PEERLESS Partner PP-120, Partner PP-80, Partner PP-40, Partner PP-60 Installation, Operation & Maintenance Manual

Page 1

Partner ®

Water Heater

• RTNER _!

Installation,

Operation Et

Maintenance

Manual

pr=-ERLES$ o

PARTNER °

IN_l_t FI_D WATER HEATE_

Page 2

4 Sizes 37 to iig Gallon Capacity

295 to 513 GPH First Hour Rating

Uses the Existing Boiler as its Heat Source

• No Separate Chimney or Burner Required

• Functions as an Additional Heating Zone

Long Lasting Stainless Steel Construction

• High Grade 316L Stainless Steel Tank

• Superior Corrosion Resistance

• Drain Tapping for Draining and Flashing Tank

Cupronickel Fin-Tube Heat Exchanger

• Provides Maximum Heat Transfer for Rapid Recovery Rates

• Resists Mineral Buildup and Sealing Deposits

• 1" Boiler Connections Provide for Minimum Pressure Drop thru Heat Exchanger

Minimal Standby Temperature Loss

• 2" Polyurethane Foam Insulation

• Less Than 1/2 ° Fper Hour Standby Loss

• Minimal Boiler F#ing to Maintain Temperature

• Provides More Hot Water with Reduced Boiler Water Temperatures

Maintenance-Free Plastic Jacket

• Will Not Scratch or Rust

• Color Coordinated to Match Peerless Boiler Jackets

Enclosed Thermostat Well

• Control Can Be changed Without Draining Tank

• Honeywell Well Type Adjustable Control

• T & P Relief Valve

• Cupronickel Fin & Tube Heat Exchanger

• High Grade 316L Stainless Steel Tank

• Plastic Jackel with 2" Polyurethane Foom

Insulation

one-year tvatTanty.tot tilt, P(,(,Hes.,; Pcwlnet" lndirz_cI Fir_'d Water 1tearer: Peerless also ptz)vicles a

limited, l!]_linle tL,arr_ltlty agamsl leaks.t}om th(_ h('aa'rsjctch_'t, latllc, of h('(tl t'xchculgcr [(_F r('._icl_'tJliol applicatiotts aiid o limit

('d..]lv(_-y_,c2r tt,6ltTOlll_] ttgoitl_l I(?c_ks./}om I]lc h(!(llt'l'N,/(l(']t-_'l I(tt!]¢ or ]|C(JI t_VCh(Itl(]('!'.t()l ('Ol!ltlR'tY'i(ll tlpl)licoliotl._. [Jl('(t._(" Cotl.';ttlt

P¢'crlt's_; Boilers.l_r complett" [L'OIT(II1QI iq/ormation.

Peerless Boilers * 610-367-2153 * www.peerless heater.com

FAB PARTNER R2 (303 IM)

Prlrll_?cI it1 L} _ A

Page 3

PEERLESS

PARTN E R °

INDIRECT-FIRED WATER HEATER

PARTNER ®

Modern Coil Design

u Minimal Standby Temperature

Loss

u Rapid Recovery Rate

Long Lasting Stainless Steel

Construction

Q Easy Installation

Q No Separate Chimney or Burner

Needed

The Peerless Partner _ indirect-fired water heater provides a true

advancement in hot water generation. By utilizing the existing boiler

as its heat source, the burner fires only when necessary and

transfers heat energy through a highly efficient cupronickel, fin-tube

heat exchanger. The heater functions as a separate heating zone

and water movement is regulated from the boiler through the heater

coil by a separate circulator or zone valve.

The modem coil design of the Peerless Partner indirect-fired

water heater provides maximum heat transfer efficiency and resists

mineral buildup that discolors water. Old style coils can produce

discolored tapwater that affects taste and leaves blue bathtub rings.

The heater's cupronickel heat exchanger is highly resistant to any

scaling deposits and is positioned so entering water provides

scrubbing action, eliminating the need for chemical cleanings.

The domestic hot water is stored in a high-grade 316L stainless

steel tank. Two inch foam insulation keeps the water hot with a

standby loss of less than 1/2° F per hour. This allows the boiler to

stay off most of the day and night. The result is more hot water

with reduced boiler water temperatures and drastically reduced

standby losses.

The Peerless Partner indirect-fired water heater has two or more

times the recovery rate of gas-fired water heaters and supplies as

much as five times the amount of hot water as a comparably sized

electric water heater.

This heater is an ideal replacement for existing water heaters. It can

also be used for new applications. A vent or stack is not required. The

tank's light weight makes it very easy to position. The plastic jacketing is

maintenance free and does not scratch or rust.

The Peerless Partner indirect-fired water heater comes equipped

with an adjustable, well-type Honeywell control and a T&P relief

valve as standard equipment.

Model Storage

Number Capacity

PP-40 37 gallons

PP-6O 57 gallons

PP-80 77 gallons

PP-120 119 gallons

Heat

Pressure Exchange First Hour Ratings*

Test Working Su #ace @140 ° @115 °

300 PSI 150 PSI 15 sq ft. 200 gallons 295 gallons

300 PSI 150 PSI 15 sq ft 255 gallons 347 gallons

300 PSI 150 PSI 34 sq ft 300 gallons 400 gallons

300 PSI 150 PSI 34 sq. ft. 385 gallons 513 gallons

* Based on 90" F rise. 55_/145 _ with 180 ° F boiler water First hour rating is only one factor in product selection Refer to Installation

h_structions for additional information

Page 4

)EERLESS PARTNER®SPECS

Floor To

= High-Grade 316L Stainless Steel Tank Model Boiler Boiler Domestic

Number Height Diameter Supply Return In/Out

• Maintenance-Free Plastic Jacket PP-40 521/2" 19v4" 9" 4w' 3" 46"

PP-6O 52V2" 23V4" 9" 41/2" 3" 46"

= 2" Polyurethane Foam Insulation PP-80 72" 24" 29" 6 6" 66"

• Cupronickel, Fin-Tube Coil Assembly ___

• Enclosed Thermostat Well

• Adjustable Honeywell Control

• T&P Relief Valve

Domestic

Water

Connections

¾" N.P.T. Male

1" N.P.T. Male

1V2"N.P.T. Male

1_/2"N.P.T. Male

Approx.

Shipping

Model Weight

Number Length Width Height (Ibs.)

PP-40 2OW' 20V2" 56" 78

PP*6O 24V2" 24V2" 56" 98

PP-80 25V2" 251/2" 74" 139

PP-120 29" 29" 78" 206

Hot Water Outlet,

T&P Relief Valve

Domestic Water

Connections (See

Dimensional Data)

Cold Water

Inlet & Drain

FLOOR

2" Polyurethane Foam

-- Insulation On Outside,

Less Than 1/2 ° F Per

Hour Heat Loss R17

-- 316L Stainless Steel Tank

-- Plastic Jacket

Enclosed Thermostat Weft for

Adjustable Honeywell Control

(Boiler Water Supply

& Return 1" Threaded)

Boiler Supply

Cupronickel

Coil Assembly

Boiler Return

The residential warranty covers:

--the entire water heater, one year from date of installation.

---outside jacket, inner tank, or heat exchanger, lifetime.

The commercial warranty covers:

--the entire water heater, one year from date of installation.

--outside jacket, inner tank, or heat exchanger, second

through fifth year.

*Before purchase contact your installing contractor for complete warranty

information.

PEERLESSHEATER CO.

231 North Walnut Street

Boyer_own, PA 19512-1021

Phone: 610-367-2153 • FAX: 610-369-3284

www.peerless-heater.com

CUT pARTNER £2 ( 11/02 10M} Pr_nt_ d _n U S A _'y2002 Peerless Heater Cot_tpany

Page 5

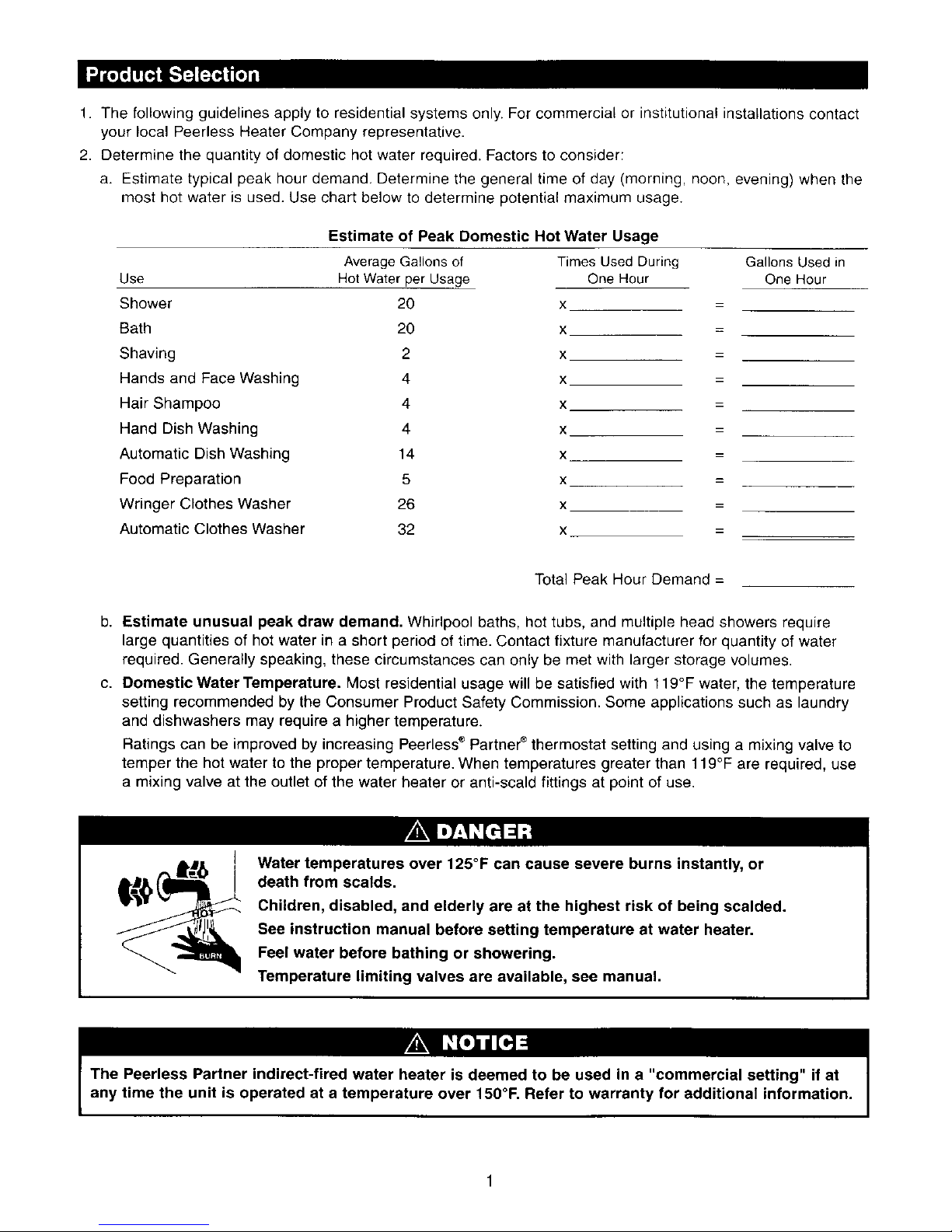

1. The following guidelines apply to residential systems only. For commercial or institutional installations contact

your local Peerless Heater Company representative.

2. Determine the quantity of domestic hot water required. Factors to consider:

a. Estimate typical peak hour demand. Determine the general time of day (morning, noon, evening) when the

most hot water is used. Use chart below to determine potential maximum usage.

Estimate of Peak Domestic Hot Water Usage

AverageGallons of Times Used During Gallons Used in

Use Hot Water perUsage One Hour One Hour

Shower 20 x -

Bath 20 x =

Shaving 2 x =

Hands and Face Washing 4 x =

Hair Shampoo 4 x =

Hand Dish Washing 4 x =

Automatic Dish Washing 14 x =

Food Preparation 5 x =

Wringer Clothes Washer 26 x =

Automatic Clothes Washer 32 x =

Total Peak Hour Demand =

b. Estimate unusual peak draw demand. Whirlpool baths, hot tubs, and multiple head showers require

large quantities of hot water in a short period of time. Contact fixture manufacturer for quantity of water

required. Generally speaking, these circumstances can only be met with larger storage volumes.

c. Domestic Water Temperature. Most residential usage will be satisfied with 119°F water, the temperature

setting recommended by the Consumer Product Safety Commission. Some applications such as laundry

and dishwashers may require a higher temperature.

Ratings can be improved by increasing Peerless ®Partner ®thermostat setting and using a mixing valve to

temper the hot water to the proper temperature. When temperatures greater than 119°F are required, use

a mixing valve at the outlet of the water heater or anti-scald fittings at point of use.

Water temperatures over 125°F can cause severe burns instantly, or

death from scalds.

Children, disabled, and elderly are at the highest risk of being scalded.

See instruction manual before setting temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are available, see manual.

The Peerless Partner indirect-fired water heater is deemed to be used in a "commercial setting" if at

any time the unit is operated at a temperature over 150°F. Refer to warranty for additional information.

Page 6

d. Boiler. PP-80, PP-120, PP-80-DW, and PP-120-DW require full boiler output listed in Table 1. If boiler is a

Category IV condensing boiler, such as Peerless" Pinnacle', the above Peerless _'Partner _"models can be

used with reduced boiler output. If boiler output is less than shown in Table 1 reduce first hour rating as

shown in Table 2. Increase boiler size only if first hour rating does not meet estimated peak hour usage.

If a boiler with listed output is not needed for space heating, an alternative to a PP-80/120 would be

a PP-40 or PP-60 piped in series with an unfired storage tank (i.e. electric water heater without heating

elements energized).

Use a water boiler only. The Peerless Heater Company cannot recommend the use of steam boilers at this

time. Contact factory for additional information.

e. Domestic water priority. First hour ratings may be less than published when boiler output is shared with

space heating. Generally a consumer will notice a drop in domestic water temperature before a drop in

space heating temperature. Giving domestic water production priority by directing entire boiler output to

Peerless Partner will maximize domestic water output. However, prioritization controls could result in an

unacceptable drop in space heating temperature when large quantities of domestic hot water are used,

and a prioritization control malfunction could result in loss of space heating.

3. Multiple Water Heaters. Peak domestic water usage (first hour rating) or unusual peak draw may not be met

with a single water heater. Multiple units can be installed as either a bank of tanks acting as a single unit, or

as multiple individual units sized and located for specific draw situations.

Table 1: Peerless Partner Ratings

Model

No.

PP-40

PP-80

PP-80

PP-120

PP-40-DW

PP-60-DW

PP-80-DW

PP-120-DW

Fi_tHourRating'[gallons]

140°F 115OF

212 292

266 370

330 440

423 564

172 251

204 288

283 391

37O 515

MinimumBoilerOutputqoAchieve

FimtHourRating[Btu_rhour]

141,000

174,000

212,000

269,000

115,000

188,000

220,000

252,000

UseableHotWater

[U.S.Gallons]3

28

46

64

94

28

46

84

94

HeatExchanger

SurfaceArea[ft_J

2O

20

34

34

20

20

20

2O

1. First hour rating based on heating water from 50°F to 140°/115°F with 180°F boiler water temperature. Gas- and oil-fired

and electric water heater first hour ratings based on DOE test procedure using 90°F temperature rise (55°F to 145°F).

2. Net I=B=R Output, Water

3. Useable hot water based on recent completion of recovery period, but no additional boiler input after draw begins.

Page 7

Table 2: First Hour Ratings for Reduced Boiler Output

BoilerOutput

[Btuperhour]

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

BoilerOutput

140°F

68

99

130

152

182

PP-40'

115°F

94

138

180

210

251

140°F

160

176

181

206

pp-60 _

115°F

221

244

251

309

pp-802_

140°F

m

216

251

290

335

345

399

460

pp-40-DW I pp-60-DW_

140°F 115°F

216 297

223 -305

230 314

269 367

311 424

359 489

pp-80-DW,_

pp-120_

115F

333

384

444

457

470

543

627

pp-120-DW2_

[Btuperhour]

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

140°F

57

85

115

143

115°F

78

117

158

197

140°F

66

100

133

156

166

171

189

200

115°F

91

139

181

215

227

236

281

272

140°F

130

147

160

178

192

210

224

243

265

115°F

179

203

222

243

265

289

309

335

366

1. 180°F Boiler Water

2. 200°F Boiler Water

3. Due to condensation in boiler, reduced output not recommended for PP-80, PP-120, PP-80-DW, and

Category IV condensing boilers, such as Peerless Pinnacle, can be used for reduced output.

140°F

136

155

168

186

199

226

251

278

361

PP-120-DW.

115°F

186

215

233

255

272

3O8

347

380

409

Table 3: First Draw at 140°F'.2(in Minutes)

Model DomesticWaterFlowRate[gpm]

No. 2.0 2.5 3,0 3.5 4.0 4.5 5.0 5,5 6,0 6.5 7.0 7.5

PP-40 16 14 12 10 9 8 7 6 5.5 5 4.2 3.7

PP-60 .... 30 24 20 17 10.3 9.5 8.2 7.8 7.1 6.1

PP-80 ............ 14 13 12 11.1 10.5 8.5

PP-120 ............ 20 18 16 15 14 12.5

PP-40-DW 16 14 12 10 9 8 7 6 5.5 5 4.2 3.7

PP-60-DW .... 30 24 20 17 10.3 9.5 8.2 7.8 7.1 6.1

PP-80-DW ............ 14 13 12 11.1 10.5 8.5

PP-120-DW ............ 20 18 16 15 14 12.5

**Unlimited hot water available at specified flow rate.

1. Based on cold start boiler with output listed in Table 1.

2. For minutes of domestic water flow at 115°F, multiply by 1.56.

1. Read these instructions completely before starting installation.

2. FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this

or any other appliance. Controls on this appliance could ignite vapors causing an explosion.

3. Install in accordance with the requirements of the authority having jurisdiction. Inthe absence of such

requirements, appliance must be wired in accordance with the National Electrical Code, ANSI/NFPA 70.

Page 8

This product complies with 1990 N.S.P.C. provided: (1) the boiler water, including additives, is practically non-

toxic, having a toxicity rating or class of 1, as listed in Clinical Toxicology of Commercial Products, 5thedition;

and (2) the boiler water pressure is limited to a maximum of 30 psig by an approved safety or safety relief valve.

4. Peerless Partner(s) may be located adjacent to boiler to reduce piping heat loss or central to points of use to

reduce response time to fixtures.

a. Install indoors in an area not exposed to freezing temperatures. De not install outdoors.

b. Position with adequate clearance for service and maintenance. Provide access to thermostat, temperature

and pressure relief valve, and drain valve.

c. Protect surrounding area and lower floors from damage due to leakage from temperature and pressure

relief valve, drain valve, boiler or domestic water piping, and tank. Locate water heater near a floor drain or

in a drain pan suitable for the capacity of the water heater.

d. Install on level surface. Water heater must be kept in vertical position.

5. Suggested equipment list. See PIPING for additional information.

a. Water Heater Thermostat: Provided.

b, Temperature and Pressure Relief Valve: Provided.

c. Brass Drain Valve: 1 per water heater.

d. Brass Tee's: 2 per water heater.

e, Heat Exchanger to Boiler Piping: 1 inch nominal copper tubing and fittings. Circulator and flow control

valve, or zone valve.

1. General

a. All plumbing must be in accordance with

the requirements of the authority having

jurisdiction.

b. Use both thread tape and pipe dope on all

mechanical connections.

c. Zone valve (if used) and circulator must be

sized to provide minimum flow rate speci-

fied in Table 4. Use 1 inch nominal copper

tubing between boiler and Peerless Partner

heat exchanger. See Table 5 and Table 6 for

sizing. Point of emphasis: using a zone

valve without a full bore may cause high

pressure drop which will adversely affect

performance. Use extreme care when

selecting zone valve.

All piping must be adequately supported.

Allow for thermal expansion.

d. High temperatures will damage plastic jack-

et. Use heat shield when soldering piping

near tank.

Table 4: Flow Specifications

Model

No,

PP-40

PP-60

PP-80

PP-120

PP-40-DW

PP-60-DW

PP-80-DW

PP-120-DW

Recommended

FlowRate

10 gpm

10 gpm

12 gprn

14 gpm

6 gpm

7 gpm

7 gpm

8 gpm

HeatExchanger

PressureDrop

7.9 ft.

7.9 ft.

9.1 ft.

11.3 ft.

7.6 ft.

10.0 ft.

10.0 ft.

13.4 ft

DomesticWater

ConnectionSizes

3/4 NPT

1 NPT

1-1/2 NPT

1-1/2 NPT

3/4 NPT

1 NPT

1-1/2 NPT

1-1/2 NPT

Table 5: Friction Loss

TubingType

Type K

Type L

Type M

)er 100 Feet of Tubing [feet]

FlowRate[gpm]

6 7 10

3.6 4.8 9.3

3.1 4.1 8.1

2.7 3.6 7.0

Table 6: Friction Loss Allowance for Copper Fittings

[feet of straight tubing]

Fitting Wrought Cast

90° Elbow 1 4

45° Elbow 1 2

Tee, Run V2 V2

Tee, Branch 3 5

90° Bend 2 --

180° Bend 2 --

Gate Valve -- 1

Page 9

2. Domestic Water

a. Cold Water In. Install brass tee and drain valve

(not provided). Install shutoff valve between

water supply and cold water inlet for ease of

service. See Figure 1.

For systems using a back flow preventer or no

return valve, install a thermal expansion tank

between cold water supply and valve to offset

expansion/pressure increase as water is heated.

See Figure 2.

b. Standard Domestic Hot Water Out. Install

brass tee and temperature and pressure relief

valve. Do not place any valves between the

temperature and pressure relief valve and the

tank. See Figure 3.

Run temperature and pressure relief valve dis-

charge piping to a suitable place to avoid dam-

age to building or injury to occupants. Do not

install reducing fittings or other restrictions.

Discharge piping must allow complete drainage

of both the temperature and pressure relief valve

and piping.

A heat trap will improve energy efficiency by

reducing piping heat loss.

c. Domestic Hot Water Out with Mixing Valve.

See Figure 4.

3. Boiler. Install Peerless Partner as a separate space

heating zone. Place boiler circulator(s) in boiler

supply piping.

For boiler with tankless heater, disconnect domestic

water piping and limit control (where used). Plug

limit tapping. Do not plug domestic water tappings.

4. Multiple Water Heaters installed as single unit.

Install boiler water piping and domestic piping in

parallel reverse return configuration. See Figure 5.

5. Peerless Partner with unfired storage tank. See

Figure 6.

COLD WATER

SUPPLY

Figure 1: Water Inlet

THERMAL

EXPANS_ON

TANK

BACK FLOW BRASS

pREVENTER I TEE

COLD WA_R _

SUpPLy

BRASS

Figure 2: Thermal Expansion Tank

TEMPERATURE PRFSSURE

RELEF VALVE ]

HOT TO

FIXTURES

Figure 3: Hot Water Outlet

TO LOW TO HIGH

TEmPErATURE TEMPERATUR E

rr×TURES FIXTURES

Figure 4: Mixing Valve

5

Page 10

T & P RELIEF

VALVE

U

NOT T & P RELIEF HOT T & P RELIEF HOT

ouT;vALvE ou vA

TAT TAT TAT

..... L ... I ........................ J

__i II I - I Ii I J

COLO__l [ It

_ATER [

SUPPLY

NOTE: ALL PIPLNG IN PARALLEL

Figure 5: Installation of Multiple Water Heaters as Single Unit

HOT WATER

I TO FIXTURES

HOT WATER

fO

FIXTURES

T & P RELIEF <

VALV£

tOLD

WATER

_UPPLy

T & P RELIEF

VALV£

PEERLESS

PARTNER

_NK CONTROL NO

VALVE

TANK _

ORCUt_.TOR

801tER /_

CONTROL.

801LER RETURN

BOILER

CIRCU_TOR

Figure 6: Unfired Storage Tank

1. The Peerless Partner must be electrically grounded in accordance with local codes. In the absence of local

codes follow the National Electrical Code, ANSI/NFPA 70.

2. Install thermostat provided with Peerless Partner. Insert bulb into immersion well. Secure to well by tightening

screws on case.

3. Wire Peerless Partner thermostat to boiler. Provide disconnect switch between thermostat and control system

to allow for vacation shutdown and/or service shutdown.

Zoning with zone valves assumes end switch is isolated - zone valve actuator powered by separate

transformer. Do not use boiler transformer to operate zone valves.

a. MI/MIH. For zoning with zone valves or three-way valve, connect zone valve end switch to limit terminals T

and TV. For zoning with circulators, refer to Figure 7.

b. DE/PSC/PDE. Provide zone control as shown in boiler's installation instructions.

d. WBV/EC/SC. Water less tankless heater. See Figure 8.

6

Page 11

TO P((_(_ SNT_T_C F_LAY

p_IT_R I_4(R'W_TAT H_ _194_A

TO _(_tESS

p_t_R C_I_LA T_

LOW _OLTAd:_

TO_l

_m_S,AT

I I

II

I I

i I

ii

I i I

I i L---_

ro e_w.(R

C_L_IC_

Figure 7: Wiring Diagram - MI/MIH

TO PEERt£SS

pARTNER ORCULATOe

TO PEERLESS

p_Rm£R _ERMOSTAT i--S_TCH_NG R£LAY

JHO_E_LL R845A TO ZC_E I

I I _1TE ROOC[_S 829A 845 SPACE _EA_N_

I I / _RUOST_T

D_SC_NECT

I I

F 1__

______

®

...... A. B_ONL_E_'_]TL_148A _ t t t t

-- --LOW VOLT_G_ TO B<MLER TO BURNER

Figure 8: Wiring Diagram -WBV, EC and SC less Tankless

1. General

a. Open hot water faucet when filling or draining Peerless Partner.

b. The Peerless Partner thermostat has three markings: Warm (120°F), Normal (140°F), and Hot (160°F).

The thermostat is adjusted to its lowest temperature position when shipped from the factory.

2. Fill tank and domestic water piping.

3. Adjust Peerless Partner thermostat to 119°F, or in accordance with authority having jurisdiction. Adjust

mixing valve (if used) to desired temperature.

I._'6 r

j --v I

Water temperatures over 125°F can cause severe burns instantly, or

death from scalds.

Children, disabled, and elderly are at the highest risk of being scalded.

See instruction manual before setting temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are available, see manual.

4. Follow manufacturer's instructions to start-up boiler. Set boiler limit at least 20°F above Peerless Partner

thermostat setting. For boiler limit with low limit, set temperature to lowest setting. For boiler limits with

adjustable differential, set differential tO 10-15°F range.

5. Operate boiler until Peerless Partner thermostat satisfied. Measure domestic water temperature at hot

water faucet. See Paragraph 3 above.

6. Draw hot water and allow Peerless Partner to operate through several recovery cycles to verify proper

operation.

Page 12

1. General Housekeeping (continuous). Keep area clear of gasoline or other flammable vapors or liquids.

Controls on this appliance could ignite vapors causing an explosion.

2. Clean Inside of Tank (monthly).

a. Mark temperature setting on Peerless Partner thermostat. Set thermostat to lowest setting.

b. Close cold water inlet shutoff valve. Open a hot water faucet,

c. Open drain valve. Allow water to flow until free of sediment. Close drain valve.

d. Open cold water inlet shutoff valve. Close hot water faucet after flow established.

e. Set Peerless Partner thermostat to operating set point.

3. Check temperature and pressure relief valve. Follow manufacturer's instructions.

4. Maintain boiler per manufacturer's instructions.

1. No Hot Water

a. No power to boiler and control system.

* Check fuse or circuit breaker.

* Check disconnect switch.

* Check wiring.

b. Zone Valve is not open.

* Check wiring.

* Repair or replace zone valve.

C. Circulator is not operating.

* Check wiring.

* Check circulator switching relay.

* Repair or replace circulator.

d. Peerless Partner thermostat not calling for heat.

* Check wiring.

* Replace thermostat.

e. Hot water from boiler not getting to Peerless Partner.

* Air trapped in boiler piping, preventing water circulation. Purge piping.

* Check boiler for proper operation.

* Check wiring.

2. Inadequate Hot Water

a. Check operation of Peerless Partner:

i. Obtain container with known volume (in gallons) and stopwatch.

ii. Open hot water faucet until boiler starts recovery period. Close faucet.

iii. Allow boiler to operate until water heater fully recovers. Set thermostat disconnect switch to OFF

position.

iv. Open hot water faucet until water is hot. Begin filling container. Use stopwatch to measure time to fill

container.

Container Volume (gallons) seconds

Flow Rate (gpm) = x 60

Time to Fill Container (seconds) minute

Page 13

v. Water temperature will remain constant within ±5°F until storage is exhausted. Continue to fill container

until temperature drops 10°E

vi. Compare total volume of water collected to Usable Hot Water in Table 1. If within 5 gallons the Peerless

Partner is operating properly. Check PRODUCT SELECTION for proper model usage.

vii. Compare calculated flow rate with first draw usage available per Table 3. If actual flow rate is greater

than first draw usage available, consider use of flow restricting fixtures or mixing valve.

b. Inadequate boiler water flow. Check circulator sizing per PIPING.

c. Boiler is undersized.

3. Slow Recovery.

See 2(b)(c) above. Approximate cold start recovery period (* use Minimum Boiler Output from Table 1 or

Boiler Rated Output, whichever is smaller):

Recovery Time [Minutes) -

Btu

Tank Capacity [gallons] x Temperature Rise [°F] x 8.33

(gallons)(°F)

Btu .

Boiler Output hr

minutes

x 60

hr

Example No.l: A Peerless Partner PP-40 with a Peerless MI-03 gas boiler (DOE Heating Capacity of 58 Mbh).

The desired water temperature is 115°E Cold water temperature is 55°E

Btu

(37 gallons) x (115°F-55°F) x 8.33

Recovery time = (gall°ns)(°F) x 60 minutes

Btu hr

58,000 --

hr

19.1 minutes

Example No. 2: A Peerless Partner PP-120 with a Peerless LC-04 (Gross I=B=R Output of 547 Mbh). The

desired water temperature is 150°E Cold water temperature is 50°E

Btu

(119 gallons) x (150°F-50°F) x 8.33

Recovery time = (gall°ns)(°F) x 60 minutes

Btu hr

300,000 --

hr

19.8 minutes

4. WaterTemperatureToe Hot

a. Peerless Partner thermostat set too high. Adjust to lower setting.

b. System piping and/or controls.

* Peerless Partner thermostat continues to call for heat after reaching setpoint. Replace thermostat.

* Check system pipingand flow control valve.Verify space heating call for heat does not cause flow through Peerless

Partner heat exchanger.

C. Mixing Valve (if used). Verify proper operation per manufacturer's instructions.

5. Leaking Temperature and Pressure Relief Valve

a. Water expands when heated.

* Install thermal expansion tank on cold water inlet.

* Reduce Peerless Partner thermostat setting.

b. Water temperature too high. See Paragraph 4 above.

c. Water pressure is too high. Instafl pressure reducing valve on cold water inlet.

d. Valve seat has deteriorated or has sediment build-up. Replace temperature and pressure refief valve.

Page 14

Hot Water Cutlet,

T&P Relief Valve

2_"Polyurethane Foam

Insulation On Outside,

Less Than 1/2° F Per

Hour Heat LOSS R 17

-- 316L Stainless Steel Tank

-- Plastic Jacket

Domestic Water

Connections (See

Dimensional Data) I

Enclosed Thermostat Weft for

Adjustable Honeywell Control

Cold Water

Inlet & Drain

(Boiler Water Supply

& Return 1" Threaded)

Boiler Supply

Cupronickel

Coil Assembly

Boiler Return

FLOOR

Figure 9: Cutaway View

Table 7: Dimensions and Specifications

Model

No,

PP-40

PP-60

PP-80

PP-120

PP-40-DW

PP-60-DW

PP-80-DW

PP-120-DW

Diameter Height

191/4 521/2

231/4 521/2

24 72

27 731/2

191/4 521/2

231/4 521/2

24 72

27 731/2

Dimensions[inches]

Floorto Floorto

'Boiler In' 'Boiler Out'

9 41/2

9 41/2

29 6

301/4 71/4

9 41/2

9 41/2

29 6

301/4 71/4

Floorto

'Cold-Drain'

3

3

6

7i14

3

3

6

7V4

Floorto

'Hot-T&P'

46

46

66

66

46

46

66

66

Pressures

[psig]

Test

300

300

300

300

300

300

30O

300

Working

150

150

150

150

150

150

150

150

Tank

Capacity

[U.S.

Gallons]

37

57

77

119

37

57

77

119

Thermostat: Honeywell L4080B1295 (Operating range = 120°F to 160°F, 15° fixed differential)

Temperature and Pressure Relief Valve: PP-40: Watts 100XL-8 (100 Mbh, 8" element)

PP-60/80/120: Watts 40XL-8 (200 Mbh, 8" element)

10

Page 15

Peerless ®Partner ®

Indirect-Fired

Water Heater

Installation,

Operation

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and

must be affixed near the water heater for

future reference.

TO THE OWNER:

This water heater should be inspected annually

by a Qualified Service Agency.

PEERLESS"

PARTNER °

INDIRECT FIRED WATER HEATER

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET • BOYERTOWN, PA 19512-1021 • PHONE 610-367 2t53

vvww.peedess heater.corn

THE PREFERRED HEATING CHOICE

@2002 Peerless Heater Company X8033 R4 (11/02 3M)

Printed in USA

Loading...

Loading...