Philips Intellivue MP60, IntelliVue 70 User manual

IntelliVue MP60/70

Service Guide

IntelliVue Patient Monitor

MP60/70

Patient Monitoring

Part Number M8000-9301E

*M8000-9301E*

1Table of Contents

1 Introduction 13

Who Should Use This Guide 13

How to Use This Guide 13

Abbreviations 13

Responsibility of the Manufacturer 14

Passwords 14

Warnings and Cautions 14

2 Theory of Operation 15

Integrated Monitor Theory of Operation 15

System Boundaries 15

Hardware Building Blocks 17

IntelliVue MP60 17

IntelliVue MP70 18

Optional Hardware 19

Compatible Devices 20

Power Supply 21

CPU Boards 22

I/O Boards 22

Data Flow 23

Data Acquisition 23

Data Provider System Service 24

Persistent Data Storage System Service 24

Display and User Interface Service 24

Data Output 24

Monitor Applications 24

Internal LAN (Measurement Server Link) 25

Philips Clinical Network 26

How does the Support Tool Work with the Monitor 26

Monitor Software Block Diagram 26

Block Diagram Legend 28

3 Testing and Maintenance 33

Concepts 33

Test Reporting 33

Recommended Frequency 34

Tests Recommended When Performing... 35

Installation 35

Repair 35

3

Preventive Maintenance 35

Performance Verifications 35

Upgrades 36

Te s t s 36

Visual Test 36

Power On Test 36

NBP Tests 36

NBP Accuracy Test 36

NBP Leakage Test 37

NBP Linearity Test 38

Valve Test 38

Microstream CO2 Performance Test 38

Barometric Pressure Check and Calibration 39

Leakage Check 39

Pump Check 40

Flow Rate Check and Calibration 41

Noise Check 41

CO

Gas Measurement Calibration Check 41

2

Calibration Verification 42

Reset Time Counters 42

Temperature Accuracy 43

ECG/Resp Performance Test 43

ECG Performance 43

Respiration Performance 44

Invasive Pressure Performance Test 44

SpO2 Performance Test 44

Cardiac Output Performance Test 44

Service Tool Procedure, Version 1 45

Service Tool Procedure, Version 2 45

BIS Performance Test 45

PIC/DSC Test 45

Nurse Call Relay Performance Test 45

Phone Jack Type Connector Test (Traditional Nurse Call) 46

Multi-Port Nurse Call Connector Test (Flexible Nurse Call) 46

ECG Sync Performance Test 47

VueLink Tests using VueLink Test Module 47

Tes t P ro ce d u r e 4 8

Safety Testing 48

Warnings, Cautions, and Safety Precautions 49

Safety Test Procedures 49

Touchscreen Calibration 52

Disabling/Enabling Touch Operation 52

4 Troubleshooting 55

Introduction 55

How To Use This Section 55

4

Who Should Perform Repairs 55

Replacement Level Supported 55

Software Revision Check 56

Software Compatibility Matrix 56

Obtaining Replacement Parts 56

Troubleshooting Guide 56

Checks for Obvious Problems 57

Checks Before Opening the Instrument 57

Checks with the Instrument switched Off 57

Checks with the Instrument Switched On, AC connected 57

Initial Instrument Boot Phase 58

Troubleshooting Tables 59

How to use the Troubleshooting tables 59

Boot Phase Failures 60

Integrated Display is blank 62

Integrated Touch Display not functioning 63

External Display is blank 64

External Touch Display not functioning 65

General Monitor INOP Messages 65

Remote Alarm Device 67

Remote Extension Device 67

Speed Point 67

Keyboard/Mouse not functioning 68

Network related problems 69

Wireless Network 70

Multi-Measurement Server 71

MSL-related problems 71

Alarm Issues 73

Alarm Lamps 73

Alarm Tones 74

Alarm Behavior 74

Individual Parameter INOPS 74

Flexible Module Server 75

Integrated Module Slots 75

Printer 76

Recorder 77

MIB / RS232 78

Flexible Nurse Call Relay 79

Troubleshooting the ECG OUT 79

Data Flow Marker In and ECG Wave 79

Status Log 80

List of Error Codes 82

Troubleshooting with the Support Tool 82

Troubleshooting the Individual Measurements or Applications 82

5

5 Repair and Disassembly 83

Tools Required 83

Minimal Monitor Disassembly 83

Disconnecting the SpeedPoint 83

Removing the I/O Boards 84

Removing the ECG Out board if no MSL2 board is plugged 85

Removing the Integrated Module Slot, the Measurement Server Mount or blank covers 86

Separating the front and back half of the monitor 87

Removing Power Switch board 88

Removing the Backlights 89

Further Disassembly 89

Exchanging the Bezel (with or without Touchscreen) 89

Exchanging the LCD Assembly 91

Removing Power Supply 92

Removing the Speaker 93

Removing the ECG Out Board with an MSL2 Board plugged 94

Removing the Video Board 95

Removing the Main Board 96

Flexible Module Server (FMS) Disassembly 98

Removing the Handle and the Measurement Server Mount 98

Plug-in Modules 103

Plug-In Module Disassembly 103

tcpO2/tcpCO2 Calibration Chamber Kit 104

Recorder Module Paper 105

Disassembly Procedures for the Measurement Server Extension 106

Removing the Front Cover 106

Removing the Extension Bottom Cover 107

Removing the CO2 Scrubber 108

Removing the Pump 109

Refit Procedures for the Measurement Server Extension 109

Refitting the CO2 Scrubber 110

Refitting the Pump 110

Refitting the Extension Bottom Cover 110

Refitting the Front Cover 111

General Reassembly/Refitting Comments 111

Following Reassembly 111

6 Parts 113

MP60/MP70 Parts 114

Exchange Parts 114

Replacement Parts 115

Flexible Module Server Parts 117

Exchange and Replacement Parts 117

Multi-Measurement Server Parts 119

MMS Part Numbers - Front Bezel 120

6

MMS Exchange Part Numbers Software Revision A.05.xx and Lower

121

MMS Exchange Part Numbers Software Revision A.10.xx

122

Measurement Server Extension Parts (M3015A and M3016A) 124

Exchange Parts List 125

Plug-in Modules Part Numbers 126

Part Number Table 126

Exchange Modules, Table 1 126

Exchange Modules, Table 2 127

Plug-In Modules Replaceable Parts 128

Single-Width Plug-In Module 128

Double-Width Plug-In Module 129

Plug-in Module Replaceable Parts 129

Plug-In Module Language Specific Front Housing Kits (incl. Silicone Buttons, Frames & Bezels),

Table 1 129

Plug-In Module Language Specific Front Housing Kits (incl. Silicone Buttons, Frames & Bezels),

Table 2 130

Plug-In Module Specific Bezels 130

BIS Module Replaceable Parts 131

BIS Module Components 131

tcpO2/tcpCO2 Module Accessories 131

External Display Part Numbers 132

SpeedPoint Part Numbers 134

Remote Alarm Device Part Numbers 134

Remote Extension Device Part Numbers 135

135

7 Installation Instructions 137

Unpacking the Equipment 137

Initial Inspection 138

Mechanical Inspection 138

Electrical Inspection 138

Claims For Damage and Repackaging 138

Claims for Damage 138

Repackaging for Shipment or Storage 138

Installing the Monitor (M8005A or M8007A) 138

Mounting Instructions 139

Assembling Mounts 139

Connections 139

Installing Interface Boards 141

Connection of Devices via the MIB/RS232 Interface 141

Installing Remote Devices 141

Mounting the Remote Display (M8031A) 141

Connections 142

Mounting the 17” Remote Display (M8033A) 142

7

Connections 142

Flexible Module Server and/or Multi-Measurement Server 143

Attaching the MMS to a Mount 143

Detaching the Measurement Server from a Mount 143

Positioning the Measurement Server on a Clamp Mount 143

Mounting the MMS Mount to the FMS (M8048A) 144

Mounting the Remote Extension Device to the FMS 145

Mounting the BIS Module to the FMS 145

Mounting the FMS 147

Connections 147

MSL Cable Termination 147

Remote Alarm Devices 150

Mounting 150

Connections 150

Remote Extension Device 151

Mounting 151

Connections 152

Cabling 152

PS/2 Keyboard/Mouse 153

Philips Clinical Network (Wired) 153

Philips Clinical Network (Wireless) 153

Nurse Call Relay 153

Connections 153

ECG Out Functionality 154

Connections 154

Configuration Tasks 154

Setting Altitude and Line Frequency 155

Configuring the Equipment Label 155

8 Site Preparation 157

Introduction 157

Site Planning 157

Roles & Responsibilities 157

Site Preparation Responsibilities 157

Procedures for Local Staff 158

Procedures for Philips Personnel 160

Monitor M8005A and M8007A Site Requirements 160

Space Requirements 160

Environmental Requirements 160

Te m p e r at u r e 16 0

Humidity 161

Altitude 161

Electrical and Safety Requirements (Customer or Philips) 161

Safety Requirements 161

Electrical Requirements 161

8

Remote Device Site Requirements 161

Connecting Non-Medical Devices 162

Multi-Measurement Server M3001A or Flexible Module Server M8048A 163

Space Requirements Multi-Measurement Server M3001A 163

Space Requirements Flexible Module Server M8048A 163

Environmental Requirements Multi-Measurement Server M3001A 163

Environmental Requirements Flexible Module Server M8048A 163

Cabling Options and Conduit Size Requirements 164

Mounting 164

Remote Displays (M8031A) 165

Space Requirements 165

Environmental Requirements 165

Electrical and Safety Requirements 165

Remote Displays - M8033A 166

Space Requirements 166

Environmental Requirements 166

Electrical and Safety Requirements 166

Cabling Options and Conduit Size Requirements 166

Touch Cable 167

Remote Alarm Devices 167

Space Requirements 167

Mounting 167

Cabling Options and Conduit Size Requirements 167

Remote Extension Device 168

Space Requirements 168

Mounting 168

Cabling Options and Conduit Size Requirements 168

Input Devices 169

Local Printer 169

Philips Medical LAN 169

MIB Interface 170

Nurse Call Relay Interface 171

ECG Out Interface 171

9 Anesthetic Gas Module 173

Introduction 173

Description 173

Product Structure 173

Physical Specifications 173

Environmental Specifications 174

Performance Specifications 174

CO2 Measurement 175

AWRR derived from CO2 Waveform 175

N2O Measurement 175

O2 Measurement 175

Anesthetic Agent Measurement 175

9

Alarm Ranges 176

Alarm Delay 176

Apnea Alarm 176

INOP Alarms 176

General Measurement Principles 177

Theory of Operation 177

Main PC Board 178

Power Supply 179

Pneumatic System 179

Pump 180

Wate rt rap 180

Sample Flow Through the Pneumatic Path 181

Agent Identification Assembly 181

Measurement Principle 182

O2 Sensor 182

Specifications 182

Measurement Principle 182

Infrared Measurement Assembly 183

Installation and Patient Safety 184

Physical Installation 184

Environment 185

Label Sheet 185

Making Connections to the AGM 185

Sample Gas Connections to the Gas Exhaust 186

Returning the Gas Sample 186

Setting Up the Gas Return 187

Removing the Gas Sample 188

Setup and Configuration Procedures 188

Altitude Configuration 188

Connect Sample Input Tubing 188

Preventive Maintenance (PM) Tasks 188

Post-Installation Checks 189

Safety Requirements Compliance and Considerations 189

Explanation of Symbols Used 189

Power Supply Requirements 190

Grounding the System 190

Equipotential Grounding 191

Combining Equipment 191

Checking and Calibrating the Anesthetic Gas Module 191

Access Service Functions of the M1026A Anesthetic Gas Module 191

When and how to check the Philips M1026A Anesthetic Gas Module 193

Equipment required for checking 193

Checks and adjustments 194

Performance Leakage Check 194

Performance Diagnostic Check 195

Performance Flowrate Check 195

10

Total Flowrate Check and Adjustment in Purge Mode 195

Measurement Path Flowrate Check and Adjustment 196

Total Flowrate Check in Normal Mode 198

Zero Calibration 198

Barometric Pressure Check and Calibration 199

Span Calibration Check 200

Disposal of Empty Calibration Gas Cylinder 202

Maintaining the Anesthetic Gas Module 203

Preventive Maintenance (PM) Tasks 203

Cleaning 203

Replace PM Parts 204

Internal Nafion Tubing with Bacterial Filters and manifold Seals 204

Room-Air Filter 205

Pump Filter 206

Performance Checks 207

Other factors to maximize uptime or reduce cost of ownership: 207

Troubleshooting the Anesthetic Gas Module 207

Compatibility Criteria for the AGM and the IntelliVue Monitors 208

Flow Charts for Communication and Measurement Type Problems 208

Hardware Related Troubleshooting Strategy 213

INOPs 214

Calibration Checks 216

Calibration Checks Troubleshooting Table 217

Diagnostic Checks 218

Problem Solving Hierarchy 219

Pneumatic System Diagnostic Checks 220

O2 Assembly Diagnostic Checks 220

Optical Path Disgnostic Checks 223

IR Measurement Assembly Diagnostic Checks 224

Agent ID Assmebly Diagnostic Checks 225

Power Supply Diagnostic Checks 226

Operating Temperature Diagnostic Checks 227

Test Points, Connectors and Jumpers 227

Tes t Po in ts 2 27

Connectors 228

Jumpers 228

Repairing the Anesthetic Gas Module 230

Introduction 230

The Top Cover 232

Removal 232

Replacement 232

Lifting the IR Measurement Mounting Bracket 234

Removal 235

Replacement 235

Infrared Measurement Assembly Head 237

11

Transferring NVRAM Data to a Replacement Head 237

Sample Cell 241

Removal 241

Replacement 241

Solenoid Valve #1 245

Removal 245

Replacement 245

Power Supply Unit 247

Removal 247

Replacement 247

Main PC Board 248

Removal 248

Replacement 249

O2 Sensor 250

Removal 250

Replacement 251

Agent Identification Head 253

Removal 253

Replacement 254

Pump 255

Removal 255

Replacement 255

Fan 256

Removal 256

Replacement 256

Solenoid Valve #2 258

Removal 258

Replacement 258

Top Co ve r P C B o ar d 259

Removal 259

Replacement 259

Watertrap Manifold and Protector 261

Removal 261

Replacement 261

Power Fuses 262

Removal 262

Replacement 262

Test and Inspection Matrix 262

When to Perform Test Blocks 266

Safety Test Appendix 267

Parts List 269

Calibration Equipment 274

12

This Service Guide contains technical details for the IntelliVue MP60 and MP70 Patient Monitor, the

Multi- Measurement Server (MMS), the Flexible Module Server (FMS) and the Measurement Server

Extensions.

This guide provides a technical foundation to support effective troubleshooting and repair. It is not a

comprehensive, in-depth explanation of the product architecture or technical implementation. It offers

enough information on the functions and operations of the monitoring systems so that engineers who

repair them are better able to understand how they work.

It covers the physiological measurements that the products provide, the Measurement Server that

acquires those measurements, and the monitoring system that displays them.

Who Should Use This Guide

1

1Introduction

This guide is for biomedical engineers or technicians responsible for troubleshooting, repairing, and

maintaining Philips’ patient monitoring systems.

How to Use This Guide

This guide is divided into eight sections. Navigate through the table of contents at the left of the screen

to select the desired topic. Links to other relevant sections are also provided within the individual

topics. In addition, scrolling through the topics with the page up and page down keys is also possible.

Abbreviations

Abbreviations used throughout this guide are:

Name Abbreviation

IntelliVue MP60/MP70 Patient Monitor the monitor

Flexible Module Server FMS

Multi-Measurement Server MMS

Measurement Server Link MSL

Medical Information Bus MIB

Anesthetic Gas Module AGM

13

1 Introduction Responsibility of the Manufacturer

Responsibility of the Manufacturer

Philips only considers itself responsible for any effects on safety, reliability and performance of the

equipment if:

• assembly operations, extensions, re-adjustments, modifications or repairs are carried out by persons

authorized by Philips, and

• the electrical installation of the relevant room complies with national standards, and

• the instrument is used in accordance with the instructions for use.

To ensure safety, use only those Philips parts and accessories specified for use with the monitor. If nonPhilips parts are used, Philips is not liable for any damage that these parts may cause to the equipment.

This document contains proprietary information which is protected by copyright. All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as

allowed under the copyright laws.

Philips Medizinsysteme Böblingen GmbH

Hewlett-Packard Str. 2

71034 Böblingen, Germany

The information contained in this document is subject to change without notice.

Philips makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties or merchantability and fitness for a particular purpose.

Philips shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Passwords

In order to access different modes within the monitor a password may be required. The passwords are

listed below.

Monitoring Mode: No password required

Configuration Mode: 71034

Demo Mode: 14432

Service Mode: 1345

Consult the configuration guide before making any changes to the monitor configuration.

Warnings and Cautions

In this guide:

•A warning alerts you to a potential serious outcome, adverse event or safety hazard. Failure to

observe a warning may result in death or serious injury to the user or patient.

14

•A caution alerts you where special care is necessary for the safe and effective use of the product.

Failure to observe a caution may result in minor or moderate personal injury or damage to the

product or other property, and possibly in a remote risk of more serious injury.

2Theory of Operation

Integrated Monitor Theory of Operation

The IntelliVue Patient Monitor:

• displays real-time data

• controls the attached measurement servers

• alarms in the case of patient or equipment problems

• offers limited data storage and retrieval (trending)

• interfaces to the Philips Clinical Network and other equipment

A monitor with just a single integrated measurement server can be connected to additional building

blocks to form a monitoring system with a large number of measurements, additional interface

capabilities and multiple slave displays. These elements cooperate as one single integrated real-time

measurement system.

2

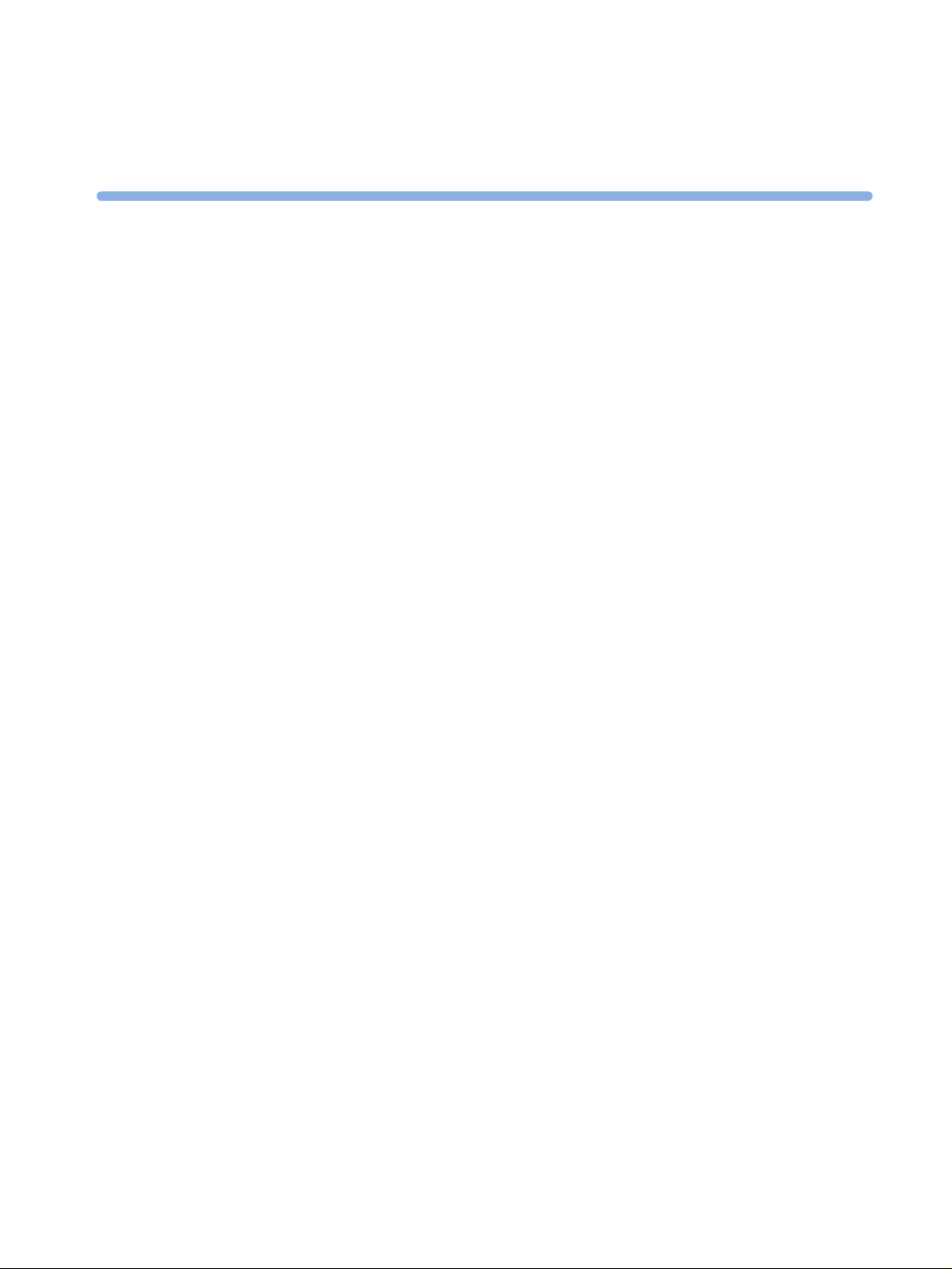

System Boundaries

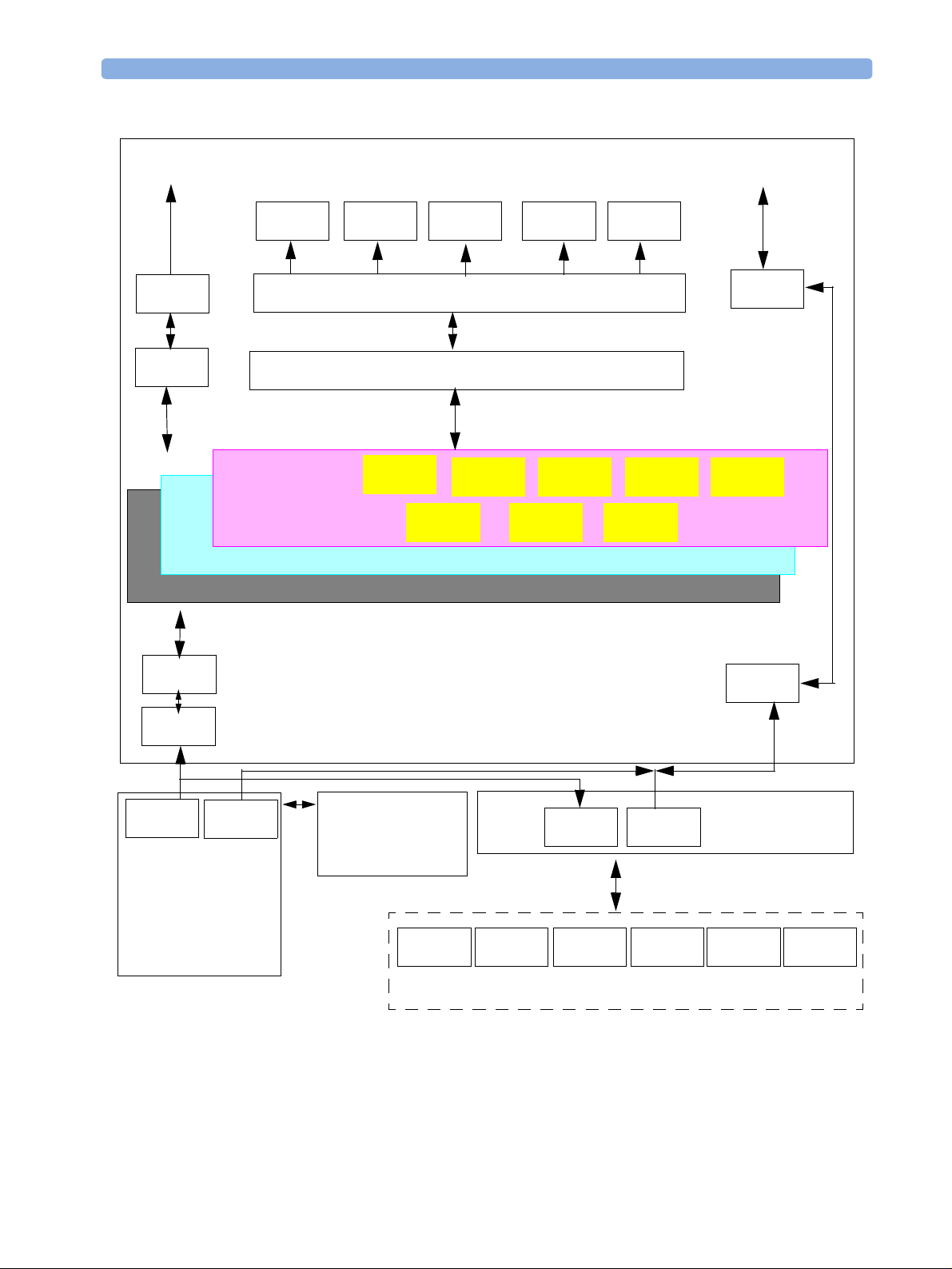

The following diagram discusses specific boundaries within the overall system with respect to their

openness and real-time requirements:

15

2 Theory of Operation Integrated Monitor Theory of Operation

Philips Clinical Network

Measurement LAN

combines components of one patient monitor;

real time requirements across all interconnected

elements

Philips Clinical Network (wired LAN)

connects multiple patient monitors,

information centers, application servers; closed

system, only Philips qualified products (tested

and with regulatory approval) are connected,

Philips is responsible for guaranteed real-time

functionality and performance

Philips Clinical Network (wireless)

like Philips Clinical Network (wired) LAN,

however due to current wireless technologies

available it has reduced bandwidth, longer

latencies, reduced functionality

Hospital LAN, Internet

Standard Network, not under Philips control,

no guaranteed service, no real-time

requirements

16

Integrated Monitor Theory of Operation 2 Theory of Operation

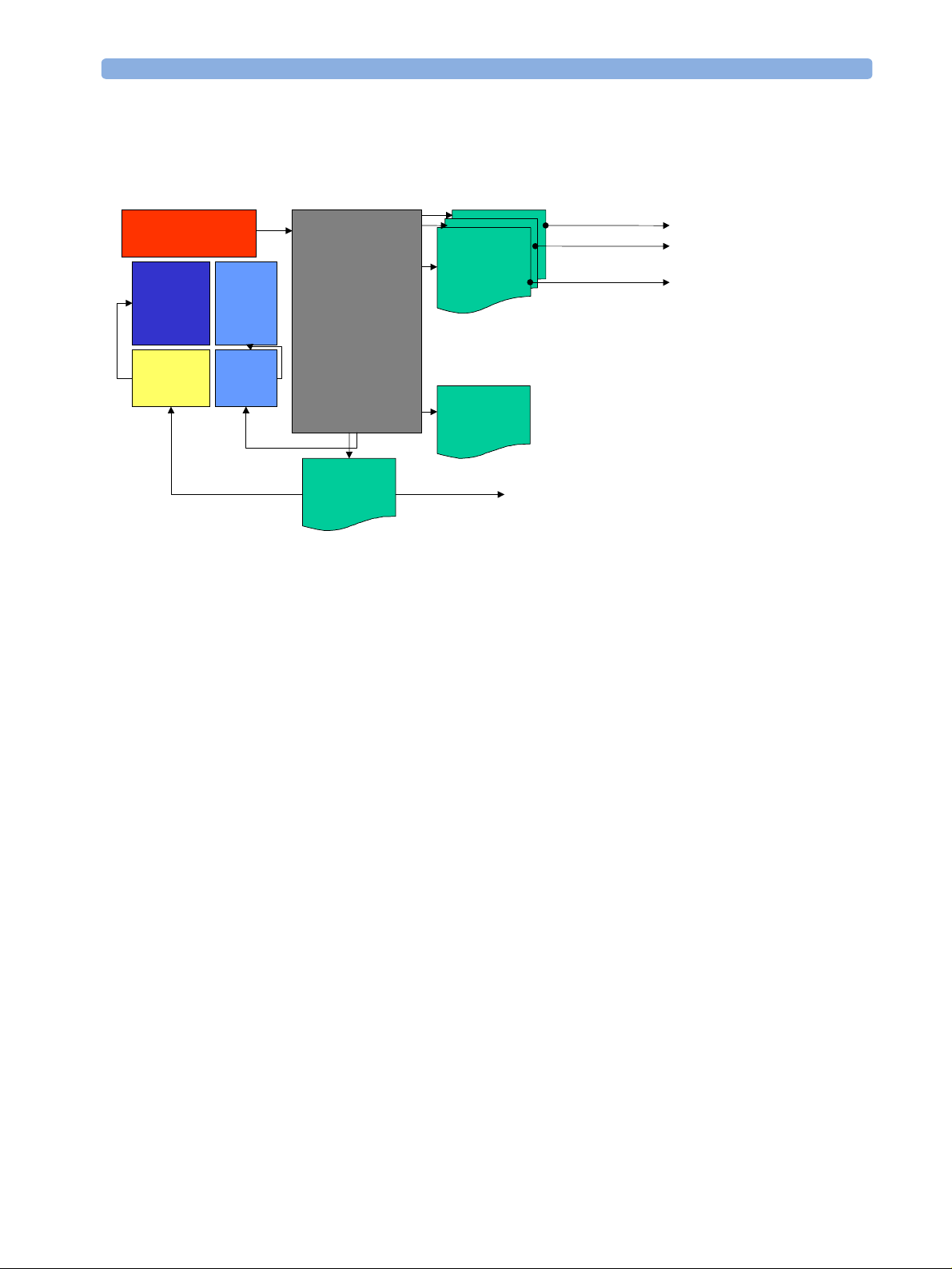

Hardware Building Blocks

The following hardware building blocks make up the monitoring system:

IntelliVue MP60

The MP60 monitor:

• integrates the display and processing unit into a single package

• uses a 15” TFT XGA Color display

• uses the Philips SpeedPoint as primary input device; computer devices such as mice, trackball, and

keyboard can be added optionally

• has an optional recorder

• supports the Flexible Module Server (FMS)

Building Blocks:

17

2 Theory of Operation Integrated Monitor Theory of Operation

|| I/F To Local Printer

Power Supply

I/F

PS/2 To SpeedPoint

Boards

LCD

Assembly

Main Board

MIB To AGM

LCD

Adapter

MSL

I/F

Video I/F

Board

To Ext. Display

ECG Out

IntelliVue MP70

The MP70 monitor:

• integrates the display and processing unit into a single package,

• uses a 15” TFT XGA Color display

• uses the Philips Touchscreen as primary input device, whereas the Philips SpeedPoint and computer

devices such as mice, trackball, and keyboard can be added optionally

18

• has an optional recorder

• supports the Flexible Module Server (FMS)

Integrated Monitor Theory of Operation 2 Theory of Operation

es

Building Blocks:

|| I/F To Local Printer

Power Supply

I/F

PS/2 To External input devic

Boards

LCD

Assembly

Touch

Panel

MIB To AGM

Main Board

LCD

Adapter

Touch

Controller

Optional Hardware

A measurement server mount and /or an integrated module slot can be ordered optionally. If the

monitor is ordered with the wireless LAN option an external wireless transmitter is required. For

further details regarding the wireless network please refer to the M3185A Philips Clinical Network

documentation.

Video I/F

Board

MSL

I/F

To Ext. Display

19

2 Theory of Operation Integrated Monitor Theory of Operation

Measurement Server

Mount

Integrated

Module Slot

Compatible Devices

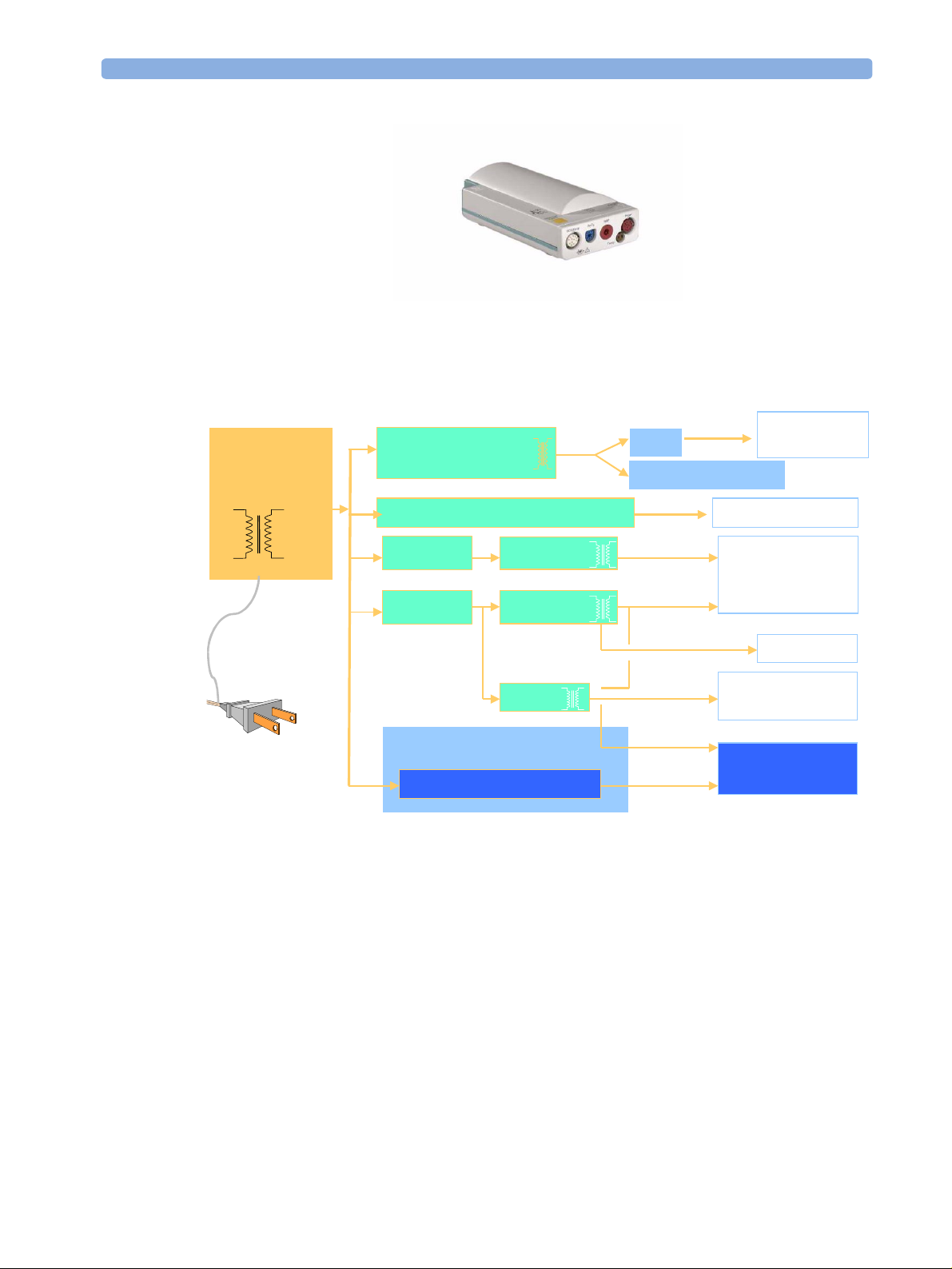

Figure 1 M8048A Flexible Module Server (FMS)

20

Integrated Monitor Theory of Operation 2 Theory of Operation

Figure 2 M3001A Multi-Measurement Server (MMS)

Power Supply

AC/DC

48V /120W

Isolating DC/DC

Converter

Backlight DC/DC Converter

DC/DC

DC/DC

DC Bus

Integrated Module Rack

DC/DC Converter

DC/DC

DC/DC

DC/DC

56 V

FMS

MMS, MMS-EXT

12 V

3.3 V

5 V

10 V AC

)

12 V

)

unreg

5 V

60 V

5 V,

60V

HIF, LED's,

Front End

Modules

Backlight

CPU

I/F boards

wireless

Front End

Modules

Figure 3 Power Supply Architecture

21

2 Theory of Operation Integrated Monitor Theory of Operation

The AC/DC converter transforms the AC power coming from the power plug into 48 V/120W DC

source and isolates the monitoring system from the AC power mains.The 48V is distributed via power

bus and supplies power to all the components of the system: The 56 V DC power needed for the FMS,

MMS and measurement server extension is created by an isolating DC/DC converter. The power

needed for the backlights is converted to 12V DC by the backlight DC/DC converter. The CPU is

supplied with 3.3 V and 5 V DC power. The transformation is performed in two steps: The first DC/

DC converter is a power regulator which reduces the variations caused by load changes on the 48V

power bus. The second DC/DC converter converts the power to the needed voltage. Interface boards

require a power of 10V AC. The HIF board and the LEDs are supplied with 12V DC unregulated

power. The integrated module slot requires a 5 V supply for the modules slots and uses the 48V and

another DC/DC converter to create 60 V in order to supply power for the modules.

CPU Boards

The CPU boards have an MPC860 50 MHz processor that provides a number of on-chip,

configurable interfaces. An array of 12 fast UARTS with configurable protocol options are

implemented in an ASIC (along with other system functions such as independent watchdogs etc.),

providing interfacing capabilities to measurement modules and I/O boards. The serial interfaces can

easily be electrically isolated. The main board contains additional video hardware.

I/O Boards

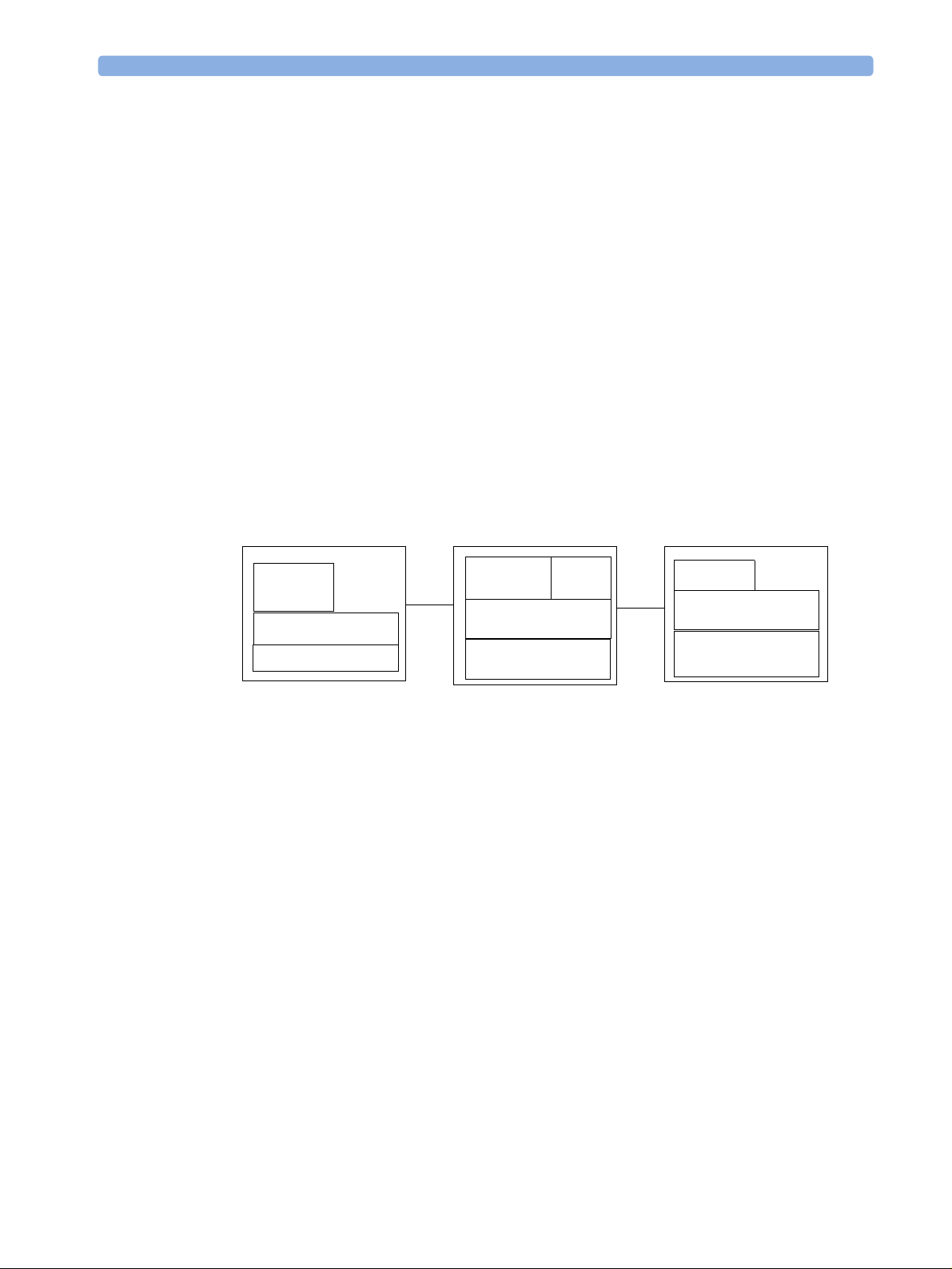

Flexible Module Server

CPU

Bank of I/Os

Modules

The CPUs provide two LAN interfaces to interconnect CPUs (via the Internal LAN) or to connect to

the Philips Clinical Network.

The CPU capabilities are identical. Different loading options are coded on serial EEPROMs to support

the automatic configuration of the operating system at boot time.

Interfaces to the monitor are implemented via I/O boards. The location of these boards is restricted by

general rules. The I/O slot designations diagram and the I/O matrix which outline the I/O board

placement rules can be found in the Installation Instructions section.

IntelliVue Patient Monitor Multi-Measurement Server

CPU Video

Bank of I/Os

CPU

Bank of I/Os

Measurement

Interfaces

Acquisition

22

The following is a list of Interface (I/O) boards which may be present in your monitor, depending on

your purchased configuration:

•MSL

•Video (analog)

• Philips Clinical Network (LAN wired or wireless)

Integrated Monitor Theory of Operation 2 Theory of Operation

•PS/2

• MIB/RS232

•Flexible Nurse Call

•Parallel printer

• Remote devices (Remote Alarm Device, Remote Extension Device)

The specifications for the above listed interfaces can be found in the technical data sheet for the

monitor and in the Specifications chapter of the Instructions for Use.

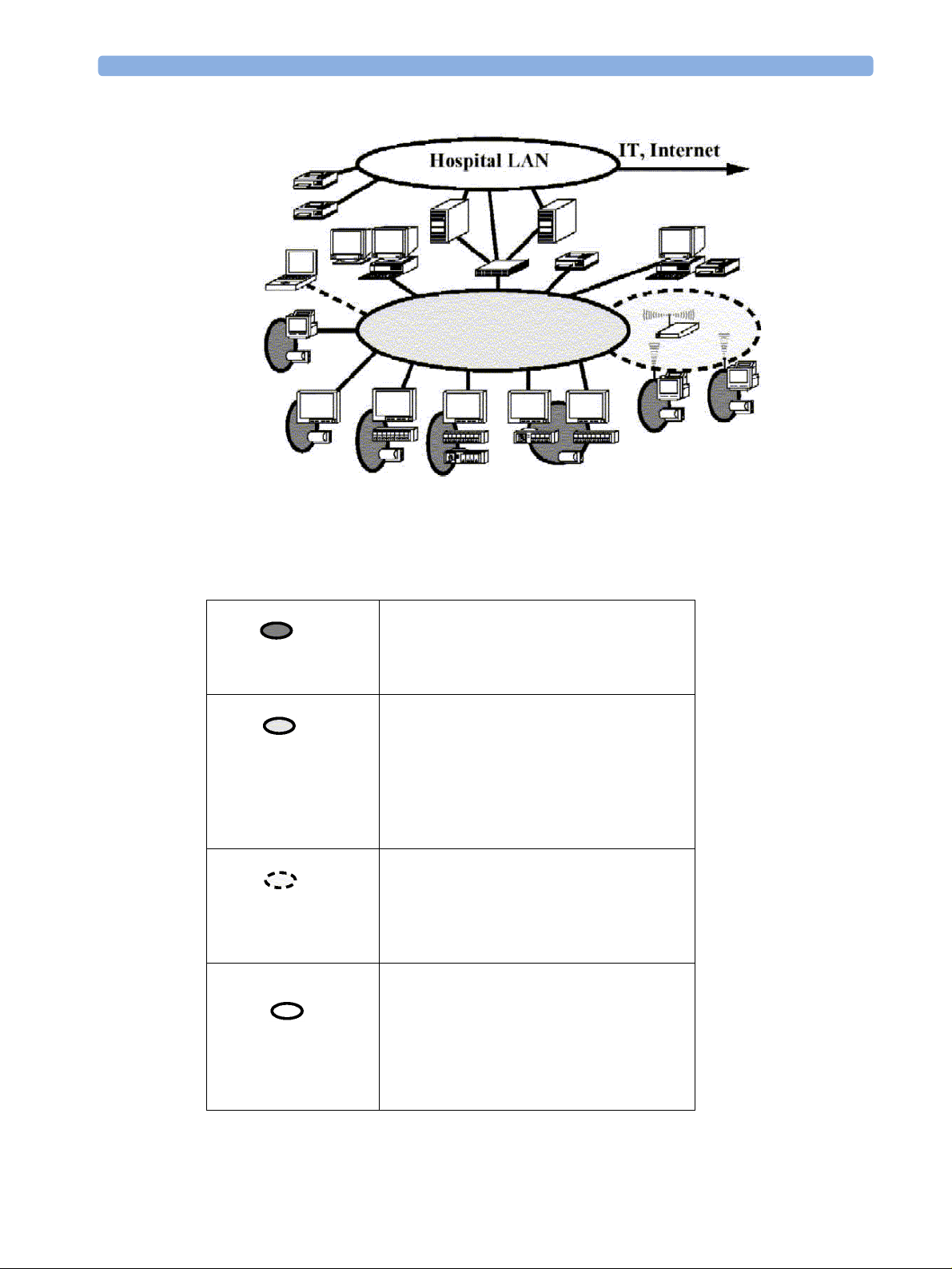

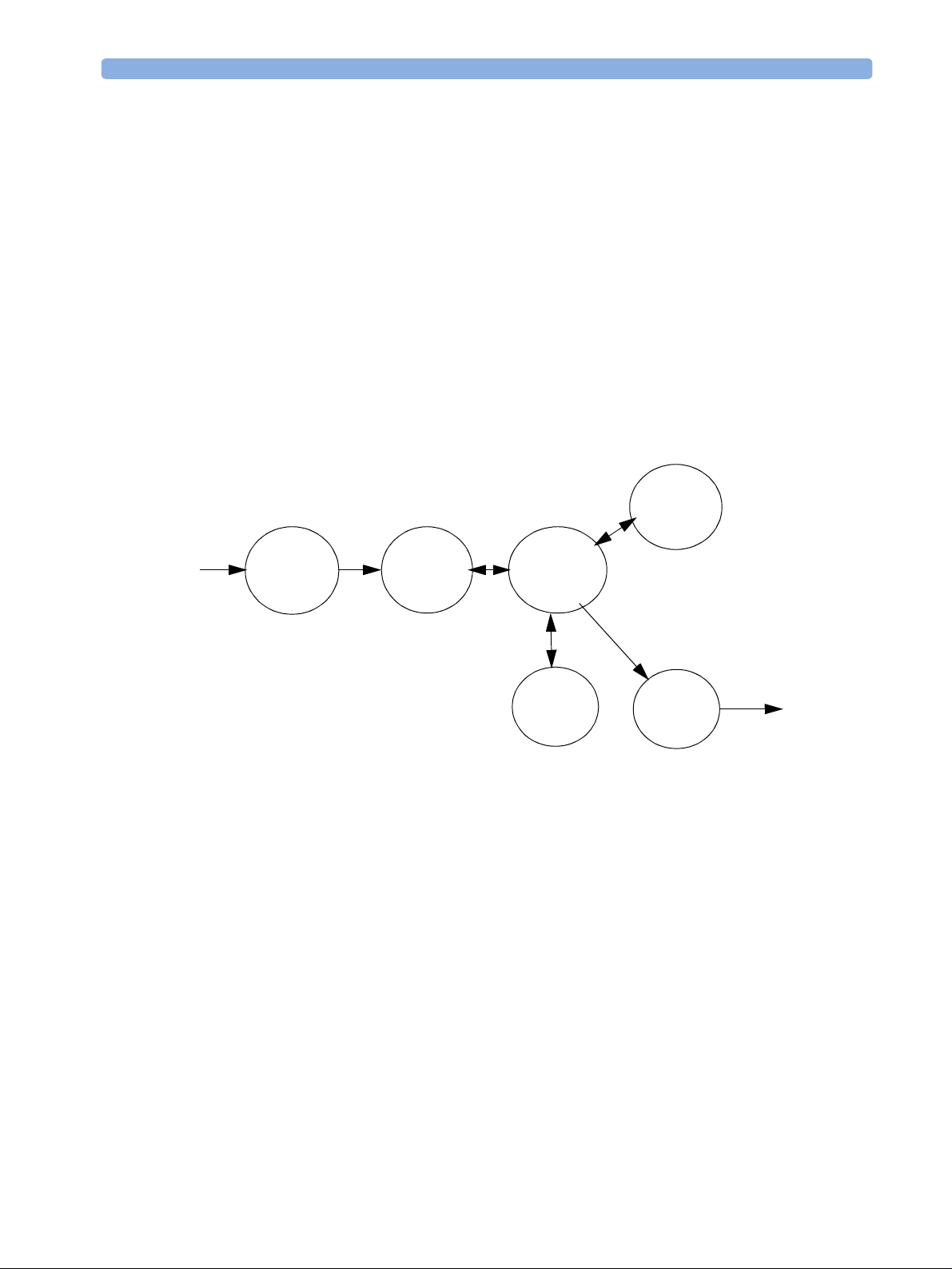

Data Flow

The following diagram shows how data is passed through the monitoring system. The individual stages

of data flow are explained below.

Display

and User

Interface

Data

Acquisition

Data

Provider

Service

Applications

Data Acquisition

Monitoring data (for example patient measurement data in the form of waves, numerics and alerts) is

acquired from a variety of sources:

•Measurement Servers

The Measurement Servers connected to the internal LAN convert patient signals to digital data and

apply measurement algorithms to analyze the signals.

• External measurement devices

Data can be also acquired from devices connected to interface boards of the monitor. Software

modules dedicated to such specific devices convert the data received from an external device to the

format used internally. This applies to parameter modules and the Anesthetic Gas Module

• Server systems on the Philips Clinical Network

To enable networked applications such as the other bed overview, data can be acquired from server

systems attached to the Philips Clinical Network, for example a Philips Information Center

Persistent

Data

Storage

Data

Output

23

2 Theory of Operation Integrated Monitor Theory of Operation

Data Provider System Service

All data that is acquired from measurement servers or external measurement devices is temporarily

stored by a dedicated data provider system service. All monitor applications use this central service to

access the data in a consistent and synchronized way rather than talking to the interfaces directly.

This service makes the applications independent of the actual type of data acquisition device.

The amount of data stored in the data provider system service varies for the different data types. for

example several seconds of wave forms and the full set of current numerical values are temorarily stored

in RAM.

Persistent Data Storage System Service

Some applications require storage of data over longer periods of time. They can use the persistent data

storage system service. Dependent on the application requirements, this service can store data either in

battery backed-up (buffered) memory or in flash memory. The buffered memory will lose its contents

if the monitor is without power (not connected to mains) for an extended period of time. The flash

memory does not lose its contents.

The trend application for example stores vital signs data in a combination of flash memory and

buffered memory, while the system configuration information (profiles) is kept purely in flash

memory.

Display and User Interface Service

Applications can use high level commands to display monitoring data or status and command windows

on the internal LCD panel. These commands are interpreted by the display manager application. This

application controls the dedicated video hardware which includes video memory and a special ASIC.

User input is acquired from a variety of input devices, for example the SpeedPoint, the touchscreen or

other standard input devices (keyboard, mouse) which may be attached to I/O boards. The system

software makes sure that the user input is directed to the application which has the operating focus.

Data Output

The monitoring system is very flexible and customizable regarding its data output devices. Built-in

devices (for example LAN, alarm lamps, speaker, video) provide the basic output capabilities.

These capabilities can be enhanced by adding additional I/O boards, as required in the specific enduser setup. The additional I/O boards typically provide data to externally attached devices, for example

to printers, RS232 based data collection devices, nurse call systems etc.

The monitor can identify I/O boards by means of a serial EEPROM device that stores type and version

information. The operating system detects the I/O boards and automatically connects them with the

associated (interface driver) application. For some multi- purpose cards it is necessary to configure the

card for a particular purpose first (for example the dual MIB/RS232 card can support external touch

display, data import, data export).

Monitor Applications

The monitor applications provide additional system functionality over the basic measurement and

monitoring capabilities. This includes for example trending, report generating, event storage or derived

measurements.

24

Integrated Monitor Theory of Operation 2 Theory of Operation

In general, the monitor applications use the data provider system service to access the measurement

data. Application interfaces to the other system services allow the application to visualize data, to store

data over extended periods of time or to output data to other devices.

Internal LAN (Measurement Server Link)

All components of the monitoring system (including measurement servers and CPUs in the monitor)

communicate using an IEEE802.3/ Ethernet LAN in the Measurement Server Link (MSL). This

network is used to distribute data between the components, for example:

• Digitized patient signals including wave data, numerical data and status information (typically from

the measurement server to a display unit)

• Control data representing user interactions (typically from the display unit to a measurement server)

• Shared data structures, for example representing patient demographical data and global

configuration items

The internal LAN allows plug and play configuration of the monitoring system. The system

automatically detects plugging or unplugging of measurement servers and configures the system

accordingly.

The components on the internal LAN are time- synchronized to keep signal data consistent in the

system. Dedicated hardware support for synchronization eliminates any latency of the network driver

software.

The integrated LAN provides deterministic bandwidth allocation/ reservation mechanisms so that the

real-time characteristic of signal data and control data exchange is guaranteed. This applies to the data

flow from the measurement server to the monitor (for example measurement signal data) and the data

flow from the monitor to a measurement server (for example to feed data to a recorder module).

Integrated communication hubs in the monitor and the FMS allow flexible cabling options (star

topology, daisy chaining of servers).

MDSE Internal LAN

MDSE

Internal

LAN

MDSE

Internal

LAN

25

2 Theory of Operation Integrated Monitor Theory of Operation

Philips Clinical Network

The monitoring system may be connected to the Philips Clinical Network, for example to provide

central monitoring capabilities or other network services. This connection may be through a normal

wired connection or through a wireless connection.

The monitor supports the connection of an external off-the-shelf wireless adapter. This allows a simple

field upgrade as well as a technology upgrade in the future. Switching between wired and wireless

networks is automatically triggered by the plugging or unplugging of the network cable.

The Philips Clinical Network protocols function very similarly to the protocols used on the internal

LAN.

After configuration, the monitoring system sends the digitized patient signals including wave data,

numerical data and status information onto the network. Control data representing user interactions

can be exchanged between the monitoring system and a central station bi-directionally.

Additional protocols are supported for networked applications, for example for the other bed overview

function, which allows viewing of monitoring data from other patients on the network.

For plug and play operation, the monitoring system uses the standard BootP protocol to automatically

acquire a network address.

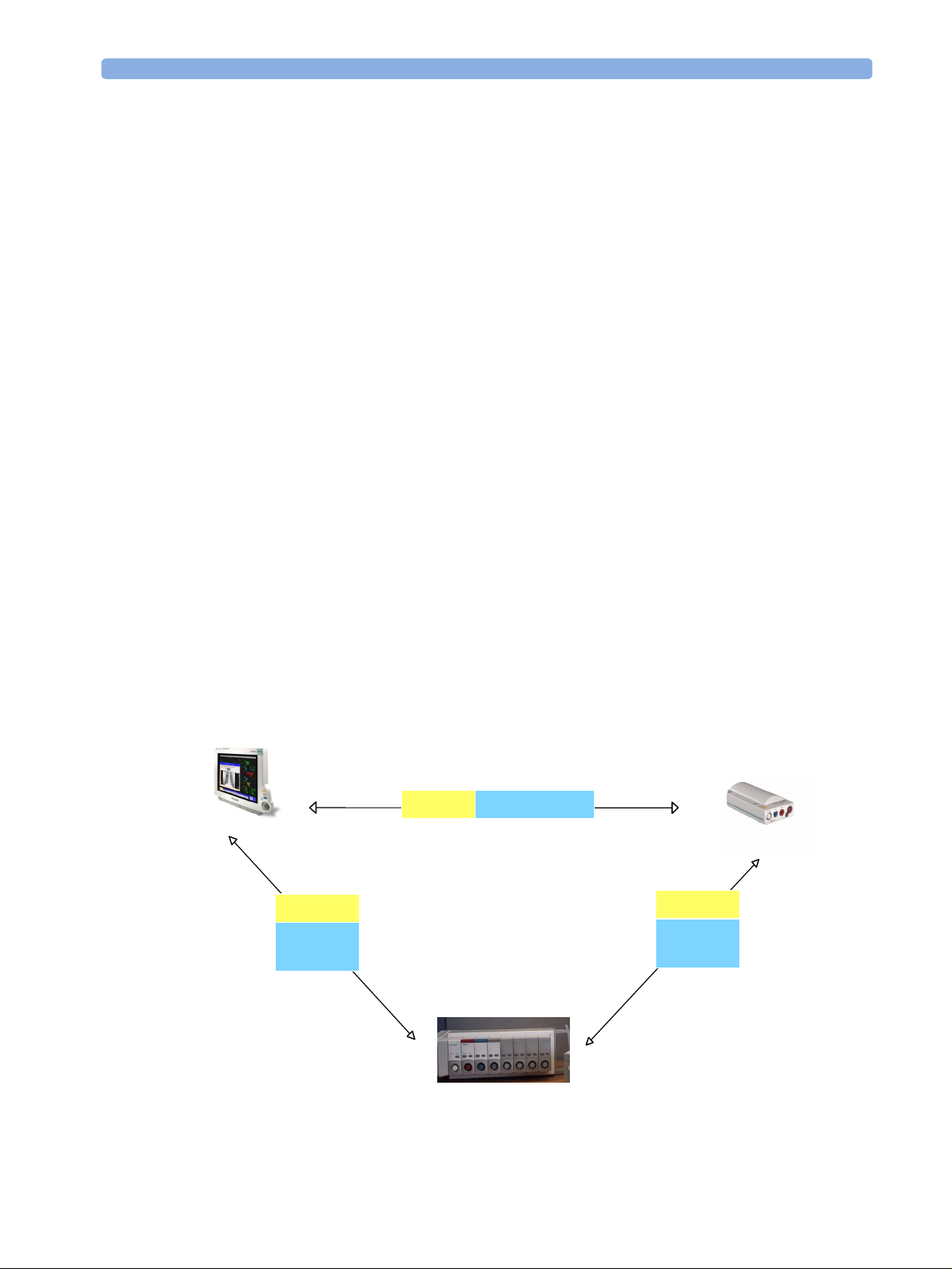

How does the Support Tool Work with the Monitor

The support tool is a Windows application typically installed on the laptop of a customer engineer or a

biomedical engineer working in the customer’s own service department.

The purpose of the support tool is to upgrade, configure and diagnose all monitoring components

(modules, measurement servers, and monitors) in the system over the network.

The service protocol developed for this purpose uses a raw access to the devices without the need for IP

addresses etc. over a standard customer network installation, so that even defective devices can be

upgraded as long as the few kBytes of initial boot code are working. The boot code itself can also be

upgraded using the same protocol.

The tool allows access to internal service information and to serial numbers. It can be remotecontrolled, for example via a dial-up connection from a response center, provided the proper

infrastructure is in place.

For details see the Instructions for Use for the Support Tool.

Monitor Software Block Diagram

Figure 4 shows the functional block diagram for the monitoring system. A legend explaining terms and

diagram elements follows. The information below varies depending on the purchased monitor options.

26

Integrated Monitor Theory of Operation 2 Theory of Operation

Philips Clinical

Network

LAN

MDSE

Video Out

Indicators

Color LCD

Display

Applications

System Services

Real Time Operating System

Visual

LEDs

Audio

Indicators

Loudspeaker Touch

Input Devices

(including PS/2)

Trim Knob

Interfaces

Interface Managers

Record Alarm Trend HiRes ADT

Reports

Calc Param

Events

ECG-Out

Marker-In

ECG-Out

Marker-In

MDSE

LAN

LAN

RS-422

M3001A MultiMeasurement Server

12-lead ECG/Resp, NBP, SpO2,

Press/Temp

M3015/16A

Measurement Server

Extension

CO2, Press/Temp

M1006B

Press

Plug-In Modules

M1012A

C.O.

LAN RS-422

M1018A

tcPO2/CO2

M1029A

Temp

RS-422

Flexible

Module

Server

M1032A

VueLink

M1116B

Recorder

Figure 4 IntelliVue Patient Monitoring System Functional Block Diagram

27

2 Theory of Operation Integrated Monitor Theory of Operation

Block Diagram Legend

Functional Block Description

Services

Operating System The Operating System (OS) provides a layer of isolation between

the specific hardware implementation and the application

software. The OS performs system checks and allocates resources

to ensure safe operation when the system is first started. This

includes internal self-tests on several hardware modules and

configuration checks for validity of configuration with the

operating software. During normal operation, the OS continues

to run checks on system integrity. If error conditions are detected

the OS will halt monitoring operations and inform the operator

about the error condition.

System Services The System Services provide generic common system services.

In particular:

It uses a real-time clock component to track time. It synchronizes

to network time sources and verifies the accuracy of the system

time information. It is also responsible for managing persistent

user configuration data for all Measurement Servers, Flexible

Module Servers and IntelliVue Patient Monitoring System

software modules. User configuration data is stored in a nonvolatile read/write storage device

Applications

Reports The Reports Service retrieves current and stored physiological

data and status data to format reports for printing paper

documentation. The following reports are supported:

•Vital Signs Report

• Graphical Trend Report

• Event Review Report

•Event Episode Report

• ECG Report (12 Lead/Multi-Lead)

• Cardiac Output Report

• Calculations Report (Hemodynamic/Oxygenation/

Ventilation)

• Calculations Review Report

•Wedge Report

•Test Report

• Other reports (e.g. Loops, Review Applications, Drug

report)

The Reports service generates report data which can be printed

on a local or a central printer.

28

Integrated Monitor Theory of Operation 2 Theory of Operation

Functional Block Description

Record The Record Service retrieves current and stored physiological

data and status data to format a continuous strip recording. A

recording can be triggered manually by the operator or

automatically by an alarm condition. The Record Service uses the

services of the Recorder Interface to control an M1116B

Recorder in the FMS. The Record Service can also send data to a

central recorder.

Alarm The Alarm Service contains logic that prioritizes alarm conditions

that are generated either by the Measurement Servers, Flexible

Module Server, or by IntelliVue Patient Monitoring System

software modules. Visual alarm signals (messages) are displayed at

the top of the IntelliVue Patient Monitoring System display and

alarm sounds are generated by a loudspeaker. Alarm conditions

may be generated when a physiological parameter exceeds

preselected alarm limits or when a physiological parameter or any

other software module reports an inoperative status (technical

alarm, for example, the ECG leads may have fallen off the

patient). The Alarm service manages the alarm inactivation states,

for example suspension of alarms, silencing of alarms, and alarm

reminder. Alarm signals may also be configured as latching (alarm

signals are issued until they are acknowledged by the operator,

even when the alarm condition is no longer true). The Alarm

service controls the visual alarm signals (alarm lamps).

Trend The Trend service stores the sample values of physiological data

and status data with a resolution of 12 seconds, 1 minute or 5

minutes for a period of up to 48 hours. The data is kept in

battery buffered read/write storage and flash memory devices to

be preserved across power failures. The stored data is protected

via consistency checks and checksums. When a new patient is

admitted, the trend database erases all data of the previous

patient.

HiRes The OxyCRG (Oxygen CardioRespiroGram) service derives a

high-resolution trend graph from the Beat-to-Beat Heart Rate,

SpO

or tcpO2, and Respiration physiological data. The

2

OxyCRG is specialized for neonatal applications, allowing the

opeartor to identify sudden drops in Heart Rate (Bradycardia)

and SpO

or tcpO2 (Desaturations), and supporting the operator

2

in visualizing Apnea situations.

ADT The ADT (Admit/Discharge/Transmit) service maintains the

patient demographics information. The operator may admit a

new patient, discharge the old patient and enter or modify the

patient demographics. The ADT service also supports the

transport of a patient (trend database) with the M3001A MultiMeasurement Server. The ADT service controls the deletion of

old patient data, the upload of trend data from the M3001A and

the switching back of all settings to user defaults. It also

synchronizes patient information with a central station on the

network.

29

2 Theory of Operation Integrated Monitor Theory of Operation

Functional Block Description

Calc Param The Calc Param (Calculated Parameters) service accesses current,

stored and manually entered physiological data as input to

calculation formulas. With these formulas, derived

hemodynamic, oxygenation and ventilation variables are

computed. The calculation results, including the input

parameters, are stored for later review using the Trend service.

Interface Managers

MDSE The MDSE (Medical Data Service Element) Interface Manager is

responsible for the exchange of real-time data between the

IntelliVue Patient Monitoring System display unit and the

Measurement Servers and Flexible Module Server as well as

between the IntelliVue Patient Monitoring System display unit

and other devices attached to the network. MDSE establishes and

maintains a data communication link between the devices. It

provides configuration information about the remote device to

applications in the local device and it allows the exchange of

measurement data and status information between the devices.

Printer The Printer Interface Manager provides a high level interface to a

printer. It provides means to:

• establish a connection to the printer

• transfer data to the printer

• get status of the printer

• close connection to the printer

The Printer Interface Manager also supervises the connection to

the printer and whether the printer accepts data (for example

paper out). The Printer Interface Manager notifies the operator

in such cases.

30

Loading...

Loading...