Page 1

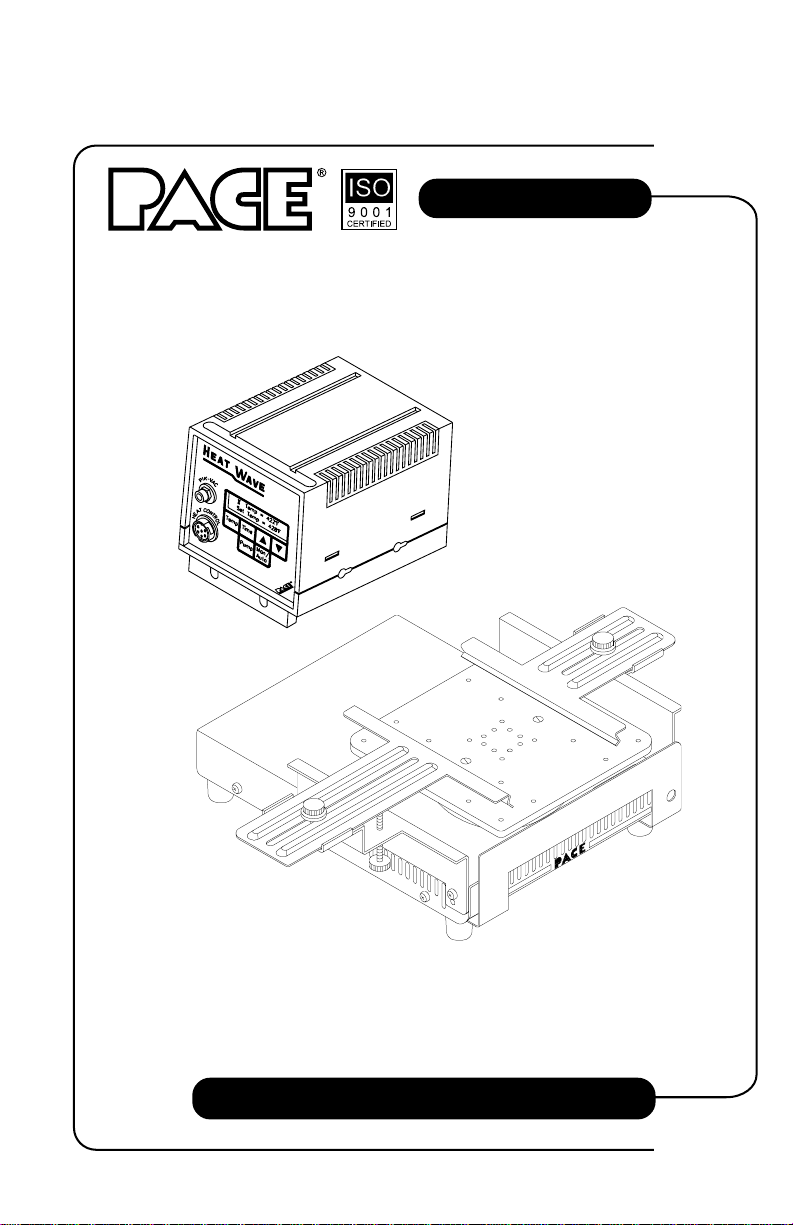

HS 200 System

HS 200 Heat Wave System

Operation & Maintenance Manual

Page 2

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of PACE

Incorporated, Laurel Maryland U.S.A. and may only be used to identify genuine

PACE products or services:

AdapTip, Arm-Evac, Cir-Kit, ComForm I, ConducTweez, CRAFT,

Dual Path, Flo-D-Sodr, FuseSet, HandiPik, HotSpot, LapFlo, MBT,

Micro Portable, MicroChine, MiniChine, Mini-Wave, PACE, Pacenter,

Ped-A-V ac, PETS, Pik-Vac, PRC, Prep-Set, Pro-Evac, Redi-Rak, ResisT weez,

SensaTemp, Snap-Vac, Sodr-Pen, Sodr-X-Tractor, SR-3, SR-4, ST,

StripTweez, SwaPlater, ThermoBond, Thermo-Drive, ThermoJet, ThermoPart,

ThermoPik, ThermoT weez, Tip-Ev ac,Ventur-Evac VisiFilter .

The following are trademarks and/or servicemarks of PACE Incorporated, Laurel

Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

Heat Wave, Pik-Tip, Pulse Plate, Sodrtek, ThermoFlo, Toolnet.

Since 1958, PACE Incorporated has provided

advanced technology training in all aspects of hand

soldering, rework and repair.

Additional copies of this manual or other PACE literature may be obtained from:

PACE Incorporated (301) 490 - 9860

Sales Administration (301) 498 - 3252 Fax

9893 Brewers Court

Laurel MD 20723-1990

Page 3

MANUAL NUMBER 5050-0406

REV. C

SYSTEM QUICK START

The HS 200 Heat Wave system is very easy to operate and can be

quickly set up for use in standard preheating operations. To begin

operation of your new system quickly, read the "Set-Up" and

"Quick Start Procedure" instructions detailed on pages 9-13

and page 18 of this manual. A shaded title bar on each of these

pages highlights their location.

For any questions regarding the following instructions, contact your local authorized

PACE dealer or contact PACE directly at:

Telephone (301) 490-9860, Fax (301) 604-8782

PACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

©1998 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

1

Page 4

Table of Contents

TITLE PAGE

General Information ............................................................................................... 4

Introduction.................................................................................................. 4

Specifications ............................................................................................... 5

Parts Identification ....................................................................................... 6

Safety ...................................................................................................................... 8

Set-Up ..................................................................................................................... 9

System.......................................................................................................... 9

Hot Plate Installation .............................................................................. 9

Heat Shield Installation ........................................................................ 10

Board Holder Mounting ....................................................................... 10

Heater Unit/Power Source Connection................................................. 12

Air Hose Connection ............................................................................ 13

System Power Up ................................................................................. 13

Preheat Guidelines ................................................................................................ 14

Introduction................................................................................................ 14

Safe, Rapid Preheating............................................................................... 16

Preheat & Soak .......................................................................................... 17

Quick Start Procedure........................................................................................... 18

Operation .............................................................................................................. 19

Introduction................................................................................................ 19

Definitions.................................................................................................. 19

Overview.................................................................................................... 20

Factory Settings ......................................................................................... 22

Password .................................................................................................... 23

Board Set-Up ............................................................................................. 24

Power Up.................................................................................................... 25

Panel Controls ............................................................................................ 25

Manual Mode ....................................................................................... 26

Auto Mode............................................................................................ 27

Adjusting Set Temperature ................................................................... 28

Adjusting Time/Day of Week ............................................................... 29

Pump Operation.................................................................................... 30

Pik-Vac Operation ...................................................................................... 32

2

Page 5

Table of Contents

TITLE PAGE

Set-Up Mode......................................................................................................... 33

Introduction................................................................................................ 33

Operation ................................................................................................... 34

Entering Set-Up Mode.......................................................................... 34

Password ............................................................................................... 35

Time Protection .................................................................................... 35

Hot Plate Temperature Offset ............................................................... 36

Temperature Limits............................................................................... 36

Time Display ........................................................................................ 37

Auto Schedule ...................................................................................... 37

Auto Off................................................................................................ 39

Corrective Maintenance ........................................................................................ 40

Spare Parts ............................................................................................................ 41

Manual Improvement & Comment Form ............................................................. 42

TABLE PAGE

Table 1 Rapid Preheat Guidelines................................................................... 16

Table 2 Preheat & Soak Guidelines ................................................................ 17

Table 3 Factory Settings ................................................................................. 22

Table 4 HS 200 Checkout Procedures ............................................................ 40

Table 5 Spare Parts ......................................................................................... 41

3

Page 6

General Information

Introduction

Thank you for purchasing the PACE HS 200 Heat Wave system. This manual will

provide you with the information necessary to properly set up, operate and maintain

the HS 200 Heat Wave system.

The HS 200 is a fully integrated system which provides temperature controlled

bottom preheating of high mass electronic assemblies and components. Users can

select forced convective (forced air) or conductive (direct hot plate contact)

preheating.

The system utilizes the PPS 28 Heat Wave power source which incorporates

microprocessor control of system features as defined by the user (e.g., temperature

limits, password lock and scheduled operations). An integral motor pump supplies

forced air (air pressure) for convective applications and vacuum for component

handling operations using the PACE Pik-Vac handpiece.

NOTE

The PPS 28 Heat Wave power source is designed specifically for use with

the HS 200 Heat Wave system only. DO NOT use with any PACE

accessories other than the Heat Wave Heater Unit.

The Heat Wave heater unit has a wide area hot plate design which protects substrates

and components from thermal shock, minimizes board (PCB) warpage and allows

rapid solder reflow during rework applications.

4

Page 7

General Information

Specifications

The HS 200 Heat Wave system operates as a bottom preheater.

The system is available in either the 115 VAC or 230 VAC versions as listed below.

The 230 VAC version system bears the CE conformity marking which assures the

user that it conforms to all the requirements of council directive EMC 89/336/EEC.

System Power Requirements:

HS 200 - Operates on 97-127 VAC, 50/60Hz

Heater Unit - 300 Watts maximum at 115 VAC, 60Hz

PPS 28 Power Source - 7 Watts maximum at 115 VAC, 60Hz

HS 200E - Operates on 197-264 VAC, 50/60Hz

Heater Unit - 275 Watts maximum at 230 VAC, 50/60Hz

PPS 28E Power Source - 8 Watts maximum at 230 VAC, 50/60Hz

Temperature Range: 38°C to 371°C (100°F to 700°F)

Standard Hot Plate Dimensions: 140mm (5.5 inches) square

Board Holding Capacity:

Standard Board Holder: 20.3cm x 20.3cm (8" x 8")

Optional Board Holder: 45.7cm x 45.7cm (18" x 18")

EOS/ESD Specifications:

Hot Plate-To-Ground Resistance: Less than 2 ohms.

AC Leakage: Less than 2 millivolts RMS from 50Hz to 500Hz.

System Calibration:

No calibration steps are necessary to maintain the accuracy of the system.

5

Page 8

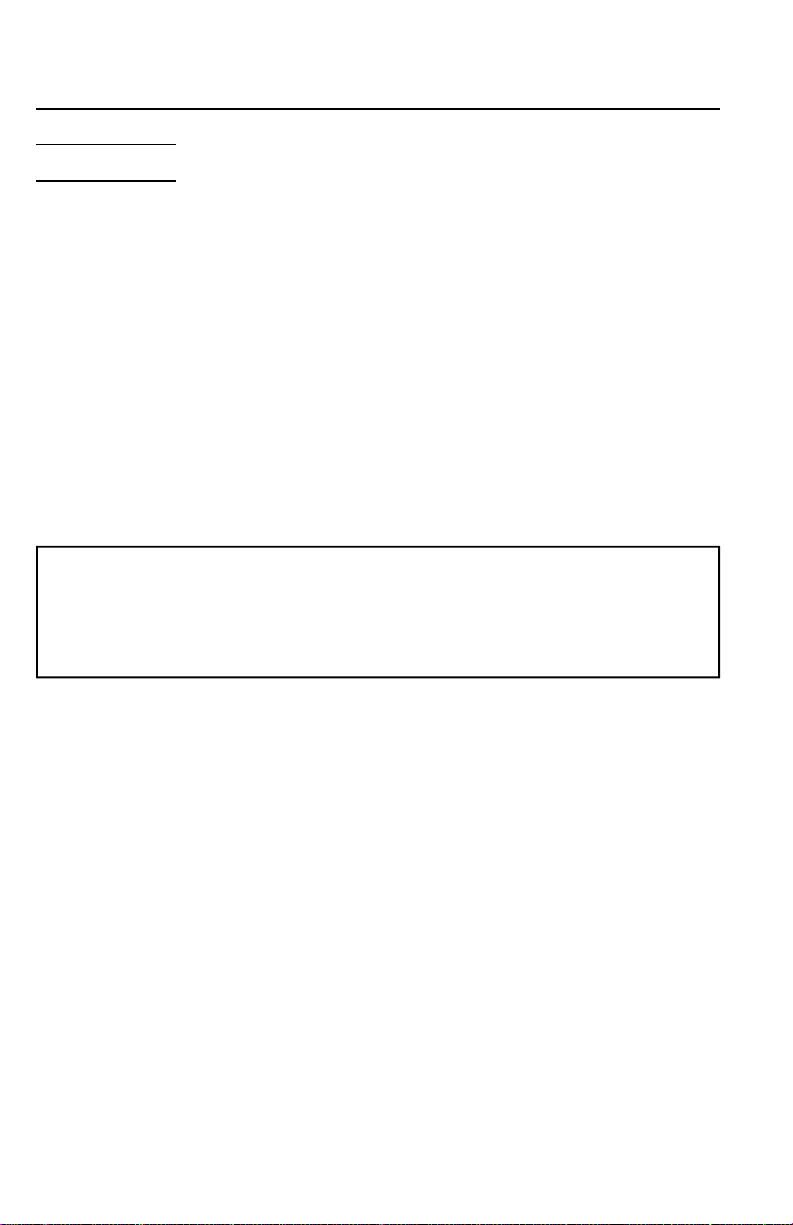

General Information

Parts Identification

PPS 28/E Heat Wave

Power Source

Heat Wave

Heater Unit

6

Page 9

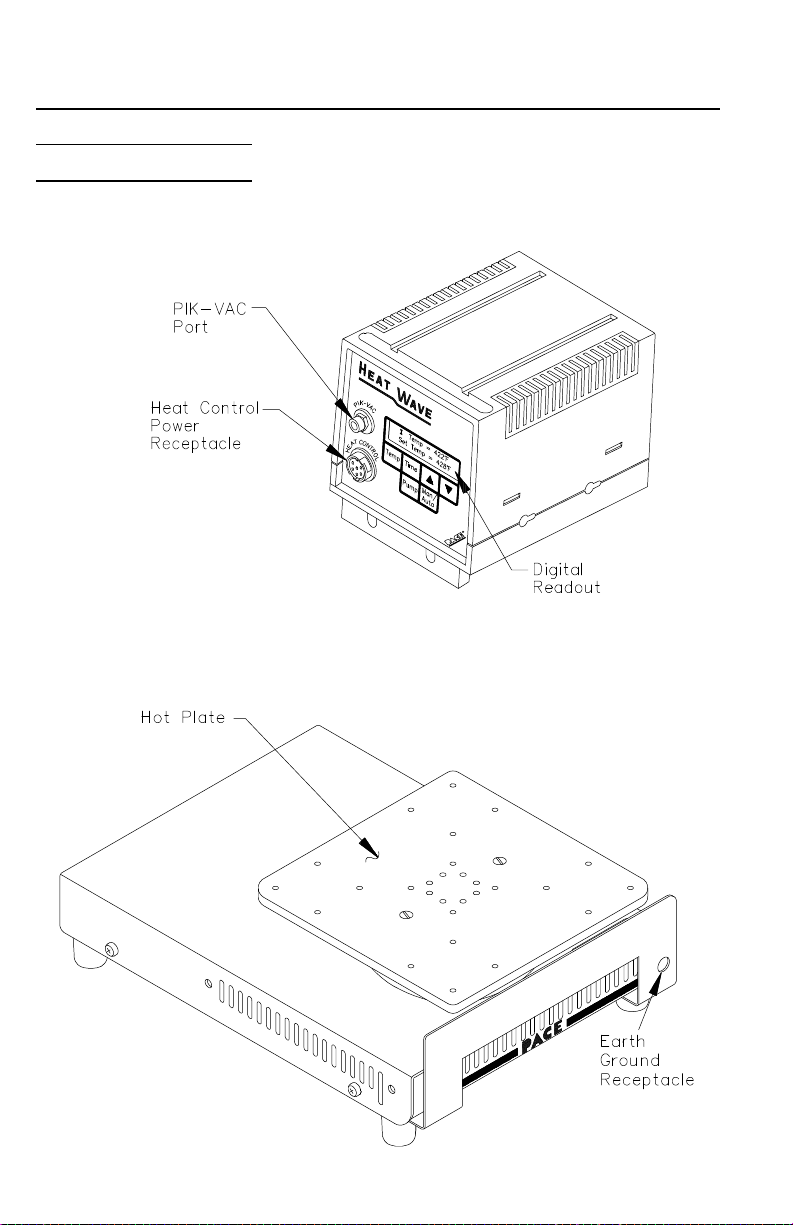

PPS 28/E Heat Wave

Power Source

General Information

Heat Wave

Heater Unit

(shown without

Heat Shield)

7

Page 10

Safety

The following are safety precautions which personnel must understand and follow

when using or servicing this product.

1. To prevent personnel injury, adhere to safety guidelines in accordance

with OSHA and other applicable safety standards.

2. Ensure that the Heat Shield is installed before the system is powered up.

Installation of the Heat Shield will help prevent accidental touching of

the Hot Plate. Severe burns may result if this shield is not installed.

3. The Hot Plate is hot when the system is powered on. Also, the Hot Plate

is hot for a period of time after the power is turned off. A "Warming UP"

message when the system is powered on or a "Cooling Down" message if

the Auto Scheduler powers the system down, may be displayed on the

Digital Readout alerting personnel that the Hot Plate is hot. Always treat

the Hot Plate as being hot. DO NOT touch the Hot Plate or areas

adjacent to the Hot Plate of the Heat Wave heater unit. Severe burns may

result.

4. Always use the system in the manner described in this manual. Use in

applications other than preheating can produce unacceptable results and

may cause damage to the system.

5. The PPS 28 Heat Wave power source is designed to power the Heat Wave

heater unit only.

6. Always use this system in a well ventilated area. A fume extraction

system such as those available from PACE are highly recommended to

help protect personnel from fumes.

7. The system should be used in a stable position on a work bench. Ensure

that the area below and immediately adjacent to the Hot Plate Heater Unit

is clear of flammable objects.

8. Exercise proper precautions when using materials (e.g., fluxes & solder

paste). Refer to the Material Safety Data Sheet (MSDS) supplied with

each material and follow all safety precautions recommended by the

manufacturer.

9. POTENTIAL SHOCK HAZARD - Repair procedures on this product

should be performed by Qualified Service Personnel only. Line voltage

parts will be exposed when the equipment is disassembled. Service

personnel must avoid contact with these parts when troubleshooting the

system.

8

Page 11

Set-Up

System

Set up the HS 200 Heat Wave system using the following steps and associated

drawings.

1. Store the shipping container(s) in a convenient location. These containers

can be reused to prevent damage if you store or ship the system.

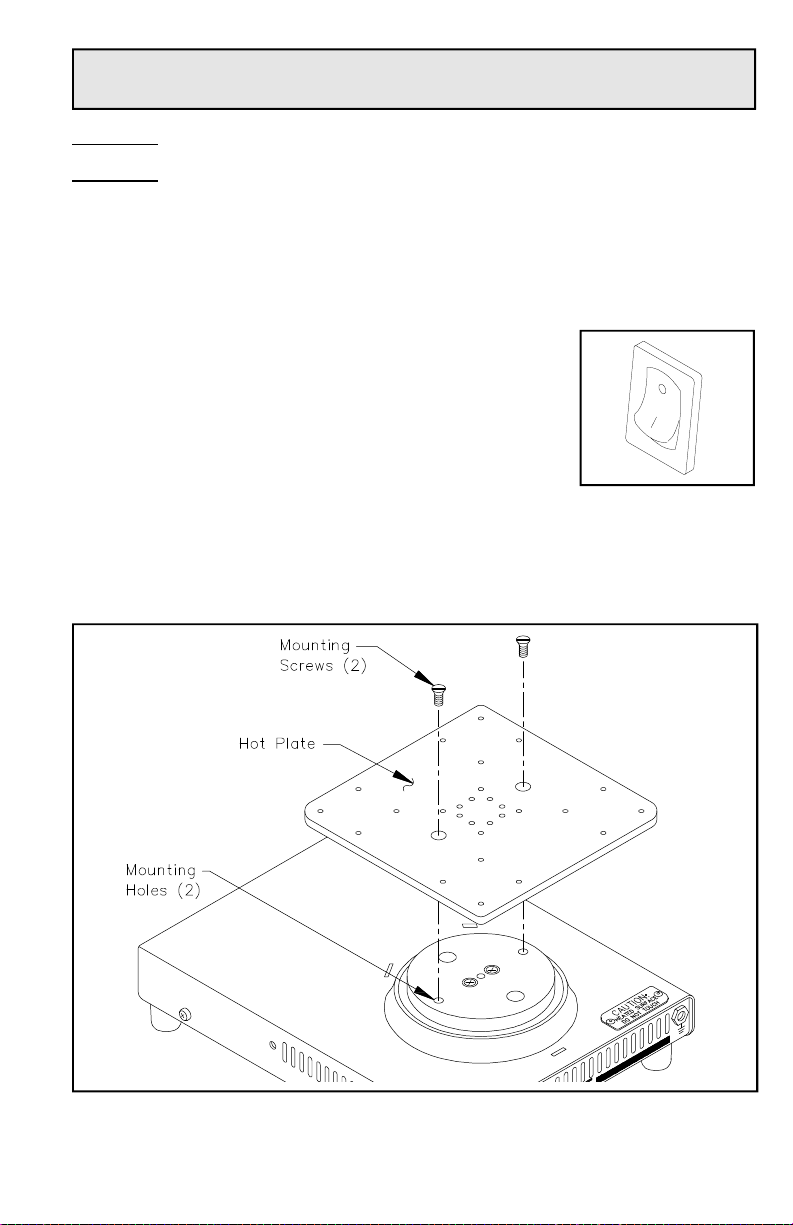

2. Place the Power Switch (on rear of Heat Wave power

source) in the “OFF” or “0” position.

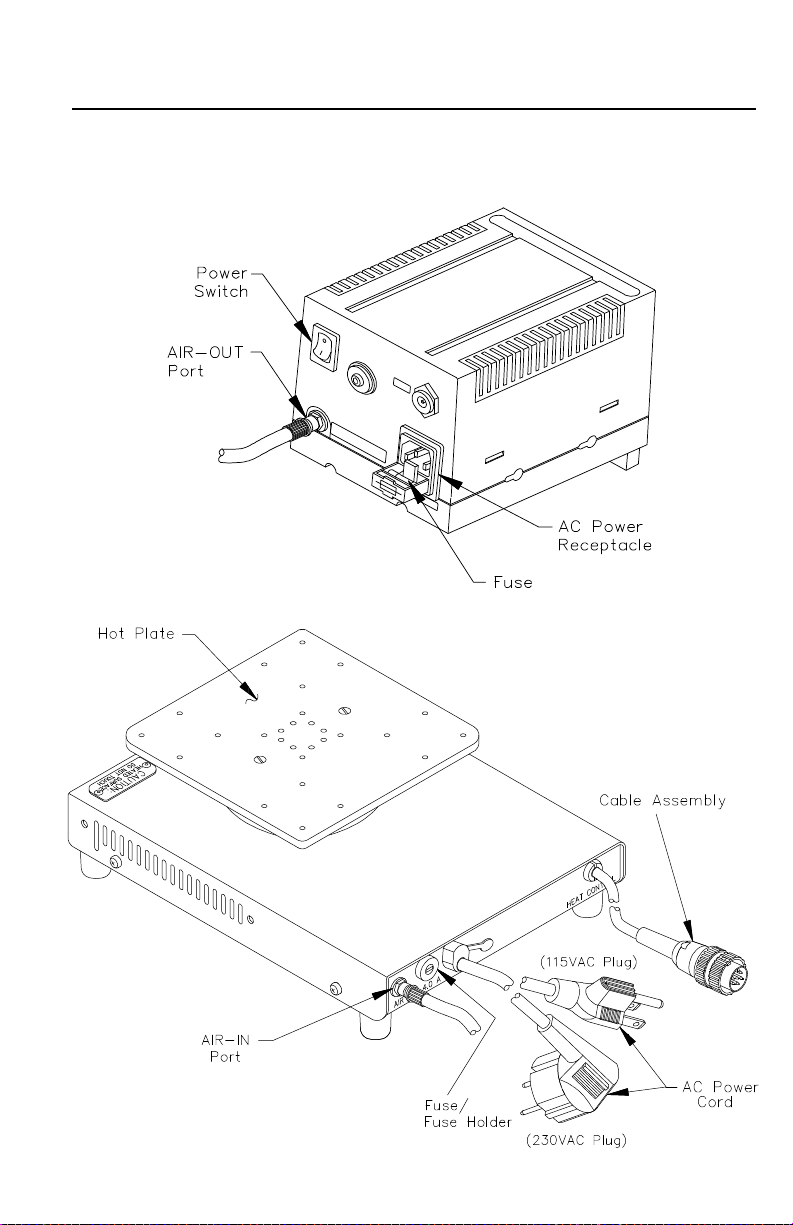

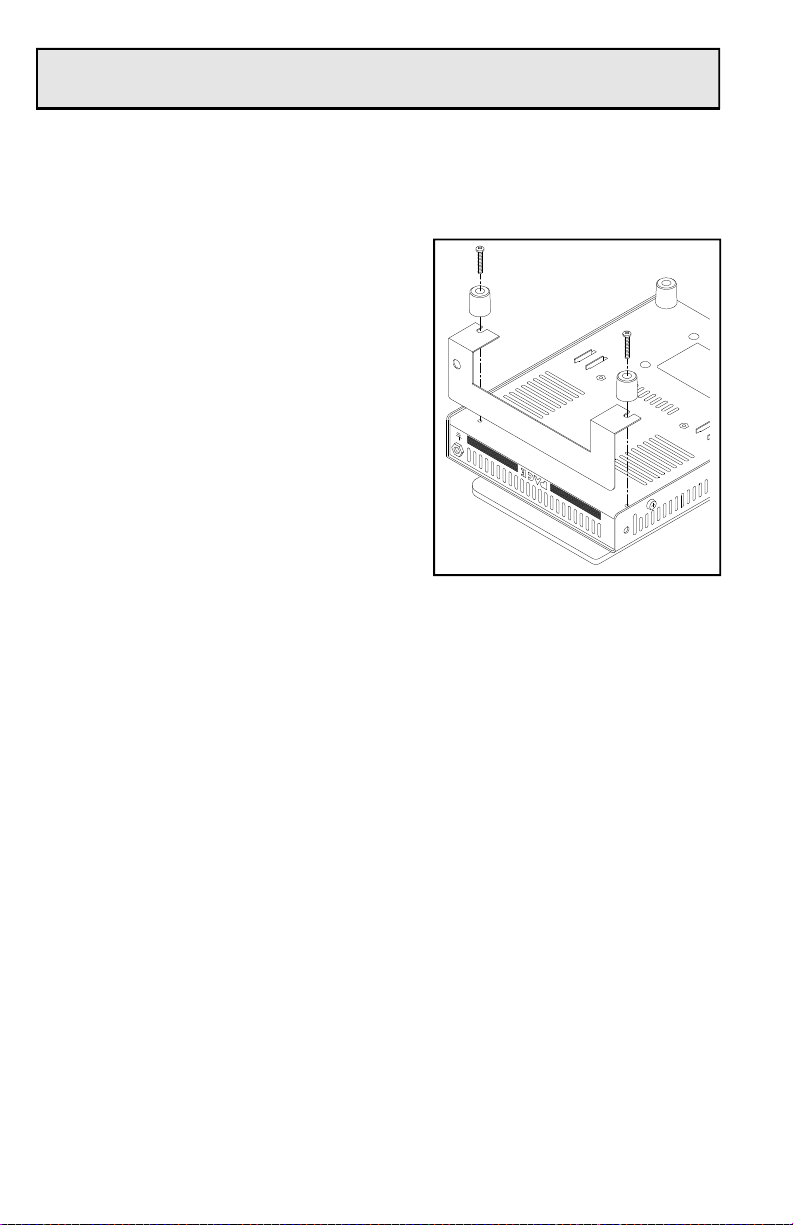

Hot Plate Installation

3. Place the Hot Plate in position on the Heat Wave heater unit with its 2

mounting holes in alignment with the 2 threaded Mounting Holes on the

heater assembly. Attach the Hot Plate to the heater assembly using the 2

enclosed Mounting Screws. Refer to illustration below.

4. Place the PPS 28 Heat Wave power source in position adjacent to the

heater unit.

9

Page 12

Set-Up

Heat Shield Installation

5. Install the Heat Shield onto the Heater Unit in the following manner:

a) Ensure that the Heater Unit is at

room temperature.

b) Place Heater Unit upside down (Hot

Plate down) on a suitable work

surface Position unit with the Earth

Ground Receptacle facing you.

c) Remove the 2 Mounting Scews

shown that secure the Rubber Feet to

the bottom, front of the Heater Unit.

DO NOT remove screws that secure

the remaining 2 Rubber Feet.

d) Place the Heat Shield in position as

shown between the 2 Rubber Feet

and the Heater Unit chassis.

e) Install the 2 Mounting Screws removed in step 5c to secure the

Rubber Feet and Heat Shield to the Heater Unit chassis.

Board Holder Mounting

The HS 200 Heat Wave system is supplied with a standard Board Holder which will

accomodate PCB sizes up to 20.3cm x 20.3cm (8" x 8"). An optional Board Holder

(part number 7900-0045) is available which accomodates PCB sizes up 45.7cm x

45.7cm (18" x 18").

6. If the optional Board Holder has been purchased, mount the holder to the

Heater Unit using the instructions included with the holder.

7. If you wish to use the standard Board Holder included with your system,

perform the following procedure. Use the illustrations as a guide.

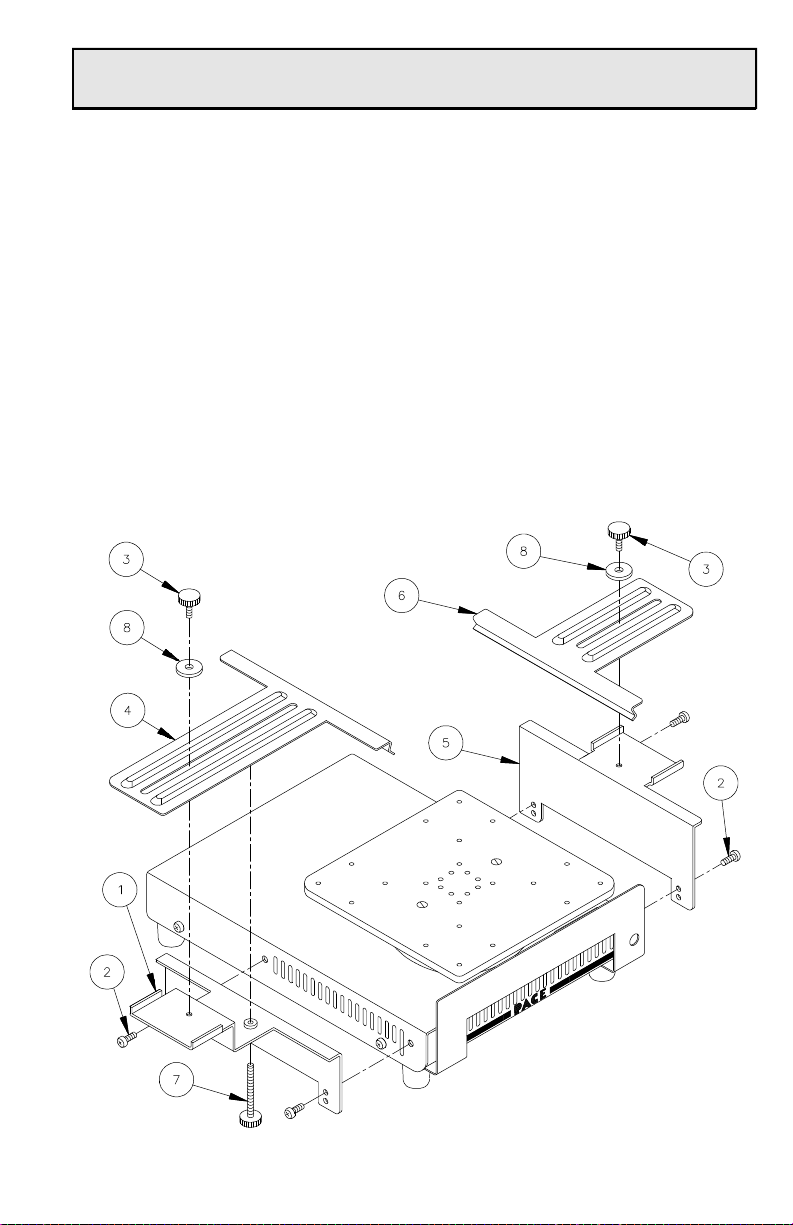

a) Position the heater unit as shown.

b) Mount large bracket (item ➀) to the side of the heater unit using 2

mounting screws (item ➁).

10

Page 13

c) Place long holding clamp (item ➃) in position on bracket (item ➀).

Secure clamp in position using locking screw (item ➂) and flat

washer (item ➇).

d) Install leveling screw (item ➆). Adjust leveling screw until its end

just touches the bottom of the long holding clamp (item ➃).

e) Mount small bracket (item ➄) to the side of the heater unit using 2

mounting screws (item ➁).

f) Place short holding clamp (item ➅) in position on bracket (item ➄).

Secure clamp in position using locking screw (item ③) with flat

washer (item ➇).

Board Holder Assembly Parts Locator

Set-Up

11

Page 14

Set-Up

Assembled

Board Holder

Board Holder Assembly

With PCB Installed

PCB

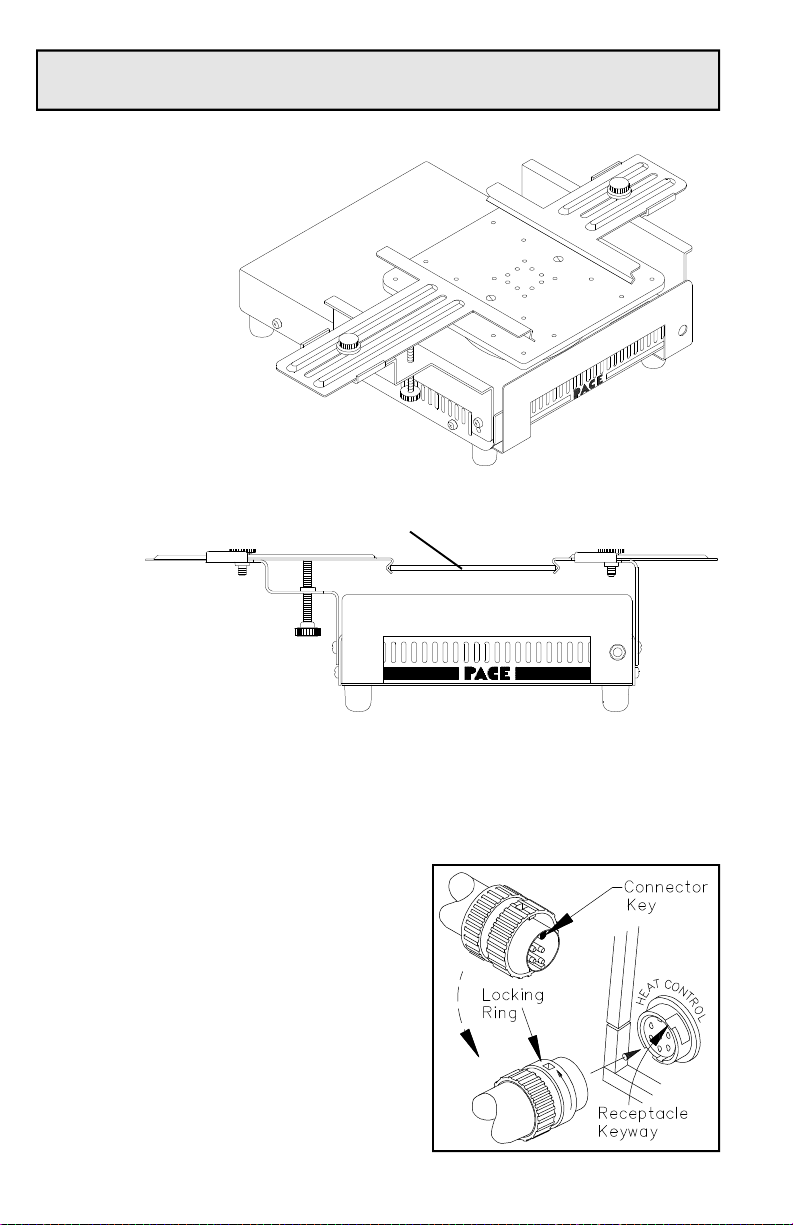

Heater Unit/Power Source Connection

8. Connect the Heater Unit Cable Assembly connector plug to the HEAT

CONTROL Power Receptacle in the following manner:

a) With the Connector Key end facing

the power source, turn the Locking

Ring fully counterclockwise.

b) Align the Connector Key with the

Receptacle Keyway.

c) Insert the connector into the HEAT

CONTROL Power Receptacle.

d) Turn the Locking Ring fully

clockwise to secure in place.

12

Page 15

Set-Up

Air Hose Connection

Two air hoses (and fittings) are included with the system. One air hose provides air

pressure for convective preheating from the Heat Wave power source to the Heater

Unit. The second air hose provides vacuum to the Pik-Vac wand for component

handling.

9. Prepare 2 Air Hose assemblies by

installing a male quick disconnect hose

mount Fitting to each end of the supplied

air hoses. Insert the ribbed end of the

Fitting into the Air Hoses.

10. Connect one air hose assembly between the power source AIR OUT Port

and the AIR IN Port on the rear panel of the Heater Unit (see drawing on

page 7).

11. Connect the remaining air hose assembly between the PIK-VAC Port of

the power source and the PIK-VAC handpiece.

System Power Up

12. Insert the female end of the loose power cord into the AC Receptacle of

the Heat Wave power source.

13. Plug the prong ends of both the Heat Wave power source and the Heater

Unit into a 3 wire grounded AC supply receptacle. The system is now

ready for operation.

CAUTION

To insure operator safety, the AC supply receptacle must be checked for

proper grounding before initial operation.

14. Read the “Quick Start Procedure” section of this manual thoroughly

before operating the system.

13

Page 16

Preheat Guidelines

Introduction

The Heat Wave system provides process control to meet your specific requirements.

Follow these steps and use the following tables as a guideline to set the process

parameters for your particular applications:

1. Determine your basic board type:

a. Simple, Double Sided Board

b. SMT/Thru-Hole Board with approximately 6 or fewer internal layers

c. High Mass Board with approximately 7 or more internal layers

2. Determine your desired preheat temperature. The tables provide data for

commonly used preheat temperatures of 80 °C (176 °F), 100 °C (212 °F)

and 120 °C (248 °F).

3. To preheat quickly (yet always slower than 3 °C per second), see Table 1.

4. To preheat (always slower than 3 °C per second) and soak the board area

prior to reflow, see Table 2. Using this method:

a) the internal pump delivers hot air for quick ramp preheating.

b) when the pump stops, the radiant convection of the hot plate provides

a controlled soak at the desired preheat temperature.

NOTE

Thermal characteristics of every board assembly will be different. The

following tables provide a base starting point for the development of the

exact preheating parameters for your rework process.

When developing processes for removal/replacement of components, PACE

recommends the use of embedded thermocouples on the test board to

ensure optimum results.

14

Page 17

Preheat Guidelines

The following graph depicts a typical preheat and soak profile for a circuit board.

Setting the parameters in Table 1 will maximize the temperature ramp rate (3°C per

second or slower). Rework can then be performed immediately when the pump

turns off. The radiant heat from the hot plate will continue to slowly increase the

temperature of the workpiece.

Use the parameters in Table 2 to achieve a true ramp and soak temperature profile as

shown below. In this case, the radiant heat stabilizes the workpiece at the desired

preheat temperature.

15

Page 18

Preheat Guidelines

Safe, Rapid Preheating

To preheat quickly at safe ramp rates, set the following temperature and pump runtime parameters for the appropriate board type. These settings will quickly preheat

the repair area over the center of the Heat Wave plate to the desired temperature (yet

always slower than 3 °C per second). The entire board area over the Heat Wave plate

will also be preheated, but at a slightly slower rate.

This method allows the operator to quickly perform any necessary rework tasks. The

temperature on the board may continue to rise (at a slower rate) even after the pump

turns off.

Heat Wave

Desired

Preheat Temp.

Simple, Double Sided Board

Set

Temperature Pump Run-time

16

80°C

(176°F)

100°C

(212°F)

120°C

(248°F)

SMT/Thru-Hole Boards With Up To 6 Internal Layers

80°C

(176°F)

100°C

(212°F)

120°C

(248°F)

High Mass Board With 7 Or More Internal Layers

80°C

(176°F)

100°C

(212°F)

120°C

371°C

(700°F)

371°C

(700°F)

371°C

(700°F)

371°C

(700°F)

371°C

(700°F)

371°C

(700°F)

371°C

(700°F)

371°C

(700°F)

371°C

Table 1. Rapid Preheat Guidelines

28 seconds

36 seconds

54 seconds

44 seconds

64 seconds

112 seconds

56 seconds

114 seconds

190 seconds

Page 19

Preheat Guidelines

Preheat & Soak

The Heat Wave can be used to preheat and soak a circuit board before reflow takes

place. This helps to bake out the laminate and to equalize temperatures across the

repair area.

To preheat at a safe ramp rate, followed by a soak time (repair area of board

remaining within ±10 °C of desired preheat temperature), set the following

temperature and pump run-time parameters for the appropriate board type.

This method provides quick ramp preheating. When the pump stops, the radiant

convection of the hot plate provides a controlled soak at the desired preheat

temperature. This prevents the board from heating more than 10°C over the desired

temperature.

Heat Wave

Desired

Preheat Temp.

Simple, Double Sided Board

80°C

(176°F)

100°C

(212°F)

120°C

(248°F)

SMT/Thru-Hole Boards With Up To 6 Internal Layers

80°C

(176°F)

100°C

(212°F)

120°C

(248°F)

High Mass Board With 7 Or More Internal Layers

80°C

(176°F)

100°C

(212°F)

120°C

Set

Temperature Pump Run-time

250°C

(482°F)

300°C

(572°F)

320°C

(608°F)

250°C

(482°F)

300°C

(572°F)

340°C

(644°F)

250°C

(482°F)

300°C

(572°F)

360°C

50 seconds

56 seconds

72 seconds

114 seconds

130 seconds

180 seconds

208 seconds

212 seconds

Table 2. Preheat & Soak Guidelines

17

Page 20

Quick Start Procedure

The following procedure assumes that the Heater Unit Hot Plate is at room

temperature and the power source is in the Manual Mode with no installed Password

(as received from factory). If not, displayed messages may be different.

1. Set-Up - Ensure that the Set-Up procedure has been performed. Check the

following:

a) Heater Unit connection to the Heat Wave power source.

b) Power cord connections (2) between the house AC supply and both

the Heater Unit & power source.

c) Ensure that the system is properly mounted (on standard Board

Holder or on large Board Holder).

2. Air Hose Connection - If you wish to use the Convective (forced air)

method of preheating, connect the Air Hose Assembly between the power

source AIR OUT Port and the Heater Unit AIR IN Port (see illustrations

on page 21).

3. Apply Power - Turn the Power Switch (on power source) to the “ON”

(“1”) position. The Digital Readout will display "Heat Wave" and then a

Version number for 2 seconds each. Then, a "Warming Up" message

(with a countdown time) or "System is OFF" message will be displayed.

4. Adjust Temperature - Press and release the TEMP Key. Press and

release the Scroll UP (▲) Key to increase or the Scroll Down (▼) Key to

decrease the desired temperature. Press and release the TEMP Key. The

Digital Readout will now display the "Warming Up" and time out

message. When the system times out, the Digital Readout will display

the actual Hot Plate temperature. Allow time for the temperature to

stabilize at the set temperature.

5. Install PCB for Repair - Place the PCB to be repaired in the Board

Holder. Position PCB repair area directly over the center of the Hot

Plate. When repairing large PCBs, you may wish to install the optional

PCB Supports supplied in kit P/N 6993-0197-P1.

6. Actuate Motor Pump - Optional Step - Press and release Pump Key to

apply convective flow of hot air to PCB repair area. Press and hold the

Pump Key for 2 seconds, then release to allow adjustment of the pump

run time.

IMPORTANT

PACE recommends that you not read the “Set-Up Mode” section until after

you feel comfortable with manual operation of the system. Please read the

“Operation” section thoroughly before changing any system settings.

18

Page 21

Operation

Introduction

The HS 200 Heat Wave system is very easy to operate. As received from the

factory, the system can be quickly set up for use in standard preheating operations.

Simply perform the Quick Start Procedure (page 14) to begin system operation.

For operations requiring user defined controls, use this portion of the manual.

Definitions

Auto Mode - Mode in which the system will turn on and off for periods of

operation as determined by the user-defined Auto Schedule settings in system

memory.

Auto Off - Safety feature which turns power off after 12 hours of continuous use in

the Manual Mode. This feature is enabled or disabled in the Set-Up Mode.

Auto Schedule - Feature which enables the operator (when in Set-Up Mode) to

program the system to turn on for a specific time period when in the Auto Mode.

The operator can select enable or disable for any day(s) of the week .

Conductive Preheating - Preheating a board (PCB) by transferring heat directly

from the hot plate to the board.

Convective Preheating - Preheating a board (PCB) by transferring heat using

forced air through the hot plate and onto the board. With convective preheating

there is no direct contact between the hot plate and the board.

Manual Mode - Mode in which the system is turned on and off as determined

by the operator.

Operating Temperature - The true temperature at which the hot plate operates

at any given time. This temperature is displayed on the Digital Readout (“Temp

= XXX”) in normal operation (Temperature Display Mode).

Password - Feature which, when enabled, will prevent unauthorized alteration

of stored system parameters and feature settings.

Set Temperature - The operator selected idle hot plate temperature (“Set Temp

= XXX”) entered into the system memory.

Set-Up Mode - Mode of operation in which the operator can quickly and easily

adjust the system parameters (e.g., temperature limits, password, auto schedule).

Temperature Display Mode (normal operation) - Normal operating mode of

the system in which the actual hot plate temperature is displayed.

Time Protected - System requires that the Password stored in system memory

be entered before the current time setting can be altered.

Time Unprotected - Current time setting can be changed without Password entry.

19

Page 22

Operation

Overview

The following is a brief summary of basic system operational functions.

1. Temp Key - Press and release to set a desired Hot Plate temperature using

the Scroll keys to adjust. Also used in Set-Up Mode.

2. Time Key - Press and release to display time of day and to select time

(hours or minutes) for change.

3. Scroll Up (▲) Key - Press and release to increase Set Temperature, Time

or Day of Week settings.

4. Scroll Down (▼) Key - Press and release to decrease Set Temperature

and time settings.

5. Pump Key - Press and release to turn pump on or off for Convective

Heating operations and for component handling operations using the PikVac handpiece. Pump run time is adjustable from 10 seconds minimum

to 1 hour maximum or for continuous operation. As received from the

factory, the pump will run continuously when the key is pressed.

6. Man/Auto Key - Toggles system between Auto and Manual Modes.

7. Digital Readout - Provides a 2 line LCD display of system information.

The Digital Readout will display:

a) ”Heat Wave” for 2 seconds on initial power up.

b) The software version of the Heat Wave power source for 2 seconds.

c) A “Warming Up” or a “Cooling Down” message plus the Set

Temperature and estimated time (in minutes and seconds) to reach Set

Temperature.

d) An “On” & "Off" time message for 5 seconds and then "Set

Schedule" if the system is in Auto Mode with no Set Schedule.

e) Temperature in °C or °F (programmable in Set-Up Mode).

f) The Operating Temperature when it stabilizes. The system is now in

Temperature Display Mode (normal operation).

20

Page 23

Operation

g) An hour glass graphic to indicate that the 12 hour timer is active and

the system will automatically power down if used for 12 continuous

hours of manual operation.

h) A variety of text messages to denote system status (e.g., “Open Sensor

Check Heater” if the Heater Unit Cable Assembly is not connected to

power source).

8. AIR OUT Port - Connect the air hose assembly between this port and the

AIR IN Port of the Heater Unit to supply forced air when utilizing

Convective Heating. Pump must be turned on when preheating in this

manner.

9. AIR-IN Port - See AIR OUT Port above.

10. PIK-VAC Port - Connect the air hose assembly between this port and the

Pik-Vac handpiece. Used to pick and place components.

21

Page 24

Operation

Factory Settings

The HS 200 Heat Wave system comes equipped with a number of features which

may be adjusted, enabled or disabled as desired by the user. Listed below are the

features and factory settings of each. To change and/or learn about any of these

features, refer to the applicable part of the "Operation" or "Set-Up Mode" portions of

this manual.

FEATURE FACTORY SETTING

Password No Stored Password

Hot Plate Size 140mm (5.5 inch) square

Temperature Scale (°C/°F) °F

"Lo" (lower) Temperature Limit 38°C (100°F)

"Hi" (upper) Temperature Limit 371°C (700°F)

Clock Format 12 Hour

Auto Scheduler

Auto Off Disabled

Pump Run Time Continuous Operation

Time To Auto Off (manual mode, continuous

operation)

Time Protection Disabled

Set Temperature (of Hot Plate) "OFF"

All Days & Times

Disabled

12 Hours, Not Adjustable

Table 3. Factory Settings

22

Page 25

Operation

Password

The Password feature of the HS 200 Heat Wave system, when activated, will prevent

unauthorized alteration of stored system parameters and feature settings. If a

Password has been installed, the Digital Readout will display an instruction to enter

a Password (a 4 key sequence of the keys on the front panel of the power source)

when a setting change is attempted or when entering the Set-Up mode.

Entry of the correct Password at this point will allow the operator to proceed with

the desired changes. The Password protection will be reactivated if the system is

turned off and then back on. Refer to the “Set-Up Mode” section of this manual for

instructions on entering, changing or removing a Password.

23

Page 26

Operation

Board Set-Up

A PC Board can be may be placed or clamped in position on the Heater Unit

utilizing the standard or optional Board Holder accessory. When working with large

PCBs, you may wish to install the PCB Supports supplied in kit part number 69930197-P1.

Standard Board Holder Mounting

(see pages 10-11 for details)

Optional Board Holder Mounting

(See instructions with Optional Board Holder for details)

24

PCB Support

(See instructions with PCB Support Kit for details)

Page 27

Operation

The following instructions assume that the Heater Unit Hot Plate is at room

temperature and the power source is in the Manual Mode with no installed Password.

If not, displayed messages may be different.

Power Up

1. Turn the Power Switch ON (“1”).

Panel Controls

2. The Digital Readout will now display “Heat Wave” for 2 seconds and

then the microprocessor revision for 2 seconds.

NOTE

If the HEAT CONTROL Power Receptacle does not have the Cable Assembly

connector plug (from Hot Plate) attached, “Open Sensor Check Heater” will be

displayed on the Digital Readout.

3. The system has 2 modes of operation: Manual and Auto. The system will

power up to the same mode as when power was last turned off. The

display on the Digital Readout is determined by the following:

a) With the system in the Manual Mode, or in Auto Mode with a set

schedule, a “Warming Up ... Set Temp” message will be displayed.

Allow time for the Hot Plate to reach the Set Temperature.

NOTE

The system is shipped from the factory to enter Manual Mode and will

display a "System is OFF" message on initial power up. A “Set Schedule”

message will be displayed if in Auto Mode & the Auto Schedule is disabled.

To enable the Auto Schedule, refer to the Set-Up Mode section of this

manual.

b) An “OFF” or “ON” time or a "Warming ... Set Temp" message will be

displayed if the system is in the Auto Mode and a schedule has been

stored in system memory.

c) If the system is in the Auto Mode but no schedule is enabled, the

current time and a “Set Schedule” message will be displayed. No

power is being applied to the Hot Plate.

25

Page 28

Operation

Manual Mode

4. If the system is displaying an “ON”, “OFF” or "Set Schedule" message

(Auto Mode), press the Man/Auto Key to change to Manual Mode.

NOTE

If a "System is OFF" message is displayed, press and release the Temp Key

& use Scroll keys to adjust desired Hot Plate temperature. Press and release

the Temp Key or wait 5 seconds; turn Power Switch OFF ("0") then back ON

("1"). The "Warming Up" message will now be displayed.

5. Notice in the upper right corner of the

“Warming Up” display is a timer clock.

This clock is displaying the estimated

time remaining to reach Set Temperature

in minutes and seconds. The bottom

line displays the Set Temperature.

6. When the temperature of the Hot Plate

nears the Set Temperature, the actual

temperature will be displayed. The

displayed temperature will increase to a

point higher than the Set Temperature.

This is NORMAL. Observe the Digital

Readout as the displayed temperature

decreases and settles in at the Set

Temperature.

26

Page 29

Operation

7. The system will now maintain the Set Temperature unless one of the

following occurs:

a) If the Auto Off feature is enabled, the system will turn off after 12

hours of continuous operation.

b) If the Set Temperature is lowered, the temperature will decrease to the

new setting.

c) If the system Power Switch is turned off.

Auto Mode

In the Auto Mode, the system will turn On and Off at predetermined times entered in

the Set-Up Mode. The Auto Schedule portion of the Set-Up Mode routine allows the

operator to set a time for system power up and power down. This selected time

period is then enabled or disabled for each individual day of the week. For example,

a power on time period of 8 am to 5 pm can be enabled for Monday through Friday

but the system will remain off (disabled) Saturday and Sunday.

8. Press and release the Man/Auto Key.

The system is now in the Auto Mode. A

time "On = ... Off = ..." message will be

displayed for 5 seconds.

9. The Digital Readout will now display

the actual temperature (Temperature

Display Mode) plus one of the

following:

a) The time the system will turn off (if

in a scheduled On period).

b) The time the system will turn On (if

in a scheduled Off period) if any day

has been enabled.

c) If all days are disabled, a "Set

Schedule" message will be displayed.

27

Page 30

Operation

Adjusting Set Temperature

10. Press and release the Temp Key. The

Set Temperature is now displayed on the

Digital Readout. If no other Key is

pressed within 5 seconds, the system

will revert to the Temperature Display

Mode (normal operation). Allow time

for the system to change back.

11. Press and release the Temp Key, then, immediately press and hold the

Scroll Up (s) Key. Observe the display as the Set Temperature increases

first in increments of 1° and then in increments of 10°. Release the key.

12. Press and hold the Scroll Down (t) key. Observe the display as the Set

Temperature decreases first in increments of 1° and then in increments of

10°. Release the key; press and release the Temp Key (or wait 5 seconds).

NOTE

The Set Temperature can only be within the set temperature limits. If a limit

(upper or lower) is reached, the lower limit would display “Off”; the upper limit

would not allow the Set Temperature to exceed that limit. Temperature limits

can be adjusted in the Set-Up Mode.

28

Page 31

Operation

Adjusting Time/Day of Week

13. Press and release the Time Key. If the

system is Time Protected, the Digital

Readout will display a request to enter the

Password before altering the time setting;

enter the Password. The current time will

now be displayed along with a bottom

line display. If no other Key is pressed

within 5 seconds, the system will revert to

the Temperature Display Mode (normal

operation). Allow time for the system to

change back.

NOTE

The time will be displayed in either a 12 hour or 24 hour format as determined

in the Set-Up Mode. Also, throughout the Time setting process (steps 14-

19), a 5 second timeout between any key actuations will cause the system

to revert to Temperature Display Mode (Normal Operation).

14. Press and release the Time Key twice; the hour portion of the time will

start to flash.

15. Use the Scroll Up (s) and Scroll Down (t) Keys to change the hour.

Ensure that the displayed hour is correct before continuing.

16. Press and release the Time Key again. The tens digit of the minutes

display will begin to flash. Use the Scroll Up (s) and Scroll Down (t)

Keys to change the minutes display in increments of 10. Ensure that the

displayed minutes is correct before continuing.

17. Press and release the Time Key again. The single (ones) digit of the

minutes display will begin to flash. Use the Scroll Up (s) and Scroll

Down (t) Keys to change the minutes display in increments of 1.

Ensure that the displayed time is correct before continuing.

29

Page 32

Operation

18. Press and release the Temp Key. The day of the week is now displayed.

Immediately press and release the Scroll Up (s) Key several times and

watch as the day changes. Ensure that the displayed day is correct before

continuing.

19. Press and release the Temp Key again or allow the system to time out

(after 5 seconds) and revert to normal operation.

NOTE

Any changes to the time or day of the week are stored in system memory

when exiting the Set-Up Mode and the system changes back to Normal

Operation (Temperature Display Mode).

Pump Operation

20. The power source has an integral motor pump which provides forced air

for Convective Heating and vacuum for component handling operations.

NOTE

The motor pump is not designed for other operations such as solder

extraction. DO NOT use the motor pump for any applications other than

those described in this manual.

To activate the pump, press and release

the Pump Key. Press and release the

key again to terminate pump operation.

30

Page 33

Operation

The Pump run time is adjustable from 10 seconds minimum to 1 hour maximum or

for continuous operation. As received from the factory, the pump will run

continuously when the key is pressed.

21. Press and hold the Pump Key for 2

seconds. The digital Readout will now

display current Pump run time as

"Cont." (Continuous) or in hours,

minutes, and seconds.

22. Press and release the Time Key.

23. Press and release the Scroll Down (t) and Scroll Up (s) Keys several

times. Notice the Pump run time change from Continuous to 1 (hour) to

0 hours. When 0 hours is displayed the minimum time displayed will be

10 seconds.

24. If the Pump run time is "Cont.", press and release the Scroll Down (t)

Key.

25. Press and release the Time Key several times. Notice the display

changes with each press and release of the Key. The hour digit will flash,

then the minutes times 10 digit, then the minutes digit, then the seconds

times 10 digit, then the seconds digit. When the digit is flashing, that

time segment is subject to change by use of the Scroll Keys (s & t).

26. Adjust the Pump run time to 1 minute (as an example) using the Time

Key plus the Scroll Up and Scroll Down Keys.

27. Press and release the Temp Key to return to normal operation.

28. Press and release the Pump Key. The

Pump is now activated. Observe the

displayed Pump run time as the timer

counts down to 0. Upon reaching zero,

the pump will turn off. Also, the pump

will turn off immediately if the Pump

Key is pressed a second time when the

pump is operating.

29. Adjust the Pump run time to the time desired for your application using

steps 21 thru 28 as a guide.

31

Page 34

Operation

Pik-Vac Operation

1. Connect the Pik-Vac air hose assembly between the

PIK-VAC Port and the back of the Pik-Vac

handpiece.

2. Install the metal tip and desired Vacuum Cup onto

the end of the handpiece.

3. Turn the Power Switch (on rear of power source)

ON (“1”).

4. Press and release the Pump Key to activate vacuum flow.

NOTE

The Pump run time should be set for continuous operation when using the

Pik-Vac handpiece.

5. Grasp the handpiece as you would a pencil with the Vacuum Cup

pointing down and the Vacuum Control Port pointing up.

6. Place the Vacuum Cup gently on the top surface of the component body.

Caution must be taken to avoid bending of leads on fine pitch devices.

7. Place one finger over the Vacuum Control Port. Vacuum is now being

applied to the component body.

8. Gently lift the component from its position.

32

Page 35

Set-Up Mode

9. Lower the component in position (illustration depicts placement of

component on land pattern).

10. Slide the finger from the Vacuum Control Port to release the component.

11. Press and release the Pump Key to stop vacuum flow.

Introduction

The menu driven Digital Readout of the HS 200 Heat Wave system in the Set-Up Mode

allows you to easily customize your system. In most cases, the operator is directed as to

which key(s) to press in order to proceed. In cases where specific instructions are not

displayed, simply press and release the Temp Key to proceed to the next step.

No calibration steps are necessary to maintain the accuracy of the system.

In Set-Up Mode, you can:

1. Enter, remove, or change a Password.

2. Select Hot Plate standard size or enter temperature offset constant for

custom size in use on Heater Unit.

3. Set the Default Temperature scale to °C or °F as desired.

4. Change the Upper and Lower Temperature limits of the Hot Plate.

5. Select a 12 hour or 24 hour time clock.

6. Program Auto Schedule for power on/off period and enable or disable for

each day of the week.

7. Enable or disable the Auto Off feature.

33

Page 36

Set-Up Mode

Operation

Entering Set-Up Mode

1. Place the Heat Wave Power Switch in the OFF (“0”) position.

2. Press and hold the Temp and Scroll

Down (▼) Keys together.

3. Place the Power Switch in the ON

(“1”) position. The Digital Readout

will display “HeatWave”, change to

read “Version XXXX” and the

change again to read “Password

Needed?”

4. Release the Temp and Scroll Down

(▼) Keys. The system is now in the

Set-Up Mode. “Enter Password"

will be displayed if a Password is

currently stored in system memory.

34

Page 37

Set-Up Mode

Password

5. If a Password has been previously stored in system memory, enter the 4

key sequence Password; an asterisk (✶) will be added to the display as

each key is actuated.

NOTE

If an incorrect Password sequence is entered, the system will immediately

revert to normal operation.

6. At this point the Digital Readout will ask you:

a) If you would like to retain the “Same” Password (if previously stored)

in the system. If you do, press the Temp Key (directly beneath

“Same”).

b) If you do not wish to have a Password stored in the system, press the

Time Key (directly beneath “No”). Any previously stored Password

will be removed from the system.

c) If you wish to enter a new Password, press the Scroll Up (▲) Key

(directly beneath “Yes”). The Digital Readout will now display

“Enter New Password”. Enter a new 4 key sequence Password. As

each key is pressed, an asterisk (✶) will be displayed. Once the fourth

key is pressed, a “Time Protected” or “Time Unprotected” message

will be displayed if the system has a Password stored in memory.

Time Protection

7. If a “Time Protected” or “Time

Unprotected” message is displayed

(Password stored in system memory), the

Scroll Up (▲) Key can be pressed to toggle

between the two messages. If you wish to

require the operator to enter the stored

Password before altering the time setting in

normal operation, the “Time Protected”

message should be displayed. Press and

release the Temp Key to continue.

The message displayed in this illustration,

indicates that the system clock can not be

changed without entering the password.

35

Page 38

Set-Up Mode

Hot Plate Temperature Offset

8. A “Select Plate” message will be

displayed. The standard Hot Plate size is

140mm (5.5”) square; this is the default

size. The system has a permanently

stored temperature offset constant which

automatically compensates for

temperature losses between the

temperature sensor and the Hot Plate.

This ensures that the plate temperature

matches the set temperature. If your

system has a different Hot Plate, actuate

the Scroll Down (t) Key. Then, use the

scroll keys to adjust the temperature

offset for your Hot Plate.

NOTE

The Digital Readout will display the standard Hot Plate size as 140mm if

temperature is being displayed in °C or as 5.5" when temperature is

displayed in °F.

Temperature Limits

9. Press and release the Temp Key. The

Digital Readout will now display

whether temperature will be shown in

°C or °F. Press and release the Scroll Up

(s) Key to change.

10. Press and release the Temp Key. The

Low (“Lo”) Temperature Limit setting is

now displayed. Use the Scroll keys to

adjust.

36

Page 39

11. Press and release the Temp Key. The

High (“Hi”) Temperature Limit setting is

now displayed. Use the Scroll keys to

adjust.

Time Display

12. Press and release the Temp Key. The

Time Mode setting is now displayed.

With a “12Hr” setting, the displayed

time will be the same as on a digital

clock (with AM and PM suffixes). A

“24Hr” setting will display 24 hour

(military) time. Use the Scroll Up (s)

Key to change the displayed time mode.

Set-Up Mode

Auto Schedule

13. Press and release the Temp Key. The

displayed message will now ask if you

wish to change the Auto Schedule. If

you wish to change settings, press and

release the Temp Key. If you do not

wish to change Auto Schedule, press and

release the Time Key; proceed directly

to step 18.

37

Page 40

Set-Up Mode

14. The stored turn on time is now

displayed. Find the horizontal line

beneath a digit of the displayed time.

Use the Time Key to change the selected

digit & the Scroll Keys to change the

value of the selected digit.

15. Press and release the Temp Key. The

stored turn off time is now displayed.

Find the horizontal line beneath a digit

of the displayed time. Use the Time

Key to change the selected digit & the

Scroll Keys to change the value of the

selected digit.

16. Press and release the Temp Key. A day

of the week message is displayed with

“is Disabled” or “is Enabled”. Press and

release the Scroll Up (s) Key to change.

If “is Enabled” is displayed, the on and

off schedule will activate the system on

that day for the specified time period

when the system is used in the Auto

Mode.

17. Press and release the Temp Key. The next day of the week will be now

be displayed. Perform steps 16 & 17 until all 7 days have been set.

38

Page 41

Auto Off

18. An Auto Off message will now be

displayed with “Disabled” or “Enabled”.

If “is Enabled” is displayed, the system

when in the Manual Mode of operation,

will remove power from the system if it

is operated for 12 continuous hours. An

hour glass graphic will also be displayed

in the upper left corner of the digital

readout (in normal operation) to indicate

that the 12 hour timer is active.

19. Press and release the Temp Key. An

“Exit Setup?” message will now be

displayed. Press and Release the Temp

Key to exit or press and release the Time

Key to restart the Set-Up Mode

sequence.

Set-Up Mode

20. When the Temp Key is actuated to exit setup, the system will revert to

normal operation and in the mode (Manual or Auto) in which the system

was last used. Any setting changes are now stored in system memory.

39

Page 42

Corrective Maintenance

Use the following Checkout Procedures (Table 4) to determine the source of a

malfunction.

Symptom

No Digital Readout;

no motor pump on

Heat Wave Power

Source. No heat to

Hot Plate.

No heat to Hot Plate.

Digital Readout on

power source

functions normally.

No heat to Hot Plate.

Digital Readout on

power source

displays "Open

Sensor Check

Heater".

No Ground

Probable

Cause

Power Switch

in "0" (Off)

position.

Blown Fuse in

power source.

Blown Fuse in

Heater Unit.

Open Heater. Contact the PACE

Heater Unit

Cable

Assembly not

connected to

Heat Wave

power source.

Open Heater

Sensor.

Oxidation on

Checkout

Procedure Solution

Check for blown

fuse in AC

Receptacle of Heat

Wave power

source.

Check Fuse in Fuse

Holder on rear of

Heater Unit.

Service Department.

Check connection

to HEAT CONTROL

Power Receptacle.

Contact the PACE

Service Department.

Check resistance -

Turn Power

Switch to "1"

(On) position.

Replace fuse

in AC

Receptacle

and recheck

system.

Replace Fuse

and recheck

system.

Replace

Heater

Assembly in

Heater Unit.

Connect Cable

Assembly

connector

plug to Heat

Wave power

source.

Replace

Heater

Assembly in

Heater Unit.

Clean Heater

Table 4. HS 200 Checkout Procedures

40

Page 43

Spare Parts

Listed below are the HS 200 system spare parts which may be ordered through your

local authorized PACE distributor. To obtain any HS 200 parts other than those

listed below, contact the PACE Service Department at Tel. #1-888-535-7223 (tollfree), Fax #(301) 483-7030.

Ite

# Description

1 Hot Plate, 140mm (5.5 inch) inches square 1335-0177

2 Detachable Power Cord for 115VAC systems 1332-0094

Detachable Power Cord for 230VAC systems 1332-0093

3 Pik-Vac Handpiece 7027-0001-P

4 Vacuum Cup Kit 6993-0154

5 PACE Screwdriver 1100-0230

6 Large Board Holder Kit (optional accessory) 7900-0045

7 PCB Support Kit 6993-0197

Part

Number

Table 5. Spare Parts

CAUTION

POTENTIAL SHOCK HAZARD - Disassembly of power source or heater

unit exposes line voltage parts. Replacement of heater unit power cord or

any internal parts must be performed by qualified service personnel only.

Contact the PACE Service Department for assistance.

41

Page 44

MANUAL IMPROVEMENT & COMMENT FORM

Instructions

1.

Duplicate this form and submit comments on the copy. Keep the original to make

future comments.

2.

Complete all requested information.

3.

Submit completed form to:

PACE Incorporated

Applications Engineering Fax: (301) 604-8782

9893 Brewers Court

Laurel, MD 20723-1990 U.S.A.

Document #

Nature of Change (Identify page and paragraph and include proposed rewrite, if

possible.)

Reason for Recommendation

5050-0406 Rev. C

Date of Submission:

Name of Submitter: Company or Organization:

Mailing Address: Telephone: ( )

Voice:

Fax:

e-Mail:

Thank you for your comments; they are greatly appreciated!

42

Loading...

Loading...