Page 1

AIRBRUSH SET PABK 60 A1

AIRBRUSH SET

Operation and Safety Notes

SÚPRAVA STRIEKACEJ PIŠTOLE

Pokyny pre obsluhu a bezpečnostné pokyny

SADA STŘÍKACÍ PISTOLE

Pokyny pro obsluhu a bezpečnostní pokyny

AIRBRUSH-SET

Bedienungs- und Sicherheitshinweise

IAN 73868

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 3 05.07.12 16:58

Page 2

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Před čtením si odklopte obě dvě strany s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte obidve strany s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 15

SK Pokyny pre obsluhu a bezpečnostné pokyny Strana 25

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 35

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 4 05.07.12 16:58

Page 3

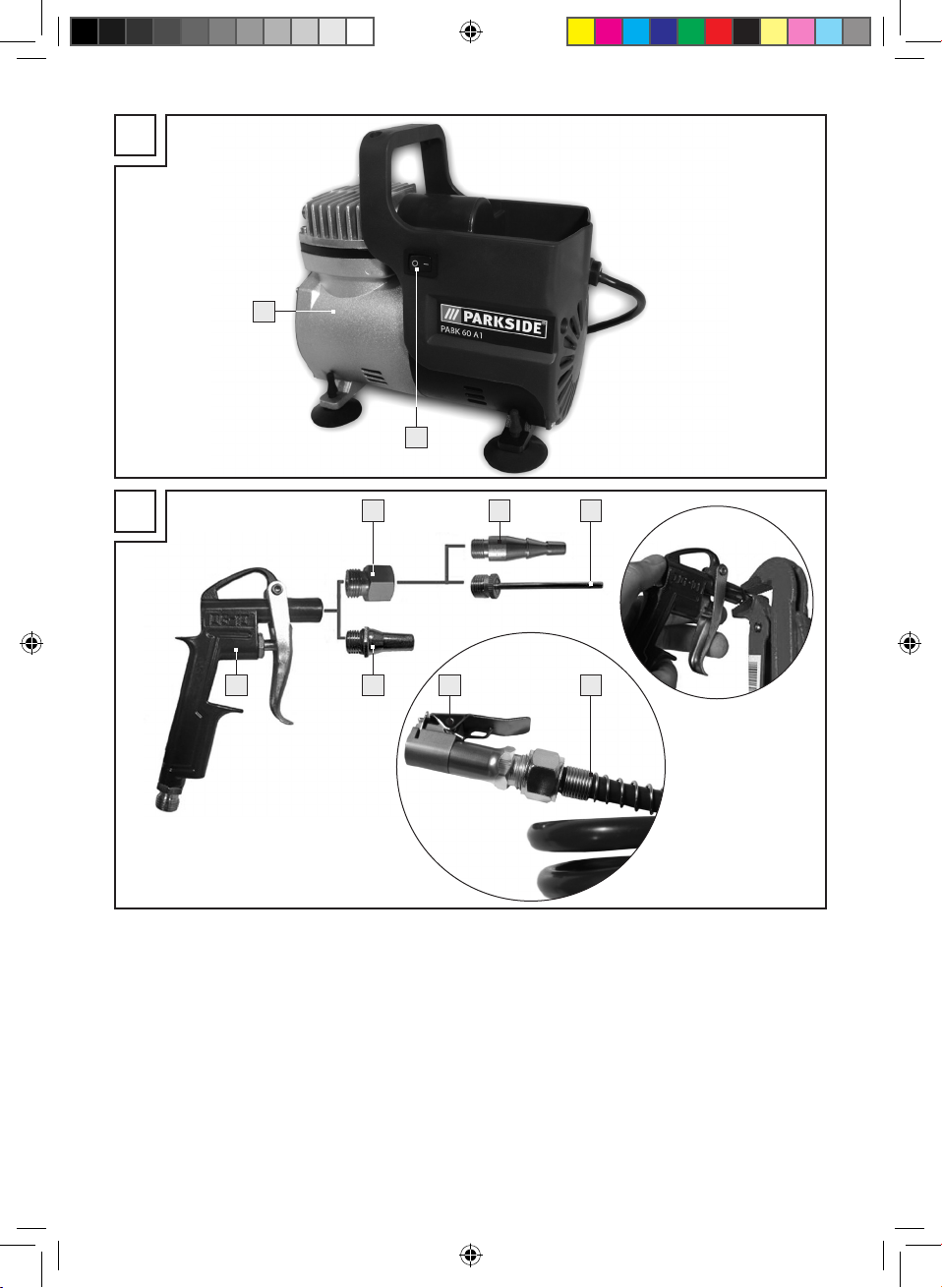

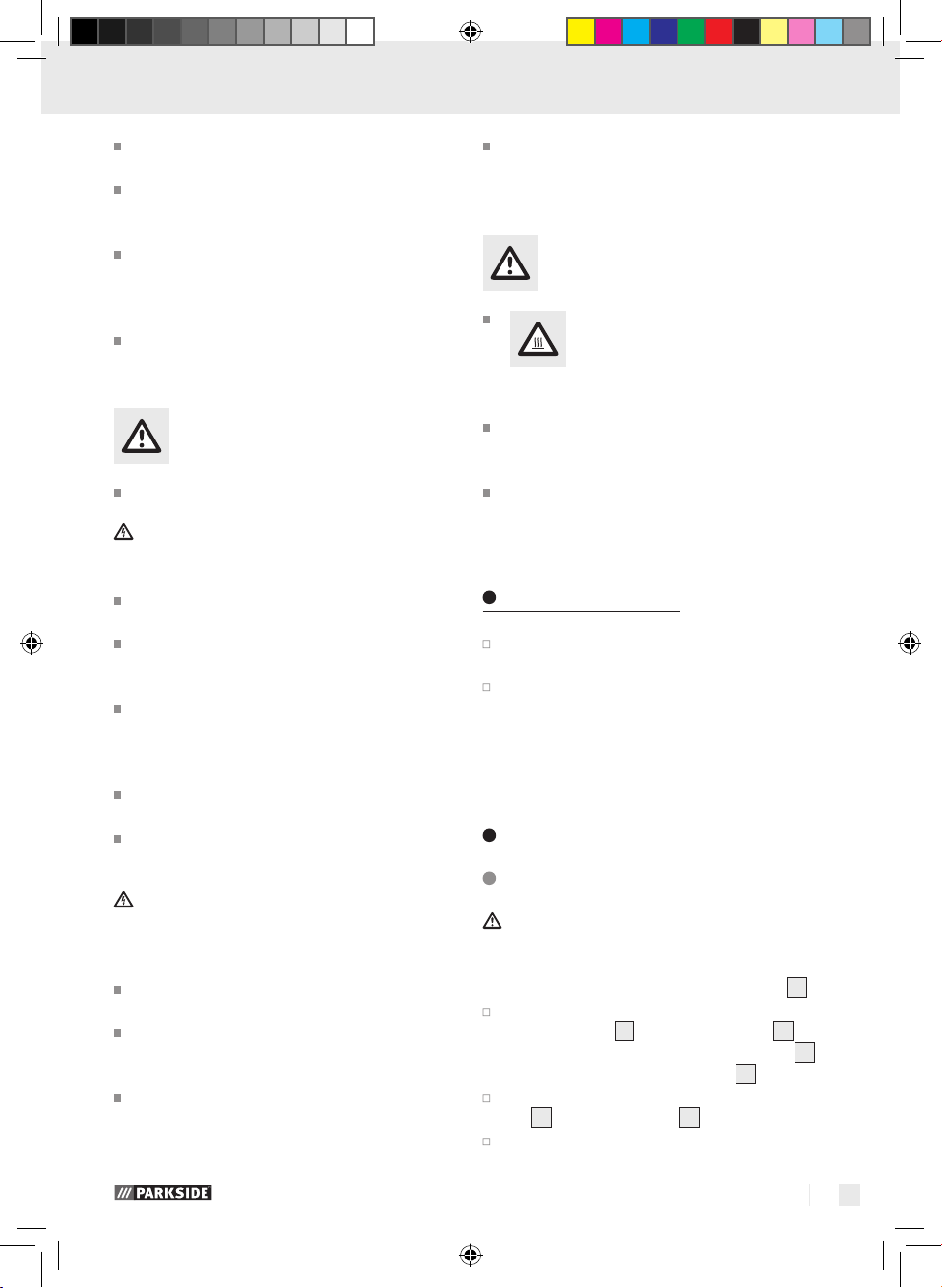

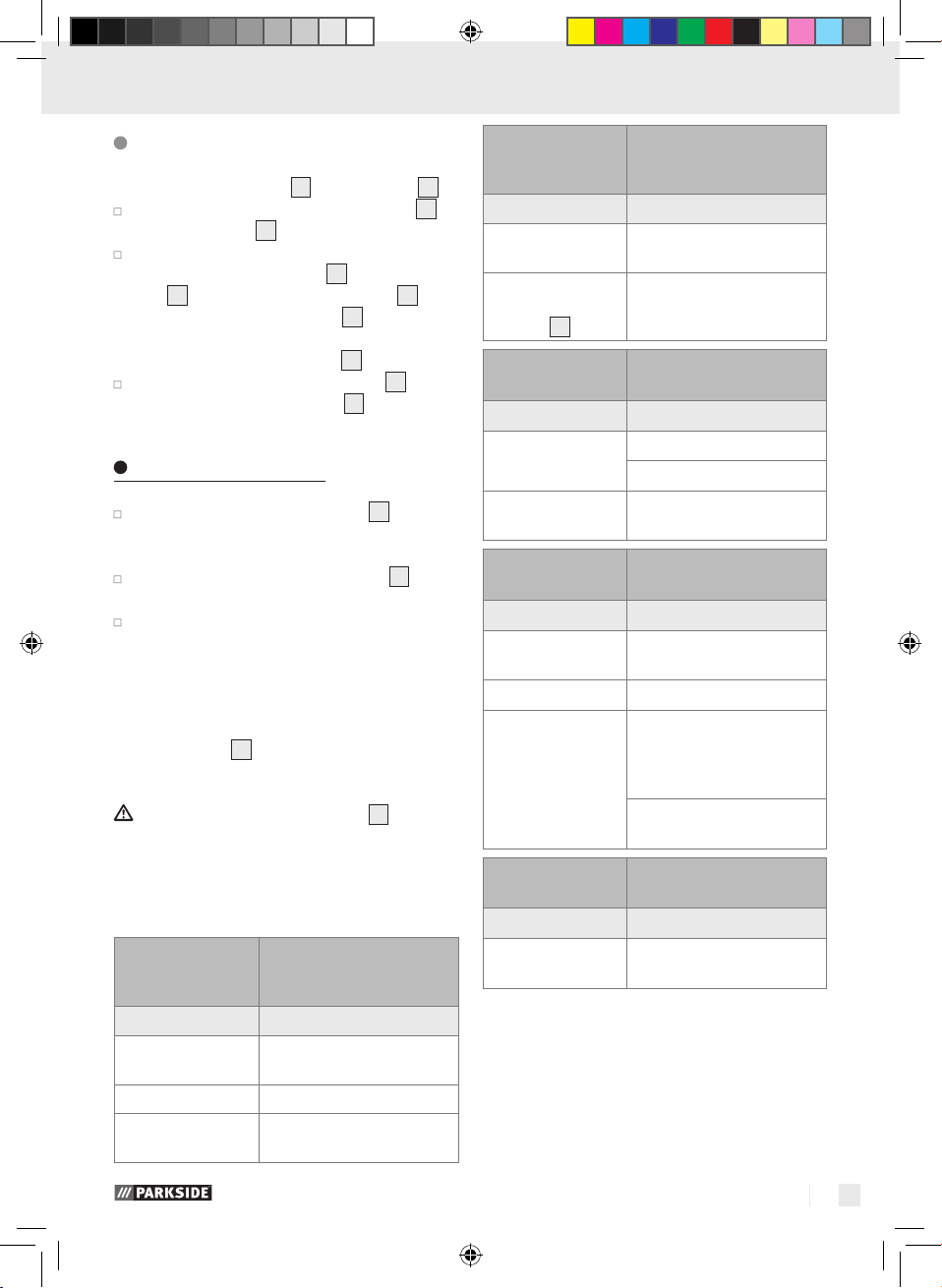

1 2

8

9

4 5 6 7

2 a

9 a

10 11 12

3

13

A

B

2

2 a

1

13

3

5

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 5 05.07.12 16:58

Page 4

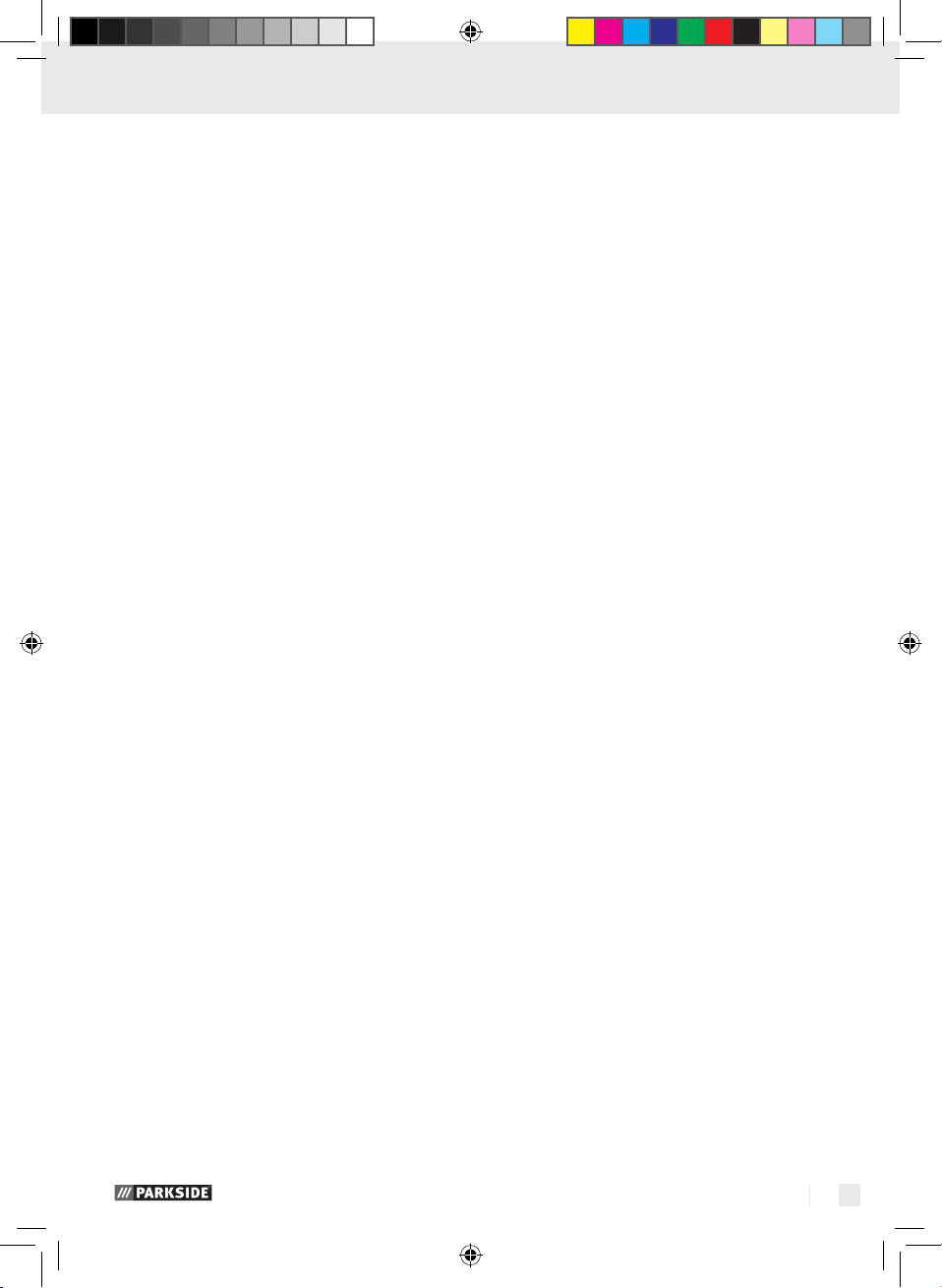

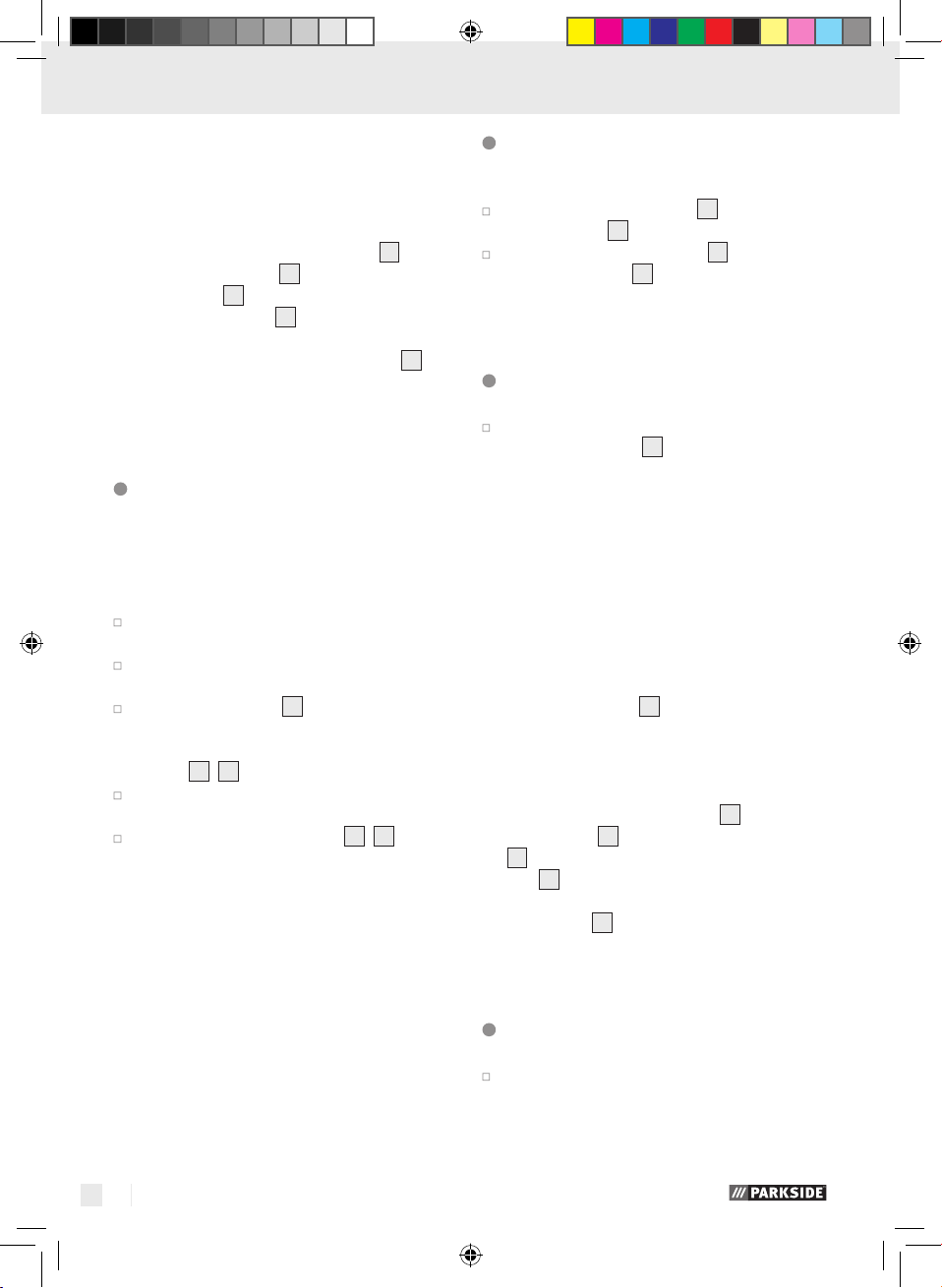

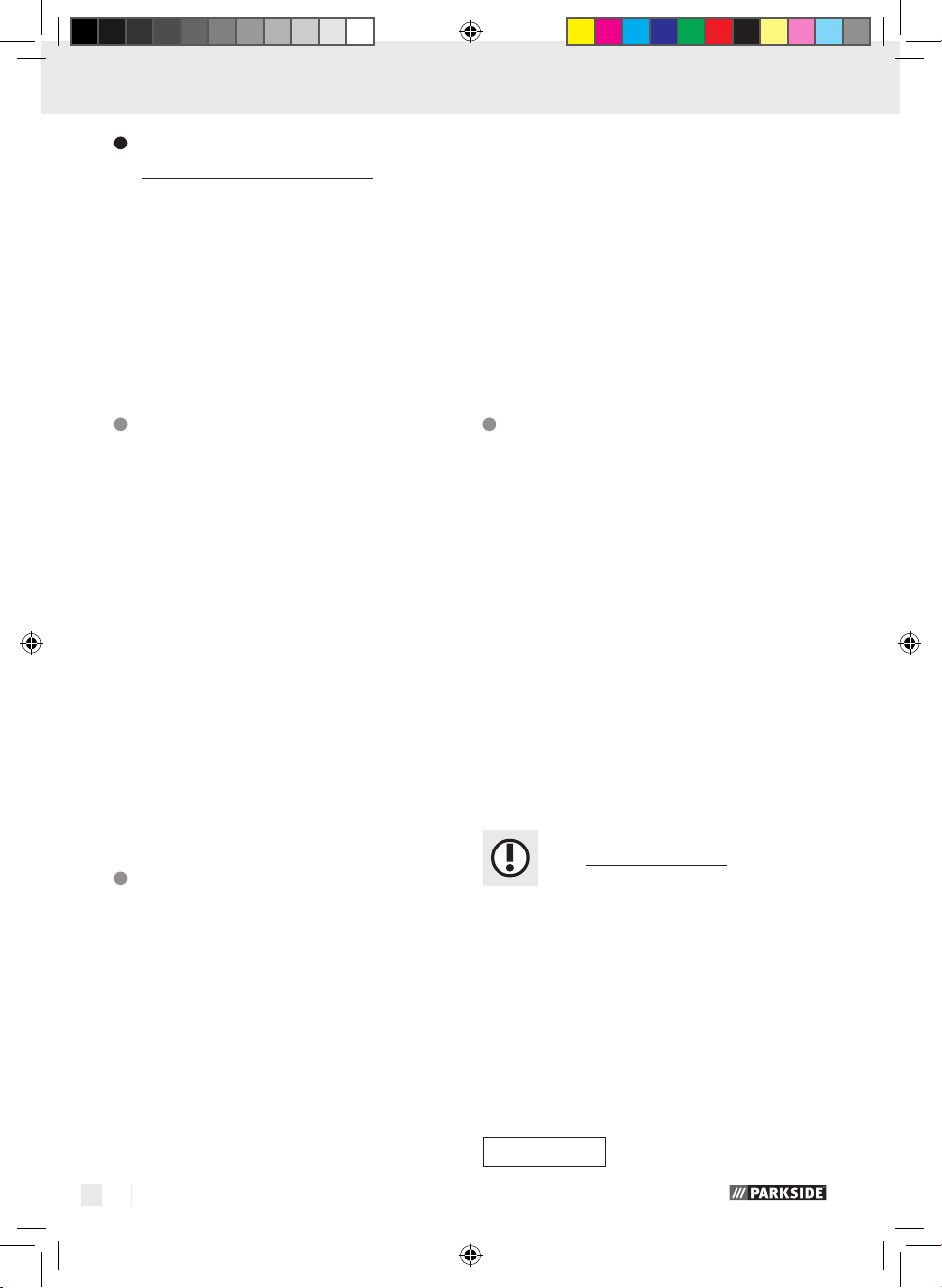

C

1

14

D

9 9a

7 12

6

10 8

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 8 05.07.12 16:58

Page 5

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features and fittings ............................................................................................................................ Page 6

Technical data ..................................................................................................................................... Page 7

General safety instructions for compressed air tools................................Page 7

General safety information for electrical devices .............................................................................Page 9

Product-specific safety instructions .....................................................................................................Page 9

Before initial use ....................................................................................................................... Page 9

Preparations for use

Connecting the airbrush set ................................................................................................................ Page 9

Mixing paints for use .......................................................................................................................... Page 10

Turning airbrush compressor on / off .................................................................................................Page 10

Regulating the air pressure ................................................................................................................. Page 10

Regulating the spraying results...........................................................................................................Page 10

Using the accessories (see Ill. D) .......................................................................................................Page 11

Cleaning and care .................................................................................................................... Page 11

Information about warranty and service processing

Warranty terms ...................................................................................................................................Page 12

Scope of warranty ..............................................................................................................................Page 12

Procedure in the case of warranty ..................................................................................................... Page 12

Environmental instructions and disposal information .............................. Page 13

Paint disposal instructions ................................................................................................ Page 13

CE Declaration of Conformity ......................................................................................... Page 13

5 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 5 06.07.12 12:26

Page 6

Introduction

The following pictograms are used in these operating instructions / on the device:

Note Supply hose

Observe caution and safety notes! Danger of electric shock

Never use hydrogen, oxygen, carbon

dioxide or other bottled gases as an

energy source.

Risk of burns!

Wear hearing protection, dust protection mask, protective glasses and

protective gloves.

Airbrush set

Introduction

Congratulations! You have chosen a

high-quality device from our company.

Familiarise yourself with the product

before using it for the first time. In addition, please

carefully refer to the operating instructions and the

safety advice below. Initial operation of this tool

must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

This device is a portable air compressor optimised for

use with airbrushes. With the accessories included,

it is suitable for use in numerous applications. It is

maintenance-free and equipped with noise suppression so it is also suitable for use in closed rooms.

Keep these instructions in a safe place. When passing this product on to others please also include all

documents. Any use other than the intended is prohibited and potentially dangerous. Damages resulting from noncompliance or misuse are not covered

by the warranty and are not included in the manufacturer‘s liability. This device has been designed

for household use and may not be used for commercial or industrial purposes.

Dispose of packaging and device in

an environmentally friendly way!

Features and fittings

Check that all the items are present and

that the product is in perfect condition

immediately after unpacking. Never use

the product if it is defective.

1

Airbrush compressor

2

Coiled hose

2 a

Coiled hose adapter

3

Spray stylus

4

Paint mixing beaker with closure lid

5

Paint mixing beaker with connection lid

6

Air mattress adapter

7

Thread adapter

8

Compressed air hose

9

Air blow gun

9a

Air blow gun nozzle

10

Universal valve connection

11

Mixing pipette

12

Ball needle

13

Open-end wrench

14

On / Off Switch

Note: This package also includes six different colours of highly concentrated, water-soluble paints in

plastic containers as well as a beaker of thinner

(transparent). These are referred to as „consumables“ in the following.

6 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 6 06.07.12 12:26

Page 7

Introduction / General safety instructions for compressed air tool

Technical data

Output power: approx. 15 l / min

Theoretical suction capacity: max. 40 l / min

Operating pressure: approx. 0.16 Mpa

Max. operating pressure: approx. 0.35 Mpa

(approx. 3 bar)

Weight without accessories: approx. 4140 g

Motor output

without load: 100 W

Operating voltage: 230 V∼, 50 Hz

Output of

compressor speed: 1440 min

Protection class: IPX 0

Protection class: I /

-1

General safety instructions

for compressed air tools

Note: When used in the following text, the terms

„compressed air device“ or „device“ refer to the

compressed air device specified in these instructions

for use.

Basic safety measures must be

followed when using compressed air devices to

eliminate the risk of fire, electric shock and personal

injury. Be sure to read and follow the notices within

these operating instructions prior to using the device

and store them in a safe location. The manufacturer

assumes no liability for damages or personal injury

resulting from failure to follow these operating instructions.

Children or persons who lack the knowledge

or experience to use the device or whose physical, sensory or intellectual capacities are limited must never be allowed to use the device

without supervision or instruction by a person

responsible for their safety.

Prevent children from playing with the device.

RISK OF INJURY! Before

performing maintenance tasks, disconnect the

compressed air supply.

Only use the device in applications for which it

was designed!

Do not overload the device.

Never use hydrogen, oxygen, car-

bon dioxide or other bottled gasses

to power this tool as doing so may

result in explosion, causing severe injuries.

Maintain and clean the device regularly as

prescribed (see Chapter „Cleaning and care“).

DANGER OF EXPLOSION!

Never use petrol or other flammable liquids to

clean the compressed air tool! Sparks could ignite residual vapours inside the compressed air

device resulting in the compressed air device

exploding. Do not use the device in explosive

environments with flammable liquids, gasses or

dust. Never work on materials which are or could

potentially be highly flammable or explosive.

Check the device for damage before bringing

it into use. Always make sure that the device is

in perfect condition each time before use.

Remain alert at all times and always watch

what you are doing! Unexpected movement of

the device may cause hazards.

Avoid placing your body in an unnatural position.

Keep proper footing and balance at all times.

By doing this you will be in a better position to

control the compressed air device in unforeseen

circumstances.

Do not use any device if its switch is defective.

A device that can no longer be switched on

and off is dangerous and must be repaired.

Store the device out of the reach of children

when it is not in use. Do not let anyone use the

device if he or she is not familiar with it or has

not read the instructions and advice. Compressed

air devices are dangerous when they are used

by inexperienced people.

Maintain the device carefully. Check that mov-

ing device parts are working properly and move

freely. Check for any parts that are broken or

damaged enough to detrimentally affect the

functioning of the device. Have damaged parts

repaired before you use the device. Many accidents have their origins in poorly maintained

devices.

Switch off the device off when it is not in use.

Always wear personal protective

device and safety glasses. Wearing

personal protective devices such as

7 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 7 06.07.12 12:26

Page 8

General safety instructions for compressed air tools

dust mask, non-slip safety shoes, safety helmet

or ear protectors, depending on the type of

compressed air tool and its application, reduces

the risk of injuries.

Check the connections and supply lines. All

maintenance units, couplings and hoses must be

equipped to meet the pressure and air amounts

specified in the device specific values. Pressure

that is too low influences the functioning of the

device; pressure that is too high can cause

damage to property and personal injury.

Protect hoses from kinks, constrictions, solvents

and sharp edges. Keep hoses away from heat,

oil and rotating parts.

Make sure that the hose clamps are always

tightly fastened. If the hose clamps are not

tightly fastened or are damaged, the air could

escape uncontrollably.

Replace damaged hoses immediately. A dam-

aged supply line may result in the air hose

whipping about and may result in injuries.

If the power cable of the device is damaged, it

has to be replaced by the manufacturer or its

service department or a similarly qualified person in order to avoid hazards.

Do not use the device when tired or under the

influence of drugs, alcohol or medications. One

moment of carelessness when using the device

may result in serious injuries.

Do not directly inhale the exhaust air. Keep eyes

away from exhaust air. Exhaust air from the

compressed air device may contain water, oil,

metal particles or contamination from inside the

compressor. This may result in injury to health.

BE CAREFUL WHEN

SETTING DOWN THE DEVICE! Always put

down the device so it does not come into contact

with the trigger. This could potentially result in

accidental activation of the device, which again

could result in hazards.

Only use suitable accessories. These may be

purchased from the manufacturer. Using nonOEM accessories may result in hazards.

Only use filtered and regulated compressed

air. Dust, caustic vapours and / or moisture may

damage the motor of a compressed air tool.

8 GB

The hose must be designed for pres-

sures of at least 8.6bar or 125PSI,

but at least 150 % of the maximum

pressure generated in the system.

The tool and supply line must be

equipped with a hose coupling to

completely remove pressure when

disconnecting the coupling hose.

Do not modify this device in any way without

the manufacturer‘s approval.

Only use the compressed air device with the

specified pressure (max. 0.35 Mpa / approx.

3 bar).

Disconnect the compressed air device from the

air supply after each use and when not in use.

Do not use the compressed air device if it leaks

or is in need of repair.

Never connect the compressed air device to an

air hose with pressure exceeding 7bar.

Keep your working area clean and well lit. Un-

tidy or poorly lit working areas can lead to ac-

cidents. Working under proper conditions will

allow you better control of the device, particu-

larly under unforeseen circumstances.

Only have the device repaired

by qualified specialist personnel using OEM

spare parts. This will ensure that your device

remains safe to use.

Keep children and other individuals away from

the device during use. Distractions can cause

you to lose control of the device.

Wear suitable clothing. Do not wear loose cloth-

ing or jewellery. Keep your hair, clothing and

gloves clear of moving parts. Loose clothing,

jewellery or long hair can become trapped in

moving parts.

Put down the trigger and device in the event of

unexpected compressor failure.

Whenever possible, use a condensate trap or

regularly empty the compressed air device

hoses and tubing before and during use to re-

move condensate (water).

ATTENTION! An undersized com-

pressed air system may minimise the

efficiency of your device.

Never point the compressed air device at your-

self, other persons or animals. Otherwise there

is a risk of injury.

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 8 06.07.12 12:26

Page 9

General safety instructions … / Before initial use / Preparations for use

Always observe all the safety advice attached

to the compressor.

Make sure that the compressor intake opening

is never blocked and the airflow is never hindered.

Clean the suction filter with a cloth when it is

dirty. Switch off the device and pull the plug

from the socket to prevent it from being accidentally switched on.

Do not allow yourself to become distracted while

working with the device.

General safety information

for electrical devices

Never connect the device to a residual current

(FI) protective switch.

Protect yourself against electric shock. As you

are working, avoid touching grounded parts

(e.g. refrigerator, water supply pipes etc.).

DANGER! Avoid contact with live lines. This

device is not insulated against electric shock.

Check extension and power supply cables reg-

ularly. Replace any faulty cables with new ones

immediately.

If the mains power cable of this device is dam-

aged, it has to be replaced by the manufacturer

or its service department or a similarly qualified

person in order to avoid hazards.

Store the device in a dry environment when it is

not being used over a longer period.

Make sure that the connection cable does not

hang over a corner or be stretched; otherwise

there is a risk of injury.

Do not use the mains lead for any purpose for

which it was not intended, e.g. to carry the

product, to hang it up or to pull the mains plug

out of the mains socket.

Never pull on the mains cable to remove the

mains plug from the socket.

Never use electrical tool in damp or wet envi-

ronments and never expose it to rain or high

humidity.

Never switch on the device in the vicinity of in-

flammable liquids or gases.

If the device is used outdoors, only use exten-

sion cables that are expressly designed for out-

door use.

Product-specific safety

instructions

CAUTION! RISK OF BURNS!

The compressor heats up after ex-

tended operation. Therefore always

use the handle on the device to move it. Never

touch the device itself!

ATTENTION! The casing of the airbrush com-

pressor may become hot during use. Do not

touch hot surfaces in order to prevent burns.

Never leave the device in operation unattended.

Built-up heat generated by the device can be a

source of danger.

Before initial use

Check that all parts of the device are in perfect

condition.

Make sure that the available mains voltage is

compatible with the voltage intended for operating the compressor.

Note: You will find the intended mains voltage

on the type plate of the device.

Preparations for use

Connecting the airbrush set

Be absolutely certain to disconnect the mains

plug before connecting the airbrush set to the

compressor and release the pressure in the lines

by actuating the vent of the air blow gun

Use the respective screw connection to connect

the spray stylus

the coiled hose to the airbrush connection

Use the included open-end wrench. 13 (see Ill. A).

Fasten the paint mixing beaker with connection

5

lid

to the spray stylus 3 (see Ill. B).

Insert the mains plug into the mains socket.

3

with the coiled hose 2 and

9

.

1

.

9 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 9 06.07.12 12:26

Page 10

Preparations for use

Note: For optimal results, professionals connect

an intermediate pressure reducer (not included

with delivery). The pressure reducer can be used

to adjust the compressed air at the spray gun

and optimise it to your needs.

Note: During use of the blow gun

corresponding hose

compressor

2 a

ning on the adapter

2

incl. adapter for the

, there is a small discharge ope-

2 a

, which releases air. This

9

with the

serves to create a more uniform airflow for easier and better handling of the blow gun

9

. This

is not a defect, rather, it serves for better handling and an improvement of the spray results by

means of a uniform airflow.

Mixing paints for use

The paints included are water-soluble. In order to

properly apply the paints, add water and stir. As

delivered, the paints are too viscous.

First fill the beaker with your selected paint

colour with water.

Now screw the cover back on the beaker and

shake it.

Now use the pipette 11 to remove two drops

of the slightly diluted paint paste and add them

to a paint mixing beaker completely filled with

4, 5

water (

Shake the beaker. Now your paint has reached

the correct consistency.

Attach the paint mixing glass (4, 5) accord-

ing to Ill. B.

Note: If desired, you can adjust the amount of

water added to influence the colour intensity

yourself as with a watercolour box. The more

water you add, the „thinner“ the colour.

You can also mix individualised colour tones

from the available colour pastes. Please take

note, there must be no paint clumps remaining

in the paint containers. The consistency should

correspond to that of water.

Note: If the paint used does not cover well, increase the amount of paint in the mixture ratio.

).

Turning airbrush compressor

on / off

Turn the airbrush compressor 1 on by setting the

on / off switch

14

to the position “I“ (see Ill. C).

Turn the airbrush compressor 1 off by setting

the on / off switch

14

in the position “0“ (see

Ill. C).

Note: Full pressure is built up after two seconds.

Regulating the air pressure

Regulate the air pressure by actuating the vent

of the air blow gun

9

to more or less of an

extent.

ATTENTION! The device has a pressure switch,

which periodically and automatically turns the device off if there is excess pressure or if it is not in use.

Shortly before reaching the switch-off point, the

compressor runs more roughly and vibrates. This

may also be the case when re-started under load.

The performance and functionality are not impaired

by this. This is not a defect, rather, serves to protect

the compressor from overloading.

Note: The blow pistol

9

blows air through the

discharge openings even without actuating the trigger. This is NOT A DEFECT.

Through actuating the trigger, the air discharge is

increased so that more air volume flows.

Note: During use of the blow gun

responding hose

2 a

sor

, there is a small discharge opening on the

2 a

adapter

2

incl. adapter for the compres-

, which releases air. This serves to create

9

with the cor-

a more uniform airflow for easier and better handling

of the blow gun

9

. This is not a defect, rather, it

serves for better handling and an improvement of

the spray results by means of a uniform airflow.

Regulating the spraying results

Regulate the amount of the paint supplied by

turning the paint nozzle of the spray stylus to

the right or left (see Ill. B).

10 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 10 06.07.12 12:26

Page 11

Preparations for use / Cleaning and care

Using the accessories (see Ill. D)

Air mattress adapter 6, ball needle

Use a pipe wrench to unscrew the nozzle

the air blow gun

9

.

Then – depending on what is needed – screw

on the air mattress adapter

12

dle

, as well as the thread adapter 7 into

the barrel of the air blow gun

Universal valve connection

6

or the ball nee-

9

10

Screw the universal valve connection 10 directly

onto the compressed air hose

8

12

9 a

.

.

Cleaning and care

Thoroughly clean the spray stylus 3 immedi-

ately after use. Otherwise the paint can dry and

cause problems during the next use.

Thoroughly rinse out the spray stylus 3 with

water.

Use the thinner included to clean any stubborn

dried paint.

Note: The thinner is not suitable for water-soluble paints. Rather, it corresponds to a varnish

for thinning paints containing solvents.

Note: If you remove the paint nozzle of the

air blow gun

threads before reattaching it so its freedom of

movement is not affected.

Never lay the entire air blow gun 9 in a sol-

vent bath.

Note: If the air intake of the compressor should

become dirty, use a dry cloth to remove the accumulated dirt.

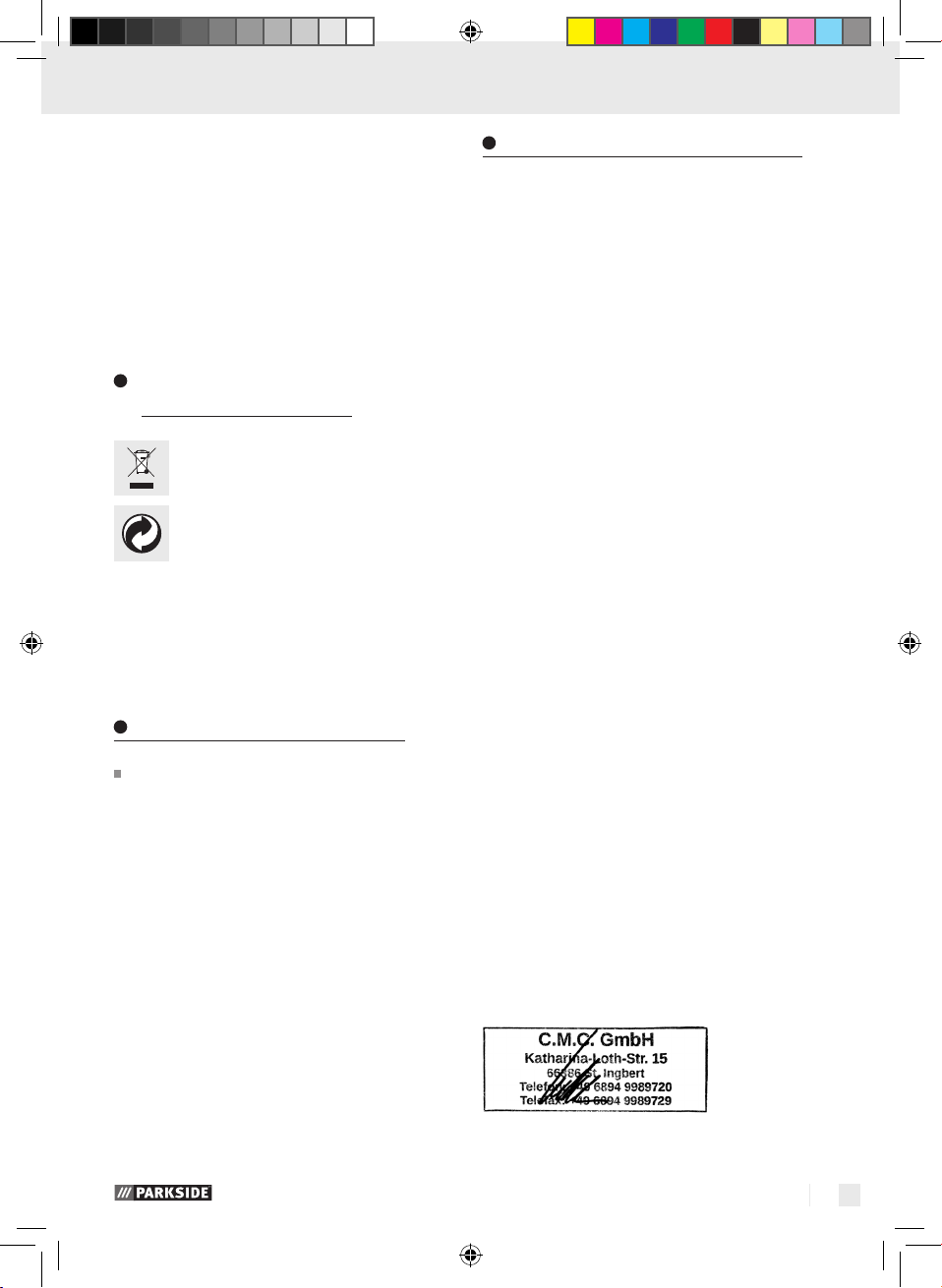

Fault Interrupted paint jet

Cause Solution

1. Paint almost

empty

2. Paint too viscous 2. Lower viscosity

3. Dry / defective

nozzle

9

during cleaning, lubricate the

or intermittent paint

delivery

1. Fill paint

3. Screw in nozzle tightly

or replace

Fault Interrupted paint jet

or intermittent paint

delivery

of

Cause Solution

4. Paint supply

4. Cleaning

restricted

5. Incorrect posi-

5. Correct position angle

tion of spray

3

stylus

.

Fault Spray pattern

incomplete

Cause Solution

1. Air head

dirty / defective

2. Nozzle dirty /

defective

1. Clean / replace air head

1. Rinse with clear water

2. Clean / replace air

nozzle

Fault Spray pattern irregu-

lar with drips

Cause Solution

1. Defective nozzle 1. Replace nozzle. Contact

a respective service centre.

2. Paint too viscous 2. Lower viscosity

3. Insufficient

working pressure

3. Increase working pressure (if necessary, not included accessories, e.g.

pressure reducer)

3. Hose defective; replace

hose

Fault Non-uniform paint

amount delivered

Cause Solution

Nozzle dirty /

Clean / replace air nozzle

defective

11 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 11 06.07.12 12:26

Page 12

… / Environmental … / Paint disposal instructions / CE Declaration of Conformity

Information about warranty and service processing

Information about warranty

and service processing

Creative Marketing Consulting GmbH

warranty

Dear customer, the warranty for this device is 3 years

from the date of purchase. In the event the product

is defective, you have legal rights vis-à-vis the retailer

of this product. Your statutory rights are not limited

in any way by our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This receipt

is required as proof of purchase.

Should this device show any fault in materials or

manufacture within three years from date of purchase,

it will be repaired or replaced - at our choice - by us

free of charge. In order for the warranty to be valid,

the defective device and the proof of purchase (receipt) must be presented within the three-year warranty

period, accompanied by a brief written description

of the nature of the defect and of the date it arose.

If the defect is covered by our warranty, you will receive the repaired device or replacement in return.

A repair or exchange of the device does not extend

a new warranty period.

Scope of warranty

This device has been manufactured to strict quality

guidelines and meticulously examined before delivery.

instructions provided in the operating instructions must

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. The warranty is void in the case of inappropriate and improper handling, use of force and

of any intervention which was not carried out by our

authorized service branch.

Procedure in the case of warranty

Please follow the instructions below to ensure quick

processing of your matter:

When inquiring about your product please have

your receipt and product number (e.g. IAN) ready

as your proof of purchase.

The item number can be found on the type plate,

an engraving, the cover page of your instructions

(bottom left) or the decal at the back or bottom. In

the event of malfunctions or other defects please

first contact the service department below by

phone or e-mail.

A product recorded as defective, along with the

proof of purchase (receipt) and a description of the

defect and when it occurred, can then be returned

free of charge to you at the service address provided.

Note:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

How to contact us:

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts

subject to normal wear and tear and which can therefore be considered as wear items, or to damage to

fragile parts, e.g. switches, storage batteries or

glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All

12 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 12 06.07.12 12:26

Name: C. M. C. GmbH

Internet address: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Telephone: +49 (0) 06894 9989752

(standard German landline

rates apply)

Registered office: Germany

IAN 73868

Page 13

… / Environmental … / Paint disposal instructions / CE Declaration of Conformity

Please note that the following address is not a

service address.

Please first contact the service centre listed above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

Environmental instructions and

disposal information

Don‘t waste, recycle!

The device, accessories and packaging

should be recycled in an environmentally friendly manner.

Do not dispose of the compressed air tool through

your household waste, or throw into fire or water. If

possible, non-operational devices should be recycled. Contact your local retailer for information.

Paint disposal instructions

Do not allow to enter sewage system, open

bodies of water or soil.

Product: Dispose of at collection facility for old

paints / varnishes.

European list of waste materials

08 01 12 waste paint and varnish other than those

mentioned in 08 01 11.

Uncleaned packaging:

Only completely emptied containers may be dis

of through recycling. Dispose of residual material

that has not hardened in the same manner as the

product.

posed

CE Declaration of Conformity

We,

C. M. C. GmbH

Documentation officer: Marc Uhle

Katharina-Loth-Str. 15

66386 St. Ingbert

declare on our sole responsibility the product

Compressed air airbrush set

Serial number: 1454

Year of manufacture: 2012 / 36

IAN: 73868

Model: PARKSIDE AIRBRUSH SET PABK 60 A1

to meet the basic safety requirements of European

Directives

EC Low Voltage Directive

2006 / 95 / EC,

EC Directive for Electromagnetic

Compatibility

2004 / 108 / EC

and its amendments.

The conformity assessment is based on the following

harmonised standards:

EN 55014–1:2000+A2:2003

EN 55014–2:1997+A1:2001

EN 61000–3–2:2000

EN 61000–3–3:1995+A1:2001

EN 60335–1:2002+A1+A11+A12+A2+A13

+A14+A15

EN 62233:2008

St. Ingbert, 30. June 2012

Karl Peter Uhle

– Managing Director –

13 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 13 06.07.12 12:26

Page 14

14

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 14 06.07.12 12:26

Page 15

Seznam obsahu

Úvod

Použití ke stanovenému účelu..........................................................................................................Strana 16

Vybavení ...........................................................................................................................................Strana 16

Technické údaje ............................................................................................................................... Strana 17

Všeobecné bezpečnostní pokyny pro pneumatické nástroje ......... Strana 17

Všeobecné bezpečnostní pokyny pro elektrické přístroje ............................................................. Strana 19

Specifické bezpečnostní pokyny kvýrobku ................................................................................... Strana 19

Před uvedením do provozu..........................................................................................Strana 19

Uvedení do provozu

Připojení soupravy airbrush ............................................................................................................. Strana 19

Míchání barev kpoužití ...................................................................................................................Strana 20

Kompresor airbrush zapnout / vypnout .......................................................................................... Strana 20

Regulace tlaku vzduchu ...................................................................................................................Strana 20

Regulace výsledku stříkání ...............................................................................................................Strana 20

Použití příslušenství (viz obr. D) .......................................................................................................Strana 21

Čistění a ošetřování ............................................................................................................. Strana 21

Pokyny k záruce a provádění servisu

Záruční podmínky ............................................................................................................................ Strana 22

Rozsah záruky .................................................................................................................................. Strana 22

Postup vpřípadě uplatnění záruky ................................................................................................. Strana 22

Ekologické pokyny a údaje pro likvidaci .........................................................Strana 23

Pokyny pro likvidaci barev ..........................................................................................Strana 23

ES Prohlášení o shodě ....................................................................................................... Strana 23

15 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 15 06.07.12 12:26

Page 16

Úvod

Vtomto návodu kobsluze / na zařízení jsou použity následující piktogramy:

Upozornění Přívodní hadice

Dodržujte bezpečnostní pokyny a

řiďte se upozorněními!

Nikdy nepoužívejte jako zdroj

energie vodík, kyslík, oxid uhličitý

nebo jiný plyn vláhvi.

Noste ochranu sluchu, protiprachovou

masku, ochranné brýle a ochranné

rukavice.

Sada stříkací pistole

Úvod

Srdečně vám blahopřejeme! Rozhodli jste

se pro kvalitní přístroj naší firmy. Před prv-

ním uvedením do provozu se seznamte s

výrobkem. Ktomu si pozorně přečtěte následující

návod kobsluze a bezpečnostní pokyny. Toto nářadí

mohou do provozu uvádět pouze zaškolené osoby.

NESMÍ SE DOSTAT DO RUKOU DĚTÍ!

Použití ke stanovenému účelu

Tento přístroj je přenosný pneumatický kompresor

optimalizovaný pro použití spřístroji na airbrush.

Sdodaným příslušenstvím se hodí pro rozmanité

použití. Je bezúdržbový a vyznačuje se nižší hladinou hluku, takže je vhodný i pro použití vuzavřených

prostorách. Tento návod si dobře uschovejte. Při

předání výrobku kněmu současně připojte i všechny

jeho podklady. Jakékoliv použití, které se liší od

použití ke stanovenému účelu, je zakázané a hrozí

potenciálním nebezpečím. Škody vzniklé nedodržením nebo chybným použitím nekryje záruka a nejsou

součástí ručení výrobce. Přístroj byl koncipován pro

domácí použití a nesmí být využíván komerčně ani

průmyslově.

Nebezpečí zásahu elektrickým

proudem

Nebezpečí popálení!

Obal i zařízení zlikvidujte ekologickým

způsobem!

Vybavení

Bezprostředně po vybalení vždy zkontrolujte úplnost dodávky a bezvadný stav

výrobku. Nepoužívejte výrobek, pokud

je vadný.

1

Kompresor na airbrush

2

Hadice

2 a

Hadicový adaptér

3

Rozprašovač

4

Sklenice na míchání barvy suzavíracím víkem

5

Sklenice na míchání barvy spřipojovacím víkem

6

Adaptér pro vzduchové matrace

7

Závitový adaptér

8

Tlaková vzduchová hadice

9

Stříkací pistole

9a

Tryska stříkací pistole

10

Přípojka univerzálního ventilu

11

Míchací pipeta

12

Jehla na hustění míčů

13

Rozvidlený klíč

14

Vypínač ZAP / VYP

Upozornění: Tato souprava navíc obsahuje šest

různých, vysoce koncentrovaných barev rozpustných

ve vodě vplastových kalíšcích a jeden kalíšek ředidla

(průhledného). Toto se dále označuje jako „spotřební

materiál“.

16 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 16 06.07.12 12:26

Page 17

Úvod / Všeobecné bezpečnostní pokyny pro pneumatické nástroje

Technické údaje

Odevzdaný výkon: cca 15 l / min.

Teor. sací výkon: max. 40 l / min.

Provozní tlak: cca 0,16 Mpa

Max. provozní tlak: cca 0,35 Mpa

(cca 3 bar)

Hmotnost bez příslušenství: cca 4140 g

Výkon motoru

bez zátěže: 100 W

Provozní napětí: 230 V∼, 50 Hz

Výkon

obrátek kompresoru: 1440 min

Druh krytí: IPX 0

Ochranná třída: I /

-1

Všeobecné bezpečnostní

pokyny pro pneumatické

nástroje

Upozornění: Výrazy „pneumatický přístroj“ nebo

„přístroj“ uvedené níže vtextu se vztahují na pneumatické přístroje uvedené vtomto návodu kobsluze.

Pokud se používají pneumatické

přístroje, musí se dodržovat základní bezpečnostní

opatření, aby se vyloučila rizika požáru, úderu elektrickým proudem a úrazů osob. Před prvním uvedením

do provozu si bezpodmínečně pročtěte a dodržujte

pokyny tohoto návodu kobsluze a návod dobře

uschovejte. Za škody a úrazy, které vzniknou

zdůvodu nedodržování tohoto návodu kobsluze,

nepřebírá výrobce žádnou záruku.

Toto zařízení není určeno k tomu, aby je použí-

valy osoby (včetně dětí) s omezenými fyzickými,

senzorickými nebo duševními schopnostmi nebo

s nedostatečnými zkušenostmi a / nebo vědomostmi, ledaže by byly pod dozorem pro

bezpečnost kompetentní osoby nebo obdržely

od ní instrukce, jak se má zařízení používat.

Zajistěte, aby si děti spřístrojem nehrály.

NEBEZPEČÍ PORANĚNÍ! Před

prováděním údržbářských prací přerušte přívod

stlačeného vzduchu.

Přístroj používejte pouze voblastech použití,

pro které byl koncipován!

Přístroj nepřetěžujte.

Nikdy nepoužívejte vodík, kyslík,

oxid uhličitý nebo jiný plyn vláhvi

jako zdroj energie pro toto nářadí,

protože to by mohlo vést kexplozi a tím i ktěžkým poraněním.

Provádějte údržbu a čistěte přístroj pravidelně

podle popisu (viz kapitola „Čištění a ošetřování“).

NEBEZPEČÍ EXPLOZE!

Kčištění pneumatického přístroje nikdy nepou-

žívejte benzin ani jiné vznětlivé kapaliny! Páry

zůstávající vpneumatickém přístroji mohou se

mohou zapálit jiskrou a způsobit explozi pneumatického přístroje. Nepracujte se zařízením

vokolí ohroženém výbuchem, vněmž se nacházejí kapaliny, plyny nebo prachy. Nezpracovávejte žádné materiály, které jsou nebo by

potenciálně mohly být lehce vznětlivé nebo

explozivní.

Před uvedením do provozu zkontrolujte přístroj

zhlediska případných poškození. Před každým

použitím se ujistěte, že je přístroj vbezvadném

stavu.

Buďte vždy pozorní! Nečekané pohyby přístroje

mohou způsobit nebezpečí.

Vyvarujte se neobvyklého držení těla. Zajistěte

vždy o bezpečnou stabilitu a udržujte neustále

rovnováhu. Tím můžete pneumatický přístroj

lépe kontrolovat vneočekávaných situacích.

Nikdy přístroj nepoužívejte, pokud je jeho

spínač vadný. Přístroj, který již nelze zapínat a

vypínat, je nebezpečný a musí se opravit.

Uchovávejte nepoužívané pneumatické přístroje

mimo dosah dětí. Zařízení nenechávejte používat osoby, které sním nejsou seznámeny nebo

které si nepřečetly tyto návody. Pneumatické

přístroje jsou nebezpečné, pokud je používají

nezkušené osoby.

Ošetřujte přístroj spečlivostí. Zkontrolujte, jestli

fungují pohyblivé díly přístroje a jestli neuvázly,

jestli díly nejsou zlomené nebo poškozené tak,

že by byla ohrožena funkce přístroje. Před použitím přístroje nechejte poškozené díly opravit.

Příčina mnoha úrazů spočívá ve špatné údržbě

přístrojů.

Pokud přístroj již nebudete používat, vypněte jej.

Noste osobní ochranné pomůcky a

vždy ochranné brýle. Nošení osob-

ních ochranných pomůcek, jako je

17 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 17 06.07.12 12:26

Page 18

Všeobecné bezpečnostní … / Před uvedením do provozu / Uvedení do provozu

Všeobecné bezpečnostní pokyny pro pneumatické nástroje

maska proti prachu, protiskluzná bezpečnostní

obuv, ochranná přilba nebo ochrana sluchu,

vzávislosti na druhu a použití pneumatického

nářadí snižuje riziko poranění.

Zkontrolujte přípojky a napájecí vedení. Veš-

keré jednotky údržby, spojky a hadice musejí

být dimenzovány sohledem na tlak a množství

vzduchu podle parametrů přístroje. Příliš nízký

tlak omezuje funkci přístroje, příliš vysoký tlak

může vést kvěcným škodám a zraněním.

Hadice chraňte před přehnutí, přiškrcení, před

rozpouštědly a ostrými hranami. Hadice udržujte

mimo dosah vysokých teplot, oleje a rotujících

částí.

Dbejte na to, aby hadicové sponky byly vždy

pevně utaženy. Neutažené nebo poškozené

hadicové sponky mohou nekontrolovaně nechat

unikat vzduch.

Poškozenou hadici neprodleně vyměňte. Poško-

zené napájecí vedení může vést ktomu, že bude

pneumatická hadice házet kolem sebe a může

tak způsobit poranění.

Pokud se připojovací vedení tohoto přístroje

poškodí, musí ho výrobce nebo jeho zákaznický

servis či podobně kvalifikovaná osoba vyměnit,

aby se zabránilo ohrožením.

Nikdy přístroj nepoužívejte, pokud jste unaveni

nebo pod vlivem drog, alkoholu a léků. Už

okamžik nepozornosti při použití přístroje může

vést kzávažným poraněním.

Odpadní vzduch nevdechujte přímo. Zabraňte

tomu, aby se Vám odpadní vzduch dostal do

očí. Odpadní vzduch pneumatického přístroje

může obsahovat vodu, olej, částečky kovu nebo

nečistoty zkompresoru. To může způsobit

poškození zdraví.

PŘI ODKLÁDÁNÍ PŘÍ-

STROJE BUĎTE OPATRNÍ! Přístroj odklá-

dejte vždy tak, aby neležel na svém vypínači.

Za jistých okolností by to mohlo způsobit neúmyslnou aktivaci přístroje, což by opět vyvolalo

hrozící nebezpečí.

Smí se používat pouze vhodné příslušenství. To

si můžete vyžádat u výrobce. Jiné než originální

příslušenství může vést ke vzniku nebezpečí.

Používejte pouze filtrovaný a regulovaný stlačený

vzduch. Prach, leptavé páry a / nebo vlhkost

mohou poškodit motor pneumatického nářadí.

18 CZ

Hadice musí být dimenzována pro

tlak min. 8,6 barů nebo 125 psi,

minimálně však na 150% tlaku,

který systém maximálně vytváří.

Nářadí a přívodní hadice musí být

opatřeny hadicovou spojkou, takže

je tlak při rozdělení spojkové hadice

plně odbourán.

Bez souhlasu výrobce se pneumatický přístroj

nesmí nijak měnit.

Používejte pneumatický přístroj pouze spřede-

psaným tlakem (max. 0,35 Mpa / cca 3 bar).

Po použití a vpřípadě nepoužívání musí být

pneumatický přístroj vždy odpojen od přívodu

vzduchu.

Pokud pneumatický přístroj není vzduchotěsný

nebo pokud potřebuje opravu, nesmí se používat.

Nikdy pneumatický přístroj nespojujte spneu-

matickou hadicí, jejíž tlak přesahuje 7barů.

Svou pracovní oblast udržujte tak, aby byla

čistá a dobře osvětlená. Nepořádek a neosvětlené pracovní oblasti mohou vést k úrazům. Díky

tomu můžete přístroj zejména vneočekávaných

situacích lépe kontrolovat.

Nechte zařízení opravovat jen

kvalifikovaným odborným personálem a jen

spoužitím originálních náhradních dílů. Tím se

zajistí, že se zachová bezpečnost přístroje.

Nedovolte dětem ani jiným osobám, aby se

přibližovaly k přístroji v době, kdy jej používáte.

Při rozptýlení byste mohli ztratit kontrolu nad

zařízením.

Noste vhodný oděv. Nenoste volný oděv nebo

šperky. Chraňte vlasy, oděv a rukavice před

pohyblivými díly. Volný oděv, šperk nebo vlasy

mohou být zachyceny pohyblivými díly.

Vpřípadě neočekávaného výpadku kompresoru

vypínač a přístroj odložte.

Pokud možno použijte odlučovač kondenzátu

nebo zhadic a vedení před použitím pneumatických přístrojů a během něj pravidelně vypouštějte kondenzát (vodu).

POZOR! Poddimenzovaný pneu-

matický systém může snížit účinnost

vašeho přístroje.

Nikdy nesměrujte pneumatický přístroj na sebe,

jiné osoby nebo zvířata. V opačném případě

hrozí nebezpečí poranění.

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 18 06.07.12 12:26

Page 19

Všeobecné bezpečnostní … / Před uvedením do provozu / Uvedení do provozu

Respektujte bezpečnostní pokyny uvedené na

kompresoru.

Dbejte na to, aby sací otvor kompresoru mohl

vždy bez překážky nasávat vzduch.

Pokud je sací filtr znečištěný, vyčistěte ho hadří-

kem. Za účelem zabránění neúmyslné aktivaci

přístroj vypněte a vytáhněte zástrčku ze zásuvky.

Během práce spřístrojem se nenechte rozptylovat.

Všeobecné bezpečnostní

pokyny pro elektrické

přístroje

Připojte přístroj pouze přes (FI) ochranný vypí-

nač proti chybnému proudu.

Chraňte se před úrazem elektrickým proudem.

Vyvarujte se toho, abyste se během práce

dotýkali uzemněných částí (jako např. lednice,

vodovodní trubky atd.).

NEBEZPEČÍ! Zabraňte kontaktu s vedením

pod napětím. Tento přístroj není izolován proti

úderu elektrickým proudem.

Pravidelně kontrolujte prodlužovací a elektrický

kabel. Vadné kabely vyměňte okamžitě za nové.

Je-li síťové napájecí vedení tohoto přístroje po-

škozeno, musí ho výrobce nebo jeho zákaznický

servis či podobně kvalifikovaná osoba vyměnit,

aby se zabránilo ohrožením.

Pokud přístroj nebudete delší dobu používat,

uskladněte jej vsuchém prostředí.

Dávejte pozor, aby připojovací kabel nevisel

přes rohy nebo nebyl natažený, jinak hrozí

nebezpečí zranění.

Síťový kabel nepoužívejte kjinému účelu jako

knošení výrobku, zavěšení zařízení nebo kvytažení zástrčky ze zásuvky.

Nikdy nevytahujte síťovou zástrčku ze zásuvky

za síťový kabel.

Nepoužívejte elektrické přístroje ve vlhkém nebo

mokrém prostředí, nevystavujte je dešti nebo

vysoké vlhkosti.

Nikdy elektrické přístroje nezapínejte vblízkosti

vysoce hořlavých kapalin nebo plynů.

Pro případné použití ve venkovních prostorách

použijte prodlužovací kabely, které jsou pro

toto použití výhradně určeny.

Specifické bezpečnostní

pokyny kvýrobku

POZOR! NEBEZPEČÍ POPÁLENÍ!

Kompresor se při delším provozu

zahřívá. Kpohybování kompresorem

proto vždy používejte rukojeť umístěnou na

přístroji. Sami se přístroje nikdy nedotýkejte!

POZOR! Kryt kompresoru na airbrush se může

používáním zahřívat. Nedotýkejte se horkých

míst, abyste předešli popálení.

Nikdy nenechávejte přístroj vprovozu bez do-

zoru. Teplo, které přístroj vytváří, se může stát

zdrojem nebezpečí.

Před uvedením do provozu

Zkontrolujte bezvadný stav všech částí přístroje.

Zkontrolujte, jestli je síťové napětí, které máte

kdispozici, kompatibilní se síťovým napětím

určeným pro provoz kompresoru.

Upozornění: Určené síťové napětí najdete

na typovém štítku přístroje.

Uvedení do provozu

Připojení soupravy airbrush

Před napojením soupravy airbrush na kompre-

sor bezpodmínečně vytáhněte síťovou zástrčku

a zbavte vedení tlaku tím, že stisknete odtah

stříkací pistole

Prostřednictvím příslušného šroubového spoje

spojte rozprašovač

sledně skompresorem na airbrush

k tomu dodaný nástrčný klíč

Připevněte sklenici na míchání barvy spřipojo-

vacím víkem

Zastrčte síťovou zástrčku do zásuvky.

Upozornění: Pro optimální výsledky používají

profesionálové vřazený redukční ventil (není

součástí dodávky). Prostřednictvím tohoto ventilu

můžete kompresorem nastavit tlak na stříkací

pistoli a optimálně jej přizpůsobit svým potřebám.

9

.

3

shadicí 2 a tu ná-

1

. Použijte

13

(viz obr. A).

5

krozprašovači 3 (viz obr. B).

19 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 19 06.07.12 12:26

Page 20

Uvedení do provozu

Upozornění: Při použití stříkací pistole 9 s

odpovídající hadicí

2 a

presor

se nachází na adaptéru

2

vč. adaptéru pro kom-

2 a

malý

upouštěcí ventil, kterým uniká vzduch. To slouží

k tomu, aby byl pro lepší a lehčí manipulaci se

stříkací pistolí

9

vytvořen rovnoměrný proud

vzduchu. To nepředstavuje závadu, ale slouží

ke zlepšení manipulace a zlepšení výsledků

postřiku rovnoměrným proudem vzduchu.

Míchání barev kpoužití

Barvy, které jsou součástí dodávky, jsou rozpustné

ve vodě. Pro správné použití barev je nutné přidat

vodu a rozmíchat. Při dodání jsou barvy pro použití

příliš husté.

Nejprve doplňte kalíšek svámi zvoleným

barevným odstínem vodou.

Nyní na nádobku opět našroubujte víčko a

protřepejte ji.

Pomocí pipety 11 odeberte dvě kapky lehce

zředěné barevné pasty a dejte je do sklenice

na míchání barvy (

naplněna vodou.

Protřepejte. Nyní barva dosáhla své potřebné

hustoty.

Připojte mísič barev (4, 5) podle obrázku B.

Upozornění: Na přání můžete prostřednictvím

množství přidané vody sami ovlivnit sytost barvy,

stejně jako u vodovek. Čím více vody přidáte, tím

„řidší“ bude barva.

Zjednotlivých barevných past si rovněž můžete

namíchat svůj individuální barevný odstín. Nezapomeňte však, že vnádobce na barvy nesmí být žádné barevné hrudky. Hustota by měla

odpovídat hustotě vody.

Upozornění: Pokud použitá barva špatně

kryje, zvyšte podíl barvy v poměru směsi.

4, 5

), která je kompletně

Kompresor airbrush

zapnout / vypnout

Zapněte kompresor airbrush 1 tak, že spínač

ZAP / VYP

14

zapnete do polohy „I“ (viz obr. C).

Vypněte kompresor airbrush 1 tak, že spínač

ZAP / VYP 14 zapnete do polohy „0“ (viz obr. C).

Upozornění: Po cca dvou sekundách se vytvoří

plný tlak.

Regulace tlaku vzduchu

Regulujte tlak vzduchu tak, že budete více nebo

méně silně tisknout odtah stříkací pistole

9

.

POZOR! Přístroj obsahuje tlakový spínač, který

přístroj při přetlaku nebo nepoužívání automaticky

vypne. Krátce před dosažením tohoto odpojení

běží kompresor drsněji a vibruje. To se může stát i

při opětovném náběhu se zatížením. Výkon a

funkčnost tím nejsou ovlivněny. Není to závada, ale

ochrana kompresoru před přetížením.

Upozornění: Stříkací pistole

9

odfoukne i bez

stisknutí kohoutku přes výstupní otvor. To NEZNA-

MENÁ ZÁVADU.

Stisknutím kohoutku se výstup vzduchu zesílí, takže

protéká větší objem vzduchu.

Upozornění: Při použití stříkací pistole

povídající hadicí

se nachází na adaptéru

2

vč. adaptéru pro kompresor

2 a

malý upouštěcí ventil,

9

s od-

2 a

kterým uniká vzduch. To slouží k tomu, aby byl pro

lepší a lehčí manipulaci se stříkací pistolí

9

vytvořen rovnoměrný proud vzduchu. To nepředstavuje

závadu, ale slouží ke zlepšení manipulace a zlepšení

výsledků postřiku rovnoměrným proudem vzduchu.

Regulace výsledku stříkání

Regulujte množství přiváděné barvy a tím i vý-

sledek stříkání tím, že otočíte barevnou trysku

rozprašovače doprava nebo doleva (viz obr. B).

20 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 20 06.07.12 12:26

Page 21

Uvedení do provozu / Čistění a ošetřování

Použití příslušenství (viz obr. D)

Adaptér pro vzduchové matrace 6,

jehla na nafukování míčů

12

Pomocí hasáku odšroubujte trysku 9a stříkací

9

pistole

.

Následně – podle potřeby – našroubujte

adaptér pro vzduchové matrace

na hustění míčů

hlavně stříkací pistole

12

či závitový adaptér 7 do

9

.

Přípojka univerzálního ventilu

6

nebo jehlu

10

Našroubujte přípojku univerzálního ventilu 10

přímo na hadici se stlačeným vzduchem

8

.

Čistění a ošetřování

Ihned po použití vyčistěte rozprašovač 3. Jinak

může barva zaschnout a způsobit problémy při

dalším použití.

Důkladně rozprašovač 3 propláchněte vodou.

Vpřípadě zatvrdlé, zaschnuté barvy použijte

dodané ředidlo.

Upozornění: Ředidlo není určeno pro laky

ředitelné vodou, ale odpovídá laku ředitelnému

rozpouštědly.

Upozornění: Pokud při čištění odstraníte ba-

revnou trysku stříkací pistole

jejím opětovným nasazením závit, aby nedošlo

komezení lehkého chodu.

Neponořujte stříkací pistoli 9 celou do roz-

pouštědla.

Upozornění: Pokud by byl znečištěn přívod

vzduchu kompresoru, odstraňte nasáté nečis-

toty pomocí suchého hadříku.

Chyba Přerušovaný proud

barvy, resp. nárazové

dávkování barvy

Příčina Řešení

1. Barva je téměř

1. Doplňte barvu

prázdná

2. Příliš vysoká

2. Snižte vazkost

vazkost

9

, namažte před

Chyba Přerušovaný proud

barvy, resp. nárazové

dávkování barvy

Příčina Řešení

3. Uvolněná / vadná

3. Dotáhněte / vyměňte

trysku

tryska

4. Zúžený přívod

4. Vyčistěte

barvy

5. Špatné držení

5. Upravte úhel držení

rozprašovače 3.

Chyba Stříkaný obraz není

kompletní

Příčina Řešení

1. Vzduchová hlavice je znečištěná / vadná

2. Tryska je znečištěná / vadná

1. Vyčistěte / vyměňte

vzduchovou hlavici

1. Propláchněte čistou vodou

2. Vyčistěte / vyměňte

trysku

Chyba Stříkaný obraz je

nepravidelný s

tvorbou kapek

Příčina Řešení

1. Vadná tryska 1. Vyměňte trysku. Obraťte

se ne vhodné servisní

místo.

2. Příliš vysoká

2. Snižte vazkost

vazkost

3. Příliš nízký

pracovní tlak

3. Zvyšte pracovní tlak

(popř. seřiďte společně

nedodané příslušenství,

např. redukční ventil)

3. Vadná hadice; vyměnit

Chyba Nerovnoměrné dáv-

kování množství barvy

Příčina Řešení

Tryska je znečiš-

Vyčistěte / vyměňte trysku

těná / vadná

21 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 21 06.07.12 12:26

Page 22

… / Ekologické pokyny a … / Pokyny pro likvidaci barev / ES Prohlášení o shodě

Pokyny k záruce a provádění servisu

Pokyny k záruce

a provádění servisu

Záruka společnosti Creative Marketing

Consulting GmbH

Vážení zákazníci, na tento přístroj obdržíte záruku

3 roky od data zakoupení. Vpřípadě závad tohoto

přístroje Vám náleží zákonná práva vůči prodejci

přístroje. Vaše práva ze zákona nejsou omezena

naší níže uvedenou zárukou.

Záruční podmínky

Záruční lhůta začíná běžet od data zakoupení.

Dobře si uschovejte originál pokladní strvzenky.

Tento podklad budete potřebovat jako doklad o

koupi.

Pokud se do tří let od data nákupu tohoto produktu

vyskytne vada materiálu nebo výrobní vada, výrobek vám – dle našeho rozhodnutí – bezplatně

opravíme nebo vyměníme. Předpokladem pro toto

poskytnutí záruky je, že vadný přístroj a doklad o

koupi (pokladní stvrzenku) předložíte během tříleté

lhůty a stručně popíšete, včem závada spočívá a

kdy se objevila.

Pokud vada bude kryta naší zárukou, obdržíte od

nás opravený nebo nový výrobek. Opravou ani výměnou výrobku nezačíná běžet nová záruční lhůta.

údržba. Pro odborné používání výrobku se musí

přesně dodržovat všechny pokyny uvedené v návodu k obsluze. Je bezpodmínečně nutné vyhnout

se účelům použití a jednáním, od kterých se vnávodu kobsluze odrazuje nebo před kterými návod

kobsluze varuje.

Výrobek je určen pouze pro soukromé, nikoliv

komerční použití. Vpřípadě nesprávného a neodborného zacházení, použití násilí a zásahů, které

nebyly provedeny našimi autorizovanými servisními

provozovnami, záruční nároky zanikají.

Postup vpřípadě

uplatnění záruky

Za účelem zaručení rychlého zpracování vaší

žádosti se laskavě riďte následujícími pokyny:

Pro všechny požadavky si připravte pokladní blok

a číslo výrobku (např. IAN) jako doklad o nákupu.

Číslo výrobku naleznete na typovém štítku, rytině,

na titulním listě návodu kpřístroji (vlevo dole) nebo

na nálepce na zadní nebo spodní straně výrobku.

Pokud se vyskytnou funkční vady, kontaktujte nejprve telefonicky nebo e-mailem níže uvedené

servisní oddělení.

Výrobek se zjištěnou závadou pak můžete spřipojením dokladu o nákupu (pokladní blok) a údajem

o tom, včem závada spočívá a kdy se objevila,

vyplaceně, bez poštovného, poslat na adresu

servisu, kterou vám sdělilo servisní oddělení.

Rozsah záruky

Přístroj byl vyroben snejvyšší pečlivostí podle přísných kvalitativních směrnic a před odesláním prošel

výstupní kontrolou.

Záruka platí na vady materiálu a výrobní vady. Tato

záruka se nevztahuje na části výrobku, které jsou

vystaveny běžnému opotřebení a které lze proto

chápat jako rychle opotřebitelné součásti, ani na

poškození lámavých částí, např. spínačů, baterií

nebo takových, které jsou zhotoveny ze skla.

Tato záruka propadá, pokud se produkt používal

poškozený, neodborně nebo pokud se neprováděla

22 CZ

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 22 06.07.12 12:26

a software.

Takto nás kontaktujte:

Název: C. M. C. GmbH

Internetová adresa: www.cmc-creative.de

E-mail: service.cz@cmc-creative.de

Telefon: +49 (0) 6894 9989752

Sídlo: Německo

Upozornění:

Na www.lidl-service.com můžete stáhnout

tento a ostatní manuály, videa produktů

(běžný tarif německé pevné sítě)

Page 23

… / Ekologické pokyny a … / Pokyny pro likvidaci barev / ES Prohlášení o shodě

IAN 73868

Vezměte laskavě na vědomí, že následující adresa

není adresa servisu.

Nejprve kontaktujte výše uvedené servisní středisko.

Adresa:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386St. Ingbert

Německo

Ekologické pokyny a

údaje pro likvidaci

Recyklace surovin místo

likvidace odpadu!

Přístroj, příslušenství a obal by se měly

recyklovat.

Neodhazujte pneumatické nástroje do domovního

odpadu, do ohně nebo do vody. Je-li to možné, měly

by být nefunkční přístroje recyklovány. Požádejte o

pomoc vašeho místního prodejce.

ES Prohlášení o shodě

My, firma

C. M. C. GmbH

Za dokument je zodpovědný: Marc Uhle

Katharina-Loth-Str. 15

66386St. Ingbert

prohlašujeme na vlastní zodpovědnost, že produkt

Tlaková souprava na airbrush

Sériové číslo: 1454

Rok výroby: 2012 / 36

IAN: 73868

Model: PARKSIDE SADA STŘÍKACÍ PISTOLE

PABK 60 A1

odpovídá podstatným ochranným požadavkům,

které jsou stanoveny v evropských směrnicích

ES Směrnice o nízkém napětí

2006 / 95 / ES,

ES Směrnice o elektromagnetické

kompatibilitě

2004 / 108 / ES

a jejich změnách.

Pokyny pro likvidaci barev

Zabraňte vniknutí do kanalizace, vod nebo do

země.

Výrobek: Odevzdejte na sběrném místě pro

staré barvy/ staré laky.

Evropský seznam odpadů

08 01 12 Odpady barev a laků s výjimkou těch,

které spadají pod 08 01 11.

Nevyčištěná balení:

K recyklaci předejte pouze obaly zbavené zbytků.

Neztvrdlé zbytky likvidujte jako výrobek.

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 23 06.07.12 12:26

K posouzení shody bylo využito následujících

harmonizovaných norem:

EN 55014–1:2000+A2:2003

EN 55014–2:1997+A1:2001

EN 61000–3–2:2000

EN 61000–3–3:1995+A1:2001

EN 60335-1:2002+A1+A11+A12+A2+A13

+A14+A15

EN 62233:2008

St. Ingbert, 30. June 2012

Karl Peter Uhle

– ředitel společnosti –

23 CZ

Page 24

24

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 24 06.07.12 12:26

Page 25

Zoznam obsahu

Úvod

Používanie v súlade s určeným účelom .......................................................................................... Strana 26

Výbava .............................................................................................................................................Strana 26

Technické údaje ............................................................................................................................... Strana 27

Všeobecné bezpečnostné upozornenia pre

pneumatické náradie.........................................................................................................Strana 27

Všeobecné bezpečnostné upozornenia pre elektrické zariadenia ..............................................Strana 29

Bezpečnostné pokyny špecifické pre výrobok ............................................................................... Strana 29

Pred uvedením do prevádzky ................................................................................... Strana 29

Uvedenie do prevádzky

Pripojenie súpravy na airbrush ........................................................................................................Strana 30

Miešanie farieb pre použitie ........................................................................................................... Strana 30

Zapnutie / vypnutie airbrush-kompresora ....................................................................................... Strana 30

Regulácia tlaku vzduchu ..................................................................................................................Strana 30

Regulácia výsledku striekania ......................................................................................................... Strana 31

Používanie príslušenstva (p. obr. D) ................................................................................................Strana 31

Čistenie a údržba ...................................................................................................................Strana 31

Informácie týkajúce sa záruky a servisu

Záručné podmienky ......................................................................................................................... Strana 32

Rozsah záruky .................................................................................................................................. Strana 32

Postup v prípade poškodenia v záruke .......................................................................................... Strana 32

Pokyny k ochrane životného prostredia a údaje týkajúce

sa likvidácie ............................................................................................................................... Strana 33

Pokyny týkajúce sa likvidácie farieb ..................................................................Strana 33

Vyhlásenie o zhode ES ......................................................................................................Strana 33

25 SK

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 25 06.07.12 12:26

Page 26

Úvod

V tomto návode na obsluhu / na prístroji sú použité nasledujúce piktogramy:

Upozornenie Prívodná hadica

Dbajte na výstražné a bezpečnostné

upozornenia!

Nikdy nepoužívajte oxidy vodíka,

kyslík, oxid uhličitý ani iný plyn vo fľašiach ako zdroj energie.

Noste ochranu sluchu, masku proti

prachu, ochranné okuliare a

ochranné rukavice.

Súprava striekacej pištole

Úvod

Blahoželáme! Rozhodli ste sa pre veľmi

kvalitný výrobok z našej výroby. Pred

prvým uvedením do prevádzky sa oboznámte s výrobkom. Za týmto účelom si pozorne

prečítajte nasledujúci návod na obsluhu a bezpečnostné upozornenia. Uvedenie zariadenia do prevádzky môžu realizovať iba poučené osoby.

VÝROBOK SA NESMIE DOSTAŤ DO RÚK

DEŤOM!

Používanie v súlade

s určeným účelom

Toto zariadenie je prenosným kompresorom na

stlačený vzduch optimalizované na použitie so

striekacími pištoľami na airbrush. Vďaka dodanému

príslušenstvu sa zariadenie hodí na použitie s množstvom aplikácií. Zariadenie nevyžaduje údržbu a vykazuje zníženie hluku tak, aby bolo vhodné aj na

použitie v uzatvorených priestoroch. Tento návod

dôkladne uschovajte. Ak zariadenie odovzdávate

tretím osobám, priložte k nemu aj všetky podklady.

Akékoľvek použitie, ktoré sa odlišuje od použitia v súlade s určením, je zakázané a potenciálne nebezpečné. Škody v dôsledku nedodržania pokynov

alebo chybného použitia nie sú kryté zárukou a

26 SK

Nebezpečenstvo zásahu elektrickým

prúdom

Nebezpečenstvo popálenia!

Obal a zariadenie ekologicky

zlikvidujte!

nespadajú do oblasti ručenia výrobcu. Zariadenie

bolo koncipované na používanie v domácnosti a

nesmie sa používať na komerčné alebo priemyselné

účely.

Výbava

Bezprostredne po vybalení vždy skontrolujte bezchybný stav výrobku. Výrobok

nepoužívajte, ak je chybný.

1

Kompresor na airbrush

2

Hadica

2 a

Adaptér pre pneumatickú špirálovú hadicu

3

Striekací nadstavec

4

Nádoba na miešanie farby s uzáverom

5

Nádoba na miešanie farby s prípojným

uzáverom

6

Adaptér na nafukovačky

7

Adaptér so závitom

8

Hadica na stlačený vzduch

9

Vyfukovacia pištoľ

9a

Dýza vyfukovacej pištole

10

Prípojka univerzálneho ventilu

11

Zmiešavacia pipeta

12

Ihla na nafukovanie lôpt

13

Vidlicový kľúč

14

Za- / vypínač

Upozornenie: V tomto balíku sa dodatočne

nachádza šesť rôzne farebných, vysoko koncentrovaných a vodou riediteľných farieb v plastových

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 26 06.07.12 12:26

Page 27

Úvod / Všeobecné bezpečnostné upozornenia pre pneumatické náradie

nádobkách, okrem toho jedna nádobka s riedidlom

(priehľadná). Tieto sa následne označujú ako

„spotrebný materiál“.

Technické údaje

Výstupný výkon: cca. 15 l / min.

Teor. nasávací výkon: max. 40 l / min.

Prevádzkový tlak: cca. 0,16 Mpa

Max. prevádzkový tlak: cca. 0,35 Mpa

(cca. 3 bar)

Hmotnosť bez príslušenstva: cca. 4140 g

Výkon motora

bez záťaže: 100 W

Prevádzkové napätie: 230 V∼, 50 Hz

Výkon

otáčok kompresora: 1440 min

Druh ochrany: IPX 0

Trieda ochrany: I /

-1

Všeobecné bezpečnostné

upozornenia pre

pneumatické náradie

Upozornenie: v texte použitý výraz “pneumatické

zariadenie“ alebo “zariadenie“ sa vzťahuje na

pneumatické zariadenia uvedené v tomto návode

na obsluhu.

Ak sa používajú pneumatické

zariadenia, musia sa dodržiavať základné bezpečnostné opatrenia, aby sa vylúčili riziká požiaru, úderu

elektrickým prúdom a poranení osôb. Pred prvým

uvedením do prevádzky si prosím bezpodmienečne

prečítajte a dodržiavajte upozornenia tohto návodu

a návod starostlivo uschovajte. Za škody alebo poranenia tela, ktoré vzniknú v dôsledku nedodržiavania tohto návodu na obsluhu, nepreberá výrobca

žiadnu zodpovednosť.

Toto zariadenie nie je určené na to, aby ho

používali osoby (vrátane detí) s obmedzenými

fyzickými, senzorickými alebo duševnými schopnosťami alebo s nedostatočnými skúsenosťami

a / alebo znalosťami, s výnimkou prípadov, ak

sú pod dozorom osoby zodpovedajúcej za ich

bezpečnosť, alebo ak od tejto osoby dostali

inštrukcie týkajúce sa používania zariadenia.

Zabezpečte, aby sa deti so zariadením nehrali.

NEBEZPEČENSTVO PO-

RANENIA! Pred údržbovými prácami prerušte

prívod stlačeného vzduchu.

Zariadenie používajte iba v oblastiach použí-

vania, pre ktoré bolo koncipované!

Zariadenie nepreťažujte.

Nikdy nepoužívajte oxidy vodíka,

kyslík, oxid uhličitý ani iný plyn vo

fľašiach ako zdroj energie pre toto

náradie, pretože to môže viesť k explózii a tým

k ťažkým poraneniam.

Zariadenie pravidelne udržiavajte a čistite podľa

zadaní (pozri kapitolu „Čistenie a údržba“).

NEBEZPEČENSTVO

EXPLÓZIE! Na čistenie pneumatického zaria-

denia nikdy nepoužívajte benzín ani iné horľavé

kvapaliny! Zvyšné pary v pneumatickom zariadení by sa mohli prostredníctvom iskry zapáliť

a spôsobiť explóziu pneumatického zariadenia.

Zariadenie nepoužívajte v okolí s nebezpečenstvom explózie, v ktorom sa nachádzajú horľavé

kvapaliny, plyny alebo prachy. Neobrábajte

materiál, ktorý je alebo by mohol byť potenciálne ľahko zápalný alebo výbušný.

Zariadenie prekontrolujte pred uvedením do

prevádzky na prípadné poškodenia. Pred každým použitím zabezpečte, aby sa zariadenie

nachádzalo v bezchybnom stave.

Buďte neustále pozorní! Neočakávané pohyby

zariadenia môžu spôsobiť nebezpečenstvá.

Vyhýbajte sa abnormálnemu držaniu tela. Za-

bezpečte si stabilný postoj a vždy udržiavajte

rovnováhu. Vďaka tomu môžete pneumatické

zariadenie lepšie kontrolovať v neočakávaných

situáciách.

Nepoužívajte zariadenie, ktorého spínač je

chybný. Zariadenie, ktoré už nie je možné

zapnúť alebo vypnúť, je nebezpečné a musí sa

opraviť.

Nepoužívané pneumatické zariadenia uscho-

vajte mimo dosahu detí. Zariadenie nesmú

používať osoby, ktoré s ním nie sú oboznámené

alebo ktoré nečítali tieto pokyny. Pneumatické

zariadenia sú nebezpečné, ak sa používajú

nevyškolenými osobami.

27 SK

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 27 06.07.12 12:26

Page 28

Všeobecné bezpečnostné upozornenia pre … / Pred uvedením do prevádzky

Všeobecné bezpečnostné upozornenia pre pneumatické náradie

Zariadenie starostlivo udržiavajte. Prekontrolujte,

či pohyblivé diely zariadenia fungujú bezchybne

a či nie sú zovreté, či diely nie sú zlomené alebo

poškodené tak, že je obmedzená funkcia zariadenia. Pred používaním zariadenia sa musia

poškodené časti opraviť. Mnoho nehôd má

svoju príčinu v zle udržiavaných zariadeniach.

Ak už zariadenie nepoužívate, vypnite ho.

Noste osobnú ochrannú výstroj a

vždy ochranné okuliare. Nosenie

osobnej ochrannej výstroje, ako je

maska proti prachu, protišmyková bezpečnostná

obuv, ochranná prilba alebo ochrana sluchu,

závisle od druhu a použitia pneumatického

náradia, znižuje riziko poranení.

Prekontrolujte prípojky a napájacie vedenia.

Všetky údržbové jednotky, spojky a hadice

musia byť dimenzované na tlak a množstvo

vzduchu podľa parametrov zariadenia. Príliš

nízky tlak negatívne ovplyvňuje funkciu zariadenia, príliš vysoký tlak môže viesť k vecným

škodám a poraneniam.

Hadice chráňte pred zalomením, zúženinami,

rozpúšťadlami a ostrými hranami. Hadice udržiavajte v bezpečnej vzdialenosti od vysokej

teploty, oleja a rotujúcich častí.

Dbajte na to, aby boli vždy pevne utiahnuté

hadicové spony. Z neutiahnutých alebo poškodených hadicových spôn môže nekontrolovane

unikať vzduch.

Poškodenú hadicu okamžite vymeňte. Poškodené

napájacie vedenie môže viesť k nekontrolovane

lietajúcej hadici na stlačený vzduch a spôsobiť

poranenia.

Ak je prípojné vedenie tohto zariadenia poško-

dené, musí ho vymeniť výrobca, jeho zákaznícka

služba alebo osoba s podobnou kvalifikáciou,

aby sa zabránilo možným rizikám.

Zariadenie nepoužívajte, ak ste unavený alebo

pod vplyvom drog, alkoholu alebo liekov. Jediný

moment nepozornosti pri používaní zariadenia

môže viesť k závažným poraneniam.

Odpadový vzduch priamo nevdychujte. Zabráňte

vniknutiu odpadového vzduchu do očí. Odpadový vzduch pneumatického zariadenia môže

obsahovať vodu, olej, kovové čiastočky alebo

nečistoty z kompresora. Toto môže viesť k poškodeniu zdravia.

28 SK

PRI ODKLADANÍ ZARIA-

DENIA BUĎTE OPATRNÍ! Zariadenie vždy

odložte tak, aby neležalo na spúšťači. Za

určitých okolností by mohlo dôjsť k neúmyselnému aktivovaniu zariadenia, čo zase môže

viesť k nebezpečenstvám.

Smie sa používať iba vhodné príslušenstvo. Toto

môžete získať u výrobcu. Neoriginálne príslušenstvo môže viesť k nebezpečenstvám.

Používajte iba filtrovaný a regulovaný stlačený

vzduch. Prach, leptajúce výpary a / alebo

vlhkosť môžu poškodiť motor pneumatického

zariadenia.

Hadica musí byť dimenzovaná na

tlak min. 8,6 bar alebo 125 psi,

minimálne však na 150 % maximál-

neho tlaku vytváraného v systéme.

Zariadenie a prívodová hadica musia

byť vybavené hadicovou spojkou,

aby bol tlak pri oddelení hadice s

hadicovou spojkou úplne odbúraný.

Bez súhlasu výrobcu sa nesmie pneumatické

zariadenie žiadnym spôsobom meniť.

Pneumatické zariadenie sa smie používať iba s

predpísaným tlakom (max. 0,35 Mpa / cca. 3 bar).

Pneumatické zariadenie sa musí po použití a pri

nepoužívaní vždy odpojiť od prívodu vzduchu.

Ak zariadenie nie je vzduchotesné alebo sa

musí opraviť, nesmie sa používať.

Pneumatická zariadenie nikdy nespájajte s ha-

dicou na stlačený vzduch, ktorej tlak presahuje

7 bar.

Vašu pracovnú oblasť udržiavajte čistú a dobre

osvetlenú. Neporiadok a neosvetlené pracovné

oblasti môžu viesť k úrazom. Vďaka tomu môžete

zariadenie lepšie kontrolovať predovšetkým v

neočakávaných situáciách.

Opravou zariadenia poverte

len kvalifikovaný odborný personál a používajte

pritom iba originálne náhradné diely. Tým sa

zaručí, že bezpečnosť zariadenia zostane

zachovaná.

Počas používania zariadenia udržiavajte deti a

iné osoby vzdialené od zariadenia. Znížená

pozornosť môže viesť ku strate kontroly nad

zariadením.

Noste vhodný odev. Nenoste široký odev ani

ozdoby. Vlasy, odev arukavice udržiavajte

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 28 06.07.12 12:26

Page 29

Všeobecné bezpečnostné upozornenia pre … / Pred uvedením do prevádzky

vzdialené od pohybujúcich sa častí. Voľný odev,

ozdoby alebo dlhé vlasy sa môžu zachytiť do

pohybujúcich sa častí.

Spúšťač a zariadenie v prípade nečakaného

výpadku kompresora odložte.

Podľa možnosti používajte odlučovač konden-

zátu alebo hadice a potrubné vedenia pravidelne zbavujte kondenzátu (vody) pred a počas

používania pneumatických zariadení.

POZOR! Poddimenzovaný pneu-

matický systém môže znížiť efektivitu

vášho zariadenia.

Pneumatické zariadenie nikdy nesmerujte na

seba, iné osoby ani zvieratá. Inak hrozí nebezpečenstvo poranenia.

Dodržiavajte všetky bezpečnostné upozornenia

umiestnené na kompresore.

Dbajte na to, aby nasávací otvor kompresora