Pioneer PDP-R05E Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

For details, refer to "Important Check Points for Good Servicing".

Serial No.

Confirm it

WYVI SS

WYVIXK UK

POWER

ON STANDBY

TIMER

PDP-R05E

ORDER NO.

ARP3225

MEDIA RECEIVER

PDP-R05E

PDP-R05XE

PDP-R05FE

THIS MANUAL IS APPLICABLE TO THE FOLLOWINGMODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PDP-R05E WYVI AC220-240V

PDP-R05E WYVIXK AC220-240V

PDP-R05XE WYVIXK AC220-240V

PDP-R05FE WYVI AC220-240V

PDP-R05FE WYVIXK AC220-240V

Please connect it to the PLASMA DISPLAY PDP-505PE or PDP-435PE for adjustment and

operation inspection.

T-ZZK NOV. 2004 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Leakage

current

E

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

tester

Reading should

not be above

0.5 mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

PDP-R05E

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

PDP-R05E

E

F

3

7

8

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 6

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 8

A

B

C

D

E

F

2.1 PACKING SECTION .................................................................................................................................. 8

2.2 EXTERIOR SECTION (1) ........................................................................................................................10

2.3 EXTERIOR SECTION (2) ........................................................................................................................14

2.4 FRONT PANEL SECTION ....................................................................................................................... 16

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................18

3.1 BLOCK DIAGRAM ................................................................................................................................... 18

3.1.1 SIGNAL ROUTE................................................................................................................................ 18

3.1.2 MR MAIN BOARD ASSY................................................................................................................... 20

3.1.3 AV BOARD ASSY.............................................................................................................................. 22

3.1.4 POWER SUPPLY UNIT ..................................................................................................................... 24

3.1.5 PC CARD MODULE .......................................................................................................................... 25

3.1.6 TUNER BOARD ASSY...................................................................................................................... 26

3.1.7 POWER SUPPLY............................................................................................................................... 27

3.2 OVERALL WIRING CONNECTION DIAGRAM........................................................................................ 28

3.3 MR MAIN BOARD ASSY (1/12)............................................................................................................... 30

3.4 MR MAIN BOARD ASSY (2/12)............................................................................................................... 32

3.5 MR MAIN BOARD ASSY (3/12)............................................................................................................... 34

3.6 MR MAIN BOARD ASSY (4/12)............................................................................................................... 36

3.7 MR MAIN BOARD ASSY (5/12)............................................................................................................... 38

3.8 MR MAIN BOARD ASSY (6/12)............................................................................................................... 40

3.9 MR MAIN BOARD ASSY (7/12)............................................................................................................... 42

3.10 MR MAIN BOARD ASSY (8/12)............................................................................................................. 44

3.11 MR MAIN BOARD ASSY (9/12)............................................................................................................. 46

3.12 MR MAIN BOARD ASSY (10/12)........................................................................................................... 48

3.13 MR MAIN BOARD ASSY (11/12)........................................................................................................... 50

3.14 MR MAIN BOARD ASSY (12/12)........................................................................................................... 52

3.15 AV BOARD ASSY (1/9).......................................................................................................................... 54

3.16 AV BOARD ASSY (2/9).......................................................................................................................... 56

3.17 AV BOARD ASSY (3/9).......................................................................................................................... 58

3.18 AV BOARD ASSY (4/9).......................................................................................................................... 60

3.19 AV BOARD ASSY (5/9).......................................................................................................................... 62

3.20 AV BOARD ASSY (6/9).......................................................................................................................... 64

3.21 AV BOARD ASSY (7/9).......................................................................................................................... 66

3.22 AV BOARD ASSY (8/9).......................................................................................................................... 68

3.23 AV BOARD ASSY (9/9).......................................................................................................................... 70

3.24 MDR ASSY ............................................................................................................................................72

3.25 SR ASSY ............................................................................................................................................... 74

3.26 FRONT ASSY ........................................................................................................................................ 76

3.27 LED ASSY ............................................................................................................................................. 78

3.28 TUNER BOARD ASSY (1/6).................................................................................................................. 80

3.29 TUNER BOARD ASSY (2/6).................................................................................................................. 82

3.30 TUNER BOARD ASSY (3/6).................................................................................................................. 84

3.31 TUNER BOARD ASSY (4/6).................................................................................................................. 86

3.32 TUNER BOARD ASSY (5/6).................................................................................................................. 88

3.33 TUNER BOARD ASSY (6/6).................................................................................................................. 90

3.34 POWER SUPPLY UNIT.......................................................................................................................... 92

3.35 WAVEFORMS........................................................................................................................................ 94

3.36 VOLTAGES............................................................................................................................................. 95

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 99

4.1 SW and MDR ASSYS .............................................................................................................................. 99

4.2 MR MAIN BOARD ASSY ....................................................................................................................... 100

4.3 AV BOARD and SR ASSY ..................................................................................................................... 104

4.4 FRONT and LED ASSY ......................................................................................................................... 108

4.5 TUNER BOARD ASSY...........................................................................................................................110

4.6 POWER SUPPLY UNIT.......................................................................................................................... 112

5. PCB PARTS LIST ......................................................................................................................................... 114

6. ADJUSTMENT ............................................................................................................................................. 132

6.1 HOW TO ENTER SERVICE FACTORY MODE...................................................................................... 132

6.2 POSSIBLE CASES WHERE READJUSTMENT IS REQUIRED ........................................................... 132

6.3 USING RS-232C COMMANDS.............................................................................................................. 133

6.4 ADJUSTMENT ITEMS........................................................................................................................... 134

6.5 TRAP SWITCH ...................................................................................................................................... 137

4

1234

PDP-R05E

5678

6.6 SERVICING USING ONLY THE MEDIA RECEIVER..............................................................................138

6.7 SERVICE FACTORY MODE...................................................................................................................139

6.8 LIST OF RS-232C COMMANDS............................................................................................................156

6.9 OUTLINE OF COMMANDS....................................................................................................................159

7. GENERAL INFORMATION ...........................................................................................................................164

7.1 DIAGNOSIS............................................................................................................................................164

7.1.1 TROUBLESHOOTING......................................................................................................................164

7.1.2 DISASSEMBLY ................................................................................................................................177

7.2 EXPLANATION.......................................................................................................................................180

7.2.1 PROCESSING IN ABNORMALITY..................................................................................................180

7.2.2 SEQUENCE .....................................................................................................................................184

7.3 PARTS....................................................................................................................................................185

7.3.1 IC......................................................................................................................................................185

7.4 CLEANING .............................................................................................................................................210

8. PANEL FACILITIES .......................................................................................................................................211

A

B

C

D

E

56

PDP-R05E

F

5

7

8

1234

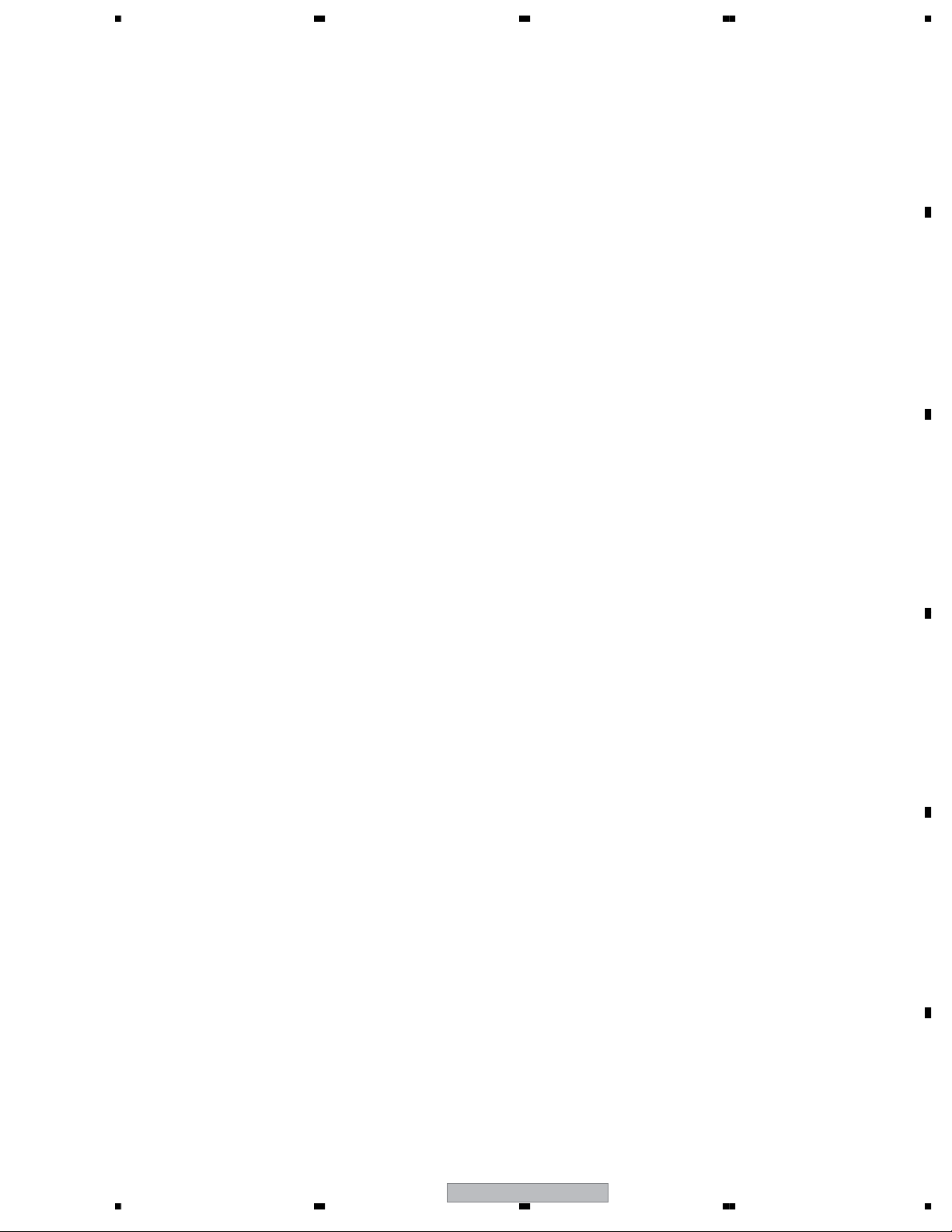

1. SPECIFICATIONS

Item Media Receiver, Model:PDP-R05XE Media Receiver, Model:PDP-R05E

Colour System

A

TV Function

(Analogue)

TV Function

(Digital)

B

Terminals

C

MONITOR OUTPUT Terminal(Rear)

SUB WOOFER OUTPUT Terminal (Rear)

PHONES OUTPUT Terminal (Front)

DIGITAL OUT Terminal

COMMON INTERFACE (Rear)

Power Requirement

Receiving System

Tuner

Auto Channel Preset

STEREO

Receiving System

Tuner

Auto Channel Preset

STEREO

Rear

Front

Analogue PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

Digital

VHF/UHF

CATV

VHF/UHF

INPUT 1

INPUT 2

INPUT 3

Antenna

INPUT 4

PC

PC CARD

PAL/SECAM Not Applicable

B/G,D/K,I,L/L ’

E2 –E69ch,F2 –F10ch,I21 –I69ch,IR A –IR Jch

Hyper-band,S1 –S41ch

99 ch,Auto Preset,Auto Label,Auto Sort

NICAM/A2

DVB-T (2K/8K COFDM)

VHF Band III (170 to 230 MHz)and

UHF Band IV,V (470 to 862 MHz)

999 ch,Auto Preset,Auto Label,Auto Sort

MPEG layer I/II,Dolby Digital

SCART (AV in,RGB in,TV out)

SCART (AV in/out,S-VIDEO in,AV link *1)Component Video

SCART (AV in/out,S-VIDEO in,RGB in,AV link *1),HDMI in

75 Ω Din Type for VHF/UHF in (Analogue)

75 Ω Din Type for VHF/UHF in (Digital)

75 Ω Din Type for VHF/UHF out (Digital)

S-VIDEO,AV in

Analogue RGB in,Audio in

PCMCIA Type II

S-VIDEO out,AV out

Variable

16 –32 Ω recommended

Digital audio output (Optical)

CA Module

220 –240 V AC ,50/60 Hz,41 W

(1.2 W Standby:Aerial Power Off)

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Not Applicable

220 –240 V AC ,50/60 Hz,35 W

(0.4 W Standby)

Dimensions

D

Weight

* 1 Switchable

• Design and specifications are subject to change without notice.

420 (W) x 90 (H) x 295 (D)mm

5.6 kg

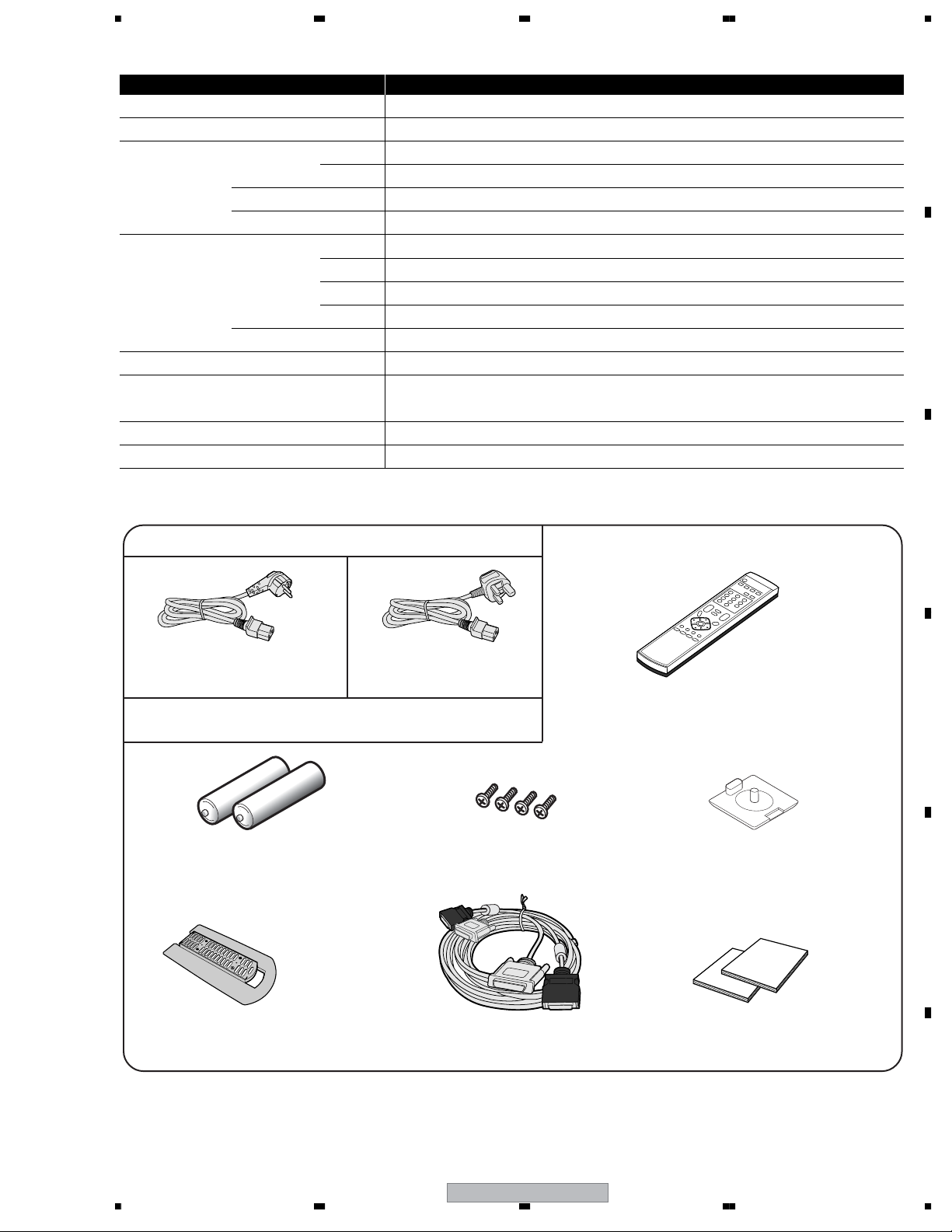

Power cord (2 m)

(For Europe, except U.K.and Eire)

E

(ADG1214)

(For U.K. and Eire)

Only the power cord that is appropriate in your country or

region is supplied.

AA size battery x 2

(Manganese battery)

F

System cable (3 m)

(ADF1026)

Stand

(AXG1013)

4.9 kg

Remote control unit

(for PDP-505XDE/435XDE)

(AXD1494)

Screw x 4 (for stand)

(PMB40P120FTB)

Three operating instructions

(for PDP-505XDE/435XDE)

(for PDP-505HDE/435HDE)

(AXD1495)

Screw hole cap x 4

(AMR3363)

Two operating instructions

(for PDP-505HDE/435HDE)

6

1234

PDP-R05E

5678

Item Media Receiver, Model:PDP-R05FE

Colour System

PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV Function Receiving System B/G,D/K,I,L/L’

Tuner VHF/UHF

CATV

Auto Channel Preset

STEREO

Terminals

Rear

INPUT 1

INPUT 2

INPUT 3

Antenna

Front

INPUT 4

MONITOR OUTPUT Terminal (Rear)

Power Requirement

E2 –E69ch,F2 –F10ch,I21 –I69ch,IR A –IR Jch

Hyper-band,S1 –S41ch

99 ch,Auto Preset,Auto Label,Auto Sort

NICAM/A2

SCART (AV in,RGB in,TV out)

SCART (AV in/out,S-VIDEO in,AV link *1)Component Video

SCART (AV in/out,S-VIDEO in,RGB in,AV link *1),HDMI in

75 Ω Din Type for VHF/UHF in

S-VIDEO,AV in

S-VIDEO out,AV out

220 –240 V AC ,50/60 Hz,27 W

(0.4 W Standby)

A

B

Dimensions

Weight

420 (W) x 90 (H) x 295 (D)mm

4.8 kg

*1 Switchable

• Design and specifications are subject to change without notice.

Power cord (2 m)

(For Europe, except U.K. and Eire)

(For U.K. and Eire)

(ADG1214)

Only the power cord that is appropriate in your country or

region is supplied.

AA size battery x 2

(Manganese battery)

Screw x 4(for stand)

(PMB40P120FTB)

Remote control unit

(AXD1491)

Screw hole cap x 4

(AMR3386)

C

D

Stand

(AXG1009)

System cable (3 m)

(ADF1026)

PDP-R05E

56

E

Two operating instructions

F

7

7

8

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

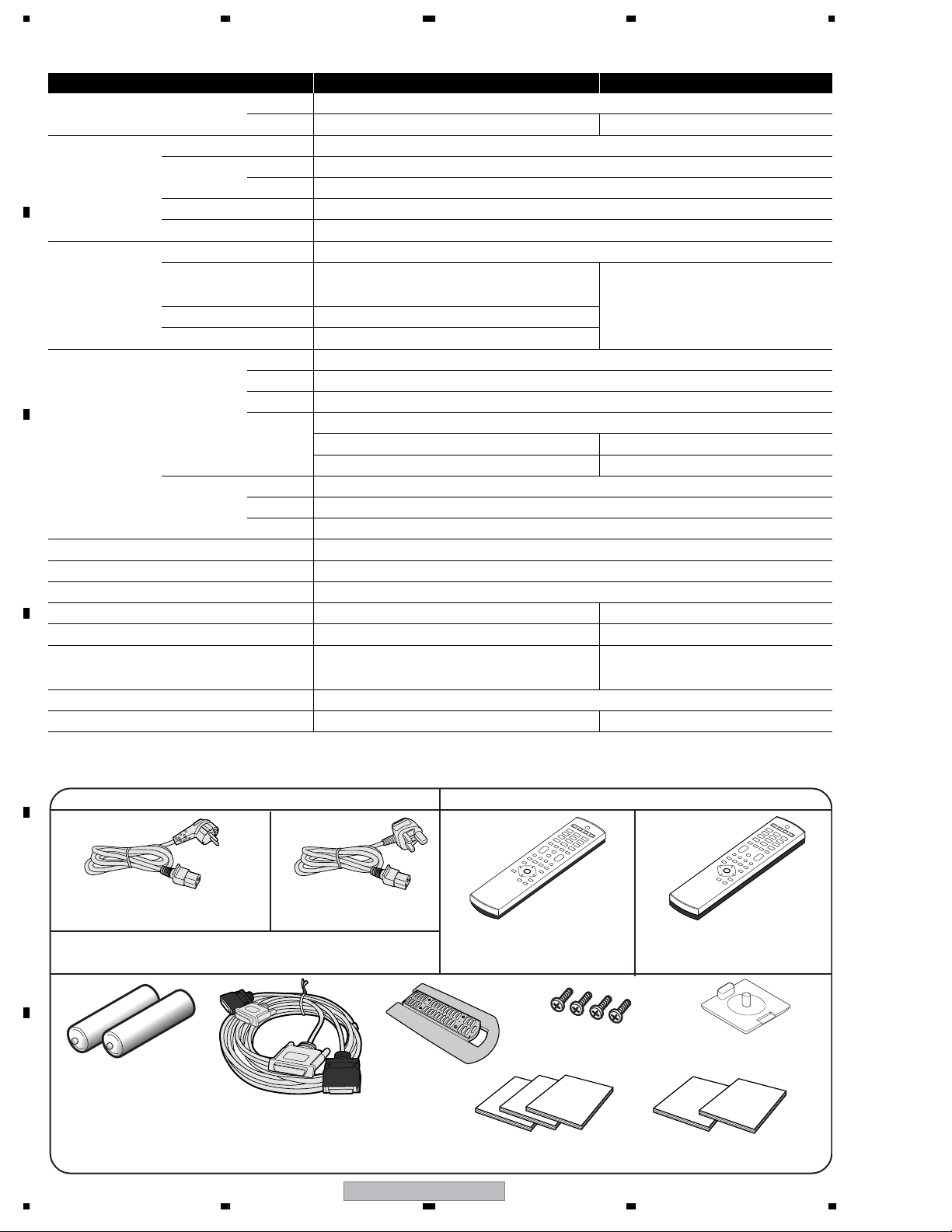

2.1 PACKING SECTION

B

5

C

20

17

1, 26, 27, 29, 30, 33, 34

24

21

31

32

22

22

14

×4 ×4

8

25

9

D

12

11

2

E

3

24

7

10

11

4

23

16

28

15

F

8

1234

18

19

PDP-R05E

FRONT

>

5678

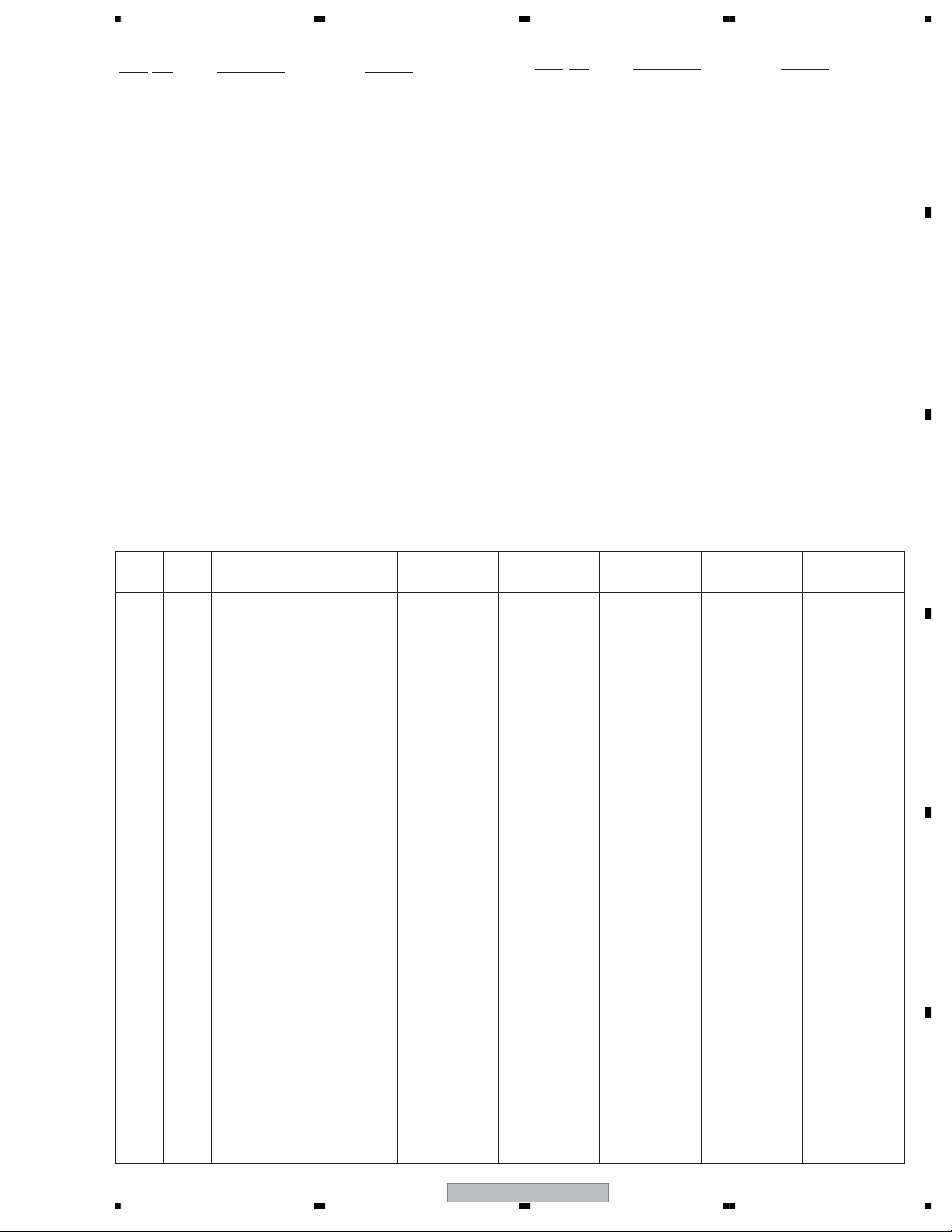

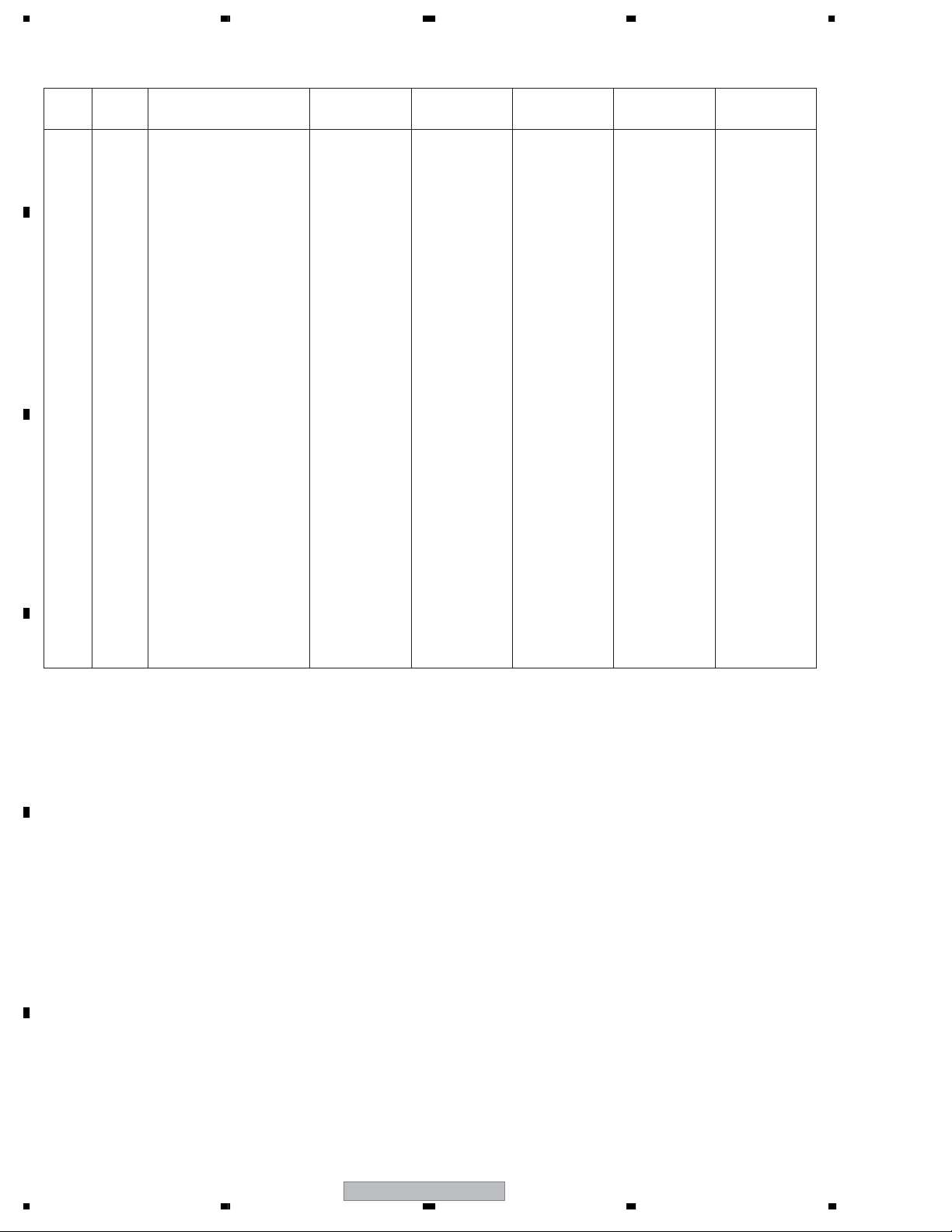

PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1 Operating Instructions See Contrast table (2)

2 Remote Control Unit See Contrast table (2)

3 Battery Cover See Contrast table (2)

4 System Cable (3m) ADF1026

5Power Cord ADG1214

6• • • • • •

NSP 7 Dry Cell Battery (R6/AA) VEM1031

8 Screw Hole Cap See Contrast table (2)

9 Stand Assy See Contrast table (2)

NSP 10 Stand See Contrast table (2)

NSP 11 Stand Cushion AEB1390

12 Laminated Sheet Bag AHG1334

13 • • • • • •

14 Pad L See Contrast table (2)

15 Pad R See Contrast table (2)

16 IM Pad See Contrast table (2)

17 Top Pad See Contrast table (2)

18 Accessory Box See Contrast table (2)

No. Description Part No.

Mark

19 Carton See Contrast table (2)

NSP 20 Literature Bag AHG1303

21 Vinyl Bag AHG1340

22 Vinyl Bag AHG1337

23 Laminated Sheet AHG1350

24 Air Capsule Bag AHG1351

25 Screw PMB40P120FTB

26 Operating Instructions See Contrast table (2)

27 Caution Card ARM1223

28 Caution Card ARM1234

29 Operating Instructions See Contrast table (2)

30 Errata See Contrast table (2)

31 User Card A See Contrast table (2)

32 User Card B See Contrast table (2)

33 Caution Manual See Contrast table (2)

NSP 34 Block Diagram See Contrast table (2)

A

B

(2) CONTRAST TABLE

PDP-R05E/WYVI, /WYVIXK, PDP-R05XE/WYVIXK, PDP-R05FE/WYVI and / WYVIXK are constructed the same

except for the following:

Mark No. Description

1 Operating Instructions ARE1391 ARE1380 ARE1380 ARE1392 ARE1383

(English/French/German)

2 Remote Control Unit AXD1495 AXD1495 AXD1494 AXD1491 AXD1491

3 Battery Cover AZN7919 AZN7919 AZN7919 AZA7424 AZA7424

8 Screw Hole Cap AMR3363 AMR3363 AMR3363 Not used Not used

8 Screw Hole Cap UE Not used Not used Not used AMR3386 AMR3386

9 Stand Assy AXG1013 AXG1013 AXG1013 Not used Not used

9 Stand Assy UE Not used Not used Not used AXG1009 AXG1009

NSP 10 Stand AMR3352 AMR3352 AMR3352 Not used Not used

NSP 10 Stand UE Not used Not used Not used AMR3382 AMR3382

14 Pad L AHA2370 AHA2396 AHA2396 AHA2370 AHA2396

15 Pad R AHA2371 AHA2397 AHA2397 AHA2371 AHA2397

16 IM Pad AHB1253 AHB1259 AHB1259 AHB1253 AHB1259

17 Top Pad AHB1256 AHB1260 AHB1260 AHB1256 AHB1260

18 Accessory Box AHC1053 AHC1056 AHC1056 AHC1053 AHC1056

19 Carton E AHD3247 AHD3293 Not used Not used Not used

19 Carton XE Not used Not used AHD3246 Not used Not used

19 Carton FE Not used Not used Not used AHD3248 AHD3283

26 Operating Instructions ARC1541 ARC1533 ARC1533 Not used Not used

(Italian/Dutch/Swedish/Spanish)

PDP-R05E/

WYVI

PDP-R05E/

WYVIXK

PDP-R05XE/

WYVIXK

PDP-R05FE/

WYVI

PDP-R05FE/

WYVIXK

C

D

E

NSP

26 Operating Instructions Not used Not used Not used ARC1542 ARC1535

(Italian/Dutch/Spanish)

29 Operating Instructions Not used Not used ARE1390 Not used Not used

(English/French/German)

(Italian/Dutch/Swedish/Spanish)

30 Errata ARX1120 ARX1121 ARX1121 ARX1120 ARX1121

31 User Card A Not used ARY1150 ARY1150 Not used ARY1150

32 User Card B Not used ARY1151 ARY1151 Not used ARY1151

33 Caution Manual ARM1263 ARM1264 ARM1264 ARM1263 ARM1264

34 Block Diagram Not used ARY1159 ARY1159 Not used ARY1159

PDP-R05E

56

7

8

F

9

1234

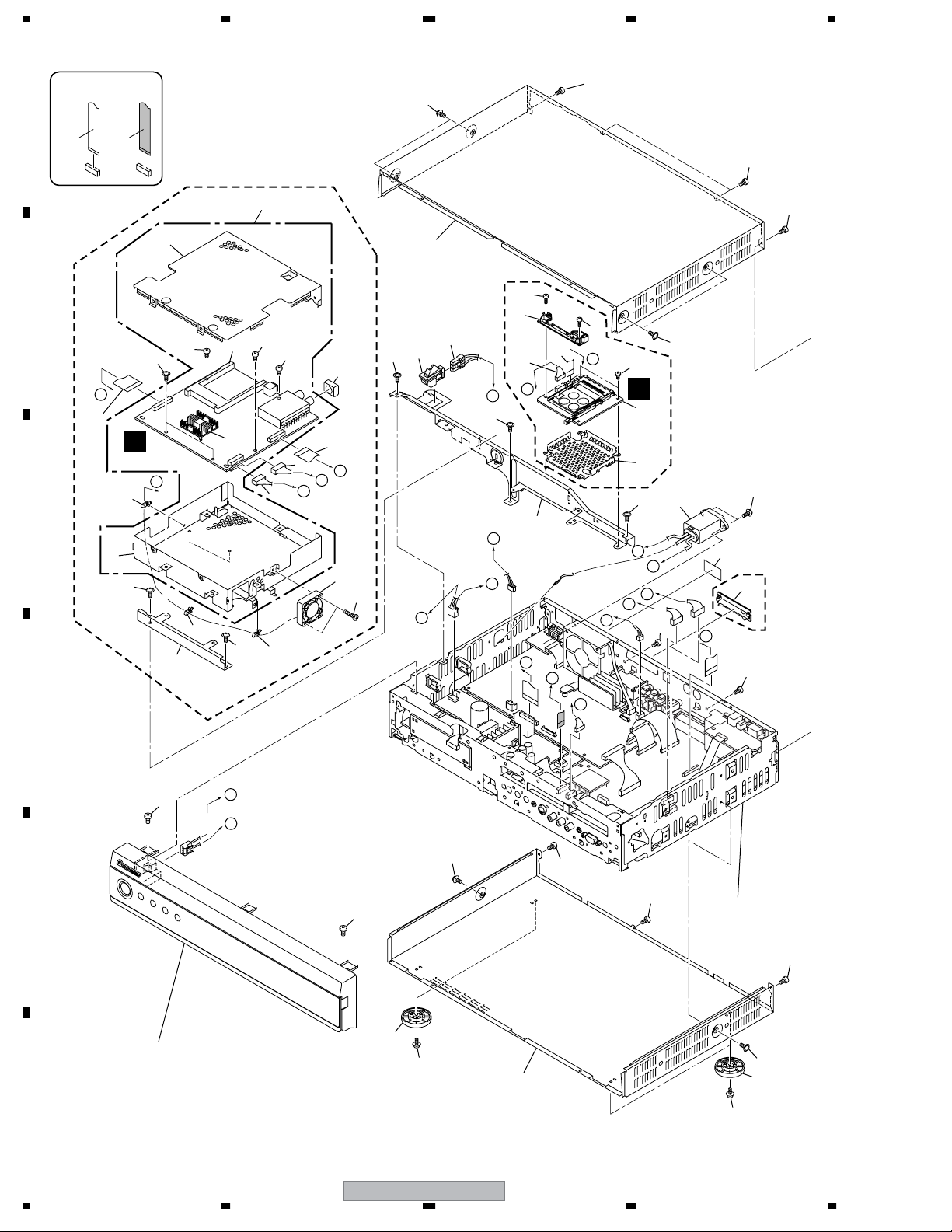

2.2 EXTERIOR SECTION (1)

A

54

59

B

C

D

NON-CONTACT

SIDE

CONTACT SIDE

53

E

4

I

18

38

53

39

41

H

68

PDP-R05XE only

1

41

44

40

18

53

9

18

41

54

54

28

61

66

65

61

59

D

57

Except

L

PDP-R05FE

62

67

53

7

2

64

C

F

53

5

8

K

J

I

63

53

3

53

12

11

F

G

55

A

E

D

C

G

B

J

I

H

54

36

K

PDP-R05XE

only

24

54

60

E

B

A

59

60

54

54

Refer to

"2.3 EXTERIOR

SECTION (2)".

54

Refer to

"2.4 FRONT PANEL SECTION".

F

10

1234

13

53

PDP-R05E

27

59

13

53

>

>

>

5678

EXTERIOR SECTION (1) PARTS LIST

No. Description Part No.

Mark

1 TUNER BOARD Assy See Contrast table (2)

2Power Switch (TRAP)(S1) ASG1089

3AC Inlet (CN1) AKP1257

4 Flexible Cable (J209) See Contrast table (2)

5 Flexible Cable (J210) See Contrast table (2)

6• • • • •

7 3P Housing Wire (J107) ADX2836

8 9P Housing Wire (J113) See Contrast table (2)

9 8P Housing Wire (J114) See Contrast table (2)

10 • • • • •

11 Fan Motor 42 x 10.5L See Contrast table (2)

12 Center Stay U ANG2564

13 Leg Assy AXG1012

14 • • • • •

15 • • • • •

16 • • • • •

17 • • • • •

18 Side Type Mini Clamp See Contrast table (2)

19 • • • • •

20 • • • • •

No. Description Part No.

Mark

50 • • • • •

51 • • • • •

52 • • • • •

53 Screw ABZ30P080FTC

54 Screw BBZ30P060FTB

55 Screw See Contrast table (2)

56 • • • • •

57 Screw ABZ30P080FTC

58 • • • • •

59 Screw See Contrast table (2)

60 Screw ABZ30P060FTB

61 Screw See Contrast table (2)

62 PC Card Module See Contrast table (2)

63 PC Shield See Contrast table (2)

64 6P Housing Wire (J111) See Contrast table (2)

65 Flexible Cable (J208) See Contrast table (2)

66 PC Guide See Contrast table (2)

67 Gasket XE See Contrast table (2)

68 Tuner Adaptor See Contrast table (2)

A

B

C

21 • • • • •

22 • • • • •

23 • • • • •

24 Rear Cover AMR3425

25 • • • • •

26 • • • • •

27 Metal Bonnet Bottom See Contrast table (2)

28 Metal Bonnet Top See Contrast table (2)

29 Serial Sheet AAX2609

30 • • • • •

31 • • • • •

32 • • • • •

33 • • • • •

34 • • • • •

35 • • • • •

NSP 36 Serial Label ARW1100

37 • • • • •

NSP 38 Bottom Can See Contrast table (2)

39 Top Can See Contrast table (2)

40 Heat Sink See Contrast table (2)

41 Screw See Contrast table (2)

42 Screw See Contrast table (2)

43 • • • • •

44 PCMCIA Ejector See Contrast table (2)

45 • • • • •

D

E

46 • • • • •

47 • • • • •

48 • • • • •

49 • • • • •

56

PDP-R05E

F

11

7

8

>

1234

(2) CONTRAST TABLE

PDP-R05E/WYVI, /WYVIXK, PDP-R05XE/WYVIXK, PDP-R05FE/WYVI and / WYVIXK are constructed the same

except for the following:

Mark No. Description

A

1 TUNER BOARD Assy Not used Not used AWE1301 Not used Not used

4 Flexible Cable (J209) Not used Not used ADD1280 Not used Not used

5 Flexible Cable (J210) Not used Not used ADD1267 Not used Not used

8 9P Housing Wire (J113) Not used Not used ADX3017 Not used Not used

9 8P Housing Wire (J114) Not used Not used ADX3018 Not used Not used

11 Fan Motor 42 x 10.5L) Not used Not used AXM1049 Not used Not used

18 Side Type Mini Clamp Not used Not used AEC2003 Not used Not used

24 Rear Cover Not used Not used AMR3425 Not used Not used

27 Metal Bonnet Bottom ANE1631 ANE1631 ANE1631 Not used Not used

B

NSP 38 Bottom Can Not used Not used XNA1004 Not used Not used

C

27 Metal Bonnet Bottom (UE) Not used Not used Not used ANE1634 ANE1634

28 Bonnet Top ANE1632 ANE1632 ANE1632 Not used Not used

28 Bonnet Top (FE) Not used Not used Not used ANE1637 ANE1637

39 Top Can Not used Not used XNG1001 Not used Not used

40 Heat Sink Not used Not used XNH1004 Not used Not used

41 Screw Not used Not used BBZ30P060FTB Not used Not used

42 Screw Not used Not used PMZ20P100FNI Not used Not used

44 PCMCIA Ejector Not used Not used ANG2673 Not used Not used

55 Screw Not used Not used BBZ30P140FTC Not used Not used

59 Screw ABZ30P080FTC ABZ30P080FTC ABZ30P080FTC ABZ30P060FTB ABZ30P060FTB

61 Screw ABZ30P180FTC ABZ30P160FTC ABZ30P160FTC Not used Not used

62 PC Card Module AXY1073 AXY1073 AXY1073 Not used Not used

63 PC Shield ANG2578 ANG2578 ANG2578 Not used Not used

64 6P Housing Wire (J111) ADX3016 ADX3016 ADX3016 Not used Not used

65 Flexible Cable (J208) ADD1226 ADD1226 ADD1226 Not used Not used

PDP-R05E/

WYVI

PDP-R05E/

WYVIXK

PDP-R05XE/

WYVIXK

PDP-R05FE/

WYVI

PDP-R05FE/

WYVIXK

66 PC Guide AMR3393 AMR3393 AMR3393 Not used Not used

67 Gasket XE Not used Not used ANK1756 Not used Not used

68 Tuner Adaptor Not used Not used ANG2672 Not used Not used

D

E

F

12

1234

PDP-R05E

5678

A

B

C

D

E

56

PDP-R05E

F

13

7

8

1234

2.3 EXTERIOR SECTION (2)

34

43

43

D

24

45

40

A

24

22

42

35

B

42

1

20

E

25

D

A

42

C

42

42

15

36

38

13

23

49

E

3

E

PDP-R05XE

only

10

A

42

12

24

NON-CONTACT

24

16

43

43

43

44

44

C

51

SIDE

43

44

43

19

CONTACT SIDE

40

43

41

F

29

K

28

D

H

E

31

18

42

14

6

42

42

33

46

30

42

8

44

40

52

42

32

26

A

30

42 42

37

F

B

B

9

B

27

2

42

42

11

C

F

4

50

17

G

5

F

14

1234

PDP-R05E

5678

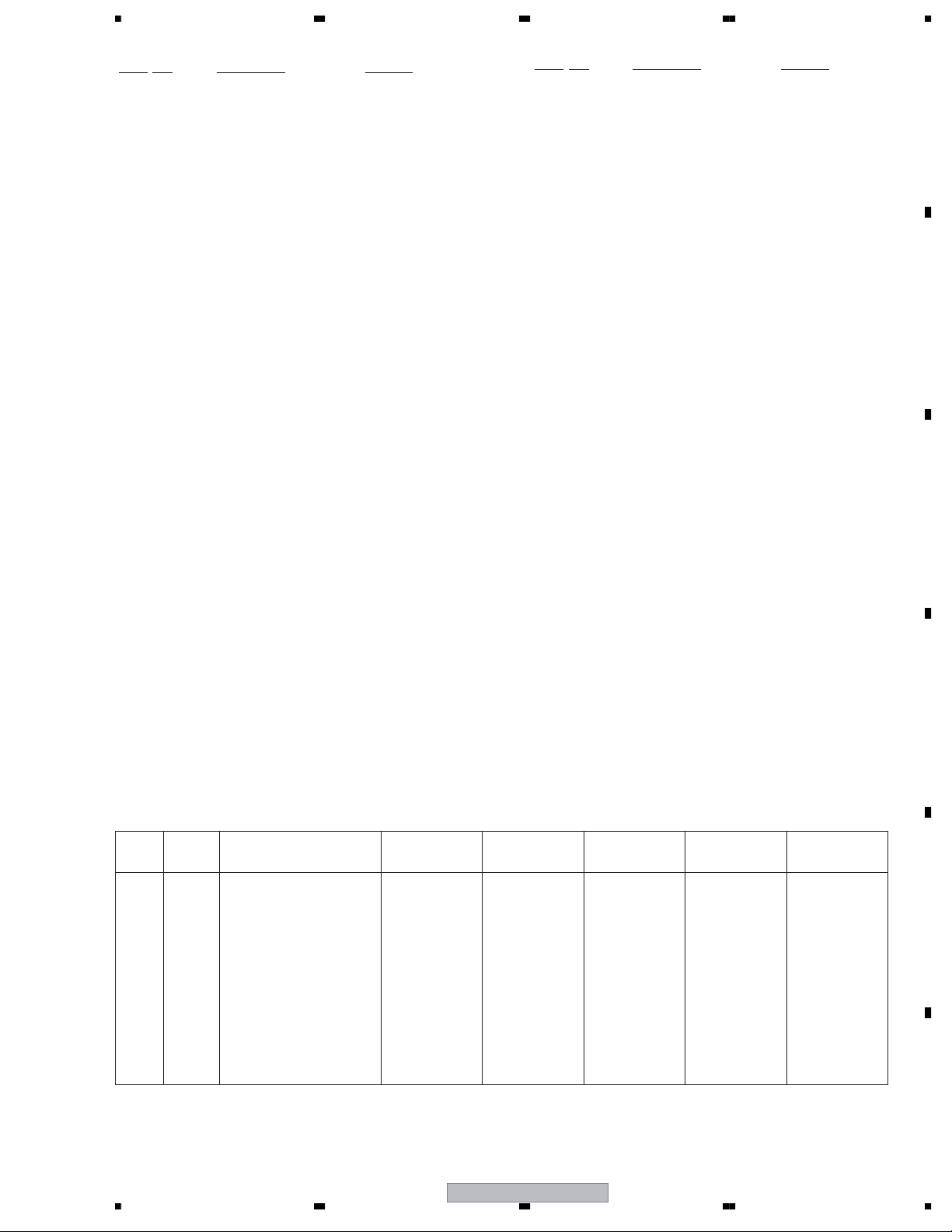

EXTERIOR SECTION (2) PARTS LIST

No. Description Part No.

Mark

1 MR MAIN BOARD Assy See Contrast table (2)

2AV BOARD Assy See Contrast table (2)

3 MDR Assy AWZ6948

4 SR Assy See Contrast table (2)

5FRONT Assy See Contrast table (2)

>

>

No. Description Part No.

Mark

31 Barrier A AEC2017

32 Re-use Wire Saddle AEC1945

33 Edge Saddle AEC1946

34 Mini Card Spacer AEC1959

35 Circuit Board Spacer AEC1964

A

6 LED Assy See Contrast table (2)

7• • • • •

8POWER SUPPLY Unit AXY1091

9 Flexible Cable (J201) ADD1209

10 Flexible Cable (J203) ADD1210

11 Flexible Cable (J206) ADD1213

12 Flexible Cable (J207) ADD1214

13 15P Housing Wire (J105) ADX2833

14 7P Housing Wire (J109) ADX3015

15 16P Housing Wire (J112) ADX2917

16 Fan Motor 60 x 25L AXM1045

17 Base Chassis ANA1811

18 Front Chassis See Contrast table (2)

19 Terminal Panel See Contrast table (2)

20 Heatsink HDMI ANH1618

21 • • • • •

22 Fan Holder ANG2568

23 HDMI Shield ANG2646

24 Insulation Rubber AEB1377

25 Silicone Sheet HDMI AEB1379

26 PCB Holder AEC1097

27 Spacer AEC1256

28 Locking Card Spacer AEC1429

29 Nyron Rivet AEC1671

30 Wire Saddle AEC1745

36 Gasket F ANK1722

37 Card Spacer A BEC1120

38 Flexible Cable (J202) ADD1209

39 • • • • •

40 Hexagon Head Screw BBA1051

41 Screw ABZ30P060FTB

42 Screw ABZ30P080FTC

43 Screw BBZ30P060FTB

44 Screw BPZ30P100FTB

45 Screw PMZ26P060FTB

46 Screw BMZ30P060FTC

47 • • • • •

48 • • • • •

49 FFC Cushion (XE) See Contrast table (2)

50 SR Holder E ANG2581

51 Gasket ANK1730

52 Front Ground Spacer AEC2016

B

C

D

(2) CONTRAST TABLE

PDP-R05E/WYVI, /WYVIXK, PDP-R05XE/WYVIXK, PDP-R05FE/WYVI and / WYVIXK are constructed the same

except for the following:

Mark No. Description

1 MR MAIN BOARD Assy AWZ6944 AWZ6944 AWZ6990 AWZ6945 AWZ6945

2AV BOARD Assy AWZ6946 AWZ6946 AWZ6986 AWZ6947 AWZ6947

4 SR Assy AWZ6949 AWZ6949 AWZ6949 AWZ6950 AWZ6950

5FRONT Assy AWZ6951 AWZ6951 AWZ6951 AWZ6952 AWZ6952

6 LED Assy AWZ6953 AWZ6953 AWZ6953 AWZ6954 AWZ6954

18 Front Chassis E ANB1867 ANB1867 ANB1867 Not used Not used

18 Front Chassis Not used Not used Not used ANB1866 ANB1866

19 Terminal Panel E ANC2363 ANC2369 Not used Not used Not used

19 Terminal Panel XE Not used Not used ANC2362 Not used Not used

19 Terminal Panel FE Not used Not used Not used ANC2364 ANC2370

49 FFC Cushion (XE) Not used Not used AEB1407 Not used Not used

56

PDP-R05E/

WYVI

PDP-R05E/

WYVIXK

PDP-R05E

PDP-R05XE/

WYVIXK

7

PDP-R05FE/

WYVI

PDP-R05FE/

WYVIXK

8

E

F

15

1234

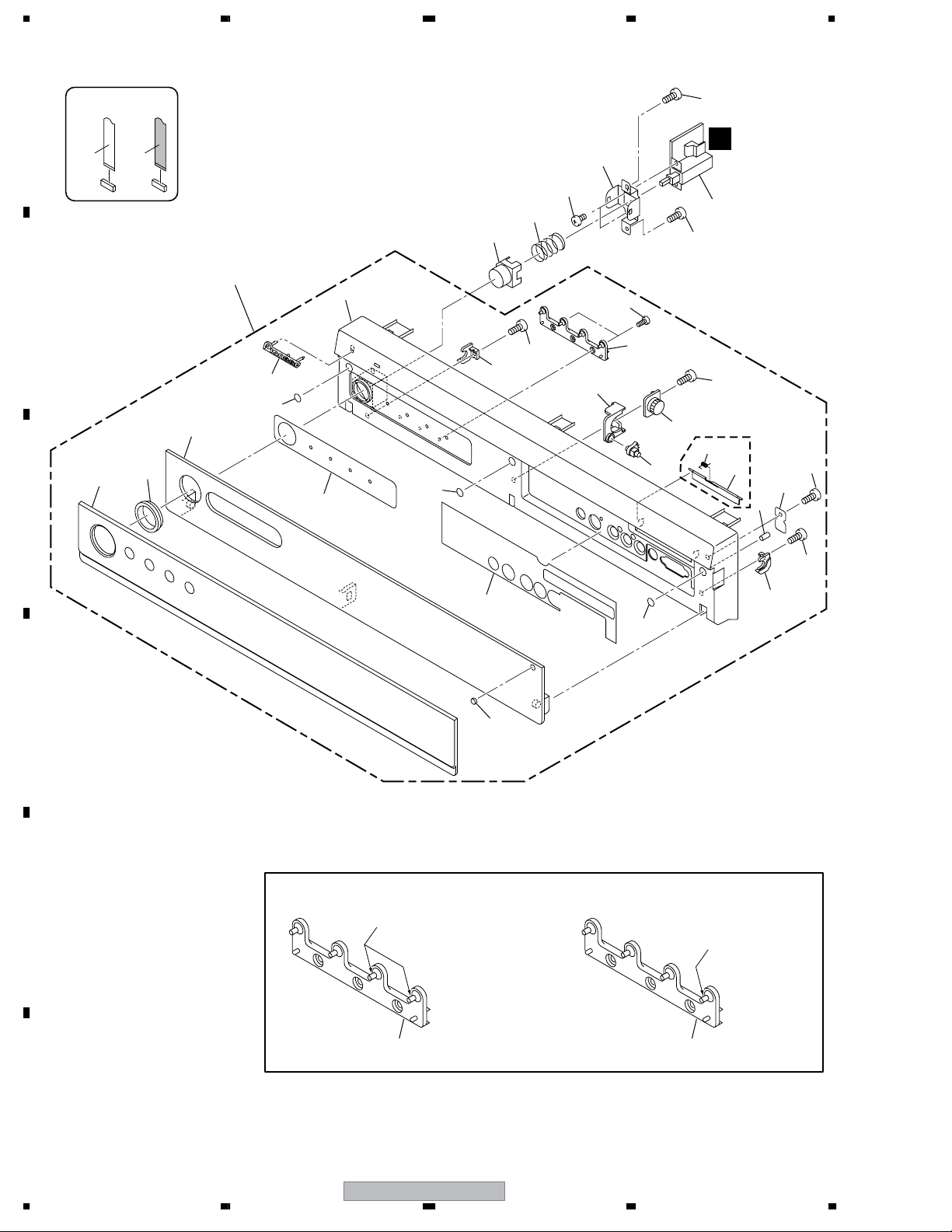

2.4 FRONT PANEL SECTION

A

23

J

2

NON-CONTACT

B

C

SIDE

11

CONTACT SIDE

4

5

13

14

20

21

12

17

21

19

23

25

23

10

1

23

Except

PDP-R05FE

27

28

23

6

8

3

24

22

Refer to below.

16

9

23

18

21

D

For PDP-R05E and PDP-R05FE

E

Please cut-off 2 portion

before assembly.

7

For PDP-R05XE

Please cut-off 1 portion

before assembly.

15

22

F

16

1234

PDP-R05E

22

5678

FRONT PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 SW Assy AWZ6920

2 SW Holder ANG2670

3 SW Spring ABH1109

4Power Button ADD4128

5Front Panel Assy See Contrast table (2)

No. Description Part No.

Mark

16 Damper Holder AMR3416

17 Escutcheon Ring ADD4130

18 Sealing Sheet See Contrast table (2)

19 Sealing Sheet S See Contrast table (2)

20 Pioneer Badge VAM1124

A

6 Magnet Holder ANG2671

7 Magnet Catcher ANG2675

8 Magnet AMF1004

9 Gear AMR3418

10 Damper AXA1018

11 Panel See Contrast table (2)

12 Door AAN1473

13 Front Panel See Contrast table (2)

14 Door Holder L AMR3414

15 Door Holder R AMR3415

21 Door Cushion See Contrast table (2)

22 LED Lens AMR3417

23 Screw BPZ30P100FTB

24 Screw JPZ20P035FNI

25 Screw BMZ30P060FTC

26 • • • • • •

27 PC Spring See Contrast table (2)

28 PC Card Door See Contrast table (2)

(2) CONTRAST TABLE

PDP-R05E/WYVI, /WYVIXK, PDP-R05XE/WYVIXK, PDP-R05FE/WYVI and / WYVIXK are constructed the same

except for the following:

Mark No. Description

5Front Panel Assy E AXG1021 AXG1021 Not used Not used Not used

5Front Panel Assy XE Not used Not used AXG1020 Not used Not used

5Front Panel Assy FE Not used Not used Not used AXG1022 AXG1022

11 Panel (E) AAK2826 AAK2826 Not used AAK2826 AAK2826

11 Panel (XE) Not used Not used AAK2825 Not used Not used

13 Front Panel (E) AMB2829 AMB2829 Not used Not used Not used

13 Front Panel (XE) Not used Not used AMB2828 Not used Not used

13 Front Panel (FE) Not used Not used Not used AMB2830 AMB2830

18 Sealing Sheet (XE E) AAL2547 AAL2547 AAL2547 Not used Not used

18 Sealing Sheet (FE) Not used Not used Not used AAL2548 AAL2548

PDP-R05E/

WYVI

PDP-R05E/

WYVIXK

PDP-R05XE/

WYVIXK

PDP-R05FE/

WYVI

PDP-R05FE/

WYVIXK

B

C

D

19 Sealing Sheet S (GC) AAL2555 AAL2555 Not used AAL2555 AAL2555

19 Sealing Sheet S (E) Not used Not used AAL2554 Not used Not used

21 Door Cushion AEB1391 AEB1391 AEB1391 AEB1394 AEB1394

27 PC Spring ABH1112 ABH1112 ABH1112 Not used Not used

28 PC Card Door AMR3365 AMR3365 AMR3365 Not used Not used

PDP-R05E

56

7

8

E

F

17

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

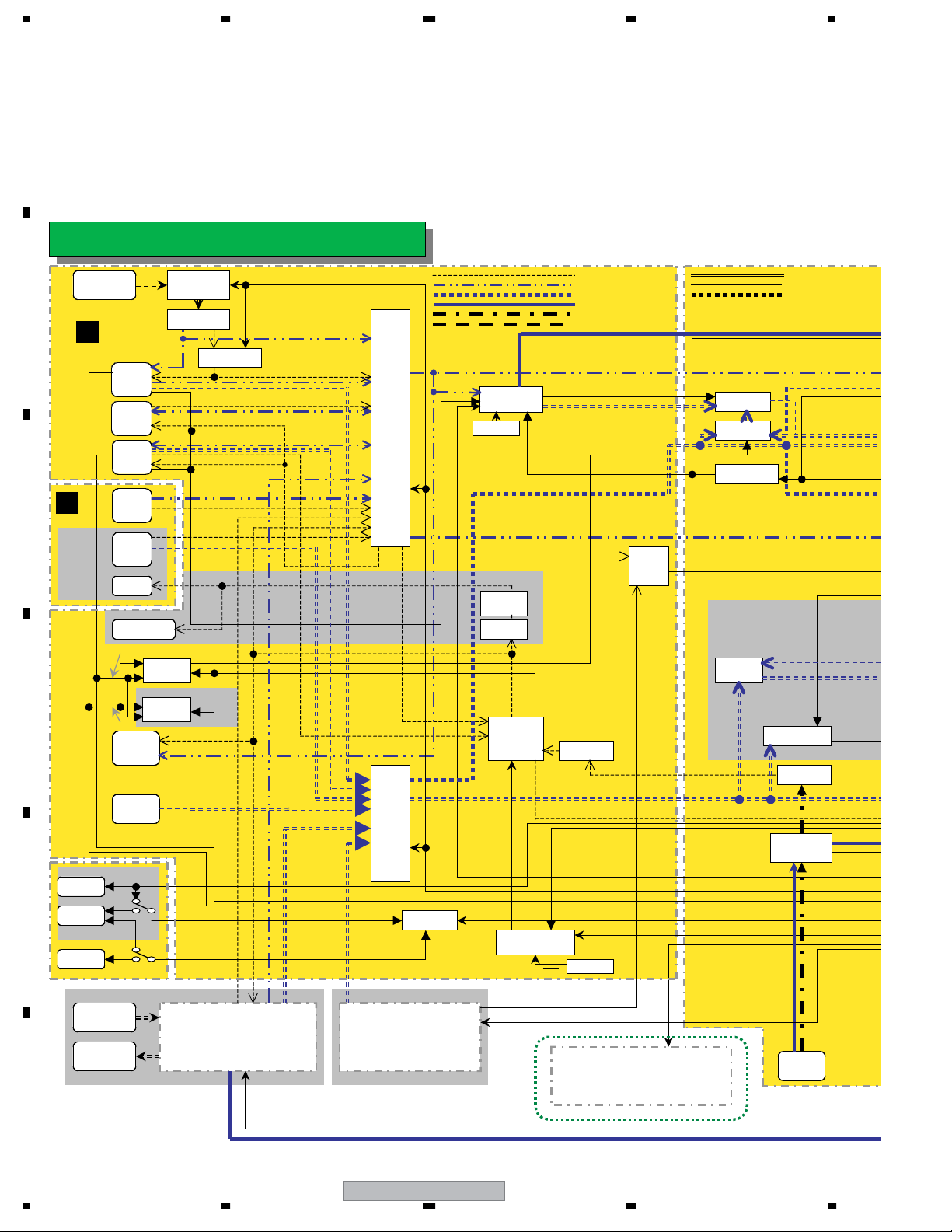

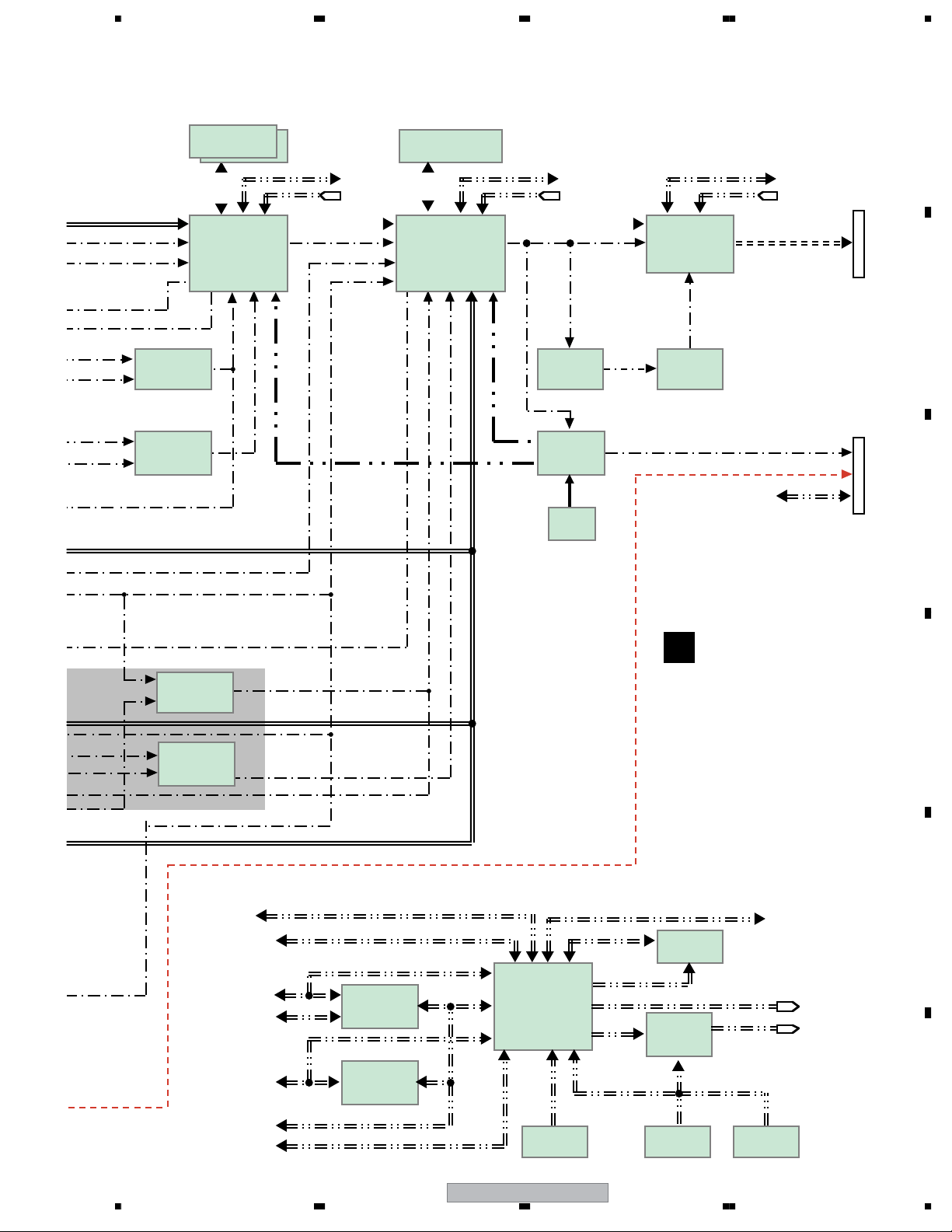

3.1 BLOCK DIAGRAM

3.1.1 SIGNAL ROUTE

A

PDP-R05XE,PDP-R05E,PDP-R05FE

Block Diagram

Antenna

Input

B

U7501

AXF1133

IC7501

TDA9818TS

B

IC7502

MSP3417G

Input1

SLOW_SW_1

Input2

SLOW_SW_2

Input3

SLOW_SW_3

Antenna

Input

Antenna

Output

Input4

PC

input

Head

Phone

SUB WOOFER

RAPID_SW_3

RAPID_SW_1

Monitor

Output

Input2

comp

PDP-R05XE

PDP-R05E

IC9105

TL4051BF

PDP-R05XE

PDP-R05E

IC9107

TL4051BF

Y/Pb/Pr

REM

REM

TXD,RXD

Digital Terrestrial

R/G/B

Board

PDP-R05XE

G

C

PDP-R05XE,

PDP-R05E

D

RS OUT

E

RS IN

RS232C

CXA2069Q

PDP-R05XE

PDP-R05E

AN15852A

R/G/B

PC Card

Module

CVBS,Y/C (Main)

IC8002

IC8005

IC8705

24LC01B

PDP-R05XE,PDP-R05E

IC8904

SDA6000

IC8901

PST9230N

VD_TXT

Y/Pb/Pr

R/G/B

CVBS,Y/C (Sub)

IC8007

BH3544AFS

IC8008

BH3540AFS

TC4052BFT

AV_SW1

SCL,SDA

HD_TXT

IC8003

AV_SW0

IC8702

HD64F3687FP

RESET

Analog Audio signal

Analog Video signal

Component signal

Digital Video signal

Digital Audio signal

Synchronized signal

IC8004

NJM12904V

HDMI_LCH

HDMI_RCH

Y/Pb/Pr

R/G/B

KEY

IC8703

PST9231IN

Power Supply

Data signal

Control signal

RF signal

TTX_R/G/B_DIG

IC6406

MM1389

IC6403

MM1389

IC7452

TC74VHC126FT

MAINC_Y

SW

R_DA_SUB

G_DA_SUB

SUBC_Y

TXD_IF

RXD_IF

REQ_IF

CE_IF

BUSY_IF

B_DA_SUB

IC6604

BA7078AF

IC6803

PCM1742KE

IC6881

SII9993CTG100

Video3

HDMI

RELAY

IC6605

MM1389

SDA_TXT,SCL_TXT

SDA_AV,SCL_AV

F

18

TXD_DT , RXD_DT

PDP-R05E

1234

5678

A

R_TXT_MAIN

G_TXT_MAIN

B_TXT_MAIN

R_DA_MAIN

G_DA_MAIN

B_DA_MAIN

HD_TXT_MAIN

VD_TXT_MAIN

IC6404

BA7078AF

HD_TXT_SUB

VD_TXT_SUB

A/3DY/CD

SM5301BS

IC6601

SM5301BS

H/V

REM,KEY

MB91F355PMT-G

IC6401

TC74VHC126FT

TC74VHC126FT

IC7207

DECODE

IC6107

PD0278A

C6405

IC6255

PD0278A

IC6603

PICTURE

OUTPUT

FOMAT

IC6402

AD80058

PCA_H_SUB

PCA_V_SUB

IC6602

AD80058

HD2_MAIN

VD2_MAIN

SDA_MA

SCL_MA

RDV2

GDV2

BDV2

IC6951

PD6435A

CKDV2

DEDV2

VDV2

HDV2

PCA_H

PCA_V

HD_MAIN

VD_MAIN

HD_SUB

VD_SUB

CK_SUB

HD_SUB

VD_SUB

DE_SUB

CLK_IC3

TXD_IC3

RXD_IC3

IC3_CE

IC3_BUSY

IC3_REQ

CK_MAIN

HD_MAIN

VD_MAIN

DE_MAIN

HD2_SUB

VD2_SUB

HD1_MAIN

VD1_MAIN

IC6408

TC74VHC126FT

IC6607

TC74VHC126FT

HD1_SUB

VD1_SUB

PDP-R05XE,PDP-R05E

CLK_IC2

TXD_IC2

RXD_IC2

IC2_OE

IC2_CE

IC7001

HV57V643220CT-7

24bit

24bit

IC7002

HV57V643220CT-7

32bit

IC7004

PE5362A

H_IC2

V_IC2

DE_IC2

FILM_IC2

CYCLE_IC2

PHASE_IC2

DCLK_IC2

48bit

IC7101

PD5855A

IC7152

MBM29PL3200BE70PFV

CLK0

VD0

HD0

DE0

24bit

16bit

IC7151

MBM29PL3200BE70PFV

TC74VCX08FT

IC7404

TC74VCX574FT

IC7403

Sii170BCL54

IC7401

KEY

A

Buff

TMDS

PLASMA DISPLAY

CN7401

WHITE

PLASMA DISPLAY

CN9301

BLACK

B

C

D

E

SCL

SDA

IC7202

TC74VHC125FT

IC7205

BR24LC64F

DVID_Y

DVID_PbPr

UARTRXD

UARTTXD

RESET

IC7203

PST3628UR

IC7209

NJM12904V

IC7211

PQ20WZ11

FAN

PDP-R05E

56

SDA_HDCP

SDL_HDCP

F

19

7

8

1234

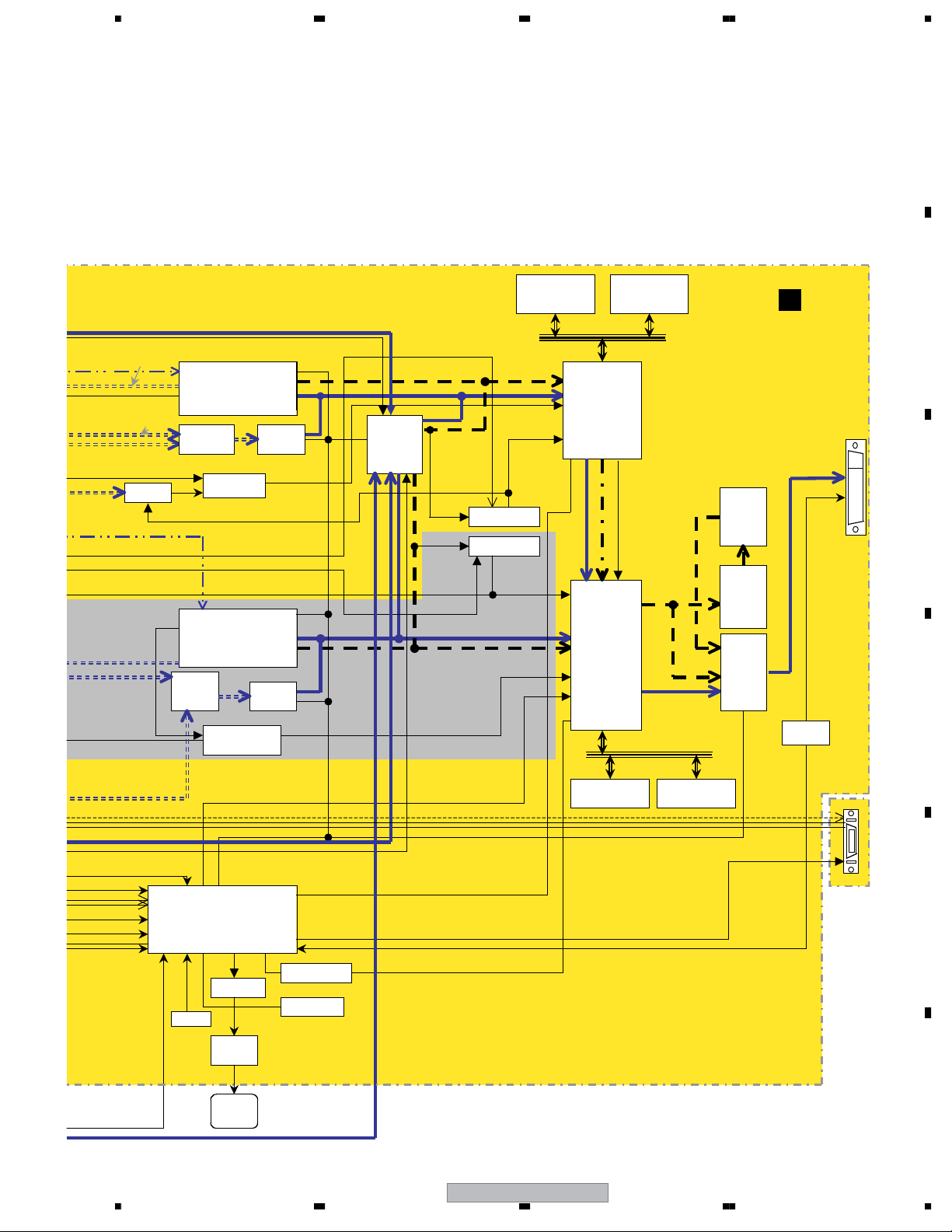

3.1.2 MR MAIN BOARD ASSY

A

: Analog Video Signal : Sync Signal : Analog Audio Signal

: Digital Video Signal : System Clock :Digital Audi Signal

: TMDS Signal : Control Signal

CN7454

AKM1201

MAIN_Y/C (CV,Y/C)

B

R/G/B_CCTXT (RGB)

16M SDRAM

IC6106

HV57161610DTC-8

SDA/SCL_MA

R/G/B_DA_MAIN (RGB) FLD_MAIN

X7001

ASS1175

(27MHz)

MIX SW

MAIN

IC6406

MM1389XFBE

BUFFER

IC6106

TC74LCX125FT

SYSCLK1S

HD/VD_TXT_MAIN

Y/C SEP.

CHROMA DEC

MAIN

IC6107

PD0278A

RA/GA/BA_MAIN [0:7] (RGB/YPbPr)

HD/VD/DE/CK_MAIN

RESETX1

HD/VD_MAIN

RESETX1

SDA/SCL_MA

LPF MAIN

IC6401

SM5301BS

MAINC_Y

RESETX1

SDA/SCL_MA

R/G/B_DA_SUB (RGB)

MIX SW

IC6605

MM1389XFBE

SM5301BS

SUB_C_Y

HDMI_AUDIO_CE/TXD/CLK

MAIN

LPF SUB

IC6601

HD/VD_TXT_SUB

MIX SW

MAIN

IC6403

IC6881

MM1389XFBE

SDA/SCL_MA

SDA/SCL_MA

R/G/BDV2 [0:7] (RGB/YPbPr)

HDV2, VDV2, DEDV2, CKDV2

I2S_SPDIF_2 [0:3]

MAINC_Y/Pb/Pr (RGB/YPbPr)

C

PCA_H/V

SUB_Y/C (CV,Y/C)

SCL/SDA_EP2

SDA/SCL_HDMI/TXT

D

SUBC_Y/Pb/Pr (RGB/YPbPr)

PCA_H/V_SUB

HD/VD_TXT

CN6951

AKM1201

GDT [0:7] (Y) , BDT [0:7] (Pb/Pr)

HDT, VDT, CKDT, DEDT

E

JA6881

AKP1232

TMDS

SCL, SDA

EEPROM

IC6880

CN7455

AKM1201

BR24L04FJ-W

TTX_R/G/B_DIG (RGB from TXT)

HDMI_L/RCH

AUDIO_L/R

F

RST_DT

RXD/TXD_DT

HDMI2 Rx

SII9993CTG100

AUDIO DAC

IC6803

PCM1742KE

SCL/SDA_AV

RXD/TXD/CLK_WR, RXD/TXD/CLK_IF

RST_IF/TXT

RAPID_DT1 RAPID_DT3

AD MAIN

IC6402

AD80058-K

SYNC SEP.

MAIN

IC6404

BA707BAF

Y/C SEP.

CHROMA DEC

SUB

IC6255

PD0278A

AD SUB

IC6602

AD80058-K

SYNC SEP.

SUB

IC6604

BA707BAF

SYNC SEL.

IC7452

TC74VHC126FT

SEL.

IC6951

PD6435A

HD/CK_MAIN

FLD_SUB

HD/CK_SUB

HD/VD/DE/CK_MAIN

HD/VD/DE/CK_SUB

RESETX1

SDA/SCL_MA

20

PDP-R05E

1234

HD/VD/DE/CK_MAIN

5678

A

64M SDRAM

IC7001, IC7002

HY57V64322OCT-7

I/P

IC7004

PE5362A

RXD/TXD/CLK__IC2

RA/GA/BA_IC2 [0:7]

RB/GB/BB_IC2 [0:7] RA/GA/BA [0:9]

(RGB) (RGB)

H/V/DE/DCLK_IC2

64M FLASH

IC7152

MBM29PL3200BE70PFV

RESIZE MIX

IC7101

PD5855A

FIELD

RXD/TXD/CLK_IC3

UART_RXD/TXD

VDO, CLKO

DVI Tx

IC7401

SII170BCLG64

SDA/SCL_HDCP

RST_HDCPRESETX2 RESETX2

TMDS

CN7401

AKP1250

CLP_MAIN

PLLHD/PLLHOLD_MAIN

SYNC SEL.

IC6408

TC74VHC126FT

5→3.3V CONV.

IC6405

TC74VHC126FT

HD/VD/DE/CK_SUB

HD/VD_SUB

SYNC SEL.

IC6607

TC74VHC126FT

SYSCLK_2

HD1/VD1_MAIN

HD2/VD2_MAIN

HD/VD/DE/CK_SUB

HD1/VD1_SUB

CLP/PLLHD/PLLHOLD_SUB

(YCbCr/RGB)

HD2/VD2_SUB

RA/GA/BA_SUB [0:7]

SYSCLK_3

HDO, DEO, CLKO

LOGIC

IC7403

TC74VHC574FT

BUFFER

IC7003

TC74LCX125FT

X7001

ASS1174

(85MHz)

HDO, DEO

HD/DE_OUT

LOGIC

IC7404

TC74VCX08FT

CN7402

AKM1234

FIELD2

MRXD, MTXD

A

MR MAIN BOARD ASSY

B

C

D

5→3.3V CONV.

IC6603

TC74VHC126FT

PDP-R05XE, PDP-R05E

RAPID_DT1

RAPID_DT3

RXD/TXD/CLK_IC2

RXD/TXD/CLK_IC3

RXD/TXD/CLK_IF

MRXD, MTX

UART_RXD/TXD

RXD/TXD/CLK_WR

HDMI_AUDIO_CE/TXD/CLK

56

RXD/TXD_DT

SCL/SDA_MA, SCL/SDA_HDCP

SCL/SDA_AV, SCL/SDA_EP2

SCL/SDA_EP

EEPRST

D

UART SEL.

IC7202

TC74VHC125FT

UART SEL.

IC7204

T74VHC125FT

MAIN UCOM

IC7207

MB91F355APMTGE1

RST2

RESET

RST_ASIC

EEPROM

IC7205

BR24L64F-W

LOGIC

IC7451

TC74VHC08FT

SCL/SDA_HDMI/TXT

RST_DT/HDCP/IF/TXT

RESETX1, RESETX2

E

F

RESET IC

IC7203

PST3628UR

PDP-R05E

7

RESET IC

IC7206

PST3628UR

RESET IC

IC7210

PST3612UR

21

8

1234

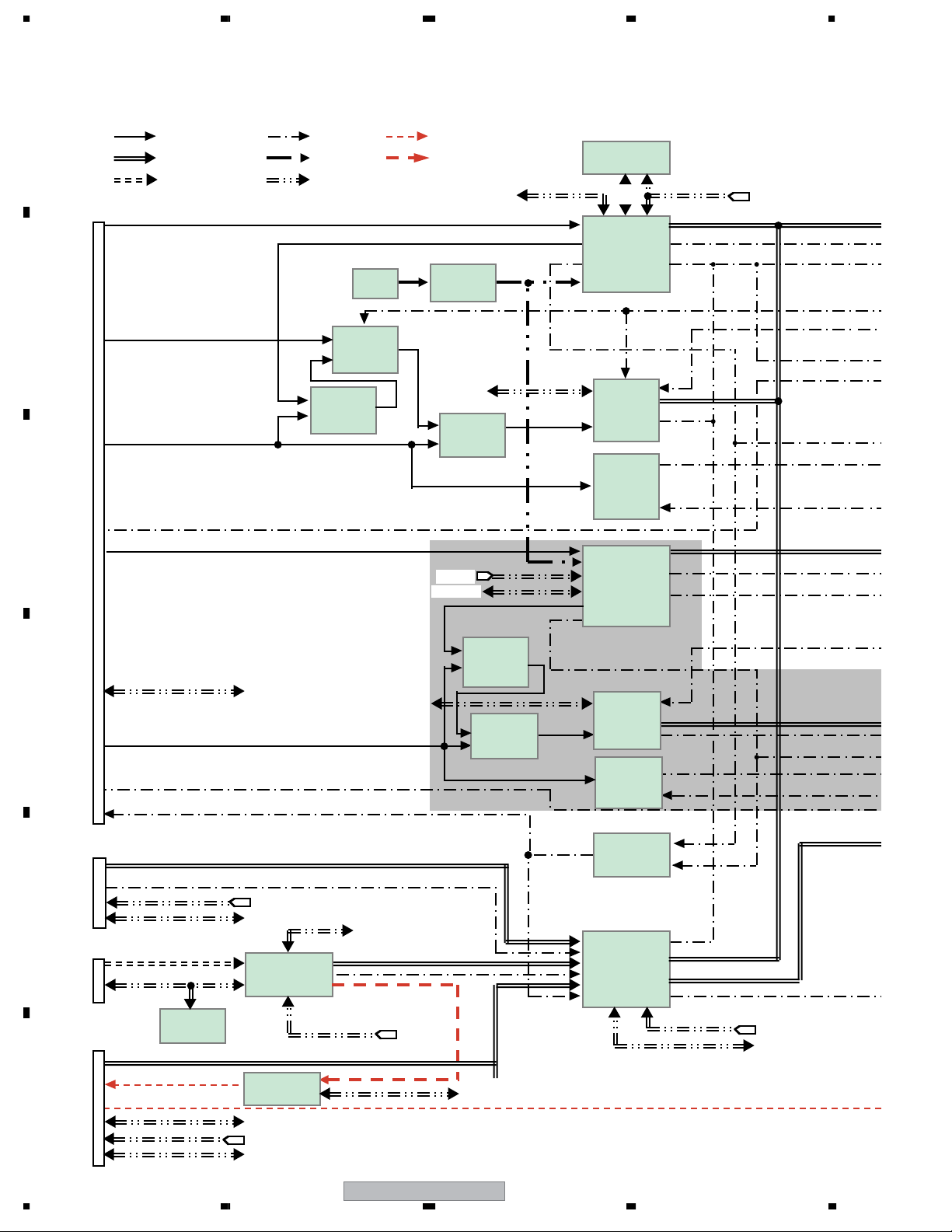

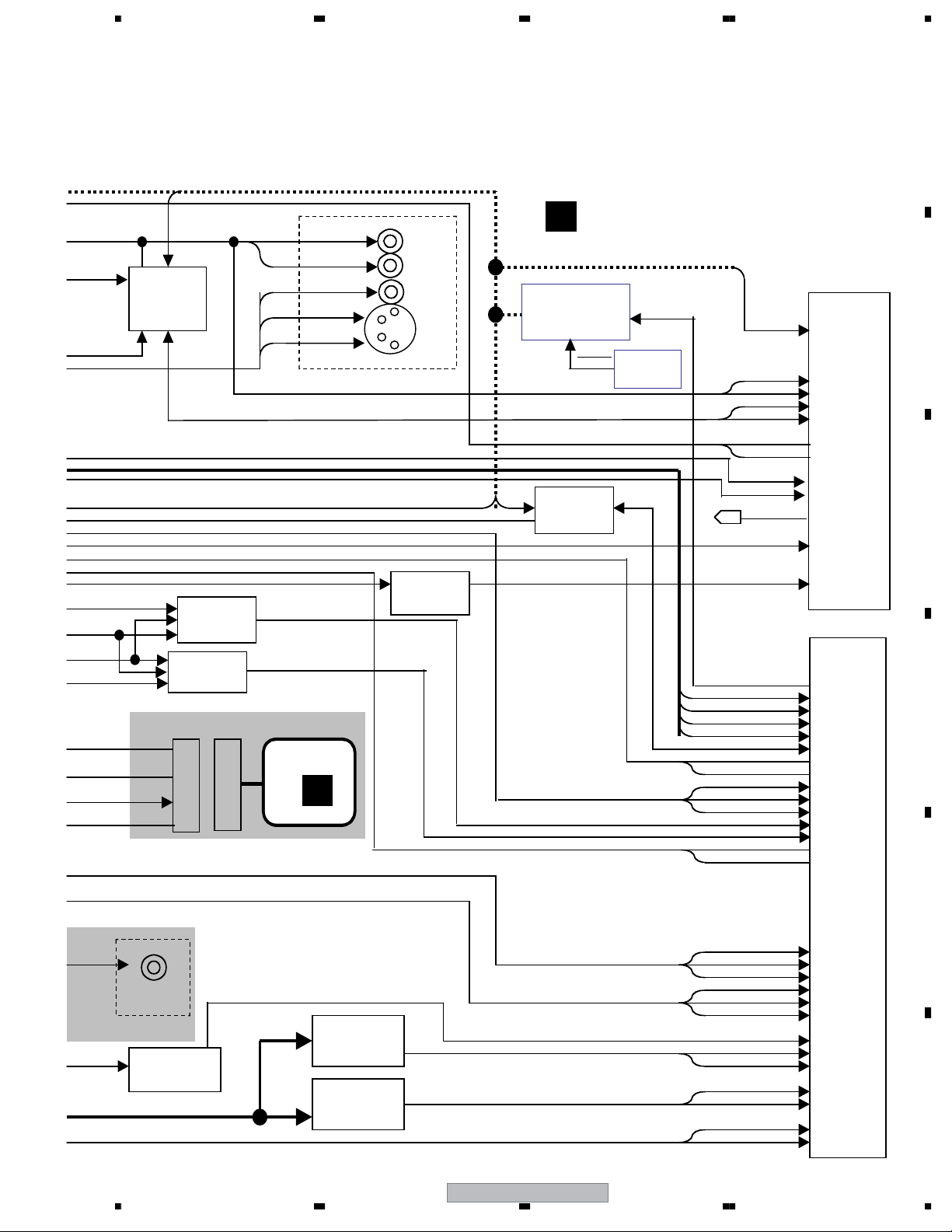

3.1.3 AV BOARD ASSY

A

B

C

D

E

F

ANTENNA

IN

VIDEO1

VIDEO2

VIDEO3

VIDEO2

Component

G

FRONT

ASSY

VIDEO4

PDP-R05XE/R05E

H.P.

PC

PDP-R05XE/R05E

PC CARD

MODULE

L

U7501

AXF1133

Y

PB

PR

IC7501

TDA9818TS

AIR_V AIR_V

AIR_R/L AIR_R/L

V1_RED/GRN/BLE

V1_V/R/L

SLOW_SW1

RAPID_SW1

SLOW_SW2

V2_V/Y/C/R/L

VOUT

AUDIO_R/L

VOUT3

RAPID_SW3 MAIN_Y

SLOW_SW3

V3_V/Y/C

DVD_RCH/LCH

AUDIO_R/L

V3_RED/GRN/BLE

CN8653

AKM1201

12 YUVD1_R

10 YUVD1_G

8 YUVD1_B

4

CARD_V

5

CARD_H

2

TXD_CARD

1 RXD_CARD

V4_Y

V4_C

V4_V

V4_R

V4_L

HP_L

HP_R

PC_LCH

PC_RCH

PC_R

PC_G

PC_B

PC_H

PC_V

V4_Y

V4_C

V4_V

V4_R

V4_L

HP_L

HP_R

PC_LCH

PC_RCH

PC_R

PC_G

PC_B

PC_H

PC_V

CN9502

AKM1201

32 19

30 21

25 26

20 31

22 29

38 13

36 15

18 33

16 35

13 38

11 40

94 2

74 4

54 6

CN8660 HFW12S-2STE1

IC7502

MSP3417G

IC8904

SDA6000

TELETEXT

UCOM

IC8901

PST9230N

IC8005

AN15852A

PDP-R05XE/R05E

IC8007

BH3544F

6dB AMP

IC8008

BH3540AFS

VOL.IC

IC8002

CXA2069Q

MAIN_SW_A/C

SUB_SW_A/C

HP_VOL

PC_V

22

PDP-R05E

1234

IC8003

TC4052BFT

AUDIO SW

5678

A

AV BOARD ASSY

AUDIO_L

AUDIO_R

VOUT

COUT

YOUT

MONITOR

OUT

B

IC8702

HD64F3687FP

UIF UCOM

RESET

IC8902

TC7W126FU

IC8703

PST9231N

UIF_UCOM

AUDIO_R 3

AUDIO_L 5

HDMI_RCH 7

HDMI_LCH 9

SCL_AV 34

SDA_AV 33

RAPID_DT_1 1

RAPID_DT_3 3

HP_VOL

TXT_RGB_DIG 12–27

AKM1201

30–32,35–40,

48,50

48

CN8654

B

C

MAIN_SW_A/C

_SW_A/C

PC_V

CN8662

AKM1303

SUB

WOOFER

IC8001

TC7WH123FU

IC9105

TC4051BF

IC9107

TC4051BF

PDP-R05XE

MAINC_Y/PB/PR

SUBC_Y/PB/PR

DTV ASSY

I

TC74VHC125FT

TC74VHC125FT

IC7701

IC7702

IC8907

TC7SH04FU

PIXEL_CLK_IN

PN2 14

MAIN_Y 49

MAIN_C 47

SUB_Y 33

SUB_C 31

WE_TXT 10

VD_TXT_MAIN 15

HD_TXT_MAIN 16

R_TXT_MAIN 37

G_TXT_MAIN 35

B_TXT_MAIN 39

FBLK_MAIN 23

FBLK_SUB 22

SCL_TXT 9

SDA_TXT 8

MAINC_Y

MAINC_PB

MAINC_PR

SUBC_Y

SUBC_PB

SUBC_PR

DSUB_DET

PCA_V

PCA_H

PCA_V_SUB

PCA_H_SUB

TXD_CARD

RXD_CARD

11

CN8652

AKM1201

41

45

43

25

29

27

13

19

20

17

18

12

11

D

E

F

56

PDP-R05E

23

7

8

1234

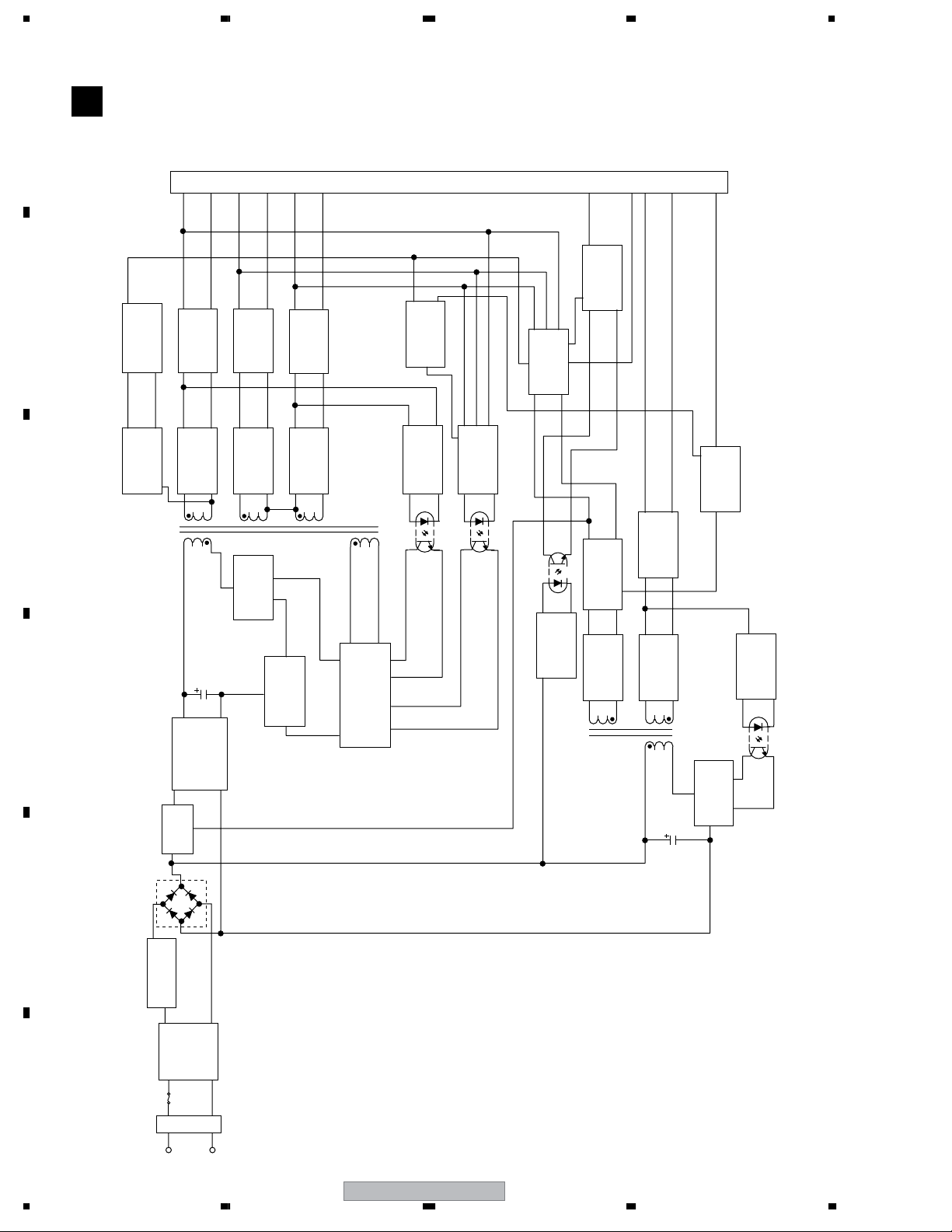

3.1.4 POWER SUPPLY UNIT

POWER SUPPLY UNIT

A

K

6 .5V7, 8

9, 10 GND

OUTPUT CONNECTOR

17V1

GND

2

12V3, 4

GND

5, 6

AC- DET16

SIGNAL

OUTPUT

PD . TRIGGER

151412

CIRCUIT

3 . 3V

GND

13

POWER ON

B

INPUT

DETECTION

CIRCUIT

RECTIFICATION

RECTIFICATION

FILTER

CIRCUIT

(SYNC)

CIRCUIT

FILTER

CIRCUIT

CIRCUIT

RECTIFICATION

RECTIFICATION

FILTER

CIRCUIT

(SYNC)

CIRCUIT

RELAY

WELDING

DETECTION

OUTPUT

VOLTAGE

CONTROL

CIRCUIT

DETECTION

OVER VOLTAGE

SIGNAL

CIRCUIT

OUTPUT

CIRCUIT

ON / OFF

C

FILTER

DEVICE

SWITCHING

POWER SUPPLY

(SIGNAL SYSTEM)

AC

DETECTION

CIRCUIT

RECTIFICATION

D

CIRCUIT

CONTROL

POWER FACTOR

RELAY

SWITCH

DETECTOR

OVERCURRENT

PWM CONTROL IC

CIRCUIT

RECTIFICATION

OUTPUT

DEVICE

SWITCHING

CIRCUIT

VOLTAGE

CONTROL

E

INRUSH

LIMITER

CURRENT

INPUT

FILTER

CIRCUIT

F

INPUT CONNECTOR

AC IN

24

PDP-R05E

1234

5678

3.1.5 PC CARD MODULE

PC CARD MODULE

J

A

IC100

(CPU)

IC400

(PCMCIA)

CN401, 2

(PCMCIA)

PC-card

IC300

(FLASH)

IC603

(VRAM)

IC301

(SDRAM)

IC600

(GDC)

1.9V

2.5V

1.7V

3.3V

3.3V

1.7V

IC302

(SDRAM)

IC600

(GDC)

IC1

IC1

IC3

IC4

CN501

TxD

RxD

Hsync

Vsync

Rout

Gout

Bout

CN1

3.3V

5V

CN501

1 YUVD1_R

2 GND

3 YUVD1_G

4 GND

5 YUVD1_B

6 GND

7 YGND

8 CARD_H

9 CARD_V

0 NC

- TXD_CARD

= RXD_CARD

CN501

1 3.3V

2 3.3V

3 GND

4 GND

5 5V

6 GND

B

C

D

E

F

56

PDP-R05E

25

7

8

1234

3.1.6 TUNER BOARD ASSY

Media Receiver European Digital Tuner PDP-R05XE

A

PCMCIA Connector

SPDIF Connector

[JA4000]

RF in RF out

[CN5000 & 9012]

I2C_tun

TS3

Data Bus buffer

[IC5003]

B

Address Bus Buffer

[IC5004 & IC5004]

CiMAX 2

[IC5002]

TS2

TS1

TS4

I2C_tun

COFDM

[IC1001]

SPDIF Converter

[IC4003]

IF Amp

[IC1000]

SAW filter

[F1000]

Tuner

[M1000]

IF

SDRAM

[IC3000]

C

Address, Data, Control

I2C_main

128Mbit

SPDIF out

Audio A/D

[IC4008]

Audio L/R in

[CN4000]

Analogue connector

OMEGA

[IC2000]

SDRAM

[IC3003]

AudioLPF

opamp

128Mbit

Video Buffer

D

[CN6003]

Digital Connector

Flash

[IC3002]

TxRx,controls

Analogue Audio out

Analogue Video out

Transistor

CPLD

[IC6000]

Digital Video out

[CN6001 & CN6002]

PSU Connector (9p & 8p)

E

F

26

PDP-R05E

1234

5678

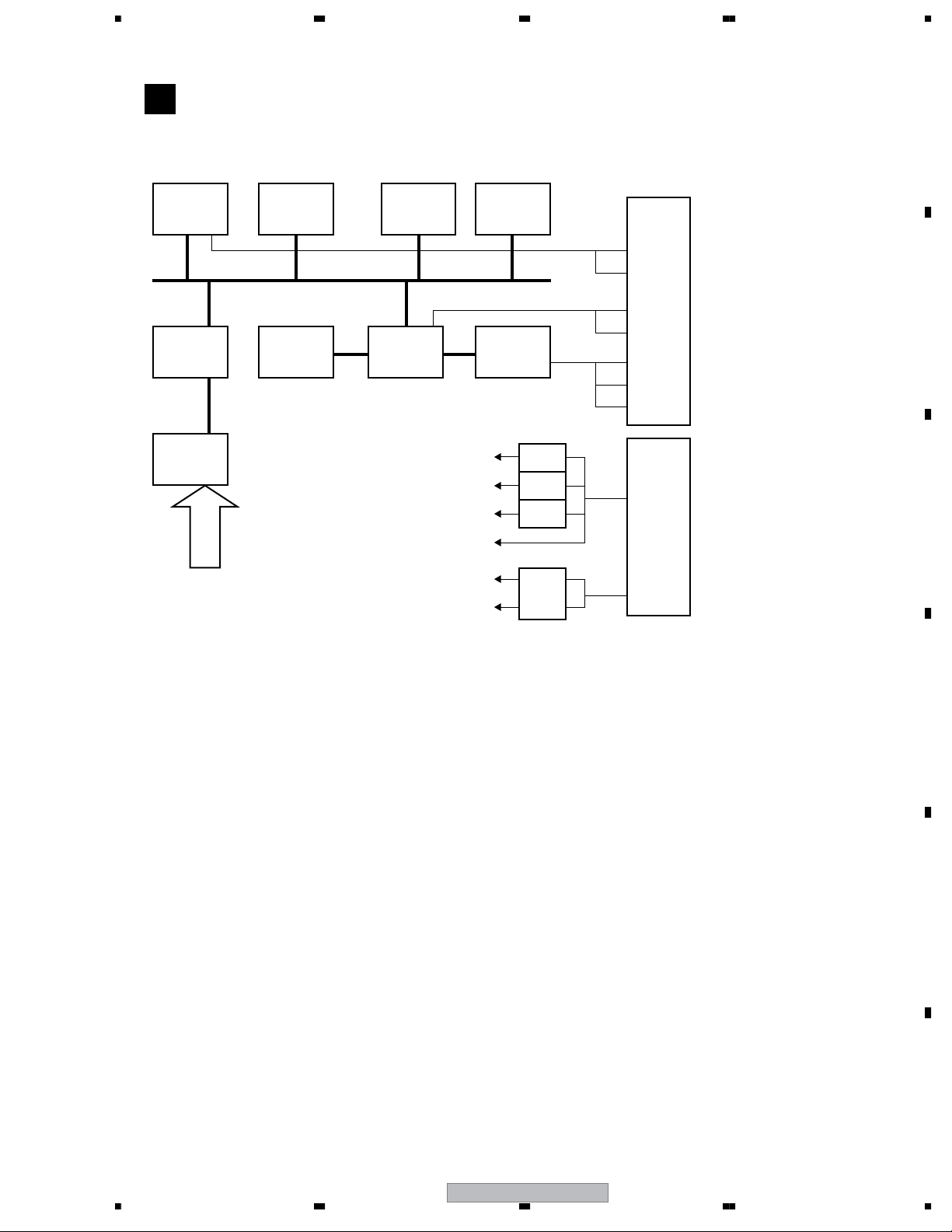

3.1.7 POWER SUPPLY

RELAY

RELAY

K

SW_REG

SW_REG

AV_BOARD MAIN_BOARDPS_MOD

V+16.5V

V+12V

V+6.5V

V+SB3VT

V+12VSTB

B

IC8509

COM_SW

ACTIVE

U8502

DC/DC_CONV

PSW1

V+12V

V+6.5V

V+3VSTB

V+3COM

V+3V_DD

V+1V_DD

PSW1

A

R7456

R7455

IC7211

REG

MDR_ASSY

• Communication

BUFF between

PANEL

IC7456

REG

IC7454

REG

IC7453

REG

E

• Main Ucom and around it

• IC2 and around it

• IC3 and around it

• IC1 and around it

V+1V_IC1

• DVI_Tx and around it

• HDMI_Rx and around it

V+5V_A

• Video A/D and around it

V+3V_A

• LPF and around it

• Sync separator and around it

• MIX_SW and around it

• Video filter for IC1 (discrete)

• DD Converter (discrete)

FAN_MOD

PANEL side

• LED and around it

• REM, KEY and

around it

A

B

C

Always

current- carrying lines

Current-carrying lines

in ACTIVE STAND-BY

Current-carrying lines

in RELAY

Current-carrying lines

in PSW1

Port (Black frame)

Control port name(H active)

Port (White frame)

Control port name(L active)

PSW1

IC8503

DC/DC_CONV

IC8502

DC/DC_CONV

R8550

R8525

R8528

R8531

R8543

R8545

Q8550

REG

IC8504

REG

I

IC8505

REG

IC8506

REG

IC8507

REG

IC8508

REG

V+5STB

V+9V

V+5V

V+5V

V+3V

V+2V

Q8518

REG

V+12V_EU

V+30V

V+1.8_DD

V+3V_DD

V+6.5_ON

V+3V_DD

V+5V_A

V+3VSTB

V+3VSTB

V+5VSTB

PC CARD_MOD

Q8511 FET_SW

DTB_MOD

LED_ASSY

SR_ASSY

H

F

V+3_DR

• LED and around it

• 232C driver and around it

• SR interface (discrete )

• Multiplex and around it

• AV_SW and around it

• Component SW and around it

• FE and around it

• TELE TEXT, memory, and SW

• IF Ucom and around it

D

E

F

56

PDP-R05E

27

7

8

1234

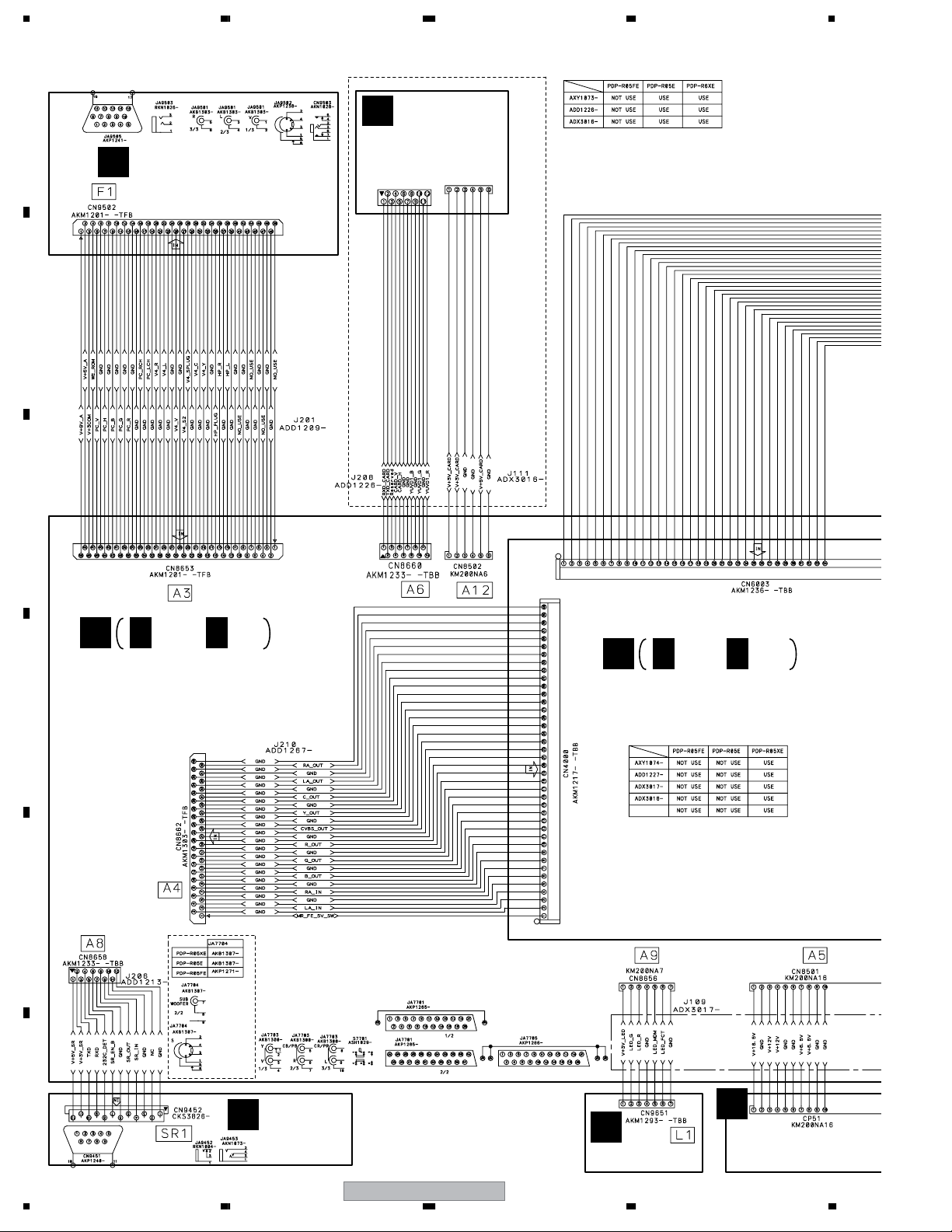

3.2 OVERALL WIRING CONNECTION DIAGRAM

A

FRONT ASSY

(PDP-R05E : AWZ6951)

G

(PDP-R05XE : AWZ6951)

(PDP-R05FE : AWZ6952)

B

C

PC CARD

L

MODULE

(PDP-R05E,

PDP-R05XE

: AXY1073)

B

AV BOARD ASSY

(PDP-R05E : AWZ6946)

D

E

(PDP-R05XE : AWZ6986)

(PDP-R05FE : AWZ6947)

B 1/9 - B 9/9

I 1/6 - I 6/6

I

TUNER BOARD ASSY

(PDP-R05XE : AWE1301)

F

28

1234

SR ASSY

F

(PDP-R05E,

PDP-R05XE

: AWZ6949)

(PDP-R05FE

: AWZ6950)

PDP-R05E

(PDP-R05E,

PDP-R05XE

: AWZ6953)

(PDP-R05FE

: AWZ6954)

H

LED ASSY

K

POWER

SUPPLY UNIT

(AXY1091)

5678

NOTES: • When ordering service parts, be sure to refer to “EXPLODED

VIEWS and PARTS LIST” or “PCB PARTS LIST”.

• The > mark found on some component parts indicates the

importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical

designation.

• : The power supply is shown with the marked box.

A 1/12 - A 12/12

A

MR MAIN

BOARD ASSY

(PDP-R05E,

: AWZ6944)

PDP-R05XE

: AWZ6990)

(PDP-R05FE

: AWZ6945)

A

B

C

SW ASSY

J

(AWZ6920)

D

E

E

MDR ASSY

(AWZ6948)

F

56

PDP-R05E

29

7

8

1234

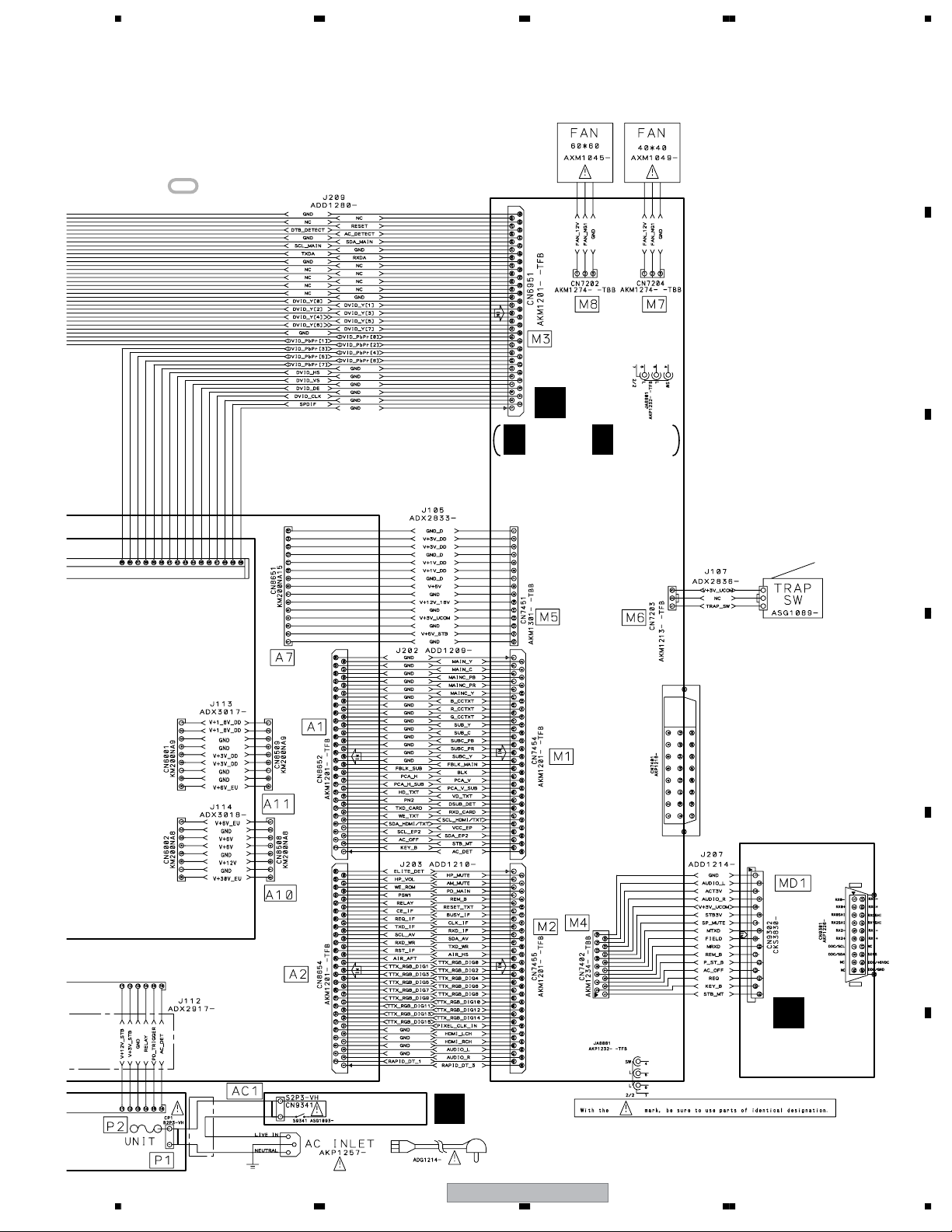

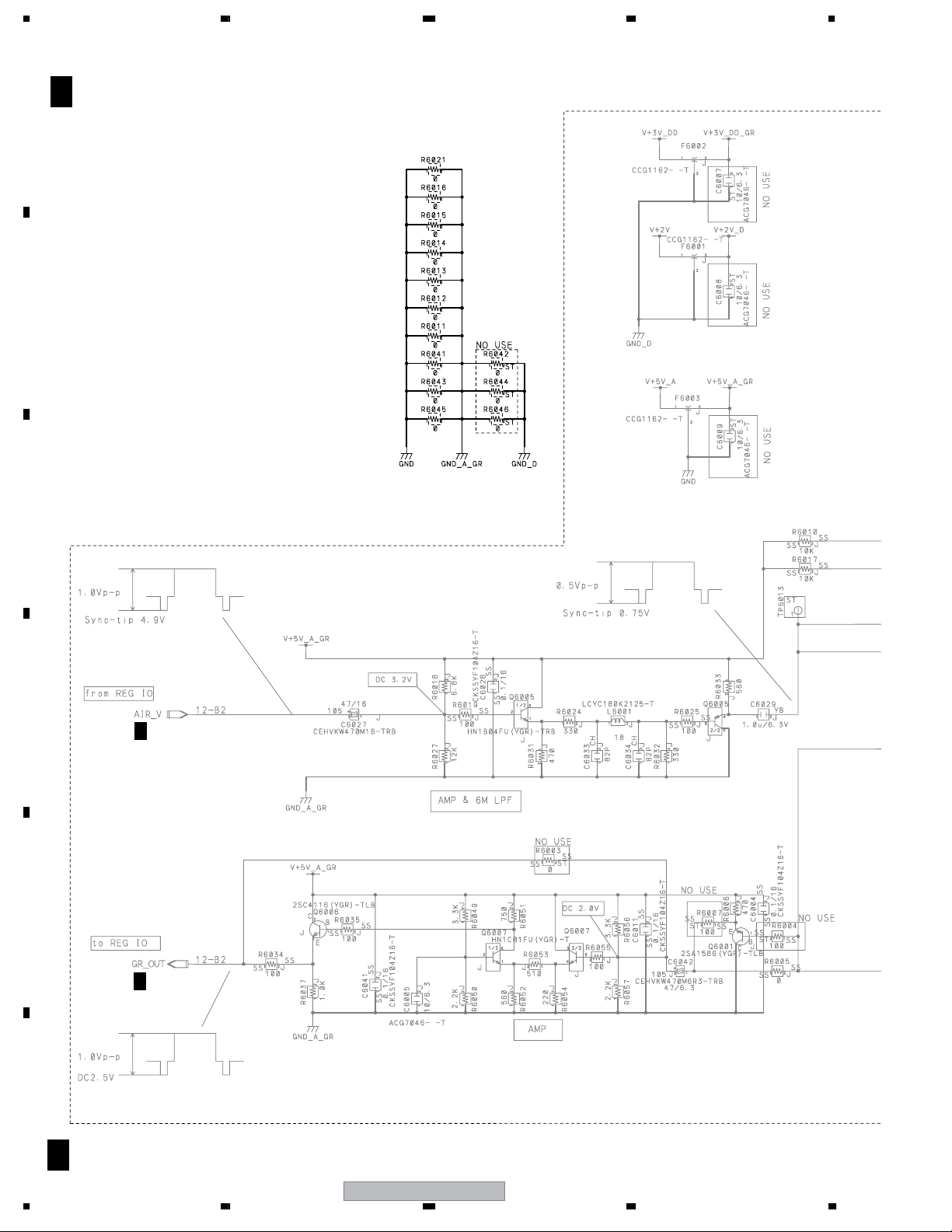

3.3 MR MAIN BOARD ASSY (1/12)

A 1/12

A

B

C

MR MAIN BOARD ASSY

(PDP-R05E : AWZ6944)

(PDP-R05XE : AWZ6990)

(PDP-R05FE : AWZ6945)

¶ GR BLOCK

NOT USED

SIDE A

D

A

12/12

E

12/12A

F

A 1/12

30

NOT USED

PDP-R05E

1234

Loading...

Loading...