Page 1

Page 2

F

£9

F

9

I,

U’

Page 3

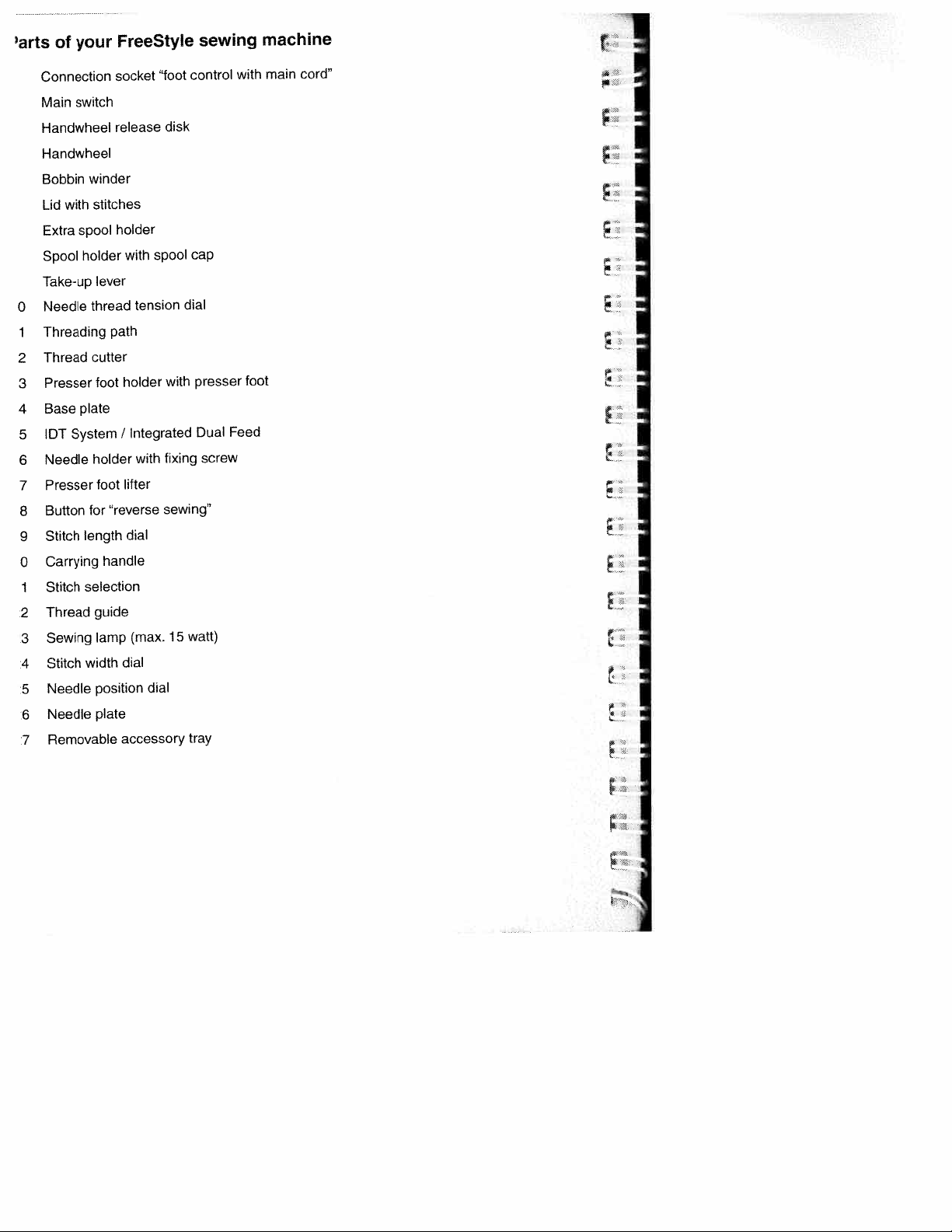

‘arts

O

1

2

3

4

5

6

7

8

9

o

1

2

3

4

5

6

7

your

of

Connection

switch

Main

Handwheel

Handwheel

Bobbin

Lid

Extra

Spool

Take-up

Threading

winder

with

spool

holder

Needle

Thread

Presser

plate

Base

System

IDT

Needle

Presser

for

Button

length

Stitch

Carrying

selection

Stitch

Thread

Sewing

width

Stitch

Needle

Needle

Removable

stitches

thread

cutter

holder

FreeStyle

socket

release

holder

with

lever

path

holder

toot

I

lifter

foot

“reverse

dial

handle

guide

lamp

dial

position

plate

accessory

“foot

disk

spool

tension

with

Integrated

fixing

with

sewing”

15

(max.

dial

sewing

control

cap

dial

presser

Dual

screw

watt)

tray

with

Feed

machine

main

foot

cord”

I

r

I

I

p

I

I

I

I

Page 4

_

.

.

-

—

—

.

_

_

—

—

—

—

—

—

—

—

—

—

—

Page 5

All

you

want,

and

Congratulations!

sewing

Pftiff

The

FreeStyle

instructions

machine

Take

caref

A

is

sewing

them.

nothing

can

design

the

it//v.

small

the

only

machine

time

investment

machine

sew

through

and

is

state-of-the-an.

are

itself

to

way to

that

Thu

hai’e

which

fi’atures

almost

technology

just

as

easy

read

thiioug/i

of

your

real/v

find

imius

to

otter

you

do

purchased

unique

anvtabric

incoiporated

You

will

to

use

as

the

instruction

ti/neiswart/i

the

all

of

how

and

not

need!

top

a

quality

advantages.

—from

in

your

(i/SO

discover that

PFA

your

manual

it!

This

options

mumake

to

thick

FF

your

the

PJiff

Your

to

new

sewing

approach

Fn’eSr’ie

most

e

new

thin.

Pfriff

these

of

if

you

always

is

So

get

turning

have any

readytohave

your

questions

happytohelp.

sewing

some

ideas

—

no

fiuu!

into

problem!

And

have

reality.

Your

a

great

PFAFF

lime

dealer

Page 6

MPORTANT

United

you

use

Read

States

an

electrical

all

instructions

For

the

When

follows:

SAFETY

only

appliance,

before

INSTRUC11ONS

precautions

safety

basic

machine.

sewing

this

using

should

iIvty

‘

i’ll,’,’

.

a

DANGER

1.

2.

3.

4

appliance

Always

Do

Do

place

not

not

unplug

reach

place

in

or

from

for

or

drop

machine

sewing

The

WARNING

allowtobe

not

Do

5.

used

Use

6.

attachments

Never

7.

properly,

to

mechanical

Never

8.

the

Never

9.

Do

10.

11.

Do

administered.

12.

To

Never

13.

Do

14.

Keep

15.

needle.

Always

16.

17.Donot

Do

18.

Switch

19.

threading

Always

20.

when

21.

Hold

or

by

sewing

this

operate

ifithas

nearest

the

operate

sewing

drop

use

not

operate

not

disconnect,

operate

unplug

not

fingers

use

use

pullorpush

not

the

unplug

making

plug

near

recommended

adjustment.

machine

or

outdoors.

the

bentorblunt

sewing

needle,

when

reduce

To

should

electric

the

before

sewing

a

store

a

water

info

To

used

children.

machine

sewing

this

been

authorized

sewing

the

and

any

insert

where

turn

all

soft

on

a

pullingoncord.

by

from

away

proper

fabric

machine

changing

sewing

other

any

rewinding

the

never

outlet

relamping.

machine

sewing

or

other

reduce

a

toy.

as

only

by

machine

dropped

dealer

machine

foot

object

aerosol

controls

surface

all

moving

needle

needles.

while

off

needle,

machine

user

into

risk

be

immediately

Replace

machine

liquid.

risk

the

Close

for

its

manufacturer

the

damaged,

or

or

control

into

(spray>

off

to

such

To

plate.

Use

stitching.

(‘0”)

from

servicing

cord

of

electric

left

has

that

of

attention

intended

it

it

has

service

with

free

any

products

(“0”)

as

unplug.

parts.

The

needles

when

threading

the

adjustments

reel.

shock:

unattended

after

with

bulb

fallen

whereitcan

burns,

is

use

as

a

damaged

dropped

or

center

air

any

opening

the

from

opening.

are

position,

or

bed

a

grasp

Special

plate

wrong

recommended

deflect

It

may

making

bobbin,

outlet

electric

allow

not

Do

when

and

using

same

type

water.

into

fallorbe

electric

fire

necessary

described

as

contained

cord

into

for

examination,

blocked.

accumulation

being

used

remove

then

where

couch

plug,

the

required

is

care

cause

can

the

any

adiustments

or

changing

when

mentioned

plug

plugged

before

rated

Unplug

pulled

when

in

in

plug,

or

water.

or

the

not

by

needle,

removing

in

whip

to

in.

cleaning

15

immediately

into

shock,

this

manual.

this

this

manual.

if

Return

repair.

Keep

lint,

of

where

plug,

not

openings

air

cord.

the

around

needle

the

manufacturer

the

causingitto

in

presser

instruction

the

when

Alw,y’

ii.

Watts.

tub

a

injury

or

sewing

not

it

is

the

electrical

ventilation

and

dust,

oxygen

the

the

to

needle

the

foot,

covers,

rewinding.

imphit

;iiik

ci

to

machire’

only

Use

working

appliance

or

openings

loose

being

is

cord.

may

sewing

break.

only.

break.

area,

etc.

lubricating,

manual.

Ii’

pceoi.

r.

cloth

blocked.

be

machine

such

i

1

as

or

$

Please

This

also

sewing

observe

machine

the

is

general

designed

safety

and

on

notes

manufactured

SAVE

opposite

HOUSEHOLD

for

THESE

page.

only

use

INSTRUCTIONS

I

Page 7

4

4

4

4

4

4

4

4

4

4

Notes

Nnte

on

FN60

335-2-28

he

user

with

regard

of

the

the

sewing

7.

When

dunng

replacing

always

mainsbypulling

3.

The maximum

sewing

4.

The

tensionofthe

adjusted

The

5.

6.

7.

8.

9.

10.Toavoid

11.

12.

13.

machine

accordance

specification

Do

not

the machine.

not

Do

thereisvisible

•

its

function

•

it

is

occur

a

warm

Do

not

cord.

by

its

this

If

purpose

ifitis

wrongly

any

liability

not

open

inside

repair.

of

our

sure

Be

The

machine

supply

and

a

When

outer

components

controlled

85

C.

therefore

damage.

on

safety

safety

for

and

must

exercise

to

theupand

needle

and

area

leaving

the

maintenance

mechanical

disconnect

permissible

lamp

is

15

PFAFF

by

a

mustbeoperated

with

plate.

insert

any

sewing

use

the

is

disturbed

wet,egwith

whenacold

room.

pull

the

mains

appliance

the

Repairs

qualified

withanominal

rated

used

Constant

is

than

that

operated,

for

any

the

risk

the machine.

machine

are

service

to

use

only

is

designed

frequencyof+7properly

foot

control

use

not

permittedinorder

household

IEC

must

while

machine

workorwhen

the

out

the

watts.

drive

the

objects

damage

condensation

machine

used

for

damage

of

electric

which

solely

original

the

ofanon-electronically

atalow

sewing

60

335-228

adequate

down

movement

constantly

sewing.

unattended,

partsoraccessories,

machine

mechanic.

indications

machine

plug

whichitis

There

staff.

voltage

can

from

mains

plug.

wattage

belt

must

in

on

into

openings

if:

is

brought

outofthe

for

another

intended

we

cannot

caused.

shock,

arenoparts

the

user

the

responsibility

PFAFF

foramains

of

4%.

temperature

reach

speed

to avoid

which

+7-

up

machines

caution

observe

the

for

only

the

socket

accept

do

can

parts.

10%

of

to

is

Environment

The

Ambient

Humidity

Storage

The

interference;

near

PCs,

the

This

be

electronic-mechanical

for

notbesubjected

sunlight,

objects.

For

on

be

firm

Careofthe

Always

which

can

dropped.

into

Cleaning

Housing

To

soft,

use

or

Please

Do

products

clean

the

in

accordance

recommended

temperature

temperature:

machine

electronic

broadcasting

sewing

supervised

static

corrosive

ventilation

operated

and

horizontal.

protect

maybecaused

and

clean

the

lint-free

a

soft

note!

not

use

such

the

with

environment

20%

to

80%

is

suppressed

however,

devices

transmitters,

machine

in

use

to:

electricity,

chemicalsorliquids.

purposes

on

an

open

machine

the

machine

display:

housing,

cloth.Toremove

cloth

with

any

insecticides

petrol

as

housing.

10

C

to

40

25Cto

and

if

should

such

as

isahigh-quality

device.Itis

the

home.Itshould

dust,

dampness,

heat-radiating

the machine

surface

from

byitbeing

use

onlyaclean,

any

alcohol.

or

chemical

or

liquid

is:

C

+60

C

immune

notbeoperated

radios.

etc.

which

chemicals

a machine

direct

must

damage

hit

or

stubborn

TVs.

is

dry,

to

both

only

dirt

to

Page 8

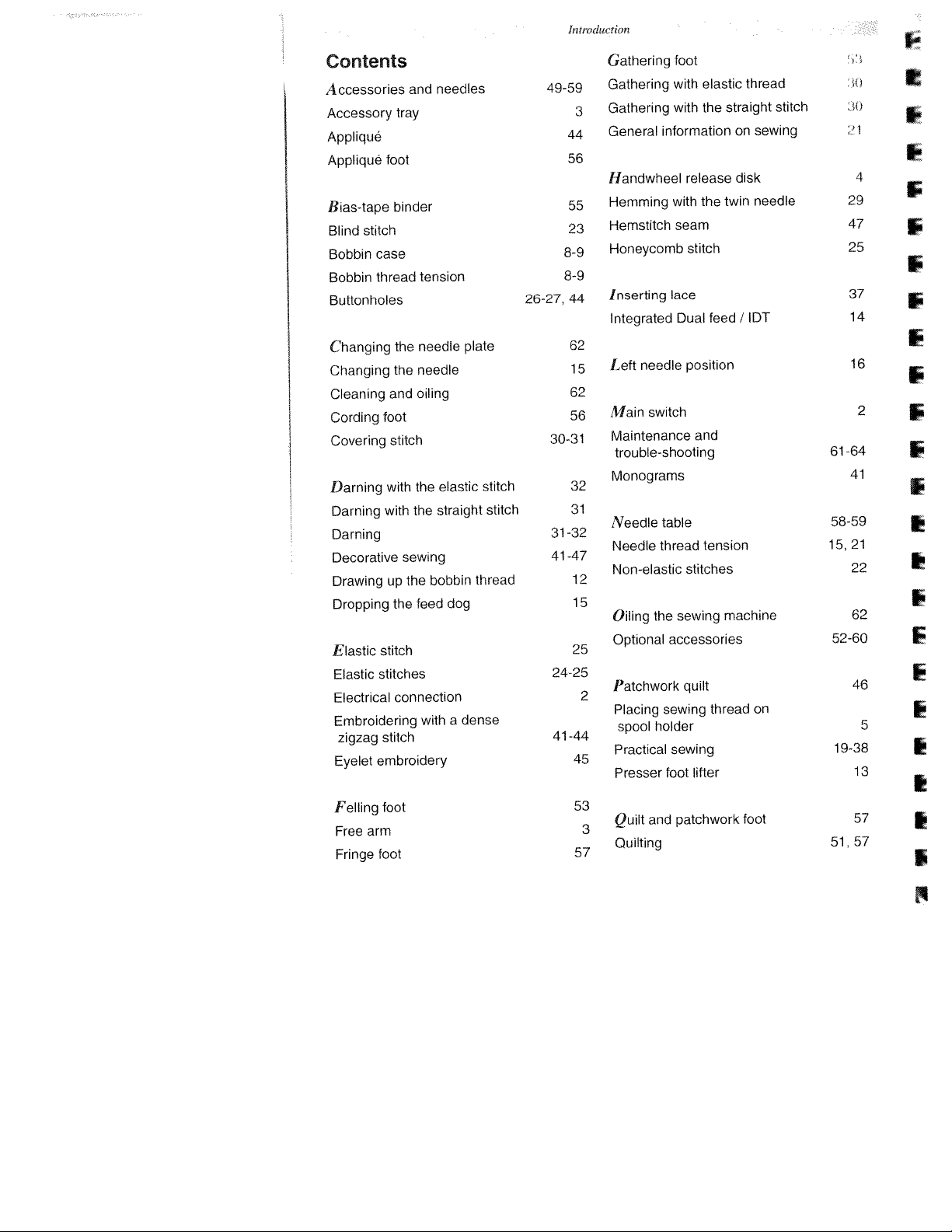

Introduction

Contents

Accessories

Accessory

Appliqué

Appliqué

Bias-tape

stitch

Blind

case

Bobbin

thread

Bobbin

Buttonholes

Changing

Changing

Cleaning

Cording

Covering

Darning

Darning

Darning

Decorative

Drawing

Dropping

Elastic

stitches

Elastic

Electrical

Embroidering

zigzag

embroidery

Eyelet

and

tray

foot

binder

the

needle

the

oiling

and

foot

stitch

with

the

the

with

sewing

up

the

the

feed

stitch

connection

stitch

needles

tension

needle

elastic

straight

bobbin

with

dog

a

plate

thread

dense

stitch

stitch

49-59

26-27,

44

56

55

23

8-9

8-9

44

62

15

62

56

30-31

32

31-32

41

-47

24-25

-44

41

3

31

12

15

25

2

Gathering

Gathering

Gathering

General

Handwheel

Hemming

Hemstitch

Honeycomb

Inserting

Left

Main

foot

with

with

information

release

with

seam

stitch

lace

needle

switch

table

thread

the

sewing

holder

Dual

position

stitches

sewing

accessories

quilt

sewing

foot

Integrated

Maintenance

trouble-shooting

Monograms

Needle

Needle

Non-elastic

Oiling

Optional

Patchwork

Placing

spool

Practical

Presser

elastic

the

the

feed

and

tension

thread

lifter

thread

straight

on

sewing

disk

twin

needle

IDT

I

machine

on

stitch

29

47

25

61-64

58-59

15,

52-60

19-38

37

14

16

2

41

21

22

62

F

46

5

13

Felling

Free

Fringe

arm

foot

foot

53

Quilt

Quilting

and

patchwork

foot

57

51,57

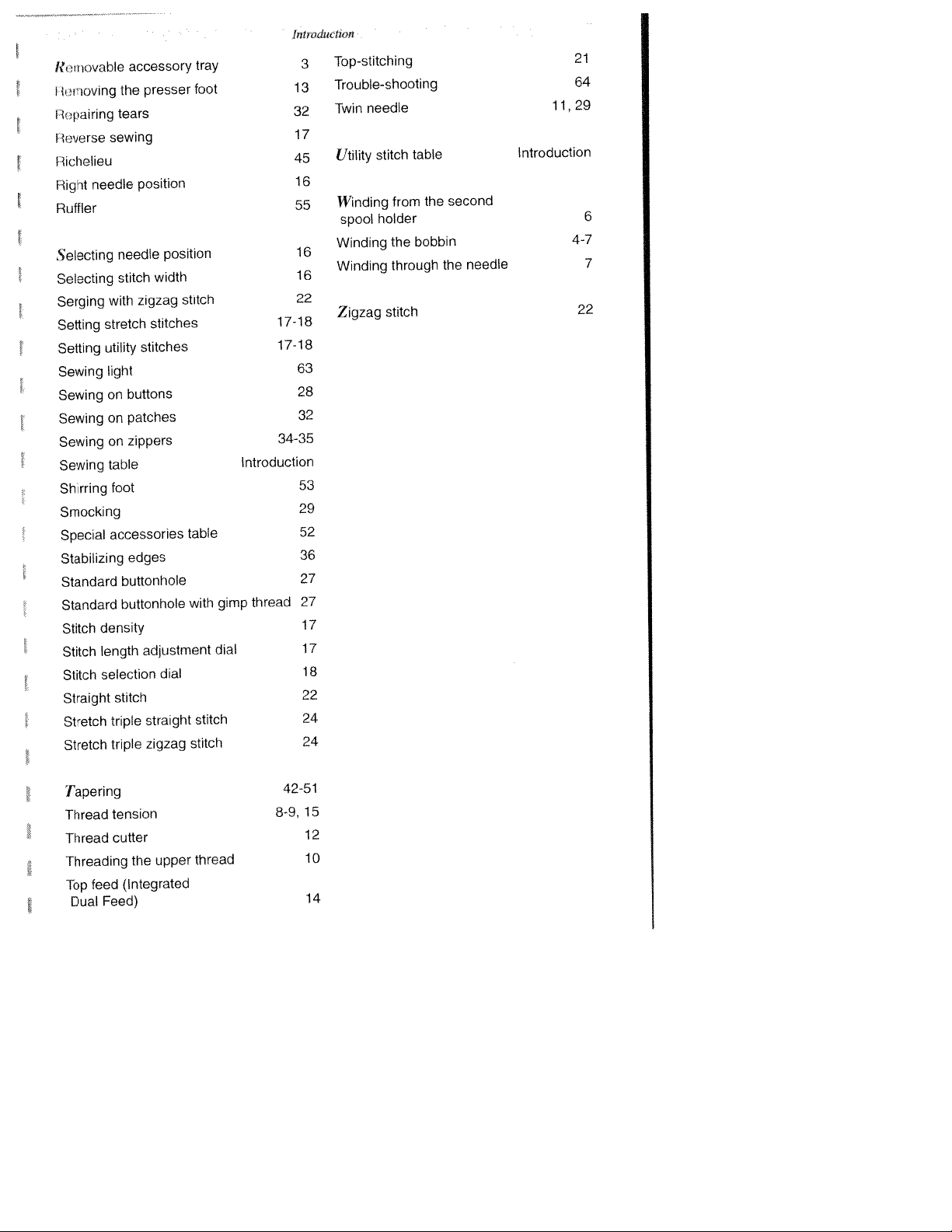

Page 9

k’tnovable

umoving

Ilopairing

Hoverse

lichelieu

needle

Right

Ruffler

Selecting

Selecting

Serging

Setting

Setting

Sewing

Sewing

Sewing

Sewing

Sewing

Shirring

Smocking

Special

Stabilizing

Standard

Standard

density

Stitch

length

Stitch

selection

Stitch

Straight

Stretch

Stretch

accessory

presser

the

tears

sewing

position

needle

stitch

zigzag

with

stretch

stitches

utility

light

on

buttons

patches

on

zippers

on

table

foot

accessories

edges

buttonhole

buttonhole

adjustment

stitch

straight

triple

zigzag

triple

position

width

stitches

dial

tray

foot

stitch

table

with

stitch

stitch

Introduction

gimp

dial

thread

Introduction

3

13

32

17

45

16

55

16

16

22

17-18

17-18

63

28

32

34-35

53

29

52

36

27

27

17

17

18

22

24

24

Top-stitching

Trouble-shooting

needle

Twin

table

stitch

Utility

Winding

spool

Winding

Winding

Zigzag

from

holder

the

through

stitch

bobbin

the

second

the

needle

21

64

11,29

Introduction

6

4-7

7

22

Tapering

Thread

Thread

Threading

feed

Top

Feed)

Dual

tension

cutter

the

(Integrated

upper

thread

42-51

8-9,

15

12

10

14

Page 10

Jn.rroductio

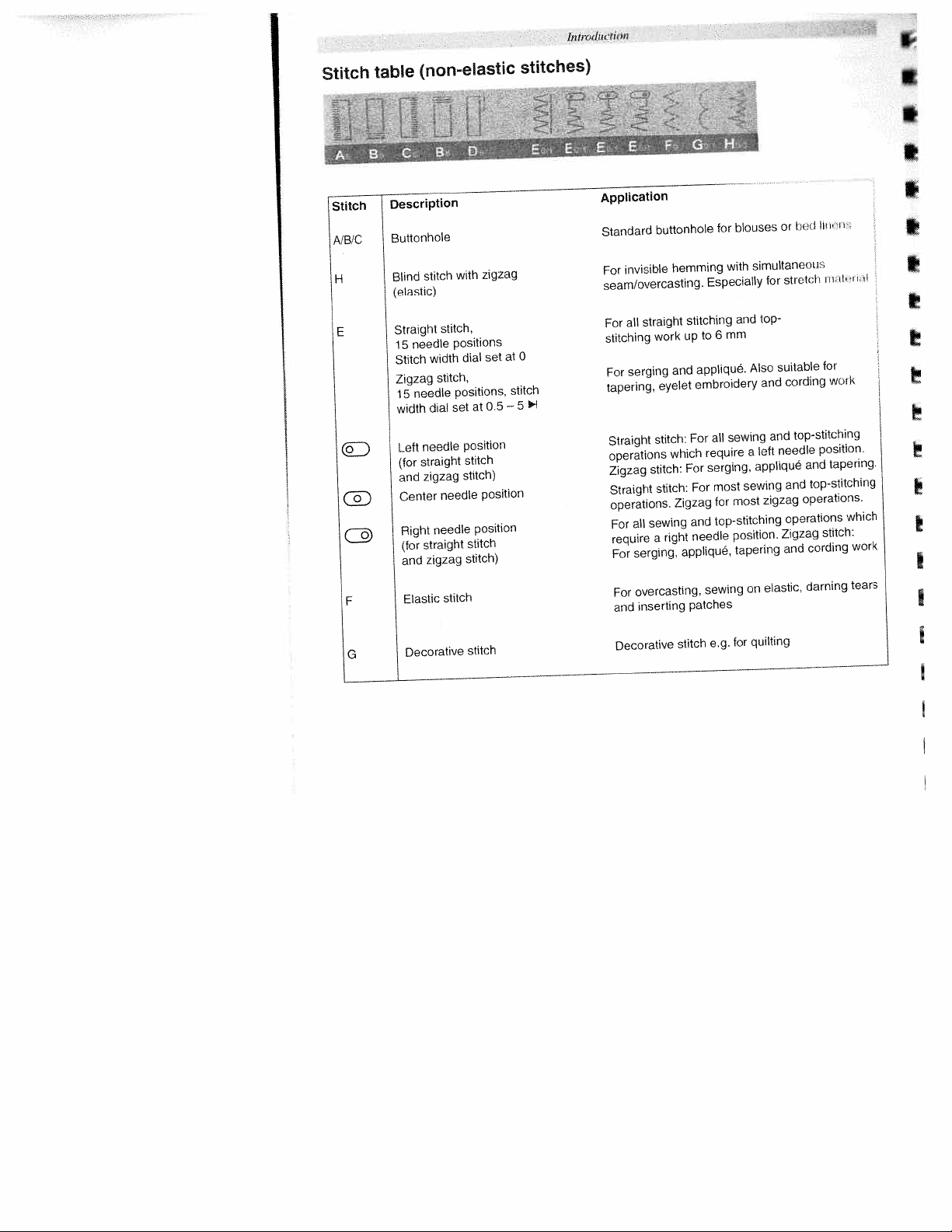

Stitch

j.

Stitch

A/B/C

H

E

F

table

.

[Description

Buttonhole

Blind

(elastic)

(non-elastic

3.J

stitch

Straight

needle

15

width

Stitch

stitch,

Zigzag

needle

15

dial

width

needle

Left

straight

(for

zigzag

and

Center

needle

Right

straight

(for

zigzag

and

Elastic

with

stitch,

positions

dial

positions,

set

position

stitch)

needle

stitch

Li

at

stitch

position

stitch

stitch)

zigzag

at

set

-

0.5

position

stitches)

0

stitch

5

!

<

>

Application

invisible

straight

all

serging

stitch:

Straight

operations.

sewing

all

For

require

serging,

For

overcasting,

For

inserting

and

buttonhole

work

eyelet

stitch:

which

stitch:

right

a

Standard

For

seam/overcasting.

For

stitching

For

tapering,

Straight

operations

Zigzag

...

hemming

stitching

to

up

appliqué.

and

embroidery

For

For

For

Zigzag

and

needle

appliqué,

sewing

patches

blouses

for

with

Especially

and

mm

6

sewing

all

a

require

serging,

sewing

most

most

for

top-stitching

position.

tapering

on

hod

oi

simultaneous

strotc:li

tor

top-

suitable

Also

cording

and

top-stitching

and

needle

left

appliqué

and

zigzag

operations

Zigzag

and

elastic,

n

in’

i.il,-o

for

woik

position.

tapering.

and

top-stitching

operations.

stitch:

cording

darning

*

d

which

work

tears

G

Decorative

stitch

Decorative

stitch

quilting

for

e.g.

Page 11

introduction

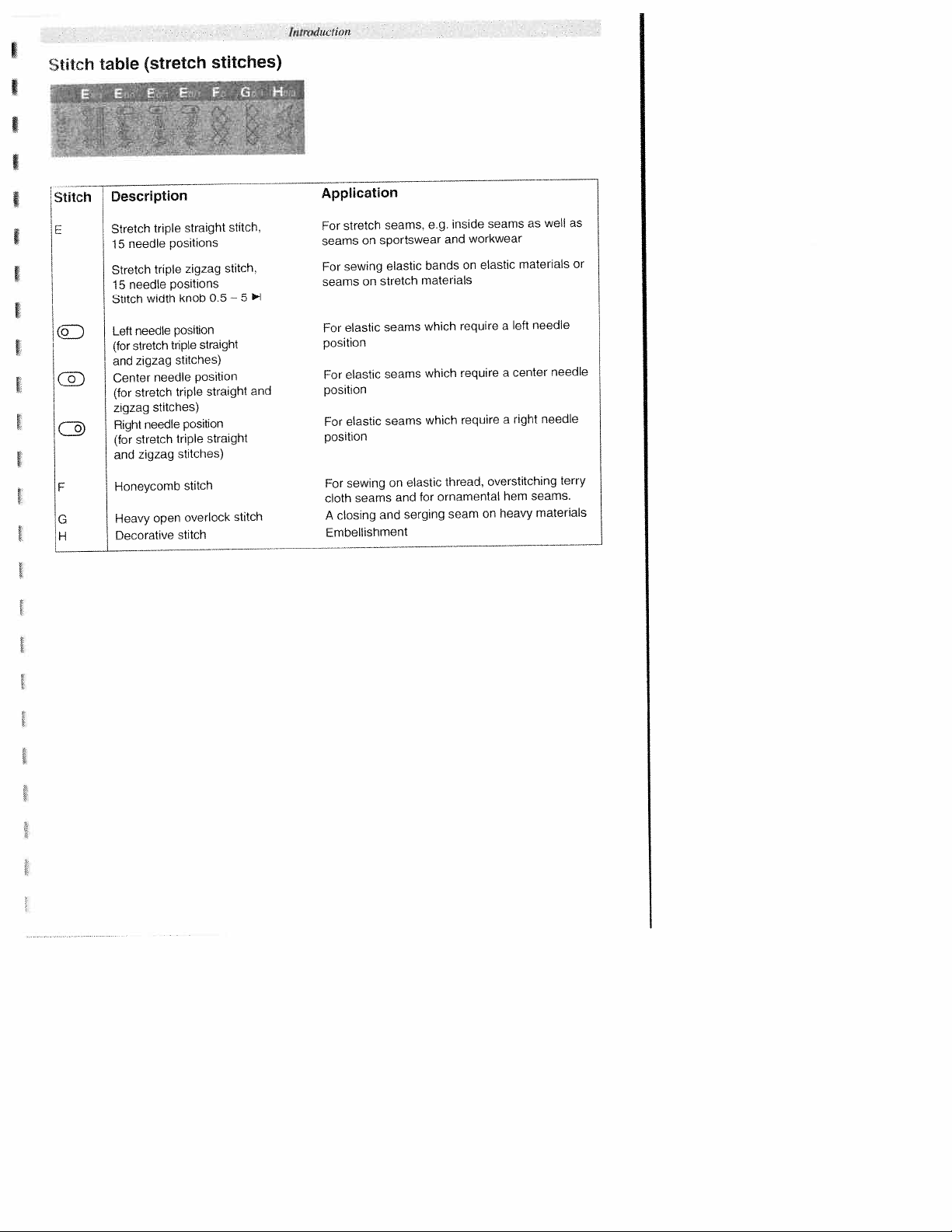

Stitch

Stitch

E

C

C

F

table

Description

Stretch

needle

15

Stretch

needle

15

Stitch

needle

Left

stretch

(for

zigzag

and

Center

stretch

(for

zigzag

Right

stretch

(for

zigzag

and

Honeycomb

Heavy

Decorative

(stretch

triple

positions

triple

positions

knob

width

position

triple

stitches)

needle

triple

stitches)

position

needle

triple

stitches)

open

stitch

stitches)

straight

zigzag

0.5

straight

position

straight

straight

stitch

overlock

stitch,

stitch,

5

—

stitch

bi

and

Application

For

stretch

sportswear

on

seams

sewing

For

on

seams

For

elastic

position

For

elastic

position

For

elastic

position

sewing

For

seams

cloth

and

closing

A

Embellishment

seams,

elastic

stretch

seams

seams

seams

on

and

bands

materials

which

which

which

elastic

for

serging

inside

e.g.

and

require

require

require

thread,

ornamental

seam

seams

workwear

elastic

on

overstitching

on

left

a

center

a

right

a

hem

heavy

well

as

materials

needle

needle

needle

seams.

materials

as

or

terry

Page 12

S

I

*

*

I

$

I

I

I

*

I

$

$

$

I

I

I

I

I

I

I

$

I

I

Page 13

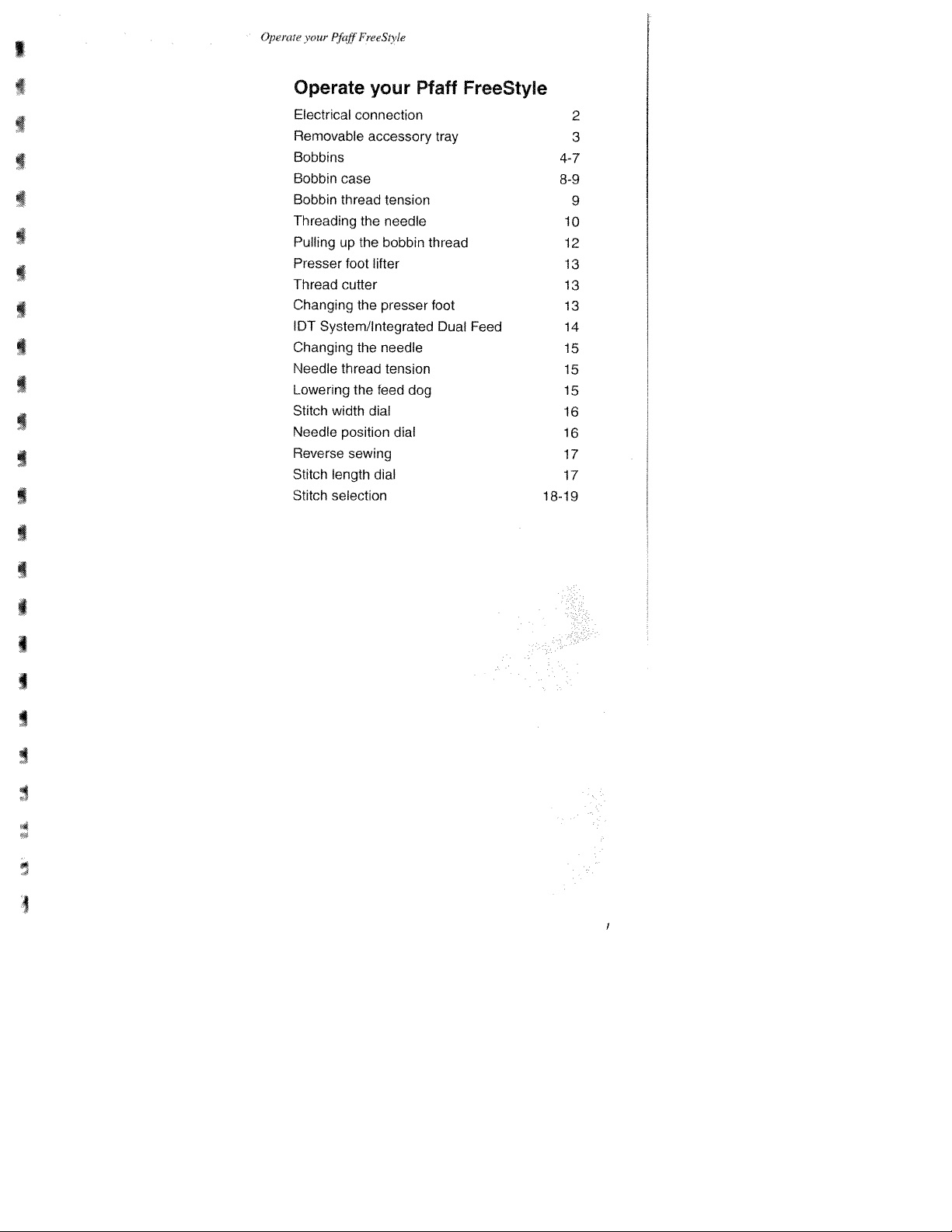

Operate

your

Pfaff

FreeStyle

Operate

Electrical

Removable

Bobbins

Bobbin

Bobbin

Threading

Pulling

Presser

Thread

Changing

IDT

Changing

Needle

Lowering

Stitch

Needle

Reverse

Stitch

Stitch

connection

case

thread

up

foot

cutter

System/Integrated

thread

the feed

width

position

sewing

length

selection

your

accessory

tension

the

needle

the

bobbin

lifter

the

presser

the

needle

tension

dial

dial

dial

Pfaff

dog

tray

thread

foot

Dual

FreeSty’e

Feed

2

3

4-7

8-9

9

10

12

13

13

13

14

15

15

15

16

16

17

17

18-19

Page 14

Op

rc4t

‘OiI

!Jf

Ic

Carryingcase

Place

instruction

carryingcase.

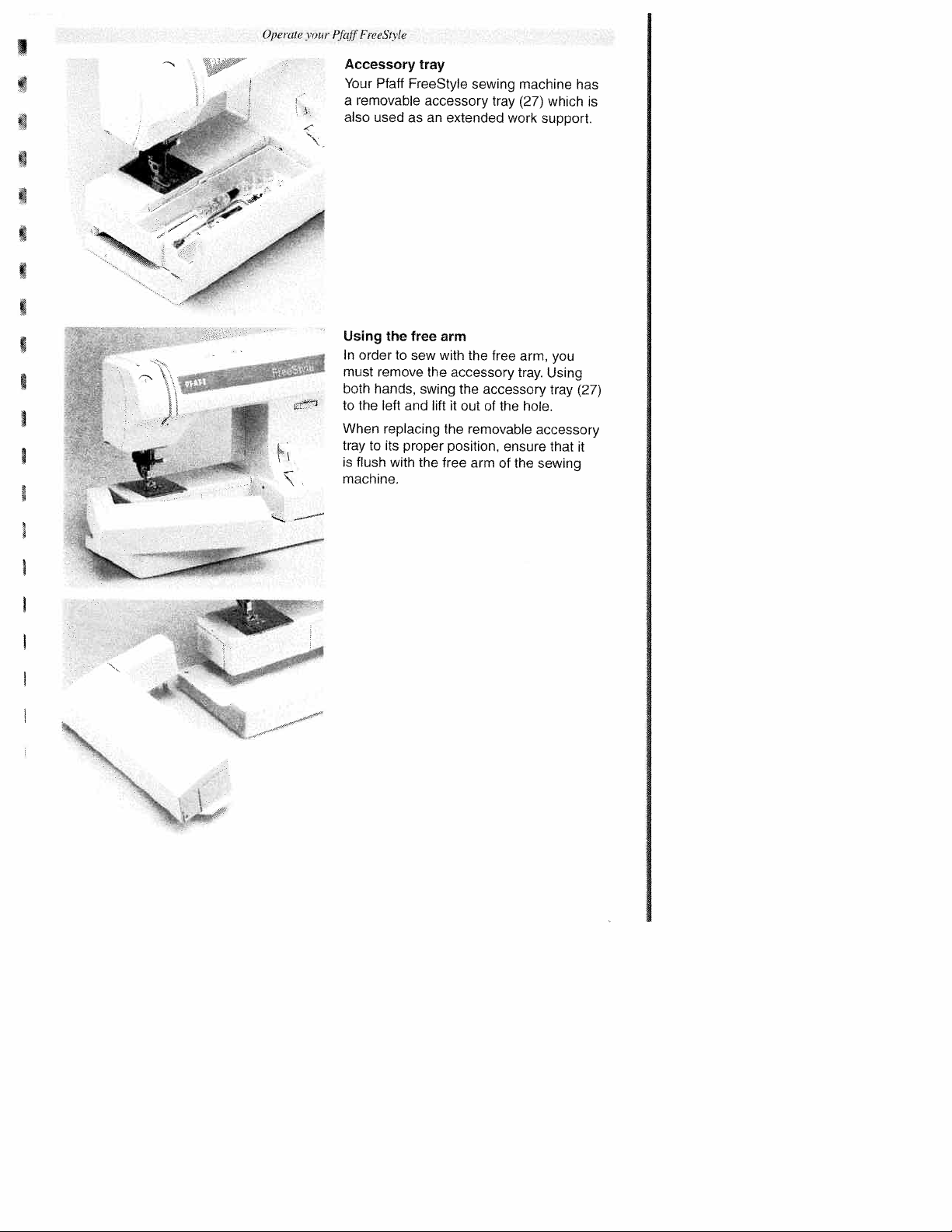

cover

Top

Open

stitches

The

illustrated

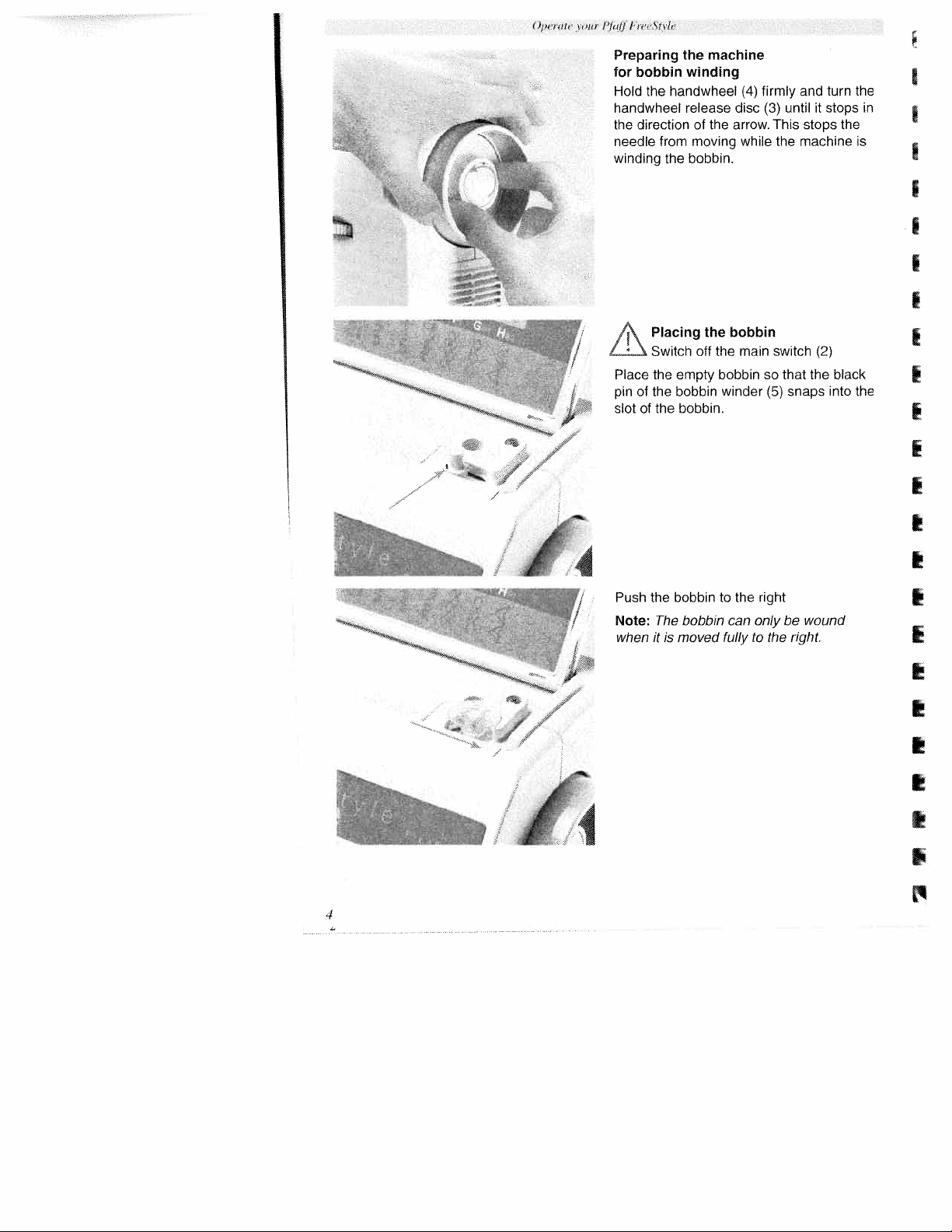

Connecting

Connect

connecting

the

machine

sewing

control.

foot

Additionally,

speed

of

part

Position

Position

For

this

AW

typ

the

the

by

the

cords,

book

folding

on

the

and

speed

moving

foot

I

=

*

sewing

0253

of

the

the

plug

to

you

half

=

or

the

is

full

coch

tool

the

in

cover

sewing

inside

foot

of

the

socket

wall

the

regulated

can

the

control.

speed

speed

machine,

013

AE

ci

conip;

upwards

(6)

macloin

the

of

control

foot

of

(1)

socket

regulate

slide

a

must

n

it

control

the

by

on

foot

Ii

tot

c

inp

sewinq

The

piooctnq

the

cwtnc

tool

the

ctntl)iI

hi.

to

I

I

I

If

o

v

Ic

Ito

0’,

a

appliance

This

blade

of

risk

in

to

fit

plug

does

plug.

the

qualified

outlet.

wider

electric

polarized

a

not

it

If

electrician

not

Do

than

shock,

fit

still

modify

has

the

outlet

fully

does

polarized

a

other).

this

in

the

not

to

install

the

plug

only

fil

plug

To

one

outlel

contact

the

in

plug

reduce

intended

is

way

reverse

proper

any

(one

If

a

way

the

the

Main

When

the

The

switch

the

sewing

sewing

main

lamp

machine

switch

lights

(2)

is

switched

cc

up.

is

*

1ff’

tu

ready

now

*

Page 15

Operat’

your

Pfriff

FreeSt’,k

Accessory

Your

Pfaff

removable

a

also

used

the

Using

In

order

remove

must

both

hands,

left

to

the

When

replacing

to

its

tray

is

flush

machine.

FreeStyle

as

free

to

sew

and

proper

with

tray

accessory

an

extended

arm

with

the

accessory

swing

the

lift

it

out

the removable

position,

the

free

sewing

tray

the

free

accessory

of

arm

machine

(27)

work

arm,

tray.

the

hole.

ensure

the sewing

of

has

which

support.

you

Using

tray

(27)

accessory

that

it

is

Page 16

\UY

nail

lu

Preparing

for

bobbin

Hold

the

handwheel

the

direction

needle

from

winding

Placing

/j\

Switch

the

Place

the

pin

of

of

the

slot

A

the

winding

handwheel

release

of

moving

bobbin.

the

the

off

empty

bobbin

bobbin.

machine

(4)

disc

the

arrow.

while

bobbin

main

the

bobbin

winder

firmly

(3)

This

the

switch

so

that

(5)

and

until

stops

machine

snaps

the

it

(2)

turn

stops

the

black

into

the

in

is

the

A

to

can

fully

the

right

only

to

the

be

right.

wound

wi

the

The

it

bobbin

is

moved

bobbin

Push

I

Note:

when

F

p

I

4

Page 17

Operate

your

Pfcff

FreeStyle

Winding

from

Place

holder

of

to

corresponding

spool

Threading

Place

through

the

few

the

the

the

the

thread

thread

the

hook

times

the

spool

sewing

(8).

thread

opening

D.

around

To

bobbin

holder

guarantee

and

spool,

to

B

Wind

thread

give

to

fit

the

into

and

the

in

the

,

on

free

additional

spool

a

size

guide

to

thread

bobbin.

II!IIJ

the

movement

cap

the

of

and

A

right

the

clockwise

spool

thread

pull

under

hold

it

a

Switch

Hold

press

will

stop

bobbin

bobbin

Don’t

Turn

back

towards

the

on

end

the

foot

the

automatically

full.

is

the

to

forget

handwheel

the

again.

you

main

of

control.

Cut

left

Then

until

the

the

and

turn

it

switch

thread

The

as

thread,

remove

release

the

snaps

firmly

winding

soon

as

push

it,

disk

handwheel

place.

into

and

the

(3)

action

the

fully

(4)

Page 18

Operate

your

Pfaff

FreeStyle

a

*

S

S

$

V

ZEE

L

t

S

S

S

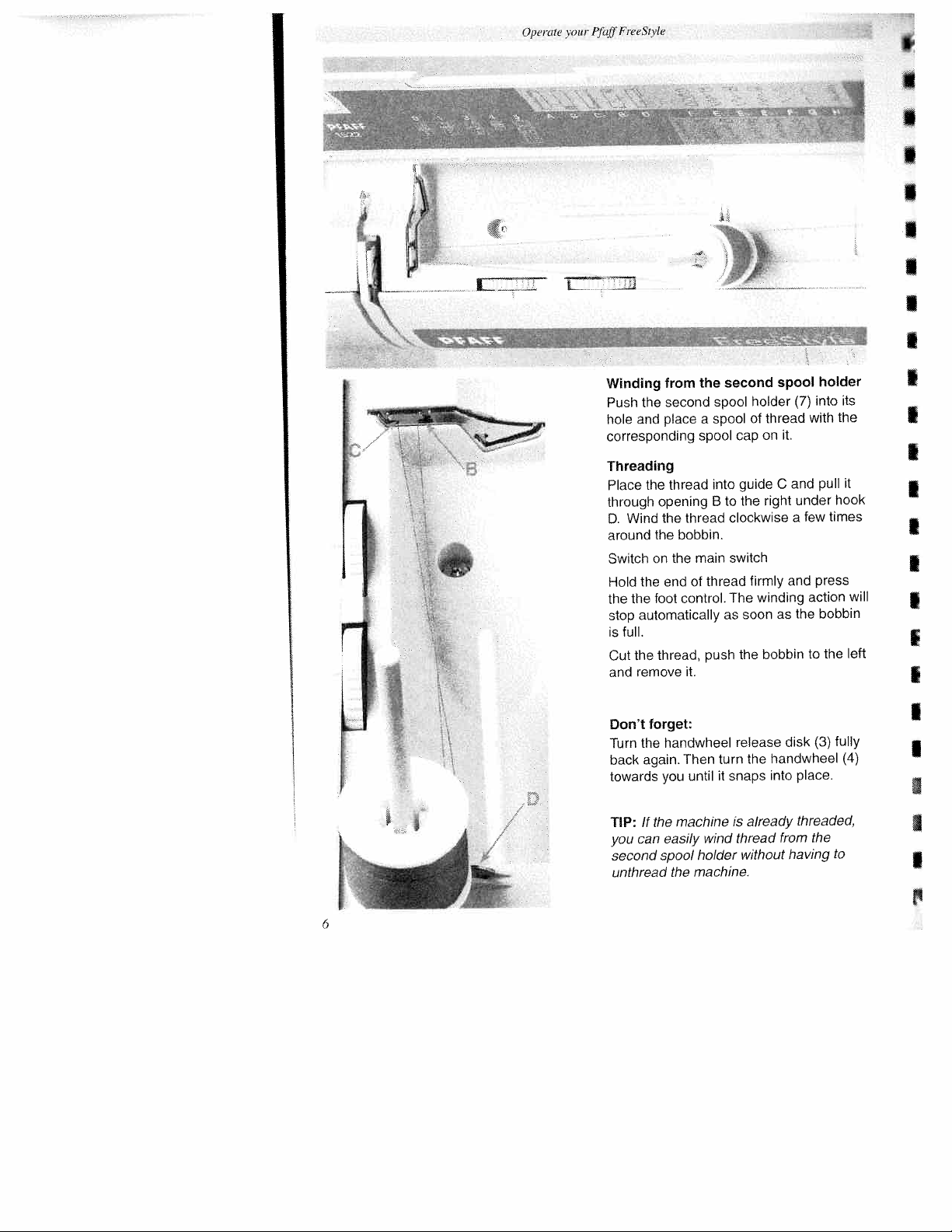

Winding

Push

hole

corresponding

Threading

Place

through

D.

around

Switchonthe

Hold

the

stop

is

Cut

and

from

the

second

place

and

thread

the

opening

the

Wind

the

end

the

the

foot

automatically

full.

thread,

the

remove

the

a

spool

thread

bobbin.

main

of

thread

control.

push

it.

second

spool

spool

cap

into

B

to

clockwise

switch

The

as

holder

of

guide

the

firmly

winding

soon

the

spool

thread

it.

on

C

right

and

as

bobbin

(7)

and

under

few

a

the

holder

into

with

pull

times

press

action

bobbin

the

to

its

the

it

hook

will

left

I

S

I

I

forget:

Don’t

(3)

place.

threaded,

the

having

fully

(4)

to

the

handwheel

into

already

without

disk

from

turn

it

snaps

wind

holder

machine.

release

is

thread

Turn

the

handwheel

Then

again.

back

If

you

the

easily

spool

until

machine

the

towards

TIP:

can

you

second

unthread

6

Page 19

Operate

PfinfFreeSvIe

your

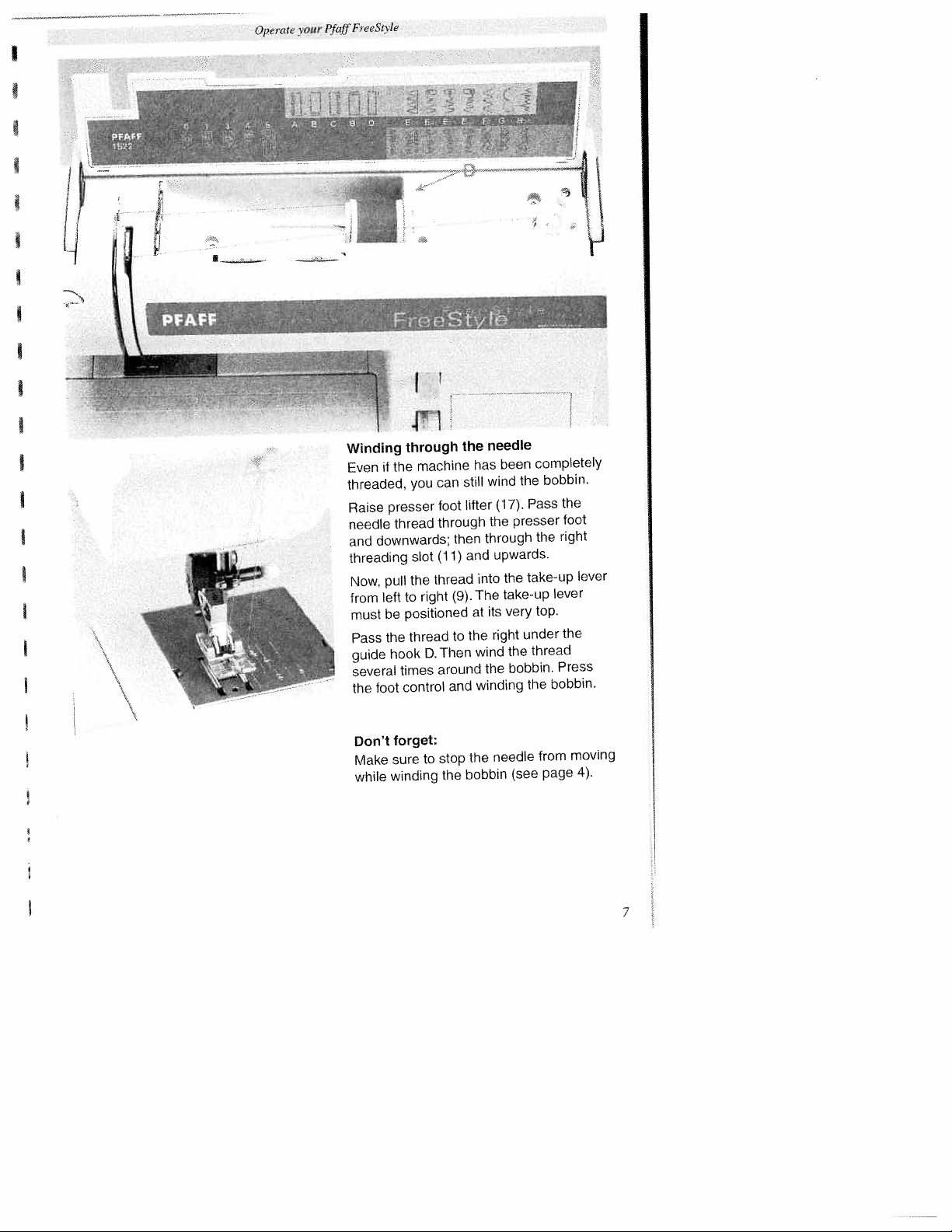

Winding

if

Even

threaded,

Raise

needle

downwards:

and

threading

Now,

left

from

must

Pass

guide

several

foot

the

through

the

you

presser

thread

slot

the

pull

to

positioned

be

thread

the

hook

times

control

I

t

machine

can

foot

through

(11)

thread

right

Then

D.

around

then

(9).

to

and

the

has

still

litter

and

into

The

at

the

wind

winding

needle

been

wind

(17).

presser

the

through

upwards.

the

take-up

very

its

right

the

bobbin.

the

completely

bobbin.

the

Pass

the

take-up

lever

top.

under

thread

bobbin.

the

the

foot

right

lever

the

Press

Don’t

Make

while

forget:

to

sure

winding

stop

the

the

bobbin

needle

(see

from

page

moving

4).

7

Page 20

Operate

vane

Ptf

FreeStyle

main

bobbin

case

lever

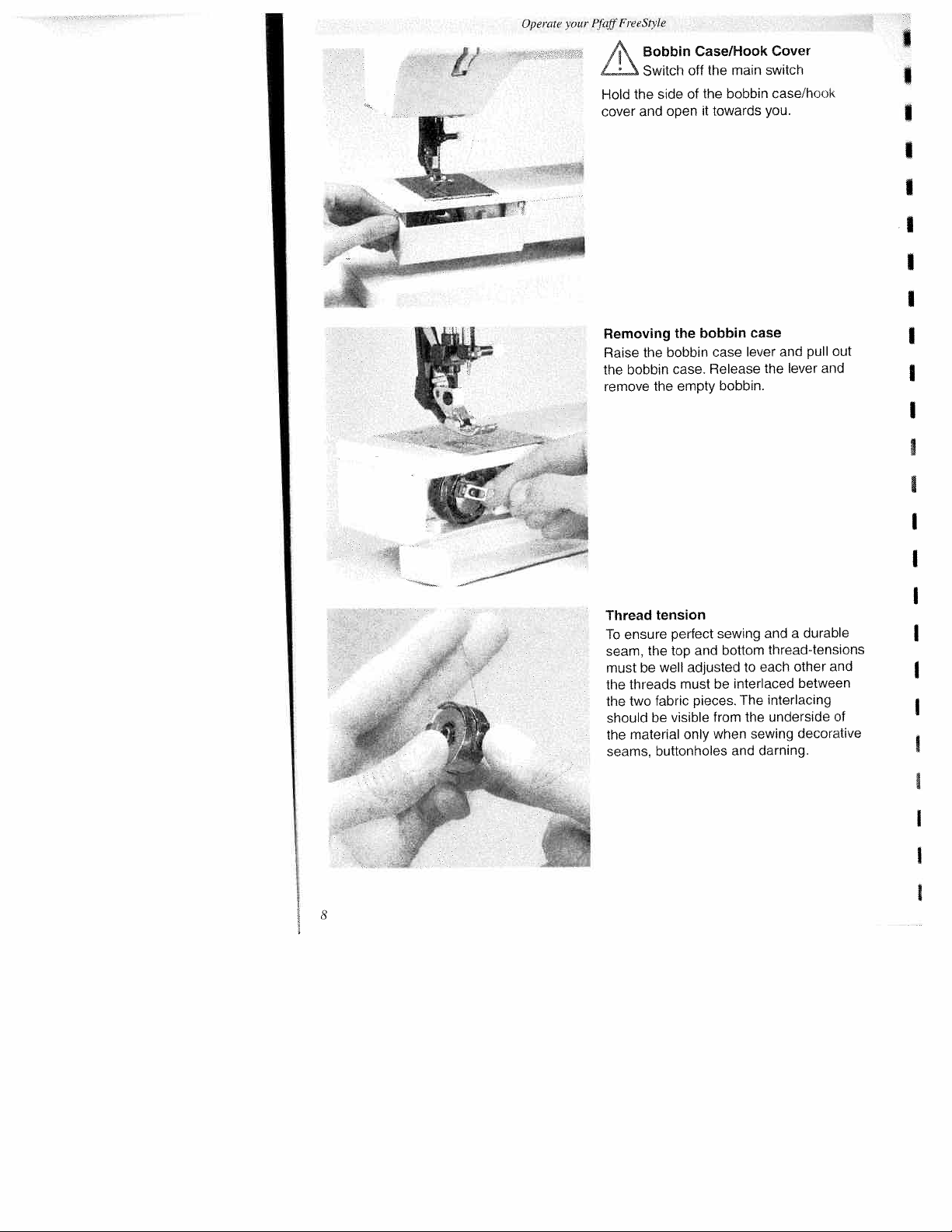

Cover

switch

case/hook

you.

and

lever

the

pull

out

and

side

open

bobbin

the

Case/Hook

off

of

the

case.

empty

the

the

it

towards

bobbin

case

Release

bobbin.

Bobbin

Switch

Hold

the

and

cover

I

f

Removing

the

Raise

bobbin

the

remove

Thread

ensure

To

seam,

must

threads

the

two

the

should

material

the

seams,

tension

perfect

the

top

well

be

fabric

visible

be

buttonholes

and

adjusted

must

pieces.

only

sewing

bottom

interlaced

be

from

when

and

and

thread-tensions

each

to

The

interlacing

the

underside

sewing

darning.

durable

a

other

and

between

decorative

of

Page 21

t

Opc’rate

viur

PftffFrcStyIe

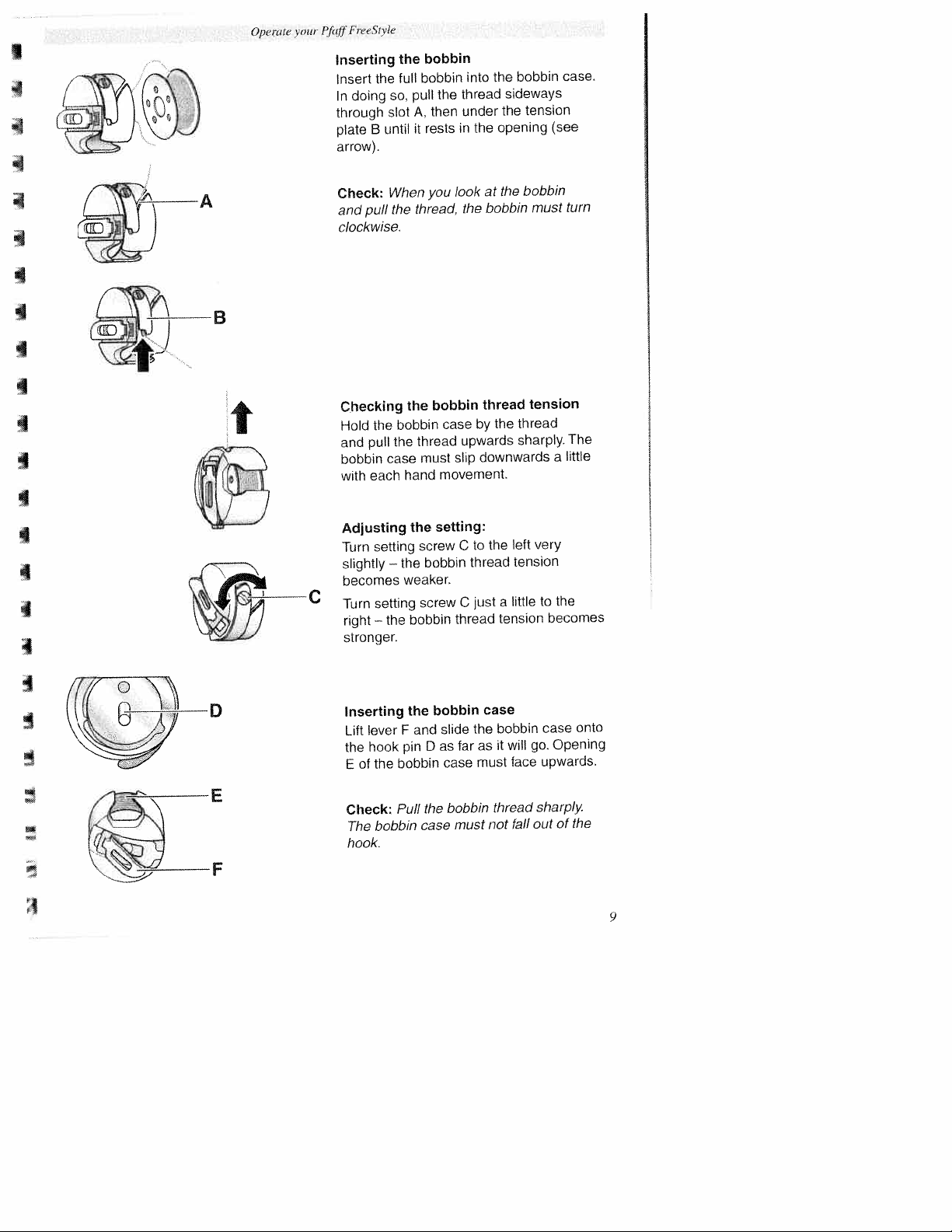

Inserting

Insert

doing

In

through

B

plate

arrow).

Check:

pull

and

clockwise.

Checking

the

Hold

pull

and

bobbin

each

with

the

the

full

so,

slot

until

When

the

bobbin

the

case

bobbin

pull

A,

it

thread,

the

thread

must

hand

bobbin

thread

the

then

in

rests

look

you

bobbin

case

upwards

slip

movement.

the

into

under

opening

the

at

bobbin

the

thread

the

by

downwards

bobbin

sideways

tension

the

bobbin

the

must

tension

thread

sharply.

(see

a

case.

turn

The

little

setting:

setting

setting

the

—

lever

hook

the

bobbin

the

—

weaker.

the

F

pin

bobbin

Pull

the

screw

bobbin

screw

bobbin

bobbin

and

D

the

case

thread

slide

far

as

case

bobbin

must

C

thread

C

to

just

case

the

as

must

the

a

tension

bobbin

will

it

thread

not

very

left

tension

little

go.

face

sharply.

out

fall

the

to

becomes

onto

case

Opening

upwards.

the

of

Adjusting

Turn

slightly

becomes

Turn

right

stronger.

Inserting

Lift

the

of

E

E

Check:

The

hook.

F

9

Page 22

FreeStyle

Pfu/f

your

Operate

swprlt

lifter

take-up

Place

pull

thread

through

slot

lever

to

left

the

in

pass

of

thrtnt

(17)

and

(8)

the

guide

(11)

around

slot

(9).

into

right

righthand

the

the

nei

Iv

th’

itt

thru,i

and

and

the

thread

two

ttt

stop

a

a

I

a

a

a

S

I

I

needle

the

off

until

to

spool

spool

hands,

both

under

and

A

the

threading

the

Pull

righthand

take-up

the

must

(9)

again

Finally,

slot.

behind

(22).

the

foot

the

the

holder

thread

threading

be

from

main

top.

cap.

thread

pulled

one

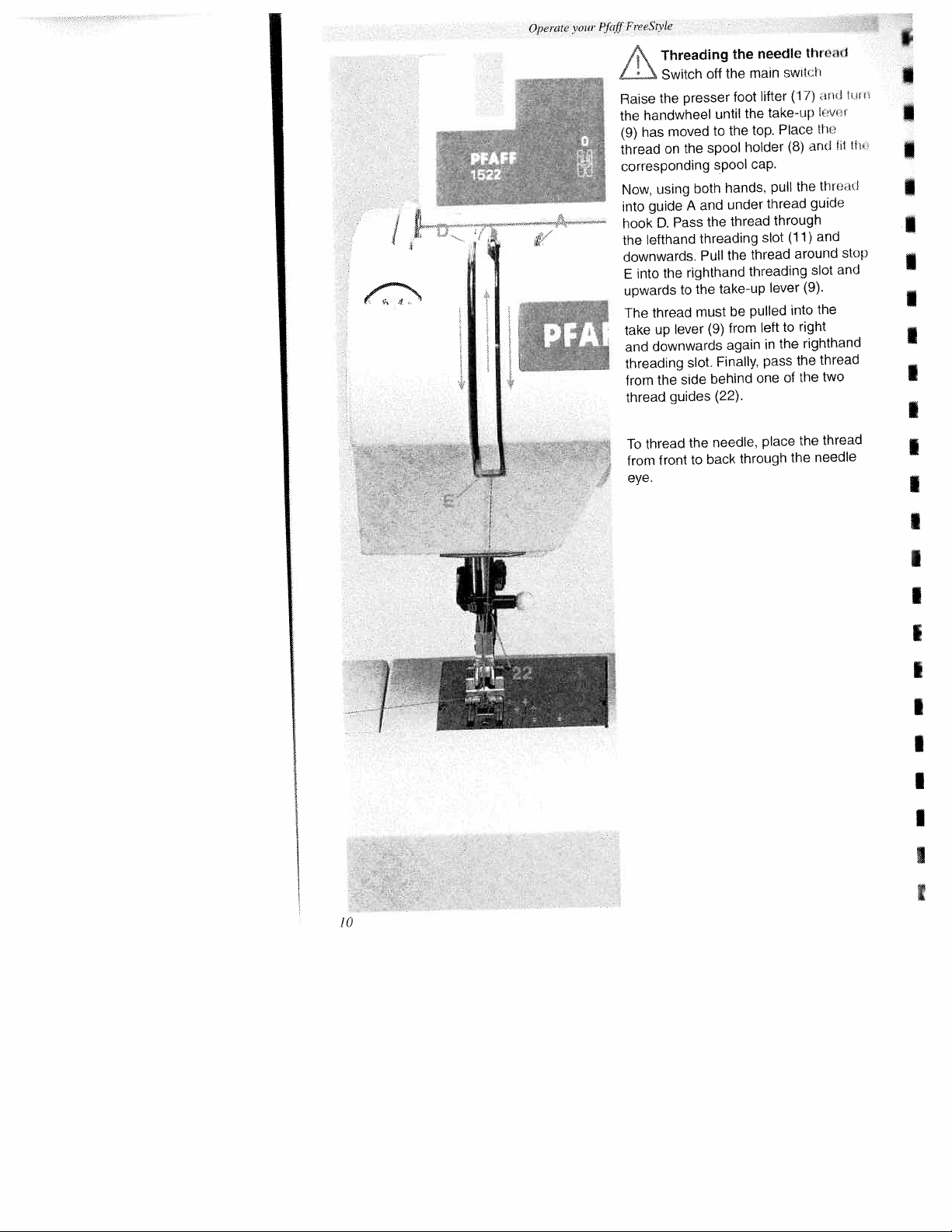

Threading

/\

Switch

the

handwheel

moved

has

on

using

guide

Pass

D.

Iefthand

the

into

thread

lever

up

downwards

the

guides

presser

the

to

side

Raise

the

(9)

thread

corresponding

p.

/

Now,

into

hook

the

downwards.

E

upwards

The

take

and

threading

from

thread

I

thread

the

To

from

eye.

thread

front

the

to

needle,

back

place

through

the

needle

I

I

I

S

I

I

I

I

I

I0

Page 23

Operate

your

FreeSr,’!e

Pfafl

Threading

Insert

the

Fit

spool

the

In

tension

sure

thread

Carry

make

with

Pull

guide

the

second

of

left

that

on

sure

each

the

(22)

twin

thread

threading

disk

you

right

threading

other.

threads

the

over

the

and

needle.

spool

A.

pass

threads

twin

each

on

During

one

tension

right

thread

needle

holder

slot

threading,

thread

in

the

are

and

the

and

holder.

(11)

disk

usual

not

left

needles.

you

left

A.

twisted

into

place

will

make

and

way,

thread

one

find

one

but

II

Page 24

)UE

Ilufi

I

i

‘lI

/j\

Raise

thread

you

and

Pull

bobbin

Bobbin

Close

pull

the

left.

until

the

the

the

Drawing

Turn

the

and

bobbin

needle

thread.

thread

the

thread

off

presser

turn

the

bobbin

the

the

needle

thread

thread

case/hook

under

up

the

main

foot.

handwheel

is

the

bobbin

switch

Hold

at

the

has

to

draw

presser

the

top

formed

up

cover

thread

needle

towards

again

a

loop.

the

and

foot

to

Thread

Pull

front

the

over

cutter

threads

the

from

thread

the

cutter

back

(12).

to

the

I

I

I

I

I

I0

I

Page 25

Operah’

f

Freestyle

Pfa/j

our

lifter

presser

presser

foot

foot

foot

is

litter

raised

(17).

lowered

or

with

j

Presser

The

the

switch

highest

back

the

foot

when

the

foot

the

raising

foot

at

from

the

the

pins

holder.

presser

the

point

the

the

at

presser

presser

the

of

presser

the

foot

presser

the

off

needle

that

so

holder

the

presser

(13)

is

in

engaged

the

main

at

foot

disengages

it

(13).

presser

foot

that

so

lowered,

presser

the

check

its

upwards

at

under

that

by

Removing

/

Position

Press

and

front

same

presser

Engaging

Place

holder

foot

lifter

foot

engage

foot

Check:

properly

is

lifter.

foot

Turn

the

presser

the

downwards

time

foot

the

(17)

Please

‘p

‘3

Page 26

Operate

tour

FneStvIe

Pfajj

The

PFAFF

difficult

This

and

top

industrial

in

fed

is

difficult

fabrics,

puckering.

Engaging

Important!

top

at

the

Raise

feed

place.

Intigrated

offers

materials:

system

bottom

precisely.

materials

the

only

feed,

back.

the

downwards

(15)

dual

the

feeds

simultaneously

sewing

When

feed

dual

Intigrated

the

all

For

use

presser

teedIlDT

soluhoi

ideal

intigratc’d

the

material

the

machinesTh

sewing

such

as

prevents

sewing

sewing

Then

foot,

until

silk

Dual

jobs

feet

it

Sy.Im

h

(

hm

a:

light

and

seam

feed

with

with

push

snaps

lc’

th

l;ilai

or

riytnr

the

cutout

the

into

top

I

I

I

I

I

I

I

I

Feed

two

the

top

also

Dual

fingers

feed

rear,

ensures

and

at

(15)

and

striped

let

the

I

it

Intigrated

Disengaging

the

Hold

marked

a

down

slowly

move

even

The

perfect

fabrics.

14

the

feed

dual

places.

and

little

upwards.

feeding

matching

Push

out

action

of

with

the

to

checked

Page 27

Operute

your

P/off

FreeStyle

Changing

Switch

To

foot

highest

fixing

needle

To

the

Lower

the

as

tighten

off

remove:

and

point.

screw

downwards.

insert:

needle

the

needle,

goes.

it

the

the

the

move

The

must

presser

Hold

fixing

needle

main

Lower

the

Now

and

(16)

flat

face

pushing

the

switch

the

needle

loosen

side

foot

itupas

screw

presser

pull

A

the

to

and

needle

(16)

to

the

the

of

its

rear.

insert

far

and

firmly.

the

sewing

dog

the

tension

thread

mark

and

and

2

e.g.

right.

tension

A.

4

is

buttonhole

3.

darning

do

To

cover

Now

to

and

5.

the

this,

the

needle

of

help

between

feed

be

to

case/hook

fully

dropped.

thread

for

darning

work,

dropped.

to

needle

Setting

Set

(10)

The

For

set

Dropping

I

For

feed

open

feed

the

required

the

with

normal

embroidering,

tension

the

certain

dog

the

slide

move

dog

the

setting

the

sewing

has

bobbin

A

is

‘5

Page 28

Operate

veer

Pfaff

Stitch

The

dial

needle

Basic

(24)

width).

Exception:

stitch

In

sewing’

recommendations

stitch

During

stitch

Fre’eStle

width

stitch

(24).

must

setting:

the

to

width

chapter

width

sewing

width.

width

When

symbol

Straight

0.

“Utility

(pages

selection

dial

can

selecting

notbein

Turn

the

1

stitch

stitches

19-38).

in

you

can

adjusted

be

the

the

material.

stitch

(maximum

sewn

is

and

you

tables

the

individual

of

also

width,

width

practi;iI

will

find

for

change

wilh

lie’

kieb

stih:li

with

the

stitche’,

tli.

the

Needle

In

14

selected

4’

<

—““--

dial

The

(25)

furthest

can

far

position

the

Note:

needle

width

width

reverse

the

position

center

the

additional

(25)

furthest

can

farasit

as

needle

achieved

be

it

will

as

needle

If

you

position,

dial

of the

applies

left

(see

by

in

of

dial

needle

position

needle

positions

turning

increments

be

go

the

must

(25)toincrease

the

needle

position

achieved

will

go

positiontothe

turning

by

to

the

needle

not

have

selected

you

left

side

also

page

42).

left.

be

can

of

for

needle

to

by

to

is

being

in

the

needle

the

left

to

turning

the

right.

the

When

the

the

now

or

reduce

stitch.

can

be

positioning

right

or

left

the

the

chit

The

right

C2)

dial

as

the

changed.

material.

right

the

use

(lie

The

positioii

S

I

I

I

I

I

I

I

K

/6

Page 29

Operate your

Pfaff

FreeStyle

Reverse

4

4

1

tI

The

long

pressed.

sewing

machine

the

as

sews

reverse

in

reverse

sewing

only

button

as

(18)

is

I

4

length

Stitch

the

With

can

6

button

the

the

further

mm

optimum

adjust

“buttonhole”

the

you

and

the

Between

find

is

buttonholes

The

higher

stitch

by

to

the

density

adjustment

length

the

turning

required

the

numbers

stitch

embroidering.

and

turn

you

stitch

of

dial

adjustment

length

the

point

length.

0

and1you

symbol.

density

dial

the

stitch.

the

dial

between

marking

This

area

for

sewing

to0,the

(19)

0

on

will

\\

To

you

dial

area.

sew

must

(19)

stretch

turn

far

as

stitches

stitch

the

as

it

will

(dark

length

go

in

background),

adjustment

the

grey

‘7

Page 30

(jYei

IiutJ

‘

I

Stitch

seIecton,

stitch

dia

Utility

stitches

stitchisidenbfied

Each

their

shown

also

the

the

stretch

stretch

and

found

dial

stitches

stitches

dial

the

is

positioned

stitch

the

the

on

the

in

(21)

stitches,

material.

(21)

grey

stitches

are

is

Turn

letterispositioned

Stretch

All

are

for

Turn

letter

Turn

willgoin

by

corresponding

of

inside

the

Introduction

the

below

i.e.

below

dial

correspondin

mark

they

the

corresponding

mark

(19)

until

withacolored

until

length

area.

ettor1l

a

lid,

the

chapk

A.

background

are

A.

as

citt

ehof

a

suitable

far

as

4

I

I

I

I

I

I

I

I

I

I

I

I

it

I

I

S

*

a

S

18

Page 31

I

111%

‘IL

(Ind

cVIi

pi

ifl

at

(

4

I

4

Utility

and

Sewing

General

Non-elastic

Elastic

‘4

Buttonhole

Button

Hemming

Smocking

Gathering

Darning

sewing

4

Stabiiizifl9

4

Sewing

stitches

practical

chart

sewing

stitches

stitches

sewing

with

zippers

on

edges

lace

aids

the

sewing

needle

twin

20

21

22

23-24

26-27

28

29

29

30

31-32

33-35

36

37

1

I

I

‘9

Page 32

lirditv

stiiche.s

and

pracikal

.ewing

Explanation

following

The

recommended

technique.

charts

These

instructions

the

sewing

choice

The

needle

the

of

sewing

the

switched

Always

(

on

use

if

not

instructions.

the

of

charts

settings

also

are

that

selected

sewing

the

of

thread

carried

is

off.

or

‘center”

the

otherwise

sewing

show

for

provide

necessary

stitches.

tension

out

specificed

chart

the

each

you

foot,

with

needle

with

when

the

and

the

stitch

further

setting

whether

top

position

the

in

or

feed

sbtch

I

Stitch

Stitch

Stitch

Dual

Thread

Presser

number

width

length

feed

tension

foot

‘

mm

in

in

mm

on

off=

number

flUJ

=

0

20

Page 33

Needle

(‘nsure

I

nindle

perfectly

be

normal

range

Check

stitch.

between

If

the

threads

the

fabric.

the

low,

lower

adjustment

The

tension

bobbin

thread

and

setting

4-5.

of

the

The

the

needle

the

If

threads

fabric.

is

thread

tension

sewing

perfect

thread

bobbin

to

tuned

utility

for

tension

threads

described

with

must

fabric

two

thread

interlaced

are

needle

are

of

the

tensiononpage

results,

tensions

each

stitches

wide

a

be

pieces.

tension

thread

interlaced

needle

page

on

Urilils

other

zigzag

interlaced

is

too

above

tension

below

thread

15

8.

the

The

is

the

and

stitches

must

the

in

high

top

too

is

the

the

and

p

actical

sewing

Perfect

Too

Too

high

low

tension

tension

tension

I

I

Topstitching

15

various

that

along

The

wish

you

edge,

guide

the

The

and

A

ensure

a

piece

workpiece.

stitch

you

edge

aid

Straight

of

way

foot

work.

determined

If

fabric

the

use

No.8).

hole

Sewing

To

beginning

recommend

on

the

E

can

needle

can

fabric

the

top-stitch

the

by

top-stitch

to

simply

marks

guide

edge

is

secured

thick

for

consistent

a

sewing

supporting

fabric

of

always

needle

guide

on

the

(standard

guide

at

of

be

sewn

positions

guide

for

edge

needle

position

farther

the

needle

inserted

is

with

seams

feed

thick

a

the

same

the

using

in

such

the

top-stitching

position

from

fabric

plate

accessory

into

screw

fixing

when

seam,

presser

height

any

a

sewing

is

dial.

the

along

or

we

foot

A

B.

as

2]

Page 34

Utility

stitch

atul

pru

iJ

‘

tft

I

S

E

Straight

E

Stitch

length

stitch

required.

if

easier

It

is

changing

stitching

can

You

positions

Please

highest

its

needle

*

0

stitch

is

the

can

do

to

the

a

collar

select

(see

ensure

position

position.

2,5

basic

be

some

needle

or

up

page

that

I

straight

increased

sewing

position,

sewing

15

to

16).

the

when

3-5

stitch.

in

different

needle

adjusting

up

jobs

e.g.

zipper.

a

is

0/1

The

to

6

by

top-

needle

at

the

mm

2

2

2-m

E

Zigzag

addition

In

E,

stitch

suitable

case,

this

In

positioned

overcasting

When

needle

the

edge

the

width

The

2

to

up

overcasting

For

foot

stitch

sewing,

preventing

way

this

seams.

raw

The

B.You

guide

adjusting

with

Important:

for

used

select

width

stitch

any

use

E

1-2

stitch

to

overlock

stitch

overcasting

for

the

halfway

goes

alternately.

overcasting

for

mm.

No.

thread

the

curling

can

you

edge

can

When

overcasting

right

the

in

other

width

material

into

difficult

is

3

sew

must

adjust

screw

the

needle

the

needle

‘

e

5

under

the

the

very

lies

the

of

be

A.

blind

with

range

IL

3-5

stitching,

is

,

also

various

should

the

edge,

material

can

materials,

useful.

pin

over

fabric

beautiful

guided

edge

this

stitch

the

position.

3-5

of

position).

0/1

zigzag

materials.

only

sewing

make

be

When

C.

edge.

smooth

along

fool

zigzag

Choose

mm

be

toot.

sure

and

reducn

blind

thus

In

edq’

guile

is

sliliti,

(rIo

over

I

*

ri,t

Page 35

UtiIit

suchfs

and

practical

SPfliflE

Remember!

select

if

right,

make

5,

bar

the

visible

B

position

regulate

lhe

you

of

turning

by

crease.

(Z

sure

presser

on

c

the

When

position

other

width

not

does

stitches

the

If

S

adjust

screw

Use

width

the

of

the

dial

other

strike

edge

A.

needle

(24)

needle

than

than

are

guide

to

in

stitching,

blind

a

and

needle

the

foot

right

the

adjusting

and

penetration

needle

stitch

3.

side,

the

I

H

B’ind

Stitch

elastic

overcast

Fold

width.

Now

hem

Place

so

guide

Using

select

5i

stitch

a

is

H

materials.

the

at

edge

the

unfold

edge

the

the

that

B.

the

the

12

(e’astic)

stitch

blind

The

same

inwards

the

protrudes

fabric

crease

needle

needle

hem

•

for

hem

time.

by

again

by

the

under

runs

line

positioning

position

35

woven

sewn

is

the

so

about

sewing

to

hem

that

1

along

knob

the

or

and

cm

right

the

foot

edge

28,

Stitch

H

0/3

c.

crease

the

enters

needle

the

When

line,

the

must

it

fabric.

only

pick

up

one

fiber

of

23

Page 36

Utility

stitches

and

prauical

sewing

E

Stretch

This

where

inside

Turn

far

as

length.

I

stitch

great

trouser

the

as

0

triple

is

stitch

it

Stretch

straight

used

strength

seams.

length

will

go

for

for

•

stitch

sewing

is

needed,

dial

the

3-5

all

away

longest

oil

seams

e.g.

from

stitch

you

3-5

E

Stretch

stretch

The

and

elastic

suitable

very

underwear.

Serge

•

Fold

width.

•

Topstitch

I

triple

triple

decorative

the

hem

the

Stretch

zigzag

for

edge

the

•

zigzag

hems

of

the

inwards

from

hem

stitch

stitchisa

seam

T-shirts

on

hem.

at

3-5

the

the

which

required

right

0/1

highly

is

and

side.

t

Page 37

F

sewing

)

5-ø

Stretch

0/1

3-5

•

practical

and

eritches

Utility

/

1’”

/

0/1

3-5

1-2,5

5-

F

•

Elastic

Because

used

be

can

,wimwear,

Mark

elastic

Pin

markings.

Place

•

toot.

Stretch

sewing.

When

Note:

stretch

to

sowing

stitch

of

elastic

fabric

foot.

high

its

for

skirts

to

elastic

stretching

from

elasticity,

sewing

lingerie.

or

and

fabric

and

to

the

elastic

fabric

at

elastic

the

fit

front

in

quarter

under

fabric.

elastic,

and

stitch

this

on

quarters.

sewing

Begin

make

back

for

stitch

hems

stitch

hem

on

an

is

which

T-shirts

elastic

particularly

is

childrens

and

Honeycomb

honeycomb

The

decorative

and

suitable

clothes.

Fold

•

overstitch

the

hem

it.

over

double

and

sure

the

of

25

Page 38

Liii!

liv

.utf(’he

and

praclicat

ewin

Buttonholes

produce

the

to

fully

arranged

buttonhole.

the

buttonholes

does

sew

Before

the

Sewing

fabric

Buttonholes

materials.

material

To

purpose.

Mark

always

Note:

not

e.g.

from

starting

front,

at

have

generally

are

silk,

contracting

beautiful

point

sample

a

starting

i.e.

interval

an

very

is

to

be

organza

seams,

of

buttonhole

any

that

so

of

easy

turned.

onto

sewn

viscose,

and

sewing.

while

embroidering

buttonhole

the

buttonhole,

red

the

cm.

0.5

with

first.

They

all

a

always

arrow

the

piece

it

either

are

is

or

is

a

models

at

doubled

of

necessary

darning

with

the

pLish

first

the

guide

with

threads

magic

a

when

pushbullori

fabric,

use

to

pen

guide

mark.

red

determining

However,

stabilizer

are

or

the

of

The

c’iin

ideally

dress

buttonhole

red

the

hr

i

siiiloii

pin,

mod

length

i

.nui

Ii

i;i’

ol

2O

I

I

I

I

I

I

I

K

Page 39

practic

and

‘rche

Un/in

Standard

sew

To

heavy

on

recommend

1H(,

8

5.

Oil

11=

the

Insert

forward

loot

stitch

Slect

Inllonhole

fop

the

Select

holding

while

Select

buttonhole

the

of

prevous

Select

holding

while

Select

sewing

by

Carfully

scissors

buttonho’e

buttonhole

as

A.

the

to

after

thread

B

stitch

the

C.

stitch

in

side

B

stitch

the

D.

stitch

few

a

open

cut

seam

a

or

as

far

Sew

required

and

fabric

Sew

until

length.

and

fabric

Secure

stitches.

foot

the

a

sew

the

sew

your

ripper.

and

will

it

left

length.

stitches.

few

few

a

securely.

right

matches

it

few

a

securely.

the

buttonhole

slide

go.

of

side

Clip

bartacks

side

the

bartacks

buttonhole

Standard

4

S

4

S

I

the

the

with

On

important

stretching.

Lay

protrusion

underneath

the

•

(

.

butonhoe

especially

fablics,

the

knits

to

the

front.

the

Clamp

protrusion

of

the

Slide

forwards

buttonhole

model.

the

Pull

buttonhole

the

..

using

gimp

prevent

thread

gimp

and

A

the

threads

B.

buttonhole

possible

as

as

loop

wth

durable

knits

gimp

a

thread

the

pass

presser

to

described

the

of

and

qmp

buttonholes,

sportswear,

or

thread.

particularly

is

buttonhole

the

over

the

foot

left

the

runner

and

for

thread

gimp

the

cut

rear

thread

towards

and

as

sew

your

threads.

thread

we

from

ends

right

far

the

select

into

ceuin

at

4

4

yoLi

If

flp:

buttonholes,

[Inc

buttonhole

down

(24)

needle

(‘enter

would

width

approx.

to

position

like

you

with

to

can

the

3

sew

mm,

very

reduce

stitch

Use

the

width

the

dial

Page 40

3:

E

Sewing

zigzag

With

can

you

buttons.

Remove

•

feed

Turn

•

move

needle

Now

•

holds

Sew

•

that

hand

S

->1

4

on

sew

dog

the

the

enters

lower

the

on

the

hole

I

—

buttons

E

stitch

two-

on

sewing

the

handwheel

button

the

presser

the

button

button.

the

needle

the

in

C)

(stitch

and

such

in

left

off

also

button.

four-hole

foot

towards

hole

foot

the

Take

enters

Utility

2-3

width

and

way

a

in

blade.

care

4

lower

you

the

lifter;

to

the

ditches

mm)

and

that

button

this

ensure

right-

the

the

and

practkal

Sewing

Insert

Place

•

the

to

Remove

•

and

Wrap

•

with

illustrations

sewing

the

button

the

the

sewing

on

sewing

a

left.

the

buttons

match

and

the

button

shank

thread

below).

foot.

between

sew

match

apart.

with

you

it

and

and

shanks

on

have

the

as

pull

just

knot

of

holes

described

fabric

the

created

it.

(See

Securing

Select

•

width

Change

•

needle

needle

Sew

•

28

straight

dial

position

enters

few

a

(24)

the

securing

stitch

to

needle

dial

one

0.

position

of

turning

by

so

(25)

two

the

stitches.

with

that

holes.

the

the

the

F

I

F

Page 41

practical

atul

lies

stit

tt,litv

I

I

l

:i

:

I

‘

;,

P

—.

I

0

•

3

3-5

0/1

sewing

0/1

3-4

0

E

3-5

I

Hemming

twin

the

Use

topstitch

the

Using

professional

materials

or

cycling

needles

Twin

The

widths.

topstitching

from

needle

make

oust

position

needle

fold

First

•

desired

Then

side.

Finally,

back

only

Uo

‘.tsofch

I

On

ip:

wnar

1int

‘Is

sri’

ls

p:scje

Its

to

w

the

with

needle

seams.

needle

twin

touch

as

such

both

shorts

are

traditional

mm.

4

is

striking

that

sure

.

and

the

for

topstitch

the

cut

seam.

the

to

stretch

a

material!

difficult

advisable

it

is

topstitching

you

11

the

thread

twin

make

to

you

hems

to

T-shirts,

quickly

available

width

To

the

you

the

iron

hem.

hem

the

protruding

needle

materials

it.

find

will

twin

needle

beatitul

can

on

knitted

in

for

prevent

needle

select

width

from

when

such

baste

to

description

a

needle.

a

add

stretch

articles

easily.

and

different

the

plate,

the

fabric

of

the

edge

hem

sewing

as

the

you

center

right

ribbed

hem

of

Smocking

light

Fine,

silk

and

beautiful

with

work

an

use

bobbin

the

thread.

stronger

tension

the

very

at

set

forget,

Don’t

tension,

effect.

Sew

•

gather.

of

Mark

•

the

Each

•

presser

When

•

one

fabric

the

gather

Knot

•

end

effect

fabrics

particularly

are

smocking

elastic

the

additional

hand

by

elastic

the

As

the

than

the

of

low.

the

more

the

seam

test

a

first

the

and

fabric

additional

foot’s

sewing

another,

its

to

subsequent

will

threads

the

the

of

with

such

work.

bobbin

with

normal

bobbin

higher

intense

line

sew

seam

width

several

you

original

irregular.

be

seam

elastic

as

suitable