800.387.4660.

Pitney Bowes Supplies

To order genuine Pitney Bowes supplies, call the Supply Line

1.800.672.6937 or visit us online at www.pitneybowes.ca.

TM

at

SV61891 Rev. A xiii

Page 15

Contacts

xiv SV61891 Rev. A

Page 16

1 Specifications and Safety

Information

Chapter Contents

What is IntelliLinkTM ..........................................1-2

Postal Requirements ........................................ 1-3

The Quick Reference Guide .............................1-3

Specifications ...................................................1-4

Important Safety Notes .....................................1-6

Telephone Safety Instructions ..........................

1-9

SV61891 Rev. A

Page 17

1 • Specifications and Safety Information

What is

IntelliLink

TM

IntelliLink, provides you with a digital gateway to an entire suite of services

and information to help you move your mail more efficiently and enhance

your business performance. It allows you to:

Add Features On Demand

You can easily download envelope ads and optional product

enhancements such as departmental accounting.

Download Postal Rate Updates

The latest postal rates are downloaded precisely when you need them.

Keep Your System Current

Software download capability means you'll always have the latest version

of your machine's operating system.

1-2 SV61891 Rev. A

Page 18

DM230L, DM330L, DM350L Operating Guide

Postal Requirements

The postage meter on your mailing system is a Postal Security Device

(PSD) approved by the Canada Post Corporation to secure funds. Since it

is licensed by the Canada Post Corporation, you must follow a few basic

requirements.

Canada Post Corporation Requirements

• Mail must have the correct date and postage amount in the digital

indicia.

• Metered mail must bear the postal code of the location where the mail

is originated.

• If you move to another Postal Code location, you must update the Postal

Code. You can do this by calling Postage By Phone

NOTE: If you move your mailing system to a different postal code, you will

need to update your system before processing mail at your new location. (See

the Contacts section at the front of this guide for more information.)

• Each time you refill your postage meter (Postal Security Device)

through the modem, the Postage By Phone® computer automatically

performs a postal inspection. If the postage meter in your mailing

machine has not detected a modem refill transaction at certain

intervals, the message “Inspection Required” appears on the main

screen of the IntelliLinkTM Control Centre. (The system will then prompt

you to connect to Pitney Bowes and perform an inspection.)

• The postage tape you use must meet Canada Post specifications.

To order approved supplies for your mailing system refer to Chapter 8

– Supplies and Options

®

.

The Quick Reference Guide

SV61891 Rev. A 1-3

The Quick Reference Guide supplied

with your mailing system is located

in the tray under the mailing machine

base. It contains a summary of the most

common operating procedures.

Page 19

1 • Specifications and Safety Information

Specifications

Equipment

DM230L/DM330L

Size: 14"D (356 mm) x 14.5" W (368 mm) x 15" H (381 mm), not including

stacker tray.

Weight

DM350L

Size: 16.25D (413 mm) x 31" W (787 mm) x 16" H (406 mm),

not including stacker tray.

Weight

DM230L, DM330L and DM350L

Power Requirements: 120 VAC, 60 Hz, 3A

Communications Ports: 1 USB; 1 Serial (RS-232);

1 RJ-11.

Operating Temperature:

Average Throughput: 90 letters per minute maximum (DM350L).

Actual throughput will vary, depending on the material used, machine

condition and the skill of the operator.

Tape Strip: self-adhesive type. Capacity: 50 tapes (DM330L and

DM350L).

Internal Envelope Ad Storage:

Optional Departmental Accounting:

depending on option purchased.

: 17.6 lbs. (8 kg), approximate.

: 29.0 lbs. (13.2 kg), approximate.

40F (4C) to 108F (42C)

up to 20 envelope ads.

supports up to 100 accounts,

1-4 SV61891 Rev. A

Page 20

DM230L, DM330L, DM350L Operating Guide

13.39"

11.6"

3"

Maximum

4.13"

3"

1"

Minimum

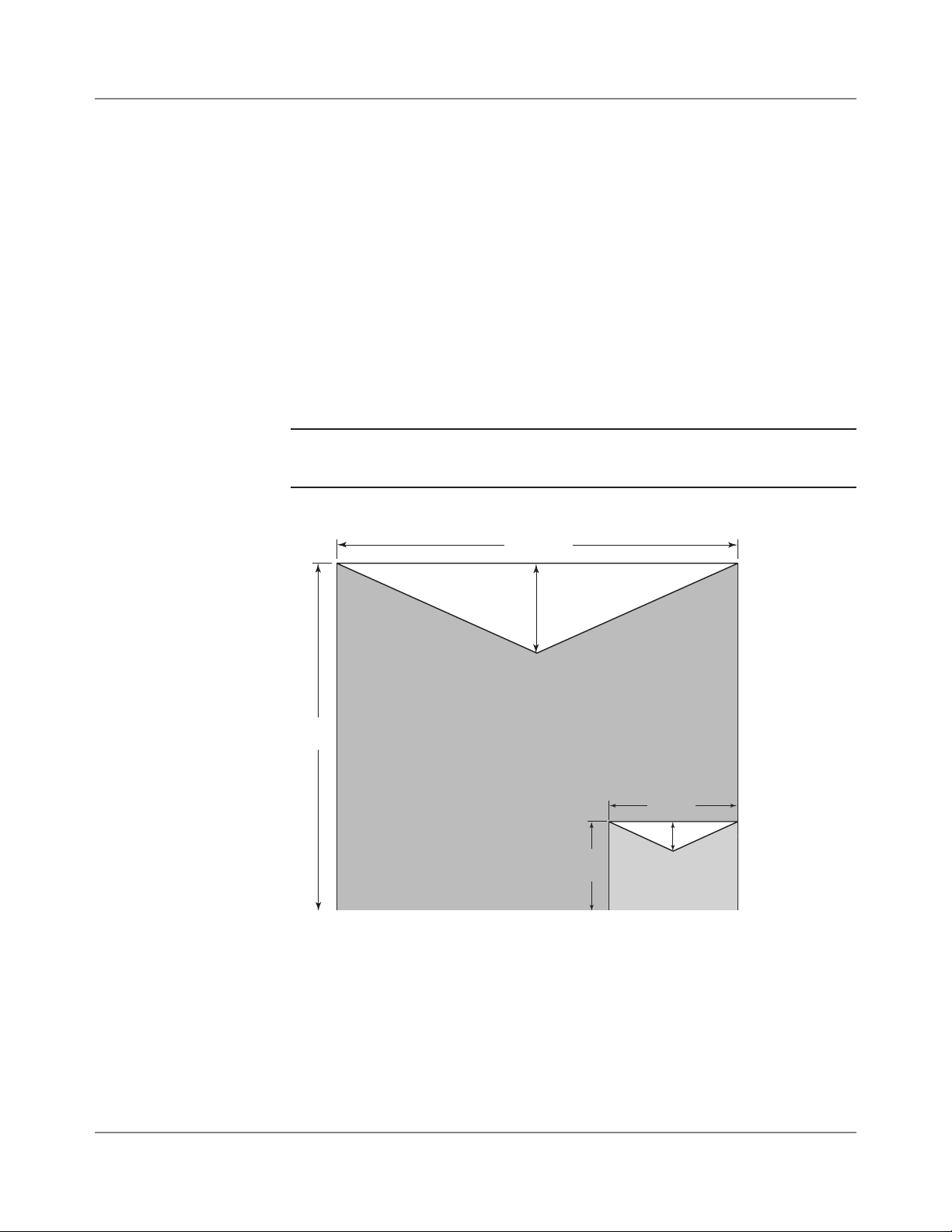

Specifications

continued…

Material

(See Figure below)

Minimum Size: 3.5" x 4.13" (89 x 105 mm), moistening;

3" x 4.13" (76 x 105 mm), non-moistening

Maximum Size: 11.6" x 13.39" (297 x 340 mm)

Minimum Flap Depth: 1" (25 mm)

Maximum Flap Depth: 3" (76 mm)

Minimum Thickness: 0.007" (0.2 mm)

Maximum Thickness: 0.25 in. (8 mm)

Maximum Stack Height for Mail on DM350L: 3"(76 mm)

IMPORTANT! For best results, always make sure your material conforms to our

published specifications.

Envelope Dimensions

SV61891 Rev. A 1-5

Page 21

1 • Specifications and Safety Information

Specifications

continued…

Important Safety Notes

Maximum Imprint: $99.99

Reset Type: Postage By Phone

Piece Count: Up to 8 digits (nonresettable)

When using the DM230L, DM330L or DM350L, follow the basic safety

precautions for all office equipment.

• Use only Pitney Bowes approved supplies, in particular aerosol

dusters. Improper storage and use of aerosol dusters or flammable

aerosol dusters, can cause an explosive-like condition that could

result in a personal injury and/or property damage. Never use aerosol

dusters labeled flammable and always read instructions and safety

precautions on the duster container.

• Use only genuine Pitney Bowes ink, tape strips, tape sheets, and

cleaning products. Call the PB Supply LineTM or visit our web site to

place orders.

If you need Material Safety Data Sheets on supplies for OSHA

requirements, please visit our web site or call the Supply LineTM.

NOTE: Refer to the Contacts section at the front of this guide for the Supply

LineTM phone number and web site information.

®

• Read all instructions before operating the equipment. Use the equipment only for its intended purpose.

• Operation of this equipment without periodic maintenance will inhibit

optimum operating performance and could cause the equipment to

malfunction. Contact your Pitney Bowes Customer Service

Representative for required service schedule.

• Use the power cord supplied with the machine. Plug it and if

applicable, all other supplied power cords into a properly grounded

wall outlet that is located near the machine and easily accessible,

meaning it is free from obstruction and there is enough room around

the unit for servicing.

1-6 SV61891 Rev. A

Page 22

DM230L, DM330L, DM350L Operating Guide

Important Safety

Notes

continued…

• The power cord wall plug is the primary means of disconnecting the

machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet. Do not

remove the ground pin from the line cord.

• Avoid using wall outlets controlled by wall switches or shared with

other equipment. Your mailing machine performs periodic maintenance

cycles automatically to assure best print quality; leave it ON at all

times. Do not route the power cord over sharp edges, or allow it to be

trapped between furniture and/or furniture and the wall.

• Avoid touching moving parts or materials while the machine is in

use. Keep hands, loose clothing, jewelry, and long hair away from all

moving parts.

• Keep your hands out of the ink cartridge refill holder.

• Do not remove covers. Covers enclose hazardous parts that should

only be accessed by properly trained service personnel.

• Before clearing a stall, be sure machine mechanisms come to a stop.

When removing stalled material, avoid using too much force to protect

against minor personal injury and damaging equipment.

• Immediately report to Pitney Bowes Service any damaged or

non-functioning components. The unit may be unsafe for use.

• To prevent overheating, do not cover the vent openings. At times vent

openings may not be visible, but still allow ample spacing around the

unit for ventilation.

• Do not place lighted candles, cigarettes, cigars, etc., on the mailing

machine.

NOTE: Always follow the specific occupational safety and health standards for

your workplace.

SV61891 Rev. A 1-7

Page 23

1 • Specifications and Safety Information

Important Telephone Safety Instructions !!!

The IntelliLinkTM Control Centre connects directly to analog telephone

lines. For your protection, basic safety precautions should always be

followed to reduce the risk of fire, electric shock, and injury to persons.

These safety precautions include:

CAUTION To reduce the risk of fire, use only 26 AWG

telecommunication line cord either supplied with the machine or

separate.

• Never install telephone wiring during a lightning storm.

• Disconnect the system's telephone line during a lightning storm.

• Avoid using a telephone or equipment that connects to a telephone

line during an electrical storm; there may be a remote risk of electrical

shock from lightning.

• Do not use the telephone or equipment connected to the telephone

line to report a gas leak in the vicinity of the leak.

• Never install telephone jacks in wet locations.

• Do not use this product near water, for example, near a bath tub, wash

bowl, kitchen sink or laundry tub, in a wet basement or near a swimming pool.

• Never touch uninsulated telephone wires or terminals unless the

telephone line has been disconnected at the network interface.

!!! Save these Instructions !!!

1-8 SV61891 Rev. A

Page 24

2 Getting to Know

Your System

Chapter Contents

This chapter describes the parts

of your DM Series systems.

Parts of the DM230L/DM330L System .............

Parts of the DM350L System ............................

DM350L Autofeeder Control Panel ................... 2-6

IntelliLinkTM Control Centre -

DM230L/DM330L .............................................2-8

IntelliLinkTM Control Centre -

DM350L ..........................................................2-10

Machine Features - Side, Rear of

DM230L/DM330L and DM350L ......................

2-2

2-4

2-12

SV61891 Rev. A

Page 25

2 • Getting to Know Your System

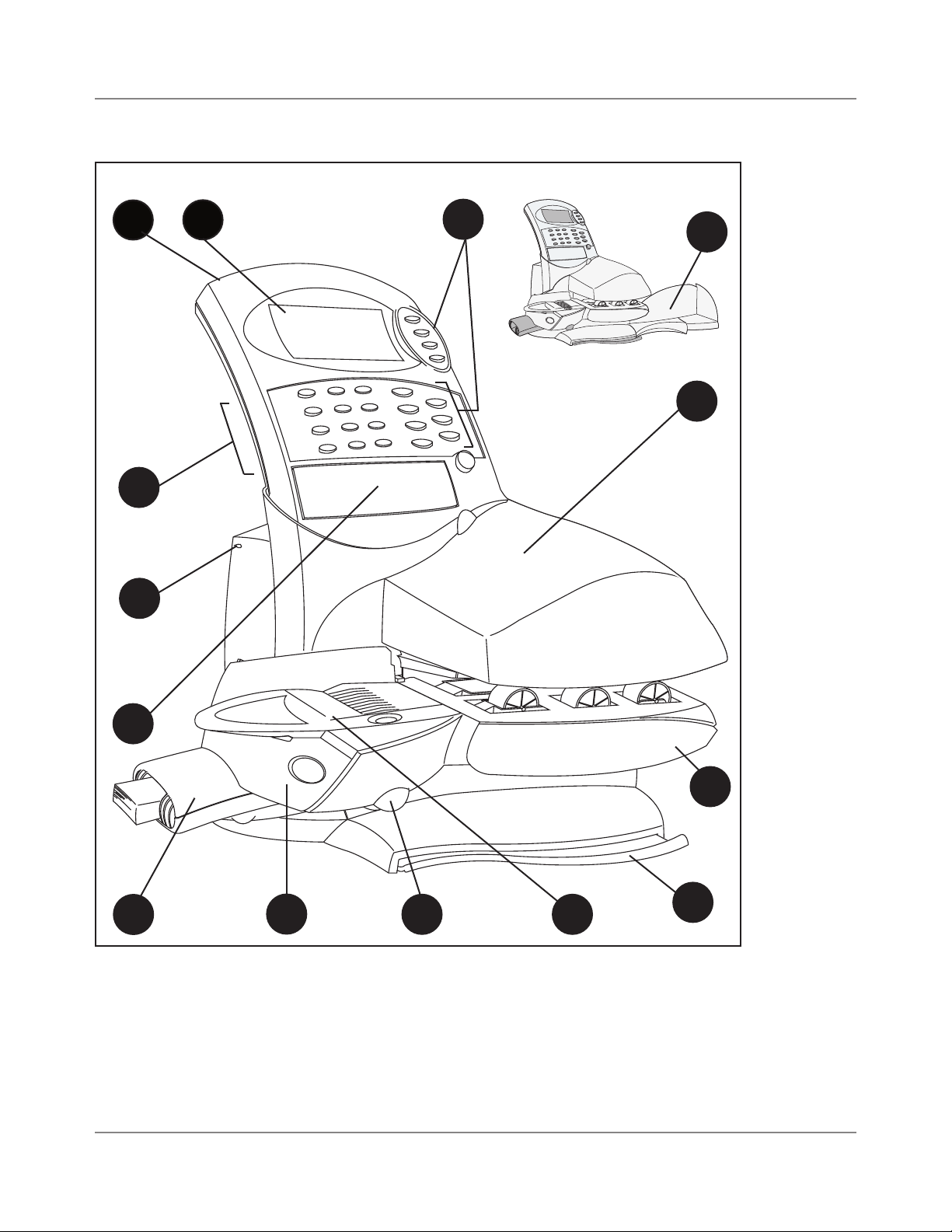

Parts of the DM230L/DM330L System

1

14

13

2

3

4

DM330L - shown with Stacker

5

12

6

11

2-2 SV61891 Rev. A

10

9

8

7

Page 26

DM230L, DM330L, DM350L Operating Guide

1. IntelliLinkTM Control Centre - Contains the operator display, keypad

and function keys for communicating with the mailing system and the

build in postage meter (Postal Security Device, PSD).

2. Operator Display - Shows the current status of your system and

prompts you through all setup operations.

3. Function Keys - Allow you to get information from the control centre

and tell it what to do. Refer to IntelliLinkTM Control Centre - DM230L/

DM330L on page 2-8 for a description of each key.

4. Stacker Tray - The mailing machine neatly stacks finished mail piec-

es here.

5. Front Access Cover - Provides access to the printhead.

6. Printer Transport Release Lever - Pull the release lever forward to

lower the transport deck and clear a stalled mail piece. The transport

deck is interlocked; the mailing machine won't run when it's open.

7. Quick Reference Guide - This contains a summary of the most com-

mon operating procedures.

8. Feed Deck - Supports your envelope, post card or tape strip as it

passes under the printhead.

9. Moistener Release Button - This allows you to remove the moist-

ener from the mailing machine.

10. Moistener - Applies sealing fluid to the envelope flap when you select

sealing.

11. Tape Feeder (DM330L only)

sized letters and packages.

12. Alpha Keypad Cover - Open the cover to use the alpha keypad. You

use the keypad to assign names to accounts and custom presets.

13. Power Lamp Indicator - Lights when mailing machine is on. Also

flashes to indicate an error condition.

14. Numeric Keypad - Use numeric keypad to manually enter weight,

postage values, (eg: Corrections, Statement of Mailings / Manifests)

or creating names for accounting departments.

- Holds 50 tape strips for use on over-

SV61891 Rev. A 2-3

Page 27

2 • Getting to Know Your System

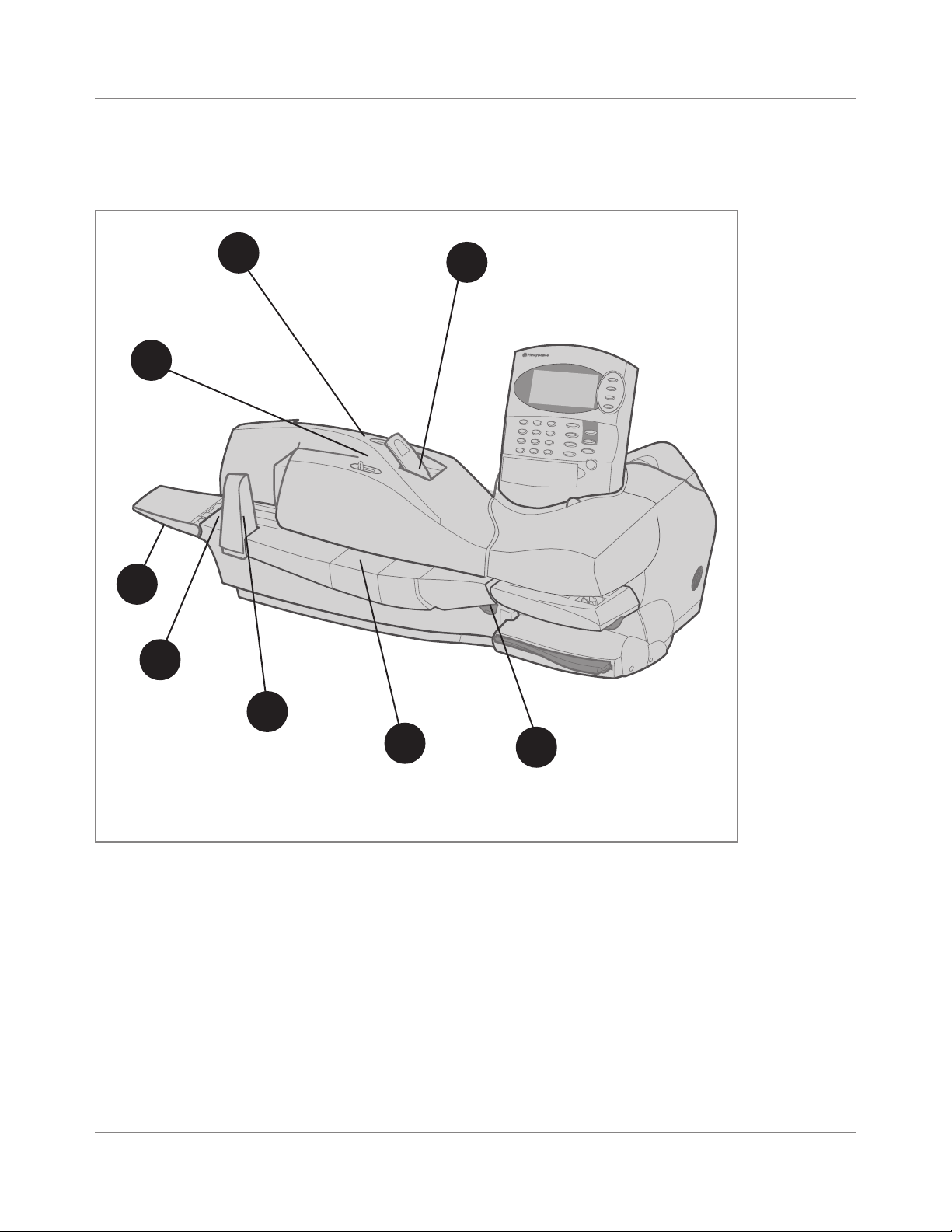

Parts of the DM350L System

2

3

1

4

5

6

7

2-4 SV61891 Rev. A

8

Page 28

DM230L, DM330L, DM350L Operating Guide

1. Autofeeder Control Panel - Contains all of the levers for the feeder

section of the DM350L. See DM350L Autofeeder Control Panel on the

next page for more information.

2. Moistener Container - Holds the sealing fluid for sealing the

envelope flap. You feed the envelopes the same way whether you

are sealing them or not.

3. Tape Feeder - Holds 50 tape strips for use on oversized letters and

packages (DM330L and DM350L).

4. Rear Feed Guide - Lower this guide when you are feeding a stack of

mail.

5. Transport Deck - This is where you load your mail.

6. Side Guide - Set this to reduce the skewing of pieces of mail as you

feed them into the feeder.

7. Moistener Assembly - This contains the brush and wick used to

moisten the envelope flaps for sealing.

8. Autofeeder Transport Release Lever - Pull this lever forward to drop

this section of the transport deck to clear stalls.

SV61891 Rev. A 2-5

Page 29

2 • Getting to Know Your System

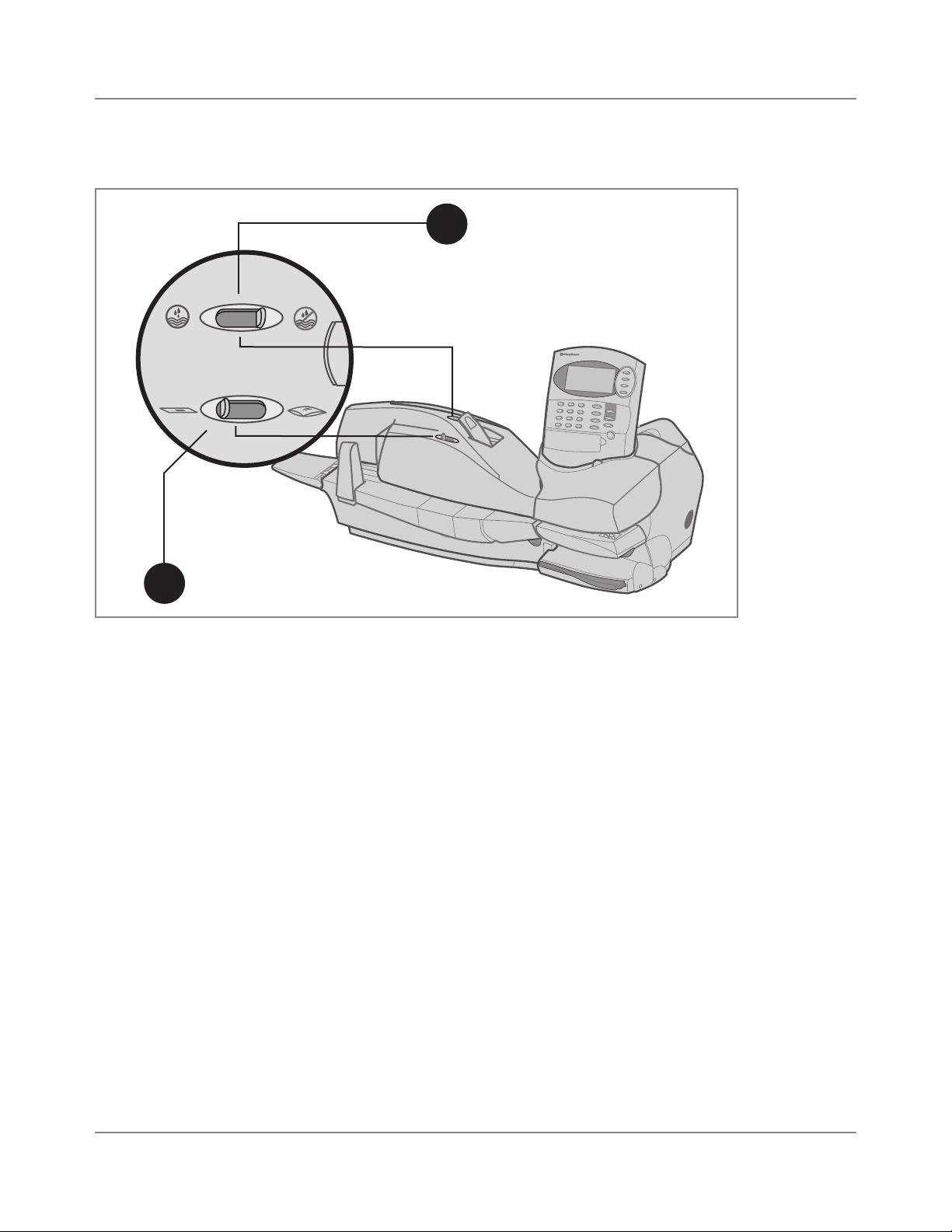

DM350L Autofeeder Control Panel

1

2

2-6 SV61891 Rev. A

Page 30

DM230L, DM330L, DM350L Operating Guide

1. Seal/No Seal - Use this to select seal or no seal. The position shown

is for no seal.

2. Thickness Selection Lever - Use this to adjust for the thicknesses of

the envelopes you are feeding into your DM350L system. The setting

shown here is for thin envelopes. The thick setting is for materials up

to 1/4" (6.3mm) thick.

SV61891 Rev. A 2-7

Page 31

2 • Getting to Know Your System

IntelliLinkTM Control Centre - DM230L/DM330L

16

1

2

3

4

0.000kg

2006.08.17

Class: None

Place mail on scale or

Enter manual weight

$0.00

5

6

7

8

9

10

11

12

13

15

2-8 SV61891 Rev. A

14

Page 32

DM230L, DM330L, DM350L Operating Guide

1. LED - Lights green when your control centre is on. Turns orange when

your control centre is in sleep mode.

2. Operator Display - Shows the current status of your control centre. It

normally displays the settings you use most often.

3. Lock Control Centre - When on, this feature prevents unauthorized

use of your control centre. Enter your four-digit password to unlock the

control centre.

4. Normal Preset - Press to return to the factory default setting.

5. Custom Presets - Press to select from a list of up to 10 custom settings. You can assign a number of values (e.g., ad, account number

and others) to each custom preset.

6. Date/Ad - Press to change the date or choose the ad you want to print.

7. Account - (This feature is optional.) Press to select from a list of

accounts. The control centre charges the postage used to the account

you select and stores the information for report printing.

8. Tape - Press to print a tape strip. Apply tape strips to oversize enve-

lopes and packages. NOTE: The Tape button is only functional with the

DM330L and DM350L.

9. Acct/Batch Totals - Press to see the total postage used and number

of pieces charged to an account. If the accounting feature is not

enabled (on), the display shows the total postage used and number of

pieces of mail processed since the batch register was last reset.

10. Class - Press to select the class of mail service. This is a required

action for all mail processing jobs.

Refill - Press to add postage to your control centre.

11.

12. Options (no) - Press to select operating mode, check print quality,

print reports or set your system up. Also press to answer “No” to a

display prompt.

13. Enter (yes) - Press to confirm an operation or answer “Yes” to a

prompt.

14. Funds - Press to see the postage funds available, funds used and

number of mail pieces processed by your system. You can also print a

funds report for your records.

15. Alpha Keypad - Use this to type in account names and other

information when you set your system up.

16. Numeric Keypad - Use this to key in postage values (Corrections,

Statement of Mailings / Manifests), refill amounts and other numerical

information. Press CE/C to clear an entry or move back through the

setup menus to exit them.

SV61891 Rev. A 2-9

Page 33

2 • Getting to Know Your System

IntelliLinkTM Control Centre - DM350L

16

1

2

3

4

0.000kg

2006.08.17

Class: None

Place mail on scale or

Enter manual weight

$0.00

5

6

7

8

9

10

11

12

13

15

2-10 SV61891 Rev. A

14

Page 34

DM230L, DM330L, DM350L Operating Guide

1. LED - Lights green when your control centre is on. Turns orange when

your control centre is in sleep mode.

2. Operator Display - Shows the current status of your control centre. It

normally displays the settings you use most often.

3. Lock Control Centre - When on, this feature prevents unauthorized

use of your control centre. Enter your four-digit password to unlock the

control centre.

4. Normal Preset - Press to return to the factory default setting.

5. Custom Presets - Press to select from a list of up to 10 custom

settings. You can assign a number of values (e.g., ad, account number

and others) to each custom preset.

6. Date/Ad - Press to change or omit the date or choose the ad you want

to print.

7. Account - Press this key to access the Account Batch Totals and

Account menu options:

• Acct/Batch Totals - Press to see the total postage used and

number of pieces charged to an account. If the accounting feature

is not enabled (on), the display shows the total postage used and

number of pieces of mail processed since the batch register was

last reset.

• Account - (This feature is optional.) Press to select from a list of

accounts. The control centre charges the postage used to the

account you select and stores the information for report printing.

8. Mail - Press to feed your mail.

9. Class - Press to select the class of mail service. This is a required

action for all mail processing jobs.

10. Tape - Press to print your tapes.NOTE: The Tape button is only func-

tional with the DM330L and DM350L.

11.

Refill - Press to add postage to your control centre.

12. Options (no) - Press to select operating mode, check print quality,

print reports or set your system up. Also press to answer “No” to a

display prompt.

13. Enter (yes) - Press to confirm an operation or answer “Yes” to a

prompt.

14. Totals - Press to see the postage funds available, funds used and

number of mail pieces processed by your system. You can also print a

funds report for your records.

15. Alpha Keypad - Use this to type in account names and other

information when you set your system up.

16. Numeric Keypad - Use this to key in postage values (Corrections,

Statement of Mailings / Manifests), refill amounts and other numerical

information. Press CE/C to clear an entry or move back through the

setup menus to exit them.

SV61891 Rev. A 2-11

Page 35

2 • Getting to Know Your System

Machine Features - Side, Rear of DM230L/DM330L and DM350L

7

1

Control centre and the

mailing system base.

6

5

4

3

2

1. Rear Cover - Open the rear cover to replace the ink cartridge. See

Chapter 6 for instructions.

2. Power Receptacle - The power cord goes here

3. Autofeeder Port - (DM350L Only) Autofeeder cable attaches here.

4. Serial Port - Use this to connect your control centre to a Pitney Bowes

serial printer.

5. Phone Jack - Plug an analog phone line here. (Fax machines are

usually connected to an analog phone line.) The jack accepts a standard RJ-11 phone plug. If your control centre is hooked to a phone

line, you can add postage anytime using the one-button refill feature.

See Chapter 5 for details.

6. USB Port - Use this to connect your control centre to external devices

that support the USB communications protocol.

7. Base LED - This stays lit when power is applied to the system and

blinks when there is an error condition in the base. Refer to Blink

Codes in Chapter 7 for details.

2-12 SV61891 Rev. A

Page 36

3 Running Mail

Chapter Contents

Before You Begin ..............................................3-2

Checklist ...........................................................3-2

The Ready Screen ...........................................3-2

Applying Postage and Running Mail ................3-3

Printing Postage on an Envelope ..................... 3-4

Printing Postage on Tape Strips .................... 3-11

Printing Postage Using Presets ......................3-17

Sealing the Envelopes Only ...........................3-18

Selecting a Class or Special Service ..............3-19

Printing an Advertisement ..............................

Printing the Date and Time

on Incoming Mail ............................................3-23

Changing the Date on Your Mail .....................

Selecting an Account ......................................3-25

Checking and Clearing the Batch Count .......3-25

Viewing the Weight in

Adding or Correcting Postage ........................3-28

Printing a Statement of Mailing / Manifest ......3-30

Test Print / Zero Dollar Indic

Imperial Units ..............3-27

ia ........................3-32

3-23

3-24

SV61891 Rev. A

Page 37

3 • Running Mail

Before You Begin

Checklist

The Ready Screen

Before you run mail on your system, review the Checklist below.

• Make sure your mailing system is plugged into a properly grounded,

110 VAC receptacle. Always follow the safety precautions in Chapter 1.

• Check the level of sealing solution in the moistener. If you need to add

sealing solution, refer to Chapter 6 in this guide.

• If you plan on printing tape strips make sure you've loaded an

adequate supply. See Chapter 6 for instructions.

• Check that you have enough postage for your mail run. Refer to

Chapter 5 for instructions on checking the amount of postage in your

system and your account.

When you power up your system, the Ready screen appears on the

Control Centre operating display. If your system has been set up to

require a lock code or password, you are prompted to enter it.

A typical Ready screen is show here:

0.000kg

2006.08.17

Class: None

Place mail on scale or

Enter manual weight

• To process a mail piece from the Ready screen you must place your

mail piece on the optional scale or enter the weight of the mail piece

manually, and then select a class. For more information on processing

mail, please refer to the specific topics later in Chapter 3.

• If you want to do something other than print postage on an envelope

or tape, press the Options key. This provides you with access to other

mailing modes and the system setup options. For information on the

setup options refer to Chapter 4 in this guide.

$0.00

3-2 SV61891 Rev. A

Page 38

DM230L, DM330L, DM350L Operating Guide

Applying Postage and Running Mail

You can select several different modes for applying postage or running

mail on your DM230L/DM330L or DM350L system. Refer to the

appropriate procedure listed here.

Printing Postage on an Envelope.

1

Printing the Postage on a Tape or Tape Strips.

2

Printing Postage Using Presets.

3

Press a key to select certain system values (for example,

postage amount) assigned to that key.

Sealing the Envelopes Only - No Postage.

4

Selecting a Class or Special Service.

5

Printing an Advertisement.

6

You can print an advertisement along with your postage,

or print only the ad.

Printing the Date and Time on Incoming Mail.

7

8

9

10

11

12

13

14

Changing the Date on Your Mail.

Selecting an (optional) Account.

Checking and Clearing the Postage Batch Count on

Your System.

Viewing Postage Weight in Imperial Units.

Adding Postage or Correcting Postage

Printing a Statement of Mailing or Manifest Payment

Test Print / Zero Dollar Indicia

SV61891 Rev. A 3-3

Page 39

3 • Running Mail

Printing

1

Postage on

an Envelope

Processing Lettermail on the DM230L/ DM330L System without the optional weight platform

The procedures for printing postage on an envelope are different for the

DM230L/DM330L and the DM350L systems. In addition, there are different

procedures if you have purchased the optional weight platform or parcel

rating module. Refer to the appropriate procedure in this section.

1. If you have the optional accounting feature press the Account button

and select an account.

TM

2. From the Ready screen on the IntelliLink

Class button and then press option # 6 for Enter Manual Weight.

3. Enter weight in kilograms (e.g., 10 grams would be 0.01 kg) and then

press Enter.

4. Press option #1 for Lettermail and press

sub-class (e.g., Domestic Standard, Domestic Other, USA, etc.) using

the appropriate numeric key and then press Enter.

NOTE: The internal rating feature will calculate the postage ammount based

on the weight and class selected. A weight input and class selection are

required for all mail jobs. You cannot enter the postage value manually using

the numeric keys.

Control Centre press the

Enter and select the desired

5. If desired select any special services (e.g., Registration, Insurance

Coverage) and press Enter. If no special services are requested press

Enter.

6. The postage amount will be displayed in the top right hand corner of

the display and another message will indicate “Ready to Print.”

If you do not want to seal the envelope:

1. Hold the envelope by its bottom edge.

2. Place the envelope ADDRESS SIDE UP on the feed deck.

3-4 SV61891 Rev. A

Page 40

DM230L, DM330L, DM350L Operating Guide

Processing

Lettermail on

the DM230L/

DM330L

System without

the optional

weight platform

continued…

3. Push the envelope to the rear (A)

so its top edge is up against the

back wall of the system.

4. Slide the envelope to the right (B)

until the system grasps it. The

system prints the postage and

ejects the envelope.

If you want to seal the envelope:

1. Hold the envelope ADDRESS SIDE UP.

2. Pull the flap slightly away from the envelope.

3. Slide just the flap under the blue edge of the feed deck as shown.

A brush below the deck wets the flap.

DM330L shown above.

4. Slide the envelope to the right until the system takes hold of it.

The system prints the postage and ejects the piece.

5. To complete sealing, compress the envelope stack.

See

SV61891 Rev. A 3-5

Chapter 6 for instructions on refilling and maintaining the

moistener.

Page 41

3 • Running Mail

Mail In a Minute – Processing a Letter Using the Integrated Weigh Platform

1. Weigh Mail Piece – Place mail piece on the integrated weigh platform.

2. Select Class – Press the Class button and select Change Class

(option 1.) then select Lettermail and press Enter to confirm.

3. Select your desired Lettermail sub-class (e.g., Dom Standard, Dom

Other, USA, International) and then press

4. Select any desired special services (e.g., Registration, Insurance

Coverage) by selecting the appropriate menu options. If no special

services are required press Enter.

5. The ready screen will now display the postage amount in the top right

hand corner of the system display, and the message “Ready to Print”

will appear.

NOTE: You cannot enter postage values manually into the mailing system

using the numeric keypad. All mailing transactions must be processed by a

combination of weight entry (integrated weight platform or manual entry) and

making a class selection. The internal rating feature calculates the accurate

postage for each mail job.

If you do not want to seal the envelope:

Enter to confirm.

1. Hold the envelope by its bottom edge.

2. Place the envelope ADDRESS SIDE UP on the feed deck.

3. Push the envelope to the rear (A) so its top edge is up against the

back wall of the system.

3-6 SV61891 Rev. A

Page 42

DM230L, DM330L, DM350L Operating Guide

Mail In a Minute

– Processing

a Letter Using

the Integrated

Weigh Platform

continued…

4. Slide the envelope to the right

(B) until the system grasps it.

The system prints the postage

and ejects the envelope.

DM330L shown above.

If you want to seal the envelope:

1. Hold the envelope ADDRESS SIDE UP.

2. Pull the flap slightly away from the envelope.

3. Slide just the flap under the blue edge of the feed deck as shown.

A brush below the deck wets the flap.

4. Slide the envelope to the right until the system takes hold of it.

The system prints the postage and ejects the piece.

5. To complete sealing, compress the envelope stack.

See

SV61891 Rev. A 3-7

Chapter 6 for instructions on refilling and maintaining the

moistener.

Page 43

3 • Running Mail

Processing and Feeding Lettermail on the DM350L System

Processing Lettermail on the DM350L requires the same process as the

DM230L and DM330L. You must first weigh the mail piece using the

integrated weigh platform or through the Manual Weight Entry feature.

You then must select a class of mail in order for the internal rating feature to

calculate the exact postage amount. For a summary of the exact keystrokes

required to process Lettermail please refer to the instructions outlined on the

previous pages for the DM230L and DM330L

1. Sort the mail according to size and thickness. For each run, feed envelopes

of the same size and similar thickness.

• If you are printing a single normal envelope, the envelope can be

up to 1/8” thick.

• If you are printing a single thick envelope, the envelope can be up

to 1/4” thick. Do not feed more than 2 thick envelopes at one time.

• If you are printing a stack of envelopes, the thickness of the stack

cannot exceed 3.0”.

• For acceptable length and width dimensions of envelopes, refer to

the Specifications section in Chapter 1 in this guide.

2. Align the stack of mail by tapping the side of the stack on a hard surface.

Fan the stack to separate the mail pieces.

3. Set the thickness selection lever (see figure below) to correspond to

the correct thickness of the envelopes. For normal mail move the

thickness selection lever all the way to the left.

4. Set the Seal/No Seal lever (figure below) to the correct position.

To seal the envelopes, move the lever all the way to the left.

Seal/No Seal selection lever

Thickness selection lever

3-8 SV61891 Rev. A

Page 44

DM230L, DM330L, DM350L Operating Guide

Processing and

Feeding Lettermail

on the DM350L

System

continued…

5. For both sealing and non-sealing mode, place the envelopes on the

feed deck with the flaps down and facing the rear wall.

Shingle the envelopes so that the bottom envelope feeds first. All

envelopes should be the same size.

Make sure the envelopes are pressed up against the back wall of the

deck. Make sure the envelopes are making contact with the feed roller.

Feed roller

Feed guide (remains flat for most mail)

6. To feed oversized envelopes:

a. Lower both feed and side guides.

b. Guide the envelope along the feed

deck with your hand.

Side

guide

SV61891 Rev. A 3-9

Page 45

3 • Running Mail

Processing and

Feeding Lettermail

on the DM350L

System

continued…

7. If the postage does not print on the envelope, it may have been

skewed when it entered the print area. If that occurs, you will get the

following error message in the display on the IntelliLinkTM Control

Centre:

“Mailpiece skewed

Reset... CE/C key”

Press the

Feed the piece of mail again.

8. If the envelope stalls in the feeder or printer area, refer to the

Envelope Feeding Problems section in Chapter 7 of this guide.

NOTE: If you get the message "envelope stall" in the message display, try

pressing the Mail button to see if this feeds the envelope. You may get an

envelope stall message if for any reason the envelope does not reach the

sensor in the feeder within a certain time interval.

CE/C key on the control centre.

3-10 SV61891 Rev. A

Page 46

DM230L, DM330L, DM350L Operating Guide

Printing

2

Postage on

Tape Sheets

and Tape

Strips

DM230L/ DM330L: Printing Tapes

The procedures for printing postage on tapes strips are different for the

DM230L/DM330L and the DM350L systems. Refer to the appropriate

procedure in this section.

Use tape strips to apply postage to larger envelopes or parcels. You can

print tape strips one at a time or in batches of up to 50. If you need to load

tape strips, see Chapter 6 in this guide.

1. From the Ready screen on the

IntelliLinkTM Control Centre, rate your

mail piece by weighing it on the optional

weigh platform or by entering the weight

manually (press Class and then select

Manual Weight Entry). Then select a

class for the mail piece and any desired

special services.

2. Press the Tape key.

3. The system display prompts you to

enter the number of tape strips you

want to print.

4. Key in the number you want. You can

enter a number ranging from 1 up to a

maximum of 50.

5. Press the Enter key. The system automatically feeds and prints the

number of tapes you entered with the postage value you selected.

The display says “Printing Tape...” and shows the number of tapes

remaining to print.

NOTE: The DM230L does not have a Tape Strip dispenser. In order to process

a parcel you must use a Tape Sheet which is run throught the feeder like an

envelope. To order Tape Sheets refer to Chapter 8 – Supplies and Options.

Load tape strips blank

side up; push them into

the feeder as far as they'll

go. You'll feel a slight resistance before they're all

the way in.

SV61891 Rev. A 3-11

Page 47

3 • Running Mail

DM350L: Printing Tapes

1. Push the tape load lever to the right as shown here and push the tapes

down into the slot. Place the tapes in the slot so that the backing faces

toward the left (toward the tape load lever).

Tape load lever

2. From the Ready screen on the IntelliLink

TM

Control Centre, rate

your mail piece by weighing it on the optional weigh platform or by

entering the weight manually (press Class and then select Manual

Weight Entry). Then select a class for the mail piece and any desired

special services.

3. Press

Enter to confirm the amount.

4. Press the Tape button. The display shows “Enter Number of Tapes”.

5. Type in the number of tapes to print.

6. Press the Tape

button.

7. If the tape stalls in the feeder or printer area, refer to the Tape Feeding

Problems in Chapter 7 of this guide.

3-12 SV61891 Rev. A

Page 48

DM230L, DM330L, DM350L Operating Guide

Processing a Parcel Without Using the Optional Parcel Rate Module

This procedure is used for processing Parcels (those mail pieces whose

dimensions – size and weight – and associated rates extend outside of

the Lettermail rating structure) if you did not purchased the optional parcel

rate module. Based on the rate structure provided in your system a Parcel

can be considered any mail piece that weighs over 500 grams. In order to

use this process you will need to weigh the mail piece on the integrated

scale or enter the weight using the manual weight entry feature, and you

will need to know the appropriate postage rate. If you need assistance

determining if a mail piece should be rated as Lettermail or as a Parcel

or need to obtain the postage rate for the mail piece, contact your local

Canada Post retail outlet or log on to www.canadapost.ca.

The following outlines the procedure for processing a parcel without the

optional Parcel rate module.

1. Place your mail piece on the integrated weigh platform or enter the

weight manually through the following steps:

a. Press the

(option 6)

b. Enter the weight in kilograms and then press

the system will take you to the class selection option menu

(skip to step 3).

2. If you used the integrated weigh platform to weigh your mail piece then

press the Class button and select Change Class (option 1).

3. Press the

options and select Other Payment (option 7.) and then press Enter to

confirm.

4. Select the

following screen will be displayed:

Class button and then select Enter Manual Weight

Enter to confirm and

Class button again to scroll down through the list of menu

Other Items option and then press Enter to confirm. The

Other Items

Selected Services: None

1. 3.50 to 99.99

5. Select the postage value range from the list provided (NOTE: there

is only one option). To do so, select option 1.: 3.50 to 99.99 and then

press Enter to confirm.

6. Enter your desired postage value using the numeric keypad and then

press Enter to confirm. Review your entry on the next screen and

press Enter (yes) or Options (no) to confirm. If you selected Enter

(yes) you will return to the Home screen and the message “Ready to

Print” will be displayed.

SV61891 Rev. A 3-13

$0.00

Page 49

3 • Running Mail

Processing a Parcel Using the Optional Parcel Rate Module

The following outlines the procedure for processing a parcel using

the optional Parcel rate module.

1. Place your mail piece on the integrated weigh platform or enter the

weight manually through the following steps:

a. Press the

(option 6)

b. Enter the weight in kilograms and then press

and the system will take you to the class selection option menu

(skip to step 3).

2. If you used the integrated weigh platform to weigh your mail piece

then press the Class button and select Change Class (option 1).

Additional sub-class selections and processing steps are required

depending on which class selection, and country destination

(Domestic, US, International) you select. The steps for the different

country destinations are outlined below.

Domestic (Canada) Destinations

3. Press the

domestic parcels you must choose either Domestic Parcel (option 2)

or Dom Priority (option 3.). Make your selection and then press Enter

to confirm.

4. Select your desired sub-class and press

information on Canada Post Distribution Services (shipping products

and services) log on to www.canadapost.ca.

5. Select which destination identifier you would like to use (Code / Zip or

Zone). Based on your selection you will need to enter the appropriate

Postal Code or Zone using the numeric keypad and / or QWERTY

keyboard. The system will prompt you when a valid entry is made.

Press Enter to confirm.

6. Select any appropriate Special Services you desire by following the

prompts on the display. Once you have completed your selection the

system will take you to the Home screen. The postage value will be

displayed in the top right hand corner and the message “Ready to

Print” will be displayed below.

7. The procedures for printing postage for parcels varies depending on

which system you have:

a.

DM230L – Insert a Tape Sheet into the Feeder to print your postage and upon completion affix the postage indicia to your parcel.

b. DM330L / DM350L – Press the Tape button. Enter the number of

Tape Strips you want to print from the Tape Strip feeder and press

Enter to confirm. Upon completion affix the postage indicia to your

parcel.

Class button and then select Enter Manual Weight

Enter to confirm

Class button and then select Change Class (option 1). For

Enter to confirm. For more

3-14 SV61891 Rev. A

Page 50

DM230L, DM330L, DM350L Operating Guide

Processing a

Parcel Using the

Optional Parcel

Rate Module

continued…

US Destinations

3. Press the

US destinations you must select USA Parcel (option 4) and then press

Enter to confirm.

4. Select your desired sub-class

US Xpresspost (option 2.) and press Enter to confirm. For more

information on Canada Post Distribution Services (shipping products

and services) log on to www.canadapost.ca.

5. The system will prompt you to enter a Zone. Key in the appropriate

Zone Code and press Enter to confirm.

6. Select any appropriate Special Services you desire by following the

prompts on the display. Once you have completed your selection the

system will take you to the Home screen. The postage value will be

displayed in the top right hand corner and the message “Ready to

Print” will be displayed below.

7. The procedures for printing postage for parcels varies depending on

which system you have:

a.

DM230L – Insert a Tape Sheet into the Feeder to print your postage

and upon completion affix the postage indicia to your parcel.

b. DM330L / DM350L – Press the Tape button. Enter the number of

Tape Strips you want to print from the Tape Strip feeder and press

Enter to confirm. Upon completion affix the postage indicia to your

parcel.

Class button and then select Change Class (option 1). For

Expedited USA (option 1) or

SV61891 Rev. A 3-15

Page 51

3 • Running Mail

Processing a

Parcel Using the

Optional Parcel

Rate Module

continued…

International Destinations

3. Press the

International destinations you must select Int’l Parcels (option 5) and

then press Enter to confirm.

4. Select your desired sub-class

2), or Int’l Xpresspost (option 3). For more information on Canada

Post Distribution Services (shipping products and services) log on to

www.canadapost.ca.

5. The system will prompt you to enter a Country name or Code. If you

know the country code enter it now. If you do not know the country

code enter the first one or two characters of the country name. A list

of all countries beginning with those characters appears in the display.

Press the number that corresponds to the country you want and then

press Enter to confirm.

6. Select any appropriate Special Services you desire by following the

prompts on the display. Once you have completed your selection the

system will take you to the Home screen. The postage value will be

displayed in the top right hand corner and the message “Ready to

Print” will be displayed below.

7. The procedures for printing postage for parcels varies depending on

which system you have:

a.

DM230L – Insert a Tape Sheet into the Feeder to print your postage

and upon completion affix the postage indicia to your parcel.

b. DM330L / DM350L – Press the Tape button. Enter the number of

Tape Strips you want to print from the Tape Strip feeder and press

Enter to confirm. Upon completion affix the postage indicia to your

parcel.

Class button and then select Change Class (option 1). For

Int’l Surface (option 1), Int’l Air (option

3-16 SV61891 Rev. A

Page 52

DM230L, DM330L, DM350L Operating Guide

Printing

3

Postage

Using Presets

Selecting the Normal Preset

The Normal Preset is the factory default setting which contains no

predetermined mail job settings (e.g., Postage Value, Class, or Weight).

Pressing the Normal Preset key will clear your current mail job settings

and take you back into Seal Only Mode. From here you can begin a new

transaction.

Selecting a Custom Preset

1. At the Ready screen on the IntelliLinkTM Control Centre, press the

Custom Presets key. The display lists all presets. “EMPTY” means

no values are assigned to the preset.

2. Press the

you want.

3. Press

password-protected account, the display prompts you to enter the

four-digit password. The display then shows the custom preset values.

4. Print the envelope as described in Printing Postage on an Envelope

this chapter, or:

Print tapes as described in Printing Postage on Tape Strips (or Sheets)

in this chapter.

If you'd like to set up custom preset values or change them, see

Chapter 4.

Custom Presets key repeatedly until you see the preset

Enter to select the preset. If the preset includes a

in

SV61891 Rev. A 3-17

Page 53

3 • Running Mail

Sealing the

4

Envelopes

Only

You can set up your mailing system to seal envelopes without printing

postage on them.

To select this mode on the DM230L/DM330L/DM350L:

1. Press the

2. Press the number for

3. Follow the instructions in the

in this chapter to feed the envelopes.

To select this mode on the DM350L:

1. Press the

2. Press the number for

3. On the autofeeder control panel, set the Seal/No Seal lever to the seal

position. To seal the envelopes, move the lever all the way to the left.

4. Follow the instructions in the

in this chapter to feed the envelopes.

Normal Preset button on the IntelliLinkTM Control Centre.

Seal Only. The seal-only ready screen appears.

Printing Postage on an Envelope section

Options key on the IntelliLinkTM Control Centre.

Seal Only. The seal-only ready screen appears.

Printing Postage on an Envelope section

3-18 SV61891 Rev. A

Page 54

DM230L, DM330L, DM350L Operating Guide

Selecting a

5

Class or

Special

Service

Before Selecting or Changing a Class

Selectiong a class is a required action in order to generate the appropriate

rate for your mail piece. The procedure for setting a class special service

or carrier depends on whether you enter the weight of the mail manually or

use the interfaced scale to weigh your mail piece. Each class has its own

set of special services. When you select a class only those options available

for that selection appear in the display.

Your system automatically calculates the correct postage for your piece of

mail based on its weight and the class of service you select.

Before selecting a class or special feature, please note the following:

• The class that appears in the Ready screen is the one you last

selected.

• If you turn off and then turn on the power to your system, the

previously selected class automatically clears.

• If you place a piece of mail on the scale, or enter a weight manually,

the system automatically prompts you to select a new class if the new

weight requires a different class.

• If your system has an attached scale, we recommend that you turn

the AutoScale option ON. Refer to the Setting Up an Attached Scale

section in Chapter 4 of this guide.

• When you are done selecting the class and/or special service, print

the envelope as described in Printing Postage on an Envelope in this

chapter or print tapes as described in Printing Postage on Tape Strips

(or Sheets) in this chapter.

SV61891 Rev. A 3-19

Page 55

3 • Running Mail

Selecting or Changing a Class

To make or change a class selection:

1. If you need to manually enter the weight of the mail, press the

key; then press the number for the Enter manual weight.

2. Use the numeric keys to enter the kgs and g values. Press the

key to confirm each value.

3. Enter the number that corresponds to the class you want and then

press the Enter key.

a. Depending on the class, the display may prompt you to make

further selections within that class.

b. After you complete all selections within a class, press the

Enter key.

4. If a Postal code or Zone is required, you are prompted to enter it.

Press Enter to accept. For more information refer to Selecting a

Postal Code or Zone in this section.

5. If a country is required, you are prompted to select it. Press

to accept. For more information, refer to Selecting a Country in this

section.

6. If special services are available for the class you selected, the display

asks if you want to add any special services.

Press Yes (

screen. Refer to Selecting Special Services in this section for

information on adding services.

Enter) to accept or No (Options) to return to the Ready

Class

Enter

Enter

3-20 SV61891 Rev. A

Page 56

DM230L, DM330L, DM350L Operating Guide

Selecting a Postal Code or Zone

Selecting a Country

If the class you select requires a Postal Code or Zone, the system display

prompts you to enter it when you select the class.

1. The display prompts you to select Postal Code or Zone.

2. Press the number that corresponds Postal or Zone.

3. For the Postal Code, key in the first three digits.

For Zone, key in the appropriate entry (1-8).

4. Press

If the class you selected provides special services, you are asked if

you want to enter them now. Refer to Selecting a Special Service

this section.

If the class you select requires you to specify a country, the system display

prompts you to enter it when you select the class.

1. The display prompts you to enter the country name or country code.

2. If you know the code for the country, enter that code now.

If you don't know the country code, enter the first one or two characters

of the country name. A list of all country names beginning with those

characters appears in the display.

Press the number that corresponds to the country you want.

3. Press

4. Press Yes (

prompts you to do so.

If the class you selected provides special services, the system display

prompts you to enter them now. Refer to Selecting a Special Service

below.

Enter to accept the Postal Code or Zone.

in

Enter to accept the country code or country name.

Enter) to confirm your selection when the system display

SV61891 Rev. A 3-21

Page 57

3 • Running Mail

Selecting a Special Service

1. When you select a class that provides special services, you are asked

if you want to add any of these services.

2. Press Yes (

available for the class. For example, if you select Priority, you can add

insurance coverage or services.

3. To select a special service, press the number that corresponds to that

service.

a. If the service requires you to enter more information, another

screen displays and you are prompted to fill in the information.

For example, to add insurance, you need to enter the amount for

which you want to insure the parcel.

b. Continue to select the special services. Each time you press a

number for a service, the selection moves to the top of the list and

has a check mark next to it.

4. When you are done, press

services and the total cost of these services. You are asked to

confirm your service selections. Press Yes (Enter) to accept and

return to the Ready screen.

To cancel, press No (Options). The display prompts you to select a

class again.

Enter) and the display lists all of the special service options

Enter and the display lists all of the

3-22 SV61891 Rev. A

Page 58

DM230L, DM330L, DM350L Operating Guide

Printing an

6

Advertisement

Printing an Advertisement with the Postage

1. Press the Date/Ad key.

2. Press the number for

3. A list of the ads available on your system are displayed.

4. Press the number for the ad you want.

5. Press

6. Print the envelope as described in Printing Postage on an Envelope

this chapter, or:

Print tapes as described in Printing Postage on Tape Strips (or Sheets)