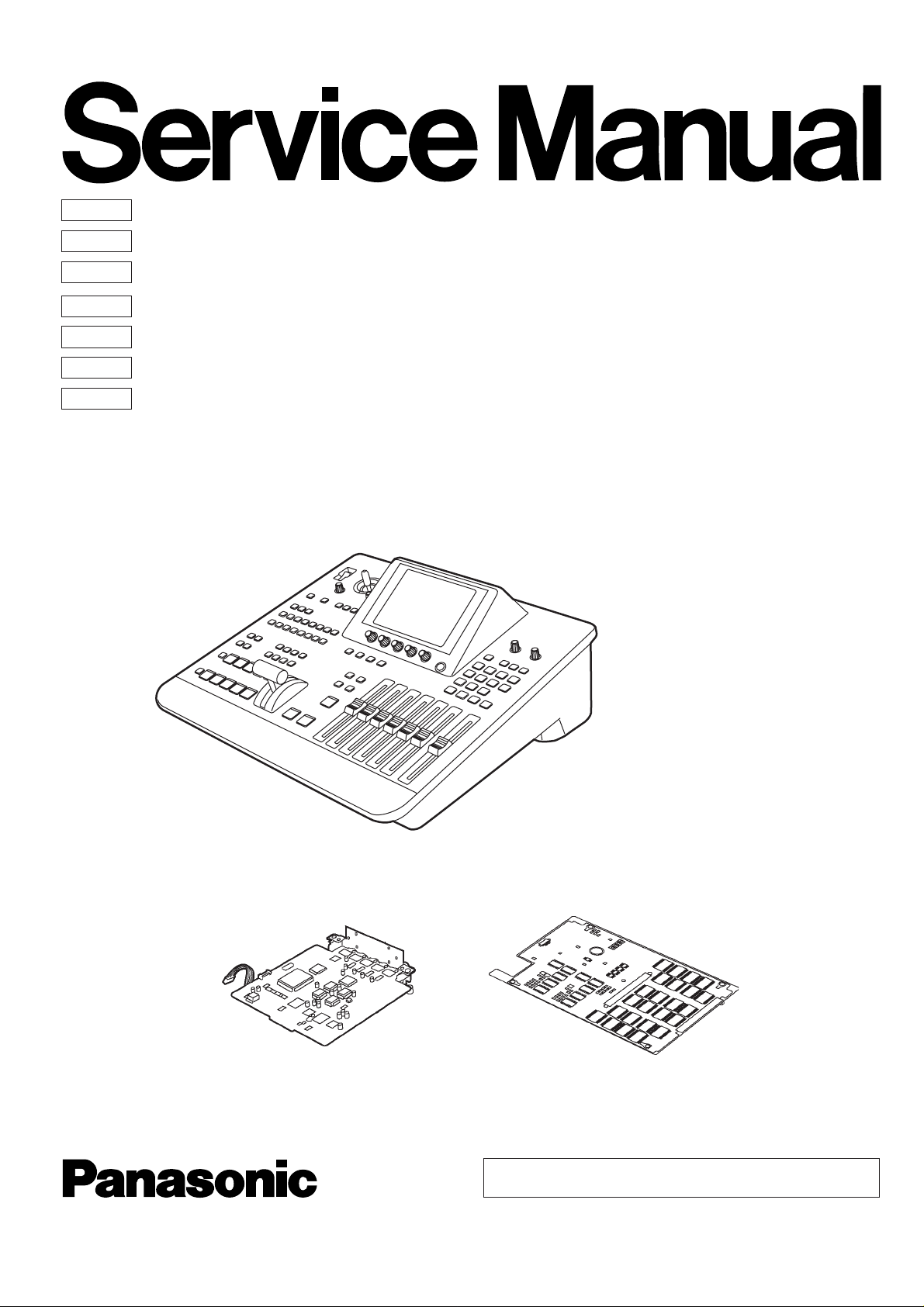

Panasonic AG-MX70 Service manual

ORDER NO. BSD0209M612

Sec. 1

Sec. 2

Sec. 3

Sec. 4

Sec. 5

Sec. 6

Sec. 7

Service Information

Disassembly Procedures

Electrical Adjustments

Block Diagrams

Schematic Diagrams

Circuit Board Diagrams

Exploded Views &

Replacement Parts Lists

Digital AV Mixer

AG-MX70E/MC

SD INTERFACE BOARD

AG-YA70P

3D EFFECT BOARD

AG-VE70P

AG-YA70P

AG-MX70E/MC

AG-VE70P

© 2002 Matsushita Electric Industrial Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicans. Any attempt to service or rep air

the product or products deal with in this service manual by anyone else could result in serious injury or death.

AG-MX70E/MC

- 1-

-

2

-

- 3-

AG-YA70P

AG-VE70P

-

4

-

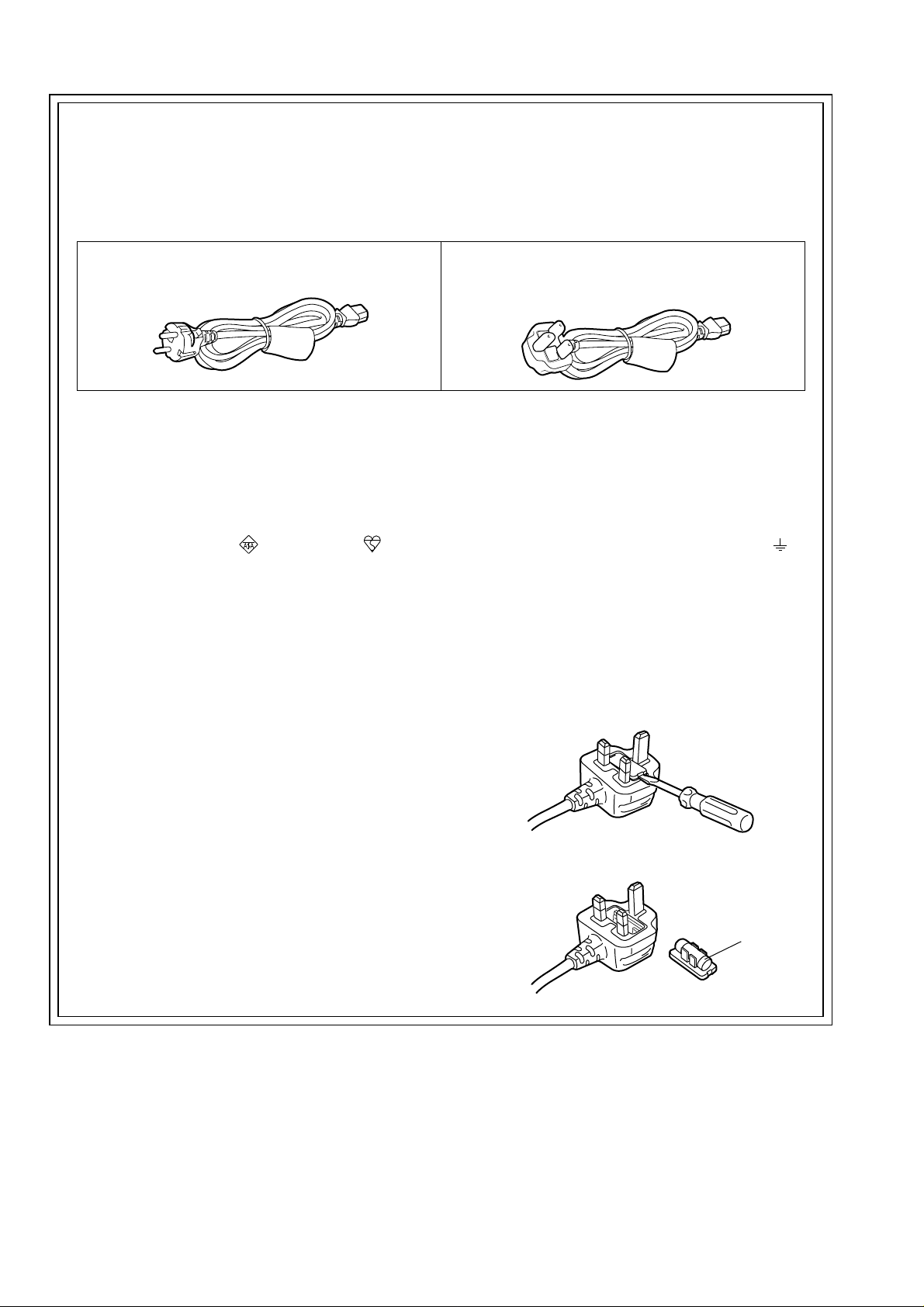

Caution for AC Mains Lead

FOR YOUR SAFETY PLEASE READ THE FOLLOWING TEXT CAREFULLY.

This product is equipped with 2 types of AC mains cable. One is for continental Europe, etc. and the other one is only for

U.K.

Appropriate mains cable must be used in each local area, since the other type of mains cable is not suitable.

FOR CONTINENTAL EUROPE, ETC.

Not to be used in the U.K.

FOR U.K. ONLY

This appliance is supplied with a moulded three pin

mains plug for your safety and convenience.

A 13 amp fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that

the replacement fuse has a rating of 13 amps and that

it is approved by ASTA or BSI to BS1362.

Check for the ASTA mark or the BSI mark on the

body of the fuse.

If the plug contains a removable fuse cover you must

ensure that it is refitted when the fuse is replaced.

If you lose the fuse cover the plug must not be used

until a replacement cover is obtained.

A replacement fuse cover can be purchased from your

local Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE

FOR THE SOCKET OUTLET IN YOUR HOME THEN

THE FUSE SHOULD BE REMOVED AND THE PLUG

CUT OFF AND DISPOSED OF SAFELY. THERE IS A

DANGER OF SEVERE ELECTRICAL SHOCK IF THE

CUT OFF PLUG IS INSERTED INTO ANY 13 AMP

SOCKET.

FOR U.K. ONLY

If the plug supplied is not suitable for your socket

outlet, it should be cut off and appropriate one fitted.

As the colours of the wires in the mains lead of this

appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as

follows:

The wire which is coloured GREEN-AND-YELLOW

•

must be connected to the terminal in the plug which is

marked with the letter E or by the Earth symbol or

coloured GREEN or GREEN-AND-YELLOW.

The wire which is coloured BLUE must be connected

•

to the terminal in the plug which is marked with the

letter N or coloured BLACK.

The wire which is coloured BROWN must be con-

•

nected to the terminal in the plug which is marked with

the letter L or coloured RED.

How to replace the fuse

1. Open the fuse compartment with a screwdriver.

If a new plug is to be fitted please observe the wiring

code as shown below.

If in any doubt please consult a qualified electrician.

WARNING: THIS APPLIANCE MUST BE EARTHED.

IMPORTANT: The wires in this mains lead are coloured

in accordance with the following code:

Green-and-Yellow:

Blue:

Brown:

Earth

Neutral

Live

2. Replace the fuse.

Fuse

- 5-

SAFETY PRECAUTIONS

GENERAL GUIDELINES

1. When servicing, observe the ori gin al l ead dre ss. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohm meter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. The

resistance value must be more than 5MΩ.

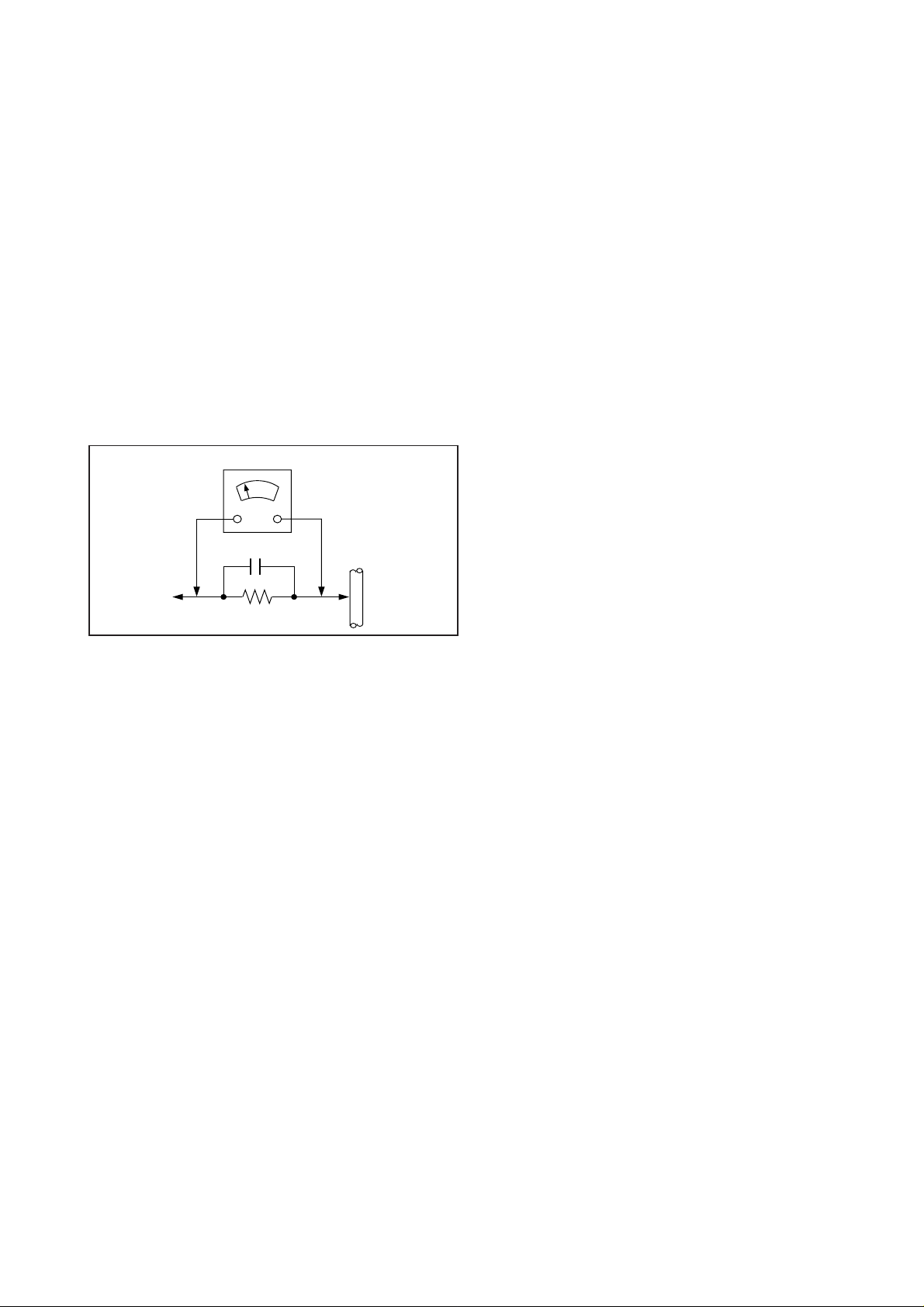

AC VOLTMETER

Hot-Check Circuit

COLD

WATER PIPE

(EARTH GROUND)

TO

APPLIANCES

EXPOSED

METAL PARTS

0.15µF

1500Ω

10W

Figure1

LEAKAGE CURRENT HOT CHECK (See Figure 1)

1. Plug the AC cord directly into the AC outlet.

Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ , 10W resistor, in parallel with a 0.15µ

F capacitor, between each exposed metallic part on the

set an a good earth ground such as a water pipe, as

shown in Figure1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverses the AC plug in the AC outlet repeat each of the

above measurements.

6. The potential at any point should not exceed 0.15 volts

RMS. A leakage current tester (Simpson Model 229

equivalent) may be use d to ma ke the hot checks, l eak age

current must not exceed 0.1 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the

customer.

ABOUT LEAD FREE SOLDER (PbF)

Distinction of Pbf PCB :

PCBs (manufactured) using lead free solder will have a Pbf

stamp on the PCB.

Caution :

1. Pb free solder has a high melting point than standerd

solder; Typically the melting point is 50-70˚F (30-40˚C)

higher. Please use a high temperature soldering iron. In

case of the soldering iron with temperature control,

please set it to 700±20˚F (370±10˚C).

2. Pb free solder will tend to splash when heated too high

(about 1100˚F/600˚C)

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically sensitive (ED) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist trap device, which should be removed

for potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder re moval devic e clas sified as

“anti-static” can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it.

(most replacement ES devices are package with leads

electrically shorted together by conductive foam,

aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpacked

replacement ES devices. (Otherwise harmless motion

such as the brushing together of y o ur c loth es f abri c or the

lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device).

X-RADIATION

WARNING

1. The potential source of X-radiation in EVF sets is the

High Voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure that

jig is capable of handling 10kV without causing xradiation.

Note :

3. Measure the High Voltage. The meter (electric type)

It is important to use an accurate periodically

calibrated high voltage meter.

reading should indicate 2.5kV, 0.15kV. If the meter

indication is out of tolerance, immediate service and

correction is required to prevent the possibility of

premature component failure. To prevent an x-radiation

possibility, it is essential to use the specified picture tube .

±

-

6

-

HCD0209NYAA425

SERVICE INFORMATION

CONTENTS

1. Equipment For Measurement ...............................................................................

2. Maintenance...........................................................................................................

2-1. Necessity For Maintenance...................................................................................................... INF-1

2-2. Maintenance Schedule............................................................................................................. INF-1

3. Up Dating The Software ........................................................................................

3-1. Software ................................................................................................................................... INF-2

3-2. Layout of parts ......................................................................................................................... INF-2

3-3. Preparations for updating the internal flash memory microprocessor ..................................... INF-3

3-4. Steps for updating the internal flash memory microprocessor................................................. INF-3

3-5. Updating the PLD (Altera) ........................................................................................................ INF-5

4. The way of attaching an option board .................................................................

4-1. Installation of the AG-YA70P ................................................................................................... INF-8

4-2. Installation of the AG-VE70P ................................................................................................... INF-10

INF-1

INF-1

INF-2

INF-8

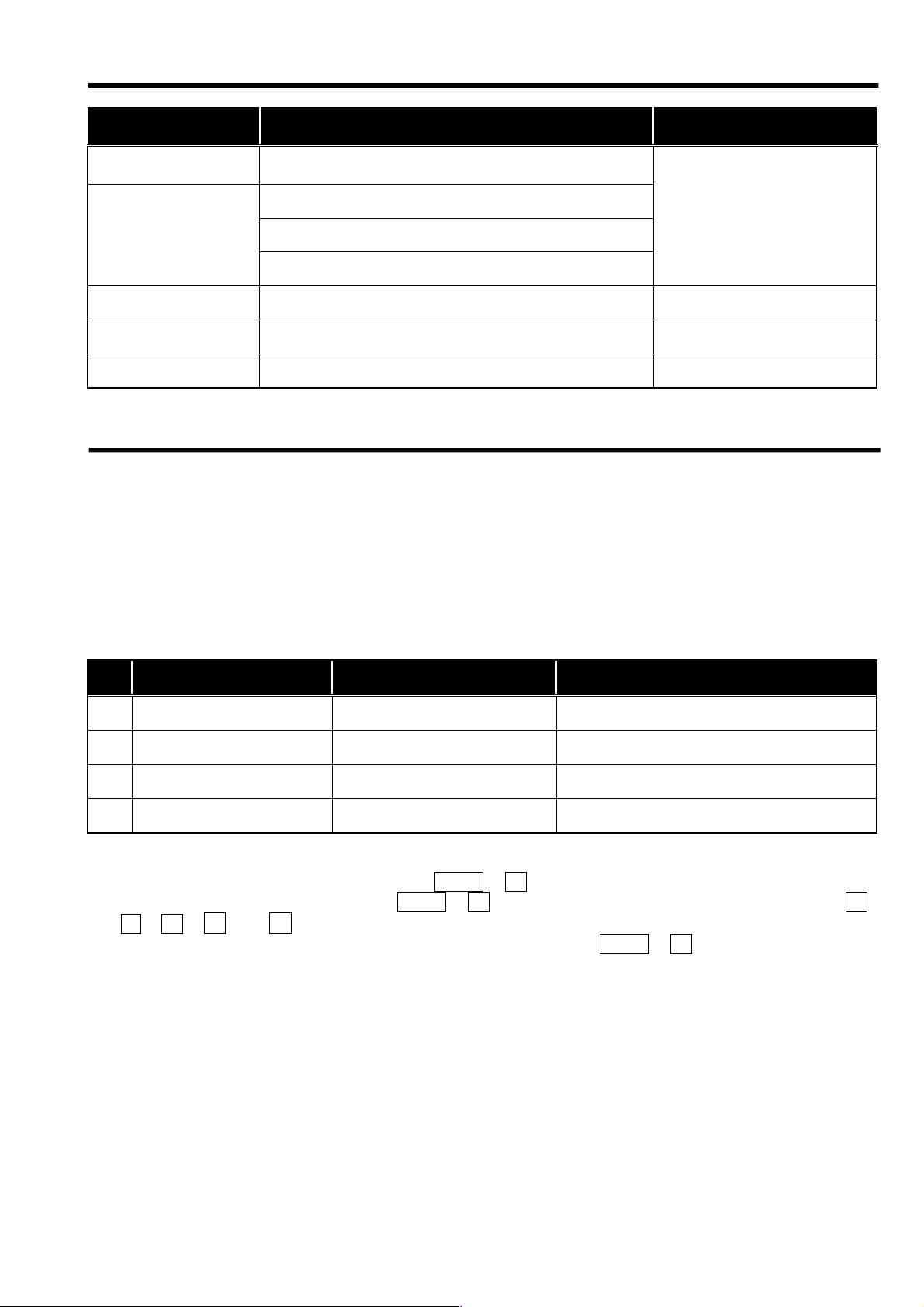

1. Equipment For Measurement

MODEL No.

(EXAMPLE)

TSG130

1760 or 1780R

PAL analog component/Composite signal

Transmitter

SCH meter (PAL)

Oscilloscope (PAL)

Vectorscope (PAL)

Audio analyzer

Digital voltmeter (D.V.M.)

Wave Frequency counter

NAME REMARKS

Techtronics

2. Maintenance

2-1. Necessity For Maintenance

The digital AVmixer has an fanmotor and LCD which are consumable items that deteriorate over time and can

cause lower performance and malfunction. You should, therefore, perform maintenance regularly to prevent

lower performance and potentially damaging malfunctions.

2-2. Maintenance Schedule

The following maintenance schedule shows approximate times to carry out maintenance. They are not the

performance lives of the various parts. There may be changes to the maintenance specifications and part

numbers so be sure to refer to the latest information.

No. PART PART NUMBER TIME FOR REPLACEMENT

1 Top case fan motor L6FALEDH0001 every ten thousand hours

2 Main case fan motor L6FALEDH0001 every ten thousand hours

3 Power unit fan motor VRF0027 every ten thousand hours

4 LCD panel unit L5ADBNL00001 every ten thousand hours

Note:

· Refer to the times displayed under the various items in the onscreen menus for replacement times. From

the SETUP (setup screen) condition, press SHIFT

· To reset the times for the items, press SHIFT

2 ,6, ---- and ¿ .

Select the item you want to reset in the rotary encoder, then press SHIFT

+7for 3 seconds to show the times.

+7for three seconds to show the times, then press 0 ,

+7to reset the time.

INF-1

3. Up Dating The Software

)

)

)

(

)

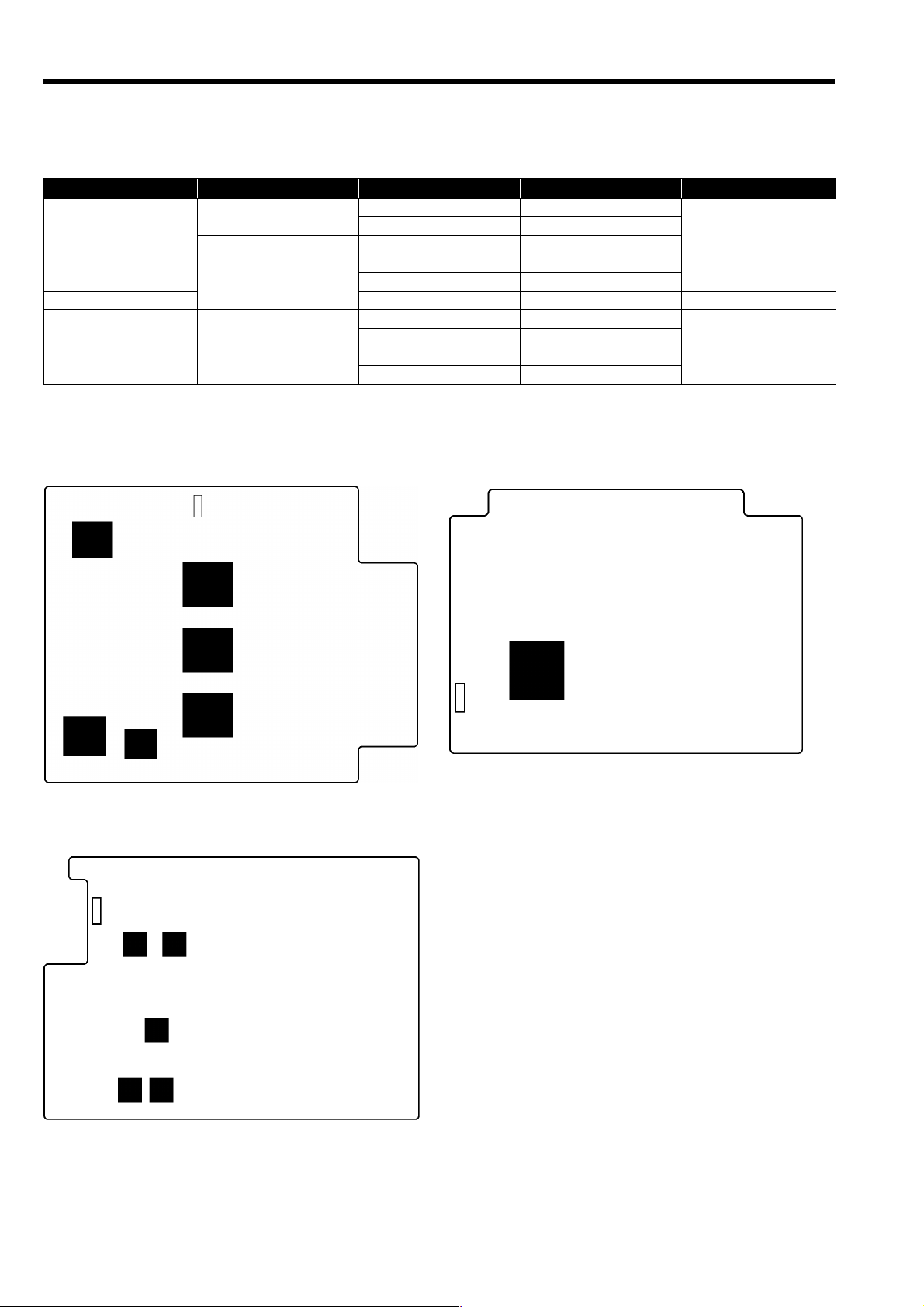

3-1. Software

AG-MX70/AG-YA70P/AG-VE70P use internal flash memory microprocessor and PLDs.

Follow the below steps to update the software.

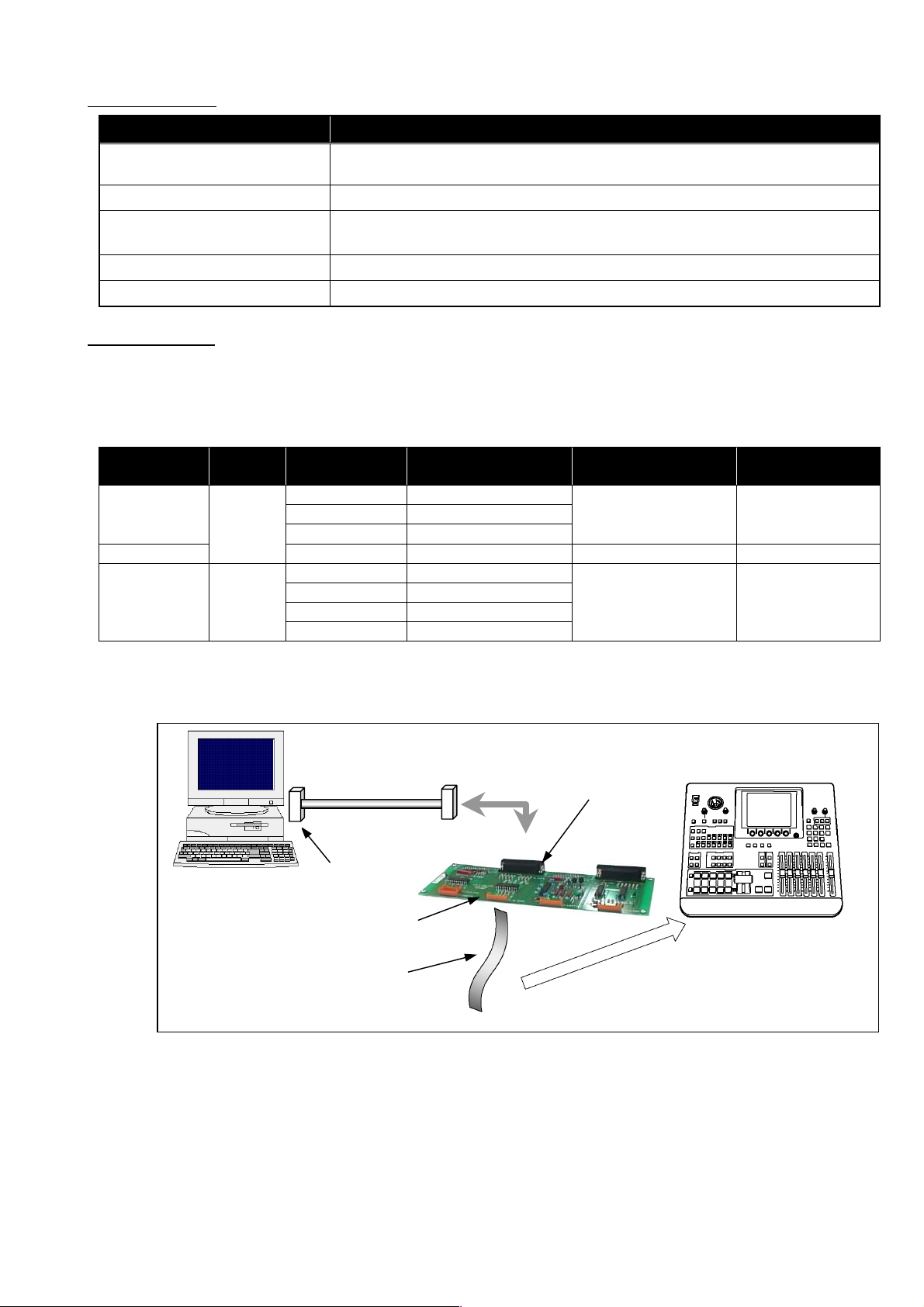

MODEL No. TYPE NAME REFERENCE No. BOARD NAME

FLASH MEMORY

AG-MX70

FPGA

AG-YA70P

AG-VE70P PLD

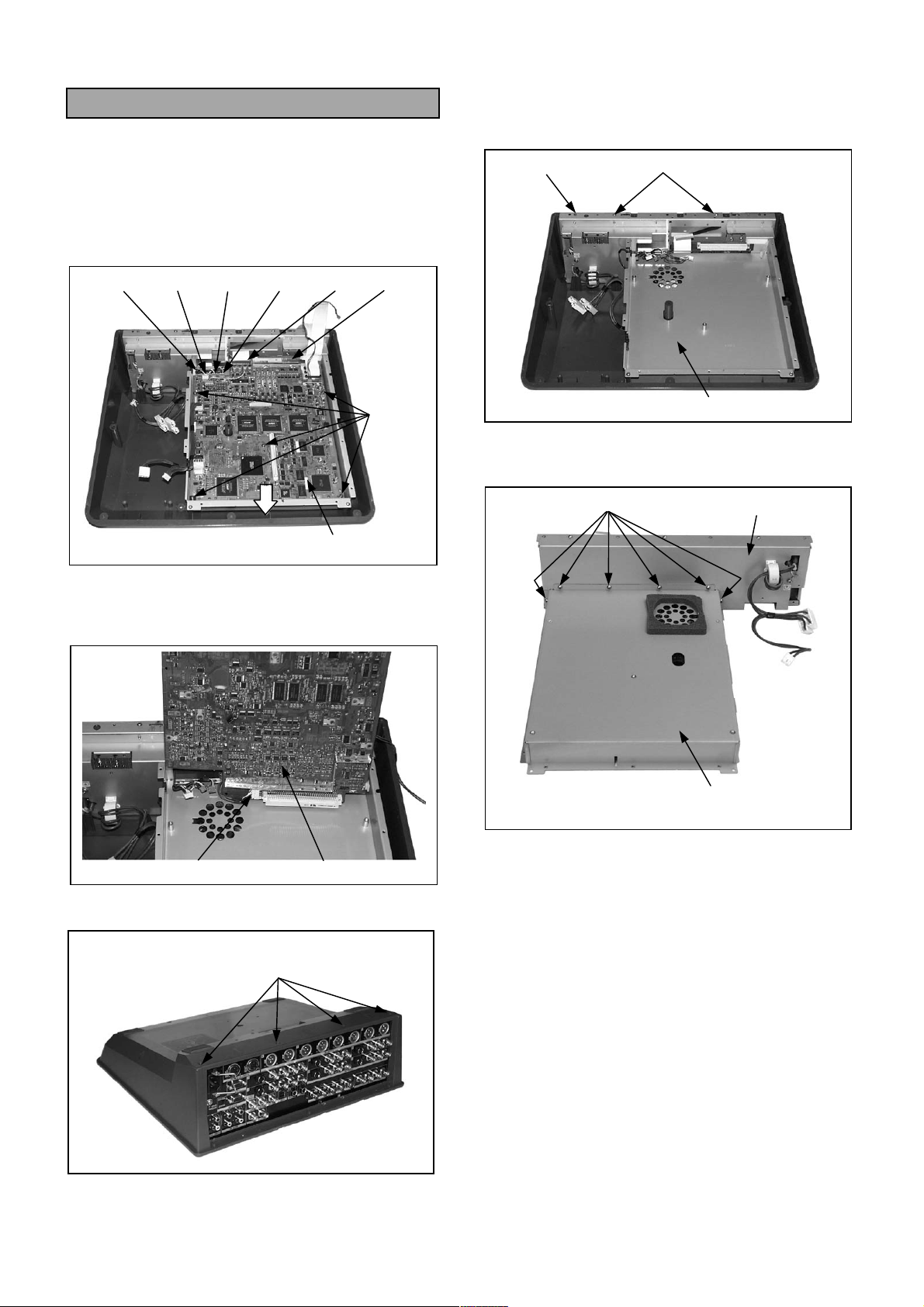

3-2. Layout of parts

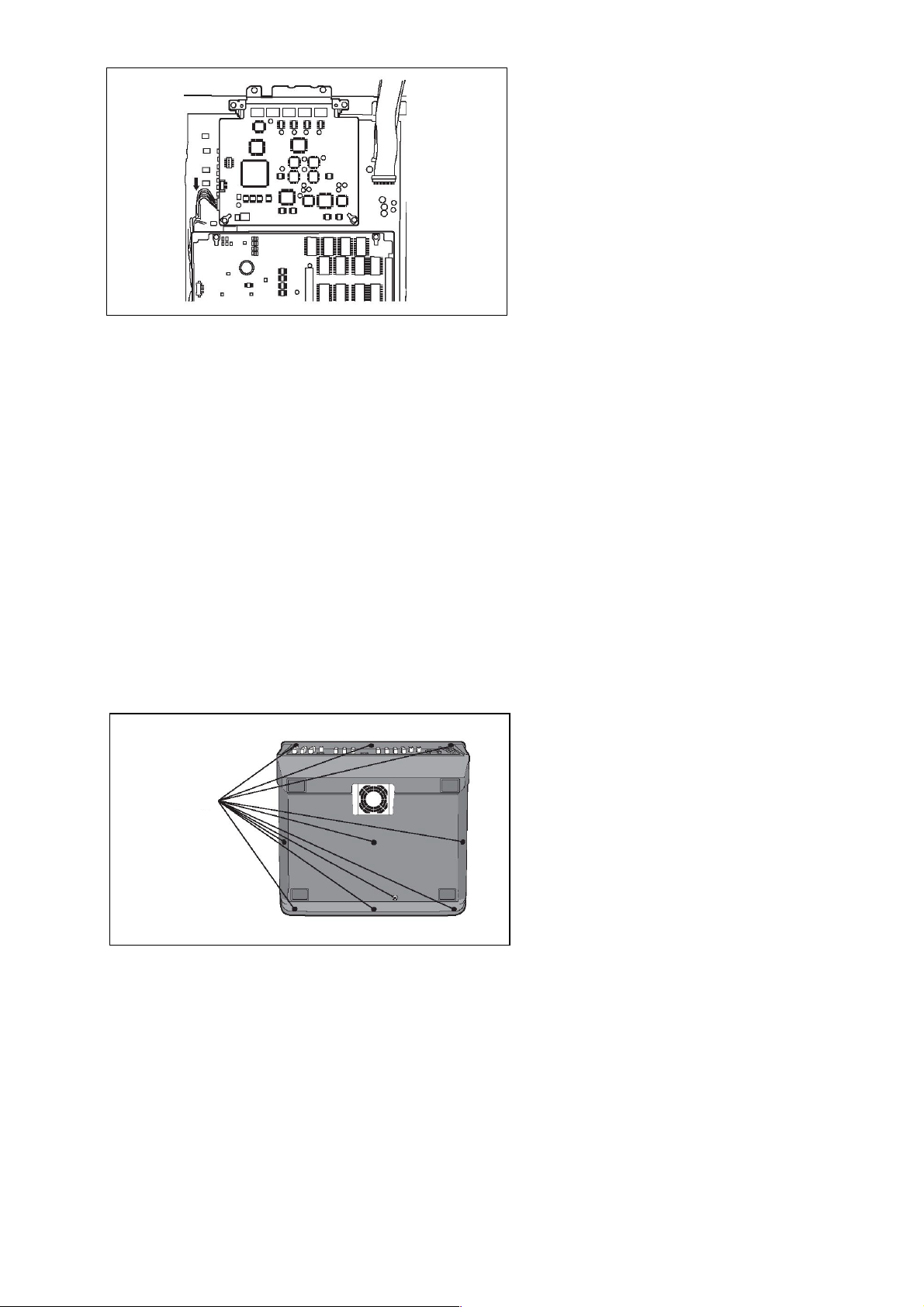

AG-MX70 AG-YA70P

Main Board (VEP66448A) Parts Layout SDI Board (VEP83586A) Parts Layout

P1110

IC1330(GMC)

IC1393(ENC)

M16C IC5

SH3 IC233

FS IC711, IC770

ENC IC1393

GMC IC1330

SDI IP502 SDI BOARD

ASPECT IP701

IO IP650

YC LPF IP256, IP306

YC MIX IP651

MAIN BOARD

3D BOARD

IC770(FS)

IC771(FS)

IC233(SH3)

IC5(M16C

AG-VE70P

3D Board (VEP63239A) Parts Layout

P250(Foil Layout

IP306

(YC LPF)

IP256

(YC LPF)

IP701

ASPECT

IP502(SDI

P500

IP650

(IO)

IP651

(YC MIX)

INF-2

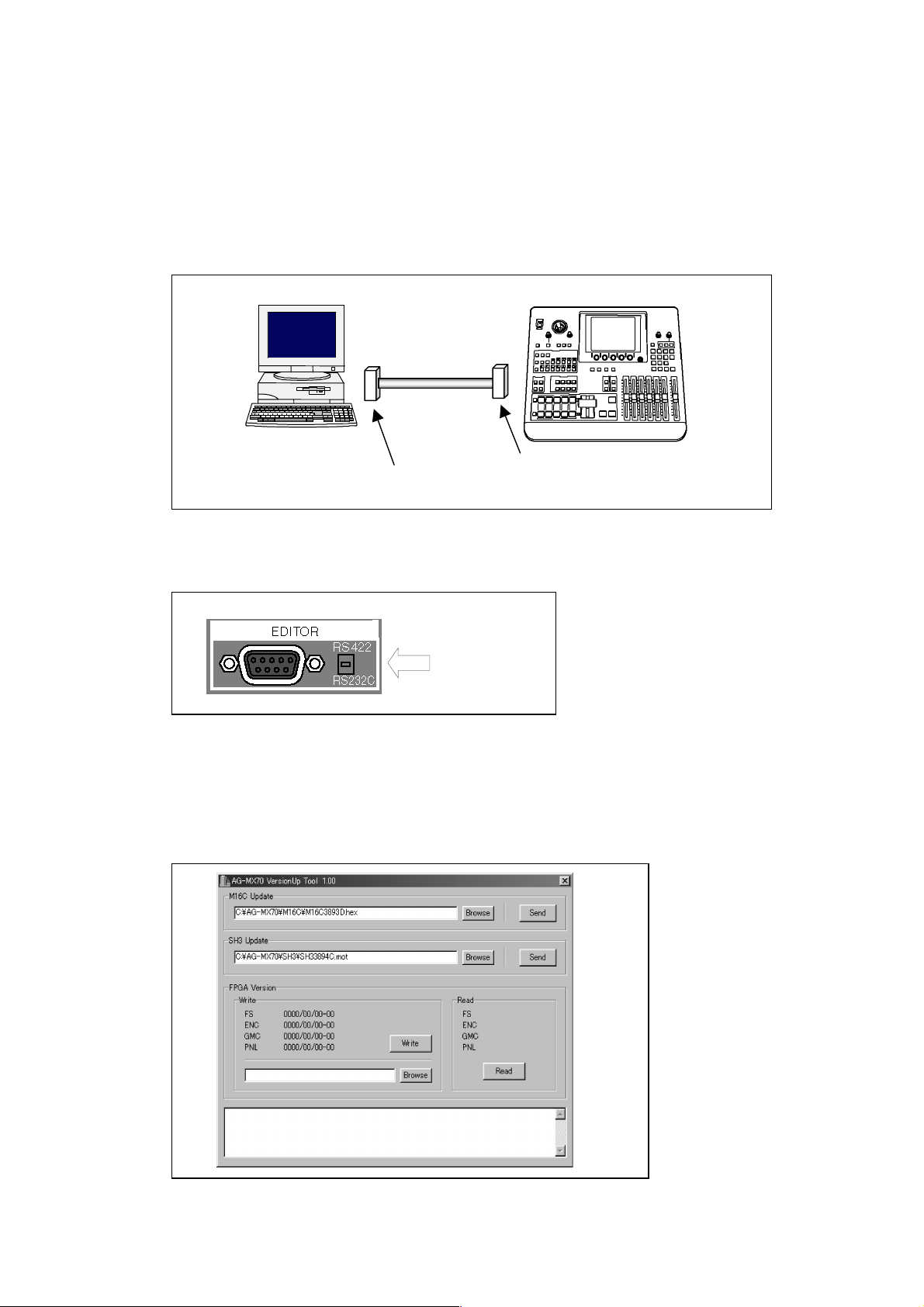

3-3. Preparations for updating the internal flash memory microprocessor

1. Things Needed For Writing

• Writing Software............ VFK1819

• WINDOWS 95/98 Computer

• RS232C cable (9 Pin Straight Cable)

2. Installation Of Writing Software

• Copy the following file into a directory in the computer.

• Program File.................. Version Up Tool. EXE

3. Connection

• With the RS232C cable (9-pin straight cable), connect the AG-MX70 jack panel’s EDITOR

terminal to the computer’s COM port.

D-SUB 9pin

straight cable

PC

Serial port

4. Settings

• Set the switch next to the AG-MX70 jack panel’s EDITOR terminal to RS232C.

Set to RS232C.

EDITOR terminal

AG-MX70

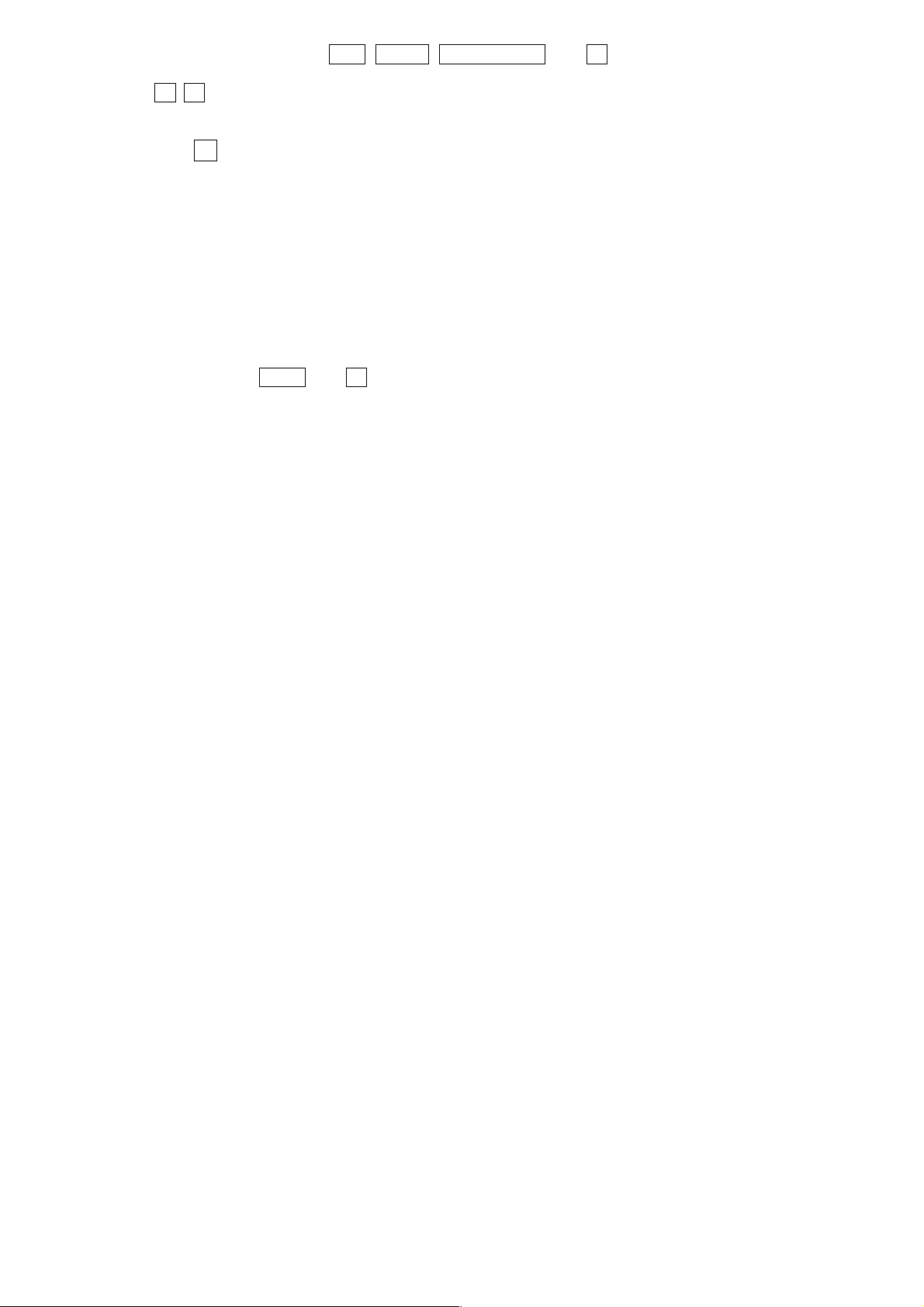

3-4. Steps for updating the internal flash memory microprocessor

1. After completing “3-3. Preparations for updating the internal flash memory microprocessor”, switch on

the computer.

2. Switch on AG-MX70.

3. Start up the writing software. Double-click on the copy of Version Up Tool.EXE.

4. “AG-MX70 Version Up Tool 1.00” opens as follows.

INF-3

5. On AG-MX70, press and hold LUM, AUDIO, EFFECTS ON and 5 and switch the power on. AGMX70 comes on in the flash memory writing mode.

6. Press

+ – on AG-MX70 to change the items on the LCD.

To up date M1C, select [MX70 Flash Write Mode]

To update SH3, select [SH3 Flash Write Mode]

Then press ¿

(the arrow key at the bottom right of the numbered buttons).

7. Wait until the display on the LCD changes from “Now Flash Erase Please Wait” to “Flash Erase Finish

Please Send Data”.

8. In Version Up Tool 1.00, press the “Browse” button in the M16C Update column to update M16C, or

the “Browse” button in SH3 Update to update SH3, and select the writing file.

This is not necessary if the writing file is already in the box.

9. Writing starts when you press the Send button, next to the Browse button.

Confirm that “Now Flash Writing” appears on AG-MX70’s LCD.

If the message doesn’t appear or an error occurs, check the connections and start again.

10. Writing is complete when “Flash Write Complete Please Restart System” appears on AG-MX70’s

LCD.

11. Switch AG-MX70 off then on again and enter the SETUP menu. The version information appears by

pressing and holding

SHIFT and 8 for 3 seconds. Confirm that the version has changed.

INF-4

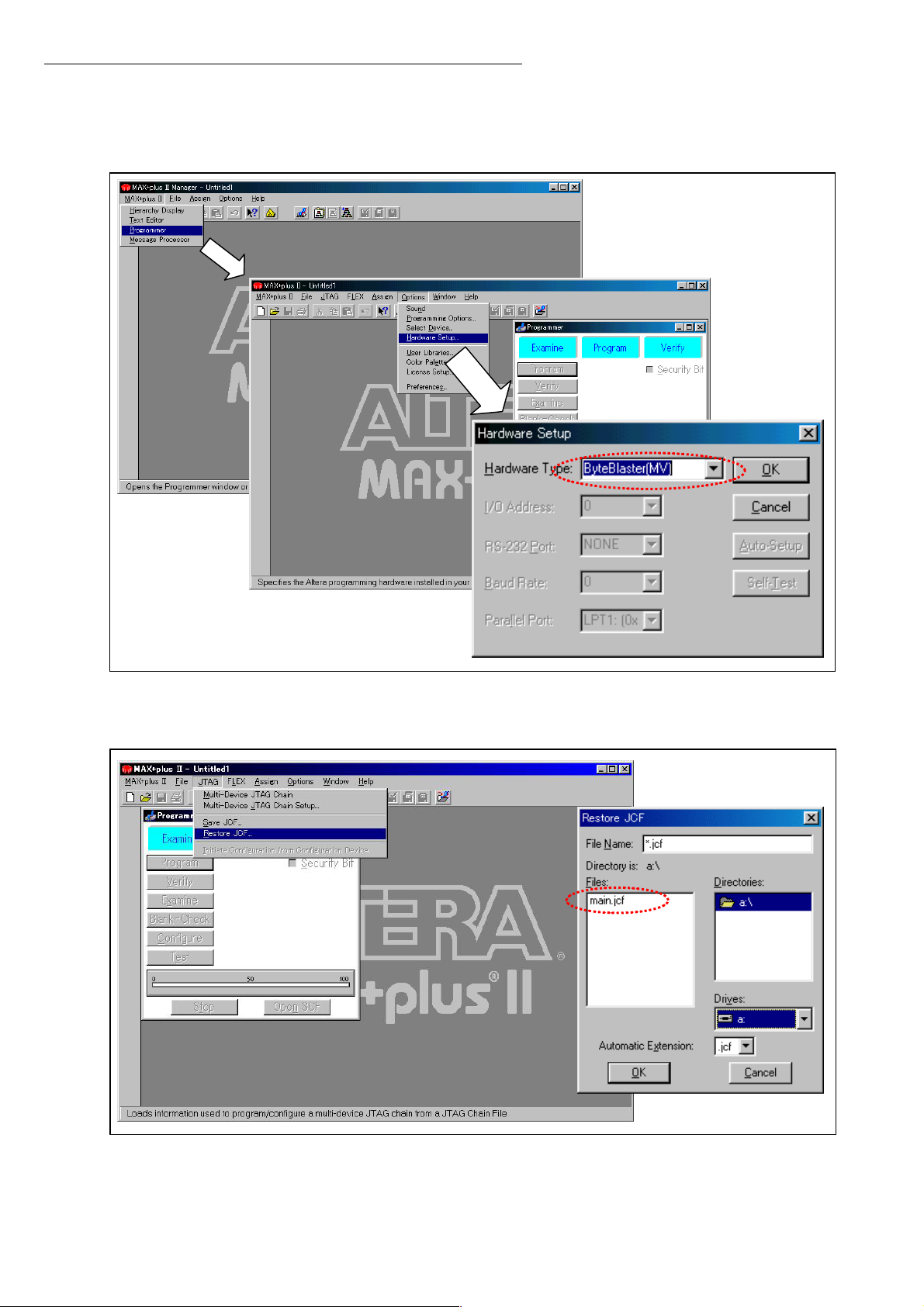

3-5. Updating the PLD (Altera)

A. Preparation

EQUIPMENT REMARKS

CPLD Writer

25-pin-25-pin Cable Straight (male-female), within 1 meter

Writing Software

Version Updater Tdf format or pof format file (Included in VSI**** file)

Computer Windows 95 or 98 installed

B. Connection

1. Connect the computer and the CN201 connector (for Altera) on the CPLD writer (VFK1590) with the 25pin-25-pin cable.

2. Connect the writing connectors on the FPGA and PGA you are updating to the P201 connector on the

CPLD writer with the cable included with the CPLD writer (VFK1590).

VFK1590

VFK1590P2 (Cable: included with VFK1590)

MAX+plus II Software: WWW.altera.com./pub/software/asap2.exe

Download from the URL and save in a directory

MODEL NO. TYPE NAME REFERENCE NO.

WRITING

CONNECTOR NO.

BOARD NAME

FS IC711, IC770

AG-YA70P

FPGA

ENC IC1393AG-MX70

GMC IC1330

SDI IP502 P500 SDI BOARD

P1110 MAIN BOARD

ASPECT IP701

AG-VE70P PLD

IO IP650

YC LPF IP256, IP306

P250 3D BOARD

YC MIX IP651

3. Start up the unit and the computer in Windows mode.

4. Copy all the VVVSI**** files including “*.jcf” to a floppy6 disc. Insert the floppy disc into your computer’s

disc drive.

Computer

D-SUB 25 pins

Cable

CPLD Writer

VFK1590

To Print Port

Connector

CN201

Connector P201

Cable

VFK1590P2

AG-MX70

Writing connectors (Refer to above table)

INF-5

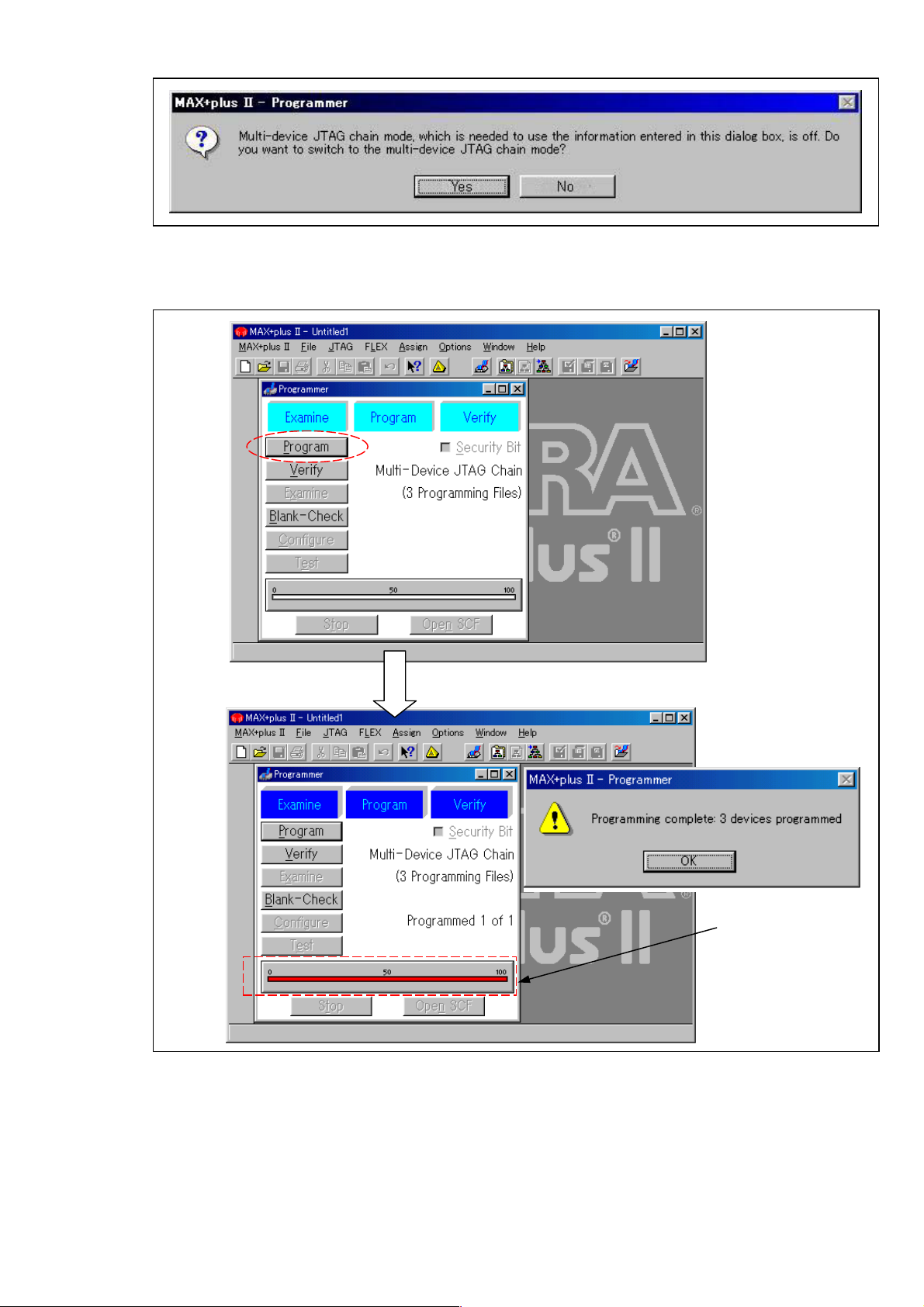

C. Starting the writing software and steps for updating

1. From the Windows START menu, select Program MAX+plus II*.*programmer only.

2. In the main window, from the MAX+plus II tab select Programmer.

3. In the main window after displaying the Programmer screen, from the Option tab select Hardware Setup.

4. In the Hardware Setup window, set Hardware Type to ByteBlaster (MV).

5. In the main window, from the JTAG tab select Restore JCF…

6. In the Restore JCF dialog, select the floppy disc drive [A:]. Next select “jcf format file (****.jcf) and click

OK.

INF-6

7. If the following dialog appears, click Yes to proceed to the next step.

8. In the Programmer dialog, click Program.

9. PLD writing is complete when the progress bar at the bottom of the dialog reaches 100. The message

“Programming complete” appears, so click OK.

Progress bar

* MAX+plus is a registered trademark of Altera Corporation in the United States and other countries.

* Windows 95 and Windows 98 are registered trademarks of Microsoft Corporation in the United States and other countries.

INF-7

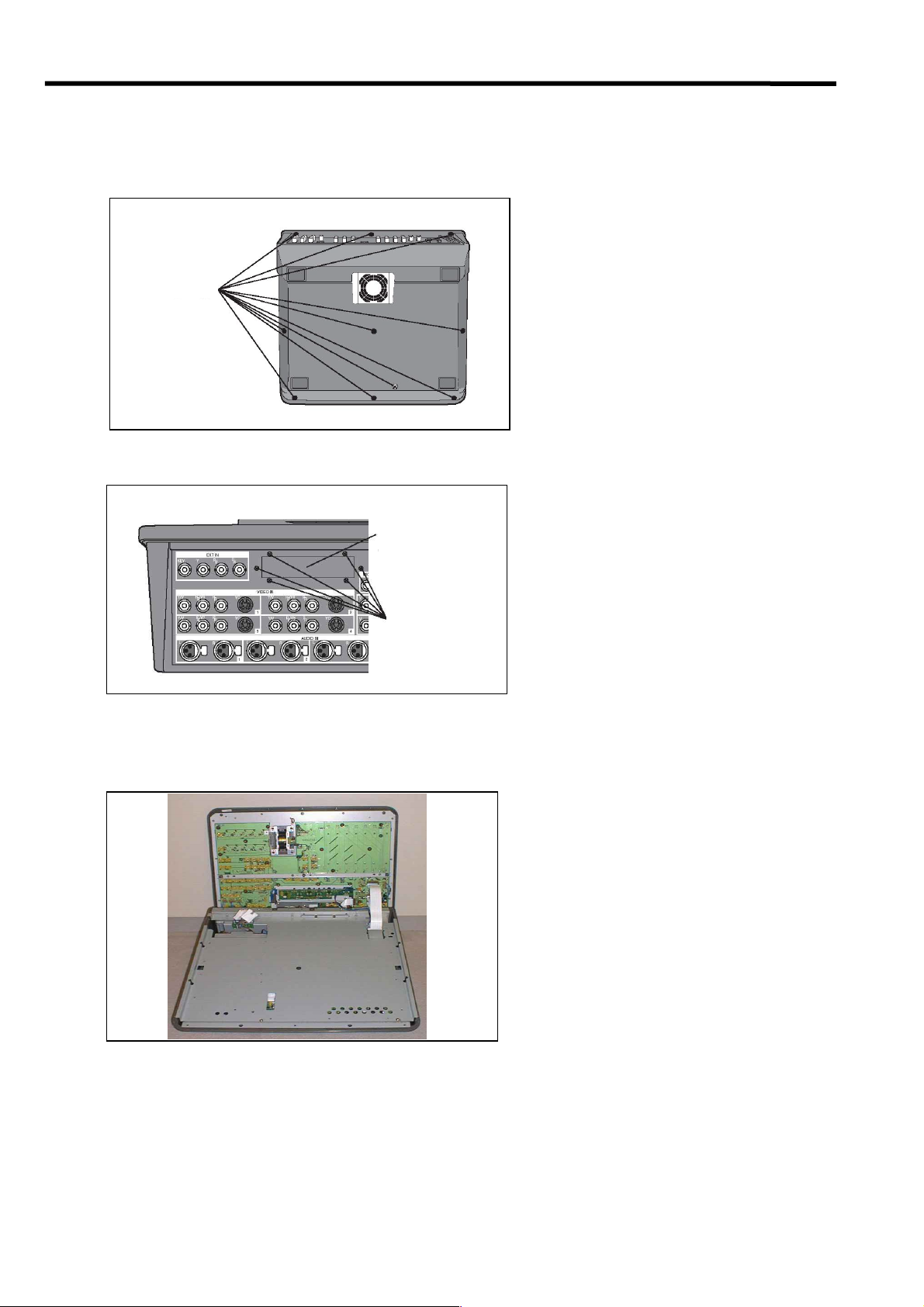

4. The way of attaching an option board

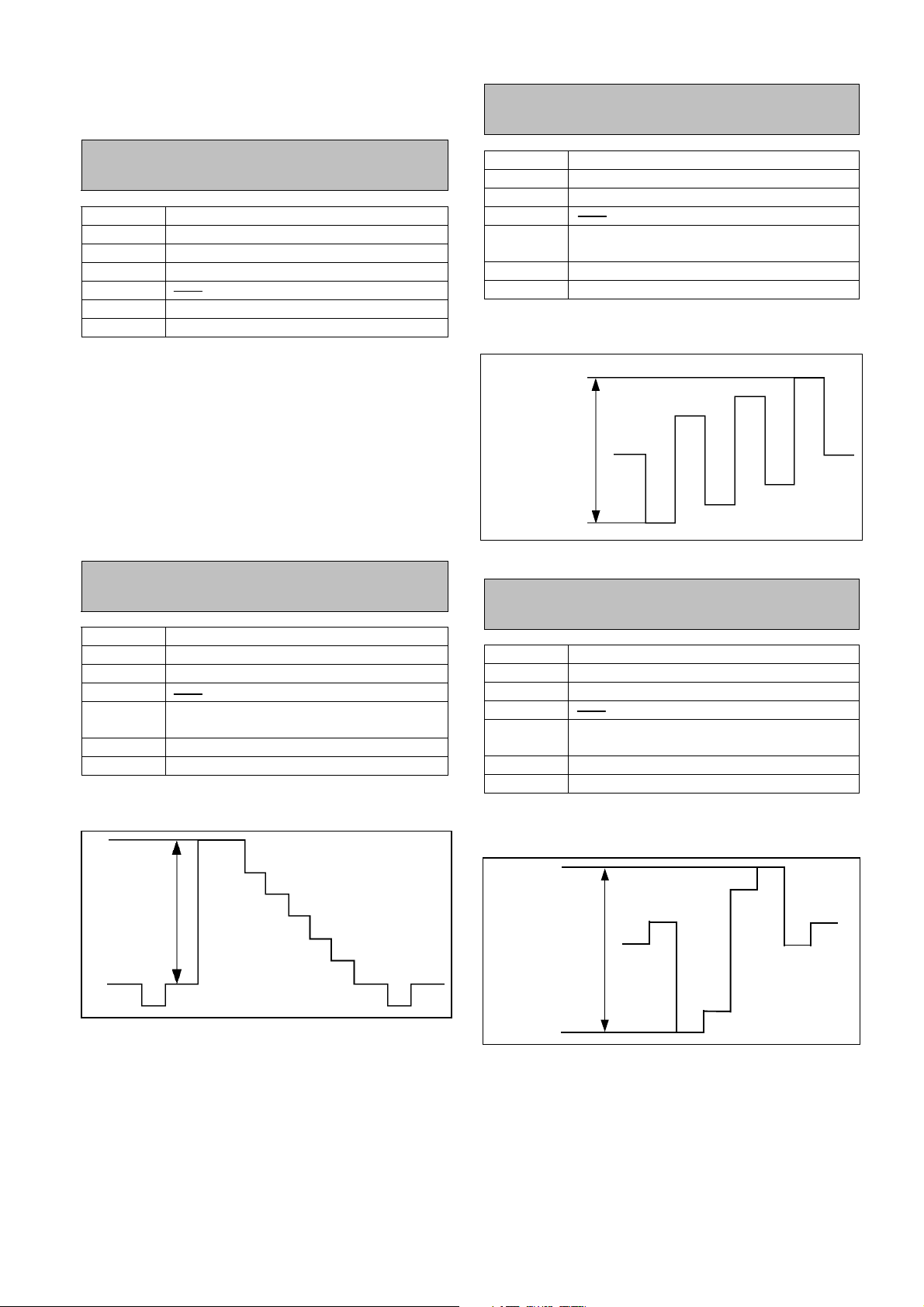

4-1. Installation of the AG-YA70P

The AG-YA70P is an interface board that enables the AG-MX70 to be connected to a serial digital interface (SDI).

Follow the procedure below to install it.

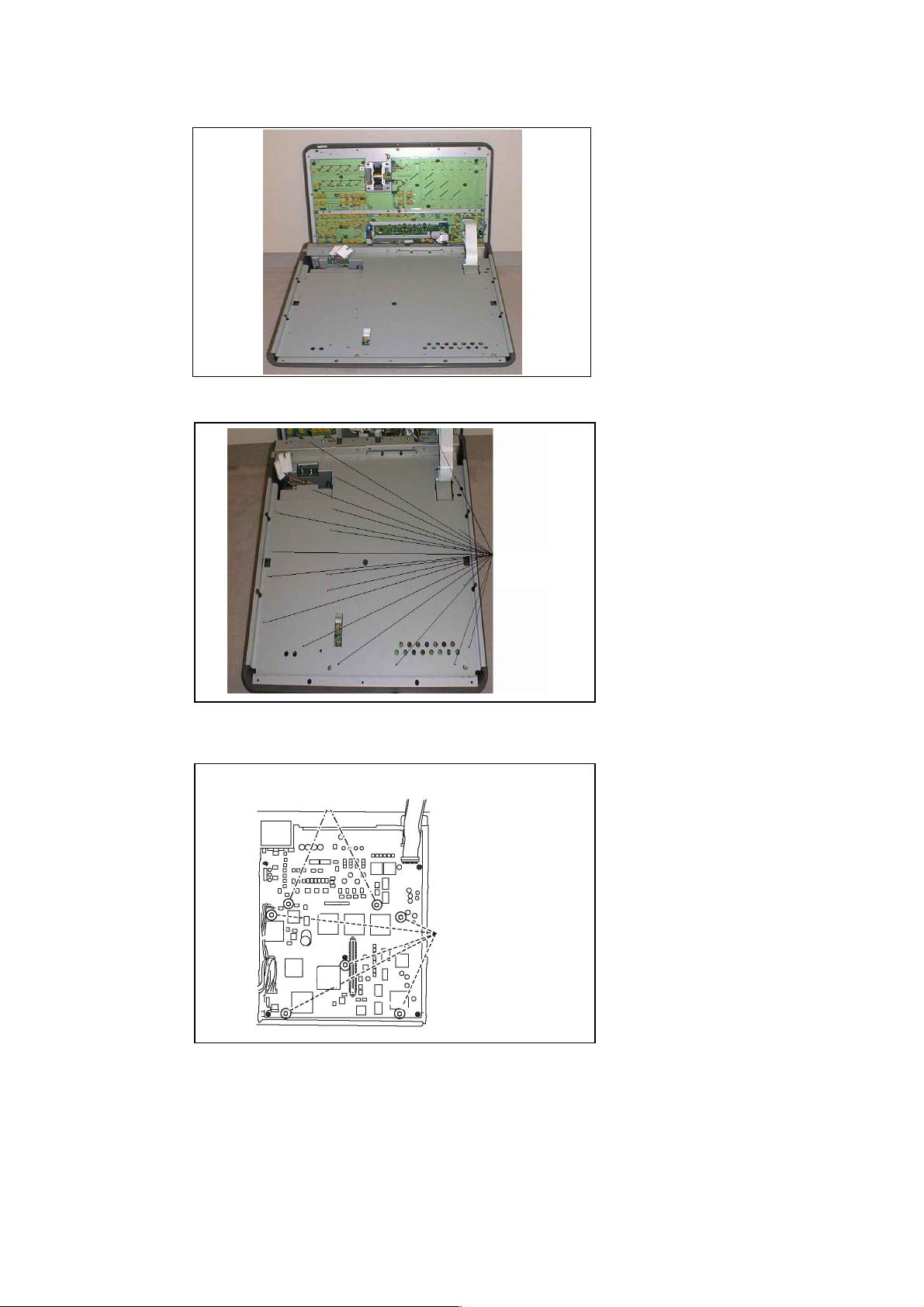

1. Turn off the power of the AG-MX70 and remove the ten screws from the bottom panel.

Screws (10 pcs)

2. Remove the six screws from the rear panel, then remove the blank panel.

Blank panel

Screws (6 pcs)

3. Open the top unit, including the LCD, from the front, then release the bands securing the flexible cable and

blue cable of the unit.

4. Fix the unit perfectly upright so it does not topple. When removing the casing, ensure the flexible and other

cables do not become detached.

INF-8

5. Remove the twenty screws from the shield casing, then remove the casing itself.

Screws

(20 pcs)

6. Remove the two hexagonal screws for anchoring the AG-YA70P to the motherboard.

Fixing screws

for AG-YA70P

Fixing screws

for AG-VE70P

7. Insert the AG-YA70P board. (Refer to the figure at left.)

INF-9

8. Insert the cable from the AG-YA70P into the connector on the motherboard. (Refer to the figure at left.)

9. Secure the two screws which were removed in step 6.

10. Secure the shield casing and the twenty screws which were removed in step 5.

11. Re-attachthebandsremovedinstep3.andclosethetopunit.

12.Securethesixscrewswhichwereremovedinstep2.

13.Securethetenscrewswhichwereremovedinstep1.

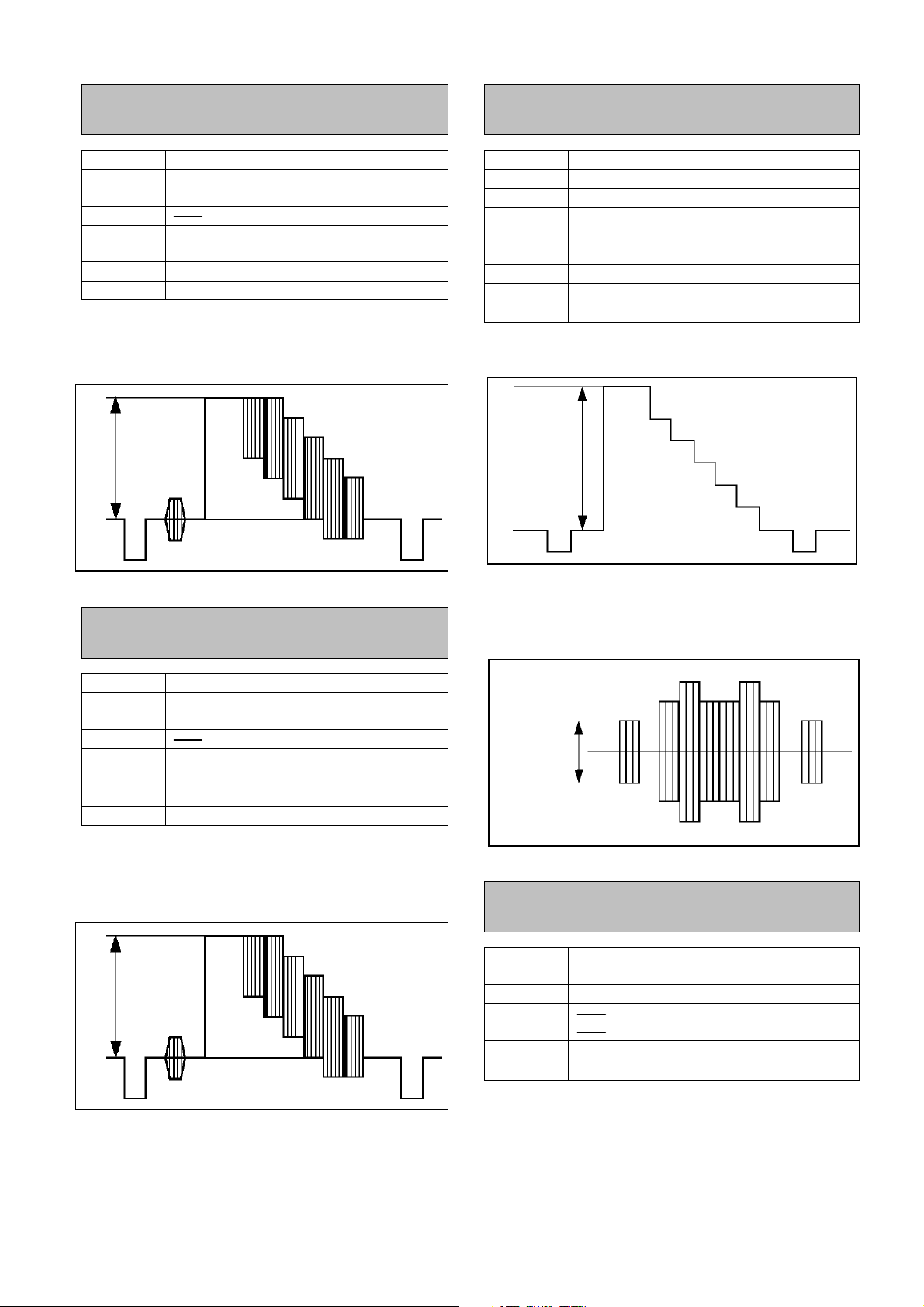

4-2. Installation of the AG-VE70P

The AG-VE70P is a 3D effect board that enables the 3D patterns, etc. of the AG-MX70 to be used.

Follow the procedure below to install it.

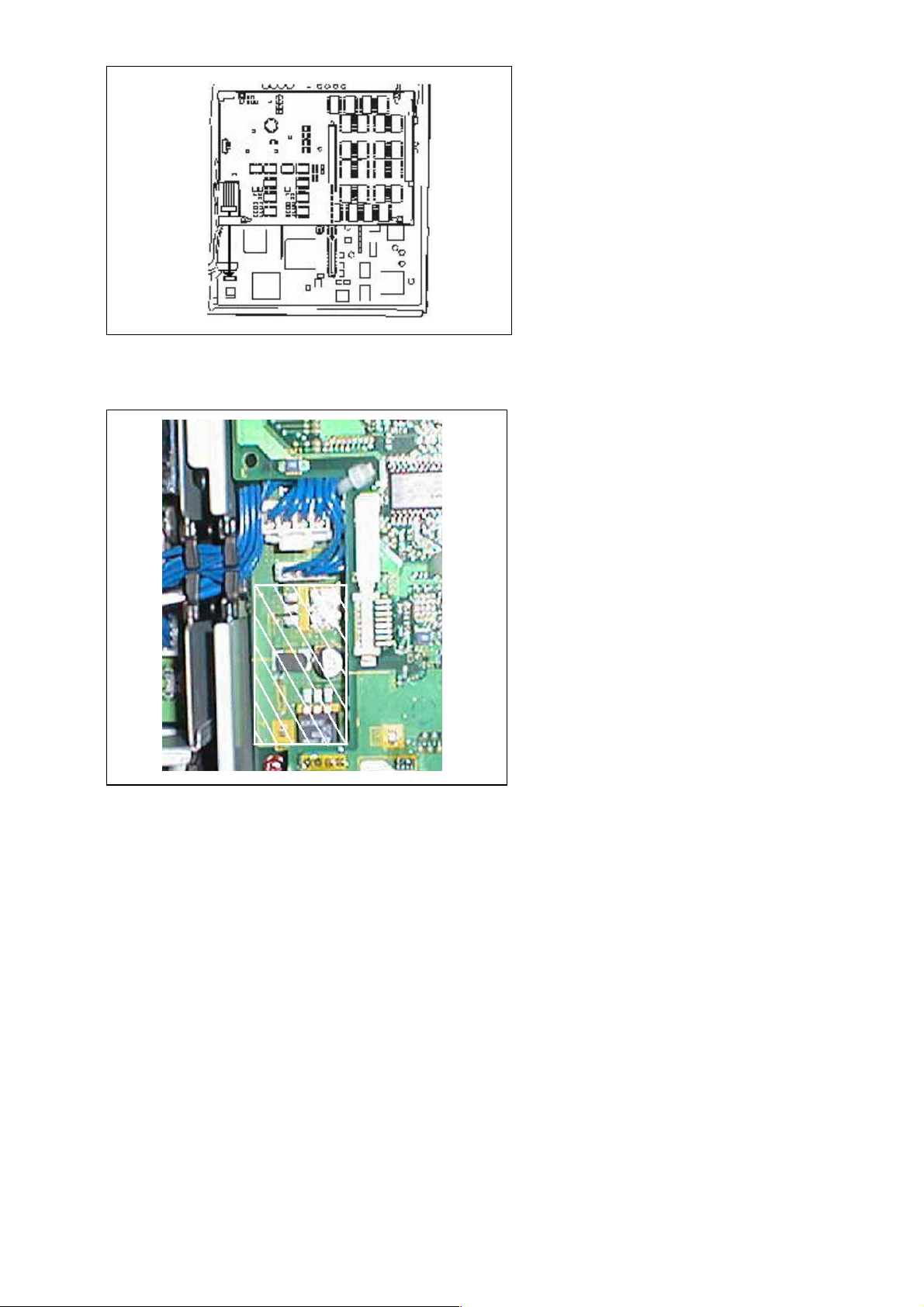

1. Turn off the power of the AG-MX70 and remove the ten screws from the bottom panel.

Screws (10 pcs)

INF-10

2. Open the unit in the top part including the LCD out toward the front, then release the bands securing the

flexible cable and blue cable of the unit.

3. Fix the unit perfectly upright so it does not topple.

When removing the casing, ensure the flexible and other c ables do not become detached.

4. Remove the twenty screws from the shield casing, then remove the casing itself.

Screws

(20 pcs)

5. Remove the five hexagonal screws for anchoring the AG-VE70P to the motherboard.

Fixing screws

for AG-YA70P

Fixing screws

for AG-VE70P

INF-11

6. Insert the AG-VE70P board. (Refer to the figure at right.)

7. Insert the cable from the AG-VE70P into the connector on the motherboard. (Refer to the figure at left.)

Route the cables while carefully ensuring that they do not make contact with the transition lever unit.

8. Securethefivescrewswhichwereremovedinstep5.

9. Securetheshieldcasingandthetwentyscrewswhichwereremovedinstep4.

10. Re-attach the bands removed in step 2. and close the top unit.

11.Securethetenscrewswhichwereremovedinstep1.

INF-12

DISASSEMBLY PROCEDURES

CO

S

NTENT

1. Removal the Top Case ...................................................................................... DIS-1

2. Removing the LCD Panel .................................................................................. DIS-1

3. Removal the Top Case Fan Motor.................................................................... DIS-2

4. Removal the Bottom Case Fan Motor.............................................................. DIS-2

5. Removal the Power Unit.................................................................................... DIS-2

6. Removal the Power Unit's Fan Motor .............................................................. DIS-2

7. Removal the Jack Unit ...................................................................................... DIS-3

1. Removal the Top Case

1. Unscrew the 9 screws (A) and the screw (B) in the

illustration.

SCREW (A)

SCREW (B)

BOTTOM

CASE

TOP CASE

2. Open the Top Case and disconnect P15 connector

on the Panel P.C.Board and the connector on AC

SW.

3. Unlock P5, P6, and P8, disconnect the flexible cable

and remove the Top Case.

SCREW (A)

SCREW (C)

3. Disconnect connectors P1102, P1103, and P1104

and remove the Inverter Angle.

SCREW (A)

SCREW (B)

INVERTER ANGLE

SCREW (C)

P1102

PANEL P.C.BOARD

P5

P6

P8

AC SW

CONNECTOR

P15

2. Removing the LCD Panel

1. Remove the Top Case.

2. Unscrew the 6 screws (A), the 3 screws (B), and the

2 screws (C) in the illustration.

P1104

4. Unscrew the 4 screws (D) and remove the LCD

Panel.

SCREW (D)

SCREW (D)

P1103

LCD PANEL

DIS - 1

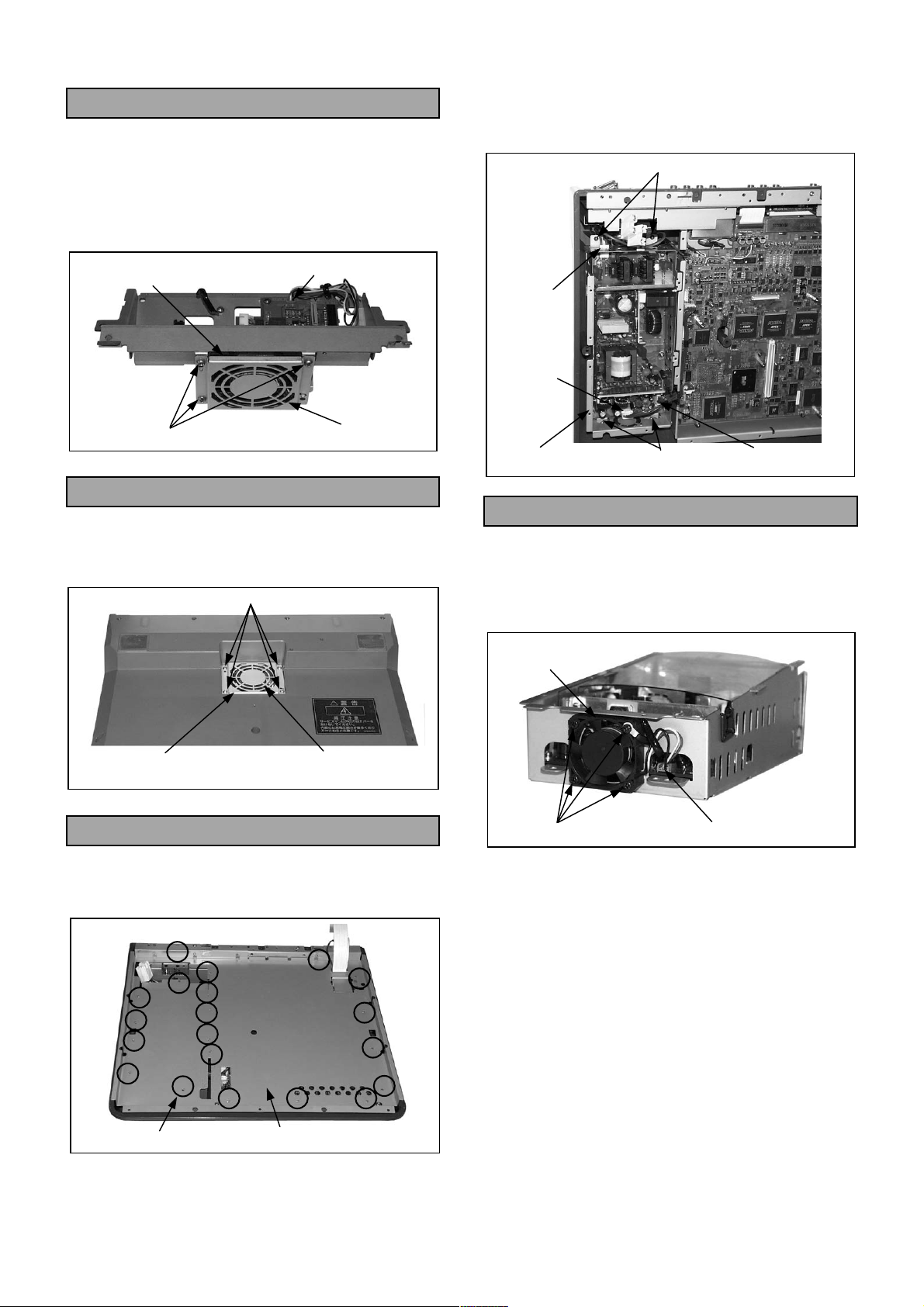

3. Removal the Top Case Fan Motor

1. Remove the Top Case.

2. Remove the Inverter Angle. (See "Removal the

LCD Panel")

3. Unscrew the 3 screws and remove the Fan Cover.

4. Disconnect connector P1105 and remove the Top

Case Fan Motor.

3. Unscrew the 4 screws (B).

4. Disconnect P1001, P1103 and P1104 and remove

the Power Unit.

SCREW (B)

TOP CASE FAN MOTOR

SCREW

P1105

FAN COVER

4. Removal the Bottom Case Fan Motor

1. Unscrew the 4 screws and remove the Fan Cover.

2. Remove the Bottom Case Fan Motor and

disconnect the connectors.

SCREW

P1001

P1104

POWER UNIT

SCREW (B)

P1103

6. Removal the Power Unit's Fan Motor

1. Remove the Power Unit.

2. Unscrew the 4 screws.

3. Disconnect connector P1106 and remove the

Power Unit's Fan Motor.

POWER UNIT’S

FAN MOTOR

BOTTOM CASE FAN MOTORFAN COVER

5. Removal the Power Unit

1. Remove the Top Case.

2. Unscrew the 20 screws (A) and remove the Main

Case Cover.

SCREW (A)

MAIN CASE COVER

SCREW P1106

DIS - 2

7. Removal the Jack Unit

1. Remove the Power Unit.

7. Unscrew the 2 screws (C) and remove the Jack

Unit along with the Main Case.

2. Unscrew the 5 screws (A).

3. Disconnect connectors P361, P366, P1111, and

P1112, unlock connector P365, and disconnect the

flexible cable.

4. Slide the Main P.C.Board in the direction indicated

by the arrow and disconnect connector P360.

P361 P366 P1112 P1111 P365 P360

SCREW

(A)

MAIN P.C.BORAD

5. Lift the Main P.C.Board as shown in the illustration,

disconnect connector P364, and remove the Main

P.C.Board.

JACK UNIT

8. Unscrew the 6 screws (D) and separate the Jack

Unit from the Main Case.

SCREW (D)

SCREW (C)

MAIN CASE

JACK UNIT

P364

6. Unscrew the 4 screws (B).

SCREW (B)

MAIN CASE

MAIN P.C.BORAD

DIS - 3

ELECTRICAL ADJUSTMENTS

CONTENTS

1. MAIN .......................................................................................................................EAD-1

1-1. PLL Free run frequency adjustment ...................................................................................... EAD-1

1-2. Adjustment of Y output gain of component signals ............................................................... EAD-1

1-3. Adjustment of PB output gain of component signals............................................................. EAD-1

1-4. Adjustment of PR output gain of component signals ............................................................ EAD-1

1-5. Adjustment of output gain of composite signals .................................................................... EAD-2

1-6. Adjust output gain of PVW (preview)..................................................................................... EAD-2

1-7. Adjustment of output gain of Y/C (S terminal) signals........................................................... EAD-2

1-8. Adjustment of output gain of ADV-REF signals..................................................................... EAD-2

1-9. Preparation before starting the adjustment menu ................................................................. EAD-3

1-10. Starting the adjustment menu................................................................................................ EAD-3

1-11. SCH adjustment .................................................................................................................... EAD-3

1-12. Adjust component Y input signal gain of the A bus............................................................... EAD-4

1-13. Adjust component PB input signal gain of the A bus ............................................................ EAD-4

1-14. Adjust component PR input signal gain of the A bus ............................................................ EAD-4

1-15. Adjust component Y input signal gain of the B bus............................................................... EAD-5

1-16. Adjust component PB input signal gain of the B bus ............................................................ EAD-5

1-17. Adjust component PR input signal gain of the B bus ............................................................ EAD-5

1-18. Adjustment of EXT input signal gain ..................................................................................... EAD-6

1-19. Adjustment of EXT input signal PB offset.............................................................................. EAD-6

1-20. Adjustment of EXT input signal PR offset ............................................................................. EAD-6

1-21. Adjustment of EXT input signal PB gain................................................................................ EAD-7

1-22. Adjustment of EXT input signal PR gain ............................................................................... EAD-7

1. MAIN

1-3. Adjustment of PB output gain

of component signals

1-1. PLL Free Run Frequency

Adjustment

BOARD MAIN BOARD

TP TP1393

ADJ. VR1490

INPUT No Input to EXT-Y, EXT-Key, and G/L

MODE

M.EQ Frequency Counter

SPEC. Within 27, 000, 000 MHz ±30 Hz

1. Measure TP1393 with the frequency counter and

adjust VR1490 so it meets the above

specifications.

Note:

If there are input signals to EXT-Y, EXT-Key, and

G/L, PLL will respond to the signals so there will be no

change even if you adjust the frequency with VR1490.

1-2. Adjustment of Y output gain

of component signals

BOARD MAIN BOARD

TP VIDEO OUT,Y1 or Y2

ADJ. VR1524 (Y)

INPUT

MODE

M.EQ Oscilloscope

SPEC. Y level: within 700±14 mV

1. Adjust VR1524 (Y) so the Y1 or Y2 level of VIDEO

OUT becomes 700±14 mV.

Cross point: A bus, B bus = INT

LCD menu: Int Video = colorbar

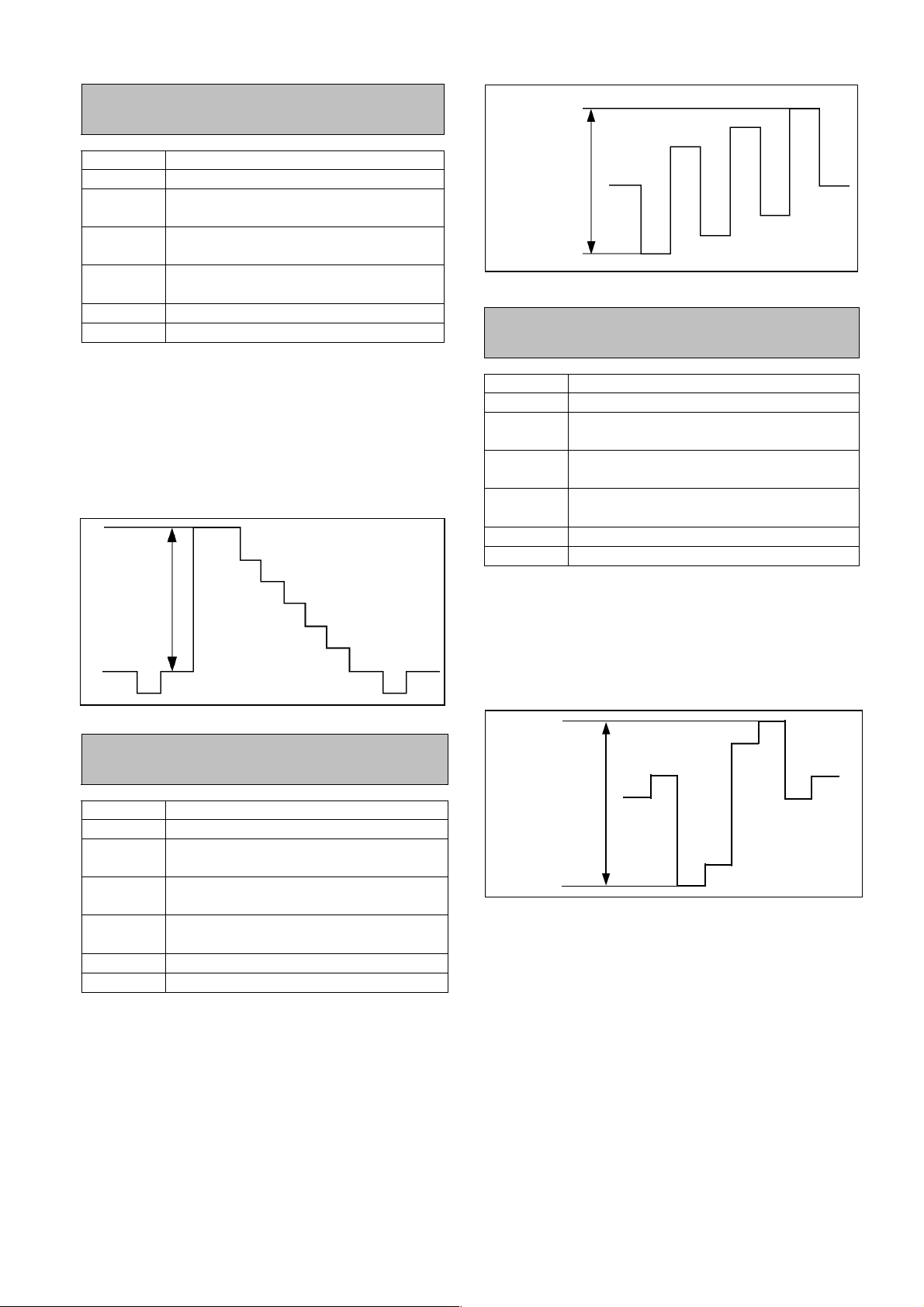

BOARD MAIN BOARD

TP VIDEO OUT, PB1 or PB2

ADJ. VR1522 (PB)

INPUT

MODE

M.EQ Oscilloscope

SPEC. PB level: within 525±10 mV

1. Adjust VR1522 (PB) so the PB1 or PB2 level of

VIDEO OUT becomes 525±10 mV.

PB LEVEL

Cross point: A bus, B bus = INT

LCD menu: Int Video = colorbar

1-4. Adjustment of PR output gain

of component signals

BOARD MAIN BOARD

TP VIDEO OUT,PR1 or PR2

ADJ. VR1520 (PR)

INPUT

MODE

M.EQ Oscilloscope

SPEC. PR level: within 525±10 mV

1. Adjust VR1520 (PR) so the PR1 or PR2 level of

VIDEO OUT becomes 525±10 mV.

Cross point: A bus, B bus = INT

LCD menu: Int Video = colorbar

Y LEVEL

EAD-1

PR LEVEL

PR LEVEL

1-5. Adjustment of output gain of

composite signals

1-7. Adjustment of output gain of

Y/C (S terminal) signals

BOARD MAIN BOARD

TP VIDEO OUT,V1 or V2

ADJ. VR1525 (VIDEO)

INPUT

MODE

M.EQ

SPEC. A = within 700±14mV

1. Adjust VR1525 (VIDEO) so the composite signal

output level of V1 or V2 level of VIDEO OUT

becomes 700±14mV.

A

Cross point: A bus, B bus = INT

LCD menu: Int Video = color bar

Oscilloscope

BOARD MAIN BOARD

TP

ADJ. VR1561 (YCT), VR1523 (YCC)

INPUT

MODE

M.EQ

SPEC.

1. Adjust VR1561 (YCT) so the Y level of YC1 or

YC2 of VIDEO OUT becomes 700 ±14 mV.

Y LEVEL

2. 2. Adjust VR1523 (YCC) so the C level of

VIDEO OUT,YC1 or YC2

Cross point: A bus, B bus = INT

LCD menu: Int Video = color bar

Oscilloscope

Y level: within 700 ±14 mV

C level: within 300 ± 6 mV

1-6. Adjust output gain of PVW

(preview)

BOARD MAIN BOARD

TP PREVIEW

ADJ. VR1521 (AUX)

INPUT

MODE

M.EQ

SPEC.

1. Adjust VR1521 (AUX) so the composite signal

output level PVW (preview) becomes

700±14mV.

A

Cross point: A bus, B bus = INT

LCD menu: Int Video = color bar

Oscilloscope

A = within 700±14mV

YC1 or YC2 of VIDEO OUT becomes 300 ± 6

mV.

C LEVEL

1-8. Adjustment of output gain of

ADV-REF signals

BOARD MAIN BOARD

TP ADV-REF

ADJ. VR1560 (REF)

INPUT

MODE

M.EQ

SPEC.

Oscilloscope

SYNC level: within 300 ±6 mV

EAD-2

1. Adjust VR1560 (REF) so the SYNC level of

3. Confirm the settings: You do not have to do this

ADV-REF becomes 300 ±6 mV

SYNC LEVEL

1-9. Preparation before starting

the adjustment menu

BOARD

TP

ADJ.

INPUT

MODE

M.EQ

SPEC.

Do the following before starting the adjustment

menu.

1. Make the pattern No.=0002.

a Press the PATTERN key (at the top left of

the 10 key block) to light it.

You do not have to press it if it is already lit.

Adjustment menu mode

if you have not changed the settings from the

default.

a In the LCD menu: Check that SETUP/Gen.

Lock/Refin = G/L. If it is not, change it so it is.

1-10. Starting the adjustment menu

BOARD

TP

ADJ.

INPUT

MODE

M.EQ

SPEC.

Start the adjustment menu.

1. Press SETUP so the SET UP screen

appears on the LCD.

2. Press and hold 9 and SHIFT (in the 10-

key block) for 3 seconds.

The adjustment menu appears on the LCD.

3. In order, press 0 , 2 , 6 , - and

¿ .

The unit is now ready to accept commands

from the rotary encoder.

Adjustment menu mode

b Press 0 ,0,0,2, ¿ in order.

The pattern No. is set to 0002.

2. Set SOURCE-1 to analog component input.

a In the LCD menu: Select the SETUP/Audio

Video/InputSetup line.

b Press ¿ once. “OK?” appears.

c Press ¿ once again.

The AudioVideoSetup screen appears.

d Change “Video” in the top line (“V S-1”) to “Y

Pb Pr” with the rotary encoder.

e Press ¿ to exit the Audio Video Setup

screen.

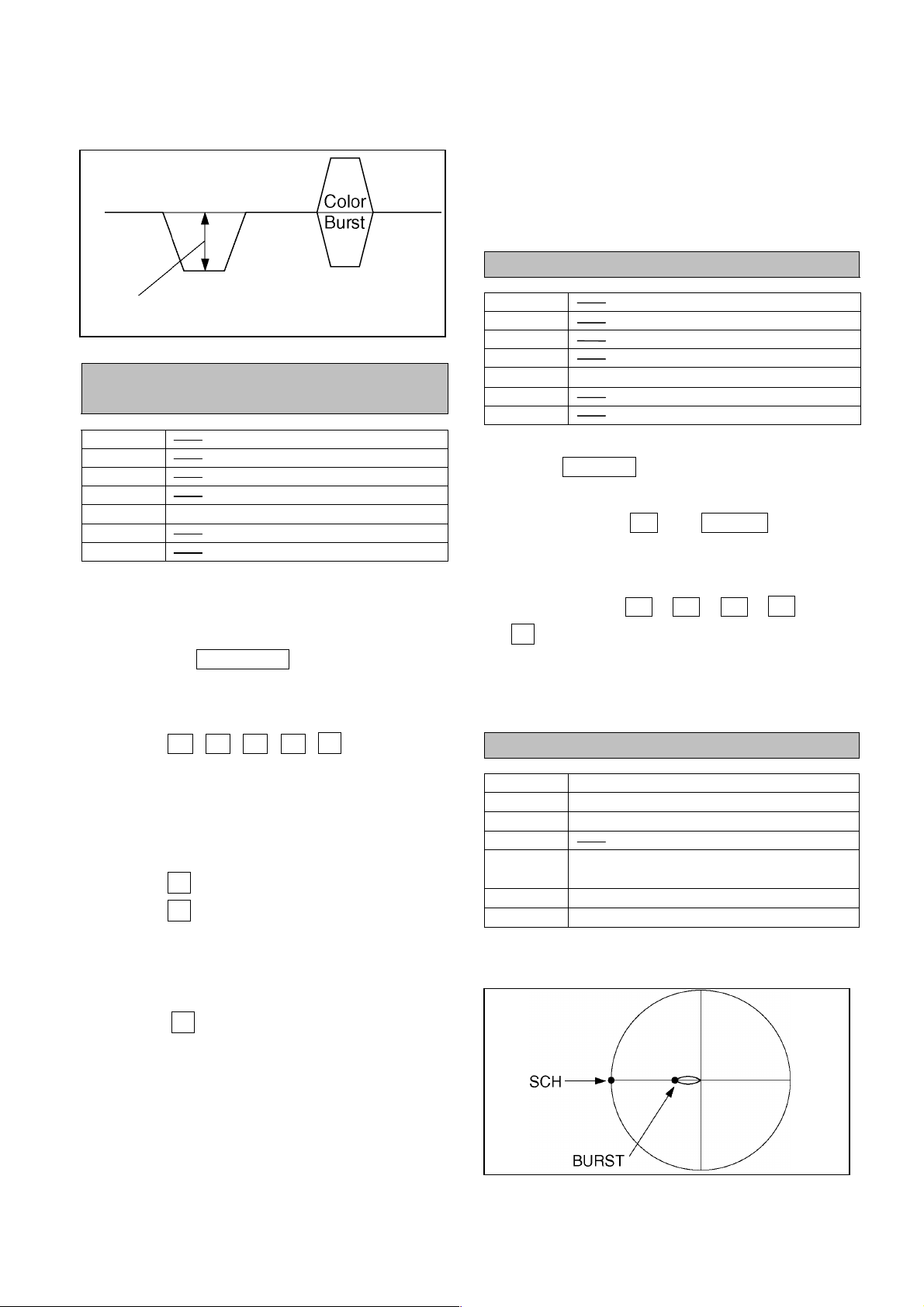

1-11. SCH adjustment

BOARD MAIN BOARD

TP

ADJ.

INPUT

MODE

M.EQ

SPEC.

1. Adjust the SCH in the adjustment menu so the

SCH of VIDEO OUT V1 or V2 becomes 0±2º.

VIDEO OUT V1 or V2

Adjustment menu/ rotary encoder

Adjustment menu, A bus, B bus =

SOURCE-1

SCH meter

SCH: within 0±2º

EAD-3

1-12. Adjust component Y input

signal gain of the A bus

BOARD MAIN BOARD

TP

ADJ.

INPUT

MODE

M.EQ

SPEC.

1. Use the rotary encoder to select “A-bus” in the

adjustment menu.

2. Use the rotary encoder to adjust “Y-Gain” so

the level of VIDEO OUT Y1 or Y2 becomes

700±

14mV.

Y LEVEL

VIDEO OUT Y1 or Y2

Adjustment menu/rotary encoder (YGain)

Analog component signal (75% color

bar, 0 setup)

A bus, B bus = SOURCE-1

Take lever to A bus side

Oscilloscope

Y level: within 700±14mV

PB LEVEL

1-14. Adjust component PR input

signal gain of the A bus

BOARD MAIN BOARD

TP

ADJ.

INPUT

MODE

M.EQ

SPEC.

1. Use the rotary encoder to select “A-bus” in the

adjustment menu.

VIDEO OUT PR 1 or PR 2

Adjustment menu/rotary encoder (Pr Gain)

Analog component signal (75% color

bar, 0 setup)

A bus, B bus = SOURCE-1

Take lever to A bus side

Oscilloscope

PR level: within 525±10mV

1-13. Adjust component PB input

signal gain of the A bus

BOARD MAIN BOARD

TP

ADJ.

INPUT

MODE

M.EQ

SPEC.

1. Use the rotary encoder to select “A-bus” in the

adjustment menu.

2. Use the rotary encoder to adjust “PB -Gain” so

VIDEO OUT PB 1 or PB 2

Adjustment menu/rotary encoder (Pb

-Gain)

Analog component signal (75% color

bar, 0 setup)

A bus, B bus = SOURCE-1

Take lever to A bus side

Oscilloscope

PB level: within 525±10mV

2. Use the rotary encoder to adjust “Pr -Gain” so

the level of VIDEO OUT PR 1 or PR 2 becomes

525±10mV.

PR LEVEL

the level of VIDEO OUT PB 1 or PB 2 becomes

525±10mV.

EAD-4

Loading...

Loading...