Page 1

Perkins New 1000 Series

This document has been printed from SPI². Not for Resale

Models AJ to AS and YG to YK

WORKSHOP MANUAL

4 and 6 cylinder diesel engines for industrial and

agricultural applications

Publication TPD 1350E, Issue 4.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in December 2001 by Technical Publications.

i

Page 2

This document has been printed from SPI². Not for Resale

This publication is written in

Perkins Approved Clear English

Chapters

1 General information

2 Specifications

3 Cylinder head assembly

4 Piston and connecting rod assemblies

5 Crankshaft assembly

6 Timing case and drive assembly

7 Cylinder block assembly

8 Engine timing

9 Aspiration system

10 Lubrication system

11 Fuel system

12 Cooling system

13 Flywheel and housing

14 Electrical equipment

15 Auxiliary equipment

16 Special tools

The following pages contain a detailed table of contents

ii

Page 3

New 1000 Series

This document has been printed from SPI². Not for Resale

Contents

1 General information

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...1

Engine views . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...2

Engine identification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...3

Safety precautions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...5

Viton seals . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6

Engine lift equipment ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...7

POWERPART recommended consumable products . ... ... ... ... ... ... ... ... ... ... ... ... ...8

2 Specifications

Basic engine data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .11

Data and dimensions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .12

Thread sealant ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .35

Standard torque tensions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .36

Specific torque tensions .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .37

Compression test data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .40

Workshop Manual, TPD 1350E, Issue 4 iii

Page 4

New 1000 Series

This document has been printed from SPI². Not for Resale

3 Cylinder head assembly

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 41

Rocker cover

Operation 3-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 42

Operation 3-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 43

Rocker ass embly

Operation 3-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 44

Operation 3-4 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45

Operation 3-5 To inspect and to correct ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45

Valve tip clearances

Operation 3-6 To check and to adjust (four cylinder engines) ... ... ... ... ... ... ... ... ... ... 46

Operation 3-7 To check and to adjust (six cylinder engines) . ... ... ... ... ... ... ... ... ... ... 47

Valve springs

Operation 3-8 To change the valve springs (with cylinder head fitted) .. ... ... ... ... ... ... 48

Manifolds ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50

Operation 3-9 To remove and to fit an intake manifold .. ... ... ... ... ... ... ... ... ... ... ... ... 50

Operation 3-10 To remove and to fit an exhaust manifold (one-piece) .. ... ... ... ... ... ... 52

Operation 3-11 To remove and to fit an exhaust manifold (three-piece) ... ... ... ... ... ... 54

Cylinder head assembly

Operation 3-12 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 56

Operation 3-13 To fit (engine types AJ to AQ and YG to YK) ... ... ... ... ... ... ... ... ... ... 58

Operation 3-14 To fit (engine types AR and AS) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 61

Valves and valve springs

Operation 3-15 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 64

Operation 3-16 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 65

Operation 3-17 To inspect and to correct .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 66

Valve guides ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 67

Operation 3-18 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 67

Operation 3-19 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 68

Operation 3-20 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 69

Cylinder head

Operation 3-21 To inspect and to correct .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 70

Operation 3-22 To correct a valve seat with a valve seat cutter ... ... ... ... ... ... ... ... ... 71

Operation 3-23 To fit valve seat inserts . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 73

iv Workshop Manual, TPD 1350E, Issue 4

Page 5

New 1000 Series

This document has been printed from SPI². Not for Resale

4 Piston and connecting rod assemblies

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .75

Big end bearing

Operation 4-1 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .77

Operation 4-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .78

Operation 4-3 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .78

Piston and connecting rod

Operation 4-4 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .79

Operation 4-5 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .80

Operation 4-6 To check the piston height above the cylinder block .. ... ... ... ... ... ... ... .82

Piston rings

Operation 4-7 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .83

Operation 4-8 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .84

Piston and connecting rod assembly

Operation 4-9 To dismantle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .85

Operation 4-10 To assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .86

Operation 4-11 To check the length of a connecting rod .. ... ... ... ... ... ... ... ... ... ... ... .87

Piston and piston rings

Operation 4-12 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .88

Connecting rod

Operation 4-13 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .89

Partially finished small end bush

Operation 4-14 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .90

Piston cooling jets

Operation 4-15 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .91

Operation 4-16 To check the jet alignment ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .92

5 Crankshaft assembly

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .93

Crankshaft pulley

Operation 5-1 To remove and to fit (four cylinder engines) ... ... ... ... ... ... ... ... ... ... ... .95

Workshop Manual, TPD 1350E, Issue 4 v

Page 6

New 1000 Series

This document has been printed from SPI². Not for Resale

Crankshaft pulley and damper

Operation 5-2 To remove (six cylinder engines) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 96

Operation 5-3 To fit (six cylinder engines) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 97

Operation 5-4 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 98

Rear oil seal assembly .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 99

Operation 5-5 To remove and to fit (one-piece assembly) . ... ... ... ... ... ... ... ... ... ... ... 99

Operation 5-6 To remove and to fit (two-piece assembly) . ... ... ... ... ... ... ... ... ... ... .. 102

Operation 5-7 To renew the rear end oil seal (two-piece assembly) ... ... ... ... ... ... .. 103

Operation 5-8 To remove and to fit a wear sleeve . ... ... ... ... ... ... ... ... ... ... ... ... ... .. 104

Thrust washers

Operation 5-9 To check crankshaft end-float . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..105

Operation 5-10 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 106

Operation 5-11 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 107

Main bearings

Operation 5-12 To remove (with the crankshaft in position) .. ... ... ... ... ... ... ... ... ... .. 108

Operation 5-13 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 109

Operation 5-14 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 109

Crankshaft

Operation 5-15 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 110

Operation 5-16 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 111

Operation 5-17 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 113

Balancer unit

Operation 5-18 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 114

Operation 5-19 To dismantle . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 115

Operation 5-20 To assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 117

Operation 5-21 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 120

Operation 5-22 To remove and to fit the needle roller bearings for the drive shaft ... .. 121

Operation 5-23 To remove and to fit the bushes for the balance weights . ... ... ... ... .. 122

6 Timing case and drive assembly

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 123

Timing case cover

Operation 6-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 124

Operation 6-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 125

Front oil seal

Operation 6-3 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 127

Operation 6-4 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 128

Operation 6-5 To remove and to fit a wear sleeve . ... ... ... ... ... ... ... ... ... ... ... ... ... .. 130

vi Workshop Manual, TPD 1350E, Issue 4

Page 7

New 1000 Series

This document has been printed from SPI². Not for Resale

Idler gear and hub

Operation 6-6 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...131

Operation 6-7 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...133

Idler gear and hub for the compressor

Operation 6-8 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...135

Operation 6-9 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...136

Fuel pump gear . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...137

Operation 6-10 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...137

Operation 6-11 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...139

Camshaft gear

Operation 6-12 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...141

Crankshaft gear

Operation 6-13 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...142

Timing case

Operation 6-14 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...143

Operation 6-15 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...144

Camshaft and tappets

Operation 6-16 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...146

Operation 6-17 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...147

7 Cylinder block assembly

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...149

Cylinder block

Operation 7-1 To dismantle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...150

Operation 7-2 To assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...151

Operation 7-3 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...152

Operation 7-4 To remove and to fit a new type ‘D’ plug to the tappet chamber ... ... ...153

Cylinder liner

Operation 7-5 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...155

Operation 7-6 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...156

Operation 7-7 To fit a service liner ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...158

Operation 7-8 To fit a partially finished liner .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...161

Cylinder bore, engine types AR and AS

Operation 7-9 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...164

Workshop Manual, TPD 1350E, Issue 4 vii

Page 8

New 1000 Series

This document has been printed from SPI². Not for Resale

8 Engine timing

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 165

Engine timing

Operation 8-1 To set number 1 piston to TDC on the compression stroke ... ... ... ... .. 167

Operation 8-2 Another method to set number 1 piston to TDC . ... ... ... ... ... ... ... ... .. 168

Operation 8-3 To check the valve timing ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 169

Operation 8-4 To check the timing of the fuel injection pump ... ... ... ... ... ... ... ... ... .. 170

9 Aspiration system

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 171

Turbocharger

Operation 9-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 173

Operation 9-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 174

Operation 9-3 To clean the impeller and the compressor casing .. ... ... ... ... ... ... ... .. 176

Operation 9-4 To remove and to fit the actuator assembly of the waste-gate unit ... .. 177

Operation 9-5 To check and adjust the operation of the waste-gate . ... ... ... ... ... ... .. 178

Turbocharger faults ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 179

List of possible causes . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 180

Open engine breather ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 181

Operation 9-6 To clean and to renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..181

Operation 9-7 To Inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 183

Closed engine breather . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 184

Operation 9-8 To renew the breather valve assembly ... ... ... ... ... ... ... ... ... ... ... ... .. 185

10 Lubrication system

General description - four cylinder engine lubrication system ... ... ... ... ... ... ... ..187

General description - Six cylinder engine lubrication system . ... ... ... ... ... ... ... .. 188

Filter canister

Operation 10-1 To renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 191

Filter head

Operation 10-2 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 192

Sump

Operation 10-3 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 193

viii Workshop Manual, TPD 1350E, Issue 4

Page 9

New 1000 Series

This document has been printed from SPI². Not for Resale

Oil strainer and suction pipe

Operation 10-4 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...194

Operation 10-5 To inspect and to correct .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...195

Lubricating oil pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...196

Operation 10-6 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...196

Operation 10-7 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...197

Operation 10-8 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...198

Lubricating oil pump idler gear shaft .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...199

Operation 10-9 To remove (six cylinder engines) . ... ... ... ... ... ... ... ... ... ... ... ... ... ...199

Operation 10-10 To fit (six cylinder engines) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...201

Operation 10-11 To remove and to fit (four cylinder engines) ... ... ... ... ... ... ... ... ... ...202

Relief valve

Operation 10-12 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...203

Operation 10-13 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...204

Operation 10-14 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...204

Flexible oil pipes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...205

Operation 10-15 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...205

Operation 10-16 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...206

Operation 10-17 To Inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...207

11 Fuel system

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...209

Cold start advance unit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...212

Typical fuel system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...215

Fuel filters .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...216

Fuel filter element

Operation 11-1 To renew - separate element type ... ... ... ... ... ... ... ... ... ... ... ... ... ...217

Operation 11-2 To renew - canister type ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...218

Operation 11-3 To renew - quick release canister type . ... ... ... ... ... ... ... ... ... ... ... ...219

Atomisers .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...220

Operation 11-4 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...221

Operation 11-5 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...222

Workshop Manual, TPD 1350E, Issue 4 ix

Page 10

New 1000 Series

This document has been printed from SPI². Not for Resale

Fuel lift pump

Operation 11-6 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 224

Operation 11-7 To dismantle . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..225

Operation 11-8 To assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 226

Operation 11-9 To test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 227

Bosch fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..228

Operation 11-10 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 230

Operation 11-11 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 232

Operation 11-12 To adjust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..234

Lucas/Delphi DP 200 Series fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ... .. 235

Operation 11-13 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 237

Operation 11-14 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 239

Operation 11-15 To adjust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..242

Operation 11-16 Electrical shut off solenoid (ESOS) . ... ... ... ... ... ... ... ... ... ... ... ... .. 243

Stanadyne fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 245

Operation 11-17 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 248

Operation 11-18 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 249

Operation 11-19 To adjust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..251

Air in the fuel system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..254

Operation 11-20 To eliminate air from the fuel system .. ... ... ... ... ... ... ... ... ... ... ... ..254

12 Cooling system

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 257

Thermostats

Operation 12-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 258

Operation 12-2 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 259

Operation 12-3 To test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 260

Coolant pump - early gear driven pumps ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 261

Operation 12-4 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 261

Operation 12-5 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 262

Operation 12-6 To dismantle . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..263

Operation 12-7 To assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 264

Operation 12-8 To remove and to fit a pressed steel cover (early coolant pumps) ... .. 267

Coolant pump - latest gear driven pumps ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..268

Operation 12-9 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 268

Operation 12-10 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 269

Operation 12-11 To dismantle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 270

Operation 12-12 To assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..273

x Workshop Manual, TPD 1350E, Issue 4

Page 11

New 1000 Series

This document has been printed from SPI². Not for Resale

Coolant pump - belt driven .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...277

Operation 12-13 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...277

Operation 12-14 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...279

Operation 12-15 To remove high position pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...281

Operation 12-16 To fit high position pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...283

Operation 12-17 To dismantle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...285

Operation 12-18 To assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...286

Fan

Operation 12-19 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...289

Fan drive (engines with gear driven coolant pumps)

Operation 12-20 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...290

Lubricating oil cooler

Operation 12-21 To remove (four cylinder turbocharged engines) ... ... ... ... ... ... ... ...291

Operation 12-22 To fit (four cylinder turbocharged engines) . ... ... ... ... ... ... ... ... ... ...292

Operation 12-23 To dismantle and to assemble (four cylinder engines) ... ... ... ... ... ...293

Operation 12-24 To remove (six cylinder turbocharged engines) . ... ... ... ... ... ... ... ...294

Operation 12-25 To fit (six cylinder turbocharged engines) .. ... ... ... ... ... ... ... ... ... ...296

Operation 12-26 To dismantle and to assemble (six cylinder engines) . ... ... ... ... ... ...298

Operation 12-27 To remove and to fit (canister type) ... ... ... ... ... ... ... ... ... ... ... ... ...300

Operation 12-28 To remove and to fit cooler bypass valve ... ... ... ... ... ... ... ... ... ... ...300

Intercoolers ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...301

Horizontally mounted intercooler

Operation 12-29 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...302

Operation 12-30 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...304

Vertically mounted intercooler

Operation 12-31 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...306

Operation 12-32 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...307

Operation 12-33 To clean and to inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...309

13 Flywheel and housing

General description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...311

Flywheel

Operation 13-1 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...311

Ring gear

Operation 13-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...312

Flywheel housing

Operation 13-3 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...313

Workshop Manual, TPD 1350E, Issue 4 xi

Page 12

New 1000 Series

This document has been printed from SPI². Not for Resale

14 Electrical equipment

Alternators . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 315

Operation 14-1 To check the drive belts ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 316

Operation 14-2 To adjust drive belt tension ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 317

Operation 14-3 To remove and to fit the drive belts ... ... ... ... ... ... ... ... ... ... ... ... ... .. 318

Operation 14-4 To remove and to fit the alternator ... ... ... ... ... ... ... ... ... ... ... ... ... .. 319

Operation 14-5 To maintain ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 319

Operation 14-6 Fault diagnosis .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 320

Starter motors ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 322

Operation 14-7 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 323

Operation 14-8 To maintain the brush gear and the commutator .. ... ... ... ... ... ... ... ..324

Operation 14-9 To test on the engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 324

Operation 14-10 Fault diagnosis ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 325

Starting aids ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 326

Operation 14-11 To remove and to fit a fuelled starting aid ... ... ... ... ... ... ... ... ... ... .. 326

Operation 14-12 To remove and to fit a twin-fuelled starting aid ... ... ... ... ... ... ... ... ..327

Operation 14-13 To check the fuelled starting aid . ... ... ... ... ... ... ... ... ... ... ... ... ... .. 328

Operation 14-14 To remove and to fit a port heater ... ... ... ... ... ... ... ... ... ... ... ... ... .. 328

15 Auxiliary equipment

Bendix Compressor

Operation 15-1 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 330

Operation 15-2 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 331

Knorr-Bremse compressor

Operation 15-3 To remove . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 333

Operation 15-4 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 334

Operation 15-5 To remove the reed valves ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 336

Operation 15-6 To fit the reed valves . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..337

Operation 15-7 To remove the top unloader valve ... ... ... ... ... ... ... ... ... ... ... ... ... .. 338

Operation 15-8 To fit the top unloader valve .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 339

Operation 15-9 To remove the crankshaft / connecting rod / piston / piston rings . ... .. 340

Operation 15-10 To fit the crankshaft / connecting rod / piston / piston rings ... ... ... .. 341

Power steering pump

Operation 15-11 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 343

Adaptor for a hydraulic pump or a steering pump with a splined drive

Operation 15-12 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 344

Operation 15-13 To dismantle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 345

Operation 15-14 To assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..346

xii Workshop Manual, TPD 1350E, Issue 4

Page 13

New 1000 Series

This document has been printed from SPI². Not for Resale

Exhauster

Operation 15-15 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...347

16 Special tools

List of special tools . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...350

Workshop Manual, TPD 1350E, Issue 4 xiii

Page 14

This page is intentionally blank

This document has been printed from SPI². Not for Resale

Page 15

New 1000 Series

This document has been printed from SPI². Not for Resale

1

General information 1

Introduction

This Workshop Manual has been written to provide assistance in the service and overhaul of Perkins New

1000 Series engines. For overhaul procedures the assumption is made that the engine is removed from the

application. The engine conforms with USA (EPA/CARB) stage 1 and EEC stage 1 emissions legislation for

agricultural and industrial applications.

Most of the general information which is included in the relevant User’s Handbook has not been repeated in

this workshop manual and the two publications should be used together.

Where the information applies only to certain engine types, this is indicated in the text.

The details of some operations will be different according to the type of fuel injection pump which is fitted. The

specific pump type used can be found by reference to the manufacturer’s identification plate on the pump body.

Generally, the type of pump fitted is as shown below.

l Lucas/Delphi - DP200 Series

l Bosch - EPVE

l Stanadyne - DB4.

When reference is made to the "left" or "right" side of the engine, this is as seen from the flywheel end of the

engine.

Special tools have been made available, for a list of these, see Chapter 16, Special tools. Reference to the

relevant special tools is also made at the beginning of each operation, where relevant.

POWERPART recommended consumable products are listed on page 8. Reference to the relevant

consumable products is also made at the beginning of each operation, where relevant.

Data and dimensions are included in Chapter 2, Specifications.

Read and remember the "Safety precautions" on page 5. They are given for your protection and must be used

at all times.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person.

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Workshop Manual, TPD 1350E, Issue 4 1

Page 16

1

This document has been printed from SPI². Not for Resale

Engine views

New 1000 Series

A0378N

A0379

2 Workshop Manual, TPD 1350E, Issue 4

Page 17

New 1000 Series

This document has been printed from SPI². Not for Resale

1

Engine identification

The Perkins New 1000 Series engines have been designed for industrial and agricultural applications. There

are both four and six cylinder engines, each of which will have three basic engine types, naturally aspirated,

turbocharged and turbocharged with an intercooler.

In this workshop manual, the different engine types are indicated by their code letters. These are the first two

letters of the engine number as indicated below:

AJ Four cylinder, naturally aspirated

AK Four cylinder, turbocharged

AM Four cylinder, turbocharged and intercooled

AP Four cylinder, naturally aspirated, belt driven coolant pump

AQ Four cylinder, turbocharged, belt driven coolant pump

AR Four cylinder, naturally aspirated, 103 mm cylinder bore

AS Four cylinder, naturally aspirated, belt driven coolant pump, 103 mm cylinder bore

YG Six cylinder, naturally aspirated

YH Six cyli nde r , turbo ch ar ged

YJ Six cylinder, charge cooled, air to air

YK Six cylinder, turbocharged and intercooled

The correct identification of the engine is by the full engine number.

The engine number is stamped on a label which is fastened to the left side (A2) of the cylinder block. An

example of an engine number is:

AK80920*U510256B*

The components of the engine number are as follows:

AK80920*U510256B*

AK Model code number

80920 Build list number

U Built in the UK

510256 Engine serial number

B Year of manufacture

Continued

21

3

A

Workshop Manual, TPD 1350E, Issue 4 3

A0043

Page 18

1

This document has been printed from SPI². Not for Resale

Date letters for engines start from the 1st of January each year. To comply with the new emissions legislation

that engines built before 1st April 1999 can be clearly identified from those built after this date, a new letter has

been used from the 1st of April 1999. The date letters used are as follows:

From the 1st of January 1999 to the 31st of March 1999 the date letter is E.

From the 1st of April 1999 to the 31st of January 1999 the date letter is F.

If you need parts, service or information for your engine, you must give the complete engine number to your

Perkins distributor. If there is a number in the area of the label marked TPL No, then this number must also be

given to your Perkins distributor.

Other identification labels fitted to the engine include:

An emissions legislation label (A3) fitted to the side of the cylinder block.

A label (A1) with the fuel injection pum p part numbers.

If a short engine has been fitted in service two engine serial numbers and a TPL number are stamped on the

engine serial number pad (B3).

Examples of the serial numbers are shown in (B).

If parts for the short engine are needed in service, use the serial number (B4). If parts which were moved from

the original engine to the short engine are needed, use the serial number (B1) and the TPL number (B2).

New 1000 Series

AK80920*U510256B*

21

3

A

4 Workshop Manual, TPD 1350E, Issue 4

A0043

AJ39770 TPL No 212

4

B

1

2

3

A0045

Page 19

New 1000 Series

This document has been printed from SPI². Not for Resale

1

Safety precautions

These safety precautions are important . You must refer also to the local regulations in the country of use.

Some items only refer to specifi c appl ic ati on s.

l Only use these engines in the type of application for which they have been designed.

l Do not change the specification of the engine.

l Do not smoke when you put fuel in the tank.

l Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a

safe place.

l Do not put fuel in the tank while the engine runs (unless it is absolutely necessary).

l Do not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training;

even then extreme care must be used to prevent injury).

l Do not make adjustments that you do not understand.

l Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions.

l Other persons must be kept at a safe distance while the engine or auxiliary equipment is in operation.

l Do not permit loose clothing or long hair near moving parts.

l Keep away from moving parts during engine operation.

Warning! Some moving parts cannot be seen clearly while the engine runs.

l Do not operate the engine if a safety guard has been removed.

l Do not remove the filler cap or any component of the cooling system while the engine is hot and while the

coolant is under pressure, because dangerous hot coolant can be discharged.

l Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the

gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially

to the eyes.

l Disconnect the battery terminals before a repair is made to the electrical system.

l Only one person must control the engine.

l Ensure that the engine is operated only from the control panel or from the operators position.

l If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

l Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons.

Protect your hands with gloves or a special solution to protect the skin.

l Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated

with oil into the pockets of clothing.

l Discard used lubricating oil in a safe place to prevent contamination.

l Ensure that the control lever of the transmission drive is in the "out-of-drive" position before the engine is

started.

l Use extreme care if emergency repairs must be made in adverse conditions.

l The combustible material of some components of the engine (for example certain seals) can become

extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with

the eyes, see "Viton seals" on page 6 for safety precautions.

l Read and use the instructions relevant to lift equipment, see "Engine lift equipment" on page 7.

Continued

Workshop Manual, TPD 1350E, Issue 4 5

Page 20

1

This document has been printed from SPI². Not for Resale

l Always use a safety cage to protect the operator when a component is to be pressure tested in a container

of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to

be pressure tested.

l Do not allow compressed air to contact your skin. If compressed air enters your skin, obtain medical help

immediately.

l Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and items away from

the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces.

l Do not clean an engine while it runs. If cold cleaning fluids are applied to a hot engine, certain components

on the engine may be damaged.

l Fit only genuine Perkins parts.

New 1000 Series

Viton seals

Some seals used in engines and in components fitted to engines are made of Viton.

Viton is used by many manufacturers and is a safe material under normal conditions of operation.

If Viton is burned, a product of this burnt material is an acid which is extremely dangerous. Never allow this

burnt material to come into contact with the skin or with the eyes.

If it is necessary to come into contact with components which have been burnt, ensure that the precautions

which follow are used:

l Ensure that the components have cooled

l Use neoprene gloves and discard the gloves safely after use

l Wash the area with calcium hydroxide solution and then with clean water

l Disposal of components and gloves which are contaminated must be in accordance with local regulations.

If there is contamination of the skin or eyes, wash the affected area with a continuous supply of clean water or

with calcium hydroxide solution for 15-60 minutes. Obtain immediate medical attention.

6 Workshop Manual, TPD 1350E, Issue 4

Page 21

New 1000 Series

This document has been printed from SPI². Not for Resale

1

Engine lift equipment

The maximum weight of the engine without coolant, lubricant or a gearbox fitted will vary for different

applications. It is recommended that lift equipment of the minimum capacity listed below is used:

Four cylinder engine s 500 kg (1100 lbs)

Six cylinder engines 600 kg (1320 lbs)

Before the engine is lifted:

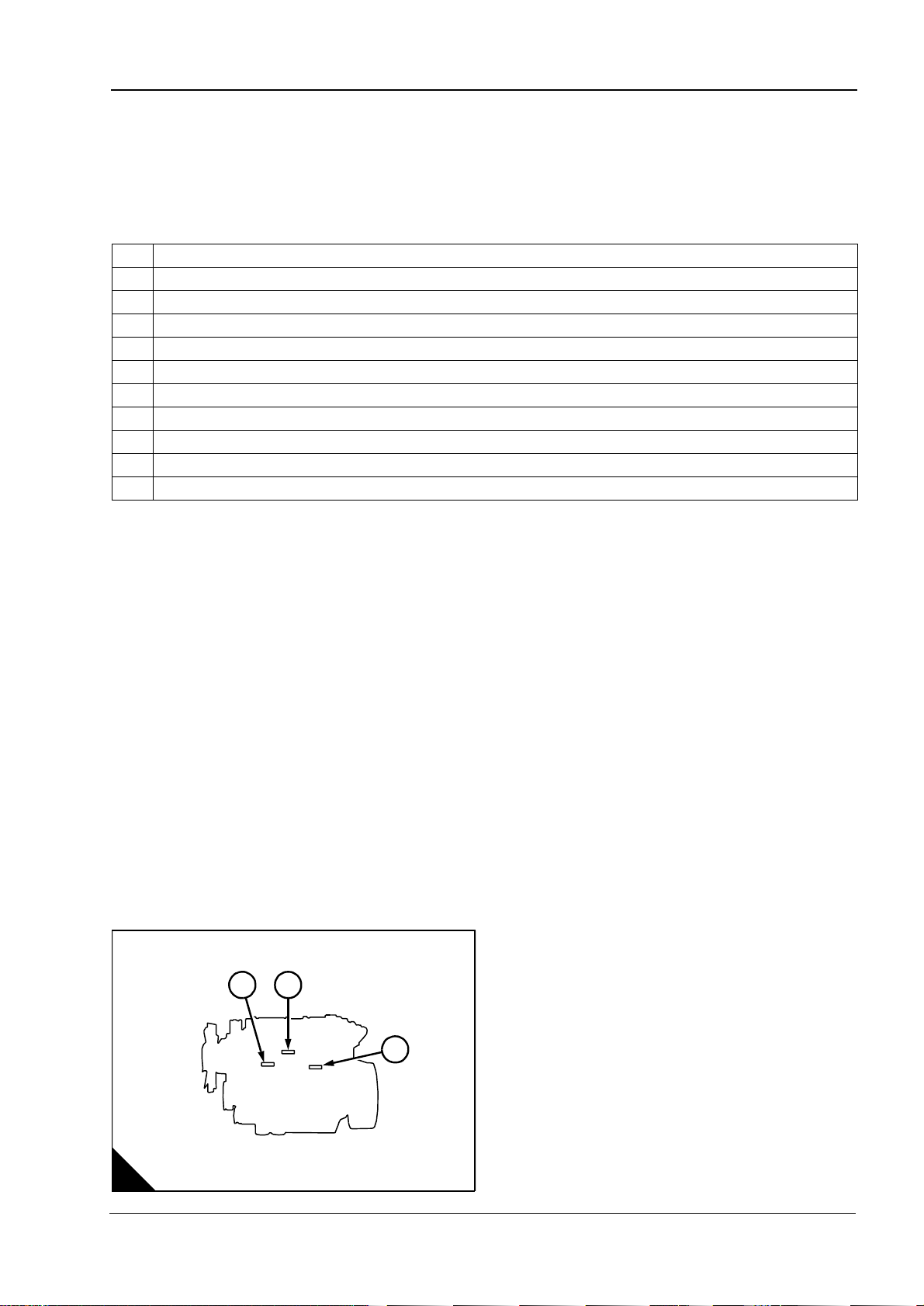

l Always use lift equipment of the approved type and of the correct capacity to lift the engine. It is

recommended that lift equipment of the type shown in (A) is used, to provide a vertical lift directly above

the engine lift brackets (A1). Never use a single lift bracket to raise an engine

l Check the engine lift brackets for damage and that they are secure before the engine is lifted. The torque

for the setscrews for the engine lift brackets is 44 Nm (33 lbf ft) 4,5 kgf m

l To prevent damage to the rocker cover, ensure that there is clearance between the hooks and the rocker

cover

l Use lift equipment or obtain assistance to lift heavy engine components such as the cylinder block, cylinder

head, balancer unit, flywheel housing, crankshaft and flywheel.

1

A

Workshop Manual, TPD 1350E, Issue 4 7

A0044

Page 22

1

This document has been printed from SPI². Not for Resale

New 1000 Series

POWERPART recommended consumable products

Perkins have made available the products recommended below in order to assist in the correct operation,

service and maintenance of your engine and your machine. The instructions for the use of each product are

given on the outside of each container. These products are available from your Perkins distributor.

POWERPART Antifreeze

Protects the cooling system against frost and corrosion. Part number 21825166.

POWERPART Easy Flush

Cleans the cooling system. Part number 21825001.

POWERPART Gasket and flange sealant

To seal flat faces of components where no joint is used. Especially suitable for aluminium components. Part

number 21820518.

POWERPART Gasket remover

An aerosol for the removal of sealants and adhesives. Part number 21820116.

POWERPART Griptite

To improve the grip of worn tools and fasteners. Part number 21820129.

POWERPART Hydraulic threadseal

To retain and seal pipe connections with fine threads. Especially suitable for hydraulic and pneumatic systems.

Part number 21820121.

POWERPART Industrial grade super glue

Instant adhesive designed for metals, plastics and rubbers. Part number 21820125.

POWERPART Lay-Up 1

A diesel fuel additive for protection against corrosion. Part number 1772204.

POWERPART Lay-Up 2

Protects the inside of the engine and of other closed systems. Part number 1762811.

POWERPART Lay-Up 3

Protects outside metal parts. Part number 1734115.

POWERPART Metal repair putty

Designed for external repair of metal and plastic. Part number 21820126.

POWERPART Pipe sealant and sealant primer

To retain and seal pipe connections with coarse threads. Pressure systems can be used immediately. Part

number 21820122.

Continued

8 Workshop Manual, TPD 1350E, Issue 4

Page 23

New 1000 Series

This document has been printed from SPI². Not for Resale

POWERPART Radiator stop leak

For the repair of radiator leaks. Part number 21820127.

POWERPART Retainer (high strength)

To retain components that have an interference fit. Part number 21820638.

POWERPART Retainer (oil tolerant)

To retain components that have an interference fit, but is in contact with oil. Part number 21820603.

POWERPART Safety cleaner

General cleaner in an aerosol container. Part number 21820128.

POWERPART Silicone adhesive

An RTV silicone adhesive for application where low pressure tests occur before the adhesive sets. Used for

sealing flange where oil resistance is needed and movement of the joint occurs. Part number 21826038.

POWERPART Silicone RTV sealing and jointing compound

Silicone rubber sealant that prevents leakage through gaps. Part number 1861108.

POWERPART Stud and bearing lock

To provide a heavy duty seal to components that have a light interference fit. Part number 21820119 or

21820120.

1

POWERPART Threadlock and nutlock

To retain small fasteners where easy removal is necessary. Part number 21820117 or 21820118.

POWERPART Universal jointing compound

Universal jointing compound that seals joints. Part number 1861117.

Workshop Manual, TPD 1350E, Issue 4 9

Page 24

This page is intentionally blank

This document has been printed from SPI². Not for Resale

Page 25

New 1000 Series

This document has been printed from SPI². Not for Resale

2

Specifications 2

Basic engine data

Number of cylinders:

AJ, AK, AM, AP, AQ, AR, AS .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4

YG, YH, YJ, YK ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

Cylinder arrangement.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .In line

Cycle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Four stroke

Direction of rotation . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Clockwise from the front

Induction system:

AJ, AP, AR, AS, YG. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Naturally aspirated

AK, AQ, YH.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Turbocharged

AM, YJ, YK .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Turbocha rg ed, int er co ole d

Combustion system. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Direct injection

Nominal bore:

AJ, AK, AM, AP, AQ, YG, YH, YJ, YK. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .100 mm (3.937 in)

AR, AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .103 mm (4.055 in)

Stroke.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...127 mm (5.00 in)

Compression ratio:

AJ, AK, AM, AP, AQ, YG, YH, YJ, YK. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..17.25:1

AR, AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18.5:1

Cubic capacity:

AJ, AK, AM, AP, AQ ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .4 litres (243 in

AR, AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4,23 litres (258 in

YG, YH, YJ, YK ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .6 litres (365 in

Firing o rder:

AJ, AK, AM, AP, AQ, AR, AS .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1, 3, 4, 2

YG, YH, YJ, YK ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1, 5, 3, 6, 2, 4

Valve tip clearances (hot or cold):

- Inlet ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,20 mm (0.008 in)

- Exhaust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,45 mm (0.018 in)

Lubricating oil pressure

AJ, AK, AM, AP, AQ, YG, YH, YJ, YK. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 280 kPa (40 lbf/in2) 2,5 kgf/cm

AR, AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 207 kPa (30 lbf/in2) 2,1 kgf/cm

(1) minimum at maximum engine speed and normal engine temperature

(1)

3

)

3

)

3

)

2

2

Workshop Manual, TPD 1350E, Issue 4 11

Page 26

2

This document has been printed from SPI². Not for Resale

New 1000 Series

Data and dimensions

Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which

are shown are those which are mainly used in the factory. The information applies to all engines, unless an

engine type code is shown.

Cylinder head

Angle of valve seat:

- Inlet.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 46° (88° included angle) or 31° (1 1 8° included angle)

- Exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 46° (88° included angle) or 31° (118° included angle)

2

Leak test pressure . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 200 kPa (29 lbf/in

Head thickness .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 102,79/103,59 mm (4.047/4.078 in)

Finish grade of head face for cylinder head joint ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1,10/3,20 micrometers

Diameter of parent bore for valve guide:

- Inlet.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..13,00/13,027 mm (0.511 8/0. 512 8 in)

- Exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..14,00/14,027 mm (0.5512/0.5522 in)

Minimum permissible thickness after head face has been machined ... ... ... ... ... ... ... ..102,48 mm (4.035 in)

Maximum permissible distortion of cylinder head

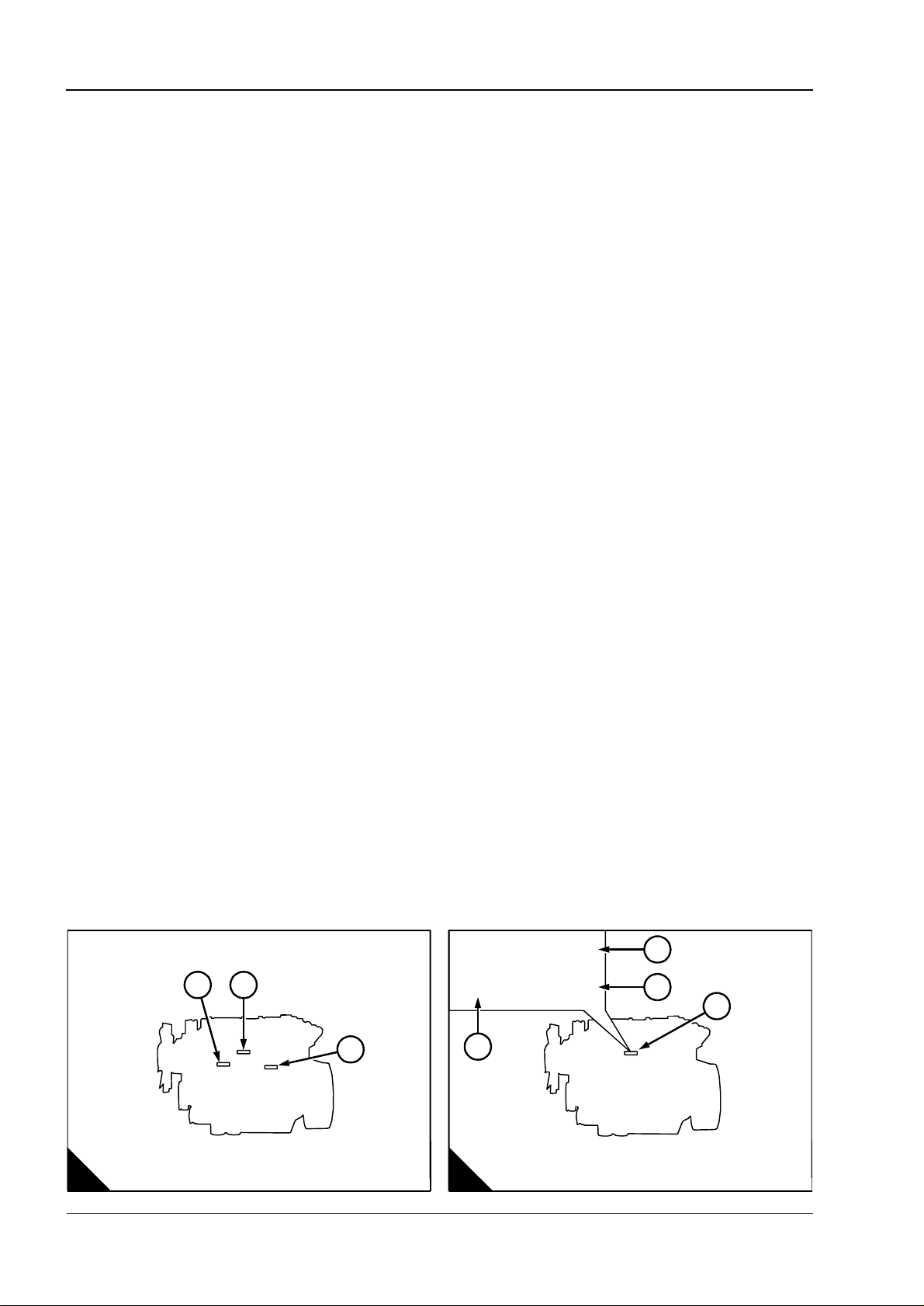

Four cylinder engines

) 2,04 kgf/cm

2

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,08 mm (0.003 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,15 mm (0.006 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,15 mm (0.006 in)

Six cylinder engines

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,13 mm (0.005 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,25 mm (0.010 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,25 mm (0.010 in)

1111111

3

2

3

2

A

12 Workshop Manual, TPD 1350E, Issue 4

A0067

Page 27

New 1000 Series

This document has been printed from SPI². Not for Resale

2

Inlet and exhaust valves

Inlet valves

Diameter of valve stem ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..8,953/8,975 mm (0.3525/0.3533 in)

Clearance in valve guide . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,025/0,069 mm (0.001/0.0027 in)

Maximum permissible clearance in valve guide:

- Production limit.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,089 mm (0.0035 in)

- Service limit... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,100 mm (0.008 in)

Diameter of valve head:

- Engine types AJ, AK, AM, AP, AQ, YG, YH, YJ, YK. ... ... ... ... ... ... ... ... ..42,88/43,12 mm (1.688/1.698 in)

- Engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..44,88/45,12 mm (1.776/1.767 in)

Angle of valve face .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..45° or 30°

Full length, engine types AJ, AK, AM, AP, AQ, YG, YH, YJ, YK. ... ... ... ..122,65/123,30 mm (4.829/4.854 in)

Full length, engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ... ..123,75/124,40 mm (4.872/4.897 in)

Seal arrangement ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Rubber seal fitted to valve guide, colour green

Depth of valve head below the face of cylinder head:

- Production limits, engine types AJ, AK, AM, AP, AQ, YG, YH, YJ, YK. ... ... ..1,40/1,70 mm (0.055/0.067 in)

- Service limit, engine types AJ, AK, AM, AP, AQ, YG, YH, YJ, YK ... ... ... ... ... ... ... ... ... 1,95 mm (0.077 in)

- Production limits, engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ..0,40/0,60 mm (0.016/0.024 in)

- Service limit, engine types AR and AS.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,805 mm (0.032 in)

Exhaust valves

Diameter of valve stem ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..8,938/8,960 mm (0.3519/0.3528 in)

Clearance in valve guide . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,040/0,84 mm (0.0016/0.0033 in)

Maximum permissible clearance in valve guide:

- Production limits ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,104 mm (0.0041 in)

- Service limit... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,121 mm (0.011 in)

Diameter of valve head:

- Engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK ... ... ... ... ... ... ... ... ..40,88/41,12 mm (1.609/1.619 in)

- Engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..41,88/42,12 mm (1.649/1.658 in)

Angle of valve face .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..45° or 30°

Full length, engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK ... ... ... ..122,65/123,30 mm (4.829/4.854 in)

Full length, engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ... ..123,75/124,40 mm (4.872/4.897 in)

Seal arrangement ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Rubber seal fitted to valve guide, colour brown

Depth of valve head below face of cylinder head:

- Production limits, engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK ... ... ..1,50/1,80 mm (0.059/0.071 in)

- Service limit, engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK... ... ... ... ... ... ... ... ... 2,05 mm (0.081 in)

- Production limits, engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ..0,40/0,60 mm (0.016/0.024 in)

- Service limit, engine types AR and AS.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,805 mm (0.032 in)

Workshop Manual, TPD 1350E, Issue 4 13

Page 28

2

This document has been printed from SPI². Not for Resale

New 1000 Series

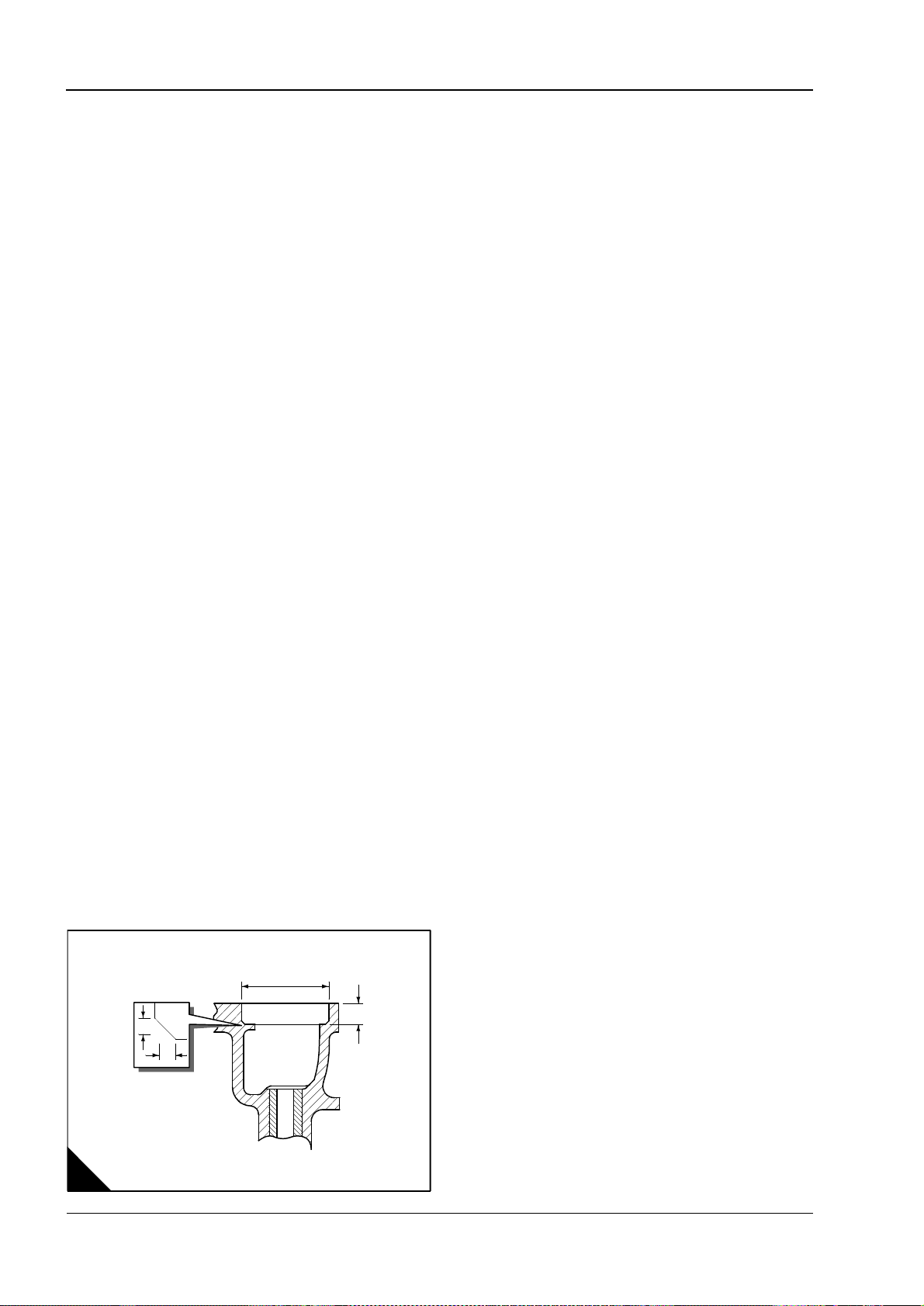

Dimensions of recesses for valve seat inserts

Engine types AJ to AQ and YG to YK

Inlet

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 10,585/10,715 mm (0.4167/0.4219 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45,535/45,560 mm (1.7927/1.7937 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Radius 0,38 mm (0.015 in) maximum

Exhaust

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 10,585/10,715 mm (0.4167/0.4219 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 43,535/43,560 mm (1.7139/1.7149 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Radius 0,38 mm (0.015 in) maximum

Engine types AR and AS

Inlet

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 10,585/10,715 mm (0.4167/0.4219 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 48,035/48,060 mm (1.8911/1.8921 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Radius 0,38 mm (0.015 in) maximum

Exhaust

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 10,585/10,715 mm (0.4167/0.4219 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 44,035/44,060 mm (1.7336/1.7346 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Radius 0,38 mm (0.015 in) maximum

2

3

3

A

14 Workshop Manual, TPD 1350E, Issue 4

1

PA068

Page 29

New 1000 Series

This document has been printed from SPI². Not for Resale

2

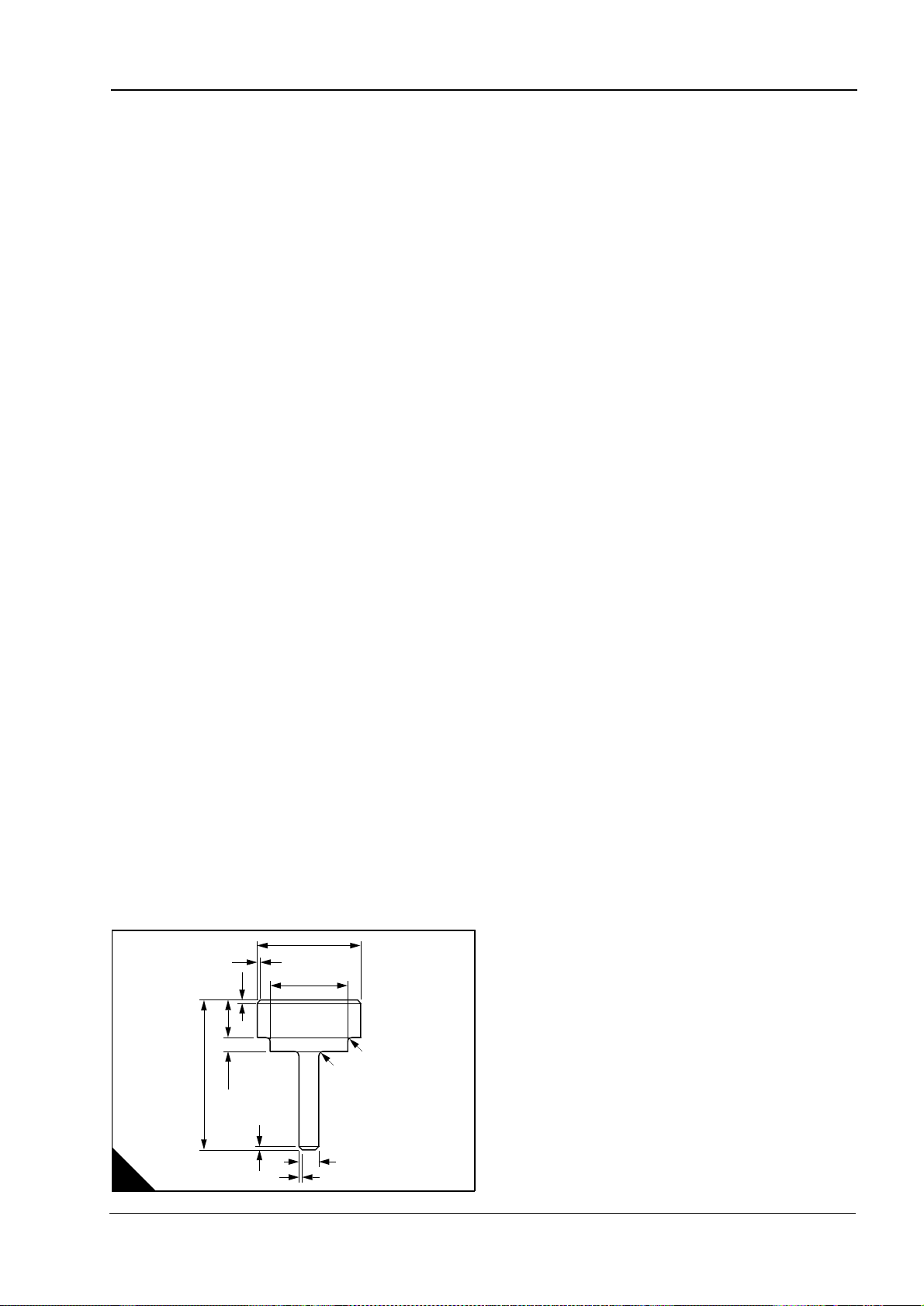

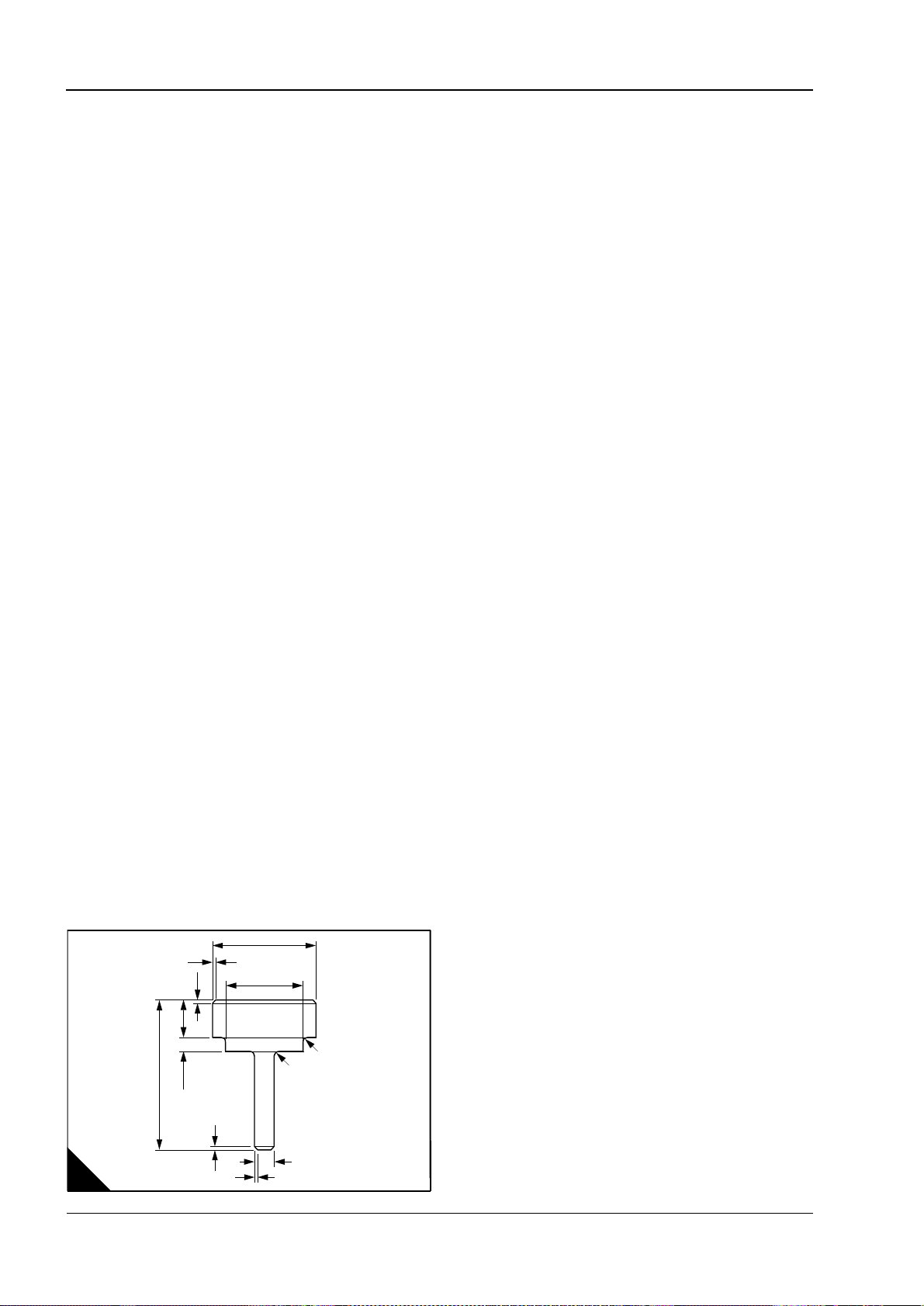

Valve seat insert tool

Inlet (for 45° valves and 30° valves), engine types AJ to AQ and YG to YK

A1 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1,5 mm (0.06 in)

A2 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...20 mm (0.800 in)

A3 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7,0 mm (0.28 in)

A4 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...100 mm (4.00 in)

A.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..37,25/37,45 mm (1.467/1.474 in)

A6 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..44,75/45,00 mm (1.772/1.762 in)

A7 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Radius 1,4 mm (0.055) maximum

A8 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Radiu s 1,5 mm (0.06)

A9 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1,5 mm (0.06 in)

A10.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..8,54/8,57 mm (0.336/0.337 in)

Exhaust (for 45° valves and 30° valves), engine types AJ to AQ and YG to YK

A1 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1,5 mm (0.06 in)

A2 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .20 mm (0.80 in)

A3 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7,0 mm (0.28 in) maximum

A4 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...100 mm (4.00 in)

A5 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..34,38/34,58 mm (1.354/1.361 in)

A6 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..42,75/43,00 mm (1,683/1.693 in)

A7 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Radius 1,4 mm (0.055 in) maximum

A8 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Radius 1,5 mm (0.06 in)

A9 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1,5 mm (0.06 in)

A10.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..8,54/8,57 mm (0.336/0.337 in)

1

1

2

3

4

A

Workshop Manual, TPD 1350E, Issue 4 15

6

5

7

8

9

10

9

A0069

Page 30

2

This document has been printed from SPI². Not for Resale

Inlet (45° valves), engine types AR and AS

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,5 mm (0.06 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .20 mm (0.800 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..7,0 mm (0.28 in)

A4... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .100 mm (4.00 in)

A5... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 37,82/38,02 mm (1.488/1.496 in)

A6... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 47,25/47,50 mm (1.860/1.870 in)

A7... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Radius 1,4 mm (0.055) maximum

A8... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Radius 1,5 mm (0.06)

A9... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,5 mm (0.06 in)

A10. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8,54/8,57 mm (0.336/0.337)

Exhaust (45° valves), engine types AR and AS

A1... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,5 mm (0.06 in)

A2... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...20 mm (0.80 in)

A3... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .7,0 mm (0.28 in) maximum

A4... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .100 mm (4.00 in)

A5... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 36,62/36,82 mm (1.441/1.449 in)

A6... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 43,25/43,50 mm (1,702/1.712 in)

A7... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Radius 1,4 mm (0.055 in) maximum

A8... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Radius 1,5 mm (0.06 in)

A9... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,5 mm (0.06 in)

A10. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8,54/8,57 mm (0.336/0.337 in)

New 1000 Series

1

1

2

3

4

A

16 Workshop Manual, TPD 1350E, Issue 4

6

5

7

8

9

10

9

A0069

Page 31

New 1000 Series

This document has been printed from SPI². Not for Resale

2

Valve guides and valve springs

Valve guides

Inside diameter of partially finished guide ... ... ... ... ... ... ... ... ... ... ... ... ..8,600/8,700 mm (0.3386/0.3425 in)

Inside diameter of finished guide. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..9,000/9,022 mm (0.3543/0.3552 in)

Outside diameter:

Inlet.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..13,034/13,047 mm (0.5131/0.5137 in)

Exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..14,034/14,047 mm (0.5525/0.5530 in)

Interference fit of valve guide in cylinder head ... ... ... ... ... ... ... ... ... ... ..0,047/0,007 mm (0.0003/0.0019 in)

Full length ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..51,25 mm (2.018 in)

Protrusion from bottom of recess for valve spring ... ... ... ... ... ... ... ... ... ... ..14,85/15,15 mm (0.585/0.596 in)

Valve springs

Fitted length. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..39,0 mm (1.54 in)

Load at fitted length:

- Engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK ... ... ... ... ... ..246/277,5 N (55.3/62.4 lbf) 25,1/28,3 kgf

- Engine types AR and AS... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...136,3/153,7 N (30.6/34.5 lbf) 13,9/15,7 kgf

Number of active coils . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .3.3

Number of damper coils .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0

Direction of coils .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Left hand

Tappets, rocker shaft, rocker levers and bushes

Tappets

Diameter of tappet stem .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..18,99/19,01 mm (0.7475/0.7485 in)

Diameter of tappet bore in cylinder block ... ... ... ... ... ... ... ... ... ... ... ... ..19,05/19,08 mm (0.7500/0.7512 in)

Clearance of tappet in cylinder block... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,04/0,09 mm (0.0015/0.0037 in)

Rocker shaft

Outside diameter . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..19,01/19,04 mm (0.7485/0.7495 in)

Rocker levers and bushes

Diameter of parent bore for bush. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 22,23/22,26 mm (0.8750/0.8762 in)

Outside diameter of bush ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..22,28/22,31 mm (0.8770/0.8785 in)

Interference fit of bush in rocker lever . ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,020/0,089 mm (0.0008/0.0035 in)

Internal diameter of fitted bush when reamed . ... ... ... ... ... ... ... ... ... ... ..19,06/19,10 mm (0.7505/0.7520 in)

Clearance between rocker lever bush and rocker shaft.. ... ... ... ... ... ... ... ... 0,03/0,09 mm (0.001/0.0035 in)

Maximum permissible clearance between rocker lever bush and rocker shaft ... ... ... ... ... 0,13 mm (0.005 in)

Workshop Manual, TPD 1350E, Issue 4 17

Page 32

2

This document has been printed from SPI². Not for Resale

New 1000 Series

Pistons and piston cooling jets

Pistons

Type... ... ... ... ... ... ... ... ... ... ... ... ... ... ..."Fastram" combustion bowl inserted top ring groove, graphite skirt

Diameter of bore for gudgeon pin.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 39,703/39,709 mm (1.5631/1.5633 in)

Height of piston above top face of cylinder block... ... ... ... ... ... ... ... ... ... ... ... 0,38/0,50 mm (0.015/0.020 in)

Width of groove for top ring:

- Engine types AJ, AK, AM, AP, AQ, YG, YH, YJ, YK ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Tapered

- Engine types AR and AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,60/2,62 mm (0.1023/0.1031)

Width of groove for second ring. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,56/2,58 mm (0.1008/0.1016 in)

Width of groove for third ring:

- Engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK .. ... ... ... ... ... ... ... ... 3,54/3,56 mm (0.1393/0.1401 in)

- Engine types, AR and AS ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3,53/3,55 mm (0.1389/0.1397 in)

Piston cooling jets

Valve open pressure.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 178/250 kPa (26/36 lbf/in

2

) 1,8/2,6 kgf/cm

Piston rings

Top compression ring:

2

- Engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK .. ... ... ... ... ... . Barrel face, molybdenum insert, wedge

- Engine types AR and AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. Barrel face, molybdenum insert, rectangular

Second compression ring .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..Taper face, cast iron, outside bottom step

Oil scraper ring... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Coil spring loaded, chromium faced

Width of top ring:

- Engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. Tapered

- Engine types AR and AS. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..2,475/2,49 mm (0.097/0.098 in)

Width of second ring .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,48/2,49 mm (0.097/0.098 in)

Width of third ring... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3,47/3,49 mm (0.1366/0.1374 in)

Clearance of top ring in groove:

- Engine types, AJ, AK, AM, AP, AQ, YG, YH, YJ, YK .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Wedge

- Engine types AR and AS only.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,110/0,145 mm (0.004/0.006 in)