Page 1

w

0

0

‘0

•ri

In

Page 2

Contents

Foreword

Essential

Engaging

Sewing

the

Electrical

Straight

Zigzag

Elastic

Removing

Winding

Inserting

Inserting

Changing

Needle

Threading

Upper

Drawing

Correct

Regulating

Length

Stitch

Reverse

Parts

Disengaging

and

Mechanism

Information

Stitching

the

Bobbin

the

Bobbin

the

Bobbin

the

the

Thread

and

the

Up

Tension

the

Regulation

Sewing

Seam

Bobbin

Needle

Bobbin

Regulation

Tensions

•

Case

Case

Chart

.

•

•

Thread

19

•

19

•

20

•

21

22

•

22

•

23

24

•

25

•

26

•

28

•

29

•

30

32

•

33

•

35

•

36

37

•

Machine

Oiling

Face

Light

Feed

Foot

Cover

Bulb

Foot

Operation

•

Machine

Dropping

1

Darning

2

All-Purpose

.

•

4

5

6

6

7

8

9

11

12

13

14

15

16

17

18

18

Fundamentals

Zipper

Quilting

Hemming

Edge

Inserting

Sewing

Button

Darning

Cording

Stitching

Cleaning

Removing

Changing

Trouble

the

and

Insertion

Finishing

Patches

Buttonholes

Sewing

Synthetics

and

the

tho

Shootin

9

Embroidery

Sewing

of

Page 3

Foreword

Your

proud

which

sewing,

come

This

machine

the

important

of

reference

gotten

Follow

your

If

you

your

tact

at

you

dream

ownerofa

enable

will

embroidering

in

a

up

instruction

book

some

these

will

Pfaff

have

Pfaff

time.

any

has

Pfaff

you

home.

book

familiarize

and

sewing

in

details.

simple

become

sewing

any

dealer.

PFAFF-Haushaltmaschinen

the

9,

master

to

darning

and

will

help

you

Keep

jobs.

case

instructions

Karisruhe-Durlach

you

a

lasting

problems,

He

should

will

You

true.

come

are

sewing

all

jobs

understand

you

with

handy

it

sewing

and

pleasure.

please

gladtohelp

be

now

machine

ordinary

that

number

a

have

GmbH

may

as

for

with

con

the

a

Page 4

Essential

Face

I

Take-up

2

Thread

3

4

Spool

Stitch

5

Needle

6

Bobbin

7

Balance

8

Stop

9

Bobbin

10

Reverse

11

Stitch

12

Bed

13

Pfaff

14

Feed

15

Needle

16

Sewing

17

Light

18

Needle

19

Presser

20

Needle

21

Sewing

22

Parts

cover

lever

retainer

pins

lever

width

position

winder

wheel

motion

knob

winder

control

feed

control

length

slide

rotary sewing

dog

plate

thumb

foot

switch

thread

lifter

bar

set

screw

foot

(A)

ever

thread

tension

(B)

retainer

hook

screw

Page 5

hese

parts

iachine:

come

with

your

sewing

bobbins

can

.leedles,Systeml3OR,

)arning

JI-purpose

io.

93-1

lastic

bag

struction

gzag

)fl

machine)

1070

774

93-009

No.

No.

91-129449-91,full

No.

sewing

accessories

for

book

foot

93-102

(not

foot

00 179-00

sewing

033-21

No.93-847

826-91

foot

ill.)

93-838954-00

No.

(not

990-00

ill,)

Zigzag

sewing

Bobbin

foot

All-purpose

Darning

sewing

Needles

foot

foot

Page 6

the

following

Felling

Hemmer

(see

p.

Buttonhole

(see

p.

Zipper

(see

p.

Button

(see

p.

Edge

guide

Cording

(see

p.

“Arrow”

(see

p.

Soft

brush

(not

ill.)

Tape

meosure

No.

93-847

No.

93-847

“Greist”

No.

91

-053

Orders

number

foot

foot

23)

26)

foot

22)

sewing

28)

kt

30)

seam

27)

No.

200-60

204-60

bios

484-91

should

No.

No.

foot

No.

No.

binder

specify

parts

93-847

93-847

93-847

No.

93-847

foot

No.

91-053

ripper

93-847

(centimeters)

(inches)

(not

ore

561-06

551

600-00

93-84’

076-25

No.

979-91

ill.)

the

available

-00

616-00

608-00

99-053

ten-digit

on

special

(4

mm

5/32”)

request

and

at

extra

cost:

I

01

Hemmer

6-91

port

Zipper

foot

foot

Felling

foot

Edge

Button

Buttonhole

“Arrow”

guide,

w/

sewing

seam

screw

foot

foot

ripper

Page 7

following

the

foot

Felling

Hemmer

23)

(see

p.

Buttonhole

26)

(see

p.

Zipper

(see

p.

sewing

Button

(see

p.

guide

Edge

Cording

(see

p.

‘Arrow”

(see

p.

brush

Soft

ill.)

(not

measure

Tape

93-847

No.

93-847

No.

“Greist”

91

No.

Orders

number

foot

foot

22)

28)

kit

30)

seam

27)

-053

should

No.

No.93-847

foot

No.

No.

No.

200-60

204-60

bias

484-91

parts

93-847

No.

93-847

foot

91-053

ripper

93-847

(cenirneters)

(inches)

binder

(not

specify

are

561-06

93-847

600-00

No.

076-23

No.

979-91

available

-00

551

616-00

93-847

99-053

HI.)

ten-digit

the

mm

(4

608-00

016-91

on

part

=

special

5/32”)

request

Hemmer

and

foot

Zipper

at

Felling

foot

extra

cost:

foot

Edge

Button

Buttonhole

“Arrow”

guide,

sewing

seam

w/

foot

foot

ripper

screw

Page 8

parts

hese

iachine:

bobbins

No.

)il

can

eedles,

)arning

Jl-purpose

93-100

o.

‘lastic

bag

nstruction

sewing

igzag

on

machine)

1070

O774

come

No.

91-129

System

foot

No.

sewing

179-00

for

book

with

033-21

93-009

449-91,

No.93-847

130

R,

93-1

02

foot

accessories

(not

ill.)

No.93-838954-00

foot

your

full

826-91

(not

sewing

990-00

ill.)

Zigzag

sewing

Bobbin

Oil

foot

con

All-purpose

sewing

Darning

Needles

foot

foot

Page 9

SL

14

6

LL—

CL

E

Page 10

PI0H

uoi

6ui5fiu

3

qou

aq

eoueeq

6U1M9S

eaqM

esoop

s)

Apeeis

wsJueqap%J

pue

un

popu

/q

dos

-ow

-

PIOH

110fl

qou

6uMos

bu!puM

weiodwj

sAMjV

eoujq

6ui6eBuasia

aq

ocuooq

wsutpaw

ujni

atM

qvm

tflM

eei

5uMaS

s

jno,c

Apoajs

9SMjoo3-Jeuno3

eem

inoA

Ul

q6ii

wsiuepa

pue

p966uesip

UJfl

pJlMo4)

peto

pue

-ow

dos

ej

‘(noA

io;

ulqqoq

Js

noc

pu

pnb

Page 11

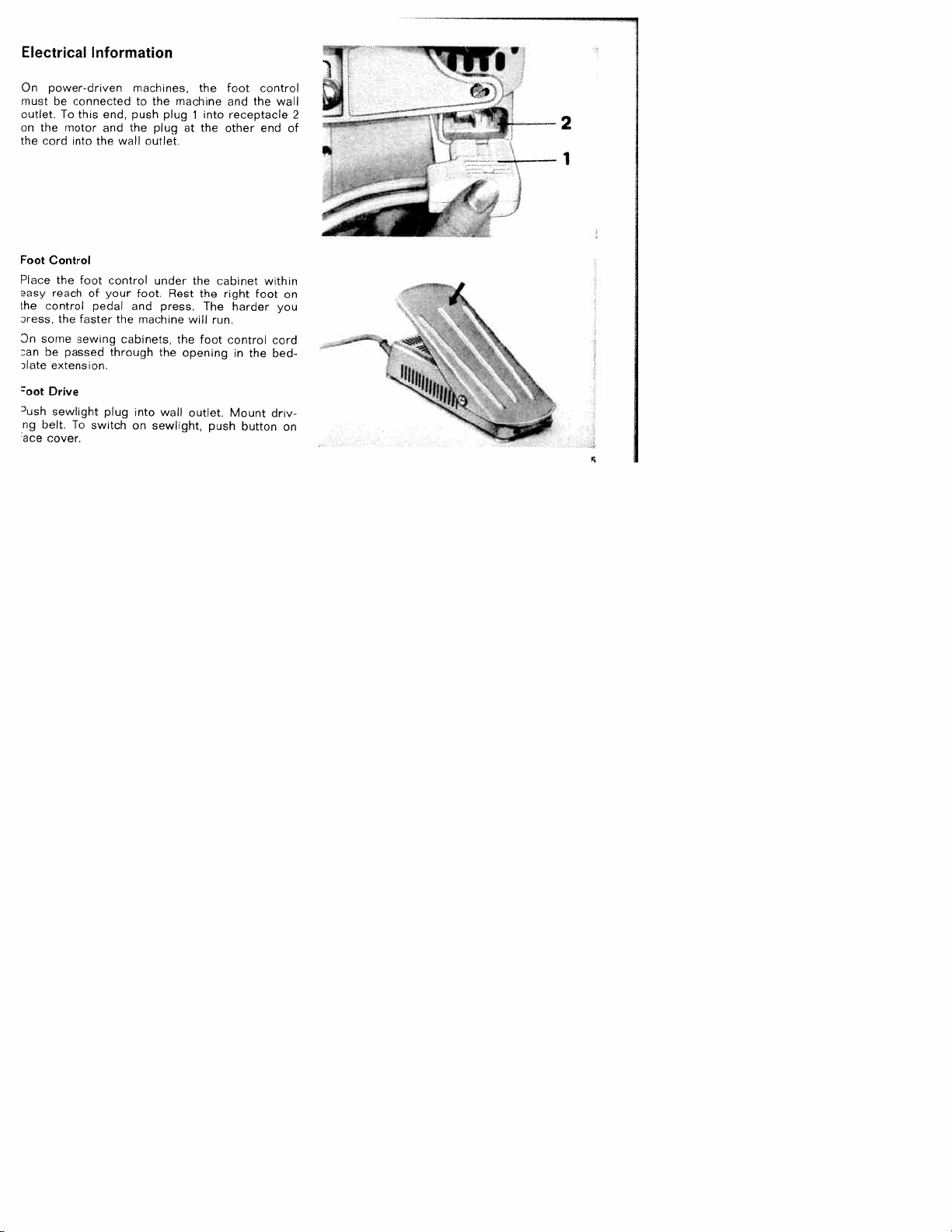

Electrical

Information

power-driven

On

mustbeconnected

outlet.Tothis

on

the

the cord

Foot

Control

Place

the

sasy

reach

Ihe

control

Dress,

Dn

some

Dan

be

late

extension,

root

Drive

ush

sewlight

ng

belt.Toswitch

ace

cover.

motor

the

passed

into

toot

of

pedal and

faster

sewing

end,

and

the

your

plug

push

the

wail

control

the

cabinets,

through

on

machines,

to

the

plug

plug

outlet.

under

foot.

Rest

press.

machine

the

into

wall

sewlight,

foot

the

machine and

into

receptacle

at

the

other

the

cabinet

the

right

The

harder

will

run.

the foot

opening

outlet.

push button

control

Mount

control

wall

the

2

end

of

within

foot

on

you

cord

in

the

bed

driv

on

2

Page 12

Straight

straight-stitch

For

Lever

Lever

On

pp.

this:

like

0,8

A

Zigzag

If

you

zigzag

width

Lever

center

straight

in

starting

stitching.

center

Stitching

0

A

B

22—32,

Sewing

want

stitching

(indicated

is

B

to

point

Lever

right.

or

Center

the

switch

to

used

right

the

stitching.

of

sewing

i

machine

flick

numbers

by

to

the

B

from

move

or

This

can

set:

lever

left

needle

be

setting

straight

A

I

the

of

applies

vibration

flicked

to

to

needle

the

is

(A

desired

4).

needle

likewise

to

indicated

0)

to

stitch

from

to

zigzag

in

the

to

the

hole

the

left.

Page 13

Removing

the

Bobbin

Case

Raise

end

hand

When

and

you

7

Lift

the

slide

of

bed

and

pull.

front

Lift

point.

highest

its

to

needle

pull

release

out

bobbin

the

latch,

case

the

with

bobbin

bobbin.

drops

out.

left

your

of

thumb

the

with

k

latch

Page 14

Winding

Disengage

place

thread

the

spool

from

guide

thread

retainer

thread

bobbin

the

the

on

bin

the

at

key

bobbin

the

in

bobbin,

around

the

start

automatically

bobbin

Then

dle.

amount

The

regulated

is

bin

accordingly.

minimum

maximum.

the

desired

screwdriver,

a

with

Bobbin

the

winder

bobbin

base

machine.

the

to

tighten

amount

position

of

this

of

Set

sewing

thread

spool

2,

stud

of

Wind

)

push

when

left

thread

by

The

down

spindle.

winder

the

The

the

and

the

turning

the

of

button

after

mechanism

spool

on

through

and

and

3

(As

spindle,

spindle

end

bobbin

the

bobbin

bobbin

remove

motion

stop

be

to

button

thread,

can

loosening

the

clockwise

to

up

you

thread

of

winder

is

it

wound

the

position

at

at

or

be

(see

1.

pin

right

bobbin

set

make

enters

the

to

Full.

From

knob

on

adjusting

position

turned

its

and

4)

p

the

Pull

scroll

around

4

bob

the

the

sure

slot

the

clockwise

and

right

stop

will

Push

spin

the

again.

bob

the

button

for

A

B

to

screw

set

on

the

the

the

in

for

1

2

I—

A

B

Page 15

Inserting

Hold

top

the

bobbin

Hold

the

pull

a

bobbin

down

case.

the

thread

Full

so

toward

bobbin

Bobbin

that

steady

into

the

the

you

case

thrad

and

in

the

insert

slot.

ind

bobbin

fdll

bobbin

case

from

into

and

Page 16

Pull

emerges

about

case.

Hold

bin

the

3

the

cannot

thread

from

of

case

fall

under

the

thread

by

out.

the

opening

hanging

open

its

tension

at

latch

from

its

so

spring

end.

the

that

until

Leave

bobbin

the

it

bob

Page 17

nserting

Raise

latch

hand.

arrow).

hook.

replacing

In

the

jammed

the

you

serted

needle

with

Turn

loose

latch

hear

the

the

Place

end

between

and

it

bobbin

Bobbin

to

thumb

bobbin

bobbin

the

press

snap

case

its

bobbin

of

bobbin

Case

highest

and

case

thread

into

will

forefinger

until

case

case,

case

against

place.

cause

point

points

slot

center

on

is

it

it

that

so

and

bobbin

An

hook.

improperly

needle

of

best

will

your

up

stud

to

not

Release

case

breakage.

right

(see

S

hold

until

of

get

in

Ii

the

lift

and

Page 18

Needle

The

Pfaff

Genuine

able

should

Chart

Changing

Bring

sewing

turn

Push

sure

back

dle

9

from

on

needle

and

new

that

and

set

machines

Pfaff

every

chosen

be

page

the

foot.

pull

needle

flat

long

screw

needles

Pfaff

13.

Needle

bar

Loosen

old

side

groove

a.

use

from

to

needle

up

of

System

of

dealer.

its

needle

as

toward

this

the

highest

out

far

shank

system

The

Needle

set

of

as

faces

you.

130

point

it

needles

and

screw

needle

will

Tighten

R

are

and

go.

toward

needles.

avail

size

Thread

lower

half

a

clamp.

Make

a

the

nee

Page 19

Size

Needle

or

70

60

80

90

100

Deterimo

0

S

ed

00

Mercerized

Chart

Thread

and

Needle

Silk

Cotton

Fabrics

of

Types

to

0

80

Fabrics

Fine

000

twist

to

100

silk.

chiffon,

lawn,

georgette,

voile,

as

batiste.

such

B

&

twist

A

to

80

70

cot-

shirt-

and

silks

woolens,

Fabrics

dress

sheer

as

Lightweight

such

tons,

draperies.

ing,

C

&

B

50

wool-

lightweight

Fabrics

as

such

Medium

twist

to

70

bro-

rayon.

silks,

muslin,

heavy

madras,

cades,

ens,

Fabrics

gabardine.

Heavy

and

D

&

C

to

40

fab-

denim,

slipcover

coating,

as

corduroy,

such

twist

50

light-

tickings,

bed

rics,

canvas.

weight

by

fabric

ned

of

Determ,

weight

Acetate

orion,

Rayon.

nylon,

inciudi.ng

Synthetics,

etc

piast,cs,

decrcr,,

Page 20

Threading

Upper

Rasethe

Place

a

the

end

drawing

(see

the

Pull

3

discs

to

over

and

slot

this,

do

ing

between

Pass

the

from

lever

into

it

pull

needle

inches

spool

(see

the

press

from

of

take-up

of

thread

right

under

thread

slot

thread

of

the

below

drawing

the

spool

right

front

thread

thread

between

so

the

through

to

from

5

through

lever

left).

that

thread

thread

and

left,

to

on

below

tension.

the

back

to

spool

through

any

right)

slips

it

check

against

hole

then

right.

and

the

its

properly

4

lead

needle

highest

pin1and

the

two

and

spring.

the

in

it

Now

pull

eye

left

of

jerk

arm

the

down

thread

about

point.

lead

scroll

tension

it

into

As

cast

take-up

three

far

the

you

and

the

4

2

‘5

Page 21

Drawing

Hold

Turn

moves

thread

needle

sewing

Up

needle

balance

down

to

hole.

foot.

the

draw

Bobbin

thread

wheel

and

Place

toward

up

bobbin

both

Thread

lightly

again.

thread

threads

n

you

Lightly

your

until

up

back

left

the

pull

through

under

hand.

needle

needle

the

the

15

Page 22

__________________________________________

interlock

to

Regulation

are

properly

in

the

sheer

prevent

center

fabrics,

puckering.

balanced

of

set

both

the

if

both

material.

tensions

Correct

The

Tension

tensions

threads

stitching

When

iittle

a

lighter

too

too

too

too

tight

loose

loose

tight

balanced

lower

or

lower

or

Both

tensions

-

Upper

properly

tension

tenson

tension

Upper

tension

Page 23

Regulating

tension

Turn

heavier

lighter

upper

The

tension,

of

one

with

numbers

degrees

specific

a

threads

hardly

need

upper

the

upper

Your

two-needle

Regulating

lower

The

special

for

turn

ed,

with

case

Turn

a

for

the

materials,

fabrics.

tension

complete

on

of

are

tension

the

the

right

it

looser

Upper

knob

from

the

tension

degree

the

be

tension

work.

the

tension

sewing

small

tip

for

tension.

right

or

is

loose

turn

tension

same

adjusted.

should

Lower

rarely

of

a

Tension

left,

designed

so

to

of

and

tension.

of

size,

has

Tension

jobs.

knurled

your

tighter

inr.rease

to

to

tight,

the

dial

are

For

set

be

third

a

needs

adjustment

If

screw

thumb

tension,

ease

can

tension

indicate

helpful

the

ordinary

on

tension

adjusting,

as

tension

tension

all

that

be

in

Provided

thread

about

the

on

follows:

or

grades

covered

The

dial.

different

restoring

both

tension

sewing,

5.

disc

except

requir

is

bobbin

it

turn

on

on

for

left

Page 24

Stitch

stitch

Ihe

,,titch

numbers

The

length

stitch).

machine

to

6

is

length,

opposite

s

row)

Length

length

(the

When

ceases

the

turn

Regulation

length

and

on

higher

inch

the

the

control

to

the

the

feeding;

(4

control

dot

limit

control

the

control

mm).

on

serves

it

in

number,

is

maximum

To

the

until

left

the

to

sewing

indicate

set

regulate

desired

of

regulate

backwards.

the

on

stitch

the

the

longer

“0”,

the

slot

the

stitch

the

the

length

stitch

number

(see

h

Reverse

sew

To

control

machine

Sewing

in

down.

resumes

reverse,

When

simply

the

forward

press

control

sewing.

the

released,

is

finger-tip

the

Page 25

Dropping

Remove

down

ever

indicated

(as

retained

be

feeding.

cease

machine

The

embroidery

raise

To

let

and

the

the

the

it

Machine

bed

slantwise,

in

and

machine

return

by

feed

cover

a

this

button

to

white

position

dropped

is

feed,

original

its

Feed

and

then

sewing.

press

to

arrow).

and

press

position.

the

for

the

rear

The

the

darning,

lever

the

drop

lever

fabric

and

feed

up

will

will

hoop

down

Darning

Remove

93-102

No.

c

clip

tighten

and

and

so

Embroidery

sewing

the

826-91

that

screw

Foot

set

foot

spring

screw,

19

foot.

the

from

the

behind

is

it

rear.

needle

Hold

darning

Attach

b.

Page 26

All

i1li

All

ticlied

Pie

the

Special

on

9n

Purpose

rjr

purpose

transparency

iperations

rig

neede

pp.

Sewing

V

instructed

as

penetrate

upplication

22—32

ew

sewing

Shoe)

of

where

Foot

foot

on

its

the

possibilities

No

page

shoe

it

fabric

93-100

is

21

facilitates

importont

are

179-00

to

discussed

all

is

sew-

watch

at

Page 27

Fundamentals

run

Never

•

•

•

•

fabric

have

Place

before

foot

Always

position

completed

machine

The

sewing

guide

is

by

ing

both

bring

before

foot

pushing

of

threaded

a

under

threads

you

the

seam.

a

will

automatically

work.

the

Machine

sewing

the

back

fabric

put

take-up

begin

you

feed

Never

pulling

or

machine

lever

and

the

try

the

Operation

unless

foot.

the

under

the

into

to

after

material

you

All

hasten

to

fabric.

sewing

machine

highest

its

you

under

have

you

have

to

feed

the

do

sewing

The

loosening

tighten

this

feet

the

thumb

can

thumb

screw

be

screw.

easily

securely

exchanged

Make

again.

sure

after

you

Page 28

Insertion

Zipper

zipper

Setting:

or

baste

Position

want the

zipper.

seam close

end

foot

from

Turn

andupthe

with

obtained

be

Machine

Pin

fabric.

you

not

the

straight

across

tinuous operation,

guide.

22

No.

your

A

closed

zipper

of

edgeofthe

fabric

Use

to

93-847

Pfaff

B

0,

zipper

depends

left

other

right

dealer).

to

edge

600-00

•

on

fabric

right

of

side

edge

wrong

on

side.

zipper,

in

of

(which

side

whether

overlap

to

one

foot

Run

stitch

con

as

can

of

or

a

a

Quilting

zipper

with

your

Machine

Zipper

quilting

at

any

Pfaff

dealer).

Setting:

foot

gauge

distance

faceofthe

along

tea

the

cosies,

ger

ive

canbequilted.

foot

No.

sews

fabric.

preceding

slippers,

No.

A

93-847

and

93-847

0,

parallel

angle

Always

B

-

600-00

guide

row

seat

600-00

rows

over

of

pads

(available

used

the

the

stitches.

of

entire

gauge

and

with

stitching

sur

Attract

covers

at

the

fin

Page 29

Hemming

hemmer

with

tained

Machine

You

can

stitches,

over

Fold

under

in

the

and

close

far

as

but

do

fabric

threads

both

edge

hem

hemmer

Avoid

this,

do

shortly

ill,

(see

edges,

into

cut

excess

ond

edge.

away

strated

from

Setting:

make

depending

edge

hemmer

material

the

as

not

into

scroll

ugly

press

before

at

hem

hem,

material

about

sketch

in

foot

your

neat

of

foot

about

the

to

rear

the

trim

the

scroll

backwards.

in

is

(top

ends

the

you

center).

first

turn

Before

/4”

No.

Pfaff

A

fabric

folded

fabric

line

by

fabric

edge

(see

of

3.

93-84]

dealer).

0

hems

the

on

so

/2”

threads

of

with

ill.).

slowing

come

If

you

end

sketch

you

the

2to3,

or

with

material.

about

that

short

edge.

edge.

(sketch

the

Feed

the

against

to

want

within

to

outwards

hem

hem

551-00

straight

i/a”,

the

of

Sew

Remove

hemmer

fabric

left

down

the

the

2).

the

sewn

(can

B

place

needle

its

1).

edge

needle

end

hem

to

1/2”

and

Then

last

first,

be

•

zigzag

or

fabric

stitches

edge

rear

backwards

work,

the

Draw

pulling

by

that

so

of

feeding.

the

of

several

corner,

of

cut

hem

edge,

as

ob

the

the

the

To

plate

hem

away

sec

cut

illu

23

Page 30

Overcasting

Machine

Overcasting

zigzag

wide

one

taking

over

24

edge

its

Edges

Setting:

prevents

stitch

stitch

A

(normal

and

into

to

2

frayed

sew

the

tension

4,

edge

fabric

B

edges.

with

setting).

..

and

Use

the

the

long,

a

needle

other

Page 31

Inserting

Machine

Large

method

ng

fabrics.

making

rhe

fabric.

holes

Cut

sure

Patches

Setting:

can

may

patch

that

A

be

be

its

4,

patched

used

slightly

grain

B

•

quickly

particularly

larger

matches

than

The

the

for

the

follow

jersey

hole

rest

of

4:1.1

Sew

of

over

close

elastic

down

medium

corners

to

joining

the

length

seams.

patch

twice.

seam.

The

For

Turn

with

added

zigzag

wide

a

fabric

strength,

over

stitches

zigzag

and

make

stitch

stitch

trim

an

I

Ic

Page 32

Sewing

Machine

Attach

21.

p

obtain

To

cotton

clear-view

and

rial

Buttonholes

Setting:

all-purpose

more

thread

filler

shoe.

regulate

A

Stitch

No.

Use

sewing

prominent

in

on

Sew

stitch

the

(first

1.5

length

50

foot

buttonholes,

the

piece

a

length

notch),

almost

embroidery

instructed

as

groove

left

of

correctly.

scrac

B

thread.

place

of

mate

*0*

the

•

on

a

buttonhole

A

tained

from

your

foot

(see

Pfaff

ill,

dealer.

may

right)

at

ob

be

Page 33

Instructions

first

1

Sew

fabric

in

foot,

Lift

2

needle

the

to

rallel

Flick

3

make

Flick

4

cord

and

first

as

left,

to

lever

4

lever

at

stop

seam.

to

Buttonholing

for

over

side

right

on

fabric

turn

pivot.

a

pull

completed

A

to

bartacking

6

A

back

of

end

about

side

filler

first

4

filler

a

of

around

Lower

line

second

first

to

seam.

to

its

cord

of

stitches,

stitches

6

cord.

throw.

clockwise,

take

foot,

taut

stitching,

notch

notch

Sew

Leave

and

(at

and

second

from

one

lay

“3”)

trim

needle

using

stitch

it

and

filler

seam

end

‘

I

to

6

sew

to

3

threads.

ripper,

your

4

4

tying

Open

but

be

Phft

27

and

notch

second

A

lever

not

ripper

to

stitches.

A

the

sewing

injure

to

may

to

with

“0”

be

and

and

your

the

bartacks.

obtained

make

filler

seam

from

lever

Flick

5

bartacking

Move

6

pa

stitches.

both

Trim

7

the

buttonhole

careful

seam

A

of

dealer.

Page 34

Button

Machine

28

Sewing

Setting:

A

Stitch

O,B

length

•

0

all-pur

under

button

Place

lever

its

sewing

foot

the

pair

hole.

1

A,

throw

zigzag

button

to

2

above

feed.

foot

or

usually

3

and

holes.

of

and

Let

tying

2

centered

is

stitches

securely.

tying

four-hole

on

reposition

process,

align

needle

stitches.

“3”,

to

as

stitches.

so

stitch

until

over

you

Move

buttons

the

stitching

that

through

Raise

needle

left

deem

lever

button,

needle

needle.

hole.

necessary

A

raise

then

through

will

hole

the

on

Sew

“0’

to

the

re

the

Drop

pose

enter

and

Move

left

as

to

and

When

sewing

peat

second

machine

sewing

right

make

of

many

fasten

make

Page 35

F-

Darning

Machine

Drop

93-102826-91.

No.

Clamp

worn

obtained

he

out

Cut

the

ing

across

high

and

with

area

torn

Triangular

best

foot

the

the

Setting:

machine

fabric

area

small

fabric

the

speed.

sew

short

darned

No

machine

work

in

is

from

hole

Then

back

stitches

around

tears,

93-838

spot.

feed

into

the

and

grain.

with

feed

A

your

with

and

the

954-00,

B

0,

and

darning

middle.

Pfaff

medium-sized

First

the

the

turn

forth

anchors

This

hole.

rips

small

of

aid

the

using

sew

and

attach

hoops

(Darning

dealer.)

stitch

machine

fabric

over

and

the

back

darninq

so

hoops

holes,

back

running

right

at

preceding

threads

thin

ordinary

hoops.

no

and

that

and

spots

forth

foot

the

may

follow

forth

angles

work

in

sewinq

Raise

at

Un-

are

over

29

Page 36

Cording

Machine

Setting:

A

Stitch

B

0,

length

a

and

may

(/32’),

cording

wide

cording

mm

cording

wide

distance

needle

foot

be

each)

wide

obtained

3.0

foot

foot

each;

foot

each)

of

2.0

distances

and

No.

and

No.

No.

and

or

cording

a

use

Pfaff,

your

on

cord

To

needle.

=

medium

)

a

twin

Twin

1.2,

of

4.0

Pin

93-847

1.2-mm

a

For

93-847

see

Wider

93-847

twin

a

2.5

Twin

From

needles

mm

tucks

narrow

ill.)

mm.

your

1.6

(/32”).

680-00

twin

675-00

and

cording

671-00

needle

needles

(/io’),

are

a

Pfaff

and

made

grooves,

(7

needle.

cording,

(5

1.6-mm

is

grooves,

(3

with

are

dealer.

cordrng

1.8,

grooves.

twin

made

needle

a

available

2.0,

with

use

feet

2.5

mm

1

1.5

needle.

with

mm

2

for

ordinary

needle

sewing

and

point

needle

securely.

b

and

(see

foot.

loosen

out

12).

p.

Attach

of

Needle

set

clamp

screw

foot

screw

and

and

Twin

lever

and

b

to

a.

insert

tighten

highest

Pull

twin

remove

screw

Changing

take-up

Bring

1

_g

—

f

30

.

—

needle

needle

Loosen

cording

Page 37

Jpper

?ach

?nds

see

3nd

oth

Fhen

fhread

iiaterial

:ension.

If

you

nent,

and

of

needle

end

you

cord

Threading:

the

of

through

14).

p.

through

threads

thread

Tension:

being

want

insert

pass

filler

of

replace

not

is

two

the

separately

the

down

each

sewn

to

filler

a

filler

the

hole

thread

the

pinched.

spool

hole

needle

Adjust

render

f

bed

Place

eyelets

and

and

cord.

cord

from

back

slide,

a

pins.

through

take-up

in

pull

from

upper

slightly

your

Remove

through

below

under

spool

Pass

of

front

cording

make

thread

thread

them

tension

(see

cording

thread

of

both

retainer

lever

into

back.

to

increase

more

the

hole

p.

sure

thread

tension

4.

slot

to

promi

bed

in

g

30).

foot.

the

on

2

3

Lead

5.

suit

lower

slide

front

Lay

As

filler

Spacing

spacing

ceding

and

between

Use

narrow

ing.

use

No.

between

between

seam

it

tucks,

50

cording,

Tucks:

parallel

one

into

guide.

a

as

the

use

embroidery

and

of

the

cording

thread

sewing

To

tucks,

For

ensure

place

grooves

larger

a

gauge.

for

for

silk

pin

of

tucks

wider

uniform

the

the

spacing

cord

pre

foot

and

31

Page 38

Stitching

u

r

C

Machine

t

a

Synthetic

n

s

Setting:

Materiais

A

terial;

about

fabrics.

be

synthetic

and

adhered

the

curtain

lower

thread

to

thread.

tensions

order

in

and

the

edge

ease

hints

laundry.

use

of

a

the

should

of

matching

upper

both

To

such

ma

depending

3,

to

1

B

2

Stitch

•:

on

length

If

somewhat.

necessary,

Both

avoid

to

Fabric

as

these

in

Diolen,

shrinking

the

the

finish

synthetic

I

P

a

s

Machine

32

t

i

c

Setting:

thread

after

sticking

an

and

or

plastic

the

oily

used

synthetic

sheets

its

in

under

removed

sole

sticky

from

with

Plastic

t

e

h

s

e

S

A

length

0

2;

to

medium.

B

Stitch

,;

bathrooms,

cotton

a

Place

sheets

sewing.

the

to

cloth.

curtains,

and

piece

which

To

sewing

are

fine

a

of

prevent

can

sewn

tissue

foot,

as

needle.

be

plastic

with

paper

easily

wipe

are

kitchens

Page 39

Dleaning

and

Oiling

Regular

the

incorporation

have

Put

ing

ing

All

maintenance-free

cleaning

service

oil

to

drop

one

hook

machine

the

is

each

other

and

your

of

life

self-lubricating

of

sewing

the

oil

of

day

oil

only.

bearings

into

you

proper

machine

hook.

the

sew

raceway

of

oiling

(see

your

will

Ihanke

bearings

ill)

machine

ire

em

r

the

to

ll

ymu

ew

the

of

oew

Use

are

Page 40

From

end

bar

vicinity

do

To

the

bobbin.

On

bottom

back

time

and

of

this,

needle

portable

of

cautiously.

time,

to

in

the

remove

plate

machines,

the

the

sewing

and

machine

clean

machine

hook

the

the

base

the

arm

with

needle,

bobbin

loosen

parts

and

a

the

as

the

at

soft

tilt

the

well

sewing

case

screw

the

needle-

as

brush.

with

machine

on

in

the

foot,

the

the

Page 41

I

Removing

change

To

needle

it

ling

the

the

end,

bar

upwards.

Face

light

remove

Cover

bulb

or

the

oil

face

the

parts

cover

Cover

Face

tip

it

d

snaps

the

into

into

slot

e

place.

and

push

face

cover

up

35

Rep’acing

the

at

by

pul

Slip

until

Page 42

hangng

the

Light

Bulb

The

area

change

To

push

When

voltage

pins

riaht.

built-in

stitching

of

the

bulb

the

inserting

agrees

socket

into

Reolace face

15-watt

perfectly.

light

into

with

a

bulb,

its

new

slots,

cover.

sewing

socket,

light

the

light

remove

line

press

turn

bulb,

voltage

bulb

illuminates

face

the

left,

make

Slide

in,

and

sure

and

the

cover.

pull

its

bulb

turn

Page 43

rrouble

Machine

Dause

incorrectly

\Jeedle

needle.

rong

Needle

Machine

Needle

Needle

2.

Cause;

above-mentioned

The

age

Thread

or

Poor

raceway

Hook

oiling.

Shooting

Skips

bent.

threaded

fine

too

Thread

tension

knotty

Stitches

inserted.

improperly.

too

or

Breaks

tight.

too

thread

jammed

is

thick

may

used.

for

cause

with

the

thread.

thread

thread

or

break-

needs

Remedy;

Push

the

sure

System

Use

Insert

Check

14.

p.

Use

13).

p.

Remedy:

See

Adlust

Use

Clean

needle

long

new

and

correct

remedies

tensions

good

and

up

groove

130

needle.

correct

needle

quality

oil

as

R

listed

as

hook

as

far

faces

needles

threading

and

under

instructed.

threads

raceway.

will

it

toward

only.

thread

above.

1.

only.

as

and

go

you.

instructed

(see

chart

make

on

on

Page 44

No.

20758

engl.

CPFAFFD

Germany

n

1070

R

Prrnted

Loading...

Loading...