Page 1

:

PFAFF

ii

Instruction

manua

PFAFF

4

—

expresS0fl2

r

-t

expreSS0fl

quilt

—

V

1

2044

w

I

I

Page 2

Page 3

—

IMPORTANT

When

Read

using

instructions

all

an

electrical

appliance,

before

SAFETY

safety

basic

household

this

using

INSTRUCTIONS

followed,

be

always

precautions

sewing

should

machine.

including

the

following:

F

F

F

F

F

F

F

plugged

type

cord

machine

blocked.

loose

and

required

is

cause

can

needle

the

adjustment

foot,

outlet

used

then

plug,

shock:

in.

rated

fire,

when

this

in

plug,

or

to

cloth.

around

the

etc.

when

manual.

or

remove

the

not

Always

max

electric

sewing

this

manual.

it

if

nearest

the

ventilation

Keep

needle

causing

the

in

removing

where

plug

cord.

Watt.

5

not

is

the

to

it

needle

oxygen

from

unplug

shock,

machine

Use

working

authorized

sewing

break.

break.

to

area,

covers,

is

outlet.

sewing

this

is

attachments

only

properly,

openings

machine

such

lubricating,

being

machine

injury

or

or

by

used

has

it

if

service

or

dealer

sewing

the

of

needle.

threading

as

when

or

administered.

the

from

person:

to

children.

near

recommended

dropped

been

center

machine

needle,

making

for

and

any

reduce

machine

immediately

before

to

this

or

repair,

the

free

away

the

bent

or

push

sewing

needle,

servicing

or

outdoors.

—To

should

used

be

machine

sewing

dropped

sewing

from

from

proper

needles.

fabric

machine

threading

sewing

the

insert

where

turn

pulling

by

the

never

after

relamping.

—To

as

only

contained

as

into

electrical

machine

the

all

needle

while

adjustments

object

any

aerosol

controls

all

on

general

DANGER

sewing

A

•

electric

Always

•

outlet

unplug

WARNING

allow

not

Do

•

sewing

this

Use

•

•

•

•

•

•

•

•

I

‘

•

I

•

I

a

•

•

•

a

•

•

Please

manufacturer

the

by

operate

Never

damaged,

or

examination,

operate

Never

controller

foot

fingers

Keep

not

not

Always

other

Never

Do

not

not

Do

disconnect,

To

not

Do

also

use

use

pull

the

unplug

user

drop

use

operate

unplug

observe

Always

Do

Do

Switch

changing

the

left

be

using

Replace

reduce

Close

toy.

a

its

for

in

machine

water.

mechanical

or

accumulation

plate.

stitching.

(0”)

off

bobbin,

into

(spray)

to

cord.

safety

parts.

mentioned

the

To

moving

machine

unattended

and

the

attention

intended

manual.

this

has

it

if

Return

any

with

The

when

changing

or

from

any

products

off

unplug,

notes

before

with

bulb

risk

use

damaged

a

the

adjustment.

air

lint,

of

Special

wrong

may

It

making

electrical

the

in

opening.

position,

(“0”)

grasp

on

page

when

cleaning.

same

of

necessary

is

as

sewing

openings

dust,

care

plate

deflect

any

presser

instruction

the

being

are

the

2.

burns,

described

electric

of

risk

THESE

and

USA

machine

in

fit

to

qualified

a

Canada

has

polarized

a

electrician

polarized

a

outlet

to

F

F

j

—

I

SAVE

the

For

sewing

This

.

..

intended

contact

iL

—I

INSTRUCTIONS

the

than

wider

blade

(one

only

install

plug

one

the

way.

proper

the

If

outlet.

plug

Do

does

not

not

modify

other).

fully

fit

the

To

in

plug

reduce

the

in

outlet,

any

the

reverse

way.

risk

of

electric

plug.

the

shock,

it

If

still

this

does

plug

not

is

fit,

Page 4

Notes

on

safety

for

domestic

sewing

machines

in

accordance

exercise

must

user

The

1.

2.

3.

4.

5.

10.

11.

12.

13.

When

6.

7.

8.

9.

observe

disconnect

maximum

The

tension

The

machine

The

not

Do

not

Do

there

•

function

its

•

is

it

•

not

Do

liability

No

intended

is

it

avoid

To

repair.

Only

The

According

caused,

the

leaving

place

use

visible

is

e.g.

wet,

pull

the

This

original

machine

should

sewing

the

machine

the

permissable

the

of

is

any

the

is

with

the

will

be

or

risk

solely

is

PFAFF

is

the

to

area

machine,

drive

put

be

to

objects

sewing

damage

disturbed

condensation

mains

accepted

is

it

if

electric

of

the

parts

designed

laws

mains

the

with

adequate

while

during

the

from

wattage

may

belt

operation

into

openings

in

machine

out

plug

for

operated

shock,

responsibility

may

a

for

concerning

power

EN

caution

working.

maintenance

by

mains

the

for

only

be

according

on

if:

that

may

socket

the

of

damage

any

incorrectly.

not

do

of

used.

be

supply

mains

electromagnetic

line

be

60335-2-28

to

with

pulling

sewing

adjusted

machine.

the

caused

be

by

caused

open

qualified

our

with

changed

regard

work

its

the

the

when

or

mains

the

out

lampis5

PFAFF

by

a

the

indications

to

introducing

by

cord.

machine

this

if

machine.

service

rated

mains

a

compatibility,

should

or

and

up

changing

plug.

watts.

mechanic.

There

staff.

voltage

no

changes

and/or

movement

down

mechanical

the

on

cold

a

is

used

no

are

of

liability

made

be

specification

machine

purpose

any

for

inside

parts

and

10%

+1-

accepted

be

can

it.

to

IEC

the

of

partsoraccessories,

plate.

into

a

the

rated

a

335-2-28

and

needle

room.

warm

than

other

machine

frequency

any

for

which

mains

constantly

always

for

that

the

of

+1-

interruptions

which

user

4%.

can

Environment

recommended

The

Ambient

Air

Storage

The

operated

itisa

dampness,

The

Treatment

Always

Cleaning

Housing

moistened

Please

Do

temperature

humidity

temperature

machine

in

machine

machine

protect

and

note!

not

use

20%

is

the

direct

is

display:

with

any

environment

10C

80%.

to

-

suppressed

vicinity

direct

for

supervised

sunlight,

used

to

be

machine

the

To

plastic

insecticides

(50°F)

25C

static

on

clean

cleanser

is:

(-13°F)

insensitive

and

electronic

of

use

electricity,

firm

a

against

the

with

chemical

or

40°C

to

+

to

the

in

and

damage

housing

maximum

(104°F)

(+140°F)

60°C

interference

to

devices.

should

It

home,

heat-producing

surface

even

which

a

use

38°’

products

This

dry,

such

sewing

which

could

clean,

alcohol.

as

according

be

operated

objects,

is

caused

be

soft.

petrol

machine

corrosive

for

open

by

lint-free

liquid

or

international

to

is

a

such

in

ventilation

being

it

cloth.

chemicals

conventions;

high-quality

that

way

a

chemicals

purposes.

dropped.

or

hit

remove

To

to

however,

electronic-mechanical

subjected

not

is

it

liquids.

or

stubborn

any

housing.

the

clean

dirt,

it

to:

shoLild

appliance;

dust,

a

use

not

severe

soft

be

cloth

Page 5

Modern,

uncomplicated

—

Sewing

push-button

by

control

Congratulations!

quality

Your

in

for

It

technology,

uncomplicated

It

the

operation

If

instruction

this

machine

If

problem!

service

So

enjoyable

product

new

stride

its

you.

features

applies

2034.

now

you

is

the

have

you

now

sewing

and

the

and

both

Should

we

take

book,

only

can

any

Your

with

you

hours

can

You

that

will

very

this

as

to

have

time

way

do,

further

PFAFF

any

have

offers

machine

sew

latest

instruction

your

2044

the

there

pointed

enough

nothing

learn

to

to

and

dealer

or

help

started!

get

creating

of

purchased

unique

can

through

design

in

PFAFF

model

any

be

that

to

go

can

all

make

questions,

will

advice

We

your

a

advantages.

any

take

and

thick

and

is

book

sewing

and

difference

separately.

out

wrong.

things

use

that

be

you

wish

fashion

the

at

need.

study

the

full

high-

material

thin

as

just

machine.

to

in

After

the

them.

of

no

is

your

many

you

ideas.

all,

2M

o

Page 6

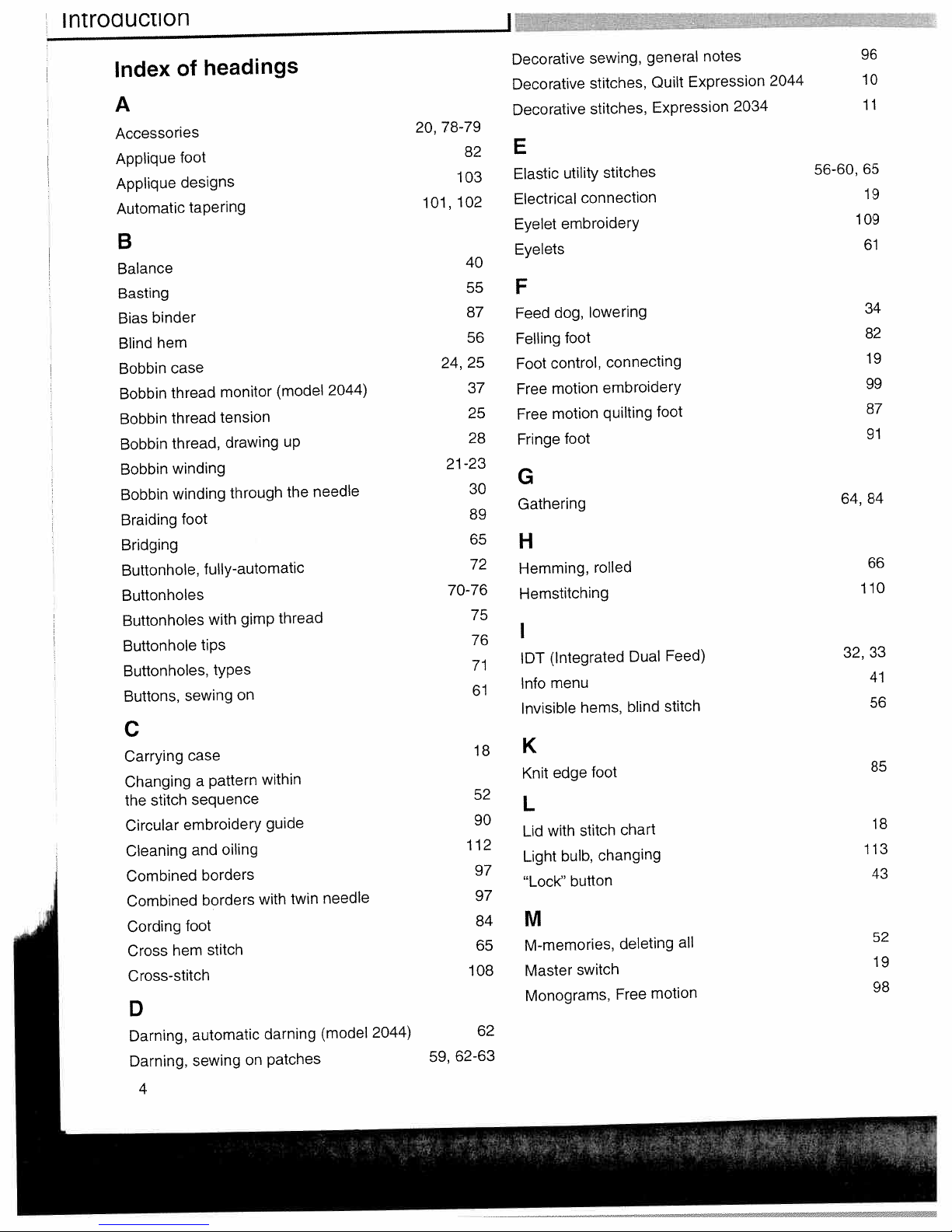

Jntroaucuori

Index

A

Accessories

Applique

Applique

Automatic

B

Balance

Basting

binder

Bias

hem

Blind

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Braiding

Bridging

Buttonhole,

Buttonholes

Buttonholes

case

thread

thread

thread,

winding

winding

Buttonhole

Buttonholes,

Buttons,

headings

of

foot

designs

tapering

monitor

tension

drawing

through

foot

fully-automatic

with

tips

types

sewing

gimp

on

(model

up

the

thread

2044)

needle

20,

101,

78-79

1

102

24,

21-23

70-76

82

03

40

55

87

56

25

37

25

28

30

89

65

72

75

76

71

61

Decorative

Decorative

Decorative

E

Elastic

Electrical

Eyelet

Eyelets

utility

embroidery

F

dog,

Feed

Felling

Foot

Free

Free

Fringe

Gathering

foot

control,

motion

motion

foot

H

Hemming,

Hemstitching

(Integrated

IDT

menu

Info

Invisible

sewing,

stitches,

stitches,

stitches

connection

lowering

connecting

embroidery

quilting

rolled

Dual

blind

hems,

general

Expression

Quilt

Expression

foot

Feed)

stitch

notes

2034

2044

56-60,

64,

32,

96

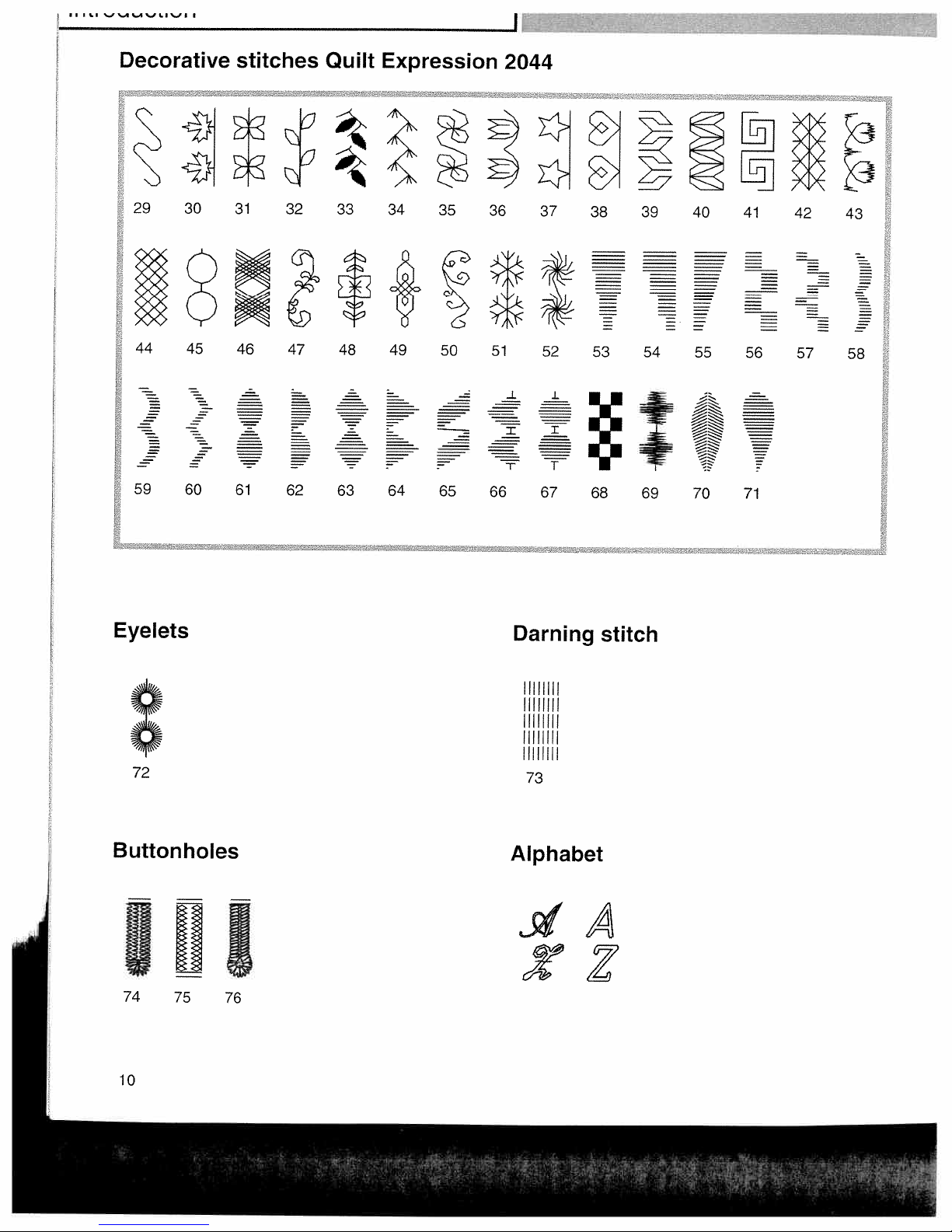

10

11

65

19

109

61

34

82

19

99

87

91

84

66

110

33

41

56

Carrying

Changing

stitch

the

Circular

Cleaning

Combined

Combined

Cording

hem

Cross

Cross-stitch

D

Darning,

Darning,

4

case

pattern

a

sequence

embroidery

oiling

and

borders

borders

foot

stitch

automatic

sewing

with

on

within

guide

twin

darning

patches

needle

(model

2044)

59,

18

52

90

112

97

97

84

65

108

62

62-63

K

edge

Knit

L

stitch

with

Lid

bulb,

Light

“Lock”

button

M

M-memories,

Master

Monograms,

switch

foot

chart

changing

deleting

Free

all

motion

85

18

113

43

52

19

98

Page 7

II

ILl

l.JUUL.11U

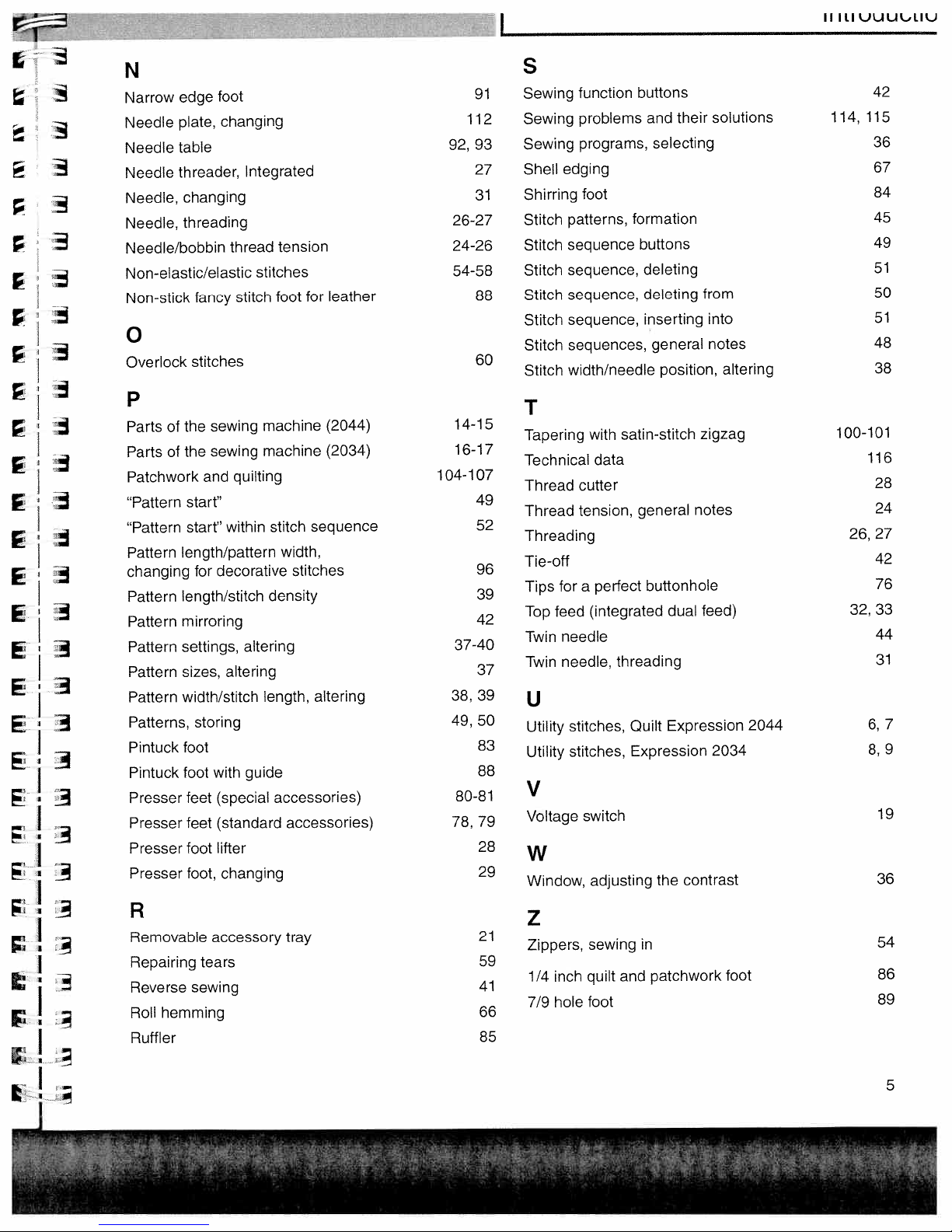

N

foot

Narrow

Needle

Needle

Needle

Needle,

Needle,

Needle/bobbin

Non-elastic/elastic

Non-stick

edge

plate,

table

threader,

changing

threading

fancy

changing

0

Overlock

stitches

P

sewing

the

of

Parts

sewing

the

of

Parts

Patchwork

“Pattern

“Pattern

Pattern

changing

Pattern

Pattern

Pattern

Pattern

Pattern

Patterns,

Pintuck

Pintuck

Presser

Presser

Presser

Presser

and

start”

within

start”

length/pattern

decorative

for

length/stitch

mirroring

settings,

altering

sizes,

width/stitch

storing

foot

with

foot

(special

feet

(standard

feet

lifter

foot

changing

foot,

Integrated

thread

stitches

stitch

machine

machine

quilting

altering

guide

tension

foot

for

sequence

stitch

width,

stitches

density

length,

altering

accessories)

accessories)

leather

(2044)

(2034)

112

92,

26-27

24-26

54-58

14-15

16-17

104-107

37-40

38,

49,

80-81

78,

91

93

27

31

88

49

52

96

39

42

37

39

50

83

88

79

28

29

S

Sewing

Sewing

Sewing

edging

Shell

Shirring

patterns,

Stitch

sequence

Stitch

sequence,

Stitch

sequence,

Stitch

sequence,

Stitch

sequences,

Stitch

width/needle

Stitch

T

Tapering

Technical

Thread

Thread

Threading

Tie-off

for

Tips

feed

Top

needle

Twin

needle,

Twin

U

stitches,

Utility

stitches,

Utility

V

Voltage

w

Window,

function

problems

programs,

foot

satin-stitch

with

data

cutter

tension,

perfect

a

(integrated

threading

switch

adjusting

buttons

and

their

selecting

formation

buttons

deleting

deleting

inserting

general

position,

general

buttonhole

dual

Expression

Quilt

Expression

the contrast

solutions

from

into

notes

zigzag

notes

feed)

2034

altering

2044

114,

100-1

26,

32,

42

115

36

67

84

45

49

51

50

51

48

38

01

116

28

24

27

42

76

33

44

31

6,

8,

7

9

19

36

R

Removable

Repairing

Reverse

hemming

Roll

Ruffler

accessory

tears

sewing

tray

21

59

41

66

85

z

Zippers,

inch

1/4

hole

7/9

sewing

quilt

foot

in

and

patchwork

foot

54

86

89

5

Page 8

Introduction

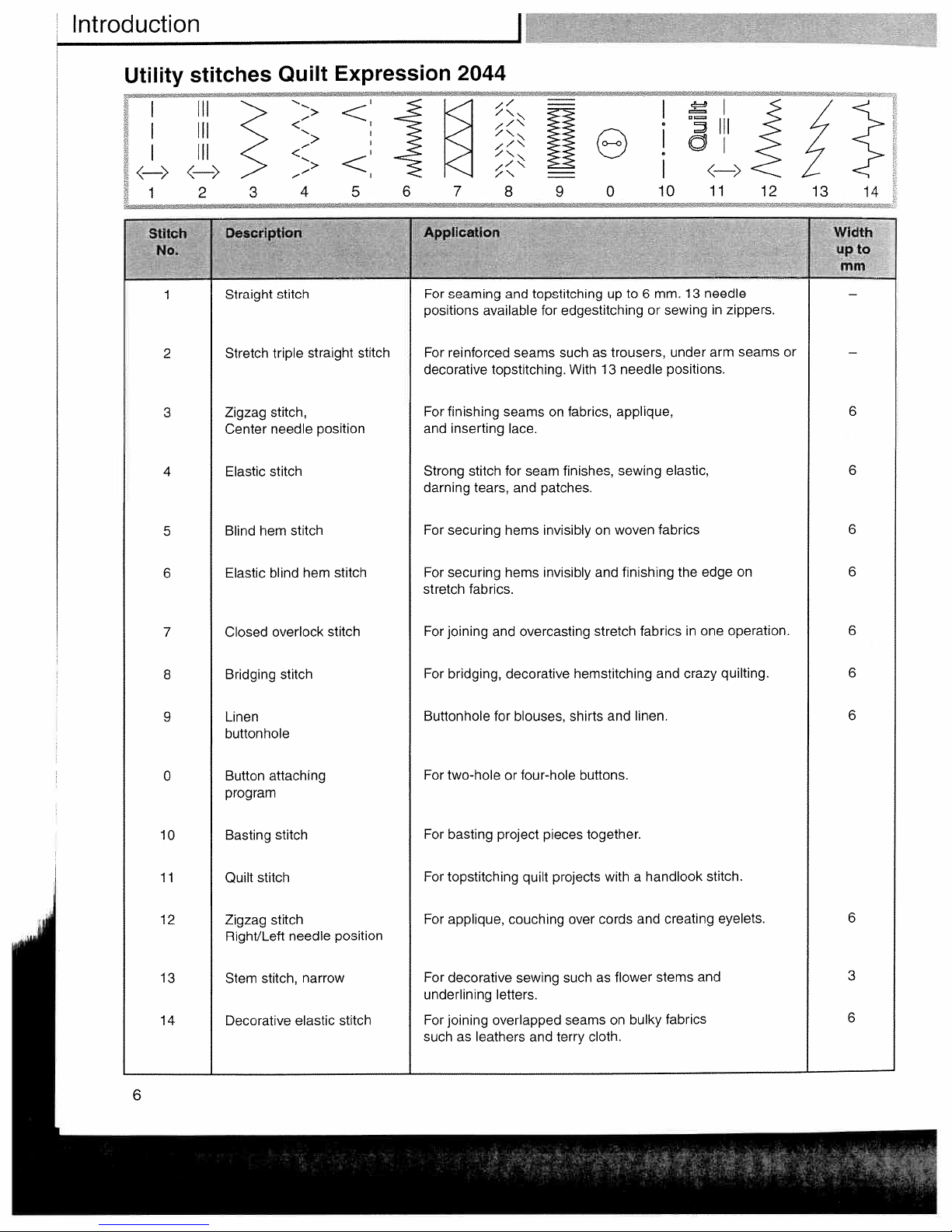

Utility

I

I

I

<—>

1

Stitch

No.

2

3

4

stitches

III

III

III

<—>

2

Description.

.

Straight

Stretch

Zigzag

Center

Elastic stitch

Quilt

3

. .

stitch

triple

stitch,

needle

-.,-.

<>

<

;>

-...

>

4

straight

position

Expression

<i

<

5

stitch

I

6

2044

7

pplication

For

seaming

positions

For

reinforced

decorative

finishing

For

inserting

and

Strong

stitch

darning

//

/\\

//\

/\\

/\

8 9

and

available

topstitching.

seams

lace.

for

tears,

and

=

H

=

topstitching

for

seams

on

seam

patches.

8

0

up

edgestitching

such

finishes,

trousers,

as

With13needle

fabrics,

applique,

sewing

I

I

lol

I

10

.

to6mm.

sewinginzippers.

or

under

positions.

elastic,

13

I

WI

11

needle

arm

seams

12

Width

upto

mm

or

6

6

10

11

12

13

14

woven

finishing

fabricsinone

and

linen.

and

stems

flower

bulky

fabrics

the

crazy

creating

fabrics

edge

stitch.

and

on

operation.

quilting.

eyelets.

For

5

6

7

8

9

0

Blind

Elastic

Closed

Bridging

Linen

buttonhole

Button

program

Basting

Quilt

Zigzag

Right/Left

Stem

Decorative

stitch

hem

blind

hem

overlock stitch

stitch

attaching

stitch

stitch

stitch

needle

narrow

stitch,

elastic

stitch

position

stitch

securing hems

securing hems

For

fabrics.

stretch

For

joining

For

bridging,

Buttonhole

For

two-hole

For

basting

topstitching

For

For

applique,

For

decorative

underlining

For

joining

as

leathers

such

and overcasting

for

letters.

overlapped

decorative

blouses,

or

four-hole

project

quilt

couching

sewing such

and

invisibly

invisibly

hemstitching

shirts

buttons.

pieces

projects

over

seams

terry

on

and

stretch

and

together.

withahandlook

cords

as

on

cloth.

6

6

6

6

6

6

3

6

6

Page 9

II

11.1

%..A.A1l.i%_I

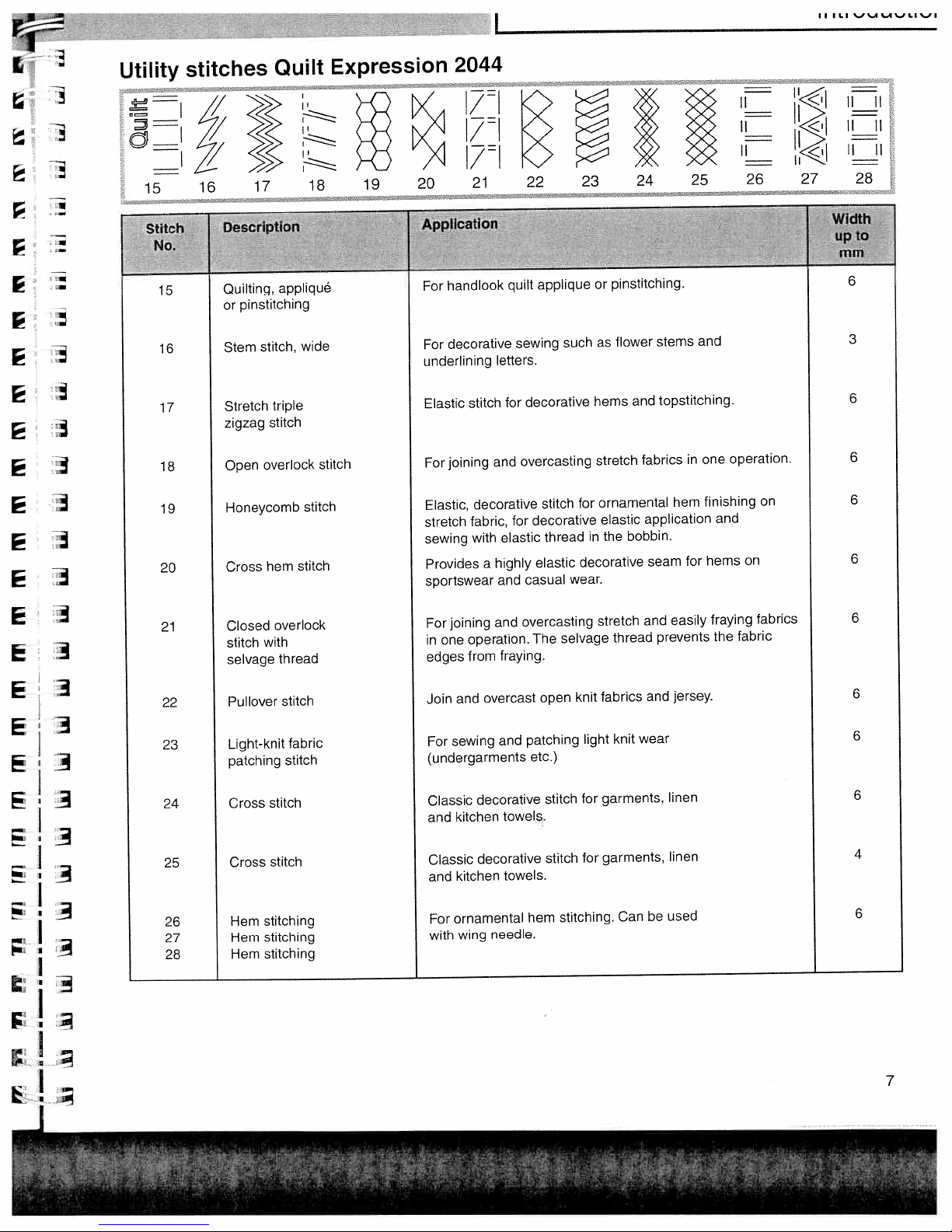

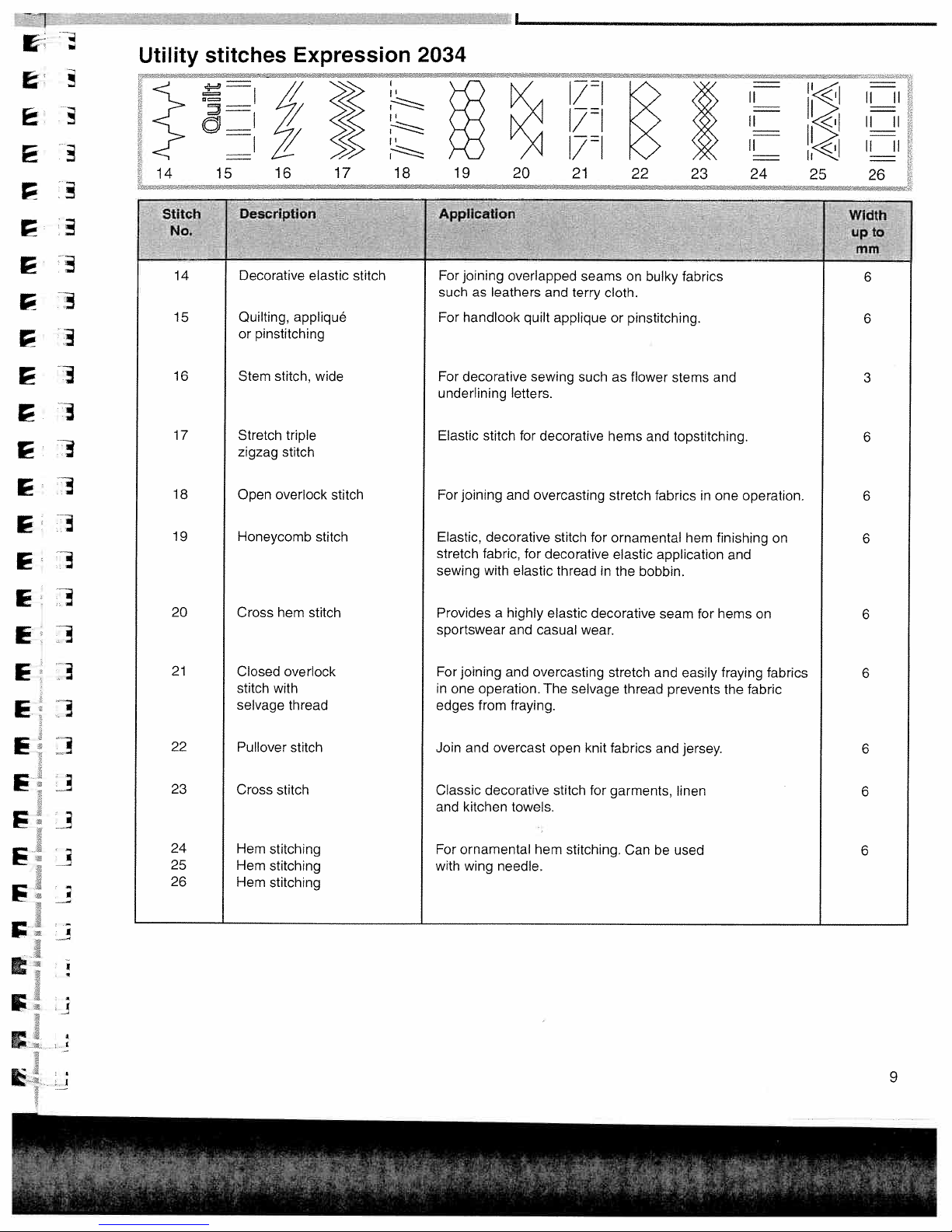

Utility

o=

1z7

15

Stitch

No

15

16

17

18

19

20

stitches

16

Description

Quilting,

or

Stem

Stretch

zigzag

Open

Honeycomb

Cross

Quilt

17

.

appliqué

pinstitching

stitch,

triple

stitch

overlock

hem

Expression

18

wide

stitch

stitch

stitch

19

2044

20

Application

handlook

For

decorative

For

underlining

stitch

Elastic

joining

For

Elastic,

fabric,

stretch

sewing

Provides

sportswear

21

quilt

sewing

letters.

for

and

decorative

for

elastic

with

highly

a

and

22

applique

such

decorative

overcasting

stitch

decorative

thread

elastic

wear.

casual

23

pinstitching.

or

flower

as

hems

stretch

for

ornamental

elastic

the

in

decorative

24

stems

topstitching.

and

fabrics

application

bobbin.

seam

hem

25

and

one

in

finishing

hems

for

26

operation.

and

on

on

27

28

Width

dpto

nlm

6

3

6

6

6

6

21

22

23

24

25

26

27

28

Closed

with

stitch

selvage

Pullover

Light-knit

patching

Cross

Cross

Hem

stitching

stitching

Hem

stitching

Hem

overlock

thread

stitch

fabric

stitch

stitch

stitch

and

joining

For

operation.

one

in

fraying.

from

edges

Join

For

(undergarments

Classic

and

Classic

and

For

with

overcast

and

sewing

and

decorative

kitchen

decorative

kitchen

ornamental

needle.

wing

overcasting

The

patching

etc.)

towels.

towels.

hem

open

stitch

stitch

stitching.

selvage

knit

light

for

for

stretch

thread

fabrics

knit

garments,

garments,

Can

and

prevents

and

wear

be

easily

jersey.

linen

linen

used

fraying

fabric

the

fabrics

6

6

6

6

4

6

7

Page 10

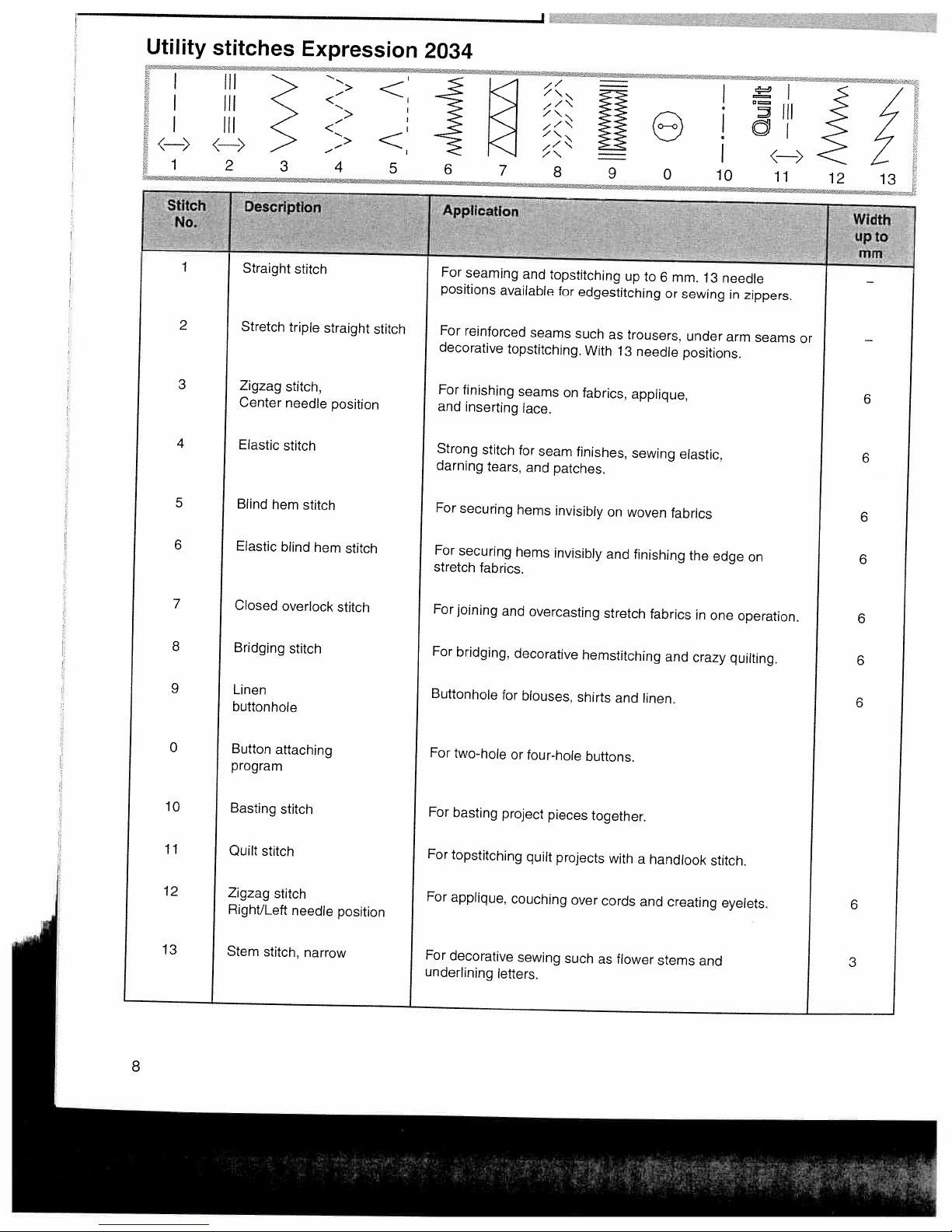

Utility

<_>

Sfltch

No.

1

stitches

Expression

<1

2

3

Description.

Straight

stitch

<

<

2034

—,

—

‘---‘

<

,

i

I

5

-

App’ication

For

positions

-

>

4

C

6

iz:1

i2t

I..-{

l

_—4

-.

-

seaming

I

7

and

available

\\

/“

/N

,/\

/\\

fle

/\

topstitching

8

for

edgestitching

=

9

up

II

III

!0i

0

10

11

Width

upto

.

mm

to

6

mm.

13

needle

sewing

or

in

zippers.

2

3

4

5

6

7

8

9

0

Stretch

Zigzag

Center

Elastic

Blind

hem

Elastic

Closed

Bridging

Linen

buttonhole

Button

attaching

program

triple

stitch,

needle

stitch

stitch

blind

hem

overlock

stitch

straight

position

stitch

stitch

stitch

For

reinforced

decorative

For

finishing

and

inserting

Strong

darning

For

securing

For

securing

stretch

fabrics.

For

joining

For

bridging,

Buttonhole

For

two-hole

topstitching.

stitch

tears,

and

for

or

seams

seams

lace.

for

seam

and

patches.

hems

invisibly

hems

invisibly

overcasting

decorative

blouses,

four-hole

such

With

on

fabrics,

finishes,

and

stretch

hemstitching

shirts and

buttons.

as

13

on

trousers,

needle

applique,

sewing

woven

finishing

fabrics

linen.

under

positions.

elastic.

fabrics

the

and

in

crazy

arm

edge

one

seams

on

operation.

quilting.

or

6

6

6

6

6

6

6

10

11

12

13

8

Basting

Quilt

stitch

Zigzag

Right/Left

Stem

stitch,

stitch

stitch

needle

narrow

position

For

basting

For

topstitching

For

applique,

For

decorative

underlining

project

couching

sewing

letters.

quilt

pieces

projects

over

such

together.

with

cords

as

flower

a

handlook

and

stems

creating

and

stitch.

eyelets.

6

3

Page 11

-]

L

Utility

stitches

Expression

2034

14

Stitch

I’4o

14

15

16

17

18

19

15

Description

Decorative

Quilting,

or

pinstitching

Stem

Stretch

zigzag

Open

Honeycomb

16

elastic

appliqué

stitch,

triple

stitch

overlock

wide

stitch

stitch

17

stitch

18

19

Application

For

joining

such

For

For

underlining

Elastic

For

Elastic,

stretch

sewing

leathers

as

handlook

decorative

stitch

joining

decorative

fabric,

with

20

overlapped

and

quilt

sewing

letters.

for

decorative

and

overcasting

for

decorative

elastic

7=1

21

seams

terry

applique

such

stitch

thread

cloth.

or

as

hems

stretch

for

ornamental

elastic

in

the

22

bulky

stems

and

fabrics

application

bobbin.

fabrics

topstitching.

on

pinstitching.

flower

23

hem

and

in

one

finishing

II

24

operation.

and

on

25

II II

II

26

Width

tipto

mm

6

6

3

6

6

6

F

E

F

F

Fl

F

F

20

21

22

23

24

25

26

Cross

Closed

stitch

selvage

Pullover

Cross

Hem

stitching

Hem

stitching

Hem

stitching

hem

overlock

with

thread

stitch

stitch

stitch

Provides

sportswear

For

joining

in

one

operation.

edges

from

Join

and

Classic

and

kitchen

For

ornamental

with

wing

highly

a

and

and

fraying.

overcast

decorative

towels.

needle.

elastic

casual

wear.

overcasting

The

selvage

open

knit

stitch

hem

stitching.

decorative

stretch

thread

fabrics

for

garments,

Can

seam

and

prevents

and

used

be

easily

jersey.

linen

for

hems

fraying

the

on

fabrics

fabric

6

6

6

6

6

9

Page 12

_______

_______

__________________________

___

______________________________

0

C

—

CD

(I)

C,

CD

Cl)

x

.

m

CD

C,’

Cl)

o.

0

E2

4PI”

C.)

C.’)

C,)

0)

-J

CO

01

C)

C.)

01

ç

iiiIIIIIIIII

iIHIIjjjIIlIIIIII

III

iii

—.J

01

11111

11111

11111

01

‘

C)

ii

‘‘IiiiiI

Ii

I

0•1

m

Co

CD

‘<

(1)

C

C)

-c-cb-

I

lib

“1111111

liii!

ilIIIIIIjliIIIIIIII

2

iI’’I’’’’’’1l

0)

I’ll’

iIliIIIIlIIIIIIIIIIl

C’)

,I’h’’’h’’’

C)

lIjili

1111111

iijii

IlIli

01

C)

II1

,ii,

II

1

iii

I’ii

.iii,

hI’’uhII’hII

C)

C)

-

-

C.)

riiiii

1111111

i

CD

EEE

4u

‘I’

—.

0

w

o

—

.

o

Cl)

I

01

o

0)

V

—

Page 13

i

L

1

i

íieJ

_______________________

________

______

La]

ai

iu

ía]

i

,al

‘i’

iAi

..J

r”

Lili

1

T1

I

jj

—

KD-KD-

°)

1IIlI

‘‘‘‘‘‘‘i’iBIBBB

4.

IlIIIIIIIIII

u

ru

mm

ni

ru

i

a’

‘

‘•

*aJ

J

.aJ

J

La]

ía]

La]

Li

LJ

J

9

UIIl

11111

t

1111!

IIIIII,IIIIIIlIIIlIIIIII

tIIIIIIIIIiIIIllhIIIIl

‘ii

.IIIIIiII.IIIIIIIIr

HIIF1IIII1—

•

LJ

i)

LL

Page 14

Page 15

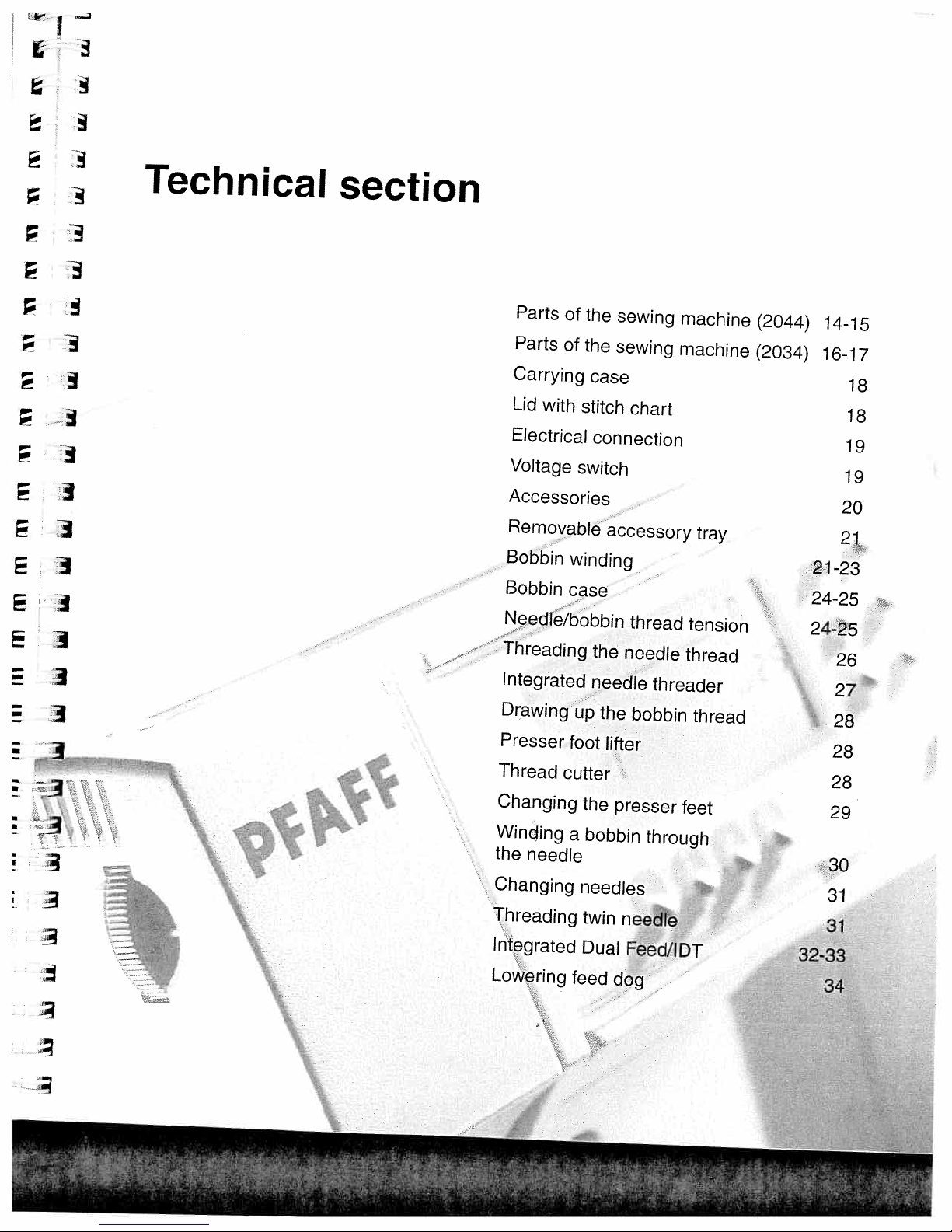

Technical

section

Parts

Parts

Carrying

Lid

I

Electrical

Voltage

Accessories

Removable

Bobbin

Bobbin

Needle/bobbin

Threading

Integrated

Drawing

Presser

Thread

Changing

Winding

the

Changing

Threading

Integrated

Lowering

with

needle

of

the

of

the

case

stitch

connection

switch

winding

case

the

needle

up

the

foot

lifter

cutter

the

a

bobbin

needles

twin

Dual

feed

sewing

sewing

chart

accessory

thread

needle

threader

bobbin

presser

through

needle

Feed/IDT

dog

machine

machine

tray

tension

thread

thread

feet

(2044)

(2034)

14-15

16-17

21

21-23

24-25

24-25

26

27

28

28

28

29

30

31

18

18

1

19

20

9

Page 16

18

19

20

21

22

23

24

25

26

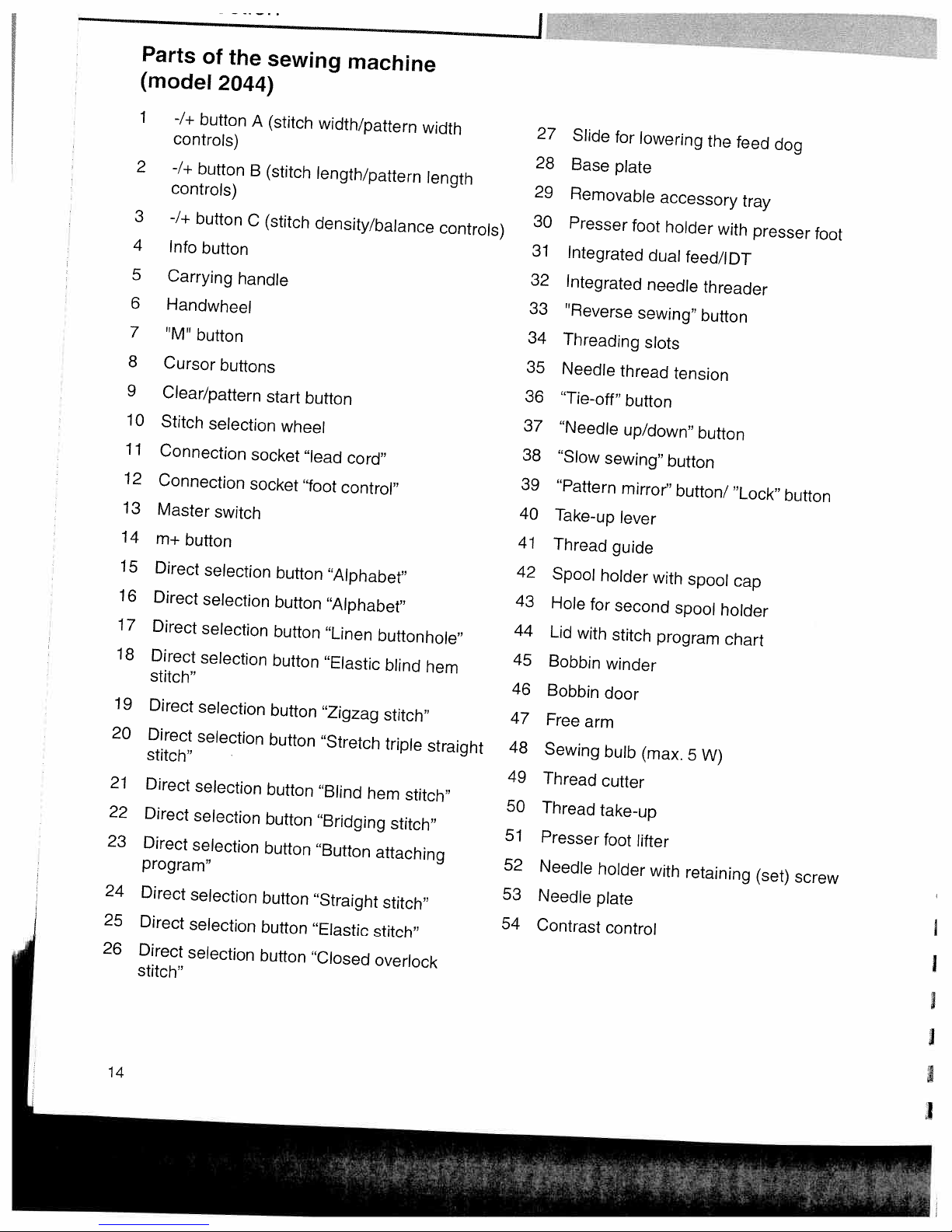

Parts

(mod&

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

stitch”

Direct

Direct

stitch”

Direct

Direct

Direct

program”

Direct

Direct

Direct

stitch”

of

-1+

button

controls)

-7+

button

controls)

-7+

button

Info

button

Carrying

Handwheel

M

button

Cursor

Clear/pattern

Stitch

Connection

Connection

Master

m÷button

Direct

Direct

Direct

Direct

selection

switch

selection

selection

selection

selection

selection

selection

selection

selection

selection

selection

selection

selection

the

2044)

A

B

C

handle

buttons

socket

socket

sewing

(stitch

(stitch

(stitch

start

wheel

“foot

button

button

button

button

button

button

button

button

button

button

button

button

machine

width/pattern

length/pattern

density/balance

button

“lead

cord”

control”

“Alphabet”

“Alphabet”

“Linen

“Elastic

“Zigzag

“Stretch

“Blind

“Bridging

“Button

“Straight

“Elastic

“Closed

buttonhole”

blind

stitch”

triple

hem

attaching

stitch”

stitch”

overlock

width

stitch”

stitch”

length

controls)

hem

straight

48

49

50

51

52

53

54

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

27

Slide

28

Base

29

Removable

30

Presser

31

Integrated

Integrated

Reverse

Threading

Needle

“Tie-off”

“Needle

“Slow

“Pattern

Take-up

Thread

Spool

Hole

Lid

Bobbin

Bobbin

Free

Sewing

Thread

Thread

Presser

Needle

Needle

Contrast

for

with

arm

for

plate

foot

thread

button

up/down”

sewing”

mirror”

lever

guide

holder

second

stitch

winder

door

bulb

cutter

take-up

foot

holder

plate

control

lowering

accessory

holder

dual

needle

sewing”

slots

tension

button

button/

with

spool

program

(max.

lifter

with

the

with

feed/IDT

threader

button

button

“Lock”

spool

5

retaining

cap

holder

chart

W)

feed

tray

presser

(set)

dog

foot

button

screw

I

14

1

Page 17

0)

0)

C)

(3C)

F’)

-3

CD

Cfl

3

0)

0)

H

1

0

01

C

flU)

)j..t4*.3

.0

*.*na

E.

—

e

W)):tV

(1D

X

U)

o

0

N.)

0

C

44

a,

3

%j

4

0)

c-fl

Page 18

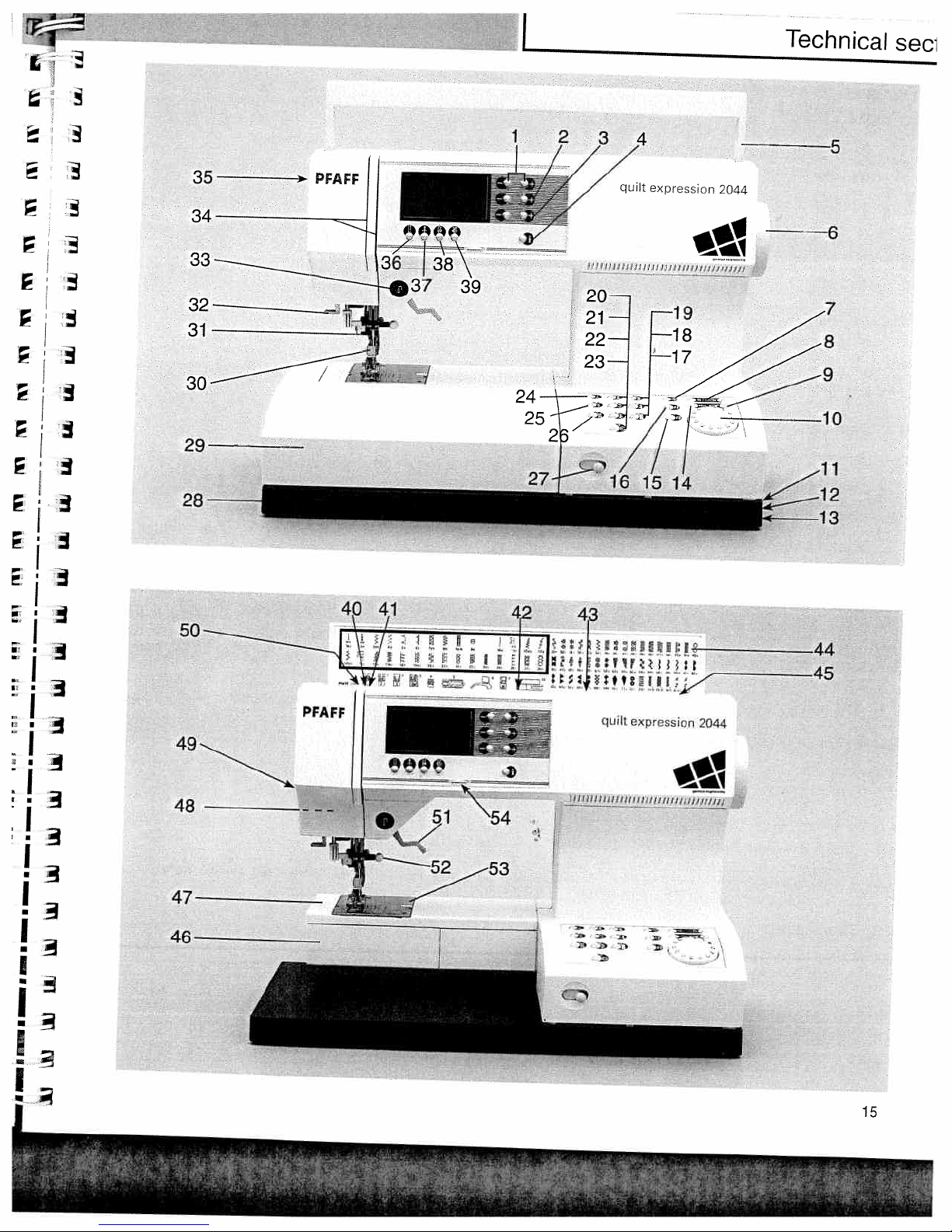

Parts

(model

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

25

26

of

2034)

-1+

button

controls)

-1+

button

controls)

-/+

button

Info

button

Carrying

Handwheel

‘M

button

Cursor

Clear/pattern

Stitch

Connection

Connection

Master

m+button

Direct

Direct

Direct

stitch”

Direct

Direct

stitch”

Direct

Direct

Direct

program”

Direct

Direct

Direct

stitch”

selection

selection

selection

selection

selection

selection

selection

selection

selection

selection

selection

selection

the

A

B

C

handle

buttons

switch

sewing

(stitch

(stitch

(stitch

start

button

socket

socket

button

button

button

button

button

button

button

button

button

button

button

machine

width/pattern

length/pattern

density/balance

button

“lead

cord”

“foot

control”

“Alphabet”

“Linen

“Elastic

“Zigzag

“Stretch

“Blindhem

“Bridging

“Button

“Straight

“Elastic

“Closed

buttonhole”

attaching

stitch”

overlock

width

length

blind

stitch”

triple

stitch”

stitch”

stitch”

controls)

hem

straight

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

27

28

29

30

31

32

33

34

35

36

37

38

Contrast

Slide

Base

Removable

Presser

Integrated

Integrated

Reverse

Threading

Needle

“Tie-off”

“Needle

“Slow

“Pattern

Take-up

Thread

Spool

Hole

for

Lid

with

Bobbin

Bobbin

Free

arm

Sewing

Thread

Thread

Presser

Needle

Needle

for

lowering

plate

foot

dual

needle

sewing”

slots

thread

button

up/down”

sewing”

mirror”

lever

guide

holder

second

stitch

winder

door

bulb

cutter

take-up

foot

lifter

holder

plate

control

accessory

holder

feed/IDT

tension

button

button/

with

spool

spool

program

(max.

with

the

feed

tray

with

threader

button

button

“Lock”

cap

holder

chart

W)

5

retaining

dog

presser

(set)

foot

button

screw

16

Page 19

it

ii

Co

0

x

C,,

0

C,,

CA)

CA)

Co

-

CA)

jr’J

I

ci

ic

rt

m

mm

Fr

rn

ri

Iii

II

CA)[0-C

[0

[0

Co

01

C

C)

CA)

L

-

-

—.jcyco

Co

x

cf

o

C,,

r.

.*

.

,.i

,.

.

—.

.

OD

/

L

Page 20

PFAFF

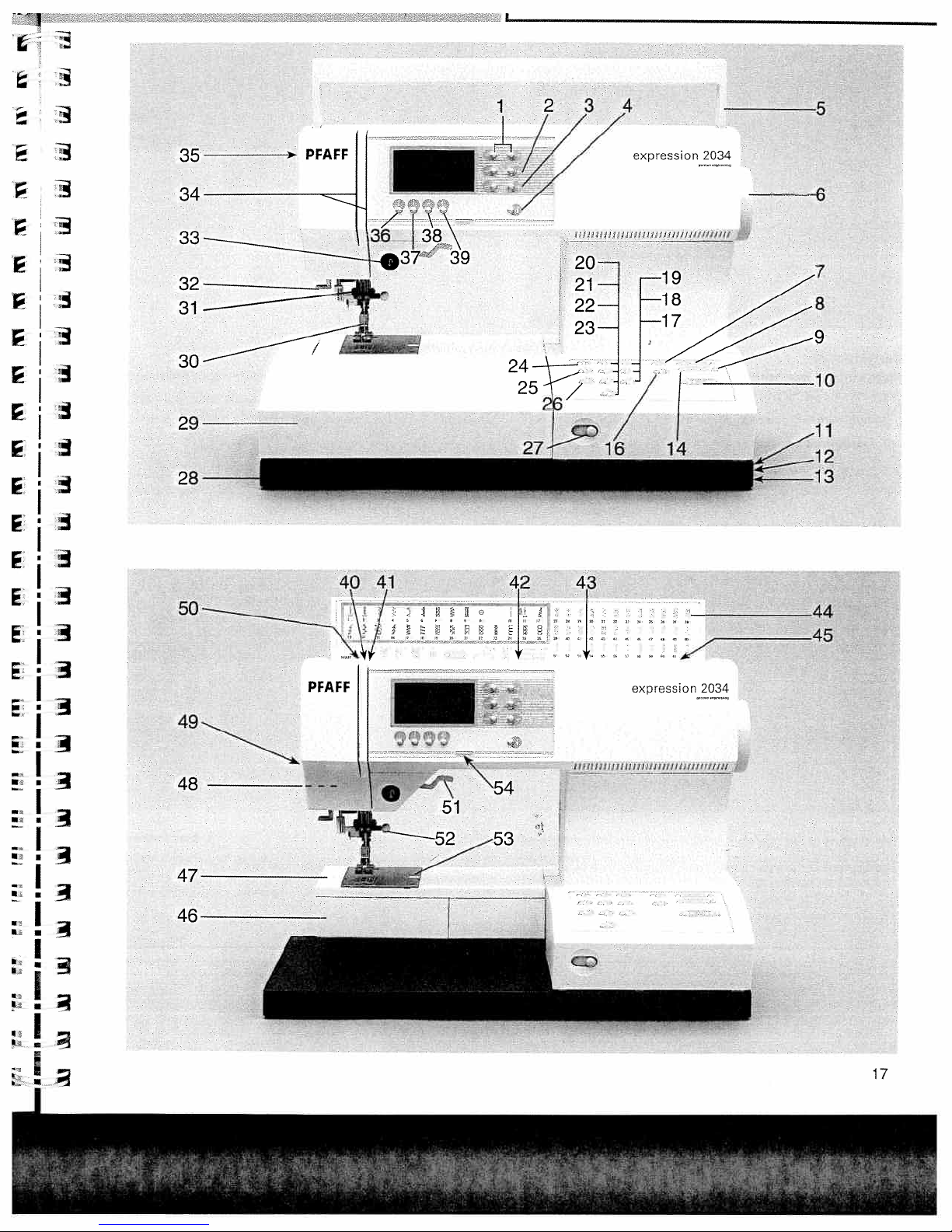

Carrying

Place

the

book

into

case

enclosed

the

compartment

PFAFF

lead

cord,

I

the

foot

control

and

of

the

carrying

case.

instruction

Lid

Open

the

folding

lid

(44)

upwards.

fl

RH

.

r::

quilt

expression

2044

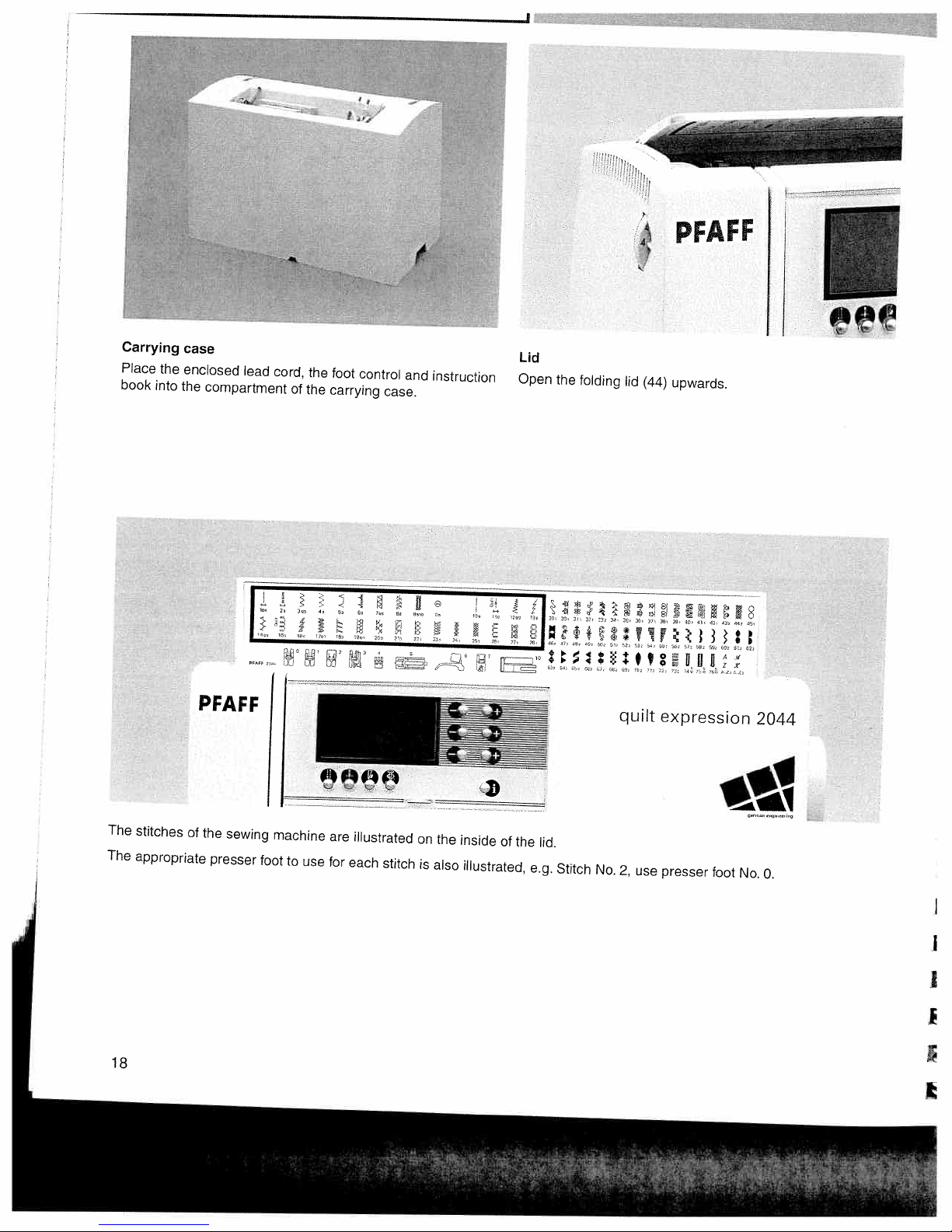

The

stitches

The

appropriate

18

of

the

presser

sewing

machine

foot

to

use

are

for

illustrated

each

stitch

on

is

the

also

inside

of

illustrated,

the

lid.

e.g.

Stitch

No.

2,

use

presser

foot

No.

0.

I

Page 21

I

-

Technical

sectio

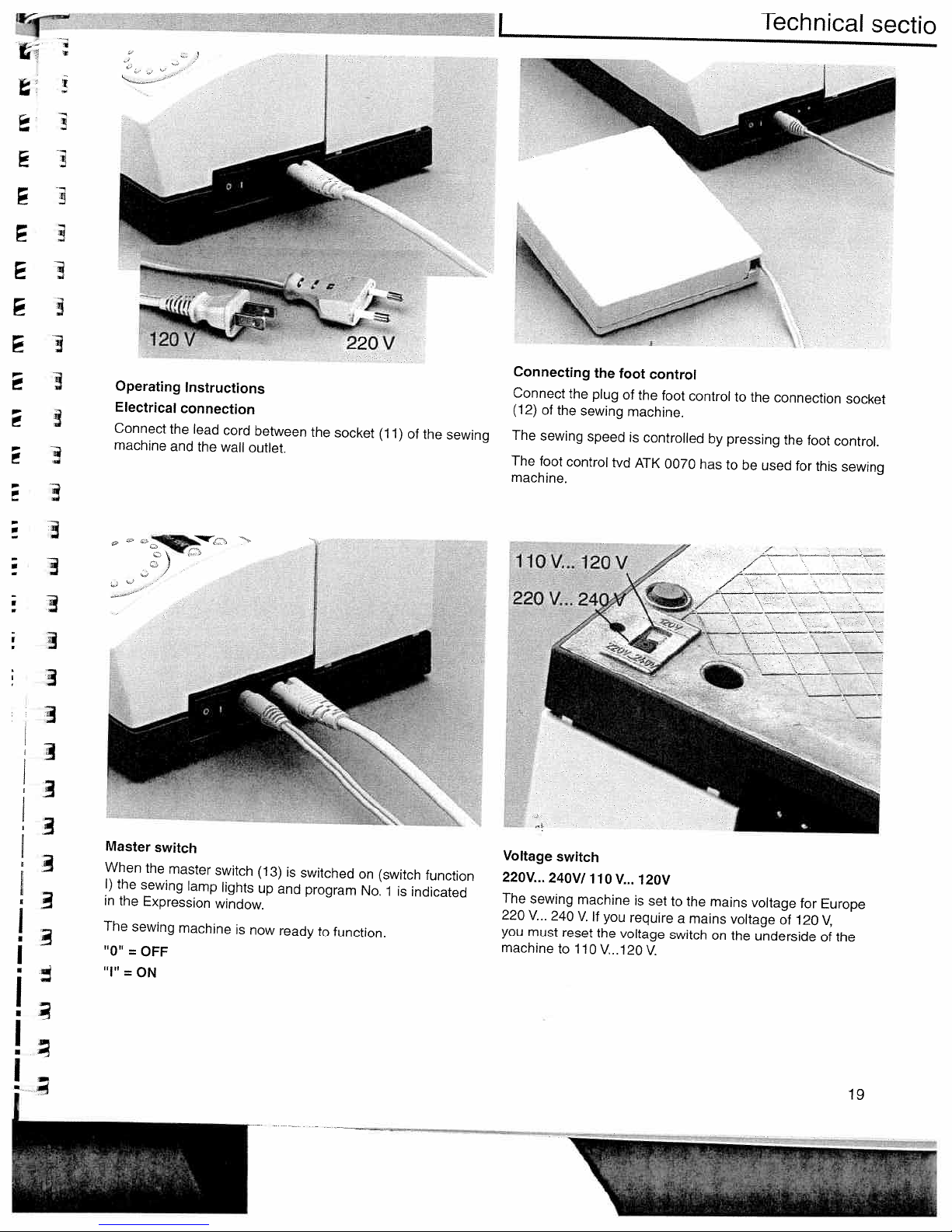

Operating

Electrical

Connect

machine

.

Instructions

connection

the

lead

and

the

cord

wall

between

outlet.

the

socket

(11)

of

the

sewing

Connecting

Connect

(12)

of

The

sewing

The

foot

machine.

11OV..

;

220

the

‘L.

the

plug

sewing

speed

control

120V

the

foot

of

machine.

is

tvd

ATK

control

the

foot

controlled

0070

control

by

has

to

the

pressing

to

be

connection

the

used

for

foot

this

socket

control.

sewing

zzz:z

Master

When

I)

in

The

“0”

“I”

the

the

=

=

sewing

ON

switch

the

master

sewing

OFF

lamp

Expression

machine

switch

lights

window.

is

now

(13)

up

is

and

ready

switched

program

to

on

No.

function.

(switch

is

1

function

indicated

Voltage

22OV..24OV/11OV...

The

220

you

machinetolloV..120V.

sewing

V...

240

must

switch

machine

V.

reset

If

you

the

120V

is

require

voltage

set

to

the

mains

a

switch

mains

voltage

on

the

voltage

of

underside

for

120

Europe

‘1,

of

the

19

Page 22

iecnnicai

section

4!—

1

w

L

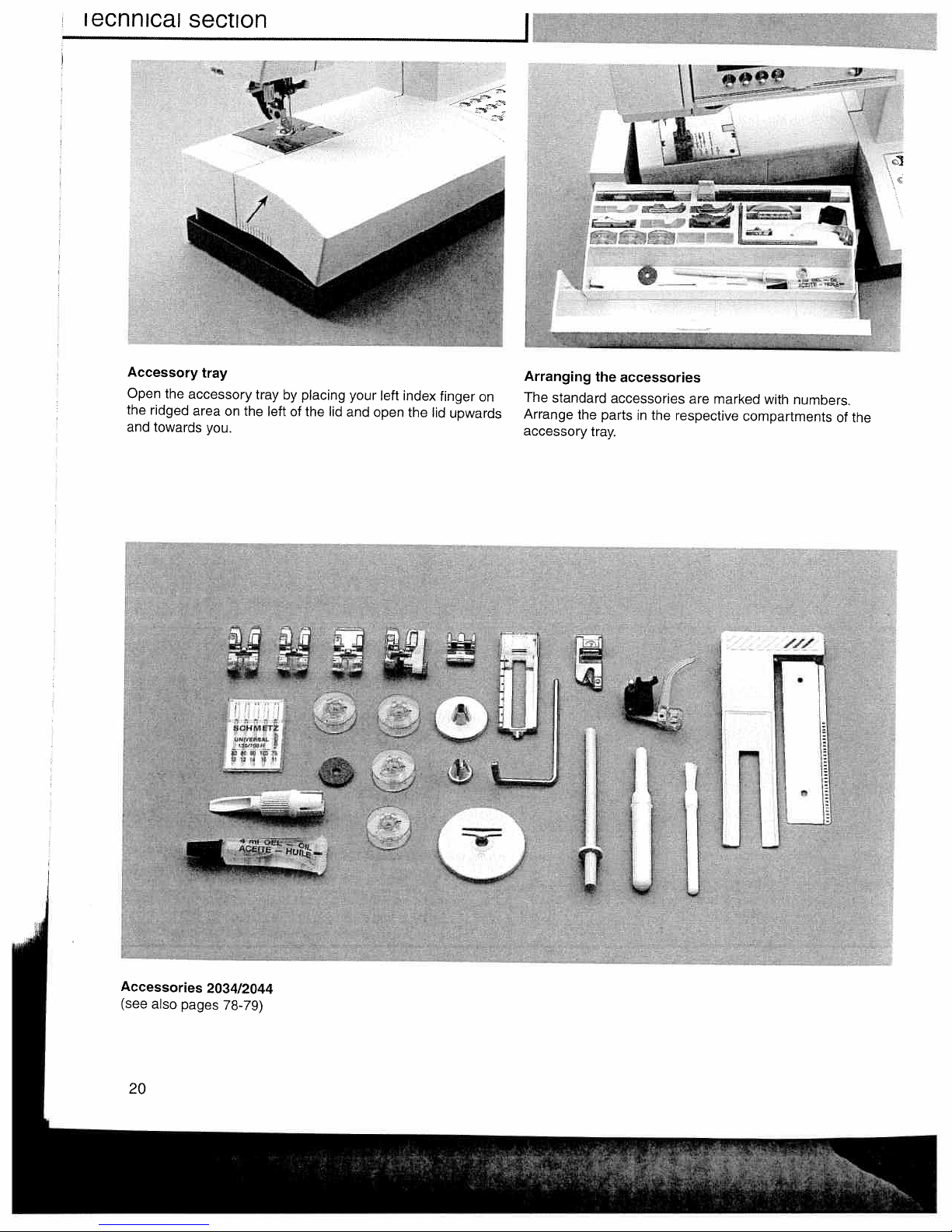

Accessory

Open

the

the

ridged

and

towards

tray

accessory

area

on

you.

traybyplacing

the

left

of

the

lid

your

and

left

open

index

the

finger

lid

on

upwards

Arranging

The

standard

Arrange

accessory

the

the

tray.

accessories

accessories

parts

in

ft

the

are

marked

respective

with

numbers.

compartments

of

the

Accessories

(see

also

20

pages

2034/2044

78-79)

Page 23

I

Technical

sectic

/6

-

-.

.

.

-,

F.

r

Removing

In

order

to

the

the

tray,

machine.

left

to

sew

and

make

the

accessory

using

it

lift

upwards

sure

it

the

is

free

flush

tray

out

arm,

with

(free

of

the

swing

the

arm)

hole.

free

the

When

arm

accessory

replacing

of

the

tray

sewing

I

I

Preparing

i•g

I

7O

73

71

U

74,

75,W

Place

winder

an

snaps

the

empty

machine

bobbin

into

the

slot

so

for

that

of

bobbin

the

the

bobbin.

winding

black

pin

of

the

bobbin

I

j

68

69

7Q

72

73

]

NI

Push

Note:

the

the

The

right.

bobbin

bobbin

to

can

the

right.

only

be

wound

if

is

it

moved

fully

to

21

Page 24

Technical

section

1.

I.

if

4.,.

,.

i

.

,

.

.

!.

.

!LJ

I

-

,

C

lit

*.,

i,

2øat

;

b

2.n

ia

15

t044

n

*,

ii

2

1

b3

B

J

4

‘-

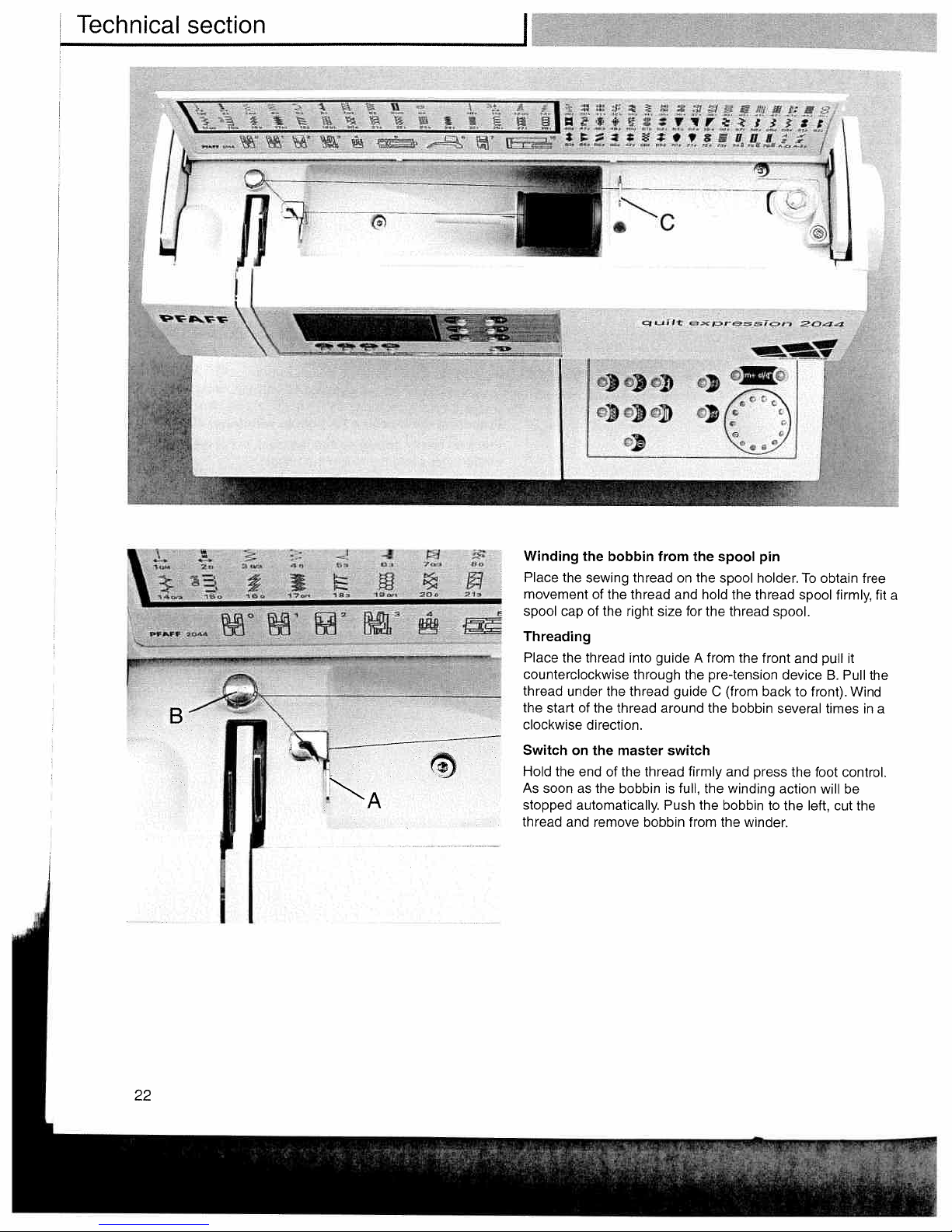

Winding

Place

movement

spool

Threading

Place

counterclockwise

thread

the

clockwise

Switch

Hold

As

stopped

thread

the

capofthe

the

under

start

on

the

soon

as

automatically.

and

the

sewing

of

thread

the

of

the

direction.

the

end

of

the

remove

bobbin

the

from

thread

thread

right

size

guideAfrom

into

through

thread

thread

around

master

thread

the

bobbinisfull,

Push

bobbin

on

and

for

the

guide

switch

firmly

from

spool

the

the

spool

hold

the

pre-tension

(from

C

the

and

the

the

bobbin

the

pin

holder.

thread

the

thread

front

the

backtofront).

bobbin

press

winding

winder.

To

obtain

spool

spool.

pull

and

deviceB.Pull

several

to

the

action

the

times

foot

will

left,

firmly,

it

Wind

control.

be

cut

the

free

the

in

fit

a

a

22

Page 25

_____

-

—

h

II

\

—

——

—

i--—

Technical

s

1.;

E’

9

‘\

V

.

i

Kr

,—

:

t.

jr,

r

secti

o)o)o)

cj

c)

(

I

j

j

I

j

-4

P’R#F

B

?

1

jO

o44

tXI

DtJ

2

DC

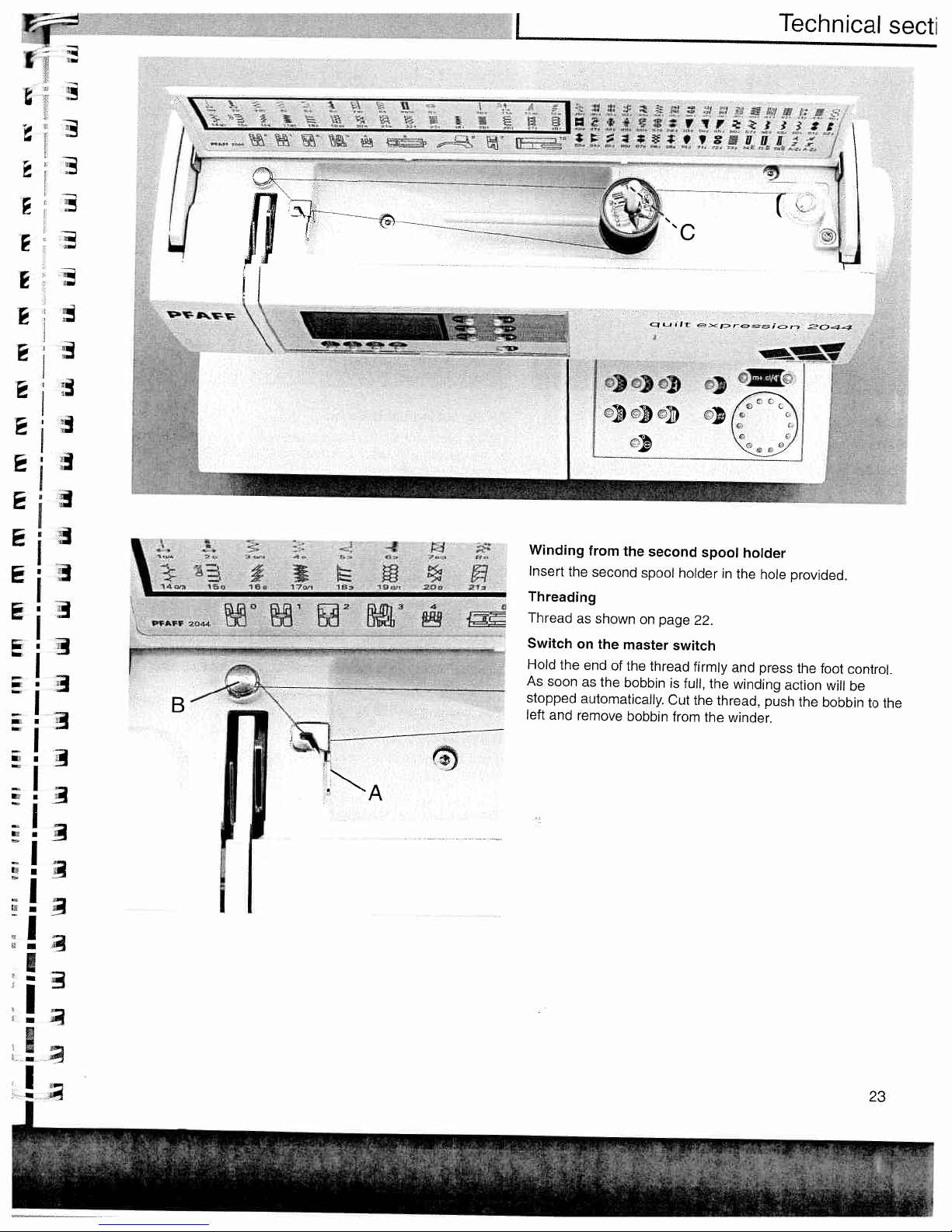

Winding

Insert

the

Threading

Thread

Switch

Hold

the

As

soon

stopped

left

and

from

the

second

as

on

end

as

automatically.

remove

shown

the

of

the

spool

on

master

the

bobbin

bobbin

second

page

switch

thread

is

Cut

from

spool

holder

22.

firmly

full,

the

the

thread,

the

holder

in

the

and

winding

winder.

hole

press

push

provided.

the

action

the

foot

will

bobbin

control.

be

to

the

3

3

I

3

I

3

I

I

I

23

Page 26

1

r

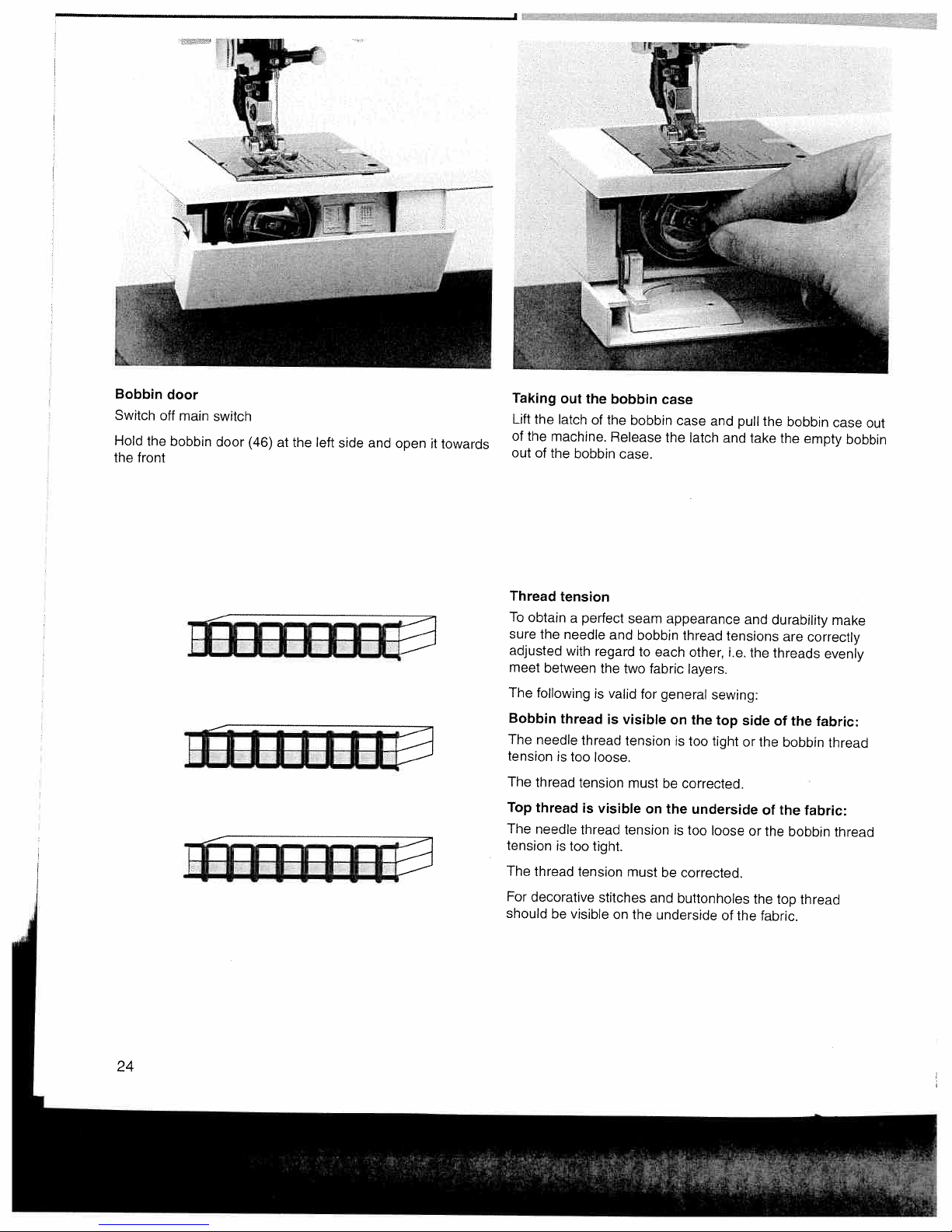

Bobbin

Switch

Hold

the

front

door

off

main

switch

the

bobbin

door

tiIIiiiI

rrrnTnI

(46)

Taking

Lift

at

left

the

side

and

open

towards

it

of

outofthe

Thread

To

sure

adjusted

meet

The

Bobbin

The

tension

The

Top

The

tension

The

For

should

out

the

latch

machine.

the

tension

obtain

a

the

needle

with

between

following

thread

needle

is

thread

thread

needle

is

too

thread

decorative

be

the

of

bobbin

perfect

regard

is

thread

too

loose.

tension

is

thread

tight.

tension

visible

bobbin

the

Release

case.

and

the

two

valid

visible

is

tension

visible

tension

stitches

on

bobbin

seam

bobbin

to

fabric

for

must

on

must

the

case

case

the

appearance

thread

each

general

on

is

corrected.

be

the

is

be

corrected.

and

buttonholes

underside

and

latch

and

other,

layers.

sewing:

the

top

tight

too

underside

too

loose

of

pull

take

and

tensions

i.e.

the

side

or

the

or

the

the

fabric.

the

bobbin

the

durability

are

threads

of

the

bobbin

of

the

the

bobbin

top

empty

correctly

evenly

fabric:

thread

fabric:

thread

case

bobbin

make

thread

out

24

Page 27

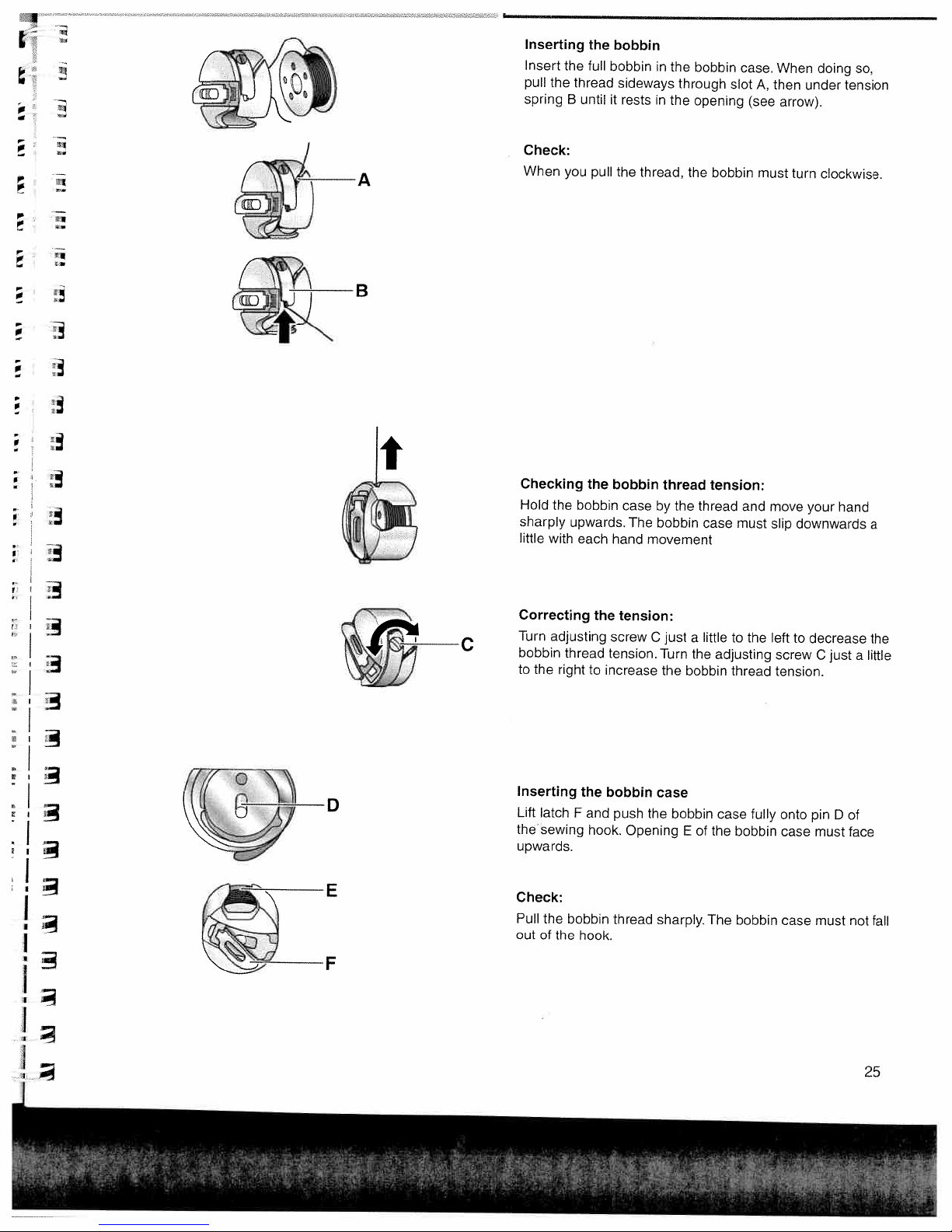

Inserting

TI

Insert

pull

spring

Check:

When

the

the

thread

B

you

the

full

until

pull

bobbin

bobbin

sideways

it

rests

the

thread,

in

in

the

through

the

the

bobbin

opening

bobbin

slot

case.

(see

A,

must

When

then

arrow).

turn

doing

under

clockwise.

so,

tension

t

Checking

Hold

sharply

little

the

with

the

bobbin

upwards.

each

bobbin

case

The

hand

thread

by

the

bobbin

movement

tension:

thread

case

and

must

move

downwards

slip

your

hand

a

Correcting

Turn

adjusting

bobbin

to

Inserting

Lift

the

upwards.

E

Check:

Pull

out

the

latch

sewing

the

of

the

thread

right

bobbin

the

and

F

hook.

the

increase

to

bobbin

hook.

tension:

screw

tension.

push

Opening

thread

just

C

Turn

the

case

the

sharply.

a

the

bobbin

bobbin

of

E

little

adjusting

case

the

The

to

the

thread

fully

bobbin

bobbin

lefttodecrease

screw

tension.

onto

case

case

C

pin

must

must

just

D

a

of

face

not

the

little

fall

25

Page 28

Technical

section

14

PFAFF

B

4—>

10/4

III

I

<-->

3

!012

4L

1/

/

16o

0/3

20

C

15o

0/3

2044

40

>

>>>

170/1

>

53

r

183

i9

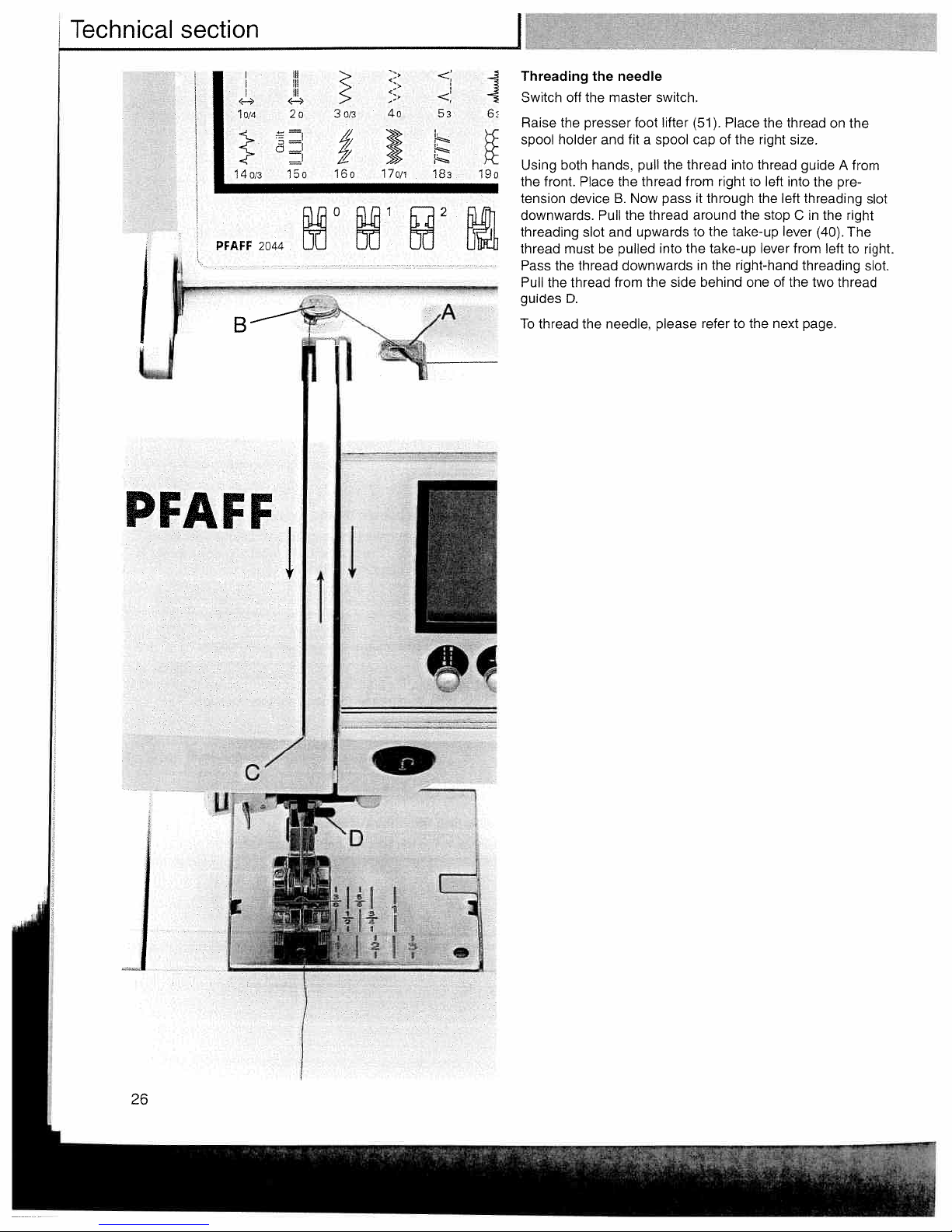

Threading

Switch

off

the

Raise

spool holder

both

Using

the

front.

tension

downwards.

threading

thread

Pass

Pull

guides

To

the

the

thread

device

must

thread

D.

the

the

presser

hands,

Place

Pull

slot

be

thread

the

needle

master

and

fit

the

B.

Now

the

and

pulled

downwards

from

needle,

switch.

lifter

foot

spooi

a

pull

the

thread

pass

thread

upwards

into

the

please

side

(51).

cap

thread

from

it

through

around

to

the

in

behind

refer

Place

of

the

into

rightioleft

the

take-up

the

take-up

the

right-hand

oneofthe

the

to

the

right

thread

the

stop

lever

next

thread

size.

guide

into

left

Cinthe

lever

from

threading

on

A

the

pre

threading

(40).

lefttoright.

two

thread

page.

the

from

slot

right

The

slot.

PFAFF

C

j

1

‘0

Is

3

le

I.-

I

26

Page 29

iei,i

IJL.,ctJ

ii

,eutji

El

El

El

L1

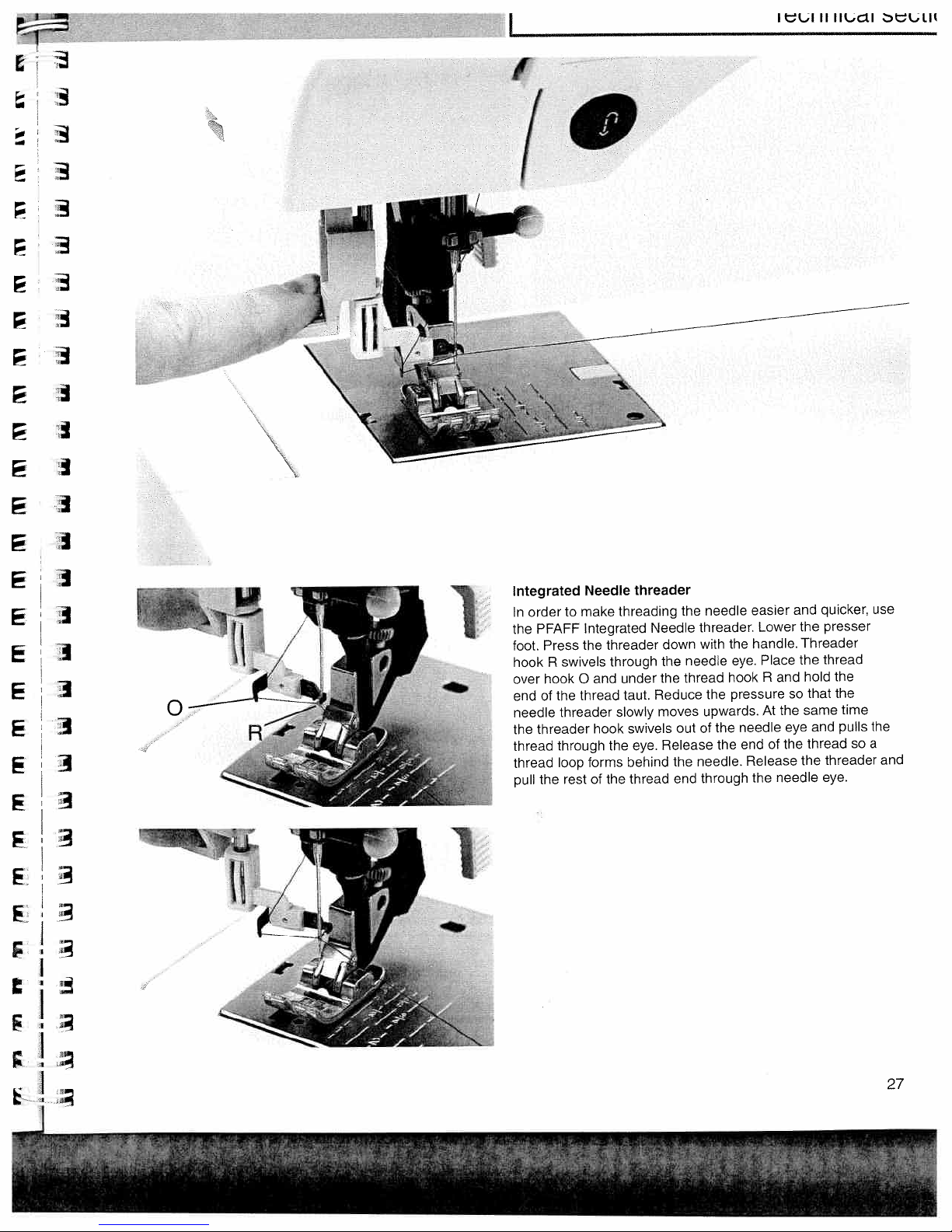

Integrated

order

In

PFAFF

the

Press

foot.

R

hook

hook

over

of

0

]

end

needle

the

thread

thread

pull

threader

the

#\

Needle

make

to

Integrated

the

swivels

and

0

thread

the

threader

hook

through

loop

forms

restofthe

L

threading

threader

through

under

taut.

slowly

swivels

the

behind

threader

Needle

eye.

thread

the

down

the

thread

the

Reduce

moves

out

Release

the

end

needle

threader.

with

needle

the

upwards.

of

needle.

through

the

eye.

hook

pressure

the

the

easier

Lower

handle.

Place

R

At

needle

end

Release

the

and

the

the

of

needle

and

the

Threader

the

hold

that

so

same

eye

thread

the

quicker,

presser

thread

the

the

and

threader

eye.

time

pulls

so

use

the

a

and

3

3

27

Page 30

I

tftE

IF

IJUdI

SULlUI

I

)

Presser

presser

The

lifter

(51).

foot

lifter

foot

is

raised

lowered

or

with

the

/

presser

foot

Drawing-up

Raise

the

Pull

press

the

thread,

up.

I

t

the

presser

the

needle

bobbin

foot.

foot

thread

thread

While

control

to

holding

the

so

draw

needle

up

the

the

end

bobbin

I,

of

moves

the

down

thread.

needle

and

Bobbin

Close

presser

28

the

foot

thread

bobbin

(46)

and

door

to

the

left

pull

the

thread

under

the

Thread

Pull

the

cutter

cutter

thread

(49).

from

the

back

front

over

the

to

the

thread

Page 31

I

I

I

j

j

j

I

j

Removing

Switch

Press

the

same

time

the

presser

off

the

the

front

the

foot

presser

master

switch

part

of

rear

part downwards

holder

the

(30).

foot

presser

foot

upwards

untilitdisengages

andatthe

from

Attaching

Place

the

that

when

the

foot

the

presser

the

engage

presser

foot

presser

in

the

foot

under

foot

lifter

presser

the

(51)

foot

presser

is

holder.

foot

lowered,

holder

the

(30),

pins

so

of

I

I

:1

I

I

A

1

pFAFF

R

Check:

Please

raising

check

the

that

presser

the

foot

presser

lifter.

I

foot

properly

is

attached

by

Setting

the required

Set

using

The

normal

darning

the needle

the

markings

setting

and

thread tension

amount

on

for

buttonhole

of

the

tension

sewing

sewing

the

needle thread

is

4-5.

3.

dial.

For

tension

decorative

(35)

sewing,

29

Page 32

_

I

1

PVAcF

0

2044

2

Winding

It

is

possible

fully

threaded.

position.

and

upward

a

Pull

\-

bobbin

to

wind

Raise

the

through

‘-

through

bobbins

needle

the

the

presser

thread

right-hand

the

even

-

needle

when

foot

lifter

underneath

threader

the

(51)

machine

to

the

presser

slot

-

the

(34).

is

top

foot

Place

the

(40).

Important:

thread

The

[

from

take-up

left

lever

l-t

to

right

must

—--C

,

r425icr,

through

be

at

the

its

take-up

highest

lever

position.

Guide

the

thread

to

the

right

clockwise

direction.

Push

the

under

bobbin

30

thread

to

the

guide

right.

C.

Hold

Wind

the

the

end

beginning

of

the

of

thread

the

thread

firmly

rC))

and

several

press

times

the

foot

around

control.

the

bobbin

in

a

Page 33

Changing

Switch

To

highest

needle

1

To

needle

Lower

the

as

and

firmly.

off

remove:

out

insert:

must

the

needle,

it

will

tighten

the

the

Lower

position.

downwards.

The

flat

face

presser

pushing

go.

Hold

the

needle

master

the

Loosen

side

to

foot

the

needle

switch

presser

the

A

of

the

rear.

and

it

upasfar

needle

screw

needle

the

insert

(52)

foot

and

screw

set

the

(52)

needle

and

!A

pull

to

its

the

E

¶1

VP

Threading

Replace

the

spool

—

and

together.

stitches

Note:

right

It

the

holders.

sides

Pull

with

is

not

the

sewing

the

the

possible

twin

of

tension

threads

twin

needle:

needle

During

needle”

to

with

threading

disk

B.

right

and

p.

use

the

a

twin

in

Continue

left

97).

integrated

needle.

the

into

Insert

left

threading

threading

the

thread

needle

the

slot

in

the

guide

threader

second

(34),

usual

and

with

spool

make

manner,

thread

twin

a

holder

sure

making

the

needle.

and

that

needles

you

sure

place

pass

(for

one

one

the

threads

additional

spool

thread

of

thread

each

do

not

details,

on

to

the

become

see

‘Decorative

each

left

of

twisted

31

Page 34

,,

I

The

IDT

For

sewing

solution:

industrial

top

and

precisely.

feed

prevents

action

striped

aligned

(Integrated

any

the

machines,

bottom

On

also

ensures

fabrics.

to

prevent

Integrated

light

puckering

fabric

at

the

fabrics

The

stretching

Dual

precisely

the

same

perfect

IDT

Dual

IDT

such

of

keeps

Feed)

PFAFF

Feed,

feeds

time.

as

the

seam.

matching

all

of

the

IDT

the

The

silk

layers

top

provides

system.

fabric

material

or

rayon

The

of

checked

of

layers.

even

quilt

from

is

the

feeding

projects

As

the

fed

and

ideal

on

the

dual

32

Page 35

Technical

V

I

sec

f:

Engaging

Important:

feet

with

Raise

the

engages.

the

For

the

presser

lOT

all

center

work

back

foot.

with

cut-out.

Press

the

the

Dual

IDT

Feed

(31)

IDT.

down

use

until

presser

it

Disengaging

Hold

the

Press

the

release

Stripes

the

and

material

Dual

the

IDT

IDT

plaids

to

the

Feed

(31)

slowly

be

IDT

with

down,

match

sewn.

two

then

upward.

perfectly

fingers

pull

due

it

at

the

away

to

the

ribbed

from

even

you

ankle.

and

feed

of

33

Page 36

I

LI

H

IR;ëtI

euuon

PFAFF

/

pa

L

—‘

__7/

fe

A

-.

Lowering

For

certain

darning

dog

has

Raise

slide

A

To

engage

Raise

the

the

and

to

to

the

sewing

when

be

presser

the

left.

the

presser

pAcF

-1

feed

dog

work

the

lowered.

foot

feed

dog

foot

-.

It

10

t

such

machine

before

move

before

as

free-motion

must

lowering

the

slide

engaging

11

,,hW/4t’*”.

I’

be

the

to

the

quilting

cleaned,

feed

the

right.

feed

dog.

dog.

the

or

feed

Push

You

can

also

lower

the

feed

dog

and

move

Raise

dog.

moving

the

the

slide

slide

presser

B

to

the

to

the

left.

foot

before

right.

by

To

lowering

34

opening

engage

or

the

the

raising

bobbin

feed

the

door

dog

feed

Page 37

Seithig

functions

Adjusting

in

the

Stitch

Bobbin

Altering

Altering

width/needle

‘1ng

ii

the

Expression

selection

thread

pattern

the

the

mg

the

*Th

‘reverse

contrast

monitor

sizes

stitch

position

pattern

length

pattern

density

ion

window

sewing

buttons

(model

button

2044)

38,

36

36

37

37

38

39

39

40

41

42

43

44

:

I

j

z

45

A

—

Page 38

‘Jc;vvii

ILII

Ij

I.jLIJI

wwww

Stitch

selectiononmodel 2044

oo

Adjusting

The

different

This

(54).

Stitch

c

There

1.

Clockwise=in

Counterclockwise=in

Model

>

in

<in

If

you

of

model

stitch

2.

With

of

the

QO

3.

With

number:Toselect

then

the

the

contrast

lighting

setting

canbereadjusted

selection

are three

With

the

selection

2034):

for

stitches.

2034:

ascending

descending

areinthe

2034)

No.

0.

the

direct

the

most commonly

selectionofthe

the

direct

press

window.

contrast

settinginthe

situations.

waysofselecting

scrolling

ascending

order

order

last

and continuetoscroll

button3.The

wheel

backward

descending

stitch,

selection

alphabets.

selection

program

on

the

window

(selection

order

No.

buttons

used stitches

buttonstochoose

stitch

Expression

may

with

the

your

and

order

76,

(No.61in

for

No.

23,

number

be

contrast

desired

buttons,

forward

will

you

instant

(0-9)

press

window

changed

stitch:

in

the

return

selection

and

the

button

appears

for

control

model

the

case

to

for

stitch

2

in

Stitch

selection

36

on

model

2034

oEp

Page 39

H

PFAFF

I

I

Instruction

manual

PFAFF

pFAFF

B

quilt

exPreSSOfl

expression

2044

2034

—

t

—

j

H

Page 40

.jcvvii

1LAI

IL,LJLII

I

Bobbin

If

(3

symbol

The

you

Altering

Adjust

position

buttons

in

thread

the

bobbin

m)].orthereisno

appearsinthe

symbol

start

disappears

to

sew

stitches

the

length,

of

stitchesbytouching

to

the

the

window.

monitor

is

nearing

again.

width,

rightofthe

(model

its

thread

window.

afterafull

balance,

window.

2044)

end

[2¾yd(2m)-3

on

the

bobbin,

bobbin

densityorneedle

the

Each

the

is

appropriate

change

¾

yd

bobbin

inserted

-1+

is

and

visible

<

<III>

To

change:

Stitch

Pattern

Needle

Stitch

Pattern

Stitch

Pattern

Balance

width

width

position

length

length

density

density

for

straight

stitches

Use

A

B

C

-1+

buttons

37

Page 41

Altering

selected

The

zigzag

the

stitch

stitch

stitch

No.

3.

width

can

be

sewn

in

various

widths,

e.g.

Altering

Straight

sewn

be

button

Altering

Stitch

For

decorative

shown

standard

in

a

A.

A

63

in

the

stitch

any

in

to

the

(Stitch

the

needle

No.

move

pattern

stitches,

window.

width

of

1,

13

the

56

position

stitch

different

needle

width,

on

the

When

can

and

No. 2

model

overall

and

needle

to

left

e.g.

2034)

entered,

altered

be

stitch

positions.

right

or

width

stitch

using

of

No.

of

the

63

11

Press

center.

pattern

comes

button

-1+

can

1+

is

up

38

Page 42

4f

Fj

Altering

The

stitch

button

B.

the

length

stitch

of

length

a

stitch

can

be

altered

using

+1-

Altering

The

using

change.

p

Altering

The

stitches,

remain

densely

density,

the

pattern

pattern

stitch

lengthofdecorative

button

-1+

the

stitch

densityofvarious

etc.)

can

constant,

or

less

when

B.

The

density

be

but

densely.

available.

length

density

changed.

the

pattern

Use

stitches

of

stitches

The

will

button

-1+

the

stitch

(buttonholes,

pattern

sewn

be

C

can

to

be

will

length

more

adjust

altered

not

satin

will

the

39

Page 43

“4”

Balance

fl

Decorative

heavy

fabric

adjusts

best

After

symbol

of

balance

way

having

the

Expression

the

witha“0

for

can

stitches

fed

is

reverse

different

selected

altered

be

can

vary

differently

feed

fabrics.

a

stitch,

after

it

window.

on

of

in

the

the

This

this

on

than

stitch

you

bottom

symbol

stitch.