Page 1

Perkins 1104 Series

WORKSHOP MANUAL

Troubleshooting

4 cylinder , naturally aspirated, and turbocharged diesel

engines for agricultural and industrial use

Publication RENR2696-00

© Proprietary information of Perkins Engines Company Limited 2004, all rights reserved.

The information is correct at the time of print.

Published by Technical Publications.

Perkins Engines Company Limited, Peterborough, PE1 5NA, England

Page 2

Table of Contents

3

Table of Contents

Troubleshooting Section

Electronic Troubleshooting

System Overview .................................................... 5

Glossary ................................................................. 9

Electronic Service Tools ........................................ 12

Diagnostic Codes .................................................. 13

Indicator Lamps .................................................... 15

Replacing the ECM ............................................... 18

Self-Diagnostics .................................................... 19

Sensors and Electrical Connectors ....................... 20

Engine Wiring Information .................................... 26

Programming Parameters

Programming Parameters ..................................... 30

Factory Passwords ................................................ 30

Flash Programming .............................................. 30

System Configuration Parameters

System Configuration Parameters ........................ 32

Troubleshooting without a Diagnostic Code

Alternator Noise (Noisy Operation) ....................... 33

Alternator Will Not Charge (Charging Problem) .... 33

Battery .................................................................. 33

Can Not Reach Top Engine RPM ......................... 34

Coolant in Engine Oil ............................................ 36

Coolant Temperature Is Too High ......................... 37

ECM Will Not Accept Factory Passwords ............. 38

ECM Will Not Communicate with Other Systems or

Display Modules .................................................. 38

Electronic Service Tool Will Not Communicate with

ECM .................................................................... 38

Engine Cranks but Will Not Start .......................... 39

Engine Has Early Wear ........................................ 41

Engine Misfires, Runs Rough or Is Unstable ........ 41

Engine Oil in Cooling System ............................... 43

Engine Speed Does Not Change .......................... 44

Engine Stalls at Low RPM .................................... 45

Engine Vibration ................................................... 45

Engine Will Not Crank ........................................... 47

Excessive Black Smoke ........................................ 48

Excessive Engine Oil Consumption ...................... 49

Excessive Valve Lash ........................................... 50

Excessive White Smoke ....................................... 51

Intake Air Temperature Is Too High ....................... 52

Intermittent Engine Shutdown ............................... 53

Intermittent Low Power or Power Cutout ............... 54

Low Engine Oil Pressure ...................................... 56

Low Power/Poor or No Response to Throttle ........ 57

Mechanical Noise (Knock) in Engine .................... 59

Noise Coming from Cylinder ................................. 59

Poor Acceleration or Response ............................ 60

Troubleshooting with a Diagnostic Code

CID 0041 FMI 03 8v Sensor Power Supply, Voltage

More Than Normal .............................................. 62

CID 0041 FMI 04 8v Sensor Power Supply, Voltage

Less Than Normal ............................................... 62

CID 0091 FMI 02 Throttle Demand Sensor Erratic Or

Intermittent .......................................................... 62

CID 0091 FMI 03 Throttle Demand Sensor Open

Circuit Or Shorted High ....................................... 63

CID 0091 FMI 04 Throttle Demand Sensor Shorted

Low ..................................................................... 63

CID 0091 FMI 08 Throttle Demand Sensor Abnormal

Signal .................................................................. 64

CID 0091 FMI 12 Throttle Demand Sensor Out Of

Calibration ........................................................... 64

CID 0100 FMI 03 Engine Oil Pressure Sensor Open

Circuit Or Shorted High ....................................... 64

CID 0100 FMI 04 Engine Oil Pressure Sensor

Shorted Low ........................................................ 65

CID 0100 FMI 10 Engine Oil Pressure Sensor, Power

Supply Open Circuit ............................................ 65

CID 0102 FMI 03 Intake Manifold Pressure Sensor,

Open Circuit Or Shorted High ............................. 66

CID 0102 FMI 04 Intake Manifold Pressure Sensor

Shorted Low ........................................................ 66

CID 0102 FMI 10 Intake Manifold Pressure Sensor

Power Supply Open Circuit ................................. 67

CID 0105 FMI 03 Intake Manifold Temperature

Sensor Open Circuit Or Shorted High ................ 67

CID 0105 FMI 04 Intake Manifold Temperature

Sensor Shorted Low ........................................... 67

CID 0110 FMI 03 Engine Coolant Temperature

Sensor Open Circuit Or Shorted High ................ 68

CID 0110 FMI 04 Engine Coolant Temperature

Sensor Shorted Low ........................................... 68

CID 0174 FMI 02 Fuel Temperature Sensor Erratic,

Intermittent .......................................................... 69

CID 0247 FMI 09 J1939 Datalink, Abnormal

Update ................................................................ 69

CID 0253 FMI 02 Incorrect ECM Software ........... 69

CID 0262 FMI 03 5v Sensor Power Supply, Voltage

More Than Normal .............................................. 70

CID 0262 FMI 04 5v Sensor Power Supply, Voltage

Less Than Normal ............................................... 70

CID 0266 FMI 02 Incorrect Crank-without-inject

inputs .................................................................. 71

CID 0320 FMI 02 Speed And Timing Sensor

Intermittent Loss Of Signal .................................. 71

CID 0320 FMI 11 Speed And Timing Sensor Loss Of

Signal .................................................................. 71

CID 0342 FMI 02 Speed And Timing Sensor No.2

Intermittent Signal ............................................... 72

CID 0774 FMI 02 Throttle Demand Sensor No.2

Erratic Or Intermittent .......................................... 72

CID 0774 FMI 03 Throttle Demand Sensor No.2

Open Circuit Or Shorted High ............................. 73

CID 0774 FMI 04 Throttle Demand Sensor No.2

Shorted Low ........................................................ 73

CID 0774 FMI 08 Throttle Demand Sensor No.2

Abnormal Signal .................................................. 73

CID 0774 FMI 12 Throttle Demand Sensor No.2 Out

Of Calibration ...................................................... 74

CID 1627 FMI 03 Fuel Injection Pump Relay Did Not

Turn Off ............................................................... 74

CID 1684 FMI 00 Fuel Injection Pump, Fuel

Temperature More Than Normal ......................... 74

CID 1684 FMI 02 Fuel Injection Pump, Software

Failure ................................................................. 75

Page 3

4

Table of Contents

CID 1684 FMI 03 Fuel Injection Pump, Fuelling

Fault .................................................................... 75

CID 1684 FMI 04 Fuel Injection Pump, Supply

Voltage Fault ....................................................... 76

CID 1684 FMI 05 Fuel Injection Pump, Invalid Pulse

Width ................................................................... 76

CID 1684 FMI 07 Fuel Injection Pump, Mechanical

Fault .................................................................... 77

CID 1684 FMI 08 Fuel Injection Pump, Crankshaft

Reference Fault ................................................... 77

CID 1684 FMI 09 Fuel Injection Pump, CAN

Fault .................................................................... 78

CID 1684 FMI 10 Fuel Injection Pump, Fuel Shutoff

Signal Error ......................................................... 78

CID 1684 FMI 11 Fuel Injection Pump, Internal

Sensor Fault ........................................................ 79

CID 1684 FMI 12 Fuel Injection Pump, Device

Failure ................................................................. 80

CID 1684 FMI 14 Fuel Injection Pump, No

Communications ................................................. 80

CID 1743 FMI 02 Engine Speed Mode Selection

Switch State, Invalid State .................................. 81

CID 1894 FMI 02 Set Speed Control Disengage

Switch State, Invalid State .................................. 81

CID 1895 FMI 02 Set Speed Control Speed Toggle

Switch, Invalid State ............................................ 81

Engine Temperature Sensor Open or Short Circuit -

Test ................................................................... 168

Fuel Injection Pump Circuit - Test ....................... 175

Indicator Lamp Circuit - Test ............................... 192

Mode Selection Circuit - Test .............................. 195

Set Speed Circuit - Test ...................................... 202

Throttle Switch Circuit - Test ............................... 210

Index Section

Index ................................................................... 219

Troubleshooting with an Event Code

Event Codes ........................................................ 83

E015 High Engine Coolant Temperature Derate ... 83

E016 High Engine Coolant Temperature

Shutdown ............................................................ 83

E017 High Engine Coolant Temperature

Warning ............................................................... 83

E025 High Intake Air Temperature Derate ............ 84

E027 High Intake Air Temperature Warning ......... 84

E040 Low Engine Oil Pressure Shutdown ............ 85

E054 High Fuel Temperature Derate .................... 85

E056 High Fuel Temperature Warning .................. 86

E100 Low Engine Oil Pressure Warning ............... 87

E190 Engine Overspeed Warning ........................ 88

E442 Engine Failed to Stop with a No-Fuel

Command ........................................................... 88

E883 Engine Failed To Stop When Fuel Solenoid

Disengaged ......................................................... 89

Diagnostic Functional Tests

5 Volt Engine Pressure Sensor Supply Circuit -

Test ..................................................................... 90

Air Inlet Heater Circuit - Test ................................. 97

Analog Throttle Position Sensor Circuit - Test .... 102

CAN Data Link Circuit - Test ............................... 111

Data Link Circuit - Test ........................................ 116

Digital Throttle Position Sensor Circuit - Test ...... 124

Electrical Connectors - Inspect ........................... 133

Electrical Power Supply Circuit - Test ................. 144

Engine Oil Level Switch Circuit - Test ................. 149

Engine Pressure Sensor Open or Short Circuit -

Test ................................................................... 154

Engine Speed/Timing Sensor Circuit - Test ........ 161

Page 4

Troubleshooting Section

Electronic Troubleshooting

i01798100

System Overview

System Operation

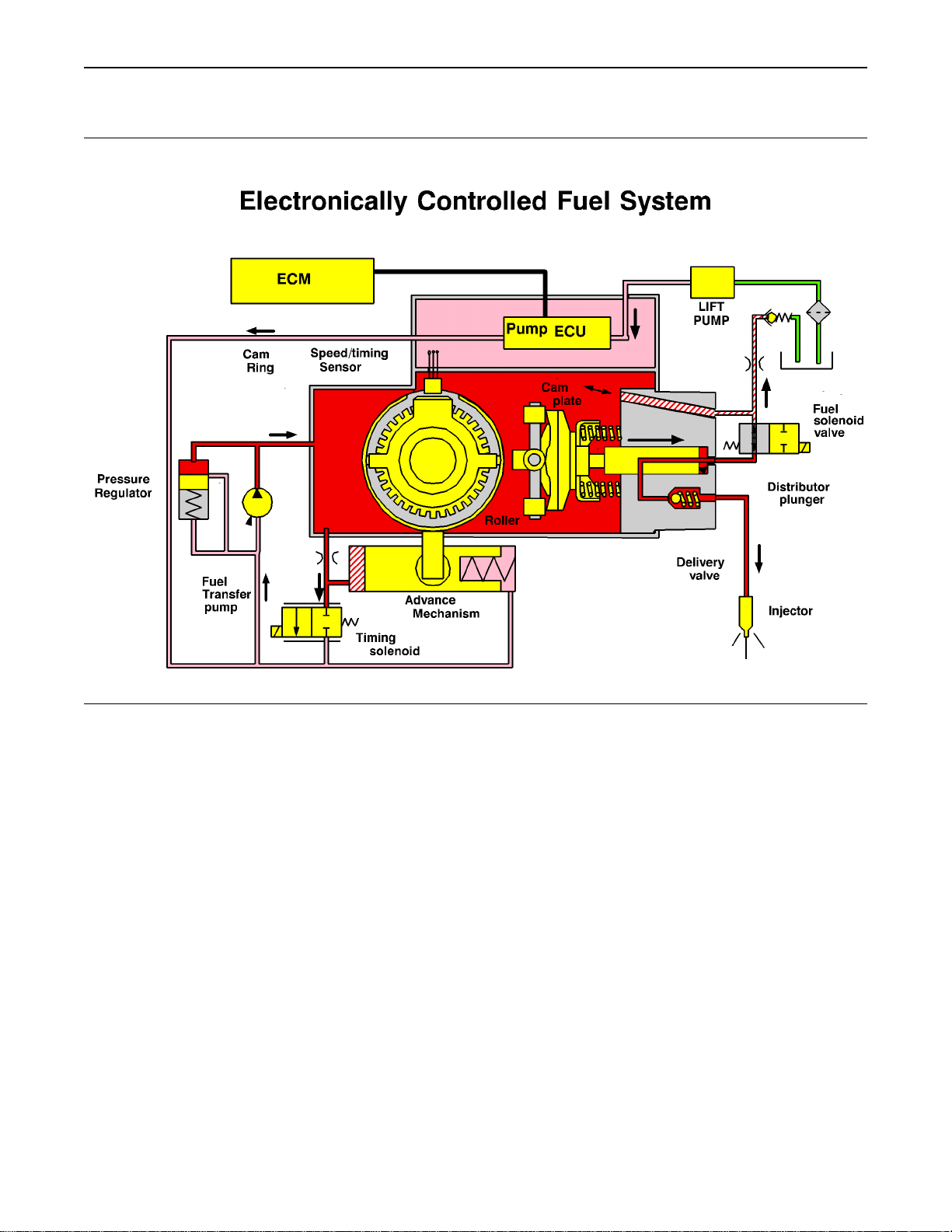

The 1104 models RF, RH, RK and 1106 model

VK engines were designed for electronic control.

The engines include an Electronic Control Module

(ECM), a fuel injection pump that is electronically

controlled, and a collection of engine sensors. The

ECM controls the engine operating parameters

through the software within the ECM and the inputs

from the various sensors. The software contains

parameters that control the engine operation. The

parameters include all of the operating maps and

customer selected parameters.

5

Troubleshooting Section

Page 5

6

Troubleshooting Section

Electronic Controls

Illustration 1

g00908788

Page 6

Troubleshooting Section

7

Illustration 2

The electronic system consists of the Electronic

Control Module (ECM), the engine sensors, and the

Machine Interface Connector (MIC). The ECM is the

computer. The personality module is the software

for the computer. The personality module contains

the operating maps. The operating maps define the

following characteristics of the engine:

Horsepower

•

Torque curves

•

Engine speed (rpm)

•

Engine Governor

The electronic controls determine the injection

timing and the amount of fuel that is delivered to

the cylinders. These decisions are based on the

actual conditions and the desired conditions at any

given time.

g00954204

The governor compares the desired engine speed

to the actual engine speed. The actual engine

speed is determined through the crankshaft position

sensor. If the desired engine speed is greater than

the actual engine speed, the governor injects more

fuel in order to increase engine speed.

Timing Considerations

Once the governor has determined the amount of

fuel that is required, the governor must determine

the timing of the fuel injection. Fuel injection timing

is determined by the ECM after considering input

from the following components:

Engine coolant temperature sensor

•

The sensor for the intake manifold air temperature

•

The sensor for the intake manifold pressure

•

Page 7

8

Troubleshooting Section

At start-up, the ECM determines the top dead

center position of the number 1 cylinder from the

speed/timing sensor in the fuel injection pump.

The ECM decides when fuel injection should occur

relative to the top dead center position. The ECM

provides the signal to the fuel injection pump spill

valve which stops fuel flow to the low pressure side.

The ECM then forces fuel to flow to the fuel injector

nozzles at the desired time. The ECM adjusts timing

for the best engine performance, the best fuel

economy and the best control of exhaust emissions.

Actual timing cannot be viewed with an electronic

service tool. Also, the desired timing cannot be

viewed with an electronic service tool.

Fuel Injection

The personality module inside the ECM sets certain

limits on the amount of fuel that can be injected.

The FRC Limit is a limit that is based on intake

manifold air pressure and engine rpm. The FRC

Limit is used to control the air/fuel ratio in order to

control the engine’s exhaust emissions. When the

ECM senses a higher intake manifold air pressure,

the ECM increases the FRC Limit. A higher intake

manifold air pressure indicates that there is more air

in the cylinder. When the ECM increases the FRC

Limit, the ECM allows more fuel into the cylinder.

The Rated Fuel Limit is a limit that is based on the

power rating of the engine and on the engine rpm.

The Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curves of a specific engine model.

These limits are in the personality module and these

limits cannot be changed.

Diagnostic Codes

When the ECM detects an engine problem, the ECM

generates a diagnostic code. Also, the ECM logs

the diagnostic code in order to indicate the time of

the problem’s occurrence. The ECM also logs the

number of occurrences of the problem. There are

two types of diagnostic fault codes. There are fault

codes and event codes.

Diagnostic Fault Codes

Diagnostic fault codes are provided in order to

indicate that an electrical problem or an electronic

problem has been detected by the ECM. In some

cases, the engine performance can be affected

when the condition that is causing the code exists.

More frequently, the operator cannot detect any

difference in the engine performance.

If the operator indicates that a performance problem

occurs, the diagnostic code may indicate the cause

of the problem. Use either a laptop computer or a

hand held diagnostic tool to access the diagnostic

codes. The problem should then be corrected.

If the operator does not indicate a problem with

the engine performance and a diagnostic code is

logged by the ECM. This situation indicates that

the ECM detected an abnormal engine condition,

but the abnormal condition did not affect engine

performance. In this situation, the system has no

faults except when either of the following conditions

exist:

There are several occurrences of the diagnostic

•

code in a very short period of time.

The ECM is indicating an active code at the

•

present time.

Diagnostic Event Codes

Diagnostic event codes are used to indicate that

some operational problem has been detected in

the engine by the ECM. This does not indicate an

electronic malfunction.

Programmable Parameters

Certain parameters that affect the engine operation

may be changed with electronic service tools.

The parameters are stored in the ECM, and the

parameters are protected from unauthorized

changes by passwords. These parameters are

System Configuration Parameters.

System Configuration Parameters are set at the

factory. System Configuration Parameters affect

emissions or power ratings within the engine.

Factory passwords must be obtained and factory

passwords must be used to change the System

Configuration Parameters.

Passwords

System Configuration Parameters are protected

by factory passwords. Factory passwords are

calculated on a computer system that is available

only to Perkins distributors. Since factory passwords

contain alphabetic characters, only an electronic

service tool may change System Configuration

Parameters. System Configuration Parameters affect

the power rating or the emissions.

Refer to Troubleshooting, “Programming Parameters”

and Troubleshooting, “Factory Passwords”.

Page 8

Troubleshooting Section

9

i01798101

Glossary

Active Diagnostic Code – An active diagnostic code

alerts the operator or the service technician that an

electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Alternating Current (AC) – Alternating current is an

electric current that reverses direction at a regular

interval that is reoccurring.

Before Top Dead Center (BTC) – BTDC is the 180

degrees of crankshaft rotation before the piston

reaches the top dead center position in the normal

direction of rotation.

Boost Pressure (Engines that are turbocharged) –

The difference between the turbocharger outlet

pressure and atmospheric pressure is commonly

referred to as boost pressure. The sensor for the

intake manifold air pressure measures the amount

of boost.

Breakout Harness – The breakout harness is a

test harness that is designed to connect into the

engine harness. This connection allows a normal

circuit operation and the connection simultaneously

provides a Breakout T in order to measure the

signals.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circuit is typically used as a test circuit.

CAN Data Link – The CAN Data Link is a serial

communications port that is used for communication

with other microprocessor based devices. In this

application, the CAN Data Link connects the ECM

to the Electronic Fuel Injection Pump.

Code – Refer to “Diagnostic Code” or “Event Code”.

Cold Mode – Cold mode is a mode for cold starting

and for cold engine operation that includes timing

that is retarded and low idle that is raised. This

mode is used for engine protection, reduced smoke

emissions and faster warm up time.

Communication Adapter Tool – The communication

adapter provides a communication link between the

ECM and the Electronic Service Tool.

Coolant Level Sensor – The coolant level sensor

detects the absence or presence of coolant at the

probe. The sensor then sends a signal to the ECM.

Coolant Temperature Sensor – The coolant

temperature sensor detects the engine coolant

temperature for cold mode operation and for Engine

Monitoring.

Data Link – The Data Link is a serial communication

port that is used for communication with other

microprocessor based devices.

Desired Engine Speed – The desired engine speed

is input to the electronic governor within the ECM.

The electronic governor uses the signal from the

throttle position sensor, the engine speed/timing

sensor, and other sensors in order to determine the

desired engine speed.

Diagnostic Code – A diagnostic code is sometimes

referred to as a fault code. These codes indicate an

electronic system malfunction.

Diagnostic Lamp – A diagnostic lamp is sometimes

called the check engine light. The diagnostic lamp

is used to warn the operator of the presence of an

active diagnostic code.

Digital Sensor Return – The common line (ground)

from the ECM is used as ground for the digital

sensors.

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with +8 VDC from the ECM.

Digital Sensor Supply – The +8 VDC supply from the

ECM is used in order to power the digital sensors.

Direct Current (DC) – Direct current is the type of

current that flows consistently in only one direction.

DT, DT Connector, or Deutsch DT – This is a type

of connector that is used on Perkins engines. The

connectors are manufactured by Deutsch.

Duty Cycle – Refer to “Pulse Width Modulation”.

Electronic Engine Control – The electronic engine

control is a complete electronic system. The

electronic engine control monitors the engine

operation under all conditions. The electronic

engine control also controls the engine operation

under all conditions.

Component Identifier (CID) – The CID is a number

that identifies the specific component of the

electronic control system that has experienced a

diagnostic code.

Electronic Service Tool – The electronic service tool

allows a computer (PC) to communicate with the

ECM.

Page 9

10

Troubleshooting Section

Electronic Control Module (ECM) – The ECM is the

control computer of the engine. The ECM provides

power to the electronics. The ECM monitors data

that is input from the sensors of the engine. The

ECM acts as a governor in order to control the

speed and the power of the engine.

Engine Monitoring – Engine Monitoring is the part

of the electronic engine control that monitors the

sensors. This also warns the operator of detected

problems.

Engine Oil Pressure Sensor – The engine oil

pressure sensor measures engine oil pressure. The

sensor sends the signal to the ECM.

Engine Speed/Timing Sensor – The engine

speed/timing sensor provides a variable amplitude

and pulse width modulated signal to the ECM. The

ECM interprets this signal as the crankshaft position

and the engine speed.

Event Code – An event code may be activated in

order to indicate an abnormal engine operating

condition. These codes usually indicate a

mechanical problem instead of an electrical system

problem.

Failure Mode Identifier (FMI) – This identifier

indicates the type of failure that has been

experienced by the component. The FMI has

been adopted from the SAE practice of J1587

diagnostics.

Flash Programming – Flash programming is the

method of programming or updating an ECM with

an electronic service tool over the data link instead

of replacing components.

Fuel Ratio Control (FRC) – The FRC is a limit that is

based on the control of the ratio of the fuel to air.

The FRC is used for purposes of emission control.

When the ECM senses a higher intake manifold

air pressure (more air into the cylinder), the FRC

increases the FRC Limit (more fuel into the cylinder).

Fuel Temperature Sensor – The fuel temperature

sensor detects the fuel temperature. The ECM

monitors the fuel temperature and the ECM adjusts

the calculated fuel rate accordingly.

Full Load Setting (FLS) – The FLS is the number

that represents the fuel system adjustment. This

adjustment is made at the factory in order to fine

tune the fuel system. The correct value for this

parameter is stamped on the engine information

ratings plate. This parameter must be programmed.

Harness – The harness is the bundle of wiring

(loom) that connects all components of the

electronic system.

Hertz (Hz) – Hertz is the measure of electrical

frequency in cycles per second.

Intake Manifold Air Temperature Sensor – The

intake manifold air temperature sensor detects the

air temperature in the intake manifold. The ECM

monitors the air temperature and other data in the

intake manifold in order to adjust injection timing

and other performance functions.

Intake Manifold Pressure Sensor – The air pressure

in the intake manifold may be different to the

air pressure outside the engine (atmospheric

pressure). This difference in air pressure can be

caused by variable air velocity within the manifold.

The difference in pressure can also be caused

by an increase in air pressure by a turbocharger

(if equipped). The sensor for the intake manifold

air pressure measures the difference between

atmospheric pressure and the air pressure in the

intake manifold.

Integrated Electronic Controls – The engine is

designed with the electronic controls as a necessary

part of the system. The engine will not operate

without the electronic controls.

J1939 CAN Data Link – This data link is a SAE

diagnostic communications data link that is used to

communicate between the ECM and the electronic

service tool.

Logged Diagnostic Codes – Logged diagnostic

codes are codes which are stored in the memory.

These codes are meant to be an indicator of

possible causes for intermittent problems. Refer to

the term “Diagnostic Code” in this glossary for more

information.

MAB – This is a Bosch acronym for the fuel shutoff

inside the “VPM30” Fuel Injection Pump. The MAB

is a signal wire from the ECM to the Fuel Injection

Pump.

Open Circuit – An open circuit is a condition that is

caused by an open switch, or by an electrical wire

or a connection that is broken. When this condition

exists, the signal or the supply voltage can no

longer reach the intended destination.

Parameter – A parameter is a value or a limit that

is programmable. This helps determine specific

characteristics or behaviors of the engine.

Full Torque Setting (FTS) – The FTS is similar

to the full load setting. This parameter must be

programmed.

Page 10

11

Troubleshooting Section

Password – A password is a group of numeric

characters or a group of alphanumeric characters

that is designed to restrict access to parameters.

The electronic system requires correct passwords

in order to change some parameters (Factory

Passwords). Refer to Troubleshooting, “Factory

Passwords” for more information.

Personality Module – This module is inside the

ECM. The module contains all the instructions

(software) for the ECM and the module contains

the performance maps for a specific engine. The

personality module may be reprogrammed through

flash programming.

Power Cycled – Power cycled happens when power

to the ECM is cycled: ON, OFF, and ON. Power

cycled refers to the action of cycling the keyswitch

from any position to the OFF position, and to the

START/RUN position.

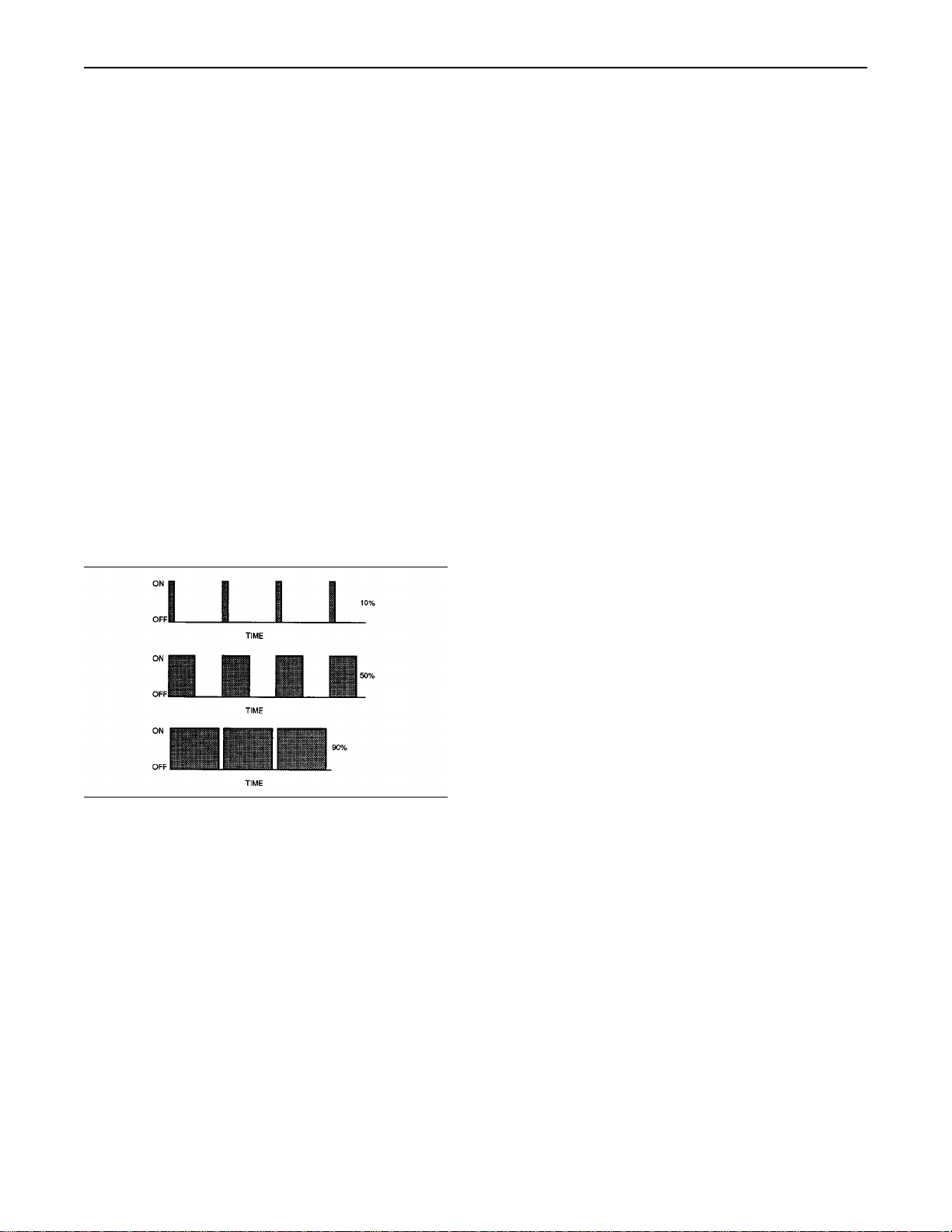

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width. These pulses occur at fixed intervals. The

ratio of “TIME ON” versus total “TIME OFF” can be

varied. This ratio is also referred to as a duty cycle.

Short Circuit – A short circuit is a condition that has

an electrical circuit that is inadvertently connected

to an undesirable point. An example of a short

circuit is a wire which rubs against a vehicle frame

and this rubbing eventually wears off the wire

insulation. Electrical contact with the frame is made

and a short circuit results.

Signal – The signal is a voltage or a waveform that

is used in order to transmit information typically

from a sensor to the ECM.

Supply Voltage – The supply voltage is a constant

voltage that is supplied to a component in order

to provide the electrical power that is required for

the component to operate. The power may be

generated by the ECM or the power may be battery

voltage that is supplied by the engine wiring.

System Configuration Parameters – System

configuration parameters are parameters that affect

emissions and/or operating characteristics of the

engine.

Throttle Position – The throttle position is the

interpretation by the ECM of the signal from the

throttle position sensor or the throttle switch.

Illustration 3

g00284479

Rated Fuel Limit – This term indicates the maximum

allowable fuel position (longest injection pulse). This

position will produce rated power for this engine

configuration.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by the ECM to a sensor. The reference

voltage is used by the sensor to generate a signal

voltage.

Sensor – A sensor is a device that is used to detect

a change in pressure, temperature, or mechanical

movement. The information that is detected is

converted into an electrical signal.

Throttle Position Sensor – The throttle position

sensor is an electronic sensor that is connected to

an accelerator pedal or a hand lever. This sensor

sends a PWM signal to the ECM that is used to

calculate desired engine speed.

Throttle Switch – The throttle switch sends a signal

to the ECM that is used to calculate desired engine

speed.

Top Dead Center – Top dead center refers to the

crankshaft position when the engine piston position

is at the highest point of travel. The engine must be

turned in the normal direction of rotation in order

to reach this point.

Total Tattletale – The total tattletale is the total

number of changes to all the parameters that are

stored in the ECM.

Voltage Load Protection Module (“VLPM”) – The

“VLPM” monitors the voltage of the electronic

system. The “VLPM”will eliminate any high voltage

conditions that occur. The “VLPM” will protect the

fuel injection pump from any high voltage conditions

that could damage the pump.

Page 11

12

Troubleshooting Section

i01798102

Electronic Service Tools

Electronic Service Tools are designed to help the

service technician with the diagnosis and repair of

electronic engines. Several tools are available to

assist the service technician.

Some of the included Diagnostic Functional Tests

in this manual require two short jumper wires. The

jumper wires are used to check the continuity

of some wiring harness circuits by shorting two

adjacent terminals together in a connector.

A long extension wire may also be needed to check

the continuity of some wiring harness circuits.

Electronic Service Tool

The electronic service tool can display the following

information:

Parameters

•

Event codes

•

Diagnostic codes

•

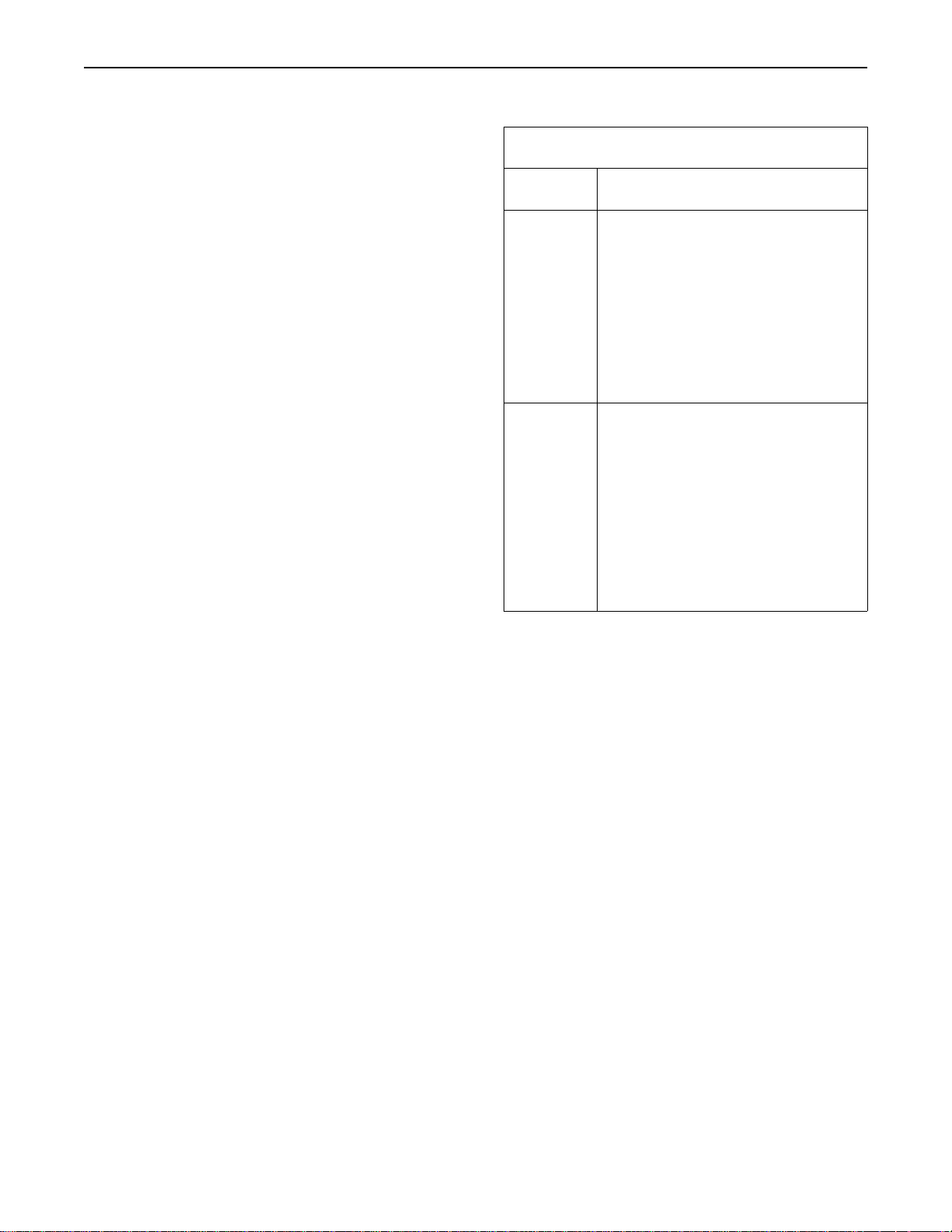

Ta bl e 1

Required Electronic Service Tools for the Use

Part

Number

of the Electronic Service Tool

Required

IBM compatible PC with

266 MHz Pentium processor

64 MB of RAM

N/A

N/A

400 MB of available hard drive space

CD-ROM drive

3.5" 1.44 MB floppy disk drive

VGA monitor or display (800 x 600)

Microsoft

NT 4.0, 98, or 95

RS232 port with 16550AF UART

Recommended

IBM compatible PC with

450 MHz Pentium III processor

128 MB of RAM

1 GB of available hard drive space

40X speed CD-ROM drive or

8X speed DVD drive

3.5" 1.44 MB floppy disk drive

Super VGA monitor or display (800 x 600)

Microsoft

NT 4.0, or 98

RS232 port with 16550AF UART

®

Windows 2000, XP, ME,

®

Windows 2000, XP, ME,

Description

Engine configuration

•

The electronic service tool can be used by the

technician to perform the following functions:

Diagnostic tests

•

Sensor calibrations

•

Flash programming

•

Set parameters

•

The following components are required to use the

electronic service tool to service the engine.

Page 12

13

Troubleshooting Section

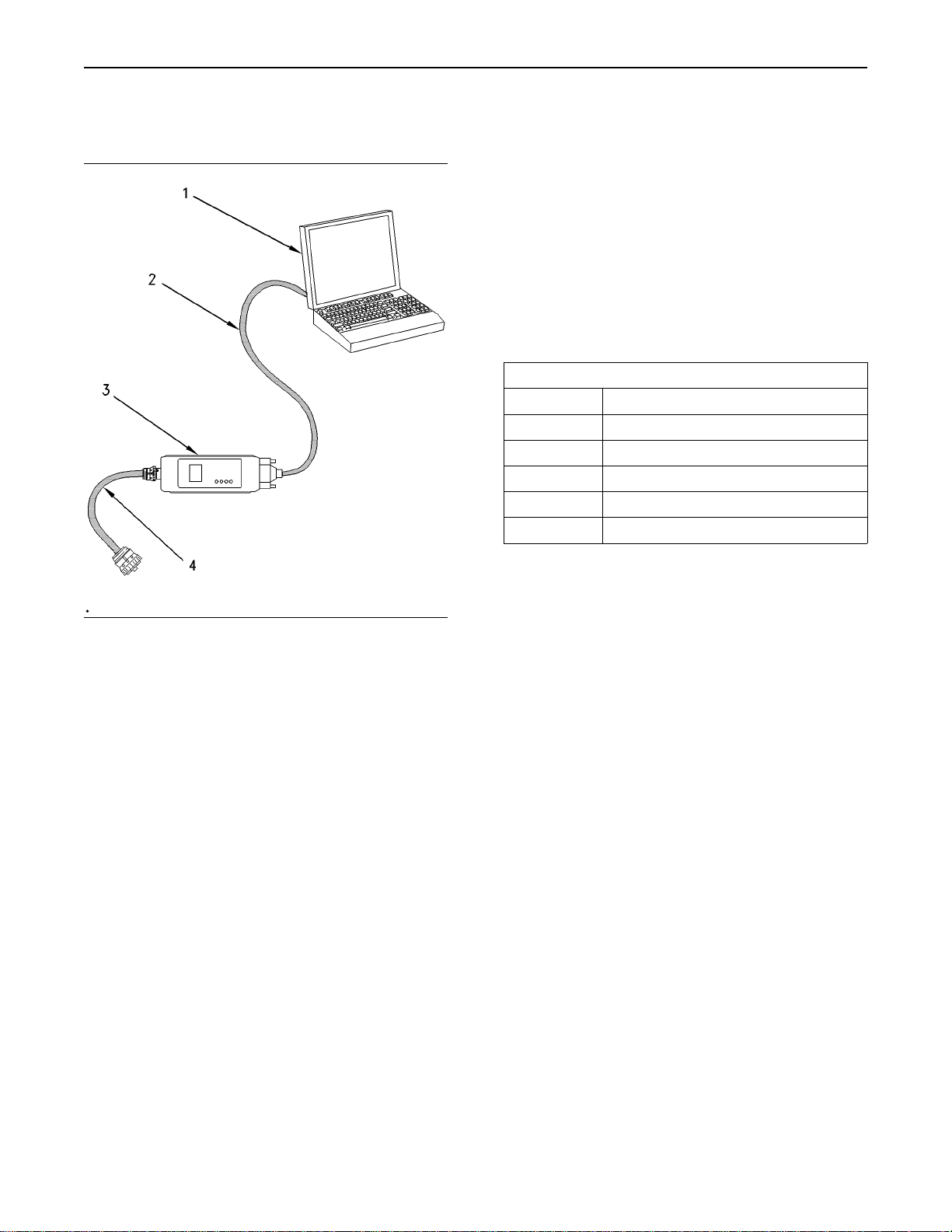

Connecting the Electronic Service Tool

and the Communication Adapter II

Support for the Electronic Service Tool

For authorization and ordering information, contact

Perkins Help Desk - Irlam.

If you are having problems with the software, you

can contact the Perkins Service Systems Support

Center.

Optional Service Tools

The following table contains service tools that may

be helpful to service the engine.

Ta bl e 2

Optional Service Tools

Part Number Description

N/A

N/A Suitable Breakout T (70 pin)

N/A Suitable Crimp Tool

N/A Suitable Cylinder Pressure Indicator

N/A Suitable Battery Load Tester

Suitable Digital Multimeter

Illustration 4

(1) Personal computer (PC)

(2) Adapter Cable (Computer Serial Port)

(3) Communication Adapter II

(4) Adapter Cable Assembly

g00647144

Note: Items (2), (3), and (4) are part of the

Communication Adapter II Gp.

Use the following procedure to connect the

Electronic Service Tool and the Communication

Adapter II.

1. Turn the keyswitch to the OFF/RESET position. If

the keyswitch is not placed in the OFF/RESET

position, the engine may start.

2. Connect cable (2) between the “COMPUTER”

end of communication adapter (3) and the

RS232 serial port of PC (1).

3. Connect cable (4) between the “DATA LINK” end

of communication adapter (3) and the service

tool connector.

4. Turn the keyswitch to the ON position. If the

electronic service tool and the communication

adapter do not communicate with the ECM, refer

to Troubleshooting, “Electronic Service Tool Will

Not Communicate With ECM”.

i01879254

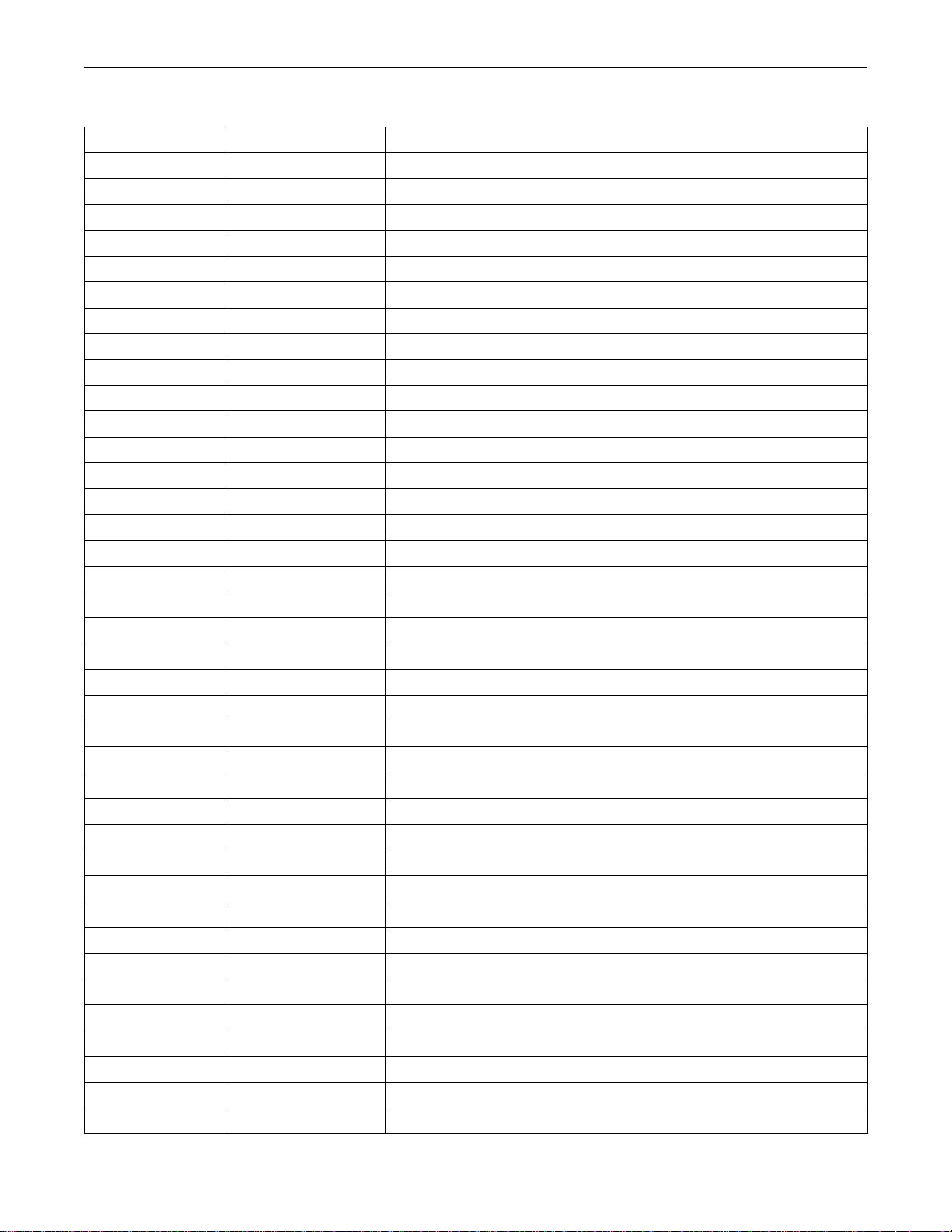

Diagnostic Codes

This list identifies the respective faults for the CID

FMI and the J Code FMI codes. The CID FMI codes

are displayed on a laptop computer. The J Code

FMI codes are displayed on a Diagnostic Code

Reader. The Diagnostic Code Reader is also known

as the Hand Held Tool.

The Component Identifier (CID) is a number that

identifies the specific component that caused a

diagnostic code to be logged.

The Failure Mode Identifier (FMI) is a number

that indicates the type of failure that has been

experienced by the component.

The J1939 Code is another system that identifies

the specific component that caused a diagnostic

code to be logged.

Note: Event codes are not supported by J1939

numbers. Event codes use (CID) and (FMI)

numbers. The following (FMI) numbers 0, 1, 15, 16,

17, and 18 are used for event codes.

Page 13

14

Troubleshooting Section

Ta bl e 3

CID FMI Code

0041 03

0041 04

0091 02

0091 03

0091 04

0091 08

0091 12

0100 03

0100 04

0100 10

0102 03

0102 04

0102 10

0105 03

0105 04

0110 03

0110 04

0168 02

0174 02

0247 09

0253 02

0262 03

0262 04

0266 02

0267 02

0320 02

0320 11

0321 02

0342 02

0590 02

0774 02

0774 03

0774 04

0774 08

0774 12

1627 03

1639 09

1684 00

J Code FMI Code Fault Description

J0678 03 8V Sensor Power Supply, voltage more than normal

J0678 04 8V Sensor Power Supply, voltage less than normal

J0091 02 Throttle Demand Sensor, erratic or intermittent

J0091 03 Throttle Demand Sensor, open circuit or shorted high

J0091 04 Throttle Demand Sensor, shorted low

J0091 08 Throttle Demand Sensor, abnormal signal

J0091-12 Throttle Demand Sensor, power supply failure

J0100 03 Engine Oil Pressure Sensor, open circuit or shorted high

J0100 04 Engine Oil Pressue Sensor, shorted low

Engine Oil Pressure Sensor, power supply open circuit

J0102 03 Intake Manifold Pressure Sensor, open circuit or shorted high

J0102 04 Intake Manifold Pressure Sensor, shorted low

Intake Manifold Pressure Sensor, power supply open circuit

J0105 03 Intake Manifold Temperature Sensor, open circuit or shorted high

J0105 04 Intake Manifold Temperature Sensor, shorted low

J0110 03 Engine Coolant Temperature Sensor, open circuit or shorted high

J0110 04 Engine Coolant Temperature Sensor, shorted low

J0168 02 Battery Voltage, intermittent or incorrect

J0174 02 Fuel Temperature Sensor, erratic or intermittent

J0639 09 J1939 Datalink, abnormal update

J0234 02 Incorrect ECM Software

J0620 03 5V Sensor Power Supply, voltage more than normal

J0620 04 5V Sensor Power Supply, voltage less than normal

Crank without injection, switch state incorrect

External Stop Switch, data erratic or incorrect

J0637 02 Speed and Timing Sensor, intermittent loss of signal

J0637 11 Speed and Timing Sensor, loss of signal

Diagnostic Reset Switch, intermittent or incorrect

J0723 02 Speed and Timing Sensor No.2, intermittent signal

ECM identified missing timing pulse

Throttle Demand Sensor No.2, erratic or intermittent

Throttle Demand Sensor No.2, open circuit or shorted high

Throttle Demand Sensor No.2, shorted low

Throttle Demand Sensor No.2, abnormal signal

Throttle Demand Sensor No.2, power supply failure

Fuel Pump Relay, did not turn off

Machine Security System Module, abnormal update

J1077 00 Fuel Injection Pump, fuel temperature more than normal

(continued)

Page 14

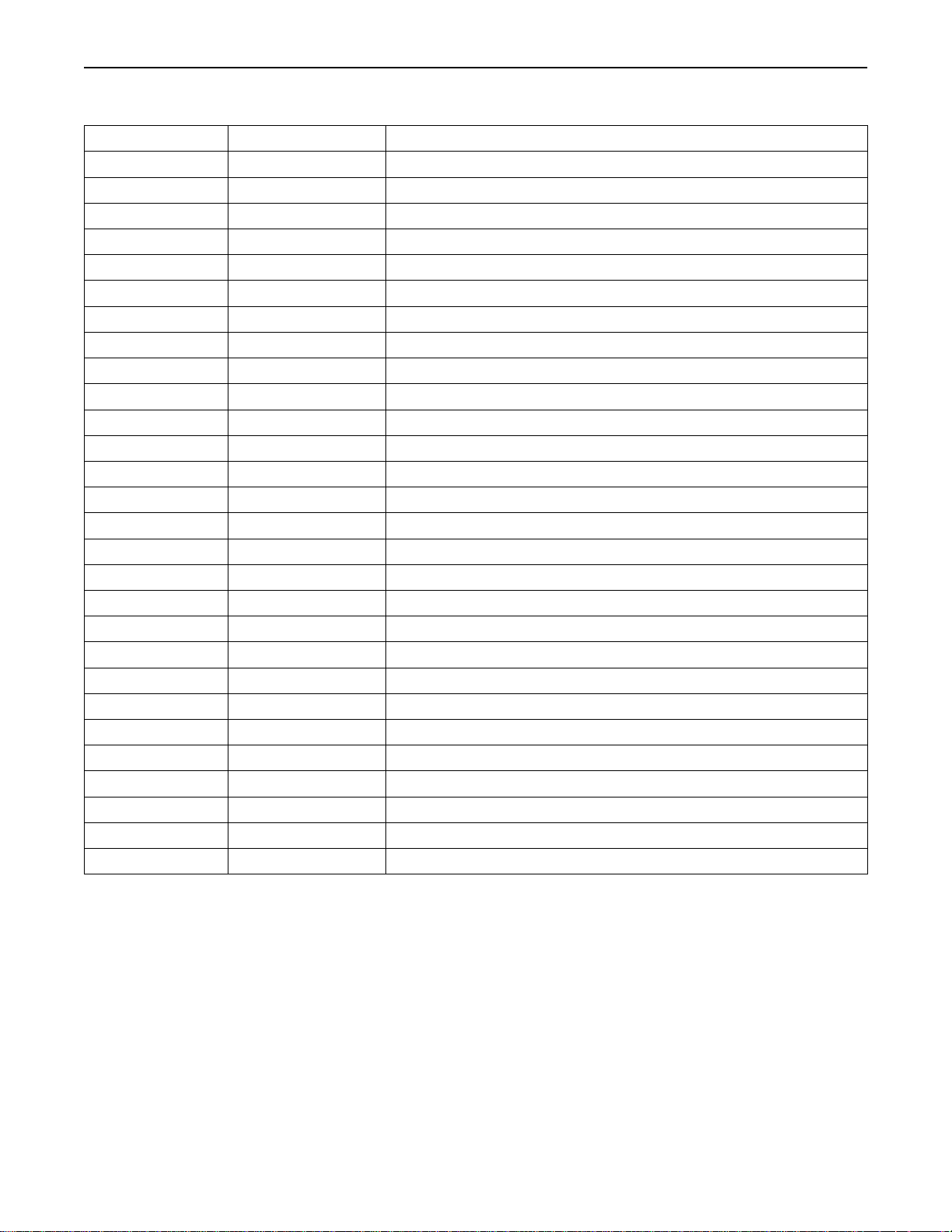

(Table 3, contd)

1684 02

1684 03

1684 04

1684 05

1684 07

1684 08

1684 09

1684 10

1684 11

1684 12

1684 14

1690 08

1743 02

1894 02

1895 02

Event Code CID FMI Code

E015

E016

E017

E025

E027

E039

E040

E054

E056

E100

E190

E442 Engine Failed To Stop With A No-Fuel Command

E883 Engine Failed To Stop When Fuel Solenoid Disengaged

J1077 02 Fuel Injection Pump, software failure

J1077 03 Fuel Injection Pump, fuelling fault

J1077 04 Fuel Injection Pump, supply voltage fault

J1077 05 Fuel Injection Pump, invalid pulse width

J1077 07 Fuel Injection Pump, mechanical fault

J1077 08 Fuel Injection Pump, crankshaft reference fault

J1077 09 Fuel Injection Pump, CAN fault

J1077 10 Fuel Injection Pump, fuel shutoff signal error

J1077 11 Fuel Injection Pump, internal sensor fault

J1077 12 Fuel Injection Pump, device failure

J1077 14 Fuel Injection Pump, no communications

Analogue Speed Control, signal abnormal

Engine Mode Selection Switch State, invalid state

Set Speed Control Disengage Switch, invalid state

Set Speed Control Speed Toggle Switch, invalid state

110 16

110 00

110 15

105 16

105 15

100 18

100 01

174 16

174 15

100 17

190 15

High Engine Coolant Temperature Derate

High Engine Coolant Temperature Sutdown

High Engine Coolant Temperature Warning

High Intake Air Temperature Derate

High Intake Air Temperature Warning

Low Engine Oil Pressure Derate

Low Engine Oil Pressure Shutdown

High Fuel Temperature Derate

High Fuel Temperature Warning

Low Engine Oil Pressure Warning

Engine Overspeed Warning

15

Troubleshooting Section

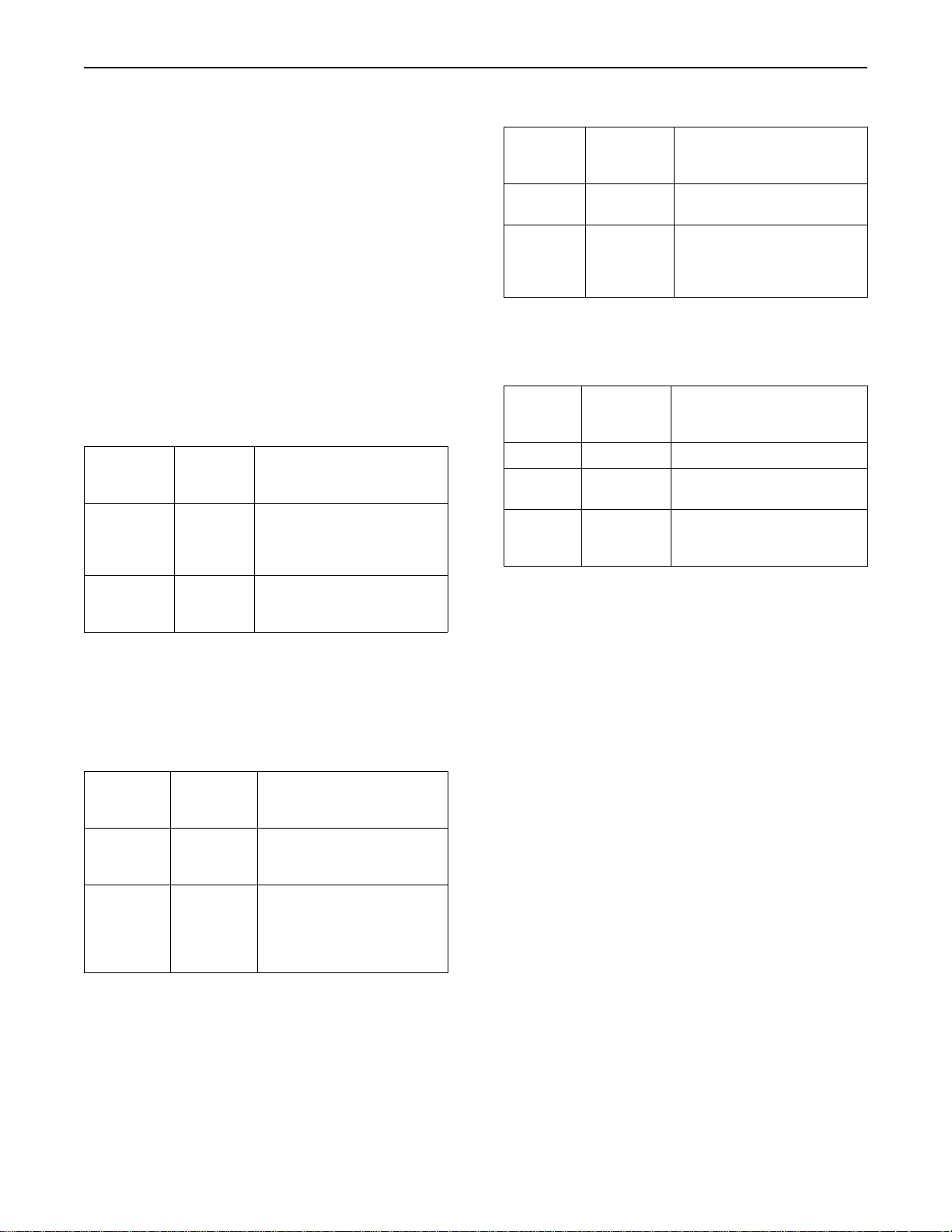

i01878735

Indicator Lamps

Some engine applications are equipped with

Indicator Lamps. Indicator lamps can be used as a

diagnostic aid. There are two lamps. One lamp has

an orange lens and the other lamp has a red lens.

These indicator lamps can be used in two ways:

The indicator lamps can be used to identify the

•

current operational status of the engine. The

indicator lamps can also be used to indicate

that the engine has a fault. This system is

automatically operated via the ignition switch.

The indicator lamps can be used to identify active

•

diagnostic codes. This system is activated by

pressing the Flash Code button.

Page 15

16

Troubleshooting Section

Use the lamps to check the engine’s

operational status or the existence

of any engine faults.

Each lamp will be illuminated in a combination of

ways in order to identify the engine’s operational

status. The lamps will also be illuminated in a

combination of ways to indicate if the engine has a

fault. These combinations of illuminated lamps have

the following meanings:

The status of the lamps before the engine is

cranked. This also acts as a lamp check.

When the ignition switch is turned ON, the lamps

will be illuminated for 2 seconds. The lamps are

then OFF unless the cold starting aid is required.

Ta bl e 4

Orange

lamp

(status)

ON ON The lamps will be illuminated

Refer to the

comments.

The lamp status with the cold starting aid in

operation and before the engine is cranked.

Red lamp

(status)

for 2 seconds or the lamps

will be illuminated until the

engine is cranked.

OFF The lamp will be OFF unless

the cold starting aid is

required.

Comments

Ta bl e 6

Orange

lamp

(status)

OFF OFF There are no apparent

ON ON The lubricating oil pressure

Red lamp

(status)

Comments

problems.

is low. This low oil pressure

was measured after the set

delay had expired.

The status of the lamps after cranking has failed

to start the engine.

Ta bl e 7

Orange

lamp

(status)

OFF OFF No faults were detected.

ON OFF An electrical fault was

OFF Flashing The engine was activated

Red lamp

(status)

Comments

detected.

when a serious fault was

detected.

Other combinations of illuminated indicator lamp

The following combinations of lamp status may also

be exhibited when the engine is either running or

when the engine has been shut down automatically.

The orange lamp will be illuminated until the engine

is ready to be cranked.

Ta bl e 5

Orange

lamp

(status)

ON OFF The status of the lamps with

Then OFF OFF This is the status of the

Red lamp

(status)

Comments

the cold starting aid still

operating.

lamps while the engine is

being cranked. The cold

starting aid is no longer

operating.

This is the status of the lamps while the engine

is being cranked.

Unless there is a fault, the engine monitoring system

will not illuminate the indicator lamps while the

engine is being cranked. For example if there is a

lack of lubricating oil pressure after the start delay

is exceeded. This type of fault will cause the stop

lamp for the engine to be illuminated.

Page 16

17

Troubleshooting Section

Ta bl e 8

Orange

lamp

(status)

OFF OFF No faults were detected.

OFF ON The oil pressure is low.

Flashing OFF Either the coolant temperature

OFF Flashing Either a fault has caused the

ON OFF An electrical fault has been

ON ON The oil pressure is low and

ON Flashing Either a fault has caused the

Flashing ON The oil pressure is low and

Red lamp

(status)

Comments

is high or the intake air

temperature is high. The

engine may be derated.

engine to be automatically

shut down or the engine has

exceeded the condition for a

derate.

detected.

there is an electrical fault.

engine to shut down or the

engine has exceeded the

conditions for a derate. There

is also an electrical fault.

either the coolant temperature

or the intake air temperature

is high. The engine may be

derated.

Use the lamps to identify active

diagnostic codes.

Ta bl e 9

CID

number

0041

0091

0100

0102

0105

0110

0174

0247

0253

0262

0320

0342

0774

1684

1743

1894

1895

Description Flash

8 Volt Power Supply

Throttle Position Sensor

Engine Oil Pressure Sensor

Intake Manifold Pressure

Sensor

Intake Manifold Air Temperature

Sensor

Engine Coolant Temperature

Sensor

Fuel Temperature Sensor

J1939 Data Link

Personality Module

5 Volt Power Supply

Engine Speed/Timing Sensor

Secondary Engine Speed

Sensor

Secondary Throttle Position

Sensor

Fuel Injection Pump

Mode Selector Switch for

Engine Operation

Cruise Control Status Switch

Toggle Switch for Cruise

Control Speed

code

517

154

157

135

133

168

165

514

416

516

141

142

155

158

144

427

428

The indicator lamps can be used to identify an

active code by flashing in a sequence that will

identify the active code. The active code that

is flashed by the indicator lamps is only the

component identifier (CID). The indicator lamps

cannot identify the fault with the component. The

active code that is flashed by the indicator lamps is

not a Failure Mode Identifier (FMI).

When the Flash Code feature is activated the

indicator lamps will flash the codes of all active

codes. Activation of the indicator lamps is achieved

by cycling the keyswitch OFF and ON twice within

3 seconds.

There will be a delay of 2 seconds before the lamps

start to flash the identity of any active code.

An active CID with two digits will be flashed in

the following sequence. There will be a number of

flashes. The number of flashes will equal the first

digit. There will be a delay before a second number

of flashes. The second number of flashes will equal

the second digit. For example, a CID code of 41 will

be four flashes, a delay and the one flash. A three

digit CID code will have two delays between the

sequence of flashes. A four digit CID code will have

three delays between the sequence of flashes.

Each flash of the lamp will be 0.5 seconds long.

There will be a delay between each flash of 0.3

seconds.

Page 17

18

Troubleshooting Section

Each delay between each digit of the code will be

2 seconds.

After one active code has been identified there will

be a delay of 5 seconds before the next active

code is flashed.

The sequence of flashing the active codes may be

restarted at any time by reactivating the cycling of

the keyswitch.

i01798103

Replacing the ECM

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

The engine is equipped with an Electronic Control

Module (ECM). The ECM contains no moving

parts. Follow the troubleshooting procedures in this

manual in order to be sure that replacing the ECM

will correct the problem. Verify that the suspect

ECM is the cause of the problem.

Note: Ensure that the ECM is receiving power

and that the ECM is properly grounded before

replacement of the ECM is attempted. Refer to

Troubleshooting, “Electrical Power Supply Circuit Test”.

A test ECM can be used in order to determine if

the ECM on the engine is faulty. Install a test ECM

in place of the suspect ECM. Flash the personality

module into the test ECM. Program the parameters

for the test ECM. The parameters must match

the parameters in the suspect ECM. Refer to the

following test steps for details. If the test ECM

resolves the problem, reconnect the suspect ECM.

Verify that the problem returns. If the problem

returns, replace the ECM.

Use the electronic service tool to read the

parameters in the suspect ECM. Record the

parameters in the suspect ECM. The personality

module can be flashed into the new ECM. After

the ECM is installed on the engine, the parameters

must be programmed into the new ECM.

Note: When a new ECM is not available, you may

need to remove an ECM from an engine that is

not in service. The ECM must have the same

serial number suffix. Ensure that the replacement

ECM and the Personality Module Interlock Code

match the suspect ECM. Be sure to record the

parameters from the replacement ECM. Use the

“Copy Configuration ECM Replacement” function in

the electronic service tool.

NOTICE

If the Personality Module and engine application are

not matched, engine damage may result.

Perform the following procedure in order to replace

the ECM.

1. Connect the electronic service tool to the service

tool connector.

2. Use the “Copy Configuration ECM Replacement”

function from the electronic service tool. If the

“Copy Configuration” is successful, proceed

to Step 4. If the “Copy Configuration” failed,

proceed to Step 3.

Note: You may want to record any Logged Faults

and Events for your records.

3. Record the parameters. Record all of the

parameters on the “Main Configuration” screen.

Also, record all of the parameters on the

“Throttle Configuration” screen and on the “Mode

Configuration” screen.

Note: If the parameters cannot be read, the

parameters must be obtained elsewhere. Some

parameters are stamped on the engine information

plate, but most parameters must be obtained from

the factory.

4. Remove the ECM.

a. Turn the keyswitch to the OFF position.

b. Turn the battery disconnect switch to the OFF

position.

c. Slacken the 4 mm Allen head screw

and disconnect the ECM 70-pin (P1/J1)

connectors.

d. Remove the mounting bolts from the ECM.

e. Disconnect the grounding strap from the ECM.

5. Install the replacement ECM.

Page 18

19

Troubleshooting Section

a. Use the old mounting hardware to install the

replacement ECM. The mounting hardware

should be free of damage.

b. Check that the ECM mounting hardware is

installed correctly. The rubber grommets are

used to protect the ECM from excessive

vibration. The ECM should be able to drift in

the rubber grommets.

c. Install the ground strap for the ECM on the

engine.

d. Reconnect the J1/P1 70 Pin connector to the

ECM. Tighten the Allen head screw on the

connectors to a torque of 6 N·m (55 lb in).

6. Download the Flash file.

a. Connect the electronic service tool to the

service connector.

b. Select “WinFlash” from the “Utilities” menu of

the electronic service tool.

c. Select the appropriate file.

7. If it is necessary, use the electronic service tool

to clear the rating interlock in the Personality

Module. To clear the rating interlock, enter the

factory password when the electronic service

tool is first connected. Activating the “Test ECM”

mode will also clear the rating interlock.

8. Use the electronic service tool to program the

parameters. Perform the following procedure.

a. If the “Copy Configuration” procedure was

successful, use the “Copy Configuration,

ECM Replacement” function to load the

configuration file into the ECM.

Event

•

Diagnostic Code – When a problem with the

electronic system is detected, the ECM generates a

diagnostic code. This indicates the specific problem

with the circuitry.

Diagnostic codes can have two different states:

Active

•

Logged

•

Active Code – An active diagnostic code indicates

that an active problem has been detected. Active

codes require immediate attention. Always service

active codes prior to servicing logged codes.

Logged Code – Every generated code is stored in

the permanent memory of the ECM. The codes are

logged.

Event Code – An event code is generated by

the detection of an abnormal engine operating

condition. For example, an event code will be

generated if the oil pressure is too low. In this case,

the event code indicates the symptom of a problem.

Logged codes may not indicate that a repair is

needed. The problem may have been temporary.

The problem may have been resolved since the

logging of the code. If the system is powered, it

is possible to generate an active diagnostic code

whenever a component is disconnected. When

the component is reconnected, the code is no

longer active. Logged codes may be useful to help

troubleshoot intermittent problems. Logged codes

can also be used to review the performance of the

engine and the electronic system.

b. If the “Copy Configuration” procedure failed,

configure the parameters individually. The

parameters should match the parameters

from step 2.

9. Check for logged diagnostic codes. Factory

passwords are required to clear Logged Events.

i01798104

Self-Diagnostics

The Electronic Control Module (ECM) has the ability

to detect problems with the electronic system

and with engine operation. When a problem is

detected, a code is generated. An alarm may also

be generated. There are two types of codes:

Diagnostic

•

Page 19

20

Troubleshooting Section

Sensors and Electrical

Connectors

i01798105

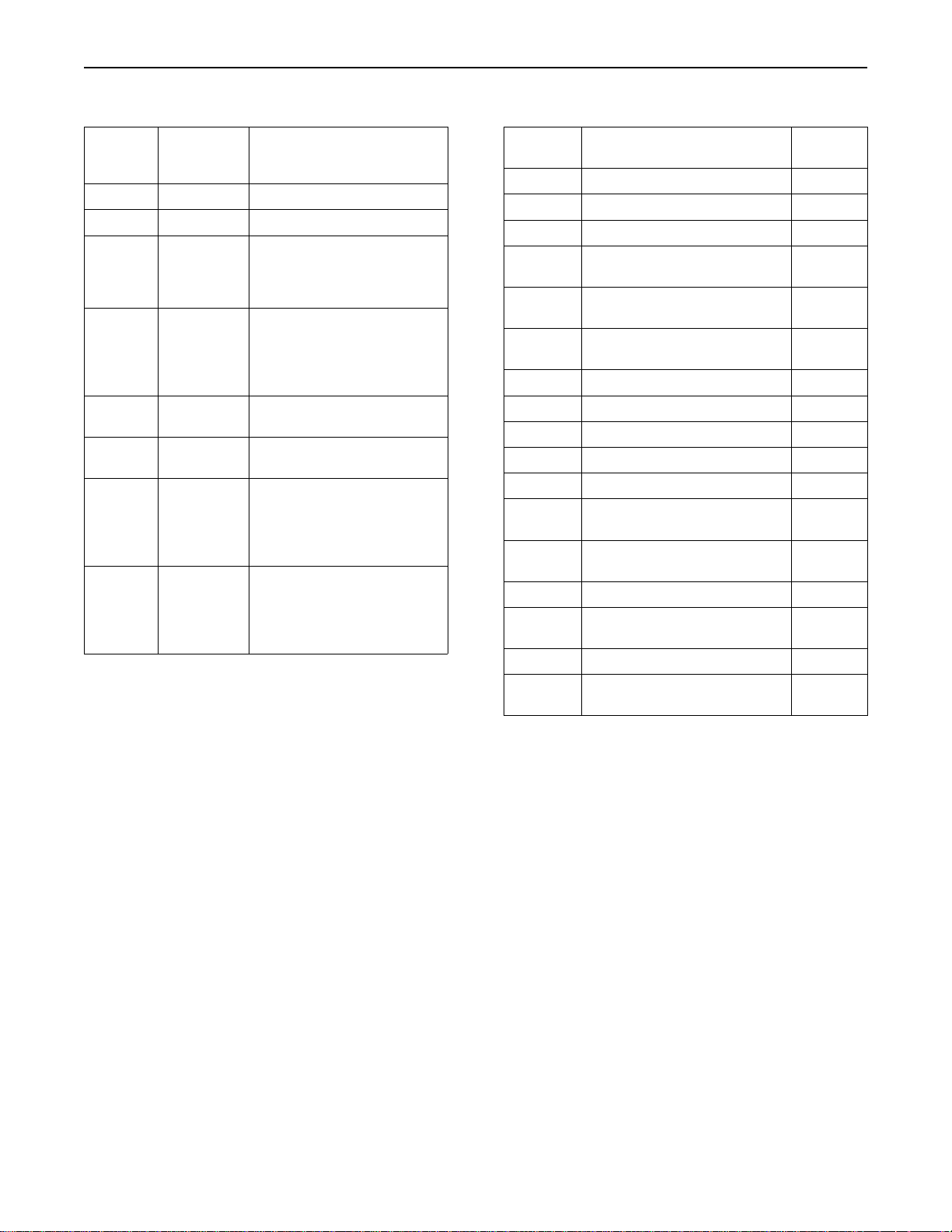

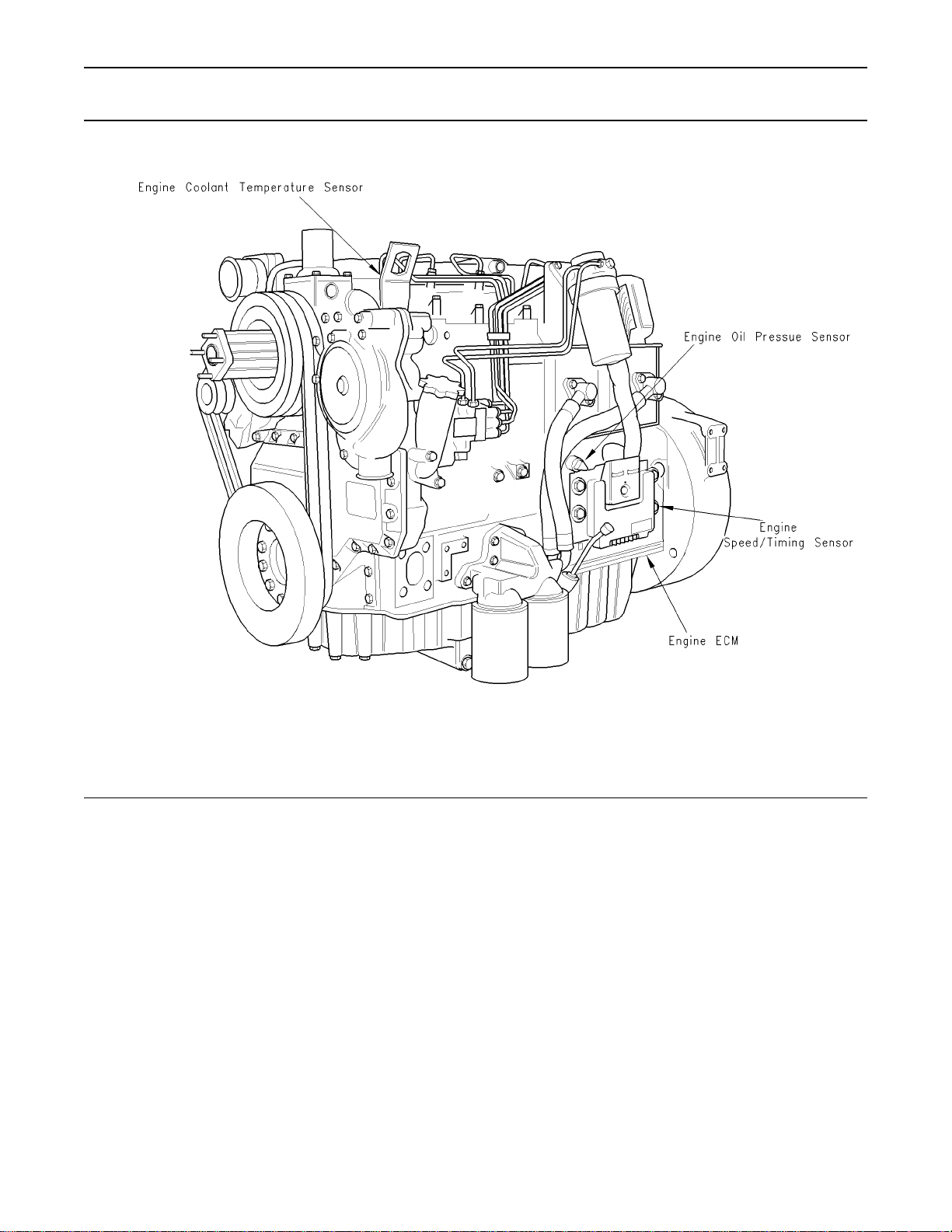

Illustration 5

1104

Typical example of left side sensor locations

g00954205

Page 20

21

Troubleshooting Section

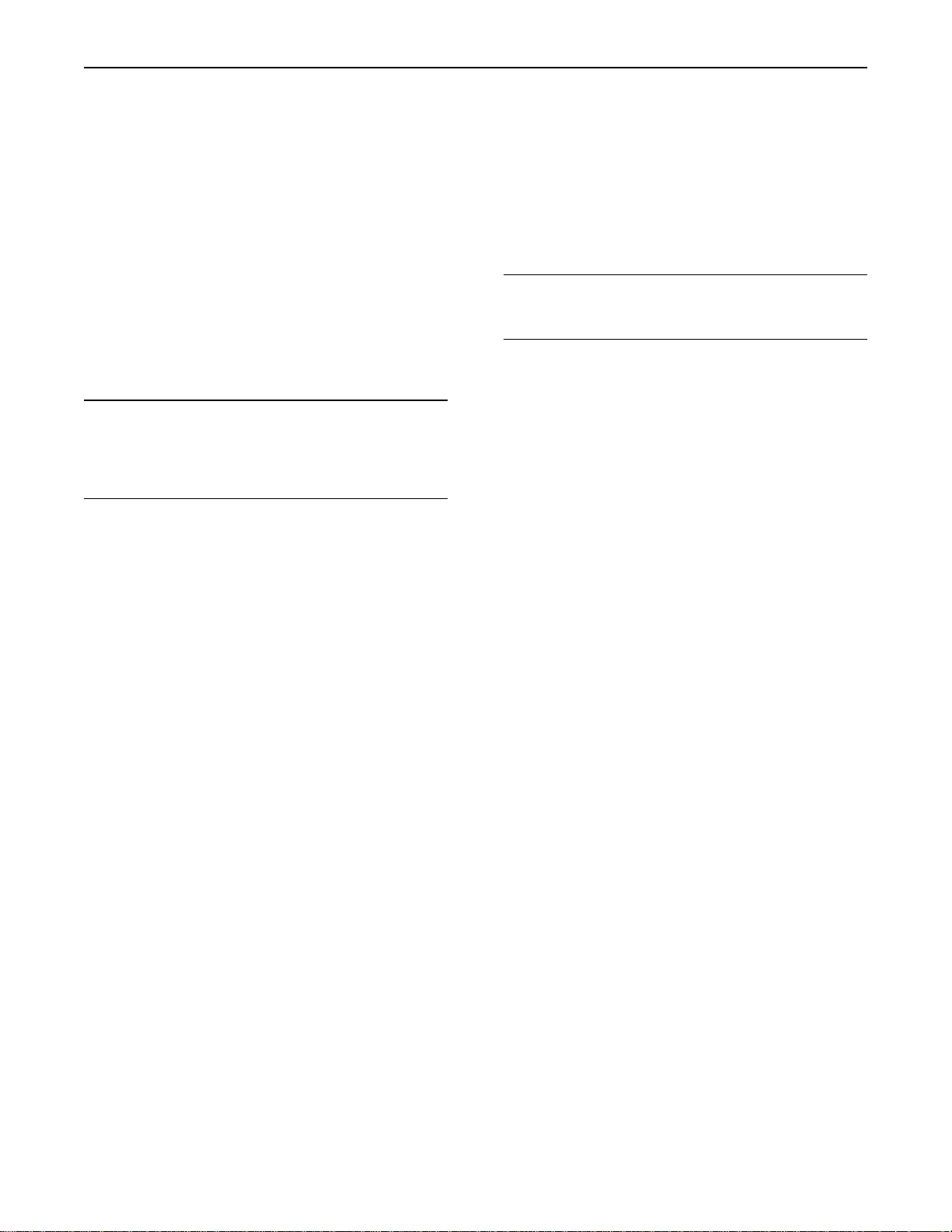

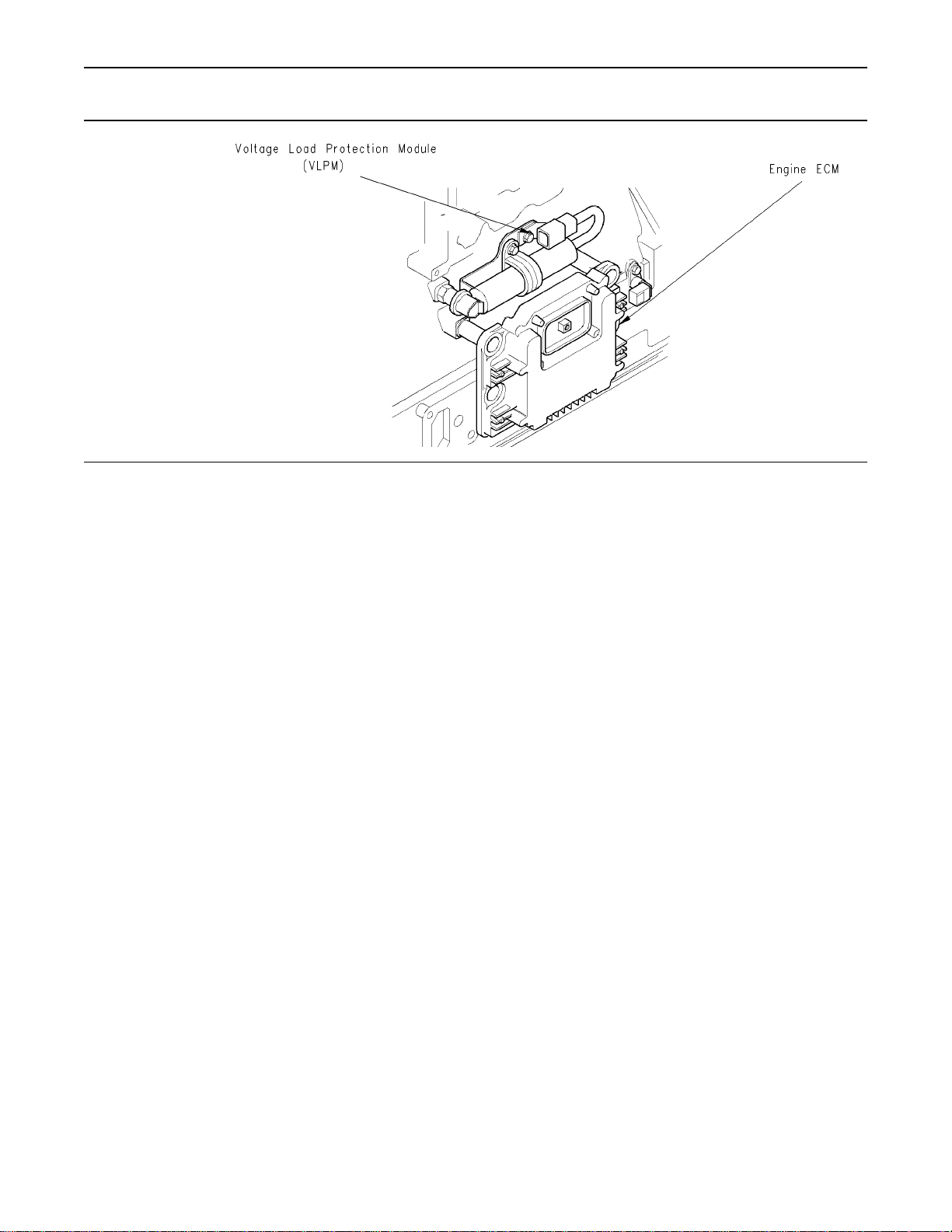

Illustration 6

1104 engine

Typical location of the VLPM

g00915379

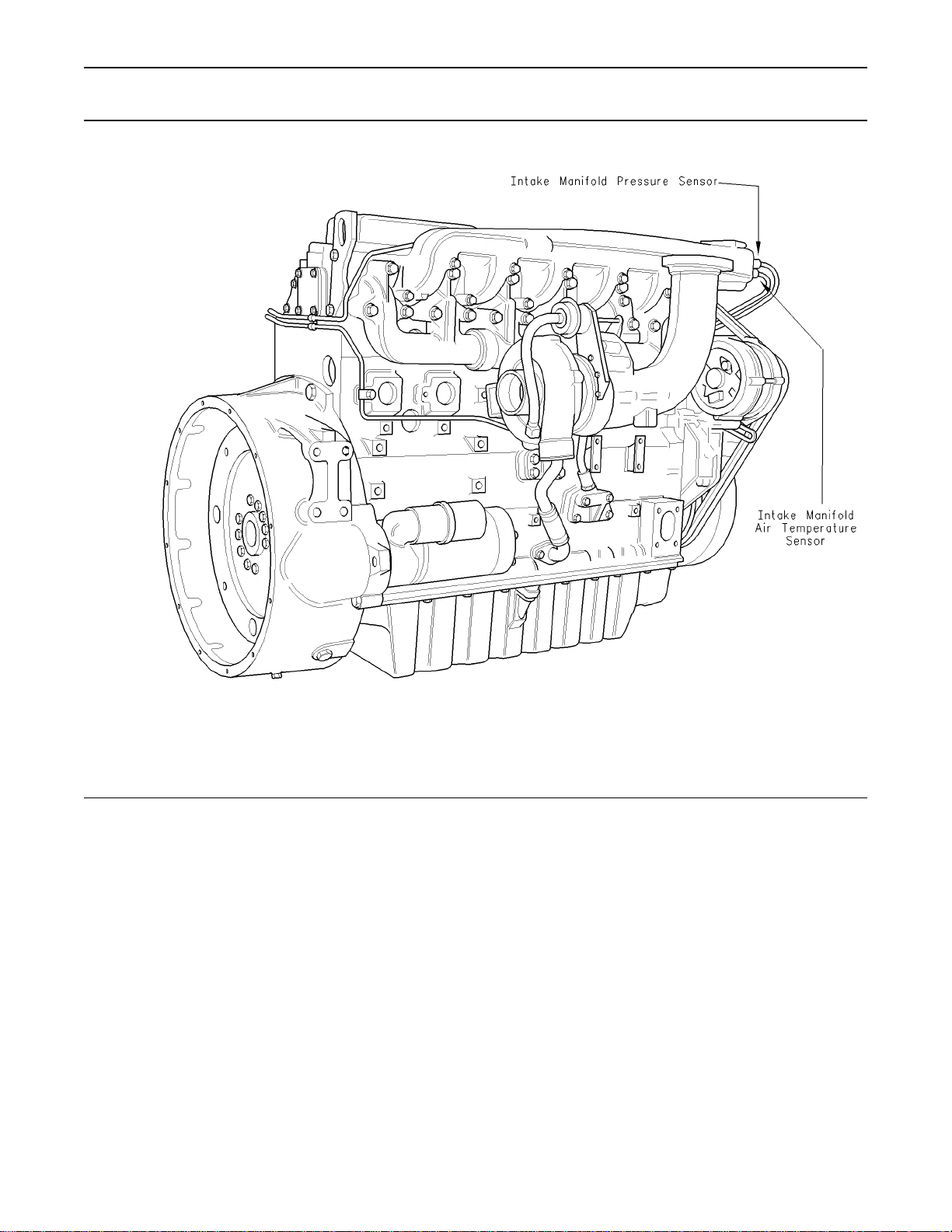

Illustration 7

1104

Typical example of right side sensor locations

g00882117

Page 21

22

Troubleshooting Section

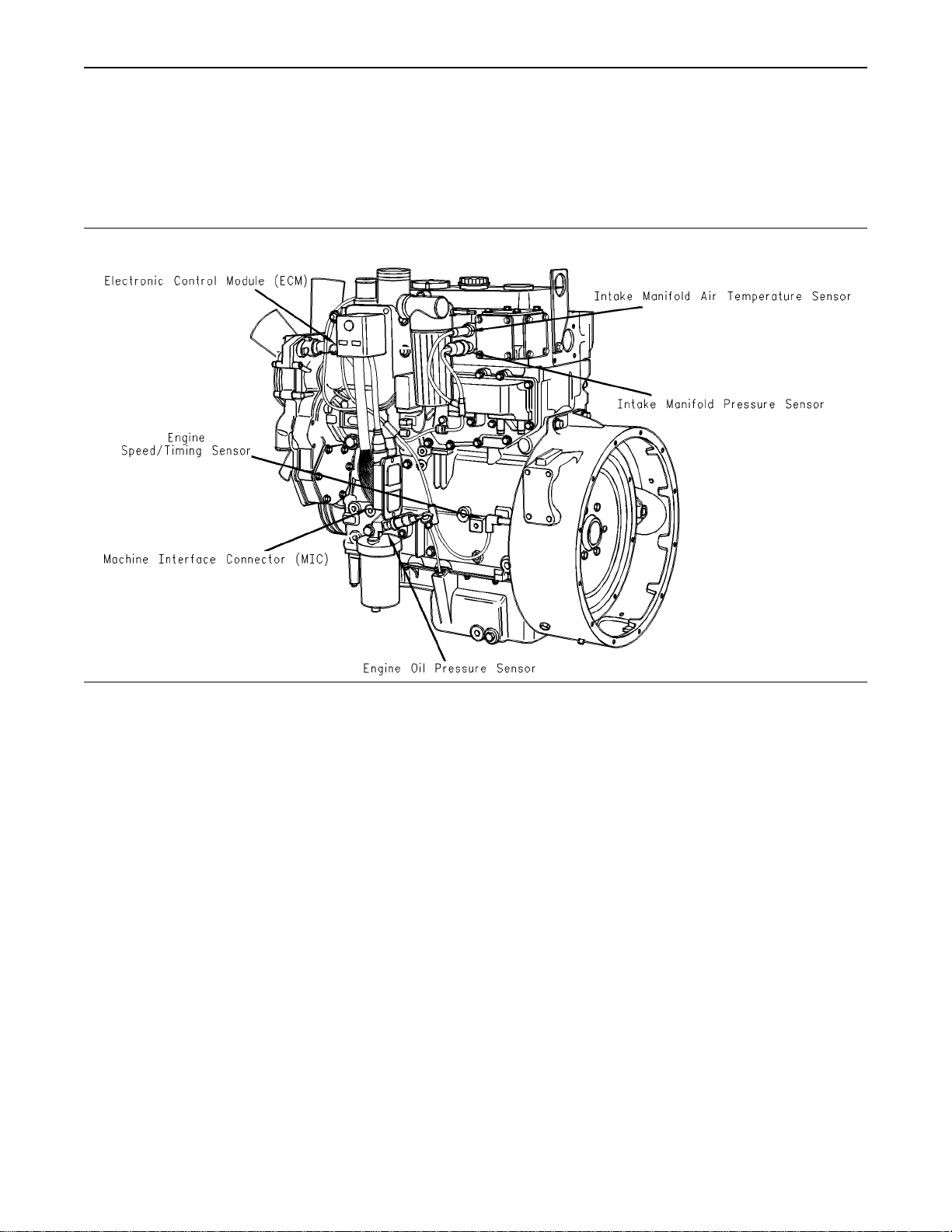

Illustration 8

1106

Typical example of left side sensor locations

g00884570

Page 22

23

Troubleshooting Section

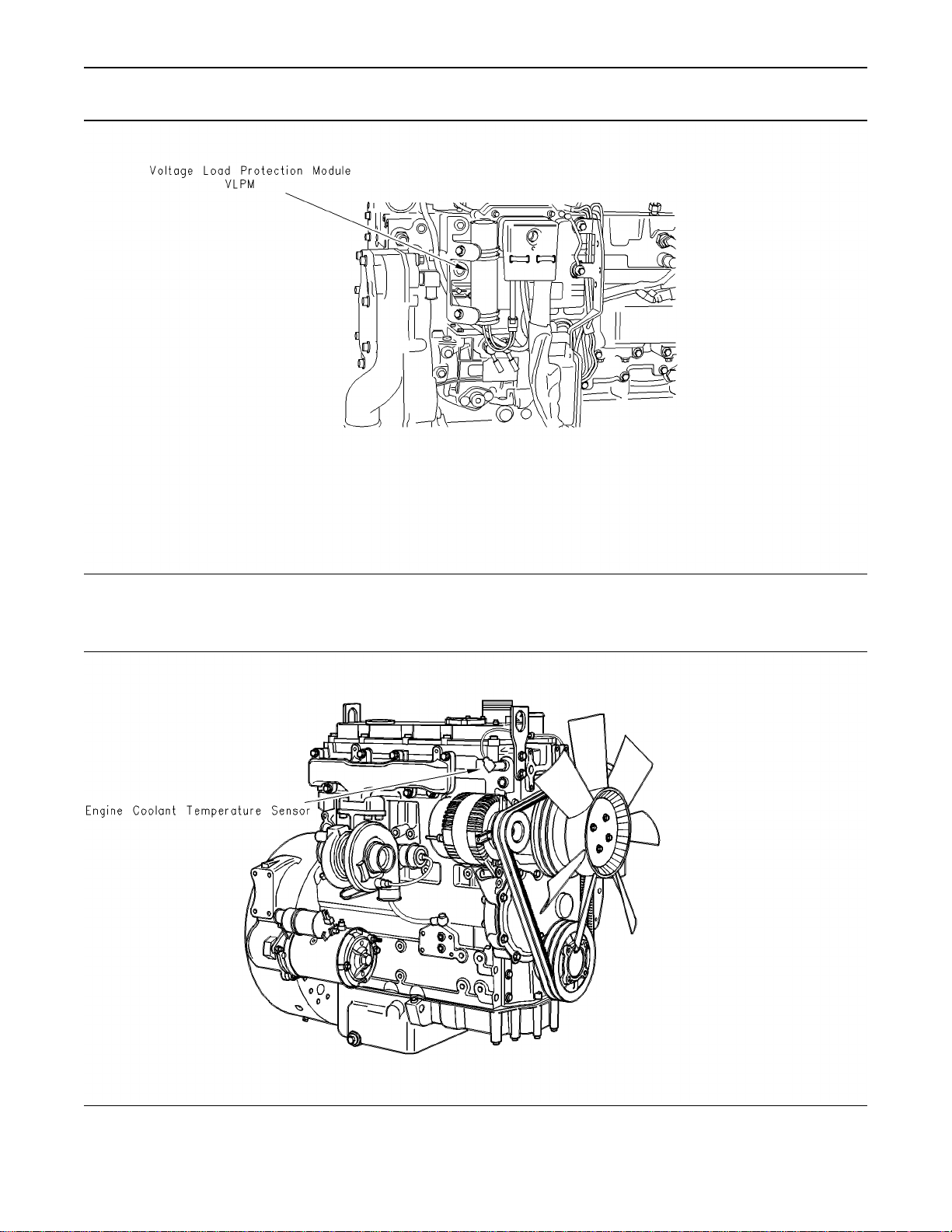

Illustration 9

1106 engine

Typical location of the VLPM

g00908929

Page 23

24

Troubleshooting Section

Illustration 10

Typical example of right side sensor locations

1106

g00954214

Page 24

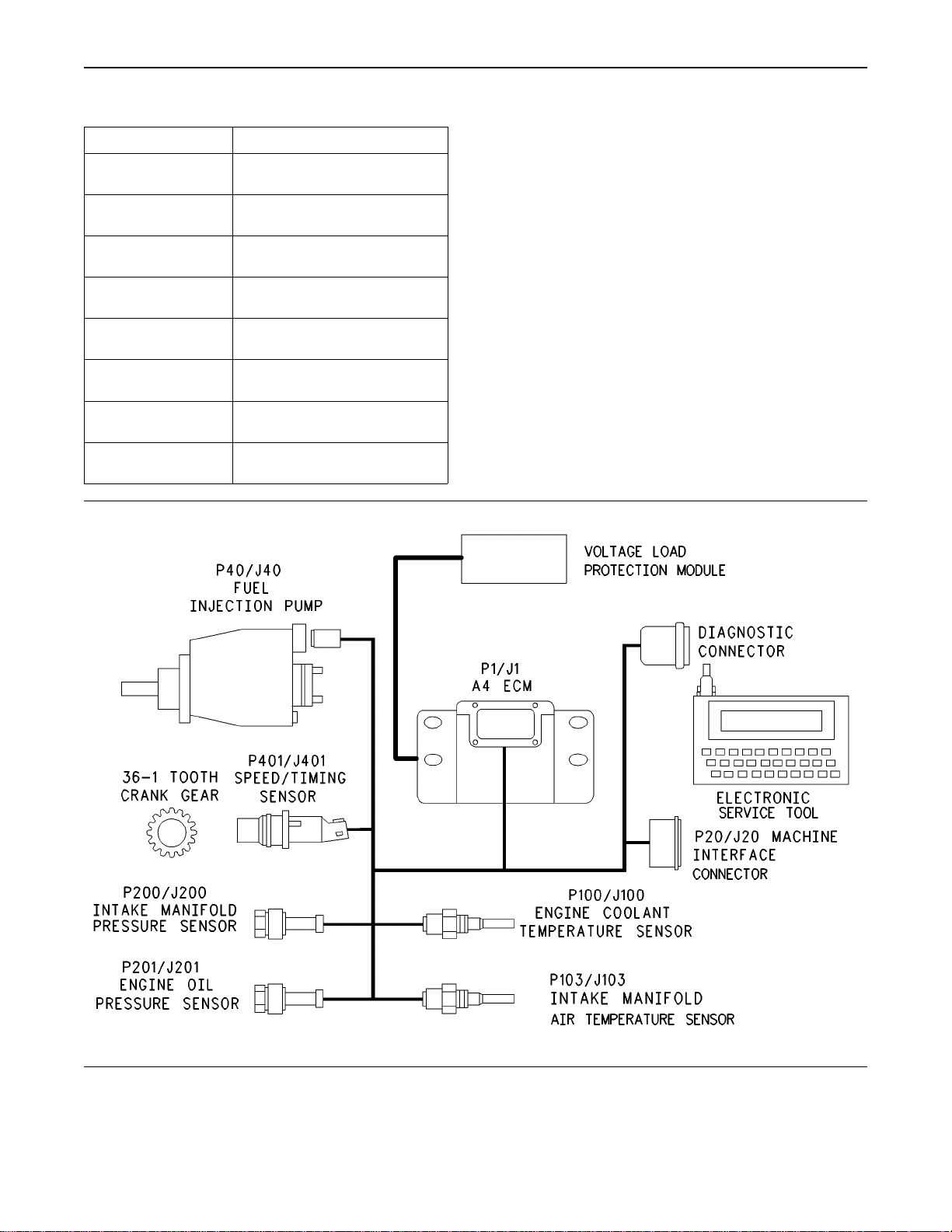

Ta bl e 1 0

Connector

Function

J1/P1 ECM Connector 70 Pin Machine

Harness

J20/P20 Machine Interface Connector

(70-Pin Engine Harness)

J40/P40 Fuel Injection Pump (3-Pin

Connector)

J100/P100 Engine Coolant Temperature

Sensor (2-Pin Connector)

J103/P103 Intake Manifold Air Temperature

Sensor (2-Pin Connector)

J200/P200 Intake Manifold Pressure Sensor

(3-Pin Connector)

J201/P201 Engine Oil Pressure Sensor

(3-Pin Connector)

J401/P401 Speed/Timing Sensor (2-Pin

Connector)

25

Troubleshooting Section

Illustration 11

Basic engine schematic

g00954204

Page 25

26

Troubleshooting Section

i01798106

Engine Wiring Information

The wiring diagrams are revised periodically. The

wiring diagrams will change with updates to the

wiring harness. For the most current information,

always check the revision number of the diagram.

Use the diagram with the latest revision number.

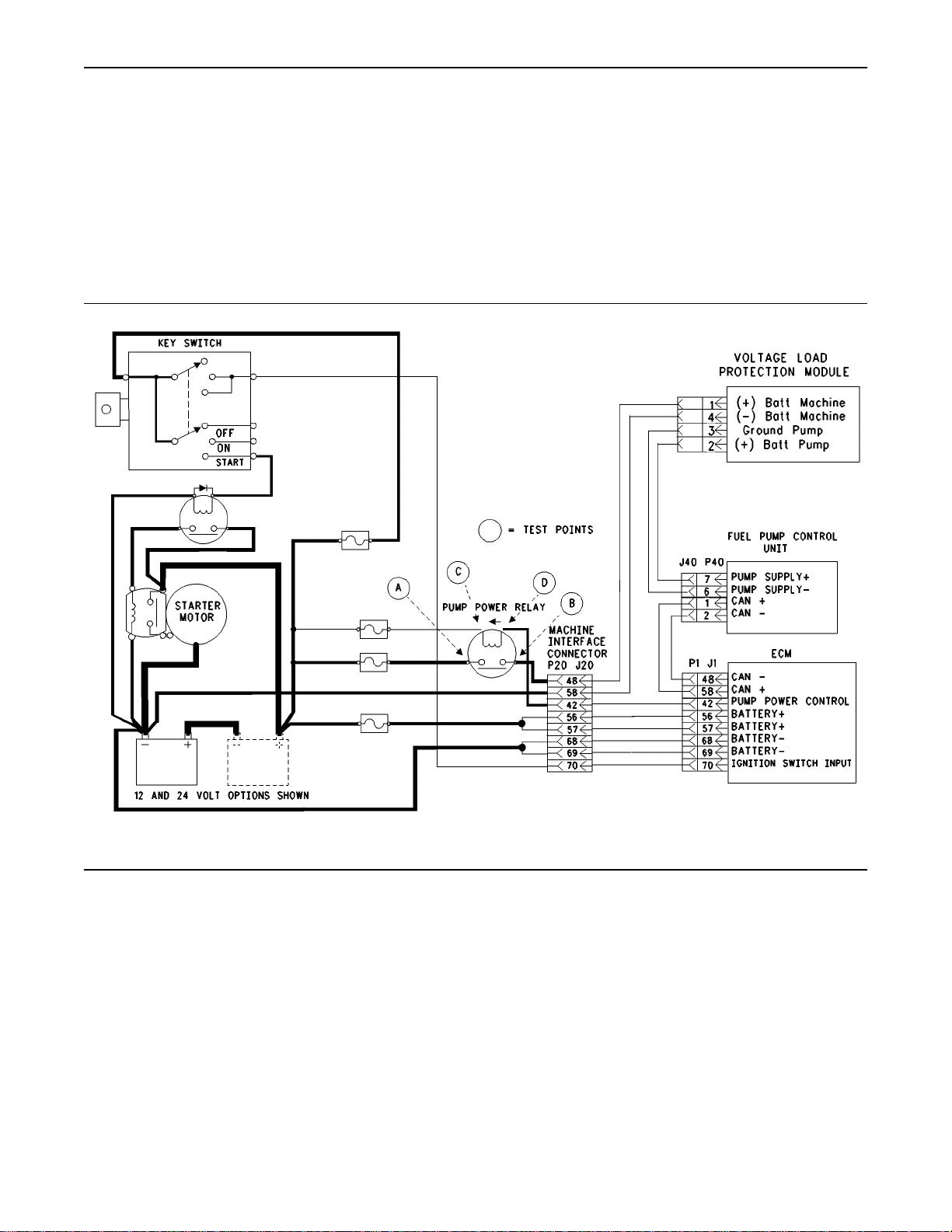

Illustration 12

Schematic for the fuel injection pump and ECM power supply

g00910876

Page 26

27

Troubleshooting Section

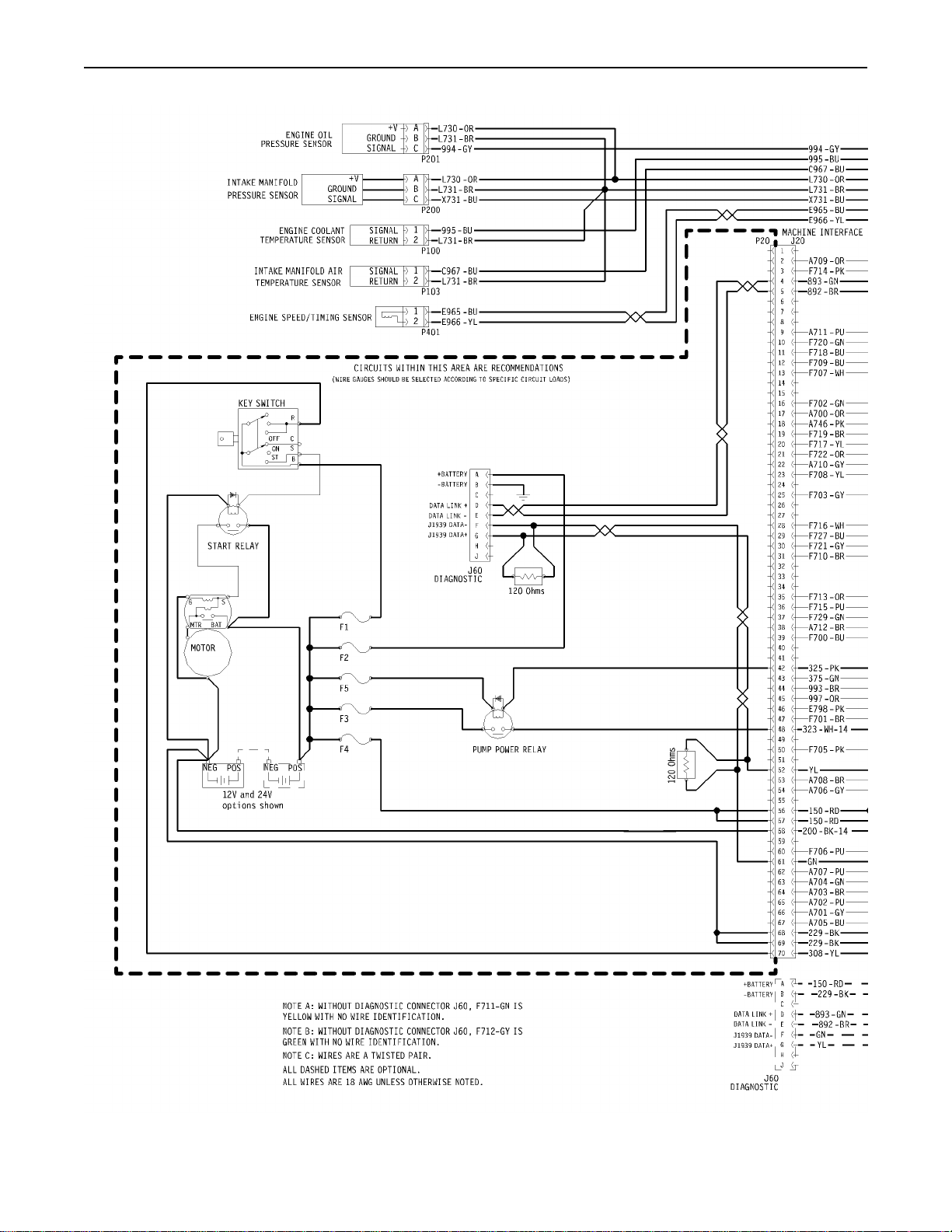

Illustration 13

g00955504

Page 27

28

Troubleshooting Section

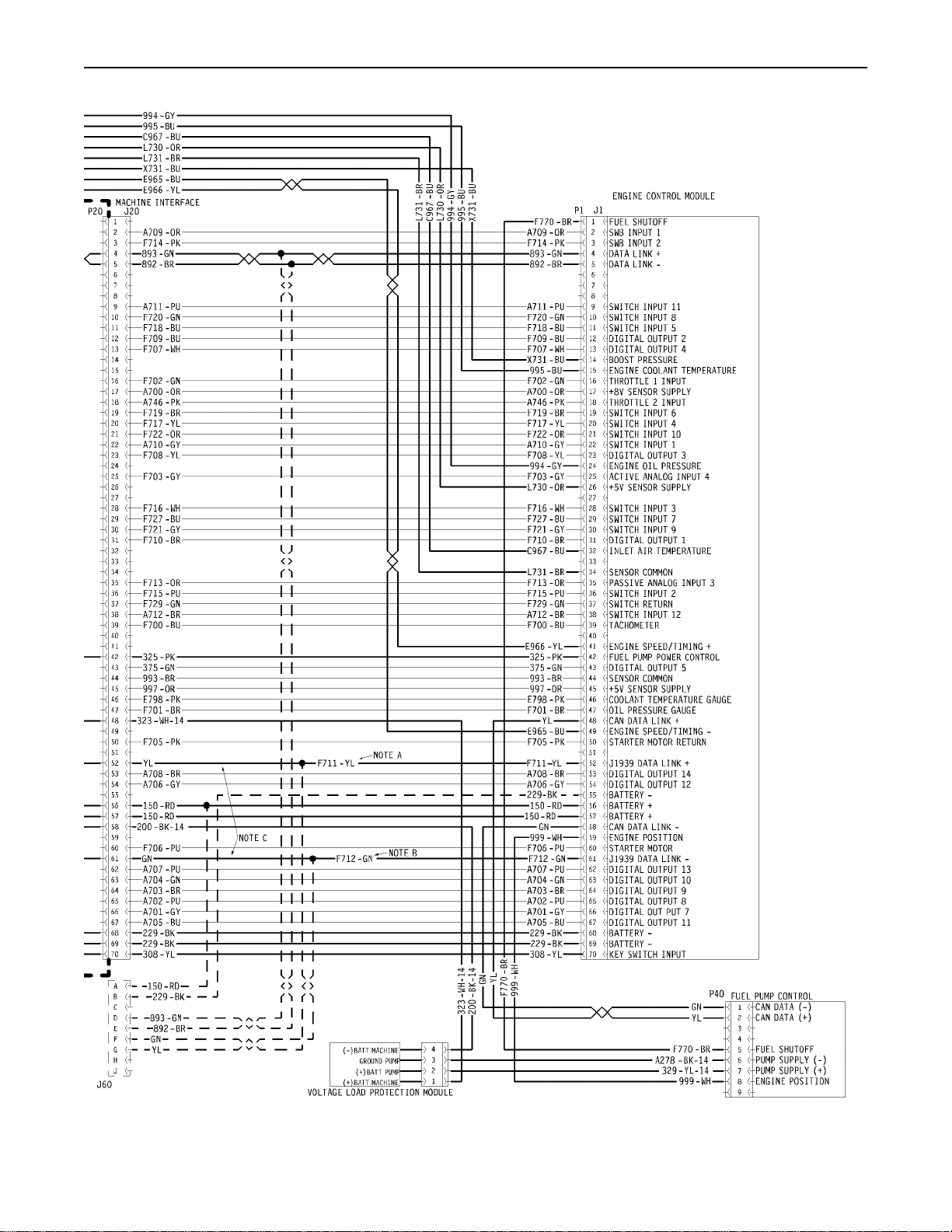

Illustration 14

g00955499

Page 28

Note: Each terminal end of the J1939 CAN data

link must be connected with a 120 ohm terminating

resistor.

Note: Digital outputs 7,8,9,10,11,12,13, and 14 are

only suitable for a 12 V system.

Harness Wire Identification

Perkins identifies all wires with eleven solid colors.

The circuit number is stamped on the wire at a

25 mm (1 inch) spacing. Table 11 lists the wire

colors and the color codes.

Ta bl e 1 1

Color Codes for the Harness Wire

Color Code Color Color Code Color

BK

BR Brown BU Blue

RD Red PU Purple

OR Orange GY Gray

YL Yellow WH White

Black GN Green

PK Pink

29

Troubleshooting Section

For example, a wire identification of F702-GN on

the schematic would signify a green wire with the

circuit number F702. F702-GN identifies the power

supply for the 8 V throttle sensor.

Note: Always replace a harness wire with the same

gauge of wire and with the same color code.

Page 29

30

Troubleshooting Section

Programming Parameters

i01798107

Programming Parameters

The electronic service tool can be used to view

certain parameters that can affect the operation of

the engine. The electronic service tool can also be

used to change certain parameters. The parameters

are stored in the Electronic Control Module (ECM).

Some of the parameters are protected from

unauthorized changes by passwords. Parameters

that can be changed have a tattletale number. The

tattletale number shows if a parameter has been

changed.

i01798108

Factory Passwords

Passwords

Note: The old interlock code is required to change

the interlock code on a used ECM. A new interlock

code is also required to change the interlock code

on a used ECM.

The electronic service tool screen for factory

passwords will display the following parameters:

Serial number of the Electronic Control Module

•

(ECM)

Engine serial number

•

Serial number for the electronic service tool

•

Reason Code

•

Total Tattletale number

•

Note: The factory passwords may only be used

for one programming session. A different set of

factory passwords will be required after you exit

the electronic service tool screen. A different set of

passwords will be required to change information

on another electronic service tool screen.

Customer Passwords

Passwords are part of a security system that helps

to prevent unauthorized reprogramming of certain

parameters. Passwords prevent unauthorized

erasing of logged events. Passwords allow the

factory to control access to engine calibration

parameters. Passwords allow the customer to

control access to certain programmable engine

parameters.

Factory Passwords

Factory passwords are required to clear any event

code. Factory passwords are required to change

certain parameters such as Full Load Setting. The

factory passwords restrict changes to authorized

personnel. When the correct factory passwords

have been entered, the changes can then be made.

In order to obtain the proper factory passwords,

certain information must be given to an authorized

Perkins distributor. Since the factory passwords

contain alphabetic characters, the electronic

service tool can be used to perform this function.

In order to obtain the factory passwords, proceed

as if you already have the factory passwords. At

some point, if the factory passwords are actually

needed, the electronic service tool will request the

factory passwords and the electronic service tool

will display the information that is required to obtain

the factory passwords.

Customer Passwords allow the customer to restrict

access to parameters that are programmable by

the customer. The customer passwords cannot be

longer than eight characters. The customer has the

option of entering one or two customer passwords.

Note: If the owner loses the owner’s customer

passwords, the owner will not be able to program

parameters that are protected by customer

passwords. By using factory passwords, one can

read customer passwords. Then use those customer

passwords to program parameters that have been

protected by customer passwords.

i01798110

Flash Programming

Flash Programming – This is a method of

programming or updating the personality module

in an ECM.

The electronic service tool can be utilized to flash

a new personality module into the ECM. The flash

is accomplished by transferring the data from a PC

to the ECM.

Page 30

Flash Programming a Personality

Module

1. Connect the electronic service tool to the service

tool connector.

2. Select “WinFlash” from the “Utilities” menu on the

electronic service tool.

“WinFlash” will try to detect an ECM.

3. When an ECM has been detected, the “ECM

Selector” window will appear. Select the

appropriate ECM that needs to be flashed and

press “Browse”.

The “Flash File Selection” window will appear.

4. The flash files are located on a disk drive and in

a directory. Select the correct disk drive and the

correct directory from “Drives” and “Directories”

on the electronic service tool.

31

Troubleshooting Section

A list of flash files will appear.

5. Select the correct file from the list of flash files.

Read the “File Info” and the “Description” in

order to verify that the correct file is selected.

Select “OK”.

6. Select the “Begin Flash” button in order to

program the personality module.

When the flash is completed, this message will

appear: “Flash Completed Successfully”.

7. Start the engine and check for proper operation.

a. If a diagnostic code of 253-02 Incorrect

ECM Software is generated, program any

parameters that were not in the old personality

module.

b. Access the “Configuration” screen under

the “Service” menu in order to determine

the parameters that require programming.

Look under the “Tattletale” column. All of the

parameters should have a tattletale of 1 or

more. If a parameter has a tattletale of 0,

program that parameter.

“WinFlash” Error Messages

If you receive any error messages during flash

programming, click on the “Cancel” button in order

to stop the process. Access the information about

the “ECM Summary” under the “Information” menu.

Make sure that you are flashing the correct file for

your engine.

Page 31

32

Troubleshooting Section

System Configuration

Parameters

i01798111

System Configuration

Parameters

System Configuration Parameters affect the

emissions of the engine or the power of the engine.

System configuration parameters are programmed

at the factory. Normally, system configuration

parameters would never need to be changed

through the life of the engine. System configuration

parameters must be reprogrammed if an ECM is

replaced. Unless the engine rating has changed,

system configuration parameters do not need to

be reprogrammed when the Personality Module is

replaced. The correct values for these parameters

are stamped on the engine information ratings

plate. The engine information ratings plate is

located on the valve cover or on the air intake

manifold. Factory passwords are required to change

these parameters. The following information is a

description of the system configuration parameters.

“Full Load Setting”

“Full Load Setting” is a number that represents the

adjustment to the fuel system that was made at

the factory in order to fine tune the fuel system.

The correct value for this parameter is stamped

on the engine information ratings plate. If the

ECM is replaced, the “full load setting” must

be reprogrammed in order to prevent a 253-02

diagnostic code from becoming active.

“Full Torque Setting”

“Full Torque Setting” is similar to “Full Load Setting”.

If the ECM is replaced, the full torque setting must

be reprogrammed in order to prevent a 253-02

diagnostic code from becoming active.

When an ECM is replaced this rating interlock code

must match the code that is stored in the ECM. If

the rating interlock code does not match the code

that is stored in the ECM, both of the following

situations will exist:

The engine will not run.

•

The diagnostic code 253-02 (Incorrect ECM

•

Software) will be active.

Note: The flash programming of a new rating

interlock replaces the old rating interlock.

This code does not need to be programmed when

the replacement ECM is from the same engine

rating.

If the ECM is from a different engine rating, then the

following components may need to be changed:

pistons, fuel injectors, and other components.

The engine information ratings plate must also be

changed in order to reflect the new rating.

Some vehicle systems such as the cooling system

or the transmission may also require changes when

the engine is rerated. Please contact the local OEM

dealer for further information.

“Engine Serial Number”

When a new ECM is delivered, the engine serial

number in the ECM is not programmed. The “Engine

Serial Number” should be programmed to match

the engine serial number that is stamped on the

engine information plate.

“ECM Software Release Date”

This parameter is defined by the rating interlock

and this parameter is not programmable. The “ECM

Software Release Date” is used to provide the

version of the software. The Customer parameters

and the software change levels can be monitored

by this date. The date is provided in the month and

the year (NOV99). NOV is the month (November).

99 is the year (1999).

Rating Interlock

The Rating Interlock is a code that prevents the

use of an incorrect power rating and/or emission

rating for a specific engine. Each horsepower rating

and each emission certification has a different

code to all other horsepower ratings and emission

certifications.

Page 32

33

Troubleshooting Section

Troubleshooting without a

Diagnostic Code

i01798099

Alternator Noise

(Noisy Operation)

Note: This is NOT an electronic system problem.

Refer to Testing and Adjusting for information on

determining the cause of this condition.

Probable Causes

Alternator drive belts

•

Alternator drive pulley

•

Alternator bearings

•

Recommended Actions

Alternator Drive Belts

i01798098

Alternator Will Not Charge

(Charging Problem)

Note: This is NOT an electronic system problem.

Probable Causes

Alternator drive belts

•

Charging circuit

•

Regulator

•

Alternator

•

Recommended Actions

Alternator Drive Belts

1. Inspect the condition of the alternator drive belts.

If the alternator drive belts are worn or damaged,

replace the belts. Refer to Disassembly

and Assembly, “Alternator - Remove” and

Disassembly and Assembly, “Alternator - Install”.

1. Inspect the condition of the alternator drive belts.

If the alternator drive belts are worn or damaged,

replace the belts. Refer to Disassembly

and Assembly, “Alternator - Remove” and

Disassembly and Assembly, “Alternator - Install”.

Ensure that the alternator drive belts are in

alignment. Inspect the alternator mounting

bracket for cracks and wear. Repair the mounting

bracket or replace the mounting bracket in order

to ensure that the alternator drive belts and the

alternator drive pulley are in alignment.

2. Check the tension on the alternator drive belts.

Adjust the tension, if necessary. Refer to Testing

and Adjusting, “V-Belt - Test”.

Alternator Drive Pulley

Loosen the nut for the alternator drive pulley and

tighten the nut to the correct torque. Refer to

Specifications, “Alternator and Regulator” for the

correct torque.

Alternator Bearings

Verify that there is excessive play of the shaft in

the alternator and that the alternator bearings are

worn. The alternator is a nonserviceable item.

The alternator must be replaced if the bearings

are worn. Refer to Disassembly and Assembly,

“Alternator - Remove” and Disassembly and

Assembly , “Alternator - Install”.

Check the tension on the alternator drive belts.

Adjust the belt tension if the tension is incorrect.

Refer to Testing and Adjusting, “V-Belt - Test”.

Charging Circuit

Inspect the battery cables, wiring, and connections

in the charging circuit. Clean all connections and

tighten all connections. Replace any faulty parts.

Alternator or Regulator

Verify that the alternator or the regulator is operating

correctly. Refer to Testing and Adjusting, “Alternator

- Test”. The alternator is not a serviceable item. The

alternator must be replaced if the alternator is not

operating correctly.

i01798112

Battery

Note: This is NOT an electronic system problem.

Probable Causes

Faulty battery

•

Auxiliary device drains the battery current.

•

Page 33

34

Troubleshooting Section

Recommended Actions

Faulty Battery

1. Verify that the battery is no longer able to hold a

charge. Refer to Testing and Adjusting, “Battery

- Test”.

2. Replace the battery. Refer to Operation and

Maintenance, “Battery - Replace”.

Auxiliary Device

1. Verify that the auxiliary device drained the battery

by being left in the ON position.

2. Charge the battery.

3. Verify that the battery is able to maintain a

charge.

i01798113

Can Not Reach Top Engine

RPM

Recommended Actions

Diagnostic Codes

Check for active diagnostic codes on the electronic

service tool. Troubleshoot any active codes before

continuing with this procedure.

Fuel Supply

1. Check the fuel pressure. Refer to Systems

Operation, Testing and Adjusting, “Fuel System

Pressure - Test”.

2. Ensure that the fuel system has been primed.

Refer to Systems Operation, Testing and

Adjusting, “Fuel System - Prime”.

3. Check the diesel fuel for contamination. Refer to

Systems Operation, Testing and Adjusting, “Fuel

Quality - Test”.

4. Check for air in the fuel system. Refer to Systems

Operation, Testing and Adjusting, “Air in Fuel Test”.

5. Check that the fuel lines are tight and secured

properly.

Note: If this problem occurs only under load, refer to

Troubleshooting, “Low Power/Poor or No Response

to Throttle”.

Probable Causes

Refer to the logged codes.

•

Fuel supply

•

Air intake and exhaust system

•

Individual malfunctioning cylinders

•

Valve lash

•

Low compression (cylinder pressure)

•

Fuel injection nozzles

•

Turbocharger (if equipped)

•

ECM parameters

•

Throttle signal from the throttle position sensor

•

6. Check for fuel supply lines that are restricted.

7. Check the fuel filters.

8. Visually check the fuel tank for fuel. The fuel

gauge may be faulty.

9. If the engine has a water separator, check for

water in the fuel.

10. Ensure that the fuel supply valve is in the full

OPEN position.

11. If the temperature is below 0

for solidified fuel (wax).

12. If the repairs do not eliminate the problem

proceed to “Air Intake and Exhaust System”.

C (32

F), check

Air Intake and Exhaust System

1. Check the air filter restriction indicator, if

equipped.

2. Ensure that the air filter is clean and serviceable.

3. Check the air intake and the exhaust system for

the following defects:

Blockages

•

Page 34

35

Troubleshooting Section

Restrictions

•

Damage to the air intake and exhaust lines

•

and hoses

4. Make all necessary repairs to the engine.

5. Ensure that the repairs have eliminated the

diagnostic code.

6. If the problem has not been eliminated, proceed

to “Individual Malfunctioning Cylinders”.

Individual Malfunctioning Cylinders

1. With the engine speed at a fast idle, loosen

the high pressure fuel line to the fuel injection

nozzle of number 1 cylinder. Note if there is any

reduction in engine speed. Tighten the high

pressure fuel line to the fuel injection nozzle.

2. Individually repeat this procedure for each fuel

injection nozzle. If there is no reduction in the

engine speed refer to “Check the Turbocharger

(if equipped)”.

3. If all cylinders have been checked and no

problems were detected proceed to “Valve

Lash”.

Valve Lash

1. Check the valve lash and reset the valve lash, if

necessary. Refer to Systems Operation, Testing

and Adjusting, “Engine Valve Lash - Inspect and

Adjust”.

Worn valves

•

Faulty cylinder head gasket

•

Damaged cylinder head

•

Checking the Fuel Injection Nozzles

1. Remove the fuel injection nozzles from the

cylinder head. Refer to Disassembly and

Assembly, “Fuel Injection Nozzle - Remove”.

2. Check the fuel injection nozzles. Refer to Testing

and Adjusting, “Fuel Injection Nozzle - Test”.

3. Ensure that the repairs have eliminated the