Perkins Engine 1104E Maintenance Manual

Operation and

Maintenance

Manual

SEBU8121

February 2005

1104E Engine

RF11-Up

RH11-Up (Machine)

RK11-Up (Machine)

(Machine)

i01658146

Important Safety Information

Most accidents t

basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous

situations before an accident occurs. A person must be alert to potential hazards. This person should also

have the necess

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate o

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings

are not heeded

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is s hown below.

The meaning of this safety alert symbol is as follows:

Attention! Be

The message that appears under the warning explains the hazard and can be either written or pictorially

presented.

Operations th

this publication.

hat involve product operation, maintenance and repair are caused by failure to observe

ary training, skills and tools to perform these functions properly.

r perform any lubrication, maintenance or repair on this product, until you have

, bodily injury or death could occur to you or to other persons.

come Alert! Your Safety is Involved.

at may cause product damage are identified by “NOTICE” labels on the product and in

Perkins cannot anticipa te e ver y p os sible c irc u mstance t hat m ight invol ve a pote n ti al hazard .

The warnings

proc edure, work me thod or ope rating technique tha t is not s pecific ally rec ommended by Perkins

is used, you must satisfy yourself that it is safe for you and for others. You should also ensure that

the product w

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was availabl

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before you

s t ar t any jo

in this publication and on the product are, therefore, not all inclusive. If a tool,

ill not be damaged or be made unsafe by the operation, lubrication, maintenance or

e at the time that the publication was written. The specifications, torques, pressures,

b . Perkins dea le rs hav e t he m os t c ur r en t i nfo rm ati on a va il abl e.

When replacement parts are required for this

product Perkins re comme nds usi ng Perkins

e ment parts or parts w ith equiva lent

re pl ac

specifications including, but not limited to, physical dimensions, type , strength and material.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

SEBU8121 3

Table of Contents

Table of Contents

Foreword ................................................................. 4

Safety Section

Safety Messages .................................................... 5

General Hazard Information ................................... 5

Burn Prevention ...................................................... 7

Fire Prevention and Explosion Prevention .............. 7

Crushing Prevention and Cutting Prevention .......... 9

Before Starting Engine ............................................ 9

Engine Starting ....................................................... 9

Engine Stopping ................................................... 10

Electrical System .................................................. 10

Engine Electronics ................................................. 11

Warranty S ecti

Warranty Information ............................................ 81

on

Index Section

Index ..................................................................... 82

Product Information Section

General Information .............................................. 12

Model Views ......................................................... 13

Product Identification Information ........................ 17

Operation Section

Lifting and Storage ................................................ 19

Gauges and Indicators .......................................... 22

Features and Controls .......................................... 23

Engine Diagnostics ............................................... 27

Engine Starting ..................................................... 29

Engine Operation .................................................. 33

Engine Stopping ................................................... 34

Cold Weather Operation ....................................... 35

Maintenance Section

Refill Capacities .................................................... 39

Maintenance Interval Schedule ............................ 52

4 SEBU8121

Foreword

Foreword

Literature Information

This manual con

lubrication a nd maintenance information. This

manual should be stored in or near the engine area

in a literatur

study and keep it with the literature and engine

information.

English is the primary language for all Perkins

publications. The English used facilitates translation

and consiste

Some photographs or illustrations in this manual

show details

from your engine. Guards and covers may have

been removed for illustrative purposes. Continuing

improvemen

may have caused changes to your engine which are

not included in this manual. Whenever a question

arises reg

consult with your Perkins dealer or your Perkins

distributor for the latest available information.

arding your engine, or this manual, please

Safety

This safety section lists basic safety precautions.

In addition, this section identifies hazardous,

warning si

precautions listed in the safety section before

operating or performing lubrication, maintenance and

repair on

this product.

tains safety, operation instructions,

e holder or literature storage area. Read,

ncy.

or attachments that may be different

t and advancement of product design

tuations. Read and understand the basic

Recommended se

appropriate intervals as indicated in the Maintenance

Interval Schedule. The actual operating environment

of the engine a

Schedule. Therefore, under extremely severe,

dusty, wet or freezing cold operating conditions,

more frequen

specified in the Maintenance Interval Schedule may

be necessary.

The maintenance schedule items are organized for

a preventive maintenance management program. If

the prevent

periodic tune-up is not required. The implementation

of a preventive maintenance management program

should mini

avoidances resulting from reductions in unscheduled

downtime and failures.

ive maintenance program is followed, a

mize operating costs through cost

rvice should be performed at the

lso governs the Maintenance Interval

t lubrication and maintenance than is

Maintenance Intervals

Perform maintenance on items at multiples of

the original requirement. We recommend that the

maintenan

near the engine as a convenient reminder. We also

recommend that a maintenance record be maintained

as part of

Your authorized Perkins dealer or your Perkins

distribu

maintenance schedule to meet the needs of your

operating environment.

ce schedules be reproduced and displayed

the engine’s permanent record.

tor can assist you in adjusting your

Overhaul

Operatio

Operating techniques outlined in this manual are

basic. Th

techniques required to operate the engine more

efficiently and economically. Skill and techniques

develop

engine and its capabilities.

The oper

Photographs and illustrations guide the operator

through procedures of inspecting, starting, operating

and sto

discussion of electronic diagnostic information.

n

ey assist with developing the skills and

as the operator gains knowledge of the

ation section is a reference for operators.

pping the engine. This section also includes a

Maintenance

The mai

The illustrated, step-by-step instructions are grouped

by service hours and/or calendar time maintenance

interv

referenced to detailed instructions that follow.

ntenance section is a guide to engine care.

als. Items in the maintenance schedule are

Major engine overhaul details are not covered in

the Operation and Maintenance Manual except

for the i

interval. Major repairs should only be carried out by

Perkins authorized personnel. Your Perkins dealer

or your P

regarding overhaul programs. If you experience

a major engine failure, there are also numerous

after f

your Perkins dealer or your Perkins distributor for

information regarding these options.

nterval and the maintenance items in that

erkins distributor offers a variety of options

ailure overhaul options available. Consult with

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

defects, and other reproductive harm. Battery

birth

posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

SEBU8121 5

Safety Section

Safety Messages

Safety Section

i02206606

Safety Me ssage s

There may be s

an engine. The exact location of the hazards and

the description of the hazards are reviewed in this

section. Ple

signs.

Ensure that a

the warning signs or replace the warning signs if

the words cannot be read or if the pictures are not

visible. Wh

cloth, water, and soap. Do not use solvent, gasoline,

or other harsh chemicals to clean the warning signs.

Solvents,

the adhesive that secures the warning signs. The

warning signs that are loosened could drop off of

the engine

Replace any damaged warning signs or missing

warning si

of the engine that is replaced, install a new warning

sign on the replacement part. Perkins dealers or

Perkins d

everal specific warning signs on

ase become familiar with all warning

ll of the warning signs are legible. Clean

en the warning signs are cleaned, use a

gasoline, or harsh chemicals could loosen

.

gns. If a warning sign is attached to a part

istributors can provide new warning signs.

Ether

The warning lab

front, the rear, or the side of the engine.

Never spray Ether starting aids into the air inl et.

el for ether is located on the top, the

g00640926

i02203039

General Hazard Information

Do not work on the engine and do not operate the

engine un

Operation and Maintenance Manual are understood.

Correct care is your responsibility. Failure to follow

the inst

result in injury or in death.

The warn

are illustrated and described.

less the instructions and warnings in the

ructions or failure to heed the warnings could

ing labels that may be found on the engine

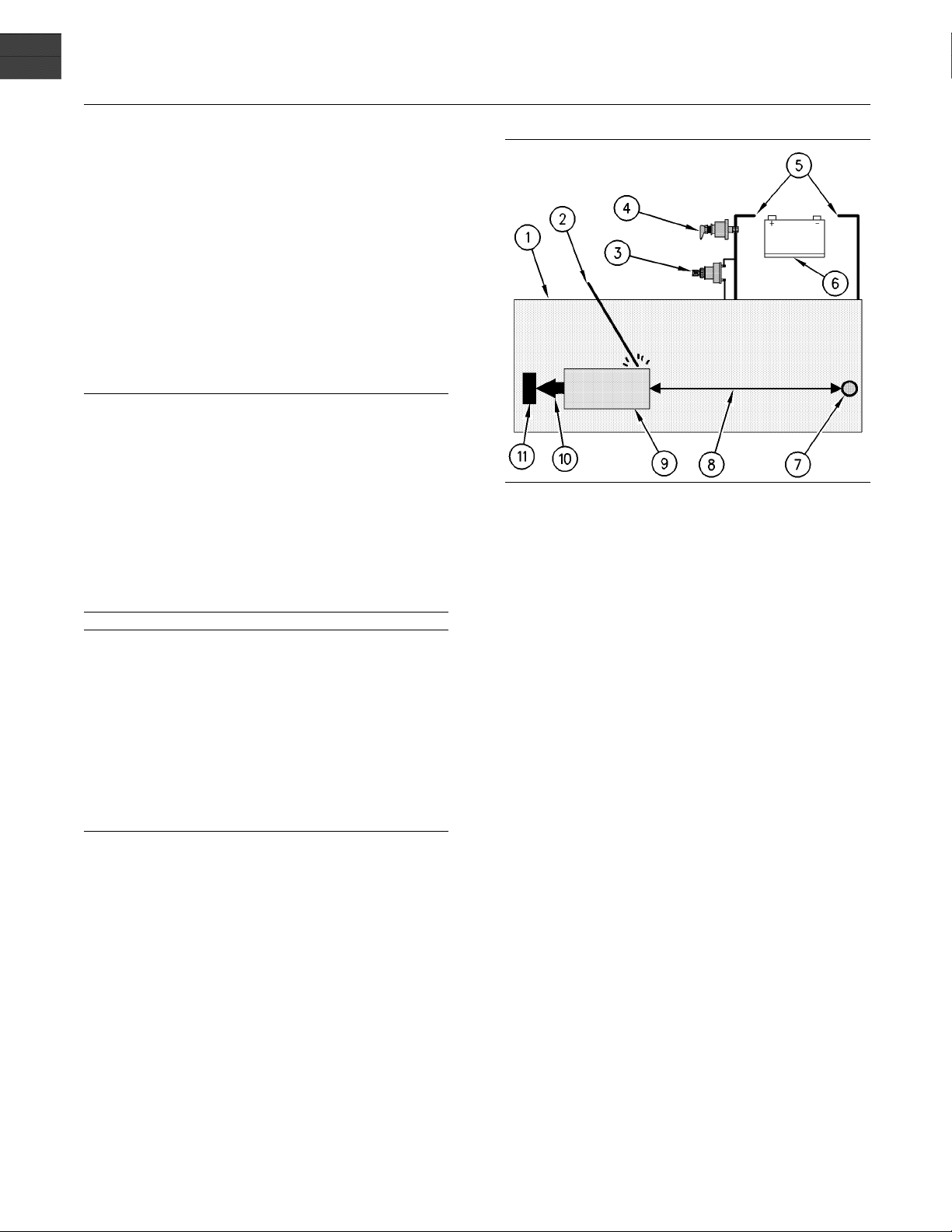

Illustration 1

Attach a “

warning tag to the start switch or to the controls

before you service the equipment or before you

repair th

Do Not Operate” warning tag or a similar

eequipment.

g00104545

6 SEBU8121

Safety Section

General Hazard Information

Illustration 2

Wear a hard hat, protective glasses, and other

protective equipment, as required.

Do not wear loose clothing or jewelry that can snag

on controls or on other parts of the engine.

Make sure that all protective guards and all covers

are secured in place on the engine.

Keep the engine free from foreign material. Remove

debris, oil, tools, and other items from the deck, from

walkways, and from steps.

g00702020

The maximum air

must be below 205 kPa (30 psi). The maximum

water pressure for cleaning purposes must be below

275 kPa (40 psi

Fluid Penetra

Pressure can be trapped in the hydraulic circuit long

after the eng

cause hydraulic fluid or items such as pipe plugs to

escape rapidly if the pressure is not relieved correctly .

Do not remove any hydraulic components or parts

until pressure has been relieved or personal injury

may occur. Do

components or parts until pressure has been relieved

or personal injury may occur. Refer to the OEM

informatio

relieve the hydraulic pressure.

n for any procedures that are required to

pressure for cleaning purposes

).

tion

ine has been stopped. The pressure can

not disassemble any hydraulic

Never put maintenance fluids into glass containers.

Drain all liquids into a suitable container.

Obey all local regulations for the disposal of liquids.

Use all cleaning solutions with care. Report all

necessary repairs.

Do not allow unauthorized personnel on the

equipment.

Note: Ensure that the power supply is disconnected

before you work on the bus bar or the glow plugs.

Unless you are instructed otherwise, perform

maintenance on the engine with the equipment in

the servicing position. Refer to the OEM information

for the procedure for placing the equipment in the

servicing position.

Pressure Air and Water

Pressurized air and/or water can cause debris

and/or hot water to be blown out. This could result in

personal injury.

When pressurized air and/or water is used for

cleaning, wear protective clothing, protective shoes,

and eye protection. Eye protection includes goggles

oraprotectivefaceshield.

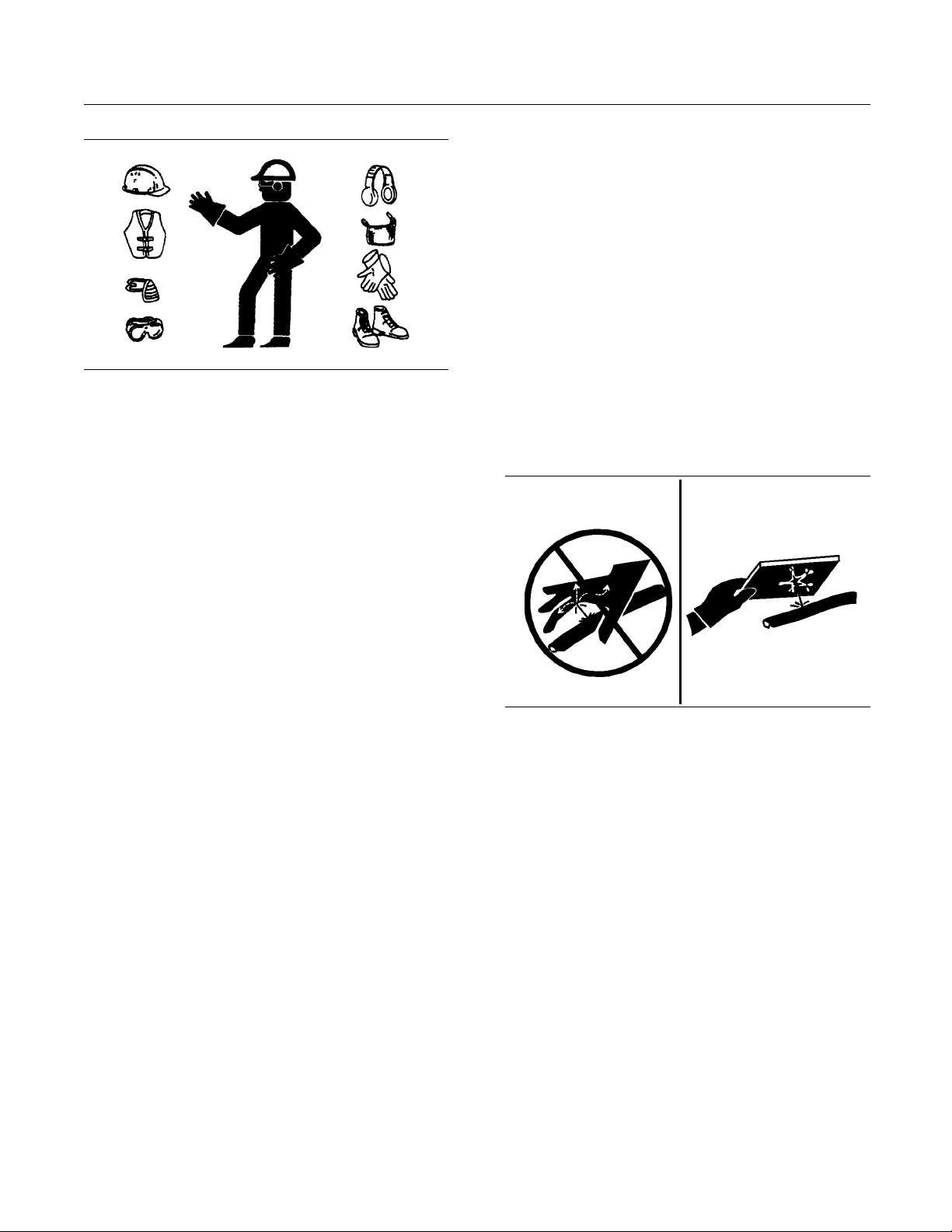

Illustration 3

Always use a board or cardboard when you check

for a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

g00687600

Containing Fluid Spillage

Care must be taken in order to ensure that fluids

are contained during performance of inspection,

maintenance, testing, adjusting and repair of the

engine. Make provision to collect the fluid with a

suitable container before any compartment is opened

or before any component is disassembled.

Only use the tools that are suitable for collecting

•

fluids and equipment that is suitable for collecting

fluids.

Only use the tools that are suitable for containing

•

fluids and equipment that is suitable for containing

fluids.

SEBU8121 7

Safety Section

Burn Prevention

Obey all local r

egulations for the disposal of liquids.

i02143195

Burn Prevention

Do not touch any part of an operating engine.

Allow the engine to cool before any maintenance

is performed on the engine. Relieve all pressure

in the air system, in the hydraulic system, in the

lubrication system, in the fuel system, or in the

cooling system before any lines, fittings or related

items are disconnected.

Coolant

When the engine is at operating temperature, the

engine coolant is hot. The coolant is also under

pressure. The radiator and all lines to the heaters or

to the engine contain hot coolant.

Any contact with hot coolant or with steam can cause

severe burns. Allow cooling system components to

cool before the cooling system is drained.

Check the coolant level after the engine has stopped

and the engine has been allowed to cool.

i02203164

Fire Prevention and Explosion

Prevention

on 4

Illustrati

All fuels, most lubricants, and some coolant mixtures

are flammab

Flammable fluids that are leaking or spilled onto hot

surfaces or

a fire. Fire may cause personal injury and property

damage.

le.

onto electrical components can cause

g00704000

Ensure that the filler cap is cool before removing the

filler cap. The filler cap must be cool enough to touch

withabarehand.Removethefillercapslowlyin

order to relieve pressure.

Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

the skin, the eyes, or the mouth.

Oils

Hot oil and hot lubricating components can cause

personal injury. Do not allow hot oil to contact the

skin. Also, do not allow hot components to contact

the skin.

Batteries

Electrolyte is an acid. Electrolyte can cause personal

injury. Do not allow electrolyte to contact the skin or

the eyes. Always wear protective glasses for servicing

batteries. Wash hands after touching the batteries

and connectors. Use of gloves is recommended.

A flash fire may result if the covers for the engine

crankcase are removed within fifteen minutes after

an emergen

Determinewhethertheenginewillbeoperatedinan

environme

drawn into the air inlet system. These gases could

cause the engine to overspeed. Personal injury,

property

If the application involves the presence of combustible

gases, co

Perkins distributor for additional information about

suitable protection devices.

Remove all flammable combustible materials or

conductive materials such as fuel, oil, and debris from

the engi

materials or conductive materials to accumulate on

the engine.

Store fuels and lubricants in correctly marked

containers away from unauthorized persons. Store

oily rag

containers. Do not smoke in areas that are used for

storing flammable materials.

cy shutdown.

nt that allows combustible gases to be

damage, or engine damage could result.

nsult your Perkins dealer and/or your

ne. Do not allow any flammable combustible

s and any flammable materials in protective

Do not expose the engine to any flame.

8 SEBU8121

Safety Section

Fire Prevention and Explosion Prevention

Exhaust shield

s (if equipped) protect hot exhaust

components from oil or fuel spray in case of a line,

a tube, or a seal failure. Exhaust shields must be

installed cor

rectly.

Do not weld on lines or tanks that contain flammable

fluids. Do no

t flame cut lines or tanks that contain

flammable fluid. Clean any such lines or tanks

thoroughly with a nonflammable solvent prior to

welding or fl

ame cutting.

Wiring must be kept in good condition. All electrical

wires must be

correctly routed and securely attached.

Check all electrical wires daily. Repair any wires

that are loose or frayed before you operate the

engine. Cle

an all electrical connections and tighten

all electrical connections.

Eliminate a

ll wiring that is unattached or unnecessary.

Do not use any wires or cables that are smaller than

the recommended gauge. Do not bypass any fuses

and/or cir

cuit breakers.

Arcing or sparking could cause a fire. Secure

connectio

ns, recommended wiring, and correctly

maintained battery cables will help to prevent arcing

or sparking.

Inspect all lines and hoses for wear or for

deterioration. The hoses must be correctly routed.

The lines

and hoses must have adequate support

and secure clamps. Tighten all connections to the

recommended torque. Leaks can cause fires.

Oil filters and fuel filters must be correctly installed.

The filter housings must be tightened to the correct

torque.

Use caution whe

n you are refueling an engine. Do

not smoke while you are refueling an engine. Do not

refuel an engine near open flames or sparks. Always

stop the engin

Illustration 6

e before refueling.

g00704135

Gases from a battery can explode. Keep any open

flames or sparks away from the top of a battery. Do

not smoke in battery charging areas.

Never check the battery charge by placing a metal

object across the terminal posts. Use a voltmeter or

ahydrometer.

Incorrect jumper cable connections can cause

an explosion that can result in injury. Refer to

the Operation Section of this manual for specific

instructions.

Illustration 5

Do not charge a frozen battery. This may cause an

explosion.

The batteries must be kept clean. The covers

(if equipped) must be kept on the cells. Use the

recommended cables, connections, and battery box

covers when the engine is operated.

Fire Extinguisher

Make sure that a fire extinguisher is available. Be

familiar with the operation of the fire extinguisher.

Inspect the fire extinguisher and service the fire

extinguisher regularly. Obey the recommendations

on the instruction plate.

g00704059

SEBU8121 9

Safety Section

Crushing Prevention and Cutting Prevention

Lines, Tubes and Hoses

Do not bend high

pressure lines. Do not install any lines that are bent

or damaged.

Repair any lines that are loose or damaged. Leaks

can cause fires. Consult your Perkins dealer or your

Perkins dist

Check lines, tubes and hoses carefully. Do not use

your bare han

cardboard to check for leaks. Tighten all connections

to the recommended torque.

Replace the parts if any of the following conditions

are present:

End fittings are damaged or leaking.

•

Outer cover

•

Wires are exposed.

•

Outer coverings are ballooning.

•

Flexible pa

•

Outer covers have embedded armoring.

•

End fittings are displaced.

•

Make sure tha

are installed correctly. During engine operation, this

will help to prevent vibration, rubbing against other

parts, and e

pressure lines. Do not strike high

ributor for repair or for replacement parts.

dtocheckforleaks.Useaboardor

ings are chafed or cut.

rt of the hoses are kinked.

t all clamps, guards, and heat shields

xcessive heat.

i02143194

Chips or other d

are struck. Before objects are struck, ensure that no

one will be injured by flying debris.

ebris may fly off objects when objects

i02157341

Before Starting Engine

NOTICE

For initial start-up of a new or rebuilt engine, and for

start-up of an engine that has been serviced, make

provision to shut the engine off should an overspeed

occur. This may be accomplished by shutting off the

air and/or fuel supply to the engine.

Overspeed shutdown should occur automatically.

If automatic shutdown does not occur, press the

emergency stop button in order to cut the fuel and/or

air to the engine.

Inspect the engine for potential hazards.

Before starting the engine, ensure that no one is on,

underneath, or close to the engine. Ensure that the

area is free of personnel.

If equipped, ensure that the lighting system for the

engine is suitable for the conditions. Ensure that all

lights work correctly, if equipped.

All protective guards and all protective covers must

be installed if the engine must be started in order

to perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

around the parts carefully.

Crushing Prevention and

Cutting Pr

Support the component correctly when work beneath

the component is performed.

Unless other maintenance instructions are provided,

never attempt adjustments while the engine is

running.

Stay clear of all rotating parts and of all moving

parts. Le

is performed. After the maintenance is performed,

reinstall the guards.

Keep objects away from moving fan blades. The fan

blades will throw objects or cut objects.

When objects are struck, wear protective glasses in

order to avoid injury to the eyes.

ave the guards in place until maintenance

evention

Do not bypass the automatic shutoff circuits. Do not

disable the automatic shutoff circuits. The circuits are

provided in order to help prevent personal injury. The

circuits are also provided in order to help prevent

engine damage.

See the Service Manual for repairs and for

adjustments.

i022072

Engine Starting

Do not use aerosol types of starting aids s uch as

ether. Such use could result in an explosion and

persona

linjury.

32

10 SEBU8121

Safety Section

Engine Stopping

If a warning tag

or to the controls, DO NOT start the engine or move

the controls. Consult with the person that attached

the warning ta

All protective guards and all protective covers must

be installed

to perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

around the pa

Start the engine from the operator’s compartment or

from the engi

Always start the engine according to the procedure

that is descr

Manual, “Engine Starting” topic in the Operation

Section. Knowing the correct procedure will help to

prevent maj

Knowing the procedure will also help to prevent

personal injury.

To ensure that the jacket water heater (if equipped)

and/or the lube oil heater (if equipped) is working

correctly

oil temperature gauge during the heater operation.

Engine exh

which can be harmful to your health. Always start the

engine and operate the engine in a well ventilated

area. If t

vent the engine exhaust to the outside.

Note: The

device for cold starting for normal conditions of

operation. If the engine will be operated in very cold

conditi

required. Normally, the engine will be equipped with

the correct type of starting aid for your region of

operati

The engines are equipped with a glow plug starting

aidinea

air in order to improve starting.

, check the water temperature gauge and the

he engine is started in an enclosed area,

ons, then an extra cold starting aid may be

on.

ch individual cylinder that heats the intake

is attached to the engine start switch

g before the engine is started.

if the engine must be started in order

rts carefully.

ne start switch.

ibed in the Operation and Maintenance

or damage to the engine components.

aust contains products of combustion

engine is equipped with an automatic

i01928905

Engine Stopping

Use the Emergen

in an emergency situation. Do not use the Emergency

Stop Button for normal engine stopping. After an

emergency sto

problem that caused the emergency stop has been

corrected.

Stop the engine if an overspeed condition occurs

during the initial start-up of a new engine or an engine

that has been

by shutting off the fuel supply to the engine and/or

shutting off the air supply to the engine.

cy Stop Button (if equipped) ONLY

p, DO NOT start the engine until the

overhauled. This may be accomplished

i02176668

Electrical S ys tem

Never disconnect any charging unit circuit or battery

circuit cable from the battery when the charging unit

is operating. A spark can cause the combustible

gases that are produced by some batteries to ignite.

To help prevent sparks from igniting combustible

gases that are produced by some batteries, the

negative “−” jump start cable should be connected

last from the external power source to the negative

“−” terminal of the starting motor. If the starting motor

is not equipped with a negative “−” terminal, connect

the jump start cable to the engine block.

Check the electrical wires daily for wires that are

loose or frayed. Tighten all loose electrical wires

before the engine is started. Repair all frayed

electrical wires before the engine is started. See

the Operation and Maintenance Manual for specific

starting instructions.

Grounding Practices

Correct grounding for the engine electrical system

is necessary for optimum engine performance

and reliability. Incorrect grounding will result in

uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

Uncontrolled electrical circuit paths can result in

damage to main bearings, to crankshaft bearing

journal surfaces, and to aluminum components.

Stop the engine according to the procedure in

the Operation and Maintenance Manual, “Engine

Stopping (Operation Section)” in order to avoid

overheating of the engine and accelerated wear of

the engine components.

Engines that are installed without engine-to-frame

ground straps can be damaged by electrical

discharge.

To ensure that the engine and the engine electrical

systems function correctly, an engine-to-frame

ground strap with a direct path to the battery must be

used. This path may be provided by way of a direct

engine ground to the frame.

SEBU8121 11

Safety Section

Engine Electronics

All grounds sho

engine alternator must be grounded to the negative

“-” battery terminal with a wire that is adequate to

handle the ful

uldbetightandfreeofcorrosion.The

l charging current of the alternator.

i01885770

Engine Electron ics

Tampering with the electronic system installation

or the OEM wir

and could result in personal injury or death and/or

engine damage.

This engine has a comprehensive, programmable

Engine Monitoring System. The Electronic Control

Module (ECM

operating conditions. If any of the engine parameters

extend outside an allowable range, the ECM will

initiate a

n immediate action.

ing installation can be dangerous

) has the ability to monitor the engine

The following actions are available for engine

monitorin

SHUTDOWN. These engine monitoring modes have

the ability to limit engine speed and/or the engine

power.

Engine Coolant Temperature

•

Engine Oil Pressure

•

Engine Spe

•

Fuel Temperature

•

Intake Manifold Air Temperature

•

System Vol

•

The Engine Monitoring package can vary for different

engine mo

However, the monitoring system and the engine

monitoring control will be similar for all engines.

Note: Many of the engine control systems and display

modules that are available for Perkins Engines will

work in un

Together, the two controls will provide the engine

monitoring function for the specific engine application.

Refer to

more information on the Engine Monitoring System.

g control: WARNING, DERATE, and

ed

tage

dels and different engine applications.

ison with the Engine Monitoring System.

the Electronic Troubleshooting Manual for

12 SEBU8121

Product Information Section

General Information

Product Information

Section

General Information

i01889424

Welding on Engines w it h

Electronic Controls

NOTICE

Proper welding procedures are necessary in order

to avoid damage to the engine’s ECM, sensors, and

associated components. When possible, remove the

component from the unit and then weld the component. If removal of the component is not possible,

the following procedure must be followed when you

weld with a unit that is equipped with an Electronic

Engine. The following procedure is considered to be

the safest procedure to weld a component. This procedure should provide a minimum risk of damage to

electronic components.

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding can

cause damage to the drive train bearings, hydraulic

components, electrical components, and other components.

Clamp the ground cable from the welder to the component that will be welded. Place the clamp as close

as possible to the weld. This will help reduce the possibility of damage.

1. Stop the engine. Turn the switched power to the

OFF position.

2. Disconnect the negative battery cable from the

battery. If a battery disconnect switch is provided,

open the switch.

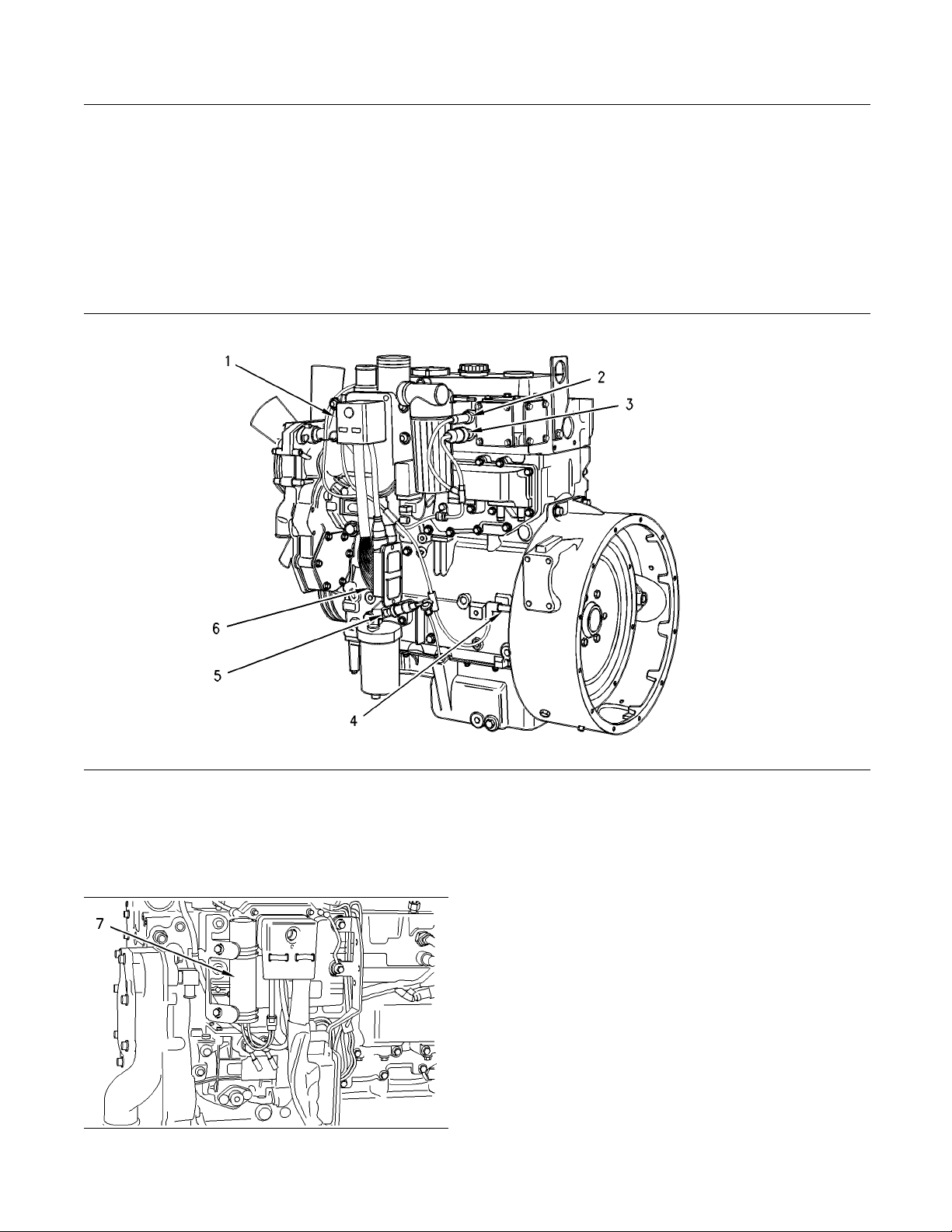

Illustration 7

Use the example above. The current flow from the w elder to

the ground clamp of the welder will not cause damage to any

associated components.

(1) Engine

(2) Welding rod

(3) Keyswitch in the OFF position

(4) Battery disconnect switch in the open position

(5) Disconnected battery cables

(6) Battery

(7) Electrical/Electronic component

(8) Maximum distance between the component that is being

welded and any electrical/electronic component

(9) The com ponent that is being welded

(10) Current path of the welder

(11) Ground clamp for the welder

4. Connect the welding ground cable directly to the

part that will be welded. Place the ground cable as

close as possible to the weld in order to reduce the

possibility of welding current damage to bearings,

hydraulic components, electrical components, and

ground straps.

Note: If electrical/electronic components are used

as a ground for the welder, or electrical/electronic

components are located between the welder ground

and the weld, current flow from the welder could

severely damage the component.

g00765012

3. Disconnect the J1/P1 connectors from the ECM.

Move the harness to a position that will not allow

the harness to accidentally move back and make

contact with any of the ECM pins.

5. Protect the wiring harness from welding debris

and spatter.

6. Use standard welding practices to weld the

materials.

SEBU8121 13

Product Information Section

Model Views

Model Views

i02247468

Model View Illustrations

1104 Engine Vi

ews

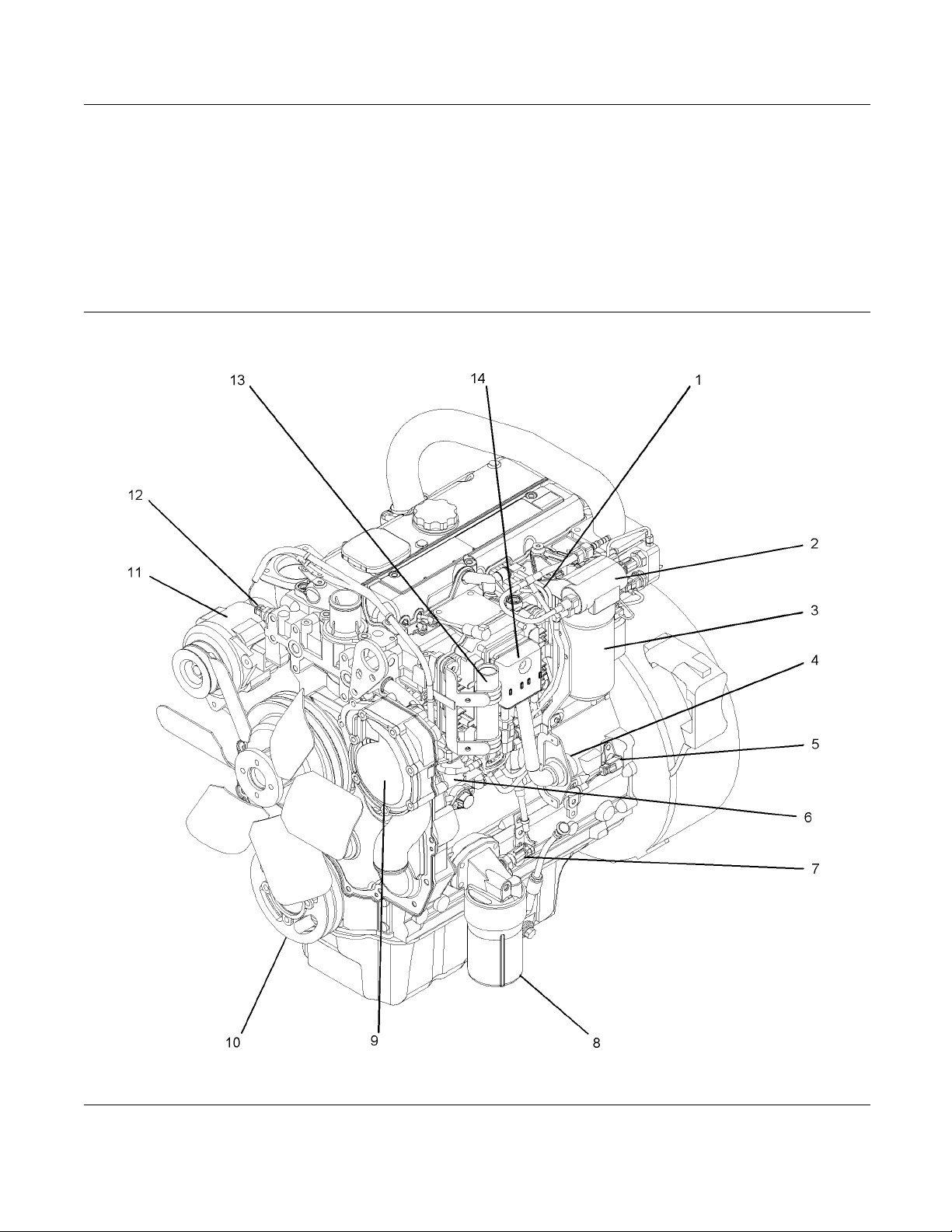

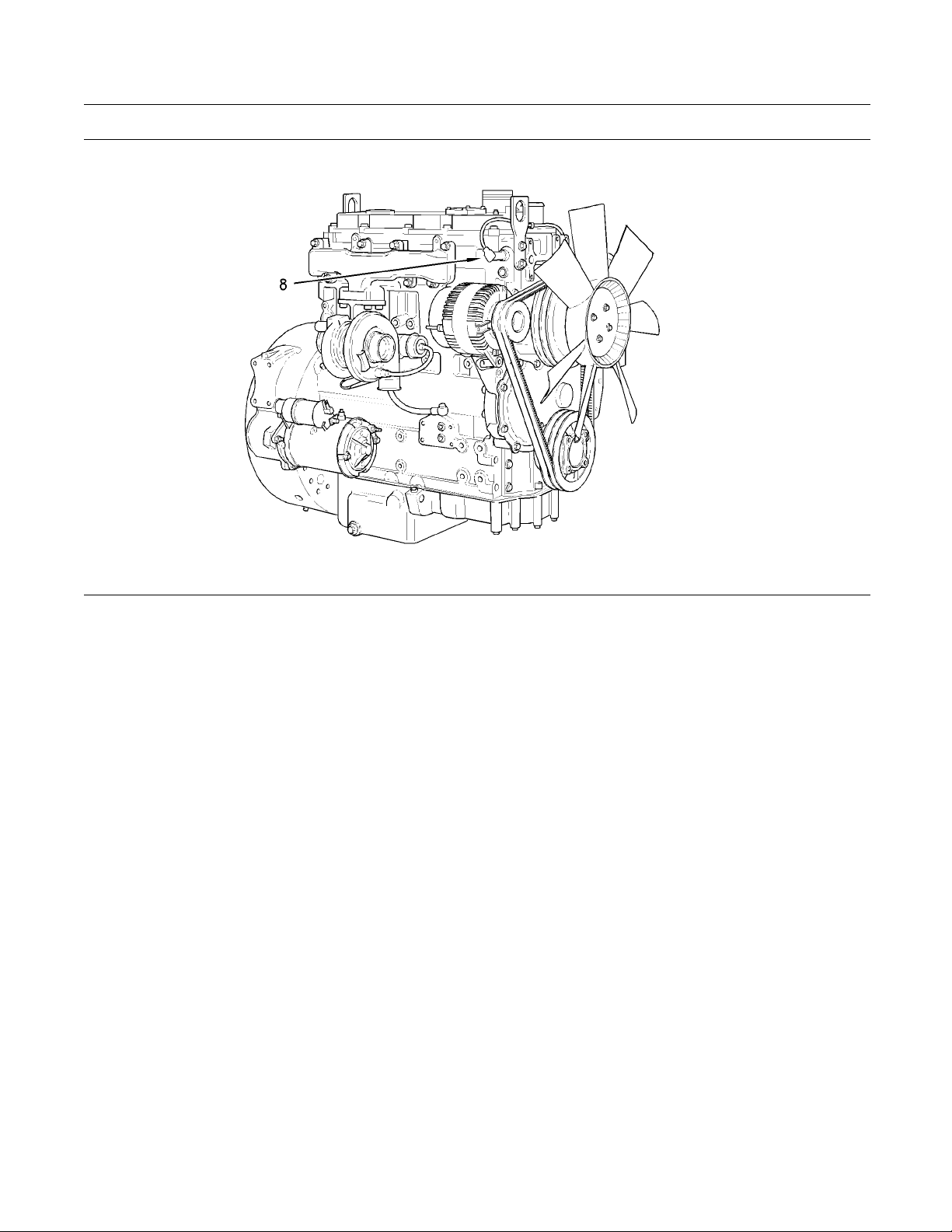

Illustration 8

Left side view of the 1104 engine

Typical example of the 1104 engine

g01131700

14 SEBU8121

Product Information Section

Model Views

(1) Fuel lines

(2) Fuel primin

(3) Fuel filter

(4) Machine int

(5) Speed/timin

(6) Electronic f

(7) Engine oil pr

g pump

erface connector (MIC)

gsensor

uel injection pump

essure sensor

(8) Engine oil f

(9) Water pump

(10) Crankshaf

(11) Alternato

(12) Engine cool

(13) Voltage loa

(14) Electronic

r

ilter

t pulley

ant temperature sensor

d protection module

control module (ECM)

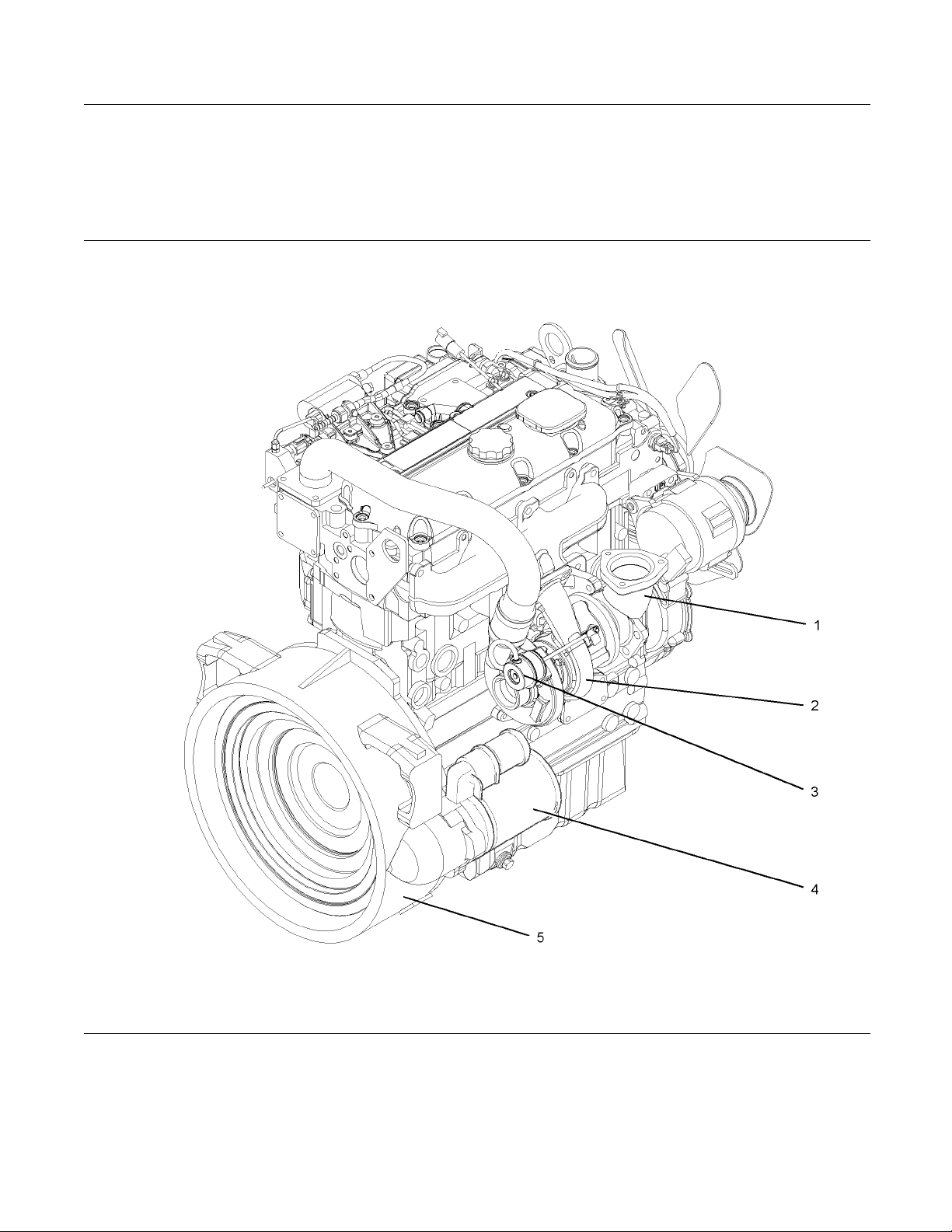

Illustration 9

Right side view of the 1104 engine

Typical example of the 1104 engine

(1) Exhaust elbow

(2) Turbocharger

(3) Wastegate actuator

(4) Starter motor

g01131701

(5) Flywheel housing

SEBU8121 15

Product Information Section

Model Views

i02247483

Engine Description

The Perkins110

the following applications: machine and industrial

mobile equipment. The engines are available in the

following typ

Turbocharged aftercooled

•

Turbocharged

•

Naturally asp

•

Engine Specif

Note: The front end of the engine is opposite the

flywheel end

sides of the engine are determined from the flywheel

end. The number 1 cylinder is the front cylinder.

4 Electronic Engine is designed for

es of aspiration:

irated

ications

of the engine. The left and the right

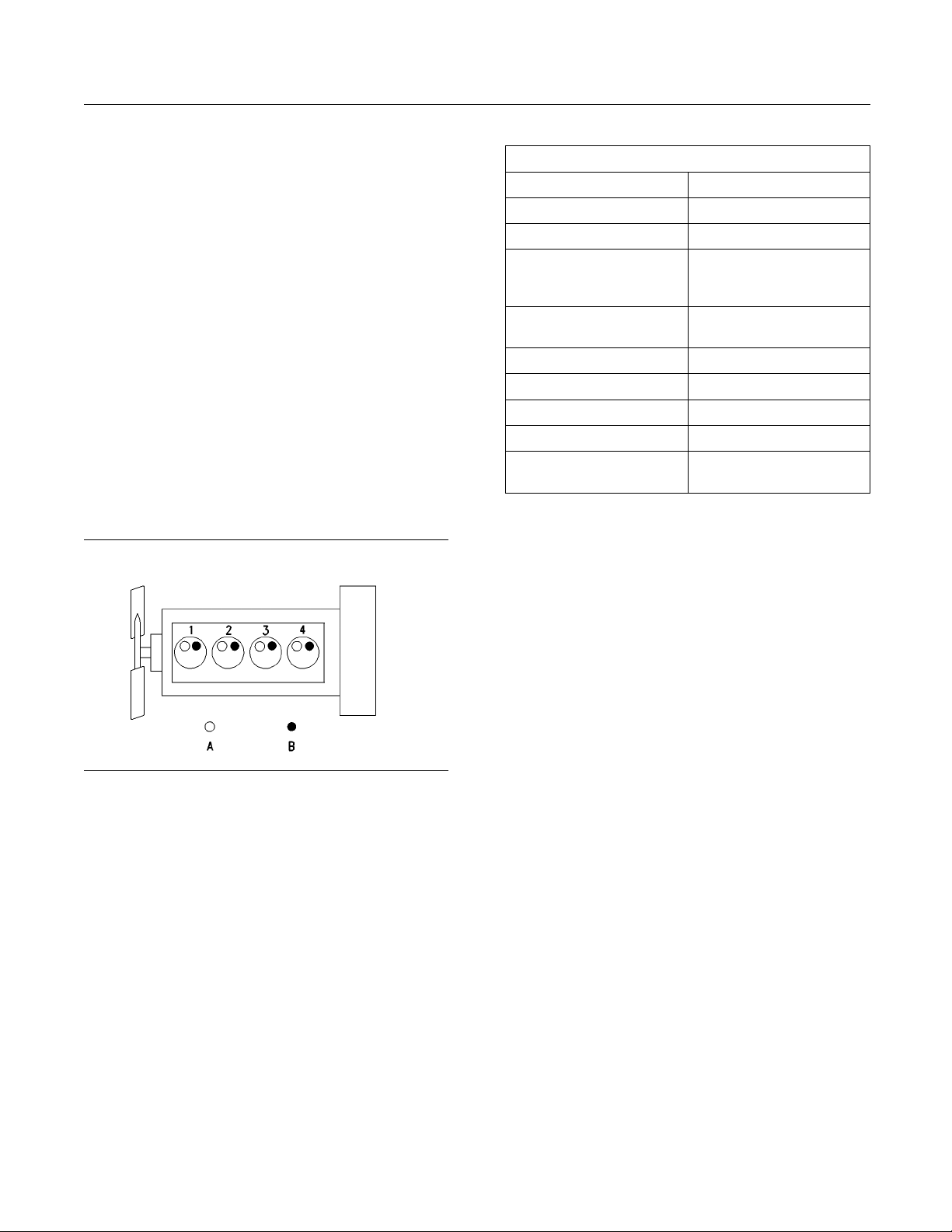

Table 1

1104 Electronic Engine Specifications

Number of Cylinders 4 In-Line

Bore

Stroke 127 mm (5.0 inch)

Aspiration

Compression

Displacement

Firing Order 1-3-4-2

Rotation (flywheel end) Counterclockwise

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting

(Exhaust)

lectronic Engine Featur es

E

The Perkins 1104 Electronic Engine is designed with

lectronic controls. The integral on board computer

e

controls the operation of the engine. Current

operating conditions are monitored. The Electronic

Control Module (ECM) controls the response of the

engine to these conditions and to the demands of the

operator. These conditions and operator demands

determine the precise control of fuel injection by the

ECM. The electronic engine control system provides

the following features:

Ratio

105 mm (4.134 inch)

Turbocharged, aftercooled

Turbocharged

Naturally aspirated

NA 19.25:1 NA

T 18.23:1 T, TA

4.4L(268in3)

0.45 mm (0.018 inch)

Illustration 10

Typical example

1104 Electronic engine

(A) Inlet valves

(B) Exhaust valves

g00984281

Engine monitoring

•

Engine speed governing

•

Cold start strategy

•

Automatic air/fuel ratio control

•

Torque rise shaping

•

Automatic altitude compensation

•

Fuel temperature compensation

•

Injection timing control

•

System diagnostics

•

For more information on electronic engine features,

refer to the Operation and Maintenance Manual,

“Features and Controls” topic (Operation Section).

16 SEBU8121

Product Information Section

Model Views

Engine Diagnostics

The Perkins 110

in order to ensure that all of the components are

functioning properly. The operator will be informed of

anychangetoa

be alerted to the condition by a “Stop or Warning”

lamp that may be mounted on the dashboard or

on the contro

engine horsepower and the vehicle speed may be

limited. The electronic service tool may be used to

display the d

There are three types of diagnostic codes: active,

logged, and

Most of the diagnostic codes are logged and stored

in the ECM. F

the Operation and Maintenance Manual, “Engine

Diagnostics” topic (Operation Section).

The ECM provides an electronic governor that

controls the injector output in order to maintain the

desired en

Engine Coo

4 engine has built-in diagnostics

programmed limit. The operator will

l panel. Under certain conditions, the

iagnostic codes.

event.

or additional information, refer to

gine rpm.

ling and Lubrication

Engine Service Life

Engine efficiency and maximum utilization of engine

performance depend on the adherence to proper

operation and maintenance recommendations. In

addition, use recommended fuels, coolants and

lubricants. Use the Operation and Maintenance

Manual as a guide for required engine maintenance.

Expected engine life is generally predicted by the

average power that is demanded. The average power

that is demanded is based on fuel consumption of

the engine over a period of time. Reduced hours of

operation at full throttle and/or operating at reduced

throttle settings result in a lower average power

demand. Reduced hours of operation will increase

the length of operating time before an engine

overhaul is required.

The cooling system consists of the following

component

Gear-driven centrifugal water pump

•

Water temperature regulators which regulate the

•

engine coolant temperature

Gear-driven oil pump (gear type)

•

Oil cooler

•

The engine lubricating oil is supplied by a gear

type pump

the engine lubricating oil is filtered. Bypass valves

provide unrestricted flow of lubrication oil to the

engine pa

can also provide unrestricted flow of lubrication oil

to the engine parts if the oil cooler should become

plugged

plugged.

Engine e

engine performance depend on adherence to proper

operation and maintenance recommendations.

Engine p

the use of recommended fuels, lubrication oils, and

coolants. Refer to the Operation and Maintenance

Manual

information on maintenance items.

s:

. The engine lubricating oil is cooled and

rts when oil viscosity is high. Bypass valves

or if the oil filter element should become

fficiency, efficiency of emission controls, and

erformance and efficiency also depend on

, “Maintenance Interval Schedule” for more

SEBU8121 17

Product Information Section

Product Identification Information

Product Identification

Information

i02280116

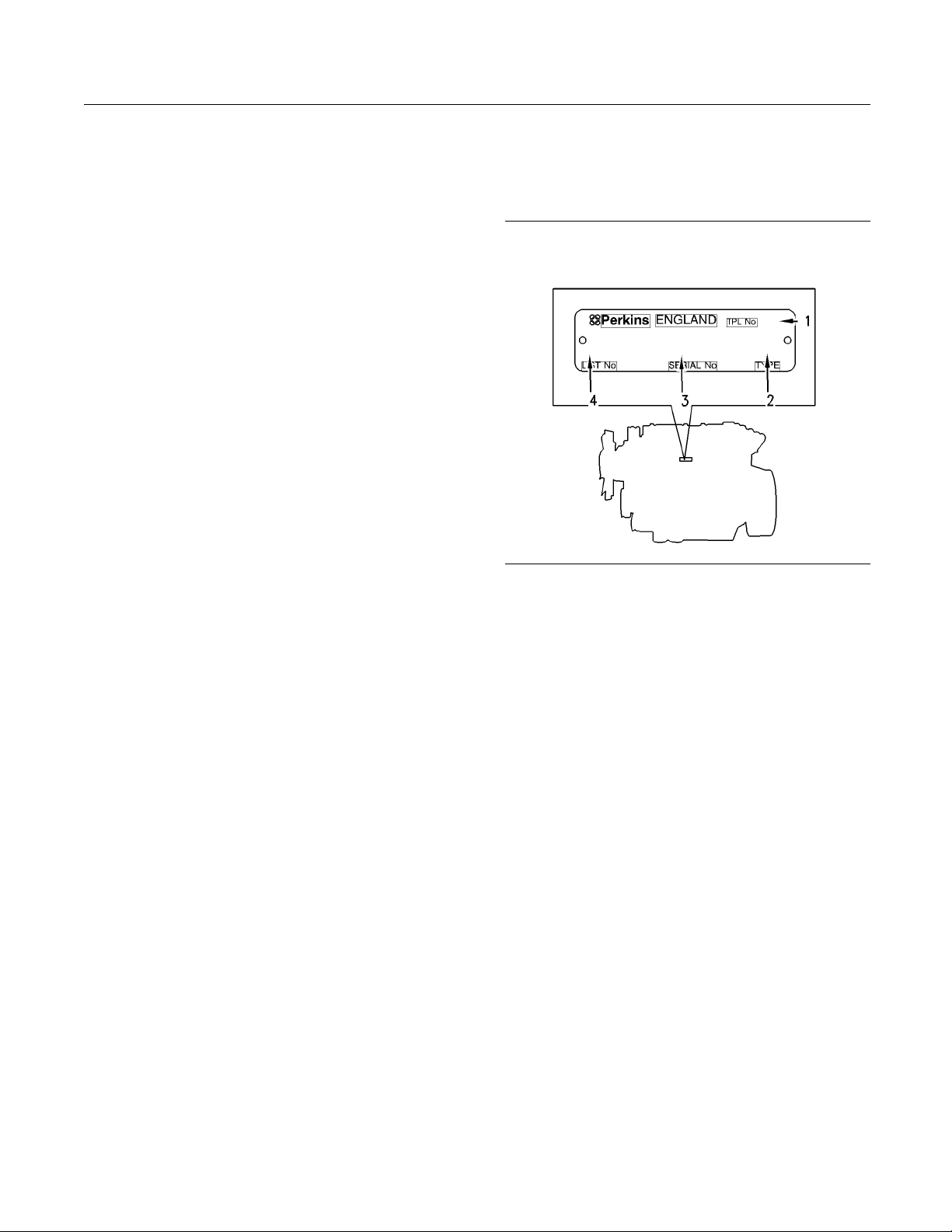

Engine Identification

Perkins engines are identified by a serial number.

This number is shown on a serial number plate that

is mounted on the left hand side of the engine block.

An example of an engine number is

RE12345U090001H.

_______________________________________ ___ Type of engine

RE

RE12345

U

____________________________Built in the United Kingdom

090001

H

________________________________ _____ Year of Manufacture

Perkins dealers need these numbers in order to

determine the components that were included with

the engine. This permits accurate identification of

replacement part numbers.

____________________________ Engine List Number

___________________________Engine Serial Number

Serial Number Plate

Illustration 11

Typical serial number plate

(1) Temporary Parts List number

(2) Type

(3) Serial number

(4) List number

i01940474

g00994966

The Serial Number Plate is located on the left side of

the cylinder block behind the high pressure pipes of

the Fuel injection pump.

The following information is stamped on the Serial

Number Plate: Engine serial number, Model, and

Arrangement number.

i02164876

Reference N umbers

Information for the following items may be needed to

order parts. Locate the information for your engine.

Record the information in the appropriate space.

Make a copy of this list for a record. Keep the

information for future reference.

Record for Reference

Engine Model _______________________________________________

Engine Serial number ____ _________________________________

Engine Low Idle rpm ______________________________________

18 SEBU8121

Product Information Section

Product Identification Information

drpm

Engine Full Loa

_____________________________________

Primary Fuel Filter _________________________________________

Water Separator Element ________________________________

Secondary Fue

l Filter Element

__________________________

Lubrication Oil Filter Element ___________________________

Auxiliary Oil Filter Element _______________________________

Total Lubrica

tion System Capacity

_____________________

Total Cooling System Capacity _________________________

Air Cleaner Element ______ _________________________________

Fan Drive Belt

______________________________________________

Alternator Belt ______________________________________________

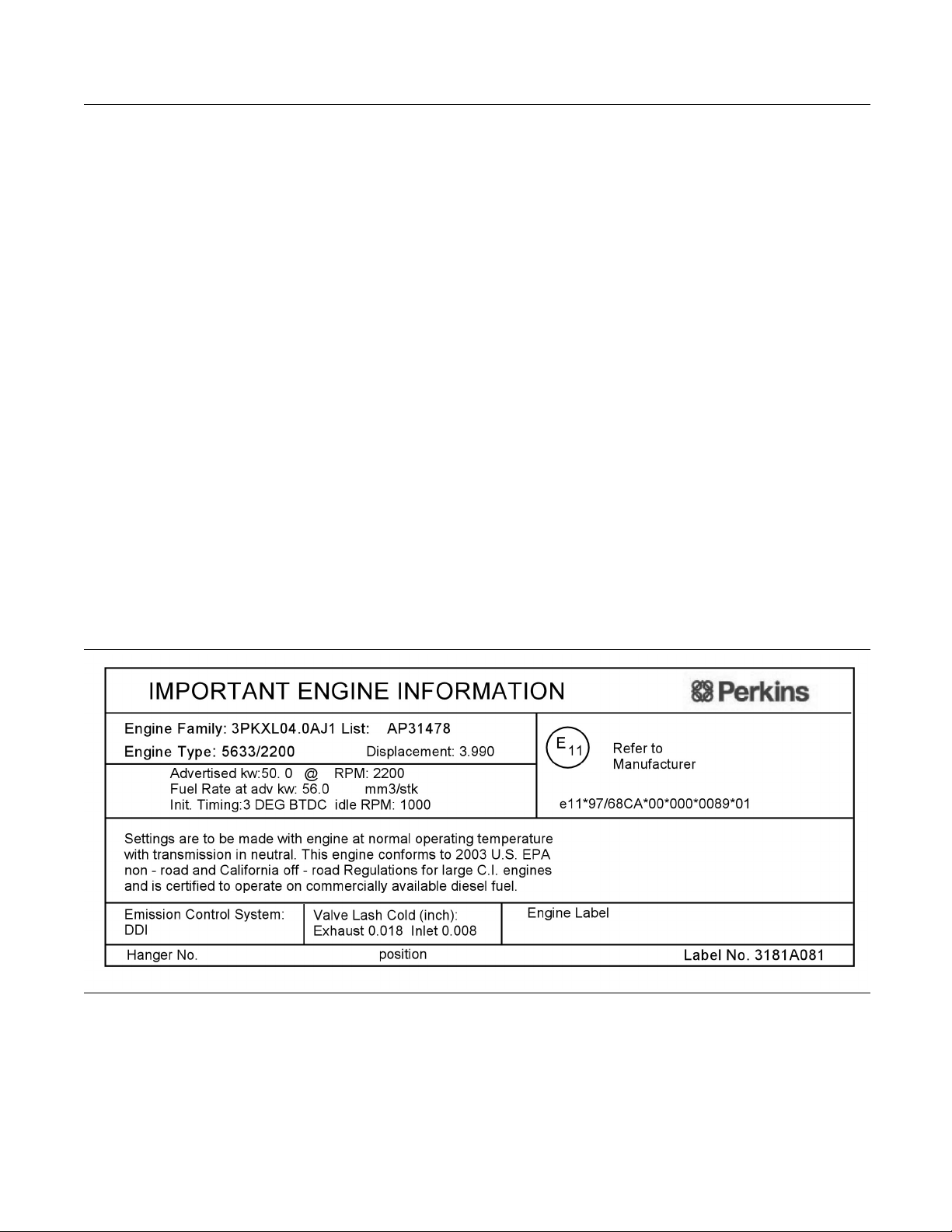

i02272778

Emissions Certification Film

Label for compliant engines

Illustration 12

Typical example

This label is installed on engines that com ply with em issions.

g01127835

SEBU8121 19

Operation Section

Lifting and Storage

Operation Section

Lifting and Storage

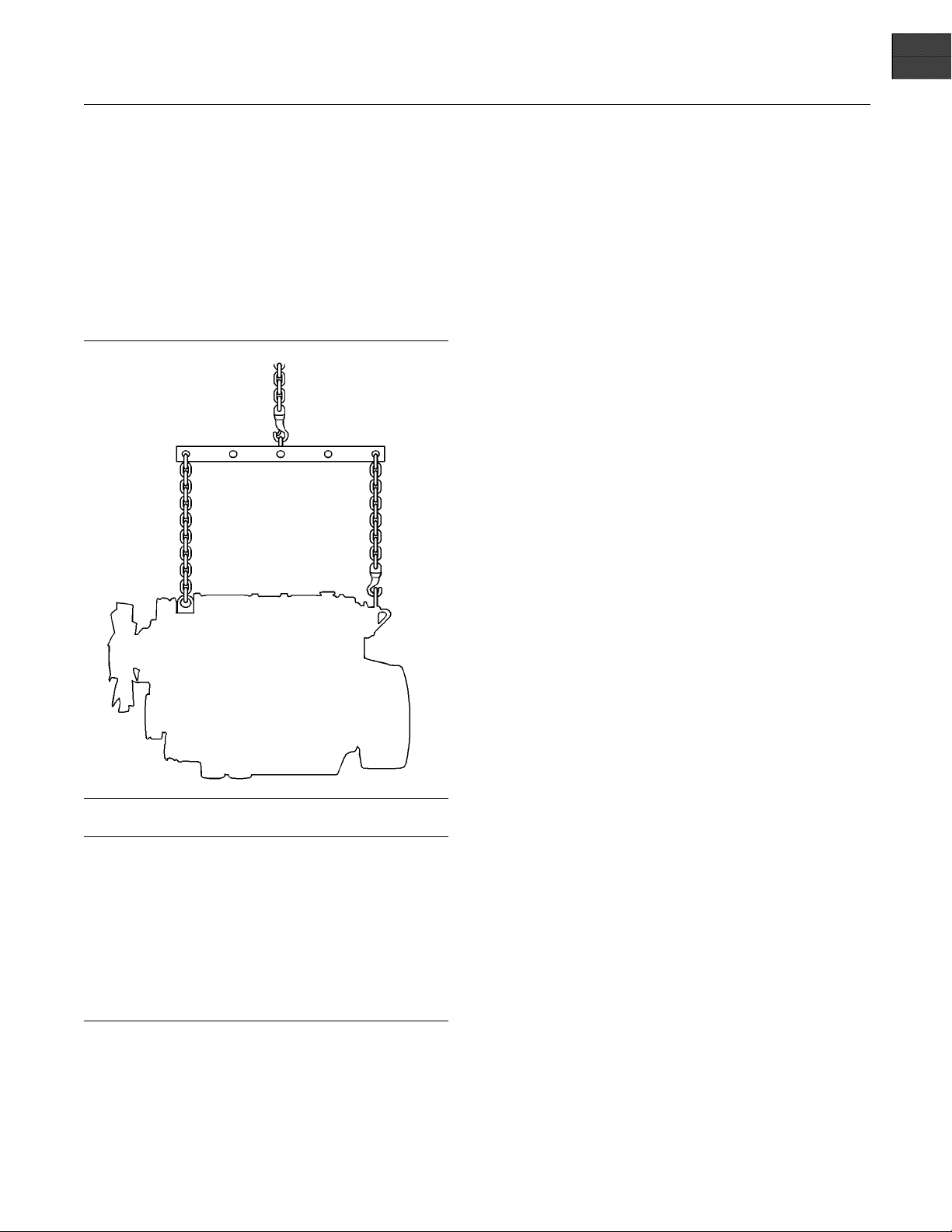

Engine Lifting

i02164186

Some removals r

obtain correct balance and safety.

To r e mov e th e e

are on the engine.

Lifting eyes a

engine arrangements. Alterations to the lifting eyes

and/or the engine make the lifting eyes and the lifting

fixtures obs

that correct lifting devices are provided. Consult

your Perkins dealer or your Perkins distributor for

information

lifting.

equire lifting the fixtures in order to

ngine ONLY, use the lifting eyes that

re designed and installed for specific

olete. If alterations are made, ensure

regarding fixtures for correct engine

i02248407

Engine Storage

If the engine will not be started for several weeks, the

lubricating oil will drain from the cylinder walls and

from the piston rings. Rust can form on the cylinder

walls. Rust on the cylinder walls will cause increased

engine wear and a reduction in engine service life.

Illustration 13

NOTICE

Never bend the eyebolts and the brackets. Only load

the eyeb

ber that the capacity of an eyebolt is less as the angle

between the supporting members and the object becomes le

When it is necessary to remove a component at an

angle, o

the weight.

Use a ho

an adjustable lifting beam to lift the engine. All

supporting members (chains and cables) should be

parall

be perpendicular to the top of the object that is being

lifted.

olts and the brackets under tension. Remem-

ss than 90 degrees.

nly use a link bracket that is properly rated for

ist to remove heavy components. Use

el to each other. The chains and cables should

g01097527

Lubrication System

To help prevent excessive engine wear, use the

following guidelines:

Complete all of the lubrication recommendations that

are listed in this Operation and Maintenance Manual,

“Maintenance Interval Schedule” (Maintenance

Section).

If an engine is out of operation and if use of the engine

is not planned, special precautions should be made.

If the engine will be stored for more than one month,

a complete protection procedure is recommended.

Use the following guidelines :

Completely clean the outside of the engine.

•

Drain the fuel system completely and refill

•

the system with preservative fuel.1772204

POWERPARTLay-Up1canbemixedwith

the normal fuel in order to change the fuel into

preservative fuel.

If preservative fuel is not available, the fuel system

•

canbefilledwithnormalfuel.Thisfuelmustbe

discarded at the end of the storage period together

with the fuel filter elements.

Operate the engine until the engine reaches

•

normal operating temperature. Stop any leaks from

fuel, lubricating oil or air systems. Stop the engine

and drain the lubricating oil from the oil pan.

20 SEBU8121

Operation Section

Lifting and Storage

Renew the canis

•

Fill the oil pan to the Full Mark on the dipstick

•

with new, clea

POWERPARTLay-Up2totheoilinorderto

protect the engine against corrosion. If 1762811

POWERPART La

preservative of the correct specification instead

of the lubricating oil. If a preservative is used,

this must be d

storage period and the oil pan must be refilled to

the correct level with normal lubricating oil.

ter(s) of the lubricating oil filter.

n lubricating oil. Add 1762811

y-Up 2 is not available, use a

rained completely at the end of the

Cooling System

To help prevent excessive engine wear, use the

following guidelines:

NOTICE

Do not drain the coolant while the engine is still hot and

the system is under pressure because dangerous hot

coolant can

If freezing temperatures are expected, check the

cooling sys

freezing. See this Operation and Maintenance

Manual, “General Coolant Information” (Maintenance

Section).

To prevent frost damage, ensure that all the coolant is

removed fr

tem is drained after it has been flushed with water, or if

an antifreeze solution too weak to protect the system

from frost

be discharged.

tem for adequate protection against

NOTICE

om the engine. This is important if the sys-

has been used.

4. Open the tap or r

bottom of the radiator in order to drain the radiator.

If the radiator does not have a tap or a drain plug,

disconnect th

5. Flush the cooling system with clean water.

6. Fit the drain plugs and the filler cap. Close the tap

or connect the radiator hose.

7. Fill the cooling system with an approved

antifreeze mixture because this gives protection

against corr

(0.2200 Imp gal) per minute in order to fill the

system.

Note: Certain corrosion inhibitors could cause

damage to some engine components. Contact the

Service Dep

8. Operate the engine for a short period in order to

circulate t

engine.

9. Disconnect

storage in a fully charged condition. Before the

battery is put into storage, protect the terminals

against co

3 can be used on the terminals.

10. Clean the c

Seal the end of the pipe.

11. Remove the

1762811 POWERPART Lay-Up 2 for one or two

seconds into each cylinder bore with the piston

at BDC.

artment of Perkins for advice.

he lubricating oil and the coolant in the

rrosion.1734115 POWERPART Lay-Up

emove the drain plug at the

e hose at the bottom of the radiator.

osion. The maximum flow rate is 1 L

the battery. Put the battery into safe

rankcase breather if one is installed.

fuel injector nozzles and spray

Illustration 14

1. Ensure that the engine is on level ground.

2. Remove t

3. Remove the drain plug (1) from the side of the

cylinde

that the drain hole is not restricted.

he filler cap of the cooling system.

r block in order to drain the engine. Ensure

g010039

12. Slowly rotate the crankshaft for one complete

revoluti

nozzles.

on and then replace the fuel injector

Induction System

Remove th

•

remove the pipes that are installed between

the air filter assembly and the turbocharger.

Spray 17

turbocharger. The duration of the spray is printed

on the container. Seal the turbocharger with

waterpr

28

Exhaust

Remove the exhaust pipe. Spray 1762811

•

POWERP

duration of the spray is printed on the container.

Seal the turbocharger with waterproof tape.

e air filter assembly. If necessary,

62811 POWERPARTLay-Up2intothe

oof tape.

System

ART Lay-Up 2 into the turbocharger. The

SEBU8121 21

Operation Section

Lifting and Storage

General Items

If the lubricating oil filler is installed on the rocker

•

cover, remove the filler cap. If the lubricating oil filler

cap is not installed on the rocker cover, remove

the rocker cover. Spray 1762811 POWERPART

Lay-Up 2 around the rocker shaft assembly.

Replace the filler cap or the rocker cover.

Seal the vent of the fuel tank or the fuel filler cap

•

with waterproof tape.

Remove the alternator drive belts and put the drive

•

belts into storage.

In order to prevent corrosion, spray the engine with

•

1734115 POWERPART Lay-Up 3. Do not spray

the area inside the alternator.

When the engine protection has been completed in

accordance with these instructions, this ensures that

no corrosion will occur. Perkins are not responsible

for damage which may occur when an engine is in

storage after a period in service.

Your Perkins dealer or your Perkins distributor can

assist in preparing the engine for extended storage

periods.

22 SEBU8121

Operation Section

Gauges and Indicators

Gauges an d Indicators

i02164190

Gauges and Indicators

Your engine m

the gauges that are described. For more information

about the gauge package, see the OEM information.

Gauges provide indications of engine performance.

Ensure that the gauges are in good working order.

Determine th

the gauges over a period of time.

Noticeable c

potential gauge or engine problems. Problems may

also be indicated by gauge readings that change

even if the r

Determine and correct the cause of any significant

change in the readings. Consult your Perkins dealer

or your Per

If no oil pressure is indicated, STOP the engine. If

maximum co

the engine. Engine damage can result.

SAE10W30

rpm.

ay not have the same gauges or all of

e normal operating range by observing

hanges in gauge readings indicate

eadings are within specifications.

kins distributor for assistance.

NOTICE

olant temperature is exceeded, STOP

Engine Oil

should be greatest after a cold engine is

started. The typical engine oil pressure with

is 207 to 413 kPa (30 to 60 psi) at rated

Pressure – The oil pressure

1. Reduce the load

2. Inspect the cooling system for leaks.

3. Determine if the engine must be shut down

immediately or if the engine can be cooled by

reducing the l

Tachometer – This gauge indicates engine

speed (rpm). W

ismovedtothefullthrottlepositionwithout

load, the engine is running at high idle. The engine is

running at th

lever is at the full throttle position with maximum

rated load.

To help prevent engine damage, never exceed the

high idle rpm. Overspeeding can result in serious

damage to the engine. The engine can be operated

at high idle without damage, but should never be

allowedtoexceedhighidlerpm.

indicator should be to the right side of “0” (zero).

is in the “ON” position.

efullloadrpmwhenthethrottlecontrol

Ammeter – This gauge indicates the

amount of charge or discharge in the

battery charging circuit. Operation of the

Fuel Level – This gauge indicates the fuel

level in the fuel tank. The fuel level gauge

operates when the “START/STOP” switch

Service Hour Meter – The gauge indicates

operating time of the engine.

and the engine rpm.

oad.

hen the throttle control lever

NOTICE

A lower oil pressure is normal at low idle. If the load

is stable

the following procedure:

1. Remove th

2. Reduce engine speed to low idle.

3. Check and maintain the oil level.

tempera

48 kPa (7 psi) is 110°C (230°F). Higher temperatures

may occur under certain conditions. The water

tempera

reading should never exceed the boiling point for the

pressurized system that is being used.

If the en

and steam becomes apparent, perform the following

procedure:

and the gauge reading changes, perform

e load.

Jacket Wa

Typical temperature range is 71 to 96°C

(160 to 205°F). The maximum allowable

ture w ith the pressurized cooling system at

ture reading may vary according to load. The

gine is operating above the normal range

ter Coolant Temperature –

SEBU8121 23

Operation Section

Features and Controls

Features and Controls

i02259828

Monitoring System

If the Shutdown mode has been selec ted and the

warning indi

take as little as 20 seconds from the time the warning indicator is activated. Depending on the application, s

avoid personal injury. The engine can be restarted

following shutdown for emergency maneuvers, if

necessary.

The Engine Monitoring System is not a guarantee

against catastrophic failures. Programmed delays

and derate schedules are designed to minimize false

alarms and provide time for the operator to stop the

engine.

The following parameters are monitored:

Coolant temperature

•

Intake manifold air temperature

•

Intake manifold air pressure

•

Oil pressure

•

Fuel temperature

•

cator activates, engine shutdown may

pecial precautions should be taken to

NOTICE

“Warning”

The “Warning” lamp and the warning signal (orange

lamp) turn “ON

continuously in order to alert the operator that one or

more of the engine parameters is not within normal

operating ra

” and the warning signal is activated

nge.

“Warning/Derate”

The “Diagnostic” lamp turns “ON” and the warning

signal (red lamp) is activated. After the warning, the

engine power

begin to flash when the derating occurs.

Theenginewi

preset operational limits. The engine derate is

achieved by restricting the amount of fuel that is

available f

reduction of fuel is dependent on the severity of the

fault that has caused the engine derate, typically up

to a limit o

predetermined reduction in engine power.

“Warning/

The “Diagnostic” lamp turns “ON” and the warning

signal (re

the engine power will be derated. The engine will

continue at the rpm of the set derate until a shutdown

of the engi

after a shutdown for use in an emergency.

A shutdow

as 20 seconds. The engine can be restarted after

a shutdown for use in an emergency. However,

the cause

Theenginemayshutdownagaininaslittleas20

seconds.

will be derated. The warning lamp will

ll be derated if the engine exceeds

or each injection. The amount of this

f 50%. This reduction in fuel results in a

Derate/Shutdown”

d lamp) is activated. After the warning,

ne occurs. The engine can be restarted

n of the engine may occur in as little

of the initial shutdown may still exist.

Engine speed/timing

•

Programmable Options and

Systems Operation

If the Warning/Derate/Shutdown mode has been

selected and the warning indicator activates,

bring the engine to a stop whenever possible. Depending on the a pplication, special precautions

should be taken to avoid personal injury.

The engine can be programmed to the following

modes:

If there is a signal for low oil pressure or for coolant

temperature, there will be a two second delay in

order to

For each of the programmed modes, refer to

Trouble

information on Indicator Lamps.

For more

your Perkins dealer or your Perkins distributor.

verify the condition.

shooting Guide, “Indicator Lamps” for more

information or assistance for repairs, consult

24 SEBU8121

Operation Section

Features and Controls

i02259829

Sensors and Electrical

Components

Sensor Locations for the 1104

Engine

Illustration 15

Left side view of the 1104 engine

Typical example of a 1104 engine

(1) Electronic control module (ECM)

(2) Intake manifold temperature sensor

Illustration 16

(7) Typical location of the voltage load protection module by the

ECM

(3) Intake manifold pressure sensor

(4) Speed/timing sensor

g00915

g00894185

(5) Engine oil pre ssure sensor

(6) Machine interface connector

275

SEBU8121 25

Operation Section

Features and Controls

Illustration 17

Right side

Typical example of a 1104 engine

(8) Engine coolant temperature sensor

view of the 1104 engine

Failure of Sensors

All Senso

A failure of any of the sensors may be caused by one

of the fol

Sensor output is open.

•

Sensor output is shorted to “- battery” or “+ battery”.

•

Measured

•

specification.

rs

lowing malfunctions:

reading of the sensor is out of the

Intake Manifold Pressure Sensor

The inta

signal which corresponds to the intake manifold

pressure to the ECM. The ECM can control injection

timing a

When the throttle is increased and when the engine

demands more fuel, the fuel limit is controlled in order

to redu

ke manifold pressure sensor provides a

nd the amount of fuel that is injected.

ce overall smoke levels of the engine exhaust.

g00915291

Engine Oil Pressure Sensor

The engin

pressure sensor that measures the engine oil

pressure in the main oil gallery. The engine oil

pressur

diagnostic purposes. The engine oil pressure sensor

sendsasignaltotheECM.

e oil pressure sensor is an absolute

e sensor detects engine oil pressure for

Intake Manifold Temperature

Sensor

The inta

the inlet air temperature. A signal is sent to the

Electronic Control Module (ECM). The intake

manifo

ECM to determine initiation of the Cold Start Strategy

and control for appropriate start of injection timing

while t

ke manifold temperature sensor measures

ld temperature sensor is also used by the

he engine is warming up.

26 SEBU8121

Operation Section

Features and Controls

Coolant Temperature Sensor

The coolant temperature sensor monitors the engine

coolant temperature. The output of the ECM can

indicate a high coolant temperature through a relay

or a lamp. The coolant temperature sensor is used

by the ECM to determine initiation of the Cold Start

Condition and control for appropriate start of injection

timing while the engine is warming up.

Speed/Timing Sensor

If the ECM does not receive a signal from the primary

speed/timing sensor the “DIAGNOSTIC” lamp will

indicate a diagnostic fault code which will be logged

in the ECM memory.

If the ECM does not receive a signal from the primary

speed/timing sensor, the ECM will read the signal

from the secondary speed/timing sensor. The ECM

continually checks in order to determine if there is a

signal from both sensors. If either sensor fails, the

faulty sensor should be replaced.

Intermittent failure of the sensors will cause erratic

engine control.

Throttle Position Sensor

The throttle position sensor (TPS) eliminates the

mechanical throttle and governor linkages. The TPS

interprets the position of the throttle lever into an

electrical signal that is sent to the ECM. The throttle

position signal and the engine speed/timing signal

are processed by the ECM in order to precisely

control engine speed.

Loading...

Loading...