Page 1

Installation and Assembly- Encore™ Projector Mount

Protected by U.S. Patent No. 6,042,068

Model: PJRL411

IMPORTANT! Read entire

instruction sheet before you

start installation and assembly .

WARNING! Installer must verify

that the ceiling will safely

support the combined weight of

the Base Unit, Projector Adapter

Plate, and video projector.

This product contains all mounting hardware for direct attachment to a wood joist

ceiling. Concrete anchors (accessory kit ACC200, see page 2) sold separately.

This product is to be used in combination with one of several Projector Adapter

Plates (PAP models).

To order Projector Adapter Plates, Extension Columns, or additional mounting

hardware call customer service at 1-800-729-0307 or 708-865-8870.

Before you start check the parts list below to make sure all of the parts shown

are included.

Peerless Industries, Inc., 1980 Hawthorne Avenue, Melrose Park, IL 60160

www.peerlessindustries.com

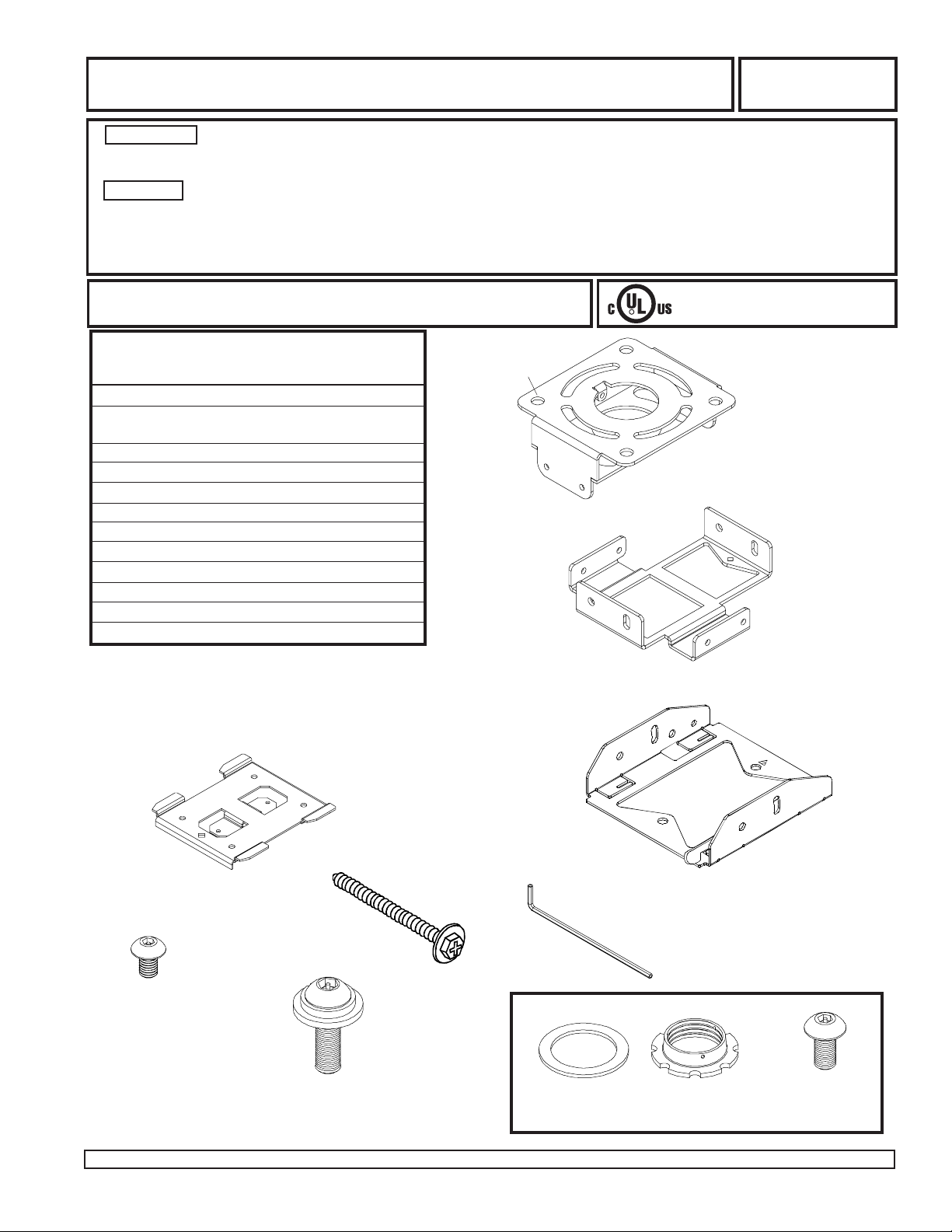

Parts List

Description

A projector mount ceiling plate

B washer head wood screw

#14 x 2.5 (6mm x 65mm)

C M6 x 1 x 20mm socket head screw

w/ flat and lock washer

D security allen wrench

E M5 x .8 x 8mm socket pin screw

F main bracket assembly

G fiber washer

H retaining collar

I M5 x .8 x 10mm socket pin screw

J roll adapter bracket

K interface bracket

Qty.

1

2

9

1

2

1

1

1

3

1

1

Part Number

054-1003

5S1-015-C03

520-1029

560-9646

520-1062

054-1044

540-9432

1800-375

520-1164

054-1050

055-1251

A

*

J

This product is intended for use with UL

R

Listed products and must be installed by a

qualified professional installer.

Note: Actual parts may appear slightly different than illustrated.

Four .406 dia. holes provided for threaded rod

*

installations. Materials and procedure for such

installations are the sole responsibility of the installer.

F

K

B

D

E

C

G

© 2003 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademark of Peerless Industries, Inc.

Encore is a trademark of Peerless Industries, Inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.

1 of 5

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

Parts G, H, and I are used only for installations that

incorporate an extension column.

H

ISSUED: 09-09-02 SHEET #: 054-9122-3 11-11-03

I

Page 2

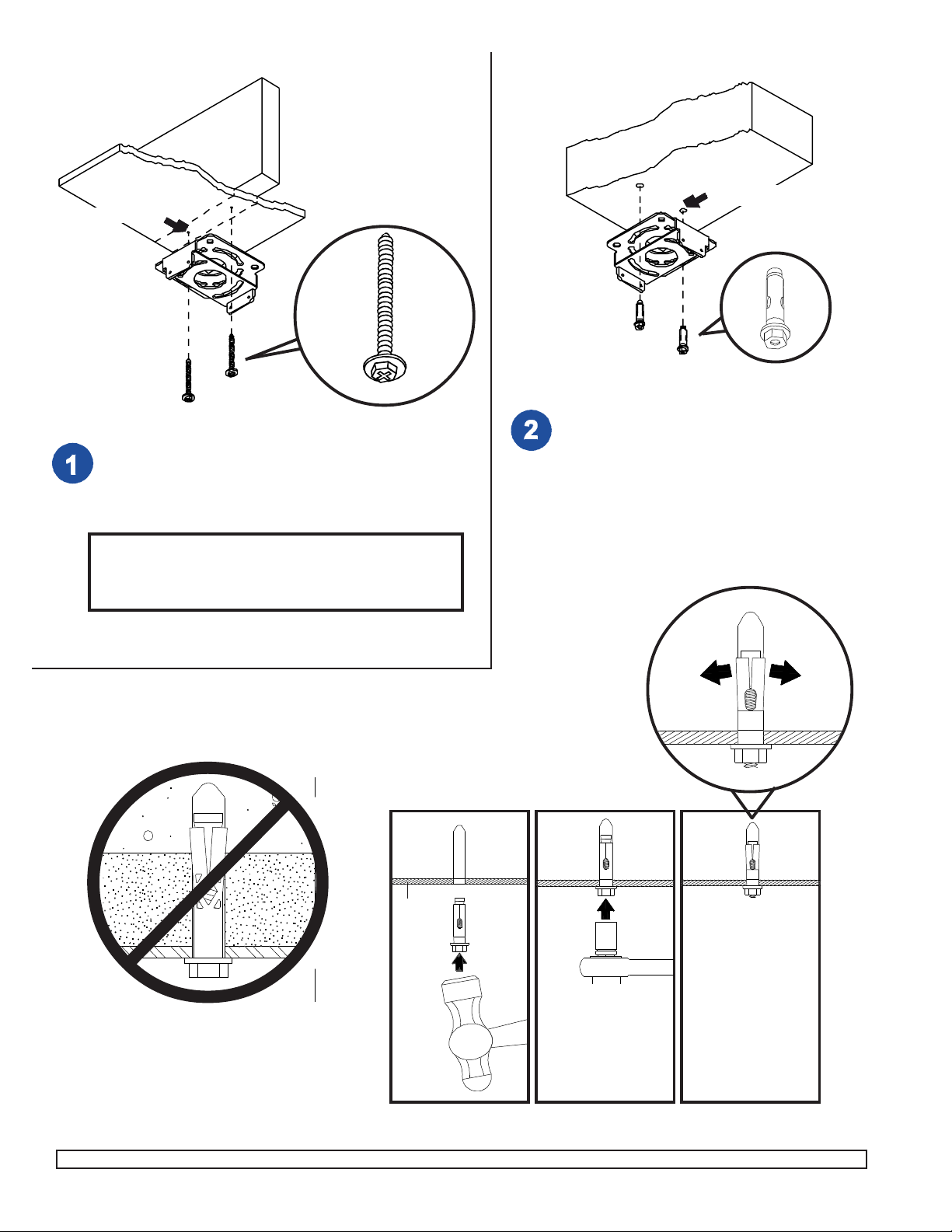

wood joist

ceiling

ceiling

∅ 5/32"(4mm)

B

A

Attachment to a Wood Joist. Use a stud finder to locate

ceiling joist. Drill two 5/32" (4mm) dia. holes 2.5"

(65mm) deep into joist center. Attach projector mount

ceiling plate (A) using #14 x 2.5" (6mm x 65mm) wood

screws (B).

CAUTION: Tighten wood screws so ceiling plate is

firmly attached. But DO NOT TIGHTEN WITH EXCESSIVE FORCE! Overtightening can cause stress damage

to wood screws, greatly reducing their holding power!

Tighten to 80 in. lbs. (9 N.M.) maximum torque.

BE SURE TO DRILL INTO JOIST CENTER!

Skip to Step 4

TM

USE ONL Y RAWL

HL814 CONCRETE EXPANSION ANCHORS

[.312 x 1.625 (8mm x 41mm)]. Order

accessory kit #ACC200.

#5005 OR HIL TI

TM

∅ 5/16"(8mm)

A

Concrete

Anchor

Attachment to a Concrete Ceiling.

NOTE: Concrete anchors are sold separately.

Order accessory kit #ACC200.

Drill two 5/16" (8mm) dia. holes 1.75" (45mm)

deep. Attach projector mount ceiling plate (A)

using two concrete anchors.

Tighten to 80 in. lbs. (9 N.M.) maximum torque.

See also CONCRETE ANCHOR INSTALLATION

below. Skip to Step 4

CROSS SECTION

concrete

ceiling

A

THESE CONCRETE ANCHORS ARE

FOR DIRECT A TT ACHMENT TO LOAD

BEARING CONCRETE ONL Y! NOT FOR

ATT ACHMENT T O CONCRETE CEILING

COVERED WITH PLASTER, DRYWALL,

TILE OR OTHER FINISHING MATERIAL!

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

CONCRETE ANCHOR INSTALLATION

2 of 5

concrete

anchor

ISSUED: 09-09-02 SHEET #: 054-9122-3 11-11-03

Tighten to 80 in.

lbs. (9 N.M.)

maximum torque.

Page 3

Extension column applications only:

Insert end of extension column into threaded fitting in

ceiling plate. Tighten securely - four or five complete

turns. Align slot in extension column with one of the

small holes in the side of the threaded fitting. Insert

and tighten one M5 x .8 x 10mm socket pin screw ( I )

into hole to lock extension column to threaded fitting.

Tighten screw allen wrench (D).

WARNING: For safety, extension column must be

locked to threaded fitting with screw ( I )!

Attach projector mount ceiling plate (A) with fiber

washer (G) and retaining collar (H). Tighten retaining

collar securely, four or five complete turns, aligning

one hole in the side of retaining collar with slot in the

end of extension column. From inside insert and

tighten one M5 x .8 x 10mm socket pin screw ( I ) into

hole in retaining collar. Tighten screw with allen

wrench (D).

I

slot

threaded

fitting

ceiling plate

(sold separately)

extension

column (sold

separately)

A

Note: Y ou may need to thread the socket pin screw

from the outside first (approximately 3 turns) to

loosen any buildup that may be on the threads.

WARNING: For safety, retaining collar must be

locked to extension column with screw ( I )!

Attach roll adaptor bracket (J) to ceiling plate (A) using four M6 x 1 x 20mm socket head security screws (C).

Tighten using 4mm allen wrench provided. Next attach main bracket (F) using remaining fasteners (C). Tighten

using 4mm allen wrench provided.

IMPORTANT: Do not lose or dispose of allen wrench.

It will be required to attach the Projector Adapter Plate.

NOTE: Arrow indicates front of main bracket (F).

I

G

H

A

C

J

F

3 of 5

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 09-09-02 SHEET #: 054-9122-3 11-11-03

Page 4

Note: Attach adapter plate to projector (see P AP instructions) prior to proceeding to step 5

Note: The Projector Adapter Plate and projector you are installing may differ in appearance from the sample illustrated

below.

Place interface bracket (K) on top of adapter

plate as shown.

#

NOTE:

*Notch on adapter bracket indicates front of projector.

Rotate interface bracket until the two holes line up with two holes

on adapter plate. Make sure that both front of interface bracket (K)

and projector adapter plate are closely aligned.

Notch on interface bracket indicates front of projector.

K

#

Fasten interface bracket (K) to adapter plate using two

M5 socket-pin screws (E). Tighten screws (E) using

4mm allen wrench (K).

*

E

4 of 5

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 09-09-02 SHEET #: 054-9122-3 11-11-03

Page 5

Position four tabs in interface bracket (K) behind four

tabs in base unit. Slide forward to engage latch. BE

SURE THAT LA TCH IS ENGAGED!

WARNING:

Do not lift more weight than you can handle! Use

additional man power or mechanical lifting

equipment to safely handle placement of the

video projector!

ceiling

(cutaway)

latch

SECURITY OPTION

Lock the latch by tightening M6 x 1 x 20mm socket

head security screw (C) through hole in base unit,

into threaded hole in latch. Tighten using 4mm

allen wrench.

IMPORTANT: Allen wrench is your key for projector

removal. Store it in a safe place.

ceiling

(cutaway)

K

C

latch

Final Alignment

To adjust Yaw (swivel) for flush mounting applications: Loosen wood screws until projector mount can be rotated.

Rotate mount to desired position and retighten screws.

To adjust Yaw (swivel) for extension column applications: Rotate mount to desired position. Insert and tighten one

remaining socket pin screw ( I ) into tab in projector mount ceiling plate (A) as shown below.

To adjust pitch (forward and backward tilt), loosen the two screws on each side of the main bracket assembly (F).

Tilt mount to desired position and tighten screws.

To adjust roll (side to side tilt), loosen the two screws on each side of the roll adapter bracket (J). Tilt mount to

desired position and tighten screws.

I

Peerless offers several Projector Mounts to fit various video projectors. New Projector Mounts are continually being

developed to meet the demands of a growing projector market. To find out if a mount is available for your particular

projector call Peerless customer service at 1-800-729-0307 or 708-865-8870.

5 of 5

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 09-09-02 SHEET #: 054-9122-3 11-11-03

Loading...

Loading...