Parkside PTK 2000 B2 Translation Of The Original Instructions

TABLE SAW PTK 2000 B2

TABLE SAW

Translation of the original instructions

STOLOVÁ KOTOUČOVÁ

Překlad originálního provozního návodu

TISCHKREISSÄGE

Originalbetriebsanleitung

IAN 273460

FŰRÉSZASZTAL

Az originál használati utasítás fordítása

STOLOVÁ KOTÚČOVÁ PÍLA

Preklad originálneho návodu na obsluhu

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

Olvasás előtt kattintson az ábrát tartalmazó oldalra és végezetül ismerje meg a készülék mindegyik

funkcióját.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte stranu s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB Translation of the original instructions Page

HU Az originál használati utasítás fordítása Oldal

CZ Překlad originálního provozního návodu Strana

SK Preklad originálneho návodu na obsluhu Strana

DE / AT / CH Originalbetriebsanleitung Seite

6

32

58

83

108

1

15

1 2

3 4 5 6

7

14

13

12

11

8

9

10

2

4

24

2122

17

5

18

2 3

4

16

3

11 12

23

a b c d e

19

9

r

s

t

f g

20

3

5

6

f

38

7

38

18

r

8

19

r

20

21

38

r

22

9

11

d,a,b,c=e

7

23

18

15

10

12

d,a,b,c=e

r

d,a,b,c=e

24

18

7

4

26

25

7

f a c

f,a,c=g

7

15

r

f

13

25

f

r

25

25

14

25

15

17

f,a,c=g

16

26

26

16

18

35

f,a,c=g

f

37

36

–

+

28

34

+

–

19

29

m a x . 3 -8 m m

29

6

20

4

r

30

27

2

5

G B

Content

Introduction ....................................6

Intended purpose ............................7

General description ......................... 7

Extent of the delivery ....................... 7

Overview ....................................... 8

Functional description ....................... 9

Technical data ................................. 9

Safety Instructions ............................ 9

Symbol and icons ............................9

Symbols on the appliance .................9

Assembly ...................................... 17

Mounting of the Frame .................... 17

Mounting the table width and length

extension ...................................... 18

Mounting the Suction Adapter ......... 18

Mounting the Riving Knife ............... 18

Mounting/dismounting the

Saw Blade Guard .........................19

Replacing the Table Insert ................ 19

Adjusting/mounting the Riving Knife . 19

Attaching/changing the Saw Blade .. 20

Before putting into operation ........... 20

Operation .................................... 20

Switching on and off ..................... 20

Adjusting the Cutting Depth ............. 21

Angle Adjustment ........................... 21

Working with the Parallel Stop ......... 21

Adjusting the Stop Height ............... 21

Turning the Stop Rail ....................... 21

Adjusting the Cutting Width ...........21

Adjusting the Stop Length ................ 22

Adjusting the Parallel Stop .............. 22

Transverse stop .............................. 22

Adjusting the Scale of the

Transverse Stop ............................. 23

Using the Laser ............................. 23

Adjusting the Laser ........................ 23

Operation .................................... 23

Performing Longitudinal Cuts .......... 24

Cutting narrow Workpieces ............ 24

Cutting very narrow Workpieces ..... 24

Performing Bevel Cuts .................... 25

Performing Transverse Cuts ............. 25

Cutting Chipboard ........................ 25

Transport ...................................... 25

Cleaning and Servicing ................. 26

Cleaning ....................................... 26

Storage......................................... 26

Waste disposal and environment

protection ..................................... 26

Spare parts/accessories

Guarantee ...................................28

Trouble Shooting ............................ 30

Service-Center ..............................31

Importer ....................................... 31

Translation of the original

EC declaration of conformity ......... 134

.................27

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has

been checked for quality and subjected to

a nal inspection. The functionality of your

equipment is therefore guaranteed.

6

The operating instructions constitute part of

this product. They contain important information on safety, use and disposal.

Before using the product, familiarise yourself with all of the operating and safety

instructions. Use the product only as de-

scribed and for the applications specied.

Keep this manual safely and in the event

that the product is passed on, hand over

all documents to the third party.

G B

Intended purpose

The table circular saw is used for cutting all

types of wood lengthwise and crosswise

(only with the transverse stop), depending

on the machine size. All types of round

timbers must not be cut with it. The machine may be used only for its prescribed

purpose.

Any other use beyond that is considered to

be not in accordance with the designated

purpose. The user/operator is liable for all

types of resulting damage or injury and not

the manufacturer.

The only saw blades which may be used

are those which are suitable for the machine (HM or CV saw blades).

The use of any type of HSS saw blades

and cutting discs is prohibited. Use in accordance with the designated purpose is

also deemed to include observance of the

safety instructions, as well as the assembly

and operating instructions in the operating manual.Individuals who operate and

maintain the machine must be familiar with

it and must have been instructed in possible hazards. Moreover, the latest accident

prevention regulations must be strictly ob-

served. Other general rules in the elds of

occupational health and safety technology

must be complied with.

Caution!

When using equipment, certain safety

precautions must be complied with in order

to avoid injuries and damage. You should

therefore read these operating instructions

/ safety instructions carefully. Keep these

in a safe place so that the information is

available to you at all times. Should you

give the device to anyone else, please give

them these operating instructions / safety

instructions as well. We assume no liability

for accidents or damage caused by failure

to observe these instructions or the safety

instructions. Changes to the machine will

cause the manufacturer‘s liability with

respect to any resulting damage to be completely excluded. Even when the device is

used in accordance with the designated

purpose, it is nevertheless not possible to

completely eliminate certain residual risk

factors. Due to the design and structure of

the machine, the following risks may occur:

• Touching the saw blade in the area of

the saw which is not covered;

• Reaching into the running saw blade

(cuts)

• Kickback of workpieces and workpiece

parts.

• Saw blade breaks.

• Ejection of faulty hard metal parts of

the saw blade.

• Hearing damage if the necessary hearing protection is not used.

• Emissions of wood dust which are

harmful to the health when used in closed rooms.

Please note that the use of our devices in

accordance with the designated purpose

does not include commercial, handicraft or

industrial applications. We assume no warranty if the device is used in commercial,

handicraft or industrial businesses or for

equivalent purposes..

General description

Extent of the delivery

Carefully unpack the appliance and check

that it is complete:

- - Saw table with pre-assembled, carbide-

tipped saw blade with 24 teeth

- Carbide-tipped saw blade with 48 teeth

- Blade guard

7

G B

- Suction hose

- Suction adapter with rubber seal

- Riving knife with laser

- Batteries 1.5V AAA (2x)

- Parallel stop

- Stop rail

- Transverse stop

- Table width extender (2x)

- Table length extender

- Push stick

- Legs (4x)

- Cross struts (2x)

- Longitudinal struts (2x)

- Central struts, short (2x)

- Central struts, long (2x)

- Rubber feet (4x)

- Stand brackets (2x)

- Table supports, short (4x)

- Table supports, long (2x)

- Translation of the original instructions for use

Mounting Material

- Bag A for legs and central struts: Hexago-

nal bolt with mounted washer/

spring washer (f), 8 pieces;

Hexagonal bolt (g) = lock

washer (b), 2x washer (a), nut

(c), 4 pieces;

Round head bolt, M6 x 12 (e) =

washer (a), lock washer (b), nut

(c), 8 pieces each

- Bag B for stand bracket and upper struts:

Round head bolt, M6 x 12 (d) =

washer (a), lock washer (b), nut

(c), 20 pieces each

- Bag C for table length/width extension:

Hexagonal bolt with mounted

washer/spring washer (f),

12 pieces;

Hexagonal bolt (g) = lock

washer (b), 2x washer (a), nut

(c), 6 pieces

Tools

- Jaw spanner SW 22

- Hexagon socket wrench HX 6

- Jaw spanner SW 8/10

The illustrations are on the

fold-out pages.

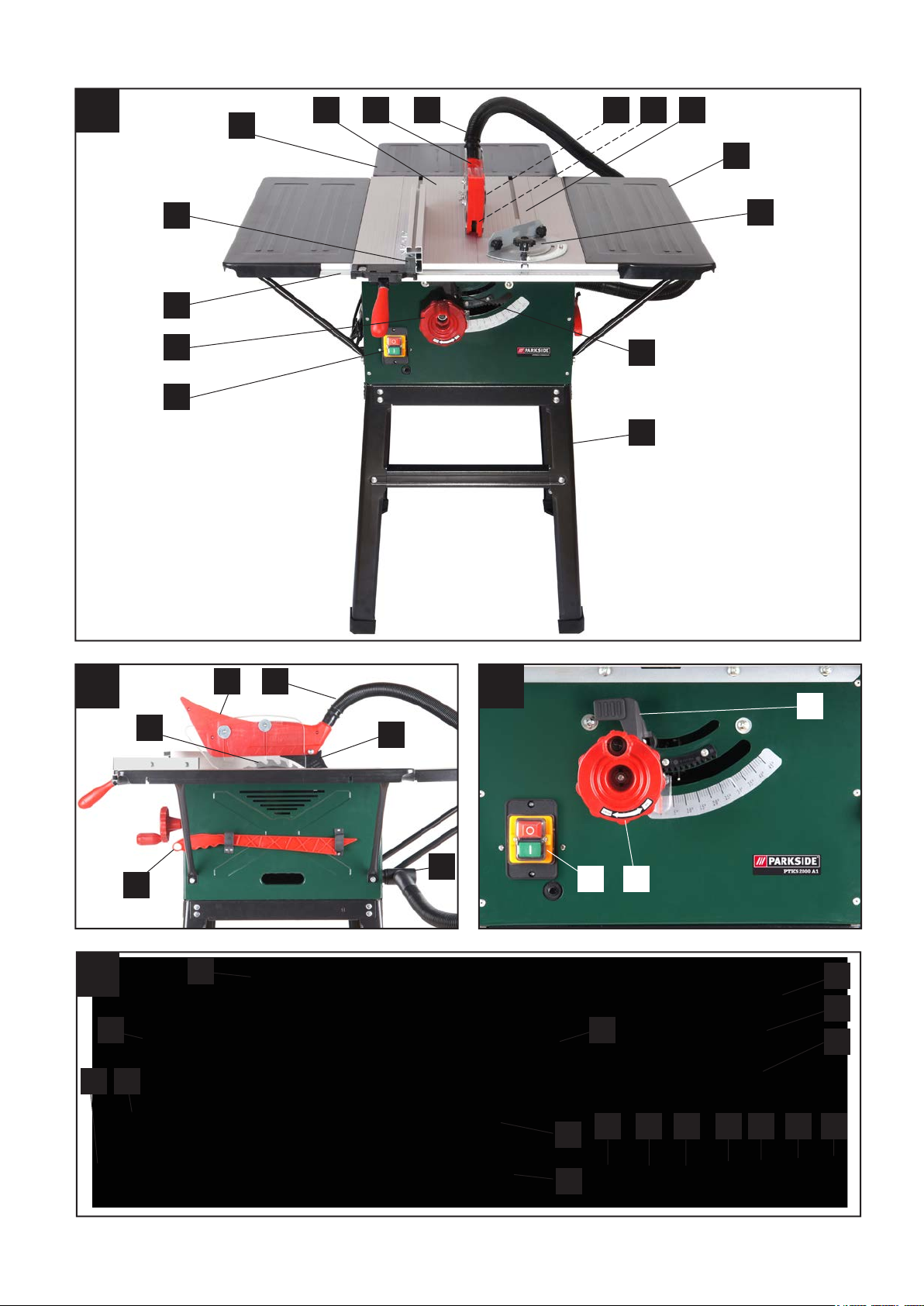

Overview

1 Saw table

1

2 Blade guard

3 Suction hose

4 Riving knife

5 Saw blade

6 Table insert

7 Table width extender

8 Transverse stop

9 Locking handle

10 Base

11 On/off switch

12 Handwheel

13 Guide rail

14 Parallel stop

15 Table length extender

16 Suction adapter with Rubber seal

17 Push stick

18 Legs

19 Cross struts

20 Longitudinal struts

21 Central struts, short

22 Central struts, long

23 Rubber feet (4x)

24 Stand brackets (2x)

25 Table brackets, short

26 Table brackets, long

27 Bolt with wing nut

28 Slot in the riving knife

29 Countersunk screws of the table

insert

30 Fixing bolts of the riving knife

31 Cam lever

32 Groove

33 Knurled screw

34 Laser

8

G B

35 Laser switch

36 Screws for battery compartment

37 Battery cover

38 Attachment points

39 Stop rail

Functional description

The table circular saw is used for cutting all

types of wood lengthwise and crosswise

(only with the transverse stop), depending

on the machine size. All types of round

timbers must not be cut with it.

Technical data

Bench circular saw.........................PTK 2000 B2

AC motor .......................... 230 V~ 50Hz

Power ................................... 2000 Watt

Operating mode .......................S6 40%*

Safety class .......................................... I

Protection category...........................IP20

Idling speed ...........................4800 min

Carbide saw blade ø 254 x ø 30 x 2,8 mm

Number of teeth ......................... 24 / 48

Thickness riving knife ................... 2,5 mm

min. Workpiece size WxLxH 10x50x1 mm

Table size .........................630 x 445 mm

Table width extender

left/right ..........................620 x 250 mm

Table length extender rear ..435 x 320 mm

Cutting height max. 90° ................ 73 mm

Cutting height max. 45° ................ 63 mm

Height adjustment ................... 0 - 73 mm

Saw blade, swivelling ................... 0 - 45°

Extraction connection ................. ø 34 mm

Weight (including accessories),

......................................approx 29,5 kg

Laser class

Laser wavelength ........................650 nm

Laser power ..............................< 1 mW

Laser module power supply

............................2 x 1,5 V Micro (AAA)

........................................... 2

Sound pressure level

(L

) .....................92 dB(A); KpA = 3 dB

pA

Sound power level (L

measured ............105 dB(A); K

WA

)

WA

guaranteed .........................108 dB(A)

* Operating mode S6 40%: Continuous operation with intermittent load (cycle time 10 min). In

order not to heat the motor more than permitted,

the motor may only be operated for 40% of the

cycle time with the stated nominal power and

must then continue running for 60% of the cycle

time without a load.

Technical and optical changes may be

undertaken in the course of further development without notice. All dimensions,

references and information in this instruction manual are therefore not guaranteed.

Legal claims made on the basis of the

instruction manual can therefore not be

considered as valid.

-1

Safety instructions

Ensure that the safety instructions are observed when operating the appliance.

Symbols and icons

Symbols on the appliance:

Carefully read these Operating In-

structions.

Wear eye protection.

Wear ear protection.

Wear breathing protection.

Caution - Risk of injury. Never re-

ach into the running blade.

= 3 dB

9

G B

108

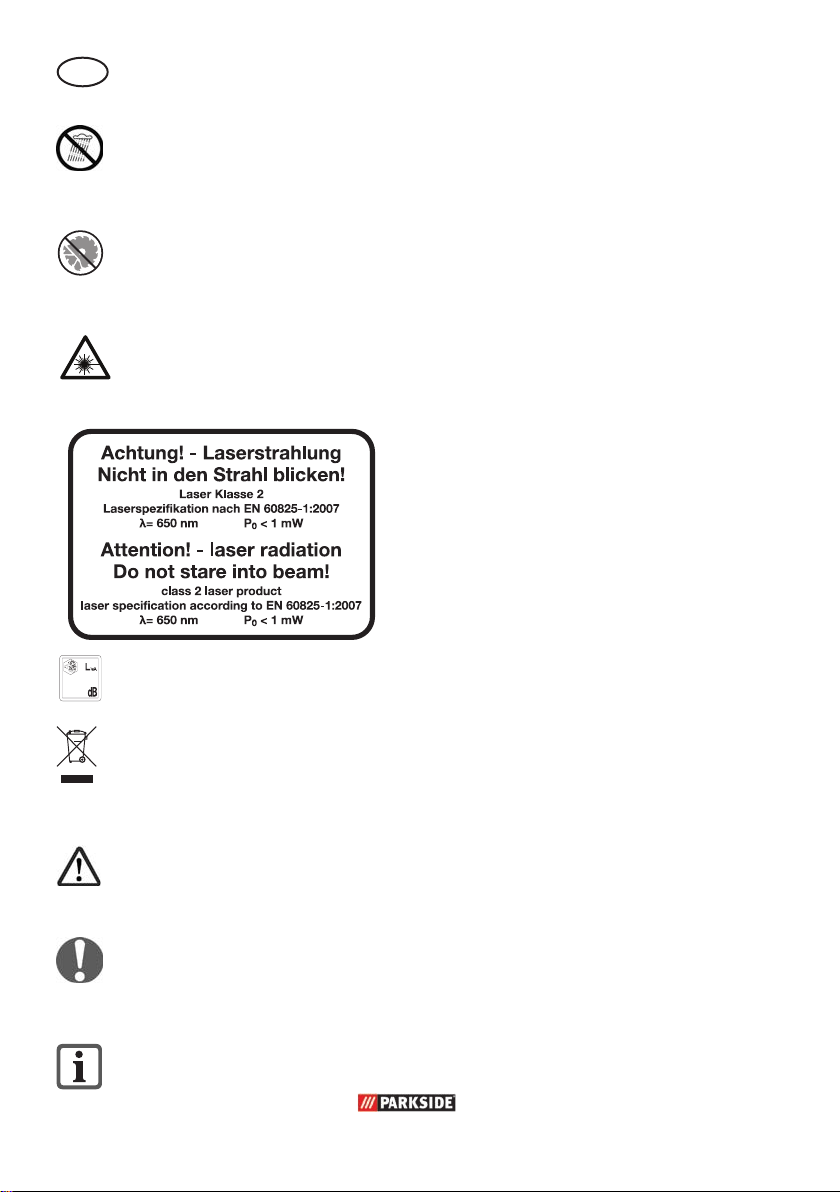

Do not expose the unit to rain. The

device must not be wet, nor should

it be operated in a moist environment.

Caution - a damaged blade must

not be used under any circumstances. Replace the saw blade immediately.

Caution! - Laser radiation. Do not

look into the beam.

Laser class 2

Information of the acoustic power

level L

Electrical appliances must not be dis-

posed of with the domestic waste.

Symbols in the manual

Warning symbols with in-

formation on damage and

injury prevention.

Instruction symbols (the instruction is

explained at the place of the exclamation mark) with information on

preventing damage.

WA

in dB.

Safe operation

1 Keep work area clear.

– Cluttered areas and benches invite

injuries.

2 Consider work area

environment.

– Do not expose tools to rain.

– Do not use tools in damp or wet

locations.

– Keep work area well lit.

– Do not use tools in the presendce

of ammable liquids or gases.

3 Guard against electric shock

– Avoid body contact with earthed

or grounded surfaces (e.g. pipes,

radiators, ranges, refrigerators).

4 Keep other persons away!

– Do not let persons, especially child-

ren, not involved in the work touch

the tool or the extension cord and

keep them away from the work

area.

5 Store idle tools

– When not in use, tools should be

stored in a dry locked-up place,

out of the reach of children.

6 Do not force the tool.

– It will do the job better and safer at

the rate for which it was intended.

7 Use the right tool.

– Do not force small tools to do the

job of a heavy tool.

– Do not use the power tool for such

purposes for which it is not inten-

ded. Use for example no circular

saws to cut tree branches or logs.

– Do not use the electric tool to the

rewood saws.

Help symbols with information on

improving tool handling.

1 0

G B

8 Dress properly.

– Do not wear loose clothing or

jewellery, they can be caught in

moving parts.

– Non-skid footwear is recommen-

ded when working outdoors.

– Wear protective hair covering to

contain long hair.

9 Use protective equipment.

– Use safety glasses.

– Use face or dust mask if working

operations create dust.

10 Connect dust extraction

equipment

– If the tool is provided for the

connection of dust extraction and

collecting equipment, ensure these

are connected and properly used.

– Indoor operation is permitted only

with a suitable extraction system.

11 Do not abuse the cord.

– Never yank the cord do disconnect

it from the socket. Keep the cord

away from heat, oil and sham

edges.

12 Secure work.

– For long workpieces, an additional

supporting surface (table, trestles,

etc.) is required in order to prevent

tipping of the machine.

– Always press the workpiece rmly

against the working surface and

stop in order to prevent wobbling

or twisting of the workpiece.

13 Do not overreach

– Keep proper footing and balance

at all times.

– Avoid awkward hand positions

in which one or both hands could

touch the saw blade as the result

of a sudden slip.

14 Maintain tools with care

– Keep cutting tools sharp and clean

for better and safer performance.

– Follow instruction for lubricating

and changing accessories.

– Inspect tool cords periodically and

if damaged have them repaired by

an authorized service facility.

– Inspect extension cords periodi-

cally and replace if damaged.

– Keep handles dry, clean and free

from oil and grease.

15 Disconnect tools.

– Never remove loose splinters,

chips or jammed pieces of wood

when the saw blade is running.

– When the electric tool is not in

use, before maintenance and when

changing tools such as the saw

blade, drill bit, milling cutter.

16 Remove adjusting keys and

wrenches

– Form the habit of checking to see

that keys and adjusting wrenches

are removed from the tool before

turning it on.

17 Avoid unintentional starting.

– Ensure switch is in “off” position

when plugging in.

18 Use outdoor extension leads.

– When the tool is used outdoors,

use only extension cords intended

for outdoor use and so marked.

– Use the cable drum only in the

unrolled state.

19 Stay alert.

Watch what you are doing, use com-

mon sense and do not operate the tool

when you are tired.

20 Check damaged parts.

– Before further use of tool, it should

1 1

G B

be carefully checked to determine

that it will operate properly and

perform its intended function.

– Check whether the moving parts

are working properly and are not

becoming jammed or whether

parts are damaged. All parts must

be correctly tted and satisfy all

conditions to ensure the proper

operation of the power tool.

– The movable guard must not be

clamped when it is open.

– A guard or other part that is dama-

ged should be properly repaired or

replaced by an authorized service

centre unless otherwise indicated

in this instruction manual.

– Have defective switches replaced

by an authorized service centre.

– Do not use any faulty or damaged

connection cables.

– Do not use the tool if the switch

does not turn it on and off.

21 Warning!

– The use of any accessory or attach-

ment other than one recommended

in this instruction manual may

present a risk of personal injury.

22 Have your tool repaired by a

qualied person.

– This electric tool complies with

the relevant safety rules. Repairs

should only be carried out by qua-

lied persons using original spare

parts, otherwise this may result in

considerable danger to the user.

ADDITIONAL SAFETY

INSTRUCTIONS

1 Safety Precautions

– Warning! Do not use damaged,

cracked or deformed saw blades.

– Replace a worn table insert.

Regrinding is not allowed.

– Only use saw blades recommen-

ded by the manufacturer which

conform to EN 847-1. Warning!

When changing the saw blade

ensure that the cutting width is not

smaller and the main blade thick-

ness of the saw blade not greater

than the thickness of the riving

knife!

– Make sure that a saw blade is

selected which is appropriate for

the material to be cut.

- Wear appropriate personal pro-

tective equipment. This includes:

Hearing protection to reduce the

risk of becoming hard of hearing,

breathing respirator to reduce the

risk of inhaling hazardous dust.

- Wear gloves when handling saw

blades and rough materials.

- Whenever practicable, saw blades

should be carried in a container.

– Wear safety goggles. Any splin-

ters, chips and dusts which are

ejected from the device when it is

in operation may cause sight loss.

– Connect the power tool to a dust

collection device when sawing

wood. Among other things, the

emission of dust is affected by the

type of material to be machined,

the importance of local deposition

(capture or source) and the correct

setting of hoods/deector plates/

guide mechanisms.

- Do not use any saw blades made

of high-alloy high-speed steel

(HSS).

– Always store the push stick or

push block in its holder on the

power tool when not in use.

1 2

G B

2 Maintenance and Servicing

– Always remove the mains plug

when carrying out any adjustments

or maintenance work.

– The cause of the noise is inuenced

by various factors, including the

properties of the blades, the condition of the saw blade and power

tool. If possible, use saw blades

that are designed to reduce the

noise level, service the power tool

and tool attachments regularly and

repair them if necessary to reduce

noise.

- Report any faults to the power tool,

safety devices or the tool attachment as soon as they are discovered to the person responsible for

safety.

3 Safe Working

– Use the push stick or the handle

with push block to pass the workpiece safely past the saw blade.

– Make sure that the riving knife

is always used and that this is

correctly adjusted.

– Use the upper blade guard and

adjust it correctly.

– Use only saw blades whose maxi-

mum speed is not lower than the

maximum spindle speed of the tool

being used and which are suitable

for the material to be cut.

– Do not create any rebates or

grooves unless a suitable protective

device, such as a tunnel guard, is

attached above the saw table.

– Circular saws must not be used for

slotting (cutting grooves which end

in the workpiece).

– When transporting the power

tool, use only the transport devices

supplied. Never use the guards for

handling or transporting the tool.

- During transport, make sure that

the top part of the saw blade is covered, for example with the guard.

– Ensure that the only spacer

washers and spindle rings which

are used are suitable for the purpose stated by the manufacturer.

– The oor around the machine must

be at, clean and free of loose

particles such as chips and cutting

residues.

– Working position always to the

side of the saw blade.

– Do not remove any cutting residues

or other parts of the workpiece

from the cutting area for as long

as the machine is running and the

sawing unit is not yet in the rest

position.

– Secure long workpieces against

tilting at the end of the cutting

operation (e.g. unwinding stand or

roller stand).

– Caution! long workpieces against

tilting at the end of the cutting

operation (e.g. unwinding stand or

roller stand).

– Caution! Never remove any loose

splinters, chips or jammed pieces

of wood when the saw blade is

still running.

• Always switch off the machine and

remove the plug before repairing

any faults or removing jammed

pieces of wood.

• Always switch off the motor and

remove the plug before carrying

out any conversions or adjustment,

measurement and cleaning work.

• Before switching on, check that

the spanners and adjustment tools

have been removed.

1 3

G B

Warning! During operation, this power

tool produces an electromagnetic eld.

Under certain circumstances, this eld may

negatively affect active or passive medical

implants. In order to reduce the danger of

serious or fatal injuries, we recommend

that individuals who wear medical implants should consult their doctor and the

manufacturer of the implant before operating the power tool.

SAFETY INSTRUCTIONS FOR

HANDLING SAW BLADES

1 Only use tools which you know how to

handle.

2 Pay attention to the maximum speed.

The maximum speed stated on the tool

being used must not be exceeded.

Keep within the speed range if one is

specied.

3 Note the direction of rotation of the

motor and saw blade.

4 Circular saw blades with cracks in

them must be taken out of service

(repair is not permitted).

5 Tools with visible cracks must not be

used.

6 Tools must be cleaned regularly.

7 Handle the tools used with care. It is

best to store these in their original pa-

ckaging or special containers. Always

wear protective gloves to improve

your grip and further reduce the risk of

injury.

8 Before using any of the tools, ensure

that all protective devices are correctly

attached.

9 Before use, ensure that all of the tools

used by you full the technical requirements of this power tool and are

properly attached.

10 The saw blade supplied should only

be used for sawing wood and never

for working metal.

Assembly and Attachment of Tools

and Tool Parts

a) Tools and tool bodies must be tighte-

ned in such a way that they cannot

become loose during operation.

b) Attachment bolts and nuts are to be

tightened to the torques specied by

the manufacturer using appropriate

spanners etc.

c) Extending a spanner or tightening

with the help of hammer blows is not

permitted.

d) The tightening surfaces must be clea-

ned to remove any dirt, grease, oil

and water.

e) Tensioning bolts must be tightened in

accordance with the manufacturer‘s

instructions.

f) In order to adjust the borehole diame-

ter of circular saw blades to the spind-

le diameter of the machine, only rmly

inserted rings, e.g. rings which have

been pressed into place or which are

held in place by means of an adhesive

bond, may be used. The use of loose

rings is not permitted.

g) Ensure that xed reducing rings are

positioned parallel to one another.

Safety Instructions for Handling the

Laser

– Caution: Laser radiation - Do not look

into the beam - Laser class 2

1 4

G B

Safety Instructions for Handling

Batteries

1 Ensure at all times that the batteries

are inserted with the correct polarity (+

and –), as shown on the battery itself.

2 Do not short-circuit the batteries.

3 Do not charge up rechargeable batte-

ries.

4 Do not overcharge the battery!

5 Do not mix old and new batteries or

batteries of a different type or from

different manufacturers! Replace all

batteries of a set at the same time.

6 Remove used batteries immediately

out of the device and dispose of them

correctly!

7 Do not heat the batteries!

8 Do not carry out any welding or solde-

ring work directly to the batteries!

9 Do not take the batteries apart!

10 Do not deform the batteries!

11 Do not throw the batteries into the re!

12 Store the batteries out of the reach of

children.

13 Do not allow children to replace the

batteries without supervision!

14 Do not store the batteries close to a

re, cookers or other sources of heat.

Do not place the battery in direct

sunlight and do not use or store it in

motor vehicles in hot weather.

15 Store used batteries in the original

packaging and keep them away

from metal objects. Do not mix (up)

unpacked batteries! Otherwise this

may cause the battery to short-circuit,

resulting in damage, burns or even the

danger of re.

16 Remove batteries from the device if this

is not going to be used for a prolonged period, unless it is to be used in

emergencies!

17 NEVER touch batteries which have

leaked without appropriate protection.

If the leaked liquid comes into contact

with the skin, you should rinse off this

area of the skin immediately under

running water. Make sure at all events

that your eyes and mouth do not come

into contact with the liquid. If they do,

seek medical advice immediately.

18 Clean the battery contacts and the

equivalent contacts in the device before inserting the batteries.

Residual Risks

This power tool has been constructed in accordance with the latest

technology and the generally recognised safety regulations. Nevertheless, it is possible that individual

residual risks may occur during

operation.

• Electrical hazard if improper electrical

connection cables are used.

• In addition, concealed residual risks

may be present in spite of all the

precautions that have been taken.

• Residual risks can be minimised by

observing the „Safety instructions“ and

„Use in accordance with the designated purpose“, as well as the operating

instructions.

• Do not put any unnecessary stresses

on the machine: excessive pressure

during sawing will quickly damage

the saw blade. This may result in a

1 5

G B

reduction in the performance of the

machine, as well as a reduction in the

cutting accuracy.

• Avoid switching the machine on by

accident: when inserting the plug into

the socket, the power button must not

be pressed.

• Use the tool which is recommended

in this manual. This will ensure the

optimal performance of your saw.

• Keep your hands away from the

working area when the machine is in

operation.

• Before you carry out any adjustments

or servicing work, turn the device off

and remove the mains plug.

5. Electrical Connection

The installed electric motor is

connected ready for operation.

The connection complies with the

relevant VDE and DIN regulations.

The customer‘s network connection

and any extension cable used must

comply with these regulations.

• The product meets the requirements

of EN 61000-3-11 and is subject to

special connection conditions. This

means that its use at freely selectable

connection points is not permitted.

• If the network conditions are unfa-

vourable, the device may result in

temporary voltage uctuations.

• The maximum permitted mains

impedance at the electrical connection point of 0.107 ohm must not be

exceeded.

• As the user, you must ensure – in

consultation with your electricity supply company if necessary – that the

continuous current carrying capacity

of the network at the connection point

to the public mains is sufcient for the

connection of the product.

Important Instructions

If the motor is overloaded, it switches

itself off automatically. After cooling down

(times vary), the motor can be switched on

again.

Faulty Electrical

Connection Cable

Insulation damage often occurs to electrical

connection cables.

The causes of this may be as follows:

• Pressure points if connection cables

are routed through windows or door

gaps.

• Kinks caused by improper attachment

or routing of the connection cable.

• Cut surfaces caused by vehicles driving over the connection cable.

• Insulation damage caused by tearing

out of the wall socket.

• Cracks resulting from the insulation

becoming old.

Such faulty electrical connections must not

be used and may endanger life due to the

damage to the insulation.

Electrical connection cables should be

checked regularly for damage. Ensure that

during such checks, the connection cable is

not connected to the mains.

Electrical connection cables must comply

with the relevant VDE and DIN regulations. Only use connection cables with the

marking H05VV-F.

It is stipulated by law that the type of connection cable must be printed on it.

1 6

G B

Alternating Current Motor

• The mains voltage must be 230 V~.

• Extension cables up to 25 m in length

must have a cross-section of 2.5 mm².

Connections and repairs to the electrical

equipment may only be performed by

a qualied electrician. If you have any

queries, please provide the following

information:

• Current type of the engine

• Data from the machine type plate

• Data from the motor type plate

Assembly

Assembly, Replacement of Parts

and Adjustments

Caution! The mains plug must be

removed before all servicing, retooling and assembly work.

Place all of the parts supplied on a at

surface. Form groups of the parts which

are similar.

Note: If connections are secured with a

bolt (round head/or hexagonal), hexagonal nuts and a washer, the washer must be

placed under the nut.

Insert the bolts from the outside to the inside in each case, securing the connections

with nuts from the inside.

Note: Tighten the nuts and bolts during assembly only to the extent that they cannot

fall off.

If you tighten the nuts and bolts any further

before nal assembly, it is not possible for

nal assembly to be carried out.

Additional tool required:

- Phillips screwdriver

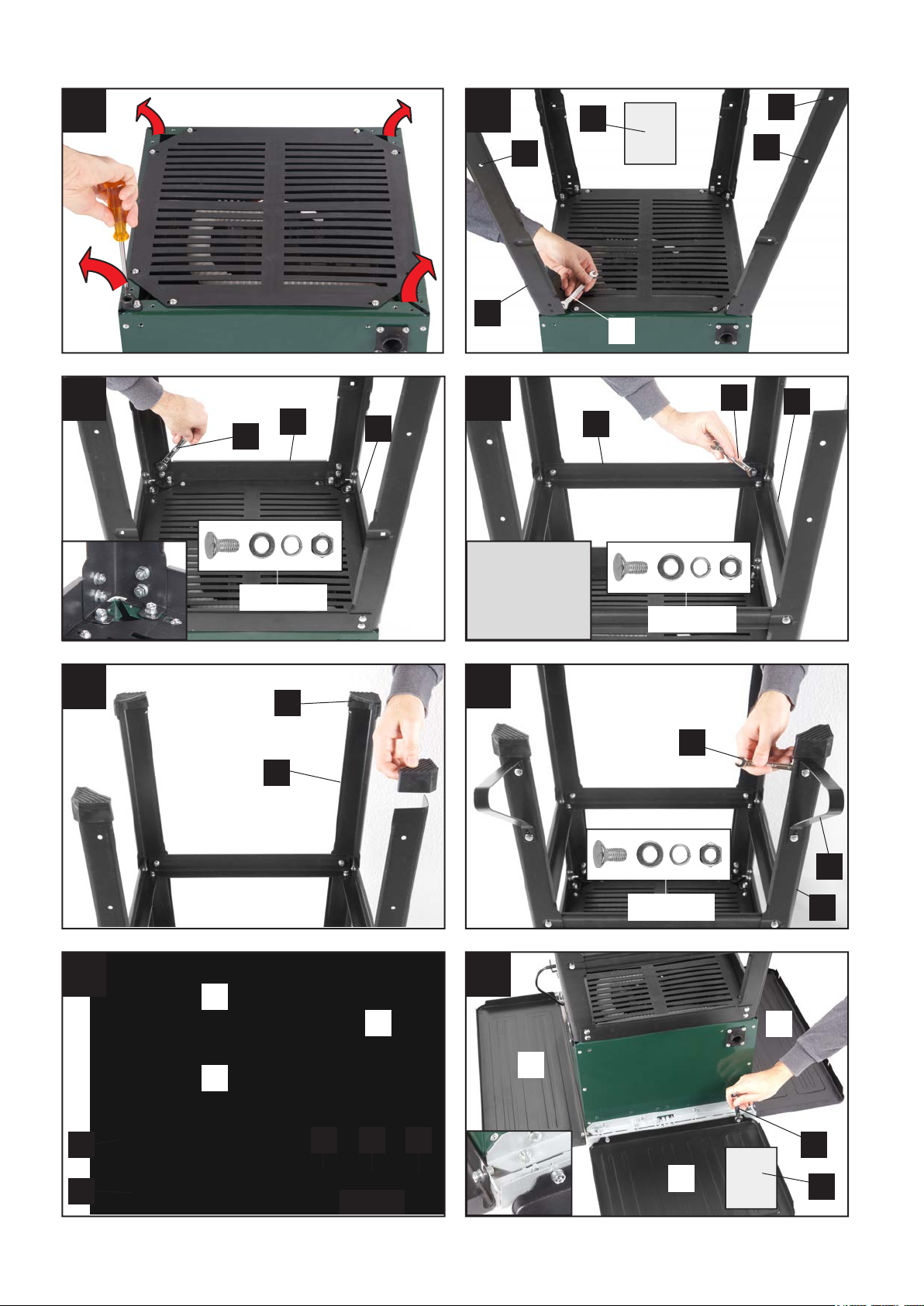

Mounting of the Frame

Abb.4-10

1. Turn the table circular saw over and

place it on the oor.

2. Unscrew the four mounted rubber feet

with a Phillips screwdriver (Figure 5).

3. Screw the four legs (18) with the

hexagon bolts (e) loosely on to the

saw (Figure 6). Use the jaw spanner

(r) supplied for this.

Caution! 2 of the legs have

holes (38) drilled into the rear,

into which the stand brackets

have to be xed. (Figures 6

and 10) Ensure that these are

attached at the rear of the machine.

4. Now take the cross struts (19) (marked

A) and longitudinal struts (20) (marked

B). Screw these loosely together with

the four central struts (21, 22) to the

legs. Mounting material: Round head

bolts (d), washer (a), spring washer (b)

and nuts (c), (Figure 6-8).

5. The round head bolts (d) and nuts (c)

should only be loosely tightened.

Caution: The longer struts

(marked B) must be used at the

side. Secure the central struts

with the hexagon bolts, as

shown in detail in Figure 8.

6. Now attach the rubber feet (23) to the

legs (Figure 9).

7. Screw the stand brackets (24) into the

rear legs using the drill holes. Mounting material: 2 each: round head

bolts (d), shims (a), spring washer (b)

and nuts (c), (Figure 10).

1 7

G B

Caution! Both stand brackets

must be attached to the rear

of the machine at attachment

points 38!

8. Then tighten all of the bolts and nuts of

the base.

Mounting the table width

and length extension

(Figures 11-14)

1. Loosely tighten the table width extension (7) and table length extension (15)

on the saw table using the hexagon

bolts (f). (Figure 12).

2. Loosely tighten the table supports

(25, 26) on the housing of the table

circular saw using hexagon bolts (f). In

addition, the table supports (25, 26)

also have to be loosely tightened to

the table width and length extensions.

Mounting material: Hexagon bolts (e),

washer (a) and nut (c). The short supports (25) are for the table widening

extension, the long supports (26) for

the length extension, (Figures 13, 14).

3. Turn the saw over with the base and

place it on the oor.

4. Align the table width and length exten-

sion ush with the saw table.

5. Then tighten all bolts.

Mounting the Suction

Adapter

(Figure 15)

1. Insert the suction adapter (16) into

the opening provided on the rear of

the machine. The side outlet is now

pointing outwards.

2. The suction adapter has a rubber seal;

make sure that this is mounted.

3. The adapter is secured by means of

a bayonet lock. Insert the vacuum

cleaner adapter (16) as shown in

Figure 15 and lock this in place with a

quarter turn in a clockwise direction.

Mounting the Riving Knife

(Figures 16-19)

Caution! Remove the mains plug!

The setting of the saw blade (5)

must be checked whenever a blade

has been replaced.

1. Inserting the batteries (Figure 16):

- Turn the laser on/off switch (35) to the

0 position (laser off).

- Remove the battery compartment cover

(37) by loosening the screw (36).

Now remove the battery compartment

cover (37) by bending at the side.

- Insert the batteries supplied (type

AAA), ensuring the correct polarity

(see Figure 16).

- Put the battery compartment cover (37)

back in position and tighten it with

the screw (36). Notes concerning the

batteries:

- If you are not going to use the laser

for a prolonged period, please remove

the batteries from the battery compartment. Otherwise, the leaking of

battery uid might damage the device.

- Do not place the batteries on radiators or expose them for a prolonged

period to strong sunlight; temperatures

above 50° could damage the device.

2. Adjust the saw blade (5) to a max.

cutting depth, move to the 0° position

and lock in place.

3. Release the screws (29). Remove the

table insert (6) (Figure 17).

1 8

G B

4. Release the two attachment bolts (30)

and insert the riving knife (4) between

the metal plate and the mount (see

Figure 18).

5. The distance between the saw blade

and riving knife (4) should be between

3 mm and max. 8 mm, (Figure 19).

6. Retighten the attachment bolts (30)

and mount the table insert (6) (see

Figure 17).

Mounting / dismounting

the Saw Blade Guard

(Figures 20/21)

1. Before initial assembly, the batteries

of the laser have to be inserted (see

Mounting the Riving Knife 1).

2. Dismantle the bolt with wing nut and

shim (27) of the saw blade guard (2).

Place the saw blade guard (2) from

the top onto the riving knife (4).

3. Mount the bolt with the wing nut and

shim (27) so that the bolt sits rmly in

the slot (28).

4. Do not overtighten the bolt (27). The

saw blade guard must be able to

move freely.

5. Place the suction hose (3) on the

suction adapter (16) and the suction

connector of the saw blade guard (2).

Connect a suitable woodchip extraction system to the suction adapter (16),

(Figure 21).

6. Dismantling is carried out in reverse

order. Caution! Before you start sawing, the saw blade guard (2) has to

be lowered onto the item being sawn.

Replacing the Table Insert

(Figures 17 and 22)

1. If it is worn or damaged, the table insert (6) has to be replaced, as otherwise there is an increased risk of injury.

2. Remove the 3 countersunk screws (29).

3. Take out the worn table insert (6).

4. The new table insert is mounted in

reverse order.

Adjusting / mounting the

Riving Knife

(Figures 16-19)

Caution!

Remove the mains plug! The setting

of the saw blade (5) must be checked whenever a blade has been

replaced.

1. Adjust the saw blade (5) to the max.

cutting depth, move to the 0° position

and lock in place.

2. Dismantle the saw blade guard (2)

3. Take out the table insert (6).

4. Loosen the attachment bolts (30).

5. Push the riving knife (4) upwards.

6. The distance between the saw blade

(5) and riving knife (4) should be max.

8 mm. (Figure 19)

7. Retighten the attachment bolts (30)

and mount the table insert (6).

8. Reattach the saw blade guard (2).

1 9

G B

Attaching/changing the

Saw Blade

(Figure 22)

1. Caution! Remove the mains

plug and wear protective

gloves.

2. Dismantle the saw blade guard (2).

3. Remove the table insert (6) by releasing the three countersunk screws (29)

(see Figure 17)

4. Place the hexagon socket key (s) (HX

6) on the bolt and use the jaw spanner

(t) (SW 22) to stop the motor spindle

from turning (see Figure 22).

5. Caution! Turn the bolt in the direction

of rotation of the saw blade.

6. Remove the outer ange and take the

old saw blade off the inner ange by

pulling downwards and diagonally.

7. Clean the saw blade anges carefully

with a wire brush before attaching the

new saw blade.

8. Insert and tighten the new saw blade

in reverse order.

Caution! Note the direction of

motion; the slope of the cutting

edge of the teeth must face the

direction of motion, i.e. forwards (see the arrow on the

saw blade guard (2).

9. Reattach and adjust the table insert (6)

and the saw blade guard (2).

10. Before you work with the saw again,

a check must be carried out to ensure

that the protective devices are working

properly.

Before putting into

operation

• The machine must be set up on a stable surface, i.e. on the base or similar

item. For this, use the drill holes which

are located in the frame of the machine. For safe use on a work bench, four

mounted rubber feet are provided

(g. 5).

• Before the machine is put into operation, all covers and safety devices must

be properly attached.

• The saw blade must be able to move

freely.

• In the case of wood which has already

been worked with, check for foreign

bodies such as nails or screws etc.

• Before pressing the on/off switch,

make sure that the saw blade is correctly attached and that moving parts

are free-running.

• Before connecting the machine, check

that the data on the type plate matches

those of the mains system.

• The machine must only be connected

to a properly installed safety socket

which is protected by a fuse of at least

16A.

• If possible, connect the device only to

a socket with a residual current circuit

breaker (RCCB) with a tripping current

of not more than 30 mA.

Operation

Switching on and off

(Figure 23)

- The saw can be switched on by

pressing the green pushbutton „I“.

Before you start sawing, wait until the

saw blade has reached its maximum

speed.

2 0

G B

- In order to switch the saw off again,

the red pushbutton „0“ has to be

pressed.

Adjusting the Cutting

Depth

(Figure 23)

By turning the hand wheel (12) to adjust

the height, the saw blade can be set to the

desired cutting depth (continuous).

Important: the hand wheel (12) has

to be pulled out to adjust the cutting depth. When the hand wheel is

pressed in, this adjusts the cutting

angle.

- Anticlockwise: increases the cutting

depth

- Clockwise: reduces the cutting depth

Check the adjustment by means of a

test cut.

Angle Adjustment

(Figure 23)

With the table circular saw it is possible to

make bevel cuts to the left at an angle of

0° to 45° to the stop rail. Before each cut,

make sure that no collision is possible between the stop rail (39), cross-cutting gauge

(Figure 1, no. 8) and the saw blade (5).

- Release the locking handle (9)

- Set the desired angle on the scale

by pressing in and turning the hand

wheel (12).

- Lock the locking handle (9) in the

desired angular position.

Working with the Parallel

Stop

Adjusting the

Stop Height

(Figures 24-26)

- The stop rail (39) of the parallel stop

(14) has two guide surfaces at different heights.

- Depending on the thickness of the materials to be cut, the stop rail (39) has

to be used differently. For thin material

(workpiece thickness less than 25

mm), use Figure 24. For thick material

(workpiece thickness more than 25

mm), use Figure 26.

Turning the Stop Rail

(Figures 24-26)

- In order to turn the stop rail (39), rst

of all release the two wing nuts (h).

- Now the stop rail (39) can be pulled

off the guide rail (14) and pushed

back over this again with the correct

guide mechanism.

- Retighten the wing nuts (h).

Adjusting the Cutting

Width

(Figures 27-28)

- When wooden pieces are being cut

lengthwise, the parallel stop (14) has

to be used.

- The parallel stop should be mounted

on the right-hand side of the saw

blade (5).

- Insert the parallel stop into the side of

the guide rail (13) (Figure 28).

2 1

G B

- On the guide rail for the parallel stop

(13) there are 2 scales (j/k). These

show the distance between the stop

rail (39) and saw blade (5) (Figure

27).

- Select the suitable scale according to

whether the stop rail (39) has been

turned around for working with thick

or thin material:

High stop rail (thick material):

scale (j)

Low stop rail (thin material):

scale (k)

- Adjust the parallel stop (14) to the

desired level on the sight glass (l) and

x in place with the cam lever (31).

Adjusting the Stop Length

(Figure 29)

- In order to prevent the material being

cut from jamming, the stop rail (39)

can be moved in the longitudinal

direction.

- Rule of thumb: the rear end of the

stop abuts on an imaginary line. This

begins at about the middle of the saw

blade and runs towards the back at an

angle of 45°.

- Adjust the required cutting width.

- Release the wing nuts (h) and push

the stop rail (39) forwards until the

imaginary 45° line is touched.

- Retighten the wing nuts (h).

Adjusting the Parallel Stop

(Figure 30)

- Caution! Remove the guard.

- Adjust the saw blade (5) to the maximum cutting depth.

- Adjust the parallel stop (14) such that

the stop rail (39) touches the saw

blade (adjustment for thick material.

- If the parallel stop (14) is not parallel

to the saw blade (5), please proceed

as follows. Release the screws (m) on

the parallel stop until the parallel stop

(14) can be aligned to be parallel with

the saw blade (5) (Figure 30).

- Retighten the screws (m).

Transverse stop

(Figure 31)

- Push the transverse stop (8) into a

groove (32) of the saw table.

- Loosen the knurled screw (33).

- Turn the transverse stop (8) until the

desired angle is set. The notch on the

guide bar shows the angle that has

been set.

- Retighten the knurled screw (33).

- When the wood is being cut to

size, the transverse stop (8) must be

extended with the stop rail (39) of the

parallel stop (14) (Figure 31)

- In order to extend the transverse stop

(8) with the stop rail (39), the stop

rail (39) has to be removed from the

parallel stop (14). Now the stop rail

has to be mounted as shown in Figure

31; use the star grips (q) for this.

Caution!

- Do not push the stop rail (39) too far

in the direction of the saw blade.

- The distance between the stop rail (39)

and saw blade (5) should be approximately 2 cm. (Figure 31).

2 2

G B

Adjusting the Scale of the

Transverse Stop

(Figure 32)

- Create a 90° stop angle with respect

to the saw blade (5).

- Connect the transverse stop (8) to the

stop rail (39) of the parallel stop 14)

(see also Transverse Stop).

- Loosen the knurled screw (33) of the

transverse stop (8).

- Position the transverse stop (13) such

that the stop rail is at an angle of 90°

to the saw blade (5). Now align the

transverse stop precisely with the help

of the 90° angle to the saw blade and

retighten the knurled screw (33).

- Check whether the transverse stop

shows exactly 90°. If this is not the

case, please proceed as follows:

- Release the two screws (o) with which

the scale (p) of the transverse stop (8)

is attached to it. Now the scale can be

adjusted to the correct position.

- Now retighten the screws (o) (see

gure 31).

Using the Laser

(Figures 33-34)

- The laser (34) enables you to carry out

precision cuts with your circular saw.

- The laser light is produced by a laser

diode supplied by two batteries. The

laser light is expanded to form a line

and is emitted through the laser exit

aperture. You can then use the line as

an optical marking for the cutting line

of the precision cut. Please note the

laser safety information.

- Insert the batteries

- Switch on the laser: turn the laser on/

off switch (35) to I. When the saw blade guard (2) is mounted, the laser on/

off switch (35) is accessible through a

recess in the guard (Figure 33). A red

laser beam is now projected out of the

laser exit aperture. If you guide the

laser beam along the cutting line mark

while sawing, you will achieve clean

cuts.

- Switch the laser off: turn the laser on/

off switch (35) to 0. The laser beam

goes off. Please always turn the laser

off when it is not required in order to

save the batteries.

- The laser beam may be blocked by

dust deposits and chips. You should

therefore remove these particles from

the laser exit aperture after every use

(with the device switched off).

Adjusting the Laser

(Figure 34)

If the laser (34) no longer shows the

correct cutting line, this can be readjusted.

To do this, open the screws (z). Adjust the

laser with the help of the adjusting screw

(y) such that the laser beam impinges on

the cutting teeth of the saw blade (5).

Operation

Working Instructions

After each new adjustment, we recommend

a trial cut in order to check the set dimensions. After the saw has been switched on,

wait until the saw blade has reached its

maximum speed before you carry out the

cut.

Secure long workpieces against tilting at

the end of the cutting process (e.g. unwinding stand etc.)

2 3

G B

Caution with incision cutting.

Operate the device only with a suction system. Check and clean the suction channels

regularly.

Suitability of the saw blades:

- 24 teeth: soft materials, high chip

removal, rough cut image

- 48 teeth: hard materials, lower chip

removal, ner cut image

Performing Longitudinal

Cuts

(Figure 35)

Here, a workpiece is cut in its longitudinal

direction. One edge of the workpiece

is pressed against the parallel stop (14)

while the at side lies on the saw table (1).

The saw blade guard (2) must always be

lowered onto the workpiece. The working

position during longitudinal cutting must

never be in a straight line with the cutting

line.

- Adjust the parallel stop (14) according

to the workpiece height and the desired width.

- Switch on the saw.

- Place your hands with the ngers

closed together at on the workpiece

and push the workpiece along the

parallel stop (14) into the saw blade

(5).

- Guide from the side with your left or

right hand (depending on the position

of the parallel stop) only up to the front

edge of the saw blade guard (2).

- Always push the workpiece through to

the end of the riving knife (4).

- The cutting waste remains on the saw

table (1) until the saw blade (5) is

back in its resting position.

- Secure long workpieces against tilting

at the end of the cutting process! (e.g.

unwinding stand etc.)

Cutting narrow

Workpieces

(Figure 36)

Longitudinal cuts of workpieces with a

width of less than 120 mm always have to

be cut with the help of a push stick (17).

The push stick is included in the scope of

delivery. Replace a worn or damaged

push immediately.

• Adjust the parallel stop according to

the planned workpiece width.

• Advance the workpiece with both

hands, making sure that you use a

push stick (17) as a pushing aid in the

vicinity of the saw blade.

• Always push the workpiece through to

the end of the riving knife.

Caution! In the case of short workpieces, the push stick should be

used from the beginning of the

cutting process.

Cutting very narrow

Workpieces

(Figure 37)

For longitudinal cuts of very narrow workpieces with a width of 30 mm and less, a

push block must be used without fail. There

is no push block included in the scope of

delivery! (Available from specialist shops)

Replace a worn push block as soon as

possible.

• The parallel stop should be adjusted to

the cutting width of the workpiece.

2 4

G B

• Press the workpiece with the push

block against the stop rail and push

the workpiece with the push stick (17)

through to the end of the riving knife.

Performing Bevel Cuts

(Figure 38)

All bevel cuts are made using the parallel

stop (14).

- Adjust the saw blade (5) to the desired

angle.

- Adjust the parallel stop (14) according

to the workpiece width and height.

- Perform the cut according to the workpiece width

Performing Transverse

Cuts

(Figures 31, 39)

- Push the transverse stop (8) into one of

the two grooves (32) of the saw table.

Adjust to the desired angle. The left

groove (32) is to be used if the saw

blade (5) also has to be positioned

at an oblique angle. This will prevent

your hand and the transverse stop

from coming into contact with the saw

blade guard.

- Use the stop rail (39).

- Press the workpiece rmly against the

transverse stop (8).

- Switch on the saw.

- Push the transverse stop (8) and workpiece in the direction of the saw blade

in order to perform the cut.

- Caution: Always hold the guided

workpiece rmly and never the free

workpiece which is cut off.

- Always push the transverse stop (8)

so far forwards until the workpiece is

completely cut through.

- Switch the saw off again. Only remove sawing waste when the saw blade

has come to a standstill.

Cutting Chipboard

In order to prevent the cut edges chipping

when the chipboard is cut, the saw blade

(5) should be adjusted so that it is not

more than 5 mm above the thickness of the

workpiece.

Transport

(Fig. 40/41)

1. Turn the power tool off before it is

transported and disconnect it from the

power supply.

2. At least two people should carry the

power tool. Do not hold the power

tool by the table width extensions.

Please use only the transport handles

for transporting the machine (Figure

40/41). These are punched into the

housing on both sides of the device.

3. Protect the power tool against knocks,

jolts and strong vibrations, e.g. when

it is transported in motor vehicles.

4. Secure the power tool against tilting

and sliding.

5. Never use the protective devices for

handling or transport.

2 5

G B

Cleaning and Servicing

Remove the mains plug before car-

rying out any adjustments, maintenance or repair work.

You should have any repair and

maintenance work that is not described in these instructions carried

out by our Service Centre. Only use

original parts.

Perform the following cleaning and maintenance work regularly. This guarantees

reliable use for a long time.

Cleaning

The device must not be spra-

yed with water or placed in

water. Otherwise there is a

risk of electric shock.

• Keep the safety devices, air vents and

motor housing as free of dust and dirt

as possible. Wipe the device off with

a clean cloth or blow it out with compressed air at a low pressure.

• We recommend that you clean the device immediately after every use.

• Clean the device regularly with a damp

cloth and some soft soap. Do not use

any detergents or solvents; these might

attack the plastic parts of the device.

Make sure that no water can get into

the interior of the device.

• Oil the moving parts once a month in

order to extend the tool life. Do not oil

the motor.

Storage

• Store the appliance in a dry place well

out of reach of children..

Waste disposal

and environmental

protection

Take the batteries out of the device and recycle the device, batteries, accessories and

packaging in an environmentally friendly

manner.

Electrical machines do not belong

with domestic waste.

• Dispose of the batteries according to

local standards. Hand in the batteries

at a used battery collection point

where they are recycled in an environmentally friendly manner. For more

information, please contact your local

waste management provider or our

service centre.

• Defective units returned to us will be

disposed of for free..

2 6

G B

Spare parts/Accessories

Spare parts and accessories can be obtained at

www.grizzly-service.eu

If you do not have internet access, please contact the Service Centre via telephone (see

“Service-Center” page 31). Please have the order number mentioned below ready.

(14) Parallel stop, complete

(8) Transverse stop, complete ............................................... Order number 91103531

(2) Blade guard, complete ................................................... Order number 91103532

(15) Table length extender ................................................... Order number 91103533

(6) Table insert .................................................................... Order number 91103534

(7) Table width extender (right/left) ....................................... Order number 91103535

(34) Laser .......................................................................... Order number 91103536

(4) Riving knife ................................................................... Order number 91103537

(12) Handwheel, complete.. ................................................. Order number 91103538

(3) Suction hose .................................................................. Order number 91103539

(17) Push stick .................................................................... Order number 91103540

(11) On/off switch, complete ............................................... Order number 91103541

(24) Stand brackets (both sides) ............................................ Order number 91103542

(10) Base, complete ............................................................ Order number 91103543

(23) Rubber feet .................................................................. Order number 91103544

(r+s) Tool Set ...................................................................... Order number 91103545

(5) Saw blade 24 Teeth ....................................................... Order number 03800400

(5) Saw blade 48 Teeth ....................................................... Order number 03800401

.................................................. Order number 91103530

2 7

G B

Guarantee

Dear Customer,

This equipment is provided with a 3-year

guarantee from the date of purchase.

In case of defects, you have statutory rights

against the seller of the product. These

statutory rights are not restricted by our

guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect

occurs within three years of the date of

purchase of this product, we will repair or

replace – at our choice – the product for

you free of charge. This guarantee requires

the defective equipment and proof of purchase to be presented within the three-year

period with a brief written description of

what constitutes the defect and when it occurred.

If the defect is covered by our guarantee,

you will receive either the repaired product

or a new product. No new guarantee period begins on repair or replacement of the

product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced in accordance with strict quality

guidelines and conscientiously checked

prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts that

are subject to normal wear and may therefore be considered as wearing parts (e.g.

lters or attachments) or to cover damage

to breakable parts (e.g. switches, batteries,

or parts made of glass).

This guarantee shall be invalid if the product has been damaged, used incorrectly or

not maintained. Precise adherence to all of

the instructions specied in the operating

manual is required for proper use of the

product. Intended uses and actions against

which the operating manual advises or

warns must be categorically avoided.

The product is designed only for private

and not commercial use. The guarantee

will be invalidated in case of misuse or

improper handling, use of force, or interventions not undertaken by our authorised

service branch.

Processing in Case of Guarantee

To ensure efcient handling of your query,

please follow the directions below:

• Please have the receipt and identication number (IAN 273460) ready as

proof of purchase for all enquiries.

• Please nd the item number on the rating plate.

• Should functional errors or other defects occur, please initially contact the

service department specied below by

telephone or by e-mail. You will then

receive further information on the processing of your complaint.

2 8

G B

• After consultation with our customer

service, a product recorded as defective

can be sent postage paid to the service

address communicated to you, with the

proof of purchase (receipt) and speci-

cation of what constitutes the defect

and when it occurred. In order to avoid

acceptance problems and additional

costs, please be sure to use only the address communicated to you. Ensure that

the consignment is not sent carriage

forward or by bulky goods, express or

other special freight. Please send the

equipment inc. all accessories supplied

at the time of purchase and ensure adequate, safe transport packaging.

Repair Service

For a charge, repairs not covered by

the guarantee can be carried out by

our service branch, which will be happy to

issue a cost estimate for you.

We can handle only equipment that has

been sent with adequate packaging and

postage.

Attention: Please send your equipment to

our service branch in clean condition and

with an indication of the defect.

Equipment sent carriage forward or by

bulky goods, express or other special

freight will not be accepted.

We will dispose of your defective devices

free of charge when you send them to us.

2 9

G B

qualied electrician

a) see „Electrical connection“

not sufciently

a) Cross section of the extension cable does

b) Overload by a blunt saw blade b) Change saw blade

a) blunt saw blade a) Sharpen or change saw blade

b) wrong saw blade b) Change saw blade

surface

5. Fire marks on the cutting

Trouble shooting

Problem Possible cause Fault correction

To slightly tightened fastening nut Tighten the right hand thread nut

switching off the engine

1. Blade dissolves after

b) Defective extension cable b) Replace extension cord

2. Engine will not start a) Failure mains fuse a) Check mains fuse

c) Connections on motor or switch not in order c) Repair by electrical specialist

d) Motor or switch faulty d) Repair by electrical specialist

a) Capacitor faulty a) Repair by electrical specialist

of rotation

3. Motor wrong direction

b) Wrong connection b) Exchange polarity of outlet by an

fuse is activ

4. Motor will not work, the

3 0

Loading...

Loading...