Page 1

1196,

1197

1199

1209

Compaci

Compac

Instruction

Book

PFAFF-HAN

für

Haushaltnähmaschinen

7500

Karsruhe

DELSGESELLSCHAFT

41

West-Germany

m.b.H.

Subject

Nr

21992

to

ajterations

Wi

0279

engI

in

design

Page 2

‘..‘

Take-up

1

Thread

2

Eraser

3

Utility-stitch

4

5

Spool

Bobbin

6

7

Balance

Stop

8

Ultra-Matic

9

1

Needle

0

control

11

Master

1

2

Base

1

3

Bed

14

Sewing

1

Thread

5

On

thread

1

Upper

6

1

7

Control

dropping

18Presser

machine

Needle

1

9

screw

20

Needle

21

Handle

22

Accessories

1199/1209

23

Free

24

Free

sewing

Needle

25

7’.”-,

pins

motion

(of

cover

Model

tension

arm

arm

thread

‘•IILJ

lever

retainer

button

winder

wheel

position

switch

portable

foot

cutter

1

cutter

for

reverse

the

bar

arm>

holder

plate

on

Models

cover

hook)

buttons

knob

stitch

(on

209

feed

lifter

with

with

drawer

(enclosing

control

IIIdIiIIIIe

stud

selector

and

buttonhole

machines)

presser

dual

sewing

dog

(on

needle

guide

11

on

feed

back

grooves

99/1209

Models

bar)

with

and

of

set

Some

Be

a)

your

the

needle.

Make

b)

power

want

bobbin

clean

you

have

leave

4

IMPORTANT!

Valid

The

wires

coloured

following

Live.

As

the

mains

correspond

markings

your

plug,

The

wire

be

connected

marked

is

black.

The

wire

must

be

which

coloured

Please

When

3

amperes

safety

careful

fingers

sure

cord

change

to

or

and

the

for

United

in

in

code:

colours

lead

identifying

proceed

which

with

which

connected

marked

is

red.

note:

13

amperes

fuse

rules

when

will

you

plug

needle,

needle

oil

the

interrupt

to

machine

this

mains

accordance

Blue:

of

the

this

of

with

the

is

to

the

the

is

with

has

sewing

not

be

pull

whenever

plate,

machine,

sewing

for

Kingdom

lead

Neutral:

wires

appliance

coloured

the

as

follows:

coloured

terminal

letter

coloured

to

the

the

plug

is

to

be

injured

out

the

sewing

when

or

a

while.

only!

are

with

the

in

may

terminals

blue

which

N

or

brown

terminal

letter

used

fitted.

that

by

you

foot,

you

when

and

Brown:

the

not

must

coloured

or

L

a

in

Page 3

Contents

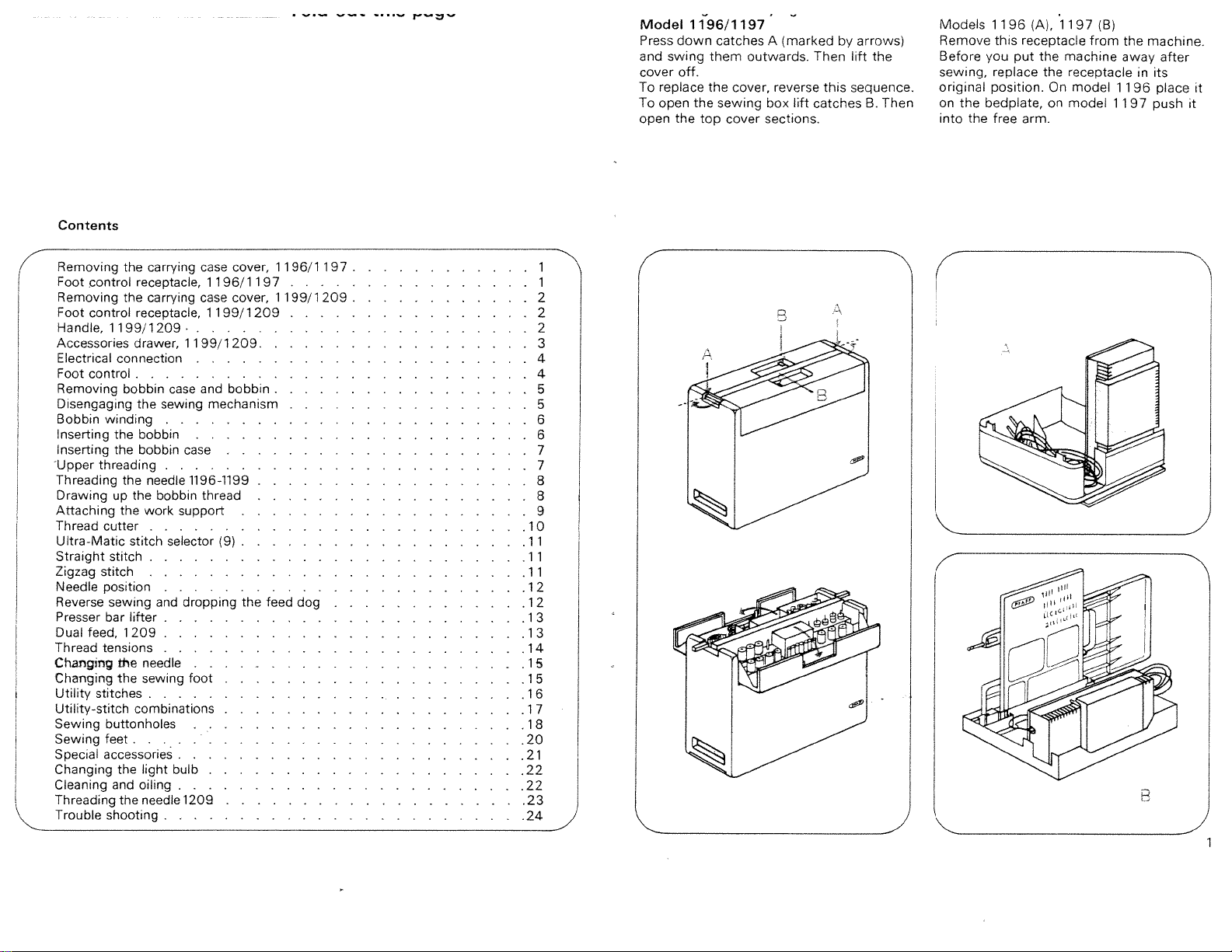

Model

Press

and

cover

To

replace

To

open

open

1196/1197

down

swing

off,

the

the

them

the

top

catches

cover,

sewing

cover

A

(markedbyarrows>

outwards.

box

sections.

reverse

lift

Then

catches

this

lift

the

sequence.

Then

B.

Models

Remove

Before

sewing,

original

on

the

into

the free

1196(A>,

this

receptacle

you

put

replace

position.

bedplate,

arm.

11

97

from

the machine

the

receptacle

On

model

on

model

(B)

the

away

11

11

97 push

machine.

in

its

96

after

place

it

it

Removing

Foot

Removing

Foot

Handle,

Accessories

Electrical

Foot

Removing

Disengaging

Bobbin winding

Inserting

Inserting

Upper

Threading

Drawingupthe

Attaching the

Thread

Ultra-Matic

Straight

Zigzag

Needle

Reverse

Presser

Dual

Thread

Changing

Changing

Utility

Utility-stitch

Sewing

Sewing

Special

Changing

Cleaning and

Threading

Trouble

control

control

1199/1209.

connection

control

the

the

threading

the

cutter

stitch

stitch

position

sewing

bar

feed.

tensions

the

the

stitches

buttonholes

feet

accessories

the

the

shooting

the

the

bobbin

stitch

lifter

1209

carrying

receptacle,

carrying

receptacle,1199/1209

drawer,

the

combinations

1199/1209

case

sewing

bobbin

bobbin

case

needle

bobbin

work

support

selector

and

dropping

needle

sewing foot

light bulb

oiling

needle

1209

cover,1196/1197

case

1196/11

cover,

case

and

bobbin

mechanism

1196-1199

thread

(9)

the

97

1199/1209

feed

dog

.2

.2

.2

.3

.4

.4

.5

.5

.6

.6

.7

.7

.8

.8

.9

.10

.11

.11

.11

.12

.12

.13

.13

.14

.15

.15

.16

.17

.18

.20

.21

.22

.22

.23

.24

4

4

)

1II

)

Page 4

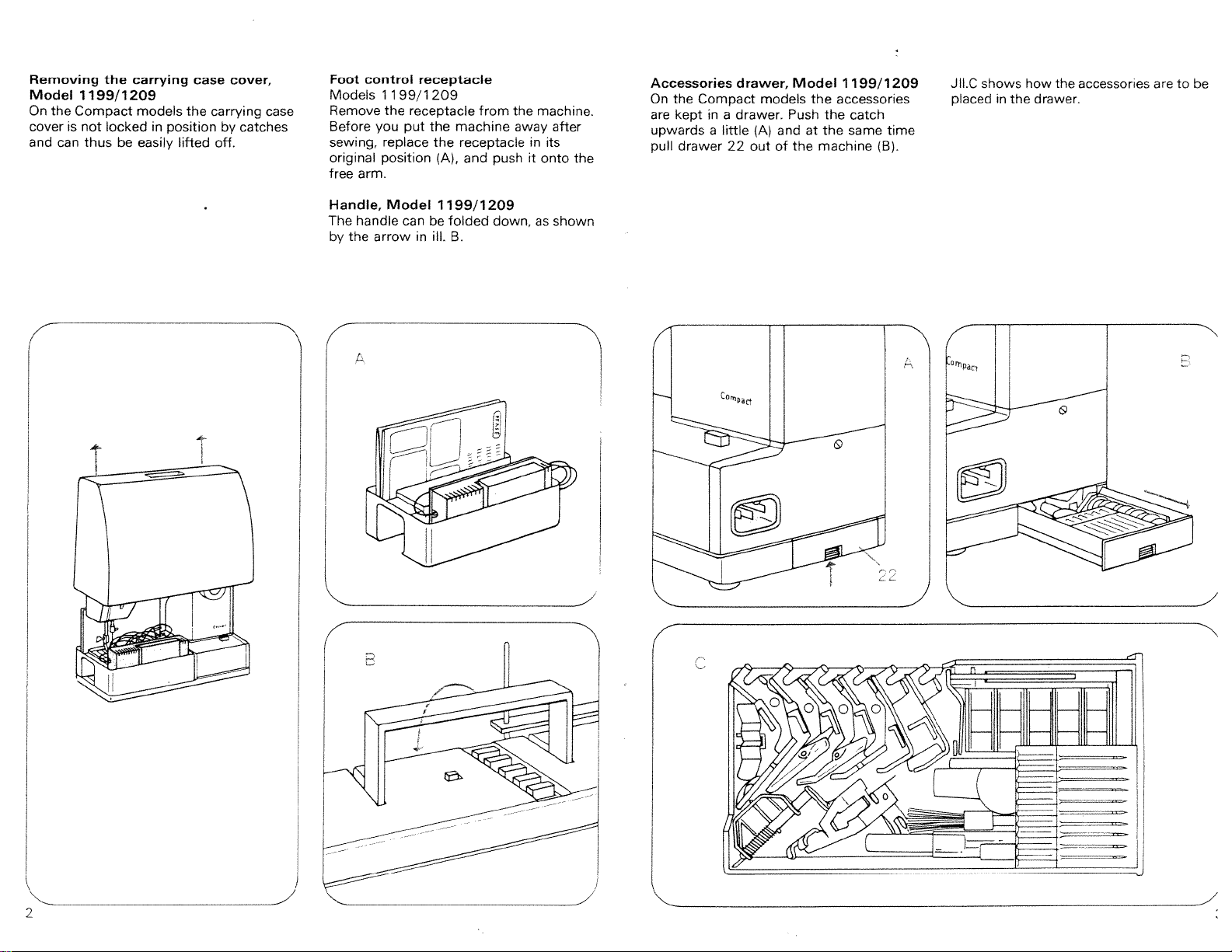

Removing

Model

On

coverisnot

and

the

can

1199/1209

Compact

thus

the

locked

be easily

carrying

models

in

case

the

position

lifted

cover,

carrying

by

catches

off.

case

Foot

Models

Remove

Before

sewing,

original

arm.

free

control

11

the

you

replace

position

receptacle

99/1209

receptacle

the

put

the

(A>,

from

machine

receptacle

and

push

the

away

machine.

after

in

its

it

onto

the

Accessories

the

On

are

upwards

pull

Compact

kept

drawer

drawer,

models

inadrawer.

little

(A>

a

out

22

and

of

Model

Push

at

the

the

accessories

the

the

machine

1199/1209

catch

same

time

(B>.

Jll.C

shows

placedinthe

how

drawer.

the

accessories

are

to

be

Handle,

The

handle

the arrow

by

Model

1199/1209

canbefolded

in

ill.

down, as

B.

shown

4

-/

Page 5

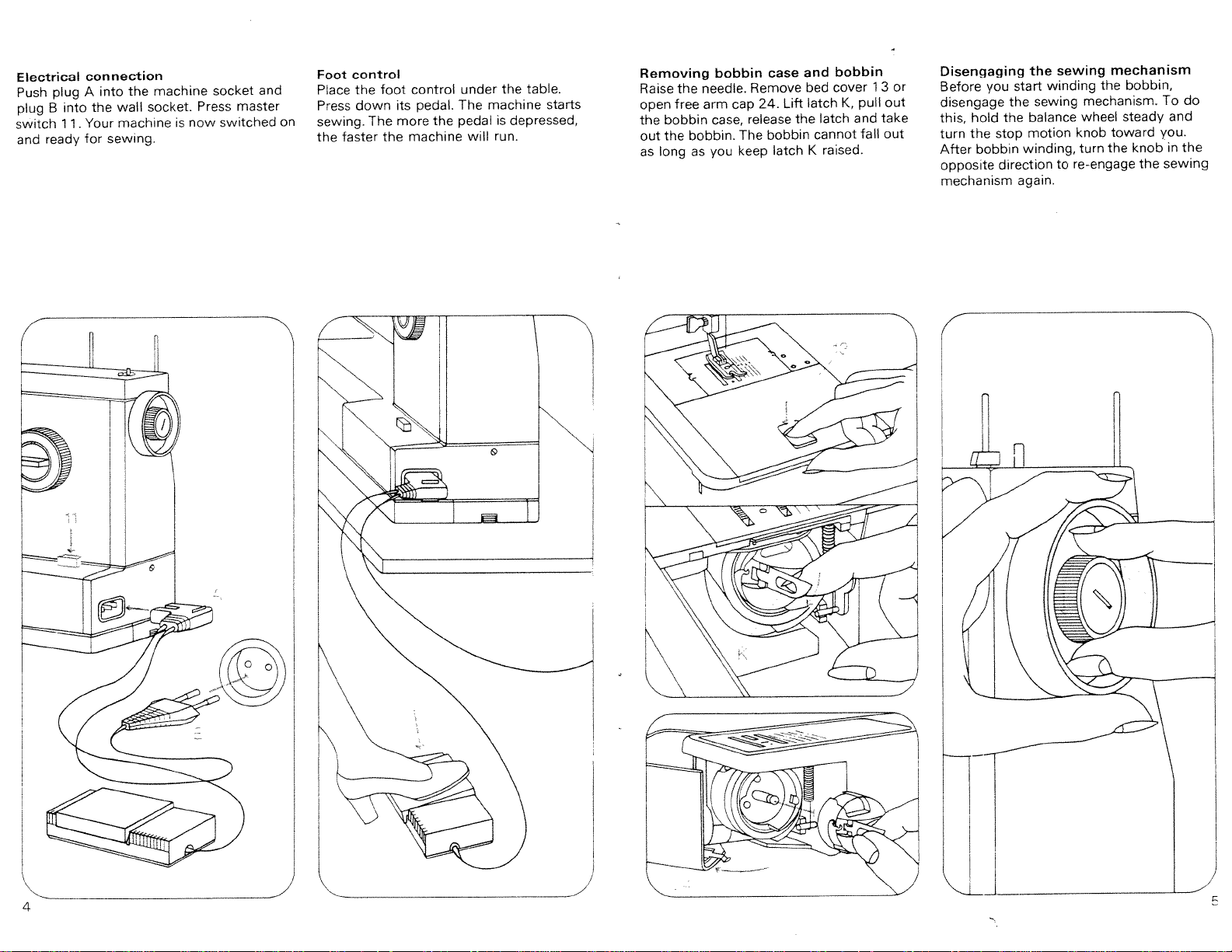

Electrical

plug

Push

B

plug

switch

ready

and

connection

A

into

.

Your

11

for

into

the

the

wall

machine

sewing.

machine

socket.

sewing

you

the

the

stop

direction

the

start

sewing

balance

motion

winding,

again.

winding

to

bobbin

and

cap

The

keep

case

Remove

24.

release

bobbin

latch

Lift

the

bed

latch

cannot

K

cover

latch

raised.

K,

pull

and

fall

1

3

Out

take

out

or

the

free

bobbin

needle.

arm

case,

bobbin.

control

Foot

and

socket

master

Press

switched

now

is

on

Place

Press

sewing.

faster

the

the

down

The

the

control

its

more

machine

foot

under

The

pedal.

pedalisdepressed,

the

will

the

machine

run.

table.

starts

Removing

Raise

open

bobbin

the

the

out

longasyou

as

Disengaging

Before

disengage

hold

this,

the

turn

bobbin

After

opposite

mechanism

mechanism

the

mechanism.

wheel

toward

knob

turn

the

re-engage

bobbin,

steady

knob

the

To

and

you.

in

the

sewing

do

Page 6

Bobbin

Disengage

pins

winder

spoolofthread

Pass

2,

and

bobbin

the

mechanism.

winding

the

5.

Place

that

so

the

thread

winditaround

push

lever

winder

bobbin

is

sewing

a

bobbin

pinAenters

on

oneofthe

around

the

against the

6

stops

full.

Re-engage

mechanism.

on

the

bobbin

slot

spool

thread

bobbin

automatically

retainer

a

few

bobbin.

the

B.

Raise

Place

pins.

times,

when

sewing

stud

The

Inserting

Insert

that

a

so

(A).

under

the

Then

the

the

the

filled

thread

draw

spring

bobbin

bobbin

unreels

the

into

thread

eye

into

the

toward

into

C.

bobbin

the

slot

B

case

back

and

Inserting

Lift

studB,making

Release

the

snapped

the

latchKand

the

bobbin

case

into

latch

place.

bobbin

push

sure

and

to

case

the

bobbin

slotApoints

lightly

press

make sure

case

upwards.

it

has

onto

against

Then

Upper

Pull

into

threading

the

slot

pull

thread

guideBand

A,

it

into

from

guides

the

spool

take-up

and

C

and

D.

draw

lever

it

1.

Page 7

Threading

Pull

fronttoback.

the

thread

the

needle

through

1196-1199

the

needle

eye

from

Drawing

Hold

the

balance

needle

take-up

out

of

toward

foot.

wheel

moves

lever

the

the

up

needle

needle

left

the

bobbin

threadalittle

toward

7

down

and

Pull

is

up.

hole

and

back

and

you

up

the

under

thread

until

again

bobbin

both

lay

taut.

the

Turn

the

and

thread

threads

sewing

the

Attaching

Model

11

96:

and

attach

97:

11

over

the

enter

the

the

1196/1197

Turn

over

it

Incline

free

two

(A).

the

arm

holes,

work

the

workplate

(B)

support,

foot

until

then

control

and

its

lower

receptacle

push

guide

it,

pins

Attaching

Model

Turn

push

it

1199/1209

over

it

over

the

the

the

foot

work

free

support,

control

armasfar

receptacle

as

and

it

will

go

C

Page 8

Thread

There

is

presser

the

Raise

cutter.

back

out

thread

in

the

downwards

cutter,

sharp-edged

a

bar

the

of

the

cutter

to

cut

Models

which

sewing

machine.

slot

them.

1196/1199

slotonthe

servesasa

foot.

Pull

the

Place

pull

and

back

thread

the

threads

them

of

work

Thread

The

dual

the

work

the

threads

them

cutter,

thread

feed

1

back

downwards

cutter

Raise

5.

outofthe

over

Model

is

located

thread

to

the

cut

1209

at

sewing

machine,

cutter

them.

the

22

back

foot.

and

Pull

Place

pull

range,

ranges

stitch

mark

stitches

5,

6,

5

toward

become

4

stitch

=

A

are

7, 8

to8,the

and

5

is

made.

sewn

in

At

and

9.

stitches

the

left,

the

increasingly

narrow

a

long,

the

the

zigzag

longer.

ranges

right

are

of

close

selector

outer

or

stitch

ring until

zigzag

above

stitch

mark

the

desired

A.

(9)

symbol

the

of

is

Ultra-Matic

Turn

of

the

straight

positioned

Zigzag

Setting

Zigzag

marked

this

Straight

Straight

from

stitch

stitches

0to4.

are

located

in

the

range

together;

stitches

In

zigzag

N

11

Page 9

Needle

The

in

the

Turn

needle

mark

position

needle

needle

knob

position

A.

central needle

=

=

right

=

left

can

be

hole.

10until

desired

needle

needle

settodifferent

symbol

the

positioned

is

position

position

position

positions

the

of

(normal)

below

Reverse

the

feed

Reverse-feed

positions:

=

Normal

A

As

B

the

Vertical

=

C

permanently

=

The

D

(for

sewing

dog

and

control

position

as

long

the

machine

position.

feed

dog

embroidering,

1

control

sews

in

reverse.

is

dropping

has

7

backwards.

The

machine

dropped

darning,

the

following

is

depressed,

etc.).

sews

Presser

Lever

1

Sewing

A

=

remove

wheel

and

B=The

sewing.

bar

8

lifter

has

two

foot

the

toward

take-up

sewing

positions:

raised,

work,

turn

you

to

lever

1.)

is

foot

(Before

the

raise

lowered

you

balance

the

for

needle

Dual

additional

This

creeping

push

place,

then

pull

feed,

dual

To

Model

feed

of

ahead

feed

15

disengage,

it

out.

1209

prevents

the

other.Toengage,

down

until

down

push

it

one

it

ply

snaps

slightly,

from

into

4

)

zz

Page 10

Upper

A

=

Lower

=

B

=

C

=

=

E

Upper

tension

tension

tension

Setting

setting

between3and

number,

tension

Regulating

looser

tension.

Both

Lower

(16)

mark.

is

in

the

tension,

tensions

tension

too

tension

too

screw.

tight.

tight.

The

the

tighter

or

are

too

too

green

5.

normal

The

the

Turn

right

correct.

loose

loose

range

higher

tension.

it

for

or

or

tension

the

left

tighter

a

lower

upper

for

The

correct

Let

the

hang

down

not

slide

should

jerk

you

a

bobbin

freely

down

gradually

your

lower

case

by

hand

tension

by

its

move

upwards

with

the

own

downwards

full

a

thread.

weight,

lightly.

bobbin

It

but

must

when

Changing

Raise

the

needle,

out

downwards.

Insert

a

(with

the

toward

will

go.

needle

loosen

new

flat

the

Then

the

System

side

back>

tighten

needle

bar.

screw

and

A

of its

Then

and

1

30/705

shank

push

screw

hold

pull

it

A.

up

the

the

needle

H

facing

as

needle

far

sewing

the

sewing

the

A.

the

needle

foot

sideways

sewing

can

Changing

Raise

the

forwards,

it

Attach

screw

it

as

foot

bar.

Loosen

removedbypulling

be

backwards.

or

foot

and

screw

tighten

until

A

—

Page 11

____

Utility

A

Elastic

B

Blindstitch

C

Elastic

D

Overlock

Cross

E

Eraser

3

buttons.

stitches

stitch

triple

stitch

button

stitch

straight

for

stitch

releasing

the

pushed

Utility-stitch

The

setting

9/10

whichisrequired

is

stitch

Setting:

A

B

=

indicated

Push

Turn

setting

of

Ultra-Matic

on

button

Ultra-Matic

the

for

stitch

stitch

a

specific

buttons.

selector

selector

utility

Utility-stitch

Pushing

produces

I

II

Ill

two

Honeycomb

Setting:

left

needle

Pullover

Setting:

left

needle

Super

Setting:

left

needle

control

combinations

buttons

new

utility-stitch

buttons

position.

stitch

buttons

position.

stretch

buttons

position,

17,

stitch

A+C,

B+C,

stitch

C+D,

simultaneously

patterns.

straight

straight

straight

raise

reverse-feed

stitch

stitch

stitch

4,

4,

4,

IV

E

stitch

Setting:

left

needle

vertical

V

Jersey

Setting:

left

needle

Table

of

All

stitches,

combinations,

Stitches.

4

buttons

position.

stitch

buttons

stitches

including

-

B+C,

position,

B+D,

position.

(Supplement)

are

shown

straight

turn

straight

the

utility-stitch

in

±

control

the

Table

I!

stitch

17to

stitch

0,

2,

of

O-2A\

A

V

1

JHLJL

=

=

=

+

±

+

I

*

II

//

17

Page 12

-

C

:3

-H

C)

a(n

CDCD

:3-aCD

CD

—

CD-

CD

CD

CD

:0-

CD

0

C)C)CD

-

-‘

CC)

a

-

—o

CDC

CD

QO)

a

-<

a

CDDO

U)

a

CD<

U)c

C

-f

J

D’

0

3

E

0

D

C)

0

C

CD

ao-•

CD

0

D

-0D

D

<

g

2

-OCD

(0

a

—

:3

3

-

C-

-

+(D

CD

co

S!

+

a

0C).-

-D

_.D)

CD

—

;j,:;

0

2c

—

0

CD

C

)_

a

o

-‘

-

Cñ

a

O)CD

‘CD

O)CCD

C)

_

U)

Ct)

-Ho

C)

a

O)CCDCOCDC

C)

CD

0

DC°

CD

(D:3

D

O

(D

Dr

:J-U)-<

COCD3

3

CD<

i

o)2

(fl

Co

CD

a

rn

-l

U)

C

0

a

C

QCDH

C)

CC)

)

-

—

=

-*

U)

-

DC

0

CD

-2s

aoo03

co

=

D

CD

c_

CD

-

o

D

-arn

0)

0)

-‘

CD

CD

Ct)

CD

0

0D

0

C

o-?

:3-—

g

-I

;;

Page 13

Sewing

A

Normal

1196—1199

Normal

O

for

special

Clear-view

C

sewing

D

Buttonhole

all

feet

sewing

sewing

sewing

sewing

and

operations

foot.

sewing

sewing

foot

foot,

foot,

Models

Model

foot;

on

1

requiring

for

ornamental

buttons.

209;

no

Zipper

E

guide

Blindstitch

F

Hemmer

G

H

Darning

darning.

I

Cording

and

or

edge-stitching

foot

foot

foot;

foot;

appliquéing.

for

embroidering

for

single-needle

foot

with

and

cording

edge

Special

The

special

obtained

accessories

accessories

from

your

Pfaff

listed

dealer.

below

are

intended

for

special

sewing

jobs.

They

can

be

20

ccessory

Cordvig

Coroing

(twin

Cording

twin

Cording

twin

Fringe

Straight-stitch

—

Needle

hole

Needle

hole

Eoge

Zipper

Felling

Zigzag

Eyeletting

Hemmer

Hemmer

Bias

Zigzag

(coated

Roller

—

\,pool

set

fool,3grooves

needle

foot.

needle

foot,

needle

sewing

plate

for

free-arm

plate

for

flatbed

guide

tool

foot

shirring

plate

foot

foot

hinder

Teflon

soiei

fool

holoer

with

grooves

5

with

7

grooves

with1.4-,

tool

fool

with

with

models

(fastening

fool

(shell-edge)

lroted

fool

2.5

1

.8-.

round

models

round

or

2.0-

1.6or1.8-

screw

edge)

3.0mm

needle

needle

2.0

1.0mm

—__________

or

2.5-

93—040

mm

needle

mm

mm

959-

gauge)

needle

needle

Ordering

No.

560—91

93-107

948—31

93—040

a

3040

gauge)

gauge)

25

950—31

93040

952—31

93—040

943-31

98—074

005—00

940—35

93—040

93—040

939—38

91—053077—25

98—501

000—27

93—040

938—31

93—847

520—06

946—45

93—040

93—847

546—00

547—00

93—847

98—055

622—00

955—91

93—040

912_21.

93—040

584—45

Sewing

Operation

cording

fine

sewing

basting

tostitching

soft

lersey.

eage

inserting

felled

shirring

eyeletting

hemming

binding

bras

sewing

sewing

thread

size

cording

size

aery

fabrics

stitching

seams

slilches

tape

materials

work

80.

701

fringes

delicate

etc

zippers

valances

edges

edges

plastic

coated

mrih

and

materials

—

3

soools

arid

with

For

needle

for

needle

For

for

For

sewing

and

silk

Far

For

For

For

For

For

zigzag

For

with

For

forsewino

svntnelic

.

,-—

For

of

2

Page 14

Changing

Push

the

pull

it

out.

its

pins

toward

light

enter

B.

the

Insert

slots

light

bulb

the

Threading

Turn

the

needle

Push

Draw

at

the

and

through

it

Cleaning

11

Remove

96:

forward

1197—1209:

remove

Remove

vicinity

the

feed

dog

not

Do

maintenance-free,

drop

oil

of

bulb

it

toward

turn

up,

new

Push

C.

light

it

up

bulb

and

so

A

turn

and

that

and

the

the

oil

and

with

the

into

take

Take

needle

bobbin

of

the

a

machine

oiling

cover

it

soft

the

1

out.

out

plate.

case.

sewing

brush.

but

hook

Pull

5.

the

screws

Open

Clean

hook

because

now and

raceway.

needle

cover

the

and

it

then

and

parts

is

plate

the

put

24.

in

a

the

balance

and

thread

thread.

the

needle

take-up

time

The

needle

the

control25down

the

same

the

wheel

under

releasing

thread

eye.

1209

toward

lever

all

the

fingers

you

1

(see

way.

A

control

is

then

to

raise

drawing).

and

B,

25

pulled

22

2

Page 15

rrouble

shooting

Cause:

Machine

1.

Needle

Wrong

Needle

Machine

Needle

2.

For

Thread

Poor-quality

or

excessive

3.

Needle

not

needle

bent

too

Needle

any

tension

thread

Needle

Needle

Needle

Needle

because

Bobbin

inserted

threaded

thin

thread

of

the

that

storage.

breaks

pushed

not

bent.

thin

too

bent

work

case

stitches

skips

used.

blunt.

or

improperly.

for

breaks

above

too

or

knotty

has

become

or

too

and

strikes

is

pushed

improperly

correctly.

thread

reasons.

strong.

thread

up

as

thick.

needle

or

inserted.

used.

too

far

used.

dry

as

plate

pulled.

/

Remedy:

go,

the

Needle

it

up

alone.

case,

place.

its

back.

as

press

far

Push

flat

Insert

Insert

Check

Select

and

See

Regulate

Use

by

go.

Insert

it

as

Insert

Note

Let

Only

When

against

will

it

shank

system

new

threading.

needle

Thread

par.

only

new

will

new

Needle

machine

guide

inserting

side

130/705

needle.

according

Chart.

above.

1

thread

good-quality

needle

go.

needle.

and

feed

the

it

until

facing

tensions.

and

Thread

the

material

the

t

snaps

toward

H

thread.

push

work

bobbin

into

needle.

to

Chart.

lightly.

will

it

far

as

as

up

needle

Cause:

Seam

4.

Tension

Thread

Bobbin

Kinks

material.

of

Machine

5.

has

Lint

rows

Feed

control

Machine

6.

Thread

is

out

thick,

too

thread

appear

accumulated

feed

of

dropped.

dog

is

at

ends

uniform

not

of

adjustment.

wound

on

feeds

dog.

left.)

works

hook

in

knotty

unevenly.

and

top

irregularly

between

(Reverse-feed

heavily

raceway.

hard.

or

bottom

or

tooth

not

Remedy:

lower

only.

pass

properly

and

control

and

tensions.

not

do

it

through

and

clean

the

to

put

hold

check

out

right.

drop

a

lint.

of

and

upper

Check

bobbin

hand,

machine

needle

thread

hook

thread

winding,

but

stud.

plate

ends

raceway.

first-class

Use

During

in

thread

retainer

thread

Thread

tensions.

both

all

at

Remove

reverse-feed

Flick

Remove

into

oil

24

Loading...

Loading...