Page 1

I

RMS

10%

1

1

100

Total

Total

half

Input

TV,

S/N

BD/DVD,

Input

TV,

Tone

BASS

TREBLE

Digital

Optical

Coaxial

HDMI

HDMI

This

I

Home Theater Audio System

SC-HTR310P

Colour

(K)... Black Type

ORDER NO. MD0808009CE

A6

Specification

Amplifier Section

output power of each channel driven

total harmonic distortion

kHz Front CH 70 W per channel (4 Ω)

kHz Center CH 70 W per channel (4 Ω)

Hz Subwoofer CH 90 W per channel (3 Ω)

RMS output power 300 W

harmonic distortion

power at 1kHz (Front CH) 0.5 % (4 Ω )

sensitivity

AUX 3 450 mV, IHF’66

at rated power (4 Ω)

TV, AUX 1, AUX 2 80 dB

impedance

AUX 3 47 kΩ

controls

50Hz,+6dBto-6dB

20 kHz, +6 dB to -6 dB

input

Input 1

Output 1

system supports “HDAVI Control 1” function.

General

Power supply AC 120V, 60 Hz

Power consumption

Main set 68 W

Standby (HDMI ON) 0.7 W

Standby (HDMI OFF) 0.3 W

I Rack System

INCLUDING SPEAKER

Dimensions (W x H x D) 1300 mm x 444 mm x 458 mm

Mass approx. 50 kg

* Mass is a Completed (AMP, Speaker Unit inc)

Maximum Loading Weight 80 kg

I Speaker System

FRONT (L/R) 1-Way 1 Speaker System

6.5 cm Cone Type Full Range x1

CENTER 1-Way 1 Speaker System

2

SUBWOOFER 1-Way 2 Speaker System

1

Notes :

1. Specifications are subject to change without notice.

2. Total harmonic distortion is measured by the digital spectrum

analyser.

6.5 cm Cone Type Full Range x1

13 cm Cone Type Woofer x2

(Bass Reflect)

(Bass Reflect)

(Bass Reflect)

© 2008 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

SC-HTR310P

CONTENTS

Page Page

1 Safety Precaution s 3

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Handling the Lead free Solder

4 Operating Procedures

5 Self Diagnosis Display Function

6 HDMI Checking Method

7 Assembling and Disassembling

8 Service Position

9 Voltage Measurement & Waveform Chart

10 Wiring Connection Diagram 103

11 Block Diagram

6

12 Notes Of Schematic Diagram

7

13 Schematic Diagram

14 Printed Circuit Board Diagrams

8

25

15 Illustration of IC’s, Transistors and Diodes

29

16 Terminal Function of IC’s

17 Exploded Views

31

84

18 Replacement Parts List

92

105

109

111

127

135

136

137

141

2

Page 3

SC-HTR310P

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to prevent the

customer from being exposed to a shock hazard.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each expose d metallic cabine t part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

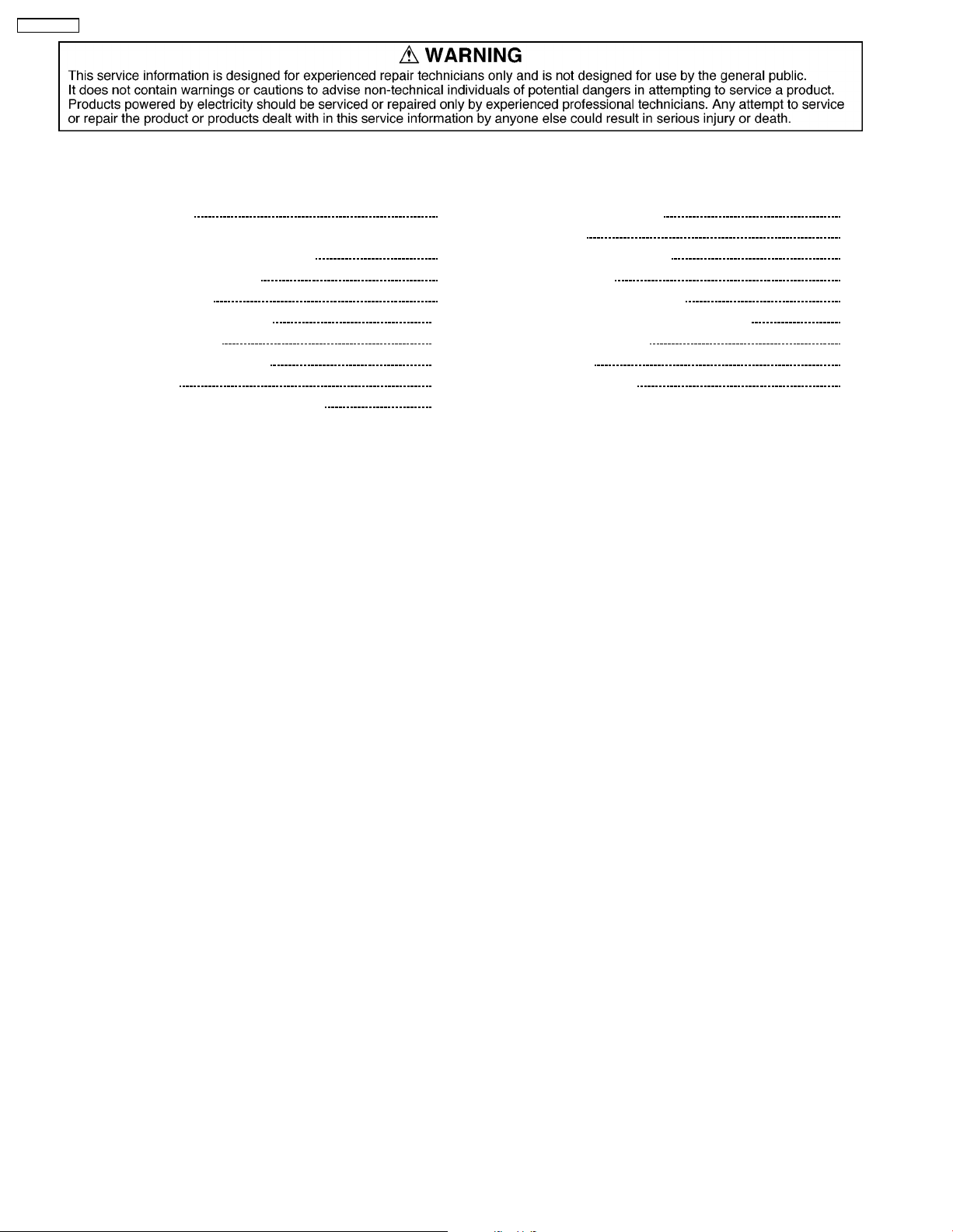

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolatio n transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

Fig. 1

3

Page 4

SC-HTR310P

1.2. Before Repair and Adjustment

Disconnect AC power, discharge ac capacitors C5712, C5808, C5805, C5813, C5816, C5824, C5517 , C5516, C5508, C5509,

C5510, C5511, C5512 and C5513 through a 10Ω, 1W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 120 V, 60 Hz in NO SIGNAL mode (at volume minimum) should be 200 ~ 800 mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connec tion wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

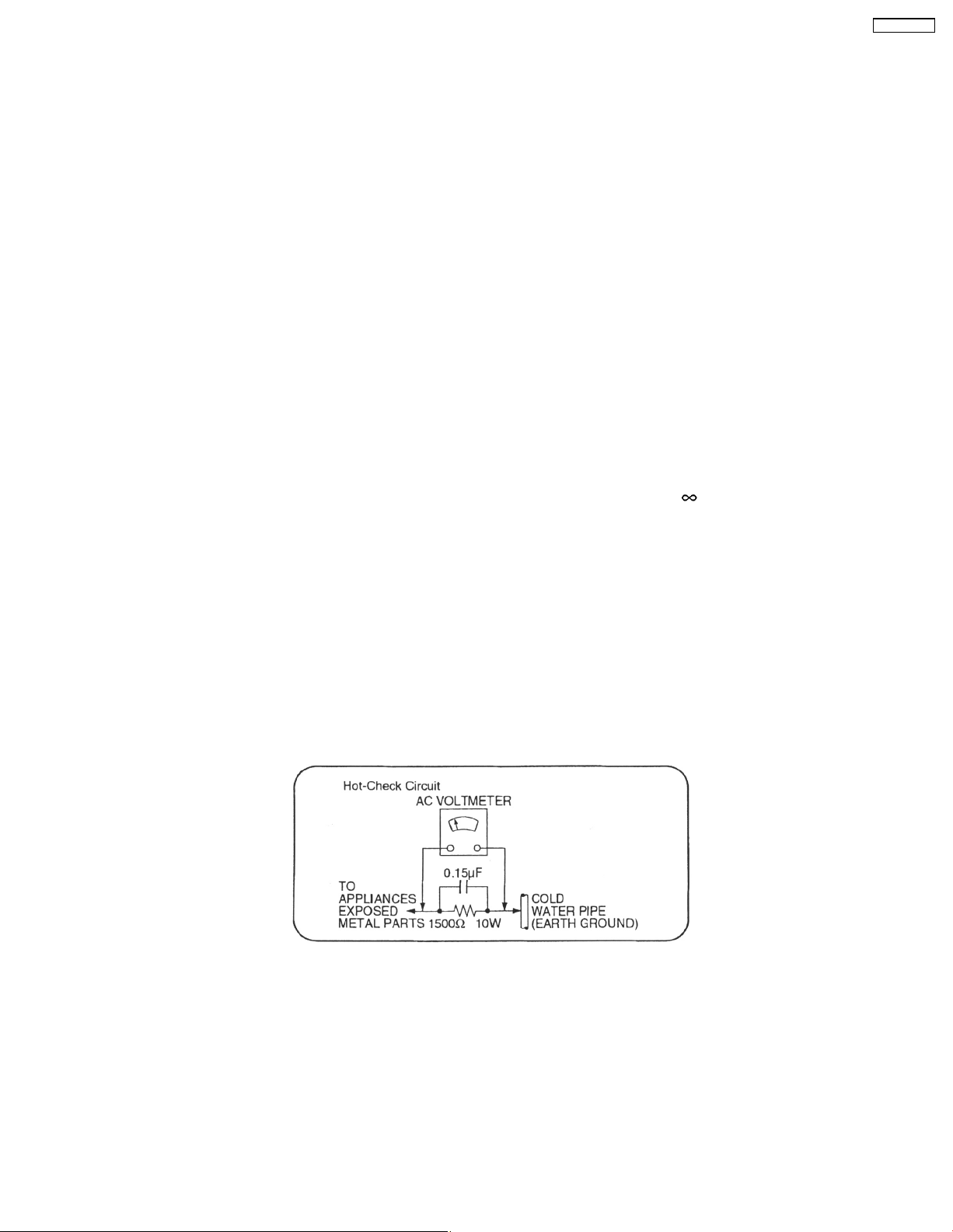

1.4. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.These parts are marked by

Schematic Diagrams & Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s

specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of manufacturer.

Table 1

Reference No. Part No. Part Name & Description Remarks

8 REXX0640-J BLACK WIRE [M]

9 REXX0641-J RED WIRE [M]

14 RKMX0141B-S1 TOP CABINET [M]

15 RGR0383D-C REAR PANEL [M]

A2 K2CB2CB00021 AC CORD [M]

A6 RFA2903 TOP GLASS ACCESSORY [M]

A8 RXQ1607 PREPARED GLASS DOOR ASSY L [M]

A9 RXQ1608 PREPARED GLASS DOOR ASSY R [M]

DZ5701 ERZV10V511CS ZENER [M]

L5701 ELF15N035AN LINE FILTER [M]

L5702 ELF22V020A LINE FILTER [M]

T701 G4D1A0000117 SW TRANSFORMER [M]

T5701 ETS42BM1A1AC TRANSFO RMER [M]

T5751 ETS19AB281AG BACKUP TRANSFORMER [M]

PC5701 B3PBA0000402 PHOTO COUPLER [M]

PC5720 B3PBA0000402 PHOTO COUPLER [M]

PC5799 B3PBA0000402 PHOTO COUPLER [M]

F1 K5D802APA008 FUSE [M]

IP701 K5H5012A0010 IC PROTECTOR [M]

IP702 K5H302100004 IC PROTECTOR [M]

TH5701 D4CAA2R20001 THERMISTOR [M]

TH5860 D4CC11040013 THERMISTOR [M]

P5701 K2AB2B000011 AC INLET [M]

PCB5 REPX0676N SMPS P.C.B. / AC INLET P.C.B. [M] (RTL)

in the

4

Page 5

1.5. Caution for fuse replacement

SC-HTR310P

5

Page 6

SC-HTR310P

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handlin g any semiconducto r component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficie nt to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conduc tive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installe d.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficie nt to

damage an ES device).

6

Page 7

SC-HTR310P

3 Handling the Lead free Solder

3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or component s side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

7

Page 8

SC-HTR310P

4 Operating Procedures

4.1. Control guide

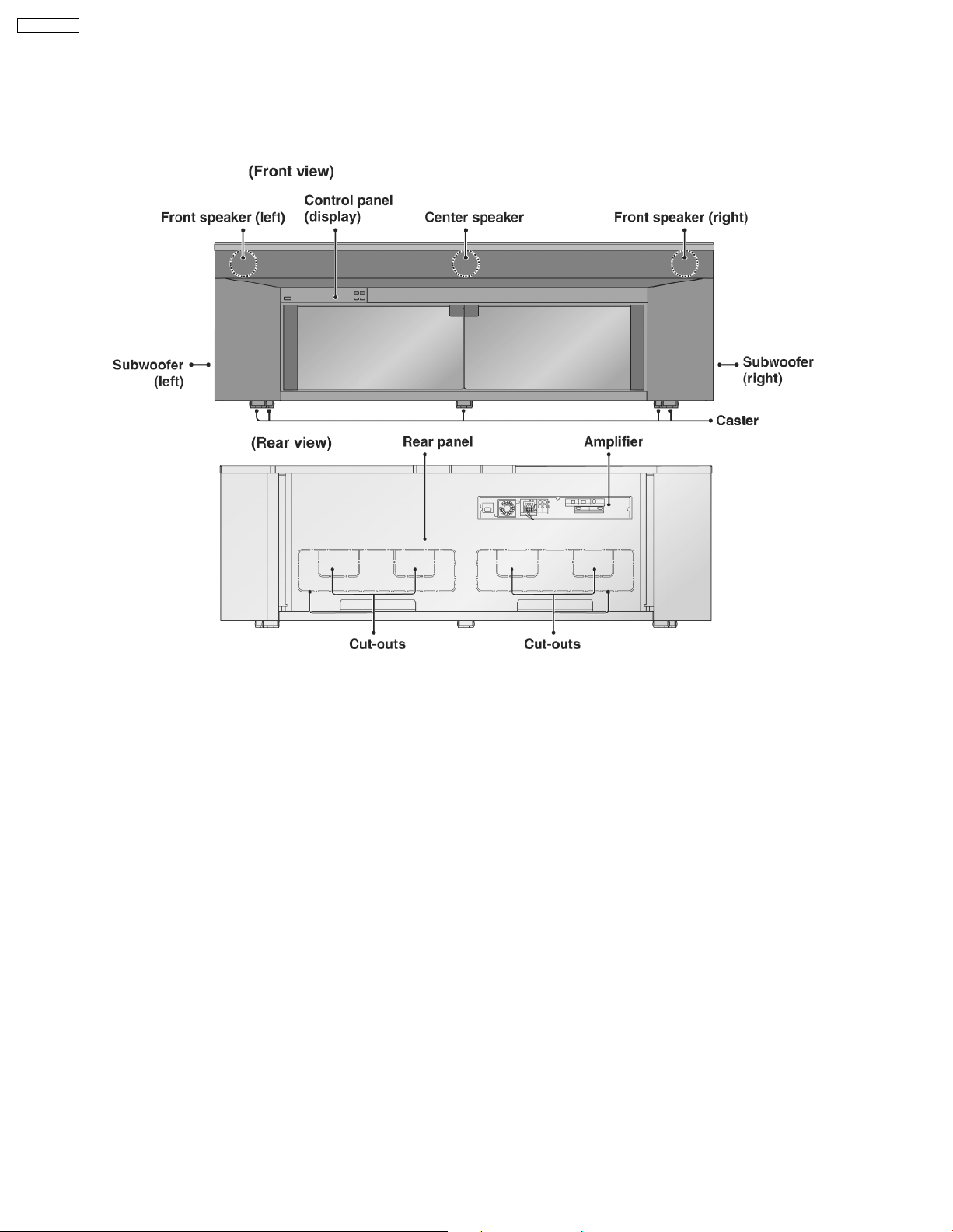

4.1.1. This system

8

Page 9

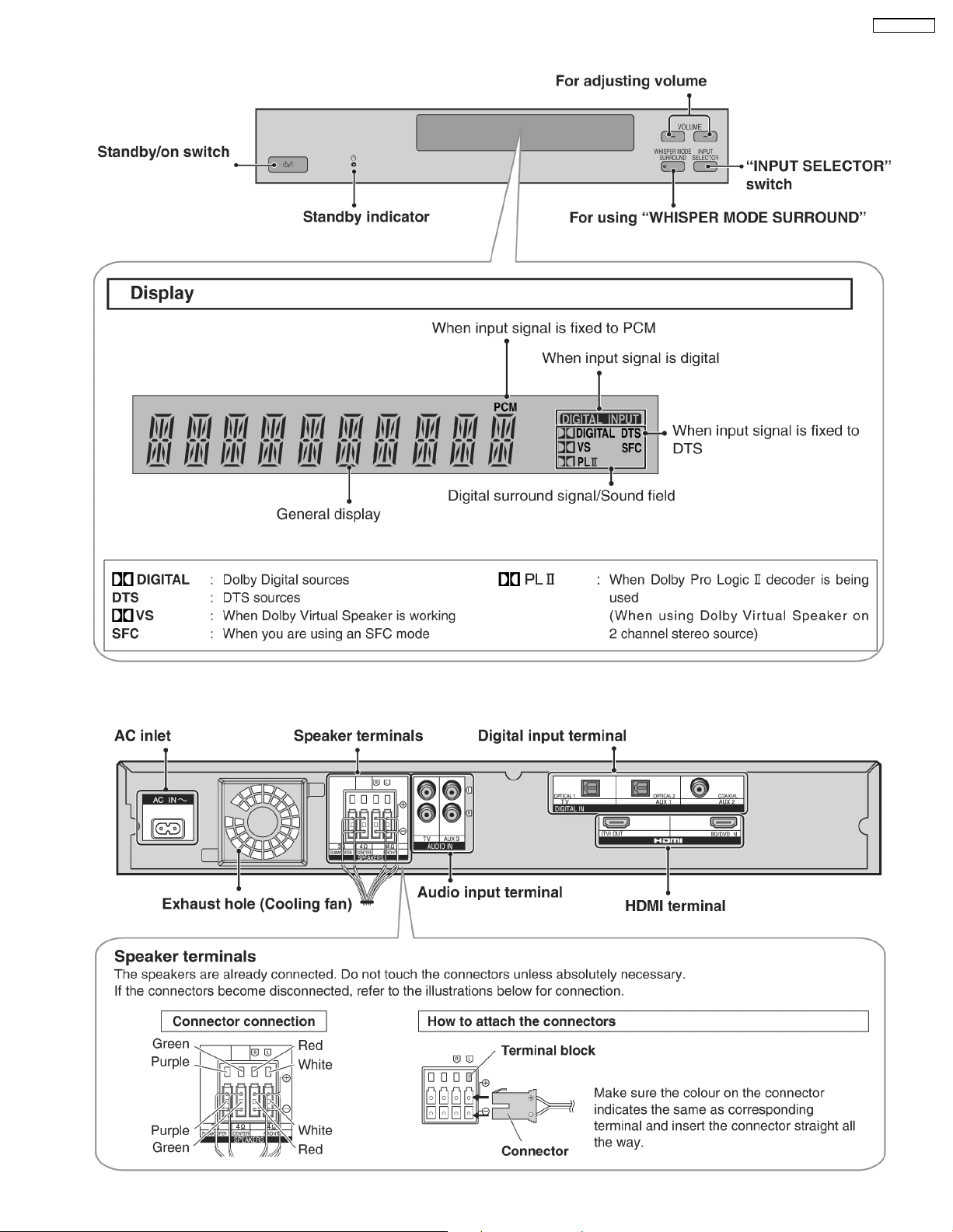

4.1.2. Control panel

SC-HTR310P

4.1.3. Amplifier

9

Page 10

SC-HTR310P

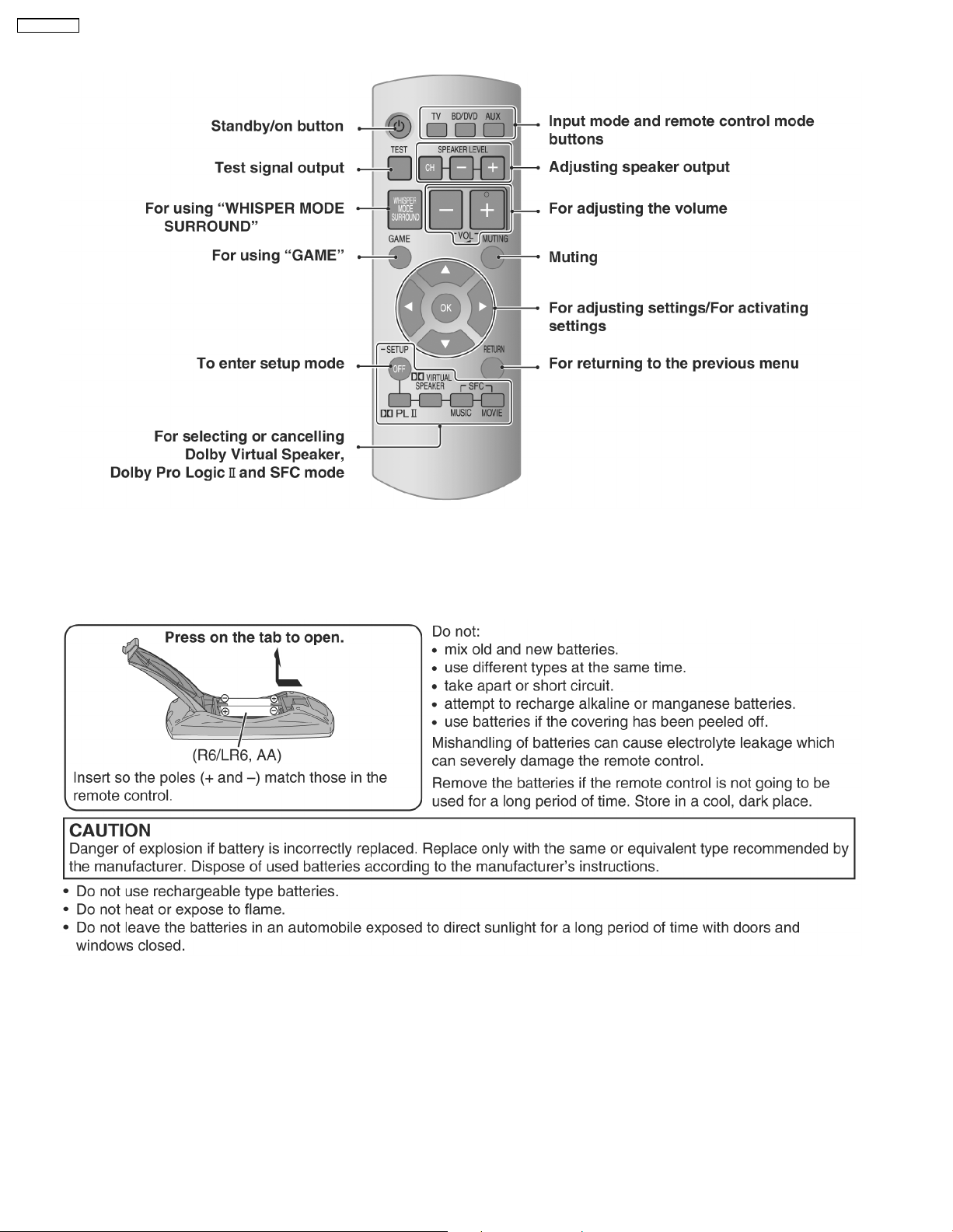

4.1.4. Remote control

4.2. Remote control preparation

4.2.1. Inserting the batteries

10

Page 11

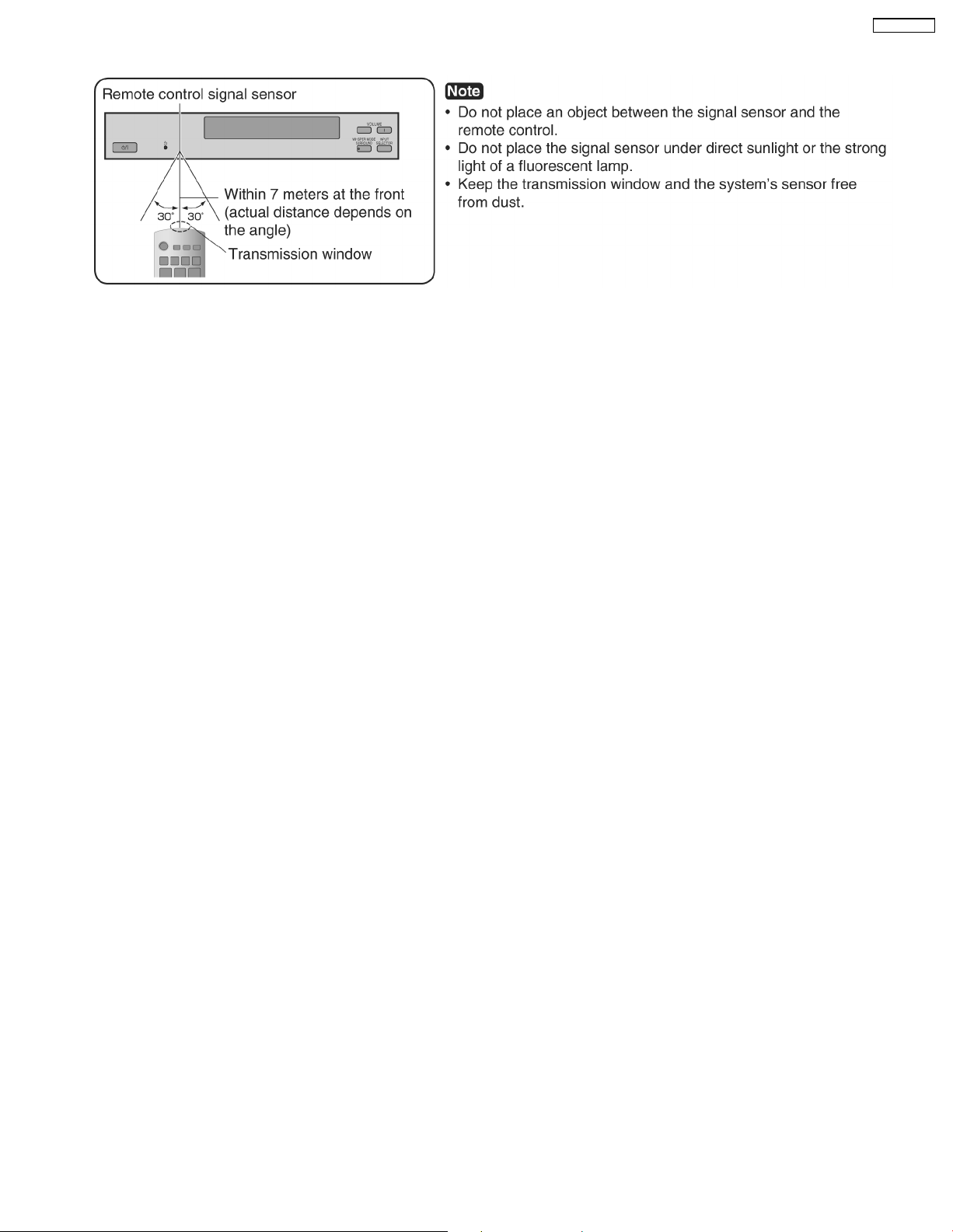

4.2.2. Using the remote control

SC-HTR310P

11

Page 12

SC-HTR310P

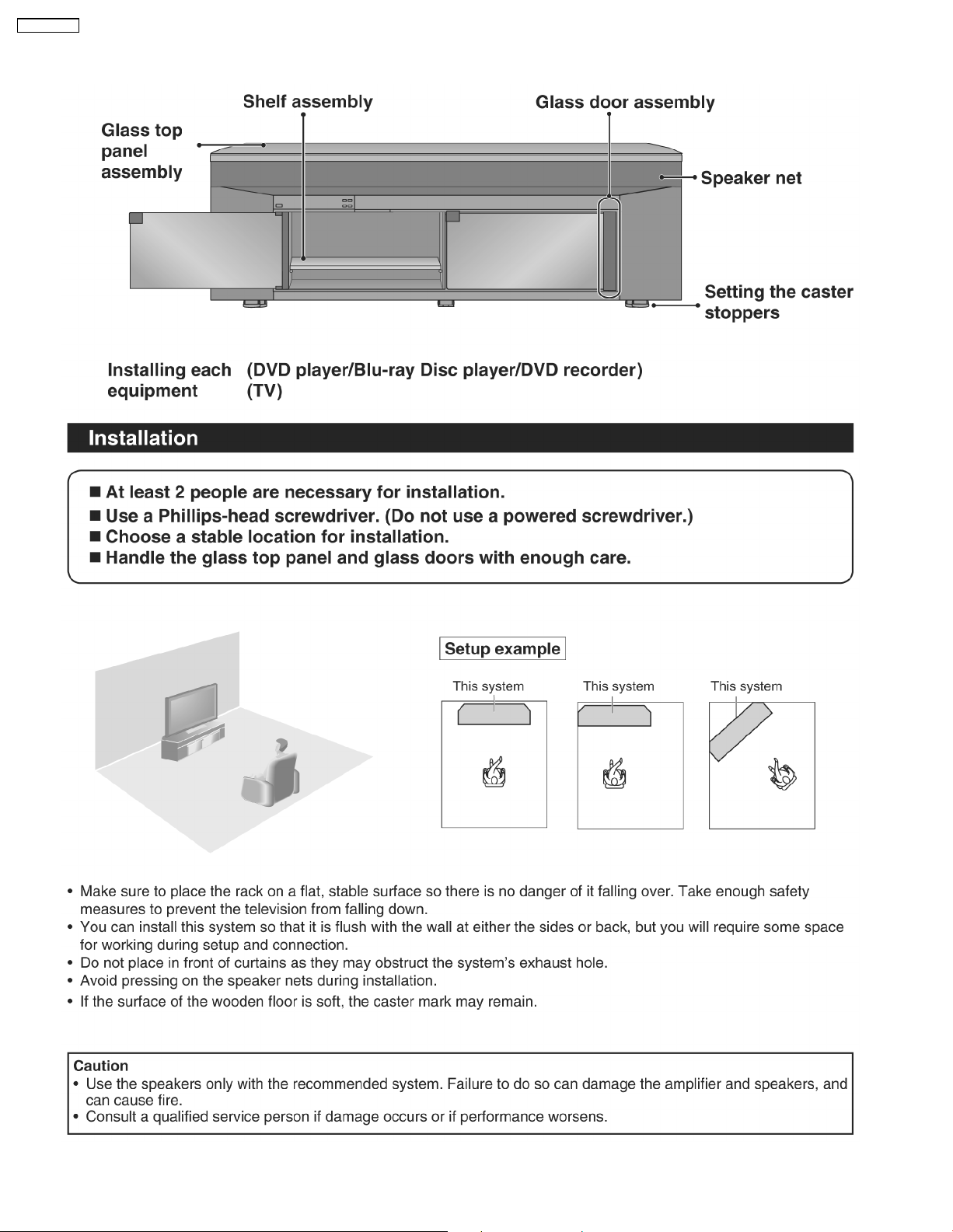

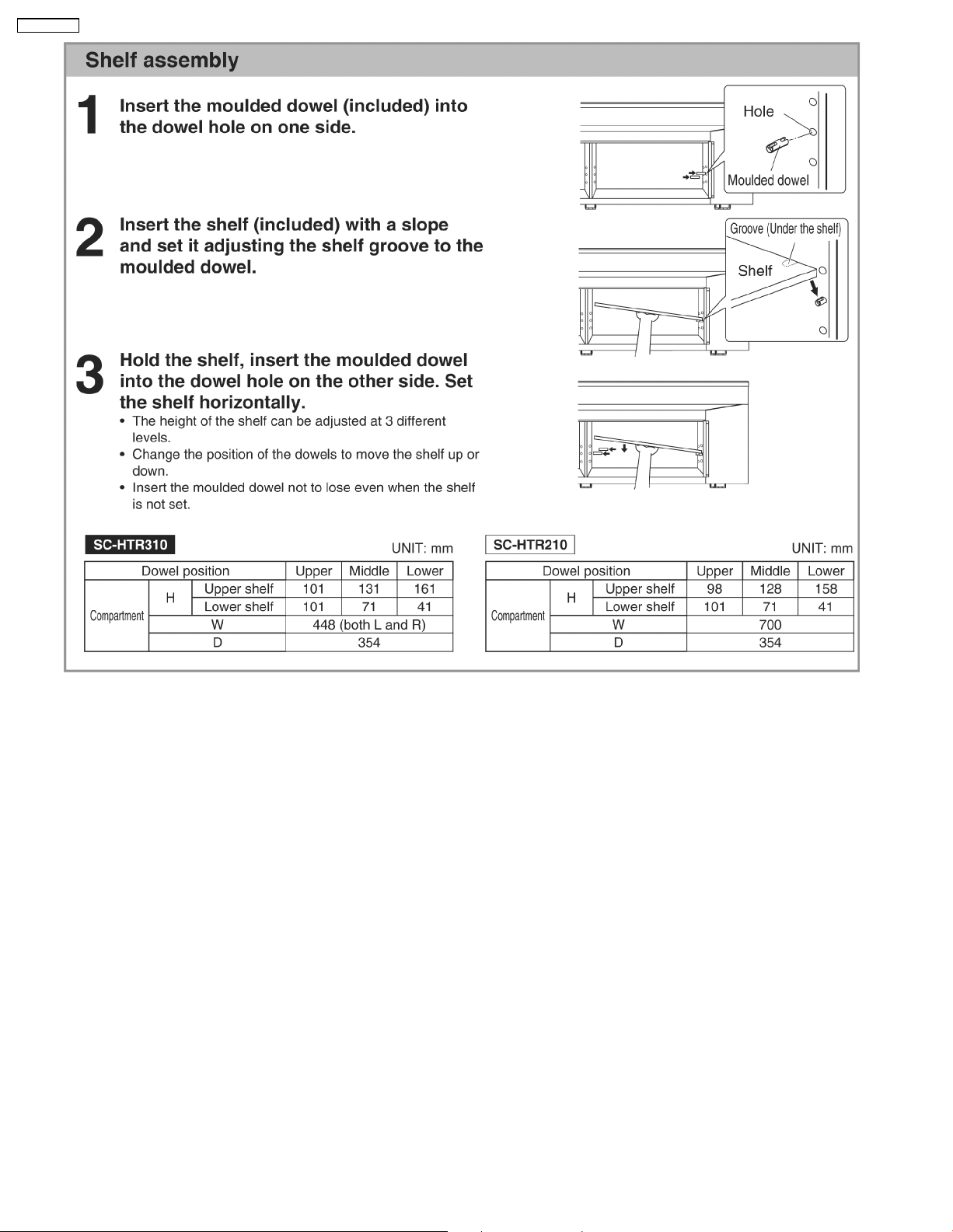

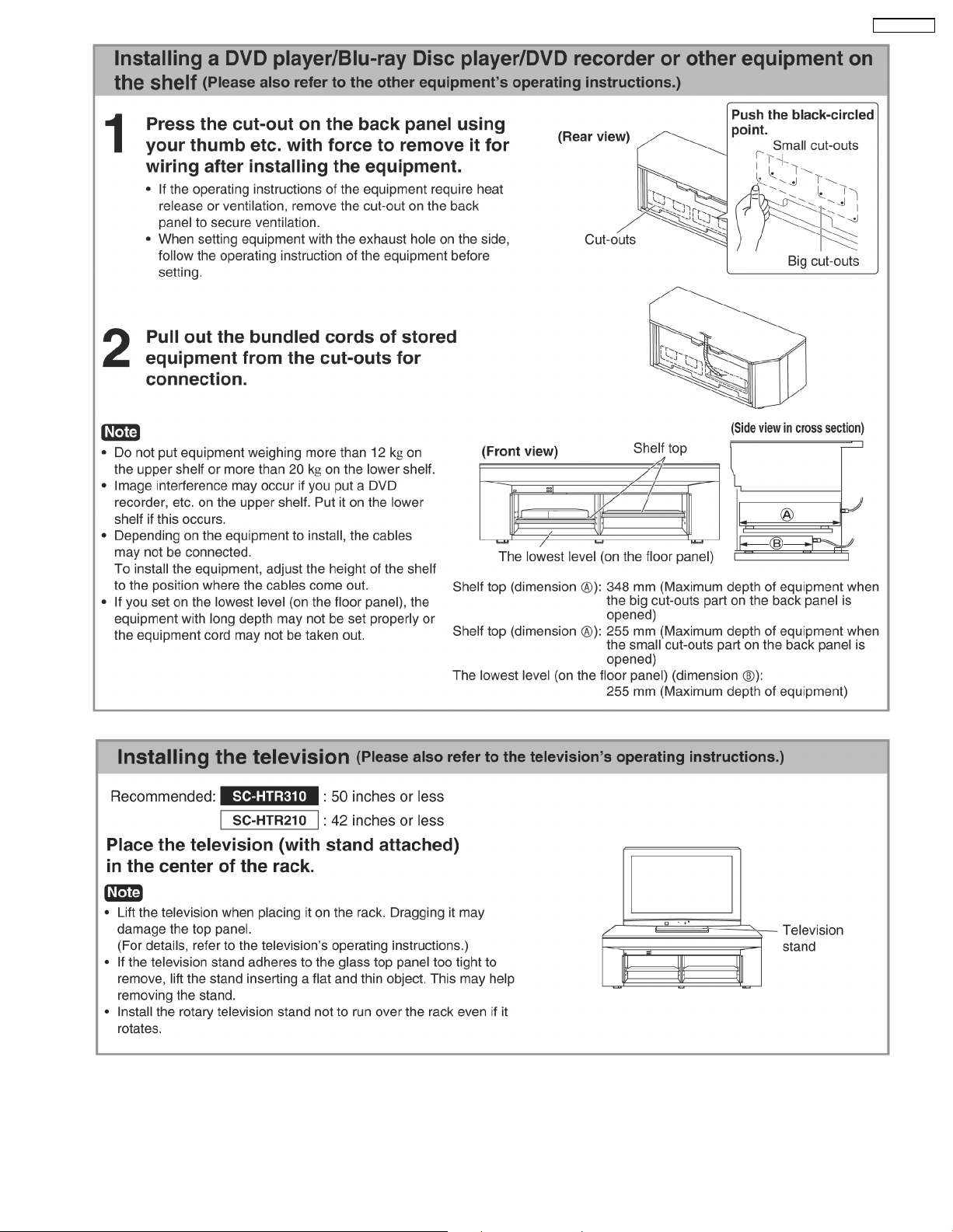

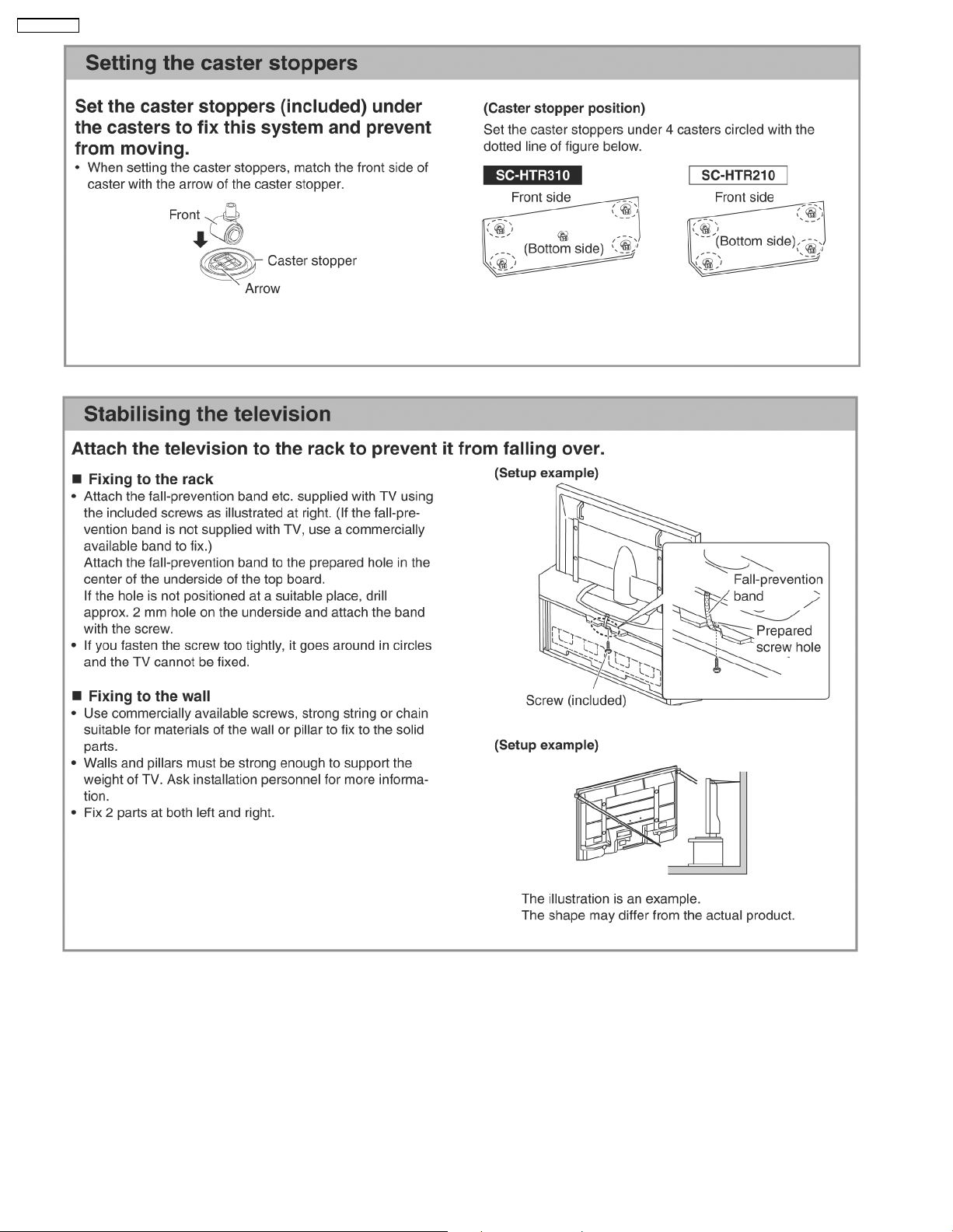

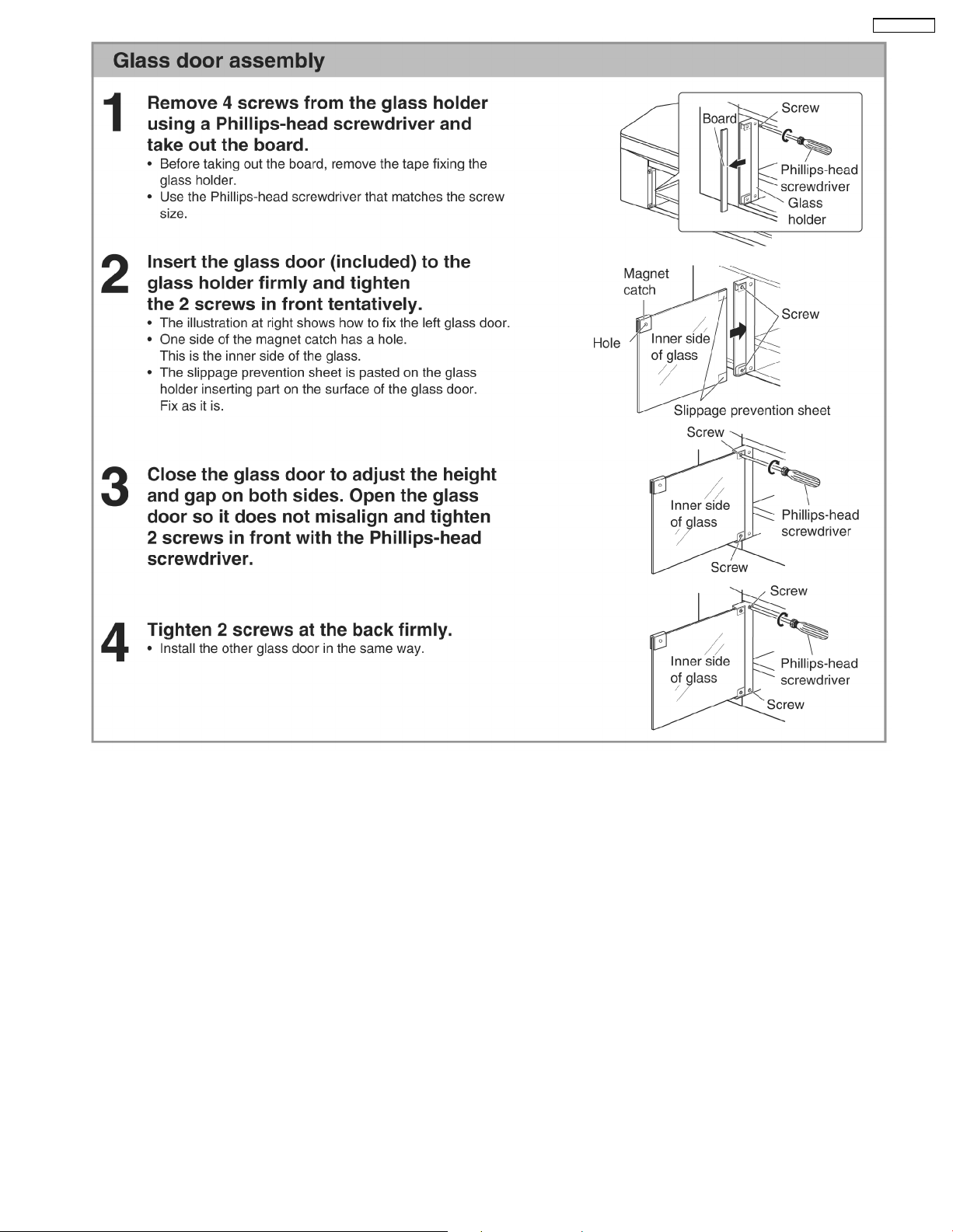

4.3. Installing and assembling the rack

12

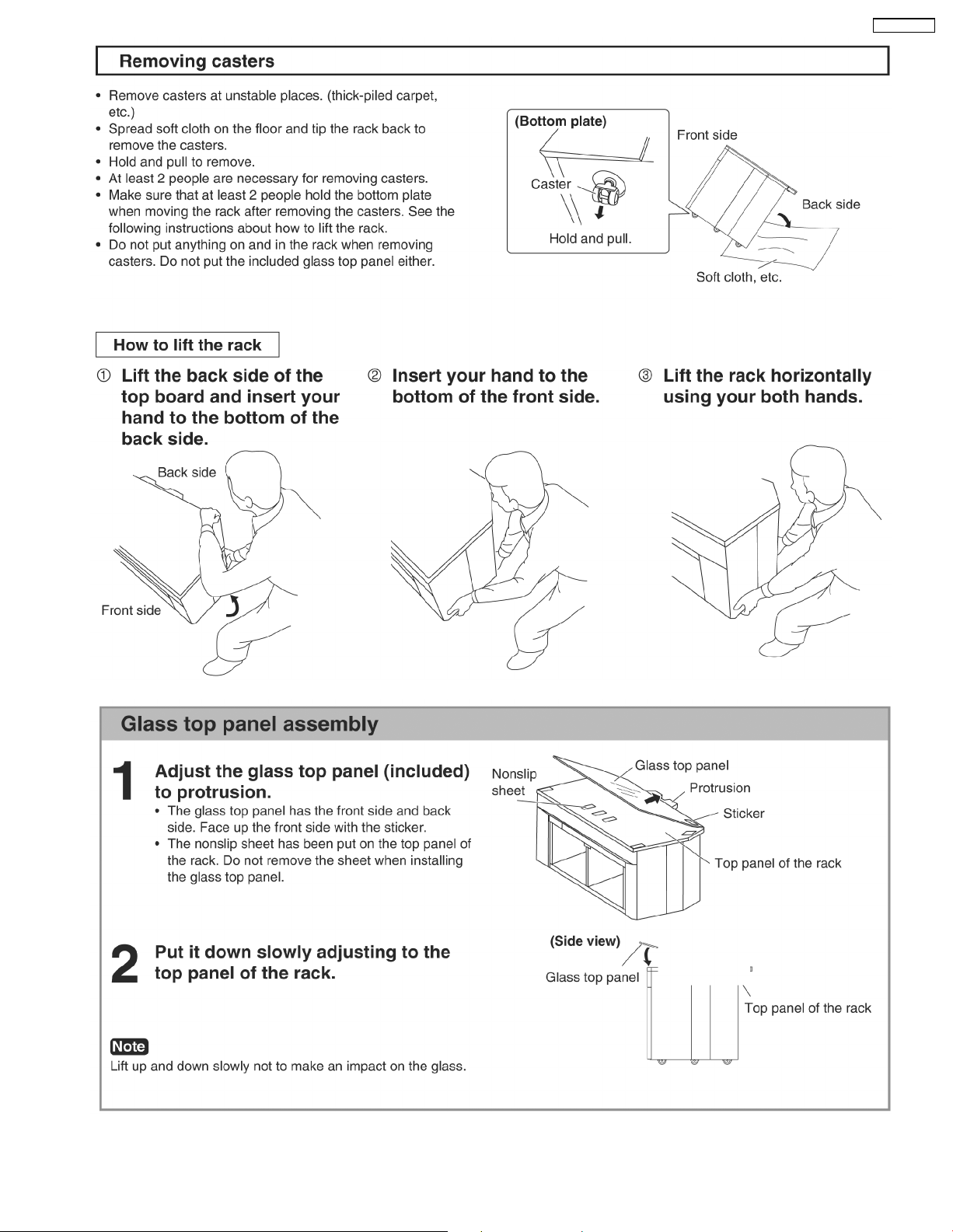

Page 13

SC-HTR310P

13

Page 14

SC-HTR310P

14

Page 15

SC-HTR310P

15

Page 16

SC-HTR310P

16

Page 17

SC-HTR310P

17

Page 18

SC-HTR310P

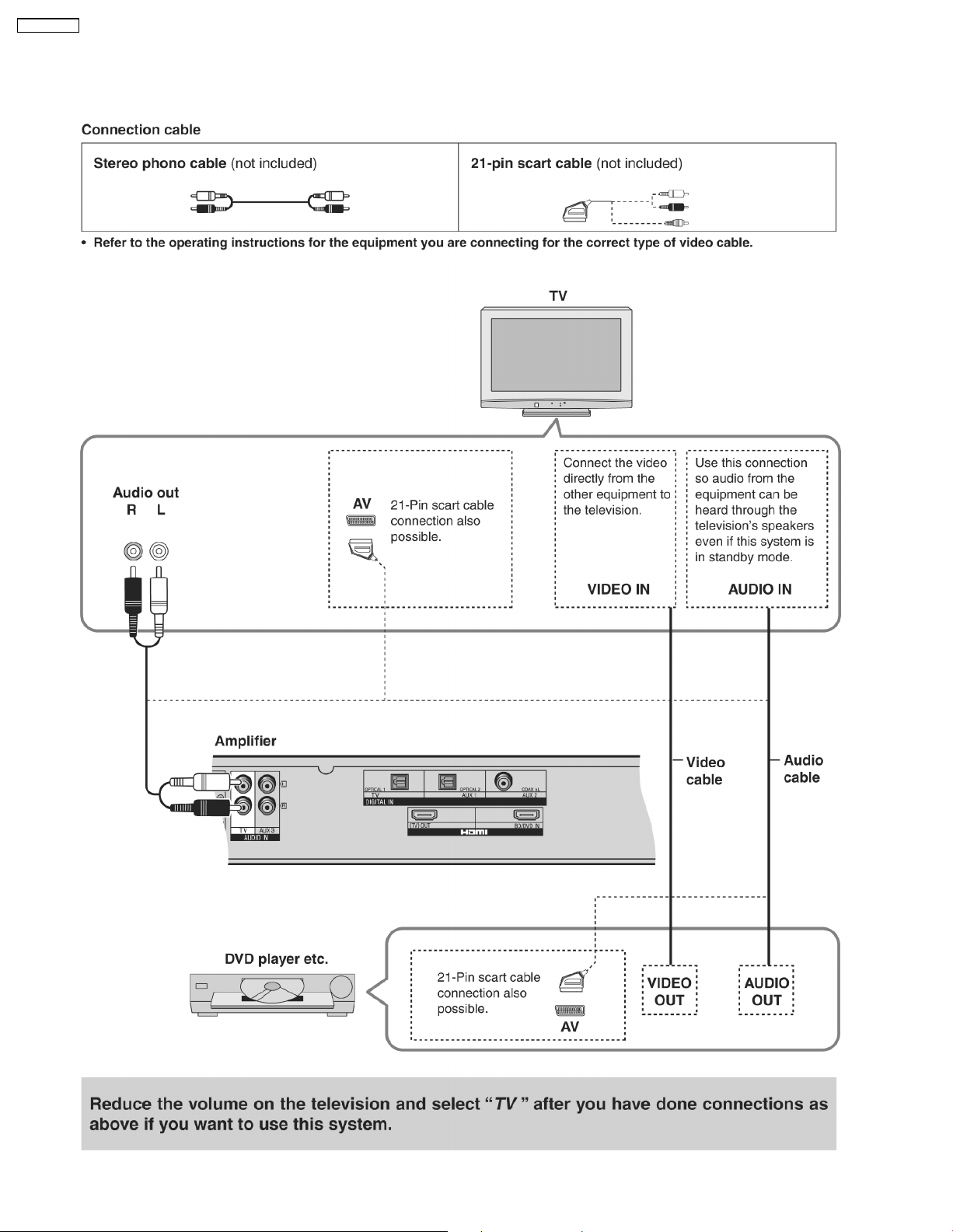

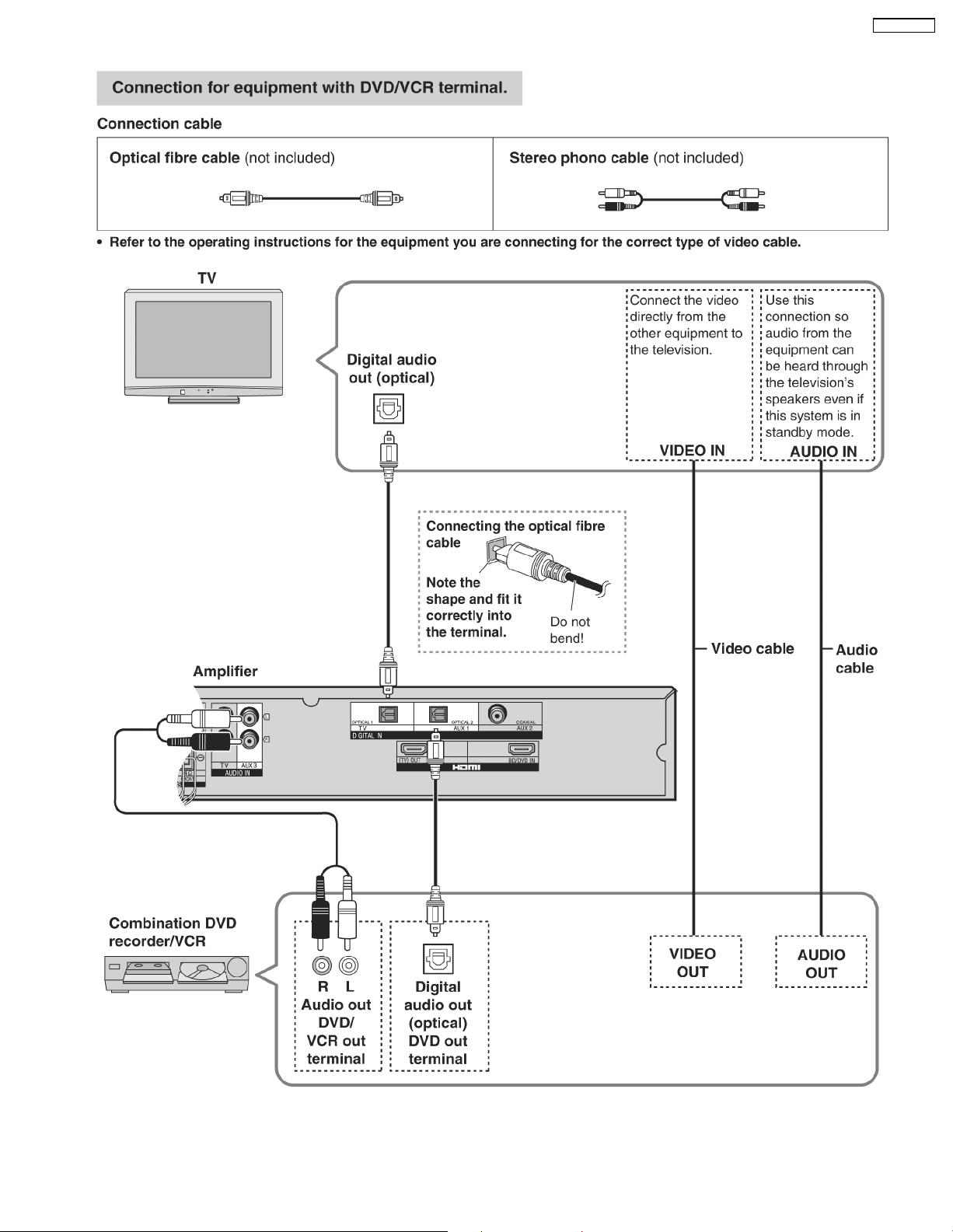

4.4. Home Theater connections

4.4.1. Basic connections

18

Page 19

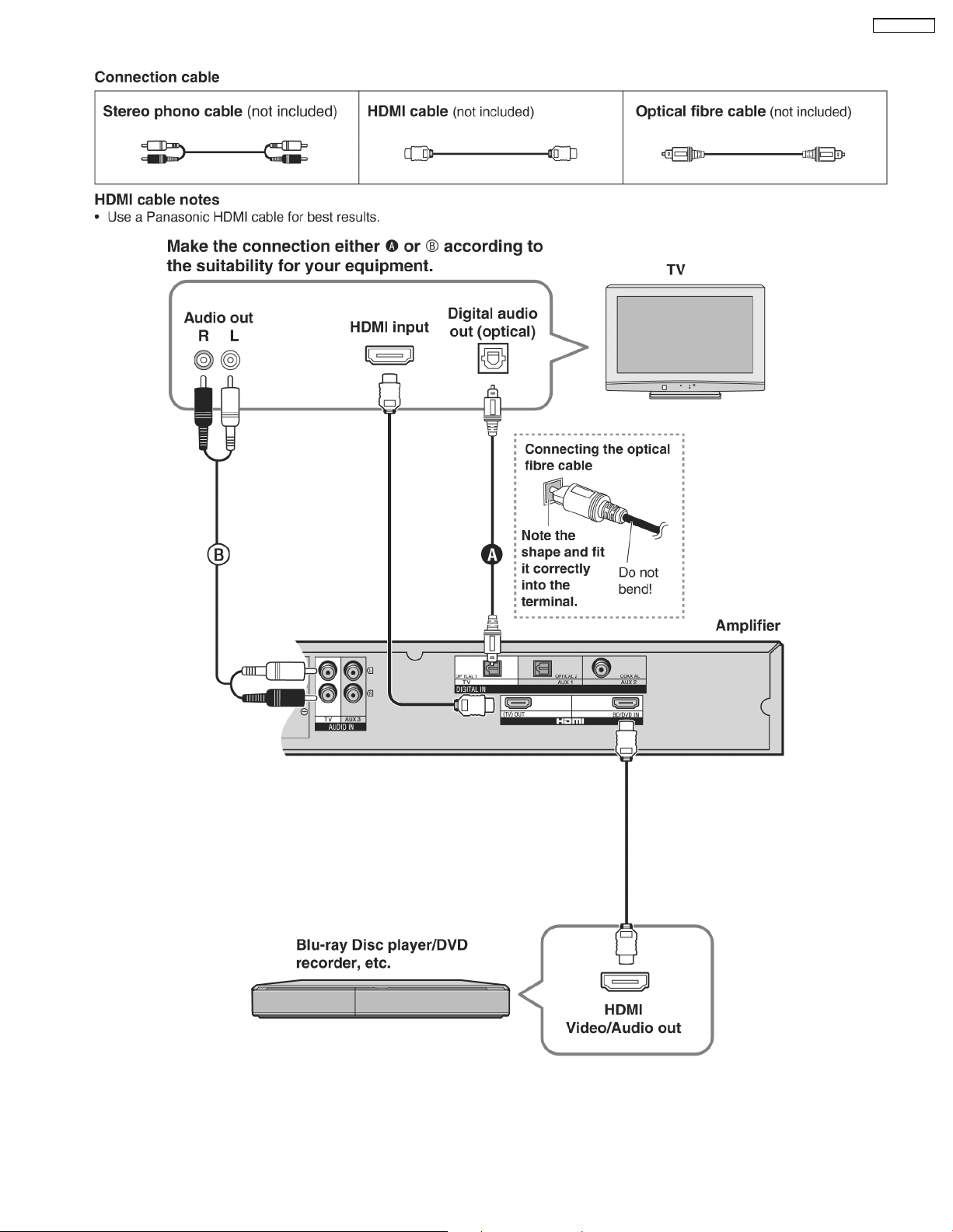

4.4.2. Connecting equipment with HDMI terminal (TV, DVD recorder, etc.)

SC-HTR310P

19

Page 20

SC-HTR310P

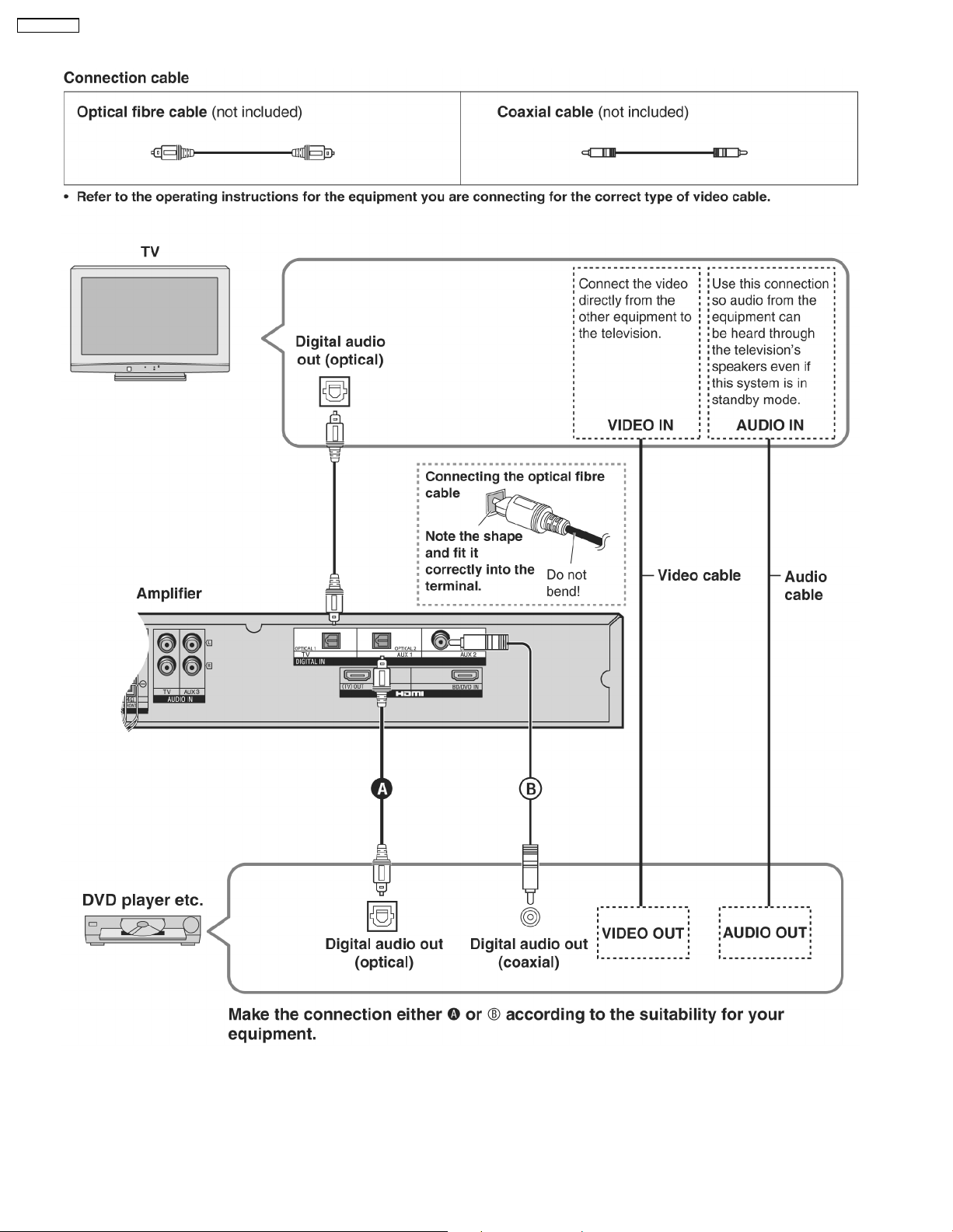

4.4.3. Connecting with digital terminal-mouted equipment

20

Page 21

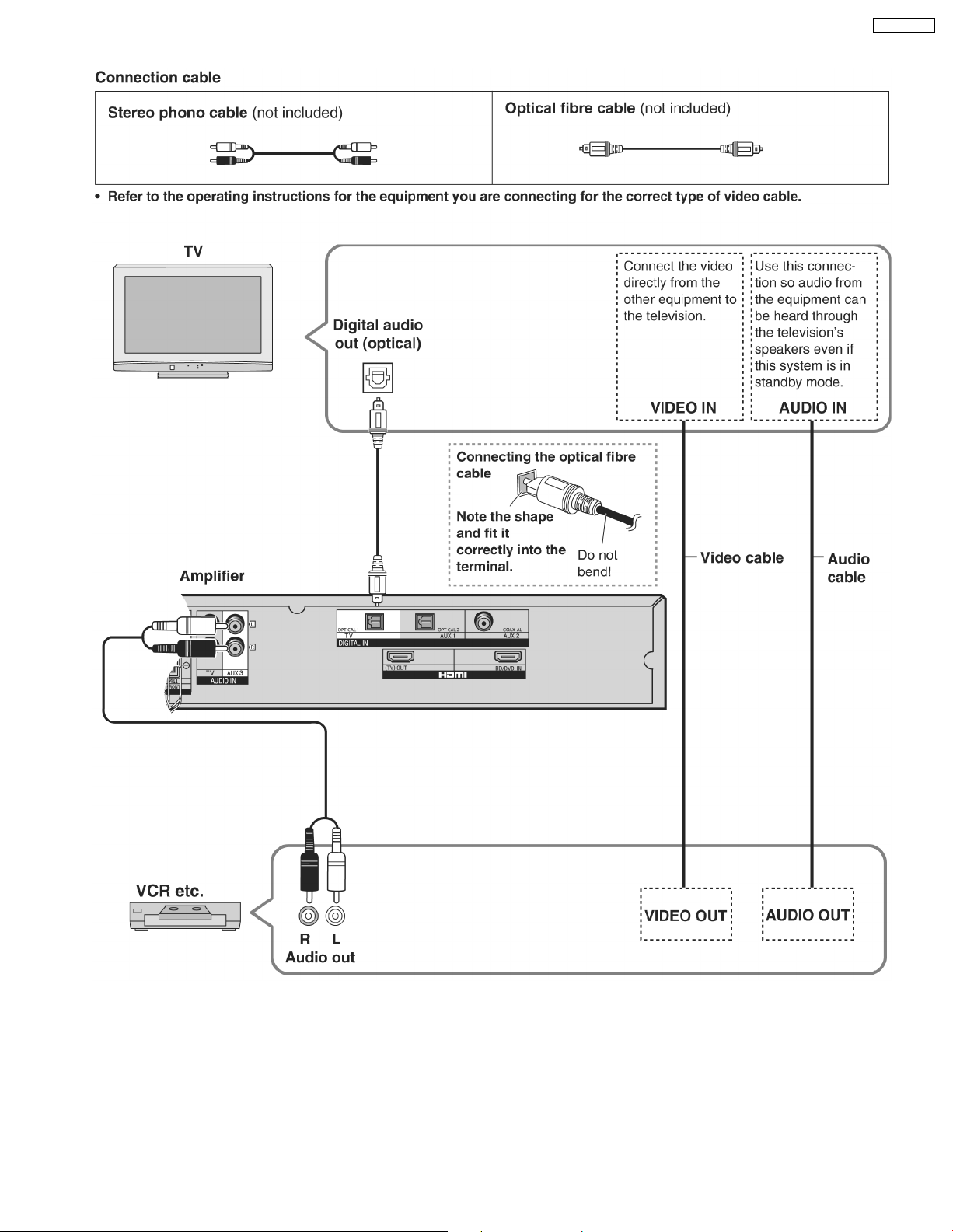

4.4.4. Connecting with VCR

SC-HTR310P

21

Page 22

SC-HTR310P

4.5. Other connections

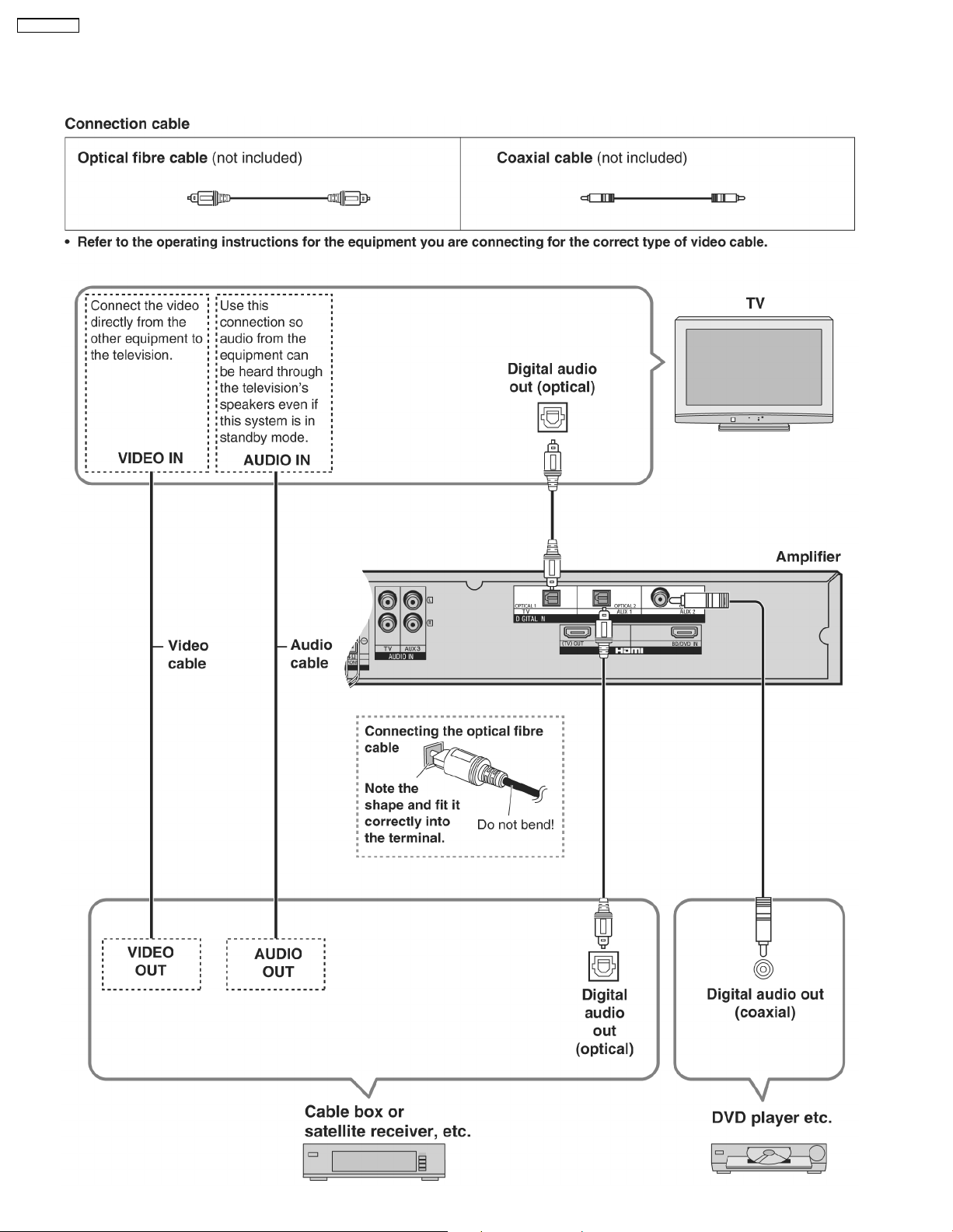

4.5.1. Connecting a set top box (cable or satellite)

22

Page 23

4.5.2. Connecting a combination DVD recorder/VCR

SC-HTR310P

23

Page 24

SC-HTR310P

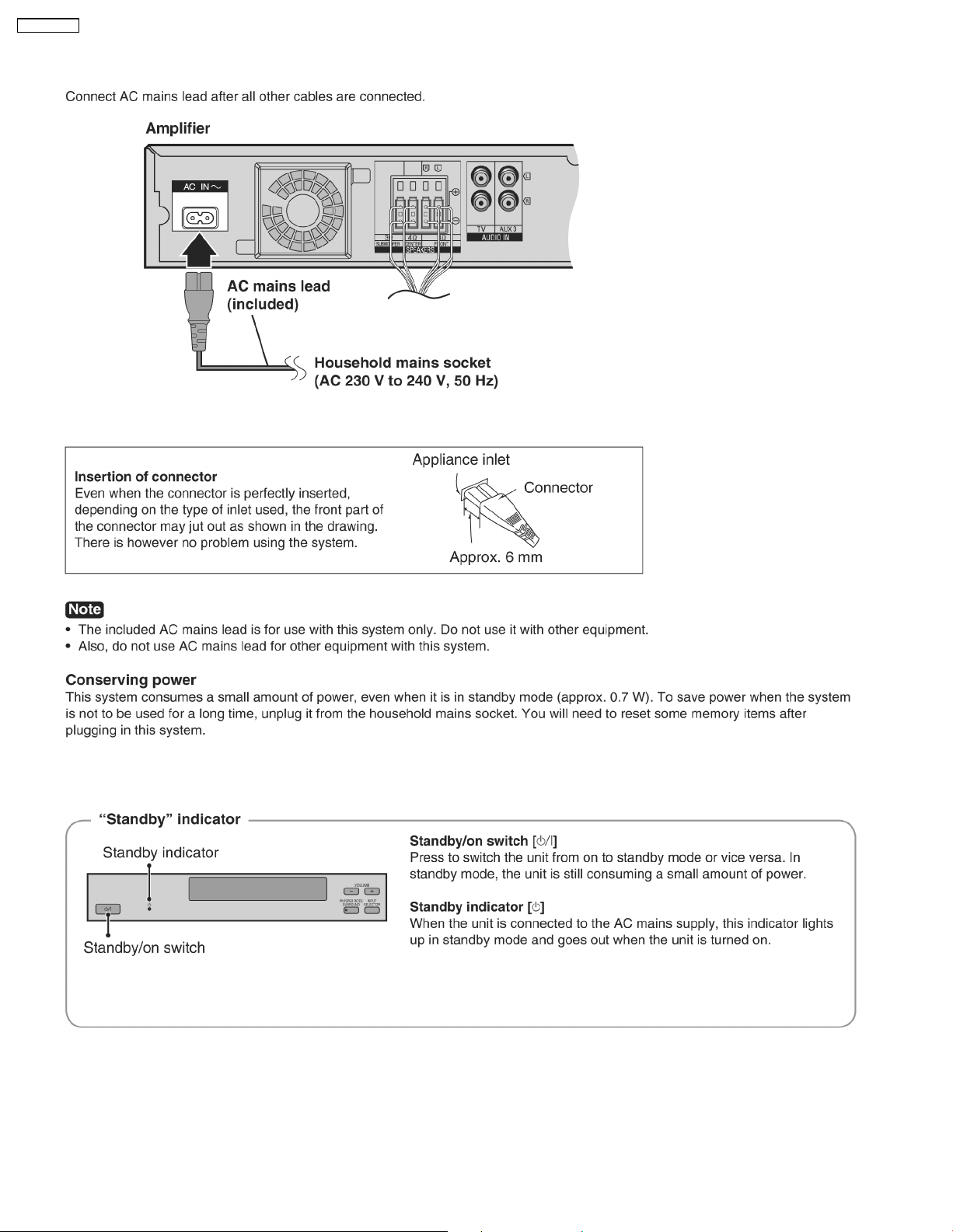

4.6. AC mains supply connection

24

Page 25

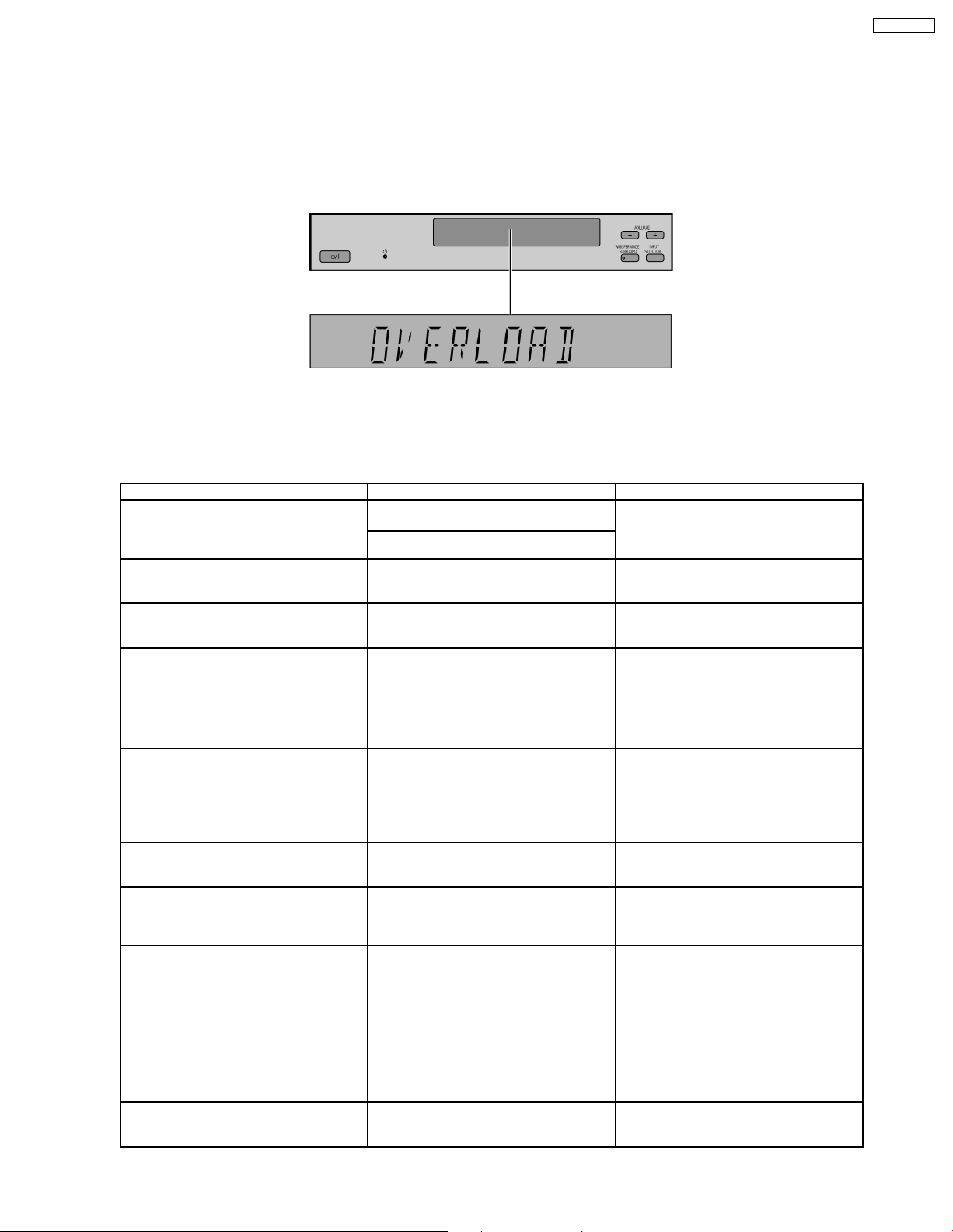

5 Self Diagnosis Display Function

SC-HTR310P

This unit is equipped with the self diagnosis display function,

during servicing.

which alarms faulty operation with error code. Use this function

5.1. Automatically Displayed Error Codes

An error code automatically appears on the display (LCD) when faulty operation is detected. Refer to Fig. 5.1.

Fig. 5.1

5.2. Display Details

Refer to the following table.

LCD display Symptom Cause and Remedy

OVERLOAD Speaker short, amplifier failure, electrical

FANLOCK Fan stopped Failure fan and fan control circuits. Check

F70 Communication error between sub micro-

F76 When the power is turned on, the unit

Remote 2

Remote 1

U70-1-1 — The equipment connected by the HDMI

U70-1-2 — The system is receiving video signals that

U70-3 — A problem has occurred with the HDMI

NOT POSSIBLE FOR THIS INPUT

SOURCE

(Scrolling)

overload etc.

Humidity protection activated

processor and its peripheral LSI

power automatically turns off; the power

cannot be turned on.

— Set the same remote control code for this

— You cannot use Dolby Virtual Speaker,

Speaker short and failure in power

amplifier, pre-amplifier circuits. Check for

faulty parts and replace with new parts if

necessary.

for faulty parts and replace with new parts

if necessary.

Failure sub-micro processor and its

peripherals LSI. Check for faulty parts and

replace with new parts if necessary.

Failure in the power circuit system of the

unit. This may happen when the direct

current electricity is supplied to speaker

terminals. Check that the speaker wires

are not shorted (bare wire touching each

other) or that the unit is in a hot

enviroment without proper ventillation.

system and remote control.

• If “REMOTE 2” is displayed, set remote

control code to “2”.

• If “REMOTE 1” is displayed, set remote

control code to “1”.

cable is not compatible with this system’s

copyright protection technology.

are incompatible with it through HDMI

connection. Check the settings of the

connected equipment.

connection. Try the following to correct the

problem. Consult your dealer if the error

code remains on the display.

• Turn the connected equipment off and

on again.

• Disconnect the HDMI cable then

reconnect it.

• Do not connect more than 2 equipment

in series to the output of this system.

Dolby Pro Logic II and SFC for dual

sounds.

25

Page 26

SC-HTR310P

LCD display Symptom Cause and Remedy

NOT POSSIBLE FOR THIS PCM

SOURCE

(Scrolling)

— You cannot use Dolby Virtual Speaker,

Dolby Pro Logic and SFC effect with PCM

signals with sampling frequency over 48

kHz.

SFC is not available for multi-channel

LPCM signal.

26

Page 27

SC-HTR310P

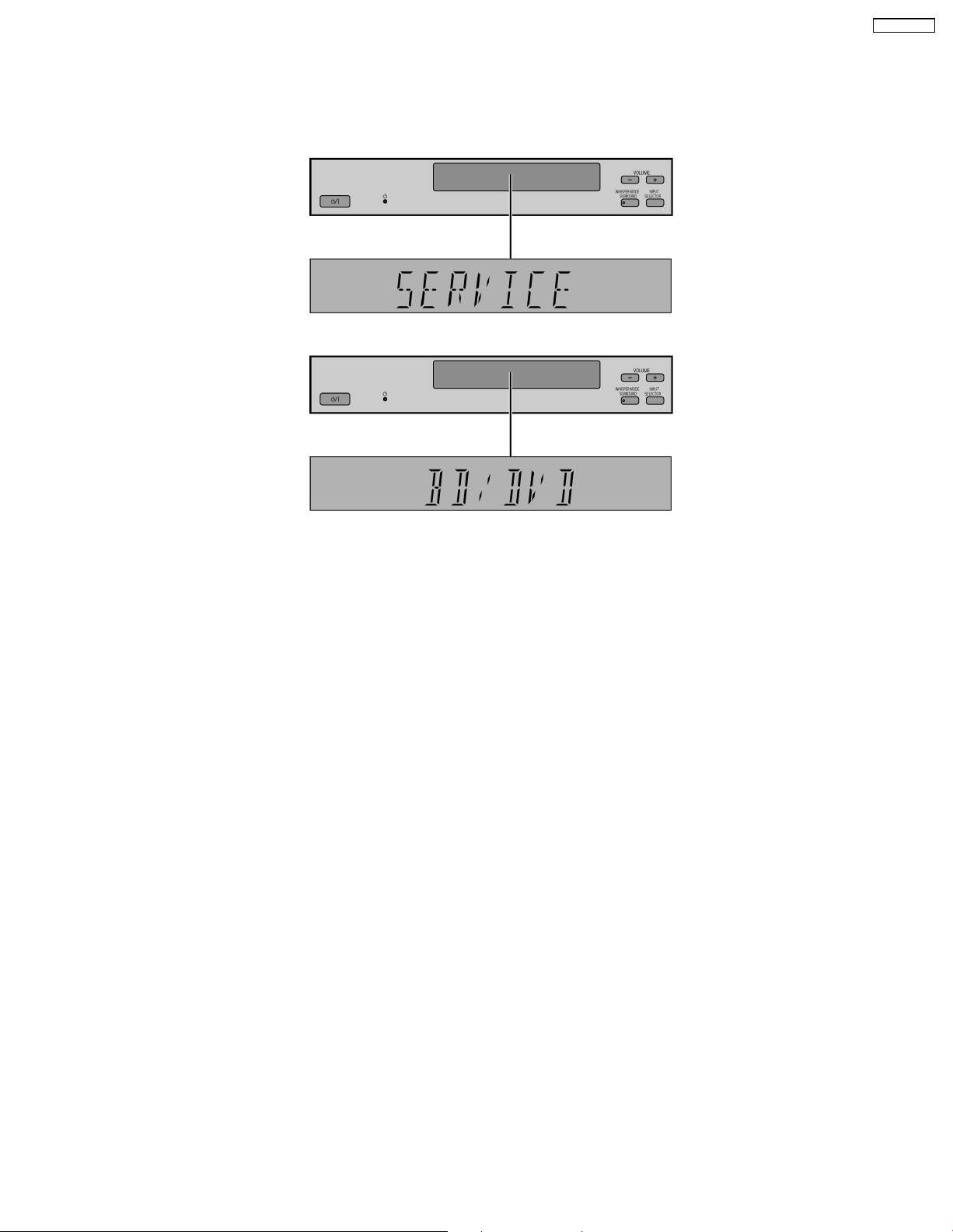

5.3. Activating Self Diagnosis Function (Servicing Mode)

This mode can be used during servicing.

1. Plug the AC adapter to the power source. Press and hold down the [VOL +] button and the [VOL -] button, and then press the

[POWER] button at the same time.

2. The message, [SERVICE] appears on the display for three seconds, and then it will display the following. Refer to Fig. 5.2.

Fig. 5.2

3. To confirm the µP software version: When [VOL +] button is pressed, [M--- ****] is display ed [---] is current main micon version;

[****] is current checksum. If no ROM correction, [NO] is display ed.

When [VOL -] is pressed, display [H***], [***] is current version of HDMI micon.

27

Page 28

SC-HTR310P

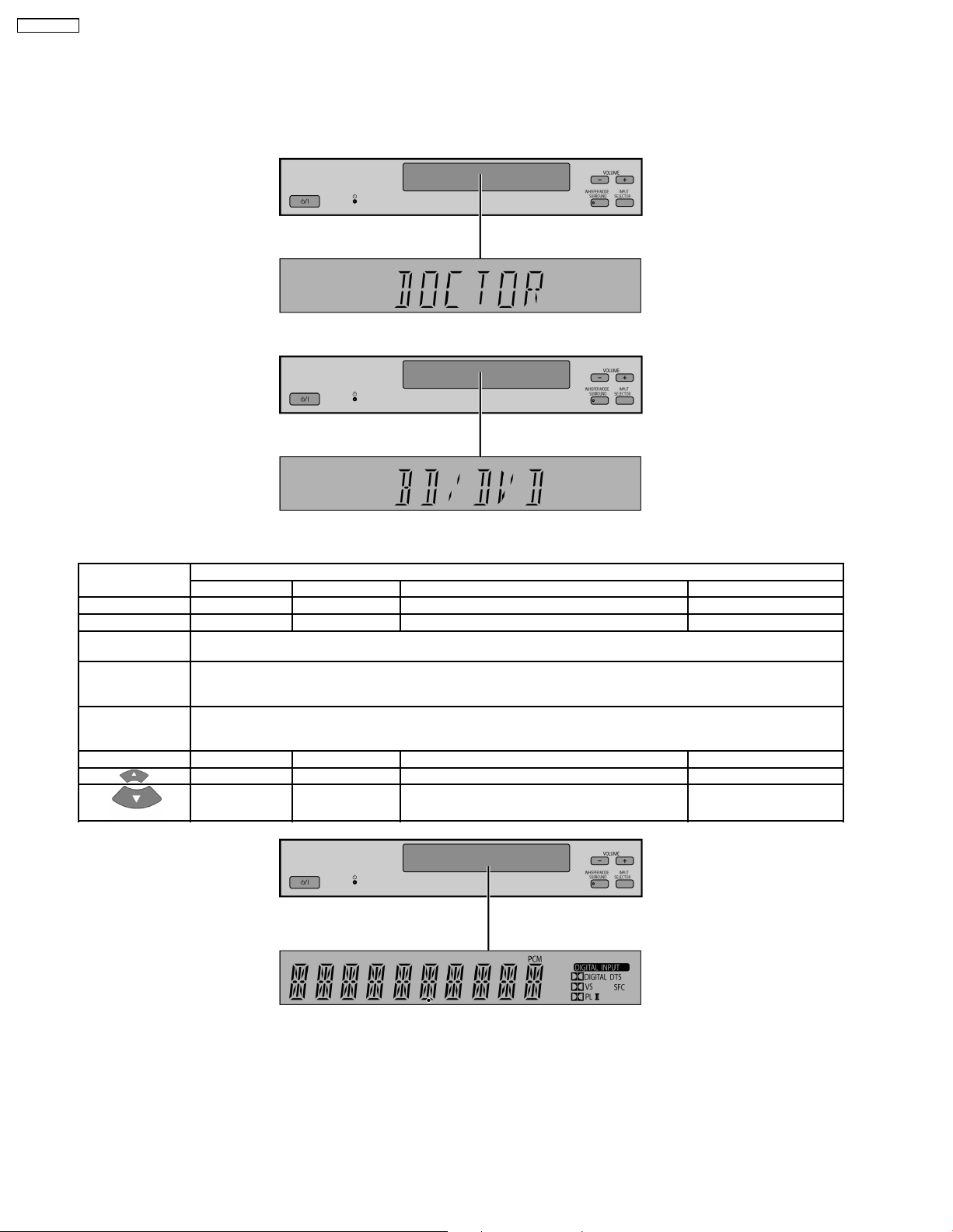

5.4. Activating Self Diagnosis Function (Doctor Mode)

This mode can be used during servicing.

1. Plug the AC adapter to the power source. Press and hold down the [INPUT SELECTOR] button and the [VOL +] button, and

then press the [POWER] button at the same time.

2. The message, “_DOCTOR_” appears on the display for three seconds, and then it will display the following. Refer to Fig. 5.3.

Fig. 5.3

3. Doctor mode function at some remote control codes as below table.

Remote Control Test Mode Function and settings

Selector Sound Mode other settings Vol/Tone

OK TV STEREO Digital (OPT 1 ) -48dB/0dB

SFC MUSIC AUX 1 STEREO Digital (OPT 2 ) -48dB/0dB

MUTING All indicators of FL are displayed. All LED are off. Refer to Fig. 5.4.

Volume Up Check Main µP software version.

Volume Down Check HDMI uP software Version.

TEST AUX2 (Analog) - All CH Output Mode -18dB/0dB

Note : After this setting, only ‘POWER’ button or ‘Checker Command’ code by the remote control can be entered.

Display [M---- ****], [----] is current version; **** is current checksum. If no ROM correction, [NO] is displayed.

Volume is still increased but not displayed.

Display [H---- ^^^^^], [----] is current version.

Volume is still increased but not displayed.

TV STEREO Balance is set to leftmost. -18dB/0dB

TV STEREO Balance is set to rightmost. -18dB/0dB

5.5. Returning to Normal Display

Press the [POWER] button on the unit to exit the function. The

power is turned off.

Fig. 5.4

28

Page 29

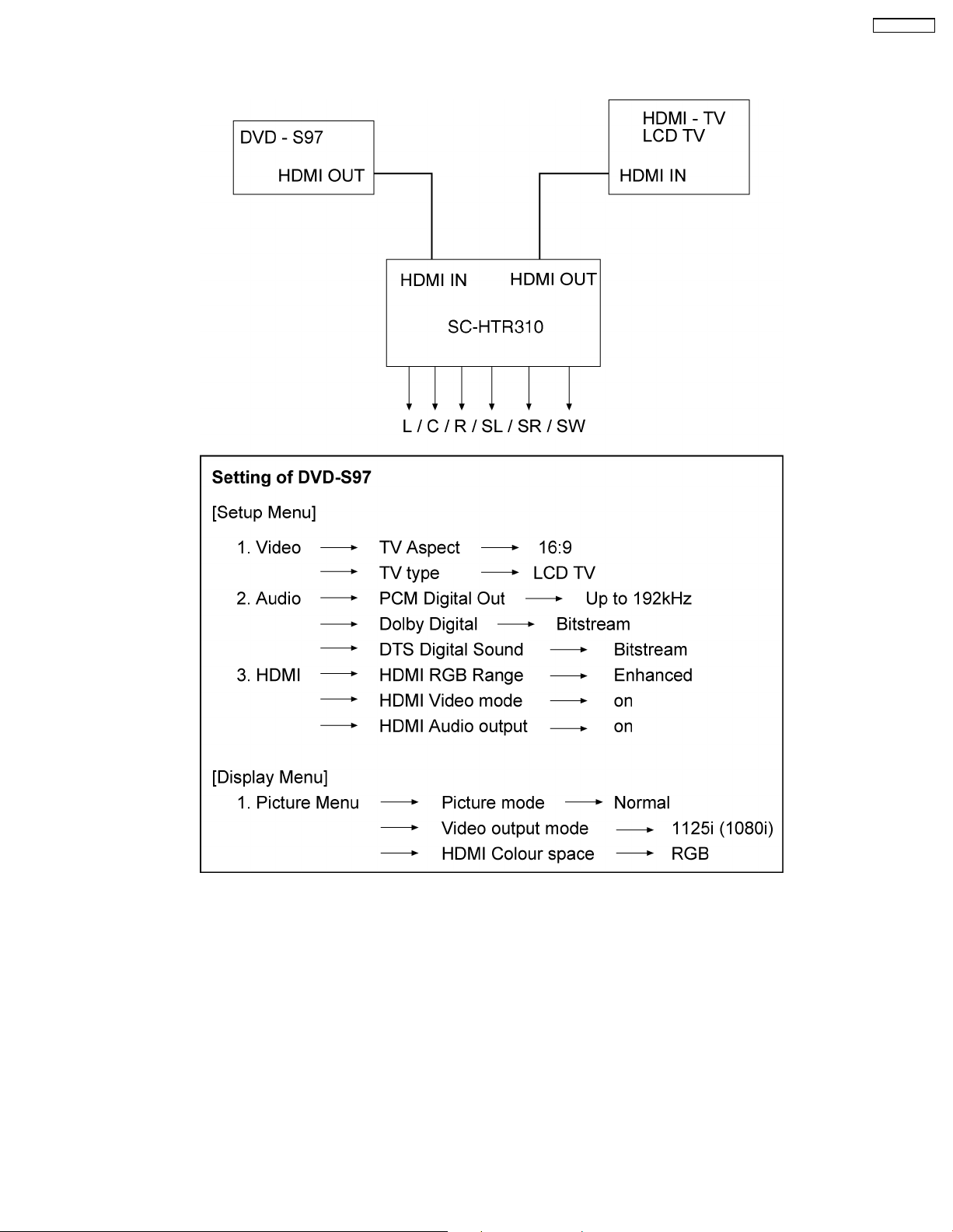

6 HDMI Checking Method

1. Connection of HDMI system

SC-HTR310P

2. Check of HDMI Sound

a. Using the [DVD AUDIO TEST DISC V-612] and DVD-VIDEO disc with Dolby Digital signal.

b. [DVD AUDIO TEST DISC V-612] - Track No. 92 (96kHz, 5.1ch). Track No. 40 (Zero) Check the Level and Noise, output from

L / C / R / SL / SR / SW / speaker or pin.

c. [DVD AUDIO TEST DISC V-612] - Track No. 7 (192kHz, 2ch)

if this source can be reproduced, it is OK.

3. Check of HDMI Picture

a. The picture quality of TV is checked by watching that using [DVD TEST DISK S-20] or DVD disc with the colour bar signal.

b. [DVD TEST DISK S-20] - Track No. 2 (Flag of the rising sun)

[Colour bar disc] - Colour bar signal.

c. Make on DVD Setup Picture

Comfirmed that there are neither distortion nor a noise on the screen.

• If it is a picture quality equal when DVD was connec ted directly to TV, it is OK

29

Page 30

SC-HTR310P

1. Connect directly DVD player to TV.

2. Connect DVD player to set then connect it to TV.

3. Do the comparison for (1) and (2) if same, it is OK.

30

Page 31

SC-HTR310P

7 Assembling and Disassembling

7.1. Caution

“ATTENTION SERVICER”

Be careful when disassembling and servicing.

Some chassis components may have sharp edges.

Special Note:

1. This section describes the disassembly procedures for all the major printed circuit boards and main components.

2. Before the disassembly process was carried out, do take special note that all safety precautions are to be carried out.

(Ensure that no AC power supply is connected during disassembling.)

3. For assembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

4. Do take note of the locators on each printed circuit board during reassembling procedures.

5. The Switch Regulator IC may have high temperature after prolonged use.

6. Use caution when removing the top cabinet and avoid touching heat sinks located in the unit.

7. Select items from the following index when checks or replacement are required.

• Disassembly of Front Net Frame

• Disassembly of Front ornament (L)

• Disassembly of Side Board Assy (L)

• Disassembly of Sub Woofer Left (SP2)

• Disassembly of Front ornament (R)

• Disassembly of Side Board Assy (R)

• Disassembly of Sub Woofer Right (SP2)

• Disassembly of Centre speaker (SP1)

• Disassembly of Front Left speaker (SP1)

• Disassembly of Front Right speaker (SP1)

• Disassembly of Front Baffle Assembly

• Disassembly of Panel P.C.B.

• Disassembly of Amplifier Unit

• Disassembly of Glass Ornament (L)

• Disassembly of Glass Ornament (R)

• Disassembly of Top Cabinet

• Disassembly of Rear Cabinet

• Disassembly of Front Cabinet

• Disassembly of AC Inlet P.C.B.

• Disassembly of Main P.C.B.

• Disassembly of D-Amp P.C.B.

• Replacement of Audio Digital Power Amp IC (IC5000)

• Replacement of Audio Digital Power Amp IC (IC5300)

• Disassembly of SMPS P.C.B.

• Replacement of Switching Regulator IC (IC5701)

• Replacement of Diode (D5702)

• Replacement of Diode (D5801)

31

Page 32

SC-HTR310P

• Replacement of Diode (D5802)

• Replacement of Diode (D5803)

• Disassembly of HDMI P.C.B.

• Disassembly of DSP P.C.B.

32

Page 33

SC-HTR310P

7.2. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

33

Page 34

SC-HTR310P

7.3. Main Parts Location Diagram (Amplifier unit)

34

Page 35

7.4. Main Parts Location Diagram (Rack Cabinet)

SC-HTR310P

35

Page 36

SC-HTR310P

7.5. Disassembly of Front Net Frame

Step 1 : Insert Steel Rule in between Front Net Frame and Rack Cabinet as arrow shown.

Step 2 : Slightly push the Steel Rule as arrow shown to push out the Front Net Frame.

Step 3 : Apply light force to remove the Front Net Frame in order of sequences (from 1 to 9).

36

Page 37

7.6. Disassembly of Front ornament (L)

• Follow the (Step 1) - (Step 3) of item 7.5.

SC-HTR310P

Step 1 : Remove 1 screw.

Step 2 : Insert the screwdriver with Cloth in between the Rack Cabinet and the Front Ornament (L), and slightly push the

screwdriver as arrow shown to release the Bosses in order of sequence.

Caution : Wrap the screwdriver with a cloth.

Step 3 : Remove the Front Ornament (L) as arrow shown.

37

Page 38

SC-HTR310P

7.7. Disassembly of Side Board Assy (L)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 3) of item 7.6.

Step 1 : Pull the Side Board Assy (L) to release the bosses as arrow shown.

Step 2 : Remove the Side Board Assy (L) as arrow shown.

Caution : Take extra care for the guide holes on the cabinet during removal and assembly of the side board assy (L).

38

Page 39

7.8. Disassembly of Sub Woofer Left (SP2)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 3) of item 7.6.

• Follow the (Step 1) - (Step 2) of item 7.7.

Step 1 : Remove 2 screws and remove Catch Holder.

SC-HTR310P

Step 2 : Remove 4 screws.

Step 3 : Detach the Black (+) and Red (-) speaker wires.

Step 4 : Remove the Sub Woofer Left (SP2) as arrow shown.

39

Page 40

SC-HTR310P

7.9. Disassembly of Front ornament (R)

• Follow the (Step 1) - (Step 3) of item 7.5.

Step 1 : Remove 1 screw.

Step 2 : Insert the screwdriver with Cloth in between the Rack Cabinet and the Front Ornament (R), and slightly push the

screwdriver as arrow shown to release the Bosses in order of sequence.

Caution : Wrap the screwdriver with a cloth.

Step 3 : Remove the Front Ornament (R) as arrow shown.

40

Page 41

7.10. Disassembly of Side Board Assy (R)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 3) of item 7.9.

Step 1 : Pull the Side Board Assy (R) to release the Bosses as arrow shown.

SC-HTR310P

Step 2 : Remove the Side Board Assy (R) as arrow shown.

Caution : Take extra care for the guide holes on the cabinet during removal and assembly of the side board assy (R).

41

Page 42

SC-HTR310P

7.11. Disassembly of Sub Woofer Right (SP2)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 3) of item 7.9.

• Follow the (Step 1) - (Step 2) of item 7.10.

Step 1 : Remove 2 screws and remove Catch Holder.

Step 2 : Remove 4 screws.

Step 3 : Detach the Black (+) and Red (-) speaker wires.

Step 4 : Remove the Sub Woofer Right (SP2) as arrow shown.

42

Page 43

7.12. Disassembly of Centre speaker (SP1)

• Follow the (Step 1) - (Step 3) of item 7.5.

Step 1 : Remove 3 screws.

SC-HTR310P

Step 2 : Prepare a Box.

Step 3 : Remove the Centre speaker unit and place on the box.

Step 4 : Pull out the Eva Cushio n partially.

43

Page 44

SC-HTR310P

Step 5 : Remove 6 screws.

Step 6 : Remove the Centre speaker panel as arrow shown.

Step 7 : Detach the White (+) and Blue (-) speaker wires.

Step 8 : Remove 4 screws.

Step 9 : Remove the Centre speaker (SP1) as arrow shown.

44

Page 45

Caution : During reassembling procedures, ensure the cable are properly dresse d.

SC-HTR310P

45

Page 46

SC-HTR310P

7.13. Disassembly of Front Left speaker (SP1)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 3) of item 7.6.

Step 1 : Remove 3 screws.

Step 2 : Prepare a Box.

Step 3 : Remove the front Speaker unit and place on the box.

Step 4 : Remove 4 screws.

Step 5 : Remove the Front speaker panel as arrow shown.

46

Page 47

Step 6 : Detach the Yellow (+) and Black (-) speaker wires.

Step 7 : Remove 4 screws.

Step 8 : Remove the Front Left speaker (SP1) as arrow shown.

Caution : During reassembling procedures, ensure the cable are properly dresse d.

SC-HTR310P

47

Page 48

SC-HTR310P

7.14. Disassembly of Front Right speaker (SP1)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 3) of item 7.9.

Step 1 : Remove 3 screws.

Step 2 : Prepare a Box.

Step 3 : Remove the Front speaker unit and place on the box.

Step 4 : Remove 4 scews.

48

Page 49

Step 5 : Remove the Front speaker panel as arrow shown.

Step 6 : Detach the Grey (+) and Blue (-) speaker wires.

SC-HTR310P

Step 7 : Remove 4 screws.

Step 8 : Remove the Front Right speaker (SP1) as arrow shown.

Caution : During reassembling procedures, ensure the cable are properly dresse d.

49

Page 50

SC-HTR310P

7.15. Disassembly of Front Baffle Assembly

• Follow the (Step 1) - (Step 3) of item 7.5.

Step 1 : Push the Glass door holder.

Step 2 : Open the Glass door as arrow shown.

Step 3 : Tilt the Shelf board (R) up slightly and remove it as arrow shown.

Note : Repeat the same step for the Shelf board (L).

50

Page 51

Step 4 : Detach cable at connector (CN601 and CN602) on Panel P.C.B..

SC-HTR310P

Step 5 : Remove 8 screws.

51

Page 52

SC-HTR310P

Step 6 : Prepare a Box.

Step 7 : Remove the Front Baffle Assembly as arrow shown and place it on the Box.

52

Page 53

7.16. Disassembly of Panel P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 7) of item 7.15.

Step 1 : Remove 2 screws.

SC-HTR310P

Step 2 : Remove 2 screws.

Step 3 : Remove the Front Panel as arrow shown.

Step 4 : Remove 2 screws.

Step 5 : Release 2 catches.

53

Page 54

SC-HTR310P

Caution : Take extra care for the locator on the Panel P.C.B. during removal and assembly of the Panel P.C.B..

Step 6 : Remove the Panel P.C.B. as arrow shown.

54

Page 55

7.17. Disassembly of Amplifier Unit

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 5) of item 7.15.

SC-HTR310P

Step 1 : Remove 2 screws.

Step 2 : Prepare a Box.

Step 3 : Remove the Front Baffle Assembly as arrow shown and place it on the Box.

55

Page 56

SC-HTR310P

Step 4 : Remove 4 screws.

Step 5 : Lift up the Main Set a bit and remove the Amp Fixtures as arrow shown.

56

Page 57

SC-HTR310P

Step 6 : Remove the main set as arrow shown.

Caution : During reassembling procedures, ensure the cable are properly dresse d.

57

Page 58

SC-HTR310P

7.18. Disassembly of Glass Ornament (L)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 7) of item 7.15.

Step 1 : Loosen the Screws for removing the Glass door.

Step 2 : Remove the Glass door as arrow shown.

Step 3 : Remove 2 screws.

58

Page 59

SC-HTR310P

Step 4 : Remove the Glass ornament (L) as arrow shown.

Caution : Be careful of losing the Pivot holder as it may fall off when the Hinge angle (L) removed from the Glass ornament

(L).

59

Page 60

SC-HTR310P

7.19. Disassembly of Glass Ornament (R)

• Follow the (Step 1) - (Step 3) of item 7.5.

• Follow the (Step 1) - (Step 7) of item 7.15.

Step 1 : Loosen the Screws for removing the Glass door.

Step 2 : Remove the Glass door as arrow shown.

Step 3 : Remove 2 screws.

60

Page 61

SC-HTR310P

Step 4 : Remove the Glass ornament (R) as arrow shown.

Caution : Be careful of losing the Pivot holder as it may fall off when the Hinge angle (R) removed from the Glass ornament

(R).

61

Page 62

SC-HTR310P

7.20. Disassembly of Top Cabinet

Step 1 : Remove 4 screws.

7.21. Disassembly of Rear Cabinet

• Follow the (Step 1) - (Step 3) of item 7.20.

Step 1 : Remove 9 screws.

Step 2 : Remove 2 screws.

Step 2 : Remove 6 screws.

Step 3 : Lift up the back part of the Top Cabinet and remove it

as arrow shown.

Step 3 : Remove the Wire Clamper to detach the fan unit

connector (CN5501) on D-Amp P.C.B..

62

Page 63

Step 4 : Detach FFC cable at the connector (CN106) on Main

P.C.B..

Step 5 : Detach FFC cable at the connector (CN2001) on

HDMI P.C.B..

SC-HTR310P

Step 7 : Lift up and remove the HDMI P.C.B. with the chassis

from the Rear Cabinet as arrow shown.

Caution : Take extra care for the catches on the Rear

Cabinet during removal and assembly of the HDMI P.C.B.

(with chassis).

Step 6 : Remove one side of the Rear Cabinet as arrow shown.

Be careful both side guides when removing the rear cabinet.

Step 8 : Remove the Rear Cabinet as arrow shown.

63

Page 64

SC-HTR310P

7.22. Disassembly of Front Cabinet

• Follow the (Step 1) - (Step 3) of item 7.20.

Step 1 : Remove 2 screws.

Step 2 : Remove 1 screw.

Step 3 : Remove the Front Cabinet as arrow shown. Be careful

both side guides and three guides at the bottom when

removing the Front Cabine t.

Caution : Do not exert too much force when releasing the

guides.

64

Page 65

7.23. Disassembly of AC Inlet P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.20.

SC-HTR310P

Step 3 : Remove Bracket as arrow shown.

Step 1 : Remove 1 screw.

Step 2 : Remove 1 screw.

Step 4 : Release the one side of the Rear Cabine t as arrow

shown. Be careful Guide when removing the Rear Cabinet.

65

Page 66

SC-HTR310P

Step 5 : Flip over the AC Inlet P.C.B..

Step 6 : Desolder Black and Red wires.

7.24. Disassembly of Main P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

Step 1 : Remove 4 screws.

Caution : Take extra care for the locator on the AC Inlet

P.C.B. during removal and assembly of the AC Inlet P.C.B..

Step 2 : Remove 2 screws.

Step 3 : Detach FFC cable at the connector (CN106, CN222

and CN200) on Main P.C.B..

Step 4 : Detach cable at the connector (CNA781) on HDMI

P.C.B..

Caution : Attach wire to Main P.C.B. with Wire Clamper

during assembly. (Replace a new Wire Clamper after

service)

66

Page 67

Step 5 : Lift up Main P.C.B. and remove it forward as arrow

shown in sequences (from 1-2).

SC-HTR310P

During reassembling procedures, ensure the P.C.B. is

seated properly at the locators.

Step 6 : Detach FFC cable at the connector (CN2201) on

HDMI P.C.B..

Step 7 : Detach cable at the connector (CN5802) on SMPS

P.C.B..

67

Page 68

SC-HTR310P

7.25. Disassembly of D-Amp P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 3) of item 7.23.

• Follow the (Step 1) - (Step 2) of item 7.24.

Step 1 : Detach FFC cable at the connector (CN200) on Main

P.C.B..

Caution : Attach wire to Main P.C.B. with Wire Clamper

during assembly. (Replace a new Wire Clamper after

service)

Step 3 : Remove 2 screws.

Step 4 : Detach cable at the connector (CN5500) on D-Amp

P.C.B..

Step 5 : Remove 3 screws.

Step 2 : Lift up Main P.C.B. and shift over the Heat Sink.

68

Page 69

SC-HTR310P

During reassembling procedures, ensure the P.C.B. is

seated properly at the locators.

Step 6 : Remove the wire clamper to detach the fan unit

connector (CN5501) on D-Amp P.C.B..

Step 7 : Open one side of the Rear Cabinet slightly as arrow

shown. Be careful guide when removing the Rear Cabinet.

Step 8 : Remove D-Amp P.C.B. as arrow shown. Be careful

with the guide.

69

Page 70

SC-HTR310P

7.26. Replacement of Audio Digital

Power Amp IC (IC5000)

• Follow the (Step 1) - (Step 3) of item 7.20.

Step 1 : Cut the 5 connecting points as indicated in the

diagram.

Step 2 : Remove the marked portion from the bottom chassis.

Step 4 : Remove 1 screw.

Step 5 : Remove the TR spring as arrow shown.

Step 6 : Remove the Audio Digital Power Amp IC (IC5000)

from the heat sink unit A.

Step 3 : Desolder pins of the Audio Digital Power Amp IC

(IC5000) on the reverse side of D-Amp P.C.B.

70

Page 71

• Assembly of the Audio Digital Power Amp IC (IC5000)

SC-HTR310P

Step 1 : Fix the Audio Digital Power Amp IC (IC5000) to the

heat sink unit A.

Step 2 : Fix the TR spring as arrow shown.

Step 3 : Screw 1 screw at digital amp IC (IC5000) to the heat

sink unit A.

Step 5 : Position the bottom chassis portion into the curves

according to the diagram shown. (Rotate the part at 180

degrees as compared to its original position.)

Step 6 : Screw 1 screw at the Chassis Portion.

Step 4 : Solder pins of the digital amp IC (IC5000) on the

reverse side of D-Amp P.C.B.

Caution : Ensure pins of the digital amp IC (IC5000) are

properly seated and soldered on D-Amp P.C.B.

71

Page 72

SC-HTR310P

7.27. Replacement of Audio Digital

Power Amp IC (IC5300)

• Follow the (Step 1) - (Step 3) of item 7.20.

Step 1 : Cut the 5 connecting points as indicated in the

diagram.

Step 2 : Remove the marked portion from the bottom chassis.

Step 4 : Remove 1 screw.

Step 5 : Remove the TR spring as arrow shown.

Step 6 : Remove the Audio Digital Power Amp IC (IC5300)

from the heat sink unit A.

Step 3 : Desolder pins of the Audio Digital Power Amp IC

(IC5300) on the reverse side of D-Amp P.C.B.

72

Page 73

• Assembly of the Audio Digital Power Amp IC (IC5300)

SC-HTR310P

Step 1 : Fix the Audio Digital Power Amp IC (IC5300) to the

heat sink unit A.

Step 2 : Fix the TR spring as arrow shown.

Step 3 : Screw 1 screw at digital amp IC (IC5300) to the heat

sink unit A.

Step 5 : Position the bottom chassis portion into the curves

according to the diagram shown. (Rotate the part at 180

degrees as compared to its original position.)

Step 6 : Screw 1 screw at the Chassis Portion.

Step 4 : Solder pins of the digital amp IC (IC5300) on the

reverse side of D-Amp P.C.B.

Caution : Ensure pins of the digital amp IC (IC5300) are

properly seated and soldered on D-Amp P.C.B.

73

Page 74

SC-HTR310P

7.28. Disassembly of SMPS P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

Step 1 : Detach FFC cable at the connector (CN200) on Main

P.C.B..

Caution : Move Main P.C.B. until creat a gap between the

Rear Cabinet.

Step 3 : Remove 4 screws.

Step 4 : Detach FFC cable at the connector (CN5500) on D-

Amp P.C.B..

Step 5 : Detach FFC cable at the connector (CN5802) on

SMPS P.C.B..

Step 2 : Lift up Main P.C.B. and shift over the heatsink.

Step 6 : Remove SMPS P.C.B. as arrow shown. Be careful

with the guide.

74

Page 75

Step 7 : Flip over the SMPS P.C.B..

Step 8 : Desolder Black and Red wires.

SC-HTR310P

7.29. Replacement of Switching

Regulator IC (IC5701)

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

• Follow the (Step 1) - (Step 6) of item 7.28.

Caution : During reassembling procedures, ensure the

P.C.B.is seated properly at the locators.

Step 1 : Desolder pins of Switching Regulator IC (IC5701) on

the reverse side of SMPS P.C.B..

Step 2 : Remove 1 screw from the switch regulator IC

(IC5701).

Step 3 : Remove the switch regulator IC (IC5701) from the

Heatsink Unit B.

Caution : Handle the heatsink unit B with caution due to its

high temprature after prolonged use. Touching it may lead

to injuries.

75

Page 76

SC-HTR310P

• Assembly of the Switching Regulator IC (IC5701)

Step 1 : Fix the switching regulator IC (IC5701) to the Heatsink

Unit B.

Step 2 : Screw 1 screw at switching regulator IC (IC5701) to

the Heatsink Unit B.

7.30. Replacement of Diode (D5702)

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

• Follow the (Step 1) - (Step 6) of item 7.28.

Step 3 : Solder pins of the switching regulator IC (IC5701) on

the reverse side of SMPS P.C.B..

Caution : Ensure pins of the switching regulator IC

(IC5701) are properly seated and soldered on SMPS P.C.B.

Step 1 : Desolder pins of the switch regulator diode (D5702) on

the reverse side of SMPS P.C.B..

Step 2 : Desolder pins of the Heatsink Unit B.

Step 3 : Remove 1 screw from the Heatsink Unit B.

76

Page 77

Step 4 : Release the Heatsink Unit B as arrow shown.

Step 5 : Remove 1 screw from Diode (D5702).

Step 6 : Remove the Diode (D5702) from the Heatsink Unit B.

Caution : Handle the Heatsink Unit B with caution due to its

high temprature after prolonged use. Touching it may lead

to injuries.

SC-HTR310P

• Assembly of the Diode (D5702)

Step 1 : Fix the Diode (D5702) from the Heatsink Unit B.

Step 2 : Screw 1 screw at Diode (D5702).

Step 3 : Fix the Heatsink Unit B as arrow shown.

Step 4 : Solder pins of the Diode (D5702) on the reverse side

of SMPS P.C.B..

Step 5 : Solder pins of the Heatsink Unit B.

Caution : Ensure pins of the Diode (D5702) are properly

seated and soldered on SMPS P.C.B.

77

Page 78

SC-HTR310P

7.31. Replacement of Diode (D5801)

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

• Follow the (Step 1) - (Step 6) of item 7.28.

• Assembly of the Diode (D5801)

Step 1 : Fix the Diode (D5801) from the Heatsink Unit C.

Step 2 : Screw 1 screw at the Diode (D5801).

Step 1 : Desolder pins of the Diode (D5801) on the reverse

side of SMPS P.C.B..

Step 2 : Remove 1 screw from the Diode (D5801).

Step 3 : Remove the Diode (D5801) from the Heatsink Unit C.

Caution : Handle the Heatsink Unit C with caution due to its

high temprature after prolonged use. Touching it may lead

to injuries.

Step 3 : Solder pins of the Diode (D5801) on the reverse side

of SMPS P.C.B..

Caution : Ensure pins of the Diode (D5801)are properly

seated and soldered on SMPS P.C.B.

78

Page 79

7.32. Replacement of Diode (D5802)

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

• Follow the (Step 1) - (Step 6) of item 7.28.

SC-HTR310P

• Assembly of the Diode (D5802)

Step 1 : Fix the Diode (D5802) from the Heatsink Unit C.

Step 2 : Screw 1 screw at the Diode (D5802).

Step 1 : Desolder pins of the Diode (D5802) on the reverse

side of SMPS P.C.B..

Step 2 : Remove 1 screw from the Diode (D5802).

Step 3 : Remove the Diode (D5802) from the Heatsink Unit C.

Step 3 : Solder pins of the Diode (D5802) on the reverse side

of SMPS P.C.B.

Caution : Ensure pins of the Diode (D5802) are properly

seated and soldered on SMPS P.C.B.

79

Page 80

SC-HTR310P

7.33. Replacement of Diode (D5803)

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

• Follow the (Step 1) - (Step 6) of item 7.28.

• Assembly of the Diode (D5803)

Step 1 : Fix the Diode (D5803) from the Heatsink Unit C.

Step 2 : Screw 1 screw at the Diode (D5803).

Step 1 : Desolder pins of the Diode (D5803) on the reverse

side of SMPS P.C.B..

Step 2 : Remove 1 screw from the Diode (D5803).

Step 3 : Remove the Diode (D5803) from the Heatsink Unit C.

Caution : Handle the Heatsink Unit C with caution due to its

high temprature after prolonged use. Touching it may lead

to injuries.

Step 3 : Solder pins of the Diode (D5803) on the reverse side

of SMPS P.C.B..

Caution : Ensure pins of the Diode (D5803)are properly

seated and soldered on SMPS P.C.B.

80

Page 81

7.34. Disassembly of HDMI P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

SC-HTR310P

Step 1 : Remove 2 screws.

Step 2 : Detach FFC cable at the connector (CN106) on Main

P.C.B..

Step 3 : Detach FFC cable at the connector (CN222) on Main

P.C.B..

Step 4 : Detach FFC cable at the connector (CNA781) on

HDMI P.C.B..

Caution : Attach wire to Main P.C.B. with Wire Clamper

during assembly. (Replace a new Wire Clamper after

service)

Step 5 : Detach FFC cable at the connector (CN2001) on

HDMI P.C.B..

Step 6 : Lift up Main P.C.B.as arrow shown.

Step 7 : Detach FFC cable at the connector (CN2201) on

HDMI P.C.B..

Step 8 : Lift up and remove the HDMI P.C.B. with the chassis

from the rear cabinet as arrow shown.

81

Page 82

SC-HTR310P

Step 9 : Remove 2 screws.

Step 10 : Remove the tape.

Step 11 : Remove the HDMI P.C.B. as arrow shown.

• Assembly of HDMI P.C.B.

Step 1 : Place back a tape after disassembly as a diagram

shown.

Caution : During reassembling procedures, ensure the

HDMI P.C.B.is seated properly at the locators.

82

Page 83

7.35. Disassembly of DSP P.C.B.

• Follow the (Step 1) - (Step 3) of item 7.20.

• Follow the (Step 1) - (Step 3) of item 7.22.

• Follow the (Step 1) - (Step 2) of item 7.24.

Step 1 : Detach FFC cable at the connector (CN1002) on DSP

P.C.B..

SC-HTR310P

Step 2 : Release the claws of the P.C.B. Suppo rt together with

the connectors (CN101 and CN103) on a reverse side of DSP

P.C.B. (Side B) to detach the DSP P.C.B..

83

Page 84

SC-HTR310P

8 Service Position

Note : For description of the disassembly procedures, see the section 7

8.1. Checking & Repairing Main

P.C.B

Step 1 : Remove the top cabinet

8.2. Checking & Repairing D-Amp

P.C.B

Step 1 : Remove the Top Cabine t

Step 2 : Remove the Front Cabinet

Step 3 : Remove 3 screws.

Step 2 : Connect 9P cable at the connectors (CN602) on Panel

P.C.B..

Step 3 : Connect 8P cable at the connectors (CN601) on Panel

P.C.B..

Step 4 : Main P.C.B. can be checked at its original position.

Step 4 : Remove 2 screws.

Step 5 : Detach 15P FFC cable at the connec tor (CN222) on

Main P.C.B..

Step 6 : Detach 10P FFC cable at the connec tor (CN200) on

Main P.C.B..

Caution : Attach wire to main P.C.B. with cable tie during

assembly. (Replace a new cable tie after service)

84

Page 85

Step 7 : Slightly lift up Main P.C.B. and shift forward Main

P.C.B. as arrow shown in sequences (from 1-2).

SC-HTR310P

Step 8 : Ensure there is a gap between Heat sink on the Main

P.C.B. and P.C.B. Support when moving of the Main P.C.B..

Step 9 : Remove 2 screws.

Step 10 : Detach 17P FFC cable at the connector (CN5050) on

D-Amp P.C.B..

Step 11 : Detach 8P FFC cable at the connec tor (CN5500) on

D-Amp P.C.B..

Step 12 : Remove 3 screws.

85

Page 86

SC-HTR310P

Step 16 : Remove Bracket as arrow shown.

Step 13 : Remove the wire clamper to detach the fan unit

connector (CN5501) on D-Amp P.C.B..

Step 14 : Open one side of the rear cabinet slightly as arrow

shown. Be careful guide when removing the rear panel.

Step 17 : Remove D-Amp P.C.B. as arrow shown. Be careful

with the guide.

Step 15 : Remove 1 screw.

86

Page 87

Step 18 : Remove 2 screws.

Step 19 : Releas e the catches and remove the fan unit.

SC-HTR310P

Amp P.C.B..

Caution : Ensure the cable is attached properly.

Step 26 : Position Fan unit and D-Amp P.C.B. with the object

support according to the diagram shown.

Step 27 : Check & repair D-Amp P.C.B. according to the

diagram shown.

Step 20 : Connect 3P cable at the connector (CN5501) on DAmp P.C.B..

Step 21 : Connect 8P cable at the connector (CN601) on Panel

P.C.B..

Step 22 : Connect 9P cable at the connector (CN602) on Panel

P.C.B..

Step 23 : Connect 15P FFC cable at the connector (CN222) on

Main P.C.B..

Step 24 : Connect 10P FFC cable at the connector (CN200) on

Main P.C.B..

Step 25 : Connect 8P cable at the connector (CN5500) on D-

87

Page 88

SC-HTR310P

8.3. Checking & Repairing SMPS

P.C.B

• Follow the (Step 1) - (Step 8) of item 8.2.

Step 1 : Remove 4 screws.

Step 2 : Detach 8P FFC cable at the connector (CN5500) on D-

Amp P.C.B.

Step 3 : Detach 11P FFC cable at the connec tor (CN5802) on

SMPS P.C.B.

Step 5 : Connect 8P cable at the connector (CN601) on Panel

P.C.B..

Step 6 : Connect 9P cable at the connector (CN602) on Panel

P.C.B..

Step 7 : Connect 8P cable at the connec tor (CN5500) on DAmp P.C.B..

Step 8 : Connect 11P cable at the connector (CN5802) on

SMPS P.C.B..

Step 9 : Check & repair SMPS P.C.B. according to the diagram

shown.

Step 4 : Remove SMPS P.C.B. as arrow shown. Be careful

with the guide.

88

Page 89

8.4. Checking & Repairing HDMI

P.C.B

• Follow the (Step 1) - (Step 4) of item 8.2.

SC-HTR310P

Step 6 : Detach 12P FFC cable at the connec tor (CN2201) on

HDMI P.C.B..

Step 1 : Detach 10P FFC cable at the connec tor (CN106) on

Main P.C.B..

Step 2 : Detach 15P FFC cable at the connec tor (CN222) on

Main P.C.B..

Step 3 : Detach 5P cable at the connector (CNA781) on HDMI

P.C.B..

Caution : Attach wire to main P.C.B. with cable tie during

assembly. (Replace a new cable tie after service)

Step 7 : Lift up and remove the HDMI P.C.B. with the chassis

from the rear cabinet as arrow shown.

Caution : Take extra care for the catches on the rear panel

during removal and assembly of the HDMI P.C.B. (with

chassis).

Step 4 : Lift up Main P.C.B..

Step 5 : Detach 10P FFC cable at the connec tor (CN2001) on

HDMI P.C.B..

89

Page 90

SC-HTR310P

Step 8 : Connect 8P cable at the connector (CN601) on Panel

P.C.B..

Step 9 : Connect 9P cable at the connector (CN602) on Panel

P.C.B..

Step 10 : Connect 15P FFC cable at the connector (CN222) on

Main P.C.B..

Step 11 : Connect 5P cable at the connector (CNA781) on

HDMI P.C.B..

Step 12 : Connect 12P FFC cable at the connector (CN2201)

on HDMI P.C.B..

Step 13 : Check & repair HDMI P.C.B. according to the

diagram shown.

8.5. Checking & Repairing DSP

P.C.B

• Follow the (Step 1) - (Step 12) of item 8.4.

Step 1 : Check & repair DSP P.C.B. according to the diagram

shown.

90

Page 91

8.6. Checking & Repairing Panel

P.C.B

Step 1 : Connect 8P cable at the connector (CN601) on Panel

P.C.B..

Step 2 : Connect 9P cable at the connector (CN602) on Panel

P.C.B..

Step 3 : Check & repair Panel P.C.B. according to the diagram

shown.

SC-HTR310P

91

Page 92

REF NO.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 2.5 0.1 0.1 2.9 0 -29.3 -29.3 29.3 11 -0.1 -29.5 -17.3 -29.5 -0.1 11 29.3 -29.3 -29.3 0 29

STANDBY 2.5 0.1 0.1 2.9 0 -29.3 -21 29.3 11 -0.1 -29.5 -17.3 -29.5 -0.1 11 29.3 -29.3 -29.2 0 29

REF NO.

MODE 21 22 23

CD PLAY -0.1 -0.1 2.5

STANDBY -0.1 -0.1 2.5

REF NO.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 2.5 -0.1 -0.1 29 0 -29.3 -29.3 29.3 11 -0.1 -29.5 -17.3 -29.5 -0.1 11 29.3 -29.3 -29.3 0 29

STANDBY 2.5 -0.1 -0.1 29 0 -29.3 -29.3 29.3 11 -0.1 -29.5 -17.3 -29.5 -0.1 11 29.3 -29.3 -29.3 0 29

REF NO.

MODE 21 22 23

CD PLAY -0.1 -0.1 2.5

STANDBY -0.1 -0.1 2.5

REF NO.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14

CD PLAY 0 5.2 5 0 2.7 2.2 0 2.5 2.6 2.6 2.5 0 5.2 5.2

STANDBY 0 5.2 5 0 2.7 2.2 0 2.5 2.6 2.6 2.5 0 5.2 5.2

REF NO.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14

CD PLAY 2.5 2.6 2.5 0 2.6 0 0 0 0 0 0 0 5.2 5.2

STANDBY 2.5 2.6 2.5 0 2.6 0 0 0 0 0 0 0 5.2 5.2

REF NO.

MODE E C B

EC B EC B E CB

ECB

CD PLAY 0 5.2 0

0 5.2 0 0 0 0.7

5.2 5.1 4.4 0 0 0.7

STANDBY 0 5.2 0

0 5.2 0 0 0 0.7

5.2 5.1 4.5 0 0 0.7

REF NO.

MODE

ECB EC B EC B E CB

CD PLAY

6.9 16.4 7.4 0 5.2 0 0 0

0.7 0 3.7 0

STANDBY

6.9 16.4 7.4 0 5.2 0 0 0

0.7 0 3.7 0

IC5000

IC5000

IC5300

IC5300

IC5500

IC5501

Q5101 Q5102 Q5601 Q5603 Q5604

!"#$%&'()*+,#-.*+*/"/0/

Q5640 Q5641 Q5642 Q5644

SC-HTR310P

9 Voltage Measurement & Waveform Chart

Note:

• Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance)

with the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

• Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point

because it may differ from actual measuring value due to difference of Measuring instrument and its measuring condition

and product itself.

9.1. Voltage Measurement

9.1.1. D-AMP P.C.B.

92

Page 93

9.1.2. DSP P.C.B.

Ref No.

MODE 123 4567891011121314151617181920

CD PLA

Y

3.7 3.7 3.7 3.7

3.2 3.7 3.7 0 3.7 3.7 1.8 3.7 3.7 0 1.7 0.8 0.9 0 1.6

STANDB

Y

0.9 0.9 0.9 0 0.9

00.90011011000000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

3.3 1.8 3.6 3.6 0 3.6 3.6 3.7 3.6 3.6 0 1.8 1.8 0 1.8 3.7 3.7 0 0 1.7

STANDB

Y

003.33.30.93.300.10000000.90.10.1110

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

0 1.7 0 1.7 0 1.7 0 1.3 0 3.3 1.7 1.7 0 1.8 1.8 0 3.3 3.3 3.3 3.3

STANDB

Y

0.1 0 0.8 0.8 0 0.7 0.8 0.1 0 0.1 0.1 0 0 0 0.9 0.8 0.7 0.7 0.7 0.8

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLA

Y

3.3 3.3 3.3 3.3 3.3 3.3 0 3.3 3.3 3.3 3.3 3.3 3.3 3.3 3.3 0 3.3 3.3 3.3 1.9

STANDB

Y

0.7 0 1 0.9 0.7 0.7 0 0.7 1 0.7 0.7 0.7 0 0.7 0.7 0 0.7 0.7 0.7 1

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLA

Y

3.33.31.80 00003.300003.31.800003.3

STANDB

Y

110 0 0011011011011010

Ref No.

MODE 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

CD PLA

Y

000 0 003.33.33.33.301.8000003.33.33.3

STANDB

Y

1 0.9 1 0.6 0 0.6 0 0.6 0.7 0.7 0.7 0 0.7 0.7 0 0.7 0.7 0.7 0.7 0

Ref No.

MODE 121 122 123 124 125 126 127 128

CD PLA

Y

3.2 0 0.4 3.6 1.8 0.5 0 3.3

STANDB

Y

000 0 0000

Ref No.

MODE 123 4567891011121314151617181920

CD PLA

Y

1.7 1.6

1.7 3.3 0 3.3 0 0 0.4 1.9 0 3.3 2.6 2.6 2.6 2.6 2.7 4.6 0 0

STANDB

Y

0.1 0

00.100.10000000.10.10.10.10.10.200

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

00

0 4.8 0 2.6 2.7 2.6 2.6 0 2.6 2.7 2.7 2.7 2.7 2.7 2.7 4.8 0 0

STANDB

Y

00

00.100.20.20.20.200000.20.20.20.20.100

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

4.8 0.4

0.1 0 0 2.4 2.4 1.8 2.4 0 3.4 0 3.3 0 1.6 0 0 0 1.6 1.6

STANDB

Y

0.1 0.1

0.100.10.10.10.10.100.1000.1000000.1

Ref No.

MODE 61 62 63 64

CD PLA

Y

1.7 0

00

STANDB

Y

00.1

0.1 0

Ref No.

MODE 123

CD PLA

Y

3.3 0

1.8

STANDB

Y

00

0

Ref No.

MODE 123

CD PLA

Y

4.8 0

3.3

STANDB

Y

00

0

Ref No.

MODE 123 45678

CD PLA

Y

1.6 1.6

00001.63.3

STANDB

Y

00

0 0 0000

IC1000

IC1000

IC1000

IC1000

IC1000

IC1000

IC1000

IC1001

IC1003

IC1004

SC-HTR310P DSP P.C.B.

IC1001

IC1001

IC1001

IC1002

SC-HTR310P

93

Page 94

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

0.91.910.800.10.1000000.100000 0 0

STANDB

Y

0 0 0 0 3.3 3.3 3.3 0 0.1 0 3.3 0 3.3 0.8 0 3.3 0.4 0 3.3 0.4

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

000 00.1000.10000000000-0.2-0.2

STANDB

Y

0 1.8 1.8 0 0 3.3 0 2.2 3 3 3.3 3.3 0.8 0 1.8 0 3.3 3.3 1.3 1.3

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

0 0 -0.2 -0.2 0 0 -0.2 -0.2 0 0 -0.1 -0.1 0.1 0 0 0.1 0 0.1 -0.2 -0.2

STANDB

Y

0 3.3 1.3 1.3 0 3.3 1.3 1.3 0 3.3 1.3 1.3 0 0 3.3 1.4 3.3 1.4 1.4 0

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLA

Y

00-0.2-0.10-0.2-0.200.10.10.1000001.70.80.10

STANDB

Y

3.3 1.3 1.3 0 3.3 1.3 1.3 0 3.3 1.3 1.3 0 0 1.8 0 3.3 0 0 1.8 0

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLA

Y

10.90.90.80.80.80.800000000000.10 0

STANDB

Y

3.13.13.13.100003.3001.80.30.31.801.61.63.30.1

Ref No.

MODE 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

CD PLA

Y

0 0.1 0.6 0.7 0.7 0 0.5 0 0 1.8 0.9 0.9 0.9 0 0 1.5 1.7 1.4 1.4 0

STANDB

Y

03.303.31.80003.30001.800000 0 0

Ref No.

MODE 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140

CD PLA

Y

1.8 0 1.8 1.8 1.8 1.8 0 0 1.8 1.8 1.8 1.8 1.8 0.1 0 1.8 1.8 0 0 1.8

STANDB

Y

03.30 0 0001.8000003.300001.80

Ref No.

MODE 141 142 143 144

CD PLA

Y

1.8 1.8 1.8 0

STANDB

Y

000 0

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

1.81.50 01.91.91.91.91.91.91.91.900000.10 0 0

STANDB

Y

0 0 0 1.8 3.3 3.3 1.8 1.3 1.3 1.3 0 0 3.3 0 0 1.8 3.3 0 1.5 1.5

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

0 0 0 0 0 2.6 2.6 0 2.6 2.6 0 2.6 2.6 0.1 2.6 21.6 0 0.1 0 0

STANDB

Y

0 0 3.3 3.3 0 0.5 0.4 3.3 1.3 1.3 0 0.9 0.9 3.3 1.2 1.2 0 3.3 0 0

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

000 0 00001.81.81.81.81.81.81.31.31.31.30 0

STANDB

Y

000 0 00001.8000000000 0 0

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLA

Y

1.81.80.90.81.71.20.90.90.90.9000001.31.31.31.31.3

STANDB

Y

000 0 0000003.3001.80000 0 0

IC2001

IC2001

IC2001

IC2001

IC2001

IC2001

IC2001

IC2001

IC2002

IC2002

IC2002

IC2002

SC-HTR310P

9.1.3. HDMI P.C.B.

94

Page 95

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

002.503.12.8000003.31.601.63.33.30.60.10.5

STANDB

Y

000.40 00.40.400003.301.61.63.33.303.33.3

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

3.33.30 0 00002.72.700000.10.100 0 0

STANDB

Y

3.33.30 0 00003300002.42.203.33.30

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

000 0 000003.33.30000000 0 0

STANDB

Y

03.300.8000003.300000000 0 0

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLA

Y

3.300 0 003.2000.7000.600000 0 0

STANDB

Y

03.30 0 00001.51.50.50000000 0 0

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLA

Y

000 0 00000000002.4003.33.33.3

STANDB

Y

000 0 00000000002.6003.33.30

Ref No.

MODE 12345

CD PLA

Y

0.1 0 - 0 0

STANDB

Y

3.3 3.3 - 0 0

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

0.100.10 0000.100.100000.10.100.60.10.1

STANDB

Y

000 0 0003.303.3003.300000 0 0

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

000.10.10.10.10.10000000000.100 0

STANDB

Y

3.303.30 00003.33.30.62.42.20003.30 0 0

Ref No.

MODE 41 42 43 44 45 46 47 48

CD PLA

Y

00.70 0 0000

STANDB

Y

000 0 0000

Ref No.

MODE 123 4 5678

CD PLA

Y

12.40 0 0101

STANDB

Y

1.2 0 1.2 0 0 1.2 0 2.5

Ref No.

MODE 123 4 567891011121314

CD PLA

Y

0.1 0 0.7 0.1 0.6 0.6 0 0.1 0.7 0.7 0.7 0 0.7 0.1

STANDB

Y

3.300 0 0000000003.3

Ref No.

MODE 123 4 5678

CD PLA

Y

0 3.3 3.3 3.3 0.1 0.1 0.1 0.1

STANDB

Y

0 3.3 3.3 0.2 3.3 3.3 3.3 3.3

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

2.31.31.41.11.31.101001.11.211.61.11.611.73.30.1

STANDB

Y

0.303.303.30030003.32.802.802.800.33.3

IC2003

IC2003

IC2003

IC2003

IC2003

IC2004

IC2005

IC2005

IC2005

IC2006

IC2007

IC2008

IC2009

SC-HTR310P

95

Page 96

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

SC-HTR310P

Ref No.

MODE 123 4 5678

CD PLA

STANDB

Ref No.

MODE 123 4 5678

CD PLA

STANDB

Ref No.

MODE 12345

CD PLA

STANDB

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

STANDB

Ref No.

MODE ECB ECB ECB ECB EC B

CD PLA

STANDB

Ref No.

MODE ECB ECB ECB ECB EC B

CD PLA

STANDB

Ref No.

MODE ECB ECB ECB ECB EC B

CD PLA

STANDB

Ref No.

MODE ECB ECB ECB

CD PLA

STANDB

0 0 3.3 0 3.3 0 0 3.3

0 0 3.3 0 3.3 3.3 0 3.3

0 0.1 0 0 2.4 2.4 0 1.1

0 0 0 0 0 2.5 0.1 1.2

00 - 0 0

3.3 3.3 - 0 0

0 0 0 1.5 1.5 0 2.4 0 2.3 0 0 2.5 0 2.3 0.1 1.4 0.1 1.4 0 0

3.303.303.30000003.303.33.33.33.33.303.3

Q2001 Q2002 Q2005 Q2006 Q2007

0 2.3 0 0 2.3 0 0.1 5 0.1 0 5 0.1 2.7 2.4 3.3

3 2.5 3.3 3 2.5 3.3 1.5 1.5 3.3 1.5 1.5 3.3 3 2.6 3.3

Q2008 Q2009 Q2010 Q2011

2.7 2.4 3.3 0 0 3.3 0 0 3.3 3 3 3 0 2.6 0

3 2.6 3.3 2.2 2.2 3.3 2.2 2.2 3.3 3 3 3 0 2.6 0

Q2016 Q2017 Q2018 QR2021 QR2022

0 0.6 -0.6 0 3.3 0 0 0 0.6 0 3.3 0 0 3.8 0

0 3.5 -1.1 0 3.3 0 0 0 0.6 0 3.3 0 0 0 2.8

QR2023 QR2024 QR2025

03.20 0 03.3 0 03.3

003.3 003.3 003.3

IC2010

IC2011

IC2012

IC2016

Q2012

SC-HTR310P HDMI P.C.B.

96

Page 97

9.1.4. MAIN P.C.B.

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

0000.160.150000000.410.040.04000000

STANDB

Y

00.010.010 00.020.01000.010.010.430.040.04000000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

0 0 0 0 0 0.15 0.37 0 0 0 0.11 0.11 0.39 0.38 0 0.1 0 0 0.29 0.29

STANDB

Y

000 0 000.390000000000000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

CD PLA

Y

0.36 0.35 0 0.01 0.01 0 0.37 0.36 0.35 0.35 0 0 0.38 0.38 0.38 0.38

STANDB

Y

0 0.17 0 0.01 0.01 0 0.19 0.19 0.19 0.19 0 0.01 0.4 0.4 0.4 0.4

Ref No.

MODE 123 4 5678

CD PLA

Y

0.1 0.1 0.1 0 0.1 0.03 0.03 0.27

STANDB

Y

0.1 0.1 0.1 0 0.1 0.04 0.04 0.26

Ref No.

MODE 123 4 5678

CD PLA

Y

0 0.03 0.1 0 0 0.1 0 0.26

STANDB

Y

0.04 0.04 0.1 0 0.1 0.1 0 0.26

Ref No.

MODE 123 4 5678

CD PLA

Y

0.4 0 0 0 0 0 0.4 0.37

STANDB

Y

0.3600 0 0000

Ref No.

MODE 123 4 5678

CD PLA

Y

0.33 0 0.33 0.41 0 0 0.31 0.37

STANDB

Y

0.31 0.1 0.1 0 0.3 0.3 0.3 0.4

Ref No.

MODE 123 4

CD PLA

Y

0 0.39 0.26 0.39

STANDB

Y

0 0.39 0.26 0.39

Ref No.

MODE 123

CD PLA

Y

4.01 0 5.88

STANDB

Y

4 0 5.88

Ref No.

MODE 123 4 5678

CD PLA

Y

0000.410000

STANDB

Y

0000.430000

Ref No.

MODE 123 4 5678

CD PLA

Y

0.06 0 0.06 0.41 0 0 0.06 0.37

STANDB

Y

0.06 0.06 0.07 0.43 0.01 0 0.07 0

Ref No.

MODE 123 4 5678

CD PLA

Y

0000.420000

STANDB

Y

000.060.430000

IC101

IC101

IC101

IC103

IC104

IC105

IC106

IC109

IC110

IC202

IC204

IC205

SC-HTR310P

97

Page 98

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

Y

03.283.280 00000003.341.6601.563.373.3603.333.34

STANDB

Y

003.330 00000003.311.6501.593.353.3403.313.32

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

03.350 0 00003.753.760000000000

STANDB

Y

03.330 0 00003.7500000000000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

000 0 00.0200.043.333.360000000000

STANDB

Y

000 0 00.0200.043.333.360000000000

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLA

Y

03.360 0 0000000000000003.33

STANDB

Y

03.350 0 0000000000000003.33

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLA

Y

3.333.333.333.33000000000.020.710.6601.343.343.360

STANDB

Y

3.333.333.333.33000000000.020.720.6601.343.333.350

Ref No.

MODE 123 4 5678

CD PLA

Y

3.74 3.73 0 0 3.74 3.73 0 3.24

STANDB

Y

3.75 3.74 0 0 0.74 3.74 0 3.75

Ref No.

MODE 12345

CD PLA

Y

3.31 3.34 0 0 1.81

STANDB

Y

3.31 3.35 0 0 1.81

Ref No.

MODE 12345

CD PLA

Y

0.57 0.15 0 0.05 0

STANDB

Y

0.57 0.15 0 0.05 0

Ref No.

MODE 12345

CD PLA

Y

5.88 3.35 0 1.21 2.19

STANDB

Y

5.88 3.35 0 1.21 2.19

Ref No.

MODE 12345

CD PLA

Y

0.57 0 0 0 0

STANDB

Y

0.57 0 0 0 0

Ref No.

MODE 12345

CD PLA

Y

5.88 0 3.34 5.88 5.34

STANDB

Y

5.88 0 3.34 5.88 5.34

Ref No.

MODE 123 4 56 123456 ECB

CD PLA

Y

000 00.670 00000.640 5.875.875.18

STANDB

Y

000 00.670 00000.640 5.885.875.18

Ref No.

MODE ECB ECB ECB ECB ECB

CD PLA

Y

0 0 0 0.42 0.12 0.12 0 0.12 0.39 0.37 0 0 0 2.2 0.01

STANDB

Y

0 0 0 0.43 0.15 0.15 0 0.15 0.41 0.4 0 0 0 2.2 0

Ref No.

MODE ECB ECB ECB ECB ECB

CD PLA

Y

0 0.01 3.34 4 3.98 4 0 4 0 4.01 0 0.59 4.01 3.98 0.59

STANDB

Y

0 0 3.34 4 3.98 4 0 4 0 0 3.98 0.59 4 0 0.59

Ref No.

MODE ECB ECB ECB ECB

CD PLA

Y

3.98 3.98 0.02 0 0.02 2.79 0 0.66 0.4 0 0.66 0

STANDB

Y

3.98 3.98 0.02 0 0.02 2.8 0 0.66 0.42 0 0.66 0

IC301

IC301

IC301

IC301

IC301

IC302

IC303

IC704

IC722

IC774

IC793

Q221 Q222 Q311

Q707

QR109 QR221 QR222 QR223 QR224

Q701 Q704 Q705 Q706

SC-HTR310P MAIN P.C.B.

QR225 QR226 QR271 QR701

SC-HTR310P

98

Page 99

9.1.5. PANEL P.C.B.

Y

Y

Y

Y

Y

Y

Y

Y

REF NO.

MODE 1234567

CD PLAY 162 0 0 19.3 0.1 1.4 0.5

STANDBY 162 0 0 19.3 0.1 1.4 0.5

REF NO.

MODE 12345678

CD PLAY 6.0 1.6 1.8 20.3 162.2 - 0 0

STANDBY 6.0 1.6 2.0 20.3 163.0 - 0 0

REF NO.

MODE 1 2 3

CD PLAY -2.2 -29.5 -26.8

STANDBY -2.2 -29.5 -26.8

REF NO.

MODE 1 2 3

CD PLAY 4.2 0 2.5

STANDBY 4.2 0 2.5

REF NO.

MODE E C B

ECB ECB

ECB

ECB

CD PLAY 5.9 6.5 5.6

19.9 19.9 19.2 0 17.0 0.1

-21.9 -2.2 -22

1.3 0

0.7

STANDBY 5.9 6.6 5.6

19.9 19.9 19.2 0 16.8 0.1

-21.8 -2.2 -22

1.3 0

0.7

REF NO.

MODE

EC B ECB

ECB

ECB ECB

CD PLAY 0 0 0.7

05.20

05.00

04.50 00.15

STANDBY 0 0 0.7

05.20

05.00

1.51.50 005

Q5802

IC5701

IC5799

IC5801

IC5899

SC-HTR310P SMPS P.C.B.

Q5860

Q5861 Q5862 QR5801 QR5802 QR5810

Q5720 Q5721 Q5722

SC-HTR310P

Ref No.

MODE 123 4 567891011121314151617181920

CD PLA

STANDB

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

STANDB

Ref No.

MODE 41 42 43 44

CD PLA

STANDB

Ref No.

MODE ECB ECB ECB ECB

CD PLA

STANDB

0 0 0 0 2.6 1.5 2.5 2.6 0 1.5 1.5 0 3.3 -18 -22 -13 -22 -18 -22 -18

0 0 0 0 0 0.4 0.4 0 0 0.4 0.4 0 0.4 0 -19 -18 -18 -18 -18 -18

-22 -22 -18 -22.3 -22 -18 -18 -22 -22 -23 -17 -23 -23 -23 -23 -23 -23 -23 -18 -18

-18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18 -18

-18 -18 3.3 0

-18 -18 0.6 0

QR402 QR601 QR603 QR604

0 2.5 0 3.3 0.6 2.5 -24 1.5 -22 3.3 -21 1.4

0 3.2 0 3.3 3.1 1.1 -20 0.6 -20 0.6 -19 0.6

IC601

IC601

IC601

SC-HTR310P PANEL P.C.B.

9.1.6. SMPS P.C.B.

99

Page 100

CN222 PIN 6

CD PLAY

3.40Vp-p (1msec.div)

CN222 PIN 7

CD PLAY

3.40mVp-p (50msec.div)

CN222 PIN 10

CD PLAY

3.44Vp-p (50msec.div)

JW602 PIN 4

CD PLAY

3.44Vp-p (10msec.div)

JW602 PIN 5

CD PLAY

3.44Vp-p (10msec.div)

JW602 PIN 6

CD PLAY

3.48Vp-p (10msec.div)

CN103 PIN 1

CD PLAY

3.48Vp-p (500usec.div)

CN103 PIN 7

CD PLAY

3.40Vp-p (500usec.div)

CN103 PIN 9

CD PLAY

3.44Vp-p (10msec.div)

CN103 PIN 12

CD PLAY

3.48Vp-p (1msec.div)

CN701 PIN 11

CD PLAY

18.8mVp-p (10usec.div)

CN222 PIN 8

CD PLAY

3.44mVp-p (25msec.div)

IC101 PIN 8

CD PLAY

724mVp-p (50usec.div)

IC101 PIN 9

CD PLAY

720mVp-p (50usec.div)

IC101 PIN 13

CD PLAY

720mVp-p (500usec.div)

IC101 PIN 14

CD PLAY

728mVp-p (50usec.div)

IC101 PIN 16

CD PLAY

278mVp-p (500usec.div)

IC101 PIN 17

CD PLAY

282mVp-p (500usec.div)

IC101 PIN 45

CD PLAY

556mVp-p (500usec.div)

IC101 PIN 46

CD PLAY

556mVp-p (500usec.div)

SC-HTR310P

9.2. Waveform Chart

100

Loading...

Loading...