Page 1

PDP-508XG

PLASMA TELEVISION

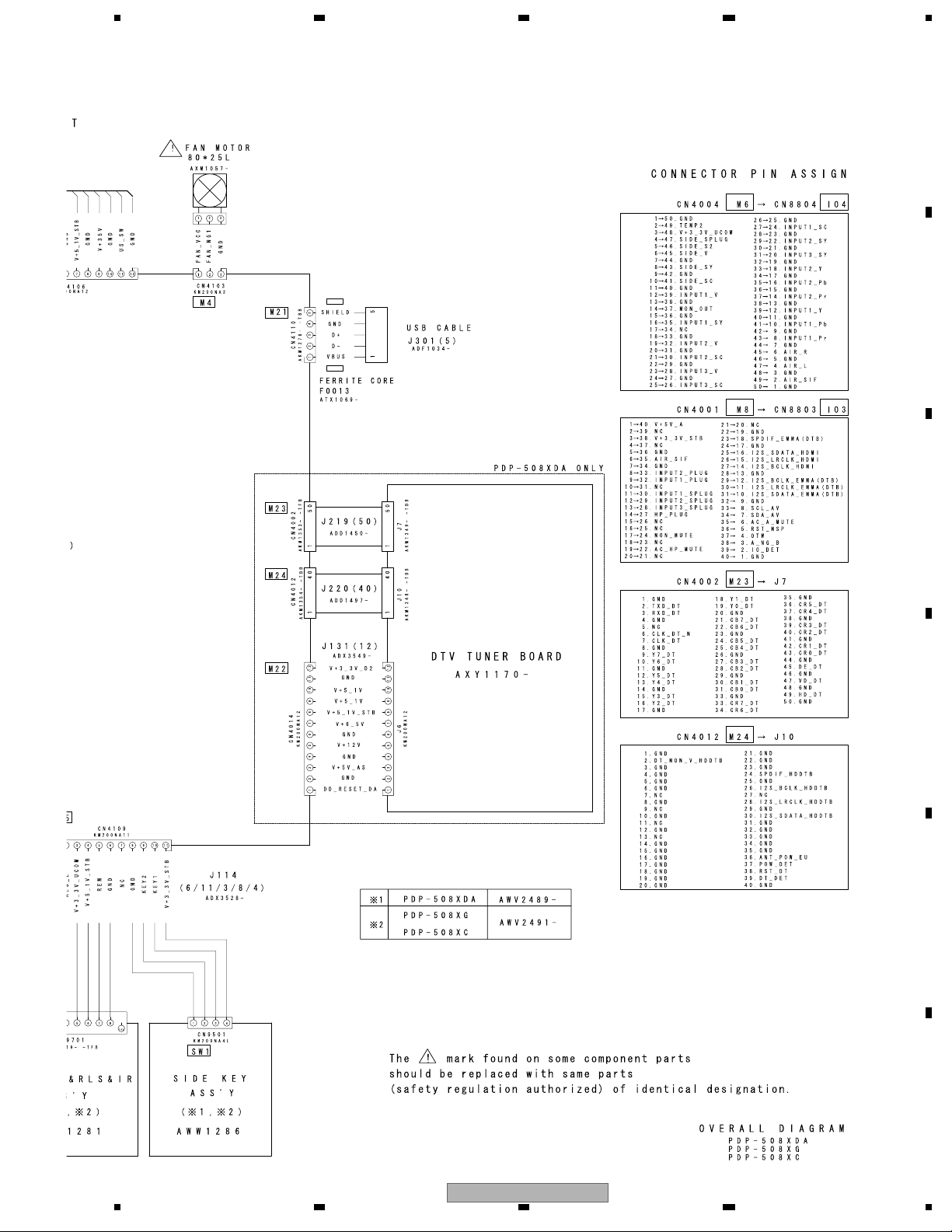

PDP-508XG

PDP-508XDA

PDP-508XC

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PDP-508XG DLFT AC 110 V to 240 V

PDP-508XDA YP AC 240 V

PDP-508XC WA5 AC 220 V to 240 V

ORDER NO.

ARP3468

This service manual should be used together with the following manual(s):

Model Order No. Remarks

PDP-5080XA/WYV5 ARP3445 EXPLODED VIEWS, BLOCK DIAGRAM, ADJUSTMENT, etc

For SPECIFICATIONS and PANEL FACILITIES, refer to the operating instructions.

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

T-ZZK-001 AUG. 2007 printed in Japan

Page 2

1234

CONTENTS

1. CONTRAST OF MISCELLANEOUS PARTS.................................................................................................... 4

2. BASIC ITEMS FOR SERVICE.......................................................................................................................... 8

A

B

C

D

E

F

2.1 QUICK REFERENCE.................................................................................................................................8

3. BLOCK DIAGRAM.......................................................................................................................................... 10

3.1 OVERALL WIRING DIAGRAM (1/2) ........................................................................................................ 10

3.2 OVERALL WIRING DIAGRAM (2/2) ........................................................................................................ 12

3.3 OVERALL BLOCK DIAGRAM .................................................................................................................. 14

3.4 POWER SUPPLY BLOCK of MULTI BASE SECTION ............................................................................. 16

3.5 TANSHI ASSY .......................................................................................................................................... 18

3.6 POWER SUPPLY BLOCK of 50LED&IR&RLS and SIDE KEY ASSYS ................................................... 19

4. DIAGNOSIS.................................................................................................................................................... 20

4.1 POWER SUPPLY OPERATION ...............................................................................................................20

4.1.1 LED DISPLAY INFORMATION ........................................................................................................... 20

4.1.2 POWER ON SEQUENCE................................................................................................................... 21

4.1.3 DETAILS OF POWER ON SEQUENCE ............................................................................................. 22

4.2 DIAGNOSIS FLOWCHART OF FAILURE ANALYSIS.............................................................................. 26

4.2.1 VIDEO SYSTEM ................................................................................................................................. 26

4.2.2 AUDIO SYSTEM ................................................................................................................................. 27

4.3 DIAGNOSIS OF SD (SHUTDOWN) ......................................................................................................... 30

4.3.1 SD (SHUTDOWN) DIAGNOSIS.......................................................................................................... 30

4.4 NON-FAILURE INFORMATION ............................................................................................................... 31

4.4.1 INFORMATION ON SYMPTOMS THAT DO NOT CONSTITUTE FAILURE....................................... 31

4.5 OUTLINE OF THE OPERATION.............................................................................................................. 35

4.5.1 SPECIFICATION OF THE FAN CONTROL ........................................................................................ 35

5. SERVICE FACTORY MODE........................................................................................................................... 36

5.1 OUTLINE OF THE SERVICE FACTORY MODE...................................................................................... 36

5.1.1 REMOTE CONTROL CODE IN SERVICE FACTORY MODE ............................................................ 36

5.1.2 INDICATIONS IN SERVICE FACTORY MODE................................................................................... 37

5.2 DETAILS OF FACTORY MENU................................................................................................................ 38

5.2.1 INFORMATION ................................................................................................................................... 38

5.2.2 OPTION .............................................................................................................................................. 41

6. EACH SETTING AND ADJUSTMENT............................................................................................................ 42

6.1 ADJUSTMENT REQUIRED WHEN THE UNIT IS REPAIRED OR REPLACED...................................... 42

7. RS-232C ......................................................................................................................................................... 43

7.1 LIST OF RS-232C COMMANDS.............................................................................................................. 43

7.2 DETAILS OF EACH COMMANDS ........................................................................................................... 44

7.2.1 QSE (DESTINATION PECULIAR INFORMATION)............................................................................. 44

7.2.2 QNG (SHUTDOWN INFORMATION OF MTB) ................................................................................... 45

8. GENERAL INFORMATION ............................................................................................................................. 47

8.1 DISPLAY METHOD OF SIGNAL LEVEL,QUALTY,AND BER INFORMATION SCREEN ........................ 47

9. SCHEMATIC DIAGRAM ................................................................................................................................. 48

9.1 MAIN ASSY (1/20) [BOARD IF0 BLOCK] ................................................................................................ 48

9.2 MAIN ASSY (2/20) [BOARD IF1 BLOCK] ................................................................................................ 50

9.3 MAIN ASSY (3/20) [POWER 0 BLOCK]................................................................................................... 52

9.4 MAIN ASSY (4/20) [POWER 1 BLOCK]................................................................................................... 54

9.5 MAIN ASSY (5/20) [POWER 2 BLOCK]................................................................................................... 56

9.6 MAIN ASSY (6/20) [AV SW BLOCK]........................................................................................................ 58

9.7 MAIN ASSY (7/20) [RGB SW BLOCK]..................................................................................................... 60

9.8 MAIN ASSY (8/20) [VDEC BLOCK]......................................................................................................... 62

9.9 MAIN ASSY (9/20) [ADC BLOCK]............................................................................................................ 64

9.10 MAIN ASSY (10/20) [HDMI SW BLOCK] ............................................................................................... 66

9.11 MAIN ASSY (11/20) [HDMI BLOCK]......................................................................................................68

9.12 MAIN ASSY (12/20) [TUNER BLOCK]................................................................................................... 70

9.13 MAIN ASSY (13/20) [VBI SLICER BLOCK] ........................................................................................... 72

9.14 MAIN ASSY (14/20) [USB BLOCK]........................................................................................................ 74

9.15 MAIN ASSY (15/20) [ARIA 0 BLOCK].................................................................................................... 76

9.16 MAIN ASSY (16/20) [ARIA 1 BLOCK].................................................................................................... 78

9.17 MAIN ASSY (17/20) [ARIA MEMORY BLOCK]......................................................................................80

9.18 MAIN ASSY (18/20) [IF UCOM BLOCK] ................................................................................................ 82

9.19 MAIN ASSY (19/20) [EMMA2 BLOCK] .................................................................................................. 84

9.20 MAIN ASSY (20/20) [EMMA2 MEMORY BLOCK] ................................................................................. 86

9.21 TANSHI ASSY (1/4) [BOARD IF BLOCK] .............................................................................................. 88

9.22 TANSHI ASSY (2/4) [IO_1 BLOCK]........................................................................................................ 90

9.23 TANSHI ASSY (3/4) [IO_2 BLOCK]........................................................................................................ 92

9.24 TANSHI ASSY (4/4) [MSP BLOCK]........................................................................................................ 94

2

1 234

PDP-508XG

Page 3

5678

9.25 SIDE IO ASSY........................................................................................................................................96

9.26 DTV TUNER BOARD (1/16) [DDR TERM/CONN BLOCK] ....................................................................98

9.27 DTV TUNER BOARD (2/16) [DDR-SDRAM BLOCK]...........................................................................100

9.28 DTV TUNER BOARD (3/16) [DVO, PIN STRAPOPTION BLOCK].......................................................102

9.29 DTV TUNER BOARD (4/16) [AUDIO BUFFER BLOCK] ......................................................................104

9.30 DTV TUNER BOARD (5/16) [VIDEO DAC OUTPUT BLOCK] .............................................................106

9.31 DTV TUNER BOARD (6/16) [DVO BLOCK] .........................................................................................108

9.32 DTV TUNER BOARD (7/16) [PCI BLOCK]...........................................................................................110

9.33 DTV TUNER BOARD (8/16) [EBI, RESET BLOCK] .............................................................................112

9.34 DTV TUNER BOARD (9/16) [I2C, UART, CLK BLOCK] .......................................................................114

9.35 DTV TUNER BOARD (10/16) [EJTAG, TS, EEPROM BLOCK]............................................................116

9.36 DTV TUNER BOARD (11/16) [USB;ETHERNET;SATA BLOCK]..........................................................118

9.37 DTV TUNER BOARD (12/16) [POWER BLOCK] .................................................................................120

9.38 DTV TUNER BOARD (13/16) [ANALOG DECOUPLING BLOCK] .......................................................122

9.39 DTV TUNER BOARD (14/16) [VIDEO BUFFERS, DIGITAL DECOUPLING BLOCK]..........................124

9.40 DTV TUNER BOARD (15/16) [FRONT END BLOCK]..........................................................................126

9.41 DTV TUNER BOARD (16/16) [INTER-CONNECTION BLOCK]...........................................................128

9.42 VOLTAGES ...........................................................................................................................................130

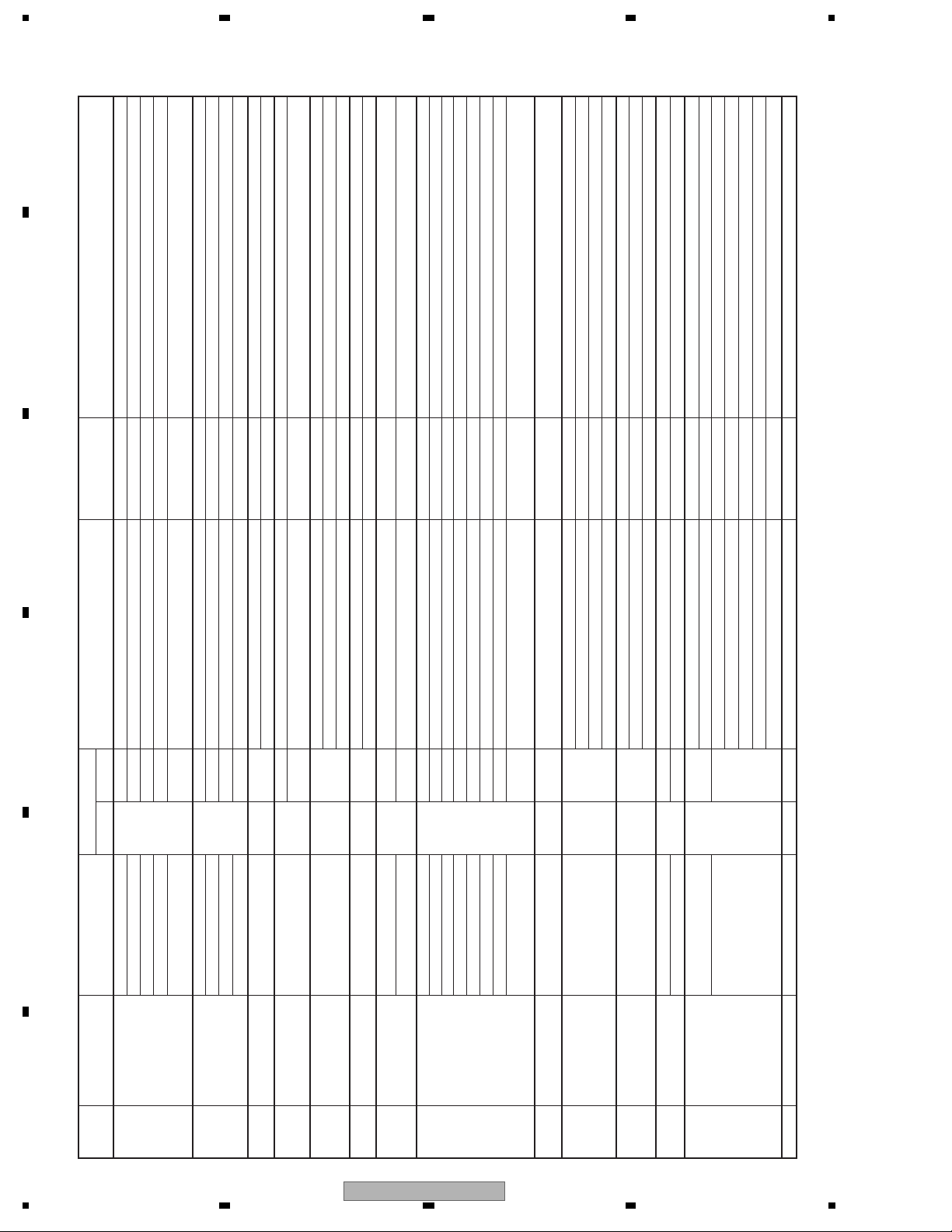

10. PCB CONNECTION DIAGRAM..................................................................................................................134

10.1 MAIN ASSY ..........................................................................................................................................134

10.2 TANSHI ASSY ......................................................................................................................................138

10.3 SIDE IO ASSY......................................................................................................................................142

10.4 DTV TUNER BOARD ...........................................................................................................................144

11. PCB PARTS LIST........................................................................................................................................146

A

B

C

D

E

PDP-508XG

56

F

3

7

8

Page 4

1234

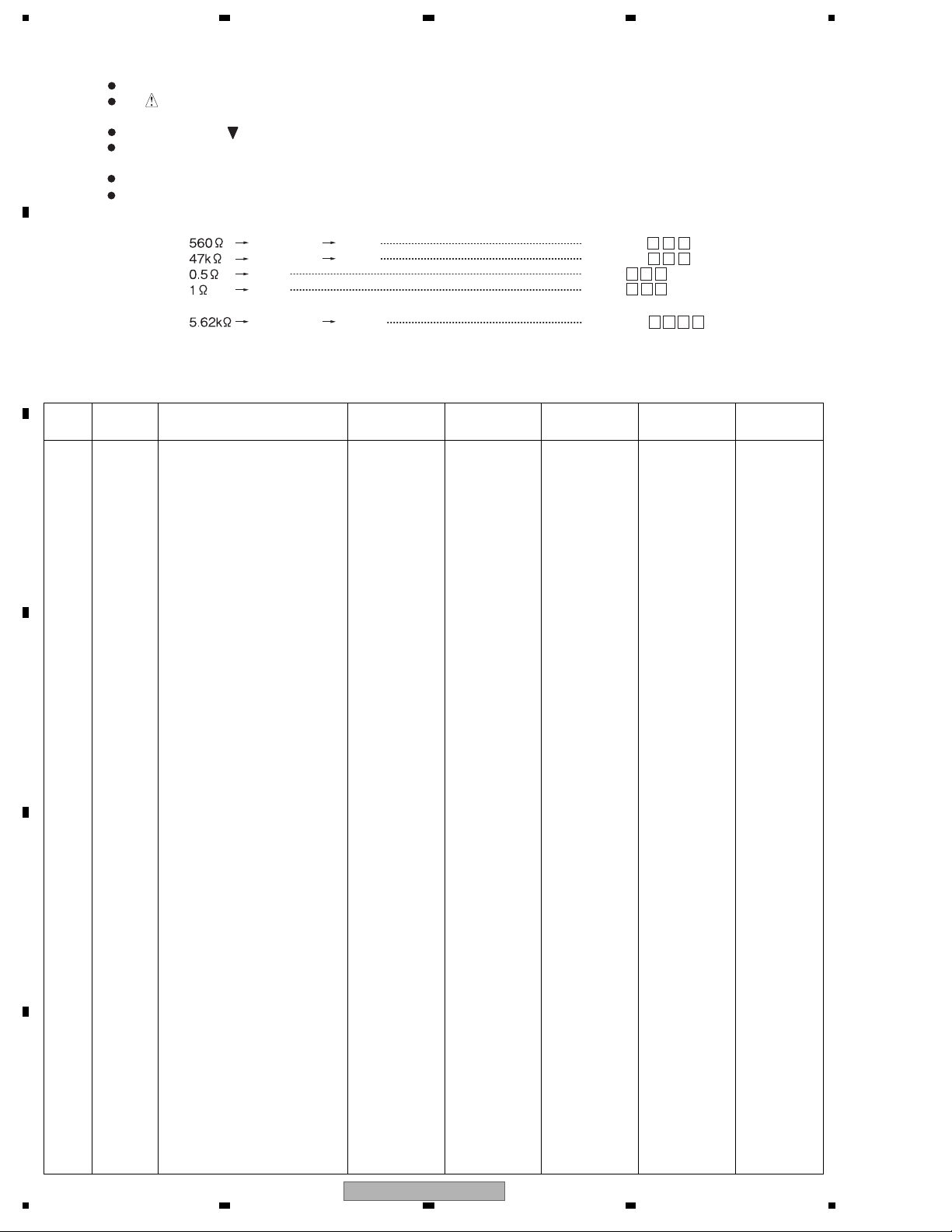

1. CONTRAST OF MISCELLANEOUS PARTS

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

Nos. indicate the pages and Nos. in the service manual for the base model.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

B

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

56 x 10

47 x 103

R50

1R0

1

561

473

1

5621 5 26 1

RD1/4PU J

RD1/4PU J

RN2H K

RS1P K

5

4 7 3

R 5 0

R 0

1

6 1

RN1/4PC F562 x 10

CONTRAST TABLE

PDP-508XD/WYV5, PDP-508XG/DLFT, PDP-508XDA/YP and PDP-508XC/WA5 are constructed the same except

for the following:

Mark No. Symbol and Description

PCB ASSEMBLIES

P173-1 MAIN Assy AWV2461 AWV2465 AWV2465 AWV2466

NSP 1..FUKUGO Assy AWV2481 AWV2491 AWV2489 AWV2491

C

P173-2 2..TANSHI ASSY AWW1248 AWW1258 AWW1256 AWW1258

P163-1 2..SIDE IO ASSY AWW1253 AWW1259 AWW1259 AWW1259

P173-3 2..232C ASSY AWW1254 Not used Not used Not used

PDP-508XD

/WYV5

PDP-508XG

/DLFT

PDP-508XDA

/YP

PDP-508XC

/WA5

Remarks

NSP 1..50 DIGITAL ASSY AWV2445 AWV2533 AWV2533 AWV2533

P169-3 2..50 DIGITAL ASSY AWW1270 AWW1337 AWW1337 AWW1337

DTV TUNER BOARD Not used Not used AXY1170 Not used *1 No. 1

PACKING SECTION

>

NSP P161-5 Dry Cell Battery (R06, AA) VEM1031 AEX1025 VEM1031 VEM1031

D

NSP P161-13 Warranty Card ARY1204 Not used ARY1192 ARY1161

NSP P161-15 Catalogue Bag AHG1340 Not used Not used

E

P161-1 Power Cord (2 m) ADG1214 Not used ADG1245 ADG1209

P161-3 Remote Control Unit AXD1551 AXD1554 AXD1555 AXD1556

P161-9 Operating Instructions

(English/French/German)

P161-10 Operating Instructions

(Italian/Spanish/Dutch)

P161-11 Caution Card ARM1232

P161-14 Polyethylene Bag AHG1337 AHG1337 AHG1336 AHG1336

P161-21 Power Cord Lid AHC1085 AHC1085 Not used Not used

P161-23 Upper Carton AHD3646 AHD3606 AHD3607 AHD3608

P161-25 After Image Caution ARM1350 Not used Not used Not used

Operating Instructions

(Simp-Chinese)

Operating Instructions (English) Not used Not used ARB1577 Not used

Operating Instructions

(English/Spanish/Portuguese

/Trad-Chinese)

ARE1484 Not used Not used Not used

ARC1601 Not used Not used Not used

ARM1232 ARM1232

Not used Not used Not used ARC1581

Not used ARE1479 Not used Not used

Not used

AHG1340

>

NSP Power Cord Not used ADG1232 Not used Not used

>

NSP

>

NSP

>

NSP

F

>

NSP

>

NSP

>

NSP

4

Power Cord Not used ADG1234 Not used Not used

Power Cord Not used ADG1236 Not used Not used

Power Cord Not used ADG1239 Not used Not used

Power Cord Not used ADG1241 Not used Not used

Power Cord Not used ADG1242 Not used Not used

Power Cord Not used ADG1243 Not used Not used

PDP-508XG

1 234

Page 5

5678

Mark No. Symbol and Description

>

NSP

>

NSP

>

NSP

Power Cord Not used ADG1244 Not used Not used

Power Cord Not used ADG1246 Not used Not used

Power Cord Assy Not used AWX1095 Not used Not used

PDP-508XD

/WYV5

PDP-508XG

/DLFT

PDP-508XDA

/YP

PDP-508XC

/WA5

PAL RF Cable (30cm) Not used Not used ADF1036 Not used

Caution Card (PC) Not used Not used Not used ARM1302

REAR SECTION

NSP P163-17 Name Label AAL3005 AAL3011 AAL3012 AAL3014

P163-19 Bolt Caution Label (E) AAX3533

AAX3533 AAX3533 AAX3550

P163-20 Label A AAX3480 AAX3485 AAX3484 AAX3485

P163-21 Label B50 AAX3543 AAX3500 AAX3520 AAX3500

P163-22 Label C AAX3504 AAX3507 AAX3521 AAX3507

Remarks

A

P163-23 Terminal Panel B ANC2454 ANC2456 ANC2456 ANC2456

P163-28 Input Cover Label E AAX3510 AAX3511 AAX3511 AAX3511

P163-38 Screw BPZ30P080FTB Not used Not used Not used

Destination Label O Not used AAX3446 Not used Not used No. 2

NSP CCC S&E Label Not used Not used Not used DRW2310 No. 3

Screw Not used BBZ30P060FTB BBZ30P060FTB BBZ30P060FTB No. 15

FRONT SECTION

P165-12 Front Case Assy AMB3025 AMB3026 AMB3027 AMB3026

MULTI BASE SECTION

P173-7 Flexible Cable (J217) ADD1494 Not used Not used Not used

P173-20 POD Cover AMR3542 Not used Not used Not used

P173-21 Multi Base Assy ANA2103 ANA2103 ANA2104 ANA2103

P173-22 Terminal Panel A ANC2441 ANC2445 ANC2446 ANC2445

12P Housing Wire (J131) Not used Not used ADX3549 Not used No. 4

Flexible Cable (J219) Not used Not used ADD1450 Not used No. 5

Flexible Cable (J220) Not used Not used ADD1497 Not used No. 6

NSP Bottom Can Not used Not used XNA1005 Not used No. 7

Top Can Not used Not used XNG1002 Not used No. 8

Screw Not used Not used ABZ30P060FTC Not used No. 9

Screw Not used Not used BBZ30P060FTB Not used No. 10

Screw Not used Not used PMB30P080FNI Not used No. 11

Gasket N Not used Not used ANK1776 Not used No. 12

Frontend Holder G Not used ANG3120 Not used ANG3120 No. 13

Screw Not used AMZ30P060FTC Not used AMZ30P060FTC No. 14

Notes : The numbers in the remarks column correspond to the numbers on the “EXPLODED VIEWS”.

For PCB ASSEMBLIES, Refer to “5. SCHEMATIC DIAGRAM” , “6. PCB CONNECTION DIAGRAM" and “7. PCB PARTS LIST”.

*1 : DTV TUNER BOARD has no service parts.

B

C

D

PDP-508XG

56

E

F

5

7

8

Page 6

1234

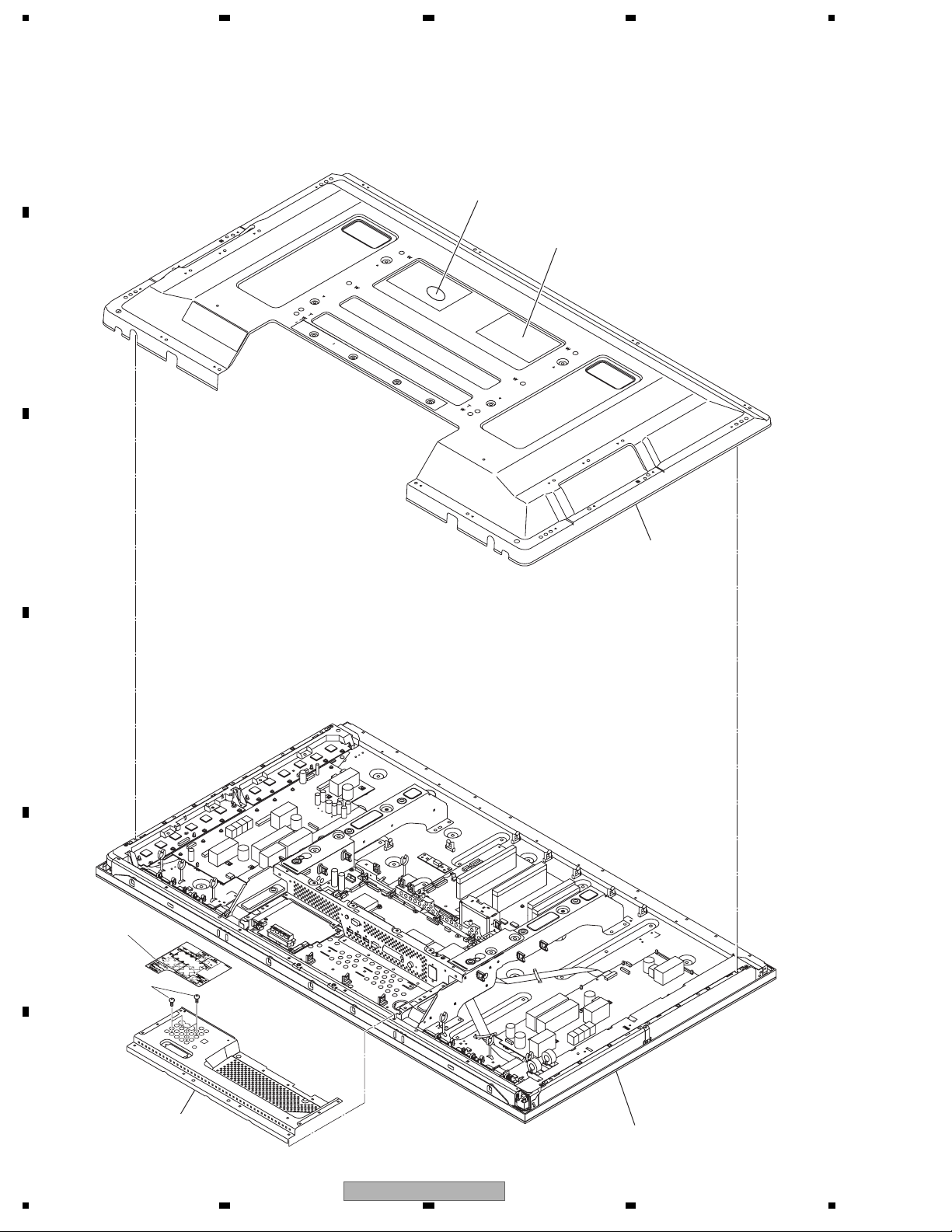

1.0.1 EXPLODED VIEWS

EXTERIOR (Rear Section)

A

B

No. 3

No. 2

C

Rear Case

D

E

Label B

No. 15

F

Terminal Panel B

Refer to

"10.3 FRONT SECTION".

6

1 234

PDP-508XG

Page 7

5678

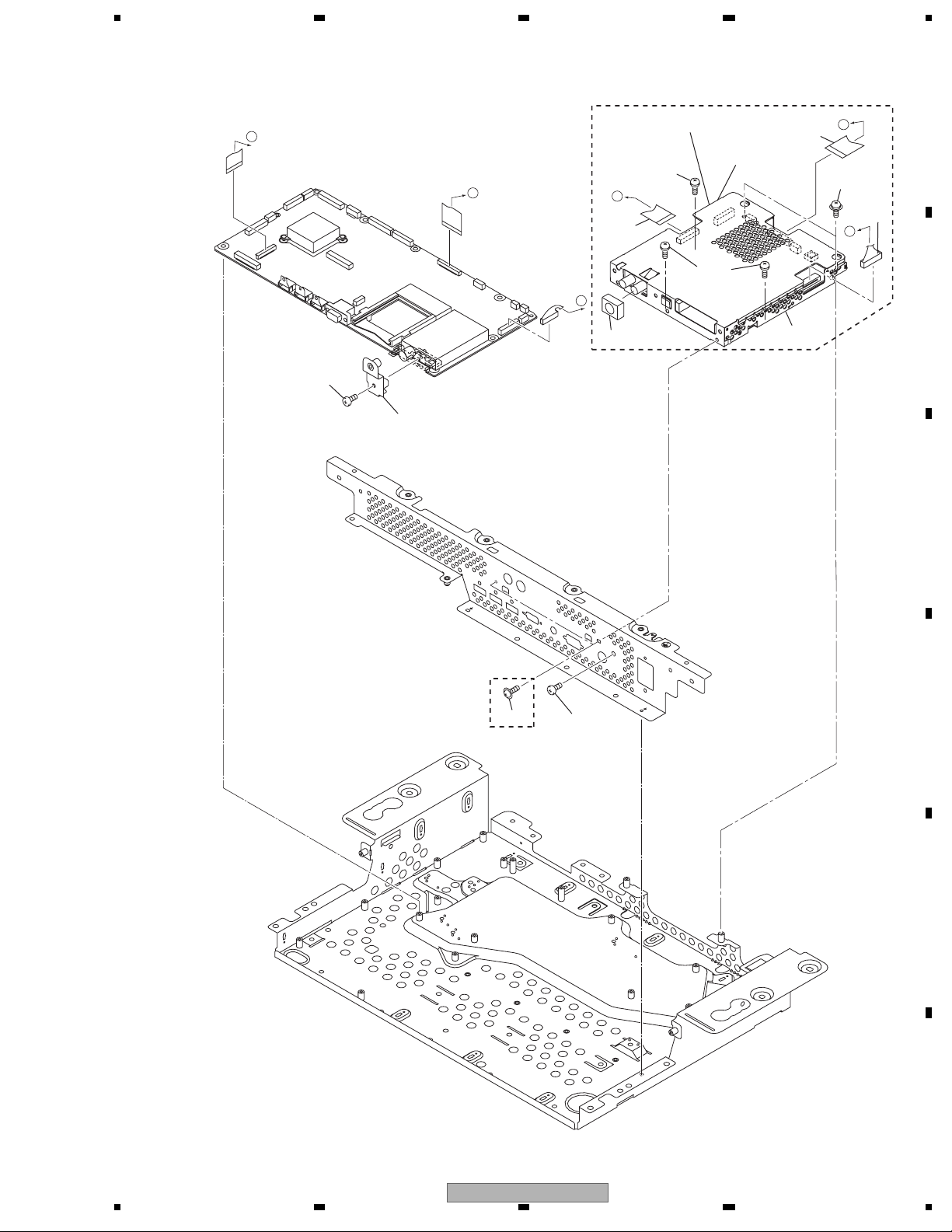

EXTERIOR (Mult Base Section)

F

PDP-508XDA only

No. 1 DTV Tuner Board

No. 5

H

A

No. 8

No. 9

H

F

No. 6

No. 11

No. 4

G

No. 9

Screw

(ABA1354)

No. 13

No. 10

PDP-508XDA

only

G

No. 14

No. 12

B

No. 7

C

D

PDP-508XG

56

E

F

7

7

8

Page 8

1234

2. BASIC ITEMS FOR SERVICE

2.1 QUICK REFERENCE

A

Quick Reference upon Service Visit 1

Notes, PD/SD diagnosis, and methods for various settings

Notes when visiting for service

1. Notes when disassembling/reassembling

1 Rear case

When reassembling the rear case, the screws must be tightened in a

specific order. Be careful not to tighten them in the wrong order forcibly.

For details, see "Rear Case" in "7. DISASSEMBLY".

2 Attaching screws for the HDMI connector

When attaching the HDMI connector after replacing the Main Assy,

secure the HDMI connector manually with a screwdriver, but not

with an electric screwdriver. If you tighten the screws too tightly

with an electric screwdriver, the screw heads may be damaged, in

B

which case the screws cannot be untightened/tightened any more.

2. On parts replacement

1 How to discharge before replacing the Assys

A charge of significant voltage remains in the Plasma Panel even

after the power is turned off. Safely discharge the panel before

replacement of parts, in either manner indicated below:

Let the panel sit at least for 3 minutes after the power is turned off.

A:

B: Turn the Large Signal System off before the power is turned off

then, after 1 minute, turn the power off.

For details, see "5.6.1 PANEL DRIVE-POWER ON/OFF

FUNCTION".

2 On the settings after replacement of the Assys

Some boards need settings made after replacement of the Assys.

For details, see "8. EACH SETTING AND ADJUSTMENT".

C

3. On various settings

1 Setting in Factory mode

After a Mask indication into the panel is performed, be sure to

set the Mask setting to "OFF" then exit Factory mode.

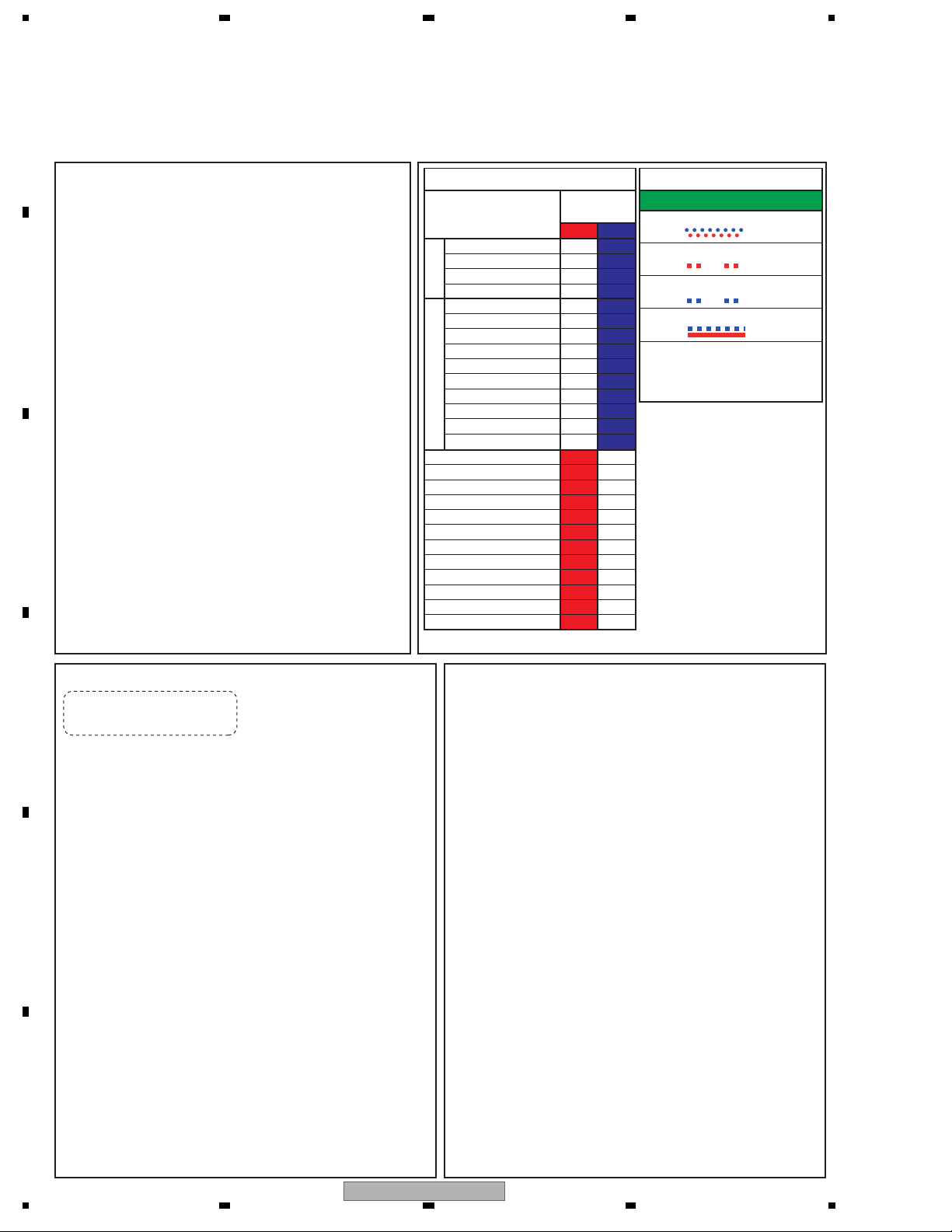

PD/SD

Item

SQ_LSI

Communication with the module IIC

DIGITAL-RST2

Panel high temperature

Panel section

Audio/

Short-circuit SP terminal

Communication with the Module UCOM

Main 3-wire serial communication

Main IIC communication

Communication with the Main UCOM

FAN

MTB section

Unit high temperature

Digital Tuner communication

MTB-RST2/RST4

Main EEPROM

POWER

SCAN

SCN-5V

Y- D R I VE

Y-DCDC

Y- S U S

ADRS

X-DRIVE

X-DCDC

X-SUS

DIG-DCDC

UNKNOWN

No. of LEDs

flashing

Red Blue

Blue 1

Blue 2

Blue 3

Blue 4

Blue 5

Blue 6

Blue 7

Blue 8

Blue 9

Blue 10

Blue 11

Blue 12

Blue 13

Blue 15

Red 2

Red 3

Red 4

Red 5

Red 6

Red 7

Red 8

Red 9

Red 10

Red 11

Red 12

Red 15

LED Display Information

1 Rewriting software

2 PD (2-15)

3 SD (1-15)

4 No backup

This indication does not display all

LED patterns.

For details, please refer to 5.1.1 LED

DISPLAY INFORMATION.

How to locate several items on the Factory menu

{ } : Item on the Factory menu

D

E

F

[ ] : Key on the remote control unit

" " : Screen indication

1. Confirmation of accumulated power-on time and power-on

count

Select {INFORMATION} then {HOUR METER}.

(After entering Factory mode, press

[j] five times.)

2. Confirmation of the Power-down and Shutdown histories

1 Panel system

PD: Select {PANEL FACTORY} then {POWER DOWN}.

(After entering Factory mode, press [MUTING] once, press

[ENTER/SET], then press

[j] three times.)

SD: Select {PANEL FACTORY} then {SHUT DOWN}.

(After entering Factory mode, press [MUTING] once, press

[ENTER/SET], then press

[j] four times.)

2 MTB section

Select {INFORMATION} then {MAIN NG}.

(After entering Factory mode, press

[j] three times.)

3. How to display the Mask indication

1 Mask indication in the panel side

1. Select {PANEL FACTORY} then {RASTER MASK SETUP}.

(After entering Factory mode, press [MUTING] once, press

[ENTER/SET], then press

2. Press [ENTER/SET], then select a Mask indication, using

[j] 8 times.)

[j] or [i].

Adjustments and Settings after replacement of the

Assys (Procedures in Factory mode)

1. Digital Video Assy: Transfer of backup data

1 Select {PANEL FACTORY}, {ETC}, then {BACKUP DATA}. (After entering Factory

mode, press [MUTING] once, press [ENTER/SET], press [j] seven times, then

press [ENTER/SET].)

2 Select {TRANSFER}, using [l], then hold [ENTER/SET] pressed for at least 5

seconds.

3 After transfer of backup data is completed, {ETC} is automatically selected, and the

LED on the front panel returns to normal lighting.

2. MAIN Assy: Execution of FINAL SETUP.

1 Select {INITIALIZE} then {FINAL SETUP}, then press [ENTER/SET]. (After entering

Factory mode, press [MUTING] three times, then press [j] four times.)

2 Select "YES", using [l]. Then hold [ENTER/SET] pressed for at least 5 seconds.

3 After "FINAL SETUP IS COMPLETE" is displayed on the screen, turn the POWER

switch of the main unit off.

3. POWER SUPPLY Unit: Clearance of the accumulated power-on count

and maximum temperature value

1 Select {PANEL FACTORY}, {ETC}, then {P COUNT INFO}. (After entering Factory

mode, press [MUTING] once, press [ENTER/SET], press [j] seven times, press

[ENTER/SET], then press [j] six times.)

2 Press [l] to select "CLEAR". Hold [ENTER/SET] pressed for at least 5 seconds.

After clearance is completed, "ETC" is automatically selected. Clear the maximum

temperature value (MAX TEMP) in the same manner.

4. Other Assys: Clearance of the maximum temperature value

1 Select {PANEL FACTORY}, {ETC}, then {MAX TEMP}. (After entering Factory mode,

press [MUTING] once, press [ENTER/SET], press [j] seven times, press

[ENTER/SET], then press [j] seven times.)

2 Press [l] to select "CLEAR". Hold [ENTER/SET] pressed for at least 5 seconds.

After clearance is completed, "ETC" is automatically selected.

8

1 234

PDP-508XG

Page 9

5678

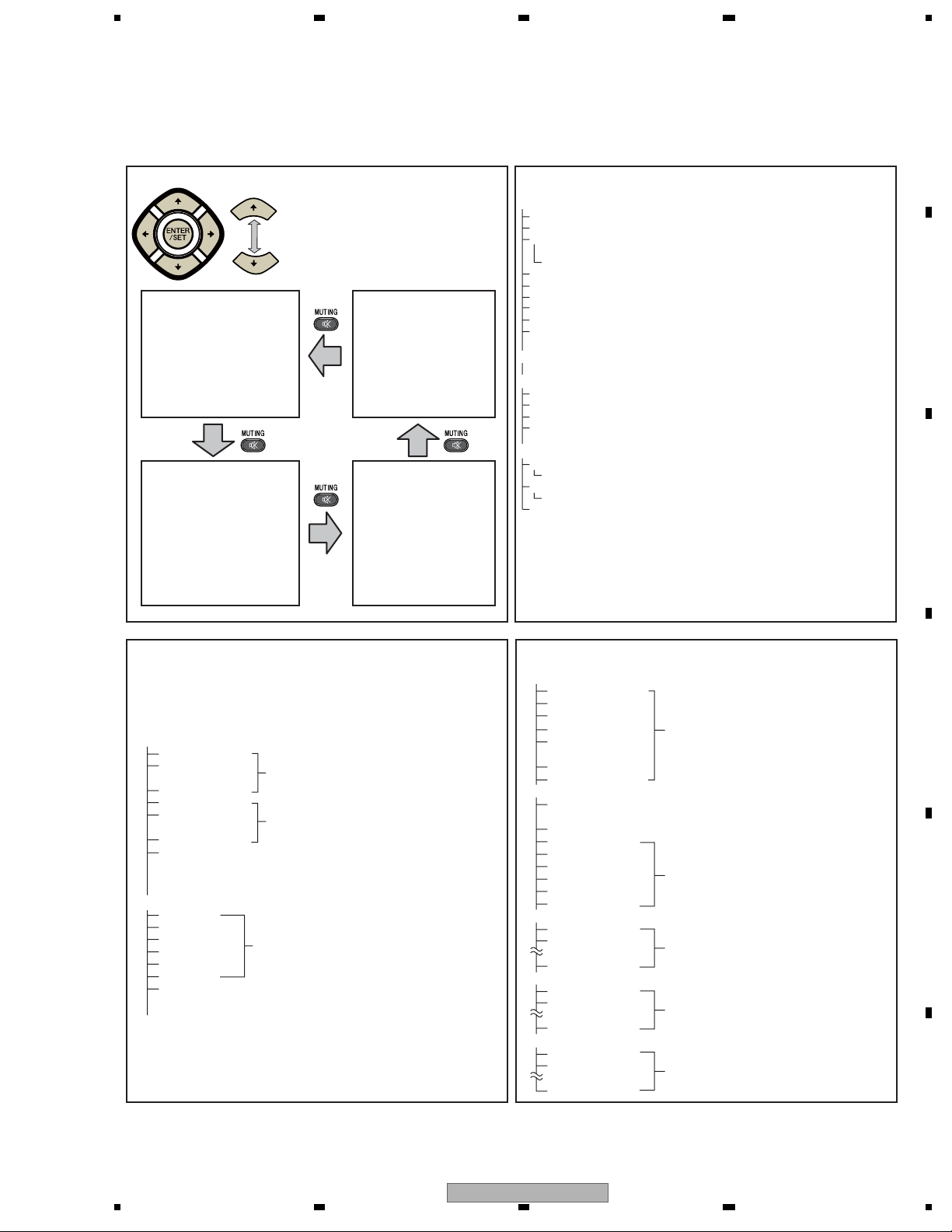

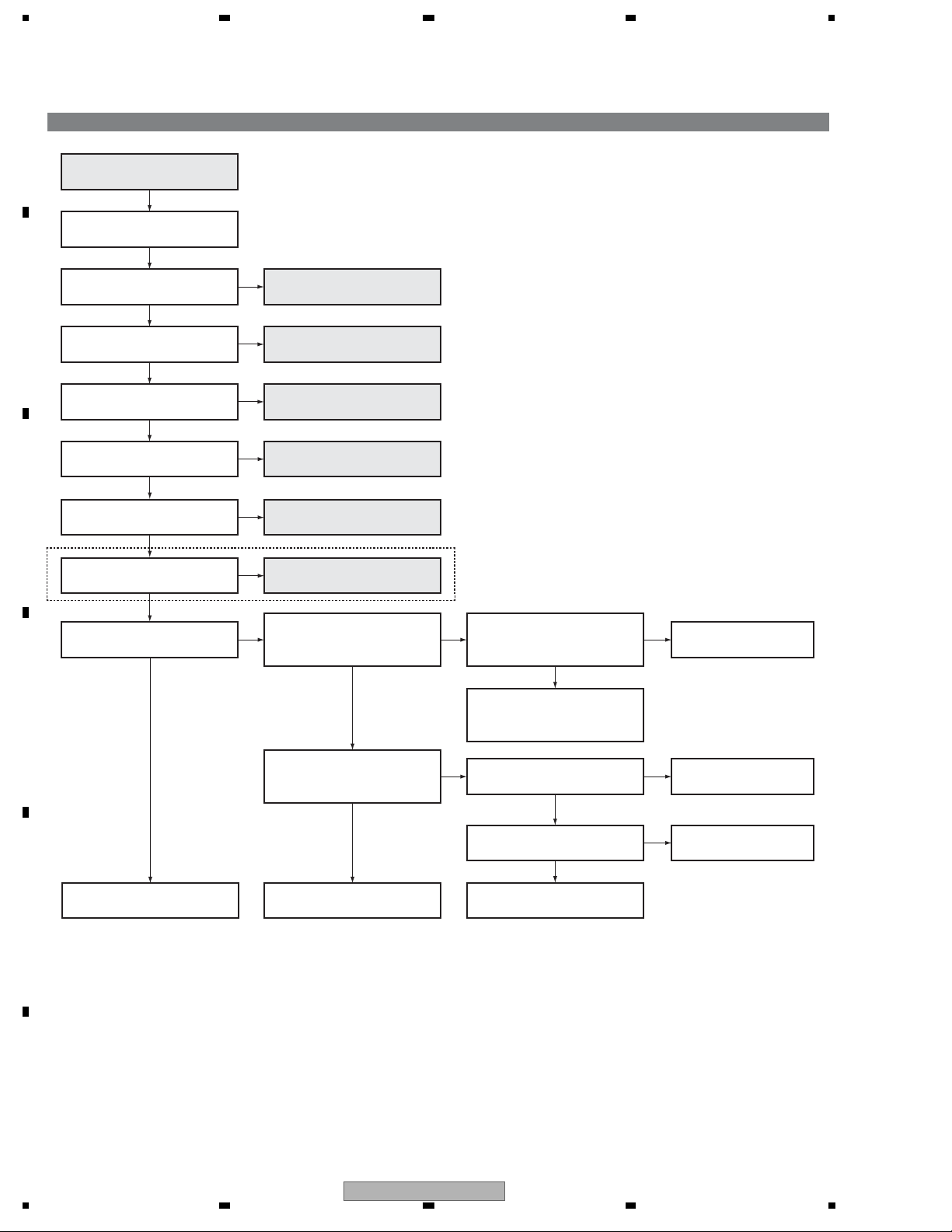

Quick Reference upon Service Visit 2

Mode transition and structure of layers in Service Factory mode

Mode transition in Service Factory mode

INFORMATION mode

1. VERSION (1)

2. VERSION (2)

3. MAIN NG

4. TEMPERATURE

5. HOUR METER

6. HDMI SIGNAL INFO1

7. HDMI SIGNAL INFO2

8. VDEC SIGNAL INFO1

9. VDEC SIGNAL INFO2

PA NEL FACTORY mode

1. PANEL INFORMATION

2. PANEL WORKS

3. POWER DOWN

4. SHUT DOWN

5. PANEL-1 ADJ

6. PANEL-2 ADJ

7. PANEL FUNCTION

8. ETC.

9. RASTER MASK SETUP

10. PATTEN MASK SETUP

11. COMBI MASK SETUP

Up

Down

• To shift to another mode, press [MUTING].

• To shift to another item in a specific mode,

press [i] or [j].

• To shift to the next nested layer below for an

item with a "(+)" indication, press [ENTER/SET].

To return to the next nested layer above,

also press [ENTER/SET].

INITIALIZE mode

1. SIDE MASK LEVEL

2. FINAL SETUP

3. Wide XGA AUTO

OPTION mode

1. EDID WRITE MODE

2. CH PRESET

3. AFT

4. SYNC DET

Structure of Layers in Service Factory Mode

INFORMATION mode

1. VERSION (1) The software versions for each microcomputer

2. VERSION (2) The Flash memory versions for each device

3. MAIN NG The shutdown message ID/event times

(Going Clear mode by [ENTER/SET] key)

3-1. CLEAR

4. TEMPERATURE The temperature/FAN rotating status/Room light sensor

5. HOUR METER The HOUR METER/P-COUNT information

6. HDMI SIGNAL INFO 1 The information of HDMI information files

7. HDMI SIGNAL INFO 2 The information of HDMI information files

8. VDEC SIGNAL INFO 1 The signal information of VDEC

9. VDEC SIGNAL INFO 2 The signal information of VDEC

PA NEL FACTORY mode Refer to [PANEL FACTORY MODE]

OPTION mode

1. EDID WRITE MODE For factory use

2. CH PRESET For production line use

3. AFT For factory use

4. SYNC DET For technical analysis

INITIALIZE mode

1. SIDE MASK LEVEL For factory use

1-1. SIDE MASK LEVEL

2. FINAL SETUP Set to Factory default settings (it should perform after

2-1. DATA RESET replacing a MAIN Assy)

3. Wide XGA AUTO For technical analysis

Select Yes by [l] key, l pressing and hold [ENTER/SET] key

A

B

C

Structure of Layers in Panel Factory Mode 1

1. PANEL INFORMATION Version indication of the panel

2. PANEL WORKS Indications of the accumulated power-on time, pulse-meter

count, and power-on count of the panel

3. POWER DOWN Indication of the Power-down history

4. SHUT DOWN Indication of the Shutdown history

5. PANEL-1 ADJ (+)

1. VOL SUS

2. VOL OFFSET

• • • • •

8. VOL YNOFS4

9. RESET1ST_KSB

10. RESET2ND_KSB

• • • • •

23. YSTL_FMR_HZ

24. SUS FREQ

6. PANEL-2 ADJ (+)

1. R-HIGH

2. G-HIGH

3 .B-HIGH Parameters for the WB adjustment of the panel, which are

4. R-LOW required during adjustment after panel replacement

5. G-LOW

6. B-LOW

7. ABL Setting of the power consumption. A setting table is

availab

To "Structure of Layers in Panel Factory Mode 2"

Settings required after replacement of the panel

Modification not required because these items

are basically for factory presetting

For AM noise prevention (Depending on the mode,

brightness of the screen changes.)

For confirmation of the result of the setting change,

the unit must be turned off then back on again.

le for each vertical signal.

Structure of Layers in Panel Factory Mode 2

7. PANEL FUNCTION (+)

1. R-LEVEL

2. G-LEVEL

3. B-LEVEL

4. ADDRESS L1 Items for use by engineers

5. ADDRESS L2

• • • • •

11. ADDRESS U4

12. STK MODE

8. ETC (+)

1. BACKUP DATA For transferring backup data (after replacement of

the DIGITAL Assy)

2. DIGITAL EEPROM To clear data of the digital video

3. PD INFO.

4. SD INFO. For clearance of data for the corresponding items.

5. HR-MTR INFO. The clearing method is the same: Select "CLEAR",

6. PM/B1-B5 using [l], then hold [ENTER/SET] pressed for at

7. P COUNT INFO. least 5 seconds. After clearance is completed, {ETC}

8. MAX TEMP. is automatically selected.

9. RASTER MASK SETUP (+)

1. MASK OFF

2. RST MASK 01 For use while Raster Mask (full mask) is displayed.

• • • • • Use [i] or [j] to select the type of mask.

26. RST MASK 25

10. PATTEN MASK SETUP (+)

1. MASK OFF

2. PTN MASK 01 For use while Pattern Mask is displayed. Use [i] or

• • • • • [j] to select the type of mask.

50. PTN MASK 49

11. COMBI MASK SETUP (+)

1. MASK OFF

2. CMB MASK 01 For use while Combination Mask is displayed.

• • • • • Use [i] or [j] to select the type of mask.

1

8. CMB MASK 17

D

E

F

PDP-508XG

56

9

7

8

Page 10

1234

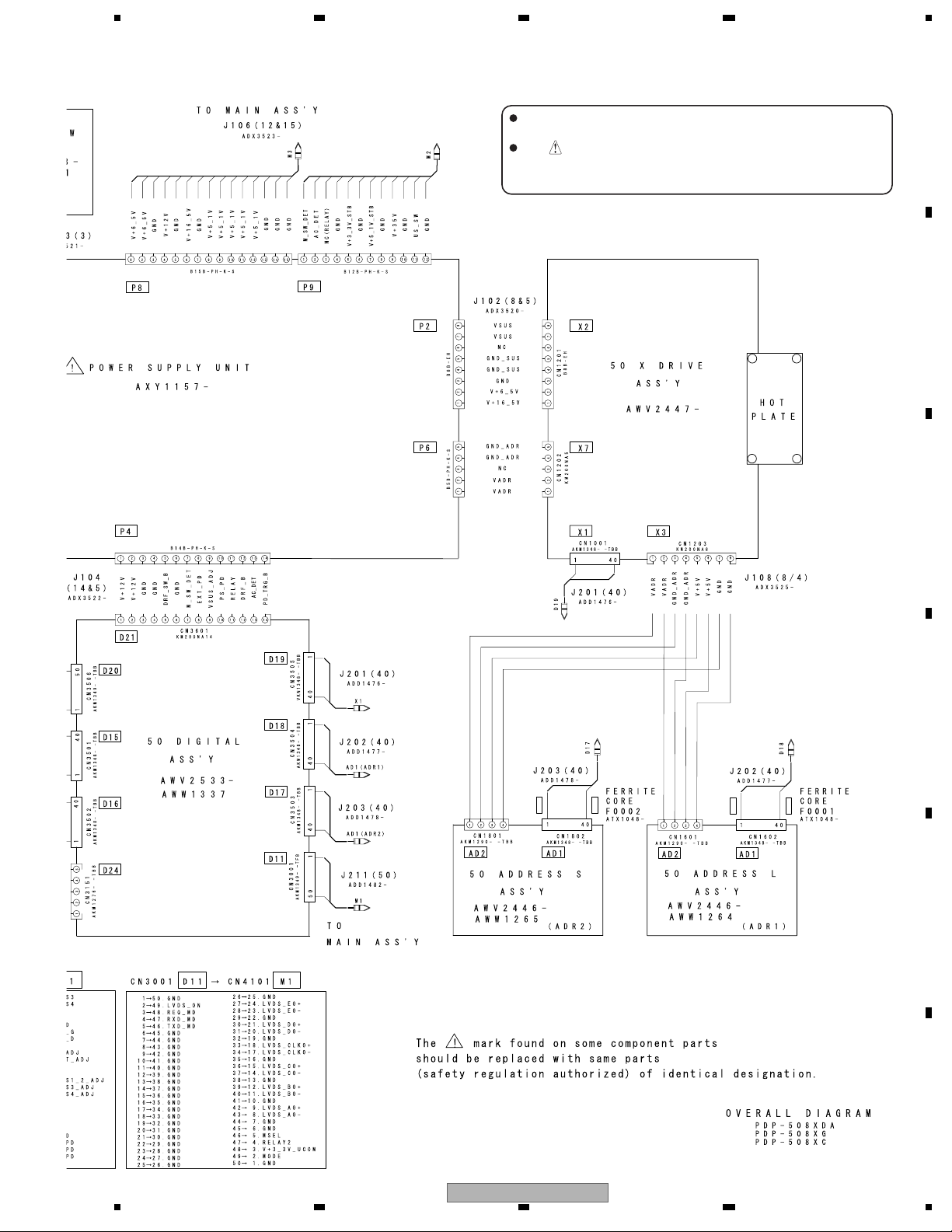

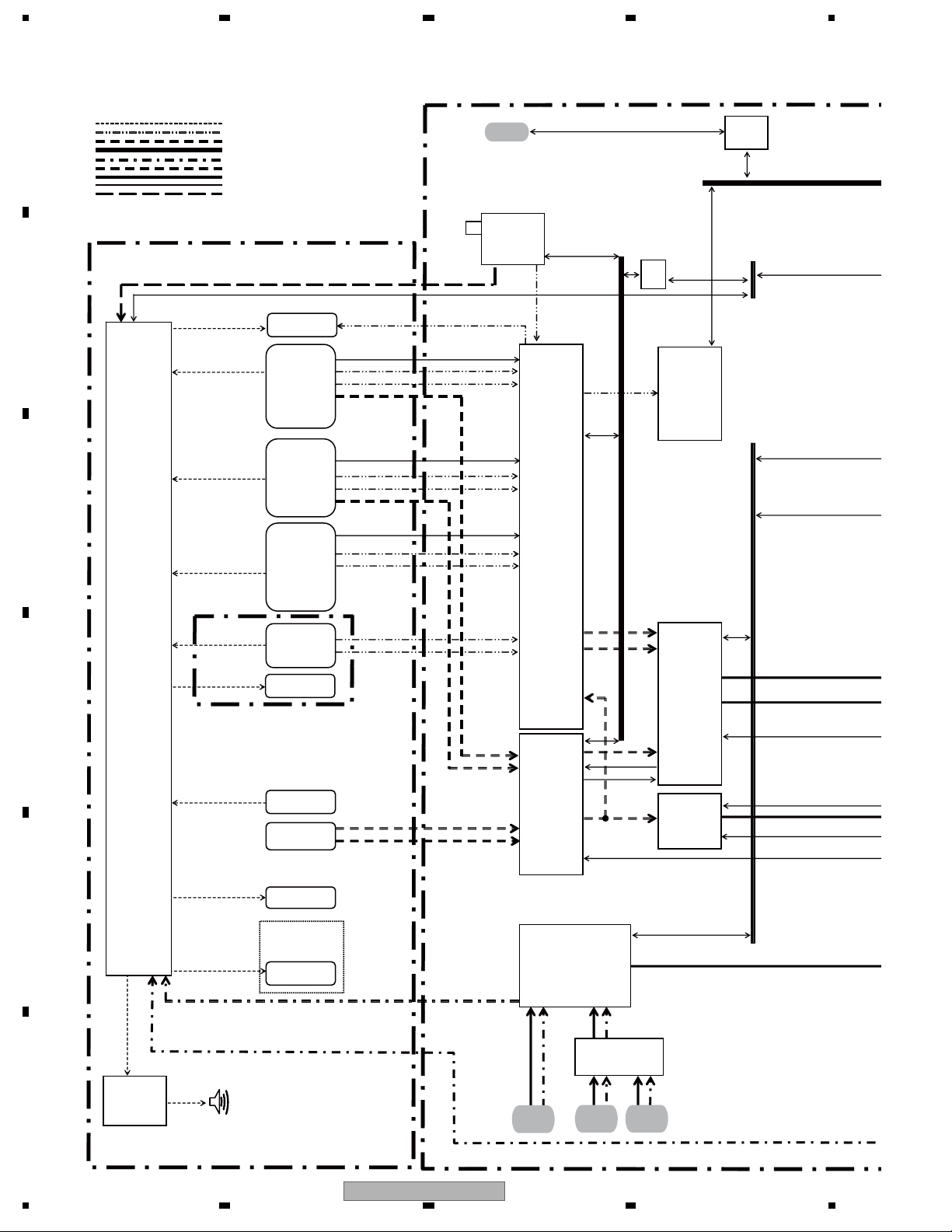

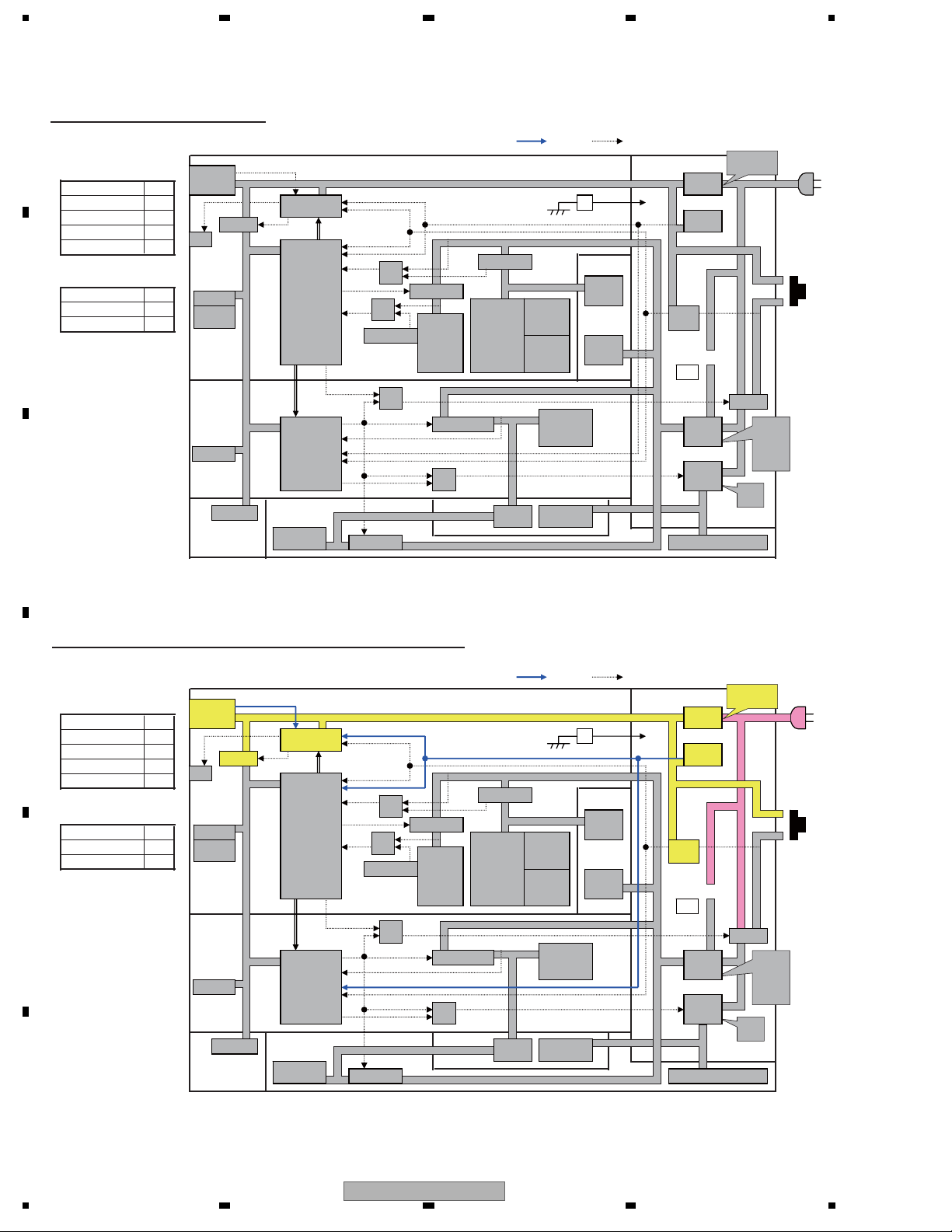

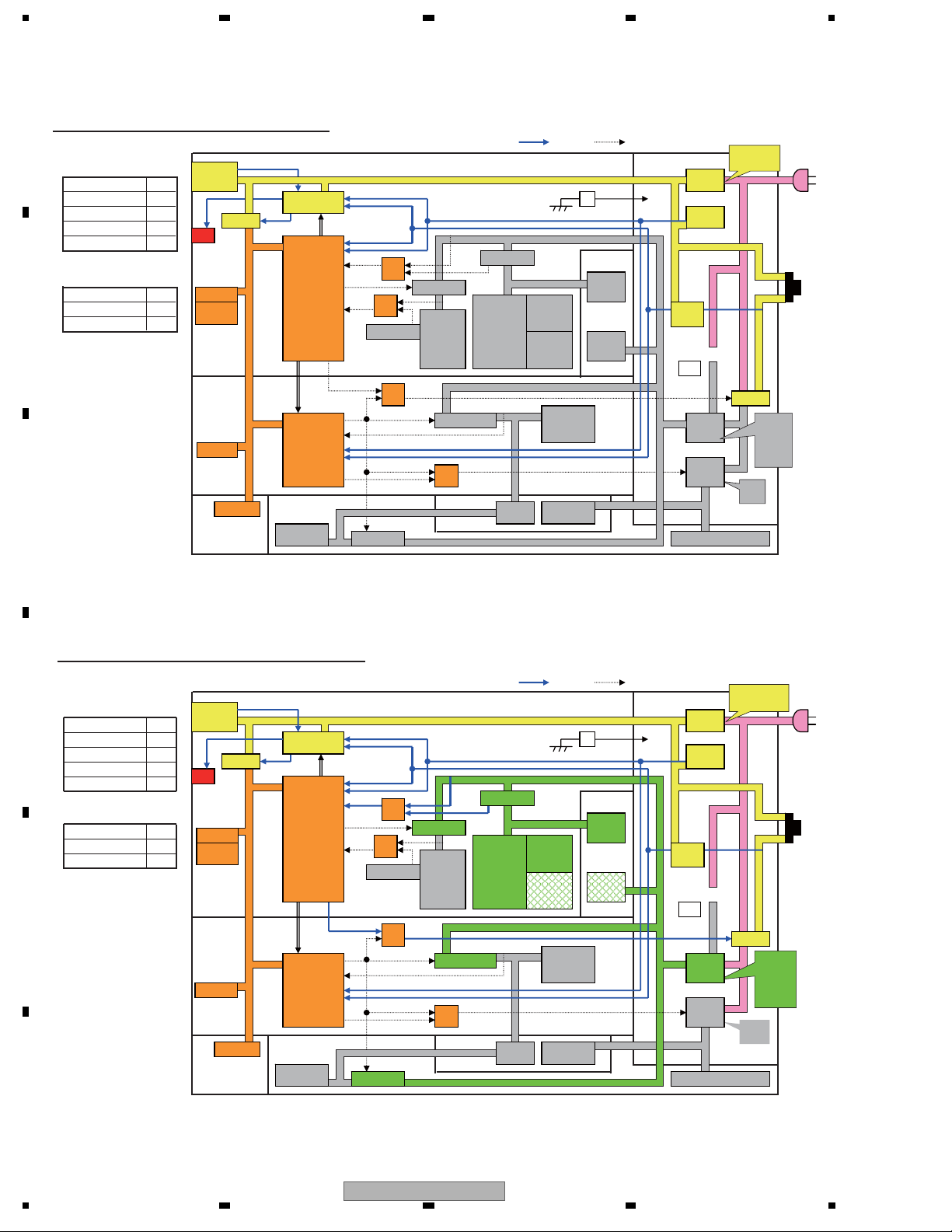

3. BLOCK DIAGRAM

3.1 OVERALL WIRING DIAGRAM (1/2)

A

B

C

D

E

F

10

1 234

PDP-508XG

Page 11

5678

When ordering service parts, be sure to refer to "EXPLODED

VIEWS and PARTS LIST" or "PCB PARTS LIST".

The mark found on some component parts indicates the

importance of the safety factor of the part. Therefore, when

replacing, be sure to use parts of identical designation.

A

B

C

D

E

F

PDP-508XG

56

11

7

8

Page 12

1234

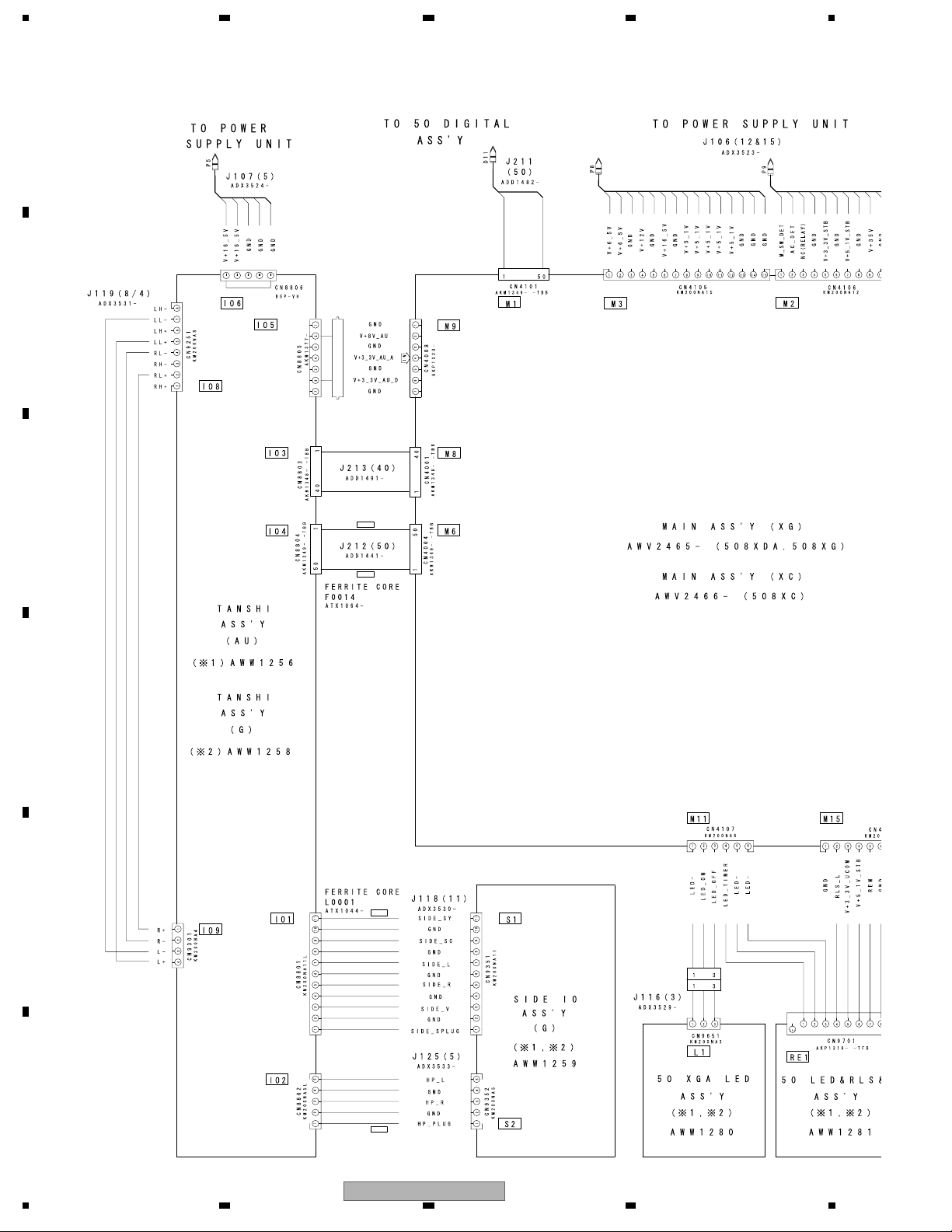

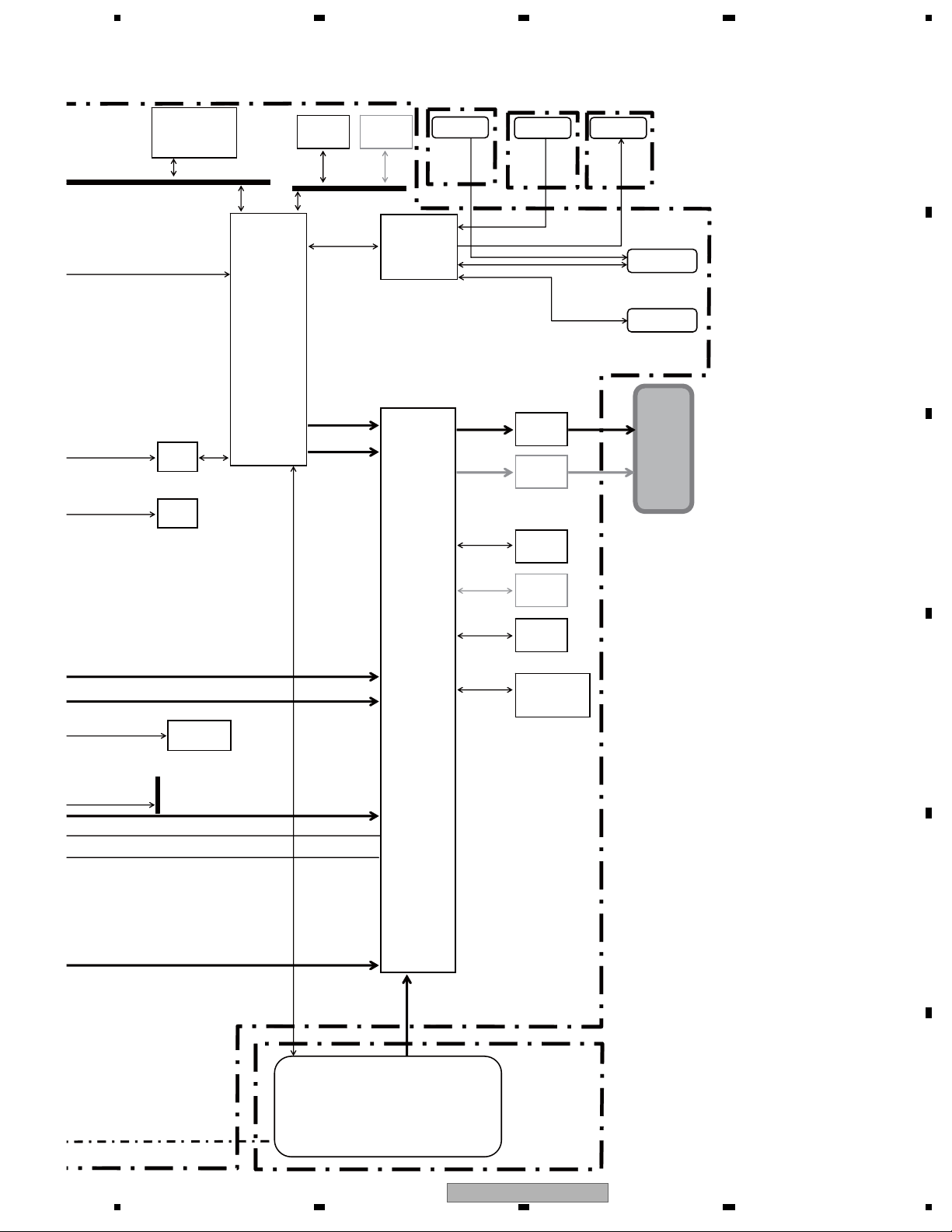

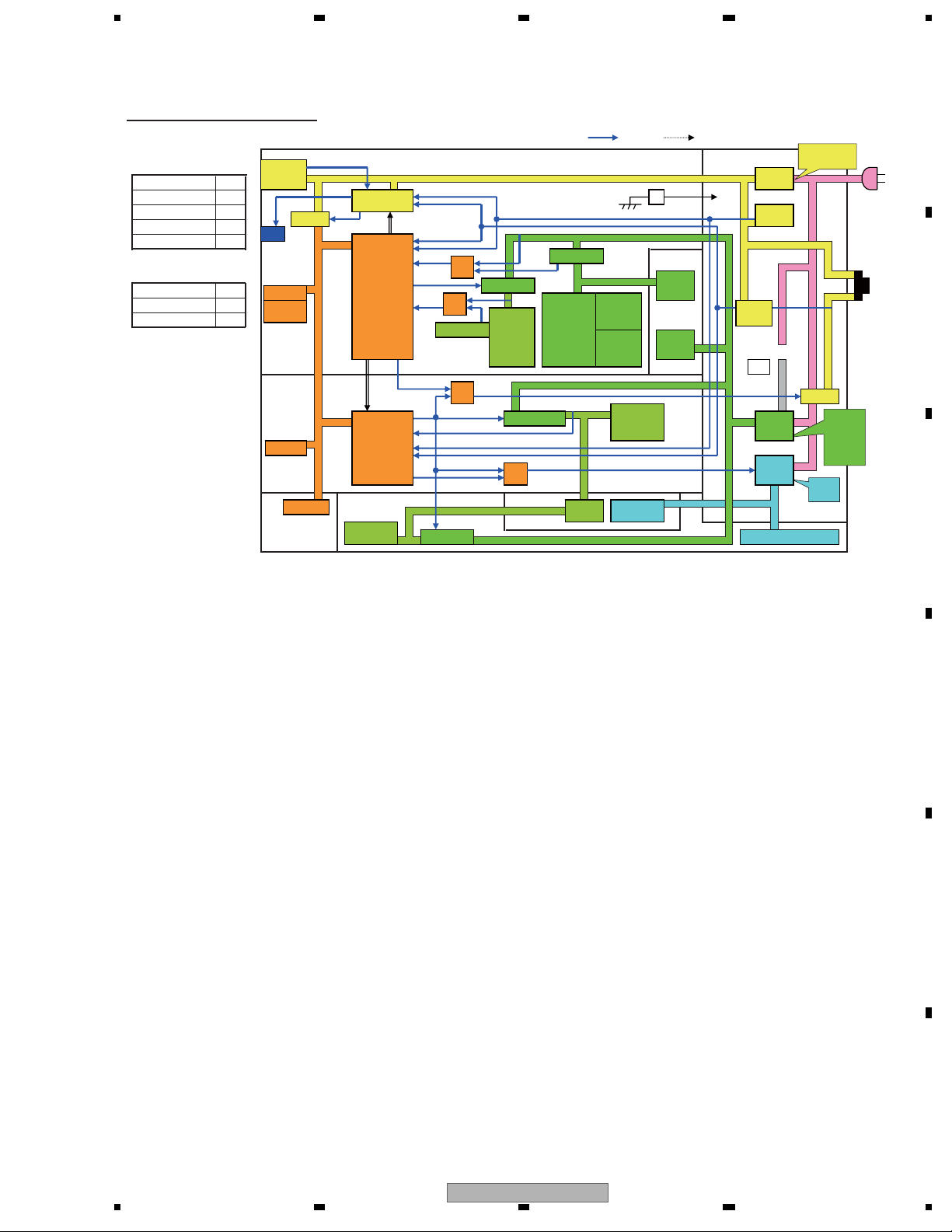

3.2 OVERALL WIRING DIAGRAM (2/2)

A

B

C

D

E

F

12

1 234

PDP-508XG

Page 13

5678

A

B

C

D

E

PDP-508XG

56

F

13

7

8

Page 14

1234

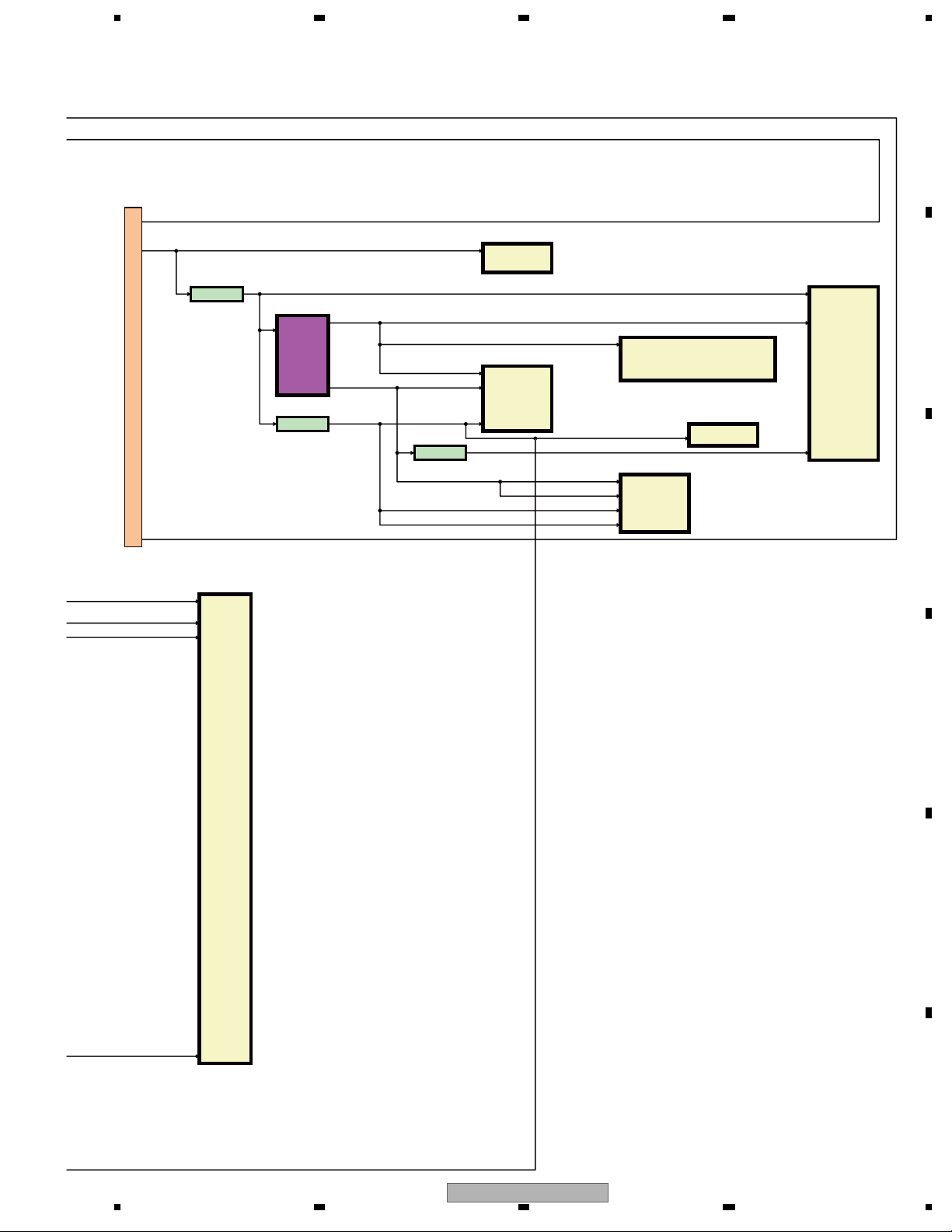

3.3 OVERALL BLOCK DIAGRAM

A

Analogue SIF

SCL_AV

B

SDA_AV

Analog Audio signal

Analog Video signal

Component signal

Digital Video signal

Digital Audio signal

Synchronized signal

Data signal

Control signal

RF signal

MON_OUT_L/R

L/R IN

L/R IN

JA8901

Monitor Out

JA8901

Input1

JA8901

Input2

MON_OUT_V

SPLUG

CVBS

Y/C

SPLUG

CVBS

Y/C

USB

U6001

AXF1180

(Tuner)

VIDEO

IC6401

M65596FP

(USB)

Add1-6

Data0-15

Add0-3

Data0-7

TSSI[0:10]

SCL_AV5

SDA_AV5

Analogue

CVBS

SCL_AV5

SDA_AV5

Q8405

SSM6N

17FU

SCL_AV

SDA_AV

IC6301

TC90173FG

(VBI)

SCL_AV

SDA_AV

C

IC4601

R2S11006FT

(AVSW)

Y/C

L/R IN

JA8901

Input3

SPLUG

CVBS

SIDE IO

IC9101

MSP5651M

(MSP)

ASSY

L/R IN

JA9351

JA9352

Input6

Y/C

CVBS

Main

Sub

SCL_MB

SDA_MB

HP_L/R OUT

D

PC_L/R IN

CN9353

Head Phone

JA9001

Audio Input for PC

CN4701

PC Input

Y/Pb/Pr

Y/Pb/Pr

PC_RGB

PC_H/V

IC4701

R2S11001FT

(RGBSW)

Y

RGB

CLP

FB

RGB/YPbPr

IC4801

CM0048BF

(VDEC)

IC5001

AD9985KSTZ

(ADC)

CLP

SW_L/R OUT

JA8901

SUB WOOFER

E

PDP-428XDA

PDP-508XDA

OPT_OUT

JA9081

SPDIF

SPDIF

I2S,SPDIF

IC9201

TAS5122DCA

ONLY

F

(D-AMP)

INPUT3

HDMI

IC5201

SII9125CTU

(HDMI RX)

INPUT4

HDMI

IC5101

CXB1442

(HDMI SW)

INPUT5

HDMI

MAIN ASSY

TANSHI ASSY

14

PDP-508XG

1 234

Page 15

5678

SCL_MB

SDA_MB

IC8602

XGA:AGC1042

FHD:AGC1047

(S29GL032A90TFIR4-K)

32Mbit Flash

Add1-17

Data0-15

ROM IF

I2C-1

IC8407

6

IC8404

BR24F64F

(EEPROM)

I2C-0

TC74HC406

IC8401

uPD61123F1

II

(EMMA

SV)

IC8601

K4H511638D

512Mbit DDR

UMI

TXD_DT

RXD_DT

Add0-12

Data0-15

OSD 8bit *4

FHD

IC8605

K4H510838D

512Mbit DDR

Add0-12

Data0-7

(M30620FCSGP-U5-K)

50LED&RLS

&IR ASSY

IR

REM

IC8301

AGC1037

IF UCOM

SIDE KEY

ASSY

KEY

KEY_AD1

KEY_AD2

IC4101

BU8254KVT

(LVDS)

IC4102

BU8254KVT

(LVDS)

IC8201

EDD1232ABBH

128Mbit (DDR)

50XGA LED

ASSY

LED

SR_OUT

TXD_SR

RXD_SR

232C_CH2

232C_CH3

232C_CH4

232C_CH8

FHD

SR_OUT

RS232C

To

Digital

Ass'y

A

B

C

SCL_AV

SDA_AV

CLP

IC4802

HY57V161610FTP

16Mbit(SDRAM)

TXD_DT

RXD_DT

656 10bit

656 8bit

8bit *3

12bit *3

IC8001

PD6568A

(ARIA)

8bit*3

IC8202

EDD1232ABBH

128Mbit (DDR)

EDD1232ABBH

128Mbit (DDR)

(S29GL016A90TFIR2-K)

IC8203

IC8204

AGC1050

16Mbit Flash

FHD

D

E

PDP-428XDA

PDP-508XDA

DTV TUNER BOARD

ONLY

I2S

PDP-508XG

56

F

15

7

8

Page 16

1234

DDC

BD8602FV-TBB

FET SW

RTQ040P02-TLB

5V Reg

PQ200WNA1ZPH-TLB

5V Reg

NJM2846DL3-05-TLB

5V Reg

NJM2846DL3-05-TLB

1.8V Reg

NJM2846DL3-18-TLB

FAN VCC Reg

PQ200WNA1ZPH-TLB

3.3V Reg

NJM2846DL3-33-TLB

USB CONNECTOR

SW

R5523N001B-TLB

FRONT END

AXF1180-

AV SW

R2S11006FT-K

FAN

FET SW

RTQ040P02-TLB

ADC

AD9985KSTZ-110-K

FET SW

RTQ045N03-TLB

VDEC SDRAM

HY57V161610FTP-7-K

1.8V Reg

NJM2846DL3-18-TLB

HDMI SW

CXB1442R-K

HDMI Rx

SII9125CTU-K

FET SW

MCH3406-TLB

LVDS Tx

BU8254KVT-K

ARIA

UPD61123F1100KA3A-K

ARIA ROM

AGC1050-A-PI-K

(S29GL016A90TFIR2K)

FET SW

UPA1917TE-TRB

MSP

MSP5651M-QK-C2-K

RGB SW

R2S11001FT-K

FPF2007-TLB

2SC4081(QR)-TLB

DDR SDRAM

EDD1232ABBH-5C-E-

DDR SDRAM

EDD1232ABBH-5C-E-

8V Reg

PQ200WNA1ZPH-TLB

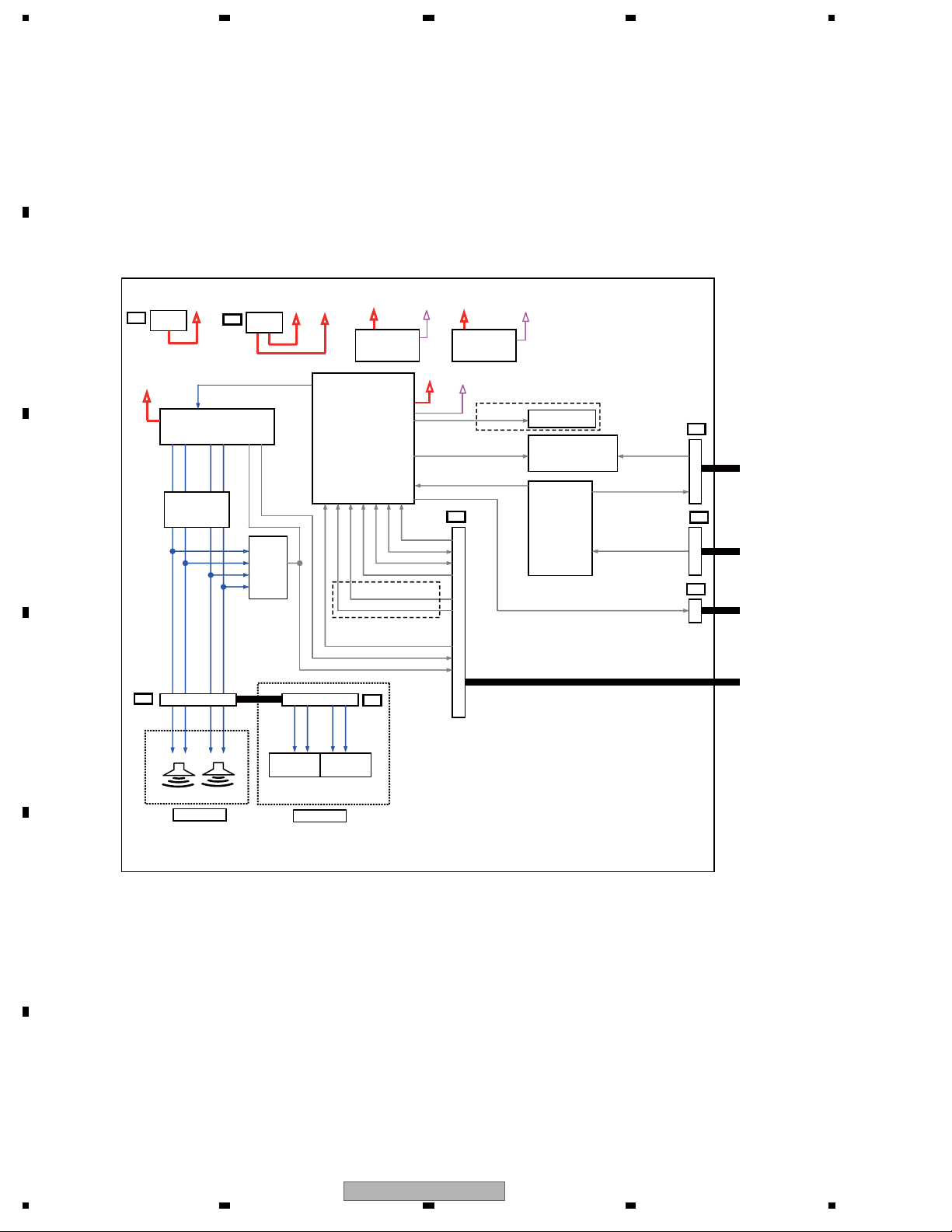

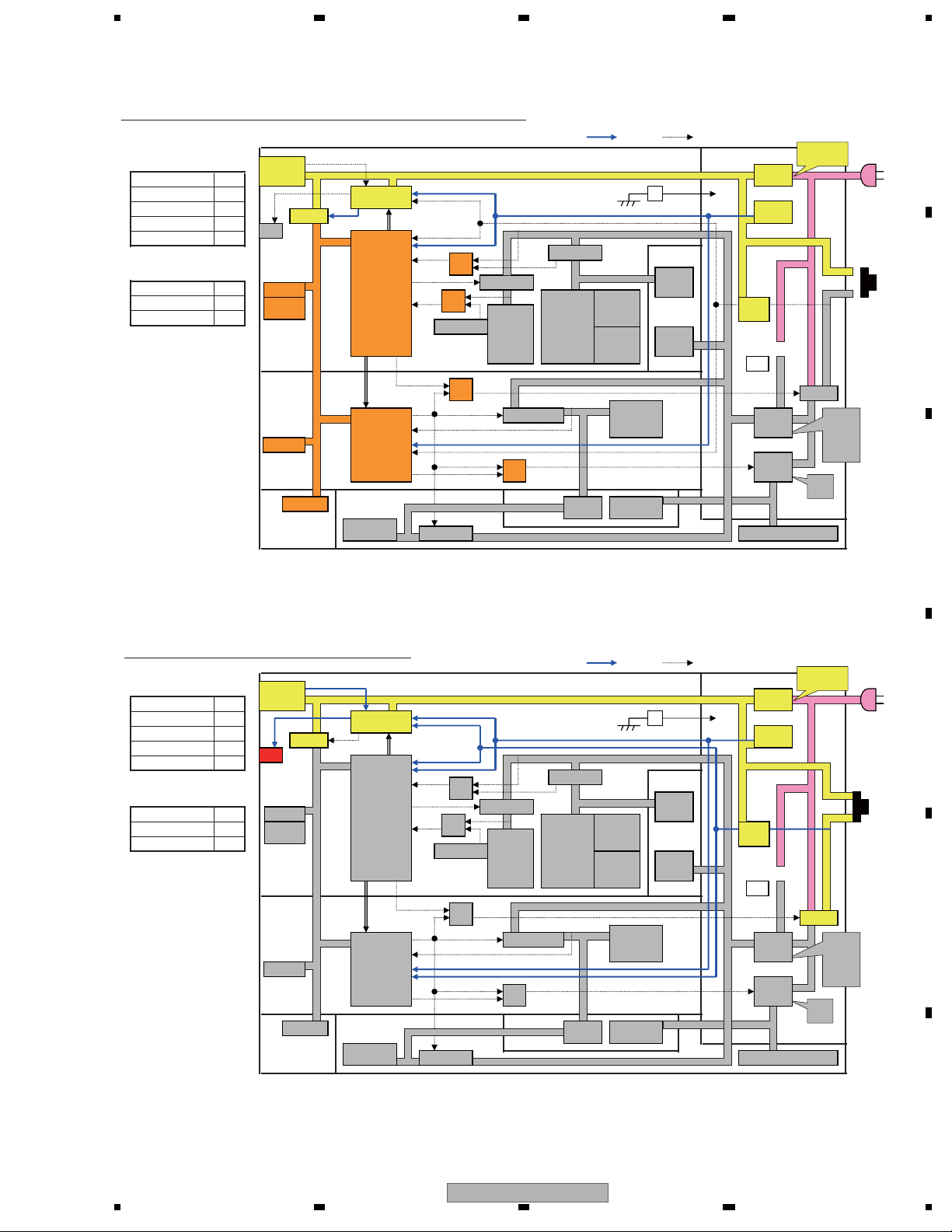

3.4 POWER SUPPLY BLOCK of MULTI BASE SECTION

CN4105

V+6_5V

A

V+12V

B

C

IC4305

V+5_1V

IC4309

IC4403

IC4307

IC4301

IC4310

V+5V_USB

V+5V_ANT

V+3_3V_D

V+5V_A

V+8V_A

FAN_VCC

Q4415

IC6403

V+3_3V_D2

USB1_VBUS

V+5V_A2 V+5V_A2_RGB

V+5V_A_AV

V+8V_A_AV

V+3_3V_D2_VDEC_SDRAM

Q4418

V+3_3V_D3

IC4802

V+3_3V_D3_HDMI

IC4404

IC4601

TANSHI Assy

V+3_3V_AU_D

V+3_3V_D3_HDMI_A

V+3_3V_D3_HDMI_IO

V+3_3V_D3_HDMI_REG

V+3_3V_D3_HDMISW

V+1_8V_A

U6001

IC9191

IC5101

V+1_8V_A_HDMI

ANT_POW_TU

V+31_5V

IC4701

V+3_3V_AU_A

V+1_8V_A_HDMI_A

V+1_8V_A_HDMI_C

V+1_8V_A_HDMI_D

V+8V_AU

V+1_8V_AU

IC4410

Q4306

IC9101

IC5201

D

E

F

IC4401

Q4404

V+1_2V_D V+1_2V_D_ARIA

V+2_5V_D

V+2_5V_D_ARIA

V+3_3V_A__AD V+3_3V_A__AD_A

V+3_3V_A

Q4409

V+3_3V_D4 V+3_3V_D4_LVDS

V+3_3V_A_VDEC

V+3_3V_D4_LVDS_OUT

V+3_3V_D4_LVDS_PLL_A

+3_3V_D4_LVDS_LVDS

V

V+3_3V_D4_ARIA_ROM

V+3_3V_D4_ARIA

V+1_2V_D_ARIA_PLL1

V+1_2V_D_ARIA_PLL2

V+1_2V_D_ARIA_PLL3

V+1_2V_D_ARIA_PLL4

V+VDDIO_ARIA

V+VDDIO_ARIA_DDR_A

V+VDDIO_ARIA_DDR_C

IC4101

IC8204

IC8203

Q4422

IC8401

IC8201

V+1_8V_A_VDEC

V+3_3V_D_AD_D

V+3_3V_A__AD_PLL

PDP-428XDA,PDP-508XDA Only

V+5_1V

V+12V

V+6_5V

V+3_3V_UCOM

IC5001

C

N4014

16

PDP-508XG

1 234

Page 17

CN4106

IF UCOM

AGC1037- -PI-K

(M30620FCSGP-U5-K)

VDEC

CM0048BF-K

FET SW

RSS090P03-TBB

DDC

LTC3407EMSE-

2-TBB

VBI SLICER

TC90173FG-K

EMMA2

UPD61123F1100KA3A-K

DDR DRAM

1:K4H511638D-UCB3-K

2:EDD5116AFTA-6B-E-K

3:HY5DU121622CTP-J

FET SW

MCH3406-TLB

USB CONROLLER

M66596FP-K

FET SW

RTQ040P02-TLB

EMMA2 FLASH ROM

AGC1042- -PI-K

(S29GL032A90TFIR4-

V+35V

V+3_3V_STB

5678

A

IC8301

V+5_1V_STB

V+1_8V_A_VDEC_D

V+1_8V_A_VDEC_PLL

V+3_3V_D2_VDEC_D

Q4512

IC4801

V+3_3V_ACT

IC4501

Q4511

V+2_5V_UCOM

V+1_5V_UCOM

V+3_3V_UCOM_USB

V+3_3V_UCOM_VBI

V+2_5V_UCOM2 V+2_5V_UCOM_VBI

V+2_5V_UCOM_DDR

V+2_5V_EMMA

V+1_5V_UCOM_EMMA

V+3_3V_UCOM

Q4505

V+1_5V_UCOM_USB V+1_5V_UCOM_USB_D

IC8401

V+1_5V_UCOM2

V+1_5V_UCOM_USB_A

V+3_3V_UCOM_USB_D

V+3_3V_UCOM_USB_A

IC8601

V+3_3V_UCOM_ROM

IC6401

IC8602

V+1_5V_UCOM_VBI

IC6301

B

C

D

V+3_3V_A_VDEC_A

PDP-508XG

56

E

F

17

7

8

Page 18

1234

for MAIN ASSY

DIGITAL AMP IC

IC9201

TAS5122DCA

MSP IC

IC9101

MSP5651M

IO3

INPUT1

INPUT2

INPUT3

INPUT6

PC AUDIO

SUB WOOFER OUT

MONITOR OUT

LPF

IO9

IO4

IO1

IO2

OUTPUT(VIDEO)

3.5 TANSHI ASSY

A

TANSHI ASSY XGA BLOCK DIAGRAM

B

IO6

+16.5V

+16.5V

IO5

PWM

+8V

+3.3V

+16.5V

REGULATOR

IC9181

NJM78M12DL1A

+3.3V

+12V

REGULATOR

IC9191

NJM2846DL3

+3.3V

+1.8V

OUTPUT(AUDIO)

INPUT(AUDIO)

+1.8V

*PDP-428XDA,PDP-508XDA only

OPT_OUT

OPTICAL OUT

INPUT(VIDEO)

C

IO8

R_OUT+

R_OUT-

L_OUT+

L_OUT-

DC

DETECT

BLOCK

RST_MSP

I2S_EMMA

SPDIF_EMMA

*PDP-508XDA,PDP-428XDA only

SPDIF_HDMI

OTW

A_NG_B

SDA

AIR_SIF

SCL

HP

INPUT6

for SIDE IO ASSY

for SIDE IO ASSY

for MAIN ASSY

D

E

F

18

R OUT

L OUT

SP TERMINAL

42inch only

50inch only

TANSHI ASS'Y

PDP-508XG

1 234

Page 19

5678

RLS

IC9704

AMS114YD01

OP AMP

IC9703

MM3012XN

MAIN ASSY

CN9501

KEY

S9501 to S9506

MAIN ASSY

CN9701

IR

IC9702

SBX3050-01

3.6 POWER SUPPLY BLOCK of 50LED&IR&RLS and SIDE KEY ASSYS

50LED&IR&RLS ASSY

V+5_1V_STB

V+3_3V_UCOM

A

B

KEY ASSY

V+3_3V_STB

C

D

E

PDP-508XG

56

F

19

7

8

Page 20

1234

4. DIAGNOSIS

DIAGNOSIS of PDP-508XG/DLFT,PDP-508XDA/YP and PDP-508XC/WA5 is the same as PDP-5080XA/WYV5 except for the following:

4.1 POWER SUPPLY OPERATION

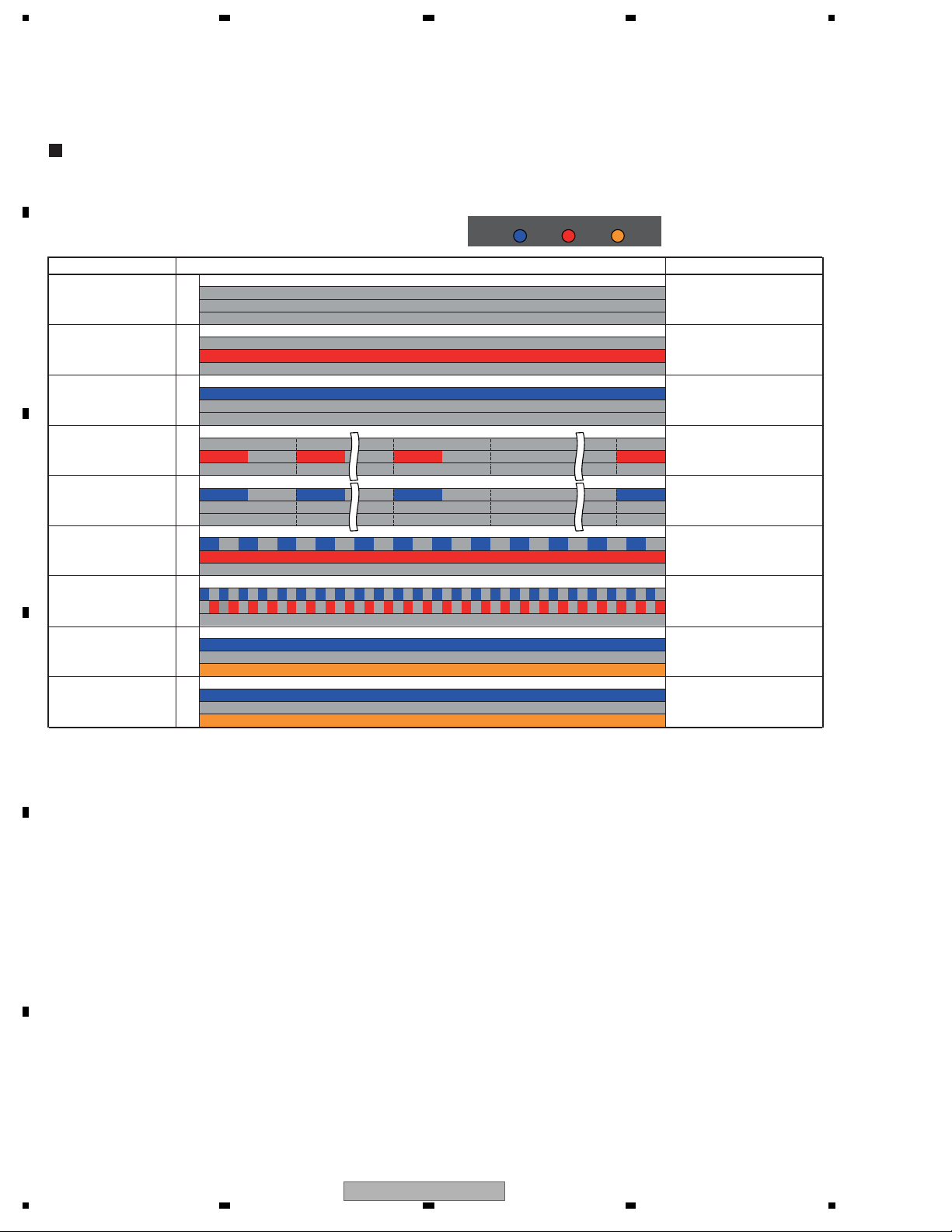

4.1.1 LED DISPLAY INFORMATION

A

LED Pattern

POWER ON STANDBY SLEEP

State

AC OFF or Main

power switch OFF

B

Standby power

management

Power ON

(Screen ON)

Power-down

Shutdown

C

No digital adjustment

data copied for

backup

In the process of

rewriting the program

of the microcomputer

During factory

operation

Sleep timer

D

LED Pattern Remarks

B

R

O

B

R

O

B

R

O

B Once Twice n times 2.5s Once

R 500ms

O

B 500ms

R Once Twice n times 2.5s Once

O

B 200ms

R

O

B 100ms

R 100ms

O

B

R

O

B

R

O

The LEDs flash only while the

panel is turned on.

E

F

20

1 234

PDP-508XG

Page 21

5678

4.1.2 POWER ON SEQUENCE

A

REM

infrared

receiver

Inv. Amp

Q9731

Inv. Amp

Q8302

REM

Inv. Amp

Q4105

SR_OUT

SR_IN

Microcomputer

1

Side Keys

1

IF

IC8301

KEY_1

KEY_2

TXD_IF

RXD_IF

CE_IF

REQ_IF

BUSY_IF

Microcomputer

TXD_MD

RXD_MD

REQ_MD

2

MOD

IC3151

3

MAIN

Microcomputer

IC8401

OR

RELAY2

Power MOD

4

RELAY Control

B

C

SR OUT Jack

JA9404

: The remote control (or KEY) signal is input to the IF microcomputer.

: The IF microcomputer sends the operation data of the remote control unit (or KEY) to the main microcomputer.

: The main microcomputer issues a startup command (PON) to the MOD microcomputer.

: The relay is controlled with logical OR interpretation of control signals by the main microcomputer and module

(MOD) microcomputer.

D

E

F

PDP-508XG

56

21

7

8

Page 22

1234

4.1.3 DETAILS OF POWER ON SEQUENCE

A

Power supply status - AC off

Microcomputer

B

C

output port state

IF: ACTIVE

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

Microcomputer

input port state

Main: RST4

Main: RST2

Module: RST2

IR/Key/

OFF

232C

OFF

OFF

OFF

OFF

OFF

OFF

OFF

LED

EEPROM

VBI/

USB

SW

ACTIVE

Main

EEPROM

Digital

BAK_EEP

X/Y Drive

Scan

Sensor

The state of AC cord is pulled out.

IF ucom

Main_

ucom

Module_

ucom

DRIVE

AC_DET

M_SW_DET

M_SW_DET_B

RST3

RST4

PSW1

RST2

RELAY2

DCDC/REG

AND

AND

EMG_USB

OR

RELAY

DRF_B

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

DCDC/REG

AND

Address

PDET

A.TUNER

A.D.TUNER

A.TUNER

D.TUNER

A.TUNER

D.TUNER

AAC-DEC

USB(Reg.)

ON OFF

DCDC/REG

AV-SW

ASIC

FAN

RGB-SW

AD

VBI

VBI

BCM

BCM

(XDA)

POD

iLink

RST2

LVDS-Rx

DAC

SQ ASIC

ADDRESS

R

I/O

US_SW

MAP

MAP

MSP

D-AMP

Power supply

STB

AC_

DET

M_SW

_DET

Jumper

P11

Vcc

Vsus

Vadr

DRIVE/SCAN

V+3.3V_STB

V+5.1V_STB

Relay

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

VSUS

VADR

Main

Switch

AC

Power supply status - Passive standby (Main switch off)

Microcomputer

D

E

F

output port state

IF: ACTIVE

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

Microcomputer

input port state

Main: RST4

Main: RST2

Module: RST2

IR/Key/

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

232C

LED

EEPROM

VBI/

USB

Main

EEPROM

Digital

Sensor

SW

BAK_EEP

IF ucom

ACTIVE

Module_

X/Y Drive

Scan

DRIVE

Main_

ucom

ucom

"kill me"

M_SW_DET_B

PSW1

RST2

RELAY2

AC_DET

M_SW_DET

RST3

RST4

AND

EMG_USB

RELAY

DCDC/REG

AND

OR

DRF_B

The user operation is invalid. (All LED: OFF)

Among standby power devices, only the IF microcomputer periphery operates.

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

DCDC/REG

AND

Address

PDET

A.TUNER

A.D.TUNER

A.TUNER

D.TUNER

A.TUNER

D.TUNER

AAC-DEC

USB(Reg.)

ON OFF

DCDC/REG

AV-SW

VBI

VBI

BCM

BCM

(XDA)

POD

iLink

RST2

FAN

RGB-SW

AD

LVDS-Rx

DAC

SQ ASIC

ADDRESSASIC

R

I/O

US_SW

MAP

MAP

MSP

D-AMP

Power supply

M_SW

_DET

Jumper

P11

Vsus

Vadr

DRIVE/SCAN

STB

AC_

DET

Vcc

V+3.3V_STB

V+5.1V_STB

Relay

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

VSUS

VADR

AC

Main

Switch

22

PDP-508XG

1 234

Page 23

5678

Power supply status - Active standby (Main switch off)

Microcomputer

output port state

IF: ACTIVE

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

Microcomputer

input port state

Main: RST4

Main: RST2

Module: RST2

IR/Key/

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

232C

LED

EEPROM

VBI/

USB

Main

EEPROM

Digital

Sensor

SW

BAK_EEP

IF ucom

ACTIVE

Module_

X/Y Drive

Scan

DRIVE

Main_

ucom

ucom

AC_DET

M_SW_DET

M_SW_DET_B

RST3

RST4

PSW1

RST2

RELAY2

DCDC/REG

AND

AND

EMG_USB

OR

RELAY

DRF_B

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

AND

Address

The user operation is invalid. (All LED: OFF)

Standby power devices (periphery of IF/Main/Module microcomputer) operate.

PDET

DCDC/REG

ON OFF

DCDC/REG

A.TUNER

A.D.TUNER

D.TUNER

A.TUNER

A.TUNER

VBI

VBI

D.TUNER

BCM

BCM

(XDA)

POD

iLink

AAC-DEC

USB(Reg.)

RST2

AV-SW

FAN

RGB-SW

AD

LVDS-Rx

SQ ASIC

ADDRESSASIC

DAC

R

I/O

US_SW

MAP

MAP

MSP

D-AMP

Power supply

STB

AC_

DET

M_SW

_DET

Jumper

P11

Vcc

Vsus

Vadr

DRIVE/SCAN

V+3.3V_STB

V+5.1V_STB

Relay

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

VSUS

VADR

AC

Main

Switch

A

B

C

Power supply status - Passive standby

Microcomputer

output port state

IF: ACTIVE

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

Microcomputer

input port state

Main: RST4

Main: RST2

Module: RST2

IR/Key/

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

232C

LED

EEPROM

VBI/

USB

SW

ACTIVE

IF ucom

Main_

ucom

"kill me"

Main

EEPROM

Module_

ucom

Digital

BAK_EEP

Sensor

X/Y Drive

Scan

DRIVE

Remote control unit waiting state. (Red LED: ON)

Among standby power devices, only the IF microcomputer periphery operates.

AC_DET

M_SW_DET

M_SW_DET_B

RST3

RST4

PSW1

RST2

RELAY2

DCDC/REG

AND

AND

EMG_USB

OR

RELAY

DRF_B

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

DCDC/REG

AND

Address

PDET

A.D.TUNER

A.TUNER

D.TUNER

USB(Reg.)

ON OFF

DCDC/REG

A.TUNER

D.TUNER

A.TUNER

(XDA)

iLink

AAC-DEC

RST2

VBI

VBI

BCM

BCM

POD

AV-SW

RGB-SW

ASIC

FAN

AD

LVDS-Rx

SQ ASIC

ADDRESS

DAC

R

I/O

US_SW

MAP

MAP

MSP

D-AMP

Power supply

M_SW

_DET

Jumper

P11

V+3.3V_STB

V+5.1V_STB

STB

AC_

DET

Vcc

Vsus

Vadr

DRIVE/SCAN

Relay

VSUS

VADR

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

AC

Main

Switch

D

E

F

PDP-508XG

56

23

7

8

Page 24

1234

A

Power supply status - Active standby

Microcomputer

output port state

IF: ACTIVE

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

ON

OFF

OFF

OFF

OFF

IR/Key/

232C

LED

SW

Microcomputer

input port state

Main: RST4

Main: RST2

B

Module: RST2

OFF

OFF

OFF

EEPROM

VBI/

USB

Main

EEPROM

Digital

C

BAK_EEP

Sensor

Remote control unit waiting state. (Red LED: ON)

Standby power devices (periphery of IF/Main/Module microcomputer) operate.

IF ucom

ACTIVE

Main_

ucom

"POF"

Module_

ucom

X/Y Drive

Scan

DRIVE

AC_DET

M_SW_DET

M_SW_DET_B

RST3

RST4

PSW1

RST2

RELAY2

DCDC/REG

AND

AND

EMG_USB

OR

RELAY

DRF_B

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

DCDC/REG

AND

Address

PDET

A.TUNER

A.D.TUNER

A.TUNER

D.TUNER

A.TUNER

D.TUNER

AAC-DEC

USB(Reg.)

ON OFF

DCDC/REG

AV-SW

VBI

VBI

BCM

BCM

(XDA)

POD

iLink

RST2

FAN

RGB-SW

AD

LVDS-Rx

DAC

SQ ASIC

ADDRESSASIC

R

I/O

US_SW

MAP

MAP

MSP

D-AMP

Power supply

M_SW

_DET

Jumper

P11

V+3.3V_STB

V+5.1V_STB

STB

AC_

DET

Vcc

Vsus

Vadr

DRIVE/SCAN

Relay

VSUS

VADR

Power

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

AC

Main

Switch

Power supply status - Functional standby

Microcomputer

D

E

F

output port state

IF: ACTIVE

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

Microcomputer

input port state

Main: RST4

Main: RST2

Module: RST2

IR/Key/

ON

232C

ON

OFF

OFF

OFF

ON

OFF

OFF

LED

EEPROM

VBI/

USB

SW

ACTIVE

Main

EEPROM

Digital

BAK_EEP

X/Y Drive

Scan

Sensor

Remote control unit waiting state. (Red LED: ON)

Standby power device and some Vcc power devices operate.

RGB-SW/AD/D-AMP are electrified, but uses the power-saving mode function of the IC.

IF ucom

Main_

ucom

"POF"

Module_

DRIVE

ucom

AC_DET

M_SW_DET

M_SW_DET_B

RST3

RST4

PSW1

RST2

EMG_USB

RELAY2

RELAY

DCDC/REG

AND

AND

OR

DRF_B

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

DCDC/REG

AND

Address

PDET

DCDC/REG

A.TUNER

A.D.TUNER

A.TUNER

D.TUNER

A.TUNER

D.TUNER

iLink

AAC-DEC

USB(Reg.)

RST2

ON OFF

AV-SW

VBI

VBI

BCM

BCM

(XDA)

POD

FAN

RGB-SW

AD

LVDS-Rx

SQ ASIC

ADDRESSASIC

DAC

R

I/O

D-AMP

US_SW

MAP

MAP

MSP

Power supply

STB

AC_

DET

M_SW

_DET

Jumper

P11

Vcc

Vsus

Vadr

DRIVE/SCAN

V+3.3V_STB

V+5.1V_STB

Relay

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

VSUS

VADR

AC

Main

Switch

24

PDP-508XG

1 234

Page 25

5678

Power supply status - ON

Microcomputer

output port state

IF: ACTIVE ON

Main: RELAY2

Main: PSW1

Module: RELAY

Module: DRF_B

Microcomputer

input port state

Main: RST4

Main: RST2

Module: RST2

IR/Key/

232C

ON

ON

ON

ON

ON

ON

ON

LED

EEPROM

VBI/

USB

Main

EEPROM

Digital

BAK_EEP

Sensor

SW

A state when it displays a picture on the PDP. (Blue LED: ON)

All devices are electrified.

IF ucom

ACTIVE

Module_

X/Y Drive

Scan

DRIVE

Main_

ucom

"PON"

ucom

AC_DET

M_SW_DET

M_SW_DET_B

RST3

RST4

PSW1

RST2

EMG_USB

RELAY2

RELAY

DCDC/REG

AND

AND

OR

DRF_B

DCDC/REG

VDEC

HDMI

ASIC

LVDS-Tx

DCDC/REG

AND

Address

PDET

ON

DCDC/REG

A.TUNER

D.TUNER

(XDA)

RST2

ASIC

AV-SW

FAN

RGB-SW

AD

LVDS-Rx

SQ ASIC

ADDRESS

DAC

OFF

R

I/O

MSP

D-AMP

US_SW

Power supply

STB

M_SW

_DET

Jumper

P11

Vsus

Vadr

DRIVE/SCAN

AC_

DET

Vcc

V+3.3V_STB

V+5.1V_STB

Relay

V+35V

V+16.5V

V+12V

V+6.5V

V+5.1V

VSUS

VADR

AC

Main

Switch

A

B

C

D

E

F

PDP-508XG

56

25

7

8

Page 26

1234

4.2 DIAGNOSIS FLOWCHART OF FAILURE ANALYSIS

4.2.1 VIDEO SYSTEM

A

Flowchart of Failure Analysis for The Video System

=> MA3

The input signal is not displayed.

Is the Terrestrial analog signal

not displayed?

B

Is the composite signal input not

displayed?

Is the S-video signal input not

displayed?

Is the component signal input not

displayed?

Is the PC signal input not

C

displayed?

Is the Terrestrial digital signal

not displayed?

Is the HDMI signal input not

displayed?

D

No

No

No

No

No

No

No

Ye s

=> ATV

Ye s

=> COMP / S1

Ye s

=> COMP / S1

Ye s

=> COMP / PC1

Ye s

=> COMP / PC2

Ye s

=> DTV

Are the data displayed on the

Ye s

"HDMI SIGNAL INFO" page of

the Factory menu correct?

Ye s

• PDP-428XDA and PDP-508XDA Only

After changing the source

No

equipment, check the "HDMI

SIGNAL INFO" data again.

OK

The source equipment previously

used is in failure.

No problem with the MAIN Assy.

NG

Replace the MAIN Assy.

No problem with the MAIN Assy.

E

F

26

Does the result of SIG mode

detection on the Factory menu

coincide with the input signal data?

Ye s

Replace the MAIN Assy.

No

Is the sync signal output from

IC5201?

Ye s

Is the sync signal input to IC8001?

Ye s

Replace the MAIN Assy.

No

Replace the MAIN Assy.

No

Replace the MAIN Assy.

PDP-508XG

1 234

Page 27

5678

4.2.2 AUDIO SYSTEM

Flowchart of Failure Analysis for The Audio System

=> AU1

Has the sound been emitted from

the speakers?

Ye s

No

Is sound muting set?

No

Is the volume set to 0?

No

Is not headphone inserted?

Ye s

Sound of all functions does not

output?

Ye s

Check the speakers and speaker

cables. Is it no problem?

Ye s

Is a voltage (+16.5 V) supplied to

IC9201?

Ye s

Is not a signal output from

CN9251? (pins 2, 4, 5, 7)

Ye s

42 43

Ye s

Cancel muting, then check again.

Ye s

Raise the volume, then check again.

No

Pull out headphone, then check

again.

No

Go to .

A

No

Replace the speakers or speaker

cables.

No

Check the cables (CN8806) from the main power and peripheral circuit.

Repair the failure points.

No

Check the CN9251 and peripheral circuit.

Repair the failure points.

A

B

C

Has the sound been emitted from

the Audio out terminal?

Ye s

Is not a PWM signal output from

IC9201?

(pins 34, 38, 46, 50)

Ye s

Is not a PWM signal output from

IC9101?

(pins 52, 53, 54, 55)

Ye s

Is a signal input to IC9101?

(pins 24, 25)

Ye s

Has I2C communication signal

arrived at IC9101?

No

Is a 12 V output from +12V_Reg

output of IC9181 normal?

Ye s

Are signals input to IC9151?

(pins 2, 3, 5, 6)

Ye s

Are signals output from IC9151?

(pins 1, 7)

44 45

46 47

48

49 50

51

No

Check between the LPF (L9255, L9256) and CN9251.

Repair the failure points.

No

Check the IC9101 and peripheral circuit.

Repair the failure points.

No

Check between the input terminals and IC9101.

Repair the failure points.

Check the peripheral circuits, the communication with the microcomputer

No

and X9101 clock output. If there was no ploblem replace the MSP5651M.

Check the IC9181 and peripheral circuit.

Repair the failure points.

Check the peripheral circuits and the communication with the

microcomputer. If there was no ploblem replace the MSP5651M.

Check the IC9151 and peripheral circuit.

Repair the failure points.

D

E

B

PDP-508XG

56

F

27

7

8

Page 28

1234

A

B

Has the sound been emitted from

the Headphones?

B

C

No

Is sound muting set?

No

Is the volume set to 0?

No

Is a signal output from IC9101?

(pins 38, 39)

Ye s

Is a signal output from IC8871?

(pins 1, 7)

Ye s

Check the cables between CN8802

and CN9352 or check around the

Headphones jack.

52

53

Ye s

Cancel muting, then check again.

Ye s

Raise the volume, then check again.

No

Check around the IC9101

Check the communications around the IC8871 and between the IC8871

No

and r

epair the failure points

.

and the microcomputer. If there was no ploblem, replace BH3544F.

NG

Replace the cables or SIDE IO Assy.

Waveforms

Input signal: L/R 1 kHz, 0.5 Vrms (VOL 30)

CN9251 - pins 2, 4

42 43

V: 2 V/div H: 1 mS/div

D

IC9101 - pins 54, 55

47 48

V: 2 V/div H: 5 μS/div

IC9101 - pins 38, 39

52 53

E

V: 1 V/div H: 1 mS/div

CN9251 - pins 5, 7

V: 2 V/div H: 1 mS/div

IC9101 - pins 24, 25

V: 2 V/div H: 1 mS/div

IC8871 - pins 1, 7

V: 1 V/div H: 1 mS/div

IC9201 - pins 34, 38

44

V: 10 V/div H: 5 μS/div

IC9151 - pins 2, 3

49

V: 2 V/div H: 1 mS/div

IC9201 - pins 44, 52

45

V: 10 V/div H: 5 μS/div

IC9151 - pins 5, 6

50

V: 2 V/div H: 1 mS/div

IC9101 - pins 52, 53

46

V: 2 V/div H: 5 μS/div

IC9151 - pin 1, etc.

51

V: 2 V/div H: 1 mS/div

F

28

1 234

PDP-508XG

Page 29

5678

A

Has the sound of the Analog

broadcasting output?

Ye s

Has the sound of the HDMI

output?

Ye s

Has the sound of the Digital

broadcasting output?

Ye s

Is a SIF signal input to IC9101?

No

(pin 68)

Ye s

Check the communications around the IC9101 and between the IC9101

and the microcomputer. If there was no ploblem, replace MSP5651M.

Is a SPDIF signal output from

No

IC5201? (pin 78)

Ye s

Is a SPDIF signal input to

IC9101? (pin 4)

Ye s

Check that the HDMI switch of the

MENU is properly set.

Check the FFC and cables between

No

the MAIN Assy and TANSHI Assy.

Does not sound output even if replace

them?

No

Is a I2S signal input to IC9101?

(pins 106 to 108)

Ye s Ye s

Check the communications around the

IC9101 and between the IC9101 and

the microcomputer. If there was no

ploblem replace the MAIN Assy.

55

54

54

5756

Check the communications between

No

the U6001 and the microcomputer

and between the U6001 and IC9101.

No

Replace the IC5201.

Poor contact of the connector or FFC, or cable is defective.

No

Replace FFC or cable.

NG

Check the communications around the IC9101 and between the IC9101

and the microcomputer. If there was no ploblem, replace MSP5651M.

Poor contact of the connector or

Ye s

FFC, or cable is defective.

Replace FFC or cable.

No

Is a signal output from IC8401 of

the MAIN Assy?

Check around IC8401

the failure points

A

NG

Replace the U6001

epair the failure points

r

No

Repare the DTB block.

and r

.

epair

and

.

B

C

DTV model only

Has the sound of the analog RCA

and PC inputs output?

Ye s

Has the sound of the side input

output?

Waveforms

Input signal: L/R 1 kHz, 0.5 Vrms (VOL 30)

IC5201 - pin 78

54

V: 1 V/div H: 1 μS/div

Is a signal input to IC9101?

No

(pins 24 to 27, 32 to 35)

Ye s

Check the communications around the IC9101 and between the IC9101

and the microcomputer. If there was no ploblem replace the MAIN Assy.

Check the cables between CN8801

No

and CN9351, and check around

the pin jack.

OK

Is a signal input to IC9101?

(pins 30, 31)

Ye s

Check the communications around the IC9101 and between the IC9101

and the microcomputer. If there was no ploblem replace the MAIN Assy.

IC9101 - pin 106

55 56 57

V: 1 V/div H: 10 μS/div

IC9101 - pin 107

V: 1 V/div H: 10 μS/div

No

Check between input terminal and

and r

5049

5049

IC9101

NG

Replace the cables.

Check between IC9101 and

No

CN8801

epair the failure points

and r

epair the failure points

.

.

IC9101 - pin 108

V: 1 V/div H: 10 μS/div

D

E

F

PDP-508XG

56

29

7

8

Page 30

1234

4.3 DIAGNOSIS OF SD (SHUTDOWN)

4.3.1 SD (SHUTDOWN) DIAGNOSIS

A

Remarks

B

unication lines (SCL_EP/SDA_EP).

SQ_IC communication not established. IC3401 may not have properly started up.

A shutdown occurs if IC3401 has not properly started up (a communication failure between IC3401 and IC3306 [FLASH]).

Check the pull-up resistor of the IIC control line and the power to the corresponding IC.

Check the pull-up resistor of the IIC control line and the power to the corresponding IC.

memory does not coincide with the actual SEQ-PROG.

Check the pull-up resistor of the IIC control line and the power to the corresponding IC.

A shutdown occurs if the SEQ-PROG that has been stored in backup

Check the pull-up resistor of the IIC control line and the power to the corresponding IC.

If RST2 does not become high after the unit is turned on, a shutdown will be generated in several seconds.

–20°C or less. Also check the connection with the SENSOR Assy.

Check if V + 12 V is started. Also check if the FU3601 on the DIGITAL Assy has been melted.

If TEMP1 that is read by the module microcomputer is 75°C or higher, a shutdown will be generated.

A shutdown occurs if the reading of TEMP1 detected by the module microcomputer is

Check if cables are firmly connected.

Check the communication lines (TXD_IF/RXD_IF/CLK_IF/BUSY_IF/CE_IF/REQ_IF).

Check the communication lines (TXD_MOD/RXD_MOD/REQ_MOD).

Check if any speaker cable is in contact with the chassis.

Check the communication lines (TXD_IC3/RXD_IC3).

Check the communication lines (TXD_IF/RXD_IF/CLK_IF/BUSY_IF/CE_IF/REQ_IF).

Check if cables are firmly connected.

Check the comm

Part

CN3001, IC3001,IC3401

IC3306, IC3151 The written SEQ-PROG is incoherent with data on the DIGITAL Assy.

C

Possible Defective

IC3401, IC3151 If BUSY_SQ remains high, a shutdown is generated.

IC3401, IC3151

IC3652, IC3151

IC3306, IC3151

POWER SUPPLY Unit,FU3601

IC3157, IC3151

IC3158, IC3151

SENSOR Assy (IC3651)

SENSOR Assy (IC3651)

JA9301

CN8803,CN4001,CN8806,P5

IC8301, IC8401

IC8001, IC8401

IC8301, IC8401

CN9551 to CN9555,CN4103,CN4108

–IC8401 Check if DTV antenna is short-circuited.

–– –

IC8404, IC8401

Checkpoint

D

Check if the video sync signal is input to IC3401.

SQNO

RTRY CLK_SQ/TXD_SQ, etc.

MAIN SUB

Log Indication in Factory Mode

BUSY_SQ

VER-HS

BUSY

SQ-LSI

Check the model number of the DIGITAL Assy and the destination of SEQ-PROS.

IIC communication line of IC3652

Check the model number of the DIGITAL Assy and the

destination of SEQ-PROS.

VER-MS

EEPROM IIC communication line of IC3156 IC3156, IC3151

MD-IIC

The 12 V power is not output.

High temperature abnormality in the panel temperature sensor

IIC communication line of IC3157

IIC communication line of IC3158

Low temperature abnormality in the panel temperature sensor

Is the output voltage of the DC-DC converter low? IC3602(BD9302FP)

TMP-H

TMP-L

TMP-NG

Periphery of the cable between IO3 and M8, and IO6 and P5

Speaker terminals

AUDIO_AMP IC9201, IC9101 Check if the AMP output is short-circuited.

Communication line between MAIN and MOD IC3151, IC8401

Periphery of the cable between D11 and M1 CN3001, CN4101 Check if cables are firmly connected.

Communication line between IF and MAIN

IF

Communication line between MULTI and MAIN

MULTI

MA-3L

Periphery of the cable between FA1 and M5, FAN and M4, and FA2 and FA5

Periphery of the fan control regulator IC4310, IC4303 –

Temperature sensor or its periphery – TEMP2 A shutdown occurs because of high temperature.

Periphery of the temperature sensor TH9091 TEMP2

Communication line between IF and MAIN

Dirt attached to the fan motor – Check the fan(AXM1057).

Periphery of the FAN CONNECT AWW1290, AWW1329 FAN NG

FE1 IIC communication line between Tuner and MAIN U6001,IC8401,IC6101 Check the communication lines (SCL_TU/SDA_TU or SCL_AV5/SDA_AV5).

MA-IIC

FAN1

MAIN –

FAN

Periphery of the cable between IO4 and M6 CN8804, CN4004 Check if cables are firmly connected.

PS/RST

TEMP2 –

DTUNER

RETRY

DC-DC converter or its periphery, RST2 IC4403, Q4404 Check if V + 3.3 V_D4 is started.

EMG_USB IC4309 Check if the voltage at a waveform check point is 5 V.

M-DCDC

The 12 V power is not output, RST4 POWER SUPPLY Unit Check if V + 12 V is started.

RST-MA

The 6.5 V power is not outputPOWER SUPPLY Unit Check if V + 6.5 V is started.

The 5.1 V power is not outputPOWER SUPPLY Unit Check if V + 5.1 V is started.

EMG_DDC DCDC converter Check if the DCDC converter is overloaded.

Periphery of the cable between P8 and M3 CN4105 Check if cables are firmly connected.

IIC communication line between EEPROM and MAIN

–

MA-EEP

E

Drive stop

Busy

Incoherent version (hardware, software)

Incoherent version (memory,

software)

Communication error

DIGITAL Assy EEPROM

SENSOR Assy EEPROM BACKUP

– RST2 –

–

DAC1 DAC1

DAC2 DAC2

– MODULE –

– AUDIO –

RGB switch RGB-SW IIC communication line between RGB-SW and MAIN IC4701, IC8401 Check the communication lines (SCL_AV5/SDA_AV5).

VDEC VDEC IIC communication line between M-VDEC and MAIN IC4801, IC8401 Check the communication lines (SCL_MB/SDA_MB).

MULTI processor

IF microcomputer

Tuner 1

MSP/MAP MSPMAP IIC communication line between MSP/MAP and MAIN IC9101, IC8401 Check the communication lines (SCL_AV/SDA_AV).

VDEC SDRAM SDRAM IIC communication line between VDEC and SDRAM IC4801, IC4802 Check the communication lines (SDRAM). Defective SDRAM

AV switch AV-SW IIC communication line between AV-SW and MAIN IC4601, IC8401 Check the communication lines (SCL_AV5/SDA_AV5).

AD/PLL ADC IIC communication line between ADC and MAIN IC5001, IC8401 Check the communication lines (SCL_AV/SDA_AV).

HDMI HDMI IIC communication line between HDMI_RX and MAIN IC5201, IC8401 Check the communication lines (SCL_MB/SDA_MB).

–

FAN1

–

DTV startup error

DTV communication error

DC-DC Converter power decrease

POWER SUPPLY RELAY

Main EEPROM communication error

Major Type Detailed Type

High temperature of the

Abnormality in the

Sequence LSI

Failure in IIC

communication with the

module microcomputer

Abnormality in RST2

power decrease

Abnormality in panel

temperature

Short-circuiting of the

speakers / D-AMP

temperature abnormality

the module microcomputer

Failure in main

microcomputer 3-wire

serial communication

Failure in IIC

communication with the

main microcomputer

Fail ure in communication

with the main microcomputer

Fail ure in communication with

F

30

Frequency of

Blue 1

LED Flashing

Blue 2

Blue 3

Blue 4

Blue 5

Blue 6

Blue 7

Blue 8

PDP-508XG

Blue 9

Blue 10 FAN NG

unit

Blue 11

Digital Tuner

Blue 12

(PDP-508XDA only)

Failure in the power

supply

Blue 13

Main EEPROM

Blue 15

1 234

Page 31

5678

4.4 NON-FAILURE INFORMATION

4.4.1 INFORMATION ON SYMPTOMS THAT DO NOT CONSTITUTE FAILURE

Information on symptoms that do not constitute failure

Symptom Cause, item to check, information

HDMI: Symptoms concerning the input format and settings

The picture color for an INPUT 3 or 4 or 5 signal is not

correct.

The video signal to INPUT 3 or 4 or 5 is not displayed, and a

message is displayed.

The audio signal input to the INPUT 3 is not output.

No HDMI signal is input.

The color setting for INPUT 3 or 4 or 5 is not compatible with that of the output equipment.

Check whether the color setting is YPbPr or RGB.

A unsupported video signal is input.

The audio setting for INPUT 3 is any setting and a video signal is not input. If the audio setting is

any setting to output an analog audio signal, the HDMI signal must be input. (If a DVI device is to

be connected, use a DVI-HDMI conversion cable.) If the HDMI video signal is not input, the

analog audio signal is not output.

A

No sound of signals to INPUT 3 or 4 or 5 is output.

The 1080p input signal is not displayed properly or at all,

although the 1080i input signal is displayed properly.

MONITOR video output

The video output signal from the MONITOR output is

deteriorated. Or when the video output signal from the MONITOR

output is recorded, its playback picture is deteriorated.

The video signal is not output when the component signal is

input to INPUT 1 or 2.

The video signal is not output when the video signal is input

to INPUT 3 or 4 or 5.

MONITOR audio output

The image displayed on the PDP is not synchronized with the

sound from the MONITOR audio output.

DIGITAL OUT (PDP-508XDA only)

Playback of the signal from the DIGITAL audio output

connector is possible, but recording is not possible.

The digital audio output signal from the DIGITAL connector is

not synchronized with that from the MONITOR video output.

Miscellaneous

The no-signal off function is not activated.

The no-operation off function is not activated.

Power management does not function.

The AUTO SETUP function is not activated.

The audio signal from the PC is not output.

Control via the SR connector is not possible. Wrong connection of the cable to the PC INPUT (AUDIO) connector is suspected.