查询TEA1211供应商

INTEGRATED CIRCUITS

DATA SH EET

TEA1211HN

High efficiency auto-up/down

DC/DC converter

Preliminary specification

Supersedes data of 2003 Aug 06

2003 Oct 13

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 ORDERING INFORMATION

5 BLOCK DIAGRAM

6 PINNING

7 FUNCTIONAL DESCRIPTION

7.1 Introduction

7.2 Control mechanism

7.2.1 PWM

7.2.2 PFM

7.2.3 Switching sequence

7.3 Adjustable output voltage

7.4 Start-up

7.5 Under voltage lockout

7.6 Shut-down

7.7 Power switches

7.8 Synchronous rectification

7.9 PWM-only mode

7.10 External synchronisation

7.11 Current limiter

7.12 I2C-bus serial interface

7.12.1 Characteristics of the I2C-bus

7.12.2 START and STOP conditions

7.12.3 Bit transfer

7.12.4 Acknowledge

7.13 I2C-bus protocol

7.13.1 Addressing

7.13.2 Data

7.13.3 Write Cycle

TEA1211HN

8 LIMITING VALUES

9 THERMAL CHARACTERISTICS

10 CHARACTERISTICS

11 APPLICATION INFORMATION

11.1 Typical Li-Ion, 2- or 3-cell application with

I2C-bus programming

11.2 Component selection

11.2.1 Inductor

11.2.2 Capacitors

11.2.3 Schottky diodes

11.2.4 Feedback resistors

11.2.5 Current Limiter

12 PACKAGE OUTLINE

13 SOLDERING

13.1 Introduction to soldering surface mount

packages

13.2 Reflow soldering

13.3 Wave soldering

13.4 Manual soldering

13.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

14 DATA SHEET STATUS

15 DEFINITIONS

16 DISCLAIMERS

17 PURCHASE OF PHILIPS I2C COMPONENTS

2003 Oct 13 2

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

1 FEATURES

• I2C-bus programmable output voltage range of

1.5 V to 5.5 V

• Single inductor topology

• High efficiency up to 94 % over wide load range

• Wide input range; functional from 2.55 V up to 5.5 V

• 1.7 A maximum input and output current

• Low quiescent power consumption

• 600 kHz switching frequency

• Four integrated very low R

• Synchronizable to external clock

• Externally adjustable current limit for protection and

efficient battery use in case of dynamic loads

• Under voltage lockout

• PWM-only option

• Shut-down current less than 1 µA

• 32-pin small body HVQFN package.

2 APPLICATIONS

power MOSFETs

DS(on)

TEA1211HN

3 GENERAL DESCRIPTION

The TEA1211HN is a fully integrated auto-up/down

DC/DC converter circuit with I2C-bus interface. Efficient,

compactanddynamicpower conversionis achievedusing

adigitally controlledpulse widthand frequencymodulation

like control concept, four integrated low R

switches with low parasitic capacitances and fully

synchronous rectification.

Thecombination ofauto-up/downDC/DC conversion,high

efficiency andlow switchingnoise makesthe TEA1211HN

well suited to supply a power amplifier in a cellular phone.

The output voltage can be I2C-bus programmed to the

exact voltage needed to achieve a certain output power

level withoptimal systemefficiency, thus enlargingbattery

lifetime.

DS(on)

power

• Stable output voltage from Lithium-Ion batteries

• Variable voltage source for PAs (Power Amplifiers) in

cellular phones

• Wireless handsets

• Hand-held instruments

• Portable computers.

4 ORDERING INFORMATION

TYPE

NUMBER

TEA1211HN HVQFN32 plastic thermal enhanced very thin quad flat package; no leads;

NAME DESCRIPTION VERSION

32 terminals; body 5 × 5 × 0.85 mm

TheTEA1211HN operatesat600 kHz switchingfrequency

which enables theuse of small sizeexternal components.

The switchingfrequency can belocked toan external high

frequency clock. Deadlock is prevented by an on-chip

under voltage lockout circuit. An adjustable current limit

enables efficient battery use even at high dynamic loads.

Optionally, the device can be kept in pulse width

modulation mode regardless of the load applied.

PACKAGE

SOT617-3

2003 Oct 13 3

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

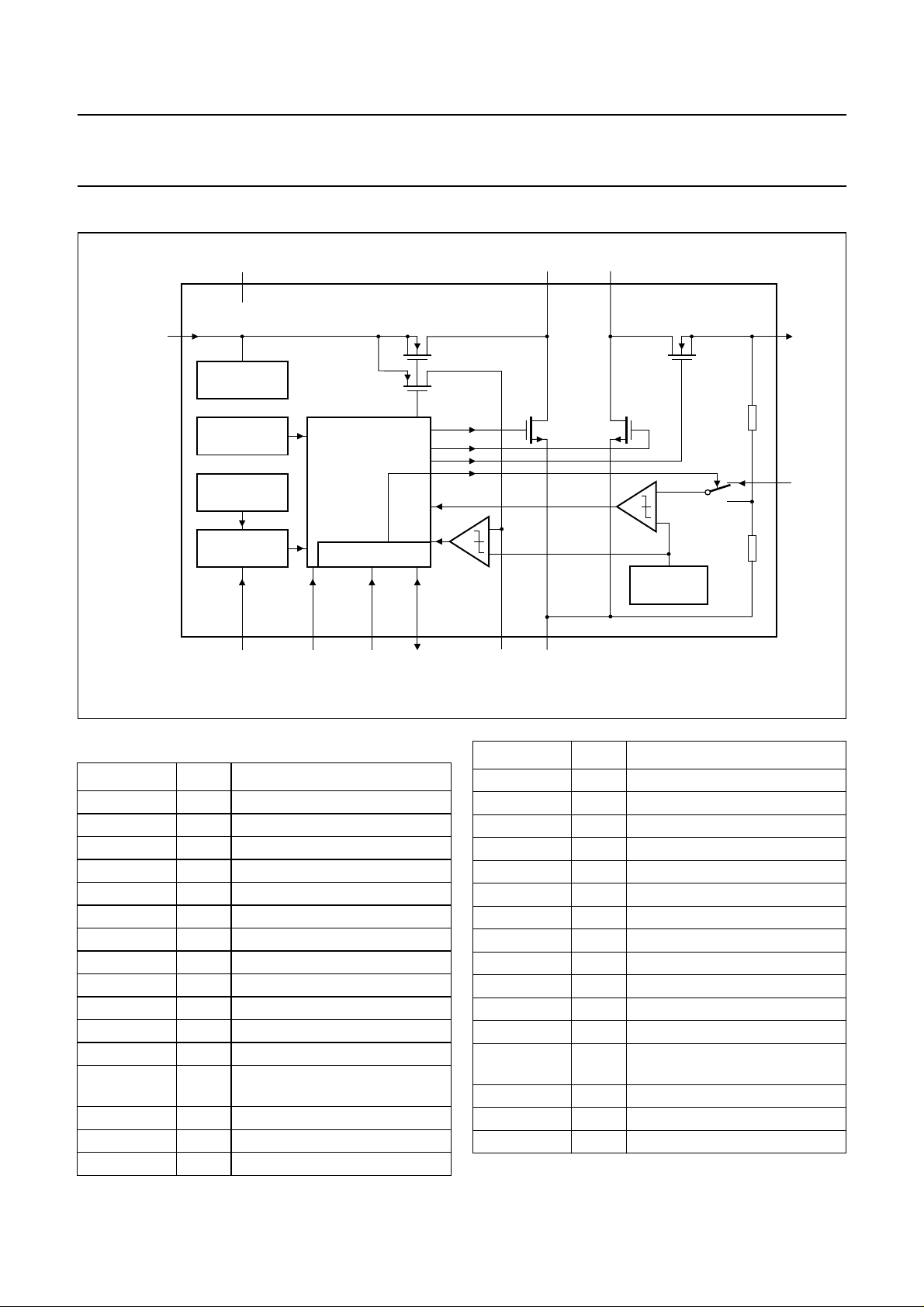

5 BLOCK DIAGRAM

handbook, full pagewidth

IN

n.c.

2, 31, 32

INTERNAL

SUPPLY

TEMPERATURE

PROTECTION

13 MHz

OSCILLATOR

CLOCK

SELECTOR

6, 8, 17, 19

TEA1211HN

I2C-BUS INTERFACE

P-type power FET

sense FET

DIGITAL

CONTROLLER

P-down

Current limit

comparator

N-down

10, 11

N-type

power FETs

LXBLXA

14, 15, 21, 22, 241, 3, 4,

N-up

P-type power FET

P-up

Window

comparator

BANDGAP

REFERENCE

TEA1211HN

23, 25, 26

OUT

27

FB

29

SYNC/PWM SHDWN SCL SDA ILIM GND

28 12 13 30

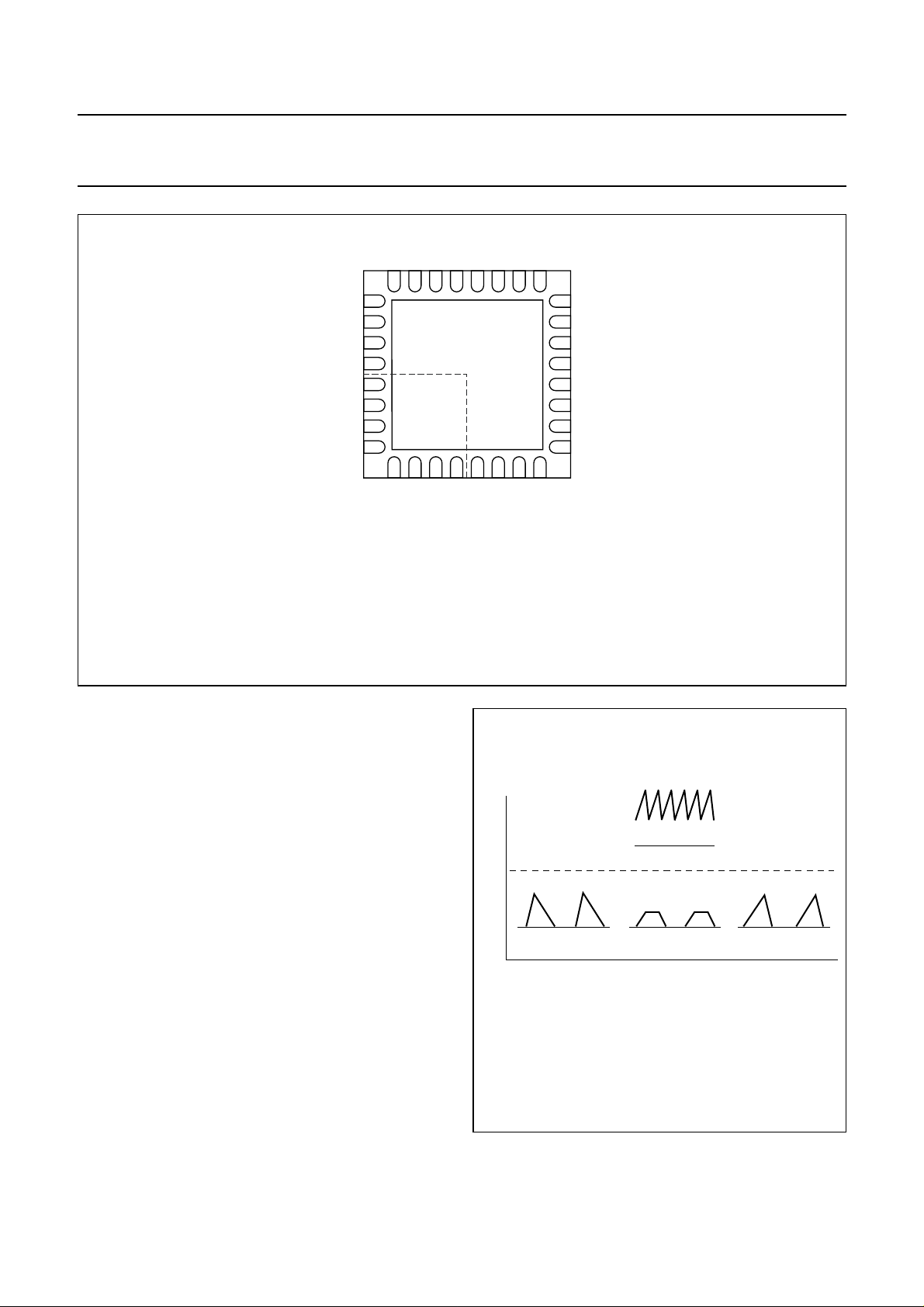

6 PINNING

SYMBOL PIN DESCRIPTION

LXA 1 inductor connection 1

IN 2 input voltage

LXA 3 inductor connection 1

LXA 4 inductor connection 1

GND 5 ground

n.c. 6 not connected

GND 7 ground

n.c. 8 not connected

GND 9 ground

LXA 10 inductor connection 1

LXA 11 inductor connection 1

2

SCL 12 serial clock input line I

C-bus

SDA 13 serial data input/output line

2

C-bus

I

LXB 14 inductor connection 2

LXB 15 inductor connection 2

GND 16 ground

5, 7, 9, 16, 18, 20

MDB001

Fig.1 Block diagram.

SYMBOL PIN DESCRIPTION

n.c. 17 not connected

GND 18 ground

n.c. 19 not connected

GND 20 ground

LXB 21 inductor connection 2

LXB 22 inductor connection 2

OUT 23 output voltage

LXB 24 inductor connection 2

OUT 25 output voltage

OUT 26 output voltage

FB 27 feedback input

SHDWN 28 shut-down input

SYNC/PWM 29 synchronization clock input,

PWM-only input

ILIM 30 current limit resistor connection

IN 31 input voltage

IN 32 input voltage

2003 Oct 13 4

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

handbook, halfpage

8

n.c.

7

GND

6

n.c.

5

GND

4

LXA

3

LXA

2

IN

1

LXA

This diagram is a bottom side view.

Pin 1 is indicated with a dot on the top side of the package.

For mechanical details of HVQFN32 package, see Chapter 12.

GND

9

32

IN

LXA

10

31

IN

SDA

LXA

SCL

11

13

TEA1211HN

282627

30

29

ILIM

SHDWN

SYNC/PWM

LXB

141215

FB

LXB

OUT

GND

16

17

18

19

20

21

22

23

24

25

MDB002

OUT

TEA1211HN

n.c.

GND

n.c.

GND

LXB

LXB

OUT

LXB

Fig.2 Pin configuration.

7 FUNCTIONAL DESCRIPTION

7.1 Introduction

The TEA1211HN is able to operate in Pulse Frequency

Modulation (PFM) or discontinuous conduction mode as

well as in Pulse Width Modulation (PWM) or continuous

conduction mode. All switching actions are completely

determined by a digital control circuit which uses the

output voltage levelas control input. This digital approach

enables the use of a new pulse width and frequency

modulation scheme, which ensures optimum power

efficiency over the complete range of operation of the

converter.

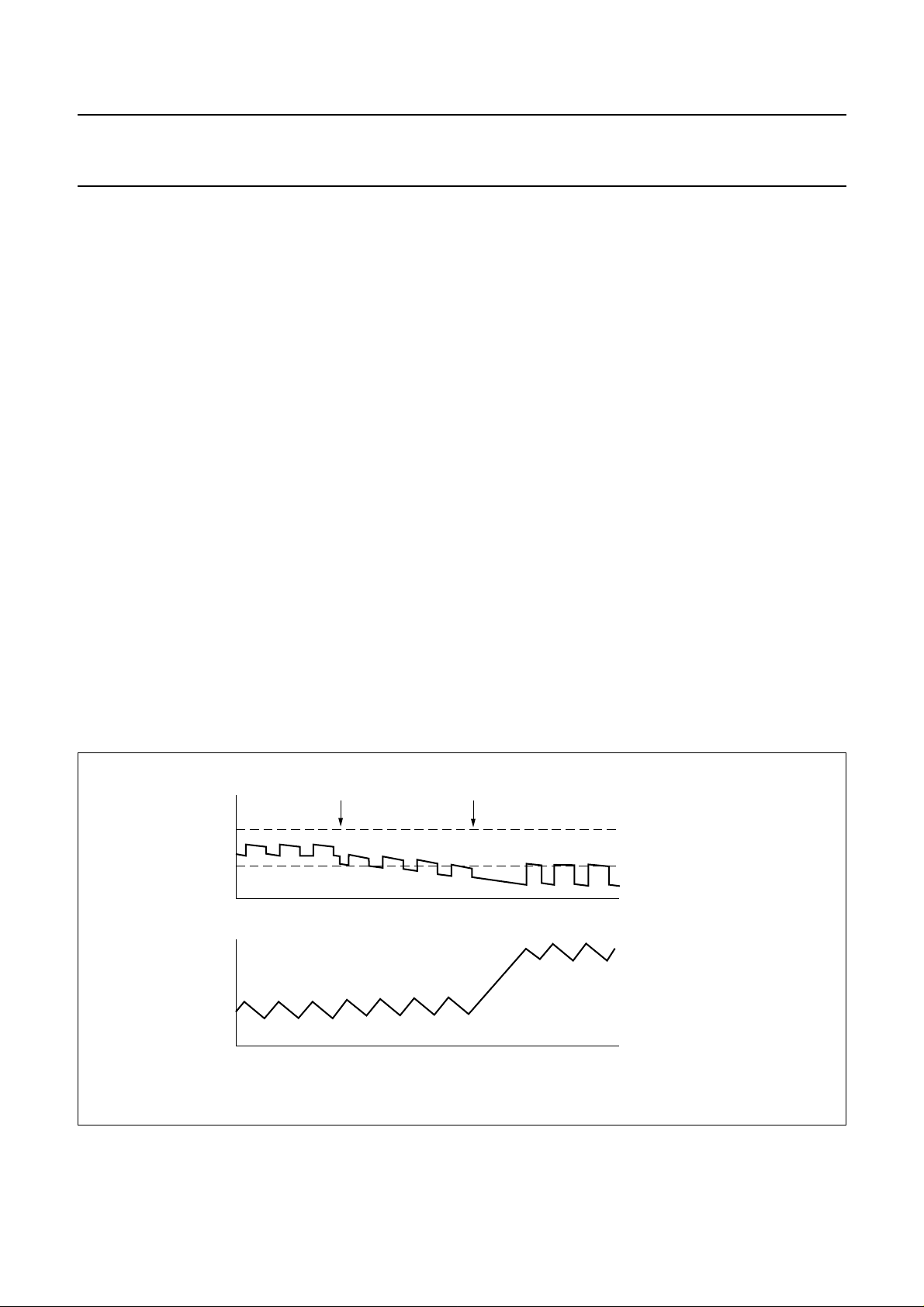

7.2 Control mechanism

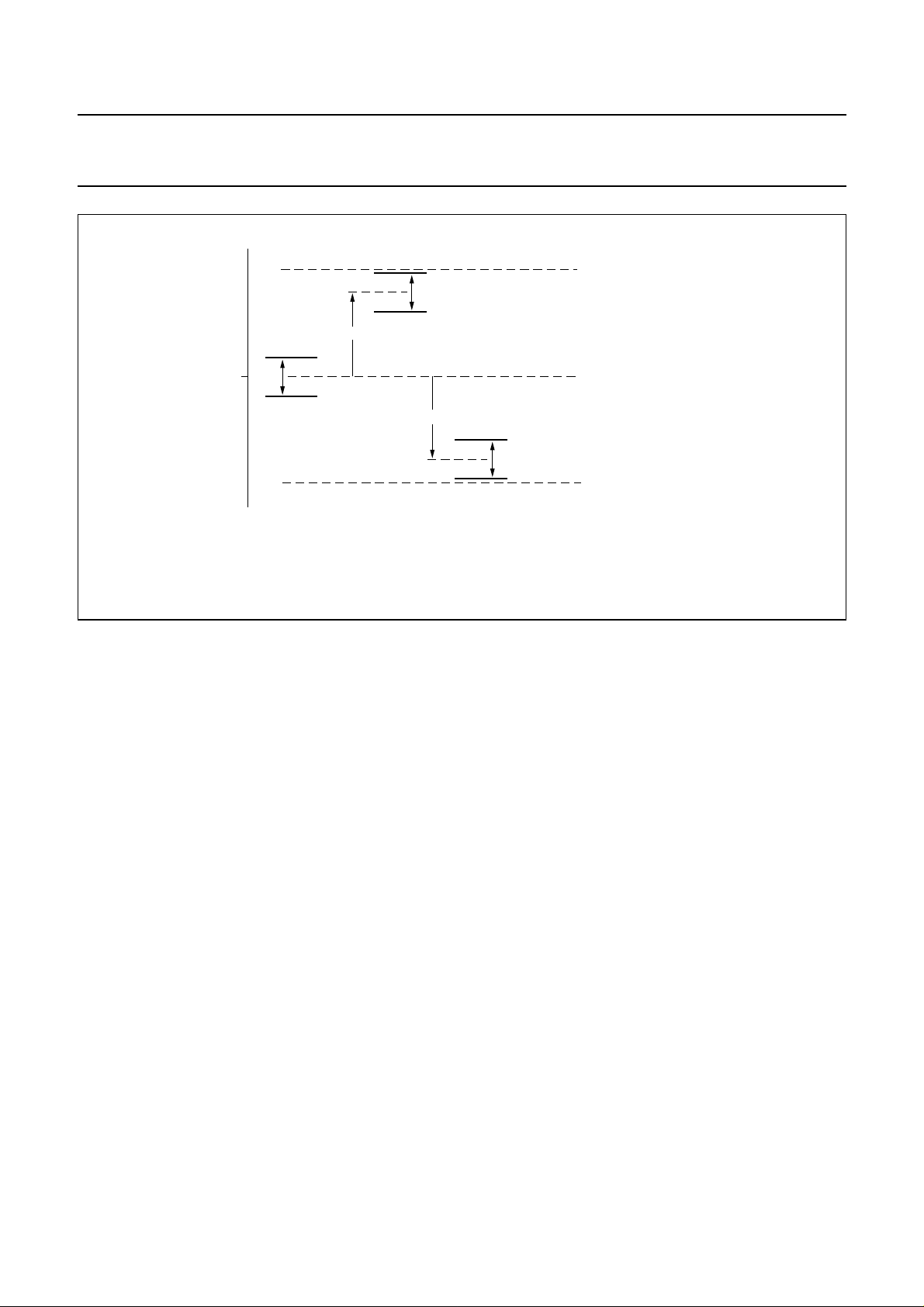

Depending on load current I

and VIN to V

load

ratio, the

OUT

controller choosesa mode ofoperation. Whenhigh output

power is requested, the device will operate in PWM

(continuousconduction)mode, whichis a2-phase cyclein

up- as well as in down mode. For small load currents the

controller will switch over to PFM (discontinuous mode),

which is either a 3- or 4-phase cycle depending on the

input to output ratio, see Fig.3.

handbook, halfpage

I

coil

0

VIN > V

OUT

down mode

VIN = V

OUT

stationary mode

Fig.3 Waveform of coilcurrentas function of I

and VIN to V

OUT

ratio.

VIN < V

up mode

PWM

PFM

OUT

MDB003

load

2003 Oct 13 5

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

7.2.1 PWM

PWM results in minimum AC currents in the circuit

components and hence optimum efficiency, cost and

EMC. In this mode the output voltage is allowed to vary

between two predefined voltage levels. When the output

voltage stays within this so called window, switching

continues in a fixed pattern. When the output voltage

reaches one of the window borders, the digital controller

immediately reacts by adjusting the duty cycle and

inserting a current step in such a way that the output

voltage stays within the window with higher or lower

current capability. This approach enables very fast

reaction to load variations.

Figure 4 shows the TEA1211HN’s response to a sudden

load increase in case of up conversion. The upper trace

showstheoutput voltage.The rippleon topof theDC level

is a result of the current in the output capacitor, which

changes in sign twice per cycle, multiplied by the

capacitor’s internal Equivalent Series Resistance (ESR).

After eachramp-down of the inductorcurrent, or whenthe

ESR effect increases theoutput voltage, the TEA1211HN

determines what to do in the next cycle.As soon as more

load current is taken from the output the output voltage

starts to decay. When the output voltage becomes lower

than the low limit ofthe window, corrective action is taken

by a ramp-upof the inductor currentduring a much longer

time. As a result, the DC current level is increased and

TEA1211HN

normal PWM control can continue. The output voltage

(including ESR effect) is again within the predefined

window.

Figure 5 depicts the spread of theoutput voltage window.

Theabsolute valueismost dependentonspread,whilethe

actualwindowsize isnot affected.For onespecific device,

the output voltage will not vary more than 2 % typically.

7.2.2 PFM

In low output power situations, TEA1211HN will switch

over to PFM mode operation in case PWM-only mode is

not activated. In this mode charge is transferred from

battery to output in single pulses with a wait phase in

between. Regulation information from earlier PWM mode

operation is used. This results in optimum inductor peak

current levels in PFMmode,which are slightly larger than

the inductor ripple current in PWM mode. As a result, the

transition between PFM and PWM mode is optimal under

all circumstances. In PFM mode, the TEA1211HN

regulates the output voltage to the limits shown in Fig.5.

Depending on the VIN to V

decides for a 3- or 4-phase cycle, where the last phase is

the wait phase. When the inputvoltagealmost equals the

output voltage, one of the slopes of a 3-phase cycle

becomes weak. Then the charge, or the integral of its

pulse, is near to zero and no charge is transferred. In this

region the 4-phase cycle is used, (see Fig.3).

ratio the TEA1211HN

OUT

handbook, full pagewidth

V

OUT

I

load

load increase

start corrective action

Fig.4 Response to load increase in up-mode.

2003 Oct 13 6

time

time

high window limit

low window limit

MDB004

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

handbook, full pagewidth

V

Vh= High window limit

Vl= Low window limit

OUT

(typ.)

2%

maximum positive spread of V

V

h

V

l

+4%

V

h

2%

V

l

−4%

maximum negative spread of V

FB

V

h

2%

V

l

upper specification limit

typical situation

lower specification limit

FB

TEA1211HN

MDB005

Fig.5 Spread of location of output voltage window.

7.2.3 SWITCHING SEQUENCE

Refer to Figures 1 and 3. In up-mode the cycle starts by

making P-down and N-up conducting in the first phase.

The second phase N-up opens and P-up starts

conducting. In down-mode the cycle startswithin the first

phase P-up and P-down conducting. The second phase

P-down opens and N-down starts conducting. In PFM

these twophases arefollowed bya thirdor waitphase that

opens all switches except for N-down, which is closed to

prevent the coil from floating.

The stationary mode or 4-phase cycle, which only occurs

in PFM, starts with in the first phase P-down and N-up

conducting. In the second phase P-down and P-up

conduct forming a short-cut from battery to output

capacitor. In the third phase P-up and N-down conduct.

The fourth or wait-phase again opens all switches except

for N-downwhich isclosed toprevent thecoil from floating.

7.3 Adjustable output voltage

Theoutput voltageof theTEA1211HN canbeset toa fixed

value by means of an external resistive divider. After

start-up through thisdivider, dynamic control ofthe output

voltage ismade possible by useof an I2C-bus. Theoutput

voltage can be programmed from 1.5 V to 5.5 V in

40 steps of 0.1 V each.Incase of Power Amplifiers (PAs)

for example the outputvoltage of the TEA1211HN can be

adjusted to the output power to be transmitted by the PA,

in order to obtain maximum system efficiency.

7.4 Start-up

If the input voltage exceeds the start voltage, the

TEA1211HN starts ramping up the voltage at the output

capacitor. Rampingstops when thetarget level, setby the

external resistors, is reached.

7.5 Under voltage lockout

As a result of too high load or disconnection of the input

power source, the input voltage can drop too low to

guarantee normal regulation. In that case, the device

switches to a shut-down mode stopping the switching

completely. Start-up is possible by crossing the start-up

level again.

7.6 Shut-down

When pin SHDWN is made HIGH, the converter disables

all switches except for N-down (see Fig.1) and power

consumption is reduced to a few µA. N-down is kept

conducting to prevent the coil from floating.

7.7 Power switches

The power switches in the IC are two N-type and two

P-type MOSFETs,having atypical pin-to-pin resistanceof

85 mΩ. The maximum continuous input/output current in

the switches is 1.7 A at 70 °C ambient temperature.

2003 Oct 13 7

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

7.8 Synchronous rectification

For optimal efficiency over the whole load range,

synchronous rectifiers insidethe TEA1211HN ensure that

in PFM mode during the phase where the coil current is

decreasing, all inductor current will flow through the low

ohmic power MOSFETs. Special circuitry is included

which detects that the inductor current reaches zero.

Following this detection, the digital controller switches off

the power MOSFET and proceeds regulation. Negative

currents are thus prevented.

7.9 PWM-only mode

When pin SYNC/PWM is HIGH, the TEA1211HN will use

PWM regulation independent of the load applied. As a

result, the switching frequency does not vary over the

whole load range.

7.10 External synchronisation

If ahigh frequency clockis appliedto pin SYNC/PWM, the

switching frequency in PWM mode will be exactly that

frequency divided by 22. PFM mode is not possible if an

external clock is applied. The quiescent current of the

device increases when an external clock is applied.

In case no external synchronisation is necessary and the

PWM-only option is not used, pin SYNC/PWM must be

connected to ground.

7.11 Current limiter

If the peak input current of the TEA1211HN exceeds its

limit in PWM mode, current ramping is stopped

immediately, andthe nextswitching phase isentered. The

TEA1211HN

current limitation protects the IC against overload

conditions, inductor saturation, etc. The current limit level

is user defined by the external resistor which must be

connected between pin ILIM and pin GND.

2

7.12 I

The serial interface of the TEA1211HN is the I2C-bus.

A detailed description of the I2C-bus specification,

including applications, is given in the brochure:

I2C-bus and how to use it”

7.12.1 C

The I2C-bus is for bidirectional, two-line communication

between different ICs or modules. The two lines are a

Serial Dataline (SDA)and a SerialClock Line(SCL). Both

lines must be connected to a positive supply via a pull-up

resistor (for best efficiency it is advised to use the input

voltage of the convertor). Data transfer may be initiated

only when the bus is not busy. In bus configurations with

ICs ondifferent supply voltages, thepull-up resistors shall

be connected to the highest supply voltage. The I2C-bus

supportsincremental addressing.This enablesthe system

controller to read or write multiple registers in only one

I2C-bus action. The TEA1211HN supports the I2C-bus up

to 400 kbit/s.

The I2C-bus system configuration is shown in Fig.6.

A device generating a message is a transmitter, a device

receivinga messageis areceiver. Thedevicethatcontrols

the message is the master and the devices which are

controlled by the master are theslaves. The TEA1211HN

is a slave only device.

C-bus serial interface

, order no. 9398 393 40011.

HARACTERISTICS OF THE I

2

C-BUS

“The

handbook, full pagewidth

SDA

SCL

MASTER

TRANSMITTER /

RECEIVER

SLAVE

RECEIVER

TRANSMITTER /

RECEIVER

Fig.6 I2C-bus system configuration.

2003 Oct 13 8

SLAVE

MASTER

TRANSMITTER

MASTER

TRANSMITTER /

RECEIVER

MDB006

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

7.12.2 START AND STOP CONDITIONS

Both data and clock lines remain HIGH when the bus is not busy. A HIGH-to-LOW transition of the data line, while the

clock is HIGH is definedas the START condition (S). A LOW-to-HIGH transition of thedata line while the clock is HIGH

is defined as the STOP condition (P) (see Fig.7).

handbook, full pagewidth

7.12.3 BIT TRANSFER

SDA

SCL

START condition

S

P

STOP condition

Fig.7 START and STOP conditions on the I2C-bus.

SDA

SCL

MDB007

One databit is transferredduring each clockpulse. The dataon theSDAline mustremain stable duringthe HIGH period

of the clock pulse as changes in the data line at this time will be interpreted as a control signal (see Fig.8).

handbook, full pagewidth

SDA

SCL

data line

stable;

data valid

change

of data

allowed

MDB008

Fig.8 Bit transfer on the I2C-bus.

7.12.4 ACKNOWLEDGE

The numberof databytes transferredbetween the STARTand STOPconditions fromtransmitterto receiveris unlimited.

Each byte of eight bits is followedbyan acknowledge bit. The acknowledge bit is a HIGH level signal put on the busby

the transmitter during which time the receiver generates an extra acknowledge related clock pulse.

A slave receiver which is addressed must generate an acknowledge after the reception of each byte. Also a master

receiver must generate an acknowledge after the reception of each byte that has been clocked out of the slave

transmitter (see Fig.9).

The device that acknowledgesmust pull down the SDA lineduring the acknowledge clock pulse, so thatthe SDA line is

stable LOW duringthe HIGH period of theacknowledge related clock pulse (set-upand hold times must beconsidered).

A master receiver must signal an end of data to the transmitter by not generating an acknowledge on the last byte that

has been clocked out of the slave. In this event the transmitter must leave the data line HIGH to enable the master to

generate a STOP condition.

2003 Oct 13 9

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

handbook, full pagewidth

DATA OUTPUT

BY SLAVE

TRANSMITTER

DATA OUTPUT

BY SLAVE

RECEIVER

SCL FROM

MASTER

TRANSMITTER

S

START

condition

Fig.9 Acknowledge on the I2C-bus.

not acknowledge

acknowledge

acknowledgement

TEA1211HN

9821

clock pulse for

MDB009

7.12.5 I2C-BUS PROTOCOL

7.12.5.1 Addressing

Before any data is transmitted on the I2C-bus, the device which should respond is addressed first. The addressing is

always carried out with the first byte transmitted after the start procedure. The (slave) address of the TEA1211HN is

0001 0000 (10h). The subaddress (or word address) is 0000 0000 (00h).

The TEA1211HN acts as a slave receiver only. Therefore the clock signal SCL is only an input signal. The data signal

SDA is a bidirectional line, enabling the TEA1211HN to send an acknowledge.

7.12.5.2 Data

The data consists of one byte, addressing the 40 voltage steps as explained in Tables 1 and 2.

Table 1 Data byte

SUBADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 2 BIT 0

00h 0 0 CVLVL5 CVLVL4 CVLVL3 CVLVL2 CVLVL1 CVLVL0

Table 2 Translation data byte to voltage level

SUBADDRESS NAME

SIZE

(BIT)

STEP NUMBER

MIN. MAX.

MIN. (V)

STEP

(V)

MAX. (V)

00h CVLVL 6 0 40 1.5 0.1 5.5

2003 Oct 13 10

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

7.12.5.3 Write Cycle

The I2C-bus configuration forthe different TEA1211HN write cycles isshown in Fig.10. The word addressis an eight bit

value that defines which register is to be accessed next.

handbook, full pagewidth

S = START condition.

P = STOP condition.

acknowledgement

from slave

R/W

WORD ADDRESS

ASLAVE ADDRESS A ADATA

S

0

Fig.10 Master transmits to slave receiver (write mode).

acknowledgement

from slave

acknowledgement

from slave

n bytes

auto increment

memory word address

P

MDB010

8 LIMITING VALUES

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

n

voltage on any pin with respect

to GND

P

tot

T

j

T

amb

T

stg

V

esd

total internal power dissipation − 1000 mW

junction temperature −40 +150 °C

ambient temperature −40 +85 °C

storage temperature −40 +125 °C

electrostatic discharge voltage

shut-down mode −0.5 +6.0 V

operational mode −0.5 +5.5 V

pins LXA note 1 −±800 V

note 2 −±200 V

all other pins JEDEC Class II; note 1 −±2000 V

JEDEC Class II; note 2 −±200 V

Notes

1. Human Body Model: equivalent to discharging a 100 pF capacitor via a 1.5 kΩ resistor.

2. Machine Model: equivalent to discharging a 200 pF capacitor via a 0.75 µH series inductor.

9 THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

thermal resistancefrom junction

to ambient

mounted on dedicated PCB in

free air

35 K/W

2003 Oct 13 11

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

10 CHARACTERISTICS

T

= −40 to +85 °C; all voltages with respect to ground; positive currents flow into theIC; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Voltage levels

V

OUT

V

IN(start)

V

IN

V

IN(uvlo)

V

FB

V

OUT(wdw)

Current levels

I

q

I

shdwn

∆I

lim

I

max

Power MOSFETs; note 2

R

DS(on)(N)

R

DS(on)(P)

R

DS(on)(P-up)

Timing

f

sw

f

sync

Digital levels: pins SYNC/PWM, SHDWN, SCL and SDA

V

IL

V

IH

Temperature

T

amb

T

max

output voltage 1.50 − 5.50 V

start voltage V

input voltage V

under voltage lockout level − V

I

load

OUT

= 3.5 V;

< 100 mA

2.45 2.55 2.65 V

IN(start)

− 5.50 V

− 0.15 − V

IN(start)

feedback voltage level 1.20 1.25 1.30 V

output voltage window as

percentage of V

OUT

PWM mode 1.5 2.0 3.0 %

quiescent current no load − 100 −µA

current in shut-down mode − <1 2 µA

current limit deviation I

maximum continuous

= 1 A; note 1 −30 − +30 %

lim

T

<70°C −− 1.7 A

amb

input/output current

pin-to-pin resistance NFETs VIN= 3.5 V − 65 85 mΩ

pin-to-pin resistance PFETs VIN= 3.5 V − 65 85 mΩ

pin-to-pin resistance P-up

V

= 1.5 V − 100 135 mΩ

OUT

FET between pins LXB and

OUT

switching frequency PWM mode 450 600 750 kHz

synchronization input

4.5 13 20 MHz

frequency

LOW-level input voltage 0 − 0.4 V

HIGH-level input voltage note 3 0.6 × VIN− VIN+ 0.3 V

ambient temperature −40 +25 +85 °C

internal cut-off temperature 120 135 150 °C

Notes

1. Current limit level is defined by the external R

2. Measured at T

amb

=25°C.

resistor, see Chapter 11.

lim

3. To avoid additional supply current, it is advised to use HIGH levels not lower than VIN− 0.5 V.

2003 Oct 13 12

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

11 APPLICATION INFORMATION

11.1 Typical Li-Ion, 2- or 3-cell application with I

handbook, full pagewidth

D1 D2

VIN =

2.55 to 5.5 V

battery

C

100 µF

123 4 10 11 14 15 21 22 24

31

32

IN

12 13 29 28 30 5 7 9 16 18 20

SCL

SYNC/

PWM

SDA SHDWN

2

C-bus programming

L1

10 µH

LXA LXB

TEA1211HN

ILIM

R

lim

1 kΩ

TEA1211HN

V

= 3.3 V

R1

120 kΩ

R2

75 kΩ

OUT

C

OUT

100 µF

MDB011

OUTIN

26

25

23

FB

27

GND

The combination of the feedback resistors R1 and R2 in parallel should be approximately 50 kΩ.

D1 and D2 are Schottky diodes

The battery can be a one cell Li-Ion, two cell Alkaline or three cell NiCd/NiMH/Alkaline.

If the I2C-bus interface isused for programmingthe output voltage, the SCLand SDA linesmust be connectedto a positivesupply via pull-up resistors

(see Section 7.12.1). If the I

Note the VIH-level (see Chapter 10).

Pins should never be left open-circuit.

No external clock is applied.

2

C-bus interface is not used, connect pins SCL and SDA to ground.

Fig.11 The TEA1211HN in a typical auto-up/down converter application.

2003 Oct 13 13

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

100

handbook, full pagewidth

(1)

η

(2)

(%)

(3)

80

60

40

20

0

(4)

(5)

1 10 100 1000

I

load

TEA1211HN

MDB013

(mA)

V

= 3.3 V.

OUT

L1=10µH, TDK SLF7032 series.

(1) VIN= 2.7 V.

(2) VIN= 3.3 V.

(3) VIN= 3.6 V.

(4) VIN= 4.2 V

(5) VIN= 4.5 V.

Fig.12 Efficiency as a function of load current.

2003 Oct 13 14

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

100

handbook, full pagewidth

η

(%)

(1)

(2)

(3)

80

60

40

20

0

2.50 3.00 3.50 4.00 4.50

(4)

(5)

TEA1211HN

MDB012

V

(V)

IN

V

= 3.3 V.

OUT

L1=10µH, TDK SLF7032 series.

(1) I

= 1000 mA.

OUT

(2) I

= 500 mA.

OUT

(3) I

= 100 mA.

OUT

(4) I

=10mA.

OUT

(5) I

= 1 mA.

OUT

Fig.13 Efficiency as a function of input voltage.

2003 Oct 13 15

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

11.2 Component selection

11.2.1 INDUCTOR

The inductor should have a low Equivalent Series Resistance (ESR) to reduce losses and the inductor must be able to

handle the peak currents without saturating.

Table 3 Inductor selection information

COMPONENT VALUE TYPE SUPPLIER

L1 6.8 µH DO3316-682 Coilcraft

L1 10 µH SLF7032T-100M1R4 TDK

11.2.2 CAPACITORS

For theoutputcapacitor the ESRiscritical. The outputvoltageripple is determined bythe product of thecurrent through

the output capacitor and its ESR. The lower the ESR, the smaller the ripple. However, an ESR less than 80 mΩ could

result in unstable operation.

Table 4 Input and output capacitor selection information

COMPONENT VALUE TYPE SUPPLIER

, C

C

IN

OUT

100 µF/10 V TPS-series AVX

594D-series Vishay/Sprague

If the I2C-bus interface is used to program the output voltage, use a larger input capacitor to prevent the under voltage

lockout level being triggered by large current peaks drawn from this capacitor.

2

Table 5 Input capacitor selection information, when I

COMPONENT VALUE TYPE SUPPLIER

C

(I2C-bus used) 220 to 470 µF/10 V TPS-series AVX

IN

11.2.3 SCHOTTKY DIODES

The Schottky diodes provide a lower voltage drop during the break-before-make time of the internal power FETs. It is

advised to use Schottky diodes with fast recovery times.

Table 6 Schottky selection information

COMPONENT TYPE SUPPLIER

D1, D2 PRLL5819 Philips

C-bus is used

594D-series Vishay/Sprague

2003 Oct 13 16

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

11.2.4 FEEDBACK RESISTORS

The fixedoutput voltage can beset with thefeedback resistors R1 andR2 (see Fig.11).Even in case I2C-bus isused for

programming the output voltage, these external resistors are required for start-up. The ratio of the resistors can be

V

calculated by: , with V

R1

------R2

The two resistors in parallel should have a value of approximately 50 kΩ:

1

+

-------

-------

R1

R2

11.2.5 C

1

1

≈

---------------50 kΩ

URRENT LIMITER

The maximum input peak current can be set by the current limiter as follows:

R

lim

-----------------------------I

IN(peak)(max)

1250

=

Remark. The output current is not limited: in down conversion, the output current will be higher than the input current,

but the maximum continuous output current is not allowed to exceed 1.7 A (RMS) at 70 °C.

------------V

Ω

OUT

ref

1–=

ref=VFB

(see Chapter 10).

Table 7 Resistor selection information

COMPONENT VALUE TYPE TOLERANCE

R1, R2 V

R

lim

dependent SMD 1 %

OUT

I

dependent SMD 1 %

lim

2003 Oct 13 17

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

12 PACKAGE OUTLINE

HVQFN32: plastic thermal enhanced very thin quad flat package; no leads;

32 terminals; body 5 x 5 x 0.85 mm

A

D

terminal 1

index area

B

E

TEA1211HN

SOT617-3

A

A

1

detail X

c

e

1

e

916

L

8

E

h

1

terminal 1

index area

DIMENSIONS (mm are the original dimensions)

(1)

A

UNIT

mm

Note

1. Plastic or metal protrusions of 0.075 mm maximum per side are not included.

max.

A

0.05

0.00

1

32 25

(1)

c

b

0.30

0.18

0.2

D

5.1

4.9

1/2 e

b

17

e

1/2 e

24

D

h

0 2.5 5 mm

scale

(1)

E

5.1

4.9

E

3.75

3.45

h

0.51

D

3.75

3.45

h

w

e

3.5

C

v

M

ACCB

M

e

2

e

3.5

L

2

0.5

0.3

1

y

C

1

0.1v0.05

w

ye

0.05 0.1

y

X

y

1

OUTLINE

VERSION

SOT617-3 MO-220- - - - - -

IEC JEDEC JEITA

REFERENCES

2003 Oct 13 18

EUROPEAN

PROJECTION

ISSUE DATE

02-04-18

02-10-22

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

13 SOLDERING

13.1 Introduction to soldering surface mount

packages

Thistext givesa verybriefinsight toa complextechnology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering can still be used for

certainsurface mountICs, butitis notsuitable forfinepitch

SMDs. In these situations reflow soldering is

recommended.

13.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

tothe printed-circuitboard byscreen printing,stencilling or

pressure-syringe dispensing before package placement.

Driven by legislation and environmental forces the

worldwide use of lead-free solder pastes is increasing.

Several methods exist for reflowing; for example,

convection or convection/infrared heating in a conveyor

type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending

on heating method.

Typical reflow peak temperatures range from

215 to 270 °C depending on solder paste material. The

top-surface temperature of the packages should

preferably be kept:

• below 220 °C (SnPbprocess) or below 245 °C (Pb-free

process)

– for all BGA and SSOP-T packages

– for packages with a thickness≥2.5mm

– for packages with a thickness <2.5 mm and a

volume ≥ 350 mm3 so called thick/large packages.

• below 235 °C (SnPbprocess) or below 260 °C (Pb-free

process) for packages witha thickness < 2.5 mm and a

volume < 350 mm3 so called small/thin packages.

Moisture sensitivity precautions, as indicated on packing,

must be respected at all times.

13.3 Wave soldering

Conventional single wave soldering is not recommended

forsurface mountdevices (SMDs)orprinted-circuit boards

TEA1211HN

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering isusedthe following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wavewith high upward pressurefollowed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackages withleads onfoursides, thefootprint must

be placedata 45° angle tothe transport direction ofthe

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placementand beforesoldering, the packagemust

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time of the leads in the wave ranges from

3 to 4 seconds at 250 °C or 265 °C, depending on solder

material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

13.4 Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads.Use a low voltage(24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

2003 Oct 13 19

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

13.5 Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

BGA, LBGA, LFBGA, SQFP, SSOP-T

DHVQFN, HBCC, HBGA, HLQFP, HSQFP, HSOP, HTQFP,

(1)

(3)

, TFBGA, VFBGA not suitable suitable

not suitable

HTSSOP, HVQFN, HVSON, SMS

(5)

PLCC

, SO, SOJ suitable suitable

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO, VSSOP not recommended

(8)

PMFP

not suitable not suitable

Notes

1. Formore detailedinformation onthe BGApackages referto the

“(LF)BGAApplication Note

from your Philips Semiconductors sales office.

2. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporizationof the moisture in them (the so called popcorn effect). For details,refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

3. These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no account

be processedthrough more thanone soldering cycleor subjected toinfrared reflow soldering withpeak temperature

exceeding 217 °C ± 10 °C measured in the atmosphere of the reflow oven. The package body peak temperature

must be kept as low as possible.

4. These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the solder

cannot penetrate between the printed-circuit boardandthe heatsink. On versions with the heatsink on the top side,

the solder might be deposited on the heatsink surface.

5. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

6. Wave solderingis suitable forLQFP, TQFP andQFP packages with apitch (e) largerthan 0.8 mm; itis definitely not

suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

7. Wave soldering is suitable for SSOP, TSSOP, VSO and VSSOP packages with a pitch (e) equal to or larger than

0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

8. Hot bar or manual soldering is suitable for PMFP packages.

SOLDERING METHOD

WAVE REFLOW

(4)

(5)(6)

(7)

suitable

suitable

suitable

”(AN01026); ordera copy

(2)

.

2003 Oct 13 20

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

TEA1211HN

DC/DC converter

14 DATA SHEET STATUS

LEVEL

I Objective data Development This data sheet contains data from the objective specification for product

II Preliminary data Qualification This data sheet contains data from the preliminary specification.

III Product data Production This data sheet contains data from the product specification. Philips

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

3. For datasheets describing multipletype numbers,the highest-level productstatus determines thedata sheetstatus.

DATA SHEET

STATUS

(1)

PRODUCT

STATUS

(2)(3)

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Relevant changes will

be communicated via a Customer Product/Process Change Notification

(CPCN).

DEFINITION

15 DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting valuesdefinition Limitingvalues givenarein

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

atthese orat anyother conditionsabovethose givenin the

Characteristics sectionsof the specification isnot implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentation orwarrantythat suchapplications willbe

suitable for the specified use without further testing or

modification.

16 DISCLAIMERS

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably beexpected toresult inpersonal injury.Philips

Semiconductorscustomers usingorselling theseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes in the products including circuits, standard cells, and/or software described or contained herein in order to improve design

and/or performance.When theproduct is infull production

(status ‘Production’), relevant changes will be

communicated via a Customer Product/Process Change

Notification (CPCN). Philips Semiconductorsassumes no

responsibility or liability for the use of any of these

products, conveys no licence or title under any patent,

copyright, or mask work right to these products, and

makes no representations or warranties that these

products are free from patent, copyright, or mask work

right infringement, unless otherwise specified.

2003 Oct 13 21

Philips Semiconductors Preliminary specification

High efficiency auto-up/down

DC/DC converter

17 PURCHASE OF PHILIPS I2C COMPONENTS

Purchase of Philips I2C components conveys a license under the Philips’ I2C patent to use the

components inthe I2C systemprovided the system conformsto the I2C specificationdefined by

Philips. This specification can be ordered using the code 9398 393 40011.

TEA1211HN

2003 Oct 13 22

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2003

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not formpart ofany quotation or contract, is believed to be accurateand reliableand may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands R54/02/pp23 Date of release: 2003 Oct 13 Document order number: 9397 750 12174

SCA75

Loading...

Loading...