Page 1

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2010

DVD AV RECEIVER

ORDER NO.

CRT4537

AVH-P5200BT/XNUC

AVH-P5200BT

AVH-P5250BT

AVH-P5200DVD

AVH-P5250DVD

AVH-P5250DVD

AVH-P5250DVD

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-3268 CRT4534 MS7 DVD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

/XNRD

/XNUC

/XNRC

/XNRD

/XNRI

/XNUC

For details, refer to "Important Check Points for Good Servicing".

K-ZZZ. MAR. 2010 Printed in Japan

Page 2

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

CAUTION:

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

- Safety Precautions for those who Service this Unit.

When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

CAUTION

CLASS 1M INVISIBLE LASER RADIATION WHEN OPEN. DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

2. During repair or tests, do not view laser beam for 10 seconds or longer.

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

Laser diode characteristics

Wave length:

DVD:660 nm to 670 nm

CD:780 nm to 800 nm

Focus lens on Maximum output:

CD:6.26 mW(Emitting period :9 sec.)

DVD:1.27 mW (Emitting period : unlimited)

Additional Laser Caution

Transistors Q1103 and Q1104 in PCB drive the laser diodes for DVD and CD

respectively. When Q1103 or Q1104 is shorted between their terminals,

the laser diodes for DVD or CD will radiate beam. If the top cover is removed

with no disc loaded while such short-circuit is continued, the naked eyes may

be exposed to the laser beam.

CAUTION

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or

other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

2

AVH-P5200BT/XNUC

Page 3

5678

56

7

8

C

D

F

A

B

E

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replaced only with the same or equivalent type recommended by the manufacture.

Discord used batteries according to the manufacture's instructions.

AVH-P5200BT/XNUC

3

Page 4

1234

1234

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

4

AVH-P5200BT/XNUC

Page 5

5678

56

7

8

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION .....................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................................................................6

1.1 SERVICE PRECAUTIONS.........................................................................................................................6

1.2 NOTES ON SOLDERING...........................................................................................................................7

2. SPECIFICATIONS.............................................................................................................................................8

2.1 SPECIFICATIONS ......................................................................................................................................8

2.2 DISC/CONTENT FORMAT.......................................................................................................................14

2.3 PANEL FACILITIES ..................................................................................................................................15

2.4 CONNECTION DIAGRAM........................................................................................................................17

3. BASIC ITEMS FOR SERVICE........................................................................................................................24

3.1 CHECK POINTS AFTER SERVICING.....................................................................................................24

3.2 PCB LOCATIONS.....................................................................................................................................25

3.3 JIGS LIST.................................................................................................................................................27

3.4 CLEANING ...............................................................................................................................................28

4. BLOCK DIAGRAM ..........................................................................................................................................30

4.1 OVERALL CONNECTION DIAGRAM......................................................................................................30

4.2 BLOCK DIAGRAM....................................................................................................................................32

5. DIAGNOSIS ....................................................................................................................................................40

5.1 OPERATIONAL FLOWCHART.................................................................................................................40

5.2 INSPECTION METHOD OF PICKUP UNIT .............................................................................................41

5.3 DIAGNOSIS FLOWCHART......................................................................................................................44

5.4 ERROR CODE LIST.................................................................................................................................62

5.5 CONNECTOR FUNCTION DESCRIPTION .............................................................................................66

6. SERVICE MODE.............................................................................................................................................67

6.1 DVD TEST MODE ....................................................................................................................................67

6.2 MONITOR TEST MODE...........................................................................................................................78

7. DISASSEMBLY...............................................................................................................................................88

8. EACH SETTING AND ADJUSTMENT..........................................................................................................103

8.1 DVD ADJUSTMENT...............................................................................................................................103

8.2 DVD AMP UNIT ADJUSTMENT.............................................................................................................108

8.3 MONITOR PCB ADJUSTMENT.............................................................................................................110

9. EXPLODED VIEWS AND PARTS LIST........................................................................................................112

9.1 PACKING................................................................................................................................................112

9.2 EXTERIOR(1).........................................................................................................................................114

9.3 EXTERIOR(2).........................................................................................................................................116

9.4 EXTERIOR(3).........................................................................................................................................118

9.5 EXTERIOR(4).........................................................................................................................................120

9.6 DVD MECHANISM MODULE.................................................................................................................124

10. SCHEMATIC DIAGRAM..............................................................................................................................126

10.1 DVD AMP UNIT(ANALOG PART) ........................................................................................................126

10.2 DVD AMP UNIT(SYSTEM PART)(GUIDE PAGE)................................................................................128

10.3 DVD AMP UNIT(POWER SUPPLY PART)...........................................................................................134

10.4 DVD AMP UNIT(MMD PART)(GUIDE PAGE)......................................................................................136

10.5 DVD AMP UNIT(I/F PART)(GUIDE PAGE)...........................................................................................142

10.6 TUNER BOX UNIT ...............................................................................................................................148

10.7 DVD CORE UNIT(MS7)(GUIDE PAGE) ...............................................................................................150

10.8 COMPOUND UNIT(A) AND COMPOUND UNIT(B).............................................................................156

10.9 PANEL PCB..........................................................................................................................................158

10.10 KEYBOARD PCB ...............................................................................................................................160

10.11 MONITOR PCB(MONITOR PART)(GUIDE PAGE).............................................................................162

10.12 MONITOR PCB(BACKLIGHT PART) .................................................................................................168

10.13 BT PCB AND BT ANT PCB................................................................................................................170

10.14 DRIVE UNIT .....................................................................................................................

..................172

10.15 WAVEFORMS.....................................................................................................................................174

11. PCB CONNECTION DIAGRAM ..................................................................................................................176

11.1 DVD AMP UNIT ....................................................................................................................................176

11.2 TUNER BOX UNIT................................................................................................................................180

11.3 DVD CORE UNIT(MS7)........................................................................................................................182

11.4 COMPOUND UNIT(A) AND COMPOUND UNIT(B) .............................................................................186

11.5 PANEL PCB..........................................................................................................................................188

11.6 KEYBOARD PCB..................................................................................................................................189

11.7 MONITOR PCB.....................................................................................................................................190

11.8 BT PCB.................................................................................................................................................194

11.9 BT ANT PCB.........................................................................................................................................195

11.10 DRIVE UNIT........................................................................................................................................196

12. ELECTRICAL PARTS LIST.........................................................................................................................197

AVH-P5200BT/XNUC

5

Page 6

1234

1234

C

D

F

A

B

E

1. SERVICE PRECAUTIONS

1. You should conform to the regulations governing the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by electrostatic

induction.

3. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors during

power-on mode may damage the ICs inside the unit.

4. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY" .

5. After replacing the pickup unit, be sure to skew adjustment.

6. When a flash ROM needs to be replaced by service, do not replace an IC but a core unit (as no encryption key is

written in a flash alone).

7. During disassembly, be sure to turn the power off since an internal IC might be destroyed when a connector

is plugged or unplugged.

8. About region codes

With the RC models, the region code may have been changed for some sale destinations.

In that case, a region display area of the name plate on the main unit has been overwritten (with a sticker).

If the region code is reset to its initial value due to replacement of the DVD unit etc., change the region code to

that written on the name plate of the main unit.

Contact the PSN Division for the region changing procedure.

9. Countermeasures to user complaints on iPhone/iPod touch lip synchronization

When a video is replayed, the video and audio may be out of synchronization depending on the connected

iPod or iPhone.

If it is annoying, perform the following operation.

However, this operation will slightly deteriorate the sound quality of the iPod source.

Also, it will disable the ASR function when the iPod source is used.

[Default]

Audio digital mode

[Switching procedure]

Press MODE and EJECT and turn on Accessory simultaneously

The above switches the “Audio digital mode” to the “Audio analog mode”.

When the mode is switching, the BEEP1 sound will be heard.

[Supplement]

• The mode switching operation can only switch the “Audio digital mode” to the “Audio analog mode”.

(The BEEP1 sound will be heard every time.)

• No indication of the mode is provided.

[Resetting the mode]

Reset or BackUP OFF

The above resets the mode to the “Audio digital mode”.

10. recautions for AEQ measurement

If the microphone is not connected securely, the microphone input signals may become inaccurate and an

error message “Plug the supplied microphone securely into the jack” may appear due to the measurement failure.

11. EJECT LOCK MODE for DVD mechanism

How to enter : Reset with [FORWARD] key and [EJECT] key pressed.

Unlocked by turning ACC ON or reset.

1.1 SERVICE PRECAUTIONS

6

AVH-P5200BT/XNUC

Page 7

5678

56

7

8

C

D

F

A

B

E

12. area and a heat sink becomes hot areas. Be careful not to burn yourself.

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1.2 NOTES ON SOLDERING

AVH-P5200BT/XNUC

7

Page 8

1234

1234

C

D

F

A

B

E

2. SPECIFICATIONS

Dimensions (W × H × D):

DIN

Chassis.....................180 mm × 5 0 mm × 160

mm

(7-1/8 in. × 2 in. × 6-1/4 in.)

Nose...........................188 mm × 58 m m × 32 mm

(7-3/8 in.× 2-1/4 in.× 1-1/4

in.)

D

Chassis...............................178 mm × 5 0 mm × 165

mm

(7 in.× 2 in.× 6-1/2 in.)

Nose.....................................17 0 mm × 46 mm × 2 7 mm

(6-3/4 in.× 1-3/4 in.× 1 in.)

Weight .........................................2.2 k g (4.9 lbs)

Display

Screen size/aspect ratio....... 7.0 inch wide/16:9

(effective display area: 154

× 86.9 mm)

Pixels ............................................345 600 (1 4 40 × 240)

Display method ........................TFT acti ve matrix, driving

type

Color system............................. NTSC

Durable temperature range (power off)

................................................... -20 °C t o +80 °C

Angle adjustment ................... 50° to 110°

(initial settings: 90°)

Audio

Maximum power output .......50 W × 4

70 W × 1/2 ohm

(for subwoofer)

Continuous power output ...22 W × 4 (50 Hz to 15000

Hz, 5 % THD, 4 ohm load,

both channels driven)

Load impedance ......................4 ohm(4 ohm to 8 ohm

(2 ohm for 1 ch) allowable)

Preout maximum output level

................................................... 4.0 V

Equalizer (8-Band Graphic Equalizer):

Frequency......................... 40/80/200/400/1k/2.5k/8k/

10k Hz

Gain ..................................... ±12 dB

HPF:

Frequency......................... 50/63/80/100/125 Hz

Slope.................................. –12 dB/oct

Subwoofer (mono):

Frequency......................... 50/63/80/100/125 Hz

Slope...................................–18 dB/oct

Gain ..................................... +6 dB to –24 dB

Phase .................................Normal/Reverse

Bass boost:

Gain ..................................... +12 dB t o 0 dB

DVD Player

System .........................................DV D video, Video CD, CD,

WMA, MP3, AAC, DivX,

JPEG system

Usable discs .............................DVD video, Video CD, CD,

CD-R/RW, DVD-R/RW/RDL

Region number ........................1

Frequency response...............5 Hz t o 44 000 Hz (with DVD,

at sampling frequency 96

kHz)

Signal-to-noise ratio............... 96 dB (1 kHz) (IHF-A net-

work) (RCA level)

Output level:

Video....................................1 .0 Vp-p/75 ohm (±0.2 V)

Number of channels ..............2 ( stereo)

MP3 decoding format ...........MPEG-1 & 2 Audio Layer 3

WMA decoding format .........Ve r. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format............ MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

USB

USB standard specification

................................................... USB 1.1, USB 2.0 full speed

Maximum current supply ....500 mA

USB Class.................................. MSC (Mass Storage Class)

File system................................. FAT16, FAT32

MP3 decoding format ...........MPEG-1 & 2 Audio Layer 3

WMA decoding format .........Ve r. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format............ MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

SD

Compatible physical format

................................................... Version 1.1

General

Power source.............................14.4 V DC (10.8 V to 15.1 V

allowable)

Grounding system...................Negative type

Maximum current consumption

....................................................10.0 A

Backup current ......................... 5.0 mA or less

AVH-P5200BT/XNUC, AVH-P5200DVD/XNUC

2.1 SPECIFICATIONS

8

AVH-P5200BT/XNUC

Page 9

5678

56

7

8

C

D

F

A

B

E

Maximum memory capacity

................................................... 2 GB

File system................................. FAT12, FAT16, FAT32

MP3 decoding format ...........MP EG-1 & 2 Audio Layer 3

WMA decoding format .........Ve r. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format............ MPEG-4 AAC (iTunes en-

coded only)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

FM tuner

Frequency range..................... 87.9 MHz to 107.9 MHz

Usable sensitivity.................... 9 dB f (0.8 μV/75 ohm,

mono,S/N: 30 dB)

Signal-to-noise ratio.............. 72 dB (IHF-A network)

AM tuner

Frequency range..................... 530 kHz t o 1 710 kH z (10

kHz)

Usable sensitivity.................... 25 μV (S/N: 20 dB)

Signal-to-noise ratio.............. 62 dB (IHF-A network)

Bluetooth

(AVH-P5200BT)

Version........................................ Bluetooth 2.0 certified

Output power ........................... +4 dBm Max.

(Power class 2)

CEA2006 Specifications

Power output .............................1 4 W RMS × 4 Ch annels (4

ohm and

1 % THD+N)

S/N ratio ......................................91 dB A (reference: 1 W into

4 ohm)

Note

Specifications and the design are subject to modifications without notice.

AVH-P5200BT/XNUC

9

Page 10

1234

1234

C

D

F

A

B

E

Dimensions (W × H × D):

DIN

Chassis.....................180 mm × 5 0 mm × 160

mm

Nose...........................188 mm × 58 m m × 32 mm

D

Chassis.....................178 mm × 5 0 mm × 165

mm

Nose...........................170 mm × 46 m m × 27 mm

Weight ........................................ 2. 2 kg

Display

Screen size/aspect ratio....... 7.0 inch wide/16:9

(effective display area: 154

× 86.9 mm)

Pixels ........................................... 345 600 (1 4 40 × 240)

Display method ....................... TFT active matrix, driving

type

Color system............................. NTSC/PAL/PAL-M/SECAM

compatible

Durable temperature range (power off)

................................................... -20 °C t o +80 °C

Angle adjustment ................... 50° to 110°

(initial settings: 90°)

Audio

Maximum power output .......50 W × 4

70 W × 1/2 ohm

(for subwoofer)

Continuous power output ...22 W × 4 (50 Hz to 15000

Hz, 5 % THD, 4 ohm load,

both channels driven)

Load impedance ......................4 ohm (4 ohm to 8 ohm

(2 ohm for 1 ch) allowable)

Preout maximum output level

................................................... 4.0 V

Equalizer (8-Band Graphic Equalizer):

Frequency......................... 40/80/200/400/1k/2.5k/8k/

10k Hz

Gain .................................... ±1 2 dB

HPF:

Frequency......................... 50/63/80/100/125 Hz

Slope...................................–12 dB/oct

Subwoofer (mono):

Frequency......................... 50/63/80/100/125 Hz

Slope...................................–18 dB/oct

Gain ..................................... +6 dB to –24 dB

Phase .................................Normal/Reverse

Bass boost:

Gain ..................................... +12 dB t o 0 dB

DVD Player

System .........................................DV D video, Video CD, CD,

WMA, MP3, AAC, DivX,

JPEG system

Usable discs .............................DVD video, Video CD, CD,

CD-R/RW, DVD-R/RW/RDL

Region number:

for Middle East Asian and South African models

......................................... 2

for Southeast Asian models

......................................... 3

Frequency response...............5 Hz t o 44 000 Hz (with DVD,

at sampling frequency 96

kHz)

Signal-to-noise ratio............... 96 dB (1 kHz) (IEC-A net-

work) (RCA level)

Output level:

Video....................................1 .0 Vp-p/75 ohm (±0.2 V)

Number of channels ..............2 ( stereo)

MP3 decoding format ...........MPEG-1 & 2 Audio Layer 3

WMA decoding format .........Ve r. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format............ MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

USB

USB standard specification

................................................... USB 1.1, USB 2.0 full speed

Maximum current supply ....500 mA

USB Class.................................. MSC (Mass Storage Class)

File system................................. FAT16, FAT32

MP3 decoding format ...........MPEG-1 & 2 Audio Layer 3

WMA decoding format .........Ve r. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format............ MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

SD

Compatible physical format

................................................... Version 1.1

General

Rated power source...............14.4 V DC

(allowable voltage range:

12.0 V to 14.4 V DC)

Grounding system...................Negative type

Maximum current consumption

....................................................10.0 A

Backup current.........................4.0 mA or less

AVH-P5250DVD/XNRC, AVH-P5250DVD/XNRI

10

AVH-P5200BT/XNUC

Page 11

5678

56

7

8

C

D

F

A

B

E

Maximum memory capacity

................................................... 2 GB

File system................................. FAT12, FAT16, FAT32

MP3 decoding format ...........MP EG-1 & 2 Audio Layer 3

WMA decoding format .........Ve r. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format............ MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

FM tuner

Frequency range......................87.5 MHz to 108.0 MHz

Usable sensitivity.....................9 dB f (0.8 μV/75 ohm

mono, S/N: 30 dB)

Signal-to-noise ratio............... 72 dB (I EC -A network)

AM tuner

Frequency range......................531 kHz t o 1 602 kH z (9 kHz)

530 kHz to 1640 kHz (10

kHz)

Usable sensitivity.................... 25 μV (S/N: 20 dB)

Signal-to-noise ratio.............. 62 dB ( IEC -A network)

Infrared remote control

Wavelength................................ 945 nm

Output ......................................... ty p; 10 mw/sr per Infrared

LED

Note

Specifications and the design are subject to modifications without notice.

AVH-P5200BT/XNUC

11

Page 12

1234

1234

C

D

F

A

B

E

Dimensions (W × H × D):

DIN

Chassis.................. 180 mm × 50 mm × 160

mm

Nose........................ 188 mm × 58 mm × 32 mm

D

Chassis.................. 178 mm × 50 mm × 165

mm

Nose....................... 170 mm × 46 mm × 27 mm

Weight ..................................... 2.2 kg

Display

Screen size/aspect ratio...... 7.0 inch wide/16:9

(effective display area: 154

× 86.9 mm)

Pixels ....................................... 345 600 ( 1 440 × 240)

Display method ..................... TFT active matrix, driving

type

Color system...........................NTSC/PAL/PAL-M/SECAM

compatible

Durable temperature range (power off)

............................................. -20 °C to +80 °C

Angle adjustment ................. 50° to 110°

(initial settings: 90°)

Audio

Maximum power output ...... 50 W × 4

70 W × 1/2 ohm

(for subwoofer)

Continuous power output ... 22 W × 4 (50 Hz to 15000

Hz, 5 % THD, 4 ohm load,

both channels driven)

Load impedance ................... 4 ohm (4 ohm to 8 ohm

(2 ohm for 1 ch) allowable)

Preout maximum output level

............................................... 4.0 V

Equalizer (8-Band Graphic Equalizer):

Frequency.......................40/80/200/400/1k/2.5k/8k/

10k Hz

Gain .................................. ±12 d B

HPF:

Frequency.......................50/63/80/100/125 Hz

Slope................................–12 dB/oct

Subwoofer (mono):

Frequency.......................50/63/80/100/125 Hz

Slope................................–18 dB/oct

Gain ................................. +6 dB to – 24 d B

Phase ..............................Normal/Reverse

Bass boost:

Gain ................................. +12 dB to 0 dB

DVD Player

System ..................................... DVD video, Video CD, CD,

WMA, MP3, AAC, DivX,

JPEG system

Usable discs .......................... DVD video, Video CD, CD,

CD-R/RW, DVD-R/RW/RDL

Frequency response............. 5 Hz to 44 000 Hz (with DVD,

at sampling frequency 96

kHz)

Signal-to-noise ratio............. 96 dB (1 kHz) (IEC-A net-

work) (RCA level)

Output level:

Video............................... 1.0 Vp-p/75 ohm (±0.2 V)

Number of channels ............ 2 (stereo)

MP3 decoding format ..........MPEG-1 & 2 Audio Layer 3

WMA decoding format ........ Ver. 7,7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format............Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

USB

USB standard specification

............................................... USB 1.1, USB 2.0 full speed

Maximum current supply .... 500 mA

USB Class............................... MSC (Mass Storage Class)

File system.............................. FAT16, FAT32

MP3 decoding format ..........MPEG-1 & 2 Audio Layer 3

WMA decoding format ........ Ver. 7,7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format...........Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

SD

Compatible physical format

.............................................. Version 1.1

Maximum memory capacity

.............................................. 2 GB

File system............................. FAT12, FAT16, FAT32

MP3 decoding format ..........MPEG-1 & 2 Audio Layer 3

General

Power source..........................14.4 V DC (12.0 V to 14.4 V

allowable)

Grounding system................. Negative type

Maximum current consumption

...............................................10.0 A

Backup current .........................4.0 mA or less

AVH-P5250BT/XNRD, AVH-P5250DVD/XNRD

12

AVH-P5200BT/XNUC

Page 13

5678

56

7

8

C

D

F

A

B

E

WMA decoding format ........ Ver. 7,7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG-4 AA C (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

DivX decoding format...........Home Theater Ver. 3, 4, 5.2,

6 (.avi, .divx)

FM tuner

Frequency range................... 87.5 MHz to 108.0 MHz

Usable sensitivity.................. 9 dB f (0.8 μV/75 ohm,

mono, S/N: 30 dB)

Signal-to-noise ratio............. 72 dB (IEC-A network)

AM tuner

Frequency range................... 531 kHz t o 1 602 kHz (9 kHz)

530 kHz to 1640 kHz (10

kHz)

Usable sensitivity.................. 25 μV (S/N: 20 dB)

Signal-to-noise ratio............. 62 dB (IEC-A network)

Bluetooth

(AVH-P5250BT)

Version..................................... Bluetooth 2.0 certified

Output power ........................ +4 dBm Max.

(Power class 2)

Infrared remote control

Wavelength............................. 945 nm

Output ..................................... typ; 10 mw/sr per Infrared

LED

Note

Specifications and the design are subject to modifications without notice.

AVH-P5200BT/XNUC

13

Page 14

1234

1234

C

D

F

A

B

E

2.2 DISC/CONTENT FORMAT

The Bluetooth word mark and logos are owned by the Bluetooth SIG, Inc.

and any use of such marks by Pioneer Corporation is under license.

Other trademarks and trade names are those of their respective owners.

(BT model only)

is a trademark of DVD Format/Logo Licensing Corporation.

(UC model only)

(UC model only)

(RC, RD, RI models)

(RC, RD, RI models)

14

AVH-P5200BT/XNUC

Page 15

5678

56

7

8

C

D

F

A

B

E

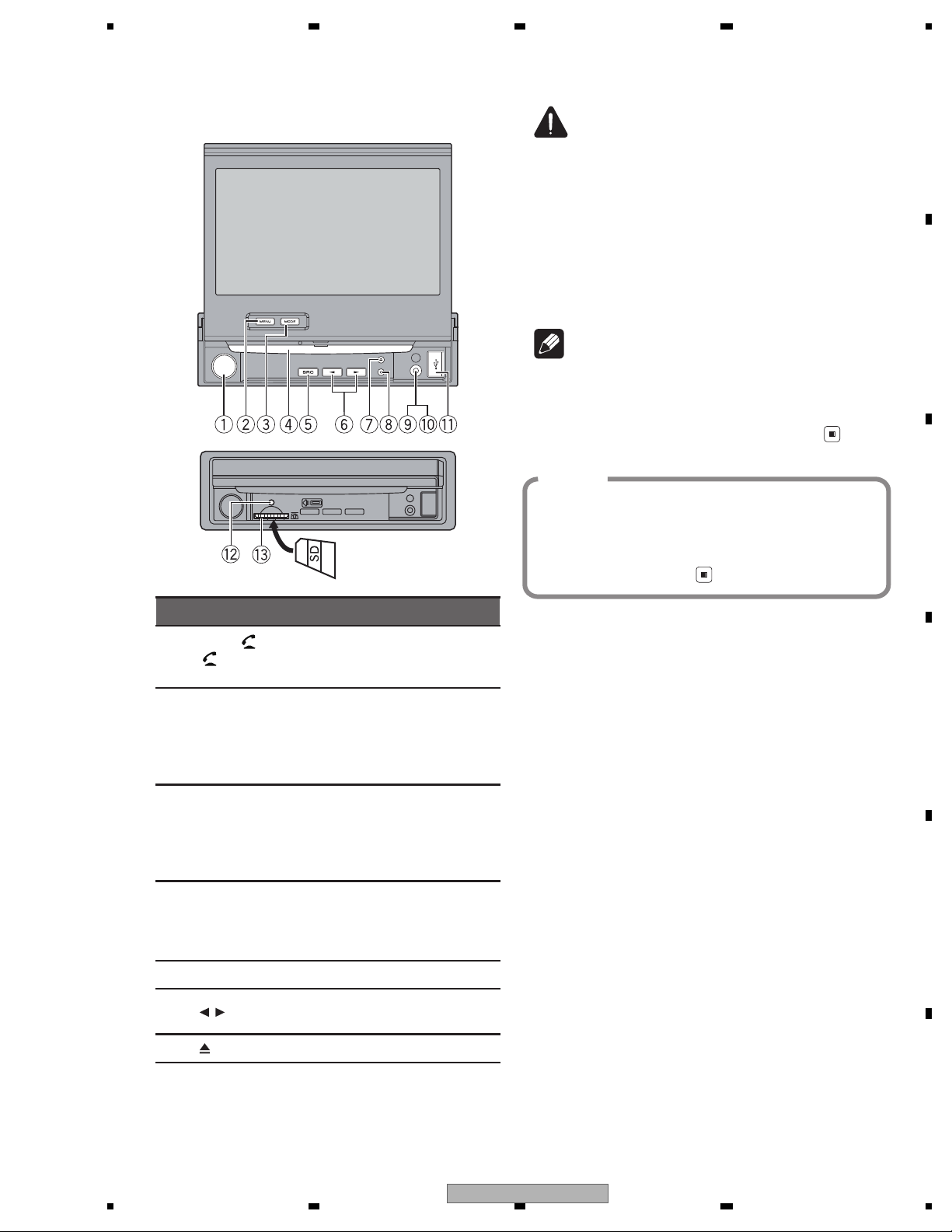

Head unit

traPtraP

1

MUTE/

( : AVH-P5200BT,

AVH-P5250BT only)

8 OPEN/CLOSE

2

MENU

Displaying the

menu.

Returning to the

normal display.

9

AUX input jack (3.5

mm stereo/video

jack)

Use to connect an

auxiliary device.

3

MODE

Turning the information display off.

a

Auto EQ microphone input jack

Use to connect an

auto EQ microphone.

4 Disc loading slot b

USB port

When connecting,

open the USB connector lid.

5 SRC/OFF c RESET

6

/ (TRACK) d

SD memory card

slot

7

(eject)

CAUTION

• Use an optional Pioneer USB cable (CD-U50E)

to connect the USB audio player/USB memory as any device connected directly to the

unit will protrude out from the unit and may

be dangerous.

• Do not use unauthorized products.

• For details on how to operate a navigation unit

from this unit, refer to its operation manual.

Note

When the navigation unit is connected, press

MODE to switch to the navigation display. Press

MODE and hold to turn the display off.

PressMODE again to turn the display on.

Optional remote control

The remote control CD-R55 is sold separately.

For details concerning operations, see the remote control manual.

UC Only

2.3 PANEL FACILITIES

AVH-P5200BT/XNUC

15

Page 16

1234

1234

C

D

F

A

B

E

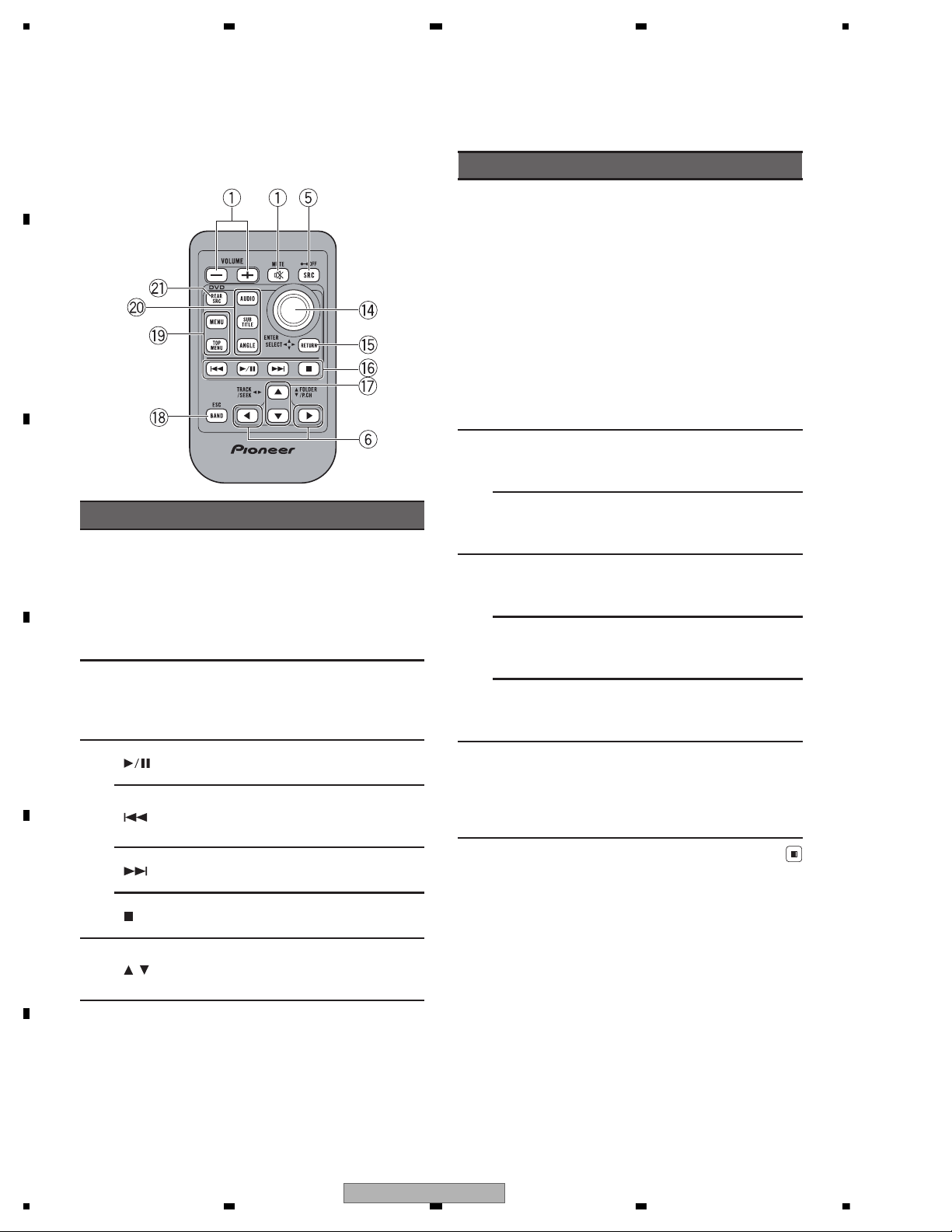

Remote control

Part Operation

e Thumb pad

Use to operate fast forward, rewind and

other track search

controls. Click to recall

Menu.

Use to select a menu

on the DVD menu.

f RETURN

Press to display the

PBC (playback control) menu during PBC

playback.

g

Press to pause or resume playback.

Press to return to the

previous track (chapter).

Press to go to the next

track (chapter).

Press to stop playback.

h

/ (FOLDER/P.CH)

Press to select the

next/previous disc/

folder.

Part Operation

i BAND/ESC

Press to select the

tuner band when

tuner is selected as a

source. Also used to

cancel the control

mode of functions.

Press to switch between modes when

playing discs with

compressed audio

and audio data (CDDA) such as CDEXTRA and MIXEDMODE CDs.

j

MENU

Press to display the

DVD menu during

DVD playback.

TOP MENU

Press to return to the

top menu during DVD

playback.

k

AUDIO

Press to change the

audio language during

DVD playback.

SUBTITLE

Press to change the

subtitle language during DVD playback.

ANGLE

Press to change the

viewing angle during

DVD playback.

l REAR SRC

Press to cycle through

all the available rear

sources.

Press and hold to turn

the rear source off.

AVH-P5250BT/XNRD, AVH-P5250DVD/XNRC, AVH-P5250DVD/XNRI,

AVH-P5250DVD/XNRD

16

AVH-P5200BT/XNUC

Page 17

5678

56

7

8

C

D

F

A

B

E

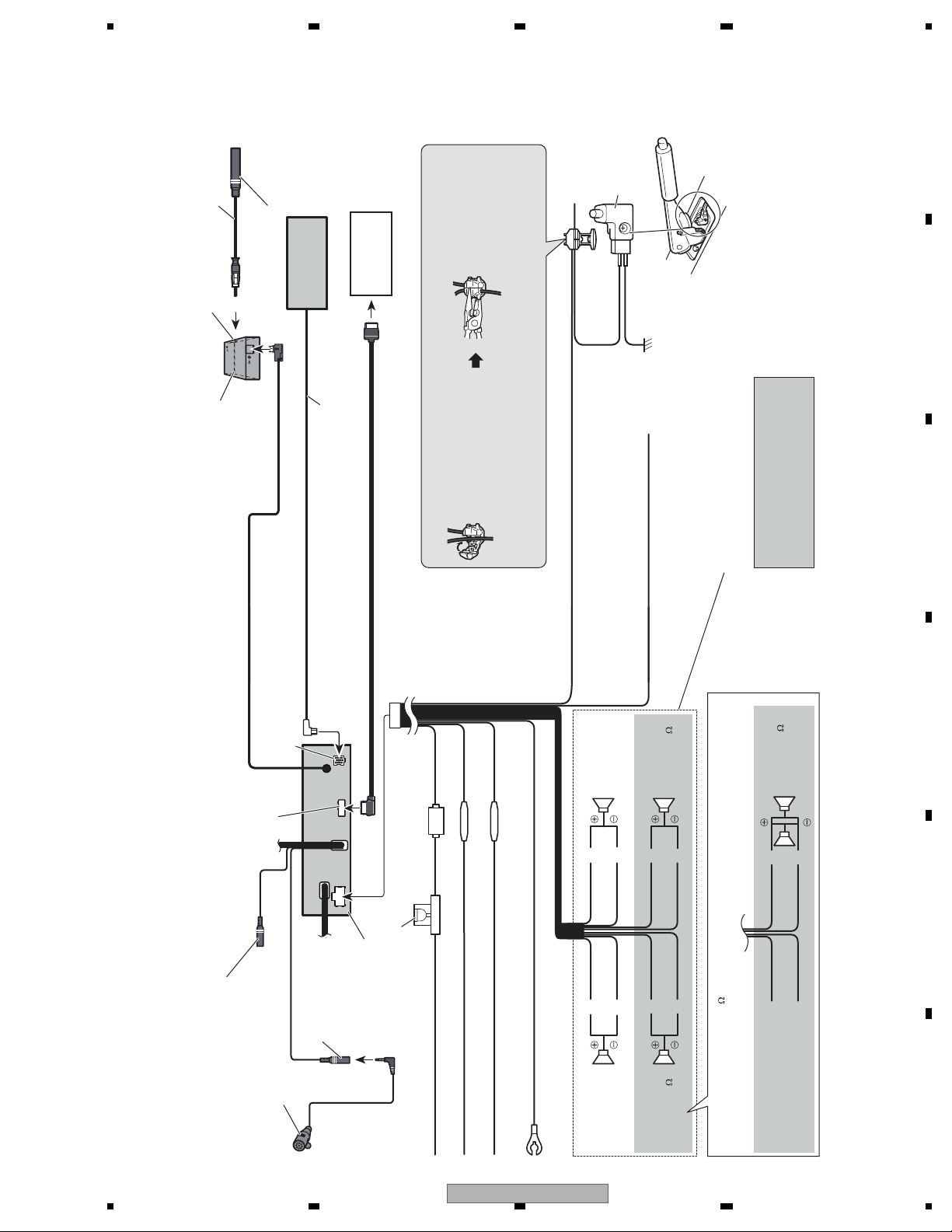

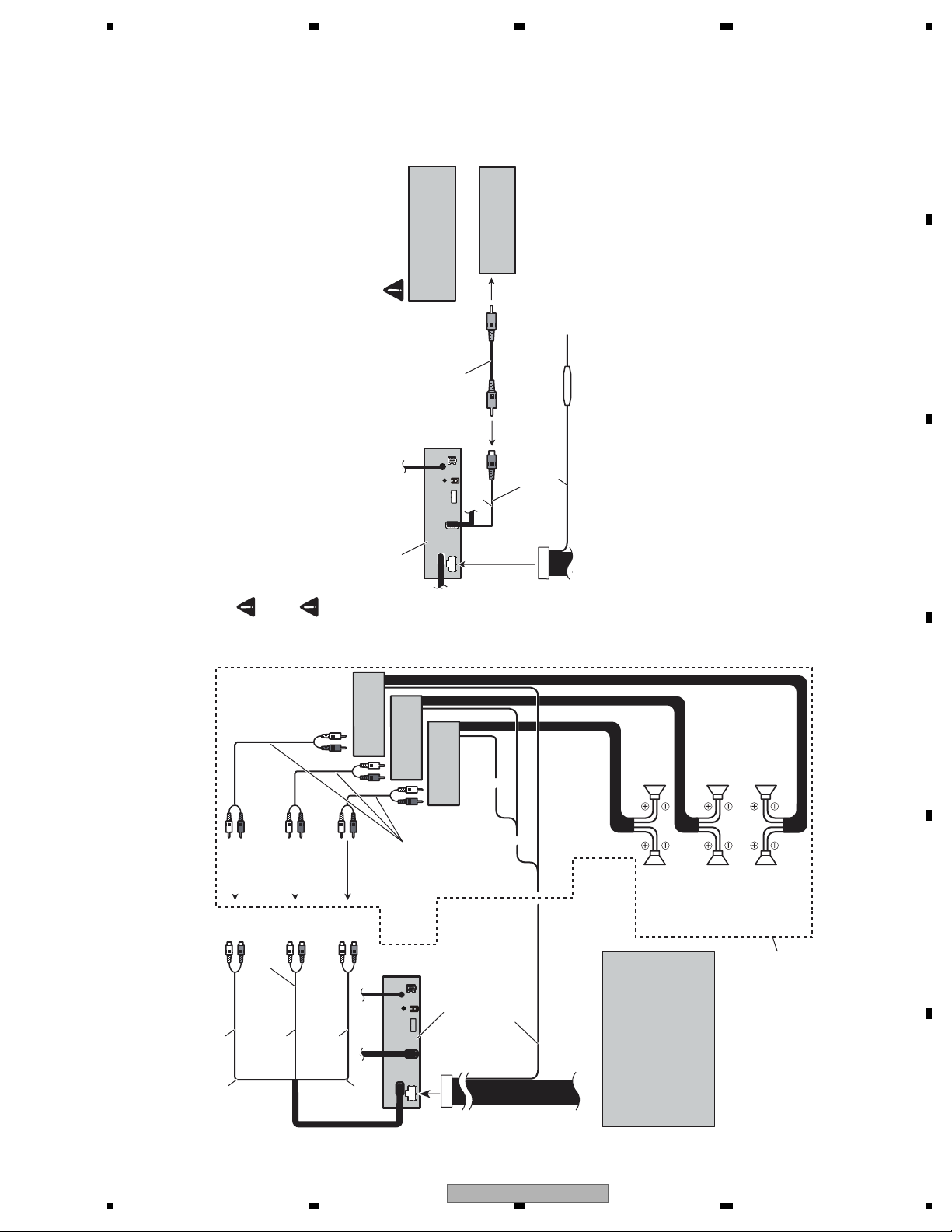

AVH-P5200BT/XNUC, AVH-P5200DVD/XNUC

Connecting the power cord

This product

Microphone (supplied)

(AVH-P5200BT only)

4 m

(13 ft. 1 in.)

Fuse (10 A)

RGB input

IP-BUS input

(Blue)

Yellow

Connect to the constant 12 V supply terminal.

Fuse resistor

Red

Connect to terminal controlled by ignition switch (12 V DC).

Black (chassis ground)

Connect to a clean, paint-free metal location.

Left Right

rekaepstnorFrekaepstnorF

Rear speaker or

Subwoofer (4

)

White Gray

Gray/blackWhite/black

Green Violet

Green/black Violet/black

Violet

Violet/black

Not used.

Green

Green/black

When using a subwoofer of 70 W (2

), be sure to connect with Violet and Violet/black leads of this unit. Do not

connect anything to Green and Green/black leads.

Subwoofer (4

)

× 2

Rear speaker or

Subwoofer (4

)

Orange/white

Connect to lighting switch terminal.

Fuse resistor

Wired remote input (WIRED REMOTE INPUT )

Hard-wired remote control adaptor can be

connected (sold separately).

Microphone input Jack (MIC )

(AVH-5200BT only)

17 cm (6-3/4 in.)

17 cm (6-3/4 in.)

Navigation unit

(AVIC-U220 (sold

separately)).

Antenna input

Tuner box (supplied)

Antenna cable (supplied)

80 cm

(2 ft. 7 in.)

IP-BUS cable

Pioneer IP-BUS

accessories

Connection method

1. Clamp the lead.

2. Clamp firmly with

needle-nosed pliers.

Note:

· The position of the parking brake switch depends on the vehicle model. For details,

consult the vehicle Owner’s Manual or dealer.

Light green

Used to detect the ON/OFF status of the parking

brake. This lead must be connected to the power

supply side of the parking brake switch.

Blue/white

Connect to system control terminal of the power amp or

auto-antenna relay control terminal (max. 300 mA 12 V DC).

Ground side

Power supply side

Parking brake

switch

With a 2 speaker system, do not connect anything to the speaker leads

that are not connected to speakers.

Note:

· Change the initial setting of this unit (refer

to the Operation Manual). The subwoofer

output of this unit is monaural.

26 pin cable (Supplied with Navigation unit)

Insert the 26 pin cable in the direction

indicated in the figure.

Please contact your dealer to inquire

about the connectable navigation unit.

80 cm

(2 ft. 7 in.)

2.4 CONNECTION DIAGRAM

AVH-P5200BT/XNUC

17

Page 18

1234

1234

C

D

F

A

B

E

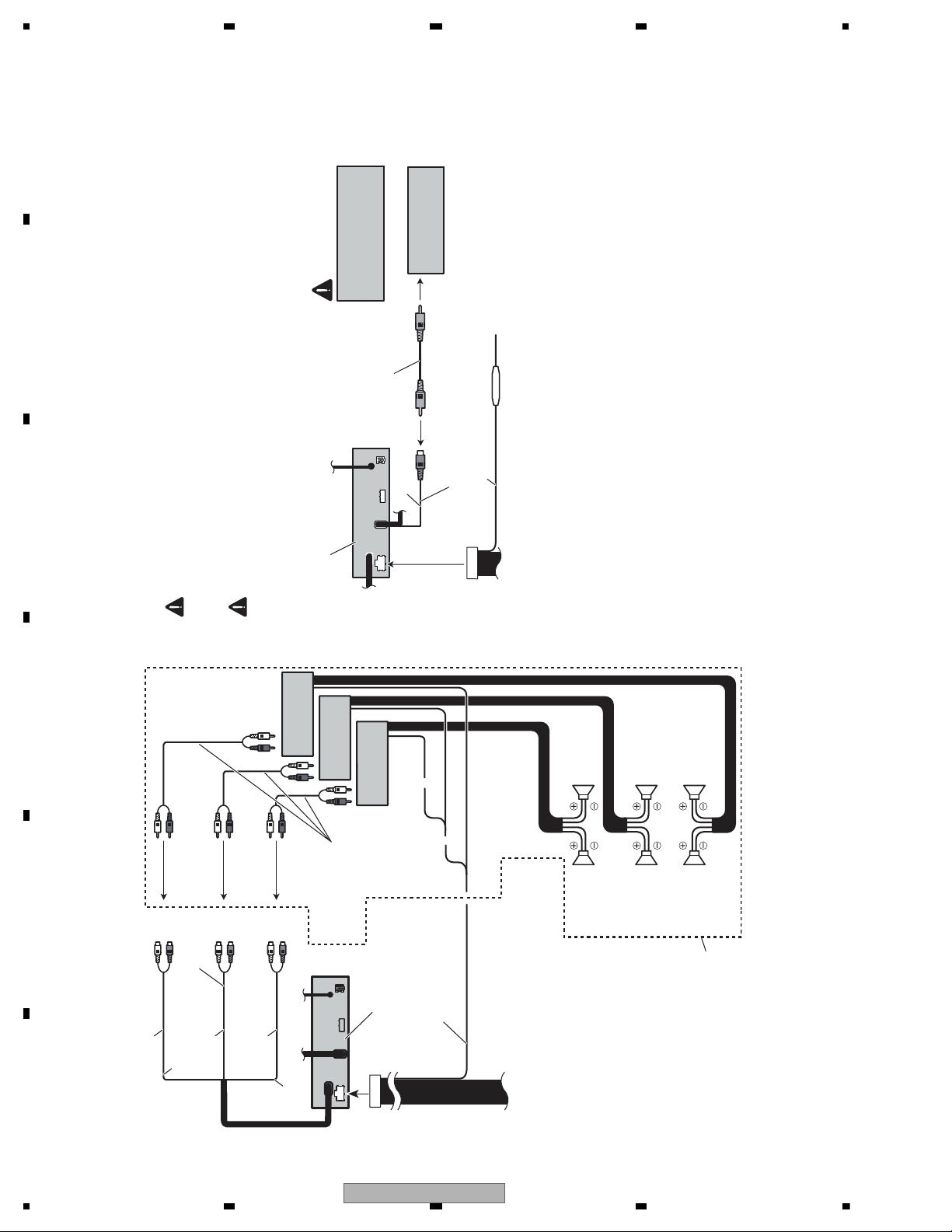

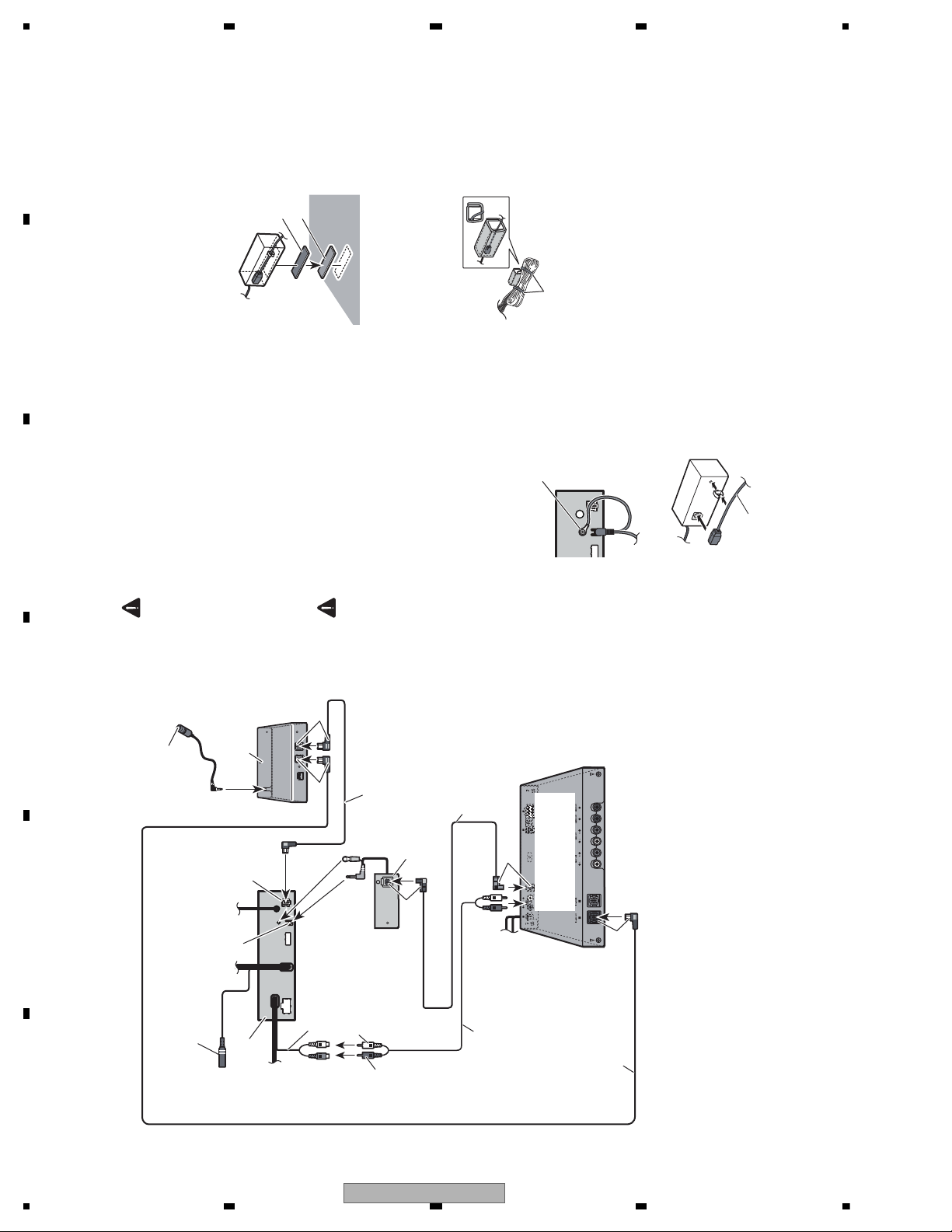

When connecting to separately sold power amp

Blue/white

Connect to system control

terminal of the power amp

(max. 300 mA 12 V DC).

Connect with RCA cables

(sold separately)

Rear speaker

Perform these connections when

using the optional amplifier.

System remote control

rekaepstnorFrekaepstnorF

thgiRtfeL

Rear speaker

Power amp

(sold separately)

Power amp

(sold separately)

Power amp

(sold separately)

Subwoofer

Subwoofer

To front output

To rear output

To subwoofer

output

This product

Rear output

(REAR OUTPUT )

Front output

( FRONT OUTPUT )

Subwoofer output

( SUBWOOFER OUTPUT )

13 cm (5-1/8 in.)

17 cm (6-3/4 in.)

13 cm (5-1/8 in.)

When connecting with a rear view camera

When this product is used with a rear view camera, it is possible to automatically switch from the

video to rear view image when the gear shif t is moved to REVERSE (R).

WARNING

USE INPUT ONLY FOR REVERSE OR MIRROR IMAGE REAR VIEW CAMERA . OTHER USE MAY

RESULT IN INJURY OR DAMAGE.

CAUTION

• The screen image may appear reversed.

• The rear view camera function is to be used as an aid for backing into a tight parking spot.

Do not use this function for enter tainment purposes.

• Objects in the rear view may appear closer or more distant than they actually are.

To video output

Rear view camera

(sold separately)

Rear view camera input (REAR VIEW CAMERA IN)

Violet/white

Of the two lead wires connected to the back lamp, connect the one

in which the voltage changes when the gear shift is in the

REVERSE (R) position. This connection enables the unit to

sense whether the car is moving forwards or backwards.

You must use a camera

which outputs mirror

reversed images.

CAUTION

Fuse resistor

This product

RCA cable (sold separately)

15 cm (5-7/8 in.)

13 cm (5-1/8 in.)

• It is necessary to set Camera Polarity properly in System Menu when connecting the rear view camera.

18

AVH-P5200BT/XNUC

Page 19

5678

56

7

8

C

D

F

A

B

E

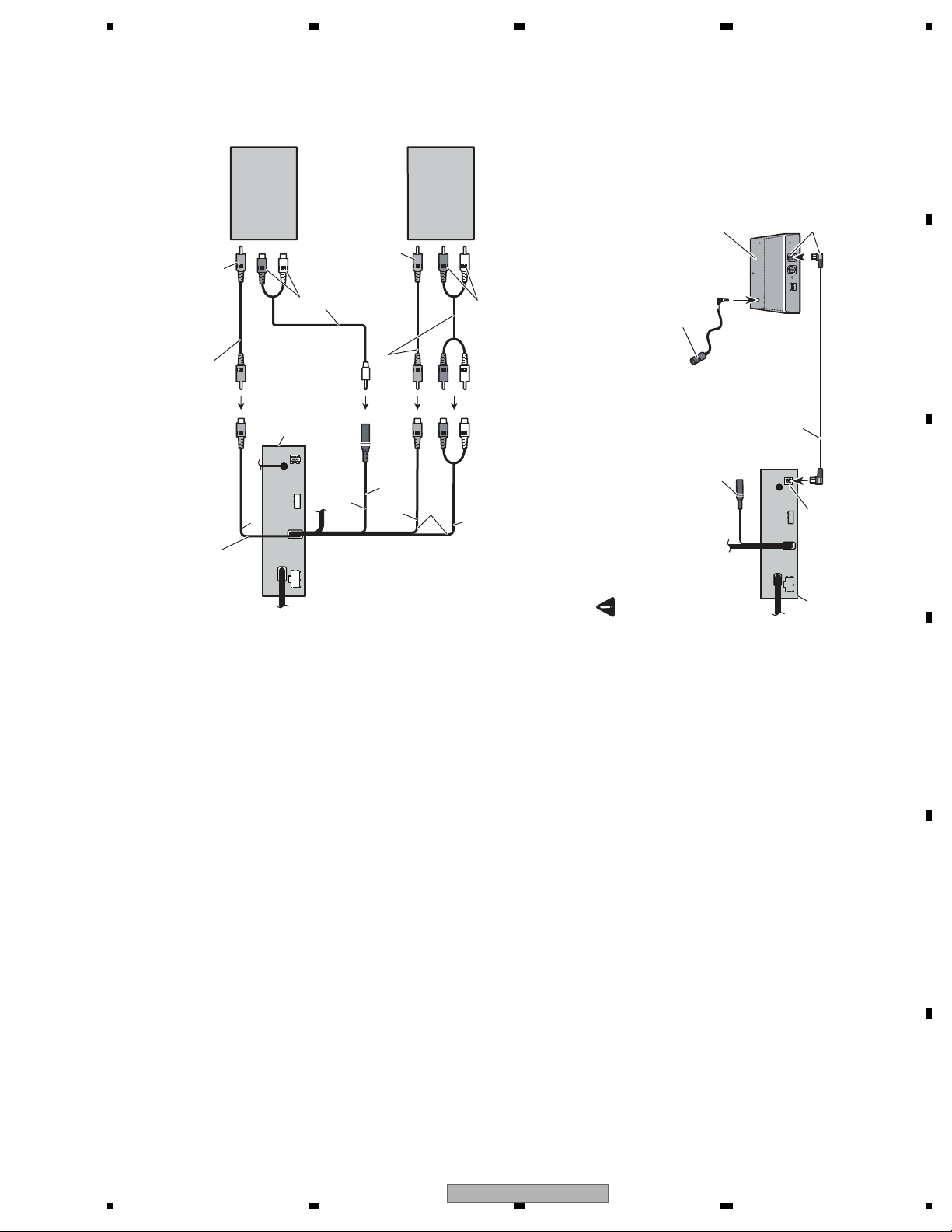

External video

component (sold

Display with RCA

input jacks (sold

separately)

To video output

separately)

Bluetooth adapter

(e.g. CD-BTB200)

(sold separately)

(AVH-P5200DVD only)

Black

To video input

RCA cables (sold separately)

13 cm (5-1/8 in.)

Rear monitor output

( REAR MONITOR OUTP UT )

When connecting the external video component and the display

To audio input

This product

Mini pin plug cable

(sold separately)

RCA cables (sold separately)

17 cm (6-3/4 in.)

Rear audio output

( REAR MONITOR OUTPUT(AUDIO) )

Microphone

for hands-free phoning

To audio outputs

13 cm (5-1/8 in.)

Video input ( VIDEO INPUT )

Audio input

(AUDIO INPUT )

• It is necessary to change AV In put in System Menu when connecting the external video

component.

WARNING

This product’s rear video output and rear audio output are for connection of a display to enable

passengersin therearseatstowatch theDVD,etc.

When using a display connected to rear video output

Never install the display in a location where it is visible to the driver while driving.

Connecting the system

(supplied with Bluetooth adapter)

Wired remote input ( WIRED REMOTE INPUT )

Hard-wired remote control adaptor can be

connected (sold separately).

IP-BUS cable

(Supplied with Bluetooth adapter)

IP-BUS input

This product

AVH-P5200BT/XNUC

19

Page 20

1234

1234

C

D

F

A

B

E

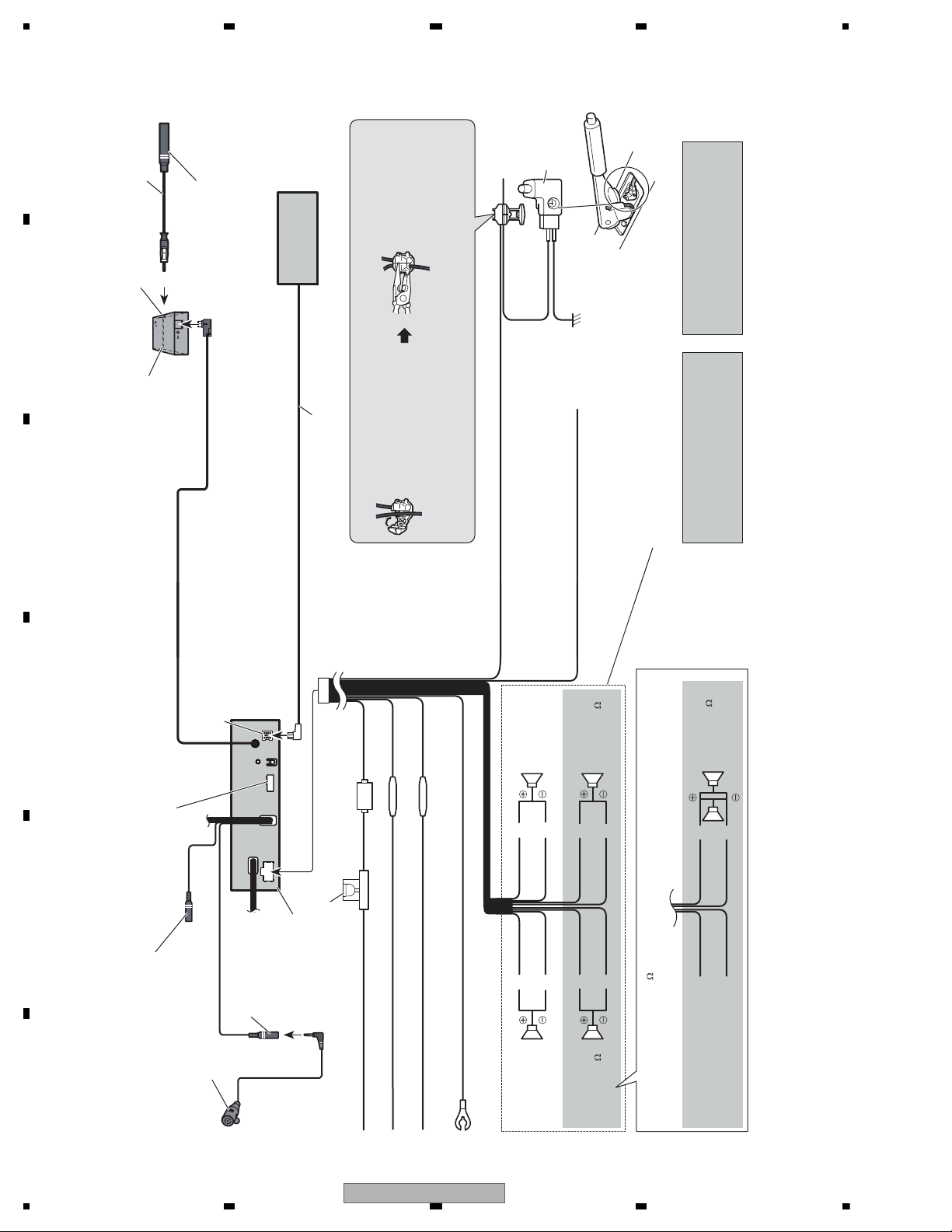

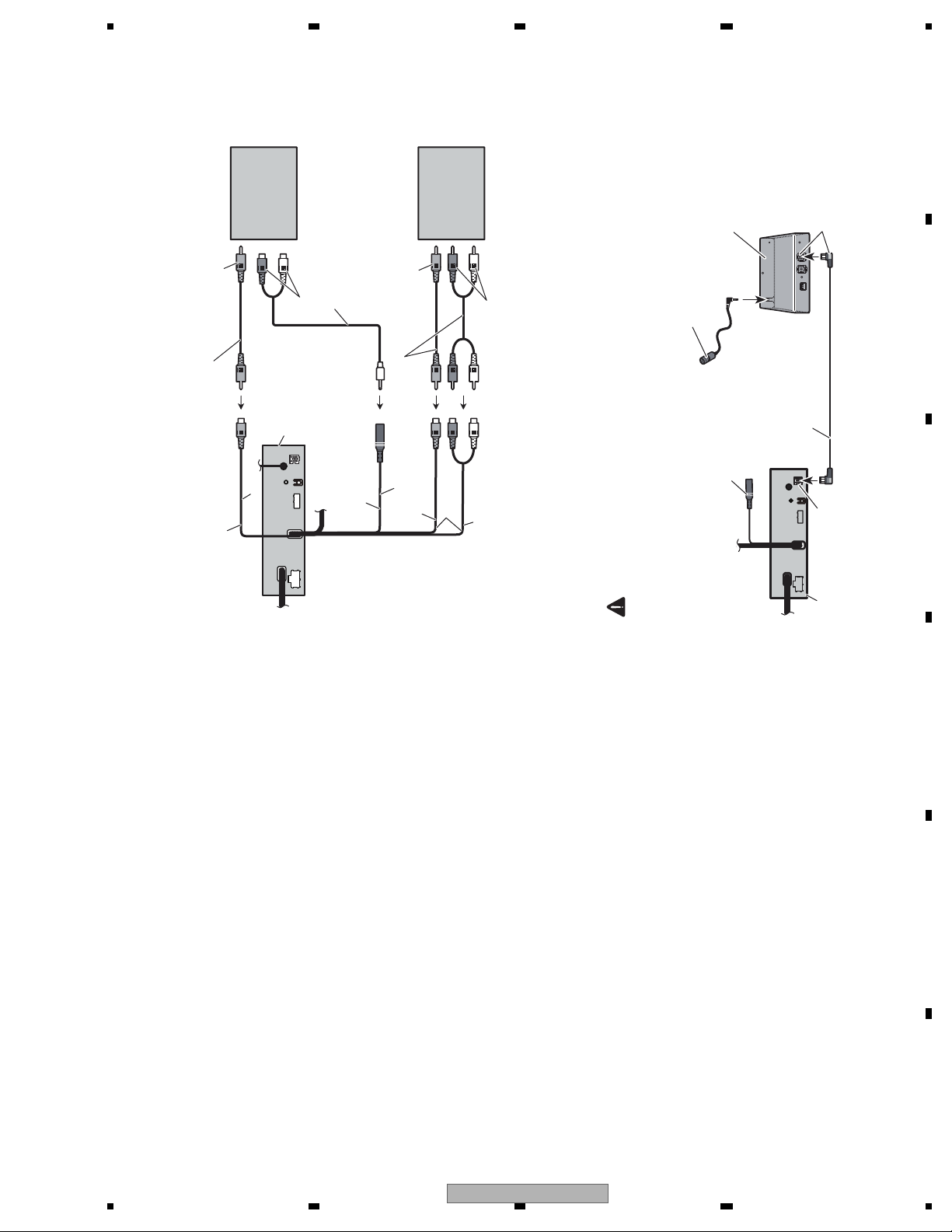

AVH-P5250BT/XNRD, AVH-P5250DVD/XNRC, AVH-P5250DVD/XNRI,

AVH-P5250DVD/XNRD

Connecting the power cord

This product

Microphone (supplied)

(AVH-P5250BT only)

4 m

Fuse (10 A)

RGB input

IP-BUS input

(Blue)

Yellow

Connect to the constant 12 V supply terminal.

Fuse resistor

Red

Connect to terminal controlled by ignition switch (12 V DC).

Black (chassis ground)

Connect to a clean, paint-free metal location.

Left Right

rekaepstnorFrekaepstnorF

Rear speaker or

Subwoofer (4

)

White Gray

Gray/blackWhite/black

Green Violet

Green/black Violet/black

Violet

Violet/black

Not used.

Green

Green/black

When using a subwoofer of 70 W (2

), be sure to connect with Violet and Violet/black leads of this unit. Do not

connect anything to Green and Green/black leads.

Subwoofer (4

)

× 2

Rear speaker or

Subwoofer (4

)

Orange/white

Connect to lighting switch terminal.

Fuse resistor

Wired remote input ( WIRED REMOTE INPUT )

Hard-wired remote control adaptor can be

connected (sold separately).

Microphone input Jack (MIC )

(AVH-5250BT only)

17 cm

17 cm

Antenna input

Tuner box (supplied)

Antenna cable (supplied)

80 cm

80 cm

IP-BUS cable

Pioneer IP-BUS

accessories

Connection method

1. Clamp the lead.

2. Clamp firmly with

needle-nosed pliers.

Note:

· The position of the parking brake switch depends on the vehicle model. For details,

consult the vehicle Owner’s Manual or dealer.

Light green

Used to detect the ON/OFF status of the parking

brake. This lead must be connected to the power

supply side of the parking brake switch.

Blue/white

Connect to system control terminal of the power amp or

auto-antenna relay control terminal (max. 300 mA 12 V DC).

Ground side

Power supply side

Parking brake

switch

With a 2 speaker system, do not connect anything to the speaker leads

that are not connected to speakers.

Note:

· Change the initial setting of this unit (refer

to the Operation Manual). The subwoofer

output of this unit is monaural.

When you connect the separately sold

multi-channel processor (DEQ-P7650) to this

unit, do not connect anything to the speaker

leads and system remote control (blue/white).

20

AVH-P5200BT/XNUC

Page 21

5678

56

7

8

C

D

F

A

B

E

Rear view camera

(sold separately)

CAUTION

You must use a camera

which outputs mirror

reversed images.

To video output

Fuse resistor

RCA cable (sold separately)

15 cm

13 cm

Rear view camera input ( REAR VIEW CAMERA IN)

Violet/white

Of the two lead wires connected to the back lamp, connect the one

in which the voltage changes when the gear shift is in the

REVERSE (R) position. This connection enables the unit to

sense whether the car is moving forwards or backwards.

This product

WARNING

When this product is used with a rear view camera, it is possible to automatically switch

from the video to rear view image when the gear shift is moved to REVERSE (R).

When connecting with a rear view camera

CAUTION

USE INPUT ONLY FOR REVERSE OR MIRROR IMAGE REAR VIEW CAMERA . OTHER USE MAY

RESULT IN INJURY OR DAMAGE.

• The screen image may appear reversed.

• The rear view camera function is to be used as an aid for backing into a tight parking spot.

Do not use this function for enter tainment purposes.

• Objects in the rear view may appear closer or more distant than they actually are.

Power amp

(sold separately)

Power amp

(sold separately)

Power amp

(sold separately)

• It is necessary to set Camera Polarity properly in System Menu when connecting the rear view camera.

rekaepstnorFrekaepstnorF

thgiRtfeL

Subwoofer

Rear speaker

Rear output

( REAR OUTPUT )

13 cm

To rear output

13 cm

Front output

( FRONT OUTP UT )

To front output

To subwoofer

output

Subwoofer output

( SUBWOOFER OUTP UT )

17 cm

Connect with RCA cables

(sold separately)

This product

Blue/white

When connecting to separately sold power amp

AVH-P5200BT/XNUC

System remote control

Connect to system control

terminal of the power amp

(max. 300 mA 12 V DC).

Subwoofer

multi-channel processor (DEQ-P7650)

to this unit, do not connect anything

to the speaker leads and system

remote control (blue/white).

processor to this unit, refer to

multi-channel processor’s installation

· When you connect the separately sold

manual for the connection method.

· When you connect the multi-channel

Rear speaker

Perform these connections when

using the optional amplifier.

21

Page 22

1234

1234

C

D

F

A

B

E

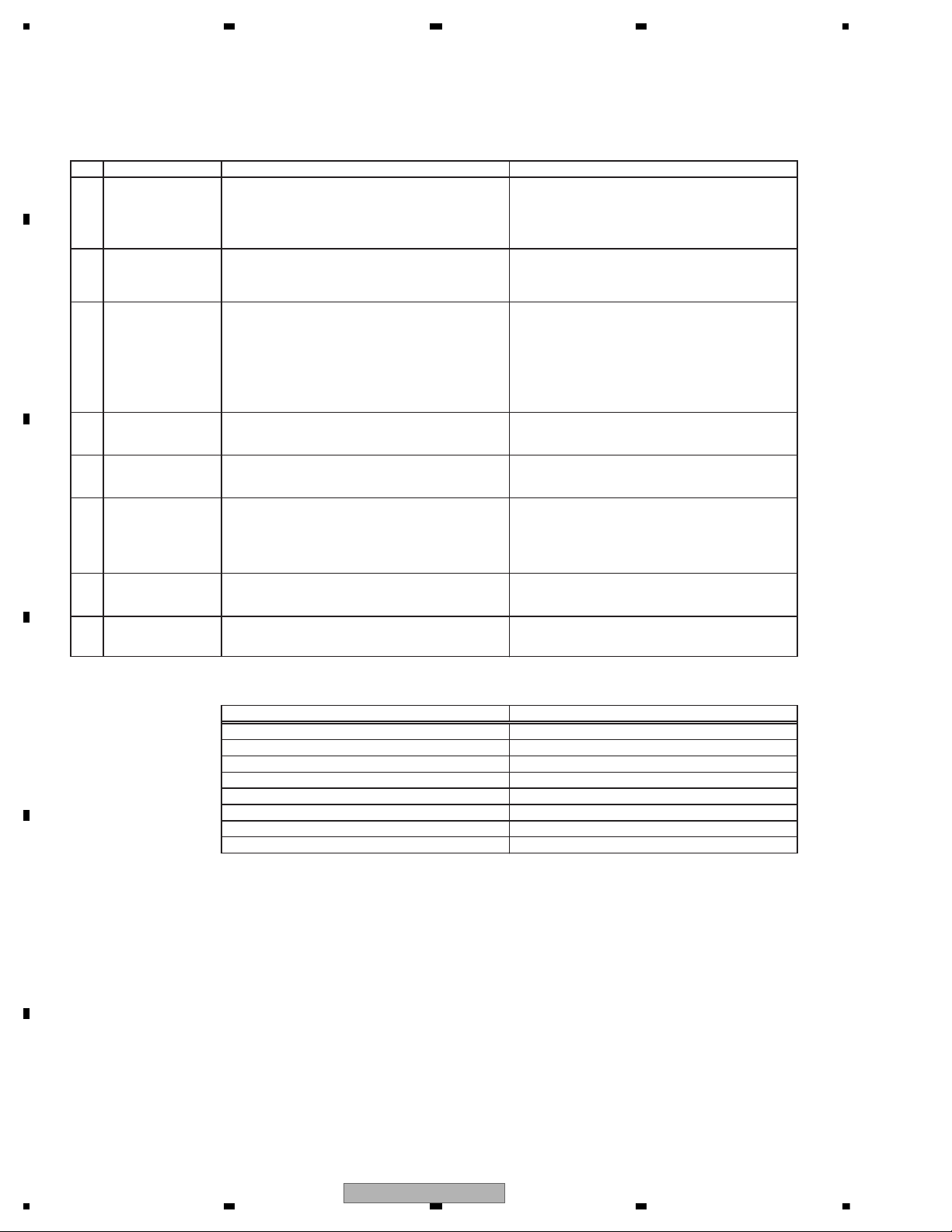

When connecting with a multi-channel processor

IP-BUS cable (supplied with

multi-channel processor)

RCA cable (supplied with

multi-channel processor)

Optical cable

(supplied with

multi-channel processor)

This product

IP-BUS cable

(Supplied with Bluetooth adapter)

Black

Bluetooth adapter

(e.g. CD-BTB100)

(sold separately)

(AVH-P5250DVD only)

Microphone

for hands-free phoning

(supplied with Bluetooth adapter)

Black

Optical cable connection box

(CD-DD25)

(sold separately)

To SWL

To SWR

Blue

Blue

Multi-channel processor

(e.g., DEQ-P7650)

(sold separately)

Black

IP-BUS input

Optical

output

Wired remote input ( WIRED REMOTE INPUT )

Hard-wired remote control adaptor can be

connected (sold separately).

17 cm

17 cm

Subwoofer output

( SUBWOOFER OUTPUT

or NON-FADING OUTPUT )

Connecting and installing the optical cable connection box

WARNING

• Avoid installing the optical c able connec tion

box in locations where the operation of

safety devices such as airbags is prevented

by this unit. Otherwise, there is a danger of a

fatal accident.

• Avoid installing the optical c able connec tion

box in locations where the operation of the

brake may be prevented. Otherwise, it may

result in a traffic accident.

• Fixtheopticalcableconnectionboxsecurely

with the hook and loop fastener or lock tie. If

the unit is loose, it disturbs driving stability,

which may result in a traffic accident.

CAUTION

• Install this unit using only the par ts supplied with

this unit. If other parts are used, this unit may be

damaged or could dismount itself, which leads to

an accident or other problems.

• Do not install this unit near the doors where

rainwater is likely to be spilled on the unit.

Incursion of water into the unit may cause smoke

or fire.

Connecting the optical cable

1. Connect the optical cable and

ground lead to the main unit.

Connect the optical cable so that it does not

protrude from the main unit, as shown in the

illustration. Fasten the ground lead to the

protrusion on the back of the main unit.

Screw

2. Connect the optical cable to the

optical cable connection box.

optical cable

Installing the optical cable

connection box

• When installing the optical cable

connection box with the hook and

loop fastener.

Install the optical cable connection box

using the hook and loop fastener in the

amplespaceoftheconsolebox.

Hook fastener

Loop fastener

• When installing the optical cable

connection box with the lock tie.

Wrap the optical cable and connection box

with the protection tap e and fasten with the

power code using the lock tie.

Wrap with the protection tape

Fasten with the lock tie

22

AVH-P5200BT/XNUC

Page 23

5678

56

7

8

C

D

F

A

B

E

Bluetooth adapter

(e.g. CD-BTB100)

(sold separately)

Display with

RCA input jacks

To video input

(sold separately)

Mini pin plug cable

To audio input

(sold separately)

External video

component

(sold separately)

To video output

To audio outputs

Microphone

for hands-free phoning

(supplied with Bluetooth adapter)

(AVH-P5250DVD only)

Black

RCA cables (sold separately)

13 cm

Rear monitor output

(REAR MONITOR OUTPUT )

When connecting the external video component and the display

This product

RCA cables (sold separately)

17 cm

Rear audio output

(REAR MONITOR OUTPUT(AUDIO) )

IP-BUS cable

(Supplied with Bluetooth adapter)

Wired remote input

(WIRED REMOTE INPUT )

Hard-wired remote control

adaptor can be connected

13 cm

Video input (VIDEO INPUT )

(AUDIO INPUT )

Audio input

• It is necessary to change AV Input in Sys tem Menu when connecting the external video

component.

WARNING

This product’s rear video output and rear audio output are for connection of a display to enable

passengersin therearseatstowatch theDVD,etc.

When using a display connected to rear video output

Never install the display in a location where it is visible to the driver while driving.

Connecting the system

(sold separately).

IP-BUS input

This product

AVH-P5200BT/XNUC

23

Page 24

1234

1234

C

D

F

A

B

E

3. BASIC ITEMS FOR SERVICE

To keep the product quality after servicing, please confirm following check points.

No. Procedures Item to be confirmed

1 Confirm whether the customer complain has

been solved.

If the customer complain occurs with the

specific media, use it for the operation check.

The customer complain must not be

reappeared.

Display, video, audio and operations must be

normal.

3 DVD Measure playback error rates at the

innermost and outermost tracks by using the

test mode with the following disc.

DVD test disc (TDV-582)

Deterioration of mecha-drive can be

checked.

The error rate must be less than the

threshold value.

(Refer to the chapter of DIAGNOSIS for the

threshold value.)

4 DVD Play back a DVD.

(Menu operation; Title/chapter search)

Display, video, audio and operations must be

normal.

5 CD Play back a CD.

(Track search)

Display, audio and operations must be

normal.

6 FM/AM tuner Check FM/AM tuner action.

(Seek, Preset)

Switch band to check both FM and AM.

Display, audio and operations must be

normal. * If the reception sensitivity is poorer

than normal, the gasket on the FM/AM tuner

unit may be damaged or lost.

7 Check whether no disc is inside the product. The media used for the operating check must

be ejected.

8 Appearance check No scratches or dirt on its appearance after

receiving it for service.

For check items concerning image and voice, please refer to the followings:

Check items concerning image Check items concerning voice

Block-noise Distortion

Crosscut noise Noise

Dot noise Low volume

Distorted image (Image skip) High volume

Low brightness Changes in level

Too bright Pause of sound

Color fading

Partial discoloration

2 Flap-mecha Check the operation of the flap mechanism. The flap mechanism operation must be

smooth without making the noise and

scratches.

3.1 CHECK POINTS AFTER SERVICING

24

AVH-P5200BT/XNUC

Page 25

5678

56

7

8

C

D

F

A

B

E

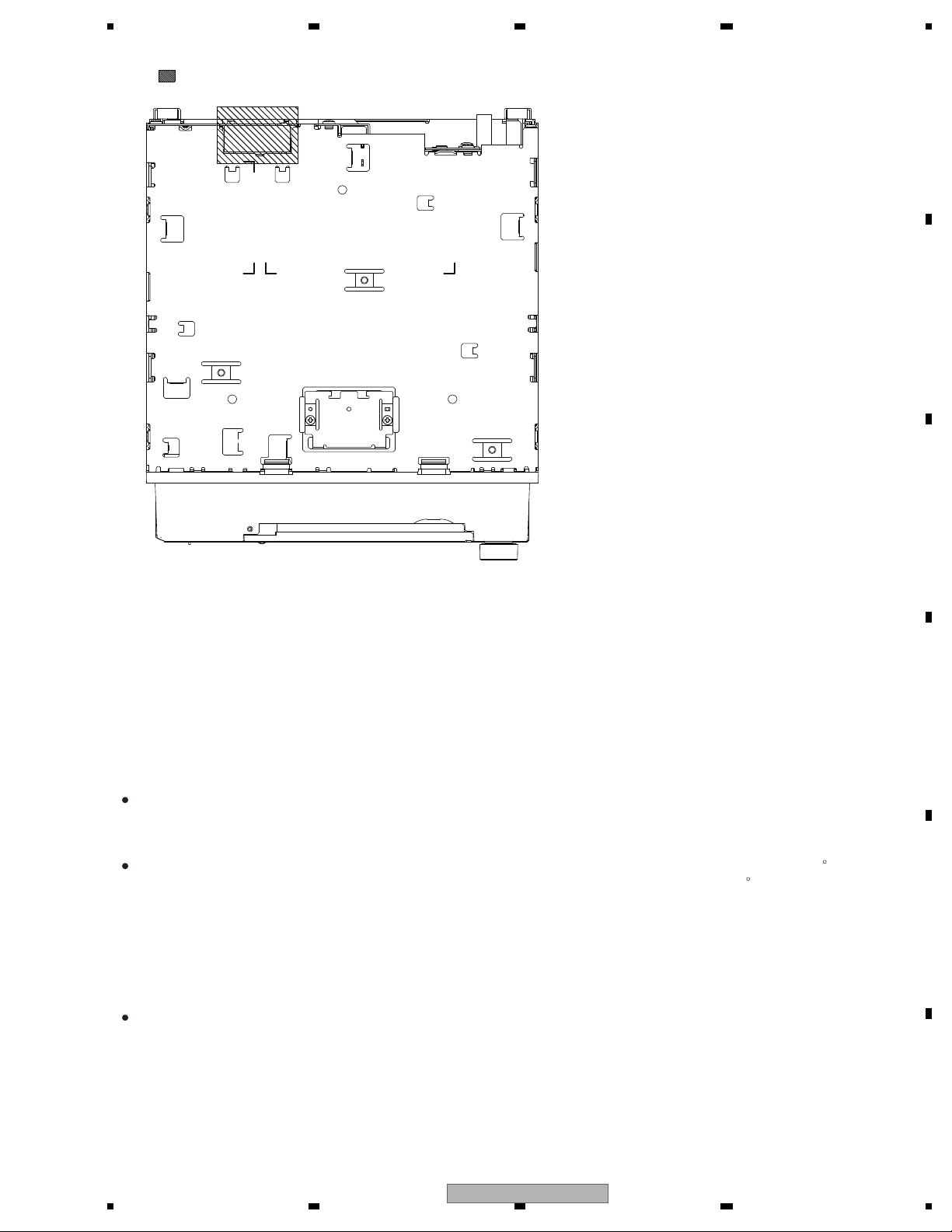

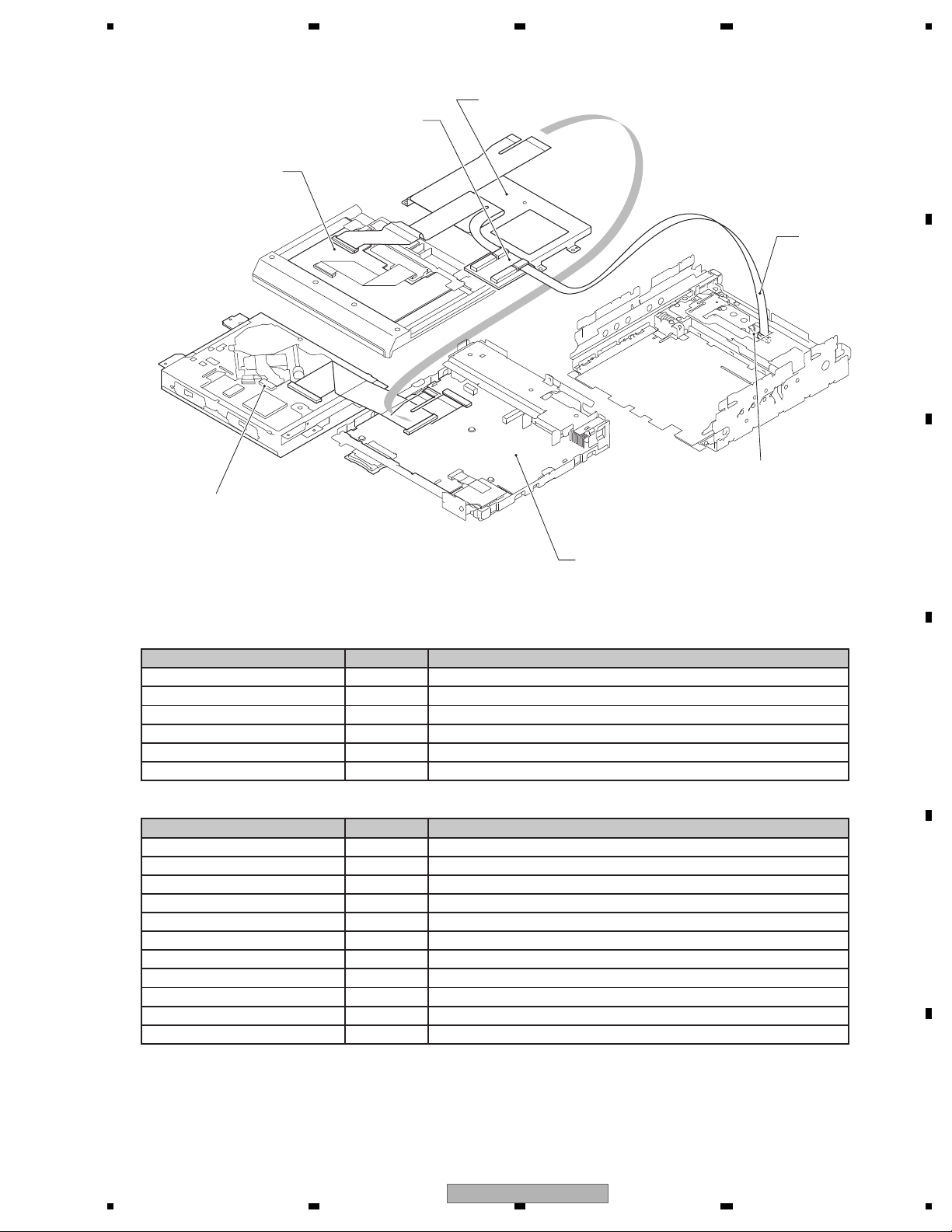

Monitor PCB

Panel PCB

DVD Amp Unit (Service)

Main PCB Unit

H

F

G

K

BT ANT PCB

J

Tuner Box Unit

B

A

BT PCB

I

M

Keyboard PCB

Volume PCB Unit

C

D

E

DVD Core Unit

(MS7)

Compound Unit (A)

Compound Unit (B)

BT Model

DVD Model

L

Switch PCB Unit

Monitor PCB

Panel PCB

DVD Amp Unit

Main PCB Unit

H

F

G

K

A

M

Keyboard PCB

Volume PCB Unit

L

Switch PCB Unit

3.2 PCB LOCATIONS

AVH-P5200BT/XNUC

25

Page 26

1234

1234

C

D

F

A

B

E

H:AVH-P5200BT/XNUC

I:AVH-P5250BT/XNRD

B:AVH-P5200DVD/XNUC

C:AVH-P5250DVD/XNRC

D:AVH-P5250DVD/XNRD

E:AVH-P5250DVD/XNRI

Unit Number : CXX2838(H)

Unit Number : CXX2839(I)

Unit Name : DVD Amp Unit(Service)

Unit Number : CWN4979(B)

Unit Number : CWN4980(C)

Unit Number : CWN4981(D)

Unit Number : CWN4982(E)

Unit Name : DVD Amp Unit

Unit Number : CWN3129(H,B)

Unit Number : CWN3130(I,C,D,E)

Unit Name : Tuner BOX Unit

Keyboard Unit

Consists of

Panel PCB

Keyboard PCB

Unit Number : CWN4996

Unit Name : Keyboard Unit

Monitor Unit(Service)

Consists of

Monitor PCB

BT PCB

BT ANT PCB

Unit Number : CXX2841(H,I)

Unit Name : Monitor Unit(Service)

Unit Number : CWN4992(B,C,D,E)

Unit Name : Monitor Unit

Unit Number : EWM5101

Unit Name : Main PCB Unit

Unit Number :

Unit Name : Switch PCB Unit

Unit Number :

Unit Name : Volume PCB Unit

Unit Number : YWX5010

Unit Name : DVD Core Unit(MS7)

Unit Number : CWX3864

Unit Name : Compound Unit(A)

Unit Number : CWX3559

Unit Name : Compound Unit(B)

26

AVH-P5200BT/XNUC

Page 27

5678

56

7

8

C

D

F

A

B

E

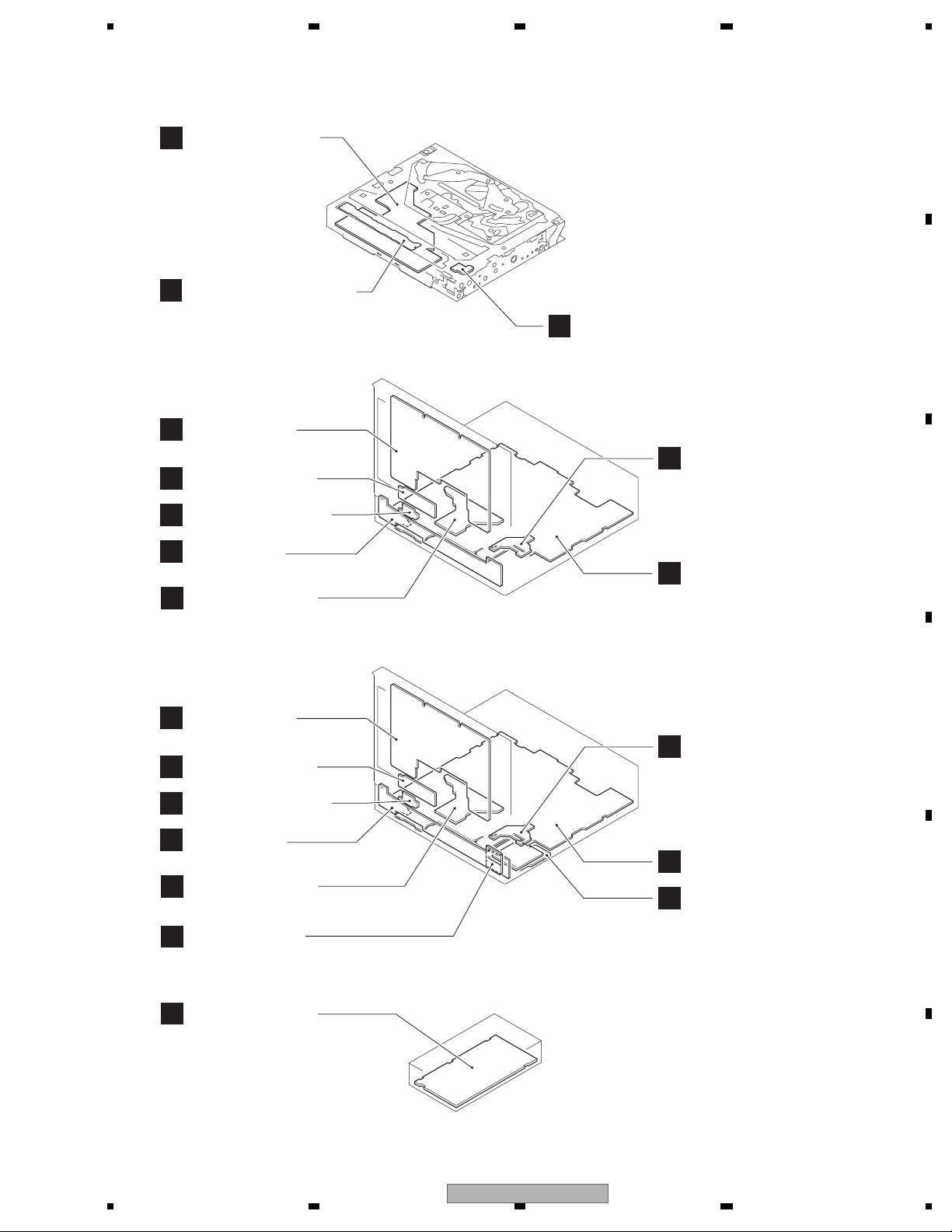

Drive Unit

GGF1461

40-Pin + 20-Pin

Extension Board

GGD1209

20-Pin FFC

DVD Mechanism Module

Bracket

Monitor Unit

DVD Amp Unit

- Jigs List

- Grease List

Name Jig No. Remarks

DVD-Video GGV1025 Skew adjustment

CD-DA TCD-782 Skew adjustment

TORX driver(T2) GGK1095 Skew adjustment

Bond GEM1033 Skew adjustment

20P FFC GGD1209 Drive Unit <--> 40P+20P Extension Board

40P+20P Extension Board GGF1461 Mother Unit (Only 20P side is used.)

Name Jig No. Remarks

Grease GEM1038 DVD Mechanism Module

Grease GEM1045 DVD Mechanism Module

Grease GEM1050 DVD Mechanism Module

Grease GEM1085 DVD Mechanism Module

Grease GEM1024 DVD Mechanism Module and Drive Unit

Grease GEM1043 DVD Mechanism Module and Drive Unit

Locking agents 1401M DVD Mechanism Module (1401M:produced by THREE BOND)

Grease GEM1011 Drive Unit

Grease GEM1047 Drive Unit

Grease GEM1071 Drive Unit

Grease GEM1072 Drive Unit

3.3 JIGS LIST

AVH-P5200BT/XNUC

27

Page 28

1234

1234

C

D

F

A

B

E

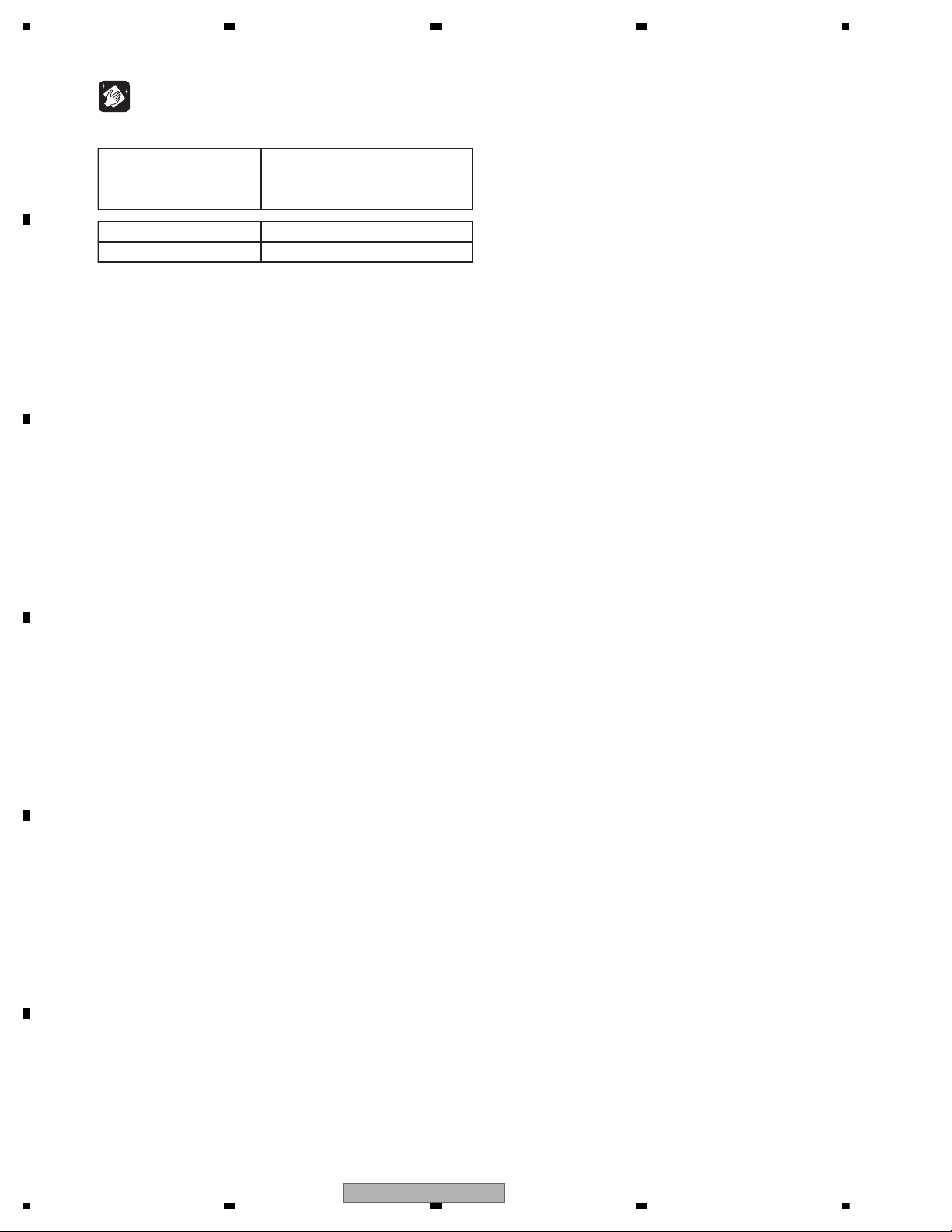

3.4 CLEANING

Before shipping out the product, be sure to clean the following portions by using the prescribed cleaning tools:

Portions to be cleaned Cleaning tools

DVD pickup lenses Cleaning liquid : GEM1004

Cleaning paper : GED-008

Portions to be cleaned Cleaning tools

Fans Cleaning paper : GED-008

28

AVH-P5200BT/XNUC

Page 29

5678

56

7

8

C

D

F

A

B

E

AVH-P5200BT/XNUC

29

Page 30

1234

1234

C

D

F

A

B

E

4. BLOCK DIAGRAM

CN331

CKS4497-A

11

CCAUR

12

GNDAU

14

ONSEI-

15

REAUR16REAUL

17

GNDRAU

18

CCREM

19

DSEN20TVON

21GION

22

MONON

23

VSW5

24

SYS_TO_NAVI

25

NAVI_TO_SYS

26

GNDD

13

ONSEI+

JA481

CKN1050-A

431

2

JA301

CKS3414-A

1

BUS+2BUSG

3

BUSLG

4

MAINTEST

5

BUS-

6

BUSRG7BUSL+

8

ASENBO

9

BUSR+

10

BUSR-

11

BUSL-

CKS5543-A

CN2001

1

ANGLE

2

LIFTPUL

3

MTRS

4

MTRPW

5

MTR2

6

MTR1

7

MTRSEL

8

ANGL0SW

9

LFTSW

10

SENSPW

11

VDD

12

NC

13

GNDD

14

GND

15

GND

16

GND

17

NC

18

BUP

19

BUP

20

BUP

CKS5732-A

CN2021

1

TEMP1

2

DIMPLS

3

MBLPW

4

BLCLK

5

BLERR1

6

PWRBL

7

PWRBL

8

PWRBL

9

NC

10

GNDBL

11

GNDBL

12

GNDBL

13

MOVBS

14

VGND

15

ANAB

16

CSYNC

17

ANAR

18

ANAG

19

VGND

20

GRST

21

GtoS

22

StoG

23

DGCLK

24

GtoD

25

DtoG

26

NC

27

ILMB

28

NC

29

GNDILM

30

NC

31

KDT1

32

NC

33

NC

34

GNDKEY

35

GNDKEY

36

ILB

37

ILG

38

ILR

39

PLYV

40

PLXV

41

ADVX

42

ADVY

43

PWGR

44

GNDD

45

GNDD

46

GNDD

47

NC

48

PWRVI

49

PWRVI

50

PWRVI

CKS6180-A

CN961

1

CD/DAT3

3

VSS1

5

CLK

7

DAT0

9

DAT2

11

GND2

13

CD/WP

14

WP

12

CD

10

GND1

8

DAT1

6

VSS2

4

VDD

2

CMD

15

NC1

16

NC2

17

GND3

18

GND4

19

GND5

20

GND6

REMIN

VCC33NCAUX_L

AUX_AGND

AUX R

12345

CKS5858-A

CN3001

REMIN

VCC33NCAUX_L

AUX_AGND

123

4

5

CKS6008-A

CN5002

PWRVI

1

PWRVI

2

PWRVI

3

NC

4

GNDD

5

GNDD

6

GNDD

7

PWGR

8

ADVY

9

ADVX

10

PLXV

11

PLYV

12

ILR

13

ILG

14

ILB

15

GNDKEY

16

GNDKEY

17

NC

18

NC

19

KEY1

20

NC

21

GNDILM

22

NC

23

ILMB

24

NC

25

DtoG

26

GtoD

27

DGCLK

28

StoG

29

GtoS

30

GRST

31

VGND

32

ANAG

33

ANAR

34

CSYNC

35

ANAB

36

VGND

37

MOVBS

38

GNDBL

39

GNDBL

40

GNDBL

41

NC

42

PWRBL

43

PWRBL

44

PWRBL

45

BLERR1

46

BLCLK

47

MBLPW

48

DIMPLS

49

TEMP1

50

CKS6062-A

CN5601

GND

1

GND

2

GND

3

NC

4

VCC

5

VCC

6

VCC

7

VCC

8

NC

9

TEST

10

TEST

11

TEST

12

VSYNC

13

HSYNC

14

GND

15

SHUT

16

GND

17

R5

18

R4

19

R3

20

R2

21

R1

22

R0

23

GND

24

G5

25

G4

26

G3

27

G2

28

G1

29

G0

30

GND

31

B5

32

B4

33

B3

34

B2

35

B1

36

B0

37

GND

38

DCLK

39

GND

40

CKS5695-A

CN5802

GNDKEY

1

ILMB

2

KEY1

3

LEDR1

4

LEDG1

5

LEDB1

6

CKS5561-A

CN5701

LED41LED32LED23LED1

4NC5

BLP6BLP7NC8TEMP19GNDD

10

CKS5561-A

CN5101

NC

1

PLYV2PLYV3PLXV

4

PLXV

5

ADVX6ADVX7ADVY8ADVY

9

NC

10

JA3001

CKN1084-A

GND

NAVI INTERFOUT

S/PDIF

IP-BUS

SD CARD

AUX

BACK LIGHT

TOUCH PANEL

AVH-P5200DVD/XNUC

AVH-P

AVH-P5250DVD/XNRD

AVH-P5250DVD/XNRI

H

AVH-P5250DVD/XNRC

C

I

E

B

AVH-

D

no BT model

C - E,I only

C - E,I only

LCD MODULE

DVD AMP UNIT

1/5

A

(ANALOG

DVD AMP UNIT

2/5

A

(SYSTEM

DVD AMP UNIT

3/5

A

(POWER

DVD AMP UNIT

4/5

A

(MMD PA

DVD AMP UNIT

5/5

A

(I/F PART

A

DVD AMP UNIT

H

MONITOR PCB

MONITOR PCB

1/2

H

(MONITOR PART)

MONITOR PCB

2/2

H

(BACKLIGHT PART)

G

KEYBOARD PCB

DRIVE UNIT

CN3500

L

K

M

4.1 OVERALL CONNECTION DIAGRAM

30

AVH-P5200BT/XNUC

Page 31

5678

56

7

8

C

D

F

A

B

E

CN101

CKM1516-A

FL-

RL-

FL+

RL+

FR-

RR-

FR+

RR+

P.B.

BGSENS

ACC

B.REM

ILM

MUTE

B.UP

GND

12345

678

9

101112

14

151613

CN401

CKS5492-A

1

WIRED

2

RCAOUT_L

3

WIREDAD

4

RCAOUT_GND

5

WIRED_GND

6

RCAOUT_R

7

BTMIC_GND

8

VCRIN_L

9

BTMIC_IN

10

VCRIN_LGND

11

BCAM_VGND

12

VCRIN_R

14

VCRIN_RGND

15

VCRIN_VGND

16

VCRAOUT_V

17

VCRIN_V

18

VCRAOUT_VGND

19

NC

20

NC

21

NC

22

NC

23

NC

24

NC

25

NC

26

NC

27

NC

28

NC

29

RCA_FL

30

RCA_FR

31

RCA_FLGND

32

RCA_FRGND

33

RCA_RL

34

RCA_RR

35

RCA_RLGND

36

RCA_RRGND

37

RCA_SWL

38

RCA_SWR

39

RCA_SWLGND

40

RCA_SWRGND

13

BCAM_IN

CN331

CKS4497-A

1

CCR2CCG3CCB

4

CCSYNC

5

GNDSIG

6

DVDVBS

7

GNDDVD

8YS9

ASENB

10

CCAUL

11

CCAUR

12

GNDAU

14

ONSEI-

15

REAUR16REAUL

17

GNDRAU

18

CCREM

19

DSEN20TVON

13

ONSEI+

CKS4674-A

CN781

RDSLOCK

1

NC

2

RDSCK 3

DSEN 4

RDSHSLK 5

TUNCE2 6

RDSDATA 7

OSCGND 8

DGND 9

BEGND

10

TUNCK 11

TUN_R 12

TUNDI 13

TUN_L 14

TUNDO 15

ROMVDD 16

TUNSL 17

LDET 18

TUNCE19

B.UP 20

CKS6025-A

CN751

1

GNDD

2

NC

3

NC

4

GNDD

5

GNDD

6

IECOUT

7

GNDD

8

NC

9

NC

10

GNDD

11

VGND

12

COMPOSIT

13

AGND

14

LOUT

15

AGND

16

ROUT

17

AGND

18

STANBY

19

MS7

SRX

20

S

MS7TX

21

IRGPWR

22

XRESET

23

AMUTE

24

VD5

25

GNDD

26

PGND

27

PGND

28

VD

29

VD

30

VD

CKS3878-A

CN795

BT_MIC1P

SYS+B

BT_MIC1N

BT_RST

BT_SPK1P

BT33

BT_SPK1N

S_BTTX

GNDBT

BT_SRX

1

2

3

4

5

6

7

8

9

10

CKS4822-A

CN1741

1

GND

2

FUN+

CKS5858-A

CN561

REMIN

VCC33NCAUX_L

AUX_AGND

AUX_R

AUX_V

AUX_VGND

USB-

USB+

USB_GND

USB_GND

USB_5V

ILM+B

DSENS

ROT_IN2

ROT_IN1

ILMGND

LED_B

LED_G

LED_R

RESET

GNDKEY

KDT1

KDT0

USB_5V

123456789

1011121314151617181920212223242526

CKS3878-A

CN8001

SYS+B

BT_MIC1P

BT_RST

BT_MIC1N

BT_SRX

GNDBT

S-BTTX

BT_SPK1N

BT33

BT_SPK1P

1

2

3

4

5

6

7

8

9

10

CKS6192-A

CN8002

U1IN

1

BT33

2

SPK1P

3

SPK1N

4

VSS

5

NBOOTS

6

U3IN

7

U3OUT

8

NRST_CPU

9

VCC_MIC

10

MIC1N

11

MIC1P

12

VSS

13

U1OUT

14

CKS5858-A

CN3001

REMIN

VCC33NCAUX_L

AUX_AGND

AUX_R

AUX_V

AUX_VGND

USB-

USB+

USB_GND

USB_GND

USB_5V

ILM+B

DSENS

ROT_IN2

ROT_IN1

ILMGND

LED_B

LED_G

LED_R

RESET

KEYGND

KDT1

KDT0

USB_5V

123

4

56789

1011121314151617181920212223242526

YKS5032-A

CN3002

1

USB5V

2

USDM3USDP

4

USGND5USGND

JA3001

CKN1084-A

AUXV

1

1

AUXL

2

2

AUXR

3

3

GND

4

4

NAVI INTERFACE

FAN

POWER SUPPLY

BTMIC_IN

FR/FL

VIDEO_IN