Panasonic SC-EN17P, SC-EN17PC Diagram

A

A

A

x

R

A

A

CD Stereo System

SC-EN17P

SC-EN17PC

Colour

S............Silver Type

System

Main Unit: SA-EN17P/SA-EN17PC

Speakers: SB-EN17P

ORDER NO.AD0502014C1

A6

Specifications

MAIN UNIT

■RADIO

Frequencyrange:

FM; 87.9 - 107.9 MHz (200kHz steps)

87.5 - 108.0 MHz (100kHz steps)

M; 520 to 1710 kHz

Intermediate Frequency:

FM/WB; 10.7MHz

M; 459kHz

Sensitivity:

FM; 3.98µV/50mW output (-3dB limit

sens.)

M; 178µV/m/50mW output (Ma

sens.)

■CD PLAYE

Sampling frequency: 44.1kHz

Decoding: 16 bit linear

Beam source: Semiconductor laser (wavelength

780nm)

Number of channels: 2 channel, stereo

Wow and flutter: Less than possible measurement

data

DA converter: MASH(1 bit DAC)

■Terminals

Input:

Output: PHONES: 3.5mm stereo (32Ω)

■GENERAL

Power supply:

Power consumption: 28W

Dimensions (W×H×D): 206×204×214mm

Mass: 4.0kg (8lb. 13oz.) with speakers

■■■■SPEAKERS

Full range: 8cm (3-1/8”), 6Ω×2

Ceramic tweeter: 1.52cm (19/32”) ×2

Dimensions (W×H×D): 115mm×211mm×215mm

Power consumption in standbymode: 3.4W

Note:

Specifications are subject to change without notice.

Mass and dimensions are approximate.

UX; 3.5mm stereo (27kΩ)

C120V, 60Hz

(8-1/8”×8-1/32”×8-7/16”)

2.4kg (5lb. 5oz.) without speakers

(4-17/32”×8-5/16”×8-15/32”)

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SC-EN17P / SC-EN17PC

CONTENTS

Page Page

1 Accessories 2

2 Location of Control

3 Safety Precaution

4 Protection Circuitry

5 Handling Precautions For Traverse Deck (Optical Pickup)

6 Precaution of Laser Diode

7 Prevention of Electro Static Discharge (ESD) To

Electrostatically (ES) Devices

8 Handling the Lead-free Solder

8.1. About lead free solder (PbF)

9 Operation Checks and Component Replacement

9.1. Checking for the motor P.C.B., main P.C.B., power AMP

P.C.B., LCD P.C.B., CD servo P.C.B. and tuner P.C.B.

9.2. Replacement for the traverse deck ass 馳

9.3. Replacement for the CD loading motor and optical pick-up

9.4. Replacement for the small DC motor ass 馳

9.5. Replacement for the gear chassis R ass 馳 and gear

chassis L ass 馳

9.6. Replacement for the CD lid unit

9.7. Replacement for the clamper, magnet and fix plate

9.8. Replacement for the CD lid unit A, CD lid unit B and slide

frame

9.9. Replacement for the lid LED lens, LED P.C.B., CD holder

A unit, CD holder A and lift plate

10 Self Diagnostic Function 17

3

4

5

5

6

7

7

7

8

8

9

10

12

13

14

15

15

16

10.1. Setting of self diagnostic Function

11 Descriptio n of Error Code

11.1. Error detection for CD Mechanism block

12 Schematic Diagram

12.1. Schematic Diagram Notes

12.2. Schematic Diagram (SB-EN17)

12.3. Schematic Diagram (SA-EN17)

13 Printed Circuit Board

14 Block Diagram

15 Wiring Connection Diagram

16 Type Illustrations of ICs, Transistors and Diodes

17 Measurem ents and Adjustments

17.1. Tuner Adjustment

17.2. Adjustment Point

18 Terminal Functions of ICs

19 Replacement Parts List

19.1. SA-EN17

19.2. SB-EN17

20 Cabinet Parts Location

20.1. SA-EN17

20.2. SB-EN17

21 Packaging

17

18

18

19

19

20

21

27

31

35

37

37

37

38

39

40

40

44

45

45

47

48

1 Accessories

· Remote control (EUR7711170).....................................1pc.

· Ac power supply cord (RJA0065-1D)............................1pc.

· Batteries

· AM loop antenna (G0ZZ00002036)...............................1pc.

2

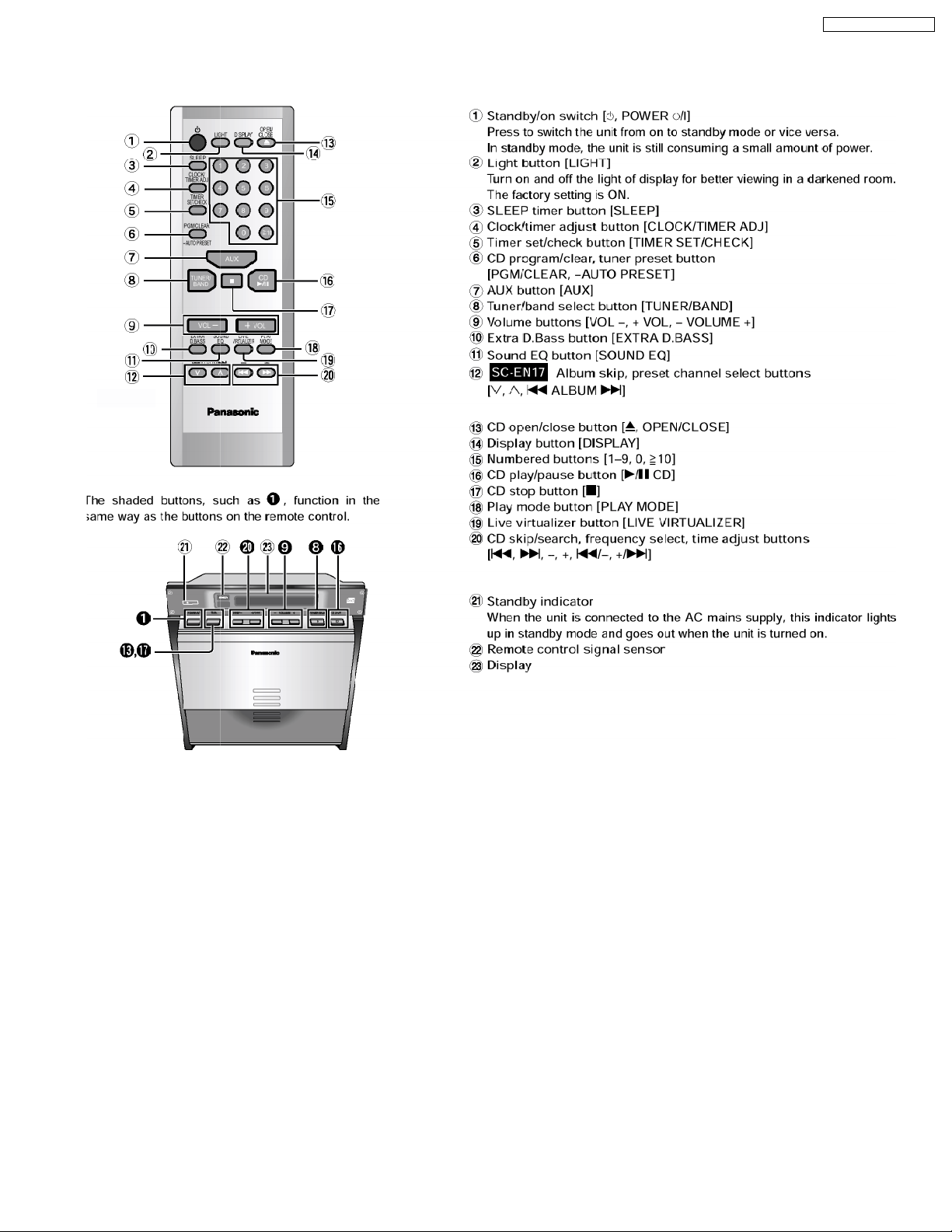

2 Location of Control

SC-EN17P / SC-EN17PC

3

SC-EN17P / SC-EN17PC

3 Safety Precaution

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to prevent the

customer from being exposed to a shock hazard.

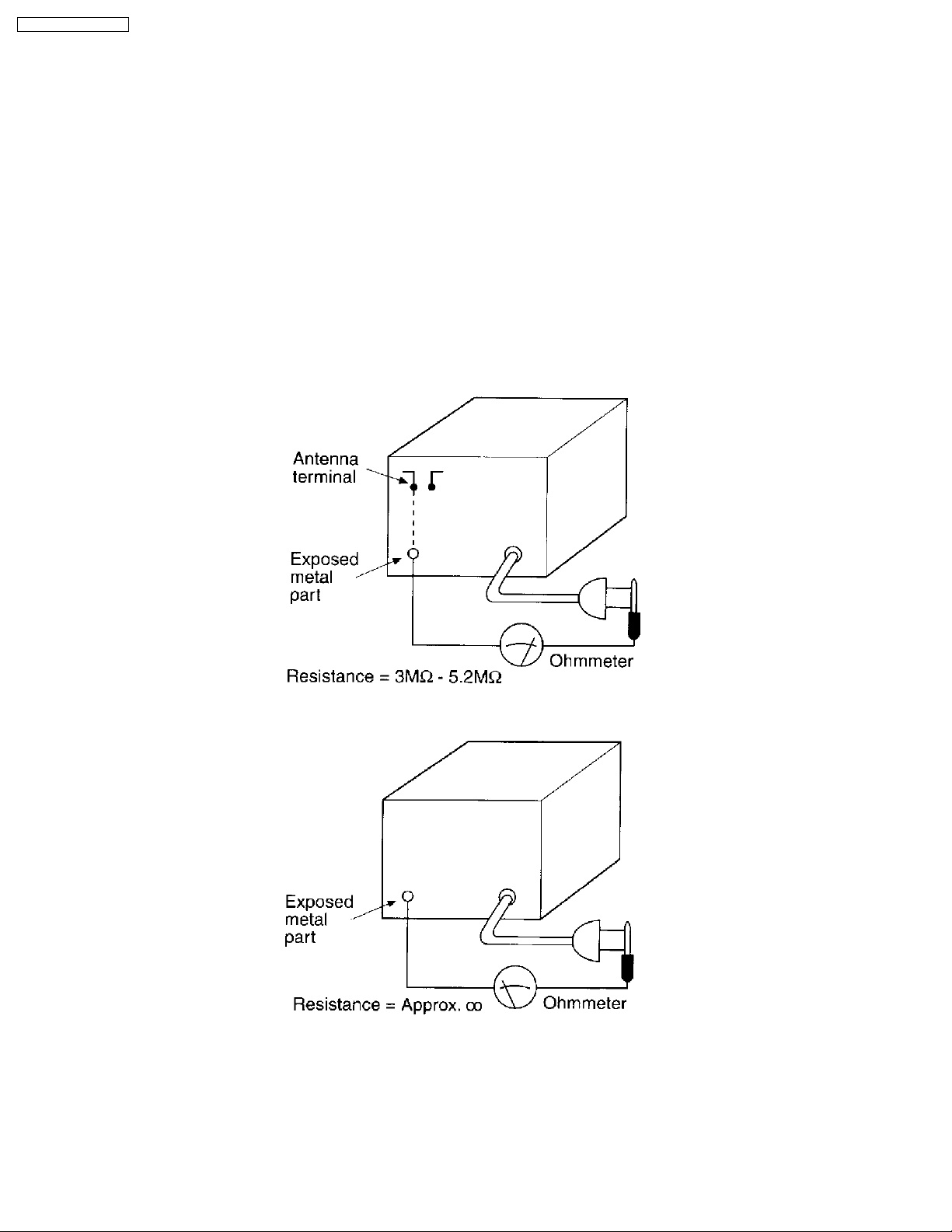

■Insulation Resistance Test

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with ohmmeter between the jumper AC plug and each exposed metal cabinet part, such asscrew

heads, control shafts, handle brackets, etc. Equipment with antenna terminals should read between 3MΩ and 5.2MΩ to

allexposedparts. (Fig. A) Equipment without antenna terminals should read approximately infinity to all exposed parts. (Fig. B)

*Note: Some exposed partsmay beisolated from the chassis by design. These will read infinity.

(Fig. A)

(Fig. B)

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard. The equipment should be repaired

and rechecked before it is returned to the customer.

4

SC-EN17P / SC-EN17PC

4 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Stop during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires

are “shorted”, or if speaker with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outline below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

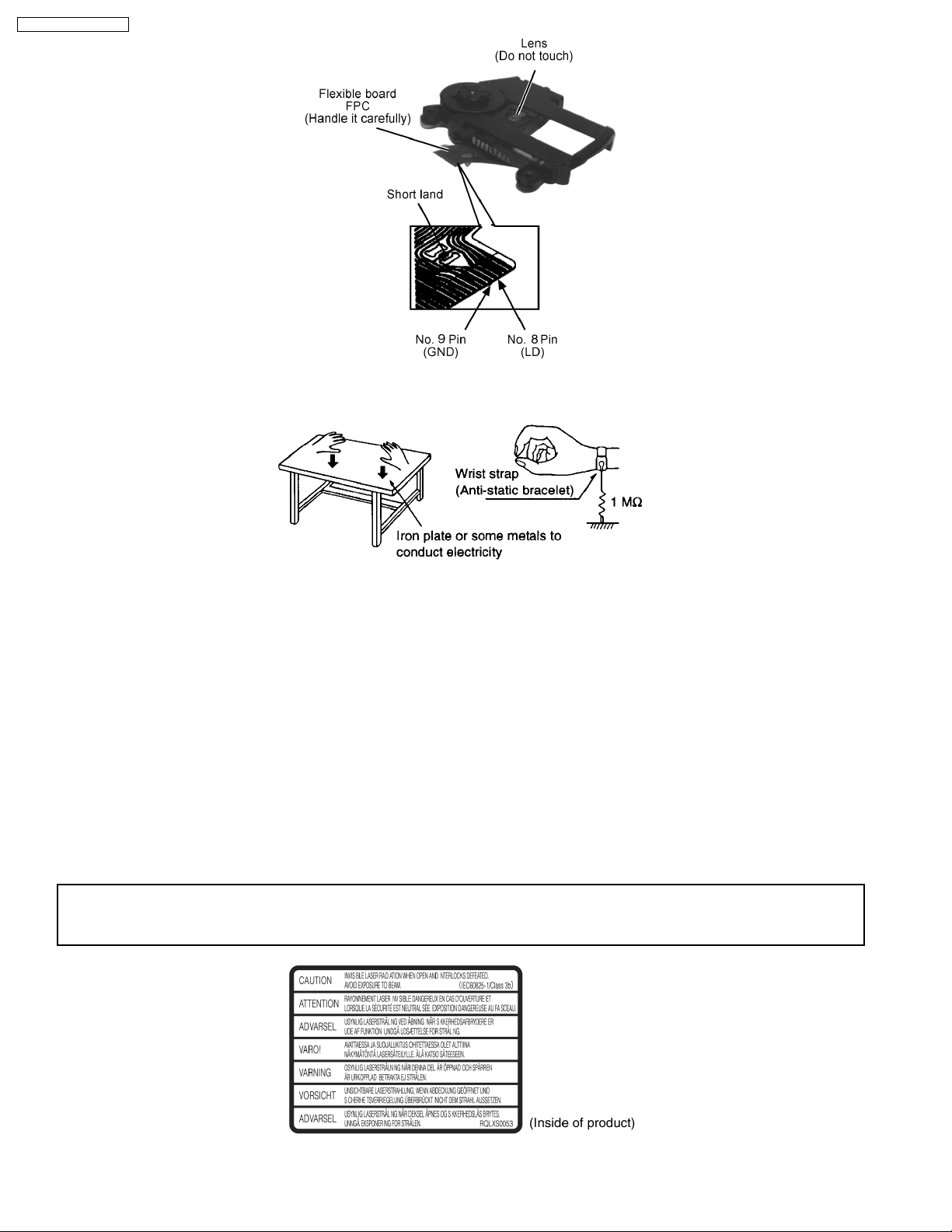

5 Handling Precautions For Traverse Deck (Optical

Pickup)

The laser diode in the traverse deck (optical pickup) may break down due to potential caused by static electricity of clothes or

human body. So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

· Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into flexible board (FFC board).(Fig.1)

3. Take care not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin, finish

the job in as short time as possible.

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

· Grounding for electrostatic breakdown prevention

1. Human body grounding (Fig.2)

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding (Fig.2)

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is place, and ground

the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch

the traverse deck (optical pickup).

Caution when replacing the Traverse Deck

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure

to remove the solder from the short point before making connections.

5

SC-EN17P / SC-EN17PC

(Fig.1)

(Fig.2)

6 Precaution of Laser Diode

Caution:

This unit utilizes a class 1 laser. Invisible laser radiation is emitted from the optical pickup lens. When the unit is turned on:

1. Do not look directly into the pickup lens.

2. Do not use optical instruments to look at the pickup lens.

3. Do not adjust the preset variable resister on the pickup lens.

4. Do not disassemble the optical pickup unit.

5. If the optical pickup is replaced, use the manufacturer’s specified replacement pickup only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

6

SC-EN17P / SC-EN17PC

7 Prevention of Electro Static Discharge (ESD) To

Electrostatically (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES Devices are integrated circuits and some field-effect transistors

and semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component

damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

Which should be removed for potential shock resons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal devices. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.(Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

8 Handling the Lead-free Solder

8.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50-70°F (30 - 40°C)

higher.Please use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to

700± 20 °F (370 ± 10°C).

· Pb free solder will tent to splash when heated too high (about 1100°F/600°C).

· When soldering or unsoldering, please completely remove all of the solder on the pins and solder area, and be sure to heat

the soldering points with the Pb free solder until it melts enough.

7

SC-EN17P / SC-EN17PC

9 Operation Checks and Component Replacement

· This section desceibes procedures for checking the

operation of the major printed circuit boards and replacing

the main components.

· For reassembly after operation checks or replacement,

reverse the respective procedures. Special reassembly

procedures are described only when required.

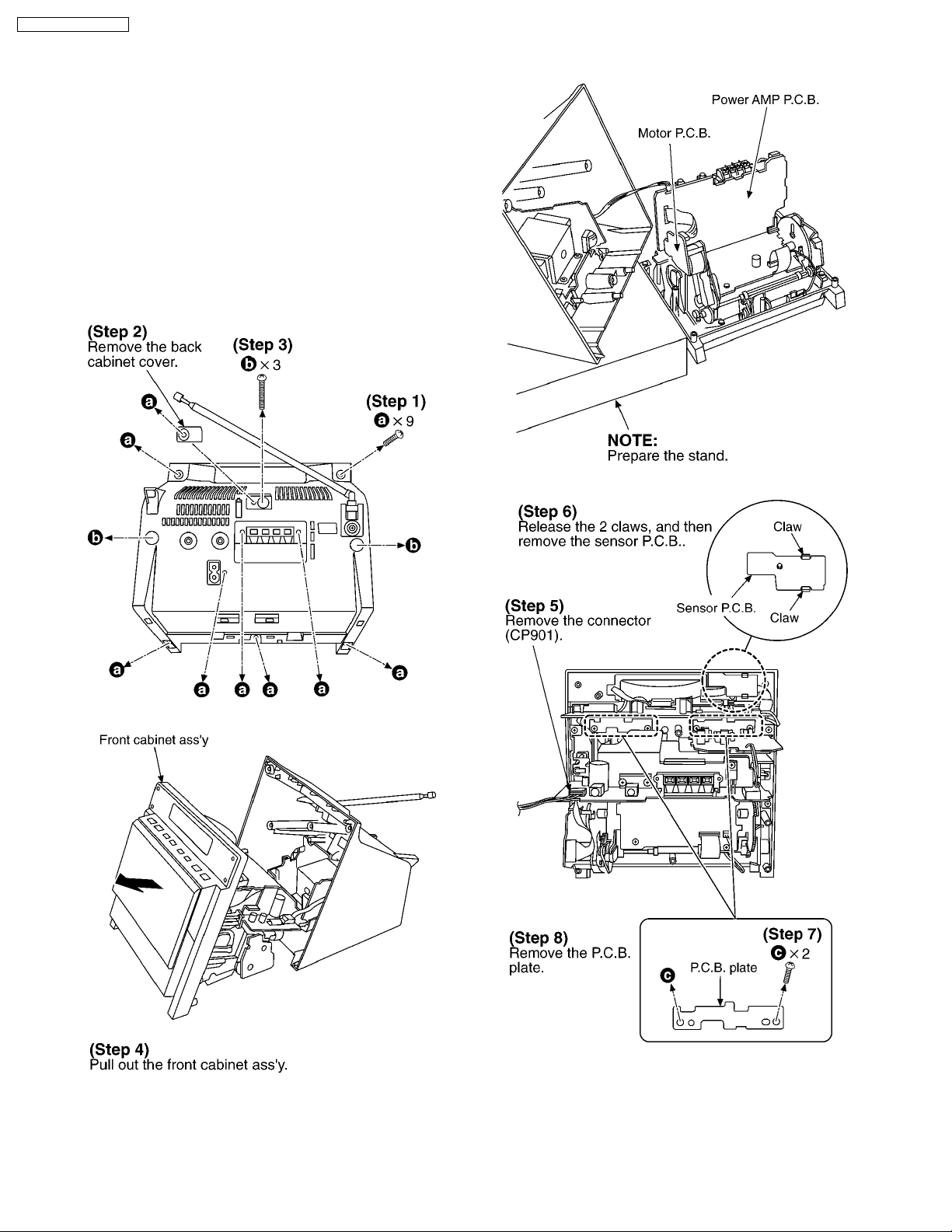

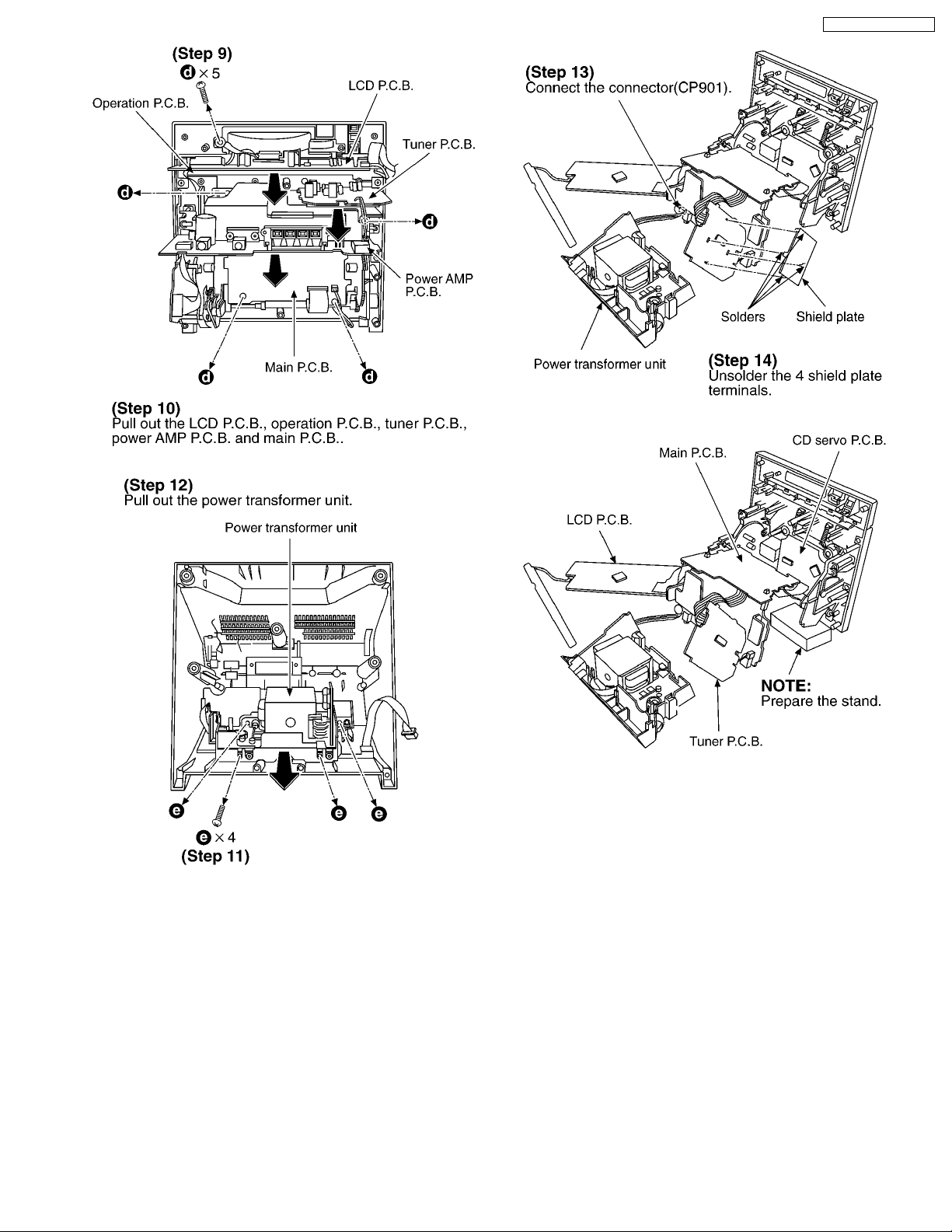

9.1. Checking for the motor P.C.B.,

main P.C.B., power AMP

P.C.B., LCD P.C.B., CD servo

P.C.B. and tuner P.C.B.

· Check the motor P.C.B. and power AMP P.C.B. as shown

below.

8

SC-EN17P / SC-EN17PC

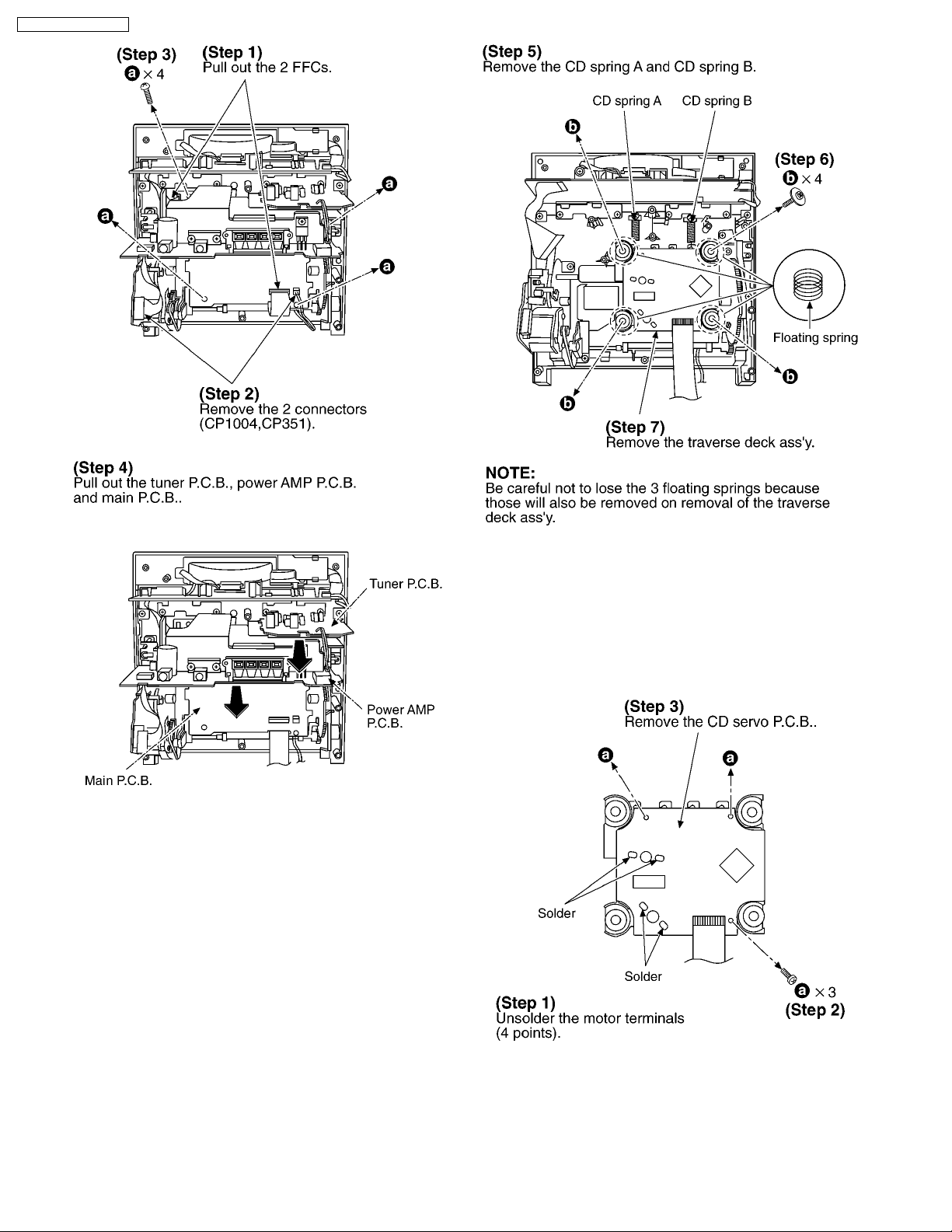

9.2. Replacement for the traverse

deck ass’y

· Follow the (Step 1) - (Step 5) of Item 9.1.

9

SC-EN17P / SC-EN17PC

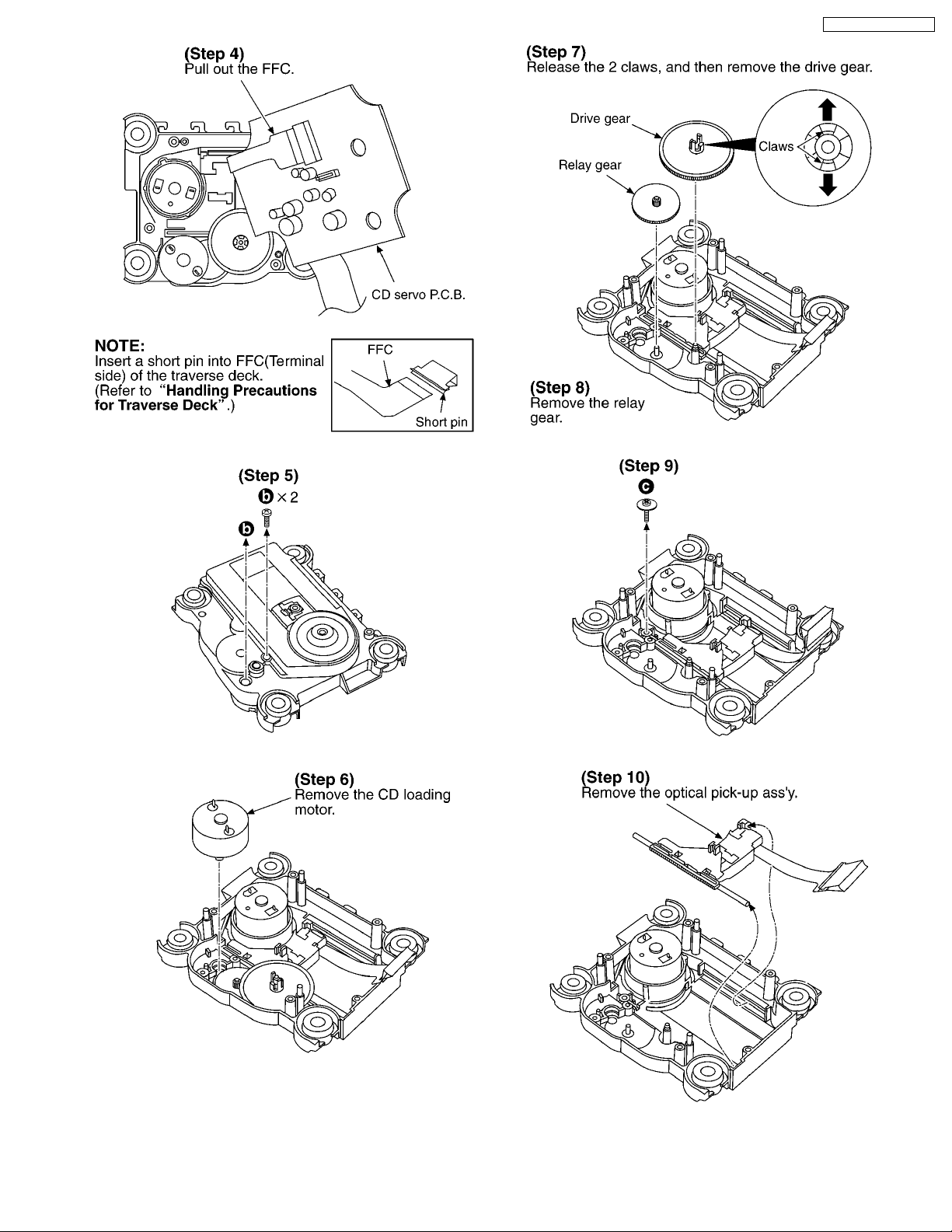

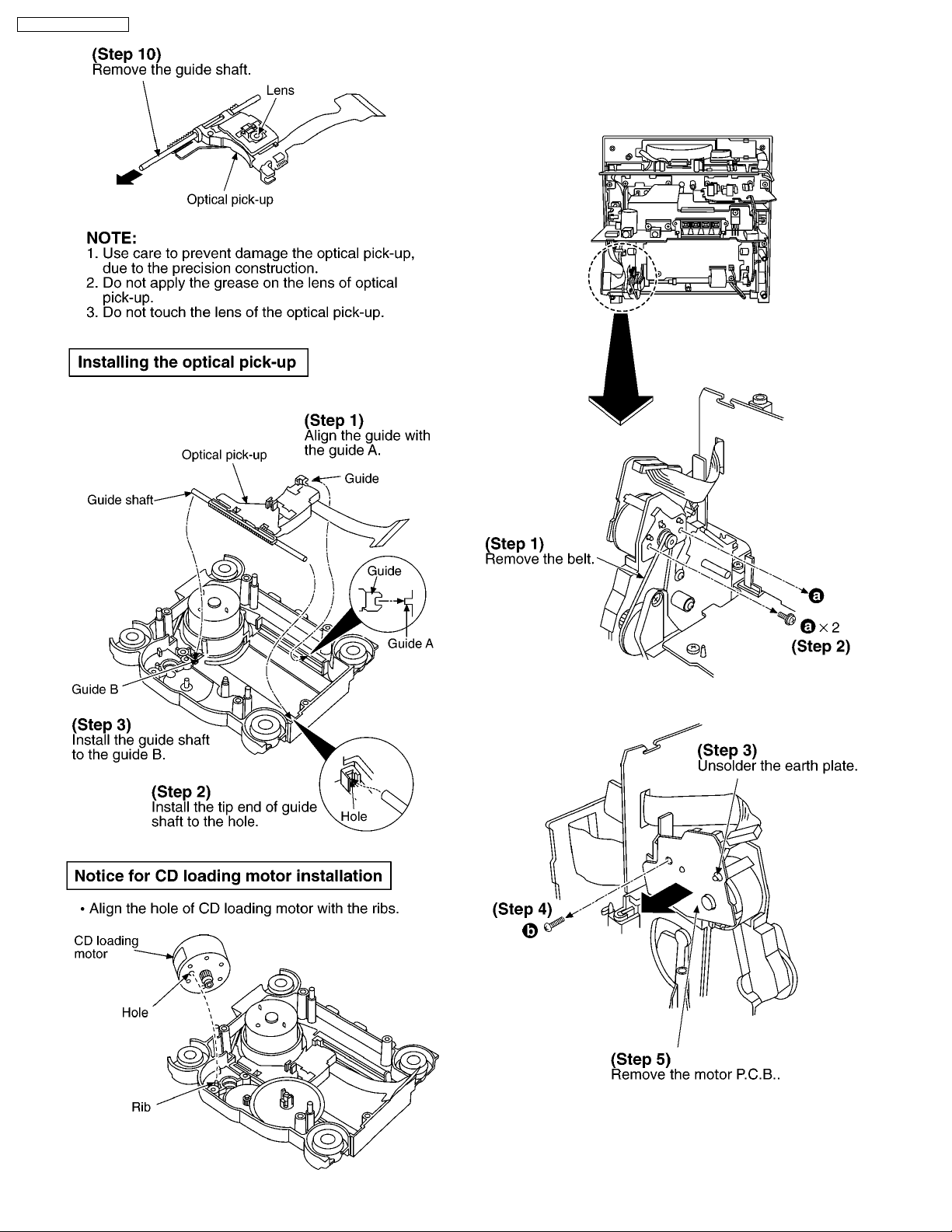

9.3. Replacement for the CD

loading motor and optical

pick-up

· Follow the (Step 1) - (Step 5) of item 9.1.

· Follow the (Step 1) - (Step 7) of item 9.2.

10

SC-EN17P / SC-EN17PC

11

SC-EN17P / SC-EN17PC

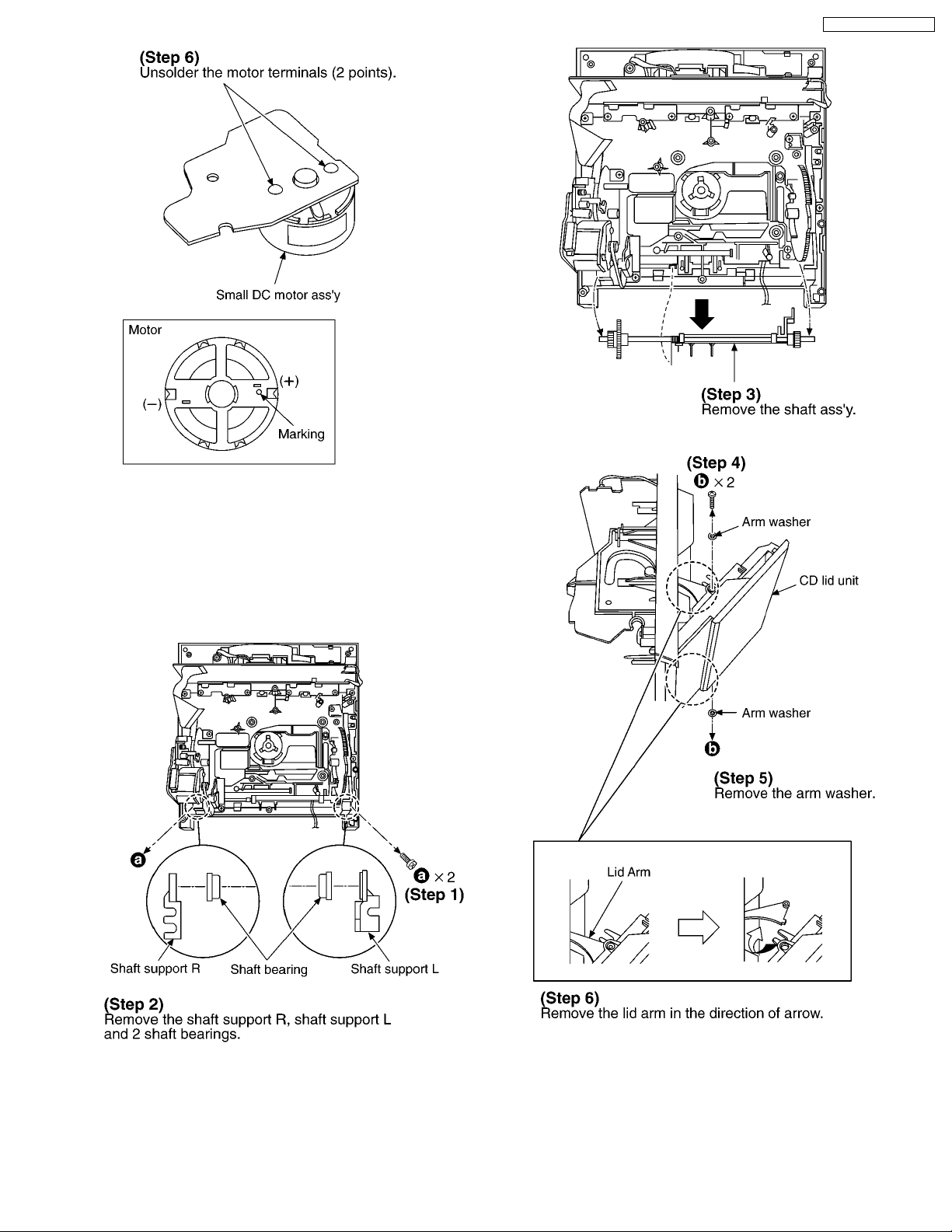

9.4. Replacement for the small DC

motor ass’y

· Follow the (Step 1) - (Step 5) of item 9.1.

12

SC-EN17P / SC-EN17PC

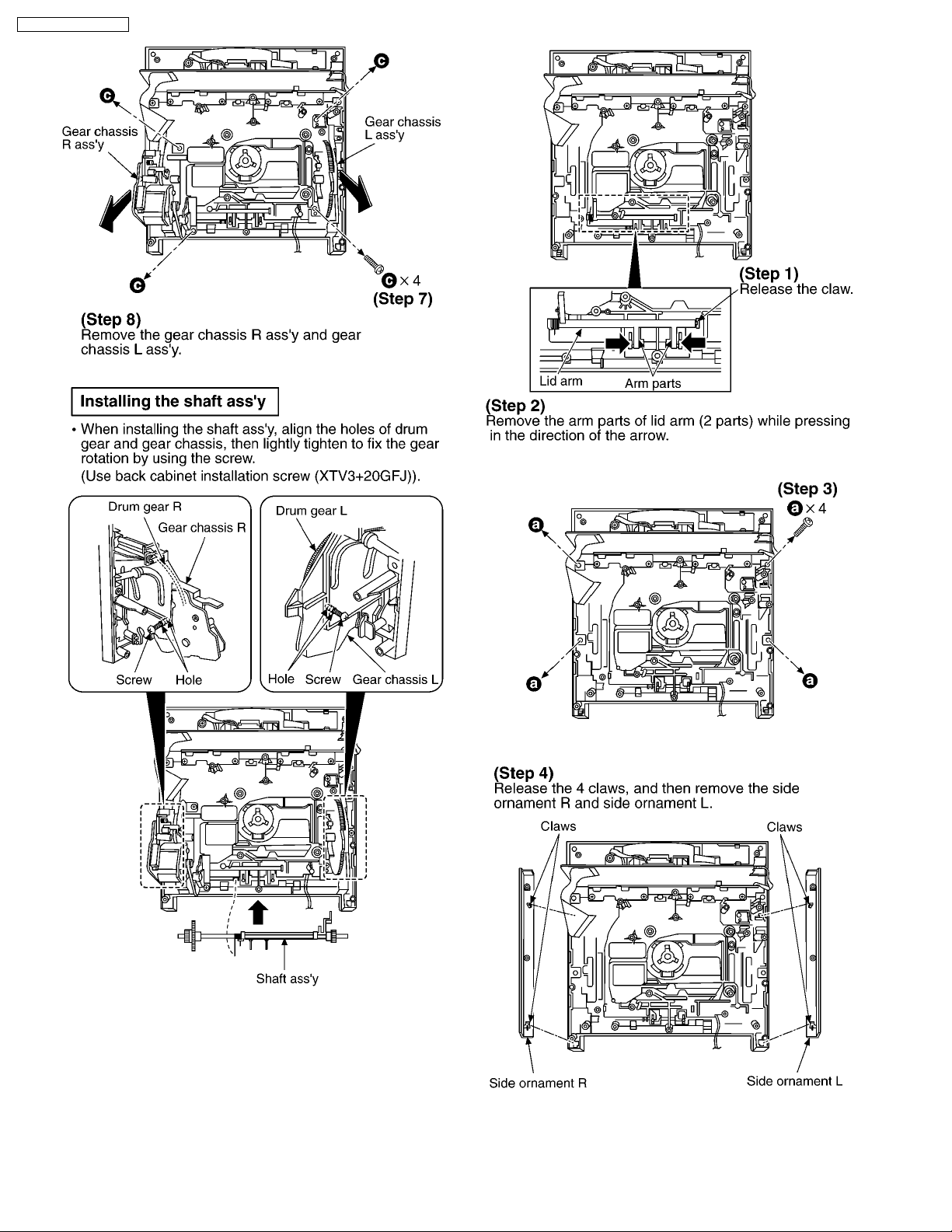

9.5. Replacement for the gear

chassis R ass’y and gear

chassis L ass’y

· Follow the (Step 1) - (Step 5) of item 9.1.

· Follow the (Step 1) - (Step 7) of item 9.2.

13

SC-EN17P / SC-EN17PC

9.6. Replacement for the CD lid

unit

· Follow the (Step 1) - (Step 5) of item 9.1.

· Follow the (Step 1) - (Step 7) of item 9.2.

· Follow the (Step 1) - (Step 8) of item 9.5.

14

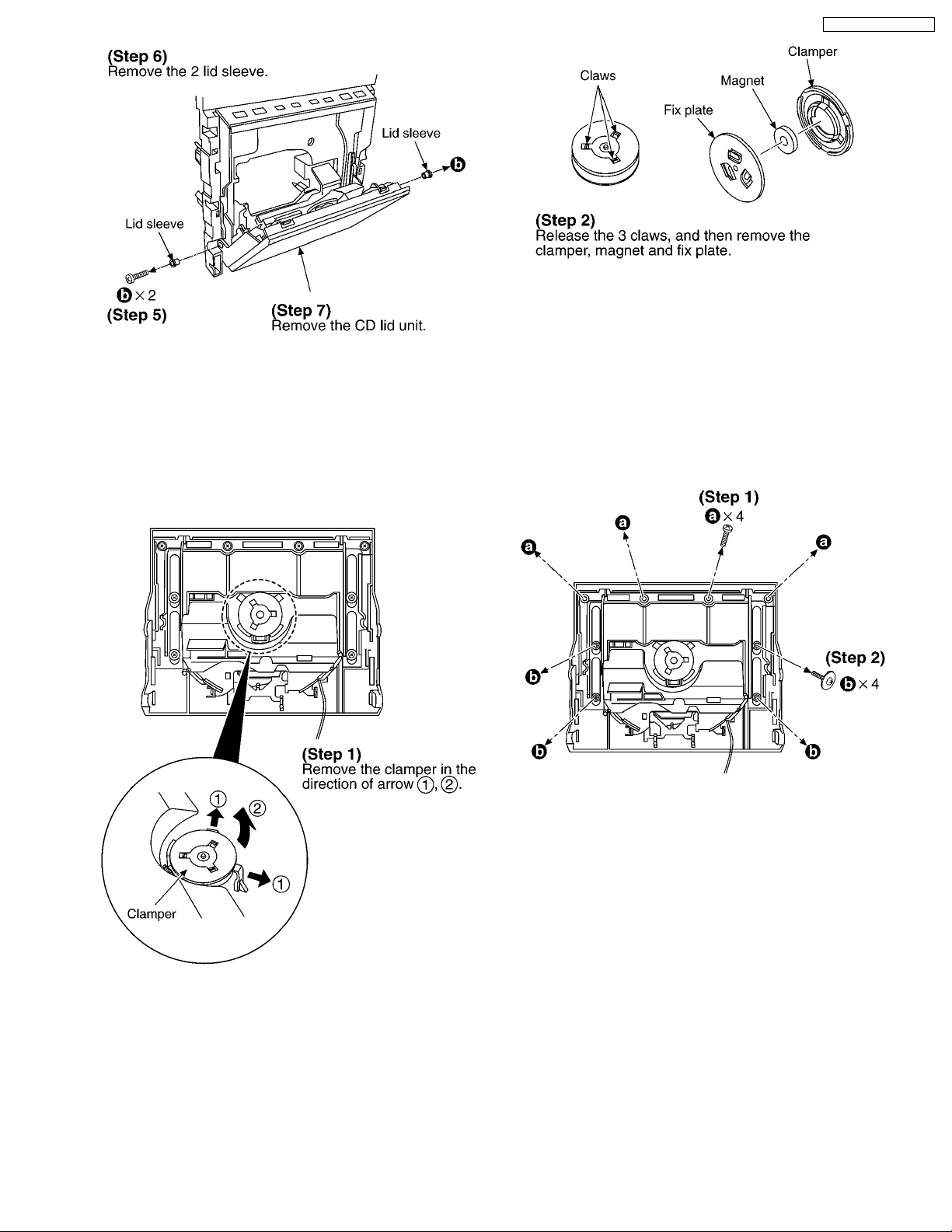

9.7. Replacement for the clamper,

magnet and fix plate

· Follow the (Step 1) - (Step 5) of item 9.1.

· Follow the (Step 1) - (Step 7) of item 9.2.

· Follow the (Step 1) - (Step 8) of item 9.5.

· Follow the (Step 1) - (Step 7) of item 9.6.

SC-EN17P / SC-EN17PC

9.8. Replacement for the CD lid

unit A, CD lid unit B and slide

frame

· Follow the (Step 1) - (Step 5) of item 9.1.

· Follow the (Step 1) - (Step 7) of item 9.2.

· Follow the (Step 1) - (Step 8) of item 9.5.

· Follow the (Step 1) - (Step 7) of item 9.6.

15

Loading...

Loading...