Page 1

®

I

INSTRUCTIONS

SOFTWARE MODULE AND

LASER SAFETY FOR THE

HIGH-SPEED SCANNING FRAP SYSTEM

This instruction manual describes the configuration and usage of the scanning FRAP

system within the Olympus

performance and familiarize yourself fully with the use of the product, we recommend that you

study this manual thoroughly before operation. Together with this manual, please also read the

hardware manual, the hardware and software manuals as well as the

instruction manuals of the microscope in order to understand overall operation methods. Retain

this manual in an easily accessible place near a system for future reference.

Imaging Stations. To ensure safety, obtain optimum

Page 2

OLYMPUS SOFT IMAGING SOLUTIONS GMBH

Johann-Krane-Weg 39

D-48149 Münster

Tel: +49 89 - 89 55 805 660

Fax +49 89 - 89 55 805 6606

Email: info@olympus-sis.com

www.olympus-sis.com

Page 3

III

Imaging Excellence

We at Olympus Soft Imaging Solutions GmbH have tried to make the information in this manual as

accurate and reliable as possible. Nevertheless, Olympus Soft Imaging Solutions GmbH disclaims any

warranty of any kind, whether expressed or implied, as to any matter whatsoever relating to this

manual, including without limitation the merchantability or fitness for any particular purpose. Olympus

Soft Imaging Solutions GmbH will from time to time revise the software described in this manual and

reserves the right to make such changes without obligation to notify the purchaser. In no event shall

Olympus Soft Imaging Solutions GmbH be liable for any indirect, special, incidental, or consequential

damages arising out of purchase or use of this manual or the information contained therein.

No part of this document may be reproduced or transmitted in any form or by any means, electronic or

mechanical, for any purpose, without the prior permission of Olympus Soft Imaging Solutions GmbH.

2010 by Olympus Soft Imaging Solutions GmbH. All rights reserved.

Manual version: September 2010

Page 4

Page 5

Manual Contents

Contents

1 Introduction......................................................................................................... 1

1.1 Abstract ........................................................................................................ 2

1.2 General ......................................................................................................... 3

1.3 Components .................................................................................................3

2 Safety Symbols ...................................................................................................5

3 Safety Precautions and Handling Instructions ...............................................9

3.1 Laser Safety Precautions ............................................................................10

3.2 General Safety Precautions ........................................................................11

4 Overview and Laser Safety Setup ................................................... 13

4.1 Setup Scheme ............................................................................................14

4.2 The Laser Safety Features – Overview and Check .....................................15

4.3 Mounting the Laser Safety Kit .................................................................... 17

4.4 Connecting the Control Unit ....................................................... 18

4.5 Connecting the LAS-BOB Laser Safety Break-out Box .............................19

4.6 The Laser Shutter Manual Control.............................................................. 20

4.7 Key Control ................................................................................................. 21

4.8 The Remote Interlock Connector of the Olympus Soft Imaging Solutions

ODB Laser Systems....................................................................................22

5 Modes of Operation.......................................................................................... 23

5.1 The User Mode ...........................................................................................24

5.2 The Maintenance Mode .............................................................................. 25

5.2.1 Exchanging Microscope or Camera Hardware...........................................25

5.2.2 Access to the Specimen without Deactivating the FRAP System .............. 26

5.2.3 Observing the Specimen Through the Ocular ............................................26

6 Operating the System.......................................................................29

6.1 System Configuration .................................................................................30

6.2 The FRAP GUI in ............................................................... 31

6.3

6.3.1 FRAP Experiments...................................................................................... 33

6.3.2 Fire On Click ...............................................................................................36

6.3.3 Pattern Bleaching – Fluorescence Speckle Microscopy ............................37

7 Appendix ..........................................................................................................39

7.1 Laser Safety Stage Cover Dimensions .......................................................40

in the Experiment Manager ........................................................ 33

Page 6

Contents

Page 7

Manual Chapter 1 –Introduction 1

1 Introduction

Thank you very much for purchasing Olympus Soft Imaging Solutions' state of art

FRAP system and for your confidence in our products and service. It is Olympus Soft Imaging

Solutions' main objective to provide you with solutions able to meet your experimental demands and

thus pave the way to your scientific success.

The

two lasers to an inverted Olympus IX2 FRAP microscope.

scanning FRAP system is designed for general laboratory use only. It allows coupling up to

scanning

1.1 Abstract ........................................................................................................ 2

1.2 General ......................................................................................................... 3

1.3 Components .................................................................................................3

Page 8

2 Chapter 1 – Introduction

scan head mounted on an IX81

1.1 Abstract

In the following sections you will find a detailed description of the components of

FRAP system, handling and alignment instructions and how to maintain the performance of your FRAP

microscope. Keep in mind that all components are designed to work together with an Olympus

Imaging Station as an integrated system. We strongly discourage taking away or replacing

single components without prior consultation of Olympus Soft Imaging Solutions, most probably it will

impair the performance of the system dramatically. The guarantee will not cover any damages to the

system due to such mishandling. All necessary tools for handling and alignment (except the laser safety

goggles) are part of the product.

If you find any information missing in this manual or you need additional support, please contact your

local Olympus representative.

scanning

Page 9

Manual Chapter 1 –Introduction 3

1.2 General

The MITICO motorized integrated TIRF illumination combiner is compatible with the Olympus

microscope frames IX81S1F-FRAP, IX81S1F-FRAP-ZDC, and IX71S1F-FRAP, as well as a range of

diode laser systems between 405 nm and 700 nm provided that they meet the following requirements:

• Every laser unit must have an input remote-control safety interlock that must be connected to the

central laser emergency stop and which interrupts the laser radiation in case of danger (EN 608251:2003, Sect. 4.4 and 10.2). Furthermore, every laser unit must have a key-activated main power

switch in the sense of EN 60825-1:2003, Sect. 4.5).

• Provided that the laser units can be operated independently they must have their own emission

warning display (audible or visible) (EN 60825-1:2003, Sect. 4.6).

• The combined power of all employed and/or connected laser powers must not exceed 500 mW.

This instructions manual describes the hardware components of the scanning FRAP system,

and their installation. It also explains the software configuration and the use o the system.

It is important to familiarize yourself with the entire system to ensure safety and optimum performance.

We recommend studying this manual as well as the software and hardware manuals of the imaging

system thoroughly before operating the scanning FRAP system. Keep this manual close to the

imaging station for future reference.

The scanning FRAP system meets the CE requirements:

• EN61326 Class A

• EN60825

1.3 Components

The scanning FRAP system consists of the following components:

a Laser shutter hand switch LAS-MC with key with emergency interrupter and key-controlled switch

to maintenance mode

b Laser safety break-out box LAS-BOB

c Laser safety stage cover with translucent laser safety glass that allows following the beam position

d Laser safety ocular shutter

e Manual

The software module for the imaging software is likewise required as well as at least

one laser, favorably a dedicated OSIS FRAP diode laser:

Furthermore the following scanner head and controller shall be used (Rapp Optoelectronic):

Page 10

4 Chapter 1 – Introduction

a illuminator featuring two fiber ports, each with adjustable line focus

b control unit

Page 11

Manual Chapter 2 –

Safety Symbols

5

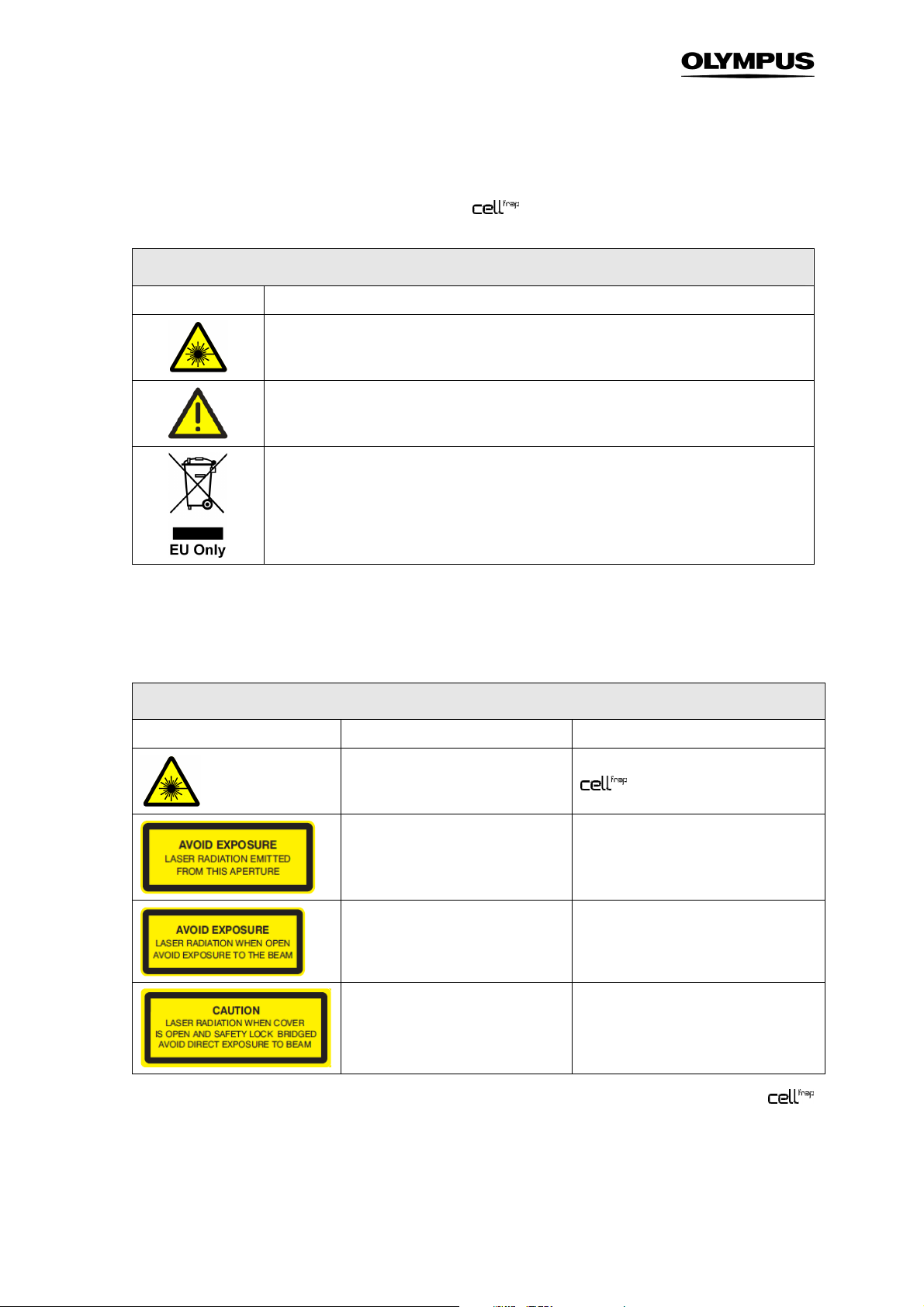

2 Safety Symbols

The deactivation of the safety systems or the dismantling of different components by the operator is

required in certain operational modes and in case of illumination alignment. As a result the Olympus

scanning FRAP system is to be classified in accordance with EN 60825-1:2003 in laser safety

class 3B and in accordance to EN 954-1:1997 in hazard category 2. Class 3B lasers are medium

power lasers with an output power of up to 500 mW within 400 – 700 nm wavelength. Laser safety

regulations require extensive labeling of all possible apertures where laser radiation might potentially

exit including such apertures that are totally covered except upon partially or totally disassembling the

system.

Page 12

6 Chapter 2 –

Safety Symbols

The following symbols are placed on the Olympus scanning FRAP system. Study the meaning

of the symbols and always use the equipment in the safest possible manner.

General symbols

Symbol Explanation

Indicates the use of a laser beam. Take special care in handling that part.

(See also following chapter)

Carefully read the instructions on the label and the manual before use. Improper use could

result in personal injury to the user and/or damage the equipment.

This symbol indicates separate collection of waste electrical and electronic equipment in the EU

countries.

Do not throw the equipment into the domestic refuse

Please use the return and collection systems available in your country for the disposal of this

product

Each laser source must be provided with a danger symbol, a sign with the classification text and a sign

on the beam exit opening. Please ensure that your microscope is labeled as shown in the table below.

For all parts labeled with the following labels special laser precautions must be considered (see

Chapter 4.1, Laser Safety Precautions)!

Laser safety symbols

Symbol Explanation Location

Indicates the use of a laser beam.

Take special care in handling this part.

Laser radiation can cause irreversible

damage to your eyes. Wear adequate

protection before opening this

aperture.

These apertures should be closed

while operating the system. Parts

connected should be dismounted by

trained personal only and when the

laser is turned off.

When system is switched to

maintenance mode laser radiation can

be emitted from this aperture. Be sure

to wear adequate eye protection.

scan head

Microscope frame, right side, left side

near C-mount; see photos 2 and 3.

Laser safety ocular shutter; see photo 4.

Laser safety stage cover; see photo 5.

Labels for the microscope components are included in the shipping list of the Olympus

scanning FRAP system. Please paste them on the microscope upon system installation. If any label is

missing please ask your Olympus representative for additional labels.

Page 13

Manual Chapter 2 –

Safety Symbols

7

1:

scan head

2: microscope frame, right side 3: fluorescence turret and C-mount

4: laser safety ocular shutter 5: laser safety stage cover

Page 14

8 Chapter 2 –

Safety Symbols

Page 15

Illumination Combiner, User Manual Chapter 3 – Safety Precautions and Handling Instructions 9

3 Safety Precautions and Handling

Instructions

The Olympus scanning FRAP system must be used with laser products belonging to the Laser

Safety Class 3B. Class 3B lasers are medium power lasers with an output power of up to 500 mW

within 400 – 700 nm wavelength. The total of the output power of the connected lasers may not exceed

500 mW. Viewing these lasers under direct beam and specular reflection conditions is hazardous. The

diffuse reflection is usually not a hazard except for higher power Class 3B and Class 4 lasers. Normally

the class 3B laser is not a fire hazard. A class 3B laser product may only be used under the control of a

laser safety officer. Before using this product be sure to be familiar with the demanded safety measures

according to EN 60825-1 and the national regulations

3.1 Laser Safety Precautions ............................................................................10

3.2 General Safety Precautions ........................................................................11

Page 16

10 Chapter 3 – Safety Precautions and Handling Instructions

3.1 Laser Safety Precautions

Caution: Control or adjustments using procedures other than those prescribed in this

manual will lead to hazardous laser beam exposure.

To avoid hazardous situations strictly follow the laser safety instructions below.

1. Before operating an Olympus scanning FRAP system check if all devices are

attached correctly and all apertures are closed.

2. The usage of a Class 3B laser is only permitted under the control of a laser safety officer.

3. A Class 3B laser can cause irreversible damage to your eyes. Thus do not stare into the

laser beam or illuminated fiber. Make sure to wear adequate eye protection during operation

of the laser in maintenance mode.

4. Always operate the scanning FRAP system in user mode unless you underwent a

detailed training in operating the system in maintenance mode. Inform your laser safety

officer if you intend to operate the system in maintenance mode. The user mode is the

safest manner to operate the system. Opening the stage cover or the binocular slider will

interrupt the laser beam in this mode.

5. Only trained Olympus service personnel is allowed to perform the installation and alignment

procedures described in the Service Manual.

6. A person in charge with the laser alignment or performing scientific experiments while

operating the laser in maintenance mode must be aware of the safety precautions adequate

to the TIRF microscope setup. He/she is responsible for the safety of any person present in

the room while operating the lasers in maintenance mode.

7. The focused laser beam or any UV light emitted from the microscope nosepiece may injure

the skin through the objective exit lens and through a free nosepiece position. Thus, avoid

exposing the hands to the laser beam when working on the microscope.

8. Do not bend, step on or pull excessively on the laser fibers. This could damage a fiber and

cause hazardous beam leakage. In case of a damaged fiber, switch off the laser immediately

and contact Olympus.

9. Be sure all apertures of your microscope system stay closed or are connected while

operating the laser. A change in camera or any microscope part should be performed only

when the laser is turned off.

10. Never cover the air outlet of the laser to prevent overheating.

Page 17

Illumination Combiner, User Manual Chapter 3 – Safety Precautions and Handling Instructions 11

Direct exposure to the laser light is possible at the following positions:

• The laser system’s housing at the fiber port if the fiber is removed

• The exit of the laser fiber

• The fiber coupling of the widefield illumination system to the scanning FRAP system

• The beam path of the microscope

• Any microscope port, which includes the entrance ports because the laser light can be reflected

within the microscope

• The light output port of the widefield illumination system

• The objective tip or – if no objective is mounted – a free nose piece position

3.2 General Safety Precautions

a. Always use power cords and power supplies provided or approved by Olympus Soft Imaging

Solutions or the manufacturer of your laser system.

b. Provide unimpaired access to the emergency shutter switch at the LAS-MC manual control and to

the main power switches.

c. Only those lasers may be connected that comply the laser safety regulations as described in

Chapter 1.2.

d. Always make sure that the grounding terminal of the laser system and the wall outlet are connected

properly. If the system is not grounded, Olympus Soft Imaging Solutions cannot warrant the

electrical safety and proper performance of the product.

e. Please refer to the user manuals of the respective laser manufacturer for adequate safety

precautions and proper usage.

f. If the equipment is not used as specified in this manual, the safety and performance may be

impaired. In addition the equipment may be damaged and warranty may be lost. Use the

equipment only as outlined in this instruction manual.

Olympus Soft Imaging Solutions GmbH accepts no liability for any health damages caused

by improper use of the lasers and laser related setup!

Page 18

12 Chapter 3 – Safety Precautions and Handling Instructions

Page 19

Manual Chapter 4 –

Overview and Laser Safety Setup 13

4 Overview and Laser Safety

Setup

The following chapter describes all components and interfaces of the Olympus scanning FRAP

system including all laser safety devices and how they are installed and connected.

4.1 Setup Scheme ............................................................................................14

4.2 The Laser Safety Features – Overview and Check .....................................15

4.3 Mounting the Laser Safety Kit .................................................................... 17

4.4 Connecting the Control Unit ....................................................... 18

4.5 Connecting the LAS-BOB Laser Safety Break-out Box .............................19

4.6 The Laser Shutter Manual Control.............................................................. 20

4.7 Key Control ................................................................................................. 21

4.8 The Remote Interlock Connector of the Olympus Soft Imaging Solutions

ODB Laser Systems....................................................................................22

Page 20

14 Chapter 4 –

top view

safety shutters

ocul

ar shutter

Overview and Laser Safety Setup

4.1 Setup Scheme

Laser fibers

scan head

Laser safety

stage cover

Laser safety

IX81,

controller

Scheme of an IX81 microscope with a scanning FRAP system, two lasers and the laser safety equipment.

LAS-BOB

FRAP lasers with

LAS-MC

PC

Connections of the laser safety devices

ODB / RS232 communication connections

TTL trigger connections

FRAP scanner communication connection

Laser fibers

Page 21

Manual Chapter 4 –

ocular shutter

Overview and Laser Safety Setup 15

4.2 The Laser Safety Features – Overview and Check

The laser safety concept of the scanning FRAP system consists of the following modules:

–

A laser safety ocular shutter

–

A laser safety stage cover

–

An emergency interrupter located on the LAS-MC manual control

–

The double-redundant laser safety shutter of Olympus laser systems

–

The LAS-BOB laser safety break-out box that connects all devices electronically

–

A double-redundant laser safety shutter in front of the exit optics of the Olympus Soft Imaging

Solutions lasers

Be sure that all listed components are correctly mounted:

• The laser safety ocular shutter must be placed in the ocular light path as shown below.

Laser safety

• The U-shaped frame of the laser safety stage cover must be fixed on the stage and the stage cover

in place.

The laser safety stage cover must be secured to the microscope stage. If the microscope

stage is not equipped with the necessary pre-drilled holes please make sure that this

modification is performed before using the system. Appendix – Laser Safety Stage Cover

Dimensions provides drawings with all dimension data necessary for such a modification.

Page 22

16 Chapter 4 –

stage cover

stage cover

Overview and Laser Safety Setup

Laser safety

Laser safety

• The 5-pin ocular shutter cable must be connected to the stage cover and this additionally to one of

the 5-pin SAFETY INTERLOCK plugs at the back panel of the control unit.

• The other 5-pin SAFETY INTERLOCK plug at the back panel of the control unit must be

connected to the 5-pin STAGE COVER plug of the LAS-BOB laser safety breakout box.

Check the safety shutter function in user mode in a completely installed FRAP system.

1. Turn the key in the LAS-MC manual control to USER MODE.

2. Switch on the FRAP laser via the software; see Chapter 6.3.1, The FRAP GUI in .

You should observe laser light through the translucent stage cover insert.

3. Open the ocular shutter slider. The indicator diode on the laser safety shutter must become

switched off immediately indicating the closure of the shutter. No laser light should be visible

anymore. Close the slider again.

4. Carefully lift the lid of the stage cover. The indicator diode on the laser safety shutter must

become switched off immediately indicating the closure of the shutter. No laser light should

be visible anymore. Mount the cover again.

The LAS-MC manual control features an emergency interrupter, the red button. If the system is

properly setup and you press the red button,

• The safety shutter of any Olympus Soft Imaging Solutions laser system connected must close

• Any other laser connected to the LAS-BOB break-out box must be switched off entirely

In order to reactivate the system you have to turn the emergency interrupter to release it from the

locked position.

Applying the laser safety emergency interrupter is not a standard test and should only be

tested if changes to the laser configuration and connections have been made. It is only for

emergency use and will cut the power supply of any laser except the Olympus Soft Imaging

Solutions laser systems.

If you have doubts or questions concerning your laser safety devices, contact your laser safety officer.

Page 23

Manual Chapter 4 –

Fixing screws

Interlock

Overview and Laser Safety Setup 17

4.3 Mounting the Laser Safety Kit

1. Remove the ocular from the microscope frame and mount the ocular laser safety shutter

onto the ocular tube (with the cable on the right hand side) and fix it as shown in the photo

below.

2. Mount the ocular back on top of the ocular laser safety shutter and tighten the holding

screw.

3. Mount the U-shaped frame of the laser safety stage cover with the connector plugs pointing

to the right onto the microscope stage fixing it with the two M4x5 fixing screws.

4. Place the lid of the laser safety stage cover on top of the stage frame so that the two pins on

the lid fit into the two holes of the frame that host the interlock switches.

switches

5. Plug the cable of the laser safety ocular shutter with one of the plugs of the laser safety stage

cover.

Page 24

18 Chapter 4 –

5-pin plugs

Transl

u

cent

6. Connect the second plug of the laser safety stage cover with the 5-pin female STAGE

Overview and Laser Safety Setup

COVER plug of the scanning illuminator using the corresponding cable.

insert

4.4 Connecting the Control Unit

The installation of the scanning illuminator is described in detail in the hardware manual. Only

the connection of the cables of the scanning illuminator and the control unit shall be repeated

here. These steps are partly repeated in the following sub-chapters as well.

1. Connect the 5-pin female STAGE COVER plug at the LAS-BOB back panel with one of the

5-pin SAFETY INTERLOCK plugs at the back panel of the control unit using the

corresponding cable.

2. Connect the other 5-pin SAFETY INTERLOCK plug at the back panel of the control

unit with one of the plugs of the laser safety stage cover (and make sure that the second one

is connected to the laser safety ocular shutter).

Page 25

Manual Chapter 4 –

3. Connect the PC RS232 plug at the back panel of the control unit with a serial port of

the system PC.

4. Connect the cable coming from the scan head with the multi-pin plug at the front panel of

the control unit.

5. Connect the TRIGGER IN TTL BNC plug of the control unit with the DIG I/O plug at

the imaging computer front panel that is configured as TTL OUT port in the software; see

Chapter 6.1, System Configuration.

6. Connect the TRIGGER OUT TTL BNC plug of the control unit with the DIG I/O plug at

the imaging computer front panel that is configured as TTL IN port in the software; see

Chapter 6.1, System Configuration.

7. Connect the LASER TTL BNC plug of the control unit with the SHUTTER TTL BNC

plug of the FRAP laser.

Overview and Laser Safety Setup 19

8. Connect the INTERLOCK OUT plug of the control unit with the INTERLOCK plug at

the front panel of an Olympus laser dedicated for FRAP usage using the Cinch cable

provided with it. Connect any other laser in an analogously.

4.5 Connecting the LAS-BOB Laser Safety Break-out

Box

1. Connect the female LAS-MC D-sub 15 plug at the LAS-BOB front panel with the female D-

sub 15 plug of the LAS-MC laser manual control using the corresponding male-male cable.

Page 26

20 Chapter 4 –

Overview and Laser Safety Setup

2. Connect the 5-pin female STAGE COVER plug at the LAS-BOB back panel with one of the

5-pin female SAFETY INTERLOCK plugs at the back panel of the control unit using

the corresponding cable. Make sure the control unit is connected with the laser

safety stage cover and the laser safety ocular shutter.

ÈÈÈÈ

3. Connect the 24 V ÿÿÿÿ–

rrrr

-

-

DC power supply plug with the 24 V DC power supply.

•

C

4. Connect the power supply with a power outlet.

The LAS-BOB additionally features on the front panel:

–

Four INTERLOCK 4 – 3 – 2 – 1 Cinch plugs. These plugs are without function in a

system.

–

Four SHUTTER 4 – 3 – 2 – 1 BNC TTL-OUT plugs. These plugs are without function in a

system.

The LAS-BOB additionally features on the back panel:

–

Two SAFETY SHUTTER 4-pin female plugs. These plugs are without function in a

system.

–

Four DIGITAL I/O 1 – 2 – 3 – 4 BNC TTL-IN. These plugs are without function in a

system.

4.6 The Laser Shutter Manual Control

Connect the female LAS-MC D-sub 15 plug at the LAS-BOB front panel with the female D-sub 15 plug

of the LAS-MC laser manual control using the corresponding male-male cable; see previous chapter.

Note that the LAS-MC manual control cannot be used to open / close the shutter of the

FRAP laser because its TTL In plug is connected to the FRAP controller and not the LASBOB.

The laser shutter manual control features additionally:

–

Four LASER 1, 2, 3, 4 switches. These plugs are without function in a system.

–

A REMOTE switch to set the laser shutters to remote control via external TTL triggers or ODB

device bus communication (typically controlled by a software like ). This switch is

without function in a system.

Page 27

Manual Chapter 4 –

Switches for up to four TTL

-

Button to

Mode lock

with key

Emergency

–

A mode lock with key to allow authorized and trained personnel to switch from standard USER

Overview and Laser Safety Setup 21

MODE to MAINTENANCE (see Chapter 5, Modes of Operation).

–

A red emergency interrupter that closes all safety shutters when pressed.

–

A BINOCULAR button to bridge the laser safety ocular shutter in maintenance mode so that

the specimen can be observed via ocular with laser illumination. This is not a toggle button; it

needs to be kept pressed in order to keep the laser safety shutter open.

Be extremely cautious when bridging the laser safety ocular shutter by pressing the red

button! Be sure that a filter cube that quantitatively blocks reflected laser light is inserted

into the light path. Otherwise hazardous and intense laser light might exit the ocular. Set

the laser to a low intensity with the attenuator before first looking through the ocular.

Switch to toggle between software control

interrupter

bridge laser

safety ocular

shutter

controlled high-speed laser

shutters

4.7 Key Control

The LAS-MC laser manual control has a lock. When the key is removed or when the lock is set to User

mode, lifting the laser safety stage cover or opening the laser safety ocular shutter causes all laser

safety shutters to close.

When set to Maintenance mode, the laser safety stage cover can be lifted and the laser safety ocular

shutter can be opened – when the red button is additionally kept pressed – without causing the laser

safety shutters to close.

The system is a Laser Safety Class 3B product and may be operated in

Maintenance mode by trained and authorized personnel only with the trained laser safety

officer being informed.

Upon leaving the system, the person in charge has to set the LAS-MC laser manual control

to User mode and remove the key to protect the system against unauthorized use.

Page 28

22 Chapter 4 –

Overview and Laser Safety Setup

4.8 The Remote Interlock Connector of the Olympus

Soft Imaging Solutions ODB Laser Systems

An INTERLOCK connector can be found at the front panel of all Olympus Soft Imaging Solutions laser

systems as Class 3B laser products. This remote interlock connector of the dedicated FRAP laser must

be connected to the INTERLOCK OUT plug at the front panel of the control via a Cinch cable.

Interlock connector

Caution. Class 3B laser products not in use must be protected against unauthorized use

by removal of the key from the key control.

In order to comply with laser safety regulations the interlock connectors of non-Olympus Soft Imaging

Solutions laser systems must be connected in the same way.

Page 29

Manual Chapter 5 – Modes of Operation 23

5 Modes of Operation

There are two modes of operation, the user mode and the maintenance mode. In user mode no laser

radiation can exit the system. The maintenance mode is for setting-up and adjusting the

scanning FRAP system. Only trained personnel are allowed to operate the system in maintenance

mode.

5.1 The User Mode ...........................................................................................24

5.2 The Maintenance Mode .............................................................................. 25

5.2.1 Exchanging Microscope or Camera Hardware...........................................25

5.2.2 Access to the Specimen without Deactivating the FRAP System .............. 26

5.2.3 Observing the Specimen Through the Ocular ............................................26

Page 30

24 Chapter 5 – Modes of Operation

5.1 The User Mode

All hardware has to be connected properly to operate the system in User mode. The user mode

ensures that the user can operate the system without being exposed to the laser beam. It is possible to

have full control of the various devices via software or manually. In User mode the system can be used

like a laser of Laser Safety Class 1.

Actions in user mode

Permitted Action Remarks Actions not permitted

Change or manipulation of specimen with laser safety stage

cover lifted

Execution of Experiment Plans in cell^M / cell^R or similar

processes in other imaging software

Live observation via camera, image acquisition in TIRF

conditions

Change of camera settings and switch of microscope

modules as long as no hardware is being dismounted

Change of filters or burner in the illumination system MT10 /

MT20 or other filter switching devices

Change of burner in a fluorescence lamp housing (if used)

Fluorescence and widefield microscopy via ocular

Safety shutter closed

automatically

Observation via binocular

Best with safety shutter

closed

Detaching the optical fiber

Safety shutter closed

automatically

Exchange of microscope

or camera hardware

Detaching the lamp

housing

Operating the scanning FRAP system in User mode:

1. Mount a specimen and search for a region of interest using widefield fluorescence

illumination. Refer to the manual of the imaging system for detailed descriptions.

2. Be sure to have a filter cube with adequate dichroic mirror in the light path.

3. Close the laser safety stage cover and ocular shutter to enable the opening of the laser

safety shutter(s) of the Olympus Soft Imaging System laser systems.

4. Turn on the laser as described in the laser manual. You need to press the START buttons of

the Olympus Soft Imaging System laser systems to open their safety shutters.

5. Open the high-speed laser shutter via software; see Chapter 6, Using the System.

Page 31

Manual Chapter 5 – Modes of Operation 25

To protect your specimen from photo-bleaching, close the laser shutter (by reversing step

5) whenever suitable, even if you interrupt observation only for a short time.

5.2 The Maintenance Mode

Actions in maintenance mode

Permitted Action Remarks Actions not permitted

Exchanging microscope or camera

hardware

Laser adjustment

Specimen manipulation under TIRF

conditions with the stage cover lifted

Specimen observation via ocular

under TIRF conditions

Mounting or exchanging of fiber or

laser

Alignment of fiber at laser exit

Only with LS shutter closed.

Adjustment necessary afterwards.

Refer to safety precautions above. Only

possible with pressed binocular shutter

interlock bridge.

Laser shutters must be closed.

Adjustment necessary afterwards.

Executing experiments with

remote control of the laser

shutters

For details concerning the setup of the hardware, refer to your hardware manuals.

Operating in Maintenance mode is only allowed to persons authorized to operate and

align Class 3B laser products according to the national regulations.

Always wear adequate protection and avoid unnecessary radiation of the laser beam.

While operating the system in maintenance mode, be sure that access to the system is

restricted to authorized persons only.

5.2.1 Exchanging Microscope or Camera Hardware

Before exchanging hardware, always consider the compliance of the new hardware to the requirements

of FRAP microscopy and the laser equipment. Ask your Olympus specialist for advice in case of

uncertainty. The best way to modify a system is with the lasers turned off. After changes affecting the

laser light path through the microscope (e.g., changing an objective or a filter cube) it might be

necessary to realign the laser fiber ports; see the

Hardware Manual.

Page 32

26 Chapter 5 – Modes of Operation

5.2.2 Access to the Specimen without Deactivating the FRAP System

For some applications it is necessary to manipulate the specimen during an experiment. In User mode,

however, the laser safety stage cover has to be in place; otherwise the FRAP system is deactivated

because all laser safety shutters remain closed.

Setting the system to Maintenance mode by authorized and trained personnel allows removing the

laser safety stage cover to gain access to the specimen without causing the laser safety shutters to

close automatically. Thus, lifting the laser safety stage cover might cause exposure to laser irradiation if

the high-speed shutter of any laser system is open.

Check the position of the laser beam through the translucent laser safety stage cover

insert. Be sure to wear adequate laser protection before opening the lid and make sure all

high-speed laser shutters are closed. Shield the specimen with a sheet of paper before

opening a high-speed laser shutter to make sure that the laser beam does not exit the

objective in an unexpected direction.

5.2.3 Observing the Specimen Through the Ocular

Authorized and trained personnel can observe the specimen in Maintenance mode via the ocular

when taking the safety precautions into account.

Before observation via the ocular, make sure to have an adequate filter cube that

quantitatively blocks the laser light inserted into the light path! The use of an inadequate or

damaged dichroic mirror or emission filter can lead to intense, hazardous laser light exiting

the ocular. This laser light can irreversibly damage your eyes!

Never change optical elements (filter, dichroic mirror, objective etc.) while observing the

specimen by eye. The switch of optical elements can lead to reflections of laser light into

the ocular.

1. Activate the Maintenance mode by turning the key on the LAS-MC laser manual control to

the MAINTENANCE position.

2. Open the ocular shutter by pulling the slider out all the way. The laser safety shutter will close

automatically.

Page 33

Manual Chapter 5 – Modes of Operation 27

Laser safety ocular

shutter, slider OUT

3. Hold a sheet of paper in front of the eyepieces.

4. Open the laser safety shutters of the lasers by pressing the red ocular safety interlock bridge

button of the LAS-MC manual control. Check the sheet of paper to control the light intensity

emitting from the ocular pieces before looking through the eyepiece.

Control or adjustment procedures other than those described will lead to hazardous laser

beam exposure!

Page 34

28 Chapter 5 – Modes of Operation

Page 35

Manual Chapter 6 – Operating the System 29

6 Operating the System

The scanning FRAP system and the Olympus Soft Imaging Solutions laser systems are fully

integrated in the imaging software This chapter describes the configuration and usage of

the scanning FRAP system.

6.1 System Configuration .................................................................................30

6.2 The FRAP GUI in ............................................................... 31

6.3

6.3.1 FRAP Experiments...................................................................................... 33

6.3.2 Fire On Click ...............................................................................................36

6.3.3 Pattern Bleaching – Fluorescence Speckle Microscopy ............................37

in the Experiment Manager ........................................................ 33

Page 36

30 Chapter 6 – Operating the System

6.1 System Configuration

1. Start the ObsConfig software to configure the excitation filters

2. Make sure that the FRAP lasers are configured on pages MicroscopeLaser as described

in the laser manual.

3. Go to page MicroscopeFRAP.

In case this page is not available right-click on OBS System Configuration (top left), open the

Components context menu and activate FRAP.

4. Click FRAP available to activate the unit.

5. Select the PC serial port (COM port) connected with the control unit. Once selected

correctly (and with the control unit powered up) the Connected field turns green.

6. Select the Laser from the shortlist. Mind that this laser will not be eligible as light source for

the Image Types.

7. TTL Synchronization, DIG I/O -> FRAP Trigger IN. Select from the short list the TTL OUT

connection at the imaging PC front panel that is connected with the TRIGGER IN

of the

control unit.

Page 37

Manual Chapter 6 – Operating the System 31

8. TTL Synchronization, FRAP Trigger OUT -> DIG I/O. Select from the short list the TTL IN

connection at the imaging PC front panel that is connected with the TRIGGER

OUT of the control unit.

9. Exit the software with OK.

6.2 The FRAP GUI in

This interface is mainly meant for calibration purpose and for opening and closing the FRAP laser

shutter. The use of in the context of "true" FRAP experiments is explained in the next Chapter

6.3, in the Experiment Manager.

Control

Disconnected / Connected. The box turns green and reads Connected if the software detects the

presence of the controller via the serial connection. The status can be update by clicking the

Update button on the right side.

Laser on/off. Use this toggle button to turn the laser connected to the (and configured

accordingly in OBS System Configuration) on or off (respectively, open or close its shutter).

Center spot. Click this button to move the scanner mirrors to their central position. This will set the

laser spot to the central image position if the system is aligned correctly.

Objective. This field displays the currently active objective. The calibration needs to be performed for

each objective that is to be used for the FRAP experiments. The currently used objective is listed here.

Calibrated. The status box turns green once the system is calibrated.

Page 38

32 Chapter 6 – Operating the System

The calibration is valid only for the objective in place during the calibration. A later manual

change of the objective does not cause a change of the status display. However, a

recalibration is required.

Set spot size. Click here to open the Enter spotsize window. Enter the spot Diameter in pixel and

confirm with OK. The default value is set in dependence of objective magnification and NA as well as

wavelength and pixel size. It presumes a perfectly focused laser. If the laser is defocused – which may

well be done on purpose – the spot needs to be imaged and measured to determine its actual size.

Laser intensity. Use the slider to attenuate the laser intensity.

Calibrate. Click here to start the calibration routine. The camera starts Live image acquisition, starts

laser emission and the Calibrate point #1 window opens.

The calibration procedure consists of two parts. First, the scanner positions corresponding to the four

corners of the camera image are determined. Afterwards, in the so-called Fine calibration, a total of 16

scanner positions distributed over the camera field of view are referenced.

The calibration is always done without binning on a full frame.

You may Adjust circle diameter by using the slide so that the red circle matches the laser spot in size.

Mind that the laser spot size in the image not just depends on the laser focus but also on the

Brightness adjustment settings in the Camera control window; see Chapter 4.2, Camera Control, in

the software manual. It is often useful to set the Max. intensity clipping to 0 % here.

Calibrate point #1. In the top left corner of the Live image a red circle is marked. Use the arrow

(cursor) keys to move the laser spot to this red circle. It is not required to do this with utmost precision

Page 39

Manual Chapter 6 – Operating the System 33

because the software will detect the bright spot when it is reasonably close. Increase the step size by

keeping the Ctrl key pressed while using the arrow key. Keep the Shift key pressed to reduce it.

Once the spot is at the position of the red circle click Next to terminate the first calibration step. The

red circle will now appear at the top right corner of the Live image and the Calibrate point #2 window

opens. Repeat the above procedure here and subsequently for point #3 and point #4 in the bottom left

and right corners, respectively.

Once the fourth corner has been determined the Start of fine calibration window opens upon clicking

Next. In this second part of the calibration routine the laser spot will move to 16 positions and needs to

be moved on with the mouse cursor on and confirmed.

Click OK. The Fine calibration window opens and the laser spot will be positioned at the top left

corner of the Live image. Move the tip of the mouse cursor over the laser spot and press the Enter key

to confirm.

The laser spot will move to the second position at top half-left. Again, move the tip of the mouse cursor

over the laser spot and press the Enter key to confirm.

Once all 16 positions have been confirmed the Calibration is finished. The calibration for the objective

in use is stored and does not have to be repeated for this objective unless the camera is rotated

relative to the C-mount.

6.3 in the Experiment Manager

6.3.1 FRAP Experiments

FRAP command icon

Types of experiments

Advanced. This selection gives access to all variable parameters.

In order to simplify the interface partly preconfigured experiments can be selected. Here different sets

of parameters are deactivated.

FRAP (Fluorescence Recovery After Photobleaching). This is the basic experiment where one or more

ROIs are bleached once. Bleaching is always done Once at Cycle 10 and the acquisition always done

Page 40

34 Chapter 6 – Operating the System

after bleaching. The Acquire radio buttons and the Condition parameters are deactivated. Manual

start during experiment is not possible.

FLIP (Fluorescence Loss In Photobleaching). In this experiment the ROIs are bleached in Every Cycle

and acquisition always done after bleaching. The Acquire radio buttons and the Condition

parameters are deactivated. Manual start during experiment is not possible.

Photoconversion. This experiment is identical to FRAP with the exception that the acquisition always

done while bleaching. The Acquire radio buttons and the Condition parameters are deactivated.

Manual start during experiment is not possible.

Use ROIs from image. Select the image containing the ROIs to be bleached from the shortlist. It lists

only images that contain ROIs.

Number of scan cycles. Set here the number of times the ROIs are to be scanned in each (Time

Loop) Cycle. The default is 1 but one may decide to scan several times, for example with reduced laser

intensity. By doing so the influence of timing differences between the bleaching of the fist positions of a

ROI and the last positions is reduced.

Calculate Timing. Click here so that the software calculates how long the scan will take. The value is

displayed next to the button. By changing the Number of scan cycles you may thus determine how

long the bleaching will last.

Acquire after photobleaching. With this option the following image acquisition is synchronized with

the end of the ROI scan(s). The laser spot will not be visible in this image. This option is automatically

selected in case of FRAP and FLIP experiments.

Acquire while photobleaching. Here image acquisition and ROI scan start simultaneously. The trace

of the scanning laser spot will be visible in the image. This option is automatically selected in case of

Photoconversion experiments.

Page 41

Manual Chapter 6 – Operating the System 35

Manual start during experiment. This check box is active only if the Advanced experiment is

selected. If the option is checked the command icon shows a hand symbol. The command icon turns

into a button.

FRAP command icon with Manual start symbol

What will happen?

After the start of the experiment the FRAP command icon will simply be ignored until clicked by the

user. Clicking is possible at any time and will immediately start the ROI scan independently of the

position of the command icon in the experiment plan and independently of the current advance of the

experiment.

Preview

Live view while bleaching button

Click here to start a live preview simultaneously with a laser scanning cycle. The scanning laser spot

will be visible in the beginning.

Live view after bleaching button

Click here to start a laser scanning cycle with a live preview following immediately after the scan is

finished.

Snapshot after bleaching button

Click here to start a laser scanning cycle with a single snapshot following immediately after the scan is

finished.

Stop FRAP preview button

Click here to stop the Live view.

Extended

Scan speed. This determines the duration of a scan and thus the time that the laser rests at each

position during the scan. Set the scan speed by use of the slider or by typing a value. The speed is

expressed as frequency in Hz. The default value is 10 kHz (10.000 Hz).

FRAP inside ROI. Mind that the ROIs drawn in the image will be "filled" with positions of the laser spot

and thus the form of the ROIs will only be approximated. This parameter defines how much the outer

laser spot positions may overlap with the ROI borders. Set the percentage by use of the slider or by

typing a value. The default value is 100%.

Page 42

36 Chapter 6 – Operating the System

Edge accuracy. The FRAP scanner controller composes the ROIs to be scanned out of subrectangles. The smaller the sub-rectangles are the higher is the resulting correspondence with the

ROIs. Set the accuracy by use of the slider or by typing a value. The default value is 5 pixels, the range

2 pixels.

Default. Click here to reset the defaults.

Condition

These options are active only if the Advanced experiment is chosen.

Enable. Check here to use the options. Otherwise the command is executed in each Time loop cycle.

Once at … Cycle. This option is used in typical FRAP experiments. Set the cycle number when the

FRAP scan is to be executed.

Every Nth … Cycle. This option is used in typical FLIP experiments. Set the interval between the

bleaching scan if time loop cycles with and without scan shall alternate.

6.3.2 Fire On Click

Fire On Click command icon

This command icon allows applying a laser flash at will during the experiment and at any spot within

the image. It can be repeated as often as wanted. This allows carrying out bleaching or photoactivation

experiments where it is not known before hand when and where an object to be exposed to the laser

will appear.

The system will Fire after a Click the next time the Fire On Click command is being cycled through in

the experiment plan. Let's take the following Experiment plan; see below. The Fire On Click command

Page 43

Manual Chapter 6 – Operating the System 37

is the first one within each cycle. At one point in time during a certain cycle a Click is being applied.

The Fire will only be carried out as soon as the next cycle is being started. Thus, while the manual Click

is unsynchronized, of course, the Fire initialized by the FARP controller is not.

The software "burns" a marker into the image following a "Fire" each time.

Bleach duration. Set here the duration of the laser flash.

Acquire after fire. With this option the following image acquisition is synchronized with the end of the

ROI scan(s). The laser spot will not be visible in this image.

Acquire while fire. Here image acquisition and ROI scan start simultaneously. The trace of the

scanning laser spot will be visible in the image.

Multiple points. This option allows to select several spots in the image with left mouse clicks– the

software internally generates a list of XY positions – and flash them all subsequently as fast as possible

upon a right click.

Interpolate lines. This option is available only if option Multiple points is checked. Activate this option

to do "line bleaching" instead of bleaching individual spots. Apply a series of (left) Clicks on certain

points of a structure. The display will show a polygon line instead of spots. Start the Fire with a right (!)

mouse click. The scanner will move the laser beam along the line – and not switch it off between the

spots as in the usual mode.

Preview: Live view while bleaching, Live view after bleaching, Stop FRAP preview. See previous

chapter for details.

6.3.3 Pattern Bleaching – Fluorescence Speckle Microscopy

Pattern Bleaching command icon

In this experiment the laser spot positions are set with predefined gaps in between. The resulting

pattern of bleached or photoactivated spot makes movements of structures relative to each other quite

visible.

Most parameters and options are explained in detail in Chapter 6.3.1, FRAP Experiments.

Pattern spacing

Spot distance factor. Set the value here. The Spot size is being multiplied with the Spot distance

factor In order to define a certain distance between each spot of the pattern.

Remember that the Spot size is defined via Set spot size in the FRAP window with the default value

presuming a perfectly focused laser; see Chapter 6.2, The FRAP GUI in . The pattern is most

regular if rectangular ROIs are being used. Other types of ROIs need to be composed of sub-rectangle

as described for the command Edge accuracy in Chapter 6.3.1, FRAP Experiments. Here the pattern

of spots will be more irregular.

Page 44

38 Chapter 6 – Operating the System

Page 45

Manual Chapter 7 – Specifications, Technical data 39

7 Appendix

This chapter lists specifications and technical data of the system.

7.1 Laser Safety Stage Cover Dimensions .......................................................40

Page 46

40 Chapter 7 –Specifications, Technical Data

7.1 Laser Safety Stage Cover Dimensions

The laser safety stage cover must be secured to the microscope stage with the M4x5 screws provided.

If the microscope stage does not have the necessary pre-drilled holes, this simple modification must be

performed before using the system. The following drawings show all dimensions necessary for such a

modification.

Page 47

Manual Chapter 7 – Specifications, Technical data 41

Page 48

Page 49

Page 50

Page 51

®

OLYMPUS EUROPA HOLDING GMBH

Postfach 10 49 08, 20034, Hamburg, Germany

Printed in Germany 2010 09 M 001

Loading...

Loading...