Page 1

MBT 250/220 CALIBRATION KIT

PACE P/N 6993-0133

OPERATION & MAINTENANCE

INSTRUCTIONS

MANUAL NUMBER 5050-0288

REV . A

For any questions regarding the following instructions, contact your local authorized

P ACE dealer or contact P ACE directly at:

Telephone (301) 490-9860, Fax (301) 604-9215

PACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

1

Page 2

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized P ACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of P ACE Incorporated,

Laurel Maryland U.S.A. and may only be used to identify genuine P ACE products or

services:

Cir-Kit, ComForm I, ConducT weez, CRAFT , Dual Path, Flo-D-Sodr, FuseSet,

HotSpot, LapFlo, MBT , MicroChine , Micro Portable, MiniChine, P acenter,

P A CE, P ed-A-V ac, PETS, PRC , PRINT, ResisTweez, SensaTemp, SMR,

Sodr-X-Tractor, StripTweez, SwaPlater, ThermoBand, ThermoPart,

ThermoPik, ThermoJet, ThermoTweez, Thermo-Drive, VisiFilter.

The following are trademarks and/or servicemarks of P ACE Incorporated, Laurel

Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

AdapTip, Arm-Evac, DEXITEST, EK O, HandiPik,PIK-VAC, Pro-Evac,

Redi-Rak, SNAP-V AC , SR-3, SR-4, ST, Tip-Evac.

P ACE Incorporated has provided training on all of its products since 1958 as well as

advanced technology training in all aspects of hand soldering, rework and

repair.

Additional copies of this manual or other P ACE literature may be obtained

from:

P ACE Incorporated (301) 490 - 9860

Sales Administration (301) 4983252 Fax

9893 Brewers Court

Laurel MD 20723-1990

©1992 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

2

Page 3

INTRODUCTION

The following procedure will allow you to effectively calibrate your MBT 250/220

system to insure accuracy and maintain peak performance.

Perform the following procedure step by step, in sequence, to:

1 . Alter Tip T emperature values.

2 . Alter Tip T emperature Offset values.

3. Determine and/or alter feature status and defaults stored in the system.

4 . Recalibrate the system for accuracy .

PROCEDURE

KEYLOCK OPTION

1 . An optional KeyLock feature is available

from P ACE which prevents unauthorized

alteration of stored data or calibration of

the system. Check the rear panel of the

system power source. If the KeyLock

feature is present there will be a KeyLock

switch located in the upper left portion of

the panel. Use the key to turn the switch

to the “Unlock” position. If the feature is

not present, there will be a round plastic

filler plug present at that location.

NOTE

The KeyLoc k switch must be turned to the “UNLOCK” position to alter any

of the data stored in memory or to recalibrate the system.

ENTERING CALIBRATION MODE

3

Page 4

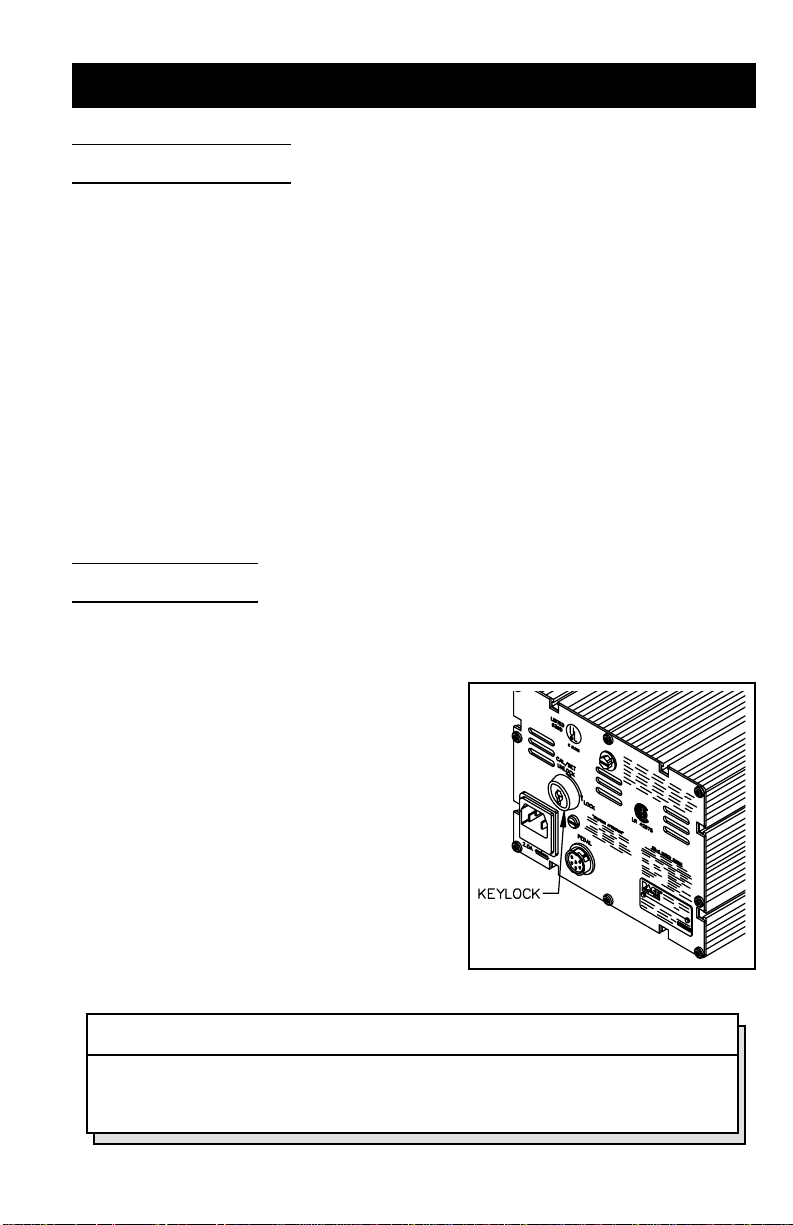

2. Place POWER Switch in the “OFF” (0)

position.

3. Press and hold the Tip Temperature Set

and Scroll Down Keys.

4. Place POWER Switch in the “ON” (1)

position. All of the system LEDs will light.

The T emperature Display will read “888”

and change to read “1-X”.

5 . Release the Tip T emperature Set and Scroll

Down Keys. The T emperature Display will

now read “CAL” and only the three

Channel LEDs will remain lit signifying

that the system is now in the Calibration

Mode.

°F/°C READOUT DEFAULT

6. Press and release the Tip Temperature Set

4

Page 5

Key . The Digital Readout will display

“S-X” (X = 1-9). Either the °F or °C will

be on. This is the default readout (e.g., if

the °C LED is on the Digital Readout will

display temperature readings in °C).

7 . Press and release the °F/°C Key to

change the default. Each subsequent

press and release of the key will change

the default.

AUTOMATIC SETBACK

8 . As received from the factory, the

temperature will read “S - -” meaning that

Automatic Setback is turned off. A

readout of 1 thru 9 on the right side of the Digital Readout indicates time

to Automatic Setback in increments of 10 minutes. For example, “S-3”

would indicate a timeout of 30 minutes.

To change the Automatic Setback

feature, press the Scroll Up Key to

increase the timeout and/or enable the

feature. Press the Scroll Down Key to

decrease the timeout.

9. Press the Tip Temperature Set Key to

store the °F/°C default and Automatic

Setback value in system memory. The

Digital Readout will revert to display

“CAL” and only the Channel 1 LED will

remain lit.

5

Page 6

AUTOMATIC SHUTDOWN

10. The system enables the Automatic

Shutdown feature only when the

Automatic Setback feature is

enabled. No additional steps are

necessary.

CHANNEL SELECTION

11 . The Channel 1 LED is now lit

signifying that Channel 1 is ready for

calibration. Perform steps 12

through 21 to calibrate. As channels

change, repeat these steps for each

channel.

NOTE

All temperature limits are stored in

system memory in degrees F.

LOWER TEMPERATURE LIMIT

SETPOINT

12. Press and release the Tip T emperature Set Key. The Digital Readout will

6

Page 7

now display “L-X” (X = 1-9). This is the stored value of the Lower

T emperature Limit in increments of 100°F.

For example, if the “L-5” is displayed, the

lower limit is 500°F .

13. Press Scroll Keys as necessary to

increase (Scroll Up Key) or decrease (Scroll Down Key) the Lower

T emperature Limit value.

14. Press and release the Tip Temperature Set

Key to store the display value into

memory.

UPPER TEMPERATURE LIMIT

SETPOINT

15. The Digital Readout now displays “H-X”

(X = 1-9). This is the stored value of the

Upper T emperature Limit in increments of

100°F in the same manner as the Lower

7

Page 8

T emperature Limit readout (see step 12).

16. Press Scroll Keys as necessary to

increase (Scroll Up Key) or decrease

(Scroll Down Key) the Upper

T emperature Limit value.

17. Press and release the Tip Temperature Set

Key to store the displayed value into

memory . The Digital Readout will now

display “C-1”.

NOTE

If you do not wish to recalibrate for readout

accuracy , press the TIP TEMPERA TURE

OFFSET Key and perform steps 12 through

17. After all channels have been calibrated,

you may exit the Calibration Mode by

pressing and releasing theTip T emperature

Offset Key again.

READOUT ACCURACY

18. Unplug the handpiece connected to the Current Channel and plug in the

#1 Calibration Assembly .

8

Page 9

19. Press and release the Tip Temperature Set

Key . The Digital Readout will flash “- - -”

to indicate that the system

microprocessor controlled circuitry is

recalibrating one aspect of the system

circuity. “C-2” will now be displayed.

20. Unplug the #1 Calibration Assembly and

plug in the #2 Calibration Assembly.

READOUT ACCURACY

CONT'D

21. Press and release the Tip Temperature Set

Key . The Digital Readout will flash “- - -”

to indicate that the system

9

Page 10

microprocessor controlled circuitry is recalibrating another aspect of the

system circuitry. “CAL” will now be

displayed indicating that calibration of

this channel is complete.

22. Press and release the Tip Temperature

Offset Key two times to exit calibration.

All values, features and defaults entered

during the calibration are now stored in

memory and all channel tip temperature

settings are turned “OFF”. All channel

Tip Temperature Offset settings are set to the default value of 6°F (3°C).

TEMPERATURE DISPLAY

MESSAGE CODES

Listed below are Message Codes and a

description of each which may be displayed on

the system power source digital readout during

the Calibration procedure.

10

Page 11

DISPLAY

DISPLAY

DISPLAYDISPLAY

MESSAGE

MESSAGE

MESSAGEMESSAGE

C-1 OR C-2

CAL Indicates that system is in the Calibration Mode.

E-5

DESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Indicates system is ready to process Digital Readout accuracy

calibration for a particular channel using the appropriate

calibration module.

Input to control circuitry unstable. Indicates that no calibration

module is connected to the channel being calibrated or the

incorrect module has been inserted.

E-6

H-X

(X = 1 thru 9)

L-X

(X = 1 thru 9)

OFF

S--

S-X

--(flashing)

Loose connection. Calibration input is out of range. Normally

occurs if incorrect calibration module is inserted.

Indicates the Current Channel is ready to accept new Upper

Temperature Limit setpoint X (X times 100°F).

Indicates the Current Channel is ready to accept new Lower

Temperature Limit setpoint X (X times 100°F).

Setpoint for this channel is below Lower Temperature Limit

setpoint.

Indicates that the Automatic Temperature Setback (and Power

Down) feature is disabled (turned off).

Indicates that the Automatic Temperature Setback (and Power

Down) feature is enabled (turned on) and will set each channels'

Set Tip Temperature back after X times 10 minutes of handpiece

inactivity (non-use).

Indicates that the system circuitry is proceeding with calibration

using the proper calibration module (C-1 or C-2).

11

Page 12

12

Loading...

Loading...