Page 1

REPORT RC055097/28116

APPENDIX A

SERVICE/OPERATING MANUAL

Page 2

MAF800-100S

MULT I-CARRIER

POWER

AMPLIFIER

USER MANUAL

Page 3

Ta ble Of Con tents

Page

Section 1 No.

General Description..............................................................................................................1

Section 2

Specifications........................................................................................................................2

Section 3

Multi-Carrier Power Amplifier Principals of Operation.......................................................3

Principals of Operation.........................................................................................................4

Principals of Operation.........................................................................................................5

Principals of Operation…………………………………………………….6

Section 4

Operating Instructio ns...........................................................................................................7

Operating Instructio ns………………………………………………………8

Section 5

Installation Instructio ns.........................................................................................................9

Installation Instructio ns........................................................................................................10

Installation Instructio ns........................................................................................................11

Section 6

Maintenance.........................................................................................................................12

Maintenance.........................................................................................................................13

Maintenance.........................................................................................................................14

Maintenance.........................................................................................................................15

Maintenance.........................................................................................................................16

Section 7

Troubleshooting……………………………………………………………17

Page 4

Section 1

Am plifier System Descrip tion

1.1 Introduction

This manual contains information and procedures for installation, operation, and maintenance of Paradigm

Wireless Systems MAF800-100S multi-carrier cellular amplifier. This manual is organized into the

following sections:

Section 1. Amplifier System Description

Section 2. Specifications

Section 3. Principals of Operation

Section 4. Operating Instructions

Section 5. Installation

Section 6. Maintenance

Section 7. Troubleshooting

1.2 General Description

The MAF800-100S is a linear, feed forward power amplifier that operates in the 25 MHz frequency range

from 869 MHz to 894 MHz. The average output power of the amplifier is 100 Watts average AMPS,

CDMA, CDMA 2000, 1xEV-DO, GSM, TDMA, and EDGE. The amplifier is designed to operate in a

maximum of two continuous modulations or a total instantaneous bandwidth of 25 MHz. The amplifier can

simultaneously transmit multiple frequencies, with a better than –13 dBm third order intermodulation

distortion. The amplifier is designed and suited for use in CDMA, TDMA, EDGE and GSM radio base

stations. A sub-rack is employed to combine the outputs of up to (4) MAF800-100S amplifiers. Each plugin module operates in parallel to produce a high peak output power and fail safe redundancy for trouble free

operation with minimum maintenance. A multi-color LED detects when a fault condition has occurred

within the amplifier. The LED will turn from GREEN to RED during an amplifier fault condition.

Each amplifier has a status connector that allows the host system to monitor the amplifier module

performance. Monitoring of the amplifiers is done through the D-subminiature connector on the back of the

MAF800-100S amplifiers. The front panel of the MAF800-100S amplifier has an ON/OFF circuit breaker.

Primary +27 Vdc power for the MAF 800-100S amplifiers is provided through the sub-rack assembly.

The sub-rack contains the fan assembly for cooling each amplifier. Cooling fans are used to pull air through

the heat sinks. Air movement across the heat sinks dissipates the heat generated by the amplifiers. Constant

airflow ensures the amplifiers performance to specifications.

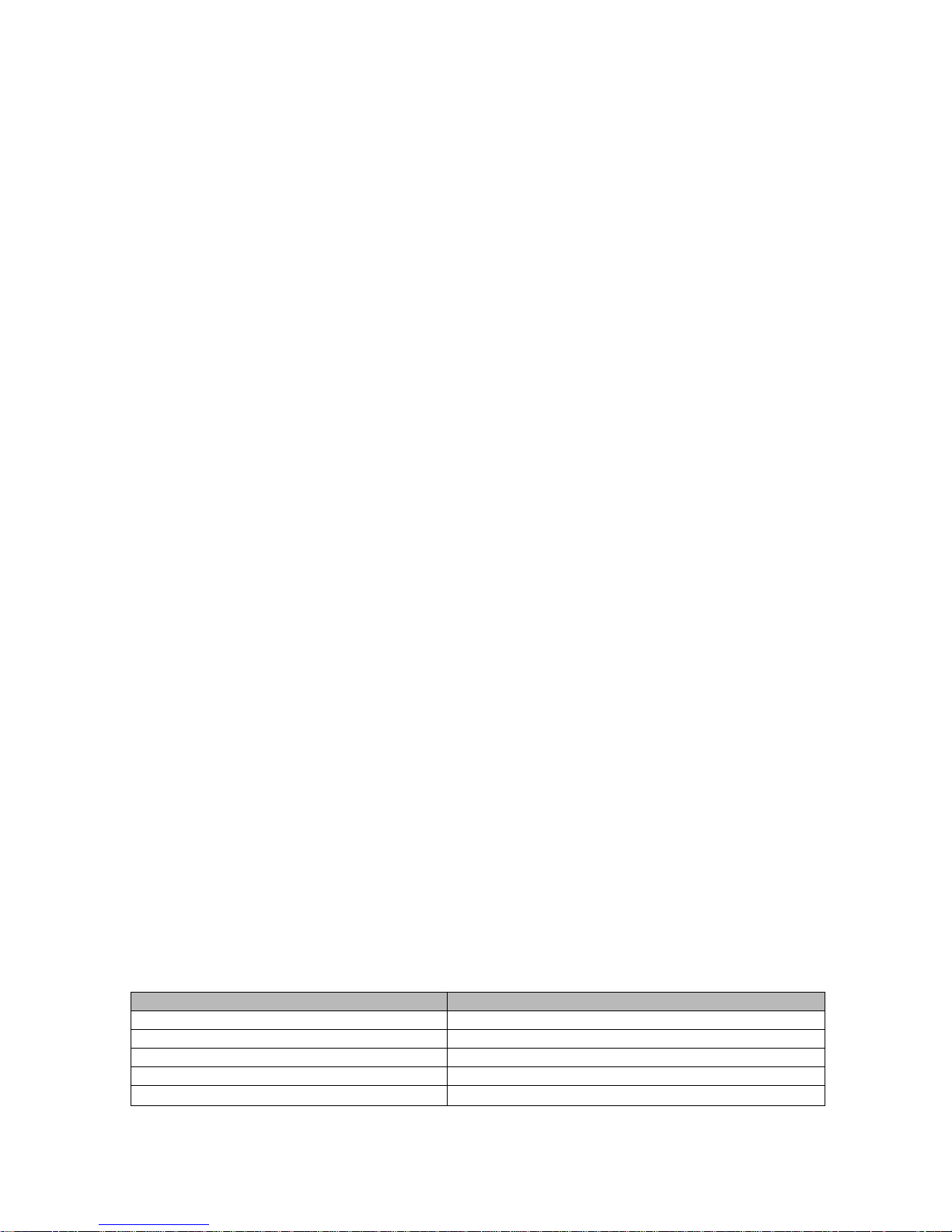

Section 2

Gain Variation over Temperature 0.3 dB

MAF800-100S Electrical Specification

Parameter Specification

Frequency 869-894 MHz

RF Gain 58 dB

Gain Flatness 0.5 dB

Intermodulation Distortion

≤

-13 dBm

1

Page 5

Out of Band Spurious

Input Power -4 dBm

Output Power 100 Watts

Modulation Type AMPS, CDMA, CDMA 2000, TDMA, EDGE, GSM, 1x

Operating Instantaneous Bandwidth 25 MHz

Input Return Loss

Output Return Loss

Output Protection Mismatched Protected

Duty Cycle Continuous

Vd c Input P o wer +2 7 Vd c

Operating Current 24 amps per amplifier

≤

-13 dBm

EV-DO

≥ 15 dB

≥ 15 dB

MAF800-100S Environmental Specifications:

Parameter Specification

Operating Temperature

Storage Temperature

Operating Humidity 5%- 95% Relative Humidity (Non-condensing)

Storage Humidity 5%-95% Relative Humidity (Non-condensing)

RF Input / Output Connector D-Sub, Hybrid, Plug-in Type RF Connector: PKZ

Status / Alarm / Control / DC Input Connector 21 Pin D-Subminiature Combo Connector

Dimensions

Weight

0° C. to 50° C.

-40° C. to + 80° C.

26-0020 series straight plug (Phoenix Co.)

Section 3

Principals of Operati on

3.1 In troduction

This section contains the functional description of the MAF800-100S multi-carrier power amplifier.

3.2 RF Input Signal

The maximum composite input power shall not exceed – 4 dBm. The reference source signal shall not

exceed the base station manufacture minimum requirements for intermodulation distortion. For proper loop

balance, the out of band components of the input signal shall not exceed –40 dBc. The input VSWR should

be 2:1 maximum

3.3 RF Output Load

The load impedance should be equal to or better than 1.5:1 in the operating band for good power transfer to

the load. If the amplifier is operated into a filter, it will maintain its distortion characteristics outside the

signal band even if the VSWR is infinite. Provided the reflected power does not exceed one-watt. A

parasitic signal of less than one-watt incident on the output will not cause distortion at a higher level than

the normal forward distortion

2

Page 6

3.4 Amplifier Functional Description

The MAF800-100S amplifier is a linear, feed-forward power amplifier that operates in the 25 MHz

frequency band from 869 MHz -894 MHz. The amplifier is designed to operate in an instantaneous

bandwidth of 25 MHz. Each amplifier is a self-contained plug in module and is functionally independent of

the other amplifier module. The amplifier modules are designed for parallel operation to achieve high peak

power output, and for redundancy in unmanned remote locations. Each amplifier in the system can

simultaneously transmit multiple carrier frequencies, at an average total power output of 100 Watts, with

better than –13 dBm intermodulation distortion.

All phase and gain corrections are performed on the signal (s) in the individual amplifier module. Each

amplifier module has an alarm board that monitors the amplifier performance. If a failure or fault occurs in

the amplifier module a multi-color LED will change from GREEN to RED. This will be displayed on the

front of the individual amplifier front panel.

3.5 MAF800-100S Amplifier Module

The amplifier module has an average output of 100 Watts power with intermodulation products suppressed

to better than -13 dBm. The amplifier provides an amplified output signal with constant gain and phase by

adding approximately 25 dB of distortion cancellation on the output signal. Continuously comparing active

paths with passive references, and correcting for small variations through RF feedback control maintain

constant gain and phase. The amplifier module is comprised of:

Preamplifiers

Main Amplifiers

Error Amplifier

Two feed-forward loops with phase–shift and gain controls

DC/DC power regulator

Alarm monitoring, control and LED display lamp

3

Page 7

MAF800-100S Block Diagram

4

Page 8

The main amplifier employs class AB amplification for maximum efficiency. The error amplifier and feed

forward loops are employed to correct signal non-linearity introduced by the class AB main amplifier. The

error amplifier operates in class AB mode. The RF input signals are amplified by a preamp and coupled to

an attenuator and phase shifted by 180 degrees and amplified in the pre-main amplifier. The output from

the pre-main amplifier is fed to the class AB main amplifier. The output from the main amplifier is

typically 100 Watts.

The signal output from the main amplifier is sampled using a coupler. The sample signal is combined with

the main input signal and input to the second feed-forward loop. The error signal is attenuated, phase

shifted 180 degrees, then passed to the error amplifier where it is amplified to a level identical to the

sampled output from the main amplifier. The output from the error amplifier is then coupled back and

added to the output from the main amplifier. The control loops continuously make adjustments to cancel

out any distortion in the final output signals.

The primary function of the 1st loop is to provide an error signal for the 2nd loop. The primary function of

the 2nd loop is to amplify the error signal to cancel out spurious products developed in the main amplifier.

The input signal is amplified by a pre-amplifier and fed to a coupler and delay line. The signal from the

coupler is fed to the attenuator and phase shifter in the 1st loop. The 1st loop control section phase shifts the

main input signals by 180 degrees and constantly monitors the output for correct phase and gain.

The 2nd loop control section obtains a sample of the distortion added to the output signals by the main

amplifiers, and then phase shifts the signals by 180 degrees then feeds the signal to the error amplifier.

There it is amplified to the same power level as the input sample and coupled on to the main output signal.

The final output is monitored by the 2nd loop and adjusted to ensure that the signal distortion and IMD on

the final output is cancelled.

3.6 Main Amplifier

The input and output of the amplifier employ two-stage, class AB amplifiers, which provide approximately

25 dB of gain in the 25 MHz frequency band, from 869 MHz to 894 MHz. The amplifier operates on +27

Vdc, and is mounted directly on a heat sink, which is temperature monitored by a thermal sensor. If the

heat sink temperature exceeds 85° C. a high temperature fault occurs. The alarm logic controls the

transistor bias voltage; this shuts down the amplifier if bias voltage is out of range.

5

Page 9

3.7 Error Amplifier

The primary function of the error amplifier is to sample and amplify the signal distortion level generated by

the main amplifier. The error amplifier cancels out the distortion and IMD when the error signal is coupled

onto the main signal at the amplifier output. The matching signal levels from the error amplifier are

injected back into the main amplifier output reducing any distortion and cancellation of IMD. The error

amplifier is a balanced multistage class AB amplifier. It has 75 dB of gain, and produces up to 65 Watt

output. The amplifier operates on +27 Vdc and is mounted directly on a heat sink.

3.8 Amplifier Status Monitoring

In the main and error amplifier stages, all normal variations are automatically compensated for by the feedforward loop control. When large variations occur beyond the adjustment range of the loop control, a loop

fault will occur. The amplifier will be disabled, and the LED will be RED. The alarms will be sent via the

21-pin connector on the rear of the module to the sub-rack summary alarm board.

3.9 Amplifier Module Cooling

Each amplifier module has its own heat sinks. All main amplifier components are mounted to the heat sink.

Forced air-cooling is used to pull air across the heat sinks for operations in the sub-rack. The fans for this

forced air-cooling is located in the sub-rack assembly. The fans are mounted in the rear of the sub-rack

assembly. Air is pulled from the front of the amplifier and exhausted out of the back of the rack.

3.10 DC Power Distribution

Primary Vdc for the system is provided by the host system to the sub-rack assembly. The sub-rack supplies

the +27 Vdc to the amplifier module. The +27 Vdc is supplied directly through the sub-rack power

splitter/combiner board. The amplifier module has a DC/DC converter that converts the +27 Vdc to +12

Vd c , + 5Vd c,

Section 4

4.1 Introduction

This section contains operating instructions for the MAF800-100S Cellular Amplifier System.

4.2 Function of Amplifier Module Controls

Primary +27 Vdc power for the MAF800-100S amplifiers is applied via the 50-amp circuit breaker on the

front panel of the amplifier. A reset switch is located below the LED on the front panel. This switch resets

the amplifier module in the event of a minor alarm. The front panel LED is a multi color LED that changes

from GREEN in normal operation to RED during major or AMBER during minor alarms.

Operating Instructions

6

Page 10

4.3 Alarm Definition

ALARM CATEGORY LED MCPA

MODULE

Over PWR Critical Red Disable High MCPA module output power

Over PWR Critical Red Disable High Input power > - 4 dBm

High TEMP Minor Red Enable Low High temperature detected

High TEMP Critical Red Disable High High temperature detected for longer

VSWR Minor Red Enable Low Reflected power detected at output >7.5

VSWR Critical Red Disable High Reflected power detected at output >26

DC Fail Minor Red Enable Low One of the internal DC voltages

DC Fail Critical Red Disable High Voltage out of range for longer than

DC Fail

(Over

Voltage)

DC Fail

(Over

Voltage)

Loop Fail Minor Red Enabled Low Loop failure detected

Loop Fail Critical Red Disable High Loop failure detected longer than two

Minor Red Disable High +27 Vdc input >28 V detected

Critical Red Disable High +27 Vdc input >28 V. for longer than

MCPA

DISABLE

SIGNAL

CONDITION

> 150 Watts

than two minutes

Watts

Watts

dropped below or exceeded the safe

threshold level

approximately two minutes.

one second after initial detection of

Vd c inpu t > 2 8 V.

minutes.

7

Page 11

4.4 Initial Start-Up and Operating Procedures

To perform initial start-up, proceed as follows:

1. Carefully remove MAF800-100S MCPA series from the shipping carton

2. Place MAF800-100S MCPA into the sub-rack assembly

Caution

When placing MAF800-100S MCPA into sub-rack gently slide MCPA into matting connector. Damage

can occur to matting connector due to abrupt handling of the unit.

Note

All RF connections to the unit will be of 50 ohm. Any changes in impedance will cause severe mismatch

and VSWR to occur. Do not operate the amplifier without a load attached to the output of the sub-rack.

3. Connect all RF input and output cables to the sub-rack.

4. Ensure that source RF power is un-keyed or turned off.

5. Connect +27 Vdc power source to sub-rack

6. Turn ON/OFF switch on the front panel to the ON position.

7. Ensure sub-rack fans are working.

8. Normalize amplifier for 1 minute in ON position. Monitor for alarms on front panel.

9. Before turning on source RF power, verify RF level is set to minimum. High source input level can

damage amplifier.

10. Turn-on 1 channel from source power. Set power level.

Note

•

If operating MAF800-100S MCPA without sub-rack, individual fans, RF attenuation, and

D-Sub connector needs to be assembled for operation. Please contact your representative at

Paradigm Wireless Systems for information.

•

During initial operation of MAF800-100S components of the unit may drift. It is

recommended that a recheck of power levels be done after a 24 hr. period of operation

Section 5

5.1

Introduction

This section contains unpacking, inspection, installation instructions and recommendations for the

MAF800-100S MCPA. It is important that the user perform the following tasks correctly and in good faith.

1. Carefully read all materials in this section prior to equipment unpacking or installation.

2. Also read and review the operating instructions in Section 4 prior to installing the amplifier.

Installation Instructions

8

Page 12

3. If applicable, carefully review the Federal Communications Commission (FCC) rules and

regulation as they apply to your installation.

5.2

El ec trical S er vice Recommendations

Paradigm Wireless Systems recommends that:

•

Proper AC line conditioning and surge suppression be provided on the primary AC input to the +27

Vdc source.

•

All electrical service should be installed in accordance with the National Electrical Code, any

applicable state or local codes, and good engineering practice.

•

Grounding of all equipment should be in accordance to Bellcore standards.

•

Circuit breakers should be thermal type, capable of handling the anticipated in rush current.

5.3 Air Conditioning

Each MAF800-100S MCPA will generate approximately 1900 BTU o f heat. When using more tha n one

amplifier it is recommended that a thermal analysis be performed. Ensuring proper cooling will extend the

Mean Time Before Failure of the unit.

5.3

Unpacking and Inspection

This equipment (as applicable) has been operated, tested, and calibrated at the factory. Carefully open and

remove the MAF800-100S amplifier from the shipping container. Retain all packing material and shipping

container in the event that the unit must be returned to the factory. Please perform the following steps:

9

Page 13

CAUTION

Exercise care in handling equipment during inspection to prevent damage caused by rough or careless

handling.

1. Vis ually inspect the MAF800-100S MCPA for damage that may have occurred duri ng ship ment.

2. Check for evidence of water damage, bent or warped chassis, loose screws, nuts or extraneous

packing material in the connector(s).

CAUTION

Before applying power, make sure that all connectors to the MAF800-100S are secure. Make sure that the

input and output of the amplifier is terminated to 50 ohms. Do not operate the system without a load

attached. Excessive input power may damage the equipment.

If possible, inspect the equipment in the presence of the delivery person.

If the equipment is damaged:

•

The carrier is your first recourse.

•

A claim should be filed with the carrier once the extent of damage is assessed. Careful, immediate

inspection is important if the carrier is suspect of damage.

If the equipment is damaged and must be returned to the factory:

•

Contact your Paradigm Wireless Systems representative.

•

Paradigm Wireless Systems may not accept returns without an RMA.

5.4

Installation Instructions

Model MAF800-100S MCPA is designed for use in a Cellular Radio Base Station. The host enclosure must

permit access to the sub-rack for DC power, RF and alarm cables as well as proper ventilation of sub-rack

the assembly.

WARNING

Verify that all circuit breakers on the MAF800-100S MCPA are in the OFF position before installation in

sub-rack. Turn OFF all external power to the sub-rack before installing MAF800-100S MCPA

1. Install sub-rack into host radio base station and secure it into place using #10 32x1/2 Phillips

screws and #10 flat washers.

2. Connect +27 Vdc using #6 gauge wire. 1- Positive (red) 1- Return/Ground (black).

3. Connect RF IN cable to sub-rack

10

Page 14

4. Connect RF OUT cable to sub-rack.

5. Connect external ALARM interface to external summary alarm board in host radio base station.

6. Before installing the MAF800-100S MCPA into the sub-rack, inspect the 21-pin-D-sub combo

connector on the rear of each amplifier. Verify that all pins are straight, no pins are recessed, and

that the alignment shield is not bent.

WARNING

Do not slam amplifiers into the sub-rack. Forcing the amplifier into the sub-rack at too fast a rate may

cause pins on the 21-pin-D-sub connector of the amplifier to become recessed or broken.

7. Continue installing MAF800-100S amplifiers into sub-rack.

8. Apply +27 Vdc power to sub-rack. Measure with VOM +27 Vdc ± 1.0 Vdc. If the input voltage is

above or below the limits. Check DC power rectifier system.

9. Verify cooling fans on sub-rack is operational.

10. Refer to Section 4 for initial turn-on and checkout procedure.

Section 6

6.1

Introduction

This section contains periodic maintenance and performance test procedures for Paradigm Wireless

Systems MAF800-100S Multi-Carrier Power Amplifier.

Maintenance

NOTE

Check your sales order and equipment warranty before attempting to service or repair the unit. Do not

break the seals on equipment under warranty or the warranty will be voided. Do not return equipment for

warranty or repair service until proper shipping instructions are received from the factory.

6.2

Periodic Maint en an ce

Periodic maintenance is recommended. Table 6-1 lists the intervals at which the task should be performed.

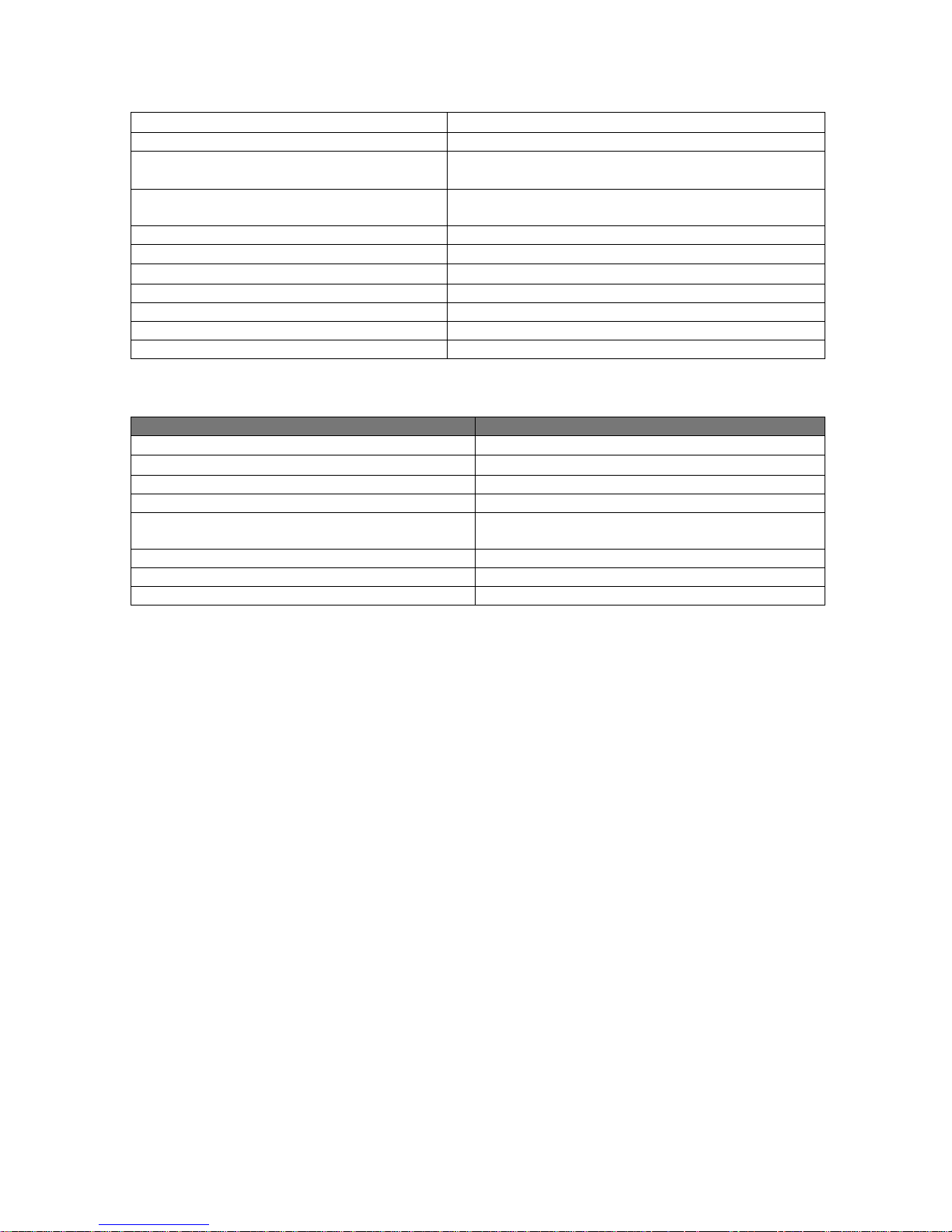

Table 6-1 Periodic Maintenance

Task Interval Action

Inspection

Cables and Connectors 3 months

Inspect signal and power cables for frayed

insulation.

11

Page 15

Check RF connectors ensure

connectors are tight

Performance Tests 12 months

Clean Fans/Heat Sinks 3 months

6.3

Test Equipment Required for Test

Test equipment required to test the amplifier is listed in table 6-2. Equivalent test equipment may be

substituted for any item. Use of a thermistor type power meter is recommended for optimum results.

Annual performance test as outlined in

paragraph 6.4

Inspect for debris. Remove dust with soft

cloth, brush or vacuum cleaner.

NOTE

All RF test equipment must be calibrated and within the calibration date. Any deviation from the nominal

attenuation must be accounted for and factored into all output readings.

12

Page 16

Table 6-2 Test Equipment Required

Nomenclature Manufacturer Model

Network Analyzer Agilent 8753 ET

Spectrum Analyzer Agilent 8560E

Power Meter Agilent E4418B

Power Meter/Sensor Agilent 437B / 8481A

Signal Generator/ESG Agilent E4432B

Directional Coupler Agilent 778D

Attenuator Weinschel Corp 53-30-34

Attenuator Narda 766-20

6.4

Performance Test

Performance test should be performed every 12 months to ensure that the amplifier meets the operational

specifications.

NOTE

The frequencies used in this test are typically within the operating band of 869 MHz to 894 MHz. Select

evenly spaced F1, F2, F3, and F4 frequencies that cover the instantaneous bandwidth of your system.

Figure 6-2

13

Page 17

6.5

Amplifier Performance Test

To perform this test proceed as follows:

Connect test equipment as shown in figure 6-2.

WARNING

DO NOT APPLY ANY RF AT THIS TIME

6.6

Amplifier Spurious Emission Test

Apply +27 Vdc from the power source. Apply 4 RF input signals (CDMA, TDMA, GSM, EDGE) equal to

the total composite operating output power. Setup Spectrum Analyzer for Center Frequency (User

Defined), Start Frequency (User Defined), Stop Frequency (User Defined MHz) Span (User Defined MHz)

RES BW (100 kHz) Video BW (100 kHz) Measure IMD and record data on Table 6-3.

6.7 Gain Test

Disconnect spectrum analyzer from the MAF800-100S. Connect Network Analyzer to MCPA.

Set Network Analyzer as follows:

a. Normalize Network Analyzer for gain and return loss.

b. Set start frequency to 860 MHz. Set stop frequency to 900 MHz. Setup Network Analyzer for 2-

chan ne l mea s ureme n t. Se t ma rke r s to us e r op e ra ting f r e q uency band .

c. Adjust input power of Network Analyzer to measure 50 watts on the Power Meter.

d. Measure and record amplifier gain on Table 6-3.

e. Measure Gain Flatness and record on table 6-3.

f. With Network Analyzer setup for 2-channel operation measure return loss using S11 data Record on.

Table 6-3.

14

Page 18

Table 6-3 MAF800-100S MCPA Test Data Sheet

Date_________________________

Module S/N___________________

TEST CONDITIONS:

Load and Source Impedance: 50 Ohms

VSWR: < 1.2:1

Supply Vol tage: +27 Vdc

Temperature: Room Temperature

TEST SPECIFICATION MIN MAX DATA

Spurious Emission Voltage = +27 Vdc

()

out

P

RF Gain Voltage = +27 Vdc

P

Gain Flatness Voltage = +27 Vdc

P

Input Return Loss Vol tage = +27 Vdc

P

=

()

out

=

()

out

=

()

out

=

57 dB

-15 dB

-57 dBc

±

0.5 dB

PASS FAIL

Tested By: _____________________

15

Page 19

6.1 Field Repl ac em ent of the MAF8 00-100S

The MAF800-100S MCPA can be replaced in the field on the site by a qualified technician with experience

maintaining RF power amplifiers and radio equipment.

To replace a power amplifier module, proceed as follows:

1. Set ON/OFF switch on front of amplifier to OFF position.

2. Loosen the thumbscrews that secure the amplifier to the sub-rack.

3. Slide amplifier out of sub-rack.

CAUTION

When removing amplifier from the sub-rack, it is important to support the amplifier

such that the rear of the module does not suddenly drop when the guide rail

disengages from the rack. A drop such as this could damage the rear of the 21-pin-Dsub connector.

4. Replacement of module is done in the reverse order of removal steps 1-3.

16

Page 20

Section 7

Troubleshooting Shooting

7.1 Introduction

This section contains a list of problems that may occur. Paradigm Wireless Systems has suggested

corrective action that may correct the problem. If the suggested corrective action does not eliminate the

problem, please contact your Paradigm Wireless Systems representative for further instructions.

NOTE

Check your sales order and equipment warranty before attempting to service or repair the unit. Do not

break seals on equipment under warranty or the warranty will be voided. Do not return equipment for

warranty or repair service until proper shipping instructions are received from the factory.

7.2 Troubleshooting

Refer to Table 7-1 for troubleshooting suggestions:

Symptom Suggested Action

Inoperative 1.Check for proper power supply voltage.

2.Verify all RF connections.

3.Contact your Paradigm Wireless Systems representative.

Over Heating Shut Down 1.Check for operation of fans on sub-rack assembly.

2.Check for debris in heat sink

3.Check air conditioning/venting unit for proper operation.

4.Contact your Paradigm Wireless Systems representative.

Over Power Shut Down 1.Verify host system radio output power level.

2.Verify sub-rack input attenuation.

3.Contact your Paradigm Wireless Systems representative.

7.3 Return for Ser vice Pr ocedures

When returning products to Paradigm Wireless Systems, Inc. the following procedures will ensure

response.

7.3. 1 Obtaining an RMA (Ret urn Mat er ial Authorization)

An RMA number must be obtained prior to returning equipment to the factory for

service. Please contact your Paradigm Wireless Systems representative to obtain this

number. Failure to obtain this number may result in delays in receiving repair service.

7.3.2 Repackaging for Shipment

To ensure safe shipment of the amplifier, it is recommended that the packaged designed for the amplifier is

used. The original packaging material is reusable.

17

Loading...

Loading...