Pioneer XV-BD122B, XV-BD422B, XV-BD122FSB Service Manual

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

2012

XV-BD422B

Blu-ray Disc receiver

XV-BD422B

XV-BD122B

XV-BD122FSB

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV4334

Model T ype Power Requirement

XV-BD422B YXE8 AC 110 V to 240 V 2 B &&&&######YY YY: Europe

XV-BD422B VXE8 AC 110 V to 240 V 2 B &&&&######GB GB: U.K

XV-BD122B YXE8 AC 110 V to 240 V 2 B &&&&######YY YY: Europe

XV-BD122B VXE8 AC 110 V to 240 V 2 B &&&&######GB GB: U.K

XV-BD122FSB YXE8 AC 110 V to 240 V 2 B &&&&######YY YY: Europe

DVD

Region No.BDRegion No.

Serial No. Remarks

K-MZV JULY

2012 Printed in Japan

1

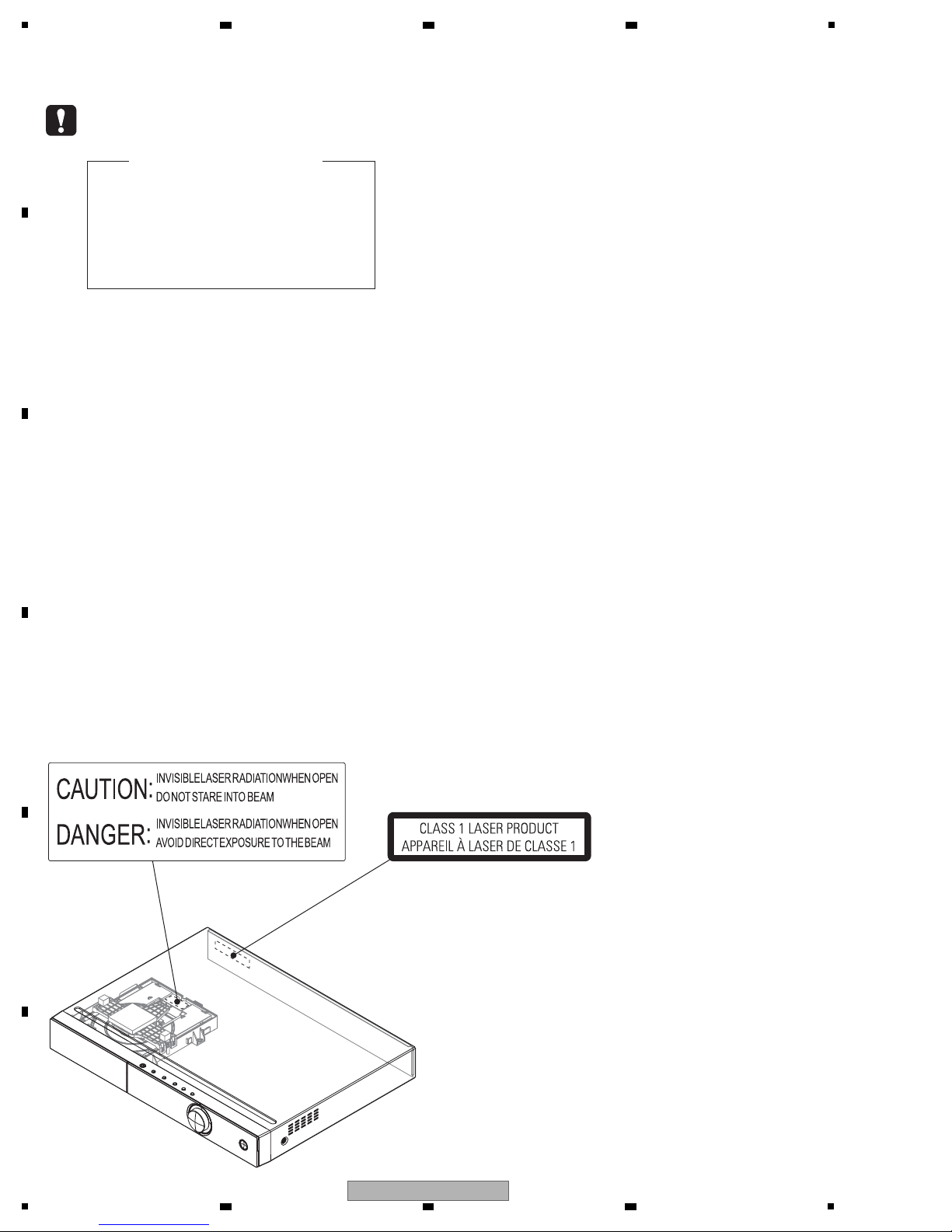

LASER DIODE CHARACTERISTICS

For BD Wave length : 398 - 412 nm

Output Power : Less than Class 1

For DVD Wave length : 650 - 664 nm

Output Power : Less than Class 1

For CD Wave length : 784 - 796 nm

Output Power : Less than Class 1

LABEL CHECK

The following caution appears on your unit.

Location: inside of the unit

(Printed on the rear panel)

SAFETY INFORMATION

A

B

2 3 4

C

D

E

F

2

1

XV-BD422B

2 3 4

5

6 7 8

CONTENTS

SAFETY INFORMATION .........................................................................................................................................................2

1. SERVICE PRECAUTIONS...................................... ..... ...... ...... ............................................ ...... ...........................................4

1.1 NOTES ON SOLDERING.................................................................. .............................................................................4

2. SPECIFICA TIO NS....................... ..... ...... ............................................. ..... ...... ...... ..... ...... ......................................................5

3. BASIC ITEMS FOR SERVICE..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING...........................................................................................................................6

3.2 JIGS LIST.......................................................................................................................................................................6

3.3 PCB LOCATIONS...........................................................................................................................................................7

4. BLOCK DIAGRAM ........................... ............................................. ...... ..... ...... ...... ..... ............................................................8

4.1 OVERALL WIRING DIAGRAM.......................................................................................................................................8

4.2 OVERALL BLOCK DIAGRAM......................................................................................................................................10

5. DIAGNOSIS .................... ...... ...... ..... ............................................. ...... ..... ...... ...... ..... ..........................................................12

5.1 TROUBLESHOOTING..................................................................................................................................................12

6. SERVICE MODE................................................................ ............................................. ....................................................15

6.1 SERVICE MODE..........................................................................................................................................................15

7. DISASSEMBLY ............................................................ ...... ...... ..... ...... ..... ...........................................................................21

8. EACH SETTING AND ADJUSTMENT................................................................................................................................28

8.1 ADJUSTMENT REQUIRED WHEN THE UNIT IS REPAIRED OR REPLACED.................................. ..... ...... ...... ..... ..28

8.2 UPDATING OF THE FIRMWARE.................................................................................................................................30

9. EXPLODED VIEWS AND PARTS LIST ..............................................................................................................................32

9.1 PACKING SECTION.....................................................................................................................................................32

9.2 EXTERIOR SECTION..................................................................................................................................................34

10. SCHEMATIC DIAGRAM....................................................................................................................................................38

10.1 MAIN BOARD ASSY (1/13)........................................................................................................................................38

10.2 MAIN BOARD ASSY (2/13)........................................................................................................................................40

10.3 MAIN BOARD ASSY (3/13)........................................................................................................................................42

10.4 MAIN BOARD ASSY (4/13)........................................................................................................................................44

10.5 MAIN BOARD ASSY (5/13)........................................................................................................................................46

10.6 MAIN BOARD ASSY (6/13)........................................................................................................................................48

10.7 MAIN BOARD ASSY (7/13)........................................................................................................................................50

10.8 MAIN BOARD ASSY (8/13)........................................................................................................................................52

10.9 MAIN BOARD ASSY (9/13)........................................................................................................................................54

10.10 MAIN BOARD ASSY (10/13)....................................................................................................................................56

10.11 MAIN BOARD ASSY (11/13).....................................................................................................................................58

10.12 MAIN BOARD ASSY (12/13)....................................................................................................................................60

10.13 MAIN BOARD ASSY (13/13)....................................................................................................................................62

10.14 FRONT BOARD ASSY.............................................................................................................................................64

10.15 AMP BOARD ASSY (1/3).........................................................................................................................................66

10.16 AMP BOARD ASSY (2/3).........................................................................................................................................68

10.17 AMP BOARD ASSY (3/3).........................................................................................................................................70

10.18 AV BOARD ASSY.....................................................................................................................................................72

10.19 SYSTEM POWER SUPPLY ASSY...........................................................................................................................74

11. PCB CONNECTION DIAGRAM........................................................................................................................................76

11.1 MAIN BOARD ASSY...................................................................................................................................................76

11.2 FRONT BOARD ASSY...............................................................................................................................................80

11.3 AMP and AV BOARD ASSYS.....................................................................................................................................82

11.4 SYSTEM POWER SUPPLY ASSY.............................................................................................................................84

A

B

C

D

5

XV-BD422B

6 7 8

E

F

3

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

4

1

XV-BD422B

2 3 4

5

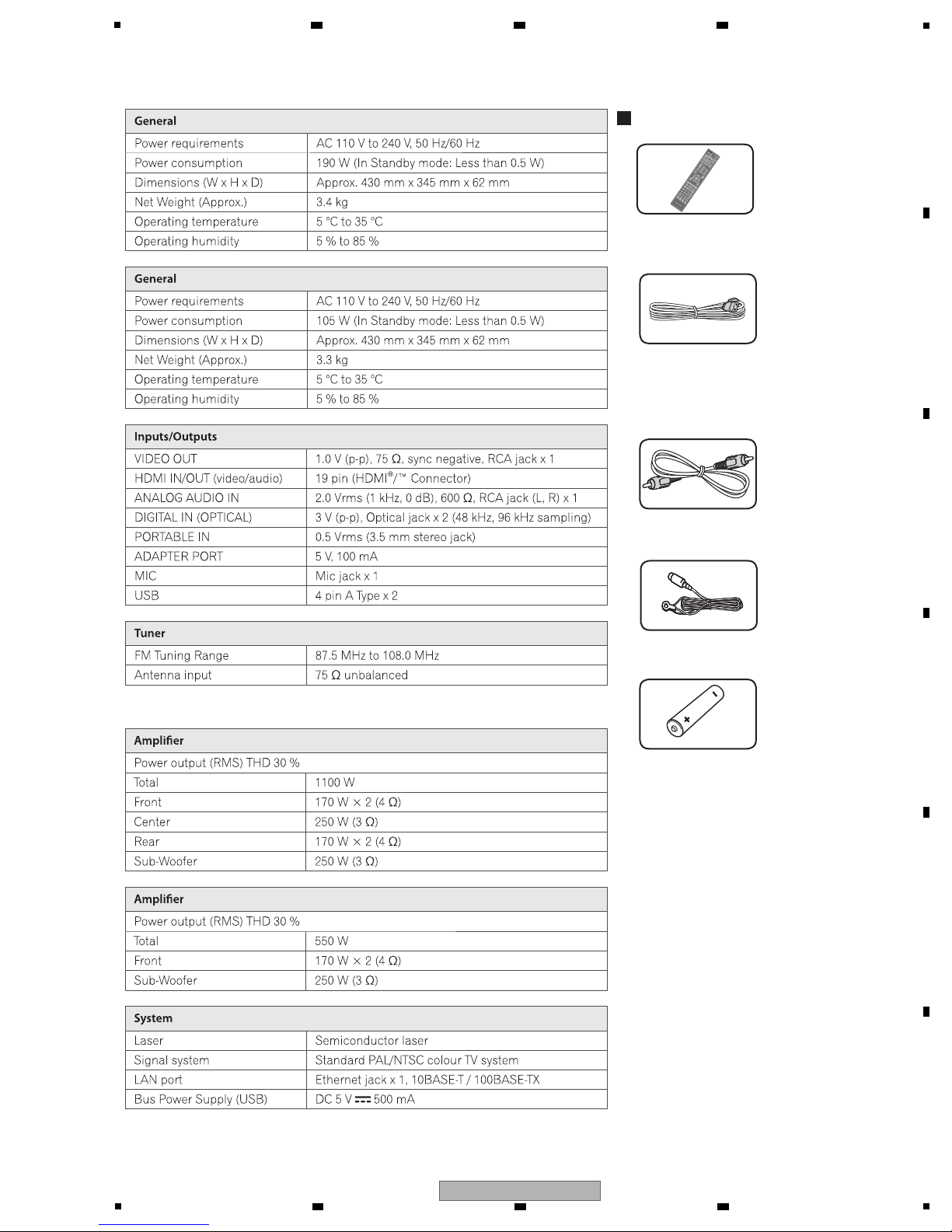

Video cable

(41-UH1200-0KK1E)

Power cord

(XV-BD422B/YXE8, XV-BD122B/YXE8,

XV-BD122FSB/YXE8: 51-DC0120-0CRA3)

(XV-BD422B/VXE8, XV-BD122B/VXE8

: 51-DC0120-0CRD4)

• Warranty card

• Operating instructions

(XV-BD422B/YXE8, XV-BD122B/YXE8,

XV-BD122FSB/YXE8: 72-BD122B-EU0B1)

(XV-BD422B/VXE8, XV-BD122B/VXE8:

72-BD122B-GBRB1)

Remote control (AXD7655)

(06-BCS727-A000)

Battery (x2)

FM antenna

(47-ANT022-XX0)

Accessories

(XV-BD422B/XV-BD122B)

(XV-BD422B/XV-BD122B)

(XV-BD122FSB)

(XV-BD122FSB)

2. SPECIFICATIONS

6 7 8

A

B

C

D

E

F

5

XV-BD422B

6 7 8

5

1

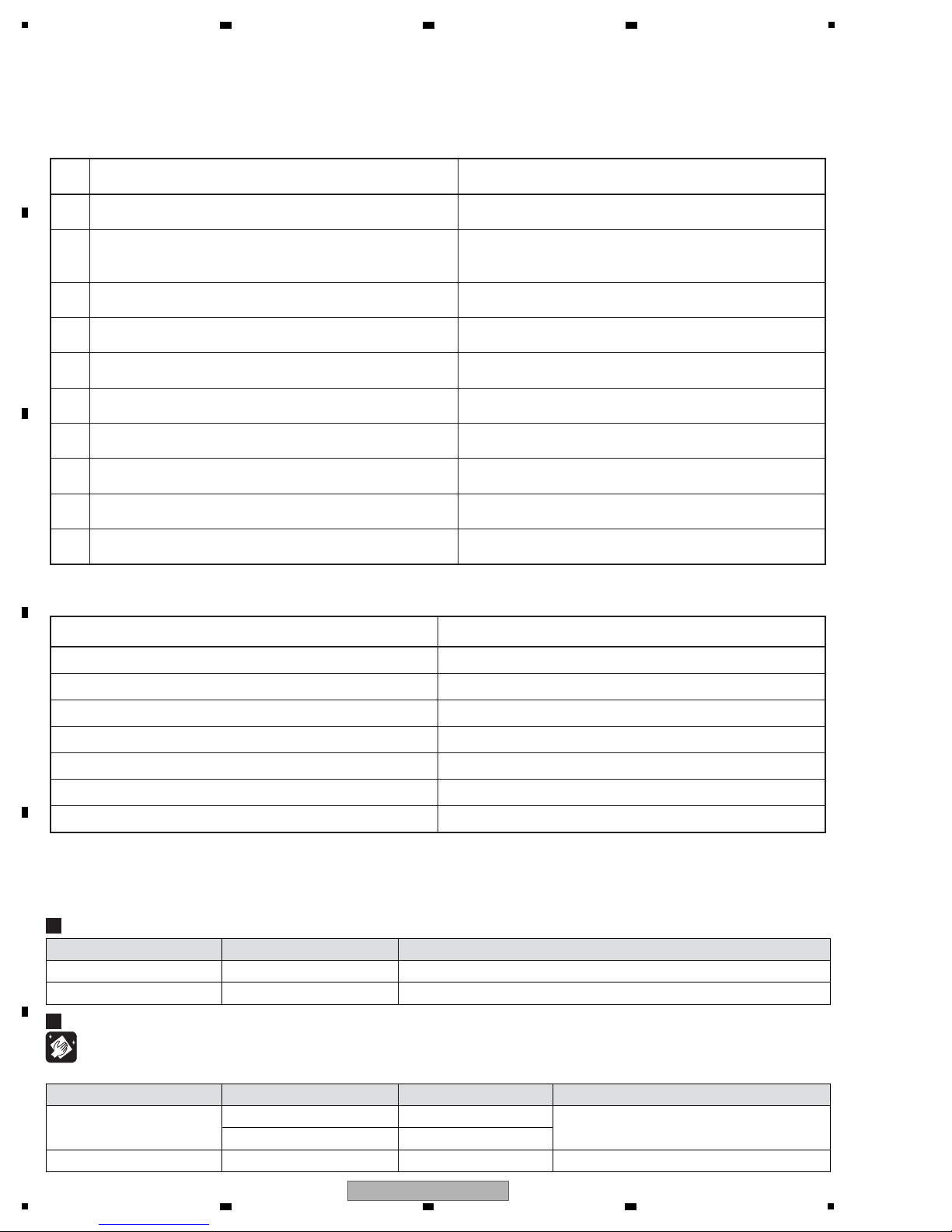

Items to be checked after servicing

To keep the product quality after servicing, confirm recommended check points shown below.

Item to be checked regarding video Item to be checked regarding audio

Block noise Distortion

Horizontal noise Noise

Dot noise Volume too low

Disturbed image (video jumpiness)

Too dark

Too bright

Mottled color

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding video and audio.

1

Confirm the firmware version on Service mode.

The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

2

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use

it for the operation check.

The customer complain must not be reappeared.

Video, audio and operations must be normal.

3

Check the CD playback.

(Track search)

Audio and operations (search etc.) must be normal.

4

Check the DVD playback.

(Operation, Title/Chapter search)

Video, audio and operations (search etc.) must be normal.

5

Check the BD playback.

(Operation, Title/Chapter search)

Video, audio and operations (search etc.) must be normal.

6

Check the tuner (FM) operations.

Video, audio and operations (search etc.) must be normal.

10

Check the appearance of the product. No scratches or dirt on its appearance after receiving it

for service.

No. Procedure Check points

7 Check supported file playback by USB memory. Video, audio and operations must be normal.

9 Select [Scan] on [Wireless Setting] and then check access

points are displayed on screen. (*)

(*) Wireless model only (XV-BD121W/122W/222W/421W/422W/921FSW/922FSW/821FSW/ 822FSW/621FSW/521FSW)

Correct access point name (SSID) must be displayed. (*)

8 Check supported file playback from same network device by

LAN connection at Home MEDIA GALLERY .

Video, audio and operations must be normal.

Cleaning

Name Part No. Remarks

Cleaning paper GED-008

Cleaning liquied GEM1004 Refer to "7. DISASSEMBLY".

Position to be cleaned

Pickup lenses

Cleaning paper GED-008 Refer to "9.2 EXTERIOR SECTION".Fan

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

Jig Name Part No. Remarks

BD Test disc GGV1368 Use with "6. SERVICE MODE".

Emergency disc ejection rod

GGF1529 Refer to "7. DISASSEMBLY".

Jigs List

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

2 3 4

XV-BD422B

5

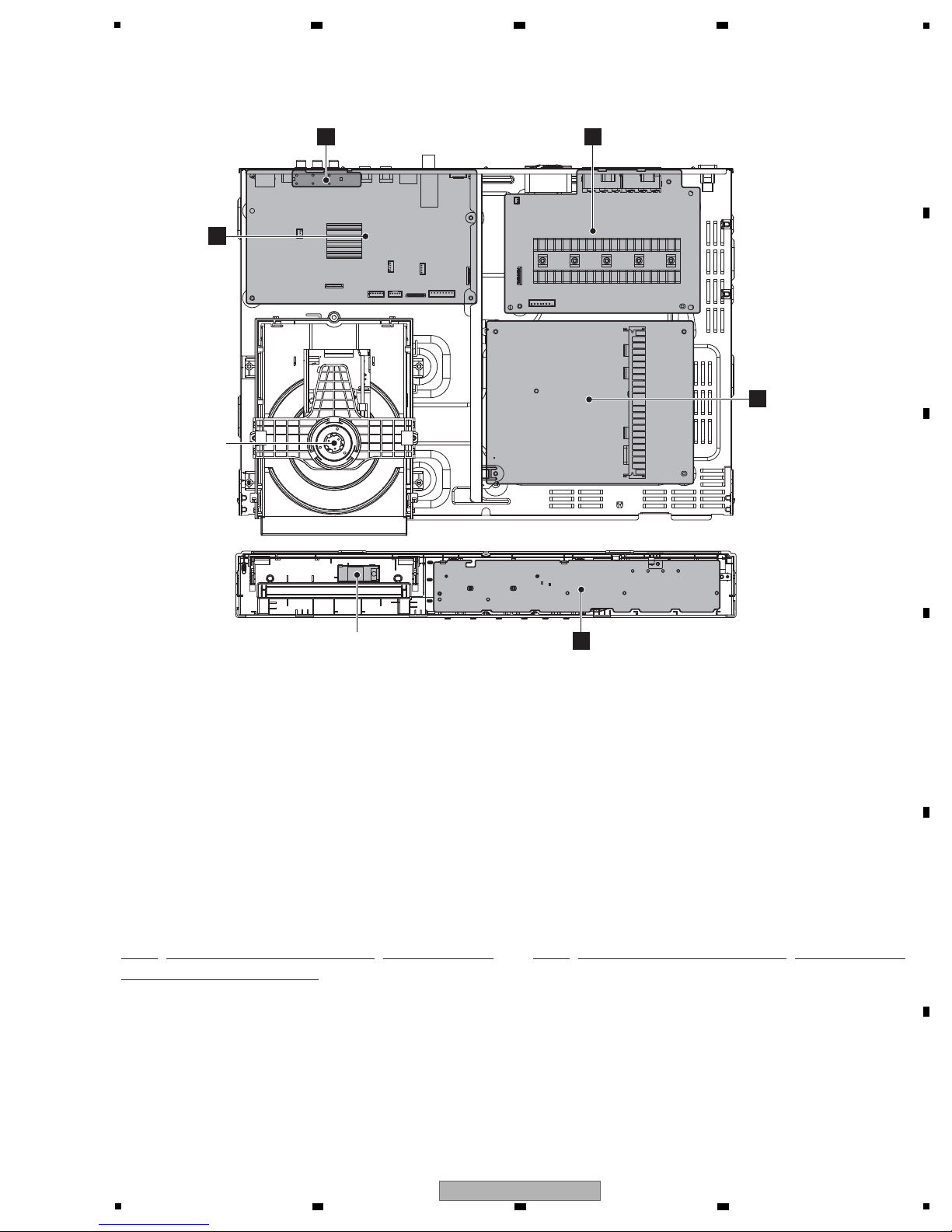

1..MAIN BOARD ASSY

08-H555DU-MA1R/YXV

1..FRONT BOARD ASSY 08-BCS727-FVY

1..AMP BOARD ASSY AZW7611

(XV-BD422B, XV-BD122B)

1..AMP BOARD ASSY AZW7612

(XV-BD122FSB)

1..AV BOARD ASSY AZW7613

1..SYSTEM POWER SUPPLY ASSY 08-K250HE-PW1

LOADER ASSY 08-LTCA19-222026

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

D

AV BOARD

ASSY

A

MAIN BOARD

ASSY

LOADER

ASSY

C

AMP BOARD

ASSY

E

SYSTEM POWER

SUPPLY ASSY

B

FRONT BOARD ASSYWi-Fi MODULE

3.3 PCB LOCATIONS

6 7 8

A

B

C

D

E

F

5

XV-BD422B

6 7 8

7

1

XP5 XP4

1J6J7J5R_XUA5

GND

L_XUA3ACR J4 J5

GND P2

1 CVBS_O 1

XP7

45

1

XP10

TPIC_A+ 8

TPIC_ATPIC_BTPIC_B+

U/C

V/W

W/V

C/U 1

XP5

TPIC_TRAYIN# 4

MGND

TPIC_LOAD+

TPIC_LOAD- 1

71PX31PX

6

1PX

102141

GND

USBP1

USBM1

WIFI_VCC

VOL+

VOL-

KEY1

KEY2

P-24V

GND

+12V_D

GND

STBY_3V3

SPI_CLK

SPI_DAT

SPI_CS

IR_IN

PWM_LED

GND

MP3_L

GND

MP3_R

GND

MIC

USB_VCC1

GND

USBM2

USBP2

USBM0

6021

606SX3PX

41

JACK603 JA

P801 P8

USB1 US

AUX R

AUX L

CVBS

Optical

IN 1

Optical

IN 2

HDMI IN 2 HDMI IN 1 HDMI OUT

LAN (10/100)

MIC

P

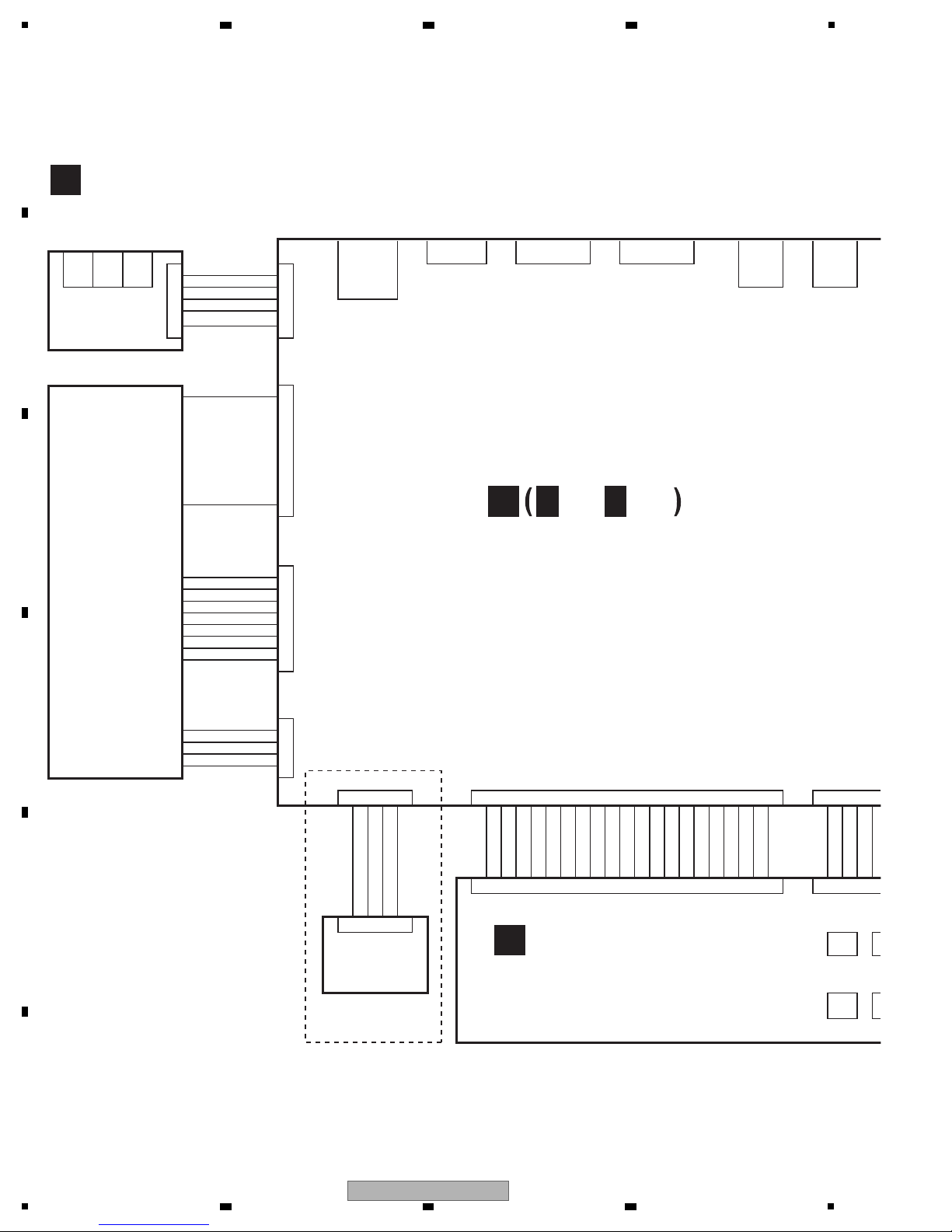

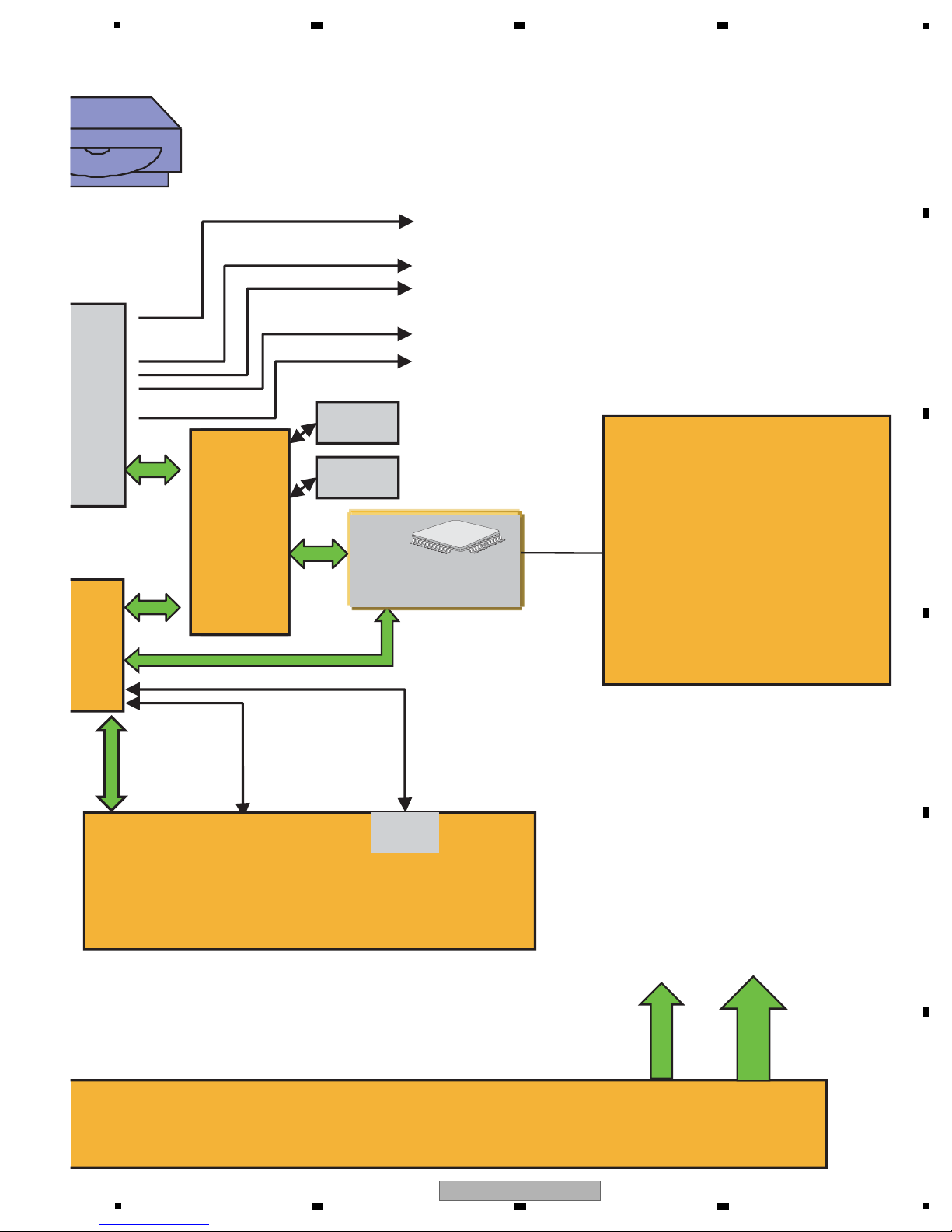

MAIN BOARD ASSY

(08-H555DU-MA1R/YXV)

NOT USED

A

FRONT BOARD ASSY

(08-BCS727-FVY)

B

AV BOARD ASSY

(AZW7613)

D

A

1/13-A13/13

LOADER ASSY

(08-LTCA19-222026)

Wi-Fi MODULE

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

2 3 4

C

D

E

F

8

1

XV-BD422B

2 3 4

XP15

J5

J8

JK701

8PX1NUT

XP11 XP703

24 BKEN_ERR 1

PDN

AMP_DET

SHUTDOWN

POWER

GND

GND

+12V_D

3.3V

+12V_D

3.3V

DSP_RST

AMP_MUTE

GND

AMP_SDA

AMP_SCL

GND

I2S_MCLK

GND

I2S_BCK

I2S_DATA2

I2S_DATA1

I2S_LRCK

1 I2S_DATA0 24

207PX1PX71PX

161861

USB_VCC1

GND

USBM2

USBP2

USBM0

USBP0

GND

VCC_D

VCC

VCC

GND

+12V

GND

-24V

GND

GND

GND

+34V

+34V

+34V

161816

305NOC205NOC606SX

JACK603 JACK602 CN501

P801 P802

USB1 USB2

Optical

IN 1

AC IN

Speaker Output

Dock

for iPod

FM

Bluetooth

Adapter

MIC

Porta

ble

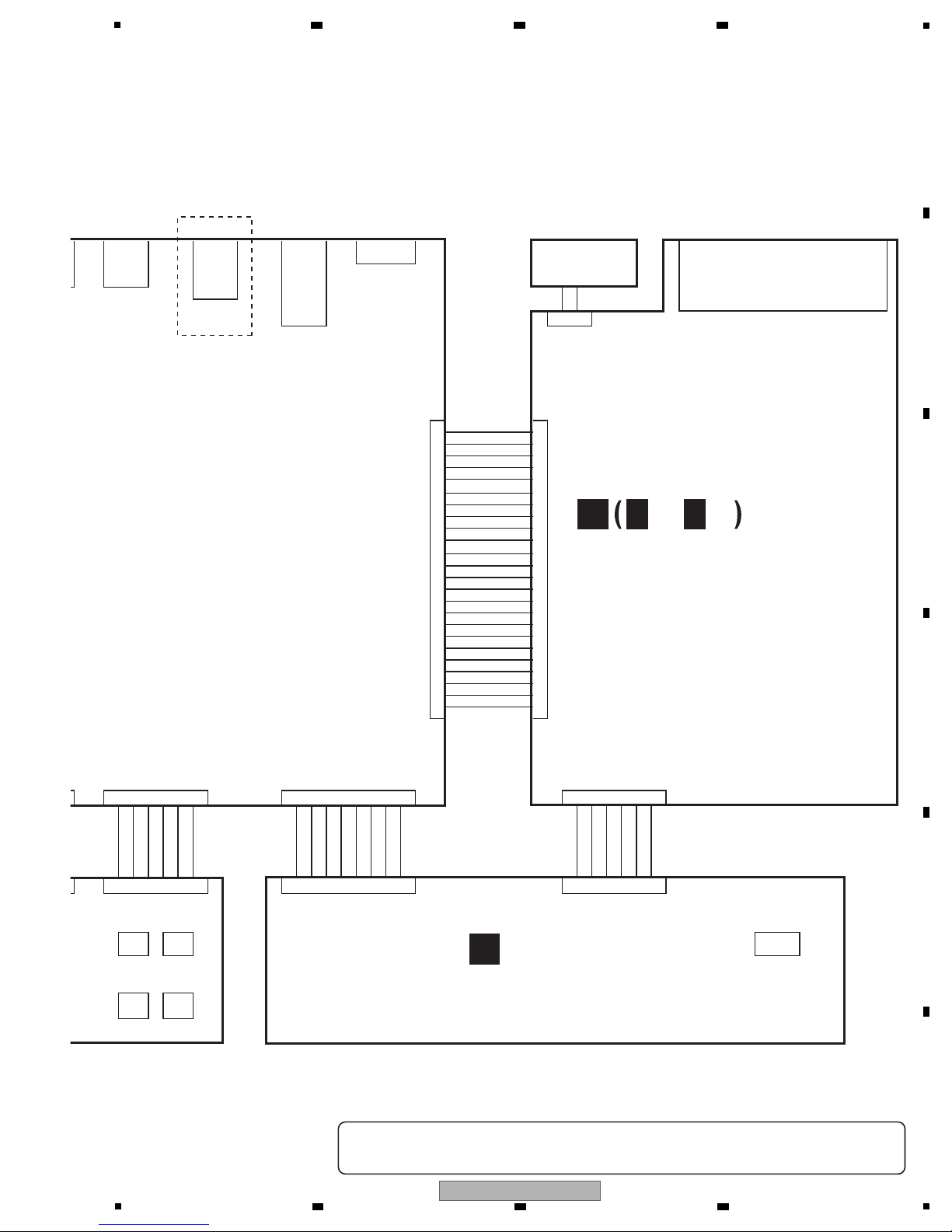

AMP BOARD ASSY

C

SYSTEM POWER SUPPLY ASSY

(08-K250HE-PW1)

E

DC FAN

C

1/3-C3/3

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

NOT USED

(XV-BD422B, XV-BD122B: AZW7611)

(XV-BD122FSB: AZW7612)

5

6 7 8

A

B

C

D

5

6 7 8

XV-BD422B

E

F

9

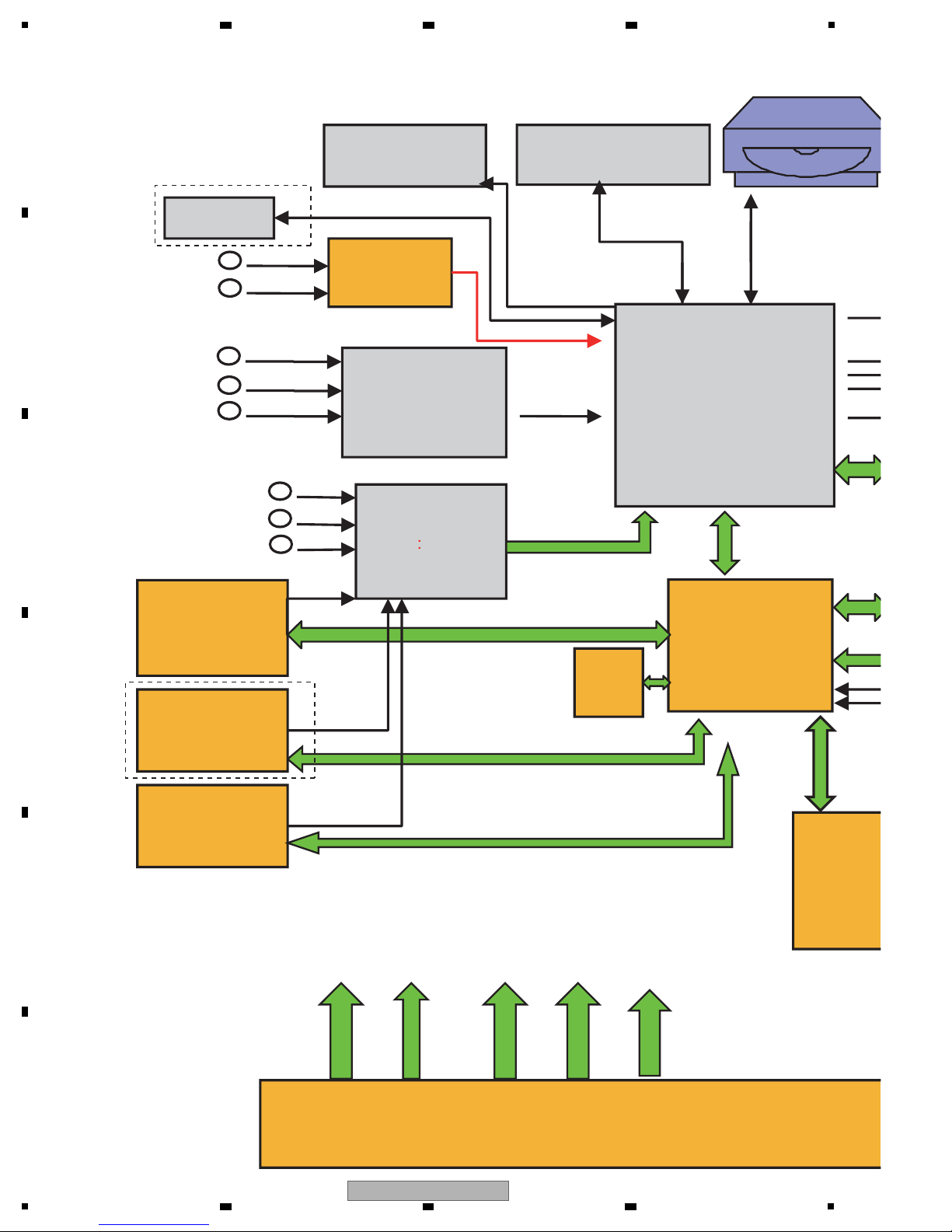

1

Tuner

FM+RDS

MPEG Deco der

AUX IN

ADC CS5346

I2S

MT8555

MCU

NUC100

RF

POWER

+12V

+5VDGND

MGND

NFLA SH

2Gbit

DDR3*4

64M*16*4pcs

DRIVER

CONTROL

I2C

SPI

KE

CO

Bluetooth)

(option)

I2C

UART

IPOD docking

analog

UART

WIFI

SPDIF change &

switch

OPTI IN

PortableIN

HDMI IN

HDMI IN

SPDIF

I2S

(HDMI)ARC IN

OPTI IN

FRON

HDMI Swtich

NXP19998L

MIC IN

CP for

IPOD

SPI

-24V

NOT USED

NOT USED

2 3 4

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

10

1

XV-BD422B

2 3 4

er

BD LOADER

I2S

USB 2.0

CVBS Output

POWER SUPPLY

I2C

+34V

AUDIO

PROCESSOR

AGND

PWM

KEY,LED

CONTROL

USB 2.0

HDMI OUT

RJ45

FRONT PANEL(VFD DISPLAY,KEY,LED)

DSP

DA707

I2S

IR

AMP: TAS5352*4

SPI

SDRAM

FLASH

5

6 7 8

A

B

C

D

E

5

XV-BD422B

6 7 8

F

11

1

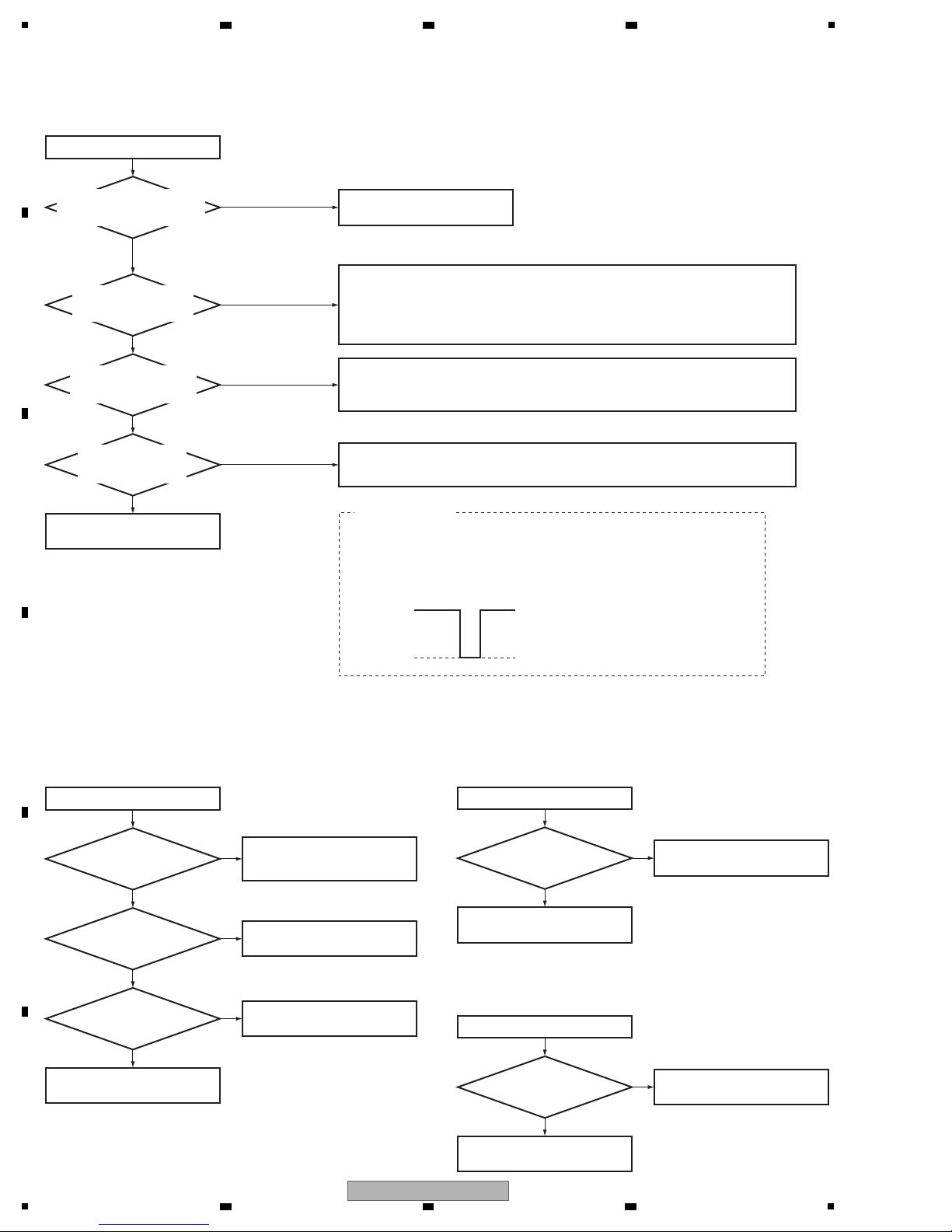

No power

No power

Which Power button, the one on

the remote control unit or on

the main unit, is disabled?

Is there 5 V on pins 5

and 6, 12 V on pin 3 of XP1

of MAIN BOARD Assy?

No

Check for any abnormality with the connection and connectors that connect the

POWER BOARD Assy and MAIN BOARD Assy.

If there is no abnormality:

· If neither 5 V nor 12 V are output, go to the flowchart for "Neither 5 V nor 12 V are output."

· If only 5 V is not output, go to the flowchart for "+5 V power is not output."

· If only 12 V is not output, go to the flowchart for "+12 V power is not output."

Check for any abnormality with the connection and connectors that connect the MAIN

BOARD Assy and FRONT BOARD Assy.

If there is no abnormality, replace the MAIN BOARD Assy.

To the flowchart for "The remote

control unit does not function"

Only the Power button

of the remote control unit

Both, or the Power button

of the main unit

Yes

Is there 3.3 V on pin 9,

12 V on pin 7 of XP3

of FRONT BOARD Assy?

No

Yes

Replace S608.

If replacement does not resolve the problem, replace the FRONT BOARD Assy.

1. Perform a conduction test, using a tester, with the main unit turned OFF.

2. Check the waveform at Pin 3 (KEY_POW) of the XP13 on the MAIN BOARD Assy.

With SW1 OFF: 3.3 V, With SW1 ON: 0 V

Checking of S608

Does S608 on the

FRONT BOARD Assy

function properly?

No

Yes

Replace the MAIN BOARD Assy.

Waveform of KEY_POW

3.3 V

0 V

Neither 5 V nor 12 V are outpu

Yes

Neither 5 V nor 12 V are output

Is the AC input voltage

normal?

Is the voltage of CE501

between 310 V to 390 V?

No

Check the connection of CN501

on the POWER BOARD Assy.

No

Chek the soldering of BD501 and

F501 are normal.

Yes

Is the voltage of CE505

between 5.8 V to 6.4 V?

No

Chek the soldering of D506 and

ZD502 are normal.

Yes

Replace the POWER BOARD

Assy.

Replace the POWER BOARD

Assy.

Replace the POWER BOARD

Assy.

+5 V power is not output

Yes

+5 V power is not output

Is the voltage of CE509

+5 V?

No

Chek the soldering of D509 and

D510 are normal.

+12 V power is not output

Yes

+12 V power is not output

Is the voltage of CE506

+12 V?

No

Chek the soldering of D508 is

normal.

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

12

1

XV-BD422B

2 3 4

5

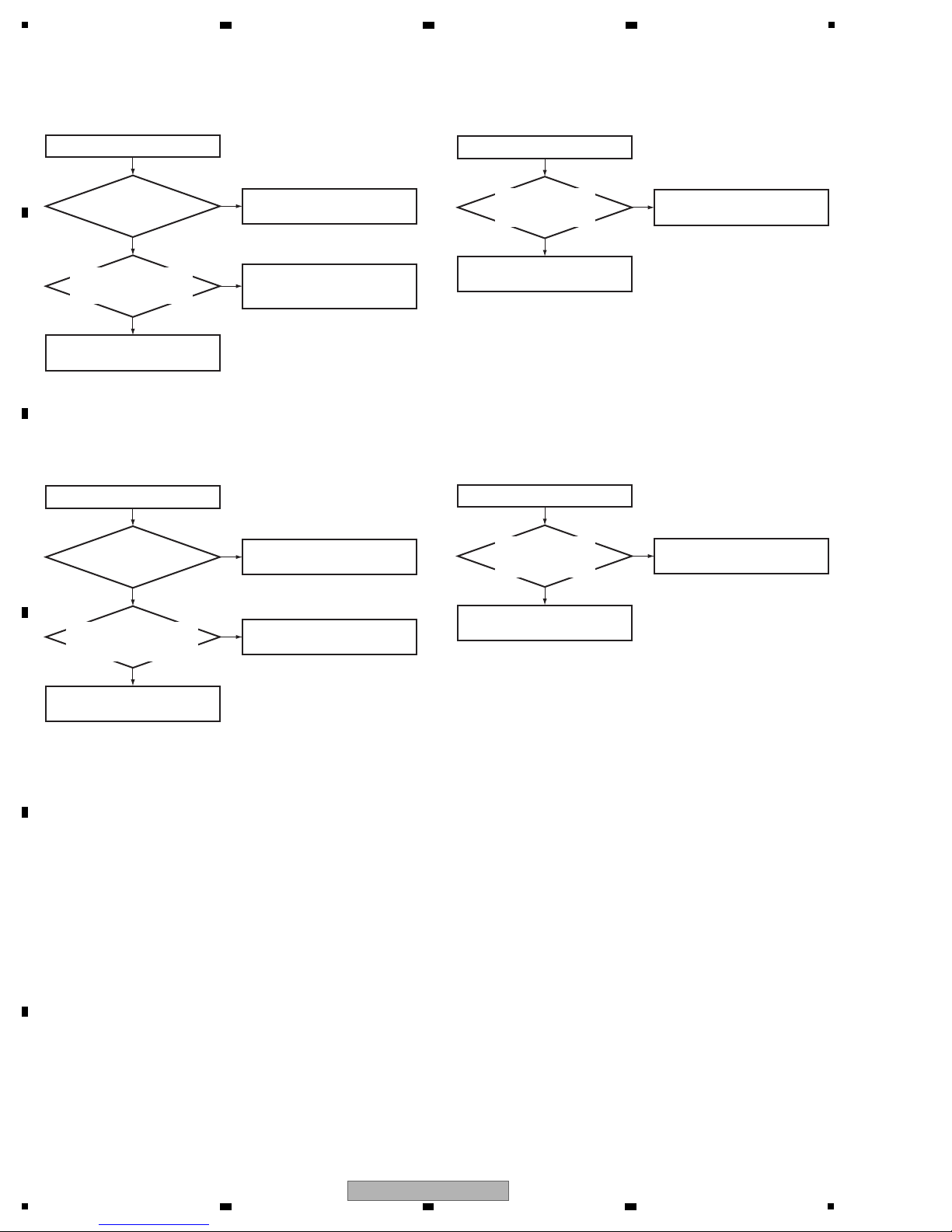

Remote control unit does not function

Remote control unit does not function

Yes

Yes

Is the battery of the remote

control exhausted?

No

No No

No

Replace the battery for remote

control.

Is remote control signal on

IR601 of FRONT BOARD

Assy normal?

Is there 3.3 V on XP3 pin 9

of FRONT BOARD Assy?

Is there remote control

signal on XP13 pin 13 of

MAIN BOARD Assy?

Yes

Yes

Replace the MAIN BOARD Assy.

Replace the FRONT BOARD Assy.

No audio output

No audio output

Yes

Yes

Yes

Yes

Are AMP IC (U710 to U713)

normal?

No

Replace U710 to U713.

Replace the speaker.

Is the +34 V voltage on AMP

board normal?

Are the output of U714 normal?

(U714: pin 40-47, pin 49-52)

Is the VALID signal (R774) high?

No

Refer to "NO +34 V output".

Are there signals of I2S?

(XP703: Pin 18, 20 to 24)

No

Check the connect line.

No

Replace U714.

Can’t read disc or can’t open the tray

Can’t read disc or can’t open the tray

Yes

Is the rotation of the

LOADER Assy normal?

No

Check the connection 4 pin cable

from the MAIN BOARD Assy.

Chek the soldering of R204 and

R205 are normal, or replace the

MAIN BOARD Assy.

No

Check the soldering of R946 and

R947 are normal. Check the voltage

of U11 (Pin 3) is OK. (about 12 V)

Yes

Are 45 pin and 8 pin cables

of MAIN board connected to

the LOADER Assy properly?

No

Connect those cables tightly.

Replace the LOADER Assy.

Is the voltage of

U11 (Pin2) normal?

(about 9 V)

No

Yes

Yes

Are R204, R205 normal?

(The voltage between two

resistance is 1.5 V.)

No display on VFD, and buttons do not work

Yes

No display on VFD,

and buttons do not work

Are the supply voltages

on MAIN BOARD Assy

normal?

1. Be soldered properly between

U135 and pins of VFD on

FRONT BOARD Assy?

2. Is not a circuit connected to

K135 to K140 and S608 broken?

Is there -24 V on pin 5, 12 V

on pin 7, 3.3 V on pin 9 of XP13

of MAIN BOARD Assy?

No

No

No

Solder parts again,

be connected correctly.

Solder parts again.

Yes

Yes

No

Replace the FRONT BOARD Assy.

Replace the FRONT BOARD Assy.

Are Q7, Q207, Q209,

U1 to U4, U15 performed

soldering of normally?

6 7 8

A

B

C

D

E

F

5

XV-BD422B

6 7 8

13

1

Can not connect to network by LAN

Can not connect to network

Yes

Yes

Is LFE8634 (U14) on

MAIN BOARD Assy

normal?

No

Check the soldering of U14 is

normal.

Are R133, R134, R579, R580

and R583 on MAIN BOARD

Assy normal?

No

Check the soldering of

R133, R134,

R579 and R580

are normal.

Replace the MAIN BOARD Assy.

No output by "OPTICAL IN 1 or 2"

No output by "OPTICAL IN 1 or 2"

Yes

Are the connector of

HDMI in J4 and J5 on MAIN

BOARD Assy normal?

No

Check the soldering of

J4 and J5

on MAIN BOARD Assy are normal.

No output by "HDMI IN 1 or 2"

No output by "HDMI IN 1 or 2"

Yes

Are the connector of

HDMI in J6 and J7 on MAIN

BOARD Assy normal?

No

Check the soldering of

J6 and J7

on MAIN BOARD Assy are normal.

Replace the MAIN BOARD Assy.

Replace the MAIN BOARD Assy.

No analog video display

No analog video display

Yes

Is P8 on AV BOARD

Assy normal?

Is the connection

of MAIN and AV BOARD

Assemblies is normal?

No

Check the soldering of

P8

on

AV BOARD Assy are normal.

Yes

No

Check whether connection of

MAIN and AV BOARD Assemblies

is normal.

Replace the MAIN BOARD Assy.

A

2 3 4

B

C

D

E

F

14

1

XV-BD422B

2 3 4

5

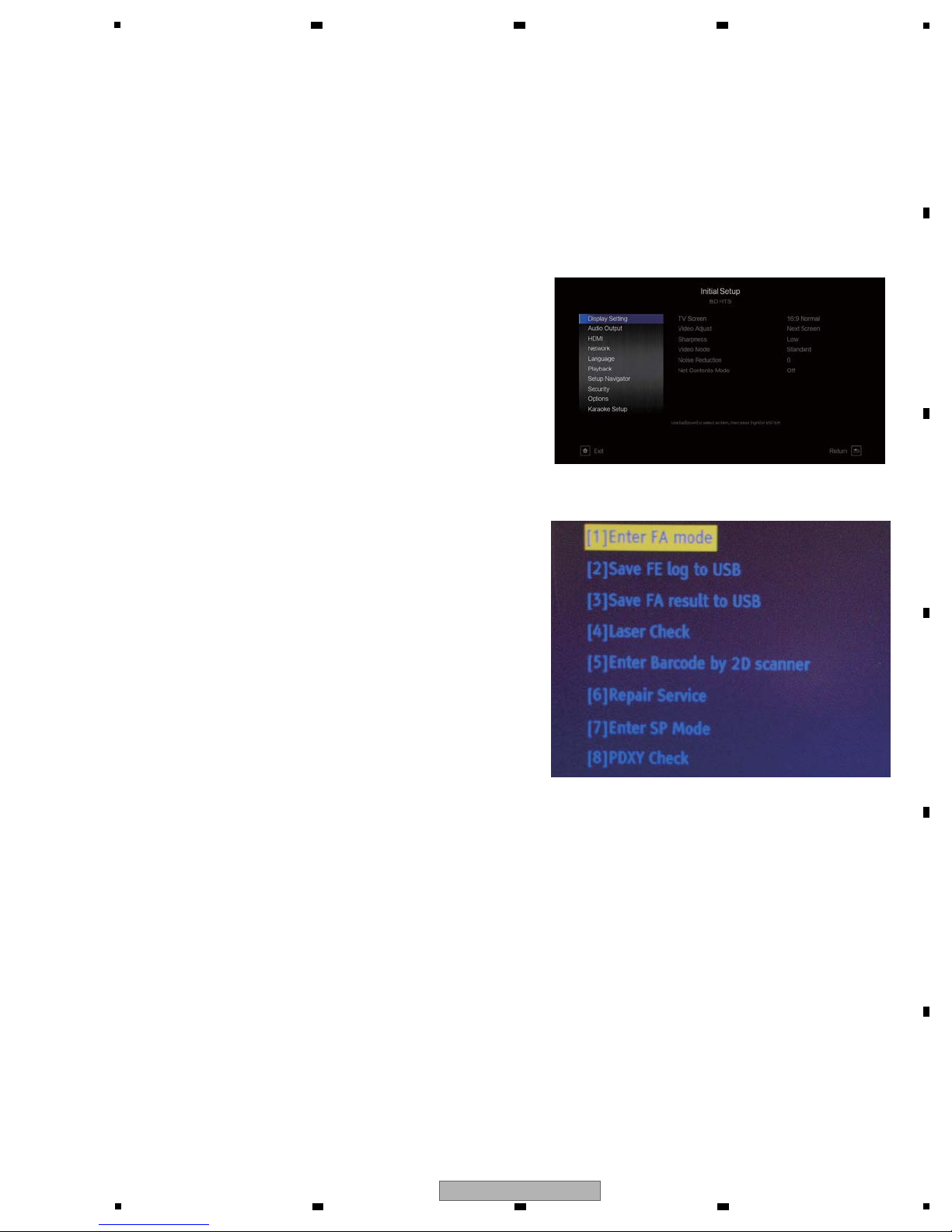

In Service Mode, there is a mixture of Design and Development, Production Line Menu and Service Menu.

Here, menu items that are usable in Service and instructions are listed.

Only use the menu explained in this document. Others are for Design and Product lines.

1. Press [Home Menu] on the remote controller and select

"Initial Setup" from the home menu.

2. Pressing the number keys on the remote control in the

following order [5] ⇒ [1] ⇒ [7] ⇒ [7] will display the Menu

screen. (If it does not appear, slowly press the number

keys with a 1 second interval.)

1. HOW TO ENTER TO SERVICE MODE

2. DESCRIPTION OF EACH ITEM

[1] Enter FA mode

Implemented when exchanging the LOADER Assy and MAIN BOARD Assy. Refer to "FA Mode" for details.

[2] Save FE log to USB

For Design and Development purposes and cannot be used for Service.

[3] Save FA result to USB

For Design and Development purposes and cannot be used for Service.

[4] Laser Check

Verifies laser diode. Refer to "Laser Check" for details.

[5] Enter Barcode by 2D scanner

For Production line purposes and cannot be used for Service.

[6] Repair Service

For the former model and will not be used to exchange this Loader.

[7] Enter SP Mode

Mainly for Production Line, but some items can be used in Service. Please see "SP Mode" for details.

[8] PDXY Check

Verifies misalignment of optical axis. Refer to "PDXY Check" for details.

6 7 8

6. SERVICE MODE

6.1 SERVICE MODE

A

B

C

D

5

6 7 8

XV-BD422B

E

F

15

1

3. DETAILED DESCRIPTION OF ITEMS USED IN SERVICE

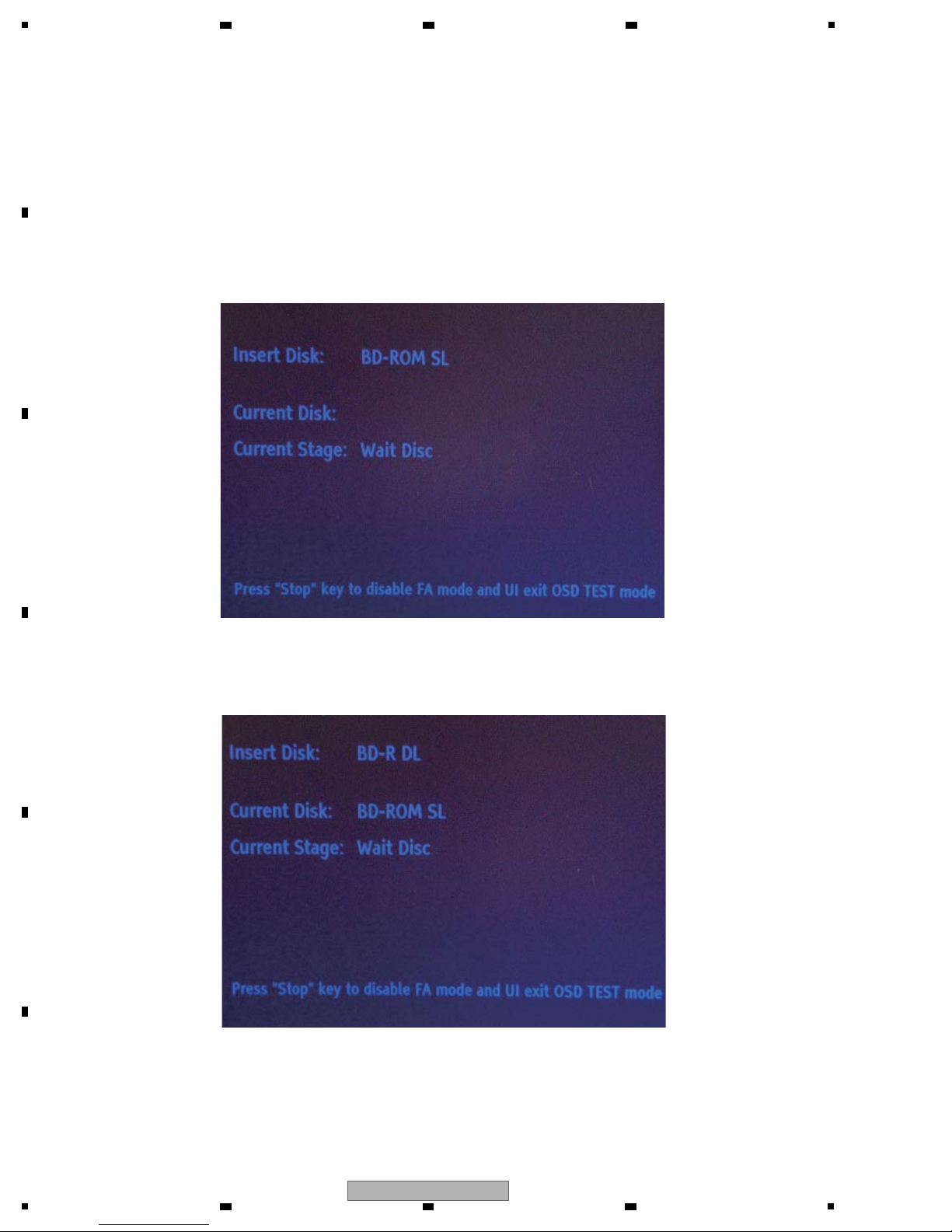

1. [1] Enter FA mode

1 Select "[1] Enter FA mode" with the up-and-down key on the remote control on the Service Mode screen and press the

[ENTER] key. (Window below will appear)

2 The tray will open automatically, so insert GGV1368 and close the tray manually. (push the tray in)

3 Adjustments will initiate, and when they are properly completed, the tray will re-open and [Insert Disc: BD-R DL]

will appear.

4 Remove the disc from the tray and press the [Stop] key.

You will exit Service Mode and return to the Home Menu screen and finish.

In "FA mode," playback of the pick-up area is adjusted first, and then playback verification processis done on all playable discs.

Adjustments on initial playback need to be made when exchanging the Loader and MAIN BOARD Assy in Service,

so implement "FA mode" as in the following instructions.

A

2 3 4

B

C

D

E

F

16

1

2 3 4

XV-BD422B

5

1 Select "[4] Laser Check" with the b key from the Service Mode screen and press the "ENTER" key.

(perform without disc in tray)

2 After a few seconds, measurement and judgment results will be displayed as follows, and the tray will open automatically.

If all Measurement values (Meas) are less than the total numeric value of the Target value (hex) and 80 (hex) combined,

[PASS] will appear, and if any of them goes over, [NG] will appear.

2. [4] Laser Check

Verifies the output value of each laser diode inside the pick-up area. Implement according to the following procedures.

3. [7] Enter SP Mode

There are 15 items in the SP Mode, the main items being for Production line and Design/Development.

The following is to explain items usable in Service. Other items require time for completion, or are not suited for

Service purposes. If you select them by mistake, press the [Stop] key to end that item you accidentally selected.

(none of the items will affect the main unit)

Example

BD

Target: 0x41d

Meas: 0x43 OK because

0x41d+0x80=0x49d

Meas is 0x49d or less

DVD

Target: 0x53c

Meas: 0x5a7 l OK

0x53c+0x80=0x5bc

CD

Target: 0x560

Meas: 0x5d7 l OK

0x560+0x80=0x5e0

BD Measurement values: The hexadecimal single-digit will not be displayed in Meas. Therefore

in the above example, Measurement values of up to 0x49 are considered OK, and 0x50 are considered NG.

("0x" is simply to express the hex, so it is not necessary in the calculation)

6 7 8

A

B

C

D

XV-BD422B

5

6 7 8

E

F

17

1

1

Select "[7] Enter SP Mode" with the b key from the Service Mode screen, and press the [ENTER] key.

2

The SP Mode window menu will be displayed, so select "Start Up" and press the [ENTER] key.

3 The tray will automatically open and the dedicated screen will appear. Place the disc you wish to useon the tray,

and push it in manually. ([Close] key will not function)

4 tart Up mode will be initiated, and count will start. Implement 20,000 times (4E20 in hex), and if no errors occur,

"Pass" will appear.If errors do occur, they will be counted. Therefore, errors can be identified without finishing the

process.

1 Select "[7] Enter SP Mode" with the b key from the Service Mode screen, and press the [ENTER] key.

2 The SP Mode window menu will be displayed, so select either "Jitter Measure ""BLER Measure,"

and press the [ENTER] key.

3 The tray will automatically open and the dedicated screen will appear. Place the disc you wish to use on the tray,

and push it in manually. ([Close] key will not function)

4 The tray will reopen automatically. Measurement will start when you push the tray in manually.

5 When test is completed, "Pass" or "NG" is displayed.

3-1. Start Up

[ Content of test ]

Implements initial movement of the disc servo continuously. Implement the following process 20,000 cycles.

Measures the Jitter or the Block Error Rate (BLER) of the disc inserted.

Only Pass or NG will be displayed, not Measurement values.

All of CD, DVD, and BD can be judged.

[ Instructions ]

[ Effective indications ]

3-2. Jitter Measure / BLER Measure

[ Content of test ]

[ Instructions ]

[ Effective indications ]

• Tray sometimes does not open, discs sometimes are not recognized, discs sometime do not playback.

(When indications are related to discs, implment on the type of disc which has been pointed out.

If it is the disc on which the indications occurred, possibility of reoccurrence is higher.)

Defect related to playback. (blocked noise, sound jumping, image jumping, disc is paused, freeze of screen etc.)

However, even if Pass is displayed after this test, it is difficult to determine that the Driver is normal with these

Pass judgments only.

If an NG is generated in a specific disc only, the defect is likely to be caused by the disc. If an NG is gener ated in

other discs t oo, t he defect is likely to be caused by the drive part.

.

Tray Close

l

.

Foucus ON

l

.

TOC Read

l

.

Tray Open

(1 cycle 15 seconds x 20000=completed in approx. 83 hours 20 minutes)

Can be implemented on all of CD, DVD, and BD. Cannot change disc during process.

A

2 3 4

B

C

D

E

F

18

1

XV-BD422B

2 3 4

5

3-3. Simple Aging

[ Content of Test ]

Performs random playback of disc randomly. Implement the following process 800 cycles.

[ Instructions ]

1 Select "[7] Enter SP Mode" with the b key from the Service Mode screen, and press the [ENTER] key.

2 The SP Mode window menu will be displayed, so select "Simple Aging" and press the [ENTER] key.

3 The tray will automatically open and the dedicated screen will appear. Place the disc you wish to use on the tray,

and push it in manually. ([Close] key will not function)

4 The tray will reopen automatically. Aging will start when you push the tray in manually.

Note 1: [Total test count] display should always be 1 (essentially, 9C40, which is the hex of the 40000, the total of

Random 50-time playback x 800 times should be displayed.

Note 2: Accumulated sum for [Current test count] is counted up until "9C3D" (39997 in decimal), however later it is

expressed as "32" and is finished.

Note 3: DVD and BD disc can be checked with Single Layer (SL) disc only.

If they are checked with Dual Layer (DL) disc, an Error is generated.

Note 4: Set [Auto Power OFF] function in the setting of main unit to [OFF].

If the function is executed in any setting status, the power supply is turned OFF at the time.

.

Error List

The following serves as the Error List generated in SP Mode.

.

Tray close l .50 times of short playback on voluntary points

.

Tray open

1cycle BD : 75 seconds x 800 times = Completed in a total of approx. 16 hours 40 minutes

DVD: Approx. 100 seconds x800 times = Completed in a total of approx. 22 hours 12 minutes

CD : Approx. 105 seconds x800 times = Completed in a total of approx. 23 hours 20 minutes

l

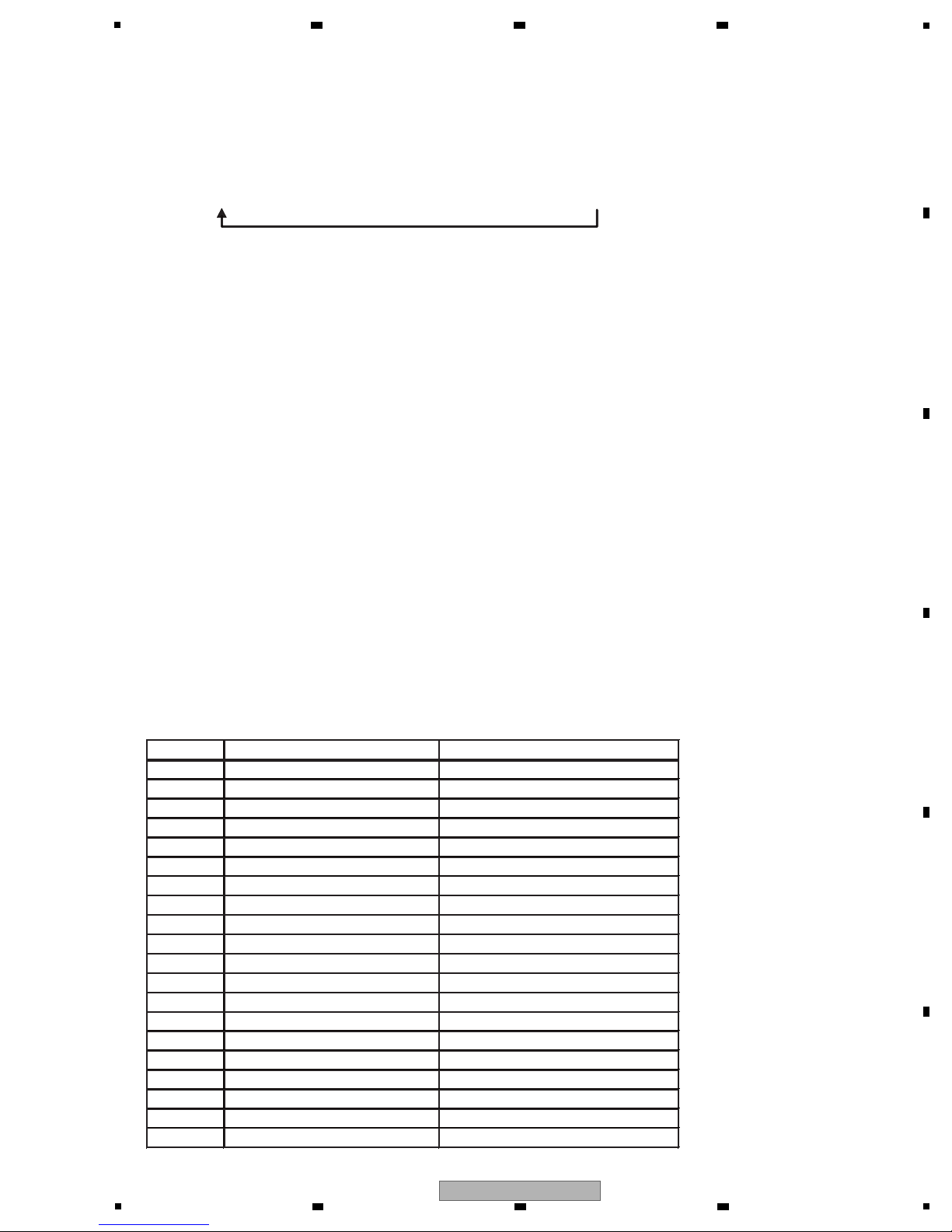

Error code Error name Discription

12 PW R_CURVE_ ERROR Power c urve chk-sum error

22 STARTUP_ TIMEOUT_ERROR Over time-out criteria

23 MEDIA_MISMATCH Wrong disc

25 DISCID_ERROR 0x25 Disc ID err o r

26 MEDIUM_SUPPORT_ERROR Unsupported disc

31 TRAYOUT_ERROR Over tray-out t ime-out crite ria

32 TRAYIN_ERROR O v er t r ay- in t ime- out criteria

33 FLASH_UPDATE_ ERROR Updating FA result failed

36 OPU_TEMP_ERROR Abnormal OPU temperature

41 SEEK_TIMEOUT_ERROR Over seek time-out crit e ria

42 SEEK_CMD_FAIL_ERROR Seek cmd fa ile d

51 READ_TOC_ERROR Read TOC cm d f ailed

52 TOC_TIM EO UT_ERROR Over read TOC time-out cr it er ia

61 PIPO_TI M EO UT_ERROR Over time-out criter ia

62 PIPO_C1C2_ERROR Read PIPO cmd failed

63 PIPO_C1C2_OVER Over PIPO criteria

71 RD_CMD_FAIL_ERROR Read cmd failed

72 RD_CMD_ERROR Cmd error or illegal mode

73 RD_TIME_OUT_ERROR Over read cmd time-out cr iter ia

81 CHECK_FA_TABLE_ERROR FA table chk-sum error

6 7 8

A

B

C

5

XV-BD422B

6 7 8

D

E

F

19

1

4. [8] PDXY Check

[ Instructions ]

[Effective indications]

Defect related to playback. (block noise , sound jumping, image jumping, dis c i s paused, freeze o f screen etc.)

If an NG is generated in a specific disc only, the defect is likely to be caused by the disc. If an NG is generated in

other discs too, t he defect is likely to be caused by the pick-up part. If the measurement val ue is very close to 40% even if

an NG is not generated, the NG is likely to be caused by the disc.

For PDXY Check, the misalignment of pick-up optical axis can be checked.

The optical axis misalignments of X-axis and Y-axis are displayed [PDX] and [PDY] with %, respectively.All of CD, DVD,

and BD can be measured. The method for calculating PDX and PDY is shown below.

1

Insert a disc (BD, DVD, CD) in a nomal mode. If the playback starts, pause it.

Display the home menu and enter into the Service Mode.

In this mode, the measurement can be carried out at an arbitrary place. After a disc is inserted, play and stop the point

you want to measure, and then enter into the Service Mode.

(The pick-up position does not return even in this status. The measurement at the place is available.)

2

Select "[8] PDXY Check" wi t h t h e b key from the Service Mode screen, and press the [ENTER] key.

3

After the measurement is started and completed, the measurement value is displayed.

If the value is within the reference value, "Pass" is displayed.

PDX = ((A+B)-(C+D)) / (A+B+C+D)

PDY = ((A+D)-(B+C)) / (A+B+C+D)

A

2 3 4

B

C

D

E

F

20

1

XV-BD422B

2 3 4

5

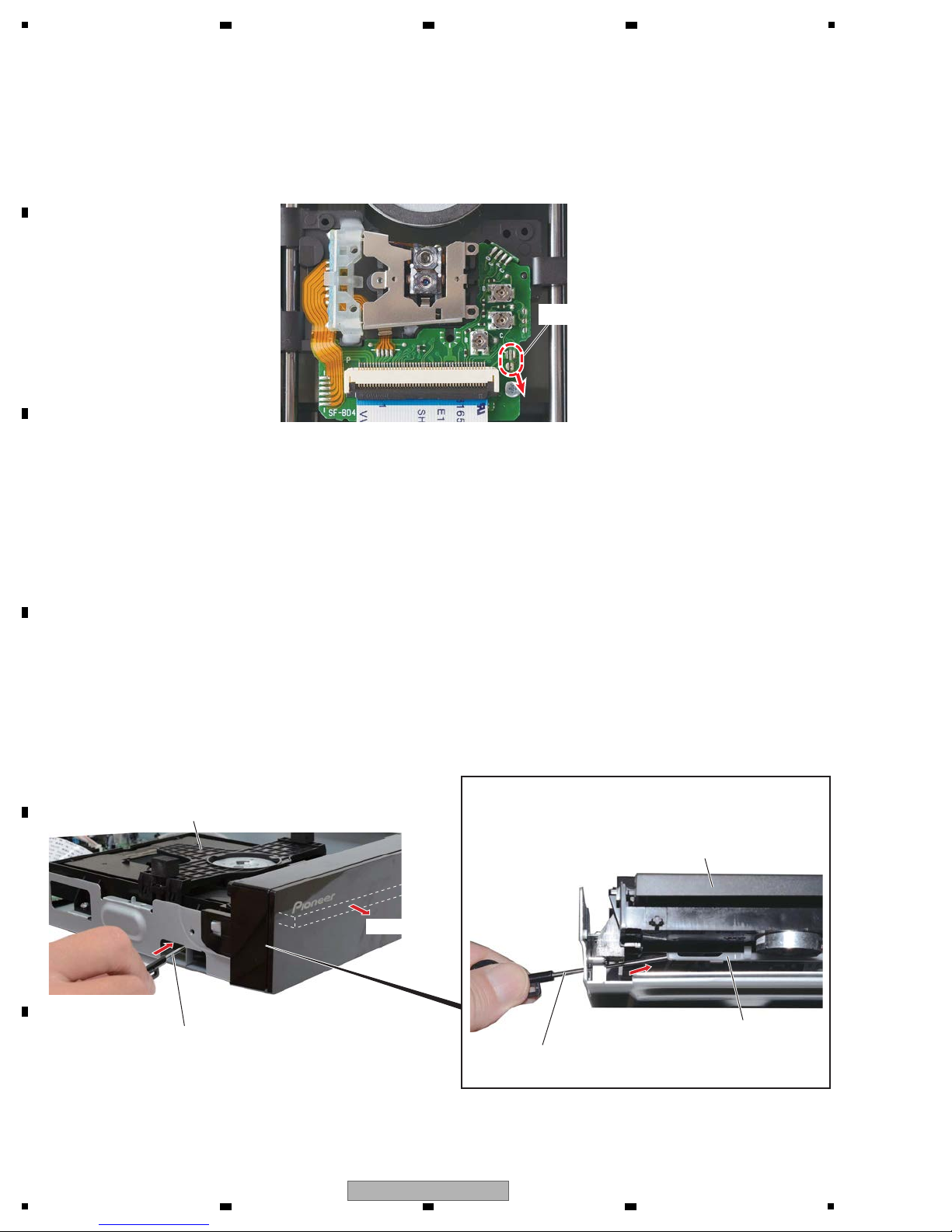

[1] LOADER Assy

(1) Disconnect the two flexible cables and one

connector.

(XP5, 7, 10)

(2) Remove the two screws.

(63-B30070-3H4)

(3) Unhook the one hooks.

(4) Remove the LOADER Assy.

2 2

3

4

LOADER Assy

LOADER Assy

XP7

XP10

XP5

11

1

• T op view

Remove the top cover by removing the six screws.

Note:

(1) Do NOT look directly into the pickup lens. The laser beam may cause eye injury.

(2) Even if the unit shown in the photos and illustrations in this manual may differ from your product, the

procedures described here are common.

6 7 8

7. DISASSEMBLY

A

B

C

D

E

5

XV-BD422B

6 7 8

F

21

1

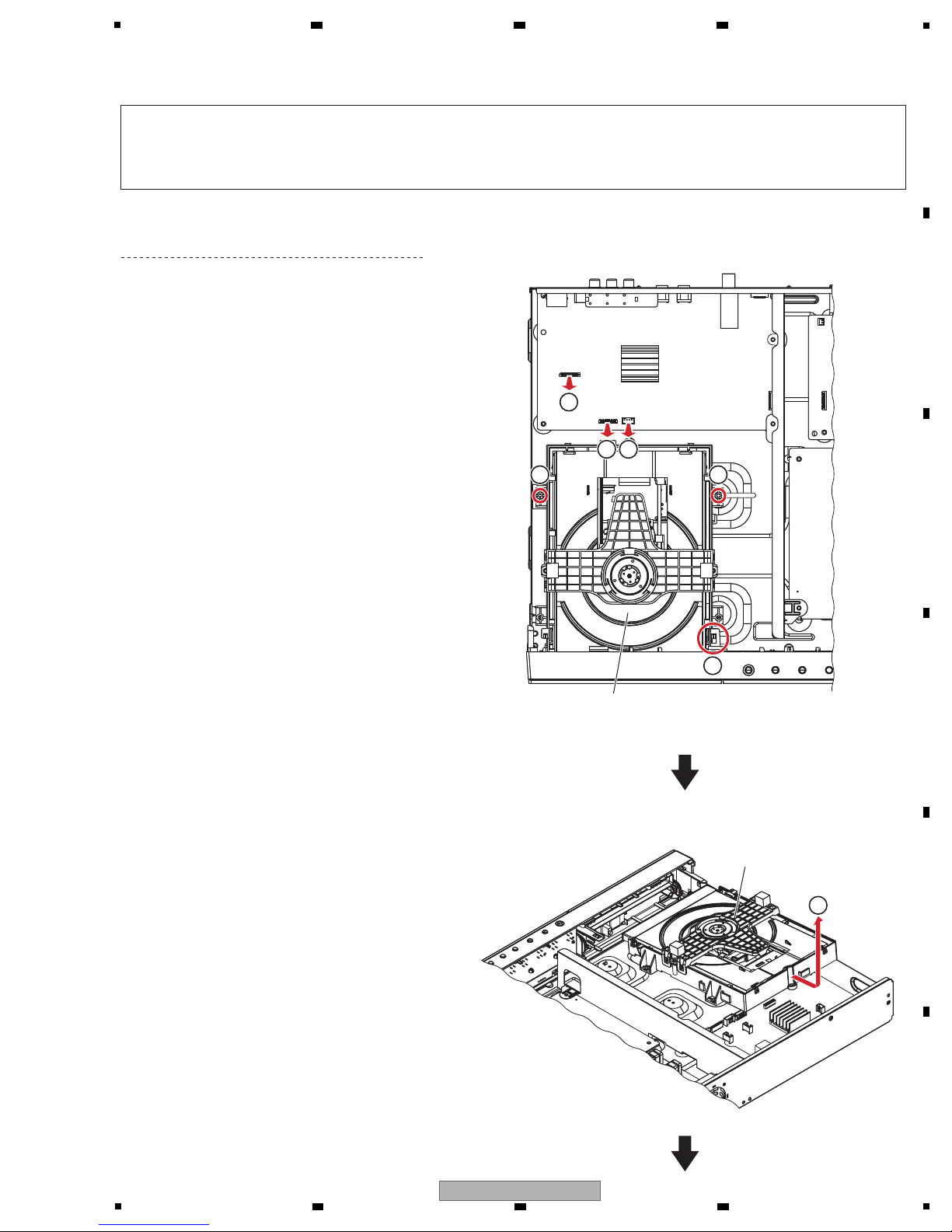

Case of replacing to a New LOADER Assy

After connecting LOADER Assy and MAIN BOARD Assy with FFC, please remove solder at protection point to the arrow-mark

direction by using soldering iron with your right-hand while holding the pick-up portion with your left-hand.

(Photo shows the situation after the removal of solder.)

Protection point

When the tray cannot be opened because the power cannot be turned on, it can be opened using the emergency disc

ejection rod (GGF1529). (A long, thin rod about 1 mm in diameter can be used in place of the rod.)

Insert emergency disc ejection rod (GGF1529) into the side located at the chassis, and slide the loading rack in the

LOADER Assy in the direction of the arrow, as indicated in the photo.

If the tray pops out a little, fully pull it out by hand.

How to open the tray when the power cannot be on

LOADER Assy

LOADER Assy

Emergency disc ejection rod

(GGF1529)

Emergency disc ejection rod

(GGF1529)

Loading rack

Tray open

Note: The Emergency disc ejection rod will not reach

the Loading rack unless it is inserted in slant

upward direction.

A

2 3 4

B

C

D

E

F

22

1

XV-BD422B

2 3 4

1 1

1 1

Front

Front

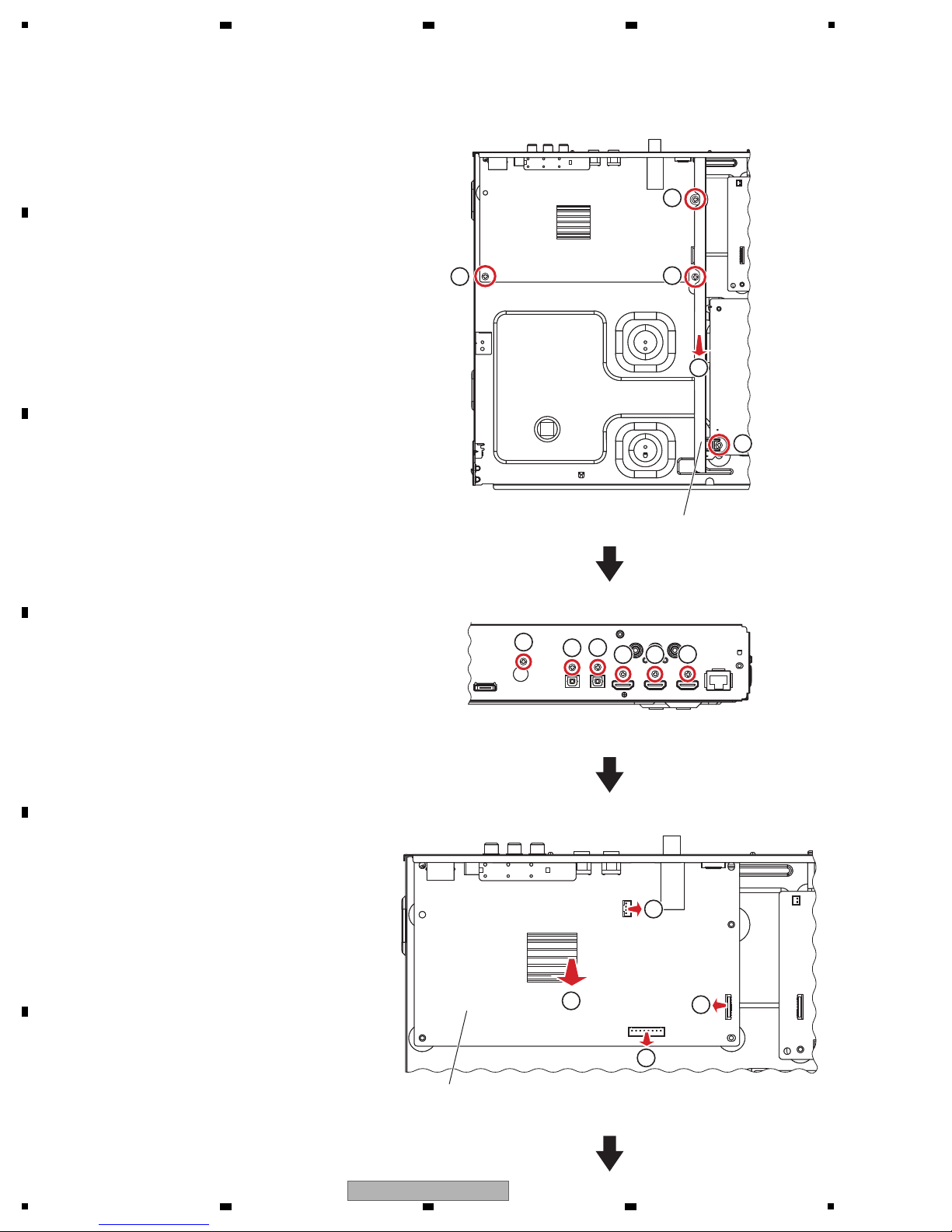

(1) Unhook the four hooks.

(2) Remove the top cover.

Top cover

2

Cleaning

Pickup lenses

Clean the pickup lenses when it is stained, using

the following cleaning materials:

Cleaning liquid : GEM1004

Cleaning paper: GED-008

Caution:

The pickup for Blu-ray is a high-precision

component; therefore, clean the lens with

enough care so as not to cause a misalignment

in the optical axis.

5

6 7 8

A

B

C

D

E

5

XV-BD422B

6 7 8

F

23

1

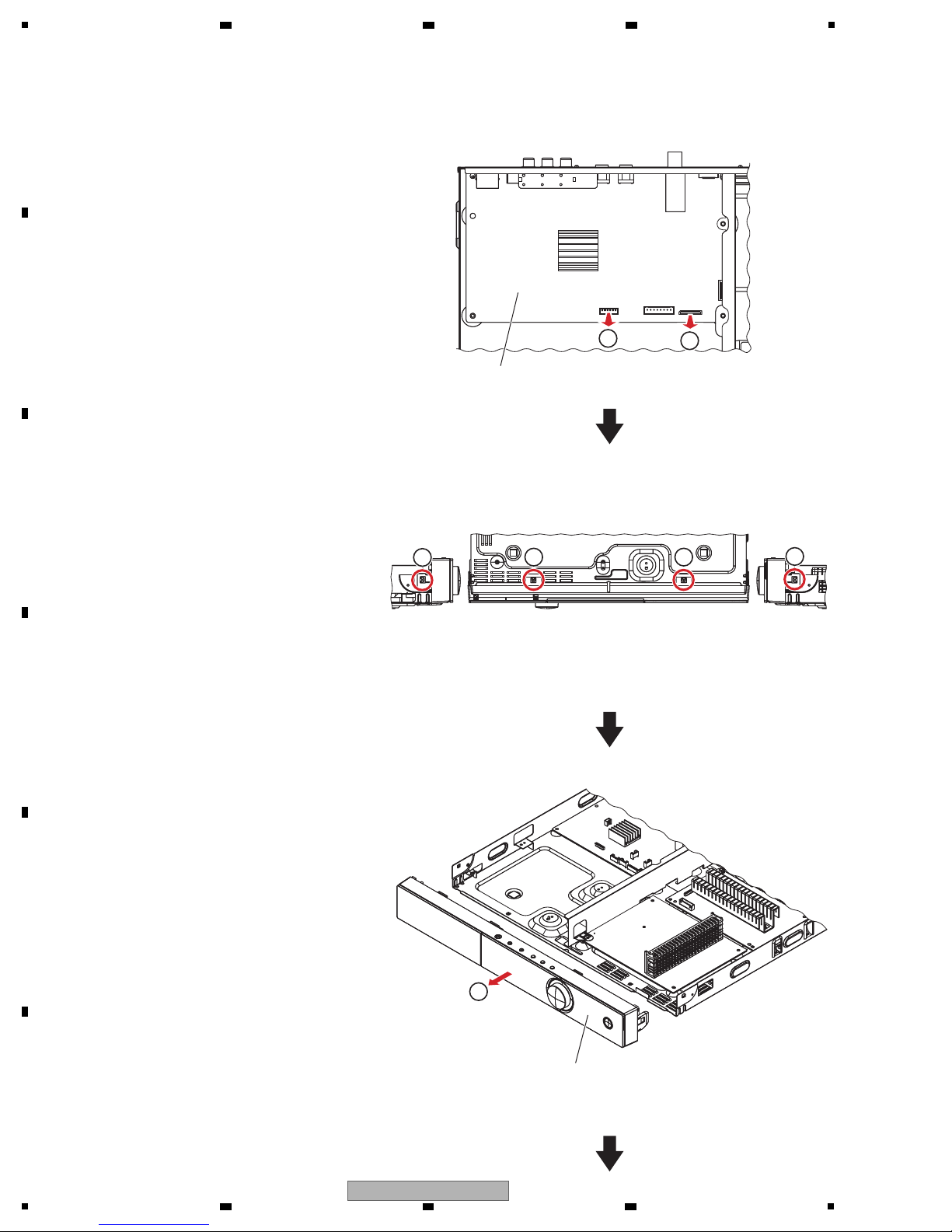

[2] Front Panel Section

(1) Disconnect the one flexible cable and one

connector.

(XP13, 17)

(2) Unhook the four hooks.

(3) Remove the front panel section.

XP13

XP17

MAIN BOARD Assy

Front panel section

2

2

3

2

2

1

• T op view

• Bottom view

1

A

B

2 3 4

C

D

E

F

24

1

XV-BD422B

2 3 4

(4) Remove the VOL knob Assy.

(5) Remove the five screws.

(63-B26080-BF4)

(6) Unhook the two hooks.

(7) Remove the FRONT BOARD Assy.

VOL Knob Assy

FRONT BOARD Assy

5 5

5

6

7

6

5 5

• Rear view

4

5

6 7 8

A

B

C

D

E

5

XV-BD422B

6 7 8

F

25

1

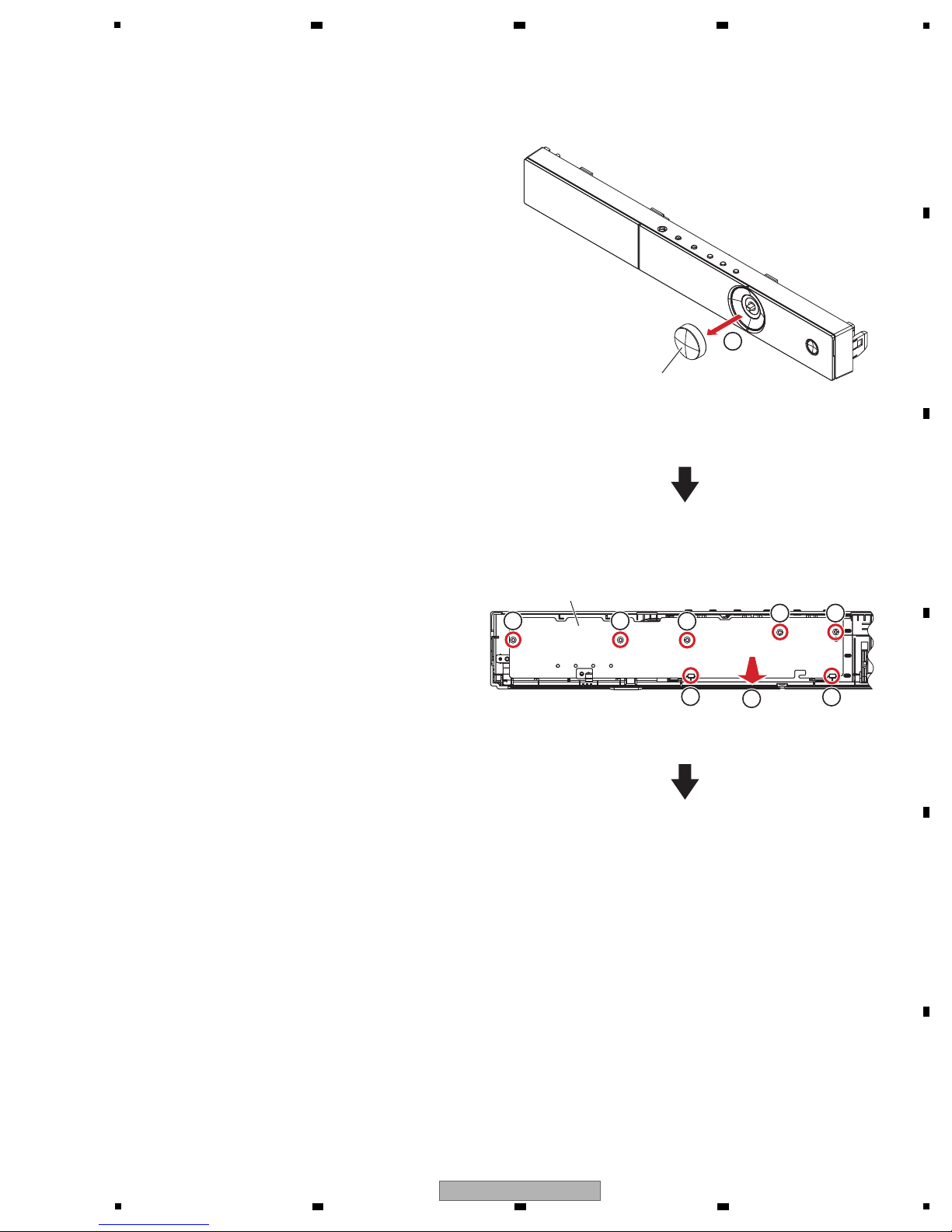

[3] MAIN BOARD Assy

(1) Remove the four screws.

(63-B30070-3H4)

(2) Remove the stay.

(3) Remove the three screws.

(63-B30070-3H4)

(4) Remove the three screws.

(64-B30040-304)

(5) Disconnect the one flexible cable and two

connectors.

(XP1, 4, 11)

(6) Remove the MAIN BOARD Assy.

Stay

4

4

4

3 3

3

1

1

1

1

• T op view

• Rear view

• T op view

2

XP11

XP4

XP1

MAIN BOARD Assy

5

5

5

6

A

B

2 3 4

C

D

E

F

26

1

XV-BD422B

2 3 4

Loading...

Loading...