Page 1

£1

PFAFF

expresscn2

J’

-1

0

r3

NN

f/f/7W/6

expression

2024

PFAFF

V

-

111117

/fff/ffffff//ff/1?fFf//

Page 2

Notes

on

accordance

must exercise

The

user

1

2

3.

4

5

6

7

8.

9.

10.

11,

t2

13

Environment

The

Ambent

Air

Storage

The

operated

it

is

dawpmte

The

Treatment

Always

Cieanmg

Nousesg

moIstened

Ptease

Do

observe

When

disconnect

maximum

The

tension

The

machineisto

The

not

Do

not

Do

•

there

function

ite

•

•itis

wef,

not

Do

liability

No

intended

it

is

avoid

To

repair

original

Only

machine

The

According

caused

-ecommended

temperature

humidity

temperature

machine

ar

amne

machine

protect

and

with

note!

not

mse

the

sewing

leaving

the

of

any

place

the

use

visible

is

is

e.g.

the

pull

will

or

risk

the

is

solely

This

PFAFF

is

the laws

to

should

20%to80%

suppressed

a

direct

the

for

supervised

direct

sunlight

is

to

be

the

machine

display;

plantic

insecticides

any

safety

with

adequate

urea

whi e

the

machine

trom

machine

permissuble

belt may

the

drive

into

be

put

in

obfects

machine

sewing

damage

disturbed

condensation

with

mains

plug

out

be

accepted

if

isoprated

it

of

electric

the

responstbility

parts

may

for

designed

concernirg

mains

power

the

environment

40

Fl

to

(50

j

13F’to

25

C

and

vicinityofelectronic

useinthe home

fic

at

usedonfirm

against

To

clean

the

cleanser

with

chem’cxi

or

woking

dr

ng

the

mains

wattage

onlybeadjusted

Oneration

openings

it

that

of

the

for

arty

incorrectly

hock

be used

mans

a

linebechanged

is

C 1104

insensitive

fricity,

ele

and

damage

ftung

maximum

domestic

for

60335-2-28

EN

caution

with

maintenance

pulling

by

for

the

sewing

according

the

on

maybe

by

socket

caused

damage

open

do

not

of

our

qualitied

upply

electromagnetic

Fj

60C-140

to

interference

devices

tf

should

heat-producing

surface

even

which

dry,

a

use

38

products

regardtothe

work

out

tamp

by

to

machine.

caused

its

cord

the

machtfle

wifh

mains

cowpatibfhty

or

Fj

This

sewing

be

which

could

clean,

alcohol

such

as

up

or

when

mains

the

is

man.

PFAFF

a

the

indications

introducing

by

it

tht

machine

The

servtce

rated

should

chanses

according

macfin

opem

ed

ot9ects,

pen

caused

be

tnt-ire

soft

petrolor‘q,rid

sewing

and

changing

plug.

watts.

5

mechanic,

i

are

staff

voltage

lability

no

international

to

in

osive

cor

ventilation

for

it

by

and/or

down

mechanical

on

the

cold

a

us

d

no

of

be

made

high

i

a

uha

chemicals

being

cloth,

chemicals

movement

specification

machine

for

arty

parts

inside

*1-

tO%

be

can

to

conventions,

quality

way

that

purposes.

hit

dropped,

or

remove

To

to

machines

IEC

needle

of

the

parts

or

accessories,

plate

info

warm

a

other

purpos

machine

the

rated

and

a

accepted

for

it

however,

electronic

it

is

not

ubf

or

liquids

an

ubbom

clean

the

hous

335-2-28

constantly

und

room.

than that

which

the

ncy

of

freq,i

arty

mains

should

it

mecfranicat

clef

to:

dust,

Ce

iff,

ng

in

always

for

which

user

*1-4%

inter’uptiono

not

appliance;

severe

cloth

soft

a

can

be

Page 3

Modern,

uncomplicated

push-button

Sewing

by

control

Congratulations!

product

quality

Your

in

for

It

technology,

uncomplicated

It

the

operation

If

instruction

this

machine

If

problem!

service

So

enjoyable

new

stride

its

you.

features

applies

2014.

you

is

you

now

now

the

have

with

sewing

and

the

both

Should

we

take

book,

only

can

any

Your

you

hours

and

do,

any

can

PFAF

I

that

will

very

this

as

to

have

time

way

further

PFAFF

have

You

offers

machine

sew

latest

instruction

your

2024

the

there

pointed

enough

nothing

to

and

help

started!

get

of

creating

unique

can

through

in

PFAFF

be

can

learn

make

to

questions,

dealer

or

advice

purchased

take

thick

design

book

sewing

model

difference

any

that

out

study

to

wrong.

go

all

the

full

will

be

you

wish

We

fashion

your

high

a

advantages.

material

any

and

and

just

is

machine.

and

to

separately.

the

After

things

them.

use

of

is

no

that

your

at

need.

you

ideas.

thin

as

in

all,

the

many

Page 4

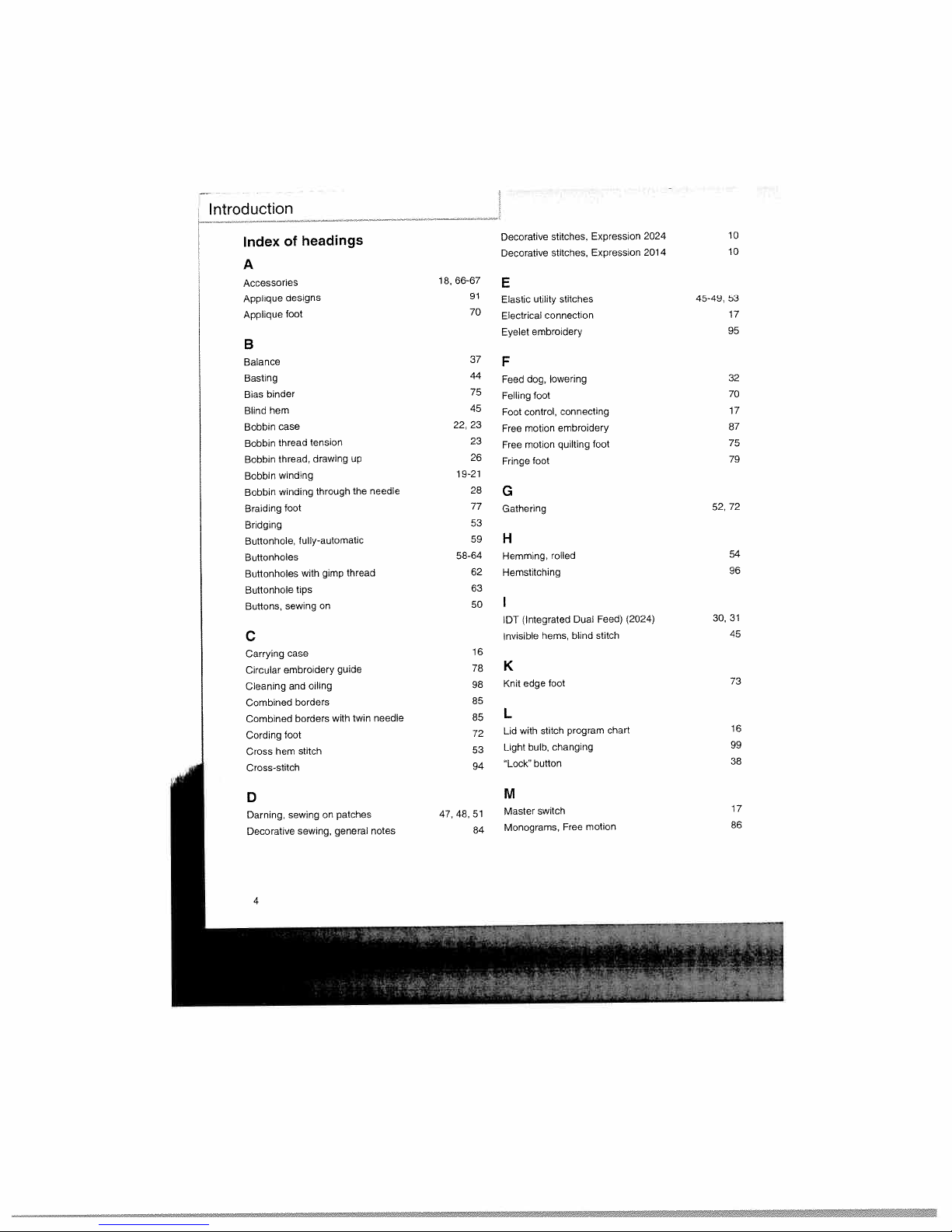

Introduction

Index

A

Accessories

Applique

Applique

B

Balance

Basting

binder

Bias

Blind

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Braiding

Bridging

Buttonhole,

Buttonholes

Buttonholes

Buttonhole

Buttons,

C

Carrying

Circular

Cleaning

Combined

Combined

Cording

Cross

Cross-stitch

of

designs

toot

hem

case

thread

thread,

winding

winding

foot

sewing

case

embroidery

toot

hem

headings

tension

drawing

through

fully-automatic

gimp

with

tips

on

and

oiling

borders

borders

stitch

guide

with

up

the

thread

twin

needle

needle

45-49,

10

10

53

17

95

Espression

Decorative

Decorative

66-67

18,

E

Elastic

70

Electrical

Eyelet

stitches,

stitches,

stitches

utility

connection

embroidery

Espression

2024

2014

F

32

70

17

87

75

79

72

52.

54

96

31

30.

45

73

16

99

38

22

19-21

58-64

23

23

26

28

53

59

62

63

50

16

78

98

85

85

72

53

g

Feed

dog,

foot

Felling

control,

Foot

motion

Free

Free

motion

foot

Fringe

G

Gathering

H

Hemming,

Hemstitching

I

IDT

(Integrated

Invisible

K

edge

Knit

L

stitch

with

Lid

bulb,

Light

button

‘Lock

lowering

rolled

hems,

toot

changing

connecting

embroidery

quilting

Dual

blind

program

toot

Feed(

stitch

(2024(

chart

0

sewingonpatches

Darning,

Decorative

sewing,

4

general

notes

47,48,51

M

switch

Master

Monograms. Free

motion

17

86

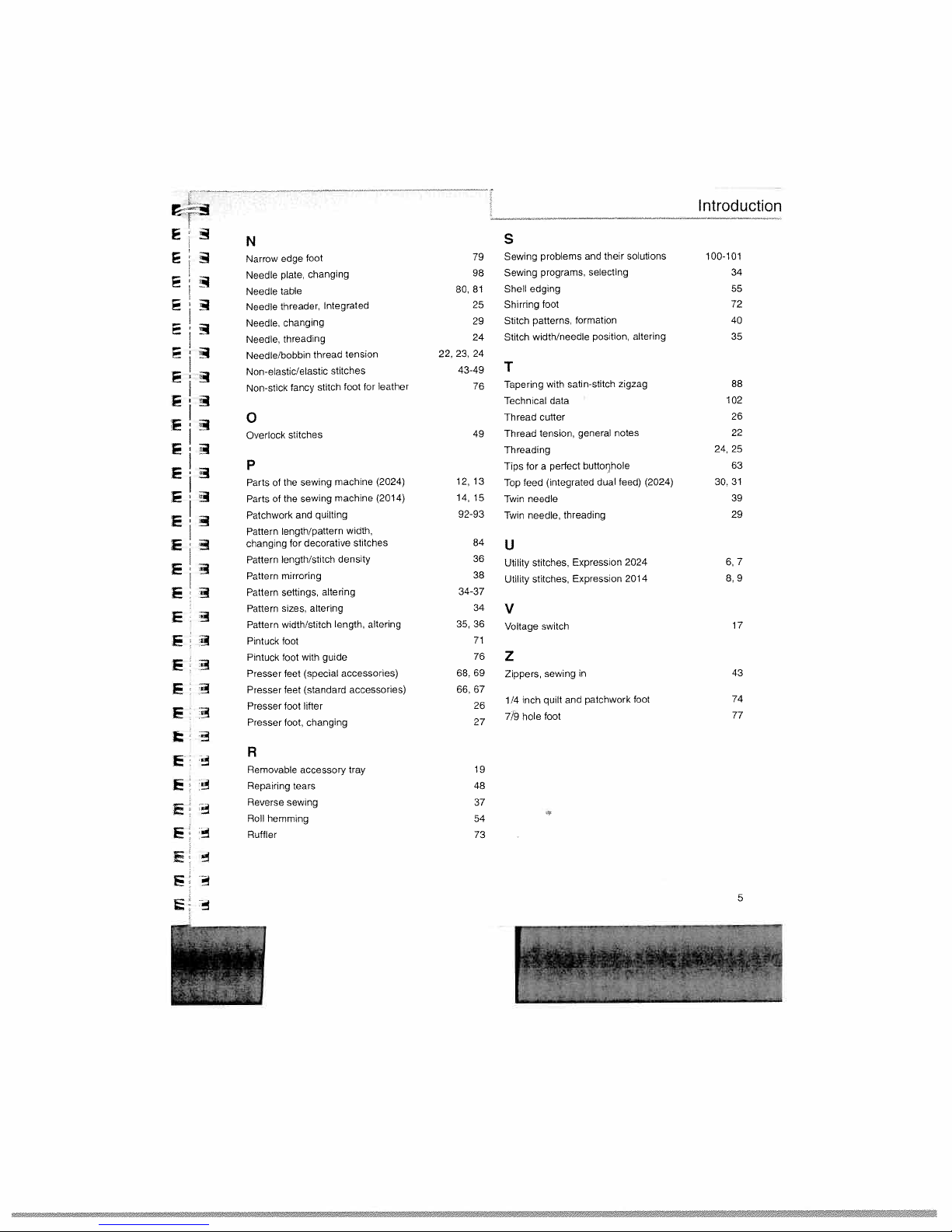

Page 5

Introduction

N

edge

Narrow

plate,

Needw

table

Neede

tnreader,

Needle

changing

Needle,

threading

Needle,

Needle’bobbin

Non-elasticelastic

fancy

Non-stick

0

St

Overlock

tches

p

ntuck

sewing

sewing

of

the

and

lengthpattern

for

length/stitch

settings,

sizes

width

foot

foot

teat (special

teat

foot

foot,

decorative

with

(standard

lifter

Partsofthe

Parts

Patchwork

Pattern

cr’anging

Pattern

Patternmrroring

Pattern

Pattern

Pattern

Pintuck

P

Presser

Presser

Presser

Presser

foot

changing

Integrated

thread

stitch

quilting

altering

altering

stitch

guide

changing

tensior

stitches

toot

machine

machine

width,

stitches

density

length.

accessories)

accessories)

for

altering

esther

(2024)

(2014)

S

their

and

selecting

on

lion,

pos

buttotthole

dual

on

patchwork

solutions

altering

zigzag

notes

feed) (2024)

2024

2014

toot

problems

Sewing

79

ng

programs,

Sew

98

Shell

81

80,

25

29

24

23.

24

22,

43-49

76

49

12,

13

14, 15

92-93

84

36

38

34-37

34

35.

36

71

76

68.

69

66,

67

26

27

edging

toot

Shirring

patterns,

Stitch

Stitch

width/needle

T

witri

Tapering

Technical

Thread cutter

tension, general

Thread

Threading

Tips

for

a

(integrated

teed

Top

Twin

needle

needle,

Twin

U

stitches,

Utility

Utility

stitches,

V

Voltage

switch

z

sewing

Zippers,

4

inch

qu

1

hole

toot

7/9

data

perfect

t

format

satin-stitch

threading

Express

Expression

in

and

100-101

24,

30.

34

55

72

40

35

88

102

26

22

25

63

31

39

29

6, 7

89

17

43

74

77

R

Removable

Repairing

Reverse

Roll

hemming

Rufter

accessory

tears

sewing

tray

19

48

37

54

73

5

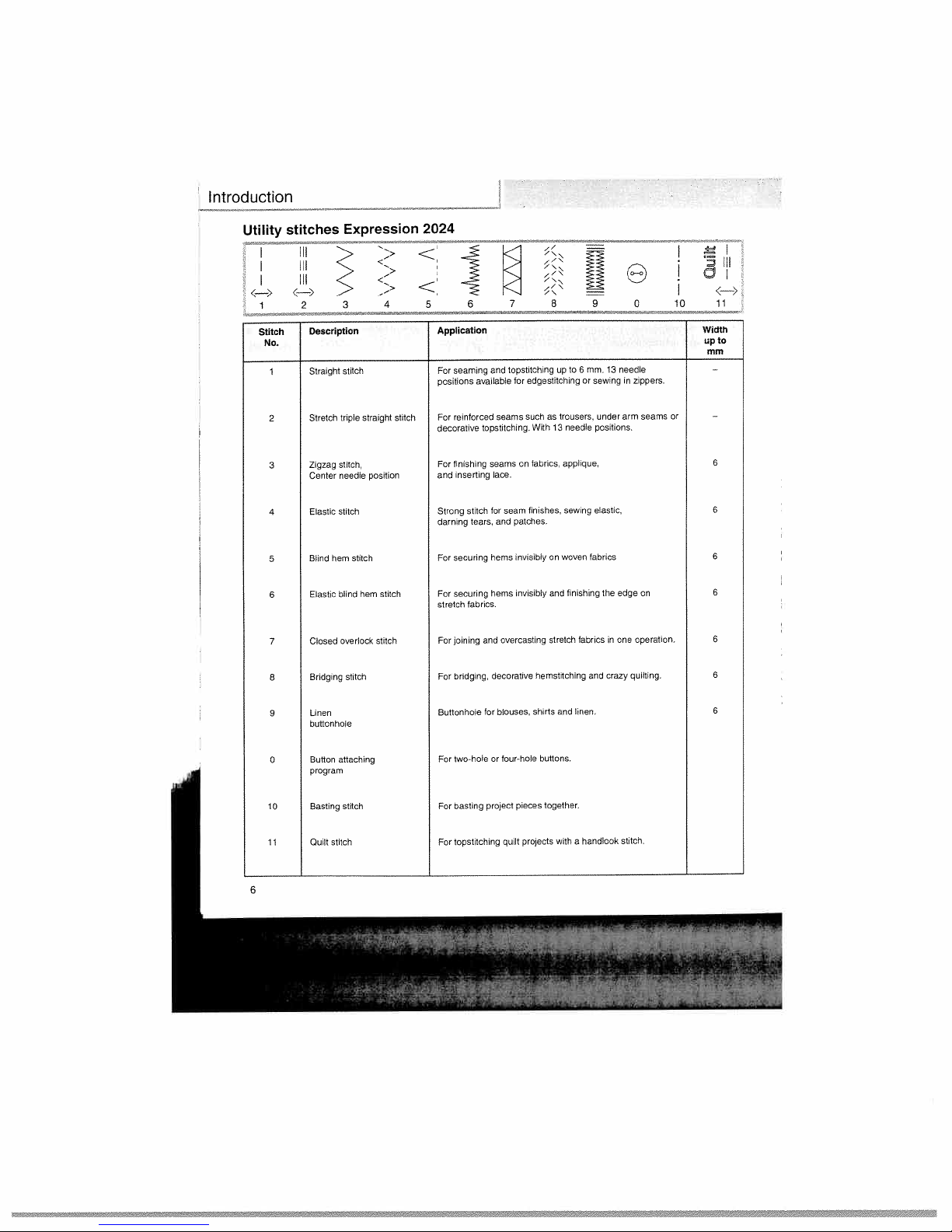

Page 6

Introduction

Utility

1

Stitch

No.

2

3

4

5

6

7

8

stitches

‘

2

Description

Straight

Stretch

Zigzag

Center

Elastic

Blind

Elastic

Closvd

Bridging

Expression

>

3

stitch

straight

triple

stitch,

needle

position

stitch

hem

stitch

hem stitch

blind

ovvrlock

stitch

_>

-->

stitch

2024

0

zippers.

seams

on

quilting.

I

I

I

11

10

Width

upto

mm

—

or

6

6

6

6

6

6

<

e

<

-1

5

4

7

6

Application

and

available

topstitching.

stitch

tears,

fabrics.

seams

seams

for

and

hems

hems

and

decorative

topstitching

for

edgestitching

such

on

seam

patches.

invisibly

Invisibly

overcasting

With

fabrics,

finishes,

hemstitching

stitch

seaming

For

positions

reinforced

For

decorative

finishing

For

inserting lace.

and

Strong

darning

For

securing

securing

For

stretch

For joining

bridging,

For

8

as

13

on

and

stretch

to6mm.

up

trousers,

needle

applique,

sewing

woven

finishing

II

or

fabrics

and

9

sewing

under

positions.

elastic.

fabrics

the

crazy

13

needle

in

arm

edge

one operation.

in

blouses,

or

four-hole

pieces

quilt

shirts and

protects

buttons.

together.

with

handlook

a

stitch.

for

Linen

9

buttonhole

Button

program

Basting

Quilt

attaching

stitch

stitch

0

10

11

Buttonhole

For

two-hole

For

basting

topstitching

For

project

linen.

6

6

Page 7

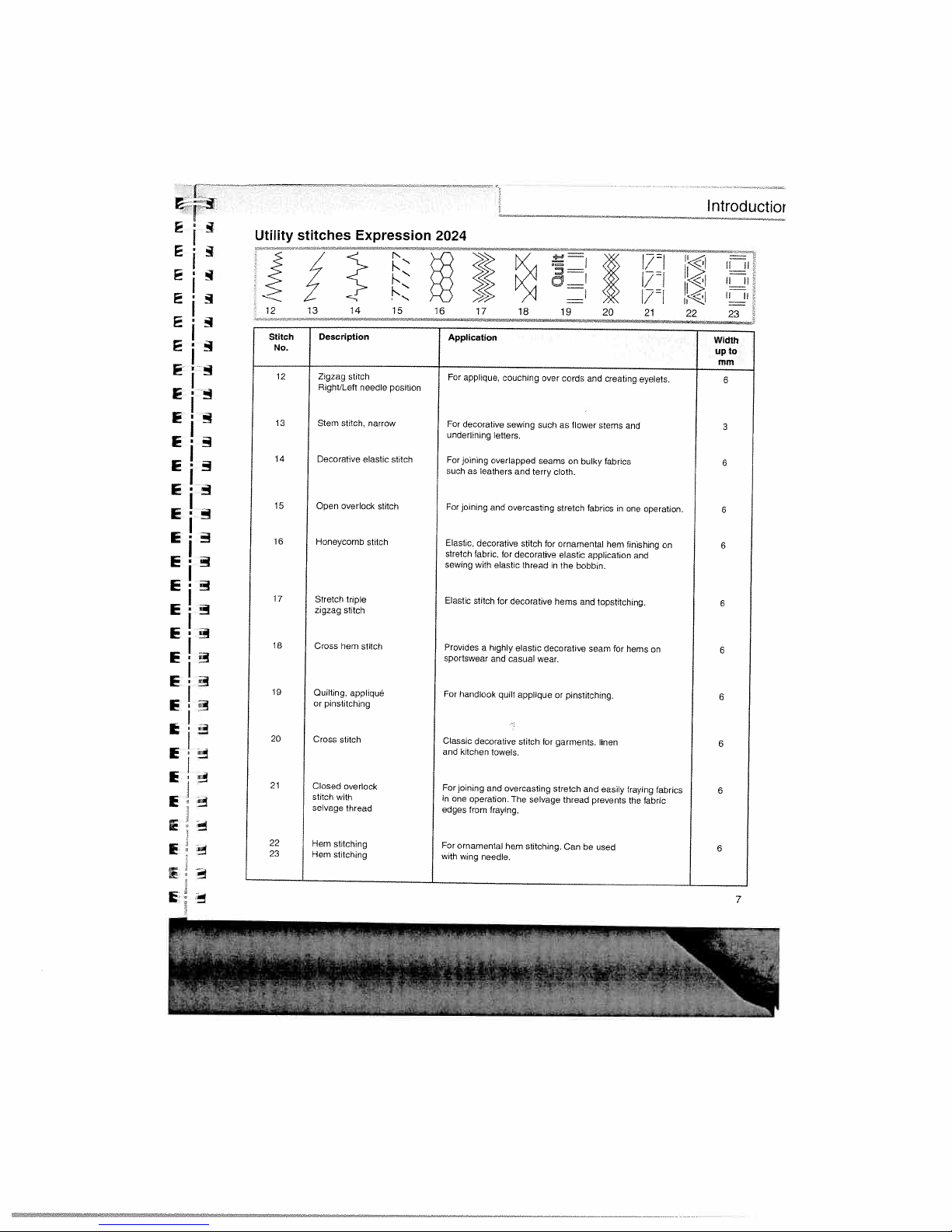

!ntroductjor

Utility

stitches

Expression

2024

-

E

E

Stitch

No.

12

13

14

15

16

17

16

Description

Zigzag

Right/Left

Stem

Stitch,

Decorat

Ope’r

overlock

Honeycomb

Stretch

zigzag

Cross

hem

stitch

triple

stitch

Application

For

applique

couching

over

cords

creafing

cloth.

for

in

hems

decorat

fiower

as

on

bulky

stretch

ornamental

elastic

the

bobbin.

and

ye

and

fabrics

application

nean’i

need

e position

narrow

elastic

stitch

ye

stitch

stitch

stitch

For

decorafive

undert

For

Joining

such

For

joini’g

Elastic.

strefcti

sewing

Elastic

Provides

sportswear

ng

n

as

leathers

oecotative

fabric,

with

stitch

a

sewing

letters.

overlapped

overcastng

and

for

elastic

for

decoratlee

highly

casna

and

such

and

terry

stitch

decorative

thread

elastic

wear.

seams

stems

and

fabrics

in

one

hem

finishing

topstrc-fvng.

for

hems

eyelets.

and

operaton

on

on

Width

uplo

mm

6

6

6

6

3

6

19

Quilting.

apphque

or

p

nstitching

20

Cross

stitch

21

Closed

overlock

stitch

with

selvage

thread

22

Hem

Hem

stitching

stitching

23

For

Classic

and

For

n

edges

For

with

handook

kitchen

smog

one

operation

from

ornamental

wing

decorative

towe

and

fraying.

needle.

quilt

overcasting

The

bern

aopliqueorpinstitching.

stitch

for

garments.

n.

stretch

thread

Can

and

be

selvage

tching.

at

linen

easilti

prevents

used

fraying

the

fabric

6

6

fabrics

6

7

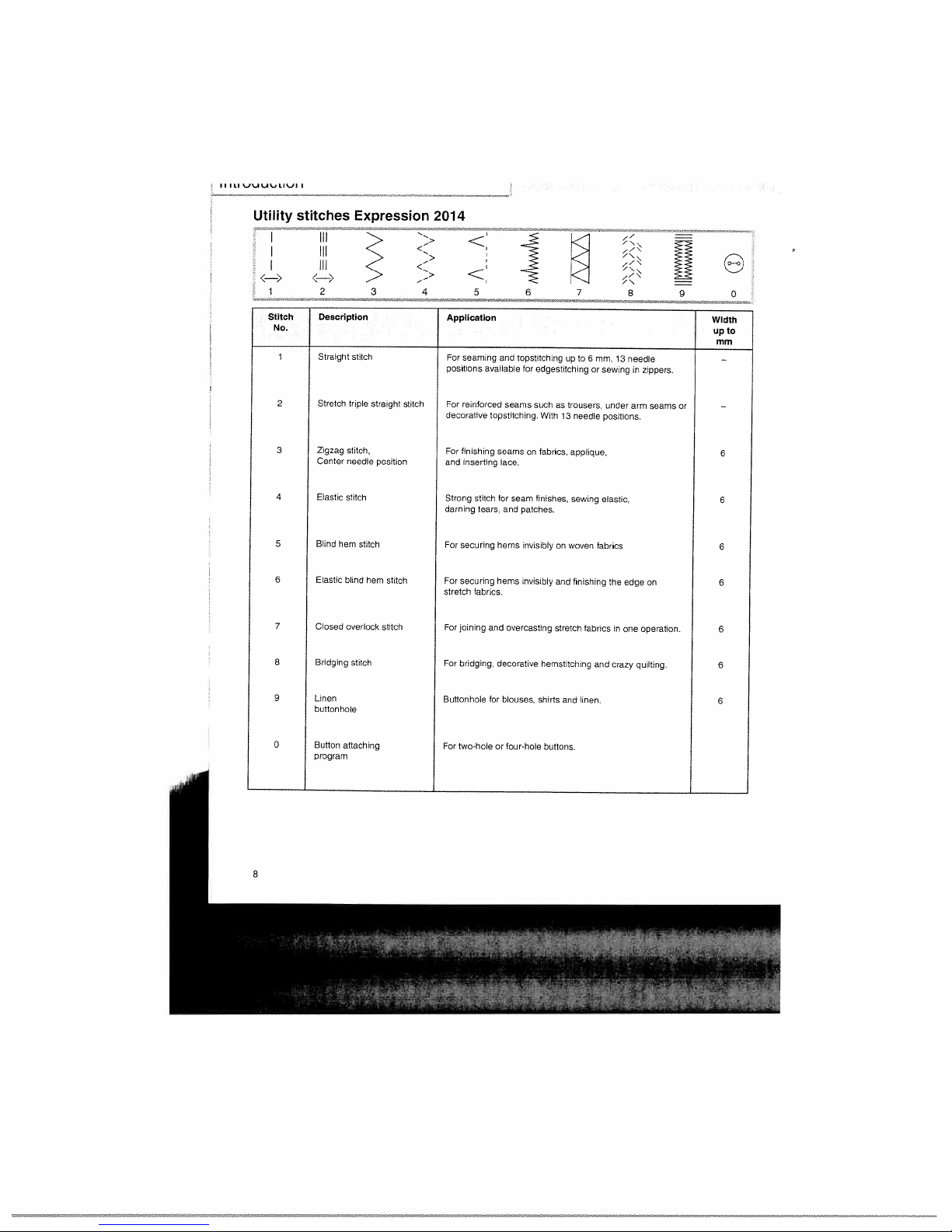

Page 8

III

r,,Js_4I.AI_,LIIJI

LI

Utility

I

>

Stitch

No.

I

2

3

4

5

6

7

8

stitches

II

4>

Description

Straight

Stretch

Zigzag

Center

Elastic

Blind

hem

Elastic

Closed

Bridging

Expression

stitch

triple

straight

stitch,

needle

position

sfitch

stitch

blind

hem

overlook

stitch

stitch

stitch

atitch

>

2014

Application

For

positions

For

decorative

For

and

Strong

darning

For

For

stretch

For

For

<;

<

seaming

reinforced

finishing

inserting

stitch

tears,

securing

securing

fabrics

joining

bridging,

and

available

seams

topstitching,

seams

lace.

for

and

hems

hems

and

overcasting

decorative

4

topstitching

for

sacs

on

seam

patches.

invisibly

invisibly

up

edgeatitching

as

trousers,

With

13

fabrics,

finishes,

on

and

stretch

hemslitchirrg

toG

needle

applique.

sewing

woven

finishing

fabrics

mm.

or

fabrics

and

sewing

elastic,

13

under

positions.

the

in

one

crazy

needle

edge

in

zippers.

arm

operation.

quilting.

seams

on

8

Width

upto

mm

—

or

—

6

B

6

6

6

6

B

Linen

buttonhole

0

Button

attaching

program

S

Buttonhole

For

twohole

for

blouses.

or

four-hole

shirts

buttons.

and

linen.

6

Page 9

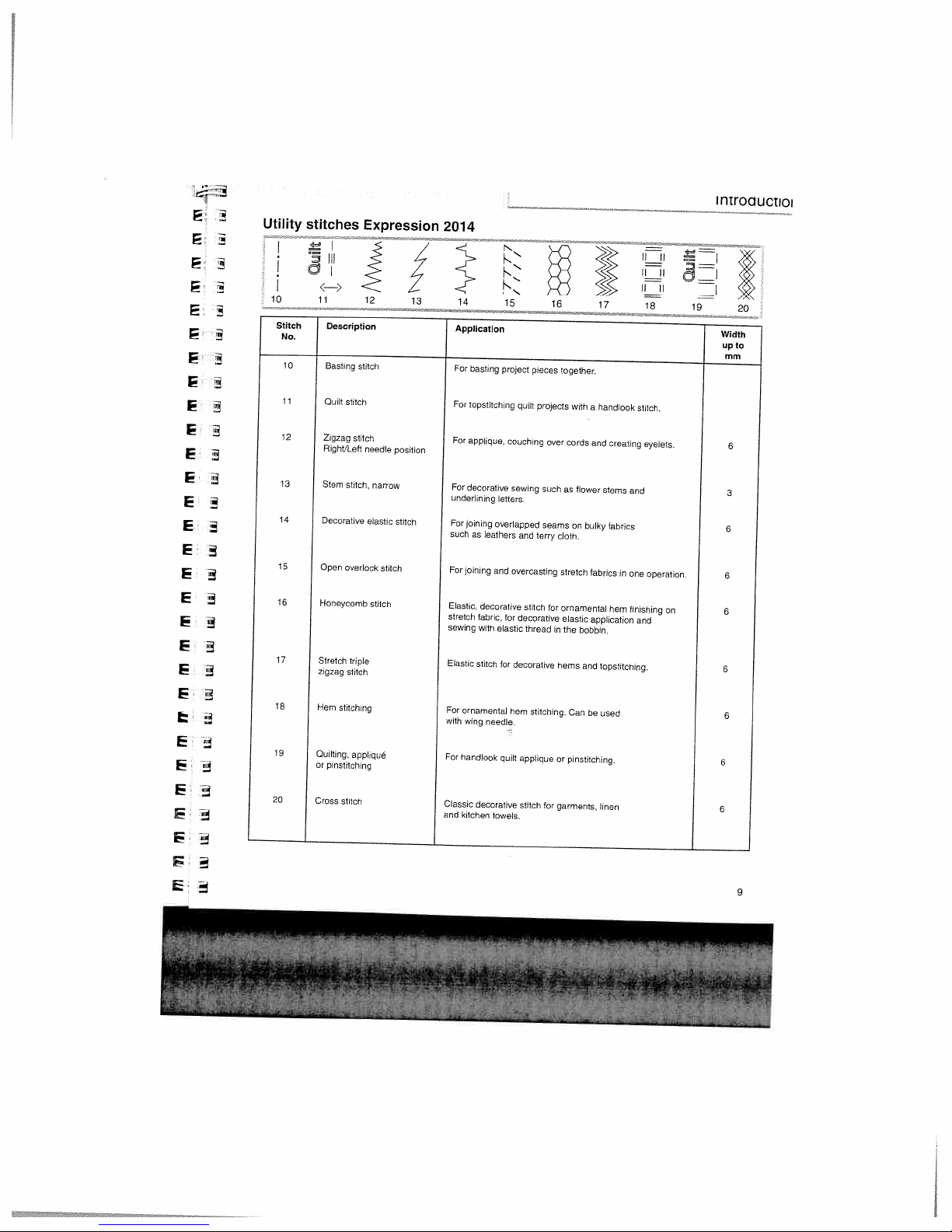

Utility

11

Stitch

No.

10

11

12

13

14

15

16

stitches

Description

Basting

Qilt

Zigzag

Right/Left

Stem

Decorative

Open

Honeycomb

Expression

stitch

sttch

stitch

needle

stitch,

narrow

elastic

overlock

stitch

stitch

positron

stitch

2014

Application

For

For

For

For

underlining

For

such

For

Elastic,

stretch

sewing

basting

topstitching

applique

decorative

joining

leathers

as

joining

decorative

fabric

with

project

quilt

couching

sewing

letters

overlapped

and

and

overcasting

for

decorative

elastic

stitch

thread

pieces

projects

such

seams

terry

over

cloth.

stretch

for

In

together.

with

cords

as

f

ower

on

bulky

ornamental

elastic

the

bobbin.

handlook

a

and

creating

stems

fabrics

fabrics

hem

application

in

IS

stitch.

eyelets

and

one

ooeration.

finishing

and

iniroauciioi

Width

upto

mm

6

3

6

6

on

6

17

Stretch

triple

zigzag

stitch

18

Hem

stitch

ng

19

Qulting,

app

plnntifching

tch

sf

que

or

20

Cross

Elastic

For

with

For

Classic

and

stitch

ornamental

wing

handlook

decorative

kitchen

needle.

towels.

for

quilt

decorative

hem

stitching

applique

stitch

hems

Can

orpnstitching.

for

garments

and

be

topstitching.

used

linen

6

6

6

S

9

Page 10

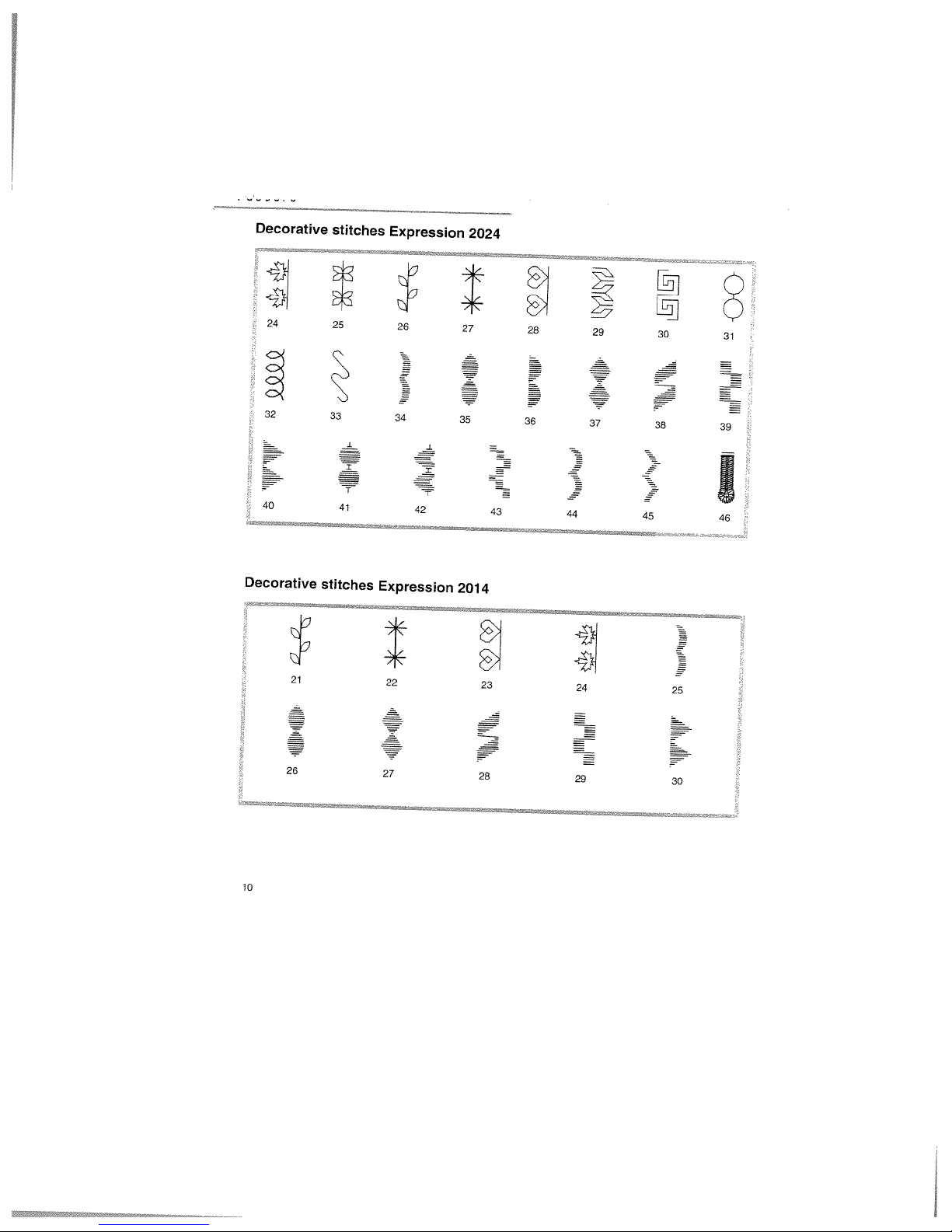

CD

L

-‘

o

CD

C)

Cfl

ni

-I

CD

0

t.3

0

C..)

)(

______

______

‘

IjIflhI

1

Q_QQQ.

U

Hijj(i

)IlI

I

iII

‘I

hHh

ih

s4,

r

in’’h

Ii’

‘h

—•

Ill

Q9

Q9

‘lUlll’

lW’

‘Ill

C.)

1

I)

jIj.

jI

“hiiil’l’’i”

-

(>Q

(.)

lilA

flfl{I

C.)

El

c)

CD

o

°

<

CD

o

CD

m

-‘

CD

U,

(0

C...)

0

‘U,

cx

0

)f(

-L

r

)f(

-‘

ArIIII

uBllt

‘I

h

I’’IJIH

‘‘1111’

jill!

‘lilPIl

‘‘lIil1l

0

Page 11

E

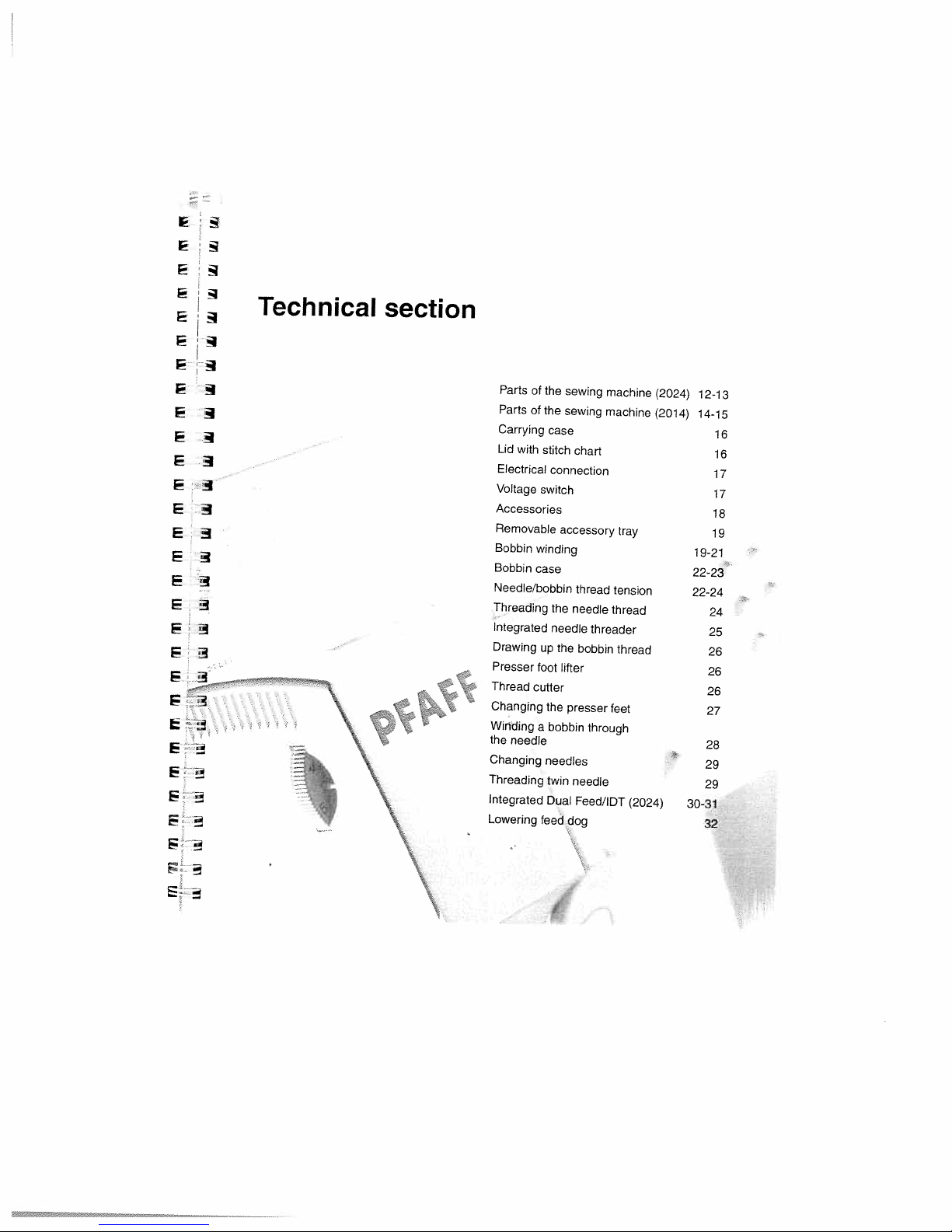

Technical

section

Parts

of

Parts

of

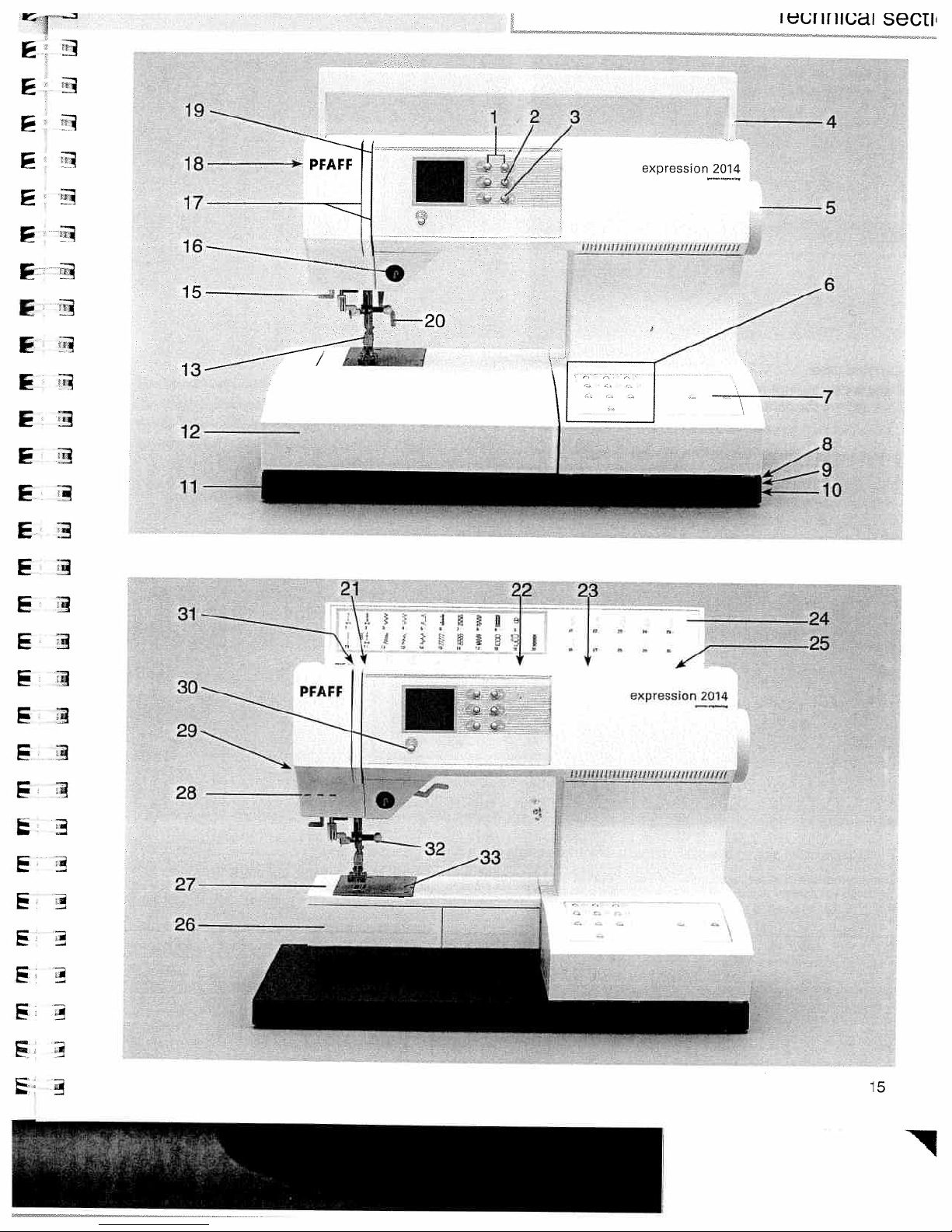

Carrying

Lid

with

Electrical

Voltage

Accessories

Removable

Bobbin

winding

Bobbin

case

Needle/bobbin

Threading

Integrated

Drawing

Presser

foot

Thread

cutter

Changing

Winding

the

Changing

Threading

Integrated

Lowering

a

needle

the

sewing

the

sewing

case

stitch

connection

switch

accessory

the

needle

up

the

lifter

the

presser

bobbin

needles

twin

Dual

feed

dog

chart

thread

needle

threader

bobbin

through

needle

Feed/IDT

machine

machine

tray

tension

thread

thread

feet

(2024)

(2024)

(2014)

12-13

14-15

16

16

17

17

18

19

19-21

22-23

22-24

24

25

26

26

26

27

28

29

29

30-31

32

j

Page 12

—

—.

—

‘—..

%_,

‘_

%J

%J

SI

I

I

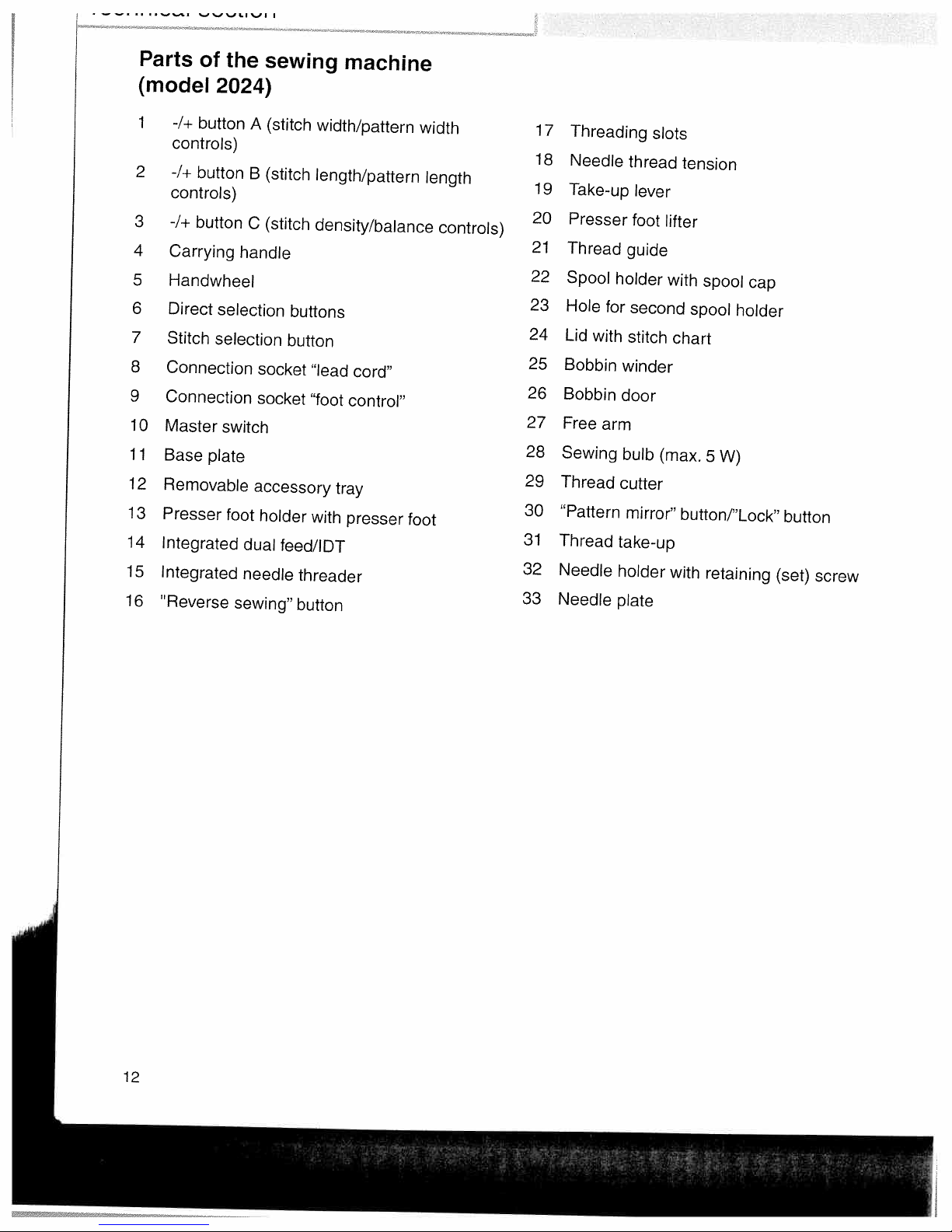

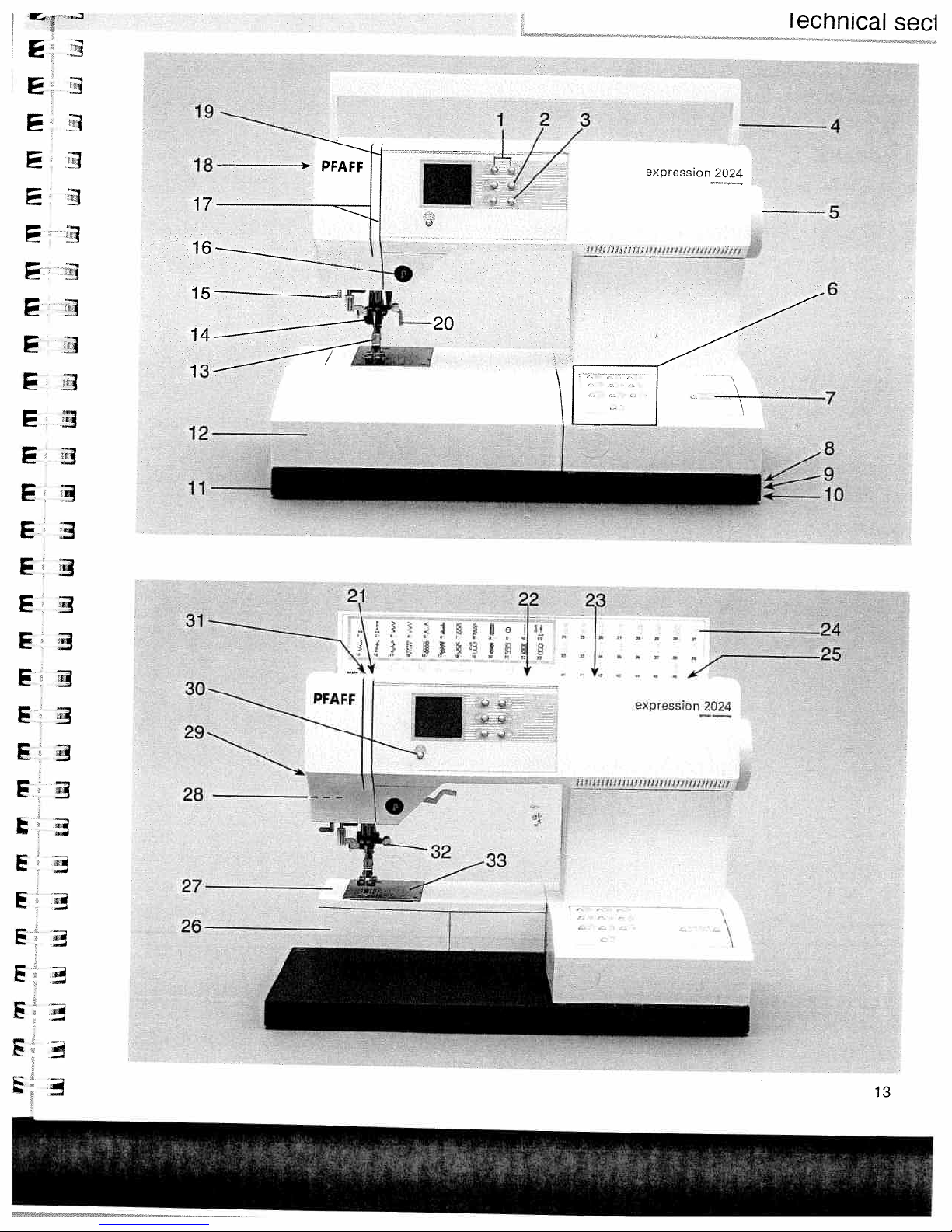

Parts

(model

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

of

2024)

-1+

button

controls)

-1+

button

controls)

-1+

button

Carrying

Handwheel

Direct

Stitch

Connection

Connection

Master

Base

Removable

Presser

Integrated

Integrated

Reverse

selection

selection

switch

plate

the

A

B

C

handle

socket

socket

accessory

foot

holder

dual

needle

sewing”

sewing

(stitch

(stitch

(stitch

buttons

button

“lead

“foot

with

feed/IDT

threader

button

machine

width/pattern

length/pattern

density/balance

cord”

control”

tray

presser

foot

width

length

controls)

27

28

29

30

31

32

33

17

18

19

20

21

22

23

24

25

26

Threading

Needle

Take-up

Presser

Thread

Spool

Hole

Lid

with

Bobbin

Bobbin

Free

arm

Sewing

Thread

“Pattern

Thread

Needle

Needle

thread

foot

guide

holder

for

second

stitch

winder

door

bulb

cutter

mirror”

take-up

holder

plate

slots

lever

tension

lifter

with

spool

spool

chart

(max.

5

W)

buttonl’Lock”

with

retaining

cap

holder

button

(set)

screw

12

Page 13

(0

-

0)

..L

-4

.k

0)

C)

x

CD

CCC

0

-U

01

•

•

()

o

C)

r’.z

co

01

4

0)

cx

-

C

1)

1’.)

C)

IL

CD

x

CD

CCC

C

-o

L

F’.)

cx

-

r\)

0)

(D

Page 14

i

ii

ii_,ci.i

oL..Li’.Ji

I

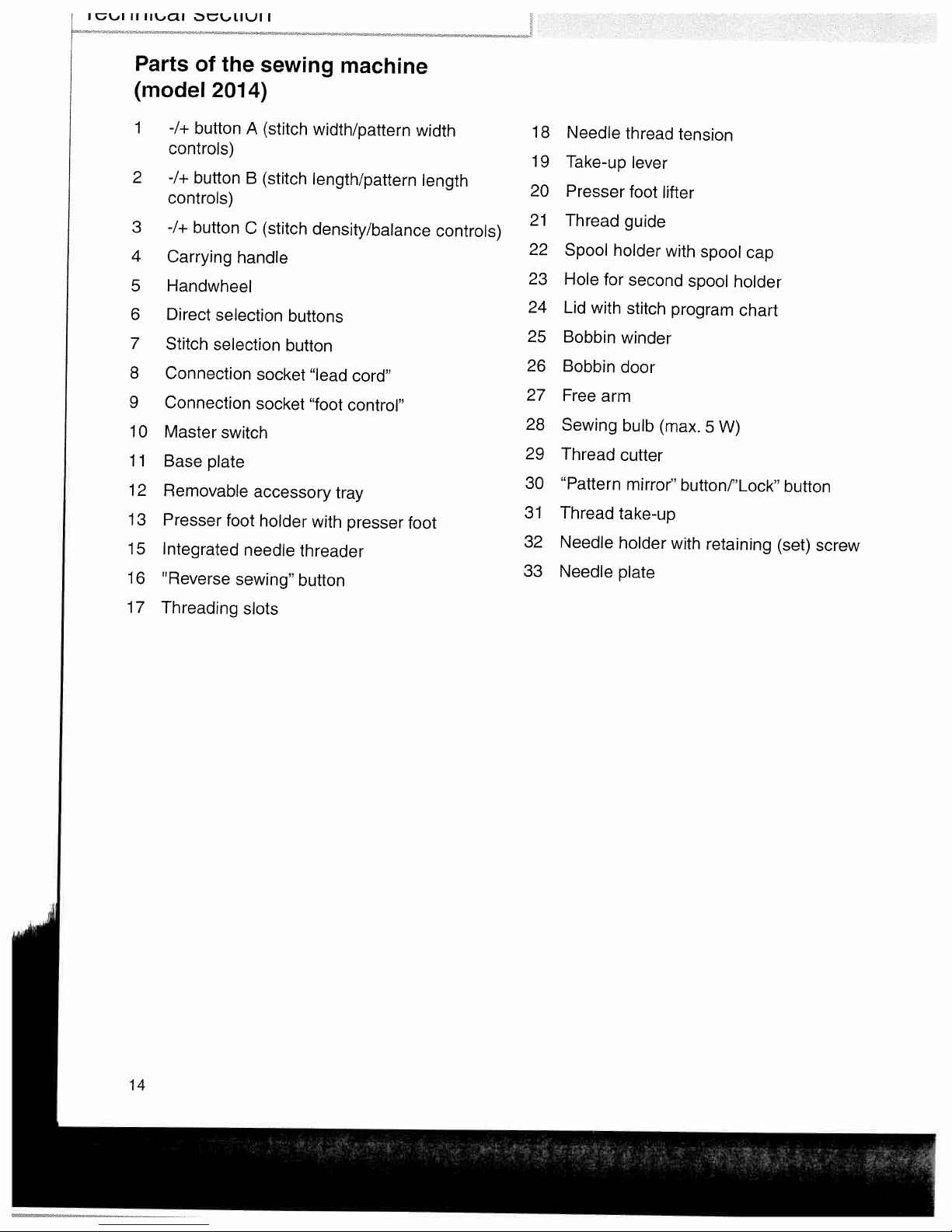

Parts

(model

1

-1+

controls)

2

-1+

controls)

3

-1+

4

Carrying

5

Handwheel

Direct

6

7

Stitch

Connection

8

9

Connection

10

Master

11

Base

12

Removable

13

Presser

15

Integrated

16

‘Reverse

of

the

2014)

button

button

button

selection

selection

switch

plate

A

B

C

handle

socket

socket

accessory

foot

holder

needle

sewing”

sewing

(stitch

(stitch

(stitch

buttons

button

“lead

“foot

with

threader

button

machine

width/pattern

length/pattern

density/balance

cord”

control”

tray

presser

width

length

foot

controls)

20

21

22

23

24

25

26

27

28

29

30

31

32

33

18

19

Needle

Take-up

Presser

Thread

Spool

Hole

Lid

with

Bobbin

Bobbin

Free

arm

Sewing

Thread

“Pattern

Thread

Needle

Needle

thread

guide

holder

for

second

stitch

winder

door

bulb

cutter

mirror”

take-up

holder

plate

lever

foot

tension

lifter

with

spool

spool

program

(max.

with

W)

5

button/”Lock”

retaining

cap

holder

chart

button

(set)

screw

17

Threading

slots

14

Page 15

Ct

-

(0

-

C’)

CD

C-)

I

IC

A.

0)

-

01

CA)

P0

f)

-L

0)

W

-ACC

CC

CLCU

I

P3

0)

•(

CD

x

C

CD

(13

CC

C

i4

01

L(Ø

0

C

P0P’)

(,1

0)

P0

r’)

1’)

J\)

C)

CD

0:’

—.1

C)

x

CD

CC

CD

CC

1,

0)

0)

I,

(31

44

Page 16

3CD

-TI

T1

C)

CD

-

CD

00

“Yvvv

-

ci

CD

-rj

8’

-

—

Ci

-o

CD

x

-

CD

C’)

C/)

1D

D

HH

CD

CD

—

a)

0

D

C)

(Q

:5

o

o

CD

CD

CD

—

0

-‘

CD

ci

g

S2.

0.

H

E

CD

0

0

(j)

0

0

CD

CD

(I)

(I,

CD

—

-D

o

p

Page 17

technical

..

sec

120

Operating

Electrical

Connect

machine

I

Instructions

connection

the

lead

and

the

cord

wall

between

outlet.

the

220

socket

V

(8)

Connecting

Connect

(9)

of

the

of

the

sewing

The

sewing

The

foot

machine.

the

sewing

speed

control

the

plug

foot

of

the

machine.

is

tvd

ATK

control

foot

controlled

0070

control

by

has

to

the

pressing

to

be

connection

the

used

for

foot

this

socket

control.

sewing

110V.120V

220

\4

Master

When

I)

in

The

“0

“I”

the

the

=

=

sewing

ON

switch

the

master

sewing

OFF

lamp

Expression

machine

switch

lights

window.

is

now

(10)

up

is

and

ready

switched

program

to

function.

on

No.

(switch

us

function

indicated

Voltage

220V..240V/110V...

The

220

you

machinetoll0V...

sewing

V..

240

must

switch

machine

V.

reset

If

you

the

120V

is

set

require

voltage

120V.

to

the

a

mains

switch

mains

voltage

on

the

voltage

of

underside

for

120

Europe

V,

of

the

17

Page 18

k,1_

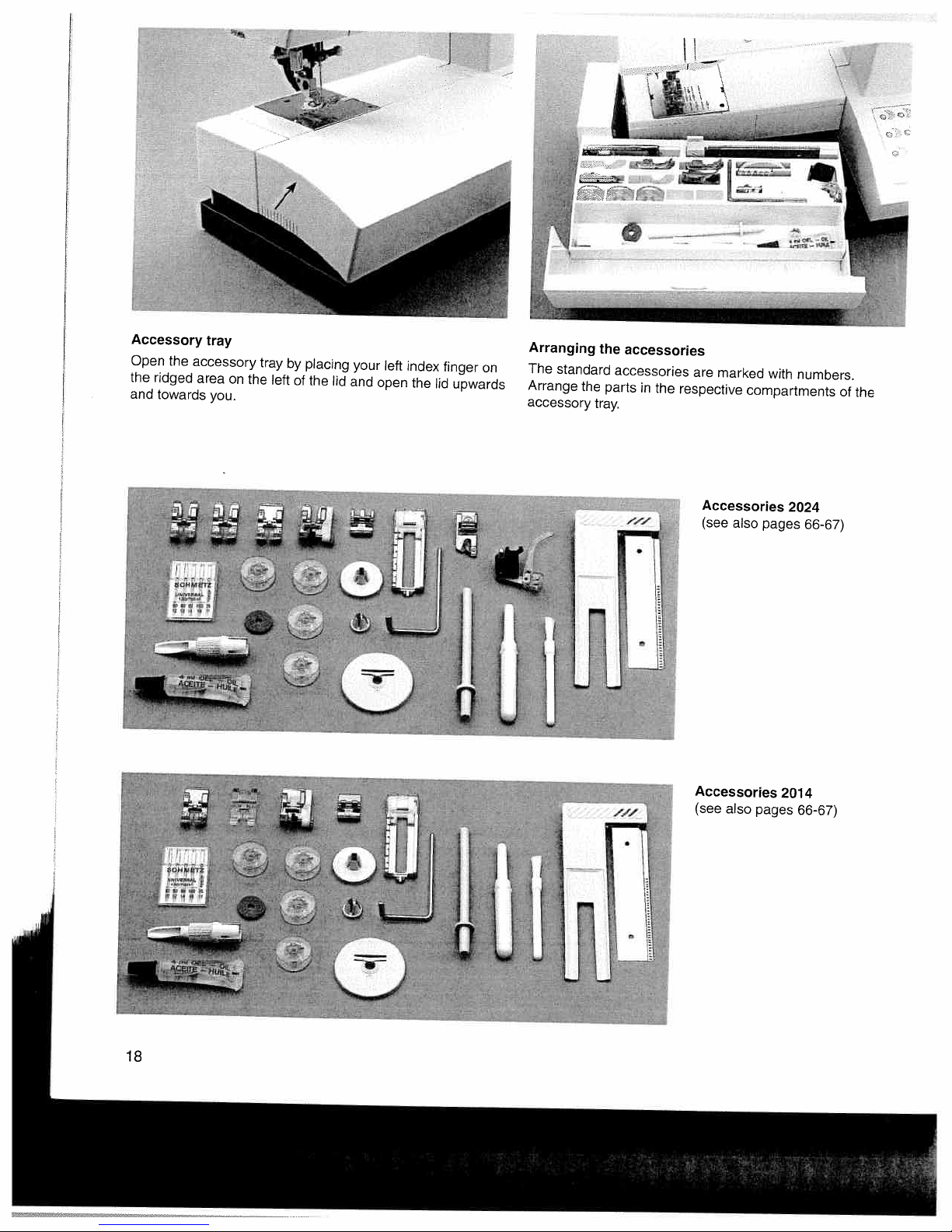

Accessory

Open

the

the

ridged

and

towards

tray

accessory

area

on

you.

the

tray

left

by

of

placing

the

lid

your

and

left

open

index

the

finger

lid

on

upwards

Arranging

The

standard

Arrange

accessory

the

tray.

the

accessories

accessories

parts

in

the

are

marked

respective

Accessories

(see

with

compartments

also

pages

numbers.

2024

66-67)

of

the

18

t1

Accessories

(see

also

pages

2014

66-67)

Page 19

Fl

1’

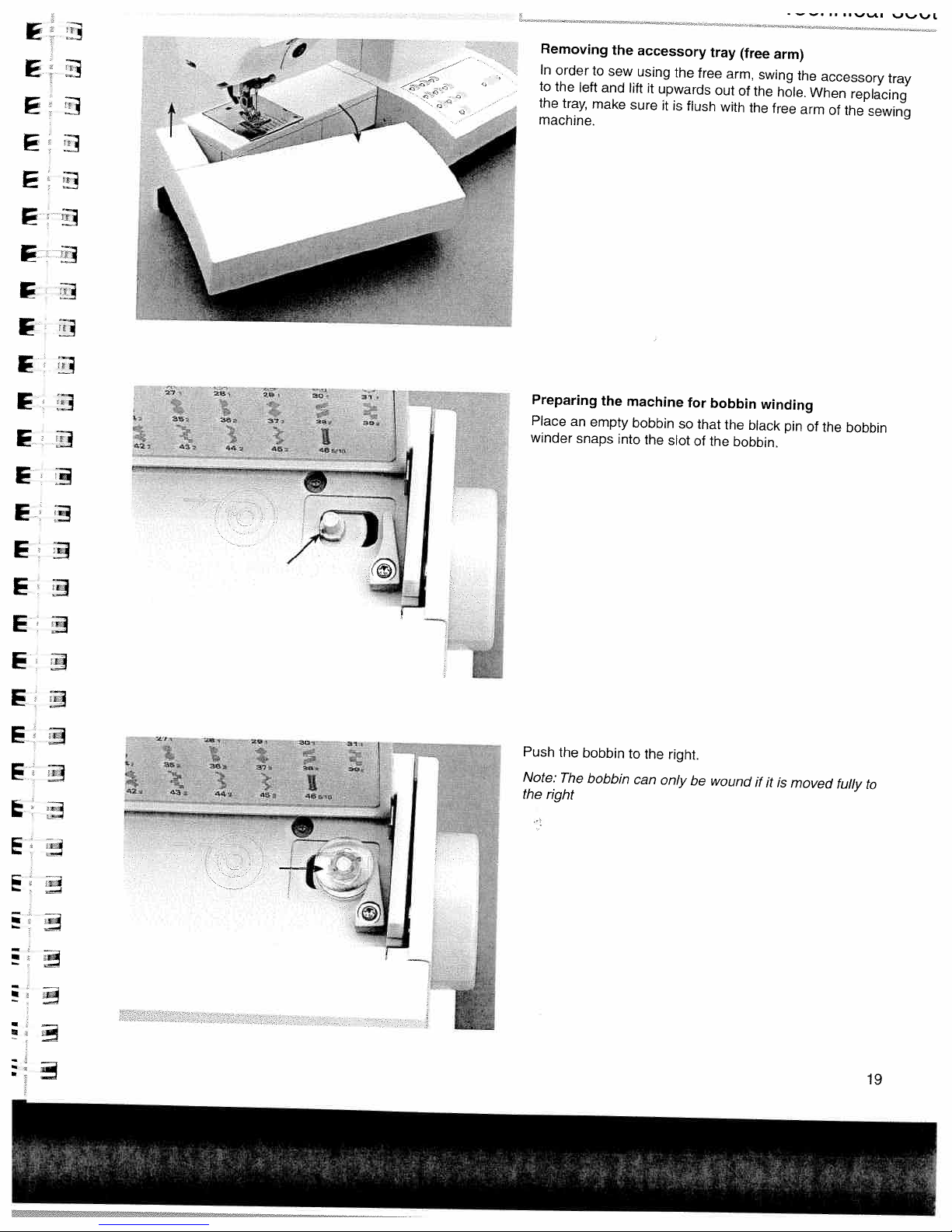

Removing

In

order

to

the

left

the

tray,

machine.

to

sew

and

make

the

accessory

using

lift

it

upwards

sure

it

the

is

free

flush

tray

out

arm,

with

(free

of

the

swing

the

arm)

hole.

free

-

the

When

arm

accessory

replacing

of

the

s—%i

%_J

tray

sewing

‘..,

%.,

L

7

)

4

422

‘2

3S

22

291

•

332

43,

364

432

442

29j

171

33

442

I

3•73

452

301

4

372

48,

11

344

4644

3,

382

392

46,2

391

Preparing

Place

winder

Push

Note:

the

right

the

The

an

snaps

bobbin

the

empty

bobbin

machine

bobbin

into

the

to

the

can

slot

right.

only

so

for

be

that

of

bobbin

the

the

bobbin.

wound

winding

black

if

it

pin

is

of

moved

the

bobbin

fully

to

I..

-1

19

Page 20

/

.

=

B

I

I

I

!

:

O

e)cprsssic,r)

2O2i

.

1

o.

A

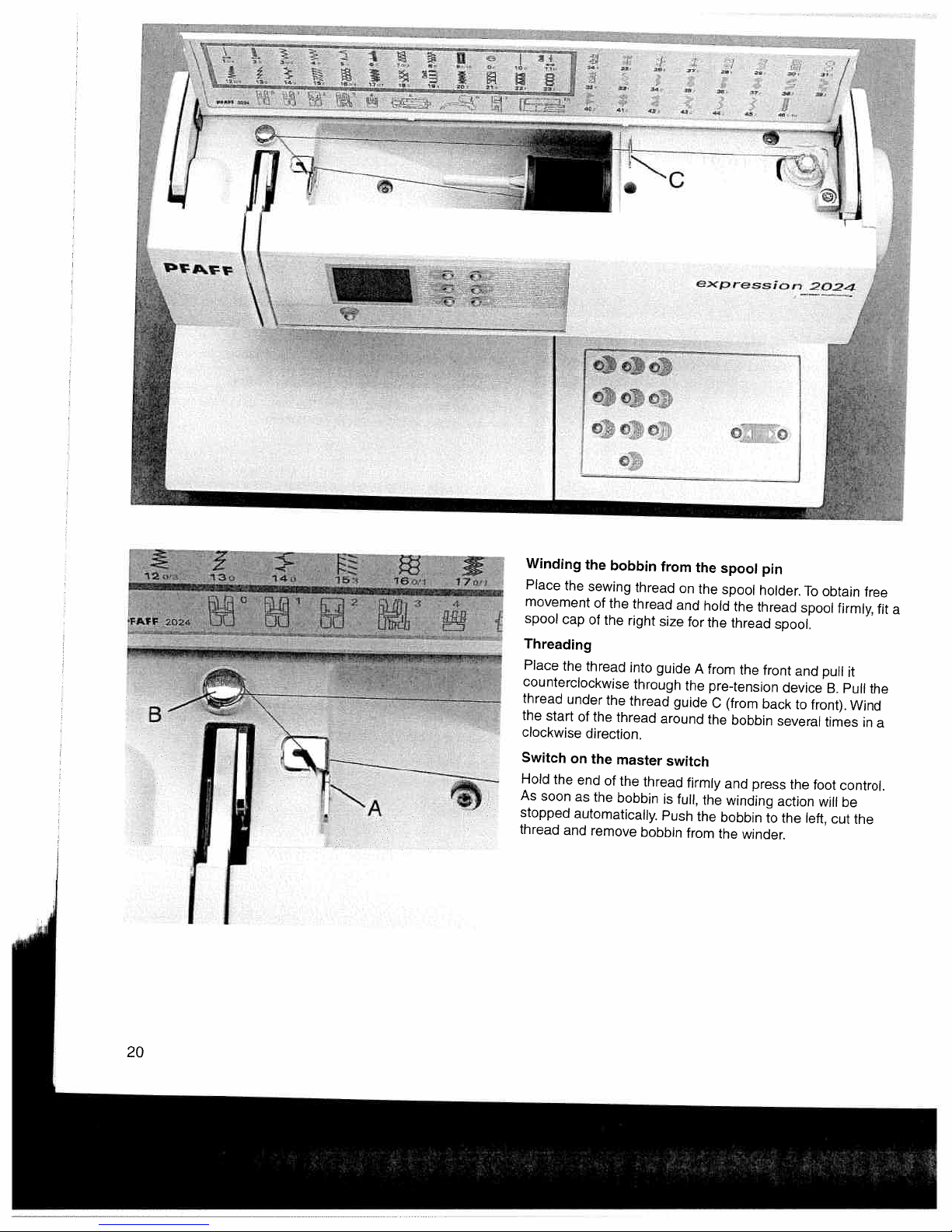

Winding

Place

movement

spool

Threading

Place

counterclockwise

thread

the

clockwise

Switch

Hold

As

stopped

thread

the

cap

the

under

start

on

the

soon

as

automatically.

and

the

bobbin

sewing

of

the

of

the

thread

the

of

the

direction.

the

end

of

the

remove

thread

thread

right

into

through

thread

thread

master

the

bobbin

bobbin

from

size

guide

around

thread

is

Push

on

and

for

the

guide

switch

firmly

full,

from

the

spool

the

spool

hold

the

thread

A

from

pre-tension

C

(from

the

bobbin

and

the

winding

the

bobbin

the

the

the

press

winder.

pin

holder.

thread

spool.

front

back

several

action

to

the

To

spool

and

device

to

the

left,

obtain

pull

B.

front).

times

foot

will

cut

free

firmly.

it

Pull

Wind

in

control.

be

the

the

fit

a

a

20

Page 21

Technical

sec

•

PcRcc

r

j

T’

T

TThflT1

L

=

—

T

—

--

IJL!J

I-

‘°

j••,

Z:

4

tj

ecp

-—

.;

occ

C

resjc),,

C

202.4

C

B

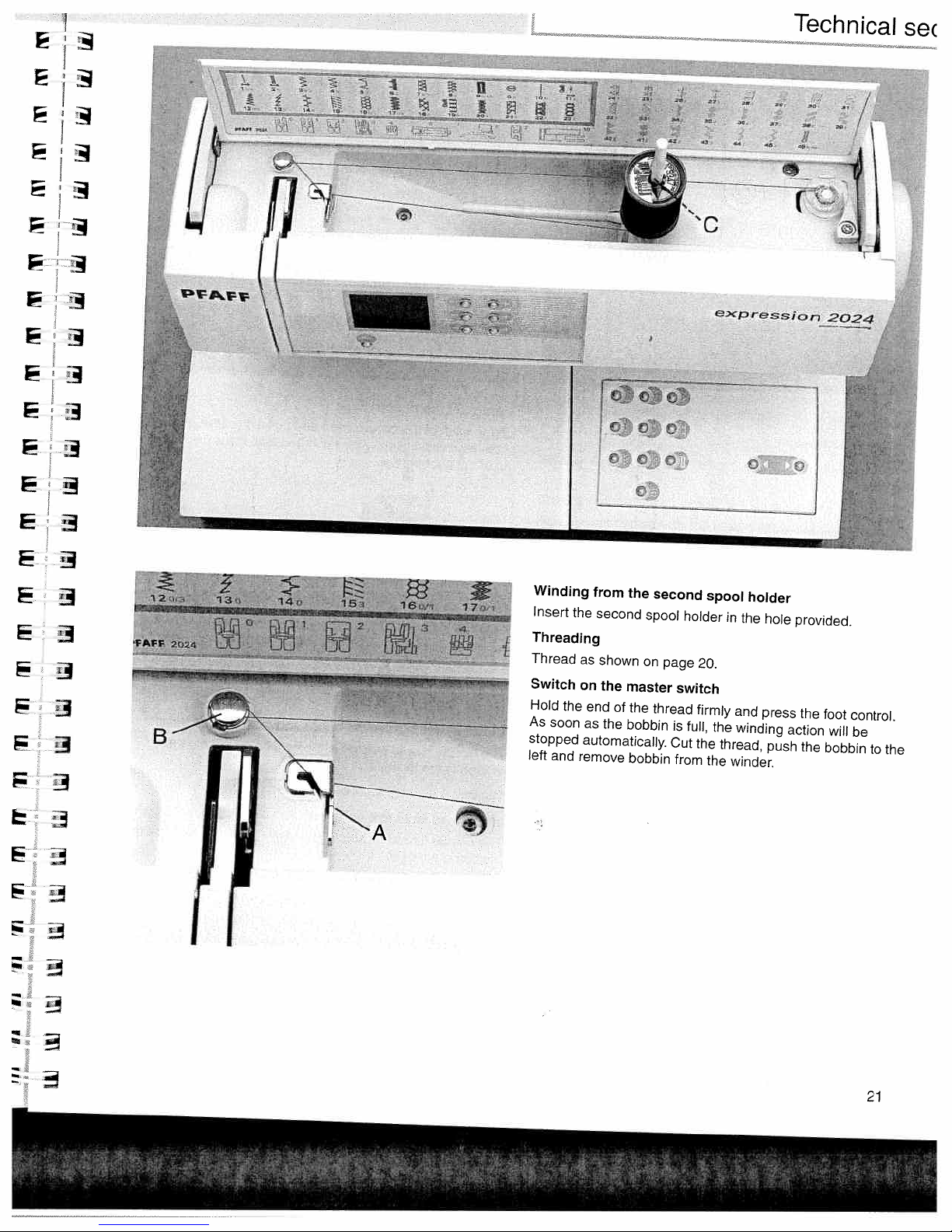

Winding

Insert

Threading

Thread

Switch

Hold

the

As

soon

stopped

left

and

from

the

the

second

as

shown

on

the

master

end

of

as

the

bobbin

automatically.

remove

bobbin

the

second

spool

on

thread

page

switch

is

Cut

from

spool

holder

20.

firmly

full,

the

the

in

the

thread,

winder.

holder

the

hole

and

press

winding

push

provided.

the

action

the

foot

will

bobbin

control.

be

to

the

21

Page 22

Bobbin

Switch

Hold

the

front

the

door

oft

bobbin

main

switch

door

(26)

Taking

Lift

at

the

left

side

and

open

it

towards

of

out

the

the

of

out

the

latch

machine.

the

bobbin

of

bobbin

the

bobbin

Release

case.

case

the

case

latch

and

and

pull

take

the

bobbin

the

empty

case

bobbin

out

DDDDDD

±u±LLa

EWELLLU

Thread

To

obtain

sure

adjusted

meet

The

Bobbin

The

tension

The

thread

Top

thread

The

needle

tension

The

thread

For

decorative

should

tension

a

the

needle

with

between

following

thread

needle

is

too

tension

is

too

tension

be

visible

perfect

regard

the

is

thread

loose.

is

visible

thread

tight.

stitches

and

two

valid

is

visible

tension

on

seam

bobbin

to

fabric

for

tension

must

on

must

and

the

appearance

thread

each

other,

layers.

general

on

the

is

too

be

corrected.

the

underside

is

too

be

corrected.

buttonholes

underside

tensions

i.e.

sewing:

top

side

tight

or

loose

the

of

and

the

the

or

the

fabric.

durability

are

threads

of

the

bobbin

of

the

the

bobbin

top

make

correctly

evenly

fabric:

thread

fabric:

thread

thread

22

Page 23

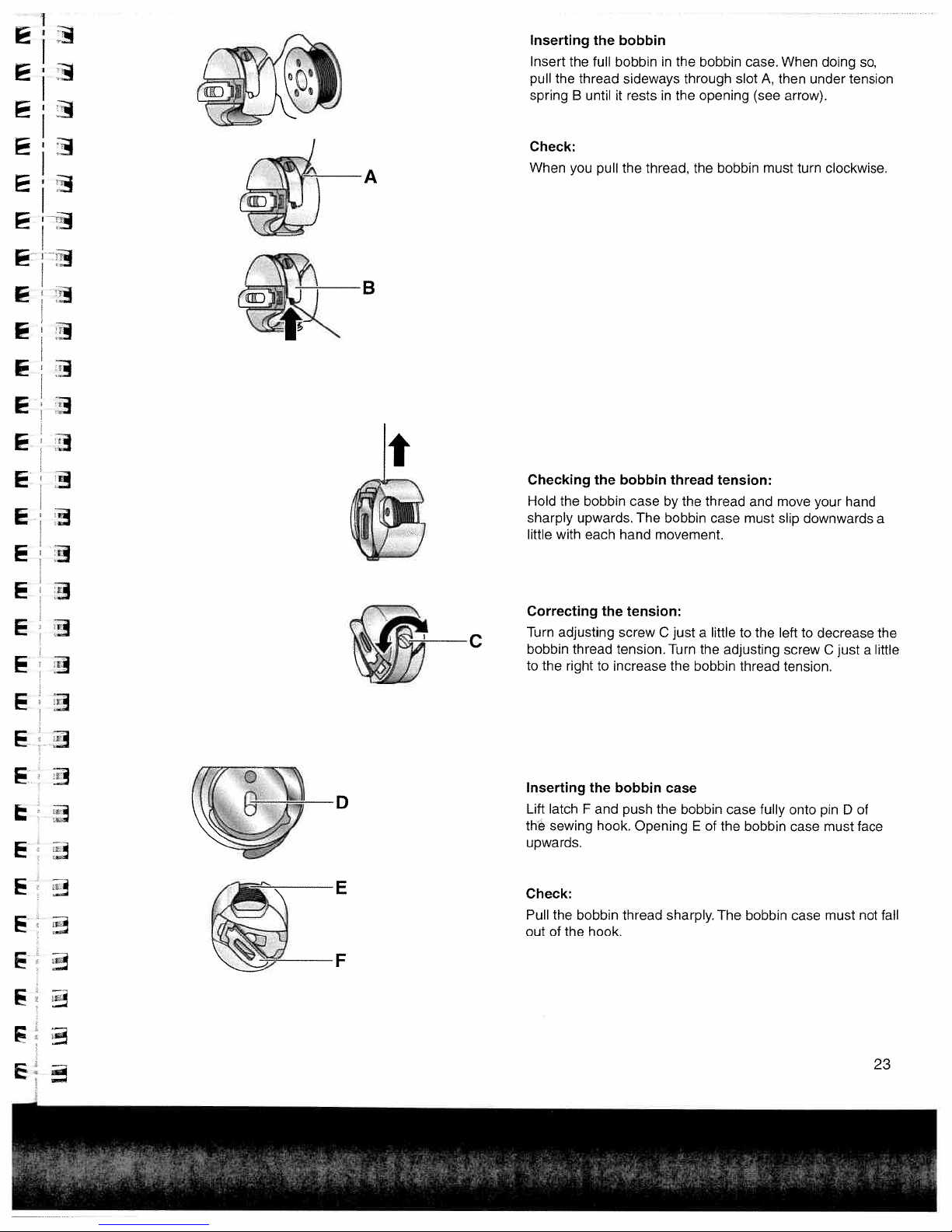

A

t

Inserting

Insert

pull

the

spring

Check:

When

Checking

Hold

the

sharply

little

with

the

the

full

thread

until

B

pull

you

the

bobbin

upwards.

each

bobbin

bobbininthe

sideways

the

in

it

rests

thread,

the

case

The

movement.

thread

by

bobbin

bobbin

hand

bobbin

through

opening

the

the

thread

case

case.

slot

bobbin

tension:

and

must

A,

(see

must

When

then

arrow).

turn

move

slip

downwards

doing

under

clockwise.

your

so,

tension

hand

a

Ei

to

the

F

and

hook.

hook.

the

screw

tension.

increase

bobbin

push

thread

tension:

the

Opening

just

C

Turn

the

case

bobbin

sharply.

a

littletothe

the

bobbin

of

the

E

The

adjusting

thread

fully

case

bobbin

bobbin

to

left

screw

tension.

onto

case

case

decrease

just

C

pin

D

must

must

a

of

face

not

the

little

fall

Correcting

Turn

C

E

adjusting

bobbin

the

to

Inserting

latch

Lift

sewing

the

upwards.

Check:

Pull

the

of

out

thread

right

bobbin

the

F

23

Page 24

4o116i

L

fl

1o

12

PFAFF

<-,

I

2024

Ill

Ill

Ill

4-

13o

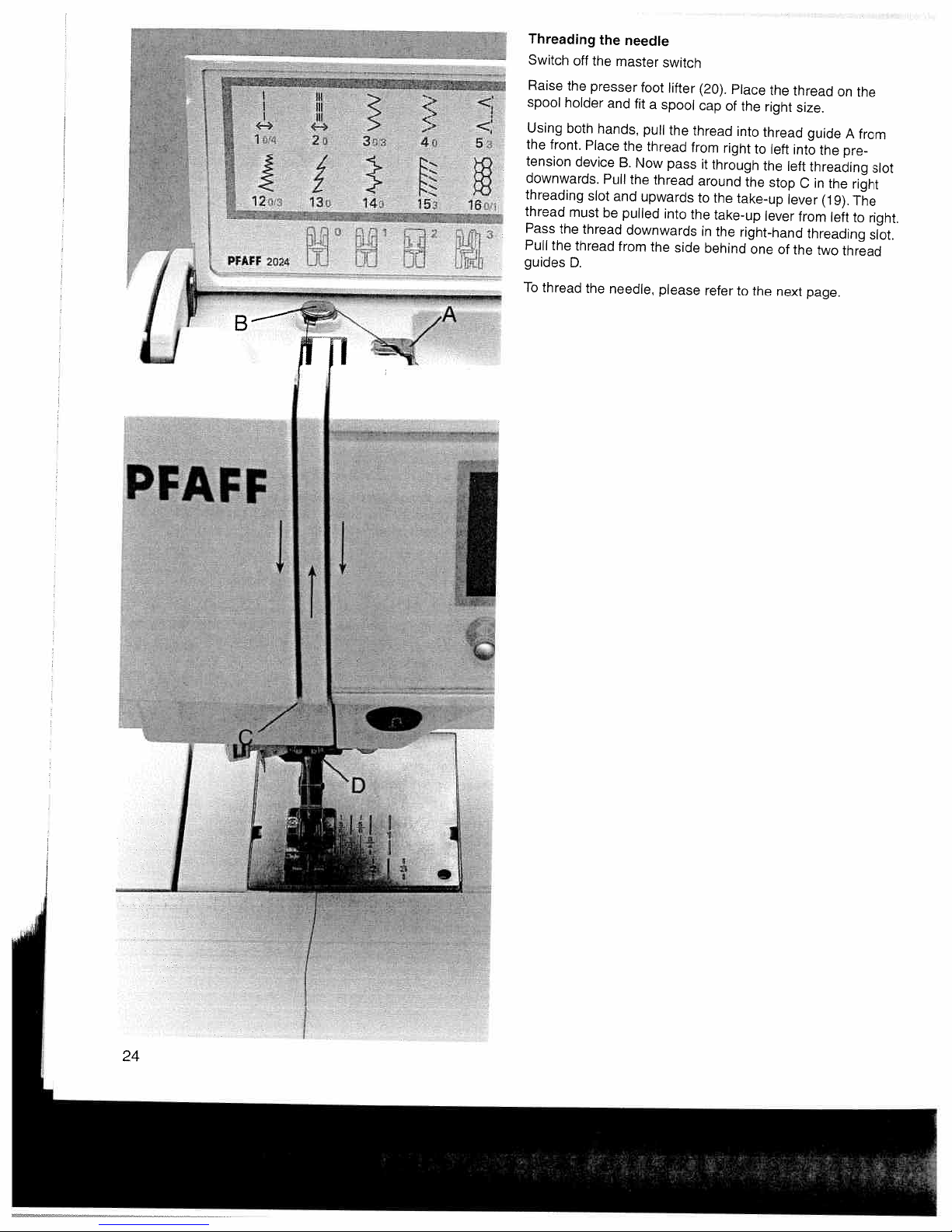

Threading

tr’-

0

—-—

r

Switch

Raise

spool

Using

the

front.

tension

downwards.

threading

thread

Pass

Pull

the

guides

To

thread

off

the

holder

both

device

must

the

thread

D.

the

the

presser

hands,

Place

Pull

slot

be

thread

the

needle

master

foot

and

fit

the

8.

Now

the

and

upwards

pulled

downwards

from

needle,

switch

a

spool

pull

thread

thread

the

please

lifter

the

pass

into

side

(20).

cap

thread

from

it

around

to

the

in

behind

refer

Place

of

the

into

right

through

the

take-up

take-up

the

right-hand

to

the

to

one

the

the

right

thread

left

the

stop

lever

of

next

thread

size.

guide

into

left

threading

C

lever

from

threading

the

page.

in

two

the

the

(19).

left

on

A

pre

right

The

to

thread

the

from

slot

right.

slot.

PEAFF

4,

.

r

II

24

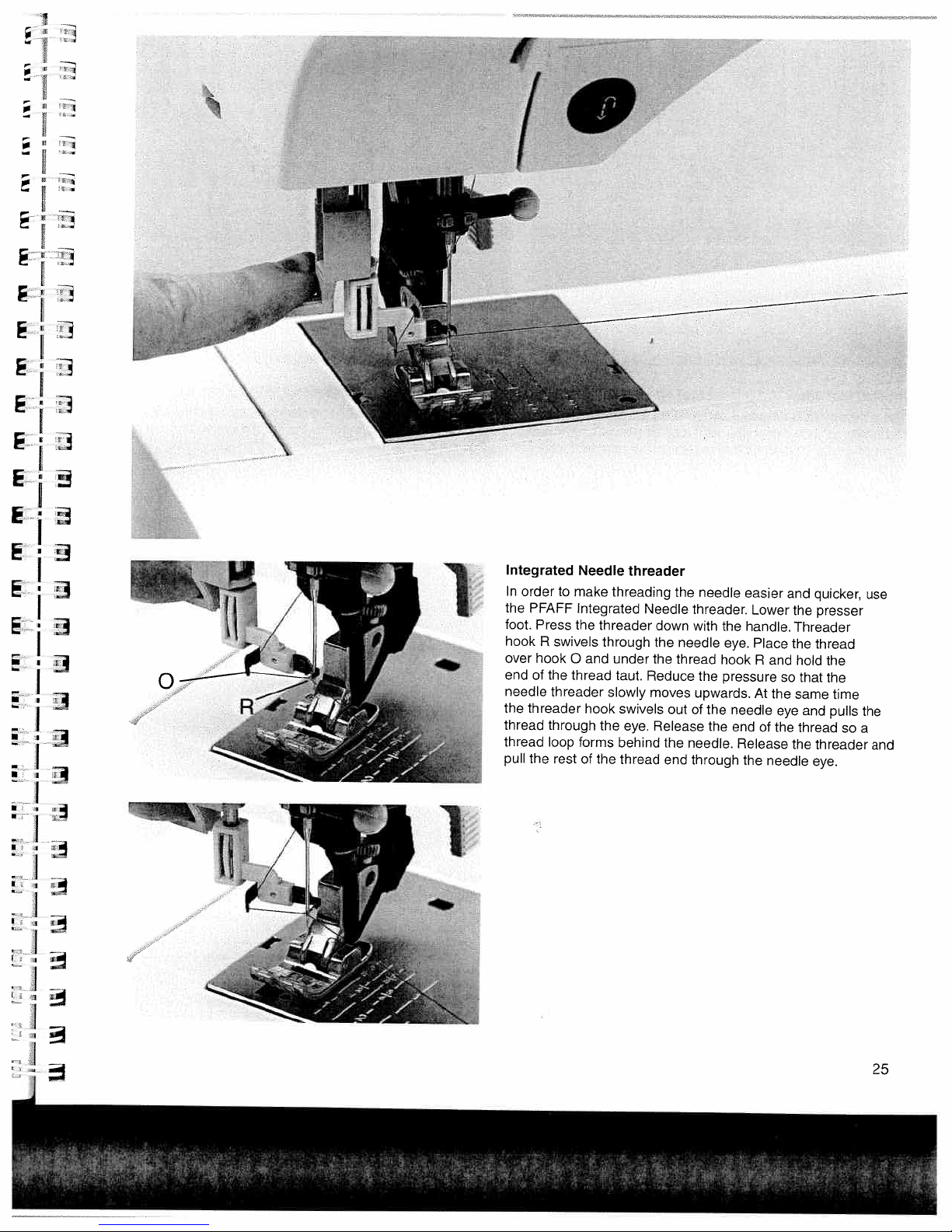

Page 25

I

Integrated

In

order

PFAFF

the

foot.

Press

hook

R

over

hook

endofthe

needle

threader

the

thread

through

thread

loop

pull

the

Needle

make

to

Integrated

the

swivels

and

0

thread

threader

hook

forms

restofthe

threader

threading

threader

through

under

taut.

slowly

swivels

eye.

the

behind

thread

Needle

down

the

the

Reduce

moves

out

Release

the

end

the

threader.

with

needle

thread

upwards.

of

needle.

through

needle

the

hook

the

pressure

the

the

eye.

needle

end

Release

easier

Lower

handle.

Place

R

At

of

the

needle

and

so

the

eye

the

and

quicker,

the

presser

Threader

the

thread

hold

that

same

and

thread

threader

the

eye.

the

the

time

pulls

so

use

the

a

and

25

Page 26

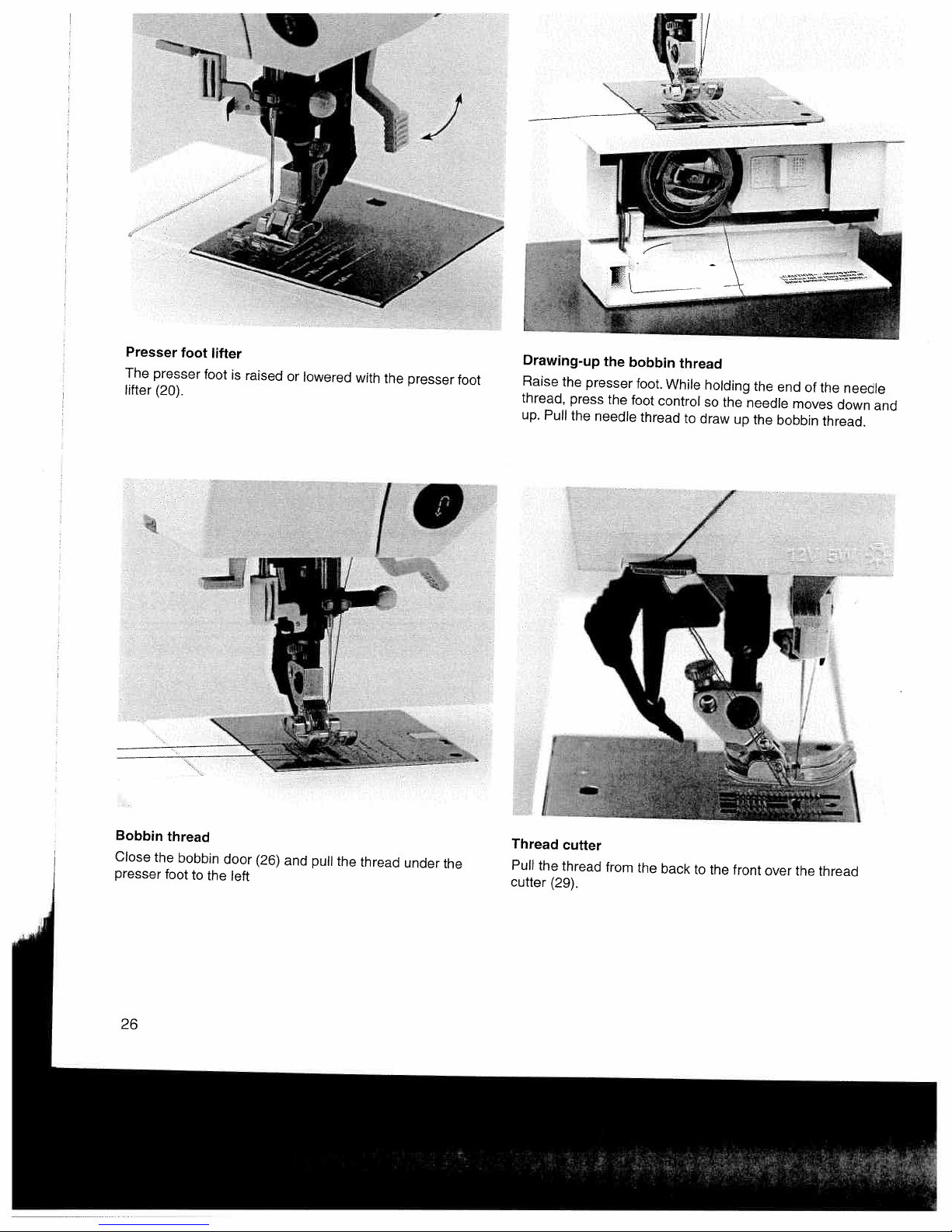

)

Presser

The

presser

lifter

(20).

foot

lifter

foot

is

raised

or

lowered

with

the

presser

foot

Drawing-up

Raise

the

thread,

up.

Pull

press

the

the

presser

the

needle

bobbin

foot.

foot

thread

thread

While

control

to

holding

so

the

draw

up

the

needle

the

end

moves

bobbin

of

the

needle

down

thread.

and

Bobbin

Close

presser

26

the

foot

thread

bobbin

door

(26)

and

to

the

left

pull

the

thread

under

the

Thread

Pull

cutter

the

cutter

thread

(29).

from

the

back

to

the

front

over

the

thread

Page 27

A

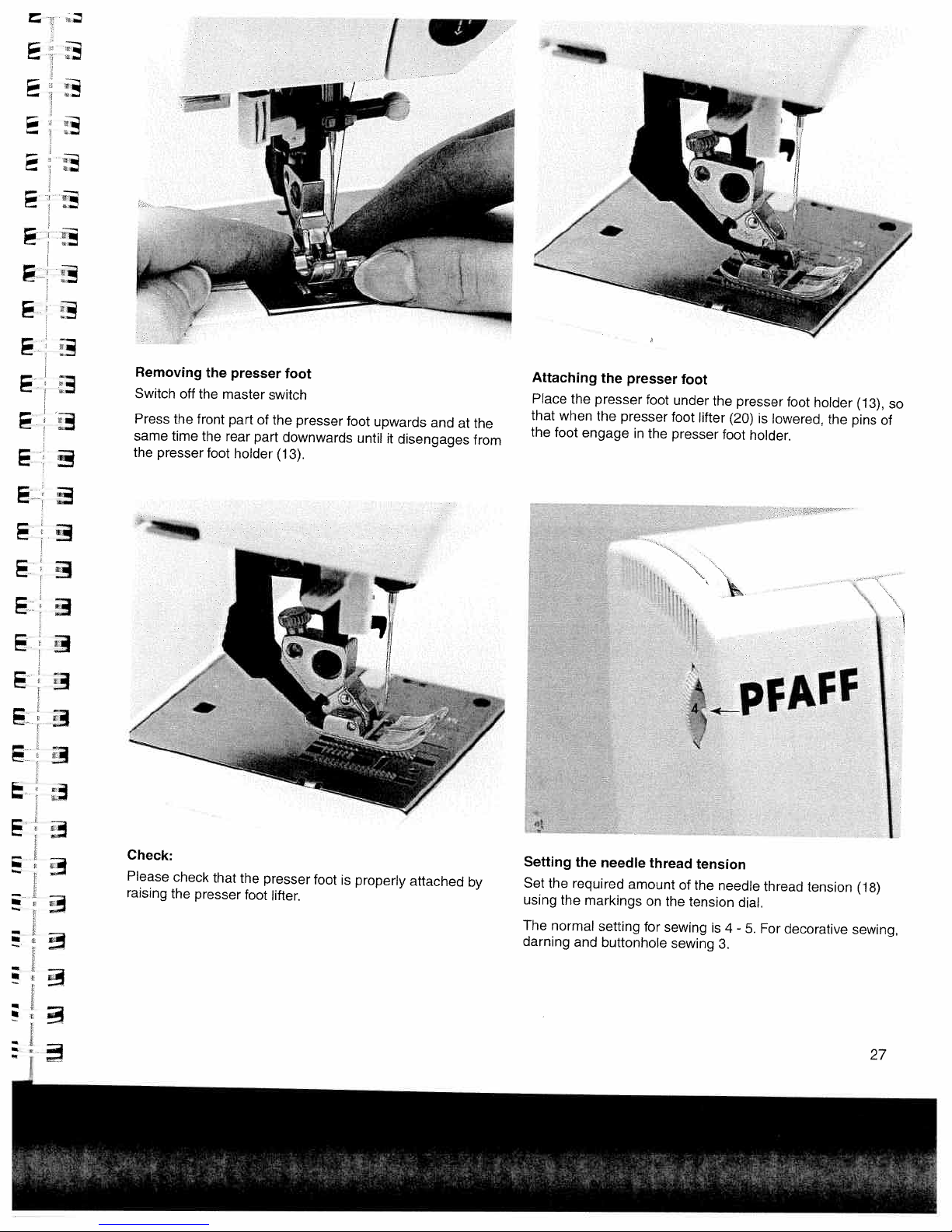

Removing

Switch

Press

the

same

time

presser

the

oft

the

the

front

the

foot

presser

master

part

rear

holder

I

of

part

switch

the

(13).

foot

presser

downwards

toot

upwards

until

it

disengages

and

at

the

from

Attaching

Place

the

that

when

the

foot

the

presser

the

engage

presser

foot

presser

in

the

foot

under

the

presser

foot

lifter

(20)

is

presser

foot

7

pFAFF

lowered,

holder.

foot

holder

the

(13),

pins

so

of

Check:

Please

check

that

the

raising

the

presser

presser

foot

foot

lifter.

is

properly

attached

by

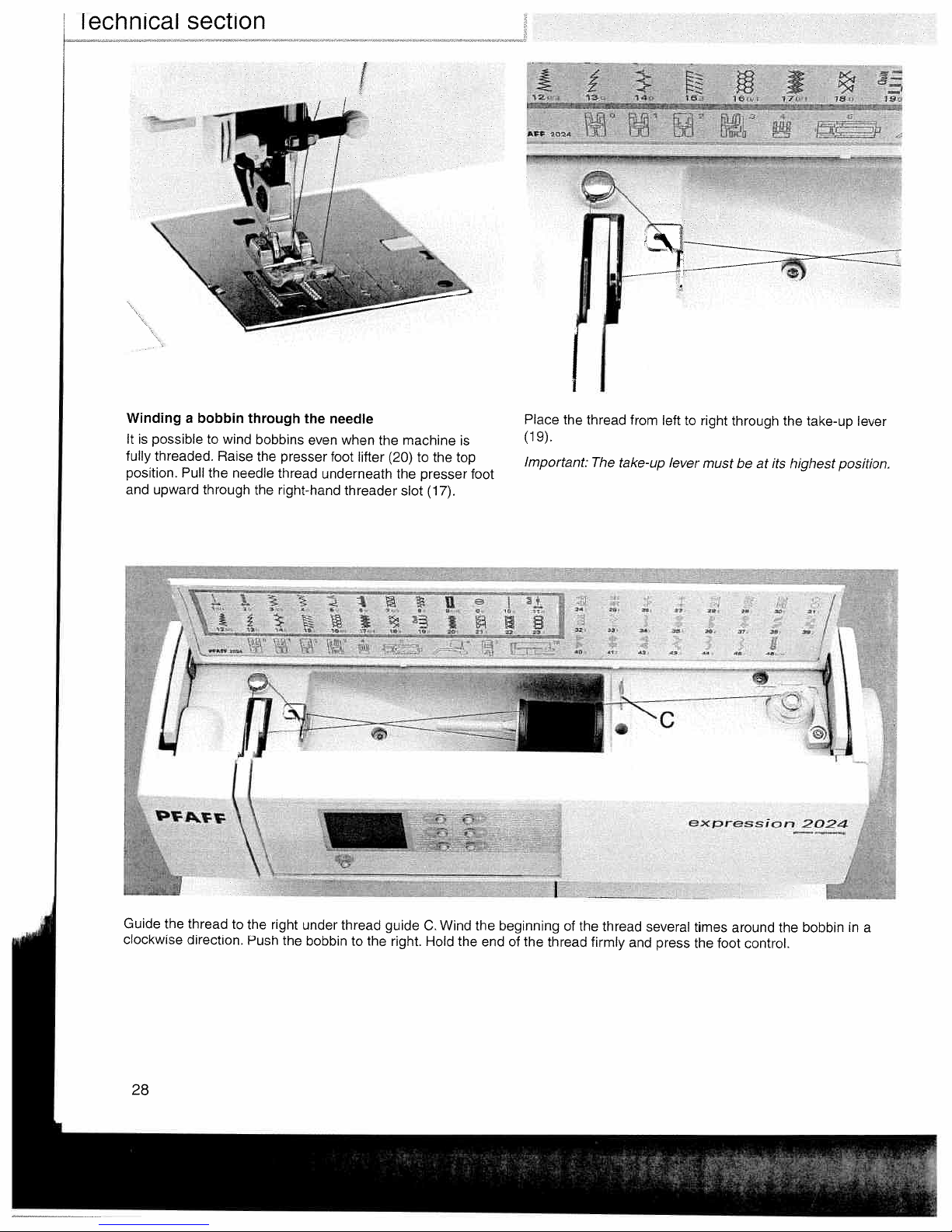

Setting

Set

the

using

The

normal

darning

the

required

the

and

needle

markings

setting

buttonhole

thread

amount

on

for

of

the

tension

sewing

sewing

tension

the

needle

is

3.

thread

tension

dial.

4

-

5.

decorative

For

(18)

sewing,

27

Page 28

lechnical

section

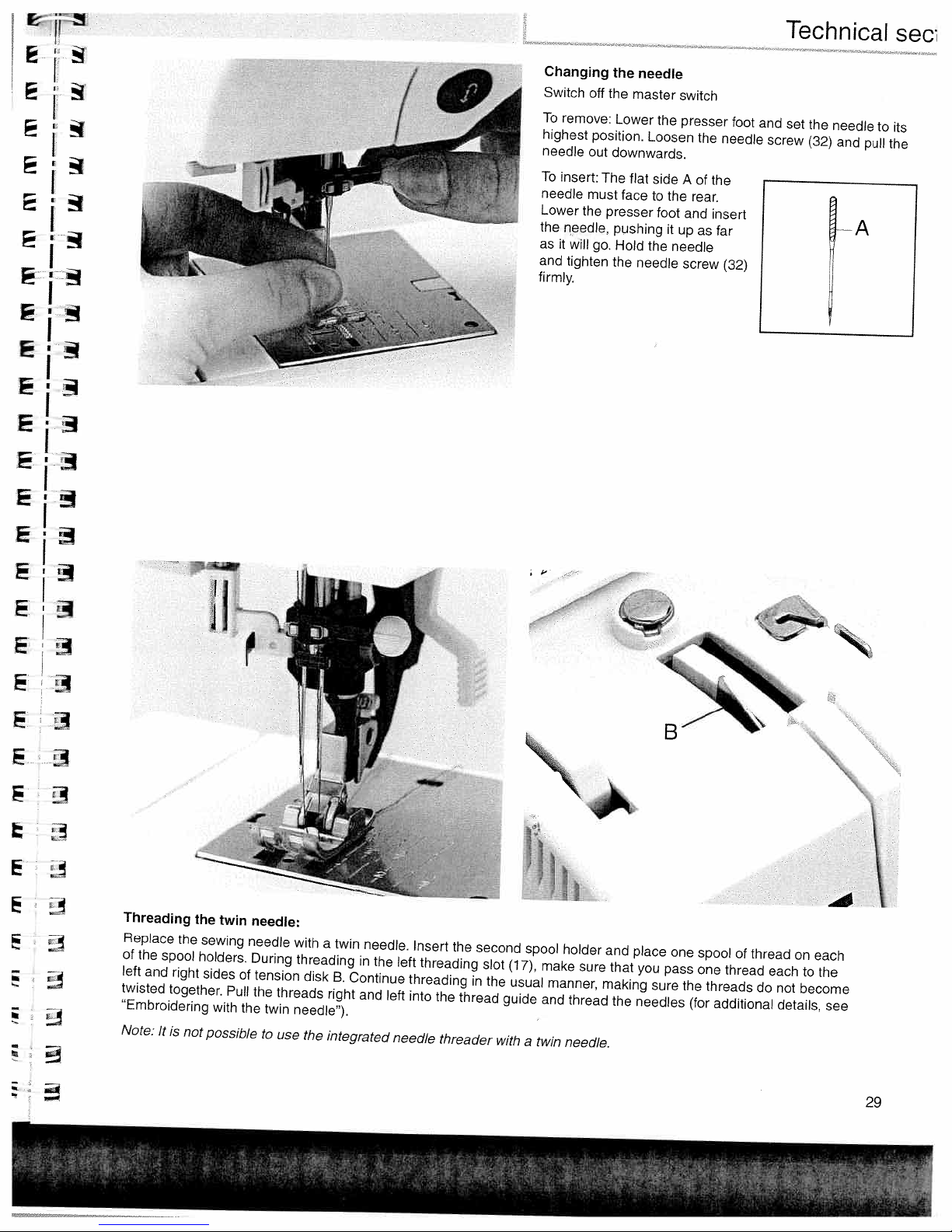

Winding

It

is

possibletowind

threaded.

fully

position.

and

Pull

upward

a

bobbin

Raise

the

needle

through

through

bobbins

the

thread

the

right-hand

the

presser

needle

even

when

foot

underneath

threader

I

lifter

the

(20)

machine

to

the

presser

slot

the top

(17).

is

foot

12o

AFF

2024

Place

the

(19).

Important:

13

r’

)L

bu

thread

The

o

“

ULd

t

take-up

14o

from

I

I

i

left

right

must

through

at

be

the

its

take-up

highest

lever

position.

to

lever

Guide

the

clockwise

‘

thread

direction.

)iJ

32

33

3432333,3939

H

“

e)(pressiG,,

7

/

2024

I

to

the

right

under

thread

Push

the

bobbin

guide

the

right.

to

C.

Hold

Wind

the end

the

beginning

the

of

of

thread

the

thread

firmly

and

several

press

times

the

foot

around

control.

the

bobbin

in

a

28

Page 29

ir

Technical

sec

3

j

Changing

Switch

To

remove:

highest

needle

To

insert:

needle

Lower

the

needle,

as

it

and

firmly.

off

position.

out

must

the

will

go.

tighten

the

needle

the

master

Lower

downwards.

The

flat

face

presser

pushing

Hold

the

needle

the

Loosen

side

to

the

foot

it

the

needle

switch

presser

the

A

of

rear.

and

up

as

screw

needle

the

insert

far

(32)

foot

and

screw

set

the

(32)

needle

and

[A

pull

to

its

the

r

Threading

Replace

of

left

twisted

“Embroidering

Note:

the

and

It

the

spool

right

together.

is

not

Ii

the

twin

sewing

holders.

sides

with

possible

Pull

needle:

needle

During

of

tension

the

the

threads

twin

to

with

threading

needle”).

use

a

disk

the

twin

needle.

in

B.

Continue

right

and

integrated

the

left

left

needle

Insert

threading

threading

into

the

threader

the

thread

second

slot

in

the

(17).

guide

with

spool

usual

a

make

manner,

and

twin

holder

sure

thread

needle.

and

that

making

the

place

you

sure

needles

B

one

pass

the

(for

spool

one

thread

threads

additional

of

thread

each

do

on

not

become

details,

to

each

the

see

29

Page 30

iecnnicai

secuon

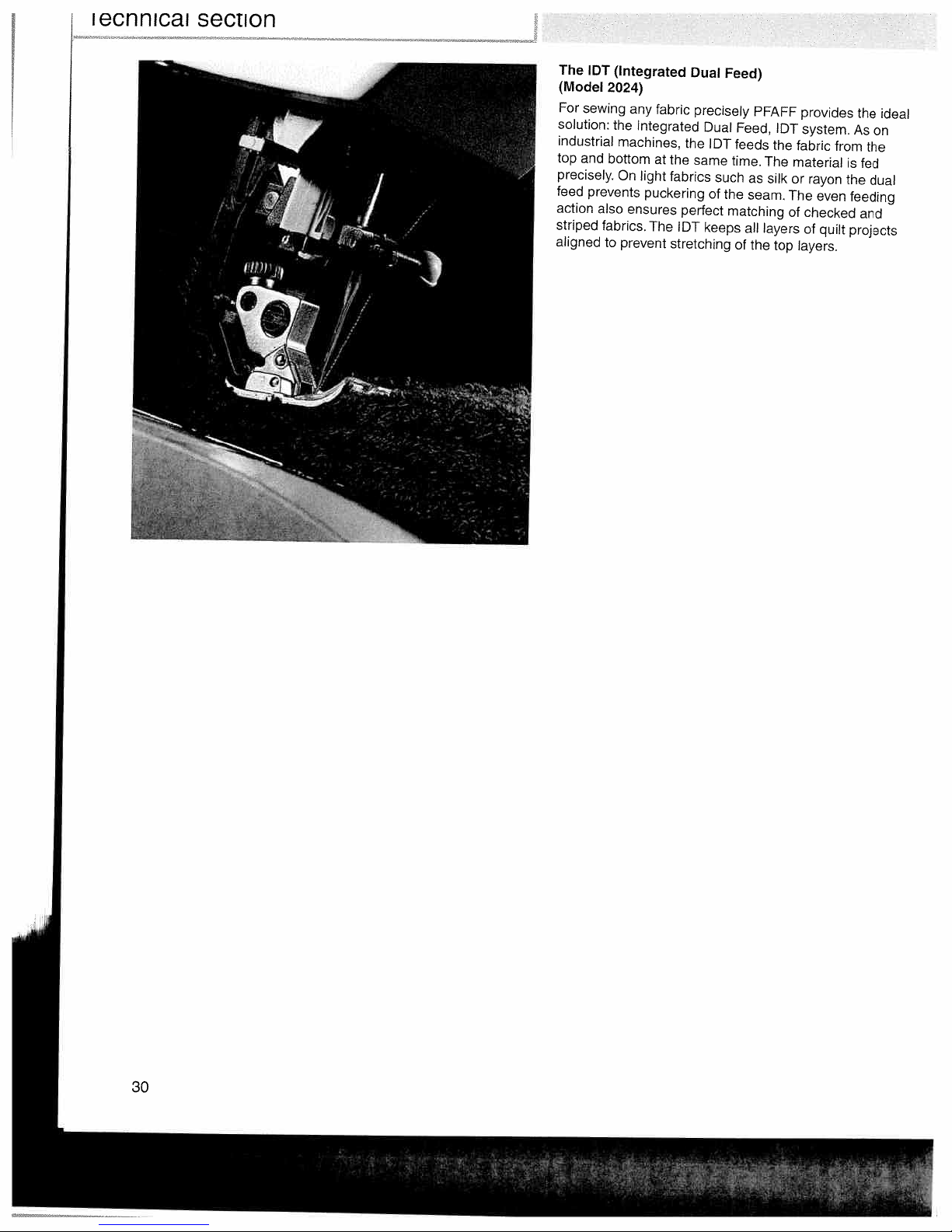

The

IDT

(Model

For

sewing

solution:

industrial

top

and

precisely.

feed

prevents

action

striped

aligned

(Integrated

2024)

any

the

machines,

bottom

On

also

ensures

fabrics.

to

prevent

fabric

Integrated

at

the

light

fabrics

puckering

perfect

The

IDT

stretching

Dual

precisely

Dual

the

IDT

same

such

of

keeps

Feed)

PFAFF

Feed,

feeds

time.

as

the

seam.

matching

all

of

the

IDT

the

The

silk

layers

top

provides

system.

fabric

material

or

rayon

The

even

of

checked

of

layers.

from

quilt

the

As

the

is

fed

the

dual

feeding

and

projects

ideal

on

30

Page 31

1’

Technical

sec

E

Engaging

Important:

feet

with

Raise

the

engages.

the

For

the

presser

IDT

all

center

(model

work

back

foot.

with

cut-out.

Press

2024)

the

the

Dual

IDT

Feed

(14)

IDT,

down

use

until

presser

it

Disengaging

Hold

the

Press

the

release

Stripes

the

the

and

material

Dual

IDT

plaids

IDT

to

the

Feed

(14)

slowly

be

lOT

with

down,

match

sewn.

(model

two

then

upward.

perfectly

2024)

fingers

pull

it

due

at

away

to

the

ribbed

from

the

even

you

ankle.

and

feed

of

—

31

Page 32

Lowering

For

certain

darning

dog

has

(26)

and

lowered.

Raise

dog.

the

the

and

to

press

To

presser

feed

sewing

when

be

lowered.

switch

slide

work

the

on

foot

dog

machine

To

B

fully

the

before

such

do

feed

as

this,

to

the

dog

lowering

free-motion

must

be

open

right.

press

or

cleaned,

the

Now

slide

raising

quilting

bobbin

the

feed

B

to

the

the

door

the

feed

or

feed

dog

is

left.

32

Page 33

Sewi1Ig

functions

A

II

•‘

4

Stitch

Altering

Altering

width/needle

Altering

width/stitch

Altering

selection

pattern

the

the

the

Lngth/stitch

rse

sewing

‘mirror

stitch

position

pattern

length

pattern

density

‘the

sizes

button

button

stitches

35,

34

34

35

36

36

37

37

38

38

39

40

(7

A

I

Page 34

C

C

Stitch

There

1.

With

forward

>

<in

If

2014),

No.

2.

With

of

3.

With

number.

then

Expression

selection

are

three

the

in

ascending

descending

you

are

and

0.

the

the

most

the

press

selection

in

the

in

the

continue

direct

commonly

direct

To

select

button

window.

ways

stitches.

order

order

last

selection

selection

of

selecting

button:

stitch,

scroll

to

used

program

3.

The

for

No.

you

buttons

stitches

buttons

No.

stitch

your

scrolling

46

(No.

will

for

to

choose

23,

press

number

desired

backward

30

return

instant

(0

-

appears

stitch:

model

to

selection

9).

the

button

and

stitch

stitch

2

in

the

4k

<

<III>

To

change:

Stitch

Pattern

Needle

Stitch

Pattern

Stitch

Pattern

Balance

width

width

position

length

length

density

density

for

straight

stitches

Altering

Adjust

position

buttons

in

the

stitches

the

length.

of

stitches

to

the

window.

right

A

B

C

width,

by

of

Use

balance,

touching

the

window.

I+

buttons:

density

the

appropriate

Each

or

change

needle

-1+

is

visible

34

Page 35

Sewing

functia

b

<?E

1

.S.

Altering

The

zigzag

Altering

,.

—‘

Straight

be

button

selected

sewn

stitch

A

the

the

stitch

in

any

move

to

stitch

stitch

No.

needle

No.

of

3.

1,

13

the

width

can

be

position

stitch

different

needle

sewn

No.

2

needle

to

left

in

and

various

stitch

positions.

or

right

widths,

No.

center.

of

1

1

Press

e.g.

can

1÷

jwI—

*

,.

—

Altering

e.g.

Stitch

For

decorative

shown

in

standard

a

A.

the

pattern

25

in

the

window.

width

stitches,

and

width

the

When

can

overall

entered,

be

altered

width

stitch

of

using

the

25

pattern

comes

4+

is

up

button

35

Page 36

Altering

The

stitch

button

B.

the

length

stitch

of

length

a

stitch

can

be

altered

using

+/-

Altering

The

using

change.

Altering

The

stitch

stitches,

remain

more

the

density,

pattern

-1+

the

density

etc.)

constant

densely

the

length

button

stitch

can

or

when

pattern

B.

of

be

but

less

available.

length

of

decorative

The

density

various

changed.

the

pattern

densely.

density

stitches

of

The

will

Use

stitches

the

stitch

(buttonholes,

pattern

be

embroidered

-1+

button

can

will

length

C

be

to

altered

not

satin

will

adjust

36

Page 37

PFAFF

Instruction

manual

PFAFF

V

1°

NN’

PFAFF

N

-

-—

-

--

—

exps’tOfl

2O24

N

N

Page 38

Balance

2fl

Decorative

heavy

adjusts

best

way

After

having

symbol

window.

of

the

can

be

The

standard

With

-1+

machine

In

the

minus

thus

the

In

plus

the

stretched

fabric

the

for

with

altered

button

from

overall

range

out.

stitches

is

fed

reverse

different

selected

a0after

This

on

this

balance

C

you

-9to(÷)9.

range

length

the

can

vary

differently

feed

of

fabrics.

stitch,

a

it

in

symbol

stitch.

setting

can

change

stitches

the

will

be

stitches

on

different

than

the

stitch

you

the

bottom

indicates

is

0.

are

sewn

sewn

are

fine

so

will

that

the

sewn

shorter.

fabric

silk.

The

it

is

sewn

see

the

right-hand

the

reverse

shorter,

longer

types

balance

in

balance

corner

balance

feed

and

or

—

the

of

the

Ei’3

11

.-

Reverse

This

button

•

when

•

manual

•

programming

sewing

has

pressed.

finish

the

will

of

the

following

reverse

buttonhole

a

buttonhole

functions:

sew

(see

page

59-61)

37

Page 39

OtVVIl

I,LILJI

ILII

ly

10

I

1,

8’Q

“Pattern

This

that

has

indicating

“Lock”

“Pattern

You

unintentional

another

Switching

Press

in

is

selection

pattern

be

Note:

symbol

can

been

button

can

pattern

the

window.

the

released.

length

altered.

You

button

mirror”

be

pressed,apoint

the

mirror”

safeguard

dial

can

(30).

will

appearinthe

mirrored.

pattern

selection

sequence

on

the

button

The

direct

The

are

width

/

still

button

button:

your

“lock”

until

symbol

now

mirror

(30)

When

be

will

(30)

sewing

another

of

by

button:

the

selection

locked.

pattern

and

a

$,

window

the

“pattern

will

appear

mirrored.

machine

sewing

means

locking

disappears

buttons

The

density

pattern

of

symbol

stitch

you

if

any

for

mirror”

below

against

program

the

when

(6)

length

I

quickly

stitch

button

the

“lock”

appears

the

and

/

balance

symbol

the

or

button.

button

the

width,

can

the

tap

38

Switching

the

Press

appears.

symbol

the

off

button

locking

The

disappears

“lock”

(30)

function

after

button:

until

the

the

is

button

unlocking

switched

now

released.

is

symbol

off.

This

Page 40

i—I

*

Twin

needle

Depending

stitch,

a

window.

cannot

be

width.

set

on

the

twin

the

This

symbol

usedtosew

needle

needle

position

warning

indicates

the

stitch

oevviiy

or

the

will

appear

that

twin

a

at

the

IUIltIC

width

in

needle

currently

of

the

EH

E

Reduce

disappears.

needle

of

the

2.0

pattern

The

mm

stitch

or

width

may

less.

until

now

the

be

warning

sewn

symbol

with

a

twin

E

39

Page 41

zw

‘

skJ

Formation

The

Some

right

adjusted.

retained.

The

always

of

any

Note:

are

formed

Do

not

window

stitch

patterns

side

patterns

retain

changes

Do

not

use

lights

of

the

formation

of

the

The

left-hand

that

the

in

use

from

one

a

twin

up

(see

stitches

are

stitch

are

right

width.

twin

a

needle

varies.

formed

changes

side

formed

side

needle

side!

if

page

of

this

39).

from

of

from

the

symbol

when

the

to

the

stitch

the

stitch,

sew

left,

so

the

is

right

regardless

patterns

in

the

only

width

always

will

the

is

that

40

,s

Patterns

change

width

that

equally

is

adjusted.

are

formed

from

the

from

right

the

and

center

the

left

will

when

the

Page 42

Utility

stitches

Sewing

Zippers

Non-elastic/elastic

Overlock

Sewing

Darning/inserting

Gathering

Bridging

Hemming

Shell

recommendations

stitches

on

buttons

stitches

edging

stitches

patches

table

43-49

47-48,

42

43

49

50

51

52

53

54

55

b

.

Page 43

Explanation

following

In

the

recommend

tables

These

selected

the

Integrated

tension

thread

for

stitches

Dual

of

the

table

different

give

Feed

setting

you

sewing

you

—

recommendations

will

find

the

purposes.

sewing

further

information

whether

(IDT)

and

you

engagedordisengaged,

recommended

settings

should

we

required

sew

presser

table

with

for

the

foot,.

sewing

needle

2024

Stitch

-%

_

2

•‘‘

‘,

*‘

1F3J

2024

2014

Stitch

Expression 2024

Expression 2014

Stitch

number

Stitch

widthinmm

Stitch length

Top

feed switched

in

switched

Needle

Number

Special

thread tension

of

presser

accessories

mm

foot

on•

off

0

42

Page 44

I

2024/

/

72014

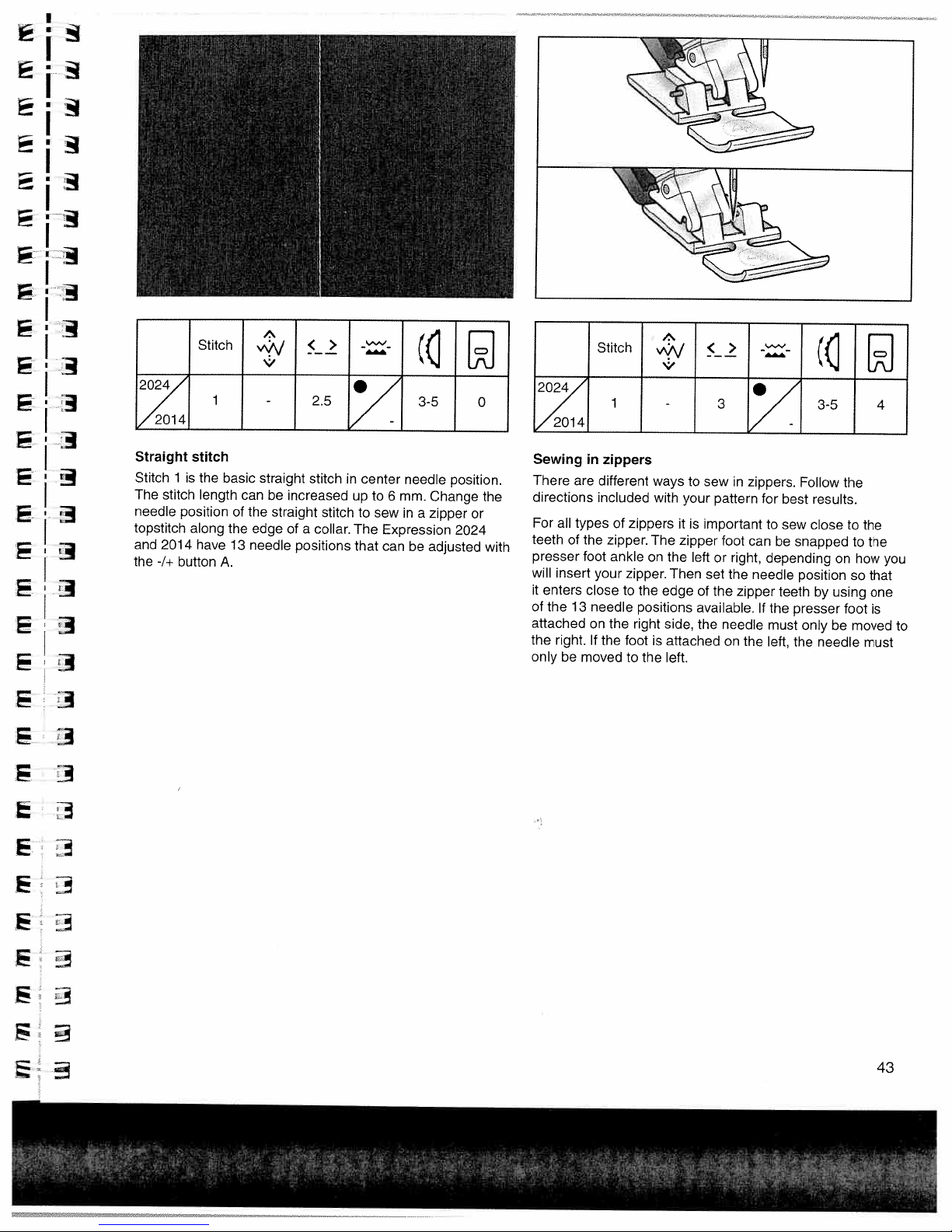

Straight

Stitch

The

stitch

needle

topstitch

and

2014

the

-1+

Stitch

stitch

1

the

is

length

position

along

have

button

-,%

,

1

-

basic

straight

canbeincreased

of

straight

the

the

edge

13

needle

A.

—

<

2.5

stitch

of

a

collar.

positions

—

>

stitch

in

up

The

that

center

to

needle

mm.

to

6

sew

in

Expression

can

be

3-5

Change

zipper

a

adjusted

0

position.

the

or

2024

with

2024

Sewing

There

directions

For

all

of

teeth

presser

insert

will

it

enters

of

the

attached

right.

the

only

be

in

are

types

the

foot

close

13

on

If

moved

Stitch

1

zippers

different

included

of

zipper.

ankle

your

to

needle

the

the

zippers

The

on

zipper.

the

positions

right

foot

to

the

-

ways

with

the

Then

edge

side,

is

attached

left.

to

your

it

is

important

zipper

left

of

available,

the

3

sew

pattern

foot

or

set

the

needle

2

in

right,

the

on

.

/-

zippers.

can

needle

zipper

If

the

--

/

Follow

for

best

to

sew

be

snapped

depending

position

teeth

the

presser

must

onlybemoved

left,

the

3-5

results.

close

on

using

by

needle

the

to

so

foot

the

to

how

4

the

you

that

one

is

to

must

43

Page 45

uiiiiy

suicries

2024/

/

/2014

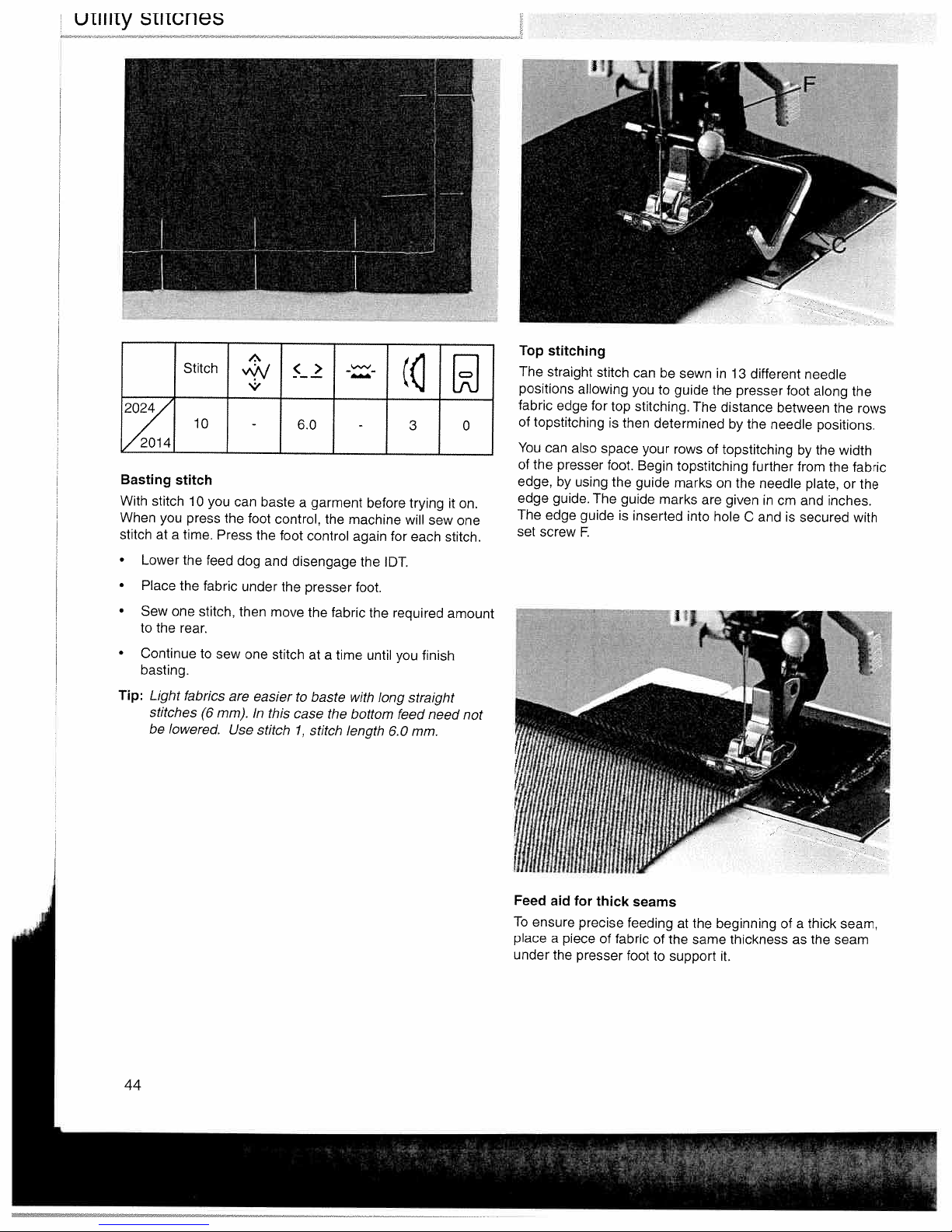

Basting

With

When

stitch

•

Lower

•

Place

•

Sew

to

•

Continue

basting.

Tip:

stitch

stitch

you

at

a

one

the

Light

stitches

lowered.

be

Stitch

10

10

press

time.

the

the

stitch,

rear.

to

fabrics

you

Press

feed

fabric

sew

mm).

(6

the

can

dog

are

Use

-

foot

the

under

then

one

easier

In

stitch

baste

control,

foot

and

move

stitch

this

<_2

6.0

garment

a

control

disengage

presser

the

the

at

baste

to

case

1,

stitch

the

fabric

a

time

the

--

-

before

machine

again

the

foot.

the

until

with

bottom

length

for

IDT.

required

you

long

feed

6.0

3

trying

will

sew

each

finish

straight

need

mm.

0

it

on.

one

stitch.

amount

not

Top

stitching

The

straight

positions

fabric

of

topstitching

You

can

of

the

edge,

edge

guide.

The

edge

set

screw

allowing

edge

also

presser

using

by

guide

F.

stitch

for

space

The

top

is

foot.

the

is

can

you

stitching.

then

your

Begin

guide

guide

inserted

be

sewn

to

guide

The

determined

rows

topstitching

marks

marks

are

into

in13different

presser

the

distance

by

the

topstitching

of

further

on

needle

the

given

in

hole

and

C

foot

between

needle

by

from

cm

is

needle

along

positions.

the

the

plate,

inches.

and

secured

the

width

or

the

rows

fabric

the

with

44

Feed

To

place

under

aid

ensure

a

the

for

precise

piece

presser

thick

of

seams

feeding

fabric

foot

of

to

the

at

the

same

support

beginning

thickness

it.

thick

of

as

seam,

a

seam

the

Page 46

Utility

stitch

2024

,/‘

/2014

Blind

The

blind

skirts,

•

Finish

•

Fold

•

Fold

approximately

of

the

beyond

side

now

•

Place

runs

•

When

a

small

the

screw

Stitch

/

hem

stitch

hem

trousers

the

and

the

finished

the

of

your

be

facing

the

along

the

amount

right

side,

A.

5

stitch

edge

press

hem

fold.

fabric

edge

needle

and

the

back

1/4

edge

The

project

up.

under

of

adjust

—f’.

‘.V

‘7

4.5

is

used

home

of

the

hem

on

inch

should

guide

swings

fabric,

2.5

to

decorating.

hem.

allowance

itself

(6

mm)

extends

wrong

the

presser

B.

into

If

edge

guide

the

make

so

the

--

invisible

inwards.

foot

fold

stitches

B

by

-

so

it

should

are

turning

,i1

3-5

hems

that

visible

on

j

the

fold

catch

on

adjusting

Stitch

3

2024/

/

/2014

Elastic

The

fabrics.

There

Create

blind

elastic

The

is

the

no

blind

hem

need

blind

6

hem

hem

is

to

hem

AJ

V

4.5

stitch

stitch

finished

finish

as

<>

1.5

is

especially

and

the

raw

described

sewn

edge

under

suitable

at

the

first.

-

same

“Blind

c&j

3-5

for

hem

E.1

3

stretchy

time.

stitch”.

E

:

;

L

_,

L

—

&

45

Page 47

2024

,/

/2014

Stitch

/

v

3

3.0

<_2

.,‘,

2.0

i1

3J

3-5

-

0

Zigzag

Raw

sure

needle

swing

stitch

edges

the

and

of

can

needle

overcasts

the

be

pierces

needle.

finished

the

the

easily

fabric

edge

Stretch

zigzag

with

on

the

of

the

fabric

left

stitch

swing

on

the

3.

of

right

Make

the

The

decorative

and

•

•

Tip:

2024

/2014

Stretch

This

needed,

the

triple

stretch

with

decorative

Fold

up

Topstitch

with

decorative

Lower

Stitch

I

/

triple

stitch

such

fabric,

triple

seam.

a

needle

2

is

used