Page 1

TPD1329E, Issue 3

July 2000

User’s

Handbook

Perkins 1000 Series

AA to AH

YA to YD

Page 2

Chapters

1 General information

Th ispu blicationis w ritt en in

Perkins A ppr ovedClearEnglish

2 Engine view s

3 Operation instructions

4 Preventive maintenance

5 Engine fluids

6 Fault diagno sis

7 Engine preservation

8 Parts and service

9 General data

The following pages contain a detailed table of contents

2

Page 3

Contents

1 General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How to care for your engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Perkins companies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Engine views

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Location of engine parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Operation instructions

How to start the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to stop the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjustment of the engine speed range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Running-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Turbocharged engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Preventive maintenance

Preventive maintenance periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How to drain the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

How to check the specific gravity of the coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

How to check the drive belt(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

How to clean the gauze strainer of the fuel lift pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fuel pre-filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to renew the element(s) of the fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

How to renew the element(s) of the separate element type . . . . . . . . . . . . . . . . . . . . . . 25

How to renew the filter canister of the canister fuel filter . . . . . . . . . . . . . . . . . . . . . . . . 26

How to renew the canister of the quick release fuel filter . . . . . . . . . . . . . . . . . . . . . . . . 27

Atomiser fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3

Page 4

How to renew an atomiser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

How to eliminate air from the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to renew the lubricating oil of the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

How to renew the canister of the lubricating oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

How to clean the closed breather system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

How to clean the integral closed breather system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The open breather system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Restriction indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

How to check the valve tip clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5 Engine fluids

Fuel specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Lubricating oil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Coolant specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6 Fault diagnos is

Problems and possible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

List of possible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7 Engine preservation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8 Parts and service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Service literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

POWERPART recommended consumable products . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9 General data

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4

Page 5

1

General Information 1

Introduction

The Perkins 1000 Series industrial and agricultural

engines are the latest developments from Perkins

Engines Limited a world leader in the design and

manufacture of high performance diesel engines.

More than sixty years of diesel production experience,

together with the latest technology, have been

applied to the manufacture of your engine to give you

reliable and economic power.

To ensure that you use the relevant information for

your specific engine type, refer to "Engine

identification" on page 7.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible

danger to the person.

Caution: This indicates that there is a possibl e

danger to the engine.

Note: Is used where the information is important, but

there is not a danger.

A

A0314

5

Page 6

1

How to care for your engine

Warning! Read the "Safety precautions" and

remember them. They are given for your protection

and must be applied at all times.

Caution: Do not clean an engine while it runs. If cold

cleaning fluids are applied to a hot engine, certain

components on the engine may be damaged.

This handbook has been written to assist you to

maintain and operate your engine correctly.

To obtain the best performance and the longest life

from your engine, you must ensure that the

maintenance operations are done at the intervals

indicated in "Preventive maintenance". If the engine

works in a very dusty environment or other adverse

conditions, certain maintenance intervals will have to

be reduced. Renew the filter canisters and lubricating

oil regularly in order to ensure that the inside of your

engine remains clean.

Ensure that all adjustments and repairs are done by

personnel who have had the correct training. Perkins

distributors have this type of personnel available. You

can also obtain parts and service from your Perkins

distributor. If you do not know the address of your

nearest distributor, enquire at one of the Perkins

companies listed on page 8.

The terms "left side" and "right side" apply when the

engine is seen from the flywheel end.

6

Page 7

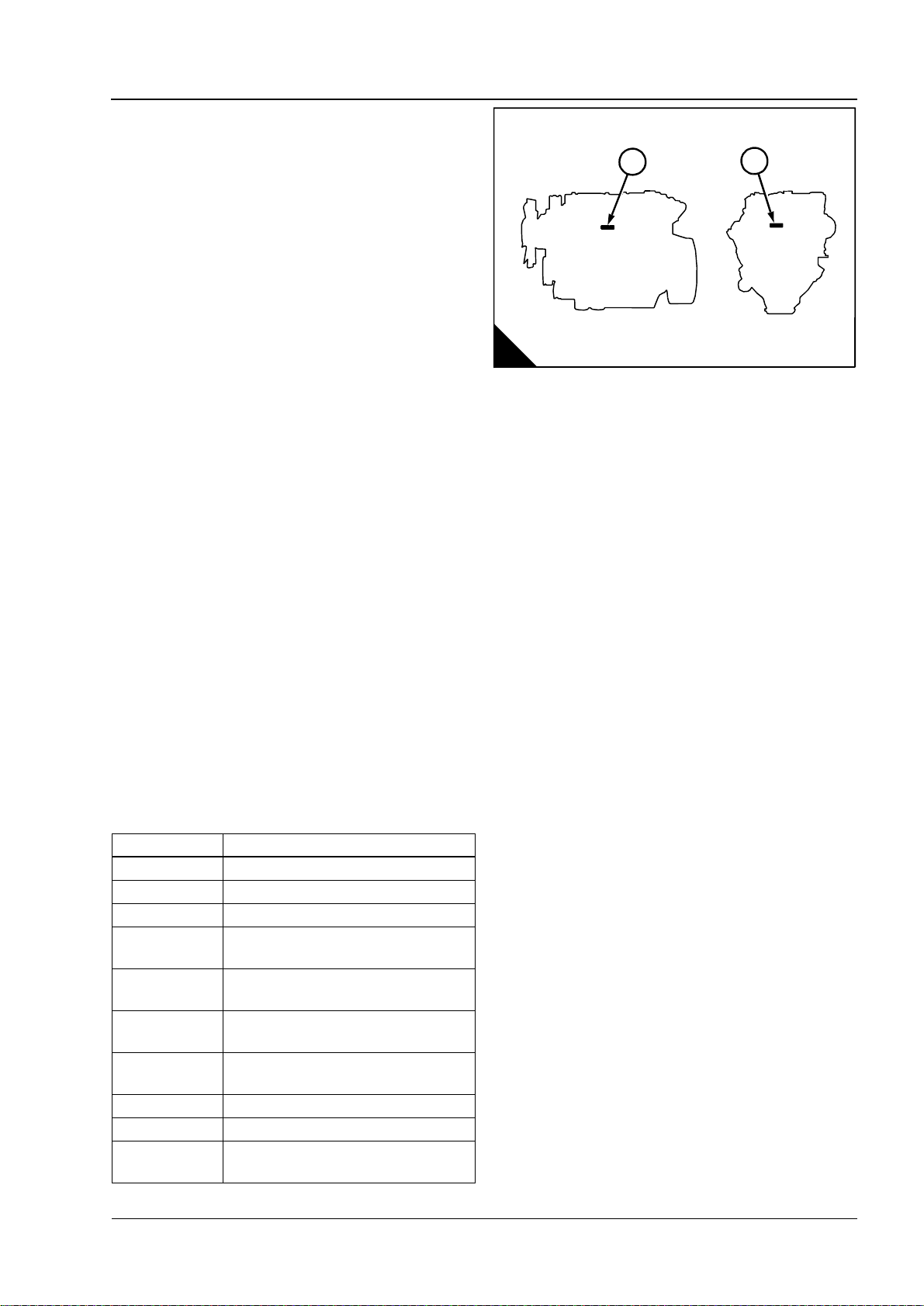

Engine identification

1

The 1000 Series consists of a range of both four and

six cylinder engines. Each range has four basic

engine types, naturally aspirated, compensated,

turbocharged and turbocharged with an intercooler.

There are different model variations within each

range. Identification of the various models is by a

system of numbers and letters, for example:

1006-60TW

1006 6 cylinder engine

-60 6 litre engine

T Turbocharged

TW Turbocharged, but with an air

to water intercooler to cool

the induction air between the

turbocharger and the

cylinders.

Engines used for generator sets have a similar

system of model identification, for example:

1006-60TWG1

1006 6 cylinder engine

-60 6 litre engine

T Turbocharged

1

A

2

A0043

The correct identification of the engine is by the full

engine number.

The engine number is stamped on a label (A1) which

is fastened to the left side of the cylinder block. Some

engines also have the engine number stamped on the

rear of the cylinder block (A2). An example of the

engine number is:

AB30126U510256N

If you need parts, service or information for your

engine, you must give the complete engine number to

your Perkins distributor. If there is a number in the

area of the label marked TPL N

o

, then this number

must also be given to your Perkins distributor.

TW Turbocharged, but with an air

to water intercooler

G Generator set

1 Rating code number

In this handbook, the different engine types are

indicated by their code letters, which are the first two

letters of the engine number as indicated below:

Code Letters Engine type

AA Four cylinder, naturally aspirated.

AB Four cylinder, turbocharged.

AC Four cylinder, compensated.

AD

AG

AH

YA

Four cylinder, turbocharged

and intercooled.

Four cylinder, naturally aspirated,

belt driven coolant pump.

Four cylinder, turbocharged,

belt driven coolant pump.

Six cylinder,

naturally aspirated.

YB Six cylinder, turbocharged.

YC Six cylinder, compensated.

YD

Six cylinder, turbocharged

and intercooled

7

Page 8

1

Perkins companies

Australia

Perkins Engines Australia Pty. Ltd,

Suite 4, 13A Main Street,

Mornington 3931, Victoria, Australia.

Telephone: 0061 (0) 597 51877

Telex: Perkoil AA30816

Fax: 0061 (0) 0597 1305

France

Perkins France S.A.S,

“Parc des reflets”

165 Avenue Du Bois de la Pie

95700 Roissy Charles de Gaulle, France.

Telephone: 0033 (01) 49 90 7171

Fax: 0033 (01) 49 90 7190

United Kingdom

Perkins Engines Company Ltd,

Eastfield, Peterborough PE1 5NA,

England.

Telephone: 0044 (0) 1733 58 3000

Telex: 32501 Perken G

Fax: 0044 (0) 1733 582240

United States of America

Perkins International - North America,

26200 Town Center Drive,

Suite 280,

Novi, Michigan 48375

USA

Telephone: 001 248 374 3100

Fax: 001 248 374 3110

Germany

Perkins Motoren GmbH,

Saalaeckerstr asse 4,

63801 Kleinostheim,

Germany.

Telephone: 0049 6027 5010

Fax: 0049 6027 501124

Italy

Motori Perkins S.p.A.,

Via Socrate 8,

22070 Casnate con Bernate (Como), Italy.

Telephone: 0039 031 4633466 / 031 4633488

Fax: 0039 031 565480 / 031 396001

Japan

Perkins Engines, Inc.,

Address Building, 8th Floor,

2-2-19 Akasaka, Minato-ku,

Tokyo 107-0052, Japan.

Telephone: 0081 (0) 3 3560 3878

Fax: 0081 (0) 3 3560 3877

Singapore

Perkins Engines Latin America Inc,

Suite 200,

701, Waterford Way (NW 62nd Avenue),

Miami, FL 33134

U.S.A.

Telephone: 001 305 476 6900

Telex: 32501 Perken G

Fax: 001 305 476 6910

In addition to the above companies, there are

Perkins distributors in most countries. Perkins

Engines Company Limited., Peterborough or one

of the above companies can provide details.

Perkins Engines (Asia Pacific) pte Ltd

20 Harbour Drive

#07-06A, PSA Vista

Singapore 117612

Telephone: (65) 874 7712

Fax: (65) 874 7722

8

Page 9

General safety precautions

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm. Battery

posts, terminals and related accessories contain

lead and lead compounds. Wash hands after

handling.

These safety precautions are important. You must

refer also to the local regulations in the country of use.

Some items only refer to specifi c appl ic ati on s.

l

Only use these engines in the type of application

for which they have been designed.

l

Do not change the specification of the engine.

l

Do not smoke when you put fuel in the tank.

l

Clean away fuel which has been spilt. Material

which has been contaminated by fuel must be

moved to a safe place.

l

Do not put fuel in the tank while the engine runs

(unless it is absolutely necessary).

l

Do not clean, add lubricating oil, or adjust the

engine while it runs (unless you have had the

correct training; even then extreme care must be

used to prevent injury).

l

Do not make adjustments that you do not

understand.

l

Ensure that the engine does not run in a location

where it can cause a concentration of toxic

emissions.

l

Other persons must be kept at a safe distance

while the engine or auxiliary equipment is in

operation.

l

Do not permit loose clothing or long hair near

moving parts.

l

Keep away from moving parts during engine

operation. Warning! Some moving parts cannot

be seen clearly while the engine runs.

l

Do not operate the engine if a safety guard has

been removed.

l

Do not remove the filler cap or any component of

the cooling system while the engine is hot and

while the coolant is under pressure, because

dangerous hot coolant can be discharged.

l

Do not allow sparks or fire near the batteries

(especially when the batteries are on charge)

because the gases from the electrolyte are highly

flammable. The battery fluid is dangerous to the

skin and especially to the eyes.

l

Disconnect the battery terminals before a repair is

made to the electrical system.

l

Only one person must control the engine.

l

Ensure that the engine is operated only from the

control panel or from the operators position.

l

If your skin comes into contact with high-pressure

fuel, obtain medical assistance immediately.

l

Diesel fuel and lubricating oil (especially used

lubricating oil) can damage the skin of certain

persons. Protect your hands with gloves or a

special solution to protect the skin.

l

Do not wear clothing which is contaminated by

lubricating oil. Do not put material which is

contaminated with oil into the pockets of clothing.

l

Discard used lubricating oil and coolant in

accordance with local regulations to prevent

contamination.

l

Ensure that the control lever of the transmission

drive is in the "out-of-drive" position before the

engine is started.

l

Use extreme care if emergency repairs must be

made in adverse conditions.

l

The combustible material of some components of

the engine (for example certain seals) can

become extremely dangerous if it is burned. Never

allow this burnt material to come into contact with

the skin or with the eyes.

l

Always use a safety cage to protect the operator

when a component is to be pressure tested in a

container of water. Fit safety wires to secure the

plugs which seal the hose connections of a

component which is to be pressure tested.

l

Do not allow compressed air to contact your skin.

If compressed air enters your skin, obtain medical

help immediately.

l

Turbochargers operate at high speed and at high

temperatures. Keep fingers, tools and debris away

from the inlet and outlet ports of the turbocharger

and prevent contact with hot surfaces.

l

Fit only genuine Perkins parts.

1

9

Page 10

This page is intentionally blank

Page 11

2

Engine views 2

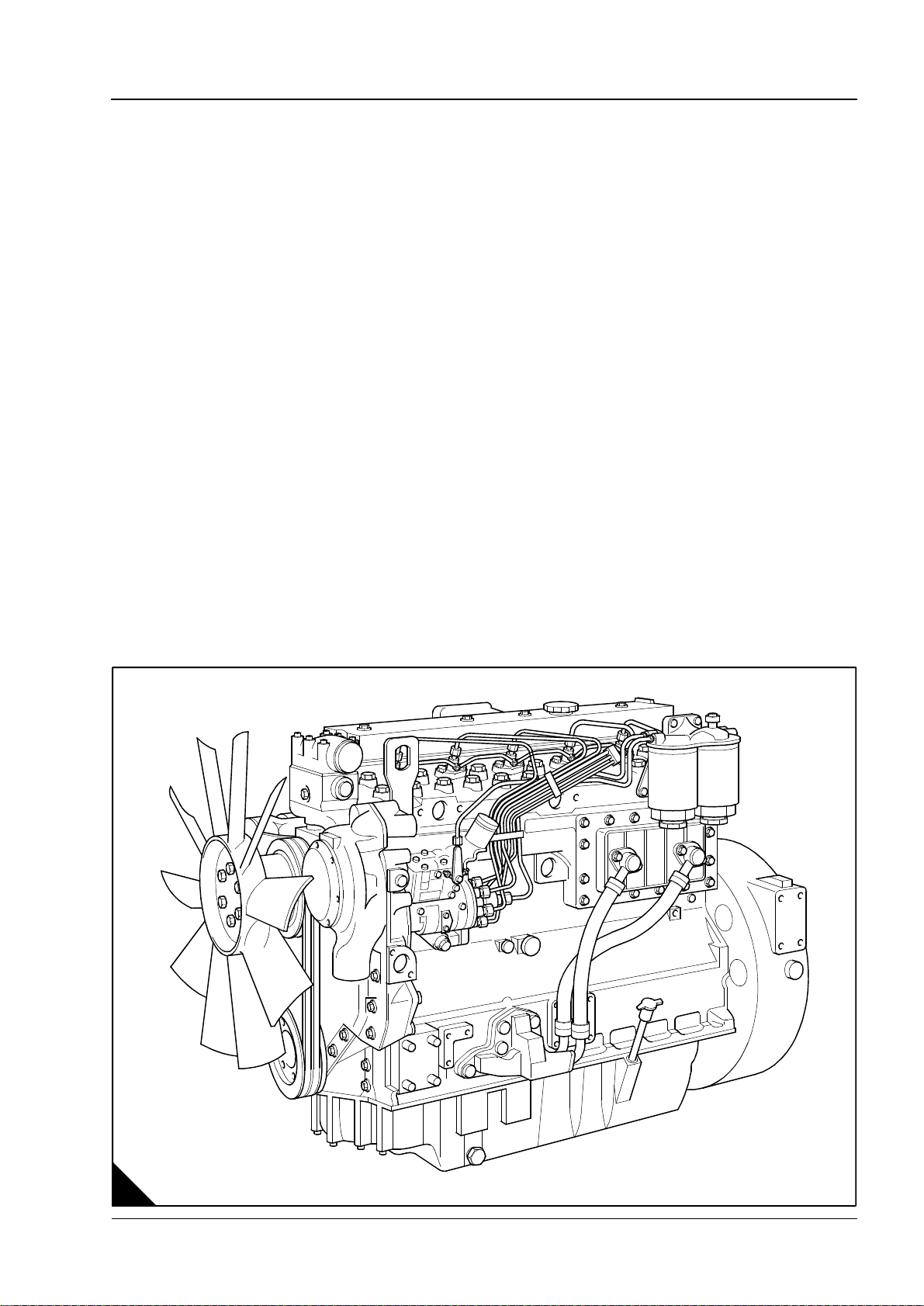

Introduction

Perkins engines are built for specific applications and the views which follow do not necessarily match your

engines specifica tio n.

Location of engine parts

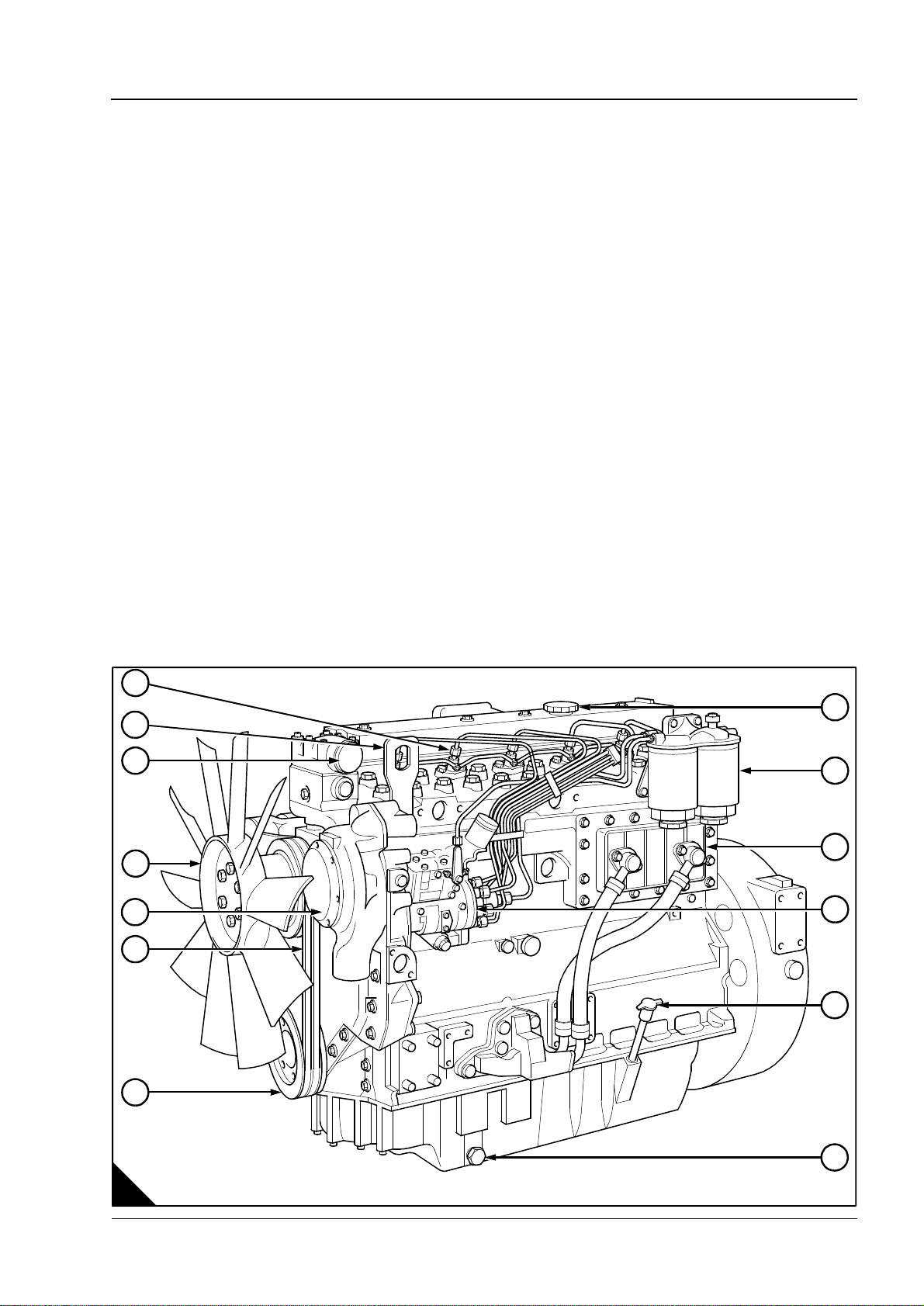

Front and left side of the YB engine (A)

1 Filler cap for the lubricating oil

2 Fuel filter

3 Lubricating oil cooler

4 Fuel injection pump

5 Lubricating oil dipstick

6 Drain plug for the lubricating oil

7 Crankshaft pulley

13

12

11

10

8Drive belt

9 Coolant pump

10 Fan

11 Coolant outlet

12 Front lift bracket

13 Atomiser

1

2

3

A

9

8

7

4

5

6

A0314/1

11

Page 12

2

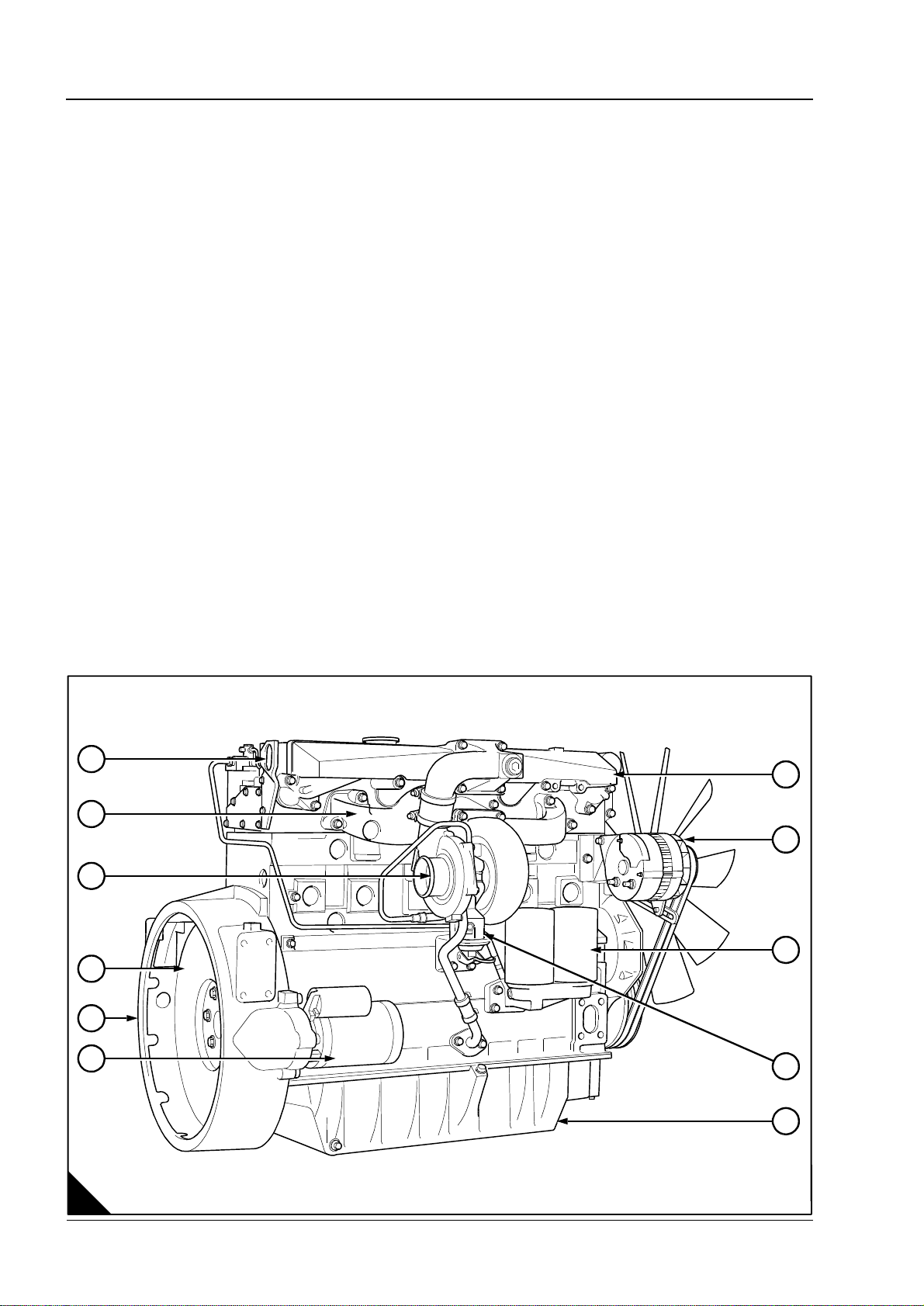

Rear and right side of the YB engine (A)

14 Induction manifold

15 Alternator

16 Lubricating oil filter

17 Fuel lift pump

18 Lubricating oil sump

19 Starter motor

20 Flywheel housing

21 Flywheel

22 Turbocharger

23 Exhaust manifold

24 Rear lift bracket

12

24

23

22

21

20

19

A

14

15

16

17

18

A0315

Page 13

3

Operation instructions 3

How to start the engine

Several factors affect engine start, for example:

l

The power of the batteries

l

The performance of the starter motor

l

The viscosity of the lubricating oil

l

The installation of a cold start system

Diesel engines need a cold starting aid if they are to

start in very cold cond itions. Nor mally, your vehicl e or

your machine will be fitted with the correct equipment

for your region of operation.

Perkins engines can be equipped with various cold

starting systems. For the 1000 Series engines these

systems are:

Fuelled starting aid

An electrically operated device which ignites a

specific amount of diesel fuel in the induction manifold

in order to heat the induction air.

Port heaters

These electrical devices are fitted in the induction

manifold and heat the induction air. They are

operated automatically when the starter motor is

engaged. When these devices are fitted, the start

procedure for a cold engine is the same as that given

for a cold engine start without starting aids.

Start Pilot

A hand pump is used to inject a cold start fluid into the

induction manifold through an atomiser. The cold start

fluid ignites at a lower temperature than diesel fuel.

The cold start fluid is contained in a separate

reservoir. Certain models use a push button to

actuate a solenoid which releases the cold start fluid

from an aerosol container.

KBi

This system uses an aerosol container filled with a

cold start fluid. The fluid is released by a solenoid,

which is operated by a push button. The cold start

fluid is sprayed into the induction manifold through a

nozzle. The cold start fluid ignites at a lower

temperature than diesel fuel.

Caution: If the engine is to be run after a period in

storage, see "Caution" on page 52.

13

Page 14

3

0RH

H

S

0

R

S

How to start a warm engine

1 If the engine is equipped with a manual stop

control, ensure that it is in the "run" position.

2 Adjust the engine speed control to the quarter open

position.

3 Turn the start key to the "HS" or "S" position (A) or

(B) to engage the starter motor.

4 Allow the start key to return to the "R" position, as

soon as the engine starts.

Always ensure that the engine and starter motor are

stationary before the starter motor is engaged again.

How to start a cold engine without starting aids

1 If the engine is equipped with a manual stop

control, ensure that it is in the "run" position.

2 Adjust the engine speed control to the maximum

speed position.

3 Turn the start key to the "S" position (B) to engage

the starter motor. Allow the key to return to the "R"

position, when the engine starts. Then adjust the

engine speed control to get an even idle speed.

4 If the engine does not start in 30 seconds, allow the

start key to the "R" position for another 30 seconds.

Then engage the starter motor again for a maximum

period of 30 seconds.

How to start a cold engine with the fuelled starting

aid

Caution: Ether type fuels must not be used at the

same time as a fuelled starting aid.

1 If the engine is equipped with a manual stop

control, ensure that it is in the "run" position.

2 Turn the start key to the "H" position (A) and keep

it there for 15 seconds.

3 Adjust the engine speed control to the maximum

speed position.

4 Turn the start key to the "HS" position in order to

engage the starter motor. Allow the start key to return

to the "R" position, when the engine starts. Then

adjust the engine speed control to give an even idle

speed.

5 If the engine does not start in 15 seconds, turn the

start key to the "H" position and hold it there for 10

seconds. Then engage the starter motor again.

A

B

A1015

A1016

14

Page 15

How to start a cold engine with manually operated

Start Pilot

3

How to start a cold engin e with K Bi or el ectr ical ly

operated Start Pilot

Caution: Start Pilot equipment must not be used with

heater type starting aids such as the fuelled starting

aid.

Do not use the hand pump until the starter motor is

engaged. The amount of fluid which is necessary for

an engine start will be found by experience.

1 If necessary, fill the reservoir with fluid. Lift the

cover of the reservoir and press the can, head down,

onto the filler plug. Hold it squarely until the fluid fills

the bowl to the maximum mark.

2 If the engine is equipped with a manual stop

control, ensure that it is in the "run" position.

3 Adjust the engine speed control to the maximum

speed position.

4 Turn the start key to the "S" position (page 14/B) in

order to engage the starter motor. Hold the start key

in this position for a maximum of 30 seconds and

operate the hand pump during this period. When the

engine starts, release the start key to the "R" position

and adjust the engine speed control to get an even

idle speed.

5 If the engine does not start in 30 seconds, allow the

start key to return to the "R" position for another 30

seconds. Then engage the starter motor and operate

the hand pump again.

In certain conditions, it is necessary to inject a little

more fluid after the engine has started in order to

ensure that the engine continues to run.

Caution: KBi equipment must not be used with

heater type cold starting aids such as the fuelled

starting aid.

1 If necessary, renew the screw type canister. Ensure

that the sealing washer remains in position when the

new canister is fitted. Each container has a safety

valve.

2 If the engine is equipped with a manual stop

control, ensure that it is in the "run" position.

3 Adjust the engine speed control to the maximum

speed position.

4 Turn the start key to the "S" position (page 14/B) in

order to engage the starter motor.

5 When the engine turns, press the starting aid button

for a maximum period of 2 seconds. If the engine

does not start after the first 2 second application, keep

the starter motor engaged. After 5 seconds, press the

button again for 2 seconds.

6 Allow the start switch to return to the "R" position,

when the engine starts. Then adjust the engine speed

control to get an even idle speed. In certain conditions

it is necessary to inject a little more fluid after the

engine has started, in order to ensure that the engine

continues to run.

The air filter at the outer end of the pump must be

inspected from time to time. If necessary, it must be

washed in kerosene.

The inside surface of the cylinder can be lightly

lubricated with a thin lubricating oil.

The nozzle can be removed from the induction

manifold and washed in kerosene, if necessary. Use

the direction mark on the nozzle body to ensure that

the nozzle is fitted in its original posit ion .

15

Page 16

3

Cautions:

How to stop the engine

Altitude

Caution: It is recommended that a turbocharged

engine is run at approximately 1000 rev/min at a

reduced load for 2-3 minutes before it is shut down.

This will allow the turbocharger to cool.

According to the equipment fitted, either turn the

engine start key to the "O" position (page 14/A or B)

or operate the manual stop control. If a manual stop

control is used, ensure that the control returns to the

"run" position after the engine has stopped. Also

ensure that the engine start key is turned to the "O"

position.

Adjustment of the engine speed range

The idle or the maximum speed settings must not be

changed by the engine operator, because this can

damage the engine or transmission. The warranty of

the engine can be affected if the seals on the fuel

injection pump are broken during the warranty period

by a person who is not approved by Perkins.

Running-in

If the naturally aspirated engine is to run at an altitude

above 600 m (2,000 ft), the fuel delivery can be

changed to reduce fuel consumption and smoke.

Perkins can give the percentage of fuel reduction

necessary if details of engine application and ambient

conditions are given. Changes to the settings of the

fuel injection pump must be made by a Perkins

distributor or by an approved distributor for the fuel

injection pump.

l

Do not operate the engine at high speeds without

a load.

l

Do not overload the engine.

A gradual running-in of a new engine or POWER

EXCHANGE engine is not necessary. Prolonged

operation at light loads during the early life of the

engine can cause lubricating oil to enter the exhaust

system. Maximum load can be applied to a new

engine as soon as the engne is put into service and

the coolant temperature has reached a minimum of

60 °C (140 °F).

The engine will benefit if the load is applied as soon

as possible after the engine is put into service.

Turbocharged engines

Because of the power characteristics of the

turbocharged engines it is necessary to maintain a

high engine speed when you climb a gradient. To

ensure that the engine is not overloaded at low engine

speeds engage a lower gear.

16

Page 17

4

Preventive maintenance 4

Preventive maintenance periods

These preventive maintenance periods apply to average conditions of operation. Check the periods given by

the manufa ctur er of th e equ ipm ent in wh ich t he e ngi ne i s inst all ed. Use the p er iod s whi ch ar e sho rte st. When

the operation of the engine must conform to the local regulations these periods and procedures may need to

be adapted to ensure correct operation of the engine.

It is good preventive maintenance to check for leakage and loose fasteners at each service.

These maintenance periods apply only to engines that are operated with fuel and lubricating oil which conform

to the specifications given in this handbook.

17

Page 18

4

Schedules

The schedules which follow must be applied at the interval (hours or months) which occur first.

A First service at 20/40 hours

B Every day or every 8 hours

D Every 400 hours or 12 months

E Every 2000 hours

C Every 200 hours or 6 months

ABCDE Operation

ll

l

ll

l

l

l

l

l

l

ll

ll

ll

ll

Check the amount of coolant

Check the concentration of the coolant

(2)

Check the tension and the condition of the drive belt

Clean the sediment chamber and the strainer of the fuel lift pump

Check for water in the pre-filter

(1)

, (or earlier if your fuel supply is contaminated)

Renew the elements of the fuel filter(s)

l

Ensure that the atomisers are checked

(3)

Ensure that the idle speed is checked and adjusted, if it is necessary

Check Stanadyne fuel injection pump for governor operation

Check the amount of lubricating oil in the sump

Check the lubricating oil pressure at the gauge

Renew the engine lubricating oil

(4) (5)

(1)

Renew the canisters(s) of the lubricating oil filter

Renew the canister of the lubricating oil filter (six cylinder naturally aspirated engines

with a single filter canister)

(4)

(3)

(3)

(1) If one is fitted.

(2) Renew the antifreeze every 2 years. If a coolant inhibitor is used instead of antifreeze, it should be renewed every 6 months.

(3) By a person who has had the correct training.

(4) The lubricating oil and the filter canister(s) must be renewed every 250 hours or 12 months for applications where the engine

normally runs at full load for periods of more than 20 minutes, for example: Generating sets or water pumps.

(5) The oil cha nge in terval wi ll change wit h the amo unt of sul phur i n the f uel (see t he tab le in f uel specif icatio n on p age 43) . The int erval

to change the canister of the lubricating oil filter is not affected.

18

Page 19

Schedules

The schedules which follow must be applied at the interval (hours or months) which occur first.

4

A First service at 20/40 hours

B Every day or every 8 hours

D Every 400 hours or 12 months

E Every 2000 hours

C Every 200 hours or 6 months

A B C D E Operation

l

Clean the engine breather system

(3)

Clean the air cleaner or empty the dust bowl of the air filter

ll

l

l

l

ll

ll

- extremely dusty conditions

- normal conditions

Clean or renew the air filter element, if it has not been indicated earlier

Ensure that the turbocharger impeller and turbocharger compressor casing are

l

cleaned

Clean the compressor air filter

l

Ensure that the exhauster or compressor

(2)

(1)

(1)

is checked

Ensure that the valve tip clearances of the engine are checked and, if necessary,

adjusted

(2)

Ensure that the valve tip clearances of the engine are checked and, if necessary,

adjusted (high rated engines)

l

Ensure that the alternator and the starter motor are checked

(2)

(2)

(2)

(1) If one is fitted.

(2) By a person who has had the correct training.

(3) The closed breather assemblies must be cleaned, see page 36 and page 37. The oil separator of the open breather assembly

should not be cleaned, but must be renewed at every overhaul of the engine or 8000 hours, see page 38. Refer to your local

distributor.

19

Page 20

4

Warnings!

How to drain the cooling system

l

Discard the used coolant in a safe place and in

accordance with local regulations.

l

Do not drain the coolant while the engine is still hot

and the system is under pressure because

dangerous hot coolant can be discharged.

1 Ensure that the machine is on level ground.

2 Remove the filler cap of the coolant system.

3 Remove the brass drain plug from the side of the

cylinder block (A) in order to drain the coolant. Ensure

that the drain hole is not restricted.

4 Open the tap or remove the drain plug at the bottom

of the radiator in order to drain the radiator. If the

radiator d oes not have a ta p or drai n plug , discon nect

the hose at the bottom of the radiator. If a lubricating

oil cooler/filter assembly (B) is fitted, this must also be

drained and flushed. To do this disconnect the hoses

(B1 and B2) at the to p of the cooler and flush the oil

cooler through the outlet connection (B1) until clean

water runs from the inlet (B2).

5 Flush the coolant system with clean water.

Caution: If the coolant system is to remain empty

temporarily after it is flushed, drain the oil cooler and

fill it with 165 ml (1/3 pint) of antifreeze. This will

protect the oil cooler against frost if any clean water

drains down from the water jacket when the machine

is moved.

1

A

1

B

L0005

2

L0006

6 Fit the hoses to the top of the cooler and tighten the

clips.

7 Fit the drain plugs and the filler cap. Close the

radiator tap or connect the radiator hose.

20

Page 21

How to check the specific gravity of the

1.08

coolant

4

40 45

60

50

A

6055

140

Warning! Do not drain the coolant while the engine

is still hot and the system is under pressure because

dangerous hot coolant can be discharged.

For mixtures which contain inhibited ethylene glycol:

1 Ensure that the machine is on level ground.

2 Operate the engine until it is warm enough to open

the thermostat. Continue to run the engine until the

coolant has circulated the cooling system.

3 Stop the engine.

4 Allow the engine to cool until the temperature of the

coolant is below 60 °C (140 °F).

5 Remove the filler cap of the cooling system.

6 Drain some coolant from the cooling system into a

suitable container.

7 Use a special coolant hydrometer that will check

the temperature and the specific gravity of the

coolant, follow the manufacturer's inst ructi on s.

Note: If a special coolant hydrometer is not available,

put a hydrometer and a separate thermometer into

the antifreeze mixture and check the readings on both

instruments. Compare the readings with the chart (A).

50

40

30

DB

20

10

0

1.04 1.05 1.06 1.07

A

C

1.09 1.10 1.11

122

104

86

68

50

A1021

Specific gravity chart

A = Percentage antifreeze by volume

B = Mixture temperature in Fahrenheit

C = Specific gravity

D = Mixture temperature in Celsius

8 Adjust the strength of the mixture as necessary.

Note: If it is necessary to fill or replenish the coolant

system in service, mix the coolant to the correct

strength before it is added to the coolant system.

Perkins POWERPART anti freez e w ith a

concentration of 50% will give protection against frost

to a temperature of -35

o

C (-31 oF). It will also give

protection against corrosion. This is especially

important when there are aluminium components in

the coolant system.

21

Page 22

4

How to check the drive belt(s)

Renew a belt if it is worn or damaged. If twin belts are

fitted, they must be renewed together.

To ensure maximum belt life, it is recommended that

a belt tensioner gauge is used to check the belt

tension. Fit the gauge (A1) at the centre of the longest

free length and check the tension. If a "Burroughs"

gauge is used, the correct tension is 355 N (8 0 lbf)

36 kgf. If the tension is 220 N (50 lbf) 22 kgf or below,

adjust it to 355 N (80 lbf) 36 kgf as indicated below:

If a gauge is not available, press down the belt with

the thumb at the centre of the longest free length and

check the deflection (B). With moderate thumb

pressure - 45N (10 lbf) 4,5 kgf - the correct deflection

of the belt is 10 mm (3/8 in).

If twin belts are fitted, check/adjust the tension on the

tighter belt.

How to adjust the belt tension

1 Loosen the pivot fasteners (B1) of the alternator

and the adjustment link fasteners (B2).

2 Change the position of the alternator to give the

correct tension. Tighten the pivot fasteners of the

alternator and the adjustment link fasteners.

3 Check the belt tension again to ensure that it is still

correct. If a new belt is fitted, the belt tension must be

checked again after the first 20 hours of operation.

1

A

1

2

A0281

22

B

A0282

Page 23

How to clean the gauze strainer of the fuel

lift pump

4

1

1 Release the fastener (A2) and remove the cover

and the joint (A3) from the top of the fuel lift pump

(A4). Remove the gauze strainer (A1). On some

turbocharged engines, it will be necessary to remove

the small heat shield which is fitted above the pump.

2 Wash carefully all of the sediment from the lift pump

body.

3 Clean the gauze strainer, the joint and the cover.

4 Assemble the lift pump. Use a good joint and

ensure that the lift pump body and the cover are fitted

together correctly because leakage at this point will let

air into the fuel system. Fit the heat shield, if one is

fitted.

5 Eliminate the air from the fuel system through the

filter vent plug, see page 30.

Fuel pre-filter

If a pre-filter is fitted between the fuel tank and the

engine. Check the filter bowl for water at regular

intervals and drain as necessary, see page 18.

2

4

A

3

L0008

23

Page 24

4

Cautions:

How to renew the element(s) of the fuel

filter

There are three types of fuel filter in use:

Warning! Discard the used element or canister and

fuel oil in a safe place and in accordance with local

regulations.

l

It is important that only the genuine Perkins parts

are used. The use of a wrong canister or element

can damage the fuel injection pump.

l

Do not allow dirt to enter the fuel system. Before a

connection is disconnected, clean thoroughly the

area around the connection. After a component

has been disconnected, fit a s uitable cover to all

open connections.

l

The pre-filter and main filter canisters must be

renewed at the same time.

The separate element type where the filter element is

held between the filter head and the bottom cover (A).

The canister type where the filter element has an

internal thread (B2) at the top and is fastened to a

threaded adaptor (B1) in the filter head (B).

A

1

A0248

2

A fuel filter with a quick release canister (C) has been

introduced on certain engines. Some engines are

fitted with a pre-filter of the same type. This filter is

fitted next to the main filter, but connected in the fuel

system before the fuel lift pump; both of the filter

elements must be renewed at the same time.

The filter can have one or two elements. When twin

elements are fitted, both of the elements must be

renewed at the same time.

B

C

A0249

A0271B

24

Page 25

How to renew the element(s) of the

separate element type

4

1

Caution: It is important that only the genuine Perkins

fuel filter element is used. The use of a wrong element

can cause damage to the fuel injection pump.

1 Clean the outside surfaces of the fuel filter

assembly. If a drain tap (A4) is fitted to the bottom of

the filter bowl, drain the fuel from the filter.

2 Hold the bottom cover of the filter element and

release the setscrew (A3) which is fitted through the

filter head (A1) above the centre of the element.

3 Lower the bottom cover of the filter.

4 Remove the element (A5) and disc ard it.

5 Clean the inside surfaces of the filter head and of

the cover.

6 Renew the seals (A2) and (A6) and lightly lubricate

them with clean fuel.

7 Put the bottom cover under the new element and

hold the element squarely to the filter head. Ensure

that the element is fitted in the centre against the joint

in the filter head. With the assembly in this position,

engage and tighten the setscrew.

8 Eliminate the air from the fuel system, see page 29.

3

2

4

5

A

6

L0009

25

Page 26

4

How to renew the filter canister of the

canister fuel filter

2

1 Thoroughly clean the outside surfaces of the fuel

filter assembly.

2 Loosen the drain device at the bottom of the filter

(A1) and allow the water/fuel to drain into a suitable

container.

3 Use a strap wrench or similar tool to loosen the filter

canister and remove the canister.

4 Ensure that the threaded adaptor (A2) is secure in

the filter head and that the inside of the head is clean.

5 Lubricate lightly the top seals (A3) of the new

canister with clean fuel. Fit the new canister to the

filter head and tighten, by hand only.

6 Eliminate the air from the fuel system, see page 29.

3

1

A

A0249

26

Page 27

How to renew the canister of the quick

release fuel filter

4

1

5

1 Thoroughly clean the outside surfaces of the filter

assembly.

2 Loosen the drain device (A4) , if one is fitted, at the

bottom of the canister and allow the water/fuel to drain

into a suitable container.

Note: If the filter does not have a drain device fitted

release the cap (A1) on top of the filter head. Remove

the nylon in sert to lower t he level of th e fuel in the filter

canister. This will prevent fuel spill when the clamp

ring is released.

3 Unscrew the sediment bowl at the bottom of the

canister, if one is fitted.

4 Support the filter canister and rotate the clamp ring

(A2) to the left, see the direction arrow, and remove

the clamp ring.

5 Remove the canister from the filter head by a direct

pull downwards, and discard the old canister (A3).

Retain the clamp ring.

6 Ensure the filter head is clean and that the seals

(A5) and (A6) are in good condition or renew them.

Align the spline (A8) with the groove in the filter head

and push the new canister fully into the filter head.

7 Support the canister, fit the clamp ring (A7) and

rotate it to the right, see the direction arrow, to fasten

the canister to the filter head.

8 If a sediment bowl is fitted, remove the bowl and

thoroughly clean the cover of the bowl.

9 Check the two ’O’ ring seals of the sediment bowl

for damage and renew if necessary.

10 Clean the threads of the sediment bowl and fit the

bowl to the canister and tighten by hand only.

11 If it was removed, fit the nylon insert used to lower

the level of the fuel in the filter canister and fasten the

cap.

12 Eliminate the air from the fuel system, see page

29.

A

8

2

3

7

4

6

A1520

27

Page 28

4

Warnings!

Cautions:

Atomiser fault

.

l

If your skin comes into contact with high-pressure

fuel, obtain medical assistance immediately.

l

Keep away from moving parts during engine

operation. Some moving parts cannot be seen

clearly while the engine runs.

An atomiser fault can cause an engine misfire.

In order to find which atomiser is defective, operate

the engine at a fast idle speed. Loosen and tighten the

union nut of the high-pressure fuel pipe at each

atomiser. When the union nut of the defective

atomiser is loosened, there is little or no effect on the

engine speed.

How to renew an atomiser

l

Atomisers must be removed and fitted by a person

with the correct training.

l

Do not allow dirt to enter the fuel system. Before a

connection is disconnected, clean thoroughly the

area around the connection. After a component

has been disconnected, fit a s uitable cover to all

open connections.

1 Remove the fuel leak-off pipe.

2 Remove the union nuts (A1) of the high-pressure

pipe from the atomiser and from the fuel injection

pump. Do not bend the pipe. If necessary, remove the

pipe clamps.

3 Remove the atomiser setscrews and remove the

clamp (A2), the atomiser (A6) and its seat washer

(A7). Remove the dust seal (A5) and the spacer (A4)

and fit the spacer and a new dust seal onto the new

atomiser.

Caution: Remove and discard the seat washer (A6).

If the original seat washer remains in the recess for

the atomiser, the nozzle protrusion will be incorrect

when a new seat washer is added.

1

2

3

4

5

6

7

A

A0027

5 Fit the high-pressure fuel pipe and tighten the union

nuts to 27 Nm (20 lbf ft) 2,8 kgf m. If necessary, fit the

pipe clamps.

6 Renew the sealing washers and fit the leak-off pipe.

Tighten the banjo bolt to 9,5 Nm (7,0 lbf ft) 1,0 kgf m.

7 Operate the engine and check for leakage of fuel

and air.

4 Put the new atomiser in position with its spacer,

new dust seal and a new seat washer, ensure that the

fuel leak-off connection (A3) is not toward the engine.

Position the clamp and engage the atomiser

setscrews. Ensure that the atomiser is not tilted and

tighten the setscrews for the clamp evenly and

gradually to 12 Nm (9 lbf ft) 1,2 kgf m.

Caution: Do not tighten the union nuts of the highpressure pipes more than the recommended torque

tension. If there is a leakage from the union nut,

ensure that the pipe is correctly aligned with the

atomiser inlet. Do not tighten the atomiser union nut

more, as this can cause a restriction at the end of the

pipe. This can affect the fuel delivery.

28

Page 29

How to eliminate air from the fuel system

There are two methods to eliminate air from the fuel

system according to the type of fuel injection pump

fitted:

The standard method is used where the fuel injection

pump has vent screws (A1/2) and (B1).

The self-vent method is used where the fuel injection

pump has a self-vent feature. These pumps have a

vent pipe (C1) fitted between a connection in the top

of the pump and the atomiser leak-off pipe. Vent

screws are not fitted to these pumps.

If air enters the fuel system, it must be eliminated

before the engine can be started.

4

1

2

A

A0264

Air can enter the system if:

l

The fuel tank is drained during normal operation.

l

The low-pressure fuel pipes are disconnected.

l

A part of the low-pressure fuel system leaks during

engine operation.

If air enters the fuel system, it must be eliminated

before the engine can be started.

In order to eliminate air from the fuel system, proceed

as follows:

Caution: Do not allow fuel from the engine to

contaminate the engine compartment. Put a drip tray

under the engine and discard old fuel in accordance

with local instructions.

1

B

A0265

1

C

A0266

29

Page 30

4

Standard method to eliminate air from the

fuel system

1 Loosen the vent plug on the top of the twin element

fuel filter (A1). If a single element filter is used, loosen

the banjo connection bolt which is fitted on the top of

the filter (B1).

2 Operate the priming lever on the fuel lift pump (C)

until fuel, free from air, comes from the filter vent

point. Tighten the vent plug or banjo connection bolt.

Note: If the cam for the fuel lift pump is at the point of

maximum lift, it will not be possible to operate the

priming lever. In this situation, the crankshaft must be

rotated one turn.

3 Ensure that the manual stop control is in the "run"

position. If an electrical stop control is used, turn the

start key to the "R" position.

4 Loosen the vent screw in the lock screw (D2) for the

hydraulic h ead. Operate the priming lever of the fuel

lift pump until fuel, free from air, comes from the vent

screw. Tighten the vent screw. Loosen the vent screw

(B1) on the governor cover. Operate the priming lever

of the fuel lift pump until fuel, free from air, comes from

the vent screw. Tighten the vent screw.

1

A

A0254

1

Continued

B

C

A0261

L0012

1

30

D

2

A0264

Page 31

Caution: Use a spanner on the flats (A1) of the

fuelled starting aid to prevent its movement when the

union nut (A2) is loosened and tightened.

5 If the pipe to the fuelled starting aid has been

drained, loosen the union nut (A2) at the fuelled

starting aid and operate the lift pump (C) until fuel,

free from air, comes from the connection. Tighten the

union nut at the starting aid. Use a spanner on the

hexagon of the fuelled starting aid to prevent its

movement when the union nut is loosened and

tightened.

6 Loosen the union nuts (B1) of the high-pressure

pipes at two of the atomisers. Operate the starter

motor until fuel free from air, comes from the pipe

connections. Tighten the high pressure-pipe

connections to 27 Nm (20 lbf ft) 2,8 kgf m.

7 The engine is now ready to start.

If the engine runs correctly for a short time and then

stops or runs roughly, check for air in the fuel system.

If there is air in the fuel system, there is probably a

leakage in the low pressure system .

4

1

2

A

A0263

B

C

1

A0031

L0012

31

Page 32

4

Self-vent method

Fuel injection pumps used on some Lucas and all

Stanadyne fuel injection pumps will automatically

remove air from the fuel system. Vent screws are not

fitted to these pumps.

Caution: Although these fuel inje cti on pum ps will

eliminate air automatically, use the procedure that

follows to remove air from the fuel system if the

system is drained or a major component is removed:

Ensure that fuel has been added to the tank or that

the leakage has been corrected.

1

1 Loosen the vent plug (A1) on the top of the filter

head.

2 Operate the priming lever on the fuel lift pump (B)

until fuel, free from air, comes from the filter vent

point. Tighten the vent plug.

Note: If the cam for the fuel lift pump is at the point of

maximum cam lift, it will not be possible to operate the

priming lever. In this situation, the crankshaft must be

rotated one turn.

Caution: Use a spanner on the flats (A1) of the

fuelled star ting ai d to prev ent it s moveme nt when the

union nut (A2) is loosened and tightened.

3 If the pipe to the fuelled starting aid has been

drained, loosen the union nut (C2) at the fuelled

starting aid and operate the lift pump (C) until fuel,

free from air, comes from the connection. Tighten the

union nut at the starting aid. Use a spanner on the

hexagon of the fuelled starting aid to prevent its

movement when the union nut is loosened and

tightened.

Continued

A

B

1

2

L0011

L0012

32

C

A0263

Page 33

Cautions:

l

Do not tighten the union nuts of the high-pressure

pipes more than the recommended torque

tension. If there is a leakage from the union nut,

ensure that the pipe is correctly aligned with the

atomiser inlet. Do not tighten the atomiser union

nut more, as this can cause a restriction at the end

of the pipe. This can affect the fuel delivery.

l

Damage to the fuel injection pump, battery and

starter motor can occur if the starter motor is used

excessively to eliminate air from the fuel system.

4 Loosen the union nuts (A1) of the high-pressure

pipes at two of the atomisers.

5 Put the electrical system switch (page 14/A) to the

"ON" position. Ensure that the manual stop control, if

one is fitted, is in the "run" position. Operate the

starter motor until fuel, free from air, comes from the

pipe connections. Tighten the high-pressure pipe

connections to 27 Nm (20 lbf ft) 2,8 kgf m. Return the

switch to the "OFF" position.

6 The engine is now ready to start.

If the engine runs correctly for a short time and then

stops or runs roughly, check for air in the fuel system.

If there is air in the fuel system, there is probably a

leakage in the low-pressure system.

4

1

A

A0031

33

Page 34

4

How to renew the lubricating oil of the

engine

Warning! Discard the used lubricating oil in a safe

place and in accordance with local regu lat ion s.

Caution: Ensure that the application is on a level

surface to ensure an accurate reading on the dipstick.

1 Operate the engine until it is warm.

2 Stop the engine, remove the sump drain plug (A1)

and its "O" ring and drain the lubricating oil from the

sump. Ensure that the "O" ring is not damaged. Fit the

drain plug and its "O" ring and tighten the plug to 34 Nm

(25 lb ft) 3,5 kgf m.

3 Fill the sump to the mark (A2) on the dipstick with

new and clean lubricating oil of an approved grade,

see page 44.

A

1

2

A0360

34

Page 35

How to renew the canister of the

lubricating oil filter

Warning! Discard the used canister and lubricating

oil in a safe place and in accordance with local

regulations.

Cautions:

l

The canister contains a valve and special tube to

ensure that lubricating oil does not drain from the

filter. Therefore, ensure that the correct Perkins

POWERPART canister is used.

l

Ensure that the application is on a level surface to

ensure an accurate reading on the dipstick.

The filter can have one or two canisters. When two

canisters are fitted, both must be renewed at the

same time.

1 Put a tray under the filter to retain spilt lubricating

oil.

2 Remove the filter canister with a strap wrench or

similar tool. Ensure that the adaptor (A1) is secure in

the filter head. Discard the canister.

3 Clean the filter head.

4 Add clean engine lubricating oil to the new canister.

Allow the oil enough time to pass through the filter

element.

5 Lubricate the top of the canister seal (A2) with clean

engine lubricating oil.

6 Fit the new canister and tighten it by hand until the

seal contacts the filter head. Tighten the canister a

further 1/2 to 3/4 of a turn by hand. Do not use a strap

wrench.

7 Ensure that there is lubricating oil in the sump. On

turbocharged engines ensure that the engine will not

start and operate the starter motor until oil pressure is

obtained. To ensure that the engine will not start,

either put the manual stop control in the "stop"

position or disconnect the electrical stop control of the

fuel injec tion pump. Oil p ressure is indica ted when the

warning light is extinguished or by a reading on the

gauge.

8 Operate the engine and check for leakage from the

filter. When the engine has cooled, check the oil level

on the dipstick and put more oil into the sump, if

necessary.

4

1

2

A

A0223

35

Page 36

4

How to clean the closed breather system

Warning! Do not direct compressed air at your skin,

if compressed air enters your skin obtain medical help

immediately

Note: The procedure below refers only to the closed

breather shown in (A) and (B).

1 Release the hose clips and remove the breather

valve (A2).

2 Release the short setscrew (A3) and the long

setscrew (A5) and remove the oil separator (A4).

3 Wash the oil separator with approved cleaning fluid

and dry it with low pressure air.

Caution: Do not put the breather valve completely

into the cleaning fluid.

4 The breather valve does not normally need to be

cleaned. If the inside of the breather valve is to be

cleaned, insert a safe approved cleaning fluid into the

valve through the pipe at the bottom. Drain the fluid

from the breather valve. Dry the breather valve with

low pressure air.

5 Check that the inside of the upper pipe (A1) is

clean. If the pipe is not clean, release the flange

setscrews (A6) and remove the pipe. Wash the pipe

with kerosene and dry it with low pressure air.

6 Ensure that the contact faces of the upper pipe

flange and the induction manifold are clean.

7 Fit the upper pipe complete with a new joint and

tighten the flange setscrews .

8 Renew the "O" ring (B1) at the bottom of the oil

separator. Clean the bore in the cylinder block for the

"O" ring of the oil separator. Lightly lubricate the "O"

ring and fit the oil separator to the cylinder block. Fit

the setscrews for the oil separator in their correct

positions and tighten them.

9 Fit the breather valve and tighten the hose clips.

1

6

2

5

4

A

1

B

3

A0241

A0242

36

Page 37

How to clean the integral clos ed breather

system

4

1

Caution: Do not use excessive force to remove the

hose (A4) from the breather outlet pipe.

Note: The procedure below refers only to the closed

breather shown in (A).

1 Release the hose clip and carefully remove the

hose from the breather outlet.

2 Remove the rocker cover.

Caution: Ensure that the lever does not damage the

cover.

3 Release the fasteners and carefully remove the

breather cover from the breather body. A suitable

lever may be necessary to release the cover from the

body of the breather. Ensure that the lever does not

damage the cover. Discard the joint (A5).

Caution: Do not clean the breather valve or the

gauze filter. The breather valve (A1) and the gauze

(A3) must be renewed every 4000 hours.

4 Release the clips (A2) from the clip retainers (A7)

and push the breather valve out of the breather cover.

Discard the breather valve.

5 Remove and discard the gauze.

Warning! Do not allow compressed air to contact

your skin. If compressed air enters your skin, obtain

medical help immediately.

6 Wash the body of the breather, the cover, the baffle

plates (A6) and the breather pipe, every 2000 hours

of operation. Use an approved kerosene cleaning

fluid and dry them with compressed air at low

pressure.

7 Ensure that the holes at the bottom of the baffle

plates in the breather body are not restricted. If

necessary, clean the holes.

3

2

7

6

5

4

A

5 Check that there is no restriction in the breather

pipe or the breather hose. Fit the breather hose to the

cover and tighten the clip.

A0341

To assemble

1 Fit the baffl e plates into the grooves i n the br eather

body.

2 Renew and fit the gauze filter into the breather

body.

3 Renew and fit the new valve into the breather

cover. Ensure that the clips are engaged correctly.

Note: The breather valve is renewed every 4000

hours.

4 Renew the joint, which is fitted dry. Put the cover

and valve assembly into position on the breather

body. Loosely fit the fasteners. Tighten the fasteners

gradually and evenly to 3 Nm (2.2 lbf ft) 0.3 kgf m.

Caution: Do not use excessive force to fit the hose

to the breather outlet pipe.

37

Page 38

4

The open breather system

Some engines have an open breather system that

has an oil separator (A1) fitted to the rocker cover.

The oil separator should not be dismantled or

cleaned, but must be renewed at every engine

overhaul or 8000 hours. Refer to your local distributor.

A

1

A1519

38

Page 39

Air cleaner

Caution: Do not use gasoline to clean the air

cleaner.

A typical wet type air cleaner is shown at (A). The wet

type air cleaner must be drained at a suitable interval.

The container and element (A1) must be cleaned with

kerosene or with another suitable fluid. Do not use

gasoline. Check that the seal (A3) is not damaged

and renew it, if necessary. Fill to the indicated level

(A2) with clean engine lubricating oil.

4

1

2

3

A

G0010

39

Page 40

4

Air filter

Environmental conditions have an important effect on

the frequency at which the air filter needs service.

Certain air filters have a separate dust bowl (A1)

which must be cleaned at intervals. The amount of

dust in the bowl shows if it has been removed at the

correct time for the conditions of operation. Do not let

dust completely fill the bowl, because this will reduce

the life of the filter element (A2).

Certain air filters have automatic dust valves (B1)

through which dust is expelled from the filter. The

rubber dust valve must be kept clean. Ensure that the

sides of the valves close completely together and that

they can separate freely.

If a restriction indicator (C) is fitted, it will indicate

precisely when the air filter element needs service.

This prevents the premature removal of the filter

element which causes extra cost or late removal of

the element which can cause loss of engine power.

The filter element must be cleaned or renewed

according to the manufacturers recommendations.

2

Restriction indicator

The restriction indicator for these engines must work

at a pressure difference of 508/558 mm (20/22 in) of

water gauge. It is fitted on the air filter outlet or

between the air filter and the induction manifold.

When the red warning indicator (C1) is seen through

the clear panel (C2) after the engine has stopped, the

air filter element must be removed for service.

After a clean element has been fitted, press the

rubber bottom (C3) or the button (C4) of the restriction

indicator to reset the red warning indicator.

A

B

1

A1039

1

A1040

40

Page 41

How to check the valve tip clearances

These are checked between the top of the valve stem

and the rocker lever (A), with the engine hot or cold.

The correct clearance for inlet valves is 0,20 mm

(0.008 in) and 0,45 mm (0.018 in) for exhaust valves.

The valve positions are shown at (B).

The sequence of valves from number 1 cylinder is

shown in the table below.

Note: Number 1 cylinder is at the front of the engine.

Four cylinder engines

4

1 Rotate the crankshaft in the normal direction of

rotation until the inlet valve (B8) of number 4 cylinder

has just opened and the exhaust valve (B7) of the

same cylinder has not closed completely. Check the

clearances of the valves (B1 and B2) of number 1

cylinder and adjust them, if necessary.

2 Set the valves (B3 and B4) of number 2 cylinder as

indicated above for number 4 cylinder. Then check /

adjust the clearances of the valves (B5 and B6) of

number 3 cylinder.

3 Set the valves (B1 and B2) of number 1 cylinder.

Then check / adjust the clearances of the valves (B7

and B8) of number 4 cylinder.

4 Set the valves (B5 and B6) of number 3 cylinder.

Then check / adjust the clearances of the valves (B3

and B4) of number 2 cylinder.

A

12 34 56 78

B

A0049

A0050

Cylinder

and

valve number

Valve

I = Inlet

E = Exhaust

1234

12345678

IEEIIEEI

41

Page 42

4

Six cylinder engines

1 Rotate the crankshaft in the normal direction of

rotation until the inlet valve (A12) of number 6 cylinder

has just opened and the exhaust valve (A11) of the

same cylinder has not closed completely. Check the

clearances of the valves (A1 and A2) of number 1

cylinder and adjust them, if necessary.

2 Set the valves (A4 and A3) of number 2 cylinder as

indicated above for number 6 cylinder. Then check /

adjust the clearances of the valves (A9 and A10) of

number 5 cylinder.

3 Set the valves (A8 and A7) of number 4 cylinder.

Then check / adjust the clearances of the valves (A5

and A6) of number 3 cylinder.

4 Set the valves (A1 and A2) of number 1 cylinder.

Then check / adjust the clearances of the valves (A11

and A12) of number 6 cylinder.

5 Set the valves (A9 and A10) of number 5 cylinder.

Then check / adjust the clearances of the valves (A3

and A4) of number 2 cylinder.

6 Set the valves (A5 and A6) of number 3 cylinder.

Then check / adjust the clearances of the valves (A7

and A8) of number 4 cylinder.

12 34 56 78 9101112

A

A0028

42

Cylinder

and

valve number

Valve

I = Inlet

E = Exhaust

123456

123456789101112

IEEIIEEI IEEI

Page 43

5

Engine fluids 5

Fuel specification

To get the correct power and performance from your

engine, use good quality fuel. The recommended fuel

specification for Perkins engines is indicated below:

Cetane number.......... 45 minimum

Viscosity .................... 2.0/4.5 centistokes at 40°C

Density................... .... 0,835/0,855 kg/litre

Sulphur ...................... 0.2% of mass, maximum

Distillation .................. 85% at 350°C

Cetane number indicates ignition performance. A

fuel with a low cetane number can cause cold start

problems and affect combustion.

Viscosity is the resistance to flow and engine

performance can be affected if it is outside the limits.

Density: A lower density reduces engine power, a

higher density increases engine power and exhaust

smoke.

Sulphur: A high sulphur content (not normally found

in Europe, North America or Australasia) can cause

engine wear. Where only high sulphur fuels are

available, it is necessary to use a highly alkaline

lubricating oil in the engine or to renew the lubricating

oil more frequently, see the table below.

Low temperature fuels

Special winter fuels may be available for engine

operation at temperatures below 0°C. These fuels

have a lower viscosity and also limit the wax formation

in the fuel at low temperatures. If wax formation

occurs, this could stop the fuel flow through the filter.

If you need advice on adjustments to an engine

setting or to the lubricating oil change periods which

may be necessary because of the standard of the

available fuel, consult your nearest Perkins distributor

or one of the companies listed on page 8.

Aviation kerosene fuels

Caution: Aviation kerosene fuels are more

flammable than diesel fuel and need careful storage

and careful management.

These fuels can be used but they can affect engine

performance. It is recommended that you consult the

Perkins Technical Service Department at

Peterborough, especially if JP4 fuel is to be used.

Percentage of sulphur in

the fuel (%)

<0.5 Normal

0.5 to 1.0 0.75 of normal

>1.0 0.50 of normal

Distillation: This is an indication of the mixture of

different hydrocarbons in the fuel. A high ratio of lightweight hydrocarbons can affect the combustion

characteristics.

Oil change interval

43

Page 44

5

Lubricating oil specification

If you need advice on adjustments to an engine

setting or to the lubricating oil change periods which

may be necessary because of the standard of

available fuel, consult your nearest Perkins distributor

or the Technical Service Department of one of the

companies listed on page 8.

Use only a good quality lubricating oil to the relevant

specification as shown in the table below.

Caution: The type of lubricating oil to be used may

be affected by the quality of the fuel which is

available. For further details see "Fuel specification"

on page 43 and the preventive maintenance

schedules on page 18.

Always ensure that the correct viscosity grade of

lubricating oil is used for the ambient temperature

range in which the engine will run as shown in the

chart (A) and in the table below.

Lubricating oil specification

Naturally aspirated engines:

Recommended viscosity grades

0W

5W20

10W30

15W40

20W50

20

30

40

-30 -20 -10 0 10 20 30 40 50

-22-4143250

A

Ambient temperarture

68 86 104 122F

o

C

o

l

ACEA E1 or E2

l

API CC, CD or CF

Turbocharged engines:

l

ACEA E2 or E3

l

API CE, CF4 or CG4

(1) For use in heavy duty applications with a lubricating oil

change period of 250 hours, see page 18.

(1)

(1)

44

Page 45

Coolant specification

The quality of the coolant which is used can have a

great effect on the efficiency and life of the cooling

system. The recommendations indicated below can

help to maintain a good cooling system and to protect

it against frost and/or corrosion.

If the correct procedures are not used, Perkins cannot

be held responsible for damage caused by frost or

corrosion.

Caution: An antifreeze which contains the correct

inhibitor must be used at all times to prevent damage

to the engine by corrosion, because of the use of

aluminium in the coolant circuit,

l

If frost protection is not necessary, it is still

extremely important to use an approved antifreeze

mixture because this gives a protection against

corrosion and also raises the boiling point of the

coolant.

l

If the approved antifreeze mixture is not available,

add a correct mixture of corrosion inhibitor to the

water. If the correct inhibitor is not used, the

engine will be damaged by corrosion. If there is

doubt about the corrosion inhibitor to be used, It is

recommended that you consult the Perkins

Service Department, Peterborough, see the

address on page 8.

Note: If combustion gases are released into the

coolant circuit, the coolant must be renewed after

repair of the fault.

5

The antifreeze which is recommended for this engine

is the latest POWERPART Antifreeze, see page 53.

This antifreeze contains the correct corrosion inhibitor

which is especially suitable for this engine.

If it is possible, use clean soft water in the coolant.

The quality of the antifreeze coolant must be checked

at least once a year, for example, at the beginning of

the cold period. The coolant must be renewed every

two years.

Caution: The antifreeze mixture must consist of

equal quantities of antifreeze and water. The

corrosion inhibitor in the antifreeze will be diluted if a

concentration of less than 50% of antifreeze is used.

Concentrations of more than 50% of antifreeze may

have an adverse effect on the performance of the

coolant.

45

Page 46

This page is intentionally blank

Page 47

6

Fault diagnosis 6

Continued

47

Page 48

6

Problems and possible causes

Possible causes

Problem

The starter motor turns the engine too slowly 1, 2, 3, 4

The engine does not start 5, 6, 7, 8, 9, 10, 12, 13,

The engine is difficult to start 5, 7, 8, 9, 10, 11, 12,

Not enough power 8, 9, 10, 11, 12, 13,

Misfire 8, 9, 10, 12, 13, 15,

High fuel consumption 11, 13, 15, 17, 18, 19,

Black exhaust smoke 11, 13, 15, 17, 19, 21, 2234, 36, 37, 38, 39, 40, 42,

Blue or white exhaust smoke 4, 15, 21, 23 36, 37, 38, 39, 42, 44, 45,

The pressure of the lubricating oil is too low 4, 24, 25, 26 46, 47, 48, 50, 51, 59

The engine knocks 9, 13, 15, 17, 20, 22, 2336, 37, 40, 42, 44, 46, 52,

The engine runs erratically 7, 8, 9, 10, 11, 12, 13,

Vibration 13, 18, 20, 27, 28 34, 38, 39, 40, 41, 44, 52,

The pressure of the lubricating oil is too high 4, 25 49

The engine temperature is too high 11, 13, 15, 19, 27, 29,

Crankcase p ressure 31, 33 39, 42, 44, 45, 52

Bad compression 11, 22 37, 39, 40, 42, 43, 44, 45,

The engine starts and stops 10, 11, 12

Checks by the user

14, 15, 17

13, 14, 15, 16, 17, 19

16, 17, 18, 19, 20, 21

20, 22

21, 22

15, 16, 18, 20, 22, 23

30, 32

Checks by the workshop

personnel

34, 35, 36, 37,38, 40, 42,

43, 44

34, 36, 37, 38, 40, 42, 43,

44

34, 36, 37, 38, 39, 42, 43,

44, 61, 63, 64

34, 36, 37, 38, 39, 40, 41,

43

34, 36, 37, 38, 39, 40, 42,

43, 44, 63

43, 44, 61, 63

52, 58, 62

53, 60

34, 38, 40, 41, 44, 52, 60

54

34, 36, 37, 39, 52, 55, 56,

57, 64

53, 60

48

Page 49

List of possible causes

1 Battery capacity low.

2 Bad electrical connections.

3 Fault in starter motor.

4 Wrong grade of lubricating oil.

5 Starter motor turns engine too slowly.

6 Fuel tank empty.

7 Fault in stop control.

8 Restriction in a fuel pipe.

9 Fault in fuel lift pump.

10 Dirty fuel filter element.

11 Restriction in filter/cleaner or air induction system.

12 Air in fuel system.

13 Fault in atomisers or atomisers of an incorrect

type.

14 Cold start system used incorrectly.

15 Fault in cold start system.

16 Restriction in fuel tank vent.

17 Wrong type or grade of fuel used.

18 Restricted movement of engine speed control.