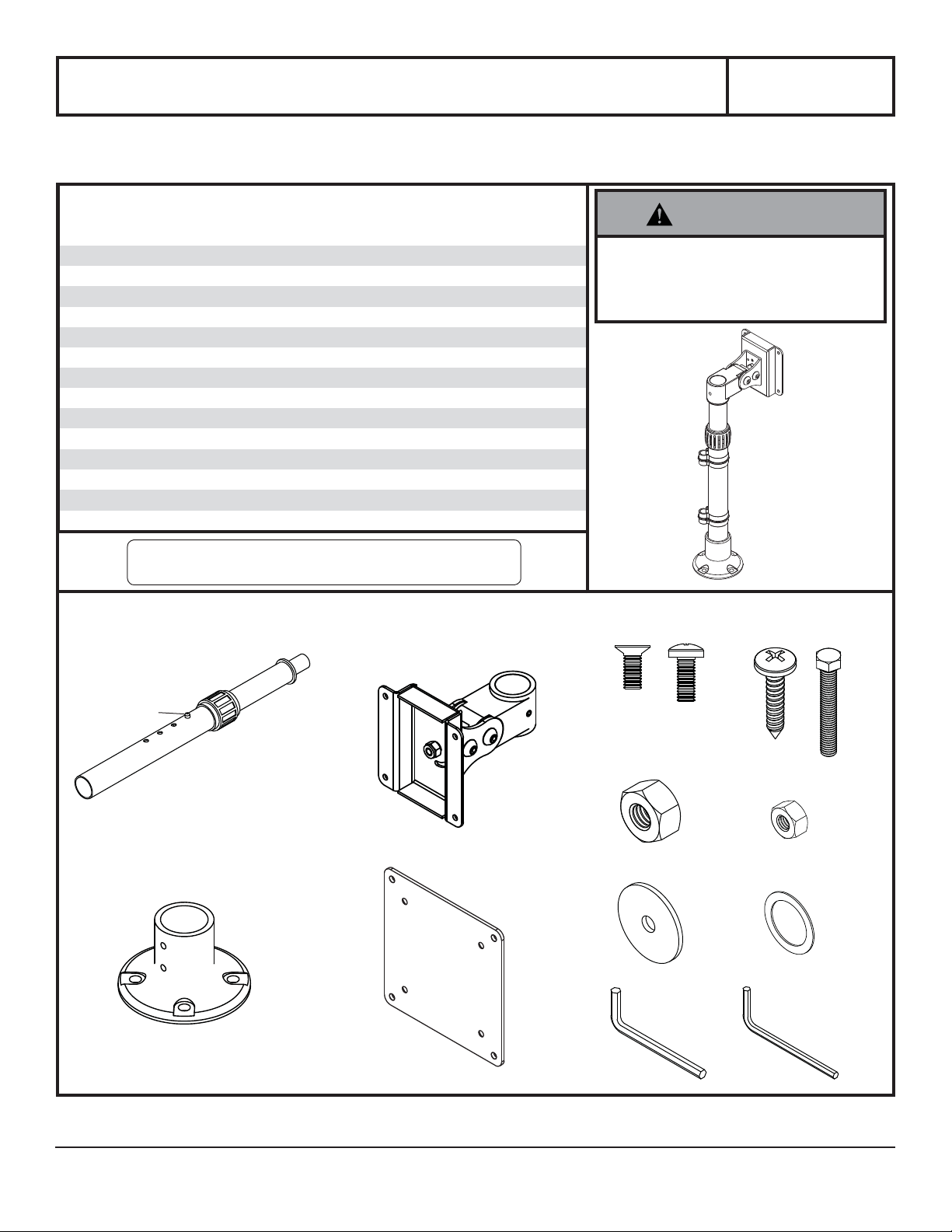

Installation and Assembly - Monitor Desktop Stand

A

Models: LCH-100

IMPORTANT! Read entire instruction sheet before you start installation and assembly.

IMPORTANT! The product is made to support screens with a Vesa compliant hole pattern.

For safe mounting, mounting screws must turn at least three times in the screen inserts.

Parts List

Description Qty. Part #

telescopic pedestal 1 091-1088

B pivot head 1 091-1090

C mounting base 1 091-1089

D adapter plate 1 095-1100

M4 x 8mm countersink screw

E

M4 x 10mm phillips screw

F

wood screw #14 x 1

G

H hex bolt 1 -

I hex nut 1 -

J M4 x 0.7mm nut 4 530-1082

K pressure plate 1 -

L nylon washer 1 540-1636

M 4mm allen wrench 2 560-0072

N 3mm allen wrench 1 560-0073

NOTE: You may not use all hardware provided.

NOTE: Some parts may not appear exactly as illustrated.

LCH-100

520-1795

4

520-1796

4

510-9159

4

MAX Load Capacity:

25 lb (11.4KG)

WARNING

SPRING LOADED PRODUCT

• Only release lock ball when screen is

installed. Do not place chin or object

above pole when releasing lock ball.

LCH-100

LOCK BALL

C

A

B

D

E

M

K

F

G

H

I

J

L

N

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerless-av.com

ISSUED: 09-30-02 SHEET #: 090-9085-6 07-23-13

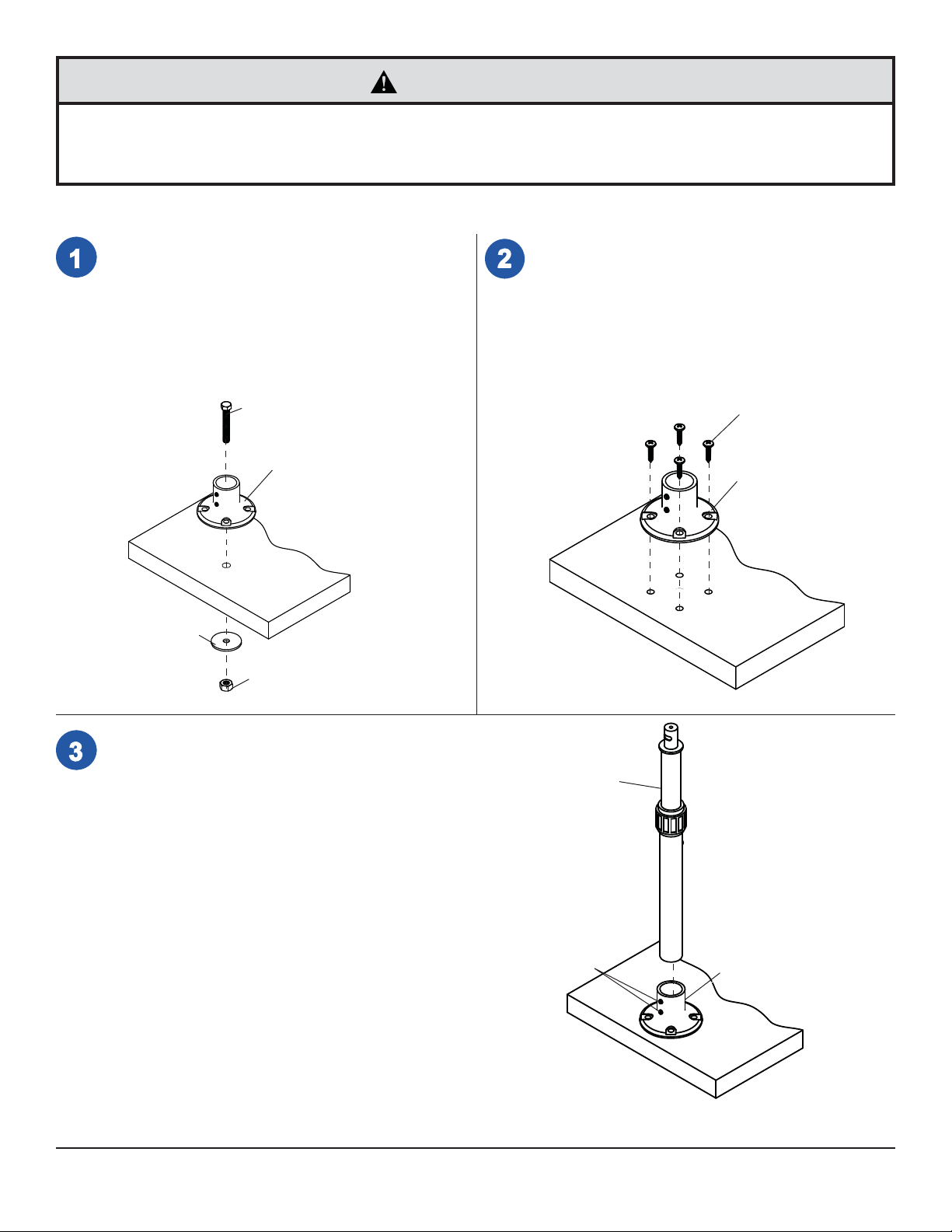

CAUTION

• Mount must be installed on wood and/or wood composition surfaces of at least 3/4" thick. However, the installer

must ensure that the mounting surface will safely hold the combined weight of the mount and the screen. See other

mounting requirements below.

There are two methods of installation. Follow step 1 for installation using hex bolt and pressure plate or

step 2 using four wood screws.

Mark hole on desktop for positioning mount.

Drill one 1/2" dia. hole through desktop. Attach

mounting base (C) to desktop using hex bolt (H),

pressure plate (K), and hex nut (I). Tighten nut

using proper sized wrench.

Important! Mount is to be installed onto desktops

3/4" to 1-5/8" thick only! For thicker mounting

surfaces, you may have to provide your own

hardware.

H

C

Use four holes on mounting base (C) to mark holes

on desktop for positioning mount. Drill four 3/16"

dia. holes through desktop. Attach mounting base

(C) to desktop using four wood screws (G).

G

C

DESKTOP

K

I

Insert telescopic pedestal (A) into mounting base (C).

Tighten set screws where shown with 3 mm allen wrench (N).

SET SCREWS

DESKTOP

A

C

2 of 5

ISSUED: 09-30-02 SHEET #: 090-9085-6 07-23-13

To install to a VESA 75 mm standard LCD monitor,

attach pivot head (B) to back of LCD monitor using four

M4 x 10 mm phillips screws (F) as shown.

Skip to step 6.

B

F

GENERIC LCD SCREEN

To install to a VESA 100 mm standard LCD monitor, attach

adapter plate (D) to pivot head (B) using four M4 x 8 mm

phillips screws (E) and four M4 x 0.7mm nuts (J) as shown in

detail 1. Attach pivot head (B) to back of LCD monitor using

four M4 x 10 mm phillips screws (F) as shown in detail 2.

E

D

B

J

GENERIC LCD SCREEN

B

F

DETAIL 1 DETAIL 2

3 of 5

ISSUED: 09-30-02 SHEET #: 090-9085-6 07-23-13

Place nylon washer (L) and pivot head (B) on top pin

of telescopic pedestal (A) as shown. To restrict rotation

of LCD screen to 90°, lineup rear set screw with slot

and tighten where shown in detail 3 using 3 mm allen

wrench (N). To completely restrict rotation, tighten rear

set screw using 3 mm allen wrench (N).

SLOT

REAR SET

SCREW

B

SET SCREWS

L

A

DETAIL 3

Turn tube nut counterclockwise to loosen. Gently hold pivot head

(B) down with one hand, and gently press on lock ball with the other

hand. Lock ball must be inserted into outer tube to obtain up and down

movement. Do not insert lock ball all the way into the inner tube.

Adjust to desired height making sure to locate lock ball into one the

four holes as shown.

NOTE: Setting the lock ball in the lowermost hole requires the removal

of the inner white plastic ring. To do this set the lock back in a

different hole. Slowly unscrew the tube nut until it comes off threads.

Remove the white plastic ring inside the tube nut. Retighten the tube

nut. Adjust the height until the lock ball reaches the lowermost hole.

B

INNER TUBE

TUBE NUT

LOCK BALL

A

OUTER TUBE

BACK VIEW

4 of 5

ISSUED: 09-30-02 SHEET #: 090-9085-6 07-23-13

For tilt adjustment use one 4 mm allen wrench (M) to

hold socket screw in place and the other 4 mm allen

wrench (M) to turn the socket screw clockwise to tighten

and counterclockwise to loosen as shown.

Turn screen clockwise by hand for landscape or portrait

orientation.

M

SOCKET

SCREW

M

Route cord(s) through cable clips for cord management.

Note: Ensure the cords have enough slack for proper clearance

and function.

5 of 5

All other brand and product names are trademarks or registered trademarks of their respective owners.

CABLE

CLIPS

MONITOR

CORD(S)

ISSUED: 09-30-02 SHEET #: 090-9085-6 07-23-13

© 2013 Peerless Industries, Inc. All rights reserved.

Loading...

Loading...