Page 1

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-4 of this booklet and to

strictly adhere to the advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize

yourself with the controls and other features of

the engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the aircraft, radio control equipment, etc.,

are accessible for checking at the same time.

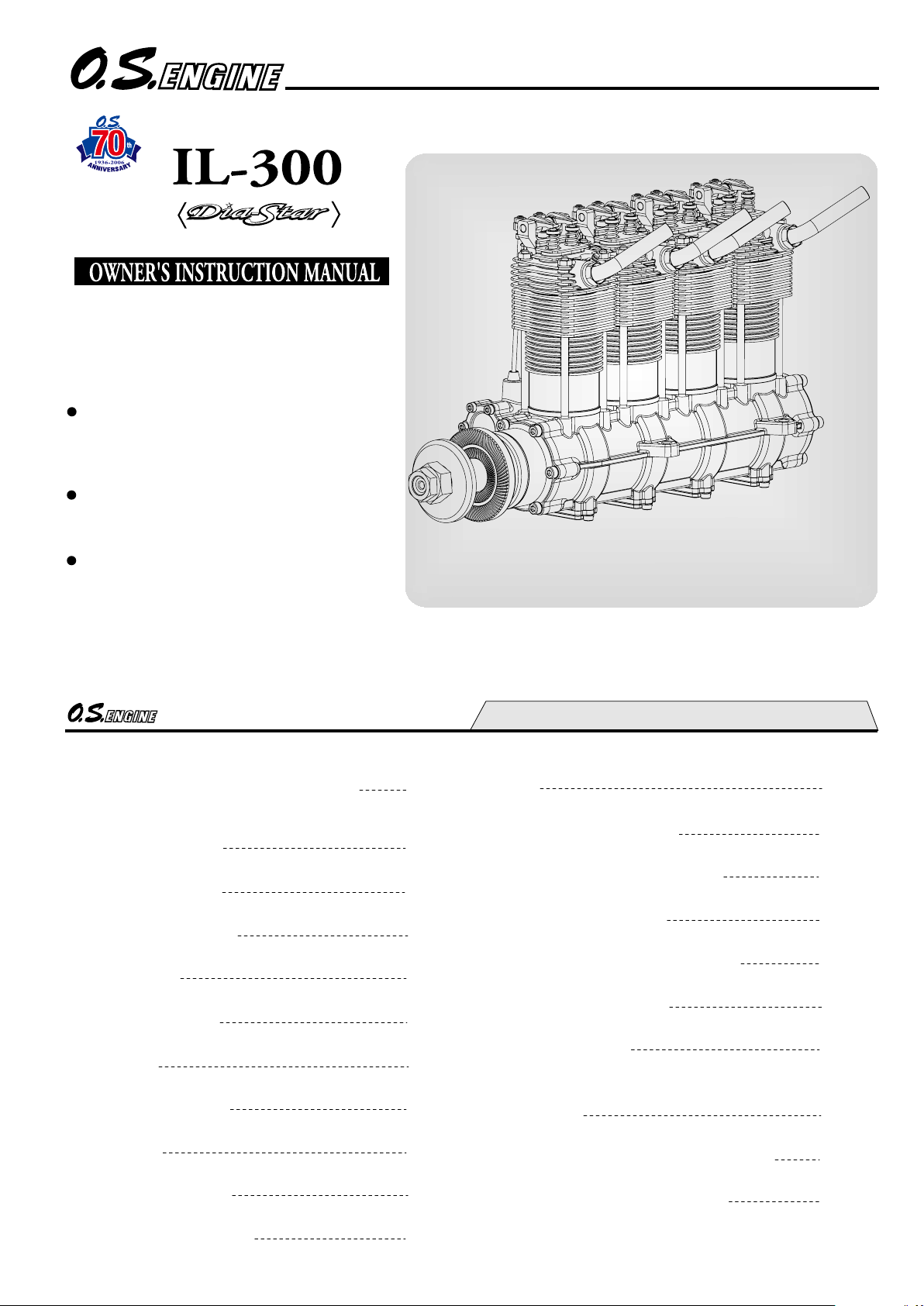

Inline four-cylinder overhead-valve

four-stroke-cycle engine

1

SAFETY INSTRUCTIONS AND

WARNINGS ABOUT YOUR O.S. ENGINE

NOTES WHEN APPLYING AN

ELECTRIC STARTER

ABOUT THE ENGINE

ENGINE PARTS NAME

INSTALLATION

FUEL TANK & LINES

GLOWPLUG

MIXTURE CONTROLS

PROPELLER

GLOWPLUG HEATING

FUEL AND LUBRICATION

CONTENTS

STARTING

RUNNING-IN ("Breaking-in")

THROTTLE VALVE ADJUSTMENT

FLIGHT & MAINTENANCE

VALVE CLEARANCE ADJUSTMENT

ENGINE EXPLODED VIEW

ENGINE PARTS LIST

CARBURETOR EXPLODED VIEW

& PARTS LIST

O.S. GENUINE PARTS & ACCESSORIES

ENGINE THREE VIEW DRAWINGS

2-4

5

6

7-8

9-10

11

12

13

14-15

16-17

18

19-22

23

24-26

27

28-29

30

31

32

33

34

Page 2

2

Remember that your engine is not a " toy ", but a highly

efficient internal-combustion machine whose power is

capable of harming you, or others, if it is misused or

abused. As owner, you, alone, are responsible for the safe

operation of your engine, so act with discretion and care at

all times.

If at some future date, your O.S. engine is acquired by

another person, we would respectfully request that these

instructions are also passed on to its new owner.

WARNINGS

These cover events which might involve serious ( in

extreme circumstances, even fatal ) injury.

NOTES

These cover the many other possibilities, generally less

obvious sources of danger, but which, under certain

circumstances, may also cause damage or injury.

SAFETY INSTRUCTIONS AND

WARNINGS ABOUT YOUR

O.S. ENGINE

The advice which follows is grouped under two

headings according to the degree of damage or danger

which might arise through misuse or neglect.

WARNINGS

Never touch, or allow any object to come into

contact with, the rotating propeller and do not

crouch over the engine when it is running.

A weakened or loose propeller may disintegrate or be thrown

off and, since propeller tip speeds with powerful engines may

exceed 600 feet(180 metres) per second, it will be understood

that such a failure could result in serious injury, (see 'NOTES'

section relating to propeller safety).

Model engine fuel is poisonous. Do not allow it to

come into contact with the eyes or mouth. Always

store it in a clearly marked container and out of

the reach of children.

Model engine fuel is also highly flammable. Keep it

away from an open flame, excessive heat, sources

of sparks, or anything else which might ignite it.

Do not smoke or allow anyone else to smoke, near

to it.

Never operate your engine in an enclosed space. Model

engines, like automobile engines, exhaust deadly carbonmonoxide. Run your engine only in an open area.

Model engines generate considerable heat. Do

not touch any part of your engine until it has

coole d. Contact with the mu ffler(silencer),

cylinder head or exhaust header pipe, in

particular, may result in a serious burn.

3

NOTES

This engine was designed for model aircraft. Do not attempt to use it for any other purpose.

Mount the engine in your model securely, following the manufacturers' recommendations, using appropriate

screws and locknuts.

If you remove the glowplug from the engine and check its condition by connecting the battery leads to it, do not hold

the plug with bare fingers.Use an appropriate tool or a folded piece of cloth.

Install a top-quality propeller of the diameter and pitch specified for the engine and aircraft. Locate the propeller on

the shaft so that the curved face of the blades faces forward-i.e. in the direction of flight. Firmly tighten the propeller

nut, using the correct size wrench.

Always check the tightness of the propeller nut and retighten it, if necessary, before restarting the engine,

particularly in the case of four-stroke-cycle engines. If a safety locknut assembly is provided with your engine,

always use it. This will prevent the propeller from flying off in the event of a "backfire", even if it loosens. Also,

check the tightness of all the screws and nuts before restarting the engine.

If you install a spinner, make sure that it is a precision made product and that the slots for the propeller blades

do not cut into the blade roots and weaken them.

Discard any propeller which has become split, cracked, nicked or otherwise rendered unsafe. Never attempt to

repair such a propeller: destroy it. Do not modify a propeller in any way, unless you are highly experienced in tuning

propellers for specialized competition work such as pylon-racing.

Use an electric starter for this engine. The wearing of safety glasses is also strongly recommended.

Page 3

4

Take care that the glow plug clip or battery leads do not come into contact with the propeller.

Also check the linkage to the throttle arm. A disconnected linkage could also foul the propeller.

After starting the engine, carry out any needle-valve readjustments from a safe position behind the rotating

propeller. Stop the engine before attempting to make other adjustments to the carburetor.

Adjust the throttle linkage so that the engine stops when the throttle stick and trim lever on the transmitter are fully

retarded. Alternatively, the engine may be stopped by cutting off the fuel supply. Never try to stop the engine

physically.

Take care that loose clothing (ties, shirt sleeves, scarves, etc.) do not come into contact with the propeller.

Do not carry loose objects (such as pencils, screwdrivers, etc.) in a shirt pocket from where they could fall through

the propeller arc.

Do not start your engine in an area containing loose gravel or sand. The propeller may throw such material in your

face and eyes and cause injury.

For their safety, keep all onlookers (especially small children) well back (at least 20 feet or 6 meters) when preparing

your model for flight. If you have to carry the model to the take-off point with the engine running, be especially

cautious. Keep the propeller pointed away from you and walk well clear of spectators.

Warning! Immediately after a glowplug-ignition engine has been run and is still warm, conditions sometimes exist

whereby it is just possible for the engine to abruptly restart if the propeller is casually flipped over compression

WITHOUT the glowplug battery being reconnected. Remember this if you wish to avoid the risk of a painfully rapped

knuckle!

NOTES

5

NOTES WHEN APPLYING

AN ELECTRIC STARTER

Do not over-prime. This could

cause a hydraulic lock and

damage the engine on application

of the electric starter.

If over-primed, remove glowplug,

close needle-valve and apply

starter to pump out surplus fuel.

Cover the head with a rag to

prevent pumped out fuel from

getting into your eyes.

Page 4

6

The O.S. IL-300 (Dia-Star) is a four-cylinder inline

overhead-valve four-stroke-cycle engine of 50cc

displacement. The engine maintains the same

features of stress free starting, super smooth idling

and high torque power which is always the hallmark

of O.S. large size multi-cylinder engines. With it’s

finely detailed design and outstanding scale

appearance, the engine’s quality is second to none.

ABOUT THE ENGINE

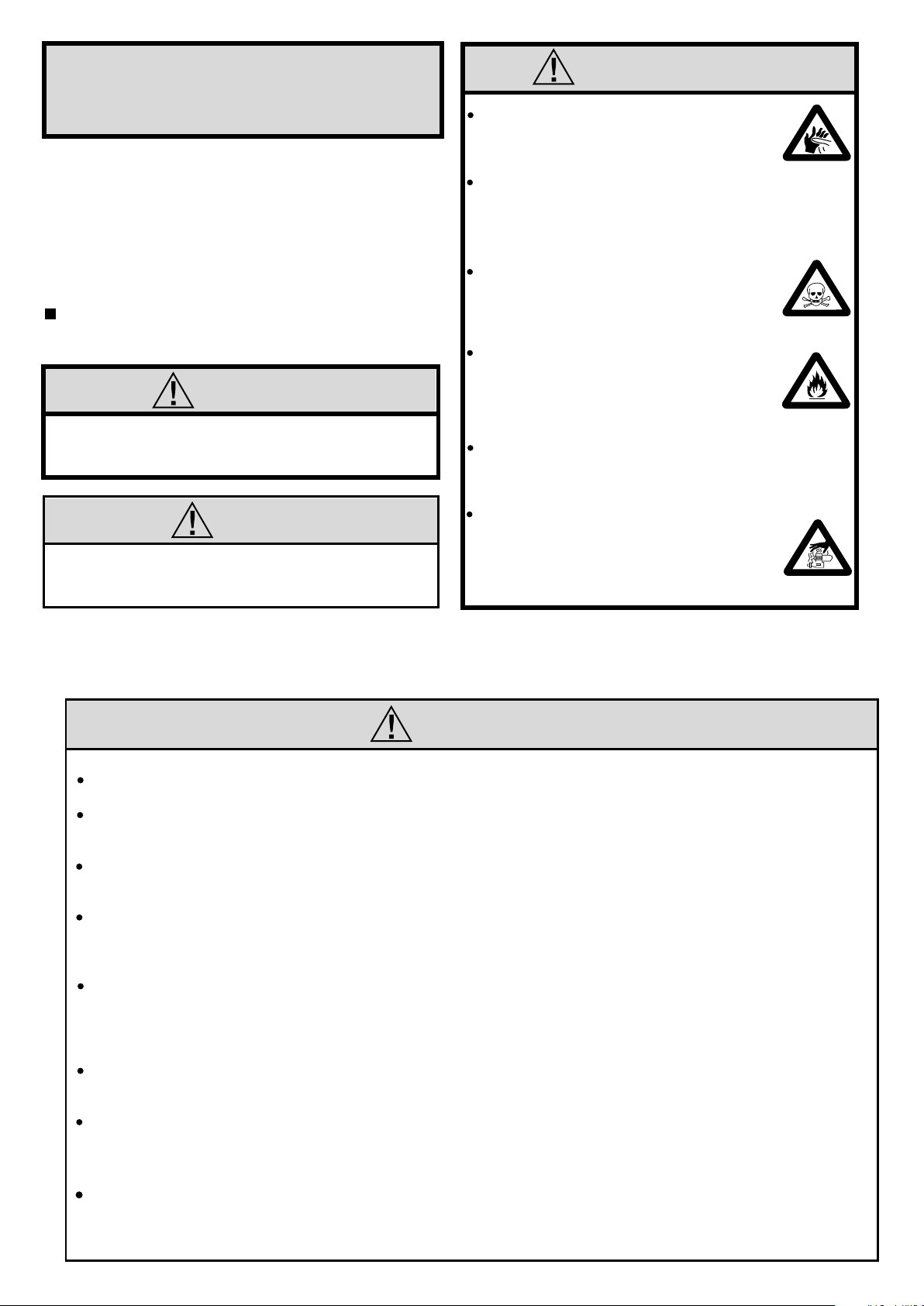

STANDARD ACCESSORIES

Glow Plug Type F

(installed on the engine)

Valve adjusting tool kit

(4pcs.)

Exhaust Pipe Assembly

Exhaust Pipe

Exhaust Pipe Lock Nut

Exhaust Gasket

Feeler gauge 0.04mm

Feeler gauge 0.1mm

Hex. key 1.5mm

Wrench 5mm

Booster Cable Set

Leads for glow plug with clip

Lead for earth (ground)

(4pcs.)

(1pc.)

Radial Motor Mount Set

Mount attachment Screws

Engine mounting screws (M5X25)

Lock washers (ø5)

Blind nuts (M5)

(4pcs.)

(4pcs.)

(4pcs.)

(4pcs.)

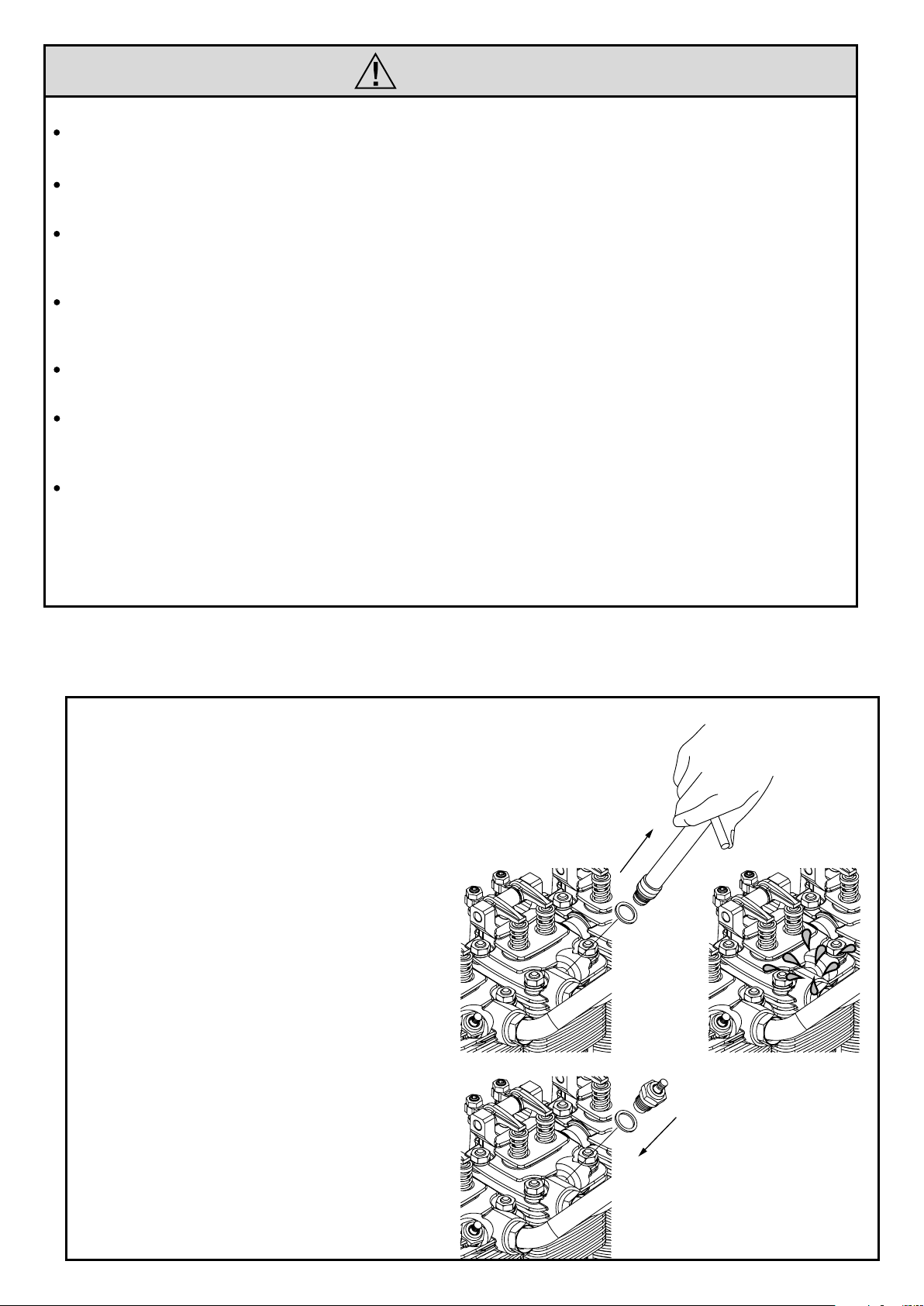

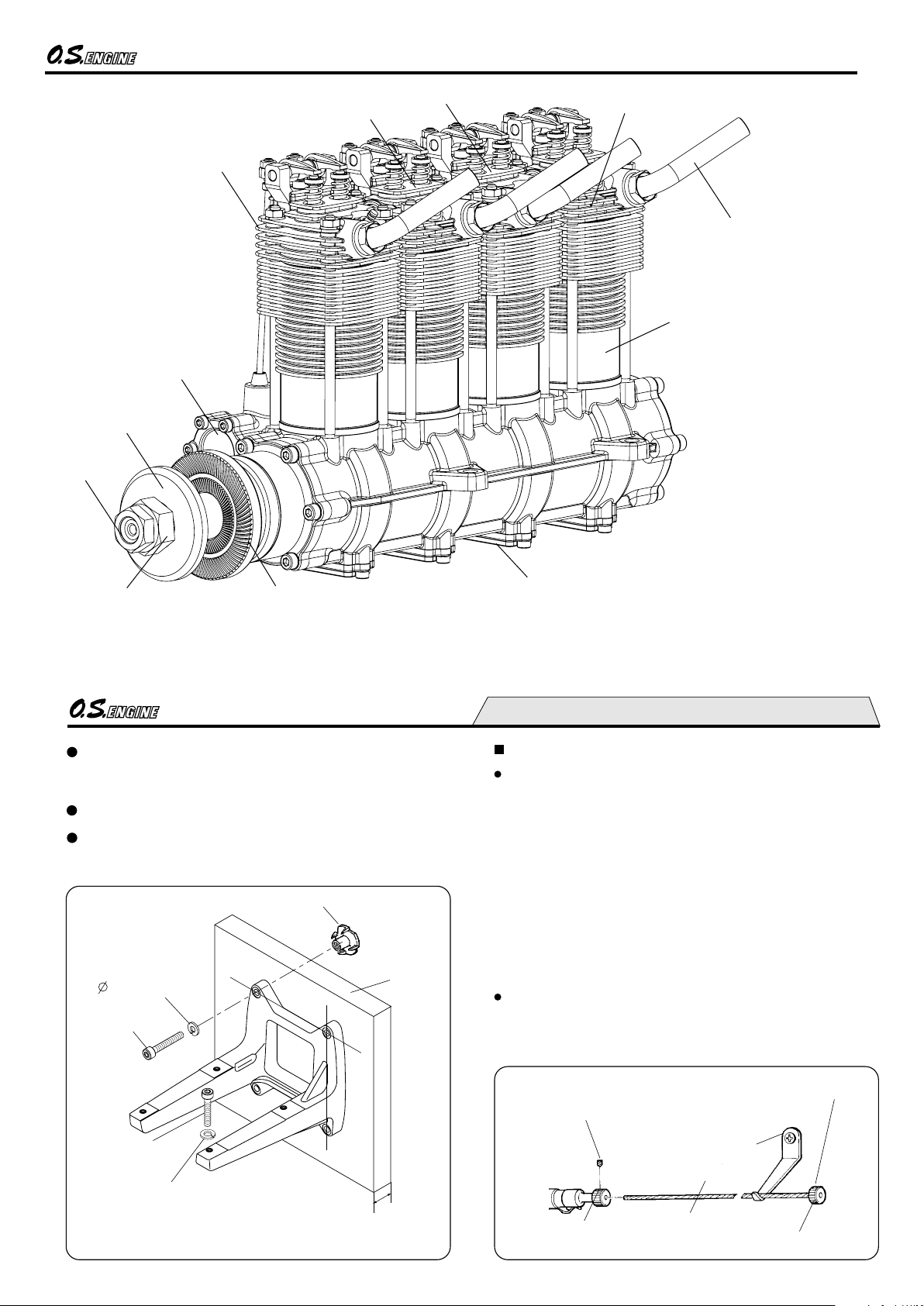

7

ENGINE PARTS NAME

Crankcase

Rear Housing

Carburetor Type 80P

Intake Manifold

Gear Cover

Center Manifold

Carburetor Extention Pipe

Push Rod

Page 5

8

Lock Nut

Propeller Washer

Propeller Nut

Cylinder Jacket

Front Housing

Exhaust Pipe

Cylinder Head 1

Drive Hub

Crankcase Under Cover

Cylinder Head 2

Cylinder Head 3

Cylinder Head 4

9

Needle-valve extension

The needle-valve with this engine is designed to incorporate

an extension so that, when the engine is enclosed within the

fuselage, the needle-valve may be adjusted from the

outside. An L-shaped rod, of 1.6-1.8mm dia. and

appropriate length, should be inserted into the needle's

center hole and secured by tightening the set-screw in the

needle-valve knob with a small Allen key. If a longer

extension cable is required it is suggested that one be

fabricated as per the illustration.

NOTE:

O.S. does not offer the extension cable as an accessory

item.

Do not use an excessively long unsupported extension as

this may vibrate and cause the needle-valve setting to vary

or even damage the needle-valve thread. Always provide a

suitable support at the outer end.

It is essential that the firewall is strong and rigid (e.g. at

least 15mm thick) and firmly integrated with the structure of

the aircraft.

INSTALLATION

M5 Blind nut

Firewall

M5x25 screw

5 Lock washer

At least 15mm (0.6")

rigid hard wood

It is suggested to install the engine upright.

M5x15 screw

Lock washer

Set-screw

Set-screw

Hook

Knob

Cable

Needle

It is suggested to use Lock Washers (available as an

optional extra) with engine installing screws or apply

LOCTITE to the screws to prevent them from loosening.

Page 6

10

Exhaust pipe adjustment

The direction of the exhaust pipes may be altered in

accordance with individual installation requirements. The

angle is easily adjusted by loosening the nut that secures

the exhaust pipe to the cylinder head. Use a 12mm

wrench.

12mm wrench

Loosen

Tighten

Lock nut

Exhaust pipe

Carburetor cleanliness

It is recommended that the fuel is passed through a filter

when the tank is filled and that a good in-line filter is

installed between the fuel tank and carburetor.

Occasionally remove the needle-valve holder from the

carburetor and rinse out the locations shown below with

methanol or fuel. Be careful not to lose the gasket when

removing the needle-valve holder from the carburetor.

Squeeze bottle

Dirt and fibrous matter

mostly accumulate here.

Dirt and fibrous matter

mostly accumulate here.

Needle-valve holder

11

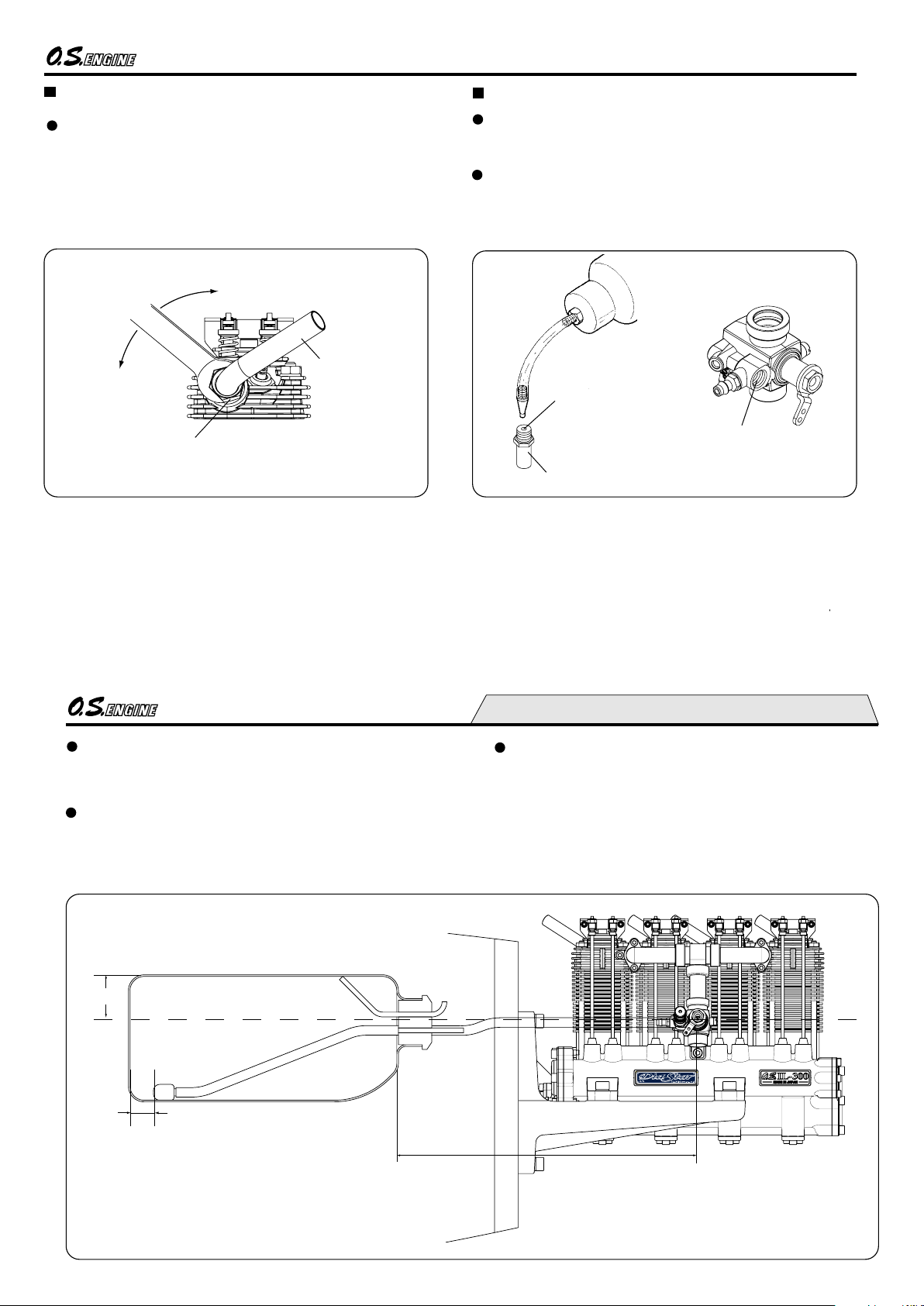

FUEL TANK & LINES

Make sure that the tank is well rinsed out with methanol or

glow fuel before installation and that the pickup weight is

well clear of the bottom of the tank when held vertically.

Locate the fuel tank as close as possible

to the carburetor, or the fuel level

difference will affect the engine running

when the model is upright or inverted.

Set the fuel tank position so that the

carburetor center line is 1/3 lower than

from the tank top when the model is

placed horizontal.

Approx. 15mm

1/3

Be sure to follow the instructions concerning the

relationship between fuel tank and carburetor position, or

the expected stable idle running will not be obtained even

with adequate carburetor adjustment.

For plumbing, use heavy duty silicone tube of 2.5mm inner

dia and 5mm outer dia.

Page 7

12

GLOWPLUG

The role of the glowplug

Glowplug life

Particularly in the case of very high performance engines,

glowplugs must be regarded as expendable items. However,

plug life can be extended and engine performance maintained

by careful use, i.e.:

Install a plug suitable for the engine.

Use fuel containing a moderate percentage of

nitromethane.

Do not run the engine too lean and do not leave the

battery connected while adjusting the needle.

With a glowplug engine, ignition is initiated by the application

of a 1.5-volt power source. When the battery is disconnected,

the heat retained within the combustion chamber remains

sufficient to keep the plug filament glowing, thereby continuing

to keep the engine running. Ignition timing is 'automatic' : under

reduced load, allowing higher rpm, the plug becomes hotter

and, appropriately, fires the fuel/air charge earlier; conversely,

at reduced rpm, the plug become cooler and ignition is

retarded.

Apart from when actually burned out, a plug may need to be

replaced because it no longer delivers its best performance,

such as when:

When to replace the glowplug

Filament surface has roughened and turned white.

Filament coil has become distorted.

Foreign matter has adhered to filament or plug body has

corroded.

Engine tends to cut out when idling.

Starting qualities deteriorate.

Since the compatibility of the glowplug and

fuel may have a marked effect on

performance and reliability, it is suggested

to use the O.S. Type F plug when it is

necessary to replace. Carefully install plug

finger-tight, before final tightening with the

correct size plug wrench.

13

MIXTURE CONTROLS

The Needle Valve

When set to produce maximum power at full throttle, this

establishes the basic fuel/air mixture strength. The correct

mixture is then maintained by the carburetor's built-in

automatic mixture control system to cover the engine's

requirements at reduced throttle settings.

The Mixture Control Valve

This meters fuel flow at part-throttle and idling speeds to

ensure reliable operation as the throttle is opened and

closed. The Mixture Control Valve is factory set for the

approximate best result. First run the engine as received and

readjust the Mixture Control Screw only if necessary.

Two mixture controls are provided on this

Carburetor.

Needle Valve

Mixture Control Valve

Mixture Control Valve of the carburetor is set at basic position

( a little on the rich side) at the factory. However, minor

readjustment will be required for a fuel used, atmospheric

conditions and a model. When a good result is not obtained

with the factory setting, readjust it according to the MIXTURE

CONTROL VALVE ADJUSTMENT section. Please note

during a running-in period flights should be made with a

slightly rich needle setting. Therefore, during a running-in

period proper carburetor responses will not be obtained.

Adjust it for optimum position after the running-in is

completed.

THROTTLE LINKAGE

Before connecting the throttle to its servo, make sure that

the throttle arm and linkage safely clear any adjacent part

of the airframe structure, etc., as the throttle is opened and

closed. Connect the linkage so that the throttle is fully

closed when the transmitter throttle stick and its trim lever

are at their lowest settings and fully open when the throttle

stick is in its fully-open position. Carefully align the

appropriate holes in the throttle arm and servo horn so that

they move symmetrically and smoothly through their full

travel.

Throttle Lever

Fuel Inlet

Rotor Guide Screw

Page 8

14

18x10-12, 20x8-10, 22x8

PROPELLER

The choice of propeller depends on the design and weight of

the aircraft and on the type of flying in which you will be

engaged. Determine the best size and type after practical

experimentation. As a starting point, refer to the props listed in

the accompanying table. Slightly larger, or even slightly

smaller, props than those shown in the table may be used, but

remember that propeller noise will increase if blade tip velocity

is raised, due to higher rpm or if a larger-diameter / lower-pitch

prop is used.

Make sure that the propeller is well balanced. An

unbalanced propeller and / or spinner can cause serious

vibration which may weaken parts of the airframe or

affect the safety of the radio-control system.

DO NOT forget the WARNINGS and NOTES on propeller

and spinner safety given on pages 2,3 and 4.

Warning:

Type

Size (DxP

)

Sport/Scale

1.

PROPELLER & SPINNER ATTACHMENT

There is a risk, particularly with powerful four-stroke engines,

of the propeller flying off if the prop nut loosens due to

detonation ("knocking") in the combustion chamber when the

engine is operated too lean, or under an excessively heavy

load.

Obviously, this can be very hazardous. To eliminate such

dangers, the O.S. Safety Locknut Assembly was devised.

Install this as follows:

To be equal

To be equal

Ream to 13.5mm dia.

Use a propeller that has a

hub of more than 40mm dia.

Ream the propeller shaft hole to 13.5mm bore with an

appropriate reamer, checking that the hole is exactly

centered.

Install the prop to the engine shaft, followed by the retaining

washer and prop nut and tighten firmly with a 17mm

wrench. (not supplied).

2.

15

3.

Add the special tapered and slotted locknut and secure

with a 14mm wrench while holding the prop nut with the

17mm wrench. (not supplied).

Propeller washer

Propeller washer

Propeller nut

Propeller nut

Locknut

Locknut

Drive hub

Drive hub

Back-plate of spinner

The Safety Propeller Locknut can

be used provided that the width is

between 21.5mm and 26mm.

Make a habit of always checking the tightness of the

propeller before starting the engine. Remember that,

especially with wooden propellers, there is a tendency for

the material to shrink, or for it to be reduced by the

serrated face of the drive hub. Retighten the propeller nut

if necessary after loosening the Safety Propeller Locknut.

The locknut should be tightened firmly after retightening

the propeller nut.

NOTE:

Page 9

16

GLOWPLUG HEATING

Glowplug battery

It is necessary to use a glowplug battery of fairly large

capacity (10Ah or more) as this is required to heat four

glowplugs simultaneously.

A heavy-duty 1.5-volt dry battery or (preferably) 1.2-volt NiCd battery may be used.

Ni-Cd (nickel-cadmium) 1.2-volt rechargeable battery

Use a 10-Ah cell, or 4 to 5 2.0-Ah cells (as commonly used

for electric-powered R/C cars) wired in parallel and with

short heavy leads (to minimize voltage drop) to the

connection point on the fuselage.

Glowplug leads

The plug leads are fitted with special snap-on connectors

that ensure firm contact with O.S. plug. They are a "click" fit

and are not suitable for use with most other makes of

glowplug.

The earth (ground) lead is fitted with a plug terminal which

should be connected to the engine by means of one of the

mounting screws.

Make sure that no part of the wiring touches the cylinder

head or cooling fins.

Keep wiring away from the fuel tank where it might cause a

fire in the event of a short-circuit.

Switch should have

sufficient capacity.

Install Ni-Cd battery in the fuselage, and switch on or off by means

of transmitter. (On-board battery)

1.2 volt Ni-Cd battery with

more than 10 Ah capacity.

1.

A commercially available glowplug heating source will

enable you to turn the current on or off by using a

transmitter auxiliary channel establishing a more reliable

idle.

17

If glowplug leads are extended

together as a single cable, use

heavier wire, e.g. 2.0mm

multi-strand copper core as

supplied for earth lead.

2

2

2.0mm

Earth (ground)

lead

Fasten to the

motor mount.

Glowplug re-heat

Under normal conditions, the engine will idle sufficiently

slowly with the throttle closed to permit a safe landing

approach. However, if conditions (atmospheric, fuel,

tank location etc.) are unfavorable, there may be a

tendency for one cylinder to cease firing if the engine is

throttled down to a very low idling speed. This can be

prevented by installing a small on-board Ni-Cd battery

which will automatically re-heat the glowplugs when the

engine is throttled down to idling speed. A suitable

switch should be installed so that it is actuated by the

throttle servo only when the engine is throttled down.

2. Connect terminals to the

fuselage.

3. Install a jack on the

fuselage.

Ni-Cd

Ni-Cd

Page 10

18

Model engine fuel is poisonous. Do not allow it to

come into contact with the eyes or mouth. Always

store it in a clearly marked container and out of the

reach of children.

Model engine fuel is also highly flammable. Keep it

away from open flame, excessive heat, sources of

sparks, or anything else which might ignite it. Do

not smoke, or allow anyone else to smoke, near to it.

Reminder!

Fuel

The IL-300 should be operated on a methanol based fuel

containing not less than 18% (volumetric) castor oil, or a top

quality synthetic lubricant (or a mixture of both), plus a small

percentage (5-20%) of nitromethane for improved flexibility

and power.

FUEL AND LUBRICATION

Lubrication

All parts of the IL-300 are automatically lubricated by the oil

content of the fuel mixture. It is suggested, however, to apply

small amount of machine oil or grease to moving parts of the

rocker arms before starting the engine.

The crankcase breather hole is located at the back of the

engine and is fitted with a brass nipple. Fit a length of silicone

tubing of approx. 2.5mm I.D. to this nipple to conduct away

the small amount of oil that escapes through the breather.

Make a habit of draining out the excess oil in the crankcase

at the end of each flying session. Leaving contaminated oil in

the crankcase for a long time will cause rust. Also, residual

castoroil will tend to solidify and lock the engine. Inject

corrosion-inhibiting oil into the crankcase to neutralize the

effects of any remaining contaminants.

Rear Housing

Breather Nipple

2.5mm Silicone tubing

Breather Nipple

19

STARTING

Precautions

For safety, please observe the following instructions

before starting the engine.

Start the engine by turning the propeller counterclockwise (i.e. normal running direction).

Do not start the engine with the throttle fully opened,

otherwise the model will tend to move forward

suddently due to the strong thrust of the propeller. Hold

both wings of the model when starting the engine.

Do not carry out carburetor adjustments (except needlevalve adjustment) while engine is running.

Use a high-torque electric starter.

Starting procedure is as follows:

Open the needle-valve 2 to 3 turns from the fully closed

position.

1.

open

Make sure that glowplugs are not connected to the battery.

Do not heat the glowplugs while priming.

2.

Close

3.

open the

throttle fully

Open the throttle fully and apply an electric starter for 5~6

seconds to prime the engine.

Page 11

20

Set the throttle valve approximately 1/4 open from the fully

closed position.

4.

Fully open

Fully closed

Set at this position

Position the throttle stick at 2-3 scales advanced from the fully

pulled down position. Turn the prop “backwards” (clockwise)

by hand until it is against compression. This is to enable the

kinetic energy of the prop to subsequently assist the starter

through the compression stroke to start the engine.

Starting with an electric starter.

5.

Make sure that the direction of rotation of the starter is

correct.

Connect the glowplug battery.

Apply the electric starter.

Connect the battery to the glowplug.

Electric starter

Make sure that the

direction or rotation

is correct.

21

When the engine starts, open the throttle valve fully and

keep it running initially (approx. 10 seconds), with original

needle-valve setting.

6.

Open the

throttle fully.

Make sure that all four cylinders are firing

7.

The engine is running properly if white smoke is emitted

through all four exhaust pipes. A slight spray of fuel will be

discharged through the exhaust pipe of any cylinder that is

not firing.

If a cylinder ceases firing, reduce the throttle setting to

approximately 1/4 open from the fully closed position and

re-connect the glowplug battery. The rpm will increase when

all cylinders are firing steadily.

A slight spray of fuel may be emitted through the exhaust

pipe if a cylinder is not firing.

Page 12

22

Now disconnect the glowplug battery.

8.

Adjust the needle-valve

9.

Abrupt adjustment of the needle-valve may cause the

engine to stop, especially when it is new and insufficiently

run-in.

As the speed of the engine does not instantly change with

needle-valve readjustment, small movements, with pauses

between, are necessary to arrive at the optimum setting.

Practical best (optimum) needle-valve setting

Approx. 40

Maximum rpm setting

("Lean")

"Rich" needle-valbe

setting when starting

the engine.

Rpm starts to decrease.

Close the needle-valve

gradually and slowly.

Engine stops.

Re-starting the engine when warm

To re-start the engine when warm, simply re-energise the

plugs and reapply the starter with the throttle in the idling

position. If the engine does not start, disconnect the battery

from the glowplugs and re-prime. Initially, the high

temperature inside the combustion chambers may turn the

liquid fuel into gas and emit it through the exhaust pipes.

Therefore, repeat the priming procedure once or twice until the

cylinders become cool enough for restarting.

Note:

Make sure that the throttle linkage is made so that the

throttle is fully closed when the throttle lever as well as

trim lever on the transmitter are fully pulled down.

How to stop the engine

Pull down the throttle lever and trim lever on the transmitter

fully.

23

RUNNING-IN ("Breaking-in")

Obtain an 18x12 or 20x8 propeller for running-in.

↓

↓

1

2

1. Running-in on the ground

Start the engine

Set the needle-valve 500-1,000r.p.m. lower than

maximum r.p.m. setting and run approx, 10 seconds.

(It is suggested to use a tachometer.)

Open the needle-valve approx. 1,000r.p.m. lower

than above setting and run approx. 20 seconds.

Repeat above procedure, i.e., richening and leaning the

mixture until the engine has approx. 10 minutes of running

time.

Keep the throttle fully open, using only the needle-valve to

change r.p.m. Prolonged running-in on the ground is not

suggested because the purpose is just initial running-in

to increace engine temperature gradually close to that of

maximam r.p.m.

NOTE:

2. Running-in in the air

Start the engine

Fly the model.

NOTE: Avoid prolonged heavy load flight.

With each successive flight, close the needle-valve slightly,

until, at the end of 10 flights, the needle-valve is set for

optimum position.

Finish running-in.

The carburetor can now be adjusted for optimum throttle

performance following the instructions given in the next

section.

Set the needle-valve approx 40 open from

optimum position (approx. 40 open from

maximum r.p.m.).

Page 13

24

THROTTLE VALVE ADJUSTMENT

Needle-valve adjustment

Adjust the needle-valve following the instructions given in

STARTING section.

Mixture control valve adjustment

The carburetor of your IL-300 has been factory set for the

approximate best result with the fuel tank located in the normal

position (i.e. close to the back of the engine and where the

level of the needle-valve is at 1/3 height of the tank), but the

setting may, in some cases, vary slightly in accordance with

fuel and climatic conditions.

After running-in is completed and the needle-valve is set at

optimum position (approx 40 open from maximum r.p.m.

position), check the idle speed and adjust only when

necessary.

25

Start the engine.

open the throttle fully .

Adjust the needle-valve.

Close the throttle gradually.

Set the idle speed.

Open the throttle fully.

Does the engine

regain full power?

Continue running at high speed

for 5 seconds.

Close the throttle.

Run at idle speed for 5 seconds.

Does the engine stop?

Apply full throttle.

Does the engine

regain full power

immediately?

OK

Re-set the idle speed

a little higher

Set the thr ot tl e op en in g by

means of the throttle trim on

the transmitter so that the lowest

practical speed, without risk of

the engine stopping,is obtained.

The position where the lowest

pos sible r.p. m. ,w ith steady

running, is obtained.

Approx 40˚ open from maximum

r.p.m. setting.

Yes.

No.

Yes.

One of the cylinders ceases firing.

Disconnect the glowplugs from the battery.

Make sure that all 4 cylinders are firing.

Make sure glowplug switch is on.

The engine hesitates before picking

up to full speed, or appears to run at

medium speed with reduced power.

Check mixture adjustment at idle

speed. Make sure that all cylinders

are firing.

Adjustment should be carried

out after stopping the engine.

Do not move needle-valve

while adjusting other controls.

Repeat the procedure while opening and closing the

throttle until the best result is obtained.

Attention: Do not leave the battery connected while adjusting the carburetor.

One of the cylinders

ceases firing.

One of the cylinders

ceases firing.

Page 14

26

Adjusting the mixture control valve

If the engine hesitates, puffing

out a good deal of smoke, before

picking up to full speed, it is

probable that the idle mixture is

too rich.

1.

Mixture Control Valve

Screwdriver

Turn 30

In this case, it will be necessary

to turn the Mixture Control Valve

clockwise to lean the mixture.

About 1/12 turn (30 ) should be sufficient.

Alternatively, if the engine stops

or is slow to pick up speed,

without smoking or a strong

exhaust note, it is probable that

the idle mixture is too lean.

2.

Turn 30

In this case, it will be necessary

to turn the Mixture Control Valve

counter-clockwise approximately

1/12 turn (30 ) .

Thirdly, if the rpm increase but the engine appears to run

with reduced power, it is probable that one of the cylinders

has ceased firing. You may detect this by the difference in

exhaust note and rpm compared with previous full-throttle

running. The cutting out of the cylinder may be caused by

the idle speed being set too low or the idle mixture being

too rich.

3.

In the case of the idle speed being too low, re-set the idle

position a little higher by means of the throttle trim on the

transmitter. In the case of the idle mixture being too rich, turn

the Mixture Control Valve clockwise about 1/12 turn (30 ).

Normal safe idle speeds are in the region of 2,000 r.p.m..

NOTE:

As this is four-cylinder four-stroke-cycle engine, firing

strokes occur every half revolution (180 ), that is, two

firings take place every one complete revolution.

Therefore, at first you may have an impression that the

engine is idling at higher r.p.m. than actual running r.p.m.

It is recommended to check the engine r.p.m. with a

tachometer.

Changing the make of glowplug or fuel may sometimes

require re-adjustment of carburetor throttle.

Realignment of mixture control valve

In the course of making carburetor adjustments, it is just

possible that the Mixture Control Valve setting may be

upset.Its basic setting can be re-established as follows:

Turn the Mixture Control Valve counter-clockwise until it stops,

then screw it out 3 turns. This is the basic position.

NOTE:

If an on-board glowplug re-heat system is installed,

mixture adjustment at idle speed should be carried out

with this in operation.

27

FLIGHT & MAINTENANCE

It is necessary to warm up the engine as with a full-size

aircraft or automobile. Do not attempt to take-off immediately

after the engine has been started. Allow the engine to run at

full throttle for at least 10 seconds before releasing the model.

Checking before flight

Make sure that all four cylinders are firing.

Make sure that engine runs steadily at idle speed.

Make sure that engine is fully warmed up.

Please pay attention to the matters described below to

ensure that your engine serves you well in regard to

performance, reliability and long life.

As previously mentioned, it is vitally important to avoid

operating the engine in conditions where dust, disturbed by

the propeller, may be deposited on the engine and enter its

working parts.

Remember to keep your fuel container closed to prevent

foreign matter from contaminating the fuel.

Install a fuel filter to prevent dirt and dust in the fuel

container from entering the fuel tank. O.S. Super Filters (L)

is available as an optional extra.

Install an in-line fuel filter between the tank and carburetor

to prevent foreign matter in the tank from entering the

carburetor.

If these precautions are neglected, restriction of fuel flow

may cause the engine to cut out, or the fuel/air mixture to

become too lean causing the engine to overheat.

Clean these filters periodically.

The use of modern high-performance alcohol based model

engine fuels, while promoting cooler running, improved antidetonation combustion and increased power, have the

disadvantage of causing corrosion due to the acid by-products

of combustion. The use of nitromethane in the fuel can also

contribute to the problem.

Care and Maintenance

Do not close the needle-valve and mixture control valve too far

as this will cause a lean setting and over heating of the engine.

This can, in turn, create nitromethane oxide leading to internal

rusting of the engine. Always adjust the needlevalve slightly on

the rich side of peak rpm.

Do not leave unused fuel in the engine at the conclusion of a

day’s flying. Accepted practice is to cut off the fuel supply while

the engine is still running at full throttle, then expel as much

fuel residue as possible by turning the engine over 20-30

seconds with the electric starter. Finally, inject some after-run

oil through the glowplug hole and turn the engine over several

times with the electric starter.

When the engine is not to be used for some months (for example,

as between flying seasons), a worthwhile precaution is to remove it

from the airframe and, after washing off the exterior with alcohol

(not gasoline nor kerosene), remove carefully the carburetor with

intake pipe, glow plug and all silicone tubing and put them safely

aside. Then, immerse the engine in a container of alcohol. Rotate

the crankshaft while the engine is immersed. If foreign matter is

visible in the alcohol, rinse the engine again in clean alcohol.

Finally, shake off and dry the alcohol ,and inject some after-run oil

in the glowplug hole and rotate the crankshaft several times by

hand. Reinstall the carburetor with intake pipe and glowplug on the

engine and keep it in a dry place after putting in a vinyl bag.

Page 15

28

0.04mm

VALVE CLEARANCE ADJUSTMENT

ALL O.S. four-stroke engines have their valve (tappet)

clearances correctly set before they leave the factory.

However, if, after many hours of running time have been

logged, a loss of power is detected, or if the engine has to

be disassembled or repaired as a result of an accident,

valve clearances should be checked and readjusted, as

necessary, with the aid of the O.S. Valve Adjusting Tool Kit.

Note:

Valve clearances of all O.S. four-stroke-cycle engines

must be checked and reset ONLY WHEN THE ENGINE IS

COLD. Procedure is as follows:

1.

Remove all the glowplugs except the one installed in the

cylinder that you want to check.

2.

Note:

Each glowplug should be re-installed in to the original

cylinder. You may start to check and adjust with any

cylinder.

Turn the propeller counter-clockwise until compression is

first felt, then turn it futher a quarter turn. At this point, both

valves should be closed. (If the prop driver ('drive hub') of

your engine is engraved with a letter 'T', this mark should

now be at the top.)

The standard valve clearance, on both inlet and exhaust

valves, is between 0.04mm and 0.1mm(0.0015-0.004 inch),

measured between valve stem and rocker arm. Use the

0.04mm and 0.1mm feeler gauges to check clearances.

(See Fig.1)

0.04mm

Feeler Gauge

Rocker Arm

Valve

3.

Note:

If the gap is found to be less than 0.04mm, it is not

necessary to readjust the clearance if the engine has

good compression and starts easily. Equally, if the gap

exceeds 0.1mm but is not more than 0.14mm (i.e. the

thickness of both feeler gauges inserted together), it is

not necessary to readjust the clearance if the engine

runs satisfactorily.

Fig.1

If a clearance is found to be outside either of these limits, it

should be reset as follows.

29

0.04m

m

0.04mm

Carefully loosen the locknut

on rocker-arm 1/4-1/2 turn

with 5mm wrench. (Fig.2)

1.

Loosen approx.1/4 to 1/2 turn.

Wrench

Locknut

2.

Turn adjusting-screw approx.

1/2 turn counter-clockwise to

open gap, using appropriate

tool-i.e. Allen hex key. (Fig.3)

Adjusting

Screw

Allen Key

Turn approx.1/2 turn.

3.

Insert 0.04mm feeler gauge

between valve stem and

rocker-arm and gently turn

adjusting screw clockwise

until it stops. (Fig.4)

0.04mm

Feeler Gauge

Turn with fingers

until it stops.

Remove 0.04mm feeler, rotate prop through two

revolutions and recheck gap.

5.

If clearance is correct, loosen the locknut on the other

rocker-arm and repeat steps 1 to 5 above.

6.

Remember:

Excessive valve clearance will cause loss of power, due

to valve (s) not opening sufficiently. On the other hand, a

total loss of clearance may cause difficult starting due to

valves not closing properly, resulting in loss of

compression.

Re-tighten locknut while holding adjusting screw stationary.

(Fig.5)

4.

Hold at the

screw head.

Tighten Locknut.

Fig.5

Fig.4

Fig.3

Fig.2

Page 16

30

1

1-1

1-2

2-1

2

3

4

5

6

6-1

6-2

6-3

6-4

7

8

9

10-2

10-1

10

11

12

13

14

15

16

17-1

17

18

19

20

19-1

21

22

23

24

25

26-1

26

27

28

29

30

32-1

31

32

43

44

45

46

47

48-1

48

49

41

50

C.M2.6x7

C.M3x8

C.M3.5x10

C.M3x14

C.M3x8

C.M2.6x7

C.M2.6x7

C.M3.5x10

C.M2.6x7

C.M2.6x7

C.M3.5x10

C.M3.5x10

C.M3x10

S.M3x3

17-2

33

34

36

35

37

38

39

40

41

42

35

79871020

79871110

79871120

79871145

79871070

M2.6x7

M3x8

M3x10

M3x14

M3.5x10

ENGINE EXPLODED VIEW

Type of screw

C...Cap Screw M...Oval Fillister-Head Screw

F...Flat Head Screw N...Round Head Screw S...Set Screw

CAP SCREW SETS

(10pcs./sets)

Code No.

Size

Front Housing (4pcs.) Under Cover (8pcs.)

Intake Manifold A (2pcs.) Gear Cover (2pcs.)

Intake Manifold B (4pcs.)

Carburetor Retaining Screw (1pc.)

Idle Gear Retaining Screw (1pc.)

Rocker Support Retaining Screw (4pcs.)

Housing Alignment Retaining Screw (2pcs.)

Front Housing (6pcs.) Rear Housing (8pcs.)

Pcs. used in an engine

1

1-1

1-2

2

2-1

3

4

5

6

6-1

6-2

6-3

6-4

7

8

9

10

10-1

10-2

11

12

13

14

15

16

17

17-1

17-2

18

19

19-1

20

21

22

23

24

25

26

26-1

27

28

29

30

31

32

32-1

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

48-1

49

50

45566000

46564000

46210100

46208010

29208200

46231000

46501600

46562100

46031005

46501000

46501500

46514300

26530008

46502100

46514000

46502300

46502200

46030008

46512000

45587180

46513200

45067319

46562000

22631019

46513000

46515000

46501816

46501800

22681953

46513100

46501700

71910100

79870050

71615009

72200071

72200060

46504300

46504310

45061202

46504410

79871120

45461610

45461510

26381501

46160000

46160100

45460200

45060309

46160400

46504110

46504210

46504100

46504200

44014010

45269000

45269100

45069200

44003400

44003200

44006000

46505000

44003100

46503300

46503400

23325340

79872035

46581000

46568300

45515000

46568000

46568100

46568200

31

PARTS LIST

The specifications are subject to alteration for improvement without notice.

Description

Code No.

No.

Description

Code No.

No.

Rocker Arm Assembly (1pair)

Rocker Arm (1pc.)

Tappet Adjusting Screw

Rocker Support Assembly

Rocker Support Retaining Screw (10pcs.)

Rocker Arm Spacer

Rocker Arm Shaft

Rocker Arm Shaft Retaining Screw

Valve Assembly (1pair)

Valve (1pc.)

Valve Spring (1pc.)

Valve Spring Seat (1pc.)

Valve Spring Retainer (2pcs.)

Cylinder Head 1&3

Cylinder Head 2&4

Cylinder Head 1&3 (W/Valve Assembly)

Cylinder Head 2&4 (W/Valve Assembly)

Head Gasket

Exhaust Pipe Assembly (1pair)

Exhaust Pipe

Exhaust Pipe Lock Nut

Piston Ring

Piston

Piston Pin

Connecting Rod Assembly

Cylinder Liner

Cylinder Jacket

Cylinder Holding Volt Set

Nut (2pcs.)

Spring Washer (20pcs.)

Carburetor Complete (Type 80P)

Carburetor Extention Pipe

"O" Ring (1pc.)

Center Manifold Assembly

Intake Manifold A Assembly

Intake Manifold B Assembly

Push Rod (2pcs.)

Cam Follower (1pc.)

Lock Nut Set

Drive Hub

Woodruff Key

Crankshaft Bearing F

Front Housing

Camshaft Bearing Spacer

Camshaft Bearing F

Crankcase

Crankcase Under Cover (1pc.)

Under Cover Gasket (4pcs.)

Crankshaft Bearing FR

Crankshaft F

Coupling Bearing

Crankshaft Coupling

Crankshaft R

Crankshaft Bearing R

Drive Gear

Drive Gear Key

Idle Gear Washer (2pcs.)

Drive Gear Retaining Screw

Camshaft

Camshaft Bearing R

Idle Gear

Idle Gear Bearing

Rear Housing Assembly Pipe (W/Screw & Nut)

Rear Housing

Breether Nipple (No.1)

Idle Gear Thrust Washer

Gear Cover

Radial Motor Mount Set

Blind Nut M5 (10pcs.)

Glow Plug Type F

Booster Cable Set

Valve Adjusting Kit

Page 17

32

1

1-1

1-2

1-3

1-4

1-5

2

3

4

5

5-1

6

7

8

9

10

27681900

27681970

24981837

26381501

27381940

26711305

22781420

22781411

46581200

26781309

24881824

45581820

22681953

46581100

45515000

79871110

S.M3X3

1-1

1-2

1-3

1-4

1-5

1

5-1

2

3

4

5

6

7

8

9

C.M3x8

10

Type of screw

C...Cap Screw M...Oval Fillister-Head Screw

F...Flat Head Screw N...Round Head Screw S...Set Screw

The specifications are subject to alteration for improvement without notice.

Description

Code No.

No.

EXPLODED VIEW & PARTS LIST

Needle-valve Assembly

Needle Assembly

"O" Ring (2pcs.)

Set Screw

Needle-valve Holder Assembly

Ratchet Spring

Throttle Lever Retaining Screw

Throttle Lever

Carburetor Rotor

Mixture Control Valve Assembly

"O" Ring (2pcs.)

Roter Guide Screw

Fuel Inlet (Nipple No.1)

Carburetor Body

Carburetor Rubber Gasket

Carburetor Retaining Screw (10pcs.)

33

(72200130)

(46210300)

(71531000)

(72403050)

(79870050)

(55500004)

(71521000)

(79871010)

(79871110)

(79871120)

(79871145)

(71531010)

(79871070)

M2.6x7

M3x8

M3x10

M3x14

M3.5x10

(46569000)

COLLECTOR EXHAUST PIPE

BOOSTER TERMINAL KIT

NON-BUBBLE WEIGHT

SUPER FILTER (L

)

LONG SOCKET WRENCH

WITH PLUG GRIP

O.S. GENUINE PARTS & ACCESSORIES

PROPELLER

LOCKNUT SET FOR 4C SPINNER

CAP SCREW SET (10pcs.)

The specifications are subject to alteration for improvement without notice.

M5

BLIND NUT (10pcs.)

LOCK WASHER (10sets)

M5

NON-BUBBLE WEIGHT

S

3/8"-M5 (L)

Page 18

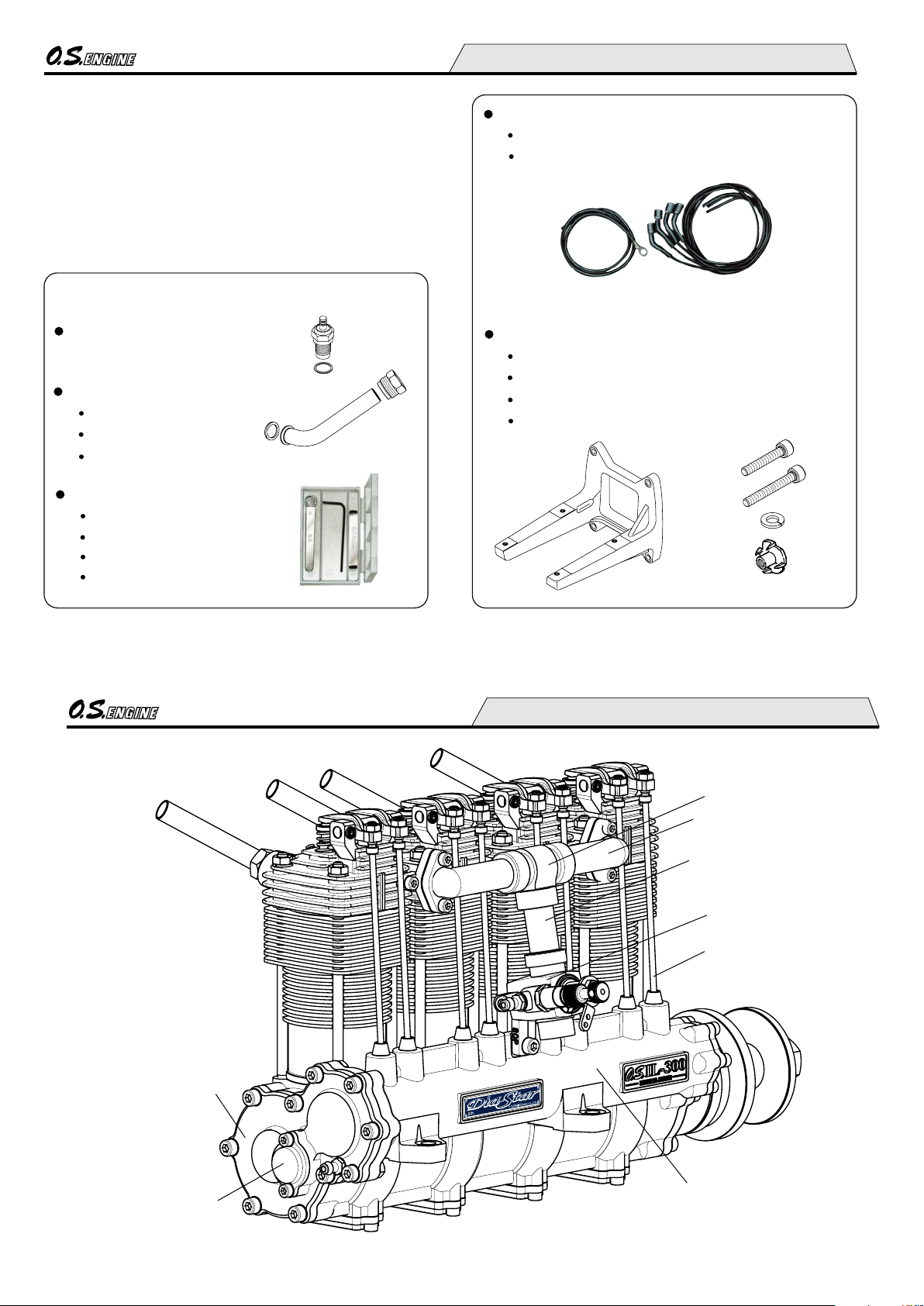

34

12.5 cc x 4 / 0.765 cu.in. x 4

25.8 mm / 1.02 in.

24.0 mm / 0.94 in.

1,800-8,000r.p.m.

2,350 g / 82 oz.

Dimensions (mm)

THREE VIEW DRAWING

Specifications

Displacement

Bore

Stroke

PracticalR.P.M.

Output

Weight

43

116

48.6

43

33

76

40

50

90

72

113

78.5

96

80

133

173

40

40 40

113

234.3

40

121.3

43

29

C

Copyright 2006 by O.S.Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan.

600 91870 1 108 03

TEL. (06) 6702-0225

FAX. (06) 6704-2722

6-15 3-Chome Imagawa Higashisumiyoshi-ku

Osaka 546-0003, Japan

URL : http://www.os-engines.co.jp

Loading...

Loading...