Page 1

PERKINS TIER

ENGINES

1100 (VK)

2DIESEL

H8.00-12.0

H13.00-16

H10.00-12

0XM (H170-280HD) [F007, G007];

.00XM (H300-360HD) [E019, F019];

.00XM-12EC (H360HD-EC) [E019, F019]

PART NO. 1541323 600 SRM 1068

Page 2

SAFETY PRECAUTIONS

MAINTENANCE AND REPAIR

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly

fastened, and that the load being lifted is balanced. Make sure the crane, cables, and

chains have the capacity to support the weight of the load.

• Do not lift heavy parts by hand, use a lifting mechanism.

• Wear safety glasses.

• DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair

on electric lift trucks. Disconnect the battery ground cable on internal combustion lift

trucks.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT

THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Mainte-

nance section.

• Keep the unit clean and the working area clean and orderly.

• Use the correct tools for the job.

• Keep the tools clean and in good condition.

• Always use HYSTER APPROVED parts when making repairs. Replacement parts

must meet or exceed the specifications of the original equipment manufacturer.

• Make sure all nuts, bolts, snap rings, and other fastening devices are removed before

using force to remove parts.

• Always fasten a DONOTOPERATE tag to the controls of the unit when making repairs,

or if the unit needs repairs.

• Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel

are flammable. Be sure to follow the necessary safety precautions when handling these

fuels and when working on these fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks

away from the area. Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this

manual:

WARNING

Indicates a condition that can cause immediate death or injury!

CAUTION

Indicates a condition that can cause property damage!

Page 3

Perkins Tier 2 Diesel Engines Table of Contents

TABLE OF CONTENTS

General ................................................................................................................................................................. 1

General Safety Rules ....................................................................................................................................... 1

Description ........................................................................................................................................................... 2

Engine Serial Number Codes.......................................................................................................................... 4

Engine Data ..................................................................................................................................................... 4

Engine Removal and Installation ....................................................................................................................... 5

Cylinder Head Assembly Repair......................................................................................................................... 5

Valve Cover ...................................................................................................................................................... 5

Remove......................................................................................................................................................... 5

Install........................................................................................................................................................... 6

Rocker Arm Assembly ..................................................................................................................................... 6

Remove......................................................................................................................................................... 6

Disassemble ................................................................................................................................................. 6

Inspect.......................................................................................................................................................... 6

Assemble ...................................................................................................................................................... 6

Install........................................................................................................................................................... 6

Valve Clearance Adjustments ......................................................................................................................... 7

Valve Springs ................................................................................................................................................... 8

Cylinder Head Assembly ................................................................................................................................. 9

Remove......................................................................................................................................................... 9

Install......................................................................................................................................................... 11

Valves and Valve Springs .............................................................................................................................. 14

Remove....................................................................................................................................................... 14

Inspect........................................................................................................................................................ 14

Install......................................................................................................................................................... 15

Valve Guides .................................................................................................................................................. 15

Inspect........................................................................................................................................................ 15

Remove....................................................................................................................................................... 15

Install......................................................................................................................................................... 15

Cylinder Head and Valve Seats .................................................................................................................... 16

Inspect........................................................................................................................................................ 16

Repair......................................................................................................................................................... 17

New Valve Seats, Install ........................................................................................................................... 17

Piston and Connecting Rod Assemblies Repair ............................................................................................... 17

Rod Bearings.................................................................................................................................................. 18

Remove....................................................................................................................................................... 18

Install......................................................................................................................................................... 18

Piston and Connecting Rod Assembly .......................................................................................................... 19

Service Note............................................................................................................................................... 19

Remove....................................................................................................................................................... 19

Install......................................................................................................................................................... 20

Piston Rings ................................................................................................................................................... 21

Remove....................................................................................................................................................... 21

Inspect........................................................................................................................................................ 21

Install......................................................................................................................................................... 22

Piston and Connecting Rod ........................................................................................................................... 22

Disassemble ............................................................................................................................................... 22

Inspect........................................................................................................................................................ 22

How to Select Correct Replacements ....................................................................................................... 23

Install......................................................................................................................................................... 24

Piston Cooling Jets ........................................................................................................................................ 24

©2004 HYSTER COMPANY i

Page 4

Table of Contents Perkins Tier 2 Diesel Engines

TABLE OF CONTENTS (Continued)

Remove....................................................................................................................................................... 24

Install......................................................................................................................................................... 25

Crankshaft Assembly Repair ............................................................................................................................ 25

General........................................................................................................................................................... 25

Crankshaft Pulley.......................................................................................................................................... 26

Remove....................................................................................................................................................... 26

Inspect........................................................................................................................................................ 26

Install......................................................................................................................................................... 26

Rear Oil Seal.................................................................................................................................................. 27

Remove....................................................................................................................................................... 27

Install......................................................................................................................................................... 27

Main Bearings................................................................................................................................................ 28

Remove....................................................................................................................................................... 28

Inspect........................................................................................................................................................ 29

Install......................................................................................................................................................... 29

Thrust Washers.............................................................................................................................................. 29

Crankshaft Axial Movement, Check ........................................................................................................ 29

Remove....................................................................................................................................................... 30

Install......................................................................................................................................................... 30

Crankshaft ..................................................................................................................................................... 31

Remove....................................................................................................................................................... 31

Inspect........................................................................................................................................................ 31

Install......................................................................................................................................................... 32

Flywheel ......................................................................................................................................................... 33

Remove....................................................................................................................................................... 33

Ring Gear, Replace.................................................................................................................................... 33

Install......................................................................................................................................................... 33

Flywheel Housing .......................................................................................................................................... 34

Remove....................................................................................................................................................... 34

Install......................................................................................................................................................... 34

Timing Case and Timing Gears Repair ............................................................................................................ 35

General........................................................................................................................................................... 35

Timing Case Cover ........................................................................................................................................ 35

Remove....................................................................................................................................................... 35

Install......................................................................................................................................................... 36

Front Oil Seal................................................................................................................................................. 36

Remove....................................................................................................................................................... 36

Install......................................................................................................................................................... 36

Crankshaft Pulley Wear Sleeve .................................................................................................................... 37

Install......................................................................................................................................................... 37

Idler Gear and Hub ....................................................................................................................................... 37

Remove....................................................................................................................................................... 37

Install......................................................................................................................................................... 38

Air Compressor Drive, Bendix ...................................................................................................................... 39

Disassemble ............................................................................................................................................... 39

Assemble .................................................................................................................................................... 39

Fuel Injection Pump Gear ............................................................................................................................. 40

Remove....................................................................................................................................................... 40

Install......................................................................................................................................................... 41

Camshaft Gear............................................................................................................................................... 41

Remove....................................................................................................................................................... 41

ii

Page 5

Perkins Tier 2 Diesel Engines Table of Contents

TABLE OF CONTENTS (Continued)

Install......................................................................................................................................................... 42

Crankshaft Gear ............................................................................................................................................ 42

Remove....................................................................................................................................................... 42

Install......................................................................................................................................................... 43

Timing Case ................................................................................................................................................... 43

Remove....................................................................................................................................................... 43

Install......................................................................................................................................................... 43

Camshaft and Tappets .................................................................................................................................. 44

Remove....................................................................................................................................................... 44

Install......................................................................................................................................................... 45

Cylinder Block Assembly Repair....................................................................................................................... 45

Description ..................................................................................................................................................... 45

Cylinder Block ............................................................................................................................................... 45

Disassemble ............................................................................................................................................... 45

Inspect........................................................................................................................................................ 46

Assemble .................................................................................................................................................... 46

Cylinder Liner................................................................................................................................................ 47

Inspect........................................................................................................................................................ 47

Cylinder Liner Condition, Check.............................................................................................................. 47

Remove....................................................................................................................................................... 48

Service Liner, Install................................................................................................................................. 49

Partially Finished Liner, Install............................................................................................................... 50

Engine Timing.................................................................................................................................................... 51

Description ..................................................................................................................................................... 51

How to Set Number One Piston to TDC on Compression Stroke........................................................... 52

How to Set Number One Piston to TDC on Compression Stroke (Alternate Procedure)...................... 53

HowtoSetNumberOnePistonto4

Valve Timing, Check.................................................................................................................................. 55

Fuel Injection Pump Timing, Check......................................................................................................... 56

Turbocharger...................................................................................................................................................... 56

General........................................................................................................................................................... 56

Remove ........................................................................................................................................................... 56

Install ............................................................................................................................................................. 57

Impeller and Compressor Housing, Clean ................................................................................................... 57

Waste-Gate Valve Check ............................................................................................................................... 58

Closed Circuit Breather System (CCB) ........................................................................................................ 59

CCB Assembly, Remove ............................................................................................................................ 59

Closed Circuit Drain Valve, Remove ........................................................................................................ 59

CCB Assembly, Install .............................................................................................................................. 59

Closed Circuit Drain Valve, Install .......................................................................................................... 59

Lubrication System Repair................................................................................................................................ 60

General........................................................................................................................................................... 60

Oil Filter, Replace.......................................................................................................................................... 60

Oil Filter Head............................................................................................................................................... 60

Remove....................................................................................................................................................... 60

Install......................................................................................................................................................... 60

Oil Filter Head Bypass Valve........................................................................................................................ 61

Remove and Install ................................................................................................................................... 61

Oil Sump ........................................................................................................................................................ 61

Remove....................................................................................................................................................... 61

Install......................................................................................................................................................... 61

After TDC on Compression Stroke ............................................. 54

iii

Page 6

Table of Contents Perkins Tier 2 Diesel Engines

TABLE OF CONTENTS (Continued)

Oil Pump ........................................................................................................................................................ 62

Remove....................................................................................................................................................... 62

Inspect........................................................................................................................................................ 62

Install......................................................................................................................................................... 63

Relief Valve .................................................................................................................................................... 64

Remove....................................................................................................................................................... 64

Disassemble ............................................................................................................................................... 64

Inspect........................................................................................................................................................ 64

Assemble .................................................................................................................................................... 64

Install......................................................................................................................................................... 64

Idler Gear Shaft, Replace .............................................................................................................................. 64

Remove....................................................................................................................................................... 65

Remove (Alternative) ................................................................................................................................ 65

Install......................................................................................................................................................... 66

Install (Alternative) .................................................................................................................................. 66

Fuel System Repair............................................................................................................................................ 67

Description ..................................................................................................................................................... 67

Fuel Injection Pump ...................................................................................................................................... 69

Remove....................................................................................................................................................... 69

Install......................................................................................................................................................... 71

Fuel System Air Removal.............................................................................................................................. 72

Fuel Filter, Replace ....................................................................................................................................... 74

Fuel Injectors ................................................................................................................................................. 74

Remove....................................................................................................................................................... 75

Inspect........................................................................................................................................................ 75

Install......................................................................................................................................................... 75

Fuel Lift Pump............................................................................................................................................... 76

Remove....................................................................................................................................................... 76

Disassemble ............................................................................................................................................... 76

Assemble .................................................................................................................................................... 76

Install......................................................................................................................................................... 77

Test............................................................................................................................................................. 77

Cooling System Repair ...................................................................................................................................... 78

General........................................................................................................................................................... 78

Thermostat..................................................................................................................................................... 78

Remove....................................................................................................................................................... 78

Install......................................................................................................................................................... 79

Test............................................................................................................................................................. 79

Coolant Pump ................................................................................................................................................ 79

Remove....................................................................................................................................................... 79

Disassemble ............................................................................................................................................... 80

Assemble .................................................................................................................................................... 82

Install......................................................................................................................................................... 84

Fan and Fan Drive ........................................................................................................................................ 85

Remove....................................................................................................................................................... 85

Install......................................................................................................................................................... 85

Oil Cooler ....................................................................................................................................................... 85

Remove....................................................................................................................................................... 85

Disassemble and Assemble....................................................................................................................... 86

Install......................................................................................................................................................... 86

Electrical Equipment Repair............................................................................................................................. 87

iv

Page 7

Perkins Tier 2 Diesel Engines Table of Contents

TABLE OF CONTENTS (Continued)

Drive Belts ..................................................................................................................................................... 87

Alternator....................................................................................................................................................... 87

Remove....................................................................................................................................................... 87

Install......................................................................................................................................................... 87

Electronic Control Module (ECM) ................................................................................................................ 88

Remove....................................................................................................................................................... 88

Inspect........................................................................................................................................................ 88

Install......................................................................................................................................................... 88

Voltage Load and Protection Module (VLPM).............................................................................................. 89

Remove....................................................................................................................................................... 89

Install......................................................................................................................................................... 89

Engine Speed and Timing Sensor................................................................................................................. 89

Remove....................................................................................................................................................... 89

Install......................................................................................................................................................... 90

Pressure Sensors (Engine Oil and Air Intake)............................................................................................. 90

Remove....................................................................................................................................................... 90

Install......................................................................................................................................................... 91

Temperature Sensor ...................................................................................................................................... 91

Remove....................................................................................................................................................... 91

Install......................................................................................................................................................... 92

Starter Motor ................................................................................................................................................. 92

Remove....................................................................................................................................................... 92

Install......................................................................................................................................................... 92

Cold Start Aid ................................................................................................................................................ 92

Air Compressor .................................................................................................................................................. 92

General........................................................................................................................................................... 92

Repair ............................................................................................................................................................. 93

Remove....................................................................................................................................................... 93

Install......................................................................................................................................................... 93

Rotary Exhauster Replacement ........................................................................................................................ 94

Remove ........................................................................................................................................................... 94

Clean .............................................................................................................................................................. 94

Install ............................................................................................................................................................. 94

Engine Specifications......................................................................................................................................... 95

Cylinder Head Assembly ............................................................................................................................... 95

Piston and Connecting Rods ......................................................................................................................... 98

Crankshaft Assembly .................................................................................................................................... 99

Crankshaft Overhaul .............................................................................................................................. 100

Timing Case and Drive Assembly............................................................................................................... 102

Engine Block Assembly ............................................................................................................................... 103

Turbocharger................................................................................................................................................ 104

Lubrication System ..................................................................................................................................... 105

Cooling System ............................................................................................................................................ 107

Flywheel and Housing................................................................................................................................. 107

Electrical Equipment................................................................................................................................... 107

Torque Specifications ....................................................................................................................................... 108

Cylinder Head Assembly ............................................................................................................................. 108

Piston and Connecting Rod Assemblies ..................................................................................................... 108

Crankshaft Assembly .................................................................................................................................. 108

Timing Case and Drive Assembly............................................................................................................... 108

Turbocharger................................................................................................................................................ 108

v

Page 8

Table of Contents Perkins Tier 2 Diesel Engines

TABLE OF CONTENTS (Continued)

Lubrication System ..................................................................................................................................... 108

Fuel System ................................................................................................................................................. 108

Cooling System ............................................................................................................................................ 109

Flywheel ....................................................................................................................................................... 109

Auxiliary Equipment ................................................................................................................................... 109

Special Torque Specifications.......................................................................................................................... 109

Flywheel and Housing................................................................................................................................. 109

Electrical Equipment................................................................................................................................... 109

Auxiliary Equipment ................................................................................................................................... 109

Special Tools..................................................................................................................................................... 110

Troubleshooting................................................................................................................................................ 115

Turbocharger Troubleshooting ........................................................................................................................ 117

This section is for the following models:

H8.00-12.00XM (H170-280HD) [F007, G007];

H13.00-16.00XM (H300-360HD) [E019, F019];

H10.00-12.00XM-12EC (H360HD-EC) [E019, F019]

vi

Page 9

600 SRM 1068 General

General

This section has the description and repair instructions for the VK model of the Series 1100 Perkins

diesel engine. All VK models are six-cylinder, turbocharged.

GENERAL SAFETY RULES

WARNING

Some seals used in this engine are made of

synthetic materials called fluoroelastomers

(a commercial name is Viton). These fluoroelastomers can decompose at temperatures

greater than 316

cause hydrofluoric acid to form on the surface

of the seal or nearby equipment.

Do not touch gaskets, seals, or O-rings which

appear charred or black and sticky after exposure to temperatures greater than 316

(600

F) or burning. Contact with this acid can

cause severe burns of the skin and eyes. Burns

can be delayed several hours after contact.

Do the following procedures to prevent exposure to hydrofluoric acid:

• Wear disposable neoprene or PVC gloves and

discard the gloves after use.

• Wash the area with 10 percent calcium hydroxide solution to neutralize any acid and

thencleanwithwater.

If burned seal by-product touches the skin or

eyes:

• Immediately flush with water for a minimum

of 15 minutes.

• Apply 2.5 percent calcium gluconate gel to affected area of skin.

• Get medical help immediately for suspected

hydrogen fluoride or hydrofluoric acid burn.

C(600F) or by burning and

WARNING

Disconnect the battery cables before doing any

disassembly and repair oftheengineorparts of

the electrical system. Put a DO NOT OPERATE

tag in the operator’s area and on the battery

connectors.

Exhaust from internal combustion engines

contains carbon monoxide and other harmful

chemicals. Carbon monoxide is a colorless,

odorless poison and can cause unconsciousness or death without warning. Long-term

exposure to exhaust or chemicals in the exhaust can cause cancer, birth defects, and

other reproductive harm. Avoid exposure to

engine exhaust.

Do not use diesel engines indoors where soot

can accumulate.

If engines are operated in confined spaces,

maintain adequate ventilation or vent exhaust

to the outside. Do not exceed applicable air

contaminant limits.

Follow the inspection and maintenance sched-

C

ule and procedures inthismanual. Do notalter

exhaust, ignition, or fuel systems.

CAUTION

Disposal of lubricants and fluids must meet local environmental regulations.

Disposal of batteries must meet local environmental regulations.

The diodes and resistors in the electrical system can be damaged if the following cautions

are not followed:

• Do not disconnect the battery when the engine is running. The voltage surge can damage the diodes and resistors.

• Do not disconnect an electric wire before the

engine is stopped and the switches are OFF.

• Do not cause a short circuit by connection

of the electric wires to the wrong terminals.

Make sure a correct identification is made of

the wire before it is connected.

• Verify the battery is the correct voltage and

polarity before it is connected.

• Do not check for current flow by making a

spark because the electronic components can

be damaged.

Long-term exposure to used engine oil can

cause skin irritation or cancer. Wash with

detergent and water.

1

Page 10

Description 600 SRM 1068

CAUTION

When setscrews or studs are fitted into holes

which are tapped through the cylinder block, a

suitable sealant must be used to prevent leakage.

Micro encapsulated anaerobic sealant

(M.E.A.S.) fasteners have been introduced

instead of jointing compounds or other

sealants when the fasteners are fitted in

through holes into oil or coolant passages. The

identification of these fasteners, as supplied,

is by a red, blue, or other color sealant around

the fastener threads.

Description

The cylinder head is cast iron and has one inlet valve

and one exhaust valve for each cylinder. The valve

seats and the valve guides are replaceable. The fuel

injectors are in the cylinder head. The overhead

valveassemblyisactuatedbyacamshaftinsideof

the engine block. A gear train, turned by the crankshaft, turns the camshaft, coolant pump, injection

pump, and a power-takeoff (PTO) which is available

for additional equipment. The hydraulic pump for

the steering function or a compressor is normally

turned by the PTO. The fuel pump is actuated by the

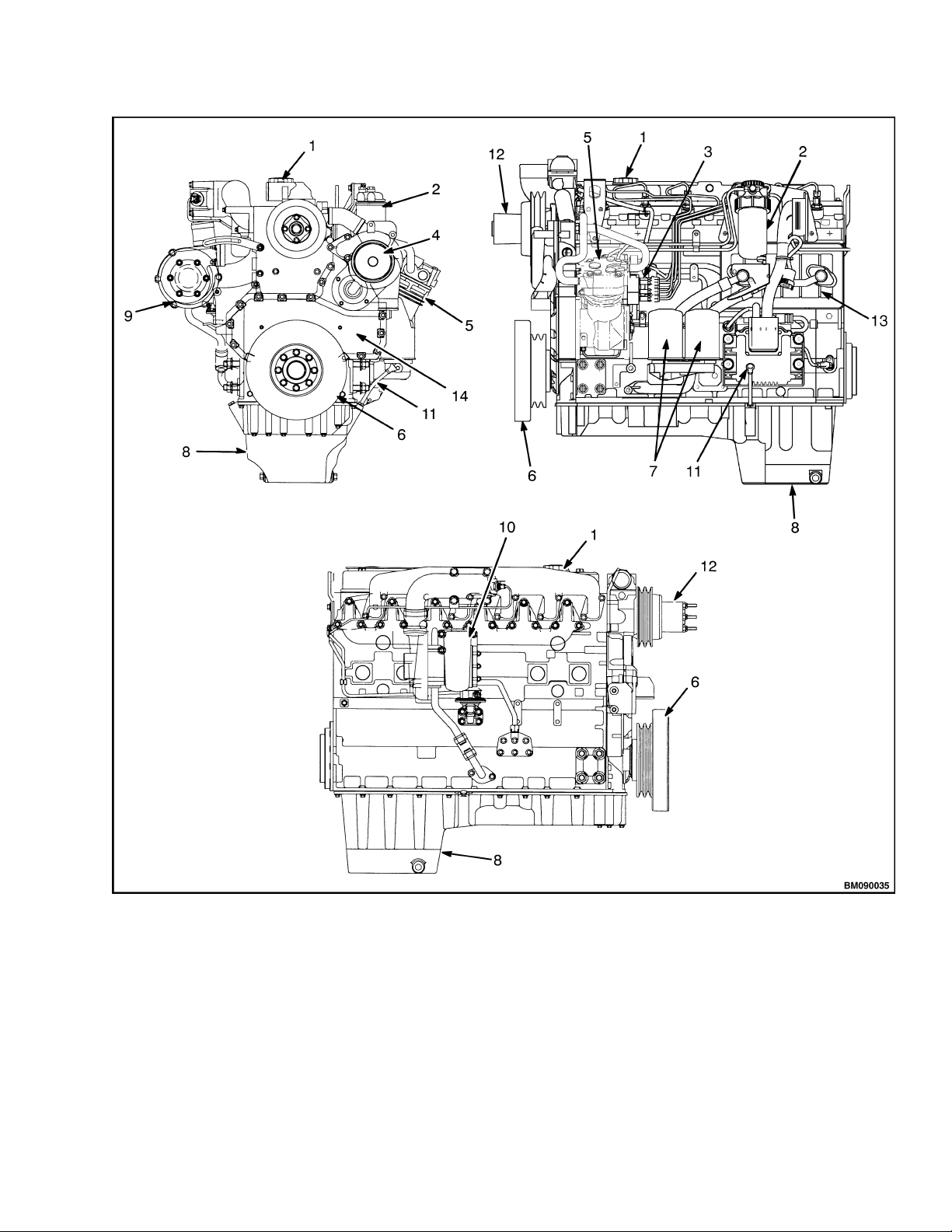

camshaft. See Figure 1.

The crankshaft has seven main bearings. The main

bearing in the center of the crankshaft is the thrust

bearing and has thrust washers on both sides of the

bearing.

With M.E.A.S. sealed studs, the sealed end must

be fitted into the cylinder head/cylinder block,

etc. Ensure that the threaded holes have a

1.59 mm (0.0626 in.), 45

M.E.A.S. sealant is not removed. If the fasteners have to be removed and fitted again, the

threads must be cleaned and a suitable sealant

used.

Observe the previous WARNING S and CAUTIONS

before repairing any equipment.

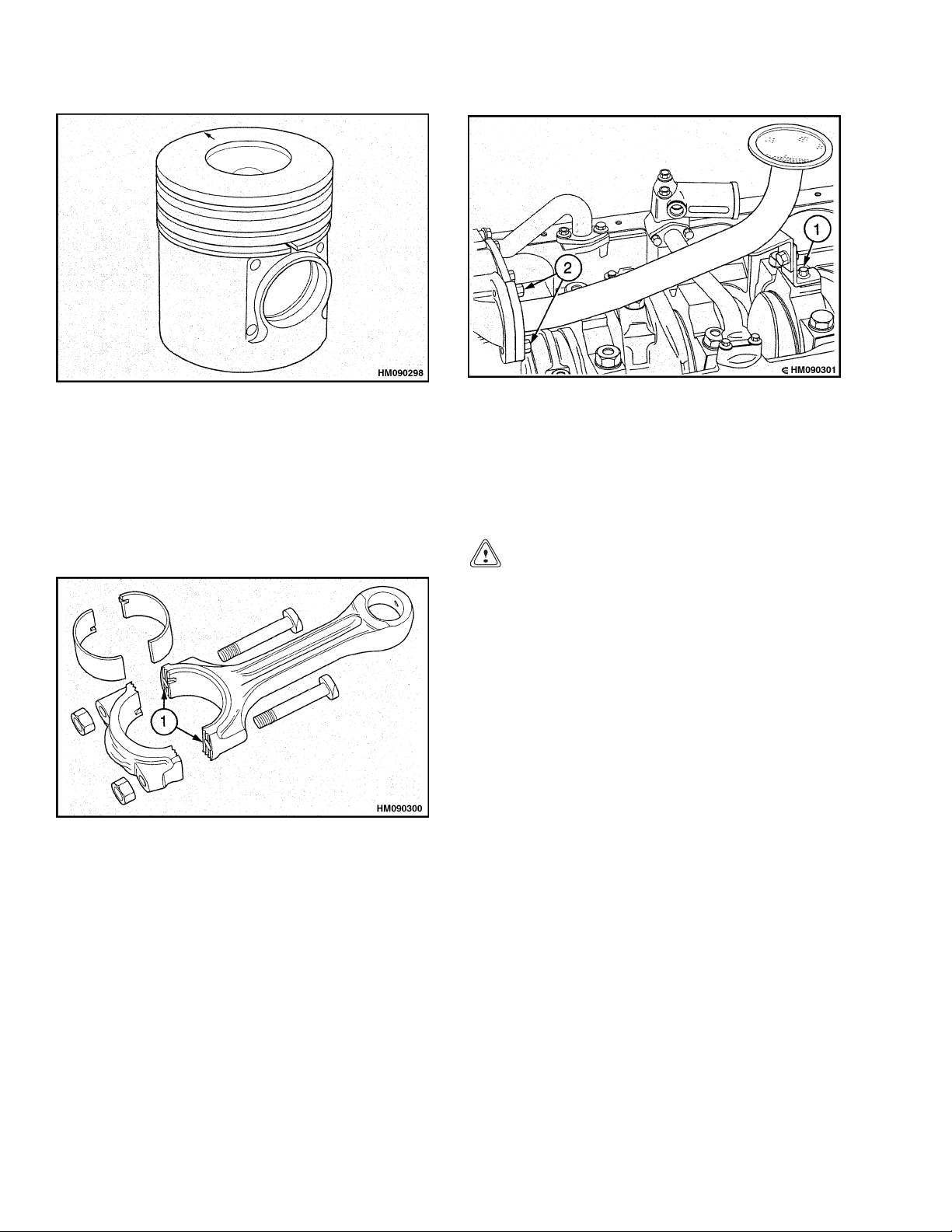

air. Each piston has three piston rings (two compression rings and an oil control ring). The top compression ring has a special insert for the groove, to reduce

wear. Axial location of the fully floating piston pin is

by circlips. The piston pin is off-center to reduce the

noise level. A jet for cooling oil to the bottom of the

piston is installed.

The cooling fan and the alternator are turned by a

drive belt. The cooling fan is not connected to the

coolant pump. The coolant pump is turned by the

gear for the fuel injection pump in the timing gear

case.

The timing, speed adjustment, and quantity of fuel

sent to the fuel injectors is controlled electronically

by the Electronic Control Module (ECM).

chamfer so that the

The cylinder block is cast iron and has cylinder liners

that can be replaced during overhaul.

A Fastram™ combustion chamber in the top of each

piston is designed to give an efficient mix of fuel and

2

A Bosch VP30 seriesfuelinjection pumpisused onall

1100 VK engines. Special tools are needed to repair

an injection pump, and they are normally sent to an

authorized repair station if repairs are necessary.

Page 11

600 SRM 1068 Description

1. FILL CAP FOR ENGINE OIL

2. FUEL FILTER

3. FUEL

4. COOLANT PUMP

5. AIR COMPRESSOR

6. VIBR

7. OIL FILTERS

INJECTION PUMP

ATION DAMPER

8. OIL SUMP

9. ALTERNATOR

10. TURB

11. DIPSTICK, ENGINE OIL

12. FAN DRIVE

13. OIL C

14. TIMING CASE

Figure 1. Engine

OCHARGER

OOLER

3

Page 12

Description 600 SRM 1068

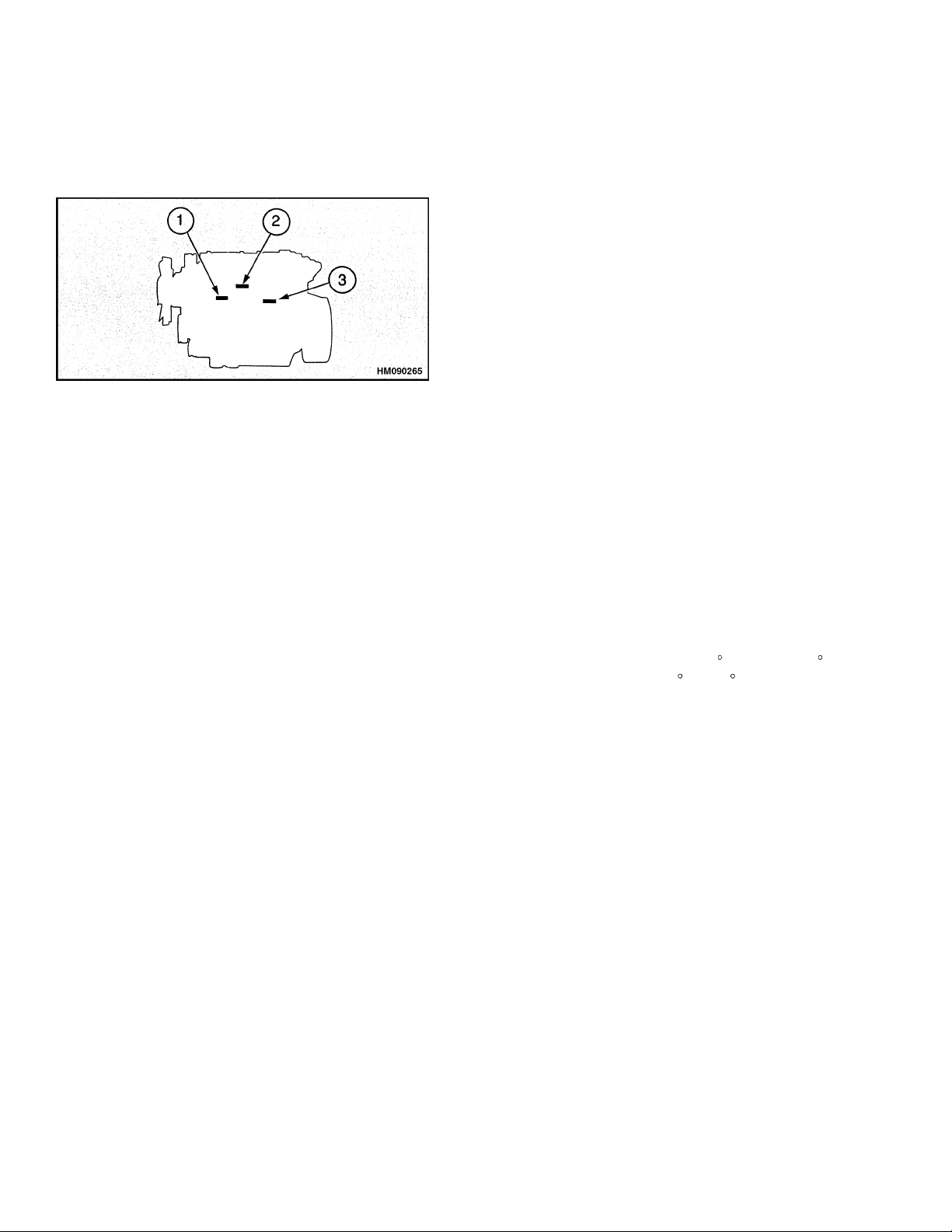

ENGINE SERIAL NUMBER CODES

The engine numberis on a label on the left side of the

engine block. See Figure 2.

1. PART NUMBERS

FOR FUEL

INJECTION PUMP

Figure 2. Serial Number Locations

A typical serial number has the following code:

VK U 090001 H

1234

where:

2. ENGINE SERIAL

NUMBER

3. EMISSIONS LABEL

ENGINE DATA

The specifications and tolerance details for engine repairareinachartattheendofthissection.

1100 (VK)

Power rating at 2300

rpm................................... 129.5 kW (173.7 bhp)

Number of cylinders........ 6

Firing order ..................... 1–5–3–6–2–4

Bore and stroke ...............

Displacemen

Compression ratio ........... 17.25:1

Minimum oil pressure

(at maximum speed

and normal operating

temperature)

Governor speed (no

load) ................................. 280 kPa (41 psi)

See the Periodic Maintenance section for your

model of lift truck.

Idle Speed ........................ 725 to 775 rp

t...................

100 × 127 mm

(3.937 × 5.000 in.)

6.00 liter (3

66 in.

m

3

)

1=Typeofengine:VK=1100

2 = Country of manufacture (U = manufactured in

the United Kingdom)

3 = Serial number

4 = Year of manufacture. The letter indicates the

year of manufacture. The letters I, O, Q, R, and Z

are not used.

If parts or service are required for your engine,

the complete engine number must be given to your

dealer.

Thermostat

Begin to open ..............

Fully open....................

Valve clearance (hot or cold)

Inlet .............................

Exhaust .......................

80 to 84

96

0.20 mm (0.008 in.)

0.45 mm (0.018 in.)

C (176 to 183 F)

C(205F)

4

Page 13

600 SRM 1068 Cylinder Head Assembly Repair

Engine Removal and Installation

See the Frame section for the procedure for removing the engine and transmission. See the Transmis-

sion section for the procedure to separate the transmission from the engine.

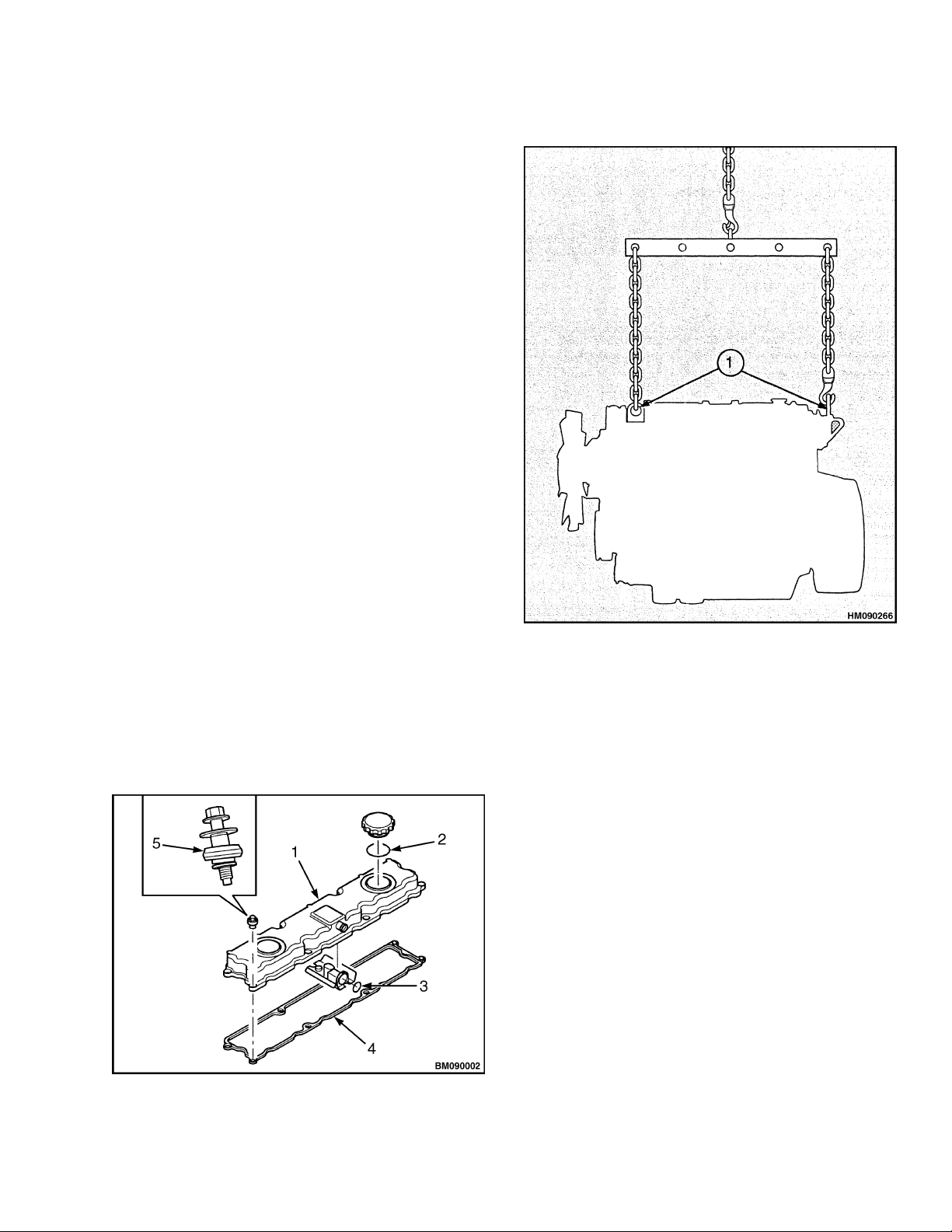

There can be a variation in the maximum weight of

the engine depending upon the components that are

attached to it. The following minimum lifting capacity is needed for an engine without coolant, lubricants, or transmission:

1100 (VK) engines 600 kg (1323 lb)

Always use a lifting device that provides avertical lift

above the engine lift brackets as shown in Figure 3.

Never use a single bracket to lift an engine.

Verify the engine brackets are correctly fastened to

the engine. Verify that the valvecover andother components are not damaged by the lifting device. Use a

lifting device to lift and move the heavy components

of the engine: cylinder block, cylinder head, flywheel

housing, flywheel, and crankshaft.

VALVE COVER

1. ENGINE LIFT BRACKETS

Figure 3. Lifting an Engine

Cylinder Head Assembly Repair

Legend for Figure 4

1. VALVE COVER

2. OIL FILLER CAP SEAL

3. OIL SEPARATOR ASSEMBLY SEAL

4. VALVE COVER GASKET

5. CAPSCREW ASSEMBLY

Remove

1. Disconnect the breather pipe.

2. Remove the capscrews and sealing washers from

thevalvecover. SeeFigure4.

3. Lift the valve cover and gasket from the cylinder

head. The valve cover gasket fits between the

valve cover and the induction manifold.

Figure 4. Valve Cover

5

Page 14

Cylinder Head Assembly Repair 600 SRM 1068

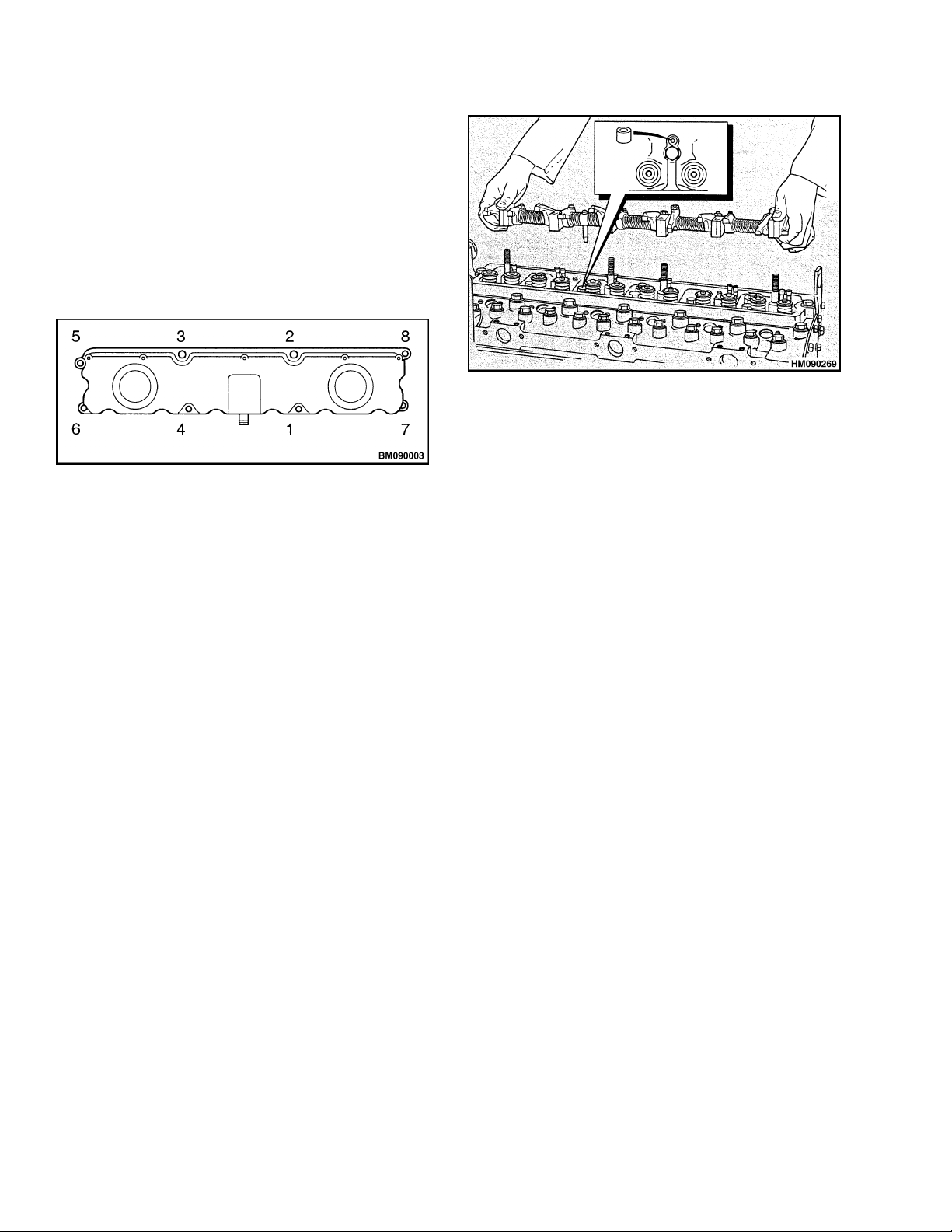

Install

1. Check the condition of the valve cover gasket,

bolts, and seal washers. Replace components as

necessary. Verify that the surfaces are clean.

2. Install the valve cover and gasket on the cylinder

head. See Figure 4.

3. Install the valve cover bolts. Torque to 9 N•m

(80 lbf in) in sequence shown in Figure 5.

Figure 6. Rubber Seal Location

Inspect

Clean and inspect all the components for wear and

Figure 5. Valve Cover Torque Sequence

4. Connect the breather pipe.

damage. Check the clearance of the rocker arms on

the rocker arm shaft. If the clearance is greater than

0.09 mm (0.0035 in.), install a new rocker arm, or

install a new rocker arm shaft if it is worn.

ROCKER ARM ASSEMBLY

Assemble

Remove

1. Verify that the lubrication holes in the rocker

1. Remove the valve cover.

2. Loosen the nuts evenly that fasten the brackets

for the rocker arm shafts to the cylinder head.

Loosen the brackets at each end of the cylinder

head first and loosen the brackets in sequence

towards the center. Remove the nuts and washers when the pressure is removed from the rocker

arms. Lift the rocker arm assembly from the

cylinder head.

3. Remove the rubber seal from the oil supply con-

nection or the hole for the oil supply in the cylinder head. See Figure 6.

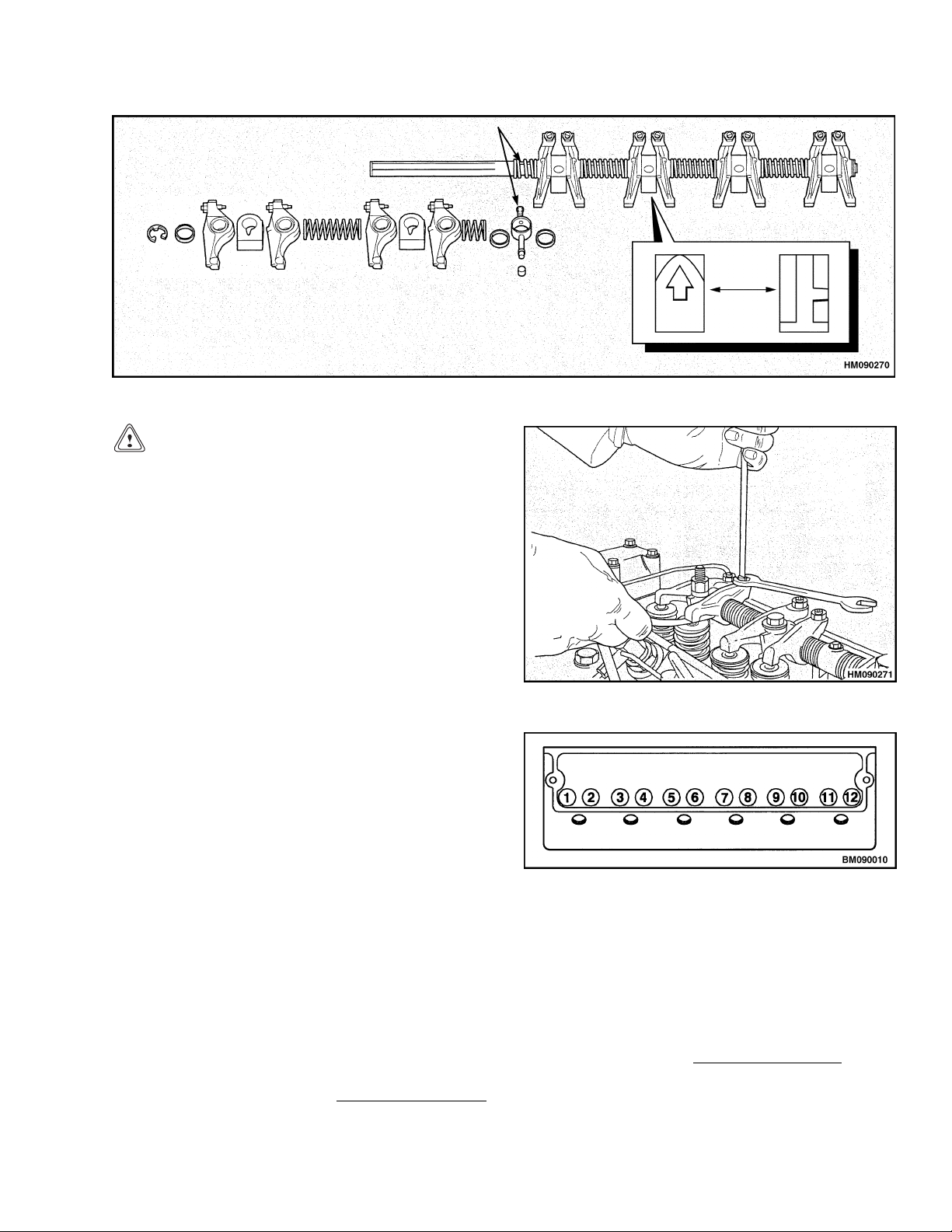

Disassemble

arms and the rocker arm shaft are open and

clean.

2. Lubricate the components with clean engine oil

as they are assembled on the rocker arm shaft.

Verify the components are assembled in the correct order. See Figure 7. Verify that the location screw for the oil supply connection is fitted

correctly in the rocker arm shaft and torqued to

4 N•m (35 lbf in). Install the clips at the ends of

the rocker arm shaft.

Install

1. Verify that the rocker arm assembly is clean and

dry.

1. Remove the clips from both ends of the rocker

arm shaft. Verify that the ends of the rocker arm

shaft are not damaged. Loosen the location screw

for the oil supply connection.

2. Make a note of the position of each component on

the rocker arm shaft so that they can be assembled correctly. Remove the components from the

rocker arm shaft.

6

2. Install a new rubber seal in the hole for the oil

supply in the cylinder head. See Figure 6.

3. Check that the push rods fit correctly in the sock-

ets for the tappets. Install the rockerarm assembly over the four studs, insert the oil supply connection into the oil supply hole in the cylinder

head.

Page 15

600 SRM 1068 Cylinder Head Assembly Repair

Figure 7. Rocker Arm Assembly

CAUTION

Loosen any tappet adjustment screws that may

tighten during the following procedure.

4. Verify that the alignment of the rocker arms

and the push rods is correct. Install the nuts

and washers on the studs that hold the brackets

for the rocker arm shafts to the cylinder head.

Tighten the nuts evenly. Begin tightening the

nuts at the center of the rocker arm shaft and

tighten in sequence towards the ends of the

shaft. The final torque on the nuts is 75 N•m

(55 lbf ft).

5. Check and adjust valve tip clearances. See Valve

Clearance Adjustments.

VALVE CLEARANCE ADJUSTMENTS

The valve clearance is measured between the top of

the valve stem and the rocker arm as shown in Figure 8.

Valve clearance (hot or cold)

Inlet

Exhaust

Number one cylinder is at the front of the engine.

The inlet valve is the first valve in the sequence. See

Figure 9.

1. Turn the crankshaft in the normal direction of

rotation until the inlet valve of number six cylinder has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

clearances of the valves of n

and adjust them as necessary.

0.20 mm (0.008 in.)

0.45 mm (0.018 in.)

umber one cylinder

Figure 8. Valve Clearance Adjustment

e9. ValvePositions

Figur

NOTE:

(21 lb

2. Turn t

The torque for the locking nut is 27 N•m

fft).

he crankshaft in the normal direction of ro-

n until the inlet valve of number two cylin-

tatio

as just opened and the exhaust valve of the

der h

cylinder has not fully closed. Check the

same

e clearances on n

valv

them as necessary.

just

umber five cylinder and ad-

7

Page 16

Cylinder Head Assembly Repair 600 SRM 1068

3. Turnthecrankshaftinthenormaldirectionofro-

tation until the inlet valve of number four cylinder has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

valve clearances on n

adjust them as necessary.

4. Turnthecrankshaftinthenormaldirectionofro-

tation until the inlet valve of number one cylinder has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

valve clearances on n

just them as necessary.

umber three cylinder and

umber six cylinder and ad-

5. Turnthecrankshaftinthenormaldirectionofro-

tation until the inlet valve of number five cylinder has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

valve clearances on n

just them as necessary.

6. Turnthecrankshaftinthenormaldirectionofro-

tation until the inlet valve of number three cylinder has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

valve clearances on n

just them as necessary.

NOTE: After valve adjustments, lubricate the rocker

assembly with clean engine oil.

umber two cylinder and ad-

umber four cylinder and ad-

VALVE SPRINGS

NOTE: This procedure is normally for changing the

valve springs of a single cylinder while the cylinder

head is still installed on the engine. If the valves and

springs must be removed from the cylinder head for

repairs, see the procedures under Valves and Valve

Springs, later in this section.

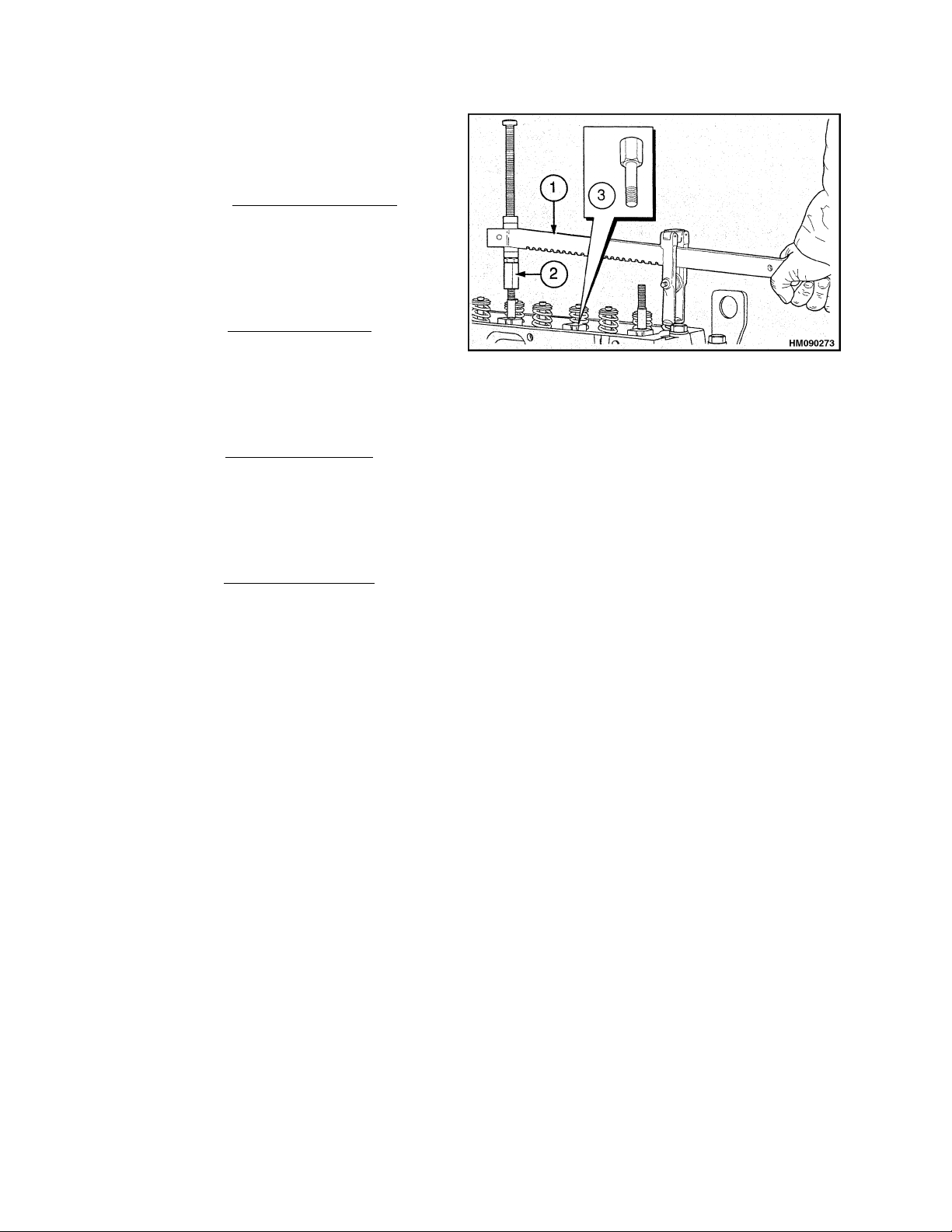

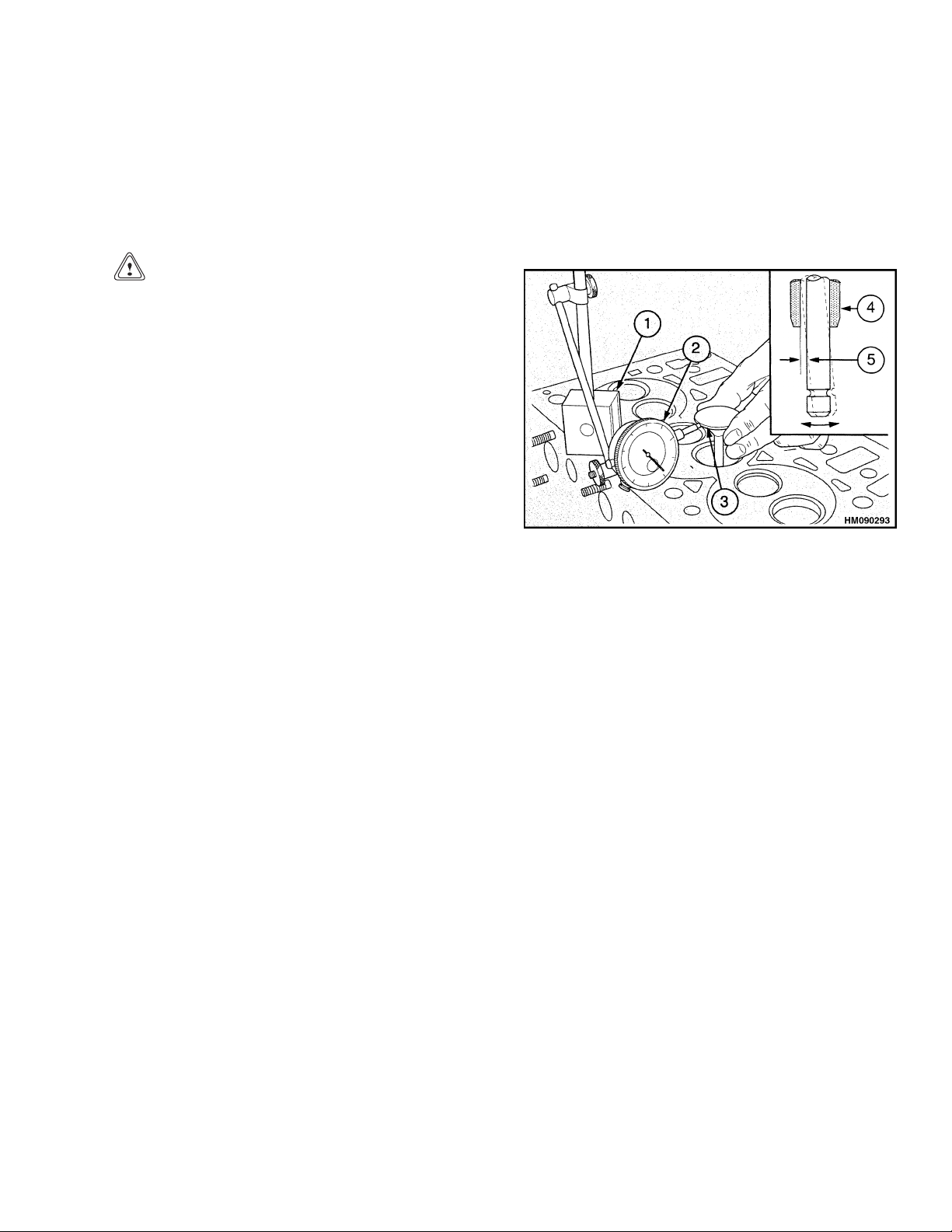

Special Tools: Valve spring compressor

Stud adapter

Setscrew adapter

1. VALVE SPRING

COMPRESSOR

2. STUD ADAPTER

Figure 10. Valve Spring Compressor

5. Compress the valve springs and remove the retainers. Verify the valve springs are compressed

parallel tothe valve stems, or the valve stems can

be damaged.

NOTE: Do not turn the crankshaft while the valve

springs are removed.

6. Release the valve spring compressor and remove

the retainer cap and valve springs.

NOTE: The outerdiameter of the exhaustvalve guide

is 1 mm (0.039 in.) larger than the inlet valve guide.

To prevent leakage past the inlet valve stem it is important that thelarger exhaust valve seal isnot fitted

into the inlet guide. The seals are color coded.

7. Install new valve stem seals on the valve guides.

Verify that the brown seal is installed on the

exhaust valve and the green seal on the inlet

valves.

8. Install the new valve springs. The springs can be

fitted with either end toward the cylinder head.

3. SETSCREW

ADAPTER

1. Remove the valve cover.

2. Turn the crankshaft in the normal direction of

rotation until the piston for the cylinder is at top

dead center (TDC). The inlet valve will just open

and the exhaust valve will not be fully closed

when the cylinder is at TDC.

3. Remove the rocker arm assembly.

4. Install the spring compressor and the adapter.

SeeFigure10.

8

9. Install the retainer cap.

10. Use the valve spring compressor to compress the

valve springs and install the retainers. Remove

the valve spring compressor.

11. Install the rocker arm assembly.

12. Check the valve clearances. See Valve Clearance

Adjustments.

13. Install the valve cover.

Page 17

600 SRM 1068 Cylinder Head Assembly Repair

NOTE: Valvespringscanbechangedintwocylinders

at a time.

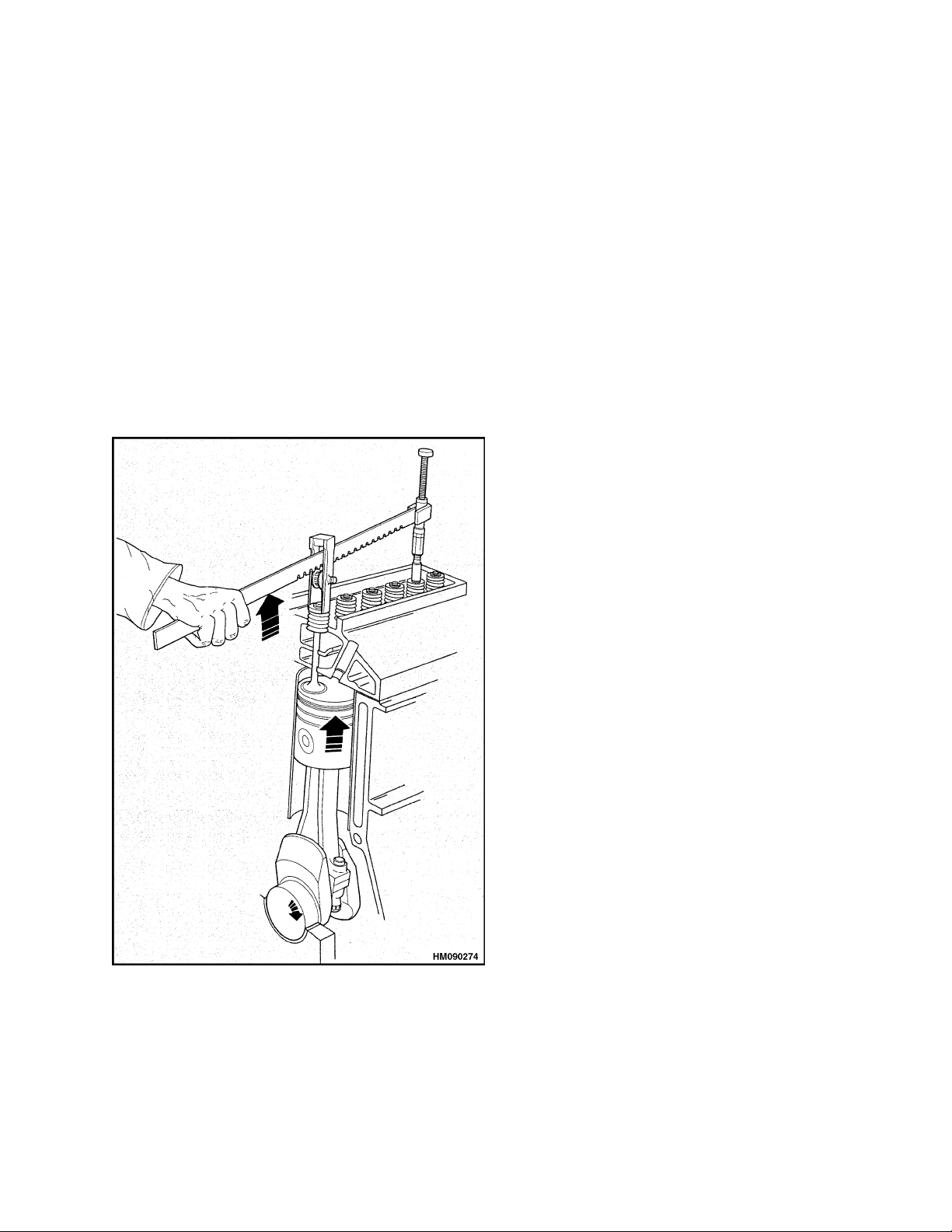

When the piston in cylinder one is at TDC, the piston

in cylinder six is also at TDC. When the piston in

cylinder two is at TDC, the piston in cylinder five is

also at TDC. When the piston in cylinder three is at

TDC,thepistonincylinderfourisalsoatTDC.

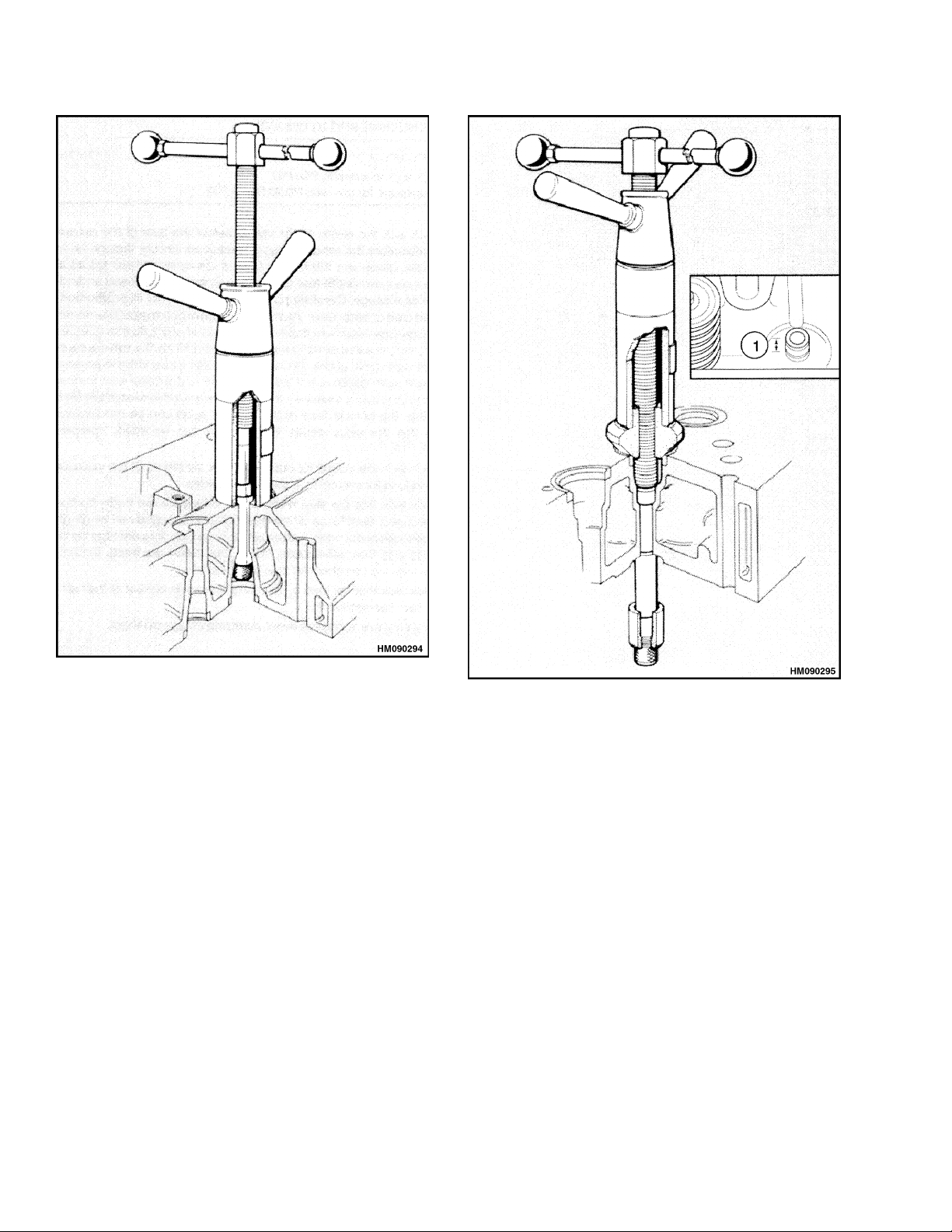

If the rocker arm assembly was removed before TDC

was found, install the valve spring compressor and

compress the valve springs to open the valve. Turn

the crankshaft by hand in the normal direction until

the piston touches the valve. Continue to turn the

crankshaft and, at the same time, release the pressure on the valve spring compressor until the piston

isatTDC.SeeFigure11.

CYLINDER HEAD ASSEMBLY

Remove

1. If the engine is still in the lift truck, do the fol-

lowing procedures:

a. Disconnect the battery terminals.

b. Drain the cooling system.

c. Disconnect the sender unit for the coolant

temperature gauge.

2. If equipped, remove closed circuit breather unit.

3. Remove the Machine Interface Connector (MIC)

connection from the mounting bracket if the

mounting bracket is attached to the cylinder

head.

4. Remove the air intake hose.

5. Removethefuellinebetweenthecoldstartaid

in the induction manifold and the fuel filter. Disconnect the electrical connection and electrical

connectors from sensors.

Figure 11. Find TDC With Valve Spring

Compressor

6. Disconnect all connections to the turbocharger

and remove turbocharger. See Turbocharger, Remove.

7. Remove the induction manifold capscrews.

8. Remove the induction manifold and gasket from

the cylinder head. Discard the gasket.

9. Remove exhaust manifold fasteners and the ex-

haust manifold.

10. Remove the low pressure fuel lines between the

fuel injection pump and the fuel filter. Remove

the fuel filter bracket and the fuel filters.

11. Removethehighpressurefuellines. Useasep-

arate wrench to prevent movement of the outlets

of the fuel injection pump when the fuel lines are

disconnected. Put plugs in the open ports of the

fuel injection pump.

12. Remove the fuel injectors from the cylinder head.

Keep the fuel injectorsclean andprevent damage

to the nozzles.

13. If an air compressor is installed, remove the

coolant pipe between the cylinder head and the

compressor. Remove the coolant pipe between

the bypass connection and the compressor.

9

Page 18

Cylinder Head Assembly Repair 600 SRM 1068

14. Loosen the hose clamp and remove the coolant

bypass hose from the cylinder head. Remove the

capscrews andremove thecoolant bypass connection and the hose.

15. Disconnect the coolant temperature sender.

16. Remove the valve cover. See Valve Cover, Re-

move.

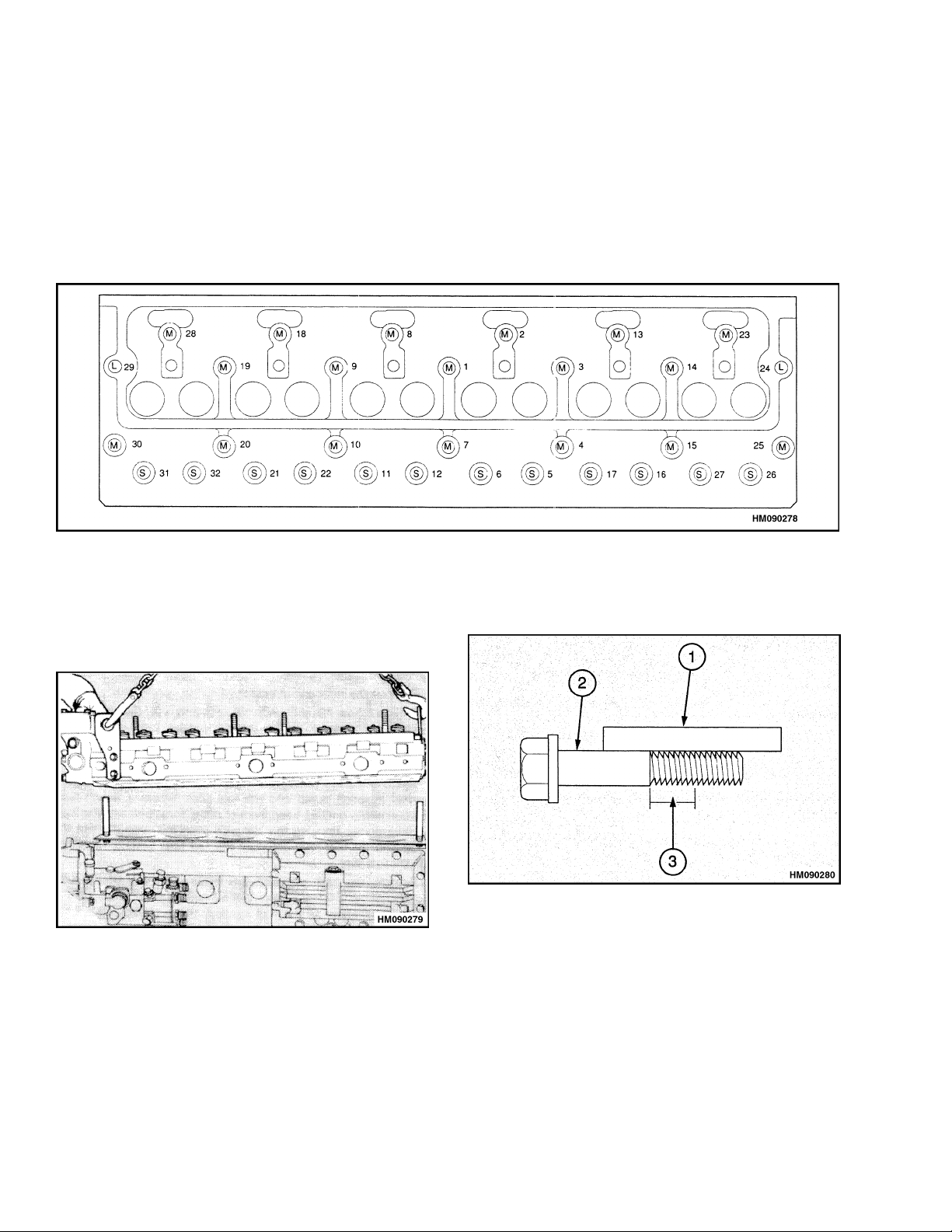

Figure 12. Cylinder Head Tightening Sequence

17. Remove the rocker arm assembly. See Rocker

Arm Assembly, Remove.

18. Remove the push rods.

19. Loosen the capscrews for the cylinder head

evenly in a reverse sequence from the sequence

showninFigure12.

20. Lift the cylinder head from the engine block. Do

not use a pry bar between the cylinder head and

theengineblock,thatcancausedamagetothe

gasket surfaces. See Figure 13.

Figure 13. Cylinder Head Removal

21. Inspect the capscrews for the cylinder head with

a straightedge. See Figure 14. Check that the

capscrews are straight and do not have distortion. If there is a reduction in the diameter of the

thread that has not been in engagement with the

cylinder block, the capscrew must be discarded.

1. STRAIGHTEDGE

2. CAPSCREW MUST BE STRAIGHT AND

WITHOUT DISTORTION

3. THREADS MUST BE IN GOOD CONDITION AND

NOT HAVE A REDUCED DIAMETER

Figure 14. Capscrews Inspection

10

Page 19

600 SRM 1068 Cylinder Head Assembly Repair

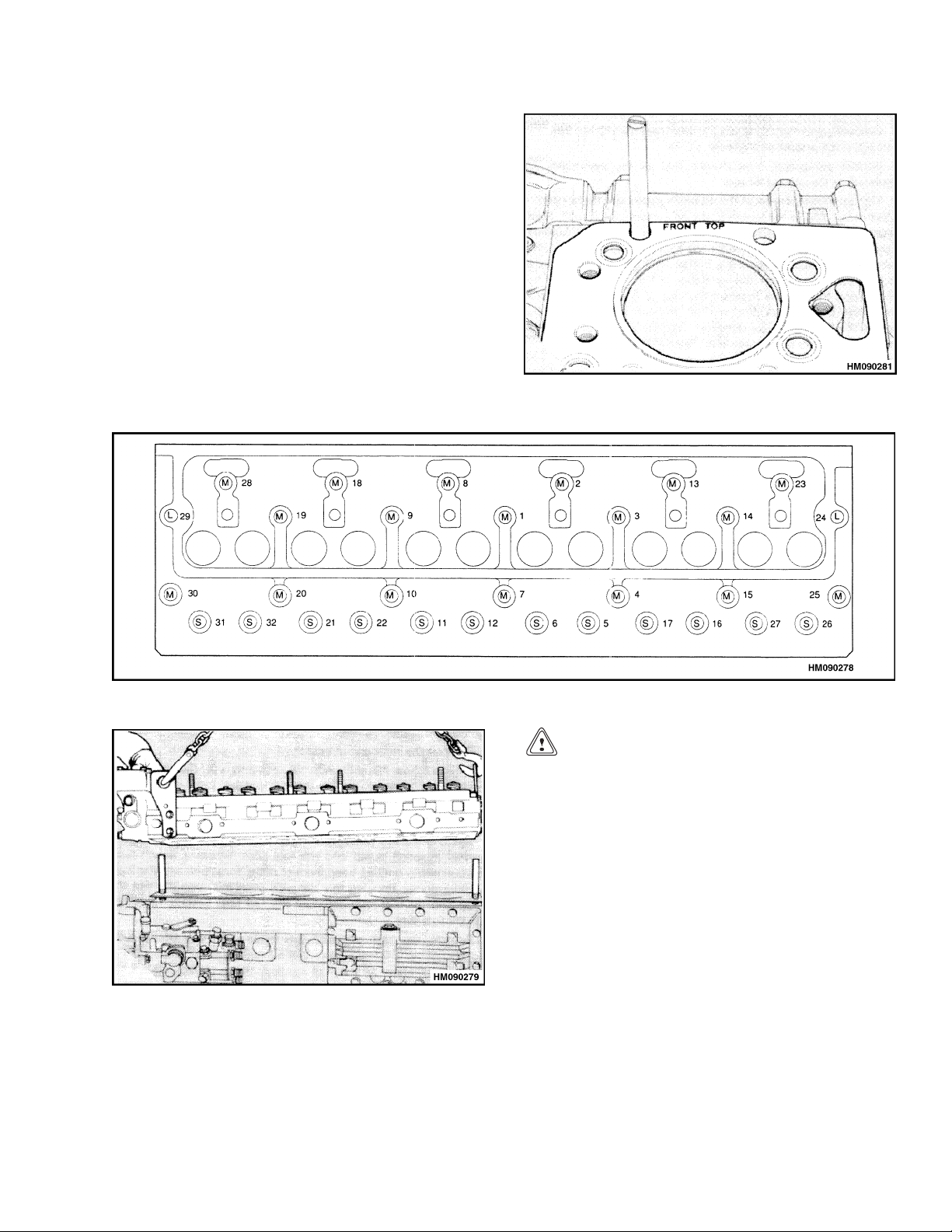

Install

Special Tools: Angle gauge to tighten the

capscrews for the cylinder head

1. Ver

2. Ins

3. Us

ify the surfaces of the cylinder head and the

oftheengineblockareclean. Verifythat

top

re is no dirt or objects in the cylinders.

the

tall the gasket for the cylinder head as shown

igure15. VerifytheTOPFRONTisinthe

in F

rect position. Do not use any gasket sealant

cor

any of the surfaces.

on

e two 1/2 UNF studs in positions 25 and 30.

e Figure 16. Lower the cylinder head into po-

Se

tion on the engine block. See Figure 17.

si

Figure 15. Head Gasket Position

Figure 16. Cylinder Head Tightening Sequence

Figure 17. Cylinder Head Installation

CAUTION

Therearethreelengthsofcapscrews.S=short,

M = medium, L = long. Figure 16 shows their positions in the engine. Verify that the capscrews

are installed in the correct positions.

4. Lubricate the capscrews with a thin coat of oil

and install them into their holes in the cylinder

head. When the cylinder head and gasket are

held in position, remove the two studs and install

the two capscrews in those positions.

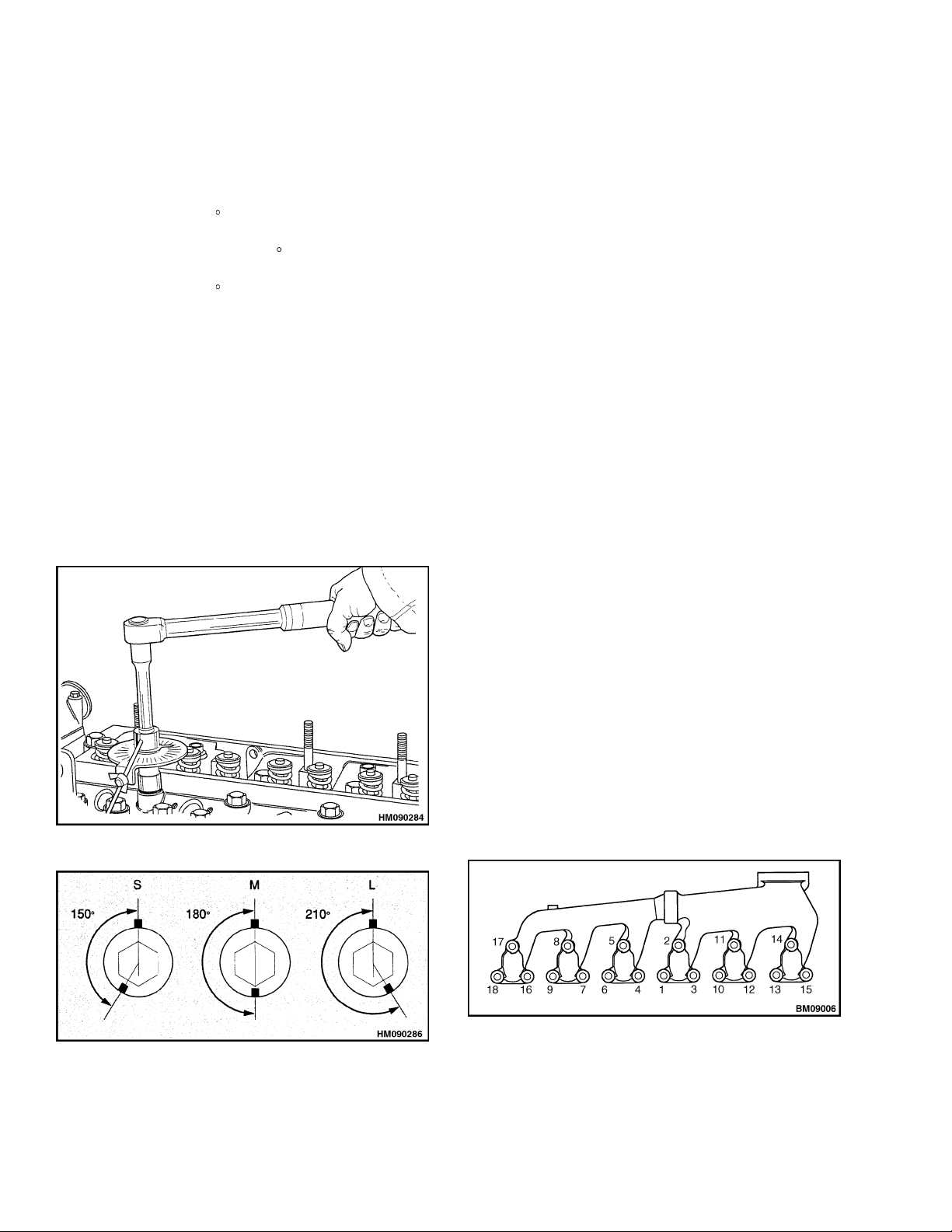

5. Evenly tighten the capscrews in the sequence

shown in Figure 16. The final torque on the capscrewsis110N•m(81lbfft).

11

Page 20

Cylinder Head Assembly Repair 600 SRM 1068

6. Verify all of the capscrews are tightened to the

correct torque described inStep5. The capscrews

must be further tightened in the sequence shown

in Figure 16 accordingtothefollowing procedure:

a. The short capscrews (S) mustbetightened an

additional 150

b. The medium capscrews (M) must be tight-

ened an additional 180

c. Thelongcapscrews(L)mustbetightenedan

additional 210

NOTE: A special tool shown in Figure 18 can be used

for this procedure to measure the tightening angles.

If an angle gauge is not available, make a mark in

alinewithoneofthecornersofthecapscrew. See

Figure 19. Make another mark at the correct angle

(counterclockwise) on the edge of the flange of the

cylinder head for each capscrew and according to the

length of each capscrew. Tighten each capscrew in

the correct sequence until the two marks are aligned.

7. Install the push rods in the engine. Verify that

the end of each push rod fits correctly in the tappet socket.

(2.5 flats).

(3.0 flats).

(3.5 flats).

8. Install the rocker arm assembly per Rocker Arm

Assembly, Installl.

9. Adjust the valve clearances per Valve Clearance

Adjustments.

10. Install the fuel injectors per Fuel Injectors, Install.

11. Install the high pressure fuel lines between the

fuel injection pump and the fuel injectors. Use

a separate wrench to prevent movement of the

outlets of the fuel injection pump when the fuel

lines are connected. Tighten the connection nuts

to 27.5 N•m (20 lbf ft).

12. Install the fuel filter and bracket. Install the lowpressure fuel lines between the fuel filter and the

fuel injection pump.

13. If equipped, reinstall the MIC to the MIC mounting bracket.

14. Install the coolant bypass connection. Tighten

the capscrews and the hose clamp.

Figure 18. Angle Gauge

15. If an aircompressor is installed on the engine, install the coolant pipe between the cylinder head

and the compressor. Install the pipe between the

coolant bypass and the compressor.

NOTE: Do not use sealant compound on gaskets of

the manifold.

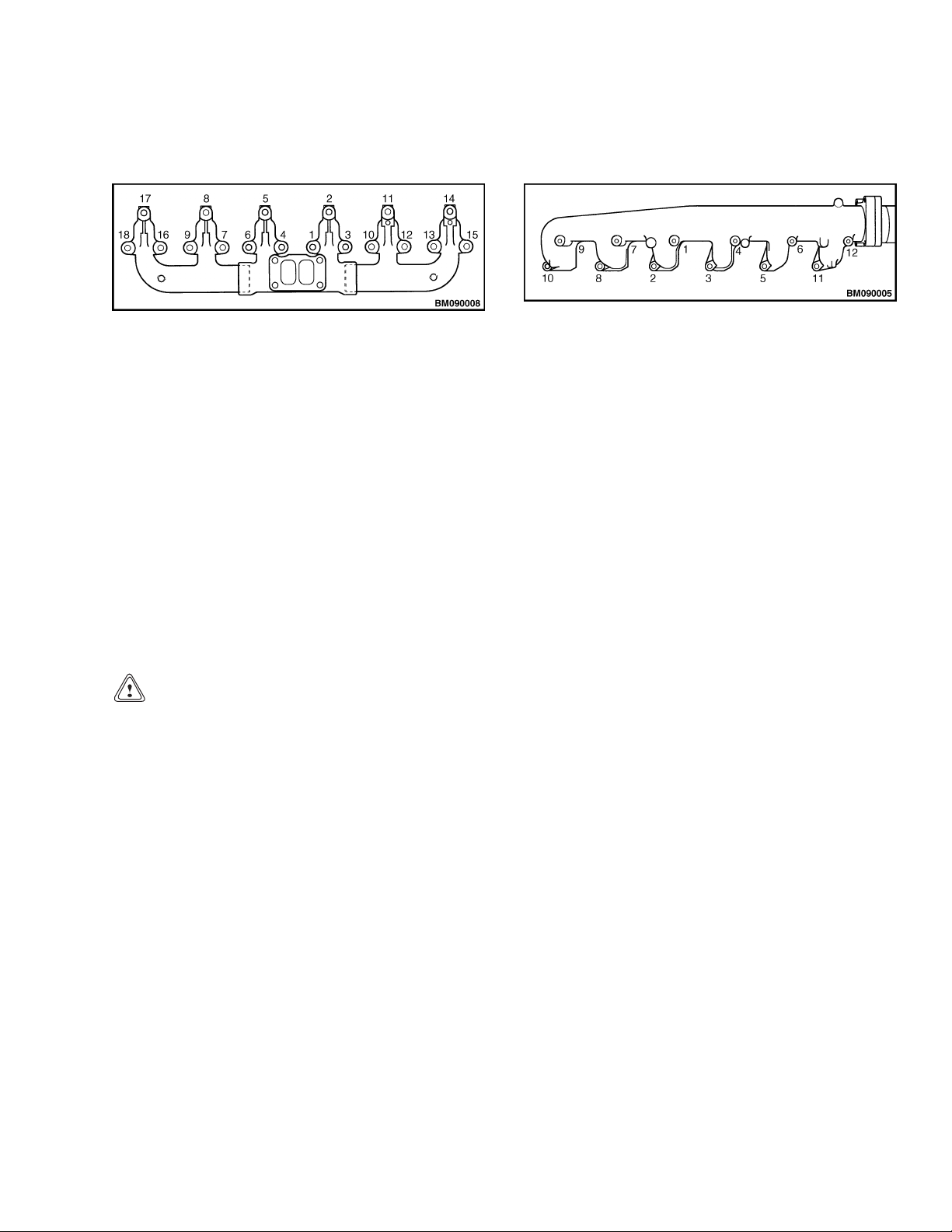

16. Verify the exhaust manifold gaskets and gasket

surfaces are clean and not damaged.

17. Place the temporary studs in the cylinder head.

a. For two-piece exhaust manifolds, place tem-

porary studs in positions 4, 8, 11, and 15 of

the cylinder head. See Figure 20.

Figure 19. Tighten Cylinder Head Capscrews

12

Figure 20. Two-Piece Exhaust Manifold

Tightening Sequence

Page 21

600 SRM 1068 Cylinder Head Assembly Repair

b. For three-piece exhaust manifolds, place

temporary studs in positions 2, 5, 14, and 17

of the cylinder head. See Figure 21.

Figure 21. Three-Piece Exhaust Manifold

Tightening Sequence

18. Place the exhaust manifold gaskets in position

over the studs. Verify the gaskets are in the correct position.

19. Reassemble the sections of the exhaust manifold

and place in position over the temporary studs.

20. Insert the capscrews into all positions that do not

have temporary studs and torque to 12.5 N•m

(9 lbf ft).

21. Remove temporary studs and insert remaining

capscrews and torque to 12.5 N•m (9 lbf ft).

22. Torque the capscrews again in sequence to

12.5 N•m (9 lbf ft). See Figure 20 and Figure 21.

CAUTION

Before the inlet manifold capscrews are installed again, any loose M.E.A.S in the cylinder

head holes must be removed to allow the manifold to be fully tightened.

25. Install the induction manifold capscrews and

torque in sequence to 22 N•m (16 lbf ft). See

Figure 22.

Figure 22. Induction Manifold Tightening

Sequence

26. Install the fuel line between the fuel filter and

the cold start aid. If the engine is inthe lift truck,

install the electrical connection to the cold start

aid.

27. Install the air intake hose.

28. Install the turbocharger. See Turbocharger, In-

stall.

29. Install the closed circuit breather assembly if

previously removed.

30. Install the fuel lines between the fuel filter and

the fuel injection pump.

31. If the engine is still in the lift truck, do the fol-

lowing procedures:

a. Connect the sender unit for the coolant tem-

perature gauge.

b. Connect the hoses forthecoolant system. Fill

the cooling system.

Do not scratch or damage the flange faces of

the inlet manifold.

NOTE: Thecapscrewsthatretainthemanifoldtothe

cylinder headhave M.E.A.S applied to the threads. If

the capscrews are removed and installed again, the

threads must be cleaned and POWERPART threadlock sealant used.

23. Place a new induction manifold gasket into posi-

tion on the cylinder head.

24. Place the induction manifold in position on the

cylinder head.

c. Connect the battery terminals.

d. If the engine is ready to operate, remove the

air from the fuel system. See the procedure

described in Fuel System Air Removal.

32. Whentheenginecanbestarted,runitatlow

speed. Check that oil flows from the holes in the

rocker arms. If the oil flow is correct, install the

valve cover. See Valve Cover, Install.

NOTE: It is not necessary to tighten the cylinder

head capscrews again with the engine hot or after a

limited period of service.

13

Page 22

Cylinder Head Assembly Repair 600 SRM 1068

VALVES AND VALVE SPRINGS

Special Tools: Valve spring compressor

Stud adapter

Setscrew adapter

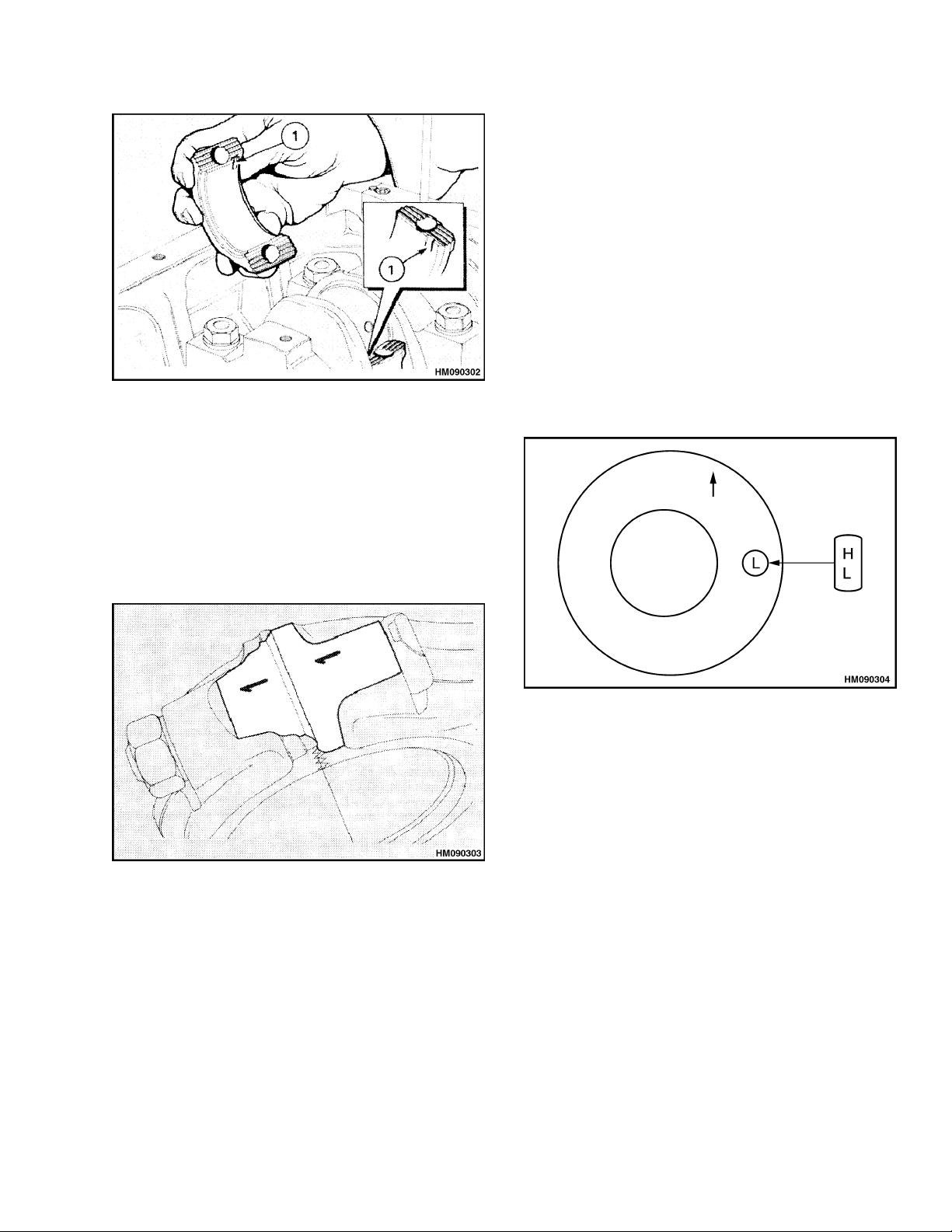

ove

Rem

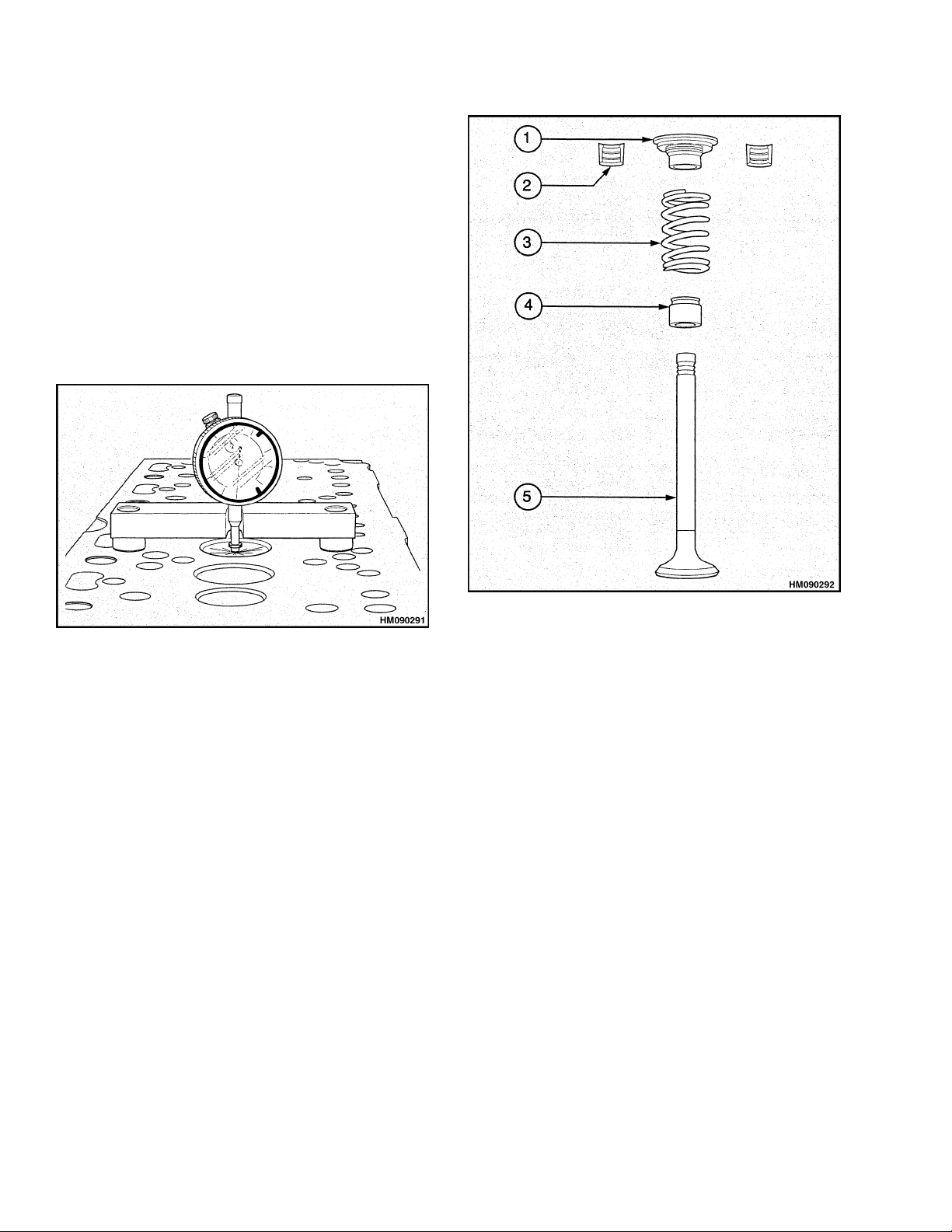

1. Rem

2. Cle

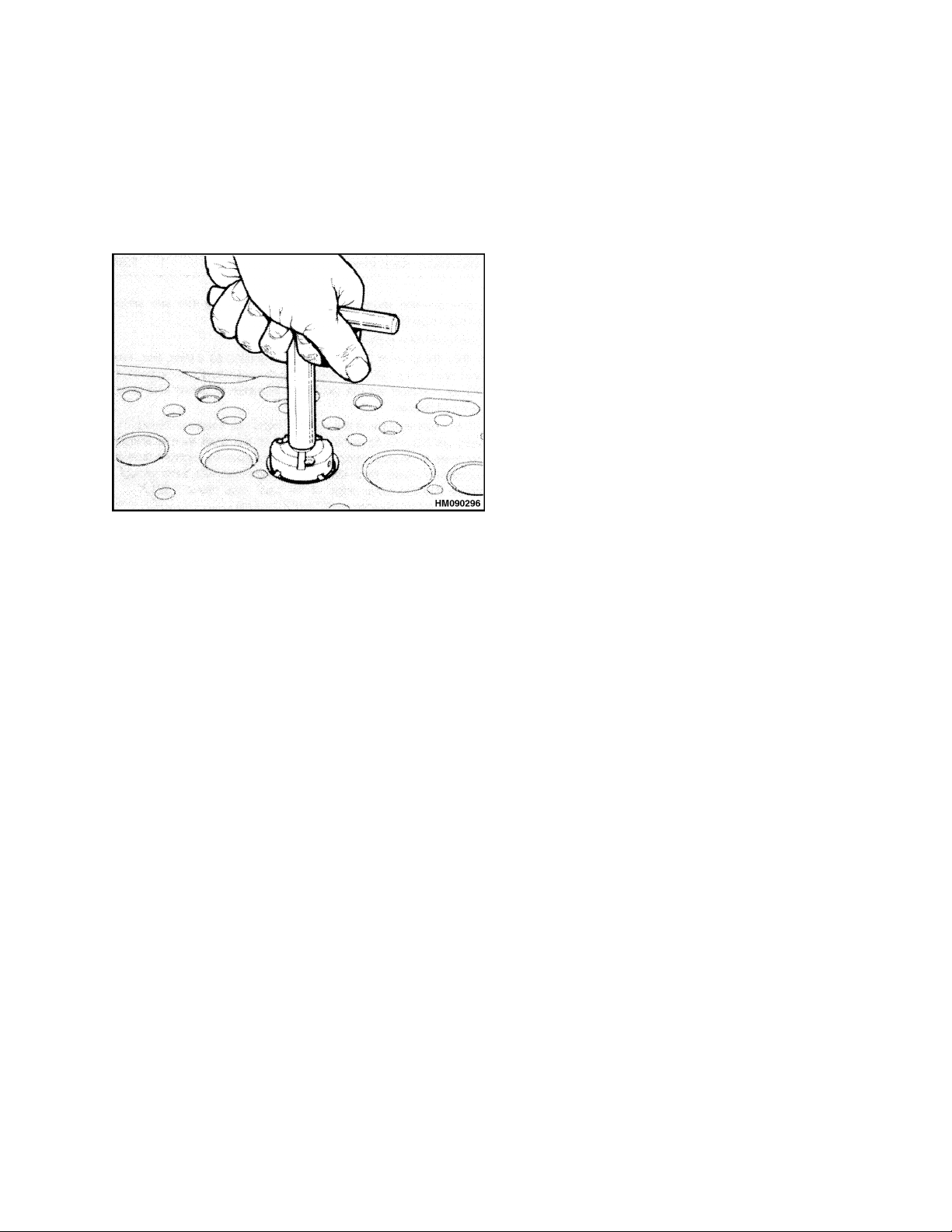

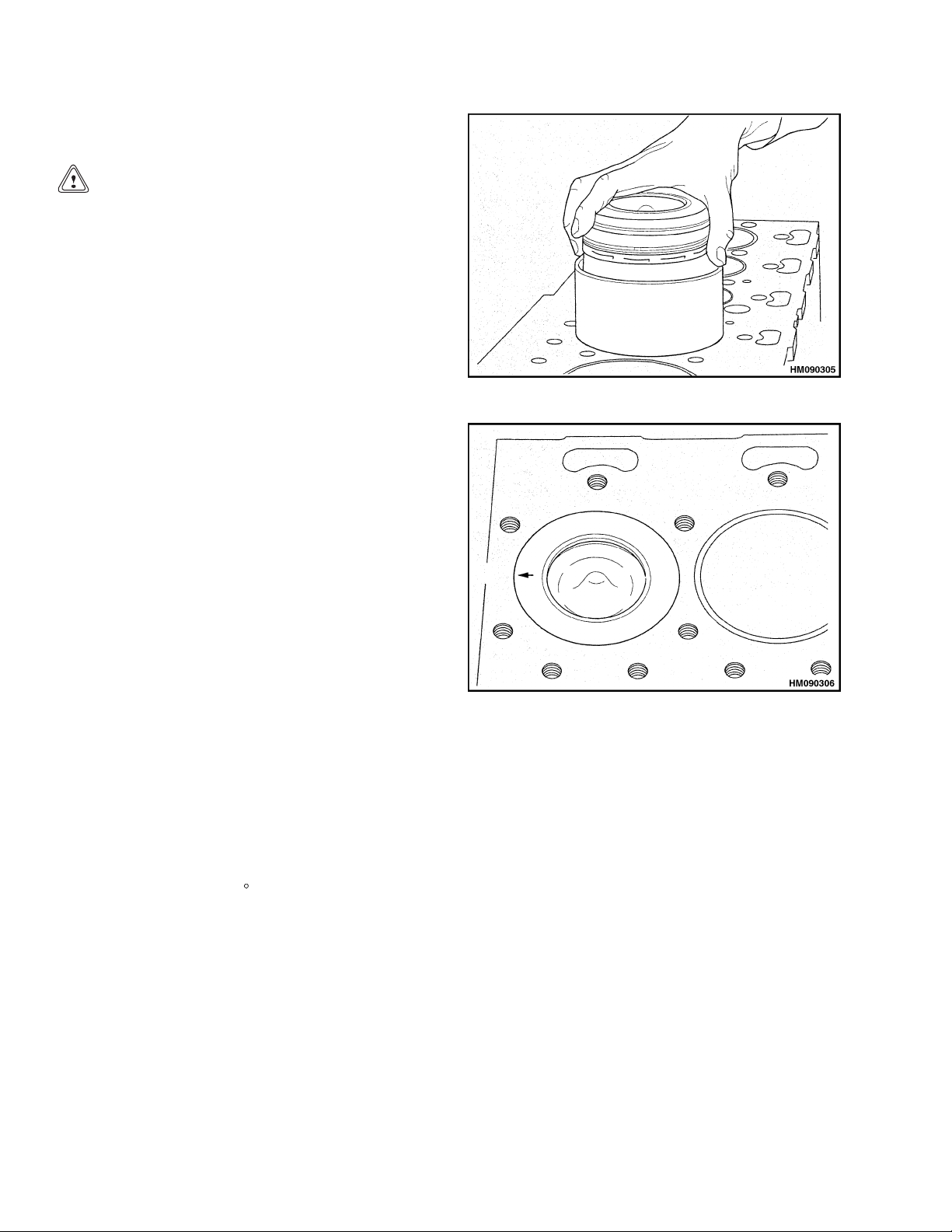

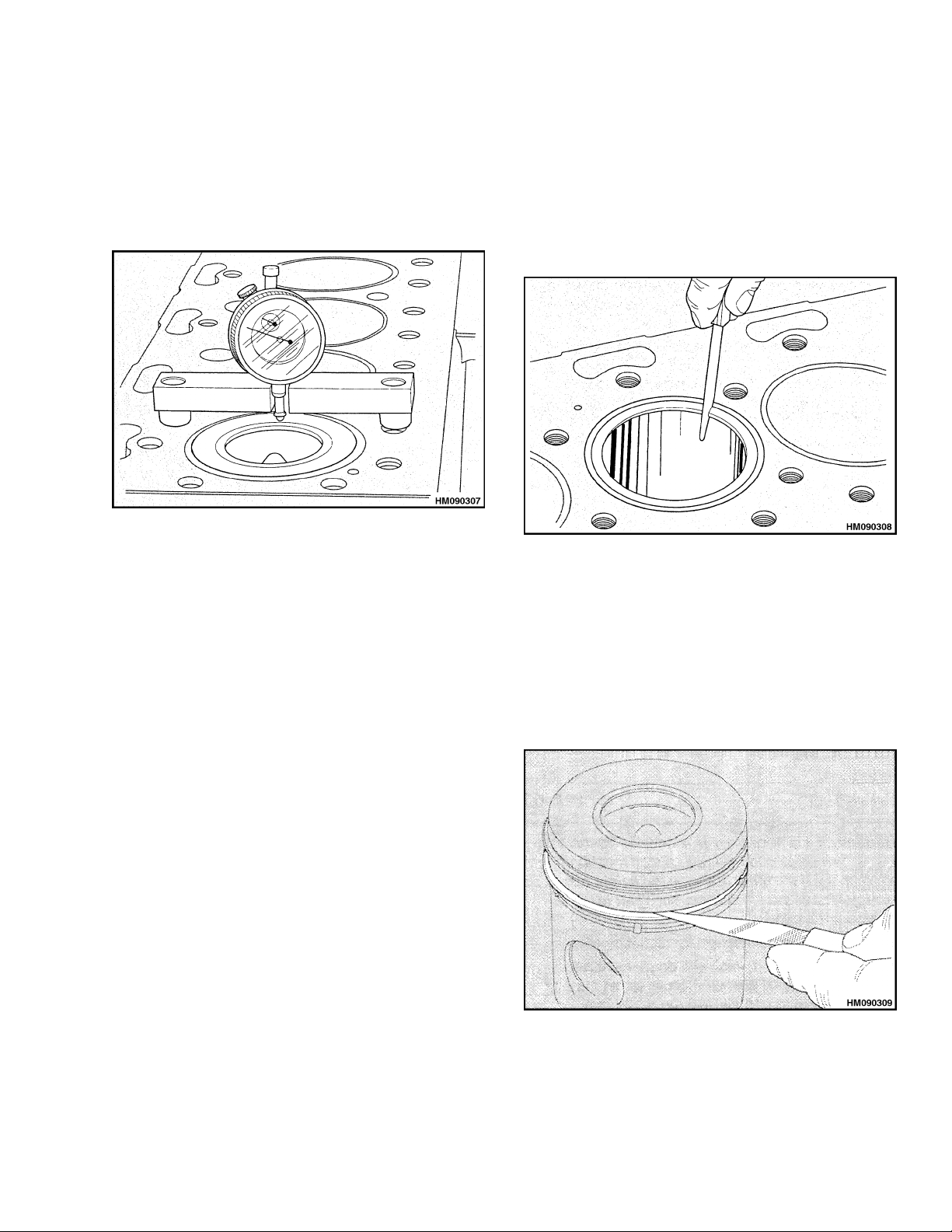

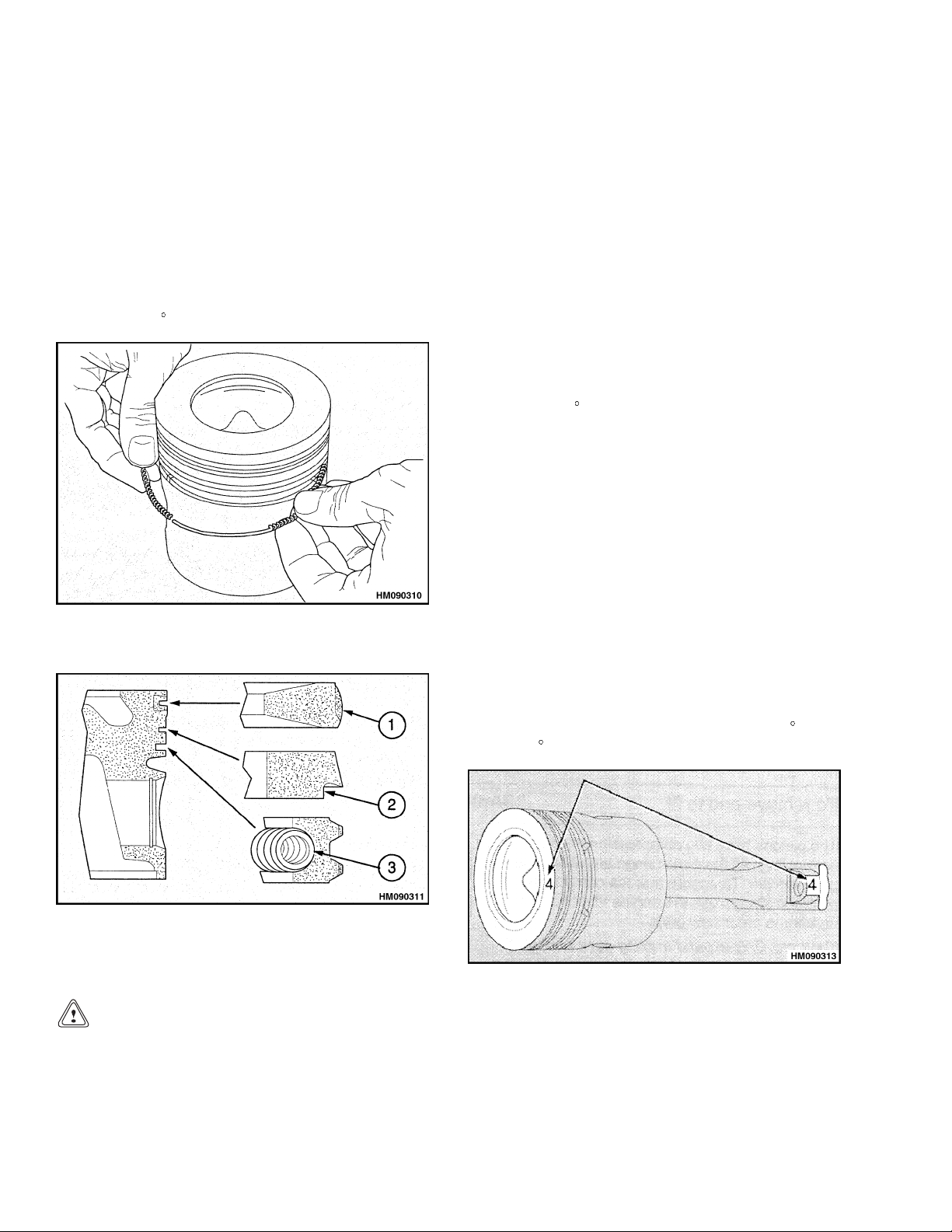

3. Check the depth of the valves below the face of

ove the cylinder head. See Cylinder Head

embly, Remove.

Ass

an the bottom face of the cylinder head and

ck the depth of the heads of the valves below

che

e face of the cylinder head. See Figure 23.

th

Figure 23. Valves Depth Check

thecylinderheadbeforethevalvespringsareremoved. Put thedial indicator and fixture orother

measuring tool on the face of the cylinder head

and set the gauge to zero. Carefully put the dial

indicator over the head of each valve and make a

note of the measurement. The maximum service

depth is shown in the Engine Specifications. If a

valve is below the depth limit, remove the valve

and install a new valve in that position. If the

valve depth is still below the limit, the valve seat

must be replaced. See New Valve Seats, Install.

1. CAP

2. COLLET (2)

3. SPRING

Figure 24. Valve Components

6. Release the valve stem compressor. Remove the

valve spring cap, valve springs, and seal.

7. Repeat Step 5 and Step 6 to remove the other

valves.

4. VALVE STEM SEAL

5. VALVE

Inspect

1. Check the valves for cracks. Check the stems of

the valves for wear and the correct clearance in

their valve guides. See Valve Guides.

4. If the valves will be used again, make a mark

on each valve head so that they can be installed

again in the same positions.

5. Usethevalvespringcompressorandthecorrect

adapter to compress the valve springs and remove the retainers. Verify the valve springs are