Partlow MIC 1401 Operating Manual

MIC 1401

1/4 DIN MICROBASED LIMIT CONTROLLER

OPERATORS MANUAL

FORM 3669

EDITION 1

© OCT. 1995 PRICE $10.00

Brand

Information in this installation, wiring, and operation manual is subject to change without notice. One manual is provided with each instrument at the time of shipment. Extra copies are available at the price published on the front cover.

Copyright © Oct. 1995, The Partlow Corporation, all rights reserved. No part of this publication may be reproduced, transmitted, transcribed or stored in a retrieval system, or translated into any language in any form by any means without the written permission of the Partlow Corporation.

This is the First Edition of the MIC 1401 manual. It was written and produced entirely on a desk-top-publishing system. Disk versions are available by written request to the Partlow Publications Department.

We are glad you decided to open this manual. It is written so that you can take full advantage of the features of your new MIC 1401 limit controller.

MIC 1401 Manual |

2 |

Edition 1 |

Table of Contents

Section 1 - General |

Page |

|

1.1 |

Product Description |

5 |

Section 2 - Installation & Wiring |

|

|

2.1 |

Installation & Wiring |

7 |

2.2 |

Preparations for Wiring |

9 |

2.3 |

Input Connections |

15 |

2.4 |

Output Connections |

17 |

Section 3 - Configuration & Operation |

|

|

3.1 |

Operation |

19 |

3.2 |

Configuration |

24 |

Appendices |

|

|

A - Glossary of Terms |

30 |

|

B - Exploded View & Board Layout |

34 |

|

|

Figure B-1 Exploded View |

34 |

|

Figure B-2 Output 2/Output 3 Removal |

35 |

|

Figure B-3 CPU PWA |

36 |

|

Figure B-4 Option PWA DC Output 3 |

37 |

C - Hardware Definition Code |

48 |

|

D - Input Range Codes |

40 |

|

E - Specifications |

42 |

|

F - Model Number Hardware Matrix |

46 |

|

G - Software Reference Sheet |

47 |

|

Edition 1 |

3 |

MIC 1401 Manual |

Figures & Tables

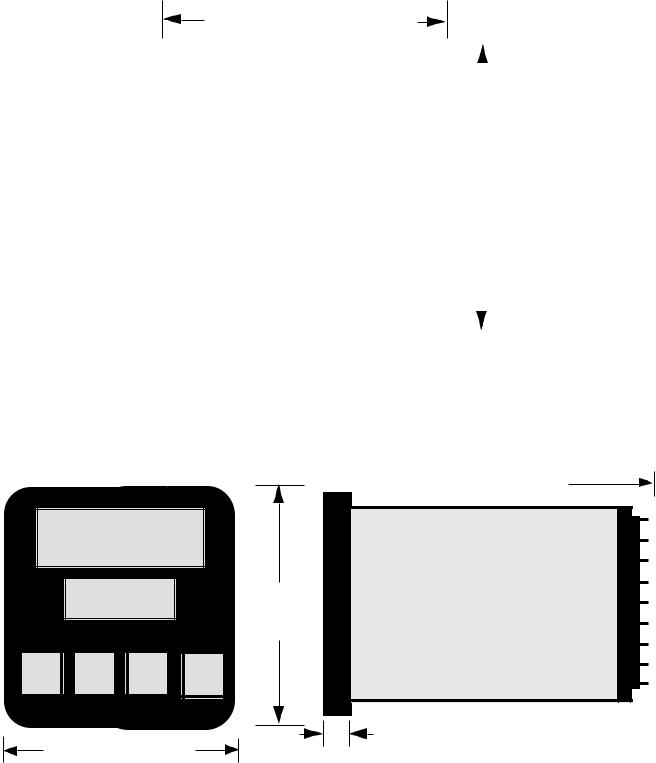

Figure 1-1 |

Display Illustration |

6 |

Figure 2-1 |

Panel Cut-Out Dimensions |

8 |

Figure 2-2 |

Main Dimensions |

8 |

Figure 2-3 |

Panel Mounting |

9 |

Figure 2-4 |

Noise Suppression |

12 |

Figure 2-5 |

Noise Suppression |

12 |

Figure 2-6 |

Wiring |

14 |

Figure 2-7 |

AC Power |

15 |

Figure 2-8 |

Thermocouple Input |

15 |

Figure 2-9 |

RTD Input |

15 |

Figure 2-10 |

Volt, mV mADC Input |

16 |

Figure 2-11 |

Remote Reset |

16 |

Figure 2-12 |

Remote Digital Connections |

17 |

Figure 2-13 |

Relay Output 1 |

17 |

Figure 2-14 |

Relay Output 2 |

17 |

Figure 2-15 |

Relay Output 3 |

18 |

Figure 2-16 |

mADC Output 3 |

18 |

Table 3-1 |

Enable Mode Configuration Procedures |

25 |

Table 3-2 |

Program Mode Configuration Procedures |

26 |

Table 3-3 |

Set-Up Mode Configuration Procedures |

28 |

MIC 1401 Manual |

4 |

Edition 1 |

Product Description 1.1

1.1.1 GENERAL

This instrument is a microprocessor based single loop limit controller, user configurable to either High Limit type or Low Limit type.

The input is user configurable to directly connect to either thermocouple, RTD, mVDC, VDC or mADC inputs. The instrument can operate from a 90-264 VAC, 50/60 HZ power supply, or optional 24 V AC/DC power supply.

Features include fail safe operation (relay de-energized by the limit exceeded condition), front panel Reset switch, time limit exceeded display and maximum/minimum tracking of excursions of the process variable.

1.1.2 DISPLAYS

Each instrument is provided with dual displays and status indicators as shown in Figure 1-1. The upper display displays the value of the process variable. The lower display displays the setpoint value. Status indication is as shown in Figure 1-1, page 6.

1.1.3 ALARMS

Alarm indication is standard on all instruments. Up to two alarm outputs are possible. Alarm type may be set as Process Direct or Reverse (high or low), Logical Combination of the two alarms and Annunciator Direct or Reverse. Alarm status is indicated by LED.

1.1.4 PROCESS VARIABLE/SETPOINT VALUE RE-TRANSMISSION OUTPUT

If the instrument is specified with this option, this output may be scaled over any desired range and re-transmitted.

Edition 1 |

5 |

MIC 1401 Manual |

FIGURE 1-1

Keys and Indicators

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MIC 1401 Manual |

|

|

Edition 1 |

|

|

||

|

|

||

6 |

|||

Installation and Wiring 2.1

Electrical code requirements and safety standards should be observed and installation performed by qualified personnel.

The electronic components of the instrument may be removed from the housing during installation. To remove the components, grip the side edges of the front panel and pull the instrument forward. During re-installa- tion, the vertically mounted circuit boards should be properly aligned in the housing.

Ensure that the instrument is correctly orientated. A stop will operate if an attempt is made to insert the instrument incorrectly. CAUTION: This stop can be over-ridden with enough force. If in doubt, check orientation again!

Recommended panel opening sizes are illustrated in Figure 2-1, page 8. After the opening is properly cut, insert the instrument into the panel opening. Ensure that the panel gasket is not distorted and that the instrument is positioned squarely against the panel. Slide the mounting clamp into place on the instrument (see Figure 2-3, page 9) and push it forward until it is firmly in contact with the rear face of the mounting panel.

Note: The mounting clamp tongues may engage either on the sides or the top/bottom of the instrument housing. Therefore, when installing several instruments side-by-side in one cut out, use the ratchets on the top/bottom faces.

Edition 1 |

7 |

MIC 1401 Manual |

FIGURE 2-1

Panel Cut-Out Dimensions

92 mm ± 0.8 (3.62” ± .031)

PANEL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

92 mm ± 0.8 |

||||

CUTOUT |

|

|

(3.62” ± .031) |

|||

SIZE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FIGURE 2-2

Main Dimensions

100 mm (3.94 in.)

100 mm (3.94 in.)

96 mm

(3.78 in)

Side View

10 mm (0.39 in.)

96 mm

(3.78 in.)

MIC 1401 Manual |

8 |

Edition 1 |

FIGURE 2-3

Panel Mounting the Controller

Mounting Clamp

Controller Housing

Tongues on mounting clamp engage in ratchet slots on controller housing

Preparation for Wiring 2.2

2.2.1 WIRING GUIDELINES

Electrical noise is a phenomenon typical of industrial environments. The following are guidelines that must be followed to minimize the effect of noise upon any instrumentation.

2.2.1.1 INSTALLATION CONSIDERATIONS

Listed below are some of the common sources of electrical noise in the industrial environment:

•Ignition Transformers

•Arc Welders

•Mechanical contact relay(s)

•Solenoids

Edition 1 |

9 |

MIC 1401 Manual |

Before using any instrument near the device listed, the instructions below should be followed:

1.If the instrument is to be mounted in the same panel as any of the listed devices, separate them by the largest distance possible. For maximum electrical noise reduction, the noise generating devices should be mounted in a separate enclosure.

2.If possible, eliminate mechanical contact relay(s) and replace with solid state relays. If a mechanical relay being powered by an instrument output device cannot be replaced, a solid state relay can be used to isolate the instrument.

3.A separate isolation transformer to feed only instrumentation should be considered. The transformer can isolate the instrument from noise found on the AC power input.

4.If the instrument is being installed on existing equipment, the wiring in the area should be checked to insure that good wiring practices have been followed.

2.2.1.2AC POWER WIRING

Neutral (For 115 VAC)

It is good practice to assure that the AC neutral is at or near ground potential. To verify this, a voltmeter check between neutral and ground should be done. On the AC range, the reading should not be more than 50 millivolts. If it is greater than this amount, the secondary of this AC transformer supplying the instrument should be checked by an electrician. A proper neutral will help ensure maximum performance from the instrument.

2.2.1.3WIRE ISOLATION

Four voltage levels of input and output wiring may be used with the unit:

•Analog input or output (i.e. thermocouple, RTD, VDC, mVDC, or mADC)

•SPDT Relays

•AC power

The only wires that should run together are those of the same category. If they need to be run parallel with any of the other lines, maintain a minimum 6 inch space between the wires. If wires must cross each other, do so at 90 degrees. This will minimize the contact with each other and reduces “cross talk”.

MIC 1401 Manual |

10 |

Edition 1 |

“Cross Talk” is due to the EMF (Electro Magnetic Flux) emitted by a wire as current passes through it. This EMF can be picked up by other wires running in the same bundle or conduit.

In applications where a High Voltage Transformer is used (i.e. ignition systems) the secondary of the transformer should be isolated from all other cables.

This instrument has been designed to operate in noisy environments, however, in some cases even with proper wiring it may be necessary to suppress the noise at its source.

2.2.1.4 USE OF SHIELDED CABLE

Shielded cable helps eliminate electrical noise being induced on the wires. All analog signals should be run with shielded cable. Connection lead length should be kept as short as possible, keeping the wires protected by the shielding. The shield should be grounded at one end only. The preferred grounding location is the sensor, transmitter or transducer.

2.2.1.5 NOISE SUPPRESSION AT THE SOURCE

Usually when good wiring practices are followed no further noise protection is necessary. Sometimes in severe electrical environments, the amount of noise is so great that it has to be suppressed at the source. Many manufacturers of relays, contactors, etc. supply “surge suppressors” which mount on the noise source.

For those devices that do not have surge suppressors supplied, RC (resis- tance-capacitance) networks and/or MOV (metal oxide varistors) may be added.

Inductive Coils - MOV’s are recommended for transient suppression in inductive coils connected in parallel and as close as possible to the coil. See Figure 2-4, page 12. Additional protection may be provided by adding an RC network across the MOV.

Edition 1 |

11 |

MIC 1401 Manual |

FIGURE 2-4

0.5 mfd 1000V

220 |

Coil |

|

|

ohms |

|

115V 1/4W

230V 1W

Contacts - Arcing may occur across contacts when the contact opens and closes. This results in electrical noise as well as damage to the contacts. Connecting a RC network properly sized can eliminate this arc.

For circuits up to 3 amps, a combination of a 47 ohm resistor and 0.1 microfarad capacitor (1000 volts) is recommended. For circuits from 3 to 5 amps, connect 2 of these in parallel. See Figure 2-5.

FIGURE 2-5

MOV

R C

Inductive

Coil

MIC 1401 Manual |

12 |

Edition 1 |

2.2.2 SENSOR PLACEMENT (Thermocouple or RTD)

Two wire RTD’s should be used only with lead lengths less than 10 feet.

If the temperature probe is to be subjected to corrosive or abrasive conditions, it should be protected by the appropriate thermowell. The probe should be positioned to reflect true process temperature:

In liquid media - the most agitated area

In air - the best circulated area

Edition 1 |

13 |

MIC 1401 Manual |

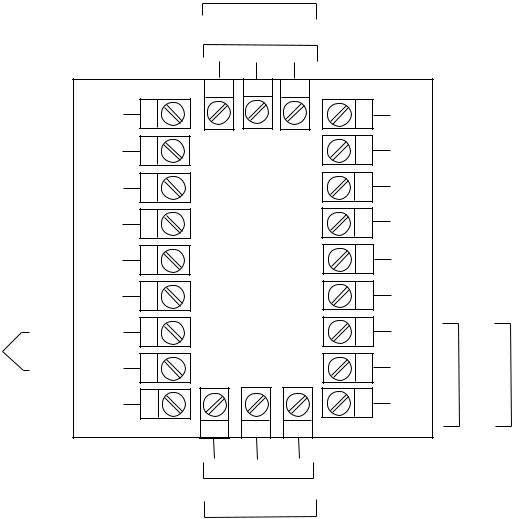

FIGURE 2-6

Wiring Label

No external connections to be made to these terminals

|

|

|

|

|

|

|

|

|

|

|

INPUT Linear(mA) |

+ |

|

|

|

|

|

|

|

|

|

|

|

(V/mV)Linear |

- |

Thermocouple |

- |

RTD |

|

|

|

|

|

|

|

|

|

||||||

- |

+ |

+ |

|

|

|

|||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

OUTPUT 3

Relay

N/C C N/O

SSR/DC

-+

10 |

11 |

12 |

9 |

|

13 |

8 |

|

14 |

7 |

|

15 |

6 |

|

16 |

5 |

|

17 |

4 |

|

18 |

3 |

|

19 |

2 |

|

20 |

1 |

|

21 |

24 |

23 |

22 |

+-

SSR/DC

N/O C N/C

Relay

OUTPUT 2

MAINS (LINE) SUPPLY

L 24V - 24V AC DC

N +

B

RS485

ASERIAL COMMS.

COM

- |

SSR/DC |

N/C |

Relay |

1 |

+ |

N/O |

OUTPUT |

||

|

|

C |

|

|

MIC 1401 Manual |

14 |

Edition 1 |

Input Connections 2.3

In general, all wiring connections are made to the instrument after it is installed. Avoid electrical shock. AC power wiring must not be connected to the source distribution panel until all wiring connection procedures are completed.

FIGURE 2-7

Main Supply

Connect the AC line voltage, hot and neutral, to terminals 13 and 14 respectively as illustrated below. Connect the positive to terminal 14 and the negative to terminal 13 for 24 VDC supply.

13 L -

14 N +

FIGURE 2-8

Thermocouple (T/C) Input

Make thermocouple connections as illustrated below. Connect the positive leg of the thermocouple to terminal 2 and the negative leg to terminal 3.

Thermocouple

-

+

3

2

FIGURE 2-9

RTD Input

Make RTD connections as illustrated on page 16. For a three wire RTD, connect the resistive leg of the RTD to terminal 1 and the common legs to terminals 2 and 3. For a two wire RTD, connect one leg to terminal 2 and the other leg to terminal 1 as shown. A jumper wire supplied by the customer must be installed between terminals 3 and 2. Input conditioning jumper must be positioned correctly (see Appendix B) and Hardware Definition Code must be correct (see Appendix C).

Edition 1 |

15 |

MIC 1401 Manual |

Loading...

Loading...