Panasonic DMR-E55PL Service Manual

A

Specifications

n AMPLIFIER SECTION

Recording system DVD video recording format (DVD-

RAM),

DVD video format (DVD-R)

Optical pick-up Systemwith 1 lens, 2 integration

units (658 nm wavelength for

DVDs, 795 nm wavelength for

CDs)

Recordable discs 12 cm 4.7 GB DVD-RAM discs

12 cm 9.4 GB DVD-RAM discs

8 cm 2.8 GB DVD-RAM discs

8 cm 1.4 GB DVD-R discs (for

General Ver. 2.0)

12 cm 4.7 GB DVD-R discs (for

General Ver. 2.0)

12 cm 4.7 GB DVD-R discs (for

General Ver. 2.0/ 4X-SPEED

DVD-R Revision 1.0)

Recording time Max. 8 hours (using 4.7 GB disc)

XP: 60 minutes

SP: 120 minutes

LP: 240 minutes

EP: 360 minutes or 480 minutes

Discs played 12 cm 4.7 GB DVD-RAM discs

12 cm 9.4 GB DVD-RAM discs

8 cm 2.8 GB DVD-RAM discs

12 cm 4.7 GB DVD-R discs (for

General Ver. 2.0)

8 cm 1.4 GB DVD-R discs (for

General Ver. 2.0)

12 cm 4.7 GB DVD-R discs (for

General Ver. 2.0/ 4X-SPEED

DVD-R Revision 1.0)

DVD-VIDEO discs

ORDER NO.MD0405181C3

DVD Video Recorder

DMR-E55PL

Colour

(S).......................Silver Type

DVD-Audio discs

CD-Audio discs (CD-DA)

Video CD discs

CD-R/ CD-RW discs (CD-DA,

Video CD, MP3 formatted discs)

n VIDEO SYSTEM

TV system NTSC system, 525 lines, 60 fields

PAL-M system, 525 lines, 60 fields

(PAL-M: Entrance only)

Recording system MPEG2 (Hybrid VBR)

Input LINE (pin jack) x3, 1.0 Vp-p; 75 Ω

S connector x3

Y: 1.0 Vp-p; 75 Ω

C: 0.286 Vp-p; 75 Ω

Output LINE (pin jack) x1, 1.0 Vp-p; 75 Ω

S connector x1

Y: 1.0 Vp-p; 75 Ω

C: 0.286 Vp-p; 75 Ω

Component video output Y: 1.0 Vp-p; 75 Ω

(480P/480i) PB: 0.7 Vp-p; 75 Ω

PR: 0.7 Vp-p; 75 Ω

ntenna reception input VHF Channel: 2ch-13ch, 75 Ω

UHF Channel: 14ch-69ch, 75 Ω

CATV Channel: 5A & A-5ch-

EEEch, 75 Ω

n AUDIO SYSTEM

Recording system Dolby Digital

Input LINE (pin jack) x3

Reference input: 309mVrms

FS: 2 Vrms (1 kHz, 0 dB)

© 2004 Panasonic AVC Networks Singapore Pte.

Ltd. (RCB REGISTRATION NUMBER: 197701580H)

All rights reserved. Unauthorized copying and

distribution is a violation of law.

DMR-E55PL

Output impedance: 47 kΩ

Output LINE (pin jack) x1

Reference output: 309mVrms

FS: 2 Vrms (1 kHz, 0 dB)

Output impedance: 1 kΩ

(Load impedance: 10 kΩ

Number of channels Recording: 2 channels

Playback: 2 channels

Other input/output connectors Digital audio optical output

connector

Operating temperature range 5°C-40°C

Operating humidity range 10 %-80 % RH (no condensation)

Clock unit Quartz-controlled 12-hiur digital

display

n LASER SPECIFICATION (Class I LASER Product)

Wave length 795 nm 658 nm

Laser power No hazardous radiation is emitted

with the safety protection

Power supply AC 110-240, 50/60 Hz

Power consumption 25 W

Dimensions Approx.

430 (W) x 79 (H) x 274 (D) mm

(excluding protrusions)

Mass Approx. 3.3 kg

Power consumption in standby

mode

Notes:

Mass and dimensions are aproximate.

Specifications are subject to change without notice.

approx. 2.9 W

CONTENTS

Page Page

1 Safety precautions

1.1. General guidelines

1.2. Caution for fuse replacement

2 Prevention of Electrostatic Discharge (ESD) to Electrostatic

Sensitive (ES) Devices

3 Precaution of Laser Diode

4 How to replace the Lithium Battery

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

6 Each Buttons

7 New Features

7.1. Function of Power Circuit (IC1150)

8 Taking out the Disc from RAM-Drive Unit when the Disc

cannot be ejected by OPEN/CLOSE button

8.1. Forcible Disc Eject

8.2. When the Forcible Disc Eject can not be done.

9 Service Explorer

10 Self-Diagn osis and Special Mode Setting

10.1. Self-Diagnosis Functions

10.2. Special Modes Setting

10.3. Service Modes

11 Assembling and Disassembling

11.1. Disassembly Flow Chart

11.2. P.C.B. Positions

11.3. Top Case

11.4. Digital P.C.B.

11.5. Front Panel

11.6. Panel P.C.B.

11.7. DVD-RAM Drive

4

4

4

5

6

7

7

7

8

9

9

12

12

12

13

16

16

17

19

23

23

23

24

24

24

25

25

11.8. Rear Panel

11.9. Main P.C.B.

11.10. Power P.C.B.

12 Service Fixture and Tools

13 Service Positions

13.1. Checking and Repairing of Power P.C.B.

13.2. Checking and Repairing of Main P.C.B.

13.3. Checking and Repairing of Digital P.C.B.

13.4. Checking and Repairing of DVD-RAM Drive

14 Adjustmen t Procedures

14.1. After replacing the RAM Drive with new one

14.2. When the unit does not operate normally after replacing

the Timer Microprocessor with new one

15 Standard Inspection Specificati ons after Making Repairs

16 Voltage and Waveform Chart

16.1. Power P.C.B.

16.2. Main P.C.B.

16.3. Panel P.C.B.

16.4. P9001 Connector

16.5. P9001 Waveform

17 Abbreviations

18 Block Diagram

18.1. Digital Block IC Pin Terminal Chart (TC1-18)

19 Schematic Diagram

19.1. MAIN (SUB POWER) CIRCUIT (P)

19.2. MAIN (MAIN NET) CIRCUIT (M)

19.3. MAIN (VIDEO I/O) CIRCUIT (V)

19.4. MAIN (AUDIO MAIN) CIRCUIT (A)

19.5. MAIN (TIMER) CIRCUIT (T)

25

26

26

27

28

28

29

30

31

32

32

32

32

33

33

33

35

35

36

37

39

53

57

57

59

61

65

67

2

DMR-E55PL

19.6. DIGITAL (GLUE NET) CIRCUIT (GN) 71

19.7. DIGITAL (RSTC) CIRCUIT (EN)

19.8. DIGITAL (AV DECODER/MAIN CPU) CIRCUIT (MC)

19.9. DIGITAL (AUDIO I/O) CIRCUIT (AI)

19.10. PANEL CIRCUIT

19.11. POWER CIRCUIT

20 Print Circuit Board

20.1. Main P.C.B.

20.2. Digital P.C.B.

20.3. Panel P.C.B.

20.4. Power P.C.B.

21 Wiring Connection Diagram

22 Illustration of IC 痴, Transistors and Diodes

76

83

23 Exploded Views

87

89

90

92

92

94

98

23.1. Casing Parts & Mechanism Section 1

23.2. Casing Parts & Mechanism Section 2

24 Parts Location and Replacement Parts List

24.1. Cabinet Parts List

24.2. Electrical Parts List

24.3. Packing Materials & Accessories Parts List

24.4. Packaging

99

100

101

102

102

103

104

105

105

114

114

3

DMR-E55PL

1 Safety precautions

1.1. General guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage current cold check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to thechassis, the reading should be between

1MΩand 5.2MΩ.

When the exposed metal does not have a return path to

the chassis, the reading must be

Figure 1

.

1.1.2. Leakage current hot check

(See Figure 1 .)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1 .

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug inthe ACoutlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliampere. In case a

measurement isoutside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

1.2. Caution for fuse replacement

4

DMR-E55PL

2 Prevention of Electrostatic Discharge (ESD) to

Electrostatic Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatic Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistorsandsemiconductor "chip" components. The following techniques should be used to help reduce the incidence of component

damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

whichshould be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparableconductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficientto damage

an ES device).

5

DMR-E55PL

3 Precaution of Laser Diode

6

4 How to replace the Lithium Battery

REPLACEMENT PROCEDURE

1. Remove the Top case and DVD-RAM drive unit with Main P.C.B. by referring the Disassembling Procedure.

2. Unsolder the Lithium Batteries: B7501 and then replace it into new one.

( As shown in 20.1. The Main P.C.B. )

NOTE:

The lithium battery is a critical component. ( Type No.: CR2354-1GUF Manufactured by Panasonic. )

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

DMR-E55PL

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher.

Please use a high temperature soldering iron. In case of the soldering iron with temperature control,please set it to 700 ±

20°F (370 ± 10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· When soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat

the soldering points with the Pb free solder until it melts enough.

7

DMR-E55PL

6 Each Buttons

8

7 New Features

7.1. Function of Power Circuit (IC1150)

1. General

We adopted IC module as the Switching Power Circuit for lower power consumption.

IC1150 is constructed with Switching materials and Control IC, and is partial resonance module.

We realized Switching Power with high efficiency, low noise and low power consumption.

2. Equivalence Circuit to IC1150

Pin No. Symbol Description

1 Z/C Trigger input terminal.

Zero detection voltage: 0.25V

It becomes less than 3V, the mode turns to

standby.

2 F/B Bias current feedback input terminal.

lSwitching ON time (min.) ~ (max.)

1.5V ~ 4.5V / 0µsec. ~ 25µsec.

lIn standby mode

Oscillation stops:less than 0.8V

Oscillation starts: over 1.8V

3 GND GND terminal

4 Vcc Power terminal of IC.

Oscillation starting voltage: Vcc = and over 14.5V

Oscillation stop voltage: Vcc = and less than 9.6V

Over voltage latching voltage: Vcc = 20V

5 Drain Drain terminal for Main switching material.

DMR-E55PL

3. Startup Circuit

When power is turned on, input voltage of the Switching

Transformer is supplied to IC1150 as the startup power.

After IC1150 has started, the startup current is cut off.

The current of Startup Circuit is supplied as constant

current source in IC1150 and as charge current for the

capacitor connected between Vcc terminal and GND out

side of IC1150 until Vcc reaches 14.4V.

When Vcc reaches 14.4V, the Startup Circuit is cut off, then

oscillation starts.

After then, power of IC1150 is supplied from control coil.

In case, the power failure or short out of the load, when Vcc

becomes 9.0V; the oscillation stops, furthermore Vcc

becomes 7.1V the Startup Circuit starts up and Vcc starts to

rise.

9

DMR-E55PL

Startup Circuit Timing Chart

Function of Z/C Terminal

When voltage of Z/C reaches 0.25V, Gate signal is output and Drain current starts to flow.

Function of F/B terminal

F/B signal decides Switching ON width in low voltage controlling.

The Switching ON width responds to change of F/B Voltage.

Standby Function

When Z/C Voltage becomes less than 3V, the unit changes to Standby mode.

10

IC1150 Block Diagram

DMR-E55PL

Signal name

Pin No. Name Symbol

1 Zero Current Det. Z/C

2 Feed back F/B

3 GND GND

4 Vcc Vcc

5 Drain Drain

11

DMR-E55PL

8 Taking out the Disc from RAM-Drive Unit when the Disc

cannot be ejected by OPEN/CLOSE button

8.1. Forcible Disc Eject

8.1.1. When the power can be turned off.

1. Turn off the power and press [STOP] [CH UP] keys on the front panel simultaneously for 5 seconds.

8.1.2. When the power can not be turned off.

1. Press [POWE R] key on the front panel for over 10 seconds to turn off the power forcibly, and press [STOP] [CH UP] keys on

the front panel simultaneously for 5 seconds.

8.2. When the Forcible Disc Eject can not be done.

1. Turn off the power and pull out AC cord.

2. Remove the Top Case.

3. Remove the Front Panel.

4. Remove 4 screws and Upper Base Unit from DVD-RAM Drive.

5. Take out the disc and put the Opener Roller on fully position for direction of Arrow.

6. Put the Upper Base Unit so that the Opener Roller is inserted into the groove.

7. Check center of Opener Roller is seen through the Opener position Checking Hole, and tighten 4 screws.

12

9 Service Explorer

Confirm “RAM-Drive Last Error” in Service Mode

Execute Service Mode

1. Press [STOP], [TIME SLIP] and [OPEN/CLOSE] simultaneously for 5 seconds when P-off.

FL Display:

*After finishing display “(7). Factor of Drive Error occurring”, press [0] [2] ~[9] [9] keys of the Remote Controller so that

99 memo ries can be displayed as maximum.

2. Press [4] [2] keys of remote controller.

Example of FL Display:

(1) Error Number is displayed for 5 seconds.

DMR-E55PL

(2) Time when the error has occurred is displayed for 5 seconds.

(3) Last Drive Error (1/2) is displayed for 5 seconds.

(4) Last Drive Error (2/2) is displayed for 5 seconds.

13

DMR-E55PL

(5) Error occurring Disc type is displayed for 5 seconds.

(6) Disc Maker´s ID is displayed for 5 seconds.

Example of Disc Maker´s ID:

DVD-R Disc

No. FL Display (Disc Maker´s ID) Disc Maker Country

1 MEI Panasonic Japan

2 PVC Pioneer Japan

3 MCC Mitsubishi Chemical Corporation Japan

4 TDK TDK Japan

5 MXL Maxell Japan

6 MCI MITUI CHEMICALS Japan

7 JVC Victor JVC Japan

8 TAIYOYUDEN Taiyo yuden Japan

TYG

9 GSC Giga Storage Taiwan

10 PRODISC Prodisc Taiwan

11 PRINCO PRINCO Taiwan

12 RITEK RITEK Taiwan

13 OPTDISC OPTDISC Taiwan

14 LEAD DATA LEAD DATA Taiwan

15 CMC CMC Taiwan

16 AUVISTAR AUVISTAR Taiwan

17 ACER Acer Taiwan

18 VIVASTAR VIVASTAR Switzerlan d

19 LGE LG Electronics Korea

DVD-RAM Disc

No. FL Display (Disc Maker´s ID) Disc Maker Country

1 MEI Panasonic

2 MATSUSHITA Panasonic Japan

3 MXL Maxell Japan

4 PRODISC Prodisc Taiwan

5 OPTDISC OPTDISC Taiwan

6 CMC CMC Taiwan

*Since an display is arbitrarily set up by the disk producer side, the above-mentioned display may be changed.

Please make it reference as an example of a display.

(7) Factor of Drive Error occurring is left displayed

Error Occurring Disc Type

FL Display Disc Type

00 DVD-ROM/Video

01 Audio-CD

02 2.6GB DVD-RAM

03 4.7GB DVD-RAM

04 DVD-R

14

Error Occurring Disc State

DMR-E55PL

15

DMR-E55PL

10 Self-Diagnosis and Special Mode Setting

10.1. Self-Diagnosis Functions

Self-Diagnosis Function provides information for errors to service personnel by “Self-Diagnosis Display” when any error has

occurred.

U14, H** and F** are stored in memory and held.

Display on FL will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

Error

Code

U12 Remote control code error Display appears when main unit and remote

U14 Abnormal inner temperature

U99 Hang-up Displayed when communication error has

H01 Inoperative fan motor Display appears when inoperative fan motor

F00 No error information Initial setting for error code in memory

F01 Drive hardware error Display appears when drive unit error is

Diagnosis contents Description Monitor Display FL display

No display

“*” is remote controller code of the

main unit.

Display for 5 seconds.

No display

“U14” is displayed for 30 minutes.

No display

Displayed is left until the

[POWER] key is pressed.

No display

Displayed is left.

No display

Displayed is left.

No display

detected

controller codes are not matched.

Display appears when the drive temperature

exceeds 70°C.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled. (Fan motor operates at the highest

speedfor the first 5 minutes. For the

remaining 25 minutes, fan motor is also

stopped.) The event is saved in memory as

well.

occurred between Main microprocessor and

Timer microprocessor.

is detected after powered on.

The power is turned off when detecting.

(Error code Initialization is possible with error

code initialization and main unit initialization.)

detected. The event is saved in memory.

F12 Initialization error when main

UNSUPPORT

NO READ Disc read error *A disc is flawed or dirty.

HARD

ERR

SELF

CHECK

Full

Program

microprocessor is started up

for program recording

Unsupported disc error *An unsupported format disc was played,

Drive error The drive detected a hard error. “DVD drive error.” Display for 5 seconds.

Restoration operation Since the power cord fell out during a power

16 programs are already set. 16 programs are already set. No display

Display appears when initialization error is

detected after starting up main

microprocessor for program recording. The

event is saved in memory.

The power is turned off when detecting.

although the drive starts normally.

*The data format is not supported, although

the media type is supported.

*Exceptionally incase of the disc is dirty.

*A poor quality failed to start.

*The track information could not be read.

failure or operation, it is under restoration

operation.

*It will OK, if a display disappears

automatically. If a display does not disappear,

thereis the possibility that defective Digital

P.C.B. / RAM drive.

Displayed is left.

No display

Displayed is left.

“This disc is

incompatible.”

Display for 5 seconds.

“Cannot read.

Please check the

disc.”

No display

16

10.2. Special Modes Setting

Item FL display Key operation

Mode name Description Front Key

TEST Mode *All the main unit´s parameters (include tuner)

Service Mode Setting every kind of modes for servicing.

Rating password The audiovisual level setting password is

Forced disc eject Removing a disc that cannot be ejected.

Forced power-off When the power button is not effective while

Aging Perform sequence of modes as * Aging

Demonstration

lock/unlock

are initialized.

*Details are described in “10.3. Service

Mode ”.

initialized to “Level 8”.

The tray will open and unit will shift to P-off

mode.

*When Timer REC is ON or EXT-LINK is ON,

execute " Forced disc eject " after releasing

TimerREC or EXT-LINK.

*This command is not effective during "Child

lock" is ON.

power is ON, turn off the power

forcibly.*When Timer REC is ON or EXTLINK is ON, execute “Forced Power-off” after

releasing Timer RECor EXT-LINK.

Action:

The tray will open, and the power will turn off.

Description shown below continually.

Ejection of the disc is prohibited.

The lock setting is effective until unlocking the

tray and not released by “Main unit

initialization” of service mode.

The display before execution

leaves.

Display in P-off mode. Press [Power] key over than 10

Display following the then mode. When the power is ON, press [CH

*When lock the tray.

“LOCK” is displayed for 3 seconds.

*When unlock the tray.

Press [SKIP (REV)], [TIME SLIP]

and [OPEN/CLOSE] keys

simultaneously for five seconds

when power is off.

When the power is off, press

[STOP], [TIME SLIP] and

[OPEN/CLOSE] keys

simultaneously for 5 seconds.

Open the tray, and press [SKIP

(REV)] and [SKIP (FWD)]

simultaneously for five seconds.

When the power is off, press

[STOP] and [CH UP] keys

simultaneously for five seconds.

seconds.

DOWN], TIME SLIP] and [OPEN /

CLOSE] simultaneously for over five

seconds and less than 10 seconds.

*The [REC MODE] should be set to

EP or LP.

*Whenthe unit has hung-up

because of pressing keys for over

10 seconds, once turn off the

power, and re-execute this

command.

“When releasing Aging mode, press

[POWER] key.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for five seconds.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for five seconds.

DMR-E55PL

ATP Initialization ATP setting is initialized, and the unit turns off

automatically.

Progressive initialization The progressive setting is initialized to

Interlace.

“UNLOCK” is displayed for 3

seconds.

*When press OPEN/CLOSE key

while the tray being locked.

Display “LOCK” for 3 seconds.

It is same with display in stop mode. When the power is on (E-E mode),

The display before execution

leaves.

Press [OPEN/CLOSE] key while the

tray being locked.

press [CH UP] and [CH DOWN]

simultaneously for five seconds.

When the power is on (E-E mode),

press [STOP] and [TIME SLIP]

simultaneously for five seconds.

17

DMR-E55PL

Aging Contents (Example):

18

DMR-E55PL

10.3. Service Modes

Service mode setting: While the power is off, press TIME SLIP, STOP and OPEN / CLOSE simultaneously for five seconds.

Item FL display Key operation

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

mode.

Error Code Display Last Error Code of U14/H/F held by Timer is

displayed on FL.

*Details are described in “10.1. Self-

Diagnosis Functions”.

ROM Version Display Region code, MAIN firm version, TIMER firm

version and DRIVE firmware versions are

displayed on FL for five seconds per each

version in order, but ROM version will be left

displayed.

Press [0] [1] in service mode

Press [0] [2] in service mode

are version displays.

19

DMR-E55PL

Item FL display Key operation

Mode name Description (Remote controller key)

White Picture Output White picture is output as component Output

from AV Decoder.

*White picture

(Saturation rate : 100%)

*It is enable to switch Interlace/Progressive by

“I/Pswitch: [1] [4]”

*Initial mode is “Interlace”. Press [1] [1] in service mode.

Switch Interlace/Progressive Press [1] [4] in White Picture Output

mode.

*I/P are switched alternately.

Magenta Picture Output Magenta picture is output with Component

Output from AV Decoder.

*Magenta picture

(Saturation rate: 100%)

*It is enable to switch Interlace/Progressive by

“I/Pswitch: [1] [4]”

RTSC Return in XP

(A & V)

L1 input signal is encoded (XP), decoded

(XP) and output decoded signal to external

without DISC recording and DISC playback.

I/P Switch Switch Interlace and Progressive in EE mode.

*Initial setting is “Interlace”.

*This command is effective during executing

“White Picture Output”, “MagentaPicture

Output” and “RTSC Return in XP (A & V)”

modes.

*Initial mode is “Interlace”. Press [1] [2] in service mode.

Switch Interlace/Progressive Press [1] [4] in Magenta Picture

Output mode.

*I/P are switched alternately.

Initial mode: EE2/ Interlace/ XP/

Press [1] [3] in service mode.

Audio 48kHz

Switch Interlace/Progressive Press [1] [4] in RTSC Return XP

mode.

*I/P are switched alternately.

Audio 44.1 kHz/ 48 kHz Switch Press [2] [4] in RTSC Return XP

mode.

*48 kHz / 44.1 kHz are switched

alternately.

Initial mode is Interlace

Press [1] [4] in I/P Switch mode.

*I/P are switched alternately.

Switch Interlace/Progressive

Audio Mute (XTMUTE) Check whether mute is applied normally by

the timer microprocessor.

Audio Mute (XDMUTE) Check whether mute is applied normally by

the Digital P.C.B. (GLUE IC).

Audio Pattern Output The audio pattern stored in the internal

memory is output

(Lch: 1kHz/-18dB)

(Rch: 400Hz/-18dB)

*Audio sound clock switching operation of

DAC can beconfirmed by sub command [2]

[4].

Laser Used Time

Check laser used time (hours) of drive.

Indiction

Delete the Laser Used

Time

Laser used time stored in the memory of the

unit is deleted.

Press [2] [1] in service mode.

Press [2] [2] in service mode.

Initial mode (Audio 48kHz) Press [2] [3] in service mode.

Audio 44.1kHz/48kHz switching Press [2] [4] in Audio Pattern Output

mode.

*48 kHz / 44.1 kHz are switched

alternately.

Press [4] [1] in service mode.

l(*****) is the used time display in

hour.

lLaser used time ofDVD/ CD in

Playback/Recording mode is

counted.

Press [9] [5] in service mode.

20

Item FL display Key operation

Mode name Description (Remote controller key)

RAM Drive Last Error RAM Drive error code display.

*For details about the drive error code, refer

to the Service Manual for the specific RAM

1. Error Number is displayed for 5

seconds.

Press [4] [2] in service mode.

Then press [0] [1] ~ [9] [9], the past

99 errors are displayed.

Drive.

*Details are described in “9. Service

Explorer ”.

2. Time when the error has occurred

is displayed for 5 seconds.

Y: Year

MM: Month

DD: Day

hh: Hour

mm: Minute

ss: Second

3. Last Drive Error (1/2) is displayed

for 5 seconds.

4. Last Drive Error (2/2) is displayed

for 5 seconds.

DMR-E55PL

Delete the Last Drive

Error

Delete the Last Drive Error information stored

on the DVD RAM-Drive.

Turn on all FL/LEDs All segments of FL and all LEDs are turned

on.

S1 signal output Forcibly superimpose the S1 signal (approx.

4.5V DC) on the EE chroma signal, and check

the output on the S terminal.

S2 signal output Forcibly superimpose the S2 signal (approx.

2V DC) on the EE chroma signal, and check

the output on the S terminal.

Front connection

inspection

Press all front keys and check the connection

between Main P.C.B. and Front P.C.B.

5. Error occurring Disc type is

displayedfor 5 seconds.

6. Disc Maker ID is displayed for 5

seconds.

Incase that the supplier cannot be

identified, display is black out.

7. Factor of Drive Erroroccurring is

left displayed

Press [9] [6] in service mode.

All segments are turned on. Press [5] [1] in service mode.

Press [5] [2] in service mode.

Press [5] [3] in service mode.

Press [5] [4] in service mode.

Production Date Display Display the date when the unit was produced.

(1) Each time a key is pressed,

segment turned on increases one

by one.

(2) Total umber of keys that have

been pressed.

Press [6] [1] in service mode.

YYY: Year

MM: Month

DD: Day

21

DMR-E55PL

Item FL display Key operation

Mode name Description (Remote controller key)

Display the accumlated

Display the accumulated unit´s working time.

working time

(Indicating unit: Second)

Display the Error History Display the Error History stored on the unit. Display reason of error for 5

seconds.

Display the time when the error has

occurred for 5 seconds..

YY: Year

MM: Month

DD: Day

HH: Hour

MM: Minute

Display the accumlated working

time to occurring of the error for 5

seconds..

Press [6] [4] in service mode.

Press [6] [5] in service mode.

Then press [0] [1] ~ [1] [9], the past

19 error histories are displayed.

(Indicating unit: Second)

Delete the Error History Delete Error History information stored on the

Press [9] [7] in service mode.

unit.

Tray OPEN/CLOSE Test The RAM drive tray is opened and closed

repeatedly.

Press [9] [1] in service mode

*When releasing this mode, press

the [POWER] button on Front Panel

“*” is number of open/close cycle

more than 10 seconds.

times.

Error code initialization Initialization of the last error code held by

Press [9] [8] in service mode.

timer (Write in F00)

Initialize Service Last Drive Error, Error history and Error

Press [9] [9] in service mode.

Codes stored on the unit are initialized to

factory setting.

Finishing service mode Release Service Mode. Display in STOP (E-E) mode. Press power button on the front

panel in service mode.

22

DMR-E55PL

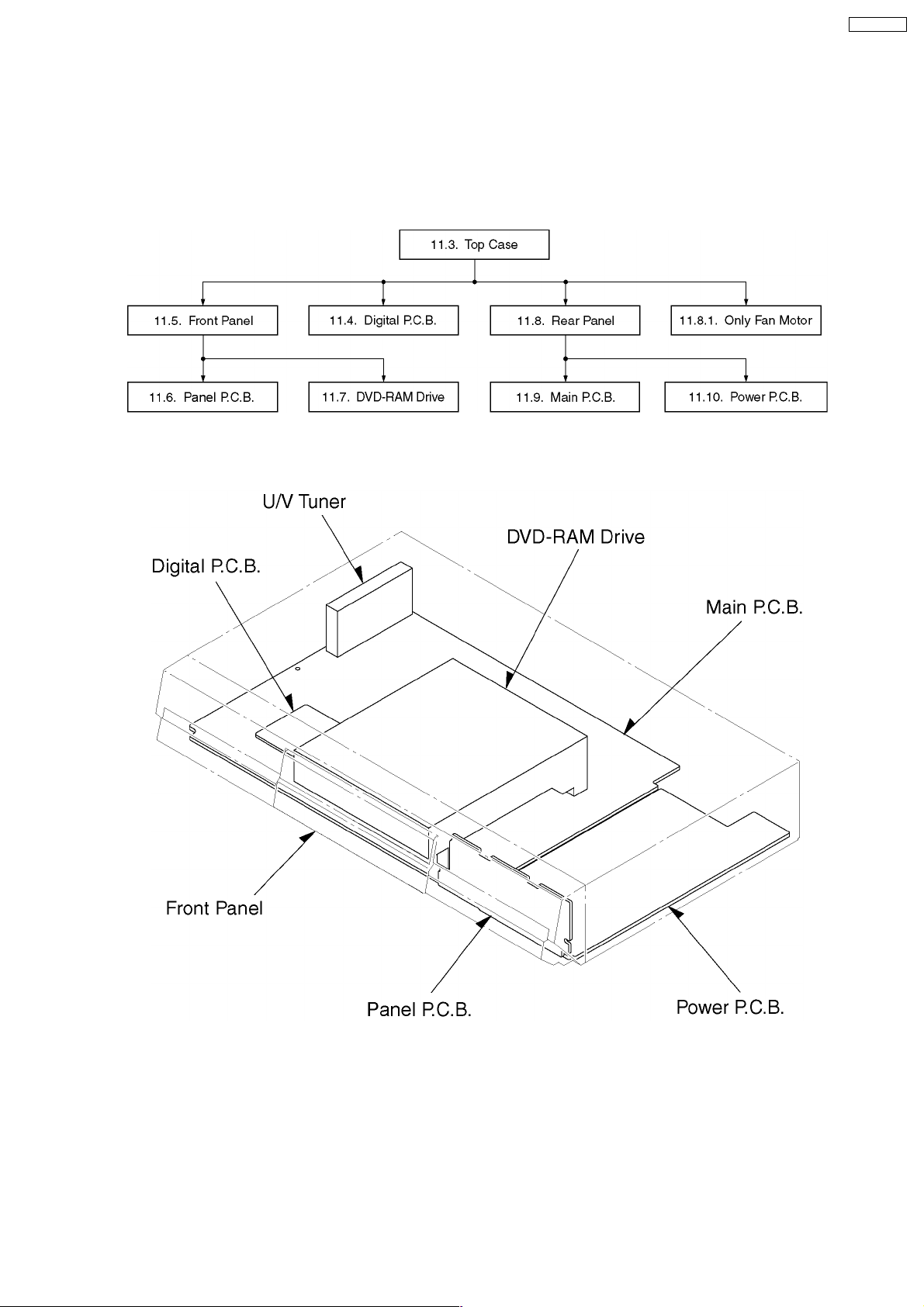

11 Assembling and Disassembling

11.1. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

11.2. P.C.B. Positions

23

DMR-E55PL

11.3. Top Case

1. Remove the 2 screws (A) and 3 screws (B).

2. Open the both ends at rear side of the Top Case a little and

lift the Top Case in the direction of the arrows.

11.4. Digital P.C.B.

1. Remove the FFC and a Screw.

2. Lift up Digital P.C.B. slightly so to disconnect Connector to

remove Digital P.C.B.

11.5. Front Panel

1. Remove 3 tabs (A) and 2 tabs (B) in this order. (The tab (A)

and (B) should be removed at the same time, respectively.)

2. Move the front panel to front side straight and slowly so to

remove it with Connector.

CAUTION:

When replacing Digital P.C.B., pay attention as below.

24

11.6. Panel P.C.B.

1. Remove 6 screws and Front Angle.

DMR-E55PL

11.8. Rear Panel

1. Remove the 5 screws (A) and screw (B).

2. Unlock 2 Locking Tabs to remove Rear Panel.

11.8.1. Only Fan Motor

11.7. DVD-RAM Drive

1. Remove 3 Screws.

2. Pull out DVD-RAM Drive vertically so to remove it with

Connector.

1. Remove the 2 screws.

2. Remove Fan Connector to remove Fan Motor.

25

DMR-E55PL

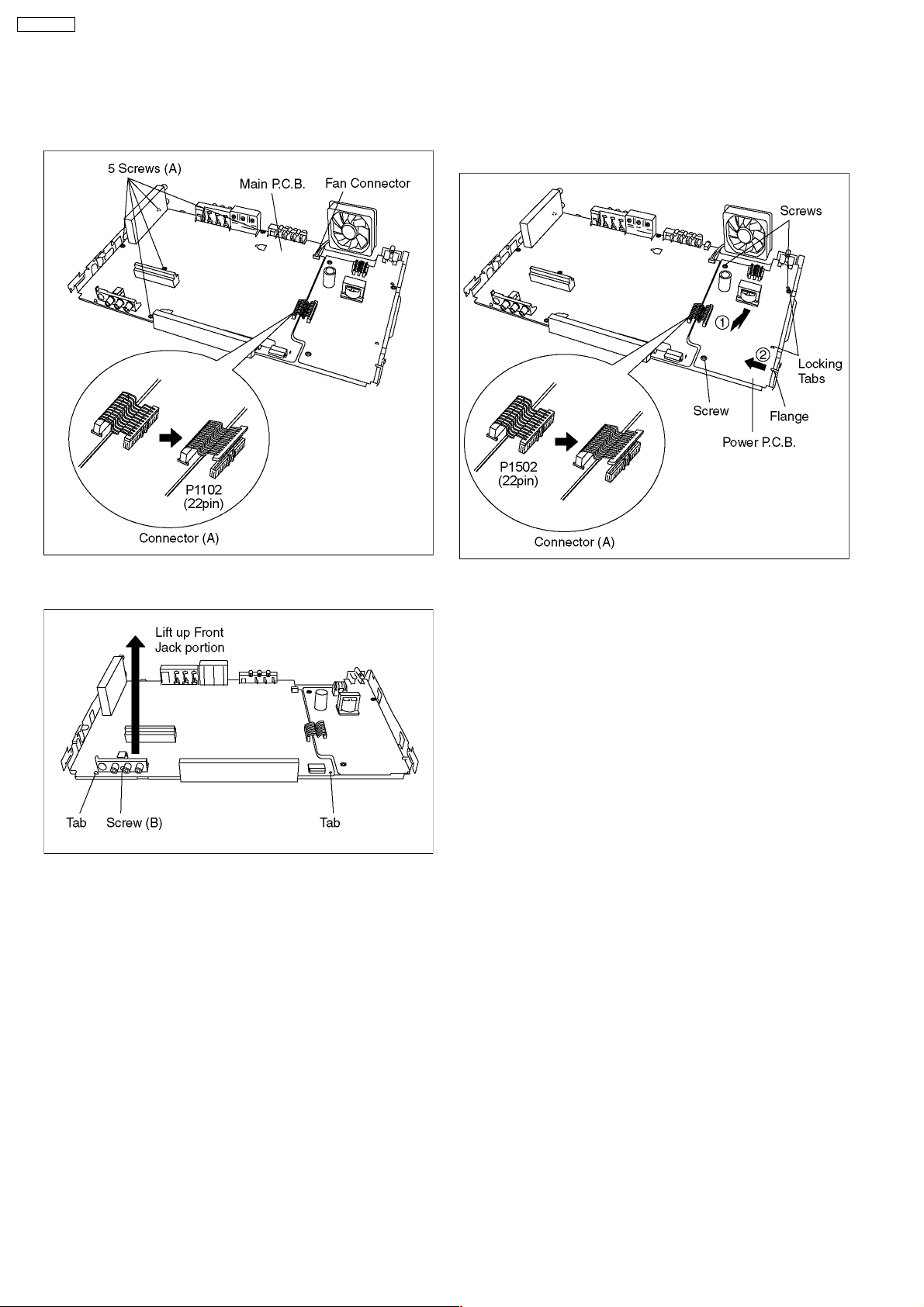

11.9. Main P.C.B.

1. Remove the 5 screws (A), Connector (A) and Fan

Connector.

11.10. Power P.C.B.

1. Remove 3 Screws and Connector (A).

2. Lift up Power P.C.B. a little so to unlock 2 Tabs and slide

Power P.C.B. so to unlock Flange to remove Power P.C.B.

2. Remove a Screw (B) and lift up Front Jack portion of Main

P.C.B. slightly so to unlock Tab to remove Main P.C.B..

26

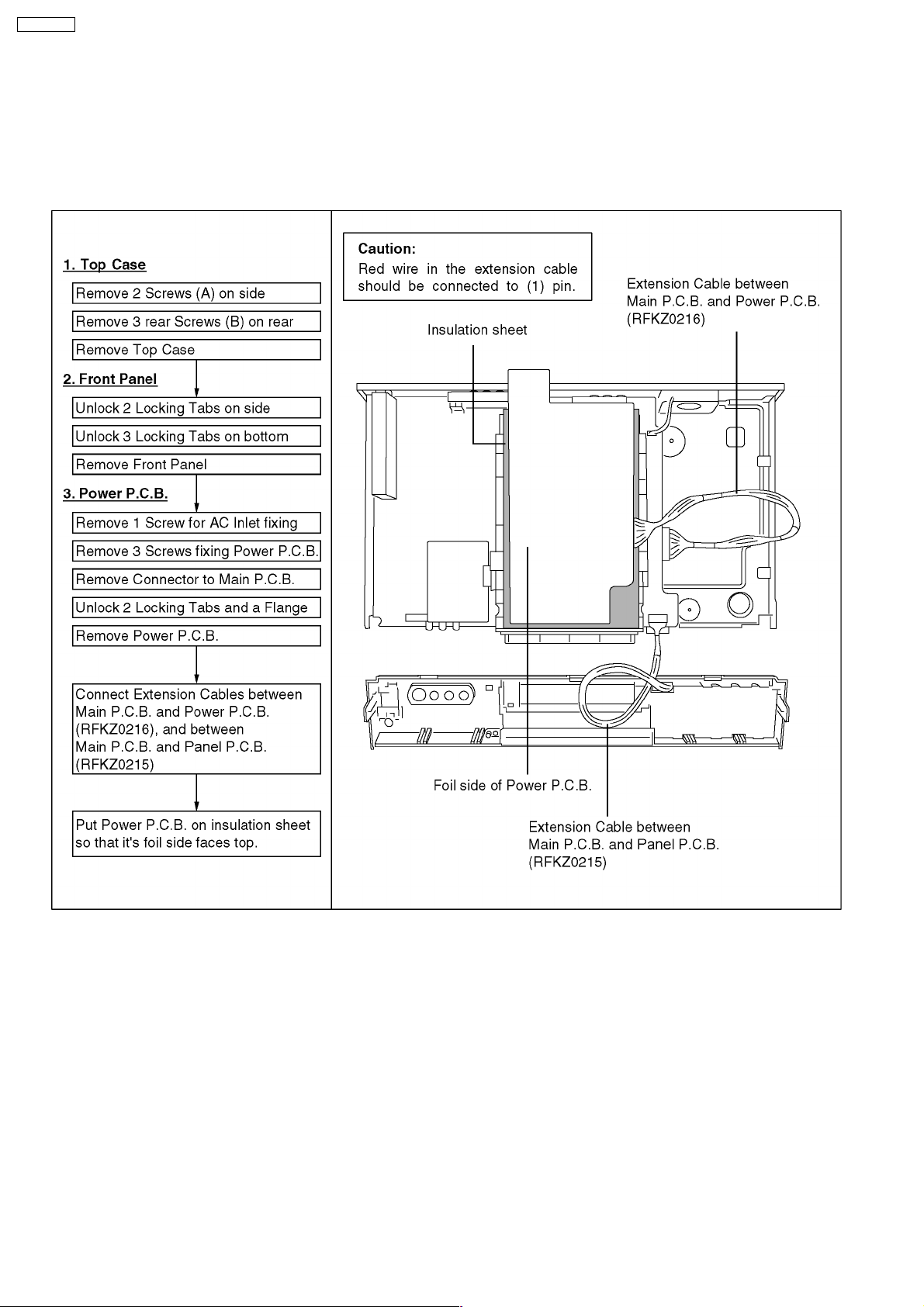

12 Service Fixture and Tools

Part Number Description Compatibility

RFKZ0125 Extension FFC (Digital P.C.B. - DVD-RAM Drive / 40 Pin) Same as E50 series

RFKZ0168 Extension Cable (Main P.C.B. - Fan / 3 Pin) Same as E50 series

RFKZ0197 Extension Cable (Main P.C.B. - DVD-RAM Drive / 8 Pin) Same as E55P series

RFKZ0214 Extension Cable (MainP.C.B. - Digital P.C.B. / 88 Pin) Same as E55P series

RFKZ0215 Extension Cable (MainP.C.B. - Panel P.C.B. / 12 Pin) Same as E55P series

RFKZ0216 Extension Cable (MainP.C.B. - Power P.C.B. / 23 Pin) Same as E55P series

NOTE:

Extension Cable RFKZ0214 has A/V Output Signal switches.

Output signals can be switched from MAIN PCB side or DIGITAL PCB side.

When checking MAIN PCB, turn switches to MAIN PCB side.

When checking DIGITAL PCB, turn switches to DIGITAL P.C.B. side.

DMR-E55PL

27

DMR-E55PL

13 Service Positions

Note:

For description of the disassembling procedure, see the section 11.

13.1. Checking and Repairing of Power P.C.B.

28

13.2. Checking and Repairing of Main P.C.B.

DMR-E55PL

29

DMR-E55PL

13.3. Checking and Repairing of Digital P.C.B.

30

Loading...

Loading...