Page 1

Optic Touch Panel

A

TY-TP42P8-S

TY-TP50P8-S

TY-TPEN6 (Option)

ORDER NO. ITD0510062CE

D18

Specifications

Power Source

Voltage DC + 5V ± 10 %

Electric current DC + 5V Max400 m

Supplysystem from USB Bus Power (DC + 5V Max500 mA)

Touch Panel

Detection system Infrared obstruction detection system

Panel window (W × H) 945.2 mm × 531.2 mm (37.2” × 20.9”)

(TY-TP42P8-S)

Detection range (W × H) 920 mm × 516 mm (36.2” × 20.3”)

(TY-TP42P8-S)

Effective detection range Detection range + 1.0 mm (0.04”) at the top, bottom, left and right

Operating modes Detection operation at input point, during initial movement and at end point *1

Resolution (W × H) 1,841 × 1,033 *1 (TY-TP42P8-S) 2,209 × 1,241 *1 (TY-TP50P8-S)

Detection pitch 2.0 mm × 2.0 mm (0.08” × 0.08”)

Output system Coordinate output

Number of optic elements (W × H) 231 × 130 elements (TY-TP42P8-S) 277 × 156 elements (TY-TP50P8-S)

Optic element pitch (W × H) 4.0 mm × 4.0 mm (0.16” × 0.16”)

1129.2 mm × 645.2 mm (44.4” × 25.4”)

(TY-TP50P8-S)

1104 mm × 620 mm (43.4” × 24.4”)

(TY-TP50P8-S)

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

y

t

t

A

TY-TP42P8-S / TY-TP50P8-S

Minimum stylus size (W × H) 6.0 mm × 6.0 mm (0.24” × 0.24”)

Scan speed Initial touch: 30 ms/frame max.; during movement: 8 ms/frame max.

Touch pen Infrared system

USB Interface (USB 1.1) Terminal No. and Signal name

(TYPE B)

No.1 Vcc No.2 -DATA

No.3 +DATA No.4 GND

Temperature When operating 0°C (32°F) to 50°C (122°F) (temperature gradient 25°C (77°F)/hrmax.) *2

When not operating: -20°C (-4°F) to 60° (140°F) temperature gradient 25°C (77°F)/hr max.

Humidit

Resistance to extraneous ligh

Panel form Flat panel (Flat type)

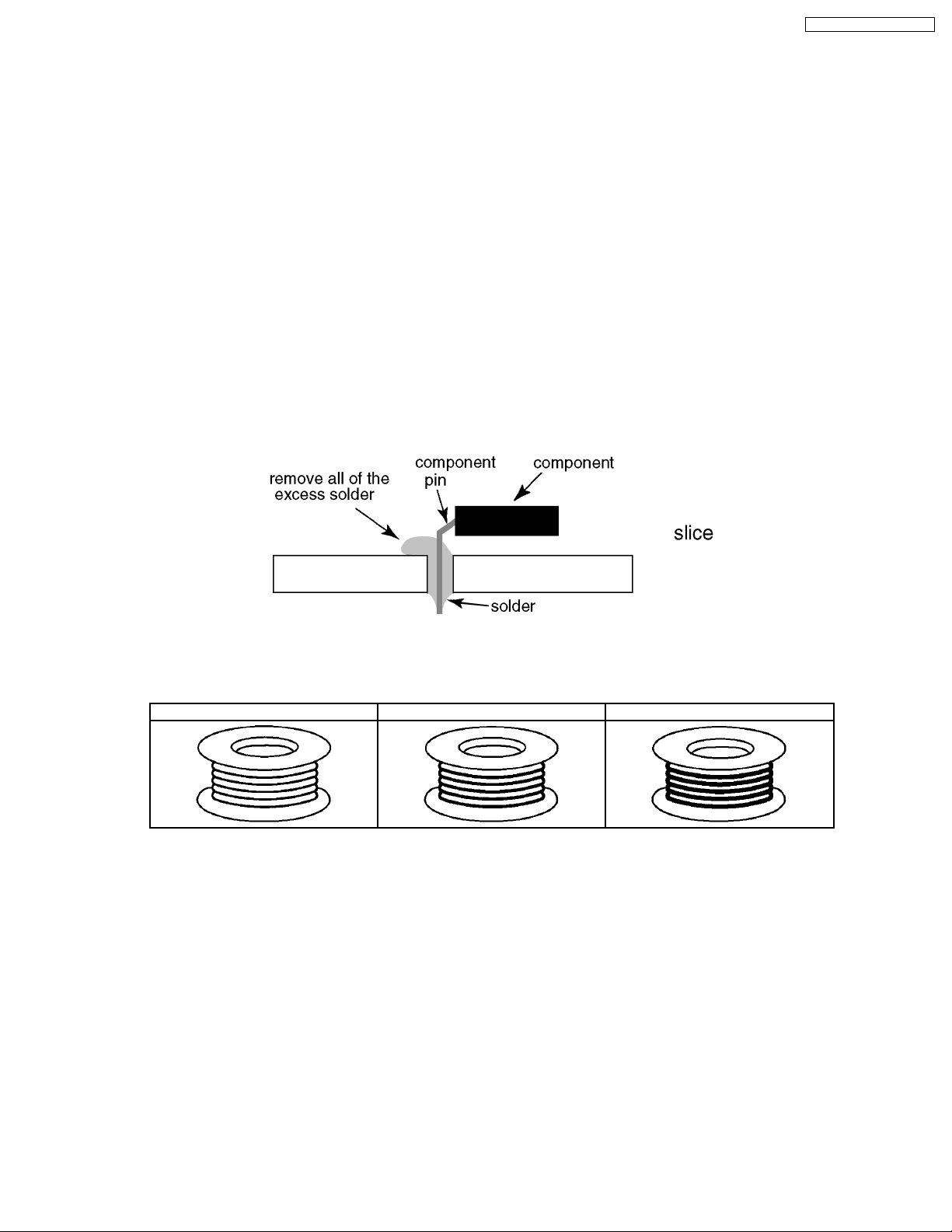

External dimensions (W×H×T) 1,073 mm × 659 mm × 69 mm

Weigh

Extruded material

When operating: 20% to 85% (must be no condensation) *2

When not operating: 10% to 95%

Lateral light: 2,000 lux MIN +20% (angle of incidence: 20°)

Frontal light: 10,000 lux MIN +20% (angle of incidence: 90°)

1,257 mm × 773 mm × 69 mm

(42.2” × 25.9” × 2.7”)

(Excluding mounting brackets)

(TY-TP42P8-S)

5.0 kg (11 lbs) Excluding mounting brackets

(TY-TP42P8-S)

luminum

(49.5” × 30.4” × 2.7”)

(Excluding mounting brackets)

(TY-TP50P8-S)

5.8 kg (12.7 lbs) Excluding mounting brackets

(TY-TP50P8-S)

Notes:

*1*2When it is used with exclusive driver software.

This applies to the touch panel alone. When the panel is attached to a device such as a PDP, follow the environmental conditions for the

device being used.

CONTENTS

Page Page

1 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

2 About lead free solder (PbF)

3 External dimensions

4 Setup for Touch Panel

5 Touch Pen (Option)

6 Printed Circuit Board Structure

6.1. TY-TP42P8-S

6.2. TY-TP50P8-S

7 Trouble shooting

7.1. Checking procedures

7.2. Test Program

8 Conductor Views

8.1. X-Photo1, X-Photo2, Y-Photo1 Board (42inch)

8.2. X-Photo1, X-Photo2, X-Photo3, Y-Photo1, Y-Photo2 Board

(50inch)

8.3. X-Photo3 Board (42inch)

8.4. X-Photo4 Board (50inch)

8.5. Y-Photo2 Board (42inch)

8.6. X-LED1, X-LED2, Y-LED1 Board (42inch)

4

5

6

7

21

22

22

23

24

24

26

35

35

36

37

38

39

40

8.7. X-LED1, X-LED2, X-LED3, Y-LED1, Y-LED2 Board

(50inch)

8.8. X-LED3 Board (42inch)

8.9. X-LED4 Board (50inch)

8.10. Y-LED2 Board (42inch)

8.11. Controller Board (42inch)

8.12. Controller Board (50inch)

8.13. Pen-Receive Board (42inch)

8.14. Pen-Receive Board (50inch)

9 Block Diagram

9.1. Overall Block Diagram (TY-TP42P8-S)

9.2. Overall Block Diagram (TY-TP50P8-S)

9.3. Detail Block Diagram (1 of 3)

9.4. Detail Block Diagram (2 of 3)

9.5. Detail Block Diagram (3 of 3)

10 Schematic Diagram

10.1. Controller Board Schematic Diagram

10.2. X-Photo 1 Board Schematic Diagram

10.3. X-Photo 2 Board Schematic Diagram

10.4. X-Photo 3 Board Schematic Diagram

41

42

43

44

45

46

47

48

49

49

50

51

52

53

55

55

56

57

58

2

Page 3

10.5. X-Photo 4 Board Schematic Diagram (TY-TP50P8-S) 59

10.6. X-LED 1 Board and Pen Receive Board Schematic

Diagram

10.7. X-LED 2 Board Board Schematic Diagram

10.8. X-LED 3 Board Board Schematic Diagram

60

61

62

10.9. X-LED 4 Board Board Schematic Diagram (TY-TP50P8-S)

10.10. Y-Photo 1 Board Schematic Diagram

10.11. Y-Photo 2 Board Schematic Diagram

10.12. Y-LED 1 Board Schematic Diagram

63

64

65

66

TY-TP42P8-S / TY-TP50P8-S

10.13. Y-LED 2 Board Schematic Diagram 67

11 Exploded View

11.1. TY-TP42P8-S

11.2. TY-TP50P8-S

12 Replacement Parts List

12.1. Replacement Parts List Notes

12.2. TY-TP42P8-S Mechanical Replacement parts List

12.3. TY-TP42P8-S Electrical Replacement parts List

12.4. TY-TP50P8-S Mechanical Replacement parts List

12.5. TY-TP50P8-S Electrical Replacement parts List

69

69

71

73

73

74

75

84

85

3

Page 4

TY-TP42P8-S / TY-TP50P8-S

1 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

Page 5

TY-TP42P8-S / TY-TP50P8-S

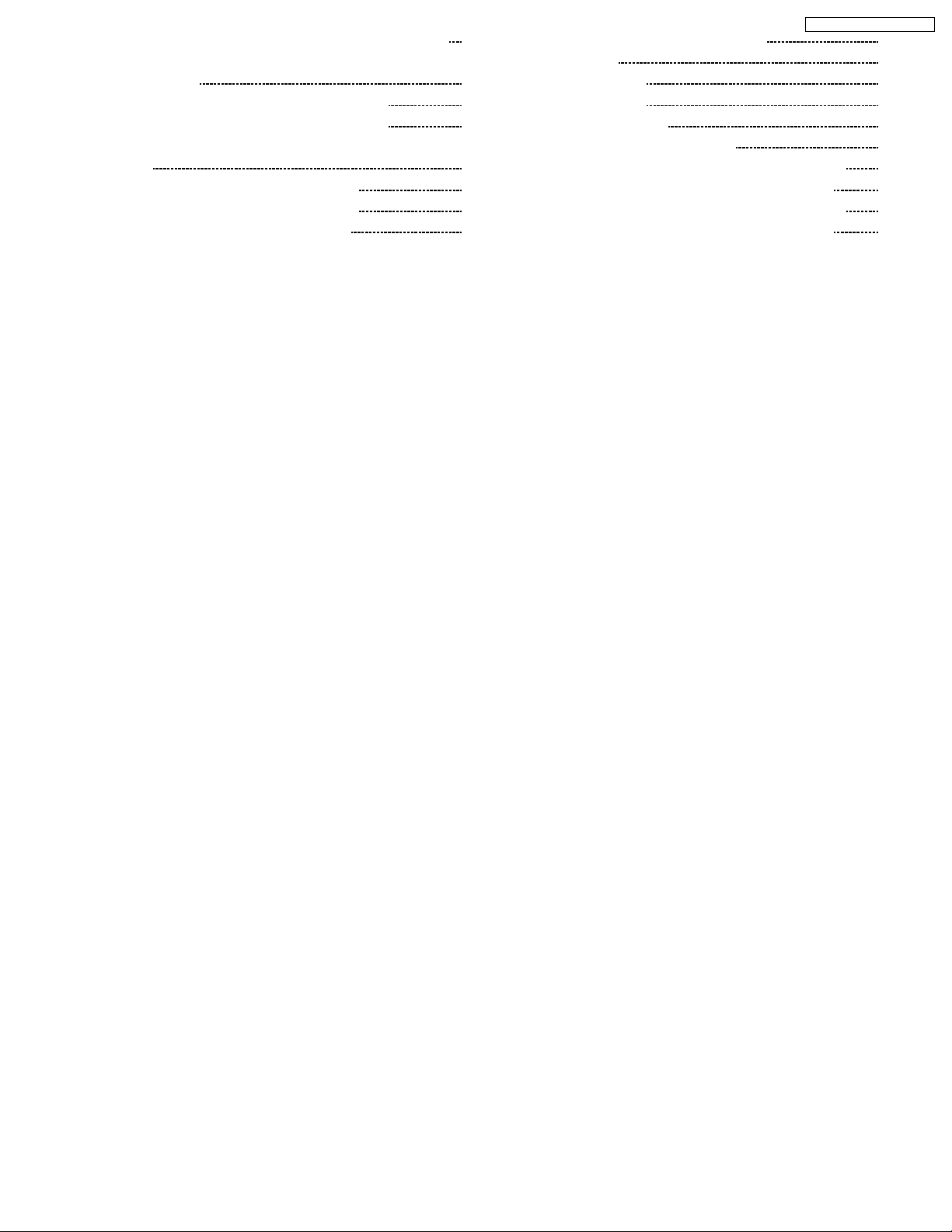

2 About lead free solder (PbF)

Note:

Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it´s manufacture due to environmental conservation issues. For service and repair work, we´d

suggest the use of Pb free solder as well, although Pb solder may be used.

Caution

· Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

· Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

· After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

0.3mm x 100g 0.6mm x 100g 1.0mm x 100g

5

Page 6

TY-TP42P8-S / TY-TP50P8-S

3 External dimensions

TY-TP42P8-S

TY-TP50P8-S

6

Page 7

TY-TP42P8-S / TY-TP50P8-S

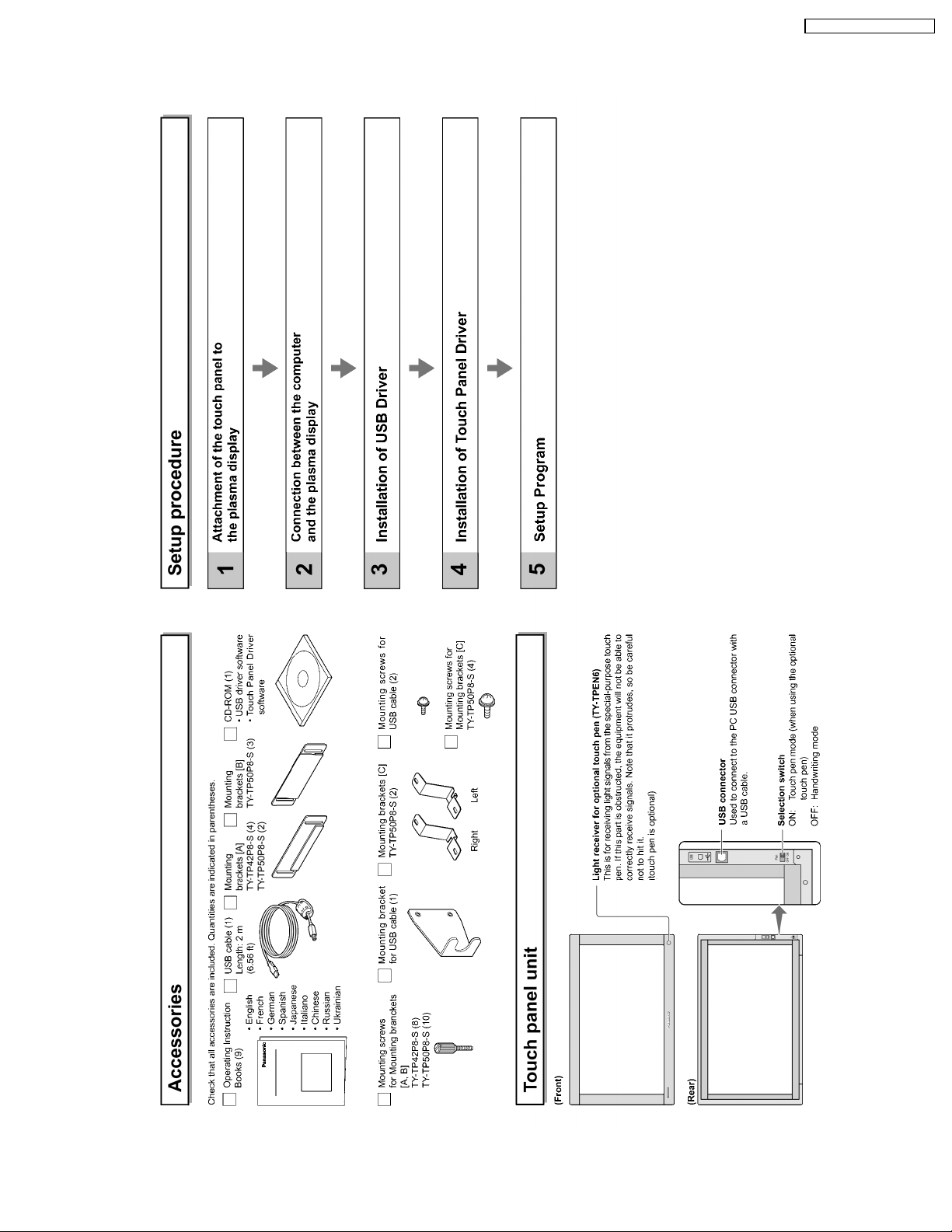

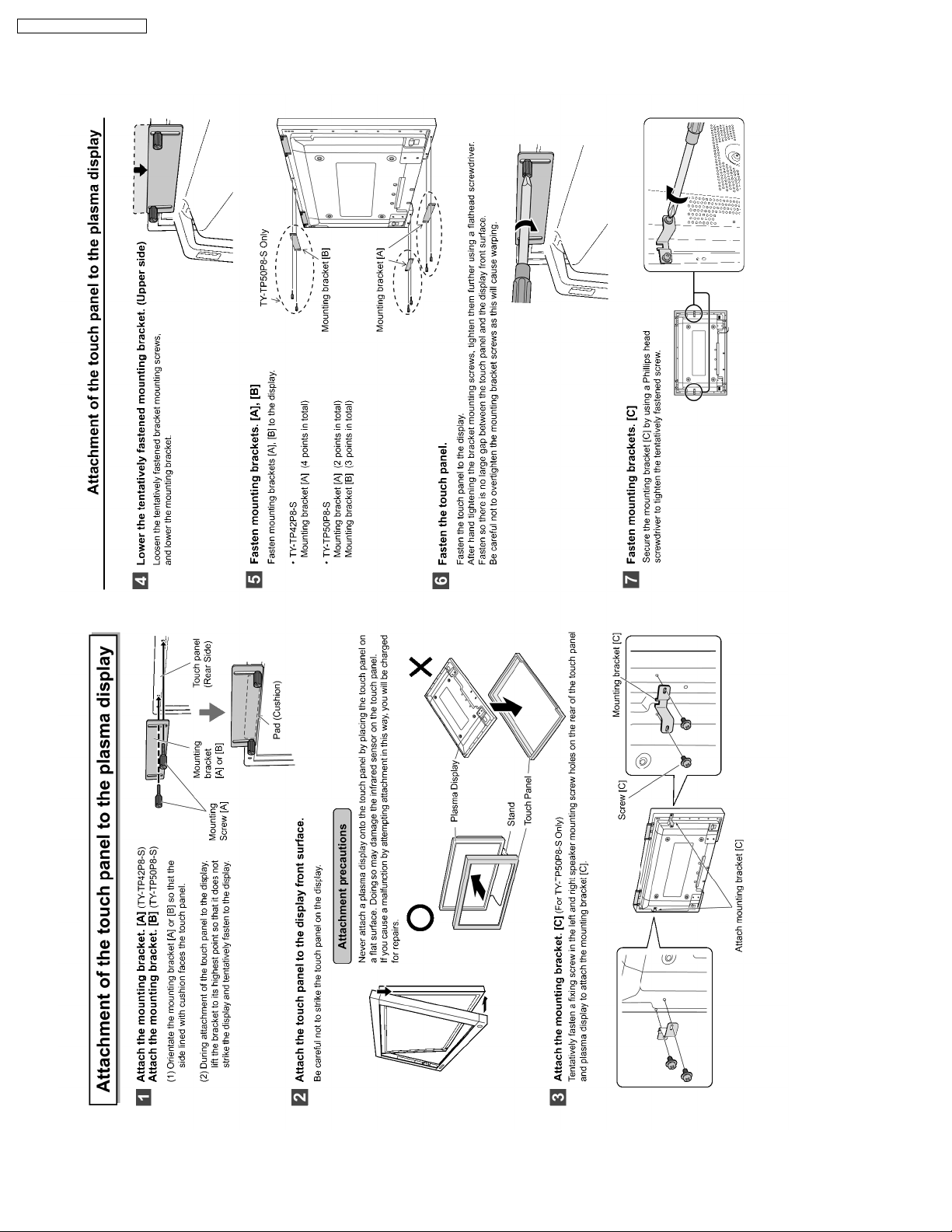

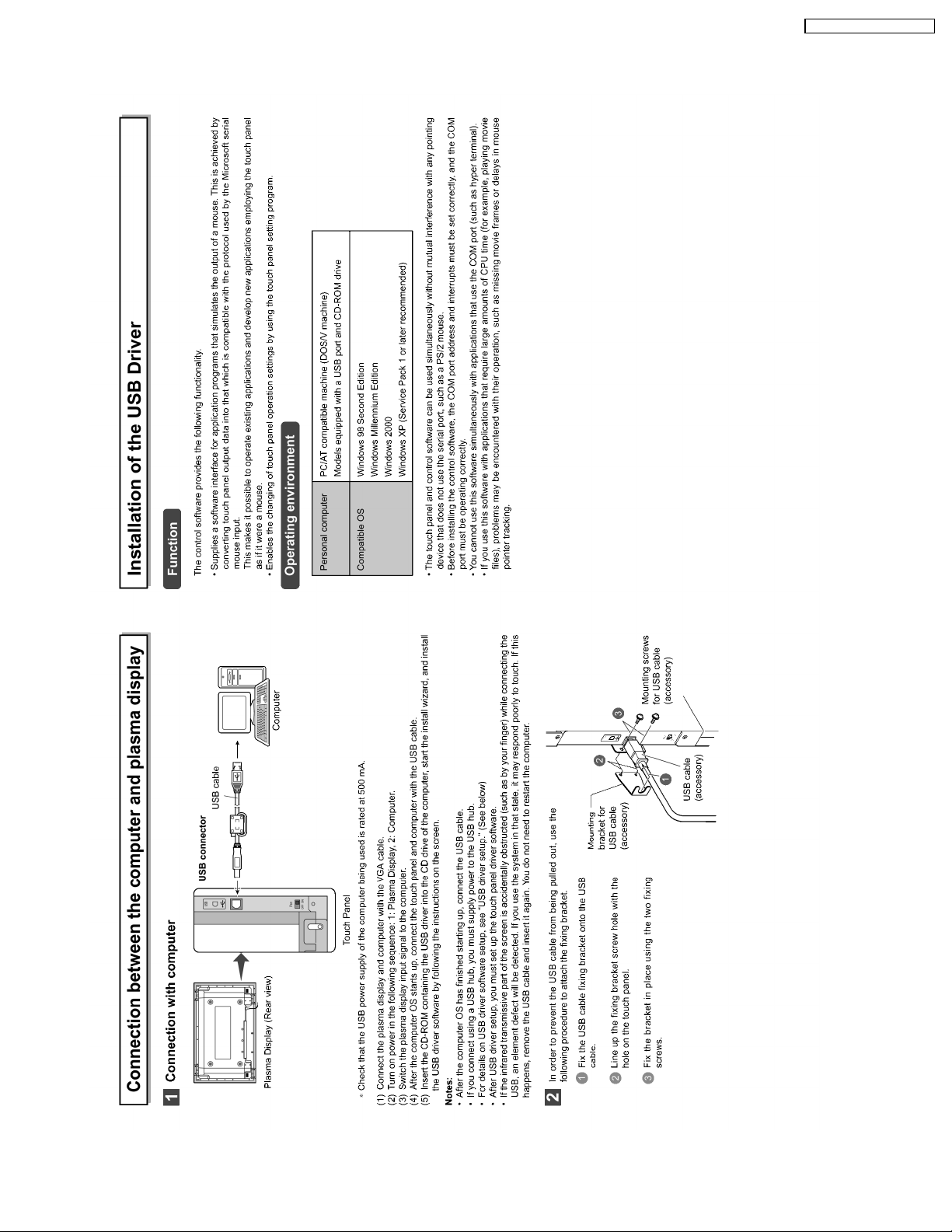

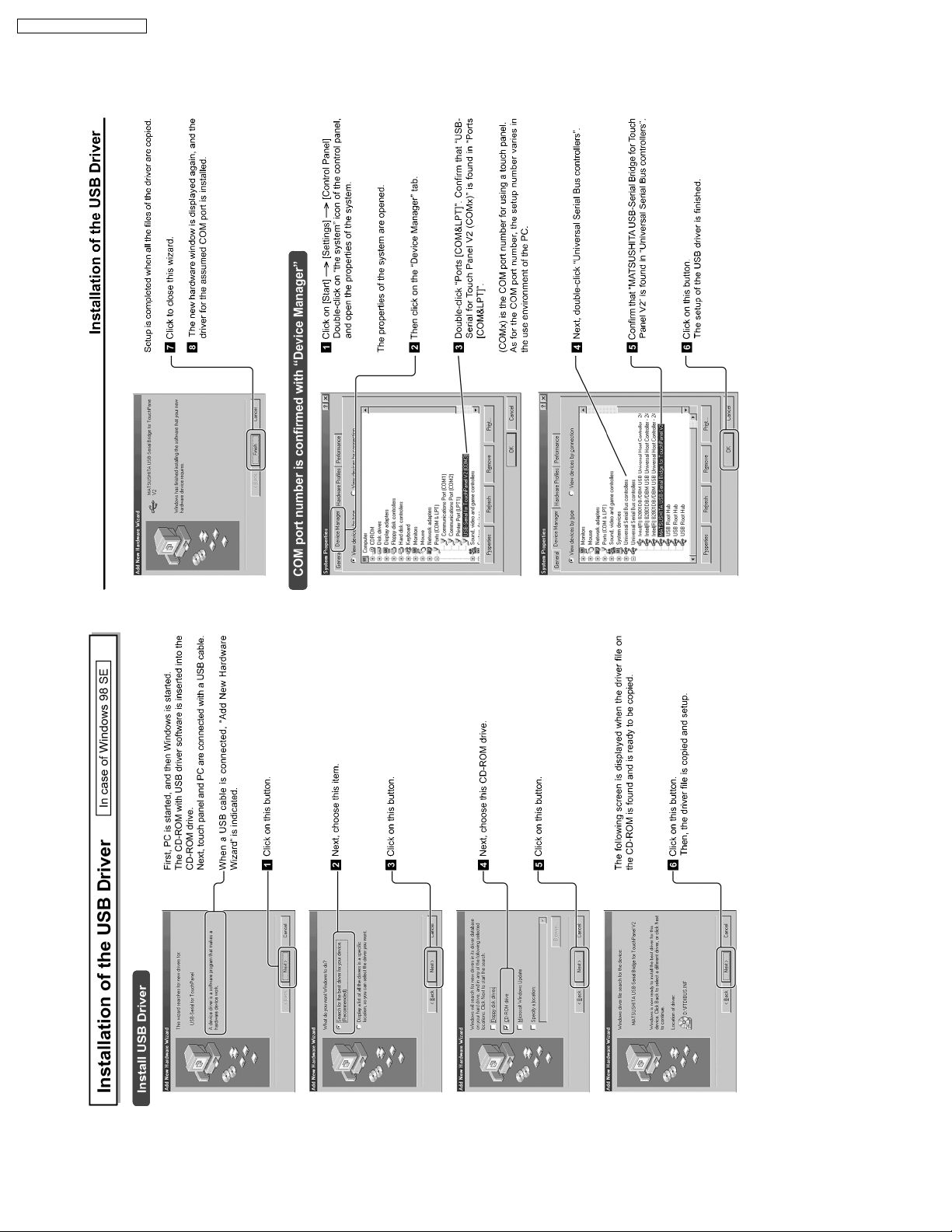

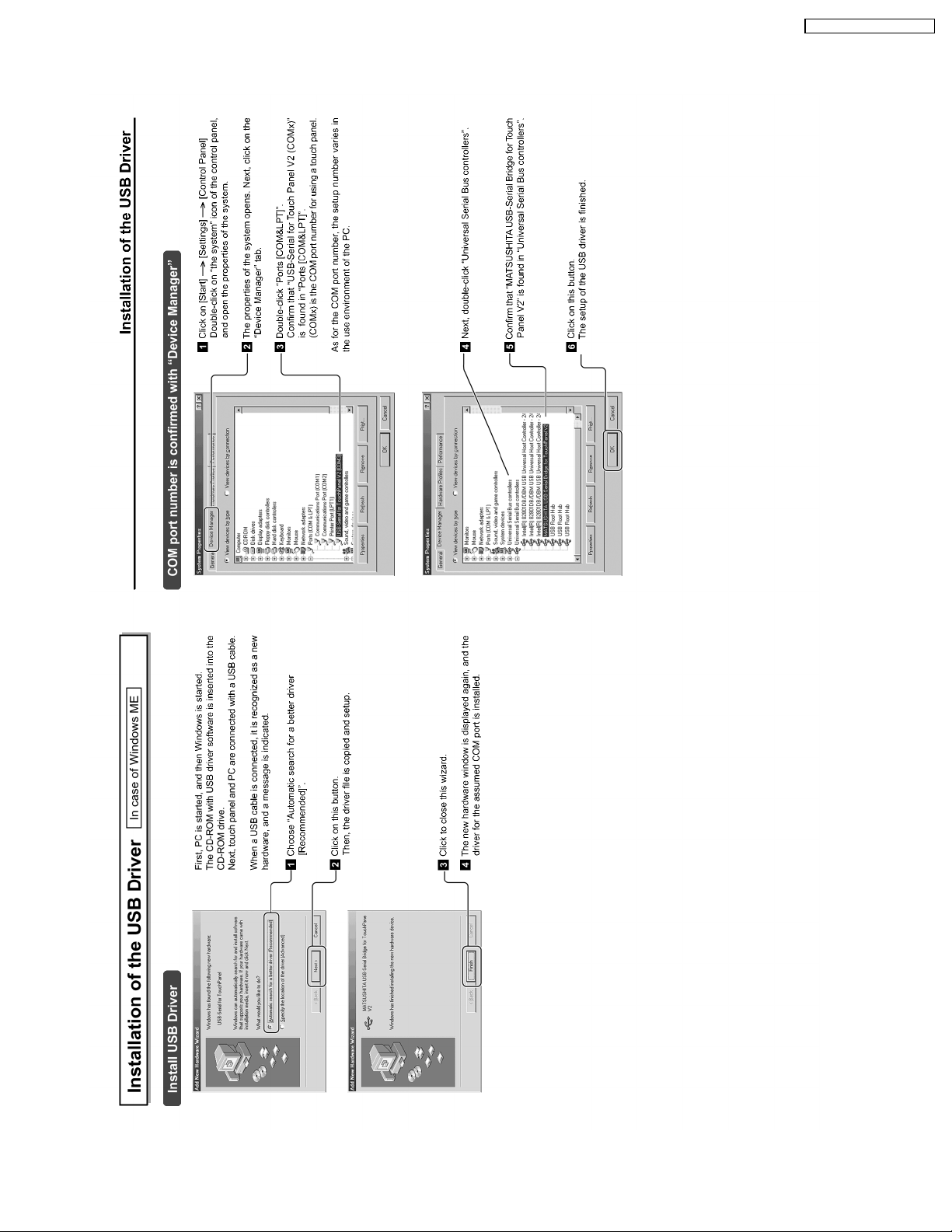

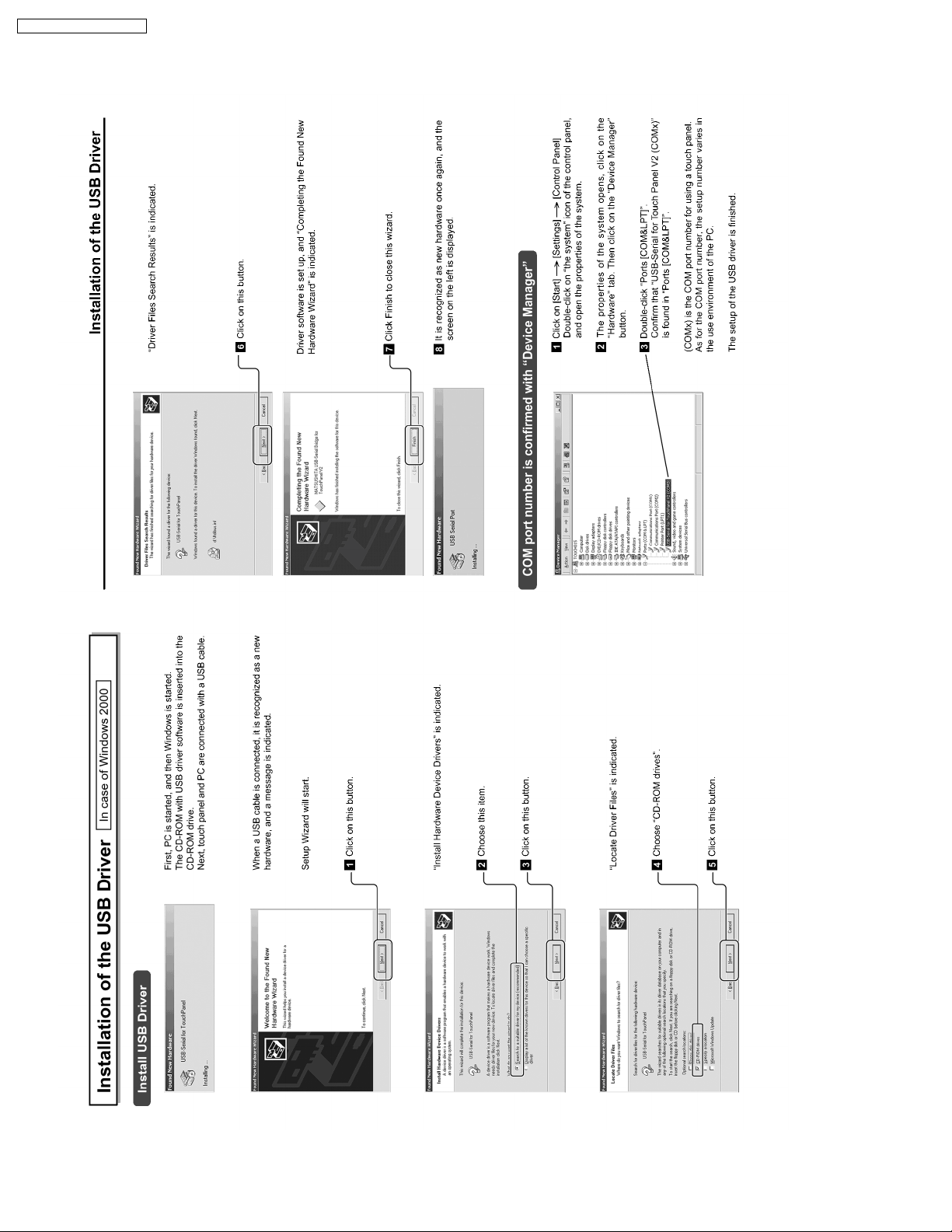

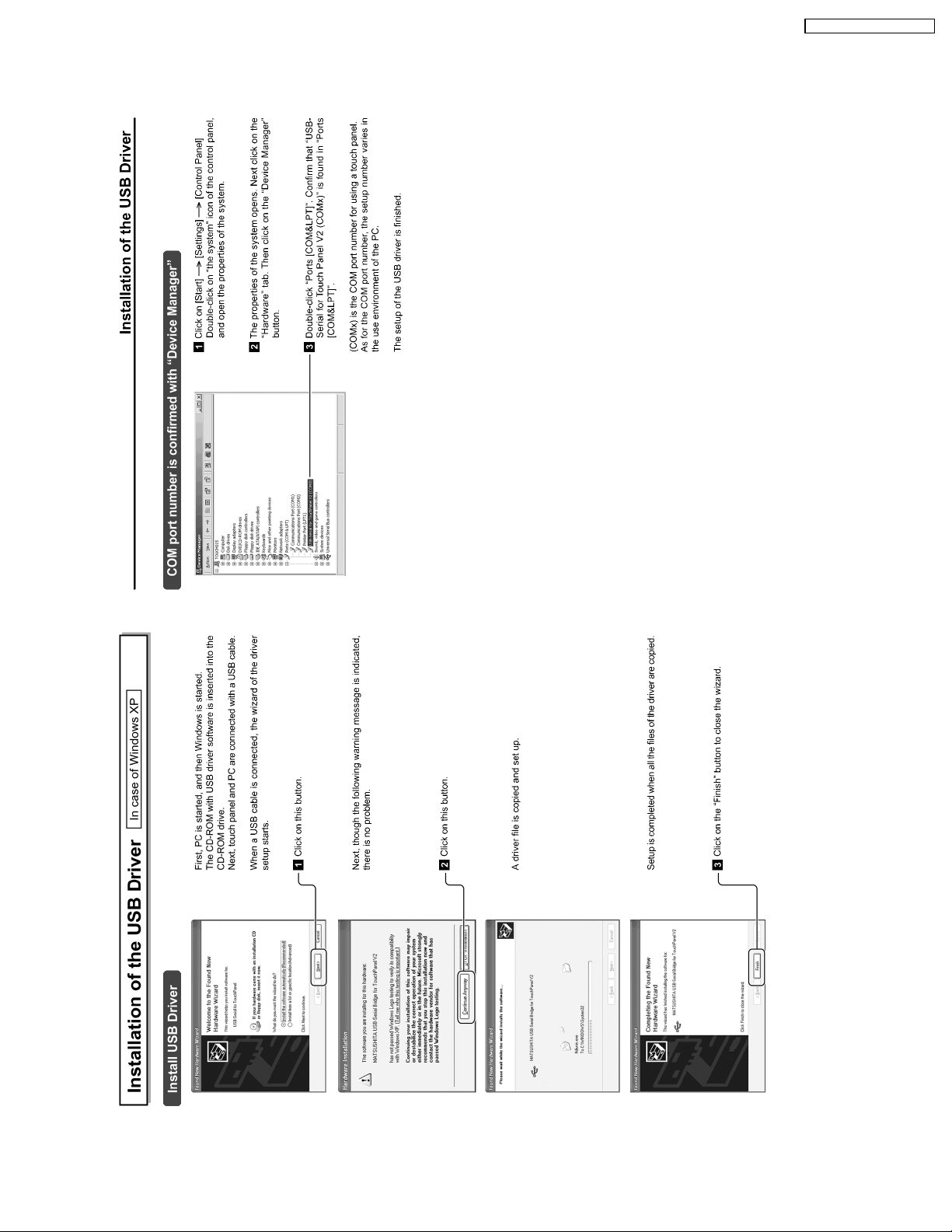

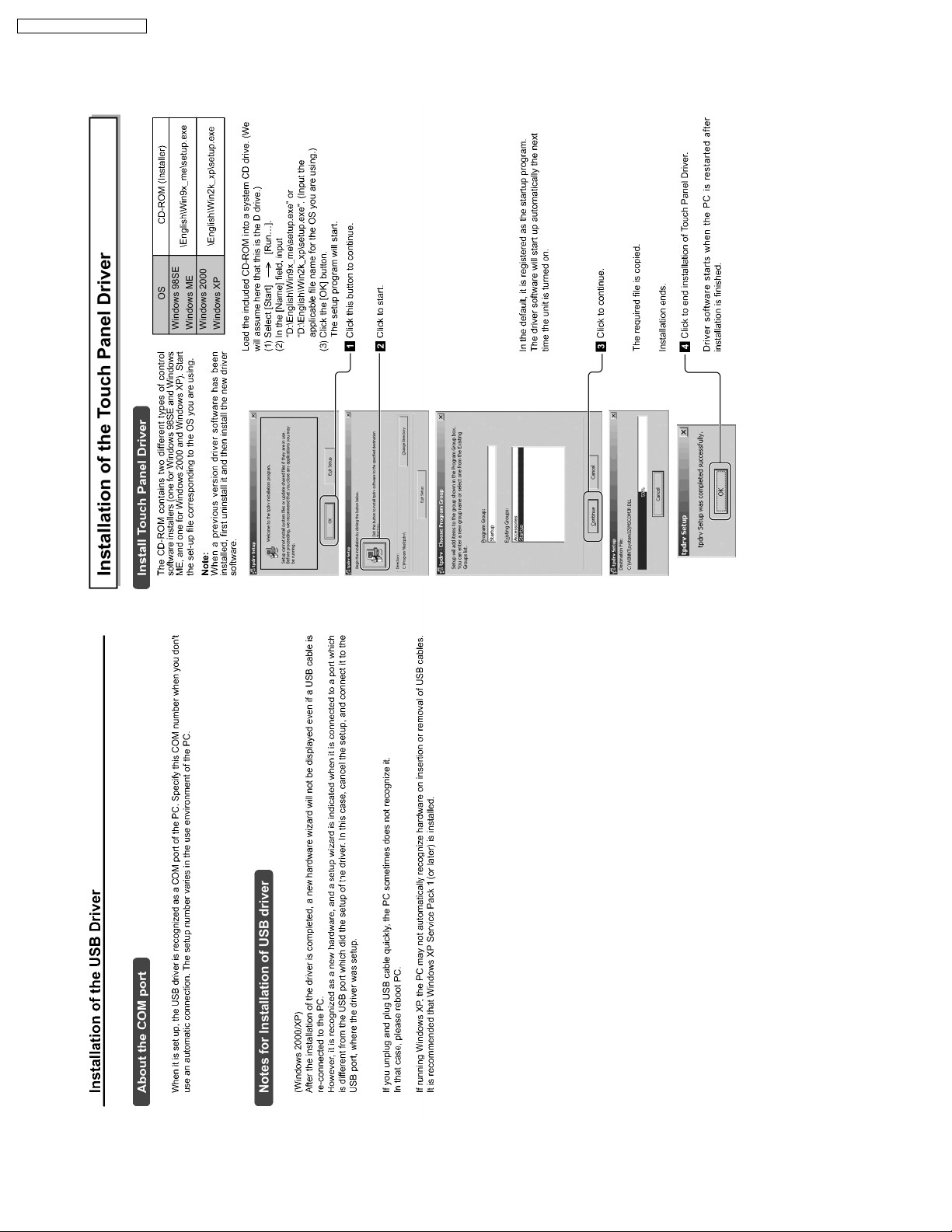

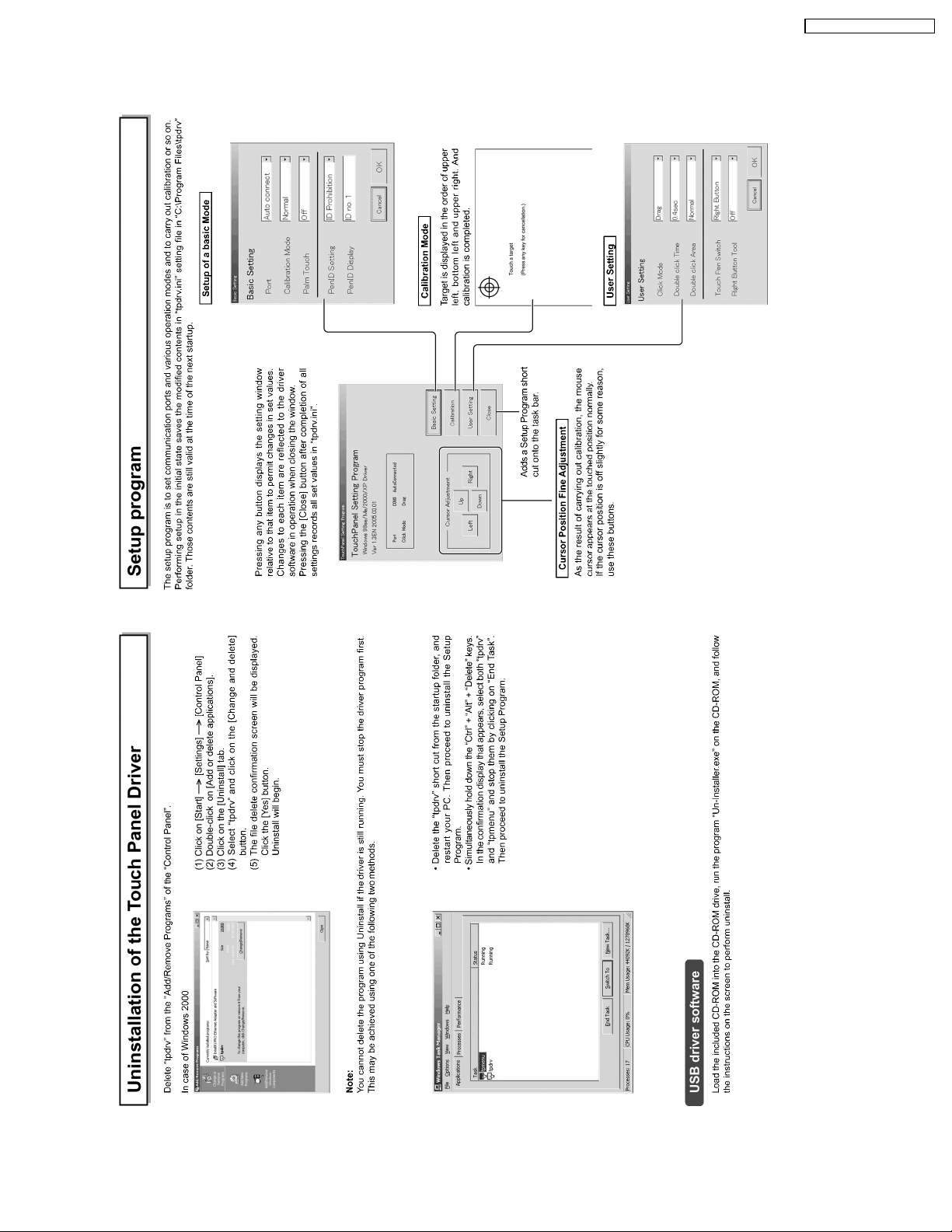

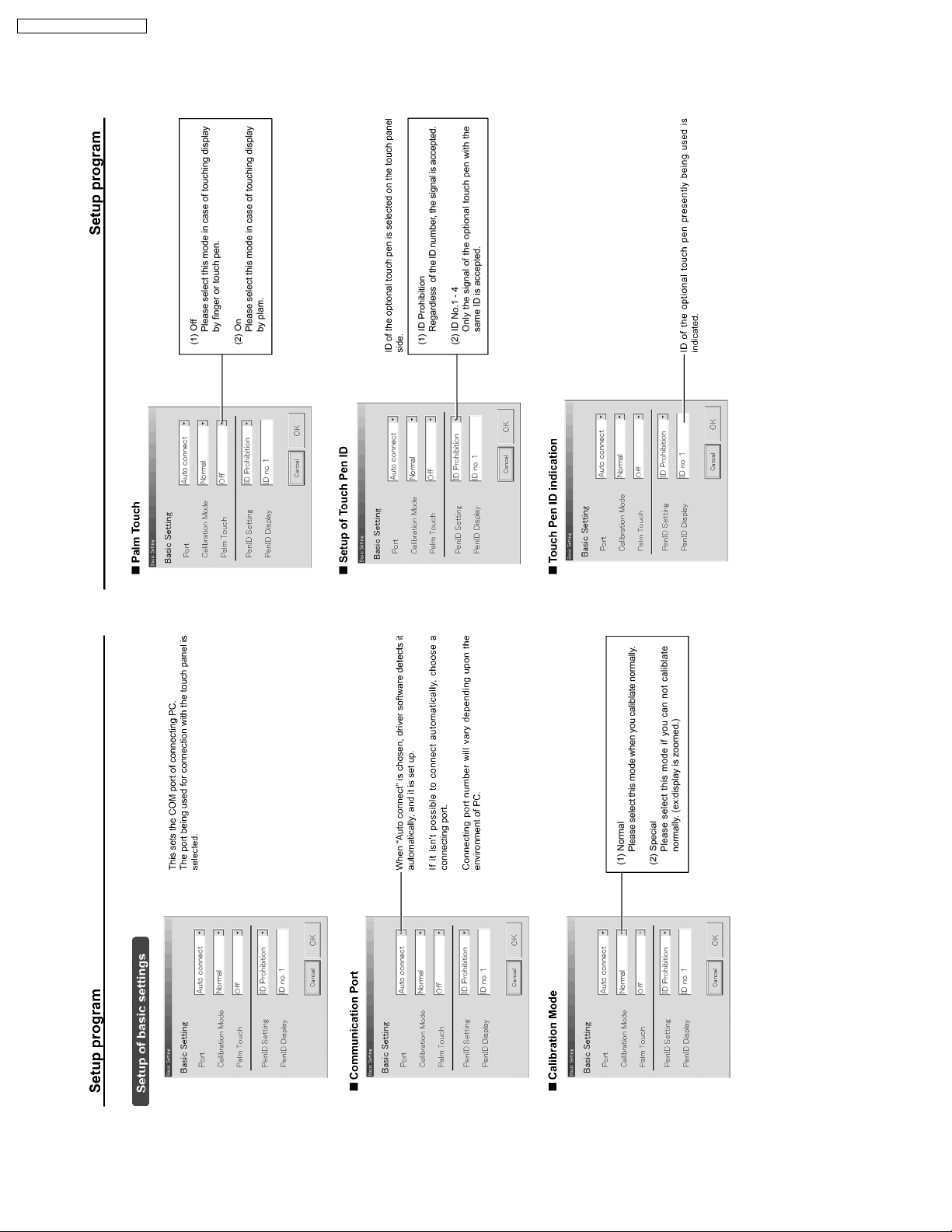

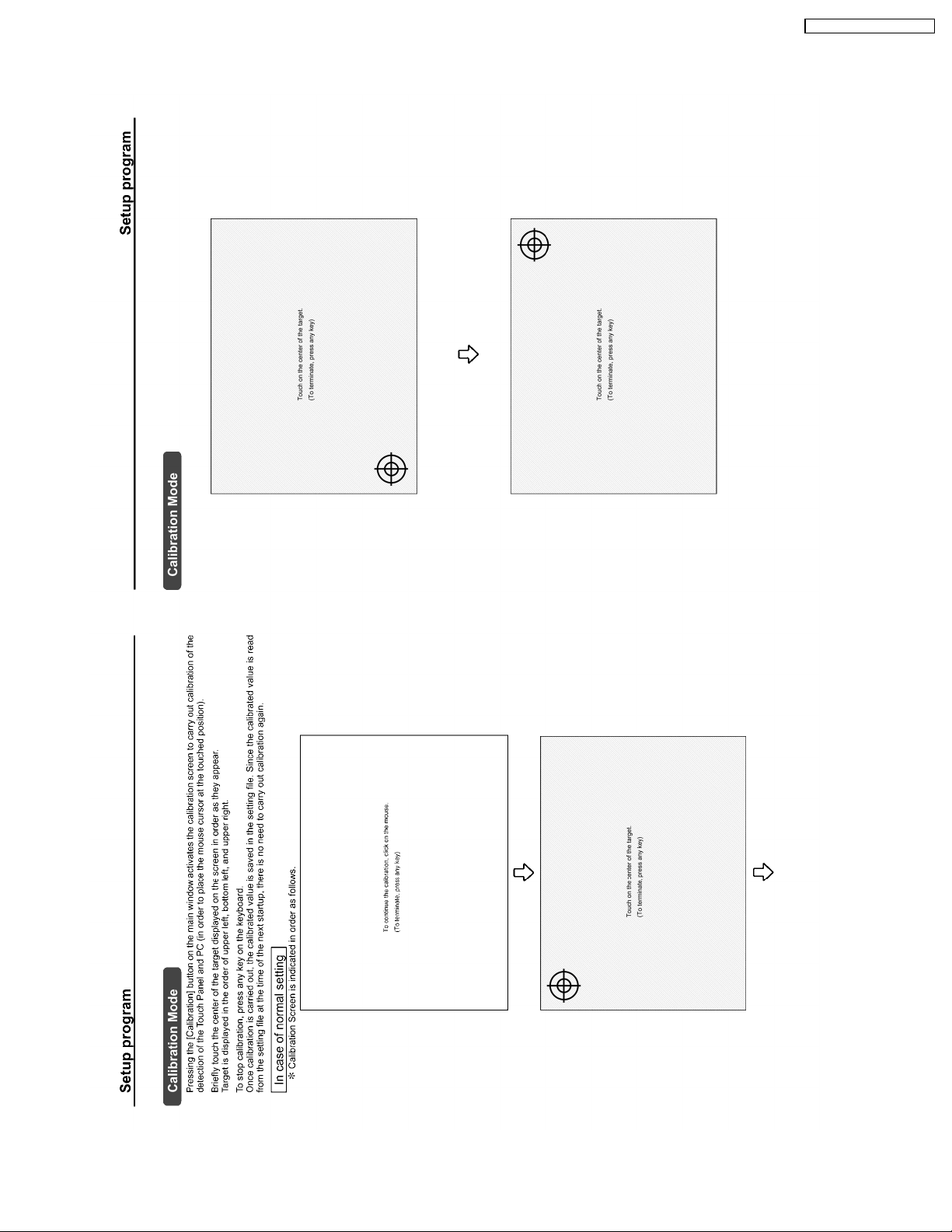

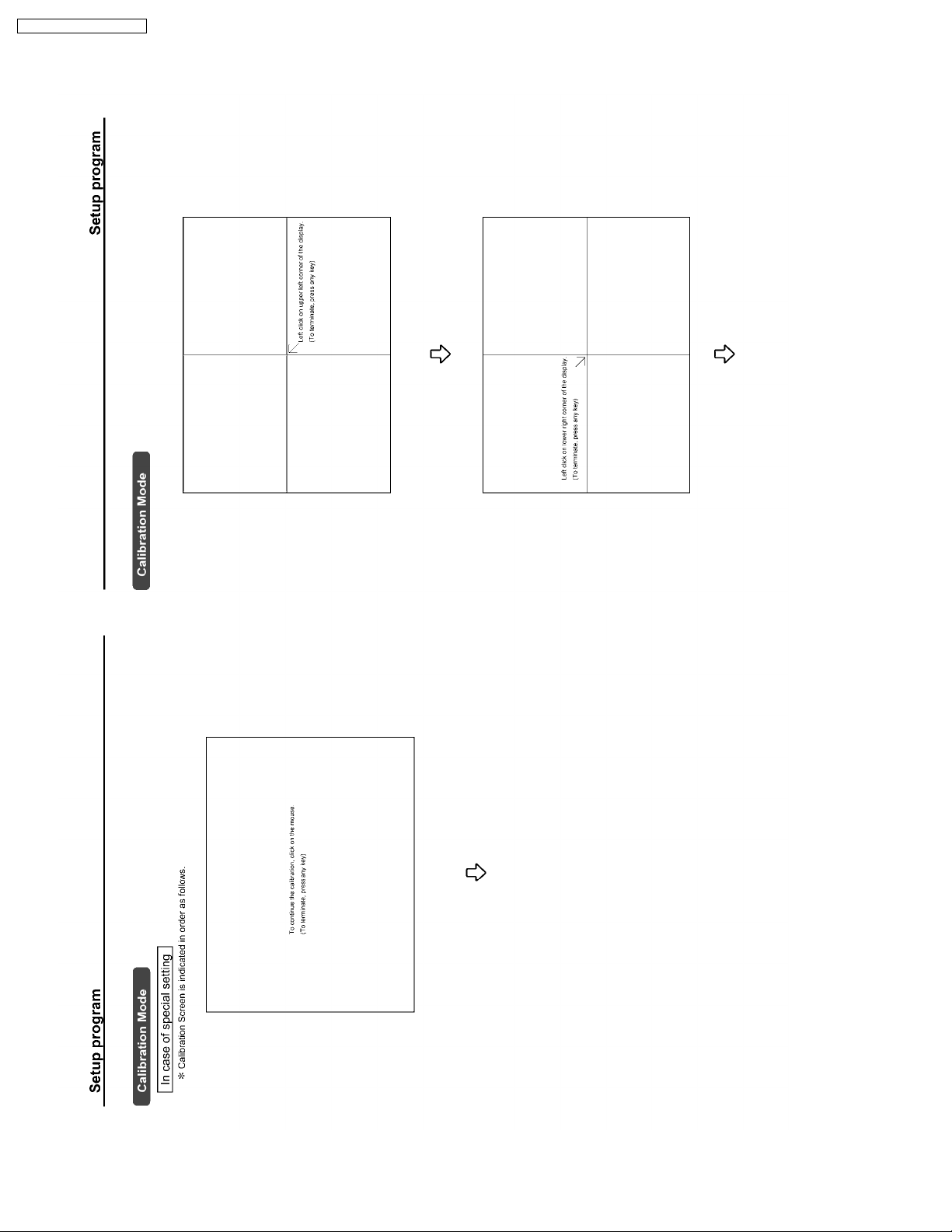

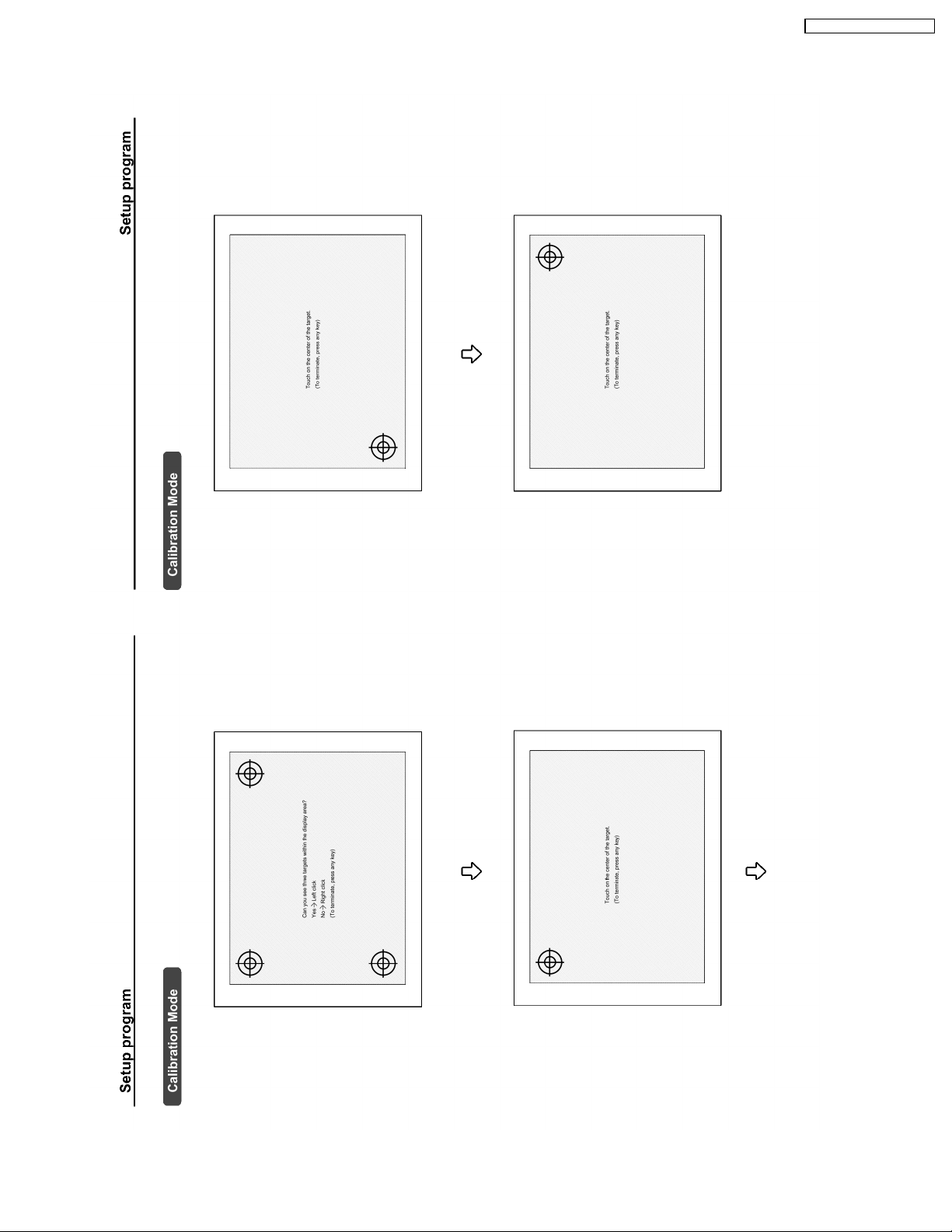

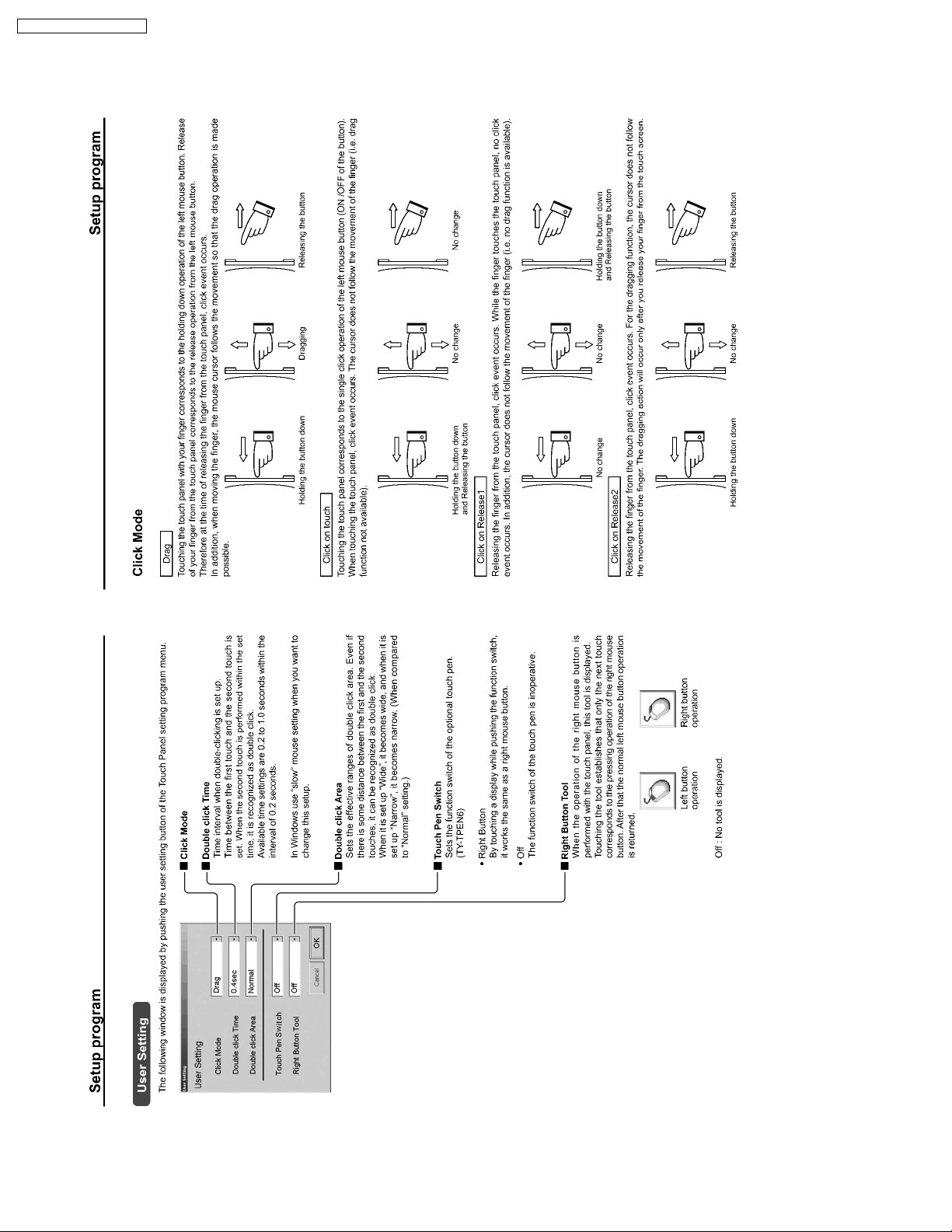

4 Setup for Touch Panel

7

Page 8

TY-TP42P8-S / TY-TP50P8-S

8

Page 9

TY-TP42P8-S / TY-TP50P8-S

9

Page 10

TY-TP42P8-S / TY-TP50P8-S

10

Page 11

TY-TP42P8-S / TY-TP50P8-S

11

Page 12

TY-TP42P8-S / TY-TP50P8-S

12

Page 13

TY-TP42P8-S / TY-TP50P8-S

13

Page 14

TY-TP42P8-S / TY-TP50P8-S

14

Page 15

TY-TP42P8-S / TY-TP50P8-S

15

Page 16

TY-TP42P8-S / TY-TP50P8-S

16

Page 17

TY-TP42P8-S / TY-TP50P8-S

17

Page 18

TY-TP42P8-S / TY-TP50P8-S

18

Page 19

TY-TP42P8-S / TY-TP50P8-S

19

Page 20

TY-TP42P8-S / TY-TP50P8-S

20

Page 21

TY-TP42P8-S / TY-TP50P8-S

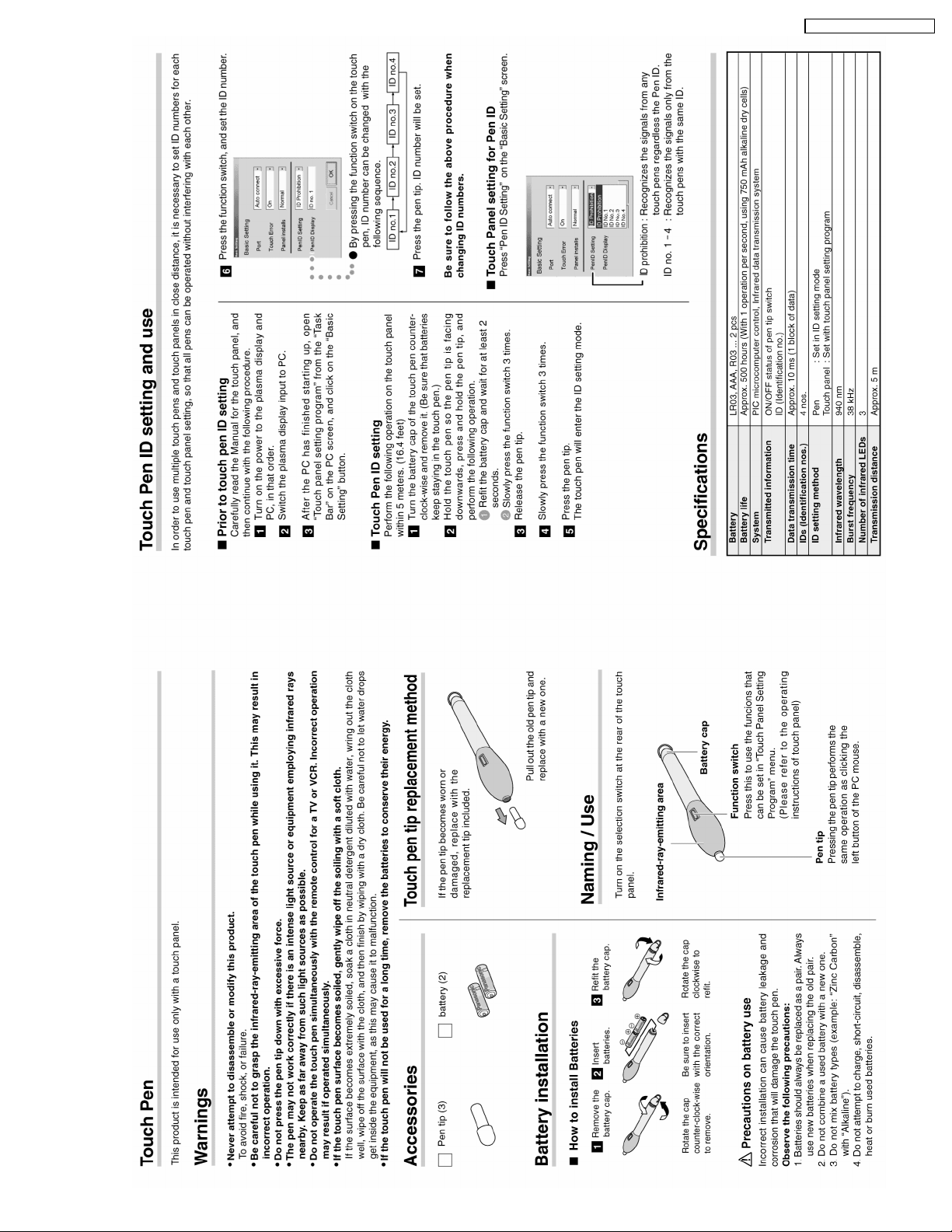

5 Touch Pen (Option)

21

Page 22

TY-TP42P8-S / TY-TP50P8-S

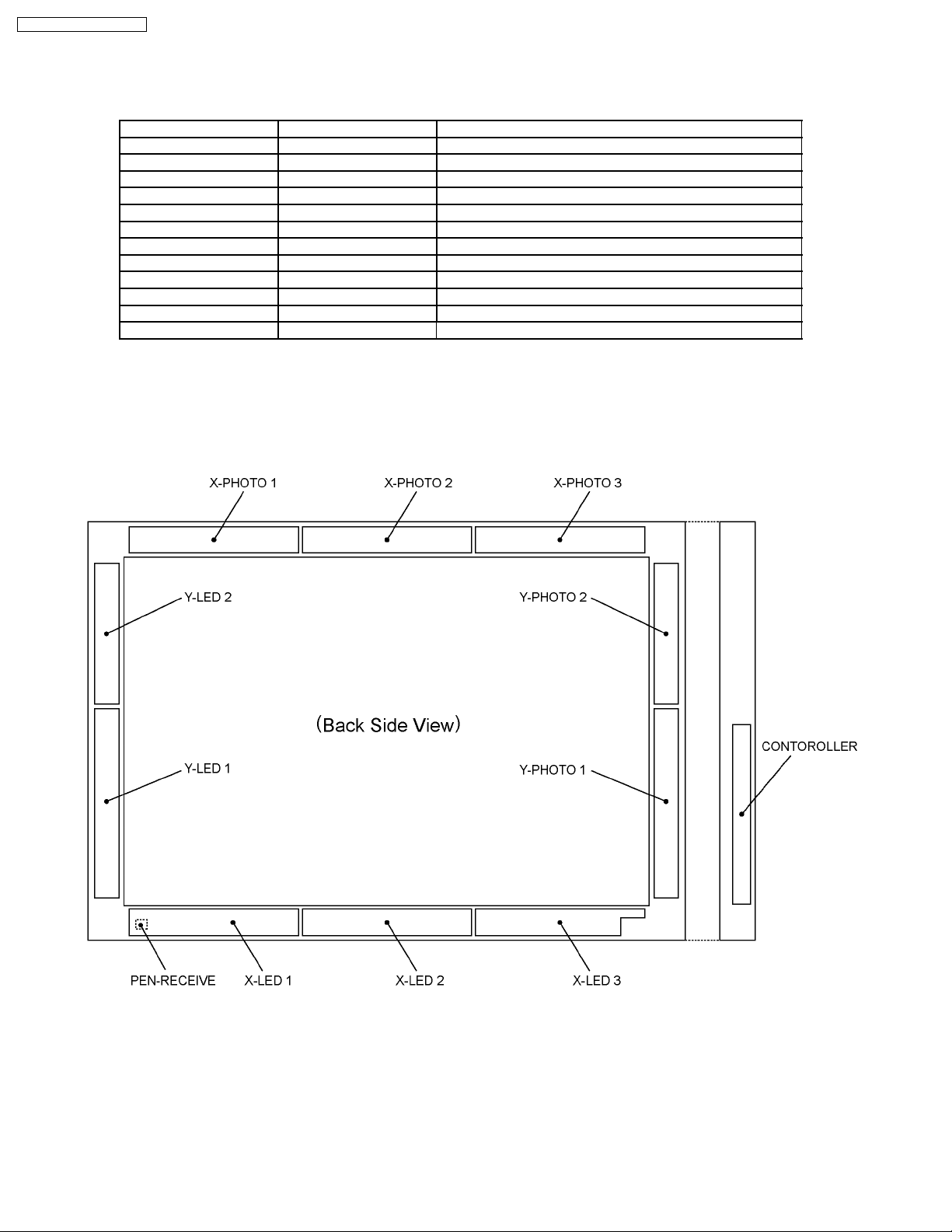

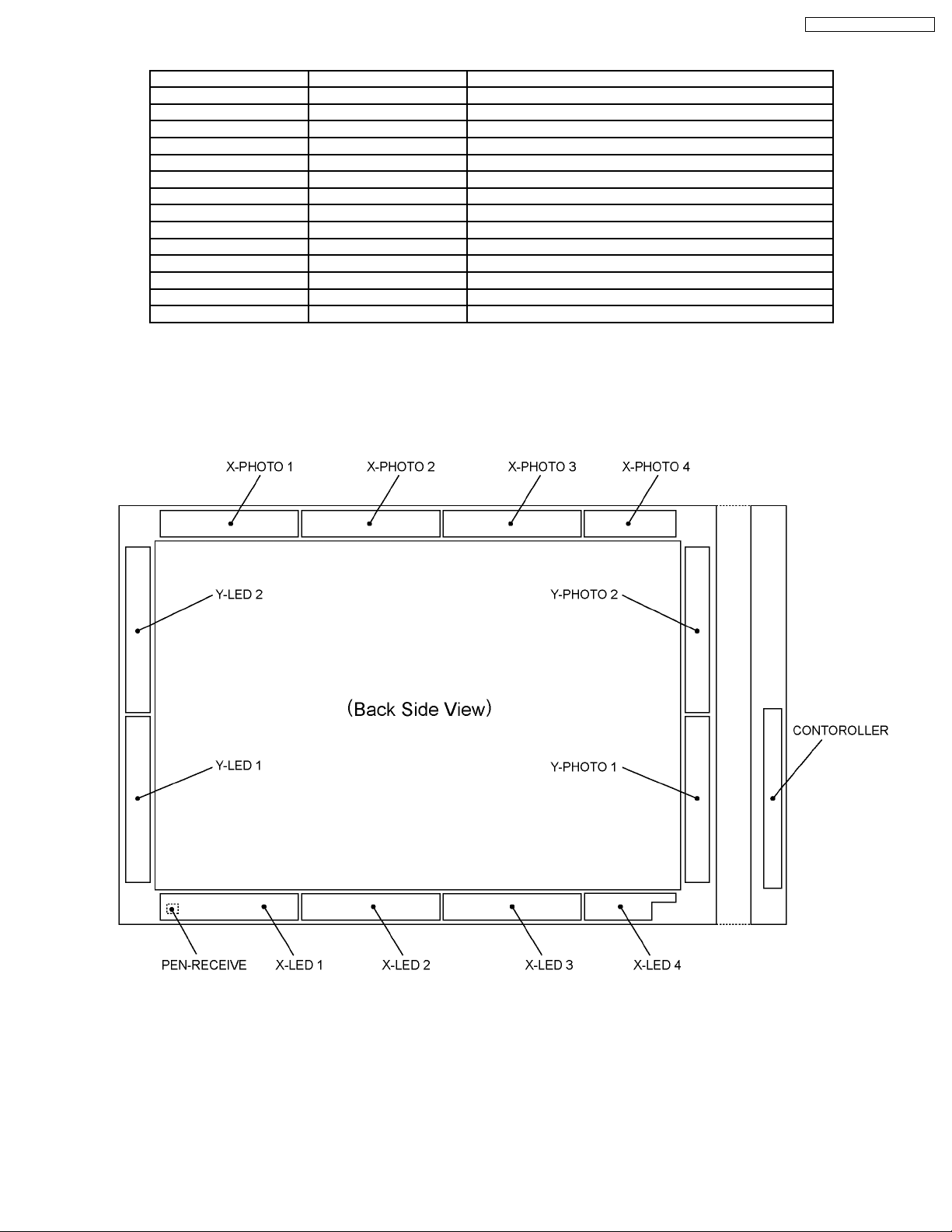

6 Printed Circuit Board Structure

6.1. TY-TP42P8-S

Board Name Board Number Function

CONTROLLER G441-K1TD11

PEN-RECEIVE G441-K1TD12 Touch Pen Remote Receiver

Y-LED 1 G441-K1TD07 IR Emitter to Y-PHOTO 1

Y-LED 2 G441-K1TD06 IR Emitter to Y-PHOTO 2

X-LED 1 G441-K1TD08 IR Emitter to X-PHOTO 1

X-LED 2 G441-K1TD09 IR Emitter to X-PHOTO 2

X-LED 3 G441-K1TD10 IR Emitter to X-PHOTO 3

Y-PHOTO 1 G441-K1TD01 IR Receiver from Y-LED 1

Y-PHOTO 2 G441-K1TD02 IR Receiver from Y-LED 2

X-PHOTO 1 G441-K1TD05 IR Receiver from X-LED 1

X-PHOTO 2 G441-K1TD04 IR Receiver from X-LED 2

X-PHOTO 3 G441-K1TD03 IR Receiver from X-LED 3

22

Page 23

6.2. TY-TP50P8-S

Board Name Board Number Function

CONTROLLER G541-K1TD13

PEN-RECEIVE G541-K1TD14 Touch Pen Remote Receiver

Y-LED 1 G541-K1TD08 IR Emitter to Y-PHOTO 1

Y-LED 2 G541-K1TD07 IR Emitter to Y-PHOTO 2

X-LED 1 G541-K1TD09 IR Emitter to X-PHOTO 1

X-LED 2 G541-K1TD10 IR Emitter to X-PHOTO 2

X-LED 3 G541-K1TD11 IR Emitter to X-PHOTO 3

X-LED 4 G541-K1TD12 IR Emitter to X-PHOTO 4

Y-PHOTO 1 G541-K1TD01 IR Receiver from Y-LED 1

Y-PHOTO 2 G541-K1TD02 IR Receiver from Y-LED 2

X-PHOTO 1 G541-K1TD06 IR Receiver from X-LED 1

X-PHOTO 2 G541-K1TD05 IR Receiver from X-LED 2

X-PHOTO 3 G541-K1TD04 IR Receiver from X-LED 3

X-PHOTO 4 G541-K1TD03 IR Receiver from X-LED 4

TY-TP42P8-S / TY-TP50P8-S

23

Page 24

TY-TP42P8-S / TY-TP50P8-S

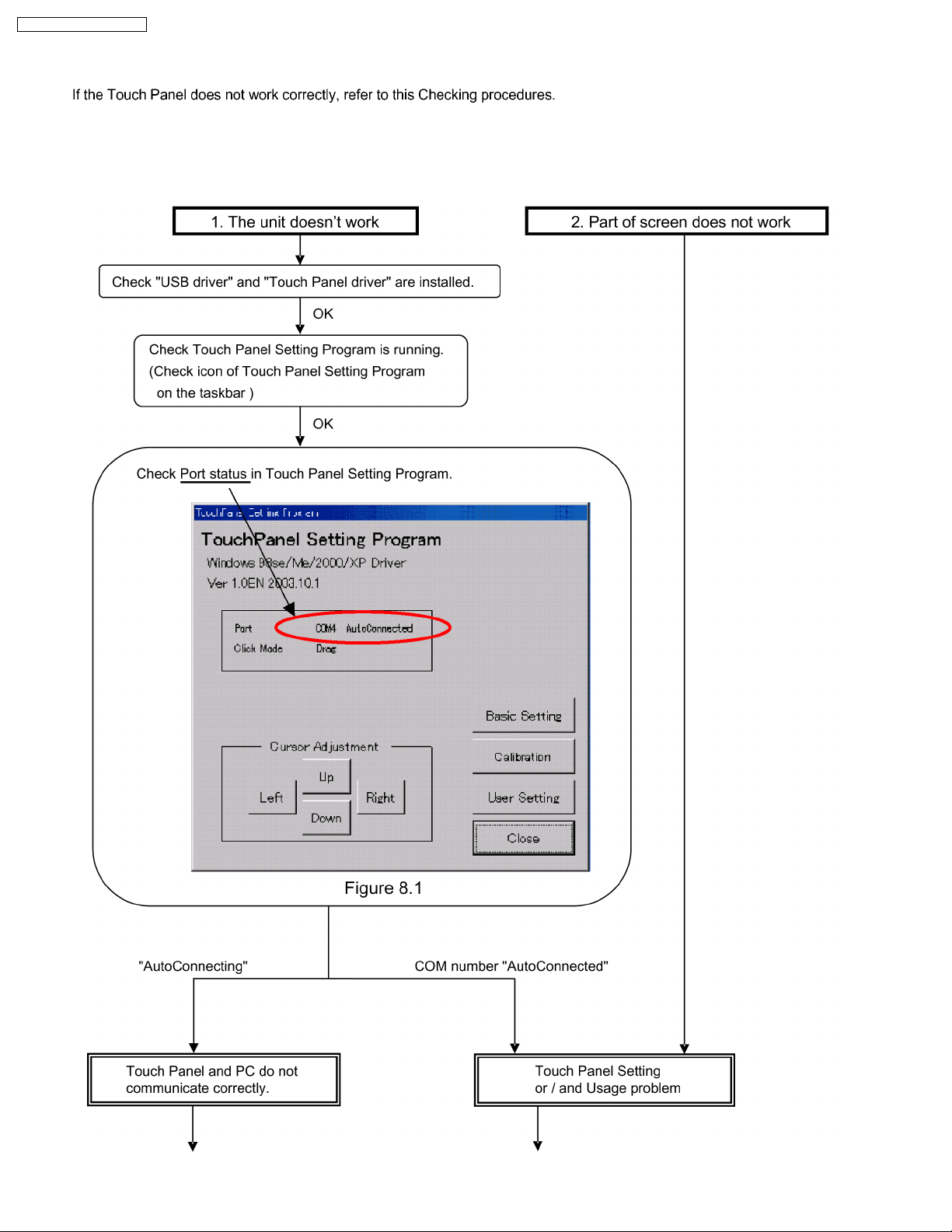

7 Trouble shooting

7.1. Checking procedures

24

Page 25

TY-TP42P8-S / TY-TP50P8-S

25

Page 26

TY-TP42P8-S / TY-TP50P8-S

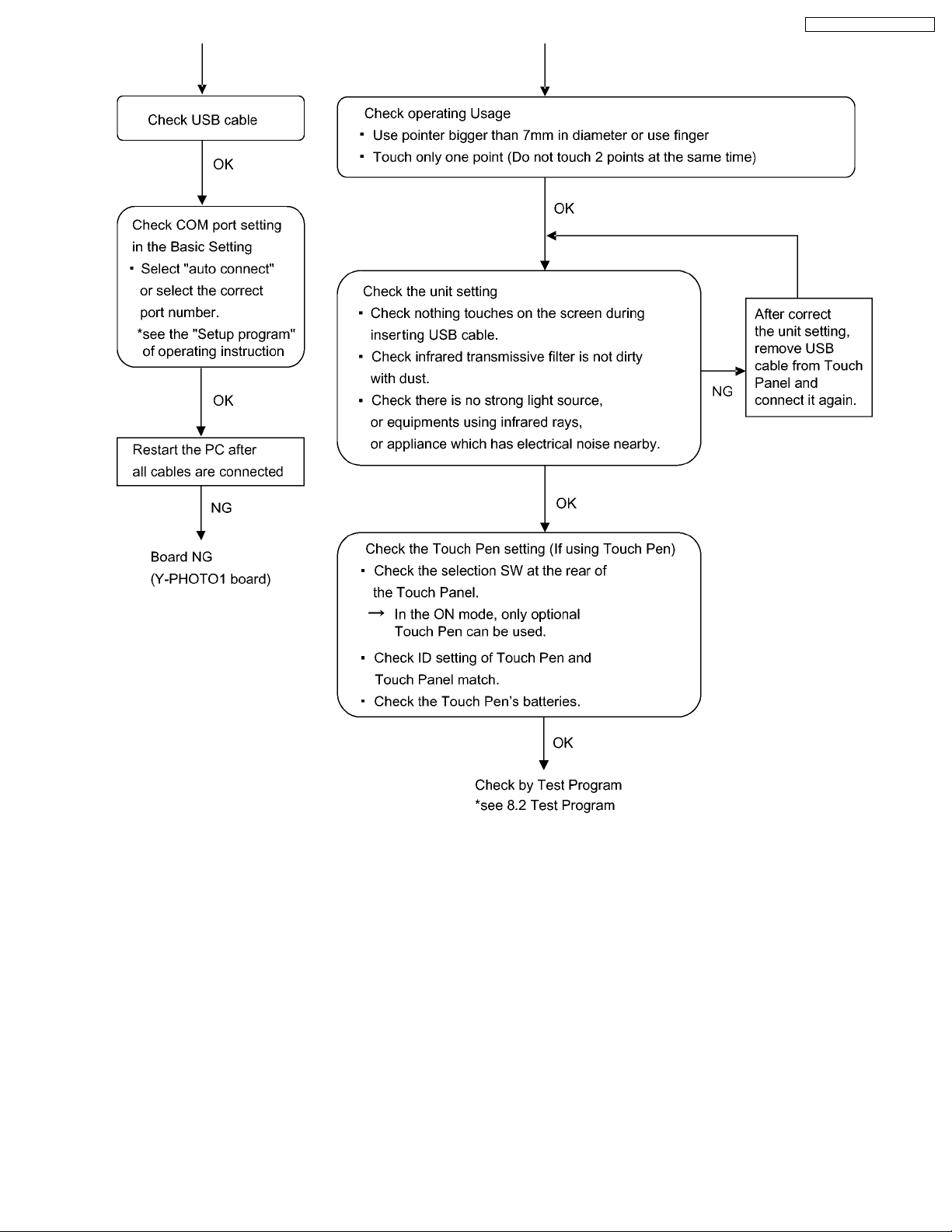

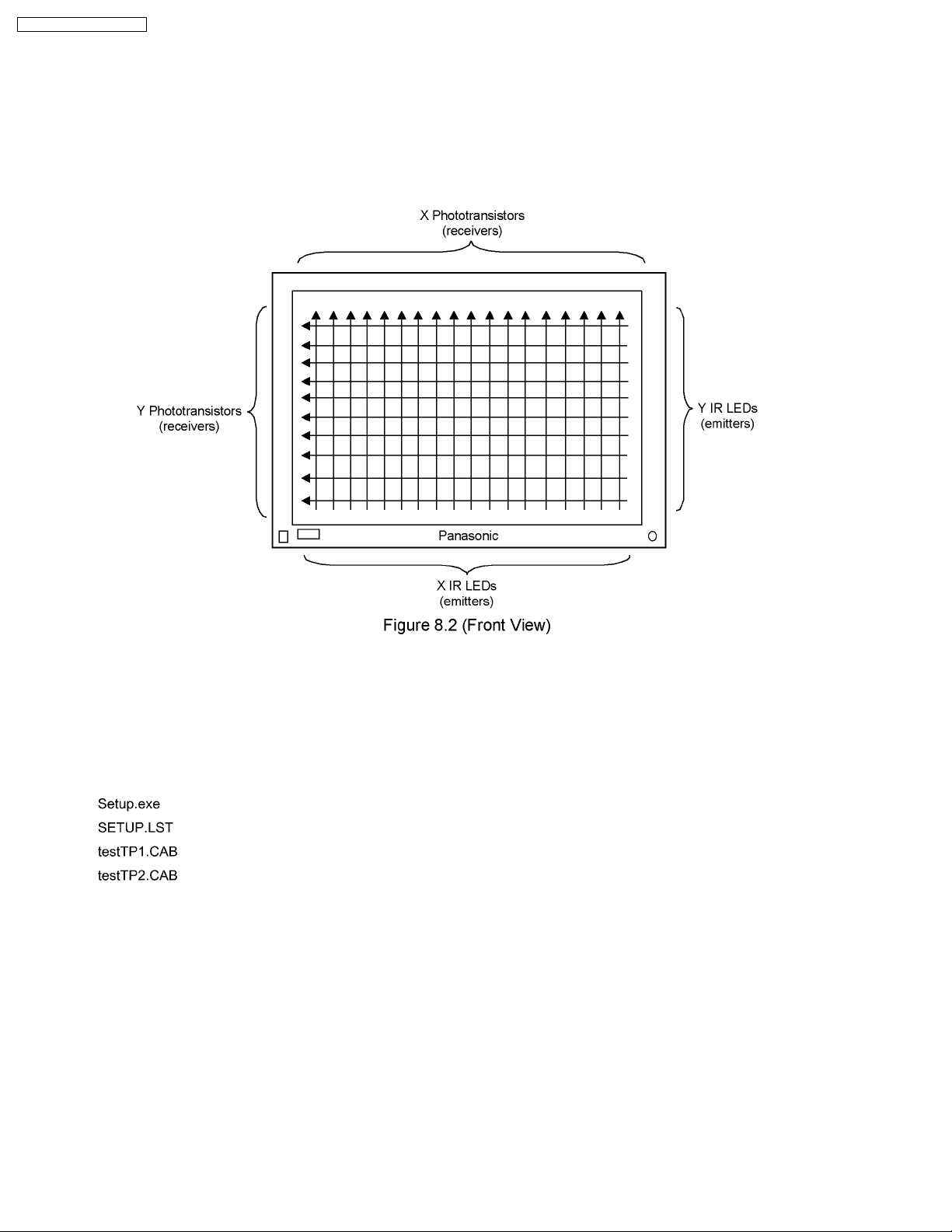

7.2. Test Program

7.2.1. Function

Touch Panel Test Program is software to check operating status.

Touch Panel detects the location by cutting off the infrared ray from IR LEDs to phototransistors.

This program checks each line of infrared ray and finds out the location of defective IR LED and phototransistor.

7.2.2. Installation

There are 2 test programs. Program name “testTP42P8” is for TY-TP42P8-S, “testTP50P8” is for TY-TP50P8-S.

The installation program consists of following 4 files under one folder. The folder name is the same as test program, “testTP42P8”

or “testTP50P8”.

Run the ”Setup.exe” and follow the instructions. The test program “testTP50P8” or “testTP42P8” will be installed to your PC.

NOTES:

To Uninstall, delete “testTP50P8” or “testTP42P8” from the “Add/Remove Programs” of Control Panel.

26

Page 27

TY-TP42P8-S / TY-TP50P8-S

7.2.3. Set up

1. Check COM port number of Touch Panel from the menu of Touch Panel Setting Program(see Figure8.1. of Trouble Shooting)

or Device Manager of Windows(See the “Installation of the USB driver” of operating instruction).

The COM port number is necessary to set for this test program(see 8.2.4-2. COM port setting).

2. Change resolution of the PC monitor to higher than XGA(1024 x 768).

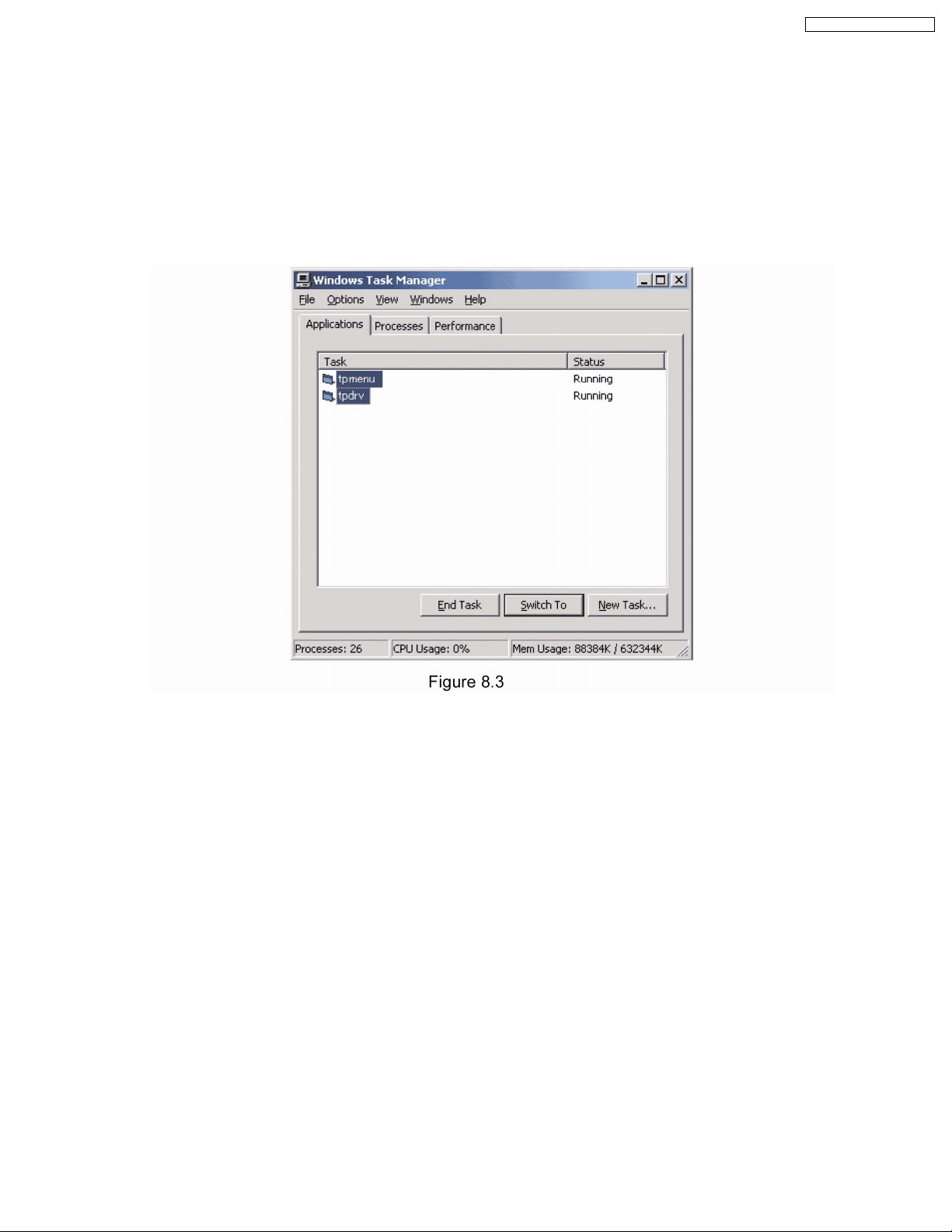

3. End the Touch Panel driver program by following procedure.

Press CTRL+ALT+DELETE to start Task Manager. Click the Applications tab, click the programs of “tpmenu” and “tpdrv”, and

then click End Task(This test program cannot be used while Touch Panel driver is running).

Below is the example of Windows XP.

27

Page 28

TY-TP42P8-S / TY-TP50P8-S

7.2.4. Operational Procedures

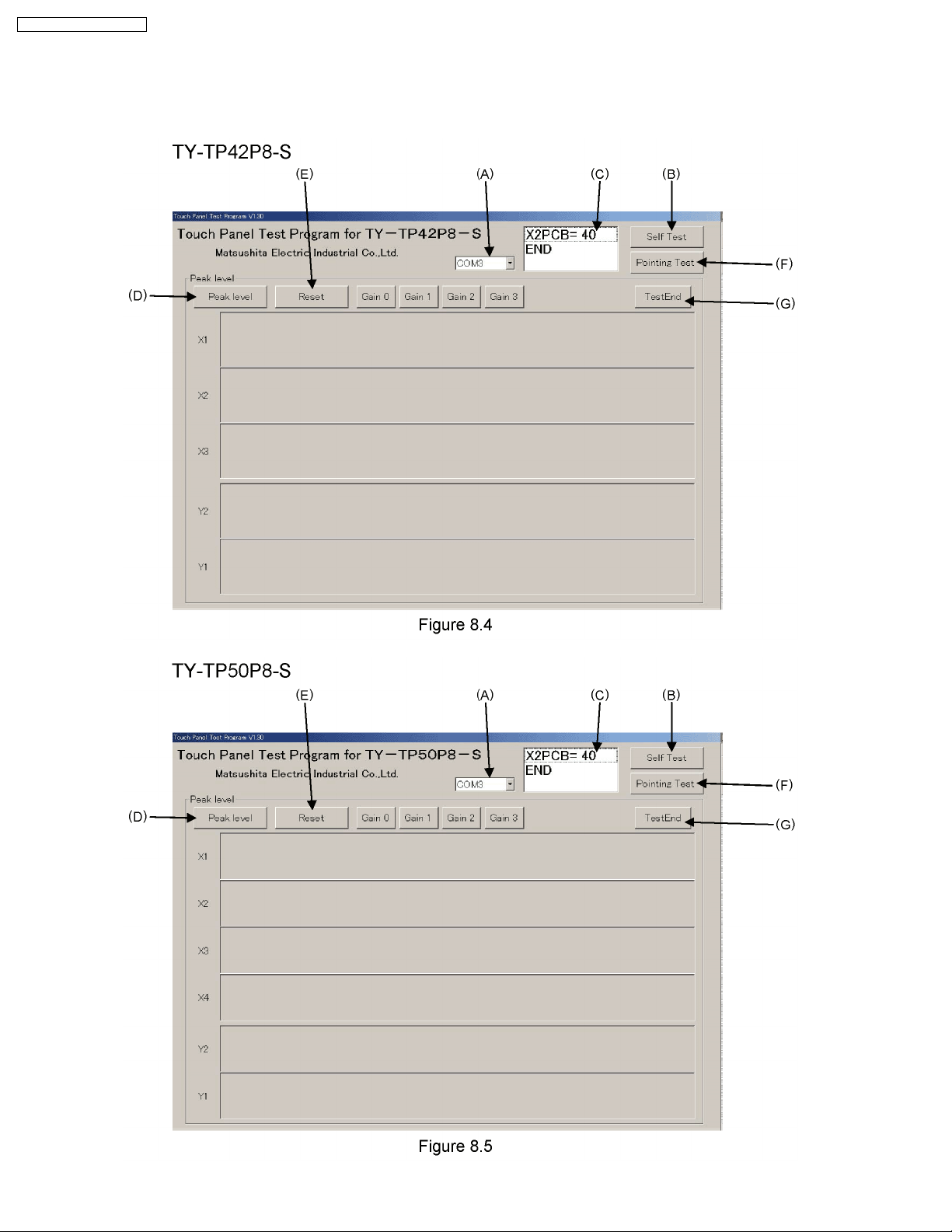

1. Start the Test Program

Click icon of “testTP42P8” or “testTP50P8” on start menu, then following window appears.

Below is an example window for “testTP42P8” or “testTP50P8”.

28

Page 29

2. COM port setting

Set the same COM port number of Touch panel(see 7.2.3.-1) into column (A).

3. Self Test

Self test is to check the operating condition of each IR LED and Phototransistor.

Click “Self Test” button (B) for initialization, and click (B) again. Then self test starts.

The result is shown in the textbox (C)

TY-TP42P8-S / TY-TP50P8-S

29

Page 30

TY-TP42P8-S / TY-TP50P8-S

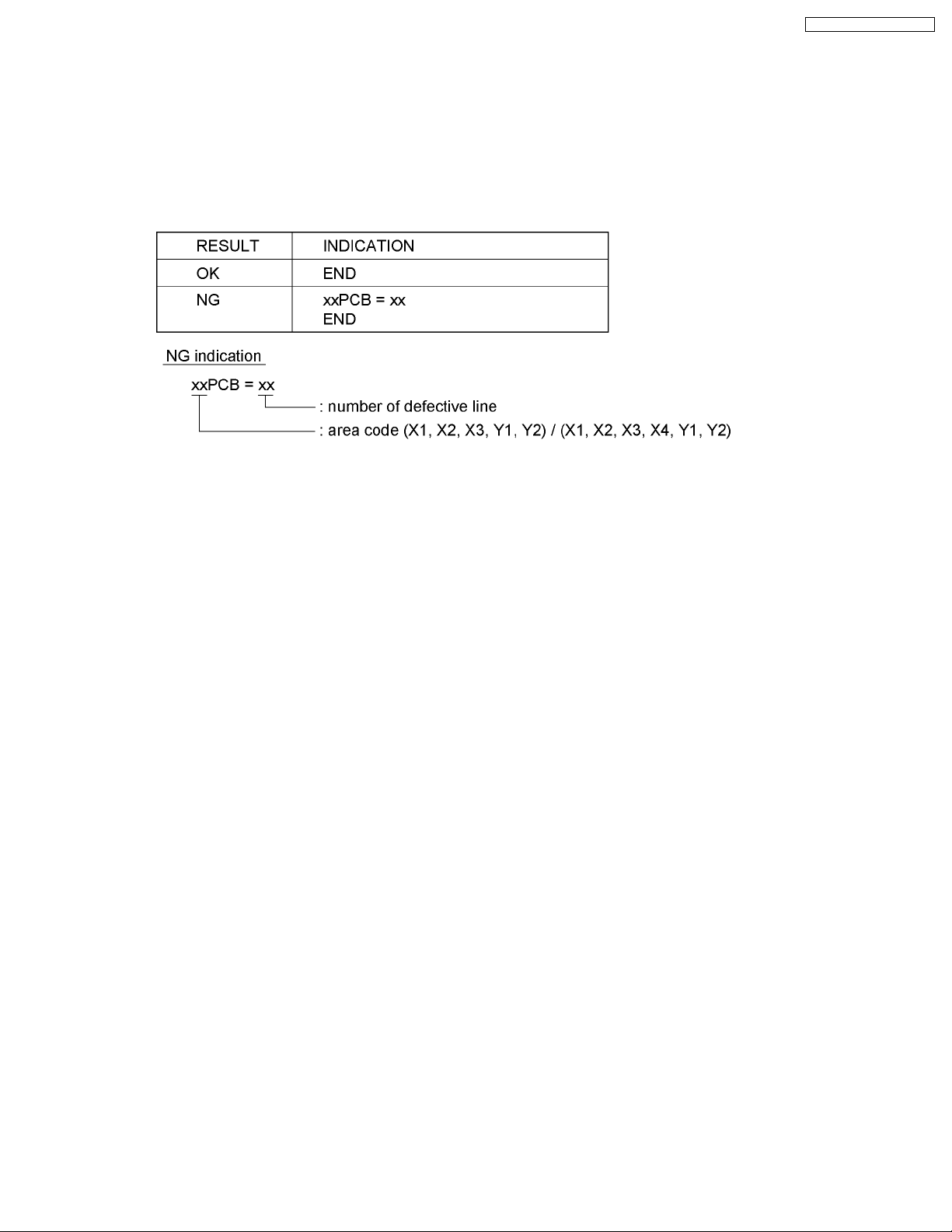

About the NG indication of the textbox C :

There are 6 areas of X1, X2, X3, Y1, and Y2. See Below “area location” for defective line. (TY-TP42P8-S)

There are 8 areas of X1, X2, X3, X4, Y1, and Y2. See Below “area location” for defective line. (TY-TP50P8-S)

30

Page 31

See Below “Location Number of defective line” for TY-TP42P8-S.

TY-TP42P8-S / TY-TP50P8-S

See Below “Location Number of defective line” for TY-TP50P8-S.

31

Page 32

TY-TP42P8-S / TY-TP50P8-S

For example, “X2PCB = 40” means 40th line of X2PCB area is defective.

NOTES:

· This program is to find out defective line. It cannot find out defective part, IR LED or phototransistor.

· If nothing appears in the textbox after clicking button(B) more than 2 times, check COM port or check if Touch Panel

driver programs is running(End the Program and restart Test Program).

· The definition of defective line is the received voltage from Phototransistor is less than 200mV.

32

Page 33

TY-TP42P8-S / TY-TP50P8-S

4. Peak level check

This is to see received level of all phototransistors.

Click “Peak Level” button(D). The received level is shown in the area of “X1”, “X2” and “X3” (TY-TP42P8),”X1”,”X2”, “X3”and

“X4” (TY-TP50P8) for vertical line, “Y1” and “Y2” for horizontal line. If the result of Self Test is NG, the received level of detected

defective line shows as lower than Red line.

Click “Reset” button(E) for ending the Peak level check.

NOTES:

The detection gain is automatically controlled while Touch Panel is operating and Self Test program is running.

33

Page 34

TY-TP42P8-S / TY-TP50P8-S

5. Pointing Test

Pointing test is to check the function of Touch Panel after repaired.

Click “Pointing Test” (F), then new window opens. The frame in window is the image of whole screen of Touch Panel.

Touch the Touch Panel then, the touched place is shown inside the frame.

Check the touch pen functions by touching the frame with the Touch Pen.

Check the Pen tip´s operation by "ON" / "OFF" shown in the Touch Pen status below.

Check the Function switch in the middle of the pen operating check by "ON" / "OFF" shown in the Touch Pen status below.

6. End

Click “TestEnd” button(G) to end the program.

After ending the test program, remove the USB cable and insert it again. Then, run the Touch Panel driver to use Touch Panel.

34

Page 35

8 Conductor Views

8.1. X-Photo1, X-Photo2, Y-Photo1 Board (42inch)

X-PHOTO1 / X-PHOTO2 / Y-PHOTO1 BOARD (COMPONENT SIDE)

G441-K1TD05 / G441-K1TD04 / G441-K1TD01

6

5

TY-TP42P8-S / TY-TP50P8-S

X-PHOTO1 / X-PHOTO2 / Y-PHOTO1 BOARD (FOIL SIDE)

G441-K1TD05 / G441-K1TD04 / G441-K1TD01

4

3

X-PHOTO1 X-PHOTO2

2

IC

U1

U2

U3

U4

U5

U6

U7

U8-U9

X-LED1 / X-LED2 / Y-LED1

TRANSISTOR

C-5

B-5

G-5

E-5

F-5

E-5

F-5

D-5

Q1 F-5

Y-PHOTO1

1

A

BCDEFGHI

35

Page 36

TY-TP42P8-S / TY-TP50P8-S

8.2. X-Photo1, X-Photo2, X-Photo3, Y-Photo1, Y-Photo2 Board (50inch)

X-PHOTO1 / X-PHOTO2 / X-PHOTO3 / Y-PHOTO1 / Y-PHOTO2 BOARD (COMPONENT SIDE)

G541-K1TD06 / G541-K1TD05 / G541-K1TD04 / G541-K1TD01 / G541-K1TD02

6

5

X-PHOTO1 / X-PHOTO2 / X-PHOTO3 / Y-PHOTO1 / Y-PHOTO2 BOARD (FOIL SIDE)

G541-K1TD06 / G541-K1TD05 / G541-K1TD04 / G541-K1TD01 / G541-K1TD02

4

3

X-PHOTO1 X-PHOTO2 X-PHOTO3

2

1

Y-PHOTO2

Y-PHOTO1

X-PHOTO1 / X-PHOTO2 / X-PHOTO3

Y-PHOTO1 / Y-PHOTO2

IC

U1

U2

U3

U4

U5

U6

U7

U8-U9

C-5

B-5

G-5

E-5

F-5

E-5

F-5

D-5

TRANSISTOR

Q1 F-5

A

BCDEFGHI

36

Page 37

8.3. X-Photo3 Board (42inch)

X-PHOTO3 BOARD (COMPONENT SIDE)

G441-K1TD03

6

5

TY-TP42P8-S / TY-TP50P8-S

X-PHOTO3 BOARD (FOIL SIDE)

G441-K1TD03

4

3

2

X-PHOTO3

IC

U1

U2

U3

U4

U5-U7

U6

U8-U9

X-PHOTO3

C-5

B-5

G-5

E-5

F-5

E-5

D-5

TRANSISTOR

Q1 F-5

1

A

BCDEFGHI

37

Page 38

TY-TP42P8-S / TY-TP50P8-S

8.4. X-Photo4 Board (50inch)

6

X-PHOTO4

X-PHOTO4 BOARD (COMPONENT SIDE)

G541-K1TD03

J17

J16

5

4

X-PHOTO4 BOARD (FOIL SIDE )

G541-K1TD03

X-PHOTO4

IC

U1

3

U2

U3-U6

U7-U8

D-5

E-5

D-5

C-5

TRANSISTOR

Q1 C-5

2

1

A

BCDEFGHI

38

Page 39

8.5. Y-Photo2 Board (42inch)

6

Y-PHOTO2 BOARD (COMPONENT SIDE)

G441-K1TD02

5

TY-TP42P8-S / TY-TP50P8-S

4

Y-PHOTO2 BOARD (FOIL SIDE)

G441-K1TD02

3

2

Y-PHOTO2

IC

U1-U2

U3

U4

U5

U6

U7

U8

Y-PHOTO2

B-5

D-5

C-5

D-5

C-5

D-5

C-5

TRANSISTOR

Q1 D-5

1

A

BCDEFGHI

39

Page 40

TY-TP42P8-S / TY-TP50P8-S

8.6. X-LED1, X-LED2, Y-LED1 Board (42inch)

X-LED1 / X-LED2 / Y-LED1 BOARD (COMPONENT SIDE)

G441-K1TD08 / G441-K1TD09 / G441-K1TD07

6

5

X-LED1 / X-LED2 / Y-LED1 BOARD (FOIL SIDE)

G441-K1TD08 / G441-K1TD09 / G441-K1TD07

4

3

2

X-PHOTO1 / X-PHOTO2 / Y-PHOTO1

IC

U1-U2

U3

U4-U5

U6

D-5

F-5

G-5

D-5

TRANSISTOR

Q1-Q9

Q10

Q11-Q16

Q17-Q18

D-5

E-5

G-5

H-5

Y-LED1

1

X-LED1 X-LED2

A

BCDEFGHI

40

Page 41

8.7. X-LED1, X-LED2, X-LED3, Y-LED1, Y-LED2 Board (50inch)

X-LED1 / X-LED2 / X-LED3 / Y-LED1 / Y-LED2 BOARD (COMPONENT SIDE)

6

G541-K1TD09 / G541-K1TD10 / G541-K1TD11 / G541-K1TD08 / G541-K1TD07

5

TY-TP42P8-S / TY-TP50P8-S

X-LED1 / X-LED2 / X-LED3 / Y-LED1 / Y-LED2 BOARD (FOIL SIDE)

G541-K1TD09 / G541-K1TD10 / G541-K1TD11 / G541-K1TD08 / G541-K1TD07

4

3

Y-LED2

2

Y-LED1

IC

U1-U2

U3

U4-U5

U6

X-LED1 / X-LED2 / X-LED3

Y-LED1 / Y-LED2

TRANSISTOR

D-5

F-5

G-5

D-5

Q1-Q9

Q10

Q11-Q16

Q17-Q18

D-5

E-5

G-5

H-5

1

X-LED1 X-LED2 X-LED3

ABCDEFGHI

41

Page 42

TY-TP42P8-S / TY-TP50P8-S

8.8. X-LED3 Board (42inch)

X-LED3 BOARD (COMPONENT SIDE)

G441-K1TD10

6

5

X-LED3 BOARD (FOIL SIDE)

G441-K1TD10

4

3

2

IC

U1-U2

U3

U4-U5

D-5

E-5

F-5

X-LED3

TRANSISTOR

Q1-Q5

Q6-Q10

Q11-Q18

C-5

D-5

F-5

1

X-LED3

A

BCDEFGHI

42

Page 43

8.9. X-LED4 Board (50inch)

TY-TP42P8-S / TY-TP50P8-S

6

X-LED4 BOARD (COMPONENT SIDE)

G541-K1TD12

5

4

X-LED4 BOARD (FOIL SIDE)

G541-K1TD12

X-LED4

X-LED4

IC

U1

3

U2-U3

U4

U5

C-5

D-5

E-5

C-5

TRANSISTOR

Q1-Q5

Q6-Q14

C-5

D-5

2

1

A

BCDEFGHI

43

Page 44

TY-TP42P8-S / TY-TP50P8-S

8.10. Y-LED2 Board (42inch)

Y-LED2 BOARD (COMPONENT SIDE)

G441-K1TD06

6

5

Y-LED2 BOARD (FOIL SIDE)

G441-K1TD06

4

3

2

Y-LED2

IC

U1

U2-U3

U4

U5

C-5

D-5

E-5

C-5

Y-LED2

TRANSISTOR

Q1-Q6

Q7

Q8-Q15

C-5

D-5

E-5

1

A

BCDEFGHI

44

Page 45

8.11. Controller Board (42inch)

CONTROLLER BOARD (COMPONENT SIDE)

G441-K1TD11

6

5

TY-TP42P8-S / TY-TP50P8-S

CONTROLLER BOARD (FOIL SIDE)

G441-K1TD11

4

3

2

CONTROLLER

IC

U1

U2

U3

U4

U5

U6

U7-U8

U9-U10

U11-U12

CONTROLLER

E-6

E-5

F-6

G-5

G-6

E-5

B-6

C-6

D-5

Q1

Q2

TRANSISTOR

E-5

C-5

1

A

BCDEFGHI

45

Page 46

TY-TP42P8-S / TY-TP50P8-S

8.12. Controller Board (50inch)

CONTROLLER BOARD (COMPONENT SIDE)

G541-K1TD13

6

5

CONTROLLER BOARD (FOIL SIDE )

G541-K1TD13

4

3

2

CONTROLLER

IC

U1

U2

U3

U4

U5

U6

U7-U8

U9-U10

U11-U12

CONTROLLER

TRANSISTOR

E-6

E-5

F-6

G-5

G-6

E-5

B-6

C-6

D-5

Q1

Q2

E-5

C-5

1

A

BCDEFGHI

46

Page 47

8.13. Pen-Receive Board (42inch)

PEN-RECEIVE BOARD (COMPONENT SIDE)

6

5

G441-K1TD12

TY-TP42P8-S / TY-TP50P8-S

PEN-RECEIVE BOARD (FOIL SIDE )

G441-K1TD12

PEN-RECEIVE

4

3

2

1

A

BCDEFGHI

47

Page 48

TY-TP42P8-S / TY-TP50P8-S

8.14. Pen-Receive Board (50inch)

6

5

PEN-RECEIVE BOARD (COMPONENT SIDE)

541-K1TD14

PEN-RECEIVE BOARD (FOIL SIDE )

G541-K1TD14

PEN-RECEIVE

4

3

2

1

A

BCDEFGHI

48

Page 49

9 Block Diagram

9.1. Overall Block Diagram (TY-TP42P8-S)

TY-TP42P8-S / TY-TP50P8-S

CONTROLLER

+5V

ALM LED

+5V

PEN MODE

SW

R-OUT

PENSW

PEN DATA

CONVERTER

J20

J21

J10

PEN DATA

SELECTION

RECEIVE from PHOTO

ADDRESS

YPHOTO-2

DECODER

(V)

ANALOG

SW

DECODER

(SEL)

YPHOTO-1

DECODER

(V)

PHOTO

Tr.

matrix

XPHOTO-3

J23 J11 J11

DECODER

(SEL)

ANALOG

PHOTO

Tr.

matrix

RECEIVER

IR RAY

RECEIVER

DECODER

(V)

J22

SW

DECODER

IR RAY

XPHOTO-2

(V)

DECODER

(SEL)

PHOTO

Tr.

matrix

IR RAY

ANALOG

SW

RECEIVER

J10

DECODER

(V)

XPHOTO-1

DECODER

(SEL)

PHOTO

Tr.

matrix

IR RAY

ANALOG

SW

RECEIVER

J10

EMITTER

YLED-2

IR

LED

matrix

YLED-1

PEN DATA

SELECTION

ADDRESS

DECODER

DECODER

DECODER

DECODER

DRIVER

(V)

(V)

DRIVER

(H)

(H)

(SEL)

DRIVER

(V)

(V)

J24

J25

J13

CPU

TXD/RXD

USB/RS232C

CONVERTER/

DRIVER

EEPROM

TY-TP42P8-S

Overall Block Diagram

RESET

+5V

POWER

FUSE

ANALOG

J9

J4

J11

SW

USB CONNECTOR

VBUS

D+

J1

D-

SW

DECODER

(SEL)

PHOTO IR

Tr.

matrix

RECEIVER

EMITTER

IR LED

matrix

IR RAY

EMITTER

IR LED

matrix

EMITTER

IR LED

matrix

matrix

EMITTER

PEN

RECEIVE

J27

DRIVER

(H)

DECODER

(H)

DECODER

(SEL)

XLED-3

(SEL)

DRIVER

(V)

(V)

J14

DRIVER

(H)

DECODER

(H)

DECODER

DRIVER

(V)

DECODER DECODER

(V)

J26

XLED-2

J14

DRIVER

(H)

DECODER

(H)

DECODER

XLED-1

(SEL)

DRIVER

(V)

DECODER

(V)

J15

J13J13

J1

LED

DECODER

DECODER

P1

PEN DATA

ADDRESS

SELECTION

DRIVER

(H)

(H)

(SEL)

TOUCH

PEN

IR RAY

TY-TP42P8-S

J14

Overall Block Diagram

49

Page 50

TY-TP42P8-S / TY-TP50P8-S

9.2. Overall Block Diagram (TY-TP50P8-S)

CONTROLLER

+5V

ALM LED

+5V

J10

J11

PEN DATA

SELECTION

RECEIVE from PHOTO

ADDRESS

YPHOTO-2

DECODER

(V)

ANALOG

SW

DECODER

(SEL)

PHOTO

Tr.

matrix

XPHOTO-1XPHOTO-2XPHOTO-3XPHOTO-4

J17 J16 J11 J11 J11J10 J10 J10

RECEIVER

DECODER

(V)

DECODER

(SEL)

ANALOG

SW

PHOTO

Tr. Tr.

matrix

RECEIVER RECEIVER RECEIVER RECEIVER

DECODER

(V)

DECODER

(SEL)

Tr.

matrix

ANALOG DECODER

SW

IR RAY

(V)

DECODER

(SEL)

PHOTO

matrix

ANALOG

SW

DECODER

(V)

DECODER

(SEL)

PHOTOPHOTO

Tr.

matrix

ANALOG

SW

EMITTER

YLED-2

IR

LED

matrix

PEN DATA

SELECTION

ADDRESS

DECODER

DECODER

DECODER

DRIVER

(V)

(V)

DRIVER

(H)

(H)

(SEL)

J13

J14

PEN MODE

SW

CPU

TXD/RXD

USB/RS232C

CONVERTER/

DRIVER

EEPROM

TY-TP50P8-S

Overall Block Diagram

R-OUT

PENSW

PEN DATA

CONVERTER

RESET

+5V

POWER

SW

FUSE

USB CONNECTOR

VBUS

D+

J1

D-

IR RAY IR RAY IR RAY IR RAY

J10

J9J4

J11

DECODER

(V)

ANALOG

SW

DECODER

(SEL)

YPHOTO-1

PHOTO

matrix

Tr.

RECEIVER

EMITTER EMITTER EMITTER EMITTER

IR LED

matrix

DECODER

(SEL)

DRIVER

(V)

DECODER

(V)(H)

DRIVER

(H) (V)

DECODER

J19

IR LED

matrix

(SEL)

DRIVER

DECODERDECODER

DRIVER

(H)

DECODER

(V)

J18

(H)

J14

IR RAY

J14

DRIVER

(H)

DECODER

(H)

IR LED

matrix

DECODER

(SEL)

DRIVER

(V)

DECODER

(V)

J14

DRIVER

(H)

DECODER

(H)

IR LED

matrix

DECODER

(SEL)

DRIVER

(V)

DECODER

(V)

EMITTER

J15 J1

J13J13J13

YLED-1

IR

LED

matrix

PEN

RECEIVE

DECODER

DECODER

DECODER

P1

PEN DATA

ADDRESS

SELECTION

DRIVER

(V)

(V)

DRIVER

(H)

(H)

(SEL)

TOUCH

IR RAY

PEN

J13

J14

XLED-4 XLED-3 XLED-2 XLED-1

TY-TP50P8-S

Overall Block Diagram

50

Page 51

9.3. Detail Block Diagram (1 of 3)

Signal explanations

Signal

AD0-6

SEL0-3

RANGE1-2

PHCOM1-4

LEDON

USB

CONNECTOR

Function

Address signals to switch LEDs and photo-transistors

Selection signals for the LED and photo-transistor boards.(active LOW)

Selection for 3 to 8 line decoder.

3 TO 8 LINE DECODER(X-PHOTO:U1,X-LED:U3)

G2A C B A

LL

LL

LH

L

L

HHHL

L

L

L

L

Y0 Y1 Y2 Y3

L

L

Selection board Selection board

X-PHOTO 2 & X-LED 2

L

X-PHOTO 3 & X-LED 3

L

X-PHOTO 4 & X-LED 4

Signals to change photo-transistor gain.

Photo-transistor output signal(analog voltage) output

from each photo-transistor board.

Signals to light IR-LED.(active LOW)

Signals to activate photo-transistor.(active LOW)PHON

CONTROLLER BOARD

FUSE2

U10

J1

FUSE1

1

VBUS

2

D-

3

D+

U7

EEPROM

U1

RESET

RESET

RESET

U6

+5V

SH2 SH1

Y1 Y

ANALOG

MULTI-

A

PLEXER

B

C

+5V

X

Y1 PWE

Z MD2

Z1

XTAL

+5V

20MHz

+

ALARM

LED

SW1

PEN

MODE

SW

VIN2

VIN1

U8

USBDM

USBSP

3 TO 8 LINE DECODER(Y-PHOTO:U2,Y-LED:U4)

G2A

OUT1

POWER

CONTROL / SW

OUT2

PWREN

EN1

EN2

USB DRIVER

TXD RXD

U3

RXD1 TXD1 TXD0 RXD0

RES

CPU

XTAL

EXTAL

Vref

ALM

PENMODE

ALLB

CY0

L

LL

LX-PHOTO 1 & X-LED 1

LH

+5V

L

L

U9

1Y

Q2

XTAL2

6MHz

AD0

AD6

SEL0

SEL3

LEDON

PHON

RANGE1

RANGE2

PENDATA

PHCOM

ILEDCOM

ROUT1

ROUT2

PENSW1

PENSW2

Y1

Y-PHOTO 1 & Y-LED 1

Y-PHOTO 2 & Y-LED 2

1B

NOR GATE

POWER SELECT

1A

U11

U12

DAT/GP0

CLK/GP1

GP4

GP5

RS232C

DRIVER

U4

BUFFER

BUFFER

PEN DATA

CONVERTER

TY-TP42P8-S / TY-TP50P8-S

TO

X-PHOTO 3 BOARD

(J23:42inch)

J20

(42inch)

TO

J10

X-PHOTO 4 BOARD

Y-PHOTO 2 BOARD

PHOUT SW

U5

PH ON,RANGE1,2

A B C

U6

OPTICAL NOISE CANCEL

+5V

J21

(42inch)

J11

(50inch)

AD0

119

J10

9151481

7

AD6

PHON

7

RANGE1

RANGE2

9

LEDON

13

10

16

20 1821

17 19

+5V

+5V

PHCOM

ILEDCOM

17

+5V

18821

SEL0

SEL3

PENDATA

20

13101514

16

PHCOM

CH0

INHCOM

SELCOM

U7

Q1

XY

ZZ1

GAIN CONTROL

SEL0-3

U2U3

3 TO 8

LINE

DECODER

Y1

U4

A B C

8ch

ANALOG

MULTI-

INH

PLEXER

COM

PH.SINK1-8

PHOTO-TRANSISTOR

MATRIX

P1-P52

(42inch)

P1-P78

(50inch)

AD0-2 AD3-6

3 TO 8

LINE

DECODER

U8,U9

(U9:50inch

ONLY)

PH.DRV1-7

(42inch)

PH.DRV1-10

(50inch)

(50inch)

(J17:50inch)

1

AD0

7

AD6

PHON

8

14

RANGE1

15

RANGE2

9

LEDON

10

SEL0

13

SEL3

16

PENDATA

20

PHCOM

21

ILEDCOM

17

+5V

+5V

18

+5V

19

+5V

Y-PHOTO 1

SEL0-3

A B C

PH.SINK1-8

BOARD

AD0-2 AD3-6

3 TO 8

LINE

DECODER

PH.DRV1-10

U8,U9

+5V

NO

J11

USE

17

+5V

18

+5V

19

+5V

21

ILEDCOM

20

PHCOM

16

PENDATA

10

SEL0

13

SEL3

9

LEDON

8

PHON

14

RANGE1

15

RANGE2

1

AD0

7

AD6

U2U3

PHCOM

CH0

PHOUT SW

COM

INH

SELCOM

3 TO 8

LINE

DECODER

Y1

U4

J4

1

7

U5

INT

GP2

10

13

9

8

14

15

16

20

21

+5V

17

18

19

AD0

AD6

SEL0

SEL3

LEDON

PHON

RANGE1

RANGE2

PENDATA

PHCOM

ILEDCOM

+5V

+5V

+5V

J9

1

7

10

13

9

8

14

15

16

20

21

17

+5V

18

19

U5

PH ON,RANGE1,2

U6

ZZ1

A B C

OPTICAL NOISE CANCEL

GAIN CONTROL

U7

INH

COM

ANALOG

MULTIPLEXER

MATRIX

8ch

Q1

X

Y

PHOTO-TRANSISTOR

P1-P78

TY-TP42/50P8-S

Detail Block Diagram (1 of 3)

TY-TP42/50P8-S

Detail Block Diagram (1 of 3)

51

Page 52

TY-TP42P8-S / TY-TP50P8-S

9.4. Detail Block Diagram (2 of 3)

J16

1

7

8

14

15

9

10

13

16

20

21

17

18

19

TO

Y-PHOTO 2 BOARD

(J20:42inch)

J23

(42inch)

J11

(50inch)

AD0

AD6

PHON

RANGE1

RANGE2

LEDON

SEL0

SEL3

PENDATA

PHCOM

+5V

+5V

+5V

J22

(42inch)

1

X-PHOTO 3 BOARD

7

8

14

15

9

10

13

16

20

21

17

18

19

U1

Y2

3 TO 8

LINE

DECODER

U3

CH0

PHOUT SW

SELCOM

INH

U5

COM

AD3-6

AD0-2

U8,U9

3 TO 8

LINE

DECORDER

U4

A

8ch

B

ANALOG

C

MULTIPLEXER

INH

COM

PH.DRV1-10

PH.SINK1-8

U6

A

B

OPTICAL

C

NOISE

CANCEL

X

GAIN

CONTROL

Y

Z

Q1

Z1

PHOTOTRANSISTOR

MATRIX

P1-P75(42inch)

P1-P78(50inch)

+5V

J10

(50inch)

14

15

10

13

16

20

21

17

18

19

1

7

8

9

AD0

AD6

PHON

RANGE1

RANGE2

LEDON

SEL0

SEL3

PENDATA

PHCOM

+5V

+5V

+5V

U7

TO

Y-PHOTO 2 BOARD

(J10:50inch)

J17

1

AD0

7

AD6

PHON

8

14

RANGE1

15

RANGE2

9

LEDON

10

SEL0

13

SEL3

16

PENDATA

20

PHCOM

21

ILEDCOM ILEDCOM ILEDCOM

17

+5V

18

+5V

19

+5V

U1

3 TO 8

LINE

SEL0-3 SEL0-3 SEL0-3

DECODER

U3

CH0

PHOUT SW

X-PHOTO 4 BOARD

U8

AD3-6

Y3

AD0-2

SELCOM

INH

COM

U5

3 TO 8

LINE

DECODER

U4

8ch

A

ANALOG

B

MULTI-

C

PLEXER

INH

COM

PH ON,RANGE1,2 PH ON,RANGE1,2 PH ON,RANGE1,2

PH.SINK1-8

Q1

PH.DRV1-6

U6

A

B

C

X

Y

Z

Z1

50inch only

PHOTOTRANSISTOR

MATRIX

P1-P43

OPTICAL

NOISE

CANCEL

GAIN

CONTROL

+5V

U7

TO

X-PHOTO 1 BOARD

(J11)

J11

1

7

8

14

15

9

10

13

16

20

21

17

18

19

U1

3 TO 8

LINE

DECORDER

U3

CH0

X-PHOTO 2 BOARD

AD3-6

Y1

AD0-2

SELCOM

INH

PHOUT SW

COM

U5

U8,U9

3 TO 8

LINE

DECORDER

U4

8ch

A

B

ANALOG

C

MULTIPLEXER

INH

COM

+5V

PH.DRV1-10

PHOTOTRANSISTOR

MATRIX

PH.SINK1-8

P1-P78

U6

A

B

OPTICAL

C

NOISE

CANCEL

X

GAIN

Y

CONTROL

Z

Q1

Z1

J10

1

AD0

7

AD6

PHON

8

14

RANGE1

15

RANGE2

9

LEDON

10

SEL0

13

SEL3

16

PENDATA

20

PHCOM

21

ILEDCOM

17

+5V

18

+5V

19

+5V

U7

X-LED 4 BOARD

U1

U5

A

B

C

G2A

G2B

3 TO 8

LINE

DECODER

3 TO 8

LINE

DECODER

L.SINK1-8

AD3-6

U3

3 TO 8

LINE

DECODER

U6

NO

USE

J19

1

AD0

7

AD6

10

SEL0 SEL0

13

SEL3

9

LEDON

21

ILEDCOM

17

+5V

18

+5V

19

+5V

AD0-2

Y3

SELCOM

INHCH0

+5V

COM

Q1-Q6

LED

DRIVE

Q7-Q14

LED

SINK

L.DRV1-6

LED

MATRIX

L1-L43

+5V

X-LED 3 BOARD

U1,U2

U5

A

B

C

G2A

G2B

3 TO 8

LINE

DECODER

3 TO 8

LINE

DECODER

L.SINK1-8

AD3-6

U3

3 TO 8

LINE

DECODER

U6

ILEDOUT SWILEDOUT SW

J27

(42inch)

J18

10

13

21

17

18

19

J14

(50inch)

1

7

9

AD0

AD6

SEL3

LEDON

ILEDCOM

ILEDCOM

+5V

+5V

+5V

1

7

10

13

9

21

17

18

19

AD0-2

Y2

SELCOM

INHCH0

+5V

COM

Q1-Q10

LED

DRIVE

Q11-Q18

LED

SINK

L.DRV1-10

LED

MATRIX

L1-L75

(42inch)

L1-L78

(50inch)

U3

3 TO 8

SEL0-3SEL0-3SEL0-3

LINE

DECODER

U6

CH0

ILEDOUT SW

J26

(42inch)

J13

(50inch)

1

7

10

13

9

21

+5V

17

18

19

AD0

AD6

SEL0

SEL3

LEDON

ILEDCOM

+5V

+5V

+5V

J14

1

7

10

13

9

21

17

18

19

X-LED 2 BOARD

U1,U2

AD3-6

AD0-2

Y1

SELCOM

INH

+5V

COM

3 TO 8

LINE

DECODER

U5

A

B

3 TO 8

C

LINE

DECODER

G2A

G2B

L.SINK1-8

Q1-Q10

LED

DRIVE

Q11-Q18

LED

SINK

L.DRV1-10

LED

MATRIX

L1-L78

TO

X-LED 1

BOARD

(J14)

J13

1

AD0

7

AD6

10

SEL0

13

SEL3

9

LEDON

21

+5V

ILEDCOM

17

+5V

18

+5V

19

+5V

TY-TP42/50P8-S

Detail Block Diagram (2 of 3)

TY-TP42/50P8-S

Detail Block Diagram (2 of 3)

52

Page 53

9.5. Detail Block Diagram (3 of 3)

TO

X-PHOTO 2 BOARD

(J10)

J11

1

AD0

7

AD6

PHON

8

14

RANGE1

15

RANGE2

9

LEDON

10

SEL0

13 13

SEL3

16

PENDATA

20

PHCOM

21

ILEDCOM

17

+5V

18

+5V

19

+5V

U1

3 TO 8

LINE

DECORDER

SEL0-3

U3

CH0

PHOUT SW

X-PHOTO 1 BOARD

U8,U9

AD3-6

3 TO 8

LINE

DECORDER

Y0

U4

A

AD0-2

SELCOM

INH

U5

COM

8ch

B

ANALOG

C

MULTIPLEXER

INH

COM

PH ON,RANGE1,2

Q1

X-LED 1 BOARD

U1,U2

AD3-6

3 TO 8

LINE

DECODER

U7

PH.SINK1-8

Q1-Q10

PH.DRV1-10

U6

A

B

C

X

Y

Z

Z1

LED

DRIVE

PHOTOTRANSISTOR

MATRIX

P1-P78

OPTICAL

NOISE

CANCEL

GAIN

CONTROL

L.DRV1-10

TY-TP42P8-S / TY-TP50P8-S

J24

(42inch)

AD0

AD6

PHON

RANGE1

RANGE2

LEDON

SEL0

SEL3

PENDATA

PHCOM

ILEDCOM

+5V

+5V

+5V

J13

(50inch)

10

13

16

21

17

18

19

1

7

9

U2,U3

(42inch)

U3,U4

(50inch)

Y1

3 TO 8

LINE

DECODER

SELCOM

CH0

INH

ILEDOUT SW

COM

Y-LED 2 BOARD

3 TO 8

LINE

DECORDER

A

B

3 TO 8

C

LINE

DECODER

G2A

G2B

(U2:50inch

ONLY)

U1,U2

AD3-6

U4(42inch)

U5(50inch)

AD0-2

U5(42inch)

+5V

U6(50inch)

L.SINK

1-8

Q1-Q7(42inch)

Q1-Q10(50inch)

LED

DRIVE

TRAN-

SISTORS

Q8-Q15(42inch)

Q11-Q18(50inch)

LED

TRANSISTORS

L.DRV1-7(42inch)

L.DRV1-10(50inch)

LED

MATRIX

L1-L52(42inch)

L1-L78(50inch)

J25

(42inch)

J14

(50inch)

J13

1191679

AD0

AD6

10

LEDON

13 17

SEL0

13

SEL3

+5V

21

18

+5V

+5V

+5V

ILEDCOM

PENDATA

17710

1921 189161

J10

1

7

8

14

15

9

10

16

20

21

17

+5V

18

19

Y-LED 1 BOARD

+5V

AD3-6

U1,U2

3 TO 8

LINE

DECODER

Q1-Q10

LED

DRIVE

L.DRV1-10

TO

X-LED 2 BOARD

(J13)

ILEDCOM

TY-TP42/50P8-S

Detail Block Diagram (3 of 3)

SEL0

SEL3

LEDON

L.SINK1-8

J1

1

2

Q11-Q18

LED

SINK

P1

PEN IR

RECEIVER

PHOTO

TRANSISTORS

LED

MATRIX

L1-L78

PENRECEIVER

BOARD

U4

3 TO 8

SEL0-3SEL0-3

LINE

DECODER

Y0

U6

TOUCH

PEN

IR RAY

J13

1

7

10

13

9

16

21

+5V

17

18

19

AD0

AD6

SEL0

SEL3

LEDON

PENDATA

ILEDCOM

+5V

+5V

+5V

J14

1

7

10

13

9

16

21

17

18

19

INHCH0

ILEDOUT SW

COM

AD0-2

SELCOM

+5V

A

B

C

G2A

G2B

U5

3 TO 8

LINE

DECODER

L.SINK1-8

Q11-Q18

LED

SINK

LED

MATRIX

L1-L78

U3

3 TO 8

LINE

DECODER

U6

CH0

INH

ILEDOUT SW

COM

J14

1

AD0

7

AD6

10

13

9

21

17

+5V

18

+5V

19

+5V

AD0-2

SELCOM

+5V

A

B

3 TO 8

C

LINE

DECODER

G2AY0

G2B

U5

+5V

J15

1

+5V

2

PENDATA

TY-TP42/50P8-S

Detail Block Diagram (3 of 3)

53

Page 54

TY-TP42P8-S / TY-TP50P8-S

54

Page 55

10 Schematic Diagram

10.1. Controller Board Schematic Diagram

TY-TP42P8-S / TY-TP50P8-S

GND

8

+5V

VDD

+5V

VCC

GND

10

+5V

VCC

GND

10

1

GP2/INT

R67

R68

+5V

C31

0.1u

C36

0.1u

2

VCC16V+

11

T1

12

R1

10

T2

9

R2

1

C1+

3

C1-

4

C2+

5

C2-

GND

16

C13

0.1u

20

18

Y1

17

Y2

16

Y3

15

Y4

14

Y5

13

Y6

12

Y7

PWEA

11

Y8

C14

0.1u

20

RANGE1

18

Y1

RANGE2

17

LEDON

16

Y3

PHON

15

Y4

SEL0

14

Y5

SEL1

13

Y6

SEL2

12

Y7

SEL3

11

Y8

U5

74HC54

BUFFER

C36

0.1u

4

VPPGP0/DAT

5

+5V

150

0

R65

14

R66

13

7

8

6

V-

C35

0.22u

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD0

AD1

AD2

AD3

AD4

AD5

AD6

PHON

LEDON

SEL0

SEL1

SEL2

SEL3

RANGE1

RANGE2

PENDATA

PHCOM

ILEDCOM

FC1

200

FC2

200

TO

YPHOTO-1 BOARD

(J9)

J4

1

AD0

2

AD1

3

AD2

4

AD3

5

AD4

6

AD5

7

AD6

8

PHON

9

LEDON

10

SEL0

11

SEL1

12

SEL2

13

SEL3

14

RANGE1

15

RANGE2

16

PENDATA

5V

17

+5V

18

+5V

19

+5V

20

PHCOM

21

ILEDCOM

22

GND

23

GND

24

GND

25

NC

26

NC

CONTROLLER BOARD

G441-K1TD11 (TY-TP42P8-S)

G541-K1TD13 (TY-TP50P8-S)

A

C6

+5V

D1

1S2835

10k

C3

0.33u

31

2

U1

MB3773

RESET

31

2

D2

1S2835

+5V

C5

0.1u

1

VCC

1

CT

2

RESET

3

CK

8

RESET

7

VS

6

VREF

GND

4

C4

0.1u

+5V

R3

R2

3.3k

1k

R4

1.5k

HD64F3067

XTAL1

20MHz

U3

CPU

63

67

1

2

66

3

0.33u

R1

C2

B

5V

C15

FUSE1

USB CONNECTOR

1.00A

J1

VBUS

1

D-32

D+

GND

4

D4

NNCD6.2MF NNCD6.2MF

C

D

E

31

13

2

D7

NNCD6.2MF

+5VUSB

C16

0.1u

31

D5

C20

0.1u

6

7

2

NC

NC

FUSE2

1.00A

+

C17

16V

2.2u

31

2

8

VCC

DOUT

GND

5

BR93L46RF-W

EEPROM

NOR GATE

POWER SELECT

+5VIN

D6

NNCD6.2MF

DIN

CS

SK

U7

U9

TC7W02

C25

0.1u

2

+5VUSB

4

3

1

2

R48

R49

XTAL2

6MHz

R52

10k

R53

2.2k

1

1A

2

1B

3

2Y 2A

FT232BL

USB DRIVER

27

27

1

2

3

C21

0.033u

+5VUSB

VCC

GND

U8

1.5k

8

4

+5VUSB

3

VCC26VCC

8

USBDM

USBP

RSTOUT

XIN

XOUT

3V3OUT

AGND

TEST

EEDATA

EECS

EESK

GND17GND

9

RESET

VCC-IC

TZDEN

PWREN

PWRCTL

TXLED

RXLED

SLEEP

7

R50

5

27

28

6

29

31

2

32

1

AVCC

C22

0.1u

4

13

25

TXD

24

RXD

23

RTS

22

CTS

21

DTR

20

DSR

19

DCD

18

RI

16

15

14

12

11

10

30

+5VUSB

+5VIN

R57

470

C23

0.1u

U10

MB3842

RXD1

TXD1

U6

74HC4053

ANALOG

MULTIPLEXER

R54

100k

R56

0

11

10

R47

9

10k

6

12

2

5

POWER CONTROL/SW

C24

0.1u

7

1Y

6

2B

R58

5

100k

Q2

FB1L2Q

+5VUSB

4

VIN1

5

VIN1

1

EN1

C26

0.01u

2

SS1

R59

R60

C27

R61

10k

3

2k

CS1

8

2k

CS2

0.01u

9

SS2

6

VIN2

7

VIN2

10

EN2

C28

R62

100k

0.1u

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

18

17

16

15

14

13

19

OC1

12

OC2

20

GND

11

GND

+5V

C30

+

C29

6.3V

0.1u

47u

+5VUSB

R63

R64

+5VIN

100k

100k

0.1u

16

VCC

A

B

C

INH

X0

Y0

Z0

VSS

VEE

PHCOM

ILEDCOM

+5V

5V

X

14

X1

13

15

Y

1

Y1

4

Z

3

Z1

78

1k

R6

1k

R7

C8

C9

3300p

470p

R10

R11

C10

+

C11

6.3V

47u

0.1u

C12

0.1u

31

D3

1S2835

R13

100

5V

R15

10k

87

88

89

90

91

93

94

95

96

97

98

99

100

2

3

4

5

6

7

8

9

58

59

60

69

70

71

72

61

78

79

R8

0

80

R9

0

81

82

83

0

84

0

85

1

+5V

R14

10k

2

6.3V

47u

+

C7

0.1u

35 68

VCCVCC

RES

XTAL

STBY

EXTAL

P90/TXD0

P91/TXD1

P92/RXD0

P93/RXD1

P80

P81

P82

P83

P84

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6/TXD2

PB7/RXD2

P60

P61

P62

P63

P64

P65

P66

P67

P60

P61

P62

P63

P64

P65

P66

P67

VCC

76

AVCC

77

VREF

86

AVSS

10

PWE

5V 5V

R16-20

73

MD0

74

MD1

75

MD2

62

64

NMI

12

13

14

15

16

P94

17

P95

36

P10

37

P11

38

P12

39

P13

40

P14

41

P15

42

P16

43

P17

45

P20

R30

46

P21

510

47

P22

48

P23

49

P24

50

P25

51

P26

52

P27

27

P30

28

P31

29

P32

30

P33

31

P34

32

P35

33

P36

34

P37

53

P50

54

P51

55

P52

56

P53

18

P40

19

P41

20

P42

21

P43

23

P44

24

P45

25

P46

26

P47

11

VSS

22

VSS

44

VSS

57

VSS

65

VSS

72

VSS

10k

ALM LED

5V

R28,29

10k

R25-27

10k

R21-24

10k

+5V

TY-TP42/50P8-S

Controller Board Schematic Diagram

TXD0

TXD1

RXD0

RXD1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PENMODE

PENSW1

PENSW2

R-OUT1

R-OUT2

TXD0

RXD0

31

D8

NNCD12F

1

2

3

4

5

6

7

16

8

9

10

11

12

13

14

15

R-OUT1

R-OUT2

PENSW1

PENSW2

PENMODE

2

U12

PIC12F629

PEN DATA

CONVERTER

6

4

2

U11

MAX202CSE

RS232C DRIVER

1

3

2

R38

10k

D9

NNCD12F

5V

R31-37

10k

U4

74HC54

C33

0.22u

C34

0.22u

1

G1

19

G2

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

BUFFER

5V

R39-46

10k

1

G1

19

G2

2

A1

3

A2 Y2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

7

6

GP1/CLK

3

GP4

2

GP5

SW1

PEN MODE SW

5

1

3

TY-TP42/50P8-S

Controller Board Schematic Diagram

3

42 7

56

81

55

Page 56

TY-TP42P8-S / TY-TP50P8-S

10.2. X-Photo 1 Board Schematic Diagram

5V

5V

5V

A

SEL0

SEL1

SEL2

SEL3

R17-20

10k

5V

B

C

PHCOM

5V

C1

0.1u

16

1

A

2

B

3

C

6

G1

4

G2A

5

G2B

1

A

2

B

3

C

6

G1

49

G2A

5

G2B

CH0

CH1

VEE

15

COM

R1

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

9

Y6

7

Y7

U1

74HC138

3 TO 8 LINE

DECODER

C2

0.1u

15

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

Y6

7

Y7

U2

74HC138

3 TO 8 LINE

DECODER

C3

0.1u

17

26

INH

5

A

4

U3

TC7W53FK

VCC

GND

8

5V

16

VCC

GND

8

5V

8

VCC

GND

3

AD0

AD1

AD2

0

R21-24

10k

U5

UPC842G

R30

2k

PHOUT SW

TO Y-LED 2 BOARD(J13)(TY-TP50P8)

TO Y-LED 2 BOARD(J24)(TY-TP42P8)

AD0

1

AD1

2

AD2

3

AD3

D

E

C23

6.3V

47u

4

AD4

5

AD5

6

AD6

7

PHON

8

SEL0

10

SEL1

11

SEL2

12

SEL3

13

RANGE1

14

RANGE2

15

5V 5V

PHCOM

17 17

5V

+

C22

0.1u

TY-TP42/50P8-S

J10 J11

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

AD0

2

AD1

3

AD2

4

AD3

AD4

5

6

AD5

7

AD6

PHON

8

9

LEDON

10

SEL0

SEL1

11

SEL2

12

13

SEL3

RANGE1

14

15

RANGE2

16

PENDATA

17

+5V

18

+5V

19

+5V

20

PHCOM

21

ILEDCOM

22

GND

GND

23

GND

24

NC

25

NC

26

TO

X-PHOTO 2 BOARD

(J10)

1

2

3

4

5

6

7

8

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

18

19

20

18

21

22

23

24

25

26

1

2

3

4

5

6

7

8

9

11

10

9

6

3

A

B

C

INH

COM

R28

100k

7

R31

100k

AD0

AD1

AD2

AD3

AD4

AD5

AD6

PHON

LEDON

SEL0

SEL1

SEL2

SEL3

RANGE1

RANGE2

PENDATA

+5V

+5V

+5V

PHCOM

ILEDCOM

GND

GND

GND

NC

NC

5V

C4

0.1u

16

13

VCC

0

14

1

15

2

12

3

1

4

5

5

2

6

4

7

VEE

VSS

7

8

74HC4051

8ch

ANALOG

MULTIPLEXER

R29

10k

5

+

6

R32

10k

U4

U5

UPC842G

PH.SINK1

PH.SINK2

PH.SINK3

PH.SINK4

PH.SINK5

PH.SINK6

PH.SINK7

PH.SINK8

5V

C5

0.1u

2

8

-

1

3

+

R33

4

2k

AD3

AD4

AD5

AD6

RANGE1

RANGE2

PHON

C6

3300p

Q1

FB1L2Q

R37

200

R38

5V

2k

1

UPC842G

5V

8

4

U7

7

R25-27

10k

-

+

R39-42

C8

0.1u

2

3

U7

UPC842G

+

-

10k

5V

11

10

9

6

14

15

4

5

6

X-Photo 1 Board Schematic Diagram

5V

C10

0.1u

16

1

A

2

B

3

C

6

G1

4

G2A

5

G2B

1

A

2

B

3

C

6

G1

49

G2A

5

G2B

5V

16

VCC

A

B

C

INH

X

Y

Z

VEE

VSS

8

OPTICAL NOISE CANCEL,

GAIN CONTROL

C9

3300p

15

VCC

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

9

Y6

7

Y7

GND

8

5V

C11

0.1u

16

VCC

GND

8

C7

0.1u

12

X0

13

X1

2

Y0

1

Y1

5

Z0

3

Z1

7

15

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

Y6

7

Y7

U6

74HC4053

U8

74HC238

3 TO 8 LINE

DECODER

R34

2k

R35

5.1k

R36

1.2k

PH.DRV1

PH.DRV2

PH.DRV3

PH.DRV4

PH.DRV5

PH.DRV6

PH.DRV7

PH.DRV8

PH.DRV9

PH.DRV10

U9

74HC238

3 TO 8 LINE

DECODER

PH.DRV5

PH.DRV4

PH.DRV3

PH.DRV2

PH.DRV1

P25P1

PH.SINK1

PH.SINK2

PH.SINK3

PH.SINK4

PH.SINK5

PH.SINK6

PH.SINK7

PH.SINK8

P2 P50

P3

P4

P5

P6

P7

P8

P17P9

P10

P11

P12

P13

P14

P15 P31

P16

C12

0.1u

P26

C14

0.1u

C

P27

P29

P30

P32

P1-P78

PT100MF0MP

P34

P35

P36

P37

P38

P39

P40

C15

0.1u

P18 P74

P19

P20

P21

P22

P23

P24

C13

0.1u

PHOTO

TRANSISTOR

MATRIX

E

X-PHOTO 1 BOARD

G441-K1TD05 (TY-TP42P8-S)

G541-K1TD06 (TY-TP50P8-S)

TY-TP42/50P8-S

X-Photo 1 Board Schematic Diagram

PH.DRV6

P49

P41

P42

P43

P44P28

P52

P45

P53

P46

P54

P55

P47

P56

P48

C16

C17

0.1u

0.1u

P65P33

P57

P66

P58

P59

P67

P68

P60

P61

P69

P70

P62

P71

P63

P64

P72

C18

C19

0.1u

0.1u

PH.DRV10

R43

P73

10k

R44

10k

R45

10k

P75P51

R46

10k

P76

R47

P77

10k

R48

10k

P78

R49

10k

R50

10k

C20

C21

0.1u

0.1u

PH.DRV9

PH.DRV8

PH.DRV7

3

42 7

56

81

56

Page 57

10.3. X-Photo 2 Board Schematic Diagram

TY-TP42P8-S / TY-TP50P8-S

5V

5V

5V

A

SEL0

SEL1

SEL2

SEL3

R17-20

10k

5V

B

C

PHCOM

5V

C1

0.1u

16

1

A

2

B

3

C

6

G1

4

G2A

5

G2B

1

A

2

B

3

C

6

G1

49

G2A

5

G2B

CH0

CH1

VEE

15

VCC

Y0

14

R2

Y1

13

Y2

12

Y3

11

Y4

10

Y5

9

Y6

7

Y7

GND

8

5V

C2

0.1u

16

VCC

GND

8

5V

C3

0.1u

8

VCC

COM

INH

GND

3

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

4

A

3 TO 8 LINE

DECODER

15

14

13

12

11

10

7

74HC138

3 TO 8 LINE

DECODER

17

26

5

TC7W53FK

U1

74HC138

U2

U3

AD0

AD1

AD2

0

R21-24

10k

U5

UPC842G

R30

2k

PHOUT SW

TO

X-PHOTO 1 BOARD

(J11)

J10 J11

1

AD0

2

AD1

3

AD2

4

D

E

AD3

5

AD4

6

AD5

7

AD6

8

PHON

10

SEL0

11

SEL1

12

SEL2

13

SEL3

14

RANGE1

15

RANGE2

17 17

PHCOM

5V

+

C23

C22

6.3V

0.1u

47u

TY-TP42/50P8-S

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

5V 5V

17

18

AD0

2

AD1

3

AD2

4

AD3

AD4

5

6

AD5

7

AD6

PHON

8

9

LEDON

10

SEL0

SEL1

11

SEL2

12

13

SEL3

RANGE1

14

15

RANGE2

16

PENDATA

17

+5V

18

+5V

19

+5V

20

PHCOM

21

ILEDCOM

22

GND

GND

23

GND

24

NC

25

NC

26

TO X-PHOTO 3 BOARD(J10)(TY-TP50P8)

TO X-PHOTO 3 BOARD(J22)(TY-TP42P8)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

AD0

1

AD1

2

AD2

3

AD3

4

AD4

5

AD5

6

AD6

7

PHON

8

LEDON

9

SEL0

10

SEL1

11

SEL2

12

SEL3

13

RANGE1

14

RANGE2

15

PENDATA

16

+5V

17

+5V

18

+5V

19

PHCOM

20

ILEDCOM

21

GND

22

GND

23

GND

24

NC

25

NC

26

5V

C4

0.1u

16

11

A

10

B

9

C

6

INH

3

COM

VSS

R28

100k

7

R31

100k

13

VCC

0

14

1

15

2

12

3

1

4

5

5

2

6

4

7

VEE

7

8

5

+

6

-

74HC4051

8ch

ANALOG

MULTIPLEXER

R29

10k

R32

10k

U4

UPC842G

U5

R33

2k

PH.SINK1

PH.SINK2

PH.SINK3

PH.SINK4

PH.SINK5

PH.SINK6

PH.SINK7

PH.SINK8

1

5V

C5

0.1u

2

8

3

+

4

AD3

AD4

AD5

AD6

5V

RANGE1

RANGE2

PHON

C6

3300p

Q1

FB1L2Q

R37

200

R38

2k

8

1

4

U7

UPC842G

R25-27

10k

5V

-

+

UPC842G

7

C8

0.1u

U7

R39-42

10k

5V

11

10

9

6

14

15

4

2

3

5

+

6

-

X-Photo 2 Board Schematic Diagram

5V

C10

0.1u

1

2

3

6

4

5

1

2

3

6

49

5

A

B

C

INH

X

Y

Z

16

VCC

Y0

A

Y1

B

Y2

C

Y3

Y4

Y5

G1

Y6

G2A

Y7

G2B

GND

8

5V

C11

0.1u

16

VCC

Y0

A

Y1

B

Y2

C

Y3

Y4

Y5

G1

Y6

G2A

Y7

G2B

GND

8

5V

C7

0.1u

16

12

VCC

X0

13

X1

2

Y0

1

Y1

5

Z0

3

Z1

VEE

VSS

8

7

U6

74HC4053

OPTICAL NOISE CANCEL,

GAIN CONTROL

C9

3300p

15

14

13

12

11

10

9

7

3 TO 8 LINE

DECODER

15

14

13

12

11

10

7

5.1k

1.2k

U8

74HC238

R34

2k

R35

R36

PH.DRV1

PH.DRV2

PH.DRV3

PH.DRV4

PH.DRV5

PH.DRV6

PH.DRV7

PH.DRV8

PH.DRV9

PH.DRV10

U9

74HC238

3 TO 8 LINE

DECODER

PH.DRV5

PH.DRV4

PH.DRV3

PH.DRV2

PH.DRV1

P25P1

PH.SINK1

PH.SINK2

PH.SINK3

PH.SINK4

PH.SINK5

PH.SINK6

PH.SINK7

PH.SINK8

P2 P50

P3

P4

P5

P6

P7

P8

P17P9

P10

P11

P12

P13

P14

P15 P31

P16

C12

0.1u

P26

P18 P74

P19

P20

P21

P22

P23

P24

C13

0.1u

P34

P27

P35

P36

P29

P37

P30

P38

P39

P32

P40

C14

C15

0.1u

0.1u

PHOTO

TRANSISTOR

MATRIX

C

E

P1-P78

PT100MF0MP

X-PHOTO 2 BOARD

G441-K1TD04 (TY-TP42P8-S)

G541-K1TD05 (TY-TP50P8-S)

TY-TP42/50P8-S

X-Photo 2 Board Schematic Diagram

PH.DRV6

P49

P41

P42

P43

P44P28

P52

P45

P53

P46

P54

P55

P47

P56

P48

C16

C17

0.1u

0.1u

P65P33

P57

P66

P58

P59

P67

P68

P60

P61

P69

P70

P62

P71

P63

P64

P72

C18

C19

0.1u

0.1u

PH.DRV10

R43

10k

P73

R44

10k

R45

10k

P75P51

R46

10k

P76

R47

P77

10k

R48

10k

P78

R49

10k

R50

10k

C20

C21

0.1u

0.1u

PH.DRV9

PH.DRV8

PH.DRV7

3

42 7

56

81

57

Page 58

TY-TP42P8-S / TY-TP50P8-S

10.4. X-Photo 3 Board Schematic Diagram

5V

A

SEL0

SEL1

SEL2

SEL3

R17-20

10k

5V

B

C

D

E

TY-TP42/50P8-S

X-Photo 3 Board Schematic Diagram

PHCOM

TY-TP50P8 use only

TO

X-PHOTO 2 BOARD

(J11)

1

AD0

2

AD1

3

AD2

4

AD3

5

AD4

6

AD5

7

AD6

8

PHON

10

SEL0

11

SEL1

12

SEL2

13

SEL3

14

RANGE1

15

RANGE2

17 17

PHCOM

5V

+

C23

C22

6.3V

0.1u

47u

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

5V 5V

17

18

5V

C1

0.1u

16

1

A

2

B

3

C

6

G1

4

G2A

5

G2B

15

VCC

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

9

Y6

7

Y7

GND

8

74HC138

3 TO 8 LINE

5V

1

VCC

A

2

B

3

C

6

G1

49

G2A

5

G2B

GND

5V

VCC

CH0

CH1

VEE

3

DECODER

C2

0.1u

16

15

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

Y6

7

Y7

8

8

74HC138

3 TO 8 LINE

DECODER

C3

0.1u

17

COM

26

INH

5

A

GND

U3

4

TC7W53FK

PHOUT SW

J10 J11

1

AD0

2

AD1

3

AD2

4

AD3

5

AD4

6

AD5

7

AD6

8

PHON

9

LEDON

10

SEL0

11

SEL1

12

SEL2

13

SEL3

14

RANGE1

15

RANGE2

16

PENDATA

17

+5V

18

+5V

19

+5V

20

PHCOM

21

ILEDCOM

22

GND

23

GND

24

GND

25

NC

26

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

AD0

AD1

TY-TP50P8

use only

AD2

R3

0

U1

TY-TP42P8

use only

R9

0

U2

TO

X-PHOTO 4 BOARD

(J16)

AD0

1

2

AD1

3

AD2

4

AD3

AD4

5

6

AD5

7

AD6

PHON

8

LEDON

9

SEL0

10

SEL1

11

SEL2

12

13

SEL3

RANGE1

14

15

RANGE2

16

PENDATA

+5V

17

18

+5V

19

+5V

20

PHCOM

ILEDCOM

21

GND

22

GND

23

GND

24

NC

25

NC

26

5V

TY-TP42P8 use only

5V

C4

R21-24

10k

11

10

9

6

3

U5

UPC842G

R30

2k

TO

X-PHOTO 2 BOARD

(J11)

1

2

3

4

55

6

7

8

9

10

11

12

13

14

15

16

17

18

0.1u

16

13

VCC

A

B

C

INH

COM

7

J22 J23

0

14

1

15

2

12

3

1

4

5

5

2

6

4

7

VEE

VSS

7

8

R28

100k

+

-

R31

100k

1

AD0

2

AD1

3

AD2

AD3

5

AD4

6

AD5

7

AD6

8

PHON

9

LEDON

10

SEL0

11

SEL1

12

SEL2

13

SEL3

14

RANGE1

15

RANGE2

16

PENDATA

17

+5V

18

+5V

19

+5V

20

PHCOM

21

ILEDCOM

22

GND

23

GND

24 GND

GND

25

NC

26

NC

5

6

U4

74HC4051

8ch

ANALOG

MULTIPLEXER

R29

10k

R32

10k

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

5V5V

17

18

TO

Y-PHOTO 2 BOARD

(J20)

U5

UPC842G

R33

2k

PH.SINK1

PH.SINK2

PH.SINK3

PH.SINK4

PH.SINK5

PH.SINK6

PH.SINK7

PH.SINK8

5V

8

1

4

AD0

1

2

AD1

AD2

3

AD34

4

AD4

5

AD5

6

AD6

7

PHON

8

9 LEDON

SEL0

10

SEL1

11

SEL2

12