Page 1

Perkins 1103 &1104 Series

WORKSHOP MANUAL

Disassembly and Assembly

3 and 4 cylinder , naturally aspirated, and turbocharged

diesel engines for agricultural and industrial use

Publication SENR9779-00

© Proprietary information of Perkins Engines Company Limited 2004, all rights reserved.

The information is correct at the time of print.

Published by Technical Publications.

Perkins Engines Company Limited, Peterborough, PE1 5NA, England

Page 2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

Table of Contents

3

Table of Contents

Disassembly and Assembly Section

Fuel Priming Pump - Remove and Install .............. 4

Fuel Filter Base - Remove and Install .................... 5

Fuel Injection Lines - Remove ............................... 6

Fuel Injection Lines - Install ................................... 7

Fuel Injector Cover - Remove and Install ................ 8

Fuel Injection Pump - Remove (Delphi DP210) ...... 8

Fuel Injection Pump - Remove (Bosch EPVE for the

1104 engines only) .............................................. 10

Fuel Injection Pump - Install (Delphi DP210) ........ 11

Fuel Injection Pump - Install (Bosch EPVE for the

1104 engines only) .............................................. 13

Fuel Injector - Remove ......................................... 14

Fuel Injector - Install ............................................ 15

Turbocharger - Remove ........................................ 16

Turbocharger - Install ............................................ 17

Exhaust Manifold - Remove and Install ............... 18

Exhaust Elbow - Remove and Install (Option for Four

Cylinder Engines Only) ....................................... 20

Inlet and Exhaust Valve Springs - Remove and

Install ................................................................... 21

Inlet and Exhaust Valves - Remove and Install ..... 23

Inlet and Exhaust Valve Guides - Remove and

Install ................................................................... 26

Inlet and Exhaust Valve Seat Inserts - Remove and

Install ................................................................... 28

Engine Oil Filter Base - Remove and Install ........ 30

Engine Oil Cooler - Remove ................................. 34

Engine Oil Cooler - Install ..................................... 36

Engine Oil Relief Valve - Remove and Install (Engine

Oil Pump) ............................................................ 37

Engine Oil Relief Valve - Remove and Install

(Balancer Unit for the 1104 engines only) ........... 39

Engine Oil Pump - Remove (Engines Without a

Balancer) ............................................................. 40

Engine Oil Pump - Install (Engines Without a

Balancer) ............................................................. 40

Water Pump - Remove ......................................... 41

Water Pump - Disassemble ................................. 42

Water Pump - Assemble ...................................... 43

Water Pump - Install ............................................. 45

Water Temperature Regulator - Remove and Install

............................................................................. 46

Flywheel - Remove ............................................... 48

Flywheel - Install ................................................... 49

Crankshaft Rear Seal - Remove ........................... 50

Crankshaft Rear Seal - Install ............................... 50

Crankshaft Wear Sleeve (Rear) - Remove............ 52

Crankshaft Wear Sleeve (Rear) - Install ............... 53

Flywheel Housing - Remove and Install ............... 53

Crankshaft Pulley - Remove and Install ............... 55

Crankshaft Front Seal - Remove ........................... 55

Crankshaft Front Seal - Install .............................. 56

Crankshaft Wear Sleeve (Front) - Remove ........... 57

Crankshaft Wear Sleeve (Front) - Install ............... 58

Front Cover - Remove and Install ......................... 58

Gear Group (Front) - Remove ............................... 59

Gear Group (Front) - Install ................................... 61

Idler Gear - Remove and Install ............................ 63

Housing (Front) - Remove ..................................... 68

Housing (Front) - Install ........................................ 69

Accessory Drive - Remove and Install ................. 70

Crankcase Breather - Remove and Install ........... 72

Valve Mechanism Cover - Remove and Install ..... 74

Rocker Shaft and Pushrod - Remove ................... 76

Rocker Shaft - Disassemble ................................ 77

Rocker Shaft - Assemble ..................................... 77

Rocker Shaft and Pushrod - Install ....................... 78

Cylinder Head - Remove ....................................... 79

Cylinder Head - Install .......................................... 81

Lifter Group - Remove and Install ......................... 84

Camshaft - Remove and Install ............................ 85

Camshaft Gear - Remove and Install ................... 86

Camshaft Bearings - Remove and Install ............ 86

Engine Oil Pan - Remove and Install ................... 87

Balancer - Remove (Some 1104 Engines Only) ... 90

Balancer - Install (Some 1104 Engines Only) ....... 91

Piston Cooling Jets - Remove and Install ............. 92

Pistons and Connecting Rods - Remove .............. 93

Pistons and Connecting Rods - Disassemble ....... 94

Pistons and Connecting Rods - Assemble ........... 95

Pistons and Connecting Rods - Install .................. 96

Connecting Rod Bearings - Remove .................... 98

Connecting Rod Bearings - Install ........................ 98

Crankshaft Main Bearings - Remove .................... 99

Crankshaft Main Bearings - Install (Crankshaft in

Position) ............................................................ 101

Crankshaft - Remove .......................................... 103

Crankshaft - Install .............................................. 105

Crankshaft Gear - Remove and Install ............... 108

Bearing Clearance - Check ................................. 109

Glow Plugs - Remove and Install ....................... 110

V-Belts - Remove and Install .............................. 111

Fan - Remove and Install ................................... 112

Fan Drive - Remove and Install .......................... 113

Alternator - Remove ............................................ 113

Alternator - Install ................................................ 114

Electric Starting Motor - Remove and Install ..... 114

Vacuum Pump - Remove and Install (Some 1104

engines only) ..................................................... 115

Hydraulic Pump (Steering) - Remove ................. 116

Hydraulic Pump (Steering) - Install ..................... 116

Index Section

Index ................................................................... 117

Page 4

4

Disassembly and Assembly Section

Disassembly and Assembly

Section

i01939024

Fuel Priming Pump - Remove

and Install

Removal Procedure

Start By:

a. Remove the assembly of the filter case and the

fuel filter element. Refer to this Disassembly and

Assembly Manual, “Fuel Filter Base - Remove

and Install”.

Note: There is an option for the three cylinder

engine. The fuel priming pump and the fuel filter

can be installed onto the application rather than

onto the engine. If this is the case, refer to the

appropriate OEM information as well as this text.

Note: Put identification marks on all fuel hose

assemblies and on all tube assemblies for

installation purposes. After being disconnected,

plug all fuel hose assemblies and plug all tube

assemblies. This helps prevent fluid loss, and

this helps to keep contaminants from entering the

system.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

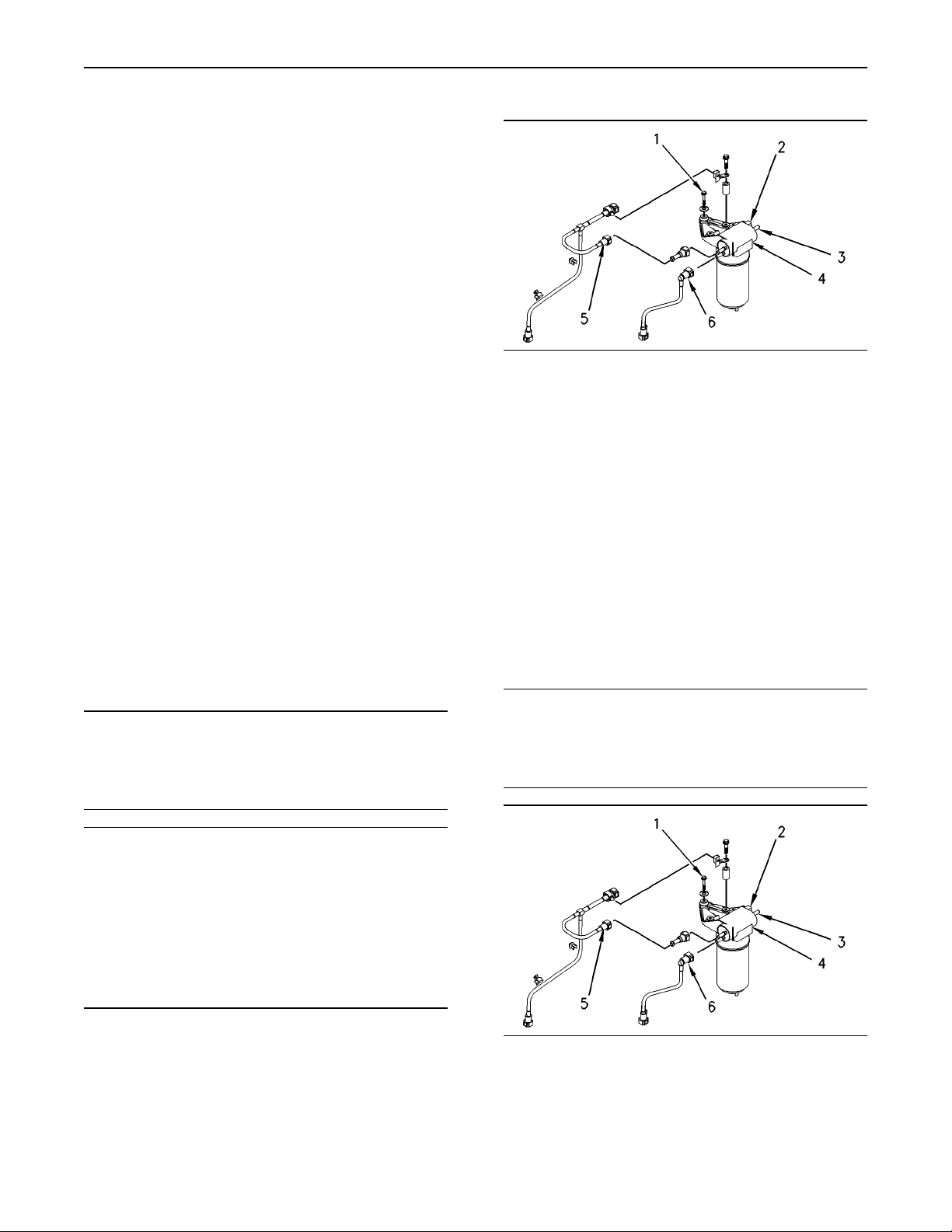

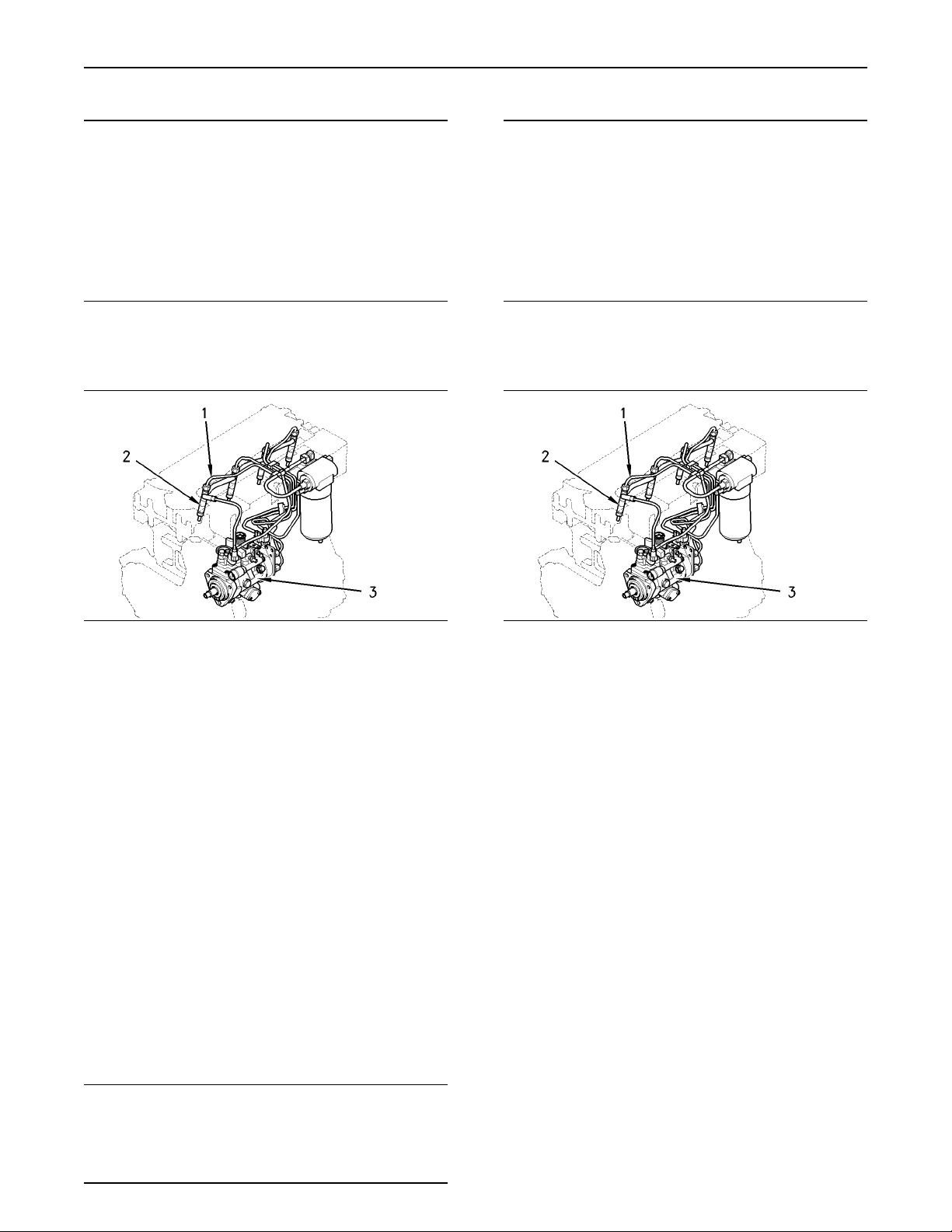

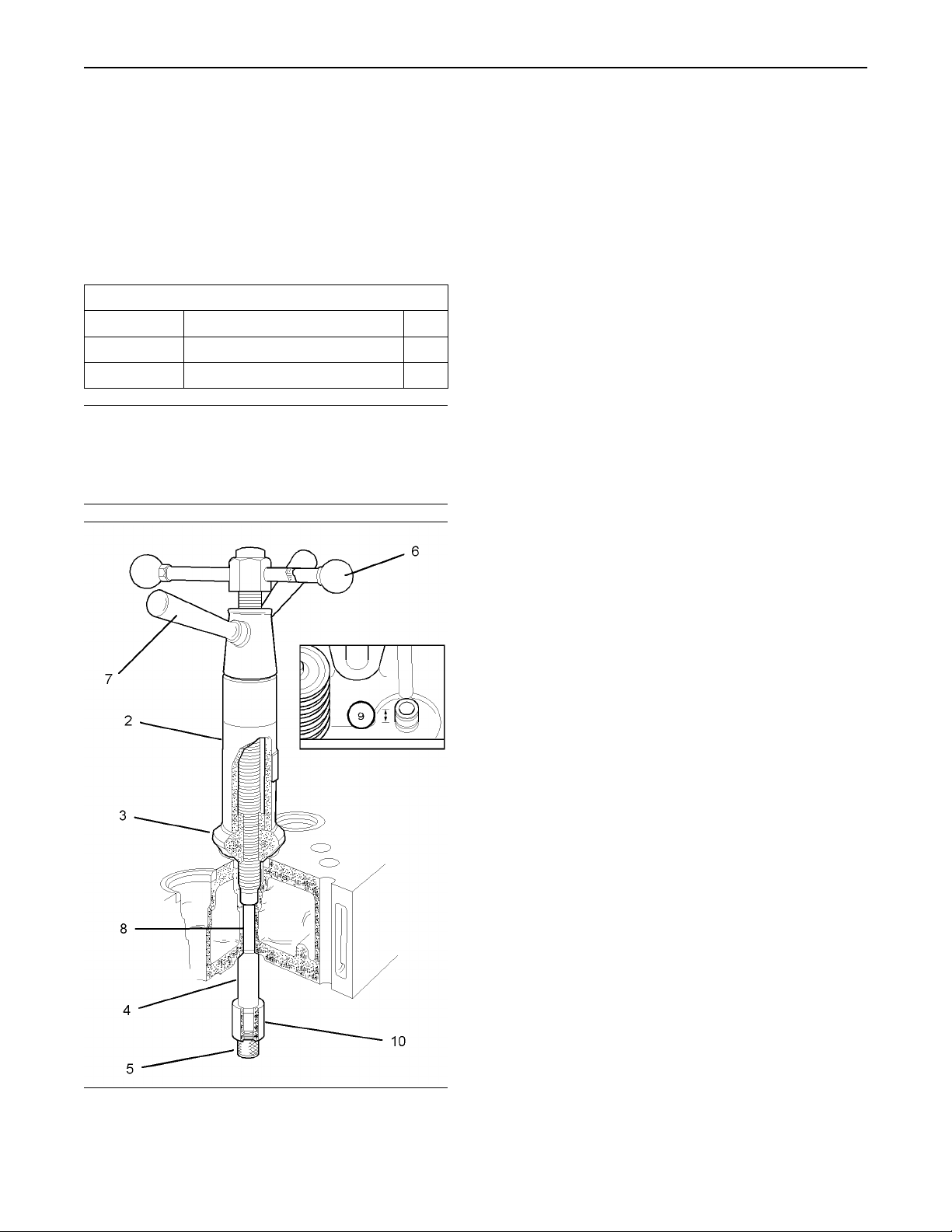

Illustration 1

Typical example

1. Disconnect the tube assembly (5). Disconnect

the tube assembly (6). Install dust covers onto

the connectors for the fuel priming pump.

2. Disconnect the fuel return line from the connector

(3). Install a dust cover to the connector (3).

3. Disconnect the harness assembly from the

connector (2).

4. Support the fuel priming pump. Remove the

three setscrews (1) and discard the rubber

washers. Remove the fuel priming pump (4).

g00952432

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Illustration 2

Typical example

1. Clean the external surfaces of the fuel priming

pump (4). Position the fuel priming pump (4) and

install the setscrews (1) and new rubber washers.

g00952432

Page 5

2. Remove the dust covers from the fuel priming

pump. Remove the plugs from the tube

assemblies. Connect the tube assembly (5).

Connect the tube assembly (6).

3. Connect the fuel return line to the connector (3).

4. Connect the harness assembly to the connector

(2).

5. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prime”.

i01939067

Fuel Filter Base - Remove and

Install

5

Disassembly and Assembly Section

Removal Procedure

Note: There is an option for the three cylinder

engine. The fuel filter and the fuel priming pump

can be installed onto the application rather than

onto the engine. If this is the case, refer to the

appropriate OEM information as well to this text.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: The removal procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

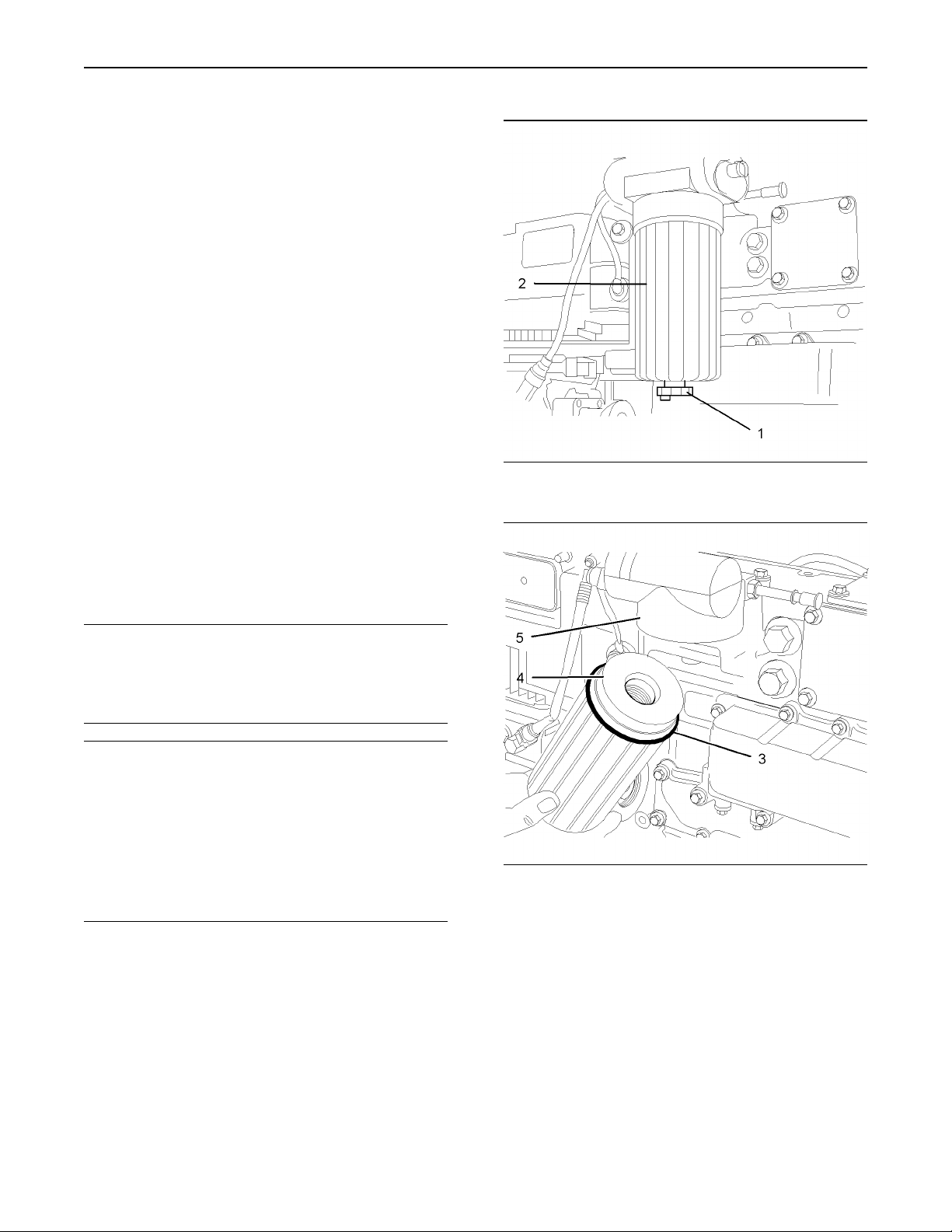

Illustration 3

Typical example

Illustration 4

Typical example

g01010637

g01010595

1. Place a suitable container below the filter in

order to collect the spilled fuel. Thoroughly clean

the outside surfaces of the fuel filter. Open the

drain (1) in order to drain the fuel from the filter.

2. Use a suitable strap wrench to loosen the filter

case (2). Remove the filter case (2) from the filter

head (5).

3. Push down against the spring pressure that is

applied to the filter element (4). Rotate the filter

element (4) counterclockwise in order to release

the filter element from the filter case (2).

4. Discard the filter element (4) and the O-ring (3).

Page 6

6

Disassembly and Assembly Section

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

1. Thoroughly clean the inside of the filter case (2)

and thoroughly clean the lower face of the filter

head (5).

2. Inspect the thread of a new filter element (4) in

order to ensure that the thread is not damaged.

Inspect the thread of the adapter in the filter

head (5) in order to ensure that the thread is not

damaged.

3. Inspect the condition of the spring and ensure

that the spring is correctly located within the

filter case (2).

4. Install the new filter element (4) into the filter

case (2). Push the filter element against the

spring pressure and rotate the filter element in

a clockwise direction in order to secure the filter

element within the filter case (2).

5. Lightly lubricate a new O-ring (3) with clean fuel

oil. Install the new O-ring (3) into the recess

within the filter case (2).

6. Close the drain (1).

7. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prime”. Remove the suitable container

and dispose of the fuel that has drained as

waste.

Illustration 5

Typical example

Illustration 6

Typical example

g01010637

g01010595

i01939856

Fuel Injection Lines - Remove

Removal Procedure

Start By:

a. Remove the cover for the fuel injectors. Refer to

this Disassembly and Assembly Manual, “Fuel

Injector Cover - Remove and Install”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Page 7

Disassembly and Assembly Section

7

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: The removal procedure is identical for four

cylinder and three cylinder engines. The illustration

shows the four cylinder engine.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustration shows the four cylinder engine.

Illustration 7

Typical example

g00955826

1. Disconnect the fuel injection lines (1) at the fuel

injectors (2).

2. Disconnect the fuel injection lines (1) at the fuel

injection pump (3).

3. If it is necessary remove the clamps for the fuel

injection lines or loosen the clamps for the fuel

injection lines. Remove the fuel injection lines (1).

4. Install dust caps onto the ports of the fuel

injectors and onto the ports of the fuel injection

pump. Install dust caps onto both ends of the

fuel injection lines.

i01939857

Fuel Injection Lines - Install

Installation Procedure

Illustration 8

Typical example

g00955826

1. Inspect the fuel injection lines (1) for wear and for

damage. Replace any fuel injection line (1) that

is worn or any fuel injection line that is damaged.

2. Loosely install the clamps for the fuel injection

lines (1).

3. Remove the dust caps from the fuel injection

pump (3) and from the fuel injectors (2). Remove

the dust caps from the fuel injection lines (1).

4. Loosely connect the nuts at both ends of the fuel

injection lines (1).

5. Ensure that each fuel injection line (1) does not

contact any other fuel injection line or any other

engine component. Tighten the fasteners for the

clamps for the fuel injection lines (1). Check that

the fuel injection lines (1) are still clear of other

components.

6. Tighten the fuel injection lines (1) at the fuel

injectors (2) to a torque of 30 N·m (22 lb ft).

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

7. Tighten the fuel injection lines (1) at the fuel

injection pump (3) to 30 N·m (22 lb ft).

Page 8

8

Disassembly and Assembly Section

8. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prime”.

End By:

a. Install the cover for the fuel injectors. Refer to

this Disassembly and Assembly Manual, “Fuel

Injector Cover - Remove and Install”.

i01940979

Fuel Injector Cover - Remove

and Install

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

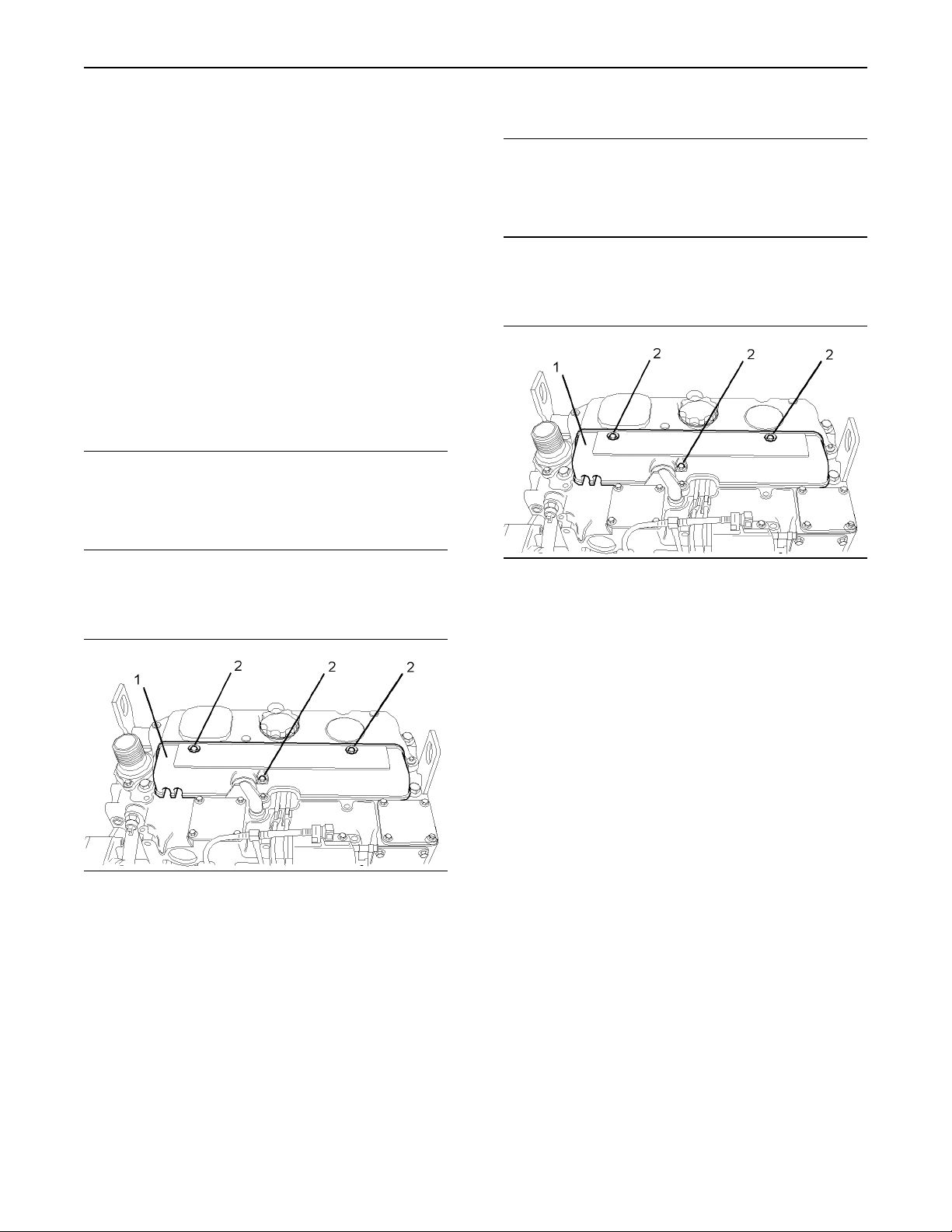

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustration shows the four cylinder engine.

Note: The removal procedure is identical for the

four cylinder and the three cylinder engines. The

illustration shows the four cylinder engine.

Illustration 9

Typical example

1. Thoroughly clean all of the outer surfaces of the

cover (1) for the fuel injectors.

2. Remove the setscrews (2) from the cover (1).

3. Remove the cover (1).

g01011111

Illustration 10

Typical example

1. Thoroughly clean all of the inner surfaces of the

cover (1) for the fuel injectors.

2. Install the cover (1).

3. Install the setscrews (2) for the cover (1). Tighten

the setscrews (2) to a torque of 9 N·m (7 lb ft).

g01011111

i01940997

Fuel Injection Pump - Remove

(Delphi DP210)

Removal Procedure

Start By:

a. Remove the fuel injection lines. Refer to this

Disassembly and Assembly Manual, “Fuel

Injection Lines - Remove”.

b. Remove the crankshaft pulley. Refer to this

Disassembly and Assembly Manual, “Crankshaft

Pulley - Remove and Install”.

Page 9

Disassembly and Assembly Section

9

c. Remove the front cover. Refer to this Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

Note: The removal procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the No. 1 cylinder is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Finding Top

Center Position for No. 1 Piston”.

4. Disconnect the fuel line (3).

5. Disconnect the harness assembly (2) from the

timing advance solenoid (7).

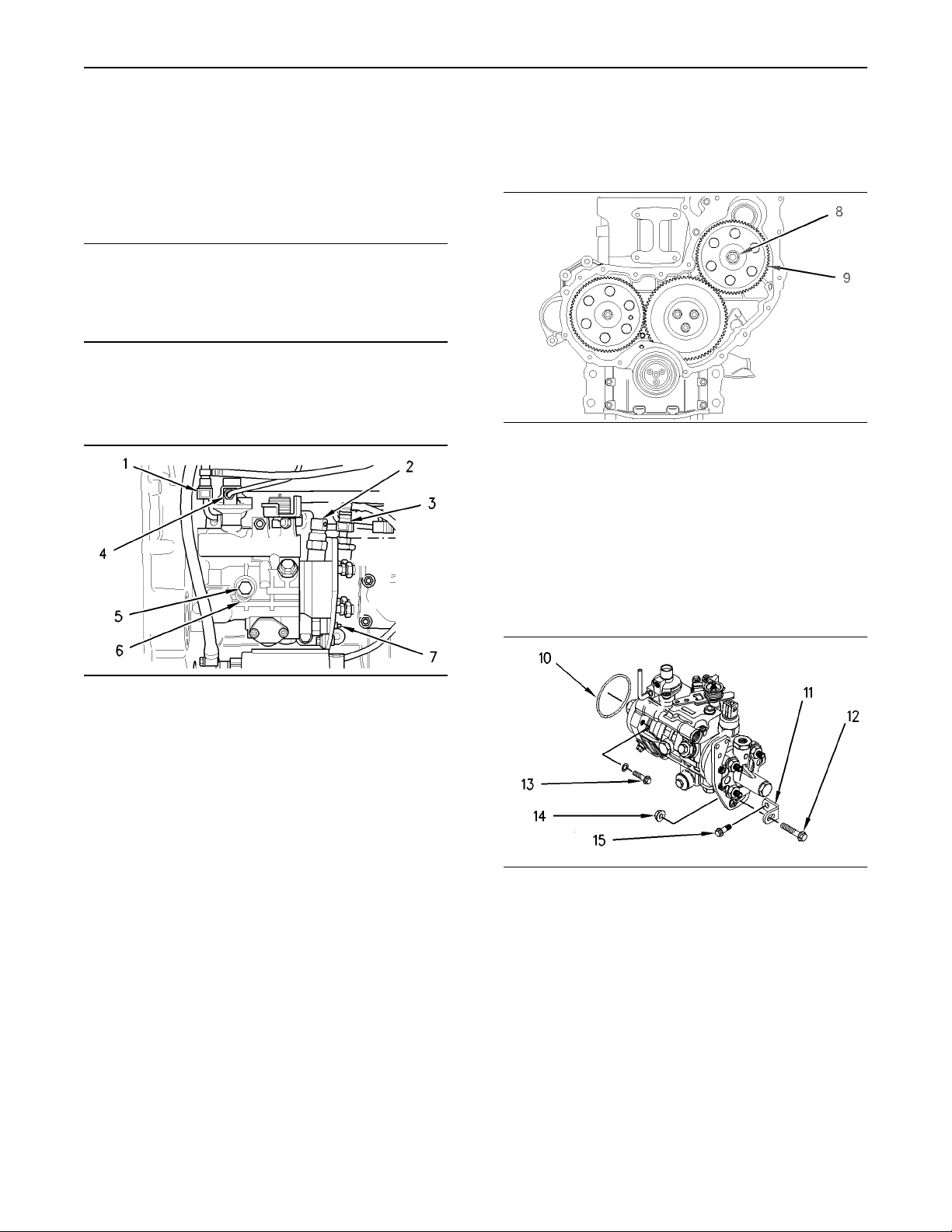

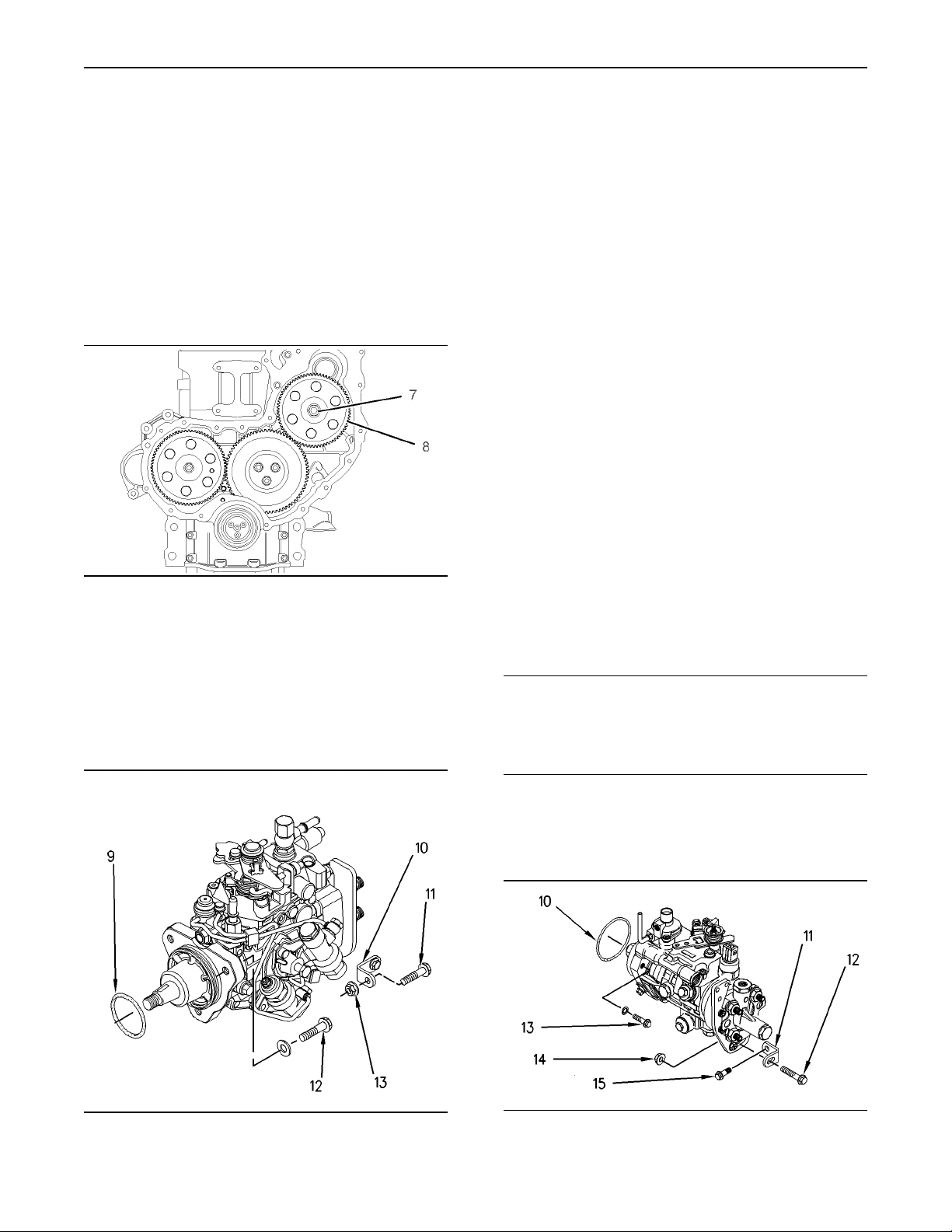

Illustration 12

Typical example

g01011369

6. Remove the nut (8) and the washer from the

shaft of the fuel injection pump.

7. Use a suitable puller in order to remove the fuel

injection pump gear (9).

Illustration 11

Typical example

g00956204

2. Loosen the locking screw (5). Rotate the spacer

(6) in order to allow the locking screw (5) to

tighten against the shaft of the fuel injection

pump. Rotate the fuel injection pump gear in a

counterclockwise direction in order to remove

the backlash. Tighten the locking screw (5) to a

torque of 17 N·m (13 lb ft).

Note: The locking screw (5) must be tightened in

order to prevent the shaft of the fuel injection pump

from rotating. The shaft of the fuel injection pump

must not be rotated after the fuel injection pump

has been removed from the engine.

Note: Put identification marks on all fuel hose

assemblies and on all tube assemblies for

installation purposes. After being disconnected,

plug all fuel hose assemblies and plug all tube

assemblies with suitable plastic plugs. Also install

dust caps on all of the connectors on the fuel

injection pump. This helps prevent fluid loss, and

this helps to keep contaminants from entering the

system.

Note: Do not pry the fuel injection pump gear (9)

from the shaft of the fuel injection pump.

Illustration 13

g00956267

8. Remove the nut (14). Remove the bolt (12).

9. If necessary, remove the setscrew (15) and the

bracket (11) from the cylinder block.

10. Remove the setscrews (13) in order to remove

the fuel injection pump.

11. Remove the fuel injection pump from the front

housing. Remove the O-ring (10) and discard the

O-ring from the fuel injection pump.

3. Disconnect the fuel return line (1). Disconnect the

tube assembly (4) from the fuel injection pump.

Page 10

10

Disassembly and Assembly Section

i01941022

Fuel Injection Pump - Remove

(Bosch EPVE for the 1104

engines only)

Removal Procedure

Start By:

a. Remove the fuel injection lines. Refer to this

Disassembly and Assembly Manual, “Fuel

Injection Lines - Remove and Install”.

b. Remove the crankshaft pulley. Refer to this

Disassembly and Assembly Manual, “Crankshaft

Pulley - Remove and Install”.

c. Remove the front cover. Refer to this Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

NOTICE

Keep all parts clean from contaminants.

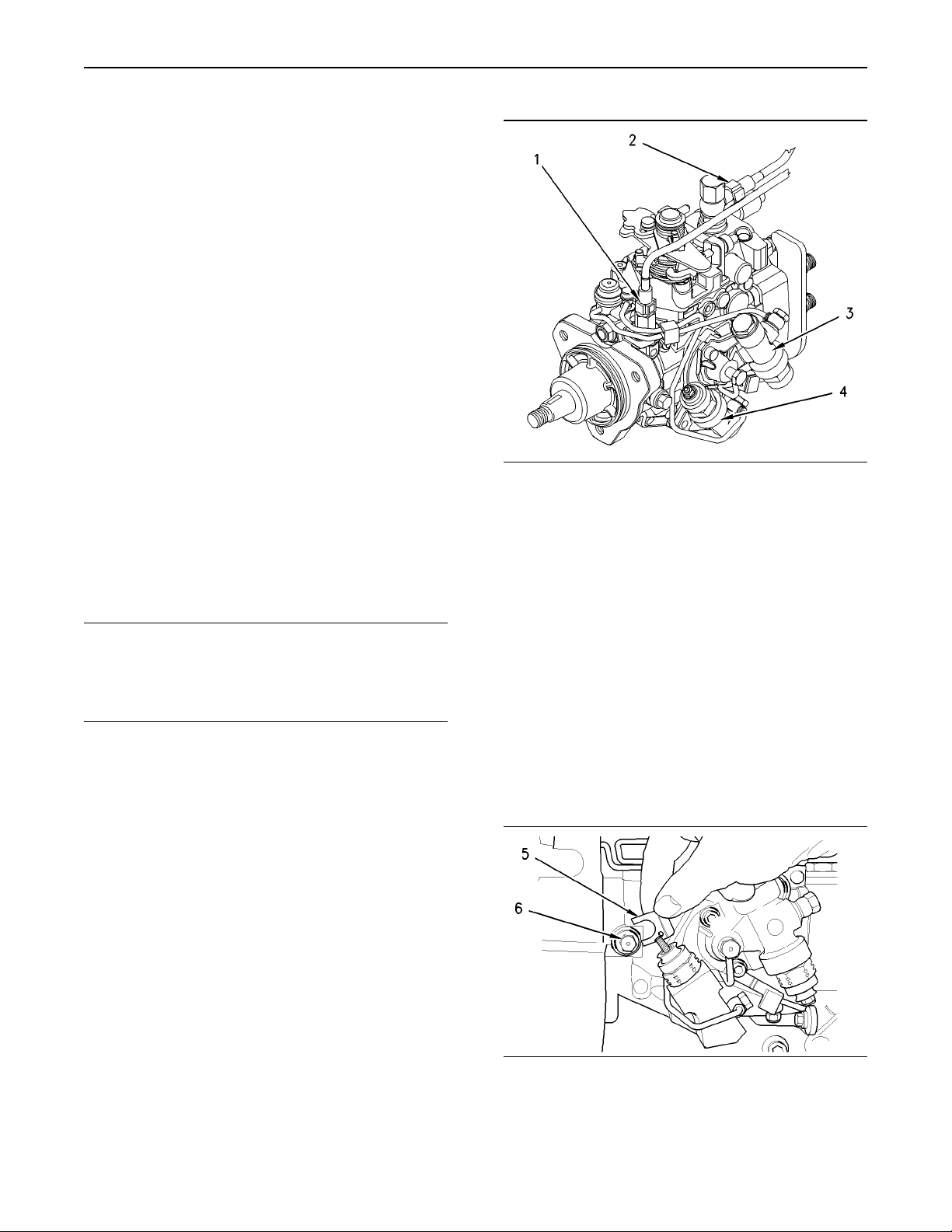

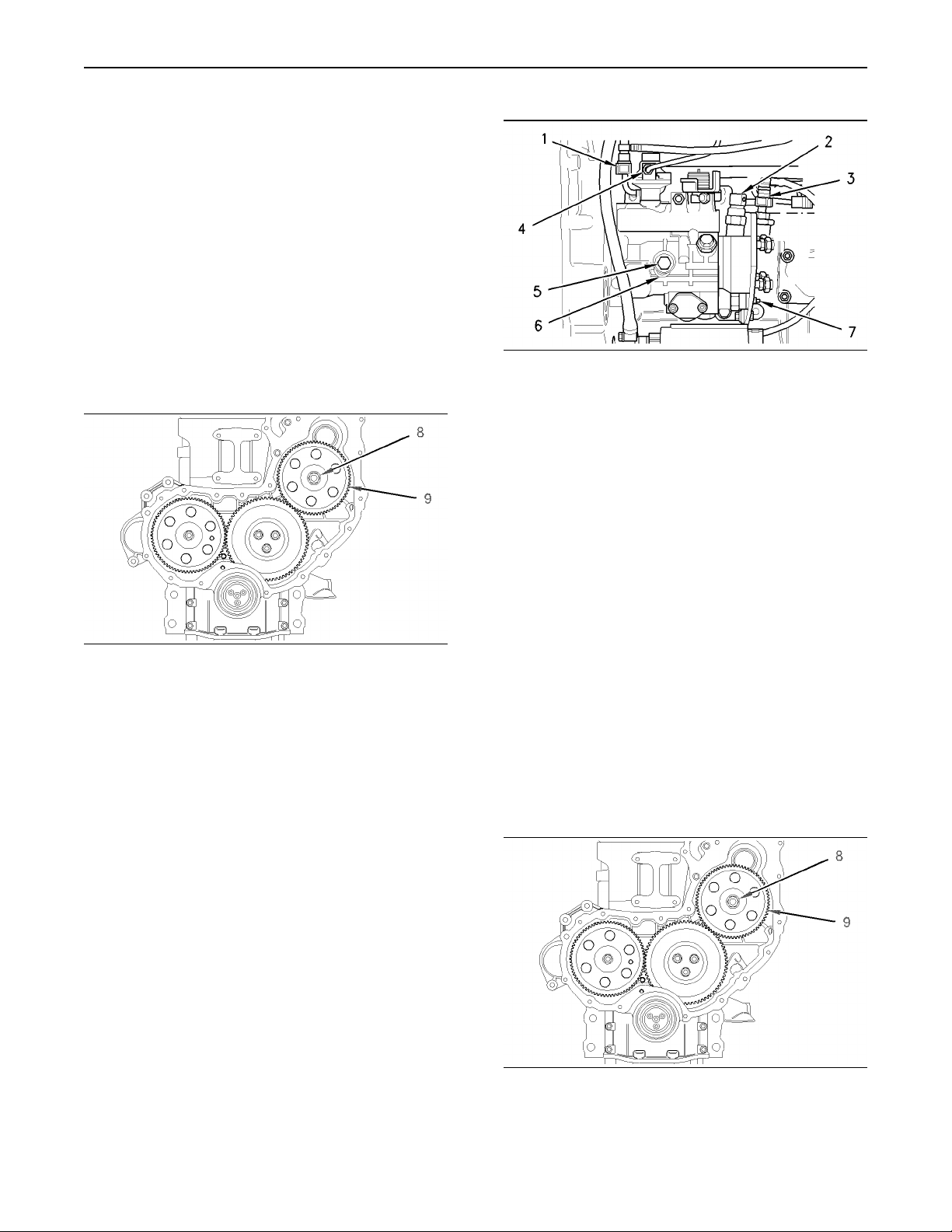

Illustration 14

Note: Put identification marks on all fuel hose

assemblies and on all tube assemblies for

installation purposes. After being disconnected,

plug all fuel hose assemblies and plug all tube

assemblies with suitable plastic plugs. Also install

dust caps on all of the connectors on the fuel

injection pump. This helps prevent fluid loss, and

this helps to keep contaminants from entering the

system.

g00996409

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the No. 1 cylinder is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Finding Top

Center Position for No. 1 Piston”.

2. Disconnect the tube assembly (1) from the fuel

injection pump. Disconnect the tube assembly

(2) from the fuel injection pump.

3. Disconnect the wiring harness assembly from

the cold start advance unit (3). Disconnect the

wiring harness assembly from the engine shutoff

solenoid (4).

Illustration 15

g00996410

Page 11

11

Disassembly and Assembly Section

4. Loosen the locking screw (6). Move the spacer

(5) in order to allow the locking screw (6) to

tighten against the shaft of the fuel injection

pump. Rotate the fuel injection pump gear in a

counterclockwise direction in order to remove

the backlash. Tighten the locking screw (6) to a

torque of 31 N·m (23 lb ft).

Note: The locking screw (6) must be tightened in

order to prevent the shaft of the fuel injection pump

from rotating. The shaft of the fuel injection pump

must not be rotated after the fuel injection pump

has been removed from the engine.

Illustration 16

g01011474

5. Remove the nut (7) and the washer from the

shaft of the fuel injection pump.

6. Use a suitable puller in order to remove the fuel

injection pump gear (8).

Note: Do not pry the fuel injection pump gear from

the shaft of the fuel injection pump.

8. If necessary, remove the setscrew and the

bracket (10) from the cylinder block.

9. Remove the setscrews (12) in order to remove

the fuel injection pump.

10. Remove the fuel injection pump from the front

housing. Remove the O-ring (9) from the fuel

injection pump and discard the O-ring.

i01943876

Fuel Injection Pump - Install

(Delphi DP210)

Installation Procedure

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

Note: The shaft of the fuel injection pump must

remain locked until the timing gear (9) has been

installed and tightened onto the shaft of the fuel

injection pump. The locking screw (5) must remain

locked until you are instructed to loosen the locking

screw. The fuel injection pump must be returned to

your Perkins Dealer if the shaft of the fuel injection

pump was rotated accidentally.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

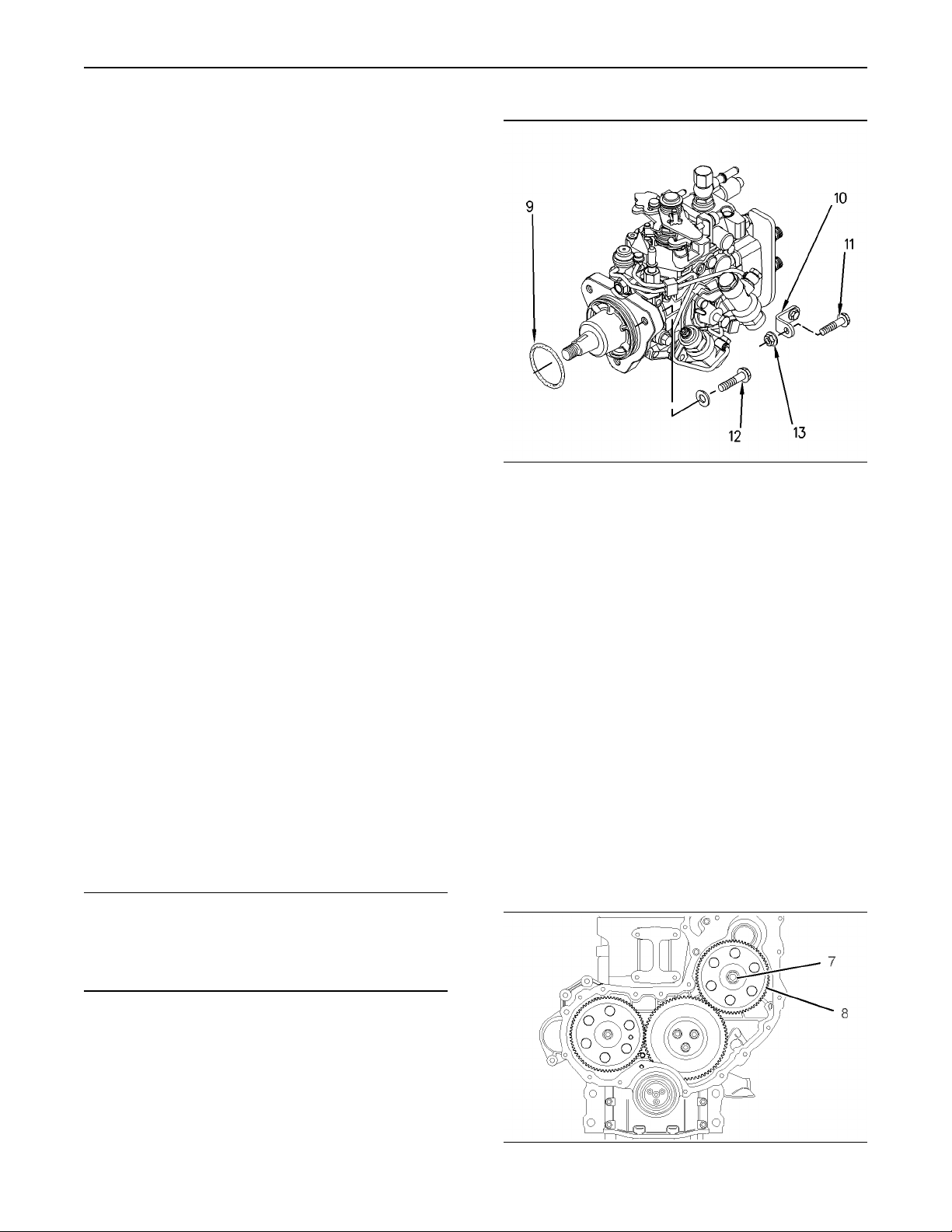

Illustration 17

g00996474

7. Remove the nut (13). Remove the bolt (11).

1. Ensure that the No. 1 cylinder is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Fuel Injection

Timing - Check”.

Illustration 18

Typical example

g00956267

Page 12

12

Disassembly and Assembly Section

Note: Do not lubricate the new O-ring (10). The

O-ring should be installed dry.

2. Install the new O-ring (10) onto the fuel injection

pump. Position the fuel injection pump onto the

front housing. Install the setscrews (13). Tighten

the setscrews (13) to a torque of 25 N·m (18 lb ft).

3. Install the setscrew (15) and the bracket (11)

onto the cylinder block if the bracket was

previously removed. Ensure that the bracket (11)

supports the fuel injection pump without applying

any other external force on the fuel injection

pump. Tighten the setscrew (15) to a torque of

44 N·m (32 lb ft).

4. Install the bolt (12) and the nut (14).

Illustration 20

Typical example

g00956204

6. Connect the harness assembly to the timing

advance solenoid (7).

7. Connect the harness assembly (2).

Illustration 19

Typical example

g01011369

Note: Ensure that the mating surfaces of the fuel

injection pump gear and the shaft of the fuel

injection pump are clean. Lubricate the threads of

the shaft for the fuel injection pump. The nut (8)

must turn freely until contact is made with the fuel

injection pump gear.

5. Position the fuel injection pump gear (9) onto

the shaft of the fuel injection pump. Install the

washer and the nut (8). Rotate the fuel injection

pump gear (9) in a counterclockwise direction in

order to remove the backlash. Tighten the nut (8)

to a torque of 24 N·m (17 lb ft).

8. Remove all of the dust caps from the connectors

on the fuel injection pump. Remove all of the

plugs from the fuel hose assemblies and from

the tube assemblies.

9. Connect the fuel line (3), the fuel return line (1),

and the tube assembly (4) to the fuel injection

pump.

10. Loosen the locking screw (5). Move the spacer

(6) in order to prevent the locking screw (5) from

tightening against the shaft of the fuel injection

pump. Tighten the locking screw (5) to a torque

of 12 N·m (106 lb in).

Note: The spacer (6) must be correctly positioned

and locking screw (5) must be tightened in order to

prevent the locking screw from contacting the shaft

of the fuel injection pump.

Illustration 21

Typical example

g01011369

Page 13

11. Tighten the nut (8) to a torque of 88 N·m

(65 lb ft).

End By:

a. Install the front cover. Refer to this Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

b. Install the crankshaft pulley. Refer to this

Disassembly and Assembly Manual, “Crankshaft

Pulley - Remove and Install”.

c. Install the fuel injection lines. Refer to this

Disassembly and Assembly Manual, “Fuel

Injection Lines - Install”.

i01943877

Fuel Injection Pump - Install

(Bosch EPVE for the 1104

engines only)

Disassembly and Assembly Section

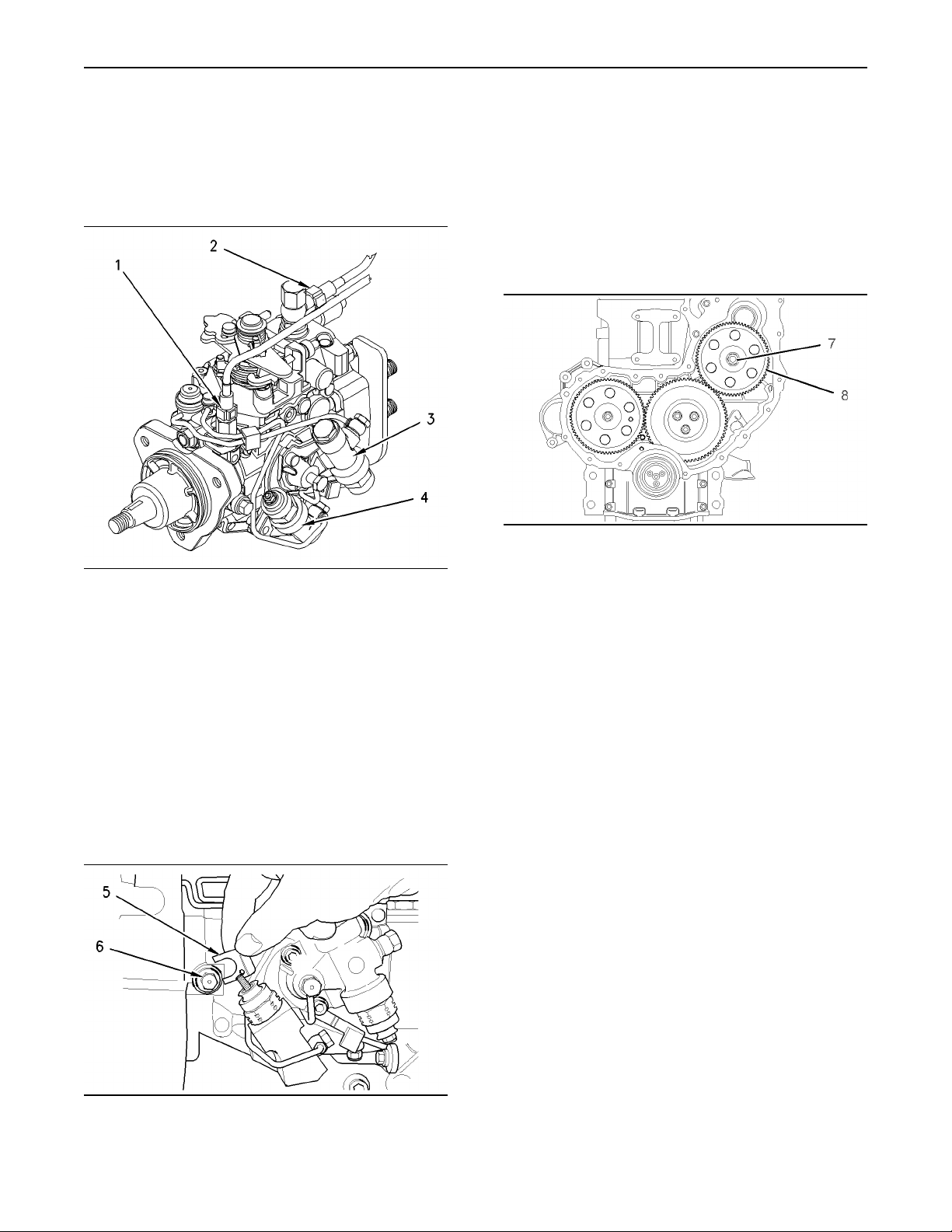

Illustration 22

2. Lightly lubricate a new O-ring (9) with Perkins

1766-501 Silicone Fluid MS200/1000. Install

the new O-ring (9) onto the fuel injection pump.

Position the fuel injection pump on the front

housing. Install the setscrews (12). Tighten the

setscrews to a torque of 25 N·m (18 lb ft).

g00996474

13

Installation Procedure

Note: The shaft of the fuel injection pump must

remain locked until the timing gear (8) has been

installed and tightened onto the shaft of the fuel

injection pump. The locking screw (6) must remain

locked until you are instructed to loosen the locking

screw. The Bosch EPVE fuel injection pump can be

timed to the engine by a technician. Refer to the

Testing and Adjusting Manual, “Fuel Injection Pump

Timing - Check and Fuel Injection Pump Timing Adjust” if the shaft of the fuel injection pump was

rotated accidentally.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the No. 1 cylinder is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Fuel Injection

Timing - Check”.

3. Install the setscrew and the bracket (10) onto

the cylinder block if the bracket was previously

removed. Ensure that the bracket (10) supports

the fuel injection pump without applying any

other external force on the fuel injection pump.

Tighten the setscrew to a torque of 44 N·m

(32 lb ft).

4. Install the bolt (11) and the nut (13).

Note: Ensure that the mating surfaces of the fuel

injection pump gear (8) and the shaft of the fuel

injection pump are clean. Lubricate the threads of

the shaft for the fuel injection pump. The nut (7)

must turn freely until contact is made with the fuel

injection pump gear (8).

Illustration 23

g01011474

Page 14

14

Disassembly and Assembly Section

5. Position the fuel injection pump gear (8) onto

the shaft of the fuel injection pump. Install the

washer and the nut (7). Rotate the fuel injection

pump gear (8) in a counterclockwise direction in

order to remove the backlash. Tighten the nut (7)

to a torque of 24 N·m (17 lb ft).

10. Loosen the locking screw (6). Move spacer (5)

in order to prevent the locking screw (6) from

tightening against the shaft of the fuel injection

pump. Tighten the locking screw (6) to a torque

of 12 N·m (106 lb in).

Note: The spacer (5) must be installed and the

locking screw (6) must be tightened in order to

prevent the locking screw from contacting the shaft

of the fuel injection pump.

Illustration 26

g01011474

Illustration 24

g00996409

6. Connect the wiring harness assembly to the

engine shutoff solenoid (4).

7. Connect the wiring harness assembly to the cold

start advance unit (3).

8. Remove all of the dust caps from the connectors

on the fuel injection pump. Remove all of the

plugs from the fuel hose assemblies and from

the tube assemblies.

9. Connect the tube assembly (2) to the fuel

injection pump. Connect the tube assembly (1)

to the fuel injection pump.

11. Tighten the nut (7) to a torque of 88 N·m

(65 lb ft).

End By:

a. Install the front cover. Refer to this Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

b. Install the crankshaft pulley. Refer to this

Disassembly and Assembly Manual, “Crankshaft

Pulley - Remove and Install”.

c. Install the fuel injection lines. Refer to this

Disassembly and Assembly Manual, “Fuel

Injection Lines - Install”.

i01938589

Fuel Injector - Remove

Removal Procedure

Start By:

Illustration 25

a. Remove the cover for the fuel injectors. Refer to

this Disassembly and Assembly Manual, “Fuel

Injector Cover - Remove and Install”.

g00996410

Page 15

15

Disassembly and Assembly Section

b. Remove the fuel injection lines. Refer to this

Disassembly and Assembly, “Fuel Injection Lines

- Remove”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

1. Disconnect the tube assemblies from the fuel

filter base for the fuel inlet and the fuel outlet.

i01938672

Fuel Injector - Install

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

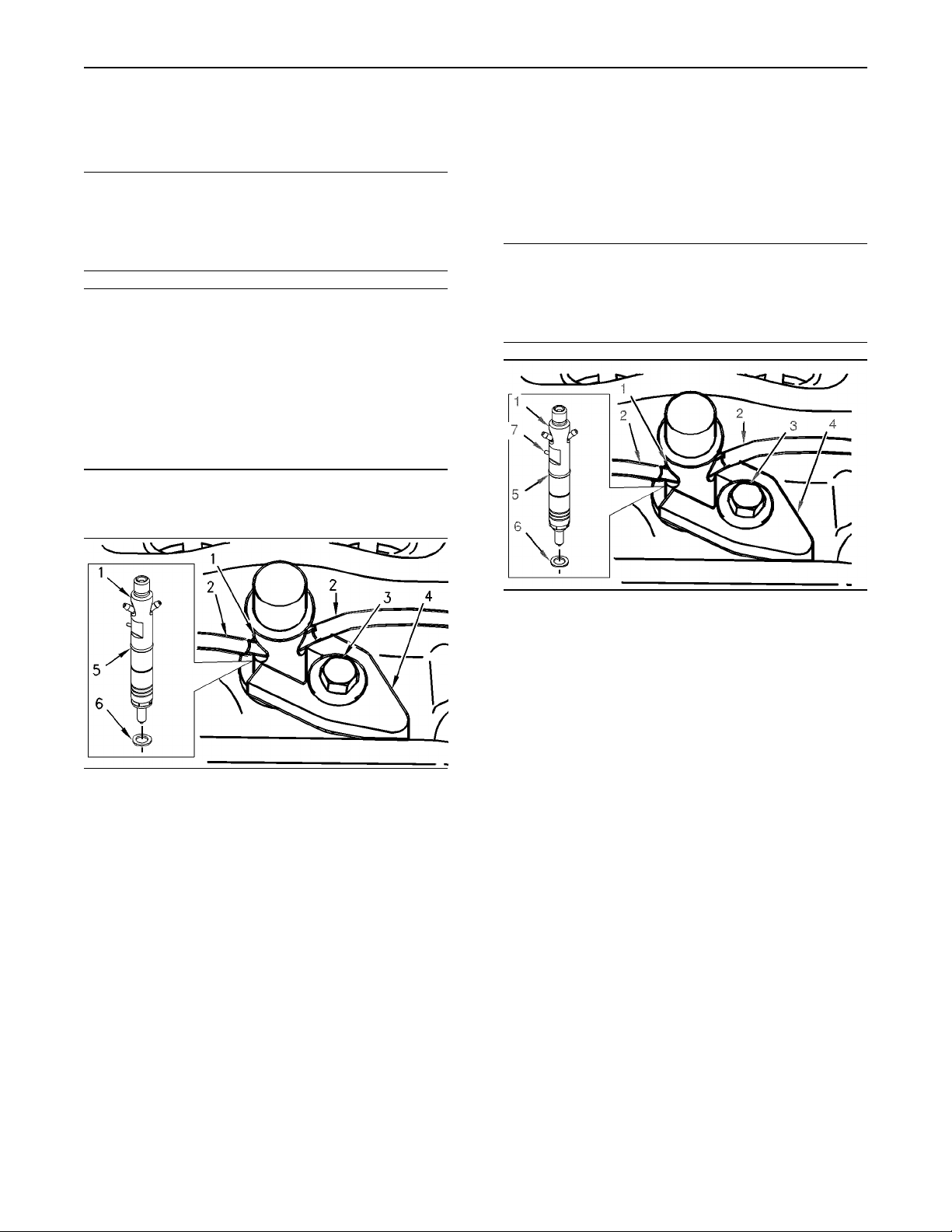

Illustration 27

g00975056

2. Remove the fuel hose (2) from the fuel injector

(1).

3. Remove the setscrew (3). Remove the clamp (4)

from the fuel injector (1).

4. Remove the fuel injector (1) from the cylinder

head. Remove the O-ring seal (5) from the fuel

injector (1) and discard the O-ring.

5. Remove the seat washer (6) from the cylinder

head and discard the seat washer.

Note: If the original seat washer is not removed, the

projection of the fuel injector will be incorrect when

a new seat washer is installed.

Illustration 28

g01008888

1. Lubricate the seat washer (6) with clean engine

oil. Install a new seat washer (6) in the cylinder

head.

Note: If the original seat washer (6) is reused, the

projection of the fuel injector (1) will be incorrect.

2. Install a new O-ring seal (5) on fuel injector (1).

Install the fuel injector (1) in the cylinder head.

Note: Alignment Pin (7) must be located opposite

clamp (4).

3. Position clamp (4) on the fuel injector (1). Install

setscrew (3). Tighten the setscrew to a torque of

27 N·m (20 lb ft).

4. Install hose (2) to the fuel injector (1).

End By:

a. Install the fuel injection lines. Refer to this

Disassembly and Assembly, “Fuel Injection Lines

- Install”.

b. Install the cover for the fuel injectors. Refer to

this Disassembly and Assembly Manual, “Fuel

Injector Cover - Remove and Install”.

Page 16

16

Disassembly and Assembly Section

i01944022

Turbocharger - Remove

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

4. If an exhaust elbow is installed, remove the

exhaust elbow. Refer to this Disassembly and

Assembly Manual, “Exhaust Elbow - Remove

and Install”.

5. Remove the nuts (2) and remove the exhaust

adapter (3) from the turbocharger (1).

6. Place a suitable container below the turbocharger

(1) in order to collect any spillage of oil.

Note: The removal procedure is identical for the

three cylinder and the four cylinder engines.

1. Thoroughly clean the outer surfaces of the

turbocharger (1).

2. Loosen the hose clamps and remove the air inlet

hose at the turbocharger compressor housing.

Note: Exhaust elbows are only an option for the four

cylinder engines.

3. Remove the exhaust pipe from the turbocharger

outlet or remove the exhaust pipe from the

exhaust elbow. Refer to the OEM provided

information for the correct procedure in order to

remove the exhaust pipe.

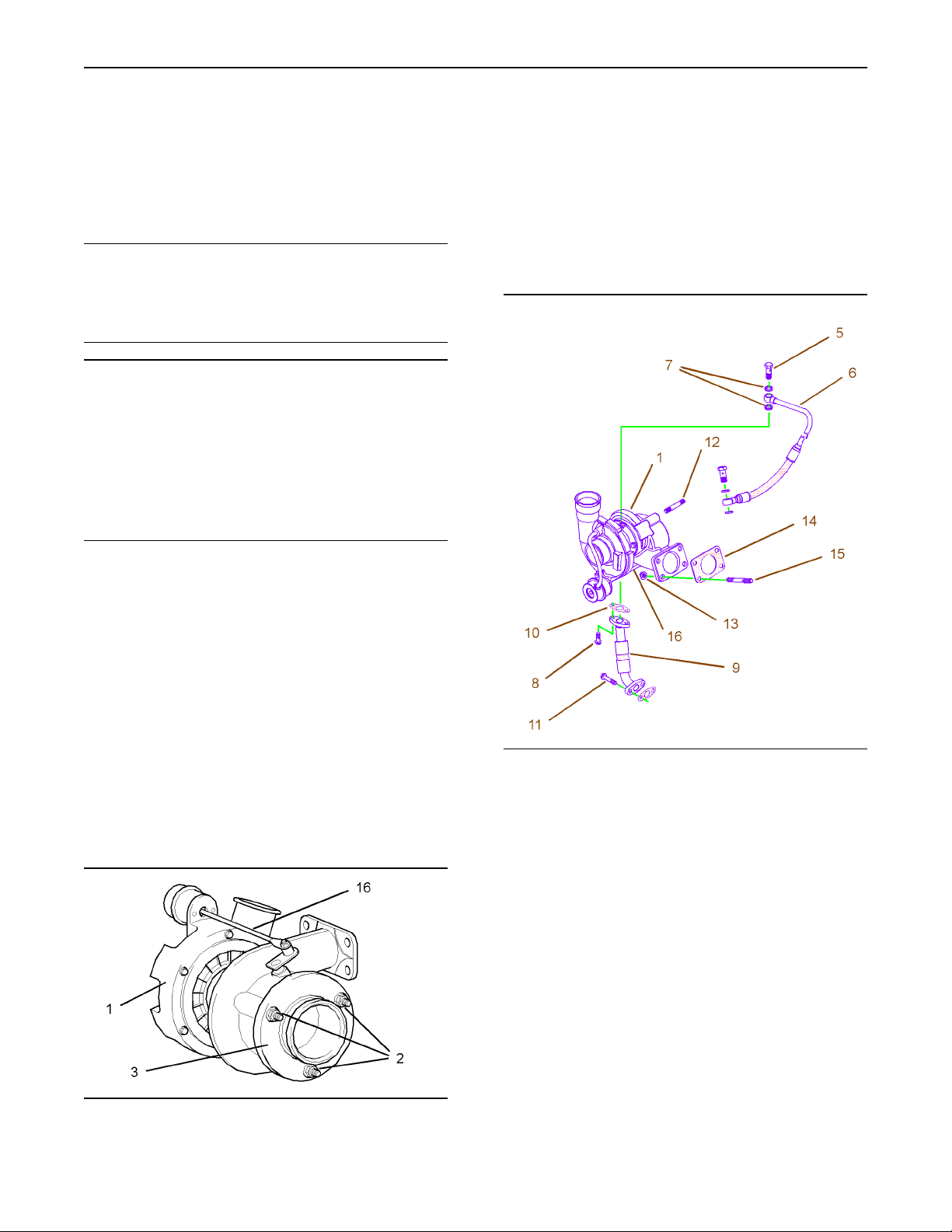

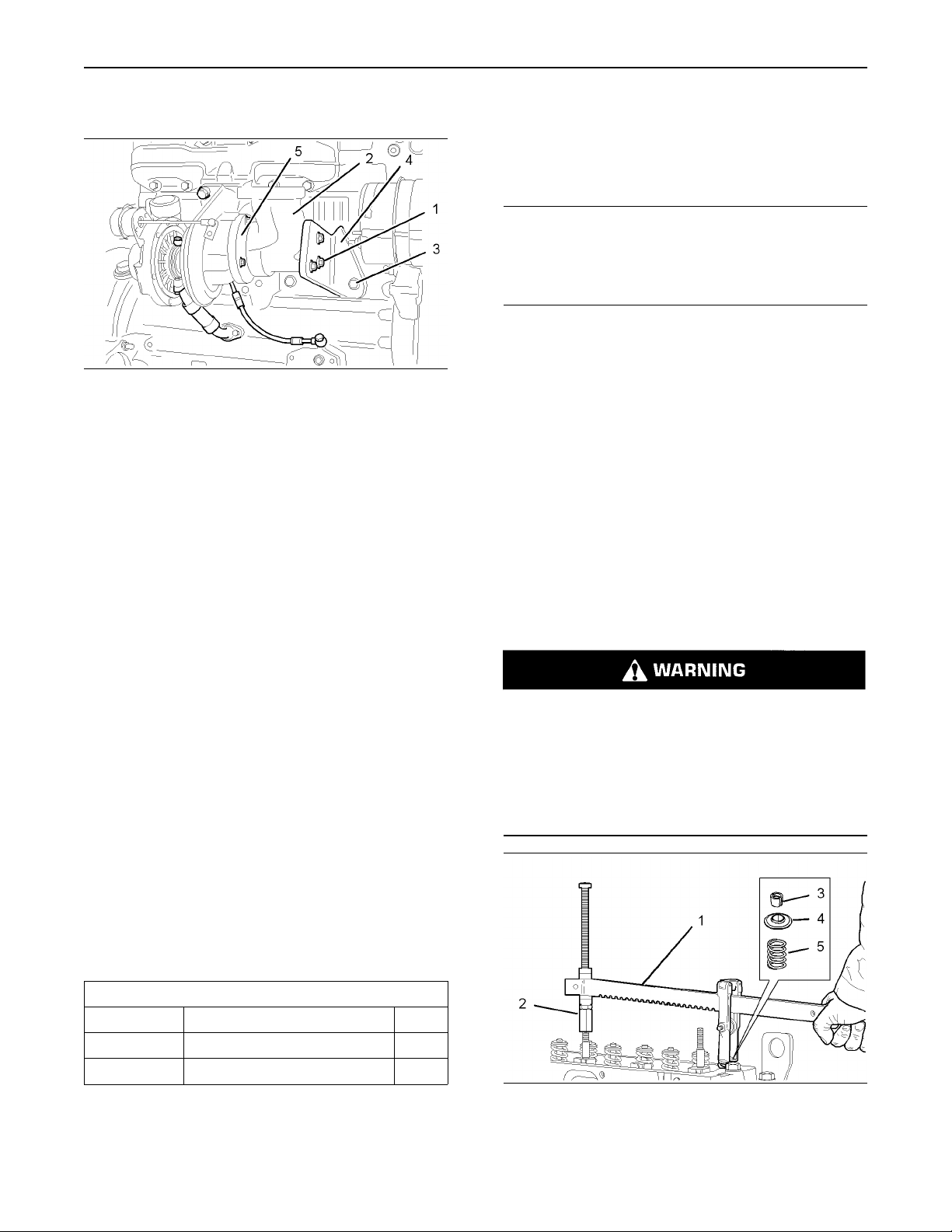

Illustration 30

Typical example

g01038396

7. Remove the banjo bolts (5). Remove the oil

supply tube assembly (6) and the washers (7)

from the turbocharger (1). Discard the washers

(7). If necessary, remove the oil supply tube

assembly (6) from the cylinder block and discard

the washers.

8. Remove the setscrews (8). Remove the oil drain

tube assembly (9) from the turbocharger (1).

Remove the joint (10) and discard the joint.

If necessary, remove the setscrews (11) and

remove the oil drain tube assembly (9) from the

cylinder block. Discard the joint.

Illustration 29

Typical example

g01038600

9. If necessary, remove the studs (12) from the

turbocharger housing.

Note: Do not use the actuator rod of the wastegate

(16) to lift the turbocharger (1).

Page 17

10. Remove the nuts (13). Remove the turbocharger

(1). Remove the gasket (14). Discard the gasket

(14). If necessary, remove the studs (15) from

the exhaust manifold.

11. Install suitable plastic plugs into the oil supply

and into the oil drain ports of the turbocharger

(1). Install suitable plastic covers to the inlet

and to the outlet of the turbocharger (1). Install

suitable plastic plugs to the oil supply tube

assembly (6) and to the oil drain tube assembly

(9). Install suitable plastic covers to the manifold

ports.

i01944024

Turbocharger - Install

Installation Procedure

17

Disassembly and Assembly Section

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

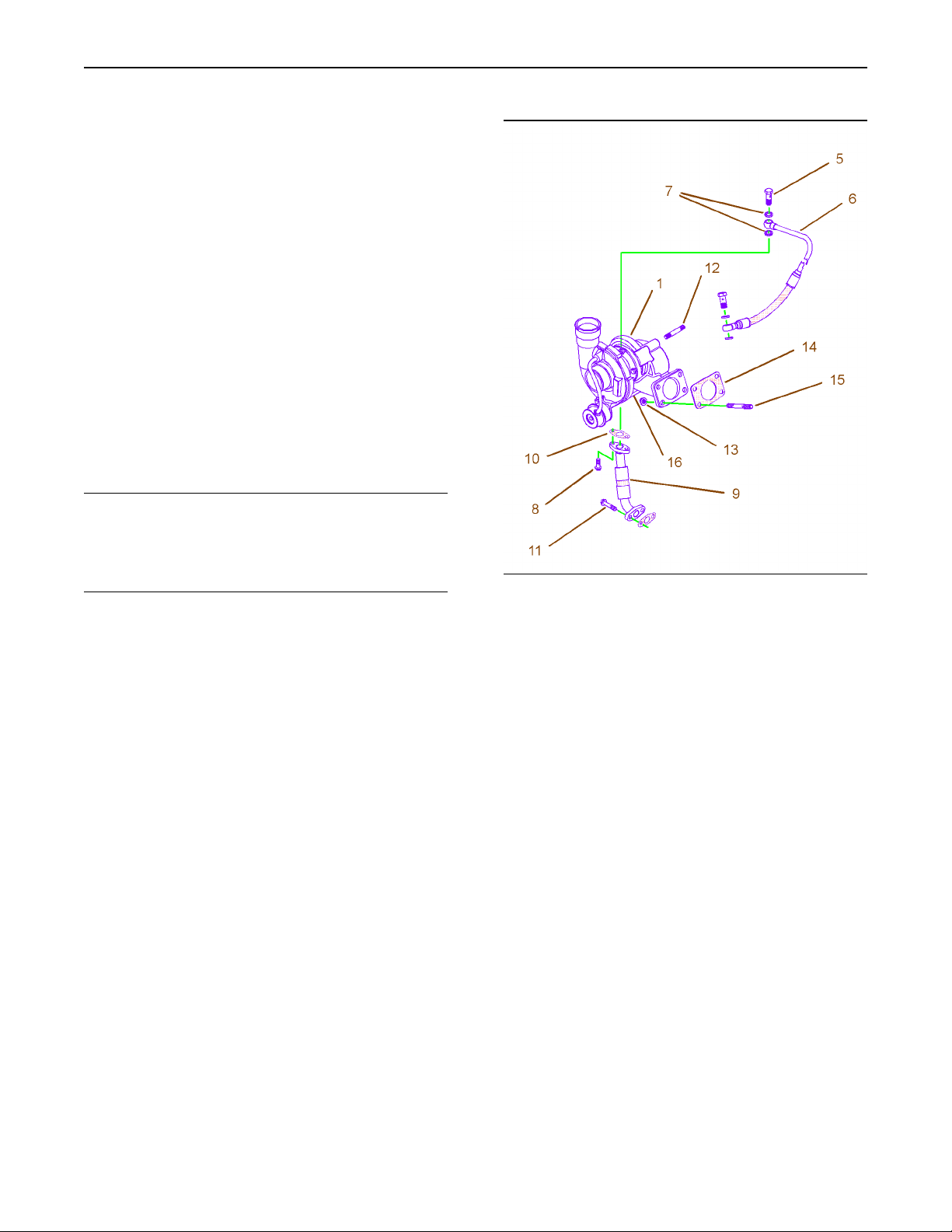

Note: The installation procedure is identical for the

three cylinder and the four cylinder engines.

1. Remove all of the plastic plugs from all of

the ports of the turbocharger (1). Clean the

mating surfaces of the exhaust manifold and the

turbocharger. Clean the mating surfaces of the

turbocharger to the oil supply tube assembly

(6) and the turbocharger to the oil drain tube

assembly (9).

2. Ensure that all of the turbocharger inlet and

outlet ports are clean and free from restrictions.

The turbocharger shaft must rotate freely.

Illustration 31

Typical example

3. If the studs (15) were previously removed, install

the studs into the exhaust manifold. Install a new

gasket (14) over the studs (15).

Note: Do not use any sealant on the gasket (14).

Note: Do not use the actuator rod of the wastegate

(16) to lift the turbocharger (1).

4. Position the turbocharger (1) onto the exhaust

manifold.

5. Install the nuts (13). Tighten the nuts (13) to a

torque of 47 N·m (35 lb ft).

6. Lubricate the bearing housing of the turbocharger

(1) with clean engine oil.

7. Inspect all of the oil hose assemblies (6 and

9). If necessary, replace the hose assemblies

(6 and 9).

g01038396

Note: The top flange of the oil drain tube assembly

(9) is secured to the turbocharger (1) with 6 mm

setscrews (8). The bottom flange of the oil drain

tube assembly (9) is secured to the cylinder block

with 8 mm setscrews (11).

8. Position a new joint (10) and the oil drain tube

assembly (9) onto the bottom of the turbocharger

(1). Install the 6 mm setscrews (8). Tighten the 6

mm setscrews (8) to a torque of 9 N·m (80 lb in).

Page 18

18

Disassembly and Assembly Section

9. Position a new joint and the oil drain tube

assembly (9) onto the cylinder block. Tighten

the 8 mm setscrews (11) to a torque of 22 N·m

(16 lb ft).

10. Position the new washers (7) and the oil supply

tube assembly (6) onto the turbocharger (1).

Install the banjo bolt (5). Tighten the banjo bolt

(5) to a torque of 22 N·m (16 lb ft).

Note: Ensure that the oil supply tube assembly

(6) does not come into contact with any other

component when the assembly is installed onto

the engine.

11. Install the new washers and the oil supply tube

assembly (6) to the cylinder block. Tighten the

banjo bolt to a torque of 22 N·m (16 lb ft).

12. If the studs (12) were previously removed, install

the studs into the turbocharger housing.

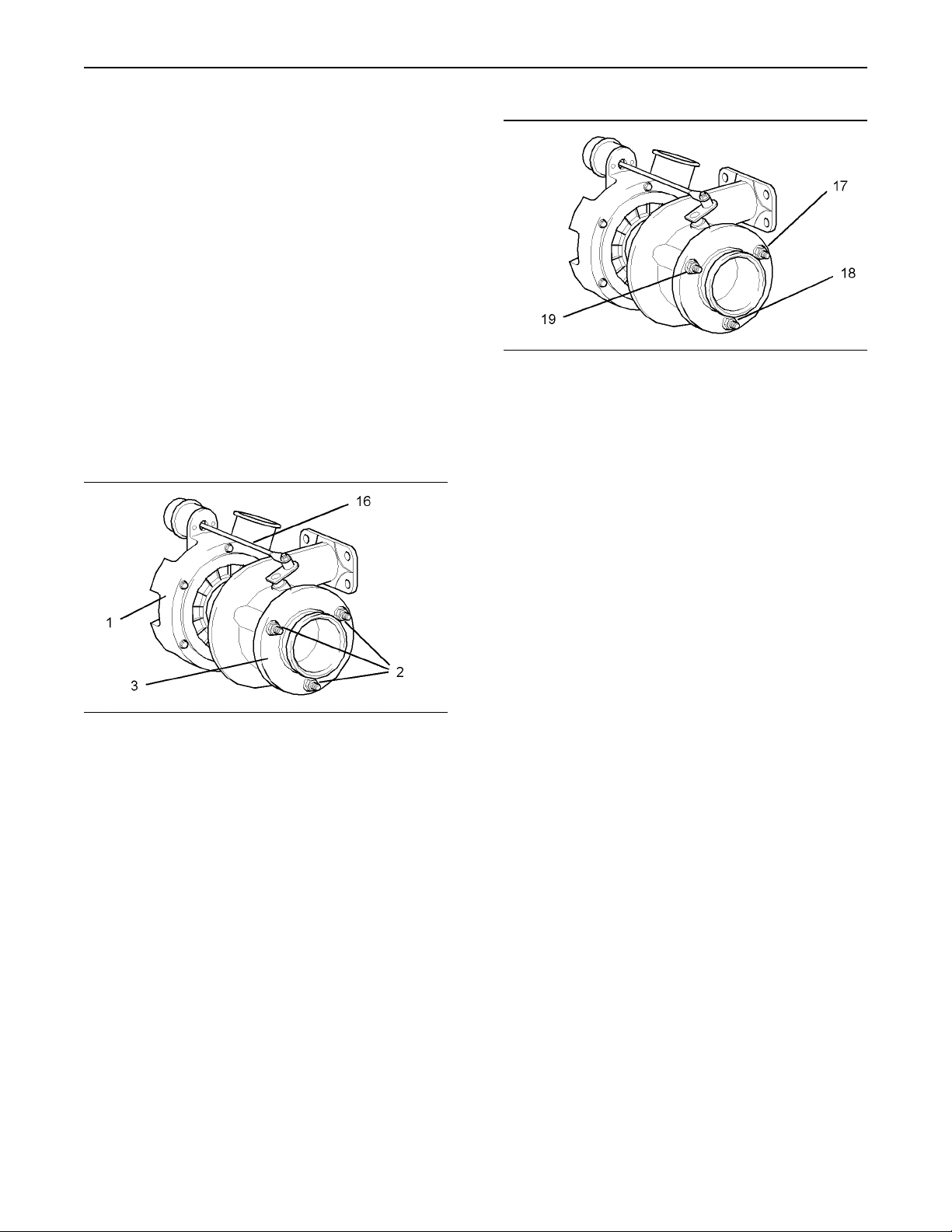

Illustration 33

15. Tighten the three nuts finger tight in the

sequence (17), (18), and (19). Tighten the nuts

(17), (18), and (19) in the same sequence to a

torque of 25 N·m (18 lb ft).

16. Ensure that there is no restriction in the

inlet hose. Position the air inlet hose on the

turbocharger compressor housing. Install the

hose clamps. Tighten the hose clamps to a

torque of 5 N·m (44 lb in).

g01038456

Illustration 32

Typical example

13. Position the exhaust adapter (3) onto the studs

(12). Install the nuts (2). Do not tighten the nuts

(2) at this time.

Note: Exhaust elbows are only an option for the four

cylinder engines.

14. If equipped, install the exhaust elbow onto the

exhaust adapter (3). Refer to this Disassembly

and Assembly Manual, “Exhaust Elbow - Remove

and Install”.

g01038406

Note: The air inlet hose has a reflective heat shield

that partially covers the hose. The reflective heat

shield must be installed toward the engine. The

reflective heat shield must be kept clean and free

from dust, oil or paint.

Note: Apply a solution of water and 5% soap to the

inlet of the turbocharger in order to install a new

air inlet hose. Do not use oil or grease in order to

install the air inlet hose.

17. Position the exhaust pipe onto the exhaust

elbow or onto the turbocharger outlet (3). Refer

to the OEM information for the correct procedure

in order to install the exhaust pipe.

i01946913

Exhaust Manifold - Remove

and Install

Removal Procedure for the Three

Cylinder Engine

Start By:

a. Remove the turbocharger, if equipped. Refer

to this Disassembly and Assembly Manual,

“Turbocharger - Remove”.

Page 19

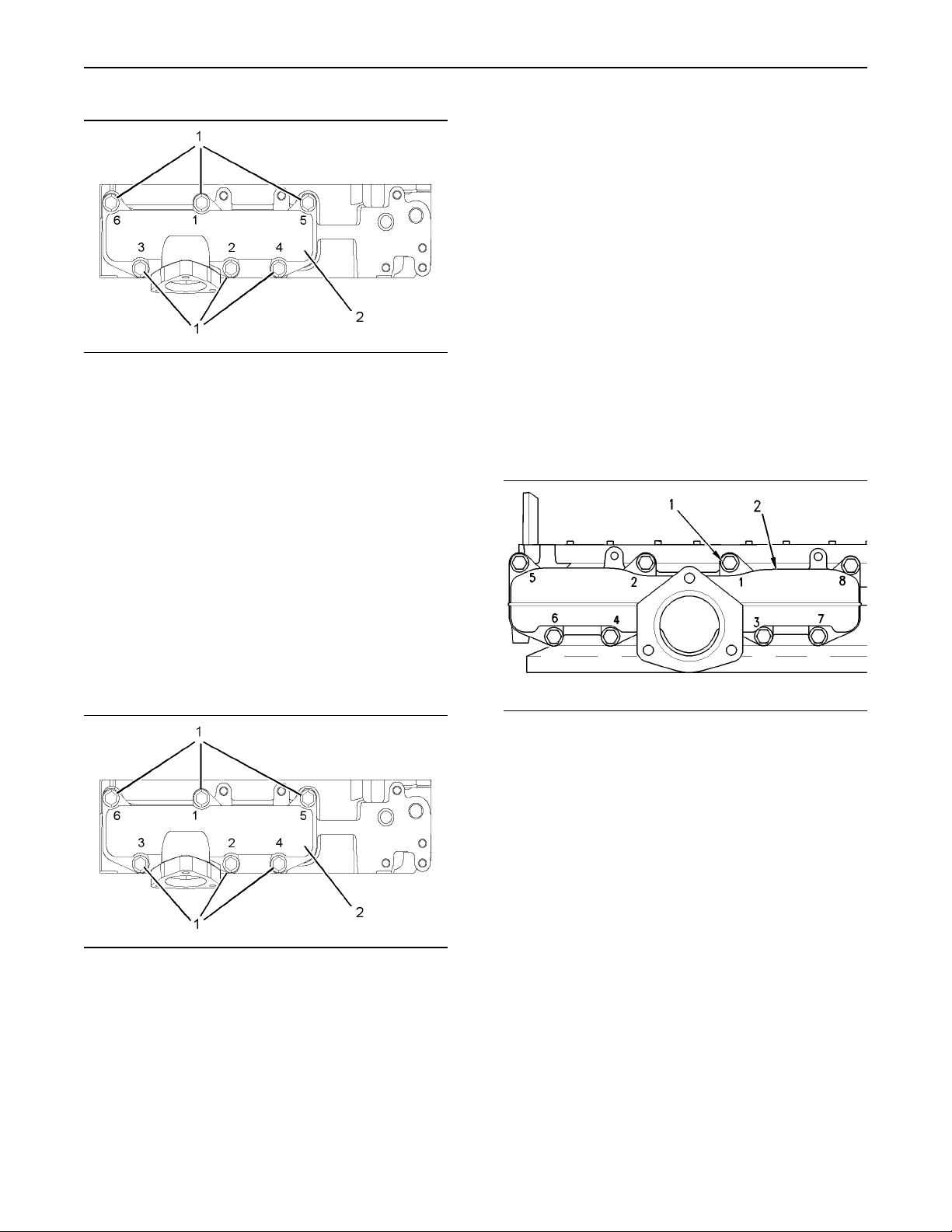

Illustration 34

1. Remove the setscrews (1) in the reverse

numerical order to the Illustration 34. This will

help to prevent any distortion of the exhaust

manifold (2).

2. Remove the exhaust manifold gasket from the

cylinder head and remove the exhaust manifold

(2). Discard the exhaust manifold gasket.

g01038601

19

Disassembly and Assembly Section

3. Remove the two studs and install the remaining

setscrews (1). Ensure that the setscrews (1)

are tightened in the sequence that is shown in

Illustration 35. Tighten the setscrews evenly to a

torque of 33 N·m (24 lb ft).

End By:

a. Install the turbocharger, if equipped. Refer

to this Disassembly and Assembly Manual,

“Turbocharger - Install”.

Removal Procedure for the Four

Cylinder Engine

Start By:

a. Remove the turbocharger, if equipped. Refer

to this Disassembly and Assembly Manual,

“Turbocharger - Remove”.

Installation Procedure for the Three

Cylinder Engine

Note: The improper installation of the exhaust

manifold (2) can result in a cracked exhaust

manifold. The setscrews (1) for the exhaust manifold

must be tightened in the correct sequence and

tightened to the correct torque.

Illustration 35

1. Loosely install two suitable studs into the holes

(5 and 6) as guides.

Note: Do not use any sealant on the exhaust

manifold gasket.

g01038601

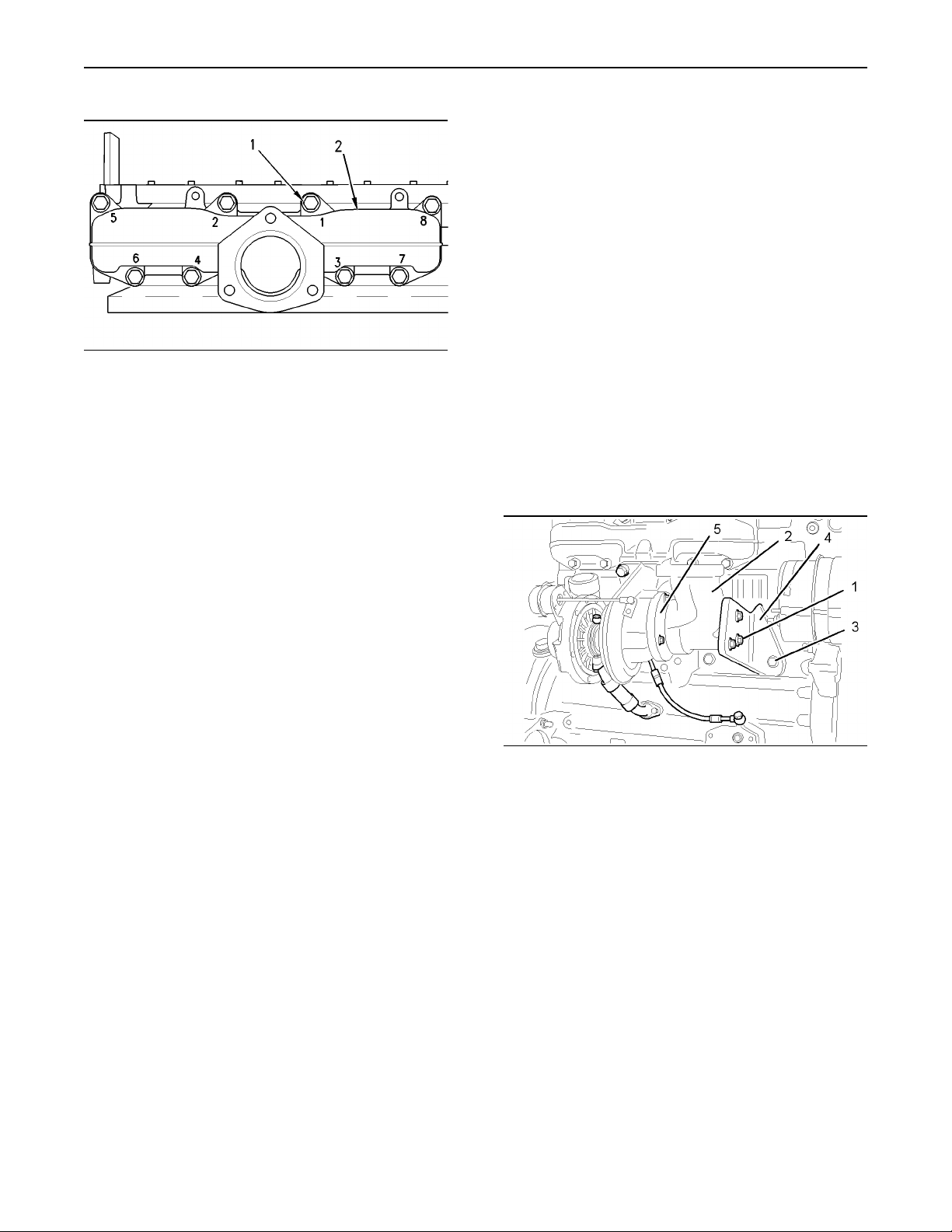

Illustration 36

1. Remove the setscrews (1) in the reverse

numerical order to the Illustration 36. This will

help to prevent any distortion of the exhaust

manifold (2).

2. Remove the exhaust manifold gasket from the

cylinder head and remove the exhaust manifold

(2). Discard the exhaust manifold gasket.

g00951398

Installation Procedure for the Four

Cylinder Engine

Note: The improper installation of the exhaust

manifold (2) can result in a cracked exhaust

manifold. The setscrews (1) for the exhaust manifold

must be tightened in the correct sequence and

tightened to the correct torque.

2. Position the new exhaust manifold gasket onto

the studs in the cylinder head. Position the

exhaust manifold (2) onto the studs. Install the

setscrews (1) finger tight in order to secure the

exhaust manifold to the cylinder head.

Page 20

20

Disassembly and Assembly Section

i01946915

Exhaust Elbow - Remove and

Install

(Option for Four Cylinder

Engines Only)

Illustration 37

1. Loosely install two suitable studs into the holes

(5 and 8) as guides.

Note: Do not use any sealant on the exhaust

manifold gasket.

2. Position the new exhaust manifold gasket onto

the studs in the cylinder head. Position the

exhaust manifold (2) onto the studs. Install the

setscrews (1) finger tight in order to secure the

exhaust manifold to the cylinder head.

3. Remove the two studs and install the remaining

setscrews (1). Ensure that the setscrews (1)

are tightened in the sequence that is shown in

Illustration 37. Tighten the setscrews evenly to a

torque of 33 N·m (24 lb ft).

End By:

a. Install the turbocharger, if equipped. Refer

to this Disassembly and Assembly Manual,

“Turbocharger - Install”.

g00951398

Removal Procedure

Start By:

a. Remove the exhaust pipe. Refer to the OEM

information for the correct procedure in order to

remove the exhaust pipe.

Illustration 38

Typical example

g01013687

1. Remove the setscrews (1) from the exhaust

elbow (2). Remove the setscrews (3) and remove

the bracket (4) from the cylinder block. Remove

the exhaust elbow (2) from the exhaust adapter

(5).

Page 21

21

Disassembly and Assembly Section

Installation Procedure

Illustration 39

Typical example

1. Thoroughly clean the exhaust elbow (2) and the

exhaust adapter (5).

2. Install the exhaust elbow (2) onto the exhaust

adapter (5). Position the bracket (4) onto the

cylinder block and install the setscrews (3).

Tighten the setscrews (3) finger tight. Align the

exhaust elbow with the bracket (4). Install the

setscrews (1) in order to secure the exhaust

elbow (2) to the bracket (4). Tighten the

setscrews (3) and tighten the setscrews (1) to a

torque of 44 N·m (33 lb ft).

g01013687

Start By:

a. Remove the rocker shaft assembly. Refer to this

Disassembly and Assembly Manual, “Rocker

Shaft and Pushrod - Remove”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The following procedure should be adopted in

order to remove the valve springs when the cylinder

head is still installed onto the cylinder block. Refer

to this Disassembly and Assembly Manual, “Inlet

and Exhaust Valves - Remove and Install” for the

correct procedure that should be used to remove

the valve springs from a cylinder head that has

been removed from the cylinder block.

Note: Ensure that the appropriate piston is at top

dead center before the valve spring is removed.

Failure to ensure that the piston is at top dead

center may allow the valve to drop into the cylinder

block.

1. Use the following procedure in order to find

the top dead center position for the appropriate

piston.

.

End By:

a. Install the exhaust pipe. Refer to the OEM

information for the correct procedure in order to

install the exhaust pipe.

i01947651

Inlet and Exhaust Valve

Springs - Remove and Install

Removal Procedure

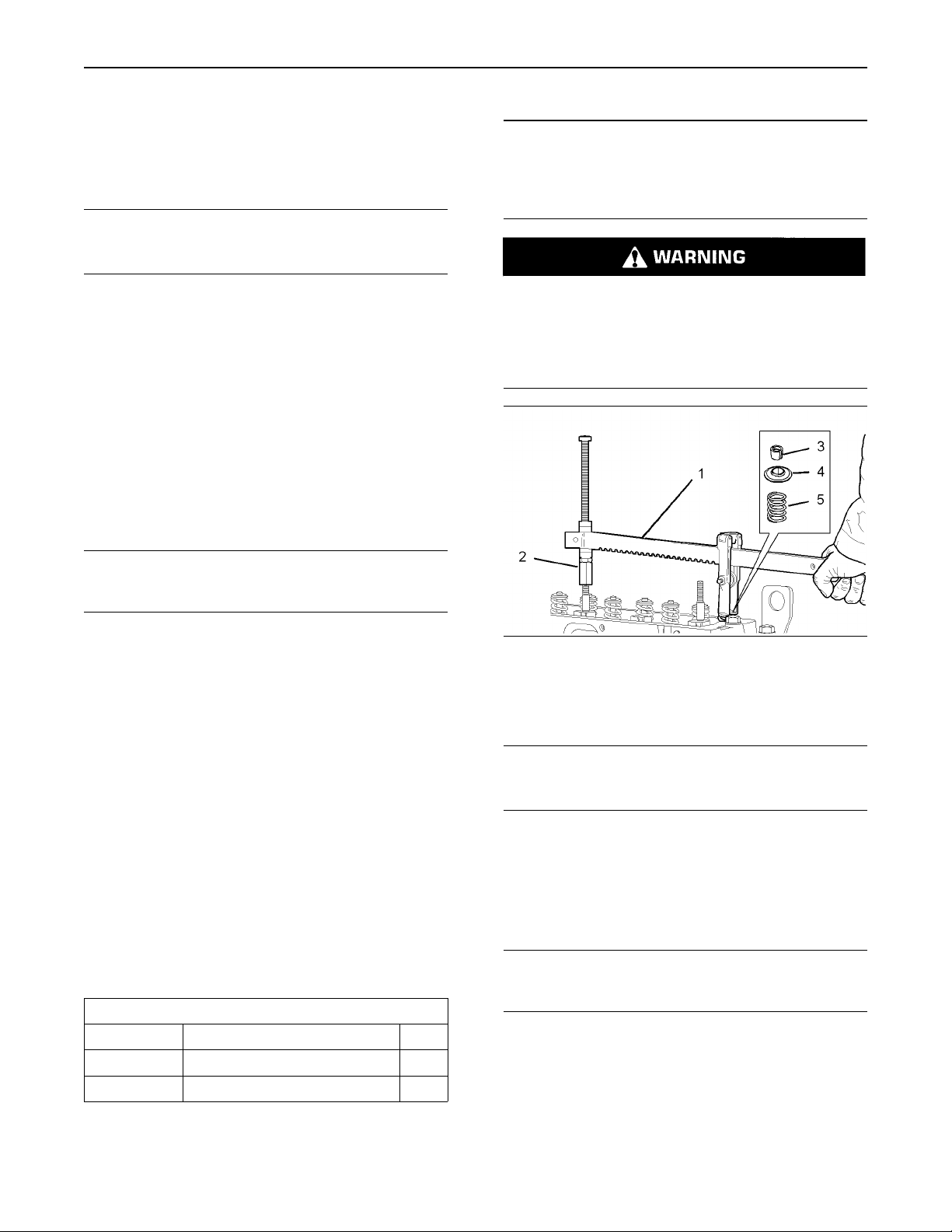

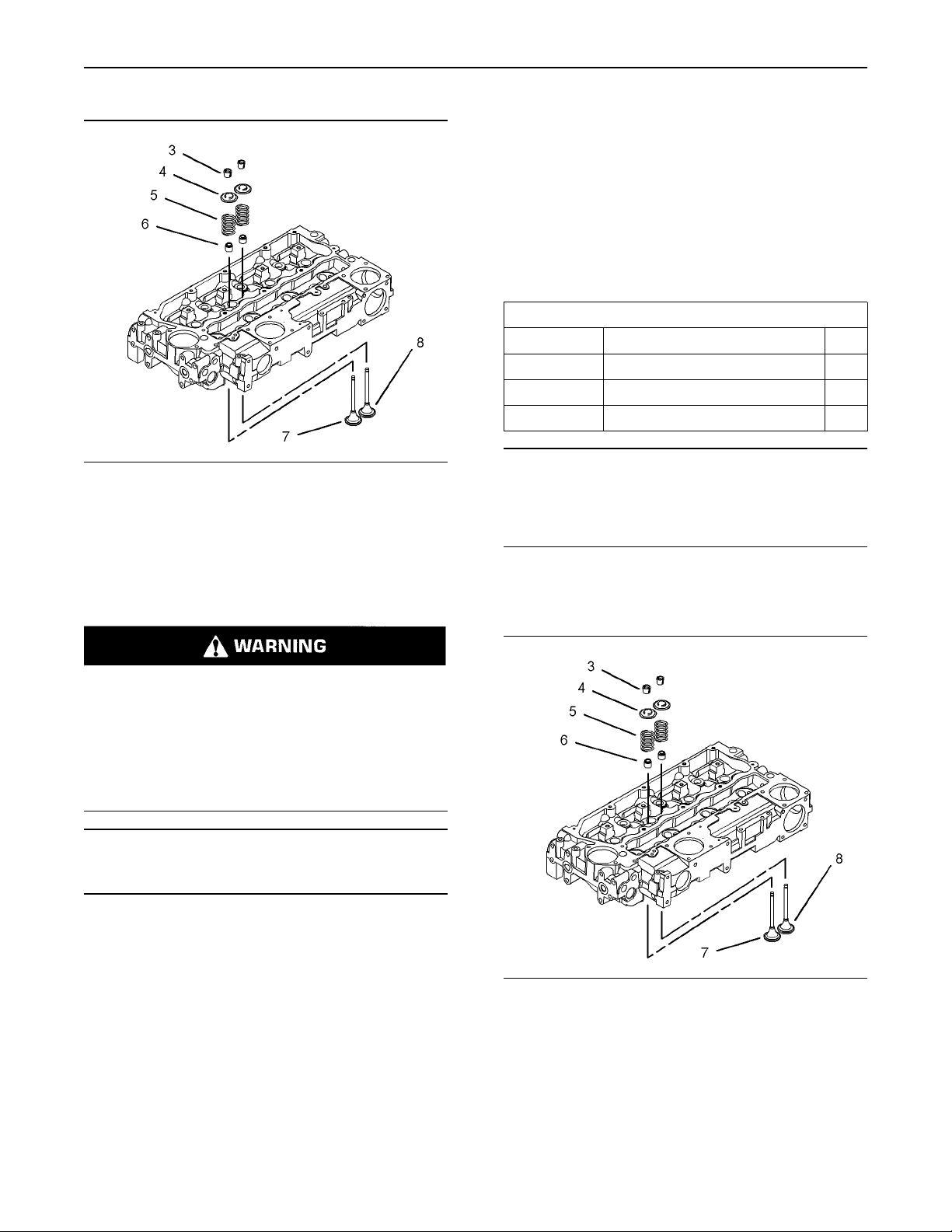

Ta bl e 1

Required Tools

Part Number Part Description

21825666

27610235

Valve Spring Compressor

Setscrew Adapter

Qty

Personal injury can result from being struck by

parts propelled by a released spring force.

Make sure to wear all necessary protective equipment.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

1

1

Illustration 40

g01015085

Page 22

22

Disassembly and Assembly Section

a. Install 21825666 Valve Spring Compressor

(1) and the appropriate 27610235 Setscrew

Adapter (2) in position on the cylinder head

in order to compress the appropriate valve

spring (5).

NOTICE

Ensure that the valve spring is compressed squarely

or damage to the valve stem may occur.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

b. Compress the valve spring (5) sufficiently in

order to open the valve only. Do not compress

the valve spring sufficiently so that the valve

keepers (3) could be removed from the recess

in the valve stem.

c. Turn the crankshaft until the piston touches

the valve.

d. Continue to turn the crankshaft until the valve

stem is at the highest point. The piston is

now at top dead center. Release the applied

pressure of the valve spring compressor (1)

at the top center position.

NOTICE

Do not turn the crankshaft while the valve springs are

removed.

2. Use the valve spring compressor (1) in order to

compress the valve spring (5). Remove the valve

keepers (3).

3. Carefully release the pressure on the valve

spring compressor (1). Remove the valve spring

retainer (4) and the valve spring (5).

Note: If you are replacing all of the valve springs,

the procedure can be done on two cylinders at the

same time. The procedure can be done on cylinder

1 and cylinder 4, and on cylinder 2 and cylinder 3.

Remember that the crankshaft must not be turned

while the valve springs are removed. Ensure that all

of the valve springs are installed before changing

from one pair of cylinders to the other pair of

cylinders.

Improper assembly of parts that are spring loaded

can cause bodily injury.

To prevent possible injury, follow the established

assembly procedure and wear protective equipment.

Illustration 41

g01015085

1. Place the new valve spring (5) into position.

2. Install the valve spring retainer (4).

NOTICE

Ensure that the valve spring is compressed squarely

or damage to the valve stem may occur.

3. Install the valve spring compressor (1) in position

on the cylinder head in order to compress the

appropriate valve spring (5). Compress the valve

spring (5).

4. Install the valve keepers (3).

Installation Procedure

Ta bl e 2

Required Tools

Part Number Part Description

21825666

27610235

Valve Spring Compressor

Setscrew

NOTICE

Do not turn the crankshaft while the valve springs are

removed.

Qty

1

1

Page 23

5. Carefully release the pressure on the valve

spring compressor (1). Remove the valve spring

compressor (1). Ensure that all of the valves are

secured in place by a valve spring and valve

keepers. Rotate the crankshaft through about

45 degrees in order to clear the piston from the

valve. Lightly strike the top of the valve with a

soft hammer in order to ensure that the valve

keepers (3) are properly installed.

Note: If you are replacing all of the valve springs

the procedure can be done on two cylinders at the

same time. The procedure can be done on cylinder

1 and cylinder 4, and on cylinder 2 and cylinder 3.

End By:

a. Install the rocker shaft assembly. Refer to this

Disassembly and Assembly, “Rocker Shaft and

Pushrod - Install”.

23

Disassembly and Assembly Section

i01947652

Inlet and Exhaust Valves Remove and Install

Removal Procedure

Ta bl e 3

Required Tools

Part Number Part Description

21825496

21825666

27610235

Valve Depth Gauge

Valve Spring Compressor

Setscrew Adapter 1

Start By:

a. Remove the cylinder head assembly. Refer to this

Disassembly and Assembly Manual, “Cylinder

Head - Remove”.

Note: Ensure that the machined face of the cylinder

head is kept on a clean, soft surface in order to

prevent damage to the machined surface.

Qty

1

1

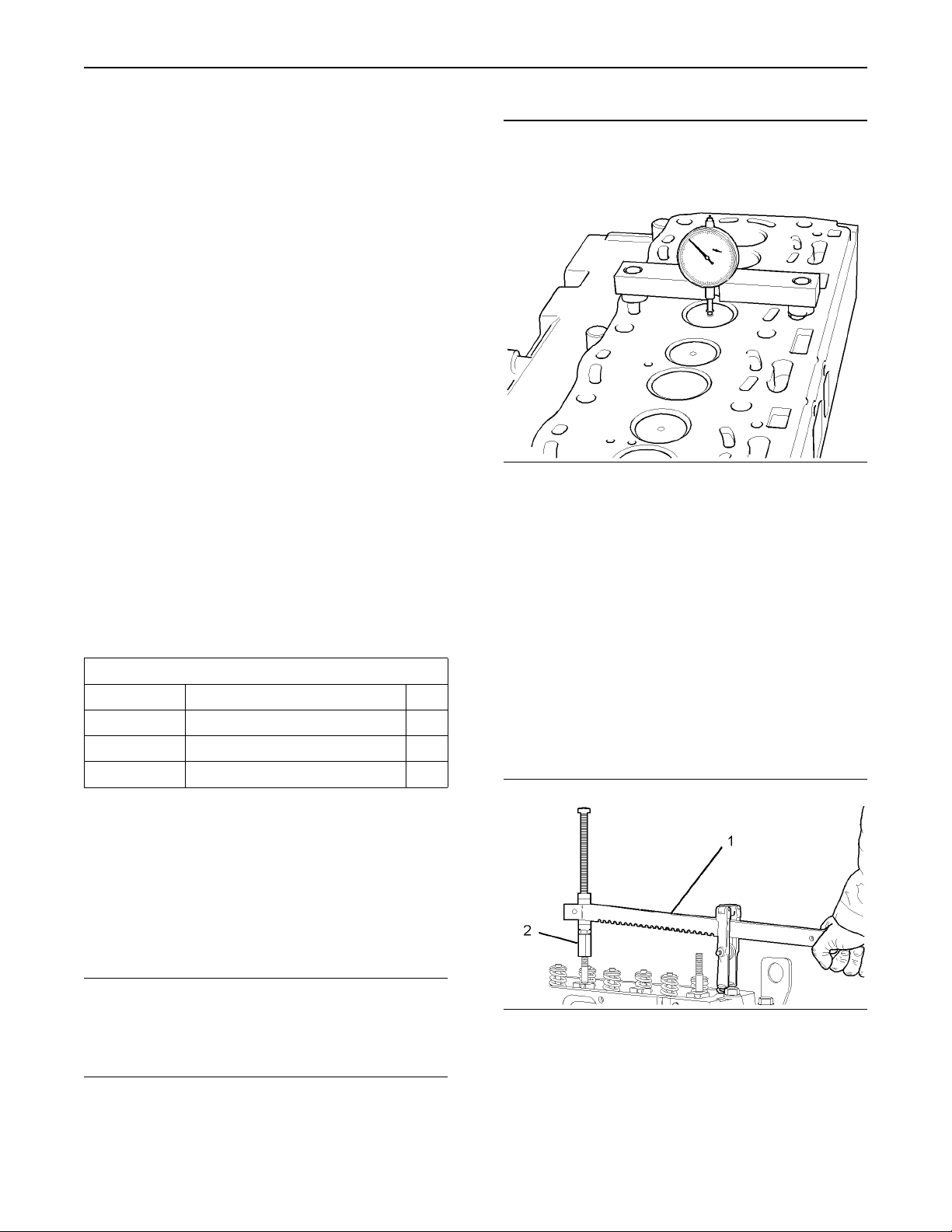

Illustration 42

Typical example

g01015306

1. Use a dial indicator to check the depth of the

valves below the face of the cylinder head

before the valve springs are removed. Refer to

the illustration 42 and refer to Specifications,

“Cylinder Head Valves” for the correct

dimensions.

Note: The head of the inlet valve has a larger

diameter than the head of the exhaust valve.

2. Place a numerical index mark on the heads of

the inlet valves and on the exhaust valves so

that each valve can be installed in the correct

sequence during installation.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The removal procedure is identical for the

three cylinder and the four cylinder engines. The

illustrations show the four cylinder engine.

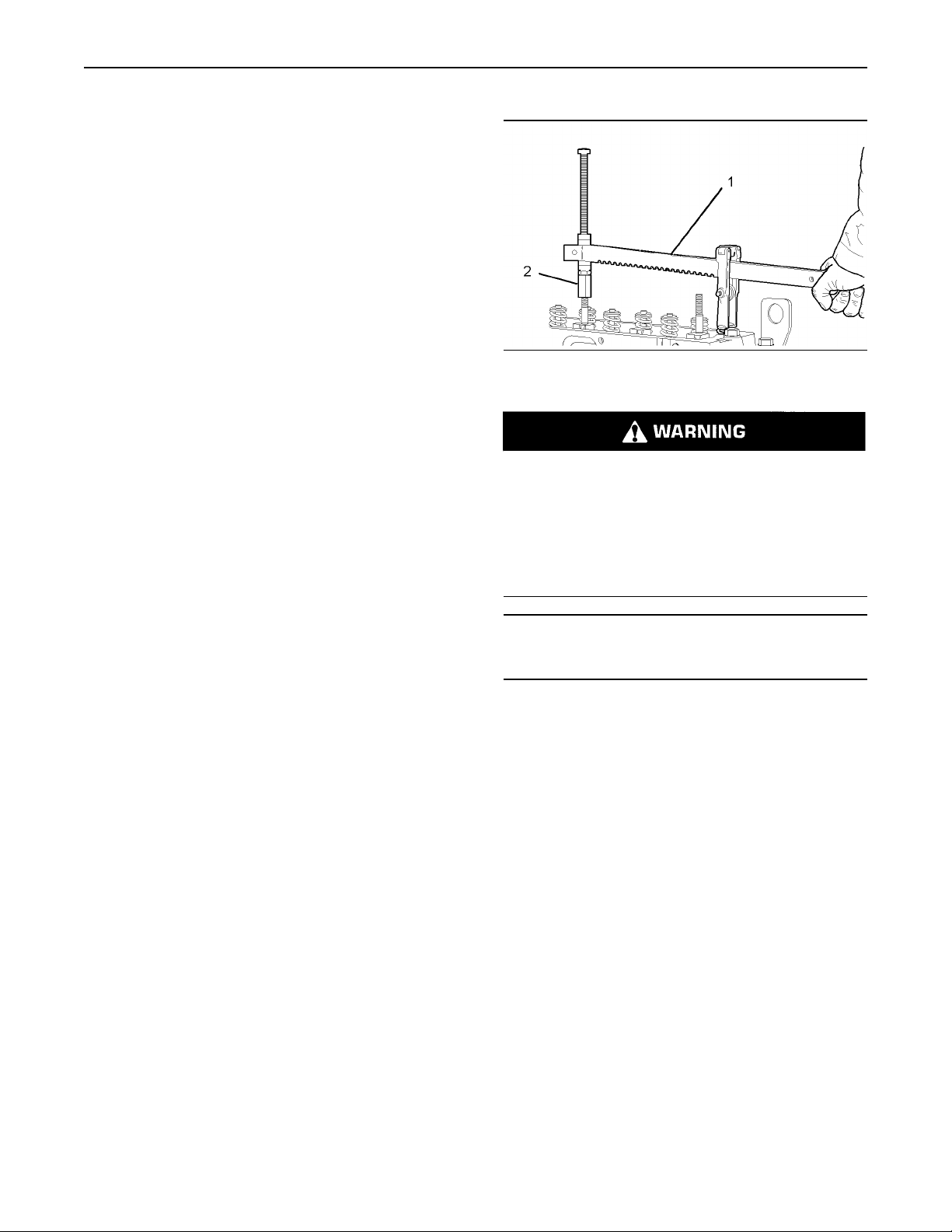

Illustration 43

Typical example

g01015303

Page 24

24

Disassembly and Assembly Section

9. Remove the valve stem seal (6). Discard the

valve stem seal (6).

10. Remove the appropriate valve (7 or 8).

11. Repeat Step 3 to Step 10 for each inlet valve (7)

and for each exhaust valve (8).

Installation Procedure

Ta bl e 4

Required Tools

Part Number Part Description

21825666

27610235

21825496

Valve Spring Compressor

Setscrew Adapter

Valve Depth Gauge

Qty

1

1

1

Illustration 44

Typical example

g01015305

3. Install 21825666 Valve Spring Compressor

(1) and the appropriate 27610235 Setscrew

Adapter (2) in position on the cylinder head in

order to compress the appropriate valve spring

(5).

Personal injury can result from being struck by

parts propelled by a released spring force.

Make sure to wear all necessary protective equipment.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

NOTICE

Ensure that the valve spring is compressed squarely

or damage to the valve stem may occur.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The installation procedure is identical for the

three cylinder and the four cylinder engines. The

illustrations show the four cylinder engine.

4. Compress the valve spring (5).

5. Remove the valve keepers (3).

6. Carefully release the pressure on the valve

spring compressor (1). Remove the valve spring

compressor (1) and the setscrew adapter (2)

from the cylinder head.

7. Remove the valve spring retainer (4).

8. Remove the valve spring (5).

Illustration 45

Typical example

g01015305

Page 25

1. Carefully clean the bottom face of the cylinder

head. Ensure that there is no debris in the inlet

and exhaust ports. Also ensure that there is no

debris in the coolant passages and in lubrication

passages. Inspect the cylinder head. Refer to

the Testing and Adjusting Manual, “Cylinder

Head Inspect” for further information.

2. Inspect all of the valve seats for wear and for

damage. Refer to the Specifications Manual,

“Cylinder Head Valves” for further information.

Also refer to this Disassembly and Assembly

Manual, “Inlet and Exhaust Valve Seat Inserts

- Remove and Install” and refer to Testing and

Adjusting Manual, “Valve Depth - Inspect ” for

further information. Replace any worn parts.

3. Inspect all of the valve guides for wear and for

damage. Refer to the Specifications Manual,

“Cylinder Head Valves” for further information.

Also refer to this Disassembly and Assembly

Manual, “Inlet and Exhaust Valve Guides Remove and Install” and refer to Testing and

Adjusting Manual, “Valve Guide - Inspect” for

further information. Replace any worn parts.

25

Disassembly and Assembly Section

Illustration 46

Typical example

g01015303

Personal injury can result from being struck by

parts propelled by a released spring force.

Make sure to wear all necessary protective equipment.

4. Inspect the valves if the valves are not

replacement parts. Refer to the Specifications

Manual, “Cylinder Head Valves” for further

information.

5. Lubricate the stems of all of the inlet valves (7)

and lubricate the stems of all of the exhaust

valves (8) with clean engine oil. Install the inlet

valves (7) and the exhaust valves (8) in the

appropriate positions.

6. Carefully turn over the cylinder head and ensure

that all of the valves remain in place. Place the

machined surface of the cylinder head onto a

clean, soft surface.

Note: The valve guides must be clean and dry

before installing the valve stem seals (6).

7. Install a new valve stem seal (6) onto each of

the valve guides.

8. Inspect the valve springs (5) for wear and

for the correct installed length. Refer to the

Specifications Manual, “Cylinder Head Valves

” for further information on the correct installed

length of the valve springs (5). Replace any

worn parts.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

NOTICE

Ensure that the valve spring is compressed squarely

or damage to the valve stem may occur.

11. Install 21825666 Valve Spring Compressor

(1) and the appropriate 27610235 Setscrew

Adapter (2) in position on the cylinder head in

order to compress the appropriate valve spring

(5).

12. Install the valve keepers (3).

13. Carefully release the pressure on the valve

spring compressor (1). Remove the valve spring

compressor (1) and the setscrew adapter (2)

from the cylinder head. Gently strike the top of

the appropriate valves with a soft hammer in

order to ensure that the valve keepers (3) are

properly installed.

14. Repeat Step 11 to Step 13 for all of the valves

(7 and 8).

9. Install the valve springs (5) onto the cylinder

head.

10. Install the valve spring retainers (4).

Page 26

26

Disassembly and Assembly Section

15. Turn over the cylinder head. Use a dial indicator

to check the depth of the new valves below the

face of the cylinder head. Refer to Illustration 42

and refer to the Specifications Manual, “Cylinder

Head Valves” for more information on the inlet

valves and the exhaust valves. If the depth of

the new valves is below the correct depth, the

valve seat inserts must be replaced. Refer to this

Disassembly and Assembly Manual, “Inlet and

Exhaust Valve Seat Inserts - Remove and Install”.

End By:

a. Install the cylinder head assembly. Refer to this

Disassembly and Assembly Manual, “Cylinder

Head - Install”.

i01947653

Inlet and Exhaust Valve Guides

- Remove and Install

Removal Procedure

Ta bl e 5

Required Tools

Part Number Part Description

21825478

21825479

Valve Guide Remover/Replacer

Valve Guide Adapter

Start By:

a. Remove the cylinder head. Refer to this

Disassembly and Assembly Manual, “Cylinder

Head - Remove”.

b. Remove the inlet valves and the exhaust valves.

Refer to this Disassembly and Assembly Manual,

“Inlet and Exhaust Valves - Remove and Install”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Qty

1

1

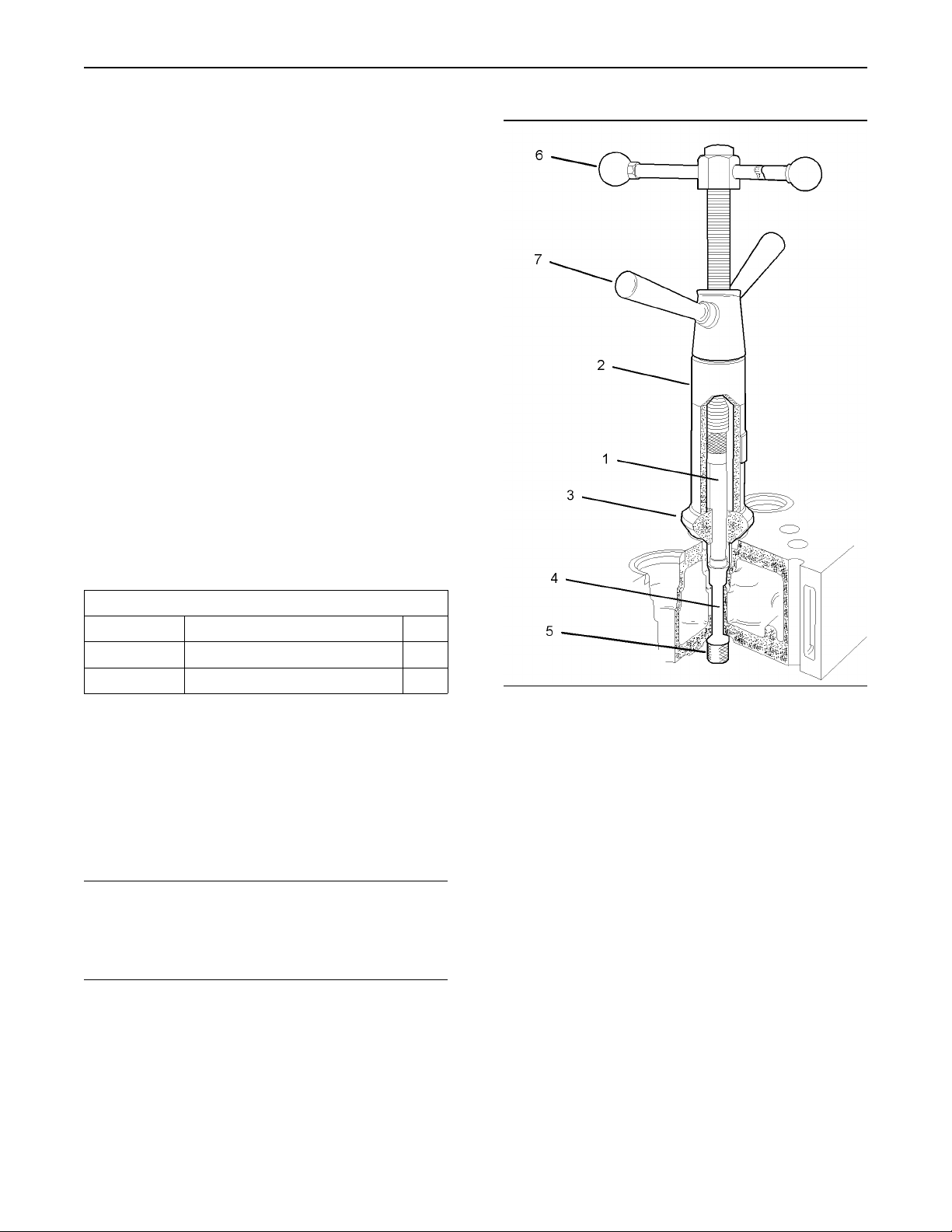

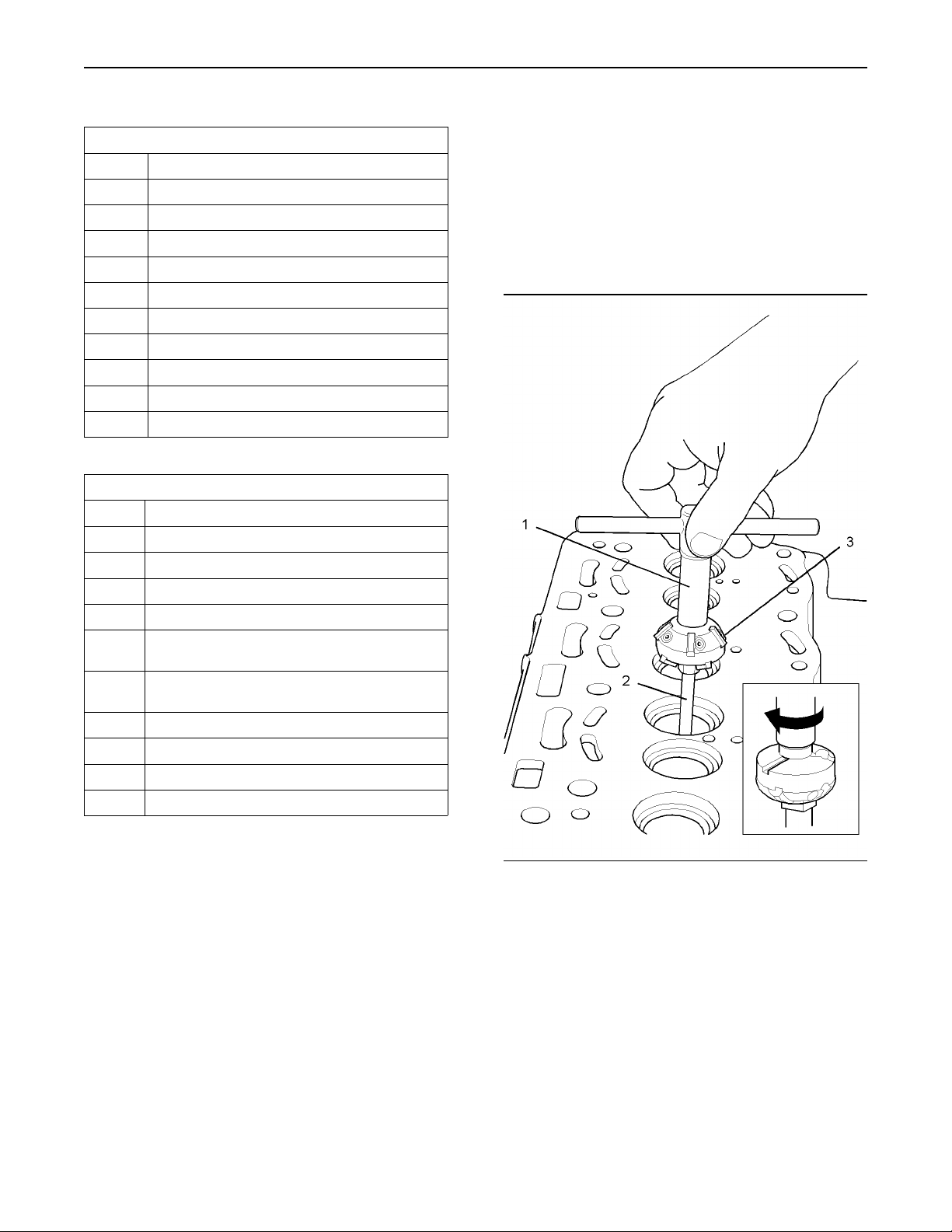

Illustration 47

g01016267

1. Install the 21825479 Valve Guide Adapter (1) into

the 21825478 Valve Guide Remover/Replacer

(2).

2. Place the spacer (3) into the appropriate valve

seat.

3. Pass the adapter (1) through the valve guide (4)

and install the valve guide remover/replacer (2)

onto the spacer (3).

4. Install the attachment (5) in order to secure the

adapter (1) to the valve guide (4).

5. Hold the top handle (6) and turn the bottom

handle (7) counterclockwise in order to push the

valve guide (4) from the cylinder head.

6. Repeat Step 2 to Step 5 in order to extract each

appropriate valve guide (4).

7. Discard all of the valve guides (4) that were

removed from the cylinder head.

Page 27

27

Disassembly and Assembly Section

Note: When new valve guides are installed, new

valves and new valve seat inserts must be installed.

8. Remove the valve seat inserts. Refer to this

Disassembly and Assembly Manual, “Inlet and

Exhaust Valve Seat Inserts - Remove and Install”.

Installation Procedure

Ta bl e 6

Required Tools

Part Number Part Description

21825478

27610234

Valve Guide Remover/Replacer

Valve Guide Adapter

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Qty

1

1

2. Install the 27610234 Valve Guide Adaptor (8) into

the 21825478 Valve Guide Remover/Replacer

(2).

3. Install the spacer (3) into the appropriate valve

seat.

4. Lubricate the outer surface of a new valve guide

(4) with clean engine lubricating oil. Pass the

adapter (8) through the parent bore for the

valve guide (4) and position the valve guide

remover/replacer (2) onto the spacer (3).

5. Install the adapter (10) beneath the valve guide

(4). Install the attachment (5) in order to secure

the adapter (10) to the valve guide (4).

Note: The valve guide (4) should protrude above

the cylinder head. Ensure that the protrusion (9) is

within limits.

6. Hold the top handle (6) and turn the bottom

handle (7) clockwise in order to pull the valve

guide (4) into the cylinder head. Continue to pull

the valve guide (4) into the cylinder head until the

correct amount of protrusion (9) is reached. The

valve guides should protrude 12.35 to 12.65 mm

(0.4862 to 0.4980 inch) above the valve spring

recess.

7. Repeat the Step 3 to Step 6 in order to install

each appropriate valve guide.

Note: The parent bores of the valve guides must be

reamed to the correct size after the valve guides

have been installed into the cylinder head. Also, the

valve inserts must be inserted and the seat faces

must be cut to the correct angle. The same tool is

used to finish both components.

8. Install the valve seat inserts and finish both

components. Refer to this Disassembly and

Assembly Manual, “Inlet and Exhaust Valve Seat

Inserts - Remove and Install”.

End By:

a. Install the inlet valves and the exhaust valves.

Refer to this Disassembly and Assembly Manual,

“Inlet and Exhaust Valves - Remove and Install”.

Illustration 48

g01016462

1. Clean the parent bores in the cylinder head for

all of the appropriate valve guides (4).

Page 28

28

Disassembly and Assembly Section

i01947654

Inlet and Exhaust Valve Seat

Inserts - Remove and Install

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Removal Procedure

Start By:

a. Remove the inlet valves and the exhaust valves.

Refer to this Disassembly and Assembly Manual,

“Inlet and Exhaust Valves - Remove and Install”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: When new valve seat inserts are installed,

new valves and new valve guides must be installed.

1. Remove the appropriate valve guides. Install

partially finished valve guides. Refer to this

Disassembly and Assembly Manual, “Inlet and

Exhaust Valve Guides - Remove and Install”.

Note: The inserts for the inlet valves are a larger

diameter than the exhaust valve inserts.

2. Use the partially finished bore of the valve guide

as a pilot bore in order to remove the valve insert

by machining. Also use the partially finished

bore of the valve guide as a pilot bore in order

to machine a recess for a new valve seat. Refer

to the Specifications Manual, “Cylinder Head

Valves” for the required dimensions of the recess

for the valve seat. Remove all debris from the

cylinder head ports and passages.

Note: If the cylinder head has been previously

ground then the bottom face of valve seat must

be ground in order to ensure that the valve seat

will be installed correctly into the cylinder head.

A 30 degree chamfer must be machined to the

outer edge of the valve seat after the back face

of the valve insert has been ground to the correct

dimensions. The 30 degree chamfer must be within

the tolerance of 0.91 mm (0.036 inch) to 1.3 mm

(0.051 inch). Also, the chamfer must be inclined to

the vertical face of the valve insert.

Note: Do not use a hammer in order to install the

valve insert into the machined recess in the cylinder

head.

Note: Do not apply any lubricant before the new

valve seat insert is installed into the cylinder head.

1. Use a suitable tool to install the valve seat insert

into the machined recess in the cylinder head.

3. Repeat the Step 2 for all of the appropriate valve

seats.

Installation Procedure

Ta bl e 7

Required Tools

Part Number Part Description

27610030

Valve Guide/Valve Seat

Reamer/Cutter

Qty

1

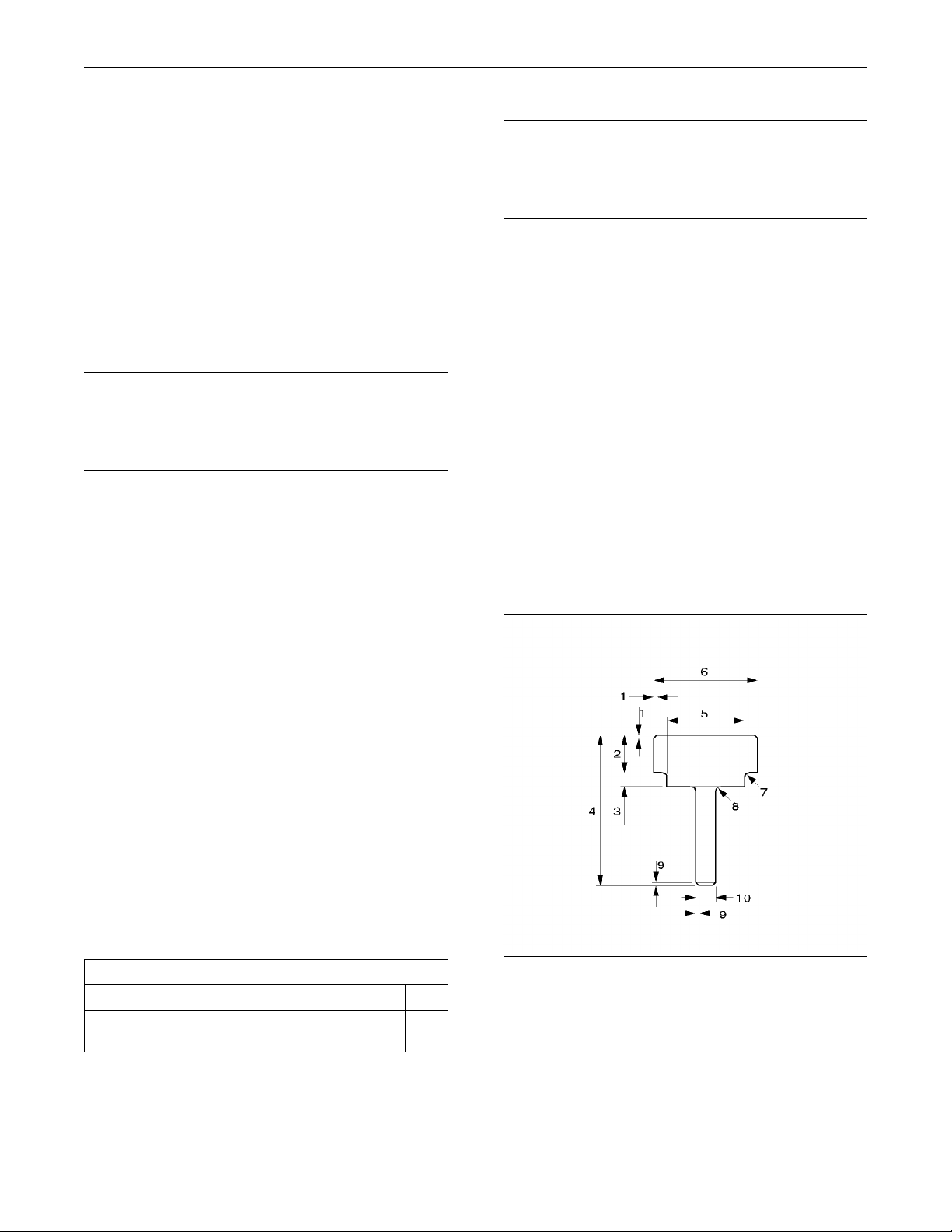

Illustration 49

2. If necessary, a suitable tool can be manufactured.

Refer to the illustration 49. Also refer to the table

8 and refer to the table 9 for suitable dimensions.

g01016768

Page 29

29

Disassembly and Assembly Section

Ta bl e 8

Callout

10

Ta bl e 9

Callout

1

2

3

4

5

6

7

8

9

10

Tool for the Inlet Valve Seat Inserts

Dimension

1

2

3

4

5

6

7

8

9

6.8 mm (0.268 inch) to 7.1 mm (0.279 inch)

38.1 mm (1.500 inch) to 38.3 mm (1.508 inch)

46.25 mm (1.82 inch) to 46.5 mm (1.83 inch)

Maximum radius 1.4 mm (0.055 inch)

Maximum radius 1.5 mm (0.06 inch)

8.77 mm (0.345 inch) to 8.80 mm (0.346 inch)

Tool for the Exhaust Valve Seat Inserts

7.2 mm (0.283 inch) to 7.5 mm (0.295 inch)

34.38 mm (1.353 inch) to 34.58 mm

41.75 mm (1.643 inch) to 42.00 mm

Maximum radius 1.4 mm (0.055 inch)

Maximum radius 1.5 mm (0.06 inch)

8.77 mm (0.345 inch) to 8.80 mm (0.346 inch)

1.5 mm (0.06 inch)

20 mm (0.80 inch)

100 mm (3.94 inch)

1.5 mm (0.06 inch)

Dimension

1.5 mm (0.06 inch)

20 mm (0.80 inch)

100 mm (3.94 inch)

(1.361 inch)

(1.653 inch)

1.5 mm (0.06 inch)

5. After installing the valve guides and valve seat

inserts, the valve guides must be reamed and

the valve seat inserts must be cut to the finished

diameter. The valve guides and valve seat

inserts are cut and reamed in one operation.

This procedure ensures the concentricity of the

valve seat to the valve guide in order to create

a good seal. Refer to the Specifications Manual,

“Cylinder Head Valves” for the finished diameter

of the valve guides and valve seat inserts.

3. Put the appropriate valve seat insert in position.

Install the special tool that was manufactured

previously, through the valve seat insert and

use the pilot bore of the valve guide in order to

center the tool and the insert into the recess.

Lightly tap the valve seat insert in order to start

the installation. Press the valve seat insert into

the recess with a suitable press. Ensure that the

bottom of the valve seat insert is against the

bottom of the recess.

4. Repeat Step 3 for the remaining valve seat

inserts.

Illustration 50

g01017975

Note: Ensure that the 27610030 Valve Guide/Valve

Seat Reamer/Cutter is assembled correctly with the

correct angle of cutter (3) for the valve seat toward

the cylinder head.

Note: Ensure that the cutter (3) for the valve seat is

not allowed to contact the valve seat insert until the

valve guide has been reamed to the correct size.

Page 30

30

Disassembly and Assembly Section

6. Set the diameter of the cutter (3) to the correct

size for the valve seat to be cut. Refer to the

Specifications Manual, “Cylinder Head Valves”

for the correct diameter. Position the reamer (2)

of the tool (1) into the appropriate valve guide.

Carefully turn the handle in a clockwise direction

and gradually move the reamer (2) into the valve

guide until the valve guide is reamed to the

finished size.

7. Continue to turn the handle in a clockwise

direction in order to cut the valve seat insert.

Remove the minimum amount of material in order

to ensure a good valve seat. Keep the valve seat

as narrow as possible.

8. Remove the tool (1). Clean the debris from the

valve guide and the valve seat.

9. Repeat Step 6 to Step 8 in order to cut all of the

appropriate valve seats.

End By:

a. Install the inlet valves and the exhaust valves.

Refer to this Disassembly and Assembly Manual,

“Inlet and Exhaust Valves - Remove and Install”.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of theproduct. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

1. Remove all dirt, oil, and grease from the engine

oil filter assembly and from the drain plug of

the engine oil pan. Place a suitable container

beneath the drain plug of the engine oil pan.

2. Operate the engine until the engine is warm.

Stop the engine.

3. Remove the oil drain plug and the O-ring from

the engine oil pan. Drain the engine oil into the

container for storage or disposal.

i01958098

Engine Oil Filter Base Remove and Install

Removal Procedure for an Oil Filter

with a Separate Filter Element

Note: This procedure is for the removal of an oil

filter with an oil filter housing and a separate oil

filter element.

Note: The oil filter can be installed vertically or the

oil filter can be installed horizontally.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

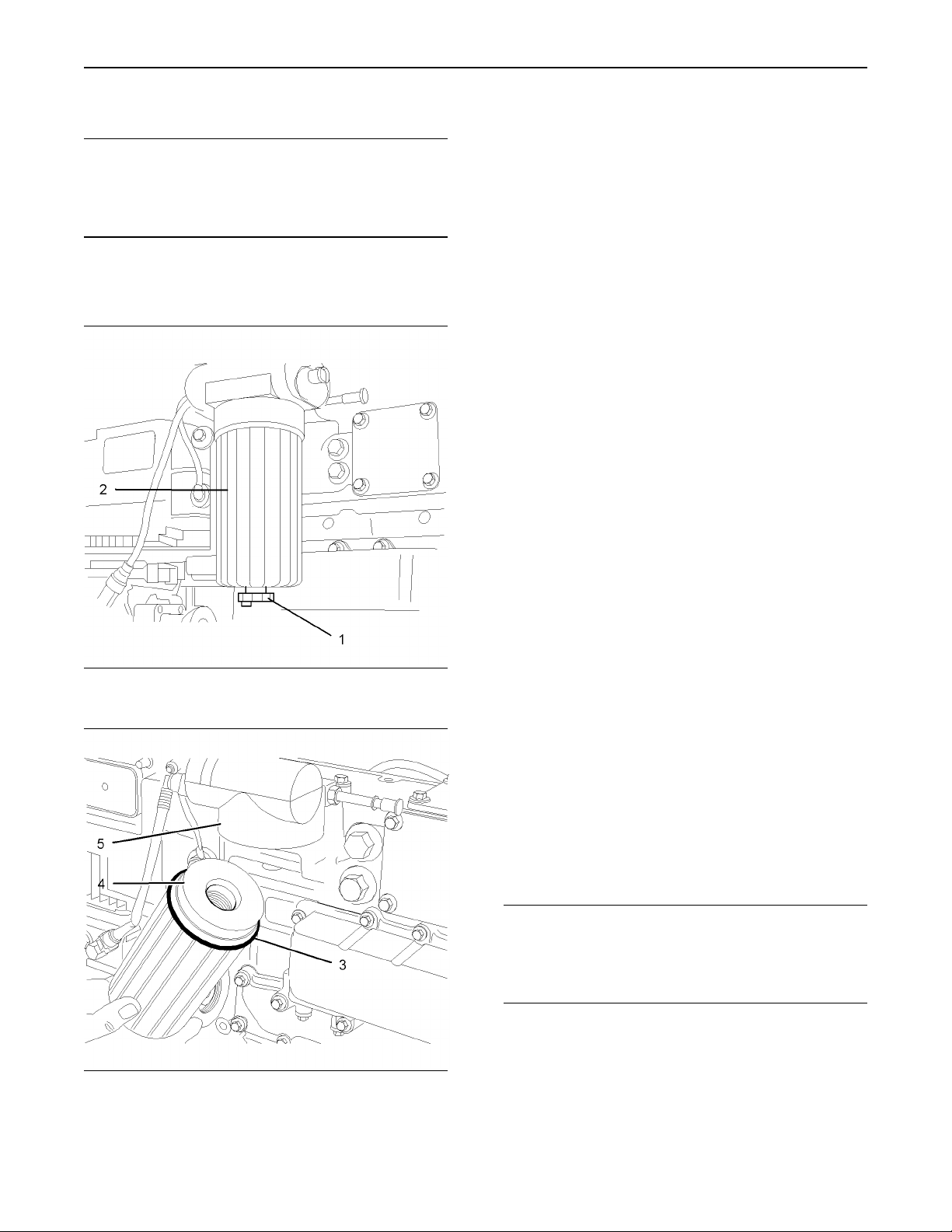

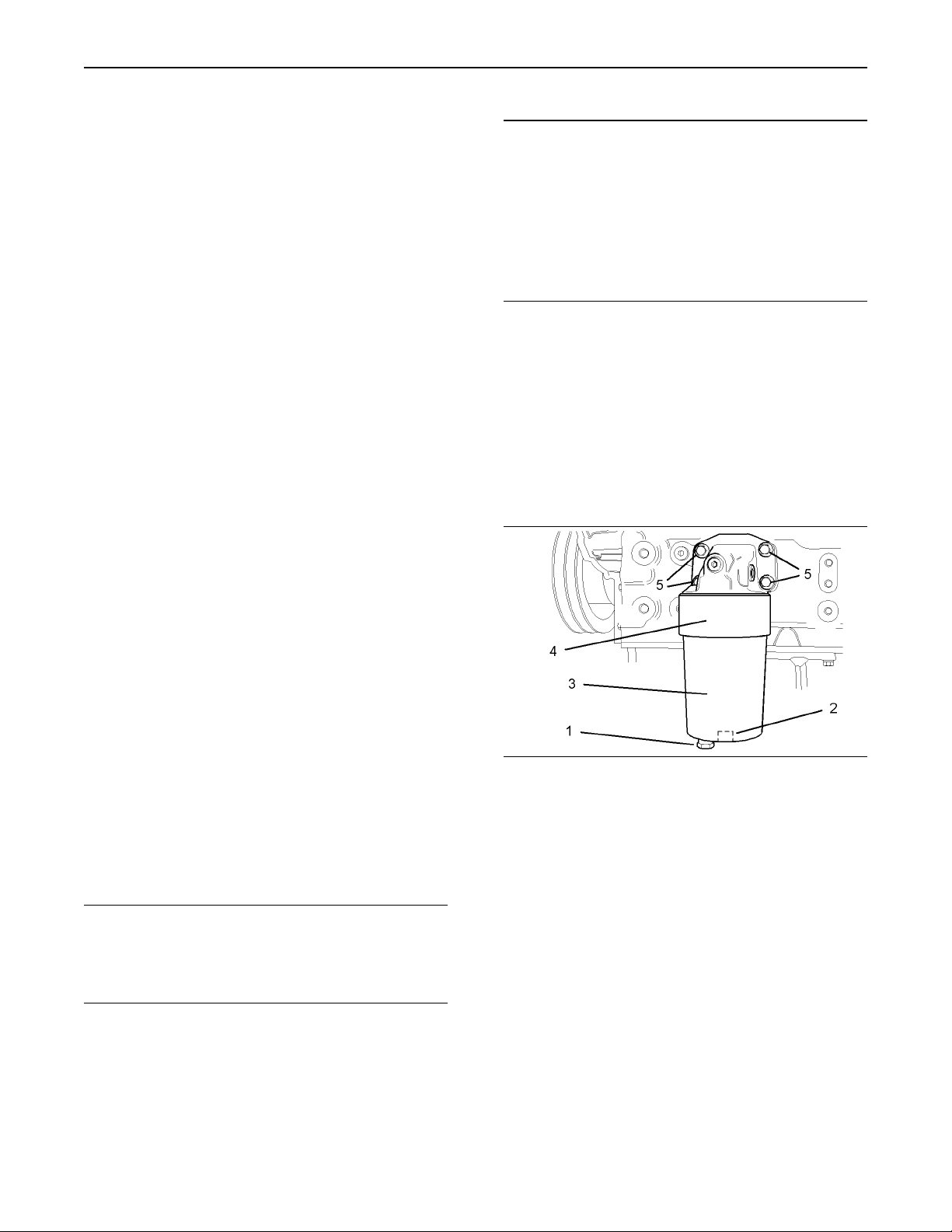

Illustration 51

Typical example

Note: The drain plug (1) in the horizontal type of oil

filter is installed in the filter head (4) instead of the

oil filter housing (3). Do not remove the drain plug

(1) from this type of oil filter.

4. Place a suitable container beneath the drain plug

(1) in the oil filter housing (3). Remove the drain

plug (1) from the oil filter housing (3) and remove

the O-ring from the drain plug (1). Discard the

O-ring. Collect any engine oil that drains from

the oil filter housing (3).

5. Install a ratchet with a 1/2 inch square drive into

the recess (2) in the base of the oil filter housing

(3) in order to remove the oil filter housing.

g01018261

Page 31

Illustration 52

Typical example

g01018307

6. Remove the oil filter element (6) from the oil filter

housing (3). Remove the O-ring (7) from the oil

filter housing (3). Discard the O-ring (7).

Note: Step 1 to Step 6 is the procedure for removing