Page 1

PFAFF

-900

Thread

Special

and

467/469

Service

List

of

Trimmer

Mechanism

High-Speed

Manual

Spare

for

Pfaff

and

Parts

461,

Seamers

463, 465,

467,

469

G.M.

PFAFF

AG•KAISERSLAUTERN

BRANCH

Page 2

A.

Operation

1.

General

Since

the

high

sewing

great

demandsonthe

tion

can

onlybeachievedbyreducing

Fittingahigh-speed

both

threads

between

This

mechanism,

be

installedinmachines

not

interfere

in conjunction with a special motor with automatic needle positioner, this thread trimmer

eliminates

and

pulling

to

manipulate

action is triggered off and the threads are cut to the proper

threads

have

if

desired,

torsto sew

in the Stop motor starting lever.

Housing

of the machine (Fig. 27).

Arranged

the

Knife cam 2 imparts an oscillating motion to shaft Avia roller lever 9. fhis motion is trans

mitted to thread catcher11via clutch fork 7, trimmerengaging shaft 36. crank 10 and connec

tion

the left pedal 26,the motorrotates the

point of its stroke and thread catcher11swings forward to trim the needle and bobbin

threads. Both threads are

and the thread catcher returns to its starting position.

The rear end of the left pedal 26 mustbe kept depressed

pleted.

A

end of the seam

the machine or impairing the trimming action.

8 of the

right

endoflower

10.1.

mechanical

as a

with

the

all

superfluous

up,

positioningorholding

the

work.Bysimply

been

trimmed,

subcl.

-900

stitch-by-stitch

thread

concentrically

Each

trimming

interlocking

while

and

speeds

manual

seamer

withasubclass

sewing

hook

special

equipped

attachmentofspecial

movements,

Maintenance

attainedbymodern

dexterity

feature,isarranged

and

the

handling

and

machine

with

all

kindsoffeeding

feet,

suchasreaching

the

threads.Itleaves

depressing

the

work

can be

exchanged

machines

main

the

canbesupplied

at the

beginning

trimming

on the

action calls for an oscillating

trimmed

device

mechanismisscrewed

sewing

shaft

3.

when the take-up lever has reached the top of its stroke

makes

machineisrunningatfull

and

hook,

machine

it possible to triggeroff the

high-efficiency

skillofthe

time.

-900

thread

feed

reduces

below

feed

dogs

forthe scissors or the balance

the

rear

and

withaninching

end

ofa

thread

catcher11is

motion.

pulley

until

speed,

sewing

machines

operators,

trimmer

the

which

the

handling

machine

any

increaseinproduc

automatically

time

toa

feed

and,

minimum.

hence,

mechanism.Inaddition,itdoes

and

needle

plates.

Supplied

both

endofthe

length.

the operator's

left

pedal,

Immediately

hands

the

trimming

after the

sewingberesumed,

device

which

enables

seam

and is

controlledbya

to the

undersideofthe

drivenbyknife

On depressing the rear end of

the needle has passed the lowest

until

the

trimming

trimming

without

causing

contact

bedplate

cam

action is

action at the

any damage to

make

trims

can

only

wheel

free

opera

2 at

com

2.

Operation

(For Illustrations,

ensure

To

passed

through

To trim both threads, depress the

causes

the right pedal 24 to swing down likewise, thus engaging the motor brake. In order

to relieve the left foot, it is advisable to depress both pedals with both feet simultaneously.

that

please

both

the

refer to pp. 18—20)

threads

additional

will be trimmed securely, check to

holeinthe

see

that the bobbin

bobbin

case.

rear

end of the left pedal 26. This pedal has a stop which

thread

is

1

Page 3

As

the

rear

endofthe

cam 30 which

cone

21. The

In

engagement

switch ES, which is

holder

17 and

nects

the

proper

rate required for the trimming action. Whiie the machine is still running at high

causes

amountoftension

with the control slot in knife cam 2. At the

synchronizer

motor

centrifugal switch 18 delays the trimmer engaging action until the machine

reduced to a

The machine

safe

keeps

left

pedal

26 is

and

located

the

a spring to be

thus

accumulatedinthe

underneath

siip ring 16,

machine via a worm

depressed,

compressed

this

engages

pedal

the

gearing

connection

between

the

spring

same

and, in

electromagnetic

and

conjunction

reduces

27

rotates

trimmer

cam and tension

is sufficient to bring roller 6

time, pedal 24

clutch. This clutch

the

machine

with

actuates

carbon

speedtothe

speed

level at which the trimming mechanism is not likely to be damaged.

running at this reduced

speed

until the needle has reached the lowest

engaging

release

limit

brush

con

speed,

has been

point of its stroke and the left carbon brush in holder 17 contacts the left switch-off track

on slip ring 16. This is the point at which the thread trimming action starts (Fig. 27). Cen

trifugal switch 18 actuates pin 19 which, in turn, pushes interlocking latch 5 down so that it

clears crank 20. This permits shaft 4. together with roller lever 9 and roller 6, to be moved

toward

knife

cam

2 by

the

slotofthe

At the

same

cam

(Fig. 28).

time,

cone21releases

actionofthe

released

pressure

spring,

causing

roller 6 to

engage

the needle thread tension and the right carbon brush in

holder 17 moves to the right switch-off track of synchronizer slip ring 16. while the motor

keeps driving the machine at low speed. Then knife cam 2 imparts an oscillating motion

to

roller

lever

9 which is

transmittedtoshaft4.crank

10,

connection

10.1

and

thread

catcher

11. causing the latter to trim the threads. The machine stops now with the take-up lever at

its

highest

position.

in

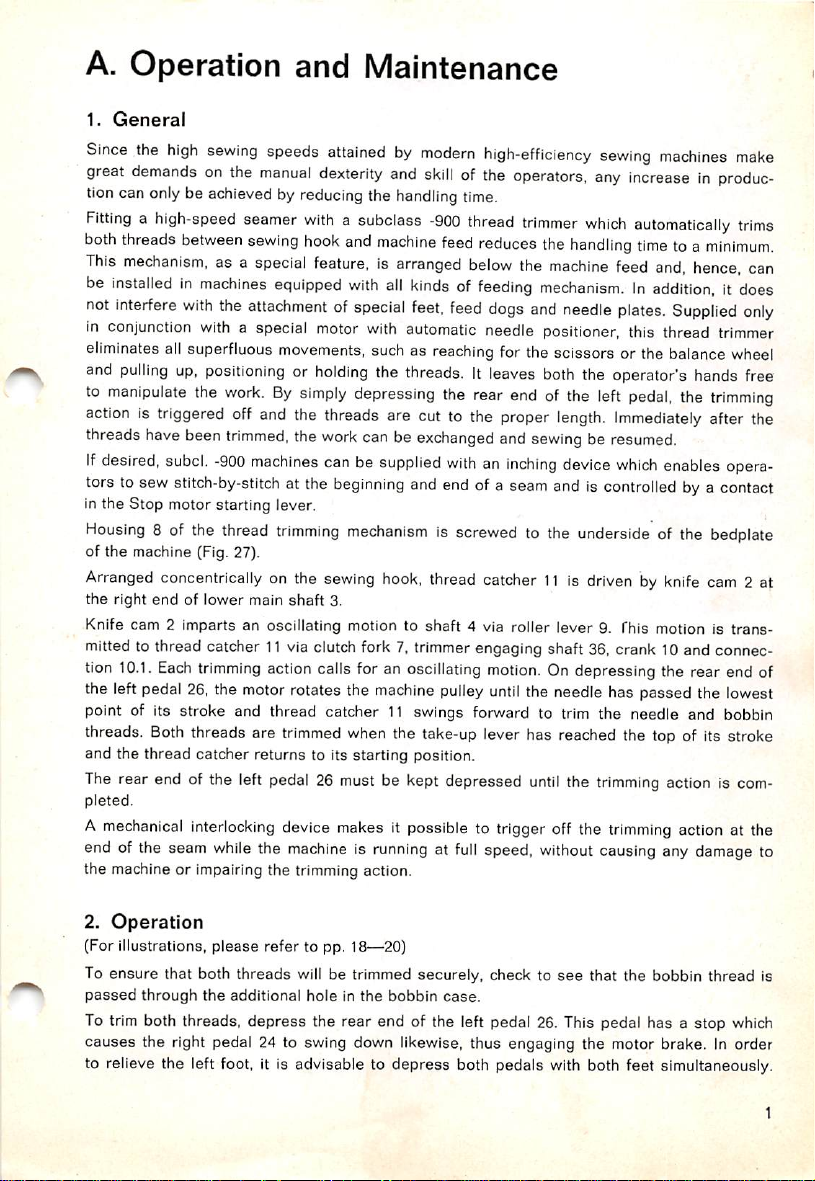

As thread catcher 11 swings forward, its tip

enters

the needle thread loop so

that

the bobbin

thread and the left leg of the needle thread loop contact its left flank, while the right leg

of

the

needle

thread

loop

contacts

its right fiank.

The thread catcher ceases to swing forward when the two threads passing to the left of its

tip have entered the

is pulled

tautbyneedle

recess

back of heel 11.1 (Fig. 1) and the thread on its right-hand

thread

retaining

edge

11.2.

W

side

Fig. 1

Page 4

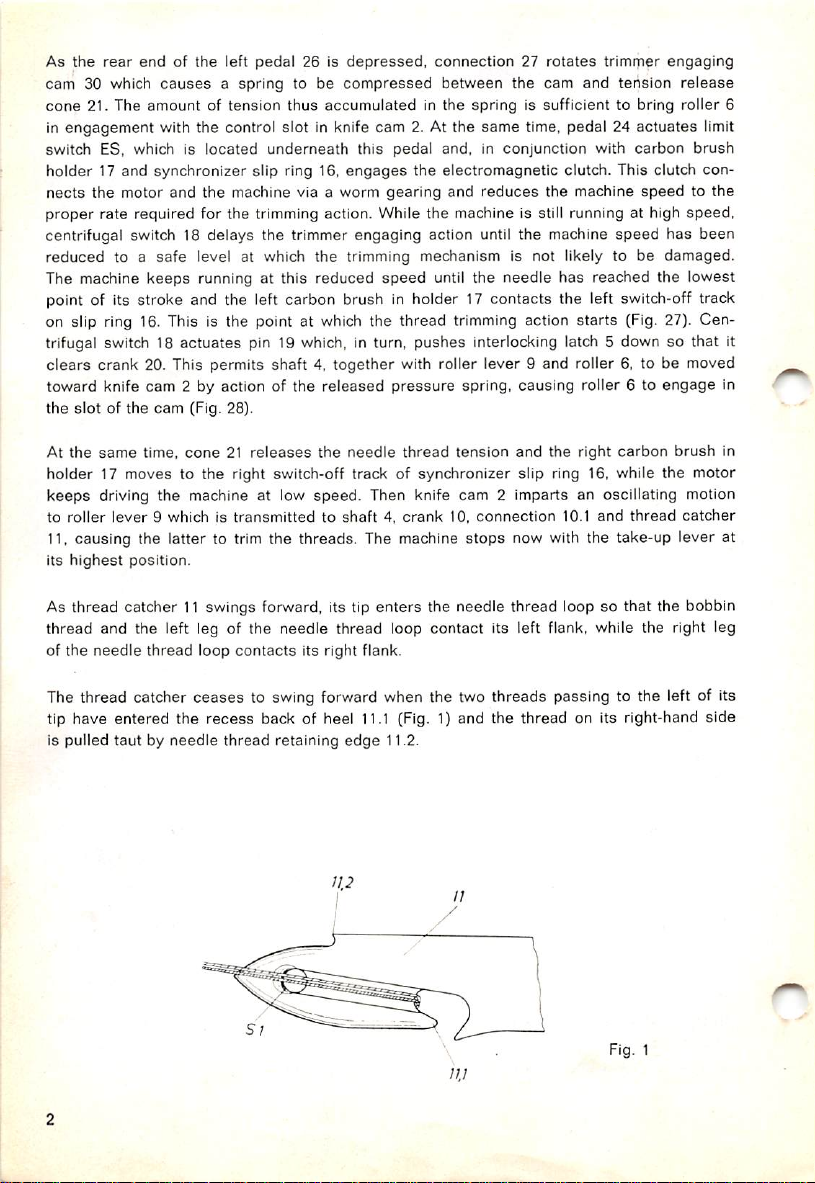

As thread catcher t1 returns to its starting position, the threads caught in the

pulled back under knife 12. Both

thread

catcher

(Fig. 1) and

the tip of the thread catcher has reached cutting

When

the

threads

and

the right switch-off track of synchronizer siip ring 16

are

severed,

can now take her foot off the left pedal. If both

are

permitted to return to their inoperative position simultaneously. It is advisable to let the

are

not

the

threads

sheared

take-up

are

protected in a groove on the

off until

lever

the

somewhat

edge

S 2 of the knife (Fig. 2).

has

reached

stops

pedals

were

depressed,

the

the machine. The

raised cutting

highest

make

recess

surface

edge

point of its

sure

are

of the

S 1 at

stroke

operator

that both

right pedai return to its starting position slightly ahead of the left because the needle will

starttodescend

In

ordertoenable

again if the right

operators

to switch from forward to

treadle

is not returned to its starting position promptly.

backward

stitching by

foot

action

on

Pfaff machines 461-900. 463-900 and 465-900, an additional feed reversing mechanism has

been mounted on feed regulating shaft (Fig. 27). When the front end of pedal 26 is depressed,

connection 27

causes

trimmer engaging cam 30 to turn forward and this motion is transmitted

to feed reversing crank 33 by means of a two-part connection.

On Pfaff machines 467-900 and 469-900, the top or differential feed can be controlled by de

pressing the front end of the left pedal. The reverse feed control of these machines must be

operated

by hand.

3.

Maintenance

A careful adjustment of the trimming mechanism

ensures

trouble-free operation.

Ail screws must be tightened securely. This applies especially to the screws on knife cam 2,

roller lever 9 and thread catcher driving crank 10 since these parts are subjected to abrupt

stress.

Special

especially between sewing hook and needle plate, are

care

should be taken that

the

dust

and lint which accumulate in this mechanism,

removed

with

a soft brush each day

the machine is in operation. By the same token, ail moving parts should be oiled daily.

When

oiling

all

moving

parts of the

trimming

mechanism each day, check to see that cen

trifugal switch 18, pin 19 and latch 5 move freely. Make particularly sure that synchronizer

slip ring 16 is

Be

suretooil

kept

the

free

from oil.

somewhat

concealed

roller6on

roller

lever

9.

Page 5

B.

Adjustment

It is

recommendedtouseagauge

catcher

No. 129 567,

which is available under No. 129 499. A

canbesupplied

for

In checking the various settings, be

1.

Adjusting

the

Interlocking

needle

plate

compound-feed

suretoproceed

Latch

14 (Fig. 30) for

gauge

feed dog, which is identified by

machines.

in the

sequence

the

adjustmentofthe

indicated below:

thread

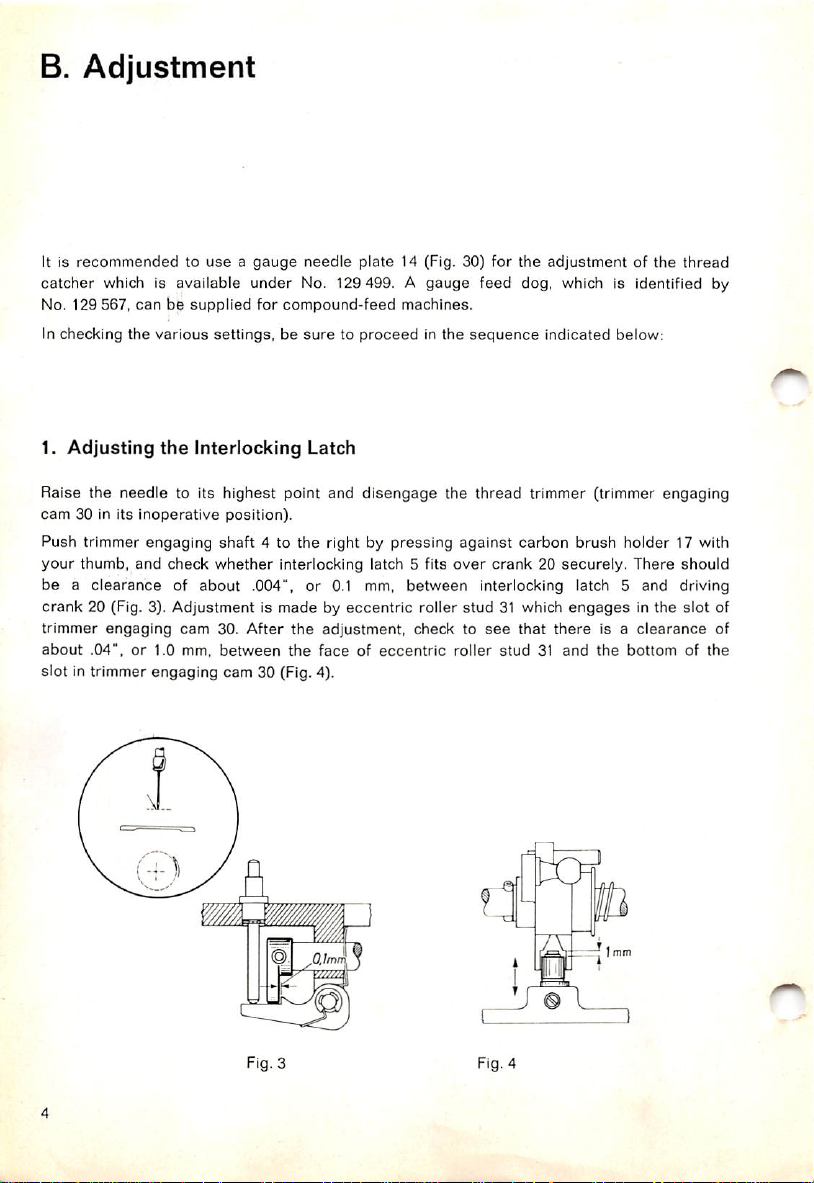

Raise the needle to its highest point and

cam

30 in

its

inoperative

Push trimmer engaging

your

thumb,

and

be a

clearanceofabout

crank

20 (Fig. 3). Adjustment is made by eccentric roller stud 31 which

trimmer

about

engaging

.04",or1.0

check

cam

mm,

position).

shaft

4 to the right by pressing

whether

interlocking latch 5 fits

.004", or 0.1 mm, between interlocking latch 5 and driving

30.

After

the

between

the

disengage

adjustment,

faceofeccentric

check to

the thread trimmer (trimmer engaging

slot in trimmer engaging cam 30 (Fig. 4).

Fig. 3 Fig. 4

against

carbon brush holder 17 with

over

crank20securely.

see

that

roller

stud31and

j©l

engages

there

There

in the slot of

is a

clearance

the

bottomofthe

should

of

Page 6

2.

Endwise

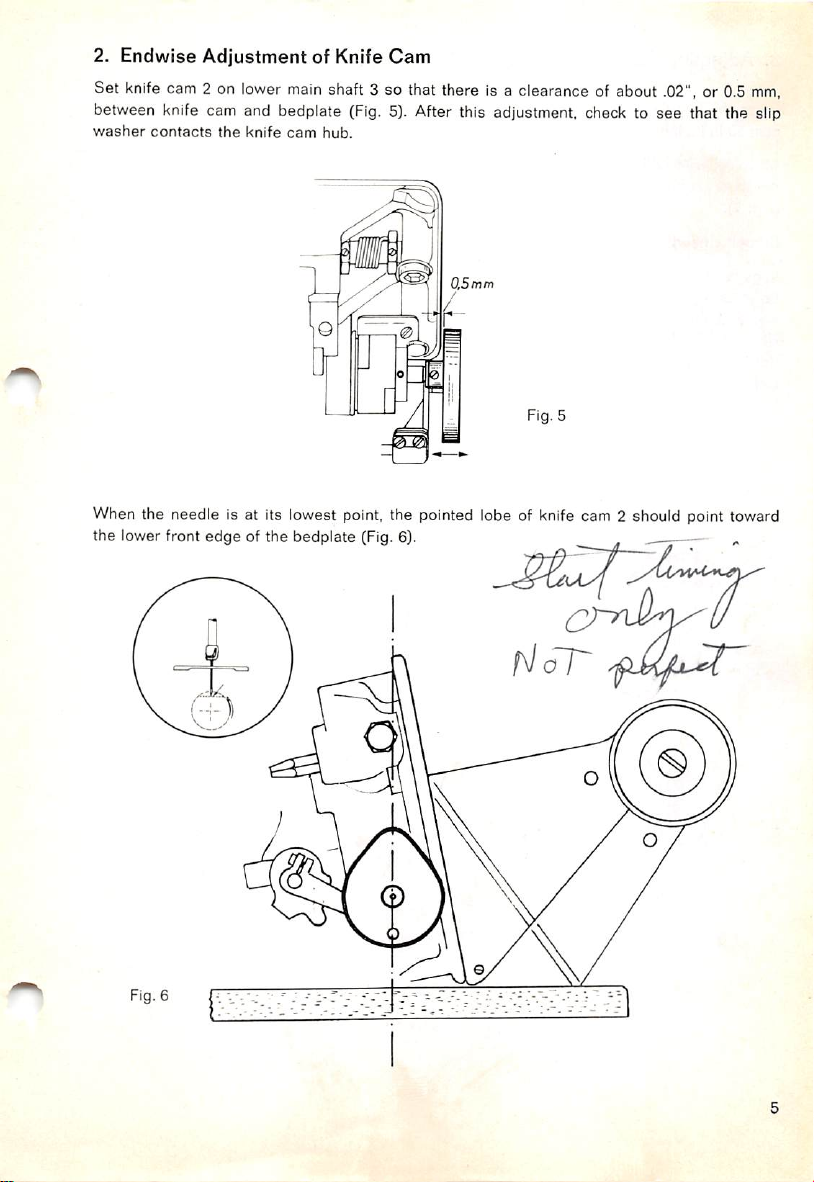

Set knife cam 2 on lower main shaft 3 so that there is a clearance of about .02", or 0.5

Adjustment

of Knife

Cam

mm,

between knife cam and bedplate (Fig. 5). After this adjustment, check to see that the slip

washer

contacts

the

knife

cam

hub.

O.Smm

Fig. 5

When the needle Is at its lowest point, the pointed lobe of knife cam 2 should point toward

the lower front

edgeofthe

bedplate (Fig. 6).

Fig. 6

a/ oT^

Page 7

3.

Adjusting

the

Roller

Lever

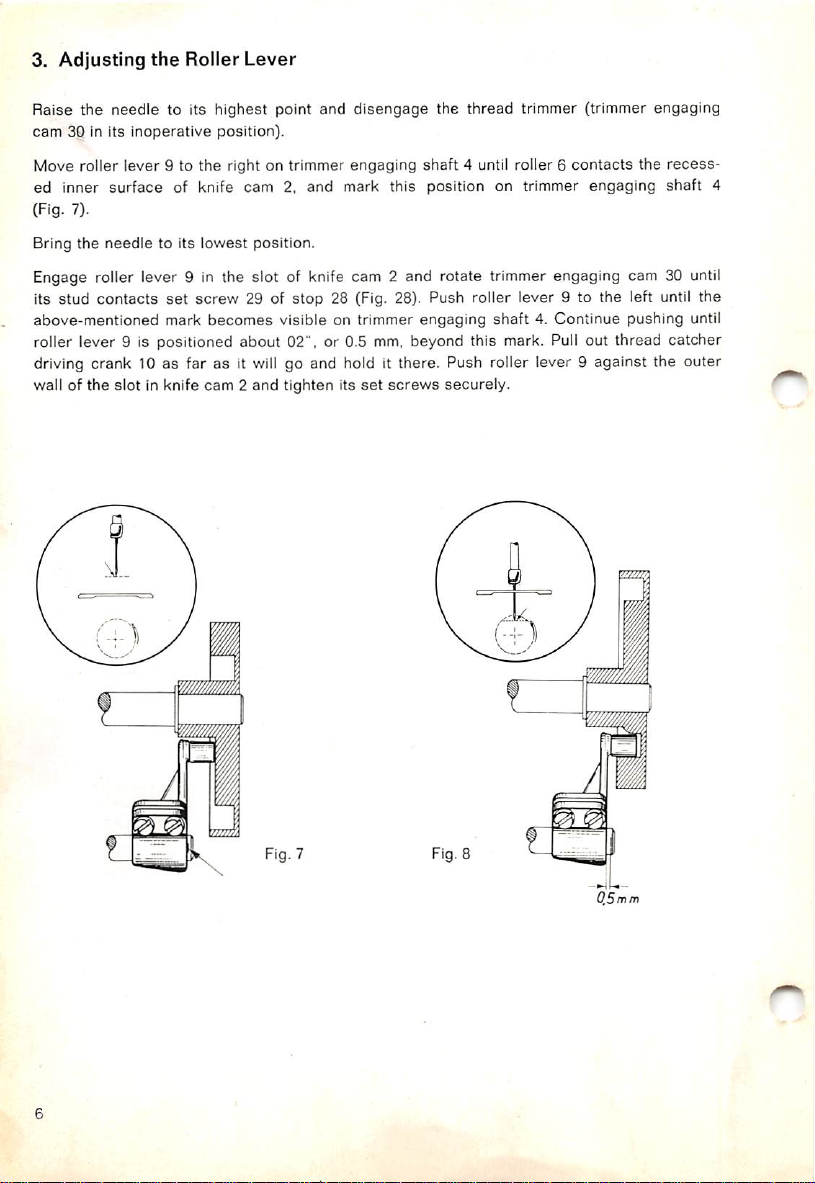

Raise the needle to its highest point and

cam

30 in its

inoperative

position).

Move roller lever 9 to the right on trimmer engaging

ed inner

(Fig. 7).

Bring

the

surface

needle

of knife cam 2, and mark this position on trimmer engaging

to its

lowest

position.

disengage

the thread trimmer (trimmer engaging

shaft

4 until roller 6

contacts

the

recess

shaft

Engage roller lever 9 in the slot of knife cam 2 and rotate trimmer engaging cam 30 until

set

its stud contacts

above-mentioned mark

screw 29 of stop 28 (Fig. 28). Push roller lever 9 to the left until the

becomes

visible on trimmer engaging

shaft

4. Continue pushing until

roller lever 9 is positioned about 02", or 0.5 mm, beyond this mark. Pull out thread catcher

driving crank 10 as far as it will go and hold it there. Push roller lever 9 against the outer

wall of

the

slot

in knife

cam2and

tighten

its

set

screws

securely.

4

Fig. 7 Fig. 8

Page 8

4. Double-checking

Adjustments

1-3

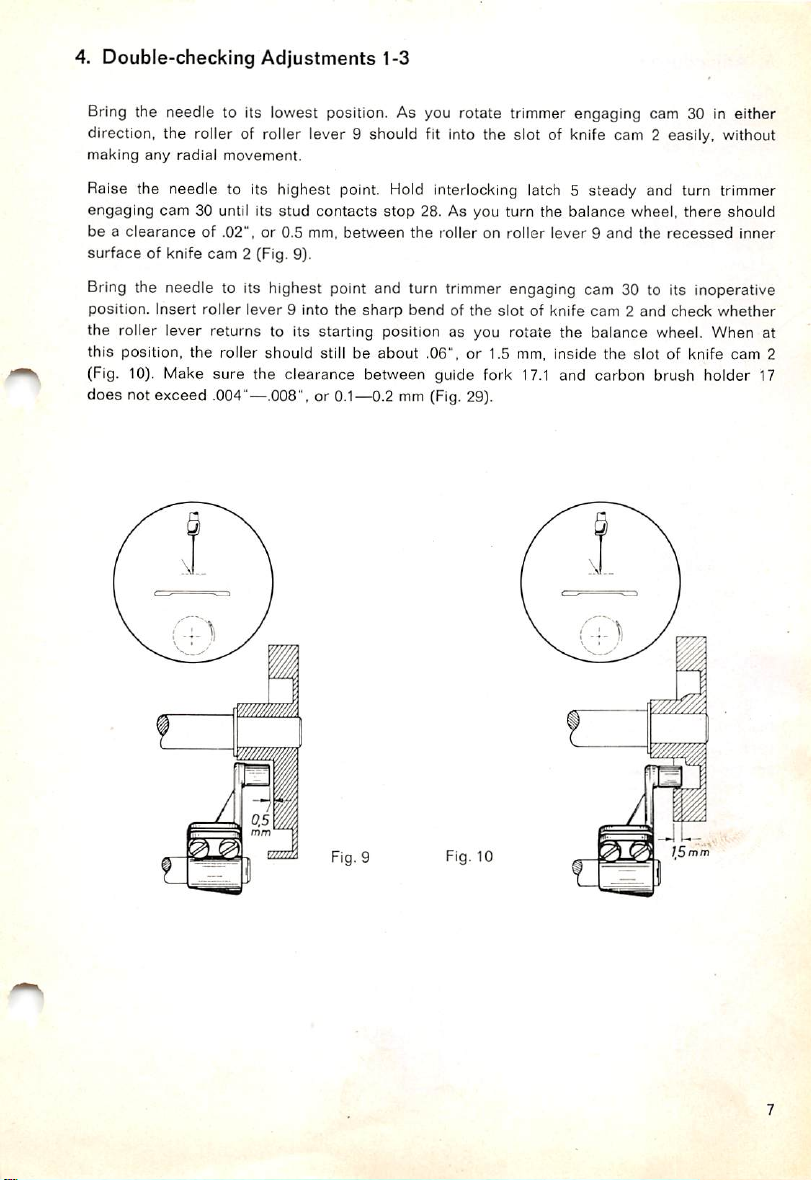

Bring the needle to its lowest position. As you rotate trimmer engaging cam 30 in either

direction, the roller of roller lever 9 should fit into the slot of knife cam 2 easily, without

making

any

radial

movement.

Raise the needle to its highest point.

engaging

beaclearance

cam

30 until its

of .02",or0.5 mm,

stud

contacts

stop

between

Hold

interlocking latch 5 steady and turn trimmer

28. As you turn the

the

rolleronroller

balance

lever9and

wheel,

the

recessed

there

should

surface of knife cam 2 (Fig. 9).

Bring

the needle to its highest point and turn

position.

Insert

roller

lever

9 into

the

sharp

bend

trimmer

of the

engaging cam 30 to its inoperative

slot

of knife

cam

2 and check

whether

the roller lever returns to its starting position as you rotate the balance wheel. When at

this position, the roller should still be

(Fig. 10). Make sure the clearance between guide fork

about

.06", or 1.5 mm, inside the slot of knife cam 2

17.1

and carbon brush holder 17

does not exceed .004"—.008", or 0.1—0.2 mm (Fig. 29).

inner

Fig. 9

Fig. 10

]Sfnm

Page 9

5. Adjusting

Remove

presser

the

foot,

Thread

needle

Catcher

plate

and

feed

dog.

Thread catcher 11 should besopositioned that its tip is in line with

needle,asviewed

Adjustmentismadebythe

Lower the

contacts

stroke.

of bobbin

driving

stop

Whenatthis

case

crank

from

above

(Fig. 11).

two

thread

catcher

set

screws.

needletothe

28.

Rotate

position,

bottom of its

the

balance

the

rear

stroke

wheel

edge

and turn trimmer

until

thread

catcher11has

of its

cutout

should

engaging

be in line with

position finger 13 (Fig. 12). If adjustment is required, reposition thread

10.asappropriate.

the

left

cam

30 until its

completed

the

side

of the

stud

its forward

front

edge

catcher

Fig. 11

6.

Adjusting

Bring

the

stop

28. Rotate the

or 2.0 mm,

this

position,

center

line of

needle

past

the

the

to its

the

tip of

bobbin

Knife

lowest

balance

center

thread

case

Cam

point

and

wheel until the heel of the thread pull-off flange is positioned Vti".

line of

bobbin

catcher11shouldbepositioned

position finger 13,

and the thread pull-off flange being about

Fig. 12

turn trimmer

case

position finger 13. With

the

total

V35",

or 4.0 mm (Fig. 13).

engaging

clearance

-f\-r

i

/

cam

between

>•

•

30 until its

the

or 2.0 mm,

thread

Fig.

stud

sewing

shortofthe

13

contacts

hook

catcher

at

11

Page 10

7. Adjusting

Bring the needle to its lowest point.

There should be a clearance of

side of the needle (Fig.14). Set knife 12 sideways so that it is centered above the thread

catcher tip.

right recessed edge of thread catcher11(Fig,15).

Make

the

Knife

particularly

764",

sure

or 3.5

though

mm.

between the tip of

that its

Fig. 14

right

edge does not

knife

12 and the obverse

protrude

from

the

35

mm

Fig. 15

8. Checking the Trimming Action

(Double-Checking Adjustments 5 and 7)

To make sure that

threadistrimmed,9?>rrectlytothe

(Fig. 1). If adjustment is required, loosen both set screws of the thread catcher and readjust,

as

instructedinpar.5above.

aread

catcher11is not inclined sideways

right

and

right

wrong

Fig. 16

leftofthe

(Fig,

highest

wrong

16), check whether the

pointofcutting

edge

8 1

Page 11

9. Preliminary Adjustment of the Synchronizer Slip Ring

Lower

the

inoperative

needletothe

position.

bottom of its

stroke

and

turn trimmer

engaging

cam

30 to its

The left carbon brush should be so positioned on the left switch-off track that there is a

clearance of .04", or 1.0

mm,

between its right side and the right edge of the track (Fig. 17).

When the needle has reached the lowest point of its stroke, the left carbon brush should

be positioned about

In

the direction of rotation

16onlower

main

^^32",

shaft3,as

or 10

mm,

(Fig,

18).

appropriate.

past the near end of the left switch-off track, as seen

If adjustment is required, rotate synchronizer slip ring

:T

[_l^

Fig. 17

10.

Adjusting

Adjust centrifugal switch 18

19

nor

the

stud

the

Centrifugal

of trimmer

sideways

engaging

Switch

so that it strikes neither the bushing of

cam

30 (Fig. 19).

Fig. 18

pressure

pin

When the beginning of the left switch-off track of slip ring 16 reaches the carbon brush,

interlocking latch 5 should be released already. It should remain released until the carbon

brush

has

reached

on

lower

main

shaft

the

end of

3 (Fig. 27).

the

switch-off track. To

adjust,

rotate

centrifugal switch 18

Fig. 19

10

Page 12

11. Timing

the

Needle

Thread

Tension

Release

Attach feed dog, needle plate and

The needle thread tension should be

presser

released

foot, and lower the latter onto the needle plate.

when trimmer engaging

shaft

4 has completed

about one half of its travel. Adjustment is made by loosening binding screw 22 and lengthen

ing or shortening the connection (Fig. 20). When trimmer engaging

left-hand position,

12.

Checking

(Pfaff

Set

the

machine

reverse

pushing

trackoftrimmer

feed

the

the

machines

for its

control.

two-part

engaging

the

needle

thread

Operationofthe

461,

463

and

longest

Turn

trimmer

connection

cam30must

tension

465)

stitch

engaging

together

mustbeoperative.

Reverse

and

reverse

completely. As you do this,

not

move

Feed

the

direction of

cam30downwards

beyond

the

shaft

Fig. 20

Mechanism

feedbydepressing

away

the

center

line of

4 is at its extreme

from

stop

28,

thus

end of

the

channel

guide

roller 31

the

(Fig. 21). If adjustment is required, turn feed reversing crank 33 on the feed regulating shaft,

as

mayberequired.

11

Page 13

13. Adjusting

To

set

pedals

of

motor

connection

the

Motor

Connection

24 and 26 in the most convenient position for operation,

25,asappropriate.

adjust

the length

If it should become necessary later to adjust the position of one of the pedals or of the

motor, follow

14.

Adjusting

Bring

the

the

needle

instructions

the

Trimmer

to its

lowest

given in

Connection

point.

par.

14 below.

Push the top end of two-part connection 27 onto the ball stud of trimmer engaging cam 30.

Rotate this cam until it contacts stop 28 and depress the rear ends of both pedals as far as

they will go. With the pedals in this position, the ball cup at the lower end of connection 27

shouldbepositioned

distance,asillustrated in Fig. 22).

about

.04", or 1 mm,

below

1mm

the ball

studonthe

pedal

(center-to-center

15.

Checking

Set

the machine for its longest stitch and

this,

the

reverse

Depress

pedal.

As you do this, roller

settings

Both

12

the

Pedal

feed

control

the

rear

end

of the left

canbeadjustedbythe

Operation

must

lever9must

not

pedal

stop

depress

make

any

26 until its

not

make

screwonthe

Fig. 23

the tip of the right pedal 24. As you do

perceptible

stop

any motion

engages

right

motion.

toward

pedal

the

undersideofthe

knife

cam

(Fig. 23).

2.

right

Page 14

16. Adjusting

the

Limit Switch

Position

before the switch operating lever

17. Final Adjustment of

limit

switch ES in the elongated holes of its bracket so that it

contacts

Fig. 24

the

Its

stop

(Fig. 24).

LAJ~

Synchronizer Slip Ring

will

be actuated shortly

Switch on the motor and depress the rear ends of both pedals. When the threads have

been trimmed, the needle should stop with its point about Vu", or 8.0 mm, above the needle

plate. To adjust, reposition synchronizer slip

par. 9, making particularly sure that Its lateral position is correct.

ring

16 on lower

main

shaft 3, as instructed in

13

Page 15

C. Trouble

1.

Machine

1.01

1.02

1.03 knife 12 Is

thread

thread

failstotrim

catcher

catcher

Shooting

the

threads

because

11 is

set

incorrectly in relation to knife 12,

11 is

set

incorrectly

set

incorrectly in relation to the needle,

in relation to the

needle,

1.04 the setting of synchronizer slip ring 16 has been disturbed,

1.05

knife

cam

2 is

out

of time,

1.06 centrifugal switch 18 fails to release the trimming mechanism,

1.07 limitswitch ES under the right pedal does not work properly,

1.08 trimmer engaging cam 30 does not make its complete travel,

1.09

the

knife

is blunt,

1.10 knife 12 does not press against thread catcher11sufficiently,

1.11

shaft4jams,

1.12 the thread

catcher

jams,

1.13 the bobbin thread has not been passed through the additional hole in the bobbin case.

1.14 thread catcher

11

is set too close to the sewing hook.

2. Machine trims threads repeatedly because

2.01

the

motor

clutchisdefective,

2.02

the

carbon

brushisnot

slip ring,

centered

correctly

on the

switch-off

track

2.03 the carbon grit has formed a "bridge" (or connection),

2.04 shaft 4 jams and does not complete its travel,

2.05 trimmerengaging cam 30 does not make its complete turn,

2.06 the line voltage fluctuates excessively,

2.07

the

motor

clutchissoiled

3. Actuatingthe pedal does not start the

3.01

limit

switchESunderthe

with oil.

right

trimming

pedal

action because

failstoswitch

inthe

trimming

3.02 trimmerengaging cam 30 does not make its complete turn,

3.03

shaft

4 jams,

3.04 the setting of synchronizer slip ring 16 has been disturbed,

3.05 roller6of roller lever9 does not run inthe groove of knifecam 2.

3.06 centrifugalswitch 18 is out of adjustment,

3.07 the motor clutch jams.

14

of the

synchronizer

mechanism,

Page 16

4.

Needle

thread

end

too

short

because

4.01

the

upper

tension

is not

open

during

the

trimming action,

4.02 the needle thread is considerably

4.03 the

4.04

4.05

5.

threads

are

trimmed before the take-up lever has reached the top of its stroke,

thread catcher11is adjusted incorrectly so that all three threads are caught behind

heel

the

Bobbin

11.1onthe

extra

thread

left-hand

springinthe

end

too

short

upper

because

retarded

sideofthe

tensionistoo

thread

as it

catcher,

strong.

enters

the upper tension,

5.01 the

5.02 the

6.

Needle

reduced

bobbin

thread

speedofthe

thread

is not

end

too

long

machine is

too

severedbythe

because

high,

cutting

edge

provided

for

this

purpose.

6.01 the extra spring in the upper tension is missing or too weak.

7.

Needle

thread

end

7.01 it

Thread

8.

8.01 the

was

held

kinks

upper

liesonmaterial

downbythe

at beginning of

tension

does

because

presser

foot.

seam

because

not work properly,

8.02 an excessive amount of thread was pulled through/the upper tension for the

action.

9.

Thread

ends

too

long

because

9.01 knife 12 has been adjusted improperly.

to.

Work

10.01

cannotberemoved

the

threads

were

not

from

trimmed,

under

the

presser

foot

because

10.02 the needle thread end is jammed between sewing hook and thread catcher

10.03

the

needleisset

too

low.

trimming

11

11.

Needle

set

too

low

after

trimming

11.01

synchronizer slip ring 16 is adjusted incorrectly,

11.02

the

voltage

fluctuates,

11.03

the

motor

clutchissoiled

12.

Needle

enters

material

after

because

with

oil.

left

pedalisreleased

because

12.01 limit switch ES under the right pedal 24 is adjusted incorrectly.

12.02 connection 27 between pedal 26 and the trimming mechanism is too long.

15

Page 17

D.

1.

1.

2.

3.

4.

Annex

Pedal

(on Pfaff

Depress

Depress

Depress

Depress

Operation

machines

tip of right pedal 24

heel of right pedal 24

tips of both pedals 24 and 26

heels

461-900;

463-900; 465-900;

of both pedals 24 and 26

and

467/469-900)

Fig. 25

Machine

Needle

Machine

sews

forward

movestoiowest

sews

backward

position

Needle moves to highest position

and

both

threads

are

trimmed.

16

Page 18

(on Pfaff

machines

467-900

and

469-900)

Fig. 26

Depress

1.

2.

Depress

3.

Depress

Depress

4.

2. Tilting

To tilt

mechanism.

tip of right

heel

tipsofboth

heelsofboth

the

the

machine

Never

pedal

of right

Machine

back,

start

24

pedal

24

pedals24and

pedals24and

Back

remove

the

connection

machine

26

26

before

connection27has

27 which

Machine

Needle

Machine

Needle

both

threads

connects

sews

forward

movestolowest

gathers

movestohighest

are

trimmed.

pedal

26 to

been

replaced

position

position

the

because

and

trimming

there

is a danger that the trimming action may have been triggered off and the trimmer may be

damagedbythe

When the connection has

high

starting

speedofthe

been

replaced, a

machine.

stoponthe

left pedal automatically switches

off the trimming mechanism at the beginning of the sewing action.

17

Page 19

Fig. 27

The trimming mechanism is disengaged.

2 idles, and interlocking latch 5 interlocks

20

3^

R

Shaft

4 is at its extreme left position, knife cam

stop

20.

9396

Fig. 28

The trimming mechanism is engaged. Interlocking latch 5 has

been

lifted

R9397

clearofstop

20,

shaft 4 has moved to its extreme right position, and roller 6 on roller lever 9 is engaged In

the

grooveofknife

18

cam

2.

Page 20

s

Fig. 29

Worm's

Fig.30 R

This is how gauge needle plate 14 is applied to adjust thread catcher 11 and knife 12.

eye

viewofcomplete

thread

trimming

mechanism

5

mm

9391

R9395

19

Page 21

Fig. 31

Power

table

mechanism.

equipped

Pedalsintheir

with

special

operative

motor

position.

for

high-speed

R9398

seamers

fitted with

thread

trimming

Fig. 32

R9399

Power table fitted with special motor. Pedals swung up to facilitate cleaning the floor or

moving

the

tabletoanother

20

location.

Page 22

Contents

A.

Operation

1.

General

2.

Operation

3.

Maintenance

B.

Adjustment

1. Adjusting the Interlocking Latch

2. Endwise Adjustment of Knife Cam

3. Adjusting the Roller Lever

4. Double-checking Adjustments 1—3

5. Adjusting the Thread

6. Adjusting

7. Adjusting

8.

Checking

9. Preliminary Adjustment of the Synchronizer Slip Ring .

10. Adjusting the Centrifugal Switch

11. Timing the Needle Thread Tension Release . . . .

12. Checking the Operation of the Reverse Feed Mechanism .

13. Adjusting

14. Adjusting

15. Checking the Pedal Operation

16.

Adjusting

17. Finai Adjustment of the Synchronizer Slip Ring

and

Maintenance

the

Knife Cam

the

Knife

the

Trimming Action

the

Motor

the

Trimmer

the

Limit

Catcher

Connection

Connection

Switch

4

5

6

7

8

8

9

9

10

10

11

11

12

12

12

13

13

C.

Trouble

1.

Machine

2.

Machine

3. Actuating

4.

Needle

5.

Bobbin

6.

Needle

7.

Needle

8.

Thread

9.

Thread

10.

Work

11.

Needle

12.

Needle

D.

Annex

1.

Pedal

2. Tilting

3.

Thread

Shooting

failstotrim

trims

the

thread

thread

thread

thread

kinks at

ends

cannot

set

too

enters

Operation

the

Machine

Trimmer

the

threads

pedal

end

end

doesnostart

too

end

too

end

too

liesonmaterial

repeatedly

short

short

long

beginningofseam

too

long

be

removed

low

after

trimming

material

after

.

Back

Illustrations

threads

left

pedalisreleased

.

the

trimming

....

....

action

.

14

14

14

15

15

15

15

15

15

15

15

15

16

17

18—20

21

Page 23

Page 24

r<

Page 25

Page 26

Z

2^

7

5.J'

-I

'*.

•

v:f-.r

.1- .

V," I

'_>• f

••.

®

(PFAFF)

o

Nr. 12310

engl.

R 466

Printed in Germany

Loading...

Loading...