Page 1

CABLE HOIST

Operation and Safety Notes

Original operating instructions

PSZ 250 A2

6

Anleitung_LB6_2255124:_ 31.05.2011 10:24 Uhr Seite 1

Page 2

2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

GB/IE Operation and Safety Notes Page 6

Anleitung_LB6_2255124:_ 31.05.2011 10:24 Uhr Seite 2

Page 3

3

1

2

1

1

13

14

9

10

11

12

3

4

5

6

7

8

3

15

16

2

Anleitung_LB6_2255124:_ 31.05.2011 10:24 Uhr Seite 3

Page 4

4

4 5

6 7

8 9

15

6

16

1

1

6

6

15

16

16

16

15

4

15

5

7

2

8

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 4

Page 5

5

10

9

10

11

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 5

Page 6

6

GB/

IE

Table of contents: Page

1. Introduction .............................................................................7

2. Safety information...................................................................7

3. Layout and items supplied .....................................................7

4. Proper use ..............................................................................8

5. Technical data ........................................................................8

6. Before starting the equipment.................................................8-9

7. Operation ...............................................................................9-10

8. Cleaning, maintenance and ordering of spare parts...............10

9. Disposal and recycling............................................................10-11

10. Declaration of conformity ........................................................12

11. Guarantee Certificate .............................................................13

The reprinting or reproduction by any other

means, in whole or in part, of documentation

and papers accompanying products is

permitted only with the express consent of ISC

GmbH.

Technical changes subject to change

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 6

Page 7

GB/

IE

7

1. Introduction

Important!

When using equipment, a few safety

precautions must be observed to avoid injuries

and damage. Please read the complete

operating manual with due care. Keep this

manual in a safe place, so that the information

is available at all times. If you give the

equipment to any other person, give them

these operating instructions as well.

We accept no liability for damage or accidents

which arise due to non-observance of these

instructions and the safety information.

2. Safety information

CAUTION!

Read all safety regulations and

instructions.

Any errors made in following the safety

regulations and instructions may result in an

electric shock, fire and/or serious injury.

Keep all safety regulations and instructions

in a safe place for future use.

Always check that the mains voltage is

identical to the voltage quoted on the rating

plate. In the event that the mains voltage is

not suitable, it may cause the machine to

work abnormally and thus result in personal

injury.

The power supply must be earthed and be

secured by a residual current operated

circuit breaker (RCCB).

Do not attempt to lift loads that exceed the

rated load.

Use the machine only for the purpose for

which it is designed. Never lift personnel

using the cable hoist.

Do not pull the power cable in order to pull

out the plug. Protect the power cable from

heat, oil and sharp edges.

Never attempt to raise fixed or jammed

loads.

Pull out the plug when the cable hoist is not

in use.

Keep children and other unauthorized

persons away from the machine.

Do not pull loads sideways or from one

side. Do not allow the load to swing.

Ensure that the hook moves in the same

direction as shown on the pushbutton.

Check the cable hoist at regular intervals for

signs of damage. The pushbutton must be

in good condition.

Have repair and servicing work carried out

only by authorized workshops by a trained

electrician. Repair work must only be

carried out by a trained electrician,

otherwise the machine may cause

accidents.

Do not switch the machine on and off

quickly (inching mode).

Always concentrate fully when operating

the cable hoist.

Do not stand or work under the raised load.

It is not permitted to lift fixed or jammed

loads.

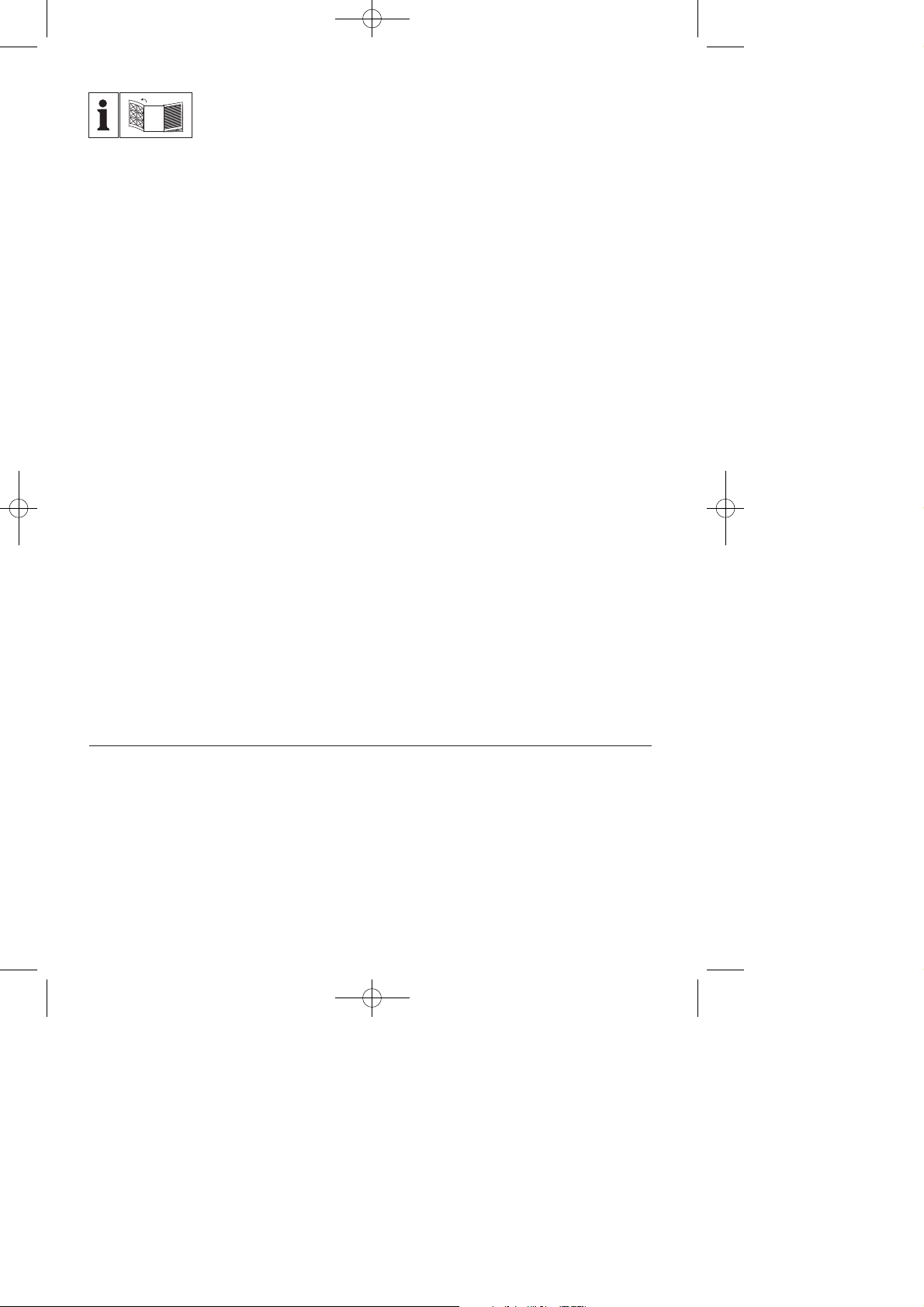

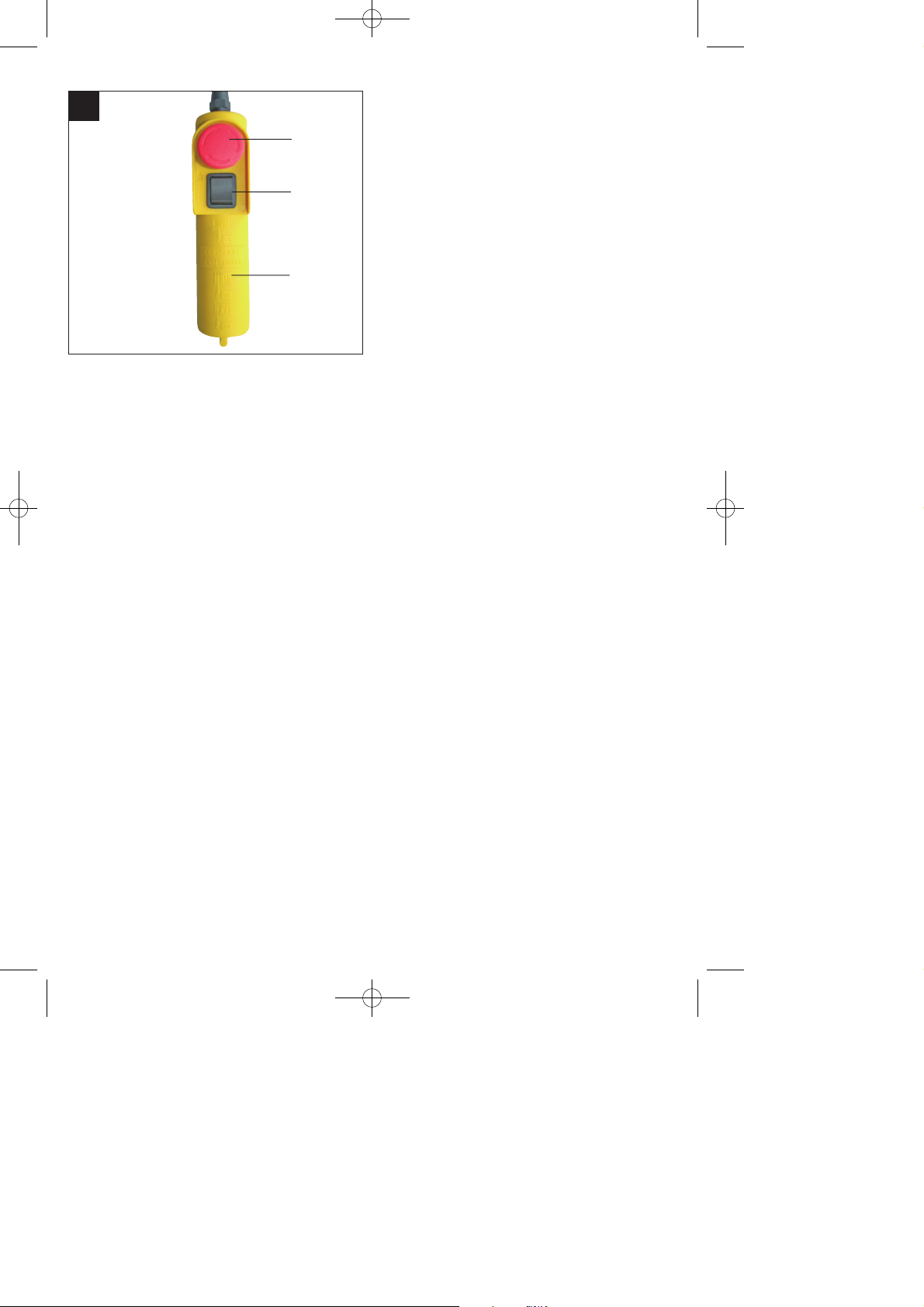

3. Layout and items supplied

(Fig. 1-2)

1. Fastening bar

2. Fastening hole for hook

3. Drum

4. Lever for maximum cable length

5. Automatic stop mechanism lever

6. Steel cable

7. Cut-out weight

8. Hook

9. Emergency Stop switch

10. Pushbutton

11. Remote control

12. Power cable

13. Control cable

14. Motor

15. Return roller

16. Additional hook

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 7

Page 8

GB/

IE

8

4. Proper use

The cable hoist is designed for lifting and

lowering loads in enclosed areas

commensurate with the machineʼs capacity.

The equipment is to be used only for its

prescribed purpose. Any other use is deemed

to be a case of misuse. The user / operator

and not the manufacturer will be liable for any

damage or injuries of any kind caused as a

result of this.

Please note that our equipment has not been

designed for use in commercial, trade or

industrial applications. Our warranty will be

voided if the machine is used in commercial,

trade or industrial businesses or for equivalent

purposes.

5. Technical data

Voltage (V) 230 V ~ 50 Hz

Rated current (A) 2.2

Power consumption (W) 500

Operating mode S3 20%:10 min

Rated load (kg) 125 / 250

Lifting height (m) 11.5 / 5.7

Rated speed (m/min) 8 / 4

Diameter of steel cable (mm) 3.0

Tensile strength of the steel cable

(N/mm²) 1870

Insulation class B

Protection class IP24

Drive unit class M1

Net weight (kg) 10.5

Operating mode S3 – 20% - 10 minutes: S3 =

Intermittent mode without influencing the

starting process. This means that the

maximum operating period over a time of 10

minutes is 20% (2 minutes).

6. Before starting the equipment

Before you connect the equipment to the

mains supply make sure that the data on

the rating plate are identical to the mains

data.

Always pull out the power plug before

making adjustments to the equipment.

The cable hoist is not suitable for

transporting hot and/or molten materials nor

is it suitable for use at low temperatures or

in environments subject to intensive

weathering.

It is in mechanical group M1.

The service life of the cable hoist is

approximately 8000 cycles (excluding

wearing parts). When the hoist has

completed 8000 cycles, all its mechanical

parts must be checked and overhauled.

Read and absorb the operating instructions

before you use the cable hoist.

Ensure that the operator knows how the

machine works and how it should be

operated.

The user must always operate the

equipment as set out in the operating

instructions.

The cable hoist is not designed for

continuous operation. Its mode of operation

is: Intermittent mode without influencing the

starting process.

The rated capacity of the machine does not

vary due to the position of the load.

6.1 Unpacking

After opening the packaging, inspect the

equipment, the steel cable, the hook, the lever

for maximum cable length and the automatic

stop mechanism lever for signs of possible

transit damage.

6.2 Assembly (Fig. 5)

The cable hoist is fitted with two fastening bars

(1) with which it has to be fastened to a

rectangular tube / swing arm. The dimensions

of the rectangular tube / swing arm must

conform with the size of the fastening bars (1)

and must be capable of supporting twice the

rated load. We recommend that you seek

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 8

Page 9

GB/

IE

9

advice from a qualified technician. All screws

must be tightened correctly. A qualified

technician should check the anchoring of the

rectangular tube / swing arm before the

machine is started.

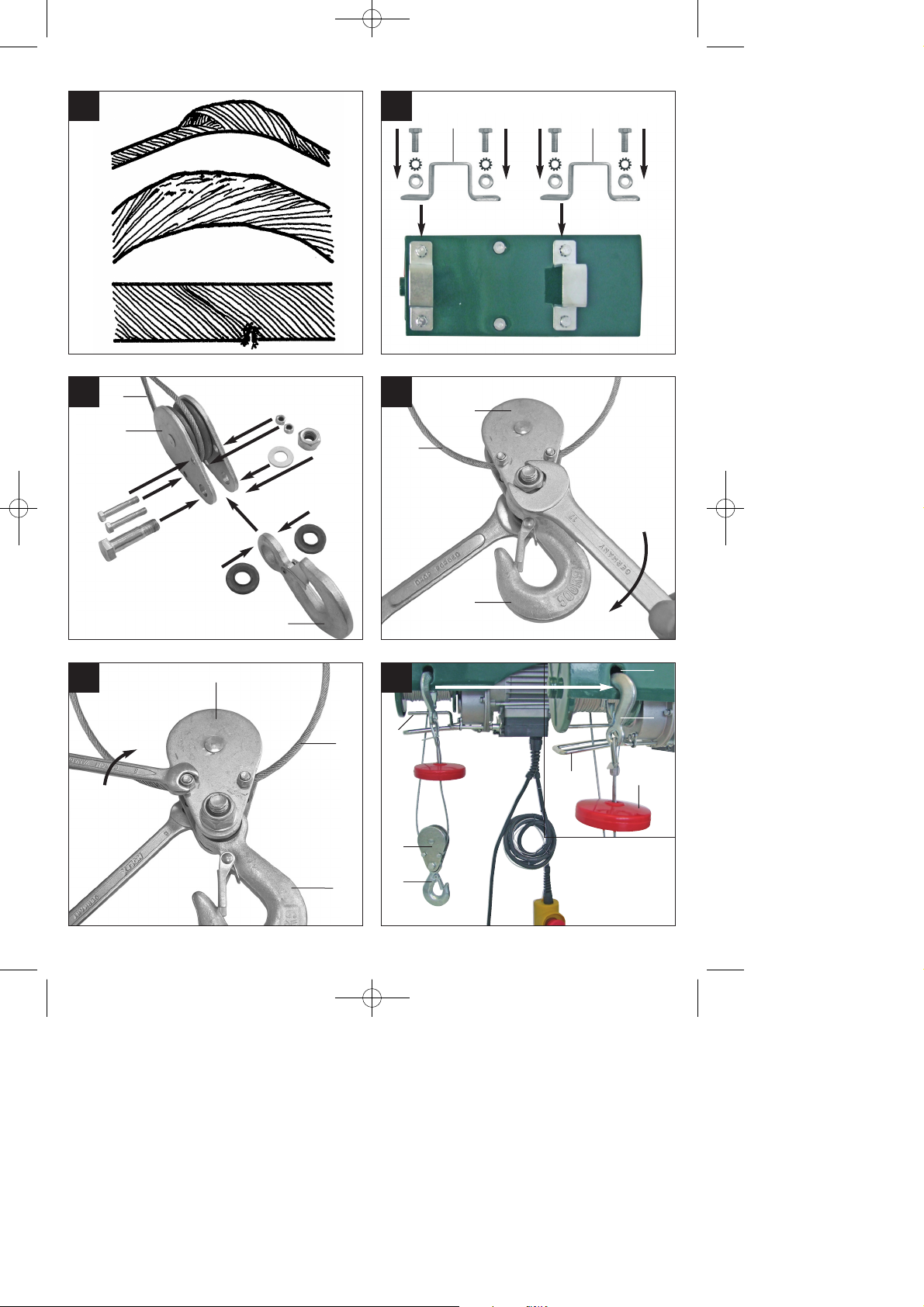

6.3 Block and tackle function (Fig. 6 – 9)

The cable hoist is fitted with a return roller (15)

and an additional hook (16). If these parts are

used correctly, the cable hoist can lift twice its

rated load.

Fit the return roller (15) and additional hook

(16) as shown in Figure 6 – 8. The permanent

hook (8) must be attached to the fastening hole

(2) (Fig. 9).

The load is now raised by two steel cables,

which means that the cable hoist can lift twice

its rated load.

7. Operation

7.1 Starting up

Remove the adhesive tape from the drum

(3) before using the hoist for the first time.

The value of the A-rated noise emissions at

the operatorʼs position is less than 70 dB.

Supply voltage: 230 V ± 10%, 50 Hz ± 1%.

The cable hoist must be operated in

ambient temperatures of between 0°C and

40°C with a relative humidity of less than

85%. Height above sea level: max. 1,000

m.

The temperature for transport and storage

may be between -25°C and 55°C. The

maximum temperature must not exceed

70°C.

The user should lift the load off the ground

at the slowest possible speed. The cable

should be taut when the load is raised.

The motor (14) for the cable hoist is fitted

with a thermostat switch. Whilst the cable

hoist is operating, the motor (14) may

therefore stop. It will restart automatically

when it has cooled down.

The electric cable hoist is not fitted with a

rated power limiter. You should therefore

not repeat attempts to lift a load if the

overload trip is limiting the hoistʼs

operation. In this case the load exceeds the

rated capacity of the cable hoist.

Do not leave any suspended loads

unsupervised without first taking the

appropriate safety precautions.

Fit the machine with a 10 A fuse or a 10 A

residual current operated circuit breaker

(RCCB) to protect the circuit

Do not use the lever (4/5) as a routine

stopping device. It should only be used to

stop the machine in an emergency.

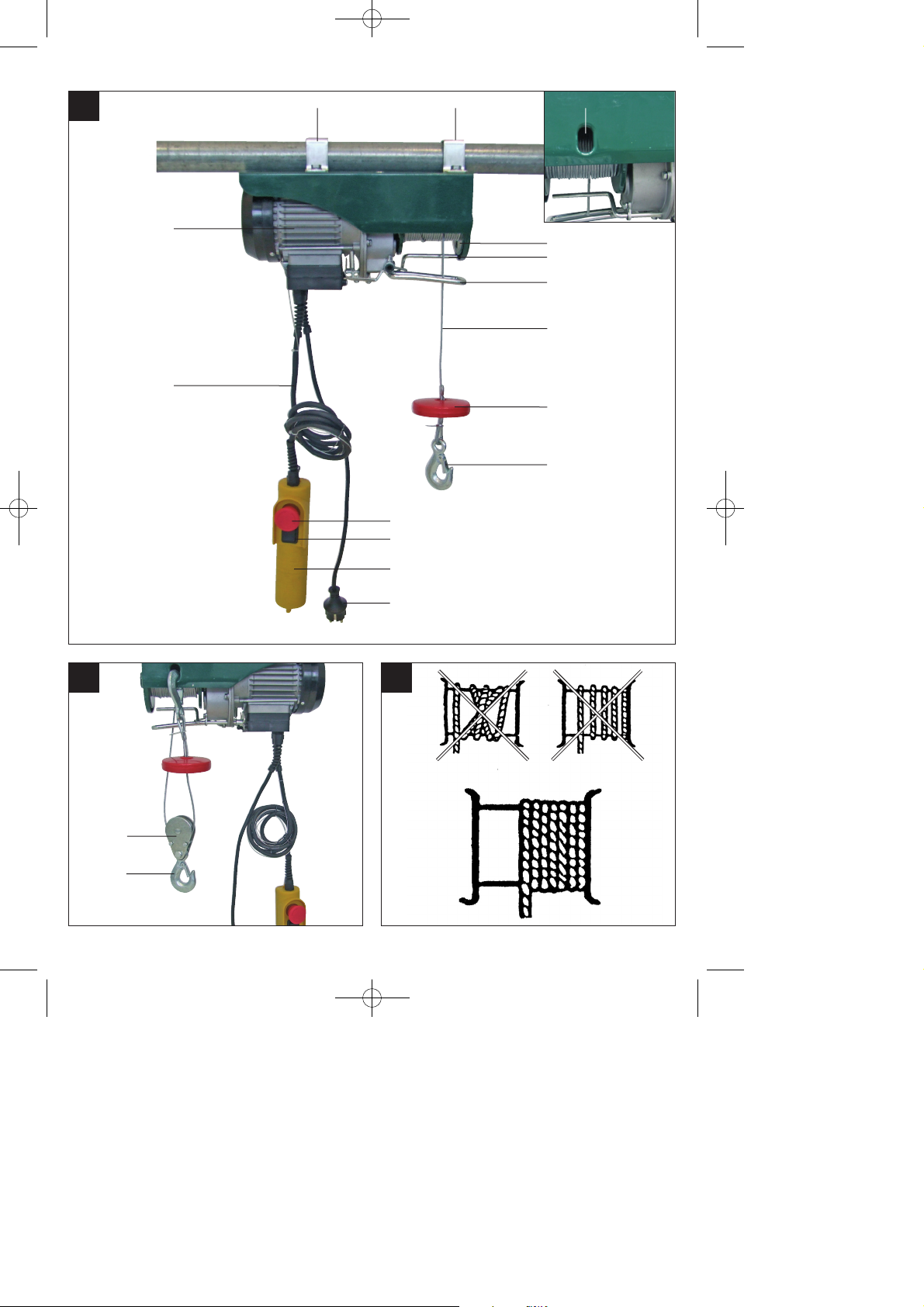

Before you start, ensure that the steel cable

(6) is correctly wound around the drum (3)

and that the spacing between the windings

is smaller than the steel cable (Fig. 3)

Ensure that the load is correctly secured to

the hook (8) or, if you are using the block

and tackle, the additional hook (16) and

always maintain a safe distance from the

load and the steel cable (6).

7.2 Operation (Fig. 9-10)

Check whether the Emergency Stop switch

(9) is pressed. Turn the Emergency Stop

switch clockwise to release it.

Press the pushbutton ▲ (10) to raise the

load.

Press the pushbutton ▼ (10) to lower the

load.

Automatic stop mechanism lever (5): When

the maximum lifting height has been

reached, the cut-out weight (7) presses the

lever (5) upwards. This trips a limit switch

after which the load cannot be raised any

further.

Lever for maximum cable length (4): When

the load has reached its lowest possible

position, a limit switch is tripped which

makes it impossible to lower the load any

further. This limit switch also prevents the

cable hoist operating in the wrong direction

(hook moving in the opposite direction to

the arrow shown on the pushbutton).

The cable hoist will stop if the Emergency

Stop switch (9) is pressed.

In an emergency, immediately press the

Emergency Stop switch (9) to stop the

cable hoist. The cable hoist cannot be

operated if the Emergency Stop switch has

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 9

Page 10

been pressed.

8. Cleaning, maintenance and

ordering of spare parts

Always pull out the mains power plug

before starting any cleaning work.

8.1 Cleaning

Keep all safety devices, air vents and the

motor housing free of dirt and dust as far as

possible. Wipe the equipment with a clean

cloth or blow it with compressed air at low

pressure.

Clean the equipment immediately after you

use it.

Clean the equipment regularly with a moist

cloth and some soft soap. Do not use

cleaning agents or solvents; these could

attack the plastic parts of the equipment.

Ensure that no water can seep

into the device.

8.2 Servicing

Important. Always ensure that the machine

is not connected to the mains supply before

you start any servicing work.

In the following: One cycle means one

raising and lowering movement of a load.

Periodic inspection means an inspection

after 100 cycles.

Test periodically that the limit switches on

the cable hoist are in correct working order.

(Test without a load) Conduct this test as

follows: When the cable has reached the

maximum height, the lever on the

automatic stopping mechanism (5) will be

actuated. The motor (14) must then stop.

When the steel cable (6) has been

unwound as far as possible, the lever for

the maximum cable length (4) will be

actuated. The motor (14) must then stop.

Inspect the mains cable (12) and the

control cable (13) periodically.

The steel cable (6) and return roller (15)

must be greased every 200 cycles.

A check must be made every 30 cycles, as

shown in Fig. 4, to find whether the entire

steel cable (6) is in good condition. If it is

damaged, it must be replaced by a steel

cable of the type specified in the technical

data.

Check every 1000 cycles whether the

screws for the fastening bars (1) and return

roller (15) are properly tightened.

Check every 1000 cycles whether the

hooks (8/16) and return roller (15) are in

good condition.

Check before using the cable hoist whether

the Emergency Stop switch (9) and

pushbuttons (10) are in perfect working

order.

Check the braking system every 1000

cycles. If the motor (14) makes any unusual

noises or cannot raise the rated load, it is

possible that the braking system requires

an overhaul:

- Replace damaged or worn parts and keep

the service documentation relating to this in

a safe place.

- Please contact an authorized service

center for any unscheduled maintenance

work.

8.3 Ordering replacement parts:

Please quote the following data when ordering

replacement parts:

Type of machine

Article number of the machine

Identification number of the machine

For our latest prices and information please go

to www.isc-gmbh.info

9. Disposal and recycling

The unit is supplied in packaging to prevent its

being damaged in transit. This packaging is

raw material and can therefore be reused or

can be returned to the raw material system.

The unit and its accessories are made of

various types of material, such as metal and

plastic. Defective components must be

disposed of as special waste. Ask your dealer

or your local council.

GB/

IE

10

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 10

Page 11

For EU countries only

Never place any electric tools in

your household refuse.

To comply with European Directive 2002/96/EC

concerning old electric and electronic

equipment and its implementation in national

laws, old electric tools have to be separated

from other waste and be disposed of in an

environment-friendly fashion, e.g. by taking to a

recycling depot.

Recycling alternative to returning the electrical

equipment:

The owner of the electrical equipment is

obligated to arrange for its proper disposal if he

no longer wants to keep the equipment in his

possession and does not want to return it. In

this case the old equipment can be taken to a

recycling depot where it is disposed of in

accordance with national recycling and waste

disposal laws. This does not apply to accessory

parts and aids which supplement the old

equipment and contain no electrical parts

GB/

IE

11

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 11

Page 12

GB/

IE

12

10. Declaration of conformity

k erklärt folgende Konformität gemäß EU-Richtlinie und

Normen für Artikel

t explains the following conformity according to EU

directives and norms for the following product

p déclare la conformité suivante selon la directive CE et les

normes concernant l’article

C dichiara la seguente conformità secondo la direttiva UE e

le norme per l’articolo

N verklaart de volgende overeenstemming conform EU

richtlijn en normen voor het product

m declara la siguiente conformidad a tenor de la directiva y

normas de la UE para el artículo

O declara a seguinte conformidade, de acordo com a

directiva CE e normas para o artigo

l attesterer følgende overensstemmelse i medfør af

EU-direktiv samt standarder for artikel

U förklarar följande överensstämmelse enl. EU-direktiv och

standarder för artikeln

q vakuuttaa, että tuote täyttää EU-direktiivin ja standardien

vaatimukset

. tõendab toote vastavust EL direktiivile ja standarditele

j vydává následující prohlášení o shodě podle směrnice

EU a norem pro výrobek

X potrjuje sledečo skladnost s smernico EU in standardi za

izdelek

W vydáva nasledujúce prehlásenie o zhode podľa smernice

EÚ a noriem pre výrobok

A a cikkekhez az EU-irányvonal és Normák szerint a

következő konformitást jelenti ki

P deklaruje zgodność wymienionego poniżej artykułu z

następującymi normami na podstawie dyrektywy WE.

e декларира съответното съответствие съгласно

Директива на ЕС и норми за артикул

H paskaidro šādu atbilstību ES direktīvai un standartiem

G apibūdina šį atitikimą EU reikalavimams ir prekės

normoms

Q declară următoarea conformitate conform directivei UE

şi normelor pentru articolul

z δηλώνει την ακόλουθη συμμόρφωση σύμφωνα με την

Οδηγία ΕΚ και τα πρότυπα για το προϊόν

B potvrđuje sljedeću usklađenost prema smjernicama EU

i normama za artikl

f potvrđuje sljedeću usklađenost prema smjernicama EU

i normama za artikl

4 potvrđuje sledeću usklađenost prema smernicama EZ i

normama za artikal

T следующим удостоверяется, что следующие

продукты соответствуют директивам и нормам ЕС

1 проголошує про зазначену нижче відповідність

виробу директивам та стандартам ЄС на виріб

5 ја изјавува следната сообрзност согласно

ЕУ-директивата и нормите за артикли

Z Ürünü ile ilgili AB direktifleri ve normları gereğince

aşağıda açıklanan uygunluğu belirtir

L erklærer følgende samsvar i henhold til EU-direktivet

og standarder for artikkel

E Lýsir uppfyllingu EU-reglna og annarra staðla vöru

Konformitätserklärung

Einhell Germany AG · Wiesenweg 22 · D-94405 Landau/Isar

Seilhebezug PSZ 250 A2 (Parkside)

Standard references: EN 14492-2; EN 60204-32;

EN 55014-1; EN 55014-2; EN 61000-3-2; EN 61000-3-3

Landau/Isar, den 18.04.2011

First CE: 09 Archive-File/Record: NAPR003513

Art.-No.: 22.551.24 I.-No.: 11031 Documents registrar: Robert Mayn

Subject to change without notice Wiesenweg 22, D-94405 Landau/Isar

Weichselgartner/General-Manager Wentao/Product-Management

x

87/404/EC_2009/105/EC

2005/32/EC_2009/125/EC

2006/95/EC

2006/28/EC

2004/108/EC

2004/22/EC

1999/5/EC

97/23/EC

90/396/EC_2009/142/EC

89/686/EC_96/58/EC

x

2006/42/EC

2004/26/EC

Emission No.:

2000/14/EC_2005/88/EC

Annex IV

Notified Body:

Notified Body No.:

Reg. No.:

Annex V

Annex VI

Noise: measured LWA= dB (A); guaranteed LWA= dB (A)

P = KW; L/Ø = cm

Notified Body:

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 12

Page 13

13

GB/

IE

11. GUARANTEE CERTIFICATE

Dear Customer,

All of our products undergo strict quality checks to ensure that they reach you in perfect condition. In the unlikely

event that your device develops a fault, please contact our service department at the address shown on this

guarantee card. Of course, if you would prefer to call us then we are also happy to offer our assistance under

the service number printed below. Please note the following terms under which guarantee claims can be made:

1. These guarantee terms cover additional guarantee rights and do not affect your statutory warranty rights.

We do not charge you for this guarantee.

2. Our guarantee only covers problems caused by material or manufacturing defects, and it is restricted to the

rectification of these defects or replacement of the device. Please note that our devices have not been

designed for use in commercial, trade or industrial applications. Consequently, the guarantee is invalidated

if the equipment is used in commercial, trade or industrial applications or for other equivalent activities. The

following are also excluded from our guarantee: compensation for transport damage, damage caused by

failure to comply with the installation/assembly instructions or damage caused by unprofessional

installation, failure to comply with the operating instructions (e.g. connection to the wrong mains voltage or

current type), misuse or inappropriate use (such as overloading of the device or use of non-approved tools

or accessories), failure to comply with the maintenance and safety regulations, ingress of foreign bodies

into the device (e.g. sand, stones or dust), effects of force or external influences (e.g. damage caused by

the device being dropped) and normal wear resulting from proper operation of the device.

This applies in

particular to rechargeable batteries for which we nevertheless issue a guarantee period of 12 months.

The guarantee is rendered null and void if any attempt is made to tamper with the device.

3. The guarantee is valid for a period of 3 years starting from the purchase date of the device. Guarantee

claims should be submitted before the end of the guarantee period within two weeks of the defect being

noticed. No guarantee claims will be accepted after the end of the guarantee period. The original guarantee

period remains applicable to the device even if repairs are carried out or parts are replaced. In such cases,

the work performed or parts fitted will not result in an extension of the guarantee period, and no new

guarantee will become active for the work performed or parts fitted. This also applies when an on-site

service is used.

4. In order to assert your guarantee claim, please send your defective device postage-free to the address

shown below. Please enclose either the original or a copy of your sales receipt or another dated proof of

purchase. Please keep your sales receipt in a safe place, as it is your proof of purchase. It would help us if

you could describe the nature of the problem in as much detail as possible. If the defect is covered by our

guarantee then your device will either be repaired immediately and returned to you, or we will send you a

new device.

Of course, we are also happy offer a chargeable repair service for any defects which are not covered by the

scope of this guarantee or for units which are no longer covered. To take advantage of this service, please send

the device to our service address.

Einhell UK Ltd

Morpeth Wharf

Twelve Quays

Birkenhead, Wirral

CH41 1LF

Tel. 0151 6491500, Fax 0151 6491501

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 13

Page 14

14

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 14

Page 15

15

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 15

Page 16

CABLE HOIST

IAN: 66764 PSZ 250 A2

Einhell Germany AG

Wiesenweg 22

D-94405 Landau/Isar

Last Information Update: 05/2011

Ident.-No.: 22.551.24 052011 - 6

6

Anleitung_LB6_2255124:_ 31.05.2011 10:25 Uhr Seite 16

Loading...

Loading...