Ref.No. : 4787

AV Receiver

TX-NR686

Final Issue

Final Issue

Service Manual

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Color Type Power Requirement Remarks

TX-NR686 B - Black MDC AC 120 V Canada/USA/(Mexico)

TX-NR686 B - Black MDF AC 120 V Taiwan

TX-NR686 B - Black MMA AC 220 V to 240 V Australia/New Zealand

TX-NR686 B - Black MMB AC 220 V to 240 V UK

TX-NR686 B - Black MMP AC 220 V to 240 V Europe

TX-NR686 B - Black MMR AC 220 V to 240 V China

TX-NR686 S - Silver MMP AC 220 V to 240 V Europe

For details, refer to "Important Check Points for good servicing".

Published by Onkyo & Pioneer Corporation Global CS Department 2018

1

2

Important Check Points for Good Servicing

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by following the safety instructions described in this manual.

D

C

B

2. Adjustments

3. Lubricants, Glues, and Replacement parts

A

4. Cleaning

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity.

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure connections and suitable usage.

Please exchange the power cord if necessary.

10 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper cleaning should be performed to restore their performances.

5 4 3

Service Notes

6

D

C

B

A

COMMON

1

2

5 4 3

6

1

2

5 4 3

6

Service Notes

1. Safety-related component warning!!

D

2. Safety check after servicing

C

3. Caution on replacing the battery

Components identified by mark on the schematic diagram and by mark “!” in the parts list are critical for risk of fire and electrical

shock. Replace these components with ONKYO parts whose part numbers appear as shown in this manual.

(1) To ensure safety, check that the covered insulating sheet or tube are removed, all parts and wires which are removed or

(2) To insure structural integrity, check that all the screws or mechanical parts have been put back in their original positions after

(3) Check that in the process of servicing or replacing parts that the surrounding area has not been contaminated or adversely affected.

(4) After servicing an insulation check on the external metal connectors and between the blades of the power plug must be performed.

disconnected while servicing have been put back to their original positions after servicing.

servicing.

Method of checking insulation resistance

Unplug the power cord and short the both ends of the plug with a jumper wire.

Using a 500V insulation resistance tester, check that the insulation resistance value between the plug of the power cord

and externally exposed metal parts is 1MΩ or greater.

※The mechanical power switch should be turned on if it is available.

Service Notes

D

C

Danger of explosion if rechargeable batteries is incorrectly replaced. Replace only with the same or equivalent type recommended by the

manufacturer. When disposing of used batteries, please comply with governmental regulations or environmental public institution’s rules

that apply in your country / area.

B

4. Other Cautions

・ When AC plug is non-polarized and if Main or Primary fuse enters in the Neutral line of AC Mains supply or if there is possibility of Main

or Primary Fuse entering in the Neutral line of AC Mains supply, then AC Mains supply must be disconnected to de-energize the circuit.

・ Be sure to use only lead free solder.

・ When soldering, please be careful not to use too much solder and affect adjacent components.

・ When you repair the CD Player, Please do not stare into the beam in Optical Instruments and do not view directly since there is visible

and invisible laser radiation when open the unit.

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer. Qualified technicians have the necessary test

equipment and tools, and have been trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty. If you are not qualified to perform the

repair of this product properly and safely, you should not risk trying to do so and refer the repair to a qualified service technician.

COMMON

1

2

5 4 3

B

A

6

1

5 4 3

2

1

6

2

5 4 3

6

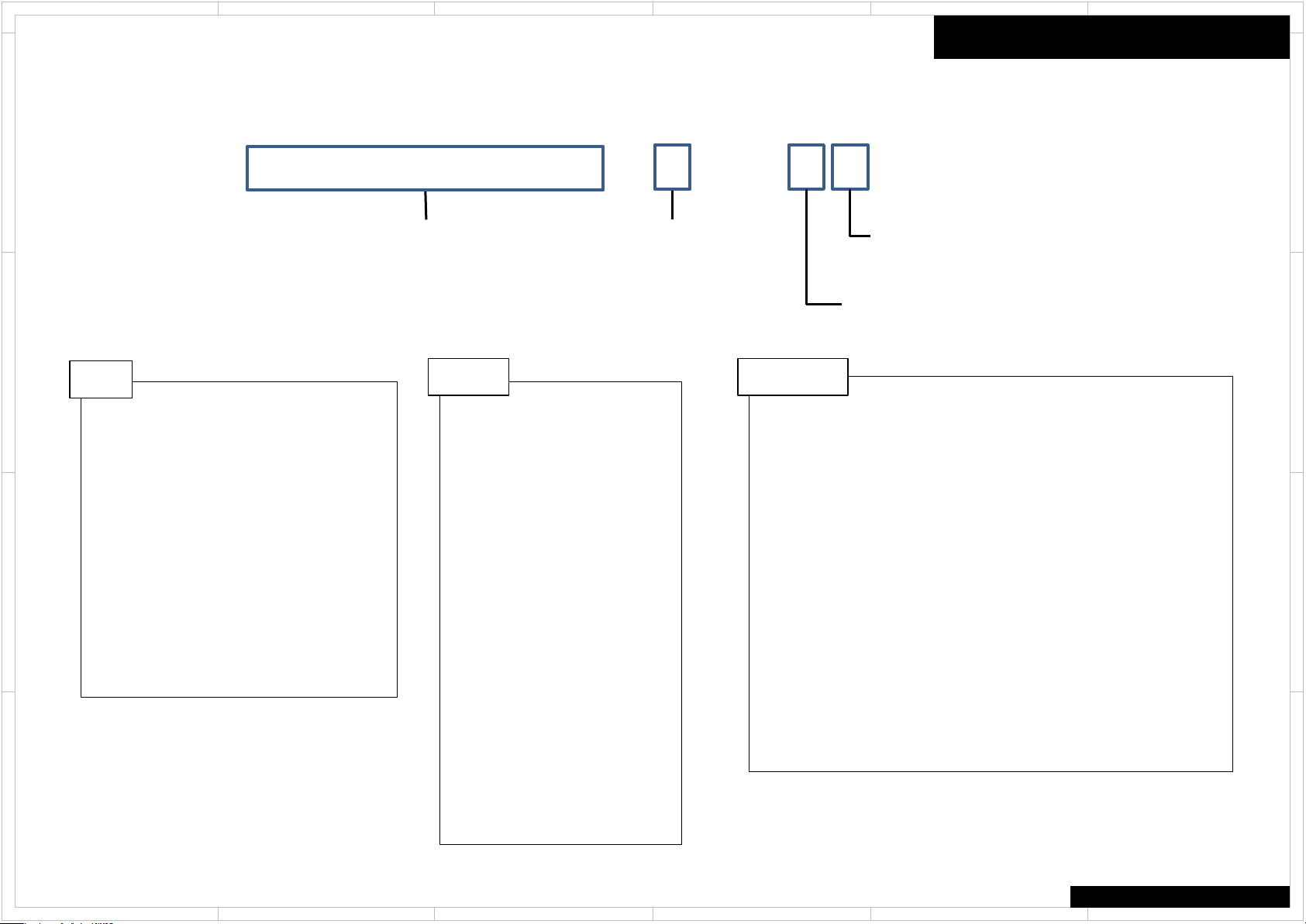

File Name of Parts List File (EXCEL File)

When parts list is EXCEL file, please refer to the following explanation about file name.

D

P L _ T X – S R 3 4 3 ( B ) M J J . x l s x

Model No. Color

C

Color

(X) Not related to color

(B) Black (M) Wood

(BR) Brown (O) Orange

(C) Cherry (P) Pink

(G) Gold (R) Red

B

A

(GR) Green (S) Silver

(H) Gray (V) Violet

(K) Black (W) White

(L) Blue (Y) Yellow

(LB) Light Blue

Voltage Destination

D 120V AC

G 220~230V

H 220~230/240V

J 100V AC

M 220~240V AC

P 230V AC

U 100~240V AC

V 110~240V

W 120V/220~240V

Z ※1

Speaker System (without AM P .) :

0 Passive Subwoofer

F Front Speaker

C Center Speaker

R Rear Speaker

B Back Speaker

Destination

Look at the rear panel serial number 6 digit.

○ ○ ○ ○ ○ J ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Voltage

Look at the rear panel serial number 5 digit.

○ ○ ○ ○ J ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

A Australia

B United Kingdom

C North American

D USA

F Taiwan

J Japan

K Korea

L Russia

P Europe

Q Hong Kong

R China

S Brazil

T Thai

U Worldwide

Note for Parts List

D

C

Speaker System (without AMP.) :

L Left channel

R Right channel

0 Center channel

B

A

※1 There is a charge function and a power supply ( adapter) is needed, but an adapter isn't bundled.

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

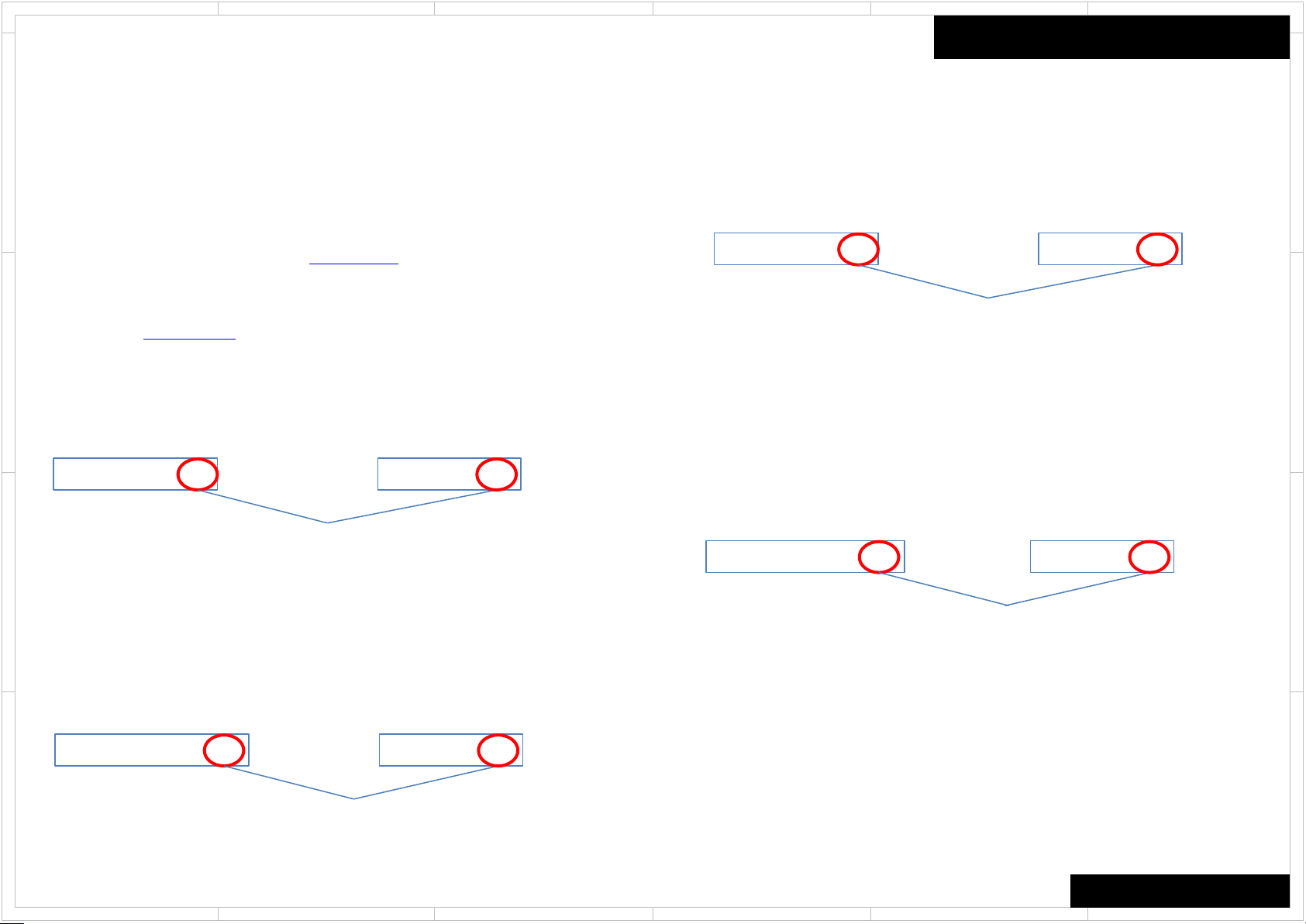

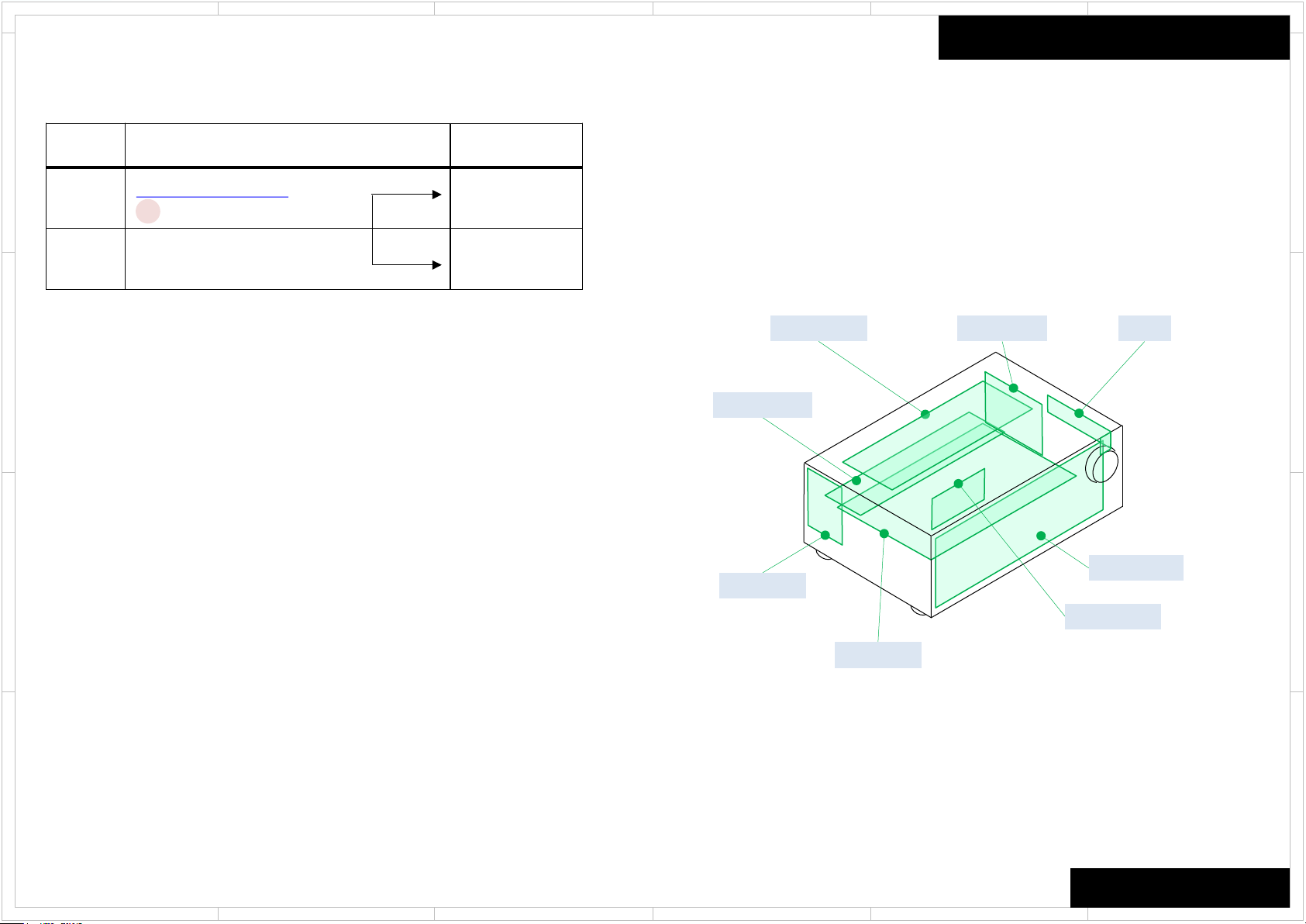

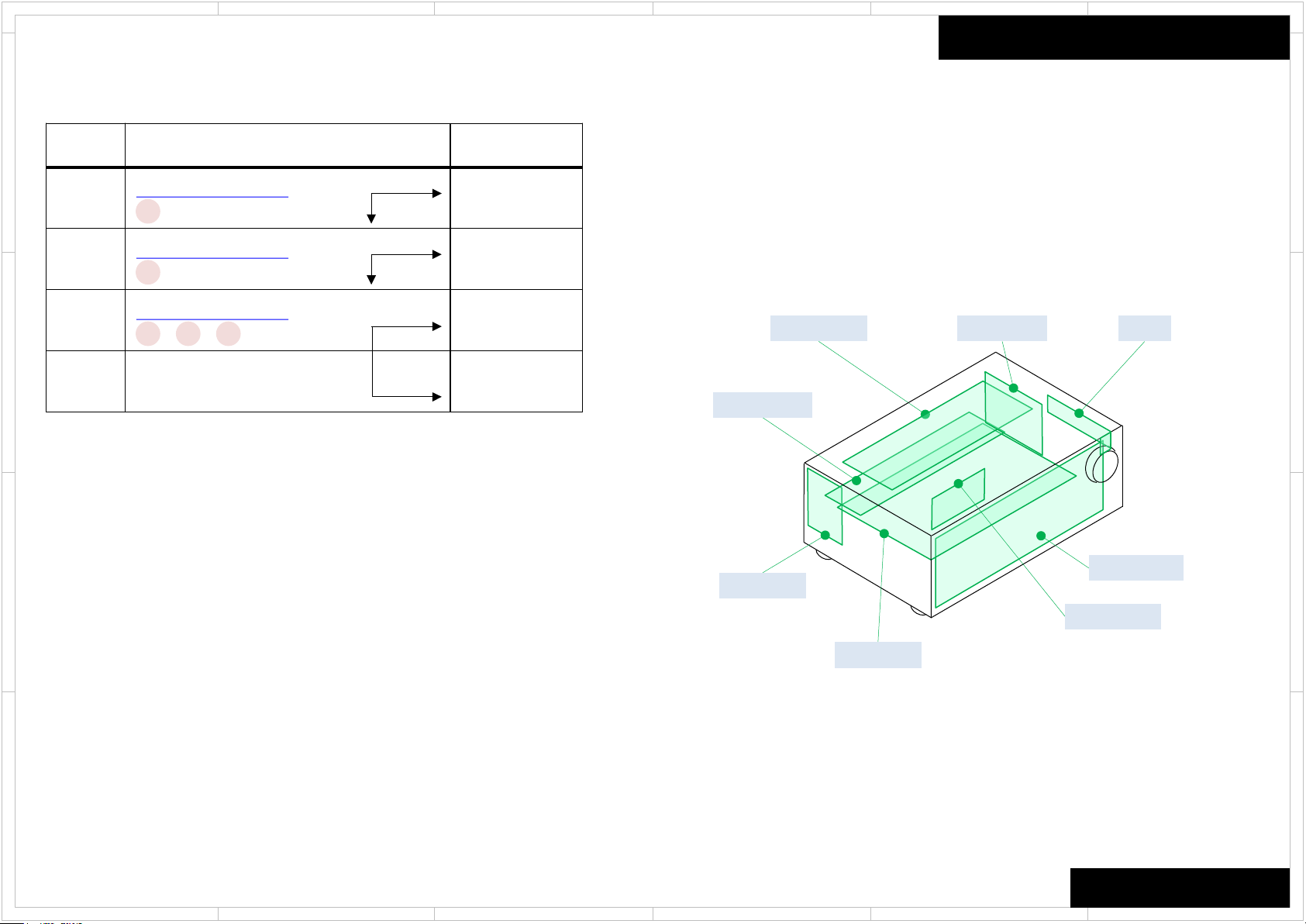

Reset

【STORE】

D

【RESET】

C

【RECALL】

Reset

D

[ SETUP ] + [ ENTER ] x 2

1. [ CBL/SAT ] + [ STANDBY ]

2. Unplug the power cor d from AVR after the di sapp eared "Clear"

of FL tube and A VR goes standby.

C

[ SETUP ] + [ RETURN ] x 2

Detail Key Operation is here.

B

A

B

A

TX-NR585/TX-NR686

1

5 4 3

2

1

6

2

5 4 3

6

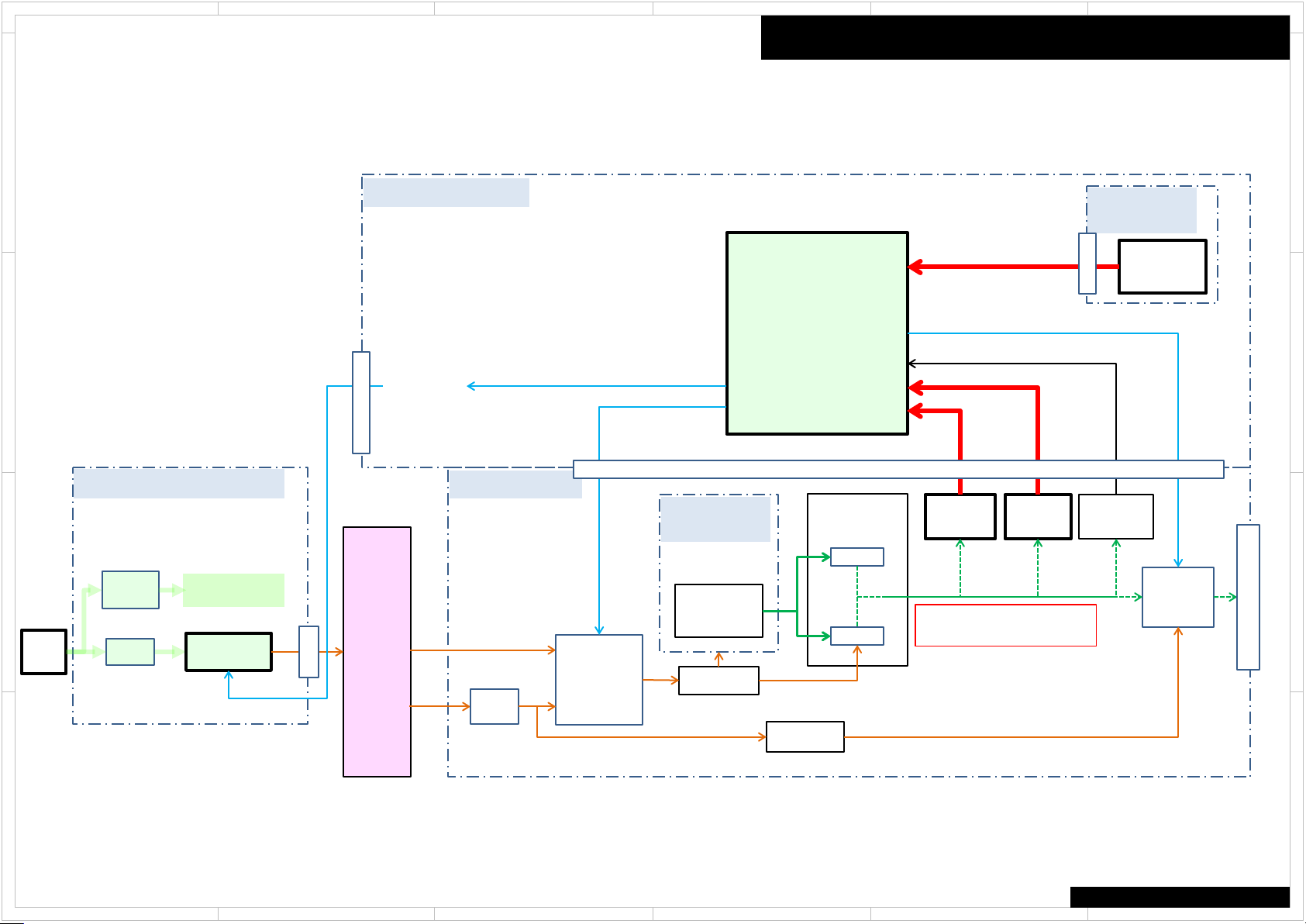

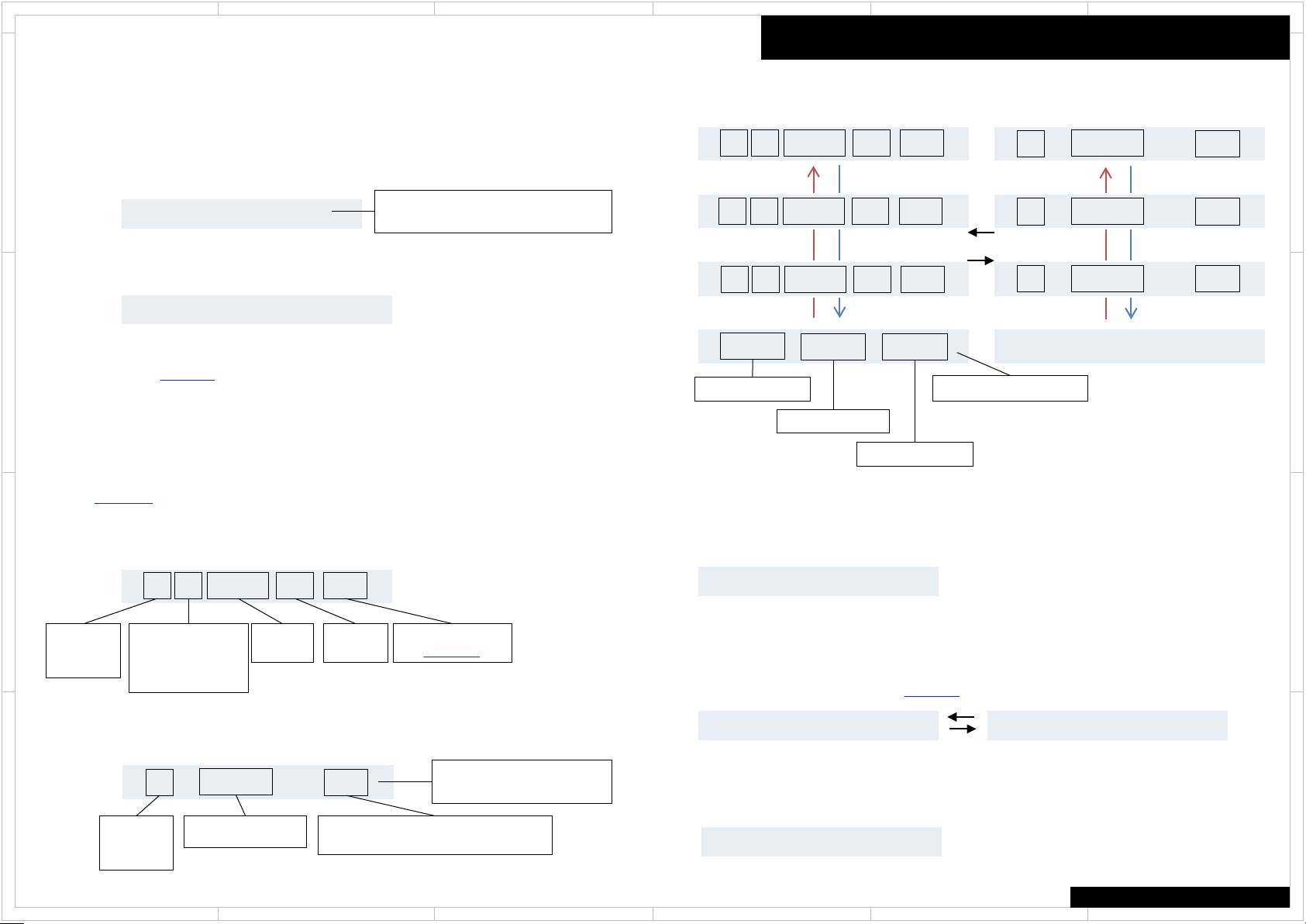

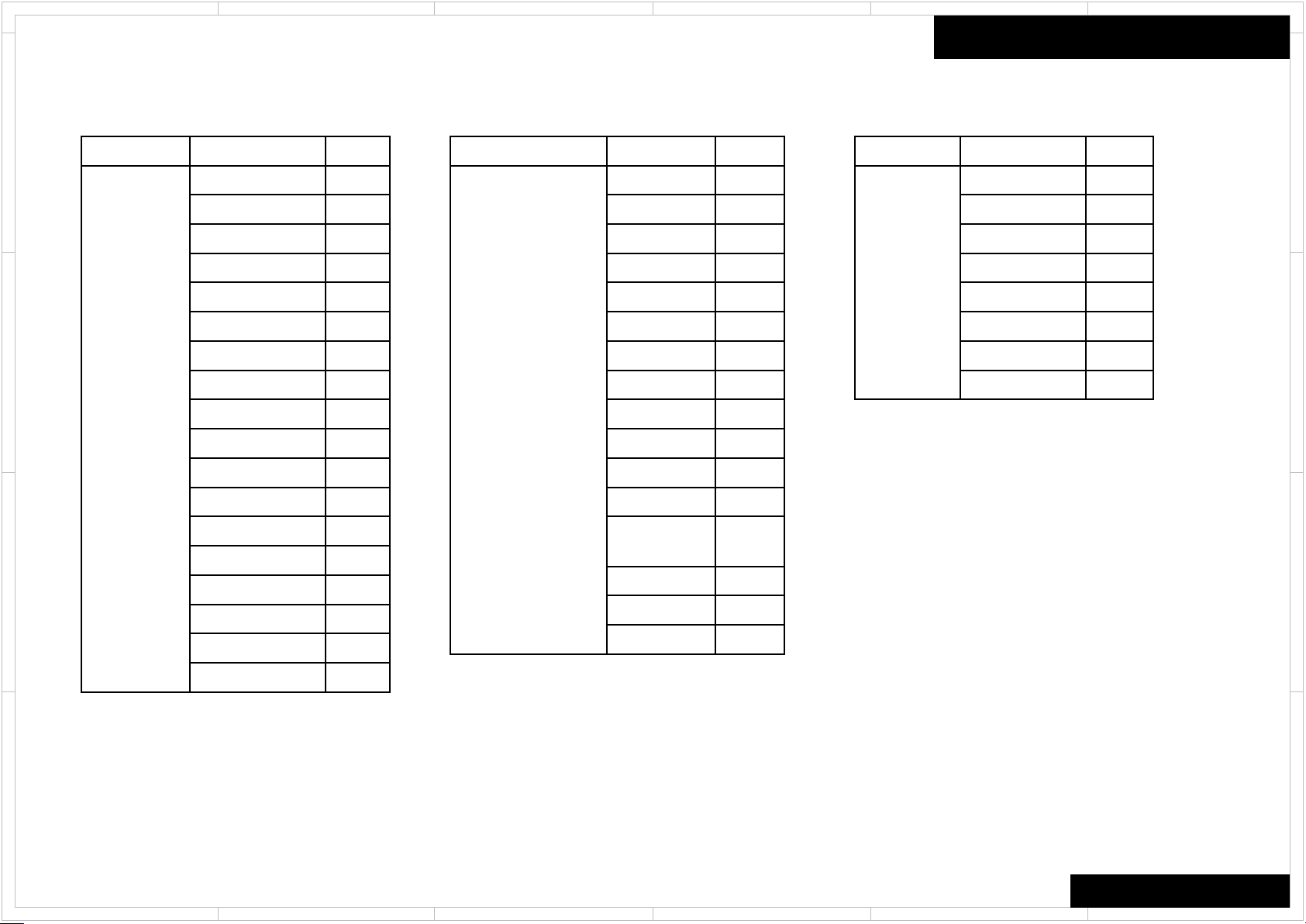

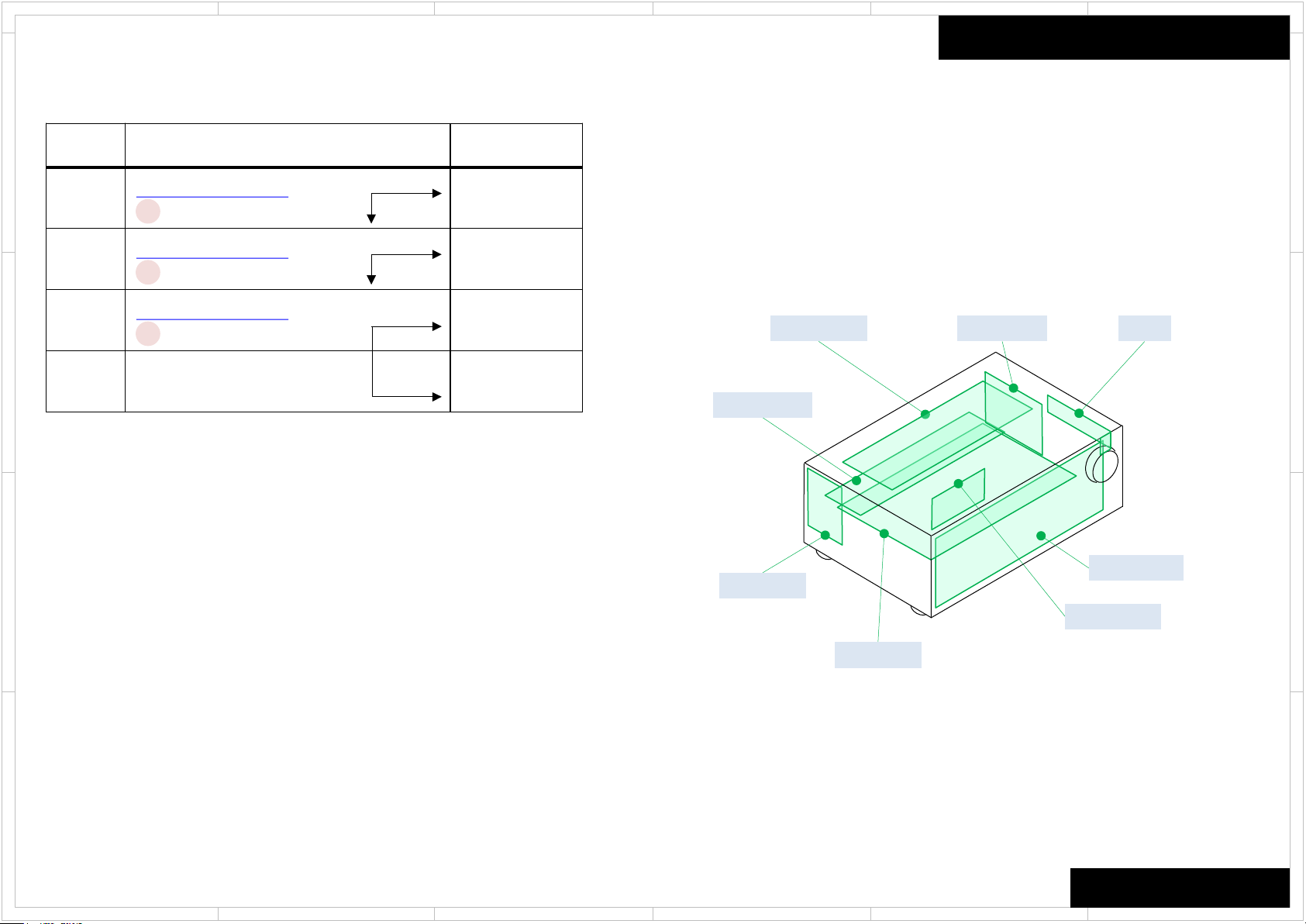

Protect Mode

Amp Diag Mode after Abnormal Conditions

The unit goes into standby automatically when detect the abnormal condition of thermal detection, dc voltage detection or current detection. (e.g. TX-NR555 block diagram below)

D

BAPRC PCB Info

THERMAL

C

B

AC IN

BAPS PCB Info

SUB

TRANS.

FUSE

F9002

Power Supply

for STANDBY

Relay

RL9001

P9002

PON_MAIN PON_MAIN

P2800B

BAAF PCB Info

BACLA PCB

POWER

Info

TRANS.

T901

VOLTAGE

DRIVE

SEC-1

(HIGH)

SEC-1

(LOW)

FUSE

F6901

F6902

(H)

RELAY

RL6911

RL6912

(L)

(H)

or

(L)

Power

Supply

SEC1H

MPU

Q7009

Power amp.

Power

Supply

SPRLF

VOLH

VPROTECT

IPROTECT

P8002

(Front L)

Q6001

Q6021

CURRENT

DETECT

IPRO

VPRO: DC voltage detection

IPRO: Current detection

DC

DETECT

VPRO

BAETC

PCB Info

THERMAL

DETECT

P6800A

VOLTAGE

DETECT

VOLH

Q6800

RELAY

RL6501

(FL/FR)

D

C

B

SPEAKER - OUT

A

A

COMMON

1

5 4 3

2

1

6

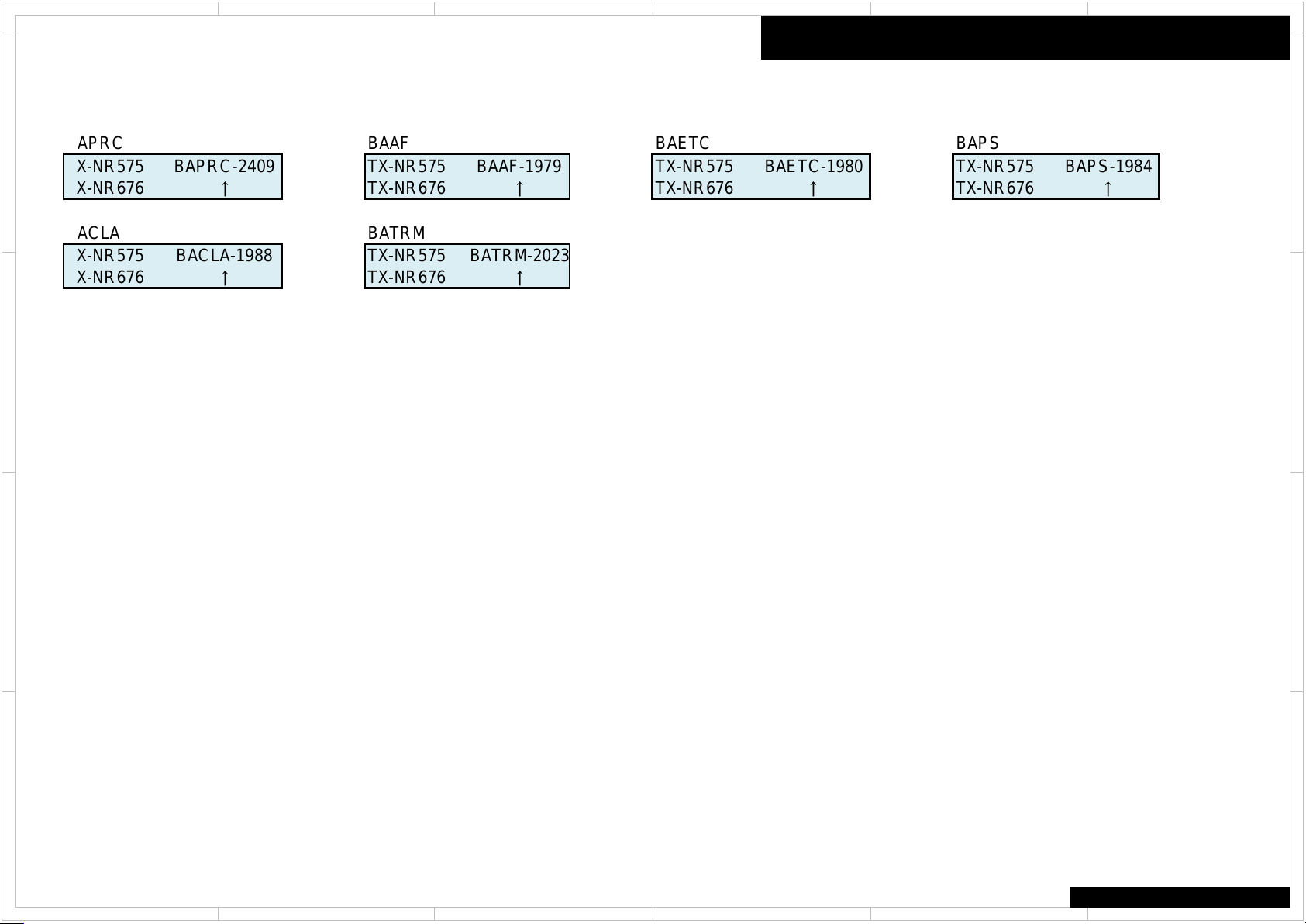

BAPRC BAAF BAETC BAPS

TX-NR575 BAPRC-2409 TX-NR575 BAAF-1979 TX-NR575 BAETC-1980 TX-NR575 BAPS-1984

TX-NR676

↑

TX-NR676

↑

TX-NR676

↑

TX-NR676

↑

BACLA BATRM

TX-NR575 BACLA-1988 TX-NR575

BATRM-2023

TX-NR676

↑

TX-NR676

↑

2

5 4 3

6

PCB Information

D

Amp Diag Mode after Abnormal Conditions

C

D

C

B

A

B

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

Self-diagnostics

This function is for avoiding the rupture of electrolytic capacitors with amplifier circuit

failure during power-ON.

Operation of Self-diagnostic

D

Self-diagnostic will start at the timing of next power on, after goes to the protect mode

by Current detection or DC voltage detection.

Only On/Standby key could work in this mode. Also remote control does not work.

However, the CLEAR operation is enabled.

During Self-diagnostic, the power supply for amplifier circuit become low voltage

state(SEC1-LOW), and the speaker relay will be turned off. Then, MPU will check each

amplifier circuits Internally by entering the test signal (20 kHz,-20 dBFS sine wave) to

each channel from DSP.

C

MPU will judge the amplifier circuit is good or not from VOLH value.

The normal range of VOLH value is 0.04 V < VOLH < 0.20 V.

If VOLH value is in the out of this range, it will be judged as NG (No good).

No problem found

When protected by current detection, and no problem found, "CHECK SP WIRE“ will be displayed.

In this State, Only the On/Standby key is effective. And if do not anything for 3 minutes, unit goes

into standby automatically.

When protected by a DC voltage detection, and no problem found, unit goes into normal

B

operation.

Problem found

When judged as there is a problem on any channel, the information of channel that has a problem

will be displayed as in the right figure.

In this State, Only the On/Standby key is effective. Also remote control does not work. If do not

anything for 3 minutes, unit goes into standby automatically. This state will keep also after unit

turn on/off, or AC unplugged.

the power supply for amplifier circuit become low voltage state(SEC1-LOW), and the speaker

A

relay will be turned off.

Amp Diag Mode after Abnormal Conditions

Display of during Self-diagnostics

2 Line FL tube type

A M P D i a g M o d e

1 Line FL tube type

A M P D i a g M o d e

“Mode” This part display the channel which is currently checked. (E.g. "[FL]", etc.)

Display of when problem found

2 Line FL tube type

N G C H :

L C R S L S R B L B

1 Line FL tube type

N G : L C R S L S R B L B R

Front L channel

L

Center channel

C

Front R channel

R

S L

S R

B L

B R

Surround L channel

Surround R channel

Surround back L channel

Surround back R channel

R

D

C

B

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

Repair Process and How to Confirm

Confirmation of the protect cause

While NG channel is displayed, You can confirm the protect cause by following the step below.

1. Press the Enter button

D

2. The protect cause are displayed for 5 seconds.

Please check the around of those amplifier circuit and repair it.

Clear of NG CH information

After repair, you can clear NG CH information by following the steps below.

1. Press the On/Standby key while pressing the Enter key.

2. Display as in the right figure appears.

C

3. Unit goes into Standby automatically after 5 seconds.

Self-diagnostic will start again at the timing of next power on.

By this, You can verify whether repair was properly or not.

If problem found after repair, please re-check the around of its circuit.

Cancel of Self-diagnostic

You can cancel this mode by clear operation (press Standby key while pressing CBL/SAT key).

After cancel this mode, receiver will be started as normal operation.

B

Manual Execution of Self-diagnostic

1. [DIMMER] + [ON/STANDBY] x 2

Main Firmware Version will appear on the main unit’s display.

2. [SETUP] or [HOME]

Service Menu will appear on the main unit’s display

3. Setup & select channel for self-diagnostic by enter service mode to “AMPChDiag”

Display as in the right figure appears. Select channel by cursor Left & Right.

4. [STANDBY/ON]

Unit will go into standby.

A

5. [STANDBY/ON]

Unit will turn on. Then self-diagnostic will start automatically.

Amp Diag Mode after Abnormal Conditions

Protected by current detection

D E T . P R O T E C T : I

D

Protected by DC Voltage detection

D E T . P R O T E C T : V

Clear of NG CH information

N G C H C L E A R

C

B

Manual Execution of Self-diagnostic

A m p C h D i a g : O f f

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

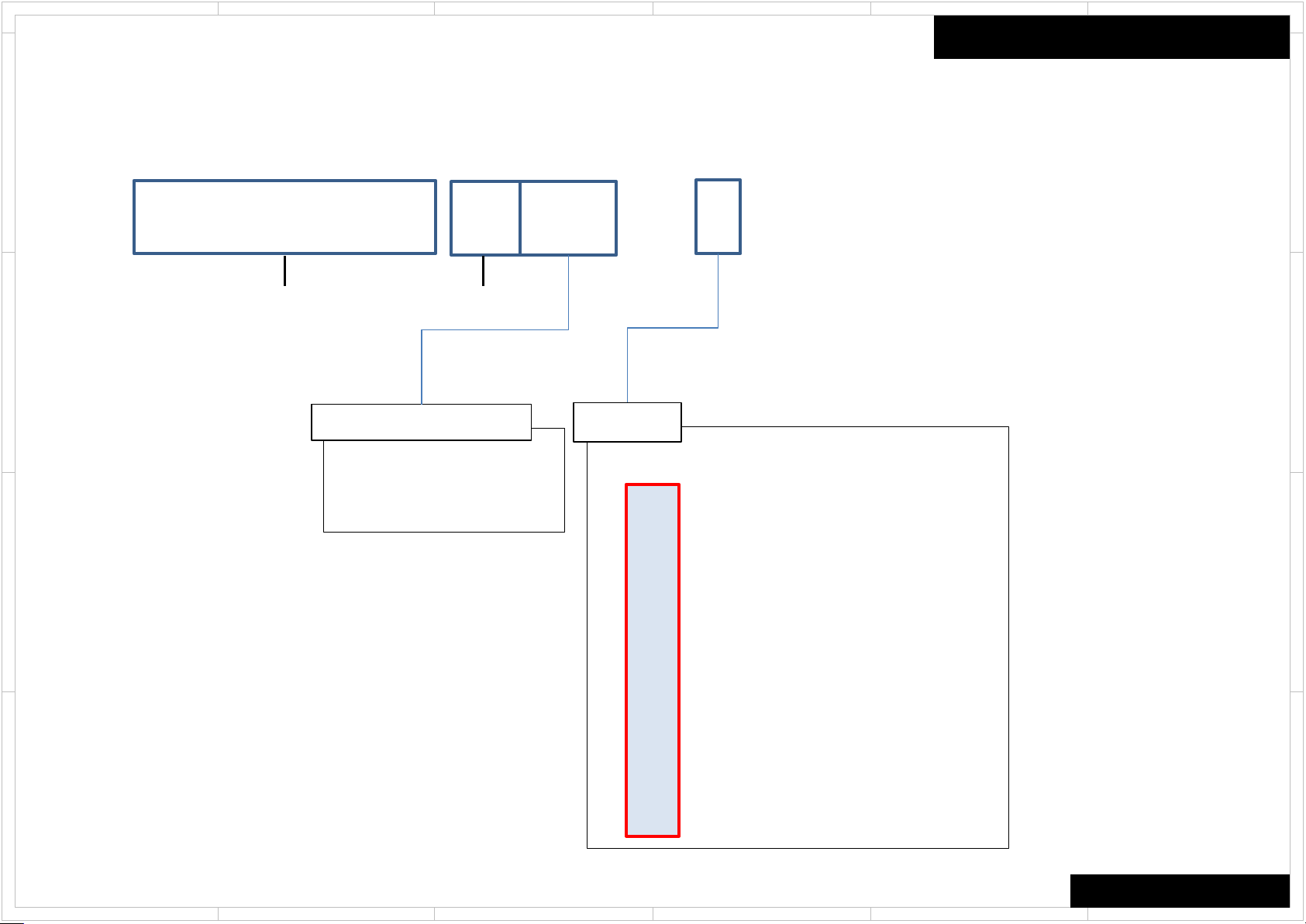

Enter Service mode, Service Information

How to enter to service mode.

Step1 :

D

[DIMMER] + [ON/STANDBY] x 2

Step2 :

[SETUP] or [HOME]

Step3:

C

Follow this Tr ee operation for each service mode.

M1.xx / xxxxxAEx

1. Service

Displaying Service information

This service information display sy stem is helpful in analy z e the status when the unit goes into

Protect mode and is powered off. Pay attention that the status will change if a button is pushed.

Follow this Tree for “ProtectData” section at the “1-1 Tech Sprt”

Step1 :

When the [ENTER] button is pressed, It w ill show error history

B

History No.

: 1 ~ 3

(1 is latest.)

Step2:

When the [ENTER] button during display error history,

the additional information of error history will be appeared.

A

History No.

: 1 ~ 3

(1 is latest.)

1 I 8 0 F 3 0 D D

PROTECT

I: Current Protect

V: Voltage Protect

T: Thermal Protect

Temperature

1 01: 23 10h

Time after Power on

xx : xx

Volume

Value

Cumulative operation time after Reset

: xx h

The version of main microprocessor.

(displayed only for 3 seconds)

Listening Mode

See This value

Information Displayed

(Record this Information)

Amp Diag Mode after Abnormal Conditions

How to change History No. 1 ~ 3.

[CURSOR LEFT] or [CURSOR RIGHT]

1 I 8 0 F 3 0 D D

[CURSOR LEFT] [CURSOR RIGHT]

2 I 9 1 F 2 7 D D

3 - 0 0 F 0 0 A

[ENTER]

T : 0 I : 2 V : 0

T : Thermal Protect

Count of each protect

I : Current Protect

V : Voltage Protect

How to exit the service mode.

Please press the [ANY INPUT SELECTOR]

Normal display

How to clear Protect Data

Step1:

Select “ProtectDataCLR” from this tree

Step2:

Press [ENTER] button

After display “DATA Cleared!”, It will be data reset and go to normal mode.

Protect Data CLR

DataCleared!

1 01: 23 10h

[CUROR LEFT] [CURSOR RIGHT]

2 01: 47 8h

3 00: 00 00h

No Use

Clear:[ENTER]

D

C

B

A

COMMON

1

5 4 3

2

1

6

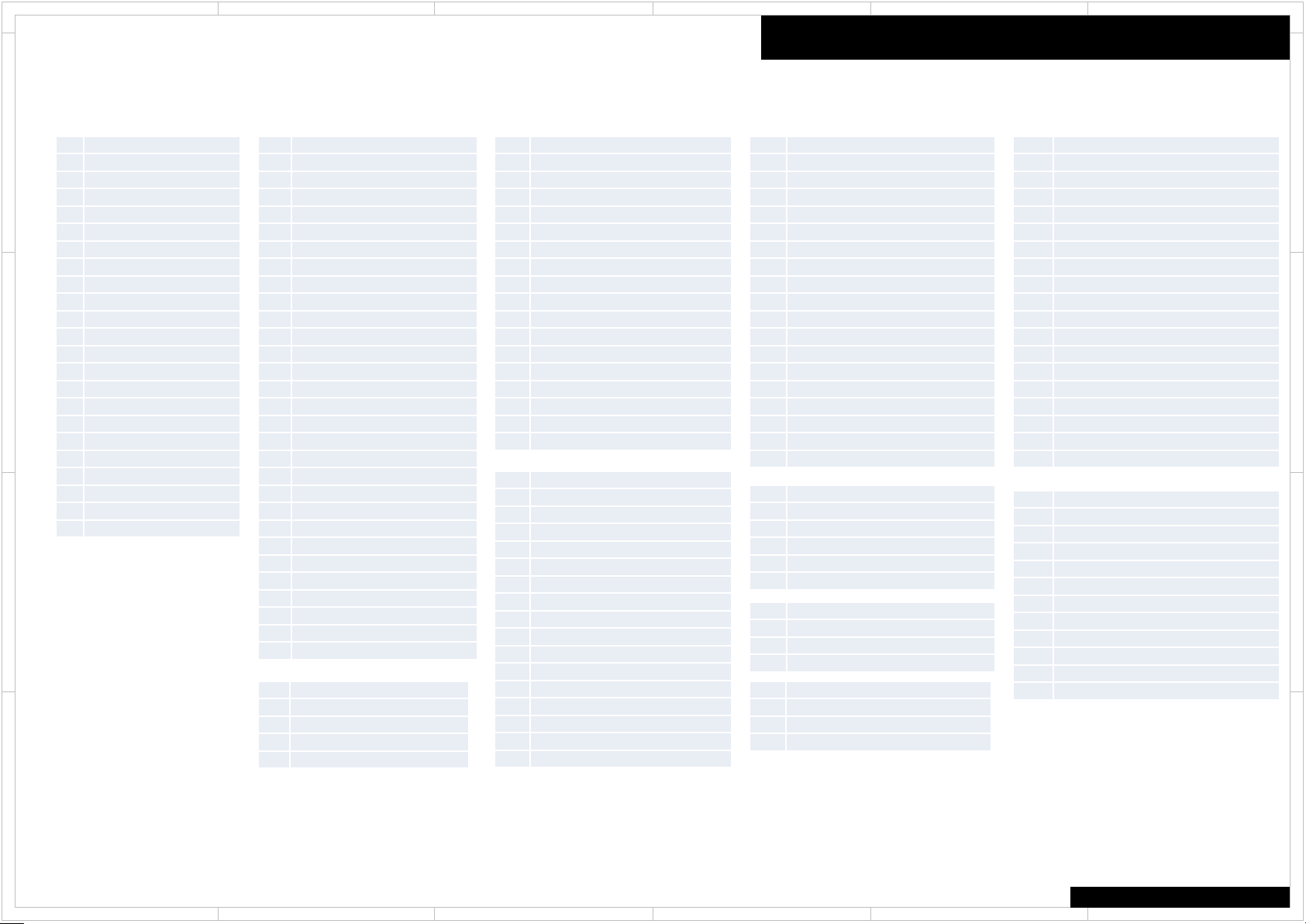

NORMAL_LMD_BEGIN

LAST

PURE

DIRECT

STEREO

MONO

ORCHESTRA

UNPLUGGED

STUDIOMIX

TVLOGIC

ALLCHST

FULLMONO

TD

RPG

ACTION

ROCKBAND

SPORTS

WHOLEHOUSE

RPG_GENRE

ACTION_GENRE

ROCKBAND_GENRE

SPORTS_GENRE

NORMAL_LMD_END

THX_MUSIC_LMD_BEGIN

THX_20_PLII_MUSIC

THX_20_PLIIX_MUSIC

THX_20_PLIIZ_MUSIC

THX_20_NEO6_MUSIC

THX_20_NEURAL_MUSIC

THX_51_OFF_MUSIC

THX_51_MTR_MUSIC

THX_51_DSC_MUSIC

THX_51_PLIIX_MUSIC

THX_51_PLIIZ_MUSIC

THX_51_NEO6_MUSIC

THX_51_NEURAL_MUSIC

THX_20_NEOX_MUSIC

THX_51_NEOX_MUSIC

THX_20_DOLBY_SURR_MUSIC

THX_51_DOLBY_SURR_MUSIC

THX_MUSIC_LMD_END

THX_GAME_LMD_BEGIN

THX_20_PLII_GAME

THX_20_PLIIX_GAME

THX_20_PLIIZ_GAME

THX_20_NEURAL_GAMES

THX_51_OFF_GAMES

THX_51_MTR_GAMES

THX_51_DSC_GAMES

THX_51_PLIIX_GAME

THX_51_PLIIZ_GAMES

THX_51_NEO6_GAMES

THX_51_NEURAL_GAMES

THX_20_NEOX_GAMES

THX_51_NEOX_GAMES

THX_20_DOLBY_SURR_GAME

THX_51_DOLBY_SURR_GAME

THX_GAME_LMD_END

THX_U2CINEMA_LMD_BEGIN

THX_51_SLCT2_CIN

THX_51_PLIIZ_SLCT2_CINEMA

THX_U2CINEMA_LMD_END

2

5 4 3

6

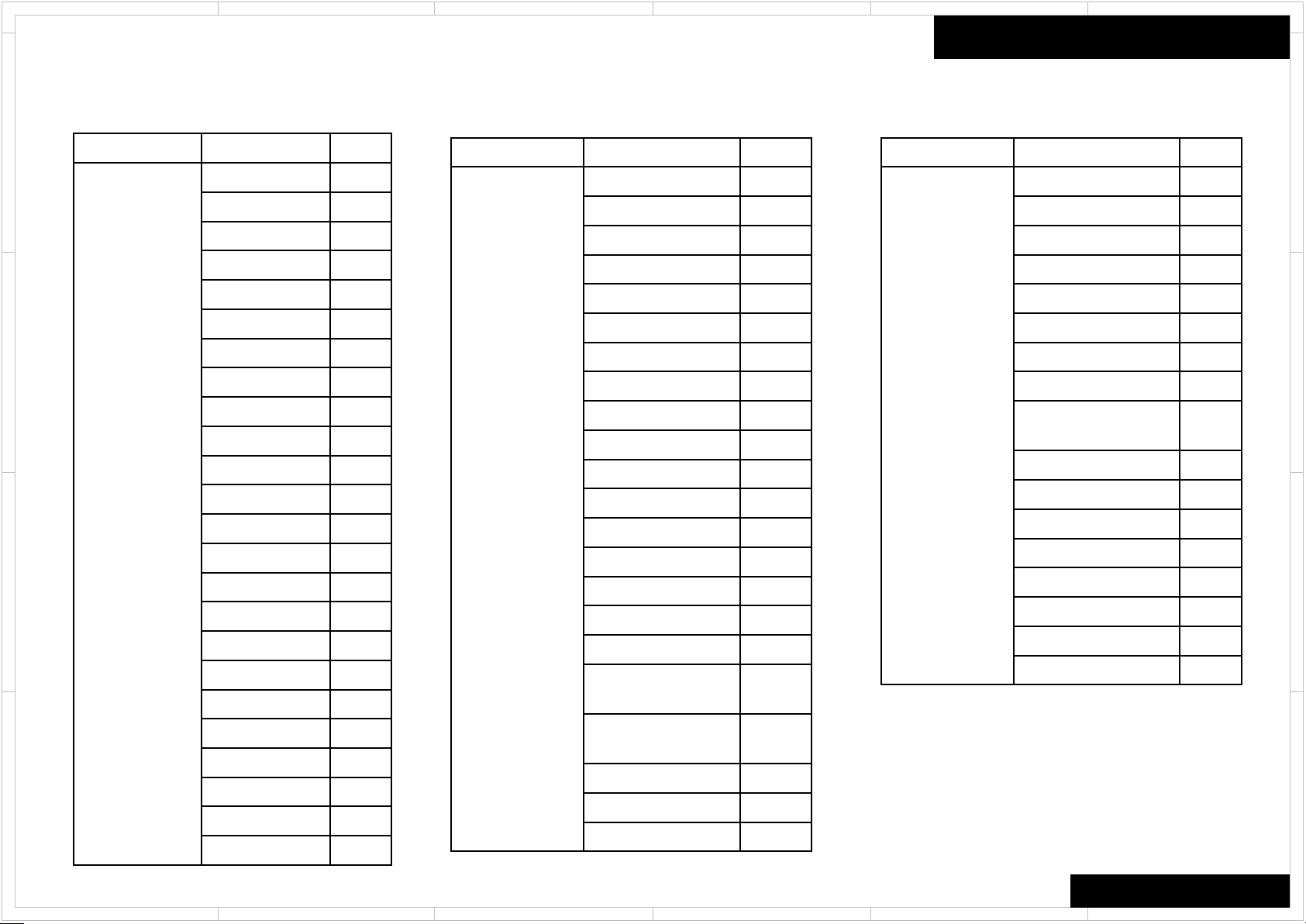

Service Information

Listening Mode Code List

D

C

B

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

12

Amp Diag Mode after Abnormal Conditions

20 SURR_LMD_BEGIN

21 SURR_20_PLII_MOVIE

22 SURR_20_PLII_MUSIC

23 SURR_20_PLII_GAME

24 SURR_20_PLIIX_MOVIE

25 SURR_20_PLIIX_MUSIC

26 SURR_20_PLIIX_GAME

27 SURR_20_PLIIZ

28 SURR_20_NEO6_MOVIE

29 SURR_20_NEO6_MUSIC

2A SURR_20_NEURAL_MUSIC

2B SURR_20_NEURAL_CINEMA

2C SURR_51_OFF

2D SURR_51_MTR

2E SURR_51_DSC

2F SURR_51_NEO6

30 SURR_51_EX

31 SURR_51_PLIIX_MOVIE

32 SURR_51_PLIIX_MUSIC

33 SURR_51_PLIIZ

34 SURR_51_NEURAL_CINEMA

35 SURR_20_NEOX_CINEMA

36 SURR_20_NEOX_MUSIC

37 SURR_20_NEOX_GAME

38 SURR_51_NEOX_CINEMA

39 SURR_51_NEOX_MUSIC

40 SURR_51_NEOX_GAME

41 SURR_20_DOLBY_SURR

42 SURR_51_DOLBY_SURR

43 SURR_LMD_END

48 DTSSS_LMD_BEGIN

49 DTSSS_20_NEO6_MUSIC

4A DTSSS_20_NEO6_CINEMA

4B DTSSS_51

4C DTSSS_LMD_END

50

51

52

53

54

55

56

57

58

5A

5B

5C

5D

5E

5F

60

61

62

70

71

72

73

74

75

76

77

78

79

7A

7B

7C

7D

7E

7F

80

90 THX_CINEMA_LMD_BEGIN

91 THX_20_PLII_MOVIE

92 THX_20_PLIIX_MOVIE

93 THX_20_PLIIZ_CINEMA

94 THX_20_NEO6_MOVIE

95 THX_20_NEURAL_CINEMA

96 THX_51_OFF_CINEMA

97 THX_51_MTR_CINEMA

98 THX_51_DSC_CINEMA

99 THX_51_NEO6_CINEMA

9A THX_51_PLIIX_MOVIE

9B THX_51_PLIIZ_CINEMA

9C THX_51_NEURAL_CINEMA

9D THX_51_EX

9E THX_20_NEOX_CINEMA

9F THX_51_NEOX_CINEMA

A0 THX_20_DOLBY_SURR_CINEMA

A1 THX_51_DOLBY_SURR_CINEMA

A2 THX_CINEMA_LMD_END

B0 THX_U2GAME_LMD_BEGIN

B1 THX_20_PLII_SLCT2_GAME

B2 THX_20_PLIIZ_SLCT2_GAME

B3 THX_51_SLCT2_GAM

B4 THX_51_PLIIZ_SLCT2_GAME

B5 THX_U2GAME_LMD_END

B6 THX_U2MUSIC_LMD_BEGIN

B7 THX_51_SLCT2_MUS

B8 THX_51_PLIIZ_SLCT2_MUSIC

B9 THX_U2MUSIC_LMD_END

BA

BB

BC

BD

D0 AUDYSSEY_LMD_BEGIN

D1 AUDYSSEY_20_PLII_MUSIC

D2 AUDYSSEY_20_PLIIX_MUSIC

D3 AUDYSSEY_20_NEO6_MUSIC

D4 AUDYSSEY_20_NEURAL_CINEMA

D5 AUDYSSEY_20_NEURAL_MUSIC

D6 AUDYSSEY_20_PLII_MOVIE

D7 AUDYSSEY_20_PLIIX_MOVIE

D8 AUDYSSEY_20_NEO6_MOVIE

D9 AUDYSSEY_20_PLII_GAME

DA AUDYSSEY_20_PLIIX_GAME

DB AUDYSSEY_51_OFF

DC AUDYSSEY_51_PLIIX_MUSIC

DD AUDYSSEY_51_PLIIX_MOVIE

DE AUDYSSEY_51_NEO6

DF AUDYSSEY_51_NEURAL_CINEMA

E0 // AUDYSSEY_51_NEUR AL _ MUSIC

E1 AUDYSSEY_51_EX

E2 AUDYSSEY_LMD_END

F0 SPECIAL_LMD_BEGIN

F1 TESTTONE

F2 TESTTHR

F3 TESTAUTO

F4 ASC

F5 FLASH

F6 DEBUGMODE

F7 FLASH2

F8 FLASH3

F9 FLASH4

FA FLASH_CHECK

FB SPECIAL_LMD_END

D

C

B

A

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

Wireless LAN 5GHz Setting

IMPORTANT!!

D

Back Ground:

It is totally different from Radio Law at the each country on 5GHz band.

It means it is totally different from enabled Channel of 5GHz band at the each country.

We define the “Country Code” for 5GHz band.

You must set up the appropriate country code to the product.

Example;

Case1:

C

When you use the “P” destination products and bring move to Russia or Israel,

If you did not setup change country code and use in Russia and Israel,

You will be on the illegal Radio Law in Russia and Israel.

Case2;

When you use “C” or “D” destination product bring move to Japan or Taiwan,

If you did not setup change country code and use in Japan and Taiwan,

You will be on the illegal Radio Law in Japan and Taiwan.

WiFi 5GHz Setting

Ser

vice Parts information:

The default country code is set on “Processing Circuit Board(PRC board)”.

You must make sure and set up the “Country Code“ when you replace the processing

circuit pc board.

Otherwise You and your customer should be on the illegal Radio Law and

IT HAS POSSIBILITY TO HAVE A RISK OF

PUNISHMENT FROM EACH COUNTRY GOVERNMENT.

If you did not make sure country code and no setup code and face any trouble,

We does not have any responsibility.

For setting up the Country Code,

Please ask the procedure of changing country code

to your distributer or our sales.

It is no described the procedure of changing Country Code on this Service Manual

D

C

B

If you have any trouble of unclear procedure for update country code,

B

Please contact our sales department.

PRC Board Default Value of Country Code

The PRC board is already set default Country Code by the representative destination.

To confirm the default country code, Please refer to the "How to read PRC Board part

number and Default value of Country Code" section.

A

TX-NR585/TX-NR-686

A

1

5 4 3

2

1

6

2

5 4 3

6

Wireless LAN 5GHz Setting

D

IMPOTANT!!

Make sure and Setup Country Code

You have to make sure country code for using or replacing “Processing Circuit PC

Board”.

It means that you have to make sure country code between using Processing Circuit

PC board( PRC Board) and your customer’s country code.

When it is not match PRC board default country code and customer’s country, you

have to setup Country Code.

Case3;

C

When you repair the “P” destination products and replace “P” destination PRC Board

and the customer live in UK, It is no necessary to setup Country Code

Because “P” destination PRC board already setup “EU” country code.

Customer: UK: EU PRC Board: EU

Match Country code

NO NECESSARY TO SETUP COUNTRY CODE

B

Case4;

When you repair the “P” destination products and replace “P” destination PRC board

and the customer live in Russia, It is necessary to setup Country Code

Because “P” destination PRC Board already setup “EU” country code.

However, the customer’s country code is “RU”. It means no match PRC Board code

and Customer’s code.

Customer: Russia: RU PRC Board: EU

A

No Match Country code

NECESSARY TO SETUP COUNTRY CODE

WiFi 5GHz Setting

Case5;

When you repair the “C” destination products and replace “C” destination PRC board

and the customer live in US, it is no necessary to setup Country Code

Because “C” destination PRC board already setup “US” country code.

Match Country code

NO NECESSARY TO SETUP COUNTRY CODE

Case6;

When you repair the “C” destination product and replace “C” destination PRC board

and the customer live in Taiwan, It is necessary to setup Country Code.

Because “C” destination PRC Board already setup “US” country code as default.

However, the customer’s country code is “TW”. It means no match PRC Board code

and the customer’s country code

No Match Country code

NECESSARY TO SETUP COUNTRY CODE

Customer: US: US PRC Board: US

Customer: Taiwan: TW PRC Board: US

D

C

B

A

TX-NR585/TX-NR-686

1

5 4 3

2

1

6

2

5 4 3

6

Wireless LAN 5GHz Country Code 1/2

D

C

Region

America

Country

USA

Canada

Mexico

Brazil

Chile

Guatemala

Puerto Rico

Trinidad

Dominican Rep

Argentina

Ecuador

Code

US

US

US

US

CL

US

US

TT

US

AR

US

Region

Asia / Oceania

Country

Japan

China

Hong Kong

Korea

Taiwan

Singapore

Malaysia

Philippines

Vietnam

Indonesia

Sri Lanka

Code

JP

CN

EU

KR

TW

SG

MY

EU

EU

ID

EU

Region

Middle East

WiFi 5GHz Setting

Country

UAE

Bahrain

Kuwait

Oman

Qatar

Lebanon

Jordan

Saudi Arabia

Code

EU

BH

KW

EU

QA

EU

JO

EU

D

C

Paraguay

Colombia

Guam

B

Panama

Costa Rica

Uruguay

Peru

A

PY

US

US

US

US

UY

PE

Australia

New

Zealand

Thailand

India

Pakistan

AU

AU

EU

IN

PK

B

A

TX-NR585/TX-NR-686

1

5 4 3

2

1

6

2

5 4 3

6

Wireless LAN 5GHz Country Code 2/2

D

C

Region

Europe / Africa

B

A

Country Code

Germany EU

UK EU

France EU

Netherlands EU

Italy EU

Switzerland EU

Denmark EU

Sweden EU

Austria EU

Belgium EU

Spain EU

Norway EU

Finland EU

Czech EU

Israel IL

Ukraine EU

Hungary EU

Slovakia EU

Luxembourg EU

Turkey EU

Portugal EU

Malta EU

Latvia EU

Poland EU

Region

Europe / Africa

Country Code

Cyprus EU

Estonia EU

Slovenia EU

Bulgaria EU

Greece EU

Romania EU

Lithuania EU

Serbia EU

Croatia EU

Ireland EU

Macedonia EU

Moldova EU

Russia RU

Andorra EU

Armenia EU

Azerbaijan EU

Belarus EU

Bosnia and

Herzegovina

Northern

Cyprus(Turkey)

EU

EU

Georgia EU

Iceland EU

Kazakhstan EU

Region

Europe / Africa

WiFi 5GHz Setting

Country Code

Liechtenstein EU

Monaco EU

Montenegro EU

San Marino EU

Vatican City EU

Kosovo EU

Kaliningrad(Russia) RU

Gibraltar(UK) EU

Canary

Islands(Spain)

Ceuta EU

Melilla EU

Morocco MA

Algeria EU

Tunisia TN

Egypt EG

Mauritius US

South Africa EU

EU

D

C

B

A

TX-NR585/TX-NR-686

1

5 4 3

2

1

6

2

5 4 3

6

How to read PRC Board part number and Default value of Country Code

D

1B5142049-2A686MDC

Board No.

C

Model Number Last 3 Digit

585 : TX-NR585

686 : TX-NR686

B

A

Suffix No.

Destination

PRC Board Default setting Country Code

Dst Code Main Country

C US North America

D US United State

S US Brazil

P EU Europe

B EU United Kingdom

Q EU Hong Kong

T EU Thai

L RU Russia

A AU Australia / New Zealand

R CN China

F TW Taiwan

K KR Korea

J JP Japan

WiFi 5GHz Setting

D

C

B

A

TX-NR585/TX-NR-686

1

5 4 3

2

1

6

2

5 4 3

6

How to check Firmware Version & Preparation of Update

Step1 : [DIMMER] + [ON/STANDBY] x 2

D

Main Firmware Version will appear on the main unit’s display.

Step2 : [TONE +1] ( Rotate “TONE” knob right 1 click)

NET Firmware Version will appear on the main unit’s display.

Step3 : [TONE +2] ( Rotate “TONE” knob right 2 click)

DSP Firmware Version will appear on the main unit’s display.

C

Step4 : [TONE +3 ] ( Rotate “TONE” knob right 3 click)

Video Firmware Version will appear on the main unit’s display.

Step5 : [TONE +4] ( Rotate “TONE” knob right 4 click)

OSD Firmware Version will appear on the main unit’s display.

Step6 : [TONE +5 over] ( Rotate “TONE” knob right 5 click over)

G Firmware Version will appear on the main unit’s display.

B

Step7 : [TONE +6 over] ( Rotate “TONE” knob right 5 click over)

Return to Display Main Firmware Version ( Return Step1)

When It is rotated left ( - ) TONE knob, It is appeared before step.

A

Firmware

[Preparation of Update]

1. Connect the USB storage device to your PC. If there is any data in the USB storage

device, remove it.

2. Download the firmware file (package file) from the Onkyo FTP-server. However European

service partners should download the f irmw ar e file (package file) from the ExtraNet.

Onkyo FTP-server: ftp://manex.onkyo.co.jp/

ID and Password are those we informed when changed.

Filename is as follows: ONKAVR0028******************.zip

Unzip the downloaded file. A following file is created.

ONKAVR0028**************.of0

ONKAVR0028**************.of1

ONKAVR0028**************.of2

ONKAVR0028**************.of3

ONKAVR0028**************.of4

3. Copy it to the USB storage device. Be careful not to copy the zip file.

4. Remove the USB storage device from your PC.

D

C

B

A

TX-NR686

1

5 4 3

2

1

6

2

5 4 3

6

How to Update (service mode) 1/2

Overwriting is also possible.

D

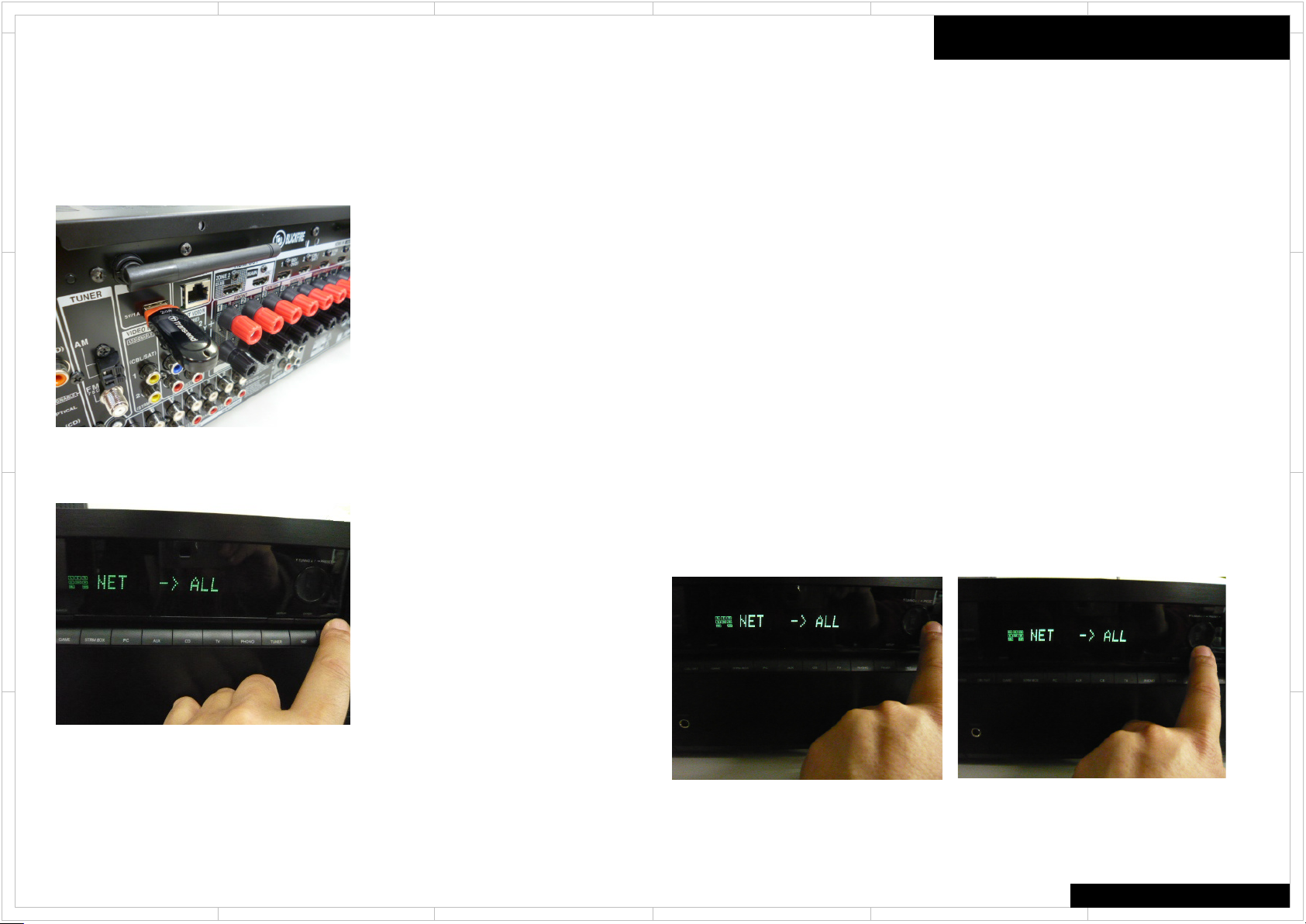

1. Connect the USB storage to the USB port on the unit.

C

B

A

2. Turn on the unit. It takes some time to start after you switch on the unit.

Press: [DIMMER] + [ON/STANDBY] x 2

3. Press [RETURN] button, Then it is displayed as below

If you need each module of the firmware update, you can select the module by pressing

PRESET < and > button.

If you need change source NET or USB, you can select the source by pressing

TUNING UP and Down key

It should be updated firmware by selecting USB -> ALL normally.

Please Do NOT choose T-SRV (it is test server)

Firmware

USB -> ALL: ALL firmware update ( default )

USB -> DSP1: DSP firmware update

USB -> OSD: OSD firmware update

USB -> VMPU: VMPU firmware update

USB -> NET: NET firmware update

USB -> MMPU: Main MPU firmware update

USB -> WORK: Compare between AVR and USB, Only update new version firmware

NET -> ALL: ALL firmware update ( default )

NET -> DSP1: DSP firmware update

NET -> OSD: OSD firmware update

NET -> VMPU: VMPU firmware update

NET -> NET: NET firmware update

NET -> MMPU: Main MPU firmware update

NET -> WORK: Compare between AVR and MMC,

Only update new version firmware by network

The default setting is “ ALL”

CAUTION: When you will update each module firmware,

you have to keep combination of firmware.

D

C

B

A

TX-NR686

1

5 4 3

2

1

6

2

5 4 3

6

How to Update (service mode) 2/2

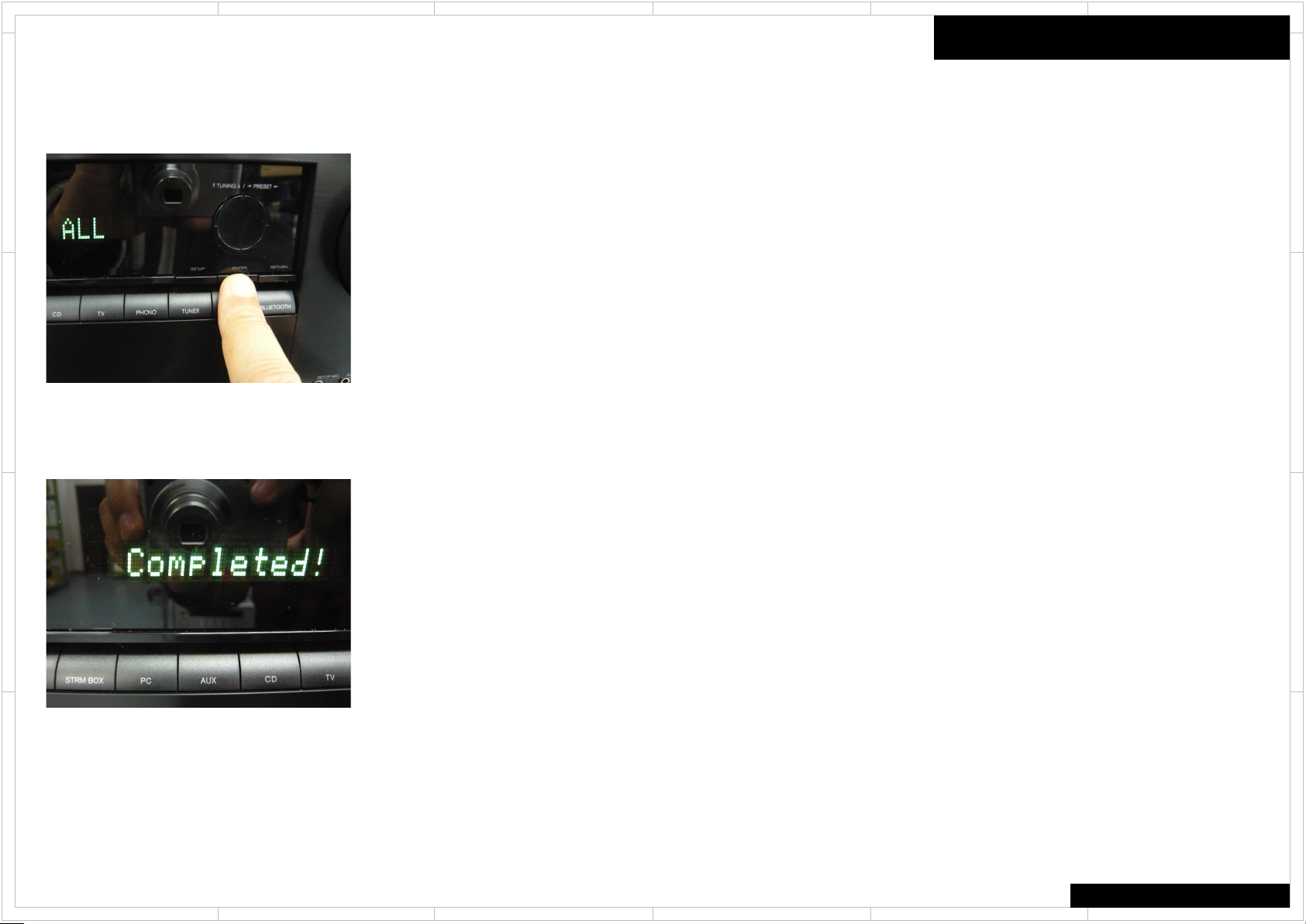

4. Press [ENTER] button. Start update firmware.

D

C

B

A

5. Wait until update is completed. When the update ends, “Completed!” is displayed. When

“ Completed!” message appeared, you can power off by pressing “ ON/STANDBY” button.

(If you leave it, it automatically turns standby mode. )

Firmware

6. Press [ON/STANDBY] button, and the unit turns on.

7. Check the new FW version number.

<Note>

If the procedure might not be successful, please select “USB -> ALL”.

D

C

B

A

TX-NR686

1

N R 5 8 5

D C

0 1 0 0

N R 6 8 6

D C

0 2 0 0

N R 6 8 6

D F

0 2 3 0

N R 6 8 6

x x

0 2 1 0

N R 6 8 6

x A

0 2 4 0

N R 6 8 6

x R

0 2 5 0

N R 6 8 6

J J

0 2 2 0

2

5 4 3

6

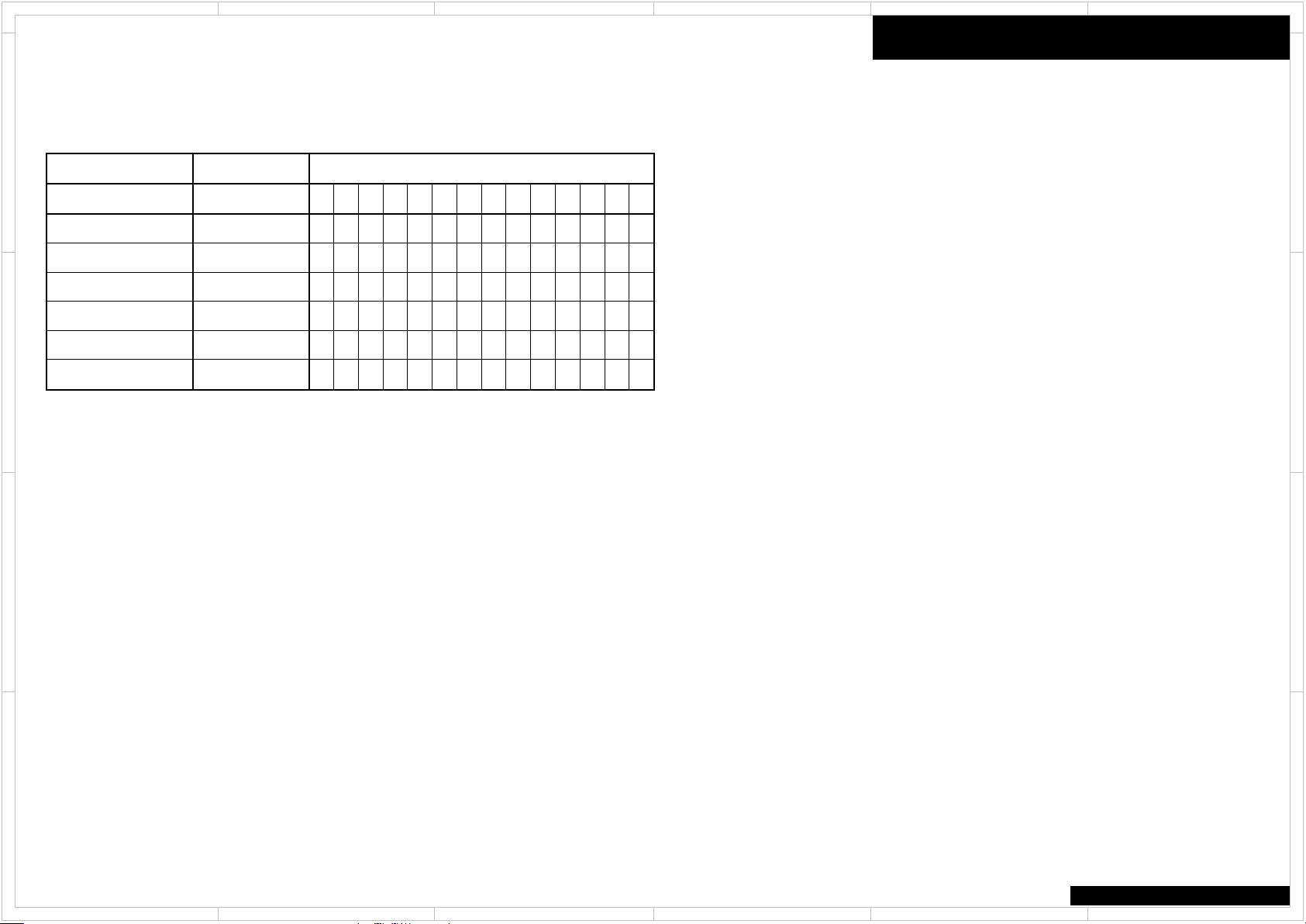

Model and Destination

[ TV ] + [ON/STANDBY] -> [ENTER] -> [ Rotate TONE encoder ] x 4

D

Model Name Destination

TX-NR585 DC

TX-NR686 DC

TX-NR686 DF

TX-NR686 xx

TX-NR686 xA

TX-NR686 xR

C

TX-NR686 JJ

FL Display

Model and Destination

D

C

B

A

B

A

TX-NR585/NR686

1

2

5 4 3

6

1

2

5 4 3

6

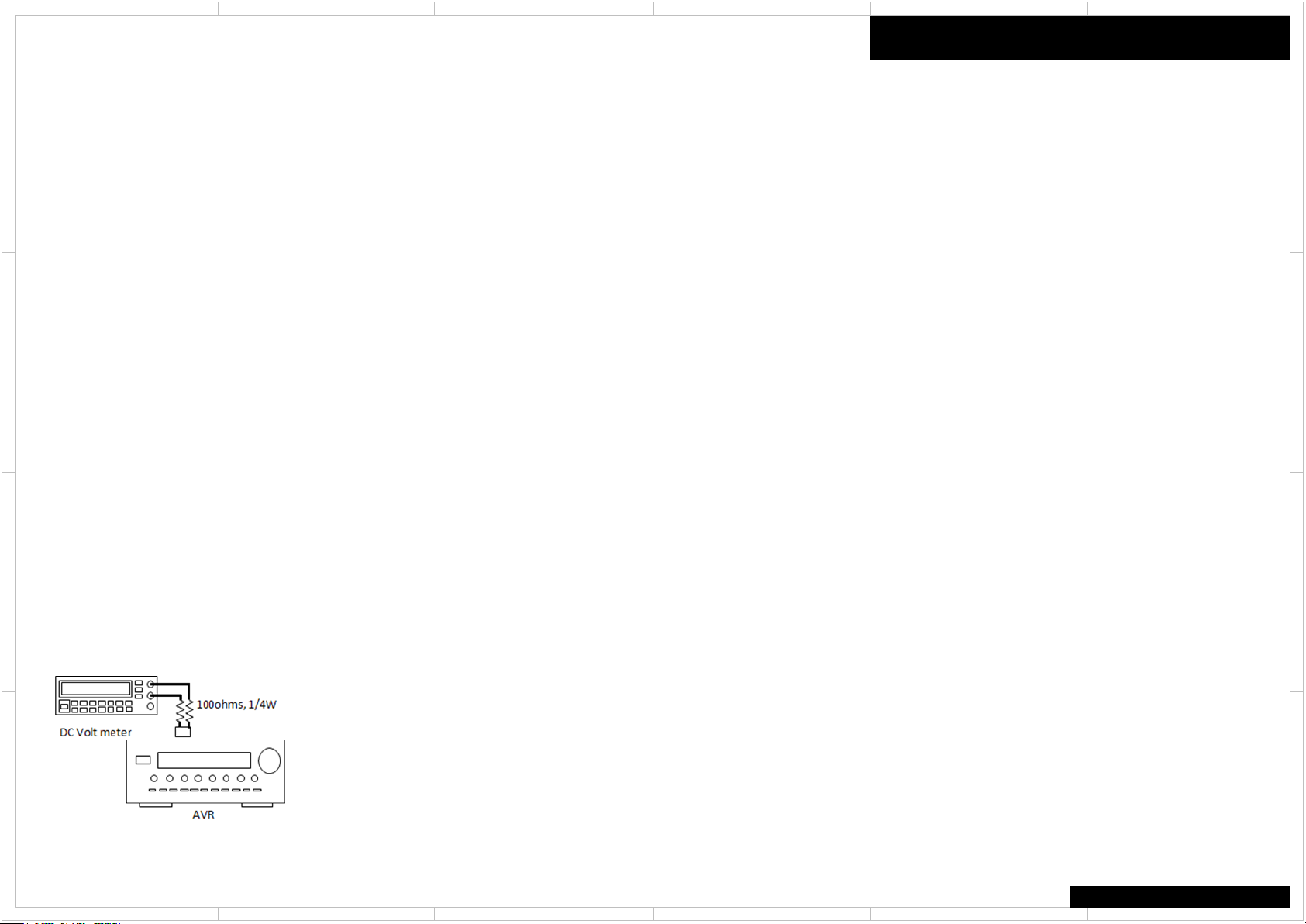

How to Check Idling Current

a. Idling Pre-check

D

Channel FL,FR,C,SL,SR,SBL,SBR

Terminals P6021,P6022,P6023,P6025,P6026,P6027,P6028 (AF1979)

*Connect 1/4W 100 ohms resisters in each probe of multi mater .

*Make sure from 0.7mV to 21mV, When it is not this range, you have to make sure again repair.

b. Aging

The AVR is turned on about 6 minutes for aging.

C

c. Idling After-check

*Connect 1/4W 100 ohms resisters in each probe of multi mater .

*Make sure from 0.7mV to 21mV, When it is not this range, you have to make sure again repair.

Check Idling Current

D

C

B

A

B

A

TX-NR585/NR686

1

2

5 4 3

6

1

5 4 3

2

1

6

2

5 4 3

6

No Sound

■ No sound from connected player

D

C

B

□ Chose input selector which is assigned to connected input terminal ?

□ Isn’t muting on ?

■ No sound from connected TV

□ Chose wrong input selector ?

□ Connect to this model’s HDMI OUT terminal from TV by HDMI cable ?

□ When TV supports ARC function, connect to his model’s HDMI OUT terminal from

TV’s HDMI input terminal for ARC function ?

□ When TV doesn’t support ARC function, connect TV to this model with optical cable

etc. ?

□ Isn’t muting on ?

■ No sound from some connected loudspeaker(s)

□ No sound loudspeaker(s) config is enabled ?

■ No sound from all connected TV or Blu-ray player etc.

□ After chose loudspeaker volume level setting, test tone is OK ?

■ No problem about above items

□ Unplug power cord

After 10 seconds, connect power cord again

□ Reset this model

Hookup and Setting

D

C

B

A

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

No Picture

■ In general

D

C

□ Connection cable is bent , twisted or damaged ?

□ Input is switched on TV ?

■ No picture from connected player by HDMI input terminal

□ Chose input selector which is connected to player ?

□ Listening mode is not Pure Audio ?

□ Don’t use HDMI-DVI adaptor. From personal computer ?

■ No picture from connected player by component video terminal

□ Output to TV connected to component video out terminal from player's picture

connected to the composite video input terminals ?

■ No problem about above items

□ Unplug power cord

After 10 seconds, connect power cord again

□ Reset this model

Hookup and Setting

D

C

B

A

B

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

No Power

■ In general

D

C

□ Check if the connection cable is bent or twisted, damaged.

■ There is time when indication on the front panel doesn't just light up.

□ Please check the connecting cord of a DISPLAY PCB.

■ No problem about above items

□ Unplug power cord

After 10 seconds, connect power cord again

□ Reset this model

Hookup and Setting

D

C

B

A

B

A

COMMON

1

5 4 3

2

1

6

2

5 4 3

6

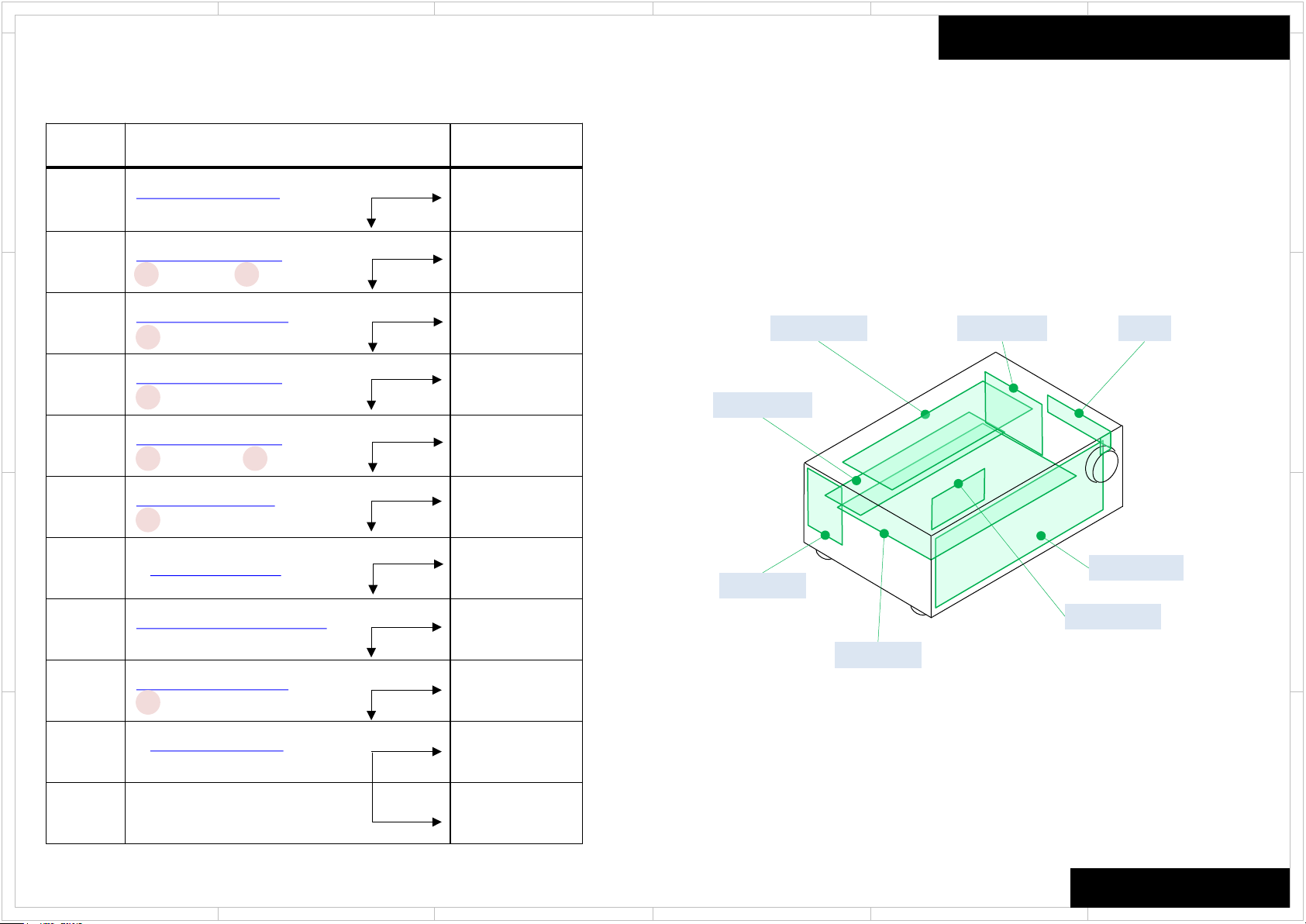

No Sound (HDMI in)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

2

3

4

5

J6504(BATRM-2023)

●+24V

P8002A(BADG-1985)

5 -15V 7 +15V

P2802B(BAPRC-2409)

1 +12V ~ +15V

P8003A(BADG-1985)

28 +3.3V

P8002A(BADG-1985)

29 Signal 30 Signal

No Good

OK

No Good

OK

No Good

OK

No Good

OK

No Good

OK

BAAF-1979

BAAF-1979

BATRM-2023

BAPRC-2409

BAPRC-2409

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

6

7

B

8

Q1501(BADG-1985)

1 Signal

J4606(BAAF-1979)

●

Q6001, Q6021(BAAF-1979)

●Base

No Good

OK

No Good

OK

No Good

OK

BADG-1985

BAAF-1979

BACLA-1988

BAPS-1984

BADIS-1983

B

BACLA-1988

BAAF-1979

9

10

A

11 BATRM-2023

P2800B(BAPRC-2409)

10 +3V (HIGH)

P6021(BAAF-1979)

●

The amplified beautiful wave.

No Good

OK

No Good

OK

BAAF-1979

BAAF-1979

A

TX-NR585/NR686

1

5 4 3

2

1

6

2

5 4 3

6

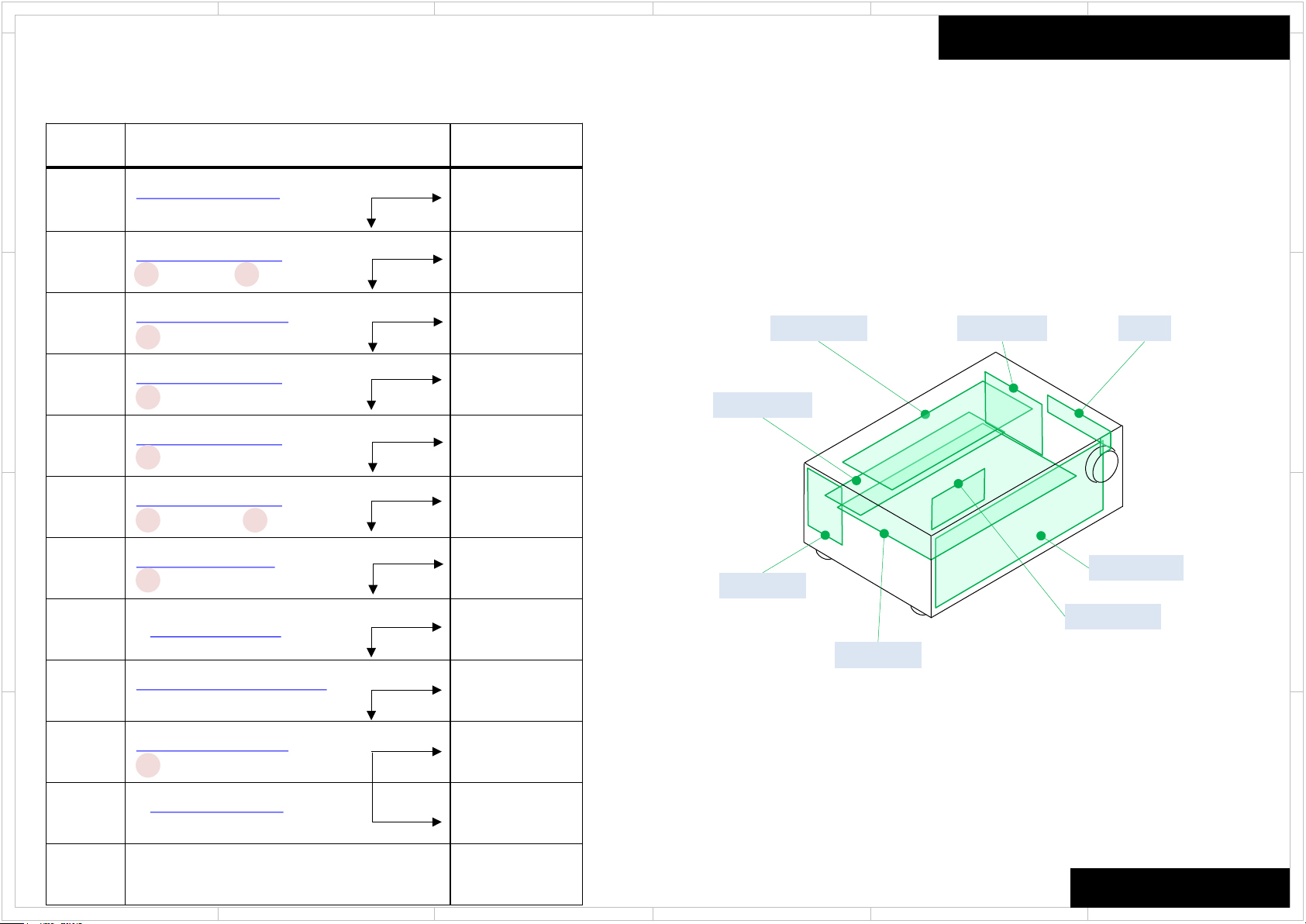

No Sound (Opt in)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

2

3

4

5

J6504(BATRM-2023)

●+24V

P8002A(BADG-1985)

5 -15V 7 +15V

P2802B(BAPRC-2409)

1 +12V ~ +15V

P8003A(BADG-1985)

28 +3.3V

P8003A(BADG-1985)

25 Signal

No Good

OK

No Good

OK

No Good

OK

No Good

OK

No Good

OK

BAAF-1979

BAAF-1979

BATRM-2023

BAPRC-2409

BADG-1985

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

6

7

B

8

P8002A(BADG-1985)

29 Signal 30 Signal

Q1501(BADG-1985)

1 Signal

J4606(BAAF-1979)

●

No Good

OK

No Good

OK

No Good

OK

BAPRC-2409

BADG-1985

BAAF-1979

BAPS-1984

BADIS-1983

B

BACLA-1988

BAAF-1979

9

10

A

11

12 BATRM-2023

Q6001, Q6021(BAAF-1979)

●Base

P2800B(BAPRC-2409)

10 +3V (HIGH)

P6021(BAAF-1979)

●

The amplified beautiful wave.

No Good

OK

No Good

OK

BACLA-1988

BAAF-1979

BAAF-1979

A

TX-NR585/NR686

1

5 4 3

2

1

6

2

5 4 3

6

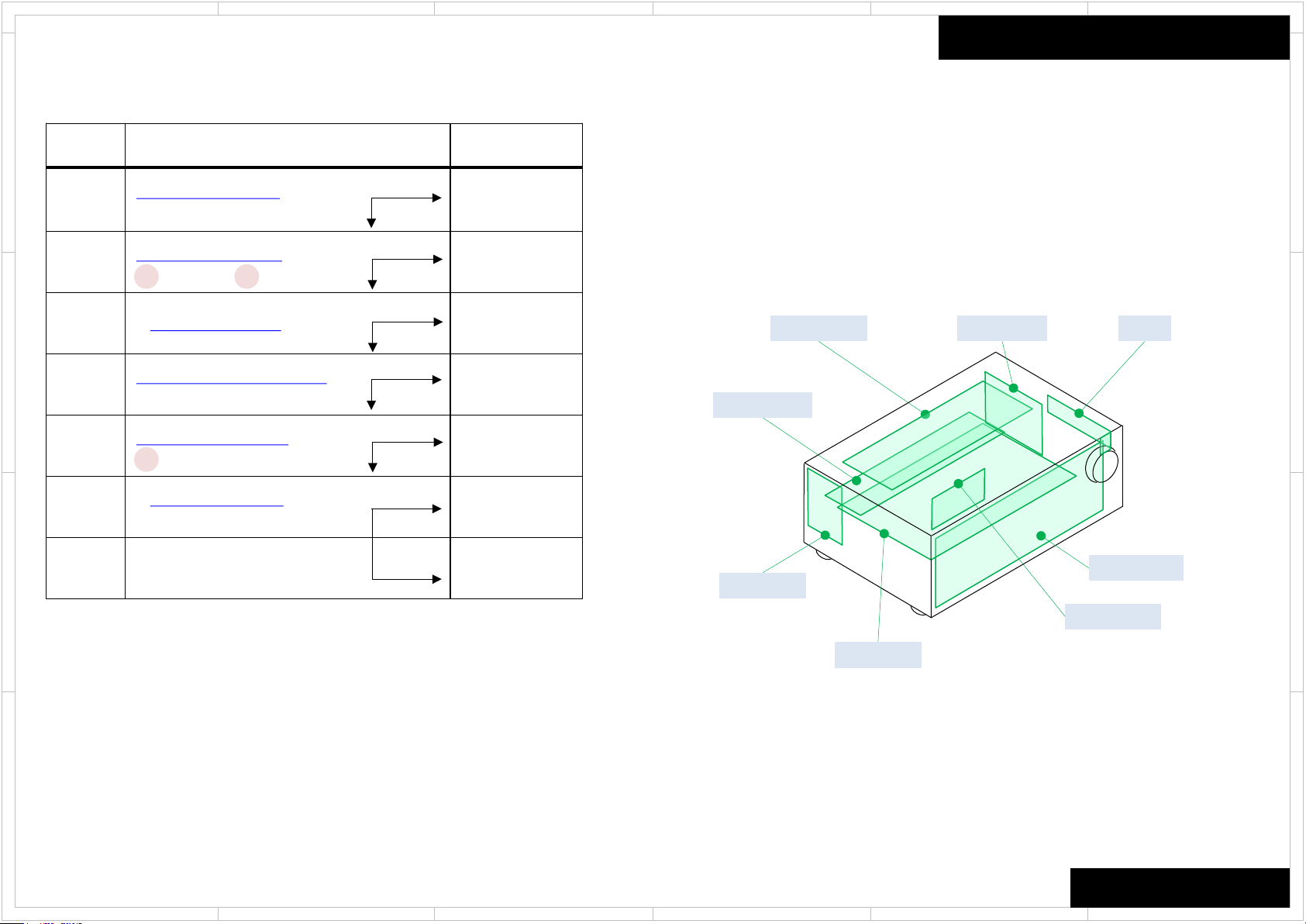

No Sound (Analog in)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

2

3

4

5

J6504(BATRM-2023)

●+24V

P8002A(BADG-1985)

5 -15V 7 +15V

J4606(BAAF-1979)

●

Q6001, Q6021(BAAF-1979)

●Base

P2800B(BAPRC-2409)

10 +3V (HIGH)

No Good

OK

No Good

OK

No Good

OK

No Good

OK

No Good

OK

BAAF-1979

BAAF-1979

BAAF-1979

BACLA-1988

BAAF-1979

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

P6021(BAAF-1979)

6

●

The amplified beautiful wave.

7 BATRM-2023

B

No Good

OK

BAAF-1979

BAPS-1984

BADIS-1983

B

BACLA-1988

BAAF-1979

A

TX-NR585/NR686

A

1

5 4 3

2

1

6

2

5 4 3

6

No Picture (HDMI in/ out)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

P2802B(BAPRC-2409)

1 +12V ~ +15V

No Good

OK

BATRM-2023

2 BAPRC-2409

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

BADIS-1983

B

BAPS-1984

B

BACLA-1988

BAAF-1979

A

TX-NR585/NR686

A

1

5 4 3

2

1

6

2

5 4 3

6

No Picture (Component in/ HDMI out)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

2

3

P2802B(BAPRC-2409)

1 +12V ~ +15V

P2800B(BAPRC-2409)

17 +5V

P2800B(BAPRC-2409)

23 19 21

No Good

OK

No Good

OK

No Good

OK

BATRM-2023

BAPRC-2409

BATRM-2023

4 BAPRC-2409

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

BADIS-1983

B

BAPS-1984

B

BACLA-1988

BAAF-1979

A

TX-NR585/NR686

A

1

5 4 3

2

1

6

2

5 4 3

6

No Picture (Composite in/ HDMI out)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

2

3

P2802B(BAPRC-2409)

1 +12V ~ +15V

P2800B(BAPRC-2409)

17 +5V

P2800B(BAPRC-2409)

19

No Good

OK

No Good

OK

No Good

OK

BATRM-2023

BAPRC-2409

BATRM-2023

4 BAPRC-2409

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

BADIS-1983

B

BAPS-1984

B

BACLA-1988

BAAF-1979

A

TX-NR585/NR686

A

1

5 4 3

2

1

6

2

5 4 3

6

No Power

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

C

Process Check Point Damaged PCB

1

2

3

4

5

6

C9001(BAPS-1984)

●AC100V~240V

●

F9002(BAPS-1984)

●

F6901, F6902(BAAF-1979)

ANY PARTS(BAAF-1979)

FFC P7001(BAPRC-2409)

P2802B(BAPRC-2409)

1 +12V ~ +15V

No Good

OK

No Good

OK

No Good

OK

No Good

OK

No Good

OK

No Good

OK

BAPS-1984

BAAF-1979

BACLA-1988

BAAF-1979

BACLA-1988

BAAF-1979

BACLA-1988

P7001(FFC)

BAPS-1984

BAPRC-2409

BATRM-2023

Trouble Shoot

BADG-1985

D

P7001

C

7

B

8

9

10

11

A

P2800B(BAPRC-2409)

5 +3V (HIGH)

P7001A(BAPRC-2409)

17 +5V

RL9001(BAPS-1984)

P9002(BAPS-1984)

●AC100V~240V

FFC P7001(BADIS-1983)

No Good

OK

No Good

OK

No Good

OK

No Good

OK

No Good

OK

12 BADIS-1983

1. When being not turned on with remote control unit only, BADIS-1983 is abnormal.

2. When being not turned on with button on the main unit only, BADIS-1983 is abnormal.

BAPRC-2409

BAPRC-2409

BAPS-1984

BATRM-2023

BAPRC-2409

P2800(FFC)

P7001(FFC)

BAPS-1984

BAAF-1979

ANY PARTS o n BAAF -1979

Check damage parts

Normal(OK) or Damage (No good)

Check the damage in the red framework part as shown with visual

inspection.

e.g. Broken, Burnout, Discoloration, etc.

BADIS-1983

B

BACLA-1988

A

TX-NR585/NR686

1

5 4 3

2

1

6

0

26

51

76

36

72

109

1

30

25142409

55

BCPRC-2409

QPWBCPRC2409

1

5

1

5

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

QR

1

1

1

1

5

1

1

1

1

1

1

1

A

A

B

B

C

C

1

1

1

30

31

23

17

1

1

9

E

E

F

F

ARM_JTAG

ARM_Write

OSD_Write

VMPU_Write

VMPU_Debug

MMPU_Debug

MMPU_Write

DSP_Write

DSP_Debug

[FAN]

[Thermal]

[POWER]

[UPDATE]

[Display]

[VD_UP]

[IR/232C/TRG]

Therm

GND

GND

+3.3V

/PTC

GND

GND

+12V

+12V

+12V

GND

Rx

Tx

GND

3.3V

TgA

TgB

TgC

IR

GND

SCL

SDA

RST

+5

+3.3

Y

Pb

Pr

PonM

PonS

AuxV

Poff2

M

M

36

37

72

73

108

144

109

1

[HDbaseT]

15

P3658

P8500B

P8001

P8021

P8611

P8621

P8631

P8641

P8651

P8661

P3651

P3654

P3601

R3418

R8238

C1119

S3201

P3655

P3656

R3032

R3033

R8430

C3445

R8431

R3035

C3446

R8432

R3036

R8240

R3421

R8243

R3424

R8244

C8460

C1125

R3425

C8461

P8701A

C8463

R1100

R3429

R1101

R1102

R1103

R1104

R1105

P6800B

R1106

R1107

R3430

R1108

C8661

R1109

R3432

C8662

R8447

R3436

C3076

C3077

R3437

C3653

R3438

C8474

R1110

C3654

R3244

R3439

C8475

R1111

C3655

R3245

C3462

R1112

C3656

R1113

C3657

P3652C

R1114

C3658

C3659

R1116

R3440

R3441

L3901

R3442

L3902

R3443

L3903

R3444

C3660

R3250

R3445

P7501

L1001

C3661

P7502

R3447

R3253

R3448

C8484

L1004

R3254

L1005

C8486

C3472

L1006

C3666

R3256

C8487

L1007

C3667

R1124

R3258

X7001

L8921

R1125

R3259

L8922

R1126

L8923

R8463

R1127

R3450

L8924

R8464

R1128

R1129

R3452

R8466

R3453

R8467

R3454

L1010

R8468

R3455

R8469

R3456

R3457

R3458

L1014

R1130

R3459

R1131

D3651

R3071

R1132

D3652

R3072

D3653

R3073

D3654

L1018

R3074

L8931

L1019

R3651

R8471

R3075

R8472

L8932

R3652

R3076

R8473

L8933

R3653

R3077

R8474

R3460

L8934

R3654

R3078

R8475

R3655

R3079

R3656

R8477

R3463

R3657

R8478

R3658

R3270

R8479

L1021

R3659

R3271

R3467

L1024

R3080

C3685

L1025

C3686

L1026

R8480

C3688

R3084

R3660

R3278

C3689

L1029

R3661

R3279

R3662

R3663

R3664

R1149

R3665

R3666

R3667

C3690

R3668

R3280

C3691

R7101

R3669

R7102

R7103

R7104

R1150

R7105

R1154

R3670

L8951

R7109

R3671

L8952

R3672

L8953

R3673

L8954

R3674

R3481

R3675

R3676

R3677

R3484

R3678

R3485

R7111

R3679

R7112

R7113

R7114

R7115

R7116

R7117

L8961

L8962

L8963

P8104

L8964

R3494

R3495

R3496

R3497

R7124

L7008

L7009

R7126

R7127

R7128

R7129

R1175

R1176

R7130

R7132

R7133

R7134

R7136

R1182

R7137

R1183

R7138

R1184

P8702

P8703

R7143

R7144

X8201

Q8300

P8900

P8710

X3001

X3002

Q8307

Q8308

X8400

C7180

C7181

Q8701

C8705

X3401

C8900

C8902

C8903

Q8900

R8303

R8304

C8911

C8912

L8001

R8311

R8312

L8002

R8313

L8003

L8004

R8314

R7180

C3904

R8315

D8701

R7181

Q3901

C1001

R8317

C1003

R8318

R8701

Q1001

C3909

R8702

Q1002

R3306

R8703

Q1003

R3307

R8704

Q1004

C1008

R3308

C8921

R8705

Q1005

C1009

R3309

C8922

C8923

C8348

R3500

C8924

D8900

R3501

C8349

R8709

Q8921

C8925

R8321

D8901

R3502

C8926

R8322

D8902

R3503

C8927

R8323

R3504

C8928

R8324

Q8730

R3310

R3505

R8901

R3311

C1011

Q8731

R3312

C3916

Q8732

R7193

R8903

R3313

C1013

Q8733

R3314

C1014

C3918

R8329

R3315

C1015

R8712

R3316

R8713

R3317

R3318

C1018

C8931

R3319

C8932

C8933

C8934

Q8931

C8935

L8021

L3201

R8332

C8936

L8022

L3202

R8333

L8023

C8937

L8024

C8938

R8334

R3320

R8335

R3321

R8336

C1022

R3322

C1023

R8338

C1024

R8721

R8339

R3901

R8723

R3903

C1027

R1000

R3904

R3328

R8725

R3905

R3329

L3402

L8416

R1002

R8727

L3403

R1003

R3907

L3404

R1004

R3908

R8729

R1005

R3909

R3715

L3406

R1006

R3716

R1007

R3717

R1008

R3718

R3719

R3331

R8346

R8922

Q8946

C1032

R8347

R8923

R3333

R8730

R8924

C3938

R8925

R3335

R3911

R8732

R8926

L3602

R3912

R3337

R3913

R8734

L3604

C1038

R3338

R3914

C8951

R1011

R3339

R3915

C8952

R1012

R3916

C8953

R1013

R3917

R1208

C8954

R1014

Q8951

C8955

R1015

R3919

R3726

C8956

R1016

C8957

R1017

C8958

C1040

R3340

R1019

X3651

R3341

R8932

R3342

R8933

R3343

R8934

R3344

R3920

L3611

R8935

R3345

L3612

R8936

L3613

R8744

R1020

R3348

R3731

C8961

R8939

R1021

R3732

C8962

R8746

R1022

R3733

C8963

R1023

R3734

C8964

R1024

R3735

Q8961

C8965

R1025

C7002

C8966

R1026

C8967

R8363

R1027

C8968

R1028

C1051

C1052

R3352

C1053

R3353

R8750

R3354

P7001A

R3355

R8752

C1056

R8753

C1057

C1058

Q7009

R1031

R3359

C1059

R8756

R1032

R8757

R1034

R1035

R1037

R3360

R1039

R3361

R8952

C1062

Q7013

R8953

C1063

R3363

C7018

R8954

R8955

R8956

Q7017

C8980

R1041

R1042

R3753

R1043

R3754

R1044

C3970

C8986

R1046

C8987

D8963

R3371

R1049

C1071

R3372

D7002

R8962

C1072

D7003

R8963

R3374

R8964

D8968

R8965

R7001

D8969

C1075

R3376

R8966

R3377

Q7028

R7005

D7009

Q7029

R7006

R1054

R1055

R1057

Q7030

Q7031

R1059

C7036

R8972

R1060

R1061

P8002B

R1062

R7017

R7018

R1064

R7019

R1066

R1067

R1069

R8790

R8984

R8791

R7021

L3661

R8985

R7022

C1096

Q1093

C1097

C1098

R7025

R1071

R7026

P8003B

R1072

R7027

R1073

R7028

R1074

R7029

R1075

P2800B

P3002

R7030

R7031

R7032

R7033

R7034

R1083

R1084

P3201

P2801B

R1087

C7064

R1088

C7065

C7066

C8007

C7067

C8008

C7068

R7042

R1090

P3401

R1091

R1092

R1093

R7048

C7070

R1094

C7071

Q8202

C8206

C7072

P2802B

C8207

C8208

R1098

R1099

C7077

X8300

R7051

C3005

Q3001

R7052

C3006

Q3003

C3007

C8210

C3008

C8211

Q8401

C3009

Q3008

C8219

Q3203

D8003

P3610

C3014

C3400

C8220

C3401

C8221

R7066

C8223

Q3400

C8224

X8701

C8225

R7069

Q3404

C8611

C8612

R8204

R7070

R7071

R8208

D3004

R8209

C8231

R7075

D3005

C3412

C8232

D3006

C3413

R7077

D3007

C3414

Q3410

R8400

C3415

R7079

C8236

R8402

C8237

C3419

C8239

C8621

R8405

D3201

R8406

R8407

R8408

R8215

R7081

R3201

R3202

R3203

R8218

C8240

R7084

R3010

C8241

R3011

C3422

R3206

C3423

R7087

R8603

R3013

R8604

C3424

R3014

R3208

C3425

R8605

R3015

R3209

D3402

R3016

R8220

R8414

R3400

R3018

R8221

C8631

R8415

R3401

X1001

C1101

R3019

C8632

R8416

C1102

R8223

R8417

C1103

R8418

C1104

R3405

R7091

R8419

R7092

R7093

R3213

R3408

R7094

R3020

R3409

R3021

R7095

R3022

R7097

R3023

R7098

R8420

C3435

R7099

C3436

R8422

R3603

R3410

R3028

R3411

R8425

R8426

R3413

R3415

R8429

R3416

R3417

R8237

C3663

C3902

C3903

C3906

C1002

C3907

C1004

C1006

C3910

C3911

C3914

C1010

C1016

C3920

C3921

C1054

C1055

C8984

C7020

C1099

C7076

C1100

D8248

D8401

Q3651

R8349

R8350

P7000

R1018

R1030

R1033

R8792

C8712

R8793

Q8734

C8713

C8711

C8714

Q3202

320

320

9096

6

7

4

7

661113133

3

009

9

C8C898

98

28

28

3232RR66R

R3

44

3

3

1

1

0

9

0

0

0

9

0

0

3

R3

7

7

1

1

0

0

0

0

C

9

9

bb]

]

9

9

R1

R1

R1

R1

R

R

1

1

1

3

3

3

R3

4

4

0

5

5

3

3

R1

R1

7

7

3

3

1

1

0

0

535R1

R1

34

34

336

6

5

5

5

C

C

C

C

10

10

99RC

RC

1

3

3

R

9

9

34

34

5

5

33335

5

OO]

]

0

0

0

0

2

2

53

53

1

1

9

9

3

3

7

7

R

Q

Q

3

3

R3

R3

7

7

1

1

9

9

1

1

0

0

8

8

3

3

3

02

02

1

31

P7001A

1

23

P2800B

1

5

GND

GND

+12V

+12V

P2802B

2

5 4 3

6

Check Point (BAPRC-2409)

D

C

1

Back

P2802B

B

A

Front

Trouble Shoot

P2802B

Check Voltage

1 +12V ~ +15V

P2800B

Check Voltage

5 +3V (HIGH)

10 +3V (HIGH)

17 +5V

Check Signal

19

6.36μS

1.2V

Input signal : Color bar(NTSC)

21

6.36μS

720mV

23

19 21 23

10 17

5

P2800B

17

P7001A

●Each voltage is shown as the reference value.

6.36μS

P7001A

17 +5V

P7001

Check damage and connection

How to check

1.Disconnect the FFC from the socket.

2.Check the contacts of the FFC.

728mV

TX-NR585/NR686

D

C

B

A

1

5 4 3

2

1

6

T6.3A 250V

2.NC

1.SEC2_2

3.SEC2_1

1

5.~SWPON

4.+12VDG

3.GNDDG

2.NC

1.MPON

1

5

3

3.GNDDG

2.RS232TXD

1.RS232RXD

9.TRGC

8.TRGB_Z3

7.IRIN

6.TRGA_Z2

5.+3.3VST

4.GNDDG

19

25142023A

1

BCTRM-2023

QPWBCTRM2023A

15

FL

FR

C

SL

SR

SBL

SBR

GNDSBR

GNDSR

GNDFR

GNDC

GNDFL

GNDSL

GNDSBL

GNDRL

+24VRL

1719

P2800A

23.ADPR

22.GNDVD

21.ADPB

20.GNDVD

19.ADCV

18.GNDVD

17.+5VVD

16.4053INH

15.CONC

14.CONA

13.CONB

12.~HPDET

11.SPRLCS

10.SPRLF

9.SPRLSB

8.SPRLZ2

7.SPRLH

6.~POFF2

5.MPON

4.~SWPON

3.HPRL

2.AUXCVIN

1.GNDVD

5.HPL

4.GNDFL

3.HPR

2.HPDET

1.GNDDG

1

23

2.RS232RXD

1.RS232TXD

3.GNDDG

1.+12VDG

2.GNDDG

3.NC

4.GNDDG

5.+12VDG

12

10

25

22

12

10

10

10

17

12

17

17

17

17

17

17

7

7

7

7

7

7

15

7 7

17

7

7

7

10

7

7

7

15

12

7

7

15

15

22

7

20

17

20

7

17

15

15

15

27

30

7

7

10

7

7

20

22

12

20

27

30

30

12

17

15

15

15

22

20

QR

FR/FL

C

SR/SL

SBR/SBL

HR/HL

Z2R/Z2L

C6546 C6545

C6526

C6525

C6548 C6547

C6528

C6527

C6540 C6549

C6520

C6529

C6592

C6591

C6572

C6571

C6541C6542 C6543

C6521

C6522

C6523

R6520

R6510

P2300

P2301

P2302

RL6505

RL6507

RL6501

RL6503

C2102

C2103

C2104

C2105C2106 C2107 C2108C2109

C2302

C2114

C2000

C2001

C2002

D2000

P2801A

F2000

P6505

P6507

P6509

P6551

J2501

P2800A

C2115

RL6510

J6510

J6520

J2505

C2116

C2118

C2112

J2102

J2121

J2513

J2503

J2509

J2508

J2504

J2500

J2507

J2506

RL6551

RL6509

P2102

P2100

P2101

J6513 J6508

J6512

J6509

J6507

J6506

J6524

J6525

J6526

J6527

J6528

J2124

J2103

J2111

J2112J2114

J2113

J2110

J2101

J2109

J2123

J2122

J2100

J2127

J2126

J2125

J2119

J2118

J2128

J2117

J2129

J2115

J2116

J2130

J2514

J6522

J2512

P6400B

D2000A

P9011B

P2000

J2502

J6530

J6529

J6531

J6534

J6535

J6536

P7880B

J6533

J6532

P6501

P7880C

P2802A

P2900A

J6538

J6537

J2510

J2107

J2106

J2108

J2105

J2104

J6505

J6523

J6521

J6519

J6518

J6517

J6515

J6514

J6504

J6516

J2131

J2132

J2120

P6401B

J6502

J6503

2

5 4 3

6

Check Point (BATRM-2023)

D

C

B

A

Back

Trouble Shoot

J6504

J6504

Check Voltage

+24V

●Each voltage is shown as the reference value.

TX-NR585/NR686

D

C

B

A

1

5 4 3

2

1

6

30.COAX

29.GNDDG

28.+3.3VDG

27.OPT2

26.ADCL

25.OPT1

24.GNDAD

23.AMUT

22.ADCR

21.SBZ2MUT

20.G_DACREF

19.Z3MUT

18.Z2L

17.Z2MUT

16.GNDAD

15.PREMUTCS

14.Z2R

13.PRERLF

12.SBL-

11.C+

10.SBL+

9.C-

8.SBR+

7.SW+

6.SBR-

5.SW-

4.SL-

3.SR-

2.SL+

1.SR+

30.FL+

29.FL-

28.FR+

27.SEC1H

26.FR-

25.VOLH

24.ADC2R

23.VPROTECT

22.GNDAD

21.PRERLSB

20.ADC2L

19.IPROTECT

18.Z3L

17.VOLLAT

16.GNDAD

15.VOLCLK

14.Z3R

13.VOLDAT

12.TUSDA

11.GNDVOL

10.TUSCL

9.VOLCLKBD

8.GNDTU

7.+15VA

6.+3.3VTU

5.-15VA

4.AUXL

3.MICOUT

2.GNDAUX

1.AUXR

1

1

5

5

10

10

15

1521 21

20

22

2

2

7.+3.3VTU

6.TULIN

5.TURIN

4.GNDTU

3.TUSDA

2.TUSCL

1.NC

1

7

P1502A

P1501A

1.TULIN

2.GNDTUA

3.TURIN

4.Z2L

5.Z2R

6.DACSBL

7.DACSBR

8.DACSL

9.DACSR

10.DACSW

11.DACCT

12.DACFL

13.DACFR

14.ADC2L

15.ADC2R

16.GNDAD

18.GNDAD

20.GNDAD

17.ADCL

19.ADCR

21.-15VA

22.+15VA

-15VA

-15VA

-15VA +15VA

+15VA

+15VA

+15VA

-15VA

1

2

5

10

15

20

25

29

30 30

29

1

2

5

10

15

20

25

4.MICOUT

5.VOLCLKBD

6.GNDVOL

7.VOLDAT

8.VOLCLKNJW

9.VOLLATNJW

10.AMUT

11.SBZ2MUT

12.Z3MUT

13.Z2MUT

14.PREMUTCS

15.Z3L

16.Z3R

18.IPROTECT

20.VPROTECT

17.PRERLF

19.PRERLSB

21.SEC1H

22.VOLH

P1502A

1.AUXL

2.GNDAUX

3.AUXR

P1501A

2022

P8003A

P8002A

-15VA

1

1

1

1

1

1

1

1

Q1501

Q1503

Q1505

Q1507

Q1521

Q1522

R1501

C1911

R1502

R1503

R1504

R1505

R1506

R1507

R1508

R1701

R1702

C1921

C1922

C1923

C1925

Q1921

C1926

C1927

C1928

R1901

C1929

R1902

R1903

R1904

Q1541

R1521

R1522

R1523

R1524

R1525

D1911

R1526

D1912

R1527

R1528

R1721

R1722

R1921

R1922

R1923

R1924 R1925

R1926 R1927

R1541

R1542

R1543

R1544

R1545

R1546

R1547

R1548

R1741

R1742

R1561

R1562

R1563

R1564

R1565

R1566

R1567

R1950

R1568

R1951

R1952

R1953

R1954

R1761

R1762

R1958

R1581

R1582

R1583

R1584

R1585

R1586

R1587

R1588

R1781

R1782

R1601

R1602

R1603

R1604

R1605

R1606

R1607

R1608

R1801

R1802

R1621

R1622

R1623

R1624

R1625

R1626

R1627

R1628

R1821

R1822

R1641

R1642

R1643

R1644

R1645

R1646

R1647

R1648

R1841

R1842

L1921L1922

R1661

R1662

R1861

R1862

R1681

R1682

R1881

R1886

R1882

R1885

R1887

R1884

R1883

R1888

2

5 4 3

6

Check Point (BADG-1985)

D

Front

C

B

A

Back

P8002A P8003A

Q1501

P8002A

Check Voltage

5 -15V

7 +15V

Check Signal

Input terminal : HDMI IN or OPT IN

Input signal(HDMI/ OPT IN) : Test disc 1kHz 0dB

Audio format : LPCM, Dolby Digital(Otherwise, CD)

Speaker Config : 2.0

29

P8003A

check Signal

Input terminal : HDMI IN or OPT IN

Input signal(HDMI/ OPT IN) : Test disc 1kHz 0dB

Audio format : LPCM, Dolby Digital(Otherwise, CD)

25

Check Voltage

28 +3.3V

Q1501

Check Signal

Input terminal : HDMI IN or OPT IN

Input signal(HDMI/ OPT IN) : Test disc 1kHz 0dB

Audio format : LPCM, Dolby Digital(Otherwise, CD)

1

Speaker Config : 2.0

●Each voltage is shown as the reference value.

Trouble Shoot

D

30

2.8V

3.3V

5.6V

TX-NR585/NR686

2.8V

C

B

A

1

5 4 3

2

1

6

BLU

RED

SBL

C

FR

SBR

1.AUX_L

IPROTECT

VPROTECT

MICOUT

AUX_R

GND_AUX

GND_A

1.TULIN

DAC_SW

DAC_SL

7.DAC_SBR

DAC_SBL

Z2L

Z2R

79M1578M15

ADCL

ADC2R

14.ADC2L

TURIN

BLK

F6901

F6902

12A/250V

25141979A

SLSR

BCAF-1979

1

22.+15V

ADCR

SW

7.VOLDATA

VOLCLKNJW

VOLLATNJW

SEC1H

22.VOLH

PRRLF

PRERLSB

22

1

AMUT

SBZ2MUT

**A**C

Q4001

VOLIC

FL

RED

L

R

ID-

ID+

ID-

ID+

ID-

ID+

C

ID+

ID-

SL

SR

ID-

ID+

SBL

ID+

ID-

SBR

ID+

ID-

BLU

GND_A

GND_A

BLK

GND_A

PREMUTCS

QPWBCAF1979A

LRC

SL

SR

SBL

SBR

Z3R

Z3L

Z3MUT

14.Z2MUT

VOLCLKBD

N.C.

DAC_SR

DAC_CT

DAC_FR

DAC_FL

-15V

PHONO

CDTV

GAME

STRM BOX

CBL/SAT

BD/DVD

Z3 OUT Z2 OUT SW OUT

FRONT OUT

CENTER OUT

SURR OUT

SBACK OUT

TTC

TTC

TTC

TTC

TTA

TTA TTA TTA

F6901/6902

**A**A**A**A**A**A **C**C**C**C**C**C

1

22

22

20

7

7

30

22

12

30

7

15

15

20

22

7

7

10

20

17

10

20

7

25

7

22

10

7

12

20

12

17

17

17

12

7

12

7

15

22

25

12

7

10

10

17

10

10

27

17

22

COM

NC

NO

COM

NC

NO

20

22

17

20

7

20

10

22

7

20

22

7

10

15

12

15

7

7

10

7

7

22

7

7

10

20

7

30

30

22

30

7

25

22

12

27

10

12

25

22

22

12

30

10

7

17

25

25

27

10

27

10

10

25

22

25

30

25

25

10

12

30

10

25

20

10

12

27

12

7

30

22

20

12

17

22

17

17

17

20

12

20

25

30

7

22

10

7

22

17

12

12

25

15

25

15

20

17

27

12

22

30

22

10

12

10

30

15

15

22

22

17

30

22

12

25

7

10

15

7

7

7

7

17

7

22

17

7

17

17

22

20

17

12

10

12

10

15

17

22

15

10

27

12

10

15

7

10

12

10

15

27

10

10

7

7

10

10

10

15

7

25

12

7

17

27

10

15

12

15

17

15

15

12

20

27

15

17

27

22

20

7

10

10

20

27

20

22

17

QR

B C EB C EB C EB C EB C EB C EB C E

B

C E

B

C E

B

C E

B

C E

B

C E

B

C E

B

C E

Q6128

C6901

J6611

C6902

J6612

J6614

J6615

J6616

R6305

R6306

R6307

R6308

J4101

J4104

J4106

J4107

J4108

J4109

J4001

J4002

J4110

J4111

J4112

J4114

J4115

J4116

J4117

J4118

J6441

J4501

J4119

J6442

J4502

J6443

J4504

R5385

J6445

R6901

R5386

J6446

J4506

R5387

J6447

J4507

R5388

J6448

J4508

J4120

J4509

J4121

J4122

J4123

J4124

J4125

J4126

C4223

J4127

J4128

C6741

C4225

J4511

J4129

C4226

C6744

R6141

R6142

R6143

R6913

J4517

R6914

J4130

R6145

J4519

J4131

R6146

J4132

R6147

J4133

R6148

J4134

J4135

J4136

J4137

C4041

J4139

C4042

C4043

C4044

J4524

C4045

RL6911

RL4201

C4046

RL6912

RL4202