OPEL

KADETT

Oct

Havnes

1984

to

L-

Oct

-

1991

rvice

and

petroi

r

-

Includes

Fault

Finding

and

MOT

Test

Check

Sections

a

For

the

car

driver...

n.---.-.

MANUAL

For

~~~~

&ng

~srsnrigjns.....'~ùy~k~

~Im~~popular~,

-and~Mkeawtmfrom

-~mm=-

-@ww~m-w

db~rmdrqmuywr~.

For

the

W

my

the

biker

motorbike-rider..

Wng

his

cycli

I

--

.

I

L'.

,,

-.,&r?

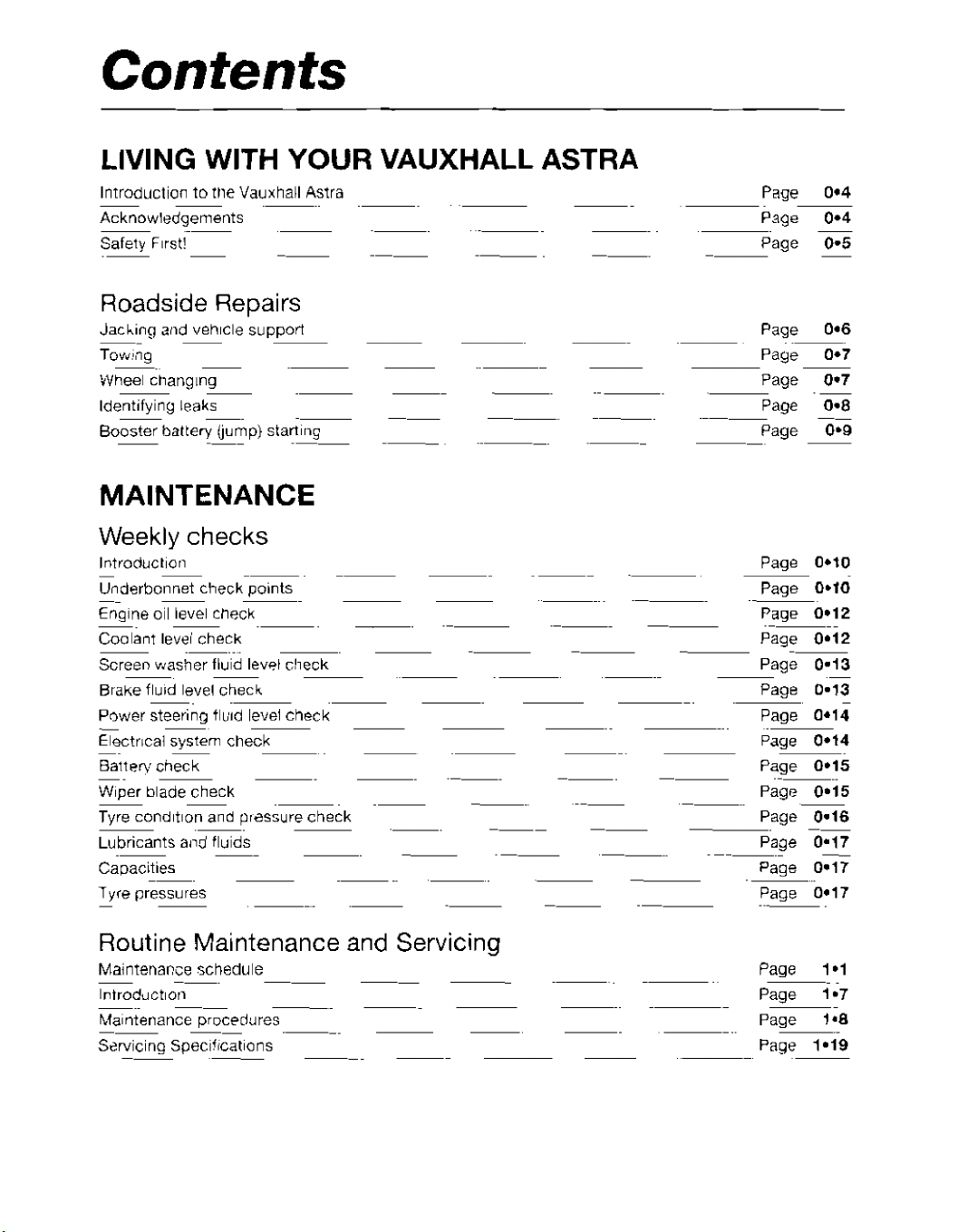

Contents

LIVING

Introduction

-

Acknowledgements

Safety First!

.-

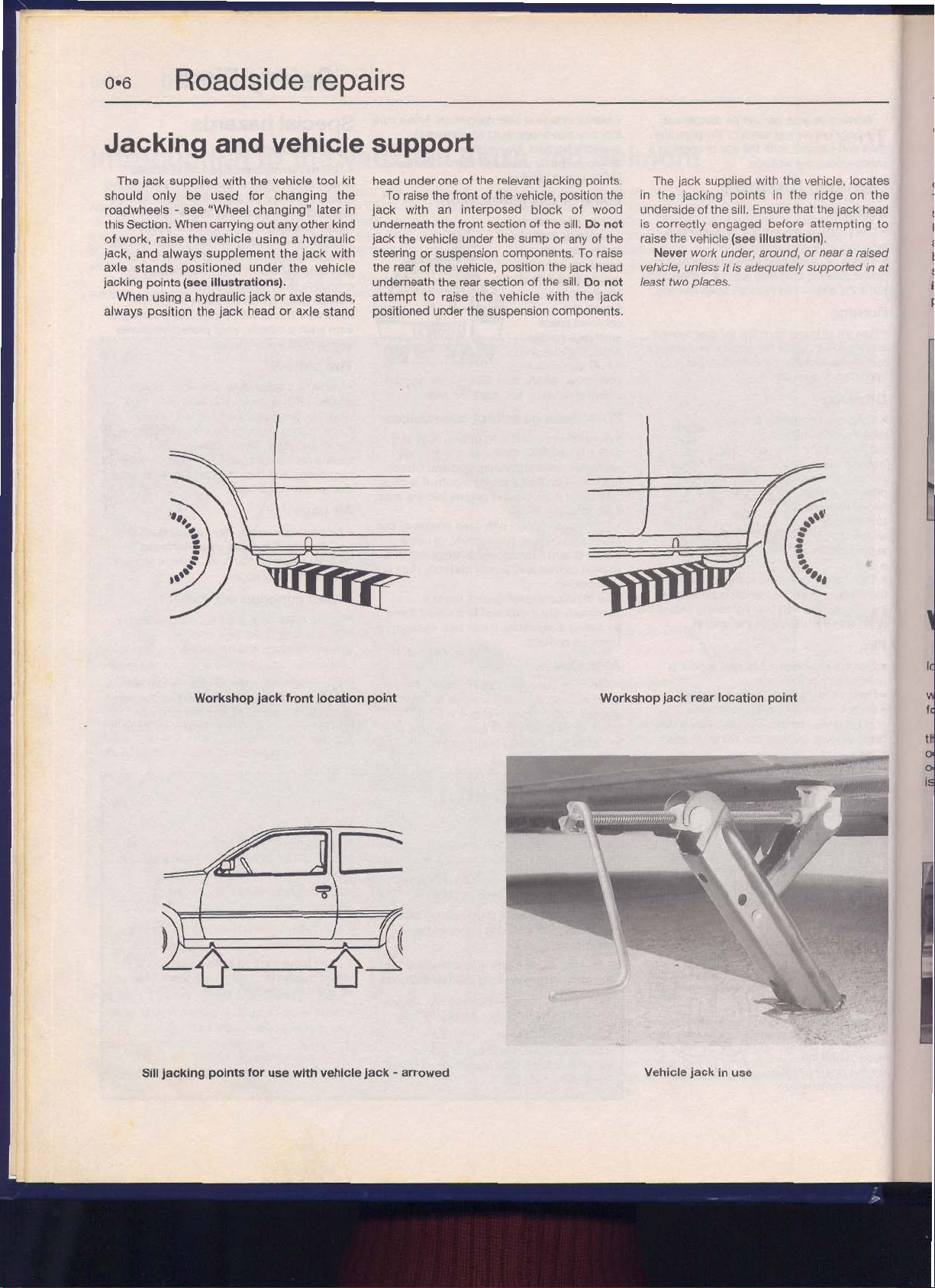

Roadside

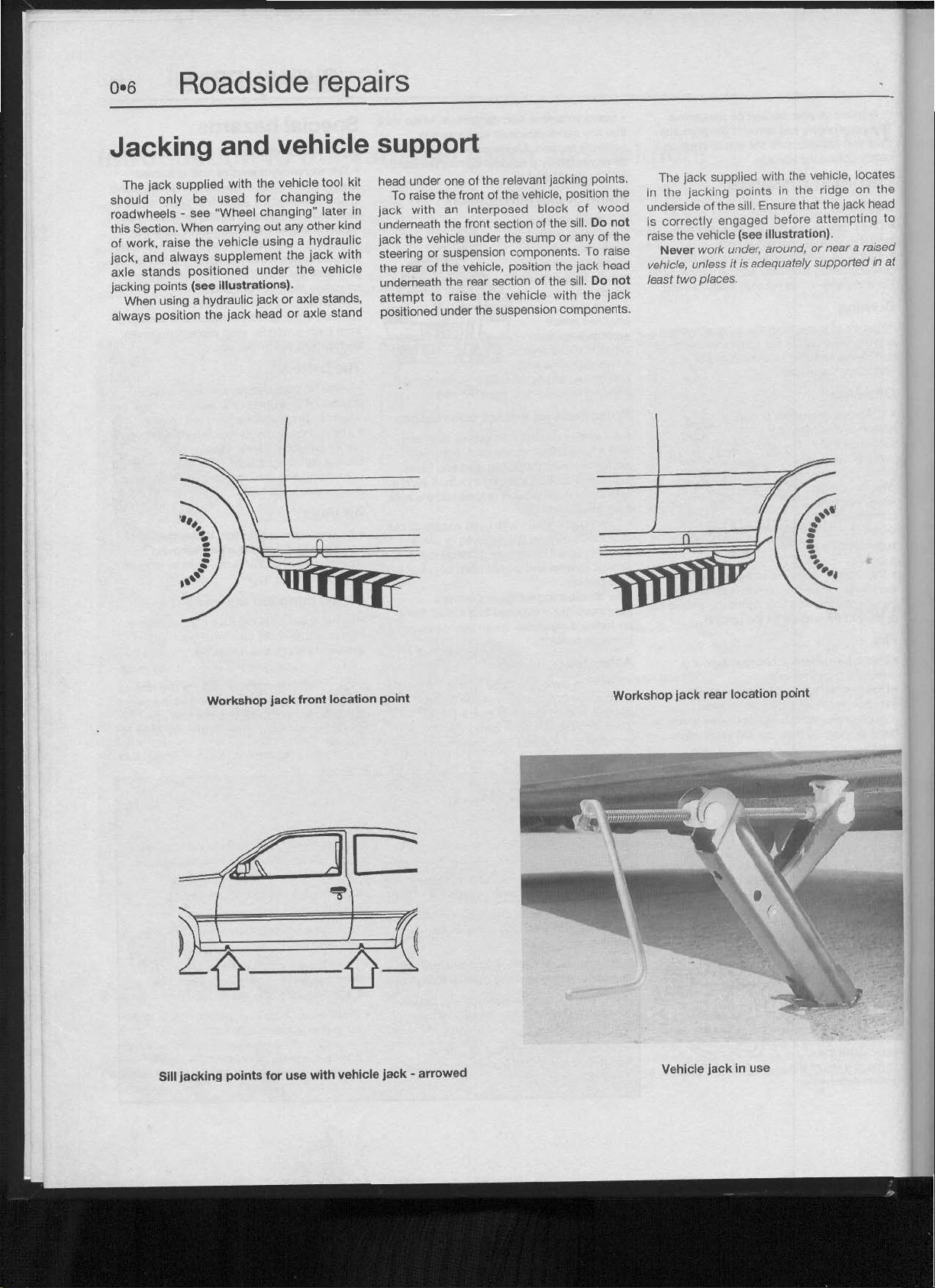

Jaching

--

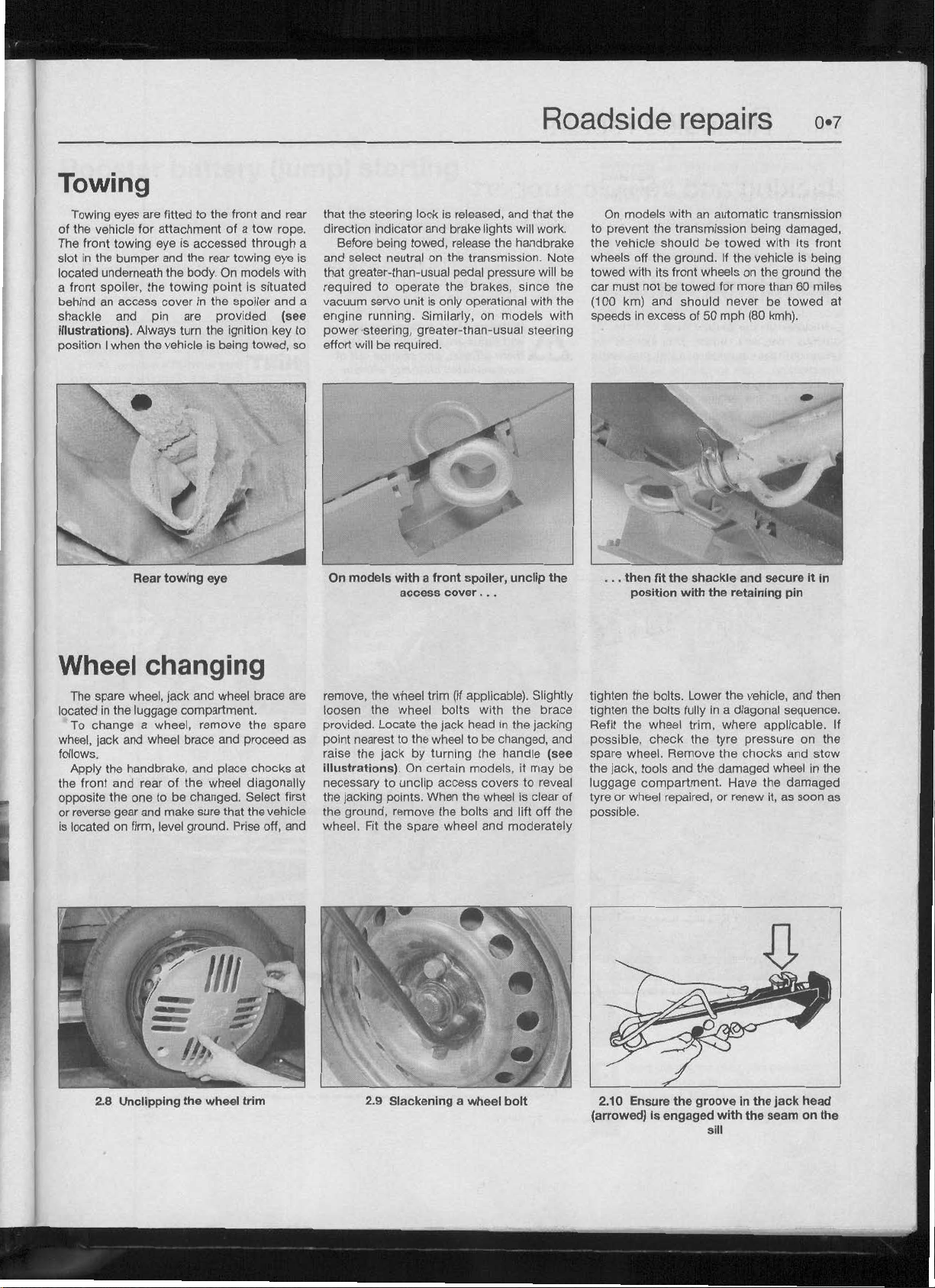

Tow!ng

-.

Wheel changing

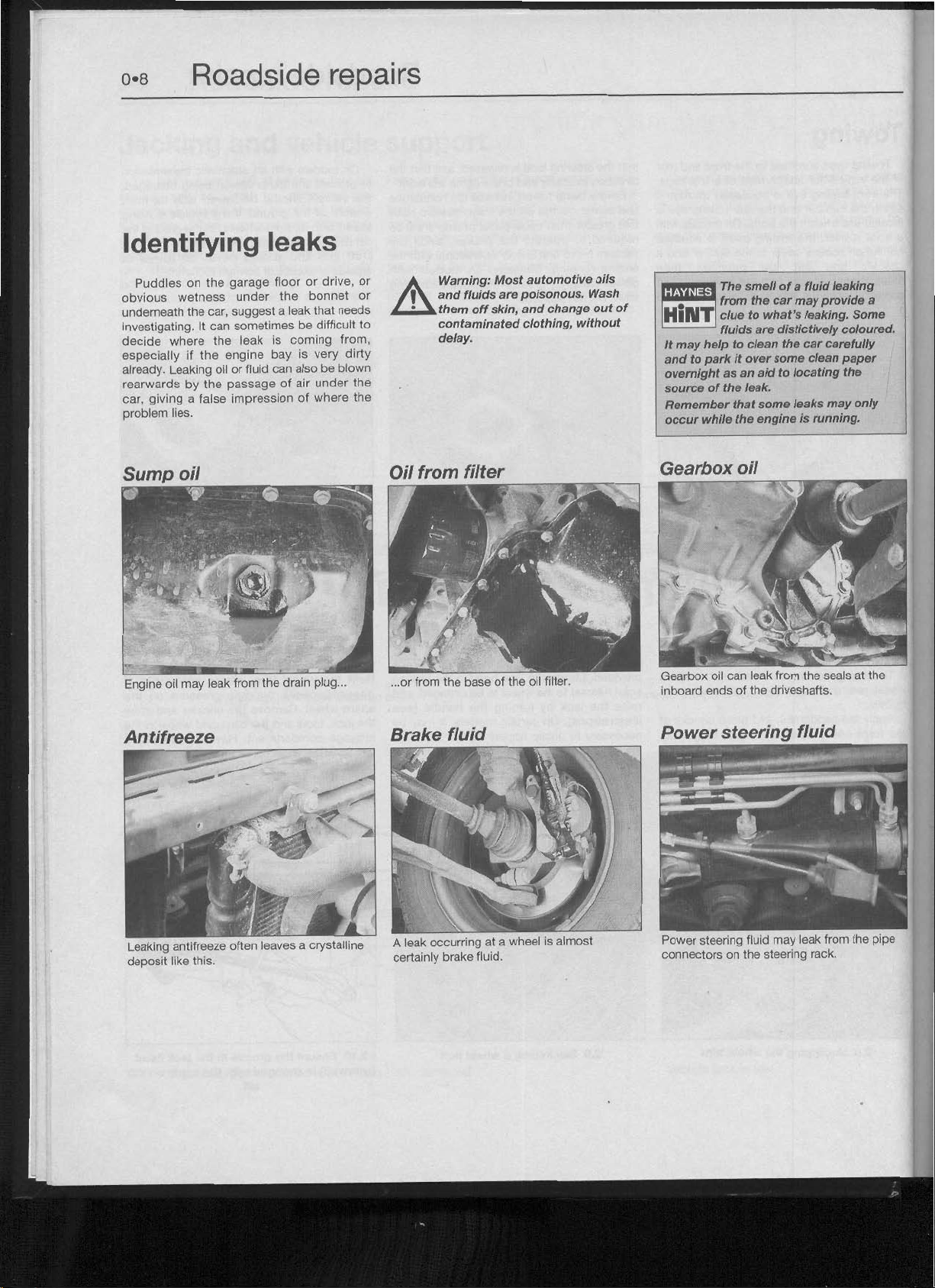

Identify ing

-

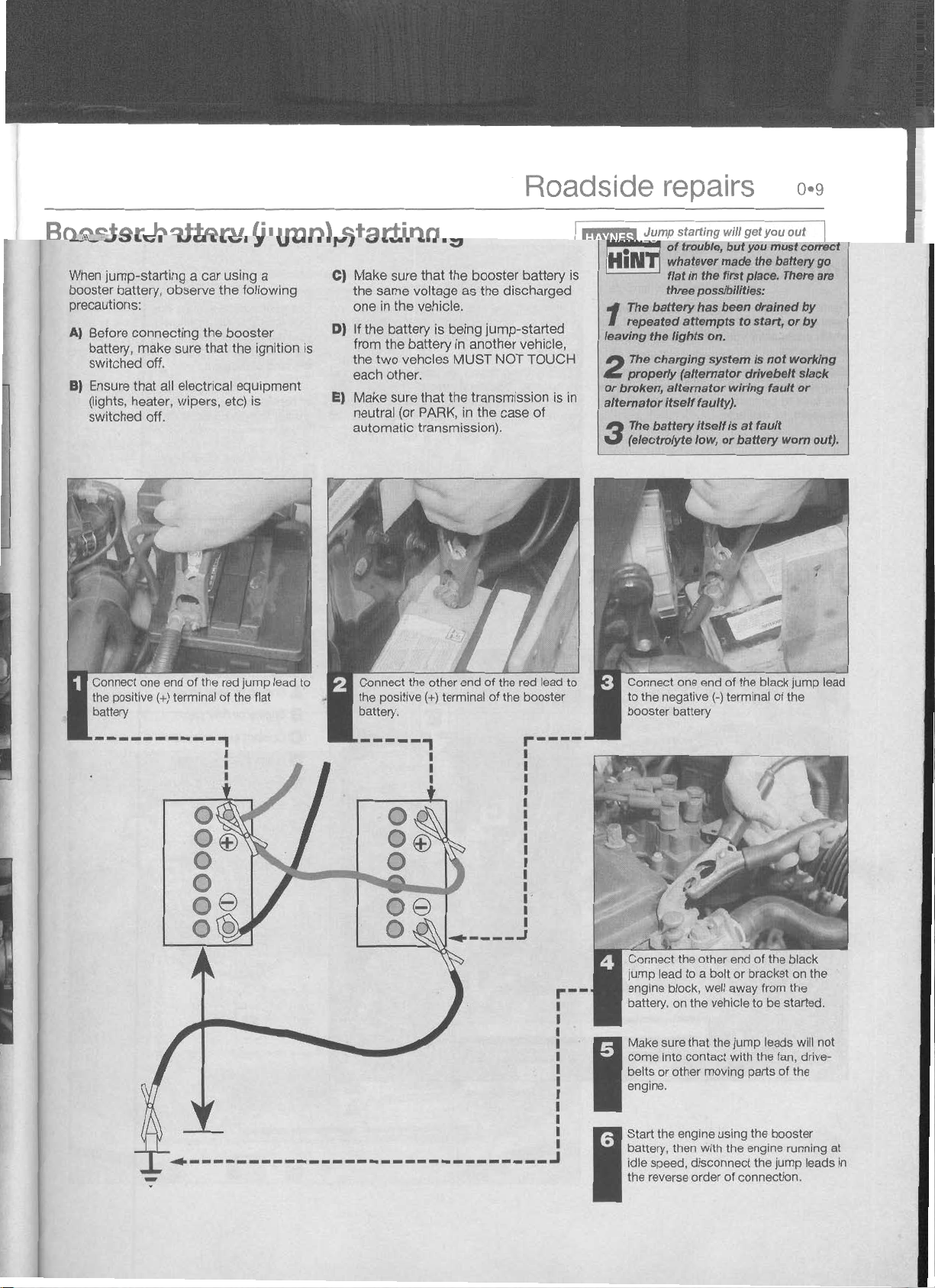

Booster

-

WITH

to

the

--

-

Repairs

aiid vehicle

-

-

leaks

-.

hattery

(jump}

YOUR

Vauxhall

suppori

Astra

-- --

.-

.-

--

startinç

MAINTENANCE

Weekly

Introduction

-

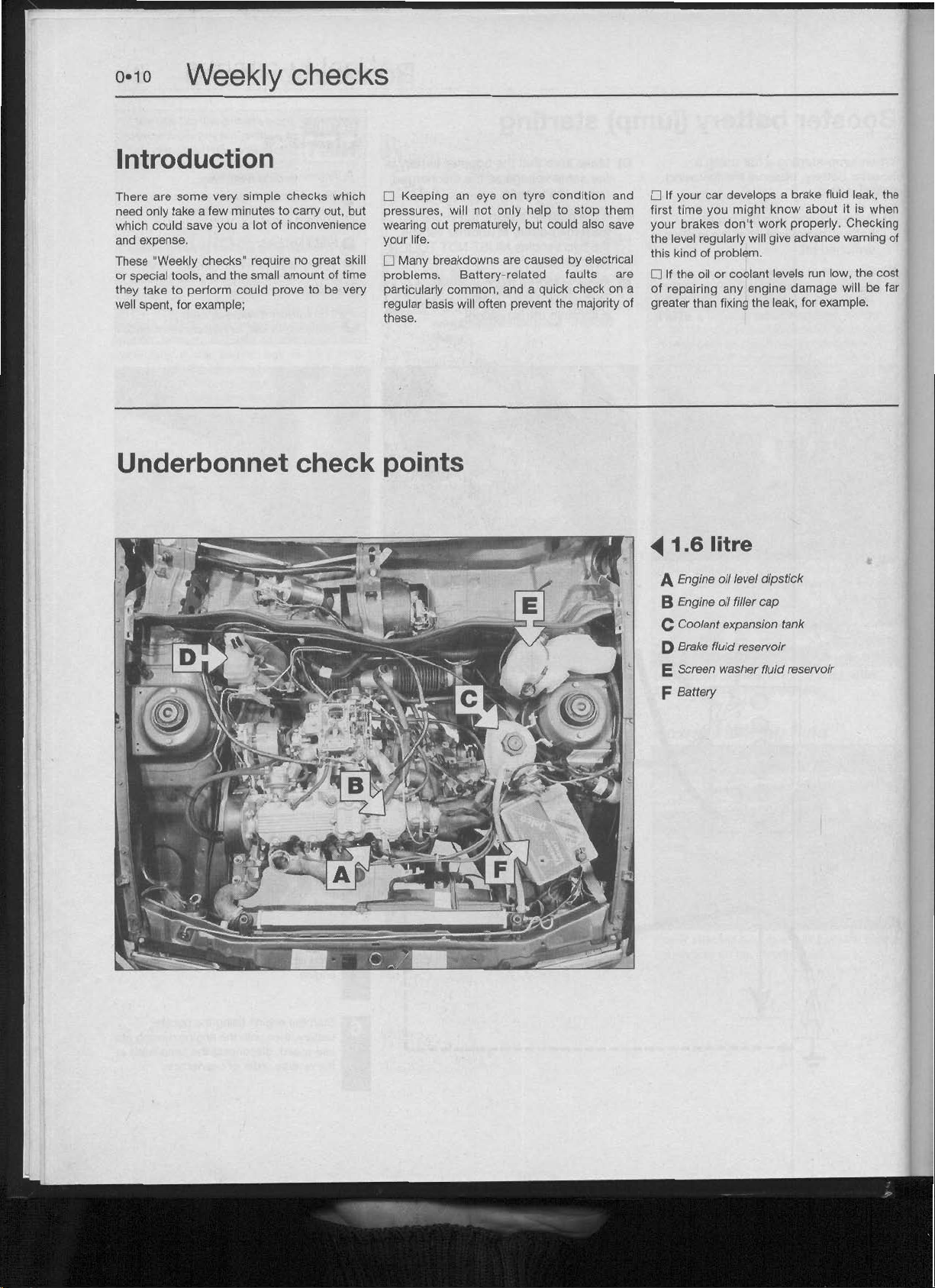

Underbonnet

--

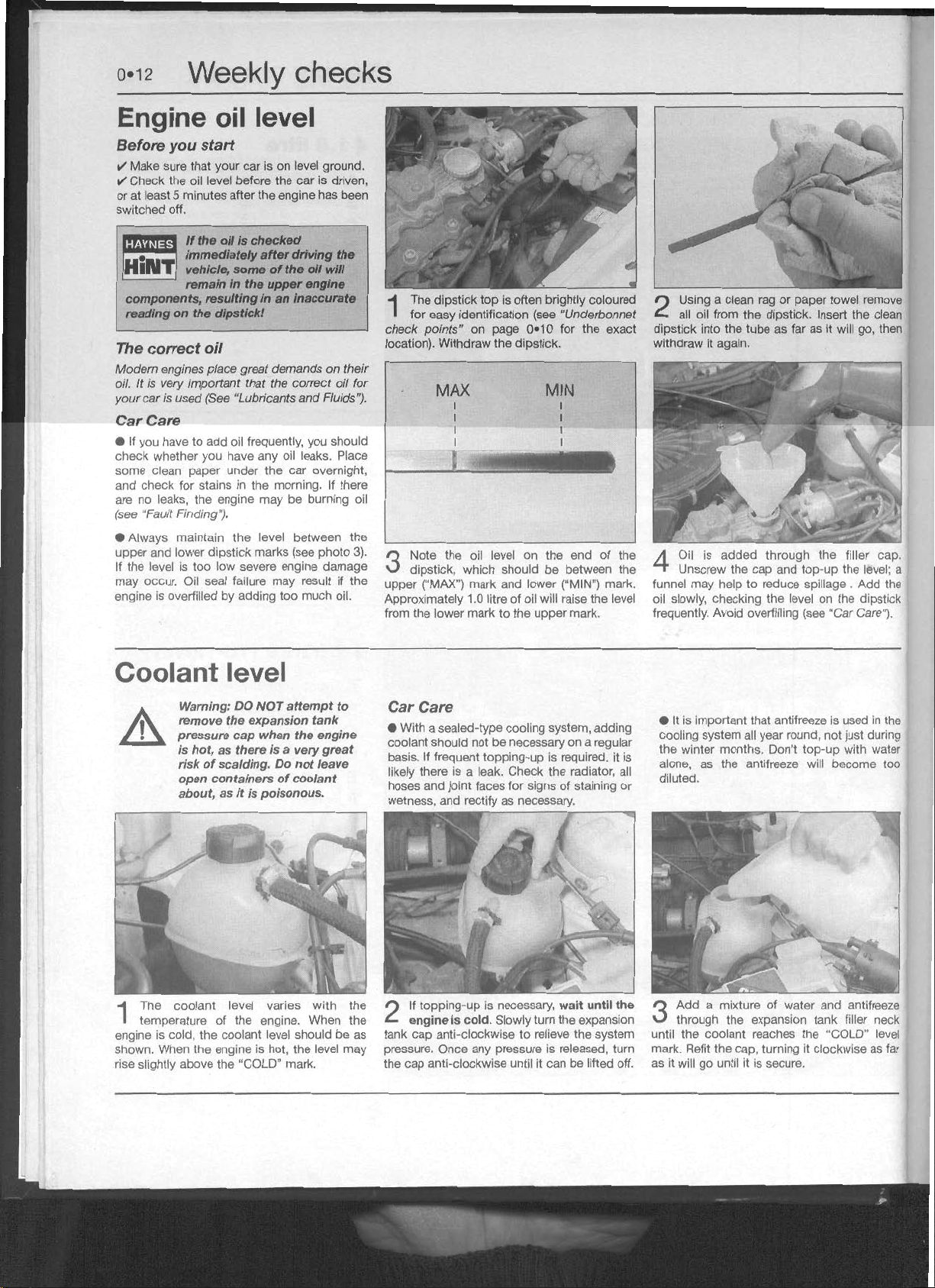

Engine oil levei

-. -.

Coolant

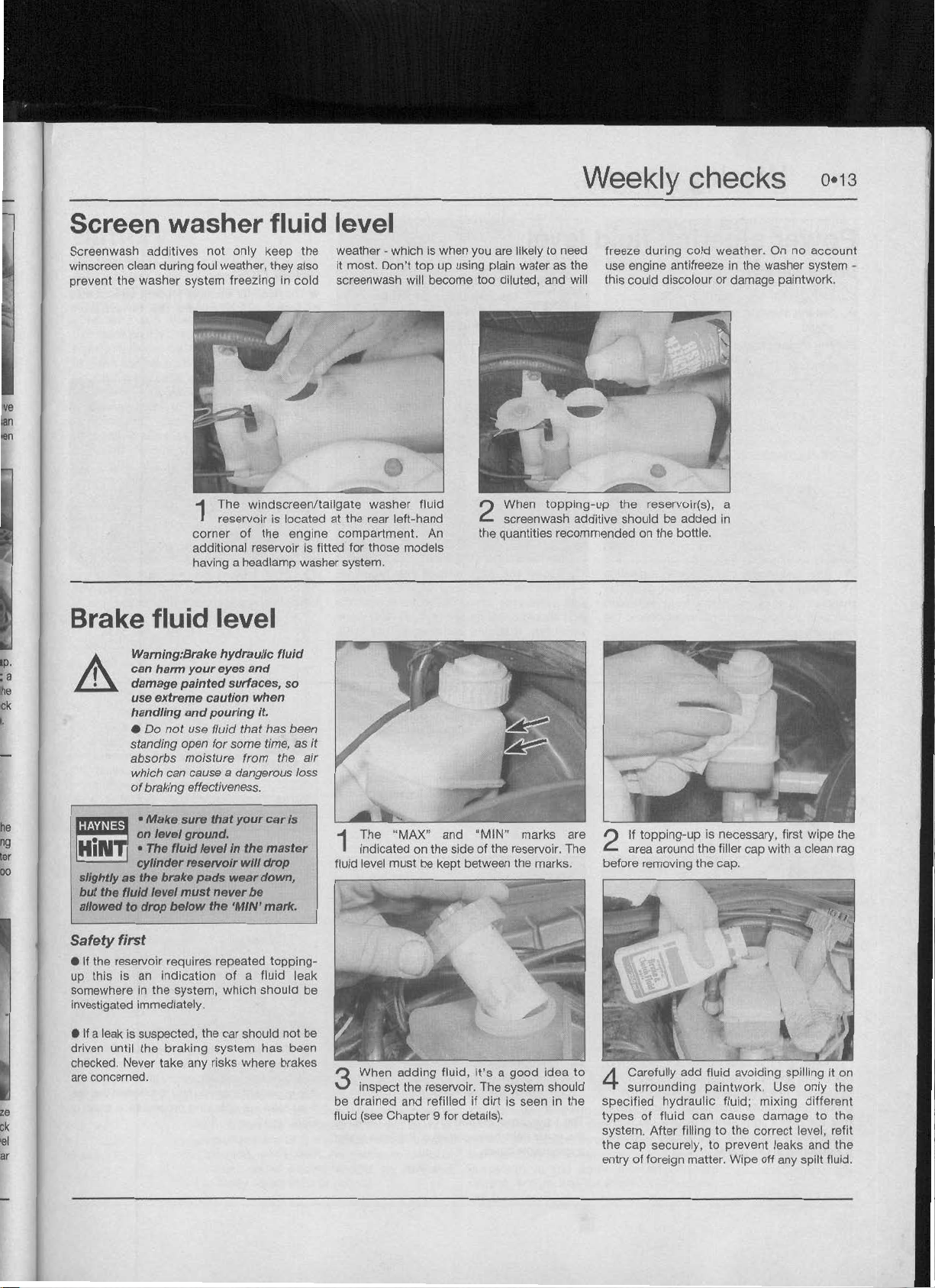

Screen

Brake

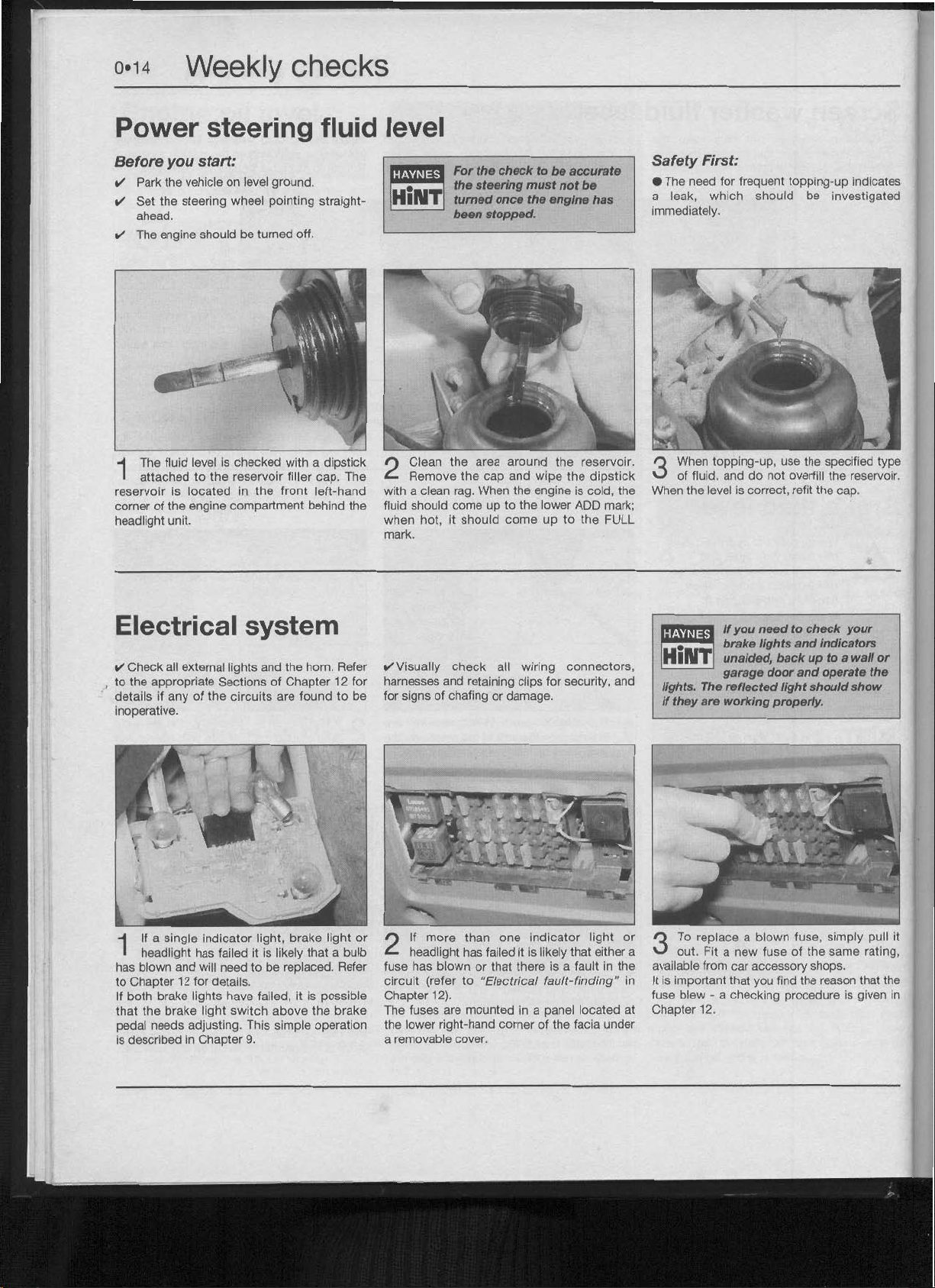

Power

Èkricalsystern

-.

Battew

-.

Wiper blade

-

Tyre

Lubricants and

.-

Capacities

Tyre

-

checks

-

check

-

check

levei

check

.

v~asher

flurd level

-.

steering fl~id levei

-

cneck

-

condition

pressures

fluid leve1

check

check

-

and

fluids

--

. -.

.-

check

przçsure

points

-.

--

check

.-

check

-. .-

-. -.

check

-.

VAUXHALL

-.

-.

.- -.

-.

.-

--

ASTRA

-.

-.

.

Page

.

Page

Page

-.

.-

Page

Page

--

-.

Page

Page

--

--

.

--

--

.-

--

Page

Page

Page

--

Page

-

Page

Page

Page

-.

-

--

--

.

--

--

..

.

-

Page

.-

Paye O*t4

Page

Page

Page

Page

Page

-

-

Page

-

.

--

-.

0*4

0*4

-

0-5

-

0*6

0*7

0*7

--

0-8

--

0.9

O*tO

O*~O

0*12

-

0.12

0.13

-

0.73

-

0414

0.15

0.15

0-16

--

0.17

-

0-17

..

0*17

.

Routine

Maintenarice schedule

-

Introductioii

hlaintenance

--

Servicing Specifcations

--

Maintenance

--

procedures

--

and

Servicing

--

-.

--

-.

-

-

-.

--

-

-

-

.

--

Page

-.

Page

Page

Page

1.1

.

1.7

--

i.8

1.19

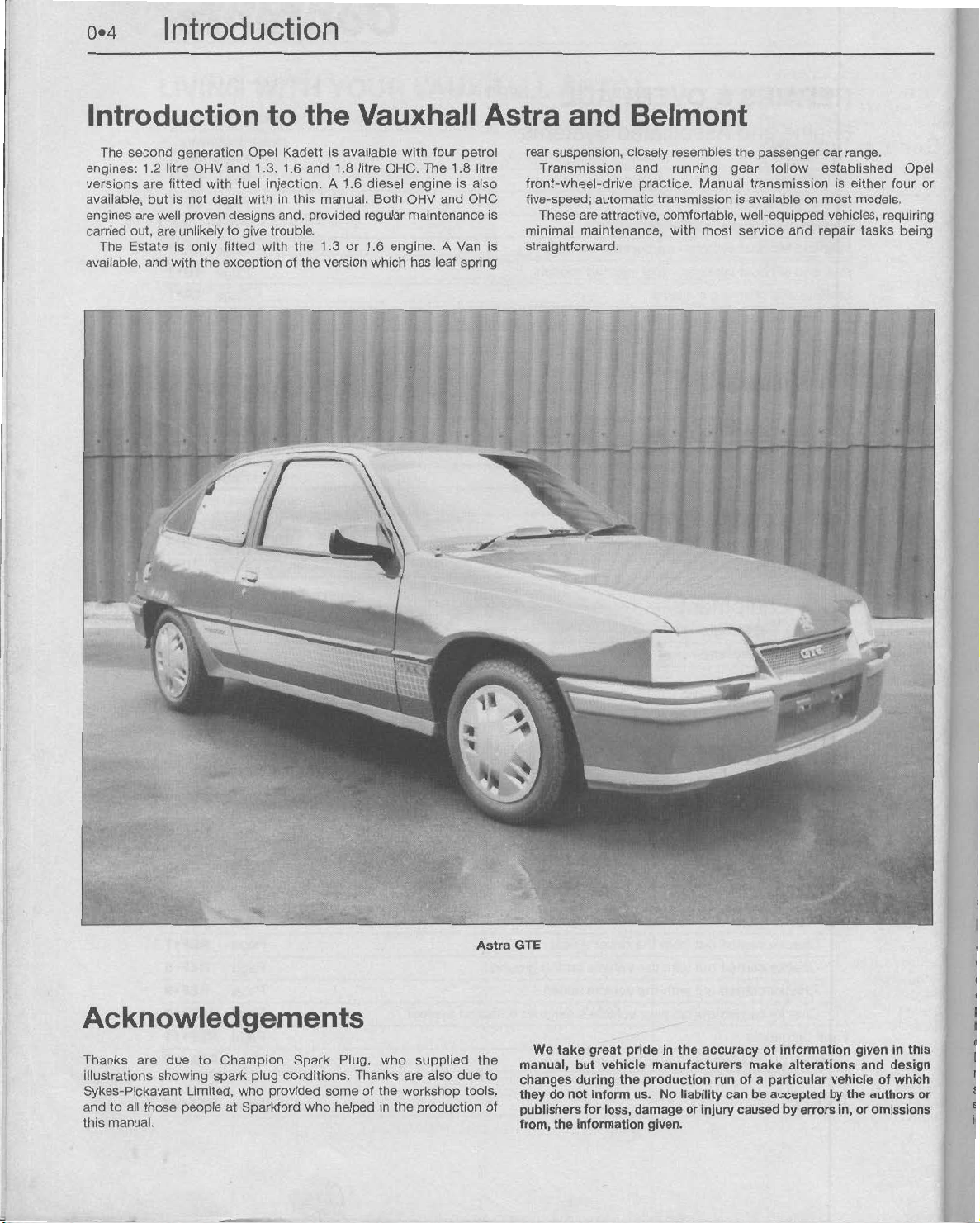

REPAIRS & OVERHAUL

Contents

Engine

OHV

~~c-~ngine

DOHC

Cooling. heating

Fuel and exhaust system -carblGtor rnodels

Fuel

Starting and charging systems

-.

Contact breaker ignition

Electronic (breakerless) ignition systems

and

Associated

Engine

(1

6-valve)

and

exhaust systems -fuel injected rnodels Page

-.

Engine

-.

and

..........

..

-.

... -.-.-.....

ventilation systems

-

.

.-.

- -

system

-

-

Systems

...-.........

-

-

-.

-

....

..

.-.

-

-

-. . -....... -.......

-.

.....

Page

.....

Page

Page

Page

Page

Page

Page

-

Page

Transmission

Clutch

Manual transmission Page

Autornatic transmission

.

.

Driveshafts

Brakes

Brakrng

Suspension

system

...

......

and

Suspension

and

steering

-.

-

.

.- .

---

.........

-..

Page

Page

Page

Page

Body Equipment

Bodywork and fittings

Body

electrical

system

.....

....

. . --.

.

Page

Page

-

-

-. ....

.

---

2A.1

-

28.1

2C.1

3*1

4A*1

-.

48.1

5A.l

-

56.1

..

5C.1

7A.1

7B*l

8*1

9*1

10*1

lt*l

12.1

.

Wiring Diagrams

. .

-. .--.

REFERENCE

Dimensions and

Conversion Factors

.....

Buying

-

Vehicle identification

-.

spare

-

......

General Repair

Tools

and

ET

Test

Checks carried out

Checks carried out with the vehicle on the around

Checks carried out with the vehicle raised

Checks carried out

Fault Diagnosis

-

.-

..

Glossary

Index

....

....

weights

parts

-

....

...

---

numbers

~tocedures

----

......

-

..

........

Working Facilities

Checks

from

the

........

on

of

Technical Terms Page

driver's seat

-.

.

your vehicie's exhaust emission

-.-.-...

-

-

- - -.-

....

.-.

--

.........

system

.-...--.

..

Page

12i15

Page

Pase

Page

Page

-

-

- ------

......

.

........

Page

Page

Page

Page

Paqe

Page

Page

--

Page

REF*1

REF*2

REF.3

REF.3

REF.4

.

REF.5

REF*7

REF.7

REF.8

REF.9

REF*IO

REF.11

REF.18

Page

REF.23

.......

-

-..---

Chapter 1

Routine maintenance and servicing

Air cleaner filter element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . .13

Automatic transmission fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . .33

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . . . . . . . . . . . .9

Battery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Brake pad, caliper and disc check . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Carburettor fuel inlet filter cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Clutch adjustment check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Driveshaft CV joint and gaiter check . . . . . . . . . . . . . . . . . . . . . . . . .20

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Fuel filter renewal - fuel injection models . . . . . . . . . . . . . . . . . . . . . .25

Fuel pump filter cleaning - carburettor models . . . . . . . . . . . . . . . . .12

Handbrake adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Headlamp aim check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Hinge and lock lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Hose and fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Idle speed and mixture adjustments . . . . . . . . . . . . . . . . . . . . . . . . .11

Ignition system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manual transmission oil level check . . . . . . . . . . . . . . . . . . . . . . . . . .27

Rear brake shoe, wheel cylinder and drum check . . . . . . . . . . . . . . .29

Rear wheel bearing adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Roadwheel bolt tightness check . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Tyre checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Vauxhall Astra/Belmont maintenance schedule . . . . . . . . . . . . . . . . . .1

Wiper blade check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

The maintenance intervals in this manual are provided with the

assumption that you, not the dealer, will be carrying out the work.

These are the minimum maintenance intervals recommended by the

manufacturer for vehicles driven daily. If you wish to keep your vehicle

in peak condition at all times, you may wish to perform some of these

procedures more often. We encourage frequent maintenance, because

it enhances the efficiency, performance and resale value of your

vehicle. If the vehicle is driven in dusty areas, used to tow a trailer, or

driven frequently at slow speeds (idling in traffic) or on short journeys,

more frequent maintenance intervals are recommended.

When the vehicle is new, it should be serviced by a factoryauthorised dealer service department, in order to preserve the factory

warranty.

1•1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult, suitable

for competent DIY

mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Contents

1

1 Vauxhall Astra/Belmont maintenance schedule

1•2 Maintenance schedule

Every 9000 miles (15 000 km) or

6 months, whichever comes first

mm Renew the engine oil and filter - early (pre-1987) models

(Section 6)

Every 9000 miles (15 000 km) or

12 months, whichever comes first

mm Renew the engine oil and filter - later (1987-on) models

(Section 6)

mm Renew the spark plugs (Section 7)

mm Check and adjust the valve clearances - 1.2 litre models

(Chapter 2A)

mm Check all underbonnet and underbody components, pipes and

hoses for leaks (Section 8)

mm Check the condition of the auxiliary drivebelt, and renew if

necessary (Section 9)

mm Check the ignition system components and renew the contact

breaker points (Section 10)

mm Check idle speed and mixture adjustments (Section 11)

mm Clean the fuel pump filter (carburettor models) (Section 12)

mm Check the throttle cable adjustment (Chapter 4A or 4B)

mm Check the automatic transmission fluid level (Section 13)

mm Check the operation of the horn, all lights, and the wipers and

washers (Section 14)

mm Check the condition of the wiper blades (Section 15)

mm Check the tightness of the roadwheel bolts (Section 16)

mm Check the condition of the front, and rear (where fitted) brake

pads (renew if necessary), and the calipers and discs

(Section 17)

mm Check the rear wheel bearings adjustment (Section 18)

mm Check the handbrake adjustment (Section 19)

mm Check the driveshaft CV joints and gaiters for condition

(Section 20)

mm Lubricate locks and hinges (Section 21)

mm Check the exhaust system for condition and security

(Section 22)

mm Road test the vehicle (Section 23)

Every 2 years

(regardless of mileage)

In addition to all the relevant items listed previously, carry out the

following:

mm Renew the coolant (Section 32)

Every 36 000 miles (60 000 km) or

4 years, whichever comes first

In addition to all the relevant items listed previously, carry out the

following:

mm Renew the automatic transmission fluid (Section 33)

mm Renew the camshaft toothed belt -

1.3, 1.4, 1.6, 1.8 and 2.0 litre 8-valve engines (Chapter 2B),

2.0 litre 16-valve engines (Chapter 2C)

Every 54 000 miles (90 000 km) or

3 years, whichever comes first

In addition to all the relevant items listed previously, carry out the

following:

mm Renew the braking system seals and hose (Chapter 9)

Every 18 000 miles (30 000 km) or

12 months, whichever comes first

In addition to all the items listed previously, carry out the following:

mm Renew the air cleaner filter element (Section 24)

mm Renew the fuel filter (fuel injection models) (Section 25)

mm Clean the carburettor fuel inlet filter (Section 26)

mm Check the manual transmission oil level (Section 27)

mm Check the clutch adjustment (Section 28)

mm Check the condition of the rear brake shoes (renew if

necessary), wheel cylinders and drums (Section 29)

mm Renew the brake fluid (Section 30)

mm Check the headlamp alignment (Section 31)

Every 250 miles (400 km) or weekly

mm See Weekly checks

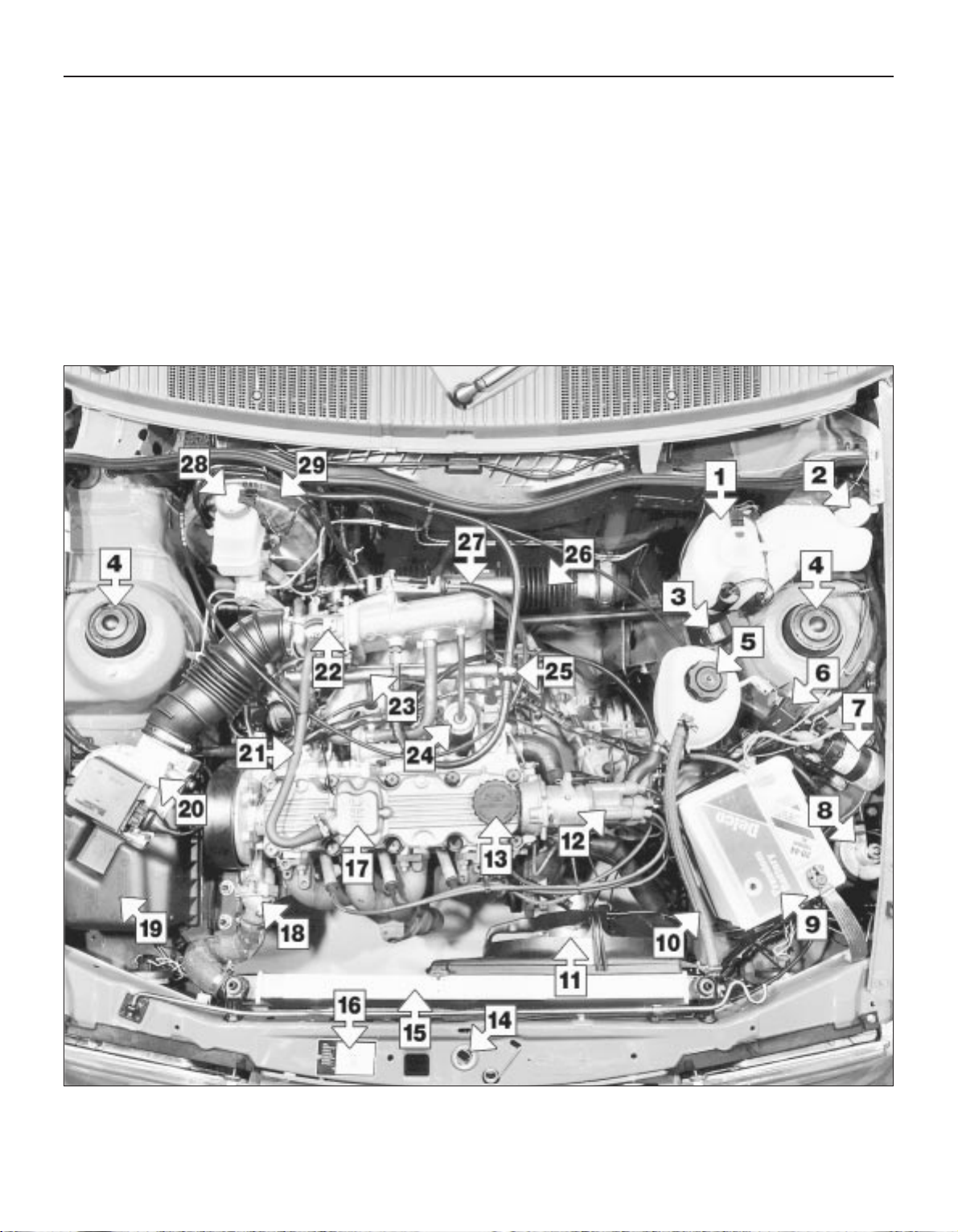

Maintenance - component location 1•3

1

1 Wiper motor

2 Heater blower motor

3 Heater blower motor resistor

4 Windscreen washer tube

5 Screen washer reservoir

6 Suspension turrets

7 Coolant expansion tank

8 Ignition coil

9 Battery

10 Coolant hose

11 Radiator cooling fan

12 Distributor cover

13 Engine oil filler

14 Bonnet catch

15 Radiator

16 VIN plate

17 Engine breather

18 Air cleaner hot air pick-up

19 Thermostat housing

20 Fuel hoses

21 Fuel pump

22 Alternator

23 Accelerator cable

24 Carburettor

25 Choke cable

26 Servo non-return valve

27 Steering rack bellows

28 Air cleaner breather hose

29 Brake fluid reservoir

30 Brake servo

Underbonnet view of an early 1.6 litre model (air cleaner removed for clarity)

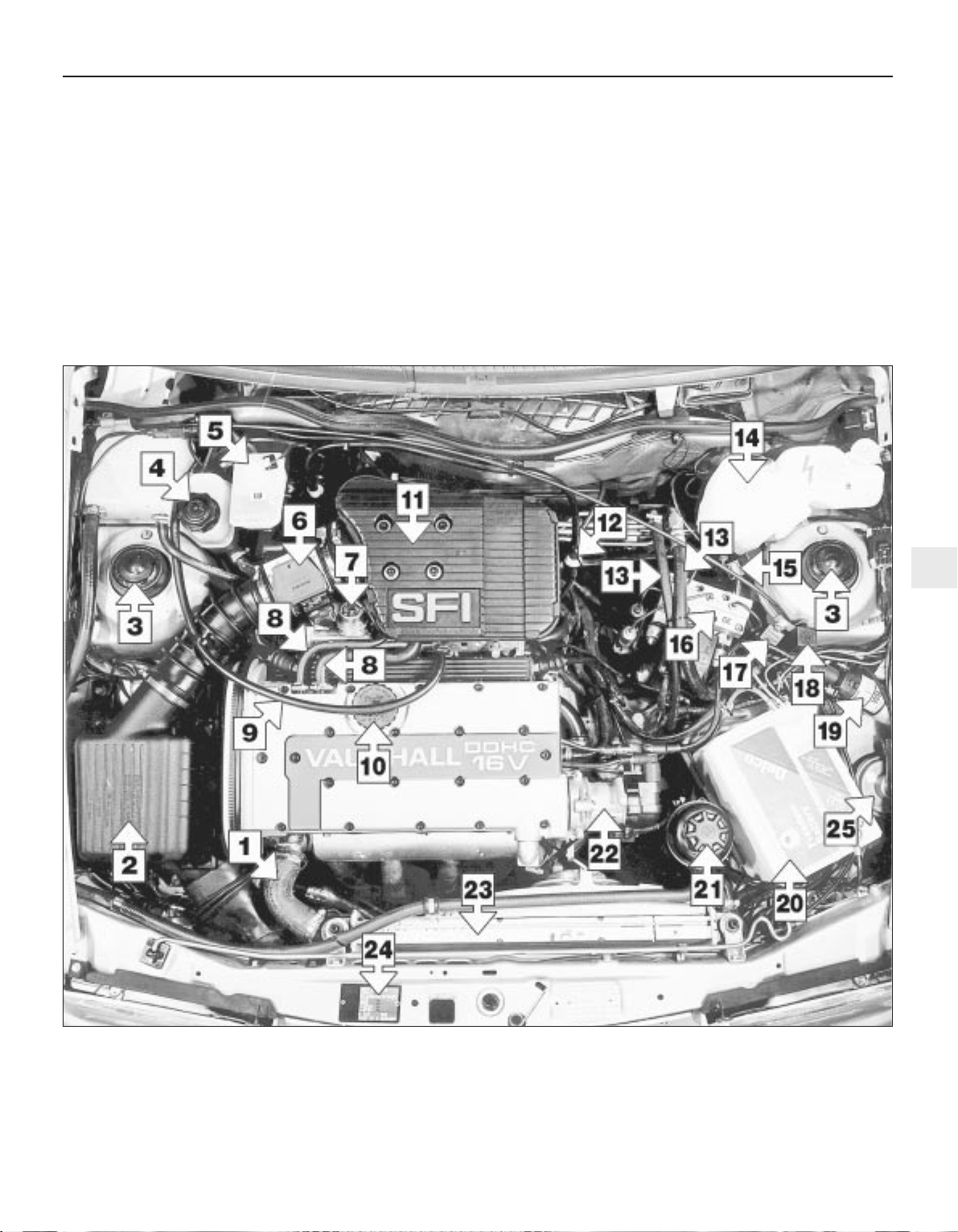

1•4 Maintenance - component location

1 Screen washer reservoir

2 Headlamp washer filler cap

3 Headlamp washer relay and fuse

4 Suspension turrets

5 Coolant expansion tank filler

6 Control relay (fuel injection system)

7 Ignition coil

8 Horn

9 Battery

10 Coolant hose

11 Radiator fan

12 Distributor

13 Engine oil filler

14 Bonnet catch

15 Radiator

16 VIN plate

17 Engine breather

18 Thermostat housing

19 Air cleaner

20 Airflow meter

21 Breather hose

22 Throttle valve housing

23 Fuel rail

24 Fuel pressure regulator

25 Servo non return valve

26 Steering rack bellows

27 Accelerator cable

28 Brake fluid reservoir

29 Brake servo

Underbonnet view of an early 1.8 litre model

Maintenance - component location 1•5

1

1 Radiator top hose

2 Air cleaner

3 Suspension turrets

4 Coolant filler cap

5 Brake fluid reservoir

6 Air mass meter

7 Fuel pressure regulator

8 Breather hoses

9 Throttle cable

10 Engine oil filler cap

11 Pre-volume chamber

12 Brake servo non-return valve

13 Power steering hoses

14 Windscreen washer reservoir

15 Headlamp washer relay

16 ABS hydraulic unit

17 ABS surge arrester relay

18 Fuel injection control relay

19 Ignition coil

20 Battery

21 Power steering fluid reservoir

22 Distributor

23 Radiator

24 Vehicle identification plate

25 Horn

Underbonnet view of a 2.0 litre 16-valve model

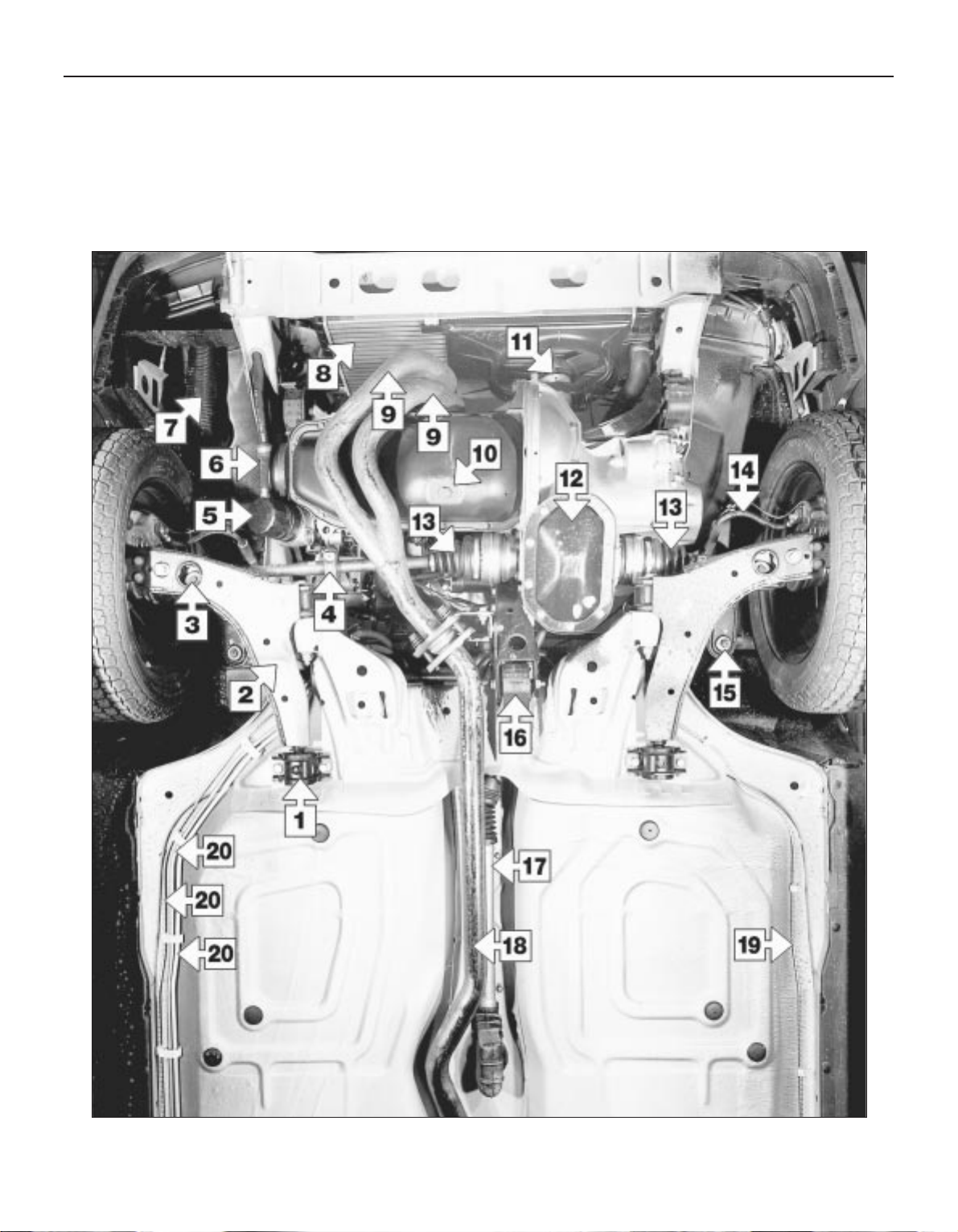

1•6 Maintenance - component location

1 Control arm rear bush

2 Control arm

3 Anti-roll bar link

4 Driveshaft damper weight

5 Engine oil filter

6 Oil cooler hose

7 Air induction trunking

8 Radiator

9 Exhaust downpipes

10 Sump drain plug

11 Radiator fan

12 Gearbox sump

13 Driveshaft bellows

14 Brake hose

15 Steering balljoint attachment

16 Engine/transmission rear mounting

17 Gearchange tube

18 Exhaust pipe

19 Brake pipe

20 Brake and fuel pipes

Front underbody view of a 1.8 litre model - other models similar

Maintenance - introduction 1•7

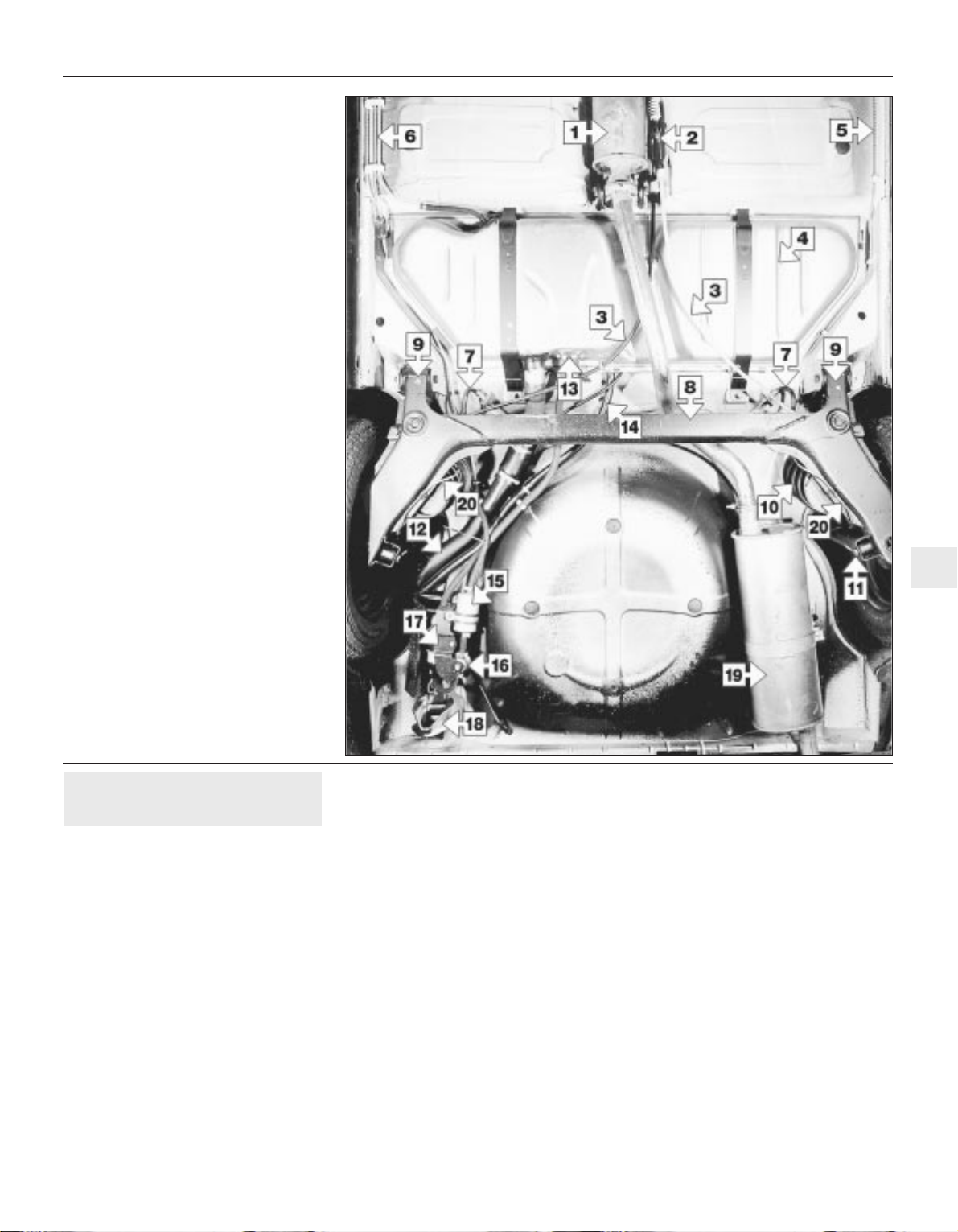

1

1 Centre silencer

2 Handbrake adjuster

3 Handbrake cables

4 Fuel tank

5 Brake pipe

6 Brake and fuel pipes

7 Brake hoses

8 Axle beam

9 Axle mountings

10 Spring

11 Shock absorber mounting

12 Fuel filler pipe

13 Fuel gauge sender/fuel tank outlet

14 Fuel tank breather

15 Fuel filter*

16 Fuel pressure regulator*

17 Fuel pump*

18 Towing eye

19 Rear silencer

20 Rear brake pipes

*Fuel injection models only

Rear underbody view of a 1.8 litre model -

other models similar

General information

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master

maintenance schedule, followed by sections

dealing specifically with each task on the

schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of the various components.

Servicing of your vehicle in accordance with

the mileage/time maintenance schedule and

the following sections will provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals, will not produce the same results.

As you service your vehicle, you will

discover that many of the procedures can and should - be grouped together, because of

the particular procedure being performed, or

because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust can be inspected

at the same time as the suspension and

steering components.

The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

sections relevant to the work to be carried

out, then make a list and gather together all

the parts and tools required. If a problem is

encountered, seek advice from a parts

specialist, or a dealer service department.

Intensive maintenance

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

If engine wear is suspected, a compression

test (Chapter 2) will provide valuable

information regarding the overall performance

of the main internal components. Such a test

can be used as a basis to decide on the

extent of the work to be carried out. If for

example a compression test indicates serious

internal engine wear, conventional

maintenance as described in this Chapter will

not greatly improve the performance of the

engine, and may prove a waste of time and

money, unless extensive overhaul work

(Chapter 2) is carried out first.

2 Introduction

1 Frequent oil and filter changes are the most

important preventative maintenance

procedures which can be undertaken by the

DIY owner. As engine oil ages, it becomes

diluted and contaminated, which leads to

premature engine wear.

2 Before starting this procedure, gather

together all the necessary tools and materials.

Also make sure that you have plenty of clean

rags and newspapers handy, to mop up any

spills. Ideally, the engine oil should be warm,

as it will drain more easily, and more built-up

sludge will be removed with it. Take care not

to touch the exhaust or any other hot parts of

the engine when working under the vehicle.

To avoid any possibility of scalding, and to

protect yourself from possible skin irritants

and other harmful contaminants in used

engine oils, it is advisable to wear gloves

when carrying out this work. Access to the

underside of the vehicle will be greatly

improved if it can be raised on a lift, driven

onto ramps, or jacked up and supported on

axle stands (see “Jacking and Vehicle

Support”). Whichever method is chosen,

make sure that the vehicle remains level, or if

it is at an angle, that the drain plug is at the

lowest point. The drain plug is located at the

rear of the sump.

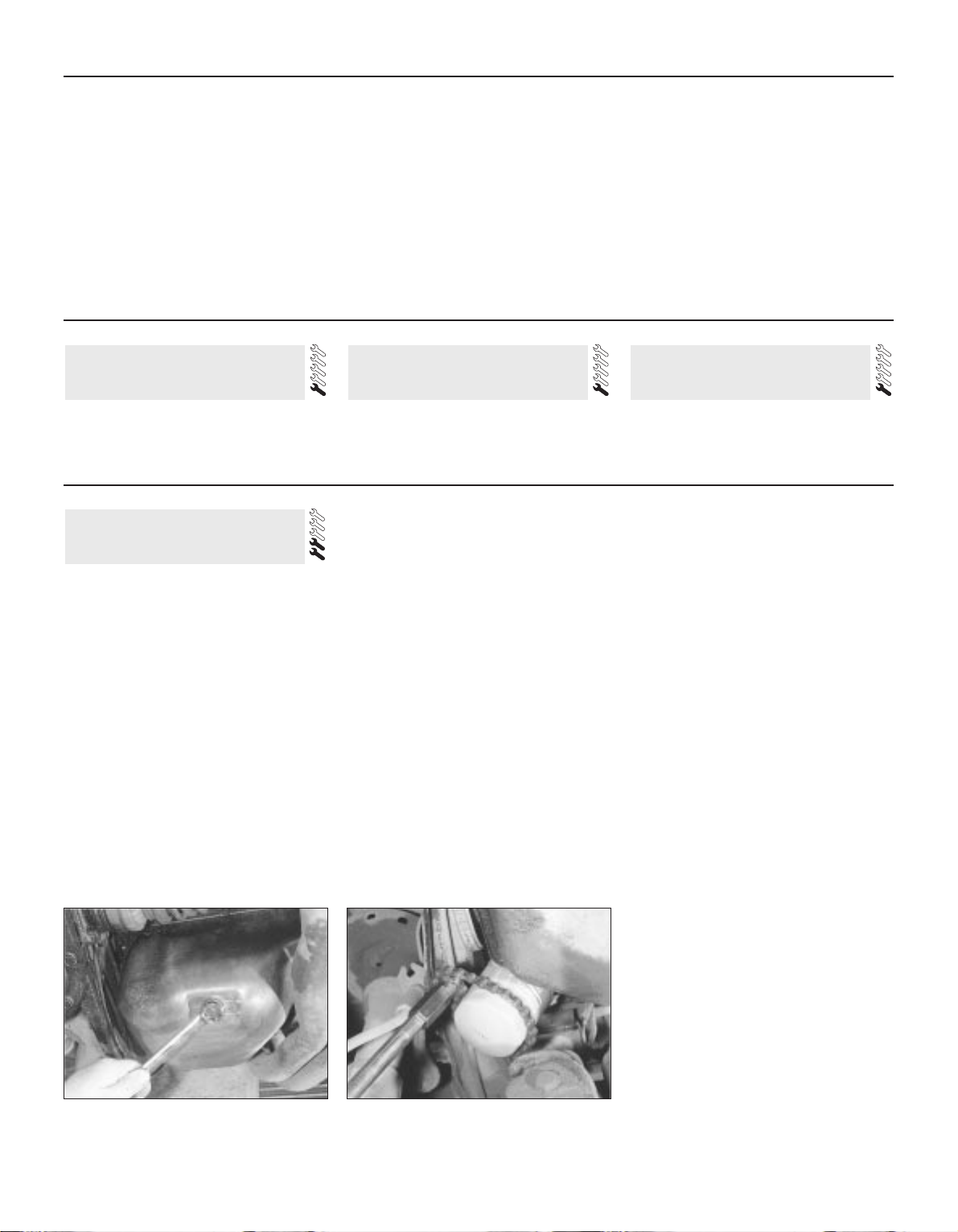

3 Remove the oil filler cap from the camshaft

cover (twist it through a quarter-turn anticlockwise and withdraw it).

4 Using a spanner, or preferably a socket and

bar, slacken the drain plug about half a turn

(see illustration). Position the draining

container under the drain plug, then remove

the plug completely. If possible, try to keep the

plug pressed into the sump while unscrewing it

by hand the last couple of turns. As the plug

releases from the threads, move it away

sharply, so that the stream of oil from the sump

runs into the container, not up your sleeve!

5 Allow some time for the oil to drain, noting

that it may be necessary to reposition the

container as the oil flow slows to a trickle.

6 After all the oil has drained, wipe the drain

plug and the sealing washer with a clean rag.

Examine the condition of the sealing washer,

and renew it if it shows signs of scoring or

other damage which may prevent an oil-tight

seal. Clean the area around the drain plug

opening, and refit the plug complete with the

washer. Tighten the plug securely, preferably to

the specified torque, using a torque wrench.

7 The oil filter is located at the right-hand end

of the engine.

8 Move the container into position under the

oil filter.

9 Use an oil filter removal tool to slacken the

filter initially, then unscrew it by hand the rest

of the way (see illustration). Empty the oil

from the old filter into the container.

10 Use a clean rag to remove all oil, dirt and

sludge from the filter sealing area on the

engine. Check the old filter to make sure that

the rubber sealing ring has not stuck to the

engine. If it has, carefully remove it.

11 Apply a light coating of clean engine oil to

the sealing ring on the new filter, then screw

the filter into position on the engine. Tighten the

filter firmly by hand only - do not use any tools.

12 Remove the old oil and all tools from

under the vehicle then, if applicable, lower the

vehicle to the ground.

13 Fill the engine through the filler hole in the

camshaft cover, using the correct grade and

type of oil (refer to Section 3 for details of

topping-up). Pour in half the specified quantity

of oil first, then wait a few minutes for the oil

to drain into the sump. Continue to add oil, a

small quantity at a time, until the level is up to

the lower mark on the dipstick. Adding a

further 1.0 litre (approx.) will bring the level up

to the upper mark on the dipstick.

14 Start the engine and run it for a few

minutes, while checking for leaks around the oil

filter seal and the sump drain plug. Note that

there may be a delay of a few seconds before

the low oil pressure warning light goes out when

6 Engine oil and filter renewal

1•8 Maintenance procedures

6.4 Removing the sump drain plug 6.9 Using an oil filter removal tool to

unscrew the oil filter

Every 250 miles or weekly

The following series of operations are those

most often required to improve the

performance of a generally poor-running

engine:

Primary operations

a) Clean, inspect and test the battery

(Section 4).

b) Check all the engine-related fluids

(Section 3).

c) Check the condition and tension of the

auxiliary drivebelt (Section 9).

d) Renew the spark plugs (Section 7).

e) Inspect the ignition system components

(Section 10).

f)| Inspect the ignition HT leads (Section 10).

g) Check the condition of the air filter, and

renew if necessary (Section 24).

h) Check the condition of all hoses, and

check for fluid leaks (Section 8).

If the above operations do not prove fully

effective, carry out the following secondary

operations:

Secondary operations

All items listed under “Primary operations”,

plus the following:

a) Check the charging system (Chapter 5A).

b) Check the fuel system (Chapter 4A or 4B).

c) Renew the air filter (Section 24).

d) Renew the distributor cap and rotor arm

(Section 10).

e) Renew the ignition HT leads (Section 10).

See “Weekly checks” See “Weekly checks” See “Weekly checks”

5 Tyre checks4 Battery check3 Fluid level checks

Every 9000 miles

the engine is first started, as the oil circulates

through the new oil filter and the engine oil

galleries before the pressure builds up.

15 Stop the engine, and wait a few minutes

for the oil to settle in the sump once more.

With the new oil circulated and the filter now

completely full, recheck the level on the

dipstick, and add more oil as necessary.

16 Dispose of the used engine oil safely, with

reference to “General repair procedures”.

1 The correct functioning of the spark plugs is

vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted

are appropriate for the engine, the suitable

type being specified at the end of this

Chapter. If the correct type of plug is used

and the engine is in good condition, the spark

plugs should not need attention between

scheduled renewal intervals, except for

adjustment of their gaps. Spark plug cleaning

is rarely necessary, and should not be

attempted unless specialised equipment is

available, as damage can easily be caused to

the firing ends.

2 To remove the plugs, first open the bonnet.

On 1.2 litre models remove the air cleaner as

described in Chapter 4A. On 2.0 litre 16-valve

engines undo the retaining screws and remove

the spark plug lead cover from the engine.

3 Mark the HT leads 1 to 4, to correspond to

the cylinder the lead serves (No 1 cylinder is

nearest the timing belt end of the engine). Pull

the HT leads from the plugs by gripping the

end connectors, not the leads, otherwise the

lead connections may be fractured.

4 It is advisable to remove any dirt from the

spark plug recesses using a clean brush,

vacuum cleaner or compressed air, before

removing the plugs, to prevent the dirt

dropping into the cylinders.

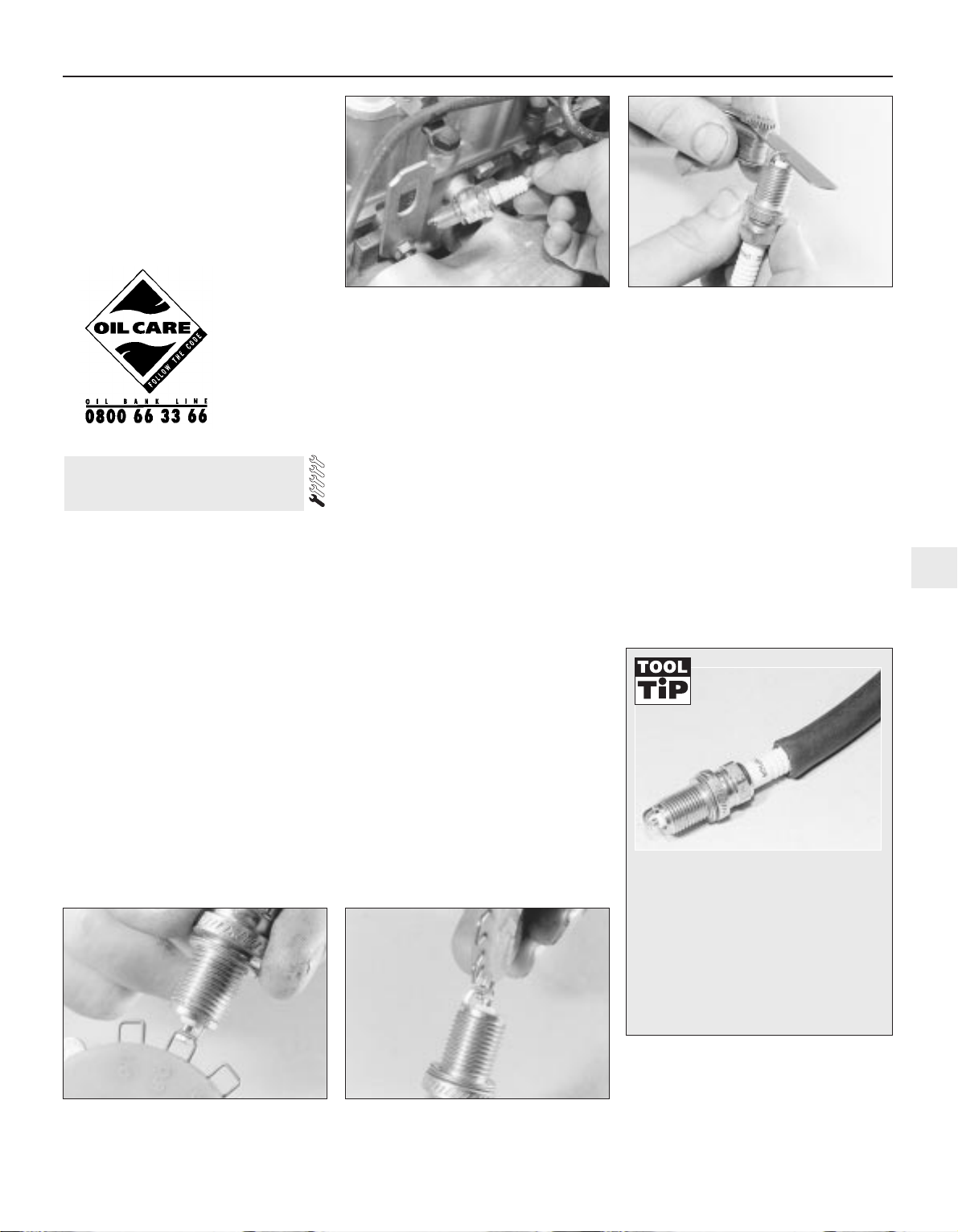

5 Unscrew the plugs using a spark plug

spanner, a suitable box spanner, or a deep

socket and extension bar (see illustration).

Keep the socket in alignment with the spark

plugs, otherwise if it is forcibly moved to either

side, the porcelain top of the spark plug may

be broken off. As each plug is removed,

examine it as follows.

6 Examination of the spark plugs will give a

good indication of the condition of the engine.

If the insulator nose of the spark plug is clean

and white, with no deposits, this is indicative

of a weak mixture or too hot a plug (a hot plug

transfers heat away from the electrode slowly,

while a cold plug transfers heat away quickly).

7 If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the idle mixture is too rich.

Should the plug be black and oily, then it is

likely that the engine is fairly worn, as well as

the mixture being too rich.

8 If the insulator nose is covered with lighttan to greyish-brown deposits, then the

mixture is correct and it is likely that the

engine is in good condition.

9 The spark plug gap is of considerable

importance as, if it is too large or too small,

the size of the spark and its efficiency will be

seriously impaired. For the best results, the

spark plug gap should be set in accordance

with the Specifications at the end of this

Chapter.

10 To set the spark plug gap, measure the

gap between the electrodes with a feeler

blade, and then bend open, or close, the outer

plug electrode until the correct gap is

achieved (see illustrations). The centre

electrode should never be bent, as this may

crack the insulation and cause plug failure, if

nothing worse.

11 Special spark plug electrode gap

adjusting tools are available from most motor

accessory shops (see illustration).

12 Before fitting the new spark plugs, check

that the threaded connector sleeves on the

top of the plug are tight, and that the plug

exterior surfaces and threads are clean.

13 Screw in the spark plugs by hand where

possible, then tighten them to the specified

torque. Take extra care to enter the plug

threads correctly, as the cylinder head is of

light alloy construction.

14 Reconnect the HT leads in their correct

order. On 1.2 litre models refit the air cleaner

(Chapter 4A) and on 2.0 litre 16-valve models,

refit the spark plug lead cover.

7 Spark plug renewal

Every 9000 miles 1•9

1

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling bank,

call this

number free.

7.10a Measuring a spark plug electrode

gap using a feeler blade

7.5 Removing a spark plug - 1.6 litre

engine shown

7.10b Measuring a spark plug electrode

gap using a wire gauge

7.11 Adjusting a spark plug electrode gap

using a special tool

It is very often difficult to insert spark

plugs into their holes without crossthreading them. To avoid this, fit a short

length of 5/16-inch internal diameter

hose over the end of the spark plug. The

flexible hose acts as a universal joint to

help align the plug with the plug hole.

Should the plug begin to cross-thread,

the hose will slip on the spark plug,

preventing thread damage to the

aluminium cylinder head.

Loading...

Loading...