Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

INVERTED RESEARCH

MICROSCOPE

This instruction manual has been written for use of the

Olympus lnverted Research Microscope Model IMT-2. Before

putting the microscope into operation, it is recommended

that you read this manual carefully in order to familiarize

yourself fully with the use of this microscope so that you

may obtain optimum performance of this instrument.

----

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

IBEFORE USE

Observe the following points carefully for operation and maintenance:

1.

Operation

@ As a microscope is a precision instrument, always handle

it with the care it deserves, and avoid abrupt motions

and shocks.

0

a

0

0

8

0

2.

To lift the microscope from the packing case, hold it

at the OM mount (A) and the fluorescence illuminator

mounting thread (B). (Fig. 1)

To move the microscope

Hold the microscope by the OM mount (A) and the

fluorescence illuminator mounting thread (B) or place

your hands under the microscope base at the microscope

side (C) and back (D).

Do not grasp the plastic hand rests, since they are not

strong enough to support the microscope.

Do not use any bulb other than the one designated by

Olympus (12V50WHAL halogen bulb).

Avoid exposure of the microscope to direct sunlight,

(Model IMT2SFR shown)

high temperature and humidity, dust and vibration.

Make it a point to use the tension adjustment ring to adjust the tension of the coarse adjustment knobs. (

not rotate the coarse adjustment knobs in the opposite directions simultaneously.)

Make sure that the line voltage selector switch is set to conform with the local mains voltage.

Disconnect the power cord from the AC outlet before fuse replacement.

Always ground the microscope.

Maintenance

:Do

@ Lens surfaces must always be kept clean. Fine dust on lens surfaces should be blown off by means of a hand

blower. Carefully wipe off oil or fingerprints on the lens surfaces with gauze moistened with a small amount

of xylene, or a cleaning medium (alcohol and ether 3 : 7).

@ Do not use organic solutions to wipe the surfaces of various plastic components.

@ Be careful not to spill the culture solution, etc. If spilt, it should be wiped off immediately. It is recommended

to use a waterproof cover optionally available.

@ When objectives are not screwed into the nosepiece apertures, seal the apertures with dust plugs, which will

protect the lenses located in the lower light path from dust, culture solutron, etc.

@ After use the microscope should be covered with the vinyl dust cover provided and stored in a place free from

humidity.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-l

Observation Procedure

.............................

10

5-2

Operation of Individual Components

..................

11

6-l

Photomicrographic System

..........................

18

6-2

Taking Pictures

...................................

20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I tern

vlicroscope

Specifications

Focus adjustment by vertical movement of the nosepiece (stage is fixed in position) by means

#sand of the coaxial coarse and fine adjustment knobs,

roller guide stroke (from the focal point on

the stage surface). 8mm upward and 2mm downward; with reduction gear, graduated rn tncrements of 2g.

\Josepiece.

Sextuple, with provision for mountrng the Nomarski slrder attachment, detachable.

Gtage:

Cross-movement stage

IMT2SVR

Square plain stage

Mechanical stage

attachment IMT2-MVR

Ilumination:

Light source

Filter holder

t

Condenser holder

200mm x 200 mm, traversing area 50mm x 50 mm;

with low positioned coaxial control knobs; 2 insert plates, outside diameter 1 lOmm,

inside diameters 20 mm and 50 mm respectively.

200mm x 2OOmm, traversing area 50mm x 50 mm;

with low positioned coaxial control knobs; 2 insert plates, outside diameter 1 IOmm,

inside diameters 20 mm and 50 mm respectively, low flexible.

160 mm x 220 mm;

insert plate, outside diameter 110 mm. Substage

provided; provision for attaching the mechanical stage IMT2-MVR.

Traversing area 110mm x 72mm; attachable at the right or left side

on the plain stage.

Provision for accommodation of various culture vessels and specimen

holders.

Halogen bulb 12V50WHAL, with bulb centering device and light intensive control; Voltage indication by bar graph voltmeter.

Provided with 4 flip-up filter holders; green interference filter and

frosted filter.

Flip-up, swing-out type; circular mounting dovetail for slide-in condenser;

vertical movement on rack-and-pinion, condenser centering

knobs; tension adjustment of the height adjustment knob.

Observation

system.

Built-in magnification changer, with centering telescope 1 X-1 .5X-CT.

Light path for photomicrography, 3-setting positions, linked with focusing retitles; for observa-

tion tube (BI), 35mm camera (OM) and multi-tube mounting port (MTU).

Binocular tube, inclined 45’; interpupillary distance adjustment from 53 mm to 75mm; constant

tube length adjustment.

Eyepieces WHKlOX, WHKIOX-H (field number 20)

OM light path: 2.5X FK photo eyeprece built-in; OM system bayonet mount.

Multi-tube light path; provision for mounting the PM-10 photomicrographic equipment directly

as well as the multi-tube attachment.

Condenser.

Objectives.

Long working distance turret condenser; N.A. 0.55, W.D. 21 mm, light annuli for 4X, 10X,

20X and 40X objectives and empty aperture; aperture iris diaphragm.

Ultra long working distance condenser,

N.A. 0.30, W D. 55mm, Light annul1 for 4X, 10X,

20X, and 40X objectives plus empty aperture; aperture Iris diaphragm.

Phase contrast objectives PC S Plan 4XPL

N.A. 0.13, W.D 15.5 mm

PC S Plan 1OXPL

N.A. 0.30,*W.D. 7.5mm

LWD-CD Plan 20XPL N.A. 0.40, W.D. 3.0 mm

with correction collar

LWD-CD Plan 4OXPL N.A. 0.60, W.D. 1.9 mm

wrth correction collar

Dimensions:

320 mm (W) x 395mm (D) x 600 mm (H) Eyepoint 405 mm

Stage height 275 mm

Weight:

20.5 kg (outfitted with standard equipment)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Component

Microscope stand,

with built-in magnification changer (1X-l .5X-CT),

built-in 2.5X photo eyepiece, 50W halogen illuminator, condenser holder, hand rests (paired), dust

cover, filter 431F550-W45 and screw driver

Power cord

Binocular tube, 45’ inclined

Intermediate tube

;extuple revolving nosepiece

jOW halogen lamp housing

jOW halogen bulbs, 2 PCS.

Iross-movement mechanical stage with right-hand

ow drive controls

:ross-movement mechanical stage with right-hand

ow flexible

Model

I MT-2-l 1 I MT-2-l 2

I MT2-F

0

0

UYCP

0

0

BH2-B145

0

0

I MT2-ATU

0 0

IMT2-RE

0

0

IMT2-LSH

0

0

JC12V50WHAL 0

0

I MT2-SVR

;quare plain stage

nechanical stage attachment with low drive controls

-ong working distance turret condenser

Jltra long working distance turret condenser

Objectives

Eyepieces

IMT2-SFR

IMT2-SP2 0 0

I MT2-MVR 0

0

IMT2-LWCD 0

IMT2-U LWCD

0

0

PCSPL4XPL

0

PCSPLlOXPL

0 0

LWDCDPL2OXPL 0

LWDCDPL40XPL

I::::::-, / : 1 i

Note: 0 indicates the compatible components for Model IMT-2-1 l/ IMT-2-12/lMT-2-21/IMT-2-31.

vlT-2-21 I MT-2-31

0 I 0

I

O I 0

T

0

0 I 0

I

0 I 0

0

0

0

0

l-

0

0

0

0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Field iris diaphragm

lever

Lamp housing

Long working distance

condenser

Stage insert plate

omarski slider

insertion slot

%\

insertion slot

Exciter filter

Multi-tube mounting

-I~ ~.

aaapTer

Main switch

(IMT-2-12 shown)

\Eyepiece

Diopter adjustment

Observation tube

ring

\

Line voltage selector

switch

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Lamp housing

/

\

Bulb horizontal centering

Bulb socket clamping/

ong working

distance

condenser

---.

Condenser height

Condenser holder

clamoina knob

Stage cross-movement

knobs

Light excluding shutter kno

Light

path selector knot

-

BI

: for binocular tub{

OM : fboa;;5mrn camen

.

I

\

Minimum line voltage

Tension adjustment knob

‘/

/ /Frne adjustment knob

1 Hand resr\ se’ector knob

e

3

Coarse adjustment knob

I

Light intensity

control lever

( IMT-2-12 shown)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

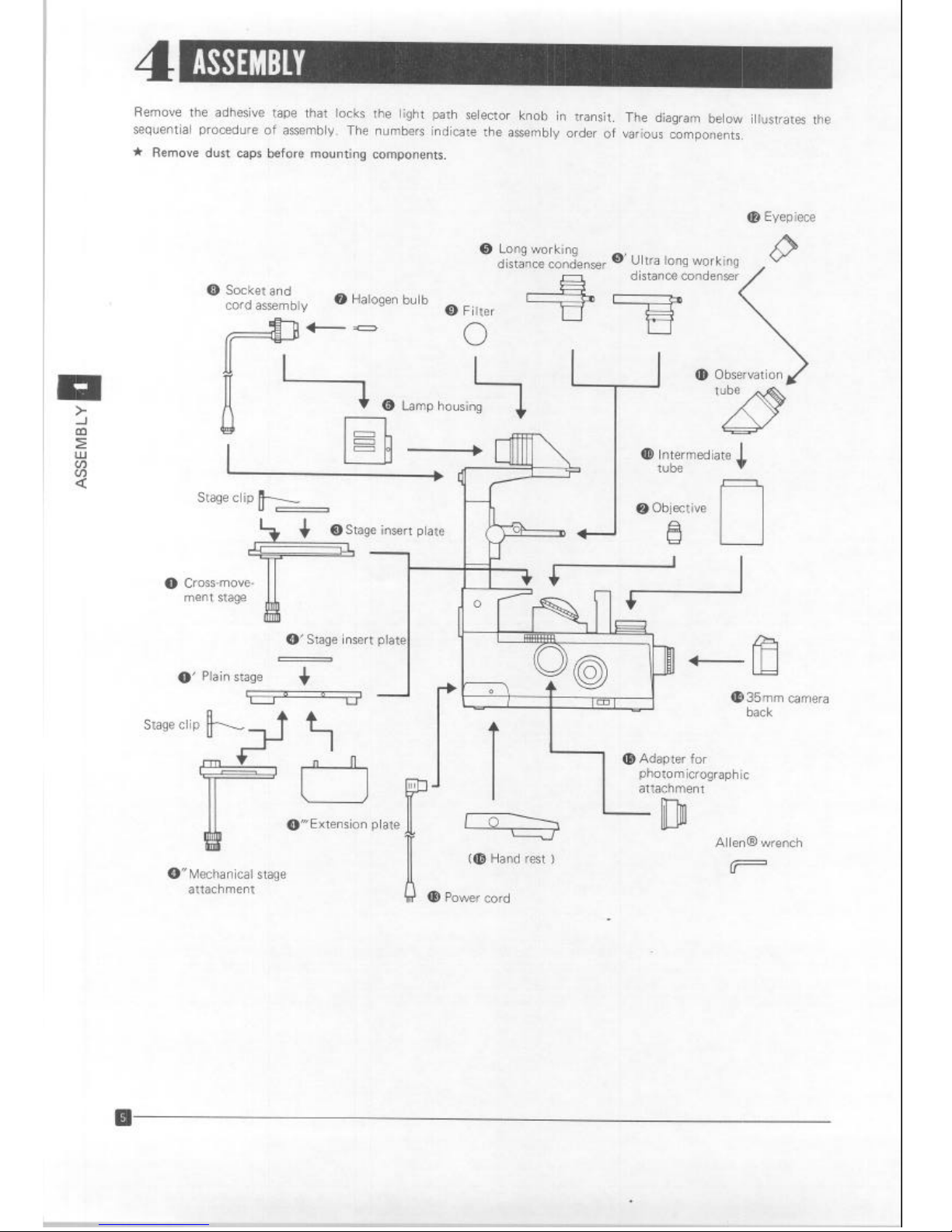

Remove the adhesive tape that locks the light path selector knob in transit. The diagram below illustrates the

sequential procedure of assembly. The numbers indicate the assembly order of various components.

It Remove dust caps before mounting components.

CD Eyepiece

(i) Long working

distance condenser

0’ Ultra long working

distance condenser

0 Socket and

cord assembly

0 Halogen bulb

@ Filter

0

Lamp housing

4

Stage clip

k

@ Objective

!!3

L

+ I

0 Cross-move- 11

0’ Stage insert plate

,

0’ Plain stage

+

I

0

o’y, ~

n. I.

R

4 A

ment stage

ii!

I

@35mm camera

back

-1

@Adapter for

photomicrographic

attachment

@“Extension plate L

lr -

Allen@ wrench

0” Mechanical stage

attachment

Cm Hand rest )

m Pnrnmr r.r\rA

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

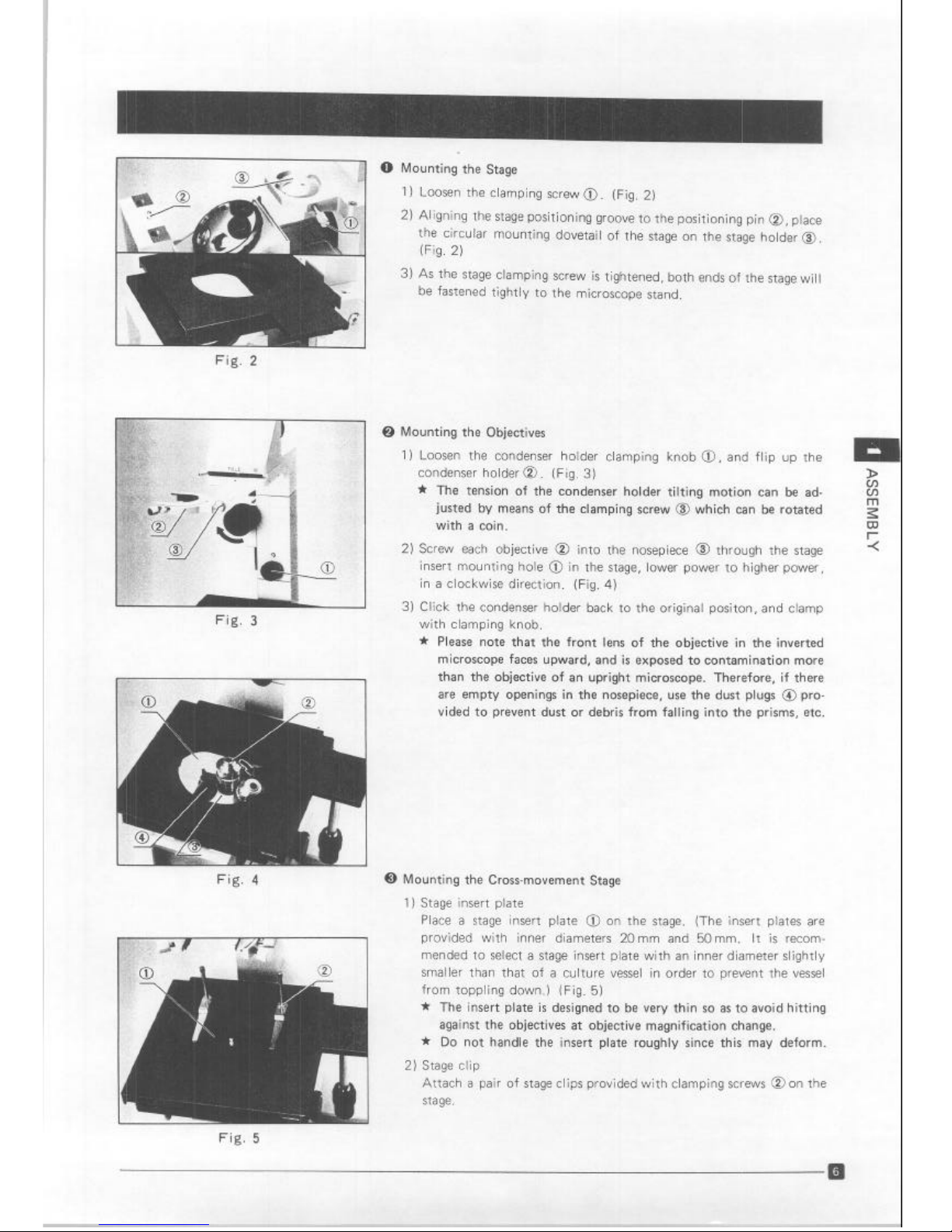

Fig. 2

L-1

q

Fig. 3 Fig. 3

Fig. 4

0

Mounting the Stage

) Loosen the clamping screw 0. (Fig. 2)

) Aligning the stage positioning groove to the positioning pin 0, place

the circular mounting dovetail of the stage on the stage holder 0.

(Fig. 2)

) As the stage clamping screw is tightened, both ends of the stage will

be fastened tightly to the microscope stand.

0 Mounting the Objectives

1) Loosen the condenser holder clamping knob 0, and flip up the

condenser holder 0. (Fig. 3)

>

* The tension

of the condenser holder tilting motian can be ad-

E

justed by means of the clamping screw @ which can be rotated

a

with a coin.

P

2) Screw each objective @ into the nosepiece @ through the stage

i

insert mounting hole @ in the stage, lower power to higher power,

in a clockwise direction. (Fig. 4)

3) Click the condenser holder back to the original positon, and clamp

with clamping knob.

* Please note that

the front lens of the objective in the inverted

microscope faces upward, and is exposed to contamination more

than the objective of an upright microscope. Therefore, if there

are empty openings in the nosepiece, use the dust plugs 0 provided to prevent dust or debris from falling into the prisms, etc.

0 Mounting the Cross-movement Stage

1) Stage insert plate

Place a stage insert plate @ on the stage. (The insert plates are

provided with inner diameters 20 mm and 50 mm. It is recommended to select a stage insert plate with an inner diameter slightly

smaller than that of a culture vessel in order to prevent the vessel

from toppling down.) (Fig. 5)

* The insert plate is designed to be very thin so as to avoid hitting

against the objectives at objective magnification change.

Ir Do not handle the insert plate roughly since this may deform.

2) Stage clip

Attach a pair of stage clips provided with clamping screws @ on the

stage.

Fig. 5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

/

/

Fig. 6

Fig. 7

0 Attaching the Plain Stage

1) Insert plate (I MT2SP2)

Aligning the guide pin @ of the insert plate with the notch @ in

the stage, mount the insert plate. (Fig. 6)

2) Mechanical stage attachment (IMT2-MVR)

Attach the mechanical stage attachment to the lower rrght side of

the plain stage, tightening the clamping screw @ with a coin. (Fig. 7)

* If no photographic equipment, such as the PM-1OAD equipment,

etc. is attached to the “MTU” light exit port of the microscope

base, the stage attachment can be attached on the left side of the

plain stage.

3) Stage extension plate

Align the guide pins of the extension plate 0 into the positioning

holes in the plain stage, and attach securely. (Fig. 8)

Fig. 8

0 Attaching the Condenser

Insert the circular dovetail of thg condenser into the condenser holder,

and clamp with knob @ (Fig. 9)

Fig. 9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

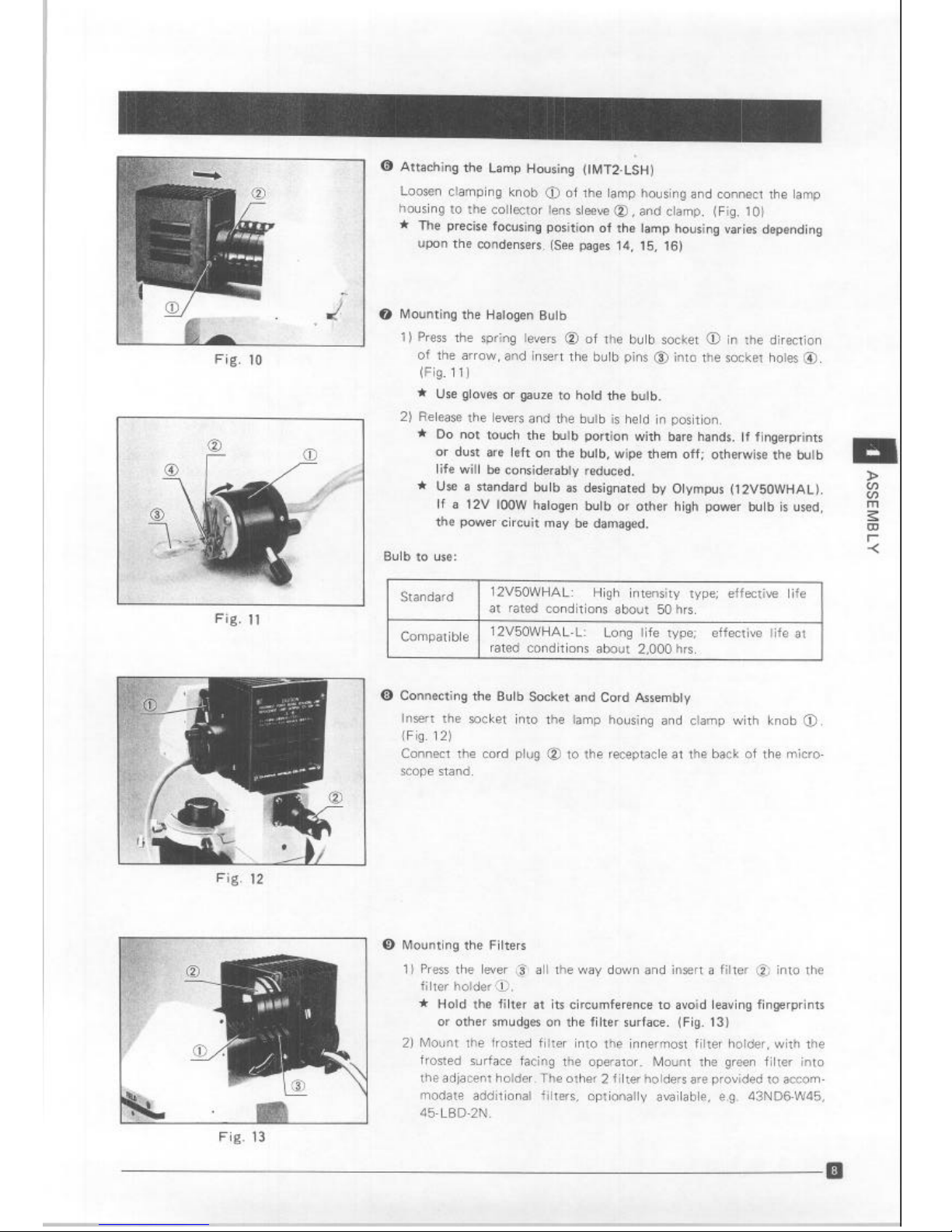

@ Attaching the Lamp Housing (lMT2-LSH)

Loosen clamping knob 0 of the lamp housing and connect the lamp

housing to the collector lens sleeve 0, and clamp. (Fig. 10)

*

The

precise focusing position of the lamp housing varies depending

upon the condensers. (See pages 14, 15, 16)

0 Mounting the Halogen Bulb

1) Press the spring levers @ of the bulb socket @ in the direction

of the arrow, and insert the bulb pins @I into the socket holes 0.

(Fig. 11)

* Use gloves or gauze to hold the bulb.

2) Release the levers and the bulb is held in position.

* Do not touch the bulb portion with bare hands. If fingerprints

or dust are left on the bulb, wipe them off; otherwise the bulb

life will be considerably reduced.

* Use a standard bulb as designated by Olympus (12V50WHAL).

If a 12V IOOW halogen bulb or other high power bulb is used,

the power circuit may be damaged.

Bulb to use:

Fig.

11

Standard

12V50WHAL: High intensity type; effective life

at rated conditions about 50 hrs.

Compatible

12V50WHAL-L: Long life type; effective life at

rated conditions about 2,000 hrs.

Fig. 12

0 Connecting the Bulb Socket and Cord Assembly

Insert the socket into the lamp housing and clamp with knob 0.

(Fig. 12)

Connect the cord plug @ to the receptacle at the back of the micro-

scope stand.

0 Mounting the Filters

1) Press the lever @ all the way down and insert a filter @ into the

filter holder 0.

* Hold the filter at its circumference to avoid leaving fingerprints

or

other

smudges on the filter surface. (Fig. 13)

2) Mount the frosted filter into the innermost filter holder, with the

frosted surface facing the operator. Mount the green filter into

the adjacent holder. The other 2 filter holders are provided to accommodate additional filters, optionally available, e.g. 43ND6-W45,

45.LBD-2N.

Fig. 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

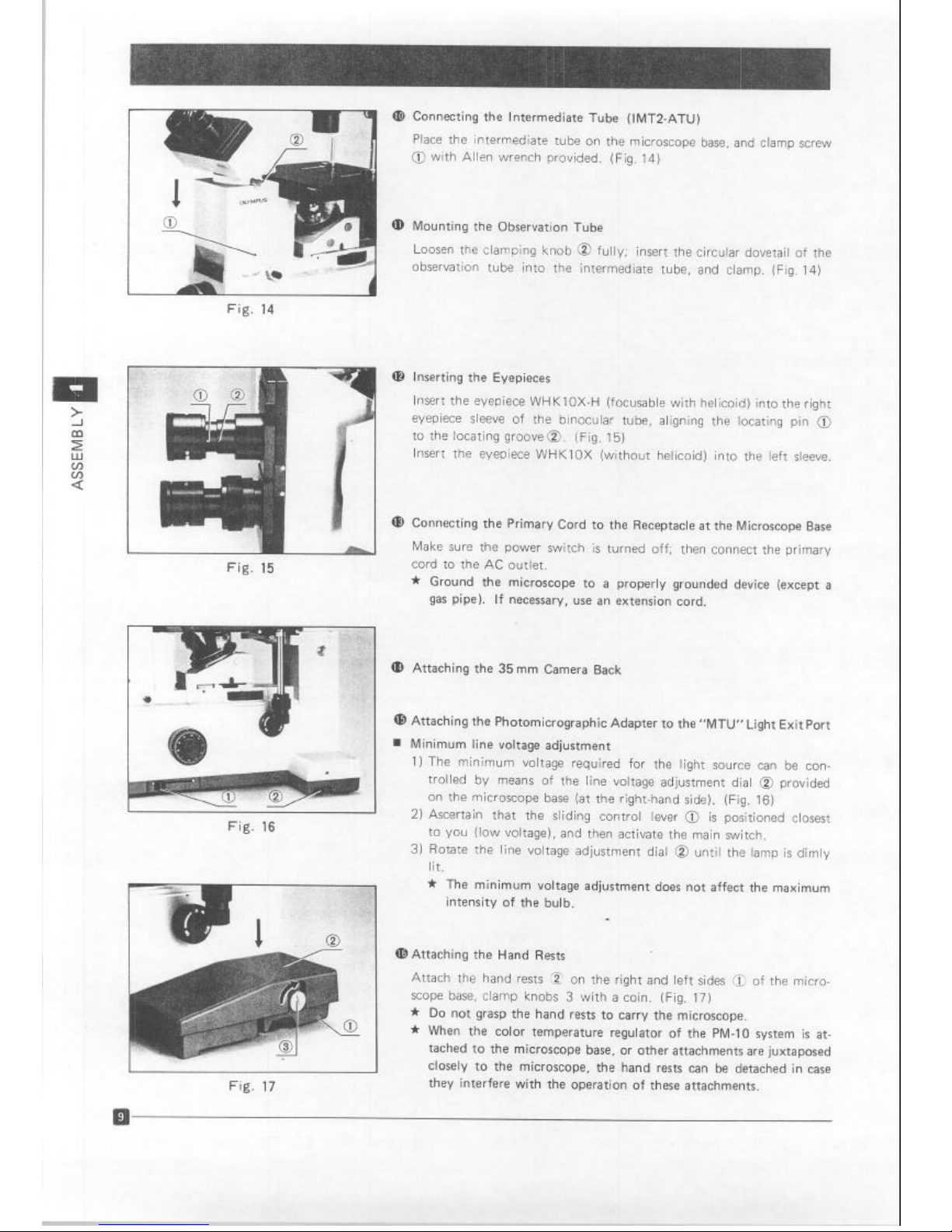

Fig. 14

Fig. 15

Fig. 16

I

I

Fig. 17

Connecting the Intermediate Tube (lMT2-ATU)

Place

the intermediate tube on the microscope base, and clamp screw

@ with Allen wrench provided. (Fig. 14)

Mounting the Observation Tube

Loosen the clamping knob @ fully, insert the circular dovetail of the

observation tube into the intermediate tube, and clamp. (Fig. 14)

@ Inserting the Eyepieces

Insert the eyepiece WHKlOX-H (focusable with helicoid) into the right

eyepiece sleeve of the binocular tube, aligning the locating pin @

to the locating groove@. (Fig. 15)

Insert the eyepiece WHKlOX (without helicoid) into the left sleeve.

@ Connecting the Primary Cord to the Receptacle at the Microscope Base

Make sure the power switch is turned off; then connect the primary

cord to the AC outlet.

* Ground the microscope to a properly grounded device (except a

gas pipe). If necessary, use an extension cord.

Attaching the 35mm Camera Back

Attaching the Photomicrographic Adapter to the “MTU” Light Exit Port

Minimum line voltage adjustment

1) The minimum voltage required for the light source can be controlled by means of the line voltage adjustment dial @ provided

on the microscope base (at the right-hand side). (Fig. 16)

2) Ascertain that the sliding control lever @ is positioned closest

to you (low voltage), and then activate the main switch.

3) Rotate the line voltage adjustment dial @ until the lamp is dimly

lit.

* The minimum voltage adjustment does not affect the maximum

intensity of the bulb.

a!) Attaching the Hand Rests

Attach the hand rests ,z on the right and left sides 0 of the microscope base, clamp knobs 3 with a coin. (Fig. 17)

* Do not grasp the hand rests to carry the microscope.

* When the color temperature regulator of the PM-10 system is at-

tached to the microscope base, or other attachments are juxtaposed

closely to the microscope, the hand rests can be detached in case

they interfere with the operation of these attachments.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Normal procedure

Adjustment necessary for operation

Swing out the_ filters.

Lower the

nosepiece.

1 Swing in the 1 OX objective.

F

Rotate the condenser turret to “ 0 @

position. Stop down the aperture iris dia- . . . . .

phragm for low contrast specimens.

I

lnterpupillary distance adjustment

. . . . . . . . . . . . . . . . .._.....

. .

Diopter adjustment

I

. . . . . . . . . . . . . . . . . . . . . . . . . . .

*

1 Focus

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

. .

FOCUS on the field iris diaphragm

Condenser centration (with magnification

changer at CT position); bulb centration

. .

1

Engage the desired objective.

+

[

Match the condenser turret.

. . .

Light annulus centration

.

1

\Finefr , oftheve,~~~~t~~~:........~,:...~.,.

Adjust the correction collar of objectrves

20X and 40X according to the thickness

.

I

Adjust light intensity.

. . . . . . . . .

Adjust the aperture iris diaphragm in

brightfield.

Relevant part

bage)

Filter holders

Coarse adjustment knob

Main switch

(8)

(14)

(11)

Light path selector knob

(4)

Specimen holder

(12)

Aperture iris diaphragm in

condenser

Eyepiece sliding dovetails

Diopter adjustment ring

Coarse and fine adjustment

knobs

Condenser height adjustment

knob

Condenser centering knob

Bulb centering knob

CT focusing ring

(14) p

(14)

(14)

(14)

(14)

(14)

. Condenser turret

(14)

Light annulus centering knob (15)

.

CT

(15)

Coarse and fine adjustment

. .

knobs

(14)

Correction collar

(16)

Sliding voltage control lever

(11)

. .

Aperture iris diaphragm

(14)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

0 Switching on the Light Source

1) AscertaIn that the line voltage selector switch @ located at the back

of the microscope stand is set to conform with the local mains

voltage. (Fig. 18) If not, adjust correctly by means of a small screwdriver.

I

Fig. 19

Fig. 20

2) Make sure that the sliding voltage contol lever @ is set at the closest

position to the operator (low voltage), then turn on the power

switch3. (Figs. 18 & 19)

Voltage adjustment and light intensity

l

As you push the control lever forward, the LED at the indicator “P”

lights up on the left side of the voltmeter @ to indicate the bulb

voltage between 0 - 3V. Then, five LED on the right side indicate

4V- 12V in increments of 2V. (Fig. 19)

l

For overvoltage beyond 12V (at local mains 115V). the extremely

right-hand LED blinks for warning.

* The effective life of a bulb will be prolonged if it is used at a

voltage lower than rated.

* For use of daylight type color film, use the LBD-2N filter with

voltage at about 8V.

@ Place a Specimen on the Stage.

A. Cross-movement stage (IMT2-SVR, IMT2SFR)

1) The traversing area of the cross-movement stage is 50 mm x 50 mm.

Select the insert plate with an inner diameter of 20 mm or 50 mm

according to the specimen, vessel, and observation area.

2) Place a specimen on the stage.

* If you rotate the nosepiece or move the cross-movement stage

after focusing on the specimen in a vessel, the lower surface of

which is positioned more than 1 mm above the stage surface,

the front lens of the objective may sometimes hit against the

insert plate from underneath. (Fig. 20) Therefore, it is necessary

to ascertain its safety before rotating the nosepiece. If there is

any possibility to impinge-it is safe to lower and then rotate the

nosepiece.

B. Plain stage (IMT2-SP2) and mechanical stage attachment (lMT2-MVR)

1 ) Placement of various vessels or glass slides

Coincide the vessel center with the center of the X scale (55mm

positon) by adjusting the position of the specimen holder 0,

0, then clamp in position with knobs 0. (Fig. 21)

(See b. 13 for setup of stage attachments in detail.)

Fig. 21

II

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Fig. 22

Fig. 23

Fig. 24

Fig. 25

Fig. 26

2) Click-stop plate

This mechanical stage attachment permits the use of the click-stop

plates for 96well micro titre plates and the 24.well micro titre plate

of other chambers in any click position for each well, as desired.

Install the click-stop plate 0. (Fig. 22)

Attach the click 0, and screw the click spring tube 0 in a manner

it clicks the stage.

Moving the stage, adjust the click position so that it clicks at the

center of each well.

3) Specimen holder

Opening the spring-loaded finger of the specimen holder with one

hand, place a specimen slide inside the holder with the other hand.

(Fig. 23)

* When the slide comes in contact with the back of the specimen

holder, slowly return the spring-loaded finger.

* If the spring-loaded finger is returned too quickly, it may cause

damage to the specimen slide, or spill the culture solution.

* If the bottom of the vessel is rounded off or shaped similarly, the

spring-loaded finger may sometimes not catch the vessel bottom.

C

z

?

3

4) Stage extension plate

The plain stage is reduced in its width to match the compact me-

chanical stage attachment. To observe a large culture vessel, connect

the extension plate to the side of the plain stage. (Fig. 24)

0 Observation Tube

1) Looking through the binocular tube, slide the knurled dovetail

mounts @ of the right and left eyepieces with both hands, until

a perfect binocular vision is obtained. (Fig. 25)

2) If your interpupillary distance setting is already known, set it on the

scale @ located between the eyepieces.

3) Diopter adjustment

a. Rotate the light path selector knob to the “OM” position.

b. Looking through the focusable eyepiece with the right eye,

rotate the helicoid ring @ on the eyepiece, until the frame reticle

can be sharply focused. (Fig. 25)

Then, looking through the left eyepiece with the left eye, rotate

the diopter ring @ until the cross lines can be sharply recognized

as two separate lines. (Fig. 26)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Setup of the mechanical stage attachment IMT2-MVR in detail

I-l

Diag. 1

J

30mm-35mm dia. Petri dish

Diag. 4

0 Attaching the click-stop plate to the mechanical stage IMT2-MVR

1) Loosen the click-stop knob 0. (Diag. 1)

2) Align the click-stop notches @ with the click-stop knob.

Pitch :

6.35mm for 60.well Terasaki plate

9mm

for 96-well microtiter plate

* The click-stop plate should be oriented with the longer marginal

portion @ (between the plate end and groove) at the operator’s

right-hand side (in the X direction) or closest to the operator

(in the Y direction). (Diag. 1)

3) Slightly tighten the click-stop plate clamping knob @ with care

that the click-stop plate can be moved slightly until the click-stop

knob @ fits into the notch. (Diag. 1)

@ Mounting the mechanical stage on the plain stage IMT2-SP

1) Rotate the Y-axis drive control knob clockwise all the way.

2) Place the mechanical stage on the plain stage in a manner that the

back @ of the mechanical stage is flush with that @ of the plain

stage. (Diag. 1)

3) Tighten two clamping knobs at the underside of the mechanical

stage to the lower right side of the plain stage with a coin.

0 Use of various specimen vessels

1) Place a specimen

vessel on the stage as shown in Diag. 2 through

6.

* For use of a 96-well microtiter plate or 60-well Terasaki plate,

align the right- and left-hand sliders @ & @ with the index

marks 0 on the X axis graduations as shown in Diag. 2, and

clamp each slider clamping knob 0.

@ Centration of the click-stop plate (96-well microtiter plate and 60-

well Terasaki plate)

1) Looking through the microscope eyepieces, rotate the low drive

control knobs until the center of the well to be observed coincides

with the center of the field of view.

2) Tighten the clamping knob @ of the click-stop plate. (Diag. 1)

60mm-90mm dia. Petri dish

Diag. 5

Slide glass

Diag. 6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Fig. 27

Fig. 28

Fig. 29

Fig. 30

0 Coarse and Fine Adjustment Knobs

1) Bring the objective as close as possible to the specimen without

touching and focus on the specimen roughly by means of the coarse

adjustment knobs 0, then fine focus with the fine adjustment

knobs 0. (Fig. 27)

Tension adjustment of coarse adjustment knobs

While the coarse adjustment motion is normally stiff and heavy, it

is freely adjustable for either heavy or light movement depending

on the observer’s preference. To adjust the tension, rotate the tension adjustment ring 8 In the direction of the arrow to tighten the

coarse adjustment knobs. (Fig. 27)

* The fine adjustment motion is not adjustable.

* Be careful not to forcibly rotate the coarse or fine adjustment

knobs against the upper or lower limit of the focusing range.

* Do not rotate the coarse and fine adjustment knobs simultane-

ously to avoid any damage to focusing adjustments.

0 Condenser Centration

The centering operations of the long working distance condenser and

the ultra long working distance condenser are the same as follows.

C

1) Set the turret @ to the ” 0 @I ” position. (Fig. 28)

2) Bring the specimen into focus by means of the 10X objective.

* It is recommended to stop down the aperture iris diaphragm 0 :

for easier focusing on an unstained specimen. (Fig. 28)

i

3) Stop down the field iris diaphragm by means of the field iris diaphragm lever @ and adjust the condenser height until the image

of the field diaphragm can be observed sharply. (Figs. 28, 29)

* Holding the right condenser knob with the right hand, rotate

the left condenser knob until the tension of the condenser height

adjustment knobs is adjusted to your preference.

4) Bring the image of the field diaphragm into the center of the field

by means of the condenser centering knobs 0. (Ftgs. 28, 29)

Re-open the diaphragm until the small pinhole image of the dia-

phragm becomes a larger polygonal area around the perrphery of the

field. For practical use, slightly open the diaphragm to circumscribe

the field of view.

0 Bulb Centration

After the complete optical setup, center the halogen bulb.

1) Rotate the magnification changer dial @to position “‘CT”. (Fig. 30)

2) Rotate the focus ring @ to focus on the exit pupil of the 10X

objective (located at the same plane as the phase annulus of the

phase objective, the light annulus of the phase contrast condenser

or the aperture iris diaphragm). (Fig. 30)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Fig. 31

Fig. 32

3) Flip up the frosted filter so that the image of the bulb.filament @

can be observed. (Fig. 31)

4) Loosening the lamp housing clamping knob, move the lamp housing

in the axial direction until the filament image is brought into focus.

* Repeat this adjustment whenever the long working and ultra long

working distance condensers are interchanged.

* if it is necessary to increase the light intensity with the phase

objective 40X, move the lamp housing so that the filament image

completely fills the image of the light annulus. If you change the

objective 40X to 4X, at this stage, you will note that the light

intensity will be somewhat reduced at the periphery of the field.

5) Center the filament image by means of the bulb centering knobs.

6) Re-engage the frosted filter.

@ Light Annulus Centration

This centering adjustment equally pertains to the long working and

ultra long working distance condensers.

*

*

*

1)

2)

The IMT-2 microscope adopted the individual centration system of

each phase annulus, so that strict centration of the light annulus

can be achieved with each objective. Therefore, match the light

annulus to the phase objective magnification whenever objectives

are changed, and re-centration is not necessary once the initial

centration has been accomplished.

Recentration, however, is required when the bottom of a culture

vessel is not flat.

This centration is applied to objectives from low to high magnifications.

Swing in the desired objective and focus on the specimen.

Rotate the magnification changer to the CT position. (Fig. 32)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Fig. 33

3) Focus on the phase annulus @ by means of the focus ring 0. (Figs.

32,33)

4) Rotate the condenser turret until the magnification of the objective

engaged appears in the front.

5) Press the light annulus centering knobs @ and rotate them until

both annuli are concentric and superimposed, then slowly disengage

the centering knobs @ (Fig. 34)

C

7

r

6) Rotate the magnification changer @ to the “IX” position, and

observe the specimen to check the phase contrast effect. (Figs. 32,

35)

Fig. 34

Fig. 35

Phase contrast

@ Use of the Correction Collar of the Objectives LWD-CD Plan 20X and

40x.

After coarse and fine adjustments, rotate the correction collar, keeping

the specimen in fine focus until optimum resolution is obtained. Proper

use of this collar is specially effective to prevent the deterioration of

the objective resolution caused by the uneven thickness of various

petri dishes, culture bottles, etc. (Fig. 36)

* The correction collar is effective with a vessel bottom from 0 up

to 2mm in thickness.

1) If the thickness of the vessel bottom is known:

Match the correc;tion collar to the thickness of the vessel bottom by

the collar scale provided,

Fig. 36

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

r

.

Fig. 37

2) If the thickness of the vessel bottom is unknown:

The optimum position for the correction collar can be obtained

from the image resolution. After focusing adjustment, if a satisfactory sharp image is not obtained, rotate the correction collar

to the right and left so that you can compare the images at both

sides. Reset the collar to the better image; then starting from this

Position, further rotate the collar to the right and left until both

images can be obtained for comparison with each other.

AS YOU

repeat this procedure several times, you have to fine focus each

time the correction collar is rotated.

0 Use of Iris Diaphragms

1) Field iris diaphragm

The field iris diaphragm controls the diameter of the ray bundle

impinging on the specimen surface and thus increases image definition and reduces glare.

2) Aperture iris diaphragm

In order to achieve optimum objective performance in brightfield,

the opening of the aperture iris diaphragm should be matched to

the N.A. of the objective in use. It is often preferable, however, to

stop down the aperture diaphragm by about 70% to 80% of the

objective N.A. (Fig. 37)

(As seen through eyepiece tube,

with eyepiece removed.)

CD Filters

Optimum use of proper filters enhances the effective observation and

photomicrography.

Drffusron

/

Interference

(green)

Neutral

density (grey)

Light balancing

*Heat absorbing

45WF Eliminates uneven illumination.

43-l F550-W45

43N D25-W45

43N D6-W45

45-LBD-2N

45-HA

Enhances phase contrast.

Reduces light intensity without

changing color temperature.

For color photomrcrography

with daylight film.

Absorbs heat waves 760nm

and higher to protect the specimen.

*This filter is built in the IMT2-LSH. It is recommended to add a heat

filter for prolonged observation or time-lapse photography of tissue

cultures, etc.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The IMT-2 microscooe features provisions for

selected according to preference.

Fig. 40

A.

OM light path (for 35mm camera back)

1) A 35 mm camera back can be mounted in the same way a camera

tens is bayonet-mounted on a camera. (Fig. 38)

* lt is not recommended to take pictures of floating specimens in

liquid or on a micro-pipette, with objectives 40X

or higher, to

avoid shutter vibration as much as possible.

* Image magnification = Objective magnif. x 2.5 x Intermediate

magnif. (IX or 1.5X)

Ex.

40 x 2.5 x 1.5X = 150 (X)

2) Focus on the specimen, looking through the binocular tube.

8.

MTU light path

mounting of ohotomicrographic attachments at 4 places, which can be

(for direct mounting of the photomicrographic attachment PM-IOAD)

You can take pictures without shutter vibration, since the attachment

is designed vibration-proof.

1) The photo eyepieces available include NFK2.5X, 3.3X, 5X and6.7X.

* Insert the photo eyepiece into the port on the left side of the

base. (Fig. 39)

* When you insert the photo eyepiece into the photo tube, you

may feel resistance midway because of a spring; make sure to

completely insert the eyepiece until it stops.

2) Mount the photomicrographic attachment as indicated in Fig. 40.

If the unit is tilted, the image will be also tilted against the focusing

reticle in the microscope. To avoid tilting, make it a point tovisually

parallelize the horizontal contour of the attachment to the horizontal line of the microscope.

3) Image magnification

= Objective magnif. x Intermediate magnif. (1X or 1.5X) x NFK

photo eyepiece magnif. x Camera magnif. (1X for 35 mm or

3X for large format)

Ex. 40x 1.5x5x 1X=300(X)

4) Focusing

Focus the frame reticle first, by rotating the helicoid mount of the

left hand eyepiece sleeve of the binocular tube, then focus the

specimen by means of the fine focus knob.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

C. Mounting the multi-photo tube to the MTU light exit

Mount the multi-photo tube to the MTU light exit port; then clamp

the photomicrographic attachment on it. (Fig. 41)

If the PM-1OAD system is used in this way, the following options are

available:

l

Spot exposure measurement (with PM-lOADS)

l

Bright frame viewer PM-VSB

. 16 mm tine-photomicrography (PM-16 mm Cine), which enables easy

film loading and prevents shutter vibration.

Fig. 41

I

Fig. 42

Fig. 43

1) Unscrew the photo adapter mounted on the MTU port and replace it

with the MTU adapter 0. (Fig. 41)

2) Insert the MTU relay tube @ into the MTU adapter @ and clamp.

(Fig. 41)

3) Loosen the base clamping screw 0, and place the base on the desk.

(Fig. 41)

4) Rotate the 4 leveling screws @ to keep them in contact with the

desk surface. (Fig. 41)

5) Clamp the base clamping knob@. (Fig. 41)

6) Attach the trinocular tube 0. (Fig. 42)

7) Insert the photo eyepiece into the photo tube.

8) Connect the PM-1OAD attachment @. (Fig. 42)

Ir When using the multi-tube unit IMT-2-MTU is used, out of focus-

ing or framing may cause, since the optical path length is long.

* Please be sure to use the focusing magnifier 0 built-in the

photographic attachment for focusing or framing.

D. Mounting the trinocular tube on the microscope frame

In place of standard binocular tube, a trinocular tube BH2-TR @ can

be attached and used for photomicrography with the PM-IOAD system

0. (Fig. 43)

* In case of fluorescence photomicrography, the bright frame viewer

PM-VSB @ may be used to facilitate focusing.

(Fig.

43)

* Rotate the light path selector knob to the BI position.

Ir In order to focus on the specimen looking through the binocular

tube, it is necessary to use a suitable finder eyepiece 0.

(Fig. 43)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Refer to the instructions provided with each photomicrographic equrpment for detailed procedure. This paragraph

is grven to explain the photomicrographic problems pertaining to the IMT-2.

0 Illumination

Accurate illumination is more important for photomicrography than

for observation since flawless pictures cannot be taken without it.

In order to avoid uneven illumination, especially with high contrast film,

adjust the illumination, following the observation procedure accuracy.

@ Radiant

Heat from the Light Source

Even optimum intensity of illumination light generates considerable

radiant heat for observation or photomicrography, especially in case

of Nomarski interference contrast. Living specimens are subject to

damage due to radiant heat. Therefore;

l

Reduce light intensity as much as possible.

l

Use additional heat filters.

l

For time-lapse photography, synchronize the light source to exposure (synch. mode).

0 Filters and Lamp Voltage

Select the filter and bulb voltage according to the film

Daylrght type color film

45.LBD-2N 8V

Tungsten type color film

45-LBT 8V

B & W film

43-l F550-W45 6V and up

* To match your preference in color rendition, it is recommended to

make test exposure for the determination of optimum bulb voltage.

0 Focusing

\/

x - //\

Fig. 44

1) Looking through the finder eyepiece, adjust the diopter ring so

that the double cross lines can be clearly observed as two distinctly

separate lines. (Fig. 44)

2) Bring the specimen into focus, rotating the coarse and fine adjustment knobs.

* Since the focusing reticle and the film plane are in precise align-

ment, the image focused through the focusing magnifier and the

image in the film plane are in focus at the same time. Therefore,

unless the adjustment just described is perfect, blurred pictures

will result.

* When using the multi-tube unit IMT-2-MTU is used, out of focus-

ing or framing may cause, since the optical path length is long.

* Please be sure to use the focusing magnifier @ built-in the

photographic attachment for focusing or framing.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

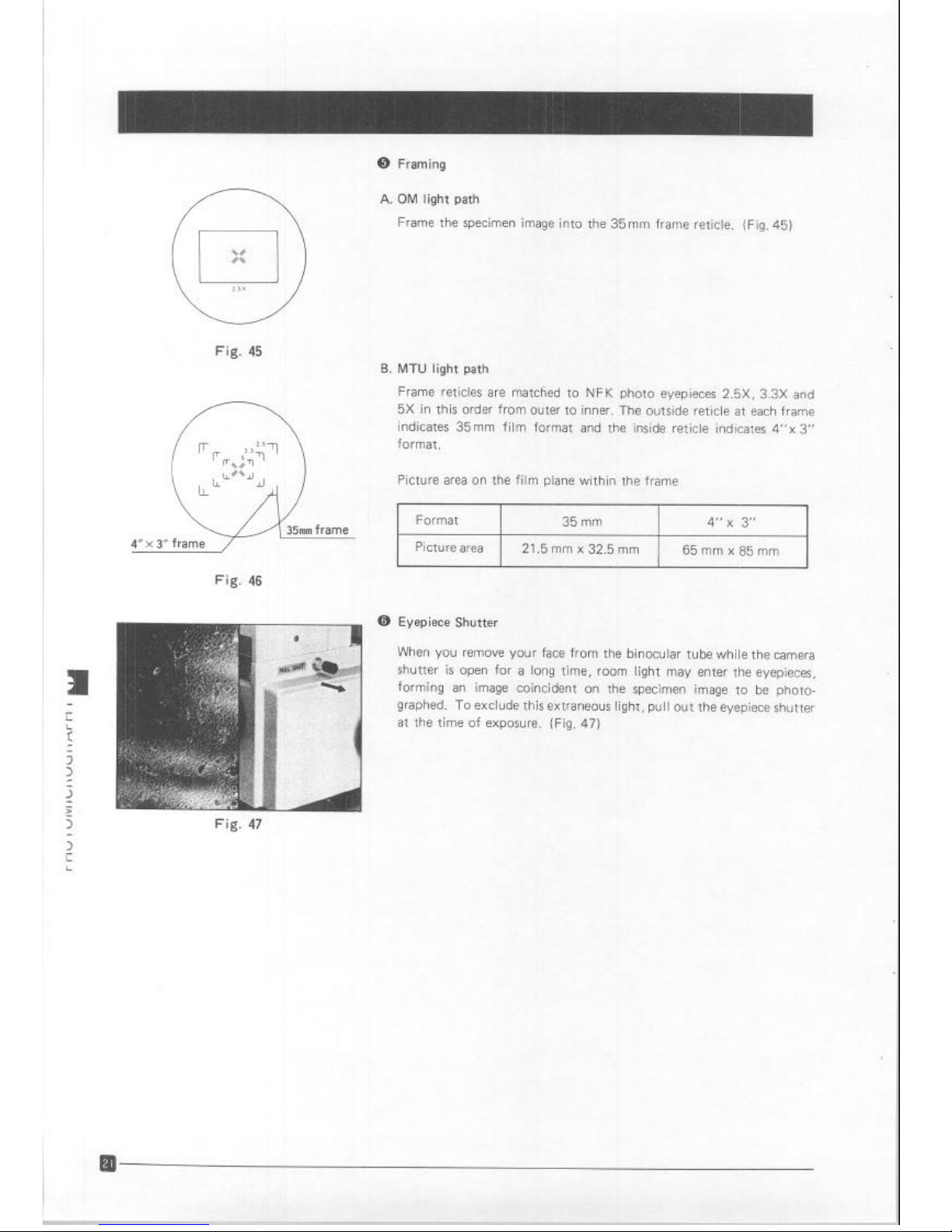

@ Framing

Fig. 45

4” x 3”

frame

Fig. 46

Fig. 47

A.

OM light path

Frame

the specimen image into the 35mm frame reticle. (Fig. 45)

B. MTU light path

Frame retitles are matctied to NFK photo eyepieces 2.5X. 3.3X and

5X in this order from outer to inner. The outside reticle at each frame

indicates 35mm film format and the inside reticle indicates 4”~ 3”

format.

Picture area on the film plane within the frame

Format

35 mm

4” x 3”

Picture area

21.5 mm x 32.5 mm

65mmx85mm

@ Eyepiece Shutter

When you remove your face from the binocular tube while the camera

shutter is open for a long time, room light may enter the eyepieces,

forming an image coincident on the specimen image to be photographed. To exclude this extraneous light, pull out the eyepiece shutter

at the time of exposure. (Fig. 47)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

If you are unable to obtain optimum performance from your microscope, please consult the table below for

trouble shooting.

1. Optical system

a) Switching on light source, field Bulb socket cord is not connected.

Connect the cord to receptacle on

of view is still dark. the microscope stand.

Bulb is burned out. Replace.

Sliding voltage control lever is set at Set it at higher voltage position.

to0

low a position.

Bulb is not centered.

Center it.

Condenser holder is not clamped in

Clamp it.

place.

Condenser is not in correct position.

Adjust condenser height until field

diaphragm image is formed in specimen plane.

Condenser is not centered.

Center it until field diaphragm

image comes in the center.

Nosepiece is not clicked in place.

Rotate it slightly until it clicks in

place.

Light path selector knob is at the

Set knob to the BI position or in-

OM or MTU position. crease bulb voltage.

Too many filters are engaged.

Reduce number of filters.

Stage insert plate blocks light path.

Remove stage and reset specimen.

Fuse is burned out.

Check electric circuit and after removal of cause, replace fuse.

Line voltage selector switch is not Adjust switch correctly.

set to conform with local mains

voltage.

b) Field of view is cut off at the Light path selector knob is stopped Click knob into place according to

periphery or illuminated uneven-

midway.

purpose.

IY.

Nosepiece and magnification

Click them into place.

changer are not positioned correct-

ly.

Condenser turret is not correctly

Click turret into place.

Condenser is not positioned or Click condenser turret Into place or

centered correctly. center correctly.

Light source is not centered.

Center light source.

Filter is stopped midway. Pull or push it completely.

c) Dust or dirt is visible in field of

Dirty specimen.

Clean slide or culture vessel.

view.

Dust on eyepiece.

Clean eyepiece.

Condenser is not correctly posi- Adjust condenser height until field

tioned and the frosted filter is in diaphragm image is formed on spe-

focus. cimen plane.

positioned.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1) Excessive image contrast.

Condenser is stopped in high posi-

Lower condenser.

tion.

Aperture diaphragm is stopped Open diaphragm.

down excessively.

?) Resolution problems: Objective is not correctly posi- Click nosepiece into place.

l

Image is not sharp. tioned in light path.

0 Insufficient contrast.

l

Image details lack definition.

Aperture diaphragm is stopped

Adjust aperture iris opening prodown excessively or opened too perly.

much.

Correction collar is not adjusted

Looking at specimen image, rotate

correctly.

correction collar until optimum

focusing position can be found.

Dust on condenser, objective, eye- Clean.

piece, culture vessel, etc.

Thickness of vessel bottom is more

Use a vessel of bottom thickness

than 2 mm.

less than 2 mm.

‘) No effective phase contrast is Bright field objective is used.

Use phase objective.

obtained.

Light annulus is not matched with Match light annulus to objective.

objective.

Light annulus and phase annulus Center them correctly.

are not centered.

g) Specimen image is partially out Objective is not correctly in light Slightly rotate nosepiece until it

of focus. path. clicks into place.

Specimen is not correctly place on

Place specimen correctly.

stage.

Vessel bottom is not flat. Use an evenly-flat bottomed vessel.

h) Image is blurred. Condenser is not correctly centered.

Center condenser.

Light source is not correctly cen-

Center light source correctly,

tered.

Condenser holder is tilted up. Lower it to stop position.

2. Electrical adjustment

a) Light source is too bright even at

Minimum line voltage adjustment

Adjust the knob until bulb is dimly

lowest bulb voltage. knob is not correctly adjusted.

lit with sliding control lever at

lowest position (nearest to you).

b) Light flickers and intensity is un-

Line voltage is unstable.

Use voltage stabilizer.

stable.

Bulb filament is likely to burn out. , Replace bulb.

Loose electrical connection.

I

i Tighten connections.

c) Fuse burns out too often.

Fuse is not a standard one. 1 Use standard fuse.

8

RI Ilh

is nnt stnnrinrri

i I ICD

hzlnnon hi,lh

rlarinnotorl

d) Pilot

bulb

is tur

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3. Coarse and fine focus adjustments

a) Coarse adjustment is too tight. Tension adjustment ring is tightened

Loosen tension adjustment ring

too much.

properly.

b) Stage drops and specimen goes

Tension adjustment ring is too Tighten ring properly.

out of focus. loose.

4. Observation tube

a) Incomplete binocular vision. lnterpupillary distance is not cor-

Correct interpupillary distance.

rectly adjusted.

Diopter adjustment is incomplete. Complete diopter adjustment.

User is unaccustomed to binocular

Prior to looking at specimen details,

vision.

try to look at the entire field of

view, or look at a far away object

before resuming observation.

5. Stage

a) Image easily goes out of focus

Stage is not clamped. Clamp stage securely.

when you touch stage.

b) Specimen stops midway on the Specimen is not correctly positioned

Adjust specimen positioned.

east-west traverse. on stage.

Objective is protruding so as to hit Lower nosepiece and then rotate.

against stage insert plate.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OLYMPUS OPTICAL CO., LTD.

San-Ei Building, 22-2, Nishi Shinjuku 1-chome, Shinjukuku, Tokyo, Japan

OLYMRUS OPTlCAL CO., (EUROPA) GMBH.

Postfach 104908, Wendenstrasse 14-16, 2000 Hamburg 1, Germany

OLYMPUS CORPORATION

4 Nevada Drive, Lake Success, N.Y. 11042-l 179, U.S.A.

OLYMPUS OPTICAL CO. (U.K.) LTD.

2-8 Honduras Street, London EClYOTX, United Kingdom

J

The design of the product IS under constant

review and whilst every effort is

made to keep this manual up to date, the rtght IS reserved to change speciflca-

tions and equipment at any time wthout prior notice

Printed in

J~DX 9011 M 04

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Loading...

Loading...